Simulation disc for low-cycle fatigue test of turbine working blade

A technology for low-cycle fatigue and testing, applied in the direction of applying repeated force/pulsation force to test the strength of materials, measuring devices, instruments, etc., it can solve the problems of failure to meet test assessment, high test temperature, increase test cost and processing cycle, etc. problem, achieve the effect of shortening the processing cycle, reducing centrifugal load, and avoiding test failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

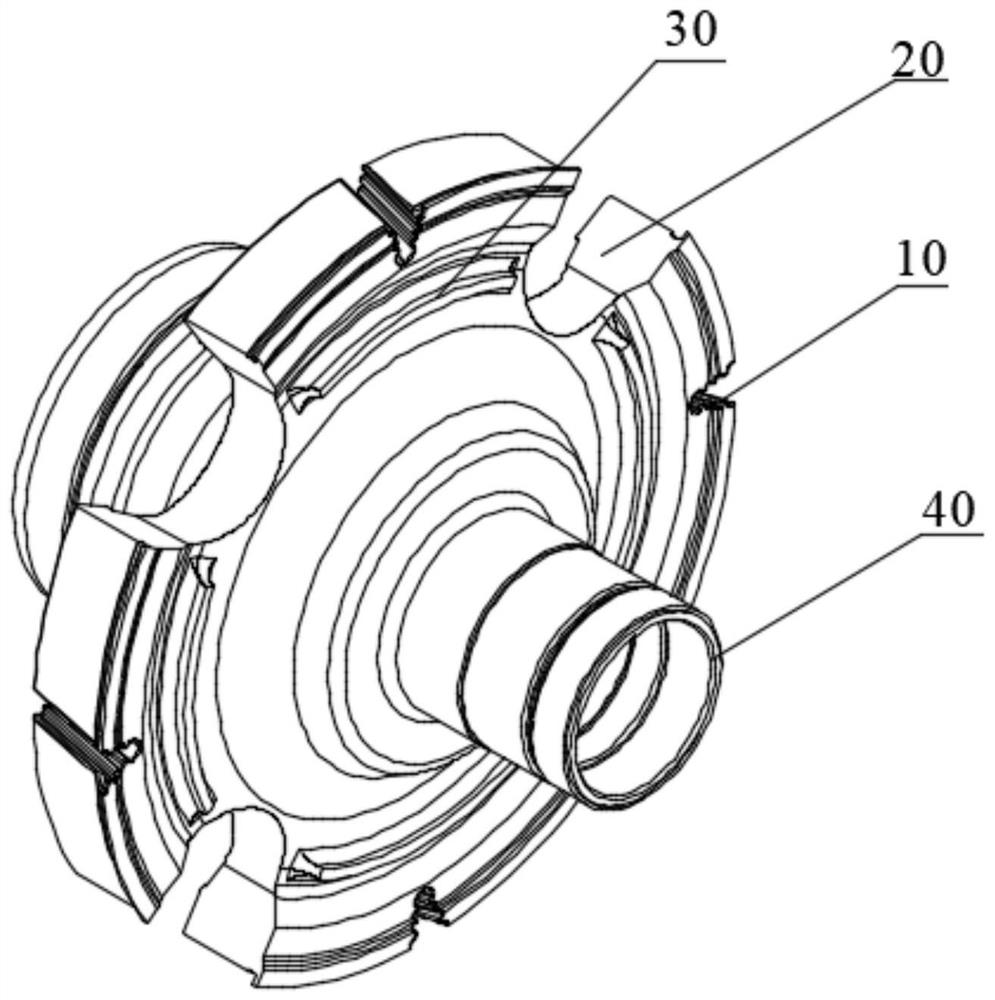

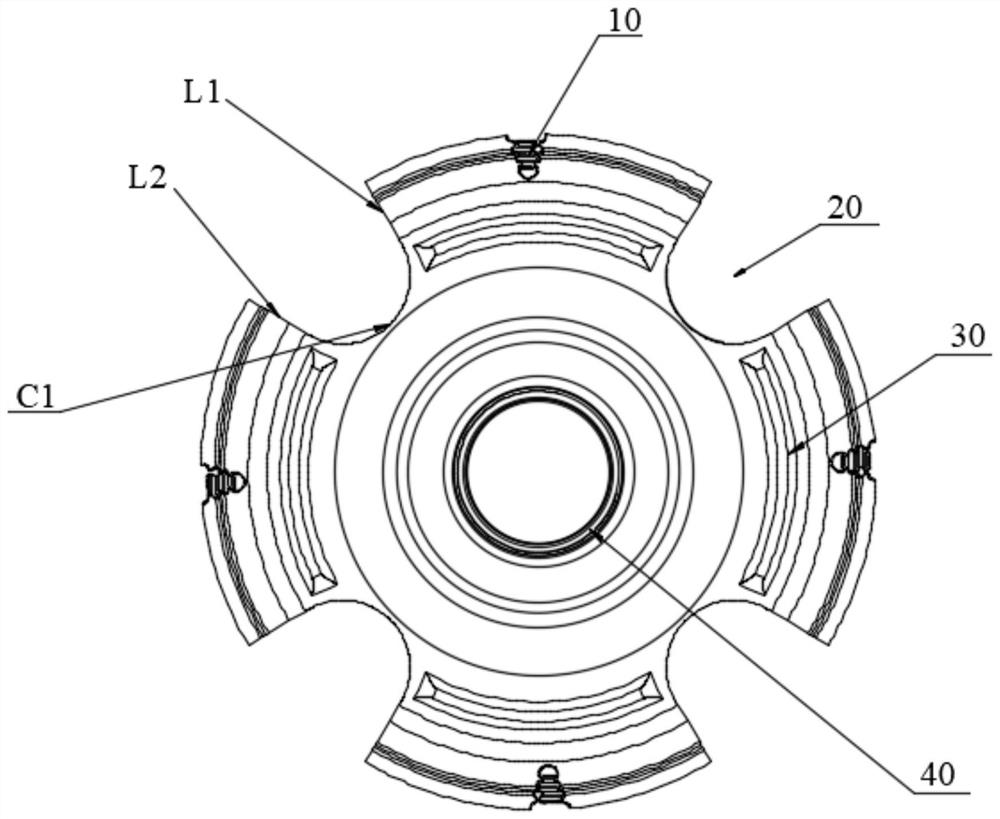

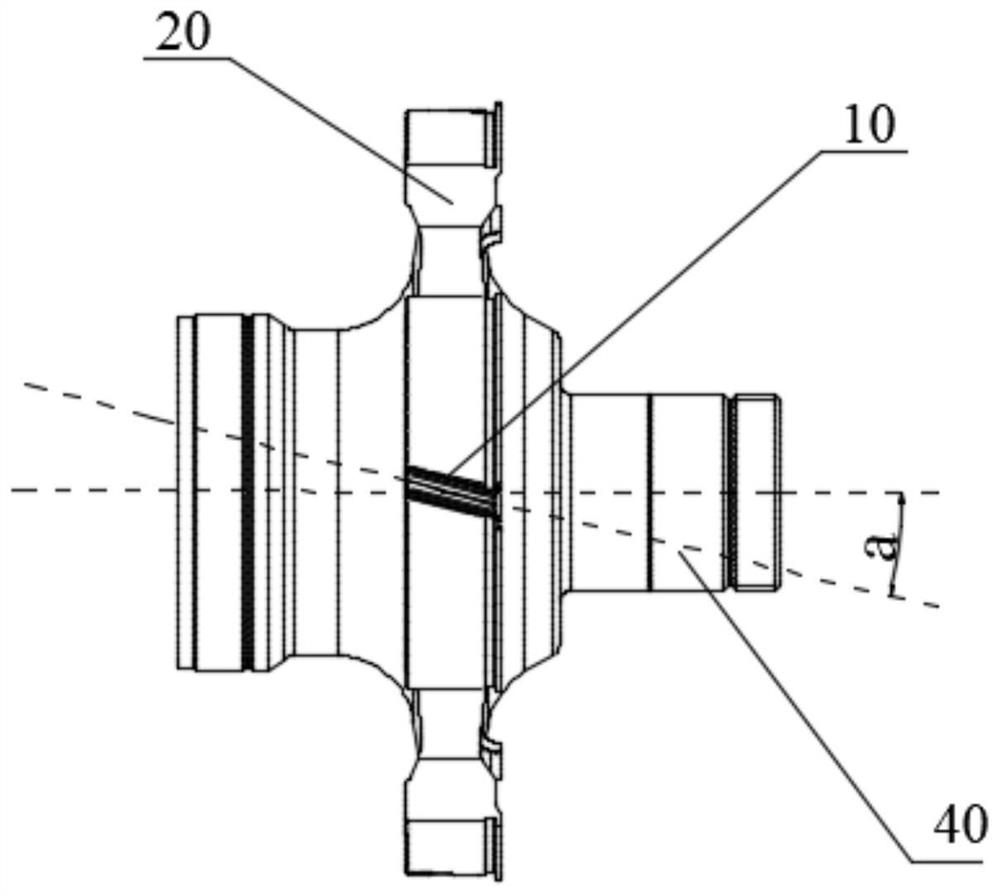

[0027] Refer Figure 1-3 As shown, preferred embodiments of the present invention provide a turbine working blade low cycle fatigue test simulation disk, including a disk, and the rim of the disc is uniformly opened in a circumferential direction, and a disk body. A U-shaped groove 20 is opened in the intermediate position of each of the two tank 10, and the U-shaped groove 20 is composed of the arc C1, the straight line L1, and the straight line L2, the straight line L1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com