Clutch based on ultrasonic suspending force control

A suspension force and clutch technology, applied in the field of clutches, can solve the problems of large clutch assembly size, low response speed, and susceptibility to electromagnetic interference, and achieve the effect of fast response speed, small volume and size, and no electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

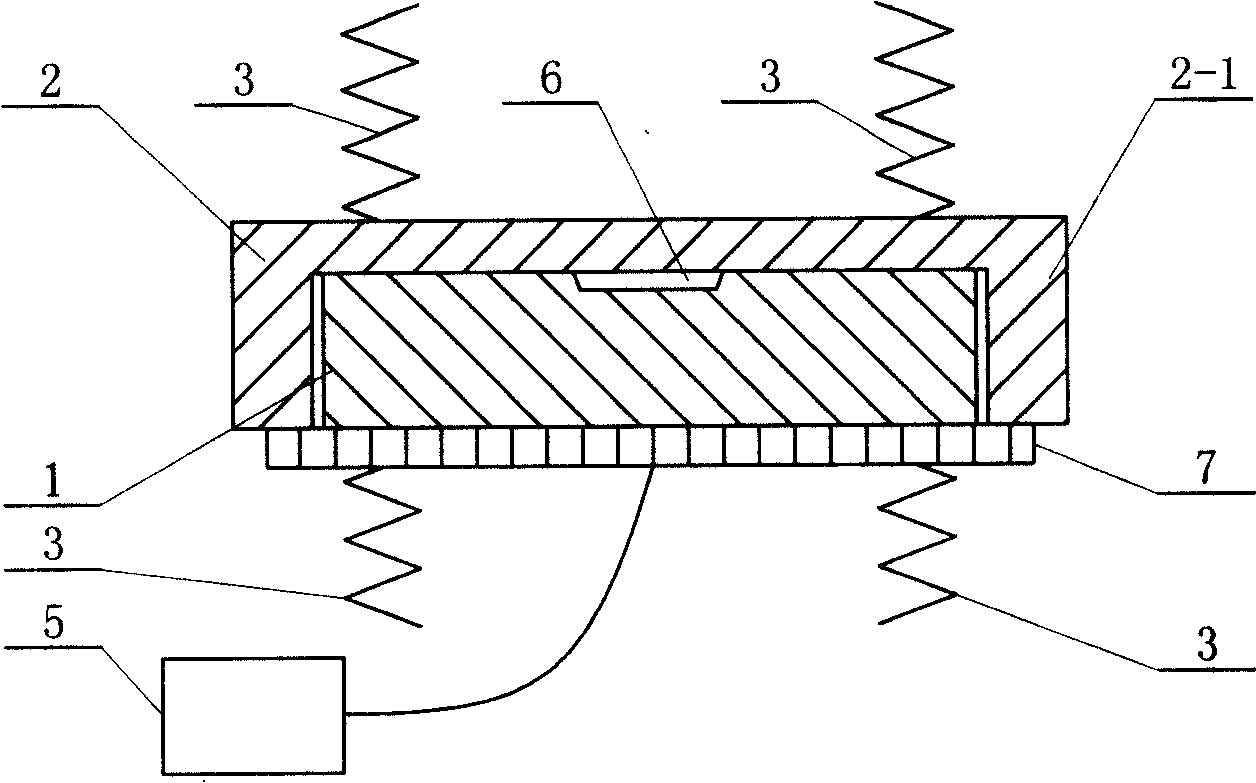

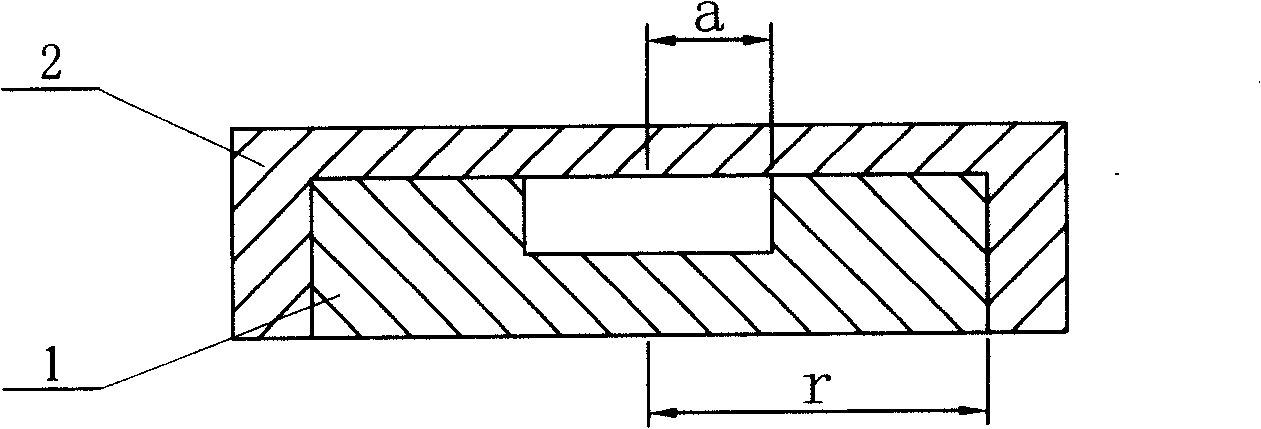

[0007] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. This embodiment consists of an active rotating disk 2, a passive rotating disk 1, a piezoelectric ceramic sheet 7, a return spring 3 and a high-frequency power supply 5. The active rotating disk 2 and the passive rotating disk 1 have the same rotation axis, and the passive rotating disk 1 Fastened in the ring body 2-1 of the active rotating disk 2, the end surface of the active rotating disk 2 is in contact with the inner end surface of the passive rotating disk 1, and the piezoelectric ceramic sheet 7 is fixed on the outer end surface of the passive rotating disk 1. The frequency power supply 5 is connected to the terminal of the piezoelectric ceramic sheet 7, and the return spring 3 is arranged on the active rotating disk 2 or the passive rotating disk 1 to keep the active rotating disk 2 and the passive rotating disk 1 in contact. The return spring 3 ...

specific Embodiment approach 2

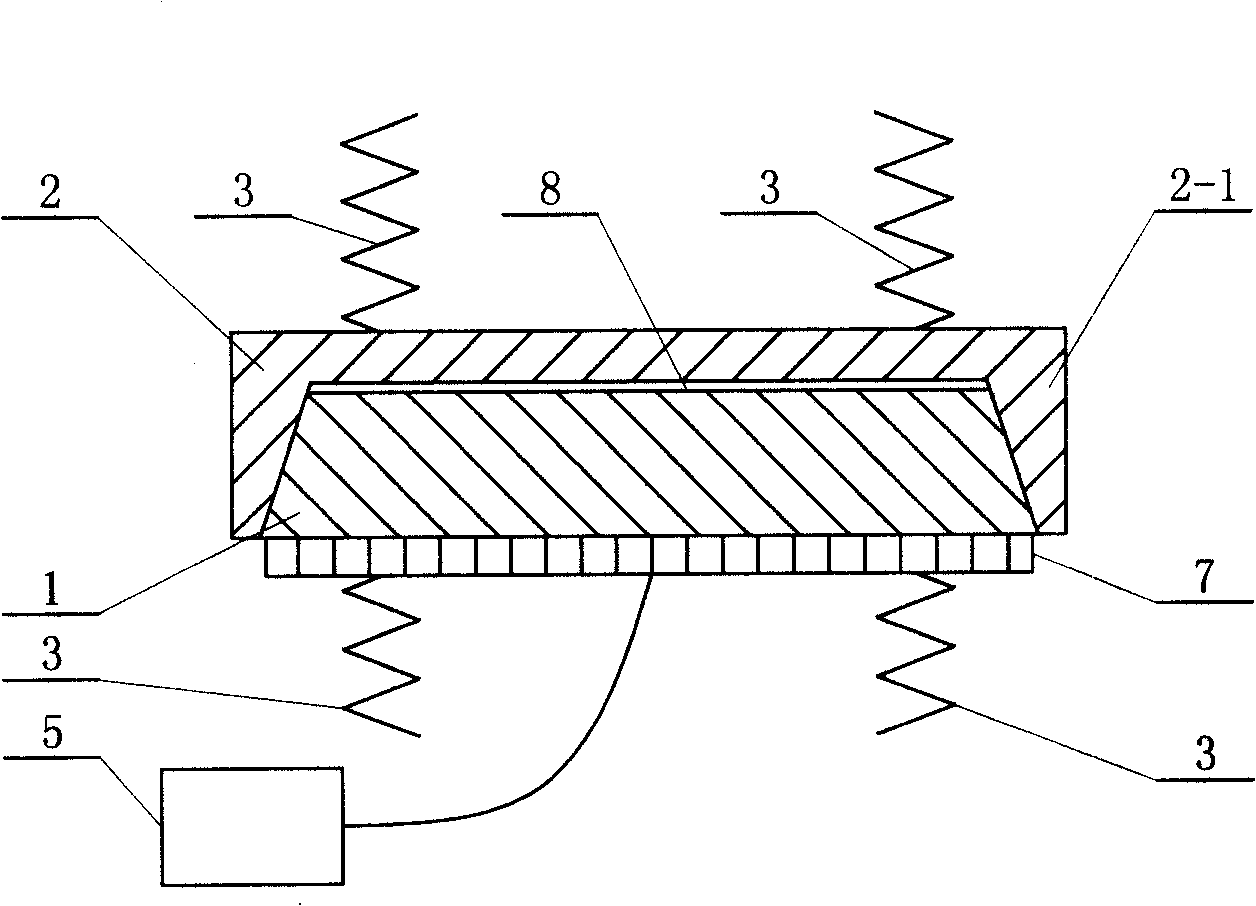

[0019] Specific implementation mode two: the following combination figure 2 This embodiment will be specifically described. This embodiment consists of an active rotating disk 2, a passive rotating disk 1, a piezoelectric ceramic sheet 7, a return spring 3 and a high-frequency power supply 5. The active rotating disk 2 and the passive rotating disk 1 have the same rotation axis, and the passive rotating disk 1 Fastened in the torus 2-1 of the active rotating disk 2, the inner surface of the torus 2-1 is conical, the rim of the passive rotating disk 1 is conical, and the inner surface of the torus 2-1 is conical. The rims of the passive rotating disk 1 are in contact, the piezoelectric ceramic sheet 7 is fixed on the outer end surface of the passive rotating disk 1, the high-frequency power supply 5 is connected to the terminal of the piezoelectric ceramic sheet 7, and the return spring 3 is arranged on the active rotating disk 2 or on the passive rotating disk 1 to keep the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com