Patents

Literature

50 results about "Stress failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

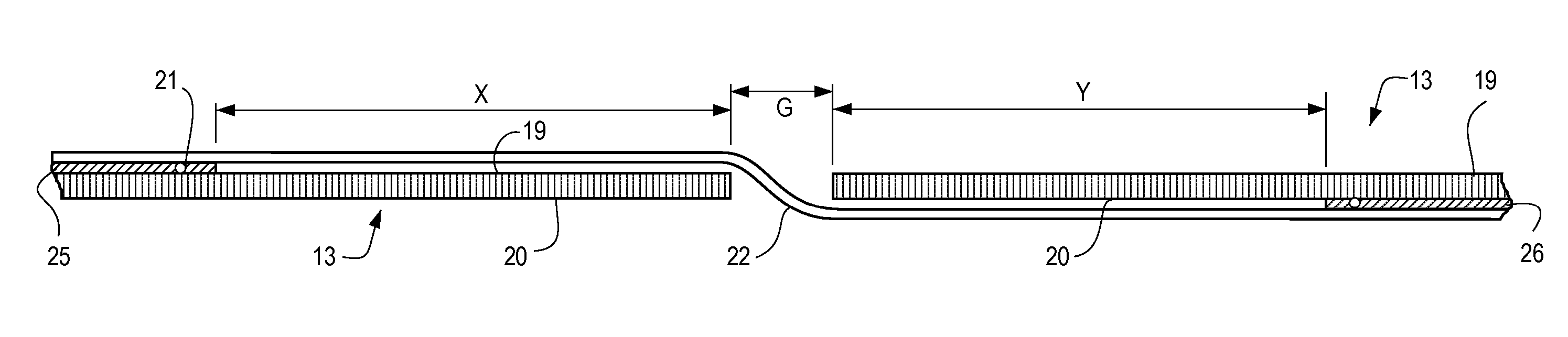

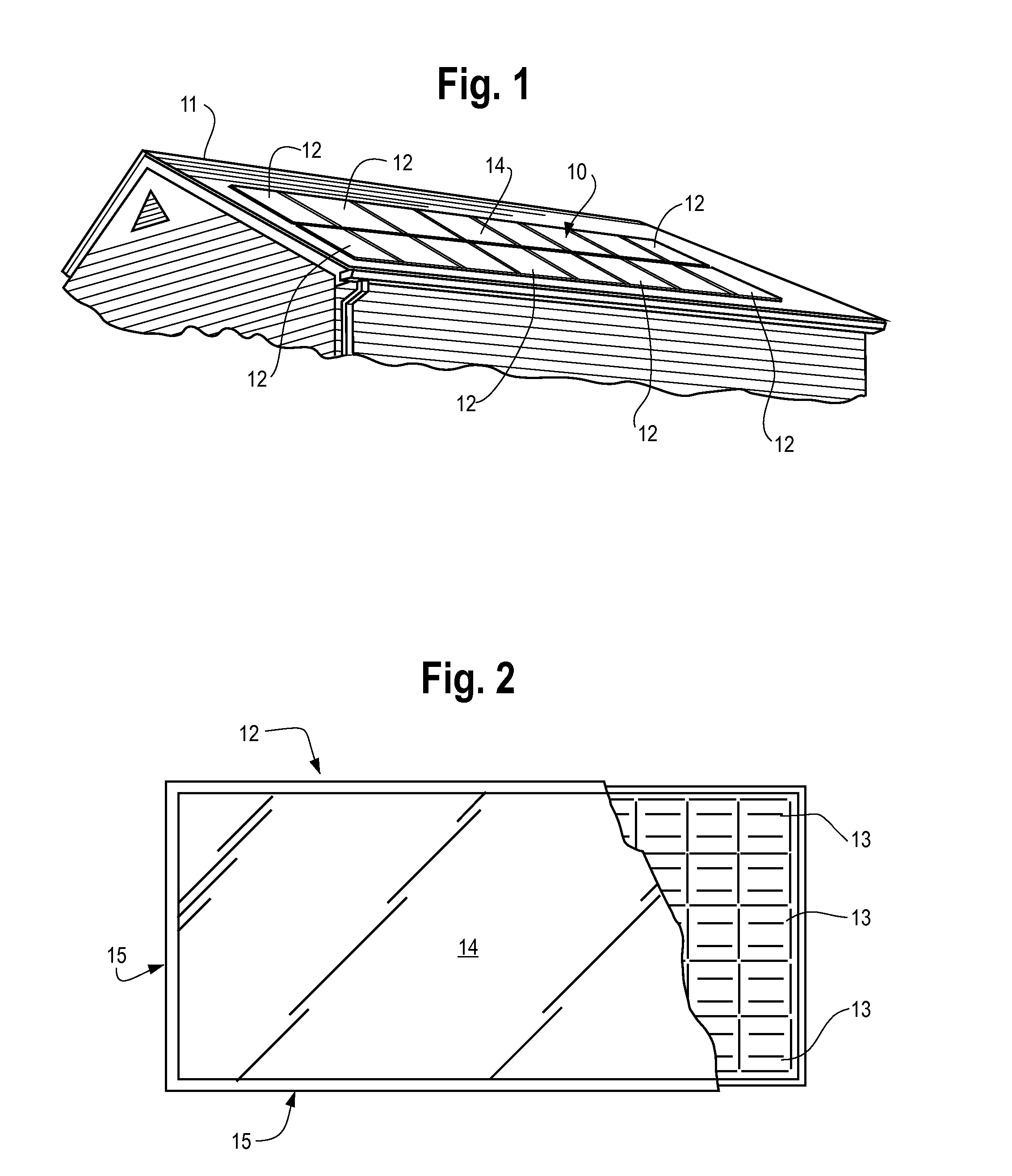

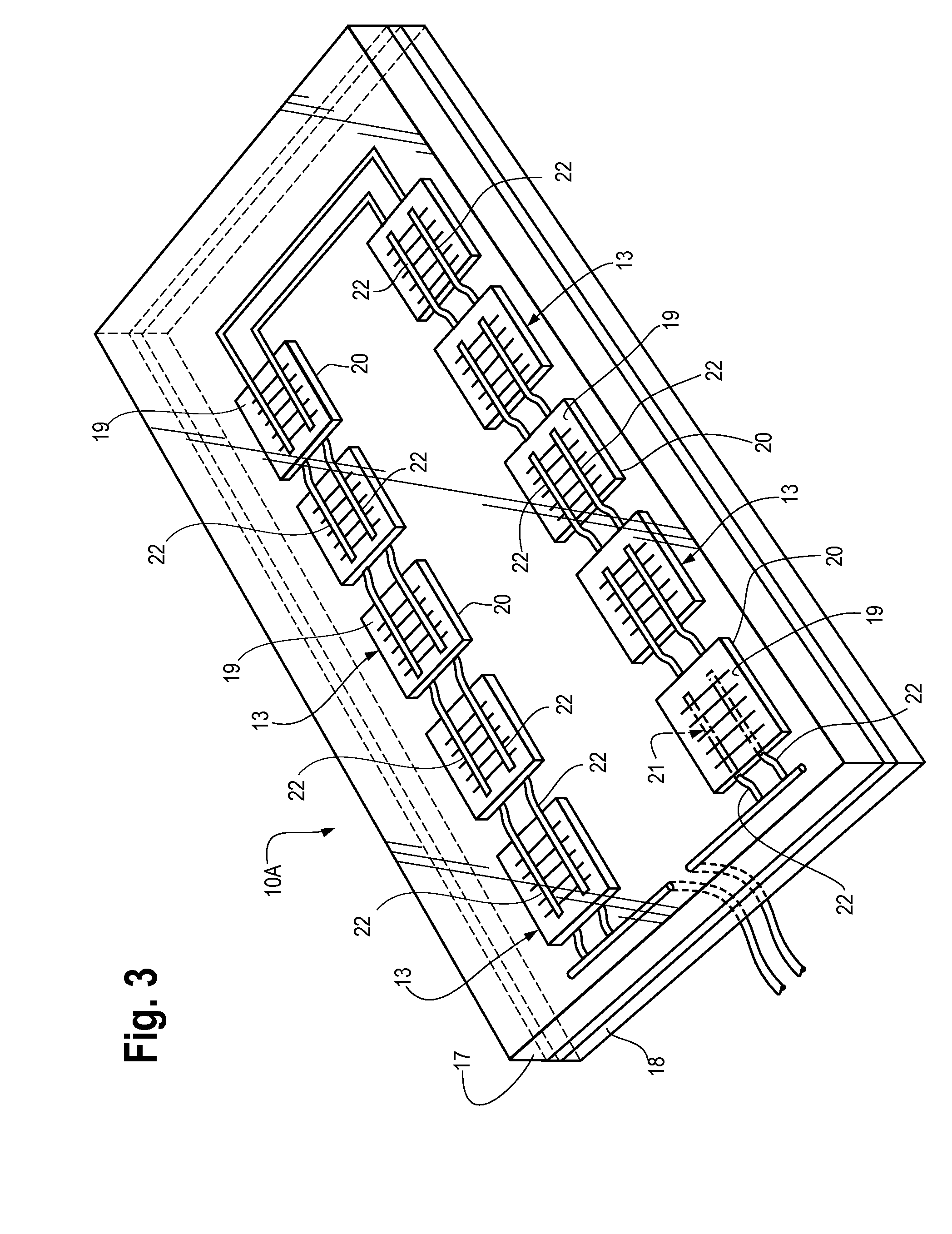

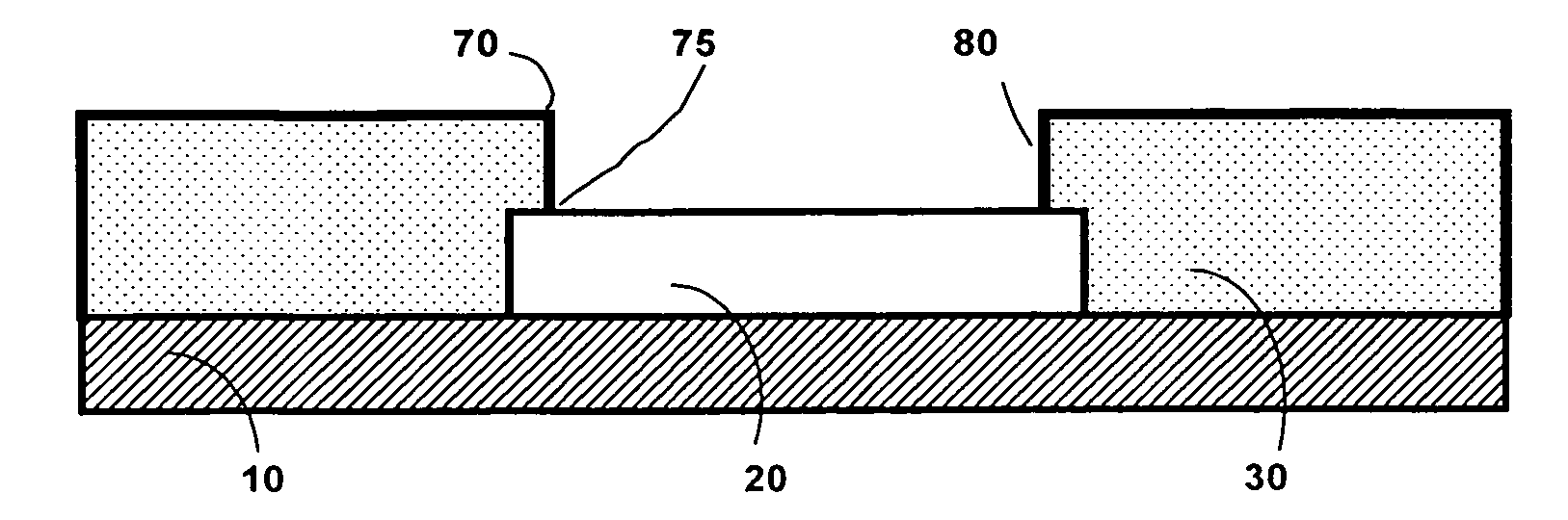

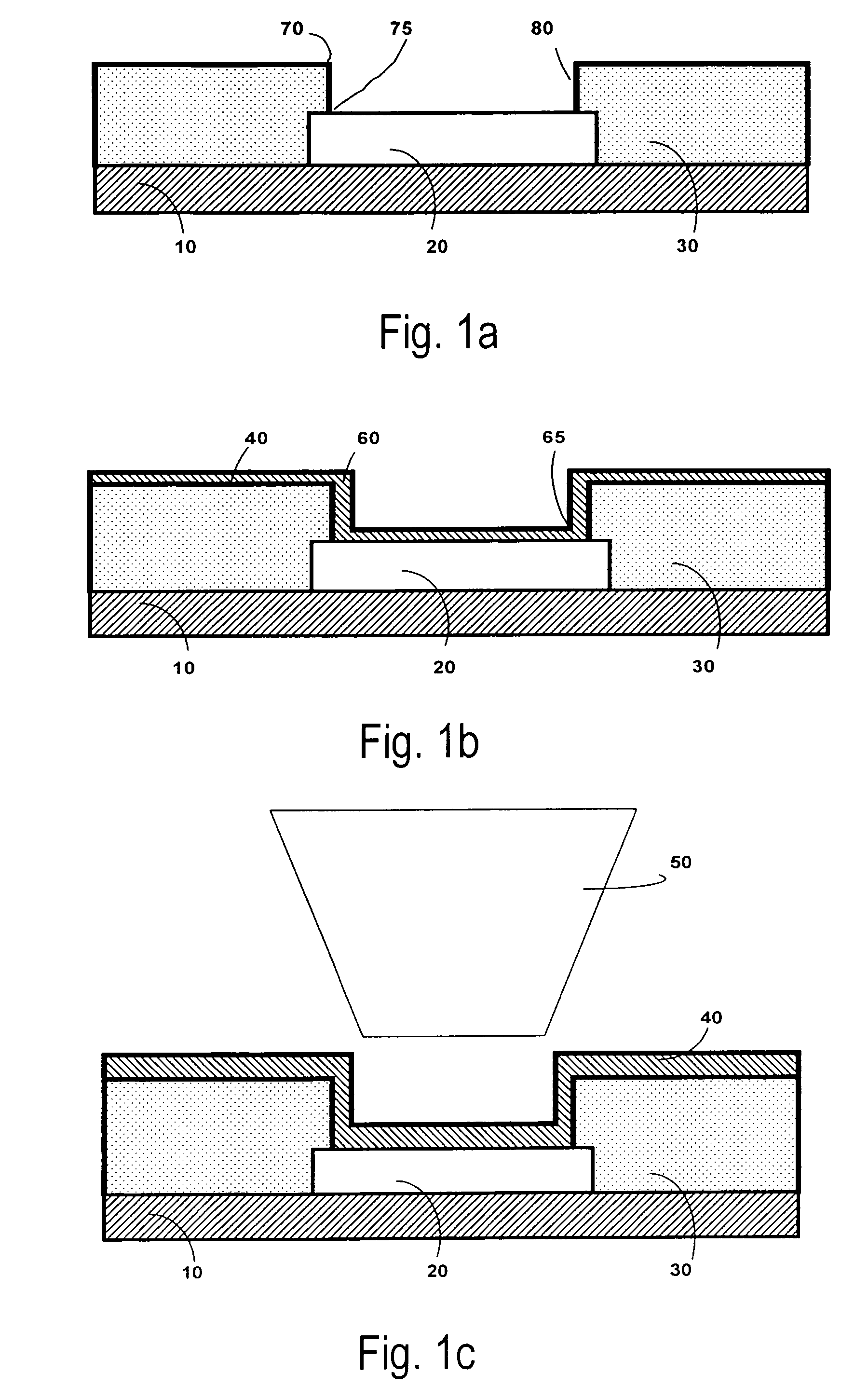

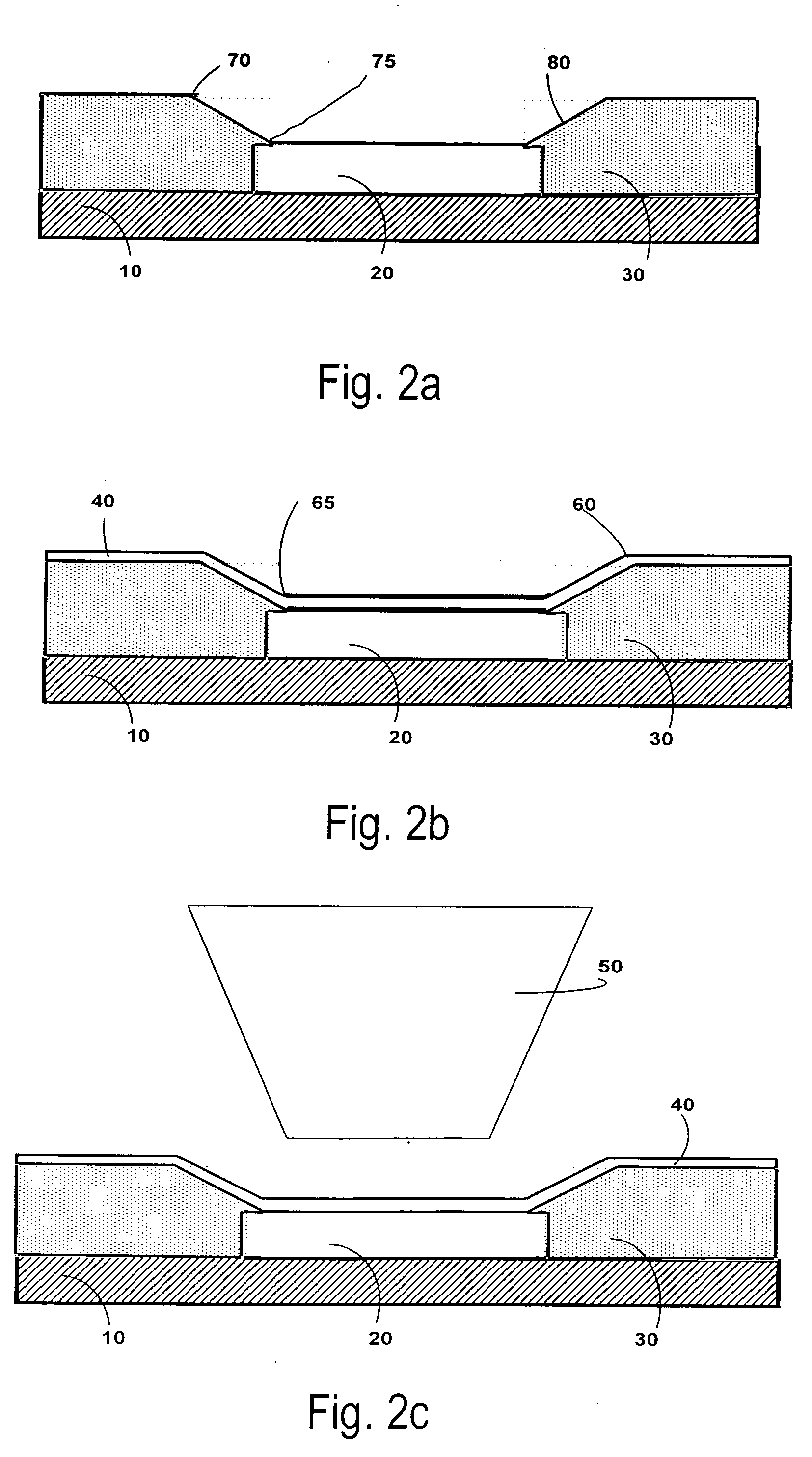

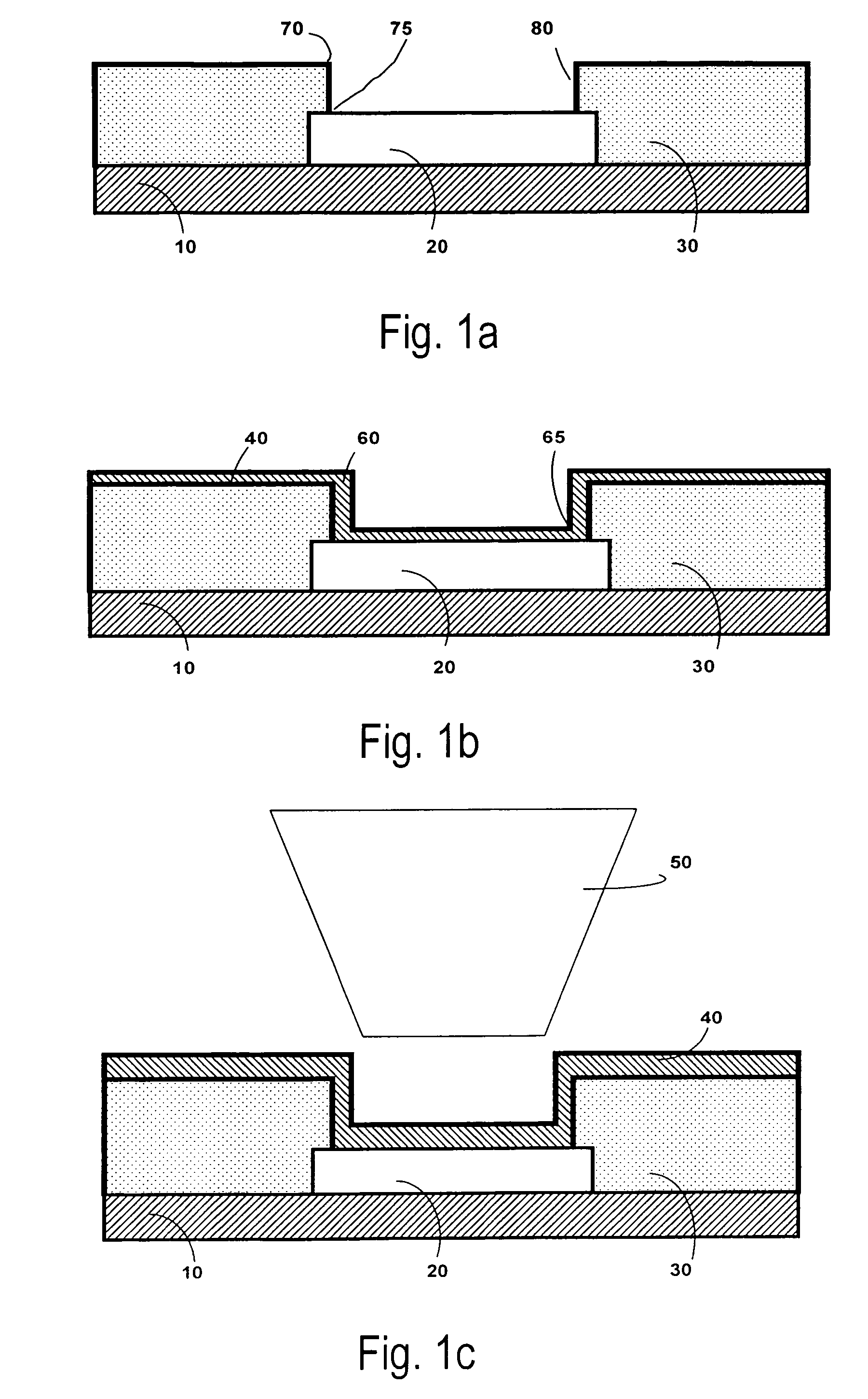

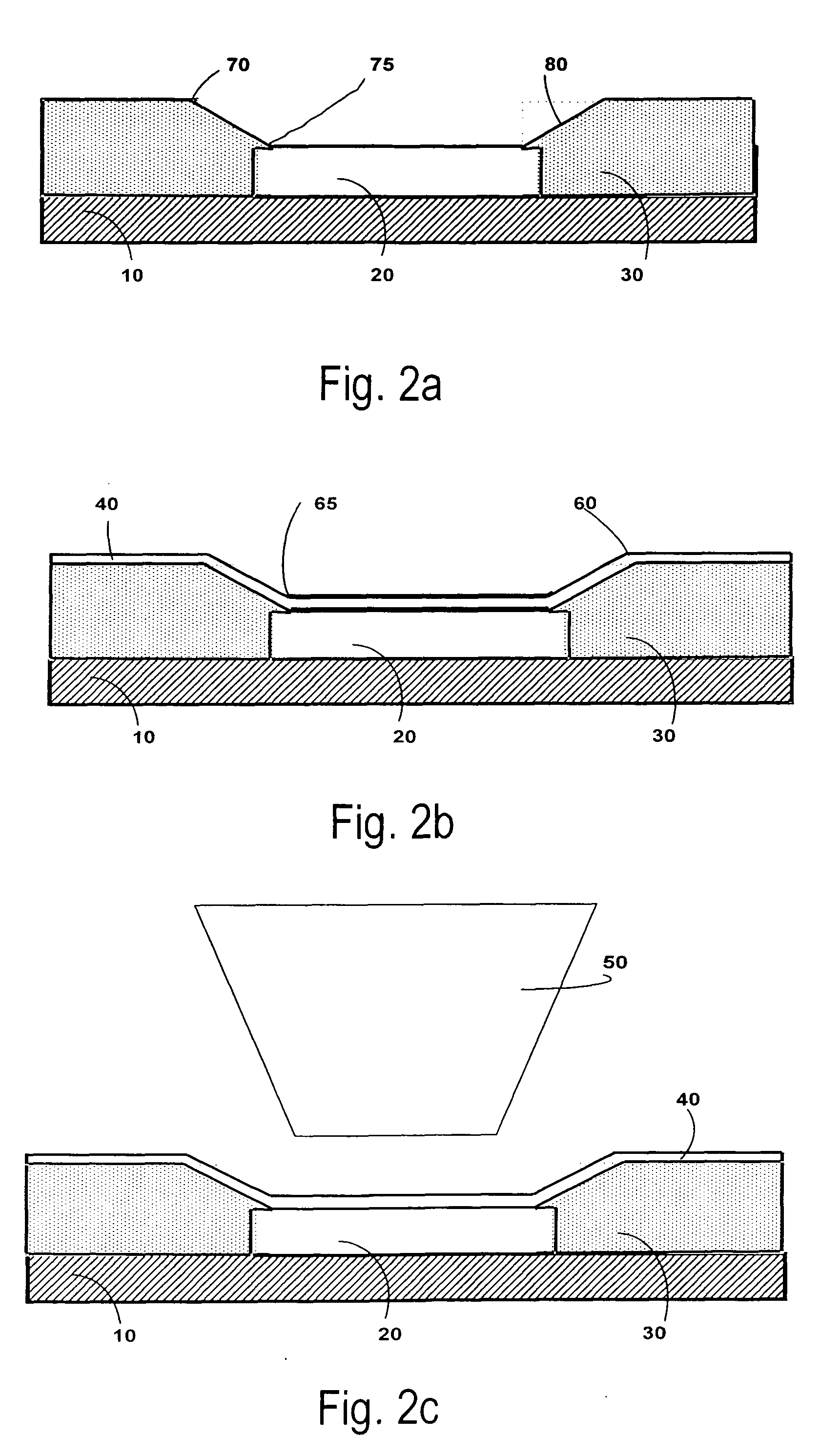

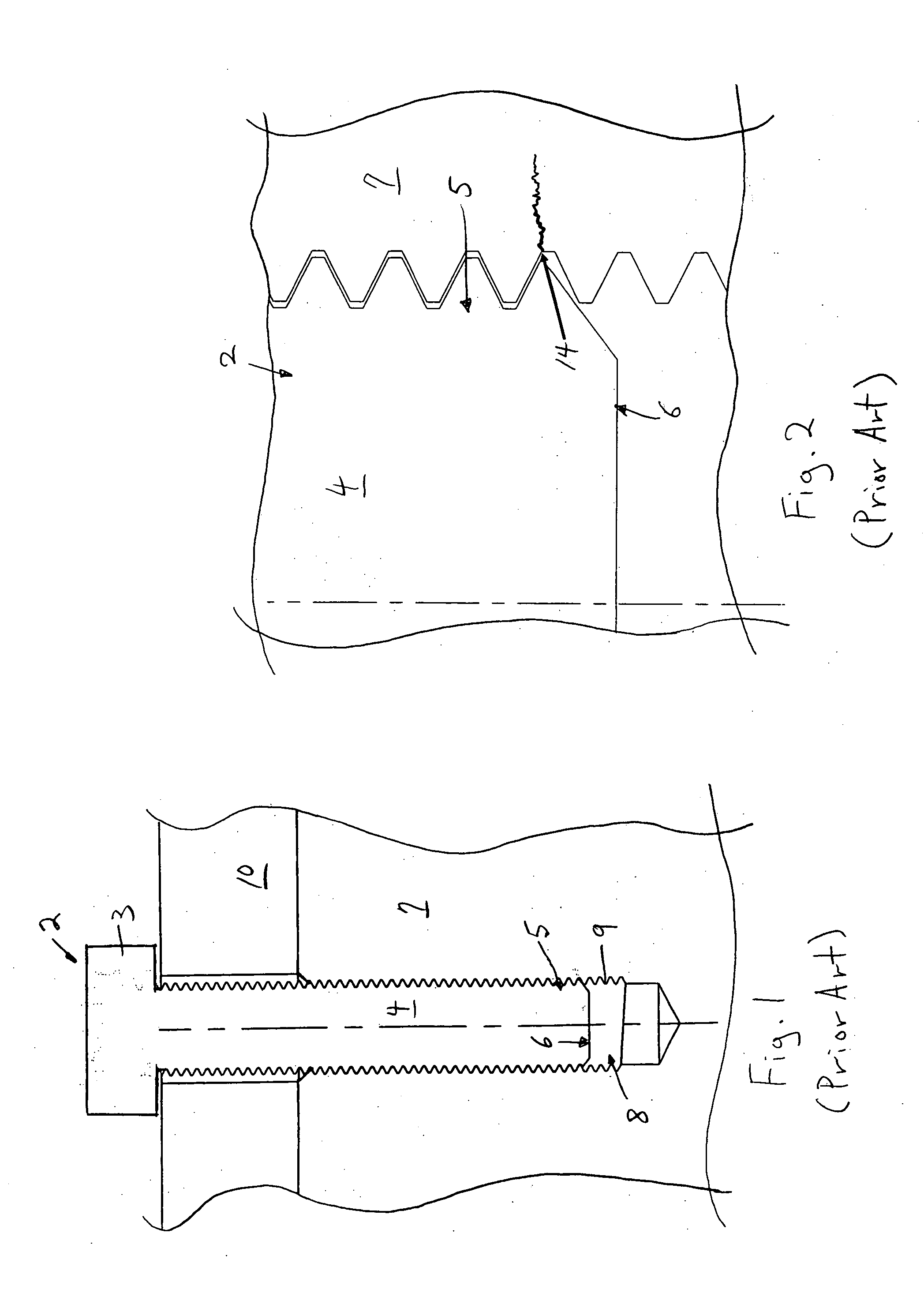

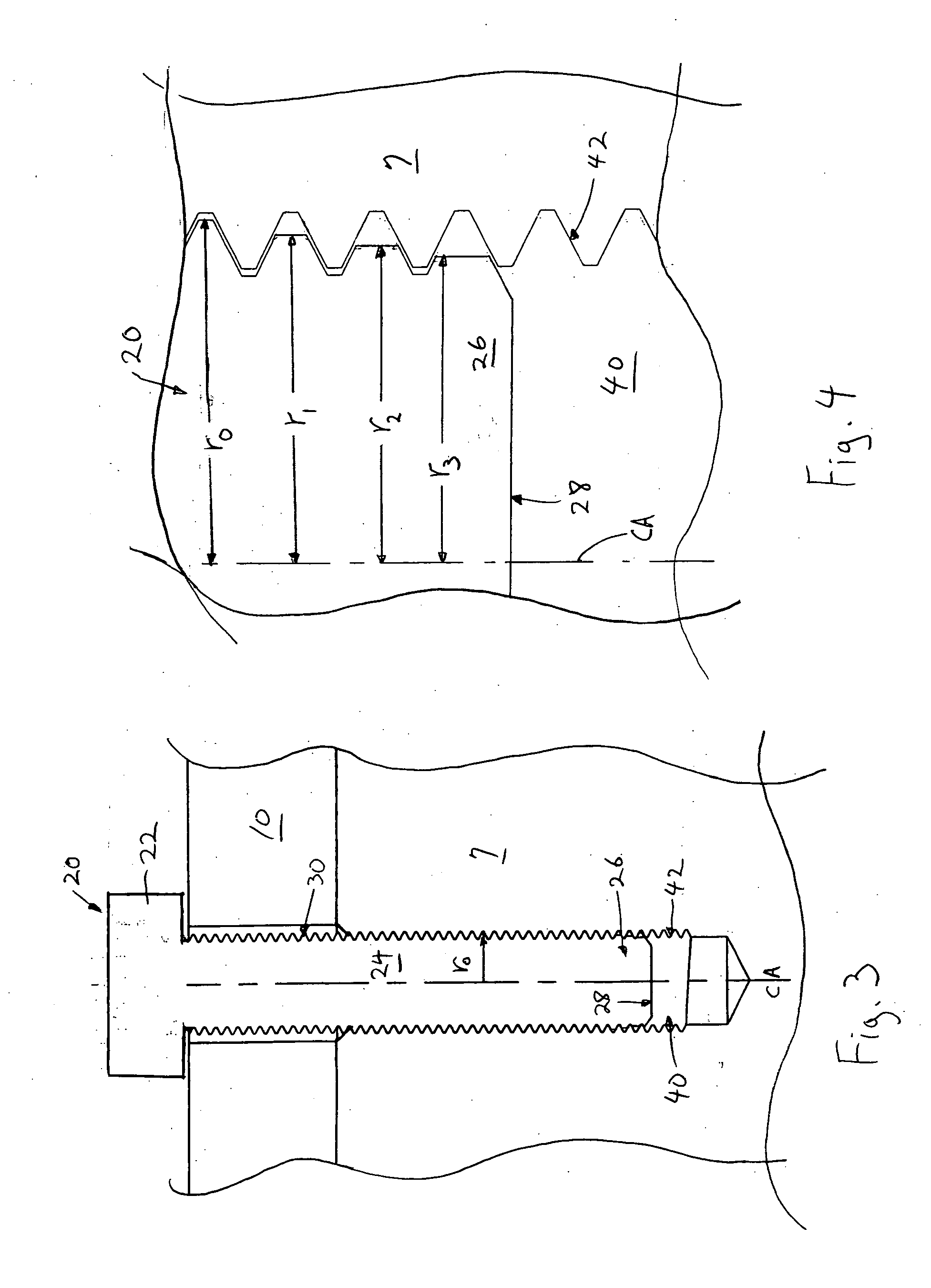

Means and Method for Electrically Connecting Photovoltaic Cells in a Solar Module

InactiveUS20070144578A1Alleviate stress failurePhotovoltaic supportsPhotovoltaic energy generationConductive materialsStress failure

A connector and method for electrically connecting adjacent solar cells together in a solar module. The terminals of the cells are connected with individual lengths of an electrically conductive material such as an electrically conductive metal ribbon. A substantial portion of the mid section of the ribbons remain unsoldered to thereby provide a stress relief zone in the ribbon between the cells to alleviate stress failures in the ribbons.

Owner:BP CORP NORTH AMERICA INC

Casinghead gas corrosion resistant pumping rod steel and manufacturing method thereof

InactiveCN101440461AImproved corrosion cracking performanceGood plasticityTemperature control deviceFurnace typesNiobiumManganese

The invention provides steel for a pumping rod resisting casinghead gas corrosion and a manufacture method thereof. The steel comprises the following chemical compositions by mass percentage: 0.05 to 0.25 percent of carbon, 0.50 to 2.00 percent of silicon, 1.10 to 2.50 percent of manganese, 0.02 to 0.50 percent of molybdenum, 0.02 to 0.50 percent of nickel, 0.50 to 1.50 percent of chromium, 0.01 to 0.10 percent of vanadium, 0.005 to 0.050 percent of aluminum, 0.02 to 0.10 percent of niobium, 0.05 to 0.50 percent of copper, 0.01 to 0.10 percent of titanium, less than or equal to 0.015 percent of sulphur, less than or equal to 0.020 percent of phosphorus, and the balance being ferrum. The method is to manufacture a pumping rod wire through a design of adding the niobium and other trace alloy elements and corresponding compositions into steel, and controlled rolling and controlled cooling organization control technology. The pumping rod manufactured by the wire has excellent oilwell medium corrosion resistance, proper strength, excellent plastic tenacity and excellent welding performance, thereby improving the service life and reliability of the pumping rod, and improving the whole stability of pumping equipment, and further solving the problem that the prior pumping rod has repeated stress failure caused by endurance of complex casinghead gas corrosion.

Owner:BAOSHAN IRON & STEEL CO LTD +1

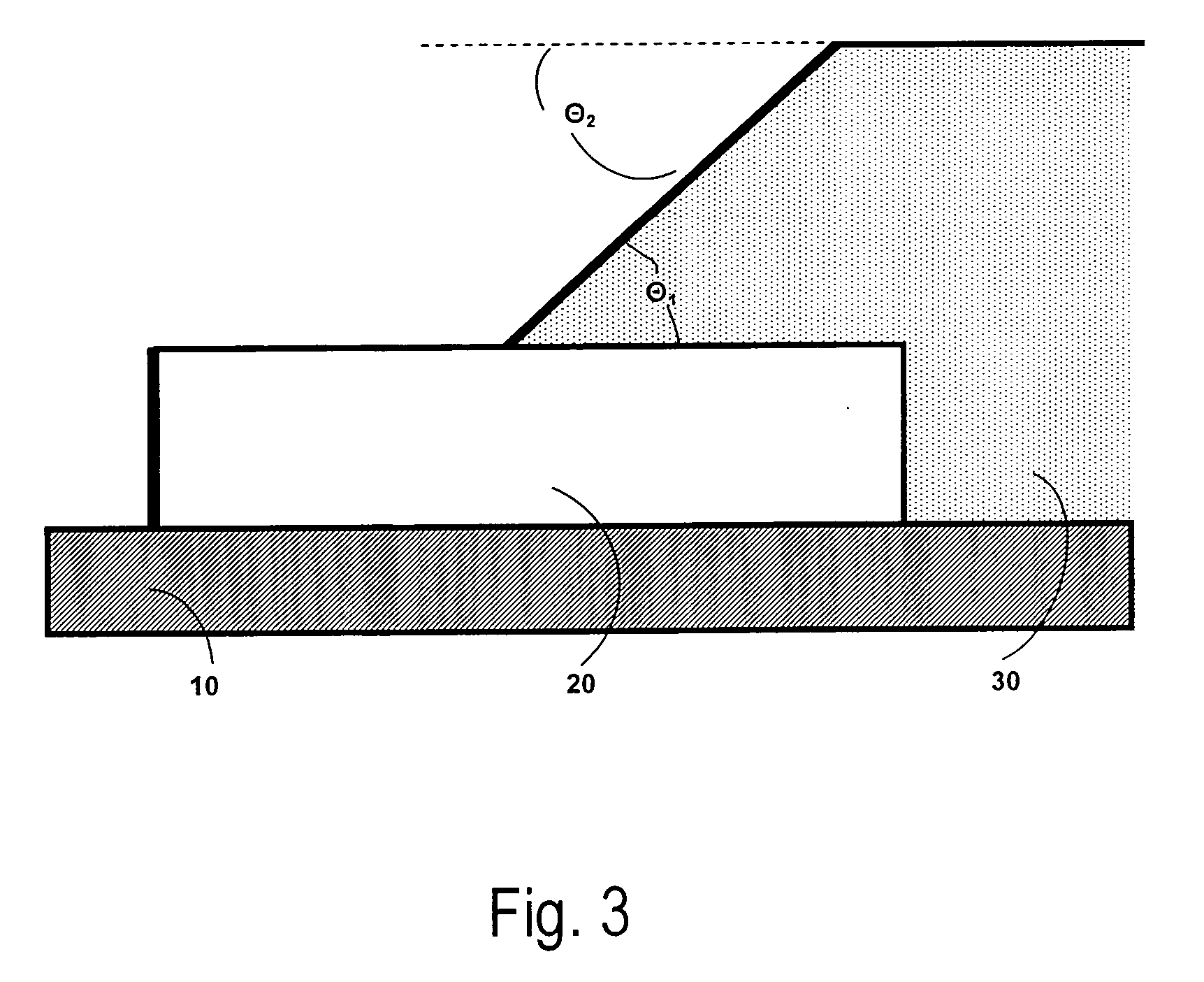

Novel positive photosensitive polybenzoxazole precursor compositions

ActiveUS20070099111A1Reduce sidewall angleAvoid stress failurePhotomechanical apparatusDiazo compound compositionsPolymer sciencePlasticizer

A heat resistant positive-working photosensitive PBO precursor composition comprising: (a) at least one polybenzoxazole precursor polymer; (a) at least one plasticizer compound; (b) at least one solvent; wherein the amount of the plasticizer present in the composition is an amount effective to reduce the sidewall angle of imaged and cured features in the coated film on the substrate to prevent stress failures in subsequent metallization of the substrate due to steep angles of the imaged features, and with the proviso that if the polybenzoxazole precursor polymer solely consists of polybenzoxazole precursor polymers that do not contain a photoactive moiety on the polymer, then (c) at least one photoactive compound is also present in the composition.

Owner:FUJIFILM ELECTRONICS MATERIALS US

Positive photosensitive polybenzoxazole precursor compositions

ActiveUS7803510B2Reduce sidewall angleAvoid stress failureDiazo compound compositionsPhotosensitive material processingBenzoxazolePlasticizer

A heat resistant positive-working photosensitive PBO precursor composition comprising:(a) at least one polybenzoxazole precursor polymer;(a) at least one plasticizer compound;(b) at least one solvent;wherein the amount of the plasticizer present in the composition is an amount effective to reduce the sidewall angle of imaged and cured features in the coated film on the substrate to prevent stress failures in subsequent metallization of the substrate due to steep angles of the imaged features, and with the proviso that if the polybenzoxazole precursor polymer solely consists of polybenzoxazole precursor polymers that do not contain a photoactive moiety on the polymer, then(c) at least one photoactive compound is also present in the composition.

Owner:FUJIFILM ELECTRONICS MATERIALS US

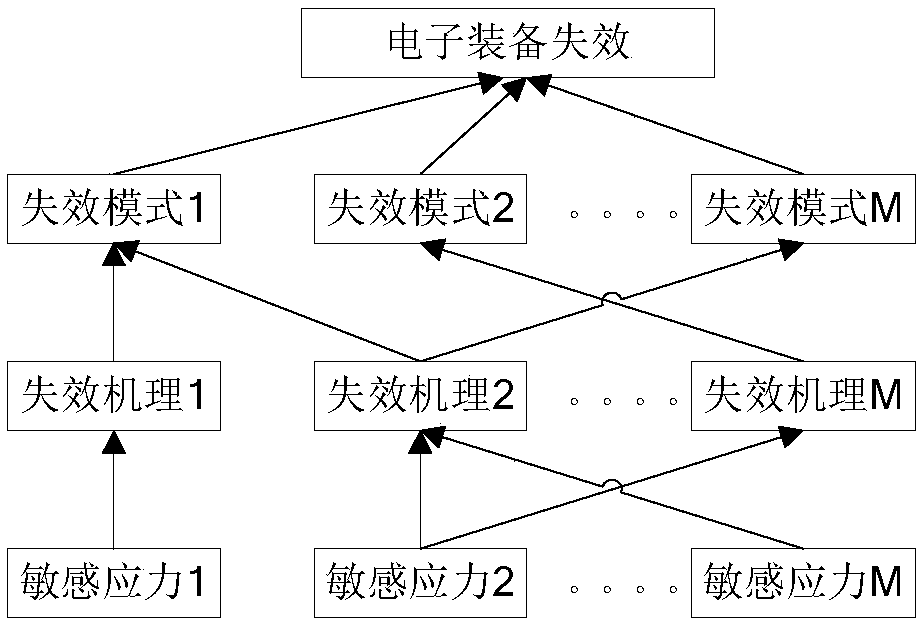

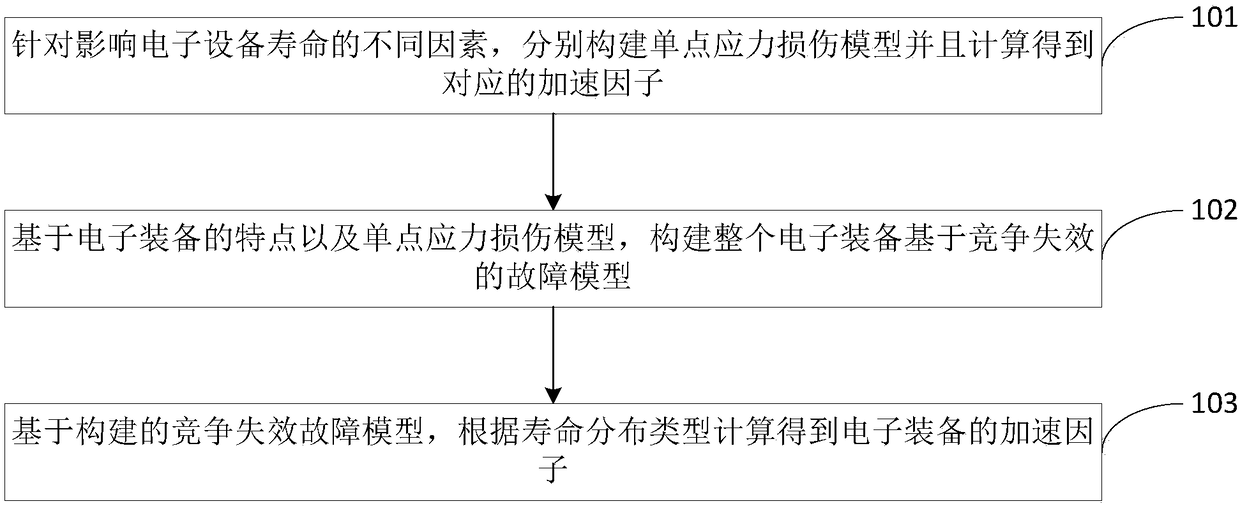

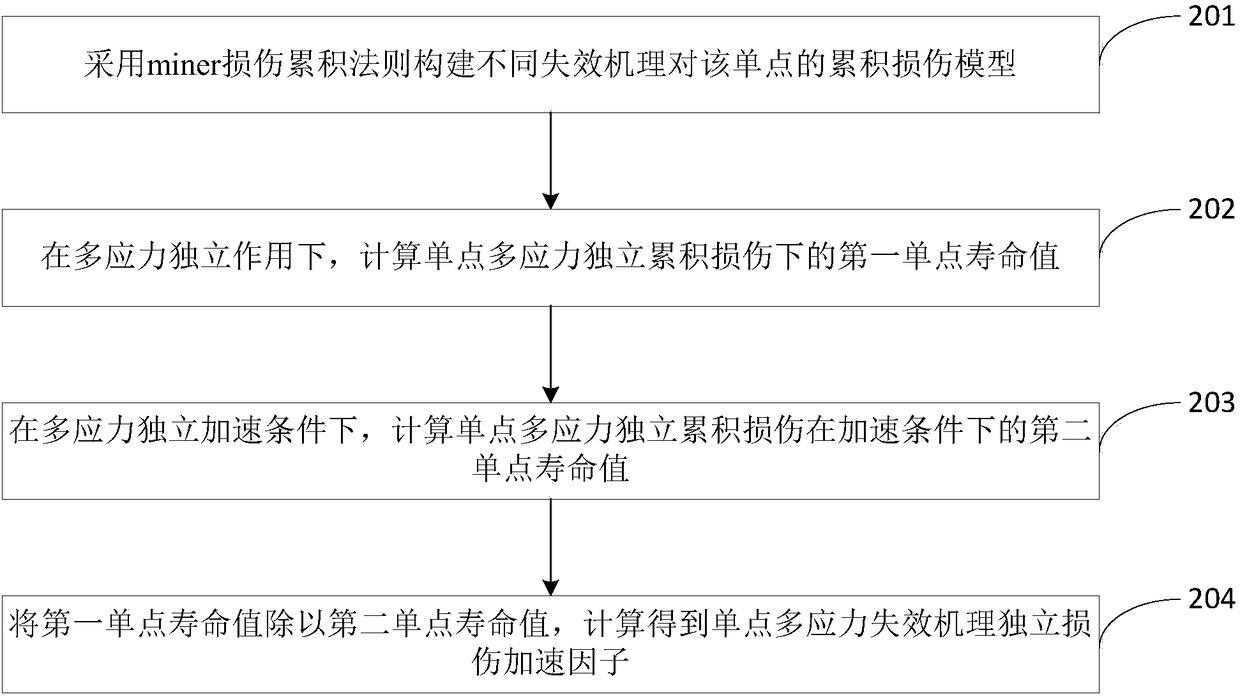

Multi-element acceleration factor calculation method of electronic equipment

ActiveCN108399278AAccelerated test is accurateAccelerated test is reliableDesign optimisation/simulationSpecial data processing applicationsStress failureFault model

The invention discloses a multi-element acceleration factor calculation method of electronic equipment. The method includes: respectively constructing single-point stress damage models for different elements influencing life of the electronic equipment, and calculating and obtaining corresponding acceleration factors; constructing a competition failure-based failure model of the entire electronicequipment on the basis of the characteristics of the electronic equipment and the single-point stress damage models; and calculating and obtaining acceleration factors of the electronic equipment on the basis of the constructed fault model of competition failure according to a statistical equivalence principle. According to the method, for the current electronic equipment of which an equipment structure and failure modes are complicated, failure mechanisms and failure forms under various stress conditions of temperature, humidity, vibration, electrical stress, combinations thereof and the likeare analyzed, a corresponding stress failure model is constructed, and thus the acceleration factors of the electronic equipment can be obtained according to the different elements, the fault model and a corresponding system life model. The method is completely suitable for accelerated testing of the entire-machine equipment, and then enables accelerated testing of the electronic equipment to bemore accurate and reliable.

Owner:CASIC DEFENSE TECH RES & TEST CENT

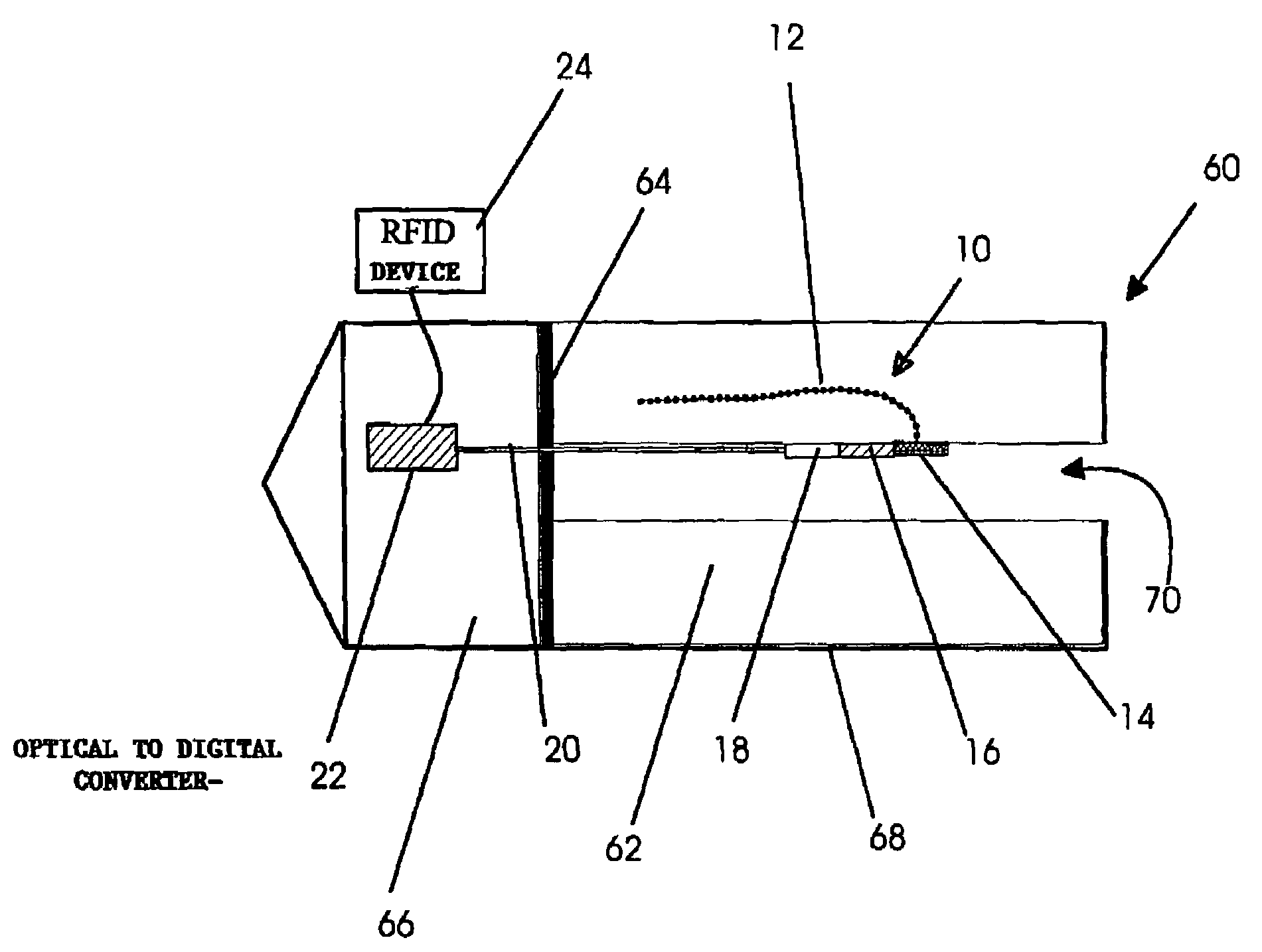

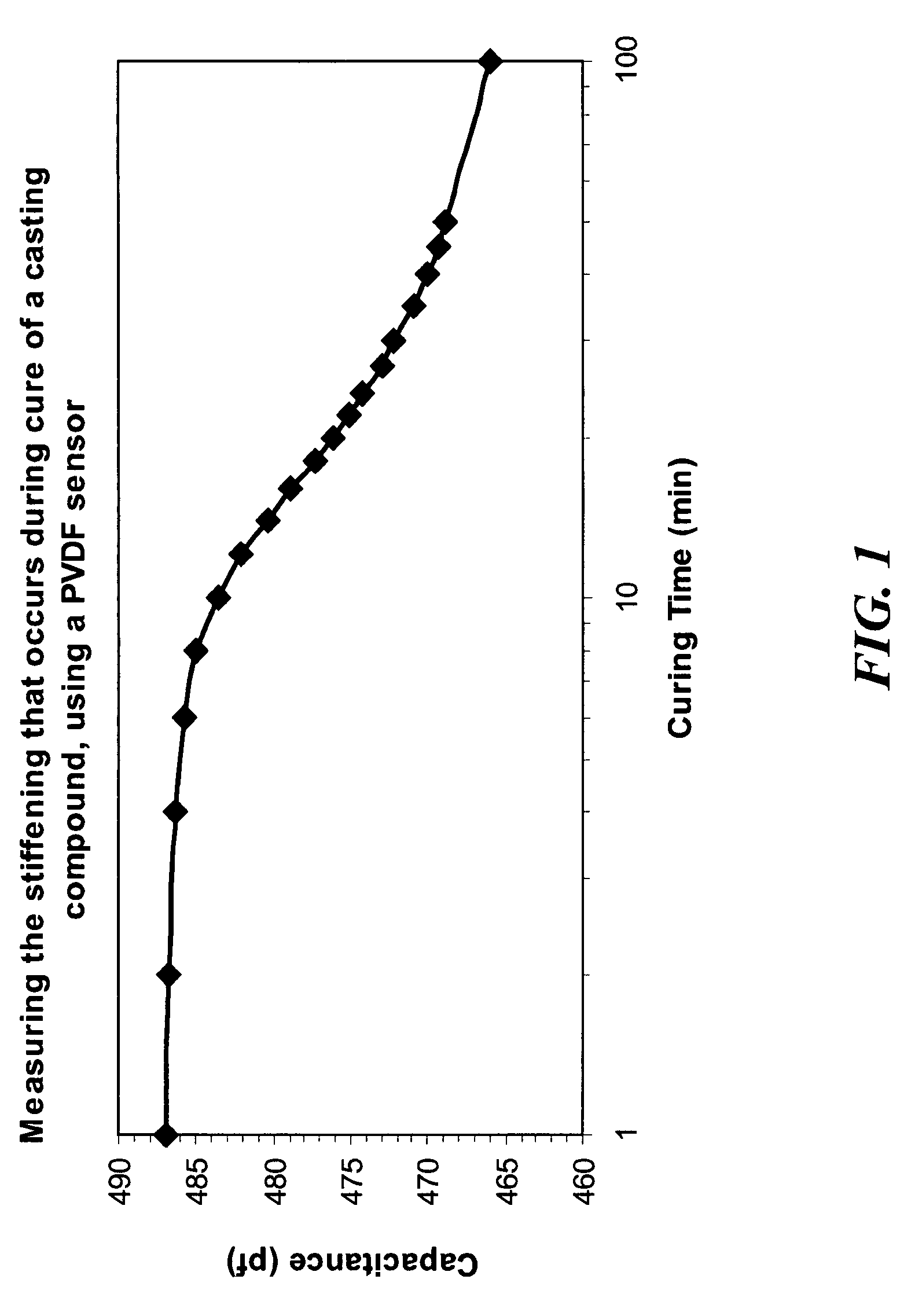

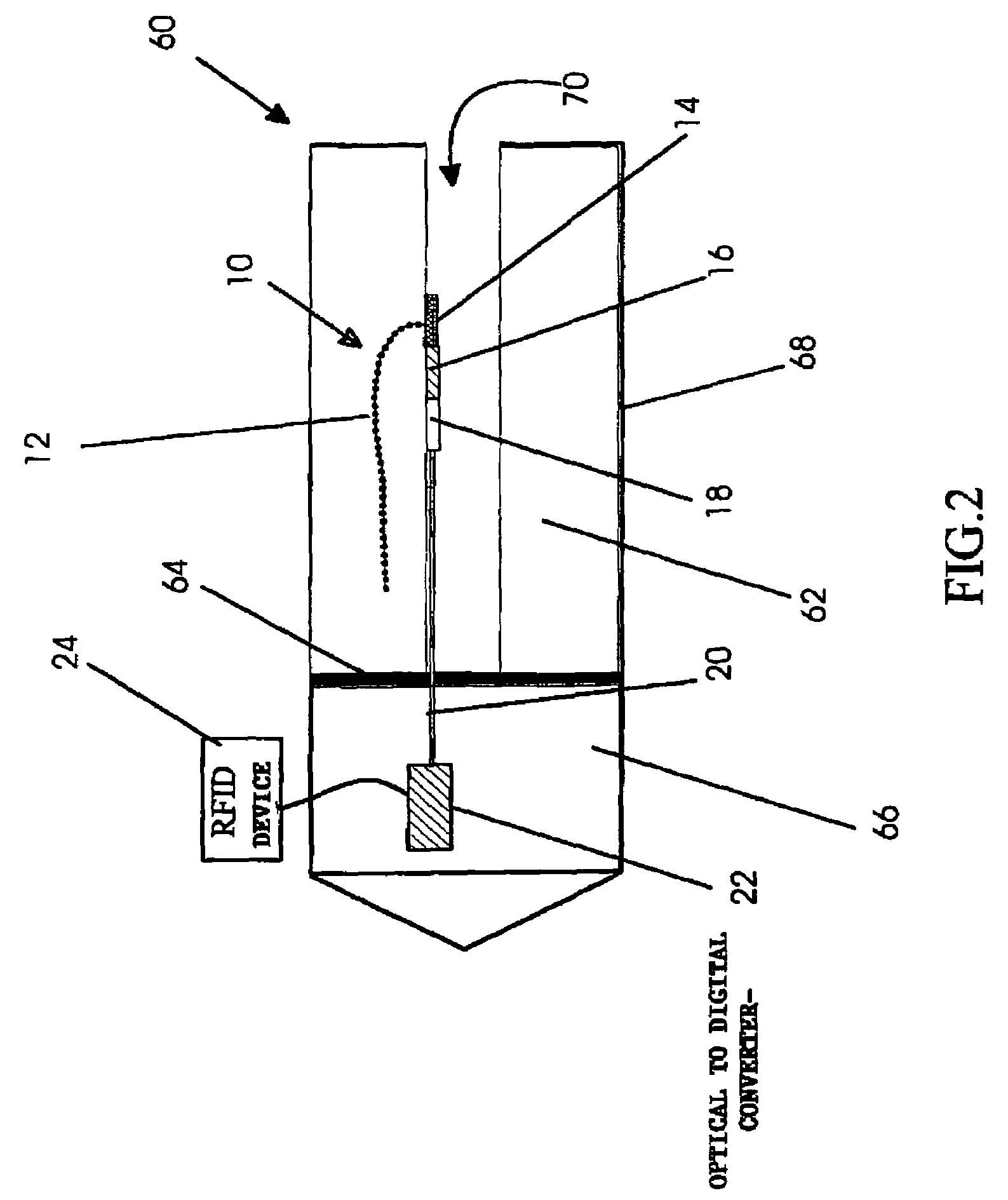

Method for measuring the health of solid rocket propellant using an embedded sensor

InactiveUS7652488B1Reduce capacitancePoor impedance matchingResistance/reactance/impedenceForce measurementElectricityShear modulus

The invented method for measuring the health of a solid rocket propellant includes embedding at least one piezoelectric capacitance sensor in the propellant, where the capacitance of the sensor is a function of a modulus of the propellant, and where the position is selected to measure manifestations of stress failure as a consequence of changes in the shear modulus. The capacitance of the sensor is measured at a predetermined frequency. The capacitance of the piezoelectric capacitance sensor is converted into a digital representation which is then converted into the digital representation of a modulus (or gradient modulus). In subsequent analysis, the modulus (or gradient of the modulus) is correlated to the health of the solid rocket propellant.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

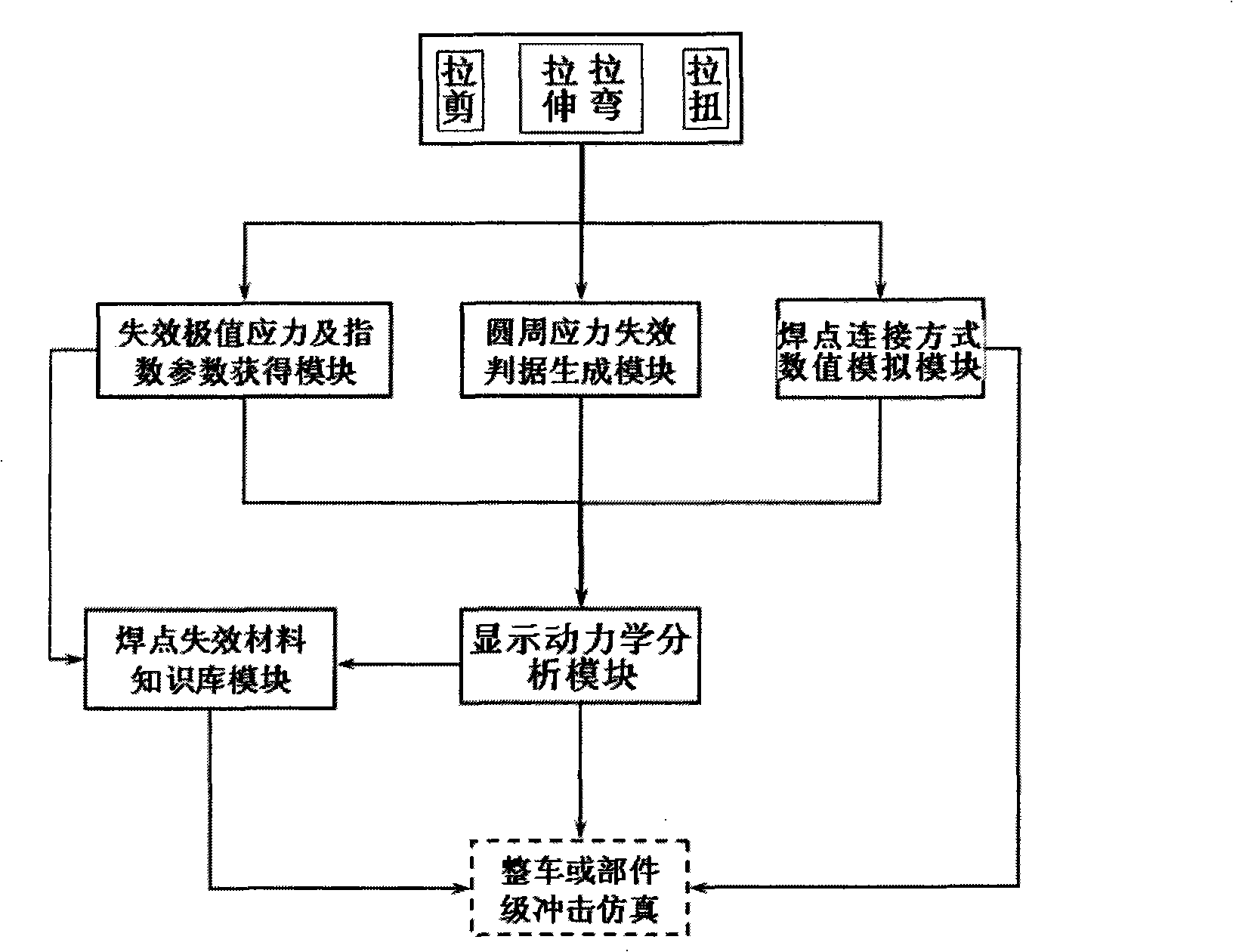

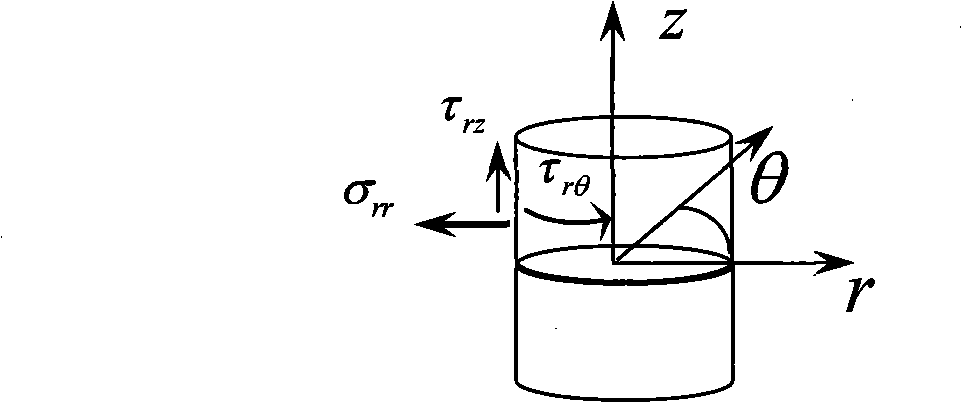

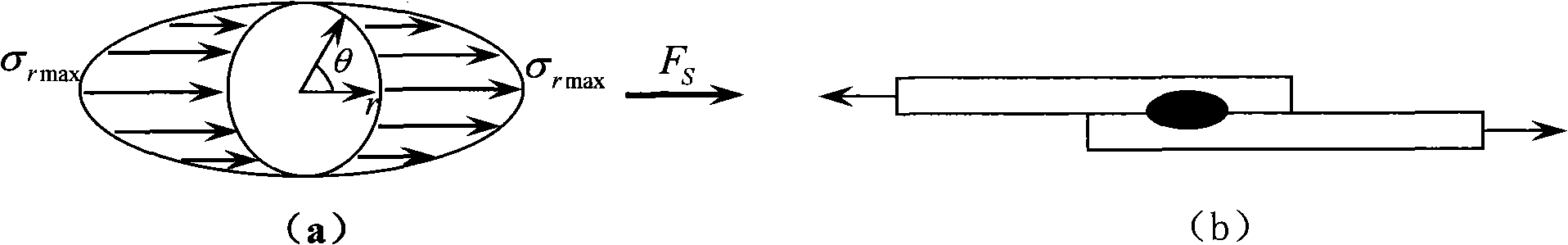

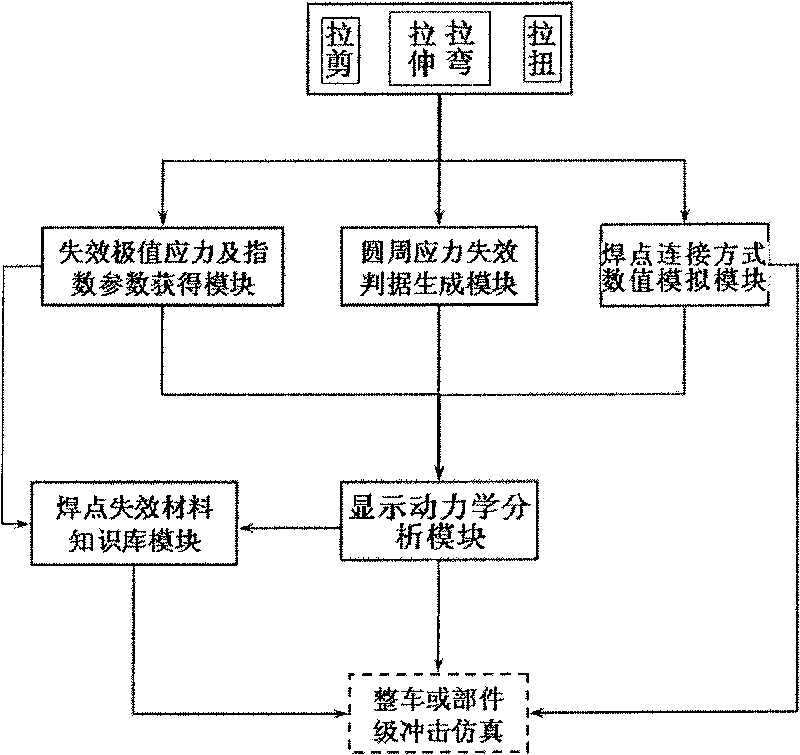

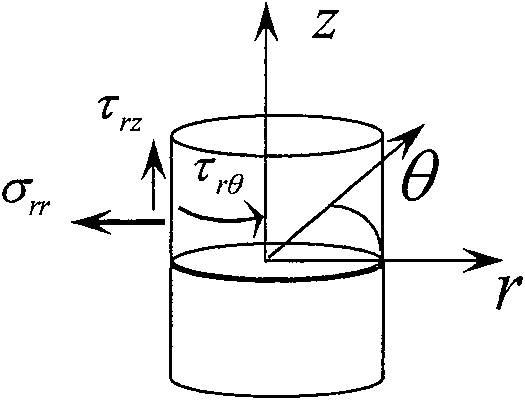

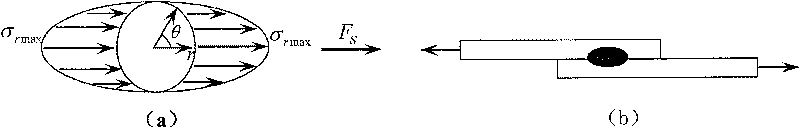

Simulation system for spot welding invalidity number value

InactiveCN101261653AEasy to determineEasy to useSpecial data processing applicationsStress distributionPeak value

The invention relates to a spot-welding connection failure value simulation system in the car bodywork manufacturing engineering field. In the invention, a circle-stress failure criterion generating module obtains nugget circle stress distribution form according to the failure mode of the spot-welding connection in a strike process to generate the circle stress failure criterion; a failure extreme value stress and an index-parameter obtaining module obtain welding-spot critical failure stress extreme values and dimensionless stress sub-item index initial values under the condition of the peak values of four exterior loads; four types of sample value models which are pulling-cutting, pulling-extending, pulling-bending and pulling-twisting are established in a welding-spot connection value simulation module; an explicit dynamics analysis module couples circle stress failure criteria and obtains the continuous distributed inner stress of a welding-spot unit model and an extreme value stress borne by the welding-spot unit during failure time by simulation; a welding-spot failure material databank module stores the critical failure stress extreme values and the dimensionless stress sub-item index initial values of each stress component. The system not only can enhance the impact simulation precision without impact on the calculation efficiency, but also can reduce the design and exploitation cost.

Owner:SHANGHAI JIAO TONG UNIV

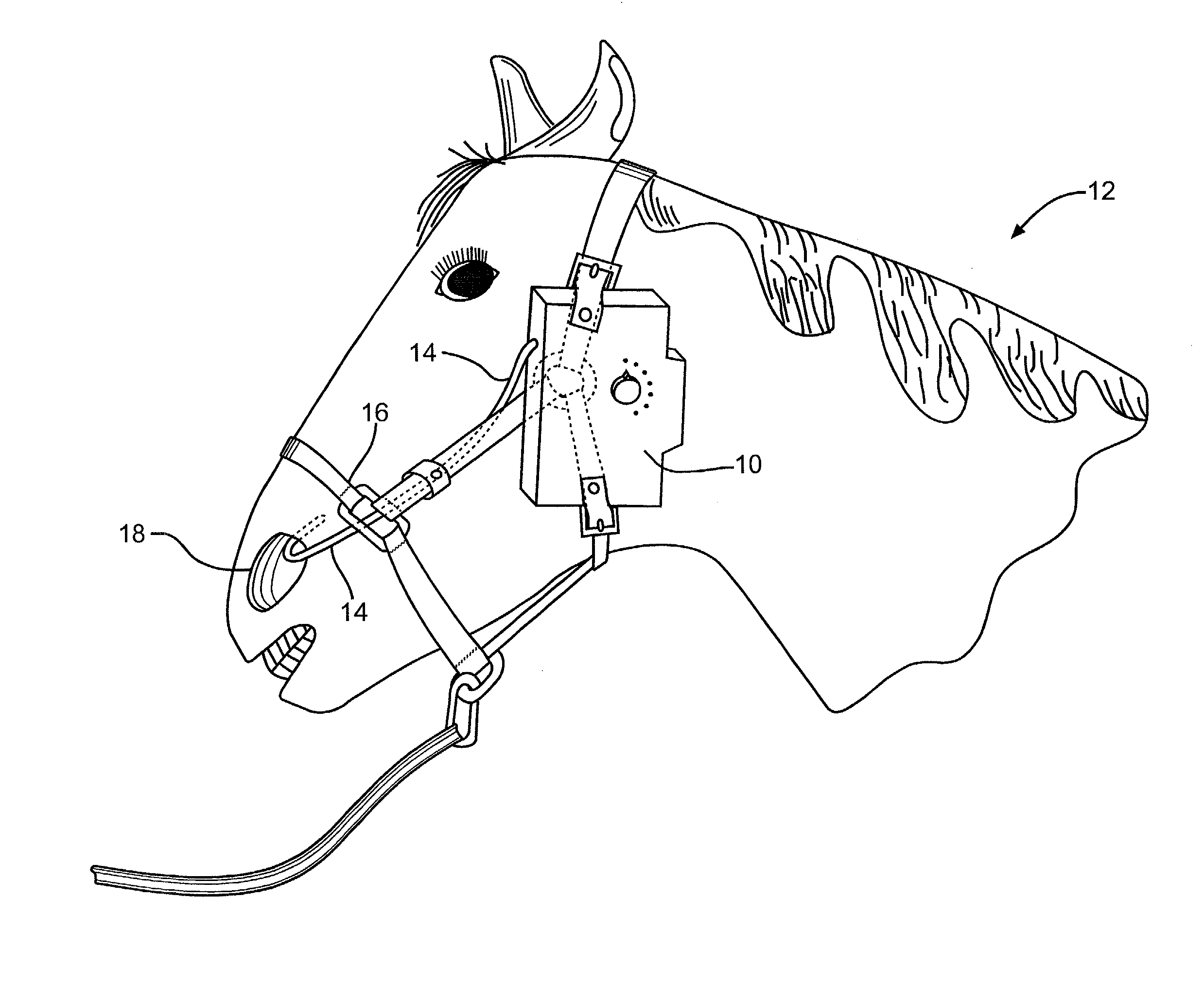

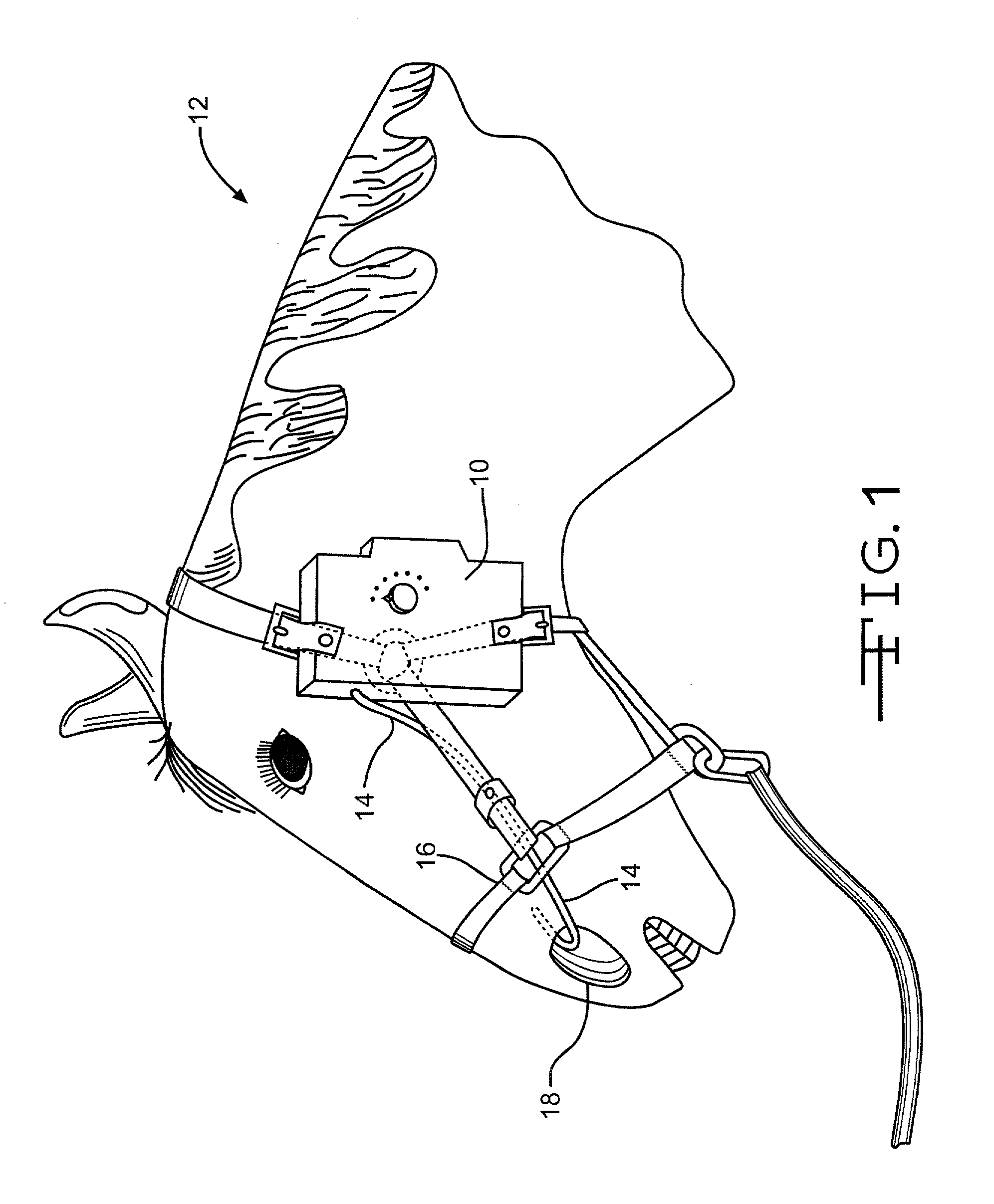

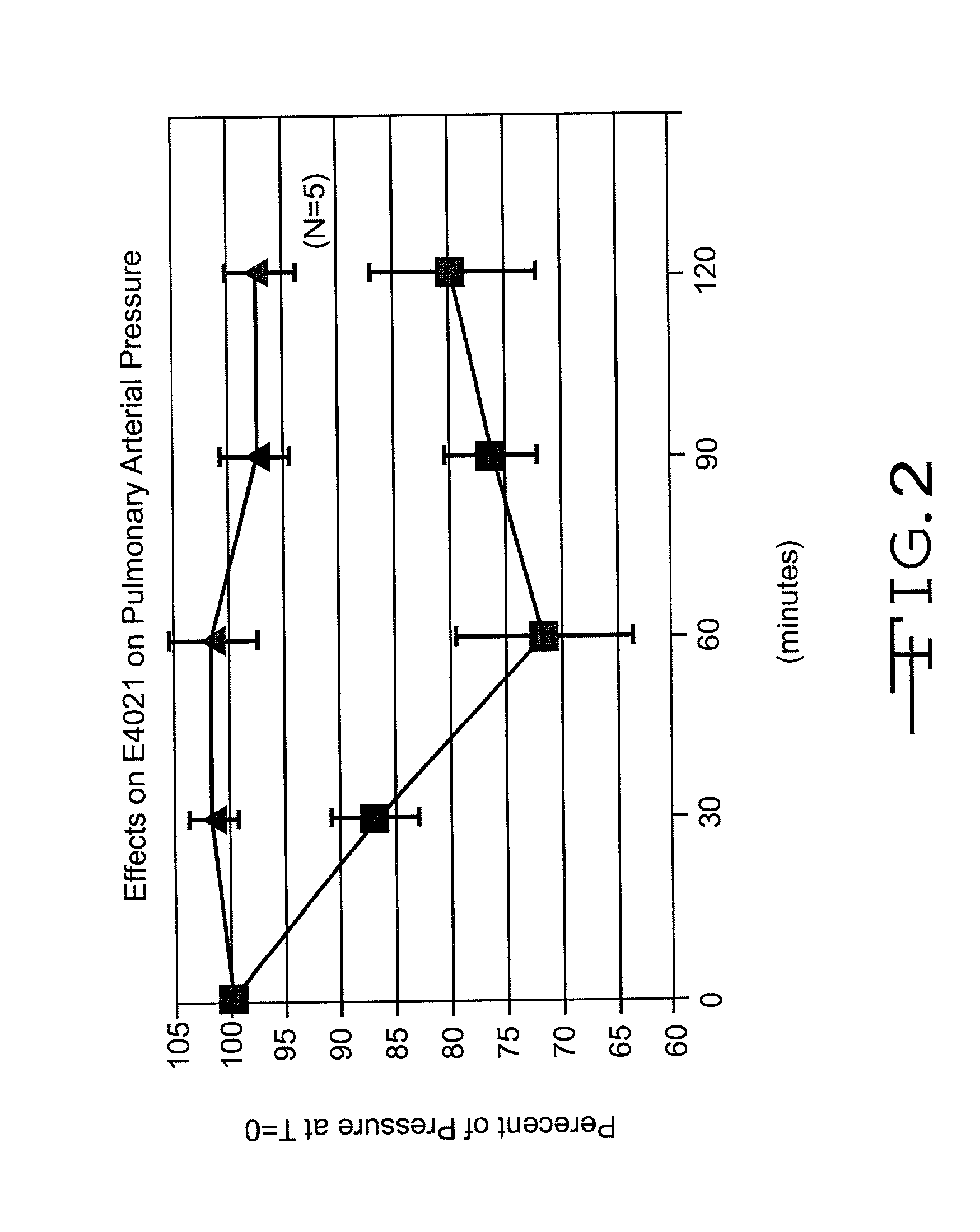

Use of aerosolized compounds in the treatment of exercise induced pulmonary hemorrhage in an equine

InactiveUS20030070674A1Prevent exercise induced pulmonary hemorrhageReduce pressureRespiratorsMedical devicesVeinTreatment modality

The administration of aerosolized nitric oxide donors or type V phosphodiesterase inhibitor in controlled doses to horses during high intensity exercise is described. Aerosolized nitric oxide donors (in conjunction with intravenous type V phosphodiesterase inhibitor) and type V phosphodiesterase inhibitor are beneficial to prevent exercise induced pulmonary hemorrhage by reducing transmural pulmonary artery pressure with a concomitant decrease in pulmonary capillary stress failure. The administration of aerosolized nitric oxide donors and type V phosphodiesterase inhibitors is viewed as a novel therapeutic modality in the alleviation of capillary stress failure and EIPH in performance horses.

Owner:PULMONOX TECH

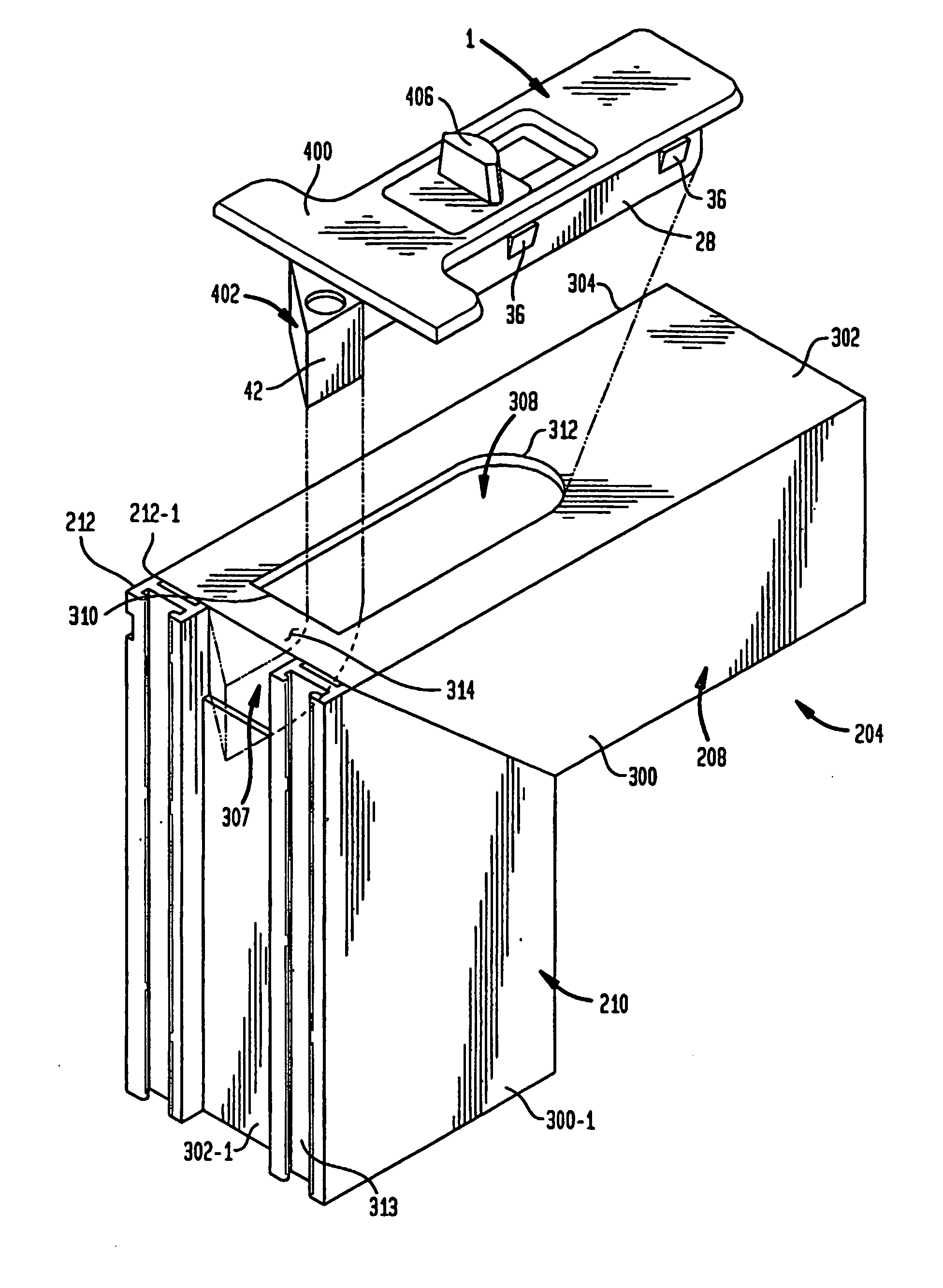

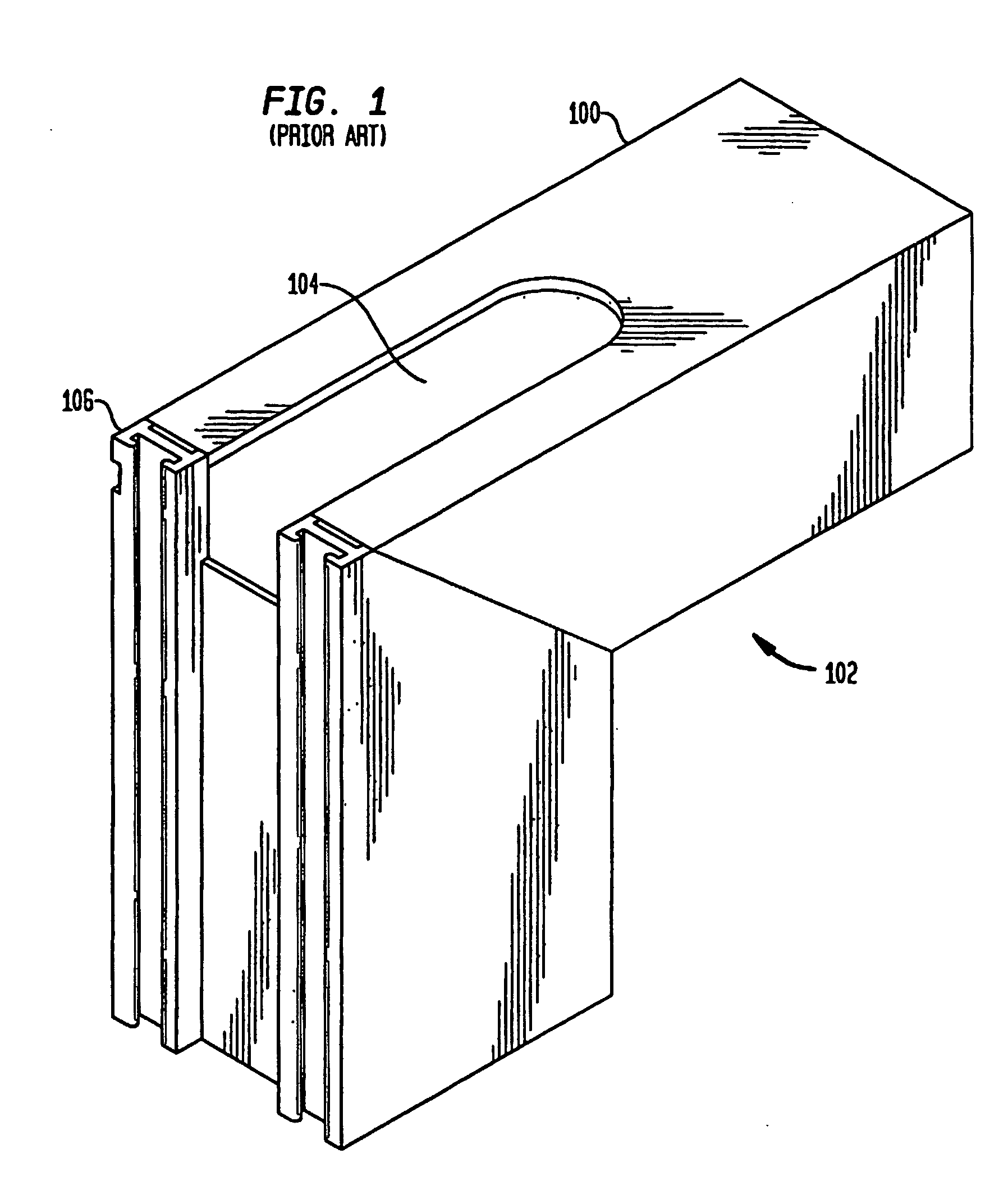

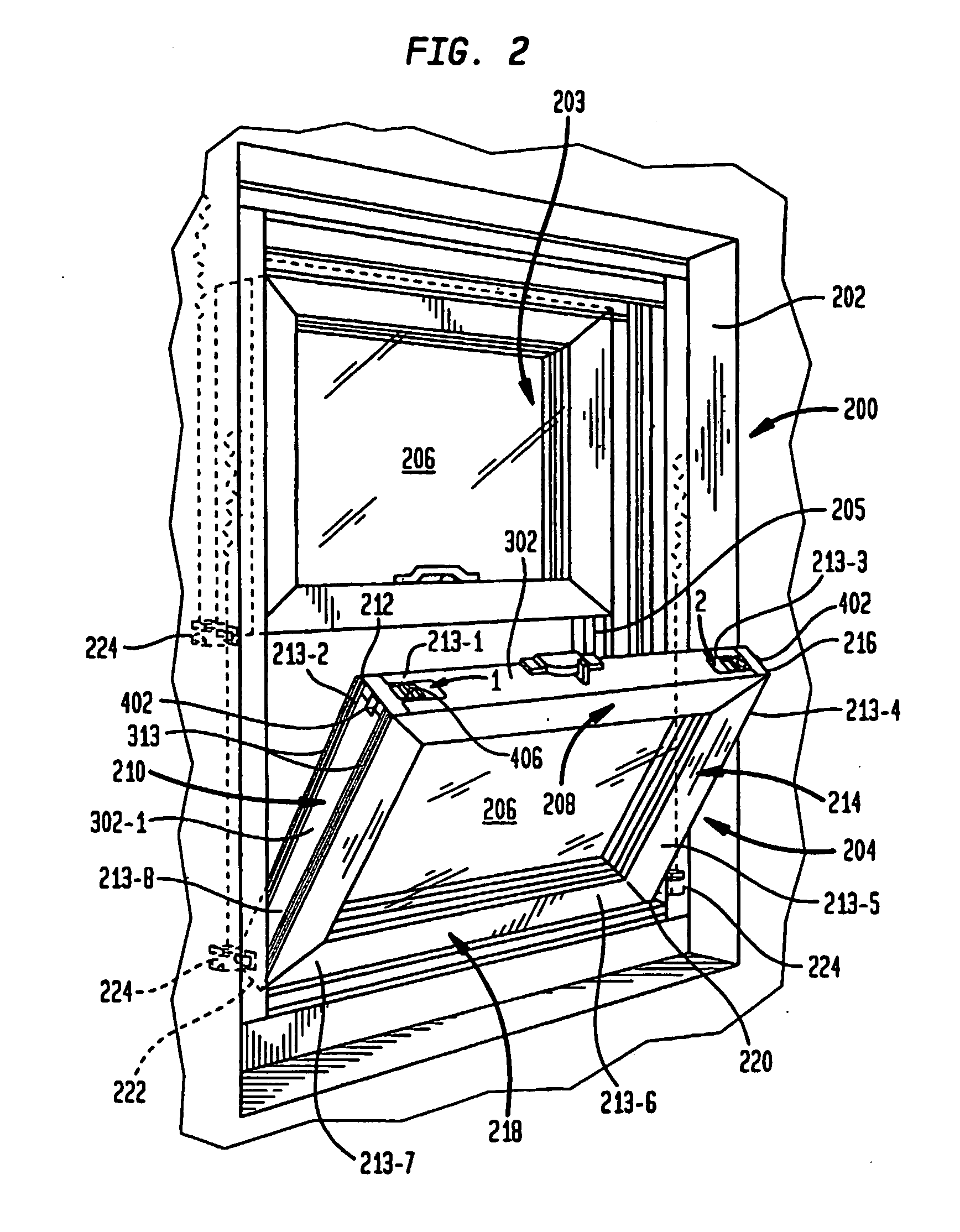

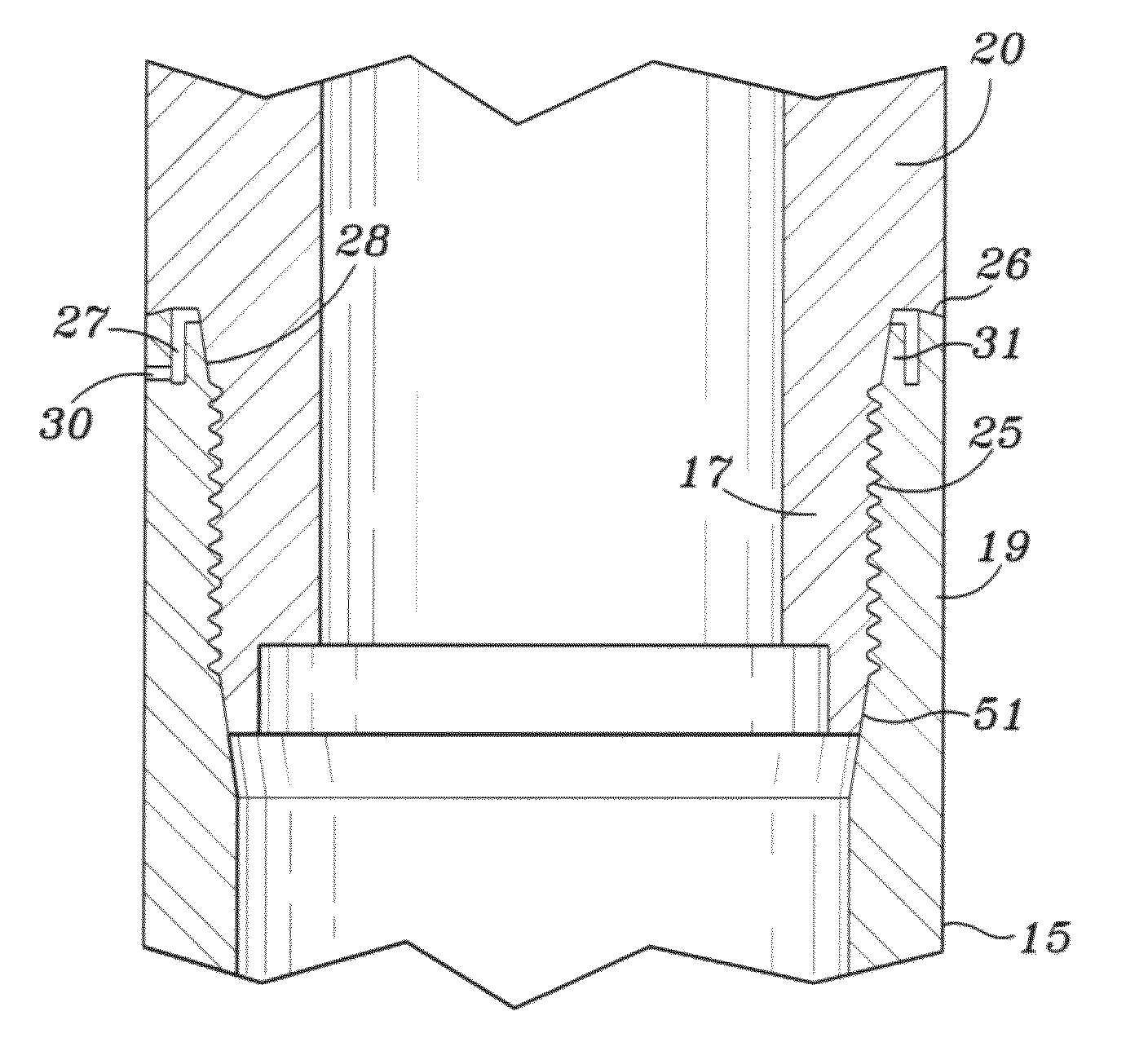

Tilt-latch and window sash assembly

InactiveUS20070056217A1Prolong lifePrevent and minimize stress failureBuilding locksConstruction fastening devicesSash windowEngineering

A window assembly is disclosed that allows a person to easily clean the exterior side of a windowpane, and prolongs the life of the window assembly. A window assembly (200) according to the present invention comprises a fixed window frame (202), tilt-latch assemblies (1, 2), and upper and lower window sashes (203, 204) comprised of a plurality of window sash rails, wherein each window sash rail has an outer wall (302), a front wall (300), and a rear wall (304). The tilt-latch assemblies (1, 2) secure the upper and lower window sashes (203, 204) within the fixed window frame (202). The tilt-latch assembly (1) is inserted into a slot (301) that is located on the outer wall (302) of the window sash rail for receiving a tilt-latch assembly (1). A lip (314) is located between a corner edge (212), wherein two sash rails meet to form a corner, and the outer edge (310) of the slot (308). The (314) can help prevent stress failure of the window sash rail.

Owner:SILVER LINE BUILDING PRODS

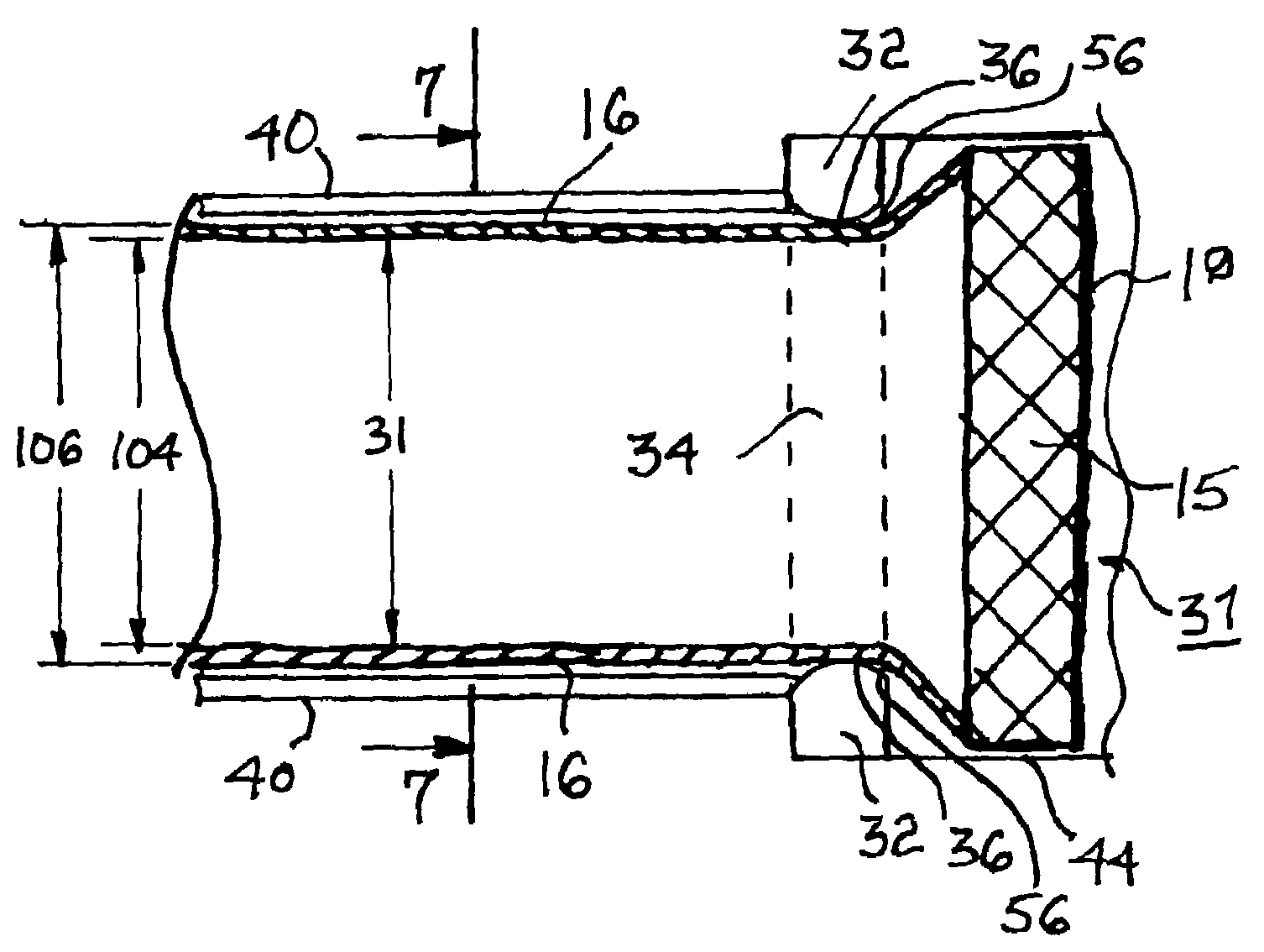

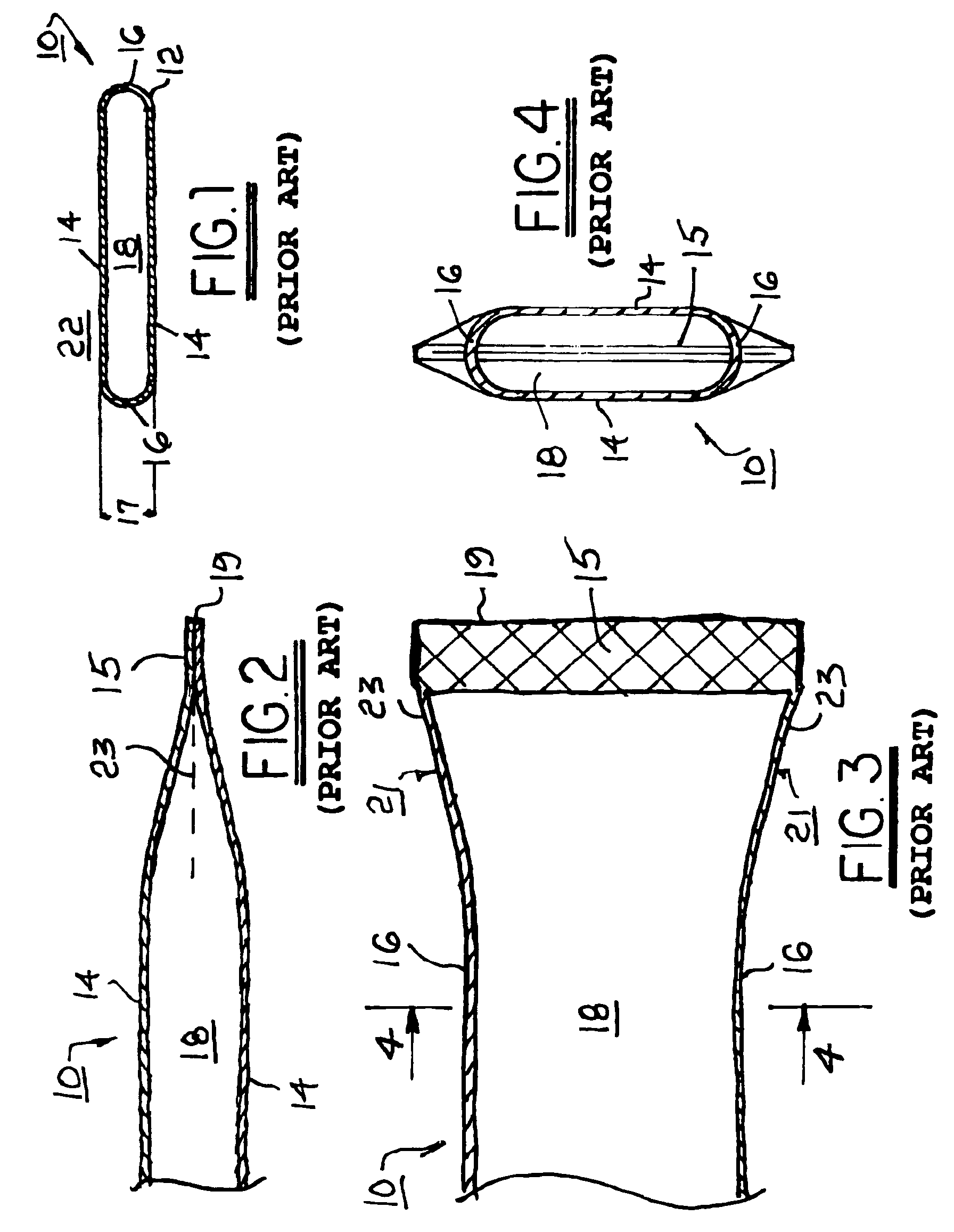

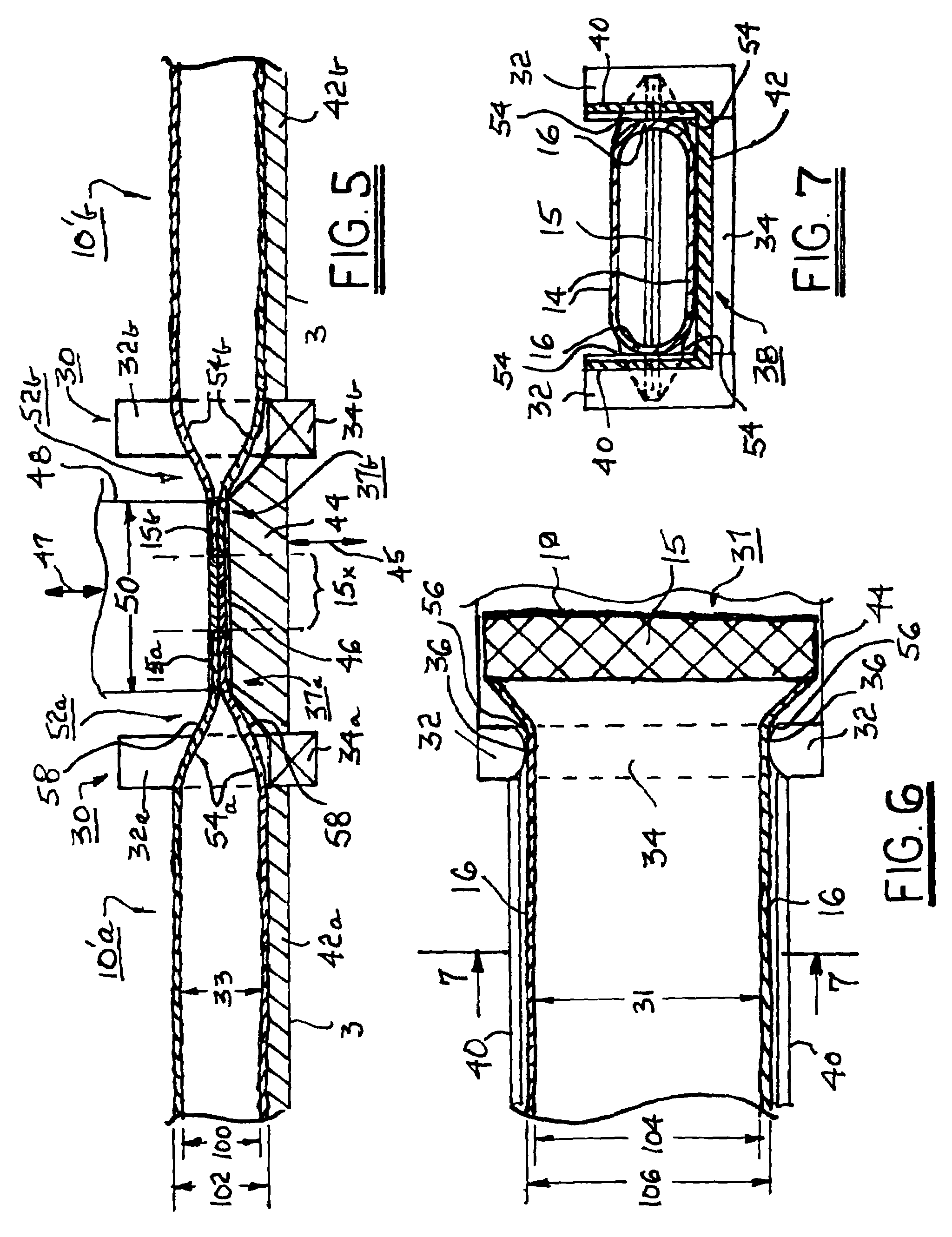

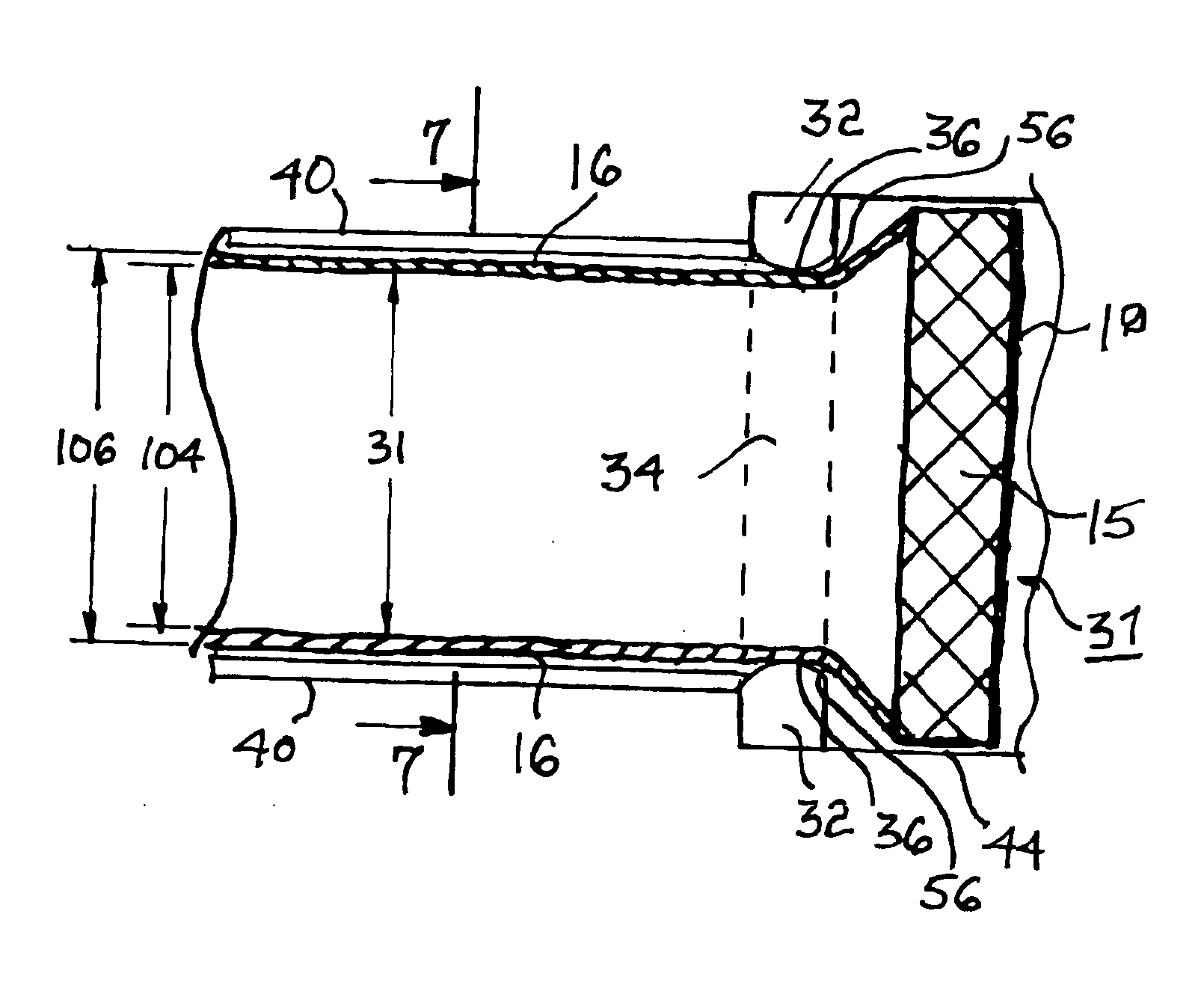

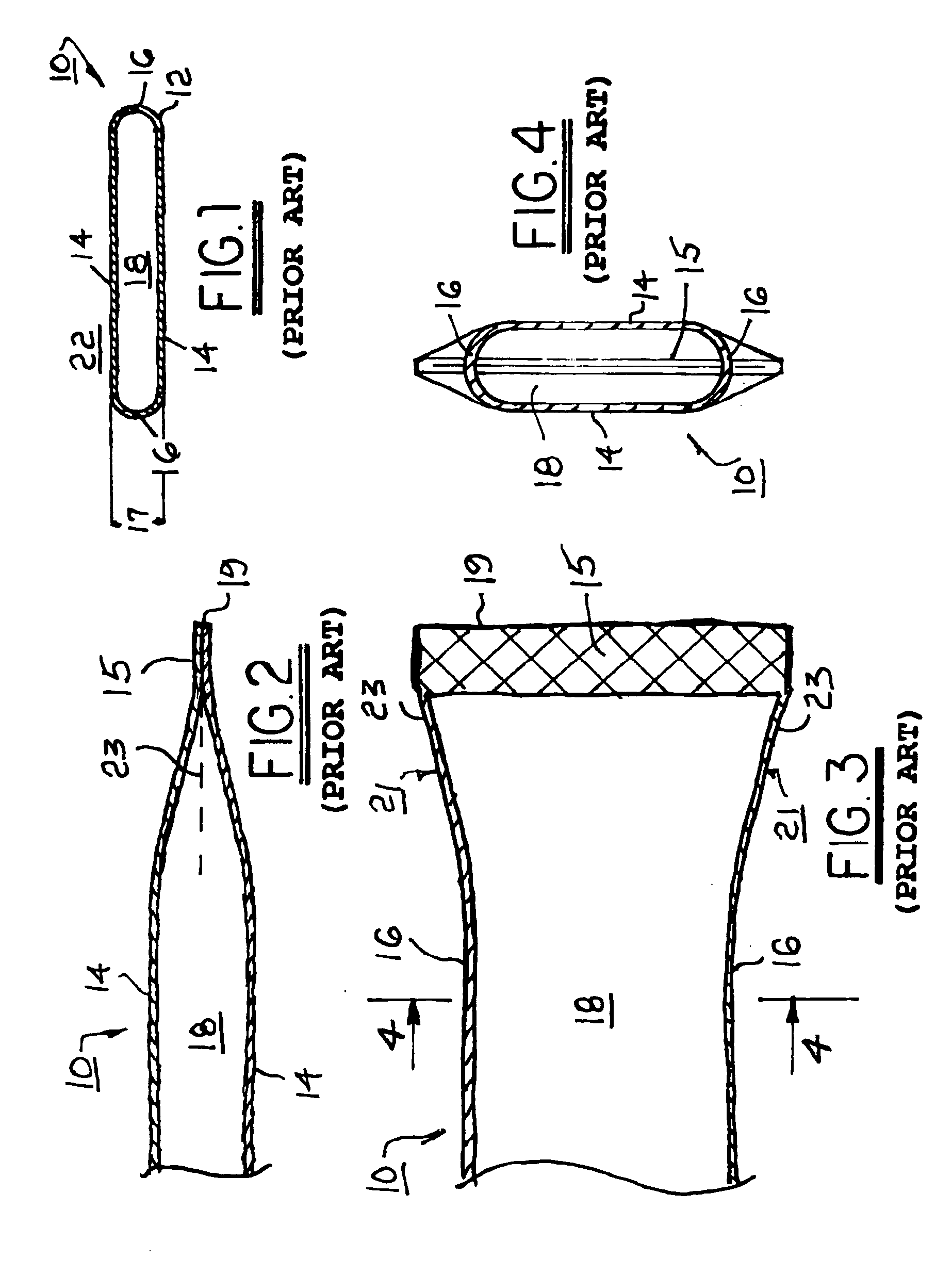

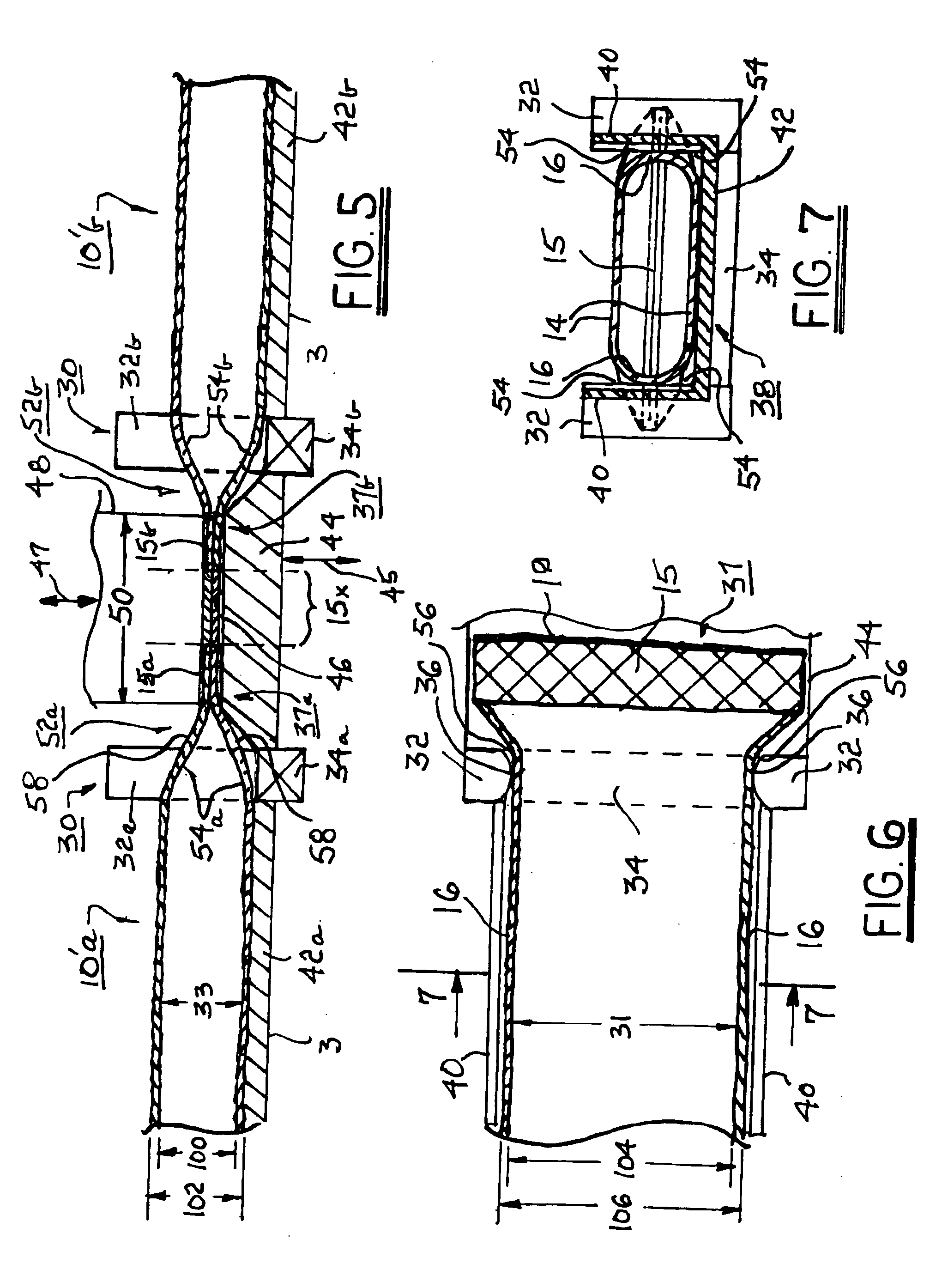

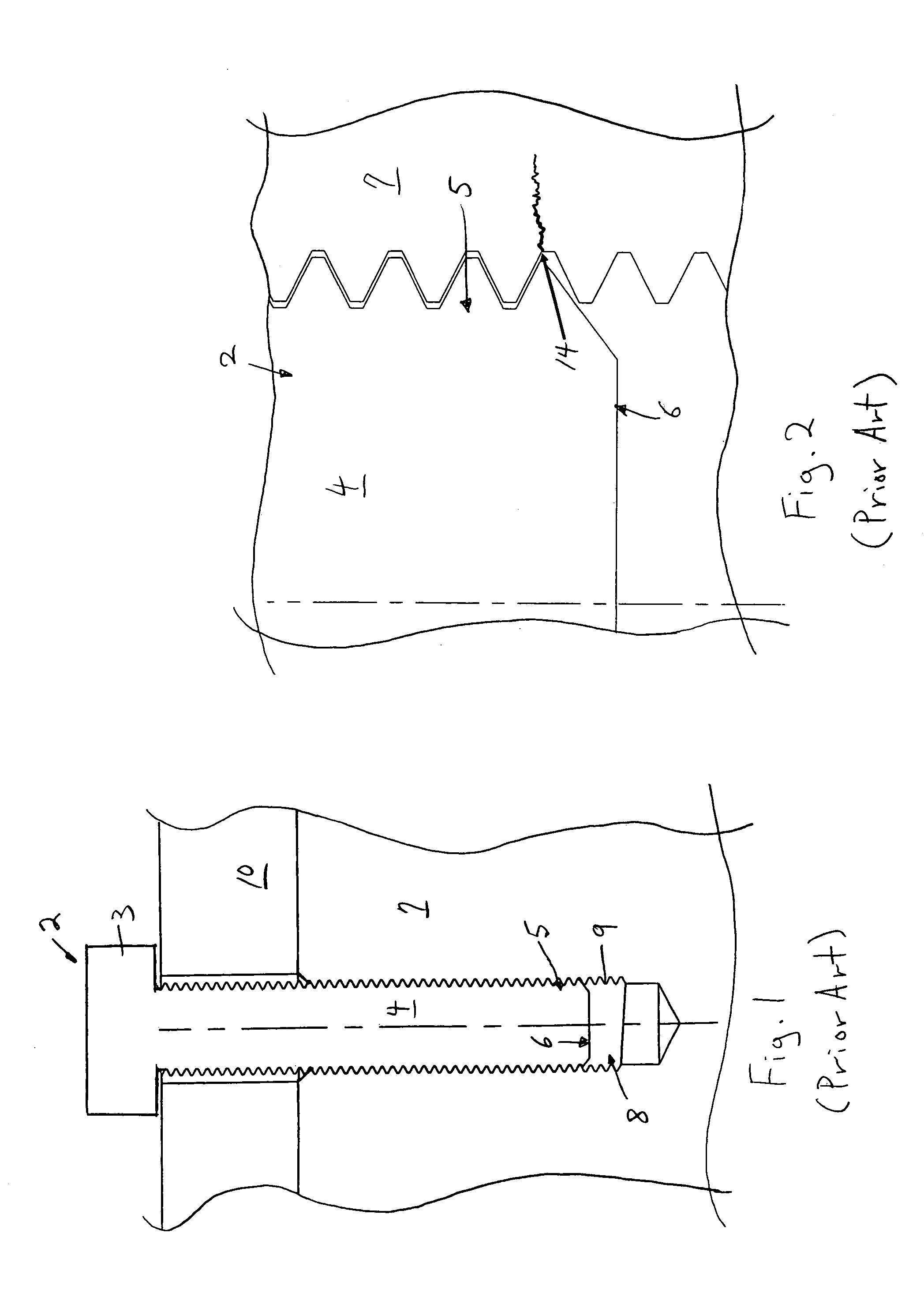

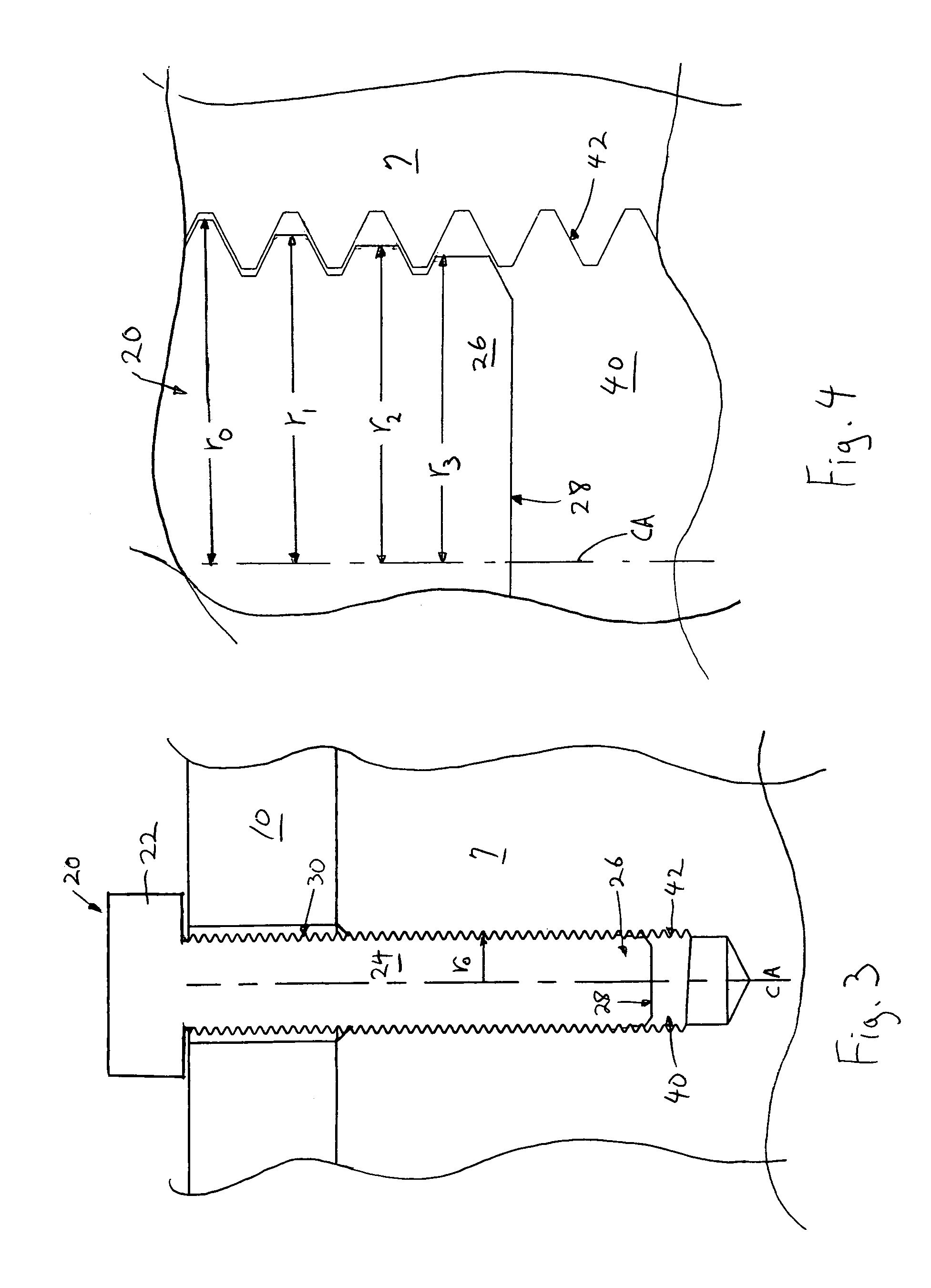

Fuel rail pulse damper with improved end crimp

InactiveUS7165535B2Eliminate areaLow-pressure fuel injectionPipe elementsExternal combustion engineStress failure

An internal pulse damper for use in a fuel rail for an internal combustion engine. The damper is formed from a length of tubular metal stock having a flat oval cross-section and ends flattened by crimping to form a captive-air pillow. The end crimps are improved through use of tooling to eliminate a creased sidewall area vulnerable to stress failure in prior art pulse dampers. Such tooling includes constraints to prevent the tubing sides from flaring out and forming a longitudinal crease adjacent the end crimp during squeezing-shut of the tube end.

Owner:DELPHI TECH INC

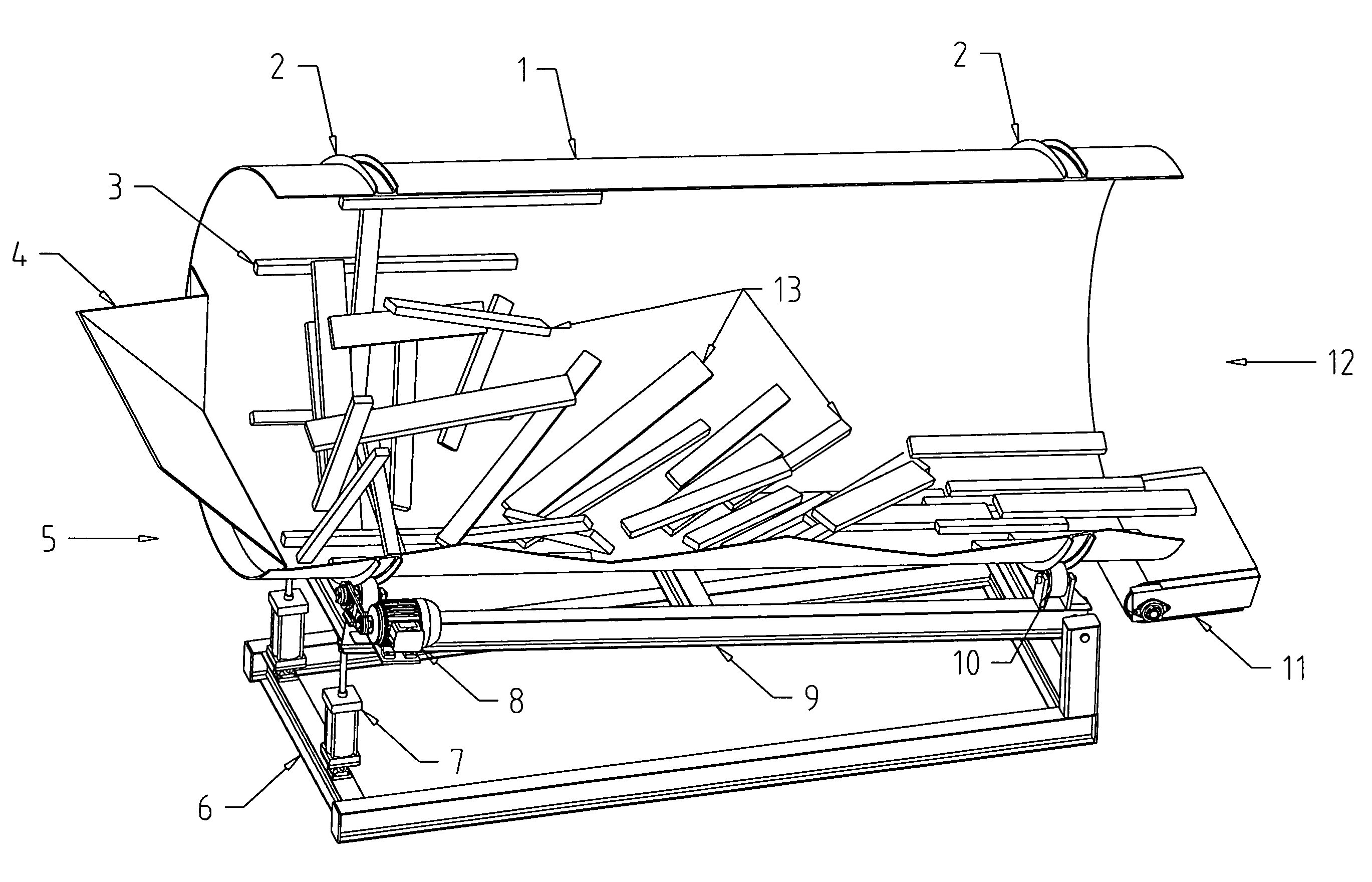

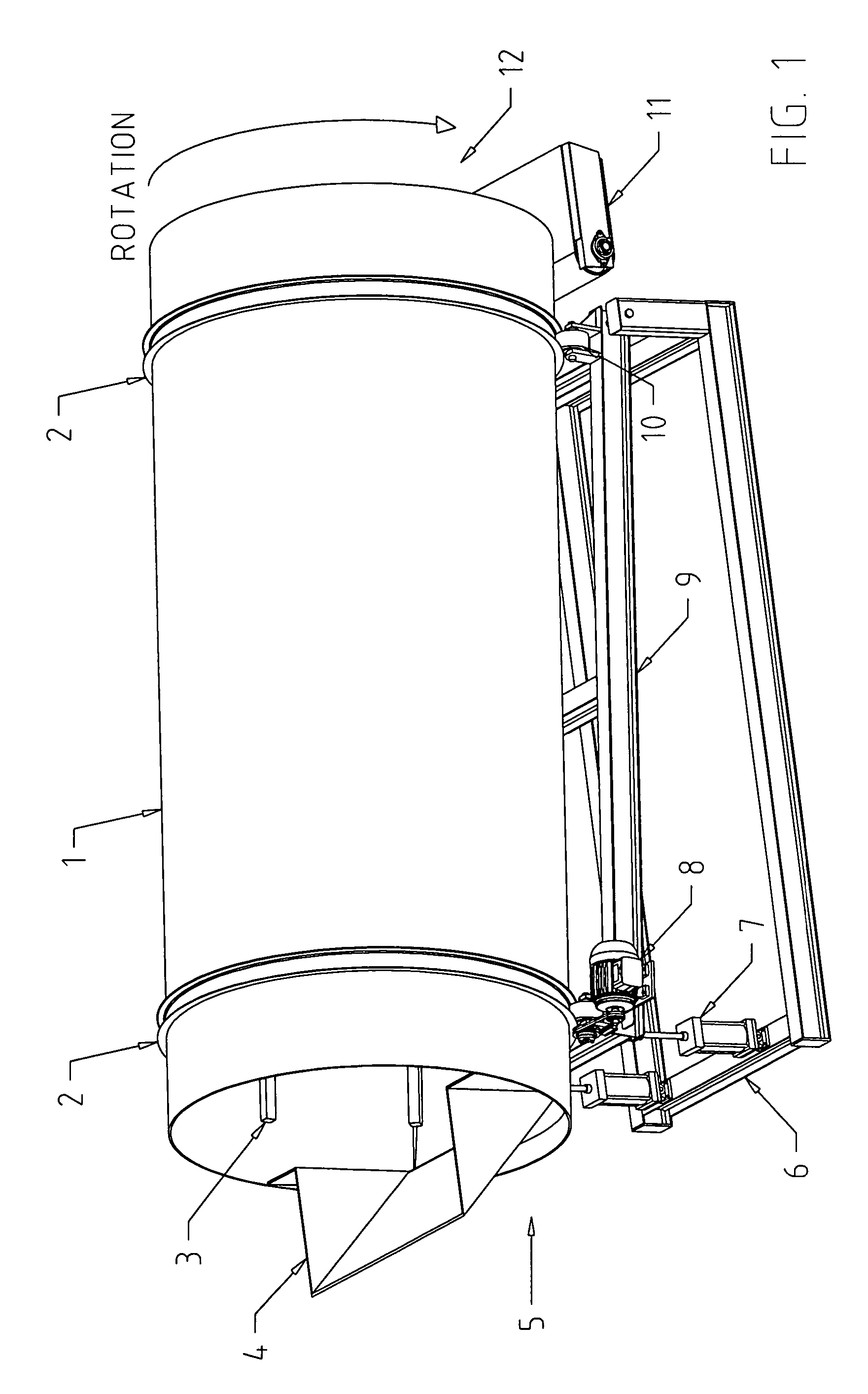

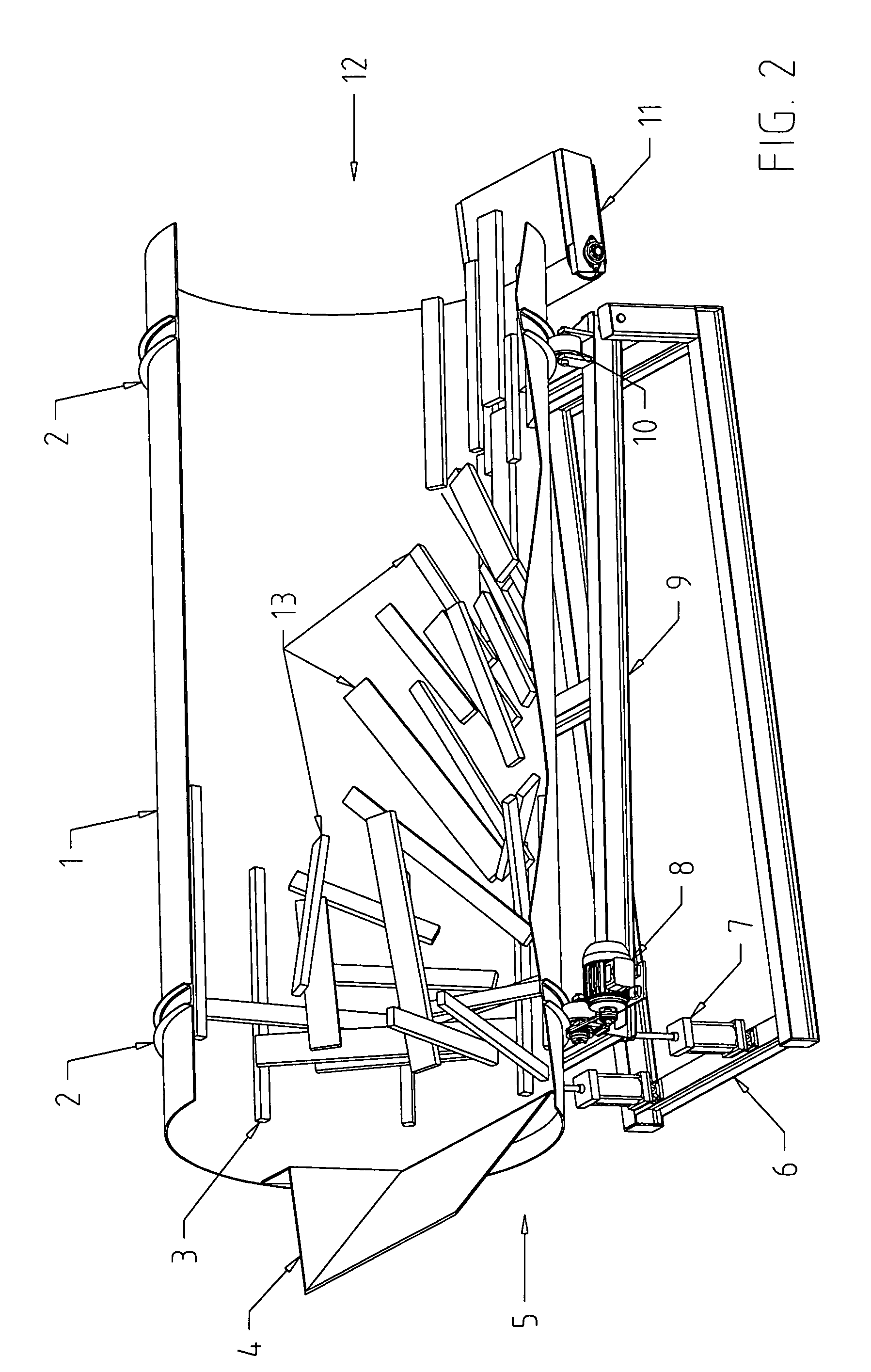

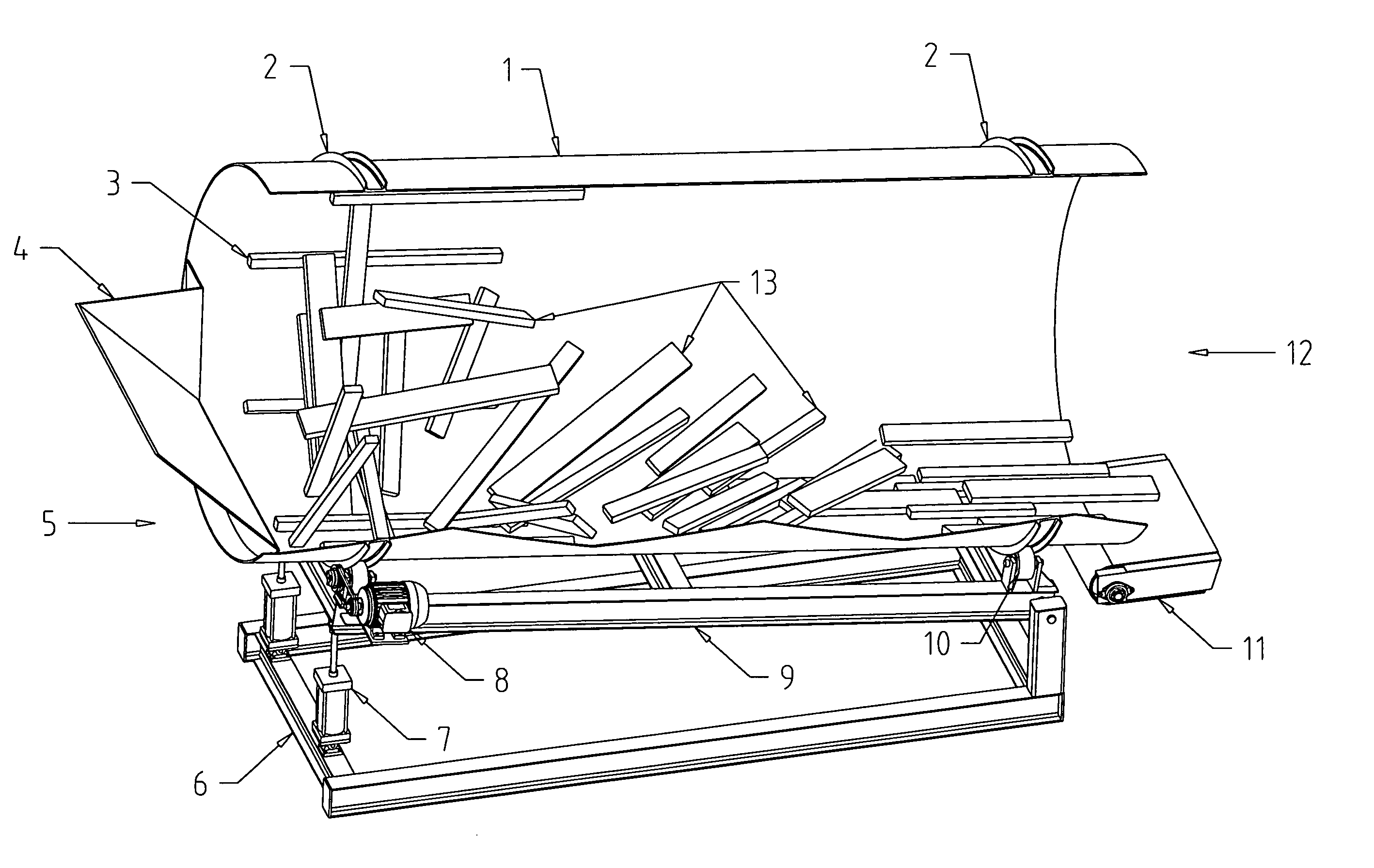

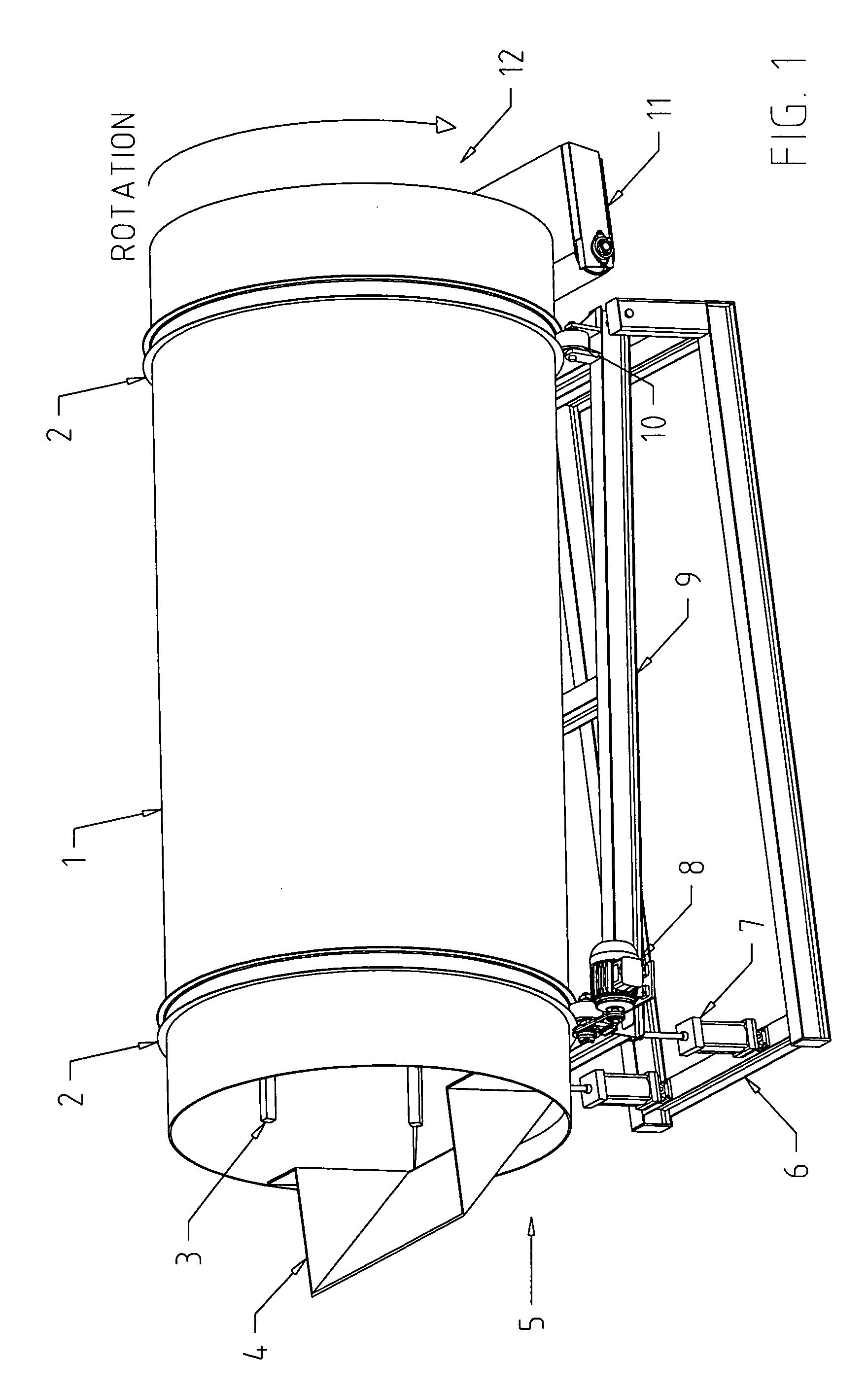

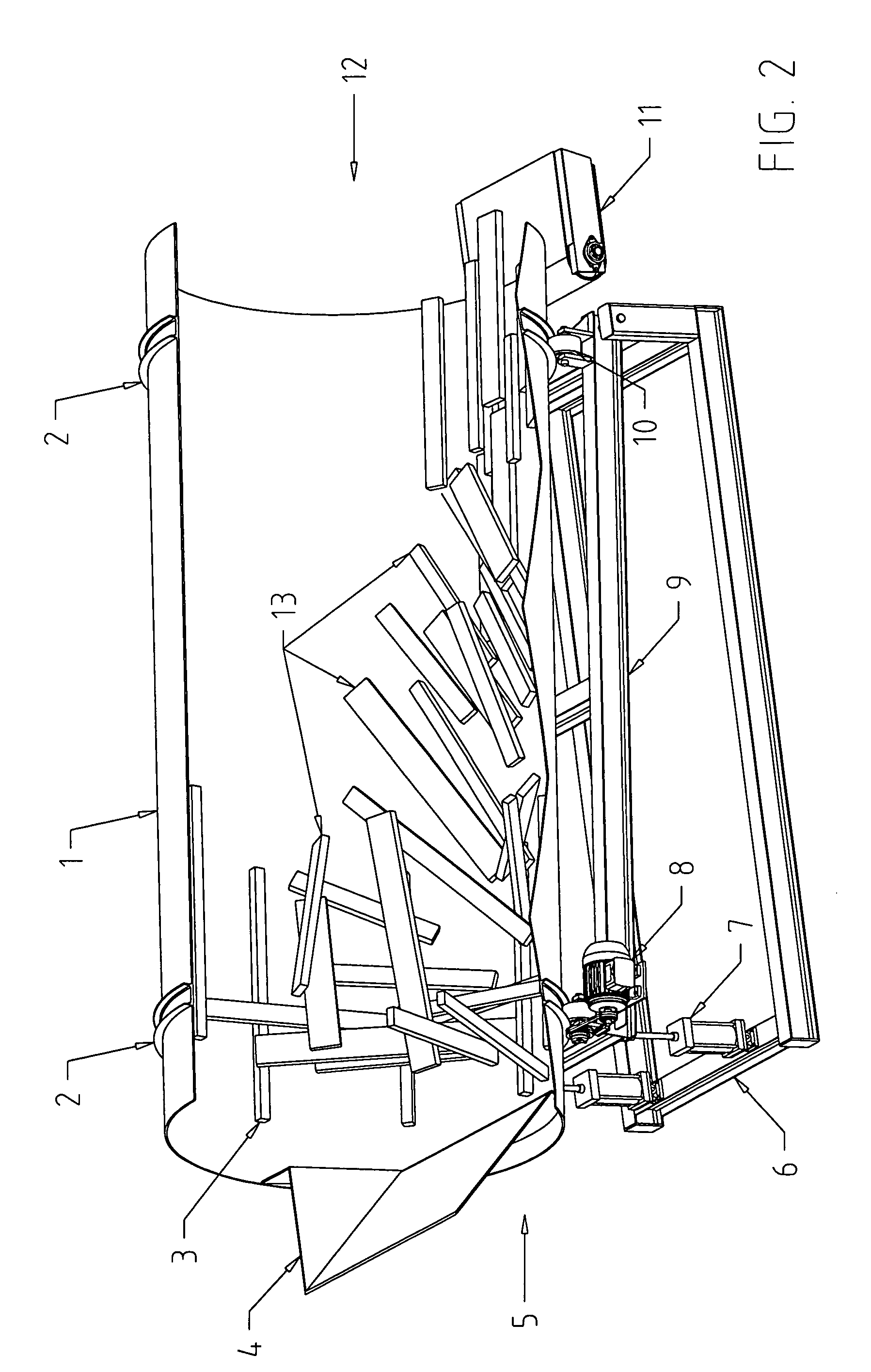

Block orientation cylinder

A rotating cylinder is used to orient wood material, such as but not limited to blocks (e.g., finger joint blocks), preparatory to further processing. The rotating cylinder uses gravity and a tumbling action of the blocks to orient the blocks and move them through the cylinder. Unlike known apparatus such as vibrating conveyors, embodiments of the invention are relatively simple, vibration free, not prone to mechanical stress failures, are quiet, and use minimal horsepower to operate. Furthermore, embodiments of invention may advantageously reduce noise-caused fatigue amongst lumber workers, as well as reduce maintenance and power costs. The rotating cylinder may be part of a larger system for orienting wood material, such as blocks, for further lumber processing.

Owner:STIBBARD JAMES SPENSER

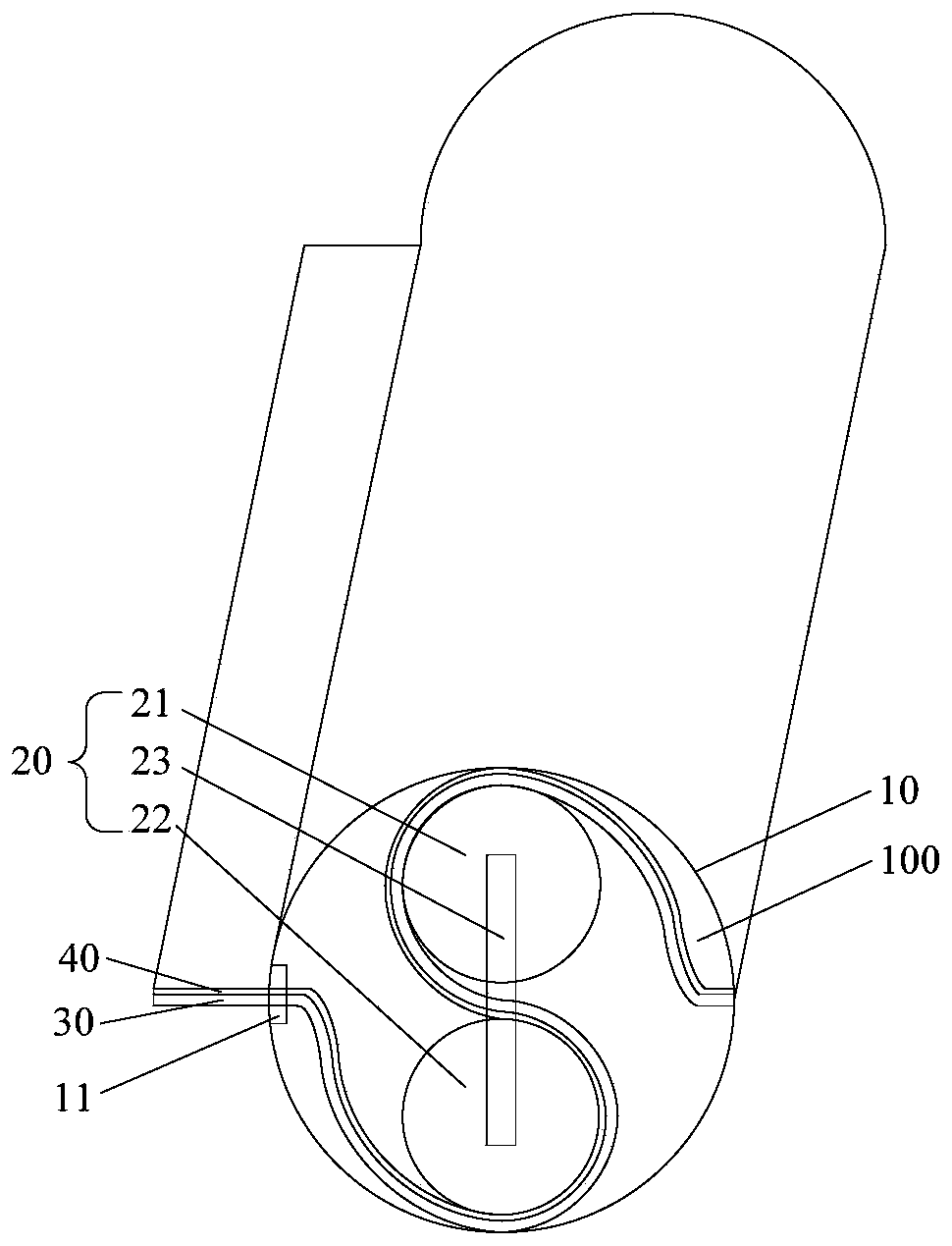

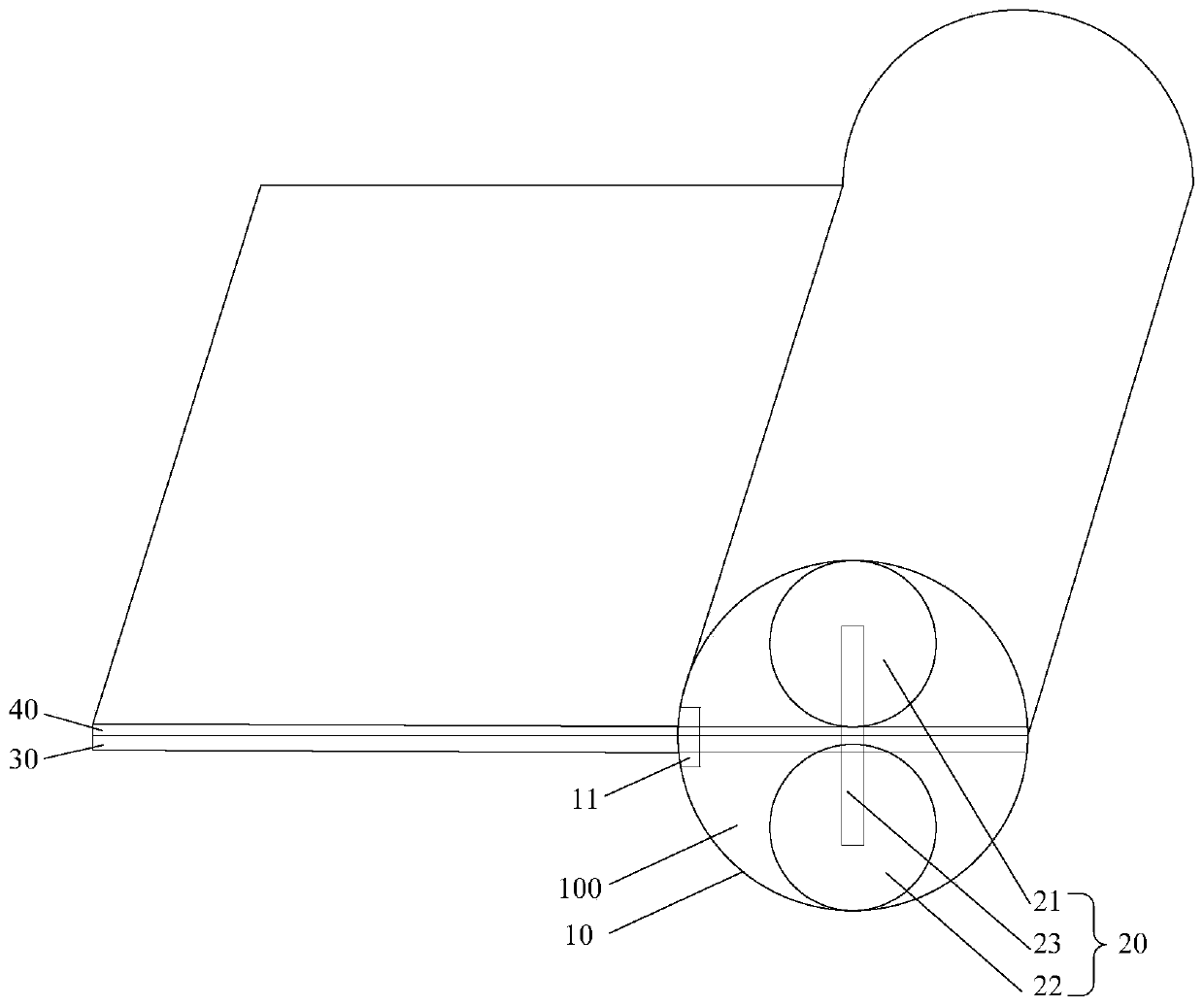

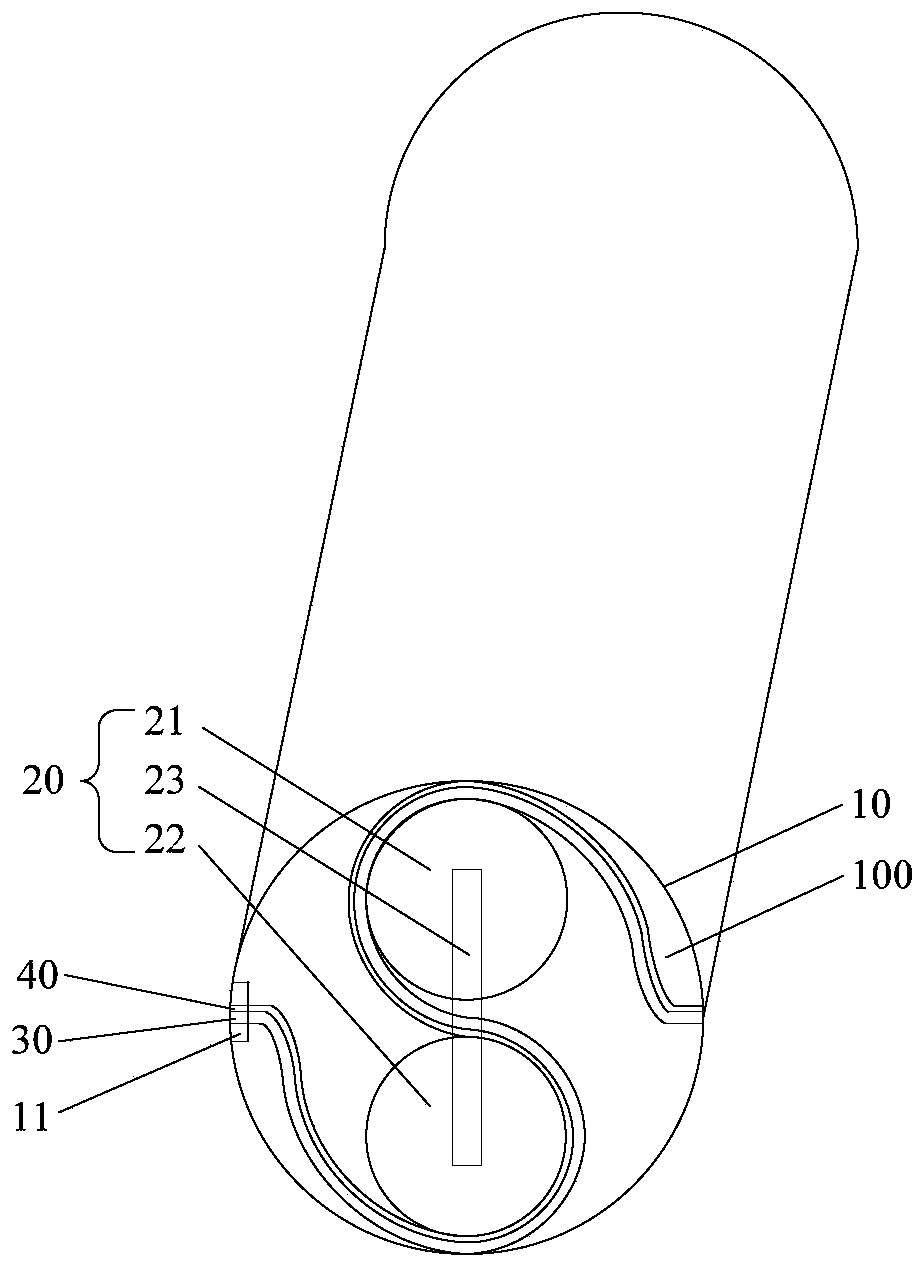

Flexible display device

The invention provides a flexible display device, which comprises a shell, a roller group, a supporting layer and a flexible display screen. The shell is cylinder-shaped, a containing cavity is formedinside the shell, and an opening is formed on the lateral side of the shell. The roller group is arranged inside the containing cavity, and comprises a first roller and a second roller and a connecting part for connecting the first roller and the second roller. The axis of the first roller and the second roller is parallel to the axis of the shell. The supporting layer winds the first roller andthe second roller, and the winding direction of the supporting layer on the first roller is opposite to the winding direction of the supporting layer on the second roller. The supporting layer extendsout of the shell from an opening. The flexible display screen is arranged on the supporting layer. The winding direction of the flexible display screen on the first roller is opposite to the windingdirection of the flexible display screen on the second roller. With the stress cancelled out, the stress failure risk of the flexible display screen is reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

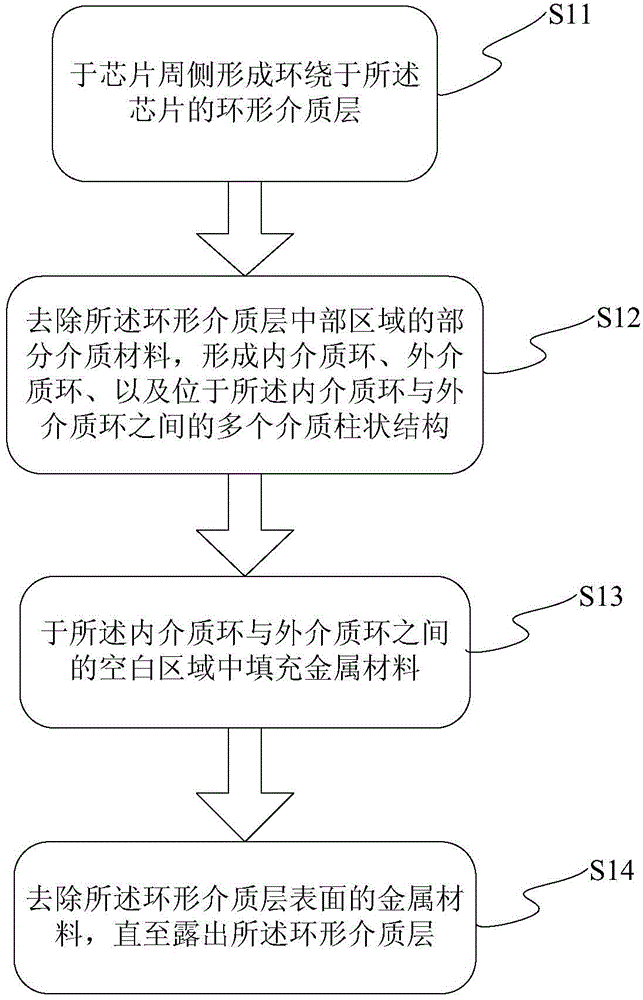

Chip sealing ring structure and manufacturing method thereof

ActiveCN105374765AImprove yieldImprove burst strengthSemiconductor/solid-state device detailsSolid-state devicesMetallic materialsStress failure

The invention provides a chip sealing ring structure and a manufacturing method thereof. The manufacturing method comprises the following steps of 1) forming an annular dielectric layer surrounding the chip at a peripheral side of the chip; 2) removing parts of dielectric materials of a central area of the annular dielectric layer and forming an inner dielectric ring, an outer dielectric ring and a plurality of dielectric cylindrical structures located between the inner dielectric ring and the outer dielectric ring; 3) filling a metal material in a blank area between the inner dielectric ring and the outer dielectric ring; 4) removing the metal material of an annular dielectric layer surface till that the annular dielectric layer is exposed. Through manufacturing the plurality of dielectric cylindrical structures and a metal material filling layer in the chip sealing ring structure, the fracture resistance intensity of a chip sealing ring is greatly reinforced so that damages in a chip, which are caused by a stress failure, are avoided during a chip cutting process and other processes and a yield rate of the chip is increased. The structure is simple, and the structure and the method are suitable for industrial production.

Owner:SEMICON MFG INT (SHANGHAI) CORP

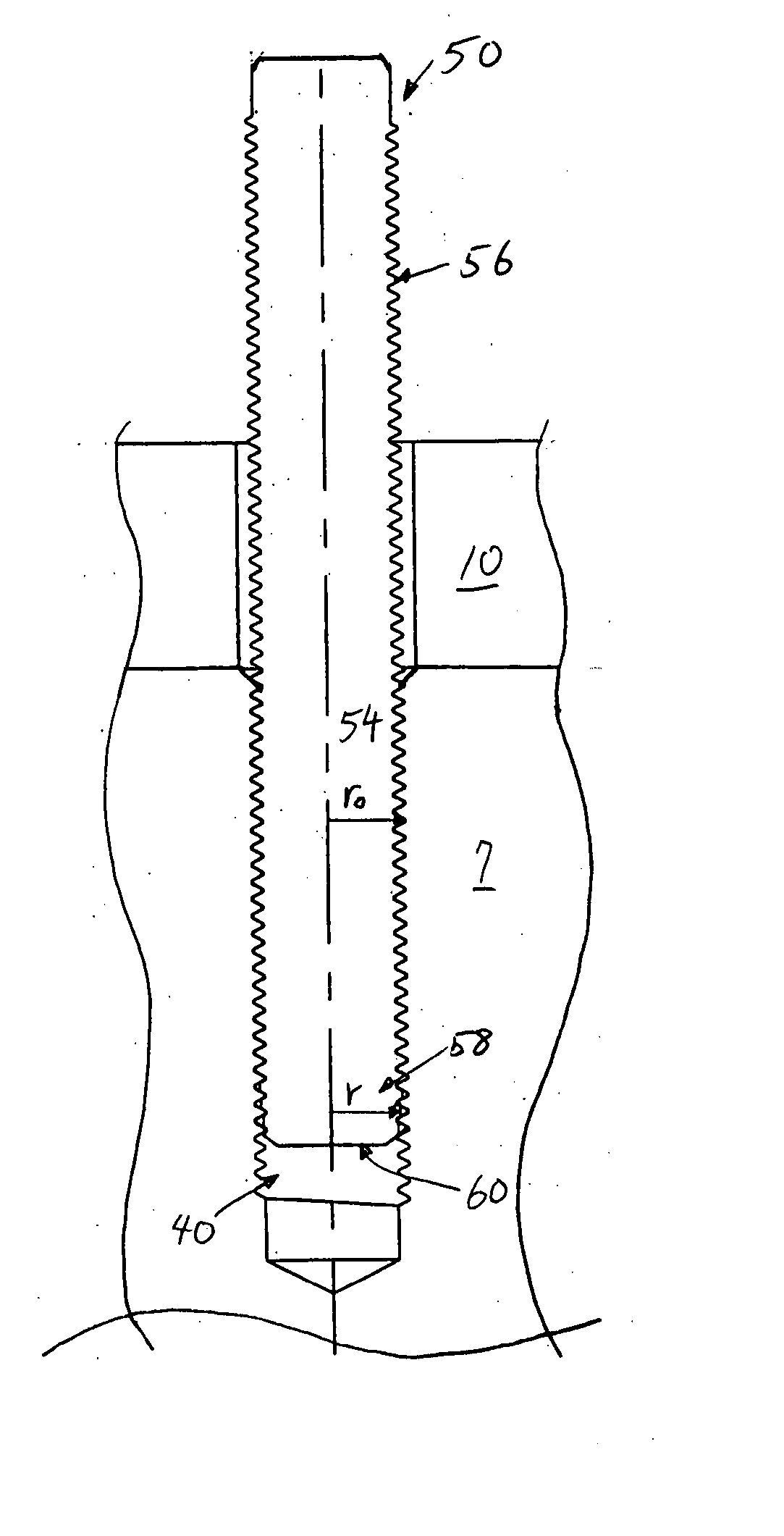

Fastener and method for reducing stress failure in an engine component

InactiveUS20060245842A1Reduces stress failureImprove carrying capacityWashersNutsStress failureEngineering

A fastener and a method for reducing stress failure in a fastening joint of an internal combustion engine component is disclosed. The threaded fastener may be a bolt or a stud secured to an engine block. The fastener has a threaded tip portion with a radius and a distal end. The threaded tip portion is inserted into a threaded hole to define a threaded interface. In one embodiment, the load carrying capability is increased by progressively reducing the radius of at least a part of the threaded tip portion. In another embodiment, the load carrying capability is increased by an axially extending hole at the distal end of the threaded tip portion, the hole having a progressively reduced diameter.

Owner:CUMMINS INC

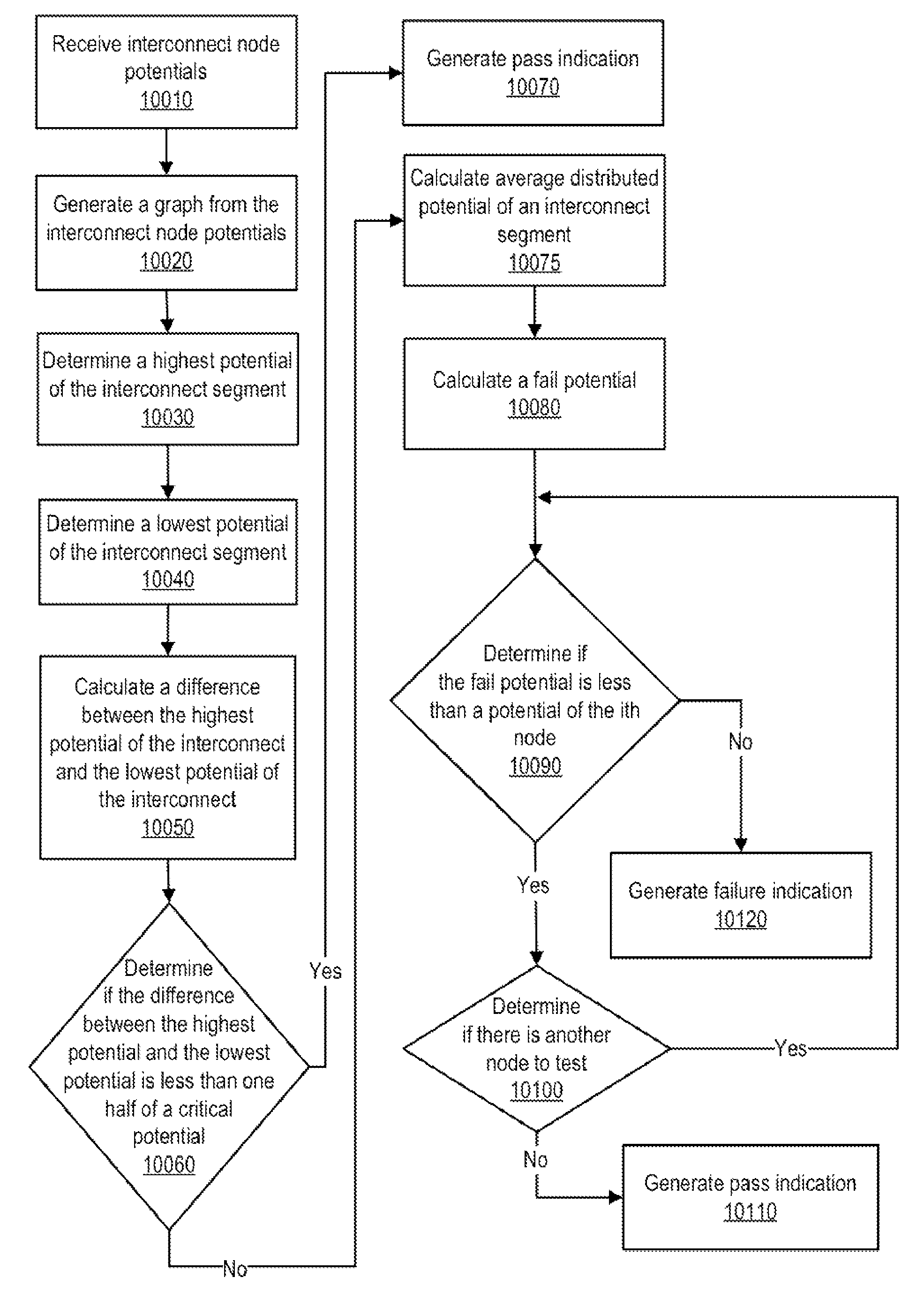

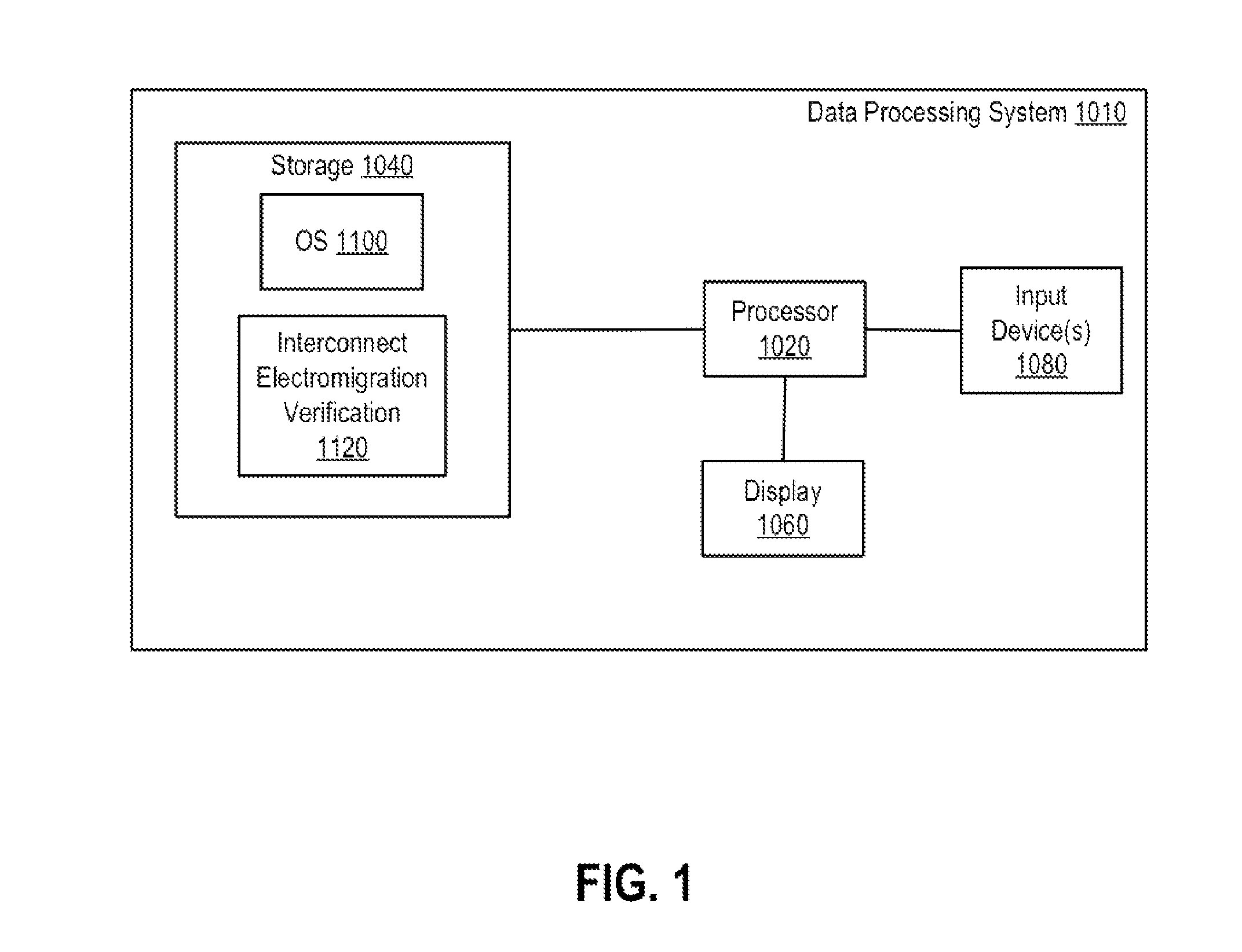

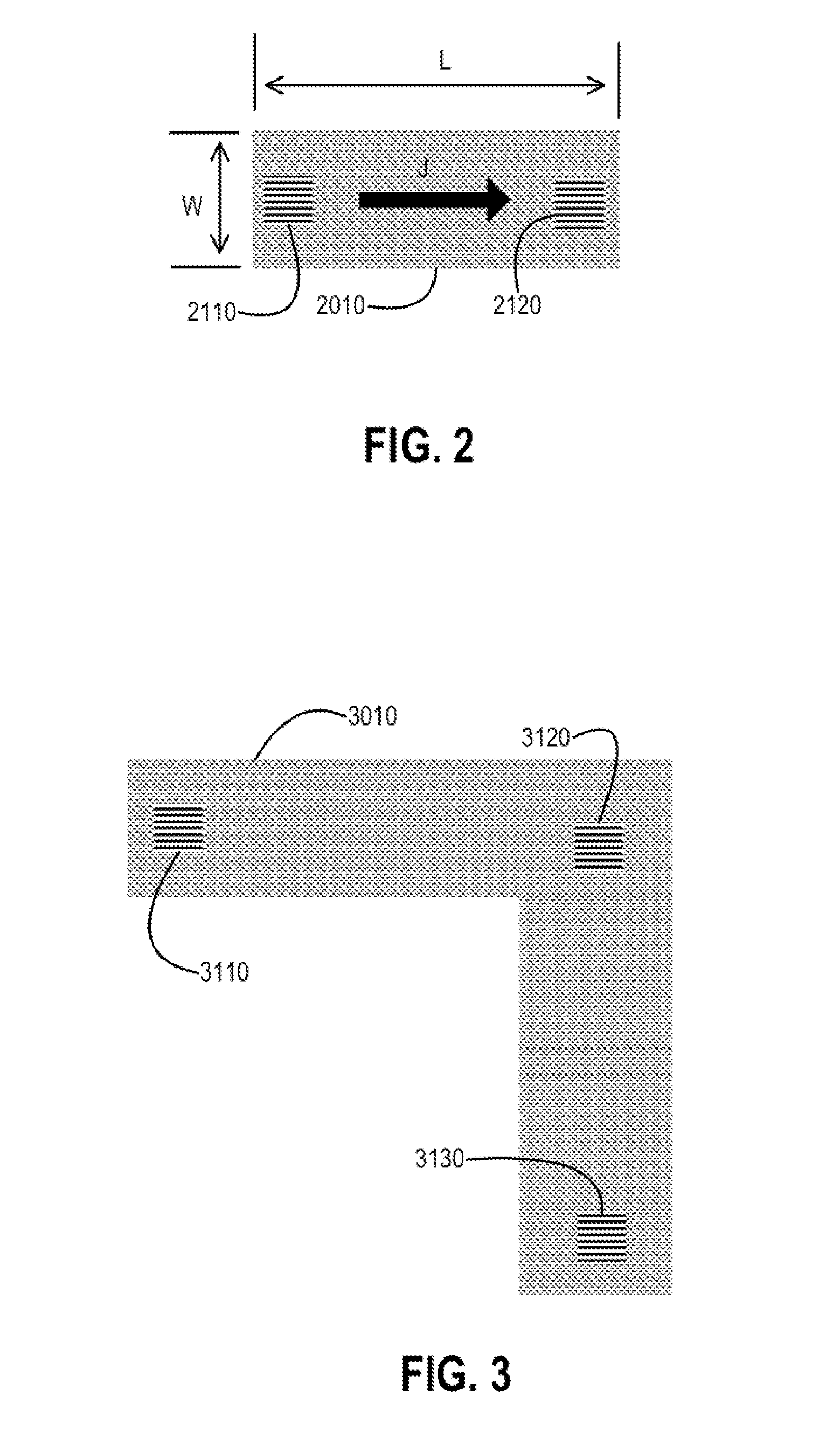

Techniques for electromigration stress determination in interconnects of an integrated circuit

In one or more embodiments, one or more methods, processes, and / or systems described can determine stress failures in interconnect segments of integrated circuit designs and correct those failure via modifying the interconnect segments of the integrated circuit designs with one or more additions to the interconnect segments of the integrated circuit designs. Potentials can be received from a simulation, and one or more failures of an interconnect segment can be determined via the potentials from the simulation. For example, a failure can be determined via a comparison with a potential from the simulation and a critical potential. An interconnect segment can be modified with a stub such that a comparison with a potential from the simulation and a critical potential to provide a non-failing, modified interconnect segment.

Owner:TAIWAN SEMICON MFG CO LTD

Fuel rail pulse damper with improved end crimp

InactiveUS20050263134A1Eliminate area of sidewallAdditional toolLow pressure fuel injectionPipe elementsEngineeringStress failure

An internal pulse damper for use in a fuel rail for an internal combustion engine. The damper is formed from a length of tubular metal stock having a flat oval cross-section and ends flattened by crimping to form a captive-air pillow. The end crimps are improved through use of tooling to eliminate a creased sidewall area vulnerable to stress failure in prior art pulse dampers. Such tooling includes constraints to prevent the tubing sides from flaring out and forming a longitudinal crease adjacent the end crimp during squeezing-shut of the tube end

Owner:DELPHI TECH INC

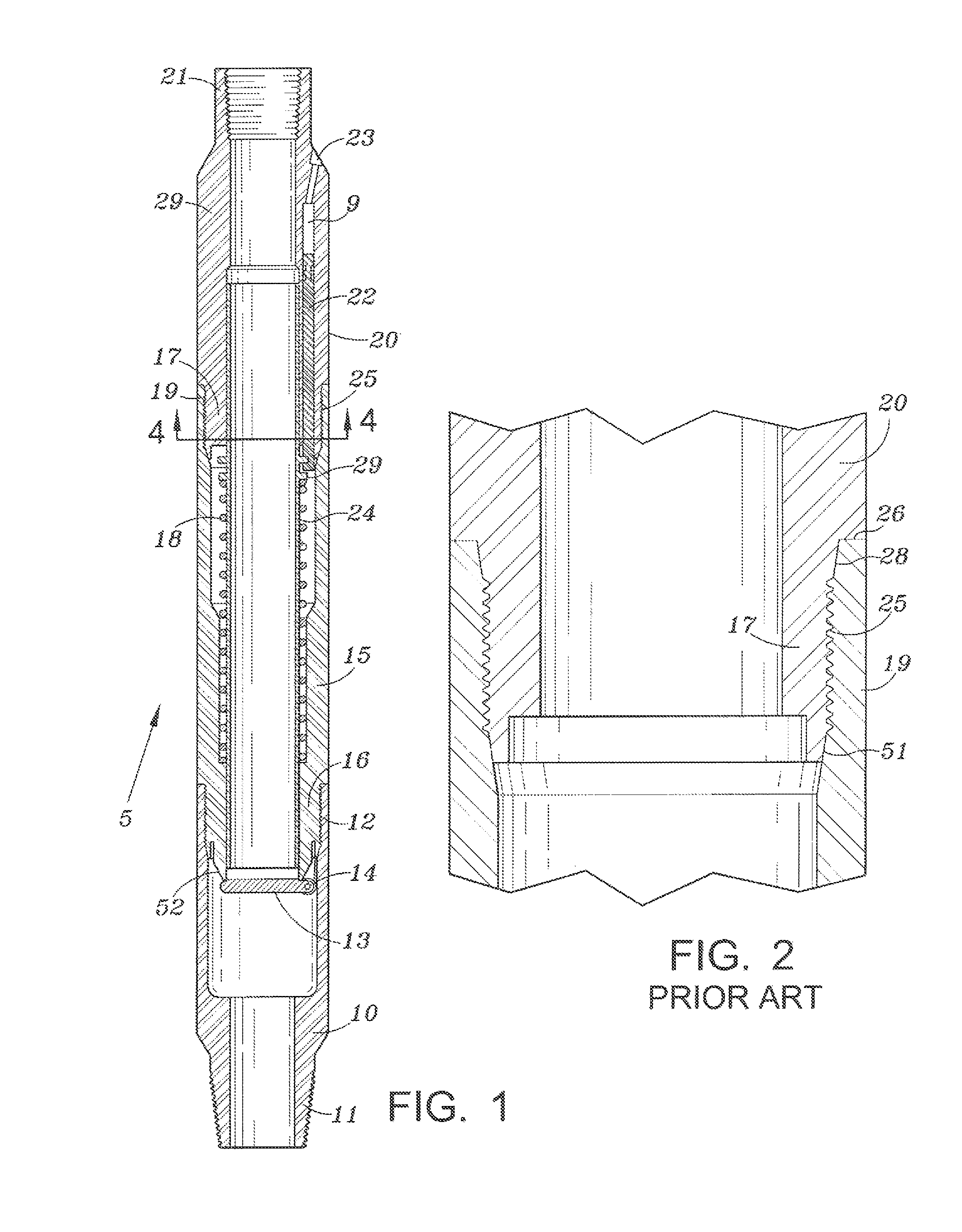

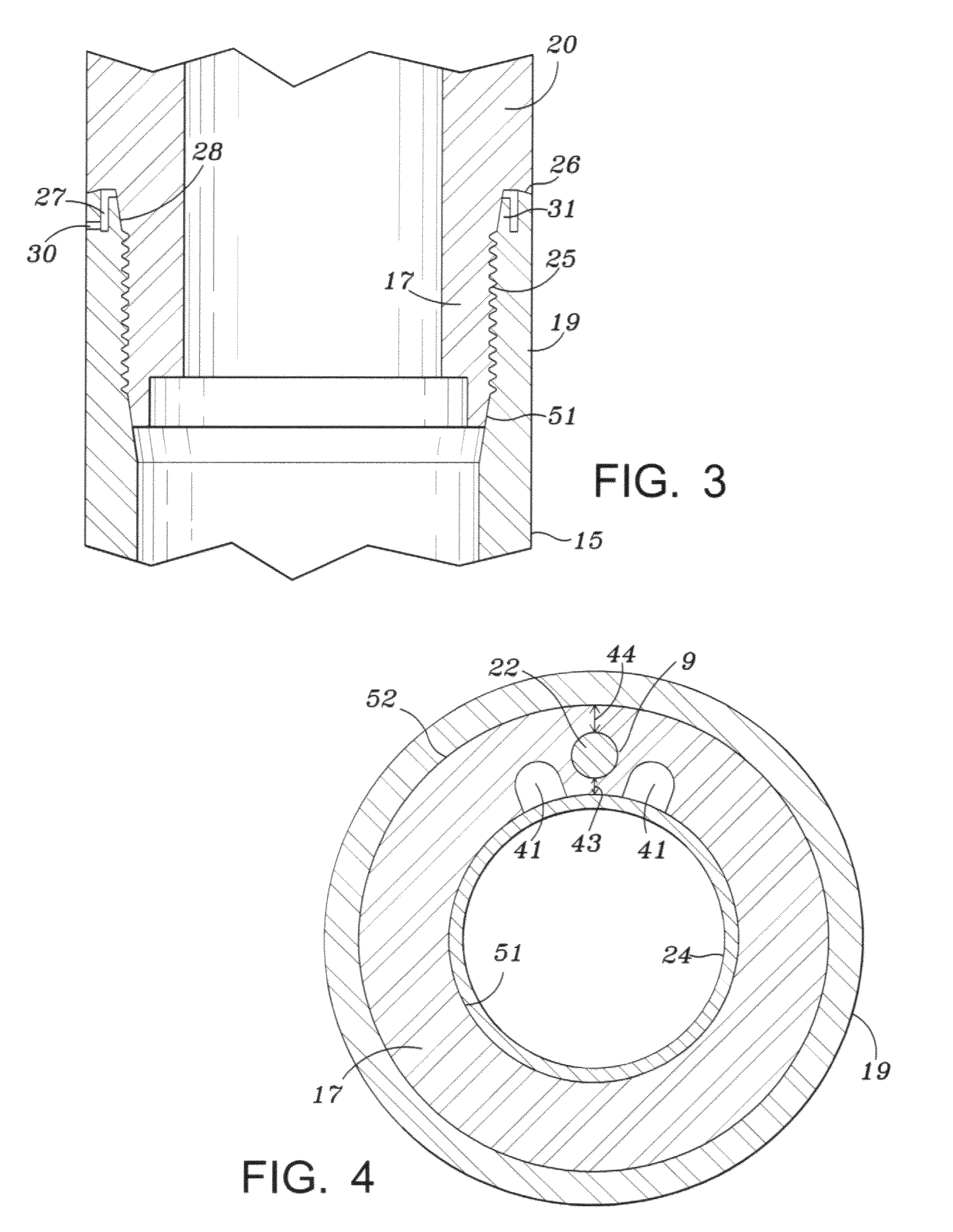

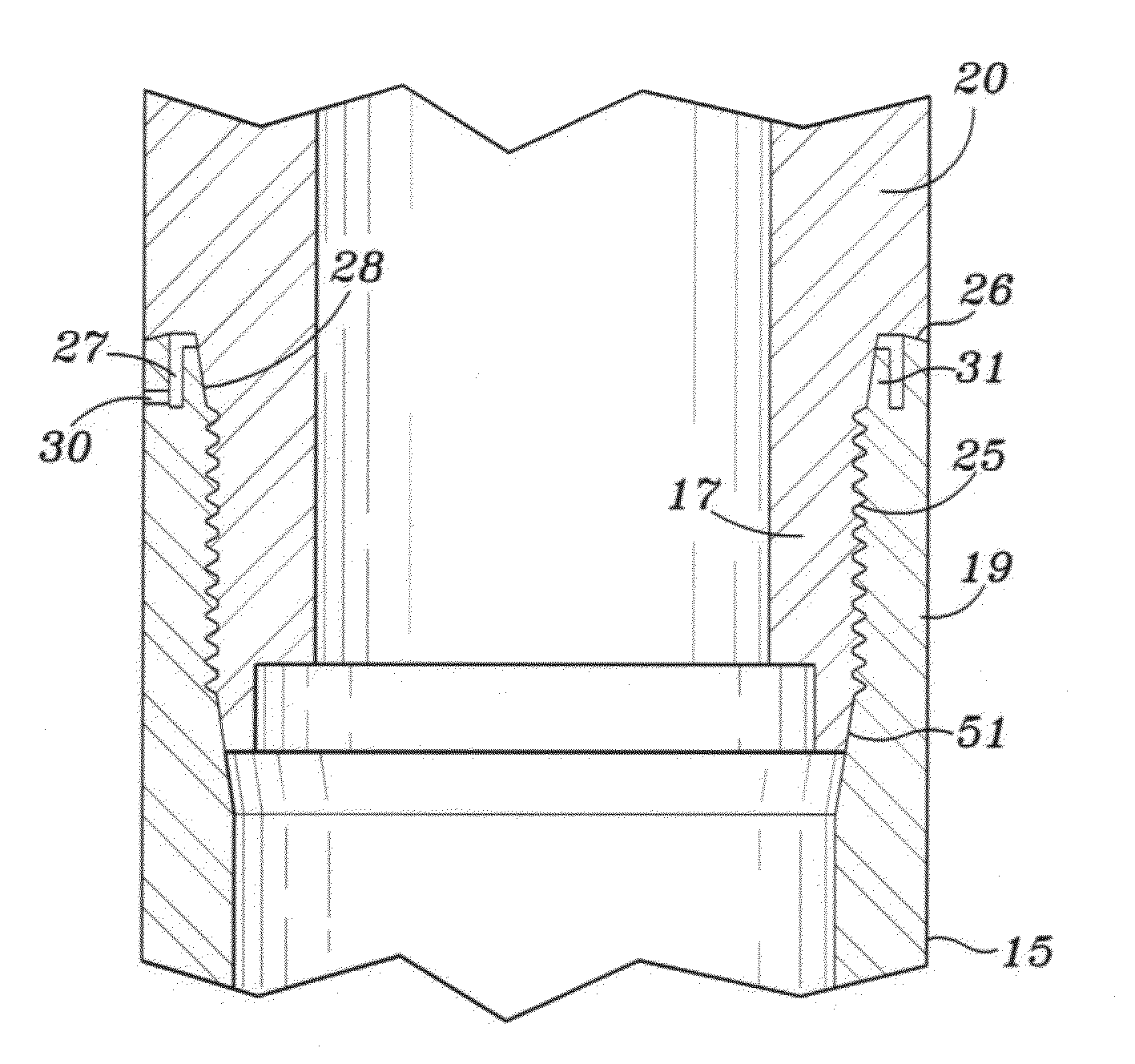

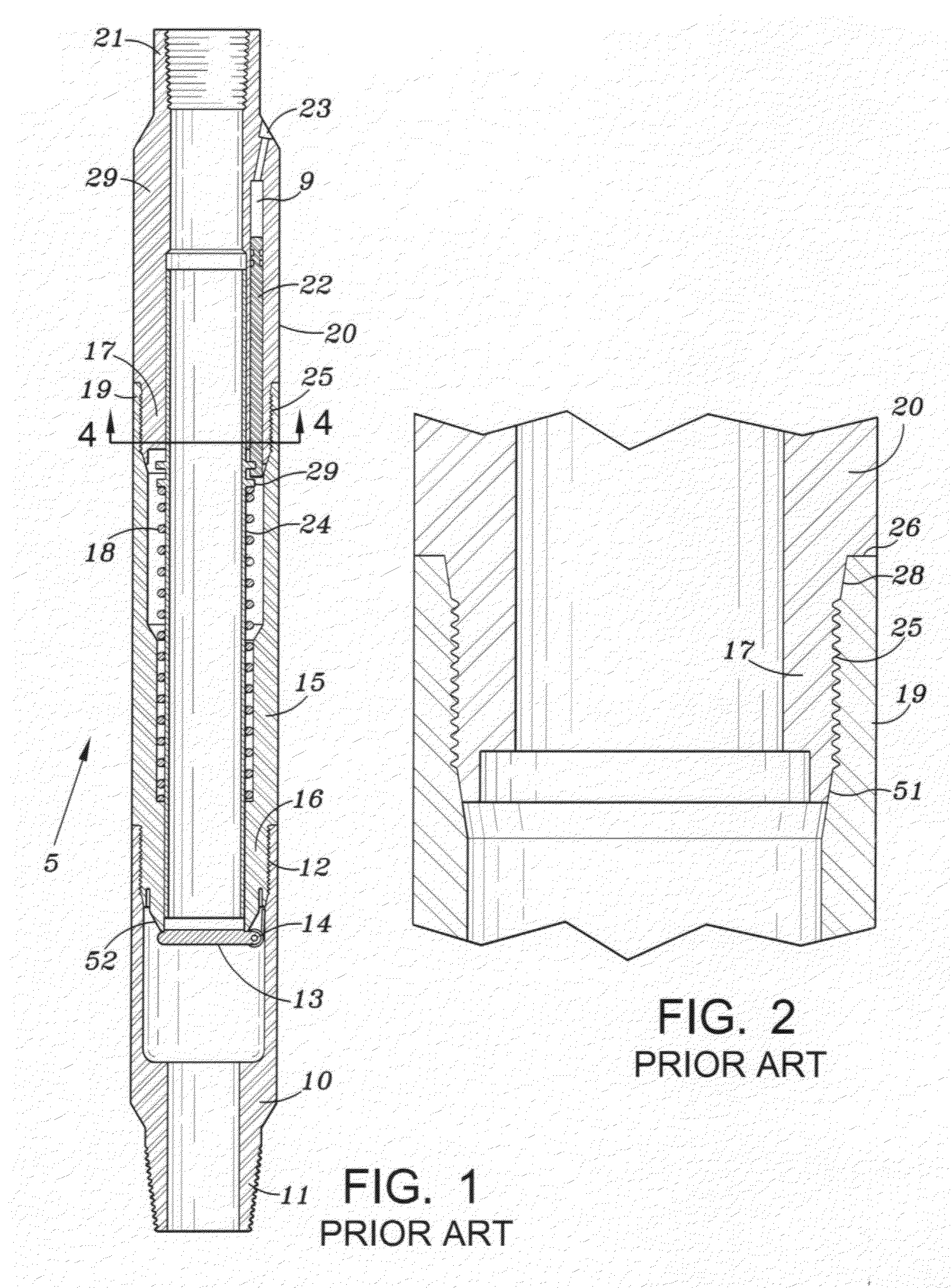

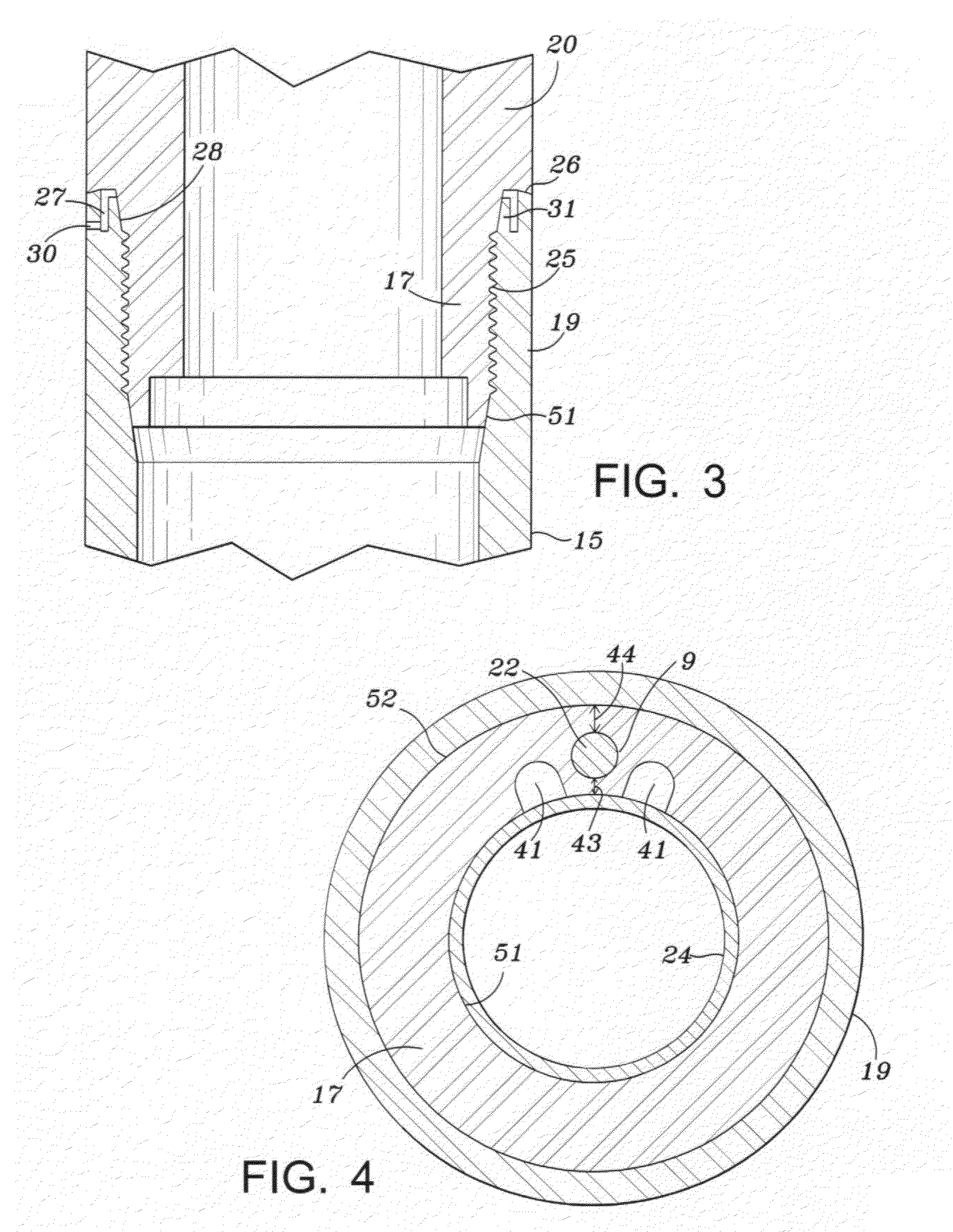

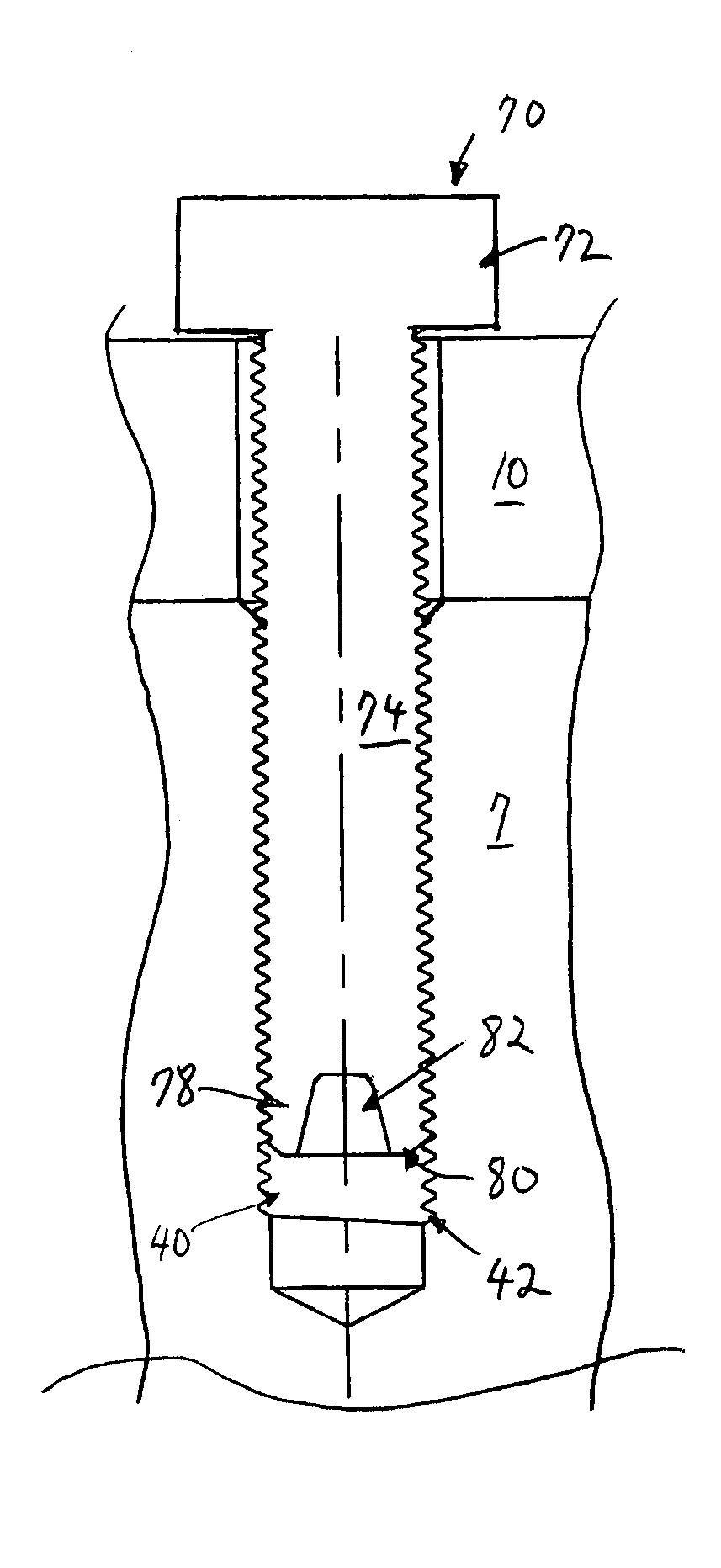

Subsurface safety valve for high temperature and high pressure wells

InactiveUS8668014B2Improve sealingIncrease contact pressureDrilling rodsConstructionsStress failureEngineering

A subsurface safety valve particularly designed for high temperature and high pressure applications has an improved tubular joint connection that provides for a compliant metal to metal seal without adversely affecting the break out torque. The valve also includes axially extending grooves in the inner surface of the tubular housing in the area of a actuating piston bore to relief stresses in that area thereby reducing the risk of stress failure.

Owner:TEJAS RES & ENG

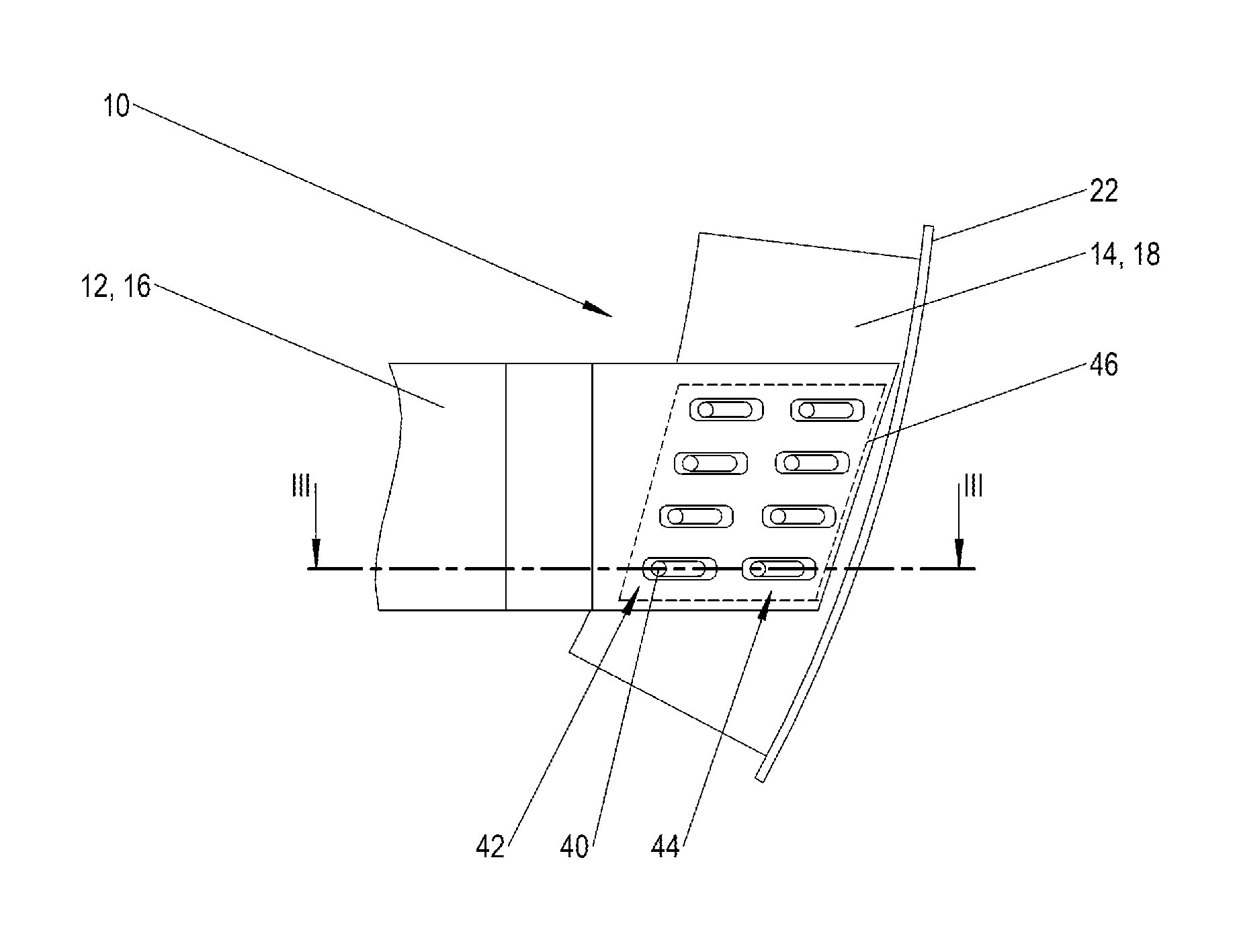

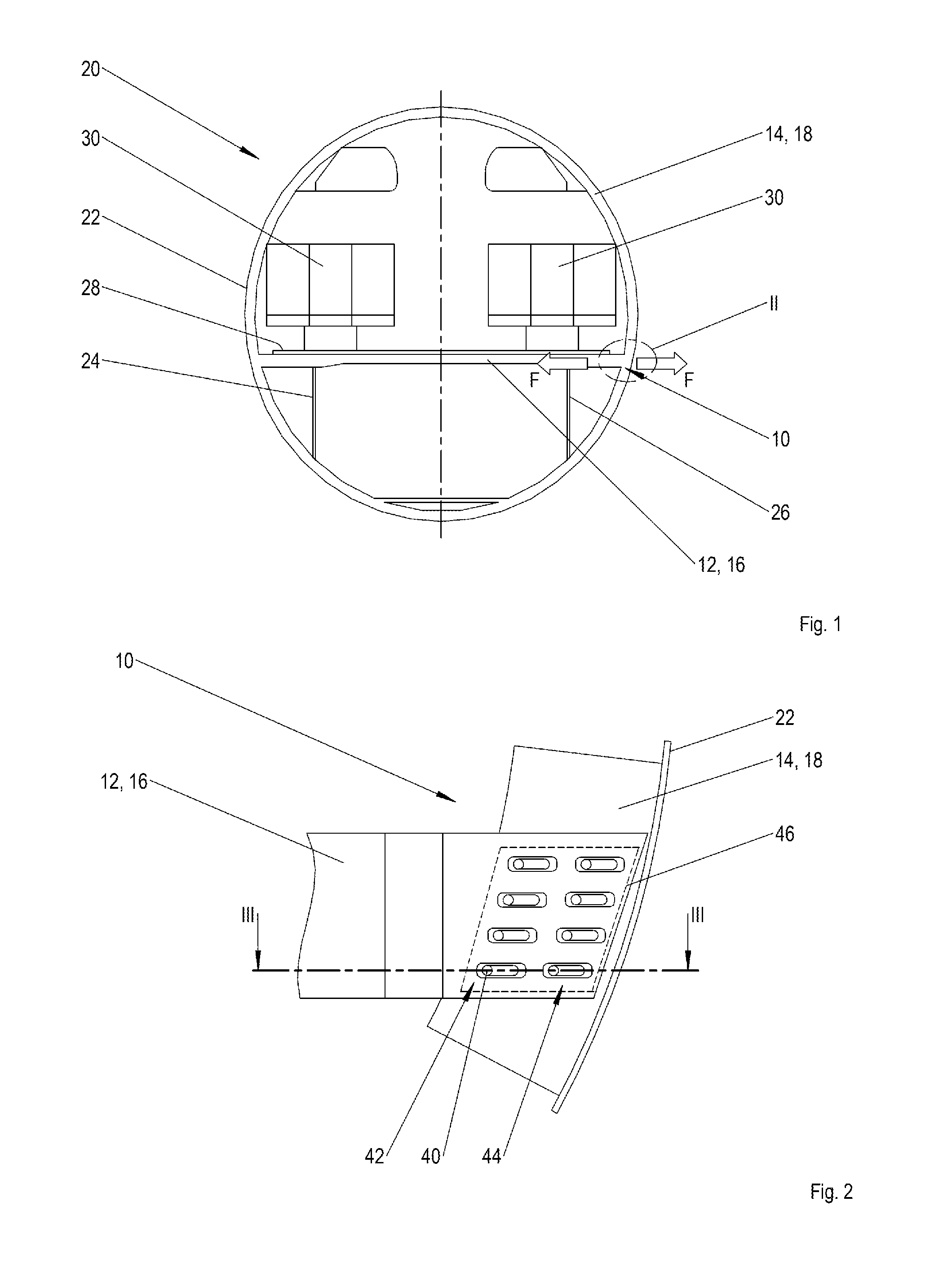

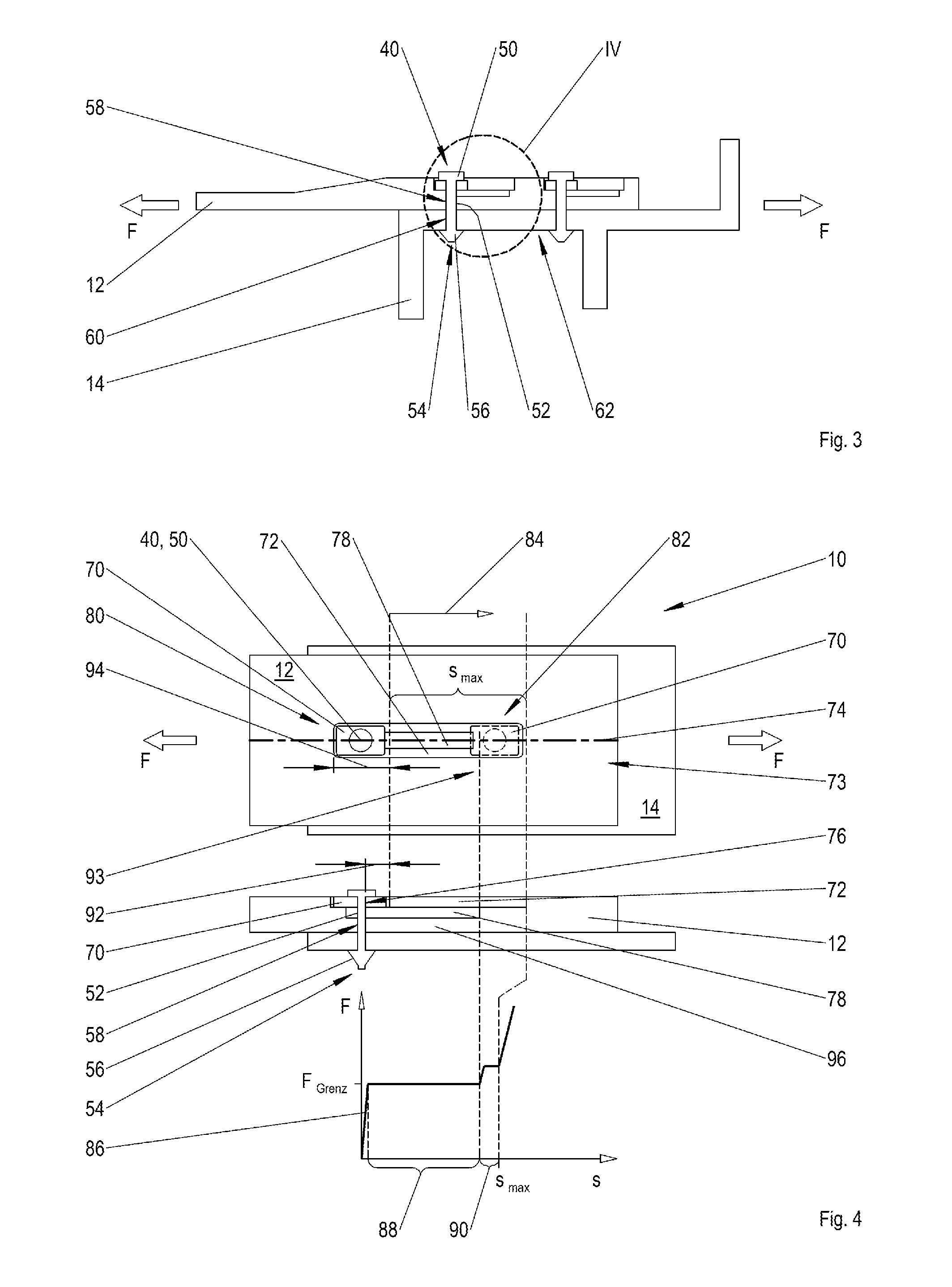

Connection arrangement and structure

ActiveUS20150151829A1Considerable energy absorptionSafely initiatableFuselage framesShock absorbersFiberPlastic materials

An energy-absorbing connection arrangement with a multitude of connectors for joining two components, such as a transverse member and a circular frame element, of an aircraft fuselage. Each connector comprises a headed shaft and the shafts reach through component boreholes. On the shaft ends facing away from the heads, counter-bearings are provided. At least one of the components comprises a fiber-reinforced plastic material. A head and / or counter-bearing of at least one connector rests against at least one underlay device. The underlay device is received in a guide groove in the first component, with the guide groove commencing in the region of the boreholes. The underlay device, upon exceeding a mechanical threshold load, is slidable away from the boreholes. Energy absorption takes place along a longitudinal center axis of the guide groove as a result of hole-bearing-stress failure and / or the shearing of the fiber-reinforced plastic material component.

Owner:AIRBUS OPERATIONS GMBH

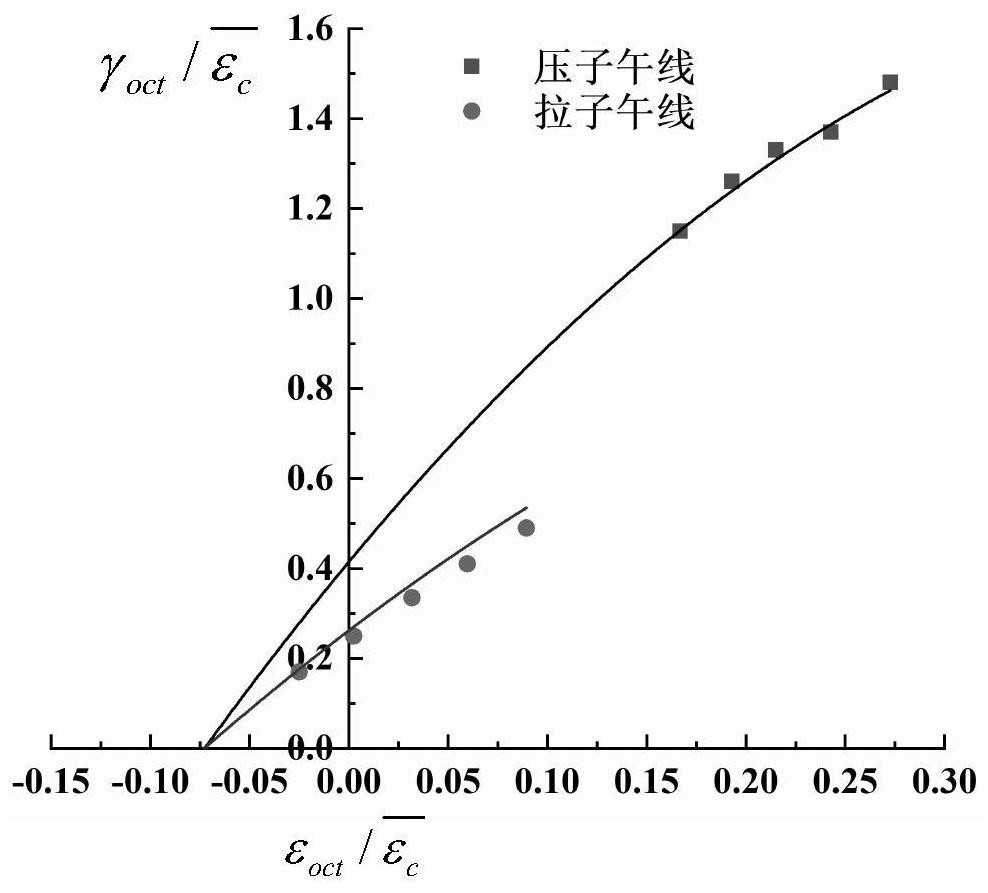

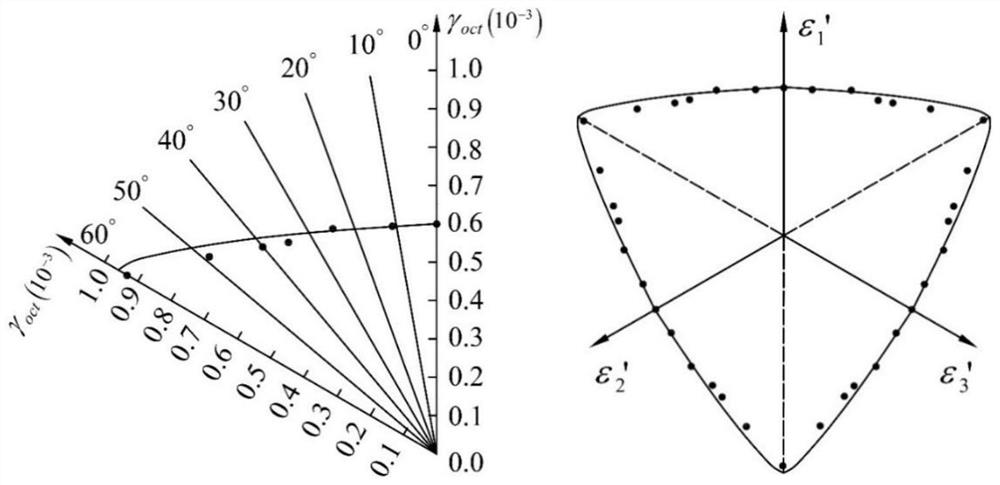

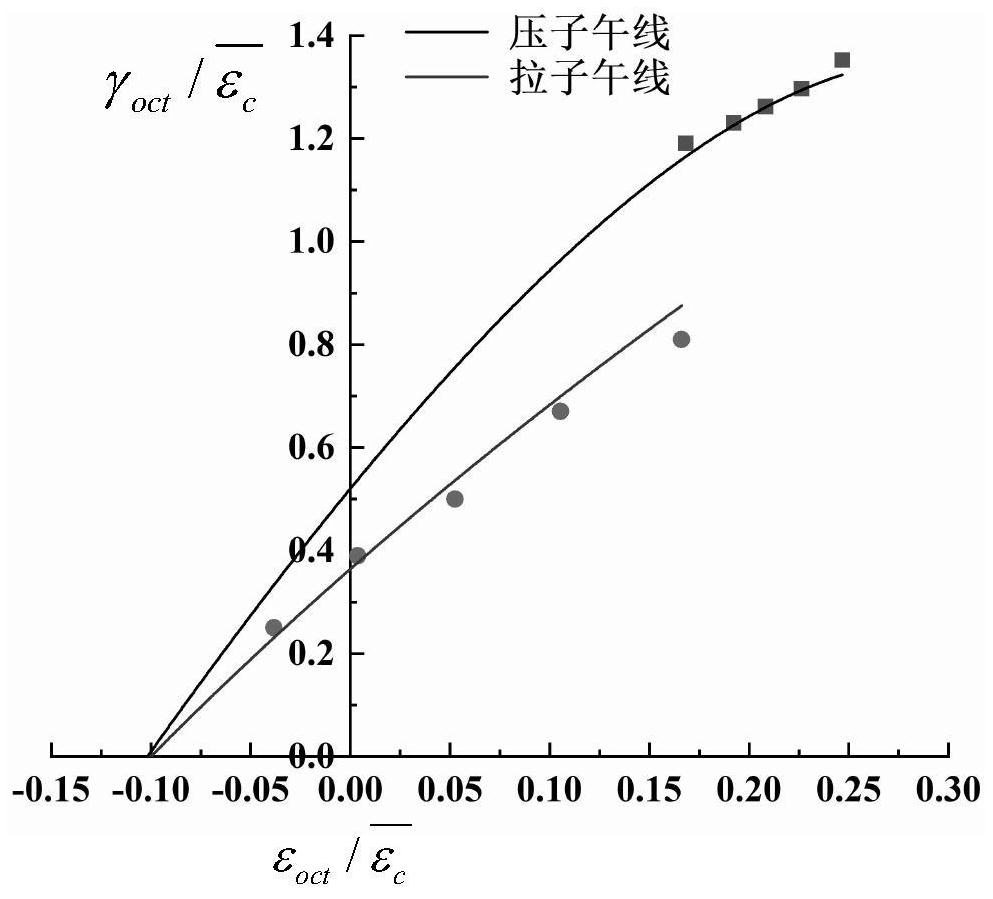

Calculation method of three-dimensional strain failure criterion model of asphalt mixture

PendingCN112014216AMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesPrincipal stressRoad surface

The invention discloses a calculation method of a three-dimensional strain failure criterion model of an asphalt mixture. The calculation method comprises the following steps: carrying out strength and rigidity tests in a complex stress state, obtaining failure principal stress of the material, and establishing a stress failure criterion model in an octahedral space and a static resilience moduluscalculation model in the complex stress state; and on this basis, based on the generalized Hooke theorem, establishing an asphalt mixture three-dimensional strain failure criterion model consideringthe rigidity influence through a conversion method. According to the model, the influence of the complex stress state on the strength and rigidity of the asphalt mixture is considered, and synergisticdestructive effect among all strain components is also considered, so that compared with a traditional failure criterion model which does not consider rigidity changes, the nonlinear strength and deformation characteristics of the asphalt mixture can be reflected more accurately, and support is provided for reasonable selection of asphalt mixture material parameters and refined design of a road surface in the complex stress state.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Application of keratinocyte growth factor-2 in preparation of medicines for preventing and curing lung injury

InactiveCN101822821AKeep the connection steadyPromote hyperplasiaPeptide/protein ingredientsRespiratory disorderFactor iiStress failure

The invention relates to an application of keratinocyte growth factor-2 in the preparation of medicines for preventing and curing lung injury. The invention has the advantages that single-medicine or medicine combination scheme is used to recombine human keratinocyte growth factor-2 (KGF-2) to cure and prevent lung injury / respiratory distress syndrome caused by any factor; and the lung injury / respiratory distress syndrome is in an important position of the special medicine such as the treatment of high altitude lung injury, the military medicine, the sports medicine and the treatment of lung injury / respiratory distress syndrome caused by other diseases. The above diseases can be subclinical, mild, moderate, severe or life-threatening lung injury. Researches show that KGF-2 can maintain the dynamic equilibrium of alveolar surfactants to promote hyperplasia, migrate cells and repair lung injury; and the KGF-2 plays an important role in protecting air-blood barrier to be intact, maintaining the cytoskeletal and intercellular splicing homeostasis, promoting the lung water to be removed and reducing or avoiding alveolus-capillary stress failure.

Owner:SHANGHAI XINSHENGYUAN BIOLOGICAL MEDICAL +1

Defect mending method and structure

The present invention provides a defect mending structure and a defect mending method. The mending structure has a structure with a plurality of layers to mend the circuit pattern with defect. Besides, the defect mending method provided by the invention mainly uses the impact pressure generated when the transfer material that is has the structure with a plurality of layers receives the irradiation of the electromagnetic wave light source, namely uses the light pressure generated form the impact of the photon and the energy of the electromagnetic wave to generate a molecular bonding breakage or an explosion phenomenon in order to transfer the material to the area to be mended. Through the structure and method provided by the invention, the phenomenon of hot influence caused by the irradiation of the light source on the mending material and the problems of easy oxidization and stress failure caused thereby can be settled.

Owner:IND TECH RES INST

Block orientation cylinder

InactiveUS20060185961A1Minimal maintenanceLow horsepowerManual conveyance devicesConveyor partsFinger jointEngineering

A rotating cylinder is used to orient wood material, such as but not limited to blocks (e.g., finger joint blocks), preparatory to further processing. The rotating cylinder uses gravity and a tumbling action of the blocks to orient the blocks and move them through the cylinder. Unlike known apparatus such as vibrating conveyors, embodiments of the invention are relatively simple, vibration free, not prone to mechanical stress failures, are quiet, and use minimal horsepower to operate. Furthermore, embodiments of invention may advantageously reduce noise-caused fatigue amongst lumber workers, as well as reduce maintenance and power costs. The rotating cylinder may be part of a larger system for orienting wood material, such as blocks, for further lumber processing.

Owner:STIBBARD JAMES SPENSER

Simulation system for spot welding invalid number value

InactiveCN101261653BEasy to determineHigh precisionSpecial data processing applicationsStress distributionStress failure

The invention relates to a spot-welding connection failure value simulation system in the car bodywork manufacturing engineering field. In the invention, a circle-stress failure criterion generating module obtains nugget circle stress distribution form according to the failure mode of the spot-welding connection in a strike process to generate the circle stress failure criterion; a failure extremevalue stress and an index-parameter obtaining module obtain welding-spot critical failure stress extreme values and dimensionless stress sub-item index initial values under the condition of the peakvalues of four exterior loads; four types of sample value models which are pulling-cutting, pulling-extending, pulling-bending and pulling-twisting are established in a welding-spot connection value simulation module; an explicit dynamics analysis module couples circle stress failure criteria and obtains the continuous distributed inner stress of a welding-spot unit model and an extreme value stress borne by the welding-spot unit during failure time by simulation; a welding-spot failure material databank module stores the critical failure stress extreme values and the dimensionless stress sub-item index initial values of each stress component. The system not only can enhance the impact simulation precision without impact on the calculation efficiency, but also can reduce the design and exploitation cost.

Owner:SHANGHAI JIAO TONG UNIV

Subsurface Safety Valve for High Temperature and High Pressure Wells

InactiveUS20120205113A1Improve sealingHigh break-out torqueDrilling rodsConstructionsStress failureEngineering

A subsurface safety valve particularly designed for high temperature and high pressure applications has an improved tubular joint connection that provides for a compliant metal to metal seal without adversely affecting the break out torque. The valve also includes axially extending grooves in the inner surface of the tubular housing in the area of a actuating piston bore to relief stresses in that area thereby reducing the risk of stress failure.

Owner:TEJAS RES & ENG

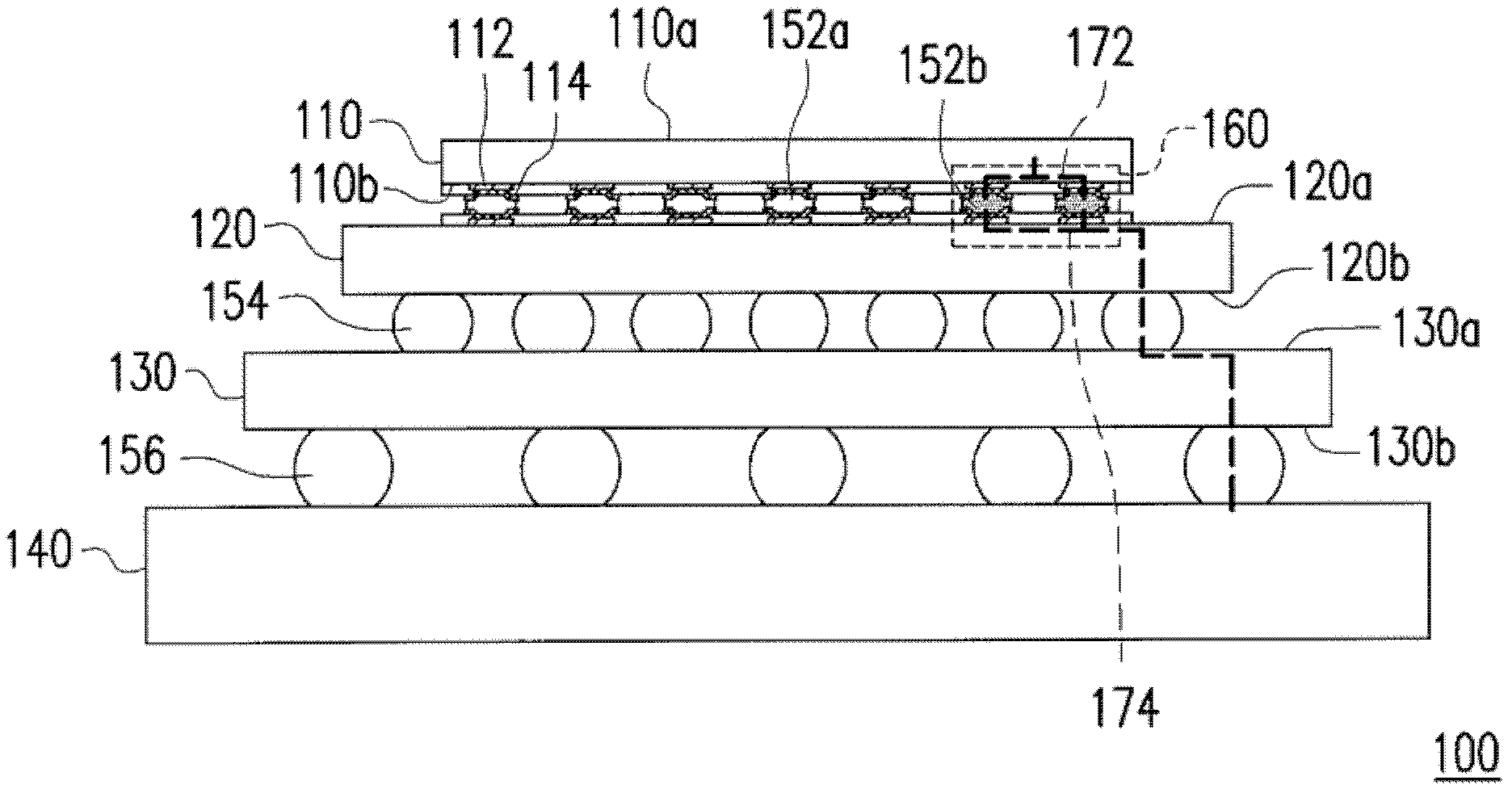

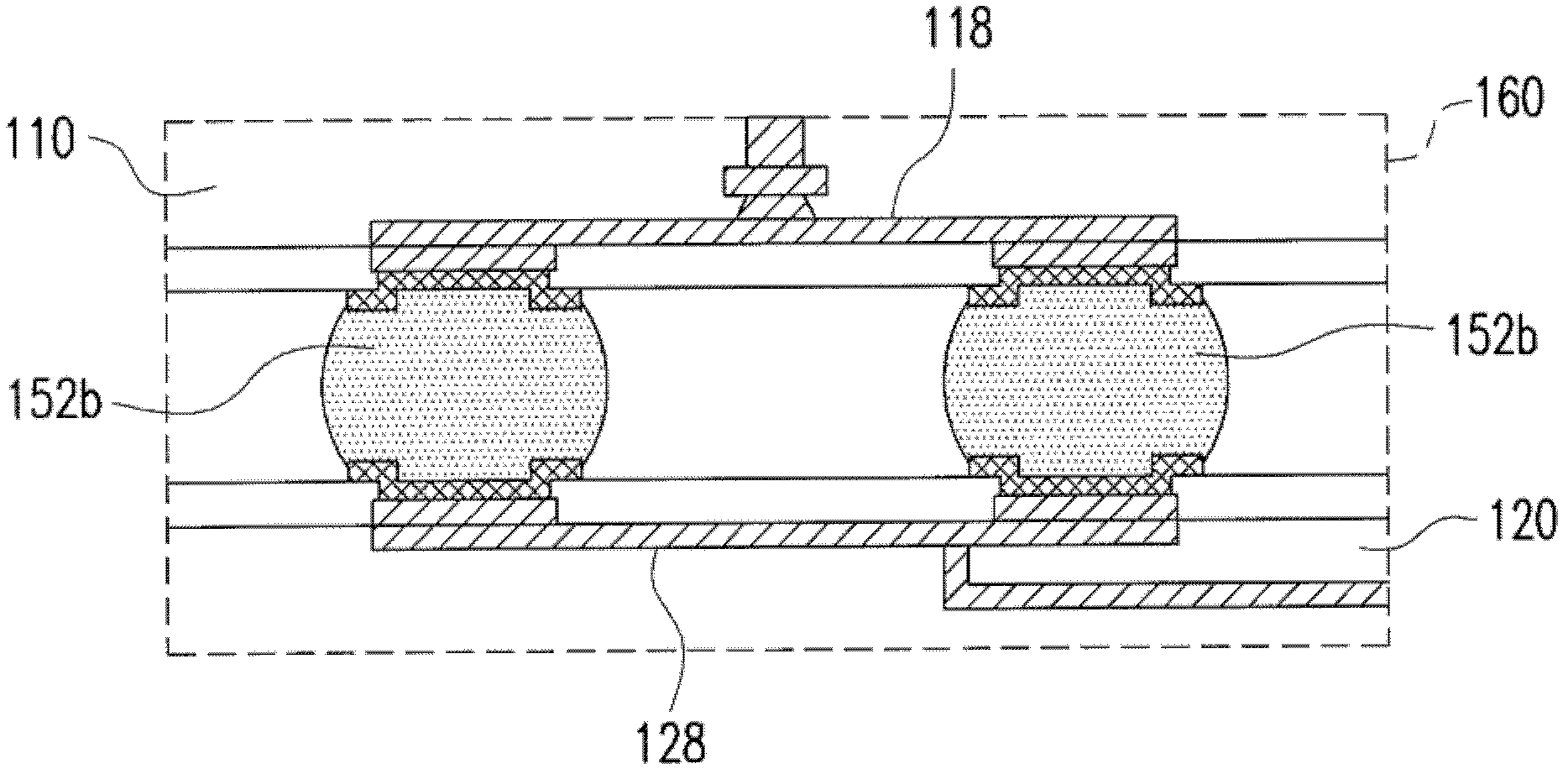

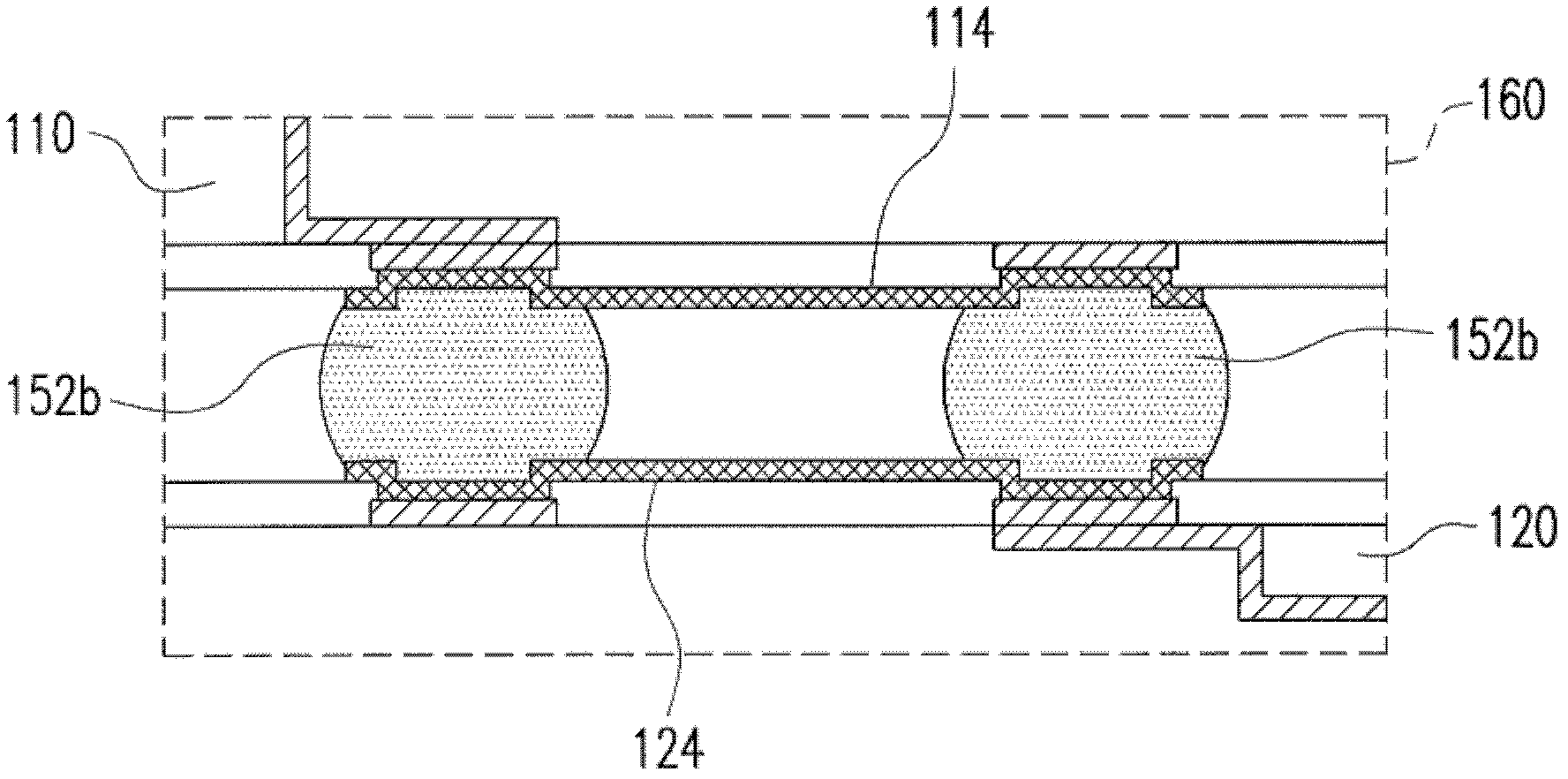

Semiconductor packaging structure with multiple convex block structures

InactiveCN102361028AIncreased crack propagation pathAvoid failureSemiconductor/solid-state device detailsSolid-state devicesElectricityElectrical conductor

The invention discloses a semiconductor packaging structure with multiple convex block structures. The semiconductor packaging structure is formed by stacking multiple semiconductor elements, wherein the corners of the connection surface of two semiconductor elements are provided with multiple convex block structures composed of multiple convex blocks which are conducted mutually; and the multiple convex block structures are used for increasing the extension paths of the cracks on the connection surface of the elements. Thus, when partial convex blocks in the multiple convex block structures lose effectiveness caused by stress failure, other convex blocks in the multiple convex block structures can still maintain normal functions, therefore, the electric connection path between the elements can be prevented from being damaged by stress and losing effectiveness, and further the reliability of the packaging structure is ensured.

Owner:ADVANCED SEMICON ENG INC

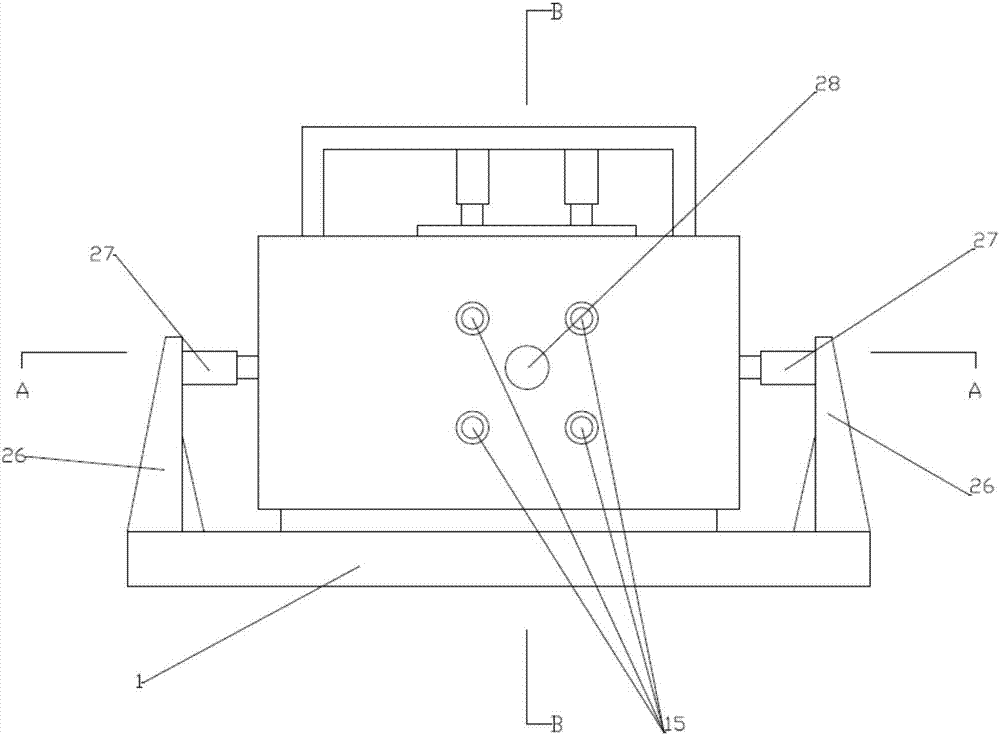

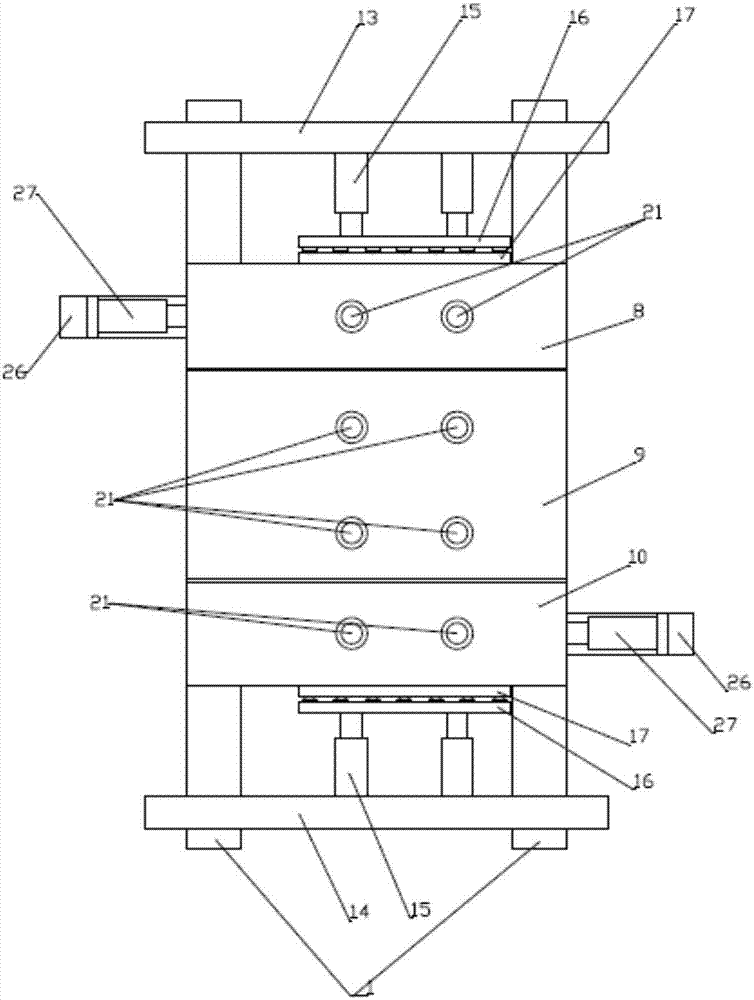

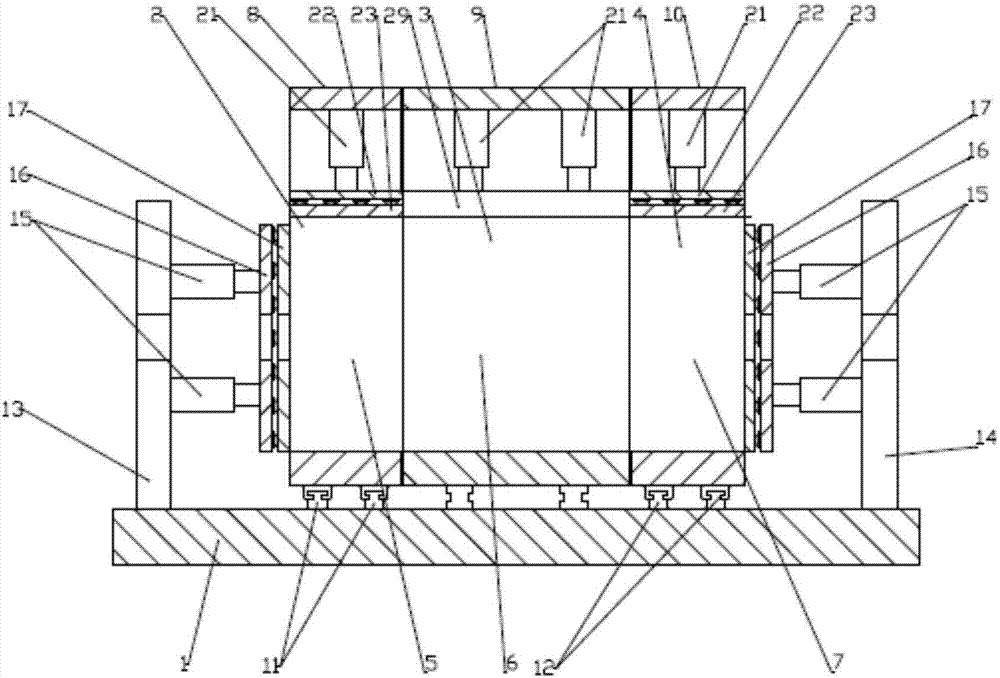

A Model Test Device for Staggered Failure of Tunnel Crossing Active Fault Zones that Can Apply Triaxial Stress

ActiveCN105067438BReliable experimental meansMaterial strength using tensile/compressive forcesActive faultDesign support system

The invention discloses a model test device for the dislocation damage of a tunnel crossing an active fault zone that can apply triaxial stress. The sample is subjected to triaxial loading, and the test in the third test chamber is subjected to triaxial loading through the second longitudinal loading device, the third lateral loading device and the third vertical loading device, and the first longitudinal loading device and the second longitudinal loading device The output force and the second lateral loading device and the second vertical loading device carry out triaxial loading on the test in the second test chamber; the first test chamber and the third test chamber are realized by the first driving device and the second driving device. In order to realize the simulation of the relative displacement between the upper and lower walls of the active fault zone and the weak geological bodies in the fault zone, to obtain the displacement distribution mode and evolution law of the geological bodies in the fault zone when the active fault zone is dislocated, In order to reveal the surrounding rock response of the tunnel (cave), the scientific design of the support system provides a reliable experimental method.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

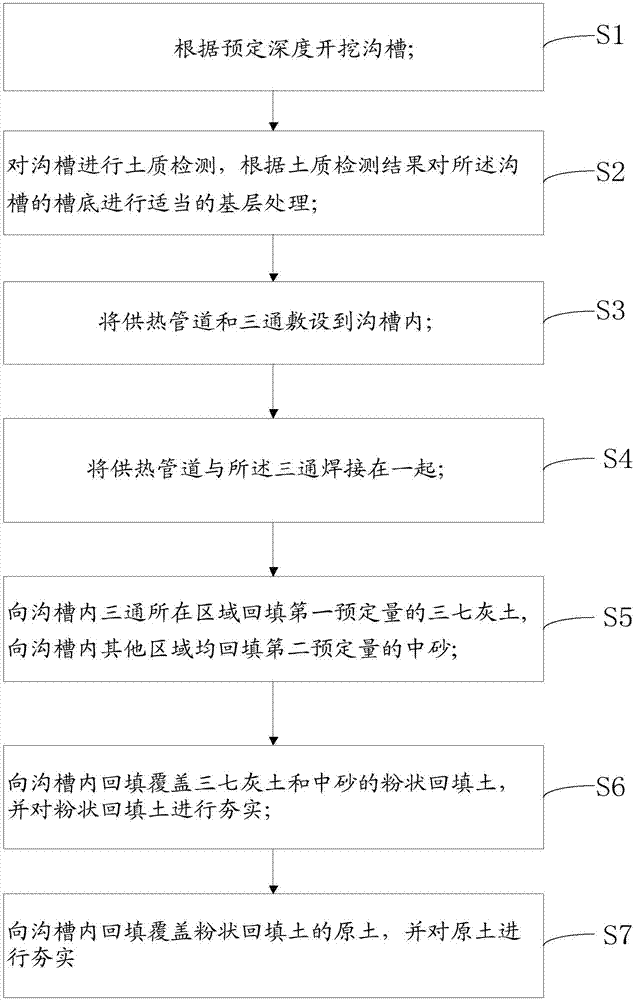

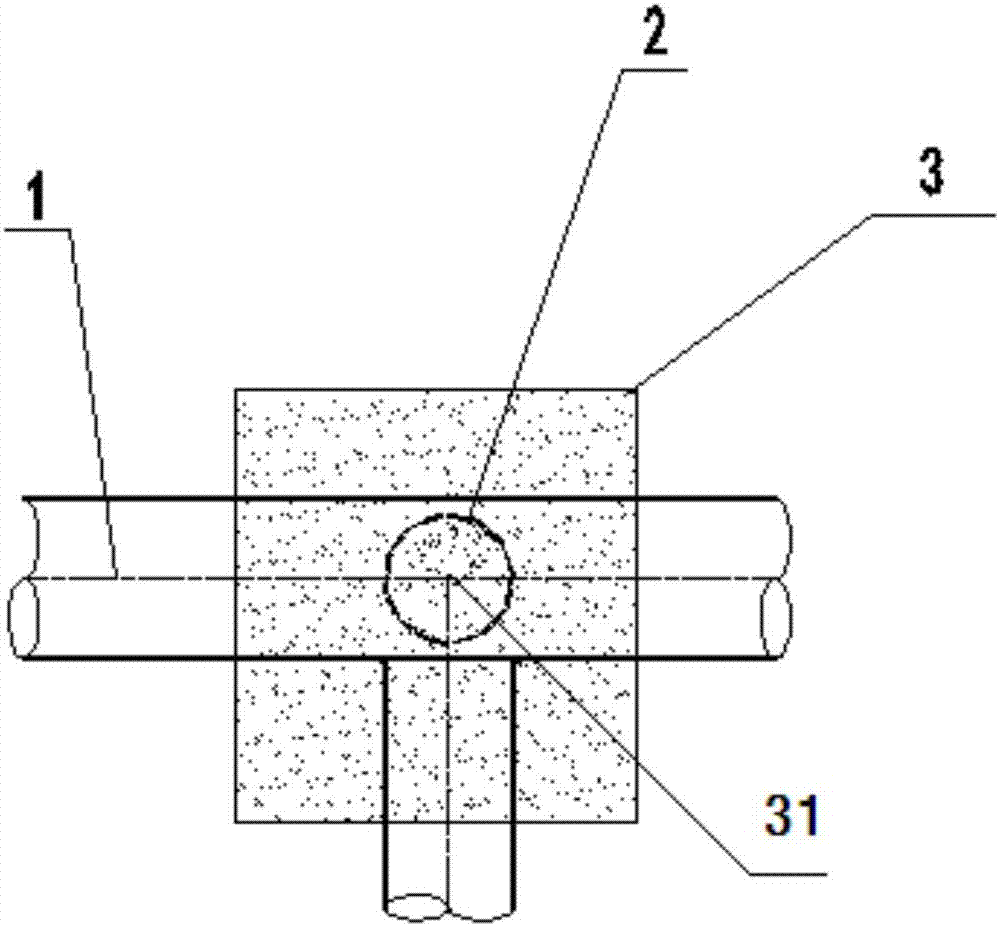

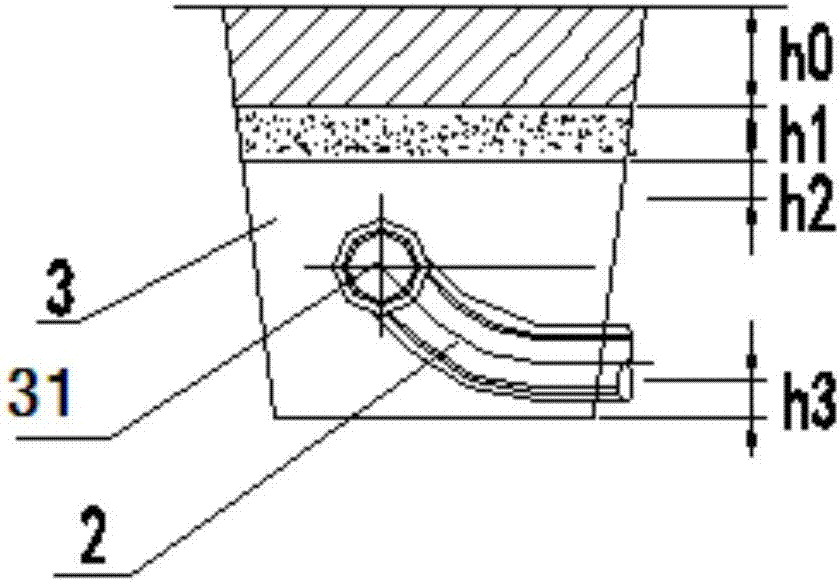

Construction method for reinforcing heat supply pipeline and tee joint

The invention relates to a construction method for reinforcing a heat supply pipeline and a tee joint. The method comprises the following steps that a trench is dug according to a preset depth; the soil quality of the trench is detected; basic treatment is conducted on the bottom of the trench properly according to the soil quality detection result; the heat supply pipeline and the tee joint are laid in the trench and welded together; a first preset amount of 37 lime soil back fills the area, with the tee joint, in the trench, and a second preset amount of medium sand back fills other areas in the trench; powder backfilling soil for covering the 37 lime soil and the medium sand back fills the trench, and is tamped; and natural soil for covering the powder backfilling soil back fills the trench and is tamped. By adoption of the construction method, the possibility of a stress failure at the tee joint of a heat supply pipe network can be effectively reduced.

Owner:BAOTOU ENG & RES CORP OF IRON & STEEL IND CHINA METALLURGY CONSTR GROUP BERIS

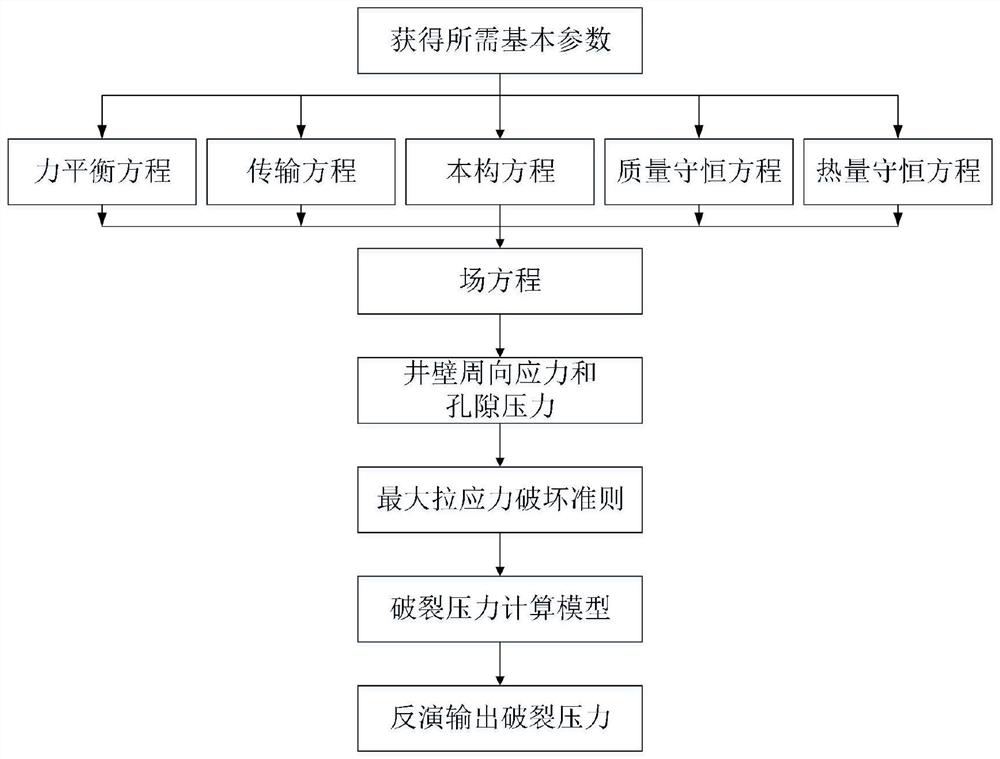

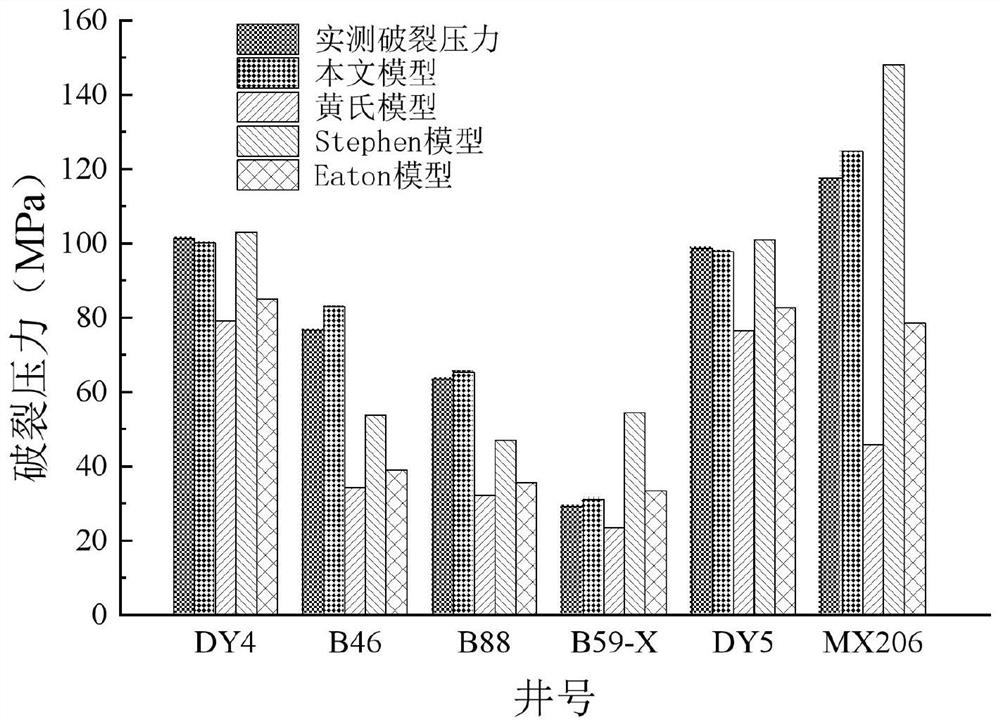

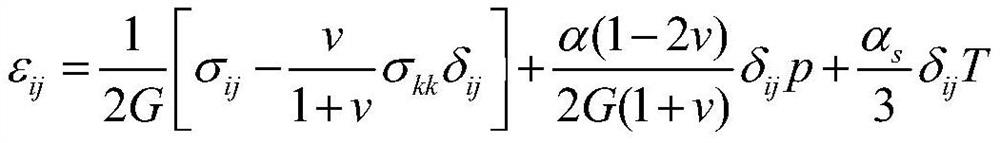

Rock crack initiation pressure calculation method based on heat-fluid-solid coupling

ActiveCN113109162AAccurate calculationMeet the evaluationMaterial strength using tensile/compressive forcesEngineeringHeat conservation

The invention discloses a rock crack initiation pressure calculation method based on heat-fluid-solid coupling. The rock crack initiation pressure calculation method comprises the steps that basic parameters of a target stratum are determined according to logging information, an indoor triaxial compression test and a Brazilian splitting test; according to the force balance equation, the constitutive equation, the transmission equation, the mass conservation equation, the heat conservation equation, the boundary conditions and the maximum tensile stress failure criterion, a rock crack initiation pressure calculation model of the Laplace space based on heat-fluid-solid coupling is established; and the rock crack initiation pressure is determined according to the basic parameters of the target stratum, the rock crack initiation pressure calculation model of the Laplace space based on heat-fluid-solid coupling and a Stehfest numerical inversion method. The coupling relation among fluid seepage, thermal diffusion and rock deformation in the shaft is fully considered; the stratum crack initiation pressure can be calculated more accurately, high-precision parameters are provided for fracturing construction design, and the requirements for reservoir evaluation and fracturing transformation guidance are met.

Owner:SOUTHWEST PETROLEUM UNIV

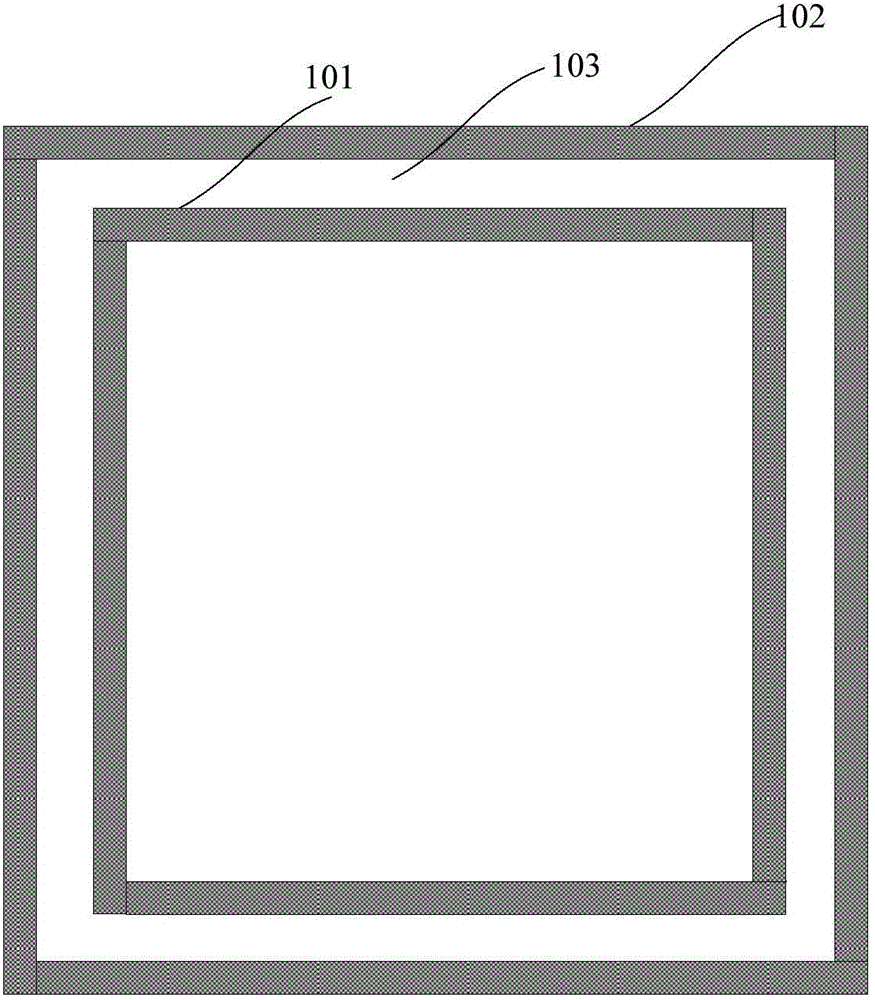

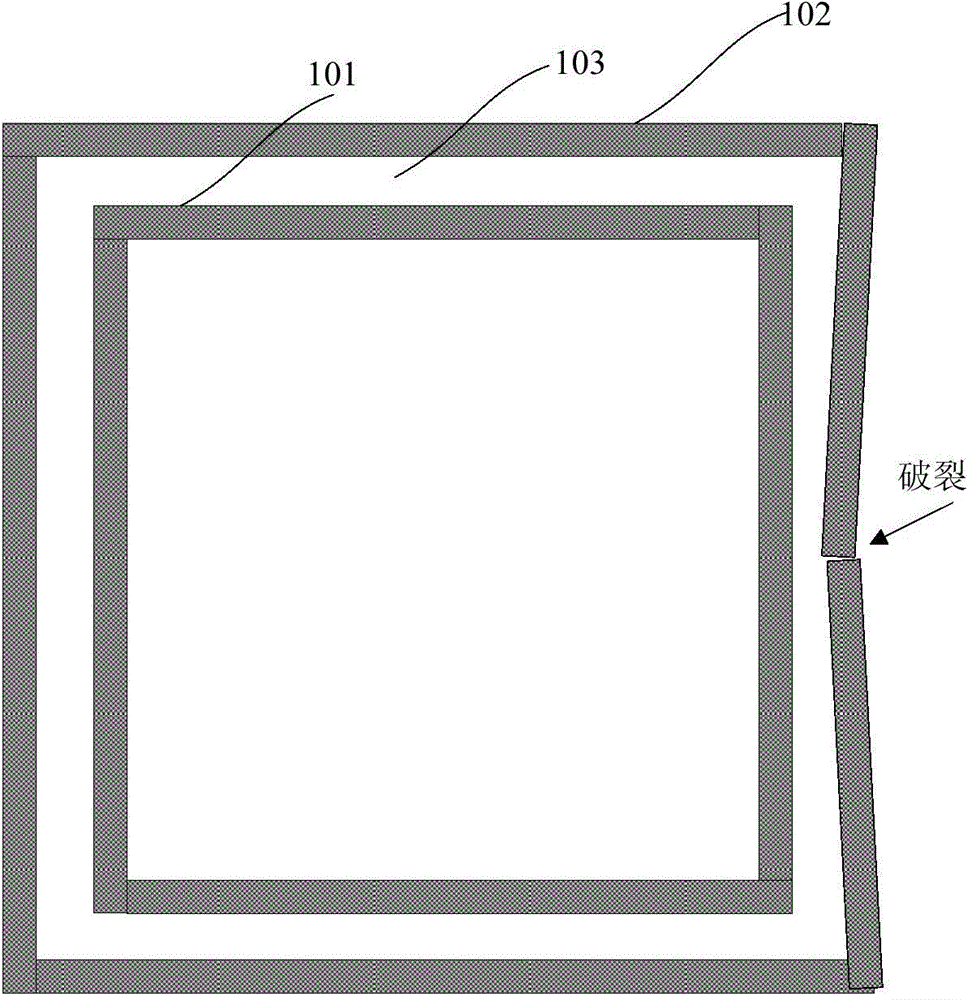

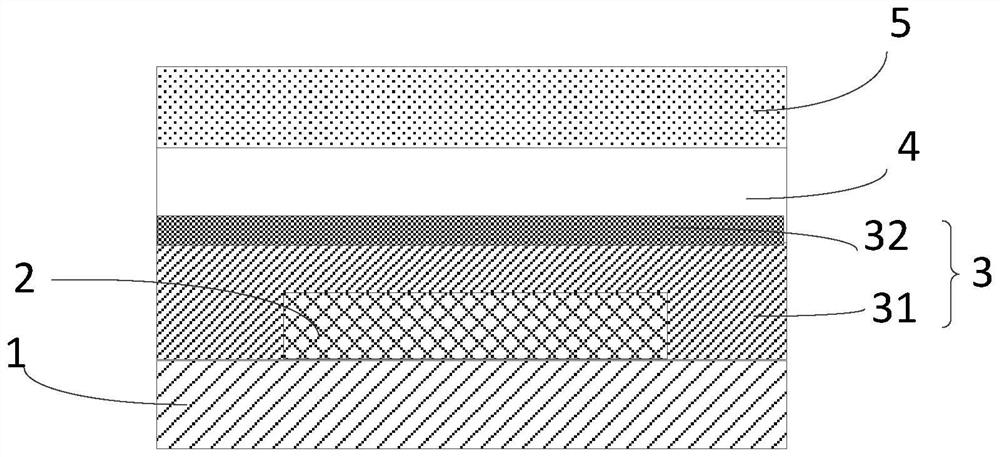

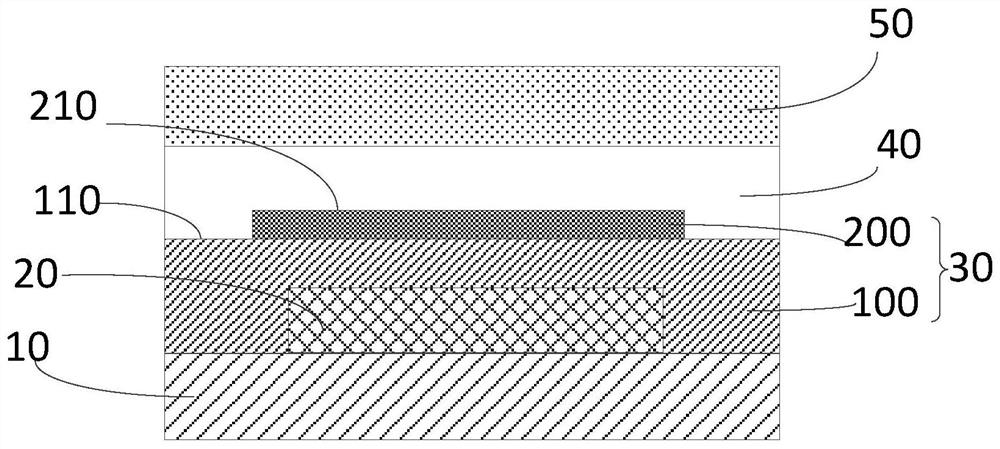

Inorganic material film layer, thin film encapsulation layer, display substrate and manufacturing method thereof

PendingCN111900261AThere will be no thinningImprove the level ofSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneStress failure

The present disclosure provides an inorganic material film layer, a thin film encapsulation layer, a display substrate and a manufacturing method thereof, the inorganic material film layer comprising:a first film layer including a first surface; and a second film layer which is formed on the first surface of the first film layer, the second film layer comprises a second surface located on the side away from the first film layer, and the surface tension of the second surface is larger than that of the first surface; the first surface comprises a central area and a peripheral area, the orthographic projection of the second film layer on the first surface is smaller than the area of the first surface, the second film layer covers the central area, and the peripheral area is not covered by the second film layer to form a peripheral exposed area. According to the inorganic material film layer provided by the invention, the organic material film layer can be fully leveled during ink-jet printing, an overflow phenomenon does not occur, the thickness of the film layer is ensured not to be too thick, and the risk of stress failure can be reduced.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com