Patents

Literature

38results about How to "Running cost can be reduced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

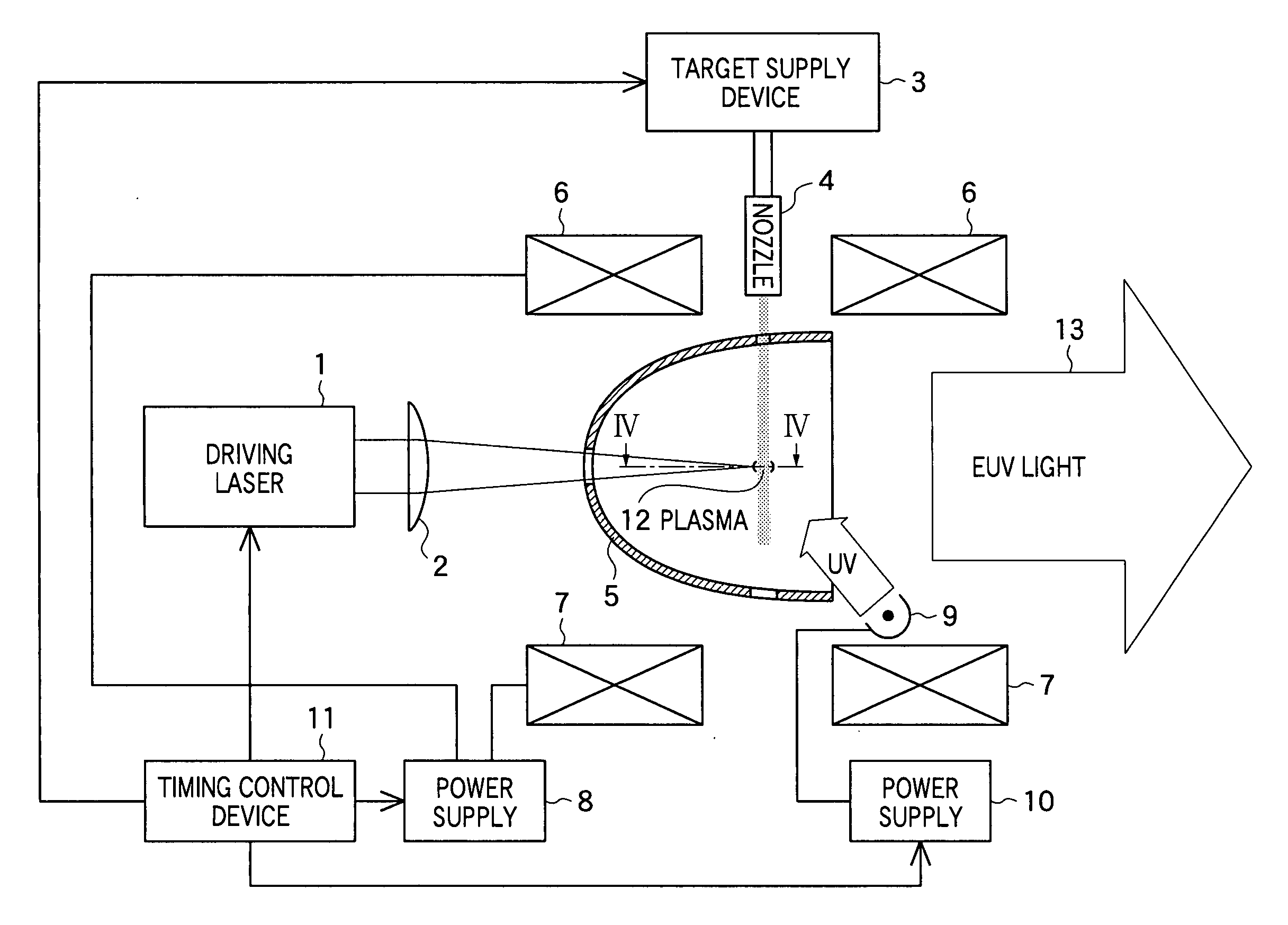

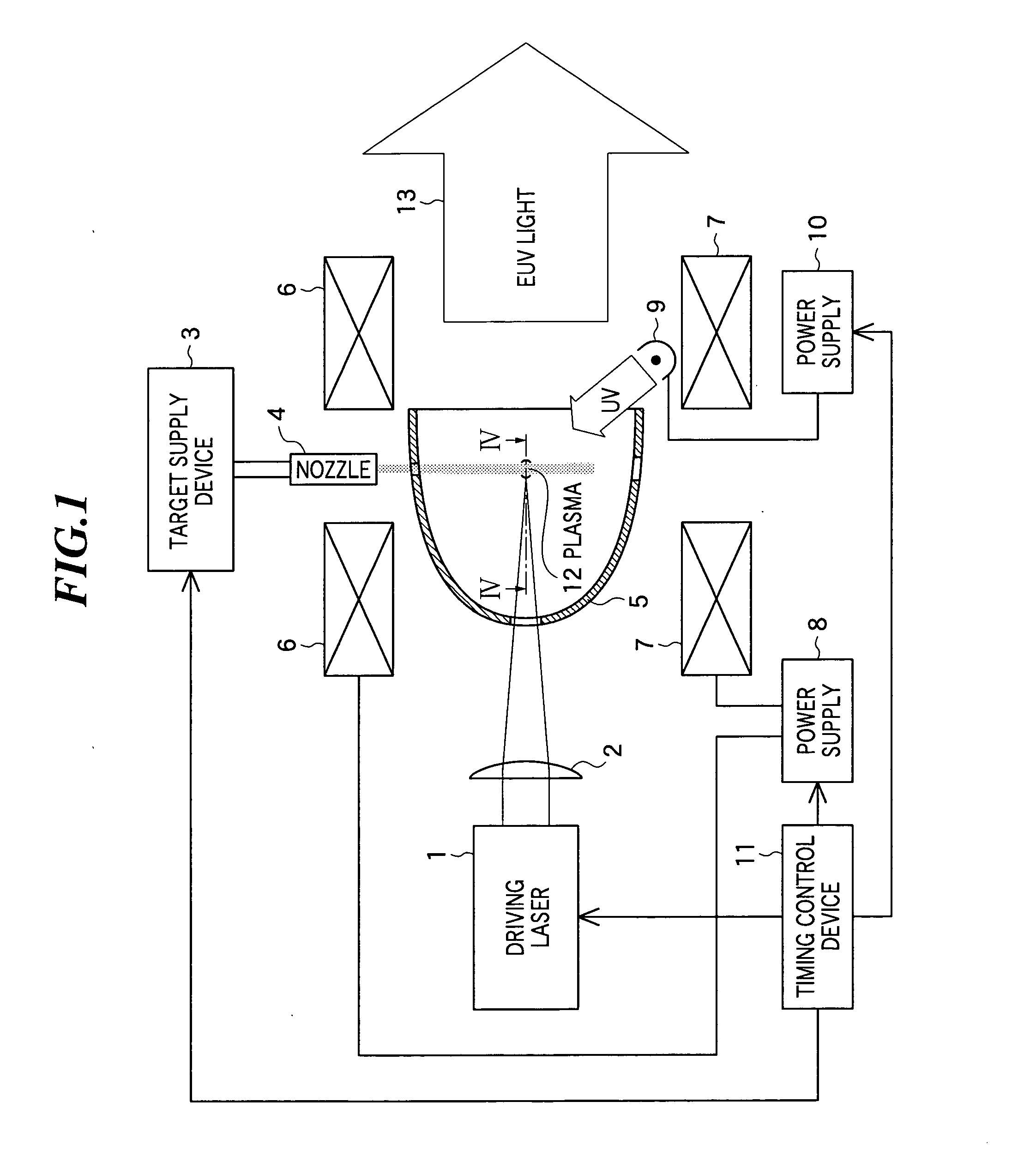

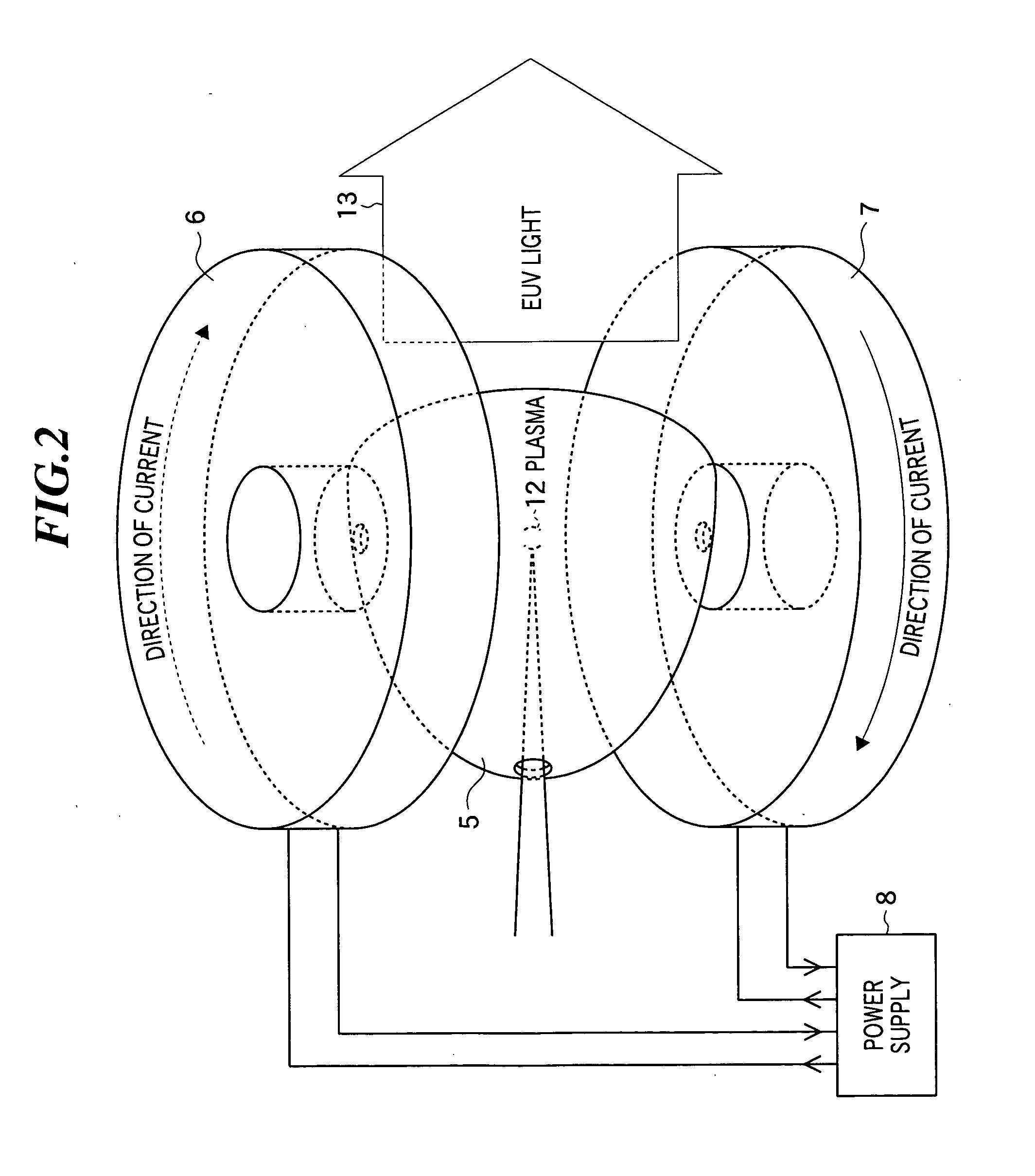

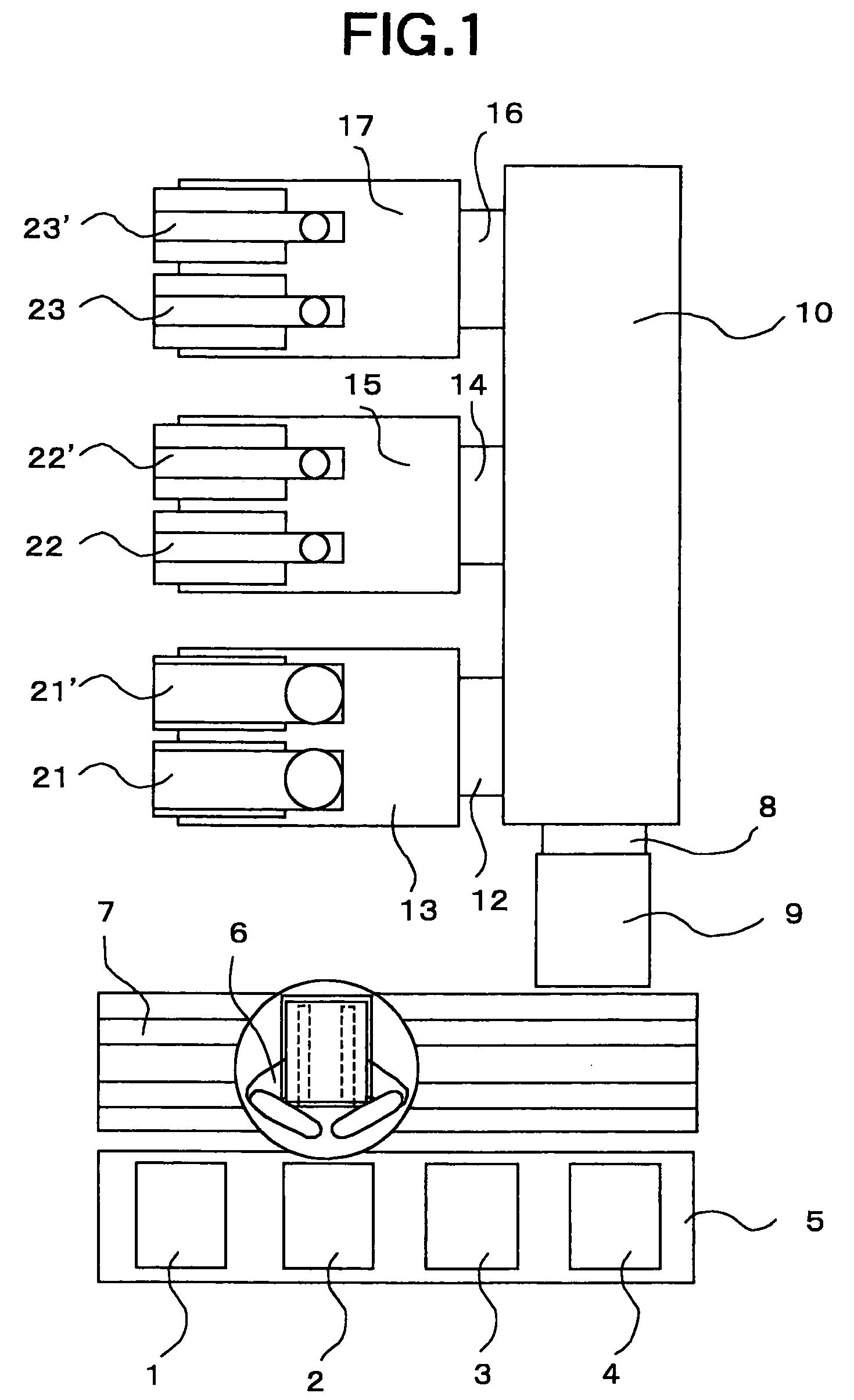

Light source device and exposure equipment using the same

ActiveUS20050167618A1Extending lifeRunning cost can be reducedNanoinformaticsMaterial analysis by optical meansSolid angleLight source

A light source device capable of extending the life of a collector mirror and reducing running cost by protecting the collector mirror from debris that is considered harmful to a mirror coating while securing the collection solid angle and collection rate of EUV light. The light source device includes a target supply unit for supplying a material to become the target; a laser unit for generating plasma by applying a laser beam to the target; a collection optical system for collecting the extreme ultra violet light radiating from the plasma and emitting the extreme ultra violet light; and magnetic field generating unit for generating a magnetic field within the collection optical system when supplied with current so as to trap charged particles radiating from the plasma.

Owner:GIGAPHOTON

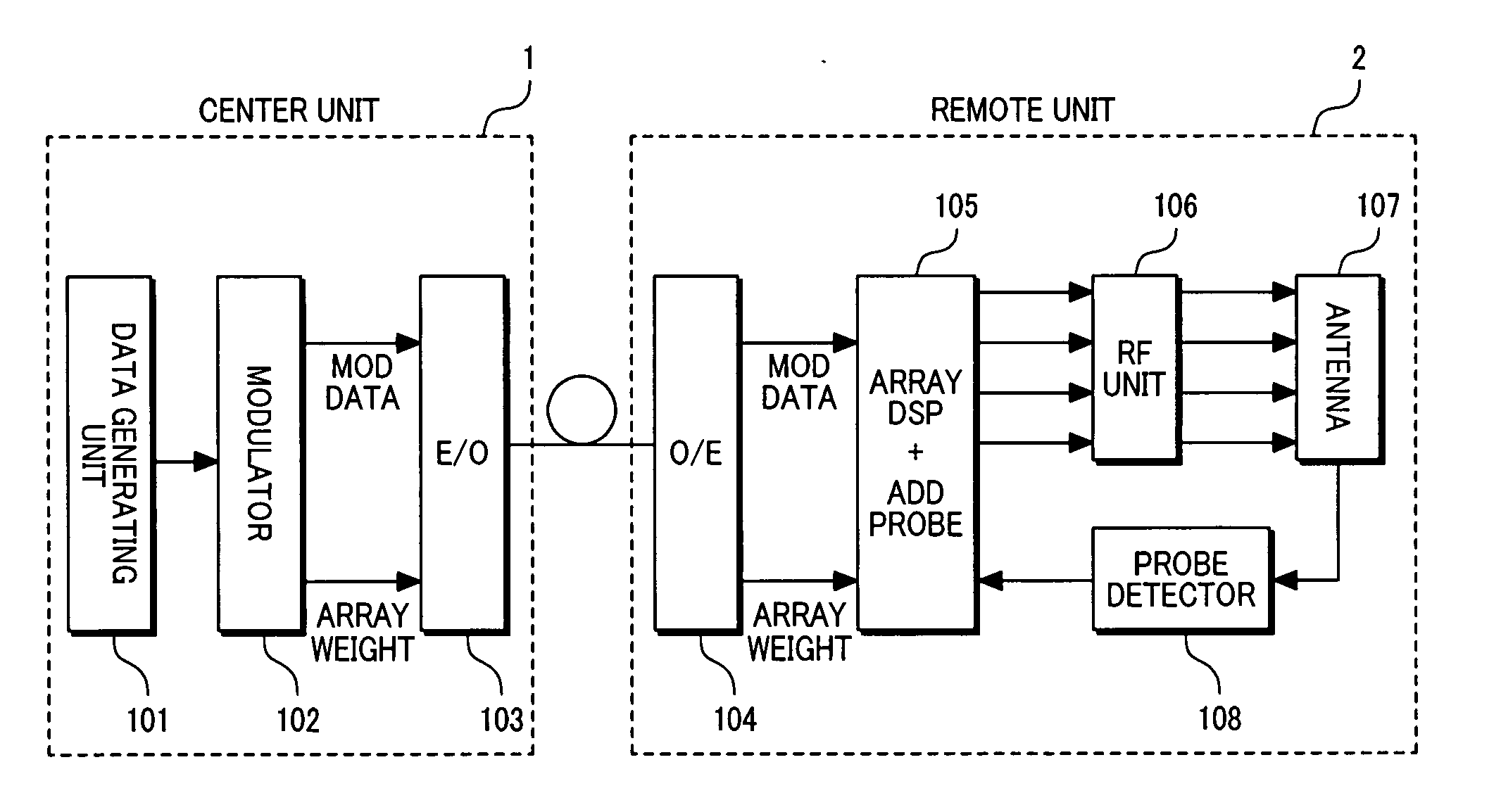

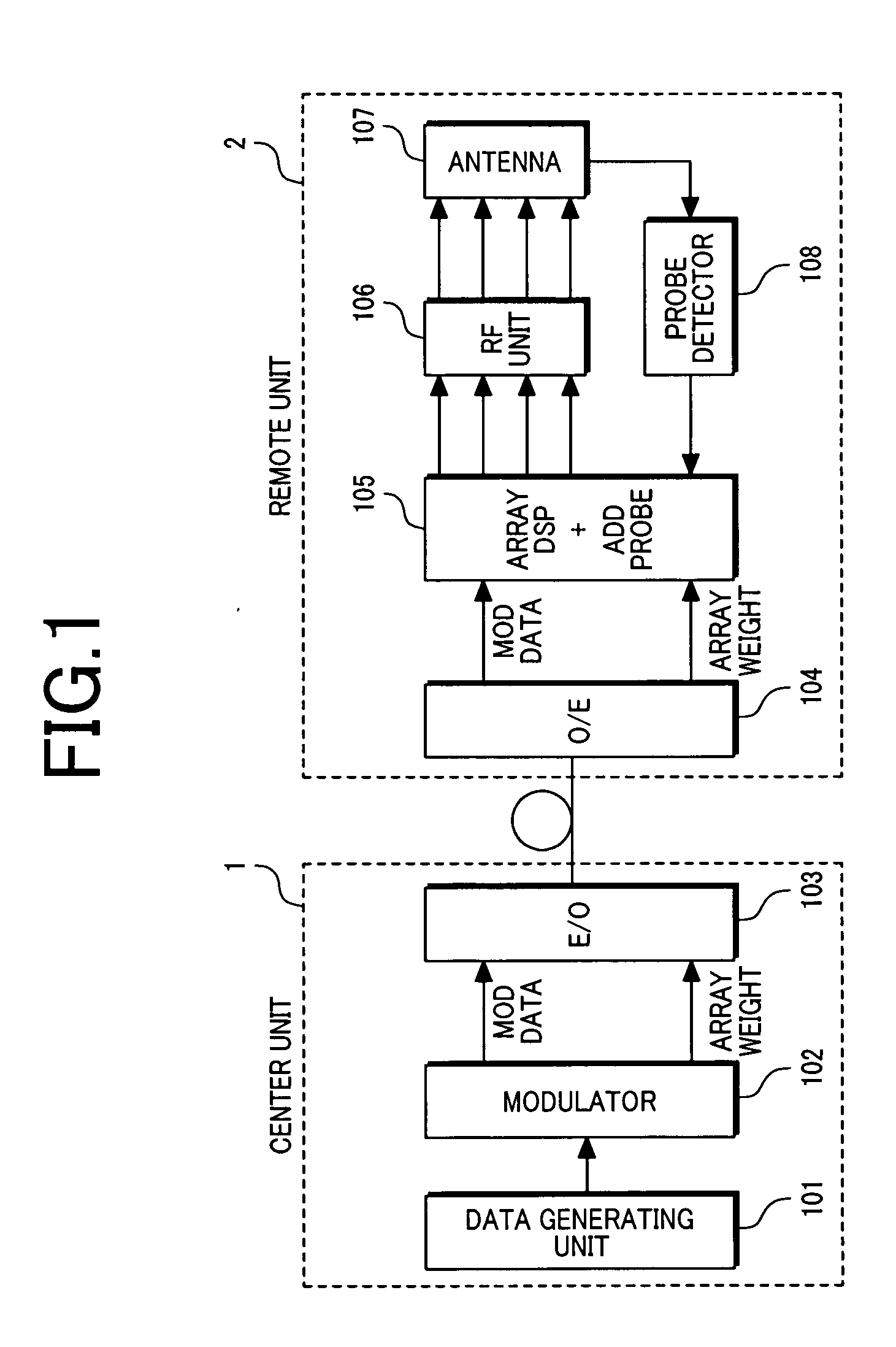

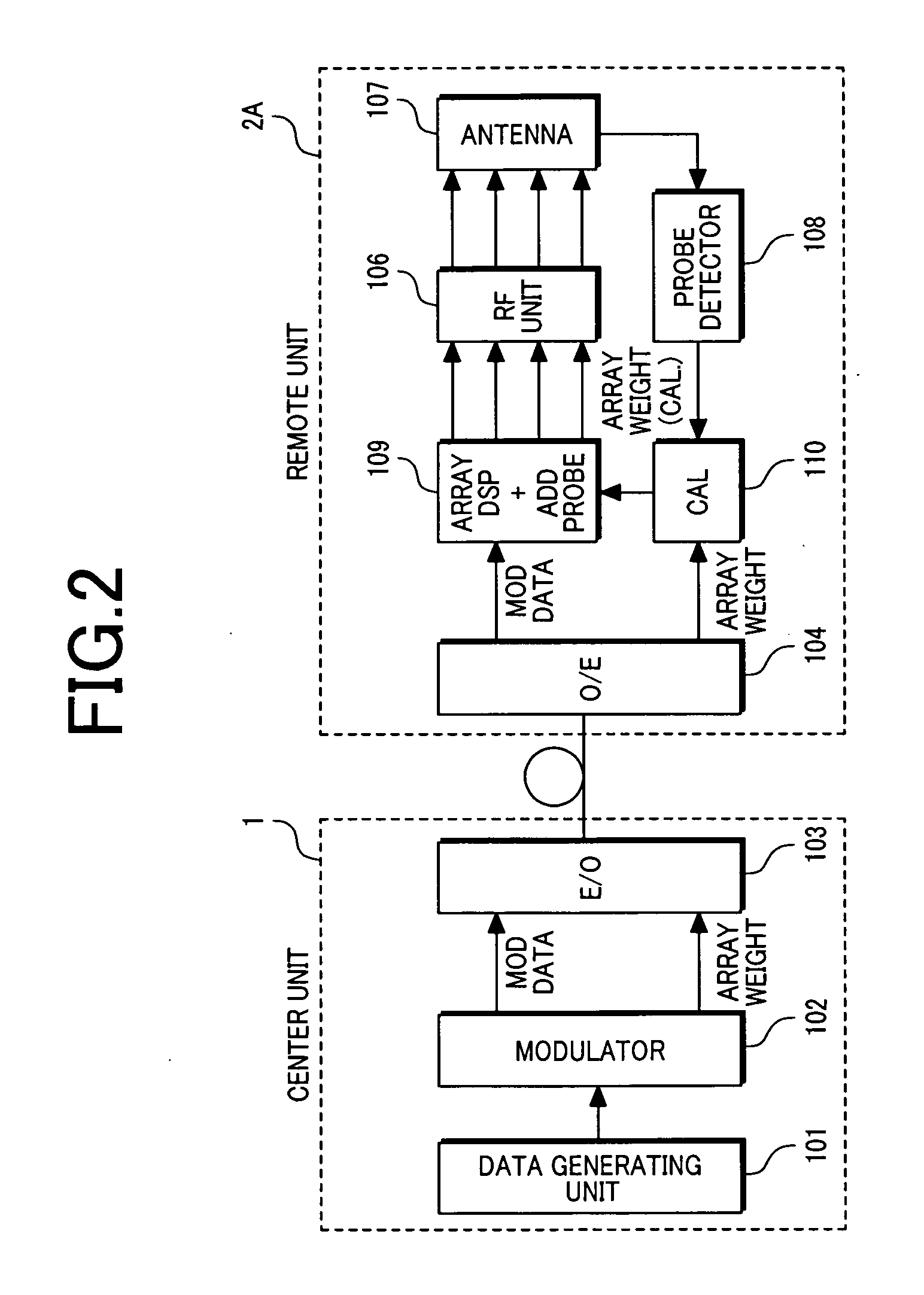

Wireless base station and communication method therefor

InactiveUS20070072646A1Attenuation bandwidthRunning cost can be reducedSpatial transmit diversityPolarisation/directional diversityAntenna elementBaseband

In a wireless base station comprising a center unit, and a remote unit provided with an array antenna and connected to the center unit through an optical fiber, the center unit outputs to the optical fiber a transmission signal in a base band state prior to array processing, the remote unit performs the array processing of transmission signals in accordance with array weights and converts the transmission signals into RF signals, thereby to localize the compensation for transmission signal deviations occurring among the antenna elements on the remote unit side.

Owner:HITACHI LTD

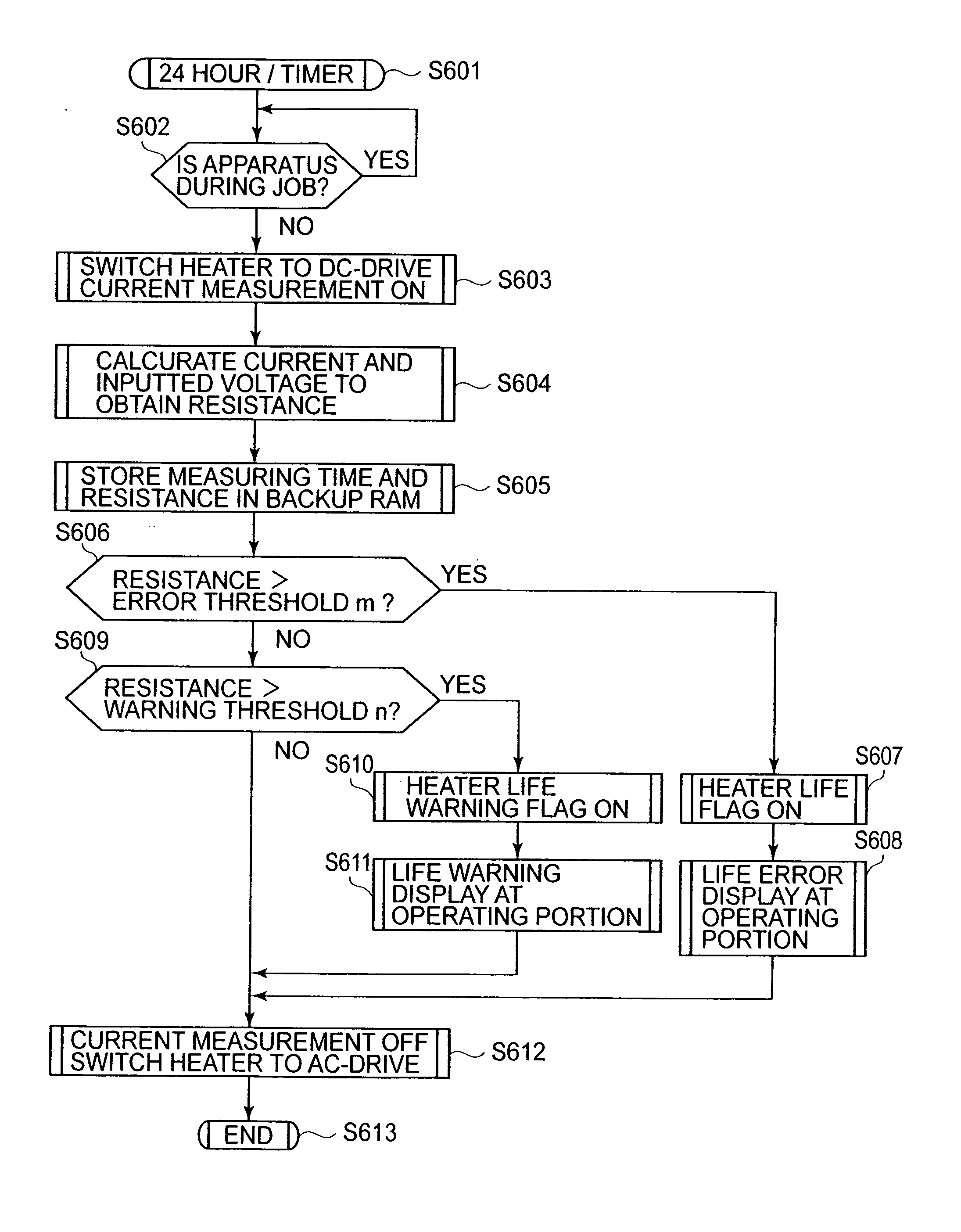

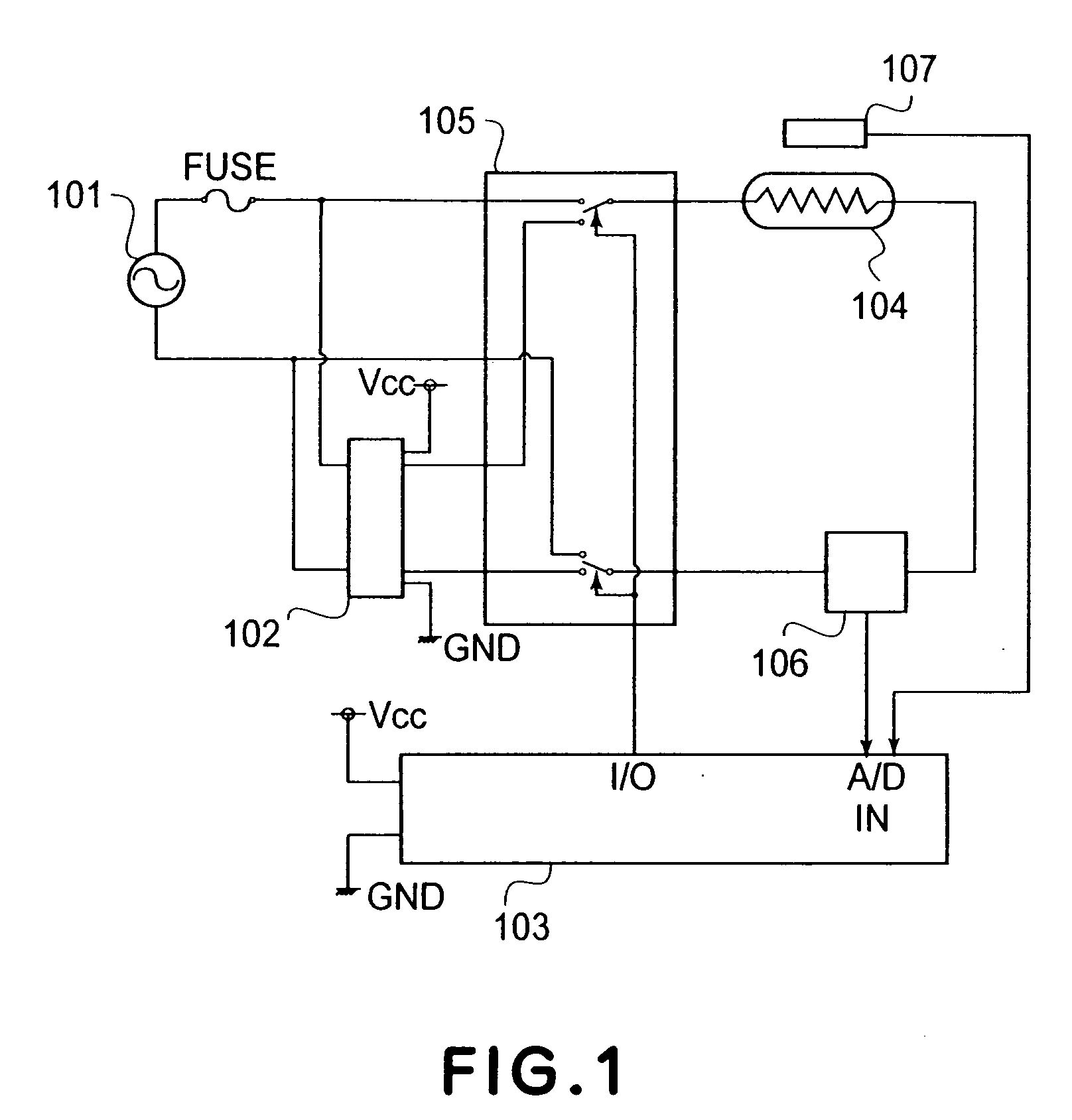

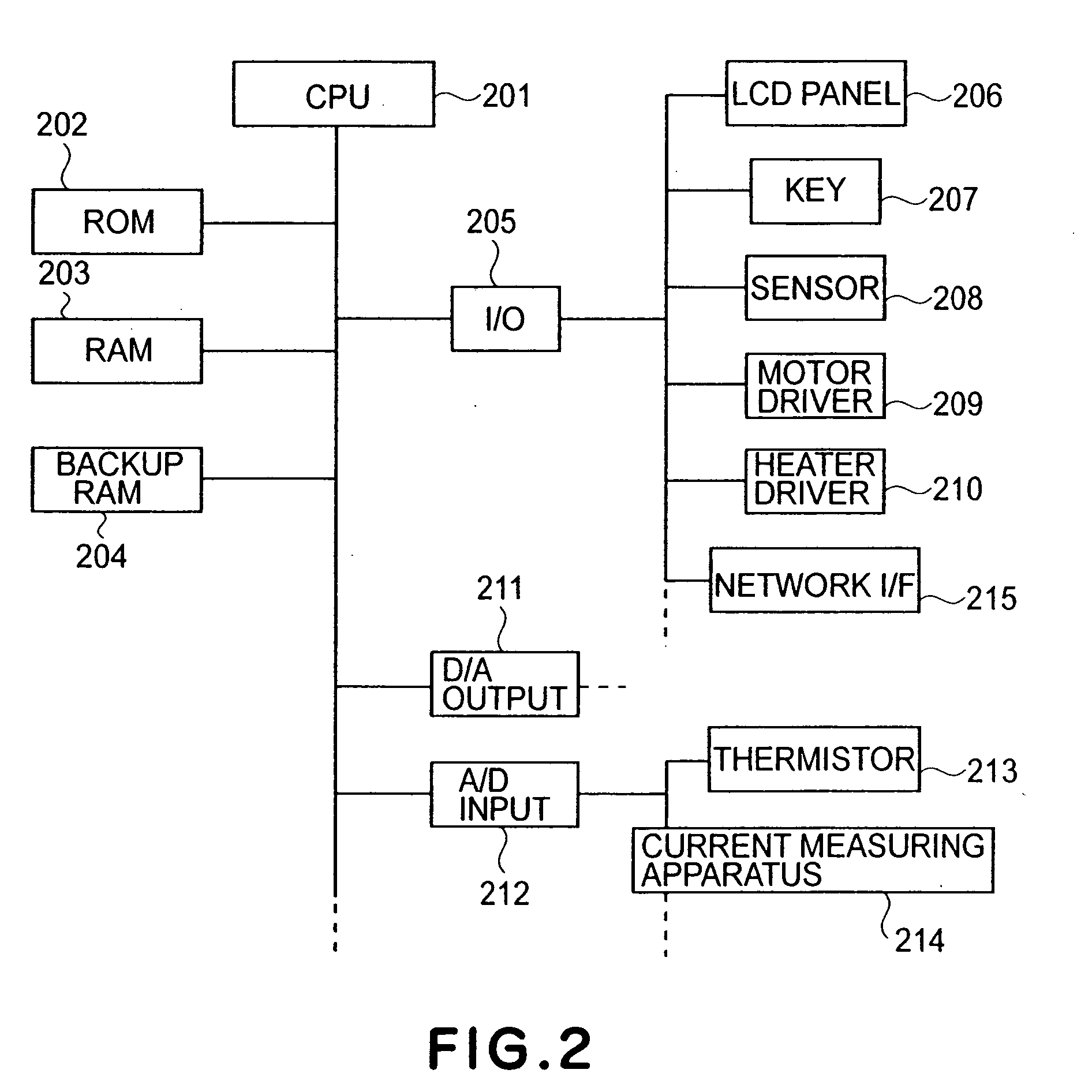

Image forming apparatus

InactiveUS20060024072A1Running cost can be reducedImprove accuracyElectrographic process apparatusElectrical currentImage formation

Owner:CANON KK

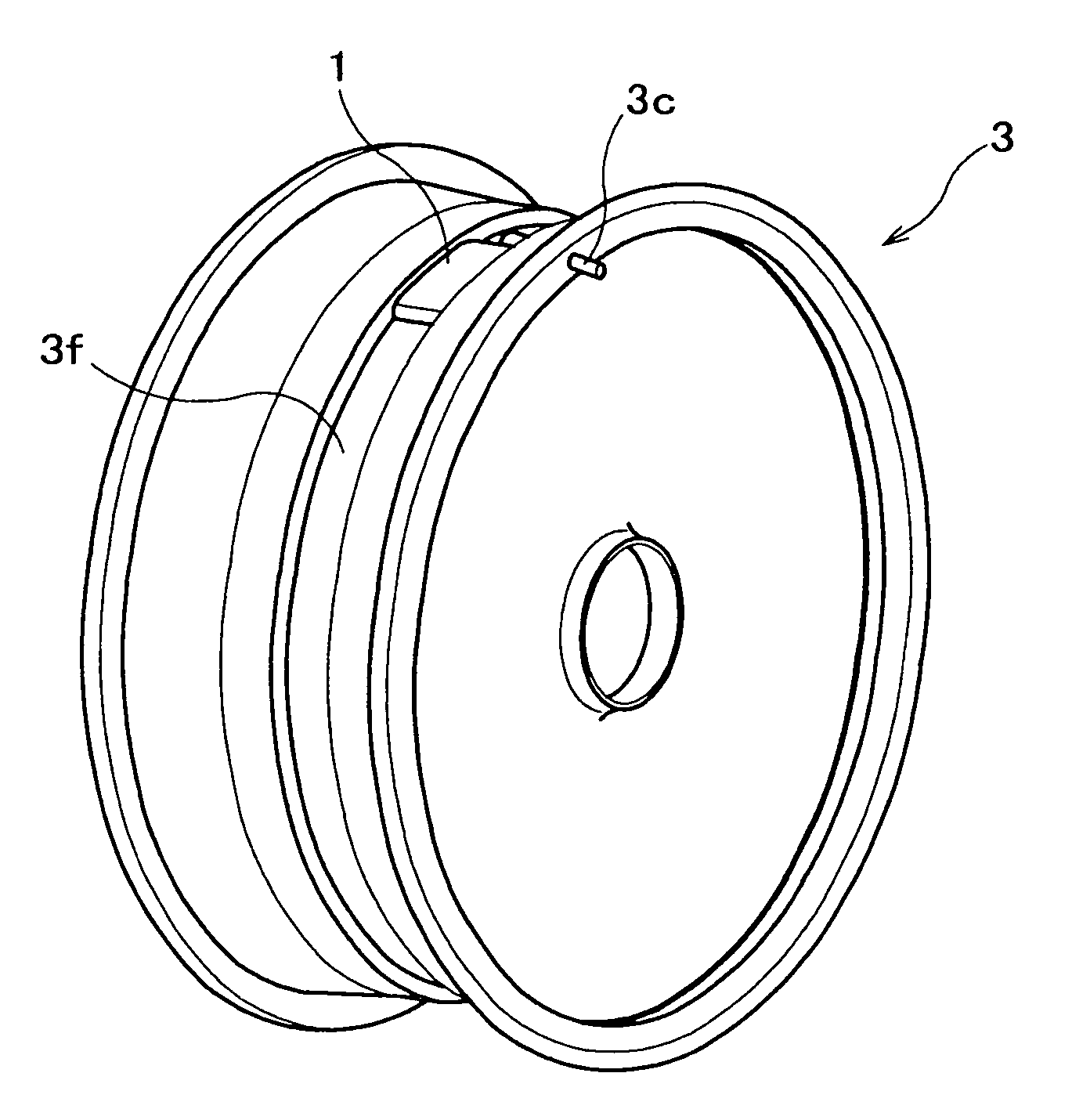

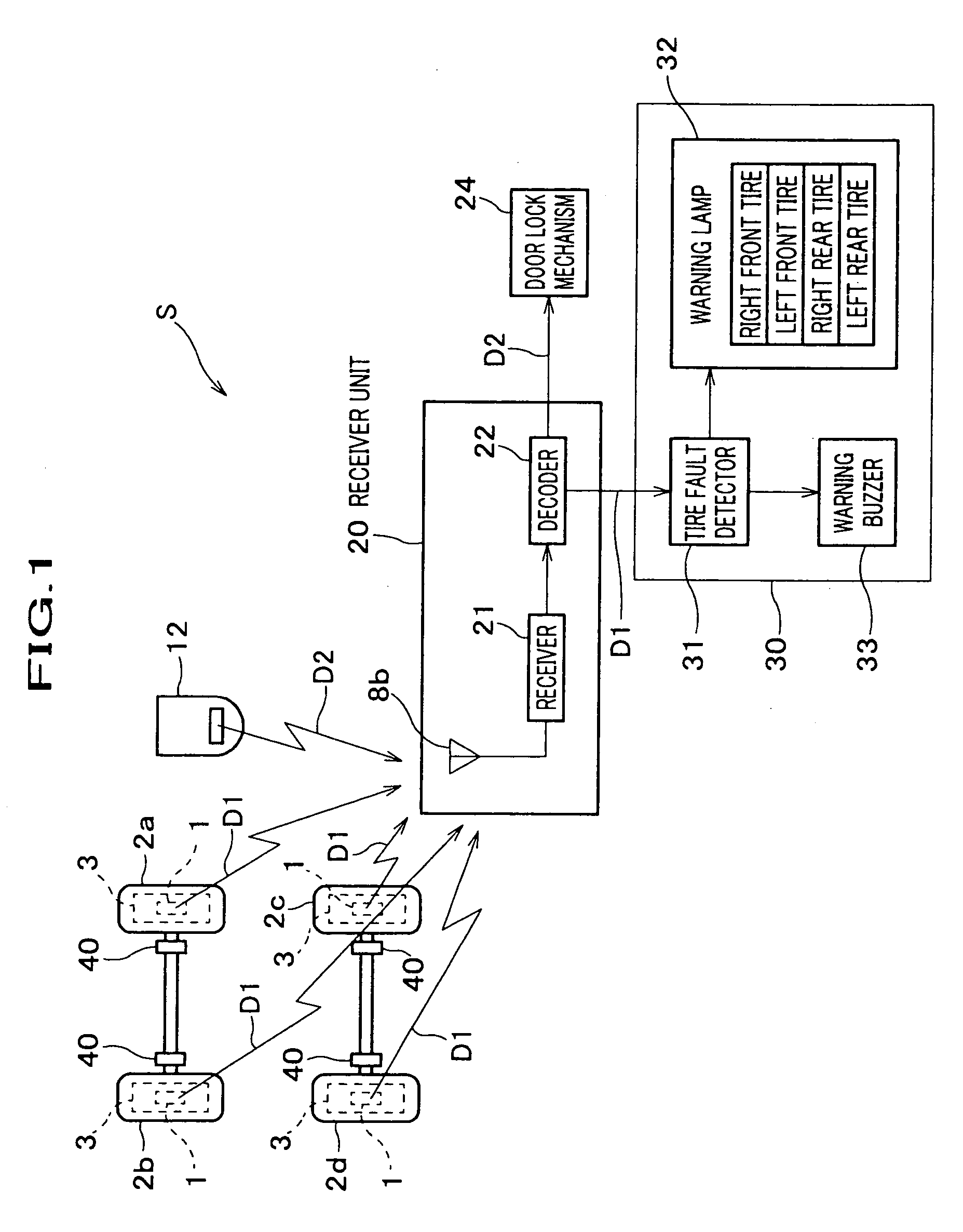

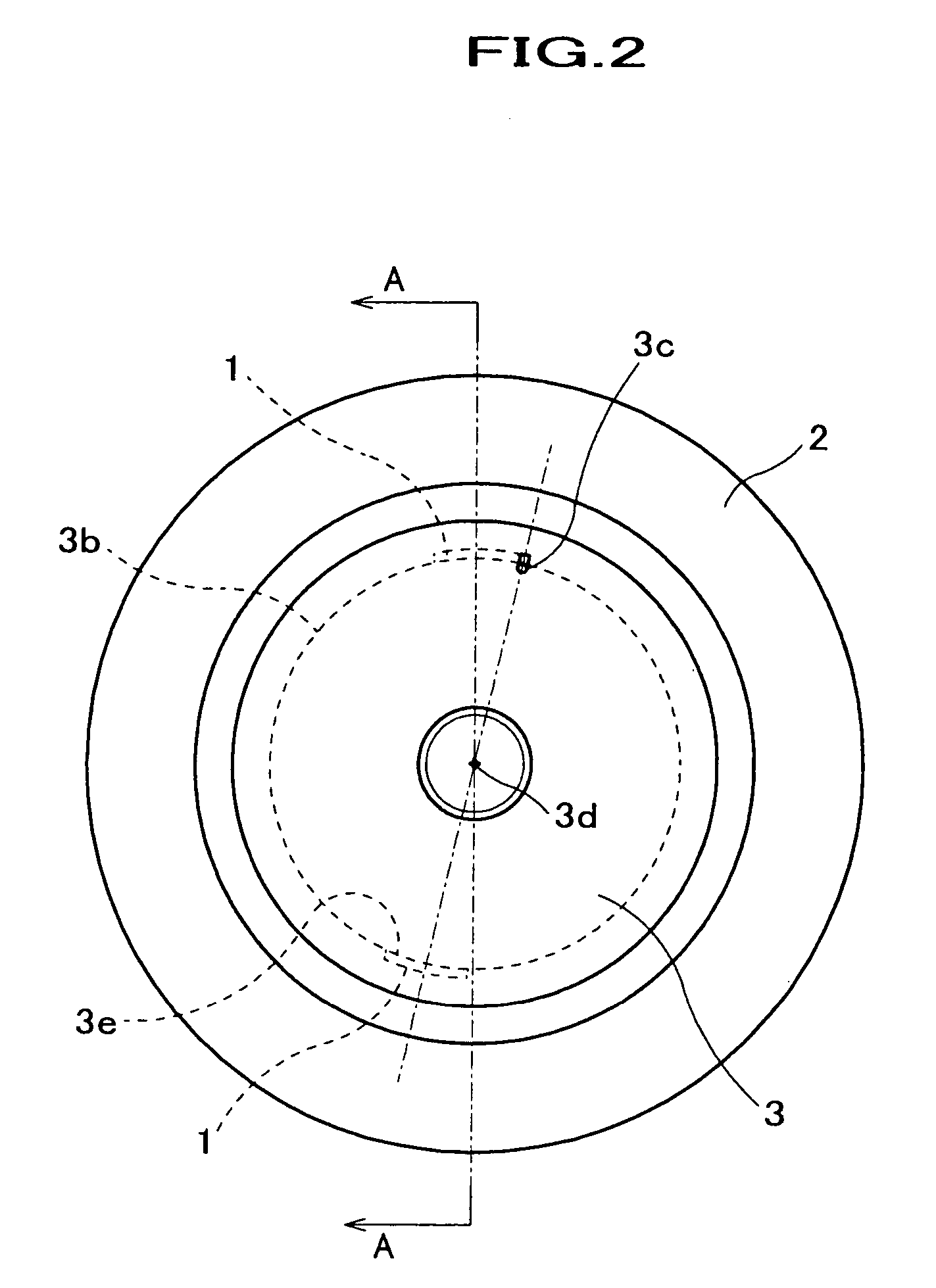

Tire pressure detection system and a wheel used therein

InactiveUS7091840B2Running cost can be reducedGuaranteed continuous useThermometer detailsInflated body pressure measurementLine sensorWireless

Owner:HONDA MOTOR CO LTD

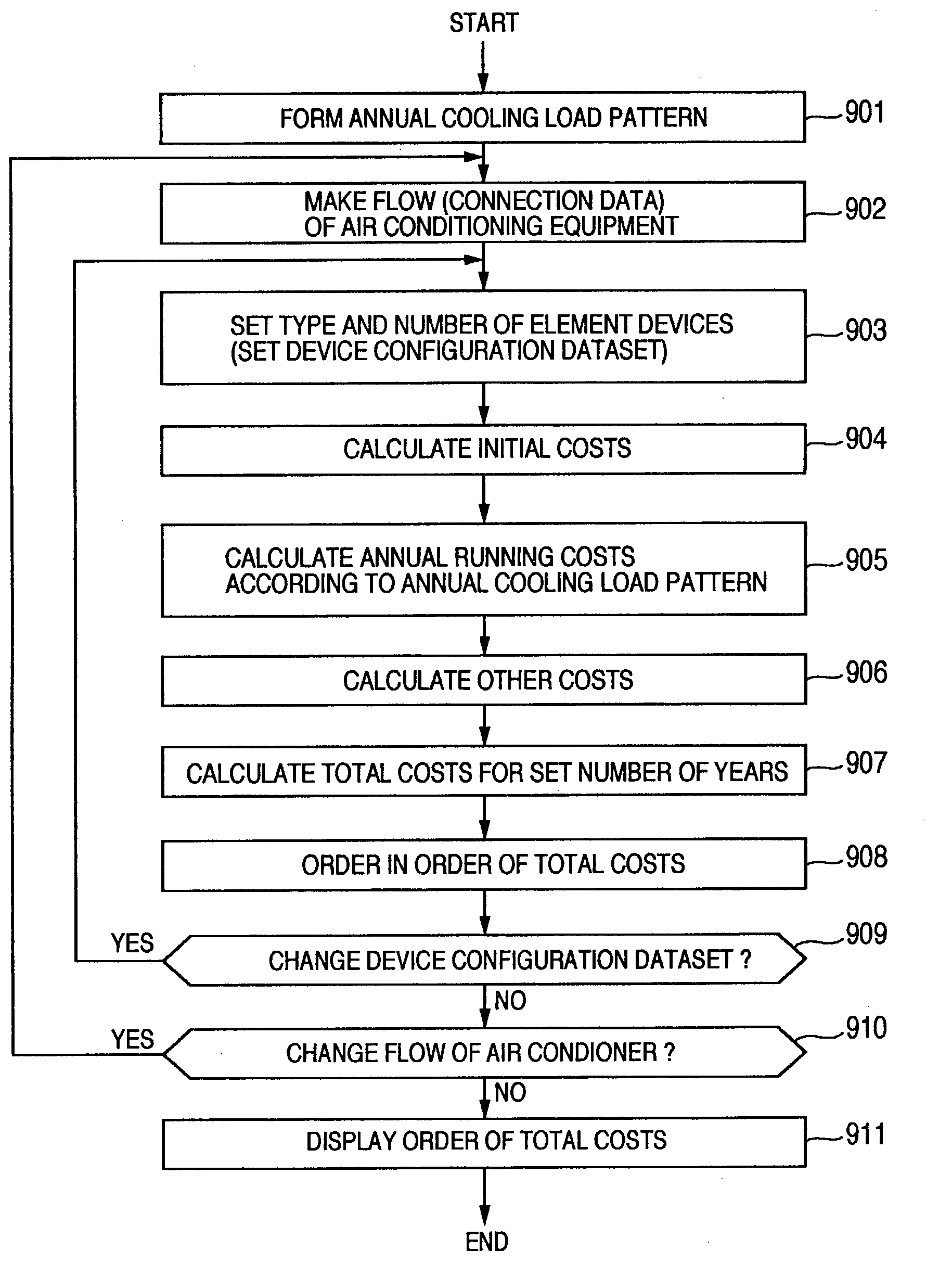

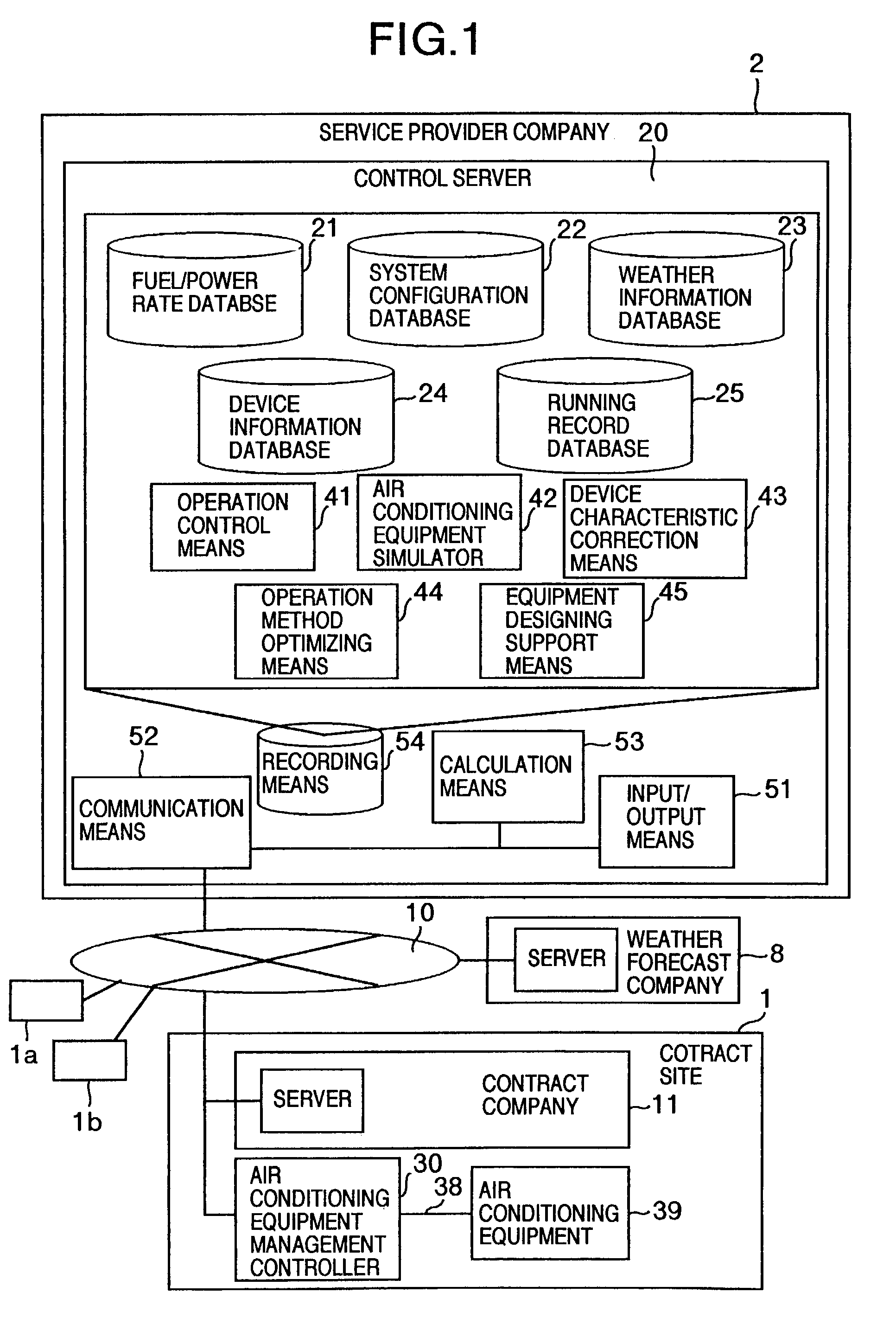

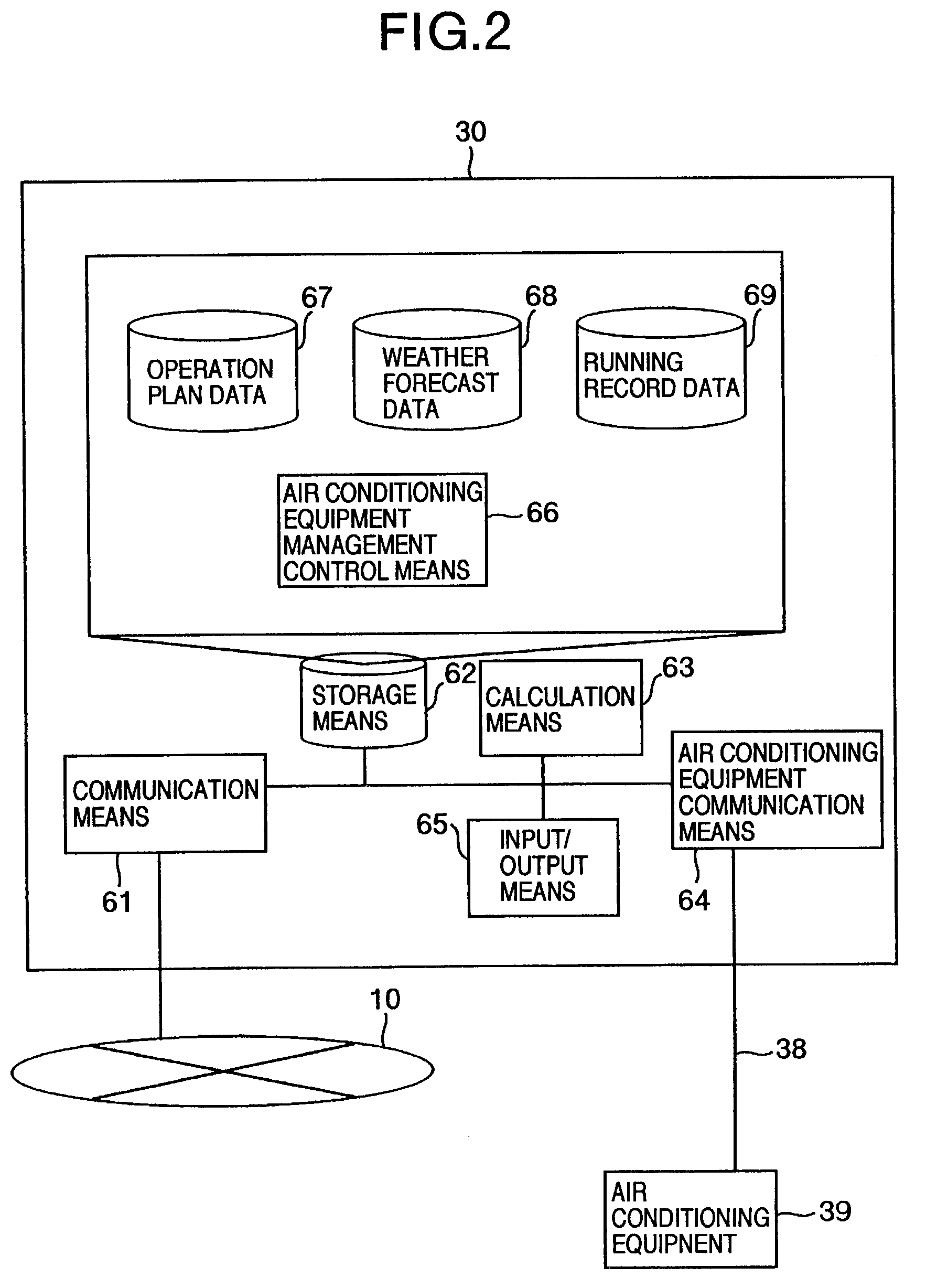

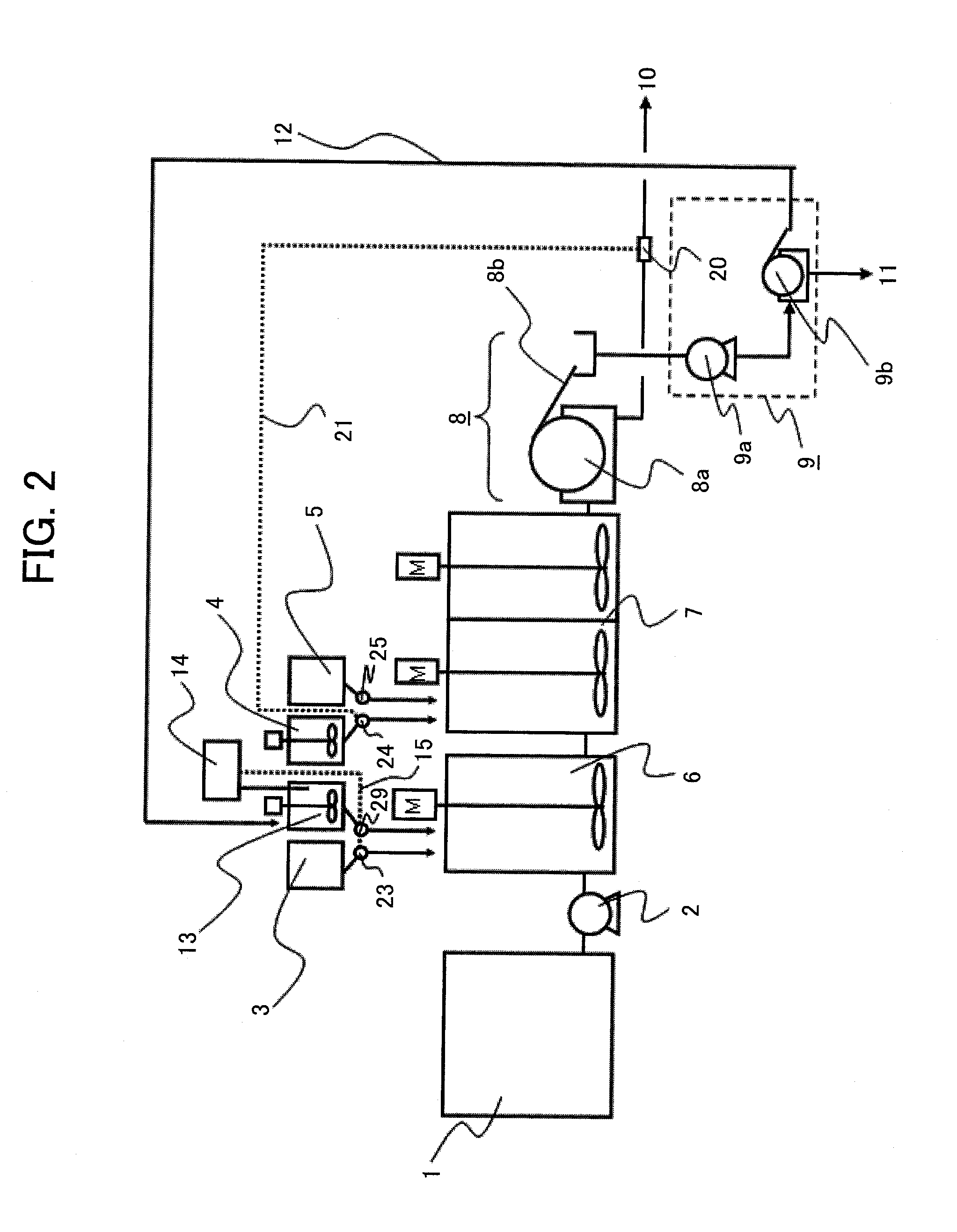

Air conditioning equipment operation system and air conditioning equipment designing support system

InactiveUS7225171B2Running cost can be reducedLow costMechanical apparatusSpecial tariff metersSupporting systemOperational system

A control server includes a device information database storing device characteristic data constituting the air conditioning equipment, a fuel / power rate database storing price and rate data regarding gas, oil, power and the like, a device characteristic and price database, an air conditioning equipment simulator for calculating running costs by using the data stored in the fuel / power rate database, and communication portion for performing communications through a network. The control server, and an air conditioning management controller for managing and controlling the air conditioning equipment provided with the communication portion for performing communications through the network, are connected to the network. An operation plan is made by the control server, the operation plan is transmitted to the air conditioning equipment management controller for controlling the air conditioning equipment through the network, and the air conditioning equipment is controlled and operated according to the operation plan.

Owner:HITACHI LTD

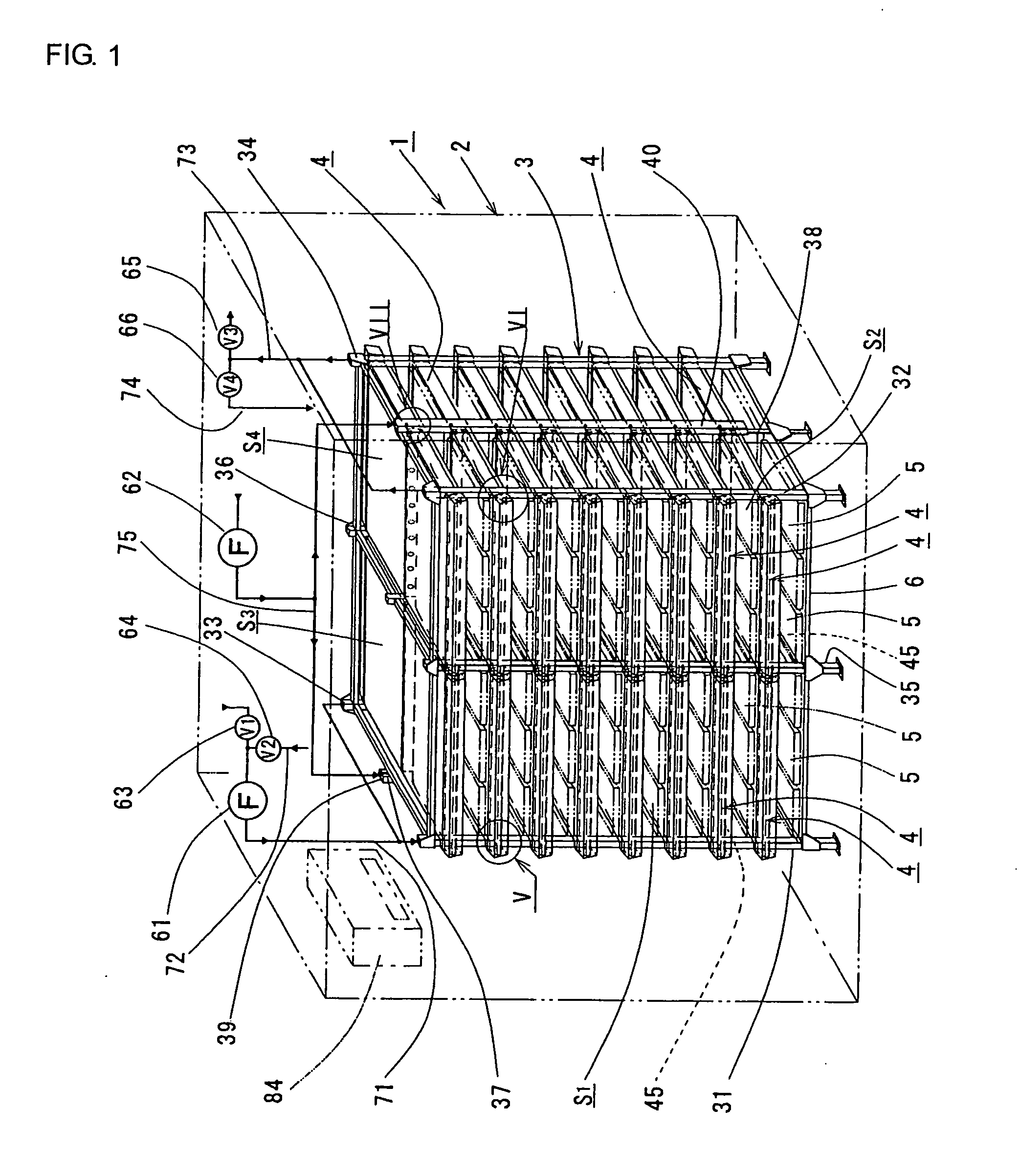

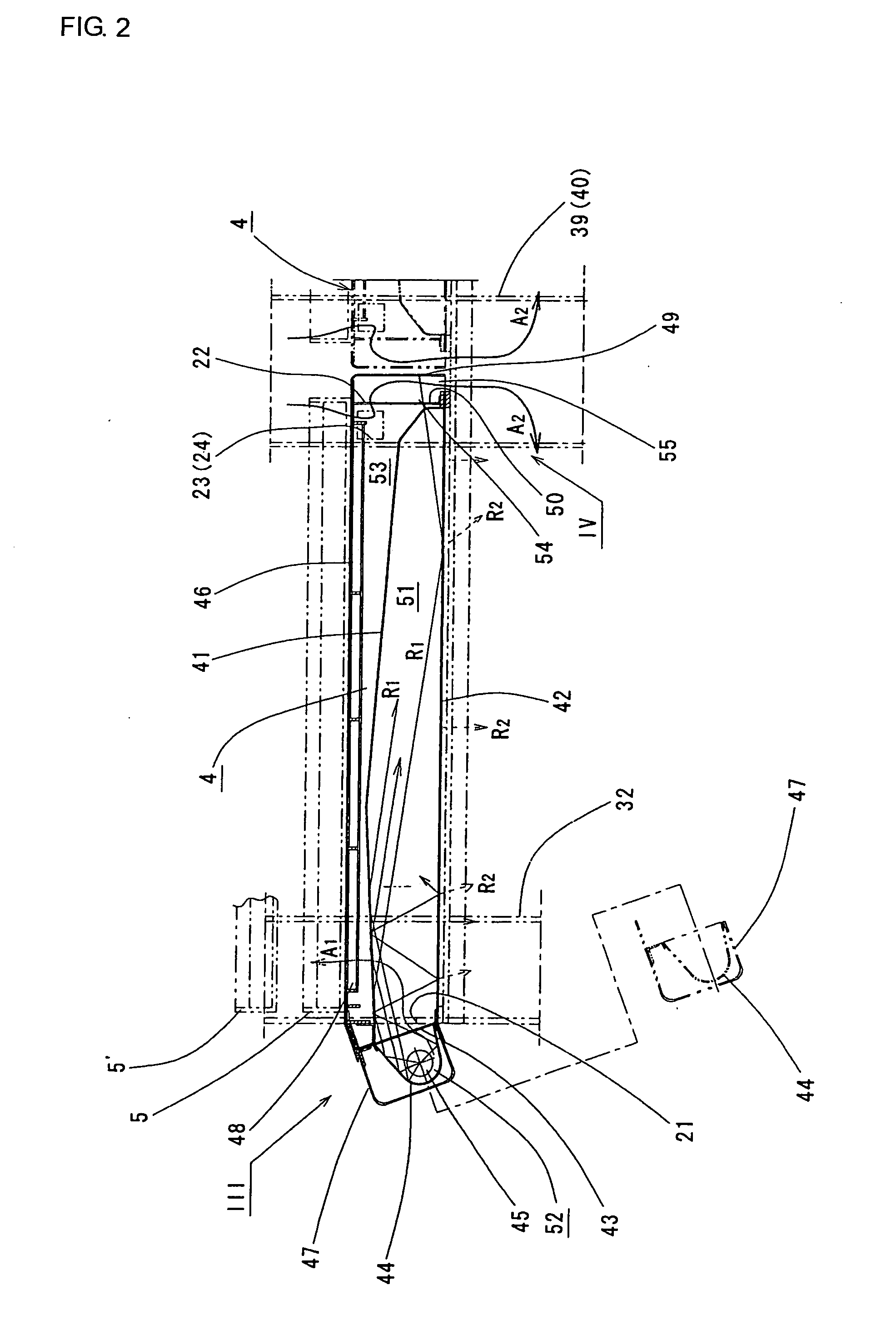

Illuminating Device and Plant Growth Apparatus Equipped With the Illuminating Device

InactiveUS20090301979A1Improve brightness uniformityReduction of plant growth costClimate change adaptationLighting heating/cooling arrangementsGrowth plantDirect illumination

An illumination device includes a light source 45, a reflection plate 41 for reflecting the light irradiated from the light source 45, and a transmissive and diffusive member 42 for transmitting and diffusing the light from the light source 45 and the reflected light from the reflection plate 41, so that the light transmitted and diffused in the member 42 may be used for illumination. With this indirect illuminating system, an entire area can be uniformly illuminated with high efficiency, almost free of luminance spots. When the illuminating device is used in a plant growth apparatus, uniformity of plant growth is enhanced and the yield of the plants is improved. In addition, space for planting can be utilized to the maximum so that the number of grown plants significantly increases as compared with the conventional direct illumination system.

Owner:TOKUJU IND

Flocculation-magnetic separation system

InactiveUS20120043264A1Running cost can be reducedQuality improvementIon-exchanger regenerationElectrostatic separationMagnetic powderEngineering

A flocculation-magnetic separation is provided which reduces the usage amount of flocculation agents as well as the usage amount of magnetic powders and realizes an improvement in the quality of treated water.In a flocculation-magnetic separation system comprising a flocculation section generating magnetic flocks by adding flocculant agents and magnetic powders to wastewater that is a target to be treated, and a magnetic separation section separating the generated magnetic flocks by magnetic force, the flocculation-magnetic separation system being adapted to remove from the wastewater substances to be eliminated, by separating the magnetic flocks, the flocculation-magnetic separation system includes a magnetic material recovery section breaking down the separated magnetic flocks by shearing force to recover magnetic materials, a recovered magnetic material returning line returning the recovered magnetic materials to the flocculation section, and a control section controlling an addition amount of the flocculant agents by a physical quantity based on the recovered magnetic materials returned.

Owner:JAPAN OIL GAS & METALS NAT CORP +1

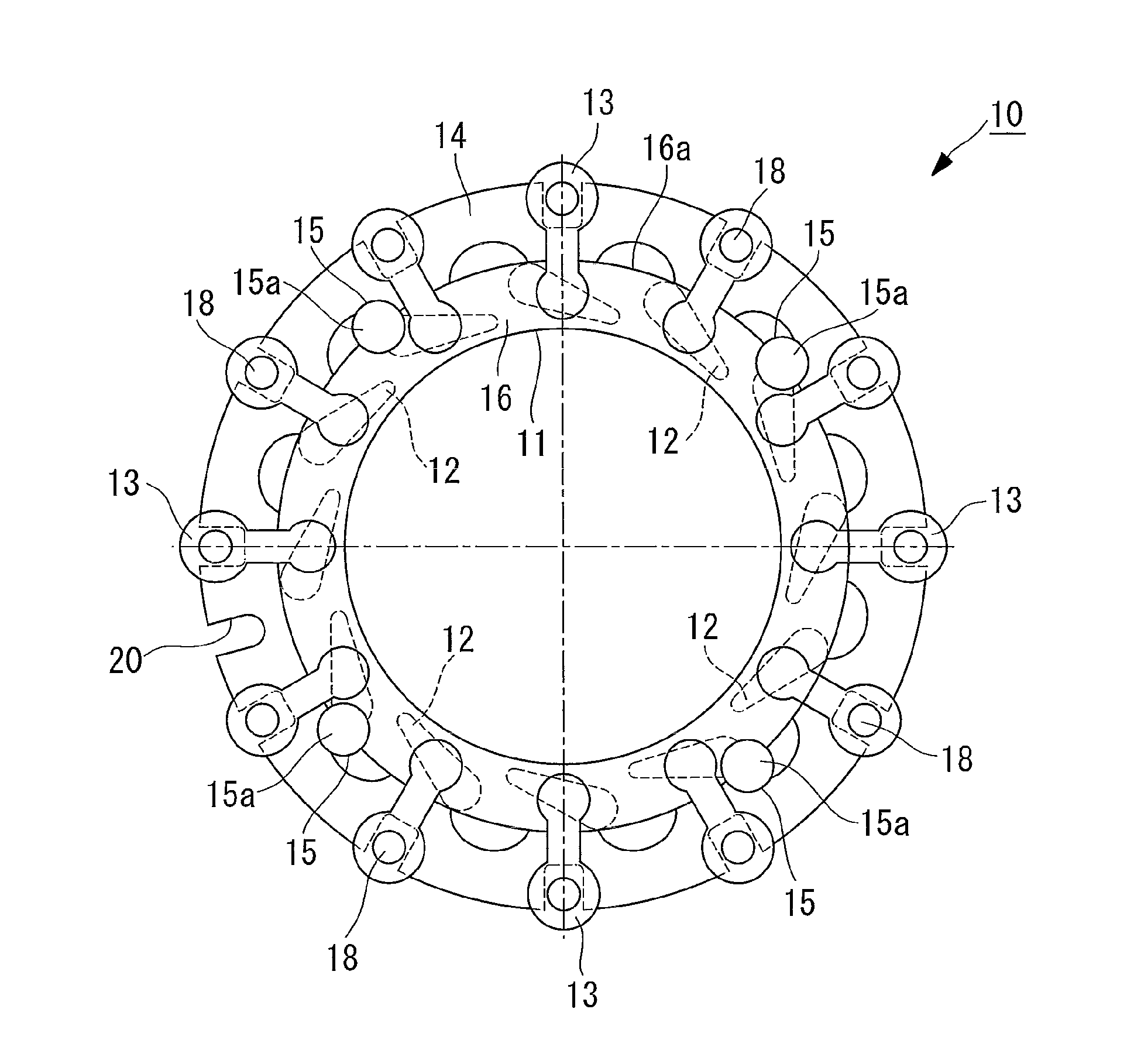

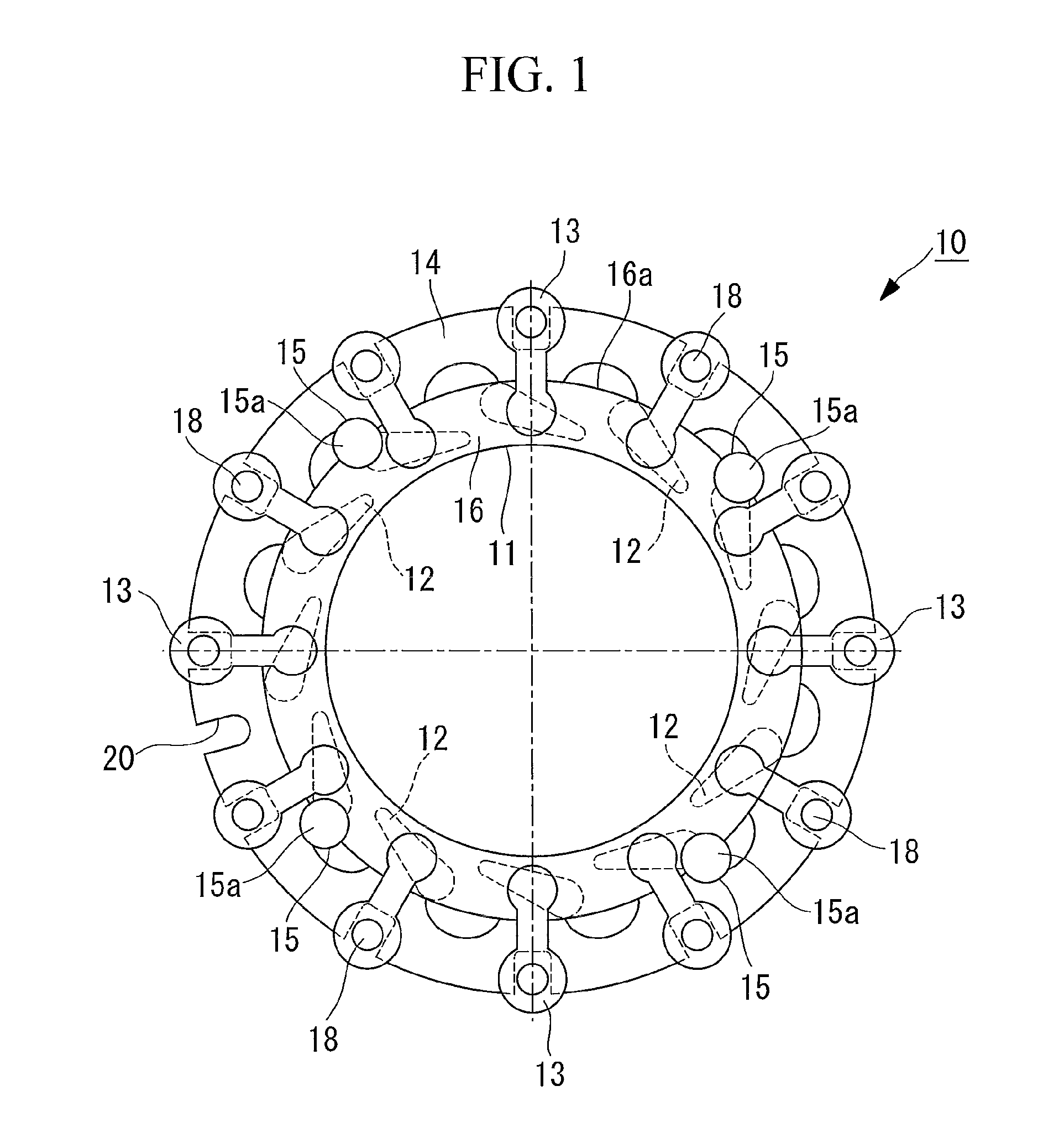

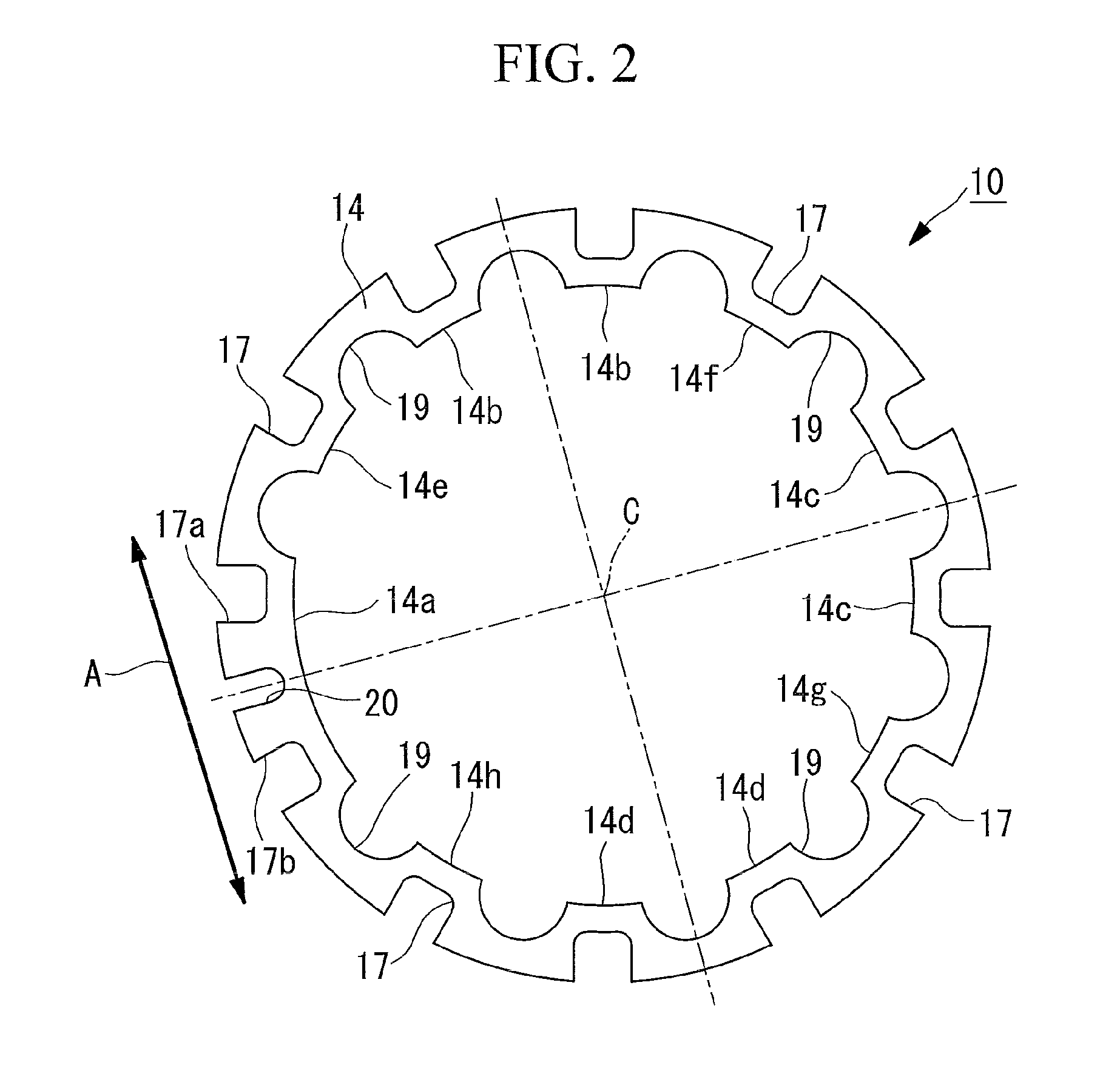

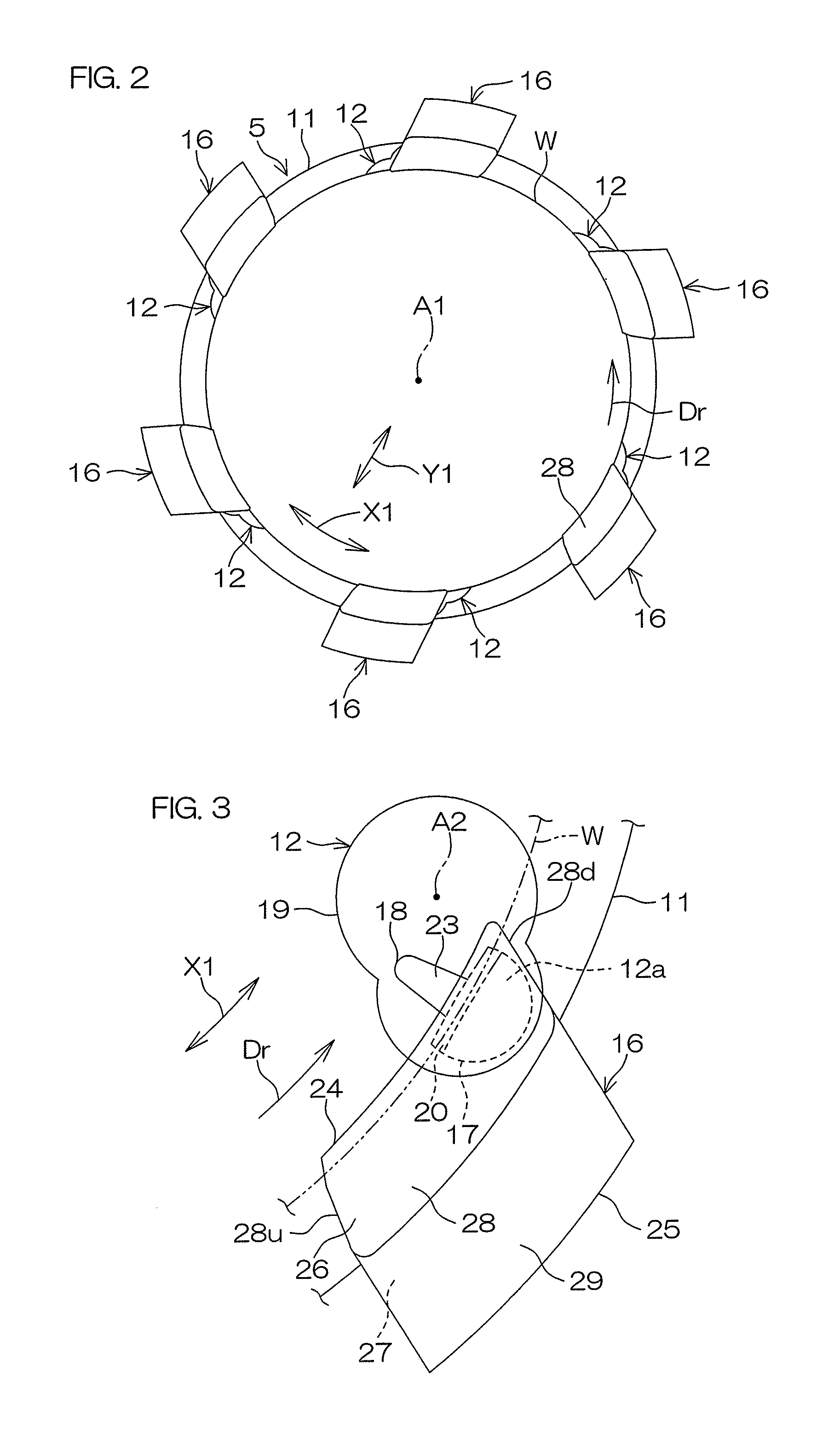

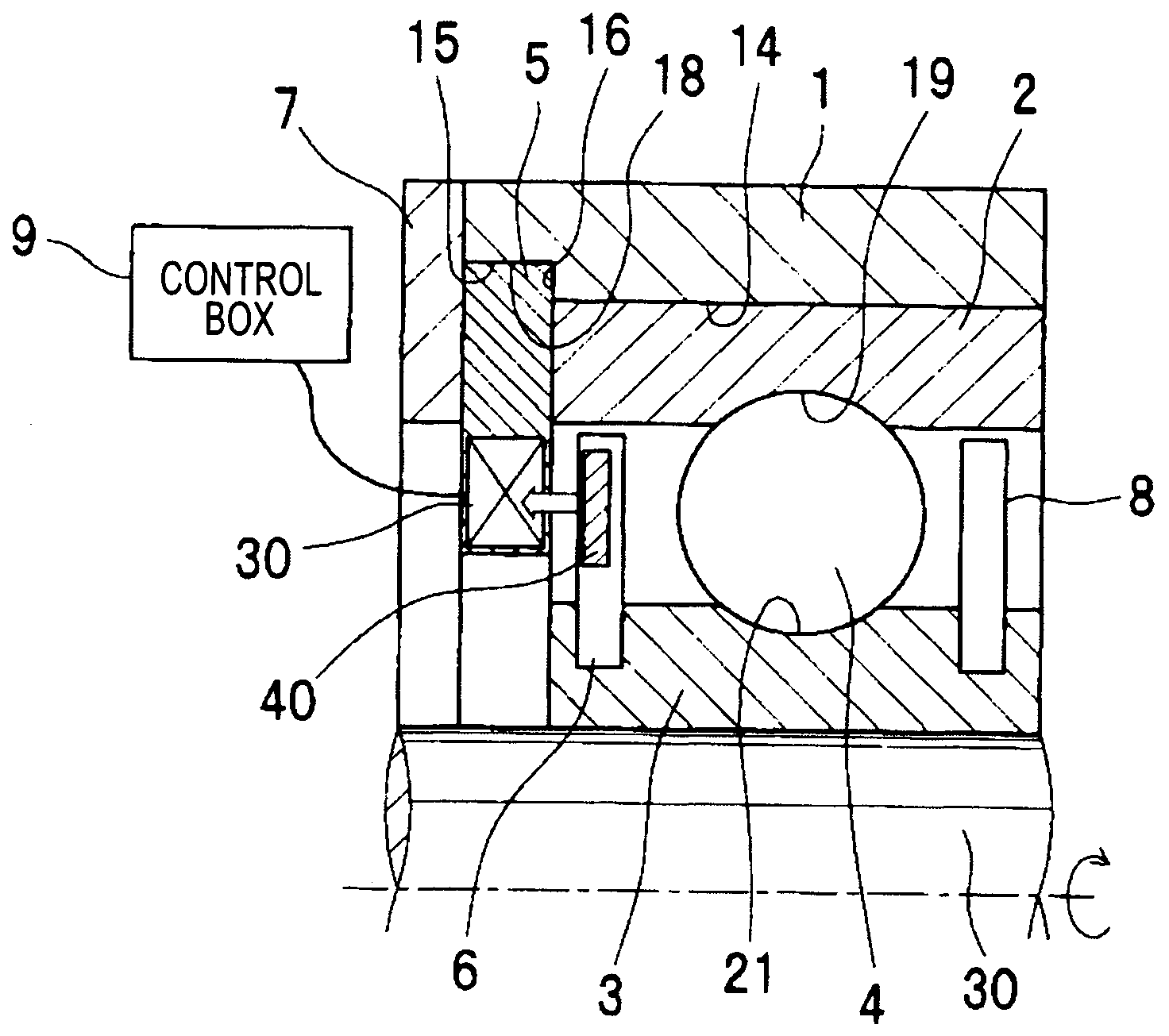

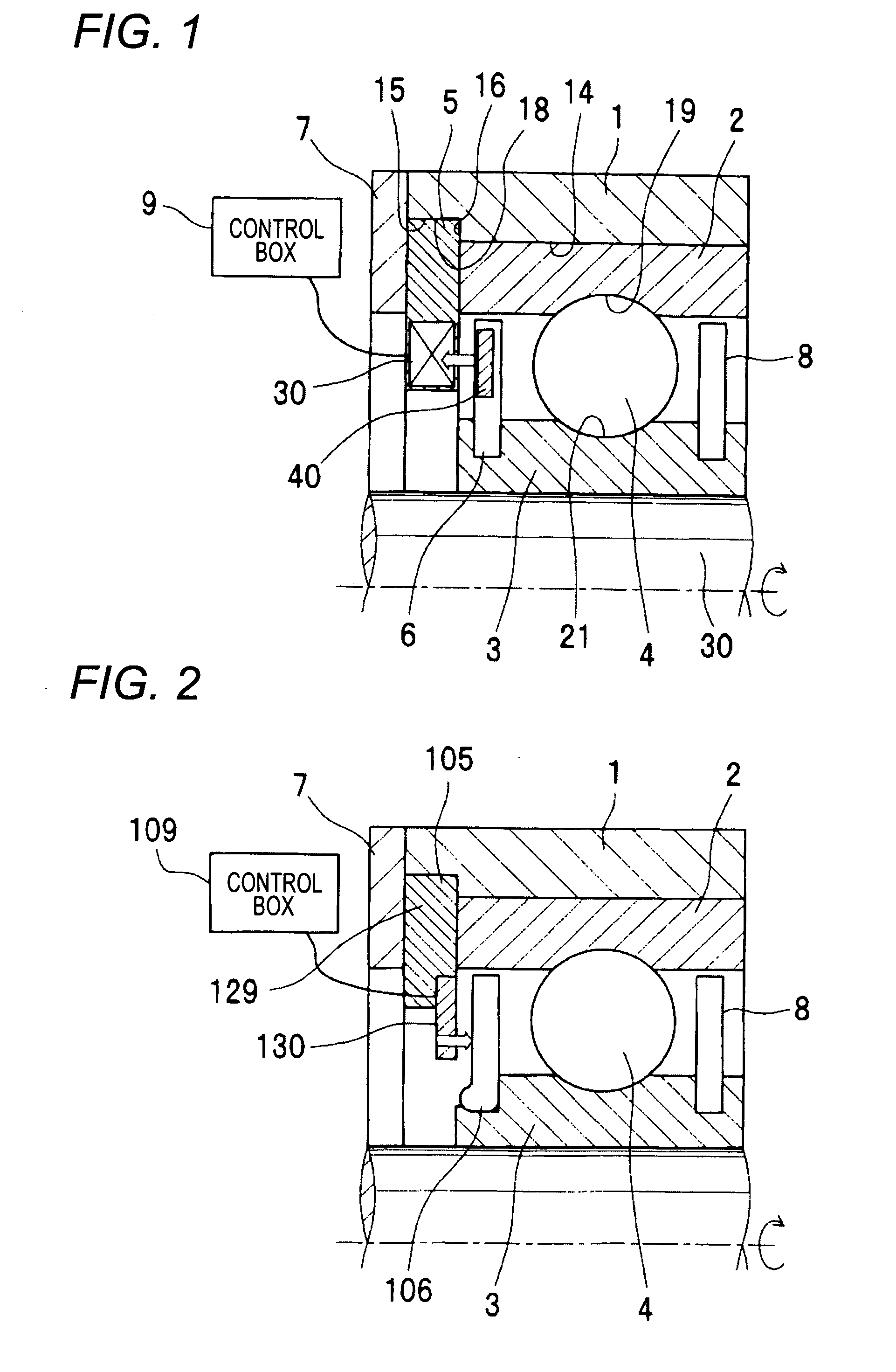

Variable nozzle mechanism

ActiveUS20100202874A1Reduce risk of damageReduce forceEngine manufactureWind motor controlEngineeringNozzle

When changing a nozzle blade angle by rotating a drive ring, a contact load generated between an inner circumferential surface of the drive ring and an outer circumferential surface of a mount can be reduced, allowing the drive ring to rotate smoothly and reducing the amount of wear and a driving force. It is also possible to reduce an impact force, such as engine vibrations, generated at the drive ring when an external force acts, reducing the risk of damage. A plurality of notches (19) are provided at an inner rim of the drive ring (14), and, among inner circumferential surfaces (14a, 14b, 14c, 14d, 14e, 14f, 14g, and 14h) located between the notches (19), when a driving force for rotating the drive ring (14) is applied, the inner diameters of the inner circumferential surfaces (14e, 14f, 14g, and 14h) where the contact load with the outer circumferential surface of a mount becomes large are made larger than the outer diameter of the outer circumferential surface.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

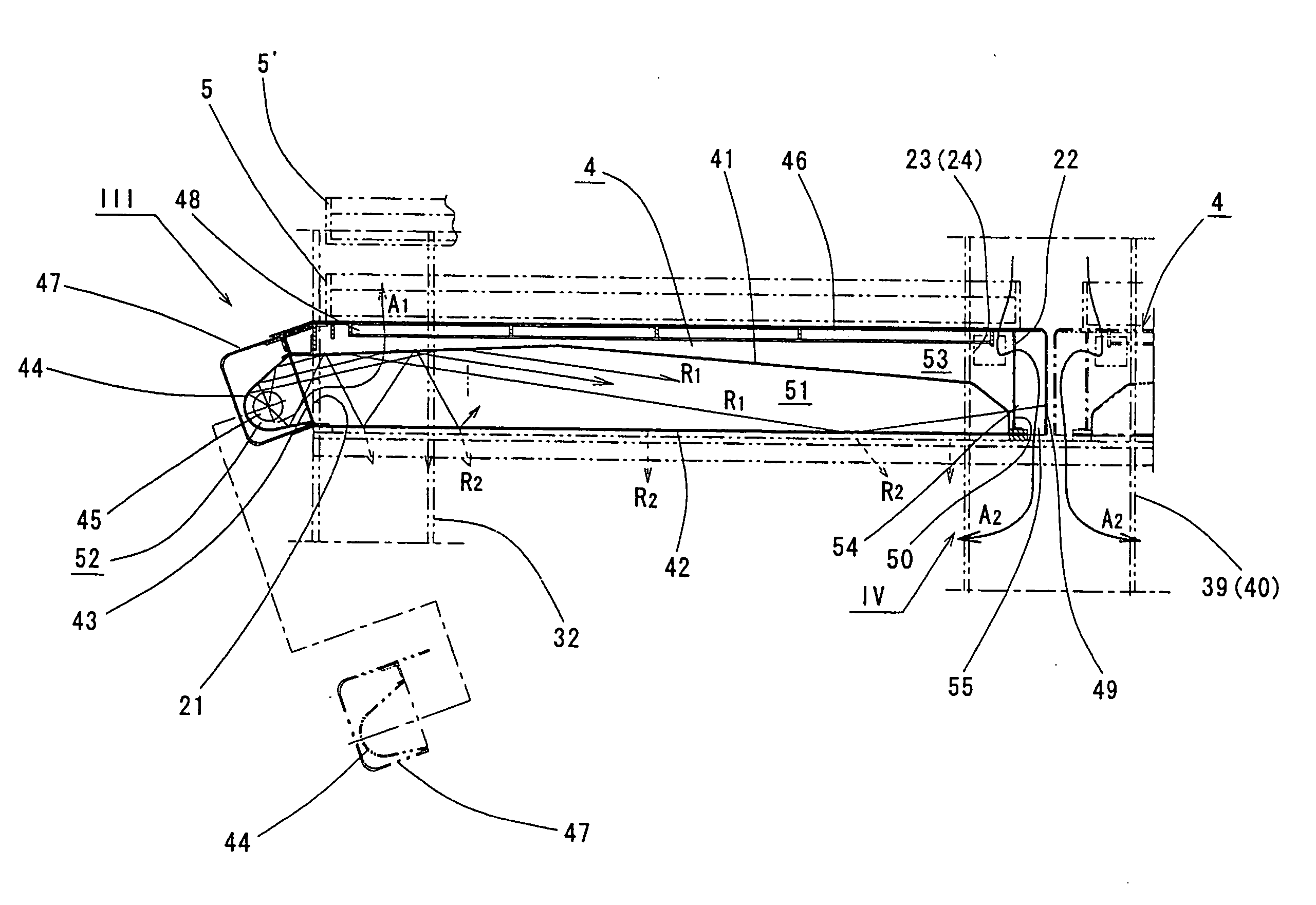

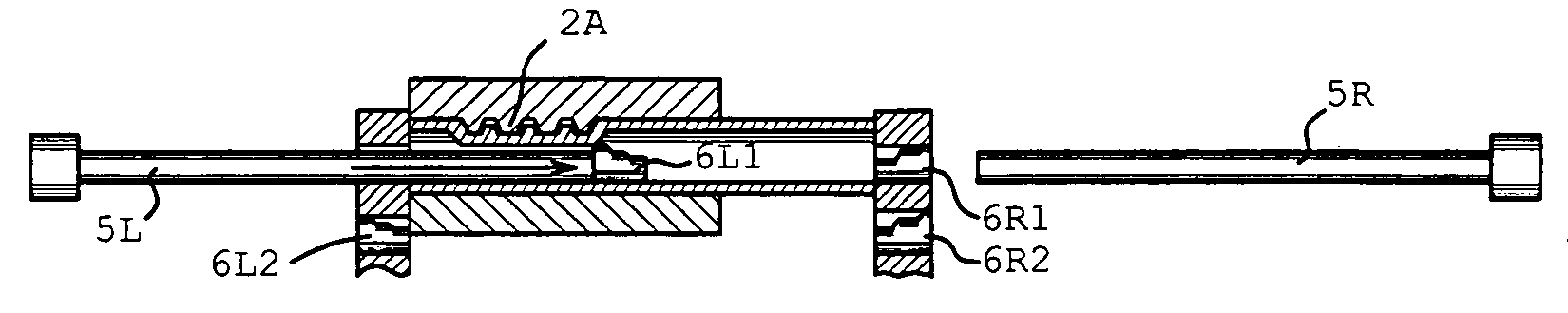

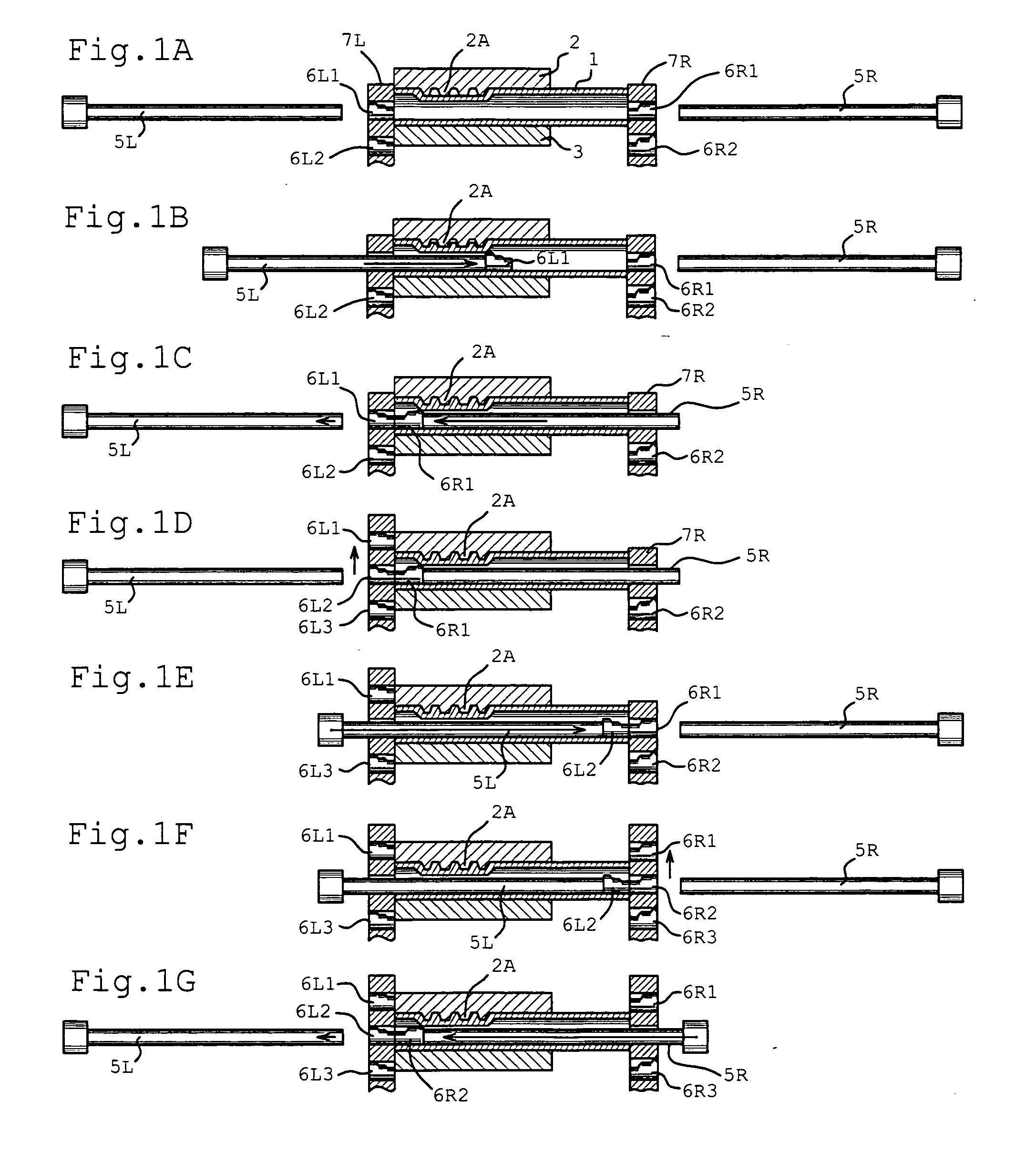

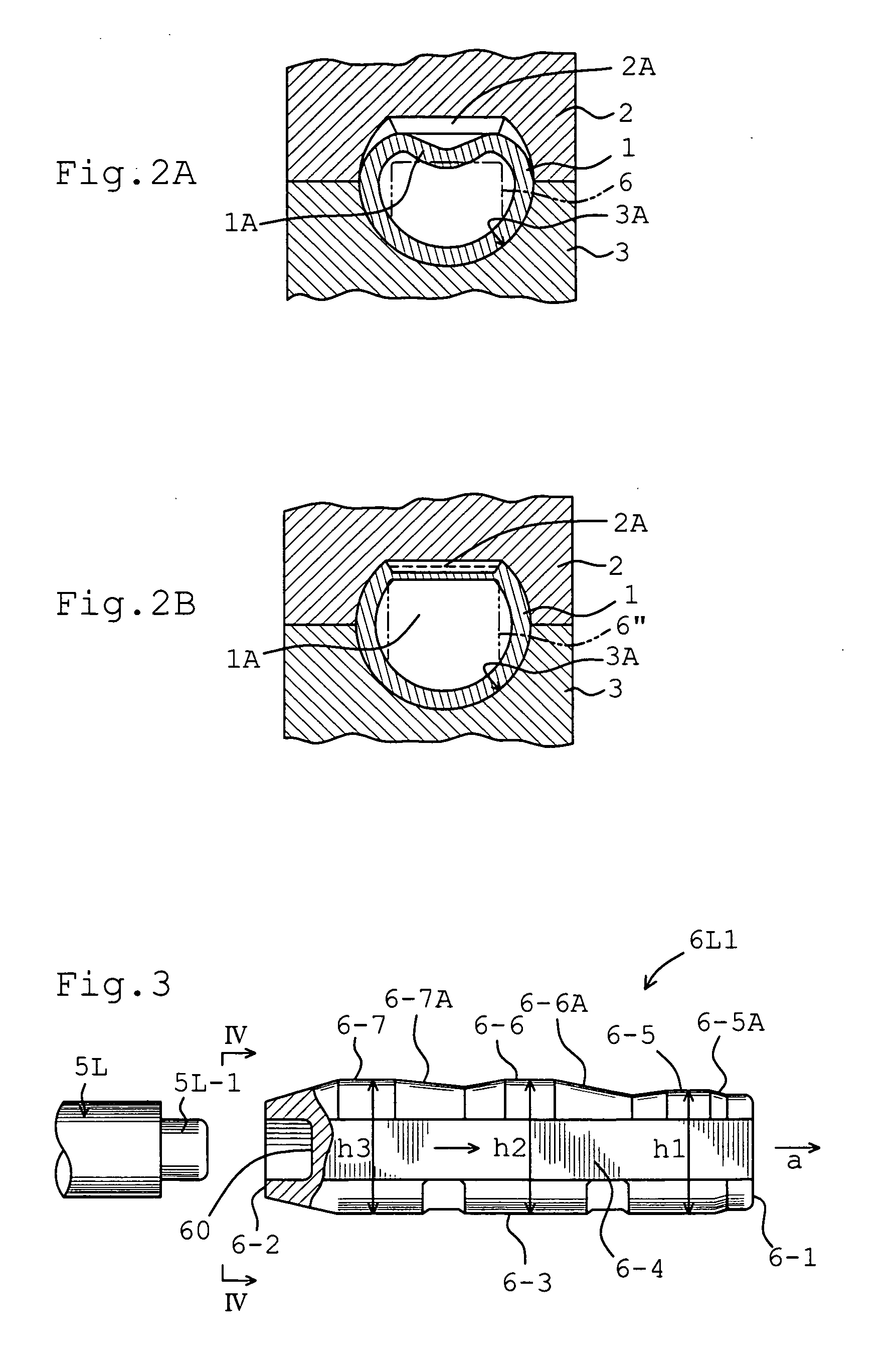

Method and apparatus for producing hollow rack bar and mandrel used for rack bar production

InactiveUS20060016238A1Low costLow running costNutsMetal-working apparatusEngineeringMechanical engineering

A system for forging a rack bar from a blank pipe. A blank pipe 1 is held between dies 2 and 3. Stockers 7L and 7R are arranged on respective sides of the die set. In the stockers 7L and 7R, left-handed shuttles 6L1, 6L2, 6L3, . . . 6Ln and right-handed shuttles 6R1, 6R2, 6R3 . . . 6Rn are stored. First, a left-handed presser rod 5L inserts the shuttles 6L1 to the blank pipe from the left-handed stocker 7L. Then, a right-handed presser rod 5R inserts the shuttles 6R1 to the blank pipe from the right-handed stocker 7R, causing the shuttles 6L1 to be entrained and returned to the left-handed stocker 7L. Vertical shift movement is alternately executed between the left-handed and right-handed stockers 7L and 7R, so that a shuttle of step-likely increased working height is selected for executing a working process.

Owner:MATSUOKA MINAKO +2

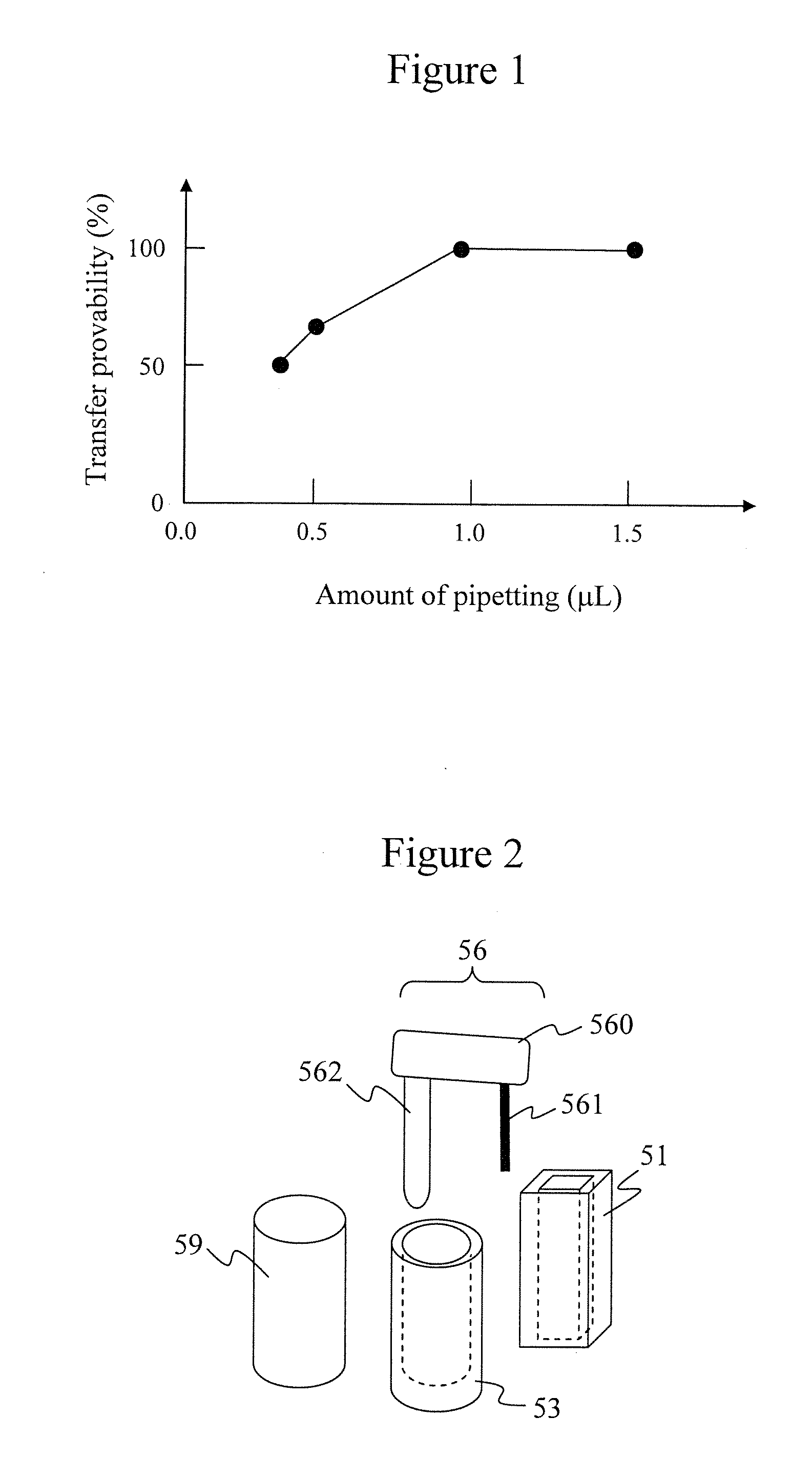

Autoanalyzer and pipetting nozzle for autoanalyzer

ActiveUS20110300035A1Superior in cutting off sample drippingLess liableMaterial analysis by optical meansBurettes/pipettesAutoAnalyzerContamination

There is provided a highly reliable autoanalyzer less liable to sample and reagent carry-over and capable of preventing contamination and precisely pipetting samples and reagents. Using a sample pipetting nozzle 27 having water-repellent surfaces, a sample is pipetted from a sample cell 25 to a reaction cell 4 having a hydrophilic bottom face.

Owner:HITACHI HIGH-TECH CORP

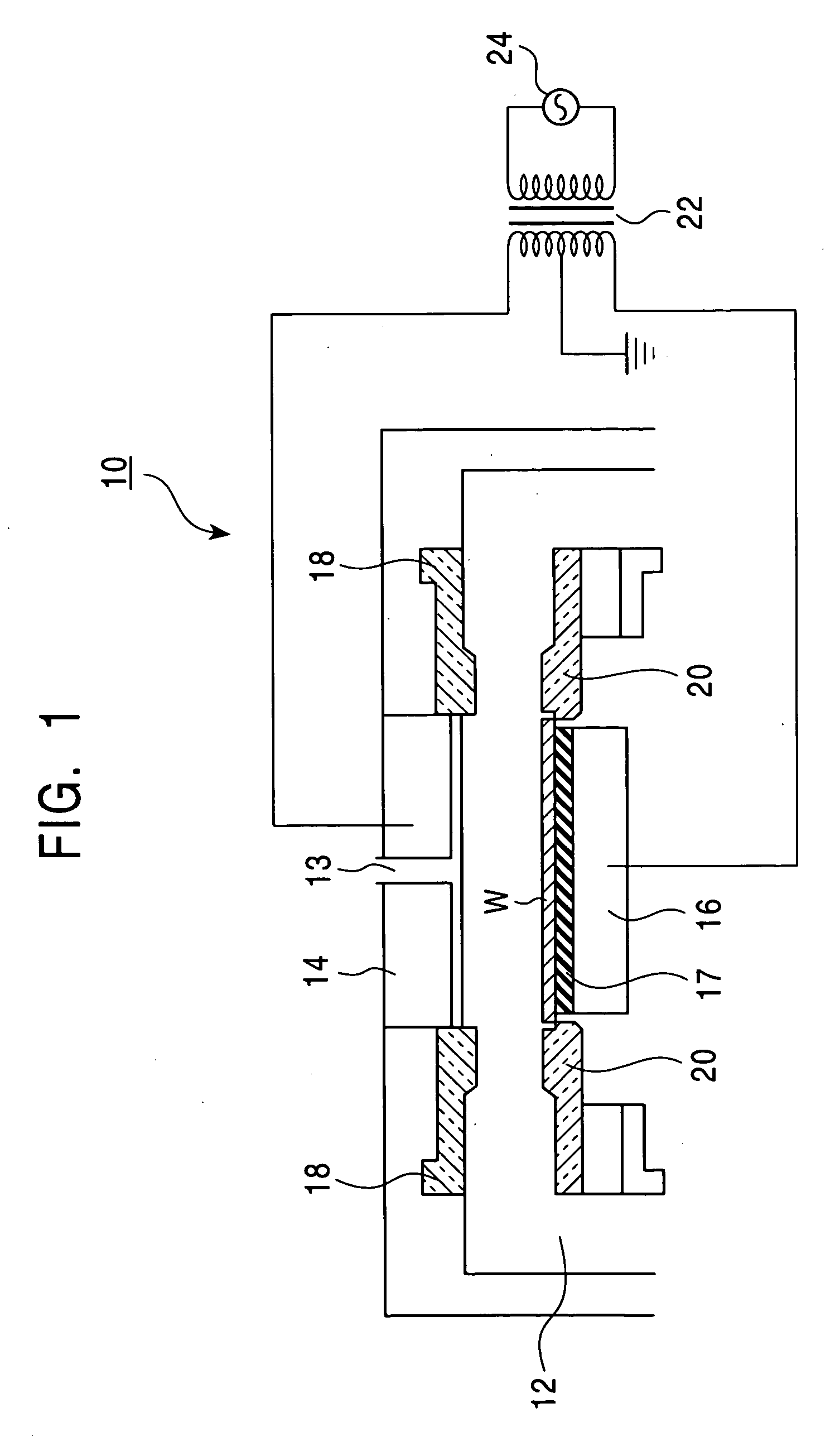

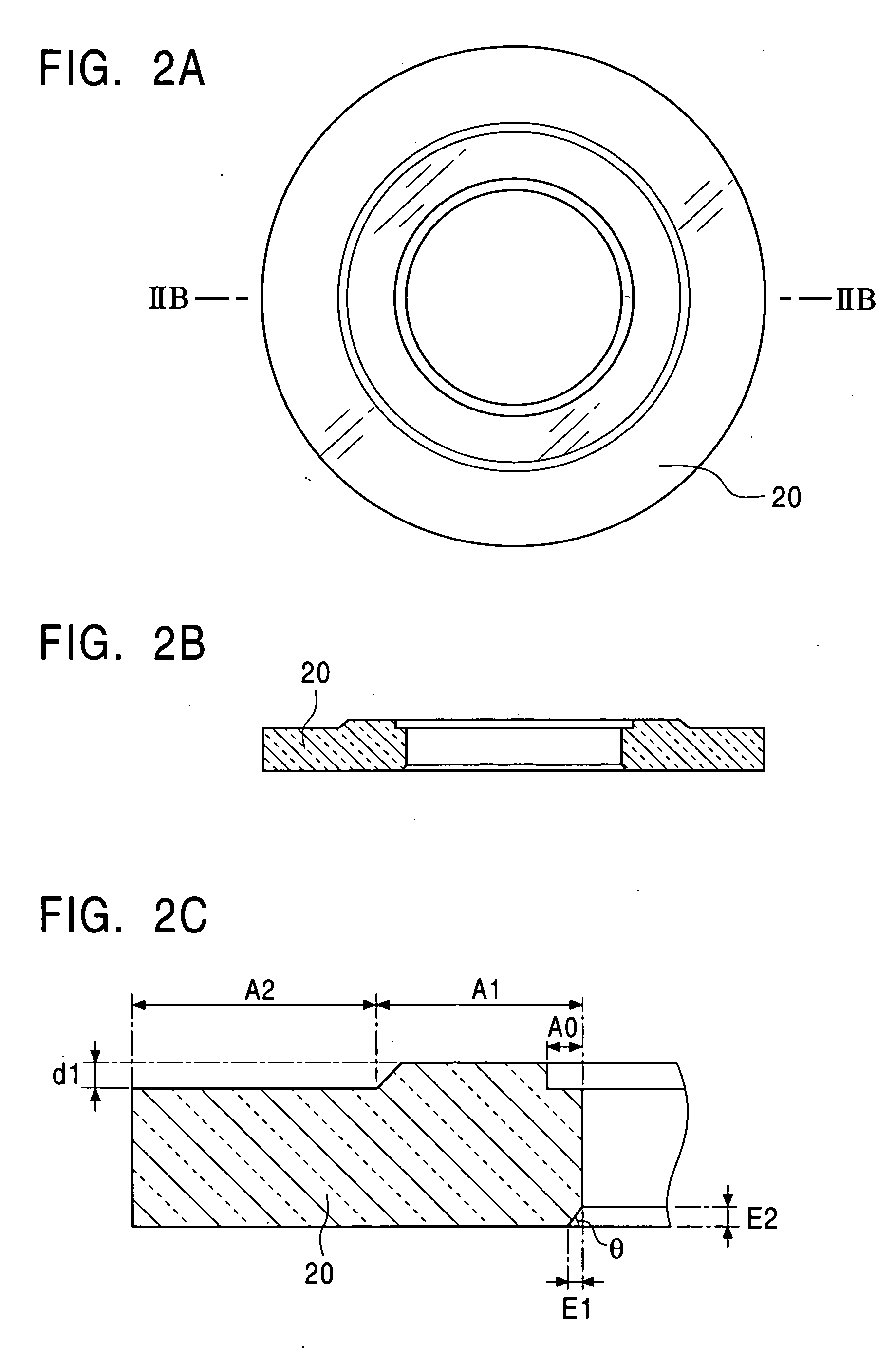

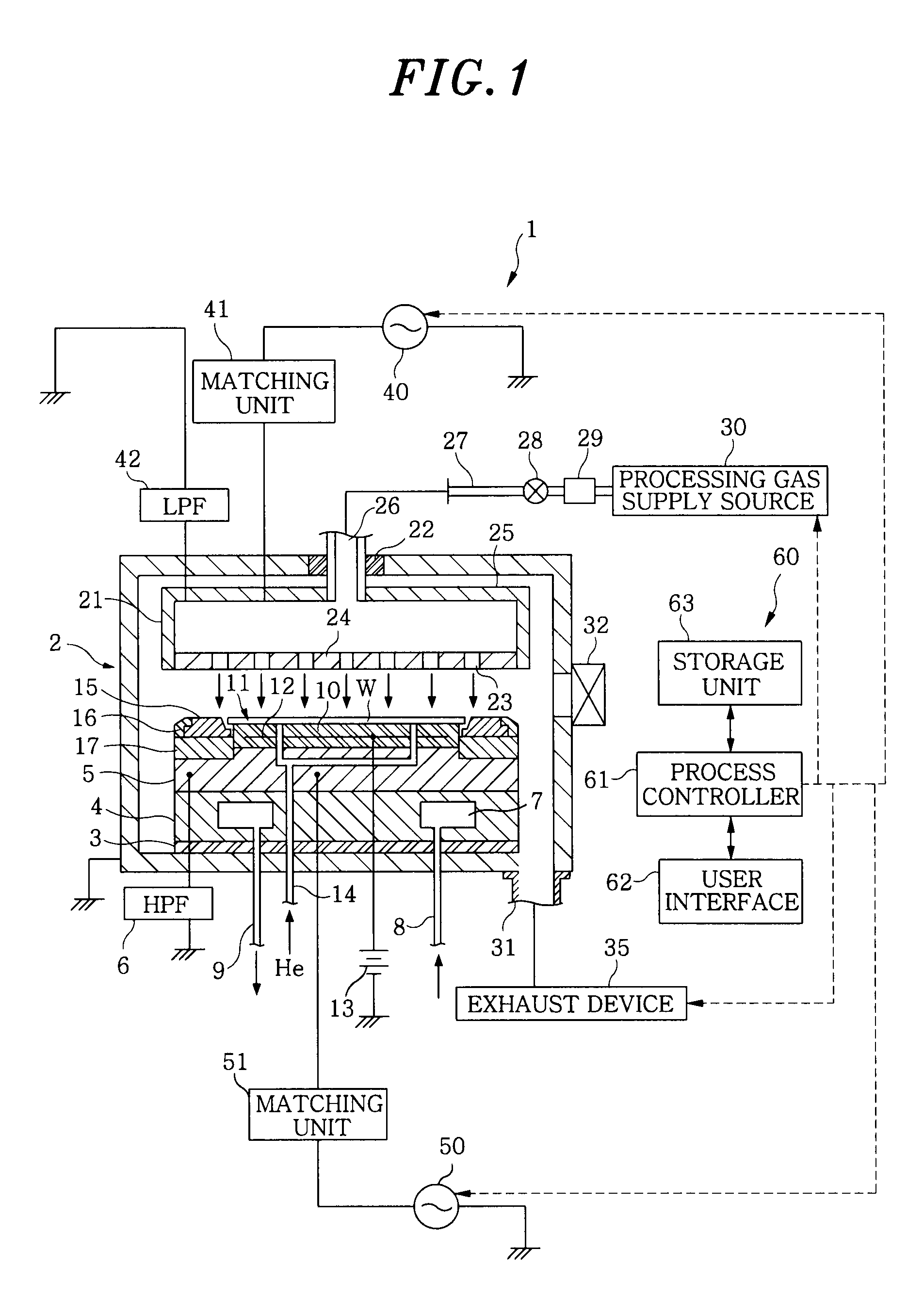

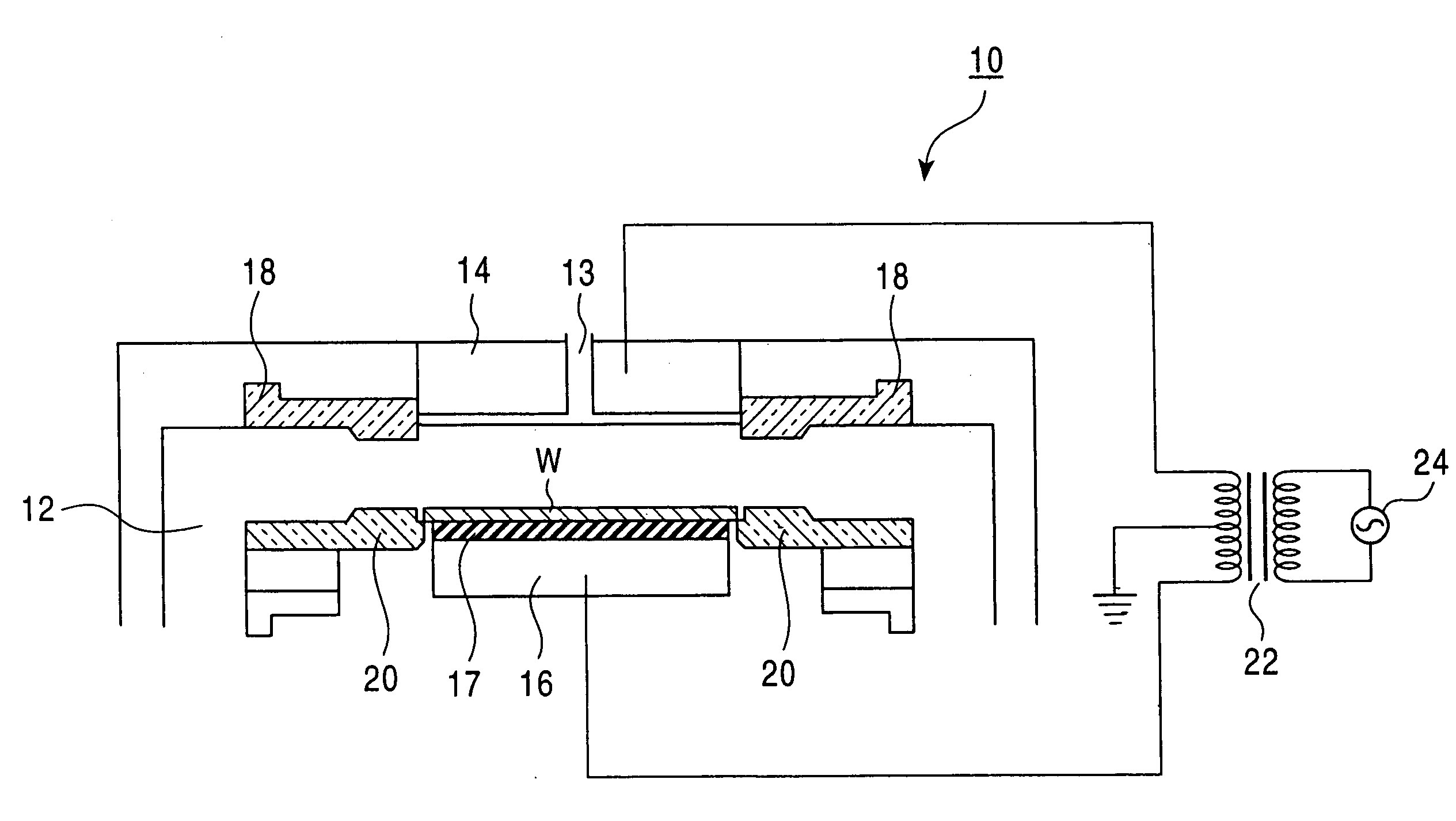

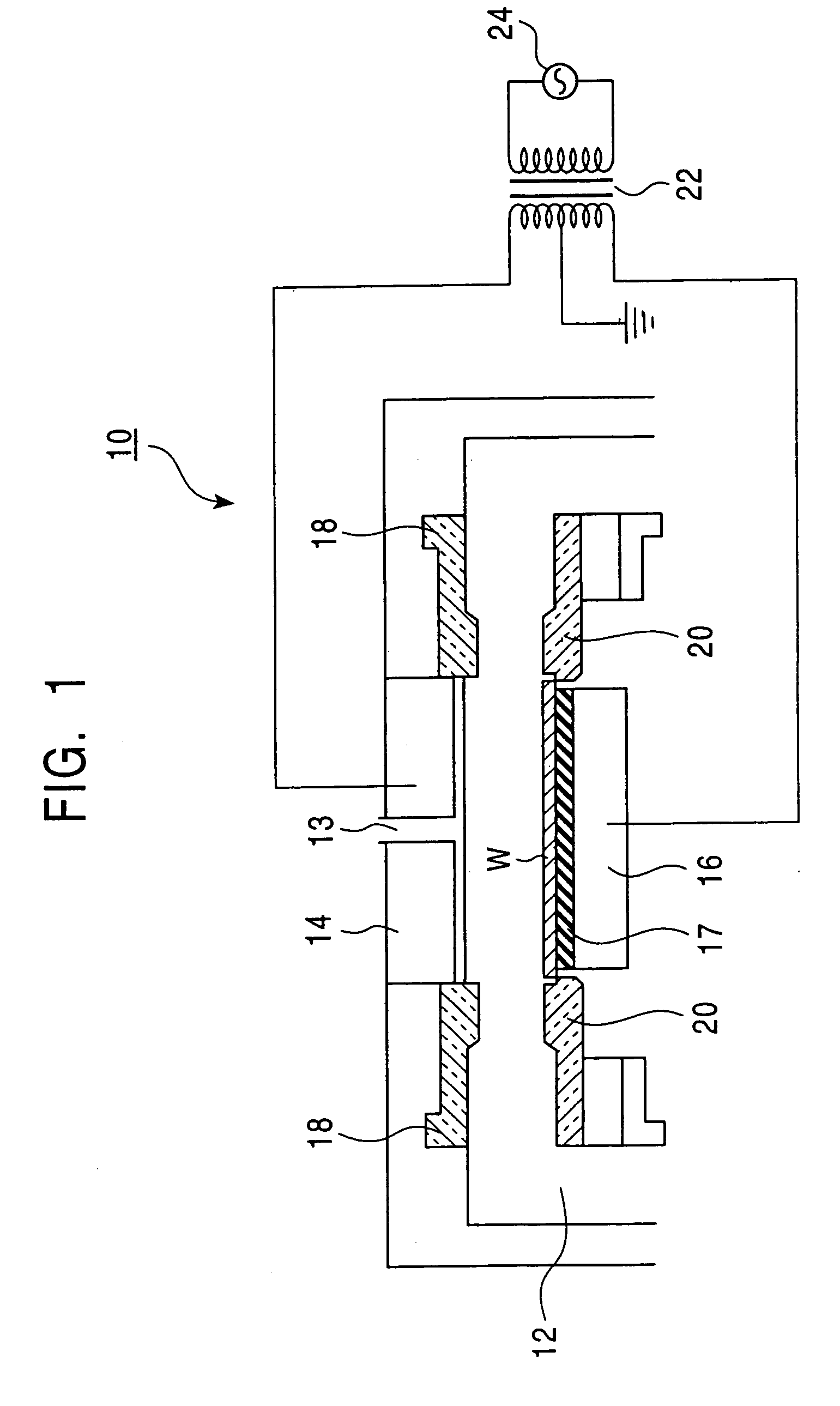

Quartz component for plasma processing apparatus and restoring method thereof

InactiveUS20040173319A1Running cost can be reducedImprove utilization efficiencyElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringQuartz

The main surface of a quartz component is divided by an offset into a first region having a larger height around an inner perimeter and a second region adjacent to the outer perimeter of the first region. Repeated restoration of a damaged component by forming a bulge on the first region and machining the bulge to make a flat surface while maintaining the offset enables long term use of the component.

Owner:KAWASAKI MICROELECTRONICS

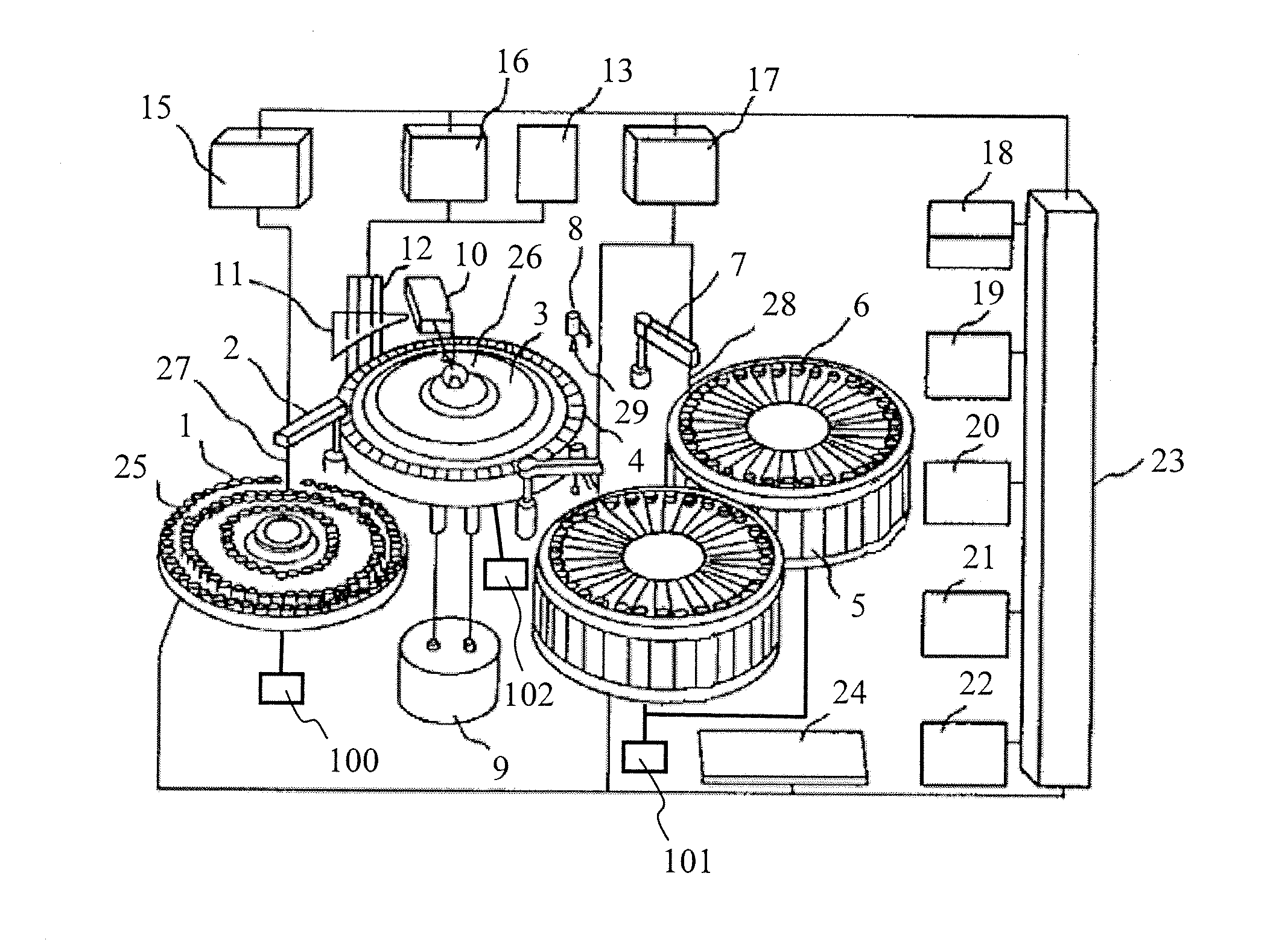

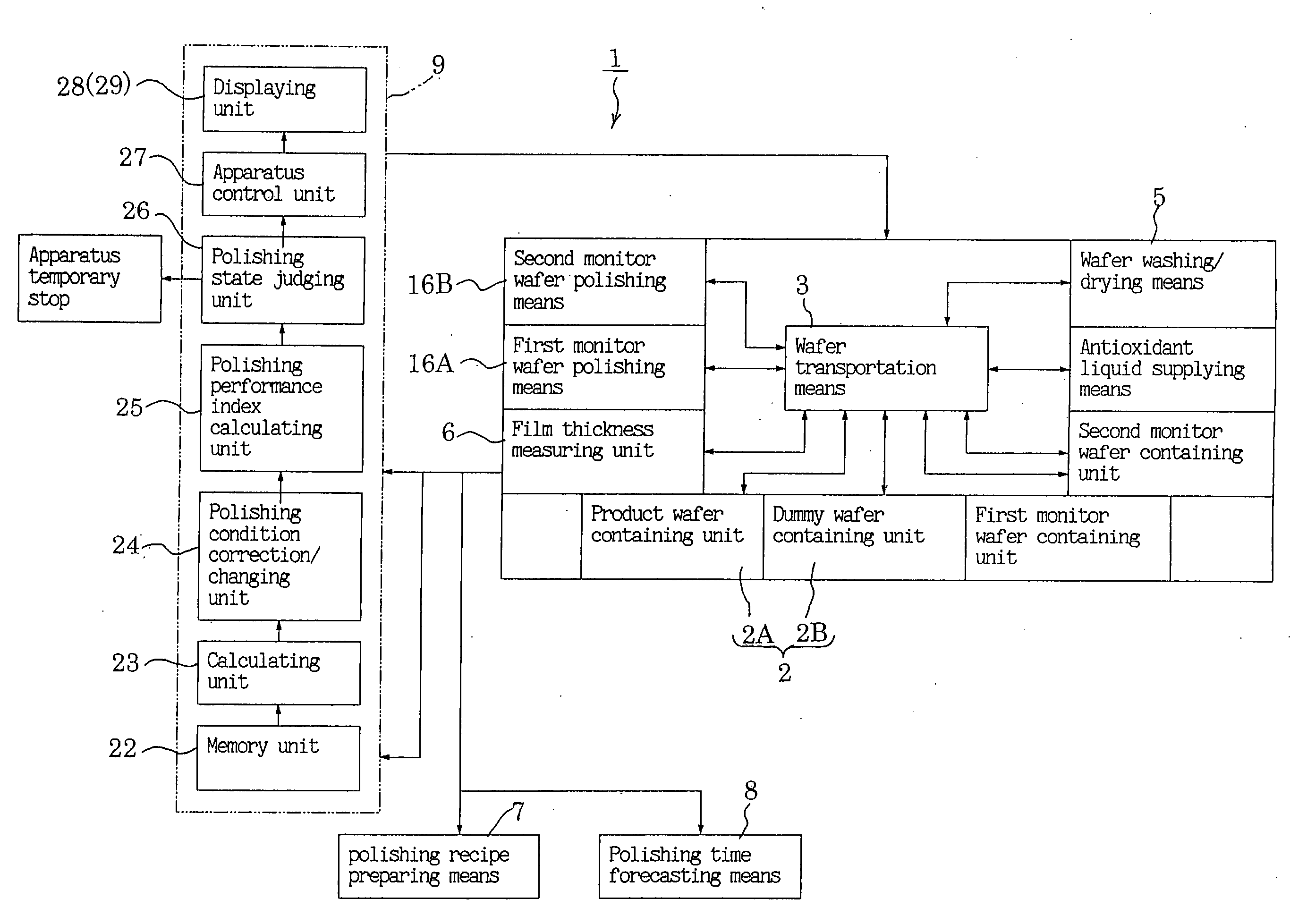

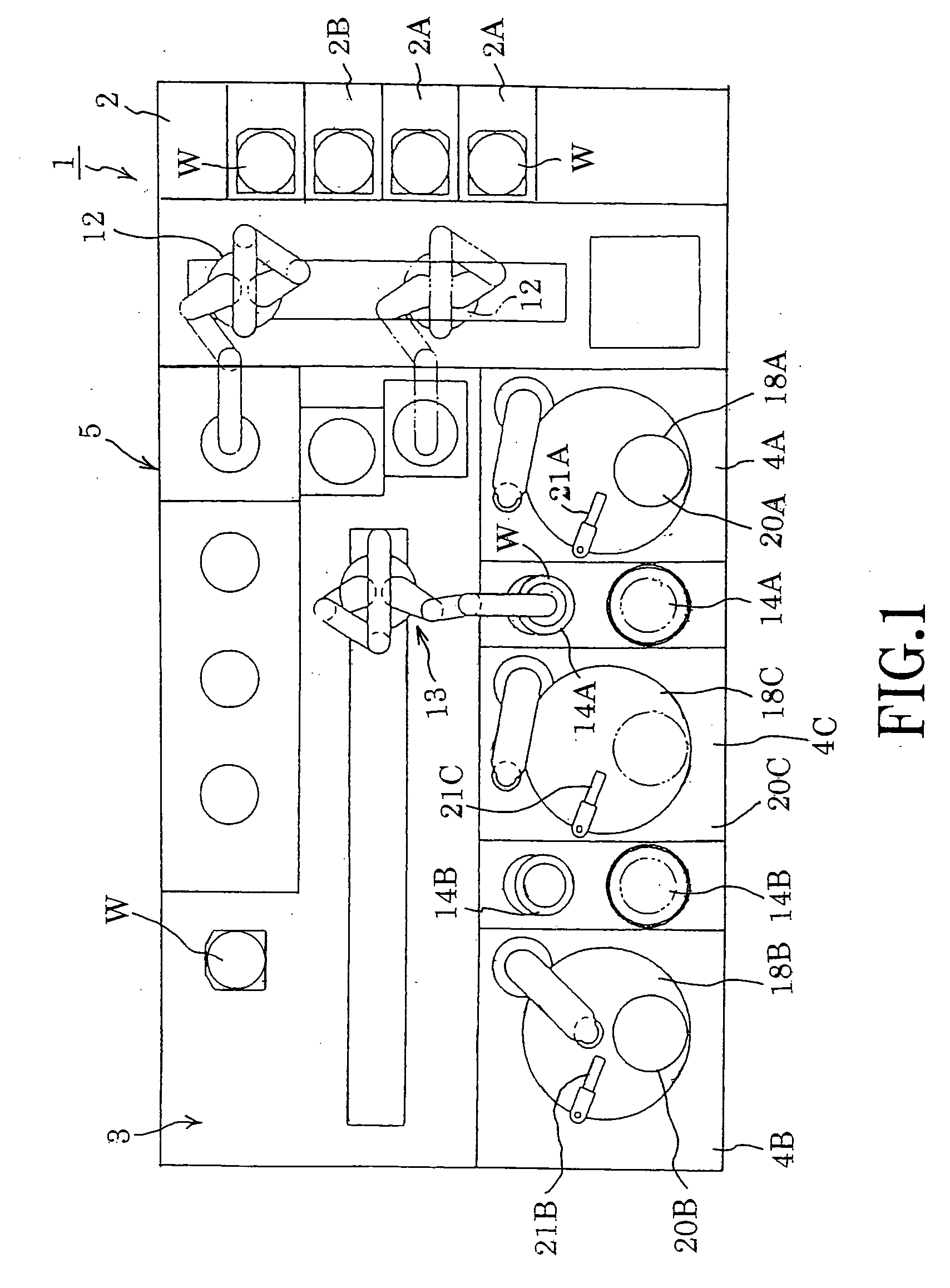

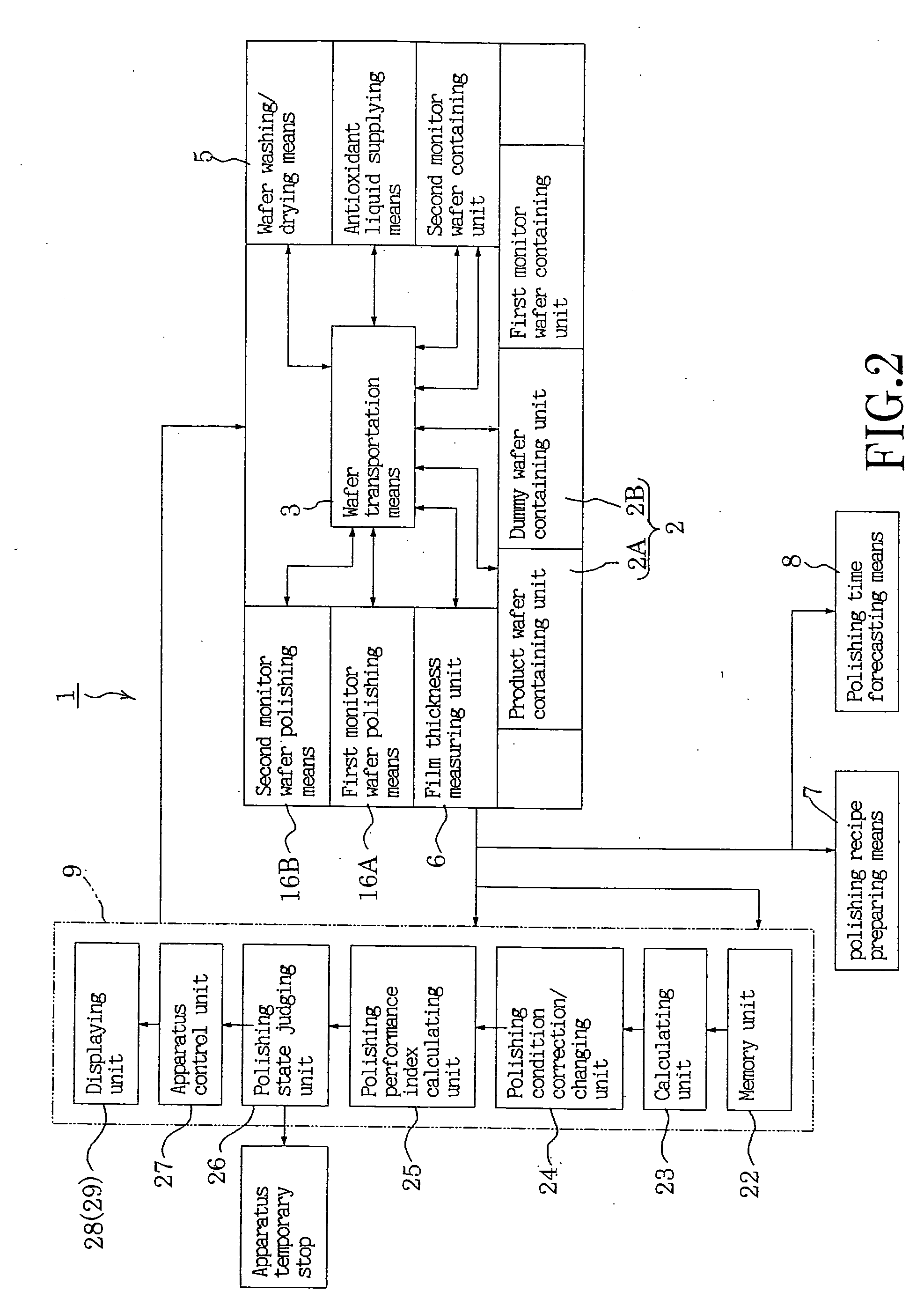

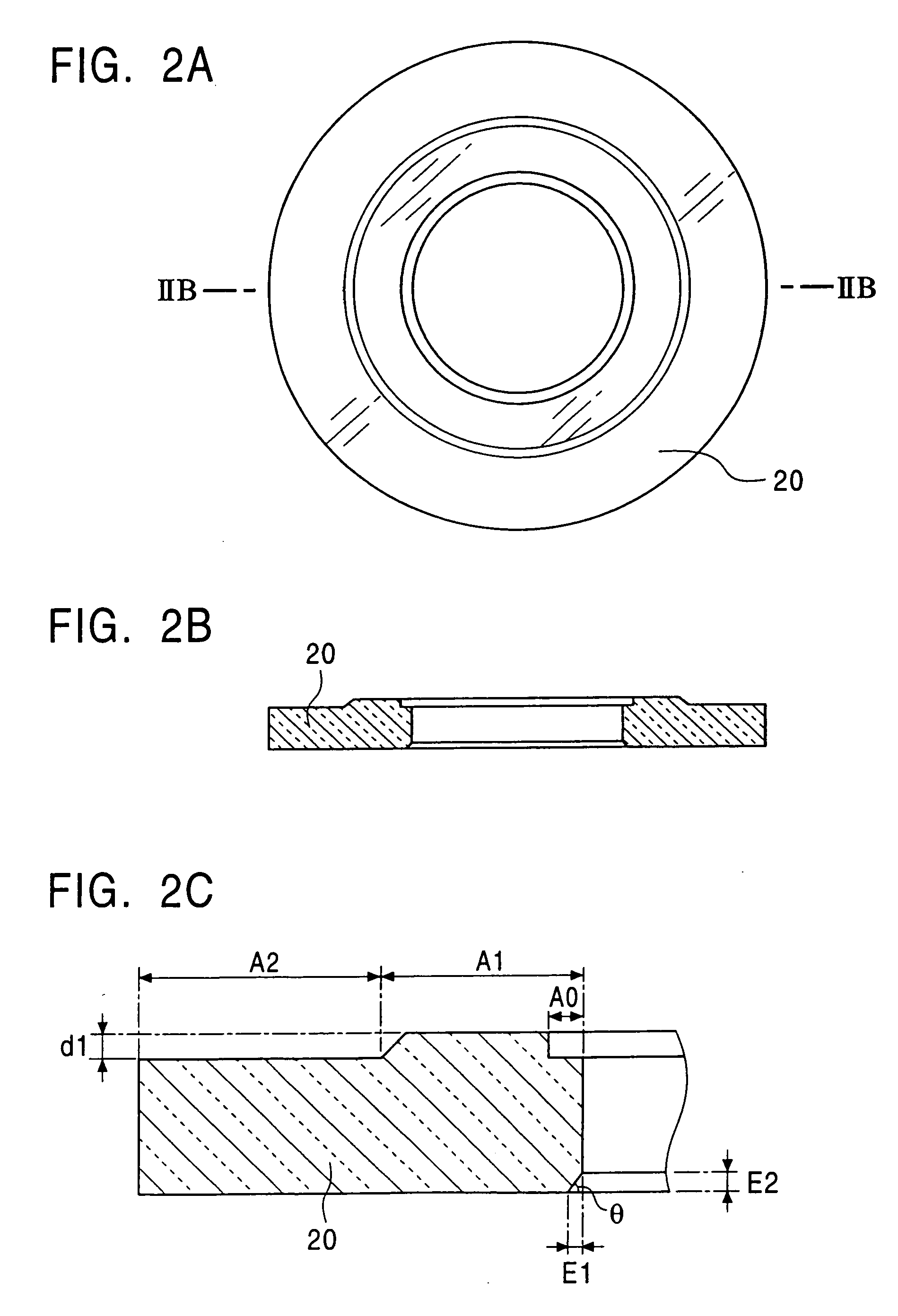

Polishing condition control apparatus and polishing condition control method of CMP apparatus

InactiveUS20080248723A1High polishing precisionAccurate predictionSemiconductor/solid-state device manufacturingLapping machinesEngineering

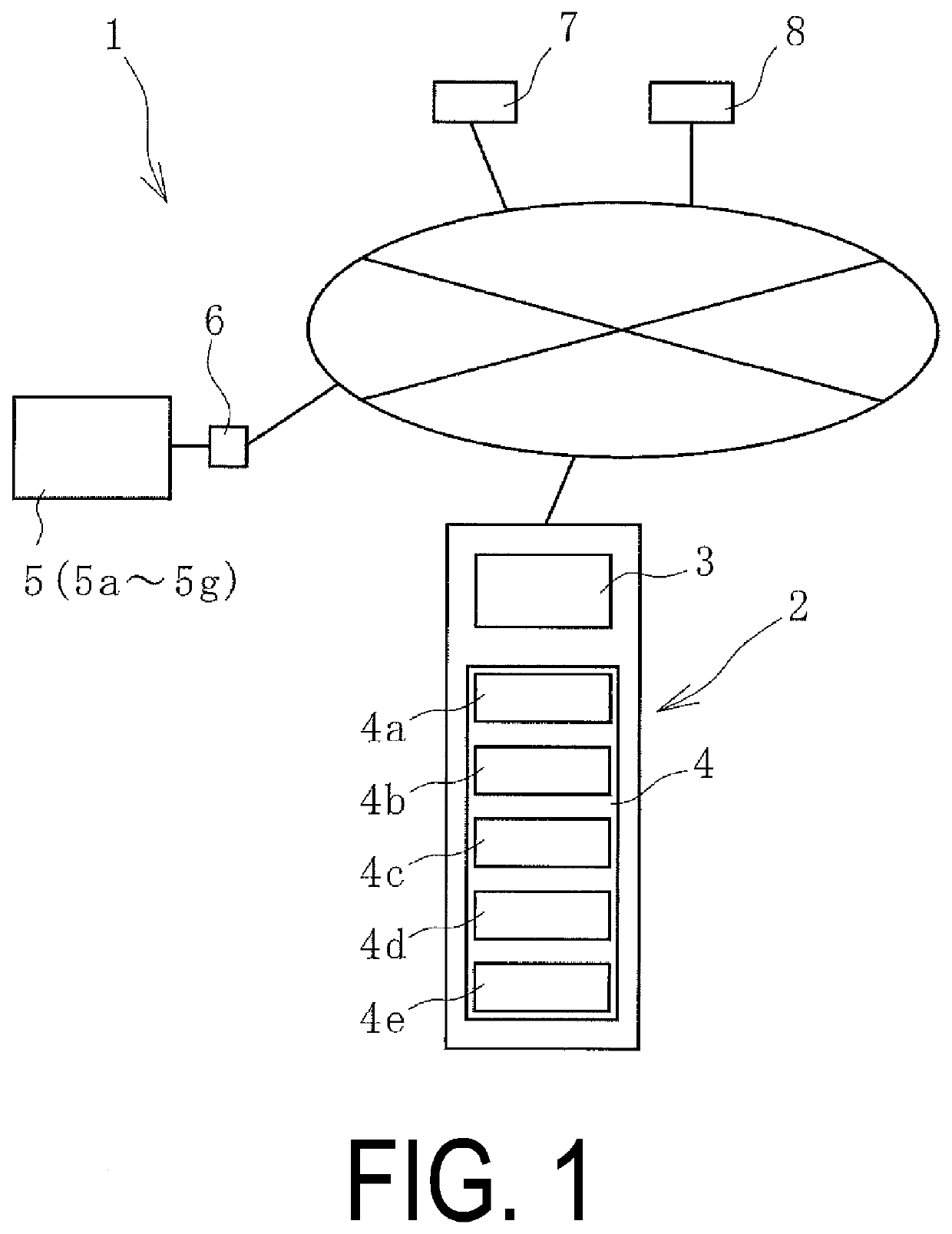

To eliminate the unevenness of the film thickness of the wafers, and increase the polishing efficiency, reduce the running cost and enhance the production yield. A CMP apparatus 1 includes a film thickness measuring means 6 that measures the film thickness of the wafers before polishing, a polishing recipe preparing means 7 that prepares polishing conditions so that the polishing conditions such as polishing speed, polishing pressure, and the like for the wafers become optimal, a polishing time forecasting means that forecasts the polishing time of the wafer on the basis of the optimal polishing condition and the measured value, a polishing time measuring means that measures the actual polishing time of the wafer, and a computer 9 that controls the polishing condition on the basis of the measured value and the like of the polishing time. Further, the computer 9 includes a calculating unit 23 that calculate the difference between the measured value of the polishing time and the forecasted value thereof, and a polishing condition correcting / changing unit 24 that corrects / changes the polishing conditions so that the calculated difference becomes minimal, and thereby, the correction / change of the polishing conditions is carried out in real time.

Owner:TOKYO SEIMITSU

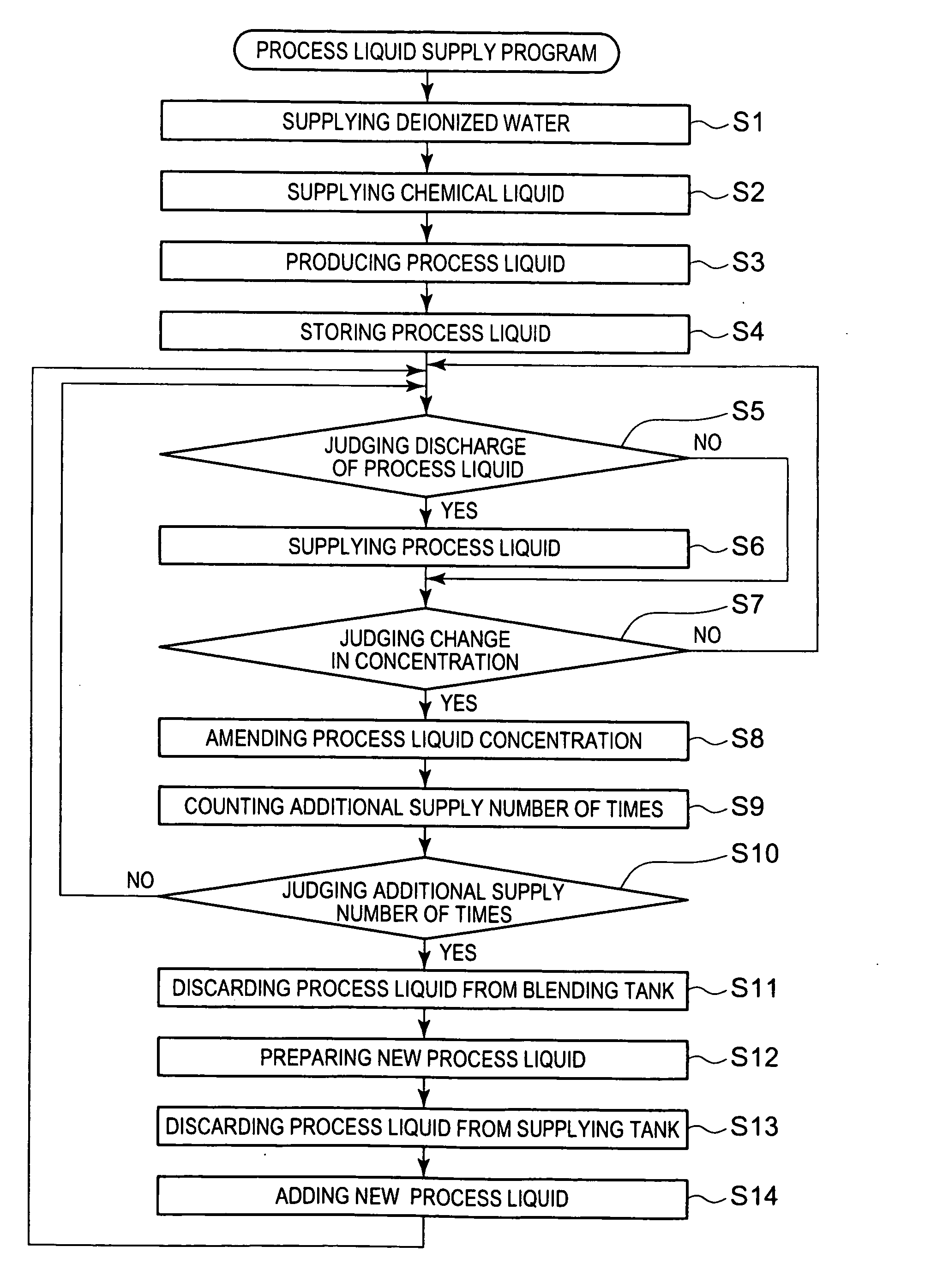

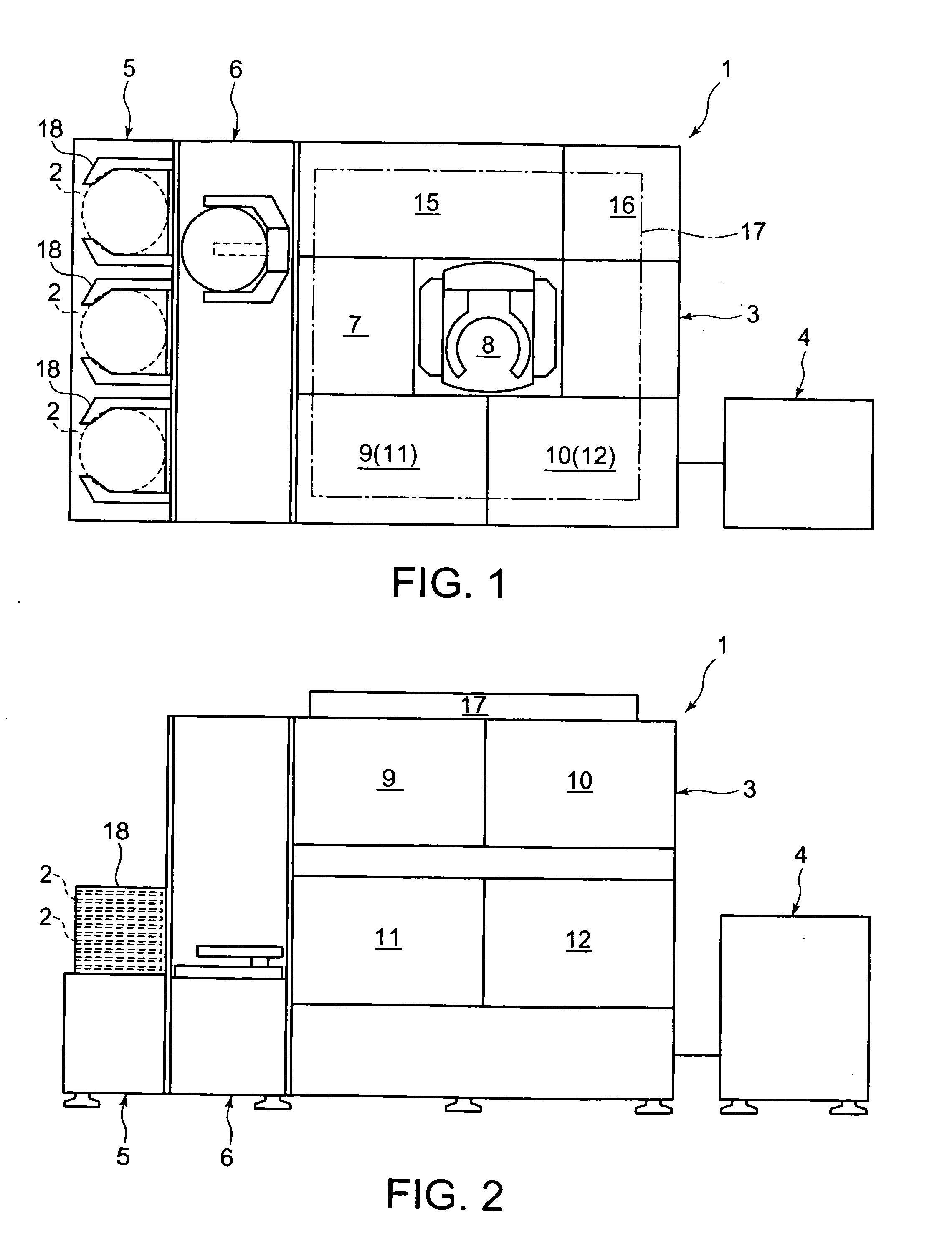

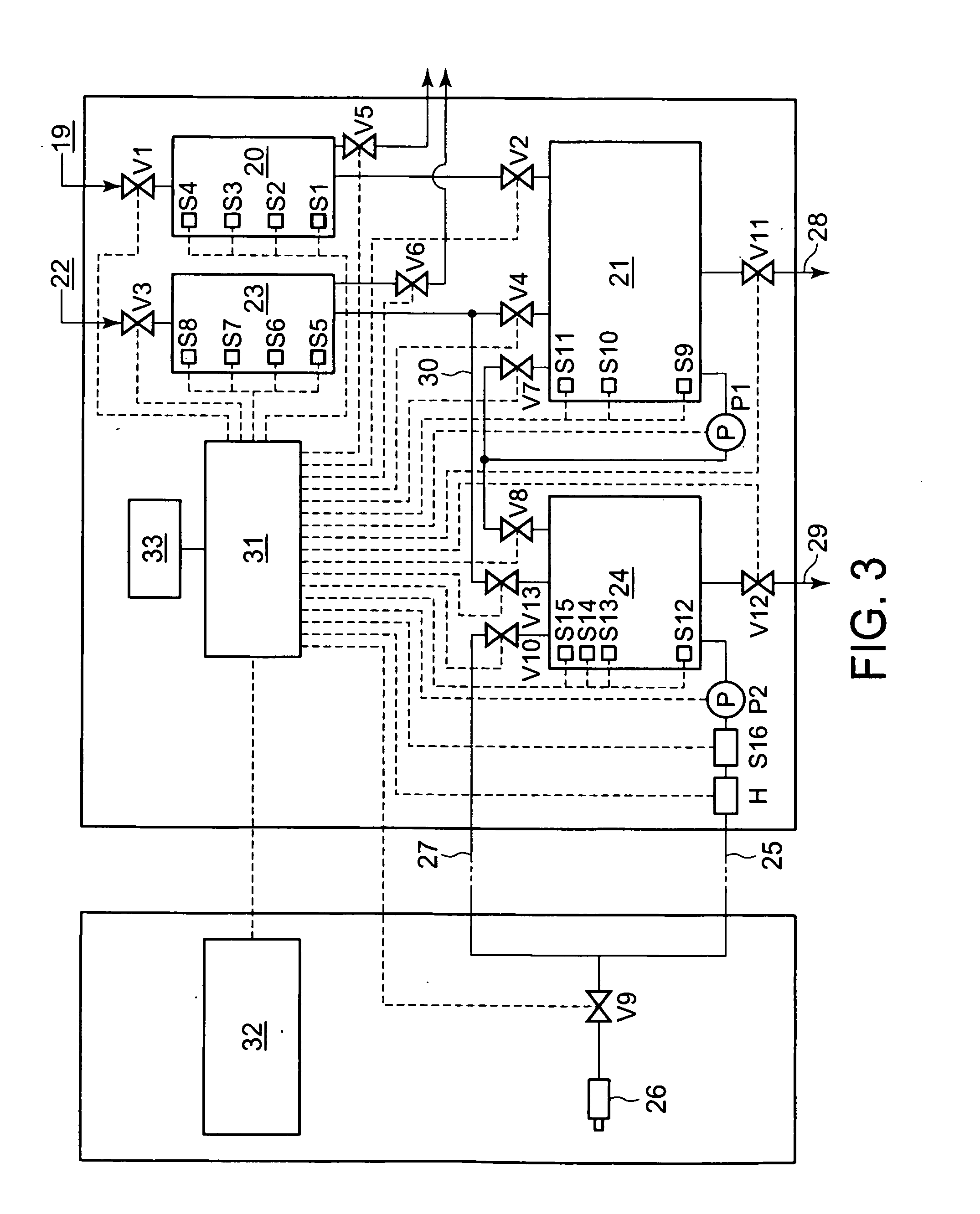

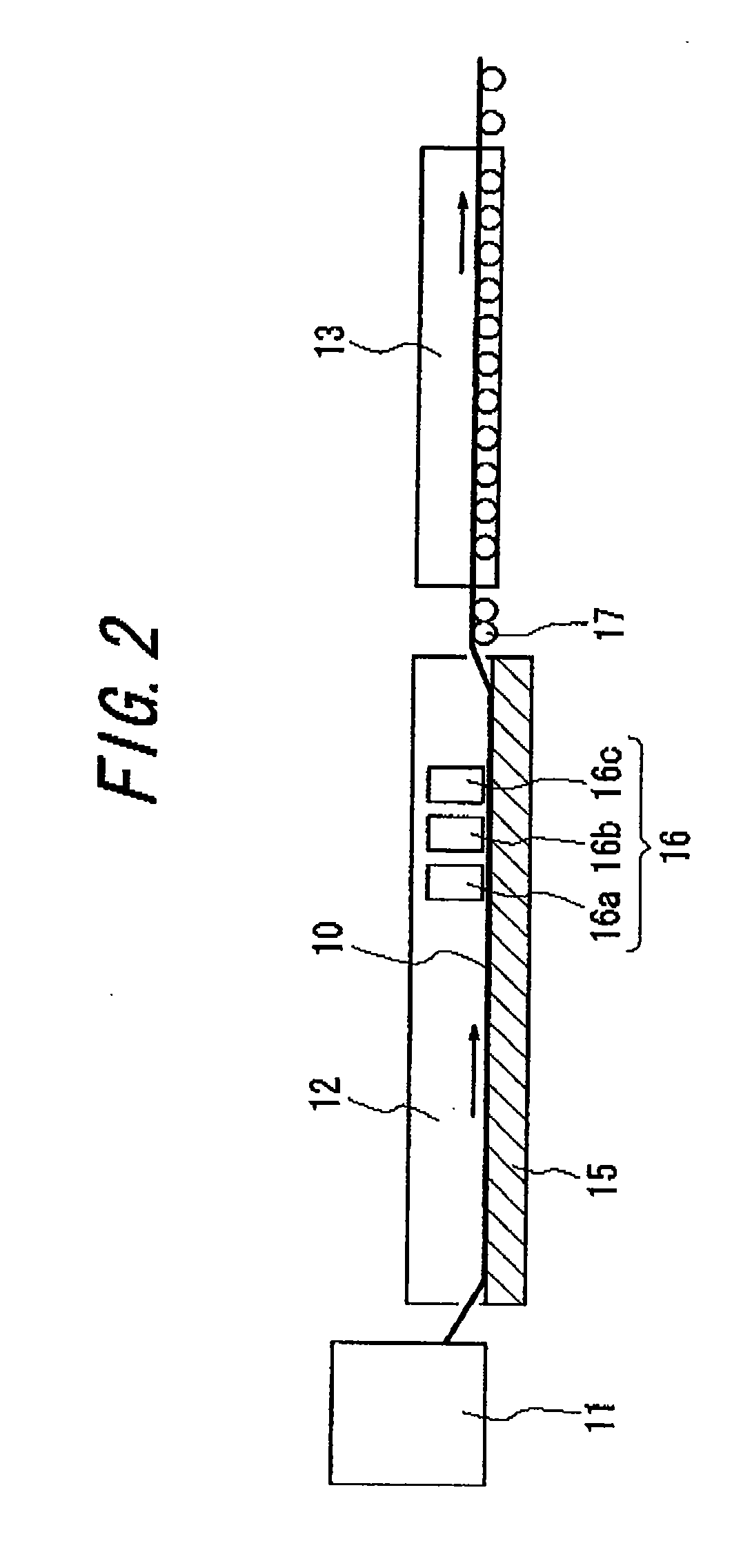

Process system, process liquid supply method, and process liquid supply program

InactiveUS20070134822A1Reduce runningInterruption of process operation can be avoidedSemiconductor/solid-state device testing/measurementTransportation and packagingProcess systemsProcess engineering

A process system produces a process liquid of a predetermined concentration in a blending tank by blending solutions respectively supplied from a plurality of solution supply sources, supplies the process liquid to a supply tank to store therein the process liquid, and supplies the process liquid from the supply tank to a process liquid discharge port. In this process system, whether a concentration of the process liquid in the supply tank has changed or not is judged. When it is judged that the concentration of the process liquid in the supply tank has changed, the process liquid is additionally supplied from the blending tank to the supply tank, or the solution is directly supplied from the solution supply source to the supply tank, so as to maintain the concentration of the process liquid.

Owner:TOKYO ELECTRON LTD

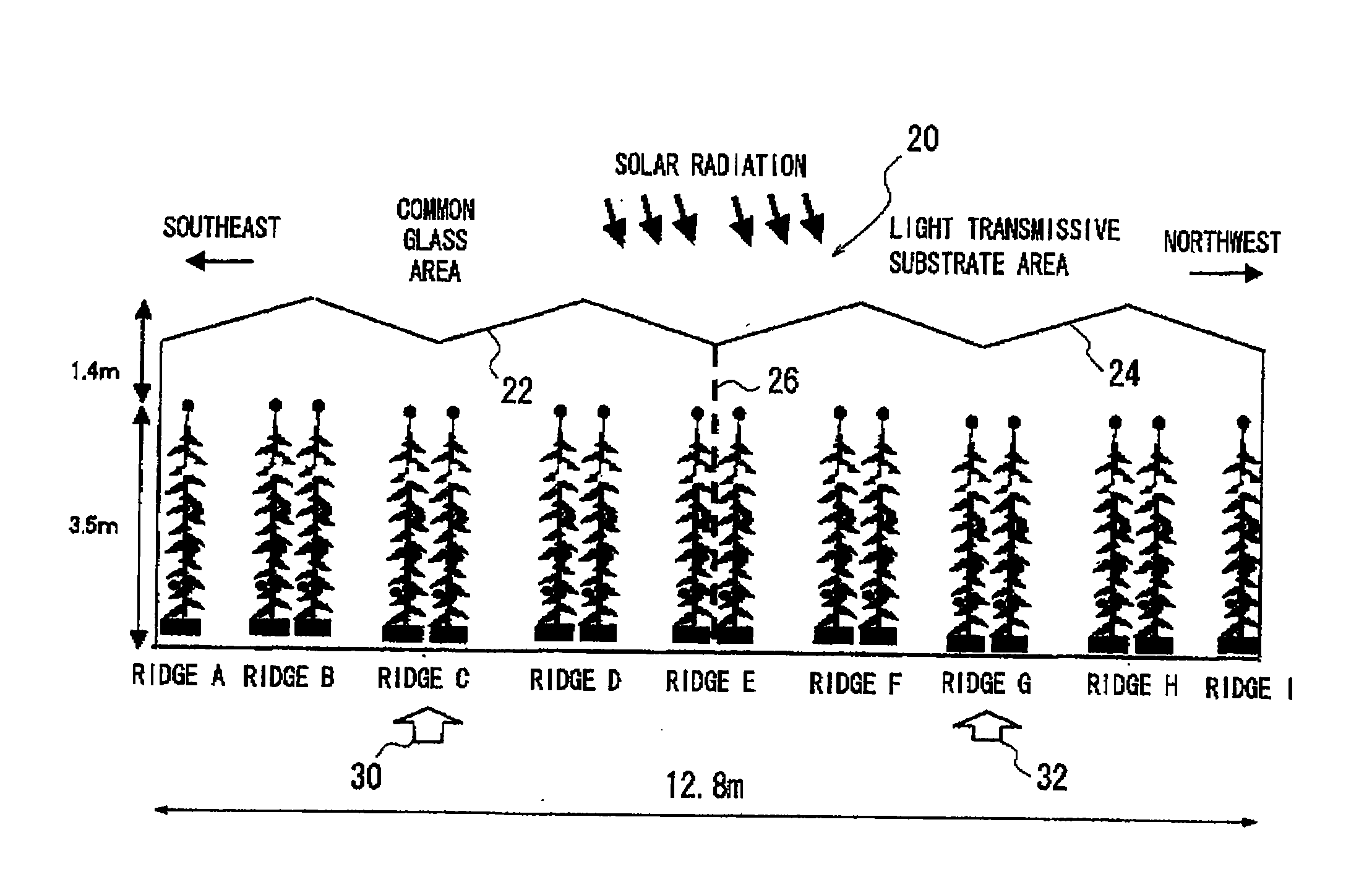

Greenhouse, method for growing plants using the same, and light transmissive substrate

InactiveUS20080216399A1Running cost can be reducedImprove the level ofClimate change adaptationSynthetic resin layered productsOptical transmittanceRadiation

There is provided a greenhouse wherein a light transmissive substrate that maintains or increases light transmittance at visible wavelengths and has an insulation effect is used to reduce the running costs considerably as well as increase the yield of plants. In the greenhouse according to the present invention, a light transmissive substrate that has a visible light transmittance of 86% or more and solar radiation transmittance of 78% or less is used as the material for covering the greenhouse.

Owner:NIPPON SHEET GLASS CO LTD +1

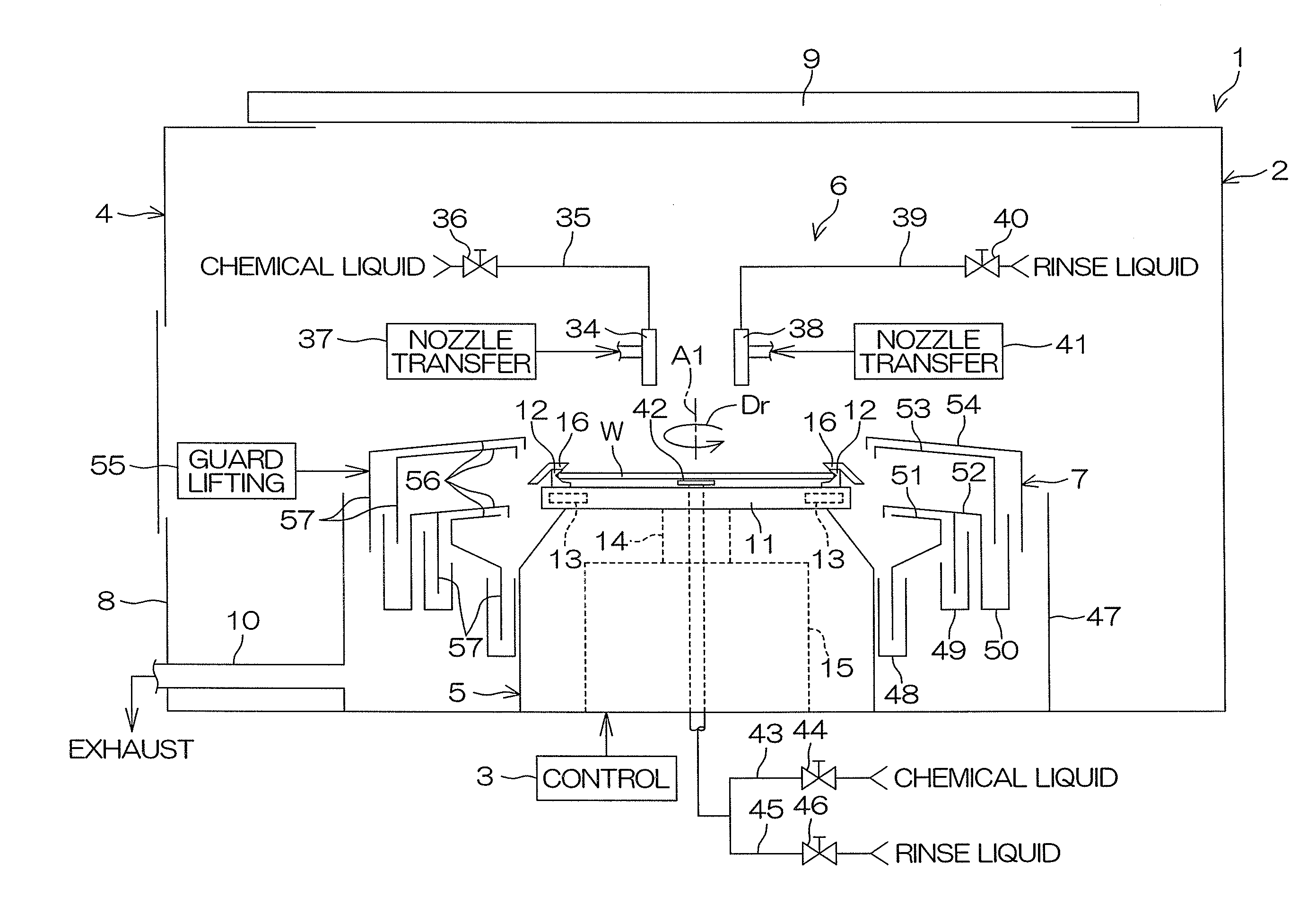

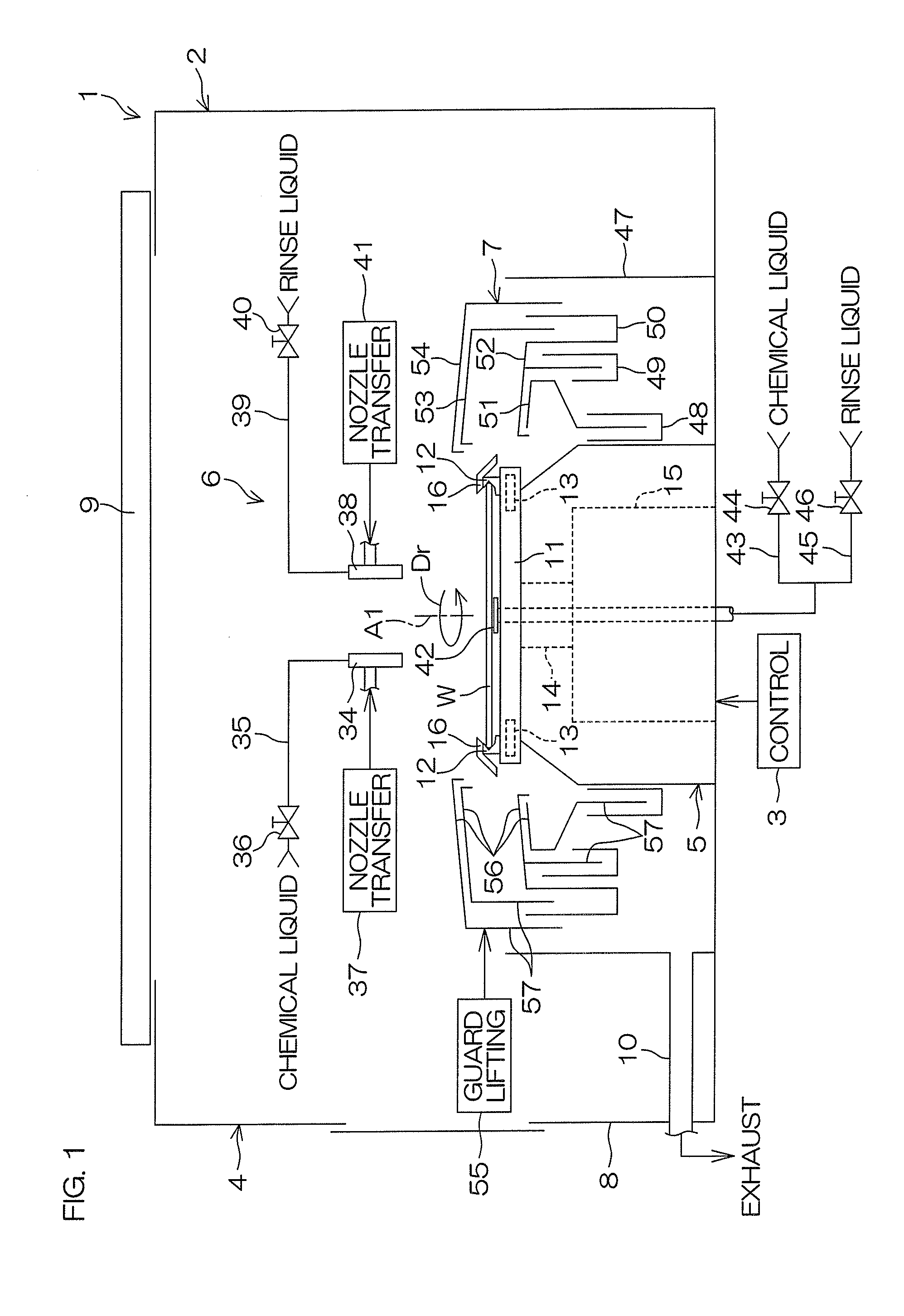

Substrate processing apparatus

ActiveUS20140261162A1Decreasing reattachmentsReduce the amount presentLiquid surface applicatorsPhotomechanical apparatusEngineeringMechanical engineering

A substrate processing apparatus for processing a substrate comprises: a plurality of chuck pins each having an accommodating groove for accommodating a portion of peripheral part of the substrate, holding the substrate at a hold position in a horizontal posture by pressing inner faces of the accommodating grooves toward portions of peripheral part of the substrate; and a plurality of guide members, being disposed on or above the respective plurality of chuck pins, guiding process liquid discharged from the substrate to a surrounding area of the substrate; wherein each of the plurality of guide member includes: an inner-edge guide disposed at a position inward and above the accommodating groove; and an outer-edge guide disposed at a position level with or below the inner-edge guide and outward the chuck pin.

Owner:DAINIPPON SCREEN MTG CO LTD

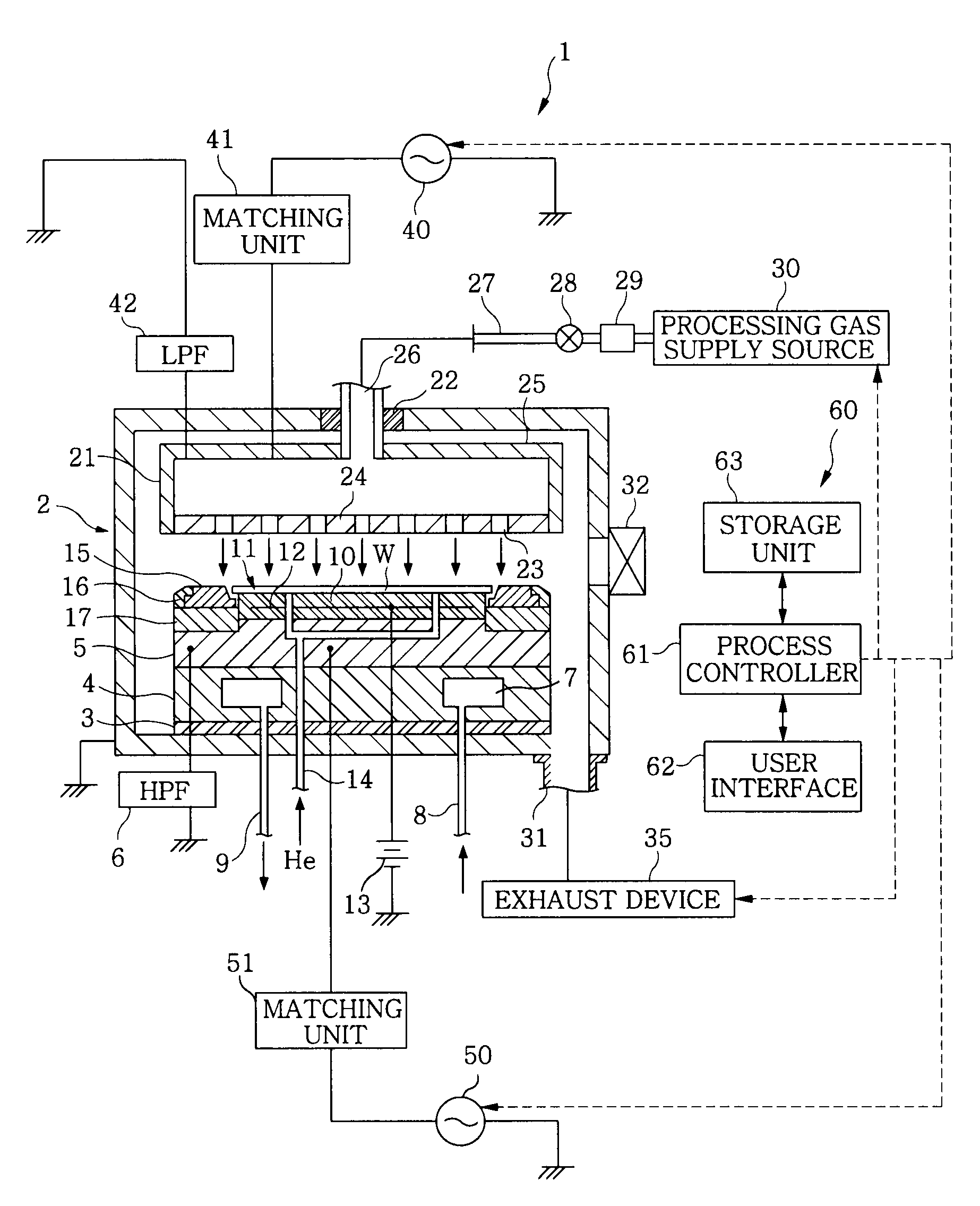

Focus ring, plasma processing apparatus and plasma processing method

InactiveUS20100041240A1Improve operating rateRunning cost can be reducedElectric discharge tubesSemiconductor/solid-state device manufacturingPhysicsPlasma processing

A focus ring of a ring shape is disposed to surround a target substrate on a lower electrode on which the target substrate is mounted in a process chamber. The process chamber receives the target substrate and subjects the received target substrate to a plasma process. At the point of time when the focus ring is first used for the plasma process, a distance between a lower side of an edge portion of the target substrate and a portion of the focus ring facing the lower side of the edge portion of the target substrate is set to be equal to or greater than about 0.4 mm.

Owner:TOKYO ELECTRON LTD

Quartz component for plasma processing apparatus and restoring method thereof

InactiveUS20080206452A1Running cost can be reducedImprove utilization efficiencyLayered productsDecorative surface effectsEngineeringQuartz

The main surface of a quartz component is divided by an offset into a first region having a larger height around an inner perimeter and a second region adjacent to the outer perimeter of the first region. Repeated restoration of a damaged component by forming a bulge on the first region and machining the bulge to make a flat surface while maintaining the offset enables long term use of the component.

Owner:KAWASAKI MICROELECTRONICS

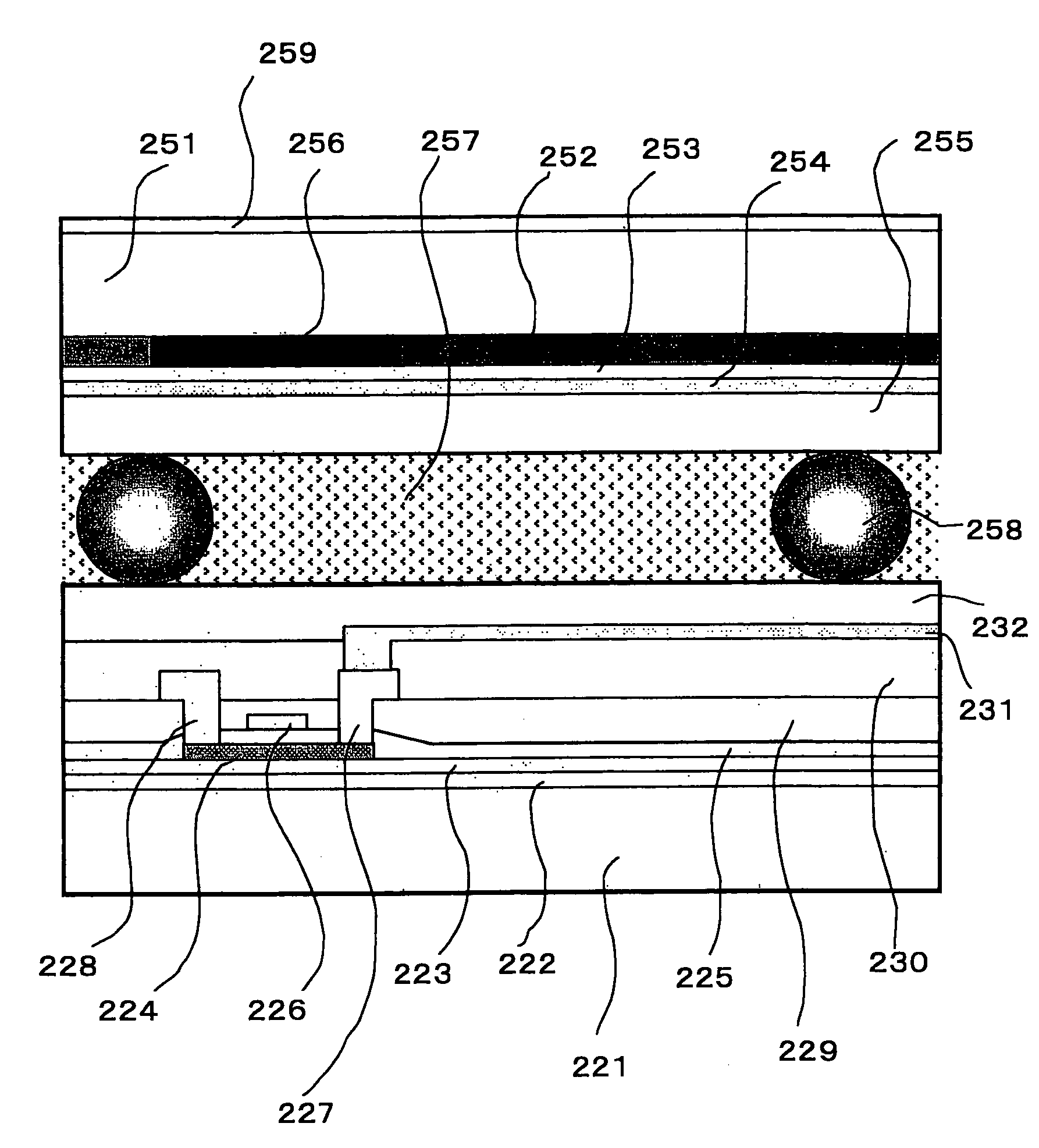

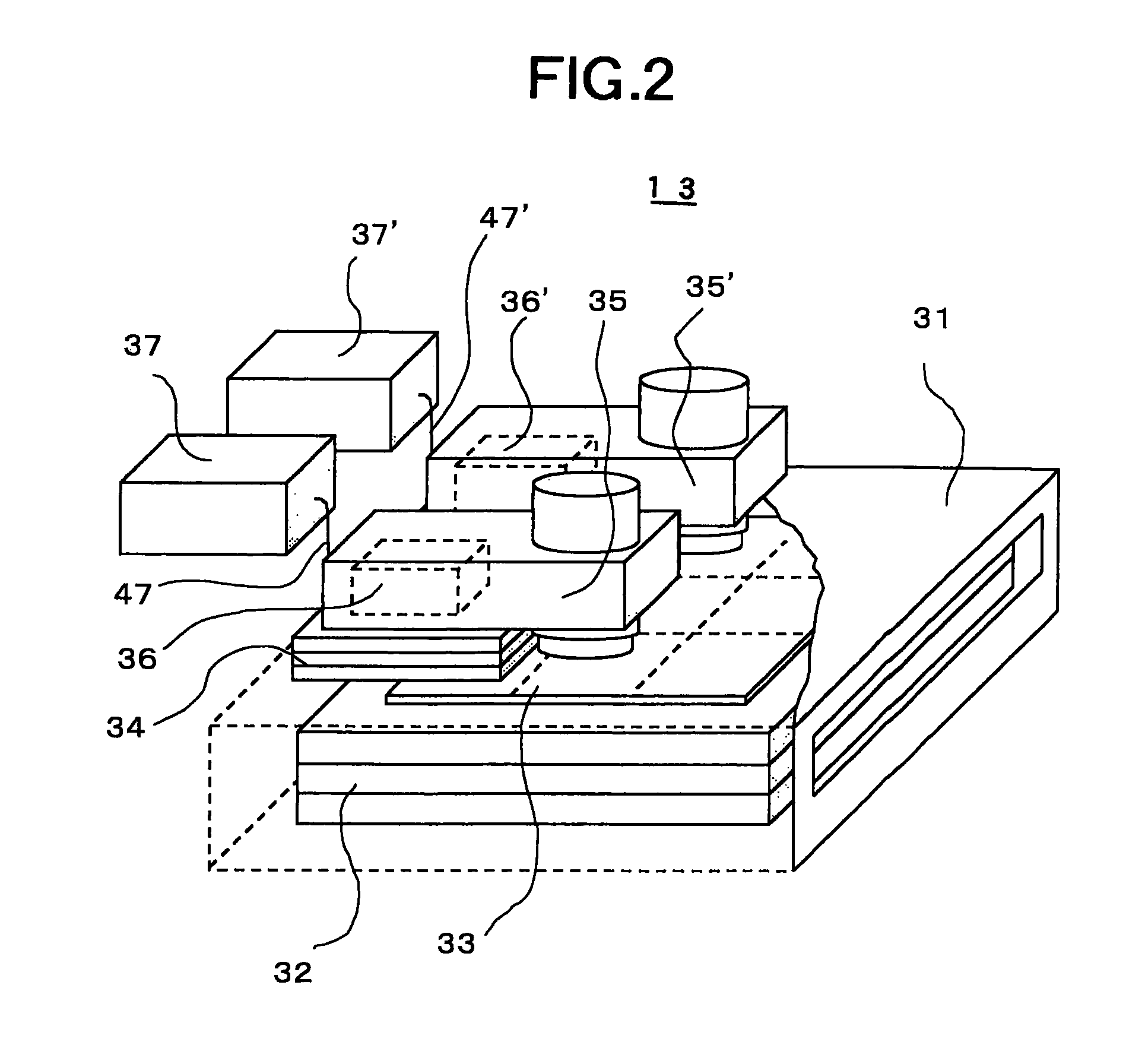

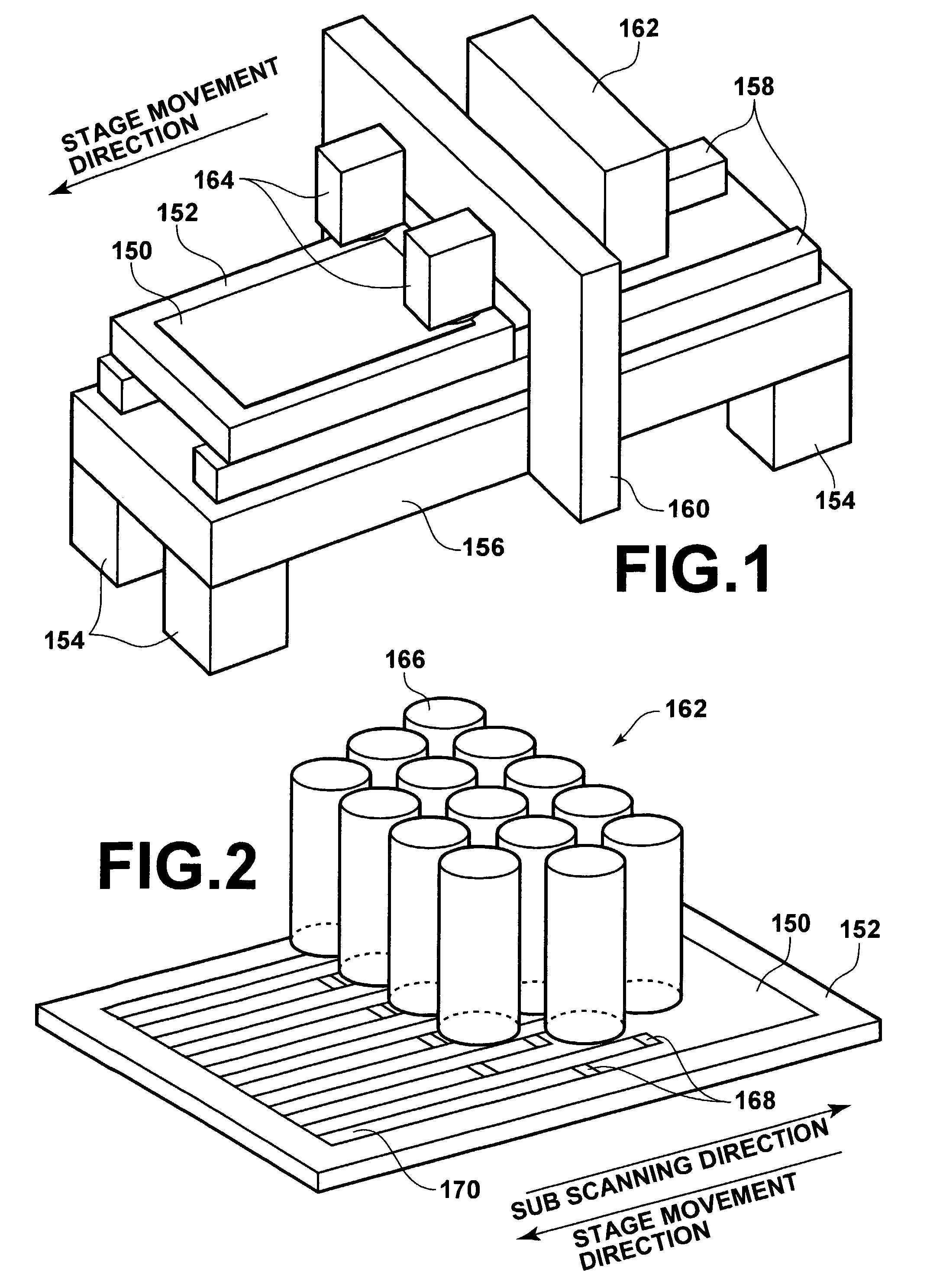

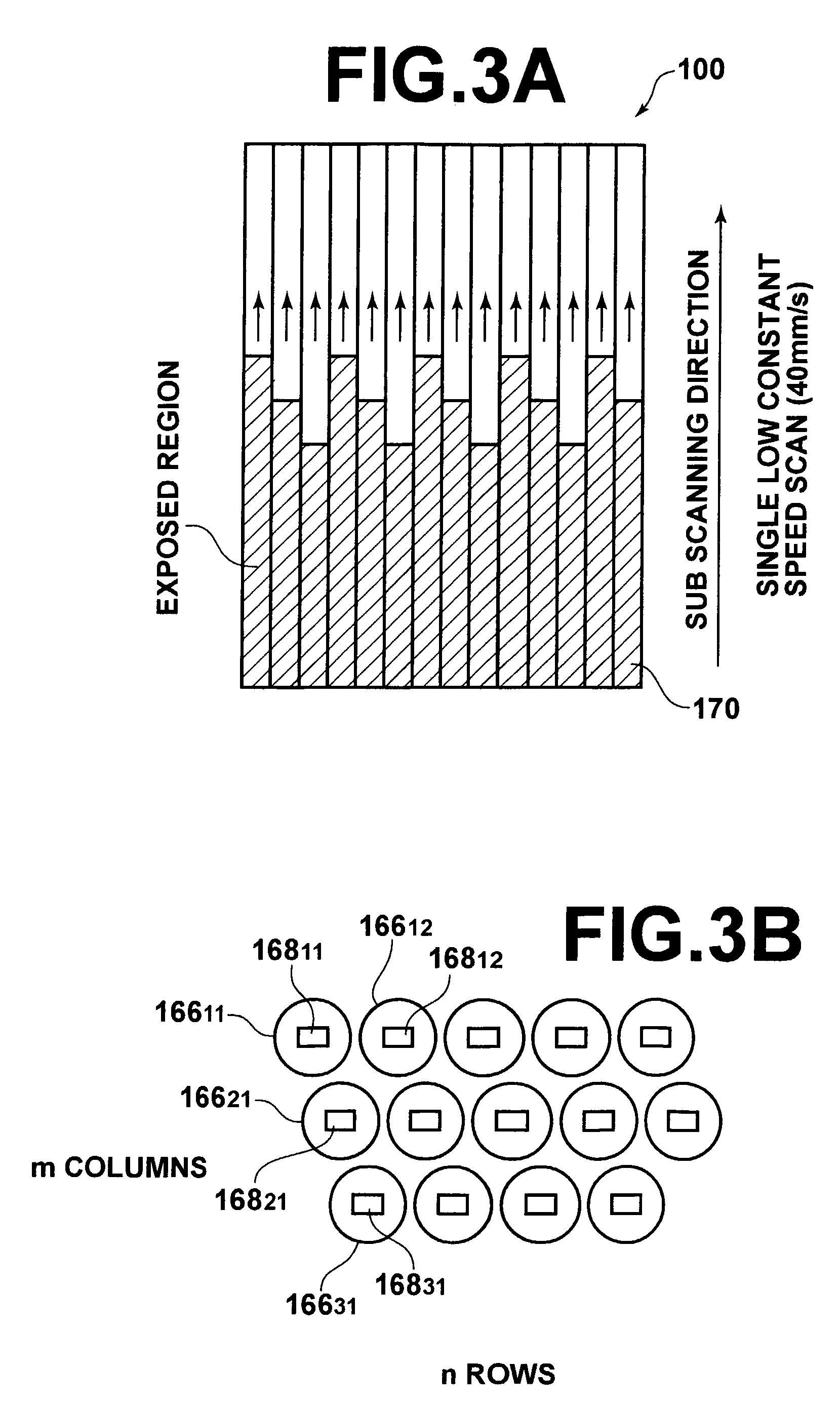

Method and apparatus for manufacturing display panel

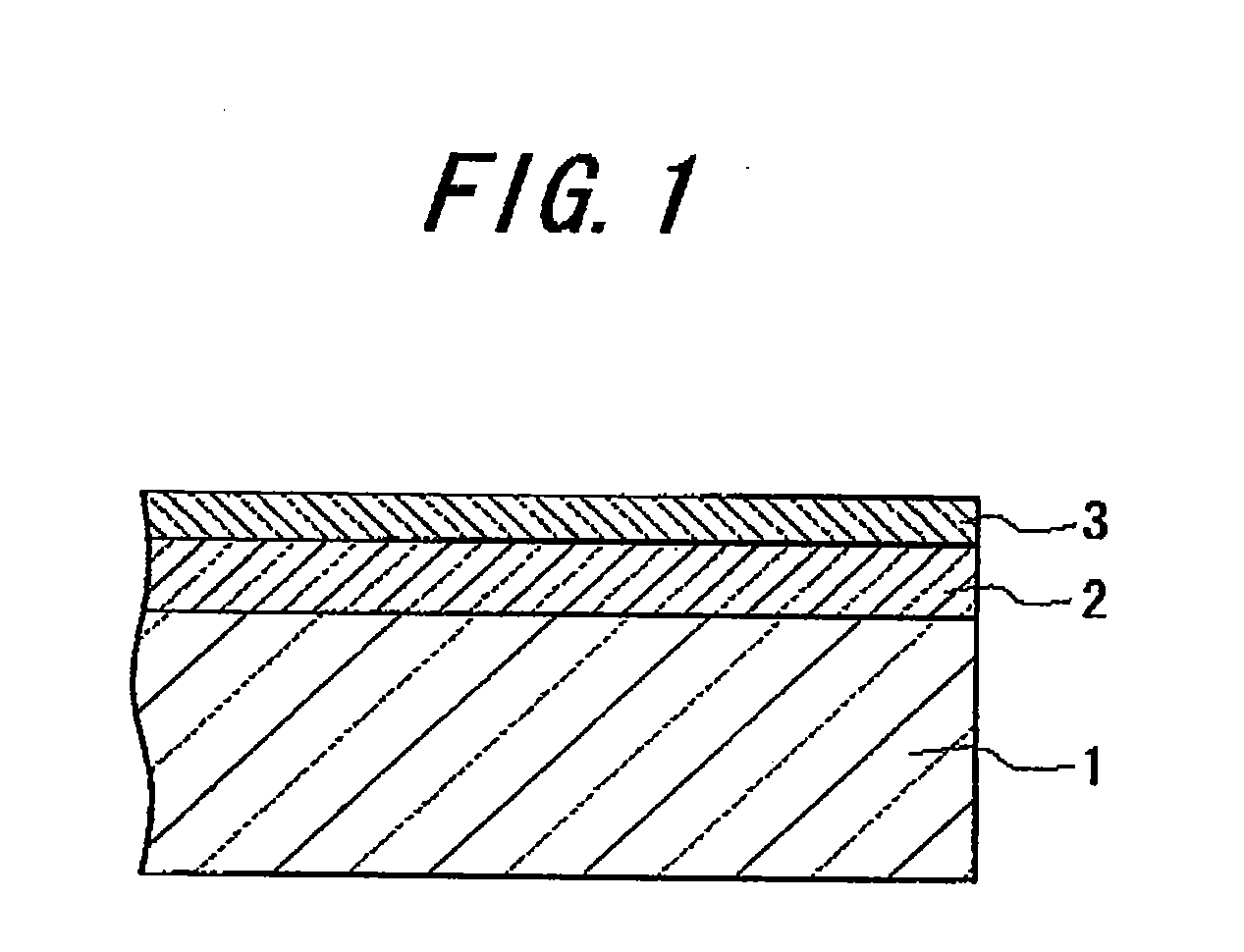

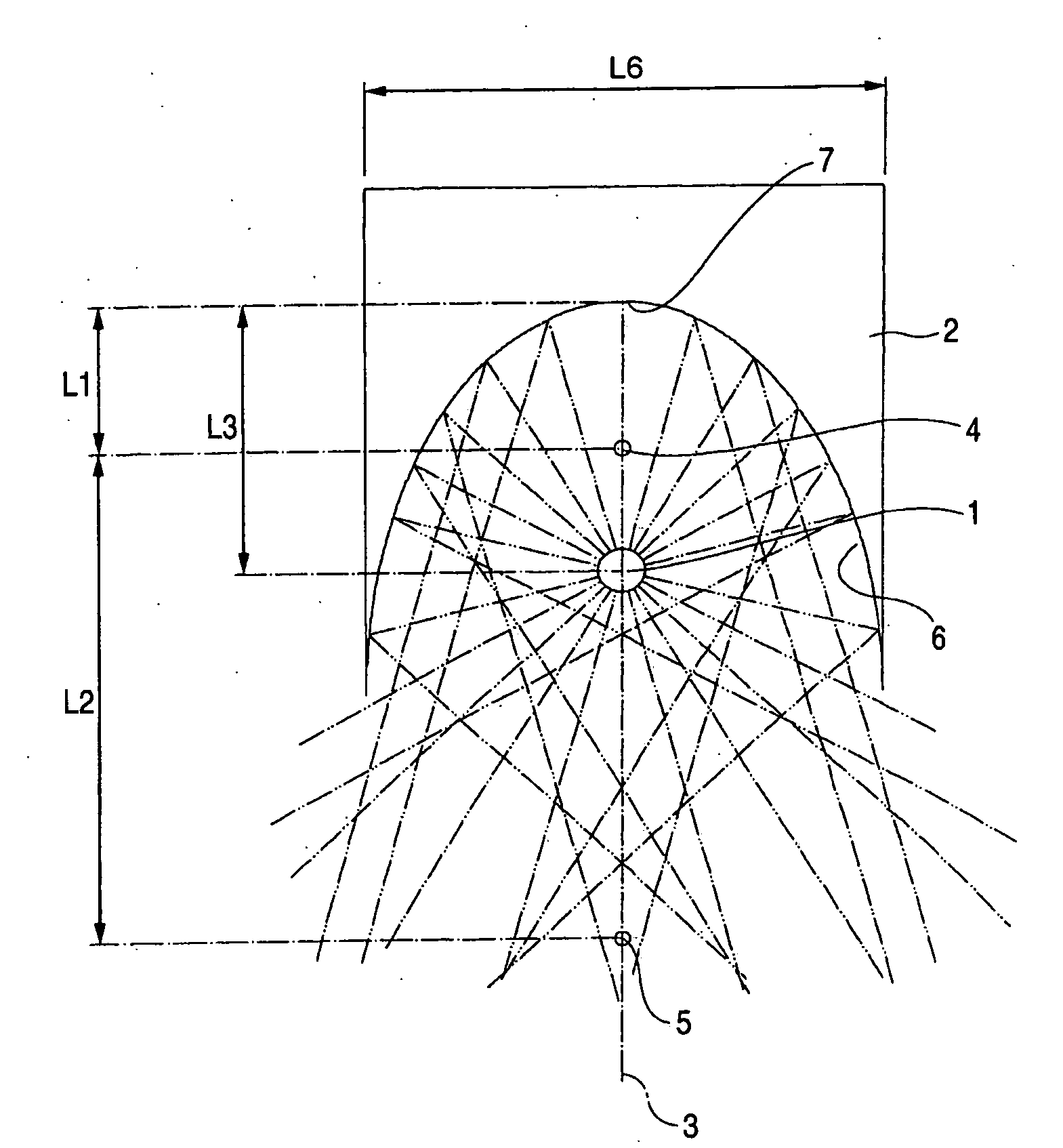

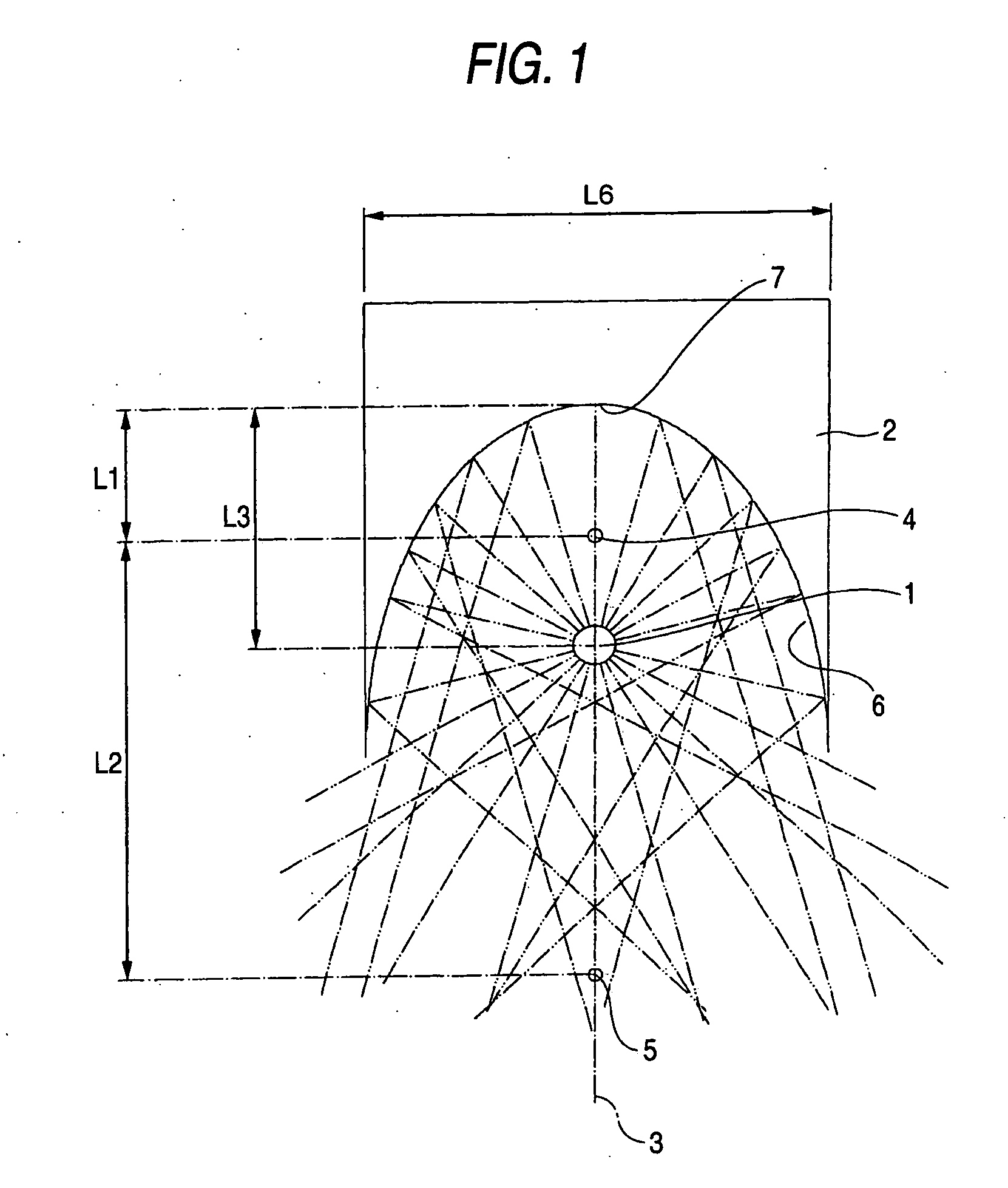

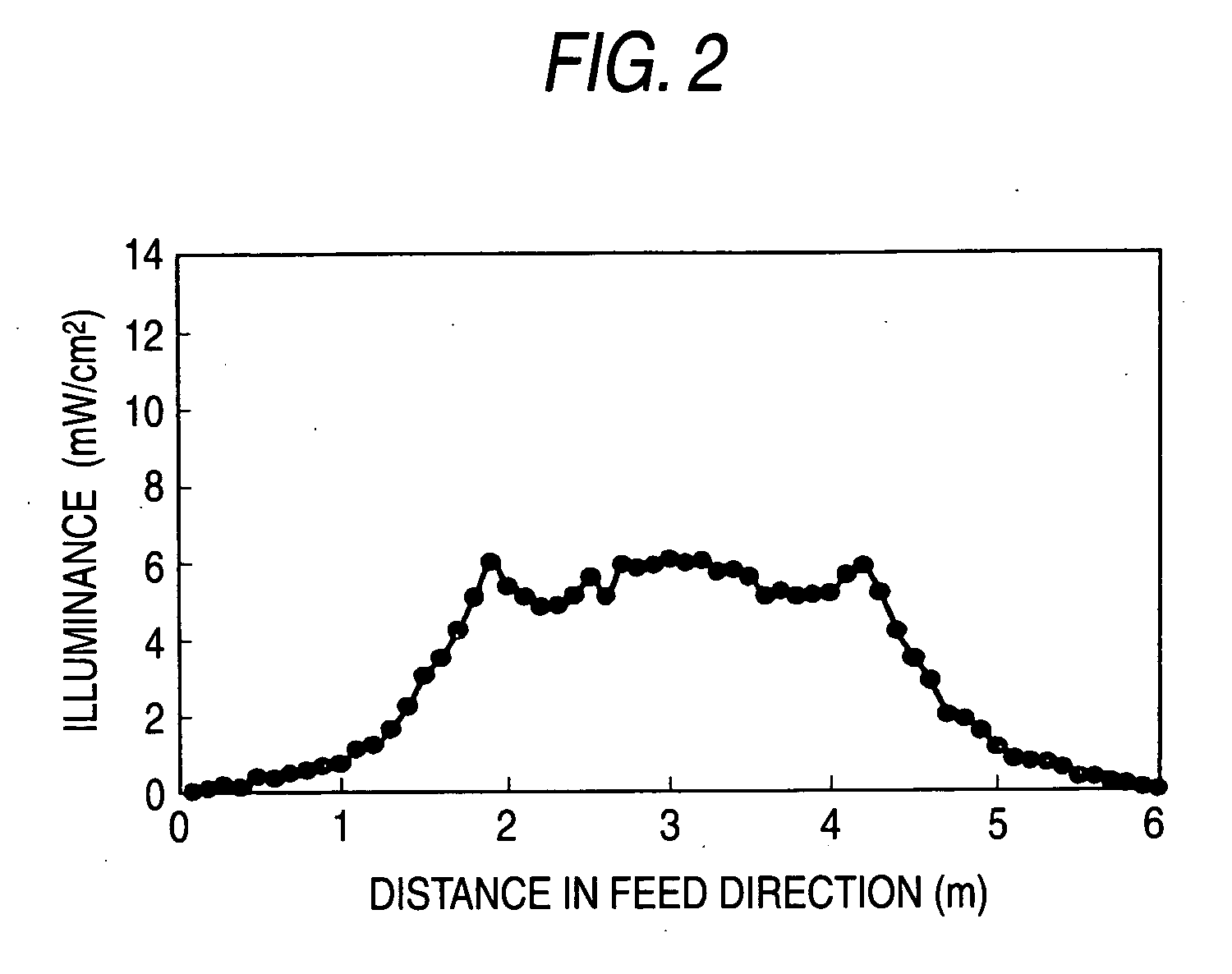

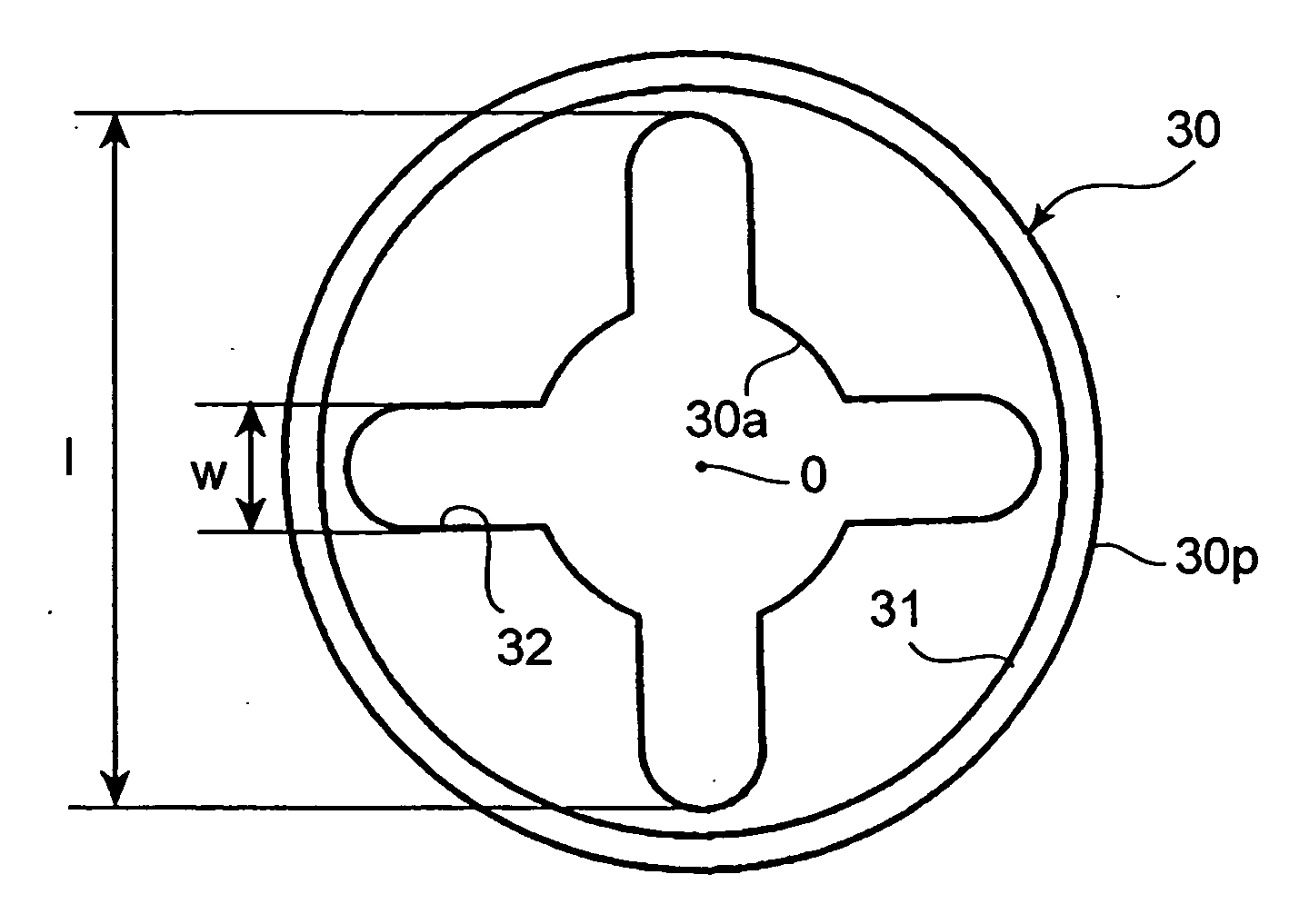

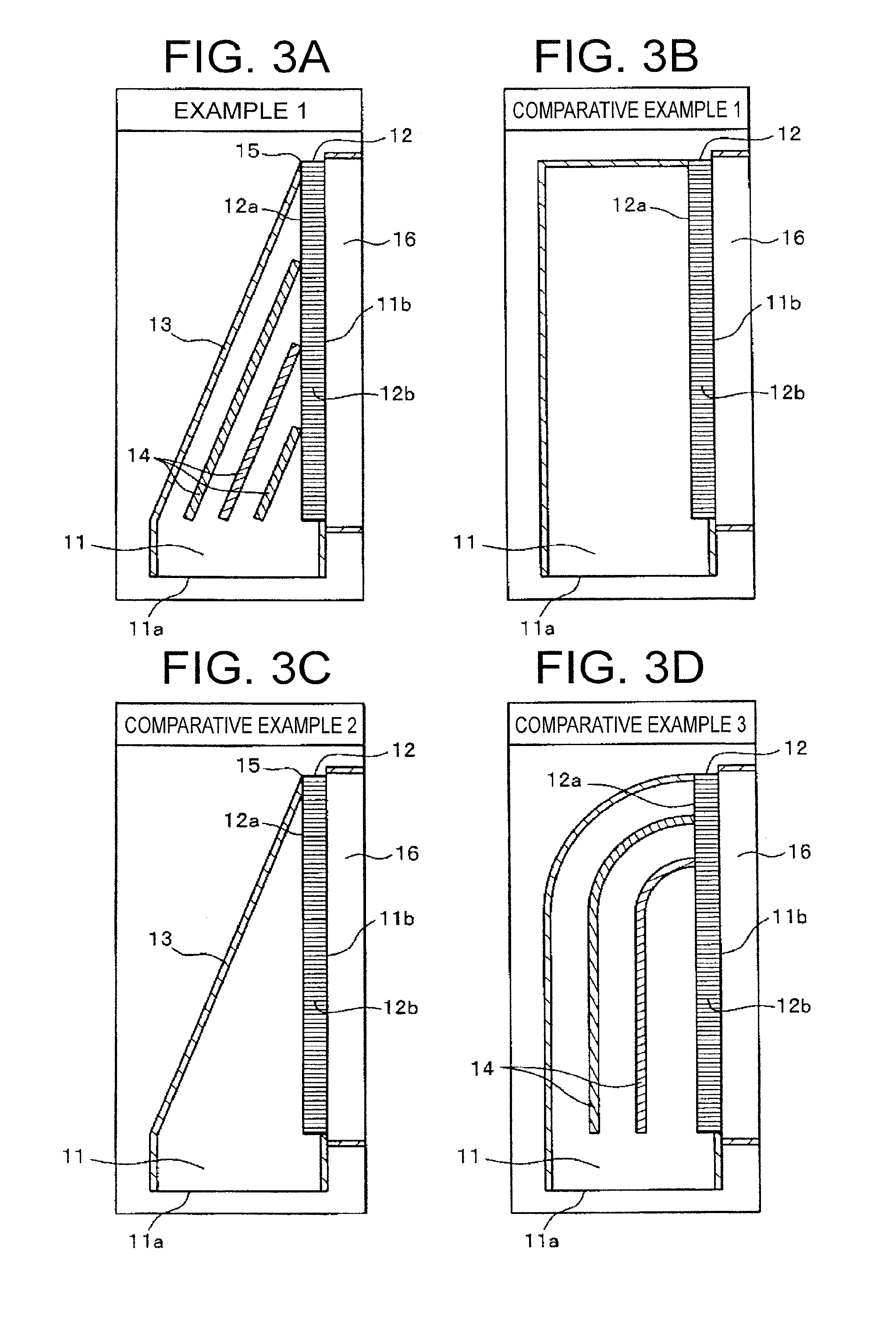

ActiveUS7132343B2Low running costRunning cost can be reducedTransistorSolid-state devicesPoly crystallinePolycrystalline silicon

The whole surface of an insulating substrate having an amorphous silicon film formed thereon is scanned / irradiated with a solid-state pulsed laser beam shaped linearly or rectangularly, to form a uniform fine poly-crystalline silicon film for forming a pixel region. The periphery of the pixel region is scanned / irradiated with a time-modulated continuous-wave solid-state laser beam formed linearly. Thus, a peripheral circuit region including a drive circuit is formed as a poly-crystalline silicon film with crystals growing up in the scanning direction. Pixel portion thin film transistors are produced in the uniform fine poly-crystalline silicon film, while a drive circuit or an interface circuit is produced in the peripheral circuit region. One of substrates of a display panel is formed thus. A display panel including transistors with uniform properties in the pixel portion and transistors with excellent properties in the peripheral circuit portion including the drive circuit is obtained.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

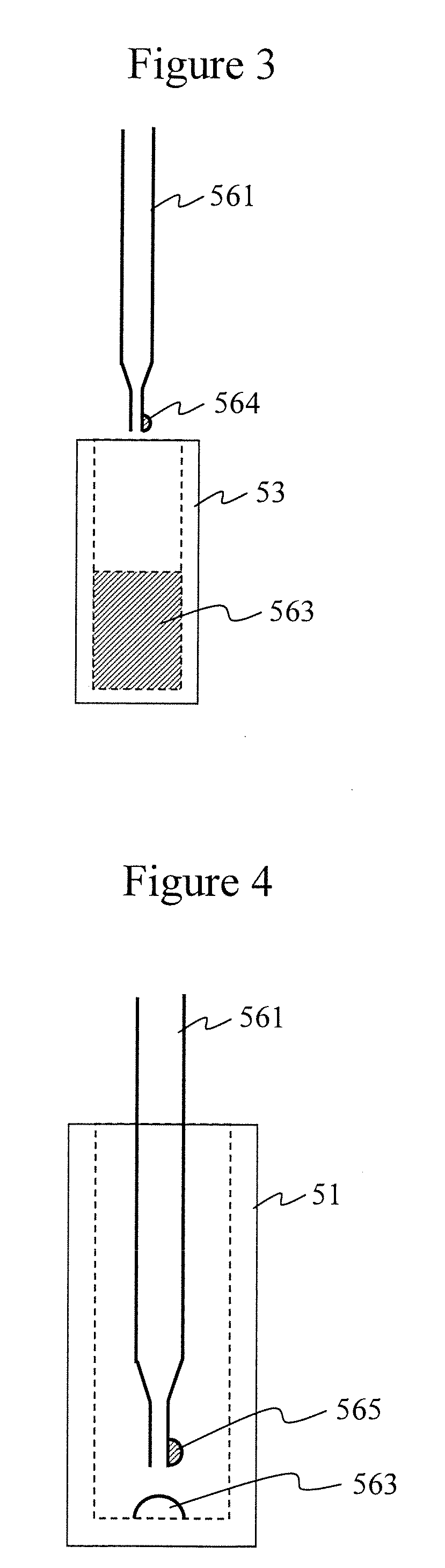

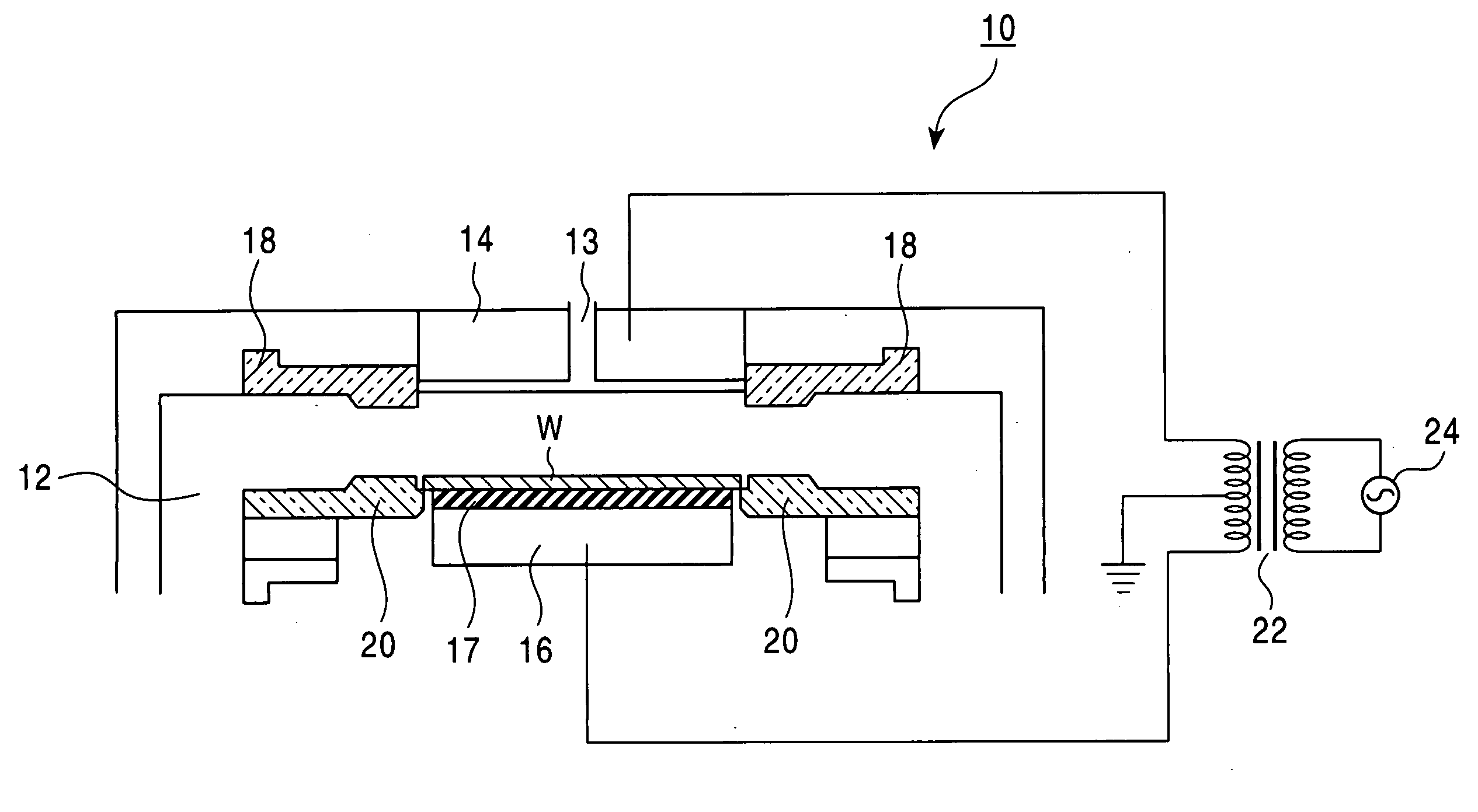

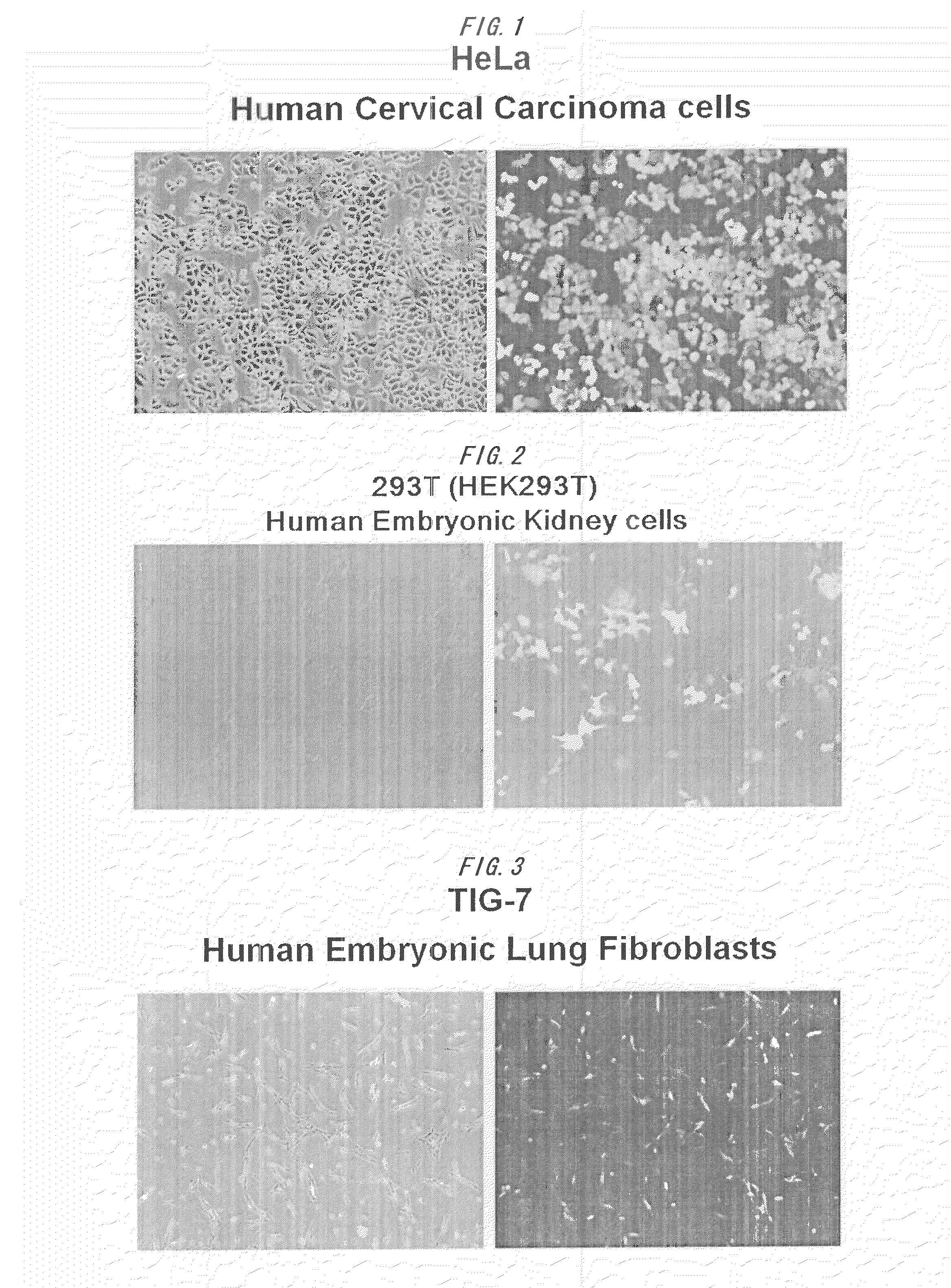

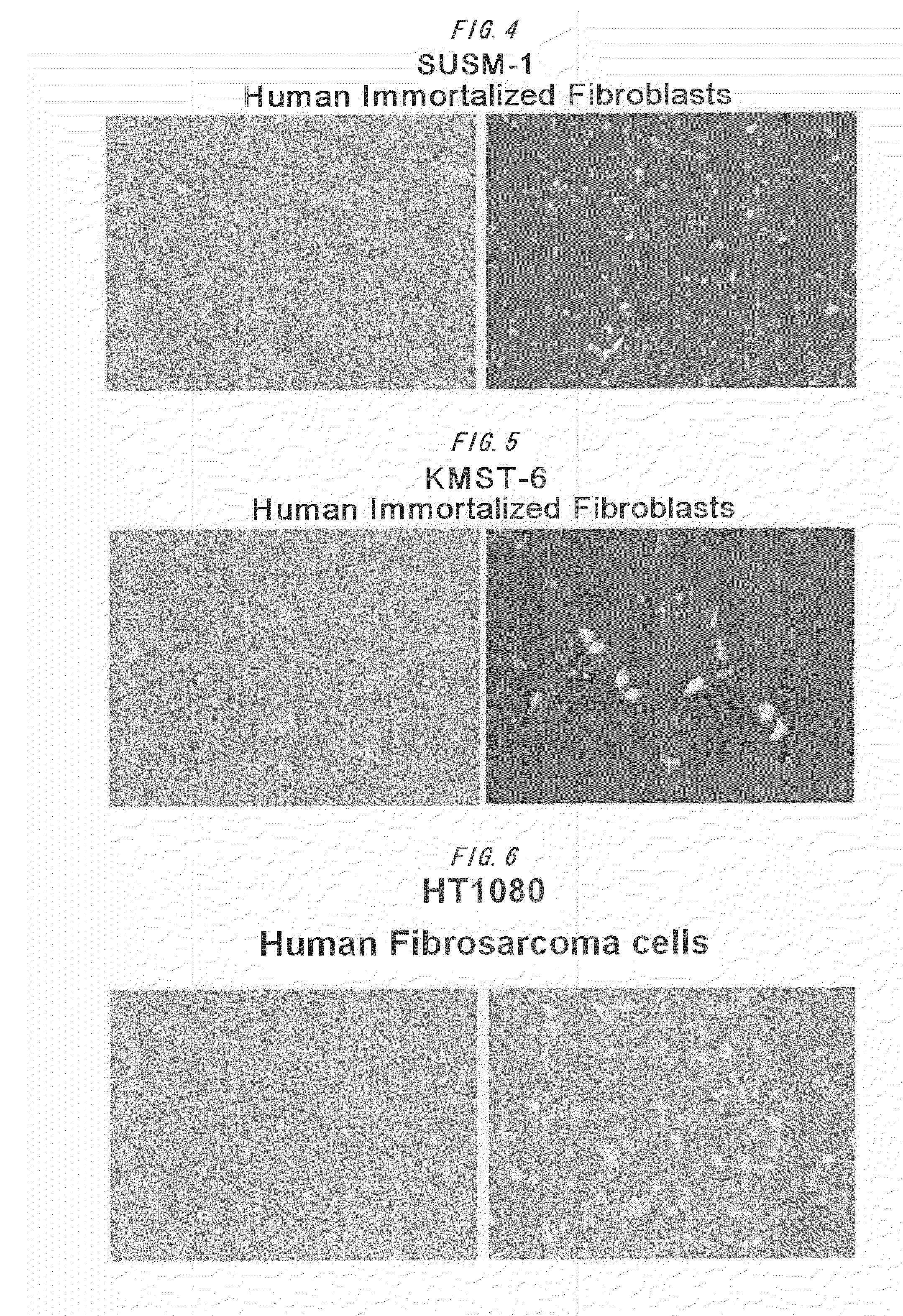

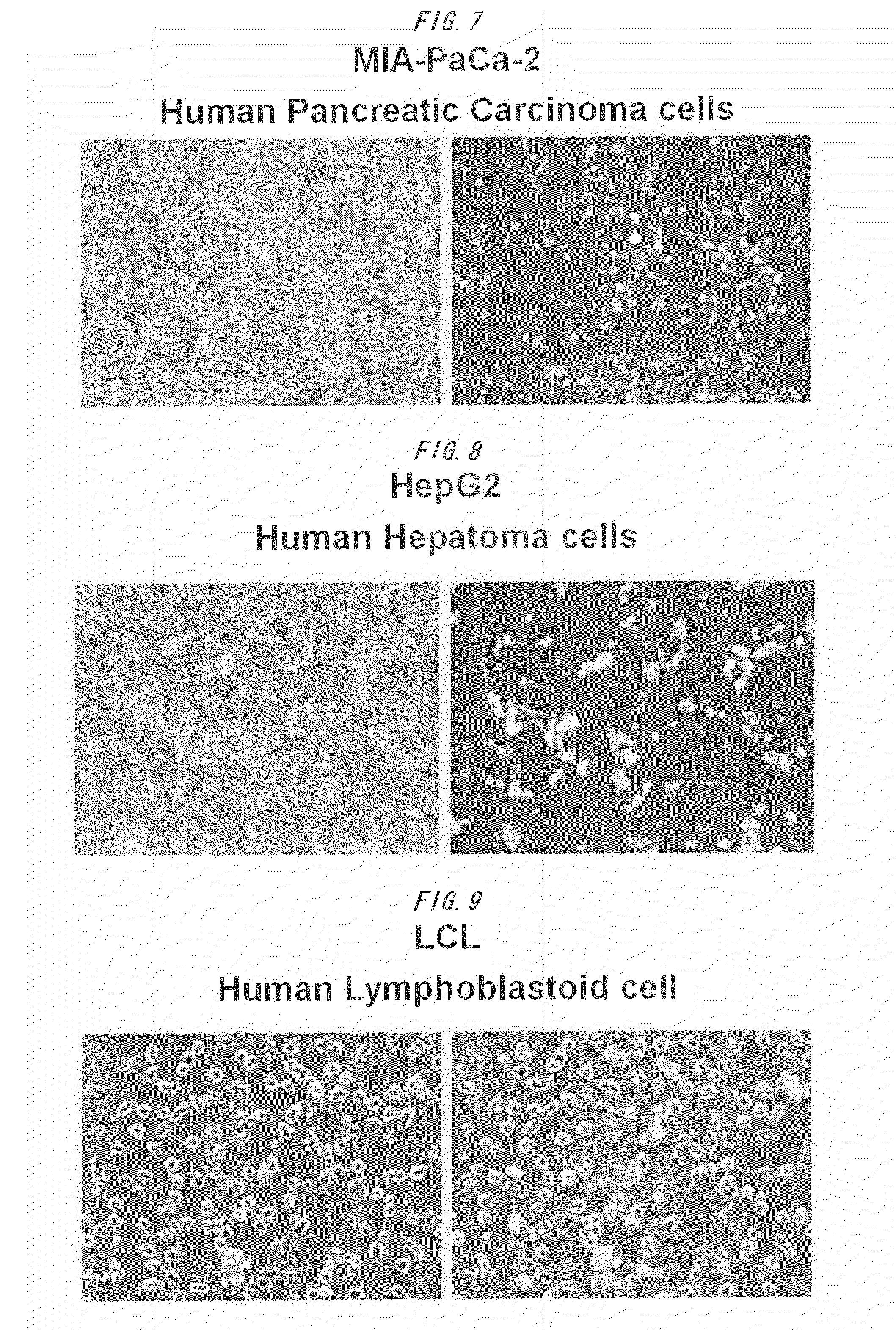

Foreign gene transfer method by electroporation technique

InactiveUS20130122592A1Improve viabilityImproved in gene transferring rateAnimal cellsOther foreign material introduction processesElectricityLiquid medium

Provided is a method for transferring an extraneous gene by an electroporation technique, which is applicable to a wide range of animal cells and is extremely remarkably improved in viability and gene transferring rate. Also provided is a method for transferring an extraneous gene by an electroporation technique with high viability and gene transferring rate even in the case where no specialized transferring buffer is used. Also provided are: a method for transferring an extraneous gene by an electroporation technique, which is remarkably improved in viability and gene transferring rate, the method including continuously applying, to an animal cell, a first electric pulse (strong electric pulse) and a second electric pulse (weak electric pulse) under specific conditions; and a method for transferring an extraneous gene by an electroporation technique, in which a liquid medium capable of being used for culturing of the animal cell is used as a transferring buffer.

Owner:NEPA GENE

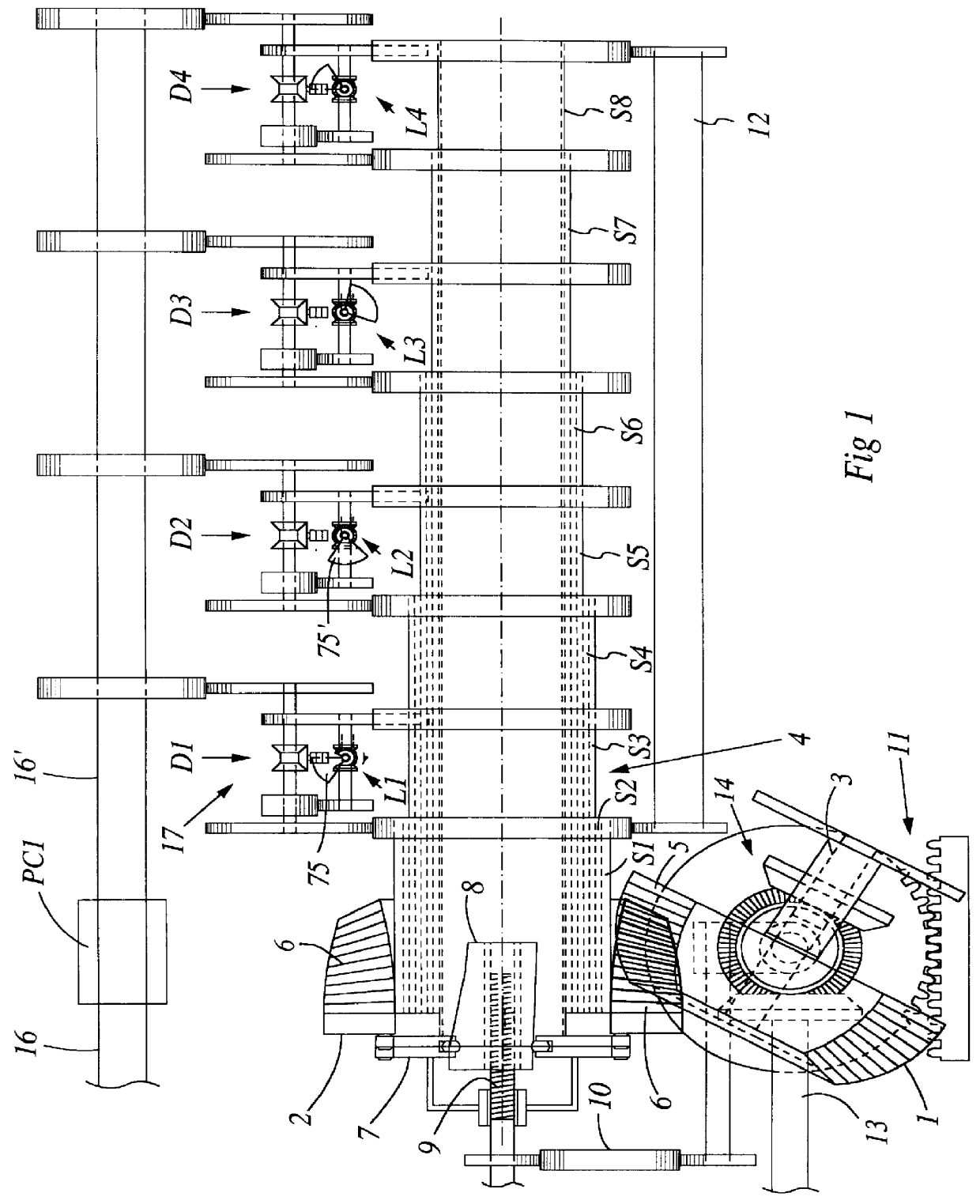

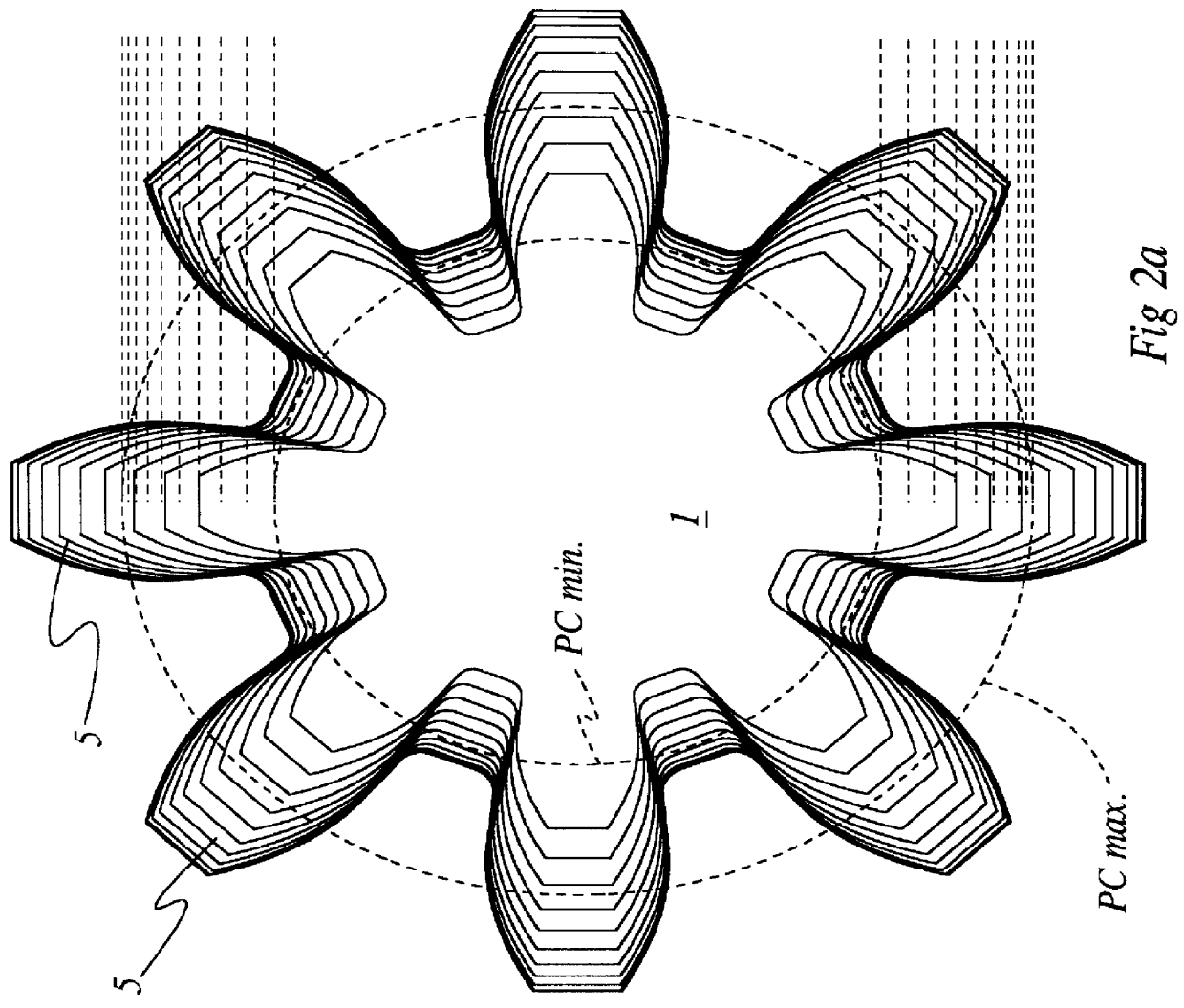

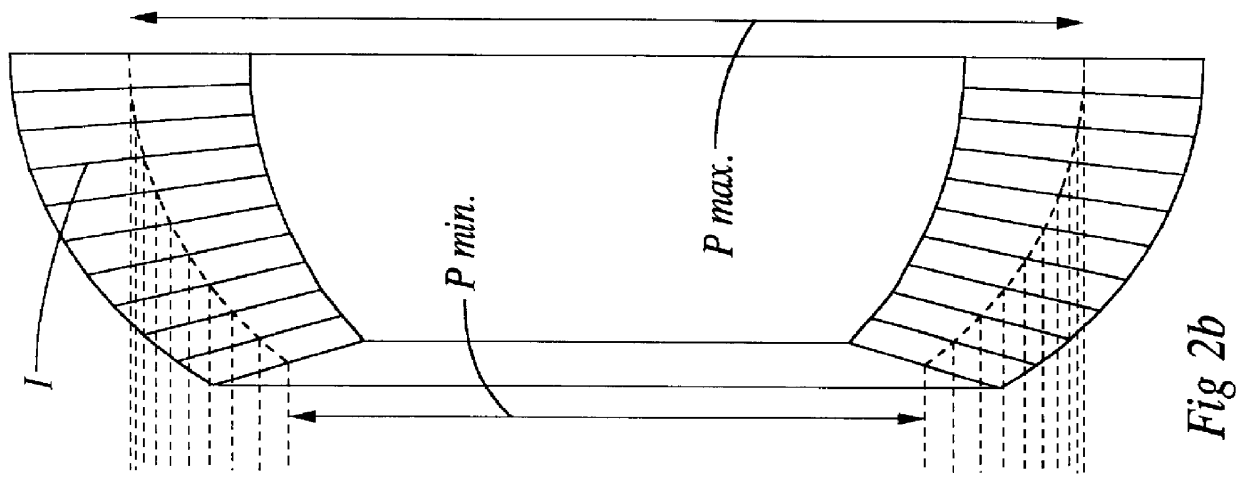

Continuously variable gear transmission

InactiveUS6066061AImprove efficiencyImprove reliabilityToothed gearingsPortable liftingEngineeringBlade pitch

A continuously variable gear transmission has a hemispherical drive gear providing an axially varying pitch diameter and an axially varying effective circular pitch, and a driven gear with a constant pitch diameter having teeth tapering axially in an opposite sense to the axially varying effective circular pitch of the drive gear. A pitch control drum guides teeth of the driven gear relatively around the shaft axis to continuously vary their effective circular pitch to match a circular pitch of the teeth of the drive gear for ensuring meshing engagement throughout the varying axial positions, whereby the velocity ratio of the transmission is varied continuously. The control drum has a guiding surface extending therearound with an axially tapering, conical guiding portion providing an arcuate guiding surface portion of constant transverse and continuously axially varying radius. An interconnected rod assembly links the adjacent movable teeth together for movement as a ring around the guiding surface of the drum so that the effective circular pitch of the teeth engaging the drive gear is determined by the radius of the guiding portion and so that a tooth engaging the drive gear has a constant angular velocity throughout such engagement, The shaft of the driven gear comprises a plurality of coaxial sub-shafts carrying respective individual teeth mounted coaxially with the drum. A mechanism continuously and simultaneously varies both an angle of intersection of the drive and driven gear shafts, bringing different circumferential locations of the drive gear having different pitch diameters into engagement with the driven gear, and a relative axial position of engagement of the gears, changing a circular pitch of the driven gear to match a circular pitch of the drive gear. A differential connects the selected teeth of the driven gear gear to a power output only when the teeth are at the constant angular velocity.

Owner:YUN YOWANG

Industrial cleaning installation with a filter arrangement and corresponding process

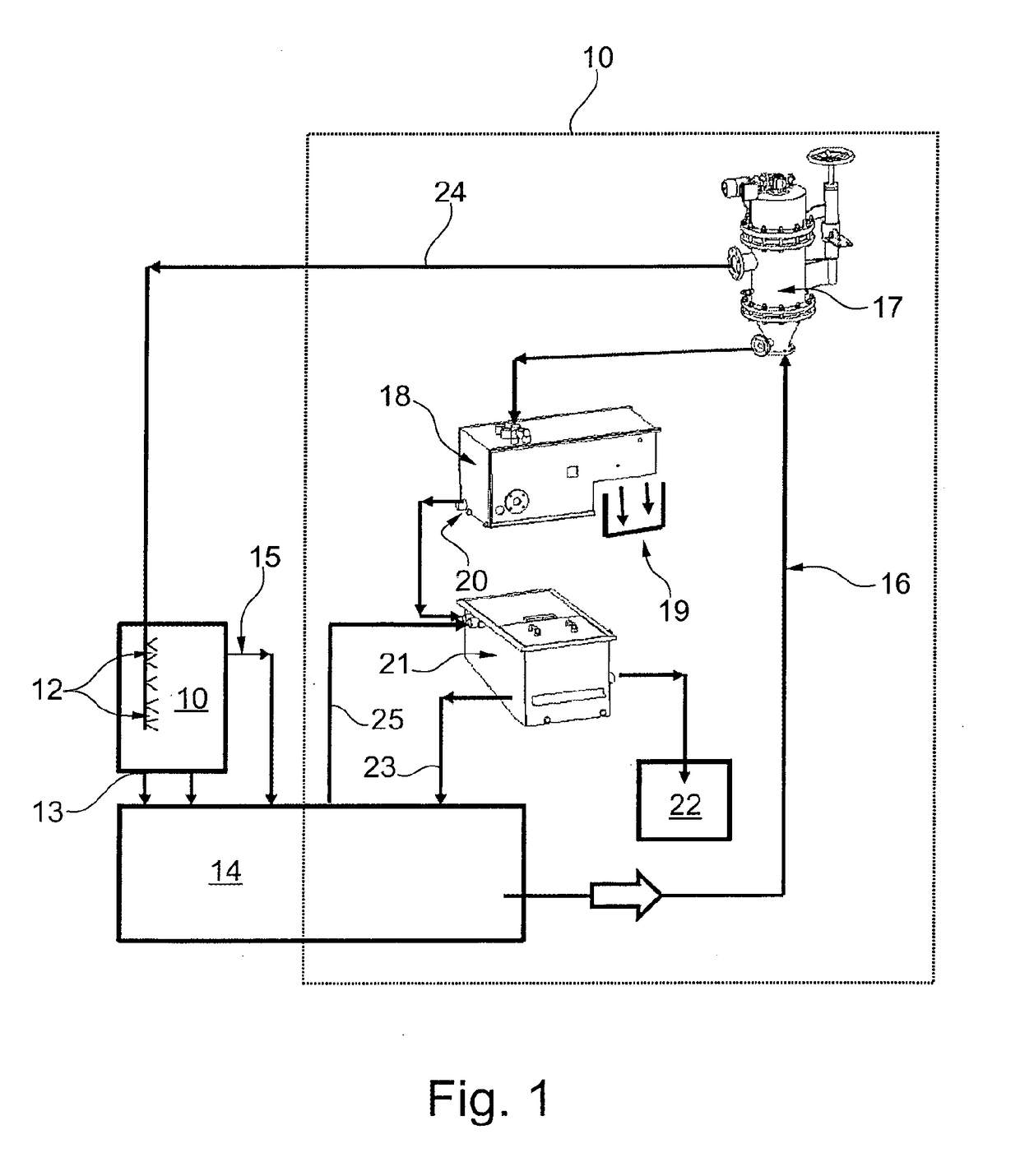

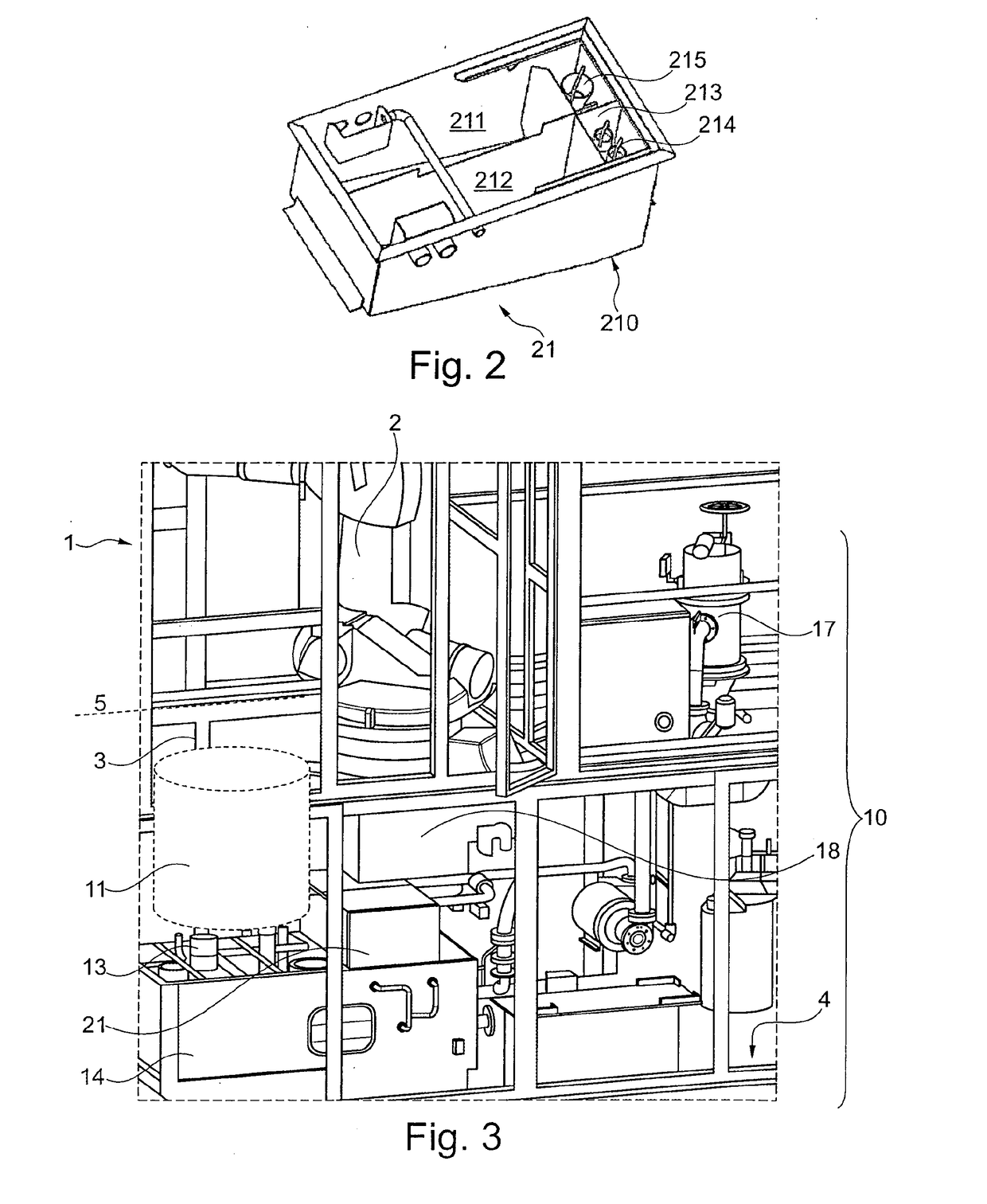

InactiveUS20190030574A1Running cost can be reducedReduce distanceLiquid suspension thickening by filtrationCleaning using liquidsEnvironmental engineeringSolid matter

An industrial installation and process for cleaning workpieces, in particular for cleaning components of engines and transmission components using a cleaning liquid, includes a first filter which is a backwash filter (17) for receiving contaminated cleaning liquid. A second filter (18) is arranged for receiving backwashed contaminated cleaning liquid from the backwash filter (17), and for removing solid matter, e.g. chips, from the contaminated cleaning liquid. An oil separator (21) is arranged for receiving contaminated cleaning liquid and for removing oil from the contaminated cleaning liquid. The oil separator (21) is fluidly connected to the second filter (18) and arranged for receiving the contaminated cleaning liquid directly from the second filter (18). The arrangement of the oil separator (21) directly following the second filter improves the filtering efficiency of the system by reducing the flow path distances of the contaminated cleaning liquid.

Owner:ELWEMA AUTOMOTIVE

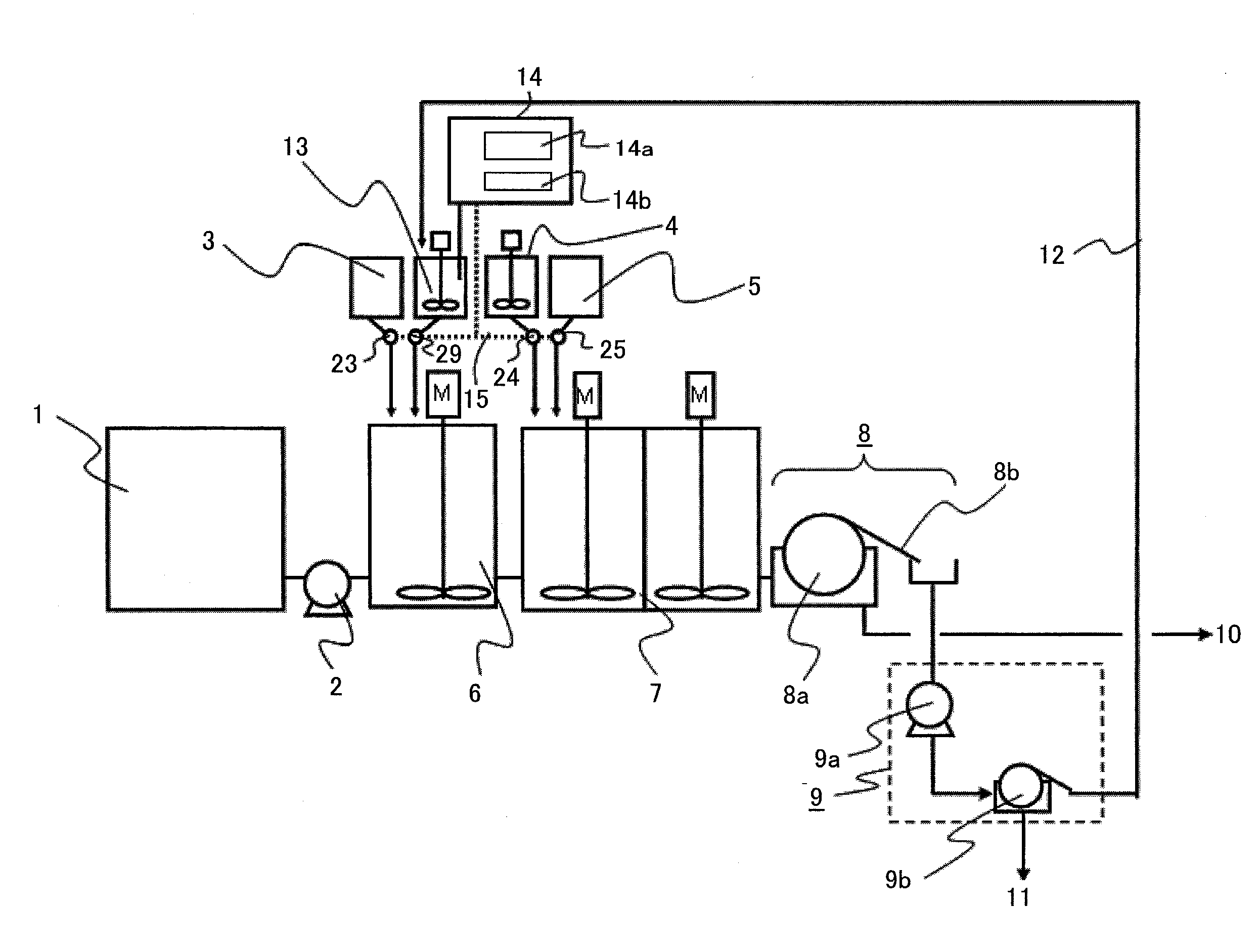

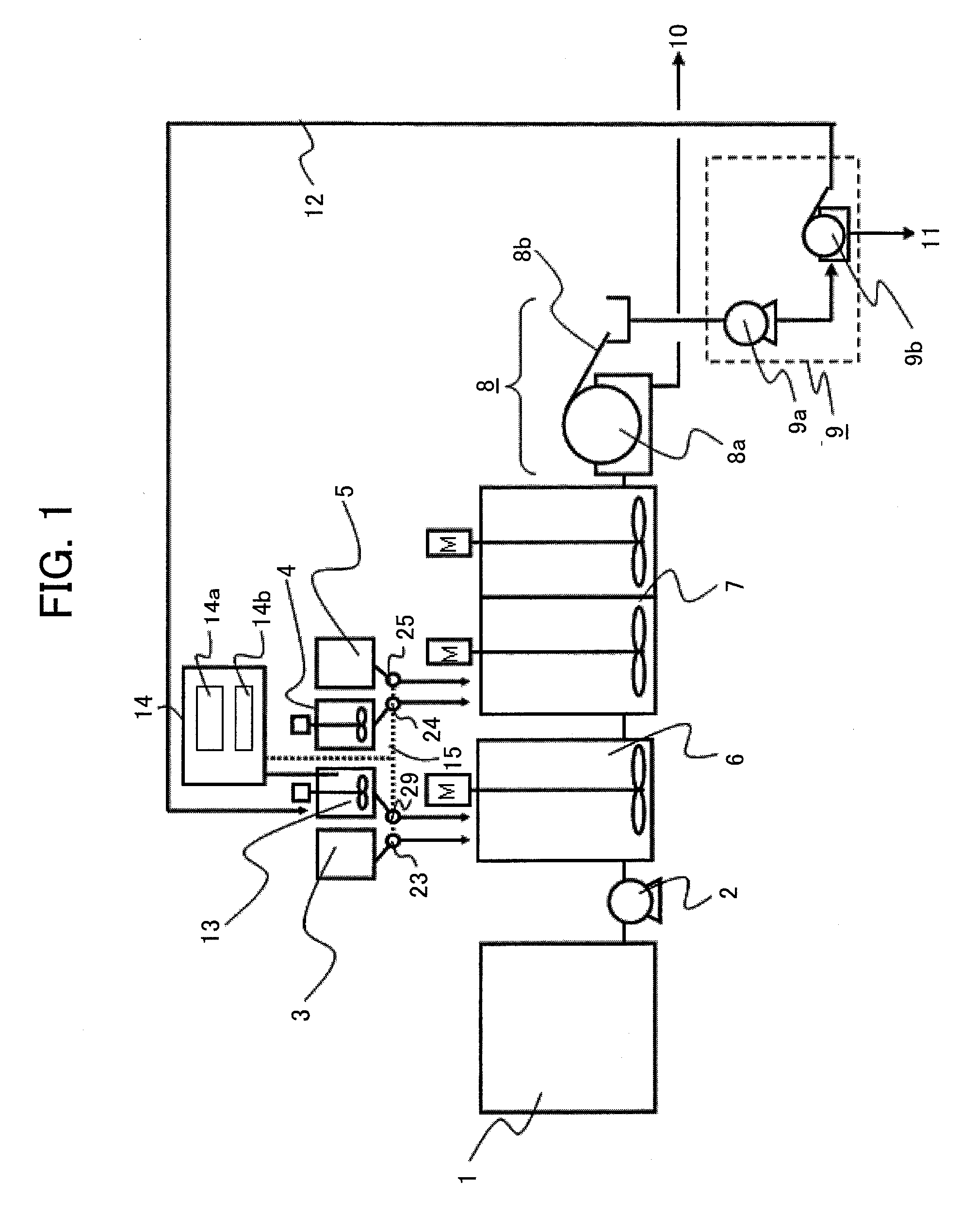

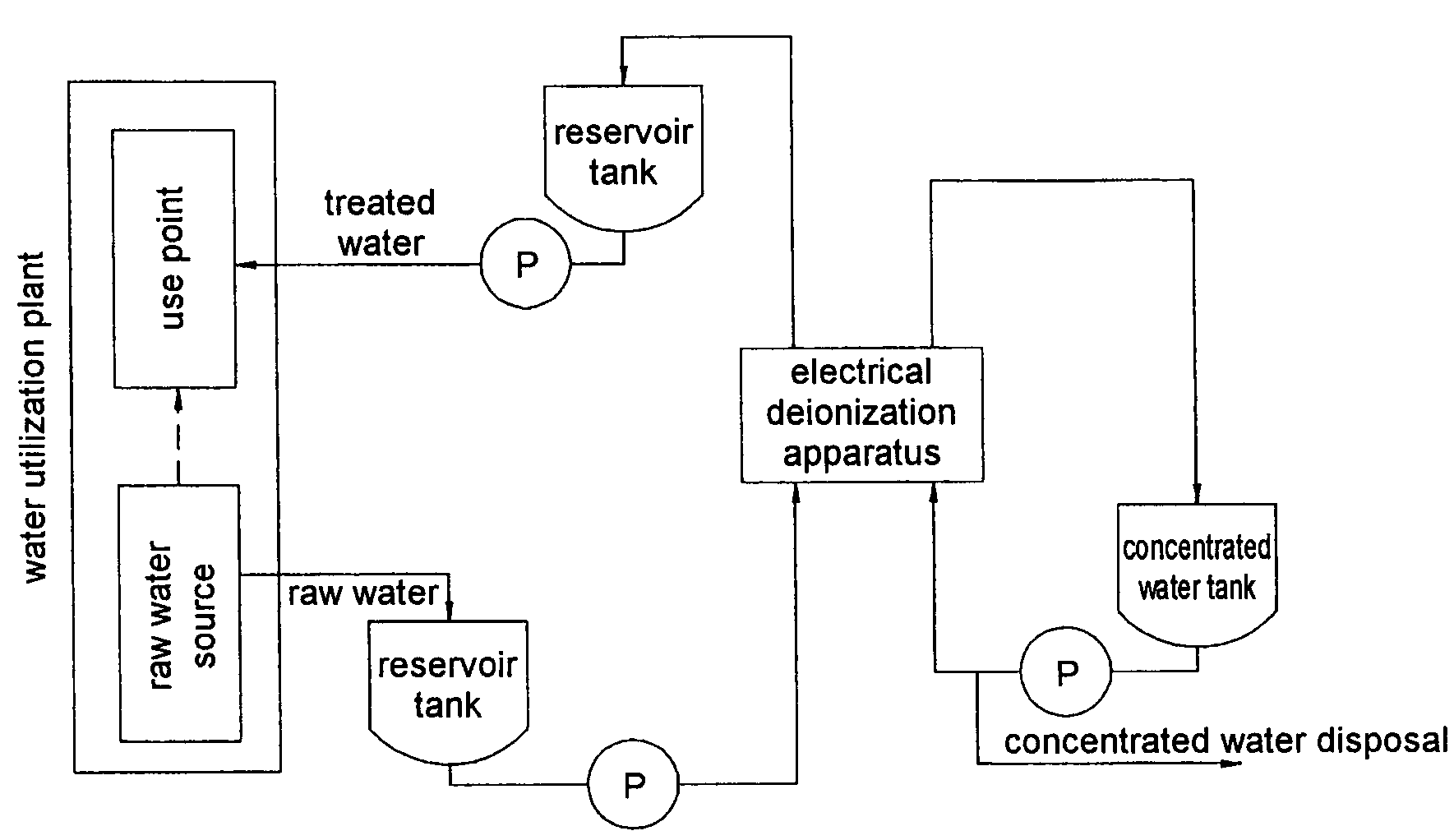

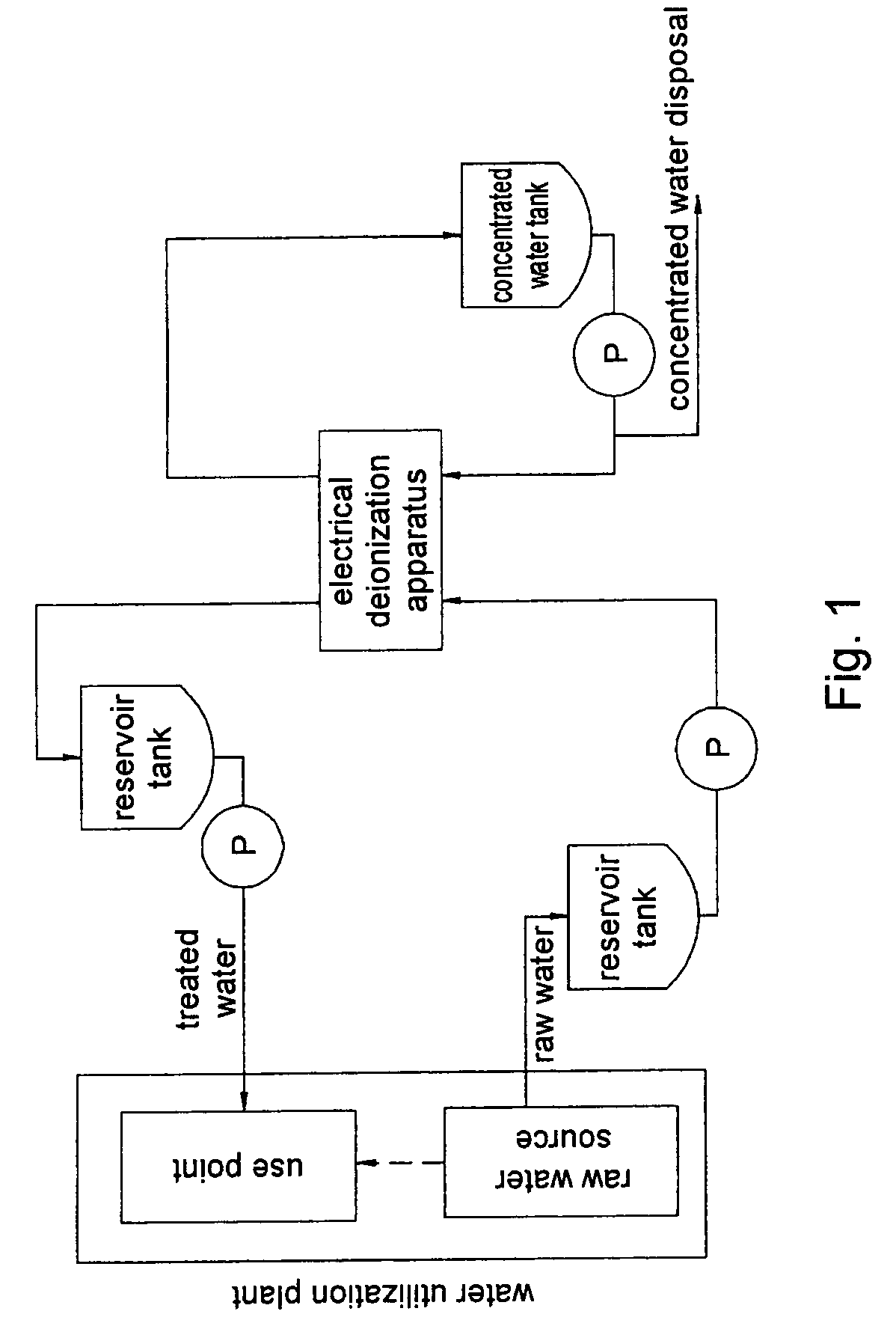

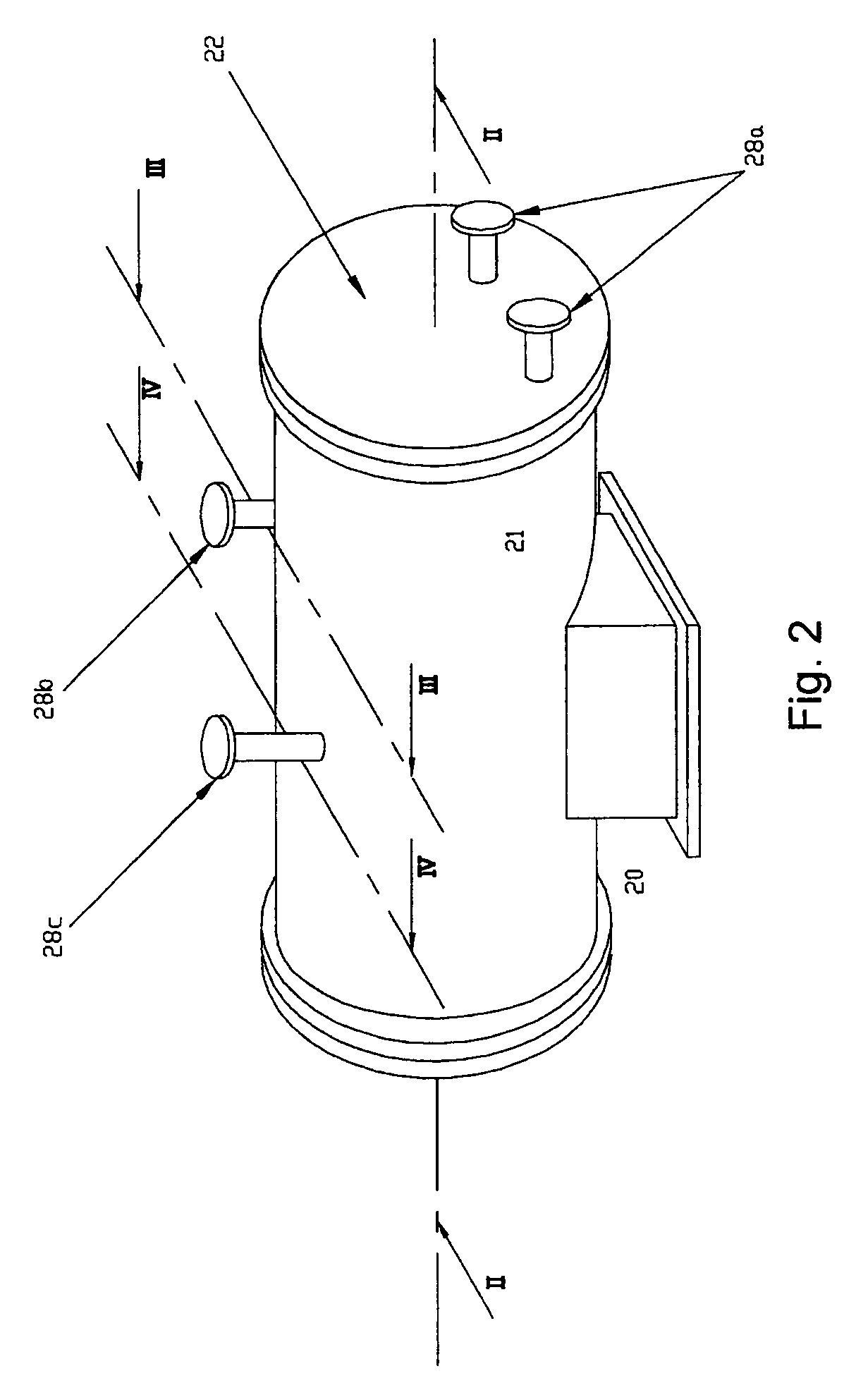

High pressure-resistant type electrical deionization apparatus, high pressure-resistant type electrical deionization system and method of producing ultrapure water using high pressure-resistant type deionization system

InactiveUS20090127117A1Running cost can be reducedDifficult to applySludge treatmentGeneral water supply conservationElectricityWater production

The present invention provides an electrical deionization apparatus suitable for an ultra pure water production system allowing high pressure raw water from an atomic power plant to be reused as the ultra water. The electric deionization stack 10 comprises a plurality of compartments defined by a compartment frame 11 and an ion exchange membrane 12. The compartments at the opposite ends construct an anode compartment 13 and a cathode compartment 14. The compartments, which are located between the anode compartment 13 and the cathode compartment 14, construct at least one concentrating compartment 15 and at least one deionizing compartment 16. Each compartment frame 11a constructing the concentrating compartment 15 has a concentrated water outlet 17. Each compartment frame 11b constructing the deionizing compartment 16 has a treated water outlet 18. In the pressure vessel 20, a concentrated water chamber 24 and a treated water chamber 25 are partitioned by a partition plate 23. Into the concentrated water chamber 24, the concentrated water flows from the concentrated water outlet 17 of the electric deionization stack 10. Into the treated water chamber 25, the treated water flows from the treated water outlet 18.

Owner:EBARA CORP

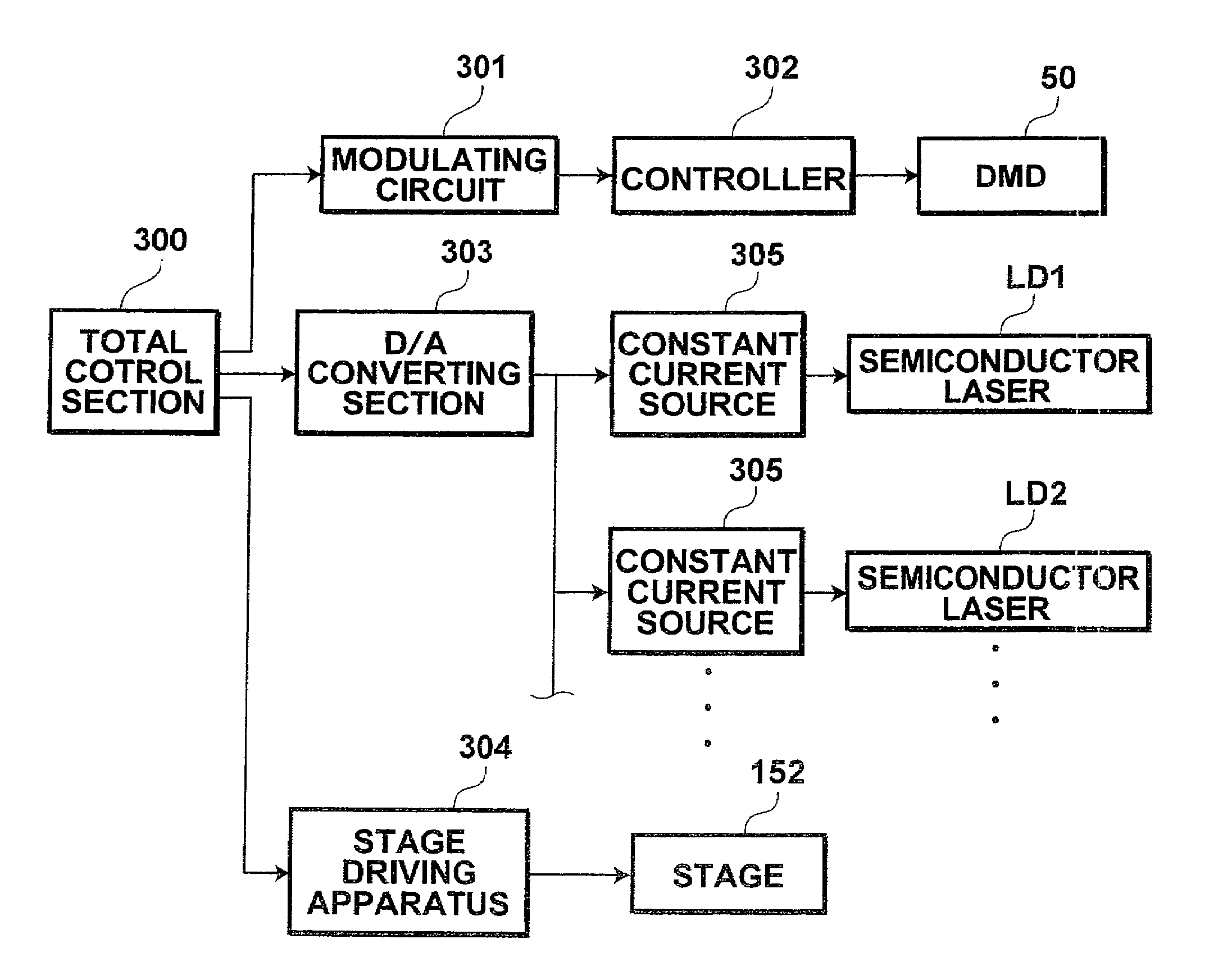

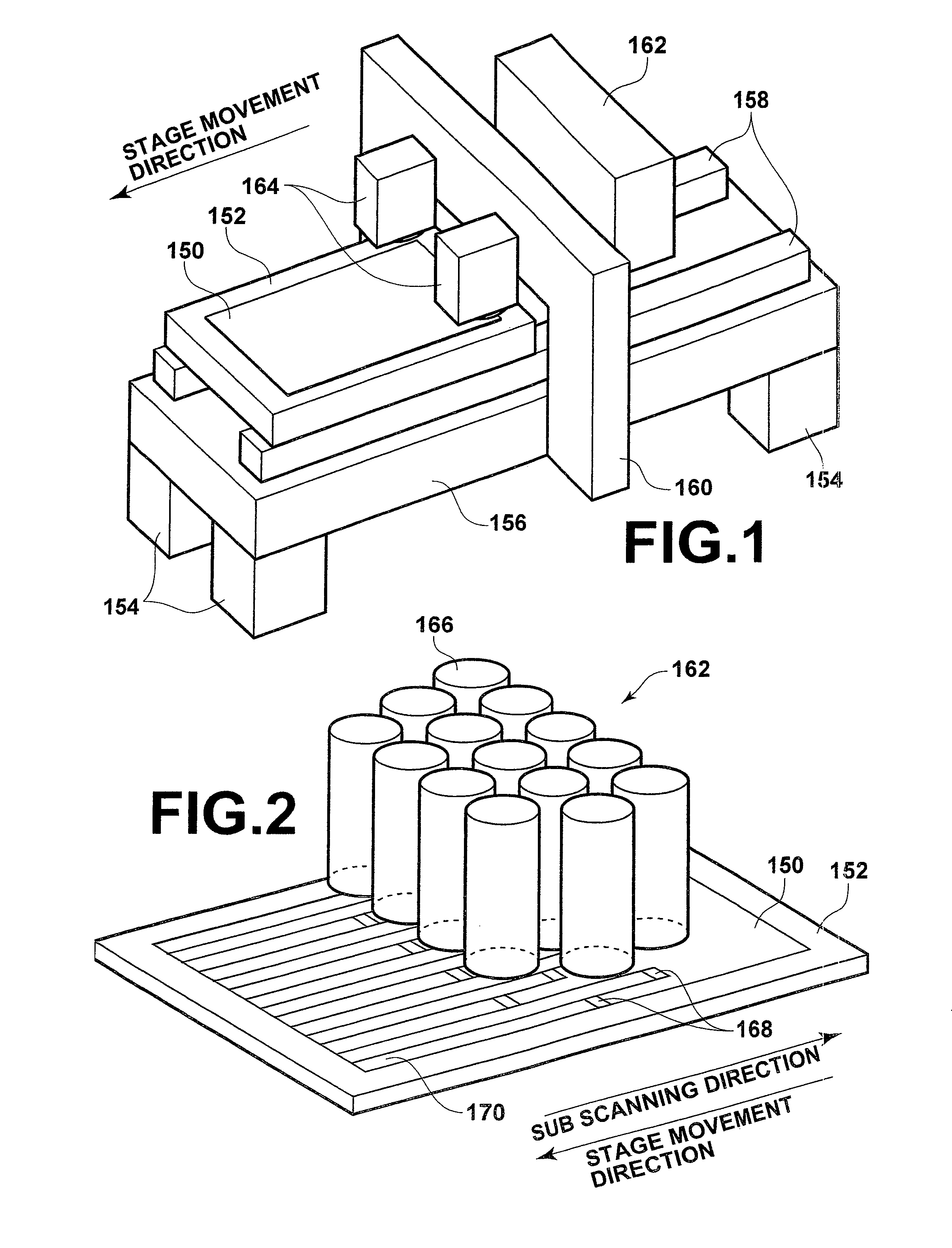

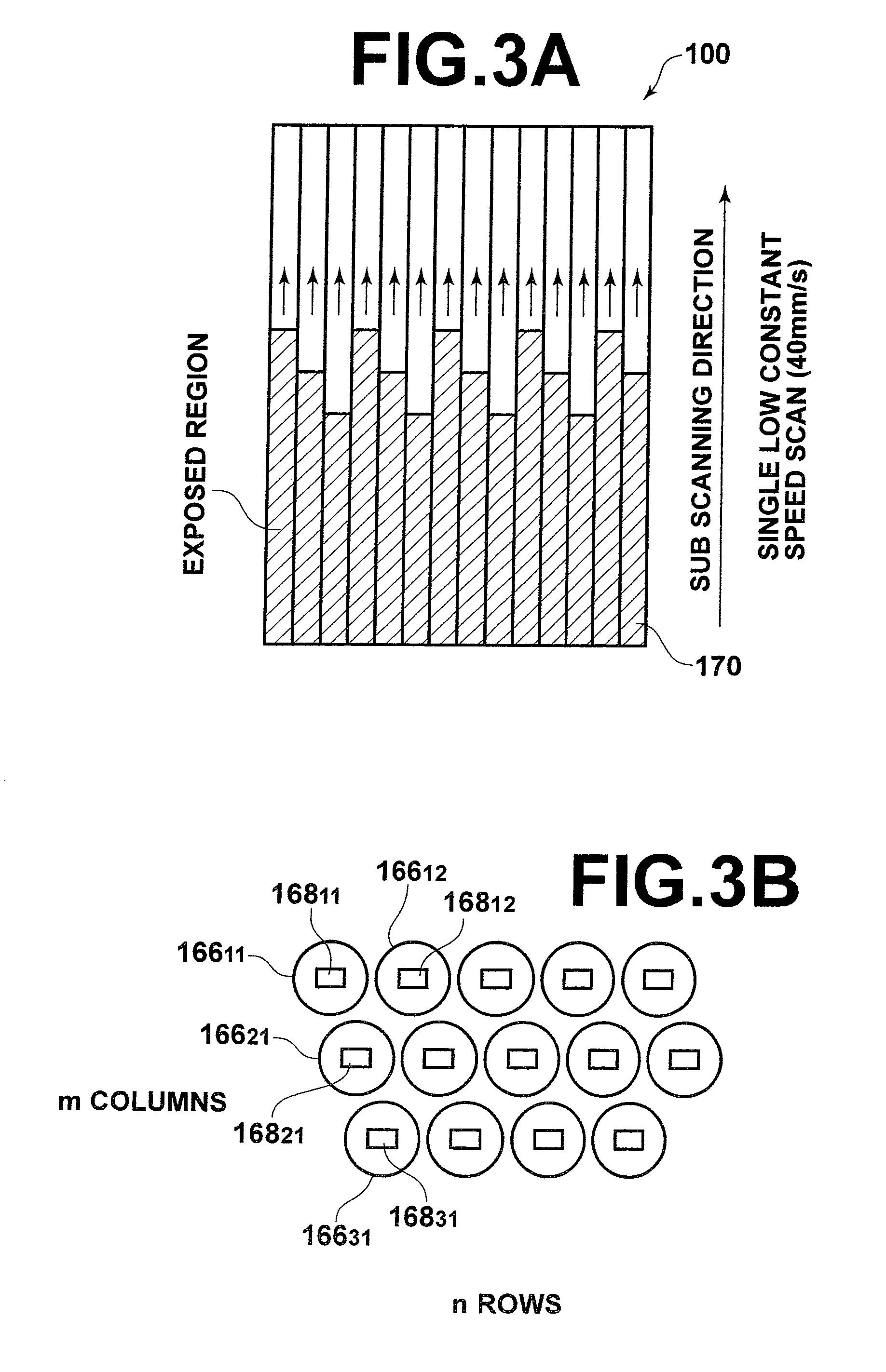

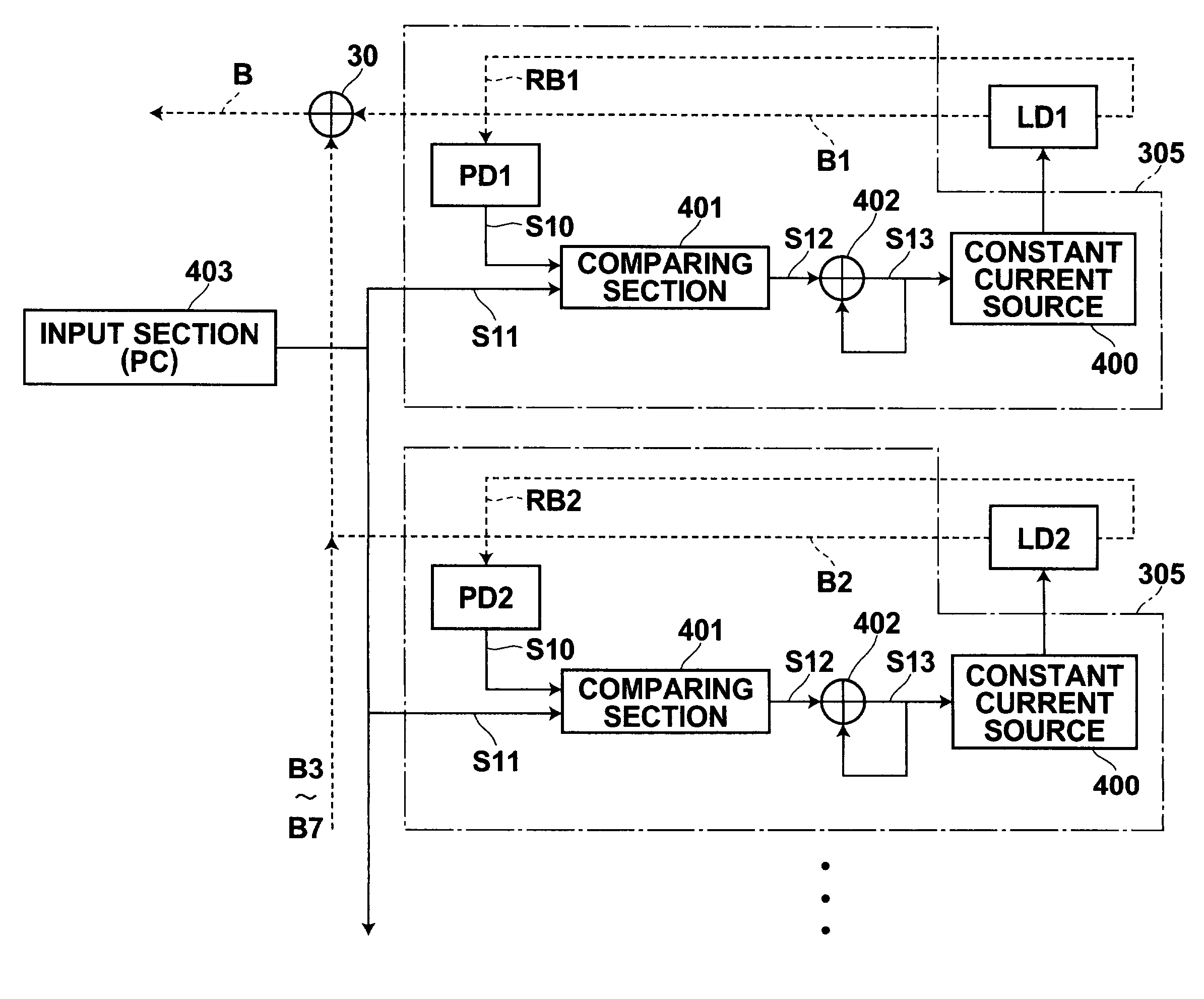

Method and apparatus for driving semiconductor lasers, and method and apparatus for deriving drive current patterns for semiconductor lasers

ActiveUS7724790B2Keep for a long timeShorten takt timeLaser detailsSolid-state devicesDriving currentStart up time

Semiconductor lasers are driven such that high output laser beams are stably obtained without a long start up time. A method for driving semiconductor lasers by automatic current control or automatic power control with a constant current source involves the steps of: generating a pattern of drive current values for the semiconductor lasers, which is defined according to the amount of time which has elapsed since initiating driving thereof, that enables obtainment of substantially the same light output as a target light output by the automatic current control or the automatic power control; and varying the drive current of the semiconductor lasers in stepwise increments according to the pattern for a predetermined period of time from initiation of drive thereof. A single pattern is used in common to drive the plurality of semiconductor lasers.

Owner:ADTEC ENG

Illumination Device, Light Irradiation Apparatus Using the Same, and Method for Producing Photoreaction Product Sheet with the Apparatus

InactiveUS20080273337A1Uniform illumination distributionReduce in quantityLighting applicationsMechanical apparatusLight irradiationEllipse

The present invention provides an illumination device including a cylindrical light source and a curved mirror for reflecting light radiated from the cylindrical light source, wherein the curved mirror has a light reflection surface which has a shape of a portion of an elliptic curve having a first focal point and a second focal point on a reference axis of the curved surface, in a cross-sectional surface perpendicular to the axial direction of the light source, and the cylindrical light source is disposed on the reference axis at a position between the first focal point and the second focal point, a light irradiation apparatus including the illumination device, and a method for producing a photoreaction product sheet using the irradiation apparatus.

Owner:NITTO DENKO CORP

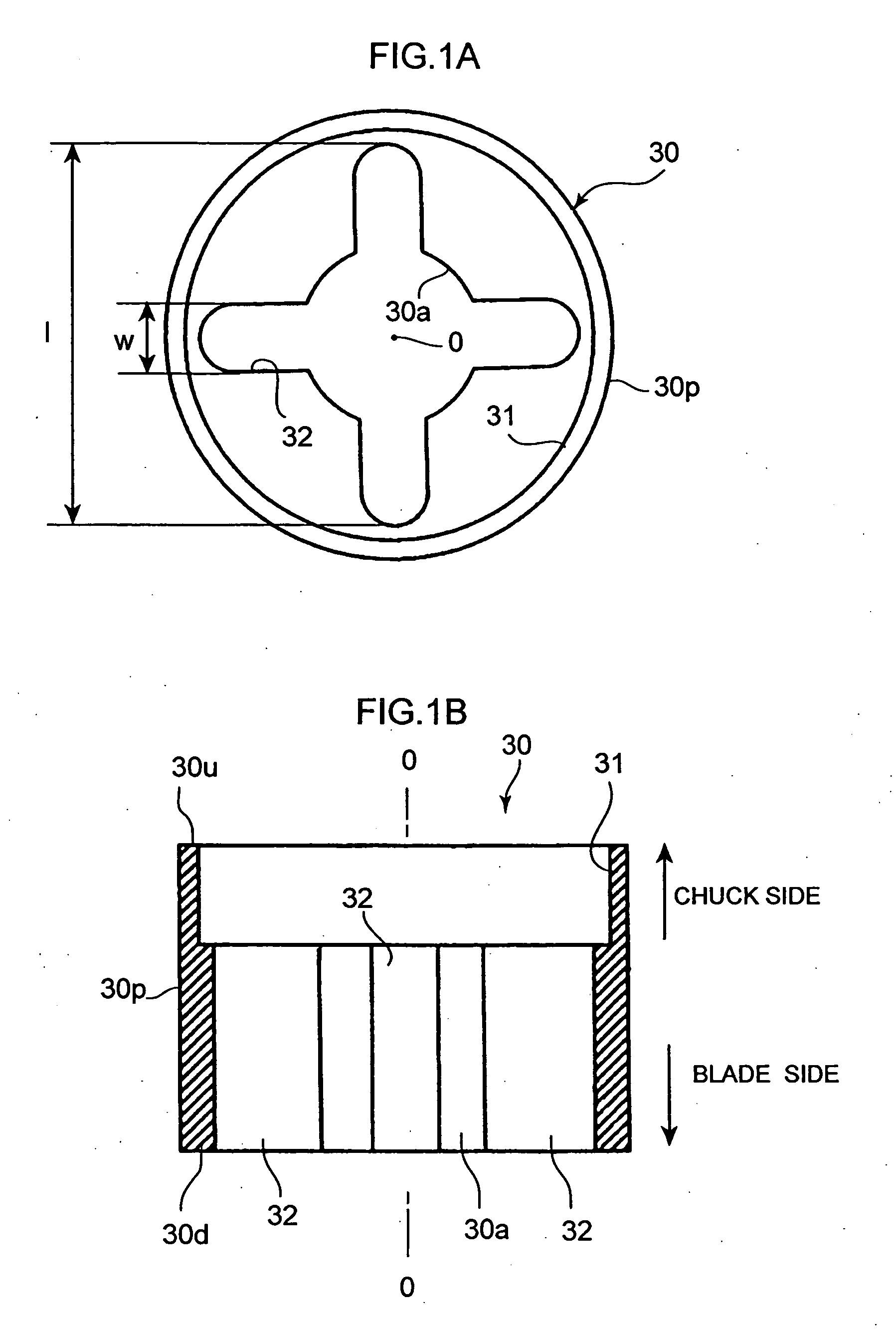

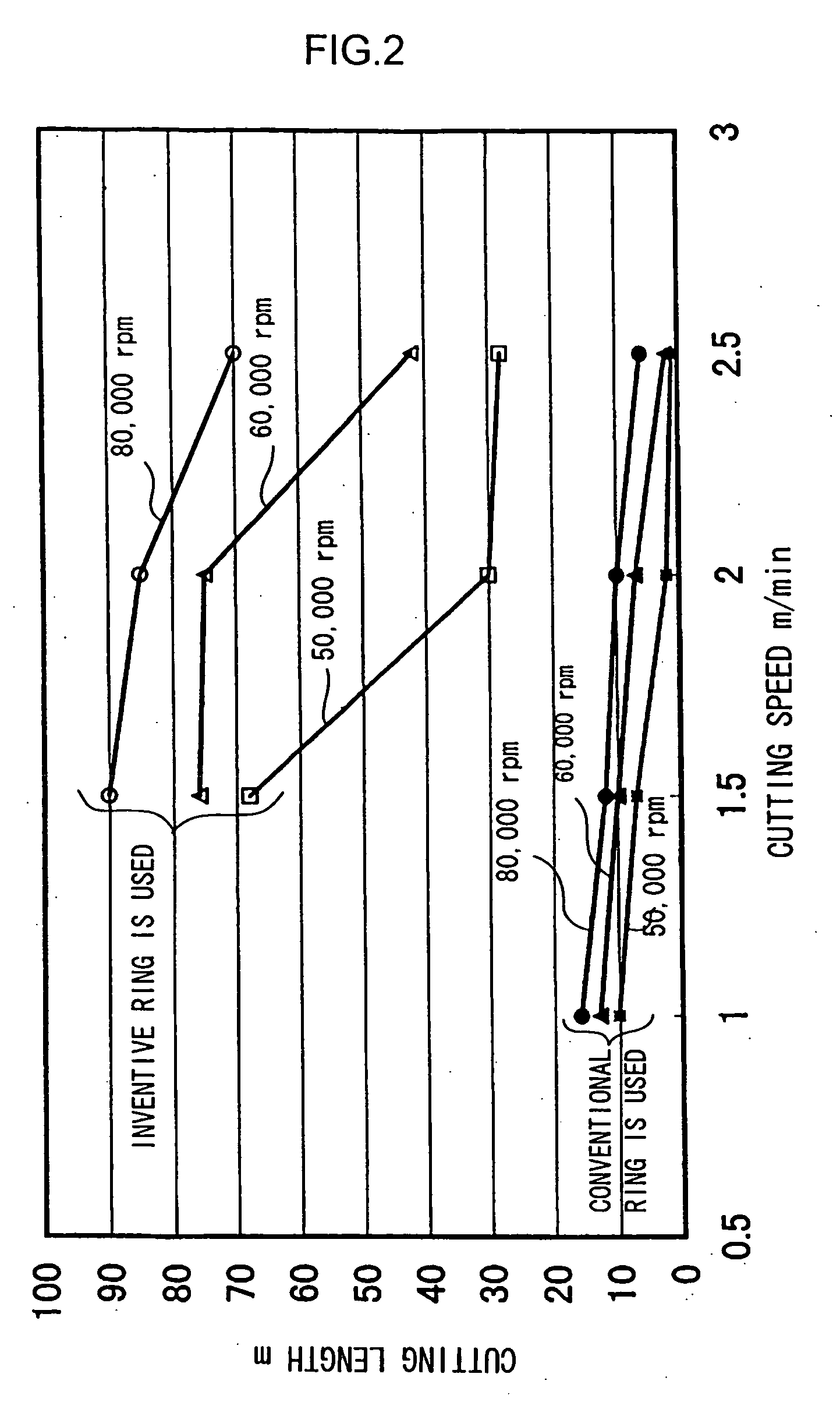

Tool positioning device and machining tool

ActiveUS20060082076A1Improve tool lifeRunning cost can be reducedThread cutting toolsDrilling/boring measurement devicesEngineeringMachine tool

There is provided a tool positioning device and a machining element whose structures are simple and which can reduce a running cost. In addition to a hole that engages with a shank of an end mill, a channel is provided so that it penetrates through the device such that one end thereof communicates with an upper face of the device and the other end communicates with a lower end of the device. In this case, it is more effective to provide a concave portion that is opened to the upper face and communicates with the hole. The same effect may be obtained by making a cylindrical hole for example instead of the channel.

Owner:HITACHI SEIKO LTD

Method and apparatus for driving semiconductor lasers, and method and apparatus for deriving drive current patterns for semiconductor lasers

ActiveUS7970029B2Reduce the amount requiredKeep for a long timeLaser detailsSemiconductor lasersDriving currentPhotovoltaic detectors

Semiconductor lasers are driven such that high output laser beams are stably obtained without a long start up time. The light outputs of a plurality of semiconductor lasers are detected by photodetectors. The semiconductor lasers are driven by automatic power control based on comparison results between the output of the photodetectors and a set value corresponding to a target light output for the semiconductor lasers. A correction pattern that corrects the set value and / or the output of the photodetectors such that the actual light output becomes uniform is generated in advance. The set value and / or the output are varied according to the correction pattern for a predetermined period of time from initiation of drive. A single correction pattern is employed in common with respect to the plurality of semiconductor lasers.

Owner:ADTEC ENG

Sealing device and rolling bearing apparatus

InactiveUS20090232433A1Increase intervalRunning cost can be reducedEngine sealsBearing assemblyRolling-element bearingElectromagnet

First portions are fixed to an outer ring, and second portions are fixed to an inner ring. Bimetal members and electromagnets are embedded in and fixed by elastic portions of the first portions and portions of the second portions are constituted by ferromagnetic members. Whereas at a normal temperature region, the first portions and the second portions are brought into contact with each other, based on deformations of the bimetal members at a temperature equal to or higher than a predetermined temperature equal to or higher than the normal temperature region, the first portions and the second portions are made to be disposed to be spaced apart from each other by intervals therebetween at a temperature equal to or higher than the predetermined temperature equal to or higher than the normal temperature region.

Owner:JTEKT CORP

Noncontact web transporting method and apparatus

InactiveUS20050034323A1Stable levitated stateRunning cost can be reducedDrying machines with progressive movementsDrying machines with non-progressive movementsAirflowEngineering

Owner:FUJIFILM CORP

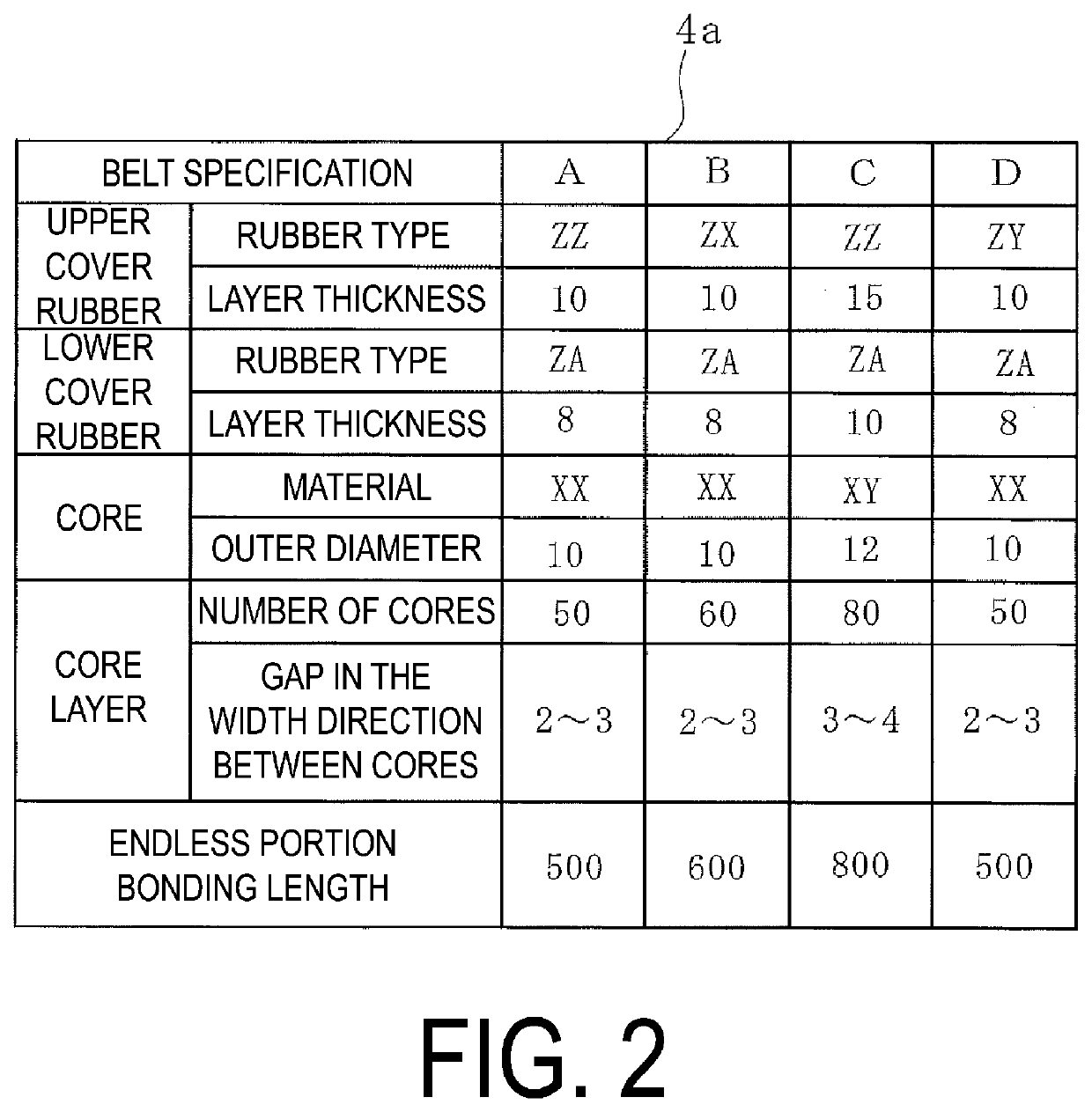

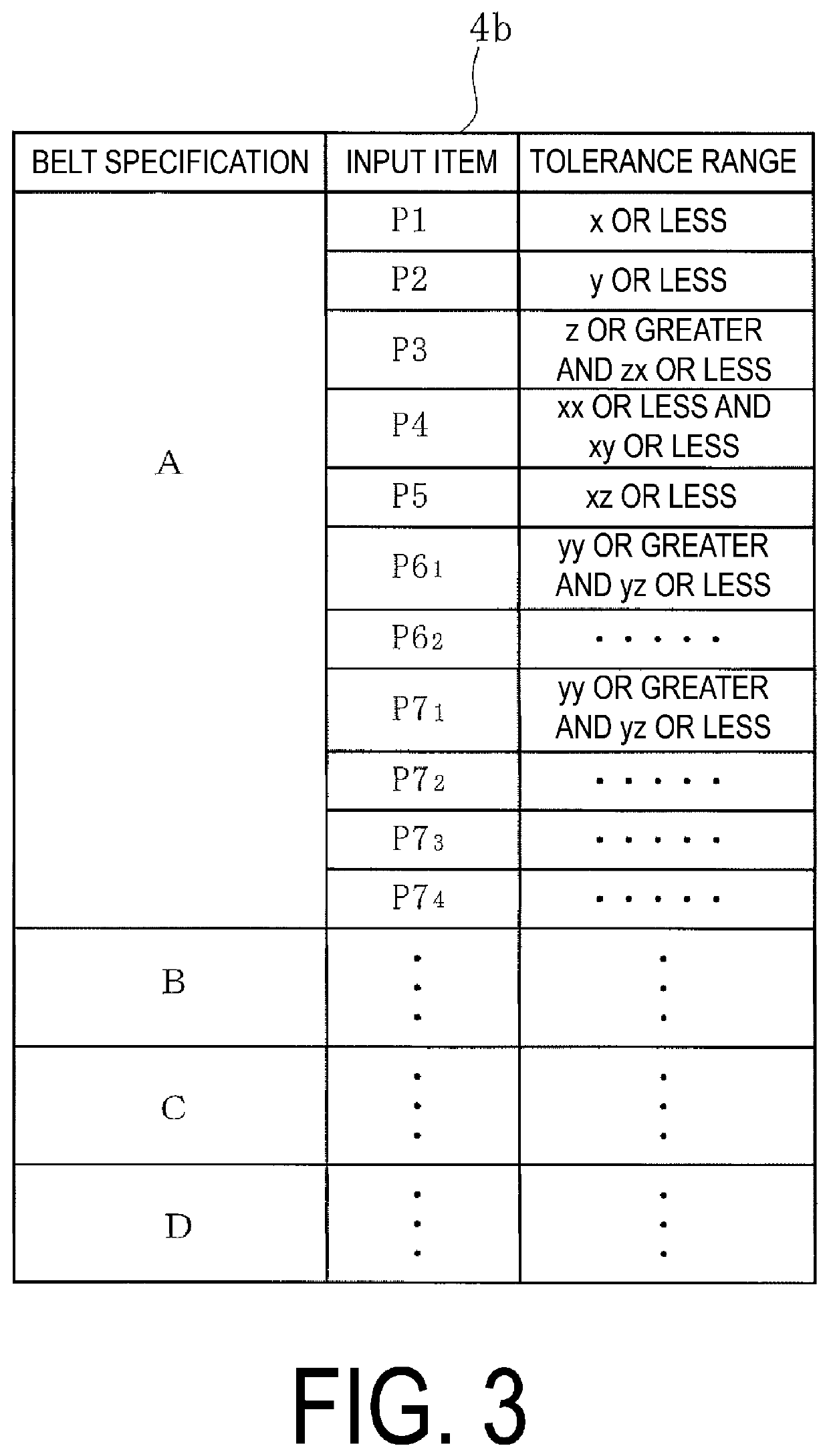

Conveyor belt management system

ActiveUS20200034756A1Easy and timelyExcess inventoryConveyorsControl devices for conveyorsControl engineeringConveyor belt

A conveyor belt management system is capable of determining a suitable replacement period of the conveyor belt. Data of an amount of wear of an upper cover rubber of the conveyor belt installed at a use site is input into a server via an input unit. A calculation unit is configured to calculate a remaining service life of the conveyor belt based on the input data and, stored in a storage unit, a belt specification database and a tolerance range database in which a tolerance range is input in advance for the amount of wear per belt specification; and calculate an expected service life of the conveyor belt before use of the conveyor belt based on a correlation between a use condition and belt specifications of the conveyor belt used up until present, the use condition of the conveyor belt, and the specifications of the conveyor belt.

Owner:THE YOKOHAMA RUBBER CO LTD

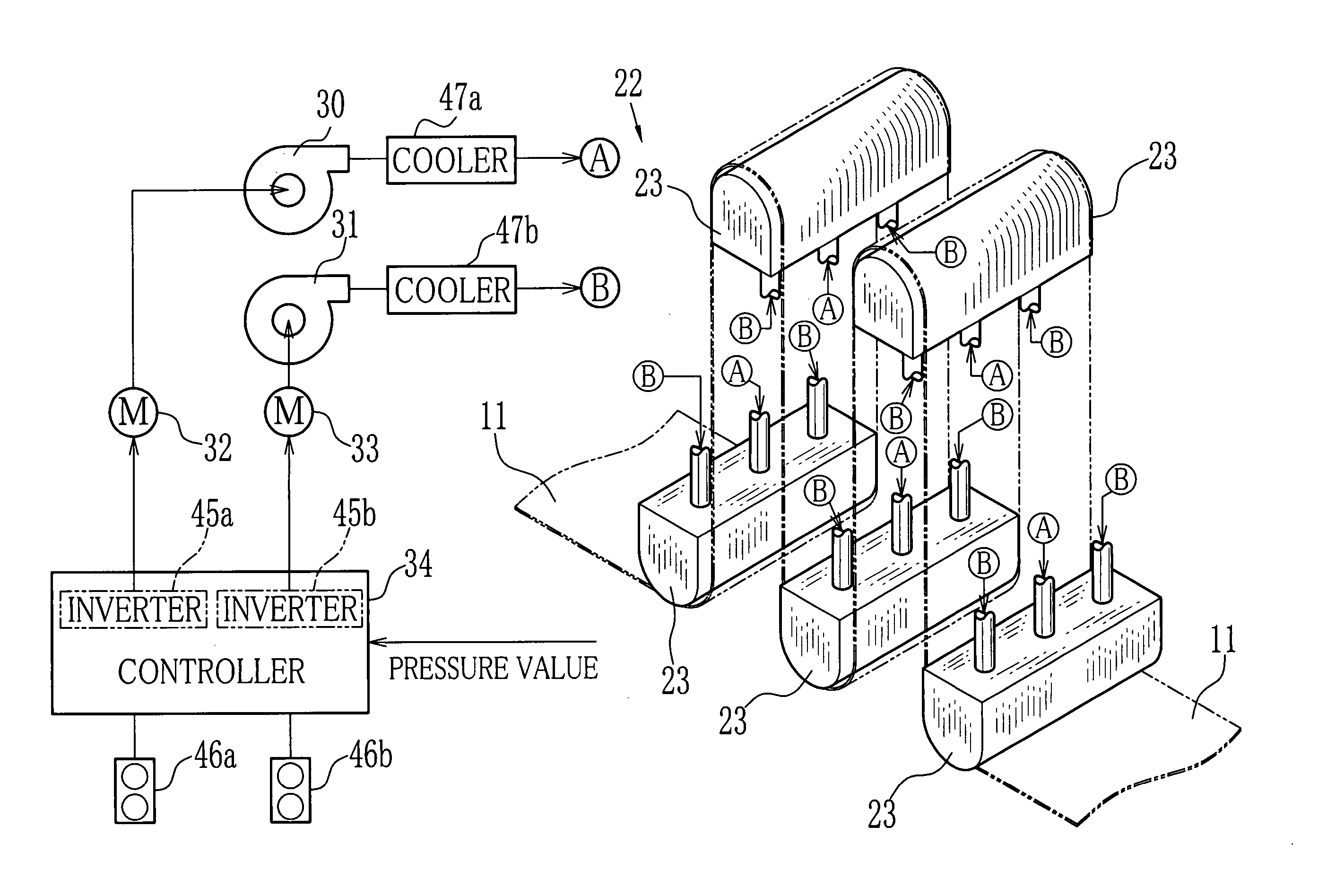

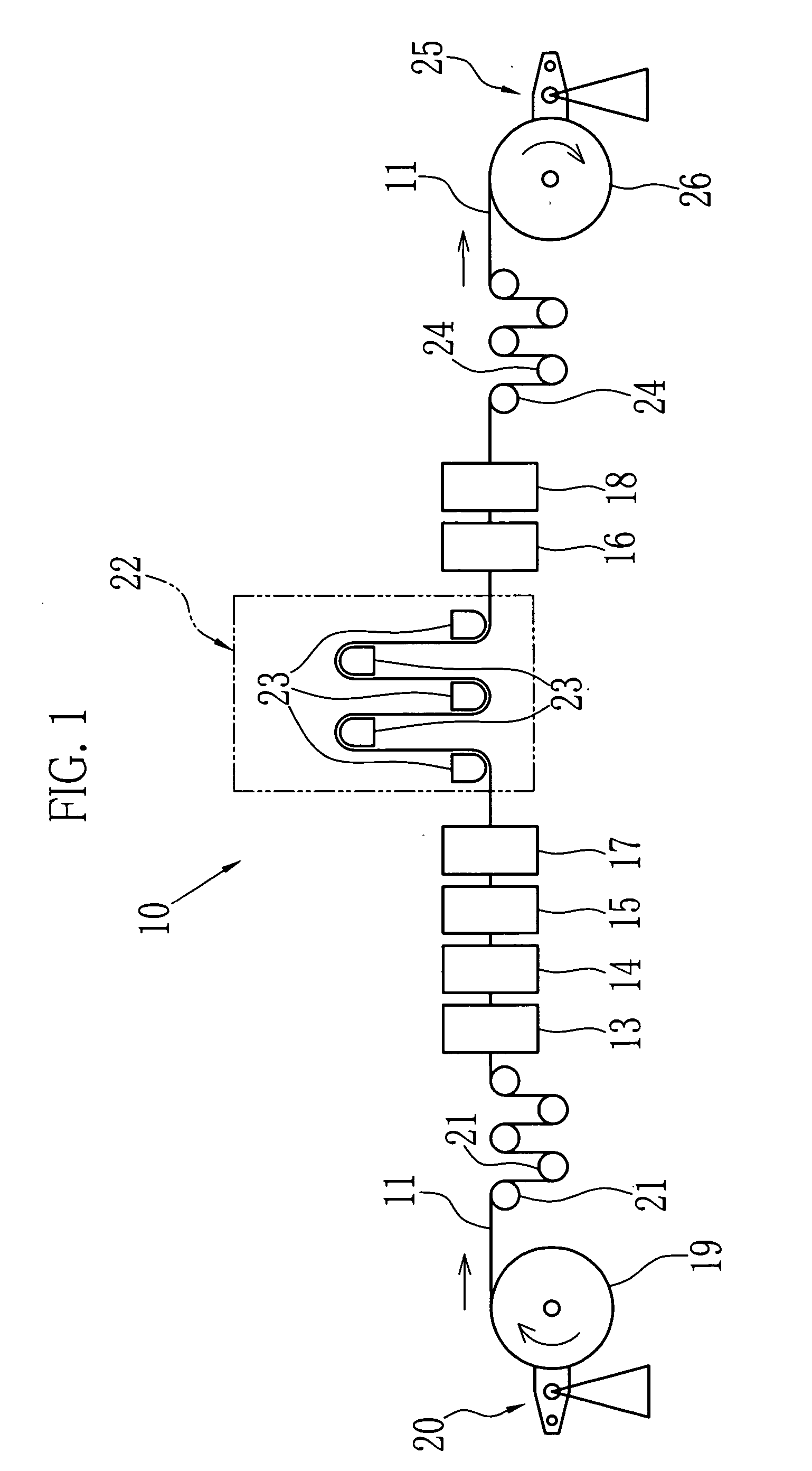

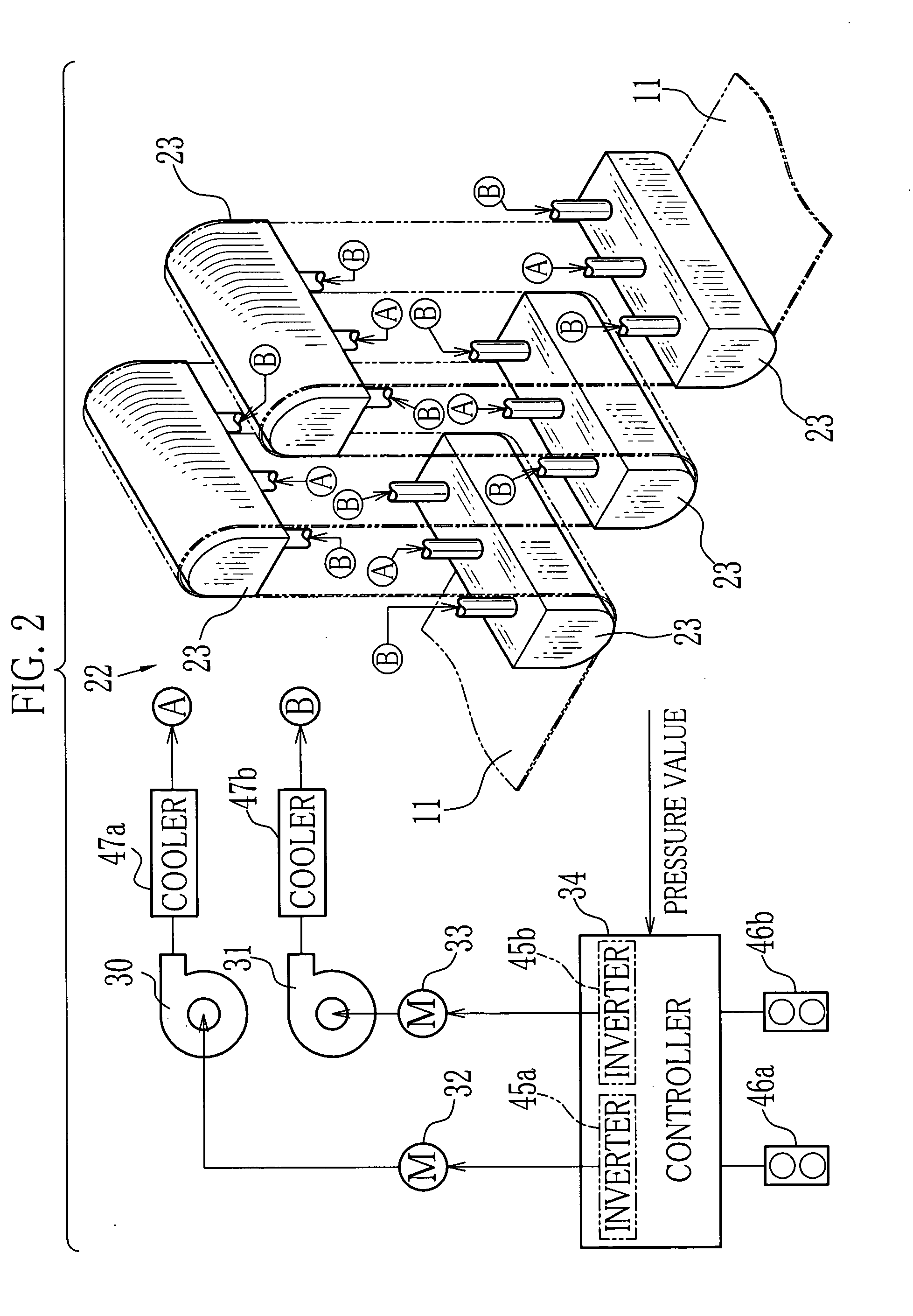

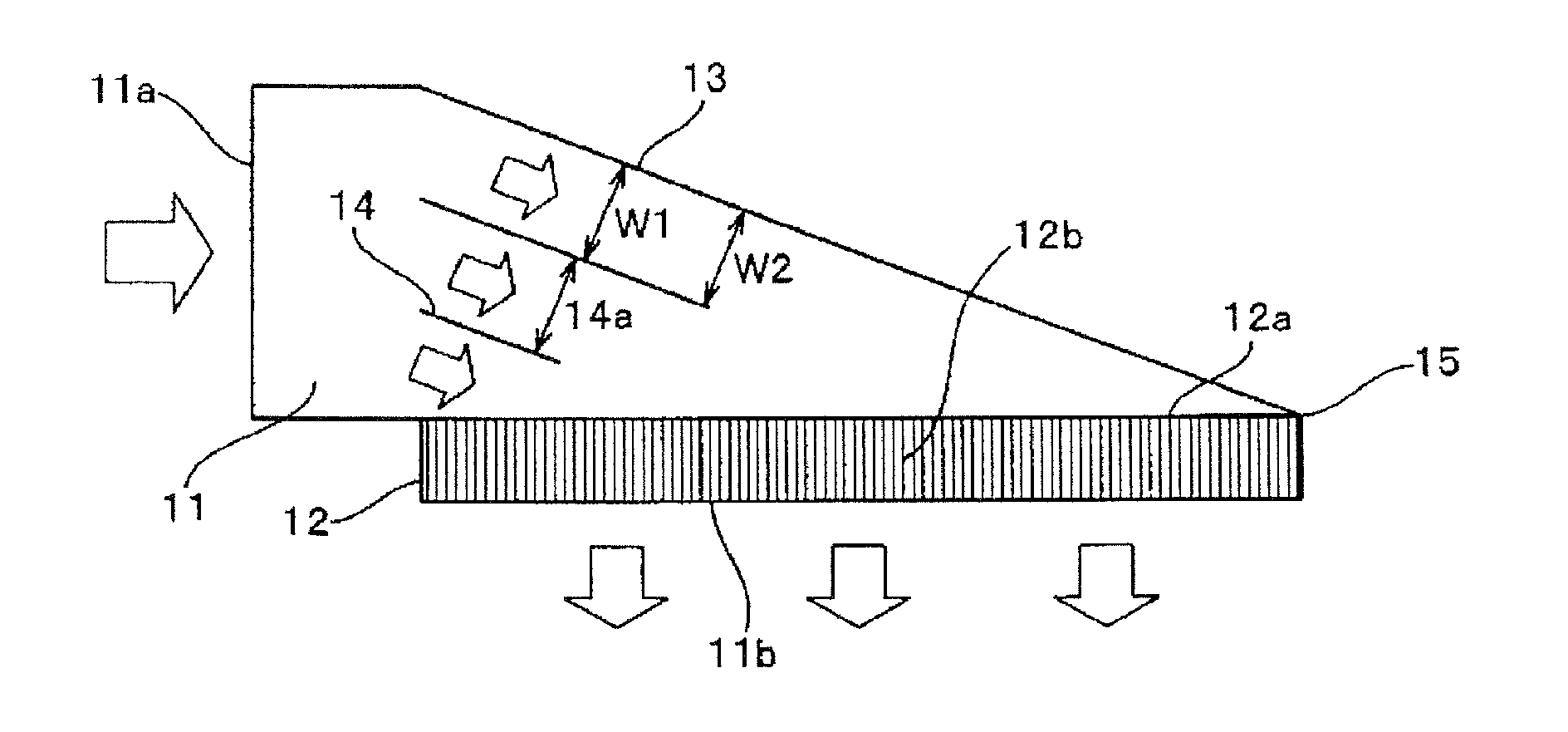

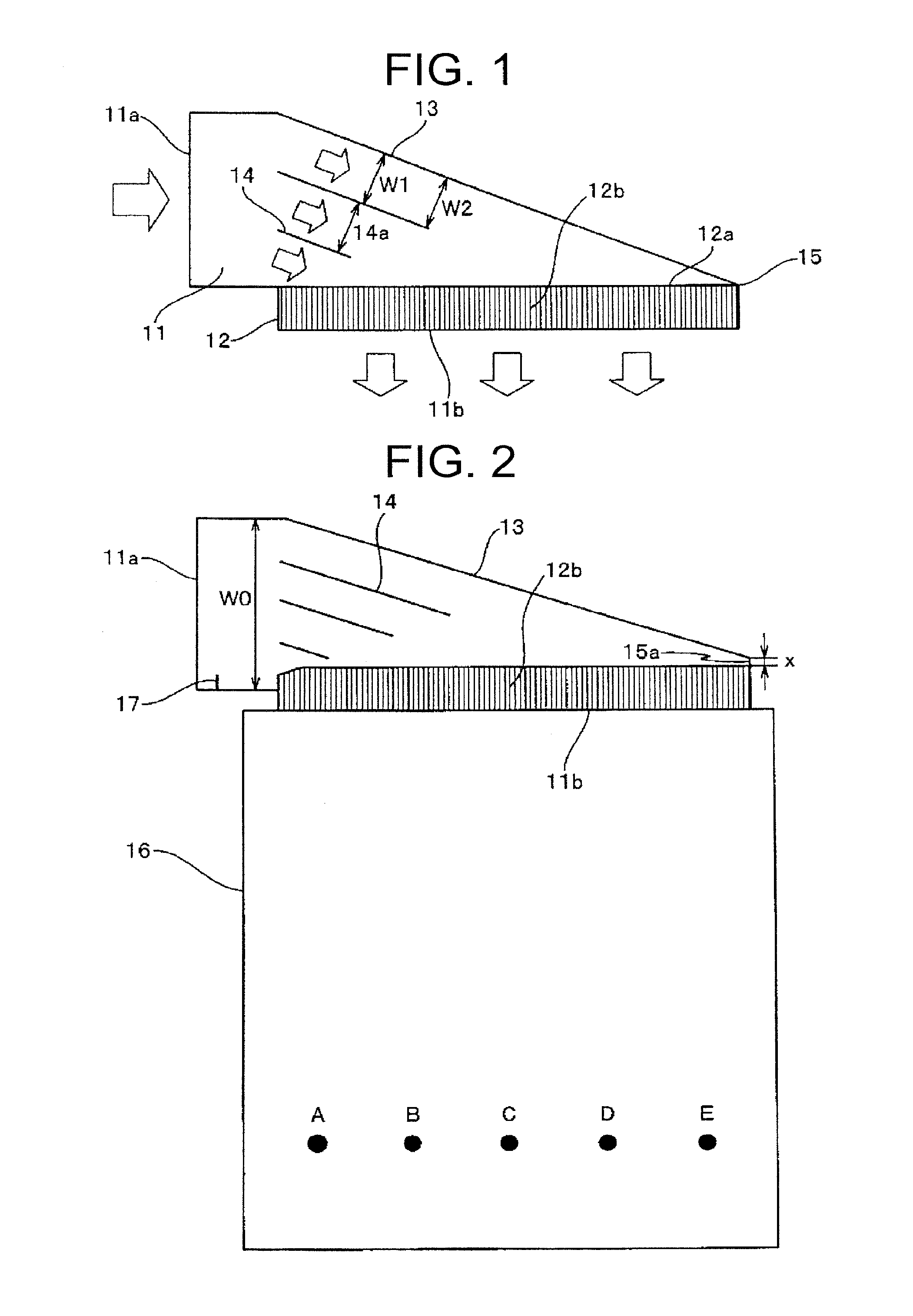

Gas supply blowout nozzle and method of producing flame-proofed fiber and carbon fiber

ActiveUS20160160395A1Inhibition resistanceReduce electricity loadDrying gas arrangementsSpray nozzlesFiberYarn

The nozzle body of the gas supply blowout nozzle (11) includes an inclined plate (13) guiding a gas flowing straightly from a gas inlet port to a rectification board (12), which is connected with the nozzle body. The rectification board (12) rectifies the flow of the gas guided by the inclined plate (13) so that the gas blows out perpendicular or parallel to a yarn from a gas outlet port. A gas guiding zone formed between the inclined plate (13) and the rectification board (12) includes one or more guide plates (14) which divide the gas supplied from the gas inlet port (11a) of the gas supply blowout nozzle (11) into two or more streams. In each gas passage formed at least one of between the inclined plate (13) and the guide plate (14) or between the guide plates (14), an upstream passage width W1 and any downstream passage width W2 thereof satisfy the relation of W1≧W2. The opening area A of the gas inlet port (12a) and the opening area B of the gas inlet of the rectification board (12) may satisfy the relation of A≦B. By means of said configuration, the wind speed in the heat treatment furnace is made uniform, the non-uniformity in the quality of the product caused by the non-uniformity of the wind speed is eliminated, longtime stable production is enabled, production efficiency is increased, and running costs are decreased.

Owner:MITSUBISHI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com