Patents

Literature

111 results about "Design support system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

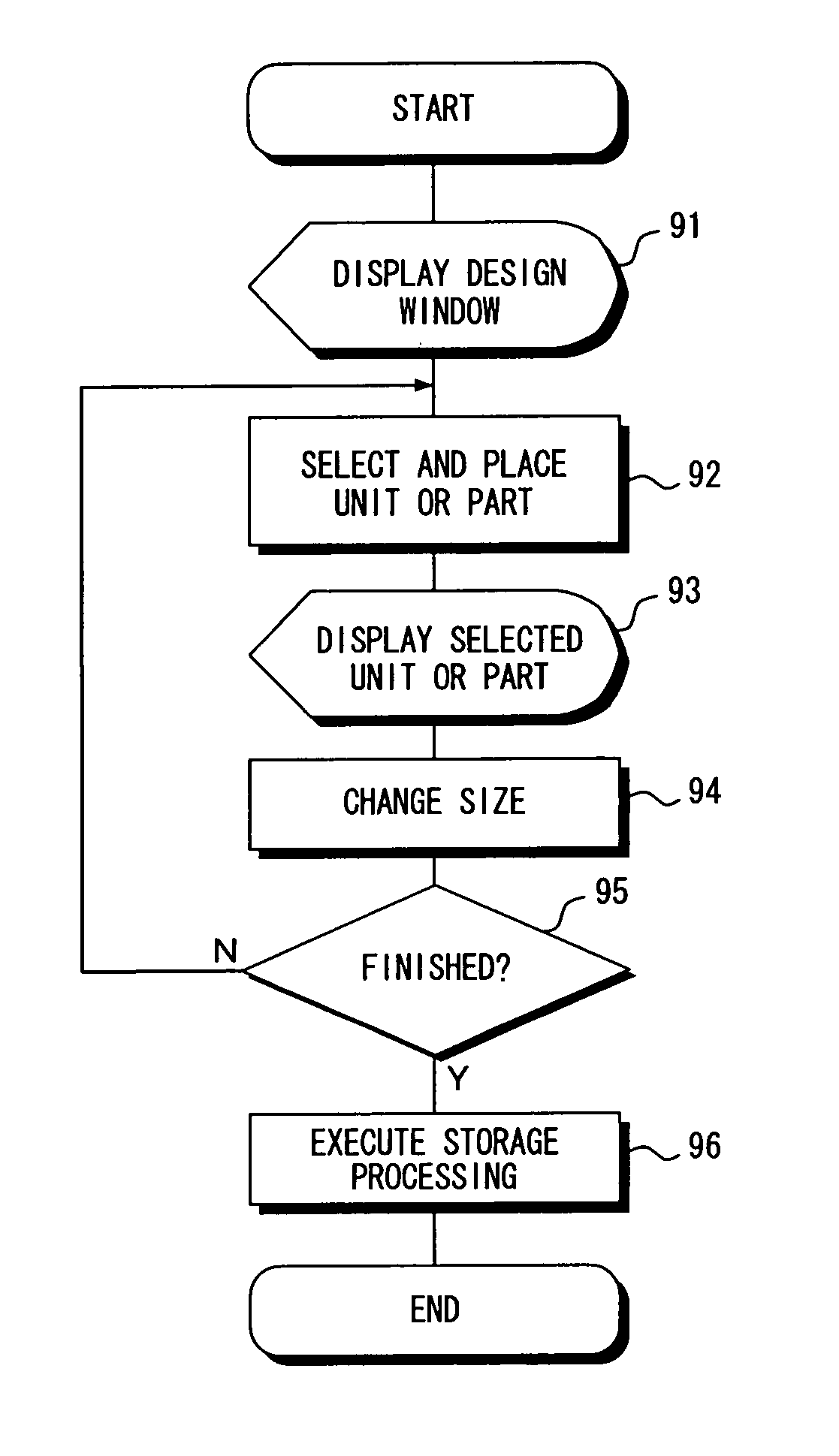

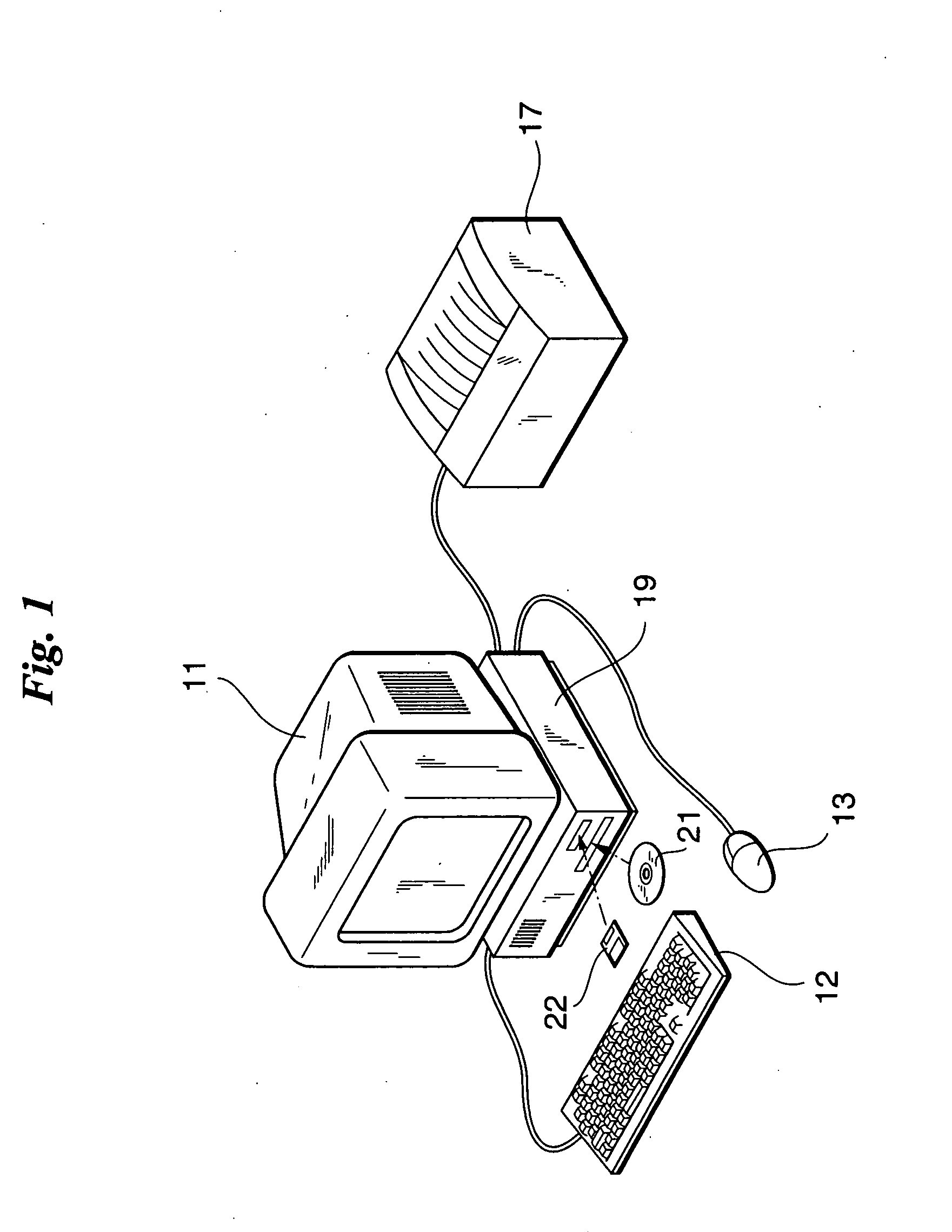

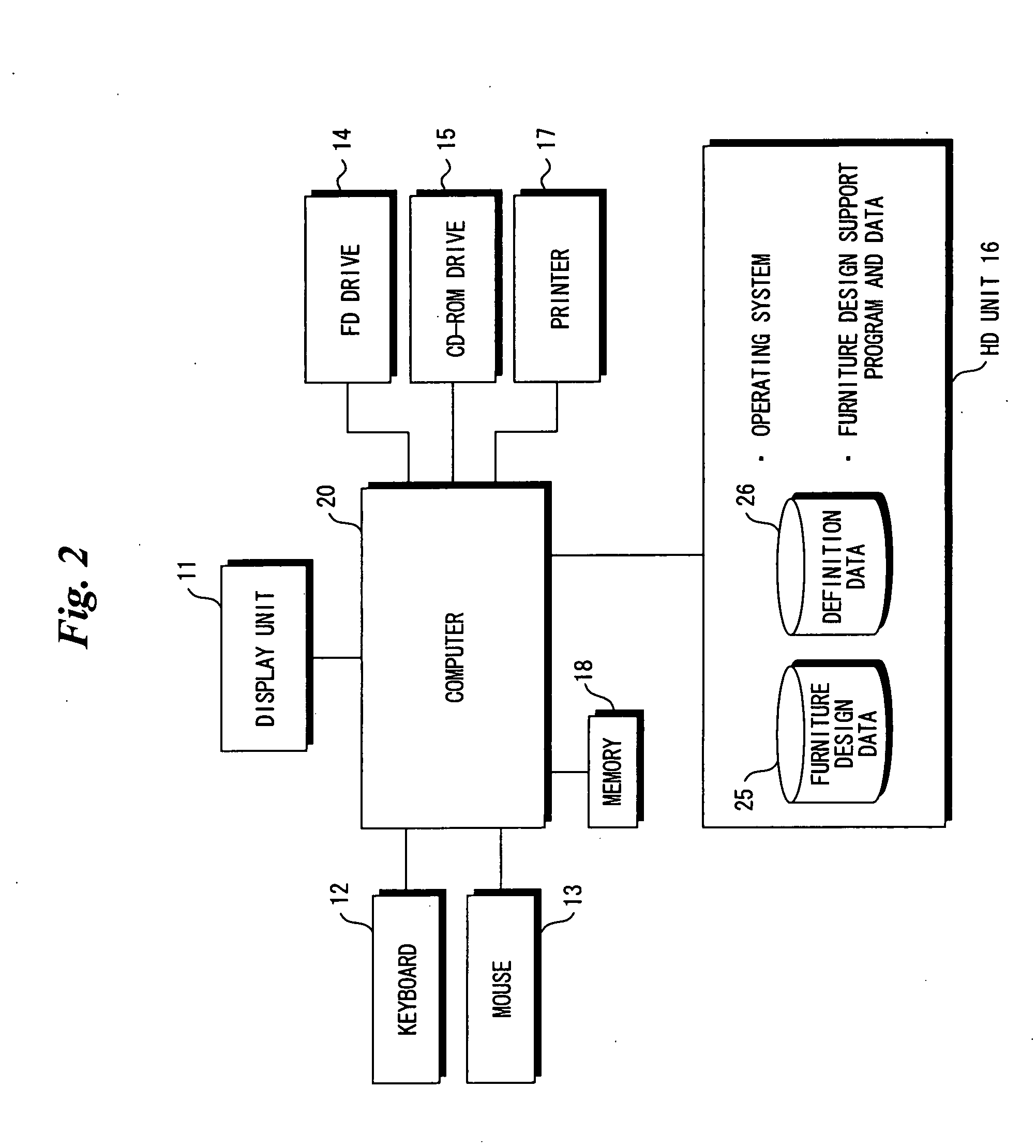

Article design support system and method and medium storing program for article design support

InactiveUS7016747B1Easy to assembleSimple designAdditive manufacturing apparatusData processing applicationsDesign support systemComputerized system

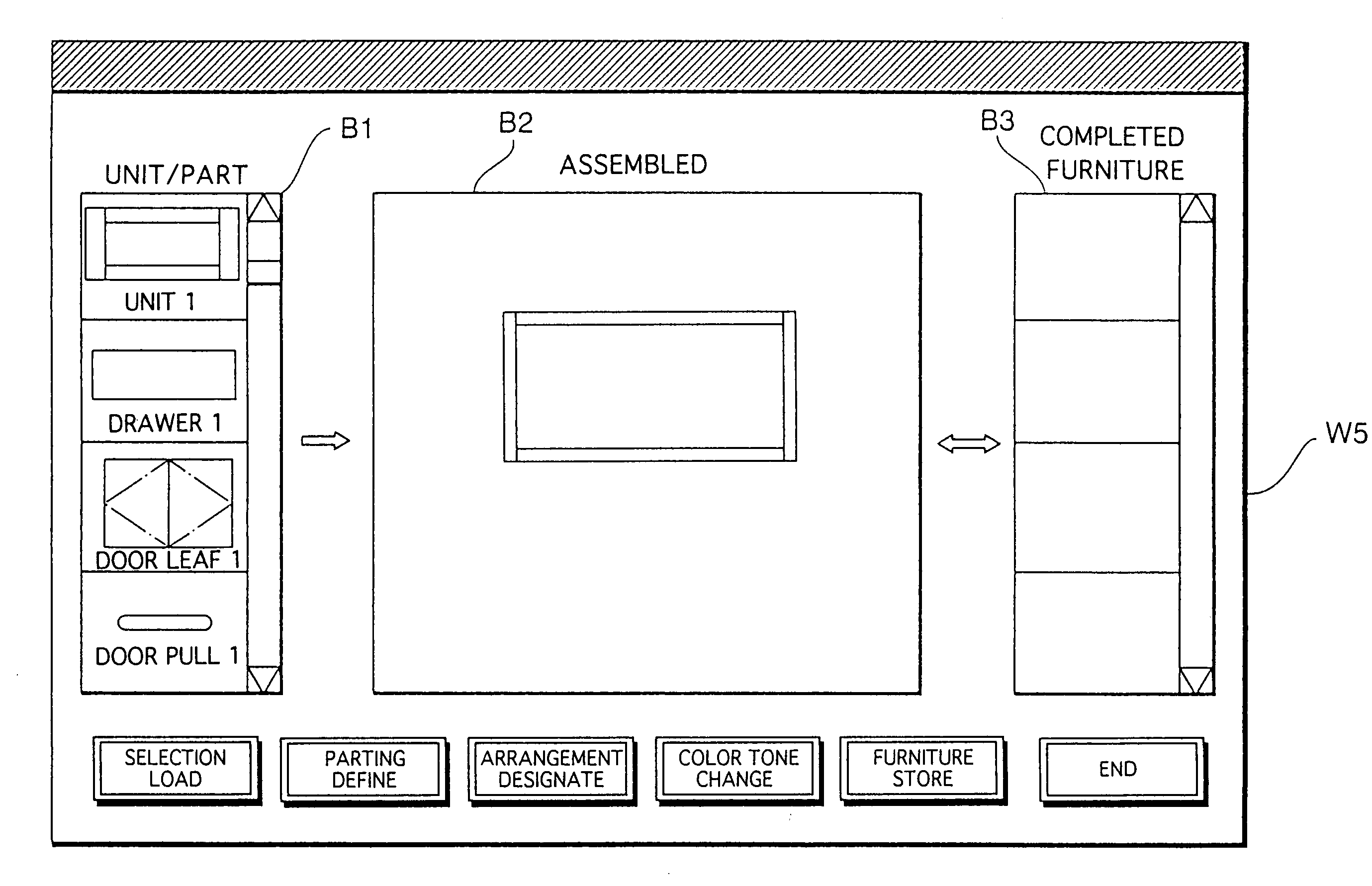

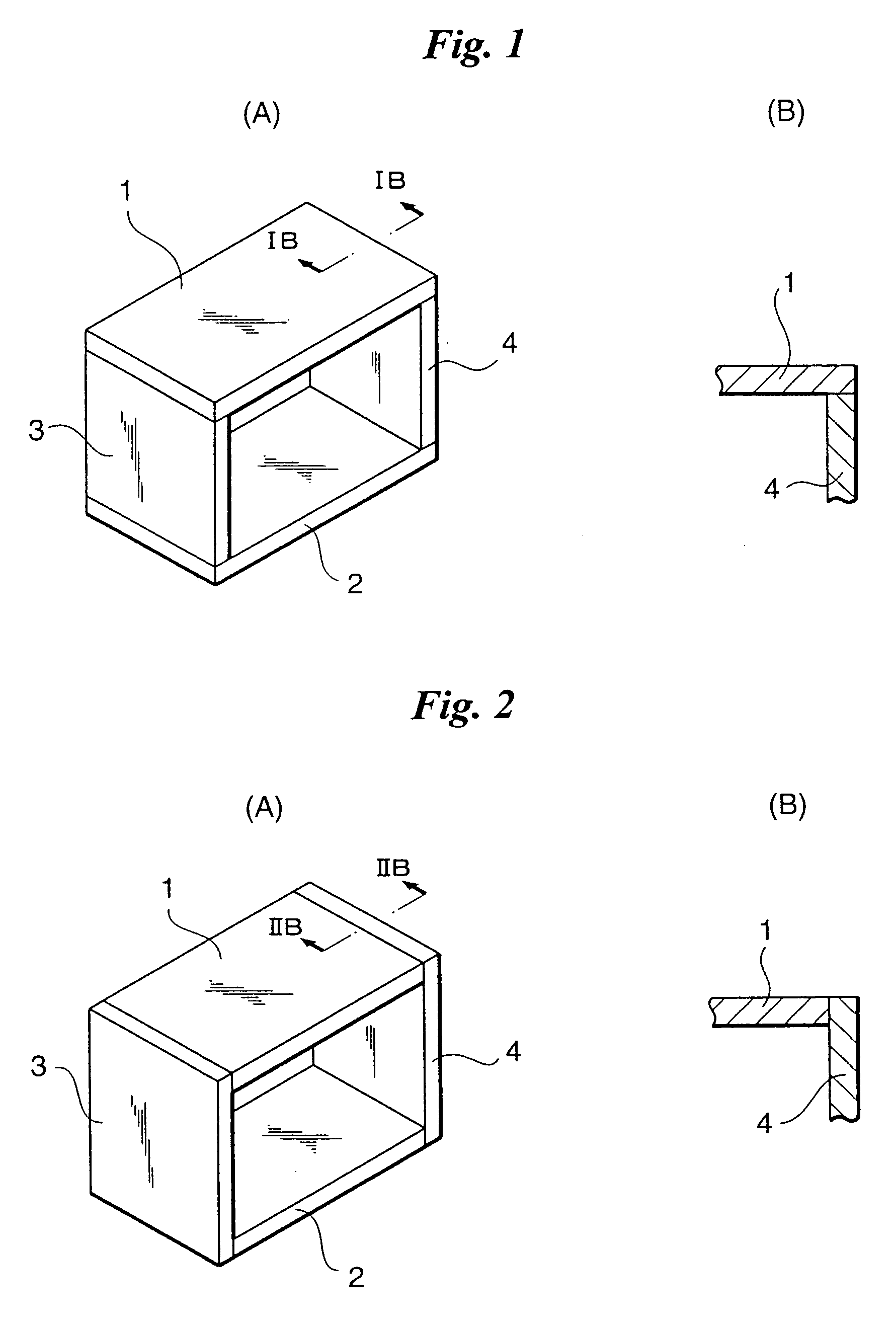

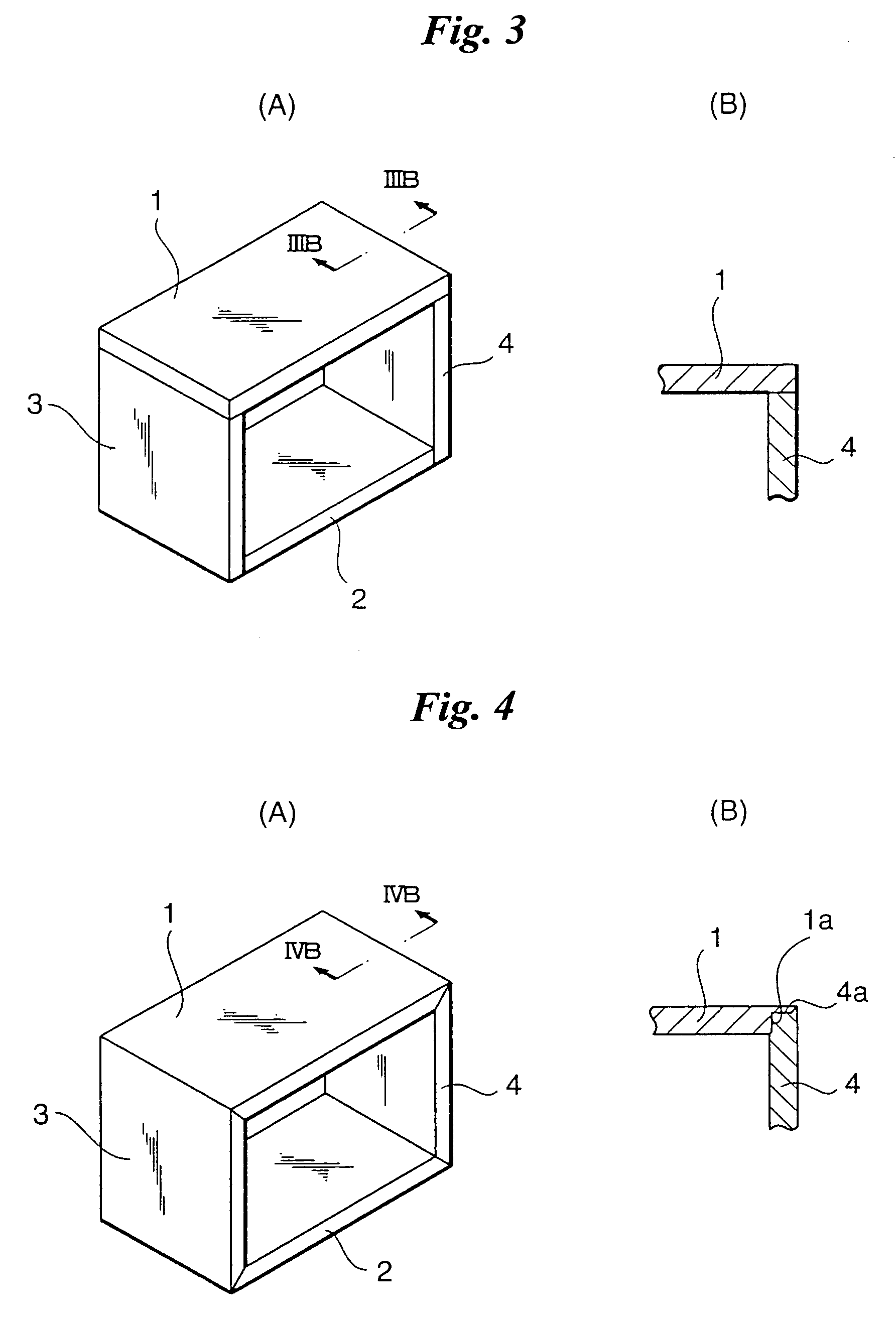

A furniture design support system comprises a computer system. The computer system comprises an HD unit, which stores a furniture design support program and data representing the basic forms of units and parts. An operator defines a size, a finishing color, a material (the kind of wood), etc. with respect to the unit to be used for furniture to be designed on the basis of the desires of a customer, and also defines a finishing color, a material, etc. with respect to the part (a drawer, a door leaf, etc.) (step 33). Completed furniture is displayed on a display screen by assembling the unit and the part on the display screen. An HD stores design data related to the completed furniture (step 34). The appearance of the completed furniture is displayed on the display screen on the basis of the design data, and a design drawing is outputted from a printer (step 35).

Owner:NINOMIYA KENICHI

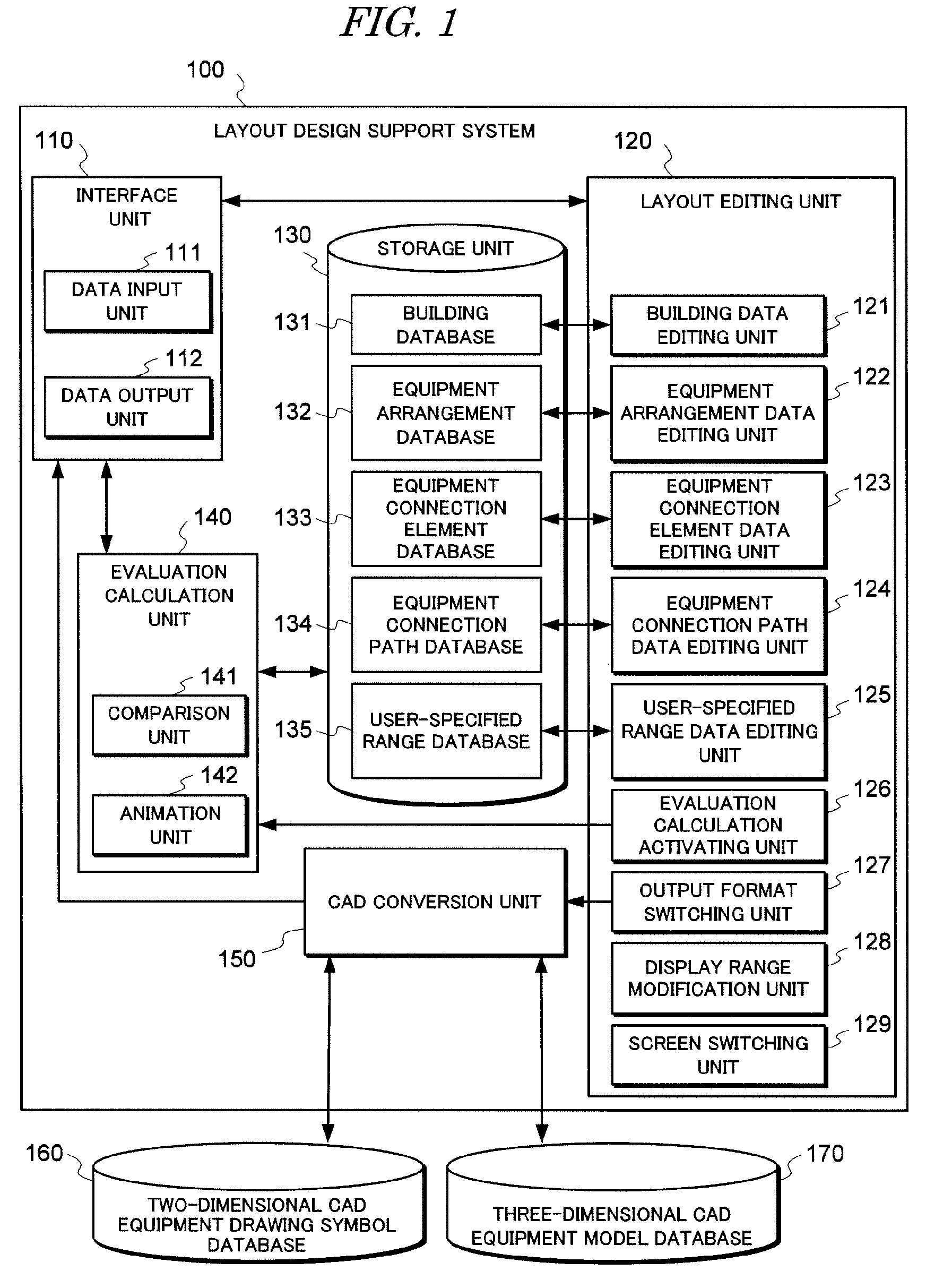

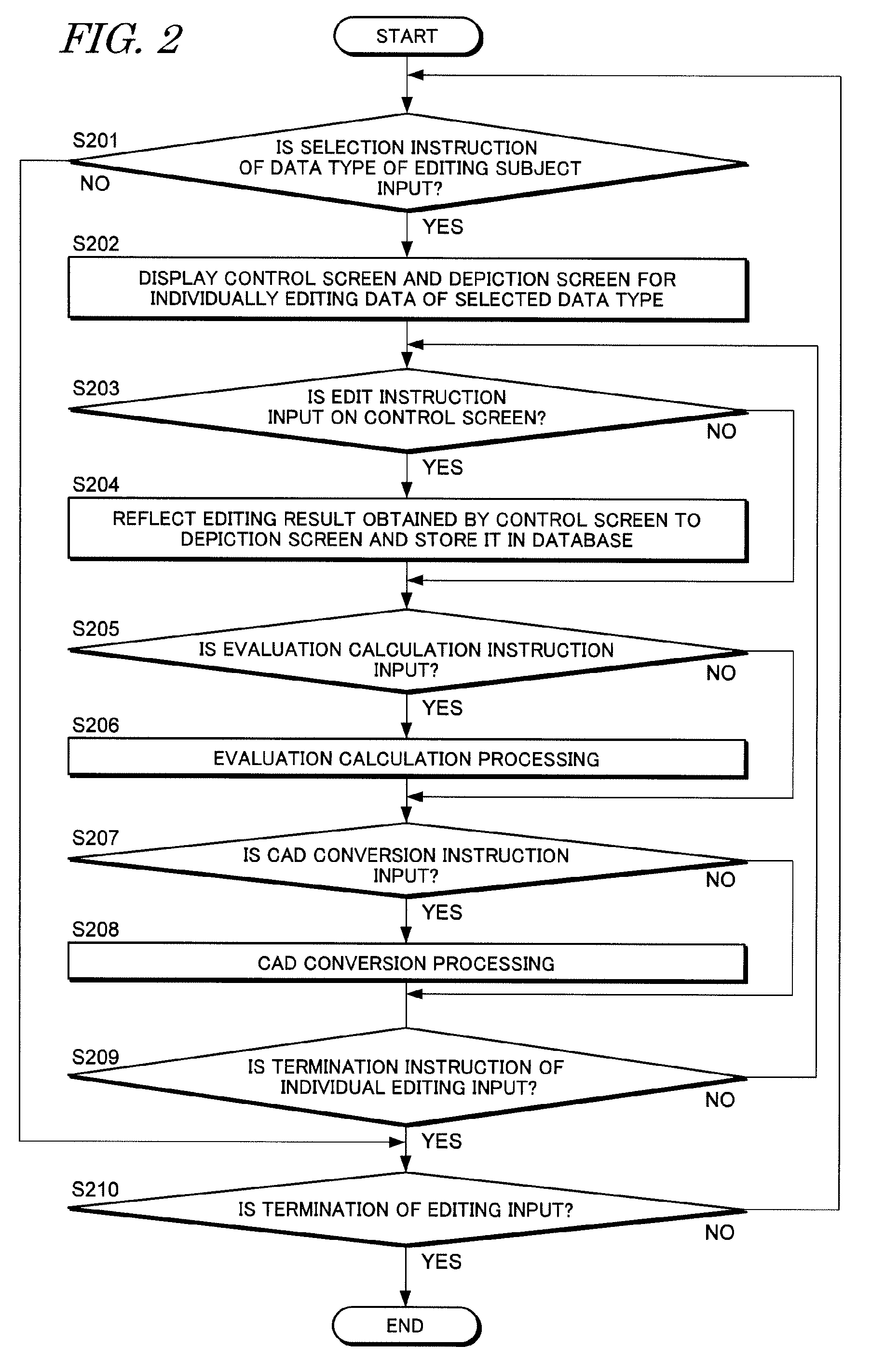

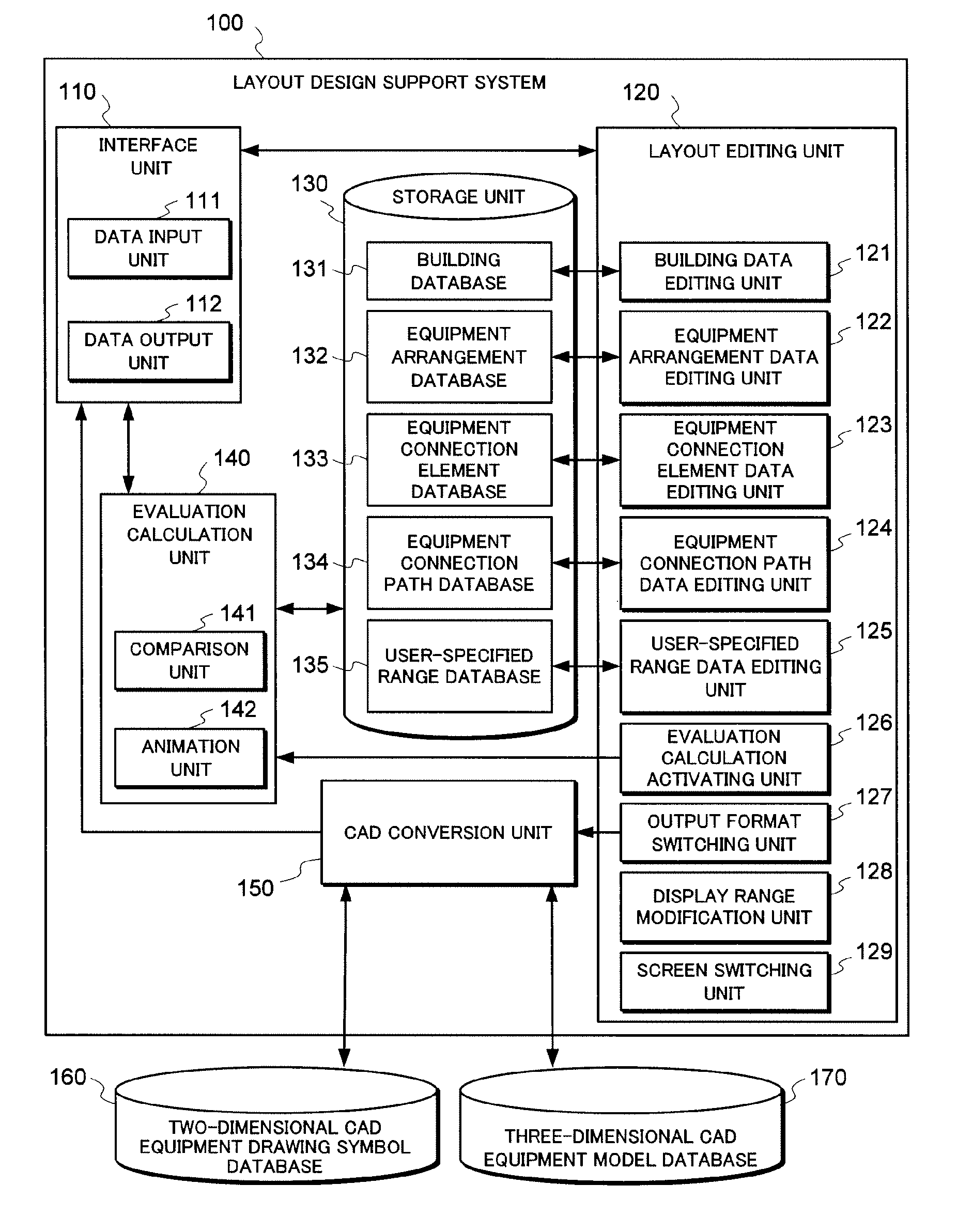

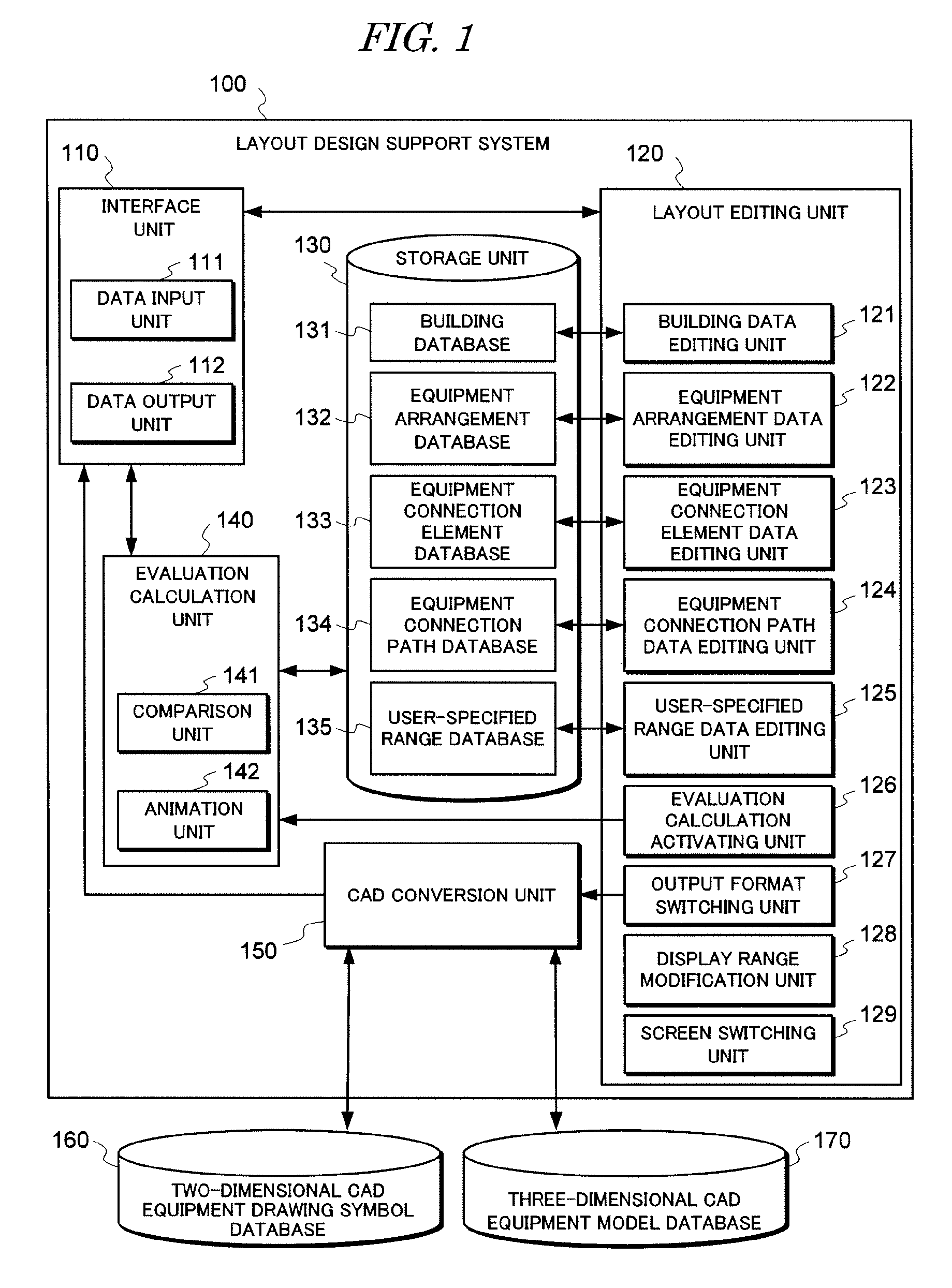

Layout design support system, method, and program

InactiveUS7676348B2Workload of the layout design process can be lightenedReduce workloadGeometric CADProgram control using stored programsDesign support systemWorkload

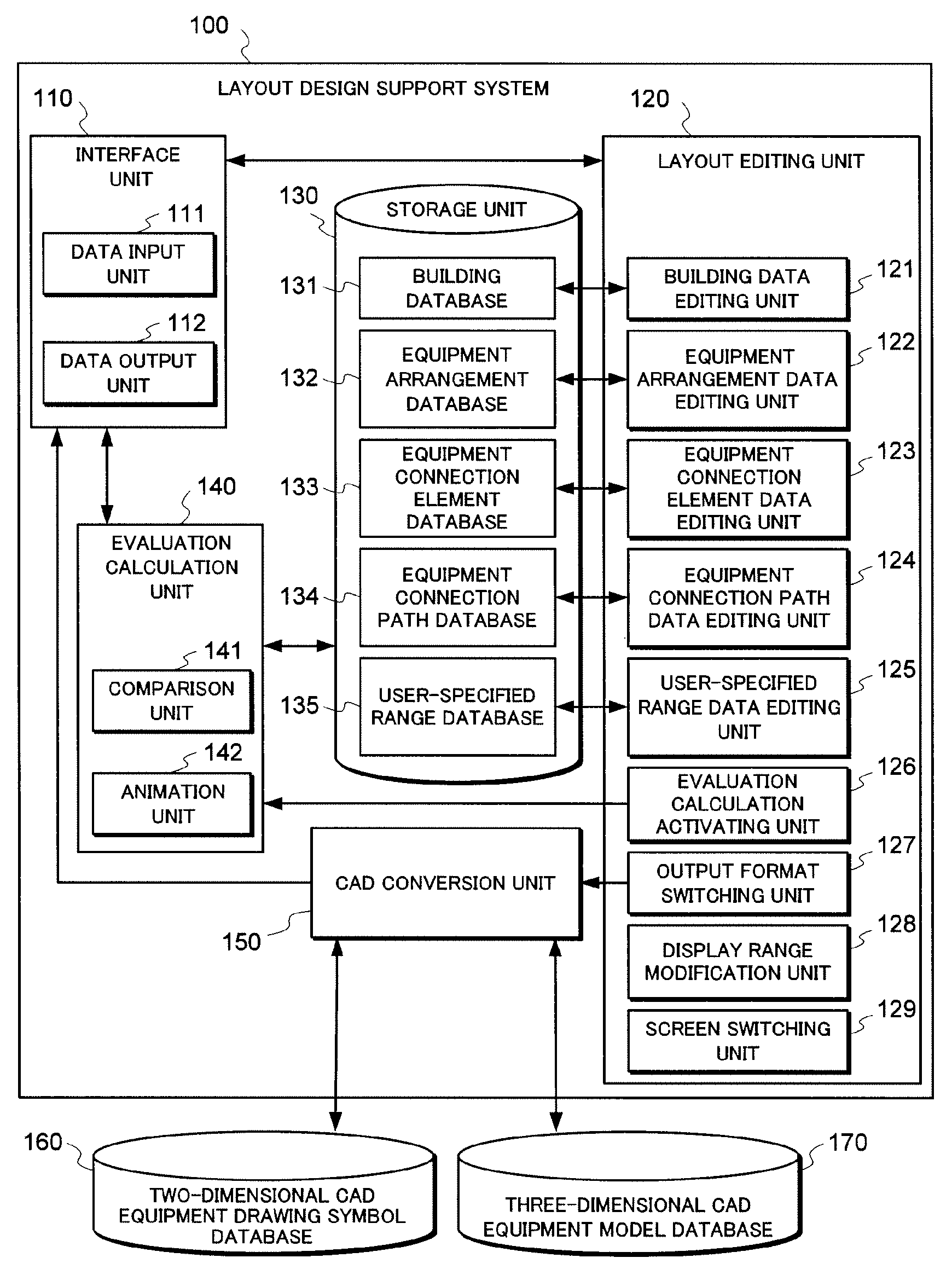

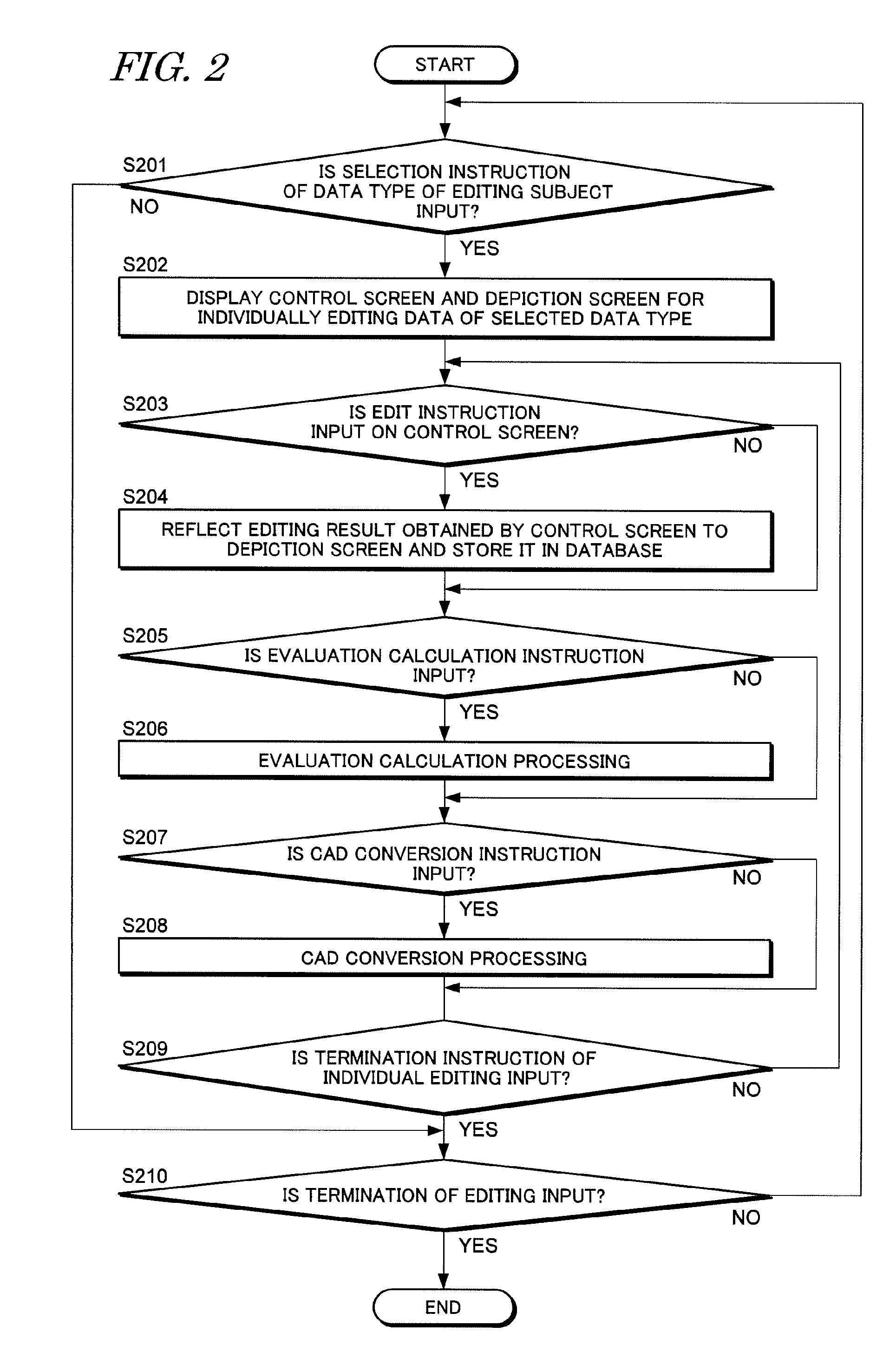

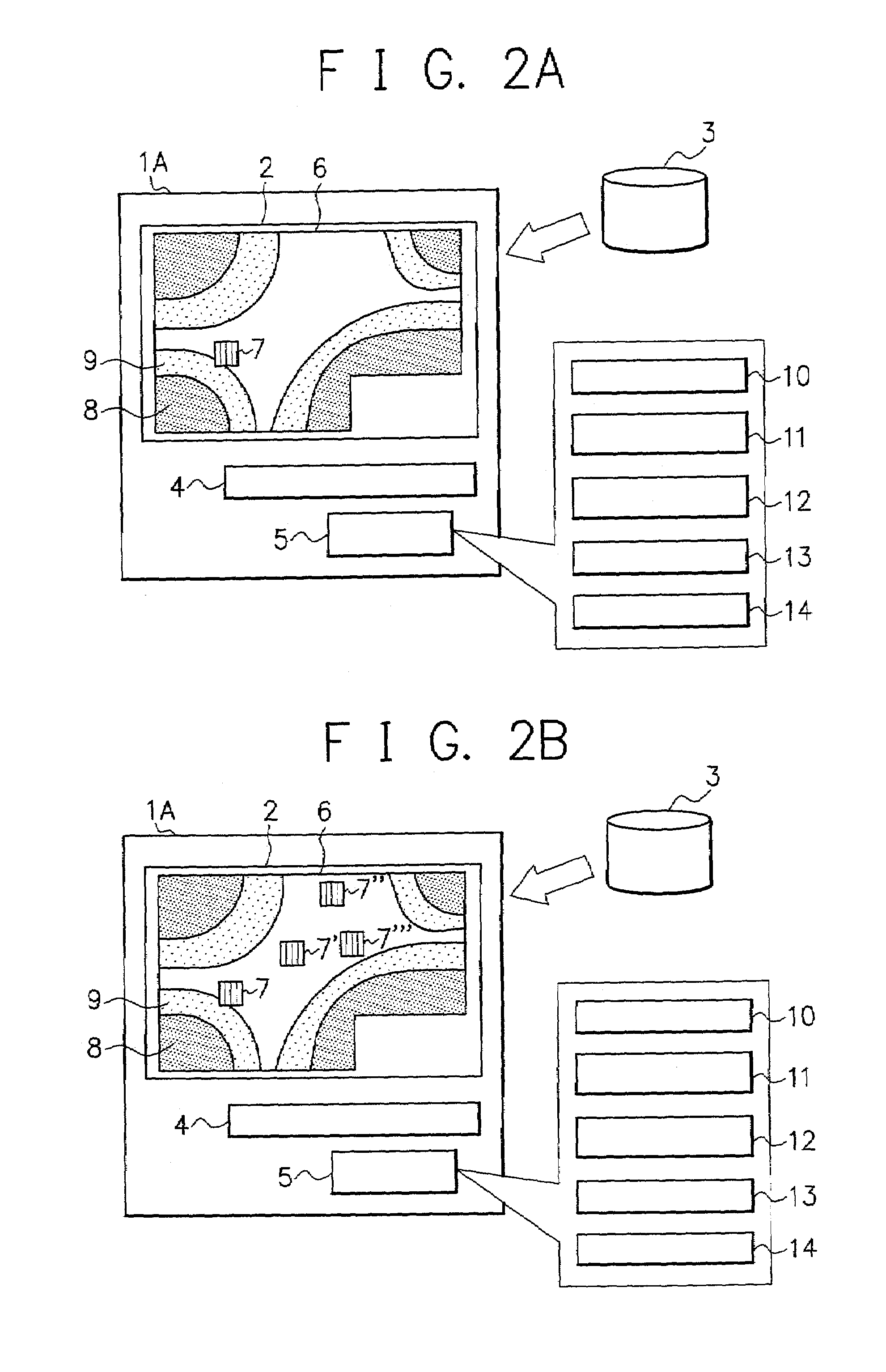

The present invention enables support of a process for creating a detailed layout design which takes construction into account, and contributes to a reduction in the workload of the layout design process. A layout editing unit causes an interface unit to display a layout design data editing screen, receives an edit instruction input onto the screen, and edits the layout design data in accordance with the edit instruction. The layout editing unit classifies the layout design data into five data types, namely building data, equipment arrangement data, equipment connection element data, equipment connection path data, and user-specified range data, and edits the data of each data type individually. A storage unit stores the editing results of the layout design data. A CAD conversion unit converts the layout design data into a two-dimensional CAD drawing or a three-dimensional CAD model, and causes the interface unit to display the two-dimensional CAD drawing or three-dimensional CAD model on a screen.

Owner:KK TOSHIBA

Layout design support system, method, and program

InactiveUS20070260432A1Reduce workloadWorkload of the layout design process can be lightenedGeometric CADProgram control using stored programsDesign support systemWorkload

The present invention enables support of a process for creating a detailed layout design which takes construction into account, and contributes to a reduction in the workload of the layout design process. A layout editing unit causes an interface unit to display a layout design data editing screen, receives an edit instruction input onto the screen, and edits the layout design data in accordance with the edit instruction. The layout editing unit classifies the layout design data into five data types, namely building data, equipment arrangement data, equipment connection element data, equipment connection path data, and user-specified range data, and edits the data of each data type individually. A storage unit stores the editing results of the layout design data. A CAD conversion unit converts the layout design data into a two-dimensional CAD drawing or a three-dimensional CAD model, and causes the interface unit to display the two-dimensional CAD drawing or three-dimensional CAD model on a screen.

Owner:KK TOSHIBA

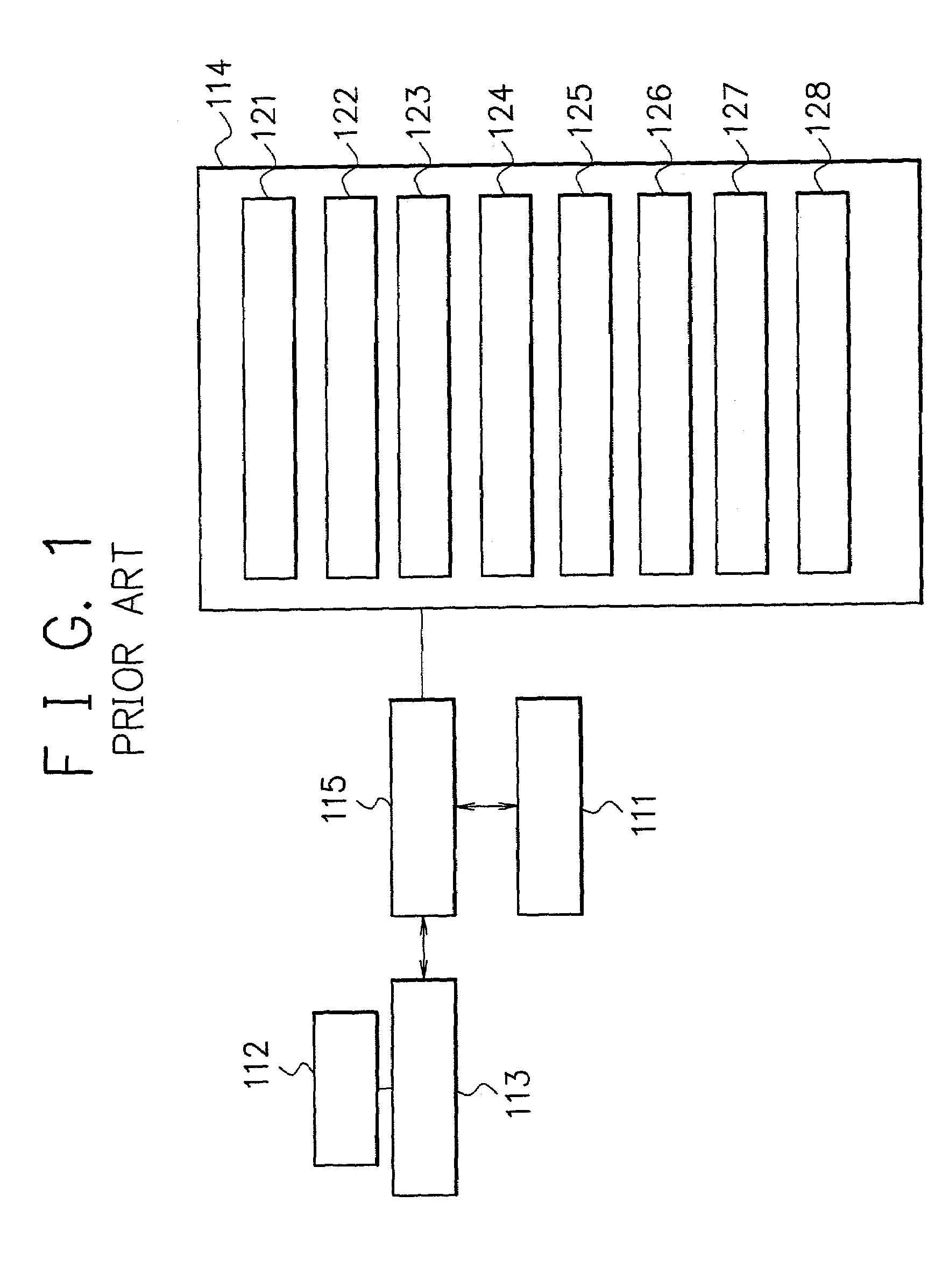

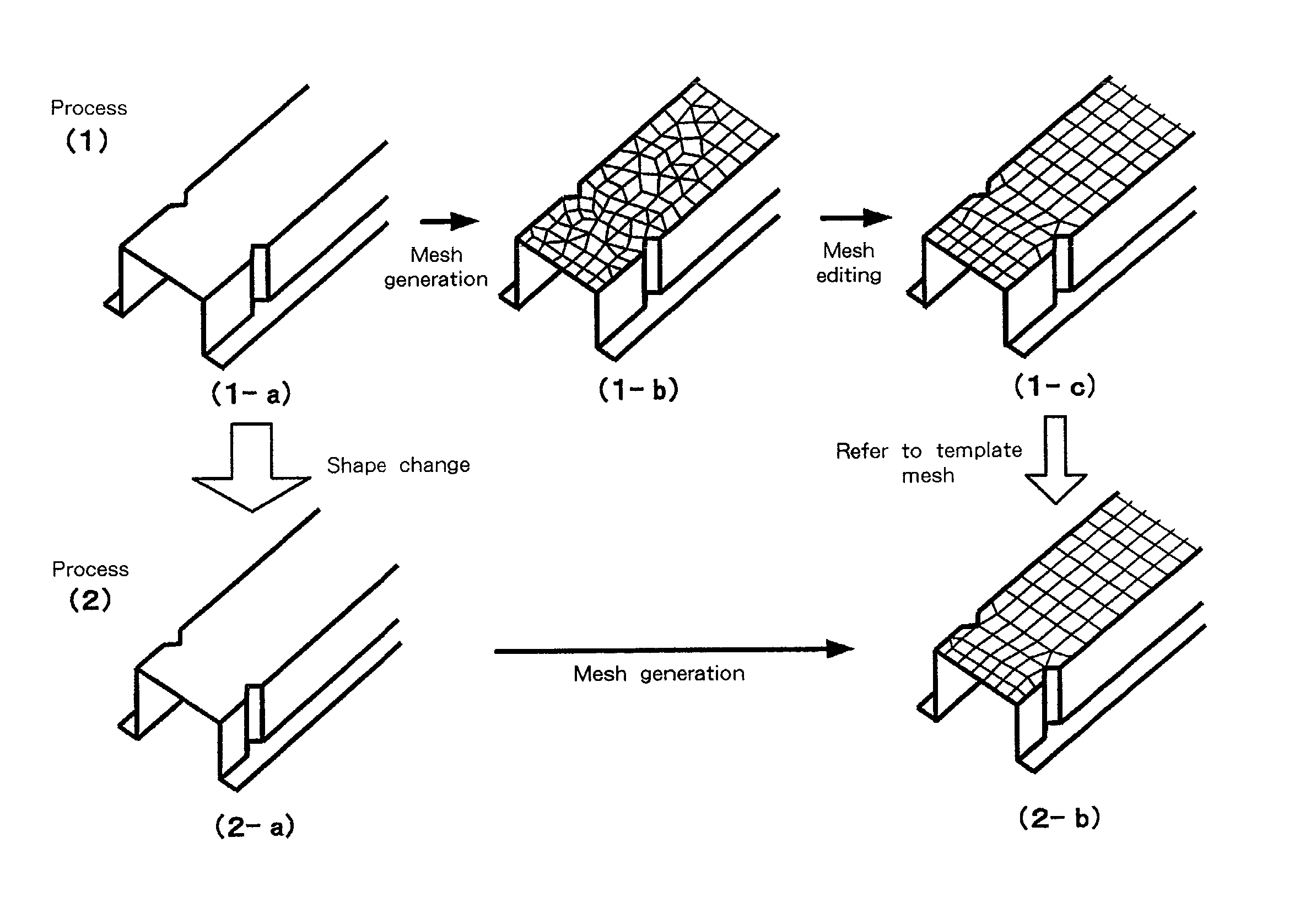

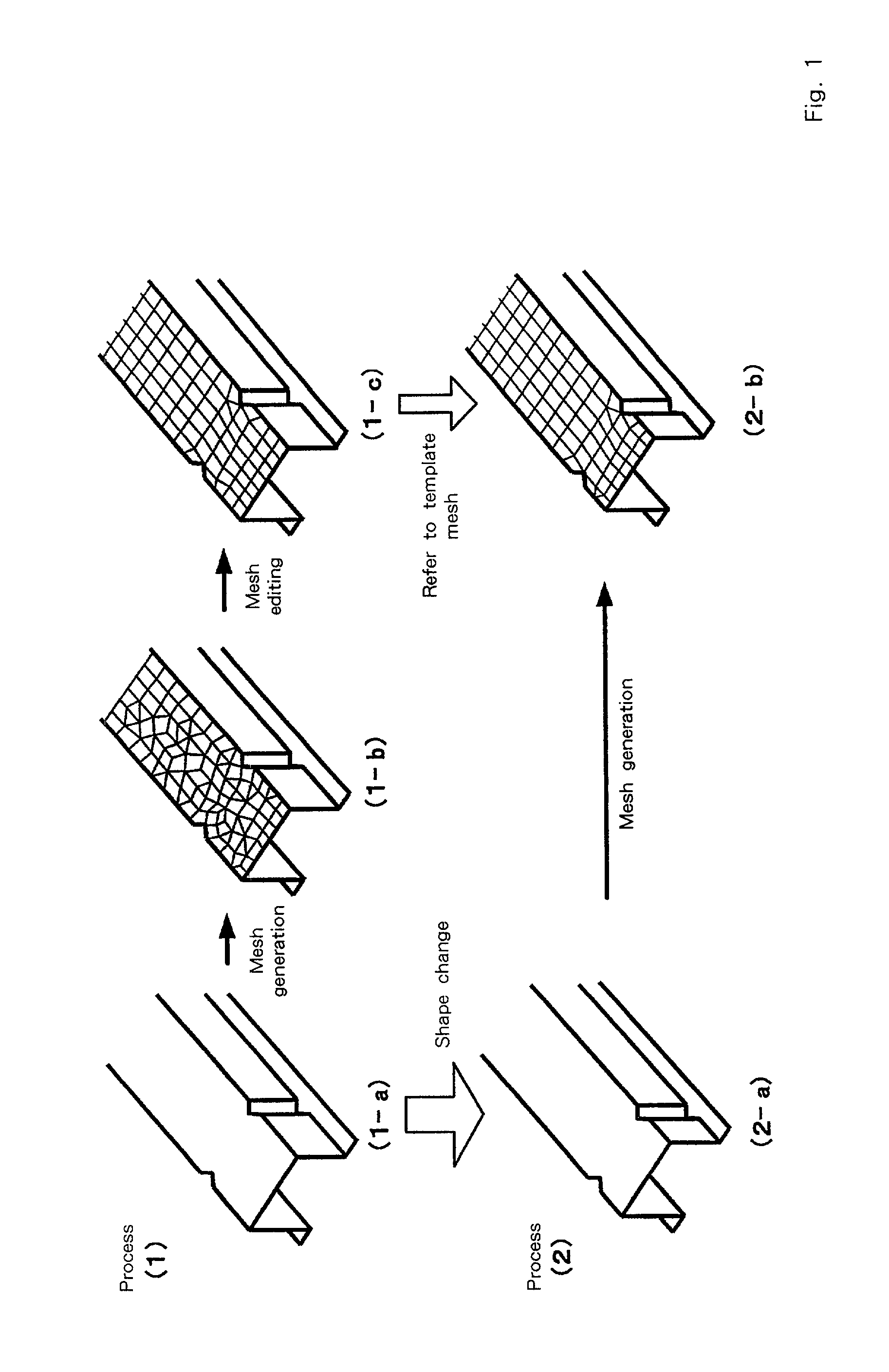

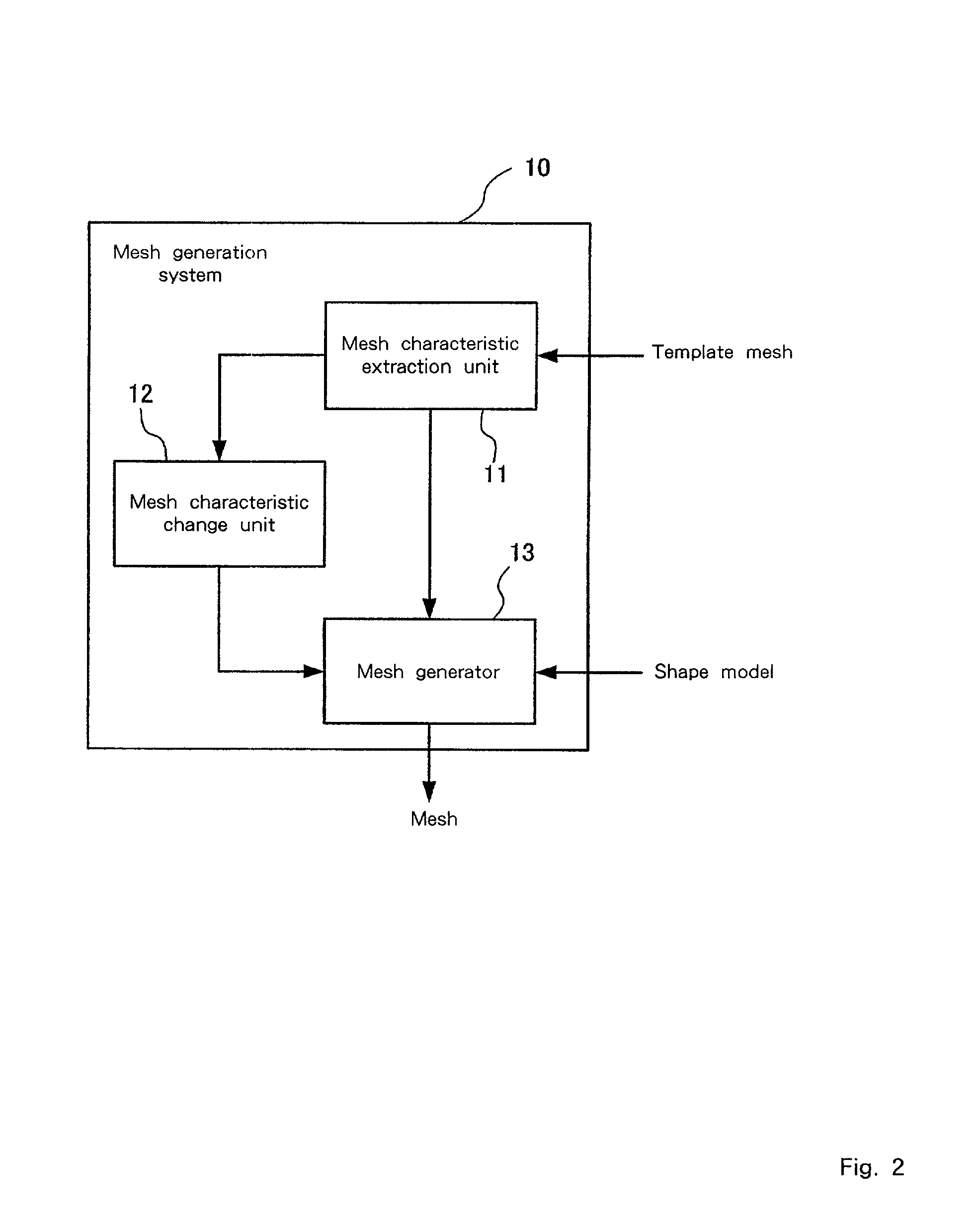

Mesh generation system, design support system, analysis system, analysis method, mesh generation method, and storage medium and program transmission apparatus therefor

InactiveUS6947879B2Detecting faulty computer hardwareComputation using non-denominational number representationElement analysisComputer graphics (images)

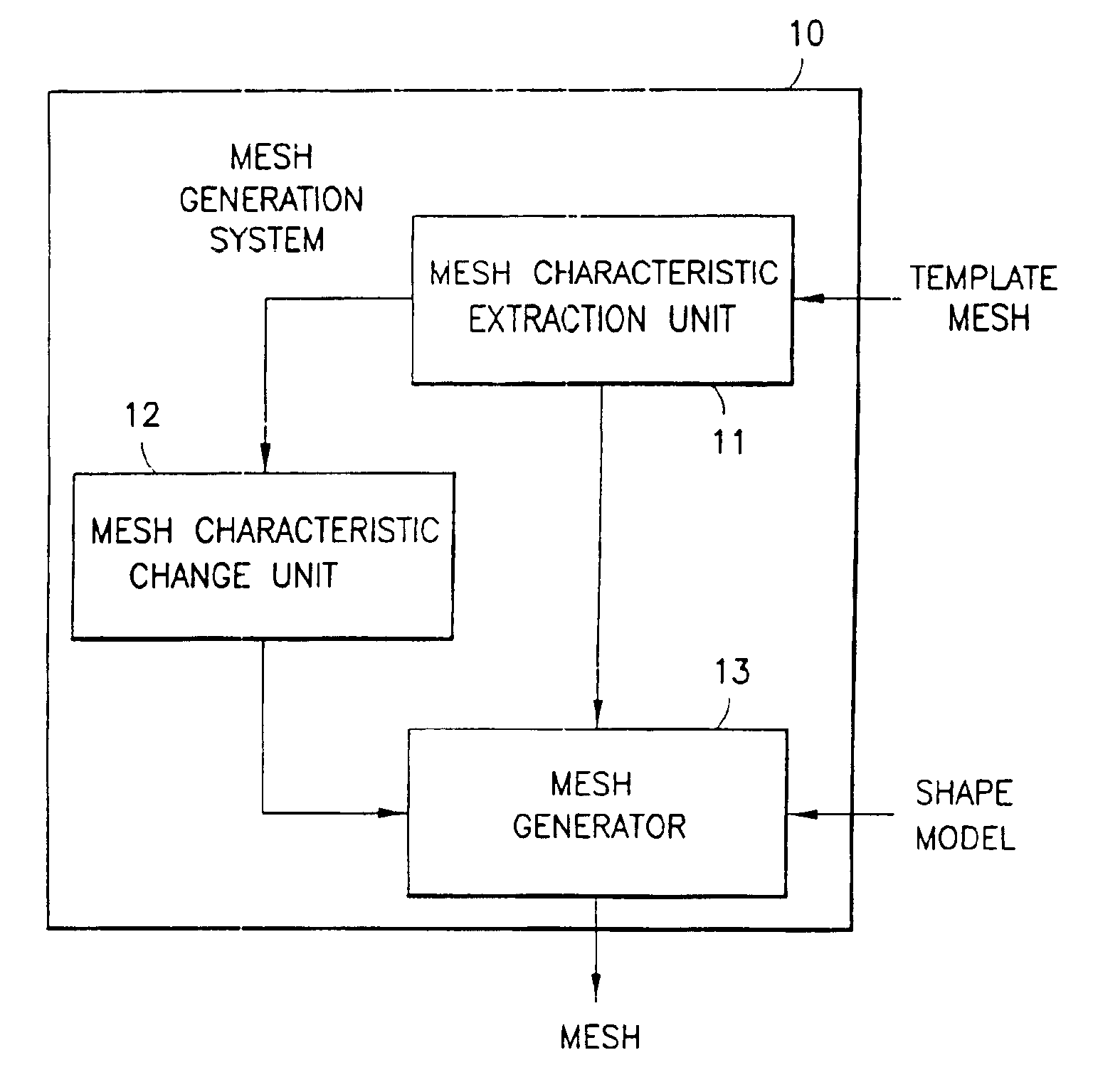

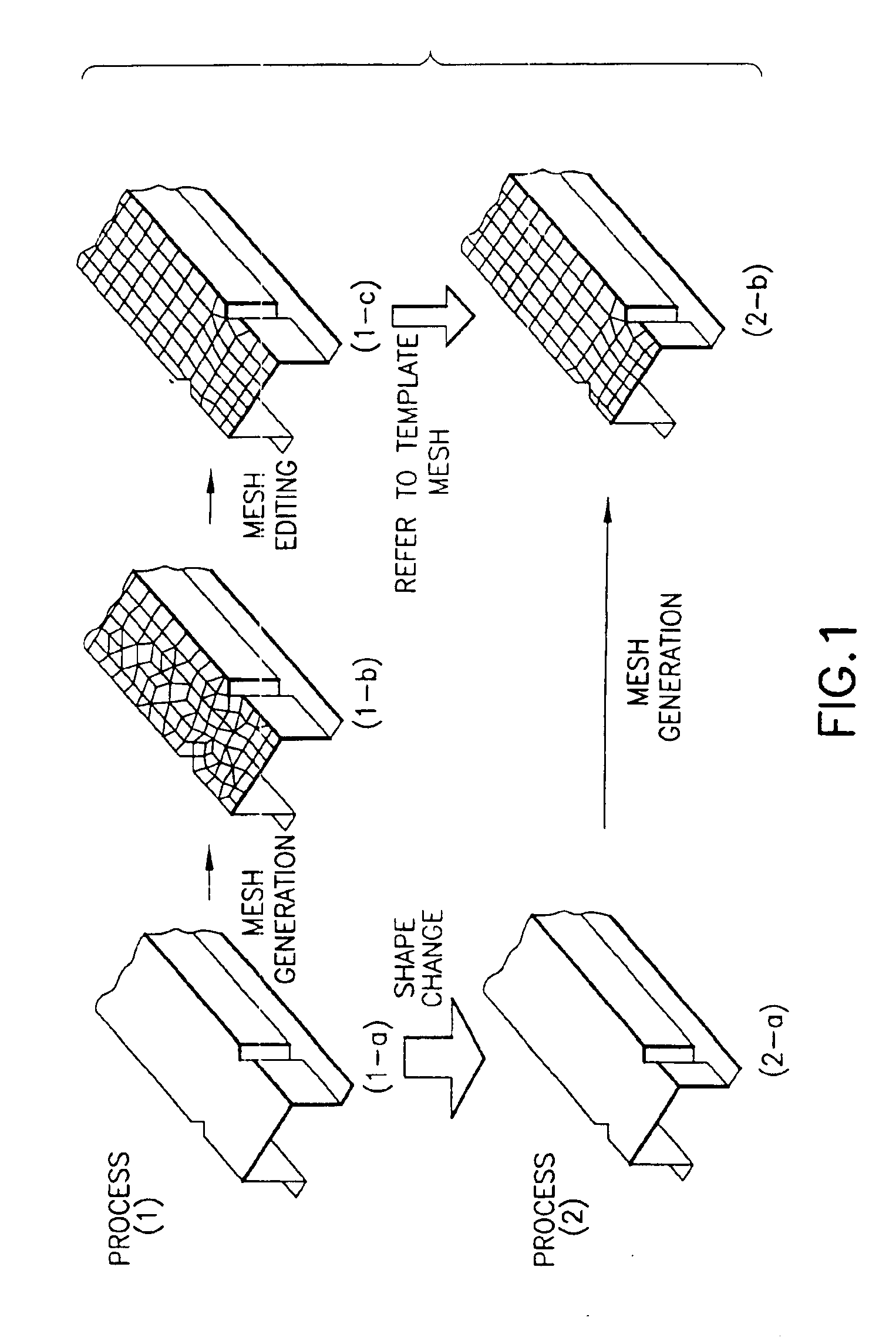

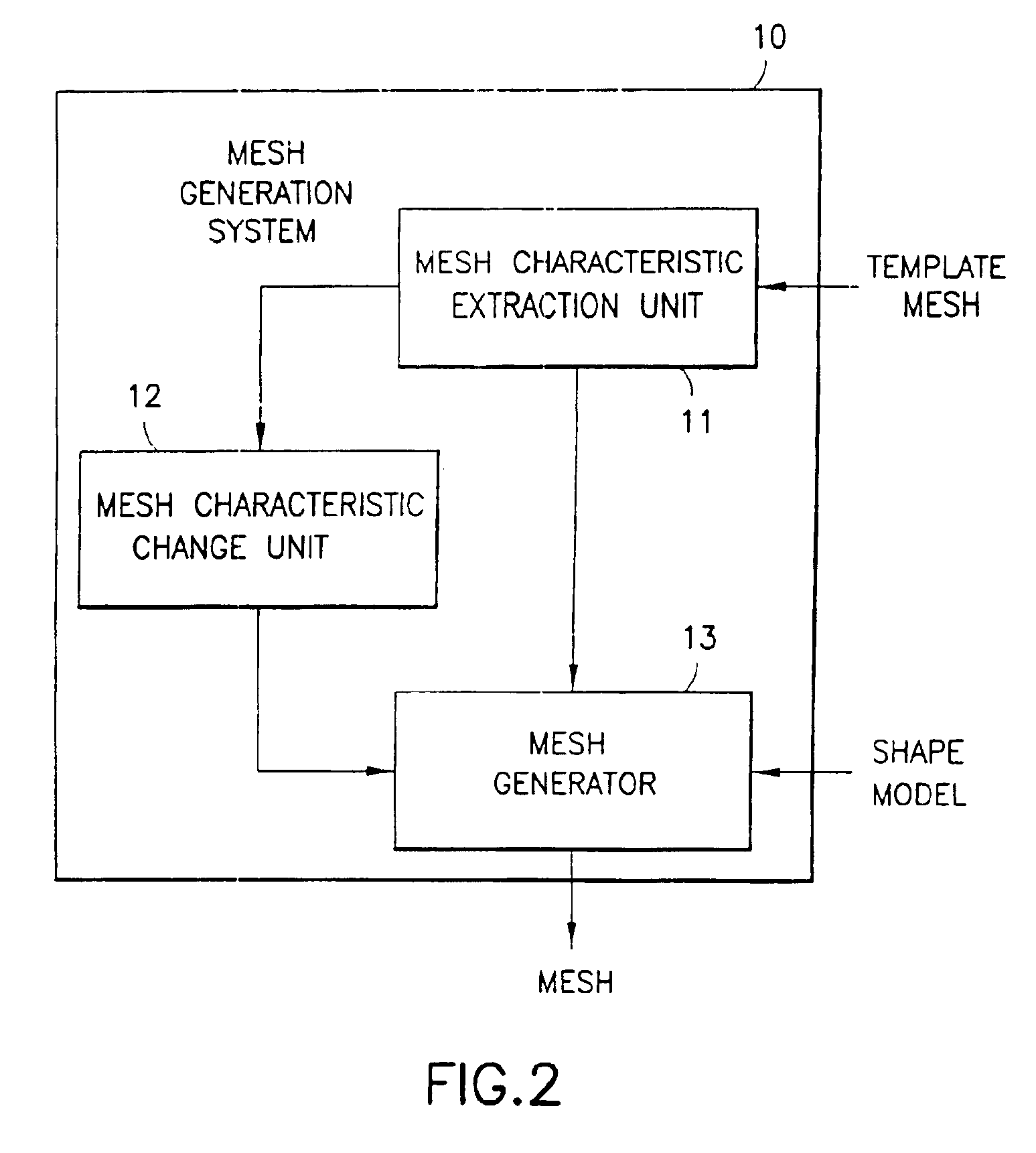

It is one object of the present invention to form a conventional mesh as a sample in order to efficiently generate a high-quality mesh for a predetermined shape model.A mesh generation system 10 for generating a mesh used for finite element analysis comprises: a mesh characteristic extraction unit 11 for receiving a conventional mesh and extracting a characteristic therefrom; and a mesh generator 13 for receiving a target shape model for mesh generation, and for generating a mesh for the shape model based on the characteristic of the conventional mesh extracted by the mesh characteristic extraction unit 11.

Owner:IBM CORP

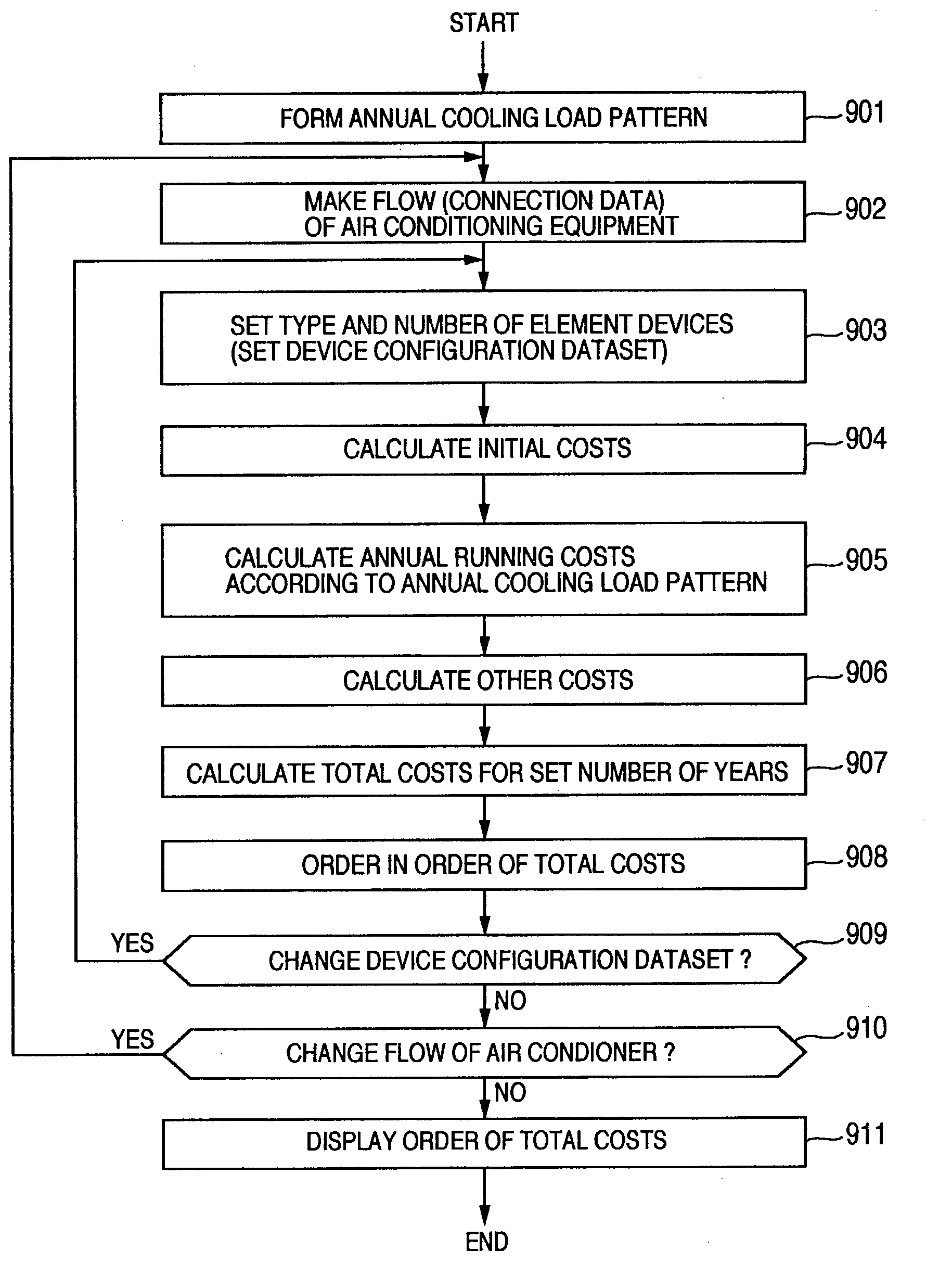

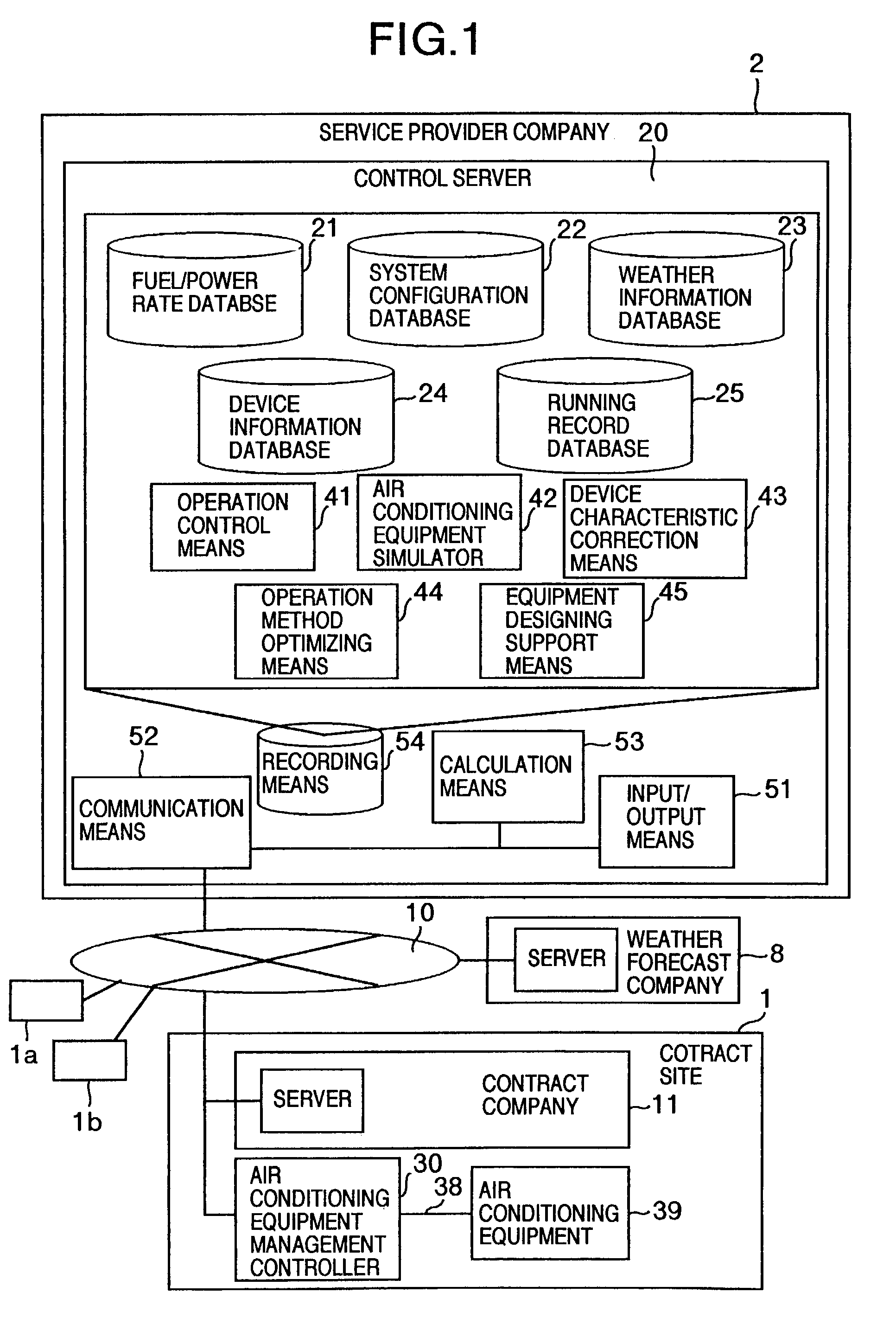

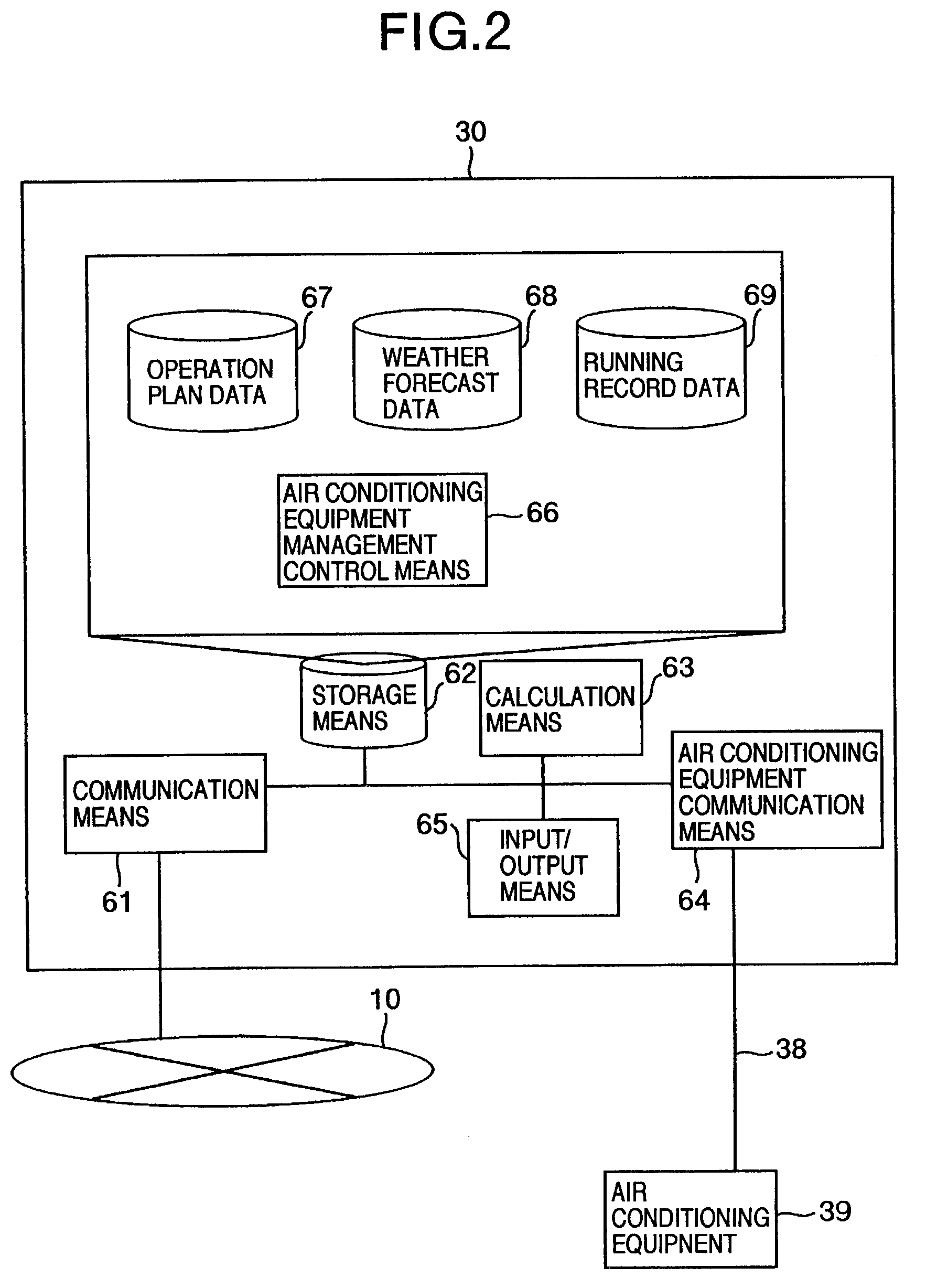

Air conditioning equipment operation system and air conditioning equipment designing support system

InactiveUS7225171B2Running cost can be reducedLow costMechanical apparatusSpecial tariff metersSupporting systemOperational system

A control server includes a device information database storing device characteristic data constituting the air conditioning equipment, a fuel / power rate database storing price and rate data regarding gas, oil, power and the like, a device characteristic and price database, an air conditioning equipment simulator for calculating running costs by using the data stored in the fuel / power rate database, and communication portion for performing communications through a network. The control server, and an air conditioning management controller for managing and controlling the air conditioning equipment provided with the communication portion for performing communications through the network, are connected to the network. An operation plan is made by the control server, the operation plan is transmitted to the air conditioning equipment management controller for controlling the air conditioning equipment through the network, and the air conditioning equipment is controlled and operated according to the operation plan.

Owner:HITACHI LTD

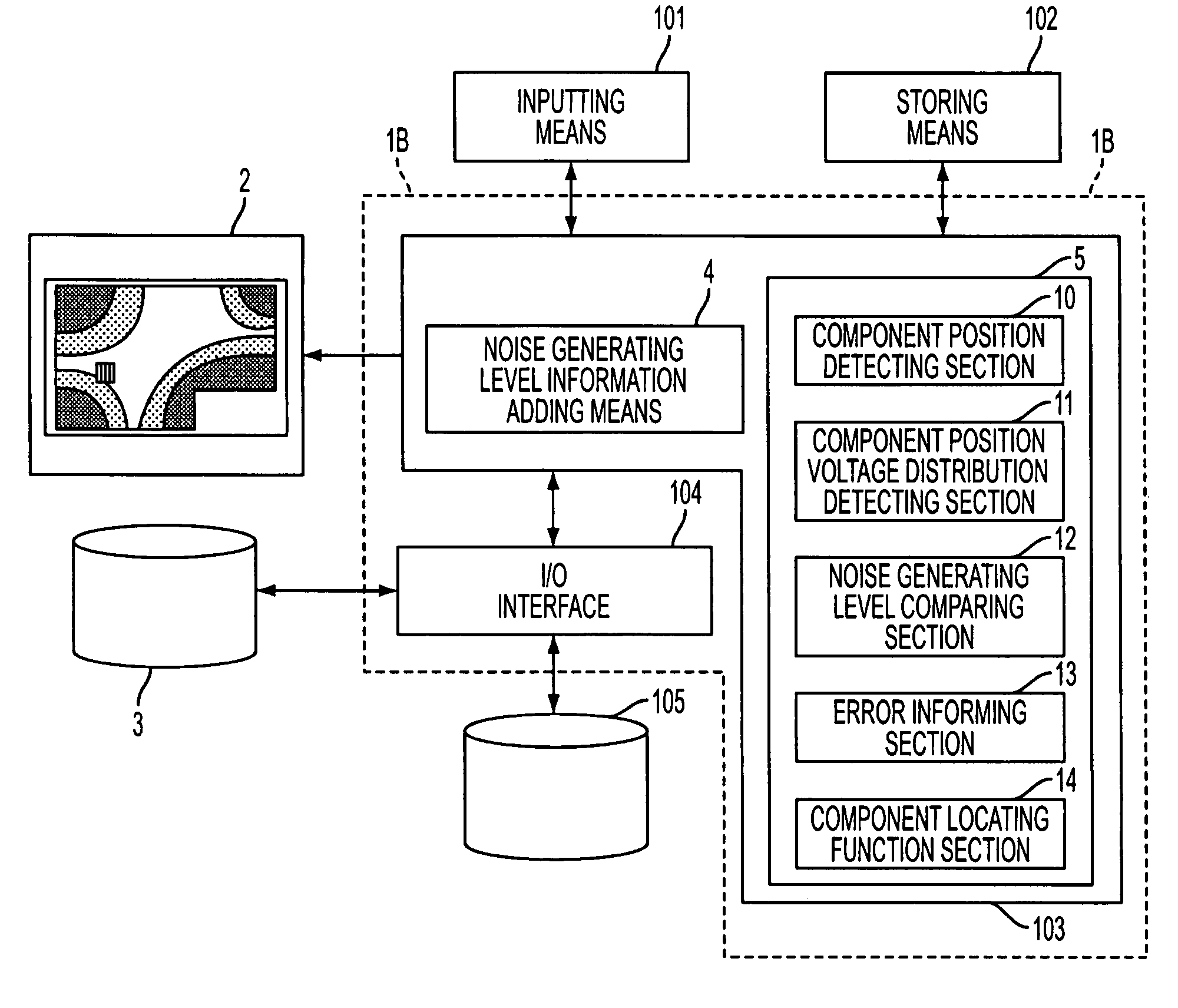

Device, system, server, client, and method for supporting component layout design on circuit board, and program for implementing the device

ActiveUS7114132B2Computer programmed simultaneously with data introductionCAD circuit designLocation detectionSupporting system

There is provided a circuit design supporting device, a circuit board design supporting system, a circuit board design supporting server, a circuit board design supporting client, a circuit design supporting method, and a program for realizing the device for designing a layout of main components such as LSI, etc. on a circuit board such as a printed circuit board wherein unnecessary electromagnetic radiation is suppressed. The circuit design supporting device comprises a noise generating level adding means and a component locating means. The noise generating level adding means adds noise generating level information to a component to be located on a printed circuit board. The component locating means includes a component position detecting section, a voltage distribution detecting section, a noise generating level comparing section, and an error informing section. The component position detecting section detects a position of the component moved on the printed circuit board. The voltage distribution detecting section detects a voltage level on the printed circuit board in the detected position of the component. The noise generating level comparing section compares the detected voltage level with the noise generating level added to the component. The error informing section informs a user of an error when the voltage level on the printed circuit board is equal to or larger than the noise generating level as a result of the comparison.

Owner:NEC CORP

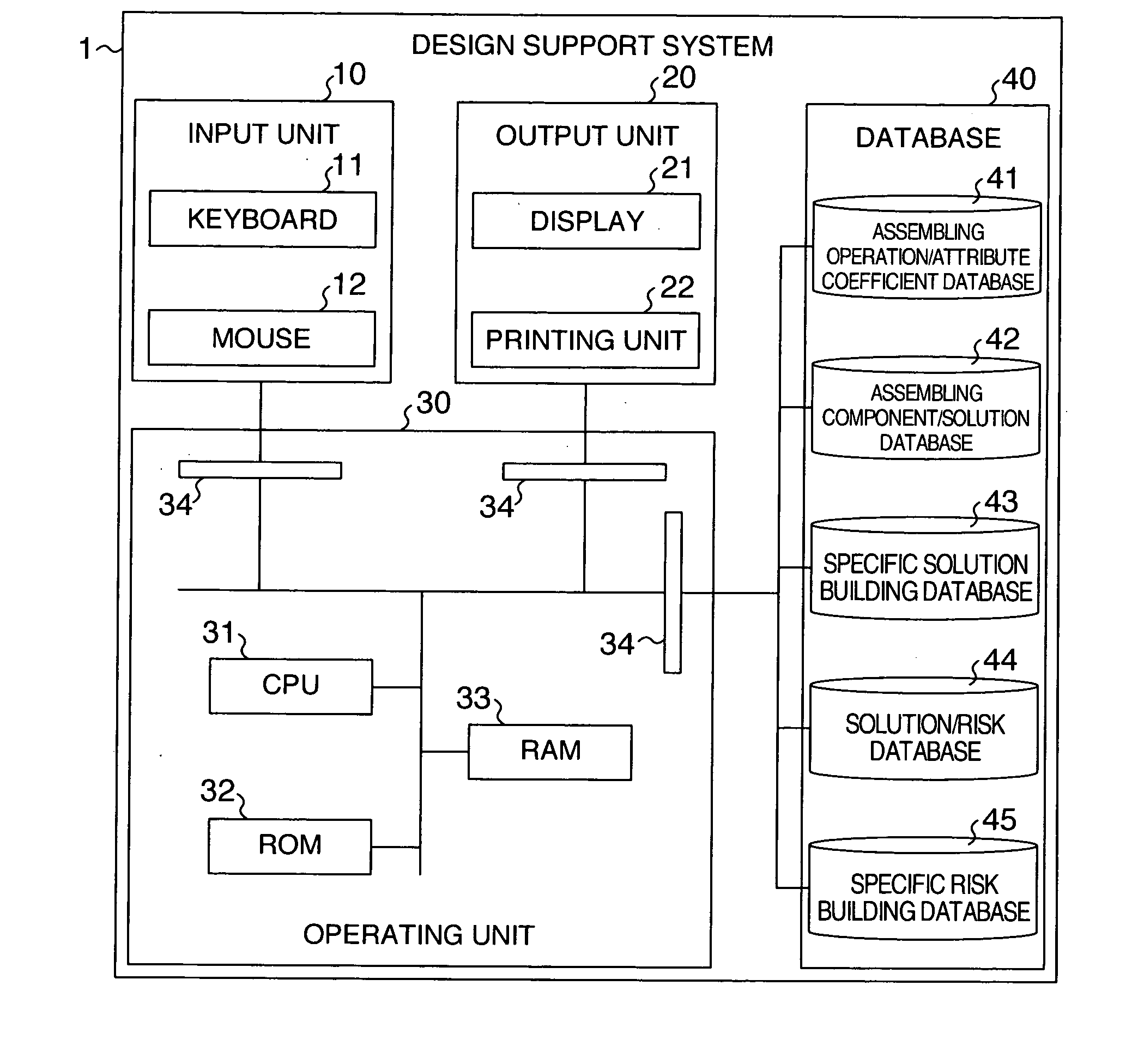

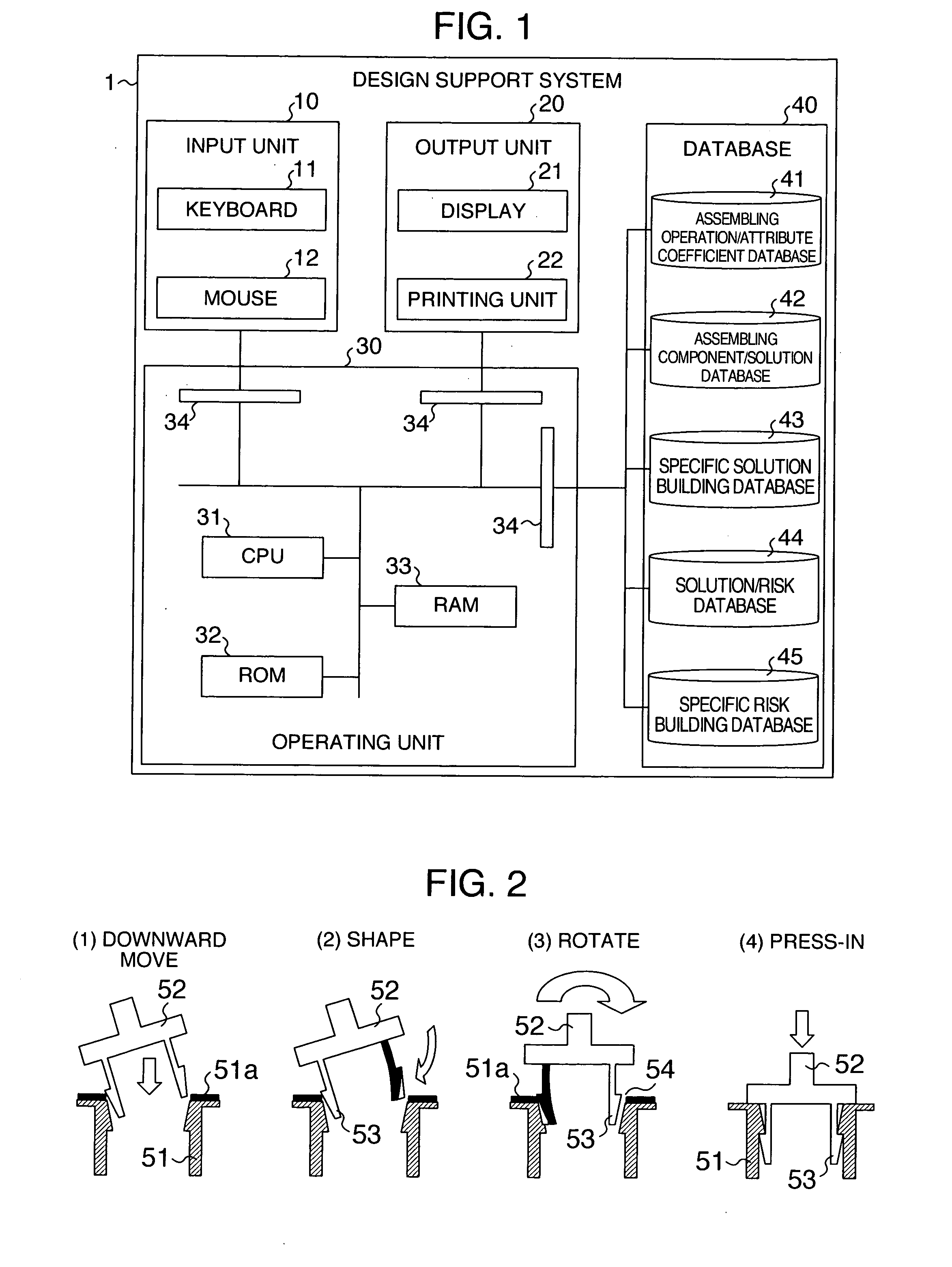

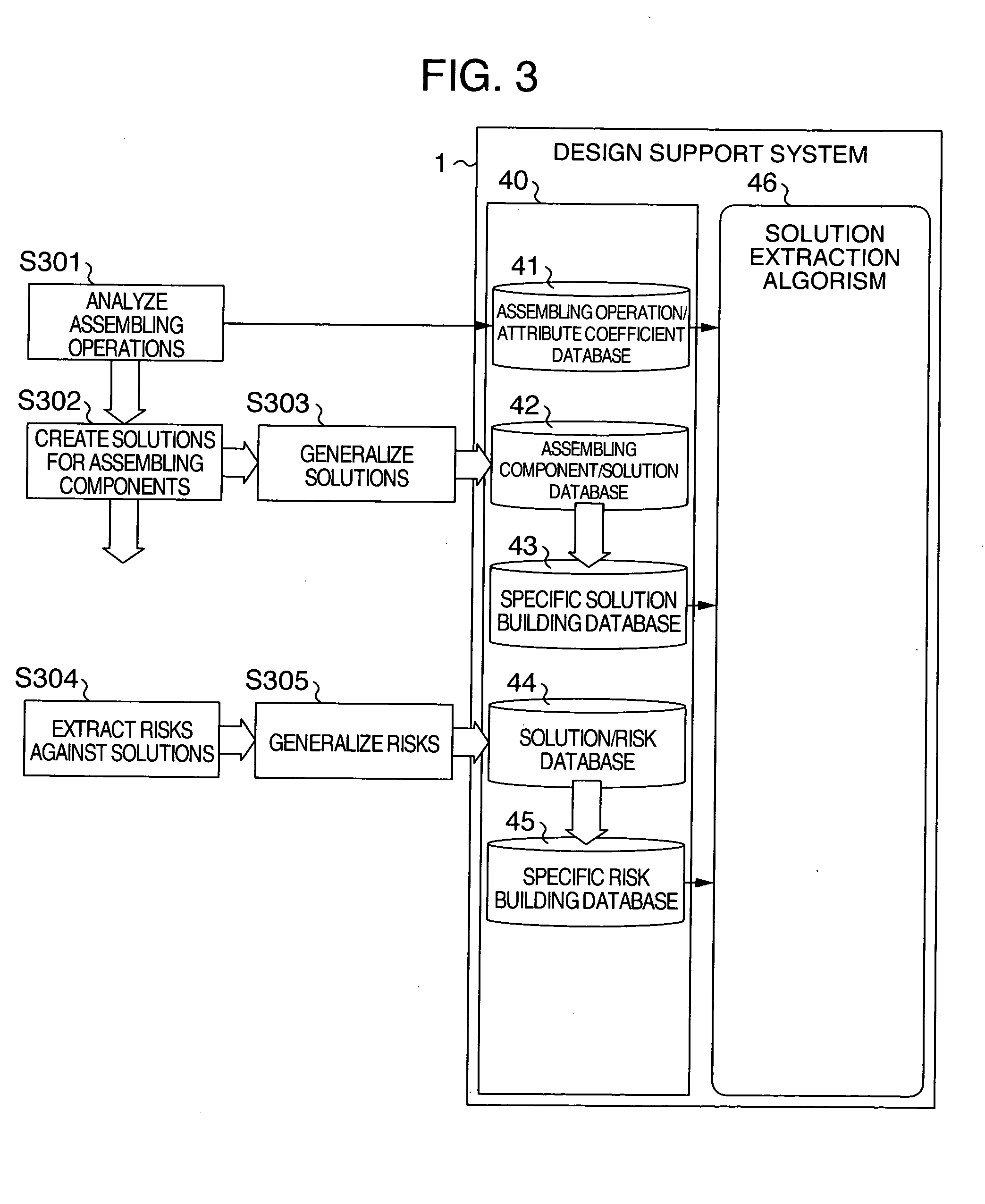

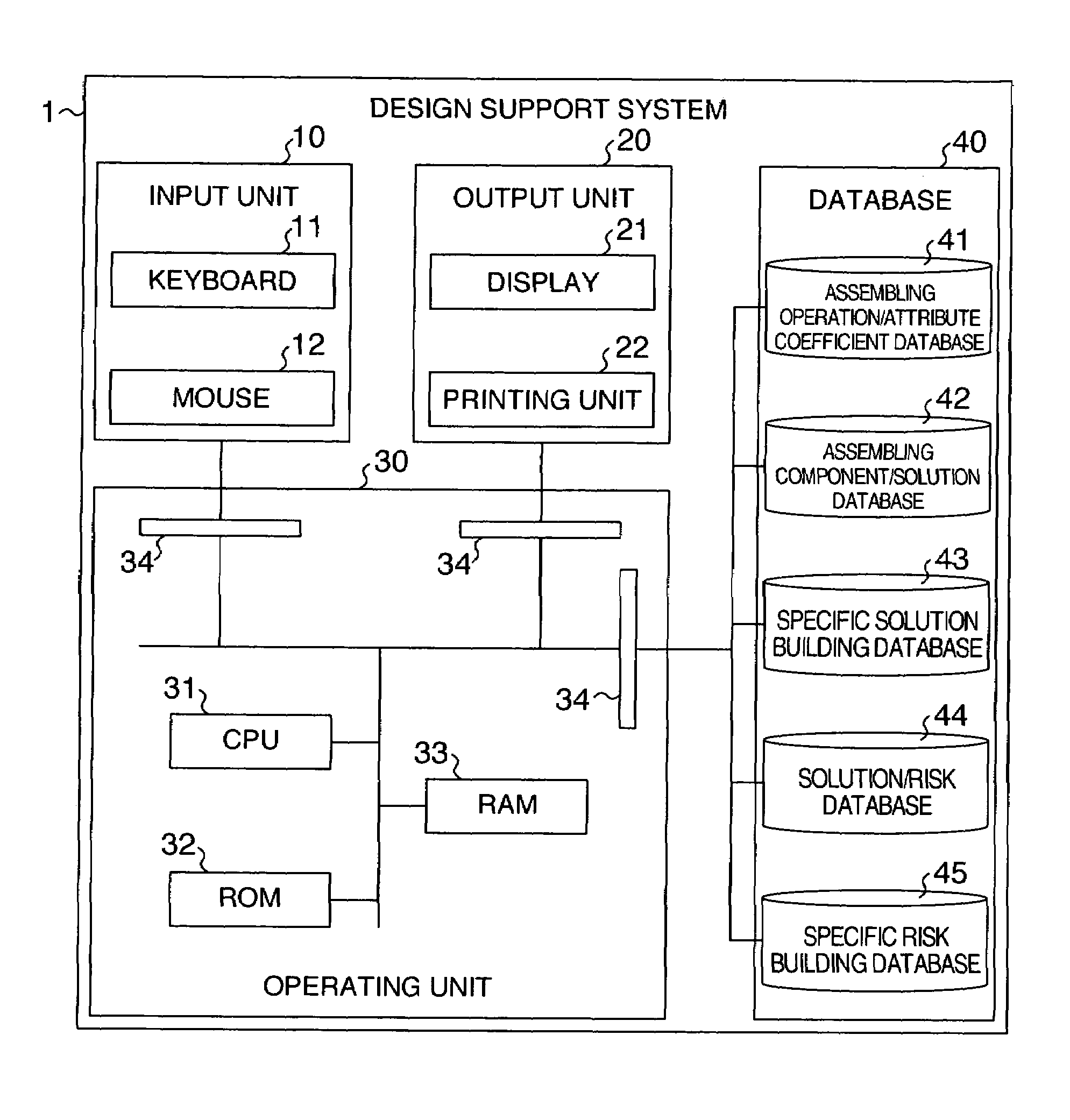

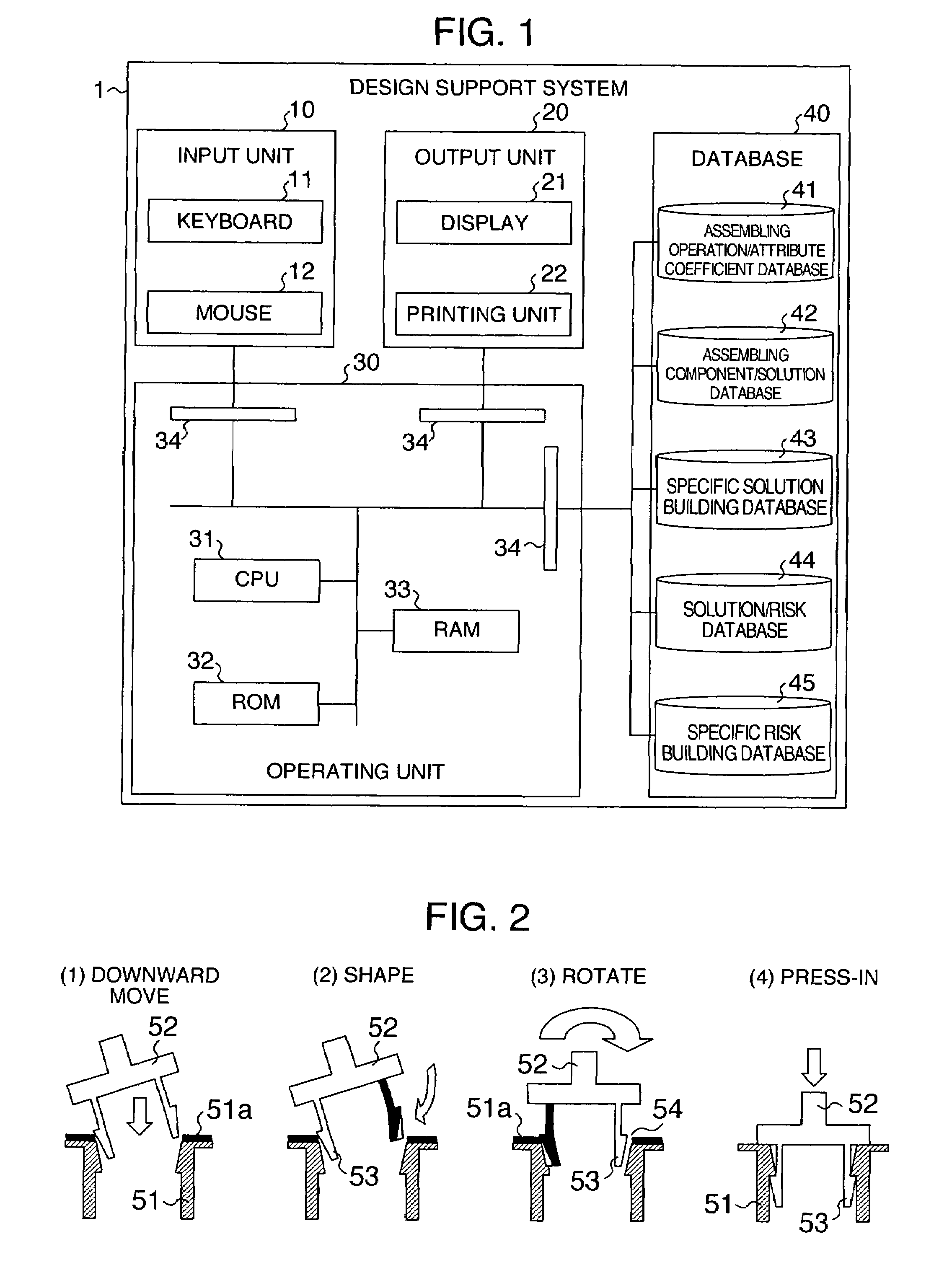

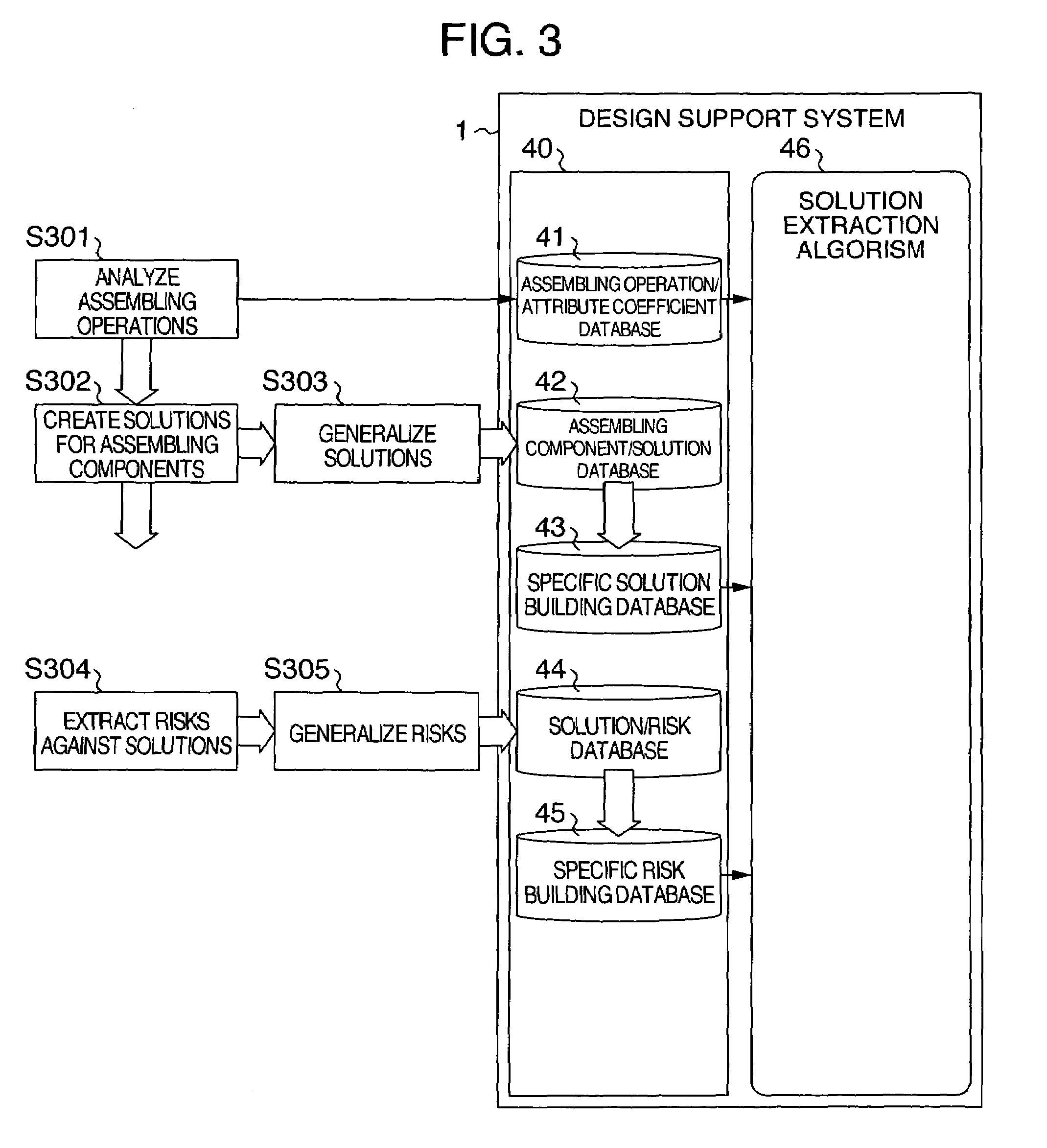

Design support method and design support system

InactiveUS20070005307A1Easily decideReduce failureData processing applicationsKnowledge representationDesign support systemSoftware engineering

In a system according to the present invention, when there occurs a failure or problem phenomenon in a new case example of designing, assembling components (parts, assembling operations and attributes thereof) are input. Failure influence indices are calculated for the assembling components respectively based on assembling operation / attribute coefficients. Assembling components to be improved are extracted, and specific solutions built for the assembling components respectively are displayed on a display so that a specific solution can be selected therefrom. Specific risks expected for the selected solutions respectively are built. The specific solutions and the specific risks are displayed on the display so as to be associated with each other.

Owner:HITACHI LTD

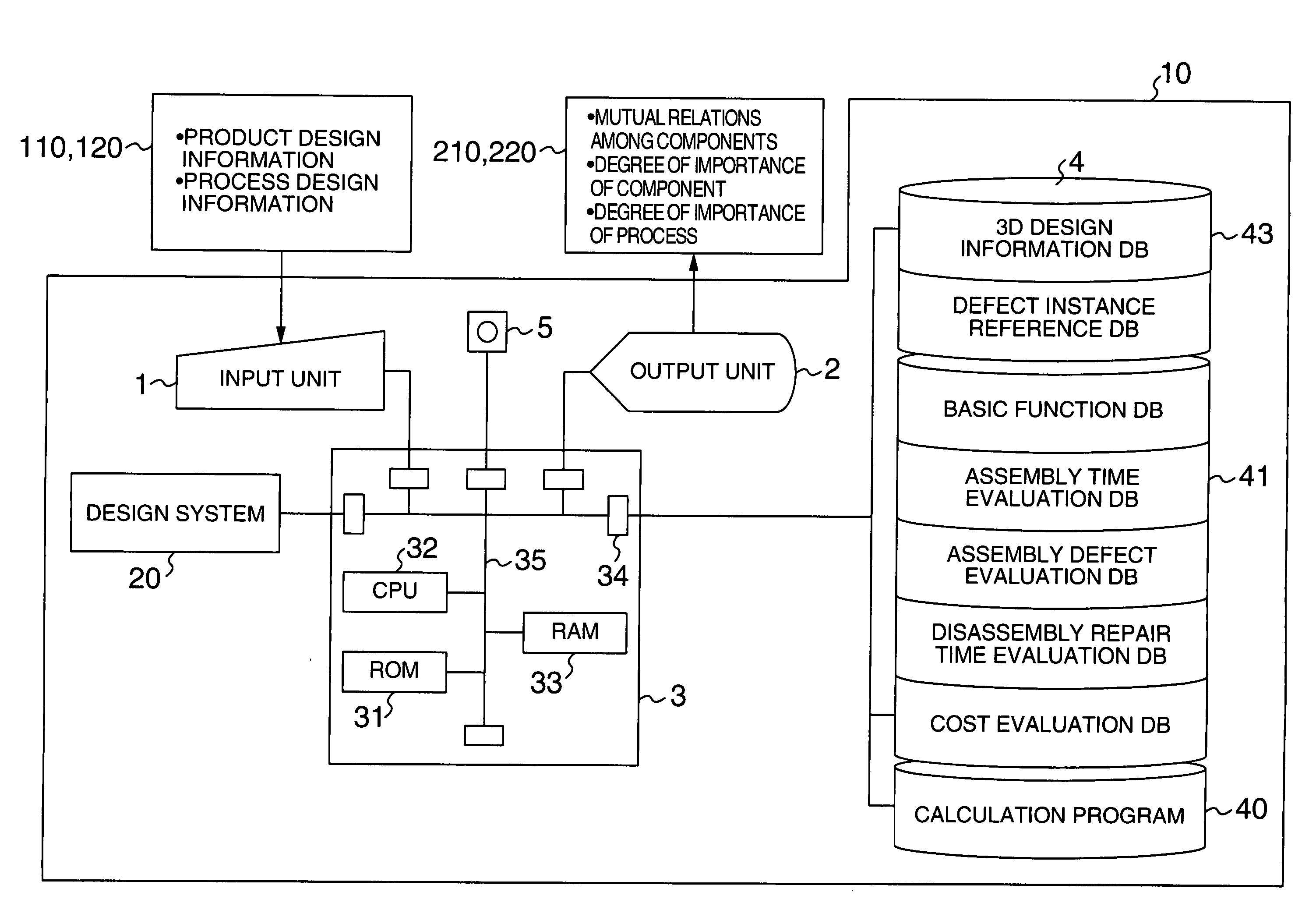

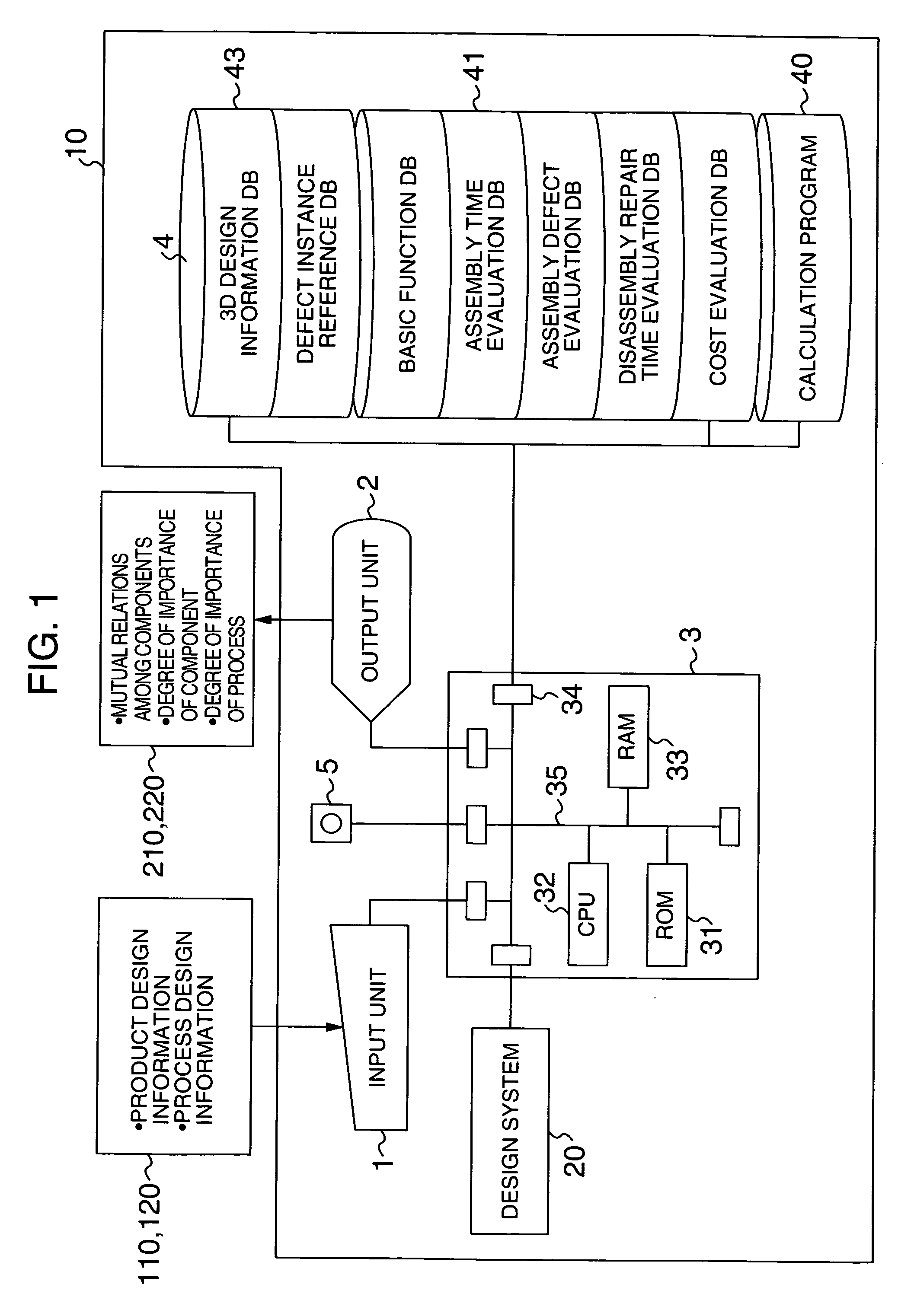

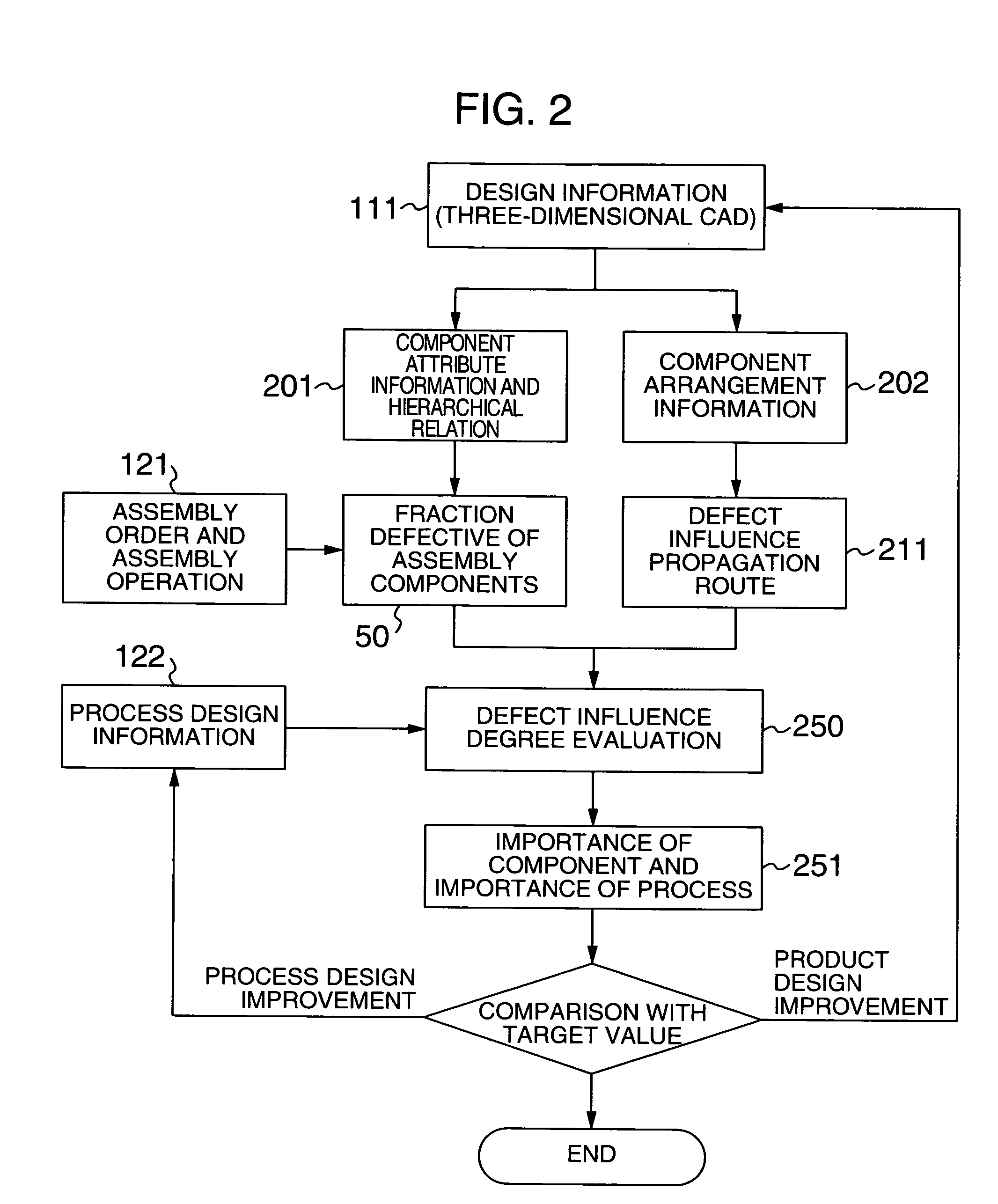

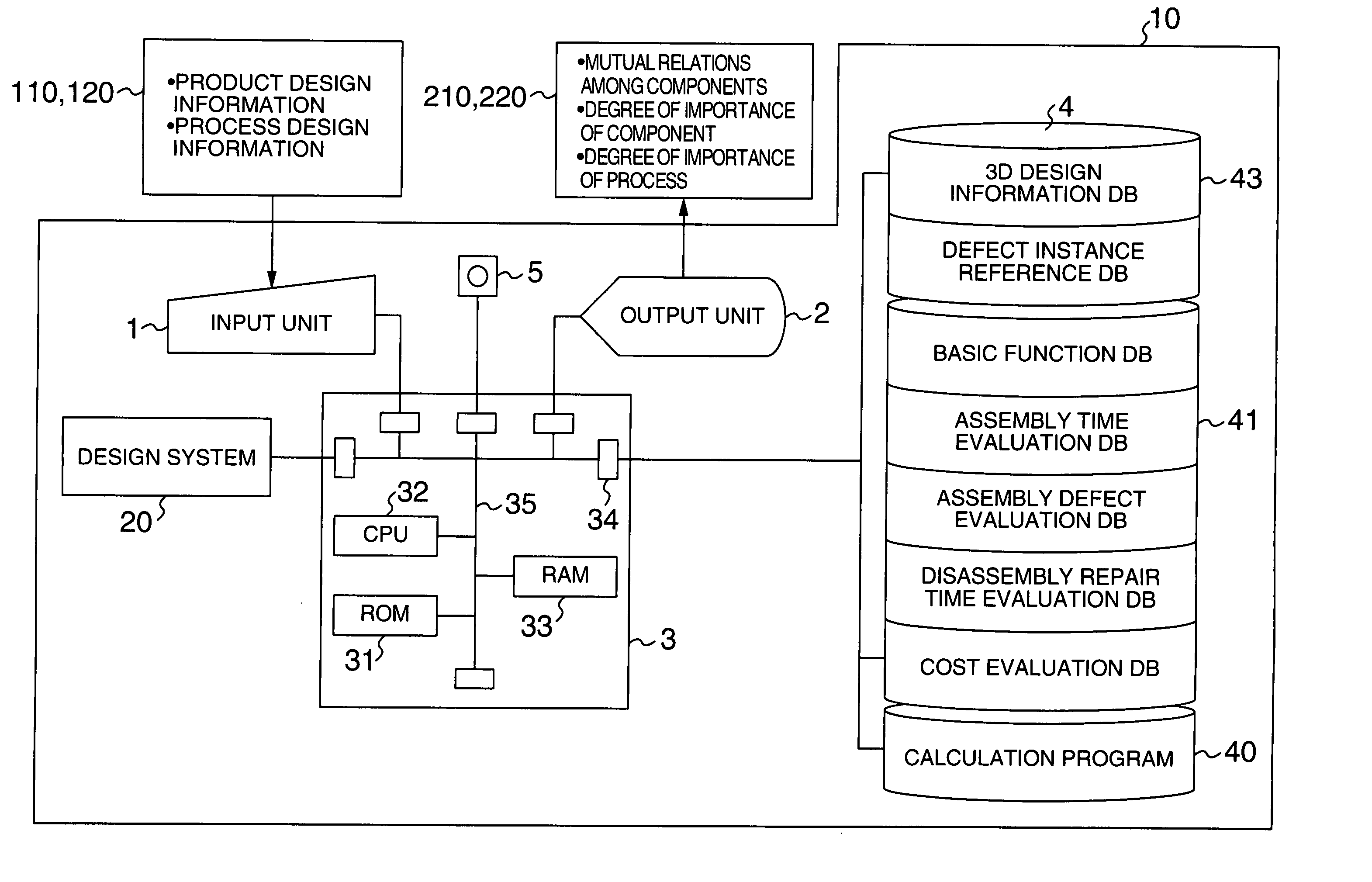

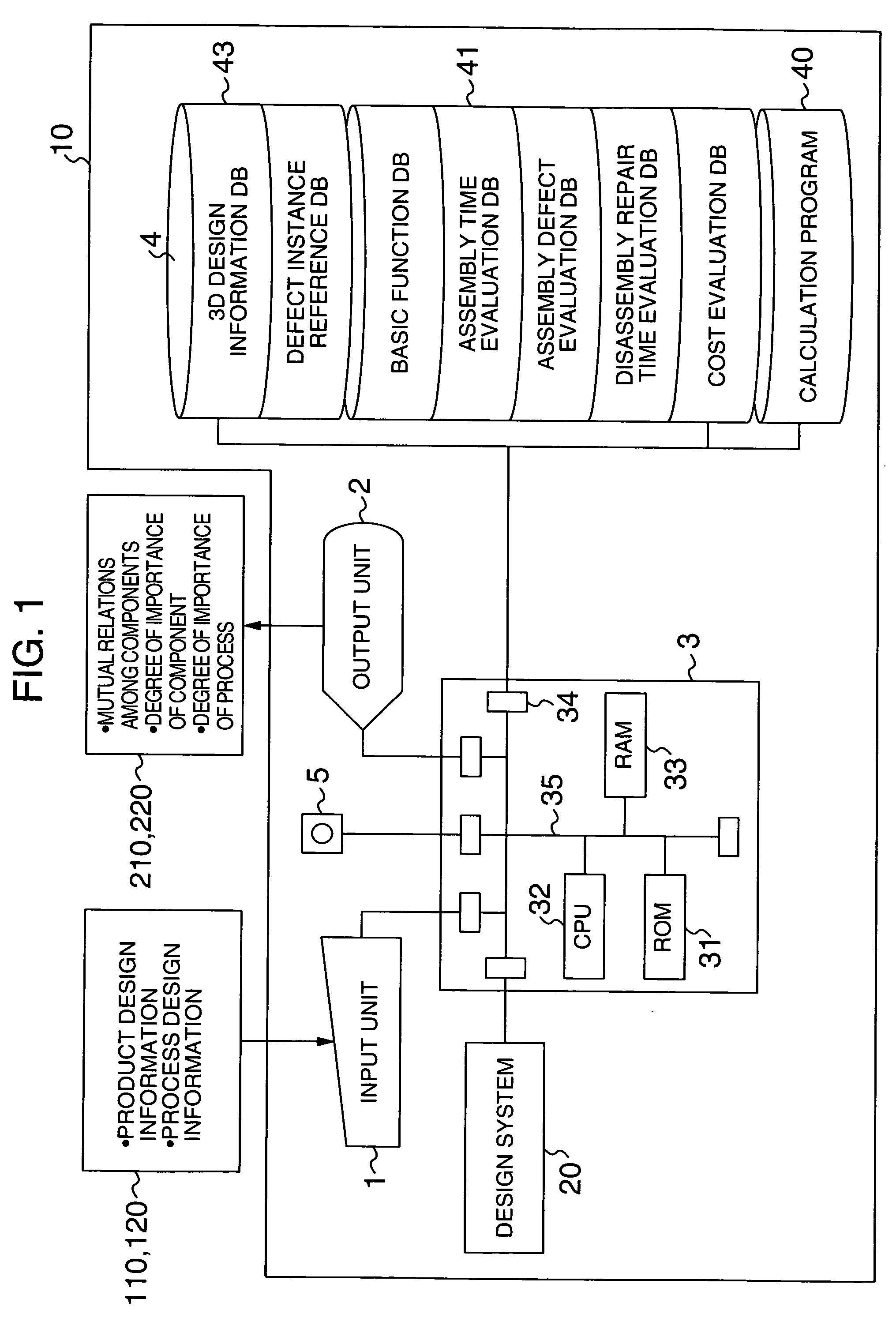

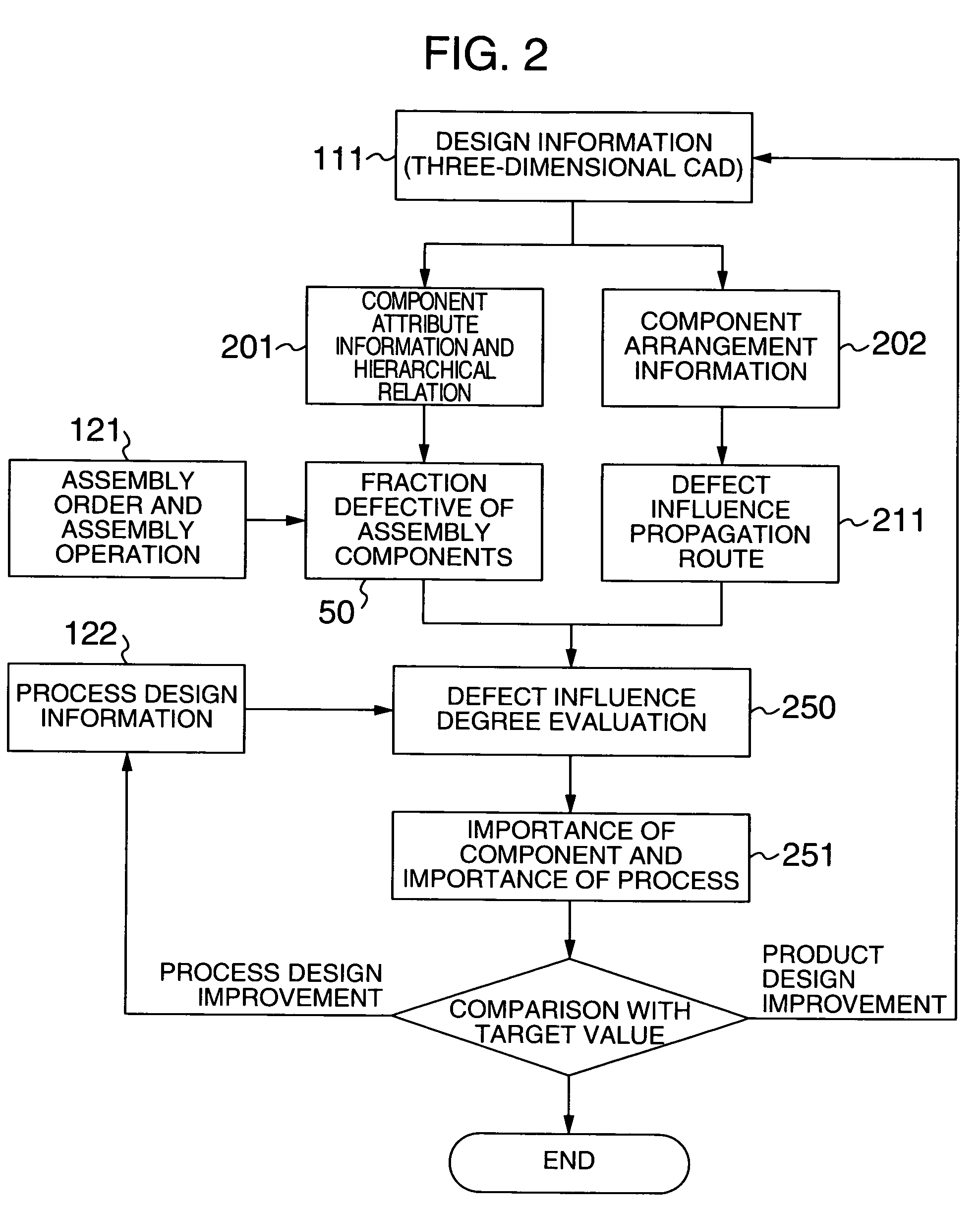

Defect influence degree evaluation method and design support system

At a stage before manufacture (product design stage or manufacturing process design stage), influence of defect occurrence in a component or process on other components and processes is estimated, and defect importance is evaluated to support the manufacturing process design. Failure rates of components are previously stored in a database. At a product design stage, an assembly fraction defective is calculated for an assembly process of each component of the product. Component arrangement relations are extracted from product design information. A component fraction defective is calculated based on the assembly fraction defective and the component failure rate. A numerical value indicating an influence degree of each assembly process is calculated by multiplying component fraction defectives by coefficients based on of the component arrangement relations and the component fraction defective, for relating components in each assembly process. Thereby, influence degrees of each component and process are evaluated.

Owner:HITACHI LTD

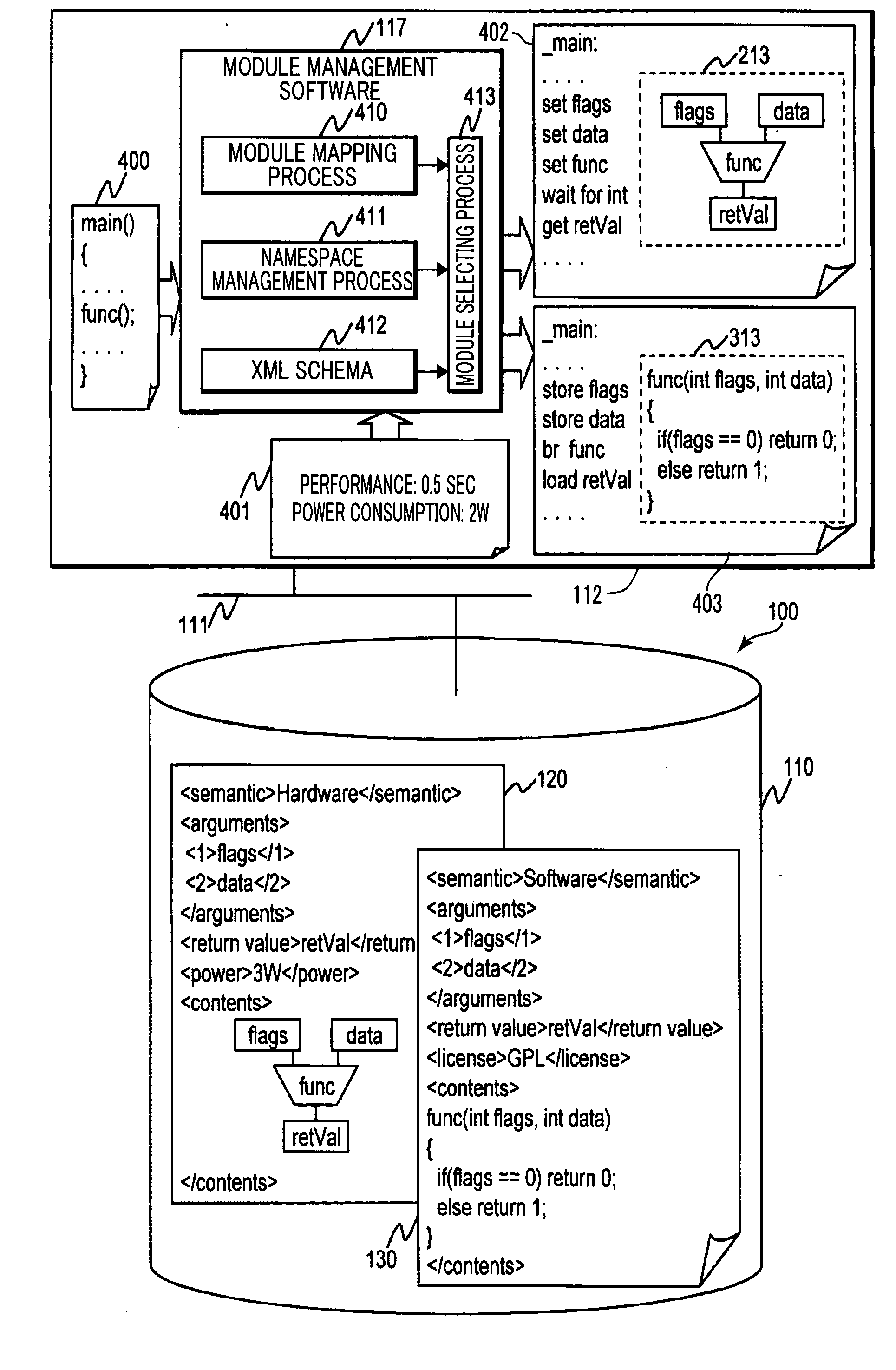

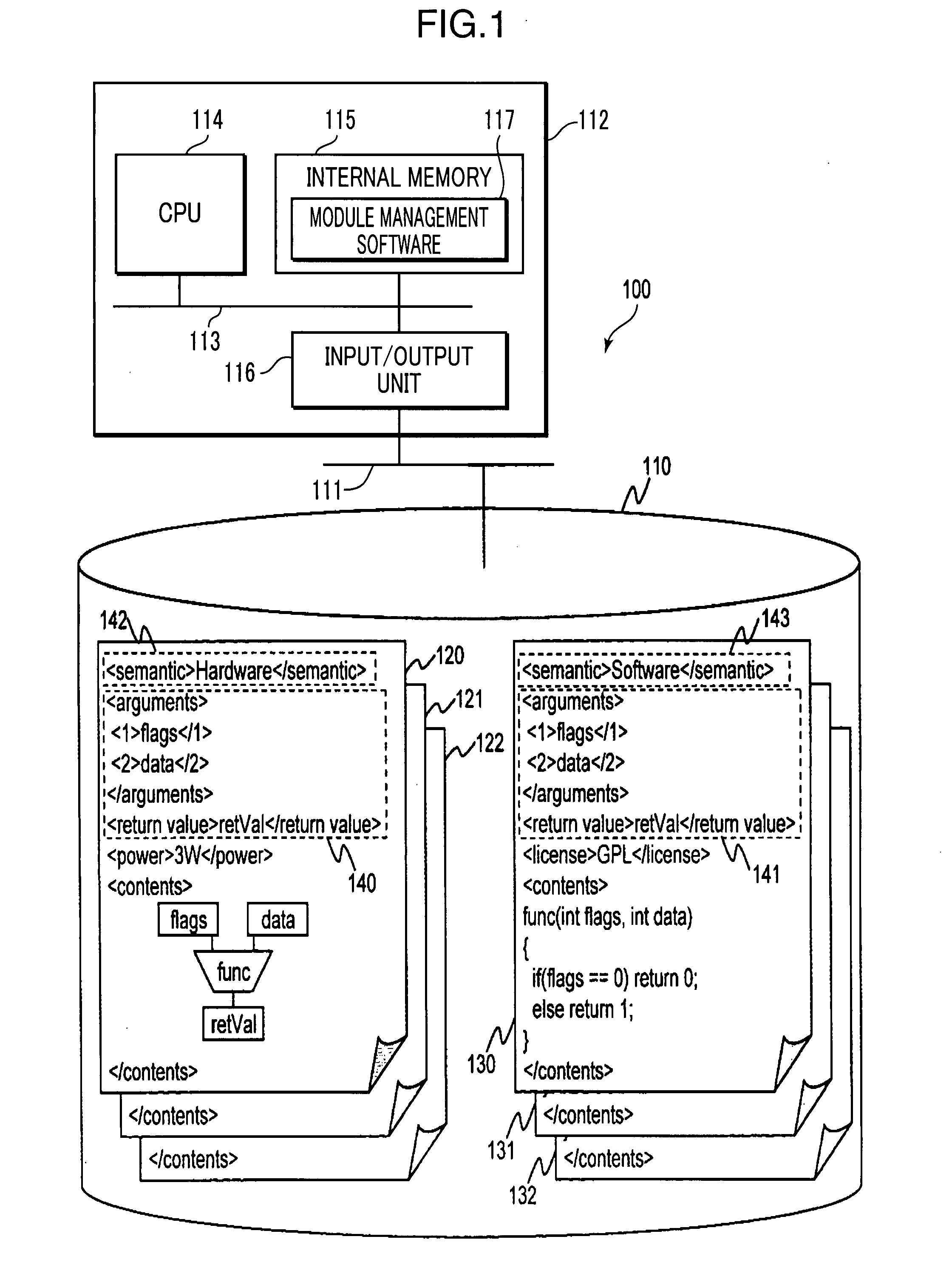

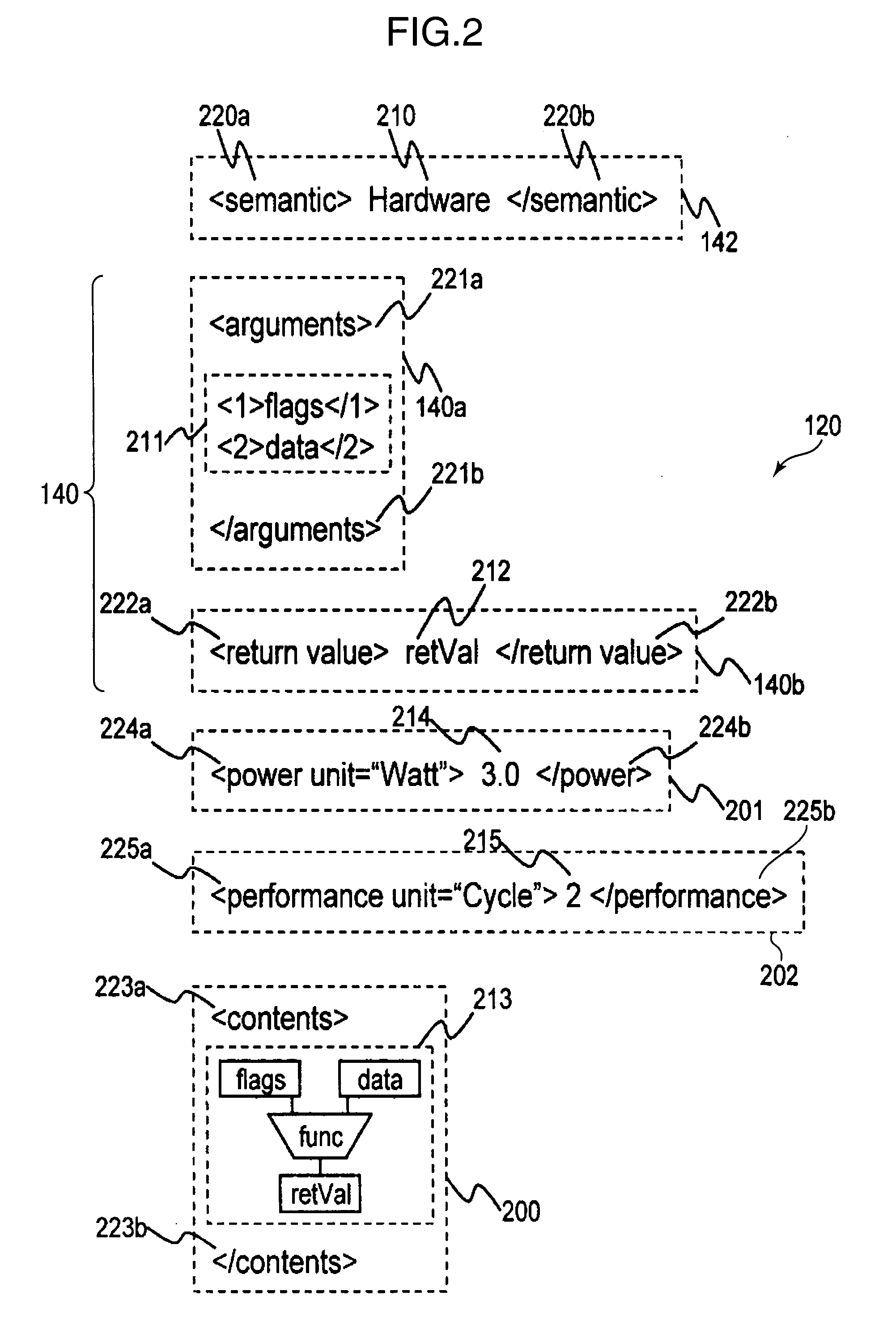

Design supporting system, design supporting method, and computer-readable recording medium recorded with design supporting program

InactiveUS20070245294A1CAD circuit designSpecific program execution arrangementsSupporting systemExternal storage

An optimum target system is designed by implementing software modules and hardware modules, without discriminating the software modules and the hardware modules one from the other. An external storage stores the software modules including a namespace identifier for identifying the software module, and the hardware modules including a namespace identifier for identifying the hardware module. A module selector specifies a process of a target system to be built, and selects the software modules and the hardware modules that execute the specified process. A namespace manager acquires the namespace identifier for identifying the software module, and the namespace identifier for identifying the hardware module. A module mapping processor implements either one of the software modules and the hardware modules in the target system, based on the namespace identifiers.

Owner:PANASONIC CORP

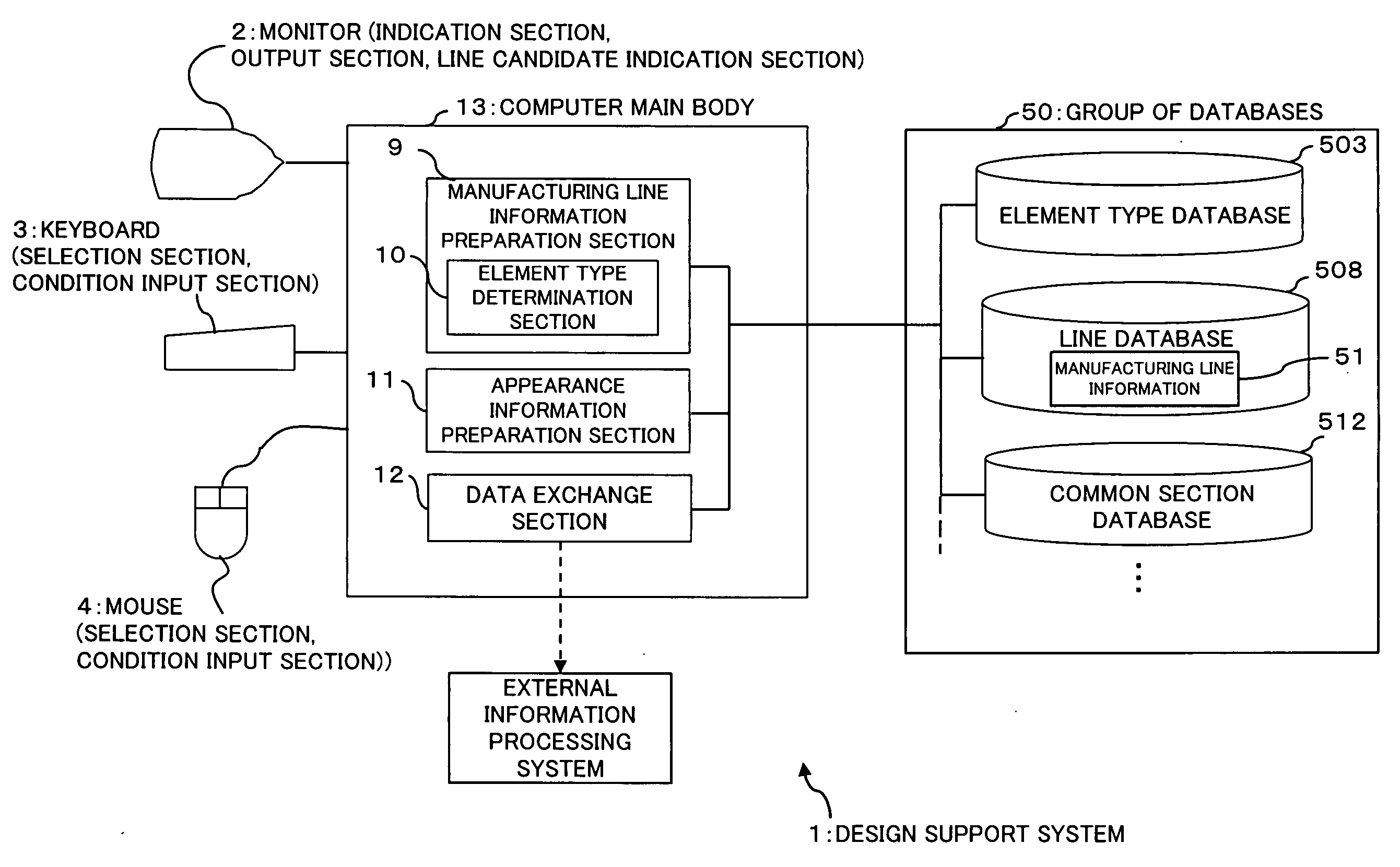

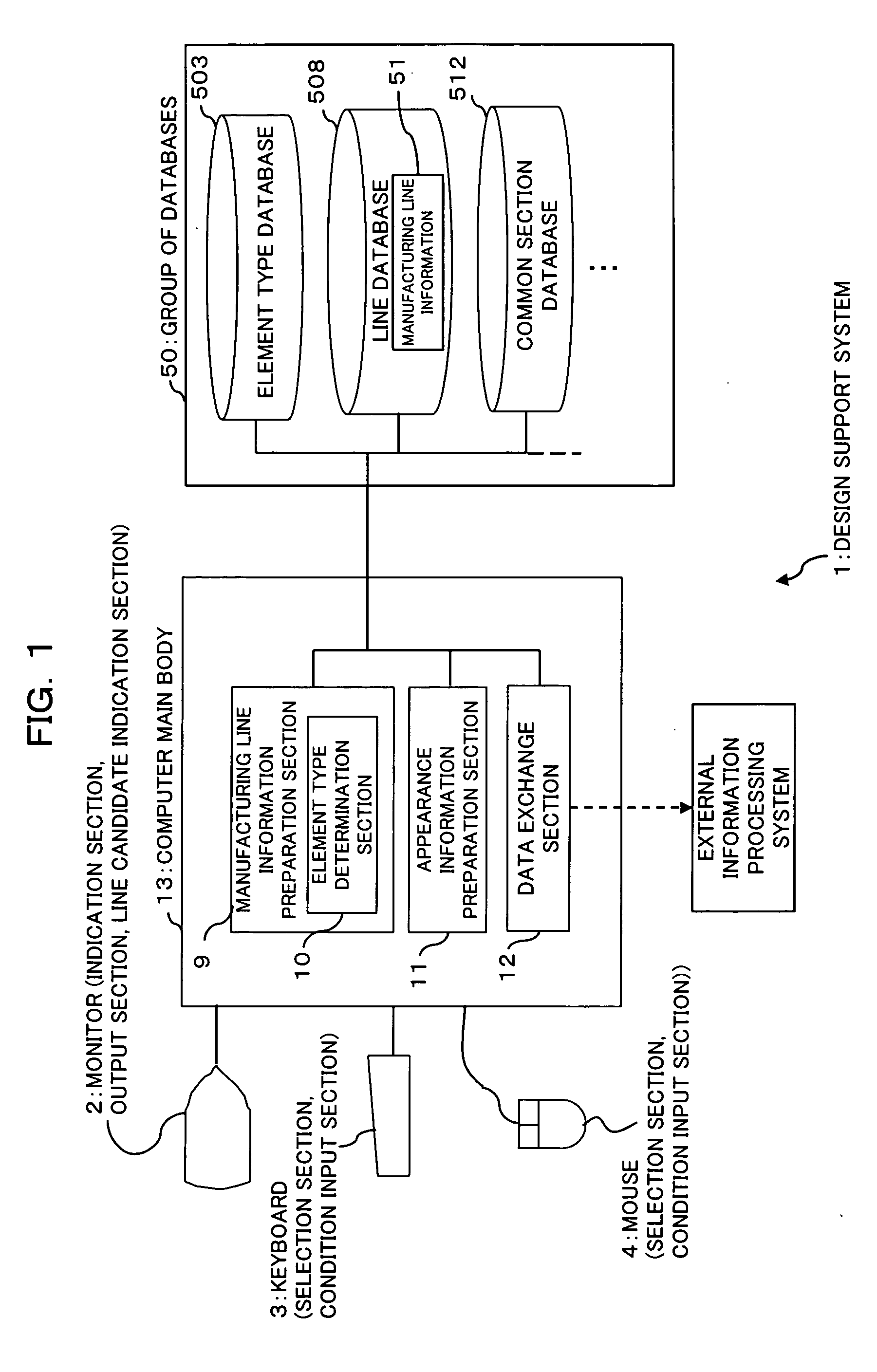

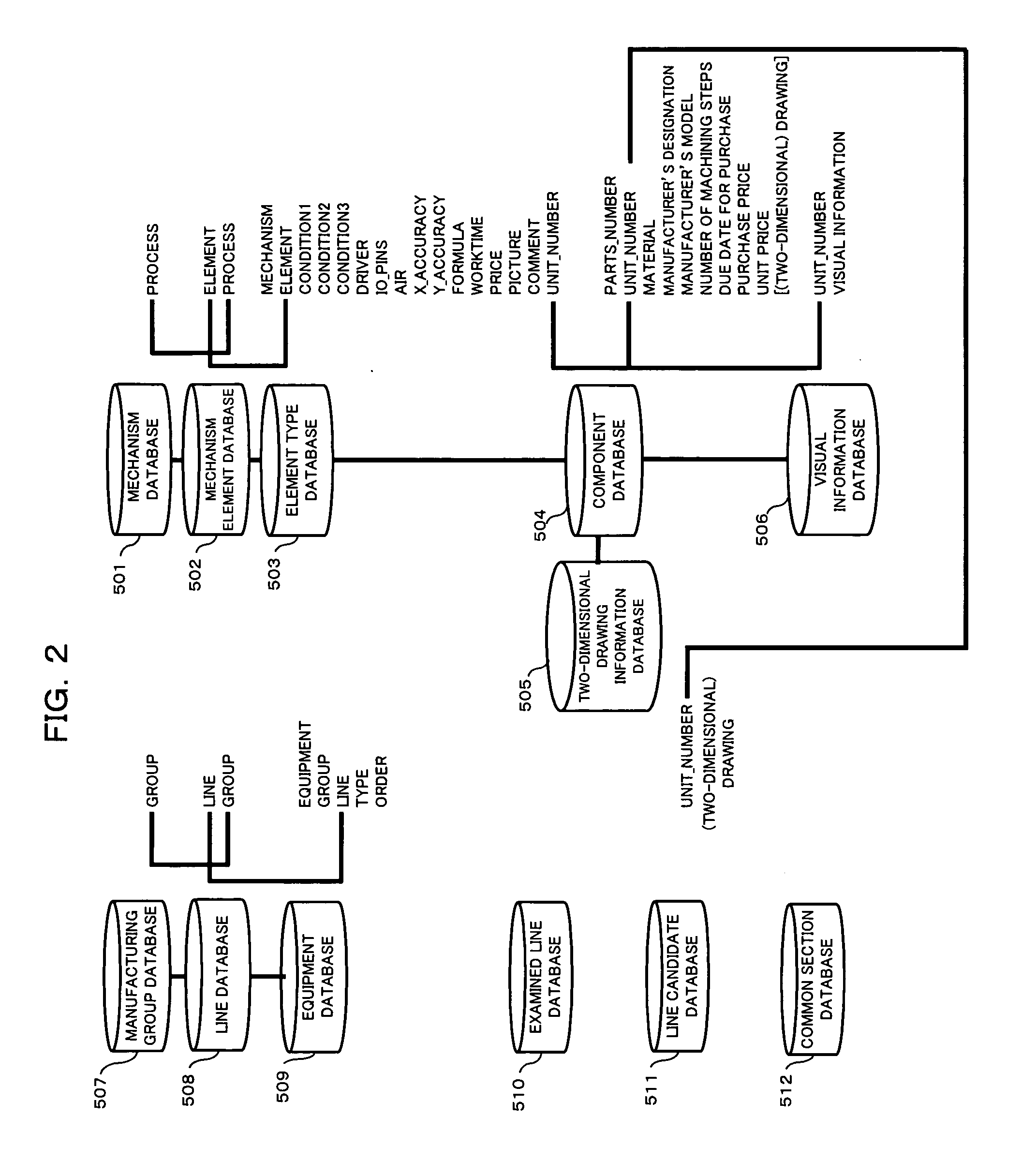

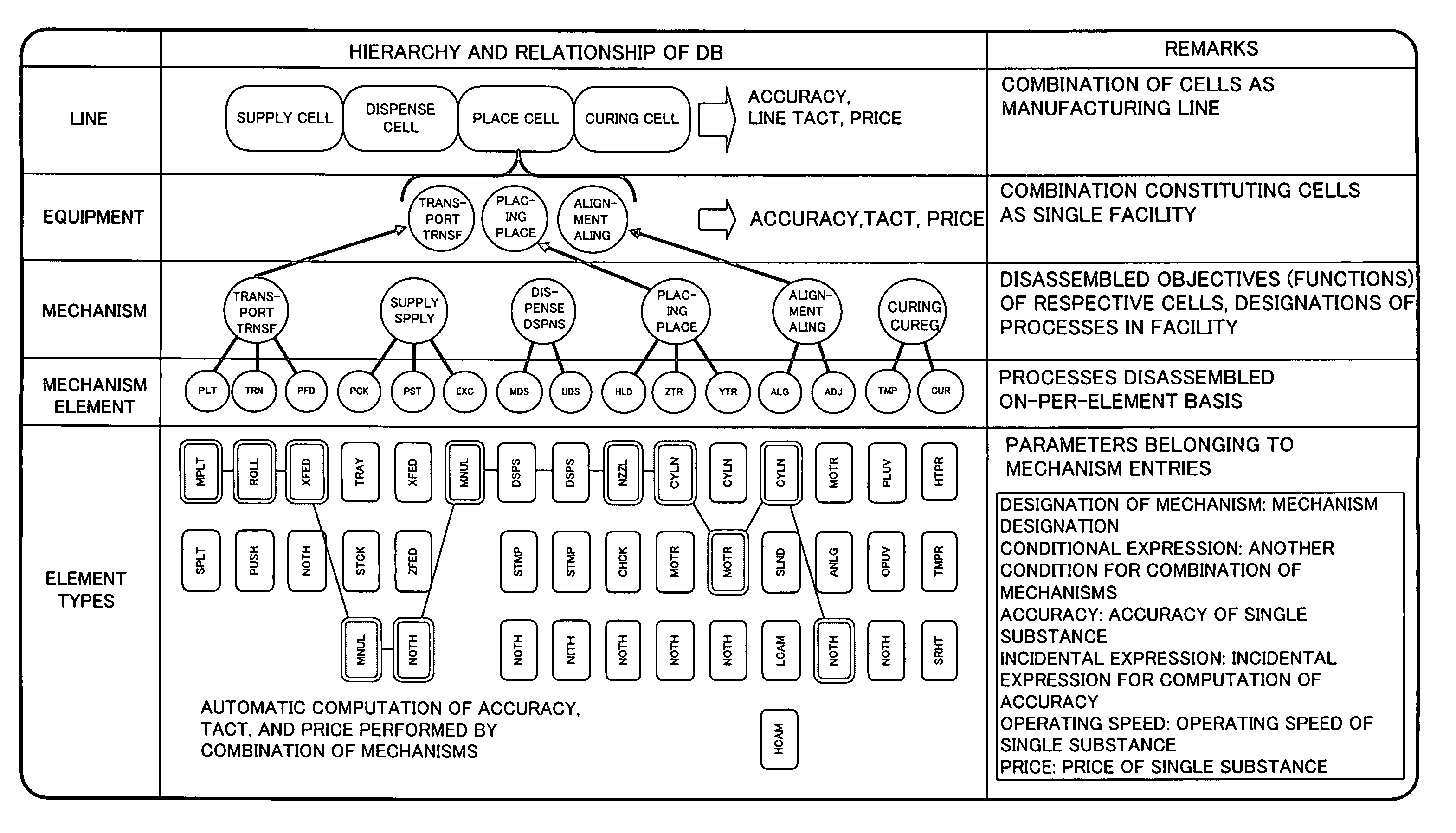

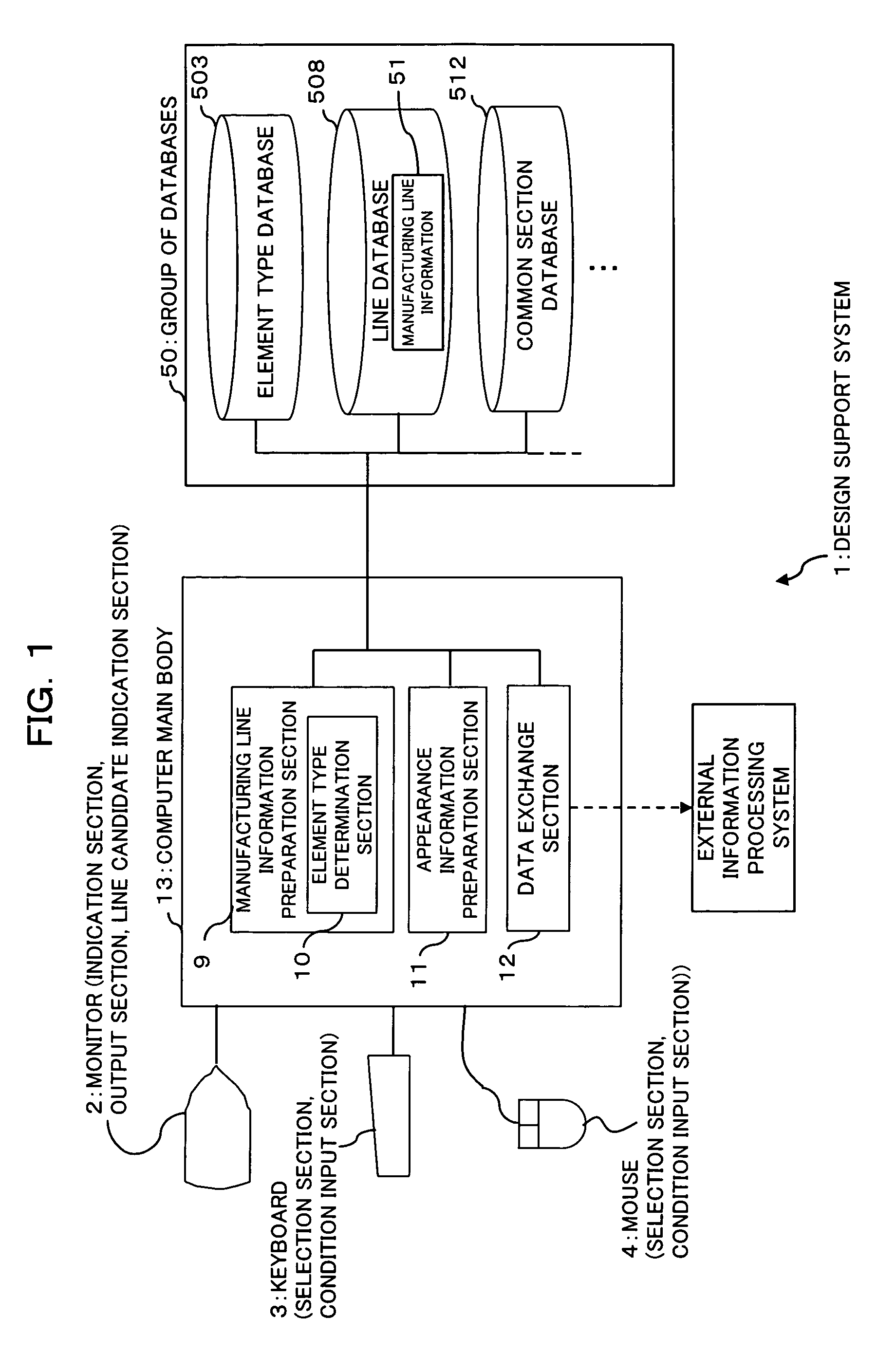

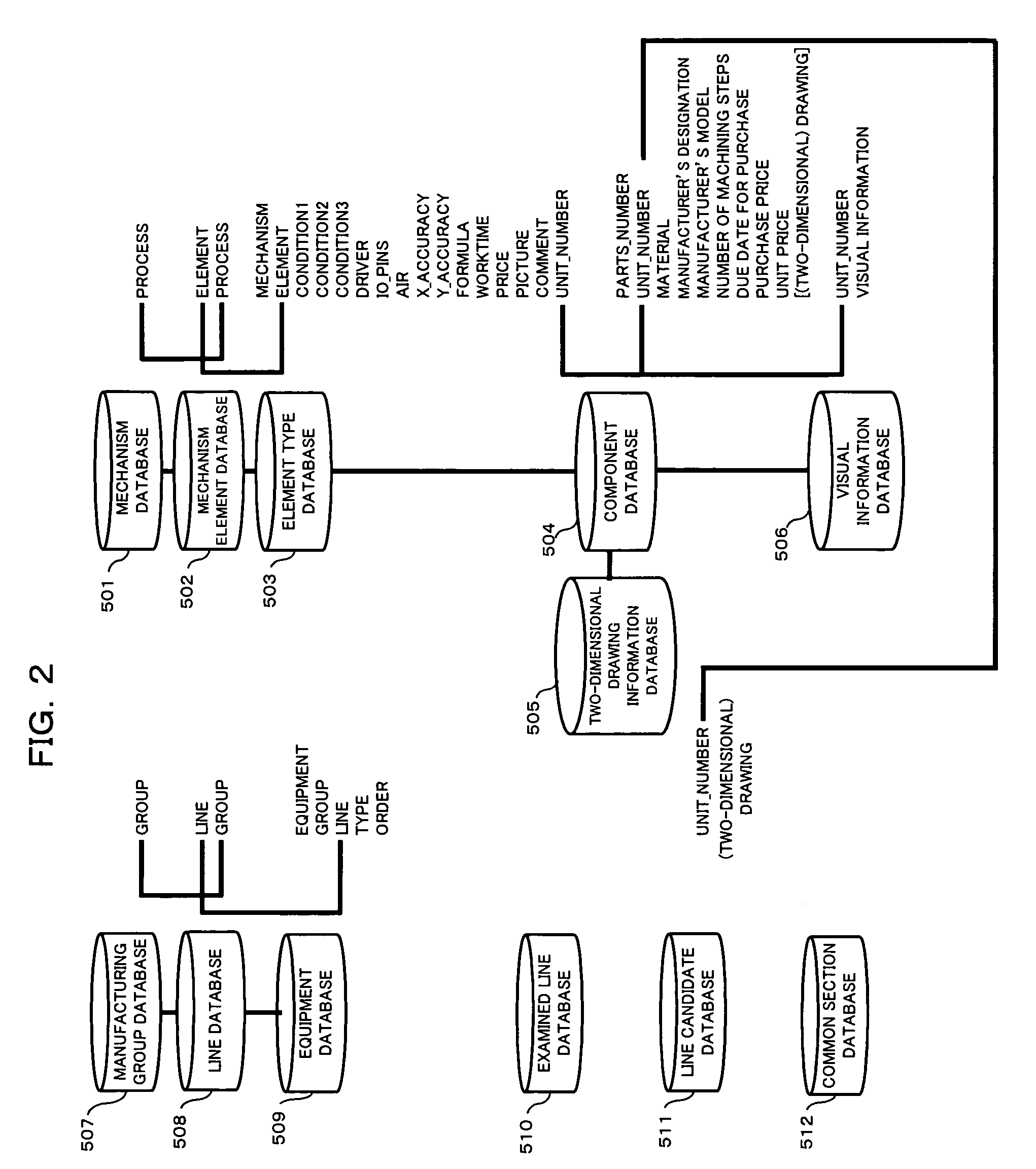

Design support system

InactiveUS20050038537A1Improve convenienceLow costSemiconductor/solid-state device manufacturingResourcesManufacturing cost reductionDesign support system

The present invention relates to a design support system constructed so as to comprise a manufacturing line information preparation section and an output section. On the basis of element types selected by a selection section as arbitrary element types to be used for constituting a manufacturing line, the manufacturing line information preparation section prepares information about the manufacturing line by means of acquiring information about element types stored in an element type database beforehand. The output section can output the information about the manufacturing line prepared by the manufacturing line information preparation section. A manufacturing line including a plurality of steps is efficiently examined, determined, and established, thereby shortening the time required to design and manufacture the manufacturing line and curtailing manufacturing costs.

Owner:FUJITSU LTD

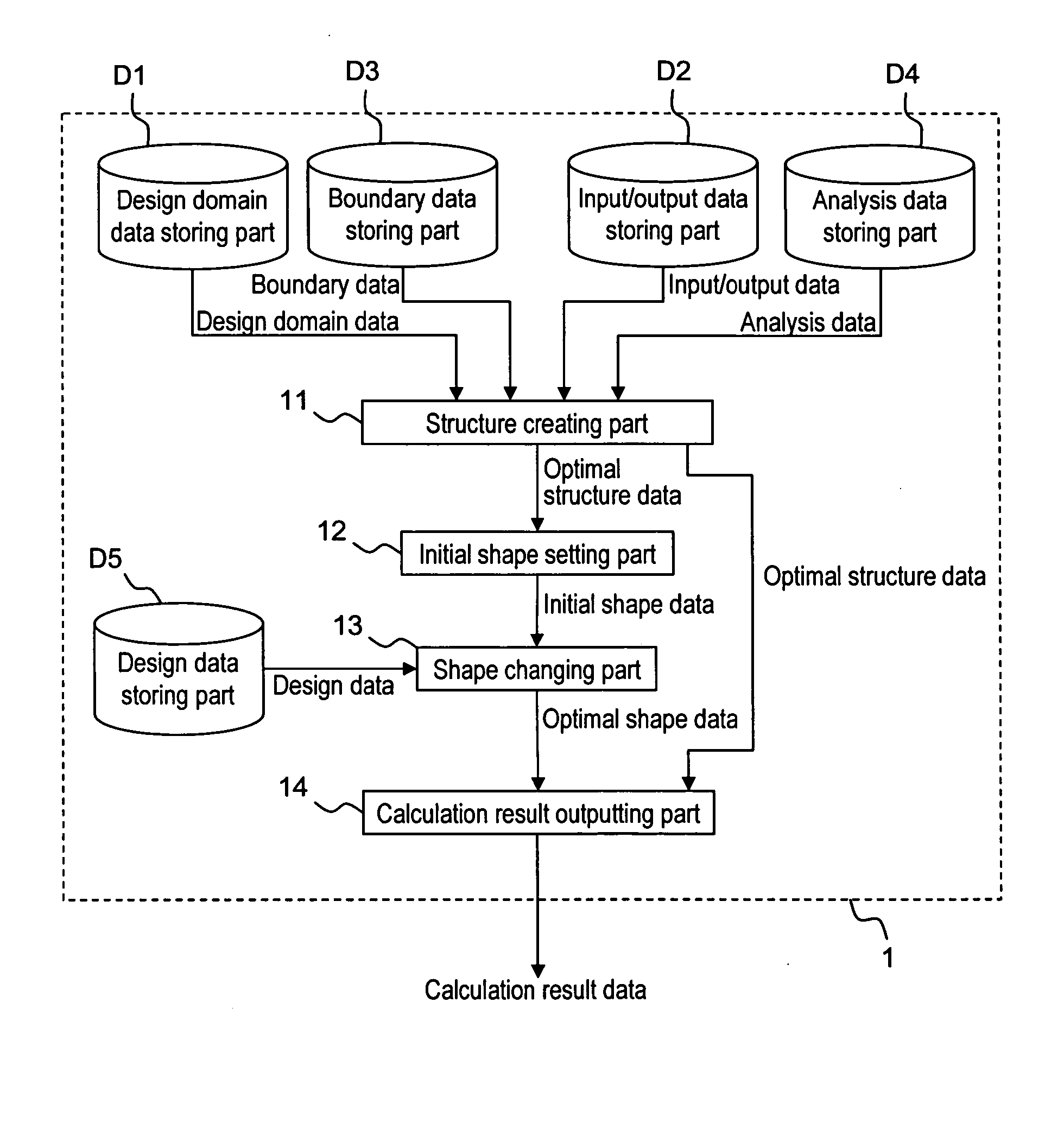

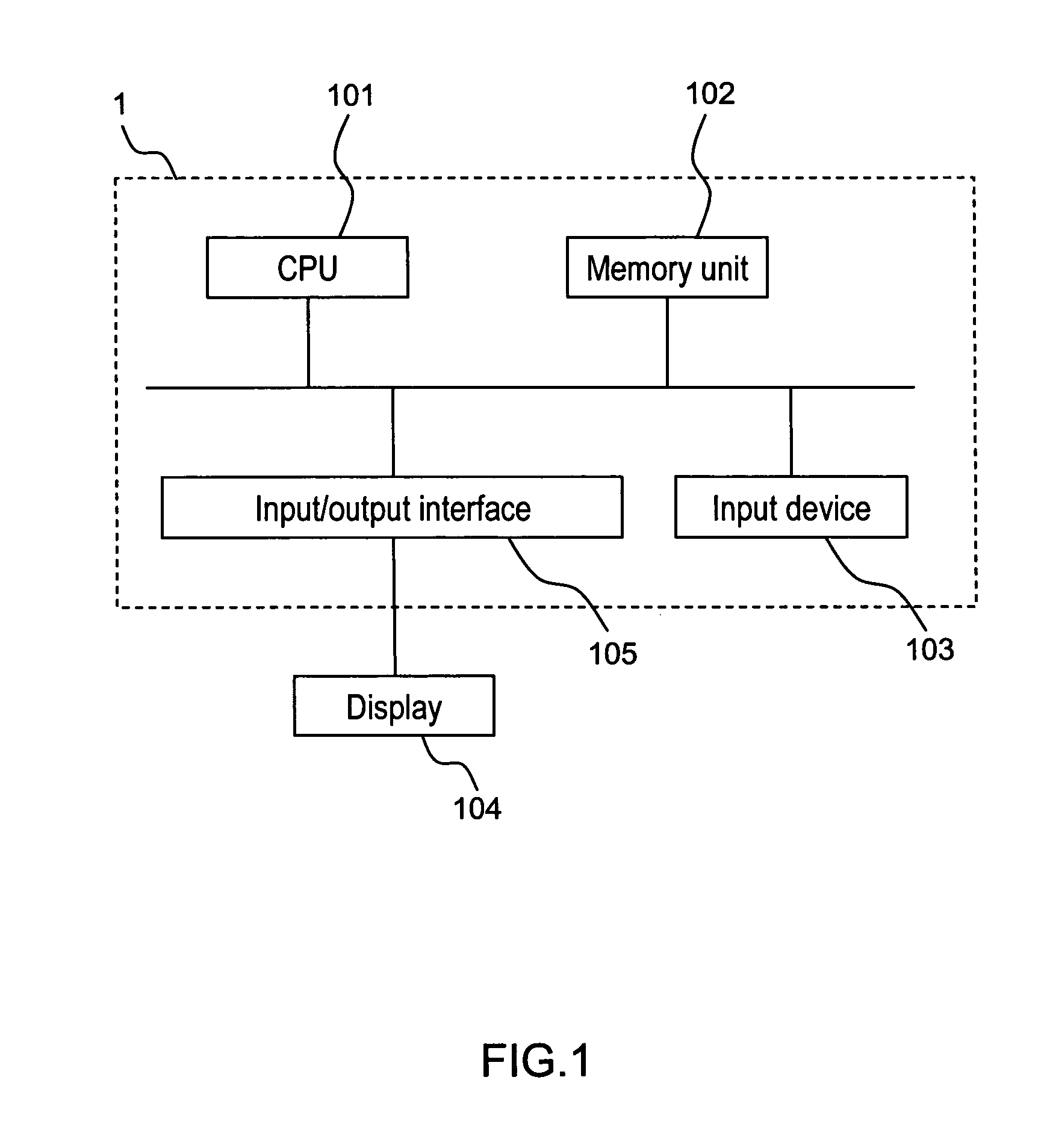

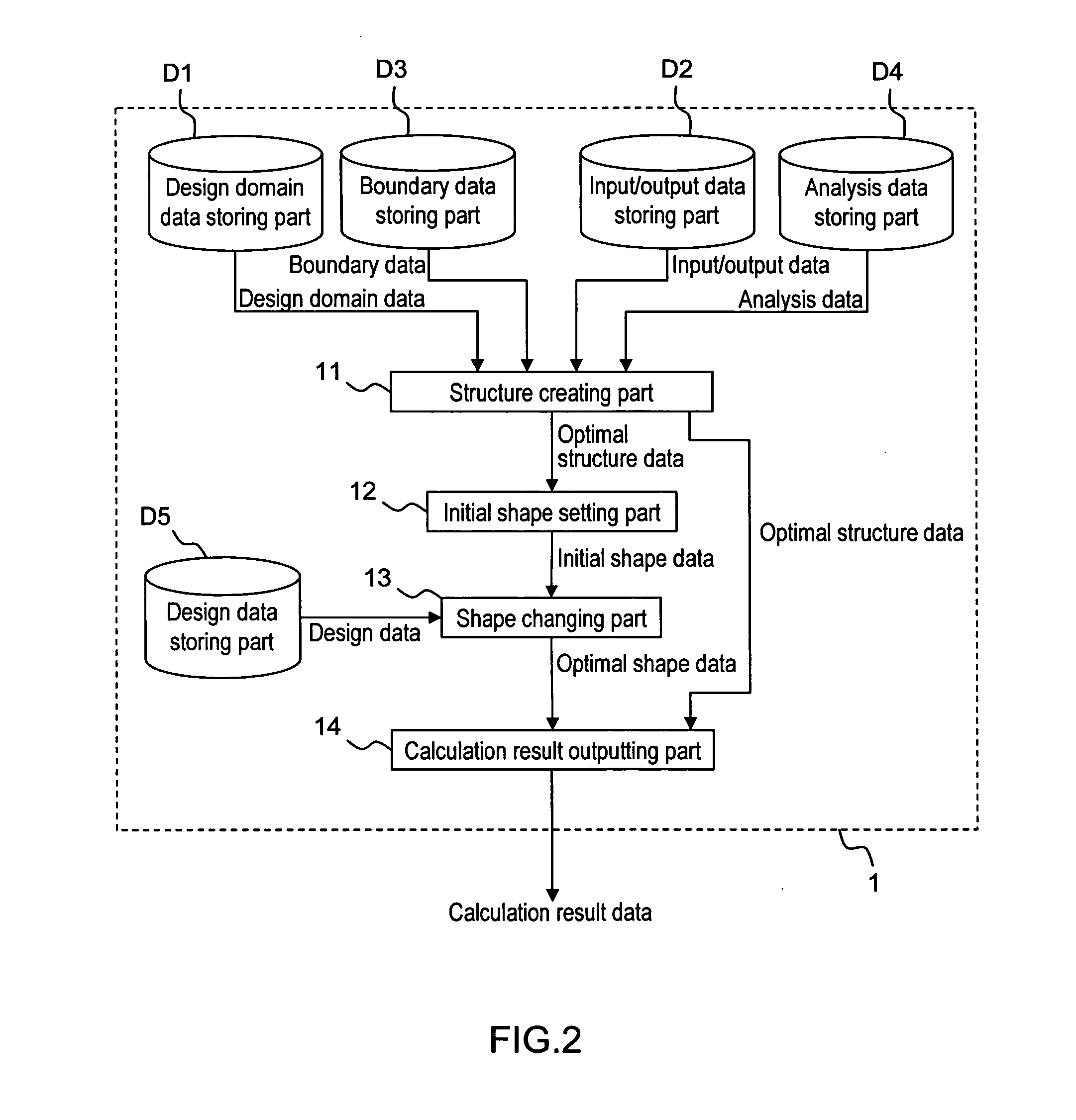

Optimal Design Support System, Optical Design Support Method and Optimal Design Support Program

InactiveUS20070239411A1Design optimisation/simulationSpecial data processing applicationsSupporting systemShape change

Owner:KYOTO UNIV

Article Design Support System and Method of Controlling Same

ActiveUS20070262982A1Increase freedomEasy to changeGeometric CADCharacter and pattern recognitionDesign support systemCell space

Provided is an article design support system featuring enhanced degree of freedom in terms of designing articles (for example, an article of furniture). A part space P surrounding a part incorporated in a cell space S is correlated with the cell space S, which is formed by a frame constituting a unit. The position (dimensions) of the part space P in the cell space S is defined by part space data specifying a relative position and relative dimensions using the cell space S as a reference. The position (dimensions) of a part in the part space P is defined by part (element) data specifying a relative position and relative dimensions using the part space P as a reference.

Owner:NINOMIYA KENICHI

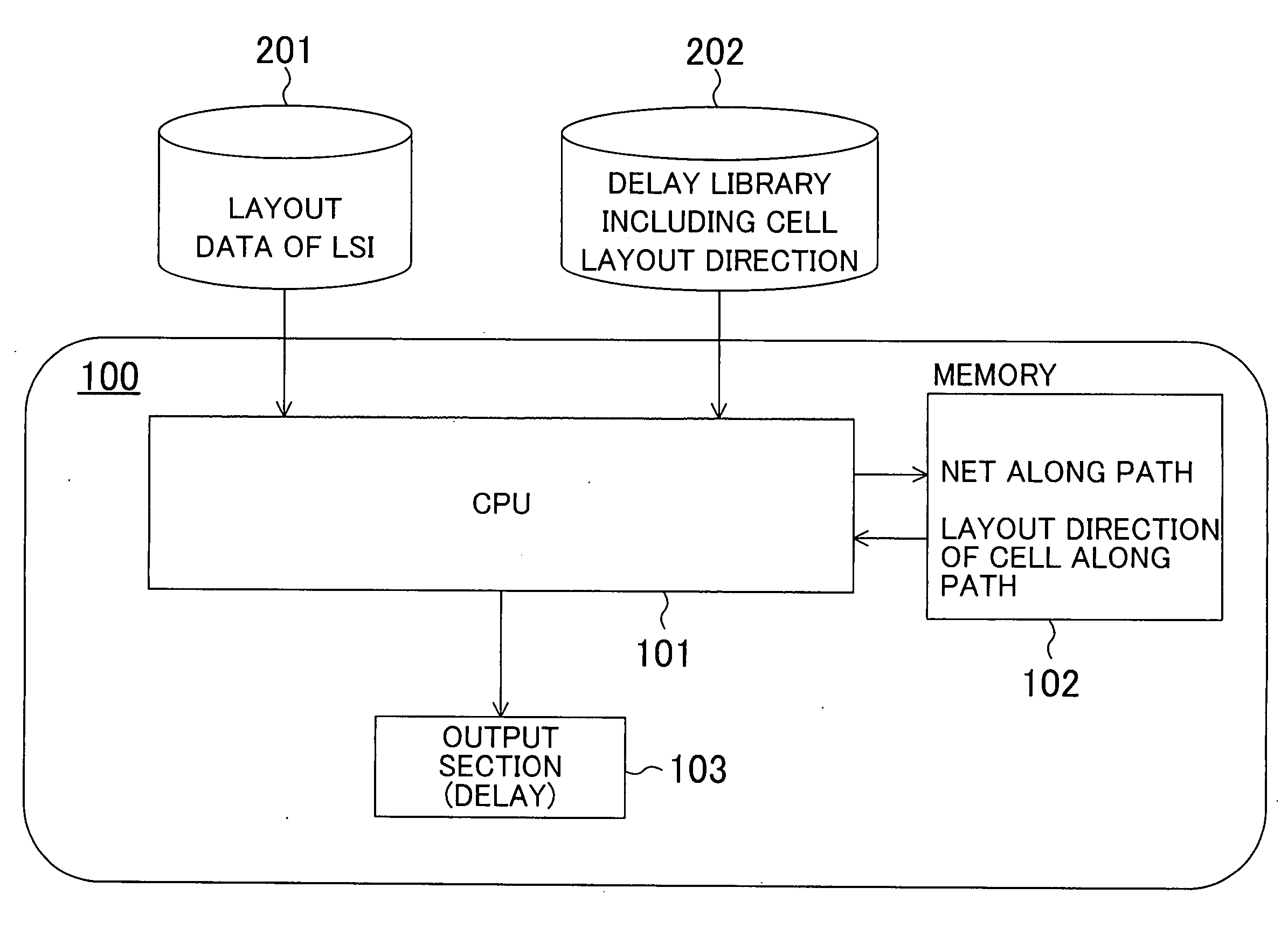

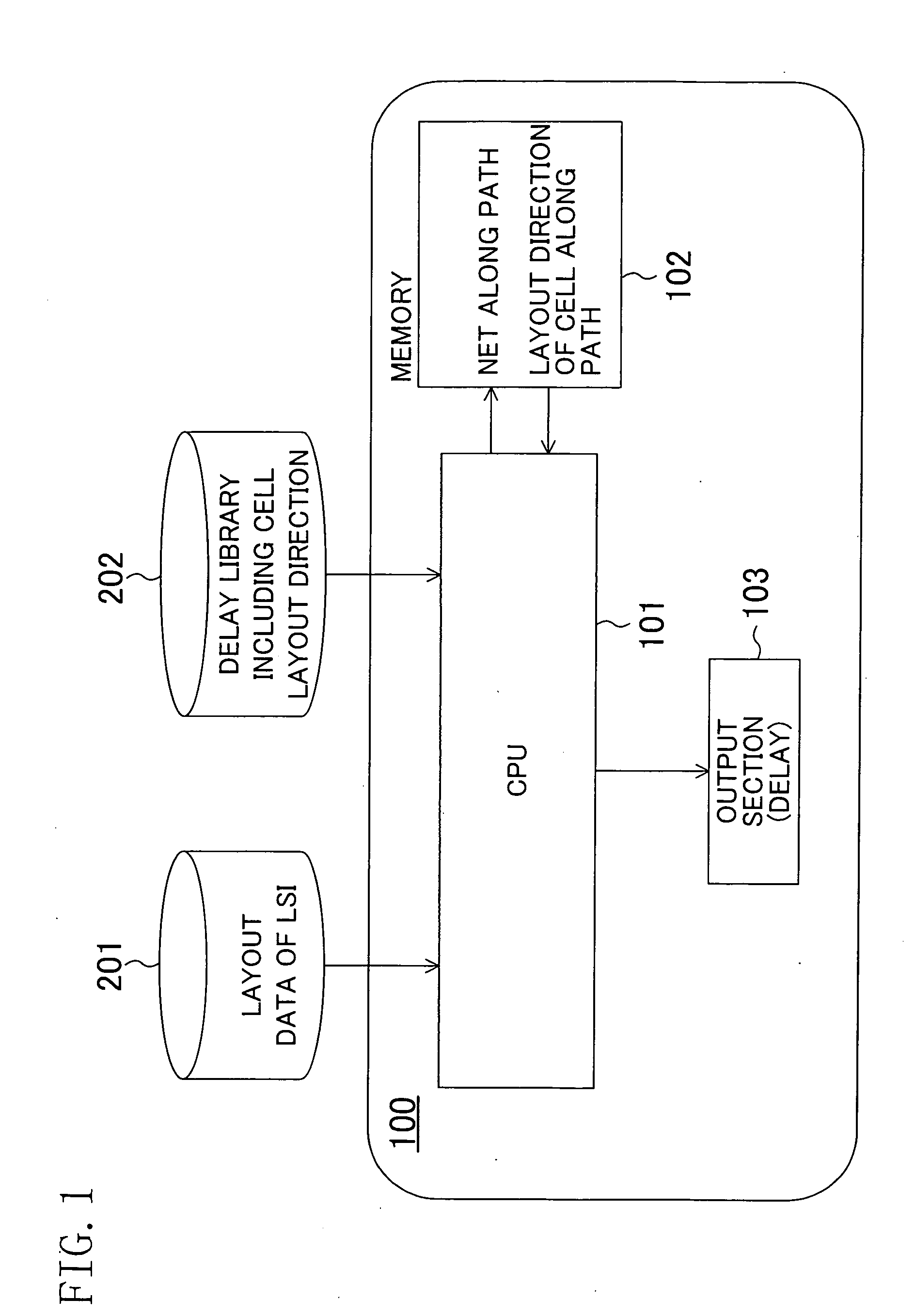

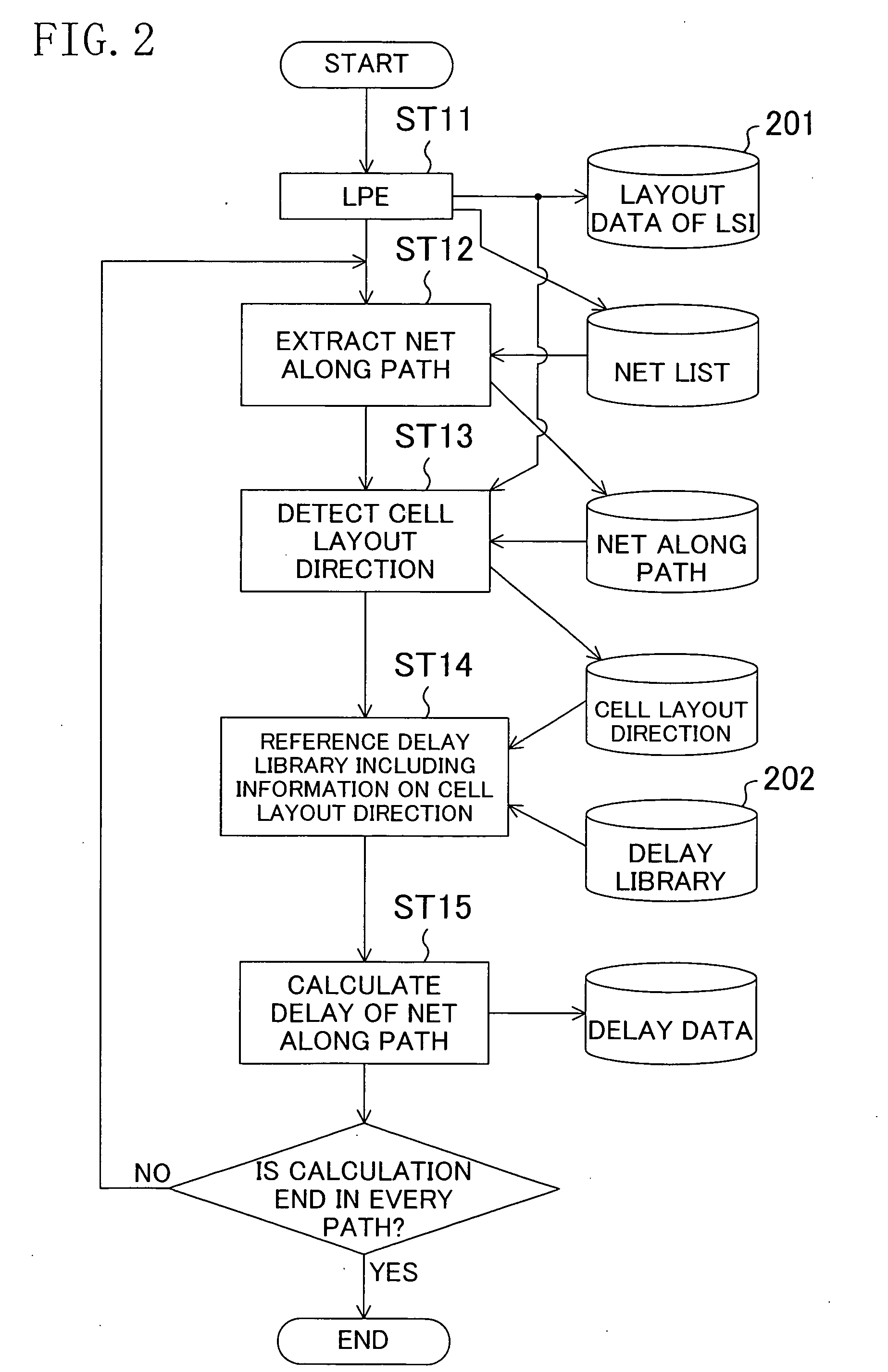

Semiconductor integrated circuit design method, design support system for the same, and delay library

InactiveUS20060010409A1Precise margin of designCreates delayDetecting faulty computer hardwareComputer aided designDesign support systemEngineering

In a semiconductor integrated circuit design method for simulating a delay of a logic circuit based on delay values which are calculated for each kind of a plurality of cells composing the logic circuit or for each signal path of the logic circuit and which are stored in a delay library, the simulation is performed to a block including at least one cell, and a delay value varying dependent on a layout direction of the cell included in the block is used as the delay value in the delay library. By this method, timing verification can be performed according to the layout direction of each cell layouted on a wafer, attaining precise margin of the design and improving yield of the semiconductor integrated circuit.

Owner:PANASONIC CORP

Design support system

InactiveUS7133733B2Shorten the timeReduce manufacturing costSemiconductor/solid-state device manufacturingResourcesDesign support systemEngineering

The present invention relates to a design support system constructed so as to comprise a manufacturing line information preparation section and an output section. On the basis of element types selected by a selection section as arbitrary element types to be used for constituting a manufacturing line, the manufacturing line information preparation section prepares information about the manufacturing line by means of acquiring information about element types stored in an element type database beforehand. The output section can output the information about the manufacturing line prepared by the manufacturing line information preparation section. A manufacturing line including a plurality of steps is efficiently examined, determined, and established, thereby shortening the time required to design and manufacture the manufacturing line and curtailing manufacturing costs.

Owner:FUJITSU LTD

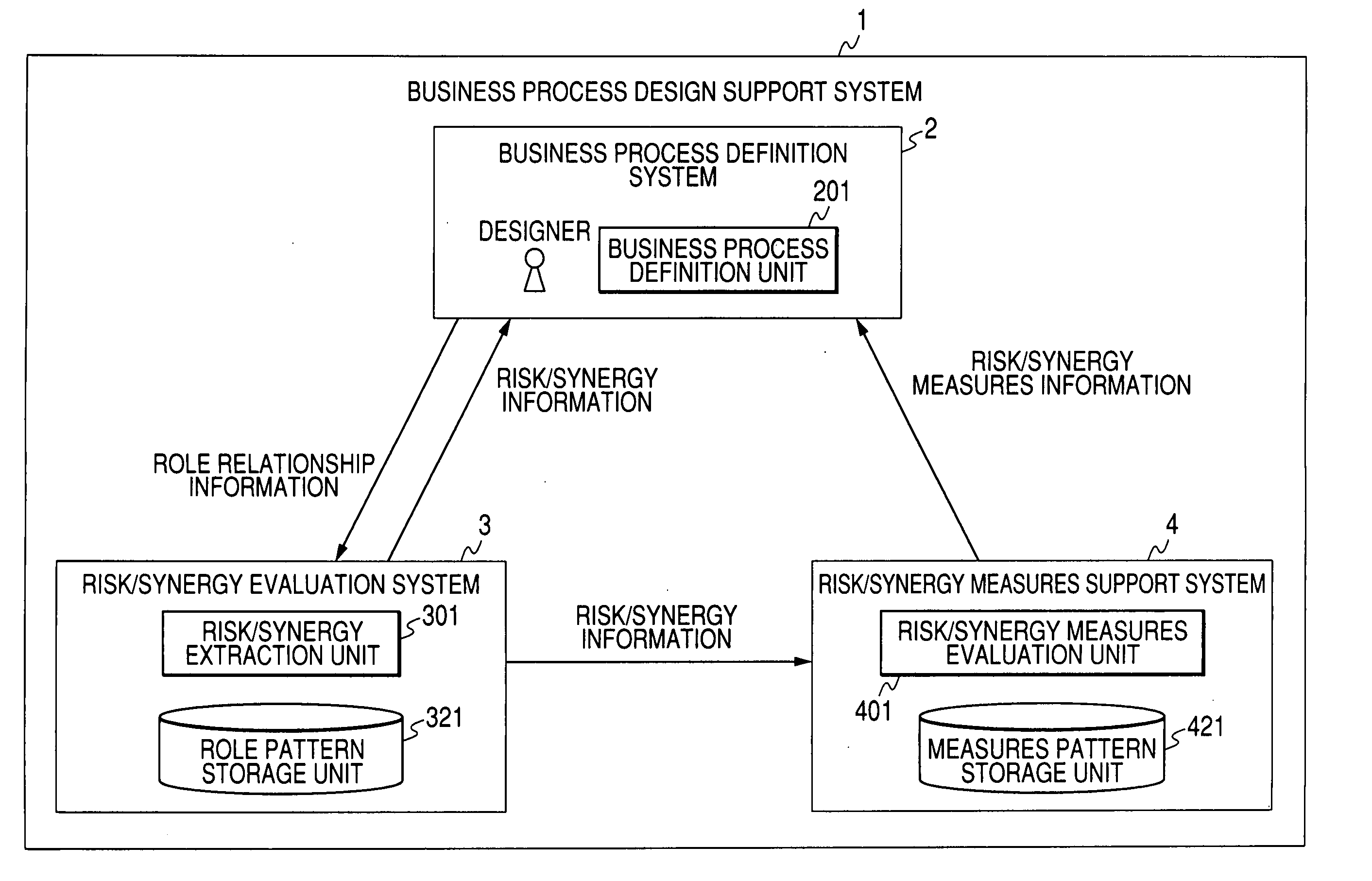

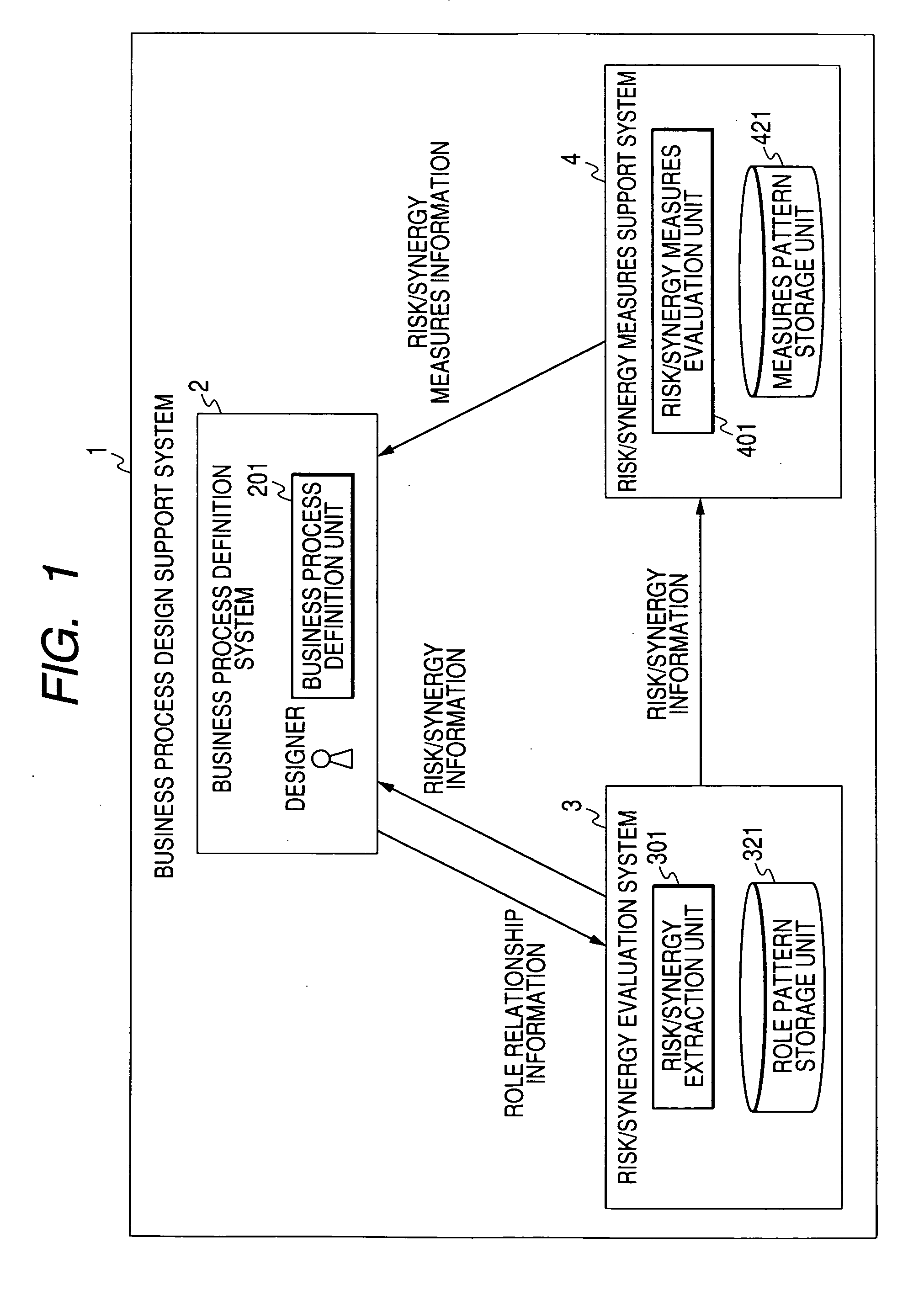

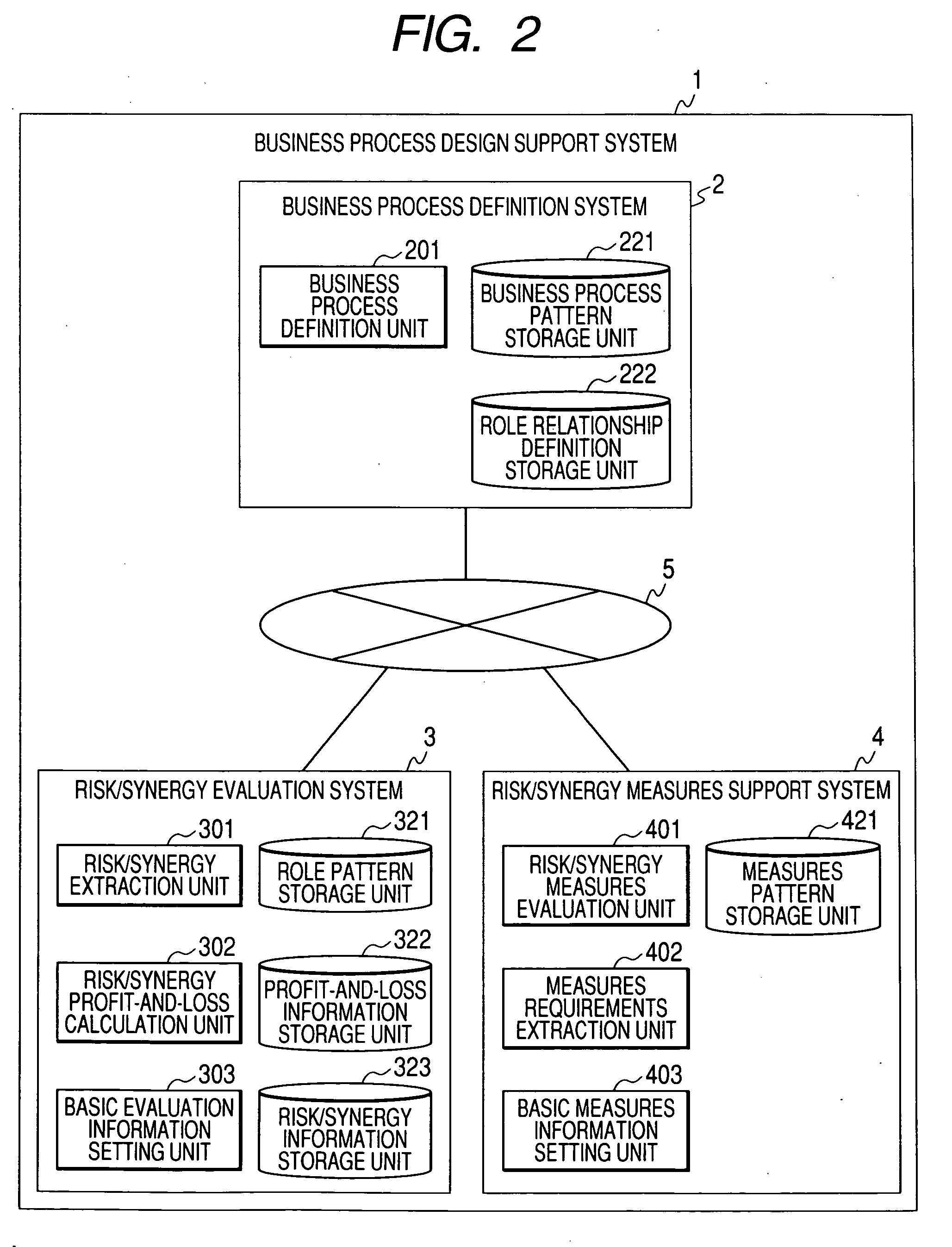

Method and system for supporting business process design by modeling role relationship

InactiveUS20070129979A1Improve balanceImprove reliabilityFinanceResourcesDesign support systemModeling role

The invention provides a method for extracting and evaluating risk information and synergy information arising out of role relationships among persons which are an essential part of a business process and realizing a safe and appropriate business process. A business process design support system in the invention includes: the business process definition unit 201 of the business process definition system 2 which receives role relationship information defined by a designer, etc. and transmits the information to the risk / synergy evaluation system 3; the risk / synergy extraction unit 301 which extracts risk / synergy factors and occurrence mechanism information based on the role relationship information; and a risk / synergy measures evaluation unit 401 which calculates risk / synergy measures candidates and estimated effects based on the risk / synergy factors and the occurrence mechanism information.

Owner:HITACHI LTD

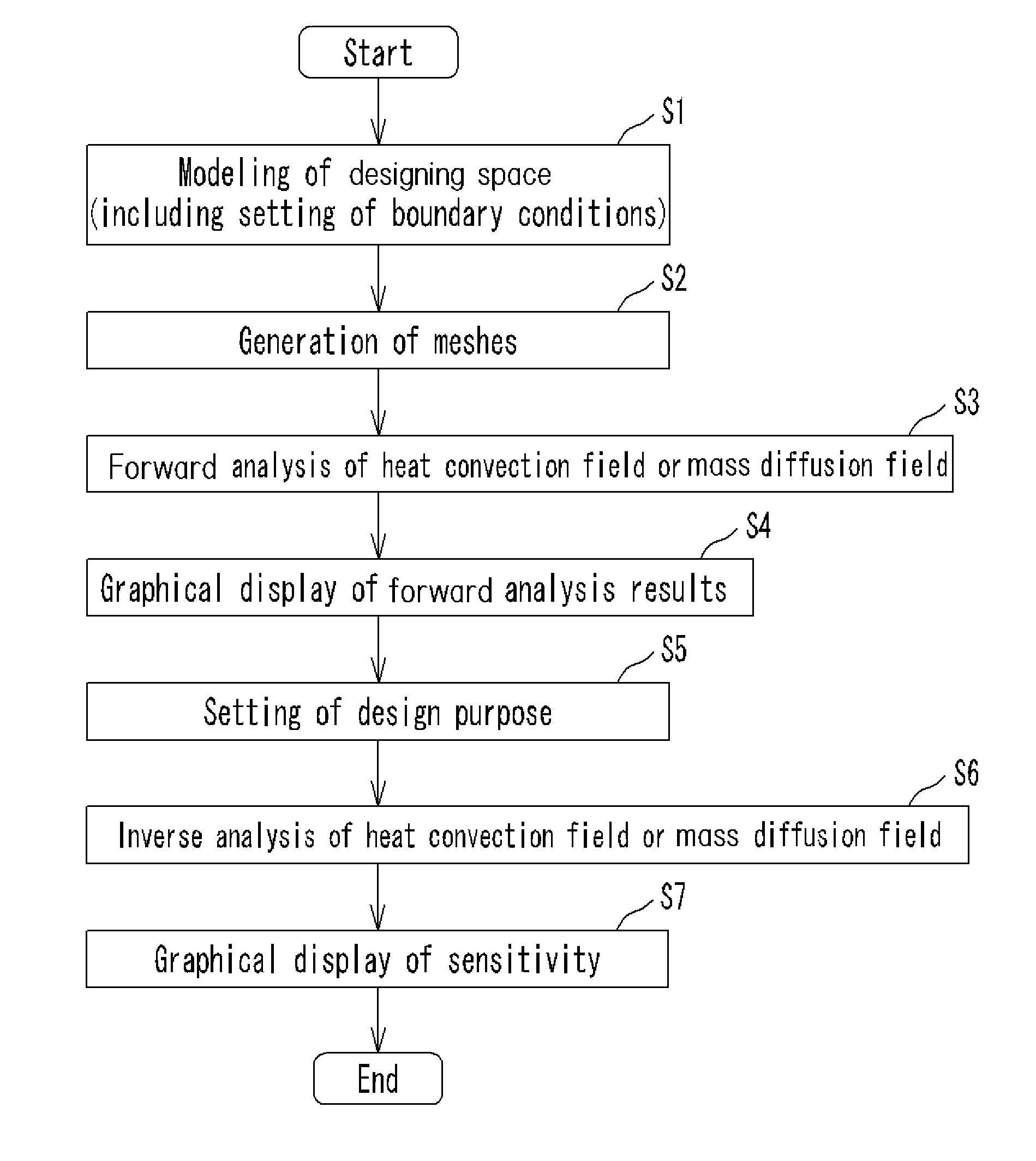

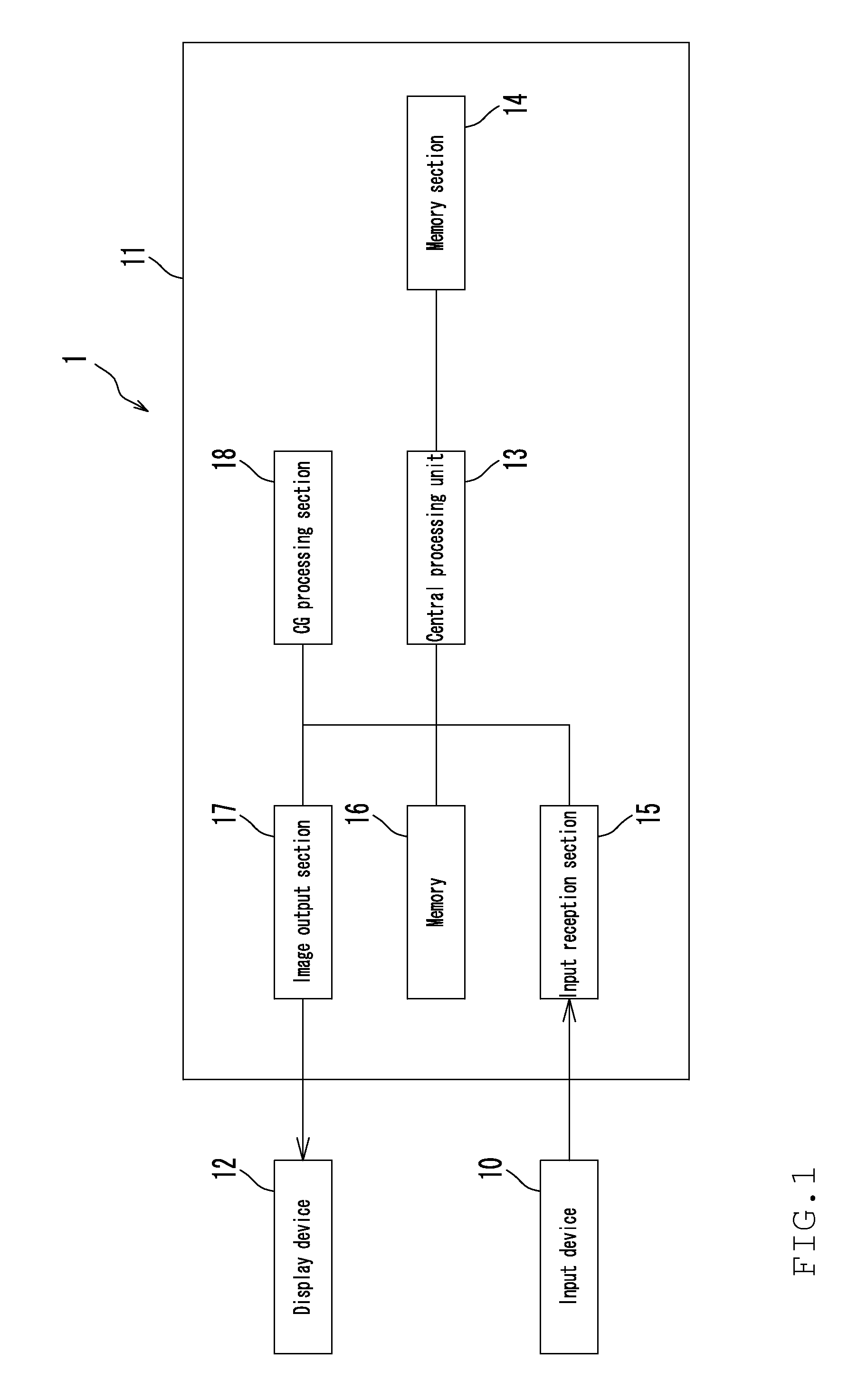

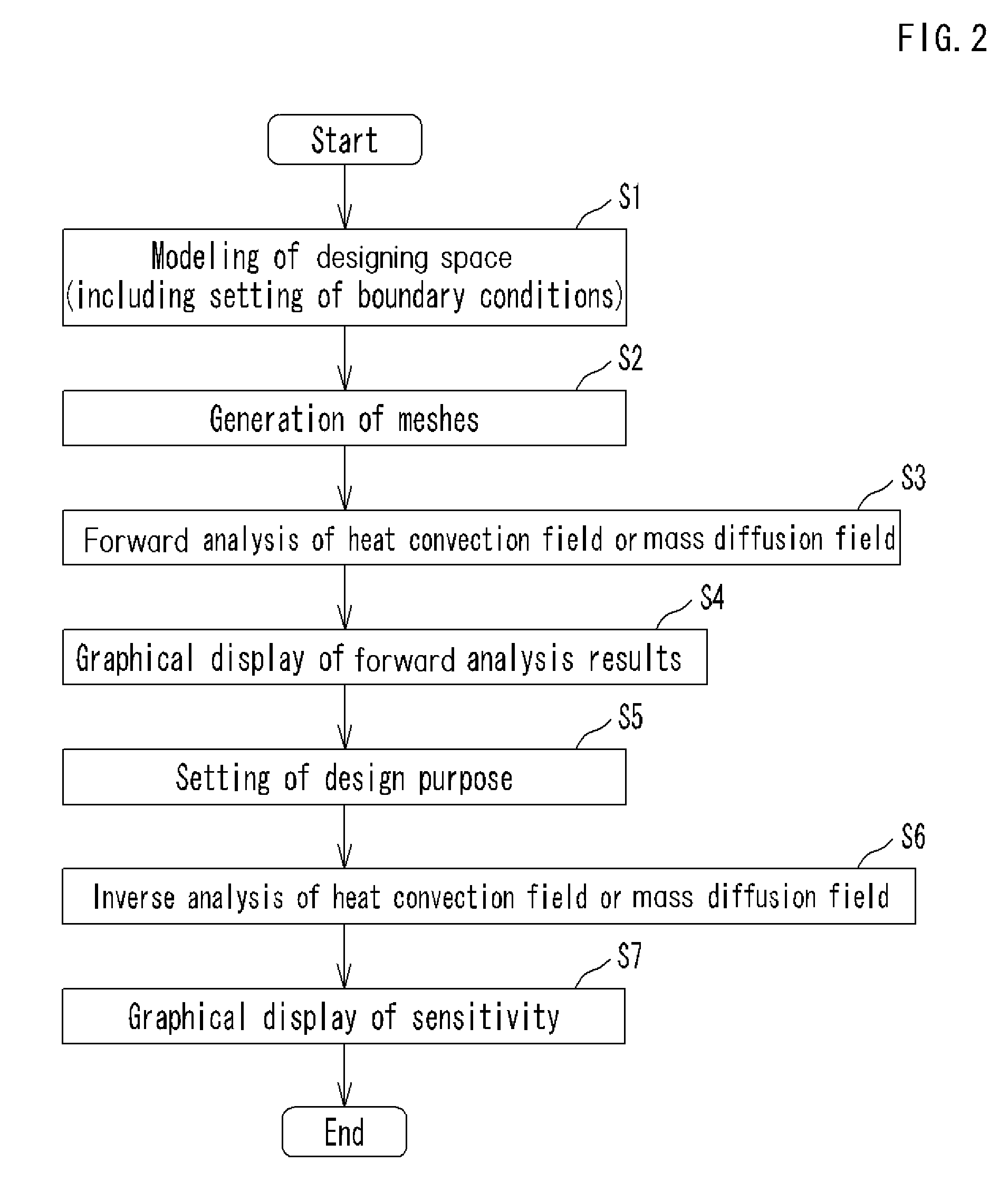

Design support method, design support system, and design support program for heat convection field

ActiveUS20090276193A1Reduces number of time of numericalShorten the timeGeometric CADDesign optimisation/simulationGraphicsDesign support system

A highly convenient design support method and design support system for a heat convection field or a mass diffusion field which significantly reduce the number of times of numerical simulation required to examine the designing parameters for achieving the design purpose. The design support method includes a forward analysis step of analyzing the heat convection field or the mass diffusion field by solving an equation of the heat convection field or the mass diffusion field based on an initially set value of a designing parameter, an inverse analysis step of analyzing a sensitivity defined by a change ratio of the design purpose to a designing parameter change by solving an adjoint equation corresponding to the design purpose based on the set design purpose, and a sensitivity display step of displaying information on the sensitivity analyzed by inverse analysis step as a graphic image on the display device.

Owner:OSAKA UNIV +1

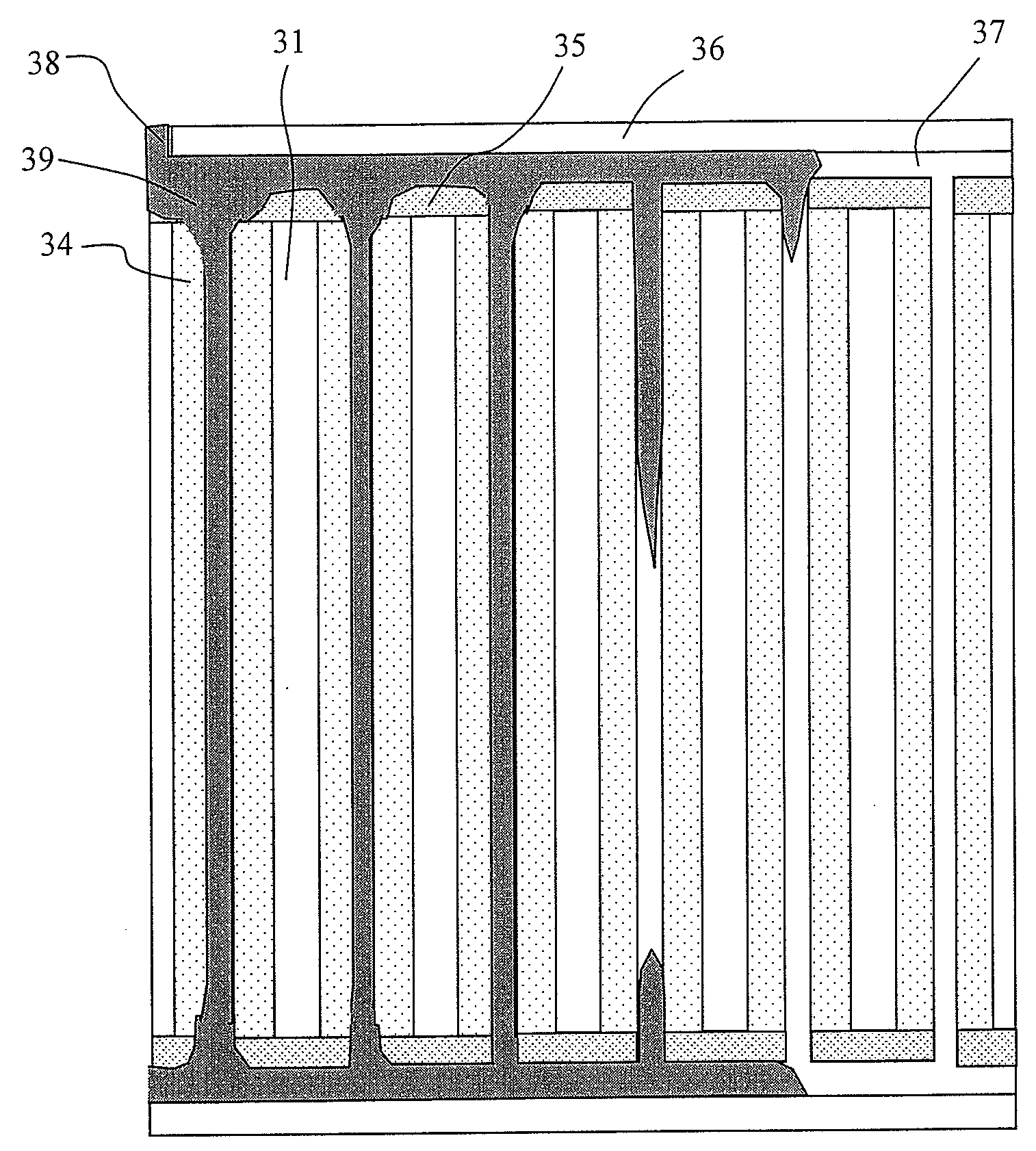

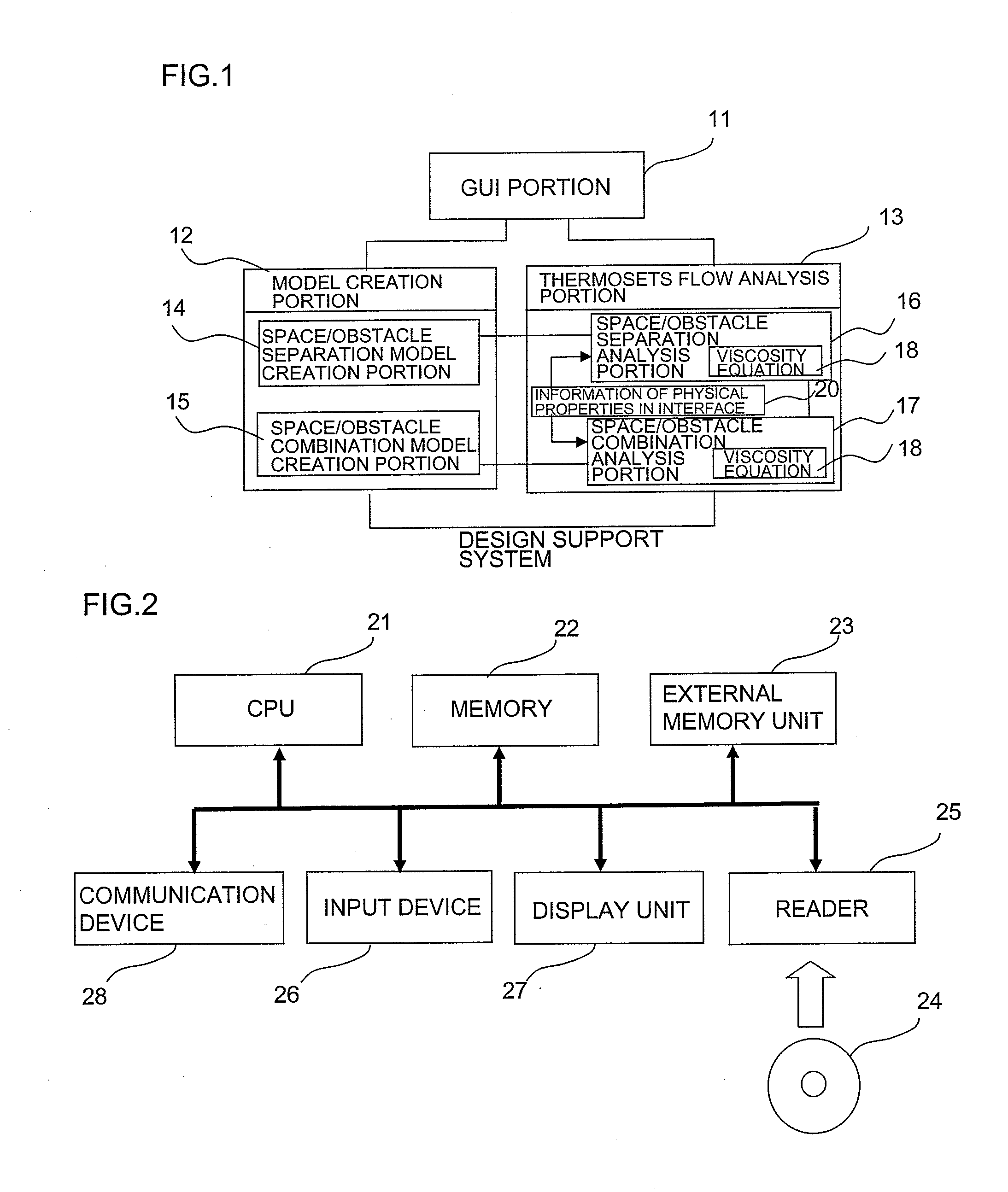

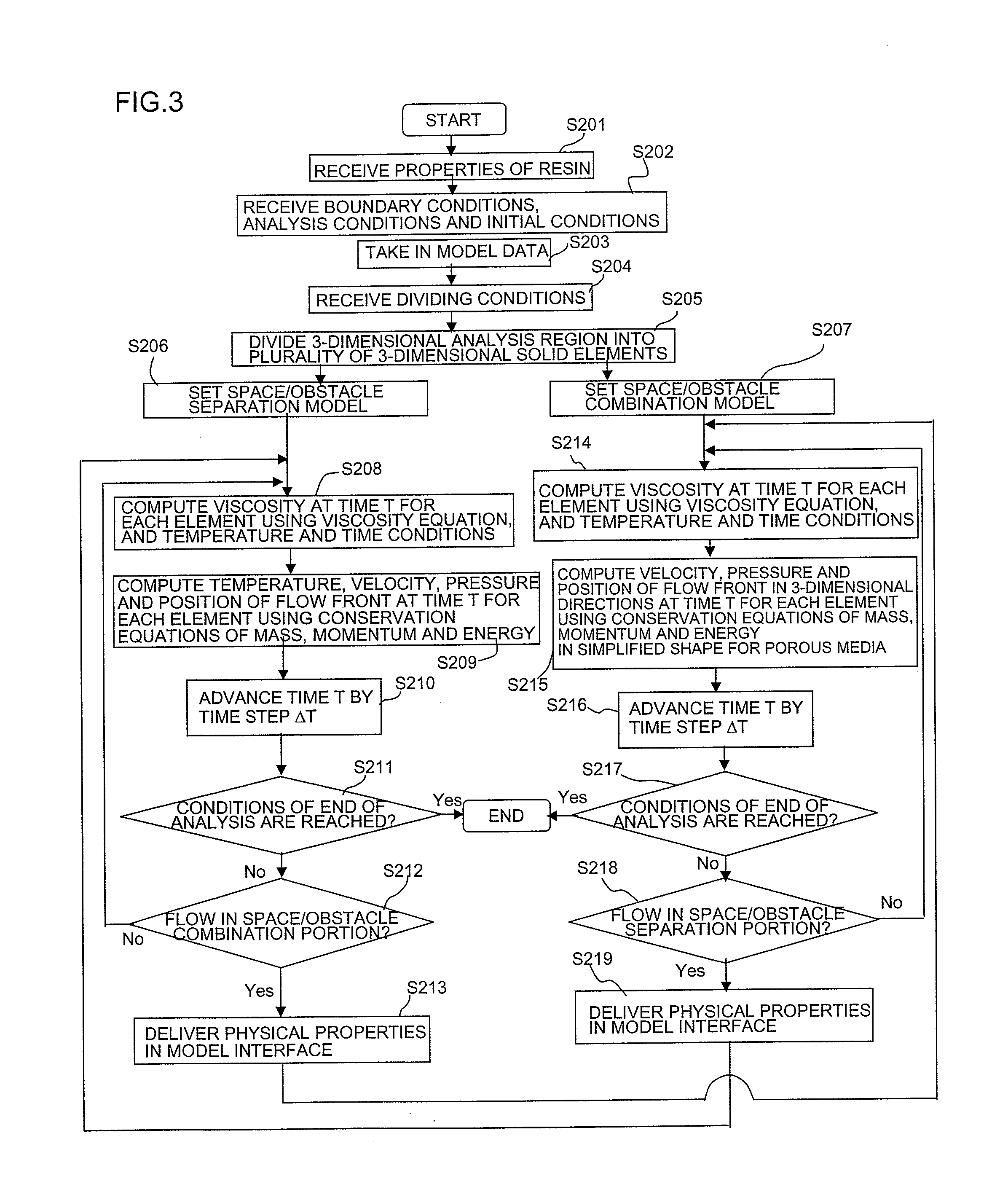

Design support system, support method and support program of resin molded article

ActiveUS20080234989A1Analysis method is simpleReduce computing timeWeather/light/corrosion resistanceComputation using non-denominational number representationMomentumPorous medium

To quick and accurately predict filling behavior at the time of injecting resin of thermosets molded articles having a complex obstacle. A model creation portion includes a space / obstacle separation model creation portion and a space / obstacle combination model creation portion. The space / obstacle combination model creation portion handles, as porous media, an obstacle in which narrow spaces are regularly arranged. A thermosets flow analysis portion includes a space / obstacle separation analysis portion and a space / obstacle combination analysis portion, and each of them has a viscosity equation for thermosets. The space / obstacle separation analysis portion analyzes by combining the viscosity equation with conservation equations of mass, momentum and energy, and the space / obstacle combination analysis portion analyzes by combining the viscosity equation with a conservation equation directed to a shape simplified as porous media. Resin flow behavior is analyzed while data in an interface between a space / obstacle separation model and a space / obstacle combination model is delivered to each other.

Owner:HITACHI LTD

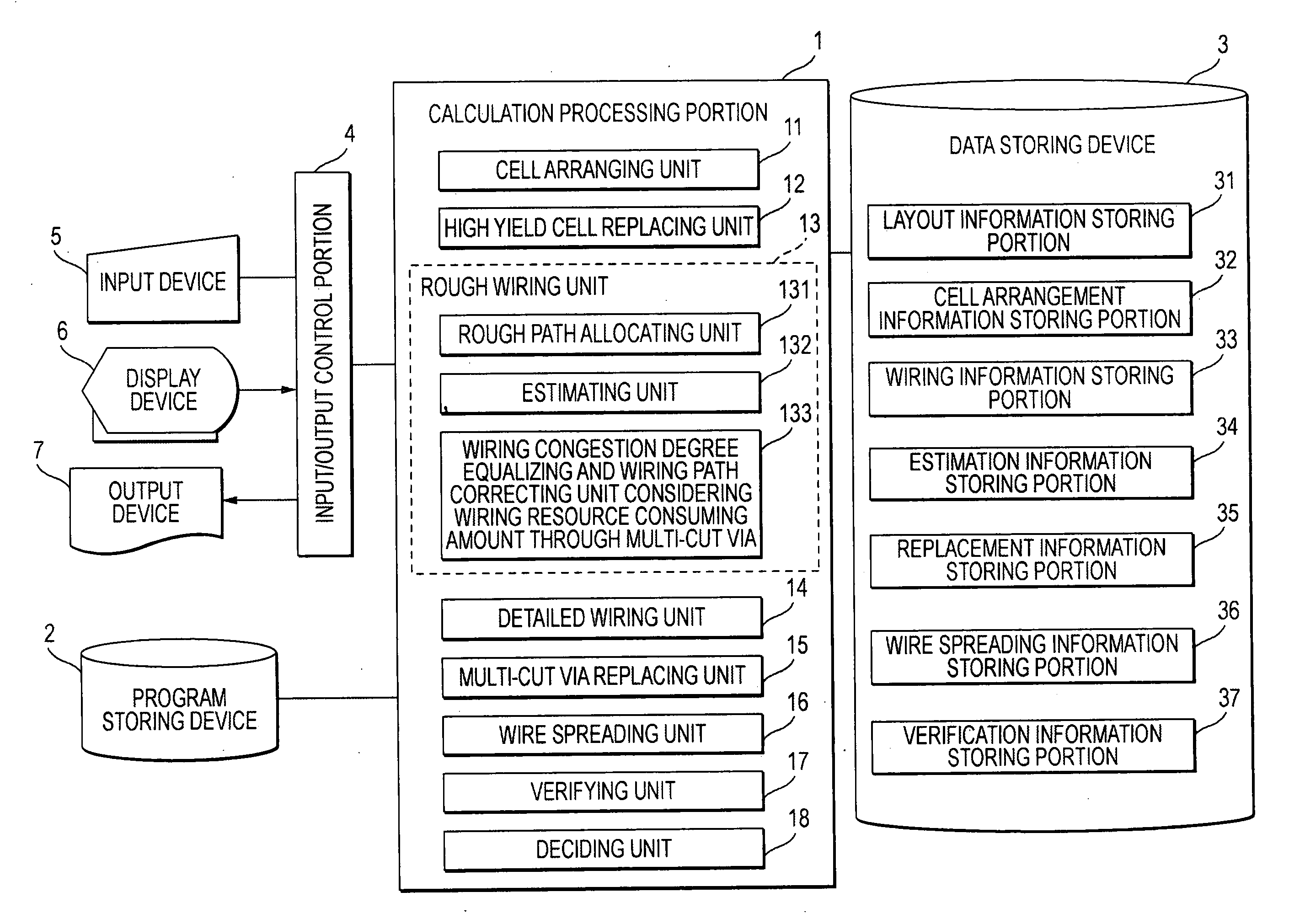

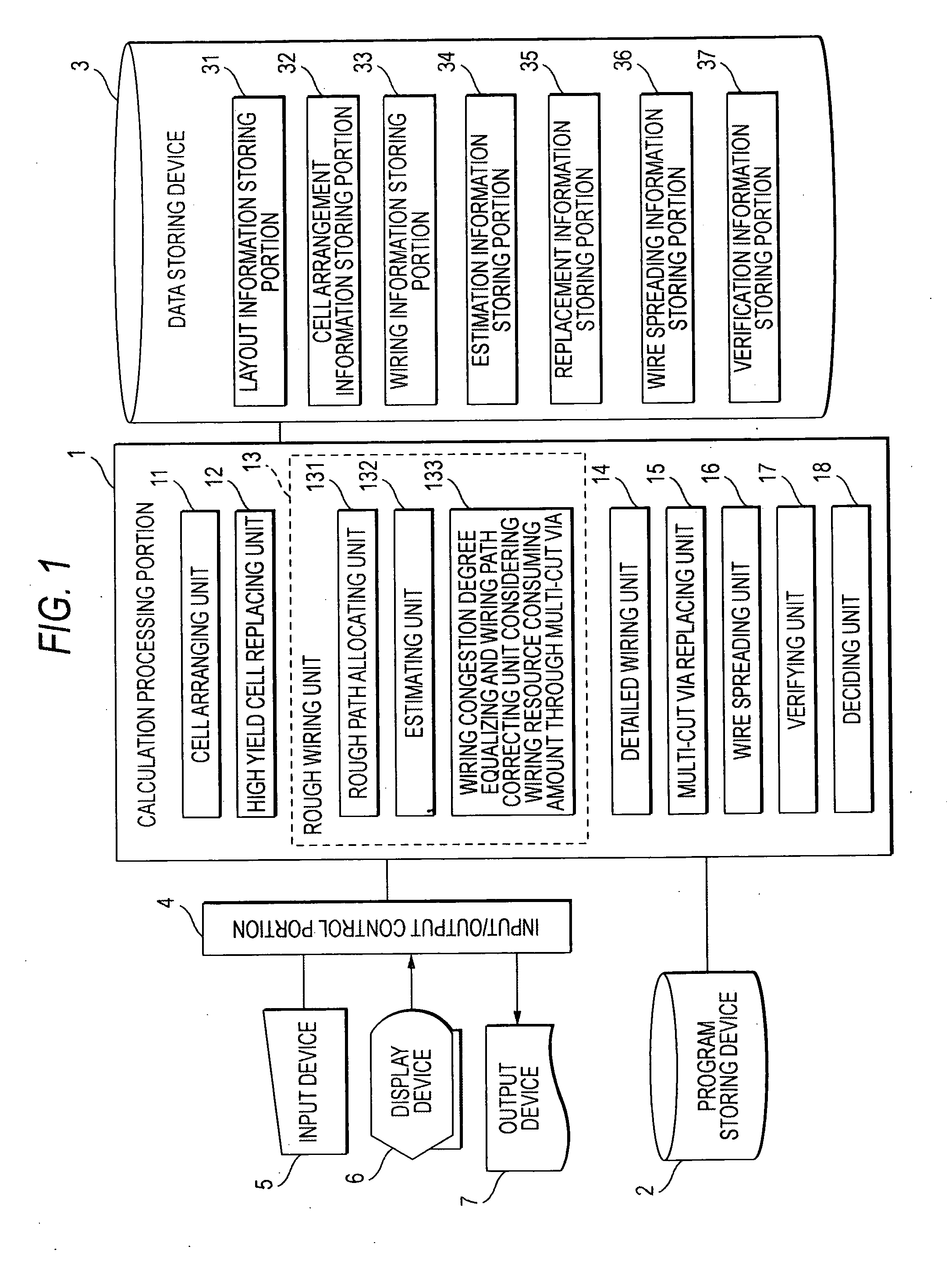

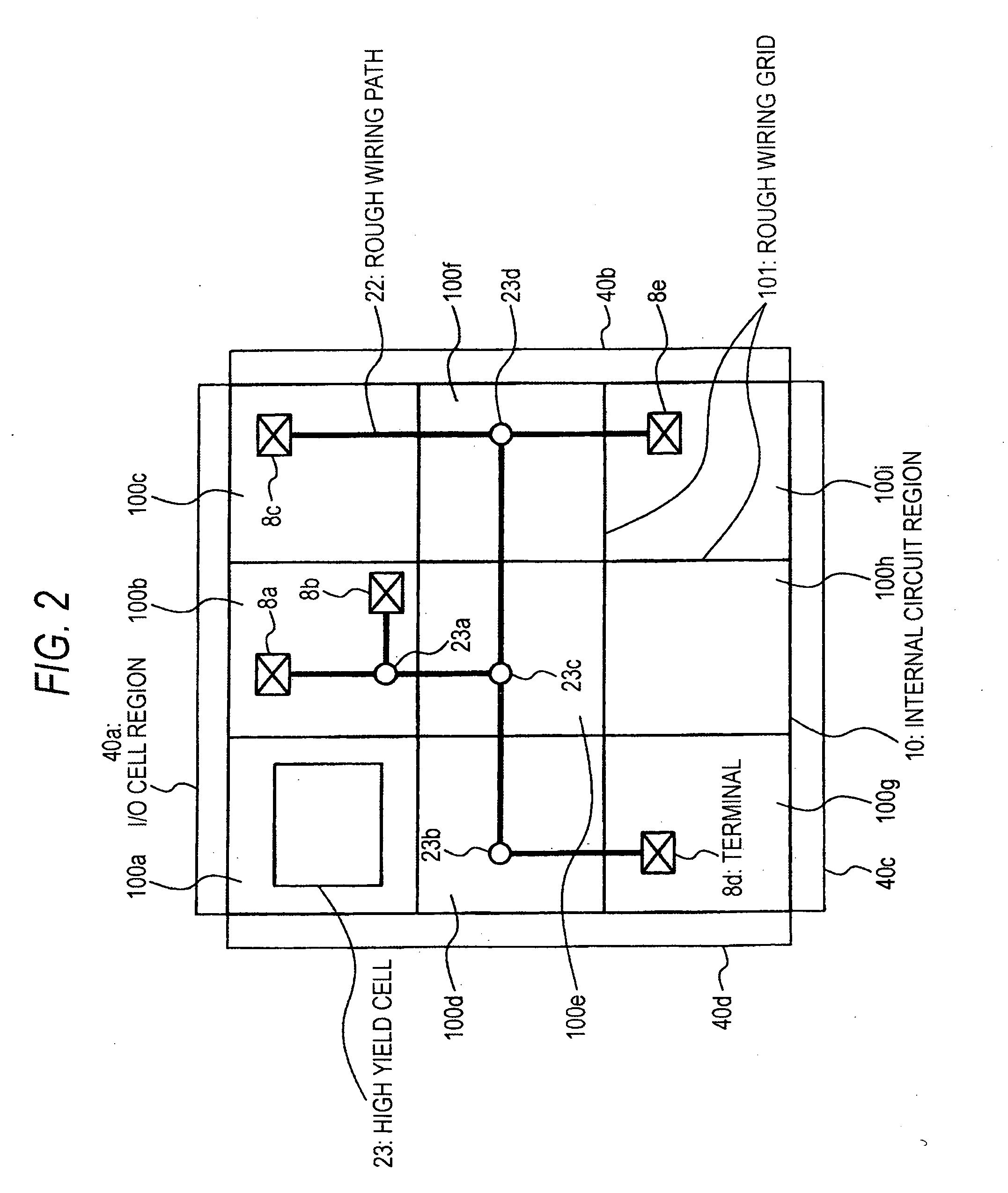

Design support system of semiconductor integrated circuit, method of designing semiconductor integrated circuit, design support program of semiconductor integrated circuit and method of manufacturing semiconductor integrated circuit

InactiveUS20070162882A1Computer aided designSoftware simulation/interpretation/emulationDesign support systemEngineering

According an aspect of the invention, there is provided a design support system of a semiconductor integrated circuit includes: a first unit configured to determine a wiring path by calculating wiring resource consuming information for carrying out a connection through a multi-cut via in case that the connection is carried out through the multi-cut via in a wiring region having a plurality of layers; and a second unit configured to replacing a single-cut via into the multi-cut via.

Owner:KK TOSHIBA

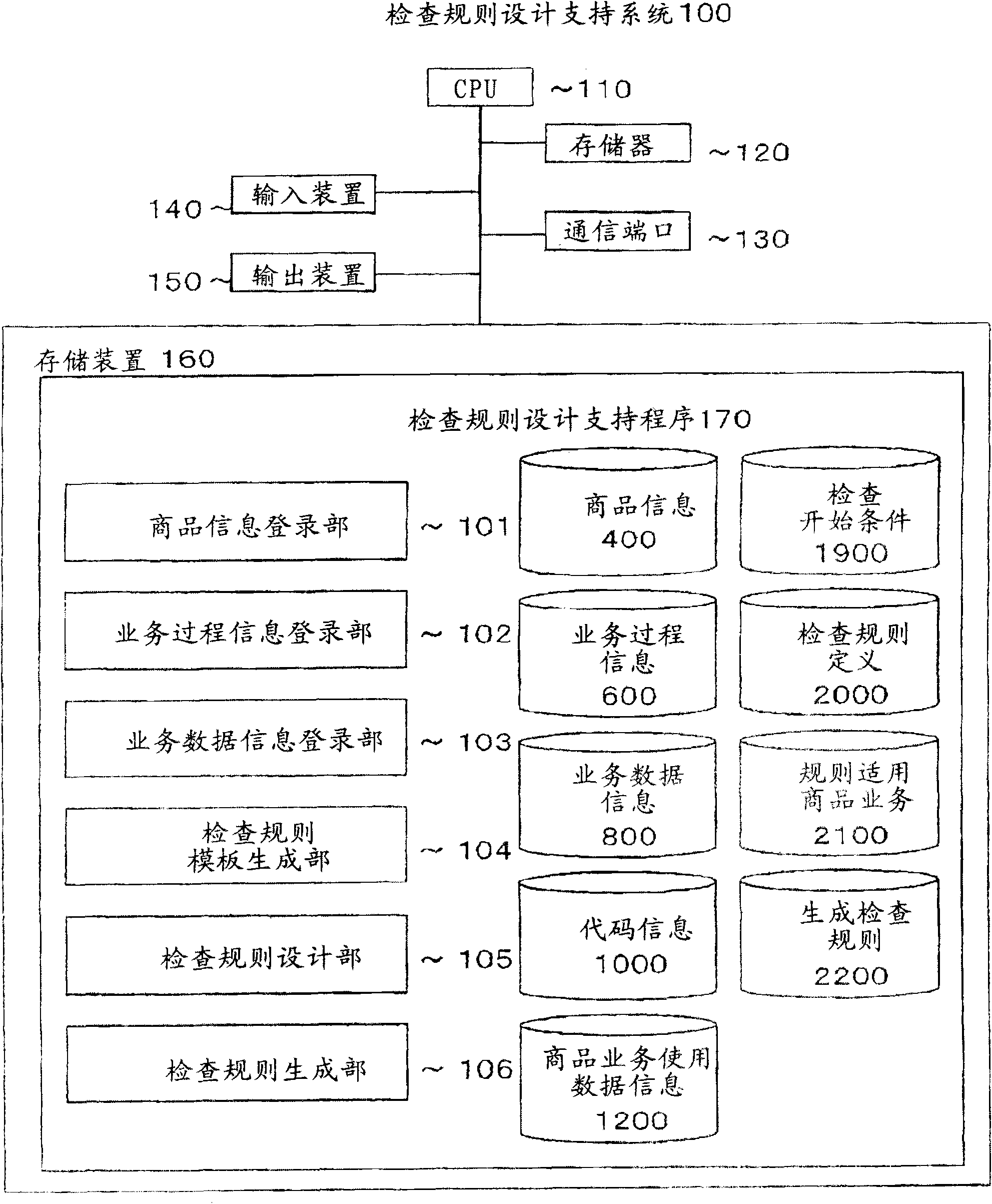

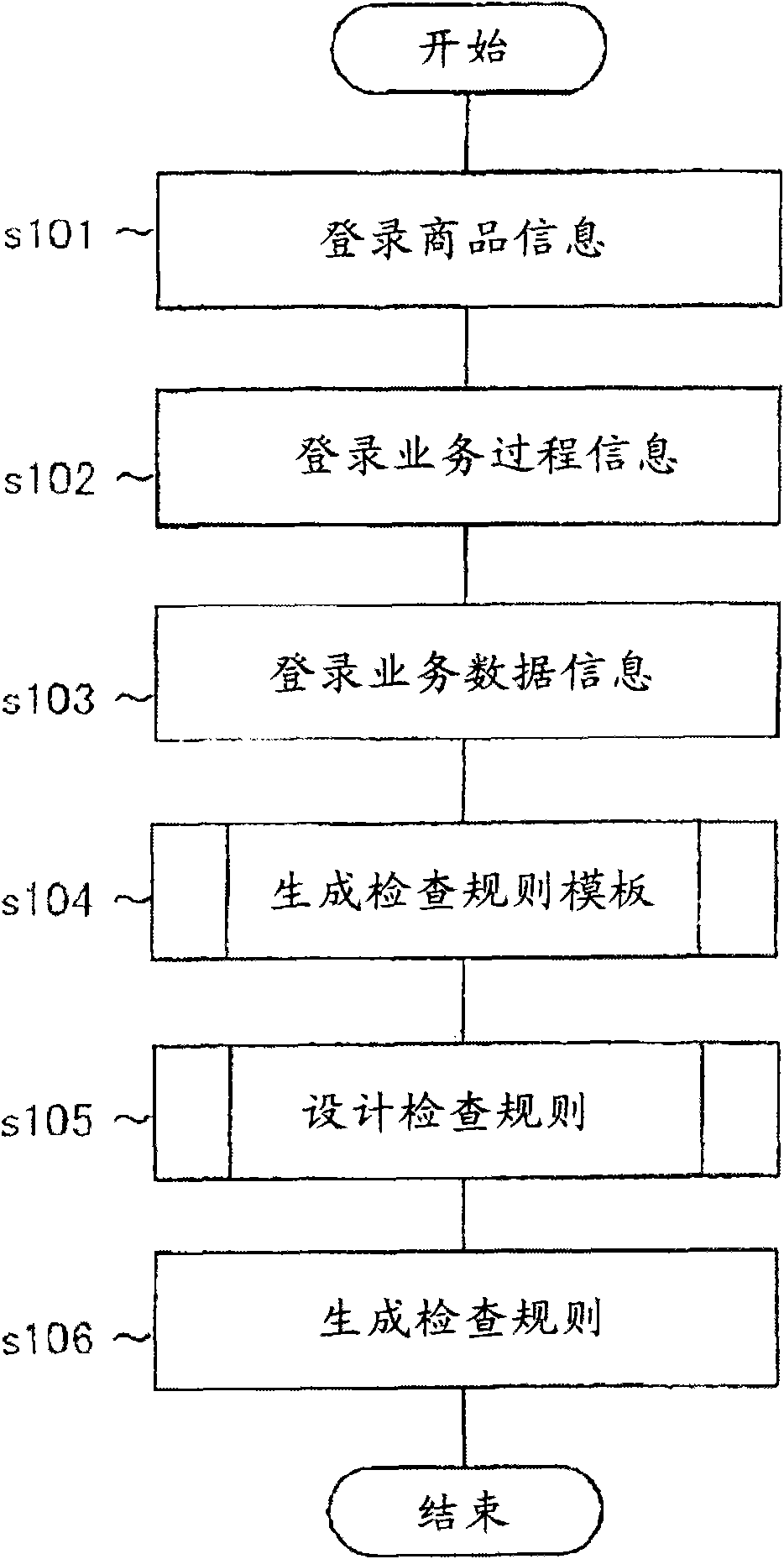

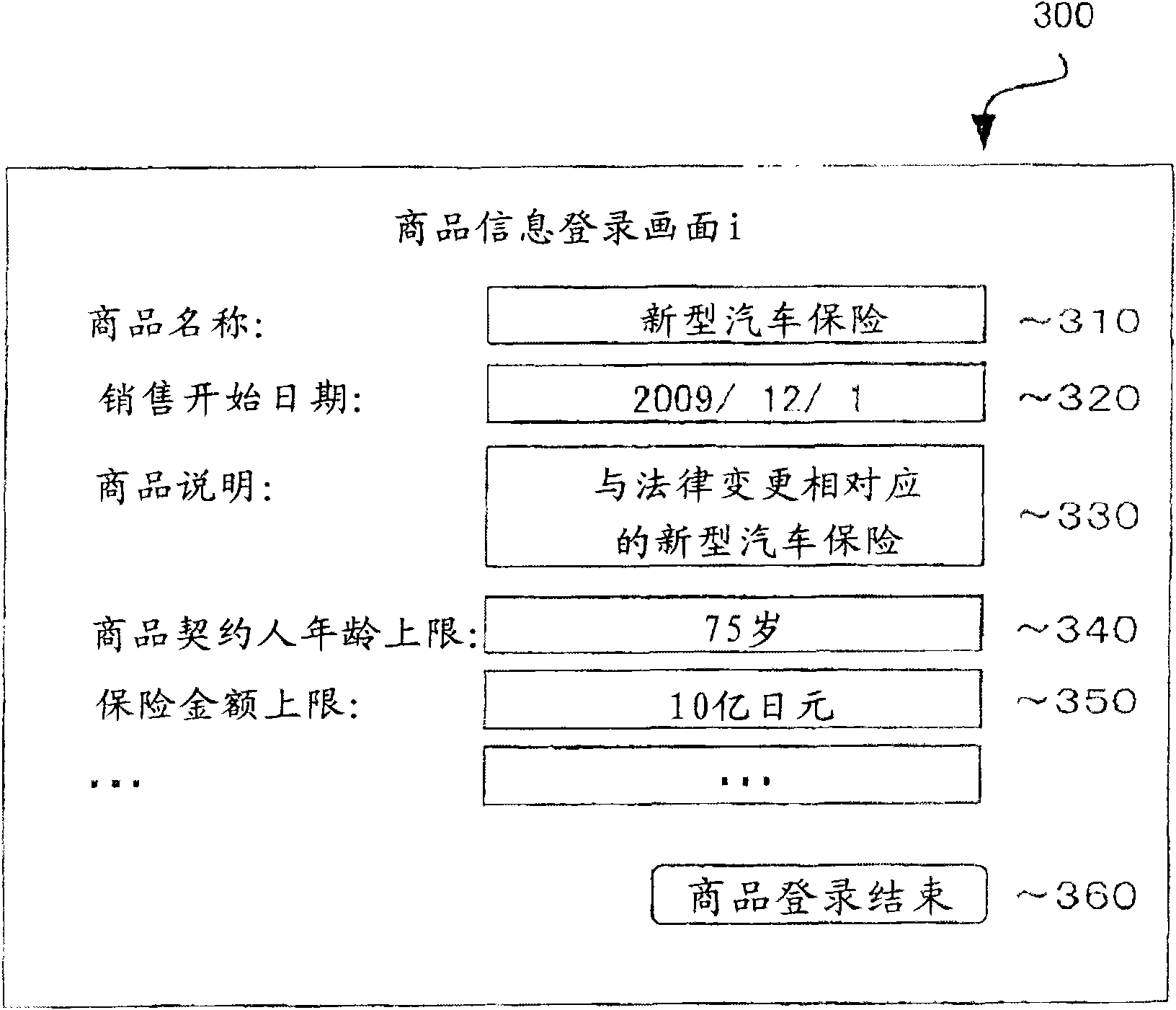

Inspection rule design support method, system and program

The invention provides an inspection rule design support method, a system and a program thereof, wherein the high efficiency of the definition and generation of inspection rules is realized.The system of the invention comprises a goods information registering part (101) for receiving and registering the goods information, a business process information registration part (102) for receiving and registering the business process information,a service data information registration part (103) for receiving and registering the service data information,an inspection rule template generation part (104) for generating and storing the inspection rule template, and an inspection rule design part (105) for receiving the service data used in predetermined goods or a predetermined service in a first region representing the inspection rule template and storing the received comparison value and comparison operators as inspection rules in a second region.

Owner:HITACHI LTD +1

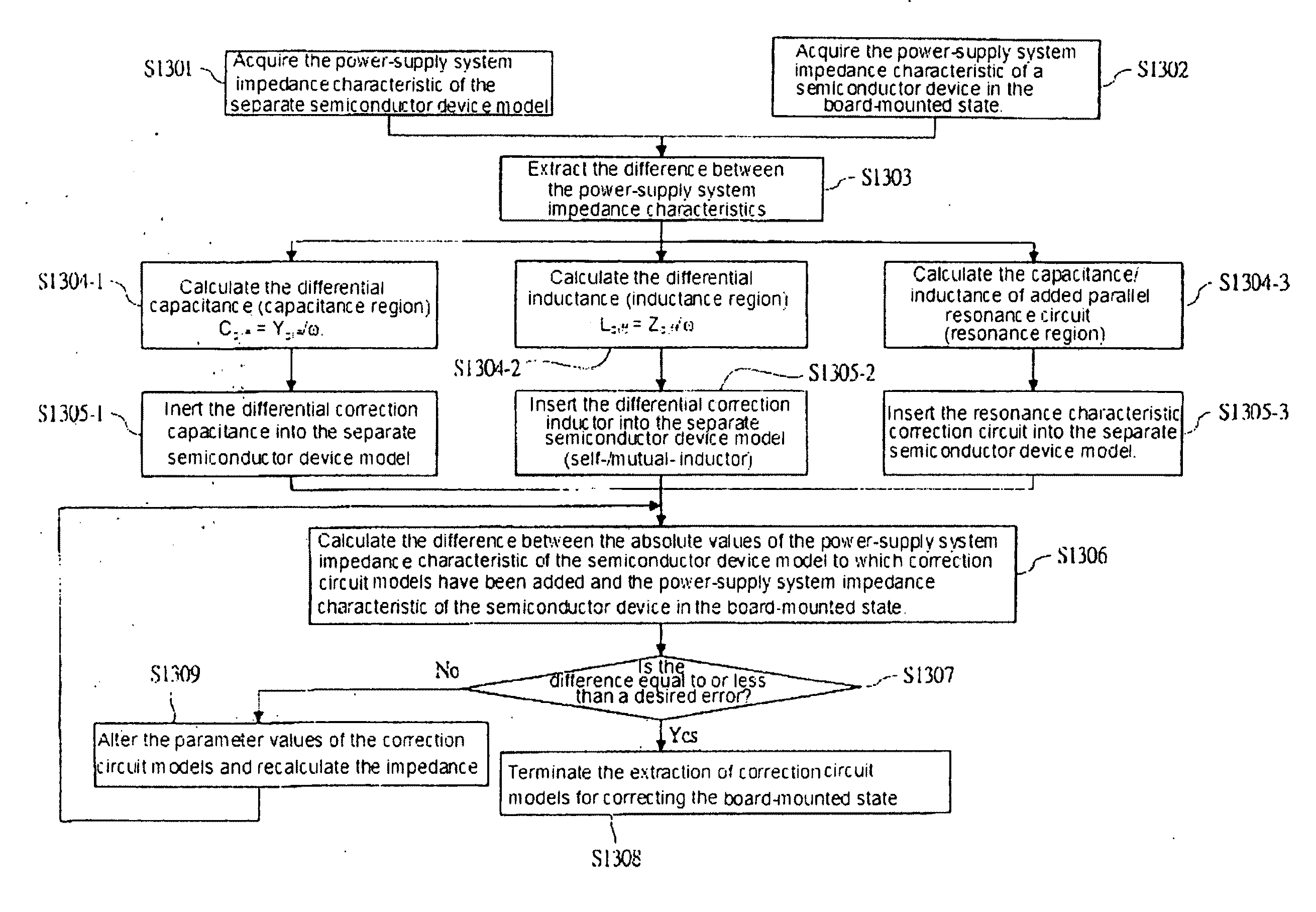

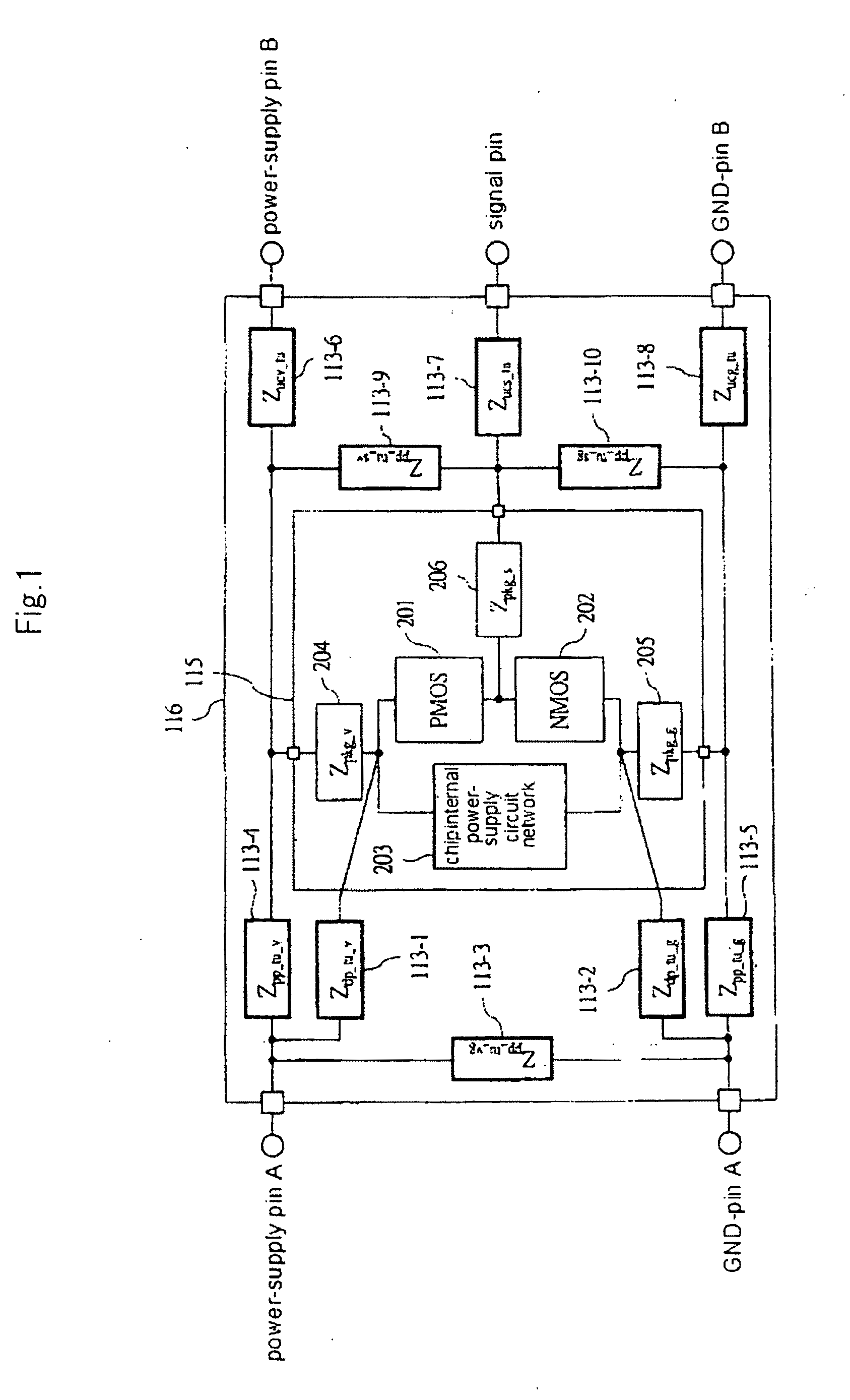

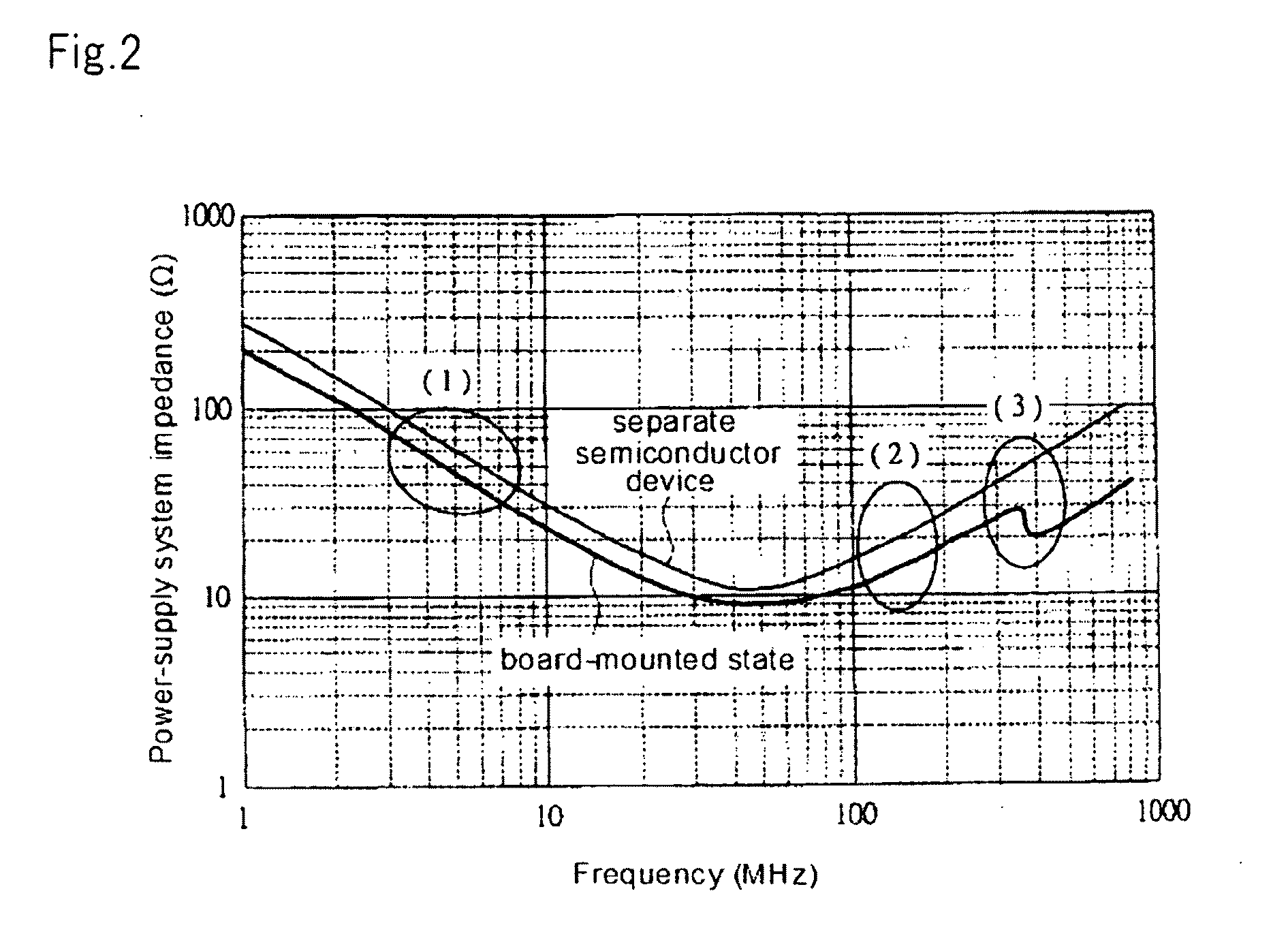

Semiconductor device or printed wiring board design method and design support system that implements settings by using a semiconductor device model that expresses parasitic elements that occur when packaged

InactiveUS20090327981A1Detecting faulty computer hardwareComputer designed circuitsElectricityDesign support system

Correction circuit models are acquired for correcting electrical characteristic parameters that change upon mounting on a board. The correction circuit models are added to a separate model that represents a separate semiconductor device in isolation to create a semiconductor device model that represents the semiconductor device in a board-mounted state. An equivalent circuit model that represents an adjustment-object system is connected to the semiconductor device model that was created, and based on the semiconductor device model to which the equivalent circuit model is connected, adjustment-object values relating to the adjustment-object system are calculated. These adjustment-object values are compared with limit values that were determined in advance, and based on the results of comparison, a design guide is determined for adjusting the adjustment-object system.

Owner:ELPIDA MEMORY INC

Mesh generation system, design support system, analysis system, analysis method, mesh generation method, and storage medium and program transmission apparatus therefor

InactiveUS20020042697A1Detecting faulty computer hardwareComputation using non-denominational number representationComputer graphics (images)Design support system

It is one object of the present invention to form a conventional mesh as a sample in order to efficiently generate a high-quality mesh for a predetermined shape model. A mesh generation system 10 for generating a mesh used for finite element analysis comprises: a mesh characteristic extraction unit 11 for receiving a conventional mesh and extracting a characteristic therefrom; and a mesh generator 13 for receiving a target shape model for mesh generation, and for generating a mesh for the shape model based on the characteristic of the conventional mesh extracted by the mesh characteristic extraction unit 11.

Owner:IBM CORP

Defect influence degree evaluation method and design support system

At a stage before manufacture (product design stage or manufacturing process design stage), influence of defect occurrence in a component or process on other components and processes is estimated, and defect importance is evaluated to support the manufacturing process design. Failure rates of components are previously stored in a database. At a product design stage, an assembly fraction defective is calculated for an assembly process of each component of the product. Component arrangement relations are extracted from product design information. A component fraction defective is calculated based on the assembly fraction defective and the component failure rate. A numerical value indicating an influence degree of each assembly process is calculated by multiplying component fraction defectives by coefficients based on of the component arrangement relations and the component fraction defective, for relating components in each assembly process. Thereby, influence degrees of each component and process are evaluated.

Owner:HITACHI LTD

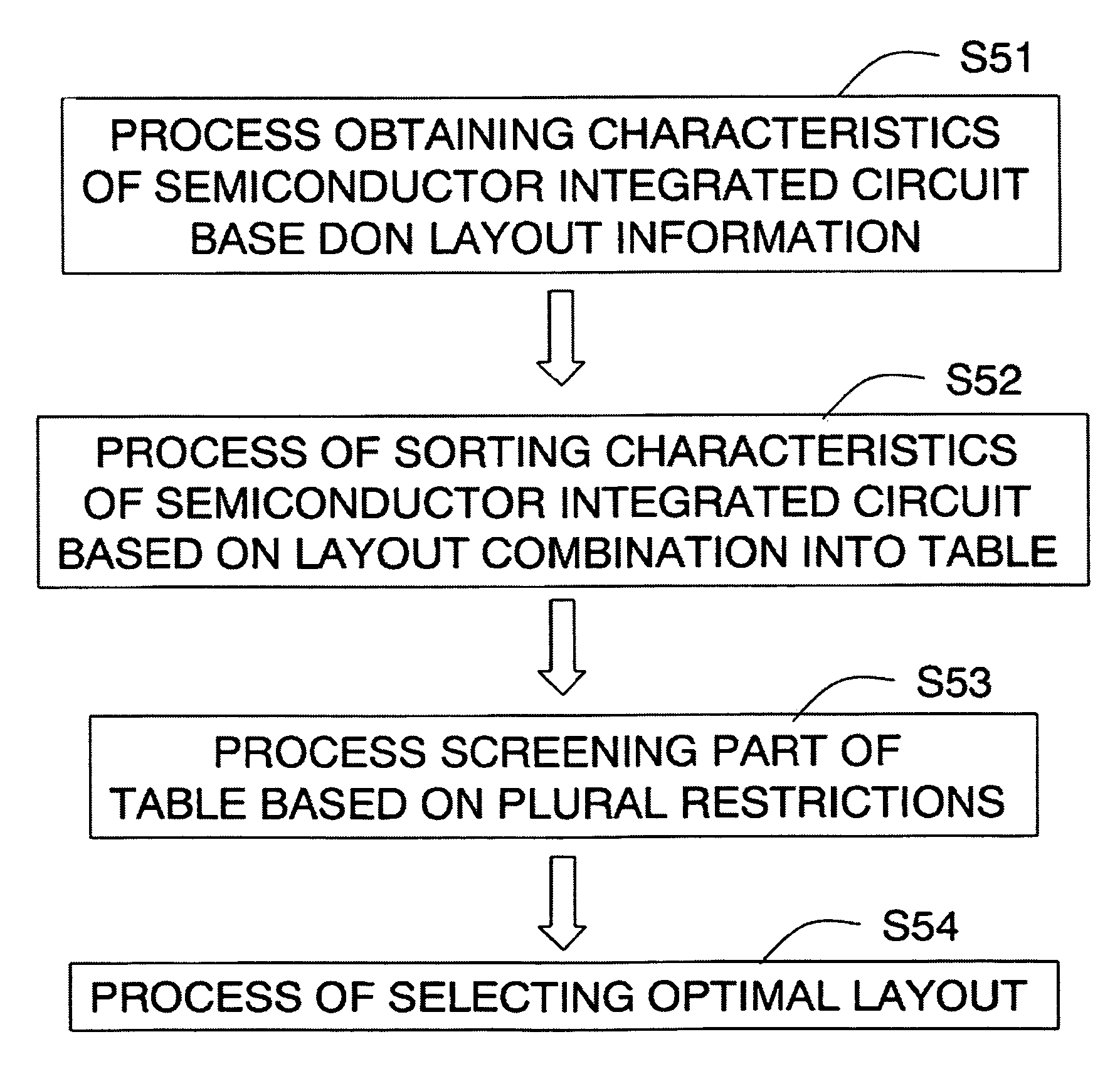

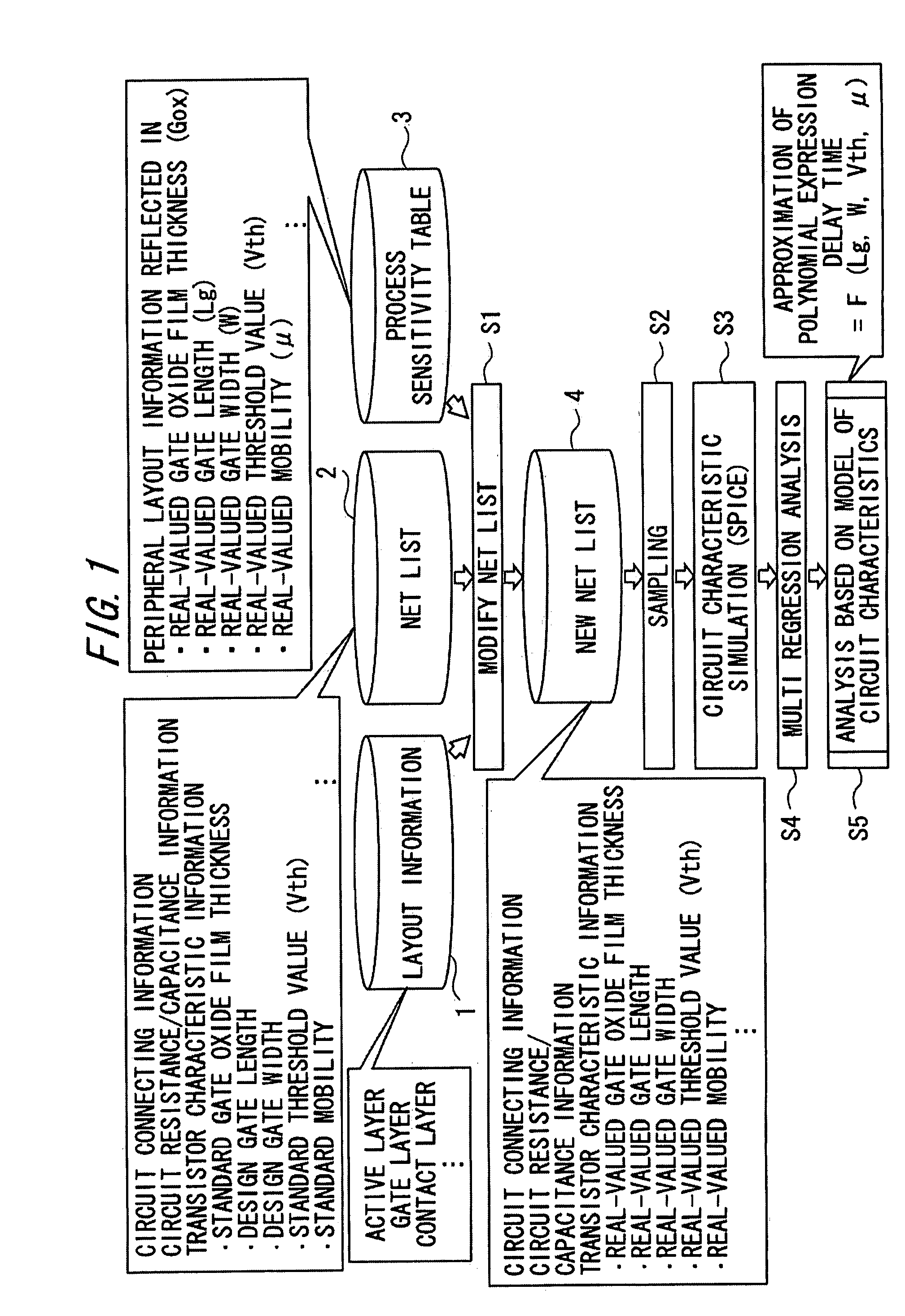

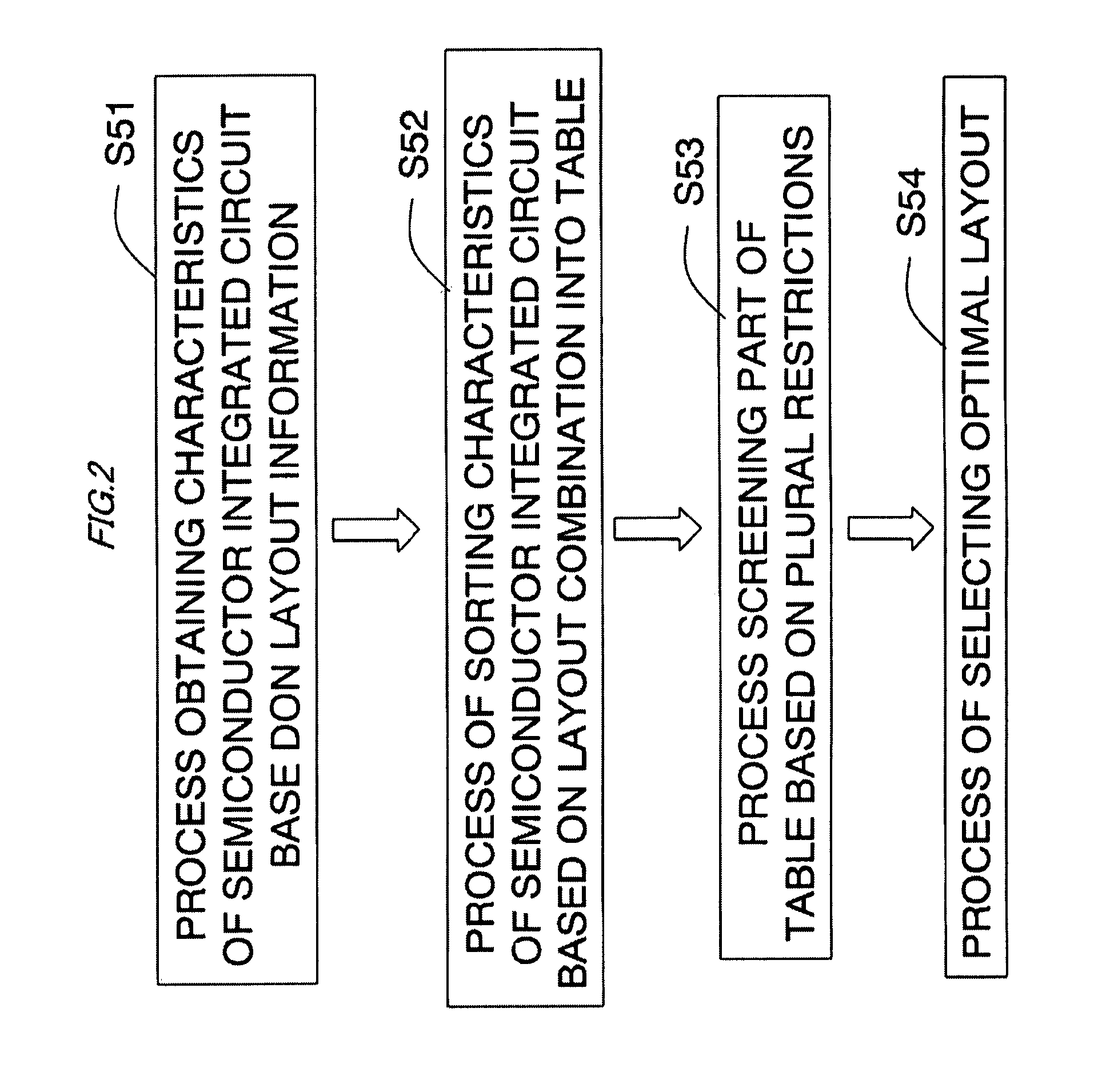

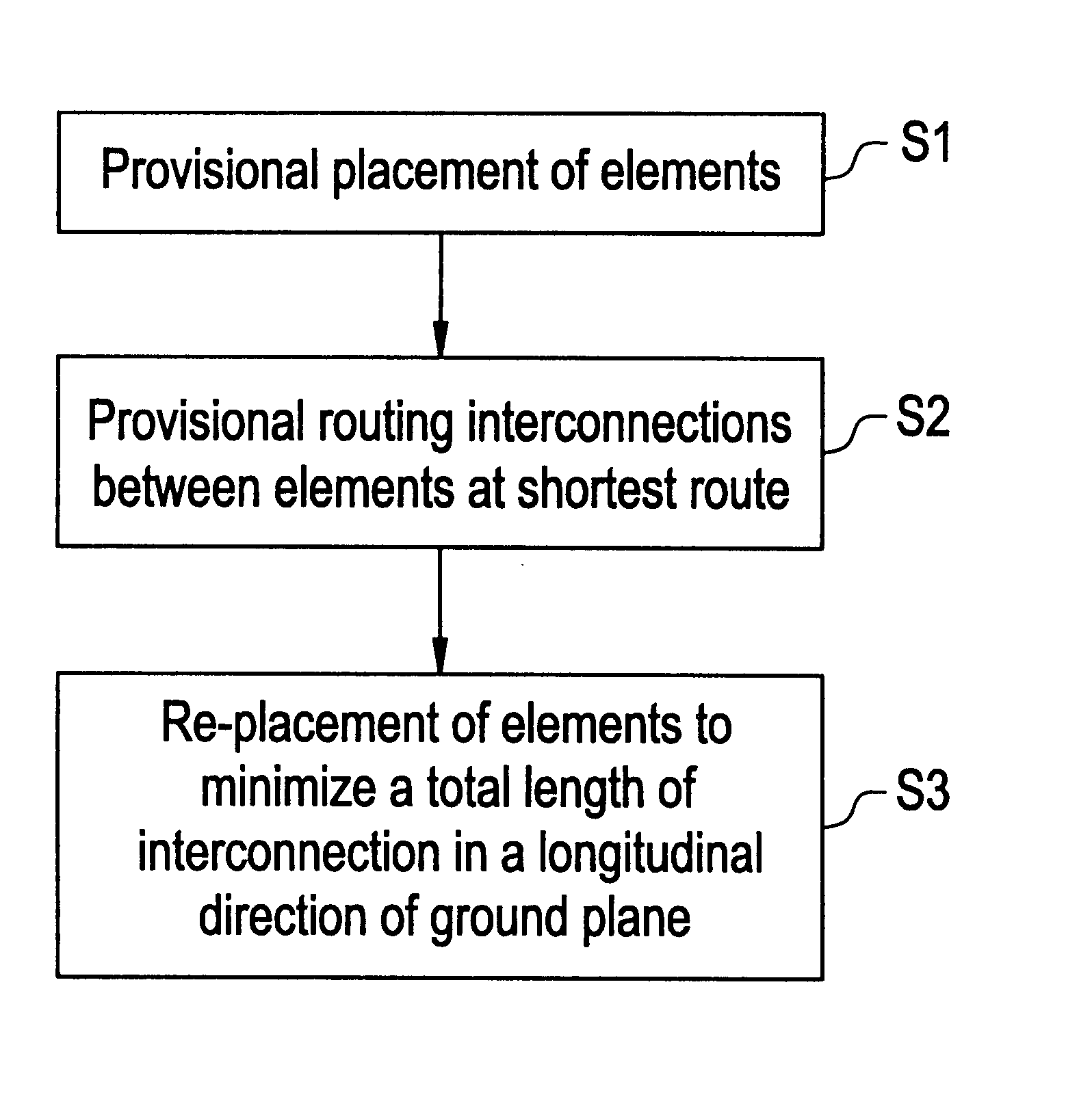

Layout method of semiconductor circuit, program and design support system

InactiveUS7934178B2CAD circuit designSpecial data processing applicationsDesign support systemSemiconductor

A method of a layout a semiconductor circuit has obtaining transistor characteristic information on the basis of layout information about regions formed with transistors, obtaining a polynomial expression representing a relationship between characteristic values of a circuit including of the transistors and the transistor characteristic information, calculating a plurality of characteristic values corresponding to plural sets of transistor characteristic information by use of the polynomial expression, selecting part of the plurality of characteristic values on the basis of a restriction about the characteristic values, the layout information or the transistor characteristic information; and obtaining the transistor characteristic information or the layout information corresponding to the selected characteristic values.

Owner:SOCIONEXT INC

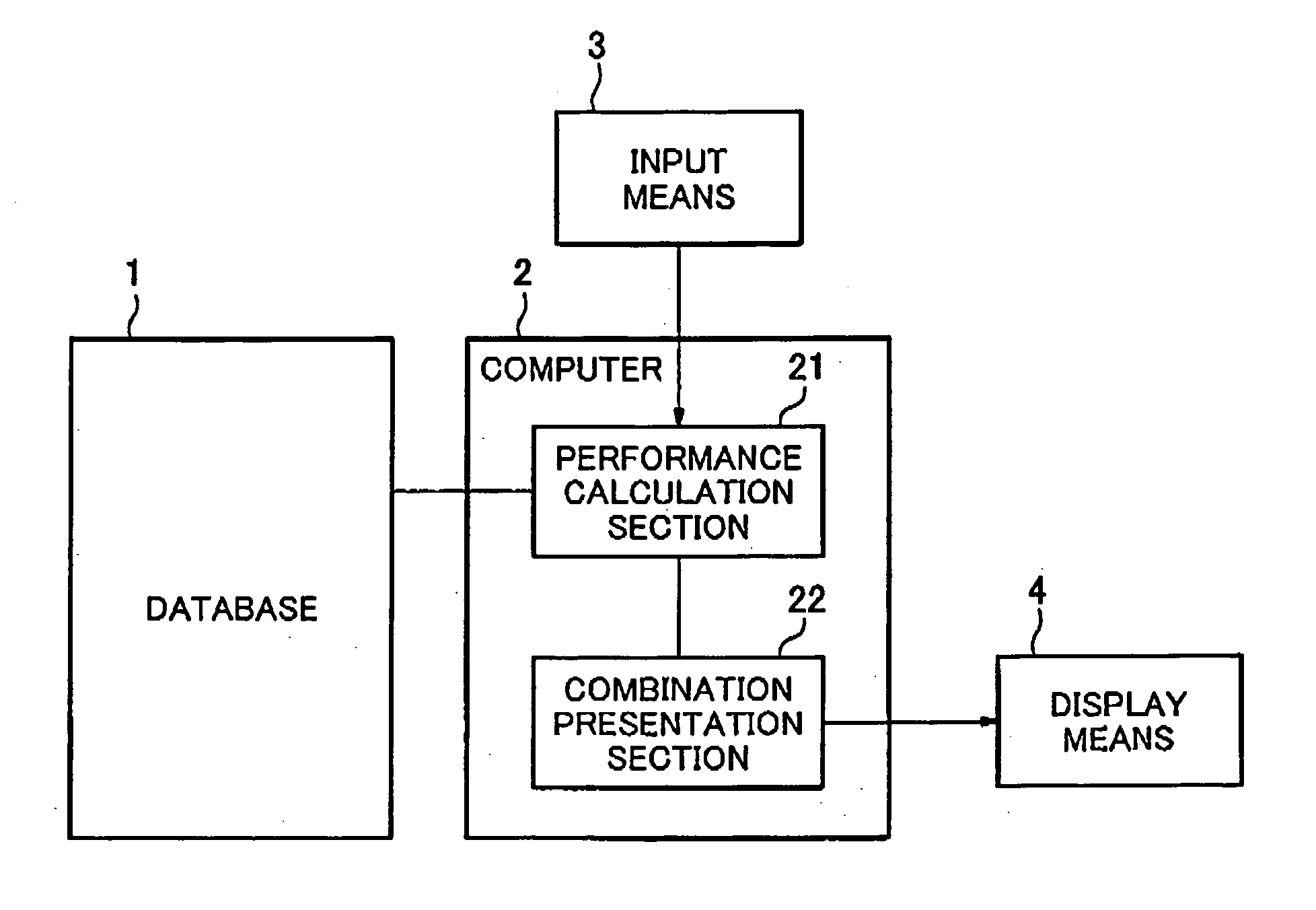

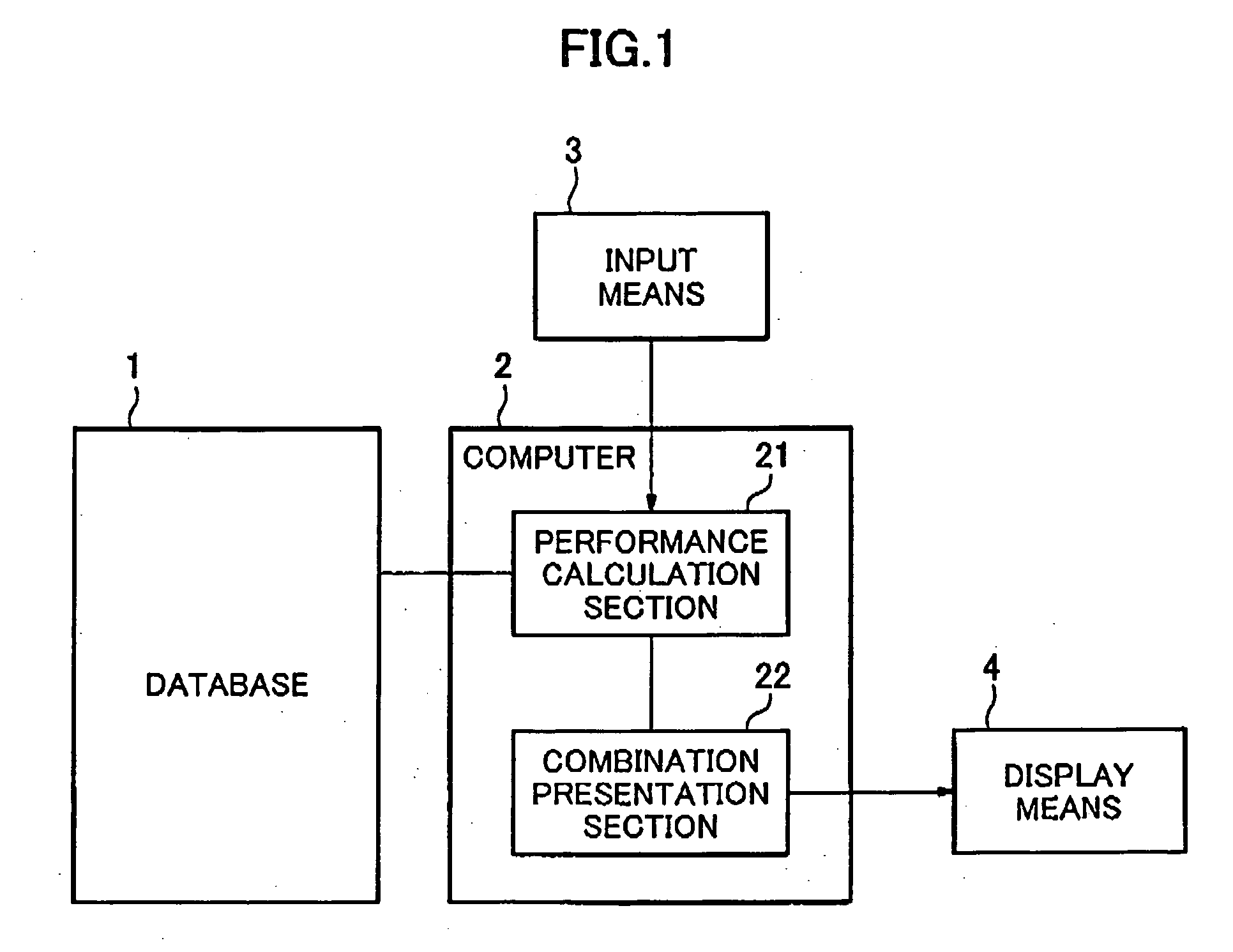

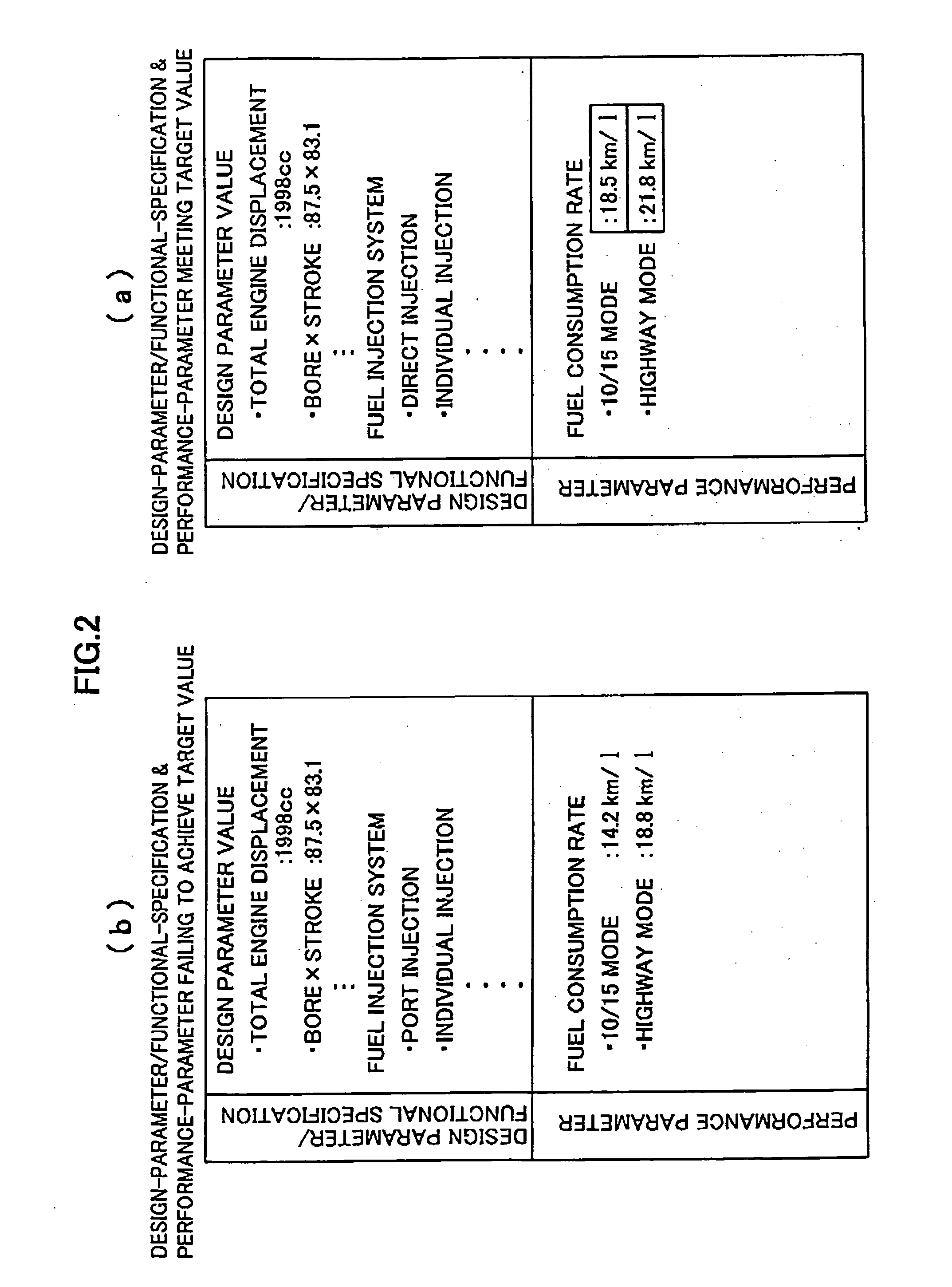

Internal-combustion engine design support system

InactiveUS20070106453A1Improve efficiencyGeometric CADAnalogue computers for vehiclesCombustionValue set

Disclosed is an internal-combustion engine design support system for presenting a combination of functional specification types or the like of a design-target engine in connection with a target performance parameter value set out in a new vehicle. The system comprises a database (1) storing data about a design parameter value of a given design parameter, a functional specification type of a given functional specification and a performance parameter value of a given performance parameter, which are associated with each of a plurality of existing internal-combustion engines, a performance calculation section (21) for calculating a performance parameter value of the given performance parameter of at least one of an internal-combustion engine model set by changing a combination of a reference design parameter value and / or a reference functional specification type of a base internal-combustion engine selected from the existing internal-combustion engines, and a combination presentation section (22) for outputting at least one combination of a design parameter value and a functional specification type of the internal-combustion engine model having the performance parameter value calculated by the performance calculation section (21), according to a given presentation condition.

Owner:MAZDA MOTOR CORP

Design support method and design support system

InactiveUS7689523B2Reduce failureEasily decideData processing applicationsKnowledge representationDesign support systemSoftware engineering

Owner:HITACHI LTD

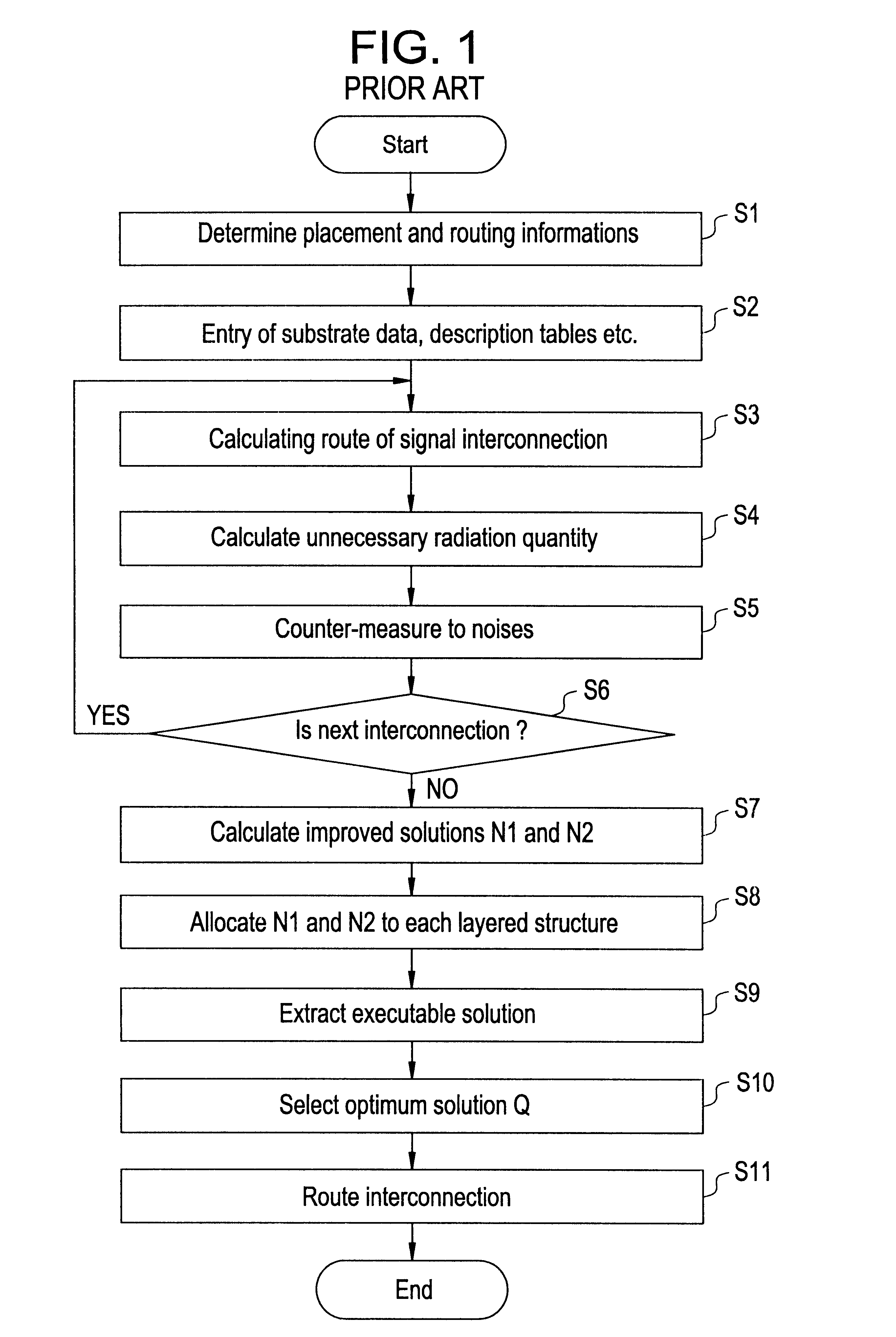

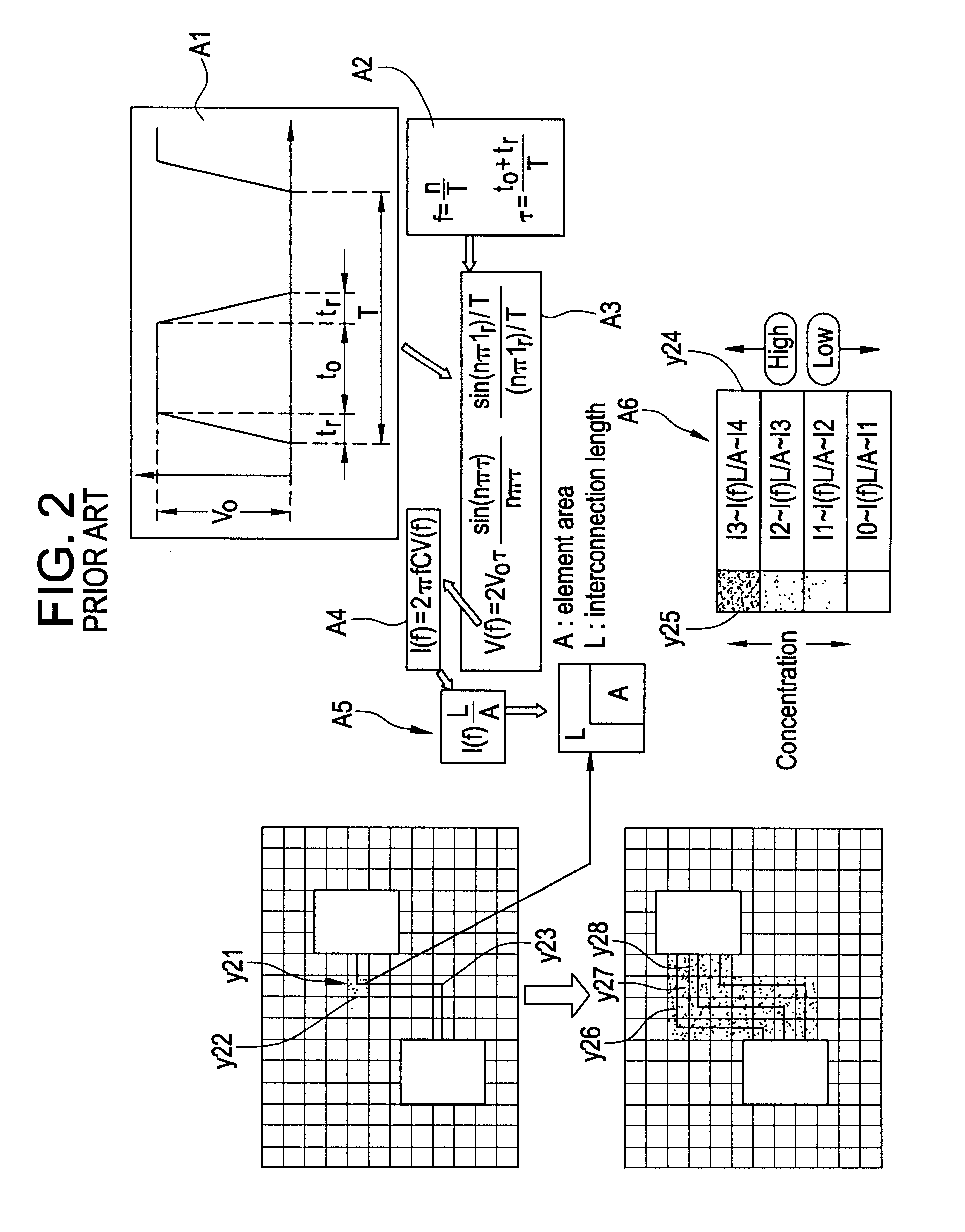

System and method for designing a printed board adapted to suppress electromagnetic interference

InactiveUS6754876B2Magnetic/electric field screeningCross-talk/noise/interference reductionDesign support systemResonance

Owner:NEC CORP

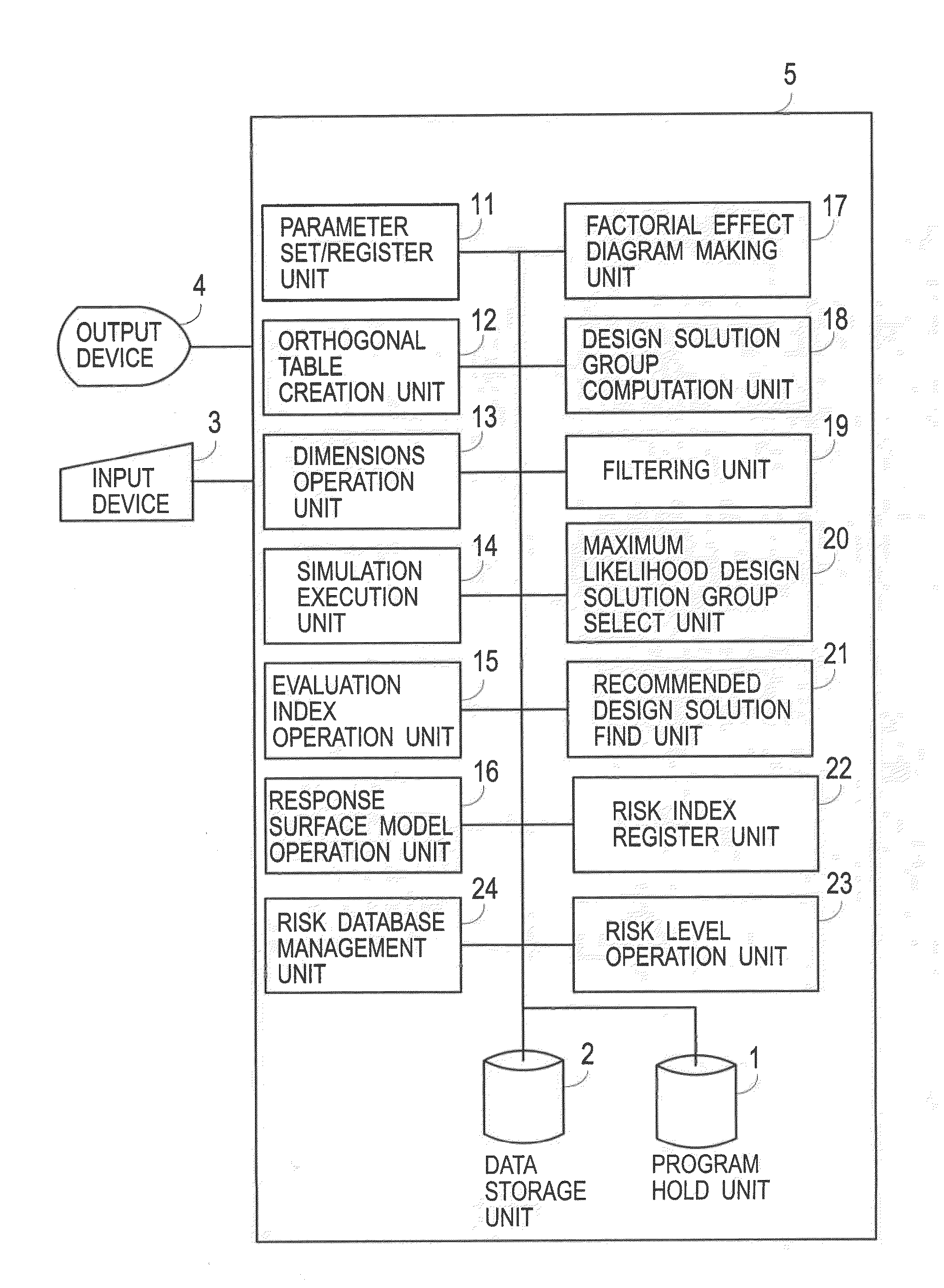

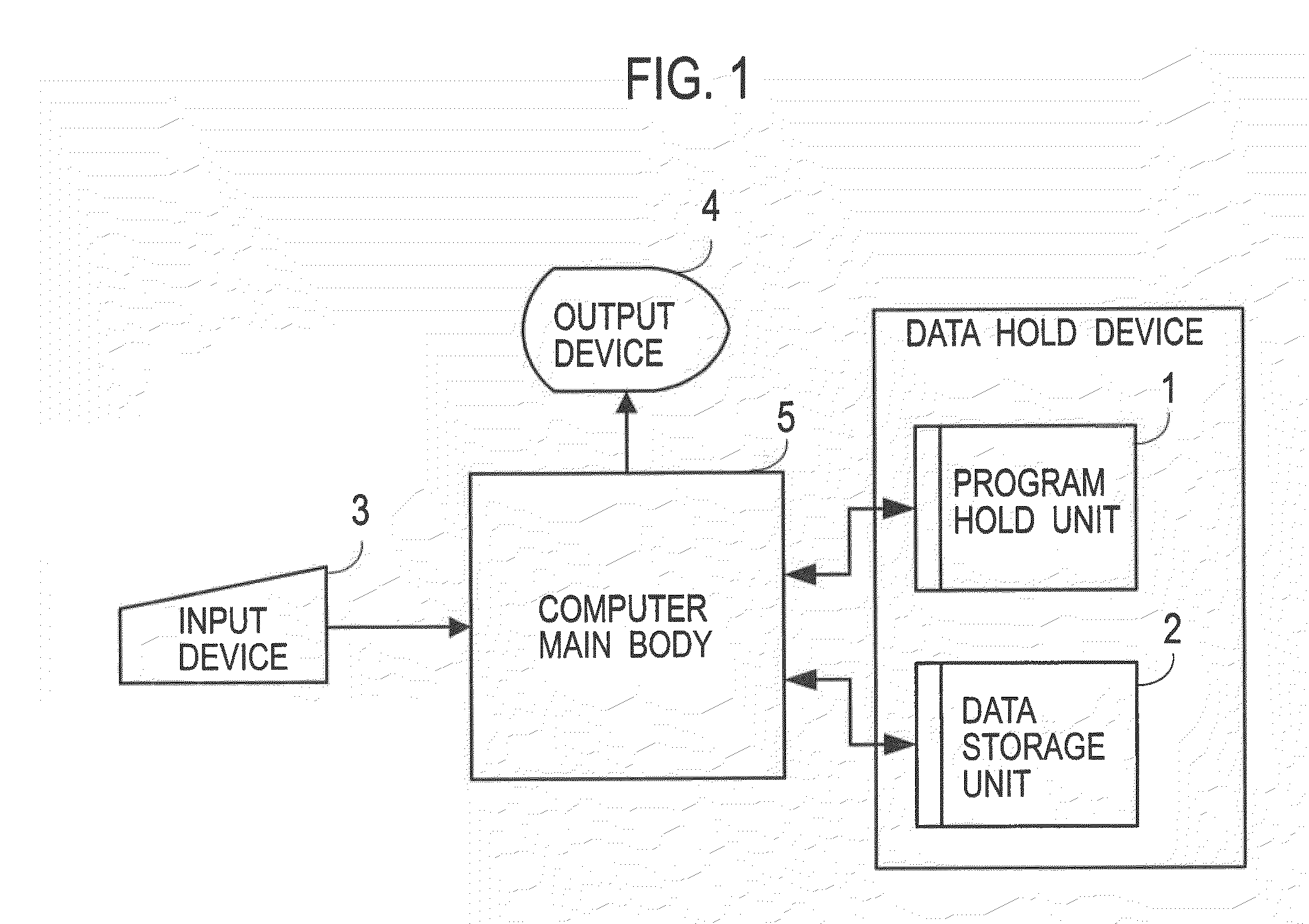

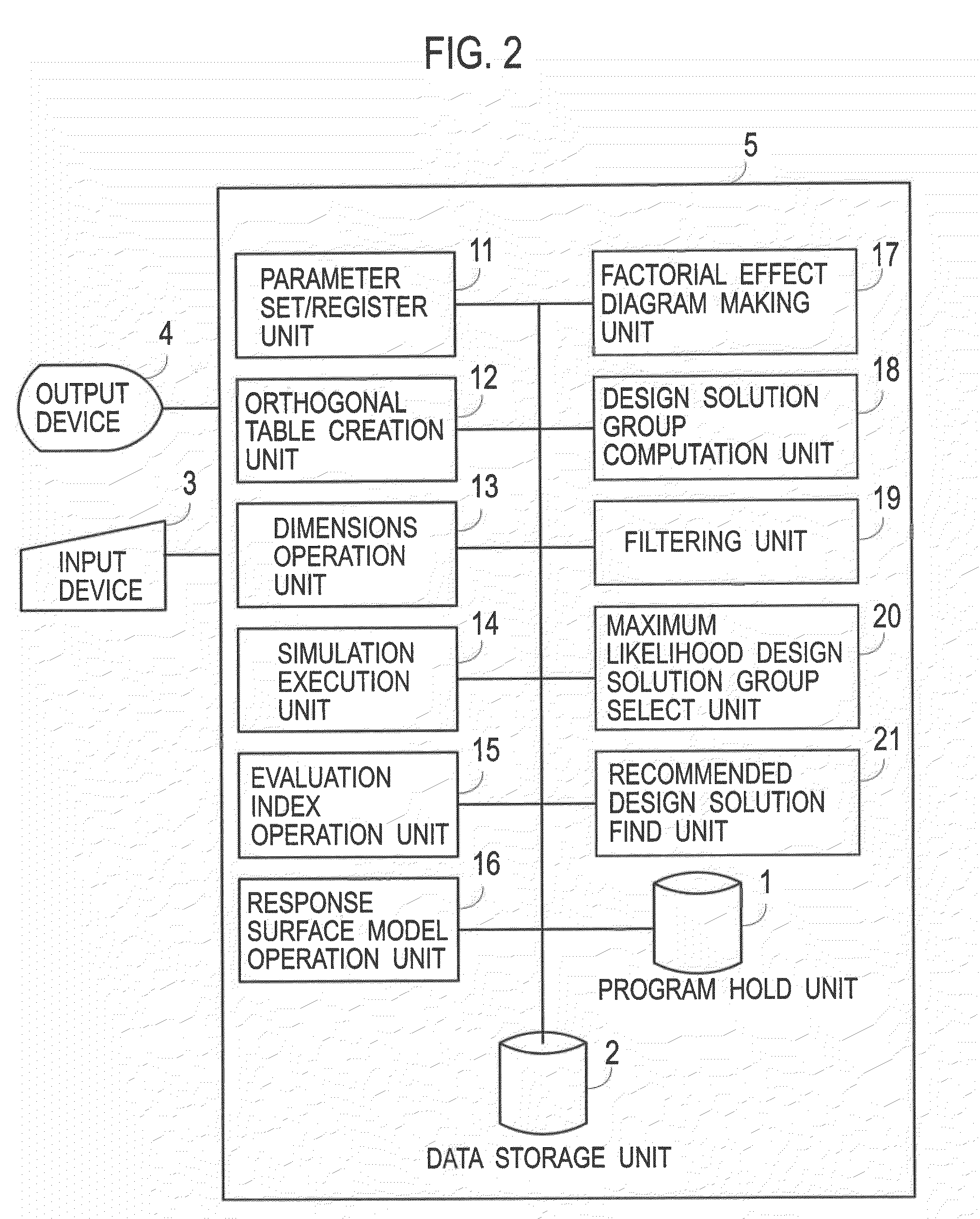

Product design support system and method for simulating a prototype of a design object

ActiveUS8589125B2Short timeSimple designGeometric CADAnalogue computers for electric apparatusSupporting systemDesign plan

The invention relates to a product design support system for supporting product design business so as to design and develop a product in a short time. The system creates an L-row orthogonal table according to set design parameters, executes many times, for each of L sets of design parameter groups, a virtual prototyping operation by adjusting the dimensional tolerance of each part, processes averages and variances of L sets of evaluation indexes obtained by the virtual prototyping operations, to form a response surface and response surface model, makes a factorial effect diagram of design parameters for each evaluation index, examines the factorial effect diagram, forms optional combinations of design parameters sensitive to the evaluation indexes, applies the combinations to the response surface model, forms many design solutions by optionally combining all design parameters that may achieve design target values, conducts filtering to extract a maximum likelihood design solution candidate group that achieves specified evaluation index limit values out of the design solutions, selects a maximum likelihood design solution group from the solution candidate group, and presents the same to a user.

Owner:IHI CORP

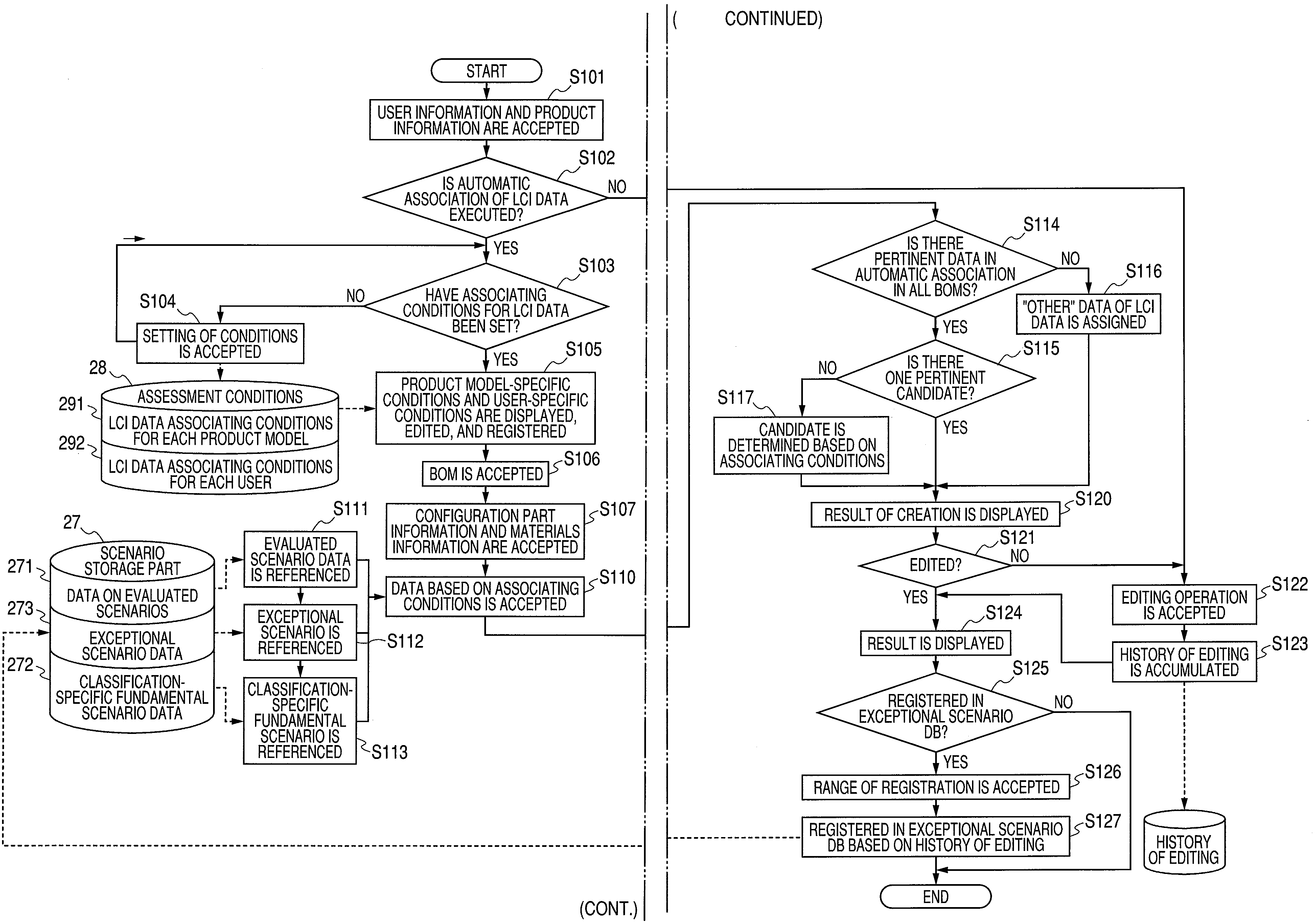

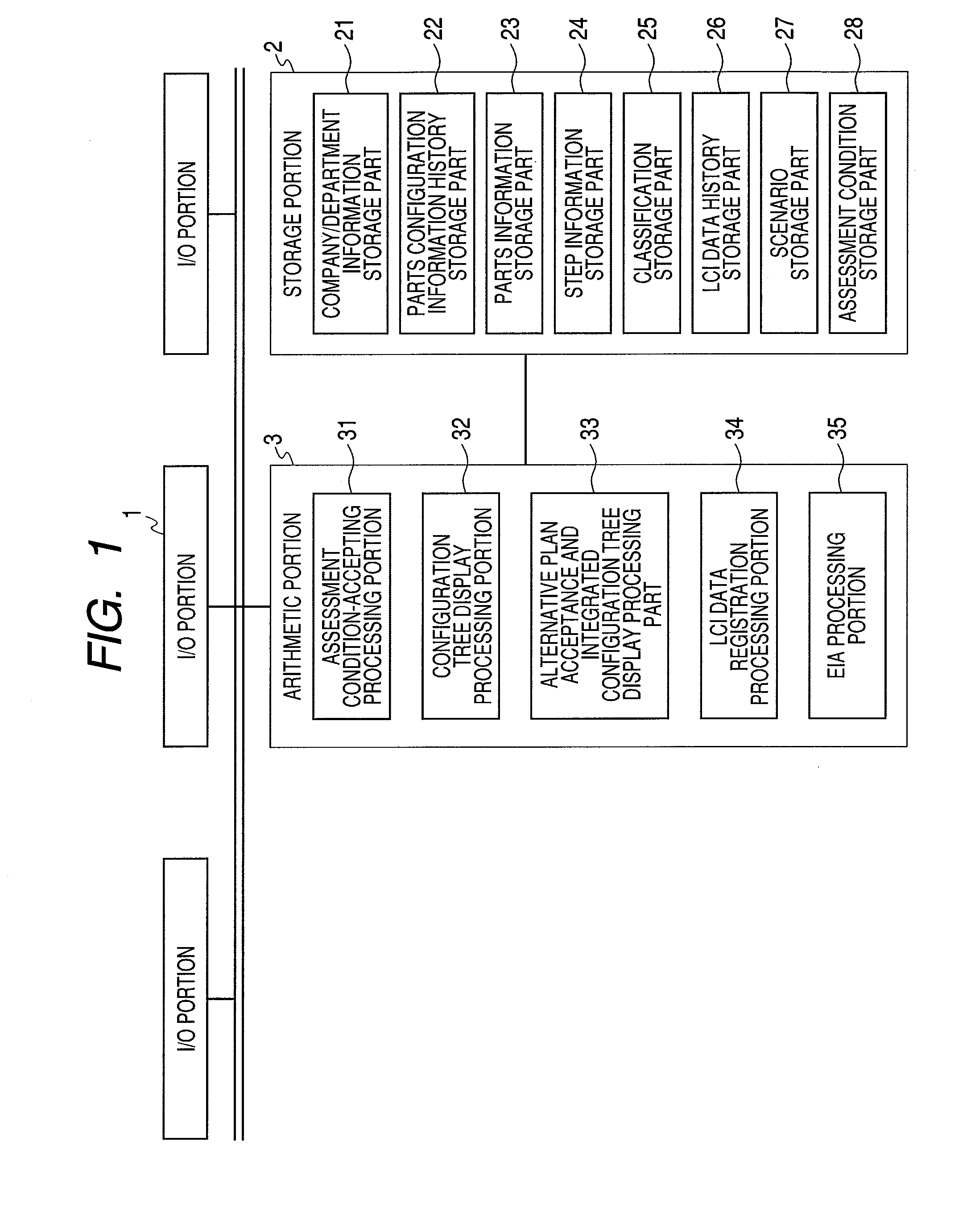

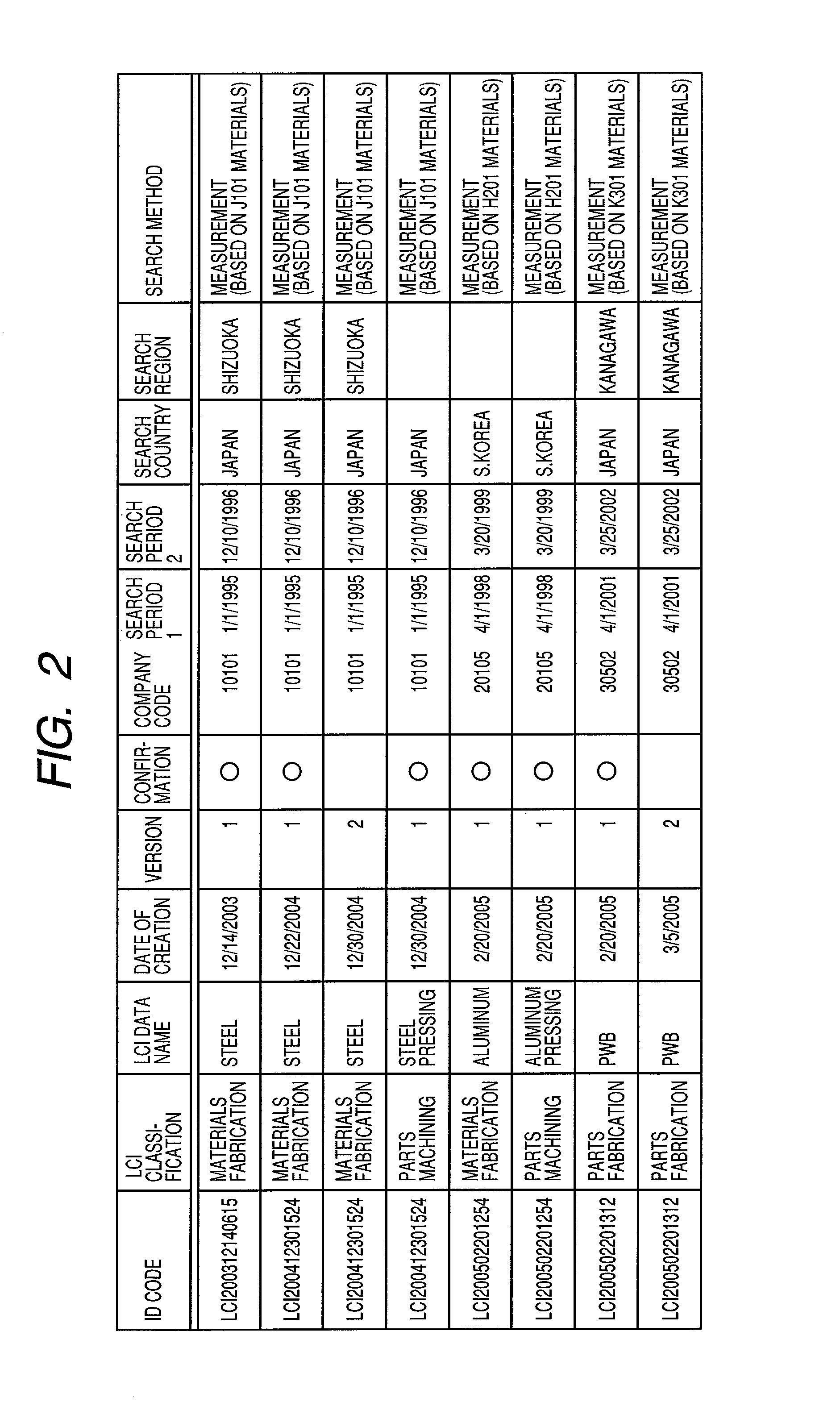

Design support system

InactiveUS20090083333A1Process environmental protectionTechnology managementResourcesState of artMaterial classification

The present invention solves the problems with the prior-art environmentally friendly design. That is, in order to achieve continual improvement, it is necessary to make a detailed evaluation based on the parts configuration. If a method of setting a basic unit for each individual part is used, a large number of process steps are required, and it is impossible to conduct accurate life cycle assessments (LCAs) frequently. The present invention provides an environmental impact assessment support and design support system incorporating a database in which information about the basic unit is associated with information about product classifications, parts classifications, and materials classifications. The system manages the information about the parts configuration and the basic unit while associating their histories of creation with each other.

Owner:HITACHI LTD

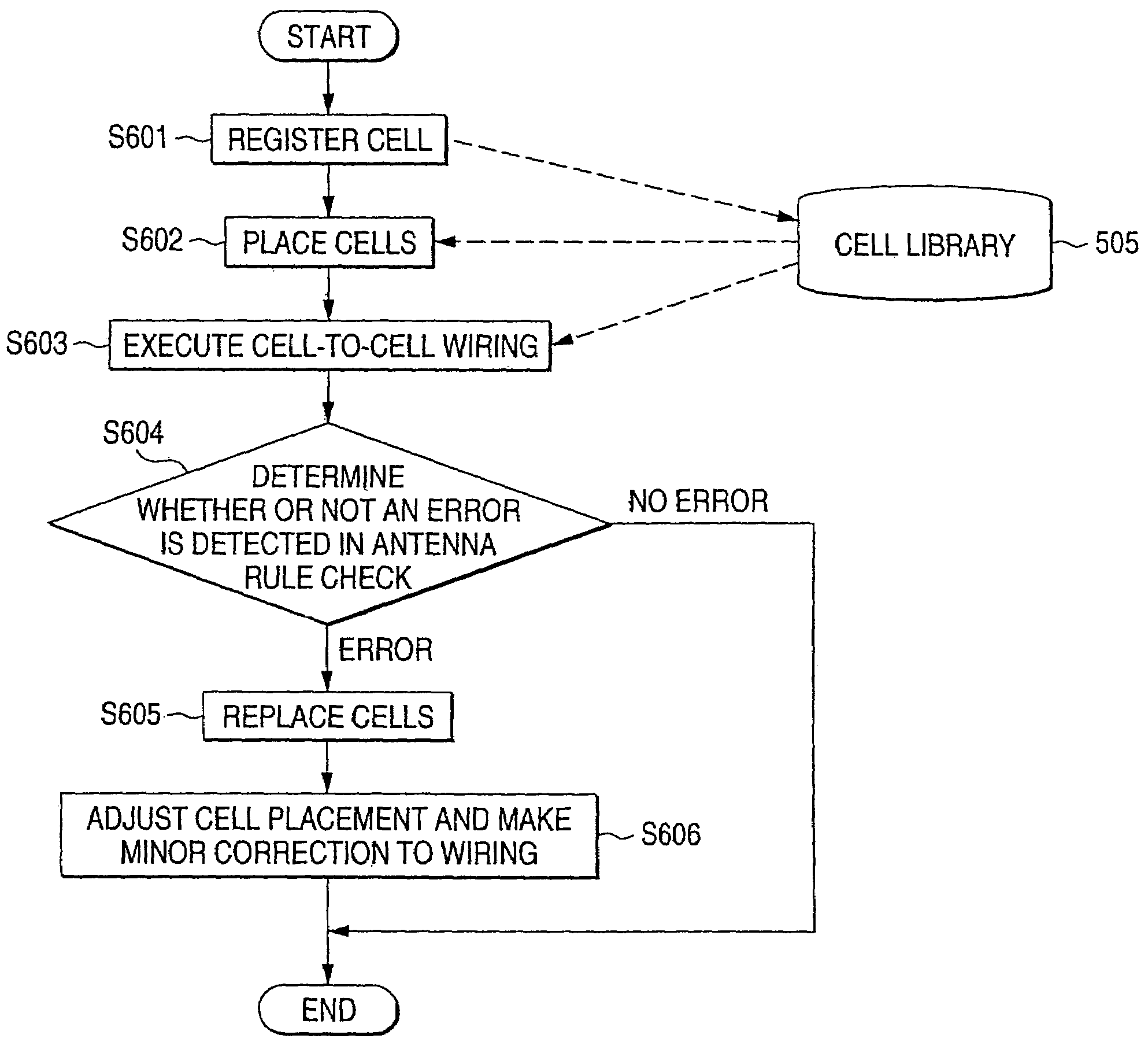

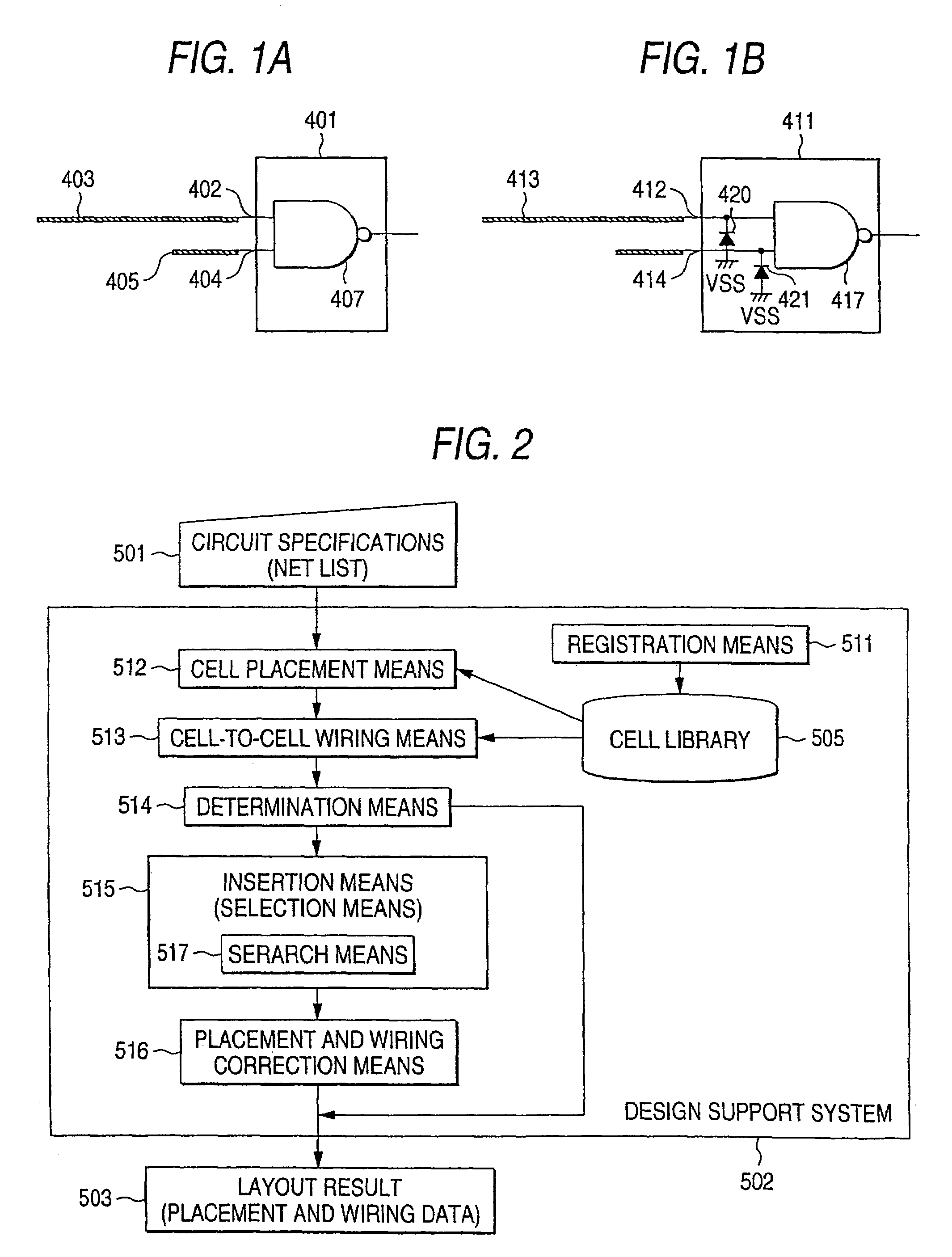

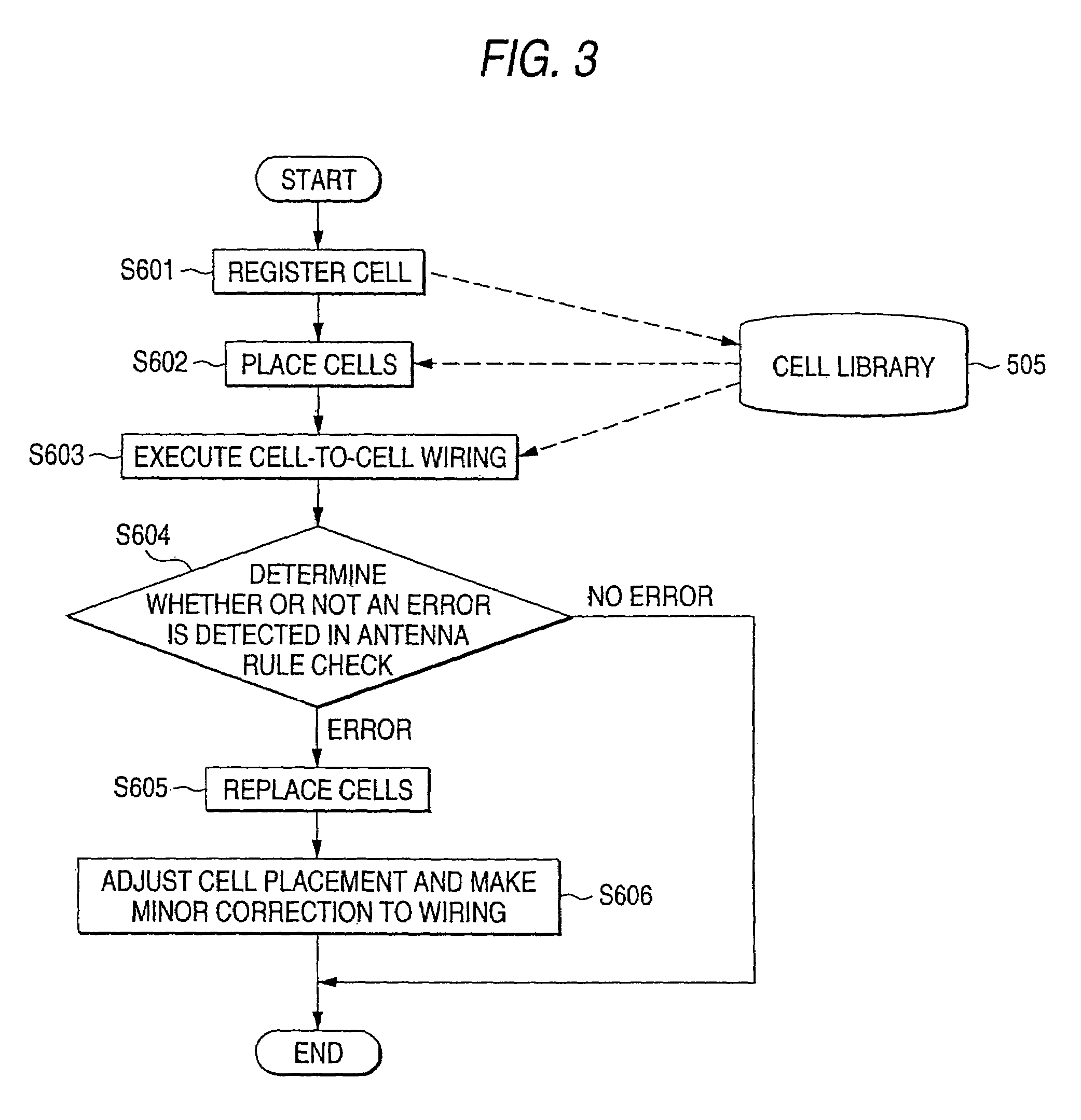

Semiconductor device, semiconductor device design method, semiconductor device design method recording medium, and semiconductor device design support system

InactiveUS7114140B2Avoid damageAvoid Antenna DamageSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDesign support system

Repeater cells each comprising a buffer or an inverter and an n+ diffusion layer-P well type protection diode or a p+ diffusion layer-N well type antenna protection diode connected to an input pin of the buffer or the inverter for preventing antenna damage or an antenna rule error from occurring are previously registered by registration means 511 as the cells to be registered in a cell library 505. Whether or not a wiring conductor conducting to a gate electrode becomes an antenna ratio exceeding an allowed antenna ratio in the semiconductor device is determined by determination means 514 and if the wiring conductor exceeds the allowable antenna ratio, one or more repeater cells are inserted into any point of the wiring conductor by selection means 515.

Owner:PANASONIC CORP

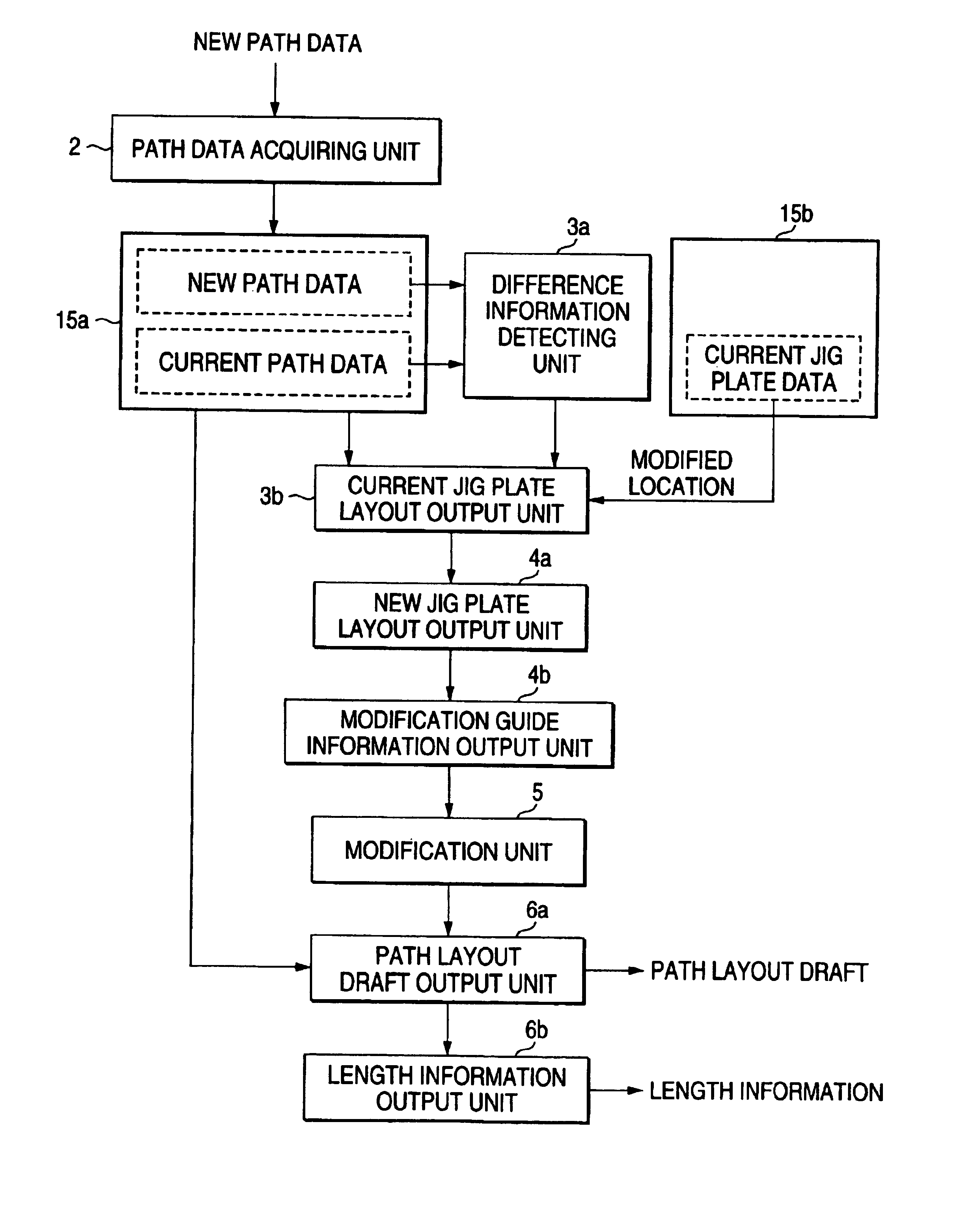

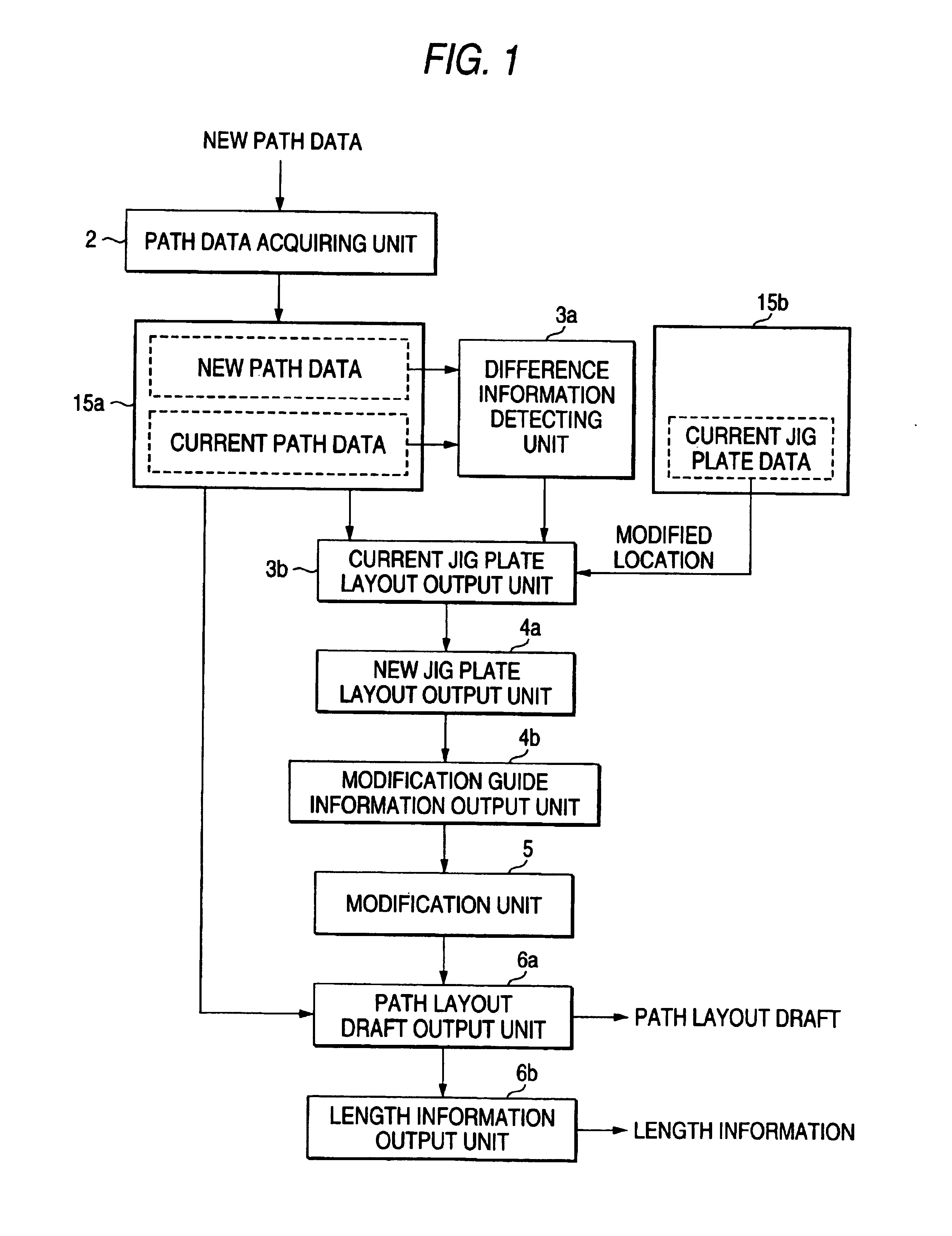

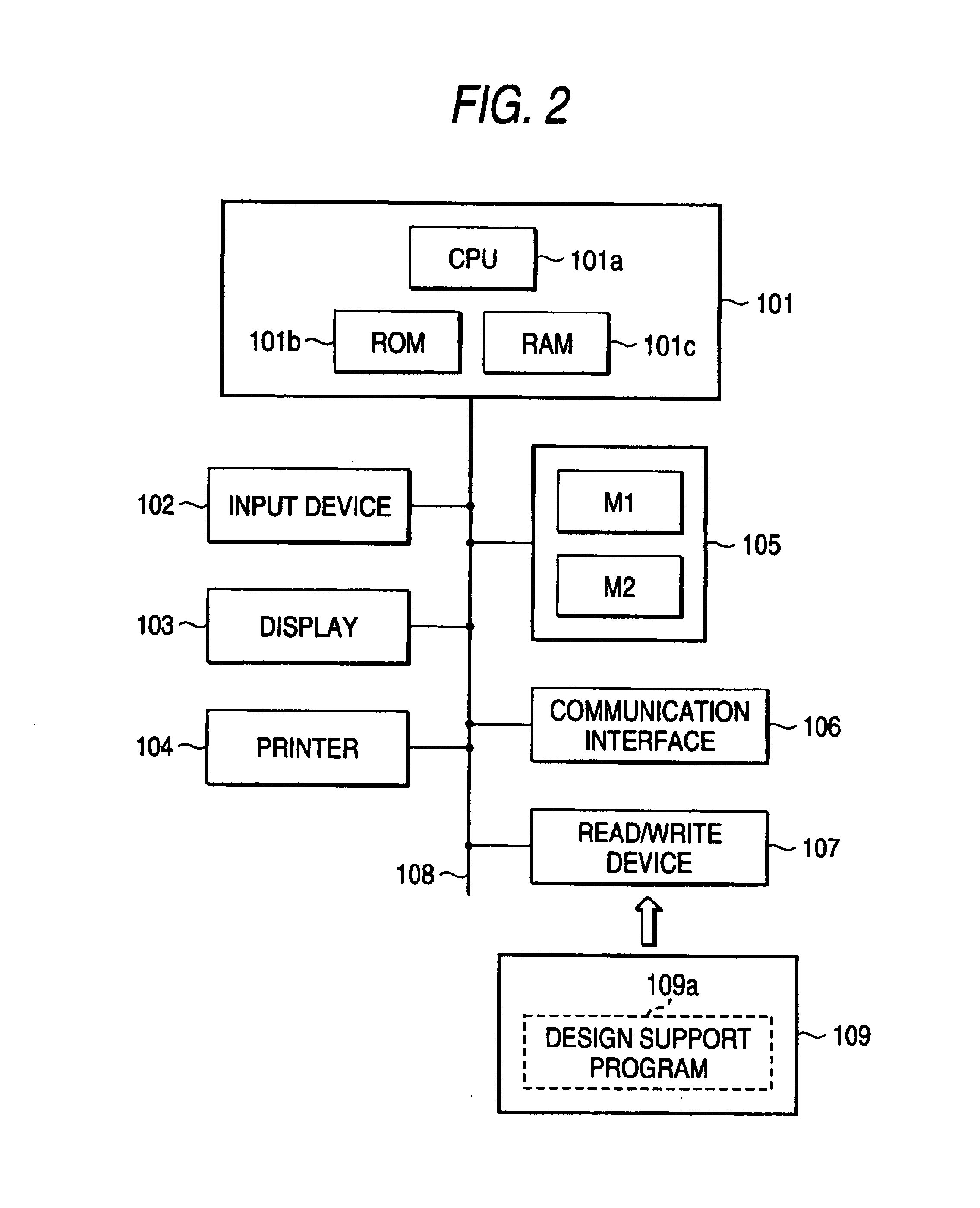

Wire harness design support system

InactiveUS6898473B2Improve design efficiencyDigital data processing detailsElectric/fluid circuitDesign support systemEngineering

The object of the invention is to provide a wire harness design support system that suitably corresponds to the frequent modification of design and enhances the design efficiency of a jig plate layout and a path layout draft in accordance with it. To achieve the object, guide information calculated based upon a request for modification from a car manufacturer for guiding a modifiable location of a jig plate layout is added to the jig plate layout and it is output. Besides, the jig plate layout can be modified according to an instruction to modify the jig plate layout utilizing the guide information. Further, a path layout draft that reflects the modification of the jig plate layout is also output.

Owner:YAZAKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com