Patents

Literature

224results about How to "Improve burst strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

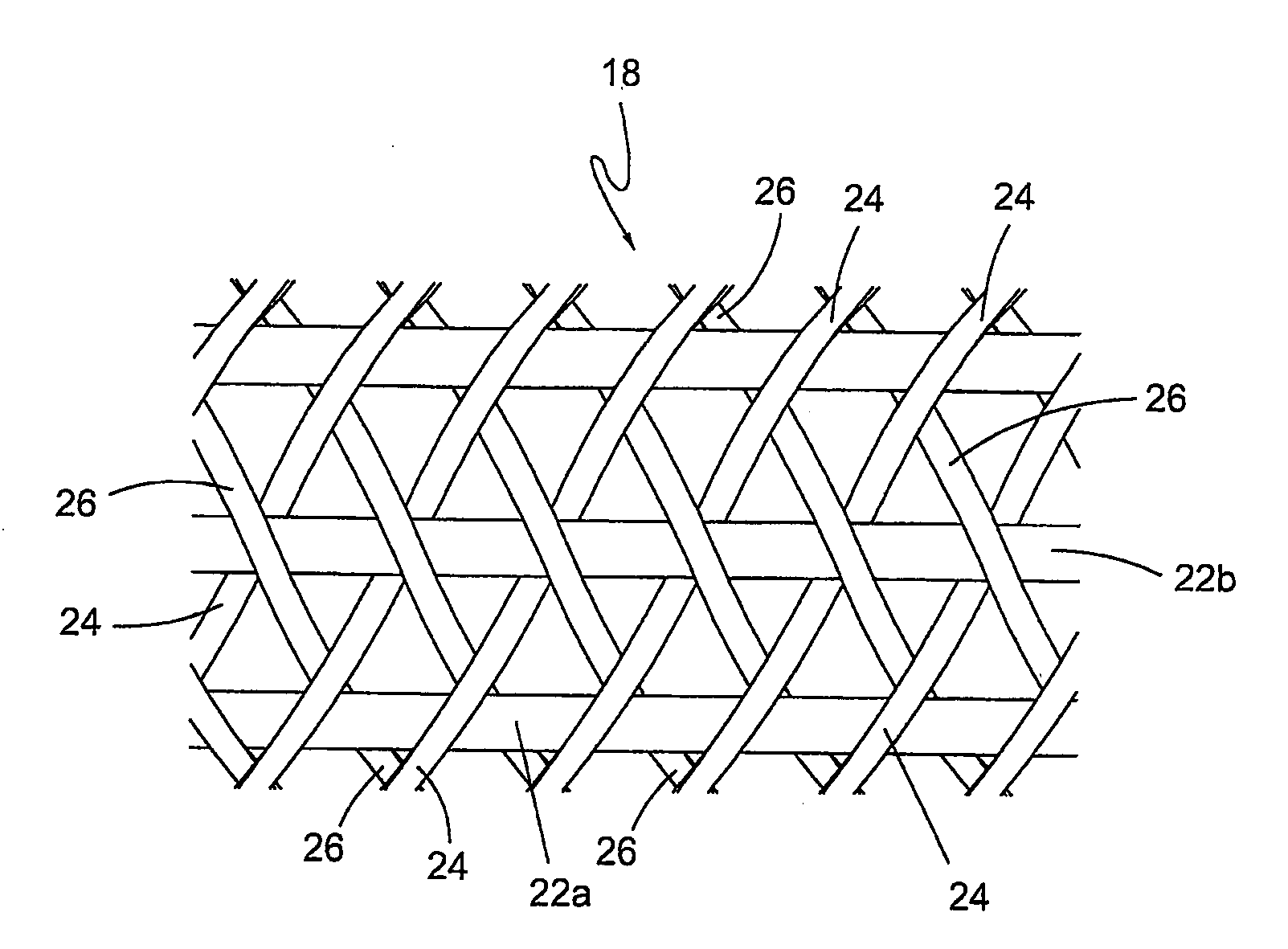

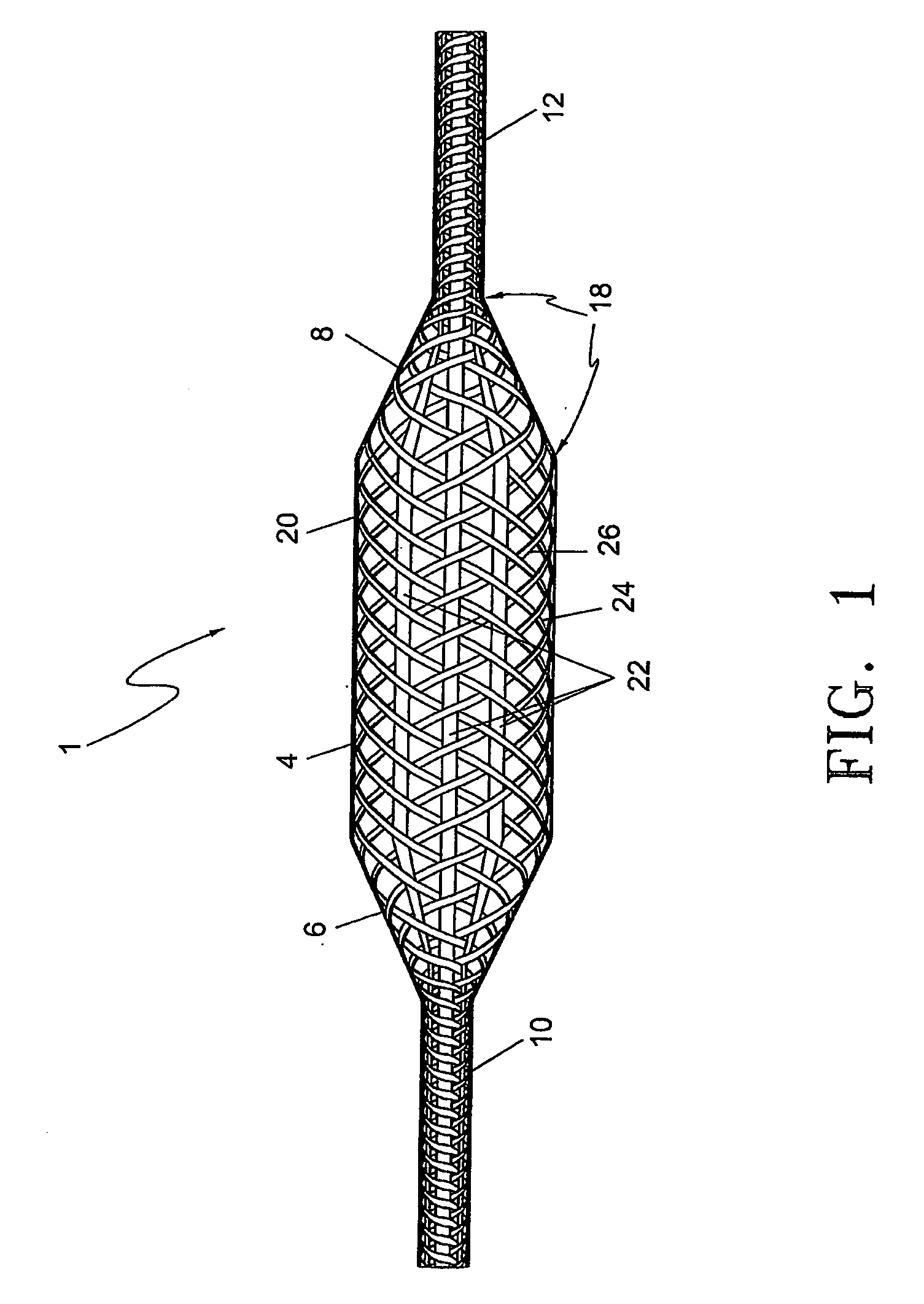

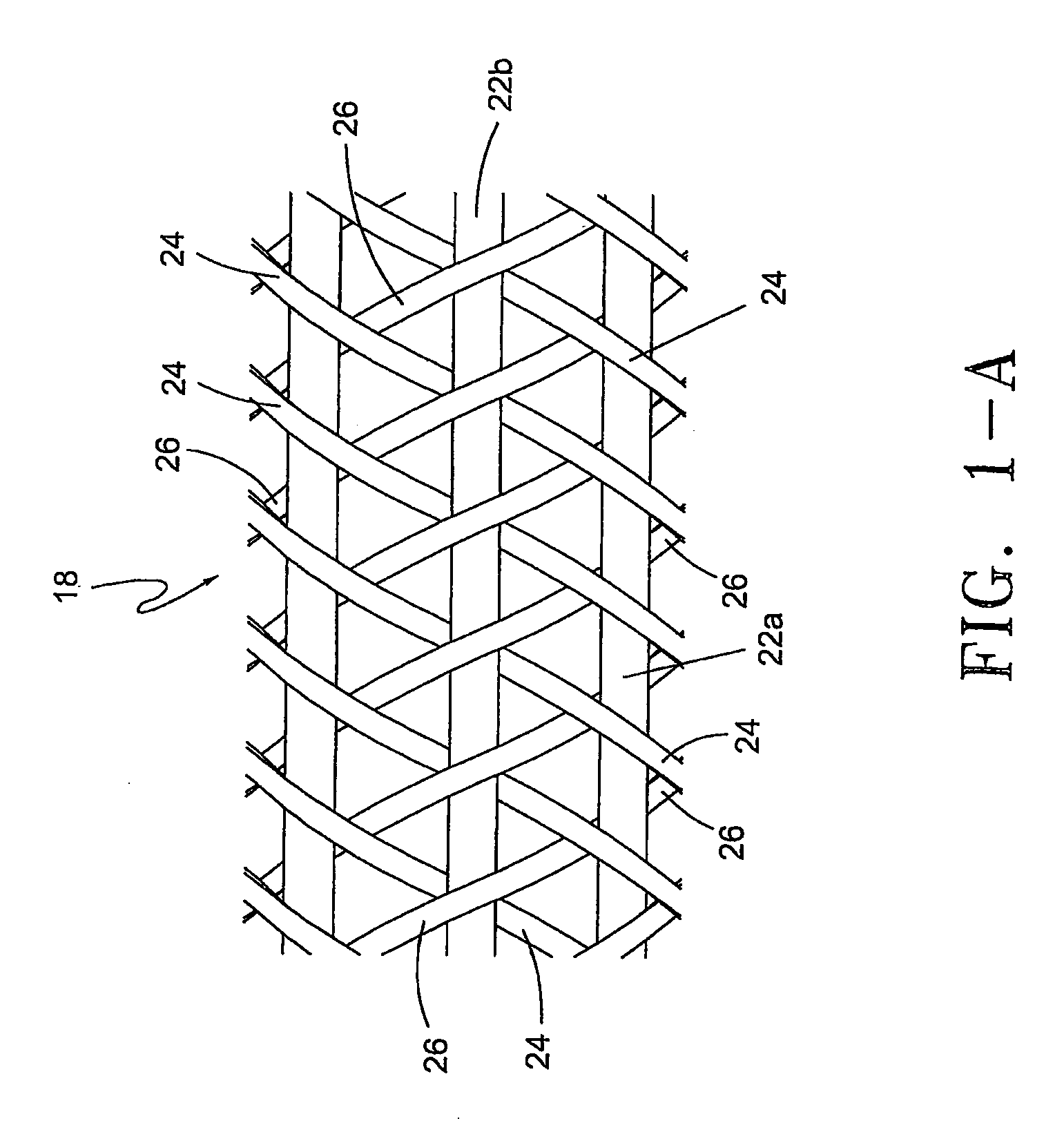

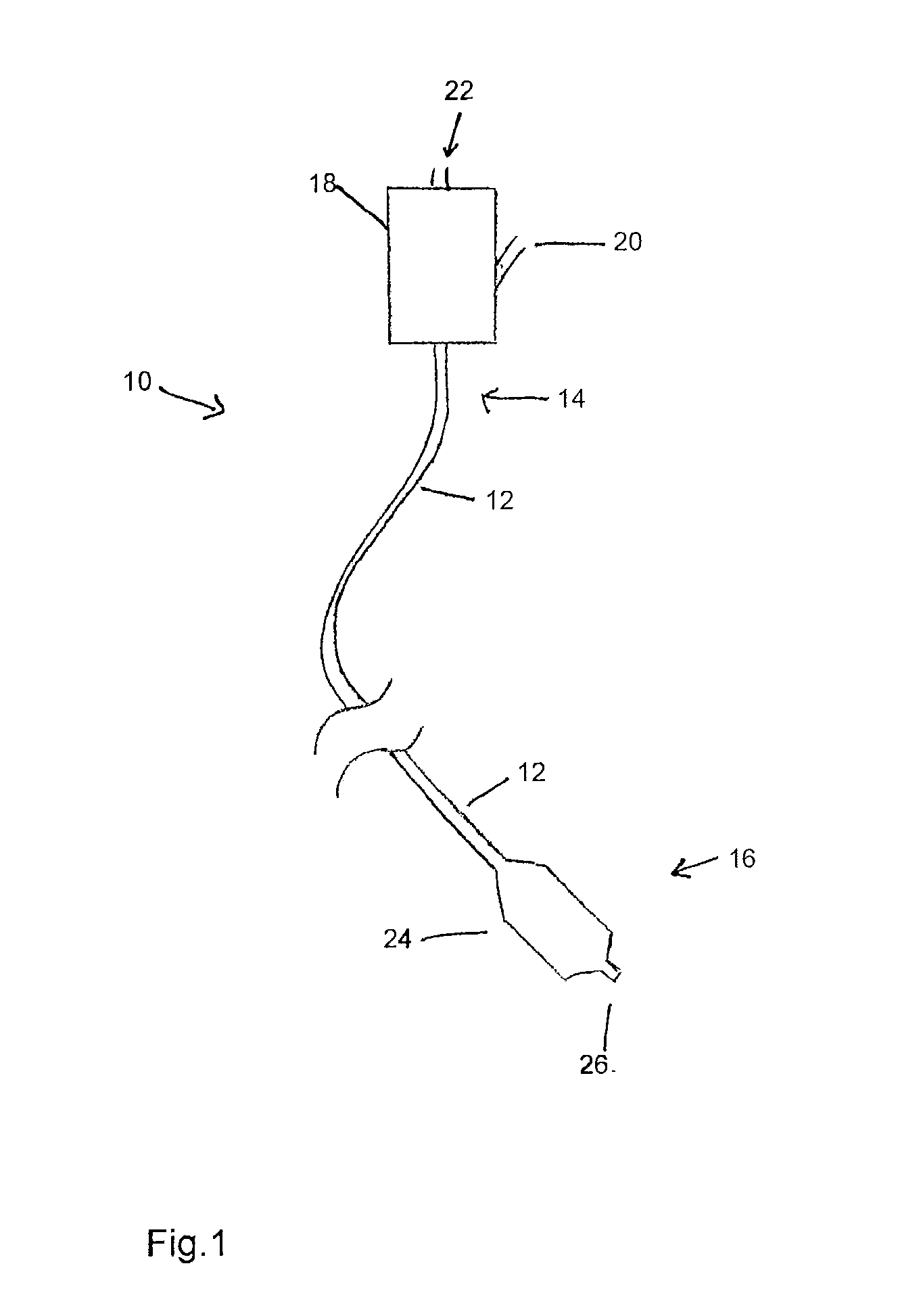

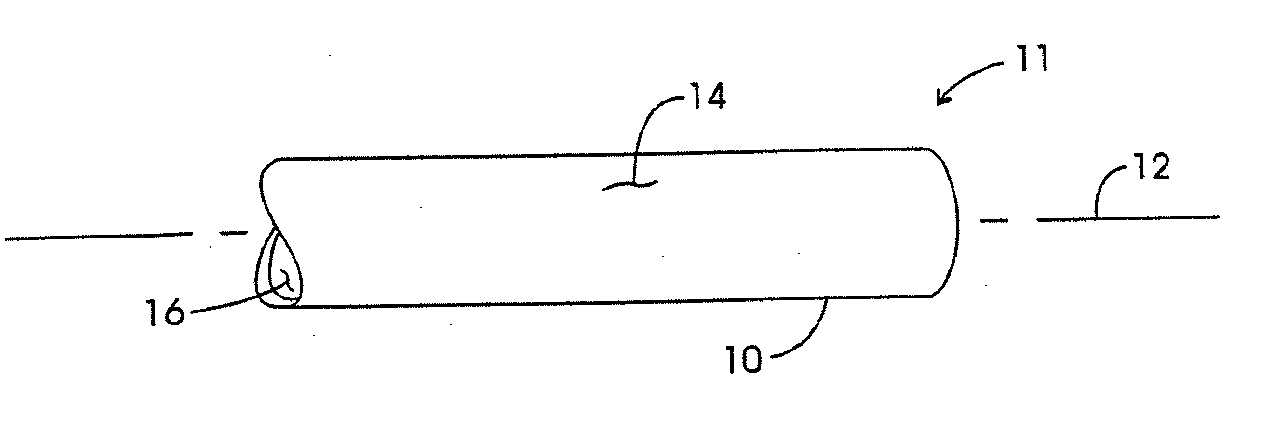

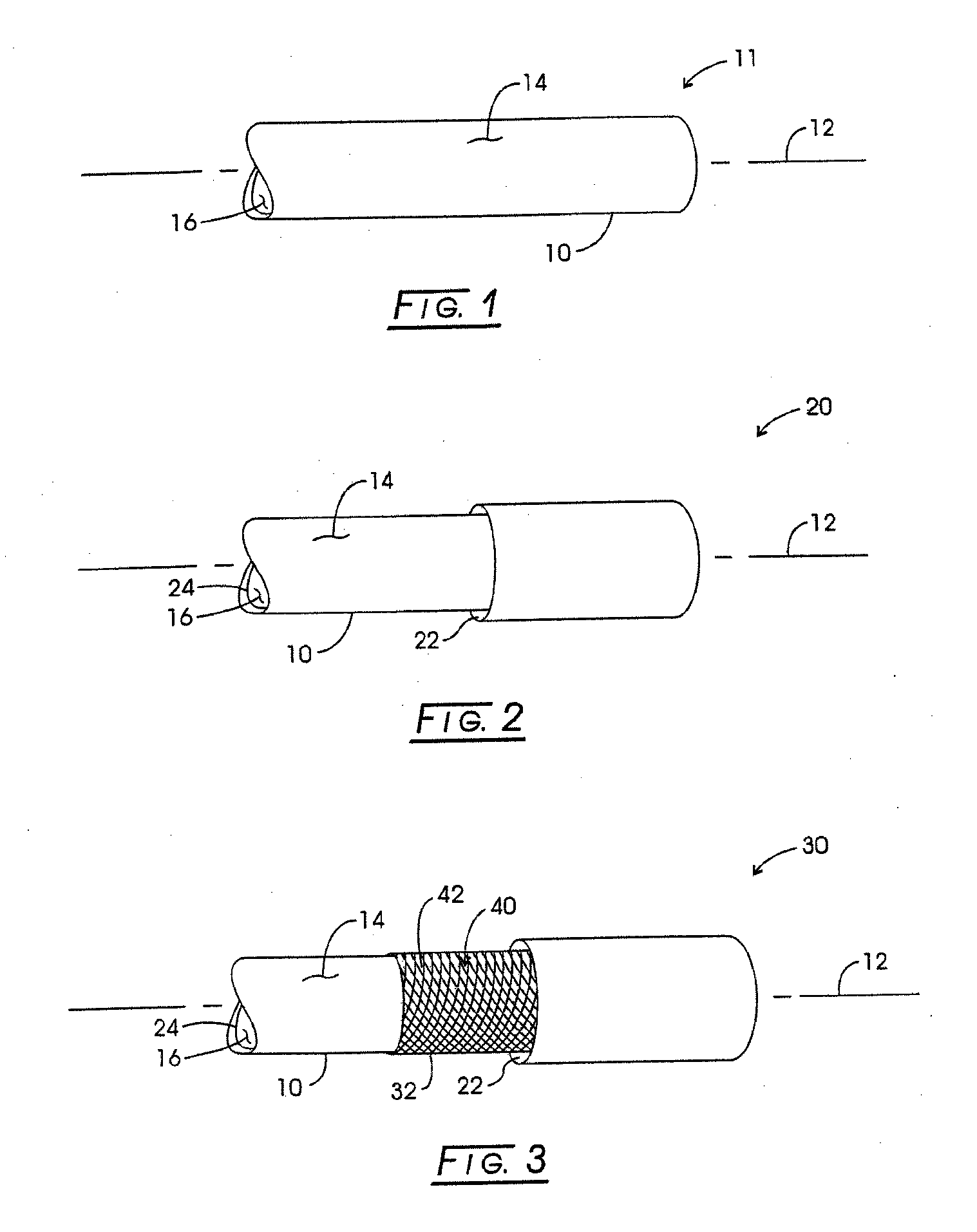

Reinforced balloon for a catheter

InactiveUS20090038752A1Rapid and low cost processImprove burst strengthStentsBalloon catheterAdhesiveHelix

Owner:ANGIODYNAMICS INC

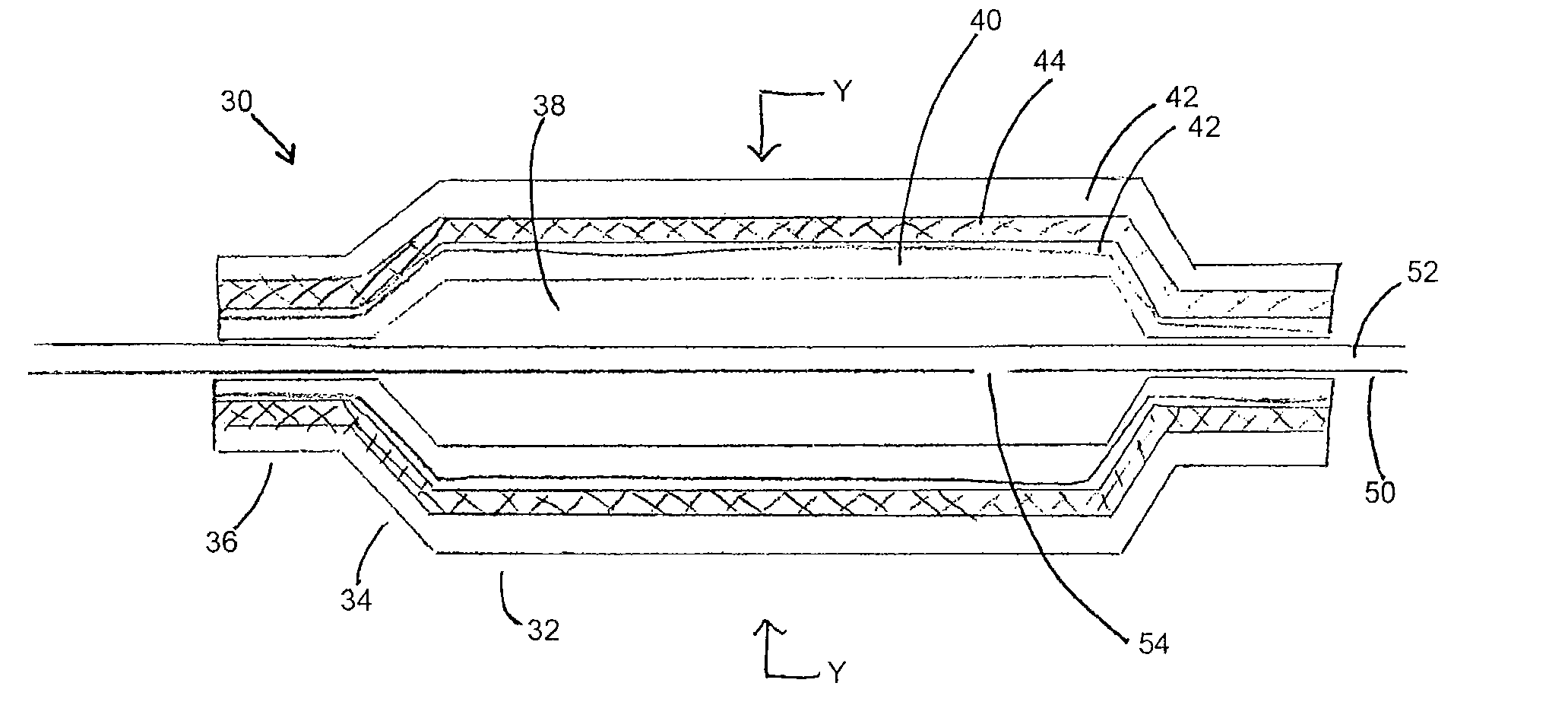

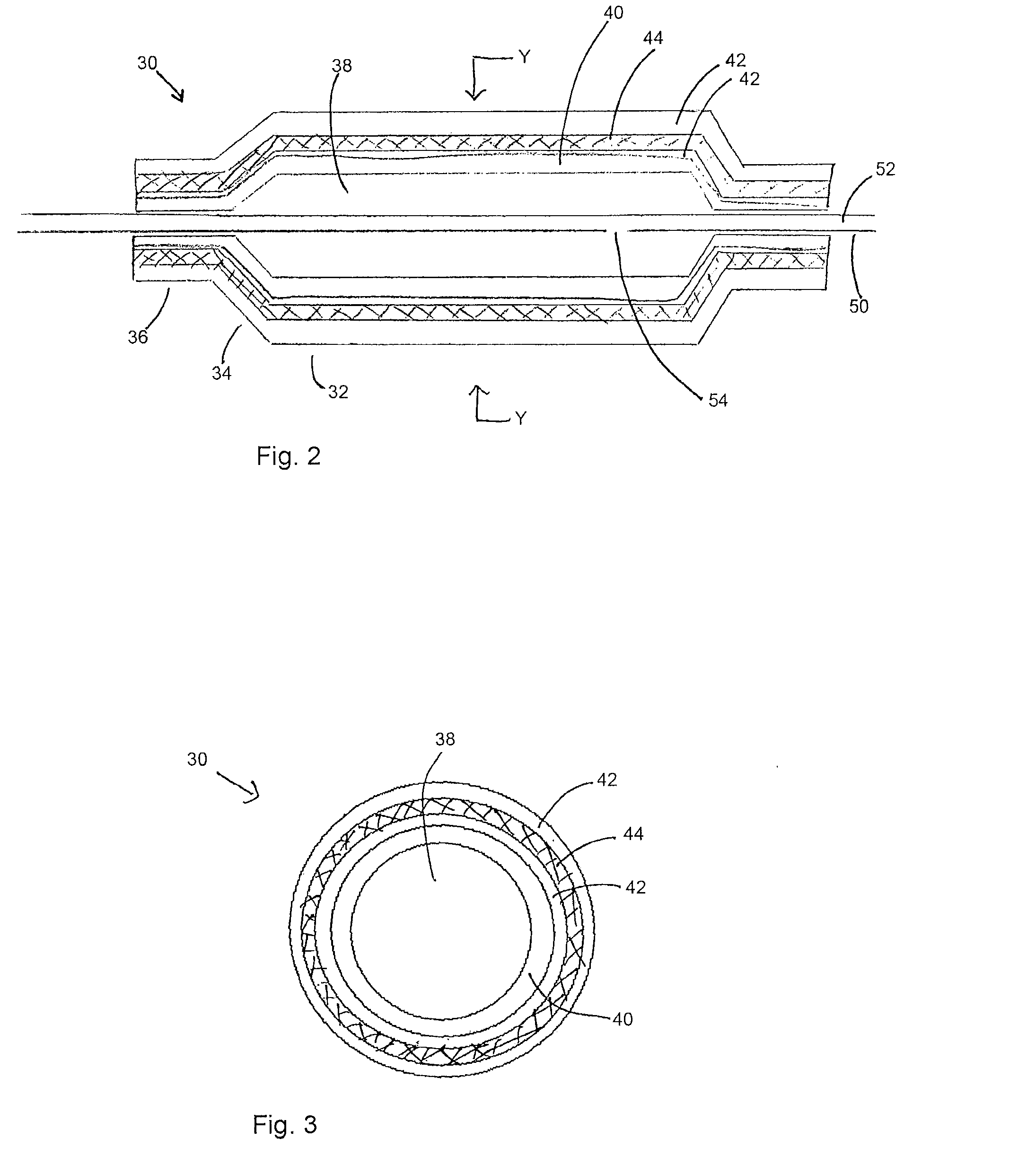

Method of making a medical balloon

ActiveUS20130261547A1Burst strength is maximizedMinimizes shrinkageLabelling non-rigid containersBalloon catheterBalloon catheterMelt temperature

A medical balloon for a balloon catheter is described. The balloon has at least a first layer made from a first material and a second layer made from a second material, said first and second layers being in overlying relationship with one another and being integral with one another; wherein the first layer has a softening or melting temperature which is higher than a softening or melting temperature of the second layer. A method of forming the medical balloon is also described, including locating a raw tubing in a mold; preheating and inflating the raw tubing so as to cause it to stretch; heating the raw tubing to soften or melt the second layer; setting the inflated raw tubing to form the medical balloon; and cooling the set balloon.

Owner:COOK MEDICAL TECH LLC

Reinforced plastic pipe

InactiveUS7600537B2Improve toughnessImprove burst strengthSynthetic resin layered productsCorrosion preventionBursting strengthPolyolefin

Plastic pipes, such as high density polyethylene plastic pipes, useful for distributing natural gas and which have improved impact resistance and burst strength. The plastic pipe has an inner and an outer surface, with the inner surface defining a channel for conveying natural gas and the like. A fabric overlies the outer surface, preferably in a helical wrap. The fabric is formed of high tenacity polyolefin fibers, preferably polyethylene and / or polypropylene fibers. The fabric provides the pipe with improved burst strength and impact resistance. The pipe can be used to transport natural gas under low pressure or higher pressures.

Owner:HONEYWELL INT INC

Reinforced plastic pipe

InactiveUS20070062595A1Adding to of cost of manufactureAdding to weightSynthetic resin layered productsCorrosion preventionBursting strengthPolyolefin

Plastic pipes, such as high density polyethylene plastic pipes, useful for distributing natural gas and which have improved impact resistance and burst strength. The plastic pipe has an inner and an outer surface, with the inner surface defining a channel for conveying natural gas and the like. A fabric overlies the outer surface, preferably in a helical wrap. The fabric is formed of high tenacity polyolefin fibers, preferably polyethylene and / or polypropylene fibers. The fabric provides the pipe with improved burst strength and impact resistance. The pipe can be used to transport natural gas under low pressure or higher pressures.

Owner:HONEYWELL INT INC

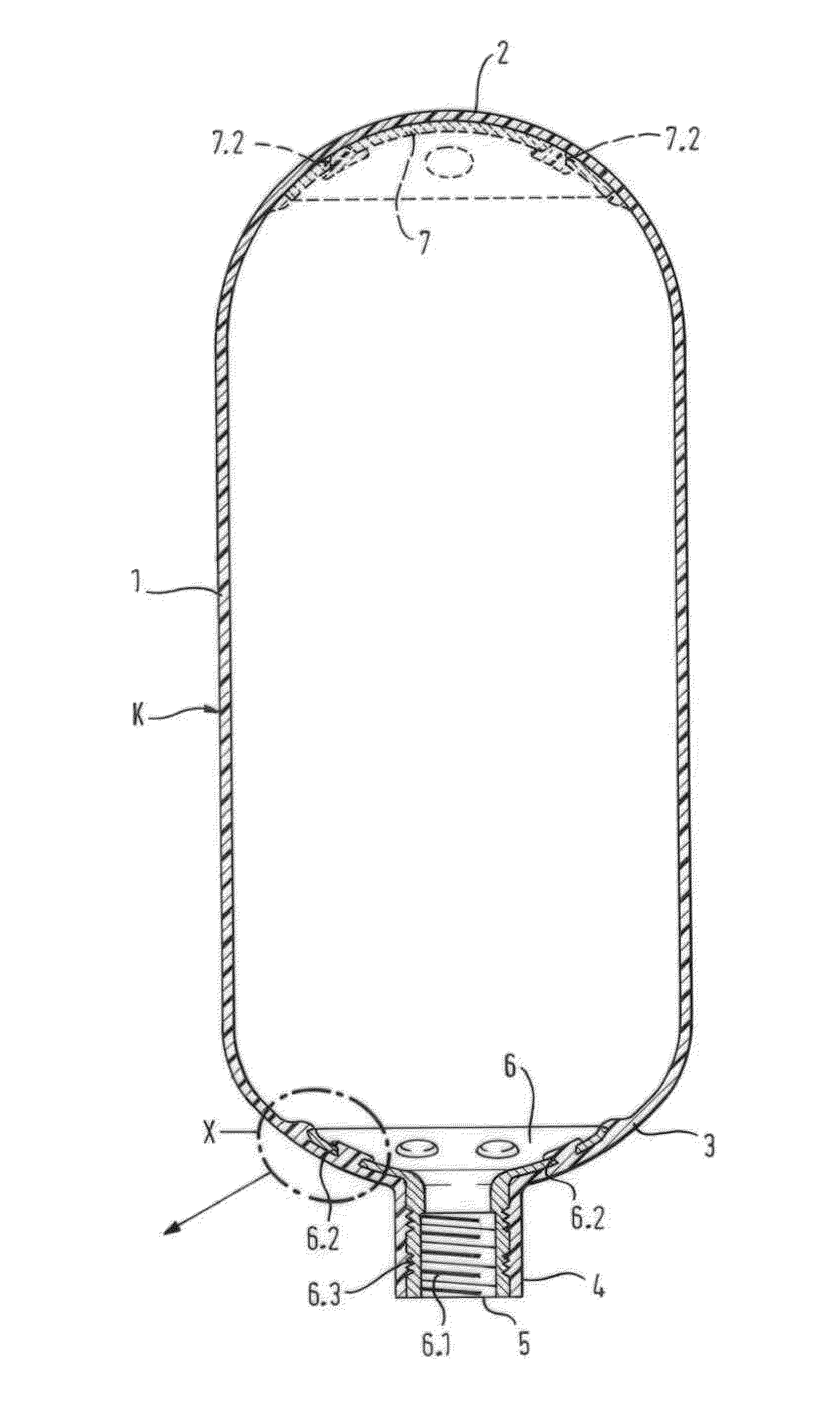

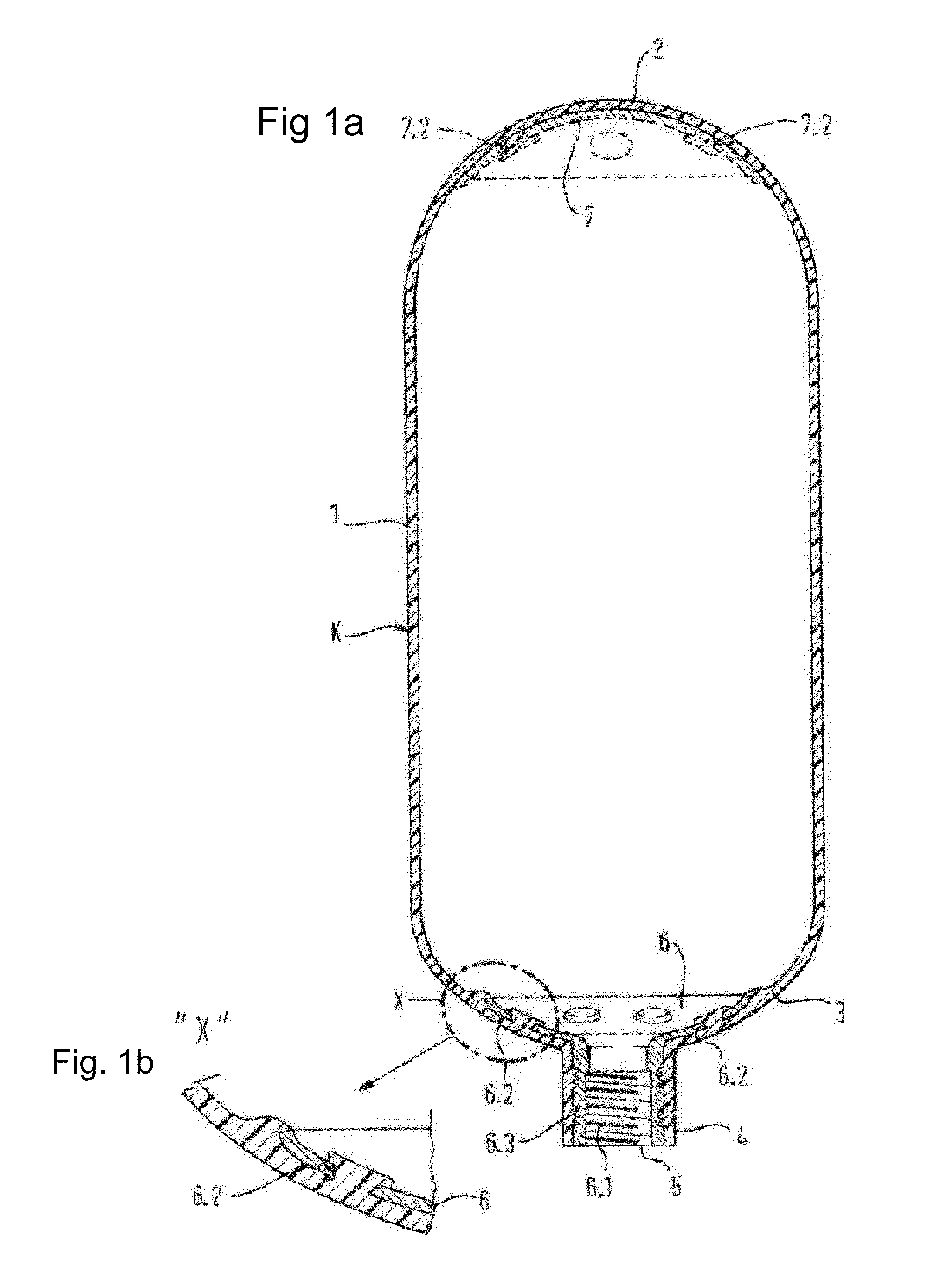

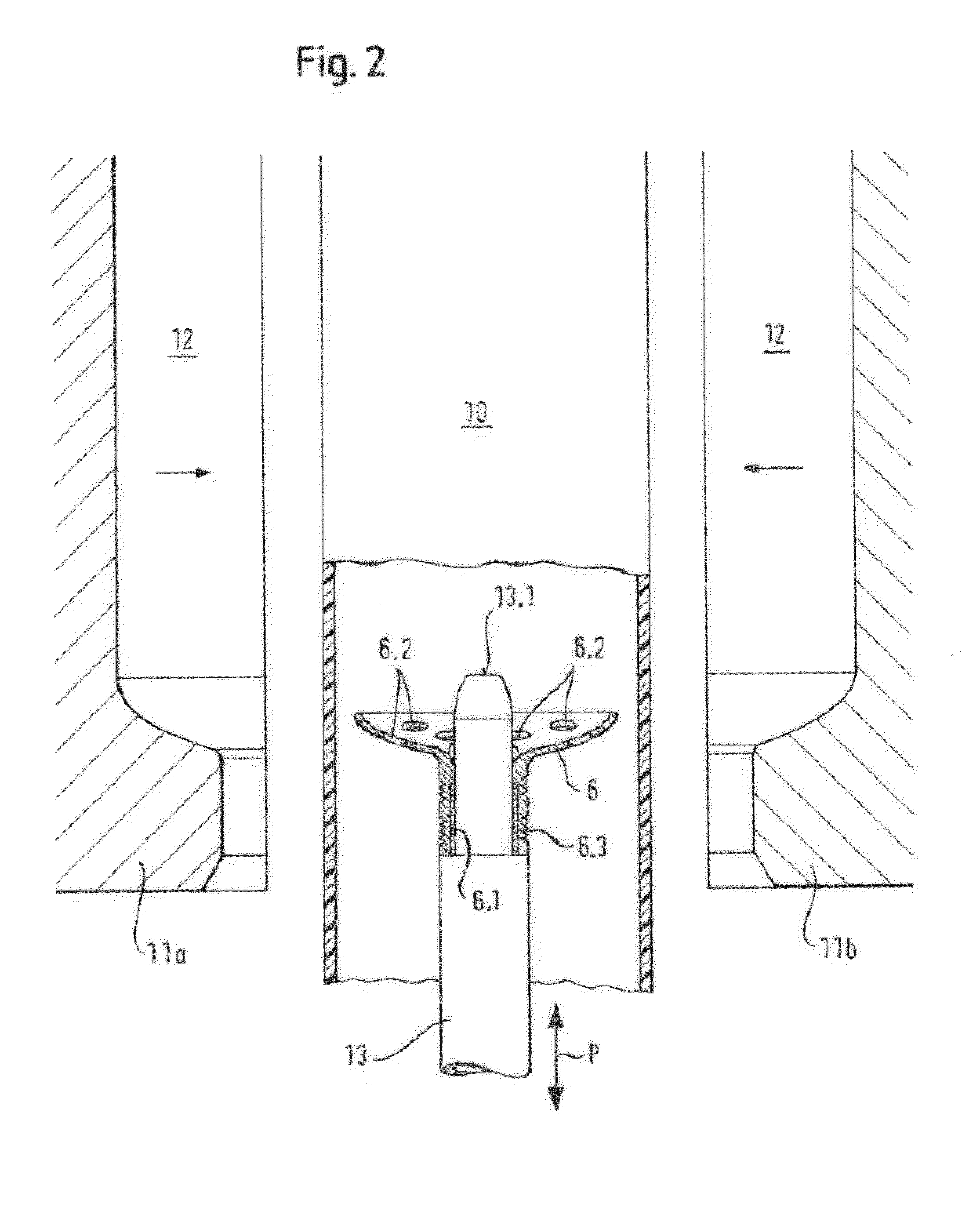

Pressure Tank and Method and Blow-Molding Station for the Production Thereof

InactiveUS20100255234A1Easy to useEasy to fixPreformed elementsThin material handlingThermoplasticBlow molding

A pressure tank blank made of a thermoplastic, having a body, which merges via a shoulder into a neck and a mouth, which is implemented for screwing in a valve, is usable for gases under high pressure, if the blank has a metal insert enveloped by the plastic on the interior to reinforce at least the shoulder of the blank. This pressure tank blank may be produced in an extrusion blow-molding method. For this purpose, with open blow mold, a metal insert having the inner contour of at least the shoulder of the blank is introduced into the corresponding area of the cavity of the blow mold and the tube, enclosing this metal insert, is extruded into the blow mold, before it is closed.

Owner:KUNSTVERARBEITUNG KOETKE

Linear low-density polyethylene composition

ActiveCN102477180AUniform viscosityEliminate cracksLow-density polyethyleneLinear low-density polyethylene

The invention relates to a linear low-density polyethylene composition comprising components of, by weight: 50-98 parts of linear low-density polyethylene with a density of 0.918-0.922g / cm<3> and a melt flow index of 0.1-10g / 10min, 0.5-45 parts of low-density polyethylene with a density of 0.910-0.925g / cm<3> and a melt flow index of 0.1-30g / 10min, 0.5-45 parts of high-density polyethylene with a density of 0.941-0.970g / cm<3> and a melt flow index of 0.5-10g / 10min, 0.5-45 parts of polypropylene with a density of 0.830-0.910g / cm<3> and a melt flow index of 0.5-50g / 10min, 0.1-20 parts of an ethylene-vinyl acetate copolymer with a density of 0.926-0.939g / cm<3>, 0.01-1 part of a rheology modifying agent, and 0.5-20 parts of a compatibilizing agent with a melt flow index of 0.5-50g / 10min. With the composition, extrusion processing performance can be effectively improved, a melt fracture phenomenon can be eliminated, and the compatibility can be improved. With the composition, the strength, flexibility and aging resistance of a product can be improved. The composition can be used for producing films, drip irrigation tapes, and pipes with various specifications.

Owner:XINJIANG TIANYE WATER SAVING IRRIGATION SYST

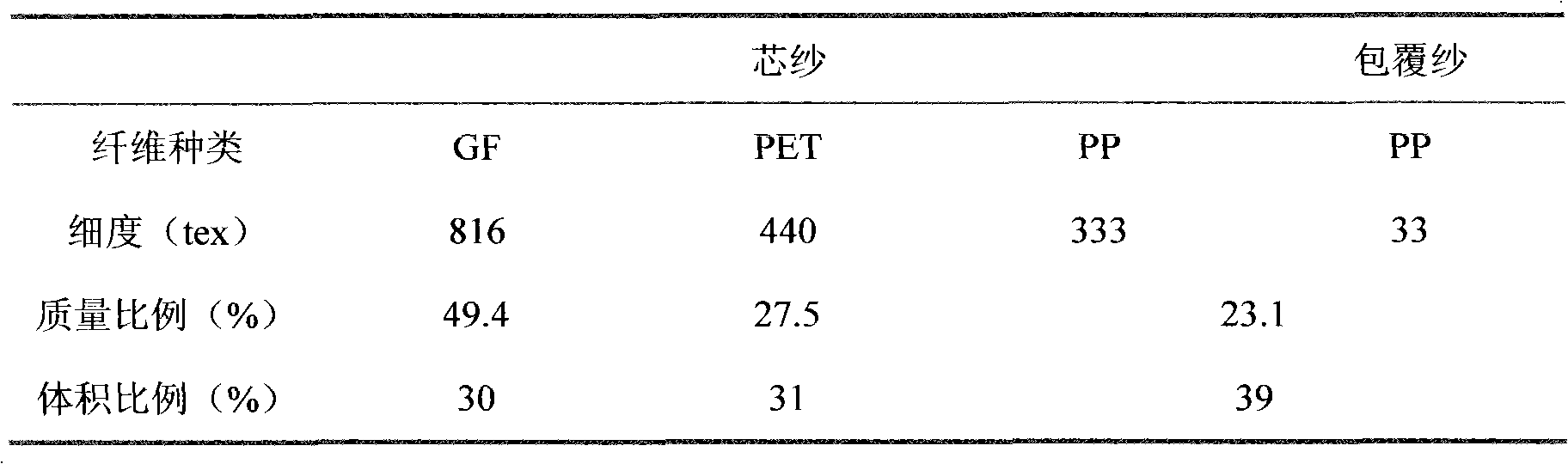

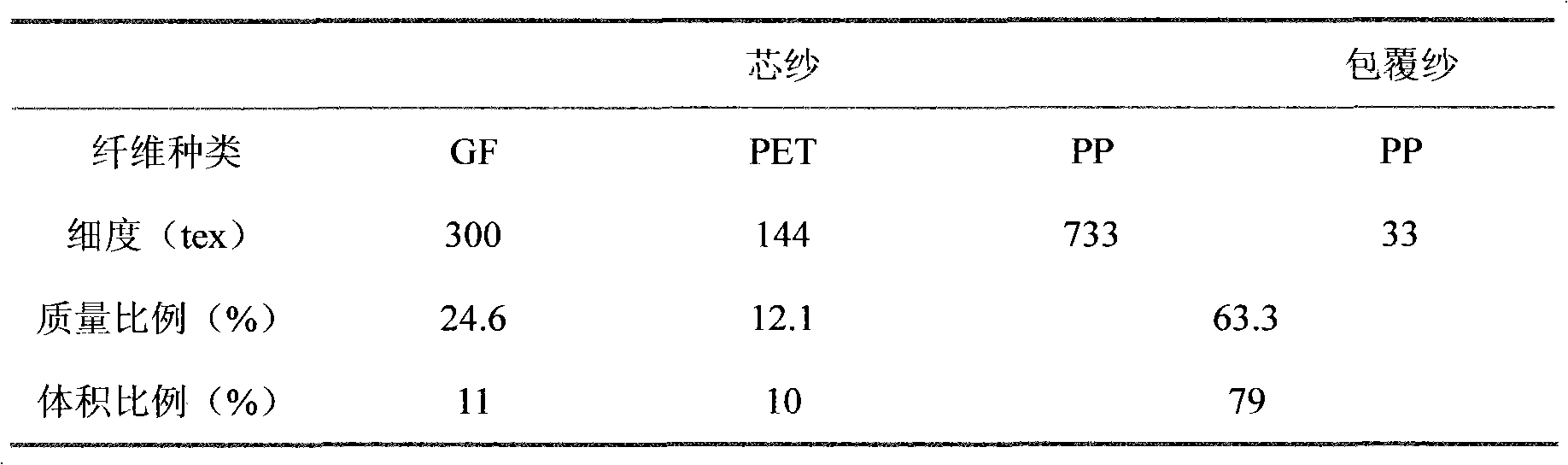

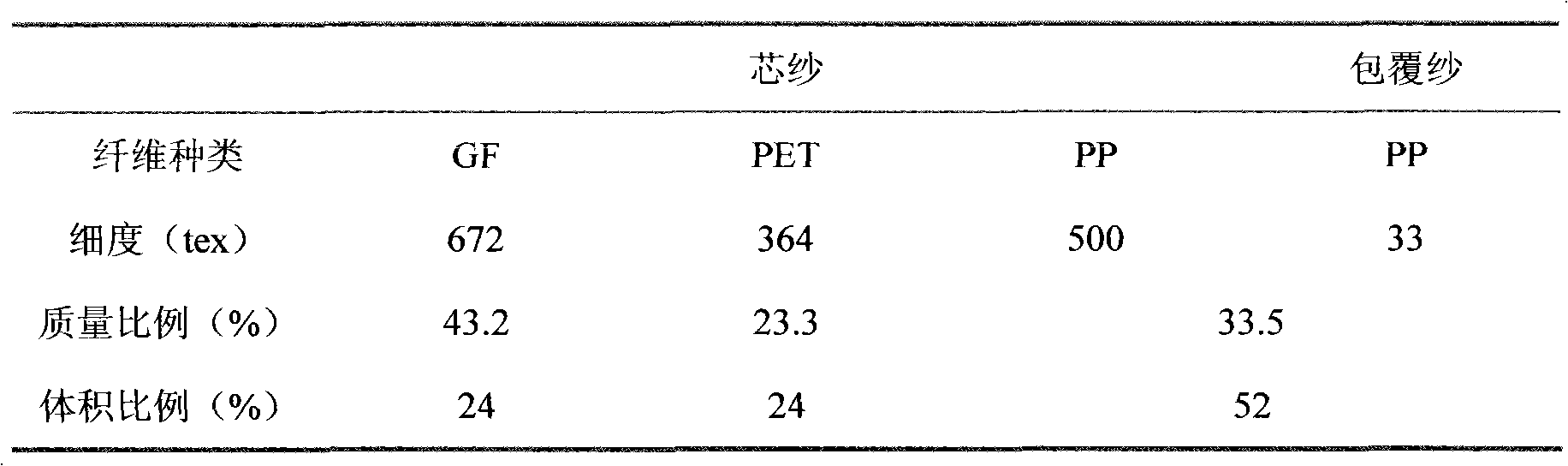

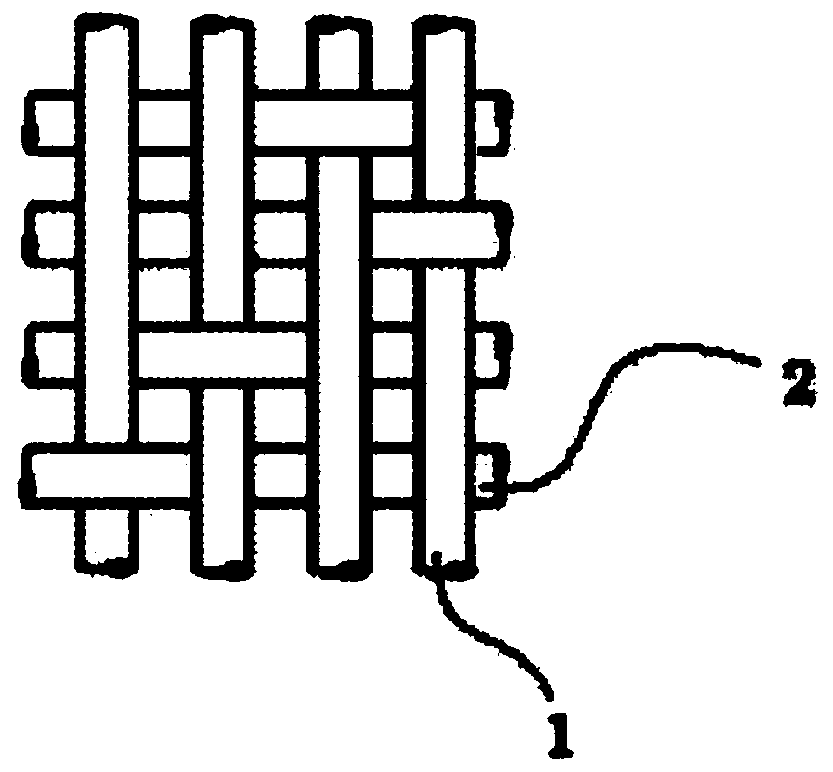

Method for preparing thermoplastic fiber-hybrid woven composite

ActiveCN102152554AGood protectionExcellent overall performanceSynthetic resin layered productsLaminationYarnThermoplastic composites

The invention discloses a method for preparing a thermoplastic fiber-hybrid woven composite and is characterized by comprising the following three steps: preparing thermoplastic fasciated yarns, weaving a pre-manufactured composite and molding the woven composite, wherein the thermoplastic wrapping yarns consist of strengthened fibers and thermoplastic resin fibers which are mixed according to the volume by adopting a fiber wrapping technology, the thermoplastic fibers are 40 to 80 volume percent and the strengthened fibers are 20 to 60 volume percent; and then the thermoplastic resin fibers are uniformly covered on the strengthened fibers to form the thermoplastic wrapping yarns. The thermoplastic composite is a big trend in the further composite development and has a bright development prospect.

Owner:ZHEJIANG MAGLIA CASHMERE FAMILY CO LTD

Grafted copolymer with modified amino and preparation method and application thereof

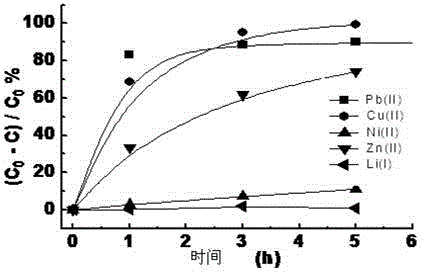

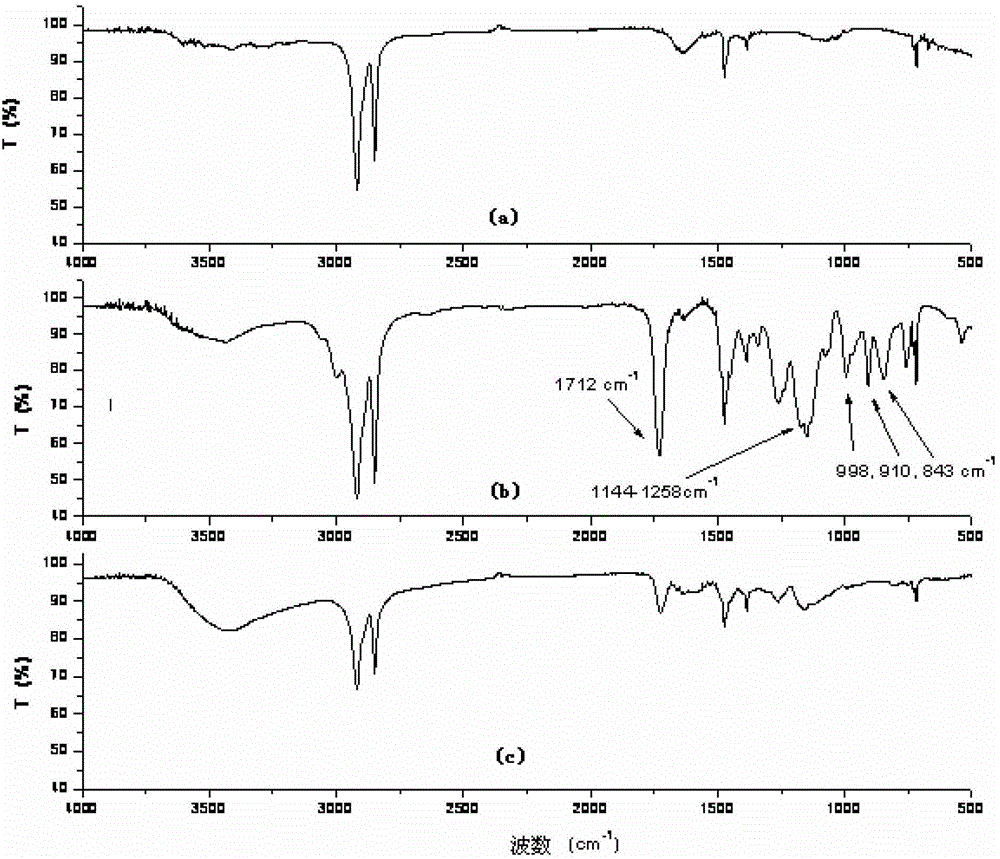

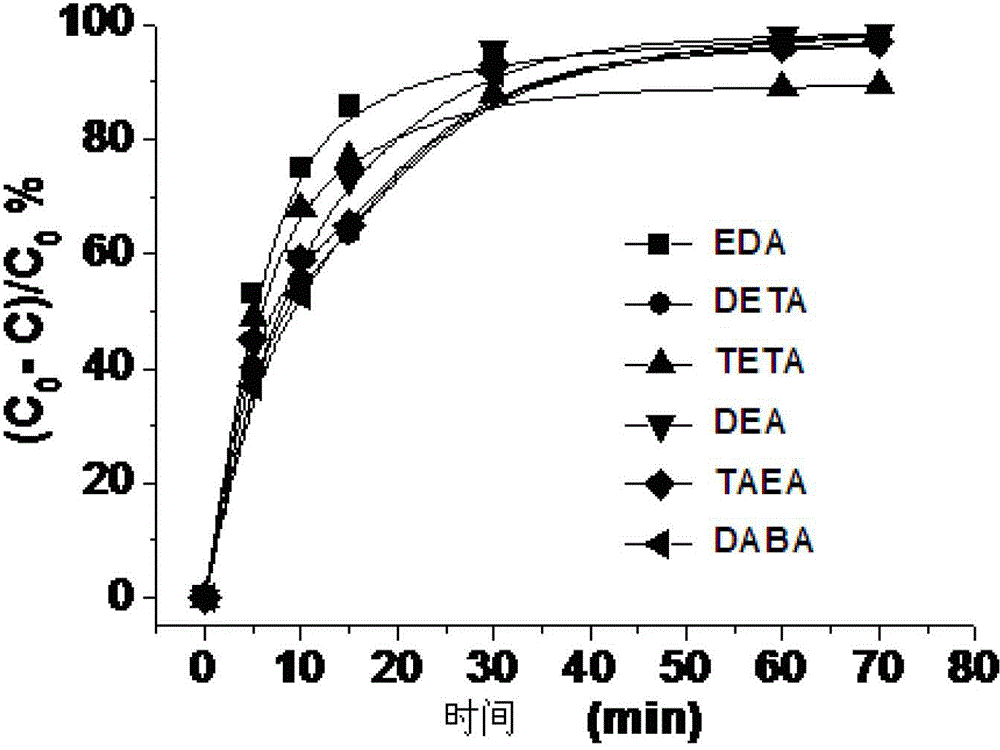

InactiveCN103147291AHigh grafting rateImplement extractionOther chemical processesProcess efficiency improvementSolventCopolymer

The invention discloses a grafted copolymer with modified amino and a preparation method and application thereof. The preparation method includes the step of enabling the grafted copolymer of vinyl type monomers containing epoxy groups in solvent to carry out epoxide ring-opening reaction with amine compound. The invention further discloses a method for utilizing the grafted copolymer with the modified amino to extract precious metal and / or heavy metal. The method includes the steps of mixing the grafted copolymer with the modified amino with a water body containing the precious metal and / or the heavy metal and then stirring. The grafted copolymer with the modified amino is capable of adsorbing the precious metal in solution, has high adsorption rate and longer service life compared with adsorbing materials in the prior art, and is favorable for being recycled.

Owner:上海迈坦技术发展有限公司

Transparent moulds made from polyamide moulding material

ActiveCN101195684AImprove heat resistanceImprove rigidityOptical partsOptical elementsShell moldingPolyamide

The present invention relates to a transparent mould product and the usage thereof, the mould product is made from special polyamide molding material and the transparence is at least 88% when the layer thickness is 2mm.

Owner:艾曼斯(苏州)工程塑料有限公司

Weatherable glass fiber reinforced polyolefin composition

ActiveUS20070135547A1Improve burst strengthHigh tensile strengthFibre treatmentSynthetic resin layered productsGlass fiberPolymer science

Glass fiber reinforced olefin compositions comprise polypropylene homopolymers, polypropylene copolymers, opacifying pigments, fibrous reinforcers, light stabilizers, lubricants and antioxidants. The opacifying pigments are advantageously ZnO, ZnS or surface treated anatase TiO2

Owner:LYONDELLBASELL ADVANCED POLYMERS INC

Tubular Copolyester Member for Tubing and Hose Constructions

InactiveUS20070087150A1Easy to installReduces migratory extrudationSynthetic resin layered productsFlexible pipesThermoplastic elastomerCopolyester

Tubular polymeric member for articles such as tubing and hoses. The member is formed of composition of a copolyester thermoplastic elastomer material.

Owner:PARKER HANNIFIN CORP

Anticorrosive anchor rod capable of preventing slurry from leaking

ActiveCN102720196AImprove burst strengthGuaranteed filling compactness requirementsProtective foundationBulkheads/pilesInjection pressureArchitectural engineering

The invention discloses an anticorrosive anchor rod capable of preventing slurry from leaking. The anchor rod comprises a rod body, wherein the rod body is sleeved with a sleeve bag; one end of the rod body is extended out of a sleeve bag opening, and an area section of the rod body, which is inserted into a drill hole, is packaged by the sleeve bag; and a sleeve pipe is sleeved on the sleeve bag and is positioned on one side of the sleeve bag close to the sleeve bag opening. The slurry is compactly injected into the sleeve bag on an anchoring section, so that the filling compaction requirement of the anchoring section of the anchor rod can be met, all-around overflow of cement slurry on the anchoring section under the action of slurry injection pressure is prevented, and the control over slurry injection project amount and the economization of construction cost are facilitated; a free section of the anchor rod is protected by a corrugated sleeve, so that the free section can pass through an orifice to crush a rock-soil area, the reduction in severe slurry leakage risks of the anchor rod in a rock-soil crushing area is facilitated while the thickness of a steel bar concrete slurry protective layer is ensured, and the economization of the construction cost is facilitated; and simultaneously, the free section is subjected to secondary slurry injection, so that the free section of the anchor rod can be provided with a plurality of anticorrosive structural layers, and the anchor rod is high in corrosion resistance.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

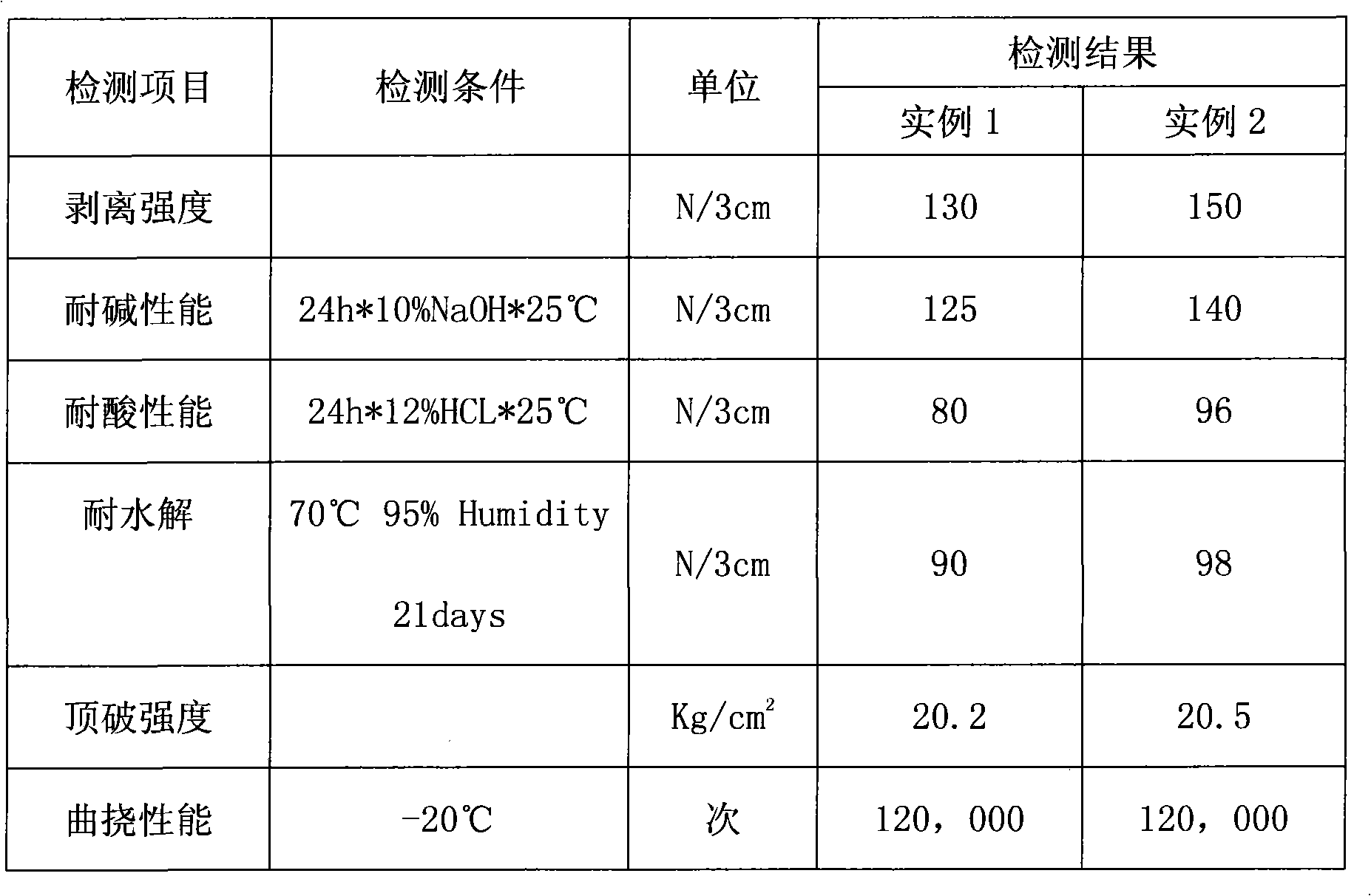

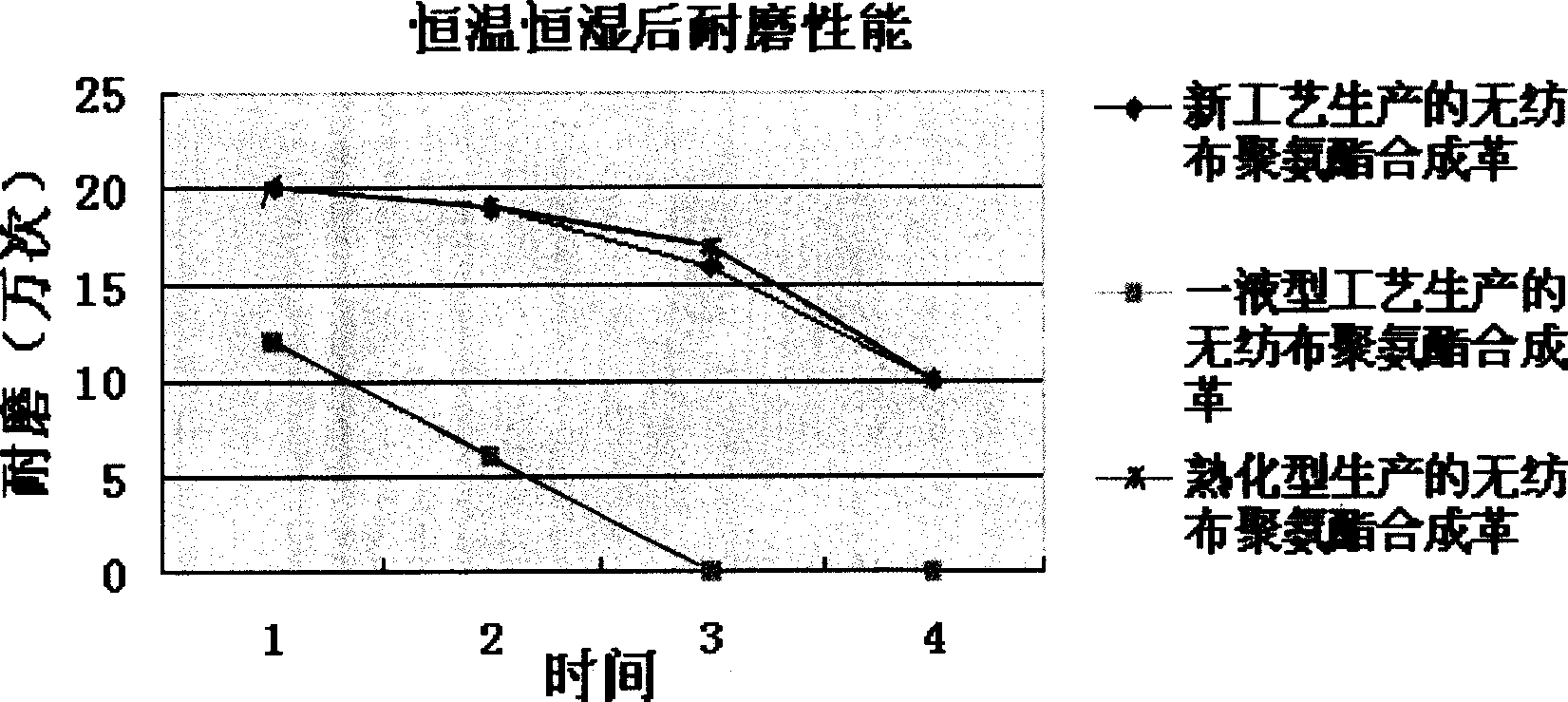

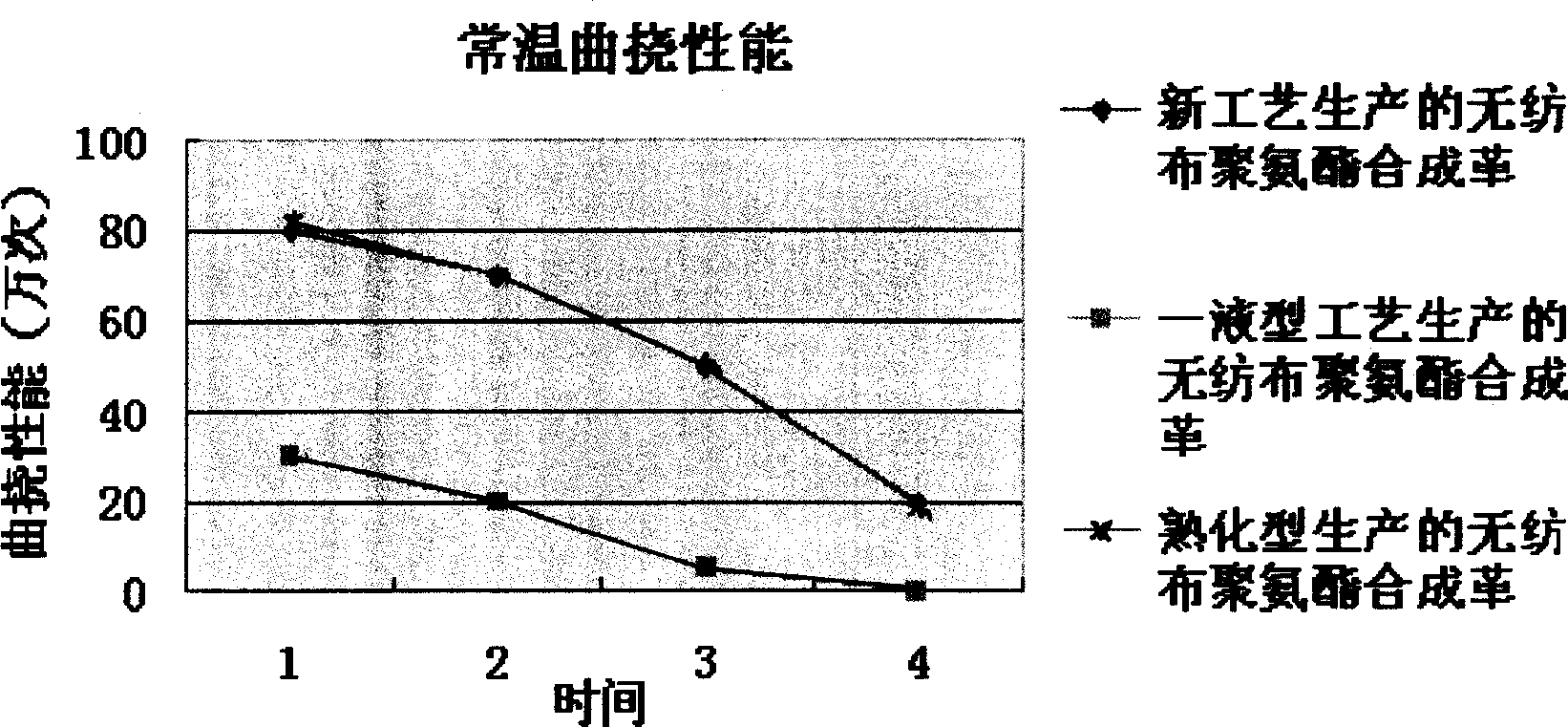

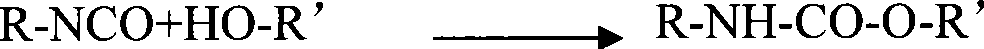

Method for manufacturing acid-proof, alkali-proof, hydrolysis-resistant and high-peel-strength polyurethane space leather

The invention relates to acid-proof, alkali-proof, hydrolysis-resistant and high-peel-strength polyurethane space leather and a method for preparing the same. In the method, non-woven fabric of a composite proportion and high physical property is adopted; 35 percent high-shrinkage terylene is added; polyester type non-hydrolysis-resistant polyurethane is selected; a fluorine high polymer is introduced into the formula to improve the hydrolysis resistance and the acid-proof and alkali-proof capability of the product; and meanwhile carbodiimide serving as a resin modifier is introduced into theformula system to improve the hydrolysis resistance of the polyurethane space leather and meet the requirement of high peel strength, wherein the product can be easily and rapidly degraded by high temperature processing after being used and does not have adverse influence on the environment. The acid-proof, alkali-proof, hydrolysis-resistant and high-peel-strength polyurethane space leather produced by the invention has the advantages of superior physical and mechanical properties such as good cut, high peel strength, high tearing strength, high bursting strength, folding resistance, low temperature resistance, hydrolysis resistance, acid resistance, alkali resistance and the like; and meanwhile, the product has soft and tough handfeel and high elasticity.

Owner:ANHUI ANLI MATERIAL TECH

Anti-pilling ultra-soft interlock fabric with polyester peach skin hand feeling and fabrication method of ultra-soft interlock fabric

ActiveCN104389087AWith anti-pilling functionImprove burst strengthBiochemical fibre treatmentSingeingEnzymeBursting strength

The invention provides anti-pilling ultra-soft interlock fabric with a polyester peach skin hand feeling and a fabrication method of the ultra-soft interlock fabric. The interlock fabric takes one or more of a cotton thread, carding cotton, a spun yarn or a cellulosic fiber as raw materials and is interwoven by 2-6 wefts. The cotton thread, the carding cotton, the spun yarn or the cellulosic fiber is subjected to anti-pilling treatment in advance, and the woven interlock fabric is subjected to sanding, raising, singeing, polishing by biological compound enzyme, biological deoxidation and dyeing treatment to form the anti-pilling ultra-soft interlock fabric with the polyester peach skin hand feeling. According to the ultra-soft interlock fabric, the raw material of the fabric, long stapled cotton is subjected to the anti-pilling treatment in advance, so that the fabric has the anti-pilling function in accordance with GB standards; the subsequent polyester peach skin sanding processing is easier and has a better effect; the strength of a single fiber is higher, which shows that the burst strength of the interlock fabric is higher; furthermore, the singeing is carried out after the sanding for a polyester peach skin processing technology of the ultra-soft interlock fabric, so that naps of the fabricated fabric are short and dense; the hand feeling is more delicate.

Owner:NINGBO DAQIAN TEXTILE

Micro-multiport tubing and method for making said tubing

InactiveUS20020125004A1Improve burst strengthHigh tensile strengthFlexible pipesRigid pipesCrystalliteMagnesium

This invention is a process for making improved micro-multiport tubing for use in heat exchangers. A multivoid heat exchanger tube is extruded from aluminum alloy billet. The alloy is a composition of cooperative elements which act with the aluminum to prevent recrystallization and grain growth which result in the necessary strength and duality of characteristics in the tubes. The composition of the alloy that is added to aluminum is some or all of the following: silicon, iron, copper, magnesium, manganese, zinc and titanium. The cold work during processing of the heat exchanger is limited to further retain the small grains.

Owner:BRAZEWAY

Two-liquid type rapid stripping synthetic leather composite overlay

ActiveCN101503861AHigh peel strengthHigh tear strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsBursting strengthTemperature resistance

The invention provides a two-liquid type quick forming instant peeling synthetic leather composite veneer, which is mainly characterized in that bonding layer resin is added with a quick crosslinker and a crosslinking catalyst, so that the two-component bonding layer resin achieves quick crosslinking, and can achieve proper degree of crosslinking through normal veneering process so as to achieve the aim of instant peeling. The high peeling hydrolysis resistant non-woven fabric polyurethane synthetic leather produced by the process has good physical and mechanical properties such as high peeling strength, tearing strength and bursting strength, bending resistance, low temperature resistance, hydrolysis resistance, acid and alkali resistance and the like.

Owner:ANHUI ANLI MATERIAL TECH

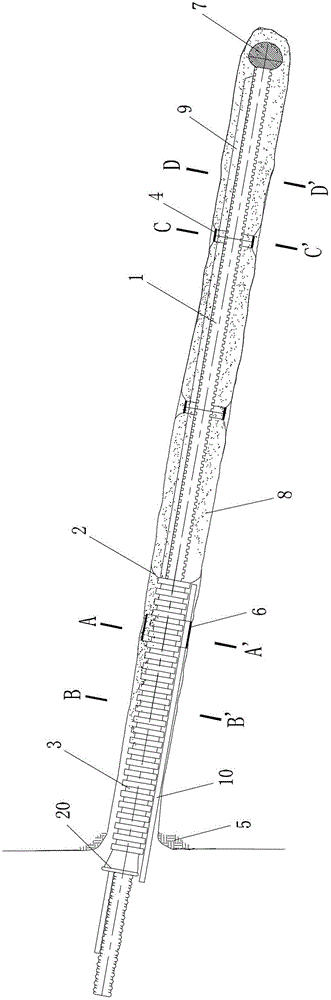

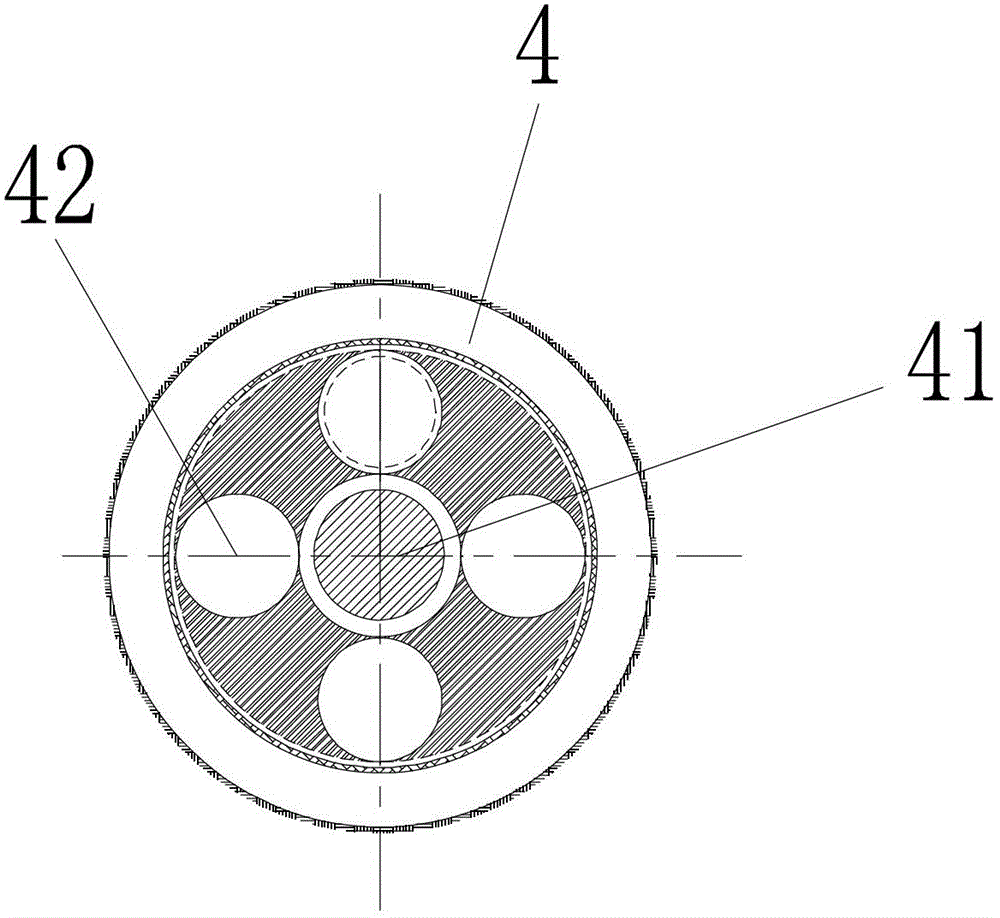

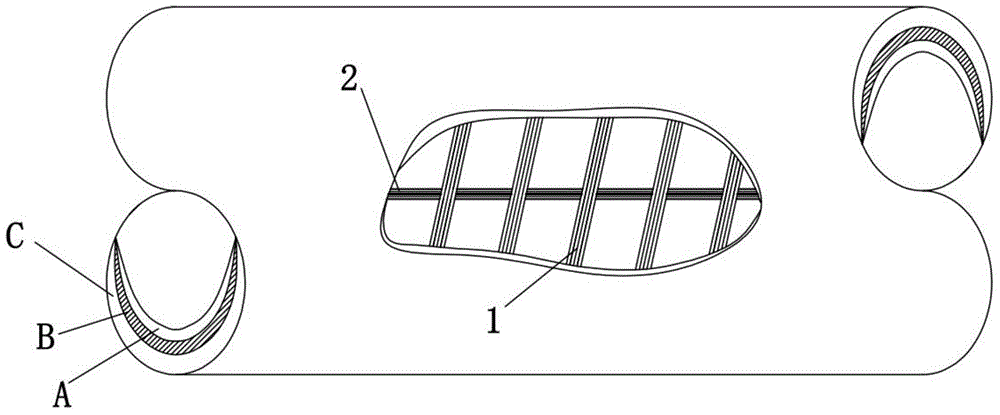

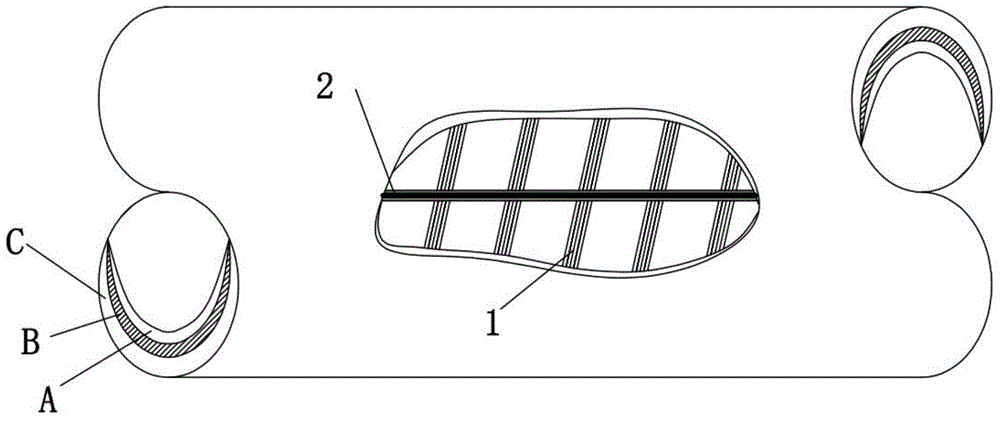

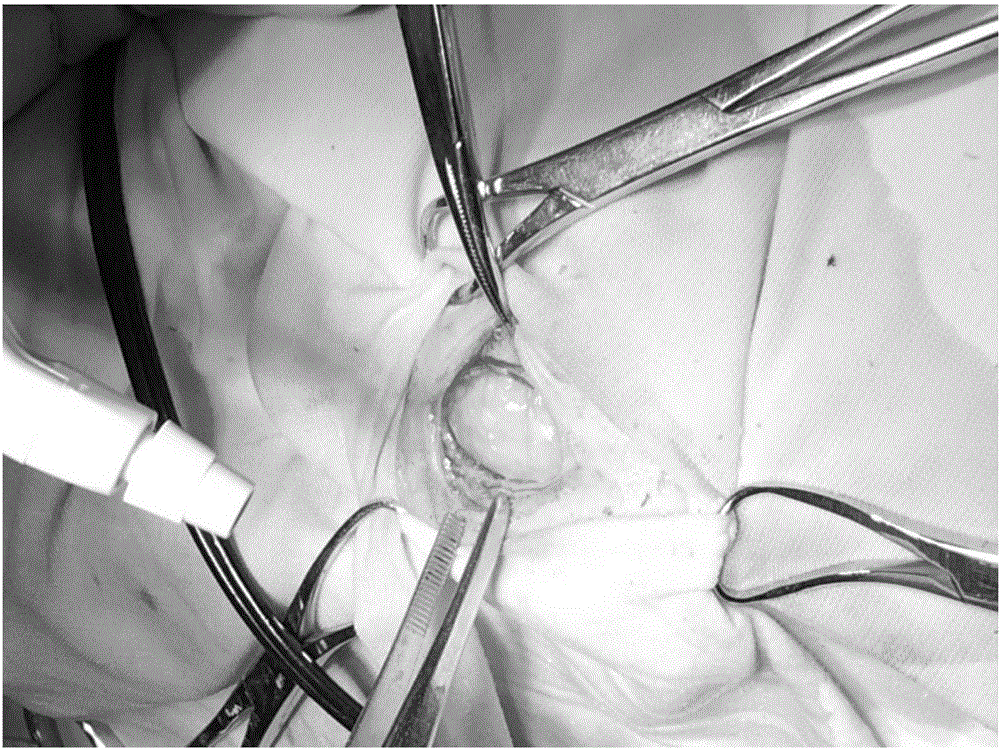

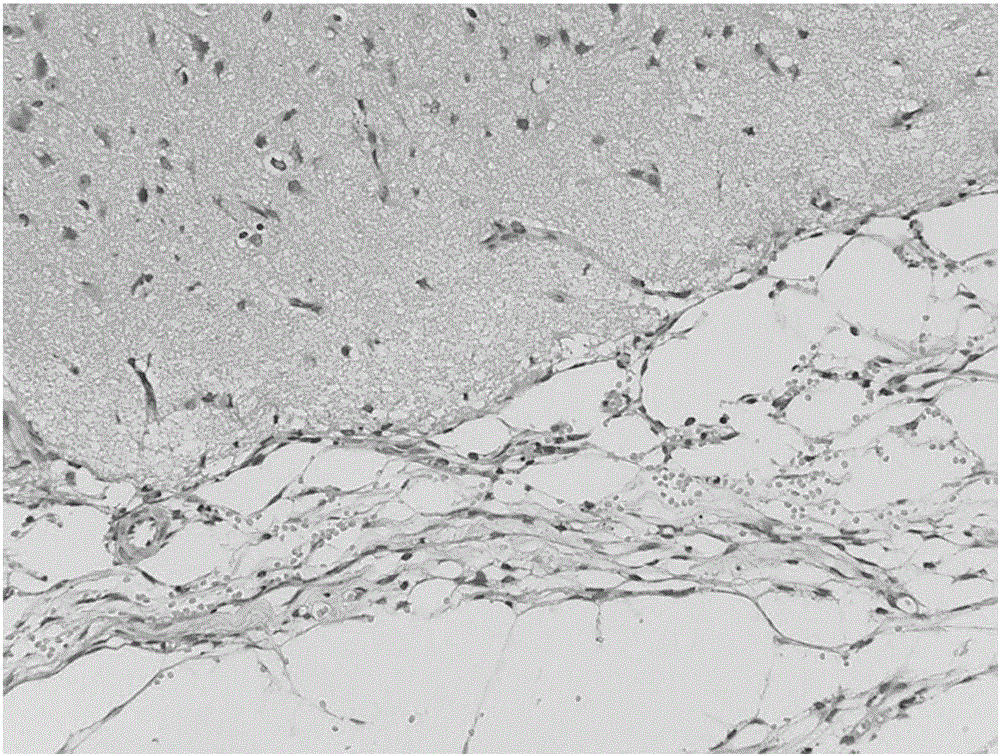

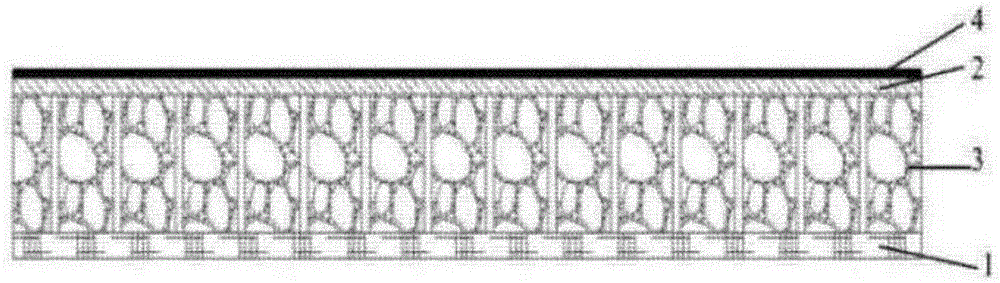

Reinforced compound sheathing canal, preparation method and application thereof

InactiveCN105105894AReduce surgical riskPrevent extensionStentsSurgeryTransport systemInvasive treatments

The invention discloses a reinforced compound sheathing canal, a preparation method and application thereof. The reinforced compound sheathing canal sequentially comprises an inner layer, a reinforced layer and an outer layer from interior to exterior, wherein the reinforced layer comprises axial reinforcing elements and a spiral reinforcing element, the spiral reinforcing element is a single spiral element or is formed by combining two or more spiral elements, the axial reinforcing elements are disposed on the inner side or outer side of the spiral element, or are inserted between the spiral elements, and various axial reinforcing elements are uniformly arranged in the circumference direction of the sheathing canal. The reinforced compound sheathing canal provided by the invention has the advantages of thin wall, high axial strength, high radial strength, high torque transitivity and the like, can be applied to a transport system for transporting medical device implants needed in a minimally invasive treatment and can reduce the outer diameter of the transport system, so that the medical device implants are easy to arrive at lesion positions, damage to the blood vessel of a patient is reduced, and sufficient technical support is provided for reliable, successful and safe transport and implantation of the medical device implants by the transport system.

Owner:NINGBO LINSTANT POLYMER MATERIALS CO LTD

Highly inhibited starch fillers for films and capsules

InactiveUS20080138402A1Similar textural and functional propertyIncrease solid loadingBiocideConfectioneryGelatinChemistry

The invention provides the addition of highly inhibited starch filler to gelatin-free films and soft capsules. The addition of the highly inhibited starch filler raises the solid levels during processing without substantially increasing the melt viscosity. The resultant films and capsules are transparent.

Owner:CORN PROD DEV INC

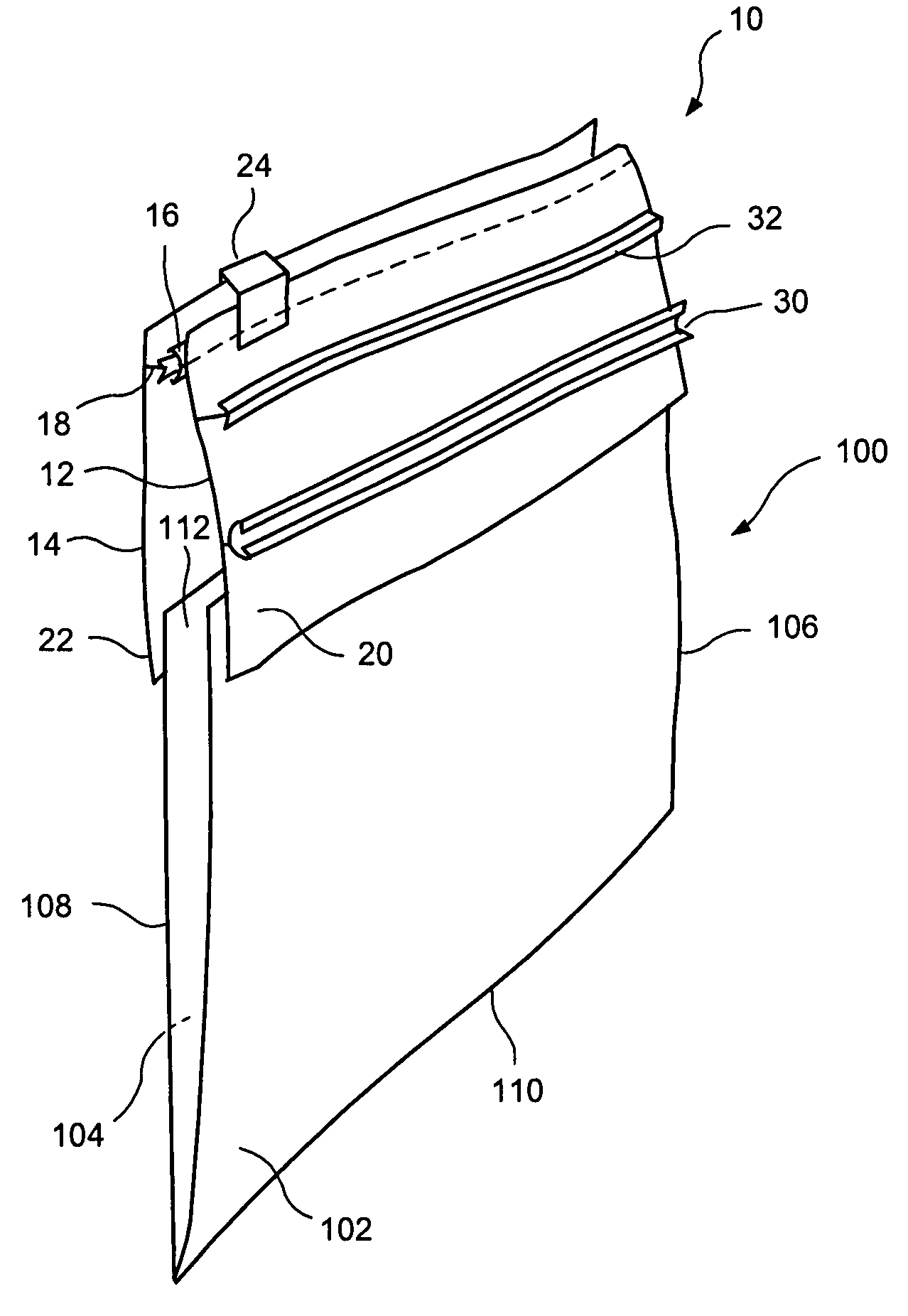

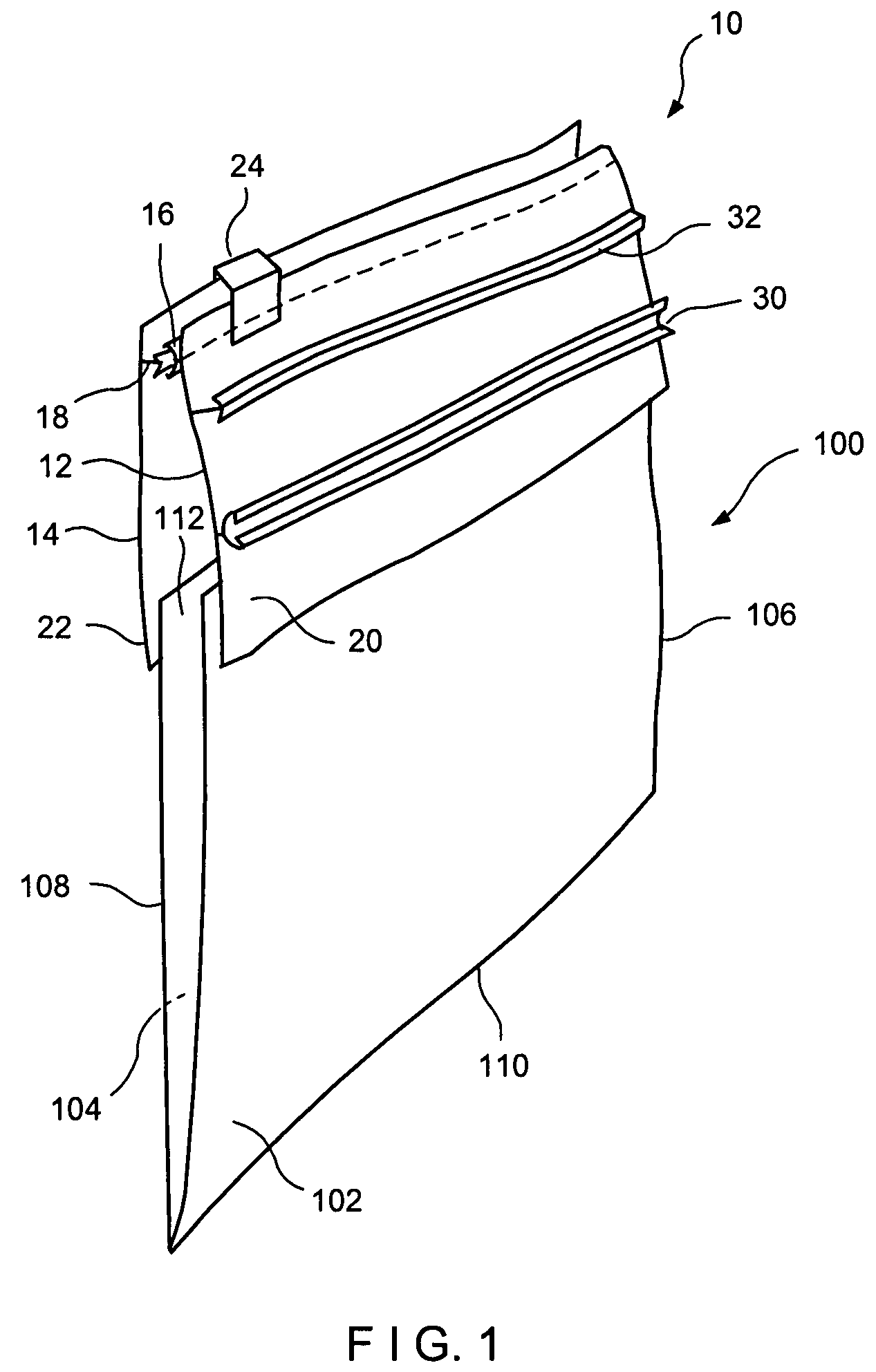

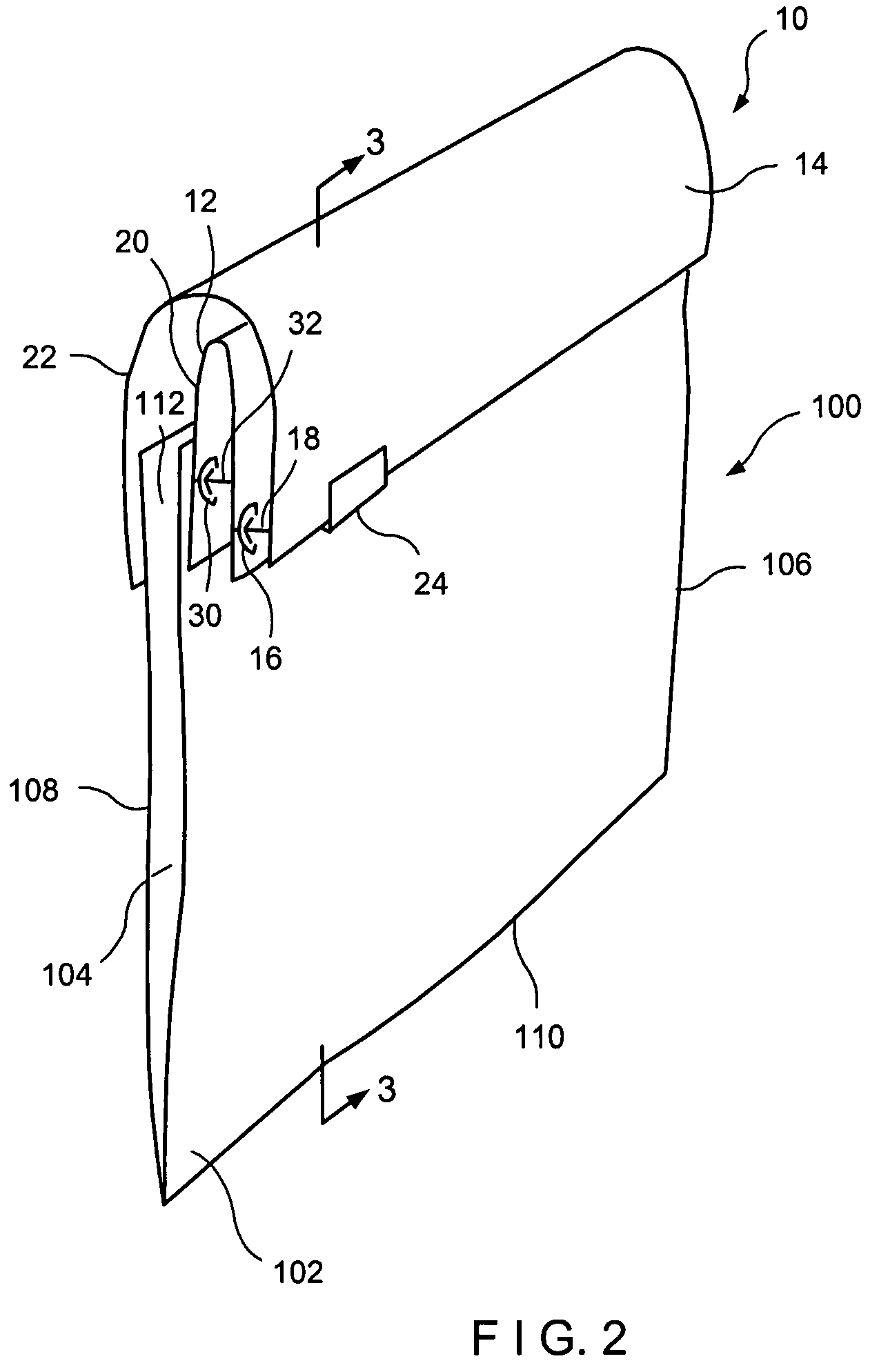

Zipper with fold over elements for reclosable package

InactiveUS7866011B2Maintain capacityImprove burst strengthSnap fastenersFlexible coversFlangeEngineering

A zipper assembly for a reclosable package or bag is disclosed. The zipper assembly includes two profiles with flanges and internal interlocking elements on the interior of the flanges. The exterior of one of the flanges includes two exterior parallel press-to-close profile-like interlocking elements which are brought into engagement with each other by folding the flanges of the zipper assembly. This increases the burst handling capability of the zipper assembly and the package or bag to which it is attached. Alternatives include substituting a peel seal for the exterior interlocking element as well as an exterior label or sticker to maintain the flanges in a folded configuration.

Owner:ILLINOIS TOOL WORKS INC

Method for improving performance of wood chemimechanical pulp through biological enzyme pretreatment

InactiveCN110607708AImprove bindingIncreased swellingPulping with inorganic basesCellulose treatment using microorganisms/enzymesEnzymeBursting strength

The invention discloses a method for improving the performance of wood chemimechanical pulp through biological enzyme pretreatment. Wood chips are subjected to material preparation, spiral extrusion,biological enzyme pretreatment, chemical impregnation and pulp grinding treatment to obtain the chemimechanical pulp, and the chemimechanical pulp is subjected to latency elimination, washing, screening and purification to form paper pulp for paper pulp performance testing. According to the method, biological enzyme pretreatment is carried out on the pulp before chemical impregnation, so that lignin on surfaces of fibers partially falls off, more fine fibers are exposed, more hydroxyl groups are exposed on the surfaces, and reaction between a chemical impregnation section and a liquid medicineis facilitated. The swelling degree of the fibers is increased, the binding force among the fibers is improved, and the interweaving force among the fibers is enhanced. When the method is used for treating broad-leaved wood such as poplar and eucalyptus, the bursting strength, tensile strength and tearing strength of the prepared chemimechanical pulp are remarkably improved, and meanwhile, pulping energy consumption is reduced.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

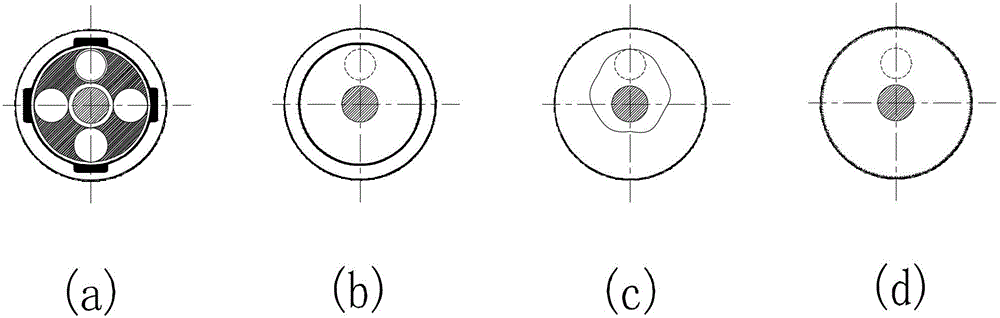

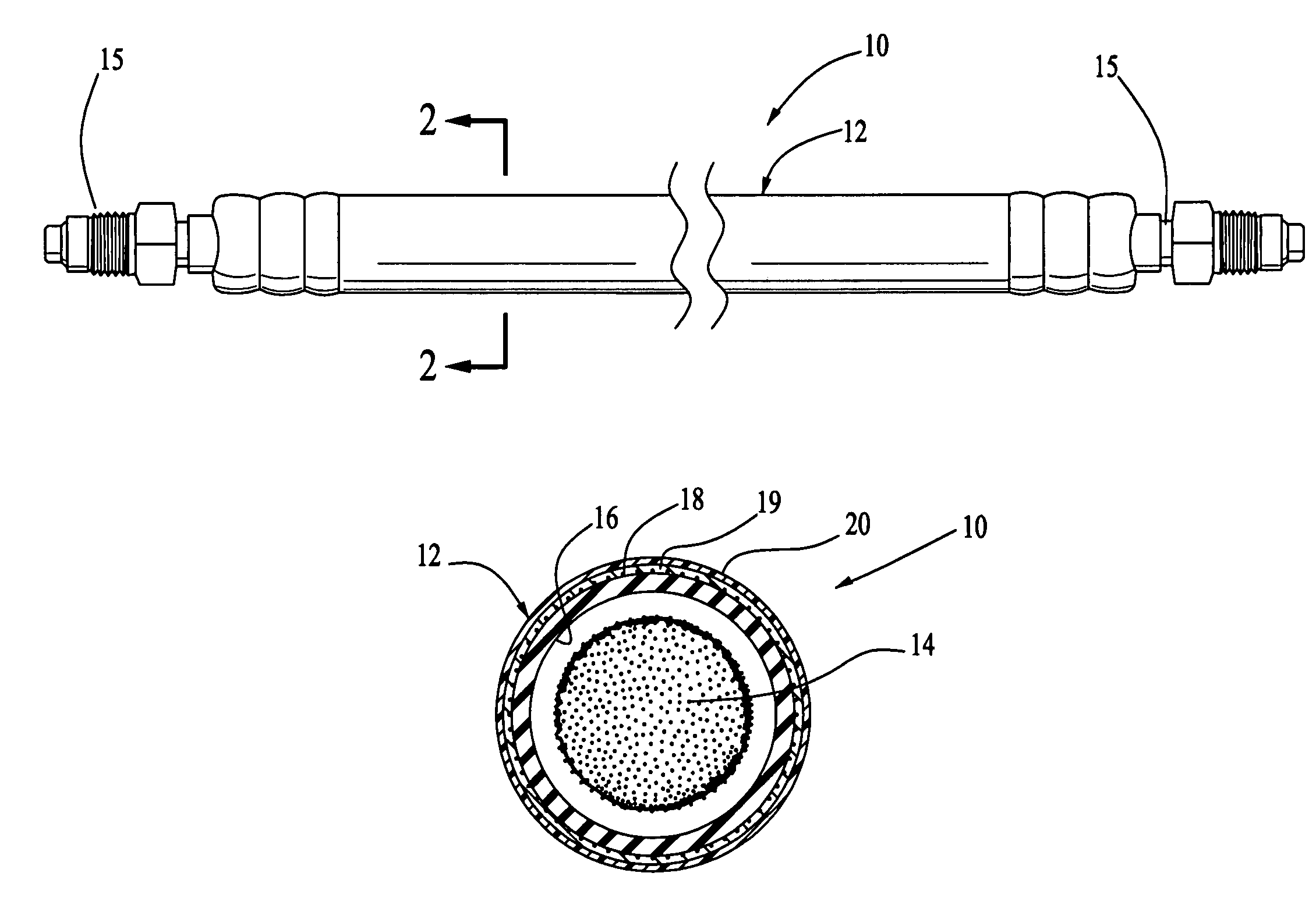

Power cable for air cooled welding torches

ActiveUS7211766B2Light weightResists stiffeningInsulated cablesPower cablesPower cableWear resistant

A power cable for use with welding apparatus for conveying power and cooling fluid from a welding machine to a welding torch. The cable includes an outer flexible conduit disposed about a flexible electrical conductor, a pair of end fittings operatively connected to the ends of the conduit and an electrical conductor for securing the power cable between the welding torch and welding machine in fluid and electrical communication therewith. The flexible conduit includes an inner tube portion formed of a flexible non-conductive rubber compound, a protective cover layer comprised of a plurality of threads braided or woven about the inner tube portion and a thin coating of a heat and wear resistant material such as polyurethane disposed over the braided or woven threads for bonding the protective cover layer to the inner tube portion, rendering the power cable heat and wear resistant without adversely affecting the flexibility thereof.

Owner:REHRIG RICHARD B

Production method of high-temperature resistant edible protein casing

InactiveCN101595902AImprove temperature resistanceUniform stateSausage casingsFood preparationChemistryEdible oil

The invention provides a production method of high-temperature resistant edible protein casing, comprising the following steps: (1) the animal inner leather is soaked in the alkaline proteinase solution of bacillus subtilis for a long time; (2) the leather after water washing and cutting is soaked in hydrochloric acid to become translucent and expanding; (3) the PH value of the material is adjusted to 2.5-3.5, then the material is cut up and pressed into tablets, and edible oil additives, soluble cellulose, water and hydrochloric acid are added into the tablets and mixed into micelles; (4) the micelles are filtrated, extruded and formed into a hollow tube shape; (5) the hollow tube is dried and cured; (6) the product is cooked at 85-95 DEG C under high humidity; and (7) the finished product can be obtained after folding and winding or shrinking. The product has the advantages of high strength, small shrinkage, uniform diameter and thickness, edible safety and high temperature resistance. The method of the invention is easy to operate; the process conditions are adjusted in multiple steps, and the aim to improve the performance of finished product is achieved by synergistic actions.

Owner:余君保

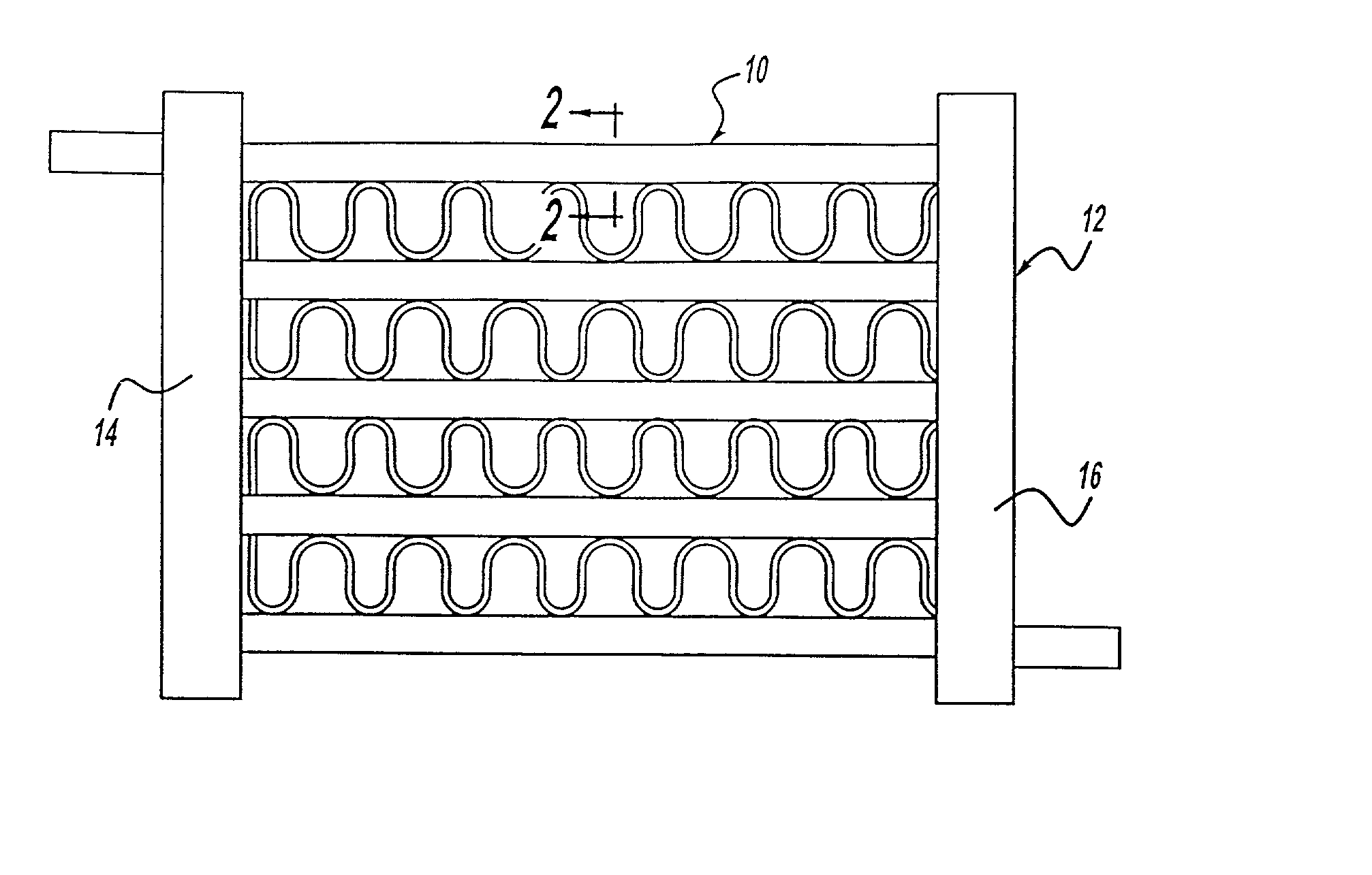

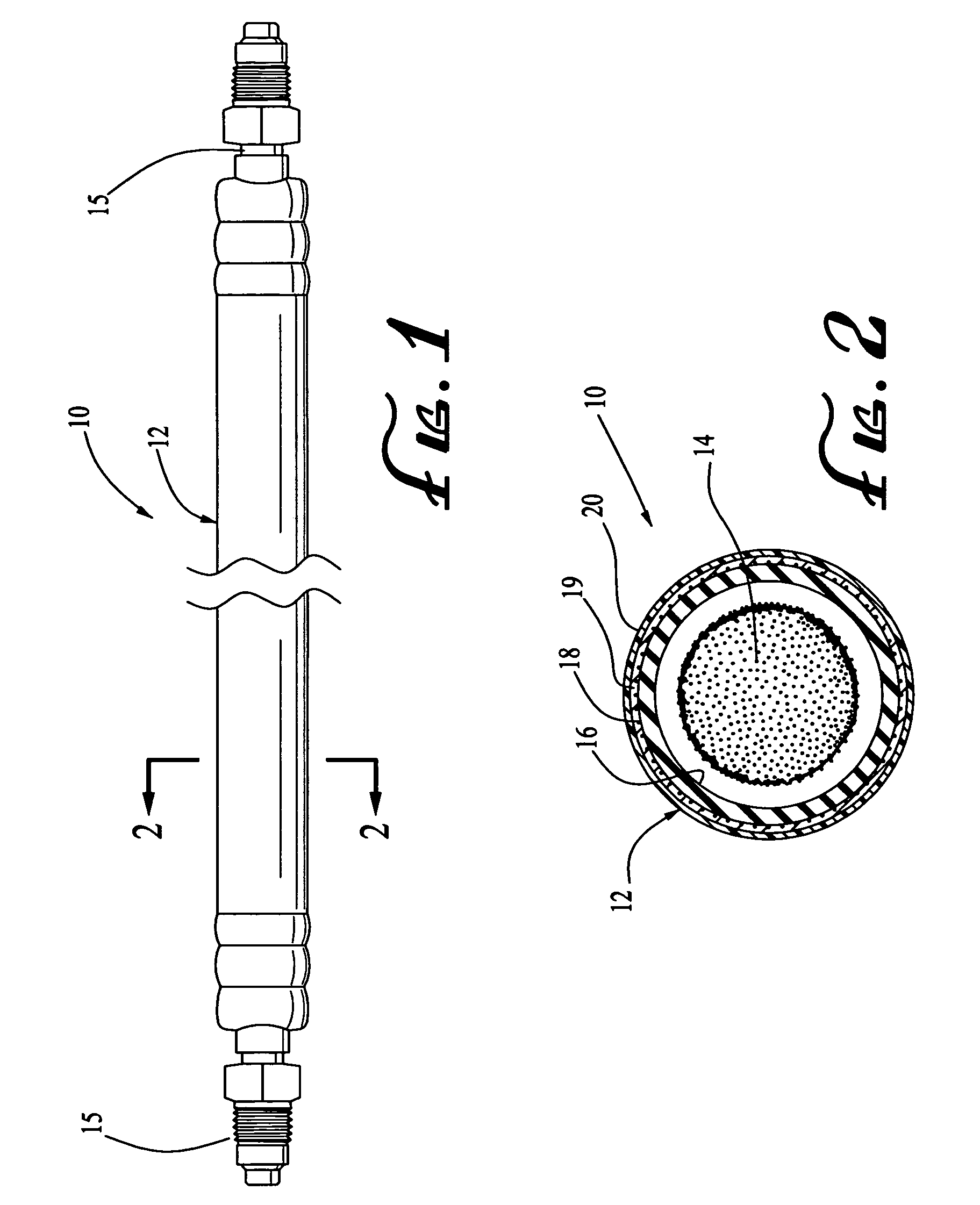

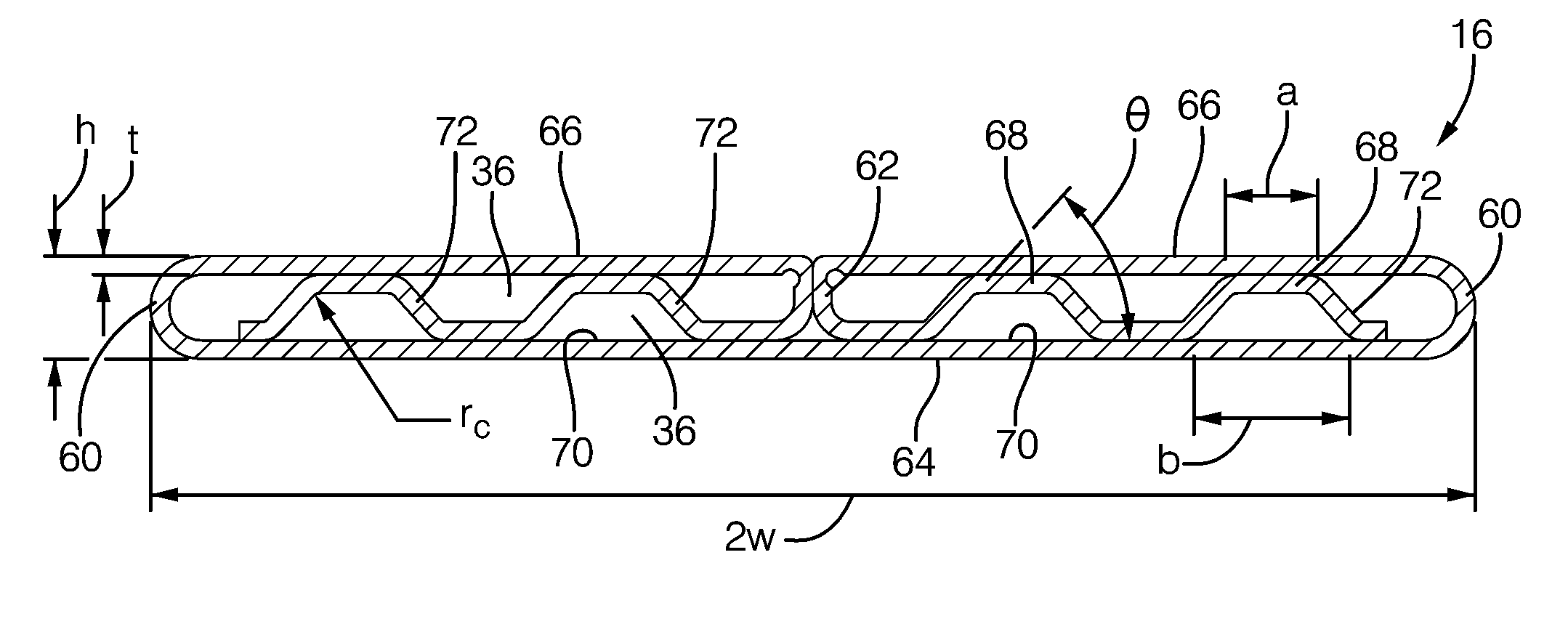

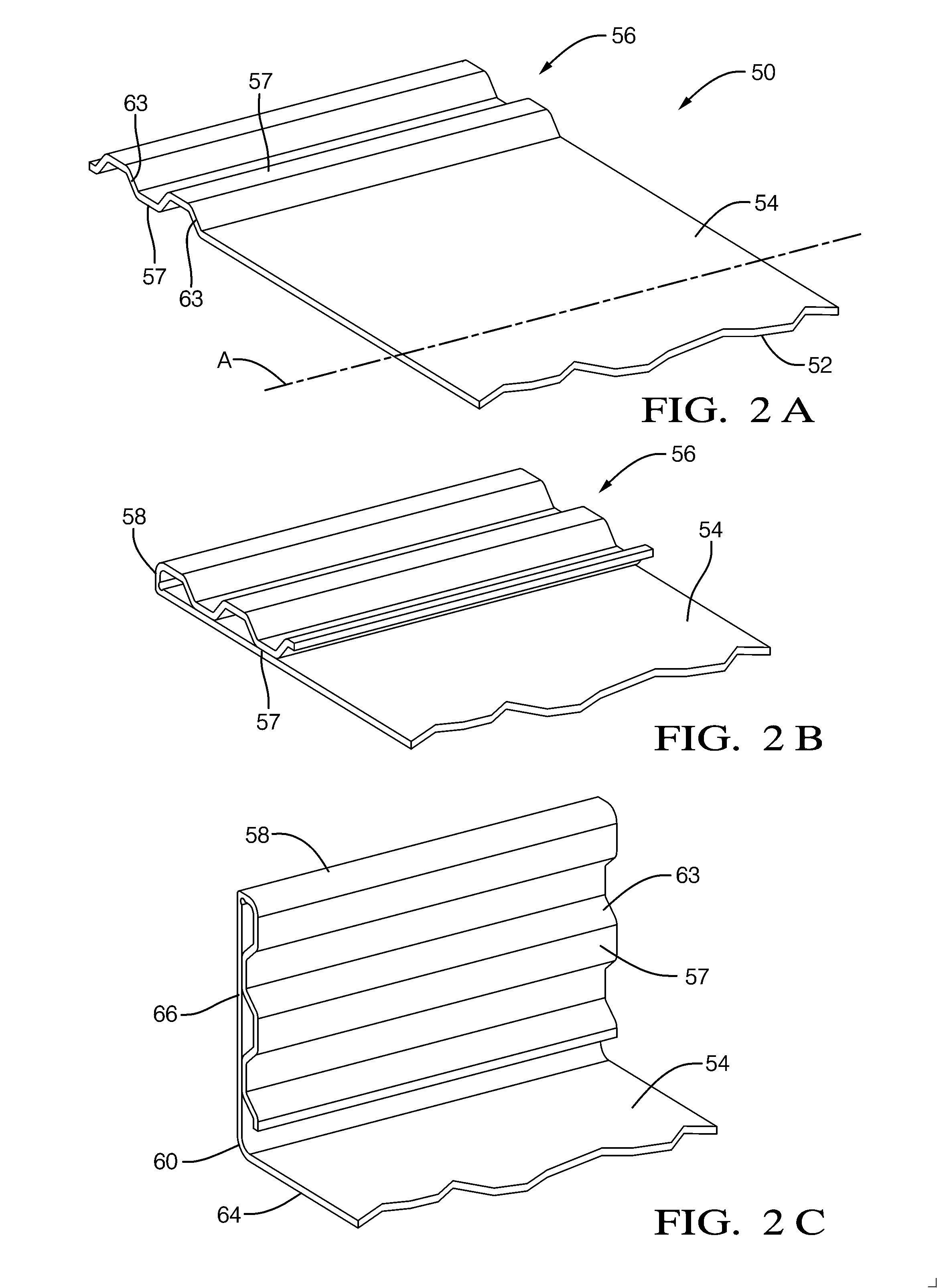

Fabricated tube for an evaporator

InactiveUS20110284195A1Improve heat transfer performanceIncrease robustnessStationary conduit assembliesHeat exchanger casingsSurface measurementEvaporator

An evaporator assembly having a first header, a second header, at least two banks of evaporator tubes extending therebetween and in hydraulic communication with the first and second headers. At least one of the evaporator tube may be folded from a unitary strip clad aluminum folded having a thickness (t). The evaporator tube includes a height (h) which is measured from the bottom exterior surface to the top exterior surface, and a corner radius (rc) defined by the transition radius from the flange segments to the channel walls. The bottom wall includes a width (2w), the corrugated portion includes alternating flange segments abutting the interior surface and channel walls connecting the alternating flange segments, at least one of the alternating adjacent flange segments includes a length (a) cooperating with adjacent the channel walls to define a channel having a width (b). The evaporator tube also includes a number of ports per millimeter width (PPMW) in a range of 0.40 to 1.0 as defined by the equation PPMW=2 / (a+b+t); a Port Shape (PS) ratio of 0.05 to 0.6 as defined by the equation PS ratio=a / b; a non-dimensional gauge (NDG) ratio of 0.11 to 0.21 as defined by the equation NDG ratio=t / h; and a non-dimensional corner radius (NDCR) ratio of 0.10 to 0.5 as defined by the equation NDCR ratio=rc / 2t.

Owner:MAHLE INT GMBH

Kraft paper and making method thereof

ActiveCN103422386AImprove burst strengthGood lookingCoatings with pigmentsPulp beating methodsBursting strengthKraft paper

The invention provides a kraft paper. The kraft paper comprises a raw paper and a coat formed on one side or double sides of the raw paper, and the absolute dry mass ratio of the raw paper to the coat is (85-90):(10-15). A paper pulp making the raw paper is a mixed pulp prepared through a step of respectively beating a bleached chemical softwood kraft pulp and a bleached chemical hardwood kraft pulp and a step of mixing, and the beating degree of the softwood pulp is lower than the beating degree of the hardwood pulp; the mass percentage content of the softwood pulp is 50-60%, and the mass percentage content of the hardwood pulp is 40-50%; and the coat is prepared through coating a coating containing co-boiled starch and pigment. The invention also provides a making method of the kraft paper. The kraft paper has a high bursting strength.

Owner:GOLD EAST PAPER JIANGSU

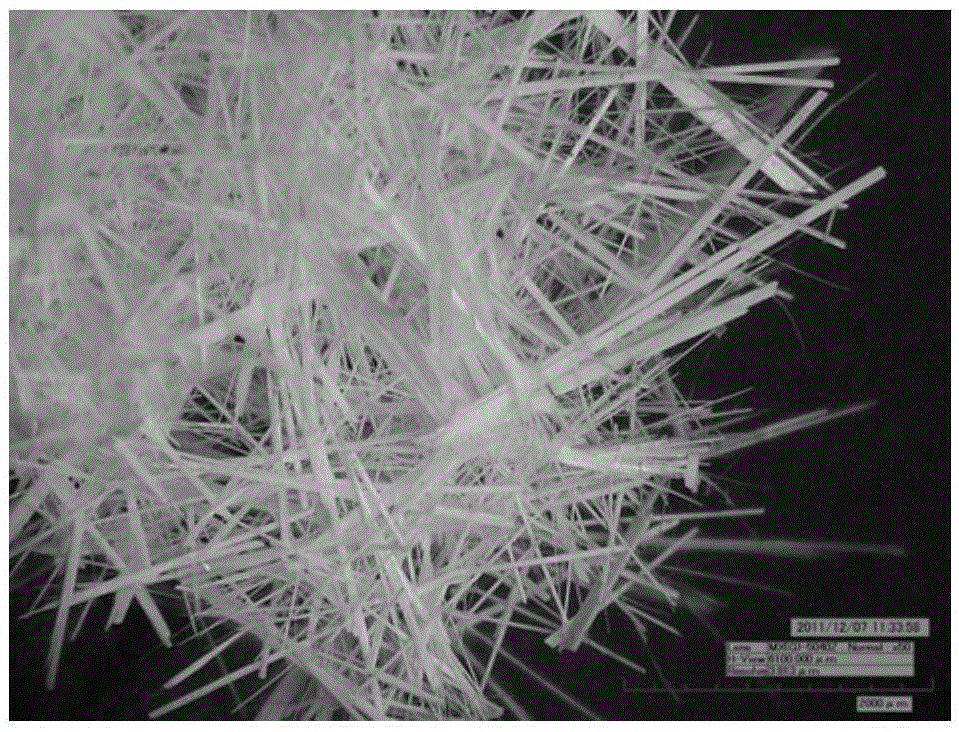

Surface modification method for calcium sulfate whiskers

InactiveCN105350084AReduce the burden onHigh hardnessPolycrystalline material growthAfter-treatment detailsAnhydrous Calcium SulfateWater processing

The invention discloses a surface modification method for calcium sulfate whiskers. The surface modification method comprises steps: anhydrous calcium sulfate whiskers are prepared; a surface modifier solution is prepared; the calcium sulfate whiskers are added slowly into the surface modifier solution with stirring, slow stirring is carried out, and a reaction is carried out; the modified anhydrous calcium sulfate whiskers are subjected to impurity removal processing. The method is simple, the steps are few, raw materials are saved, water processing burden is reduced, the anhydrous calcium sulfate whisker product has good performance, and tensile strength, the tear resistance, the folding strength and the pop strength are high. The solution synthesis method is employed, a calcium-containing industrial tail liquid is reacted with sulfuric acid, calcium sulfate whiskers are prepared, the cleaning utilization problem of calcium ions in the waste liquid is solved, which facilitates to achieve cyclic utilization of raw materials and resources are saved. The yield of the prepared calcium sulfate whiskers is high, the crystal form is structured and the length-to-diameter ratio is high.

Owner:SHANDONG UNIV OF SCI & TECH +1

Water-resistant wound paperboard tube

ActiveUS20070196602A1Improve the situationImprove burst strengthEnvelopes/bags making machineryWater-repelling agents additionBursting strengthCross-link

A wound paperboard tube having enhanced burst strength in high-moisture conditions up to and including complete and prolonged submersion in liquid water comprises a plurality of paperboard plies formed from a pulp comprising papermaking furnish and an effective amount of a size such that the paperboard plies have reduced moisture add-on when submerged in water, relative to paperboard plies formed from a pulp comprising the identical furnish but without the size. The plies are wound one upon another about an axis of the tube and adhered together with a water-resistant adhesive comprising a polyvinyl composition containing a cross-linking agent for inducing cross-linking of the adhesive.

Owner:SONOCO DEV INC

Medical tissue closing glue composition, medical tissue closing glue and preparation method and application thereof

ActiveCN106075550AImprove adhesionPlay a closed roleSurgical adhesivesPharmaceutical delivery mechanismSwelling ratioTissue fluid

The invention provides a medical tissue closing glue composition, medical tissue closing glue and a preparation method and application thereof. The medical tissue closing glue composition comprises a first component and a second component, wherein the first component comprises an amino containing natural substance and / or a first modified product obtained by modifying the amino containing natural substance with sulfydryl groups, and the amino containing natural substance and the first modified product respectively have ten or more active groups which are amino groups and sulfydryl groups; the second component comprises a second modified product obtained by modifying chitosan and / or polylysine with ten or more vinyl groups. The medical tissue closing glue has high rupture strength, a low swelling ratio and good adhesiveness, tissue wound surfaces can be quickly closed, the effect of closing tissue is effectively achieved, interstitial fluid or blood or cerebrospinal fluid is prevented from leaking, the pain of a patient can be relieved, and more danger is avoided.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Preparation method for producing deep-drawn cold-formed medicinal aluminum foil with cast-rolling billet in short process

PendingCN111549261AHigh bursting strengthGood barrierMetal rolling arrangementsTemperature treatmentDeep drawing

The invention discloses a preparation method for producing deep-drawn cold-formed medicinal aluminum foil with a cast-rolling billet in a short process. The method sequentially includes the steps of smelting, cast rolling, cold rolling, homogeneous high-temperature treatment, intermediate rolling, slitting shear trimming, intermediate annealing, finish rolling, foil rolling, coil combining, finished product rolling, parting-off, and furnace loading for annealing. Raw materials of the deep-drawn cold-formed medicinal aluminum foil include an aluminum alloy and an Al-Fe intermediate alloy with amass content of 20% or a Fe-containing additive with a mass content of 75%, and elements in the aluminum alloy include 0.025-0.10% of Si, 1.25-1.65% of Fe, 0.001-0.10% of Cu, less than 0.05% of Mn, less than 0.05% of Mg, less than 0.05% of Cr, less than 0.05% of Zn, 0.01-0.04% of Ti and the balance A. By means of the recorded preparation method, final product detection shows that the end face layer offset after parting-off is less than or equal to 0.5 mm, the width of the corrugated edge is 3 mm, and the peak value is 1 mm; the surface cleanliness dyne value is greater than or equal to 65 dyn; as for mechanical properties, the tensile strength is 80-115 MPa, the elongation rate is 23%, and the yield ratio is 42%; and the Erichsen value is 5.0 mm, the deep drawing height is 2.0 mm, the surface hardness value is 22 HV, the bursting strength is 400-800 Ka, and the surface swabbing reaches level A.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

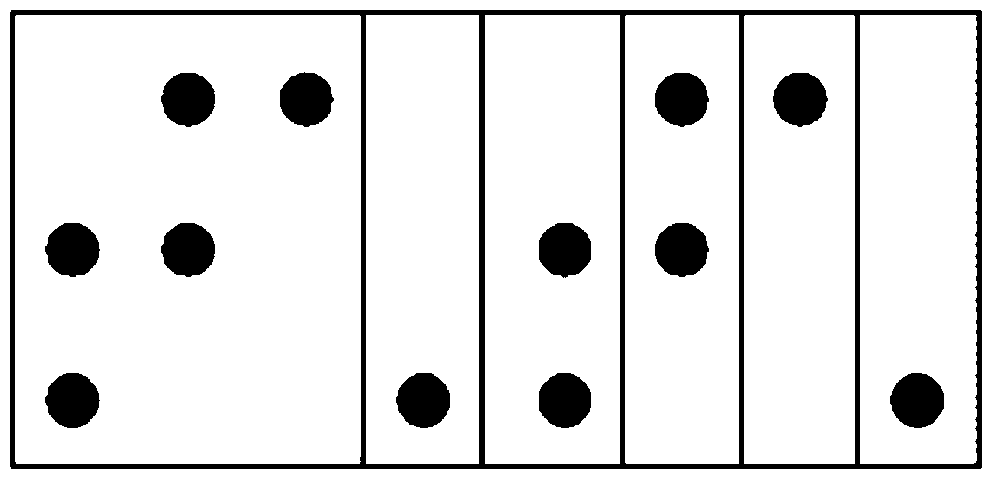

Sodium base bentonite waterproof blanket and preparation method thereof

InactiveCN105398149AGood dispersionMaximize performance potentialLamination ancillary operationsSynthetic resin layered productsYarnEnvironmental resistance

The invention belongs to the field of building materials, and particularly relates to a sodium base bentonite waterproof blanket and a preparation method thereof for water ecological system protection and remediation as well as waterproofness of buildings. The sodium base bentonite waterproof blanket comprises nonwoven geotextiles on the bottom layer, a sodium base bentonite layer in the middle and plastic woven film yarn geotextiles on the surface layer, wherein the sodium base bentonite layer is fixed between the nonwoven geotextiles and the plastic woven film yarn geotextiles by a needle-punching method. The sodium base bentonite waterproof blanket can be applied to multiple complex and severe water quality environment projects, and belongs to environmental-friendly waterproof materials, and reinforces the integral size stability and mechanical intensity greatly; the sodium base bentonite layer fully inspires the performance potential of bentonite, and the obtained high-expansion-performance sodium base bentonite is good in dispersibility in water, and is good in mud colloid performance; the plastic woven film yarn geotextiles have good impermeable effect, are beneficial to the guarantee of the quality of a product, and are stable in performance coefficient.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Gas-antirust buffering packing sheet and its making process

InactiveCN1609135ADurable anti-rust effectImprove cushioning elasticityPolyethylene matrixPolymer chemistry

The antirust buffering packing sheet is prepared with polyethylene resin 70-99 wt%, gaseous corrosion inhibitor VCI 0.55-18 wt%, assistant 0.05-12 wt% and supplementary material 0-0.5 wt%. The antirust buffering packing sheet has thickness 0.5-15 mm, pores of opened or closed structure and size 0.025-0.5 mm, and foaming rate of 10-50 %. The making process includes compounding material based on the ratio, p-treatment to form fine powder, extruding in extruder and foaming. The sheet has the comprehensive effects of preventing rust, buffering, preventing shock, preventing humidity, etc., may be reused and has wide application and low cost.

Owner:全桂媛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com