Method for manufacturing acid-proof, alkali-proof, hydrolysis-resistant and high-peel-strength polyurethane space leather

A technology of acid and alkali resistance, manufacturing method, applied in textile and papermaking, fiber type, fiber treatment and other directions, can solve the problems of high cost of synthetic leather, poor acid resistance, and synthetic leather is not easy to degrade quickly, and achieves flexible hand feel and peel strength. High, the effect of improving hydrolysis resistance and acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

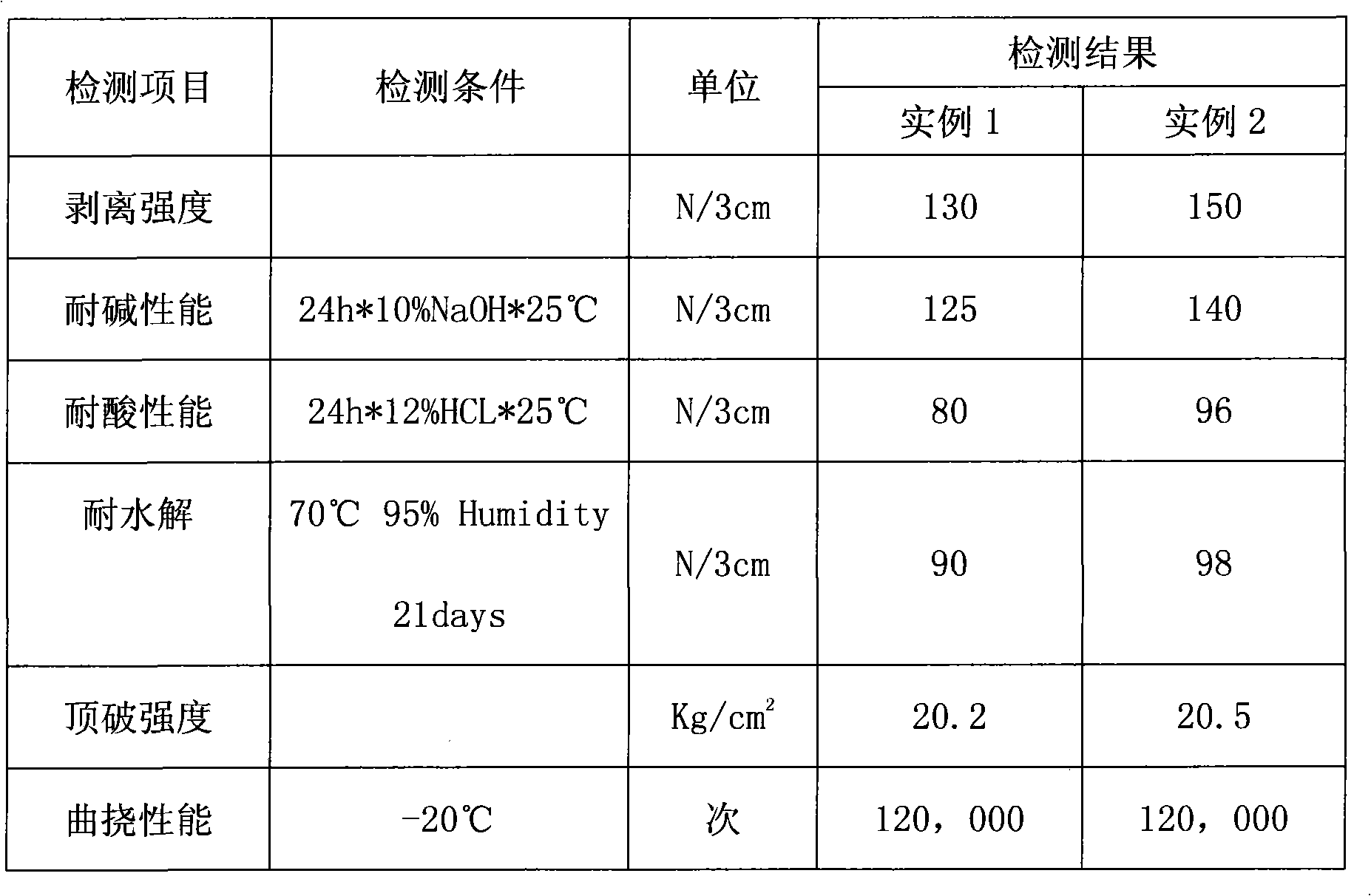

Examples

specific Embodiment 2

[0074] An acid-resistant, alkali-resistant, hydrolysis-resistant and high-stripping polyurethane space leather, comprising the base material and an impregnated compounding solution, coated with the compounding solution, and omitting the dry transfer method for veneering (just follow the normal operation process).

[0075] Ingredients (by weight)

[0076] Impregnation solution:

[0077] Polyester polyurethane (HDW-80E) with a solid content of 30-40% 100kg

[0078] Dimethylformamide (DMF) 110kg

[0079] Fluorine polymer (F-3D) 3kg

[0080] Surfactant (S-7) 2kg

[0081] Solvent-based colorant (EK-048) 10kg

[0082] Coating solution:

[0083] Polyester polyurethane (HDW-80E) with a solid content of 30-40% 100kg

[0084] Dimethylformamide (DMF) 50kg

[0085] Lignocellulose 5kg

[0086] Surfactant (S-7) 4kg

[0087] Fluorine polymer (F-3D) 3kg

[0088] Polyurethane modifier carbodiimide (CHA) 4kg

[0089] Modified silicone polymer (BYK-9520) 0.8kg

[0090] Solvent-based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com