Patents

Literature

46results about How to "Reduce hoop stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

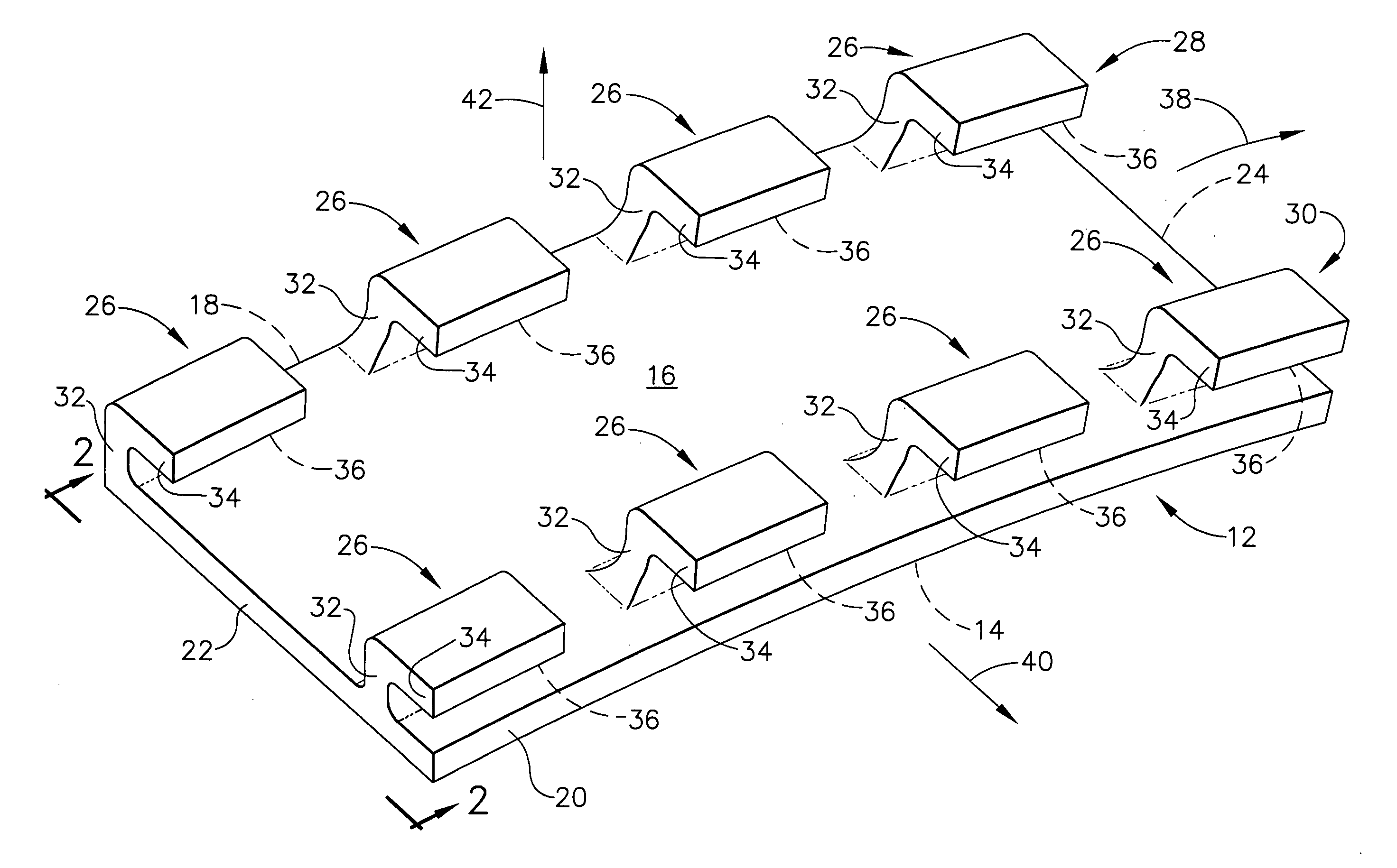

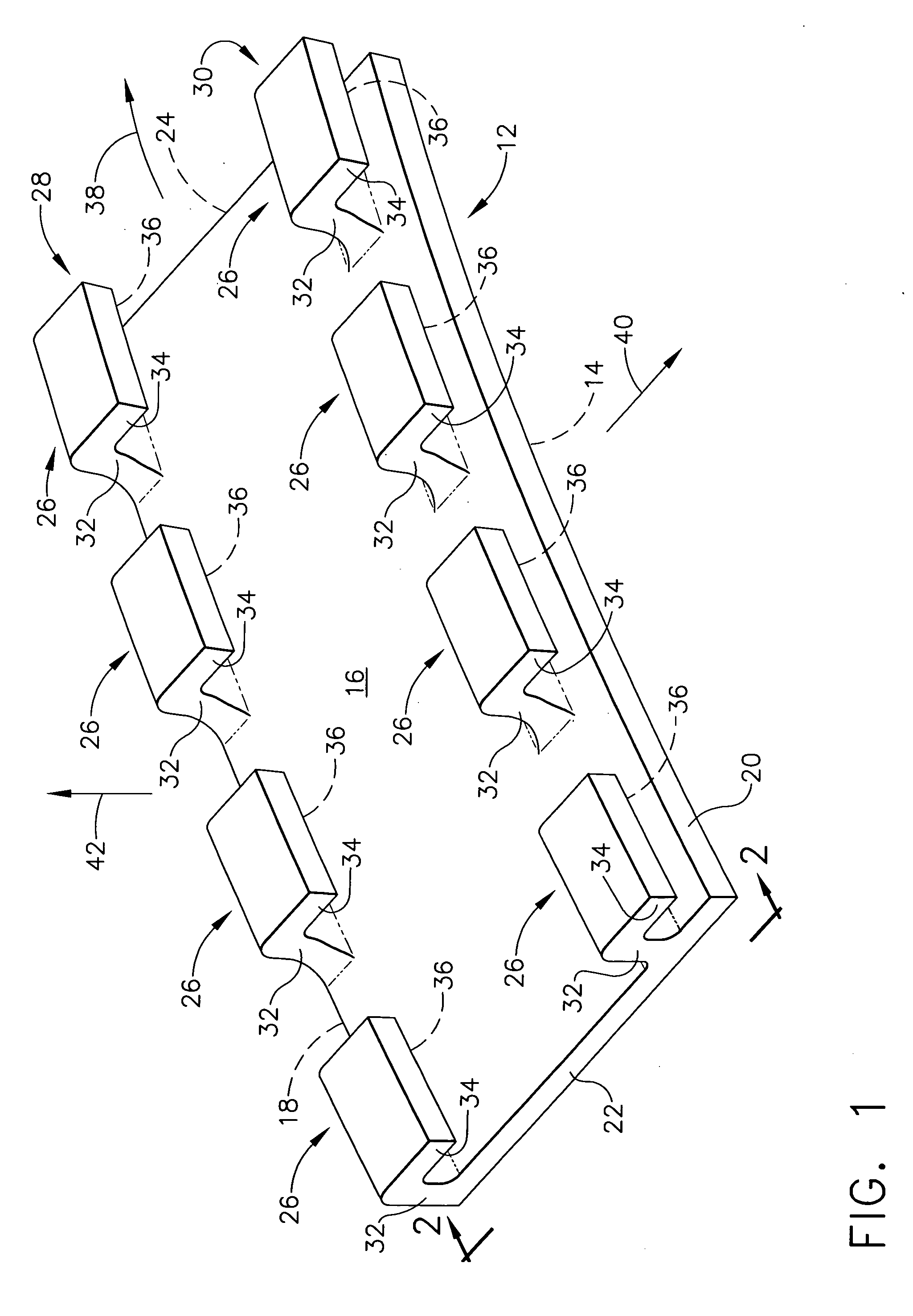

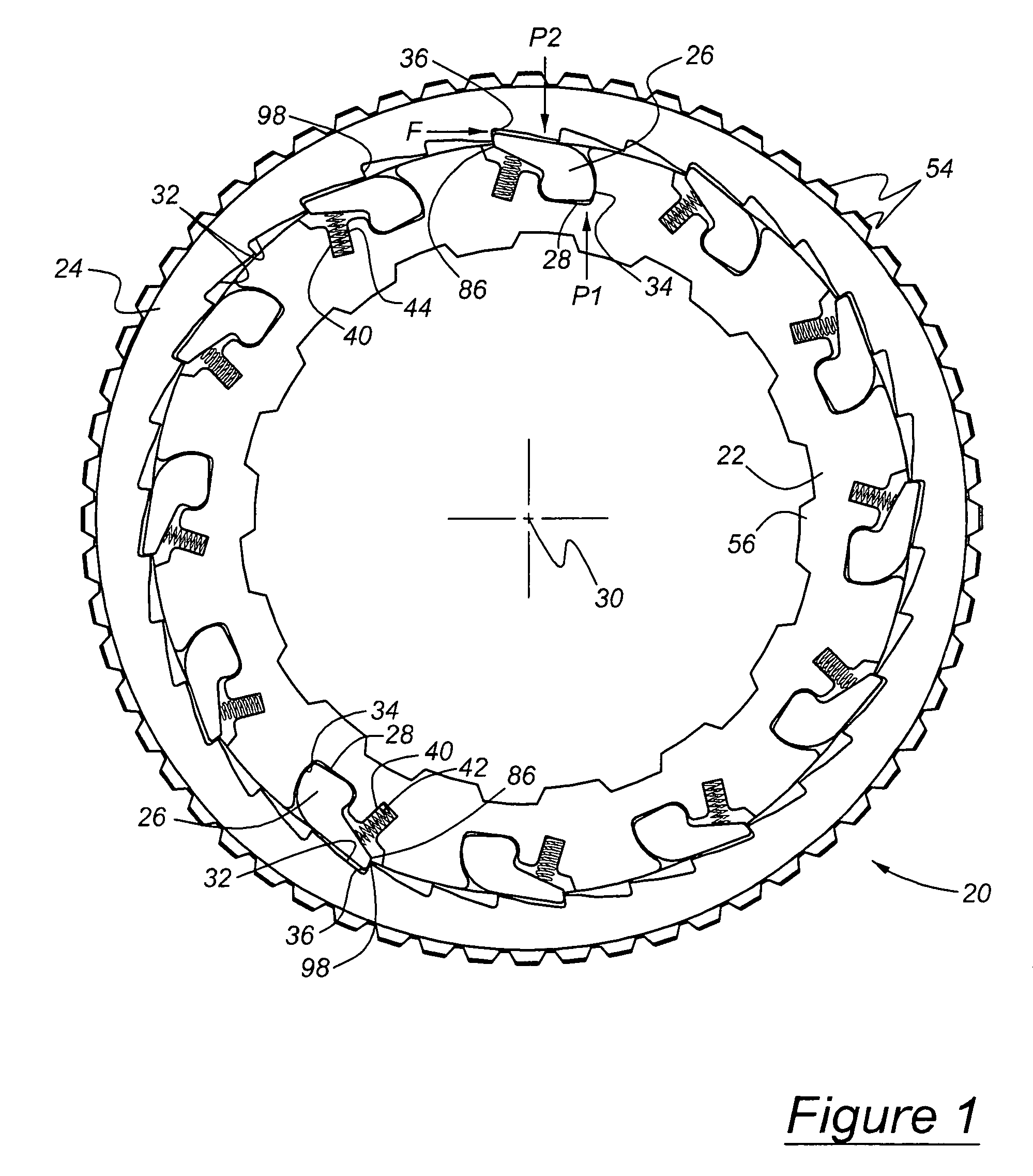

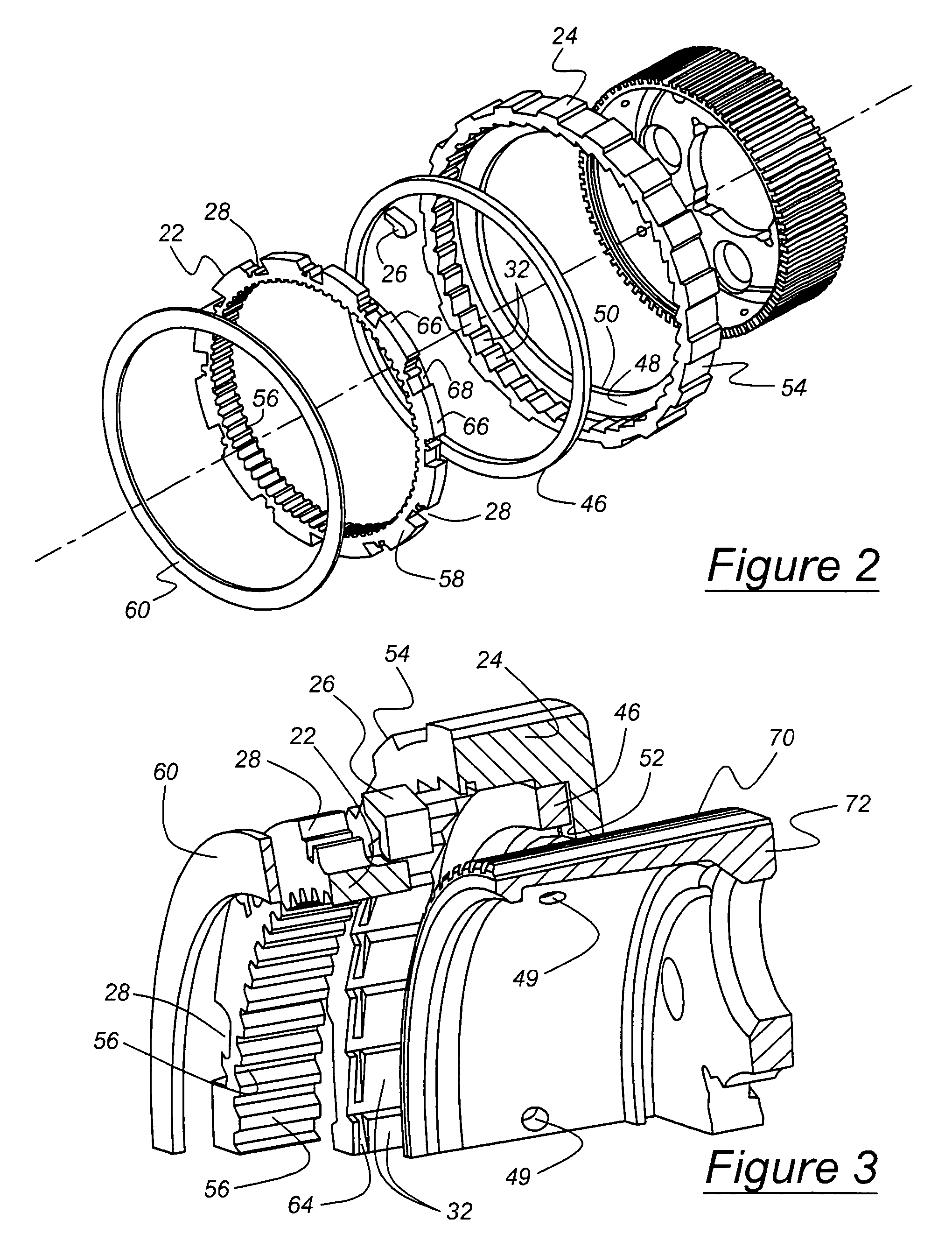

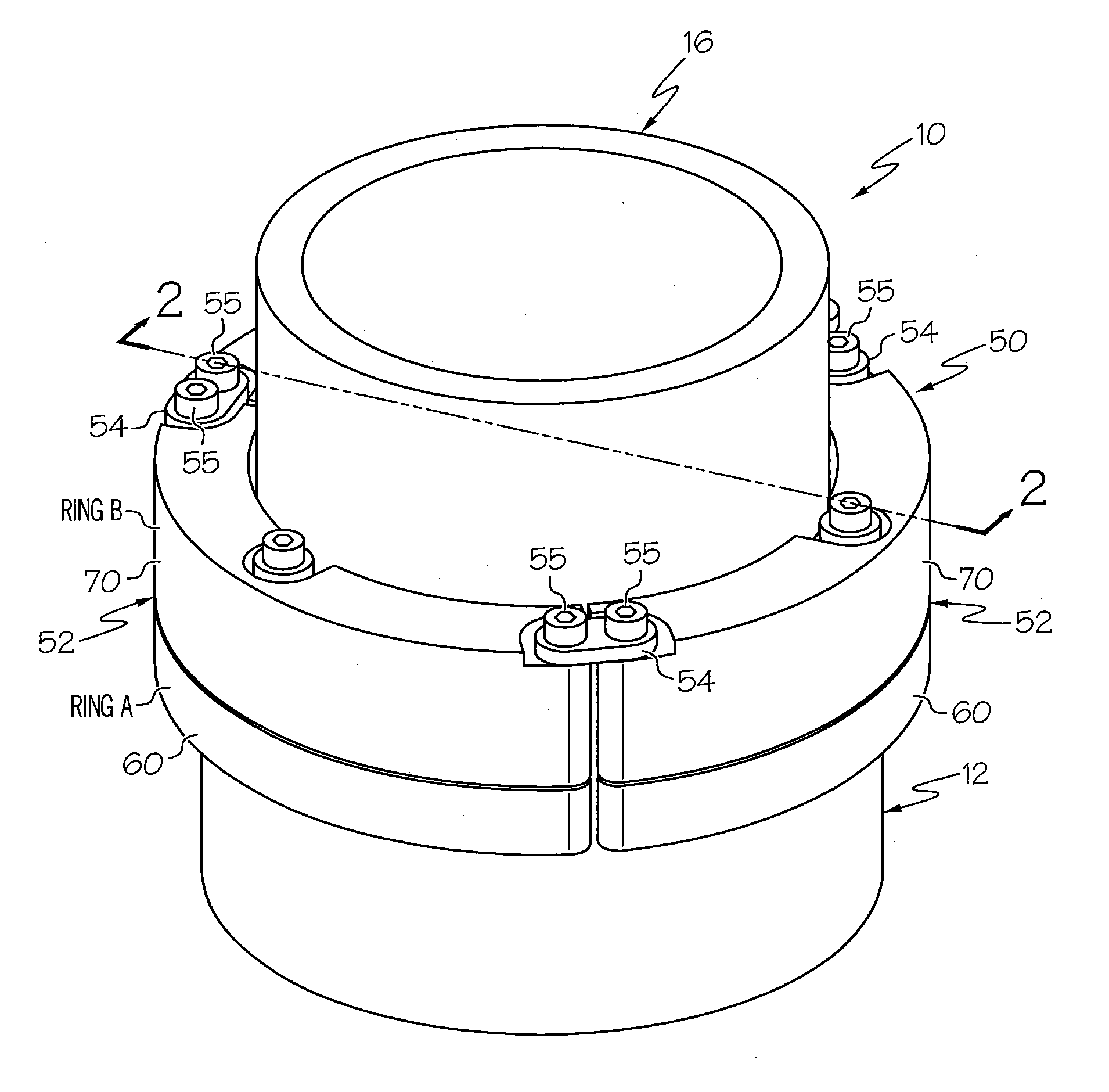

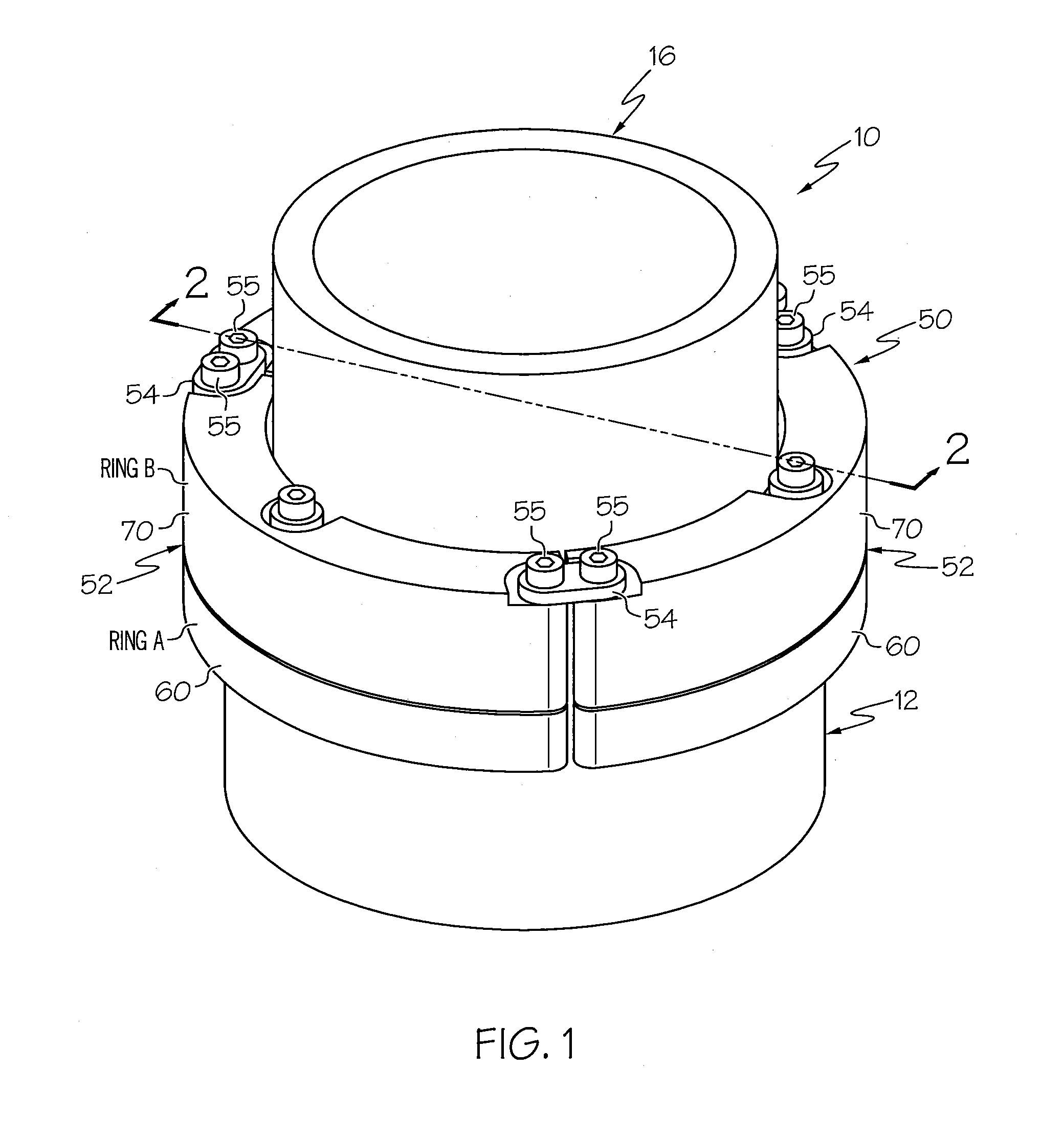

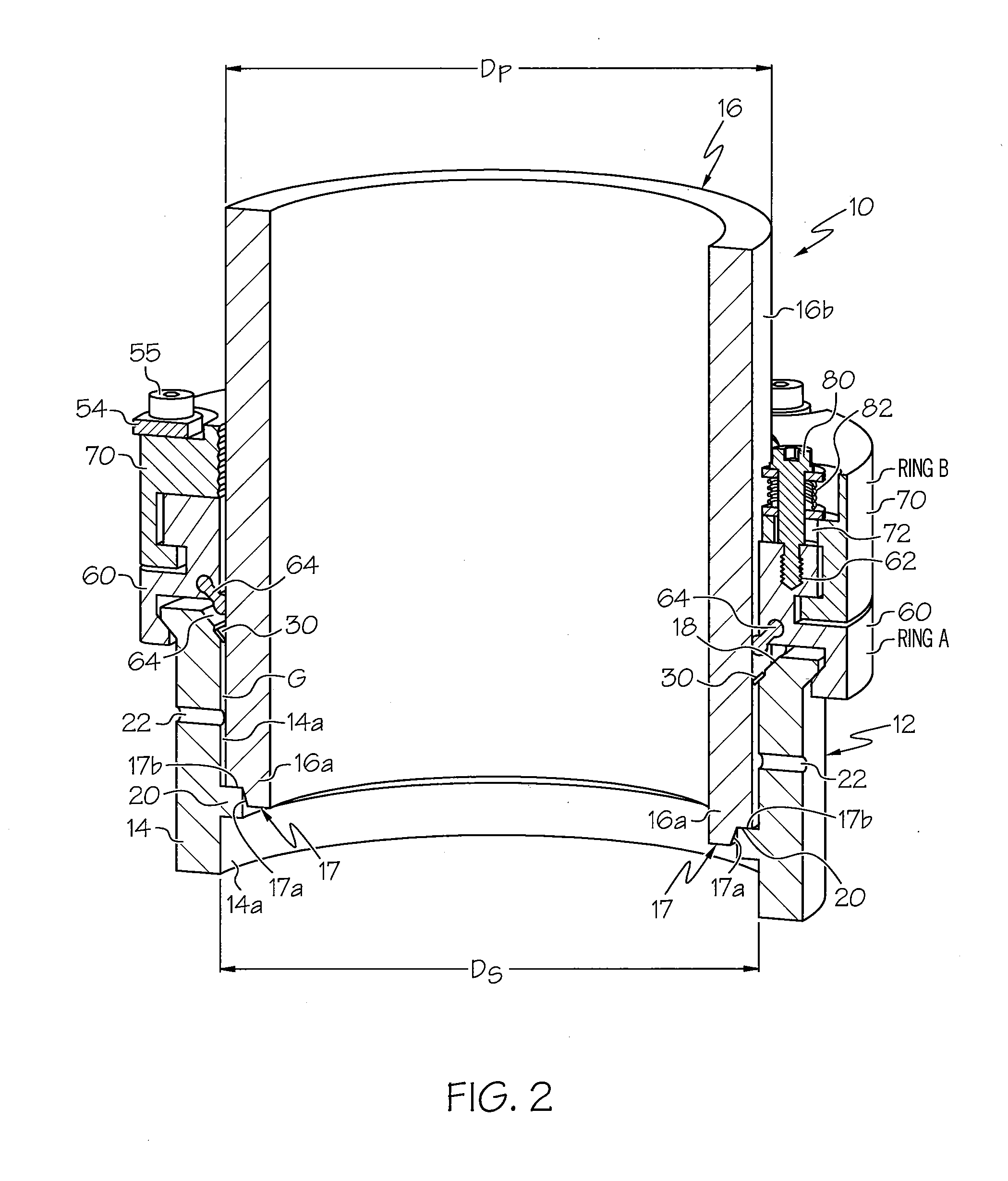

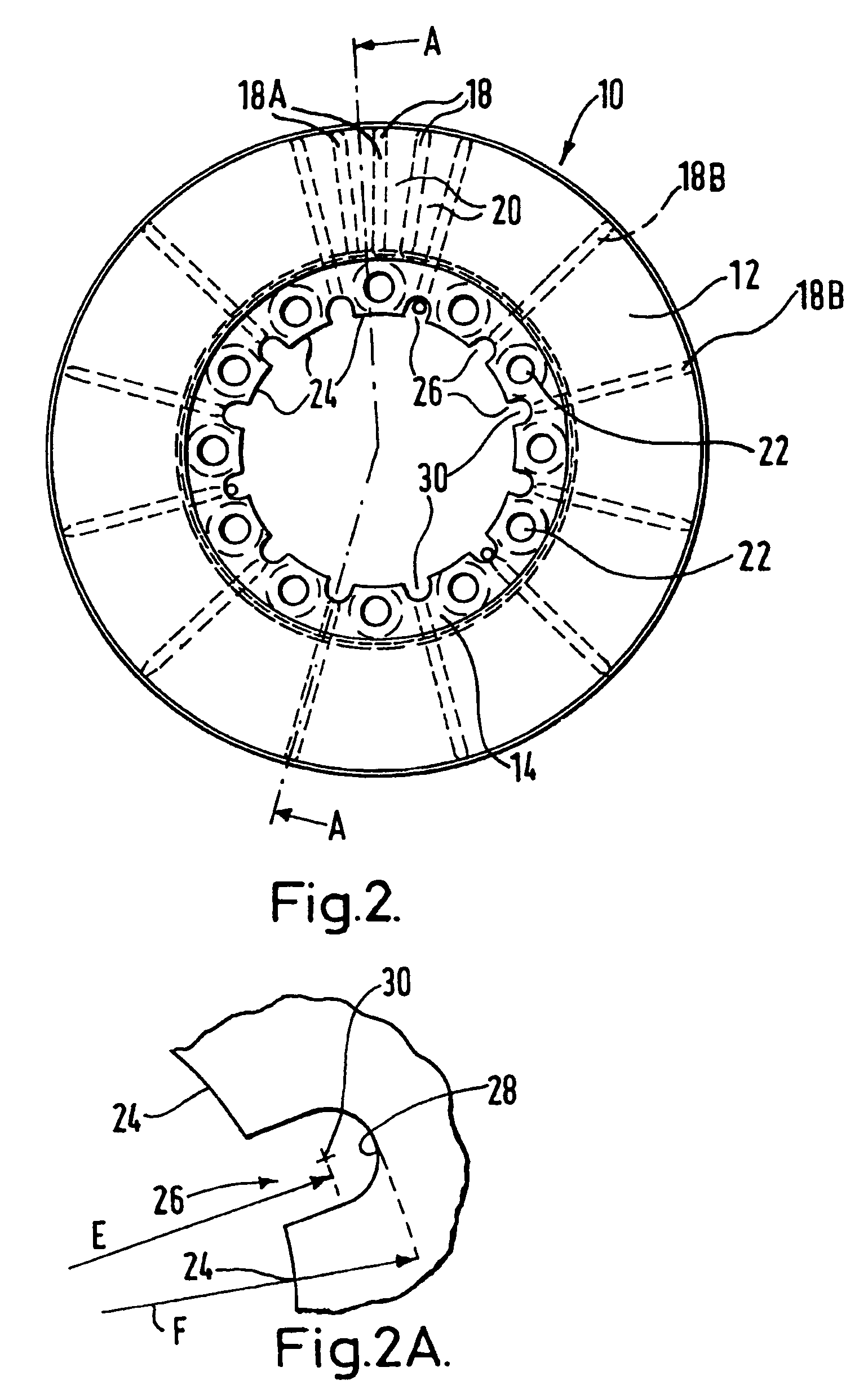

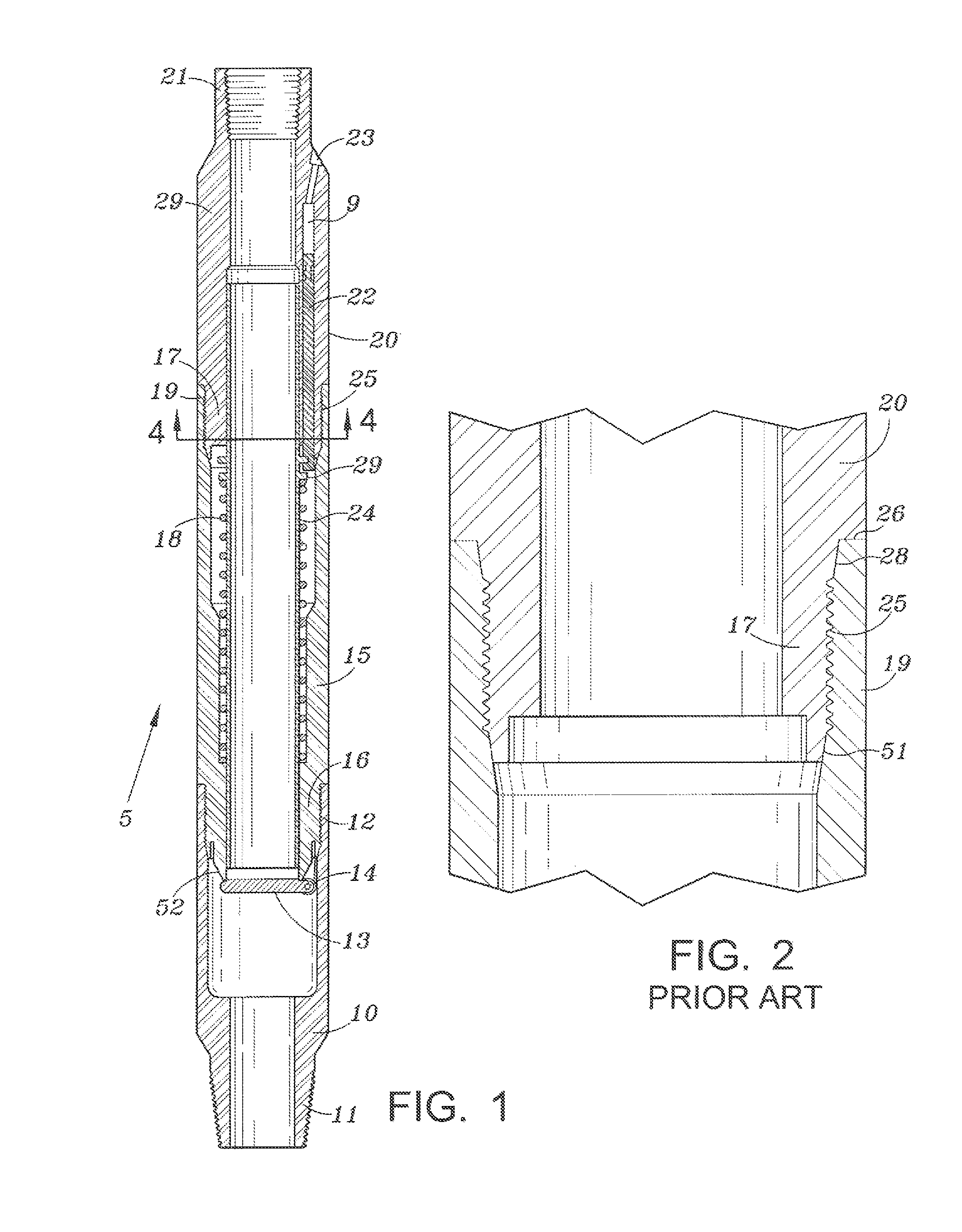

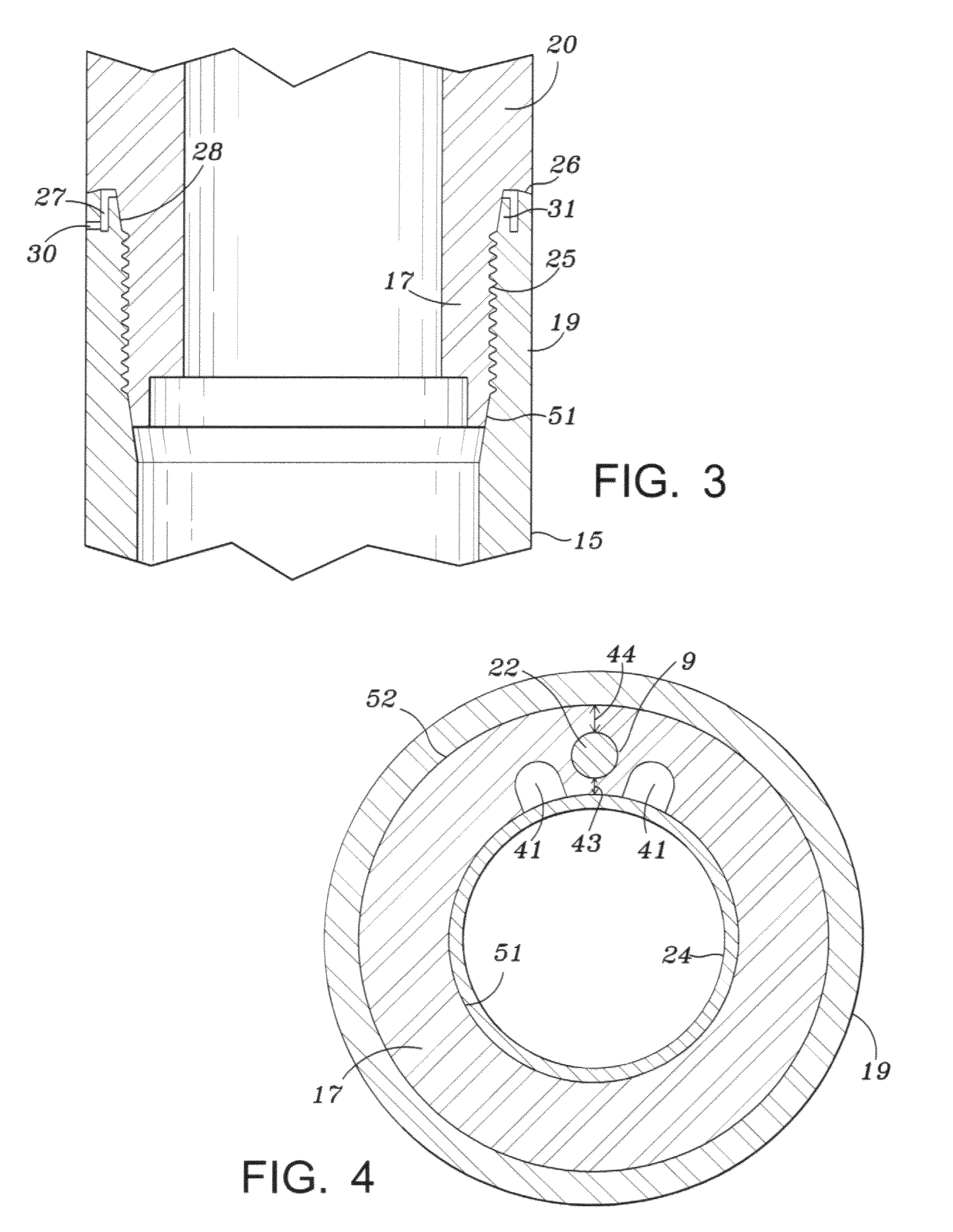

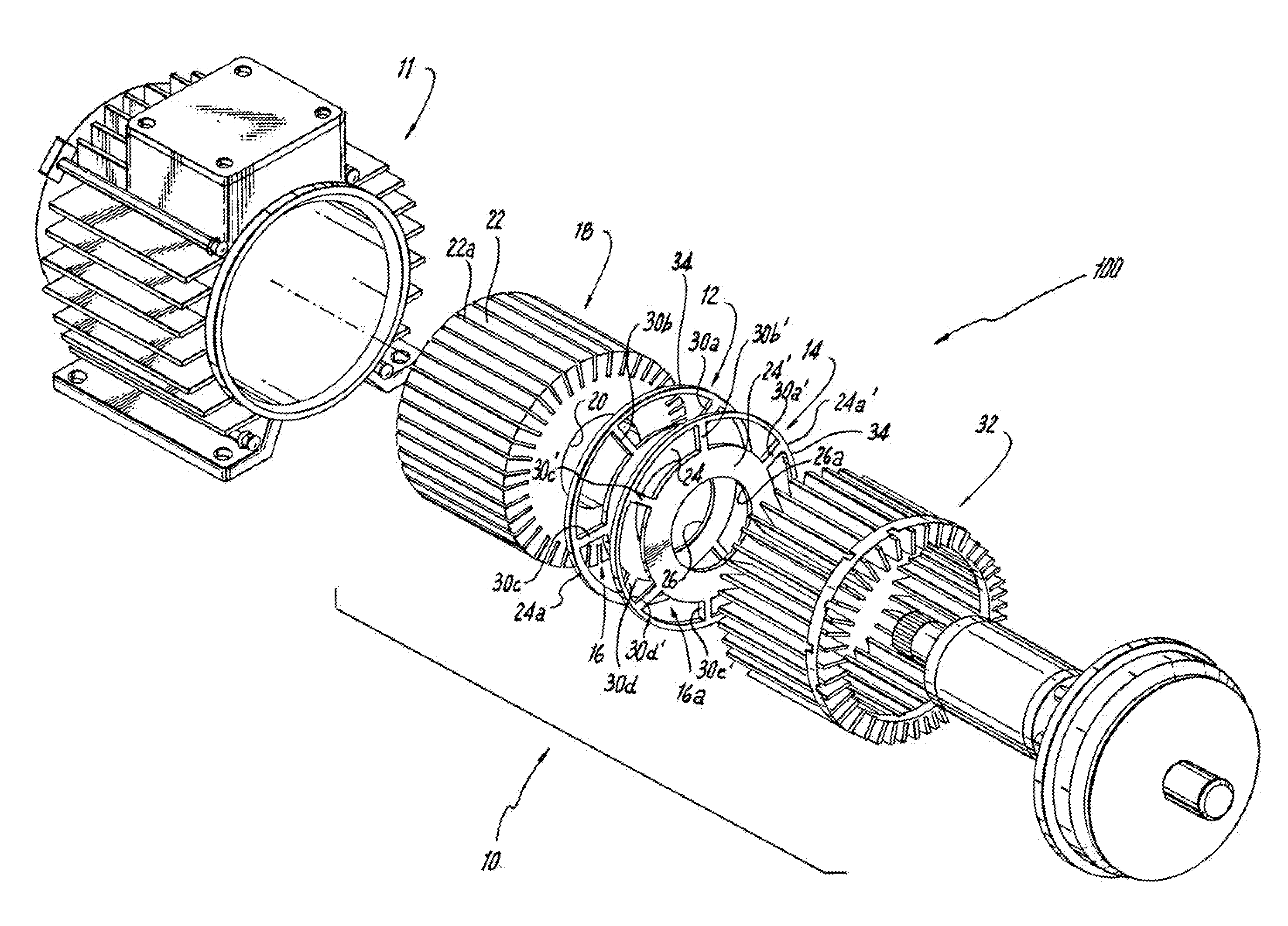

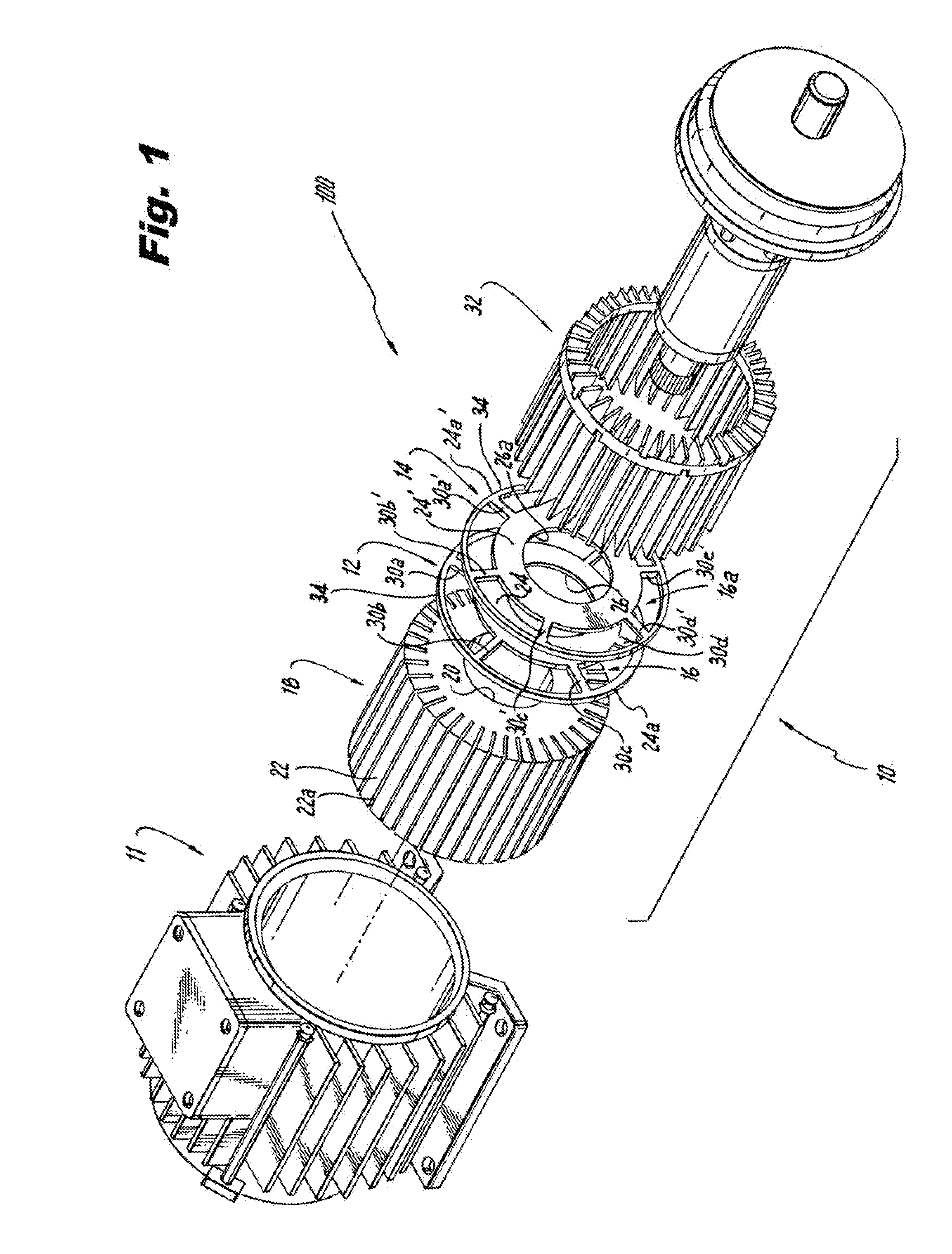

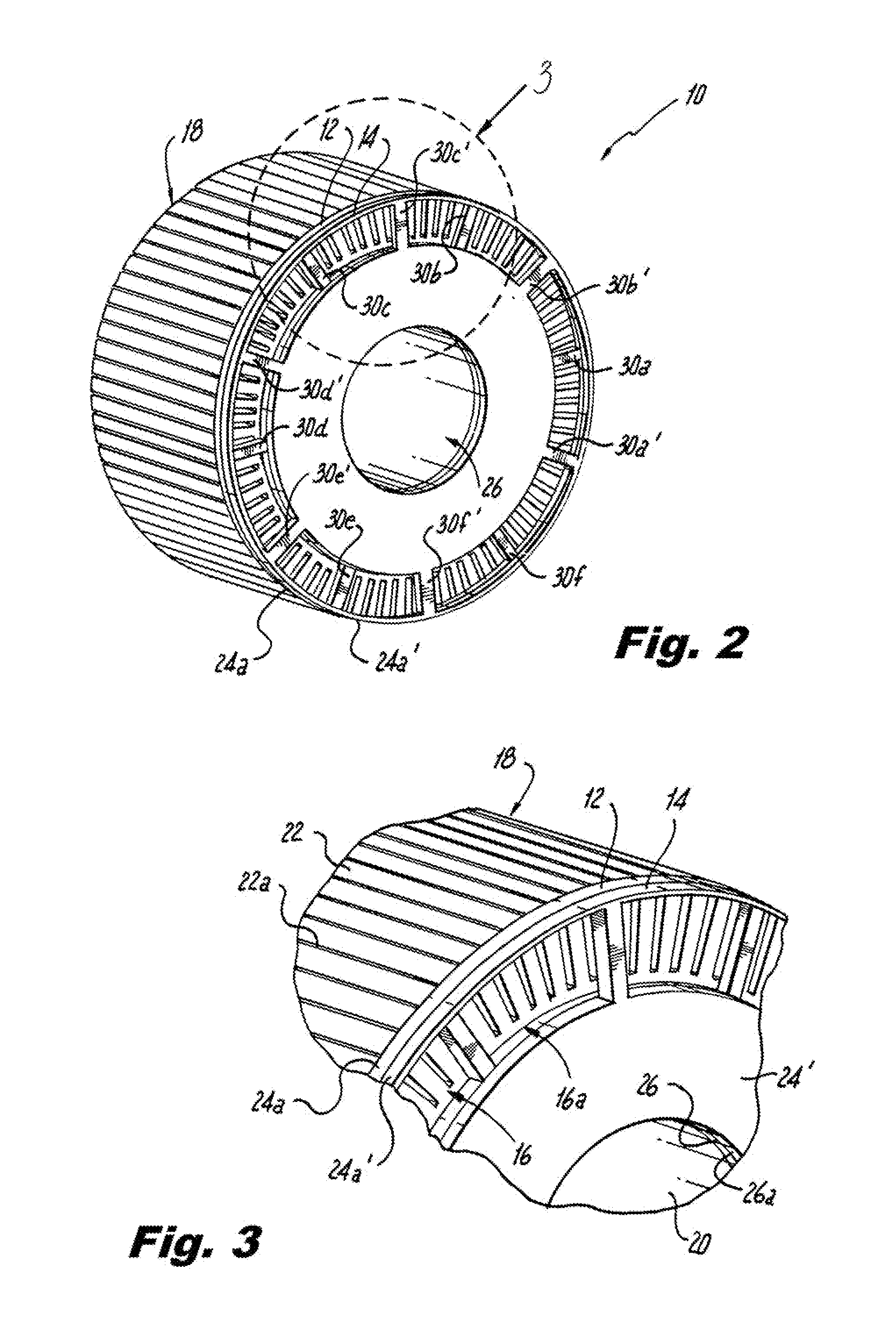

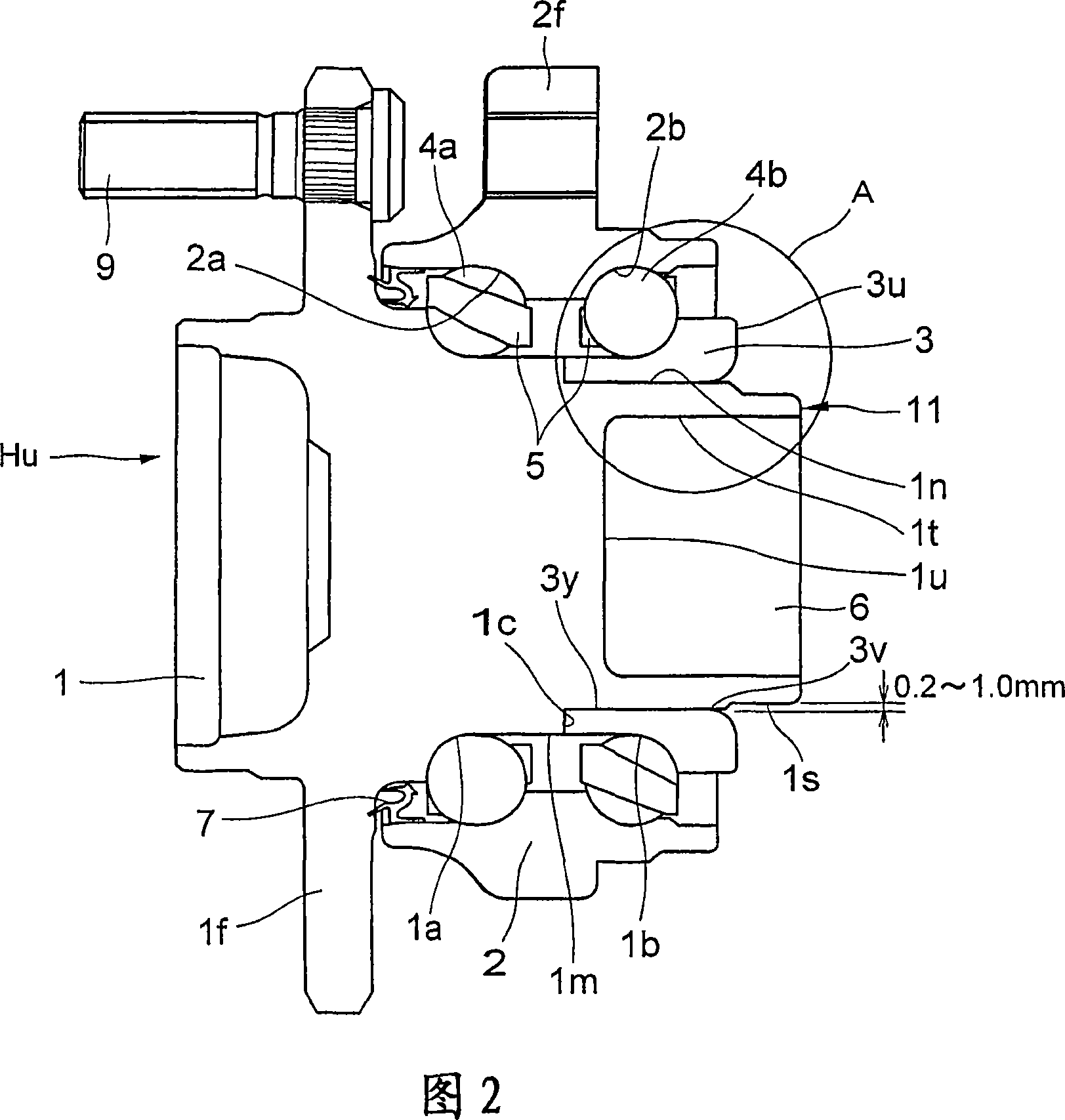

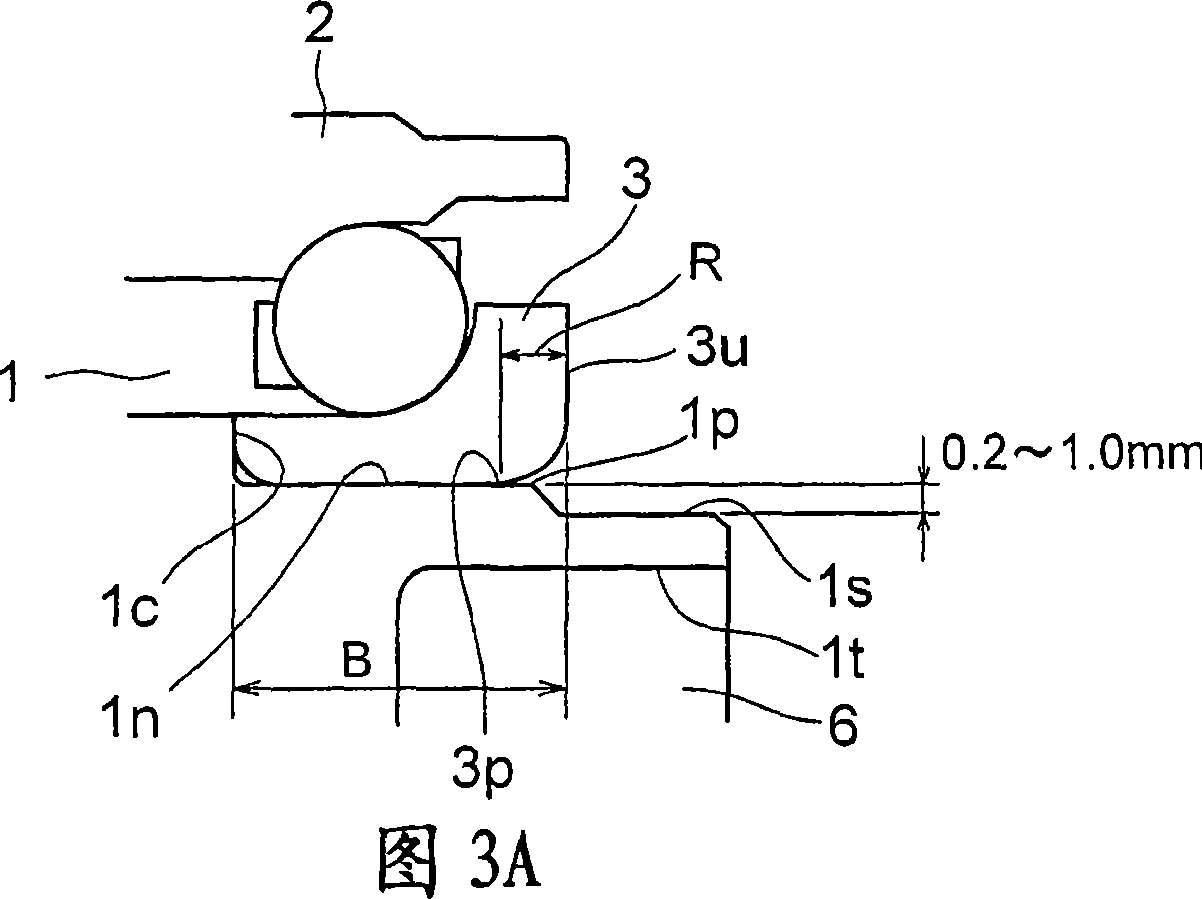

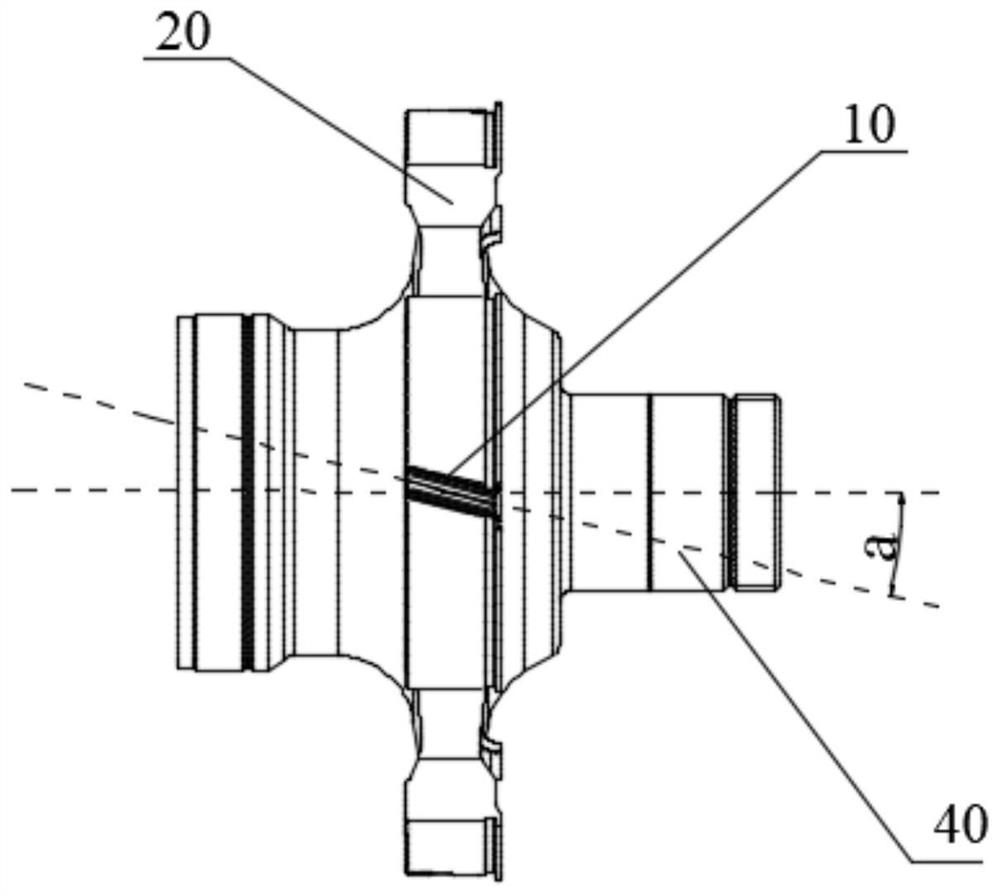

Dual-mode one-way torque transmitting device

InactiveUS20060185957A1Low costReduce hoop stressFluid actuated clutchesFriction clutchesDual modeEngineering

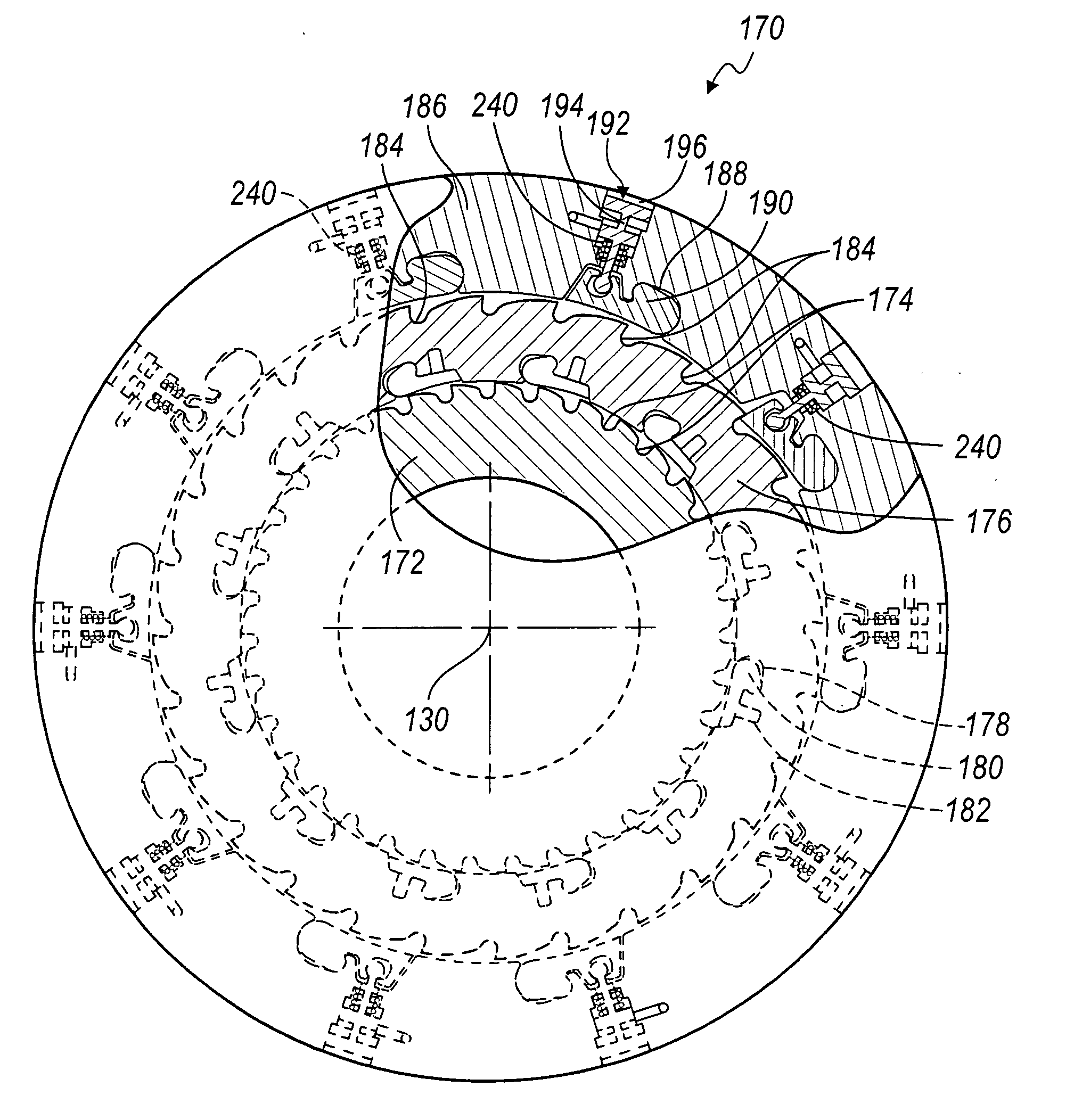

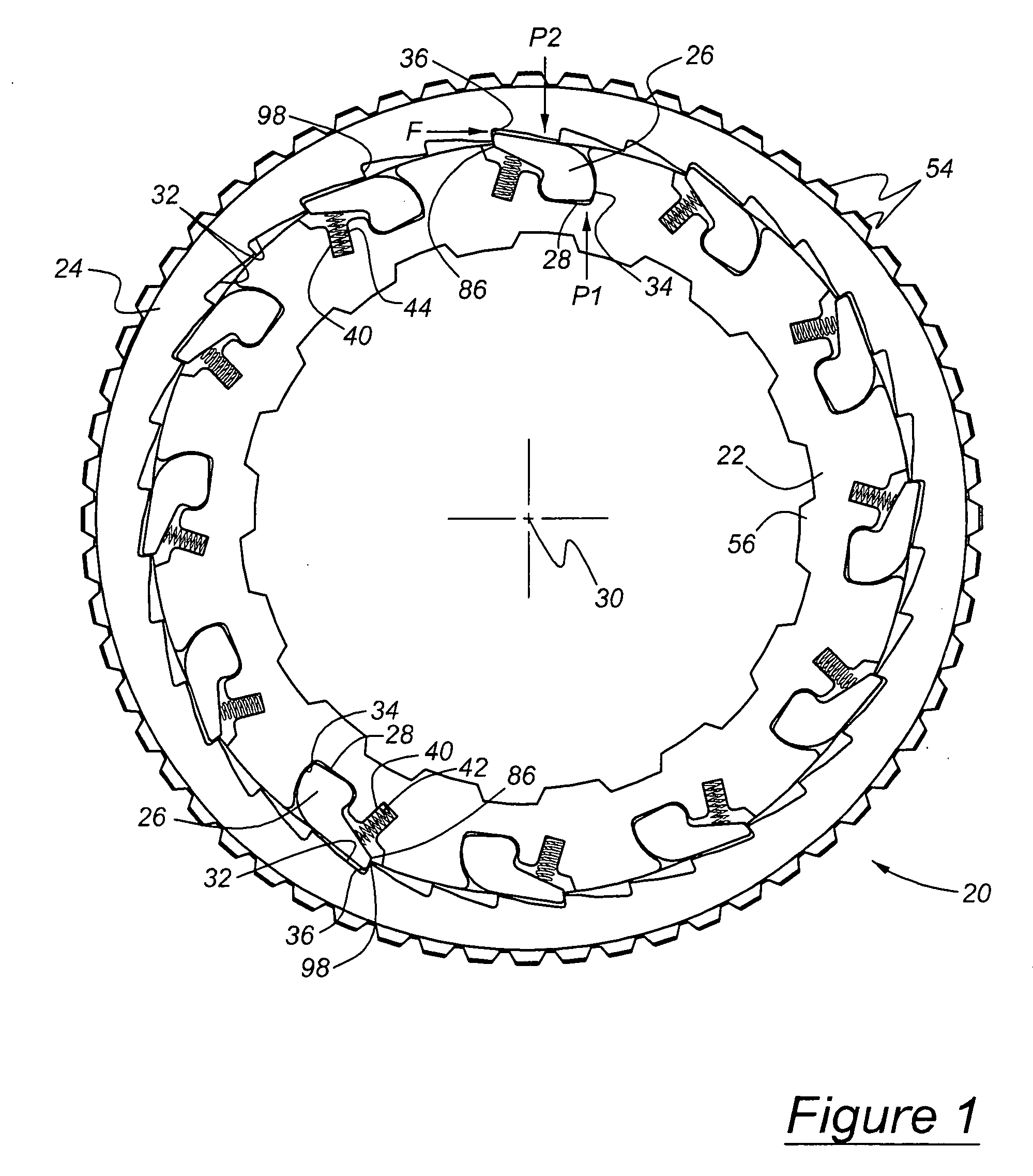

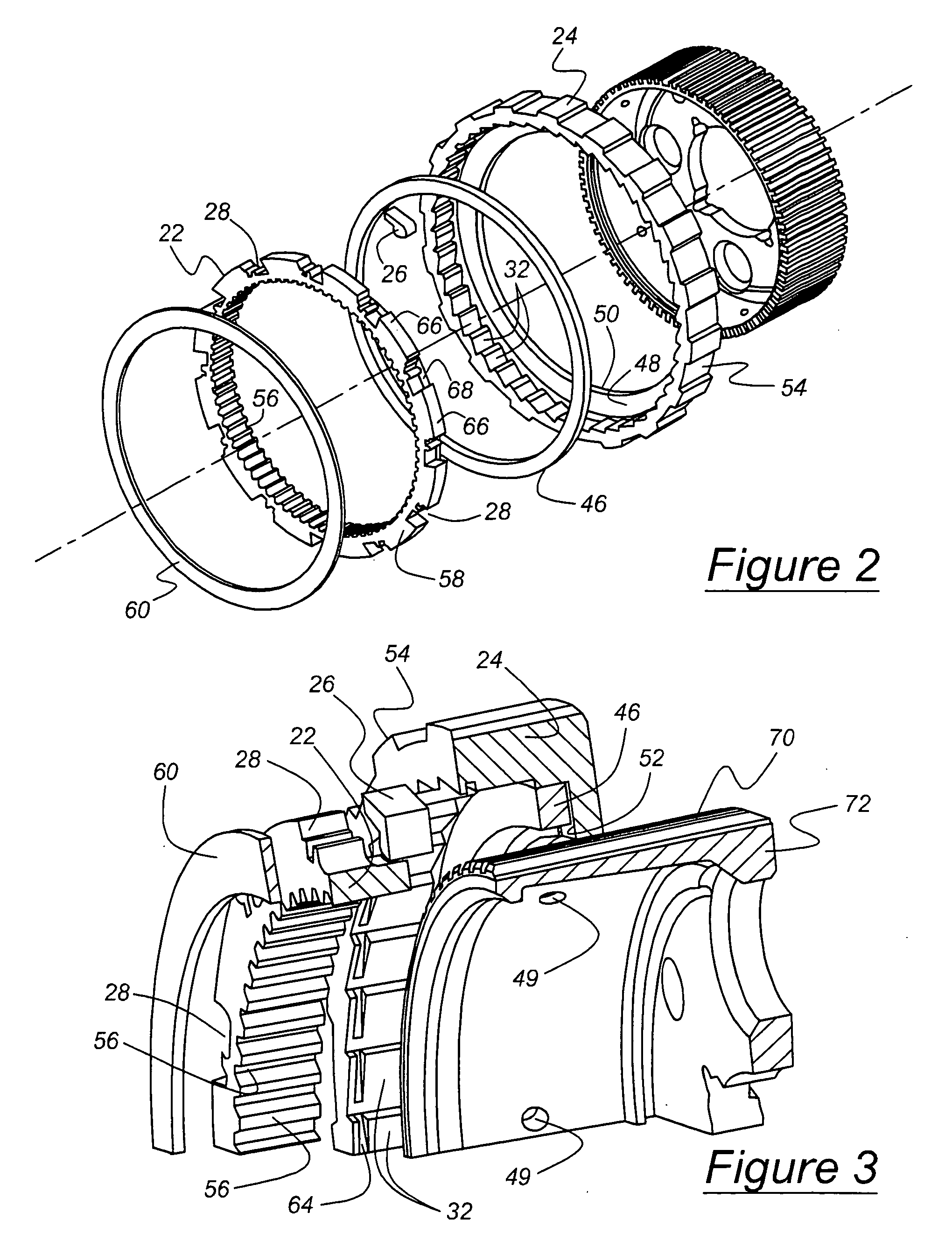

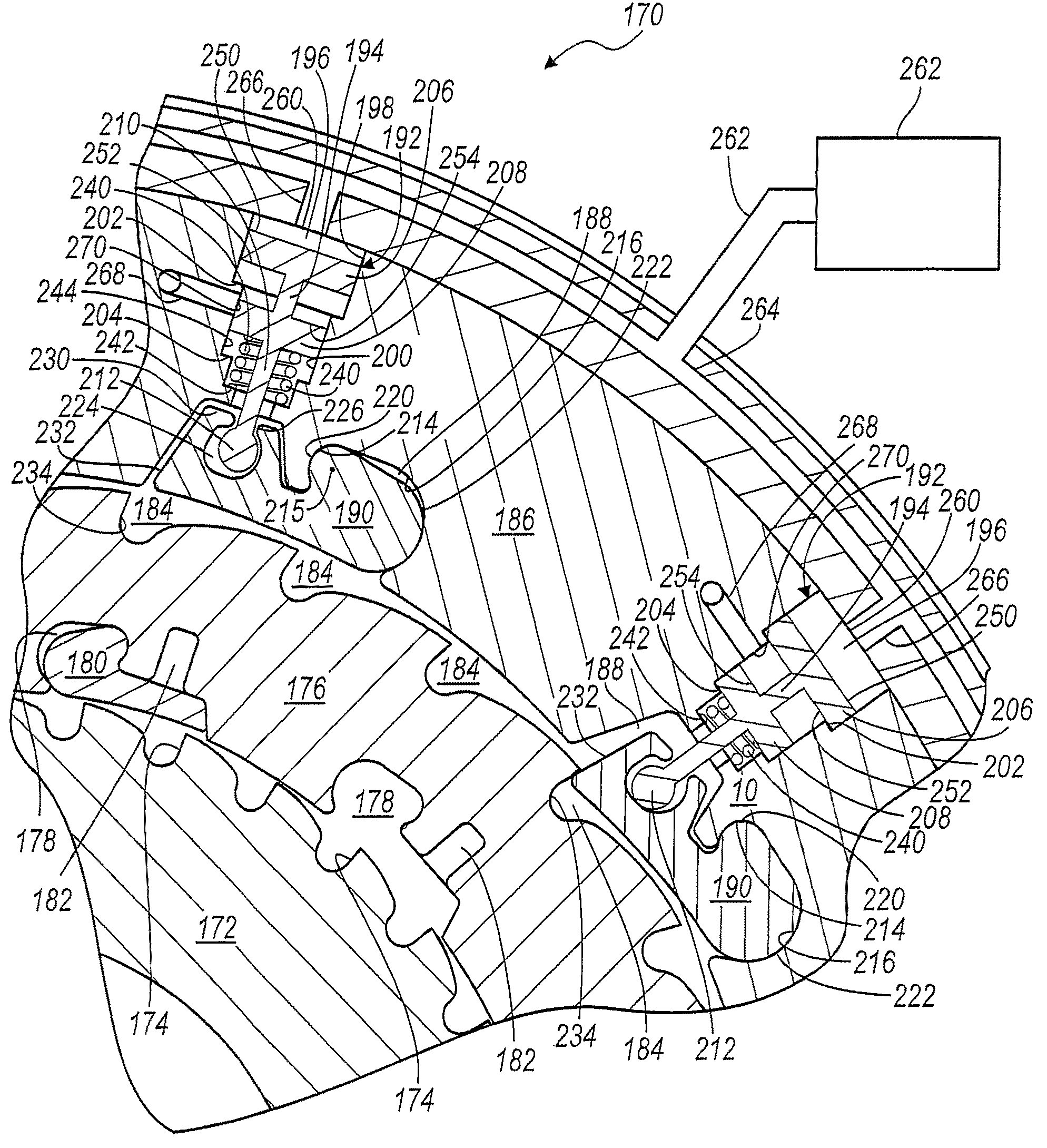

A dual mode one-way torque transmitting device includes an inner race having a first plurality of notches spaced about an axis. An intermediate race includes a second plurality of notches spaced about the axis, a first plurality of pockets spaced about the axis, and a first plurality of rockers, each rocker being located in a pocket of the intermediate race. A spring urges each rocker toward engagement with a notch on the inner race. An outer race includes a second plurality of pockets spaced about the axis, a second plurality of rockers, each rocker being located in a pocket on the outer race, and a plurality of actuators, each actuator alternately engages and disengages a rocker on the outer race and a notch on the intermediate race.

Owner:FORD GLOBAL TECH LLC

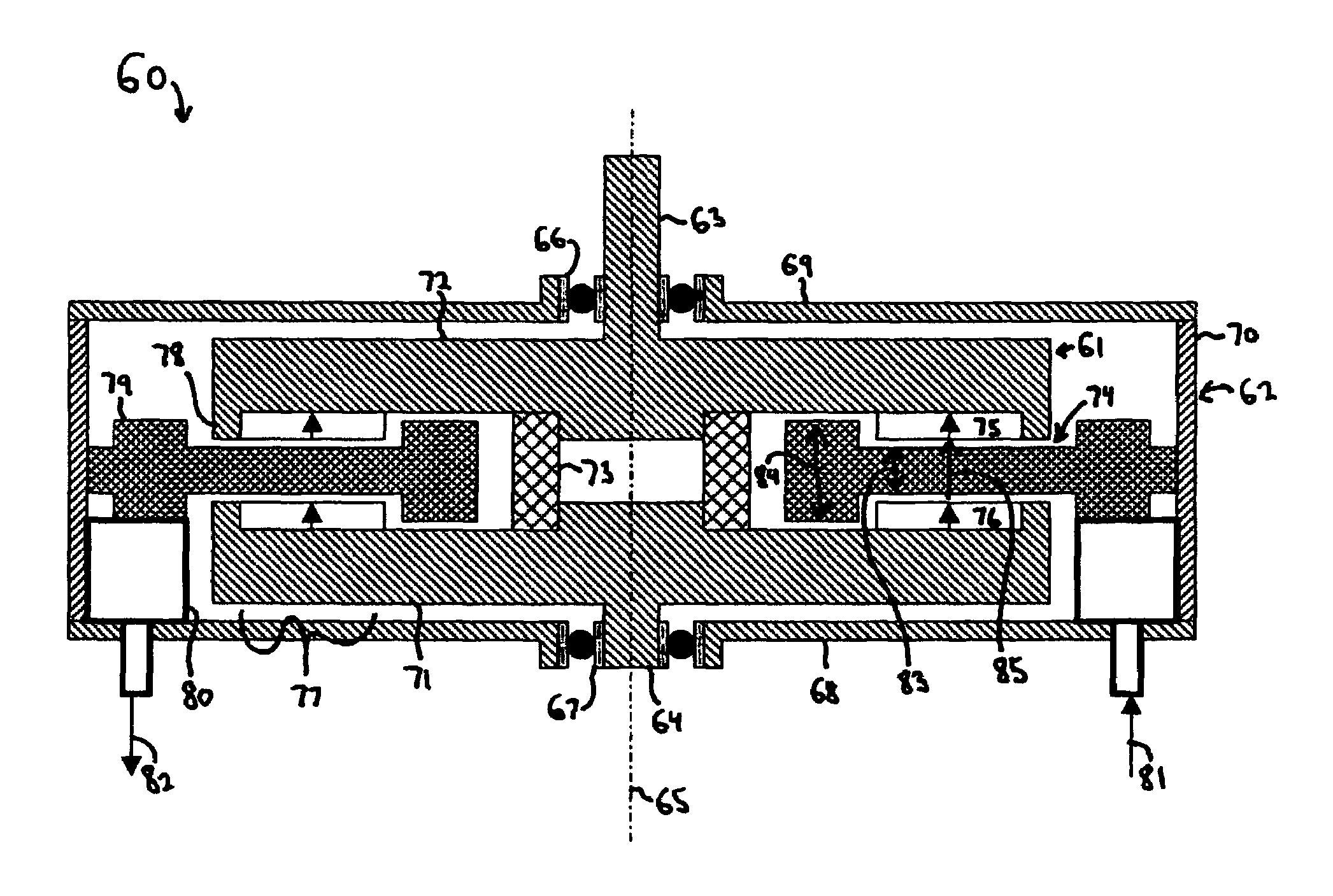

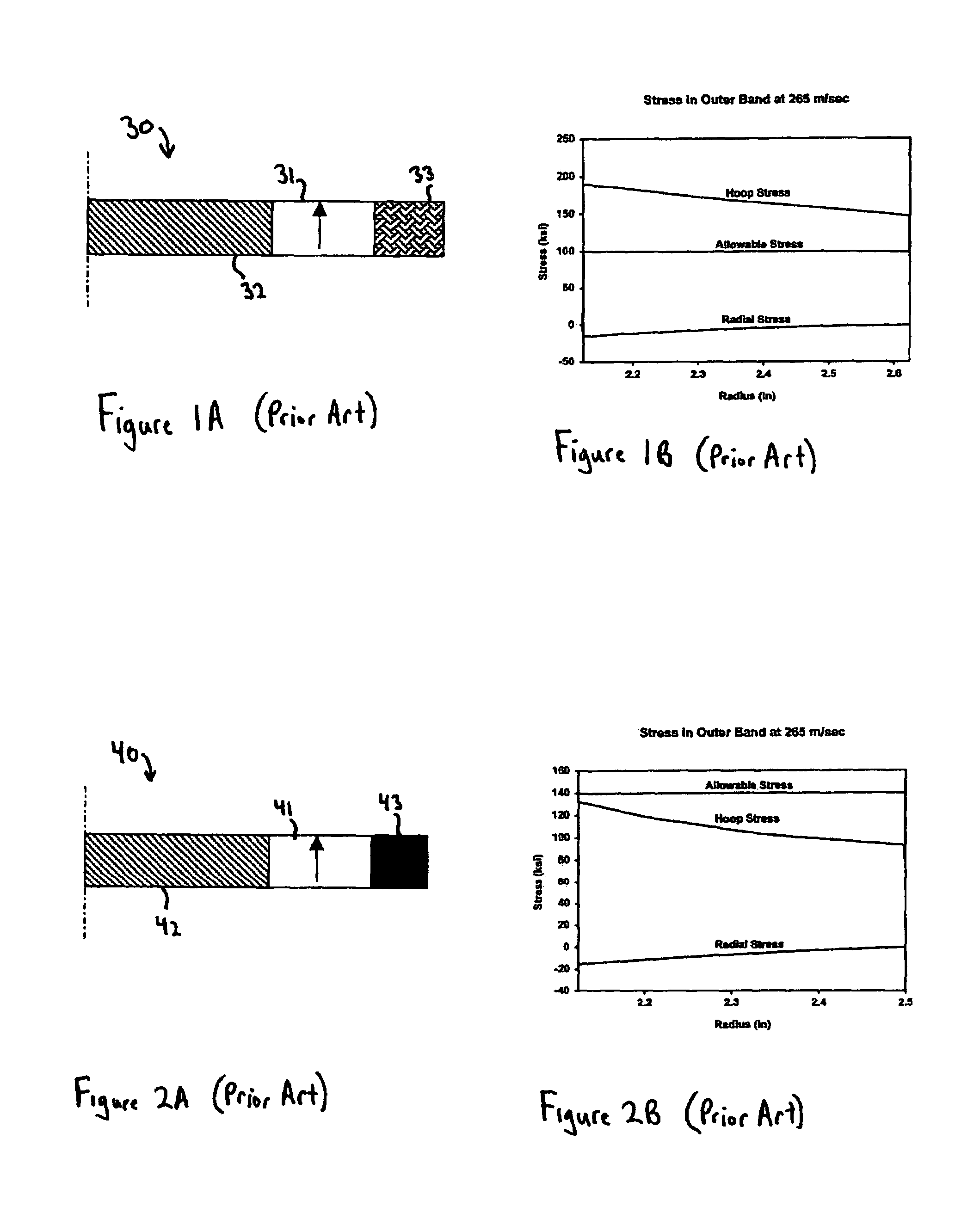

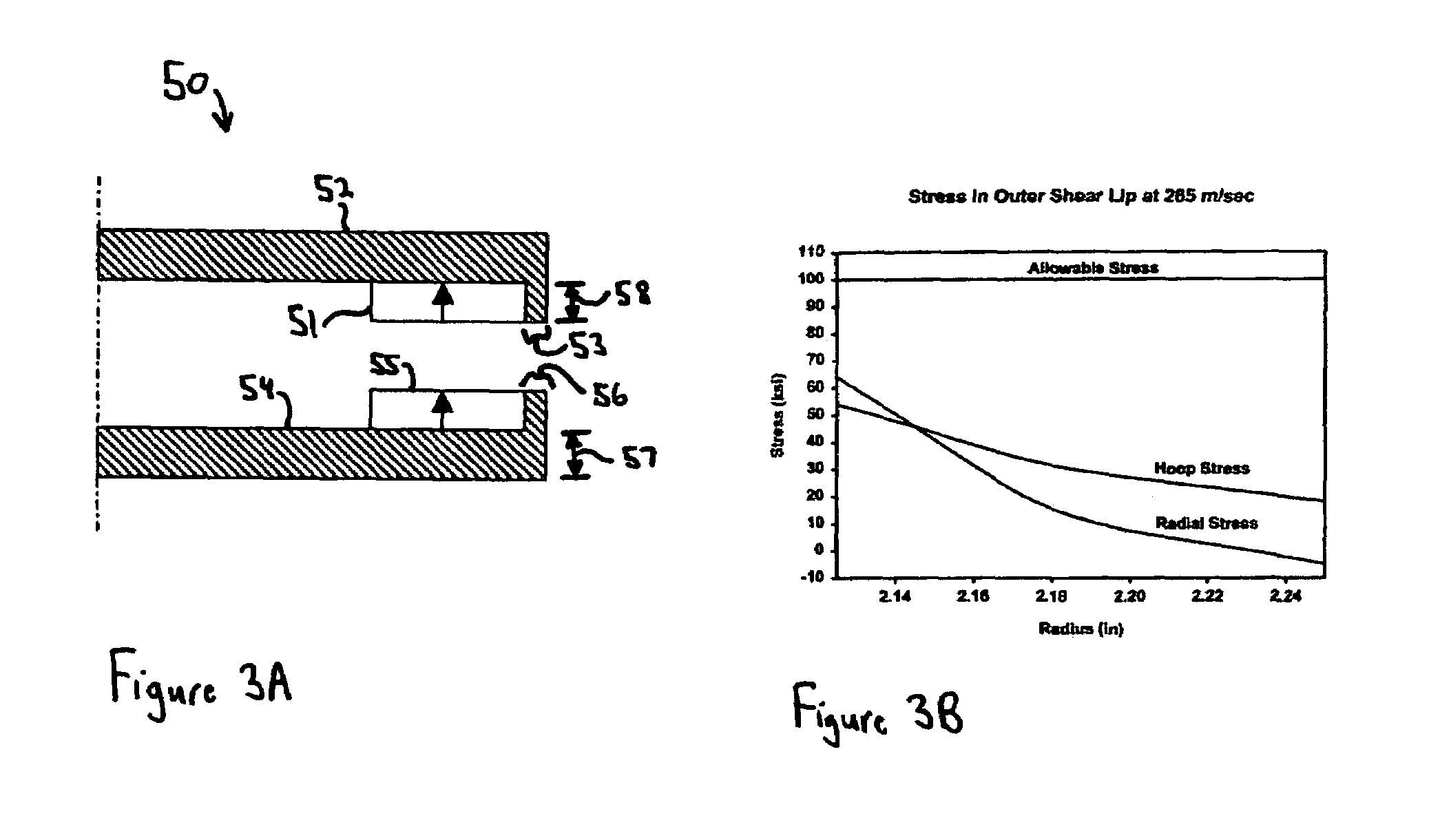

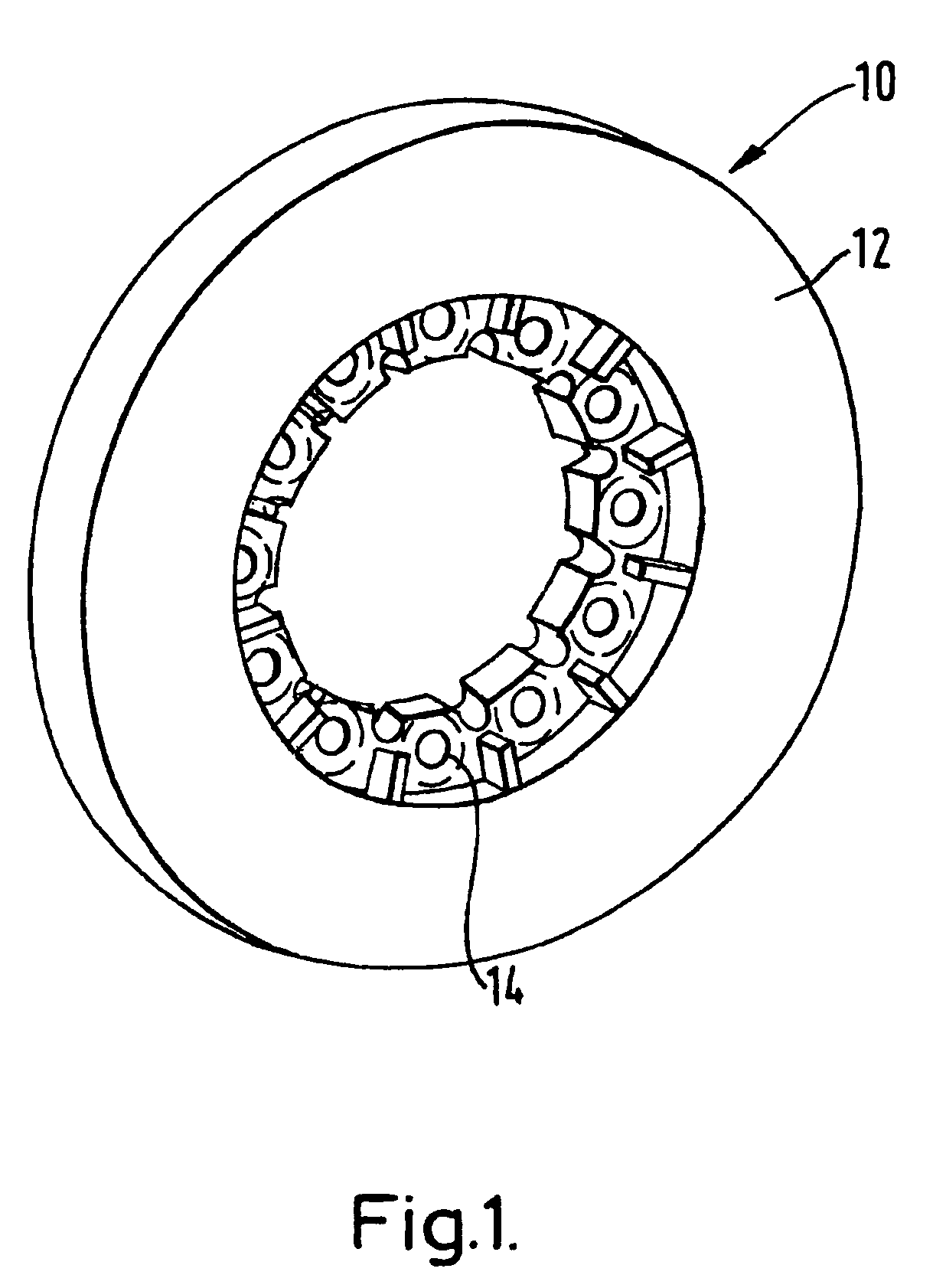

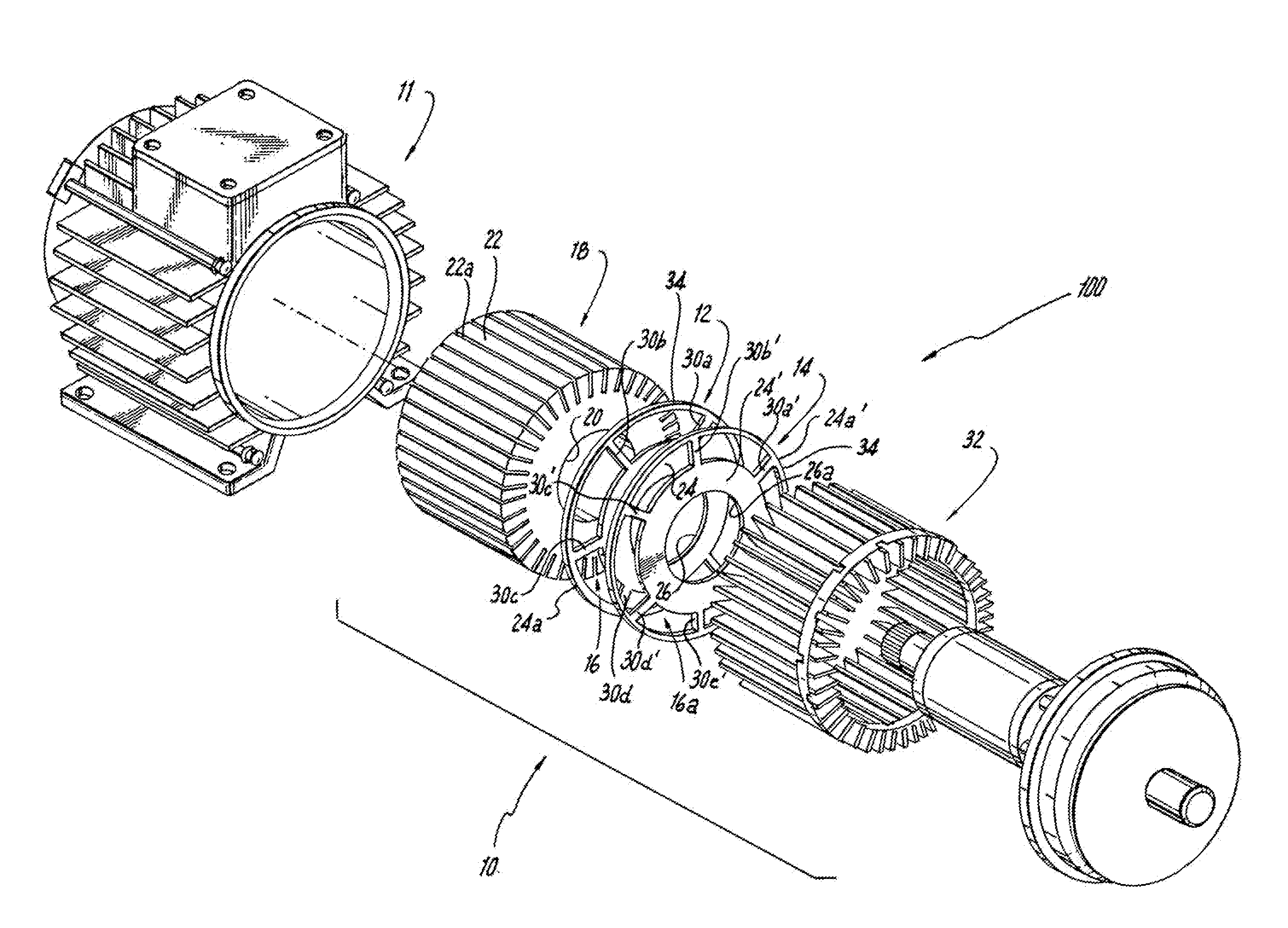

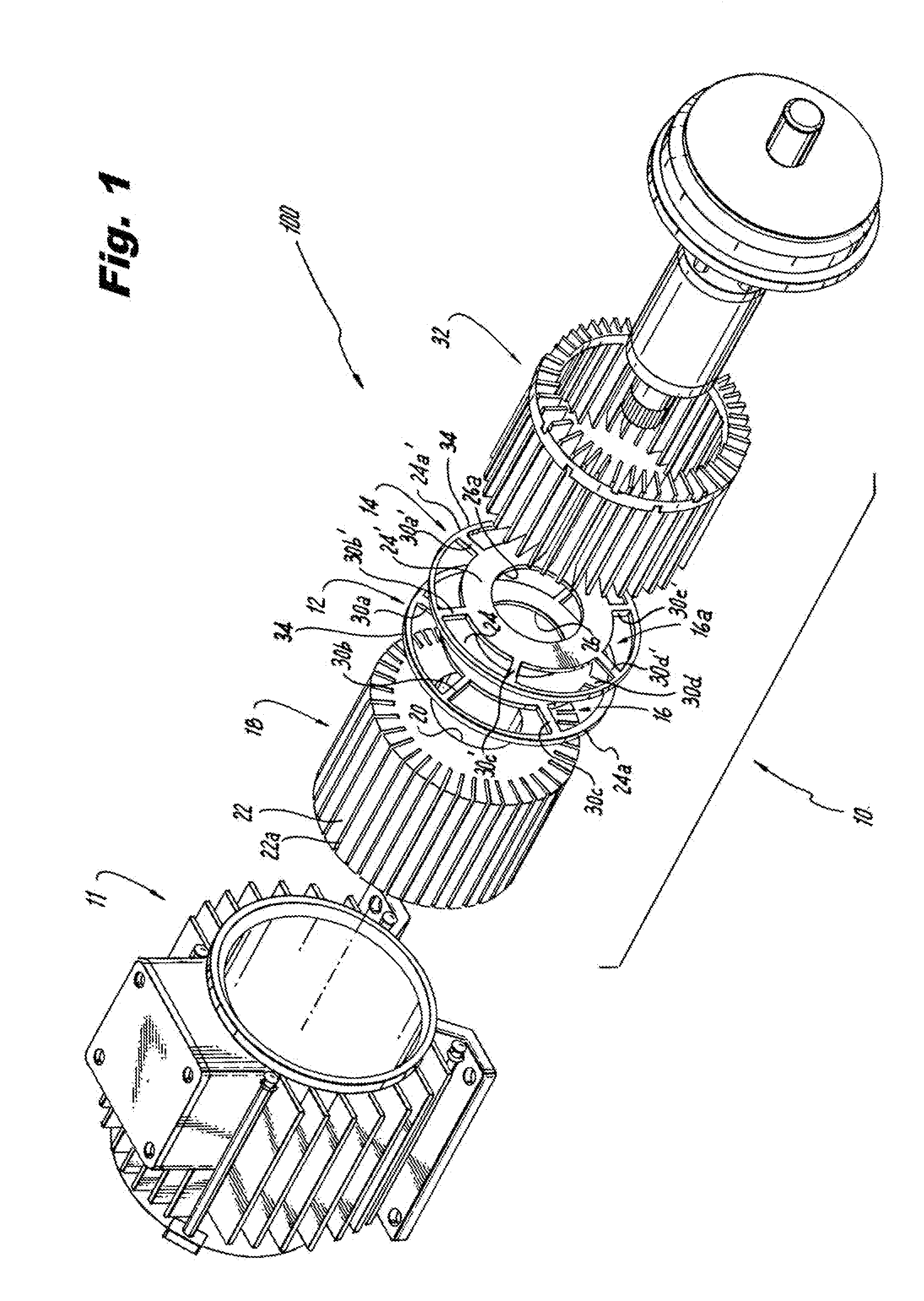

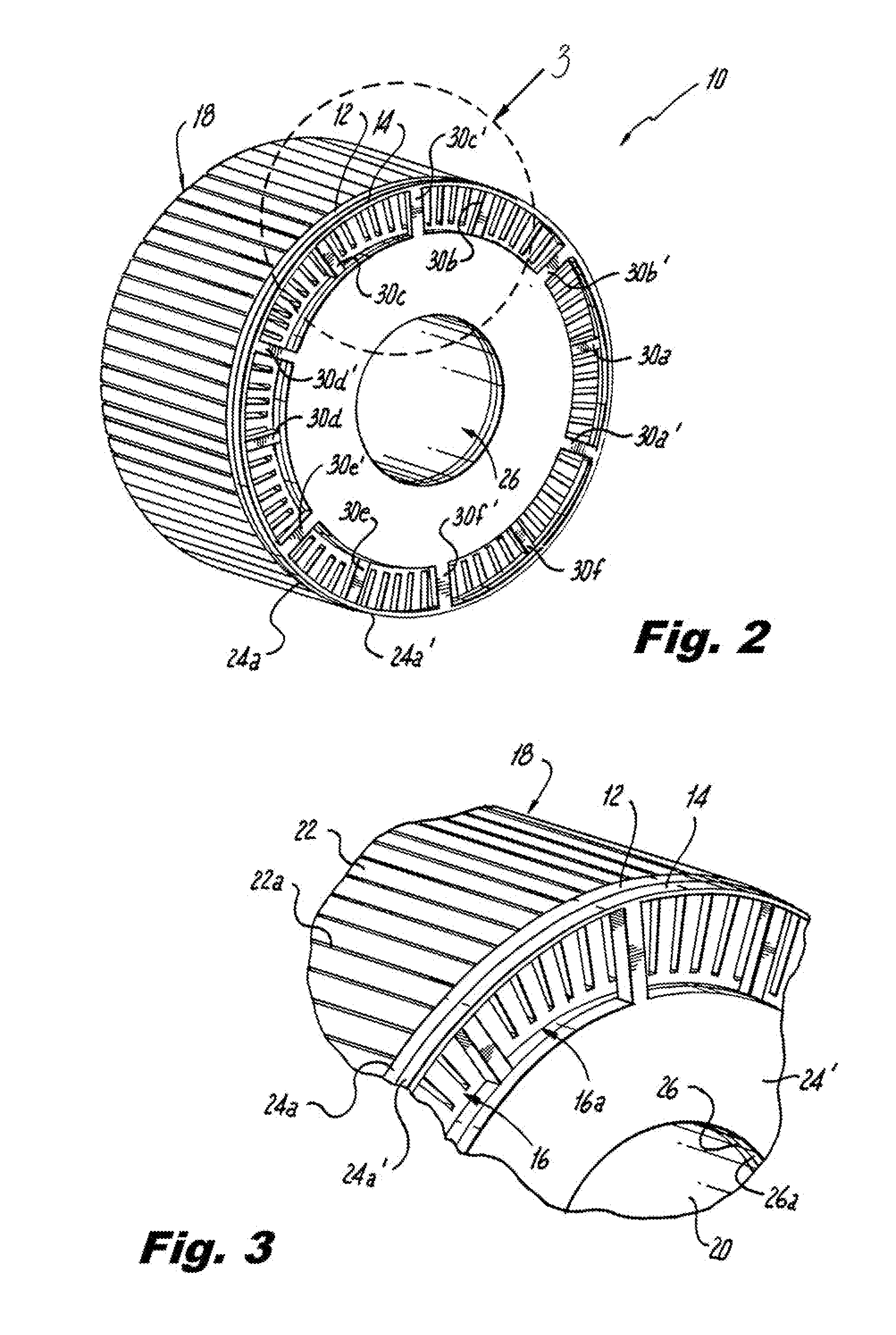

Low cost high speed electrical machine

InactiveUS7084548B1Improve power densityReduce construction costsWindingsMagnetic circuit rotating partsAir coreConductor Coil

A high speed brushless axial gap air core electrical machine includes a rotor mounted for rotation about an axis, and a stationary stator that magnetically interacts with the rotor. The rotor has two discs that are axially spaced apart to form an armature airgap. A stationary air core armature, with windings made of multiple individually insulated strand conductor wire for providing energy conversion, is located in the armature airgap. At least one of the discs carries a circumferential array of multiple alternating axial polarity permanent magnet poles facing the armature airgap. The magnets drive magnetic flux circumferentially through ferromagnetic portions of the discs and axially through the armature airgap. The discs have an integral axially extending circumferentially continuous lip outside of the array of magnet poles. The lip has a integral shear connection with the disc that substantially reduces the hoop stress in the lip that would otherwise occur from the radial containment of the magnet poles when rotated to high speed.

Owner:REVOLUTION ELECTRIC MOTOR

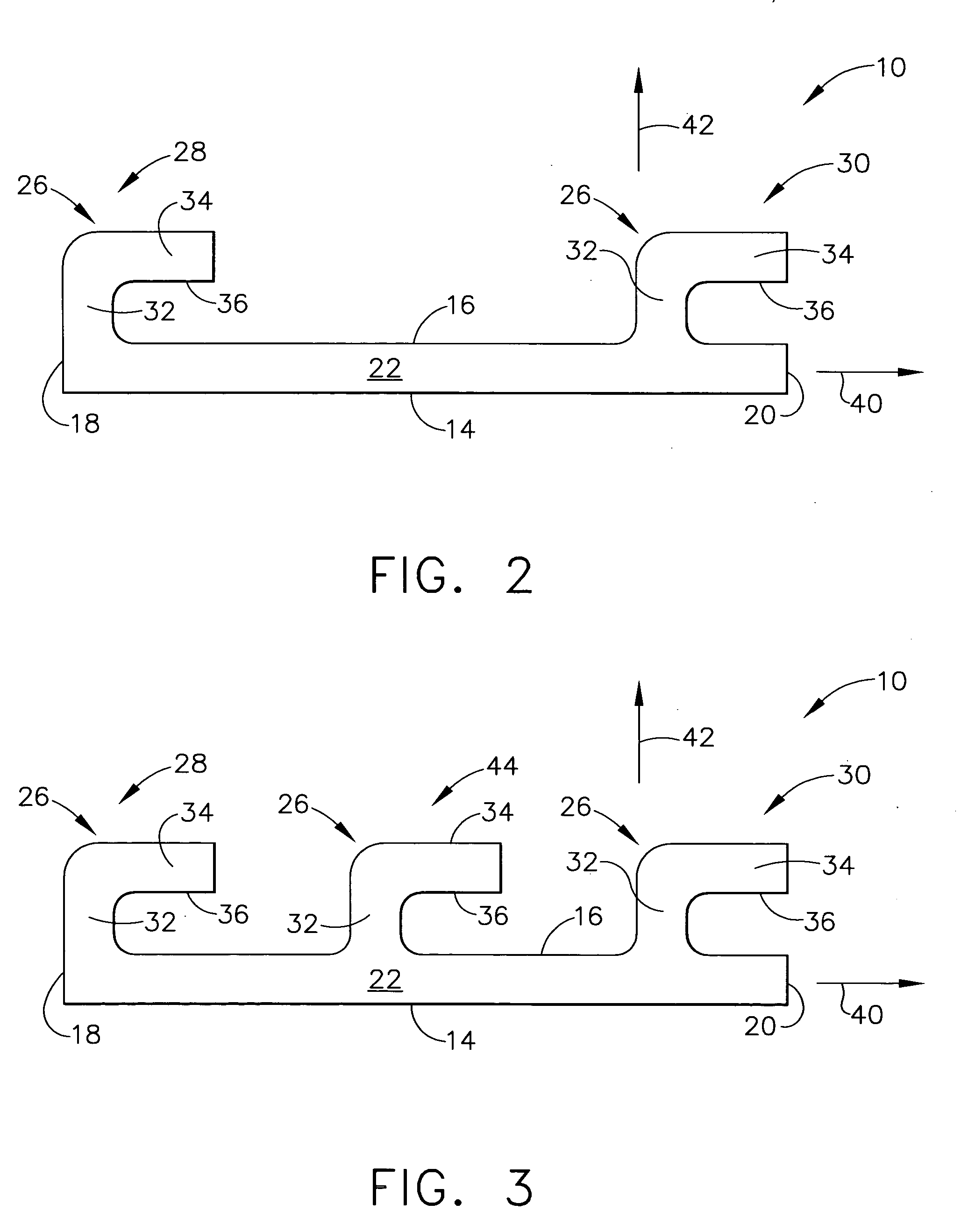

Turbine engine shroud segment

A turbine engine shroud segment comprises a body including an outer surface away from which an integral attachment system projects. The attachment system comprises a plurality of at least two axially spaced apart circumferentially extending rows of discrete projection hook segments to interrupt a potential hoop stress path through the attachment system. Each projection hook segment includes a segment support surface aligned circumferentially and radially with other segment support surfaces in a row.

Owner:GENERAL ELECTRIC CO

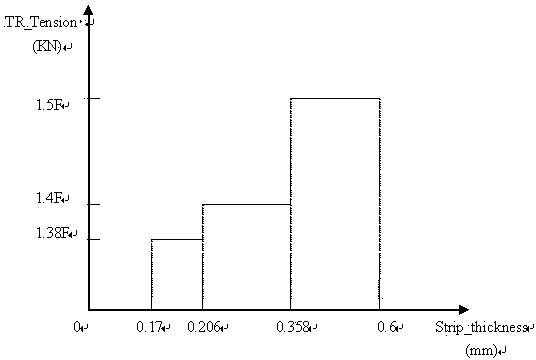

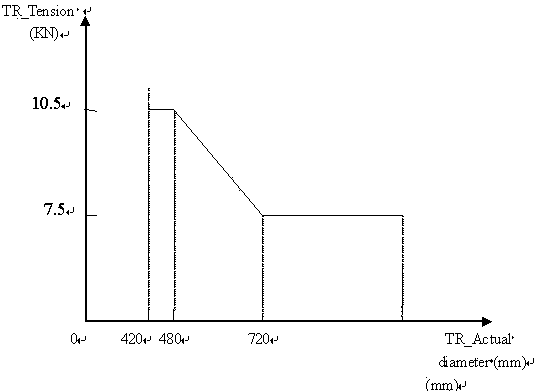

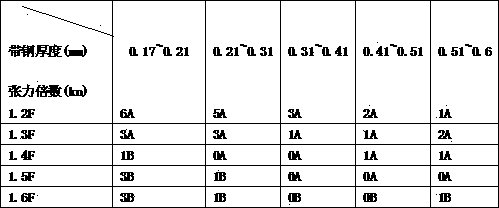

Anti-buckling coiling machine strip steel threading tension control method

ActiveCN103832897AReduce hoop stressAvoiding Collapse DefectsHot-dipping/immersion processesTinningEngineering

The invention relates to an anti-buckling coiling machine strip steel threading tension control method. Currently, in the aspect of coiling tension control of a coiling machine of an electrolytic tinning machine set, a single and fixed strip steel threading tension control mode is adopted, obvious thickness grades of tinned products are not considered, buckling and displacement are prone to happen in the coiling process, and the appearance and quality of a finished coil are affected. In the method, strip steel threading tension of a coiling machine is controlled in a graded mode according to the thickness grades of the strip steel, strip steel threading tension 1.38 times larger than set tension is adopted when the thicknesses are smaller than 0.206 mm, strip steel threading tension 1.4 times larger than the set tension is adopted when the thicknesses range from 0.206 mm to 0.358 mm, and strip steel threading tension 1.5 times larger than the set tension is adopted when the thicknesses are larger than 0.3580 mm. By means of the method, buckling caused by incorrect strip steel threading tension can be effectively avoided, and stable and effective operation of a machine set are guaranteed.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

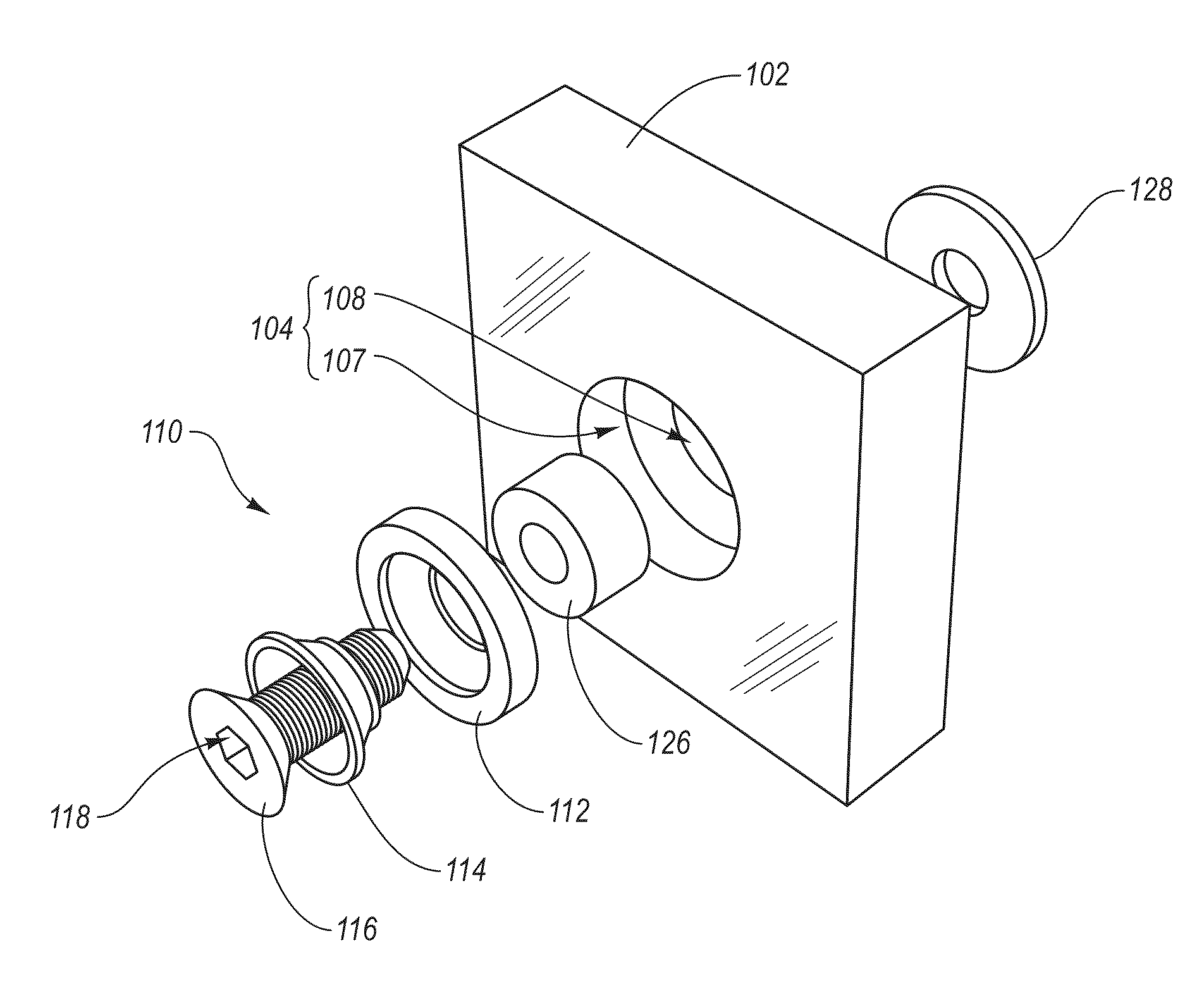

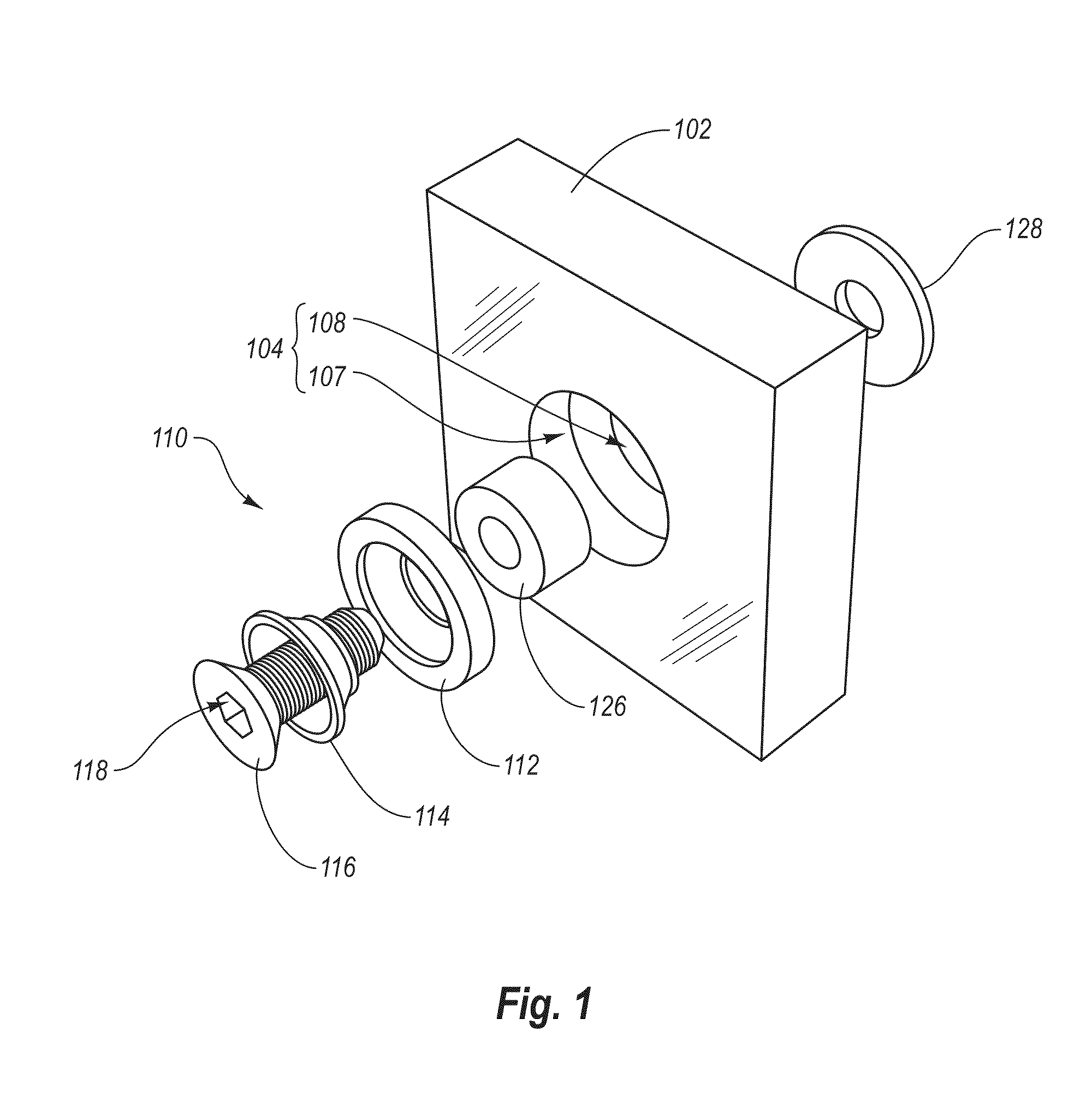

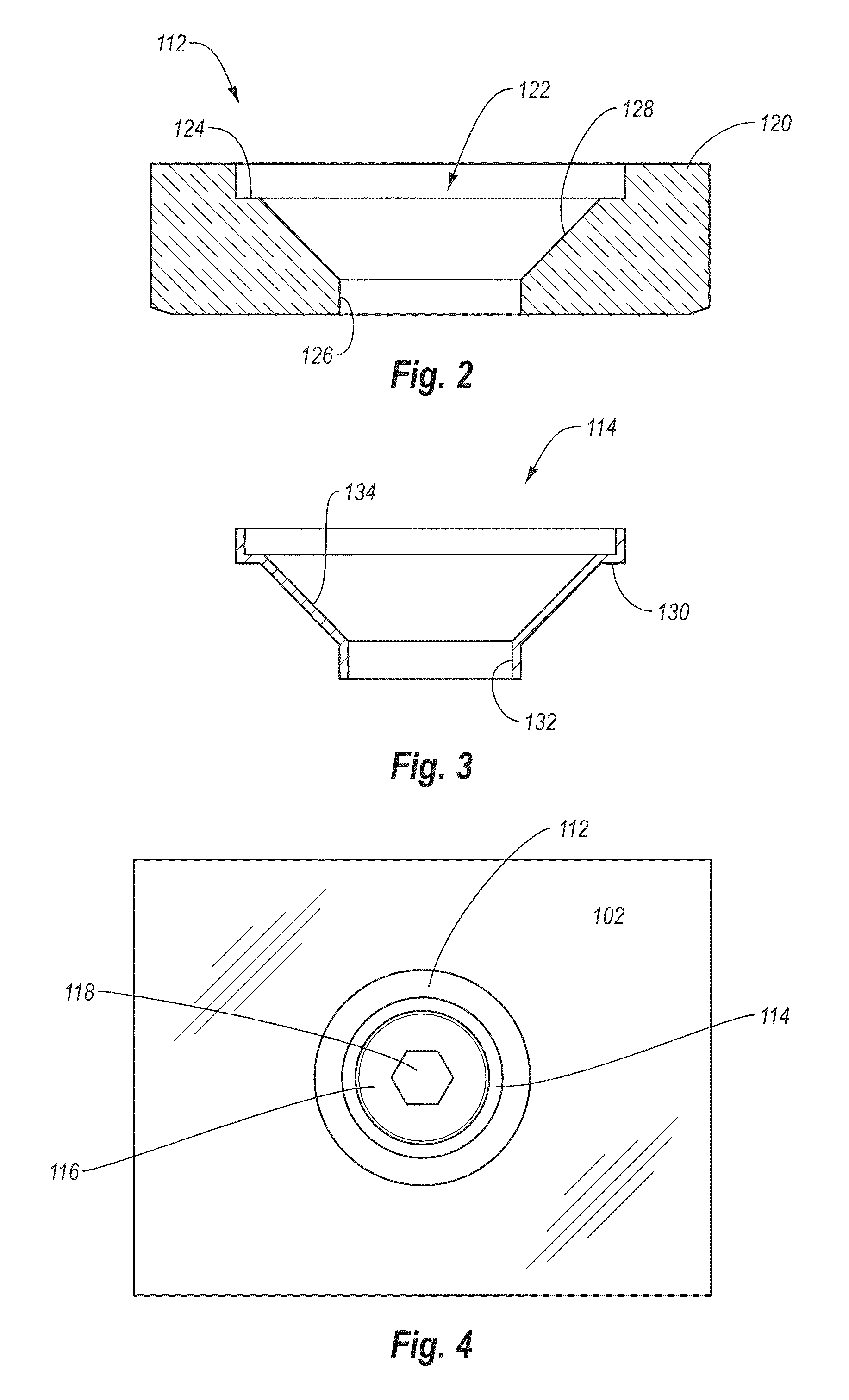

Countersunk fastener assemblies, panel mounting systems, and methods

Washer assemblies for mounting panels to a support without damaging the panels include a countersunk washer and a sleeve. In one implementation, the washer assemblies are configured to at least partially prevent the formation of hoop stresses within a panel, and uniformly transmit forces created by a fastener to a panel. The washer assemblies can be configured to enhance the function, look, feel, or aesthetic of a panel system. In addition, systems of at least one implementation of the present invention include a plurality of panels mounted to one or more supports using one or more washer assemblies and methods of mounting such systems.

Owner:HUNTER DOUGLAS INDS SWITZERLAND

Dual-mode one-way torque transmitting device

InactiveUS7500548B2Reduce hoop stressLow costFluid actuated clutchesFriction clutchesDual modeEngineering

A dual mode one-way torque transmitting device includes an inner race having a first plurality of notches spaced about an axis. An intermediate race includes a second plurality of notches spaced about the axis, a first plurality of pockets spaced about the axis, and a first plurality of rockers, each rocker being located in a pocket of the intermediate race. A spring urges each rocker toward engagement with a notch on the inner race. An outer race includes a second plurality of pockets spaced about the axis, a second plurality of rockers, each rocker being located in a pocket on the outer race, and a plurality of actuators, each actuator alternately engages and disengages a rocker on the outer race and a notch on the intermediate race.

Owner:FORD GLOBAL TECH LLC

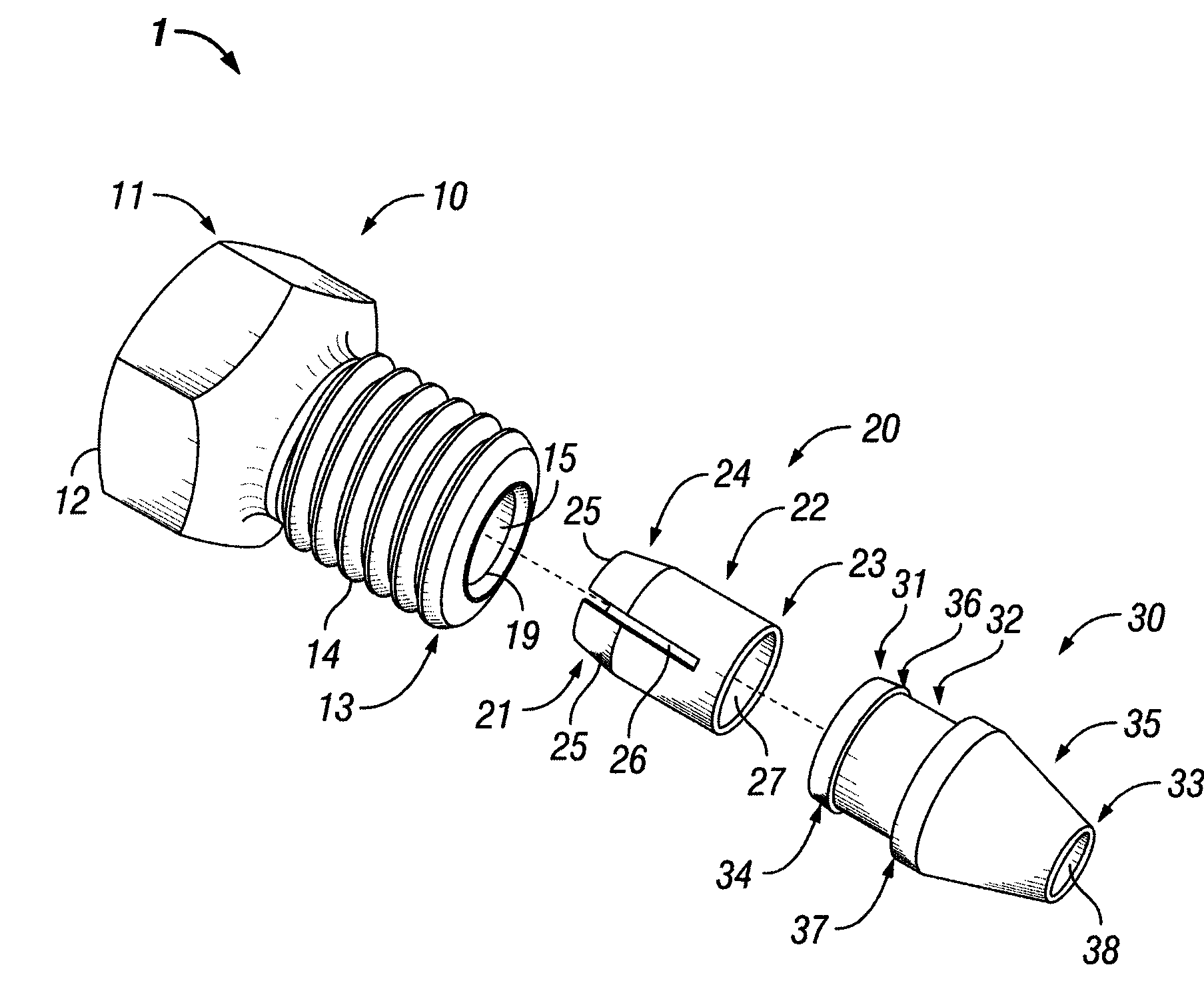

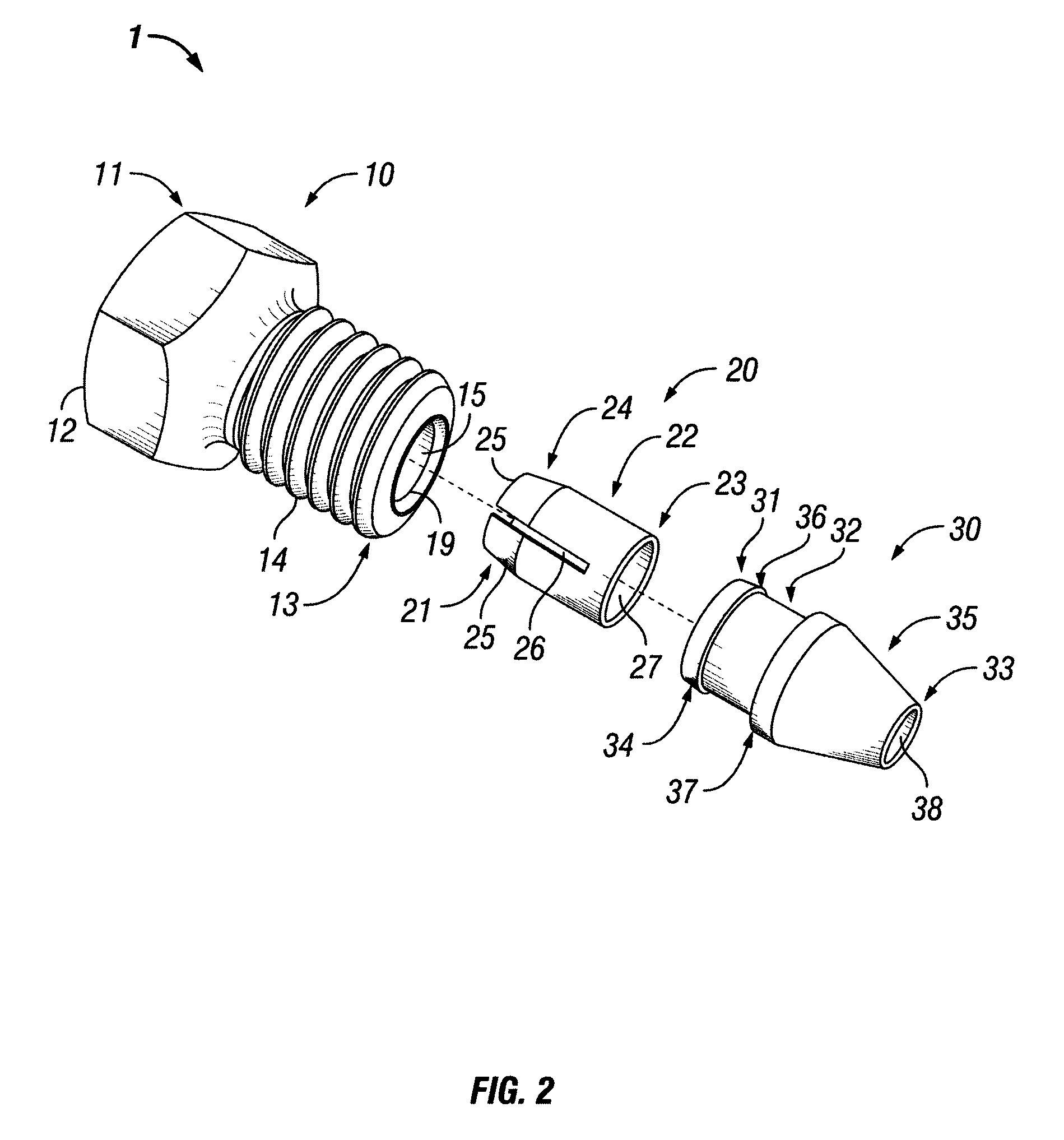

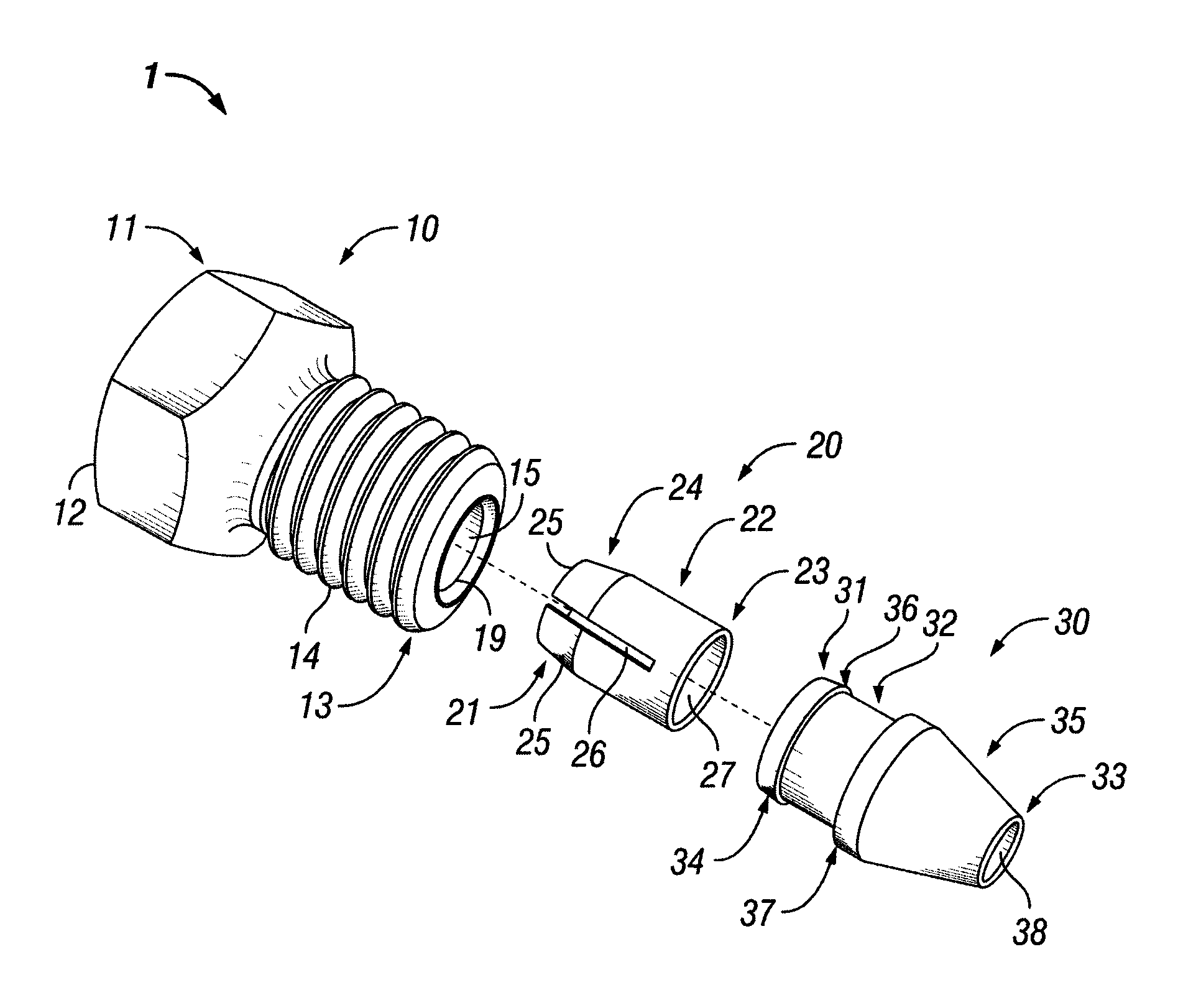

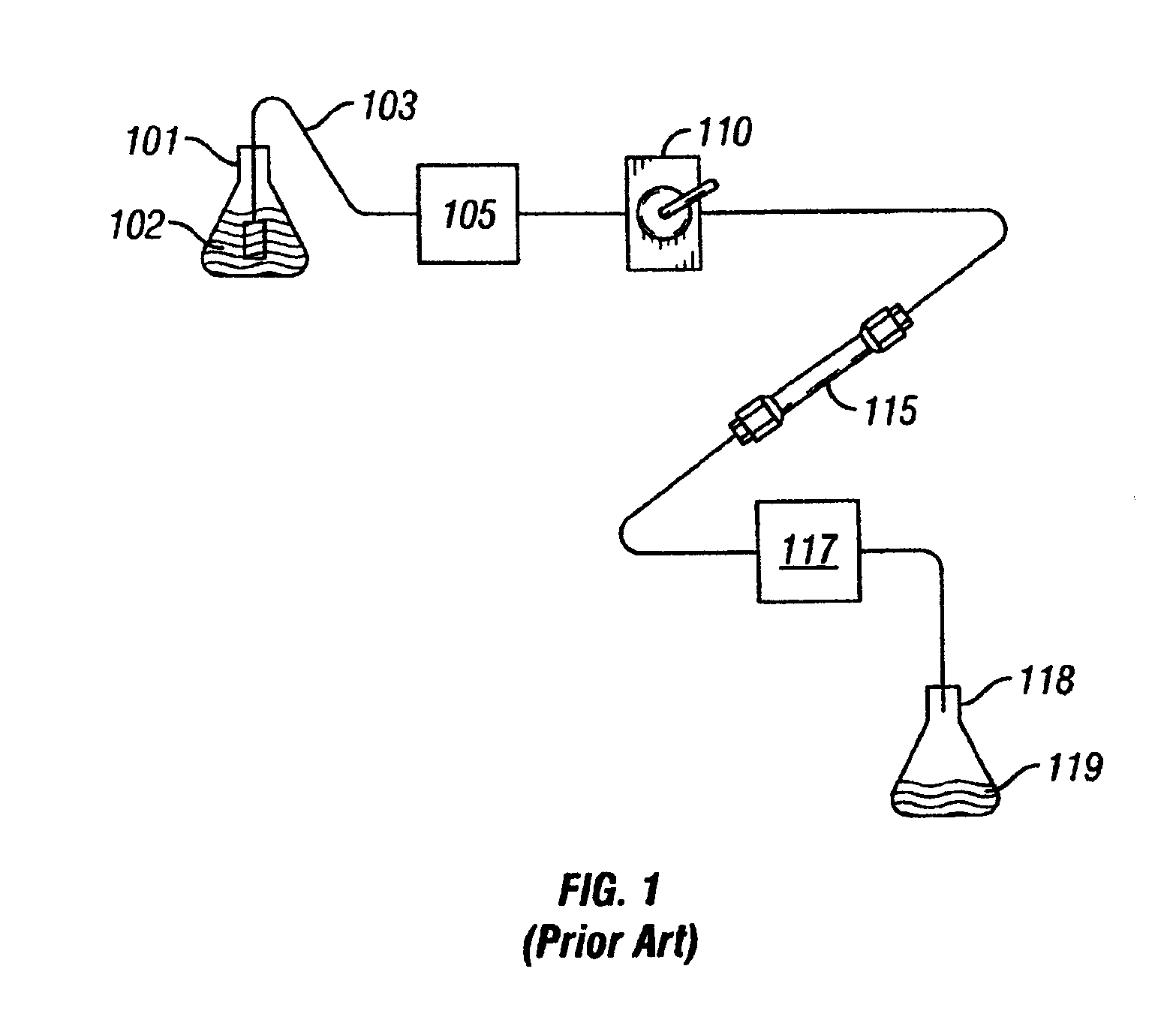

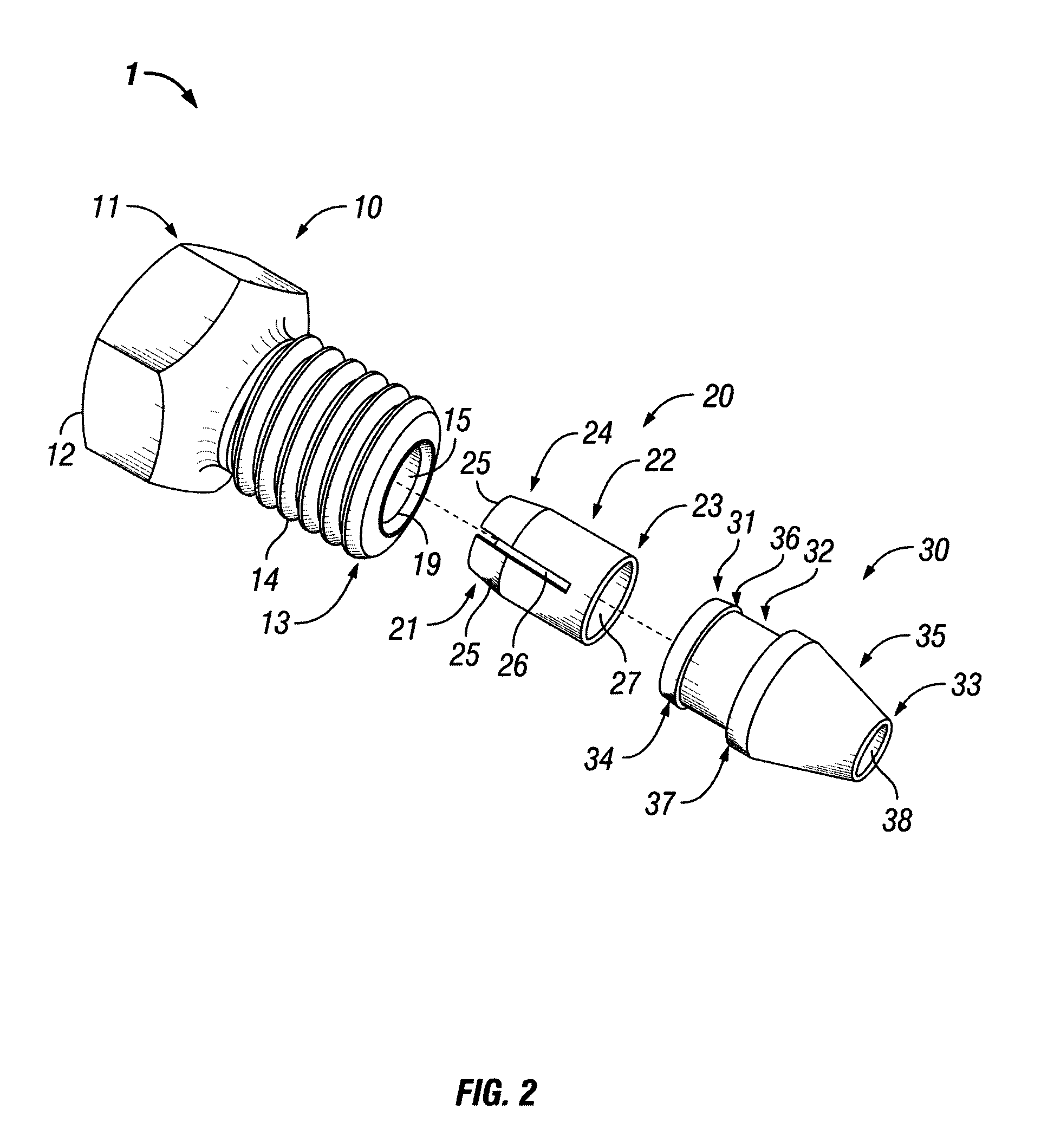

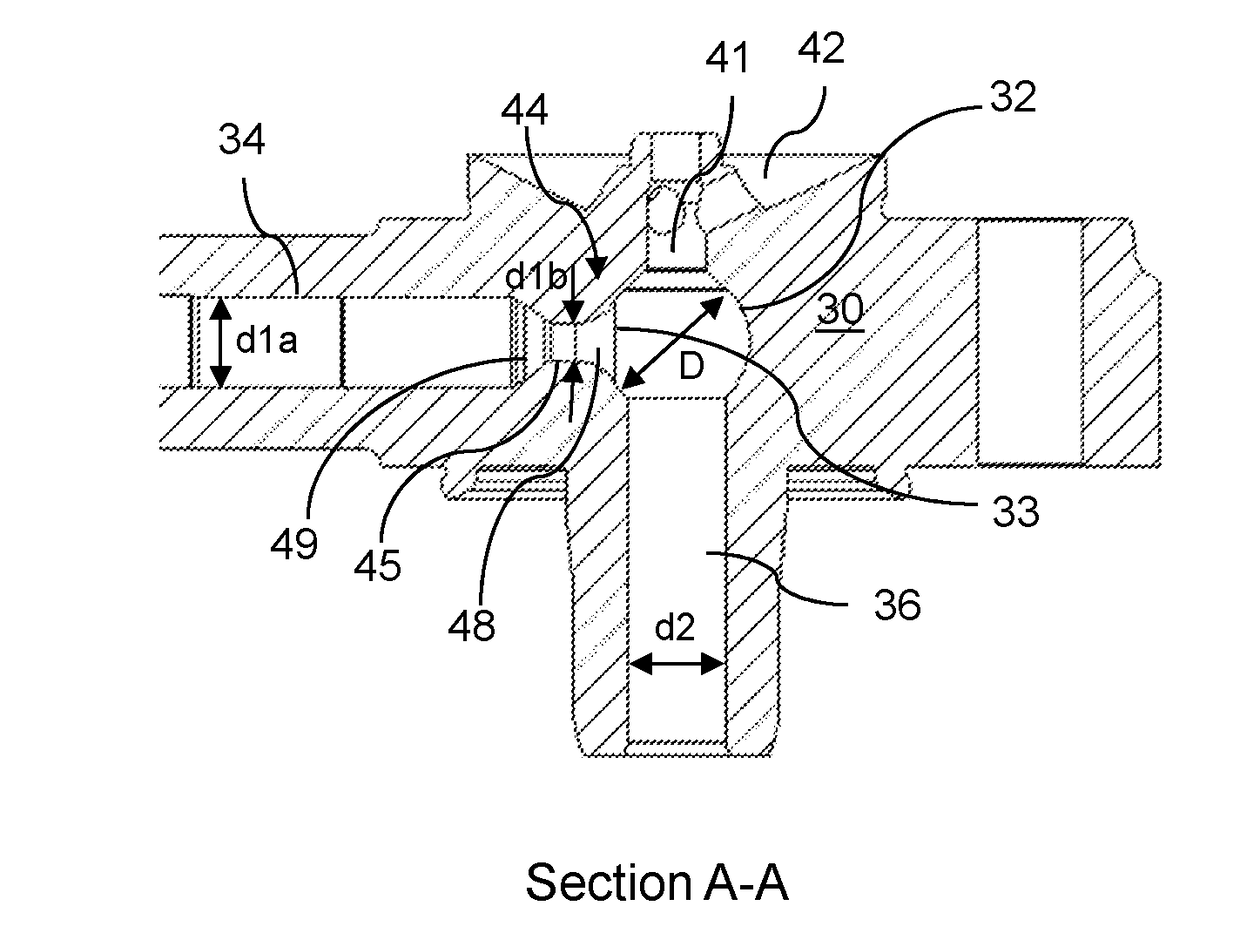

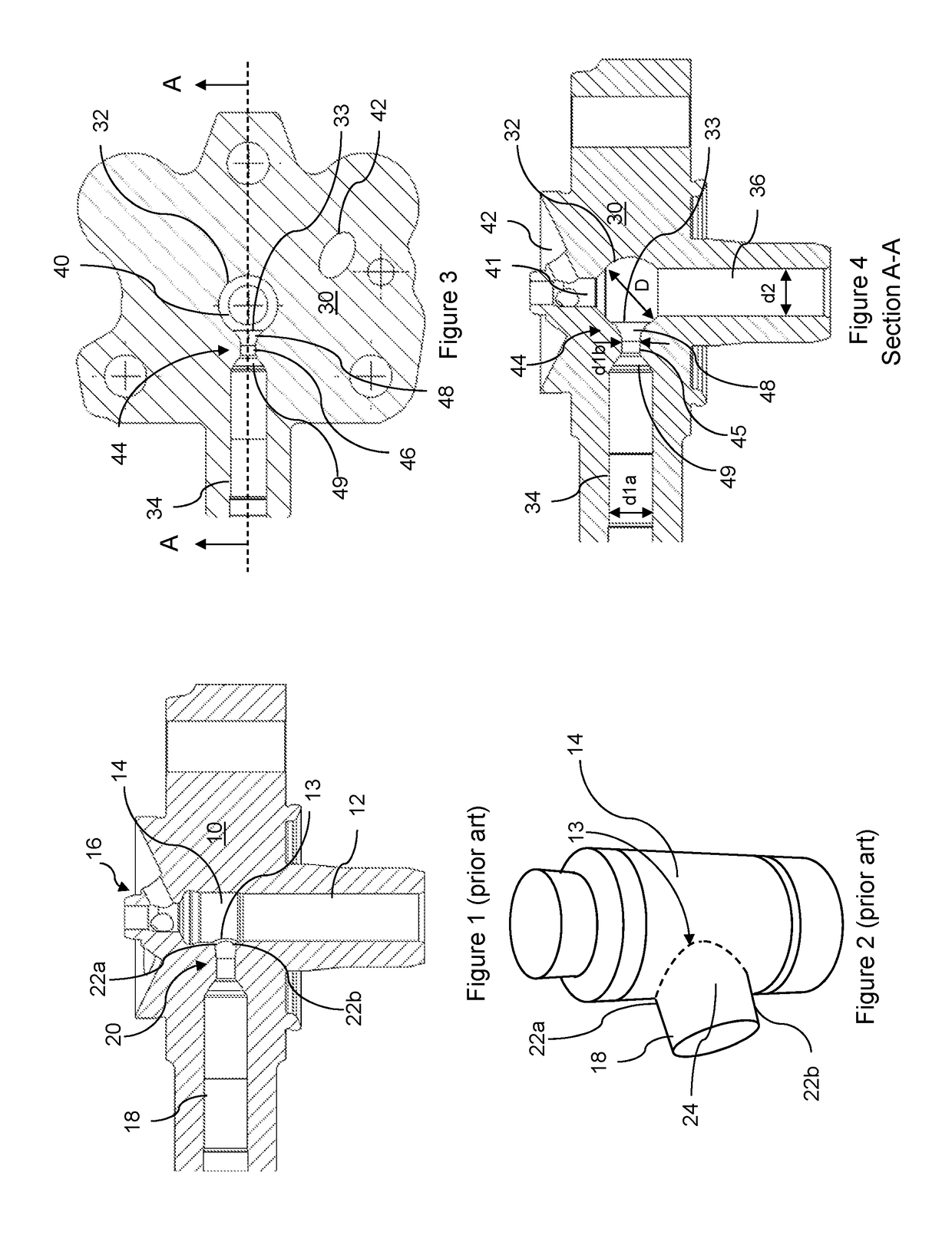

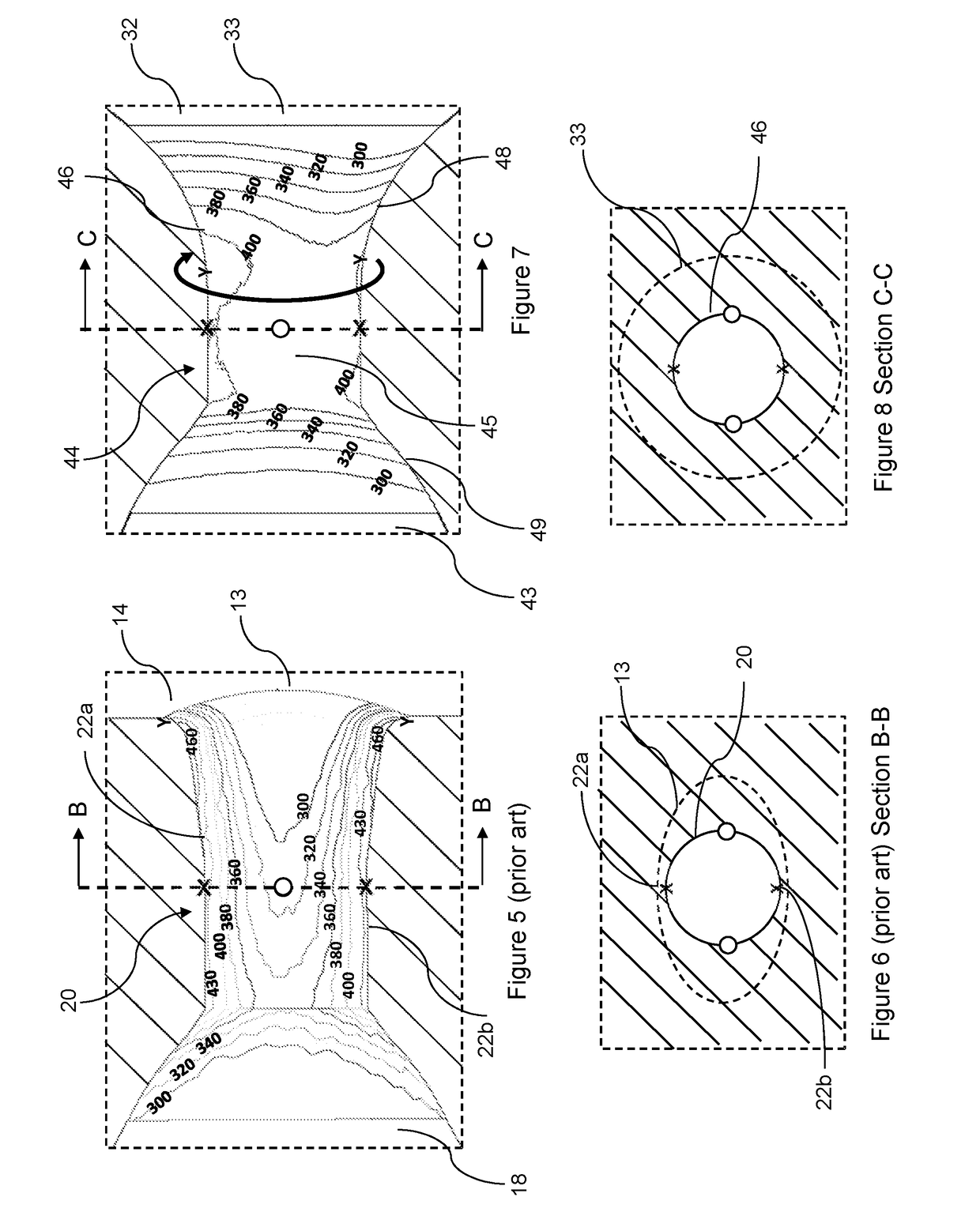

Connection assembly for ultra high pressure liquid chromatography

ActiveUS8569070B2Reduce bitesIncrease forceIon-exchange process apparatusSleeve/socket jointsUltra high pressureMechanical engineering

A fitting assembly having a nut, a ferrule, and a ferrule tip that may be assembled by an operator. The fitting assembly includes a nut with first and second ends, with the second end adapted to receive the first end of a ferrule, and a ferrule tip with a first end having an externally tapered portion adapted to abut the second end of the ferrule and a second end adapted to be received in a component or fitting of a liquid chromatography system. The nut, ferrule and ferrule tip of the fitting assembly have passageways therethrough for receiving and removably holding tubing.

Owner:IDEX HEALTH & SCI

Connection Assembly for Ultra High Pressure Liquid Chromatography

ActiveUS20120014848A1Reduce bitesIncrease forceIon-exchange process apparatusSleeve/socket jointsUltra high pressureEngineering

A fitting assembly having a nut, a ferrule, and a ferrule tip that may be assembled by an operator. The fitting assembly includes a nut with first and second ends, with the second end adapted to receive the first end of a ferrule, and a ferrule tip with a first end having an externally tapered portion adapted to abut the second end of the ferrule and a second end adapted to be received in a component or fitting of a liquid chromatography system. The nut, ferrule and ferrule tip of the fitting assembly have passageways therethrough for receiving and removably holding tubing.

Owner:IDEX HEALTH & SCI

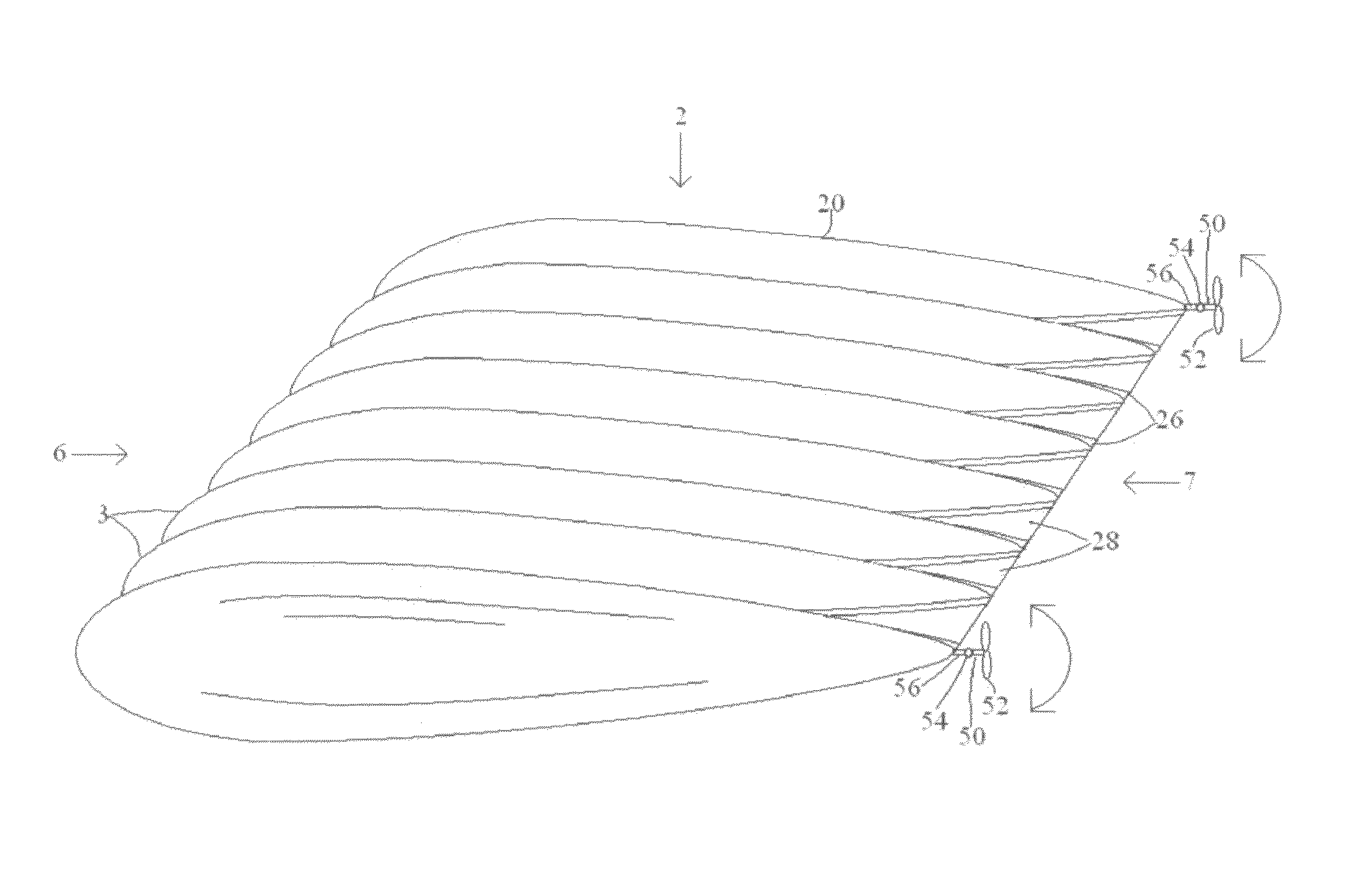

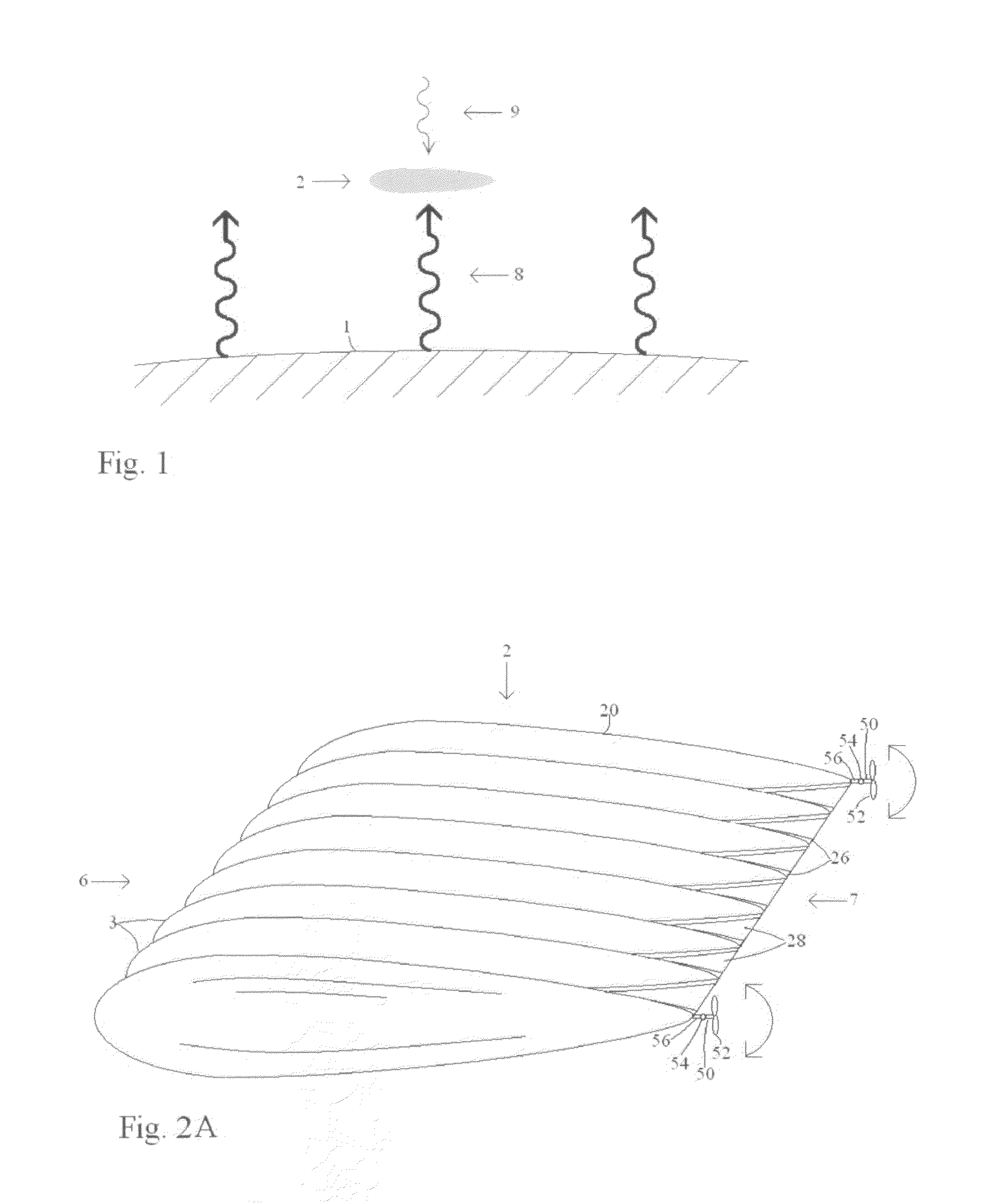

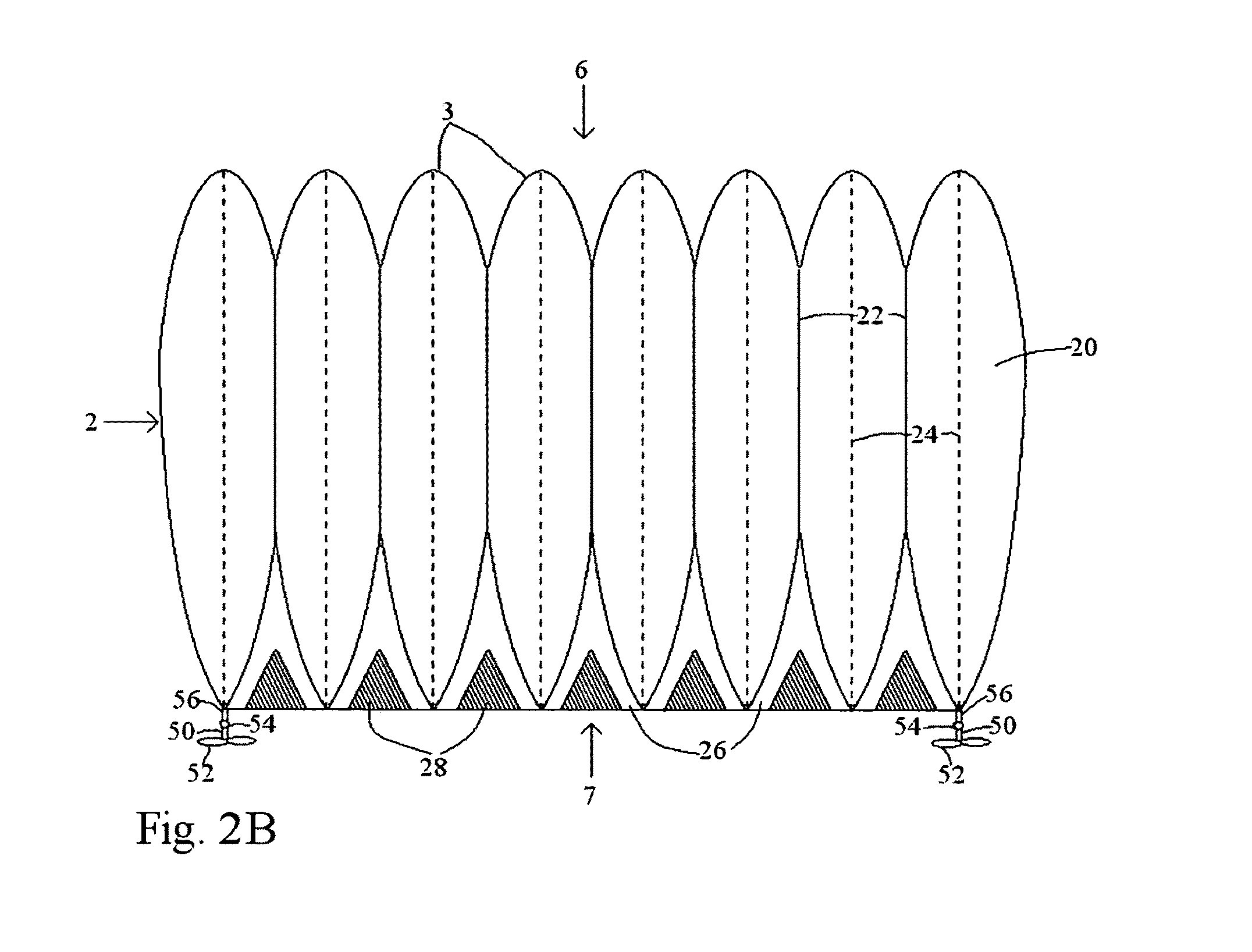

High-altitude long-endurance airship

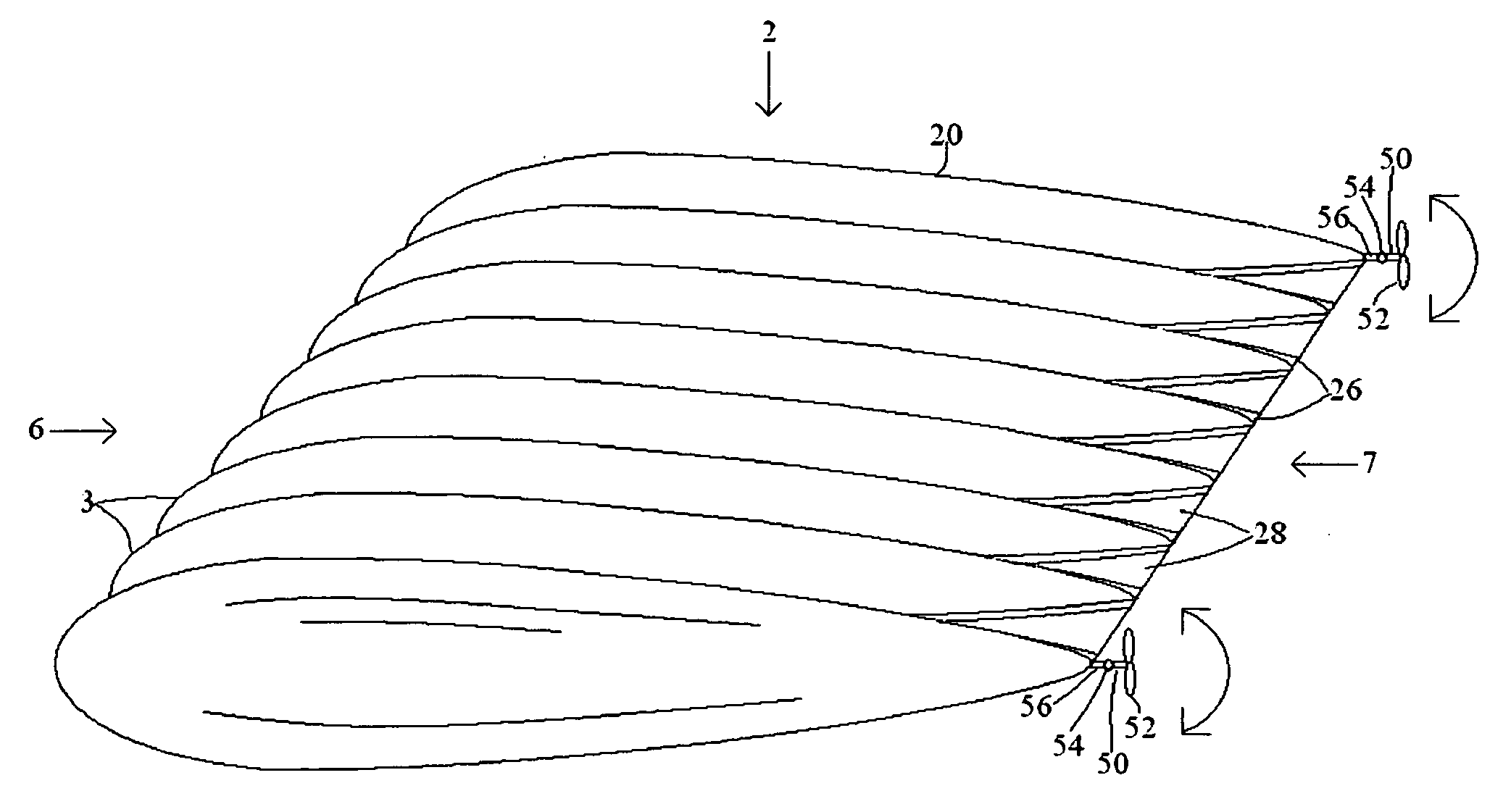

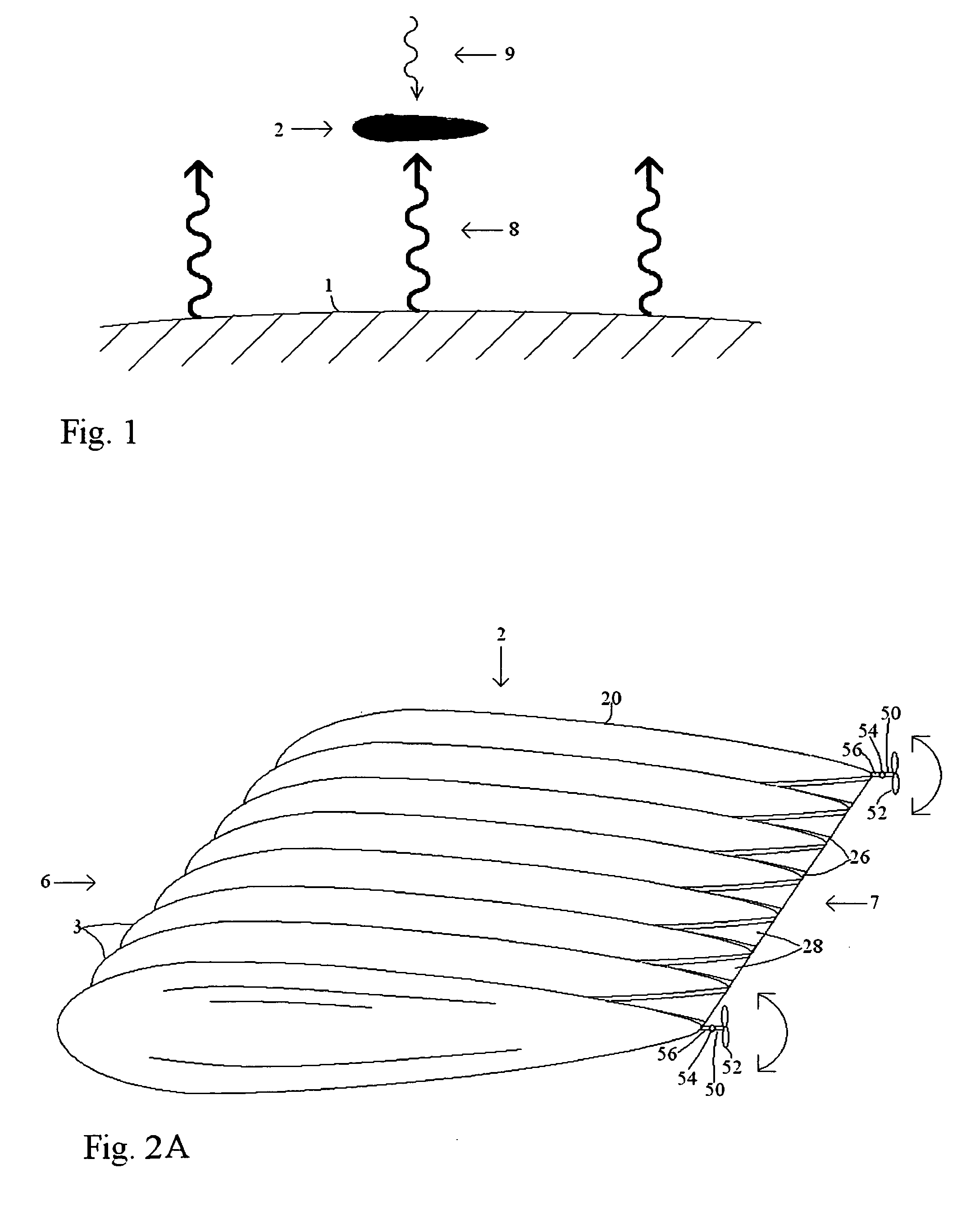

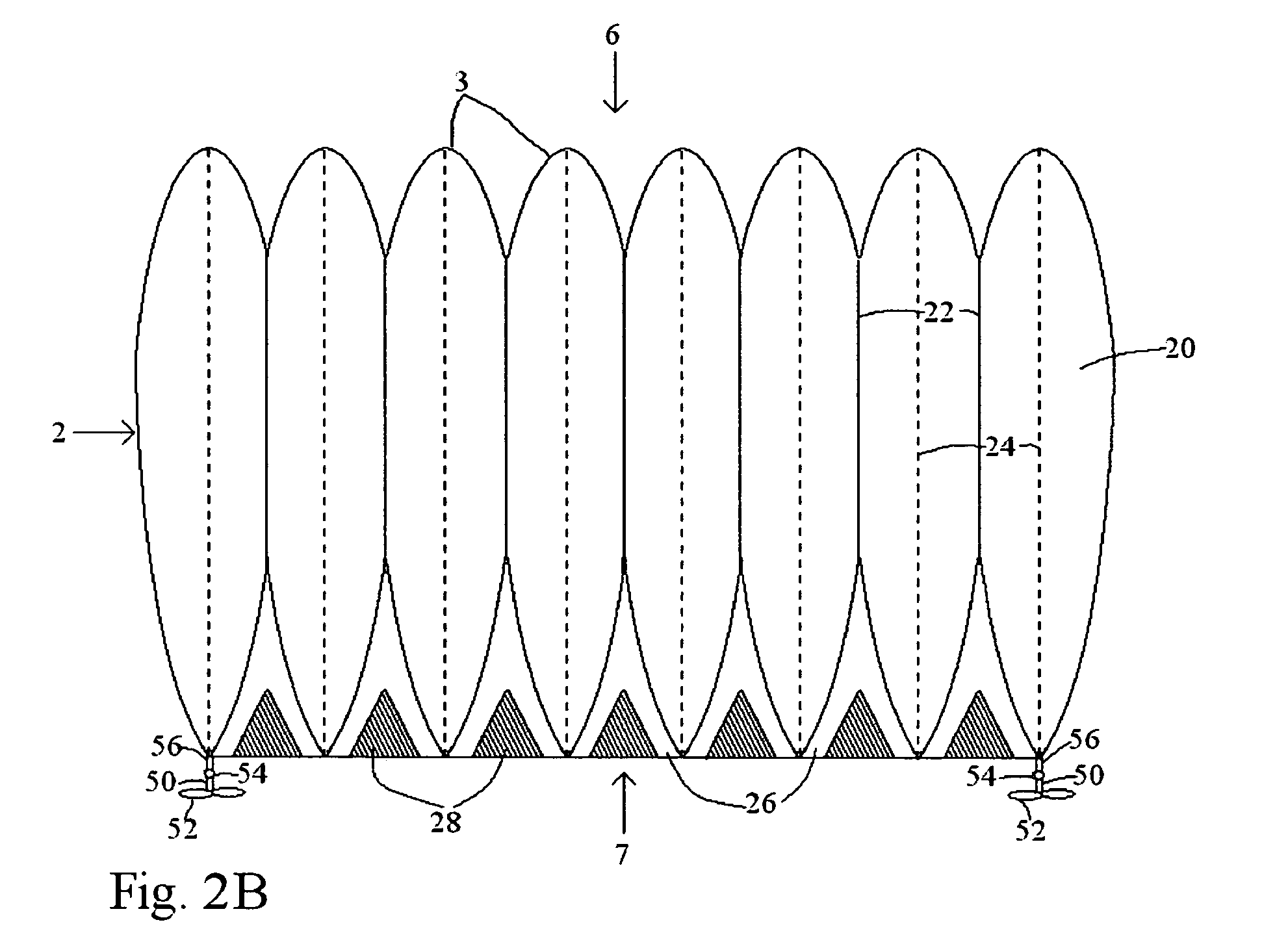

InactiveUS20090200417A1Light weightWork lessNon-rigid airshipsRigid airshipsVariable thicknessLifting gas

A high-altitude long-endurance airship with a top surface that is highly emissive of infrared radiation and a bottom surface that is highly absorptive of infrared radiation. Movable displacer blankets inside the airship separate the upper and lower portions of the airship. Lifting gas in the airship is warmed by radiation from the earth when the displacer blankets are in their upper position. Lifting gas is cooled by radiation to space when the displacer blankets are in their lower position. The whole airship is a heat engine. By expanding the volume of lifting gas when it is relatively warm and compressing the lifting gas when it is relatively cold, net power output can be recovered in the form of electric power. The overall configuration of the preferred airship is a variable-thickness flying wing. If the whole airship is alternately expanded and compressed, imbalance between its weight and buoyancy allow gliding flight.

Owner:MITCHELL MATTHEW P

Pipe Fitting Apparatus and Methods

ActiveUS20160091131A1Enhanced hoop strengthReduce hoop stressSleeve/socket jointsLaminationPipe fittingEngineering

A pipe fitting includes a tubular member comprising a socket and a centering device within the socket. The socket is configured to receive an end of a pipe section therein such that a gap exists between an outer surface of the pipe section and an inner surface of the socket. An annular pipe stop extends from the inner surface of the socket and is configured to matingly engage with the end of the pipe section. A pair of ports extend through the tubular member in circumferentially spaced-apart relationship and are in fluid communication with the gap. The centering device is configured to maintain a coaxial relationship between the pipe section and the socket and such that the gap is substantially circumferentially uniform. A removable and reusable clamp secures the pipe section within the socket as a bonding agent is extruded into the gap via one of the ports.

Owner:IPS WELD ON DIV

Brake rotor

InactiveUS6962242B2Reduce hoop stressReduce thermal stressFluid actuated brakesBraking discsEngineeringFlange

A brake rotor having an annular disc connected to an annular mounting flange, the mounting flange defining a radially inner flange wall and including a plurality of circumferentially spaced mounting holes, in which the flange wall includes a plurality of recesses, with each recess situated circumferentially between adjacent mounting holes in which the brake rotor includes ventilation vanes between opposing braking faces of the annular disc with at least some ventilation vanes including inner vane portions which extend inwardly of a radially inner edge of the annular disc.

Owner:MERITOR HEAVY VEHICLE SYST CAMERI

High-altitude long-endurance airship

InactiveUS7887007B2No energy storageLight weightNon-rigid airshipsRigid airshipsVariable thicknessLifting gas

A high-altitude long-endurance airship with a top surface that is highly emissive of infrared radiation and a bottom surface that is highly absorptive of infrared radiation. Movable displacer blankets inside the airship separate the upper and lower portions of the airship. Lifting gas in the airship is warmed by radiation from the earth when the displacer blankets are in their upper position. Lifting gas is cooled by radiation to space when the displacer blankets are in their lower position. The whole airship is a heat engine. By expanding the volume of lifting gas when it is relatively warm and compressing the lifting gas when it is relatively cold, net power output can be recovered in the form of electric power. The overall configuration of the preferred airship is a variable-thickness flying wing. If the whole airship is alternately expanded and compressed, imbalance between its weight and buoyancy allow gliding flight.

Owner:MITCHELL MATTHEW P

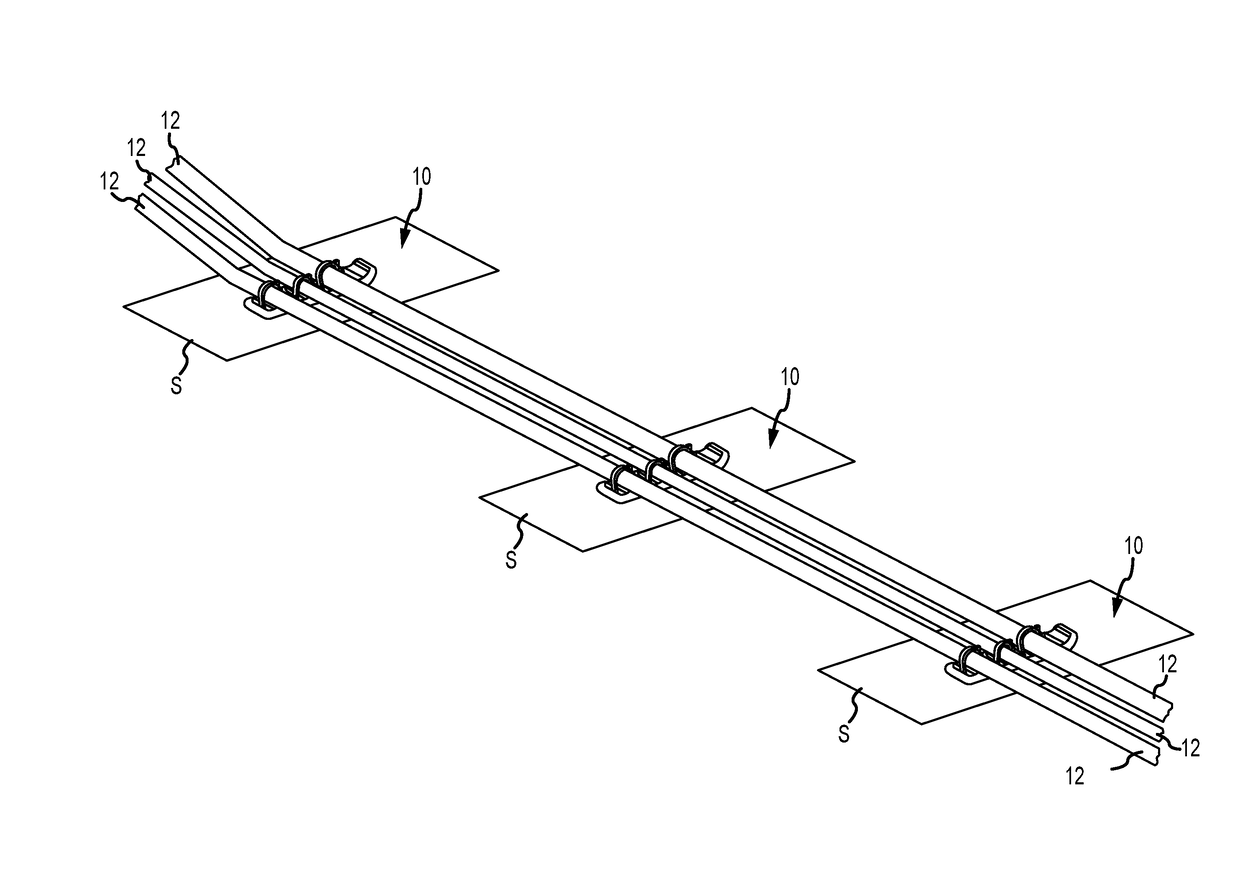

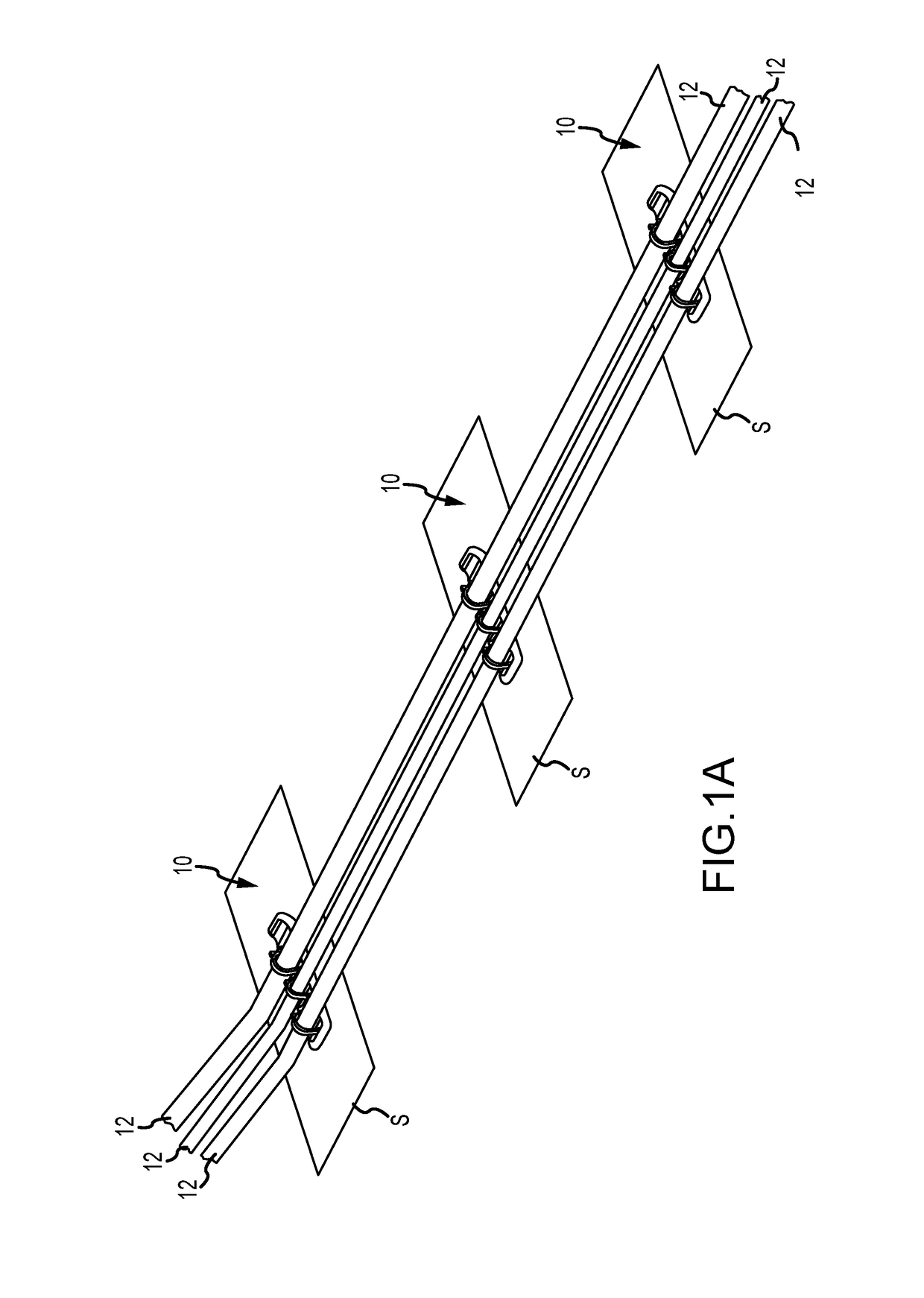

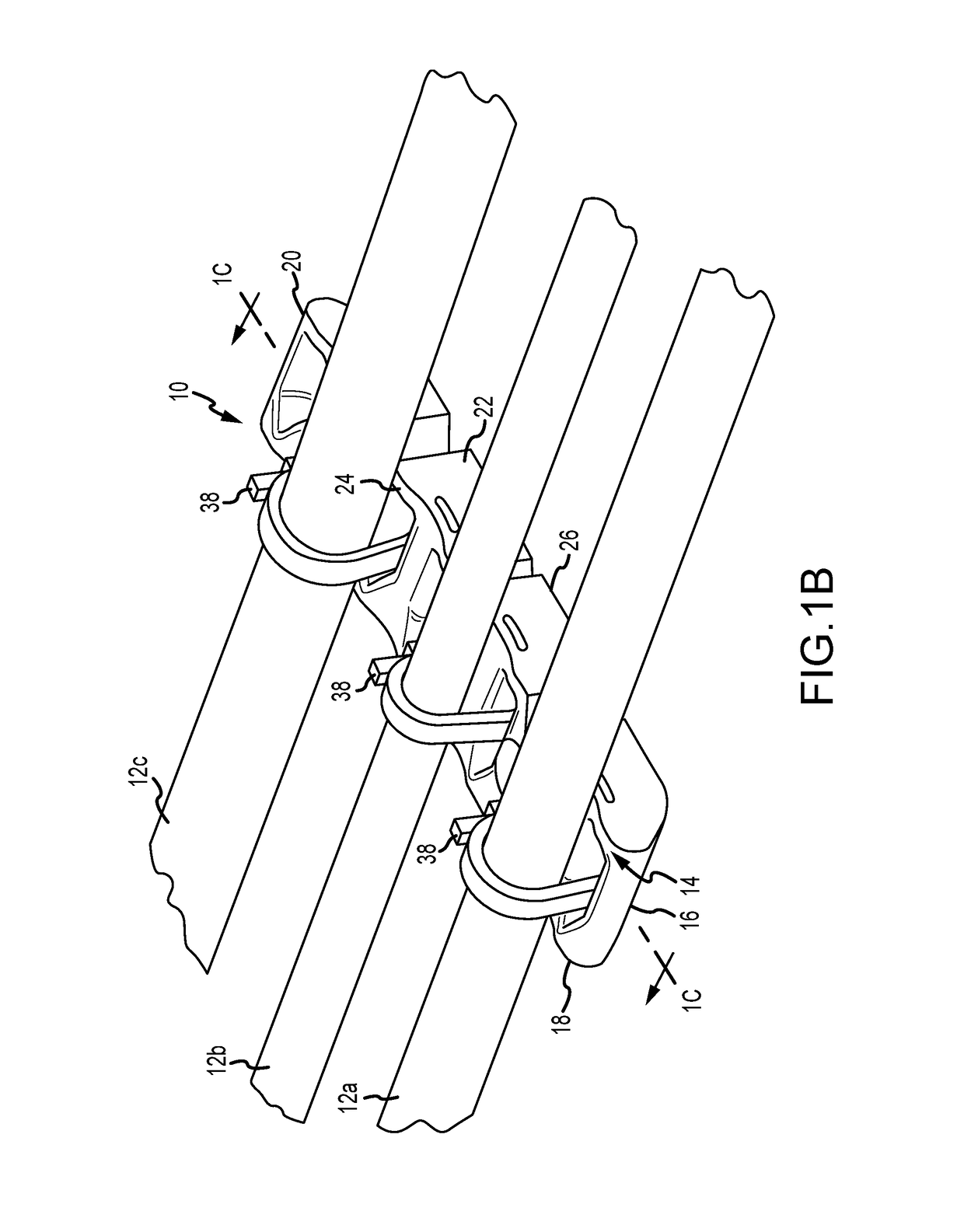

Interior channel cable and tube management bracket

InactiveUS20170292634A1Easy threadingIncrease surface area contactPipe supportsMachine supportsEngineeringFastener

A cable bracket having at least one cable support member and a subtending continuous fastener passageway with a first open end and a second open end spaced from the first open end is disclosed. The first and second open ends are oriented on the same side of the cable bracket to facilitate installation.

Owner:UNITED LAUNCH ALLIANCE

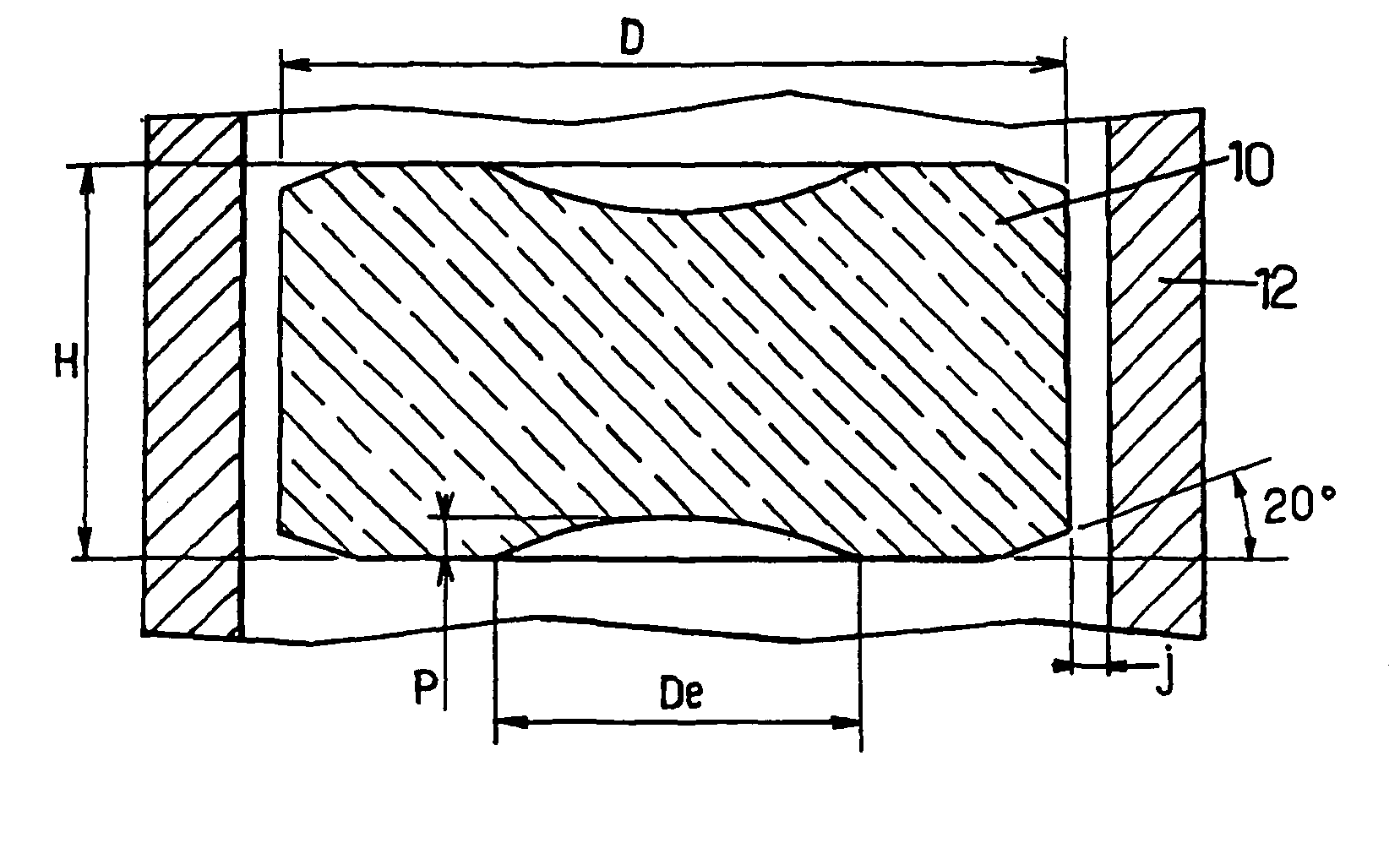

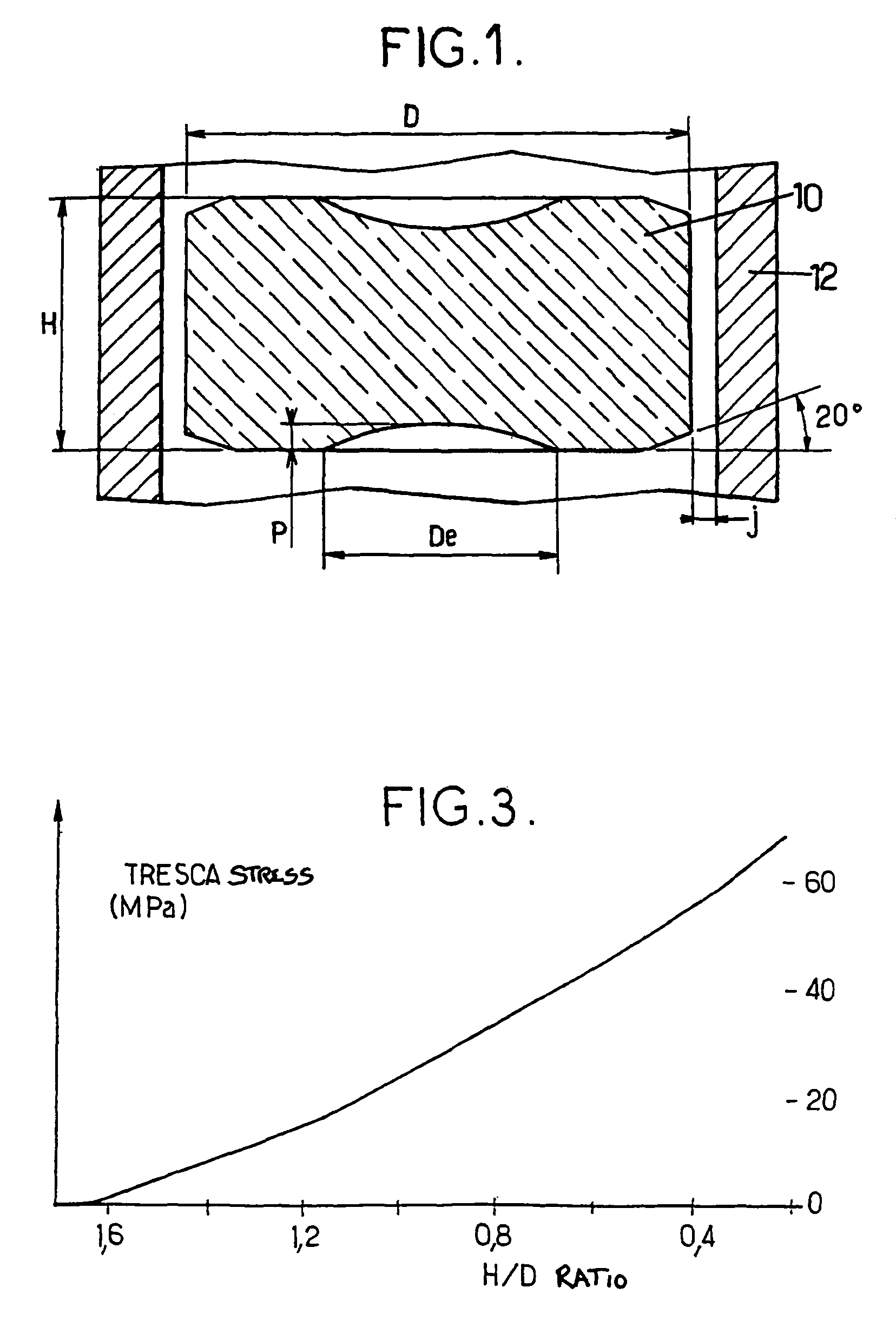

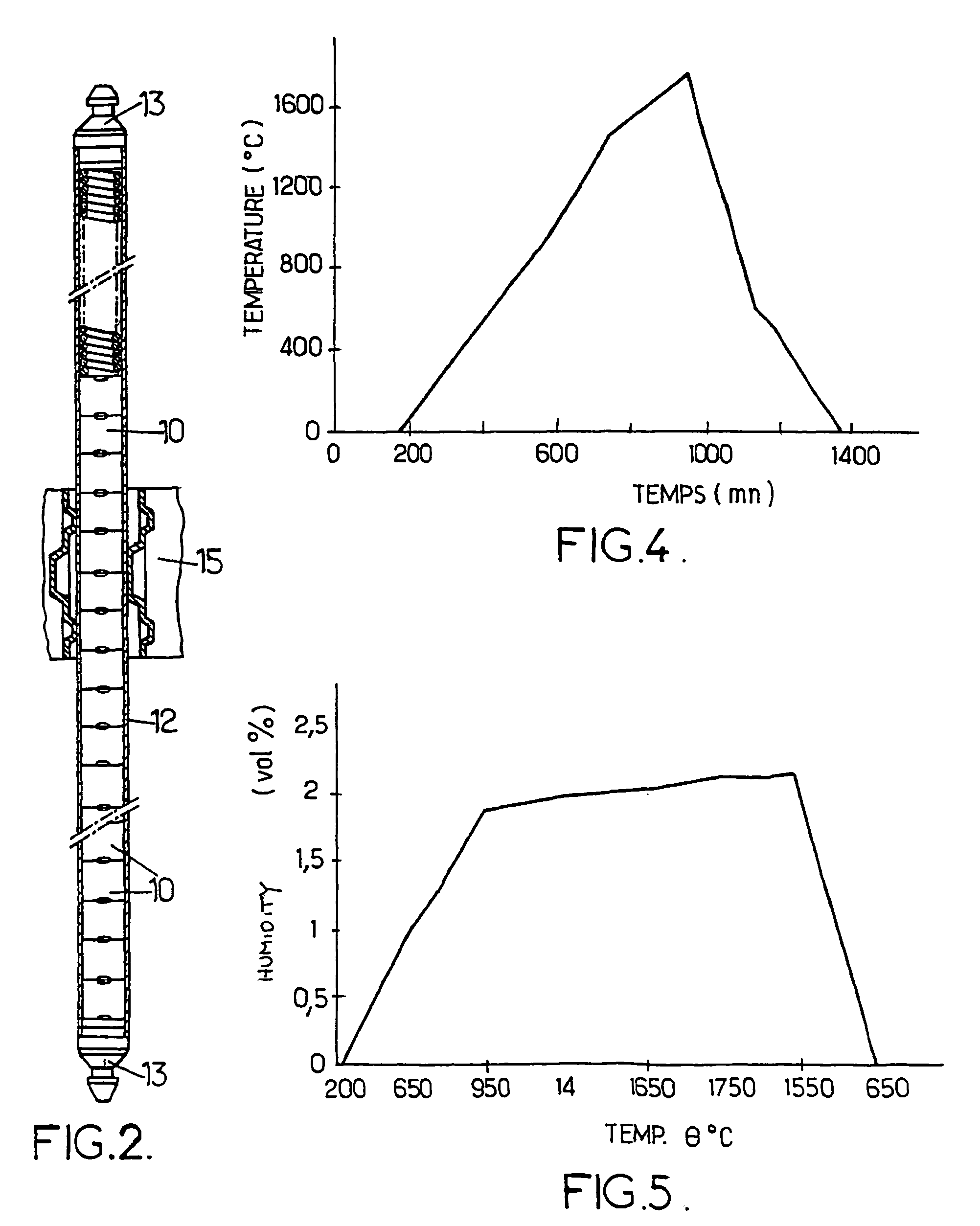

Pencil comprising a stack of oxide nuclear fuel pellets

InactiveUS9053830B2Reduce hoop stressImprove creepFuel elementsNuclear energy generationUranium oxideEnriched uranium

The rod contains substantially cylindrical oxide nuclear fuel pellets based on enriched uranium oxide. The H / D ratio of the height over the diameter of the pellets lies in the range 0.4 to 0.6. The initial diametral clearance between the pellets and the cladding does not exceed 200 μm.

Owner:FRAMATOME ANP

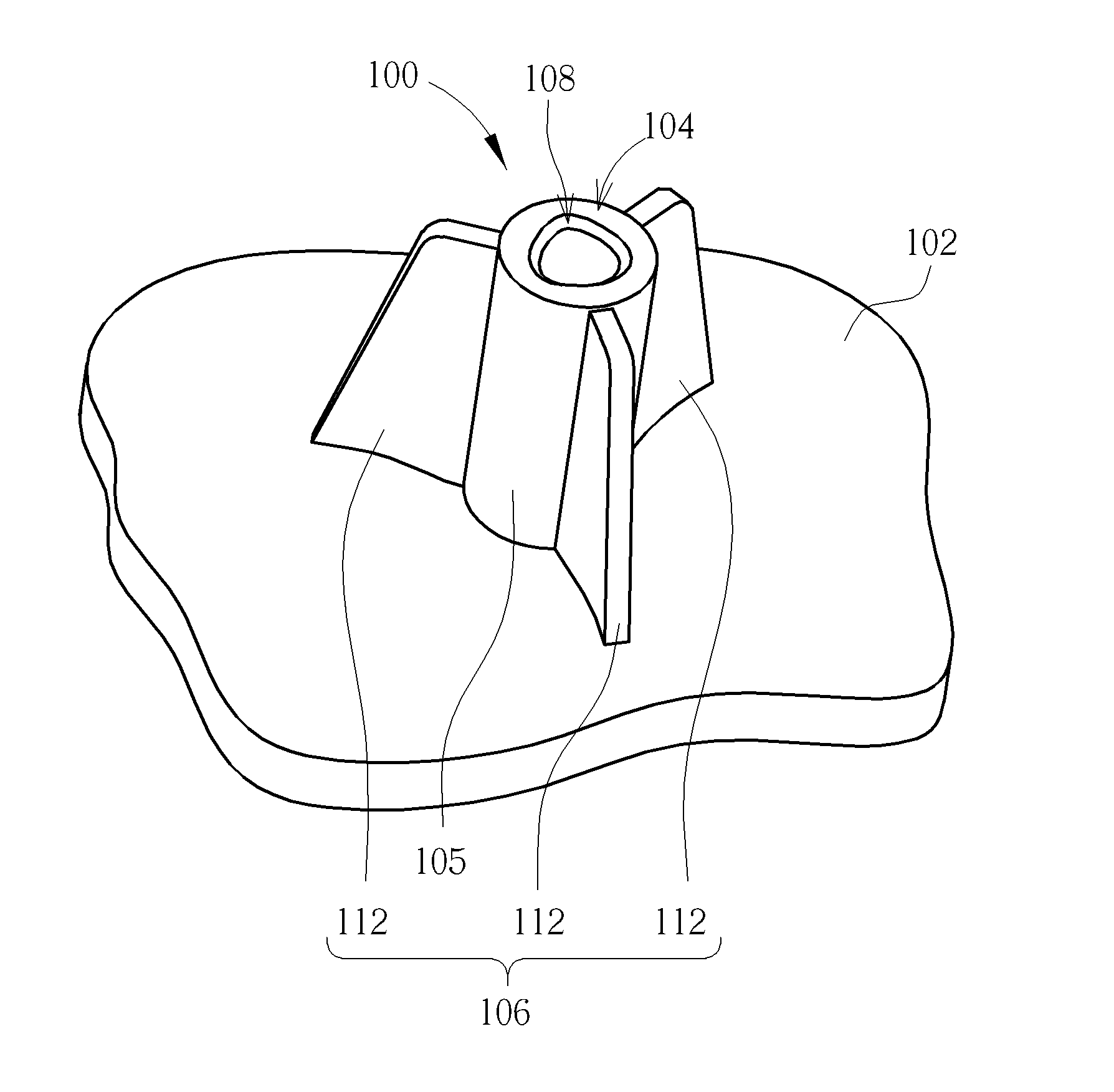

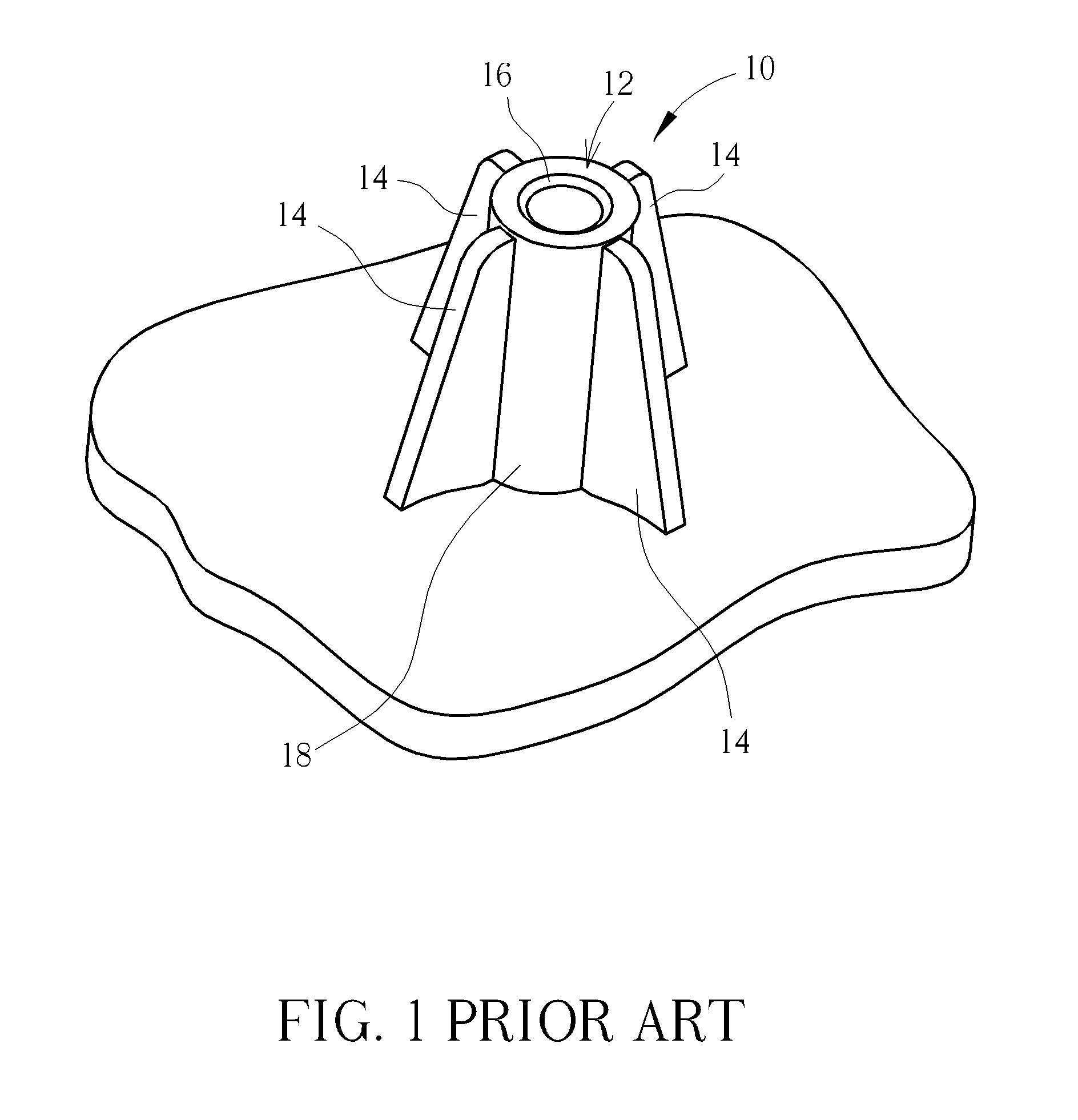

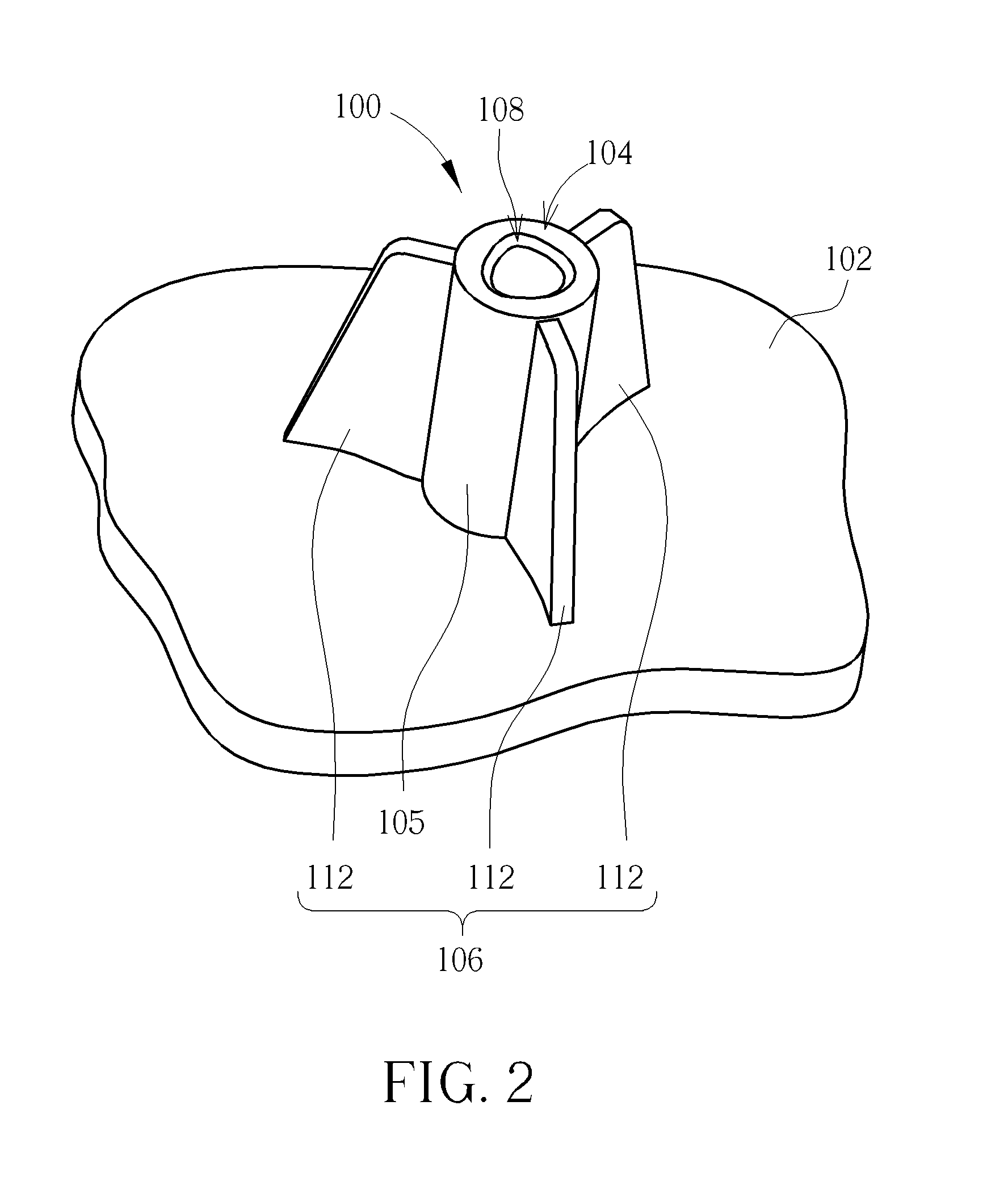

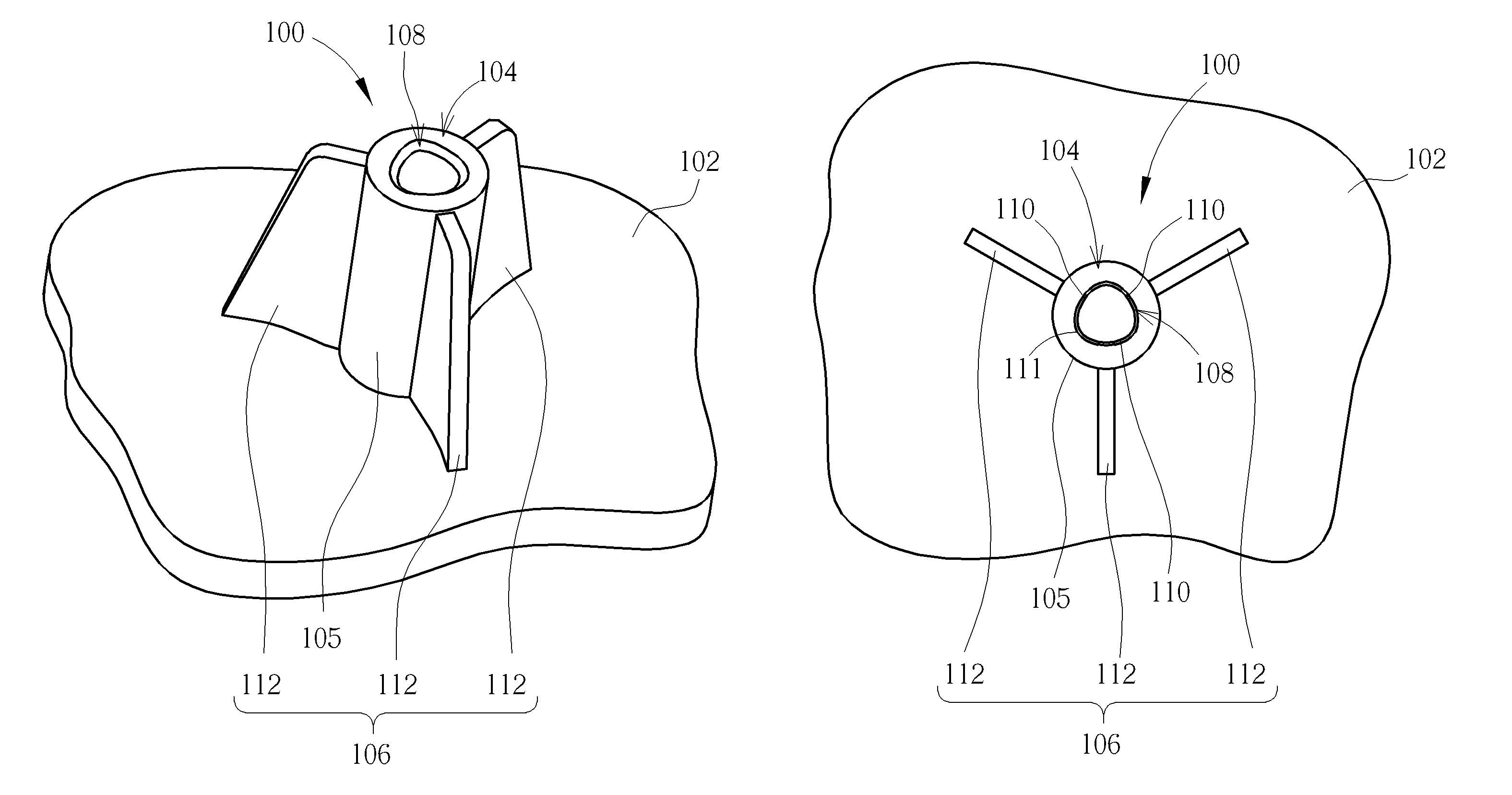

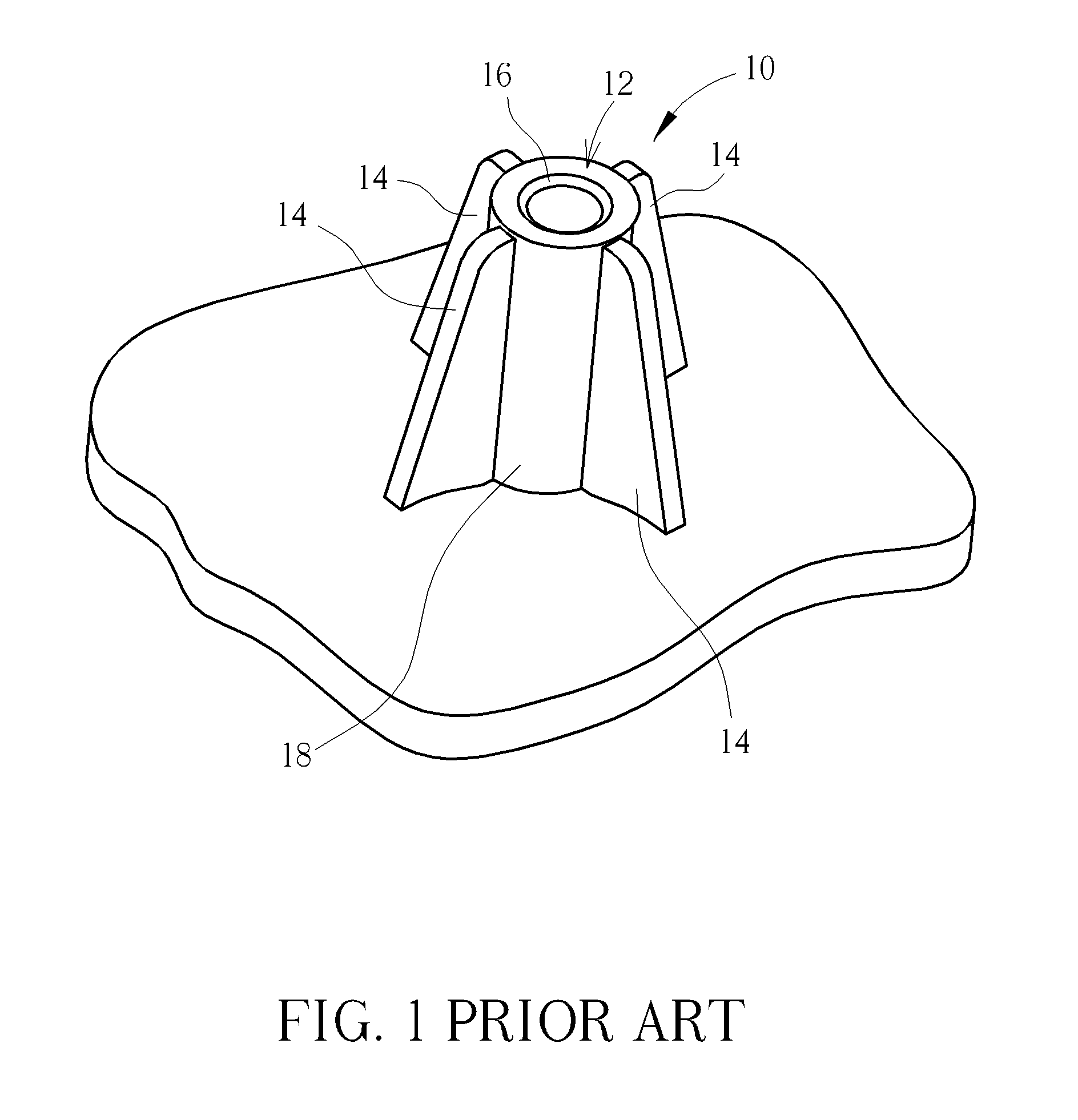

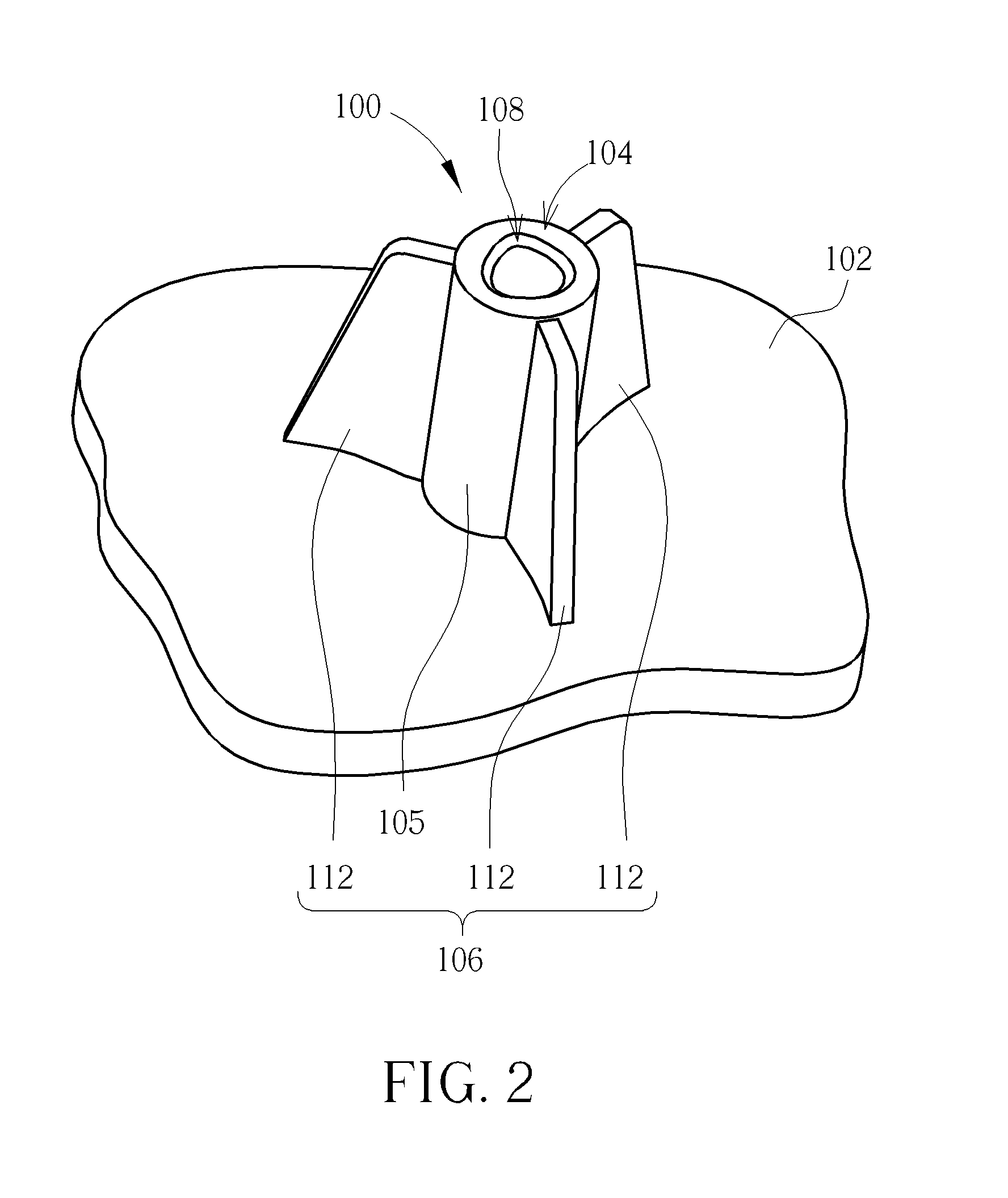

Screw post

A screw post is detachably screwed with a self-tapping screw. The screw post includes a post body and a rib structure. The post body has an approximately triangular hollow structure formed therein. The approximately triangular hollow structure has three arc-shaped sides. The rib structure protrudes from an outer surface of the post body corresponding to at least one of the three arc-shaped sides in an axially-extending manner. The self-tapping screw is screwed into the approximately triangular hollow structure.

Owner:WISTRON CORP

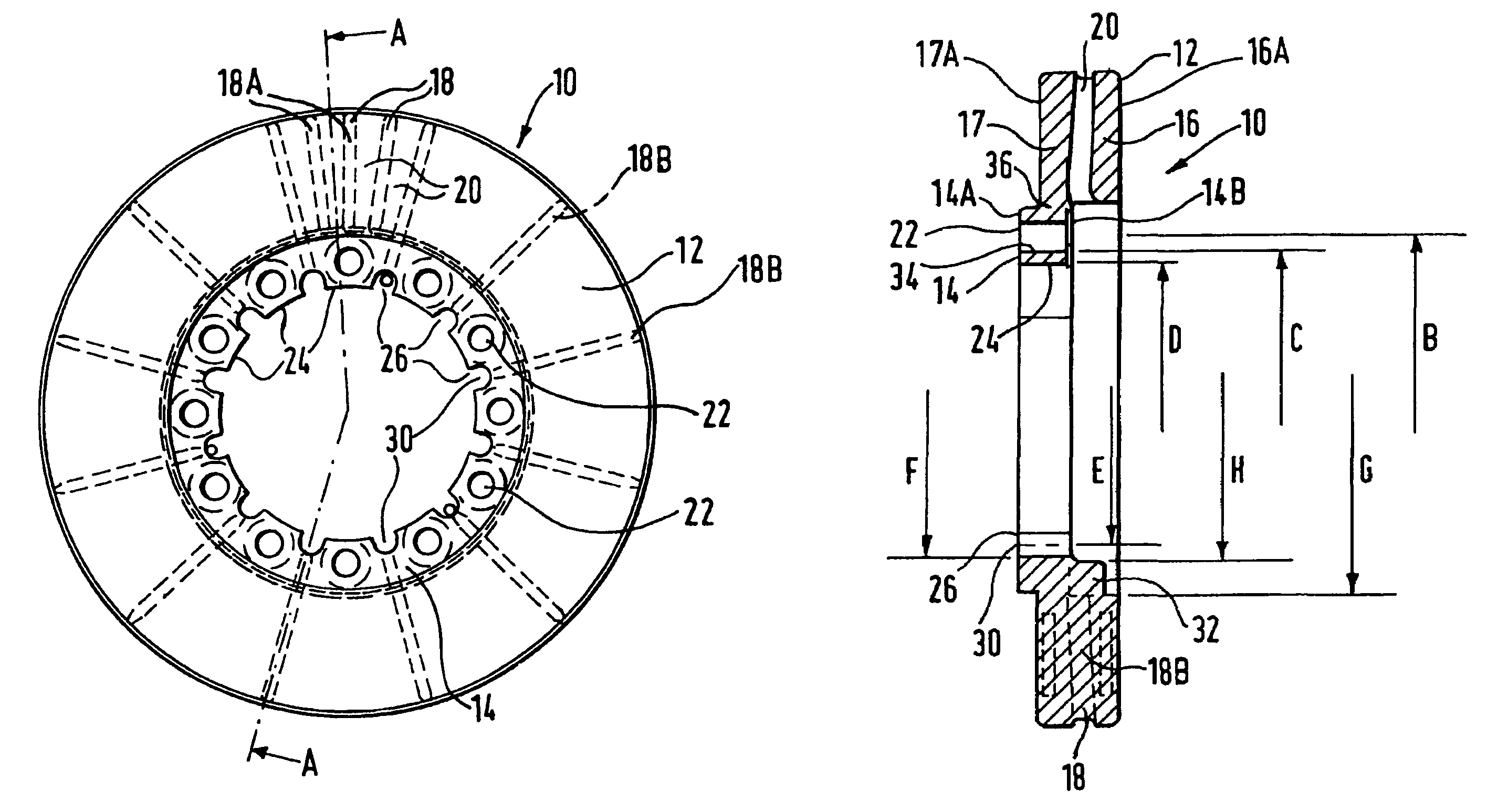

Die Cast Rotor With Steel End Rings to Contain Aluminum

InactiveUS20100171387A1Reduce hoop stressPromote growthMagnetic circuit rotating partsSynchronous motorsElectrical conductorDie casting

A rotor for an electrical inductor motor or an induction generator includes a core having spaces formed in the core. The rotor also has a first end ring. The first end ring has a first hub portion. A first ring is connected to the first hub portion by first spokes. The rotor also has a second end ring. The second end ring has a second hub portion. A second ring is connected to the second hub portion by second spokes. The first end ring is secured to the core. The second end ring is rotated a predetermined amount so the first spokes are misaligned with the second spokes. The second end ring is connected to the first end ring and the core. The core, the first end ring and the second end ring form a substrate. An aluminum conductor is cast to the substrate. The aluminum conductor fills in the spaces and around the first and second spokes to form a cast rotor.

Owner:BAE SYSTEMS CONTROLS INC

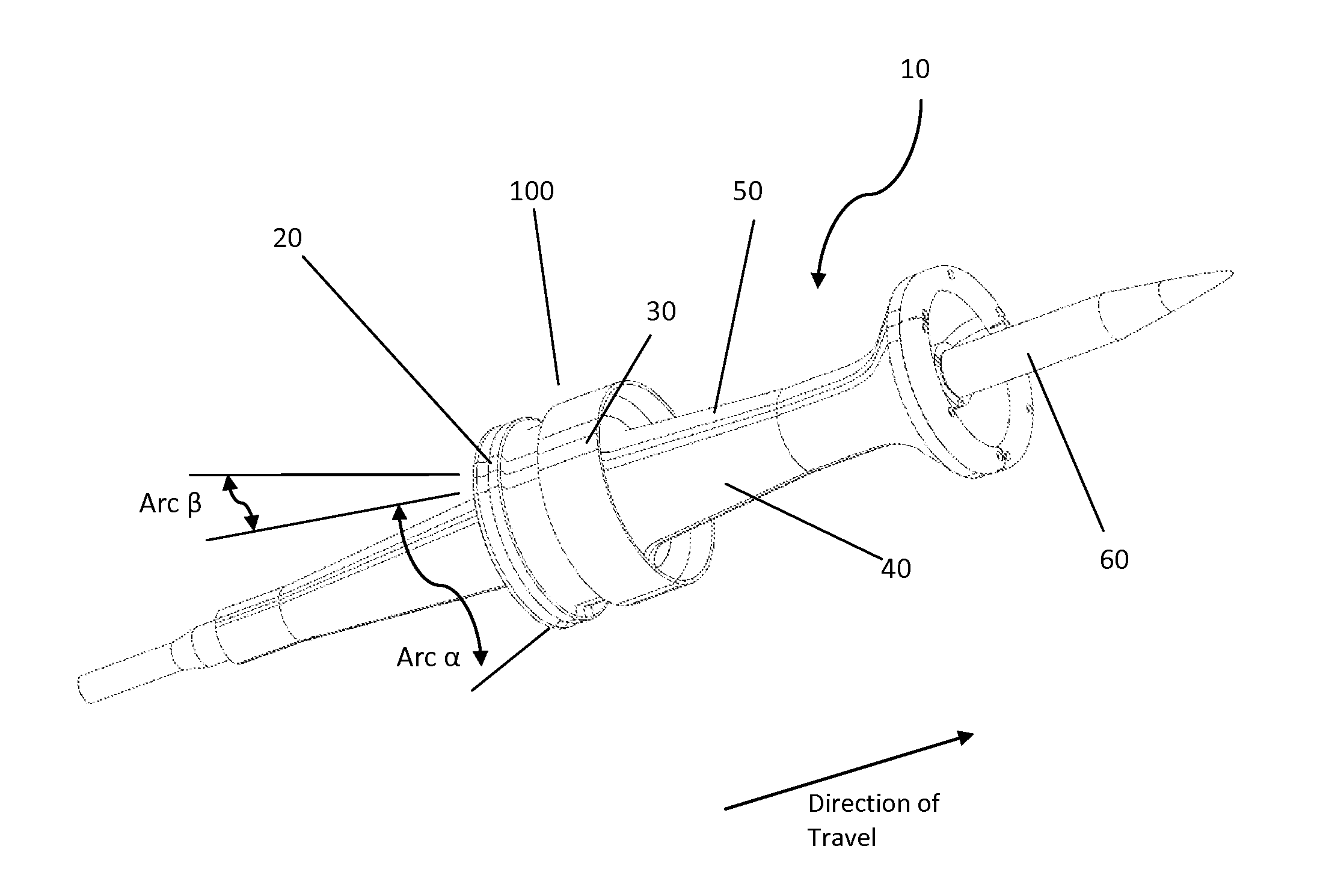

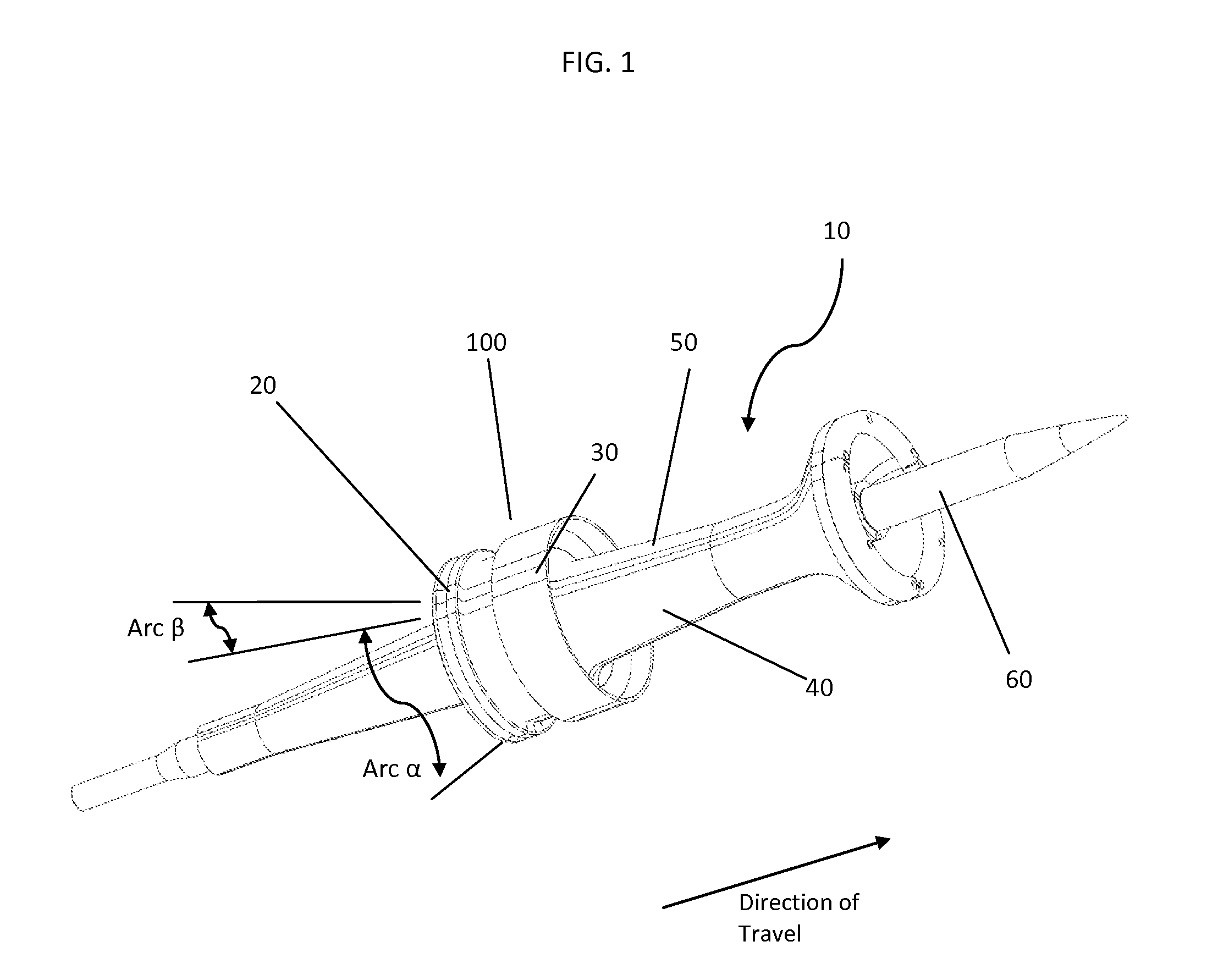

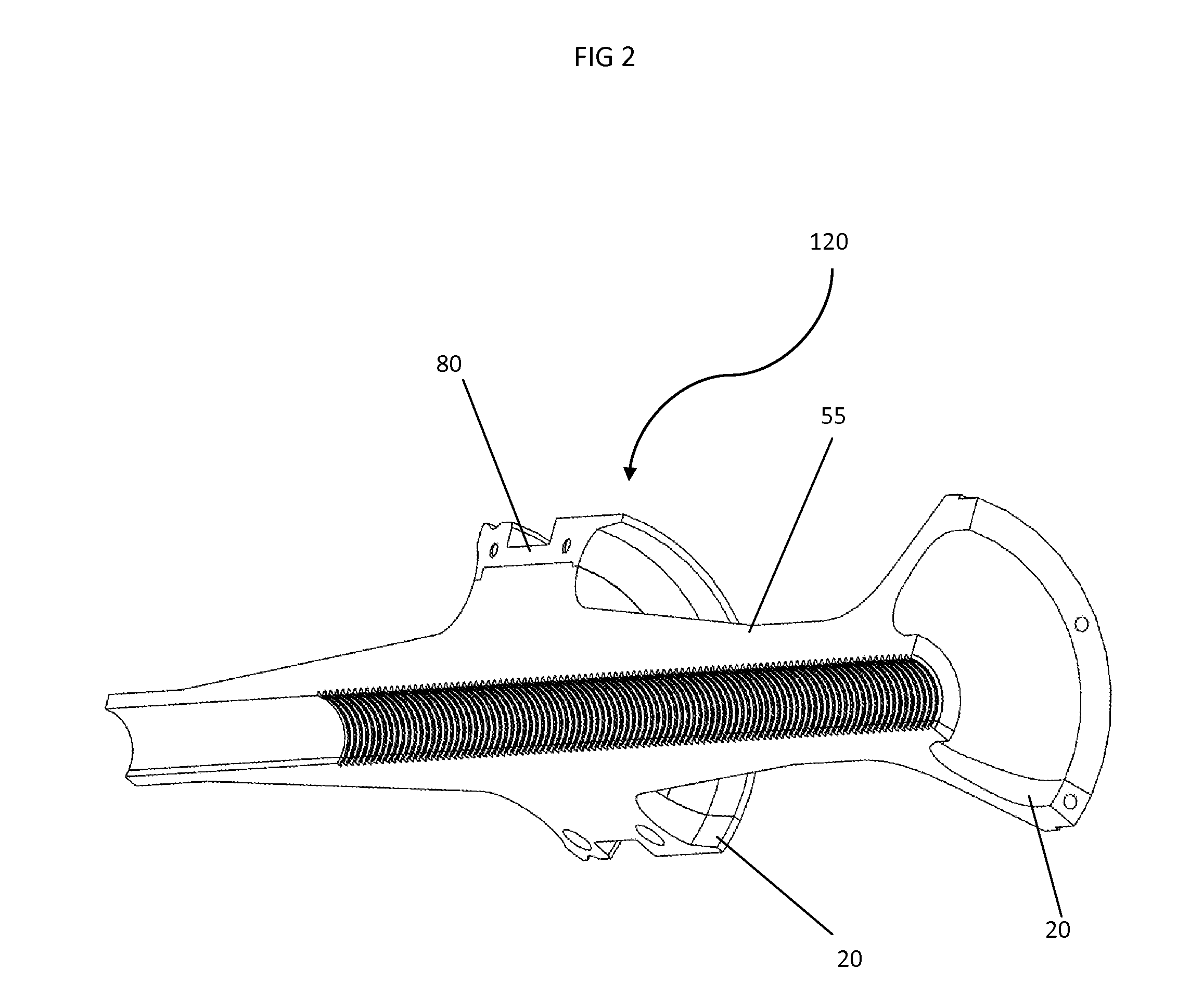

Composite sabot

InactiveUS8695507B1Improve rendering capabilitiesEnhanced armor defeatAmmunition projectilesProjectilesTorsional strengthSmall caliber

A lightweight composite sabot useful in large, medium and small caliber rifled gun systems, wherein each of the sabot segments are reinforced with thin aluminum, or other, metal wedges to increase the torsional strength of the sabot body to survive the torsional forces created when fired from a rifled gun tube. And, which composite sabot also has a metal bulkhead about the periphery thereof, to reduce the spin and resulting hoop stresses, and to help protect the composite material during firing.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

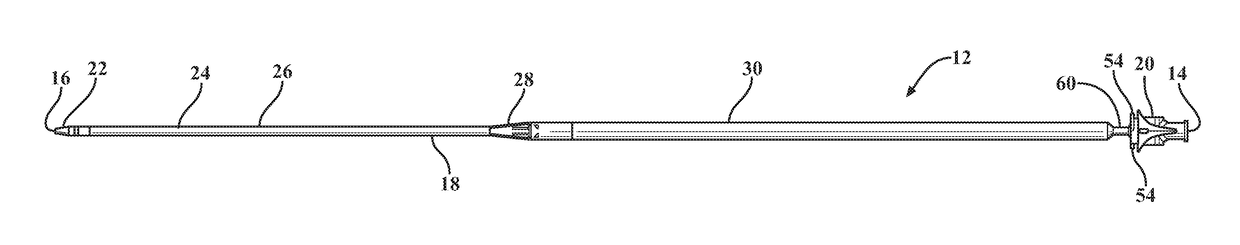

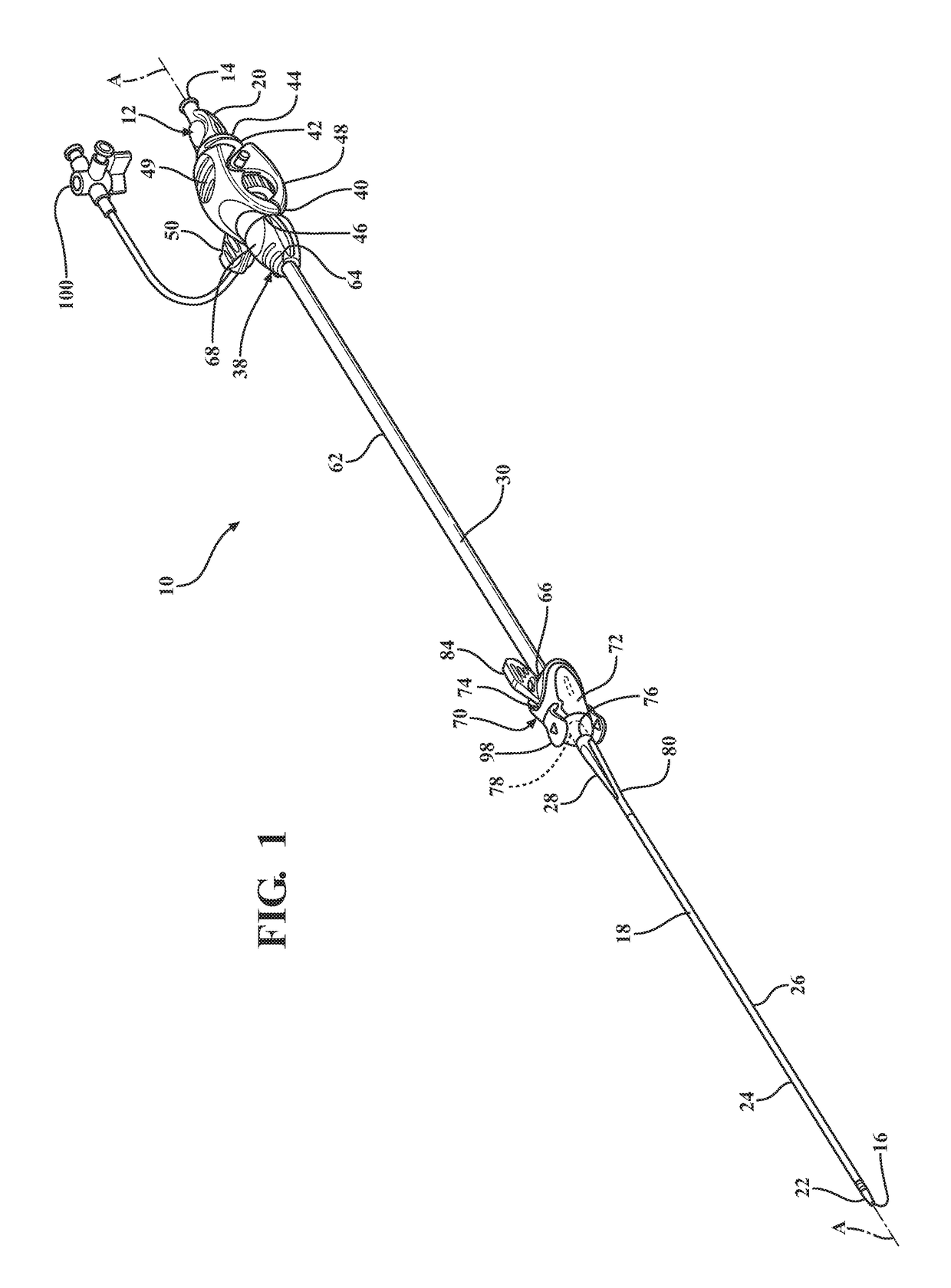

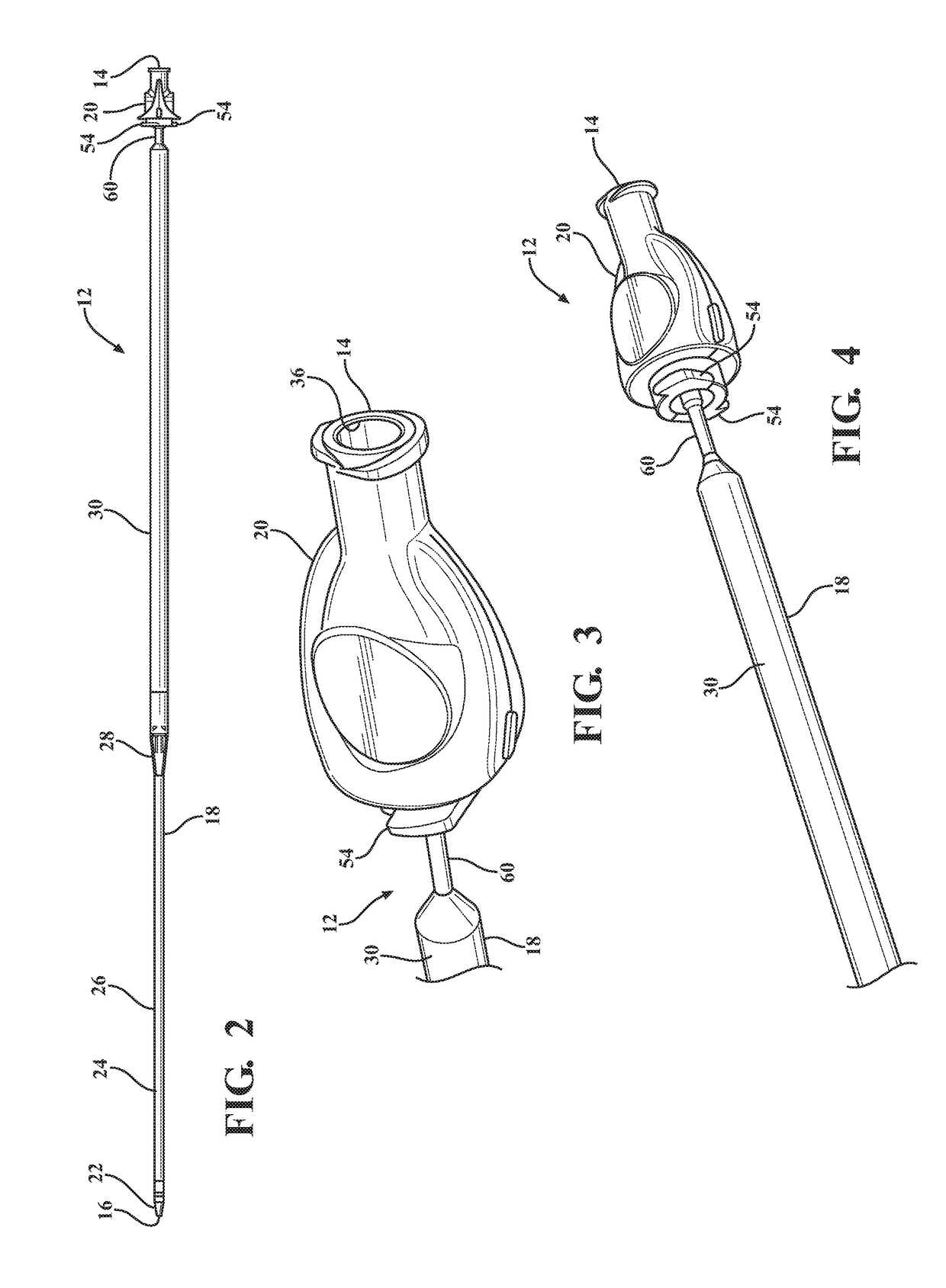

Expandable introducer assembly and method of using same

An expandable introducer assembly includes a dilator subassembly extending from a proximal end to a distal end. The dilator subassembly includes a dilator having an insertion portion disposed adjacent the distal end, an expansion portion disposed adjacent the distal end, and a tapered transition portion disposed between the insertion and expansion portions. The dilator subassembly includes a distal sheath disposed in overlaying relationship with the insertion portion of the dilator. An introducer subassembly is disposed in coaxial relationship with the expansion portion of the dilator, and includes a valve disposed adjacent the proximal end and an introducer sheath extending from the valve in overlaying relationship with the expansion portion of the dilator. An expandable sheath subassembly is releasably interlocked with the dilator subassembly and includes an expandable sheath disposed in overlaying relationship with the tapered transition portion and in nested relationship between the insertion portion and the distal sheath.

Owner:FREUDENBERG MEDICAL

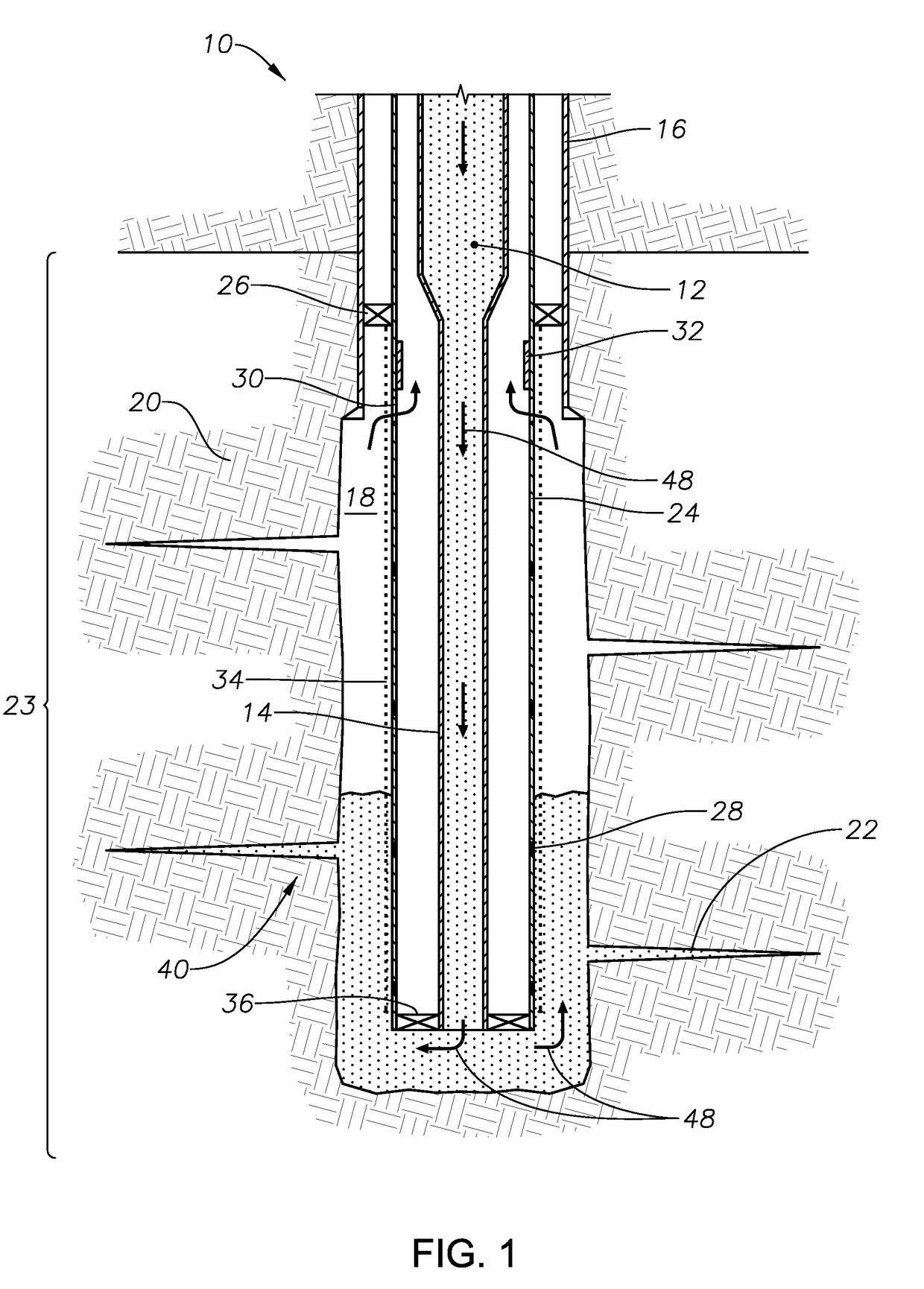

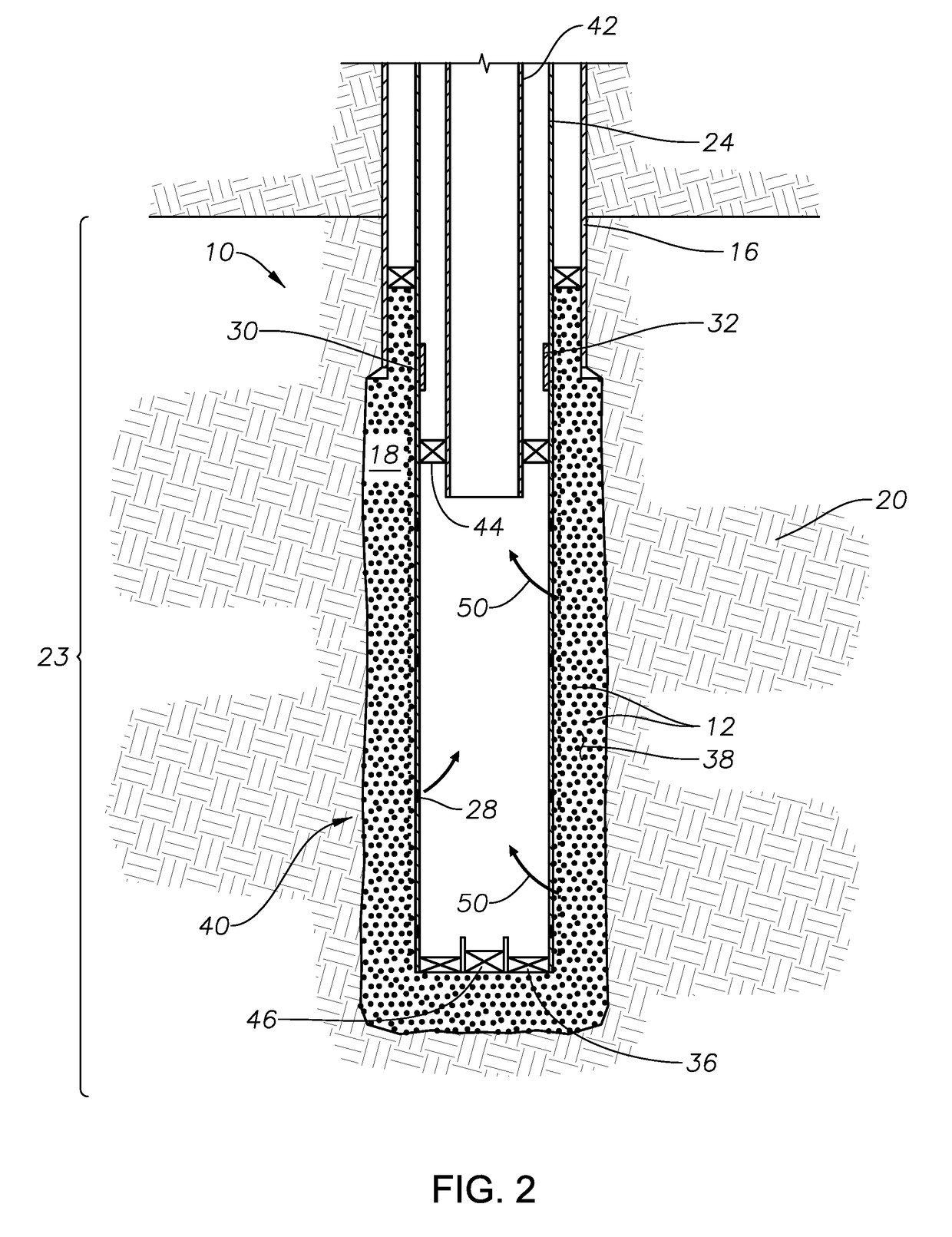

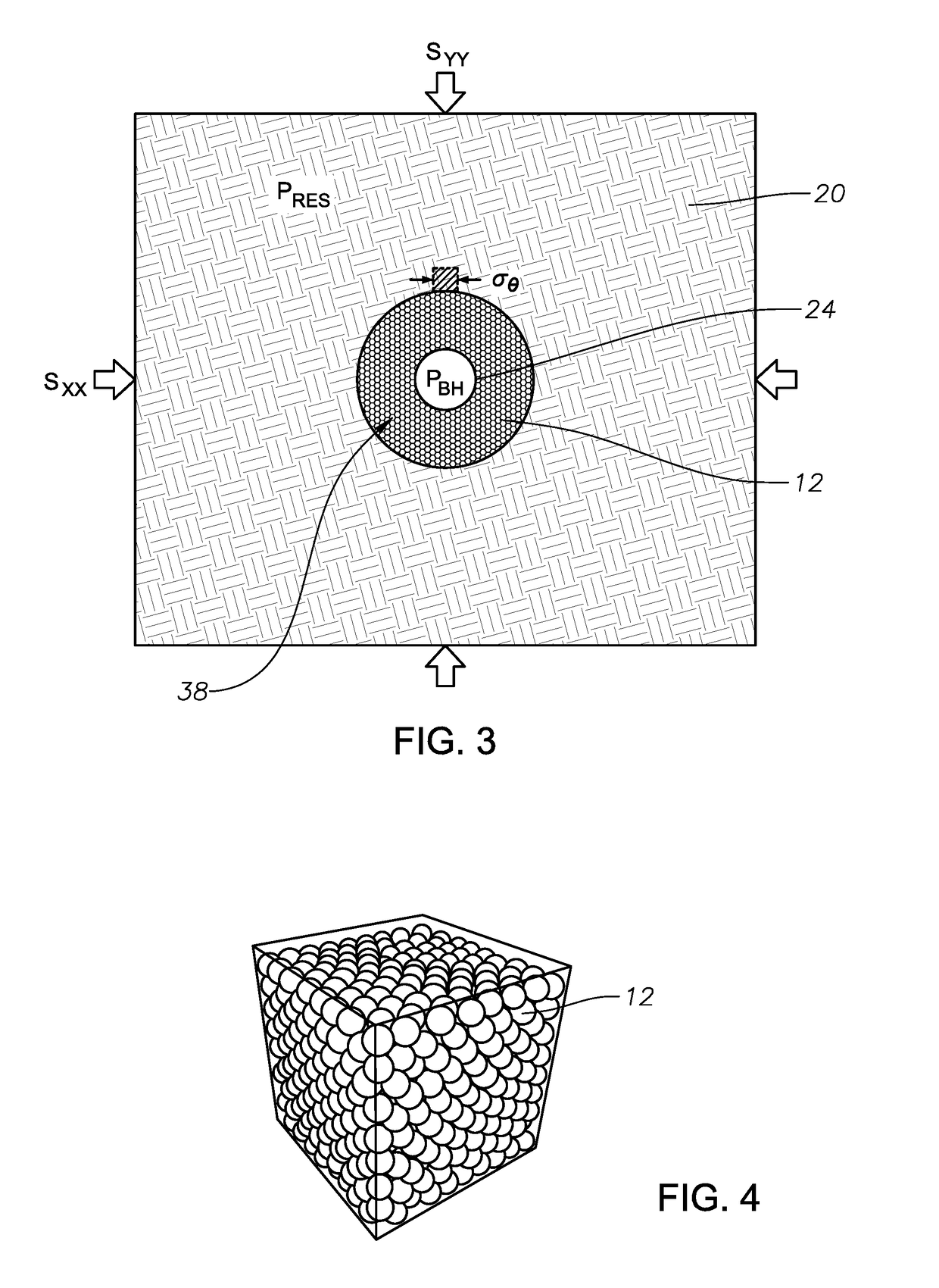

Mitigation Of Sand Production In Sandstone Reservoir Using Thermally Expandable Beads

ActiveUS20190078420A1Increased radial confining stressReduce hoop stressConstructionsFluid removalMaterials scienceProduction area

Systems and methods for producing fluids from a subterranean well include introducing expandable beads into a target region of a production zone of the subterranean well, the expandable beads being formed of thermally expandable material in an unexpanded condition with a first diameter. A radial confining stress is increased and a hoop stress is decreased within the target region by thermally expanding the expandable beads so that the beads are in an expanded condition with a second diameter, the second diameter being greater than the first diameter.

Owner:SAUDI ARABIAN OIL CO

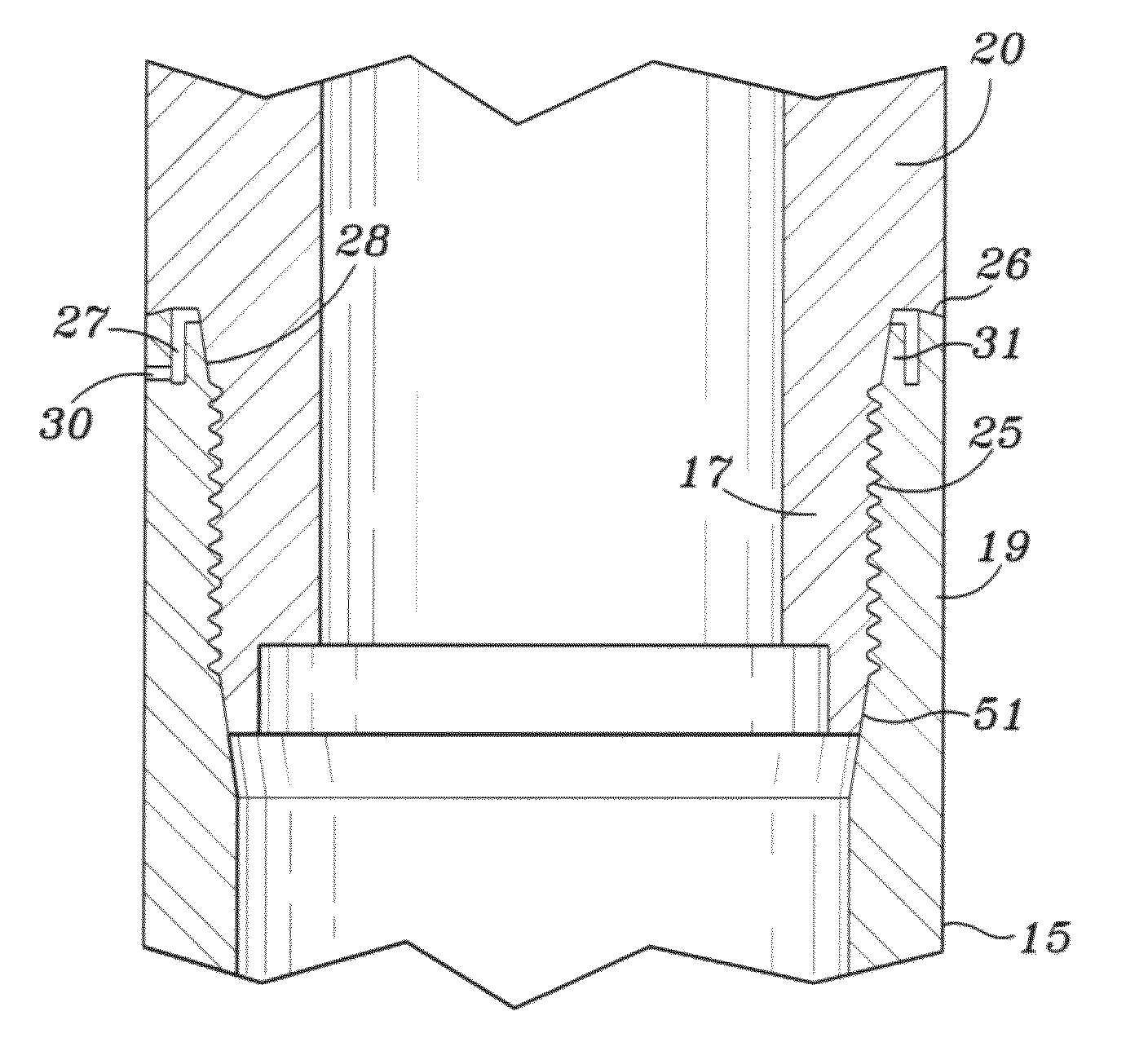

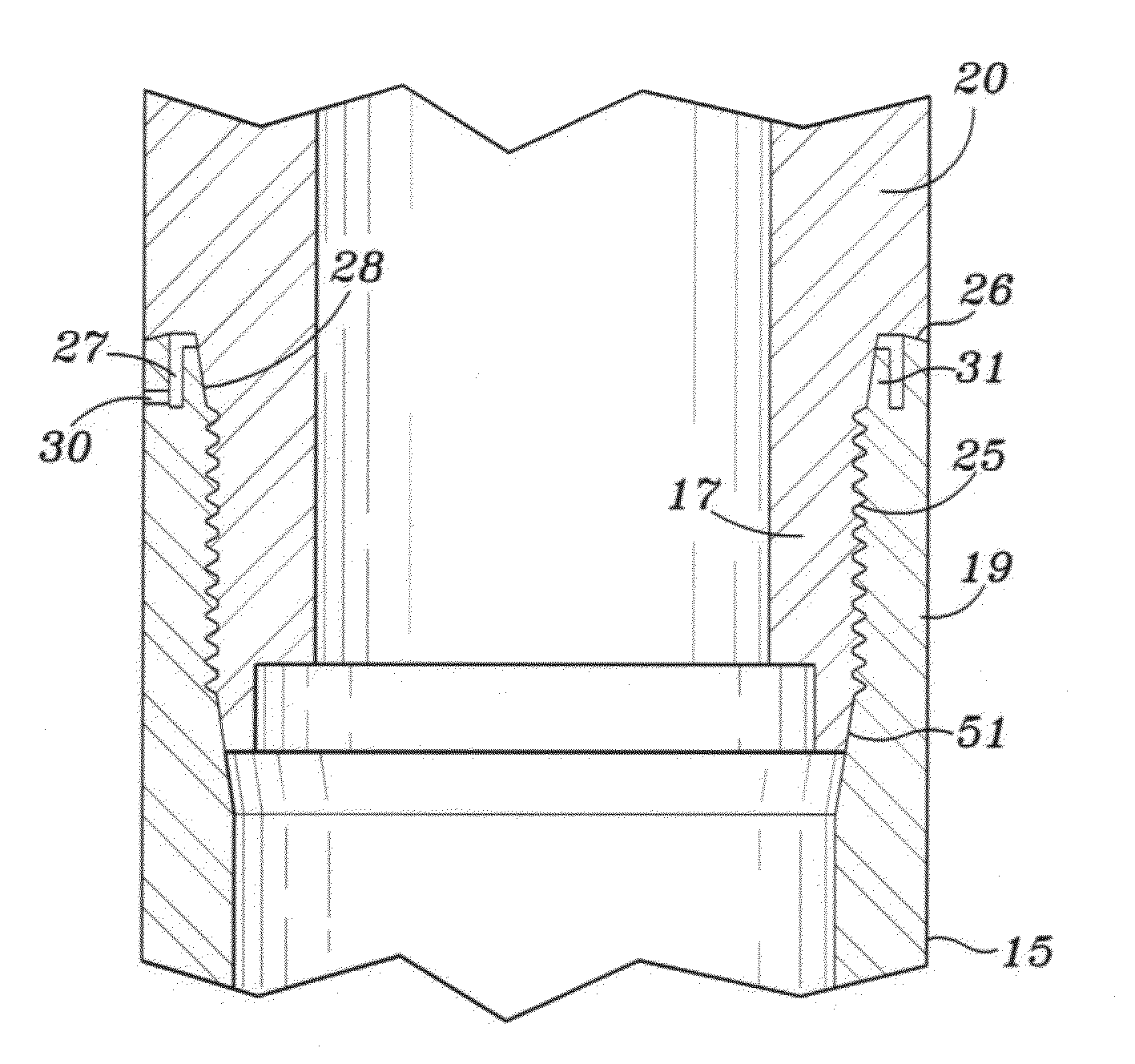

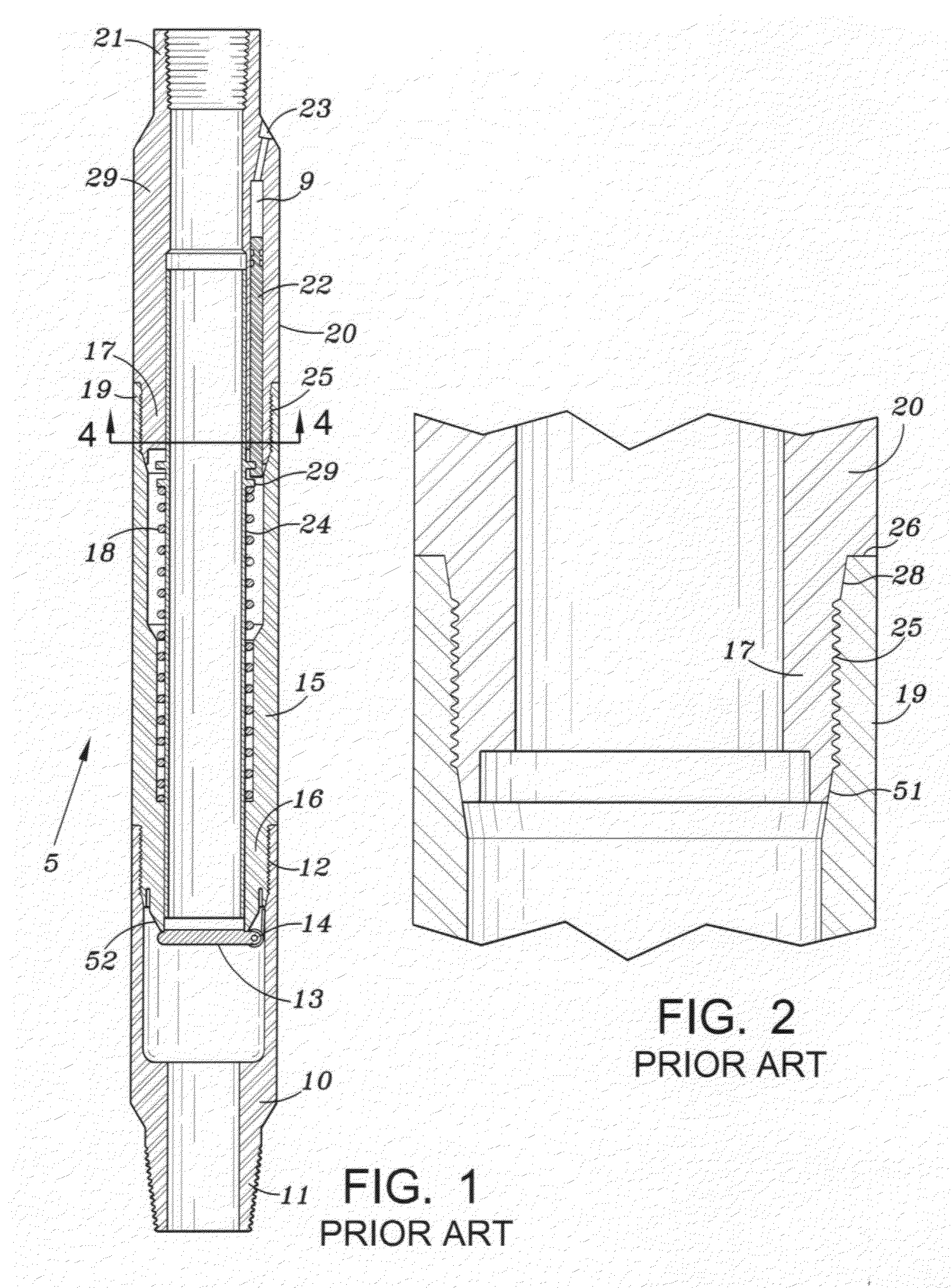

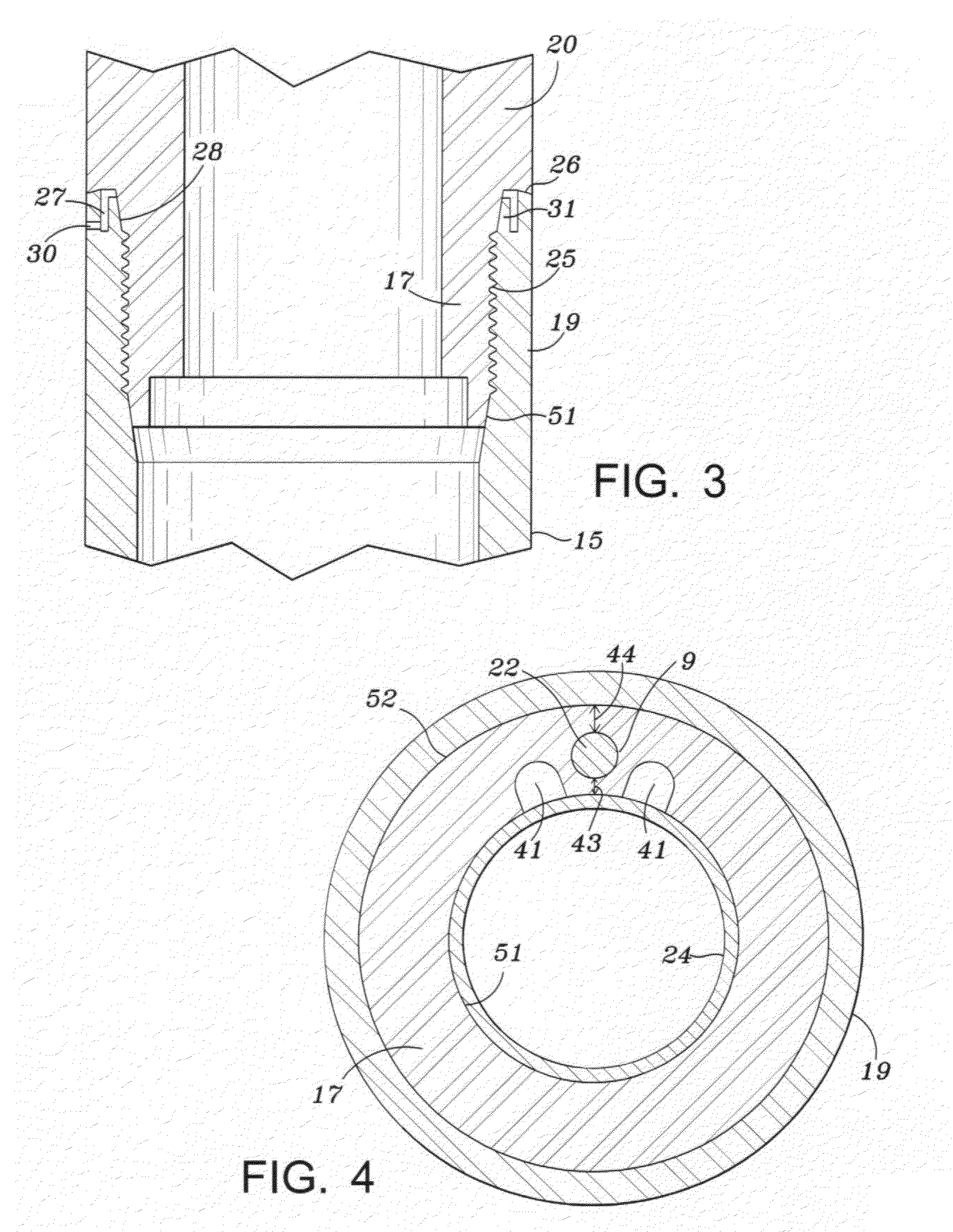

Subsurface safety valve for high temperature and high pressure wells

InactiveUS8668014B2Improve sealingIncrease contact pressureDrilling rodsConstructionsStress failureEngineering

A subsurface safety valve particularly designed for high temperature and high pressure applications has an improved tubular joint connection that provides for a compliant metal to metal seal without adversely affecting the break out torque. The valve also includes axially extending grooves in the inner surface of the tubular housing in the area of a actuating piston bore to relief stresses in that area thereby reducing the risk of stress failure.

Owner:TEJAS RES & ENG

Die Cast Rotor With Steel End Rings to Contain Aluminum

ActiveUS20110283525A1Promote growthReduce the amount requiredSynchronous generatorsWindingsElectrical conductorDie casting

A rotor for an electrical inductor motor or an induction generator includes a core having spaces formed in the core. The rotor also has a first end ring. The first end ring has a first hub portion. A first ring is connected to the first hub portion by first spokes. The rotor also has a second end ring. The second end ring has a second hub portion. A second ring is connected to the second hub portion by second spokes. The first end ring is secured to the core. The second end ring is rotated a predetermined amount so the first spokes are misaligned with the second spokes. The second end ring is connected to the first end ring and the core. The core, the first end ring and the second end ring form a substrate. An aluminum conductor is cast to the substrate. The aluminum conductor fills in the spaces and around the first and second spokes to form a cast rotor.

Owner:BAE SYSTEMS CONTROLS INC

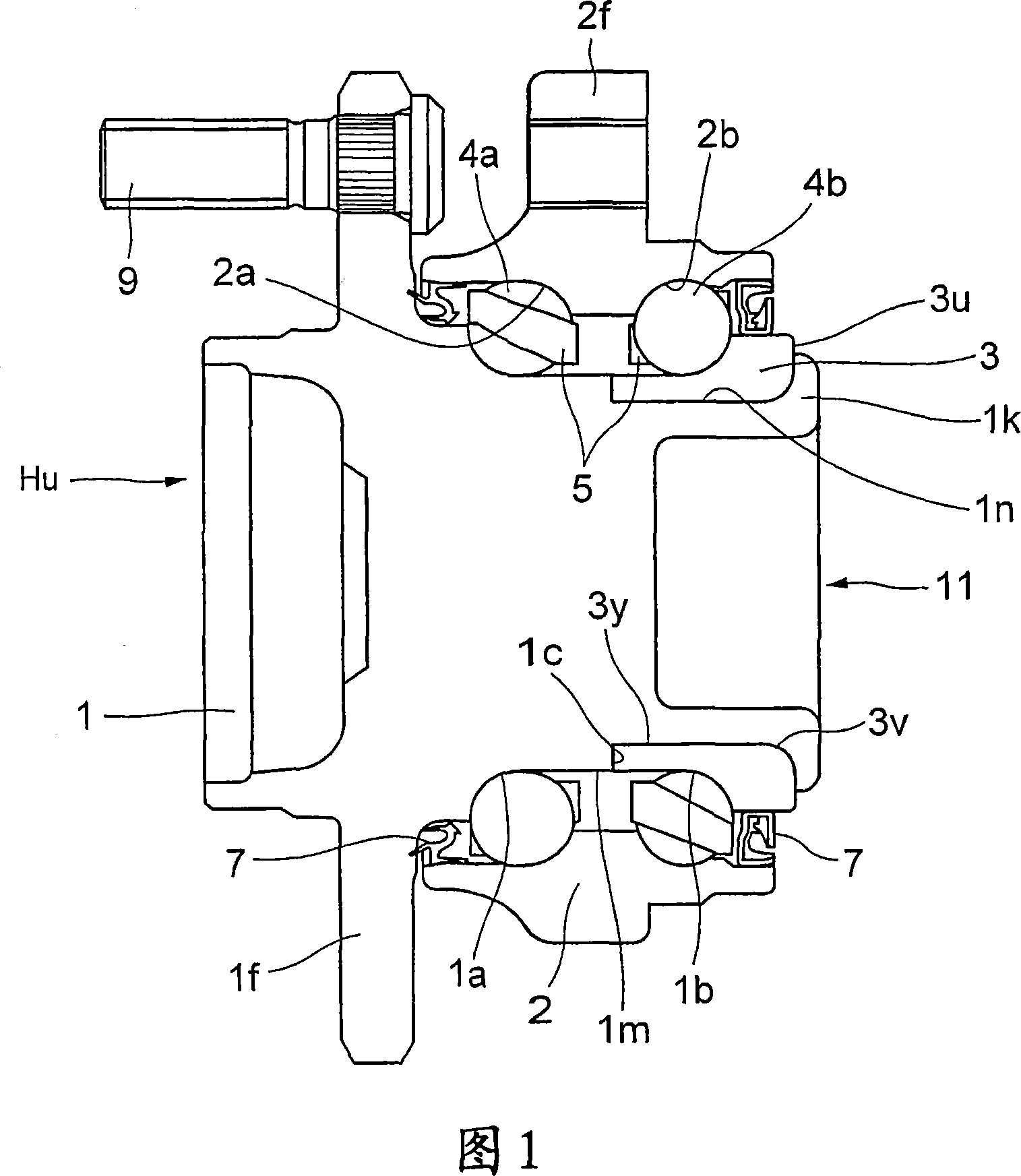

Hub unit for wheel

InactiveCN1926349AReduce distortionReduced service lifeRolling contact bearingsAxle unitsEngineeringFlange

A hub unit for a wheel, having an outer ring, a hub, an inner element, and rolling bodies. The outer ring has two rows of bearing raceways on its inner periphery. The hub has a wheel installation flange on the outer end side, has an end section on the vehicle center side in the axial direction, and has, integrally or as a separate body, on its outer periphery a first bearing raceway corresponding to a bearing raceway on the vehicle outer end side in the axial direction of the outer ring. The inner ring element is fitted on the end section side of the hub, has on its outer periphery a second bearing raceway facing the bearing raceway on the vehicle center side in the axial direction of the outer ring, and fixed to the end section of the hub by plastically deforming the end section radially outward. The rolling bodies are interposed between the two bearing raceways of the outer ring and the first and second bearing raceways. The outer diameter of the plastically deformed section of the end section is set smaller than the diameter of that section of the inner ring element which is fitted on the hub, the start point of the small diameter section is positioned between the start point of a chamfered section on the inner peripheral surface of the inner ring element and a vehicle center side end surface of the inner ring element, and the end section is plastically deformed radially outward to fasten and fix the inner ring element. Alternatively, a continuous circumferential groove can be provided close to the chamfered section of an inner end section on the inner peripheral surface of the inner ring element.

Owner:NSK LTD

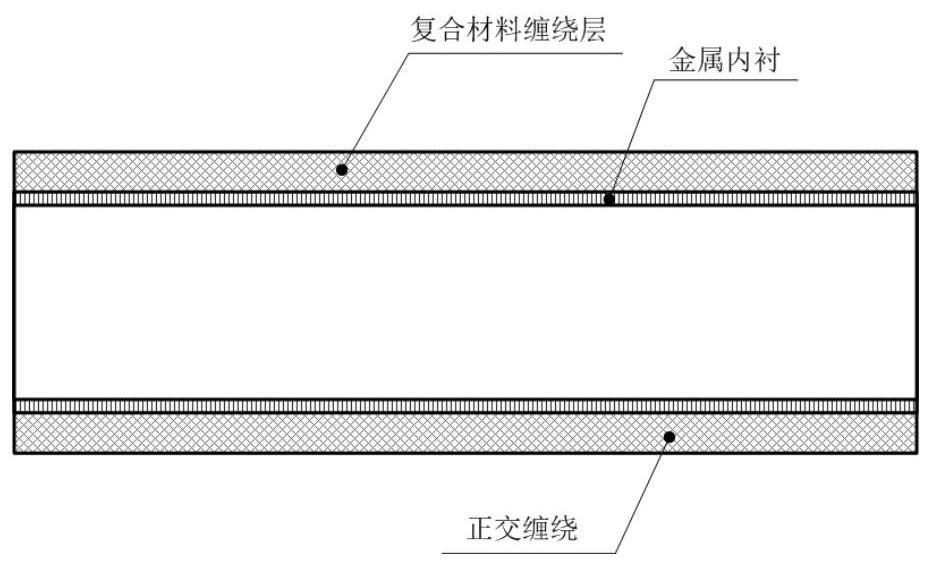

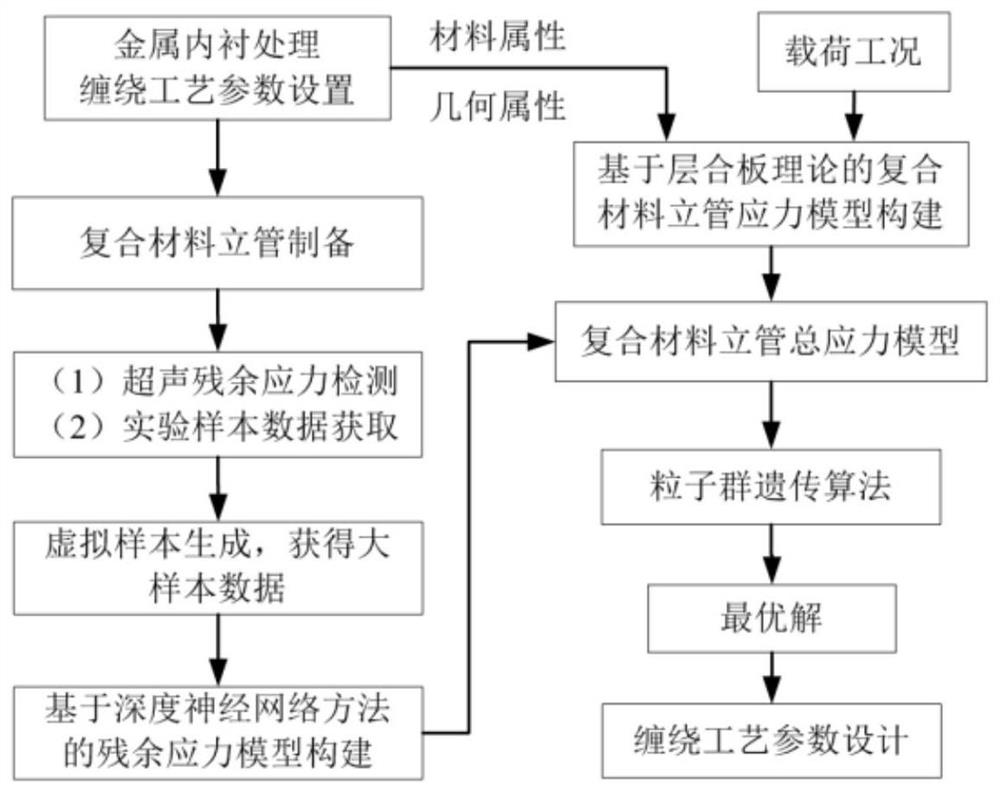

Parameter design method of composite material vertical pipe winding process

ActiveCN113761680AEfficient designHigh precisionGeometric CADArtificial lifeContinuous useVirtual sample

The invention discloses a parameter design method for a composite material vertical pipe winding process, and the method comprises the following steps: preparing a composite material winding vertical pipe according to set parameters of the composite material vertical pipe winding process; carrying out residual stress detection on the composite material vertical pipe, and constructing large sample data by utilizing a virtual sample generation technology; constructing a residual stress model based on the large sample data; according to the constructed residual stress model and the composite material vertical pipe stress model based on the laminated plate theory, constructing a composite material vertical pipe total stress model; and according to the total stress model of the composite material vertical pipe, by utilizing an optimization algorithm, obtaining process parameters meeting the performance requirements of the composite material in a winding process parameter domain. The uniformity of structural stress when the composite vertical pipe is pressed is improved, the strength of the first layer of the composite vertical pipe is improved, the problem that the first layer of the composite vertical pipe is prone to first failure is solved, the quality of the composite vertical pipe is improved, and the continuous use effect of the composite vertical pipe is guaranteed.

Owner:JIANGSU UNIV OF SCI & TECH

Screw post

A screw post is detachably screwed with a self-tapping screw. The screw post includes a post body and a rib structure. The post body has an approximately triangular hollow structure formed therein. The approximately triangular hollow structure has three arc-shaped sides. The rib structure protrudes from an outer surface of the post body corresponding to at least one of the three arc-shaped sides in an axially-extending manner. The self-tapping screw is screwed into the approximately triangular hollow structure.

Owner:WISTRON CORP

Subsurface Safety Valve for High Temperature and High Pressure Wells

InactiveUS20120205113A1Improve sealingHigh break-out torqueDrilling rodsConstructionsStress failureEngineering

A subsurface safety valve particularly designed for high temperature and high pressure applications has an improved tubular joint connection that provides for a compliant metal to metal seal without adversely affecting the break out torque. The valve also includes axially extending grooves in the inner surface of the tubular housing in the area of a actuating piston bore to relief stresses in that area thereby reducing the risk of stress failure.

Owner:TEJAS RES & ENG

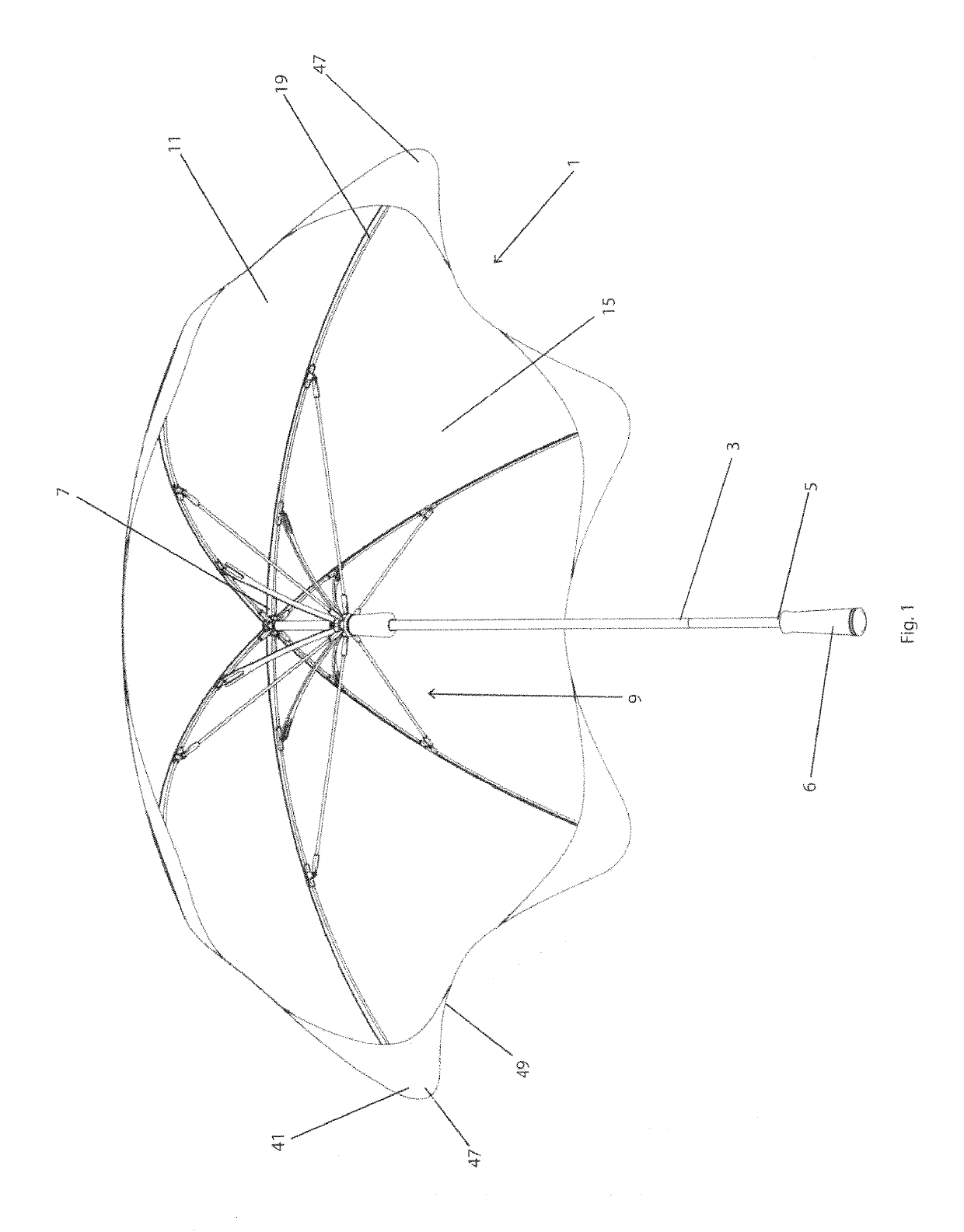

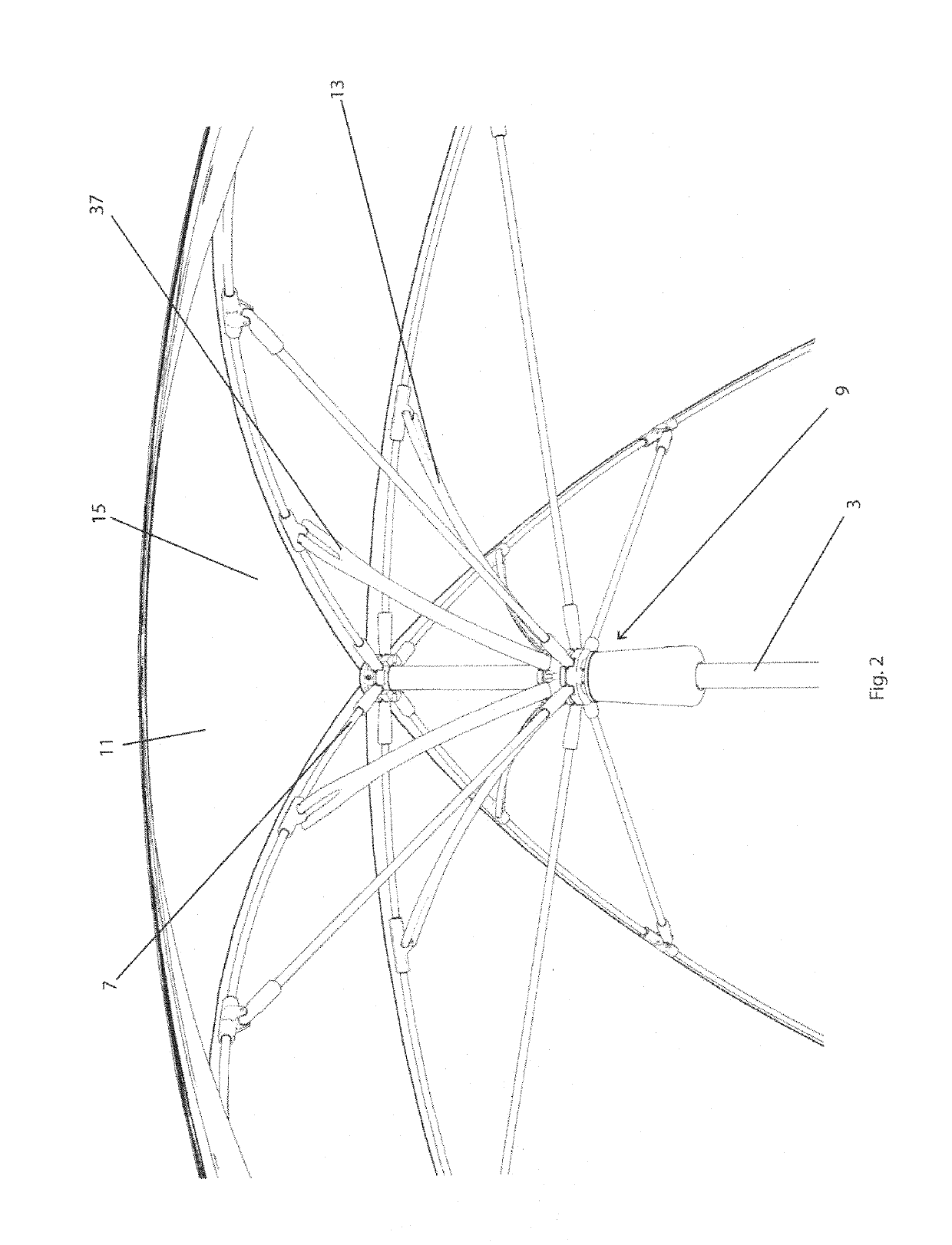

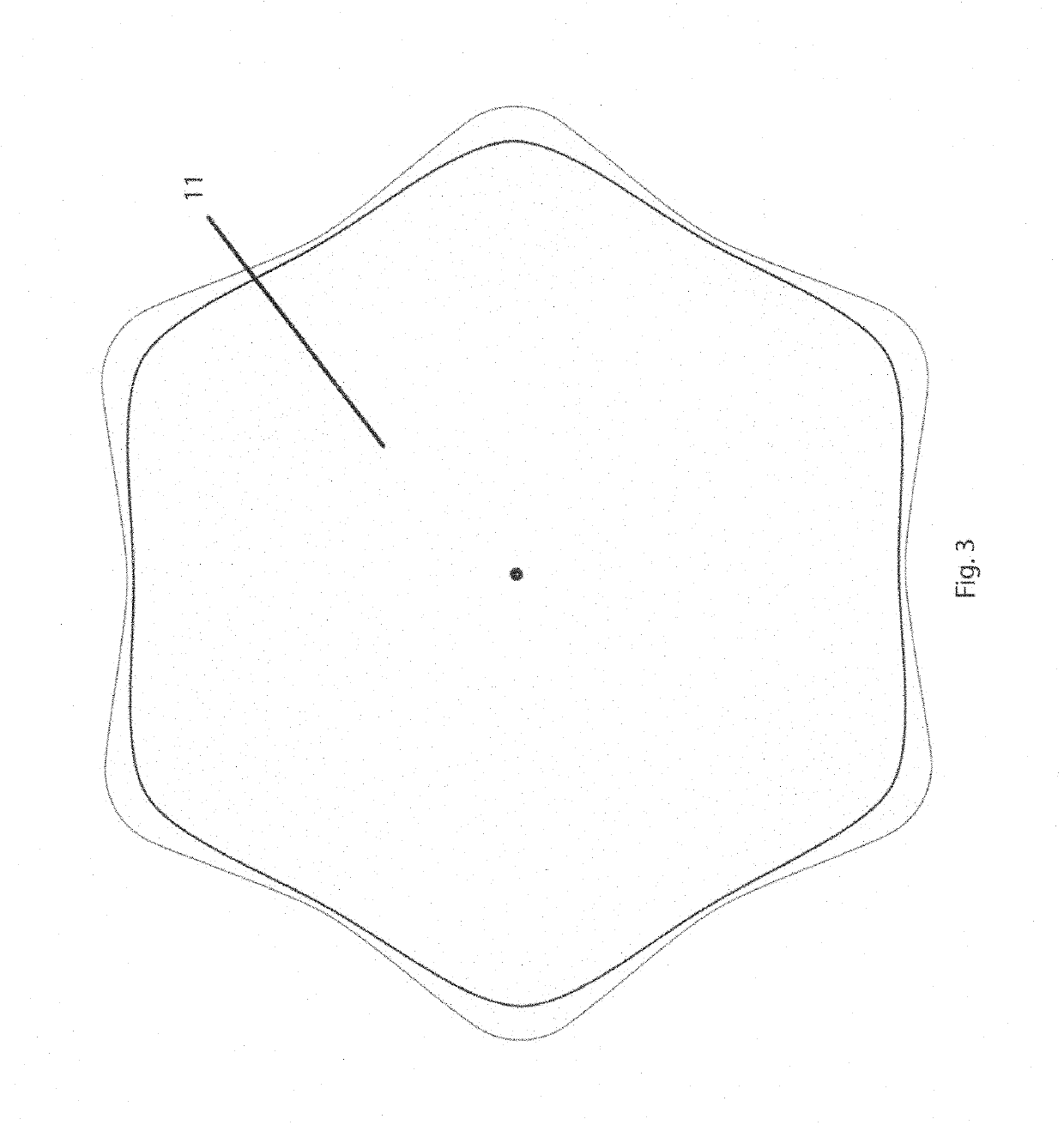

Umbrella

Disclosed is an umbrella that can be used as a canopy to protect a user against rain or sunlight. The umbrella may comprise an elongate member having proximal and distal end portions, a support structure that is connectable to a canopy able to be disposed about the distal end portion of the elongate member, the support structure being be adjustable between an erect position, whereby the canopy is able to be tensioned by the support structure, and a collapsed position, whereby the tension in the canopy is able to be released. The umbrella may also include a plurality of biasing means configured to inhibit the support structure from inverting.

Owner:BRAND DEVERS

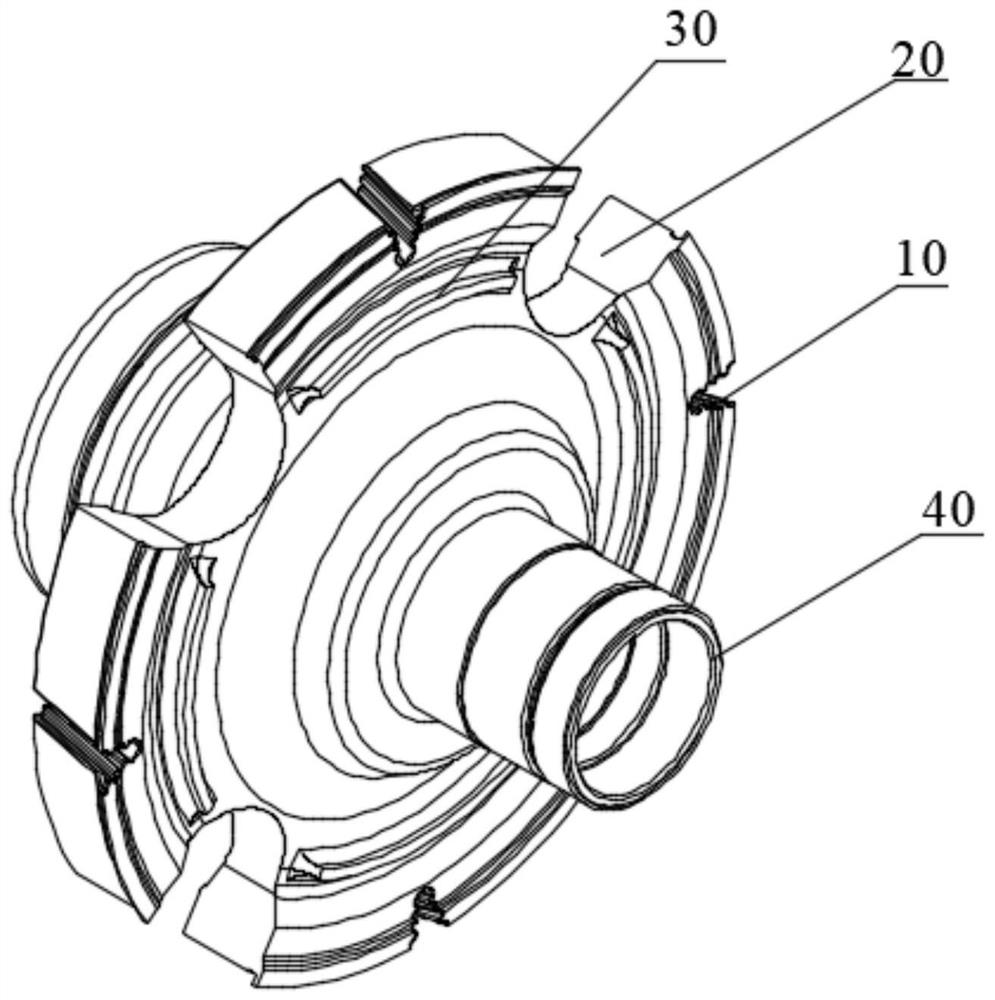

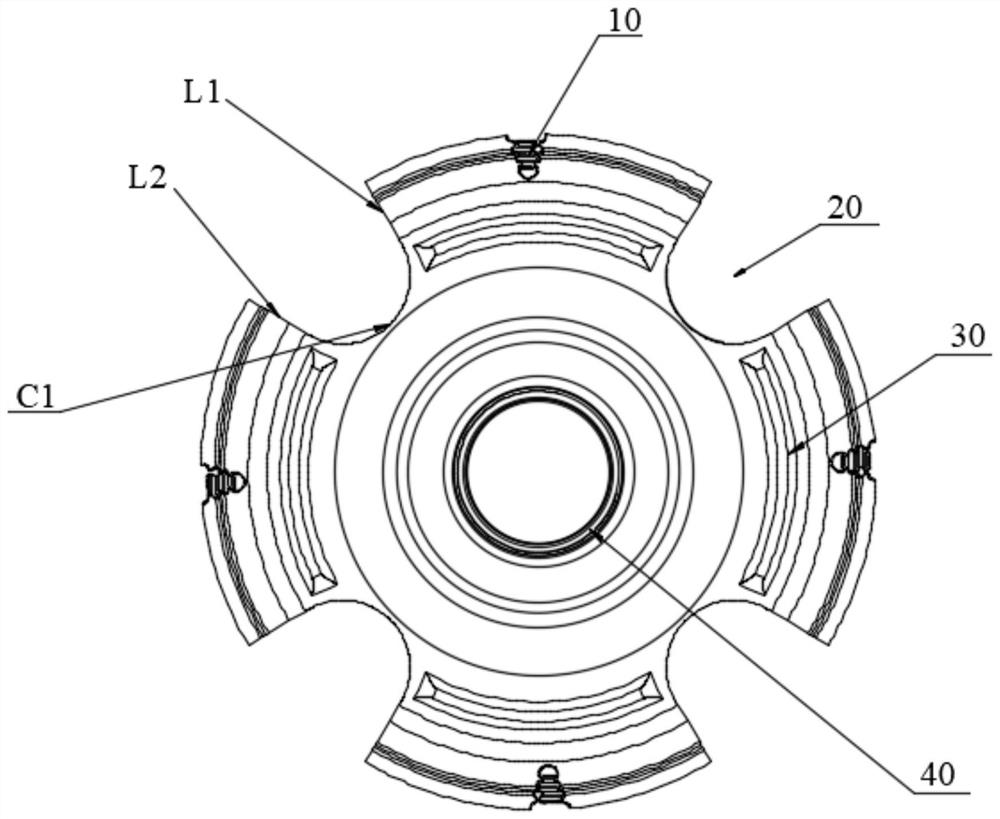

Simulation disc for low-cycle fatigue test of turbine working blade

PendingCN114034587AReduce hoop stressSufficient bending stiffnessMaterial strength using repeated/pulsating forcesStructural engineeringTest failure

The invention discloses a simulation disc for a low-cycle fatigue test of a turbine working blade, which relates to the technical field of gas turbine engines. The simulation disc comprises a disc body, 2-8 mortises are uniformly arranged on the rim of the disc body along the circumferential direction, a U-shaped groove is arranged between every two mortises on the disc body along the circumferential direction, and the profile contour of the U-shaped groove is composed of an arc C1, a straight line L1 and a straight line L2. The straight line L1 and the straight line L2 are symmetrical along the middle radial segmentation line of the arc C1, the extension lines of the straight line L1 and the straight line L2 intersect at the center of the disc body, the U-shaped groove can reduce the centrifugal load of the wheel disc, reduce the circumferential stress of the wheel center, retain enough mortise bending rigidity, reduce the mortise bending stress, remarkably reduce the stress level of dangerous parts such as the wheel disc mortise and the like, and the anti-fatigue performance of the wheel disc is effectively improved, so that the risk of test failure caused by advanced failure of the wheel disc is avoided.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

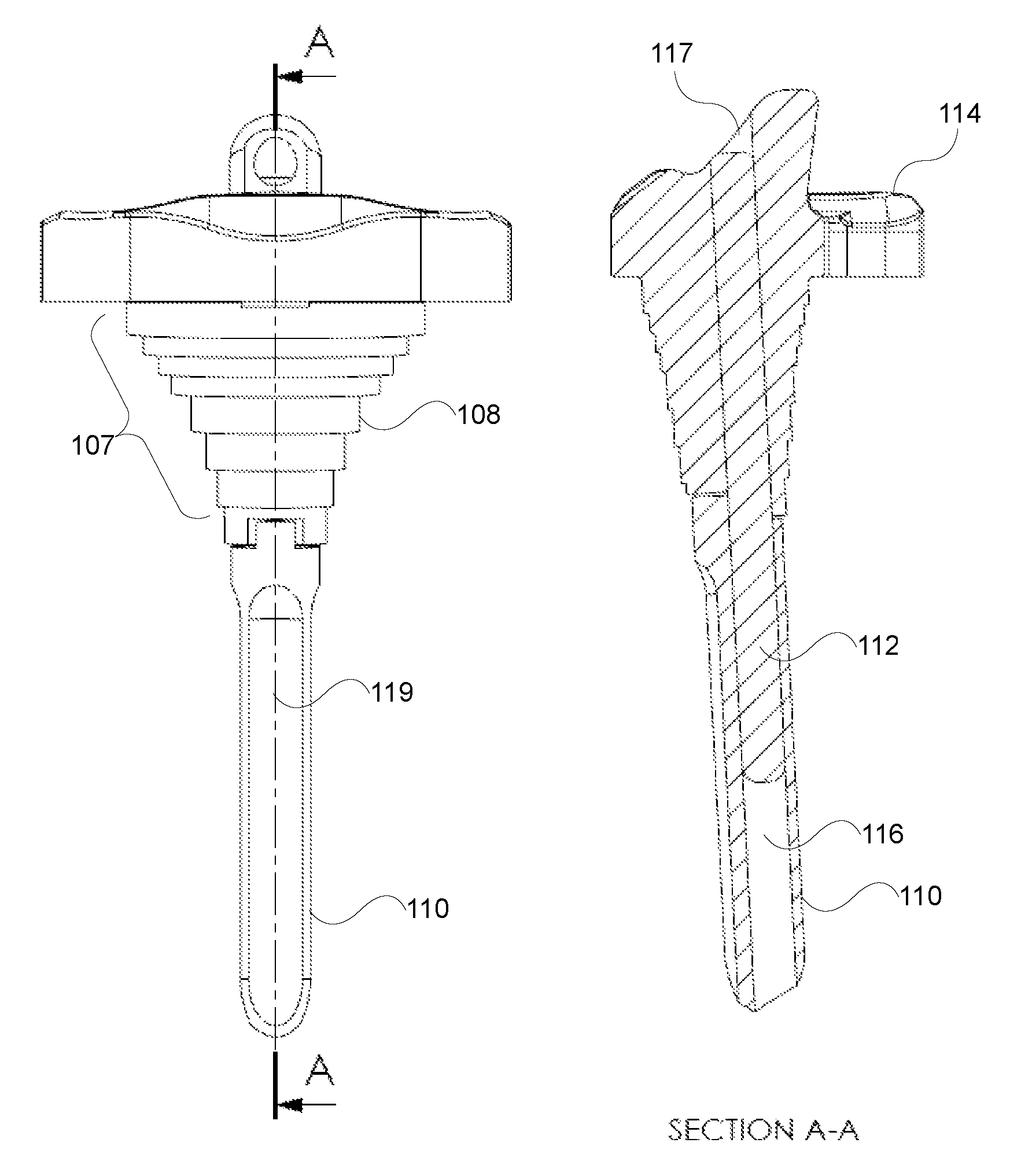

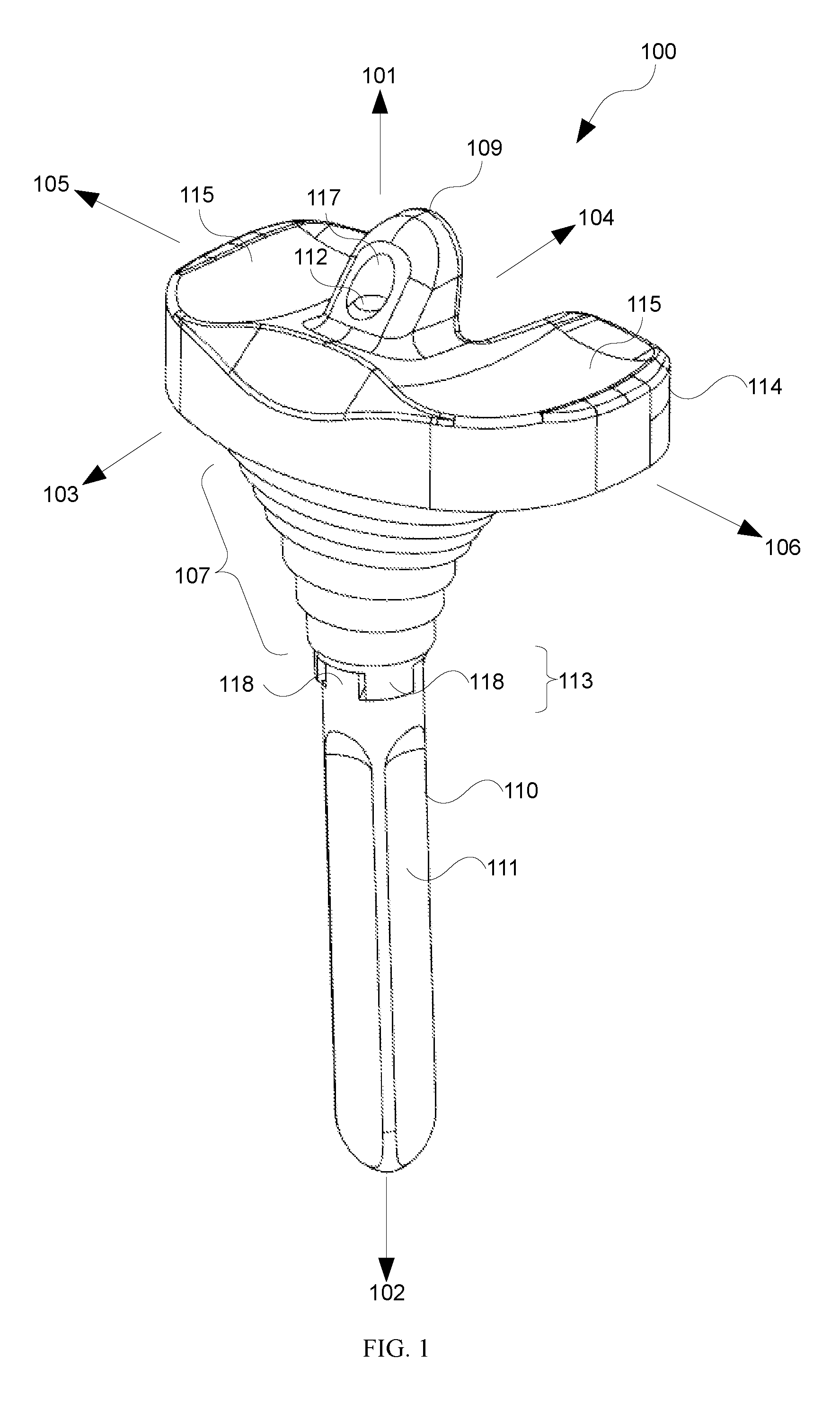

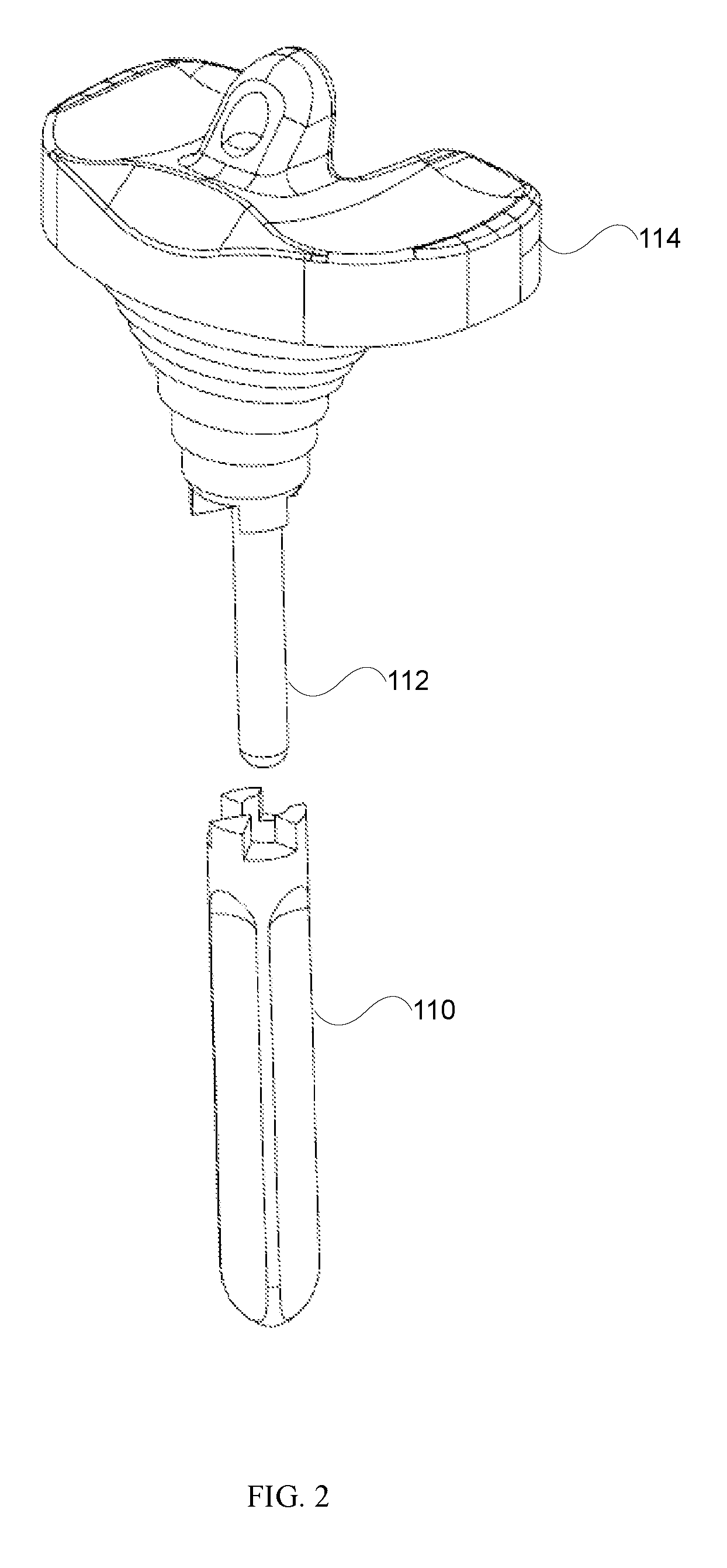

Implant system for knee prosthesis

An implant system for knee prosthesis includes a superiorly located femoral bearing block having a femoral component bearing surface and an inferiorly located stem selectively attachable to the bearing block. A strengthening rod is disposed within at least a portion of the femoral bearing block and the stem.

Owner:MICROPORT ORTHOPEDICS INC

Fuel pump housing

InactiveUS20180252193A1Relieve pressureEffective reduction of stress transitionPositive displacement pump componentsFuel injecting pumpsPump chamberEngineering

A fuel pump housing includes a pumping chamber that is substantially spherical and a drilling intersecting the pumping chamber at an opening. The drilling transitions into the pumping chamber at a transition region of progressively increasing diameter. The transition region and the spherical pumping chamber are configured such that a peak stress in the fuel pump housing is at a location that is spaced away from the opening.

Owner:DELPHI TECH IP LTD

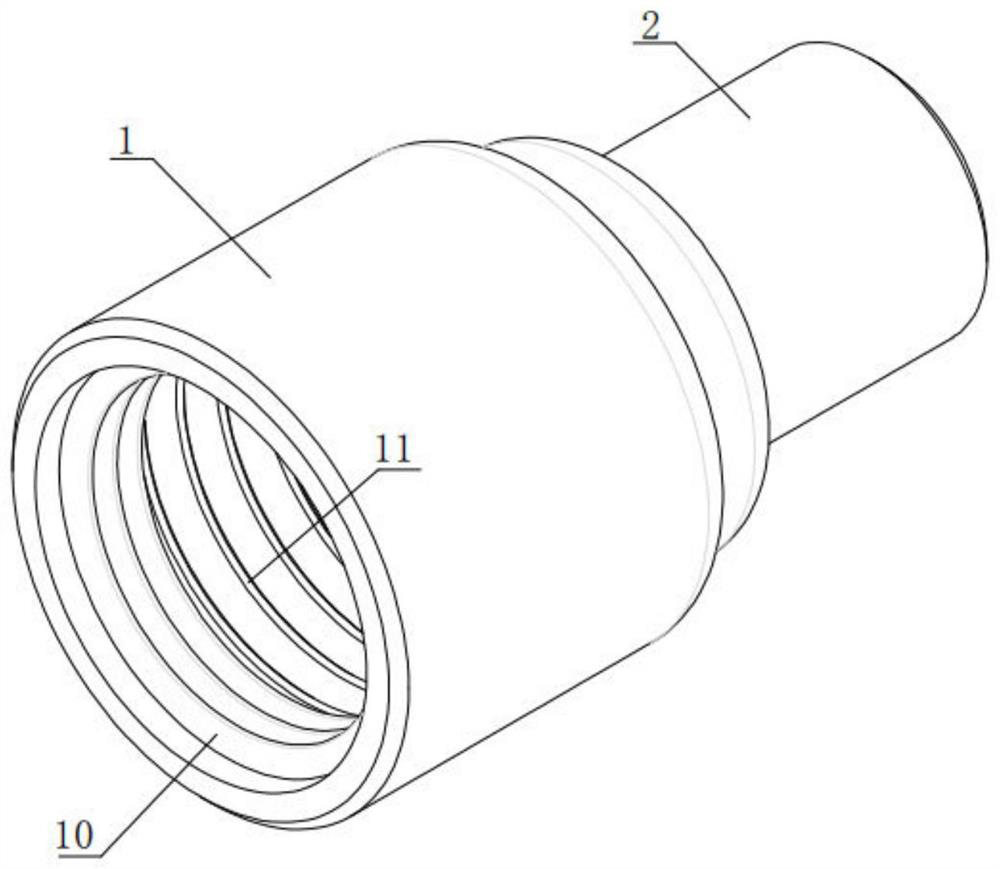

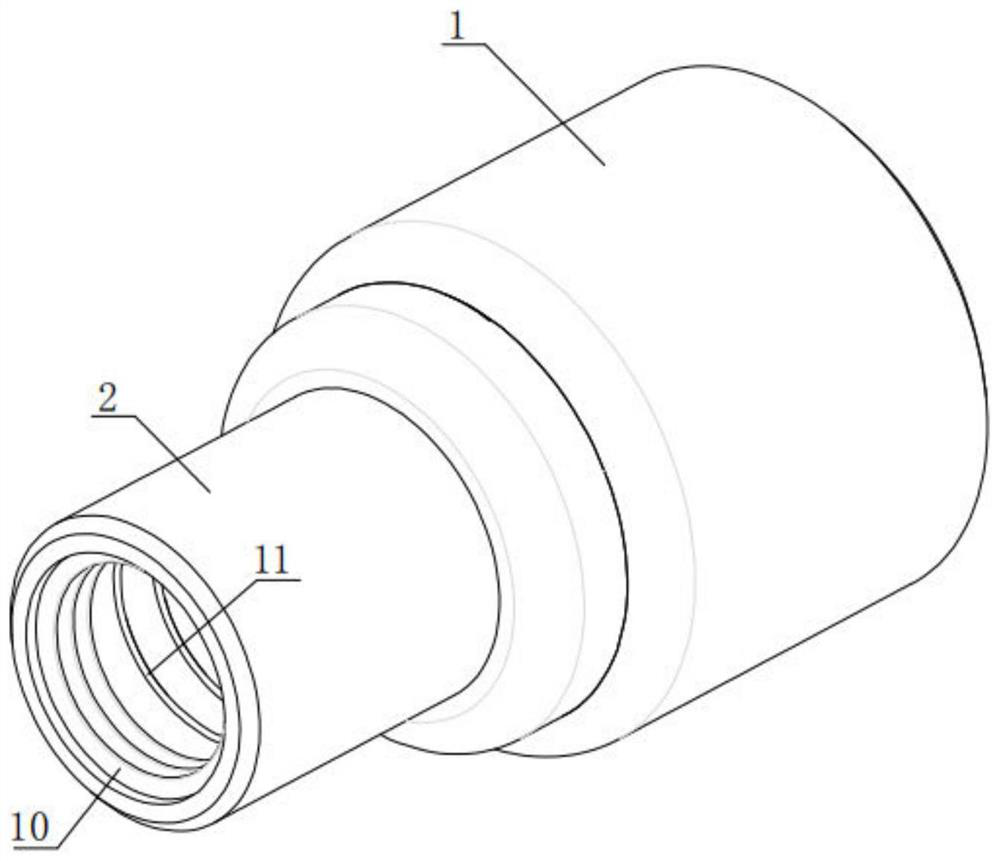

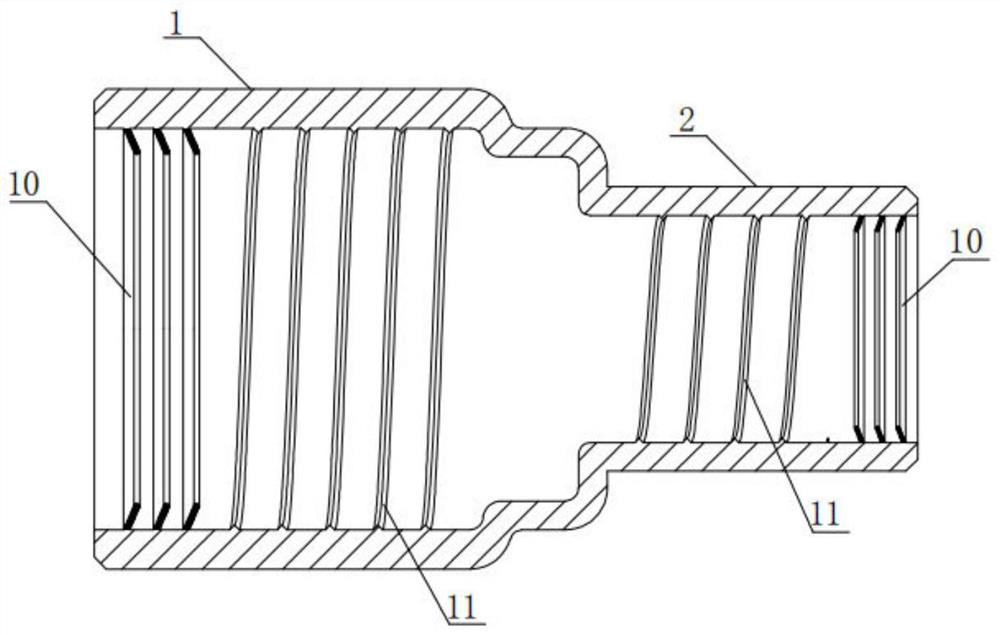

A leak-proof pipe connecting pipe

ActiveCN111594670BTo achieve the purpose of leak preventionQuick installationSleeve/socket jointsScrew threaded jointsEngineeringStructural engineering

The invention discloses a leak-proof pipe connecting pipe. The gap between the pipe and the inner wall of the connecting pipe is completely sealed by a leak-proof ring arranged inside the connecting pipe to achieve the purpose of leak-proofing. The main points of the technical solution are: a leak-proof pipeline connection pipe, including a large pipe fixing part and a small pipe fixing part, characterized in that the large pipe fixing part and the small pipe fixing part are integrated and connected internally, and the inner wall of the large pipe fixing part is provided with at least A leak-proof ring, the leak-proof ring is located at the nozzle of the large tube fixing part, the leak-proof ring is an annular sheet, and the outer wall of the leak-proof ring is fixed on the inner wall of the big tube fixing part without leaving any gaps. The leakage-proof pipe connecting pipe of the present invention can completely seal the gap between the pipe and the inner wall of the fixed part of the large pipe, and the liquid or gas flowing out of the joint of the pipe cannot be discharged outside, so as to achieve the purpose of leak prevention.

Owner:宁波普锐流体科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com