Patents

Literature

647results about How to "Eliminate cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

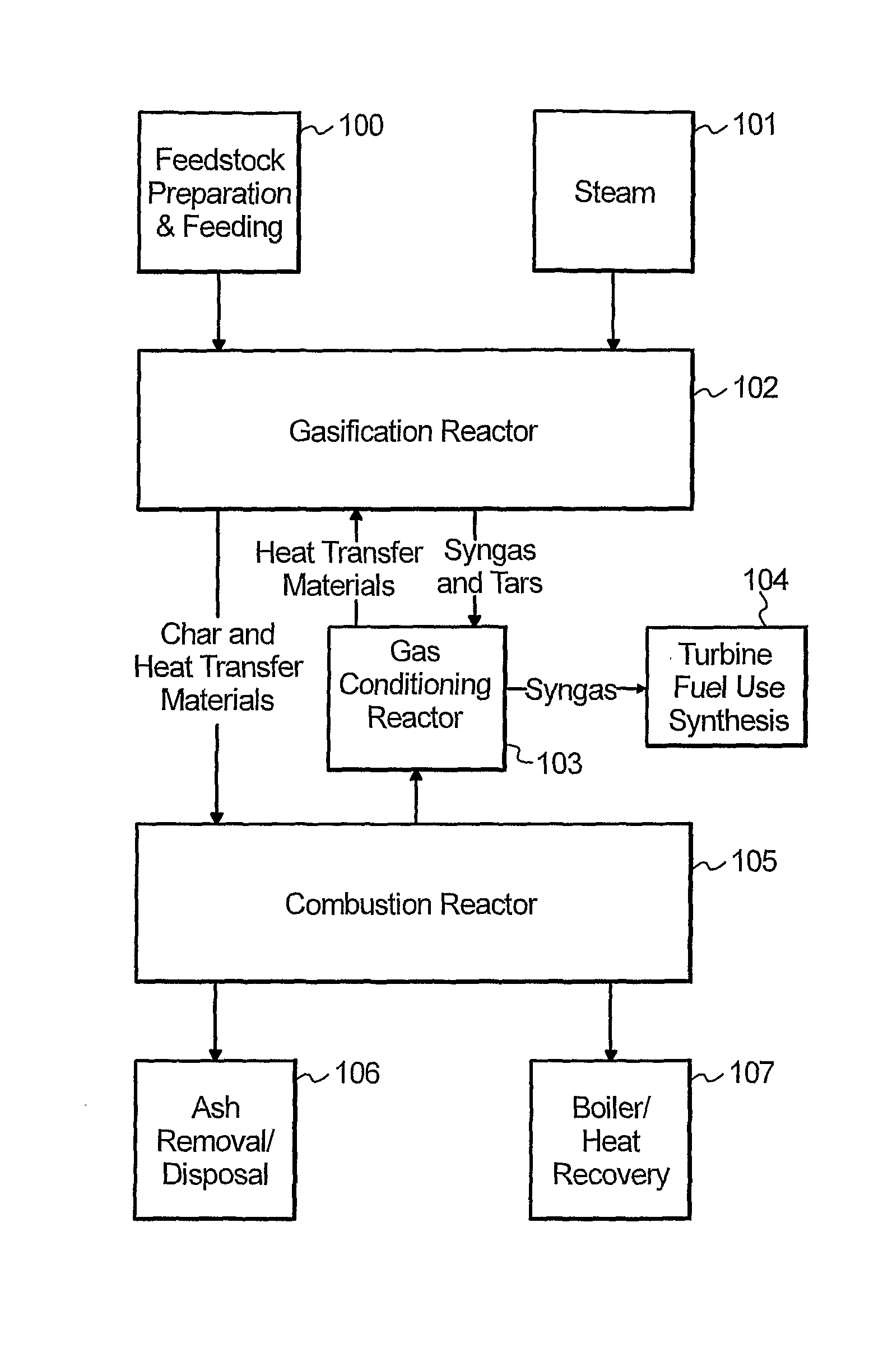

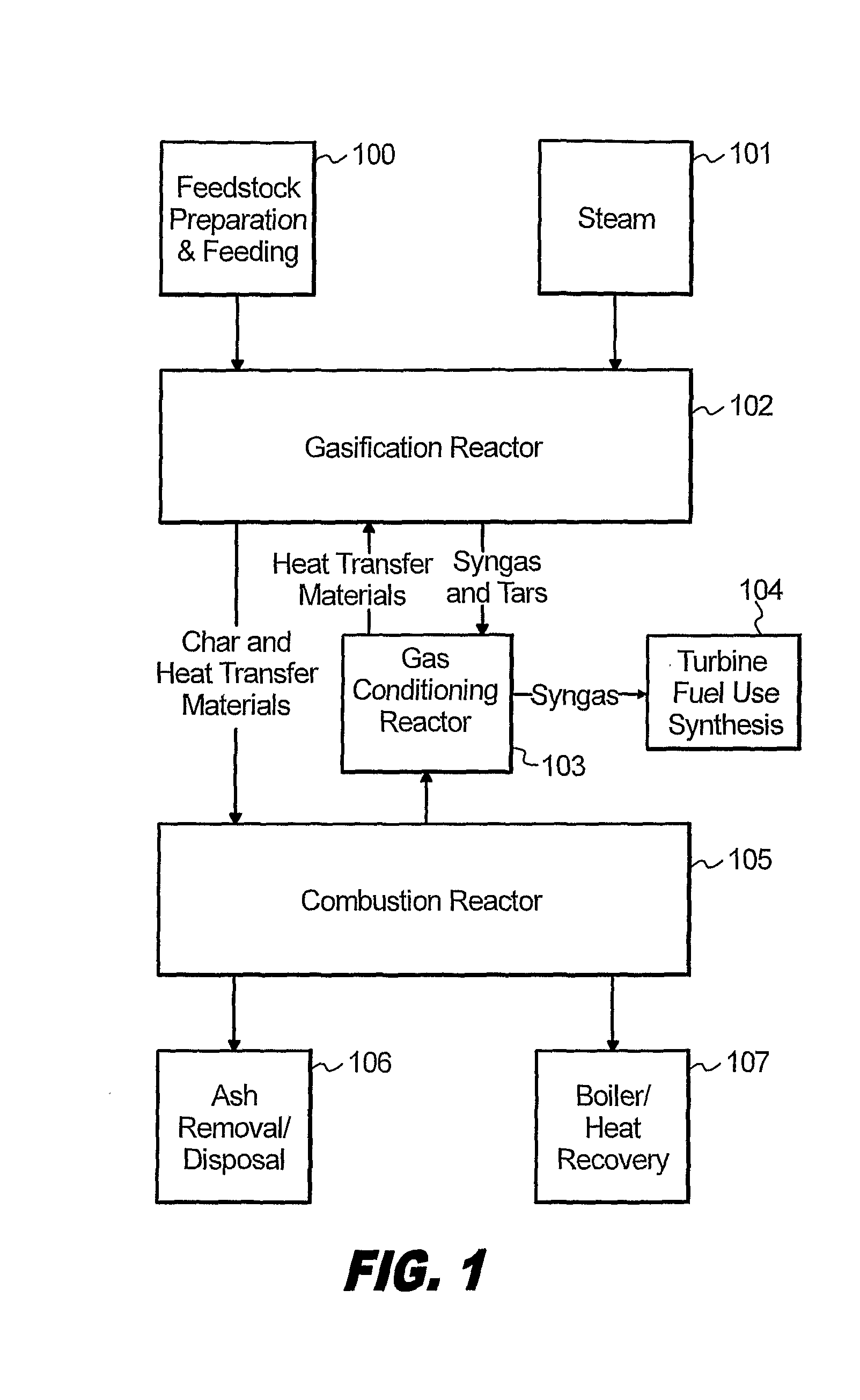

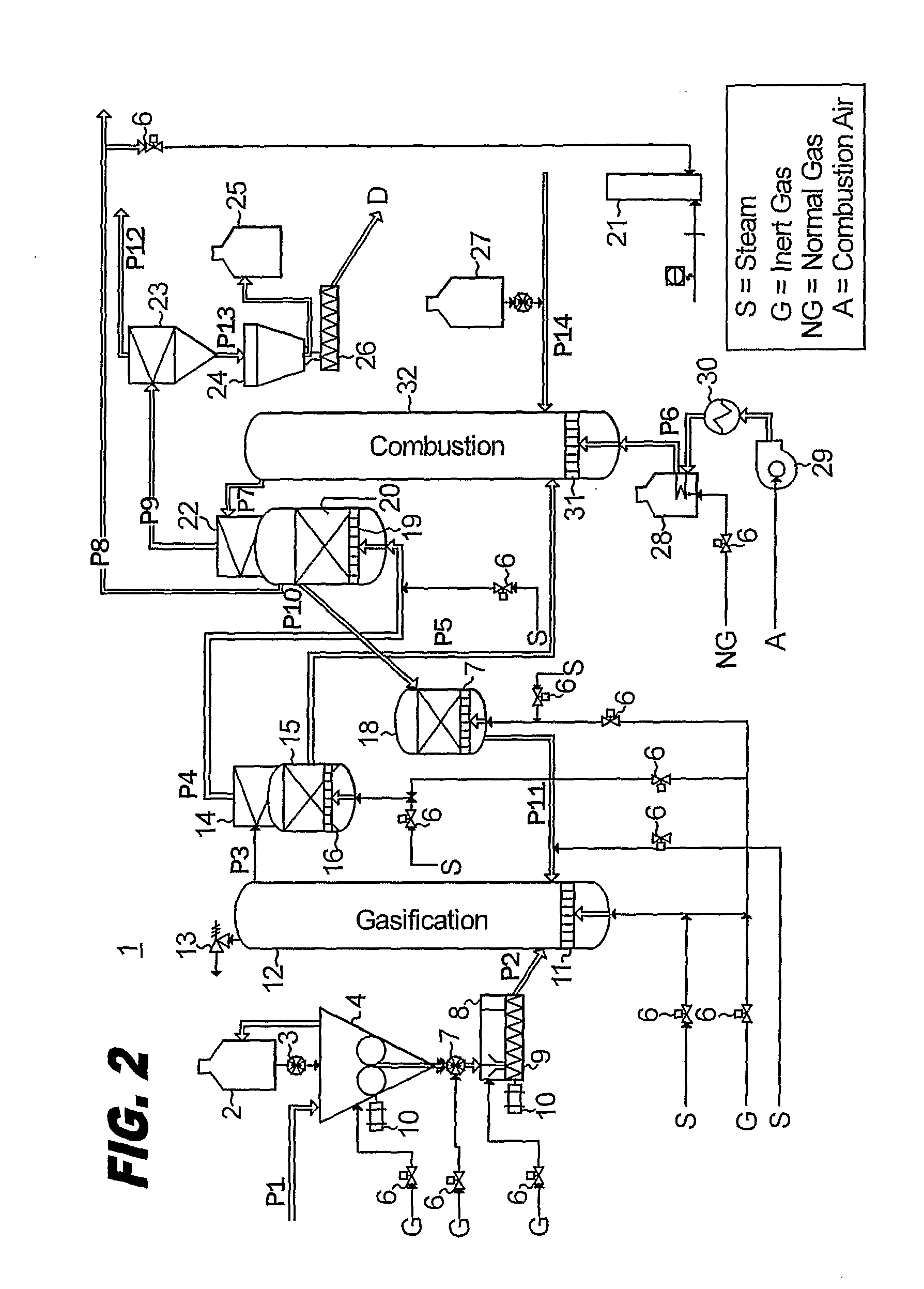

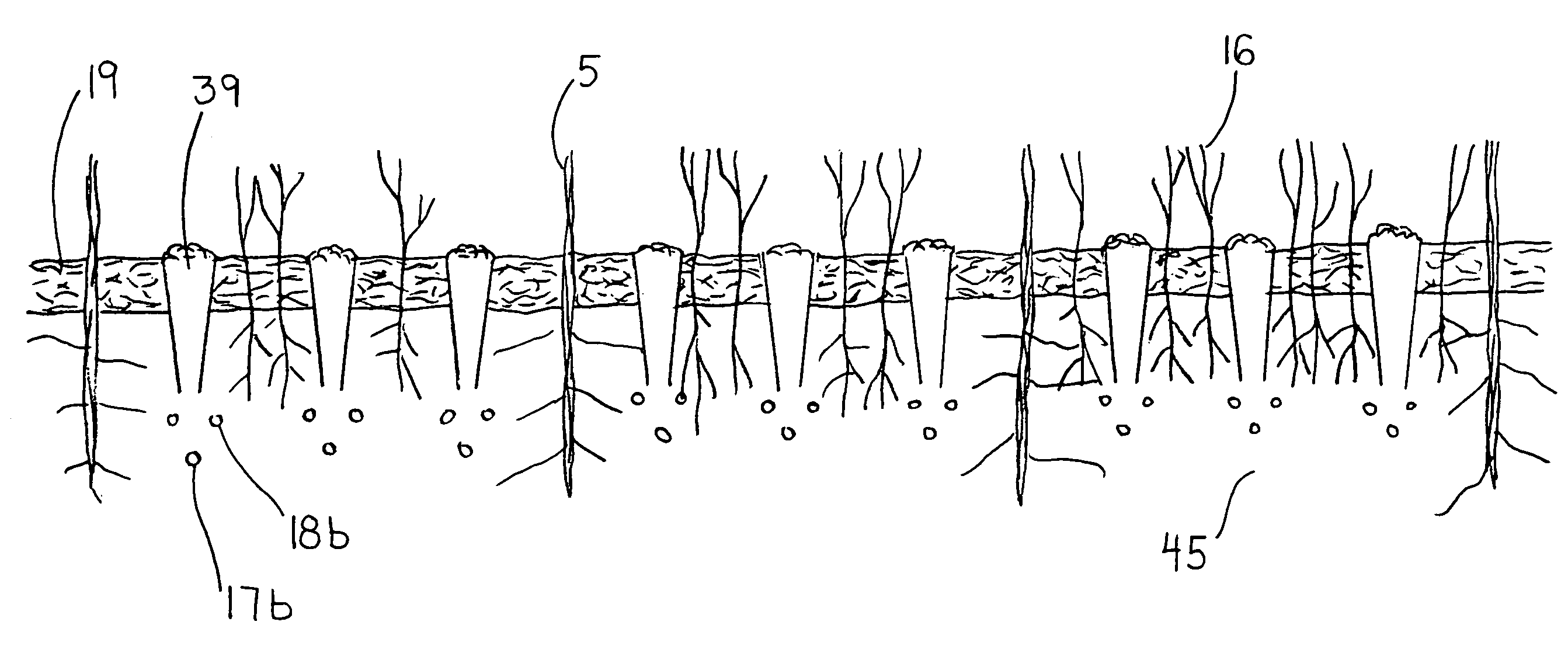

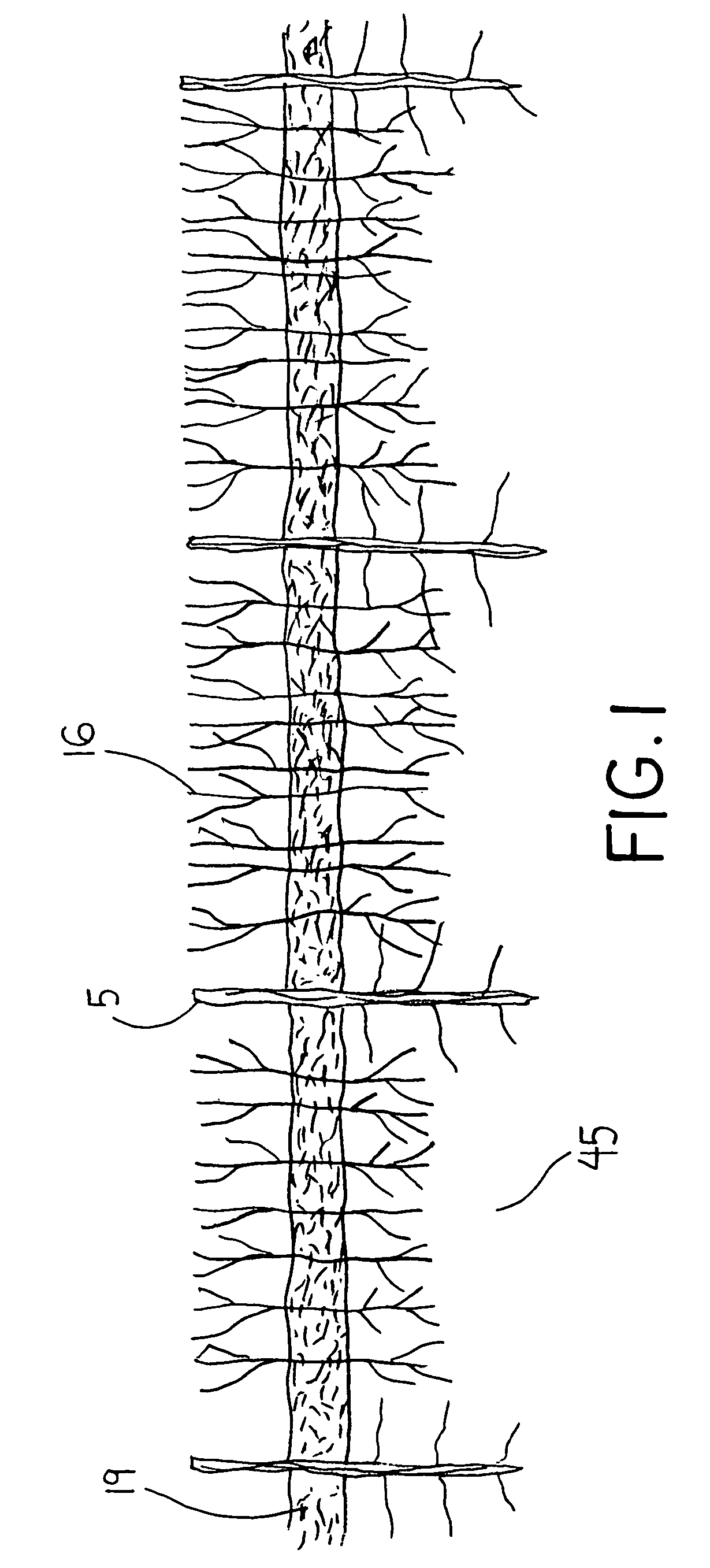

Process and System for Gasification with In-Situ Tar Removal

ActiveUS20080244976A1Simplifying downstream heat recoveryIncreased hydrogenCombustible gas catalytic treatmentCombustible gas thermal treatmentHeat carrierTar

The present invention relates to a process and system for gasifying biomass or other carbonaceous feedstocks in an indirectly heated gasifier and provides a method for the elimination of condensable organic materials (tars) from the resulting product gas with an integrated tar removal step. More specifically, this tar removal step utilizes the circulating heat carrier to crack the organics and produce additional product gas. As a benefit of the above process, and because the heat carrier circulates through alternating steam and oxidizing zones in the process, deactivation of the cracking reactions is eliminated.

Owner:TAYLOR BIOMASS ENERGY

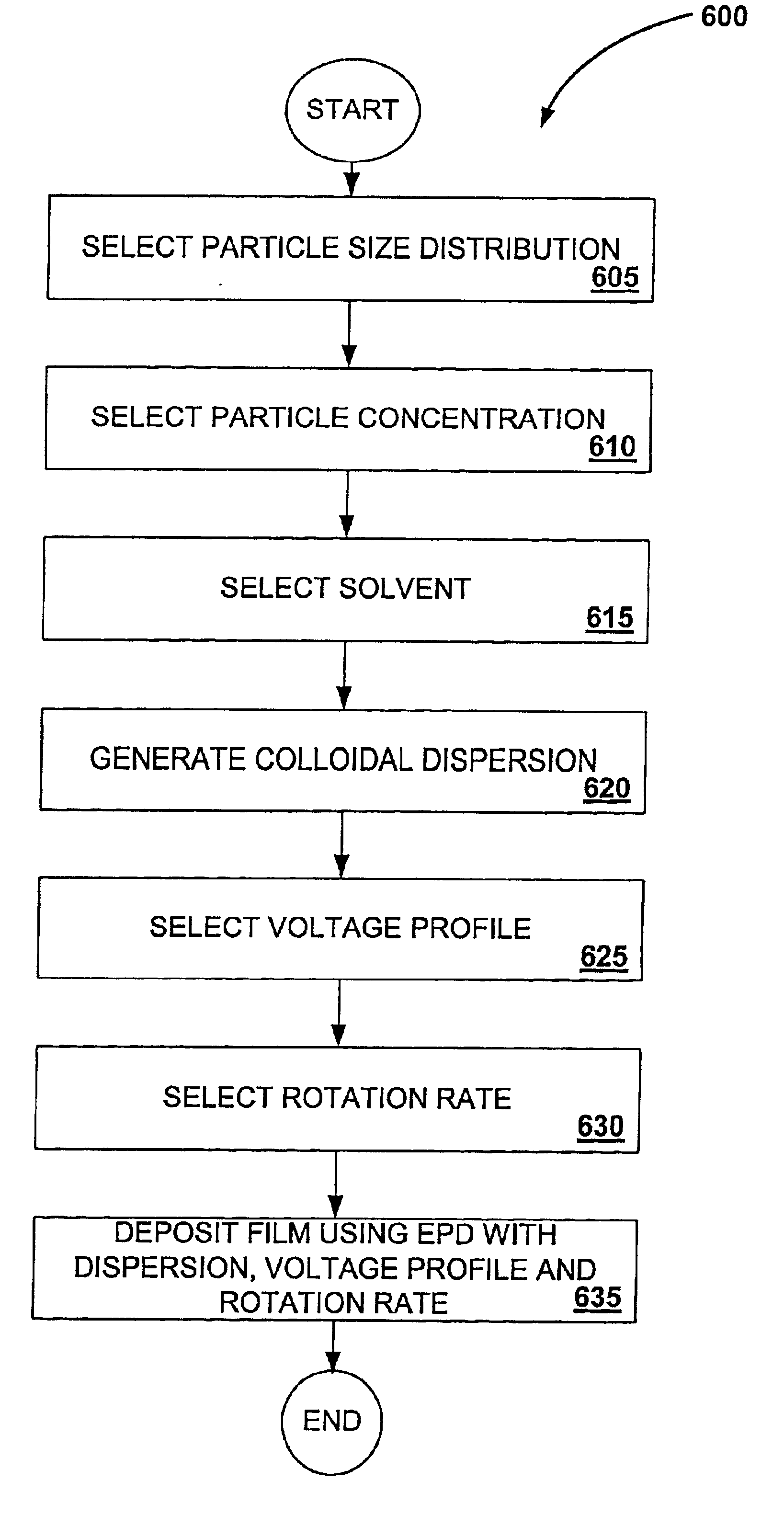

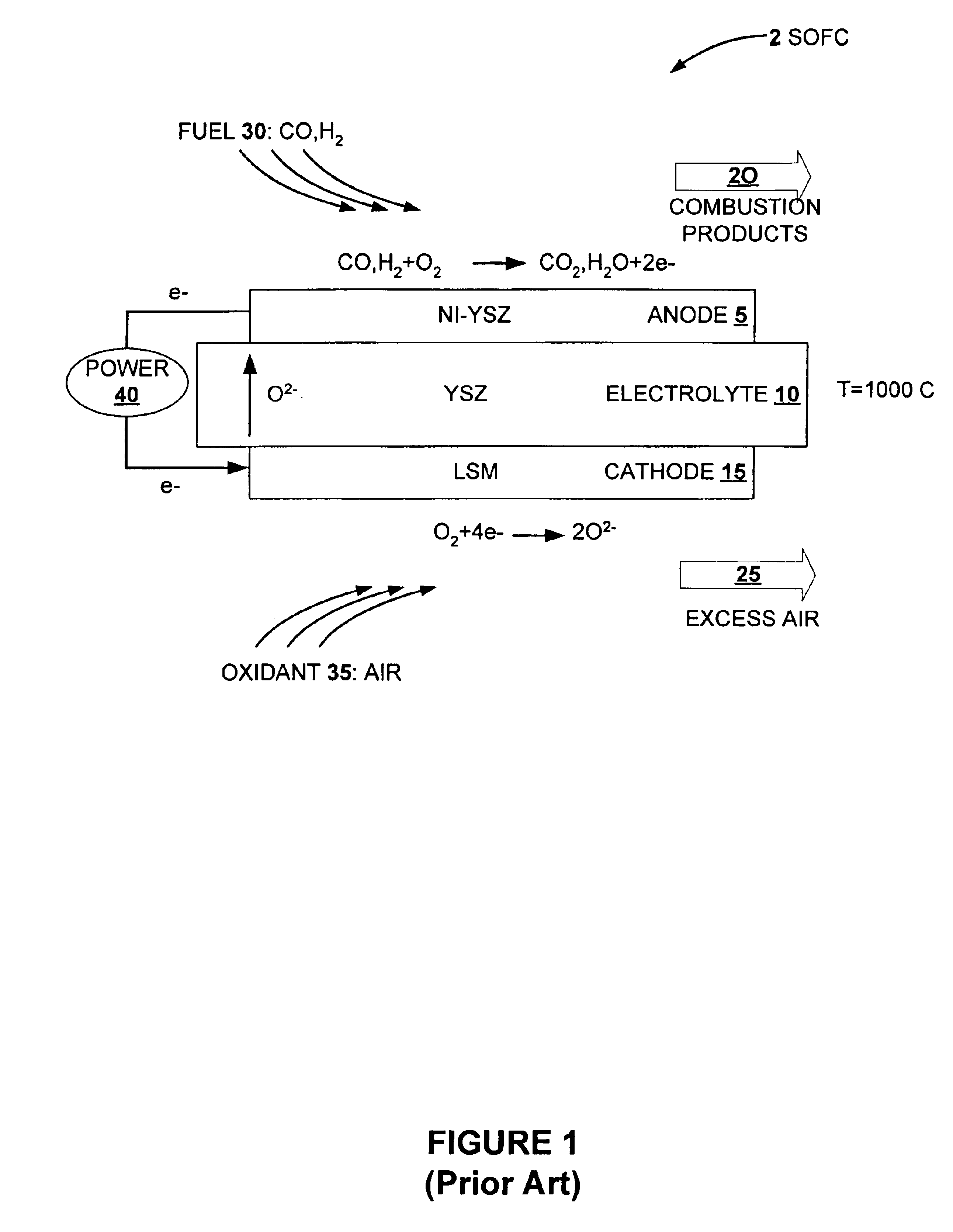

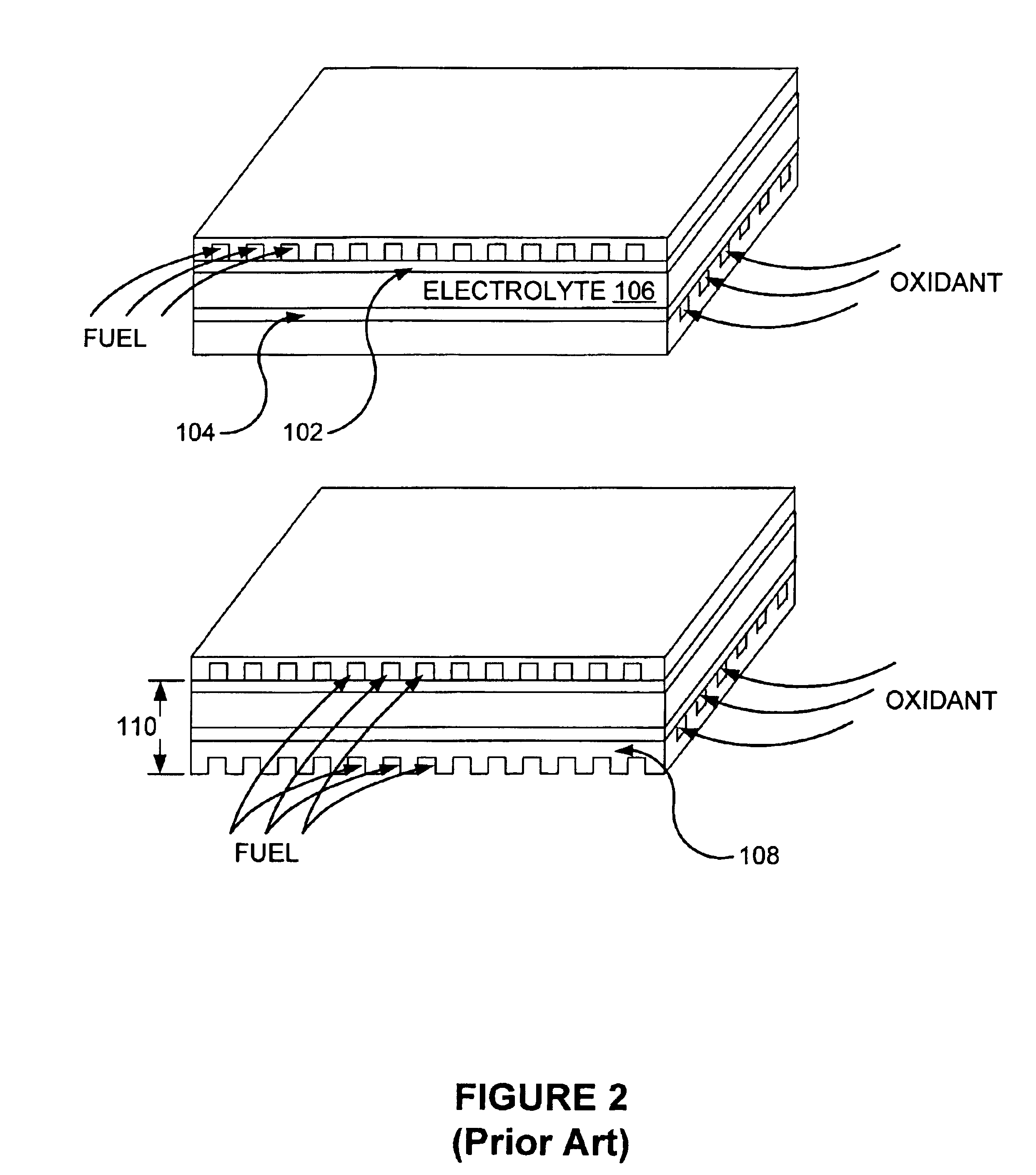

Method for making thin-film ceramic membrane on non-shrinking continuous or porous substrates by electrophoretic deposition

ActiveUS6887361B1High green densityReduce fire temperature and firing timeElectrolysis componentsFinal product manufactureElectrophoretic depositionSolid-state

A disclosed method provides techniques for forming low-cost, mechanically strong, highly electronically conductive porous structures for solid-state electrochemical devices. In particular, a method of forming a ceramic film on a substrate using electrophoretic deposition (EPD) is described. The method employs a colloidal dispersion of particles during the EPD process where a distribution of particle sizes is selected to eliminate drying cracks in the ceramic film prior to firing of the ceramic film-coated substrate. The method may be used to provide a high-density green film which can be sintered on to a non-shrinking substrate. For instance, a thin film of YSZ with a high green density may be sintered on to a non-shrinking LSM substrate. In particular embodiments, the distribution of particle sizes used in the EPD process may be selected to reduce a firing temperature and a firing time during sintering of the film coated substrate.

Owner:RGT UNIV OF CALIFORNIA

Combined intercropping and mulching method

InactiveUS7634869B1Reduce needIncrease surface moistureSeed and root treatmentFabaceae cultivationPolygonum fagopyrumMyriophyllum

A method of combined intercropping and mulching of commercial crops is described herein. Suitable annuals such as young wheat and / or buckwheat plants are planted in soil in which legumes were originally planted. A portion of the resulting upper portions of young wheat and / or buckwheat plants is mowed and blended with organic debris to provide nutrients for intercropped commercial plants such as corn and soybeans. The remaining portion is chopped blended with organic debris and sprayed onto the top layer of seeded soil as combination mulch. For larger commercial applications, conventional agricultural machines are described herein, and are modified for the most efficient intercropping. For best results, at least one intercropped commercial plant should be a legume.

Owner:WILLIAMS JR MARVIN J

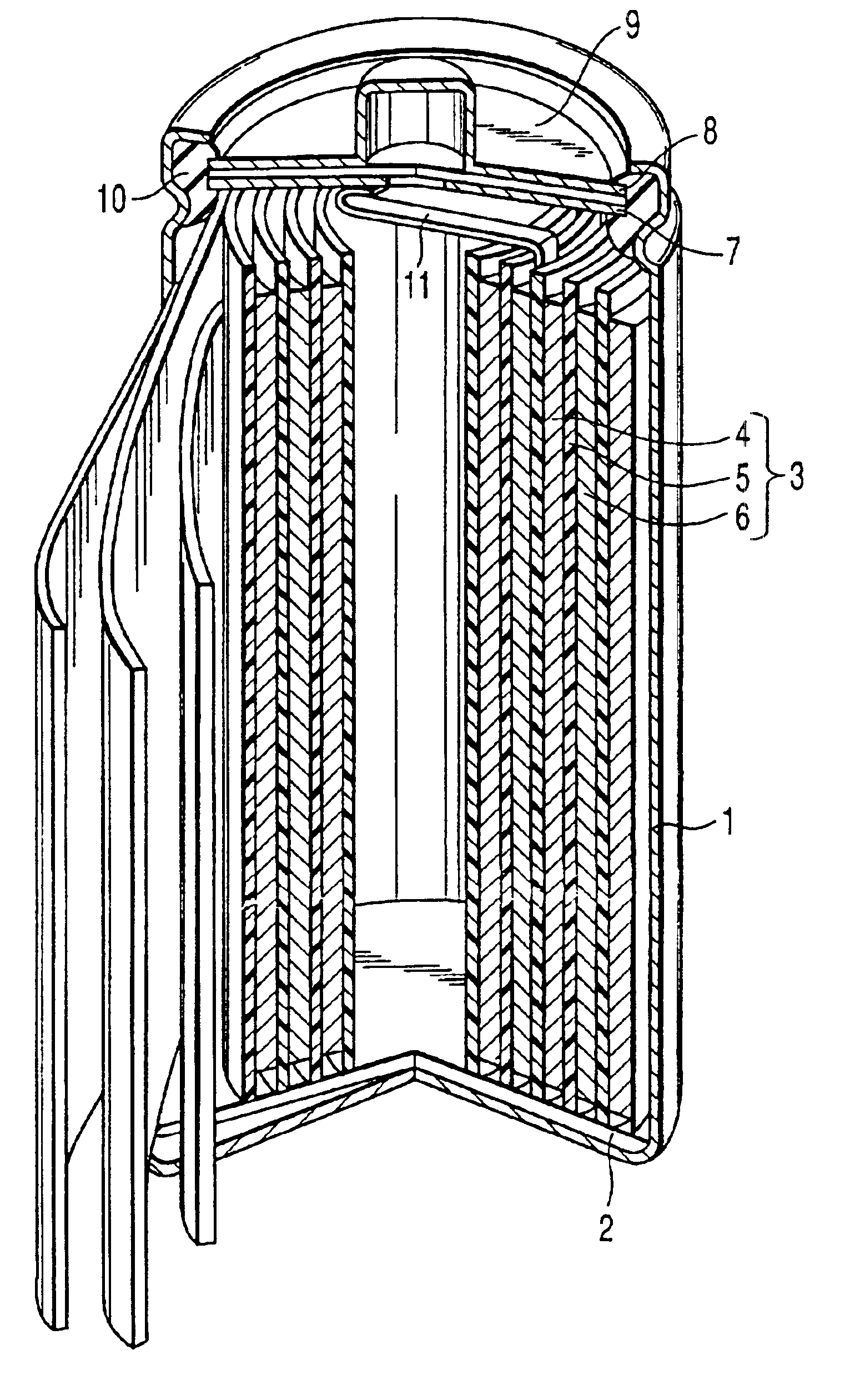

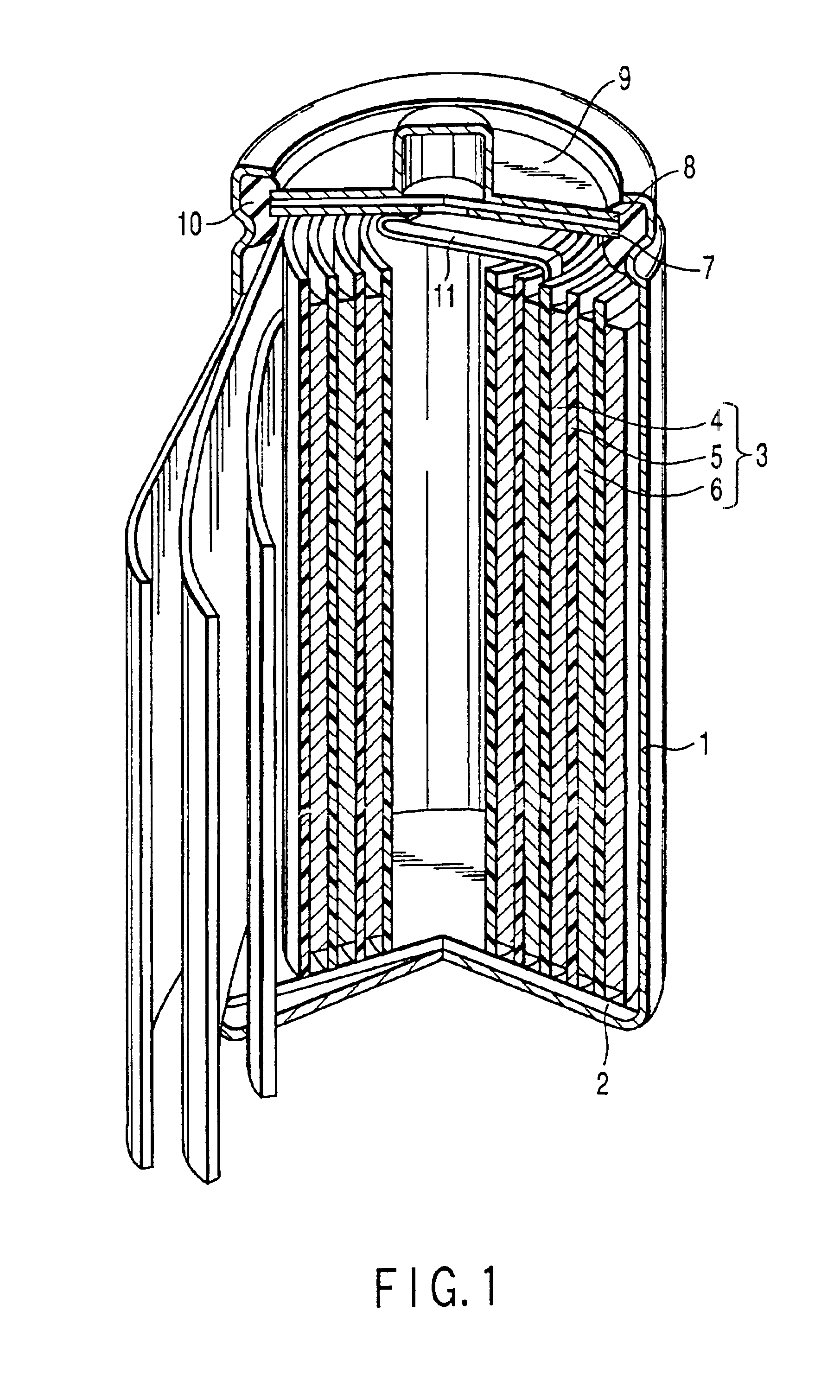

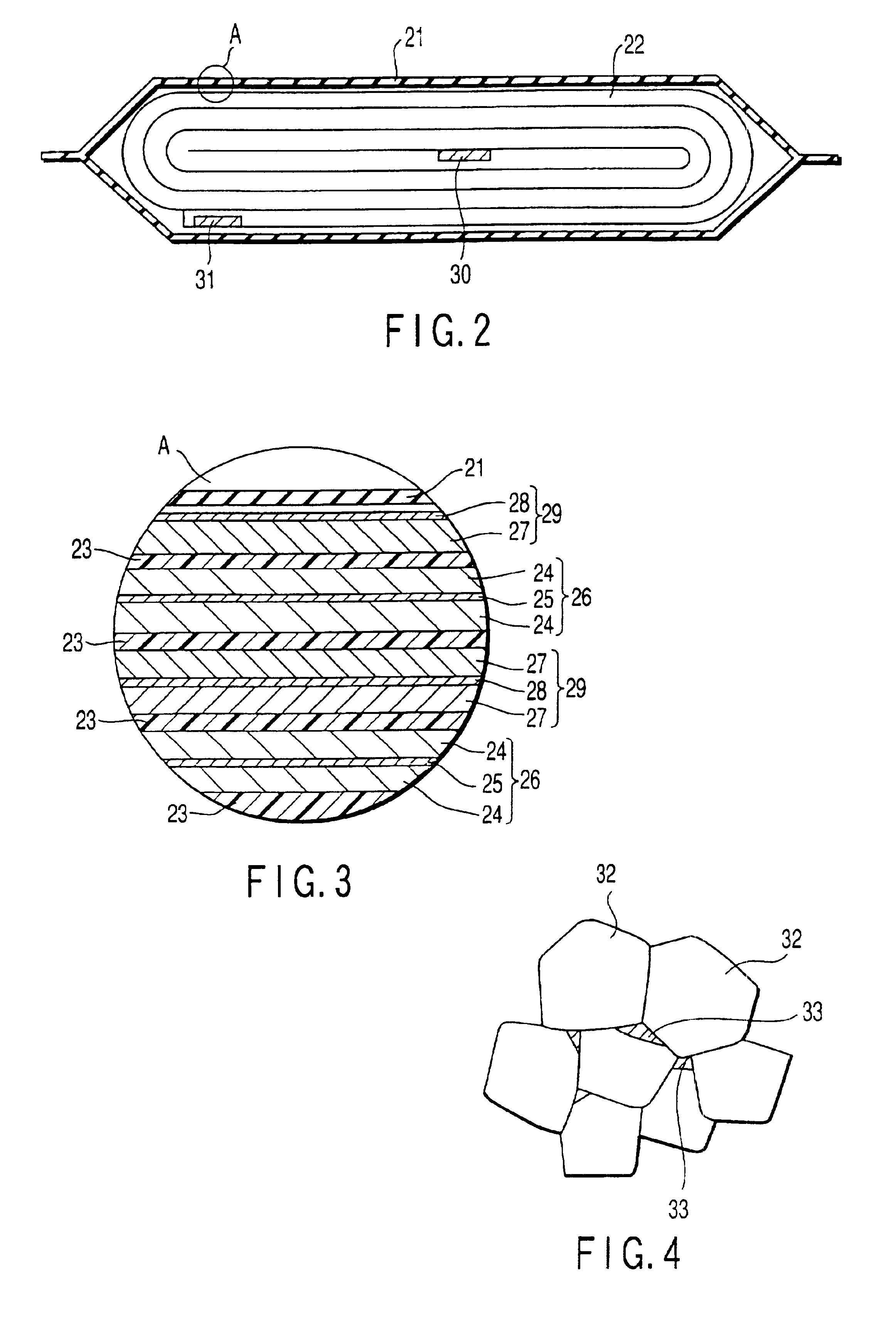

Positive electrode active material and lithium ion secondary battery

InactiveUS6872491B2Eliminate cracksLarge dischargeFluoride preparationFinal product manufactureStructural formulaComposite oxide

The present invention provides a positive electrode active material containing a composite oxide having a composition represented by a structural formula (1) given below:Lix(Ni1-yMe1y)(O2-zXz)+A (1)

Owner:KK TOSHIBA

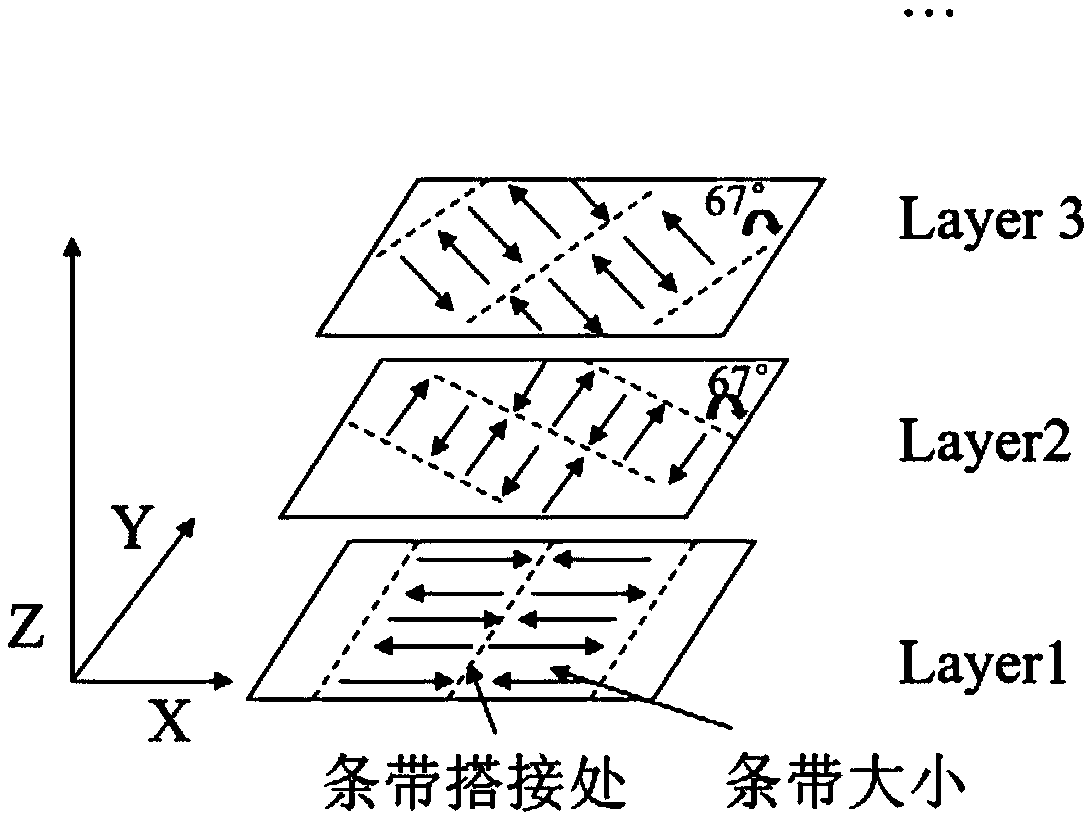

Method for removing cracks of Rene104 nickel-based superalloy during laser additive manufacturing

ActiveCN108941560AEliminate cracksInhibition of large size cracksAdditive manufacturing apparatusTransportation and packagingRoom temperatureStress relief

Owner:CENT SOUTH UNIV

Preparation method of laser fusion covered nickel base nanometer WC/Co precoating layer

InactiveCN1786272AFlat surfaceEliminate cracksPretreated surfacesHeat inorganic powder coatingAlcoholNanotechnology

The invention relates to laser melting-covering nickel base nanometer WC / Co precoating manufacturing method. It includes the following steps: weighting lac absolute ethyl alcohol in proportion of 1:10-20; adding the lac into the absolute ethyl alcohol; weighting and mixing nickel base nanometer WC / Co powder and bonding agent in proportion of 1g: 0.1mL-0.25mL; fully stirring to form precoat agent; coating the precoat agent at the workpiece surface to form precoating; drying. The prepared nickel base nanometer WC / Co precoating is adopted laser melting-covering technique to form nickel base nanometer WC / Co composite coating.

Owner:SHANGHAI UNIV OF ENG SCI

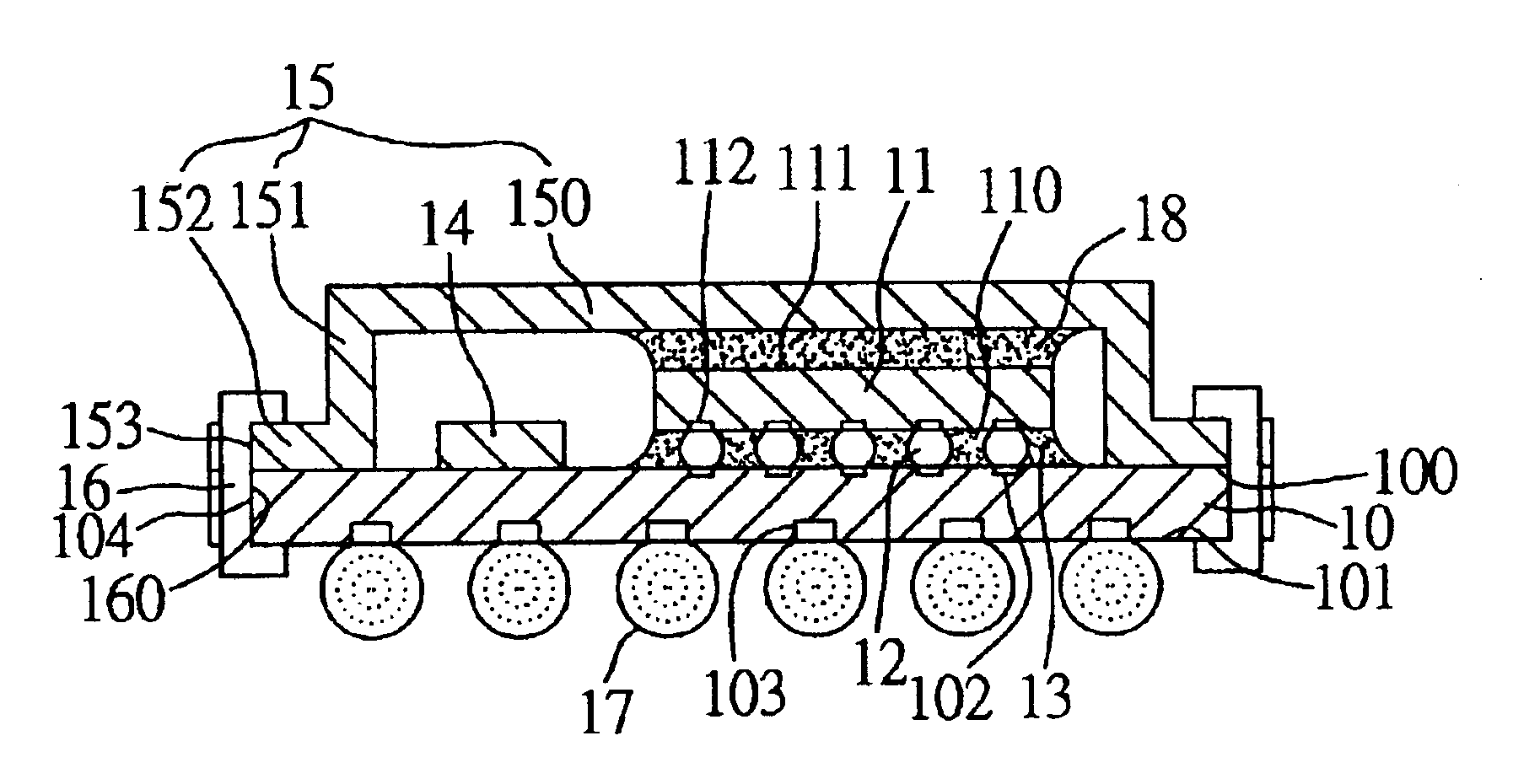

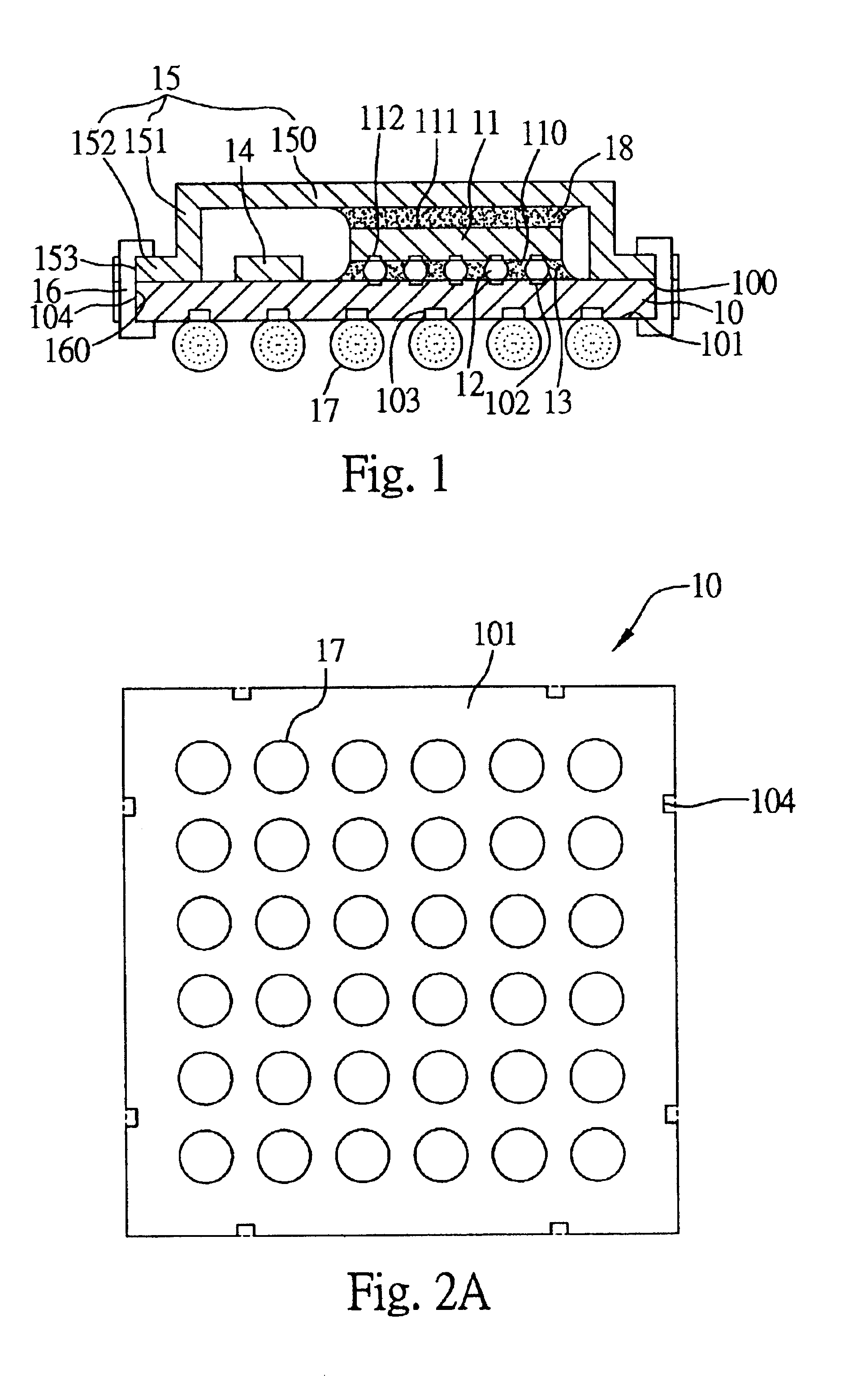

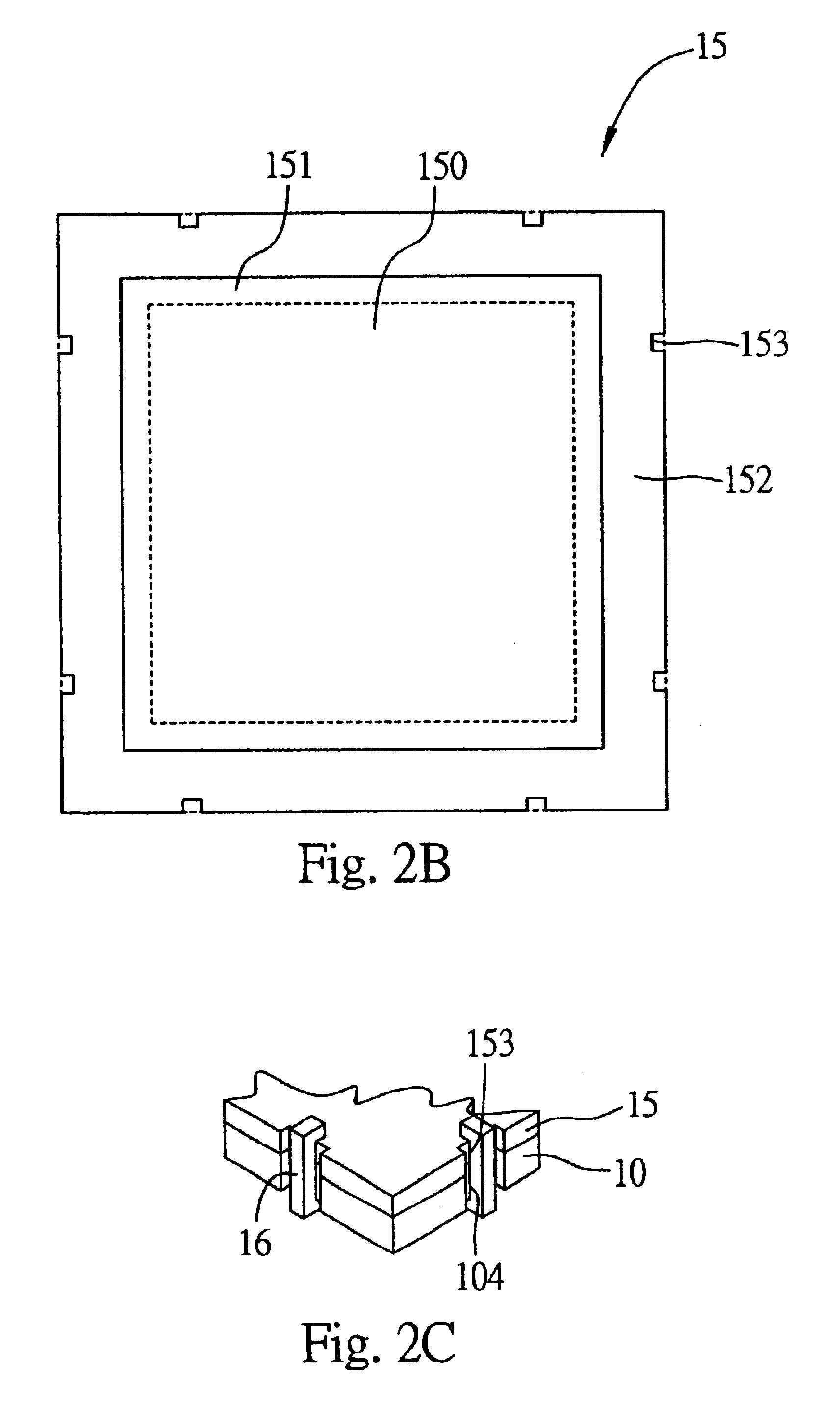

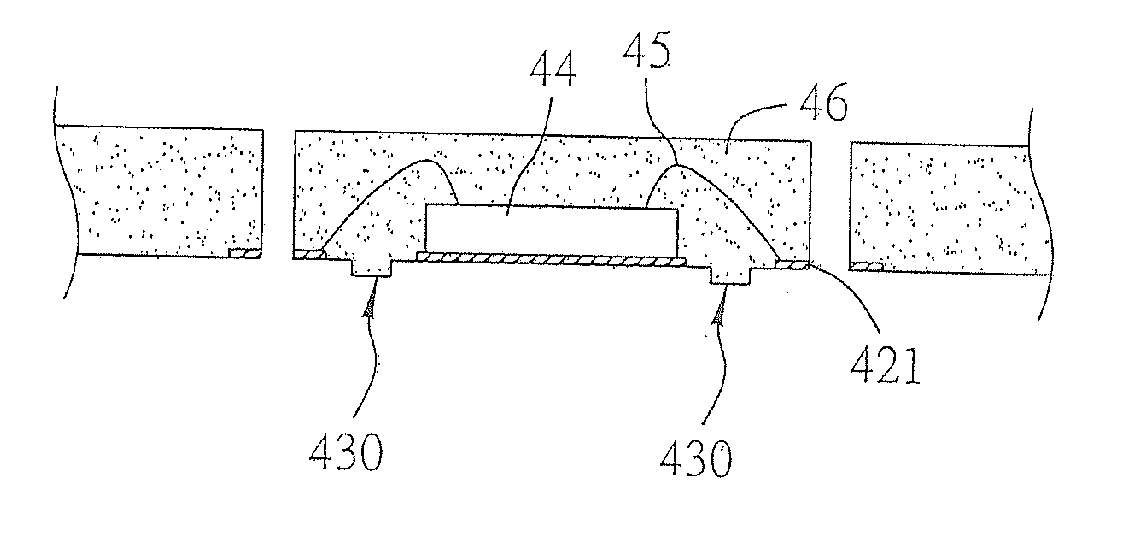

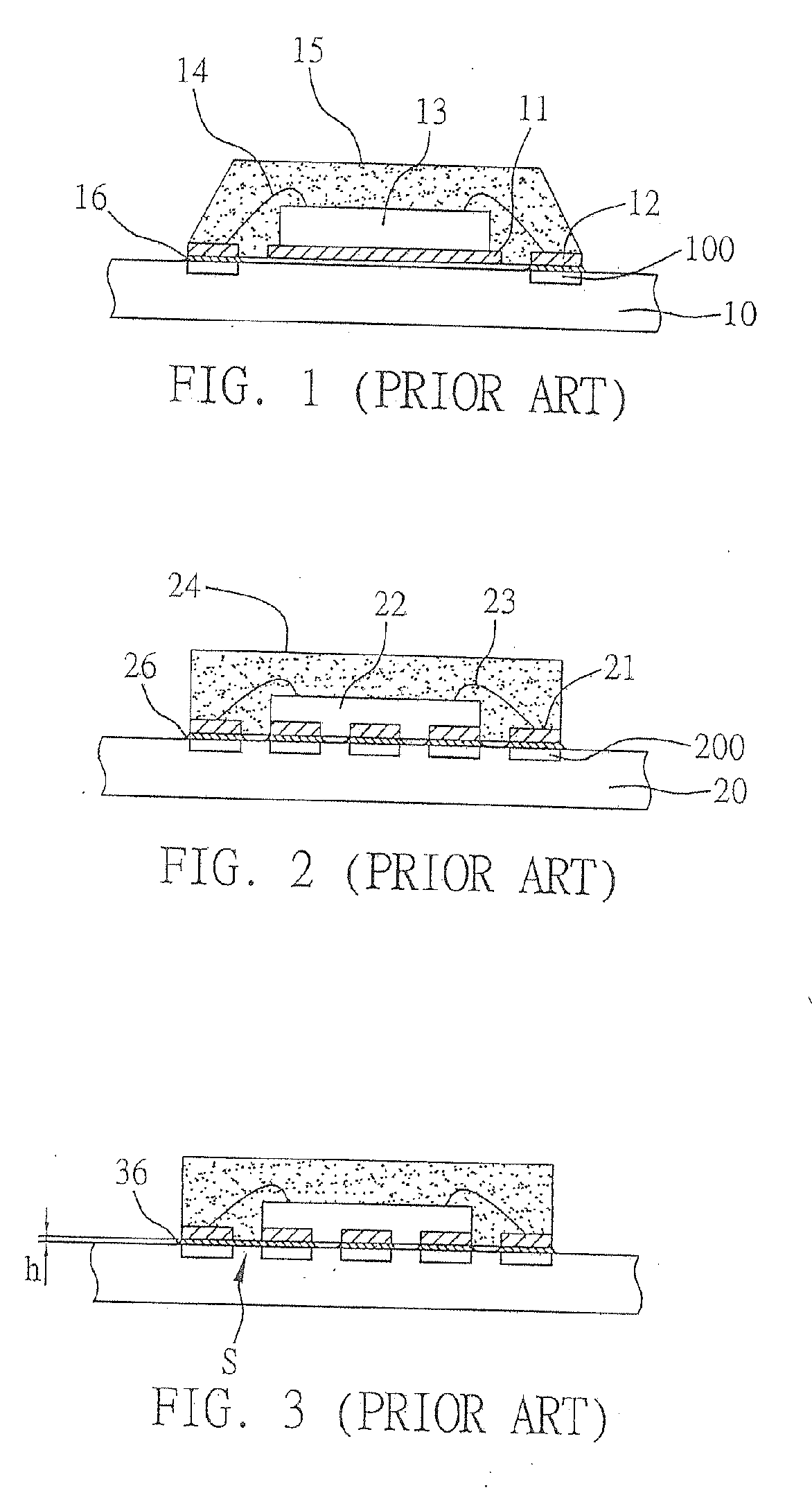

Semiconductor package with heat sink attached to substrate

InactiveUS6849942B2Avoid damageEliminates reliability issueSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageHeat sink

A semiconductor package with a heat sink is provided in which at least one chip is mounted on the substrate and covered by a heat sink. The heat sink is formed with a flange in contact with the substrate, allowing a plurality of clip members to clamp the flange of the heat sink and the substrate. Each of the clip members has a recess portion for receiving the flange of the heat sink and the substrate to thereby firmly position the heat sink on the substrate. The clip members are engaged with edges of the heat sink and the substrate, thereby not affecting trace routability on the substrate. Moreover, the heat sink is mounted on the substrate and would not be dislocated.

Owner:SILICONWARE PRECISION IND CO LTD

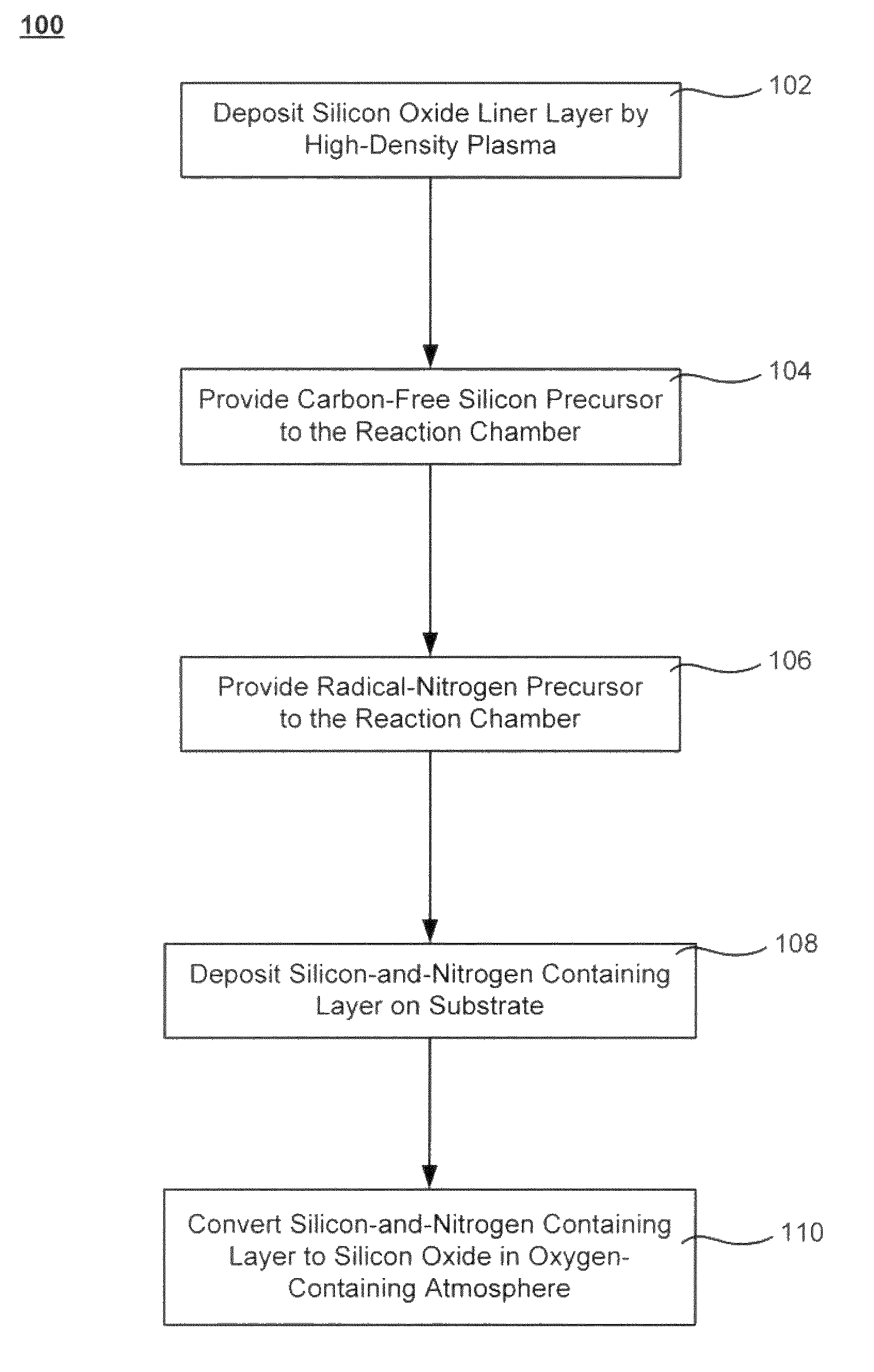

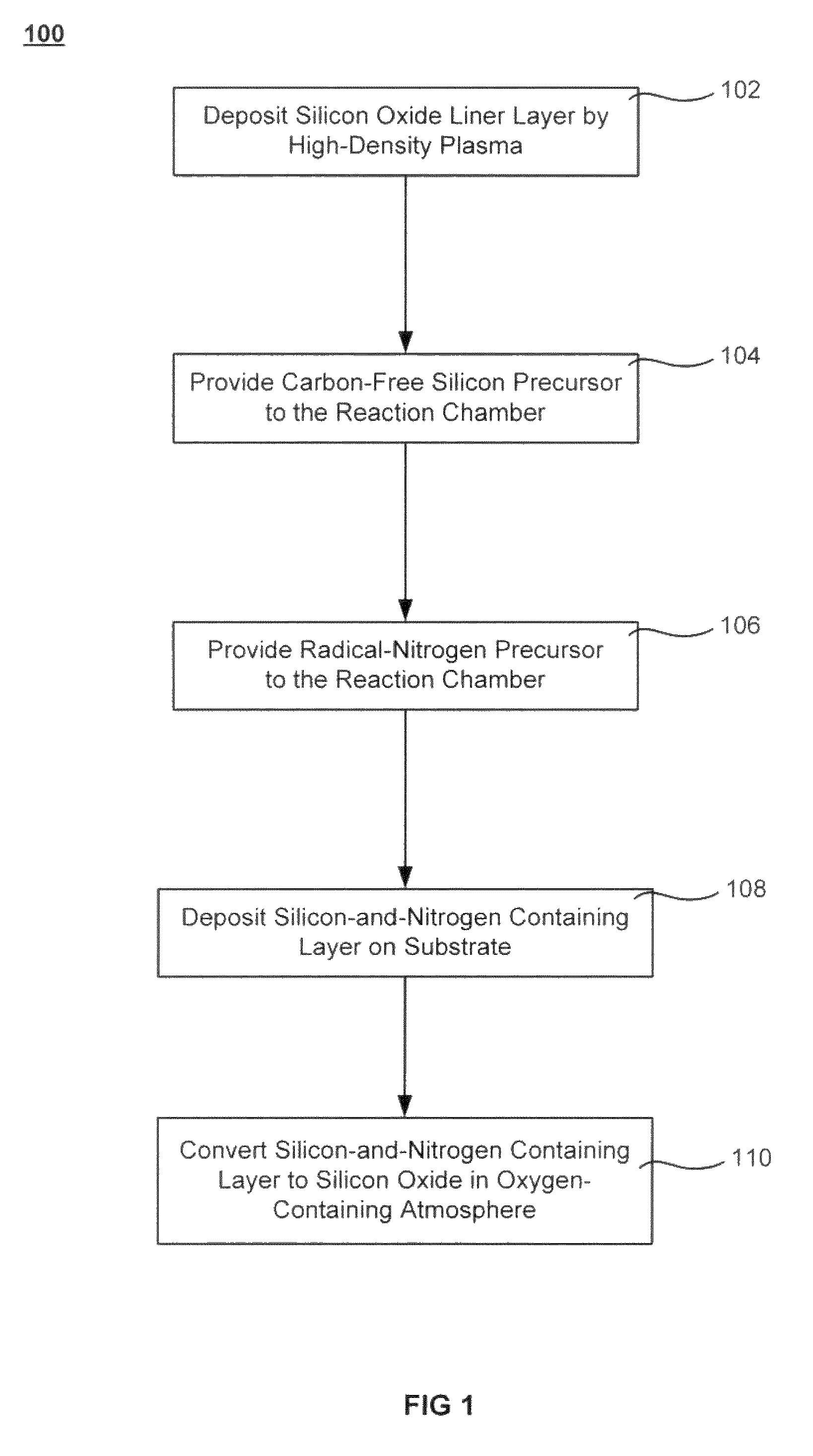

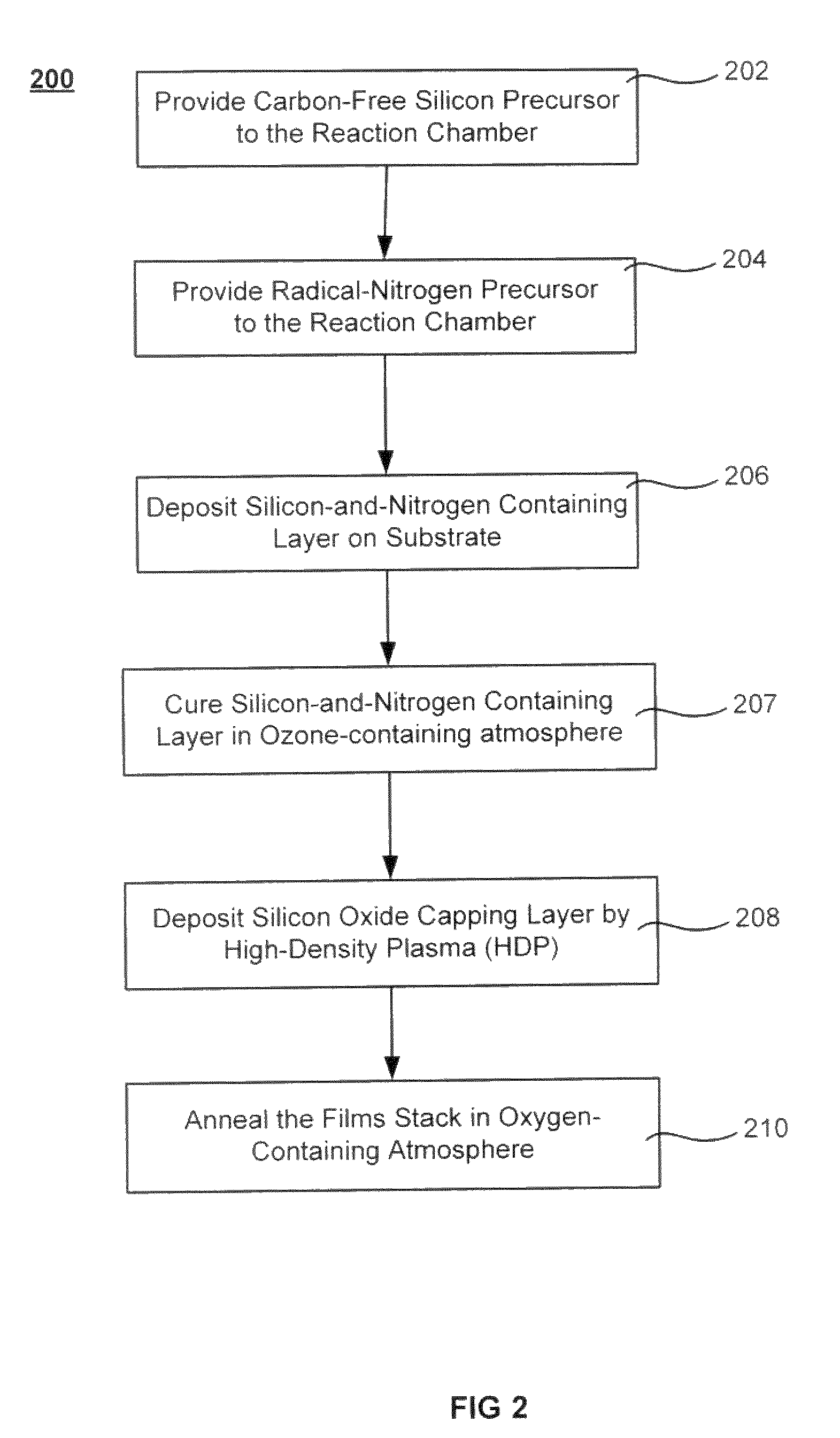

Stress management for tensile films

ActiveUS7935643B2Reduced tendency towards crackingEasy to fillSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideGap filling

The formation of a gap-filling silicon oxide layer with reduced tendency towards cracking is described. The deposition involves the formation of a flowable silicon-containing layer which facilitates the filling of trenches. Subsequent processing at high substrate temperature causes less cracking in the dielectric film than flowable films formed in accordance with methods in the prior art. A compressive liner layer deposited prior to the formation of the gap-filling silicon oxide layer is described and reduces the tendency for the subsequently deposited film to crack. A compressive capping layer deposited after a flowable silicon-containing layer has also been determined to reduce cracking. Compressive liner layers and compressive capping layers can be used alone or in combination to reduce and often eliminate cracking. Compressive capping layers in disclosed embodiments have additionally been determined to enable an underlying layer of silicon nitride to be transformed into a silicon oxide layer.

Owner:APPLIED MATERIALS INC

Silicone coating compositions and coated articles

InactiveUS20050244659A1Eliminate coat crackingImprove balanceLayered productsCoatingsCrack resistanceArame

A silicone coating composition comprising (A) a silicone resin resulting from (co)hydrolytic condensation of an alkoxysilane or a partial hydrolytic condensate thereof, (B) an aromatic-free compound for curing the silicone resin, and (C) a solvent remains stable during shelf storage. It is applied and heat cured to a plastic substrate to form a protective coat having a high hardness, mar resistance, adhesion, toughness and crack resistance.

Owner:SHIN ETSU CHEM IND CO LTD

Crack controlling means for laser deposition formed metal parts

InactiveCN1737197AImprove coagulation stateImprove liquidityMetallic material coating processesLaser beam welding apparatusClosed loop feedbackClosed loop

The invention relates to a crack-controlling method of metal parts by laser melting formation in laser material processing domain, which comprises closed-loop control of fused bath temperature, which comprises the two specific steps of exerting closed-loop feedback control on fused bath temperature by using optical imaging system and PID control device with calorific radiation transmitted from melting zone and adjusting horsepower of laser, and introduction of ultrasonic vibration, which comprises the specific steps of introducing ultrasonic vibration under the piece of work when forming by laser melting. The invention can deduce residual stress and crack, improve structure and can be used in multiple relative domains such as forming, manding and surface peening by laser melting.

Owner:SHANGHAI JIAO TONG UNIV

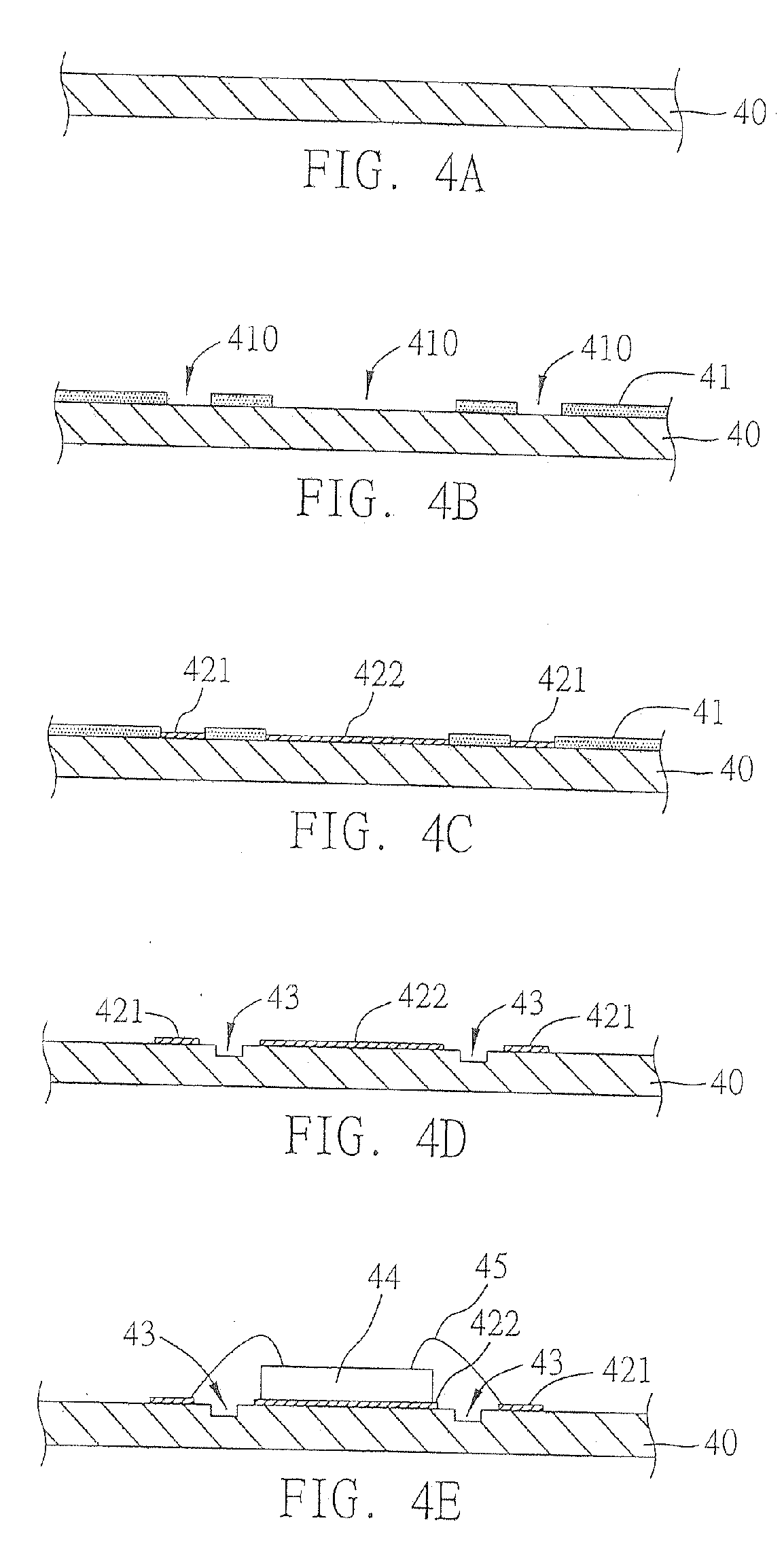

Semiconductor package with a support structure and fabrication method thereof

ActiveUS20070059865A1High thermal stressLow heightSemiconductor/solid-state device detailsSolid-state devicesEngineeringSealant

A semiconductor package with a support structure and a fabrication method thereof are provided. With a chip being electrically connected to electrical contacts formed on a carrier, a molding process is performed. A plurality of recessed portions formed on the carrier are filled with an encapsulant for encapsulating the chip during the molding process. After the carrier is removed, the part of the encapsulant filling the recessed portions forms outwardly protruded portions on a surface of the encapsulant, such that the semiconductor package can be attached to an external device via the protruded portions.

Owner:SILICONWARE PRECISION IND CO LTD

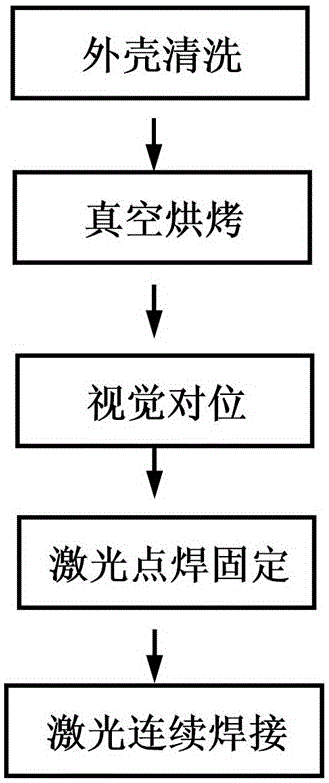

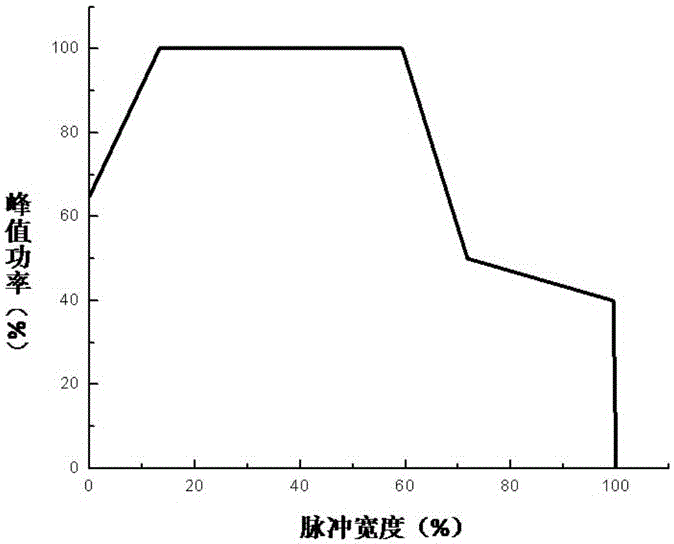

Laser seal welding technique for 3A21 aluminum alloy casing

ActiveCN105081573ASmall heat affected zoneSmall thermal deformationWelding/soldering/cutting articlesMetal working apparatusWeld seamSpot welding

The invention discloses a laser seal welding technique for a 3A21 aluminum alloy casing. The laser seal welding technique comprises the following steps of visual alignment, laser spot welding location and laser seal welding. The technological parameters of the laser seal welding are that the laser pulse peak power is 3000W-3500W, the impulse waveform is preheating thermal-insulation wave, the pulse width is 4ms-8ms, the pulse repetition frequency is 10Hz-20Hz, the welding speed is 108mm / min-180mm / min, and the defocusing amount is -1mm to -2mm. The laser seal welding technique for the 3A21 aluminum alloy casing can effectively remove cracks and air holes on welding seams of laser welding of the 3A21 aluminum alloy casing. The sealed 3A21 aluminum alloy casing has the beneficial effects of being attractive in welding seam appearance, high in air tightness, high in reliability, high in efficiency and low in cost.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

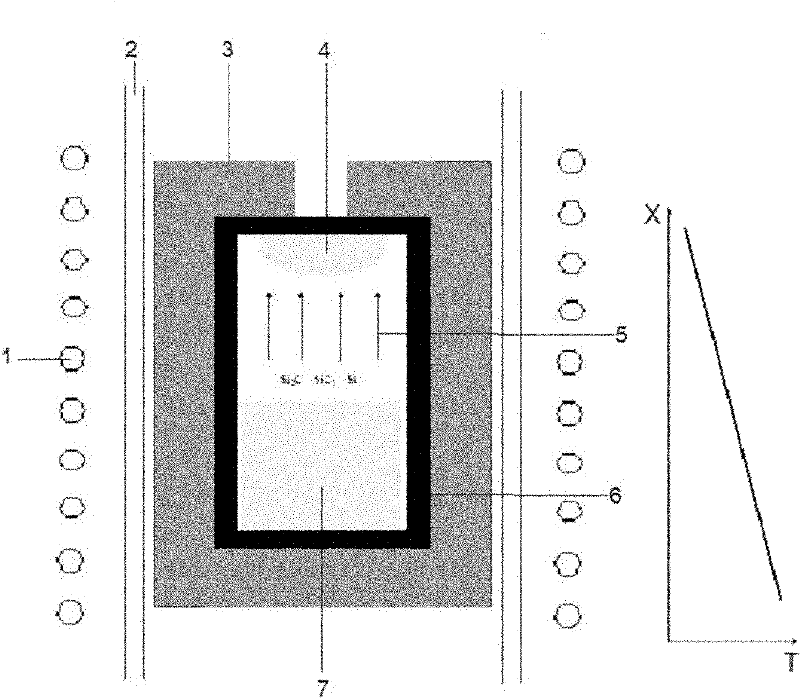

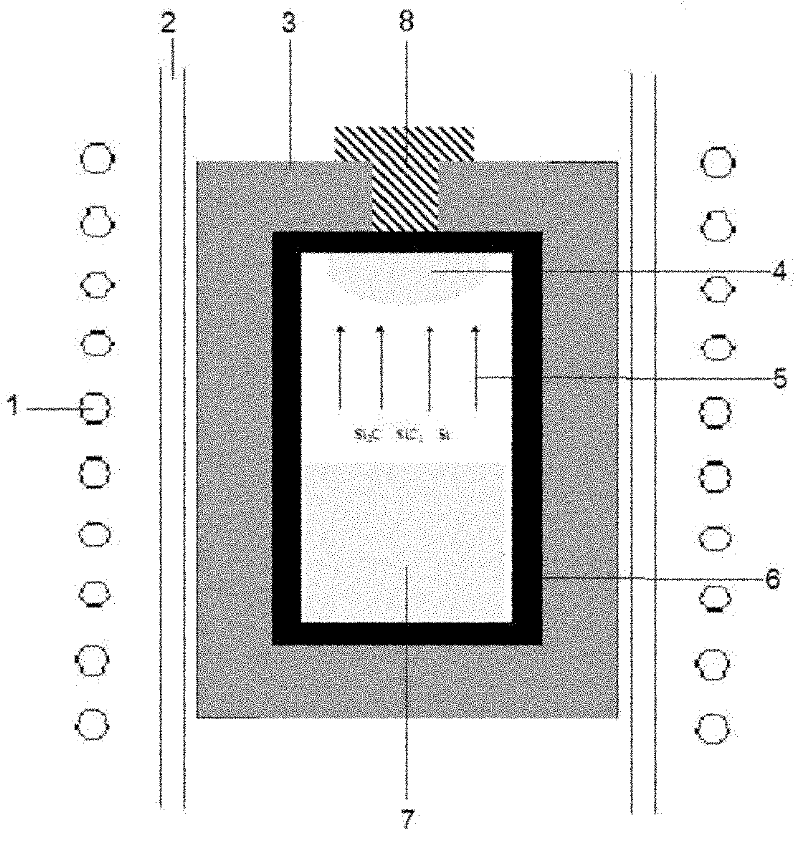

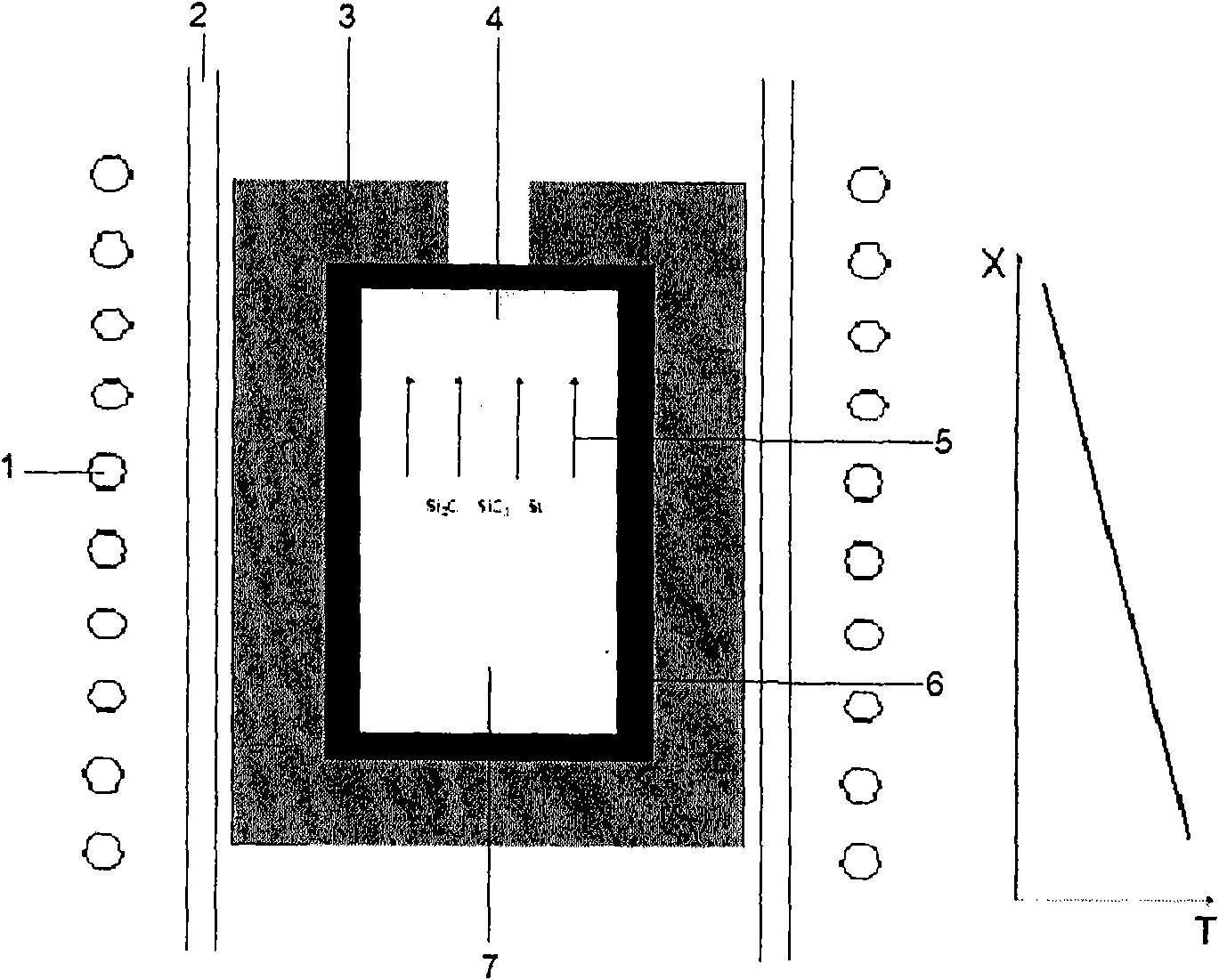

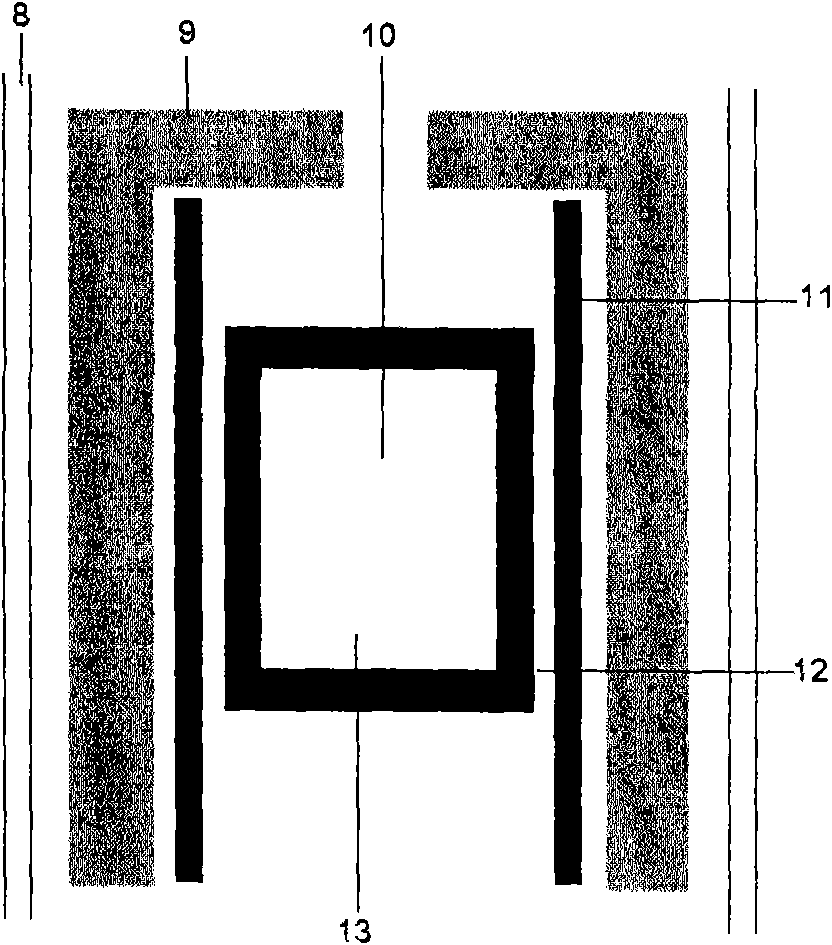

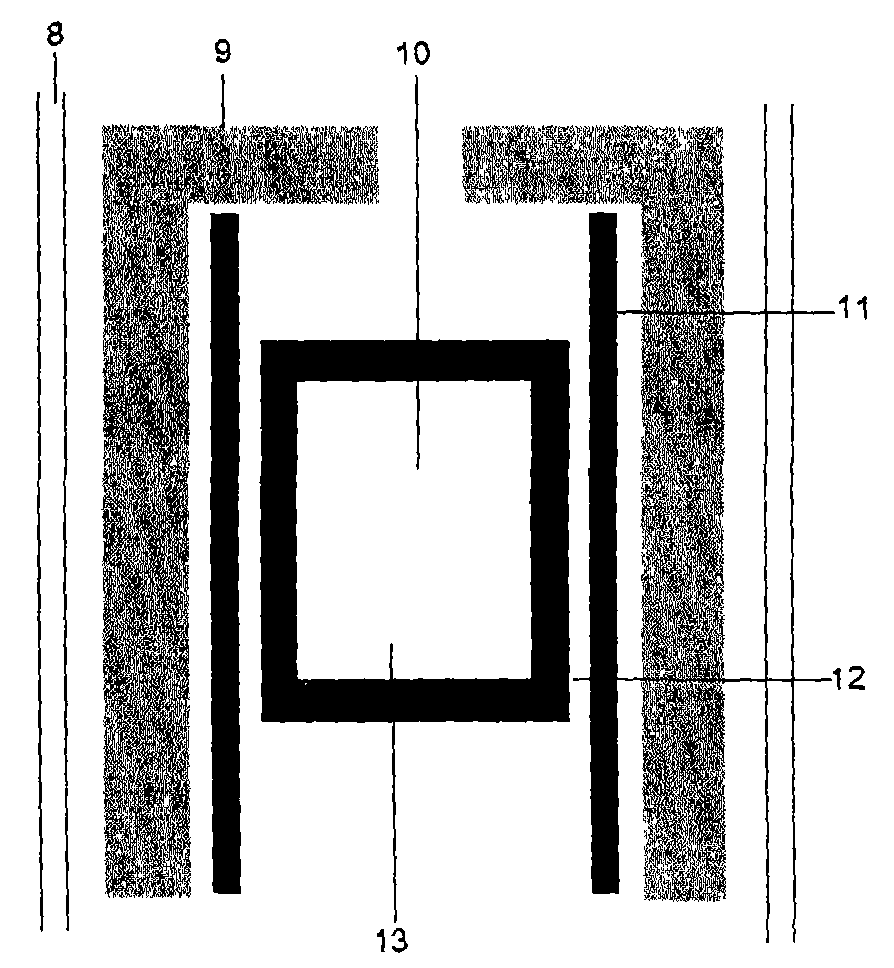

Silicon carbide crystal annealing process

ActiveCN102534805AReduce stressReduce temperature gradientPolycrystalline material growthAfter-treatment detailsCrystal growthTemperature gradient

The invention is mainly applied to the field of treatment after silicon carbide crystal growth completion and particularly relates to a silicon carbide crystal annealing process which is specifically characterized by reducing the temperature gradient (the temperature gradient of the crystals is 1-10 DEG C / cm), spending 1-5 hours in raising the temperature to the annealing temperature under the inert gases with pressure of above 0.01-0.08MPa and then spending 10-50 hours in reducing the temperature after keeping the constant temperature for 10-40 hours, wherein the annealing temperature is 2300-2500 DEG C. By adopting the annealing process, the stress between the crystals and a crucible cover and the stress inside the silicon carbide crystals are reduced, thus reducing the damage rate of the silicon carbide crystals in the follow-up processing course and improving the yield of the silicon carbide crystals.

Owner:BEIJING TIANKE HEDA SEMICON CO LTD

Linear low-density polyethylene composition

ActiveCN102477180AUniform viscosityEliminate cracksLow-density polyethyleneLinear low-density polyethylene

The invention relates to a linear low-density polyethylene composition comprising components of, by weight: 50-98 parts of linear low-density polyethylene with a density of 0.918-0.922g / cm<3> and a melt flow index of 0.1-10g / 10min, 0.5-45 parts of low-density polyethylene with a density of 0.910-0.925g / cm<3> and a melt flow index of 0.1-30g / 10min, 0.5-45 parts of high-density polyethylene with a density of 0.941-0.970g / cm<3> and a melt flow index of 0.5-10g / 10min, 0.5-45 parts of polypropylene with a density of 0.830-0.910g / cm<3> and a melt flow index of 0.5-50g / 10min, 0.1-20 parts of an ethylene-vinyl acetate copolymer with a density of 0.926-0.939g / cm<3>, 0.01-1 part of a rheology modifying agent, and 0.5-20 parts of a compatibilizing agent with a melt flow index of 0.5-50g / 10min. With the composition, extrusion processing performance can be effectively improved, a melt fracture phenomenon can be eliminated, and the compatibility can be improved. With the composition, the strength, flexibility and aging resistance of a product can be improved. The composition can be used for producing films, drip irrigation tapes, and pipes with various specifications.

Owner:XINJIANG TIANYE WATER SAVING IRRIGATION SYST

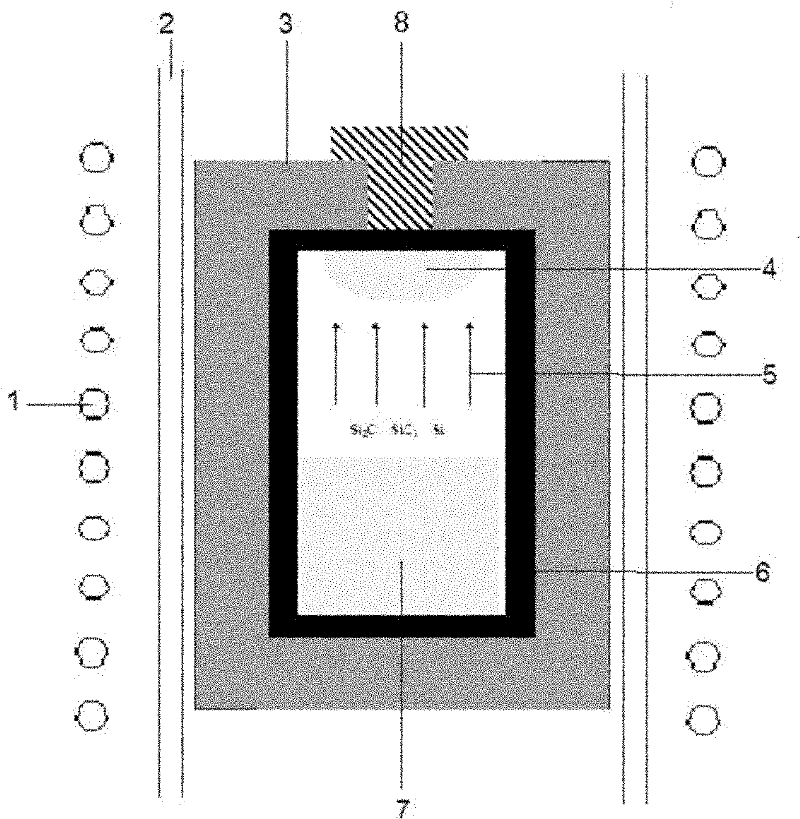

Annealing process for reducing stress of silicon carbide crystals

The invention is mainly applied in the retreatment field of the grown silicon carbide crystals. The annealing process specifically comprises the following steps: heating for 10-50 hours to an annealing temperature in an annealing furnace with good tightness and small temperature gradient (the temperature gradient of the surrounding of the crystals is 1-20 DEG C / cm) under the protection of an inert gas with the pressure of more than 10000Pa, keeping the temperature for 10-40 hours, and reducing the temperature for 10-50 hours, wherein the annealing temperature is 2100-2500 DEG C. Through the double annealing, the stress between the crystals and the crucible cover and the internal stress of the silicon carbide crystals are reduced, thus the breakage rate of the silicon carbide crystals is reduced in the subsequent processing step and the yield of the silicon carbide crystals is increased.

Owner:XINJIANG TANKEBLUE SEMICON +1

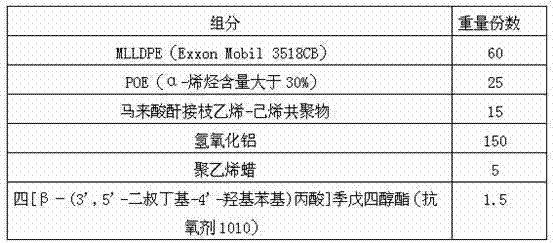

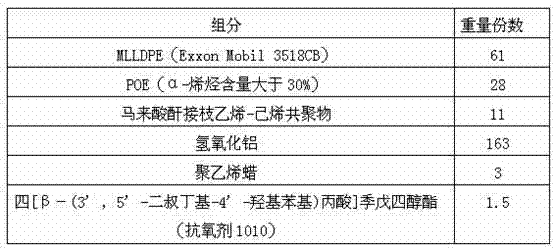

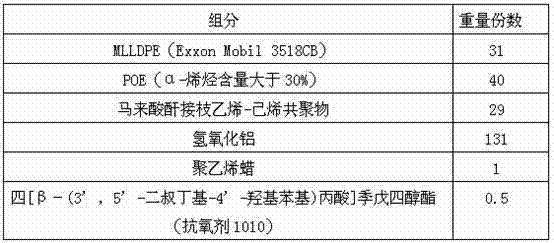

Low-temperature resistant and oil resistant low-smoke halogen-free flame retardant polyolefin cable material and preparation method thereof

ActiveCN103044761AEliminate cracksSlow down the rate of swellingPlastic/resin/waxes insulatorsInsulated cablesPelletizingPolyolefin

The invention relates to a cable material and discloses a low-temperature resistant and oil resistant low-smoke halogen-free flame retardant polyolefin cable material and a preparation method thereof. The prescription of the cable material consists of MLLDPE (metallocene polyethylene), POE (polyolefin elastomer), interfacial compatibilizer, aluminium hydroxide, antioxygen and lubricant. The preparation method comprises the following steps: extruding and pelleting MLLDPE and POE base materials, interfacial compatibilizer, aluminium hydroxide, antioxygen and lubricant in a temperature zone at 110-160 DEG C via a double screw, and then packaging to instantly obtain a low-temperature resistant and oil resistant low-smoke halogen-free flame retardant polyolefin cable material finished product. Compared with the common low-smoke halogen-free flame retardant polyolefin cable material, the material provided by the invention has the advantages that the oil-resistant property is enhanced, the low-temperature resistant property of the product is greatly enhanced and the cracking problem of the low-smoke halogen-free flame retardant polyolefin cable material under low temperature is eliminated.

Owner:JIANGSU LINRY NEW MSTAR TECH

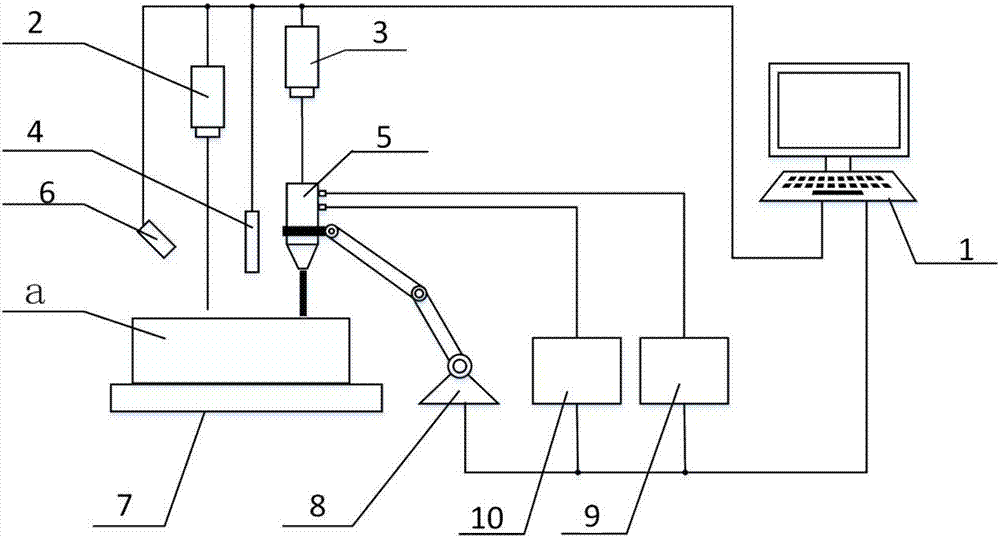

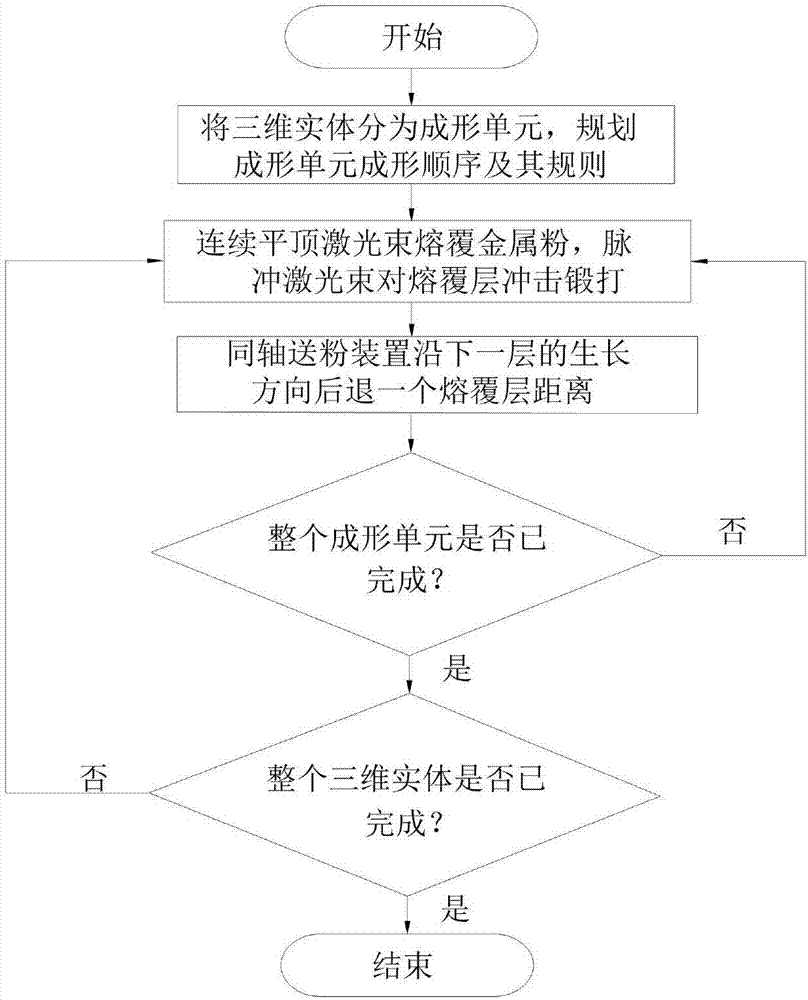

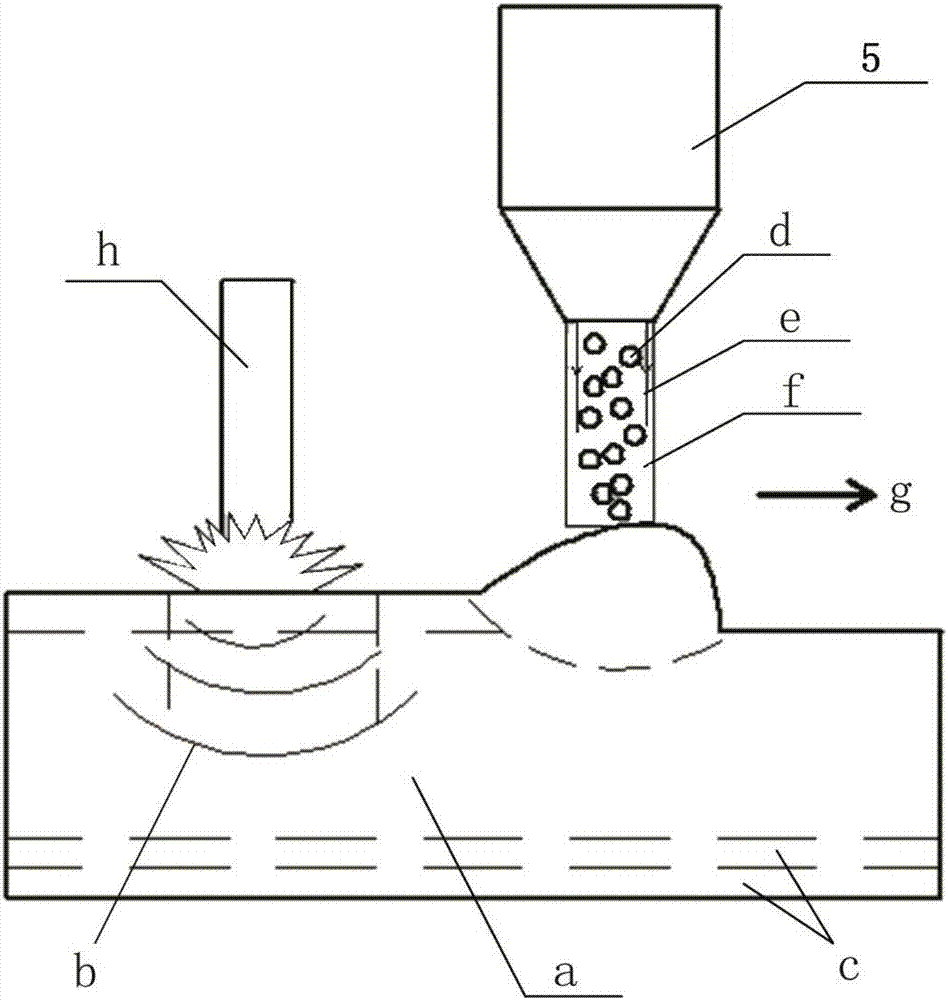

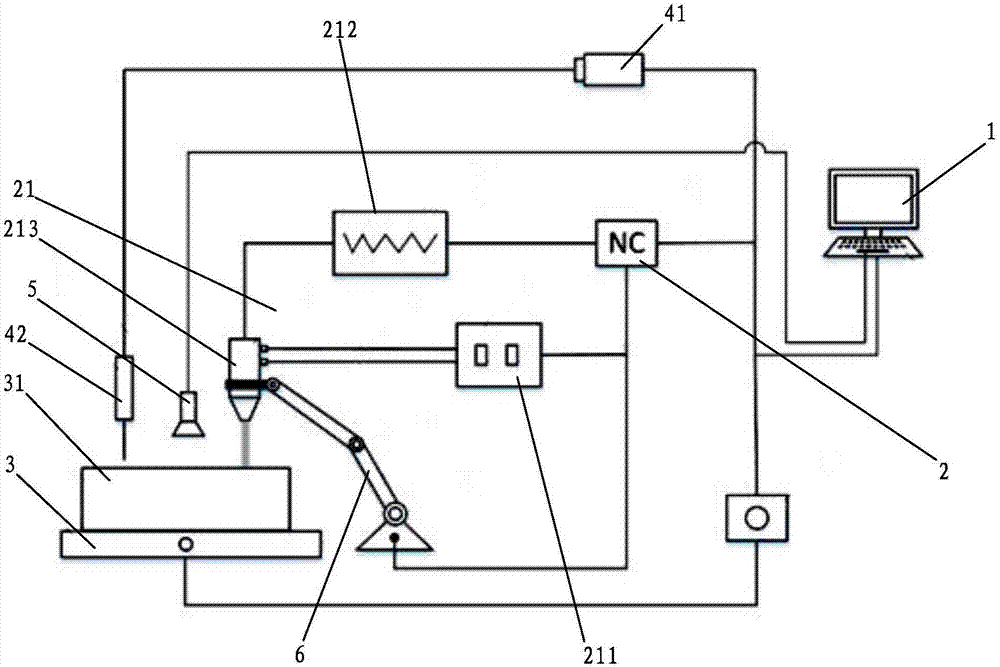

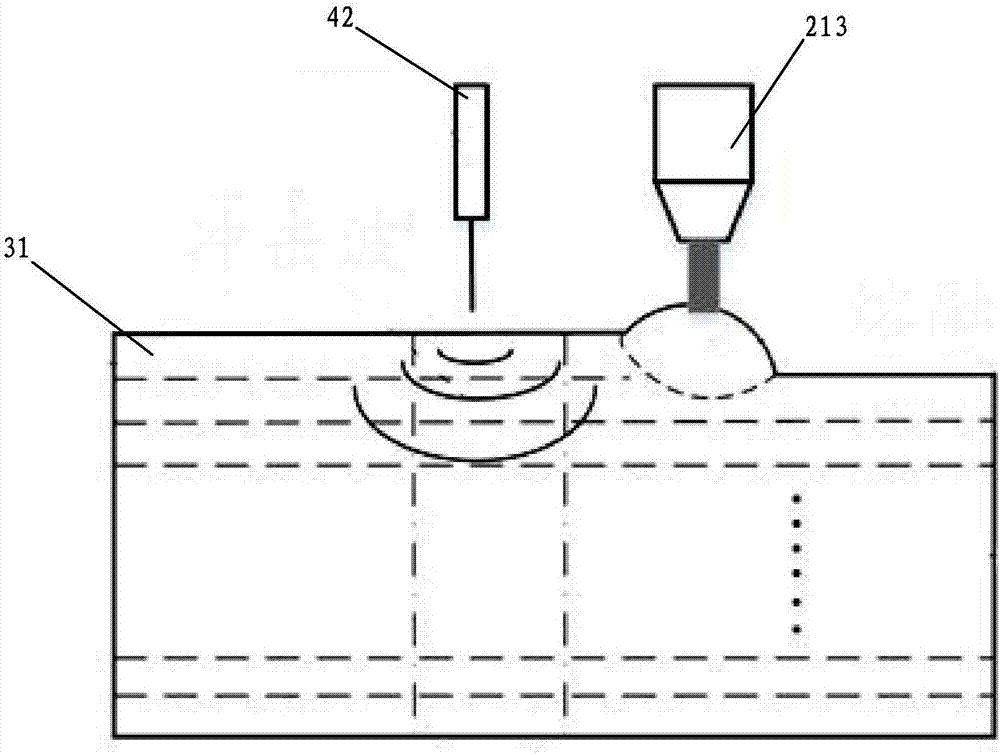

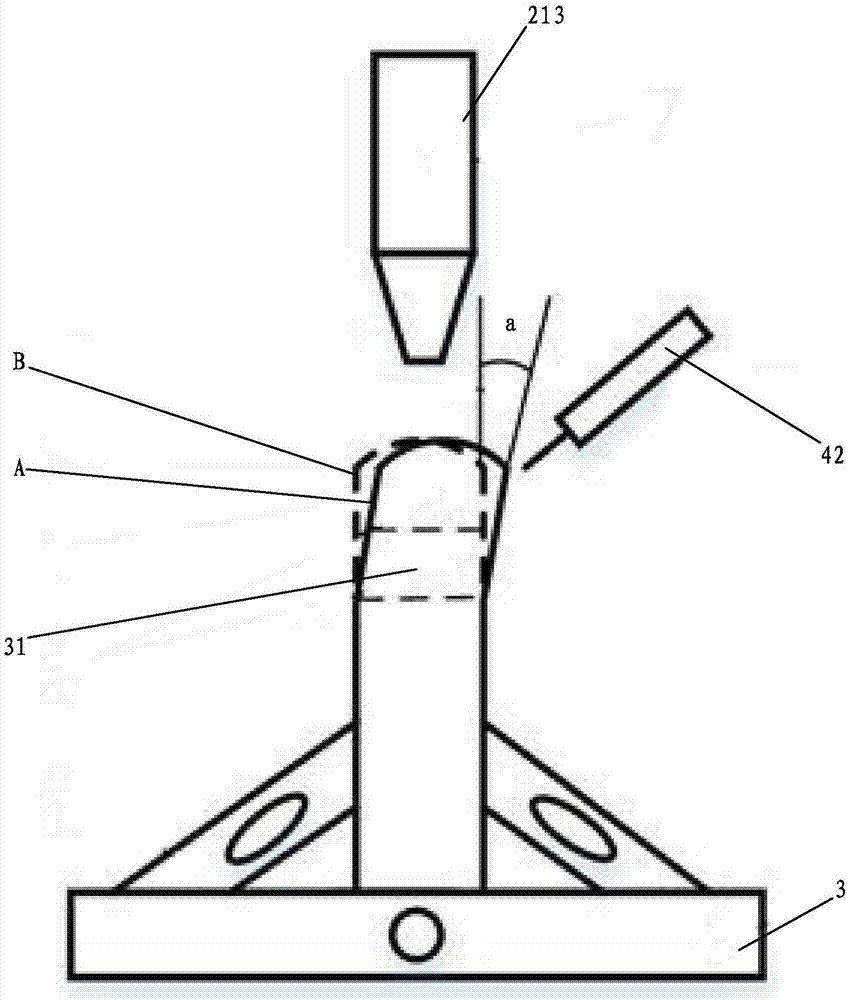

Inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method

ActiveCN107262713ASolve undermeltSolve the problem of impenetrabilityAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsInductor

The invention relates to an inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method. The device comprises a master controller, a pulse laser device, a continuous laser device, a temperature inductor, a coaxial powder feeding device, a visual tracking system, a workbench, a mechanical arm, a metal powder container and a gas container. The pulse laser device, the continuous laser device, the temperature inductor and the visual tracking system are all arranged above the workbench. The mechanical arm tightly clamps the coaxial powder feeding device, so that the coaxial powder feeding device is located between the continuous laser device and the workbench, and is coaxial with the continuous laser device. The coaxial powder feeding device communicates with the metal powder container and the gas container. The pulse laser device, the continuous laser device, the temperature inductor, the visual tracking system, the mechanical arm, the metal powder container and the gas container are all connected with the master controller. The inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method can solve the problems of insufficient fusion and incomplete fusion of the Gaussian light spot edges, inner defects of gas holes, incomplete fusion, cracks and shrinkage are effectively eliminated, and the inner stress state of a formed part is greatly improved.

Owner:GUANGDONG UNIV OF TECH

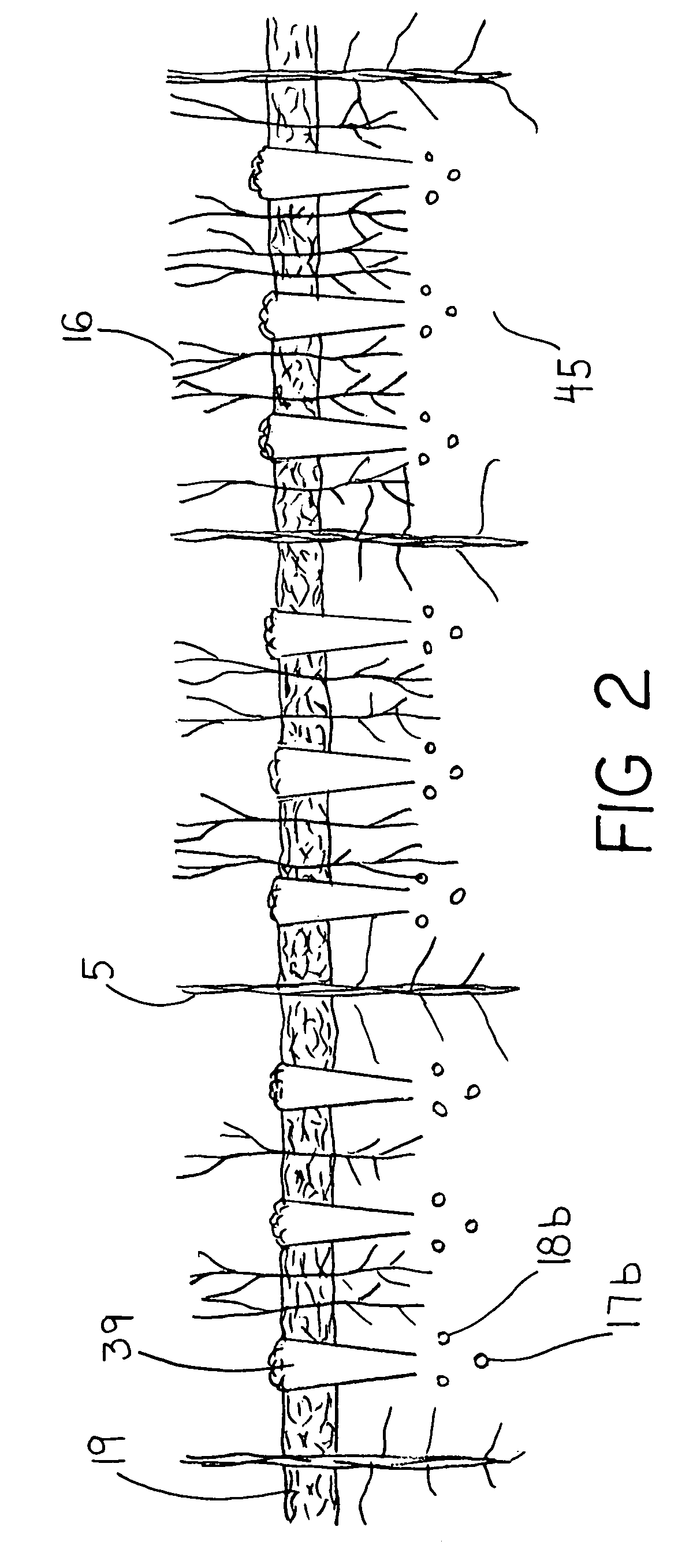

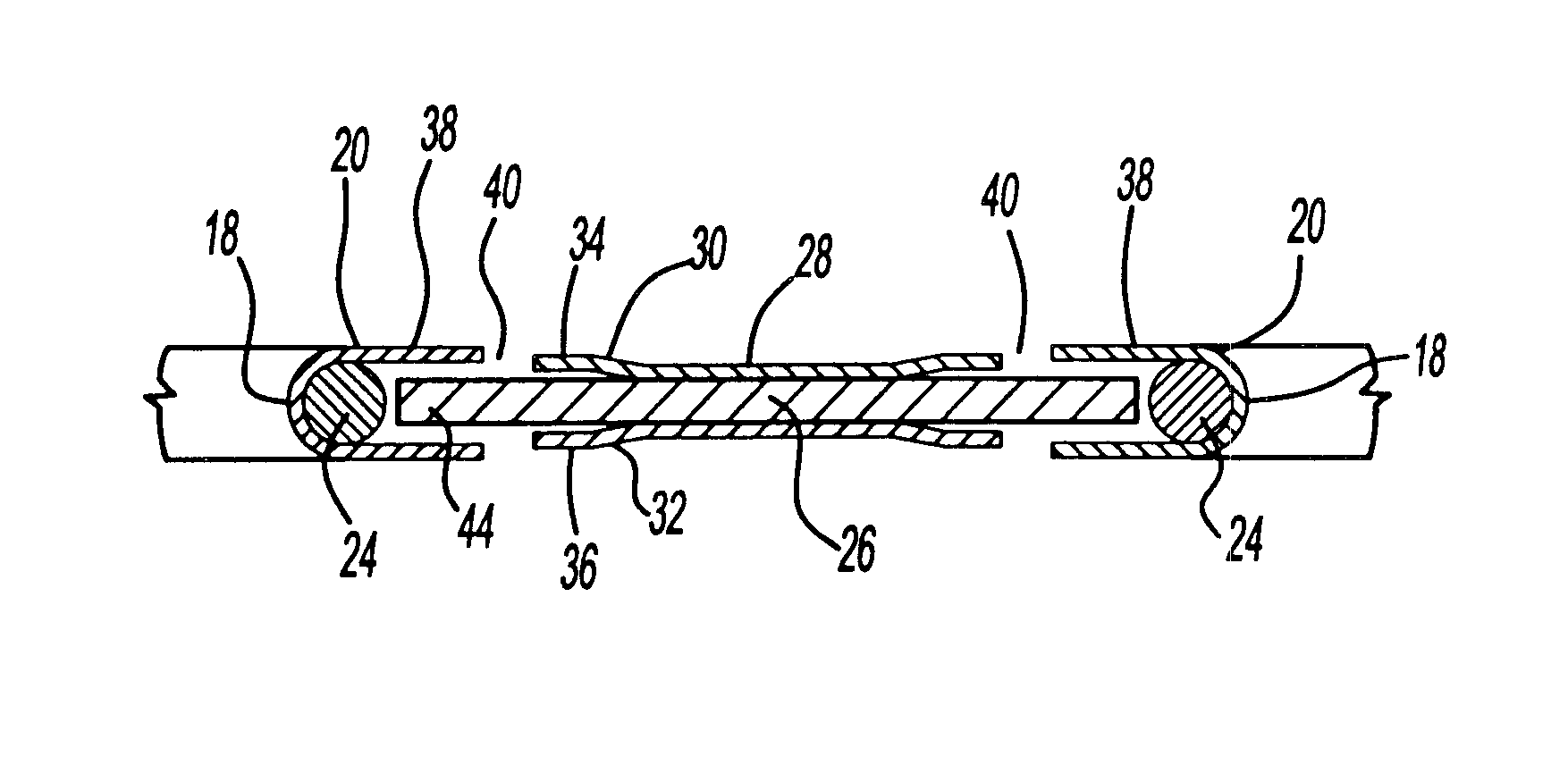

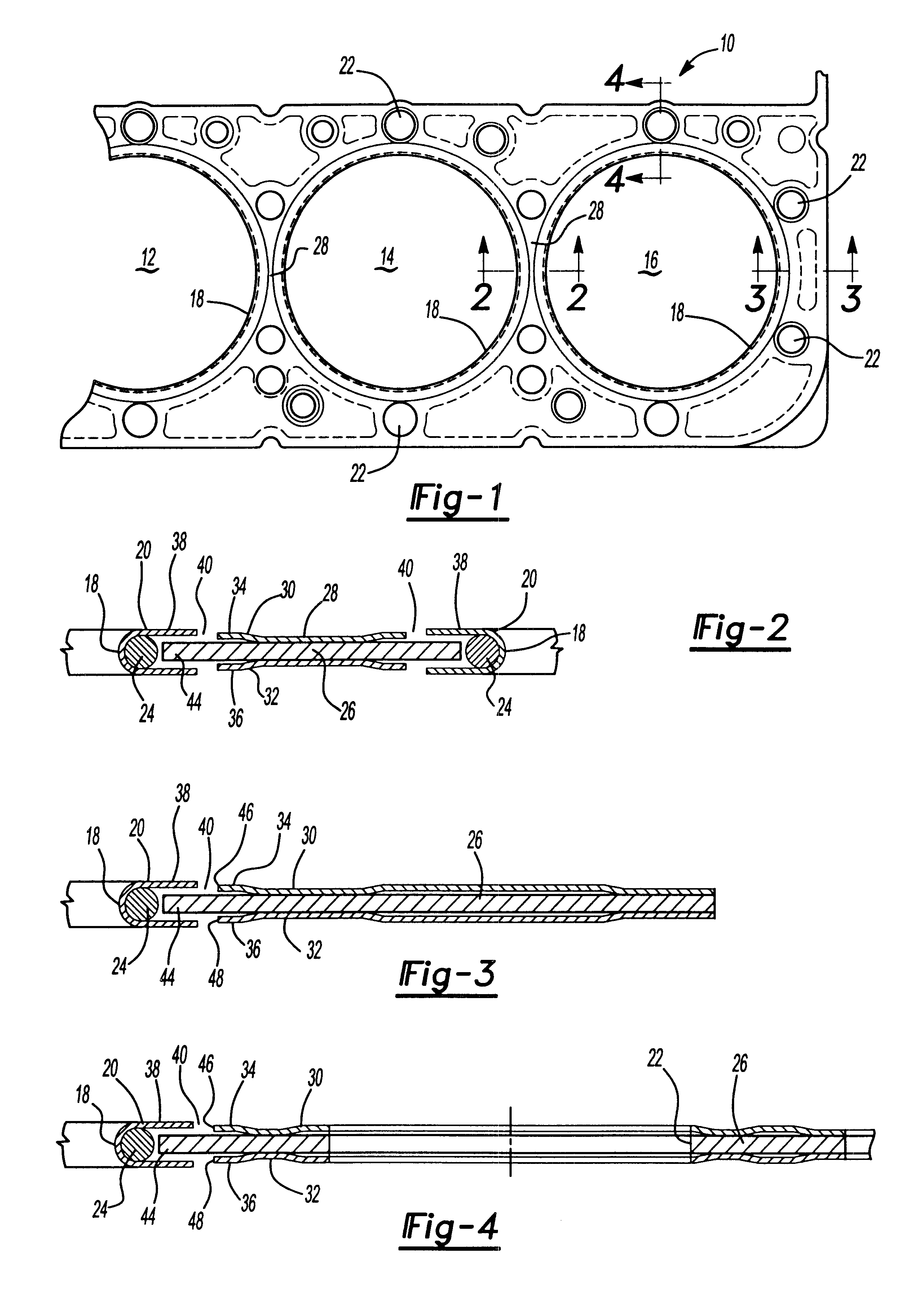

MLS gasket with wire ring stopper

InactiveUS6676134B1Eliminate bead crackingImprove consistencyEngine sealsSealing arrangements for enginesCombustionPre stress

A multi-layer steel cylinder head gasket includes a spacer layer between two beaded mirror image outer layers. A wire ring stopper extends about the boundary of a combustion opening in the stopper layer; the ring is radially spaced from the mirror image beaded outer layer extremities. The ring is covered by a flange folded thereover; the flange extends radially outwardly to overlie the boundary edge of the stopper layer at the combustion opening. The stopper ring pre-stresses the gasket interface at the combustion opening upon securement of a cylinder head to an engine block. Because the stopper ring is spaced from the beaded outer layers, the stresses imposed on the wire ring are decoupled from the beaded outer layers, and lower incidences of bead cracking are realized. In addition, the wire ring diameter is greater than the thickness of the stopper layer, reducing unnecessary compression loads on the stopper layer.

Owner:DANA AUTOMOTIVE SYST GRP LLC

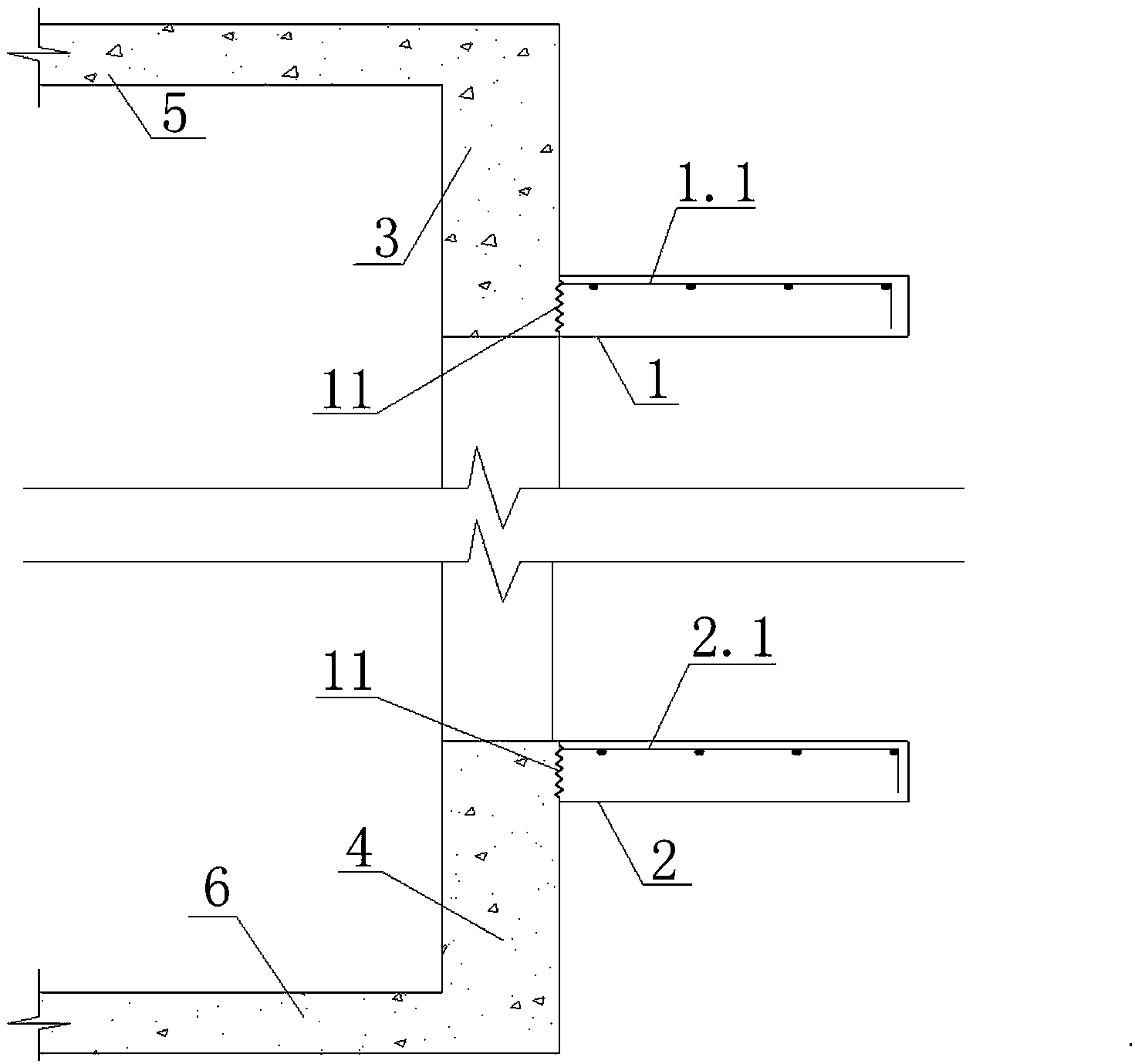

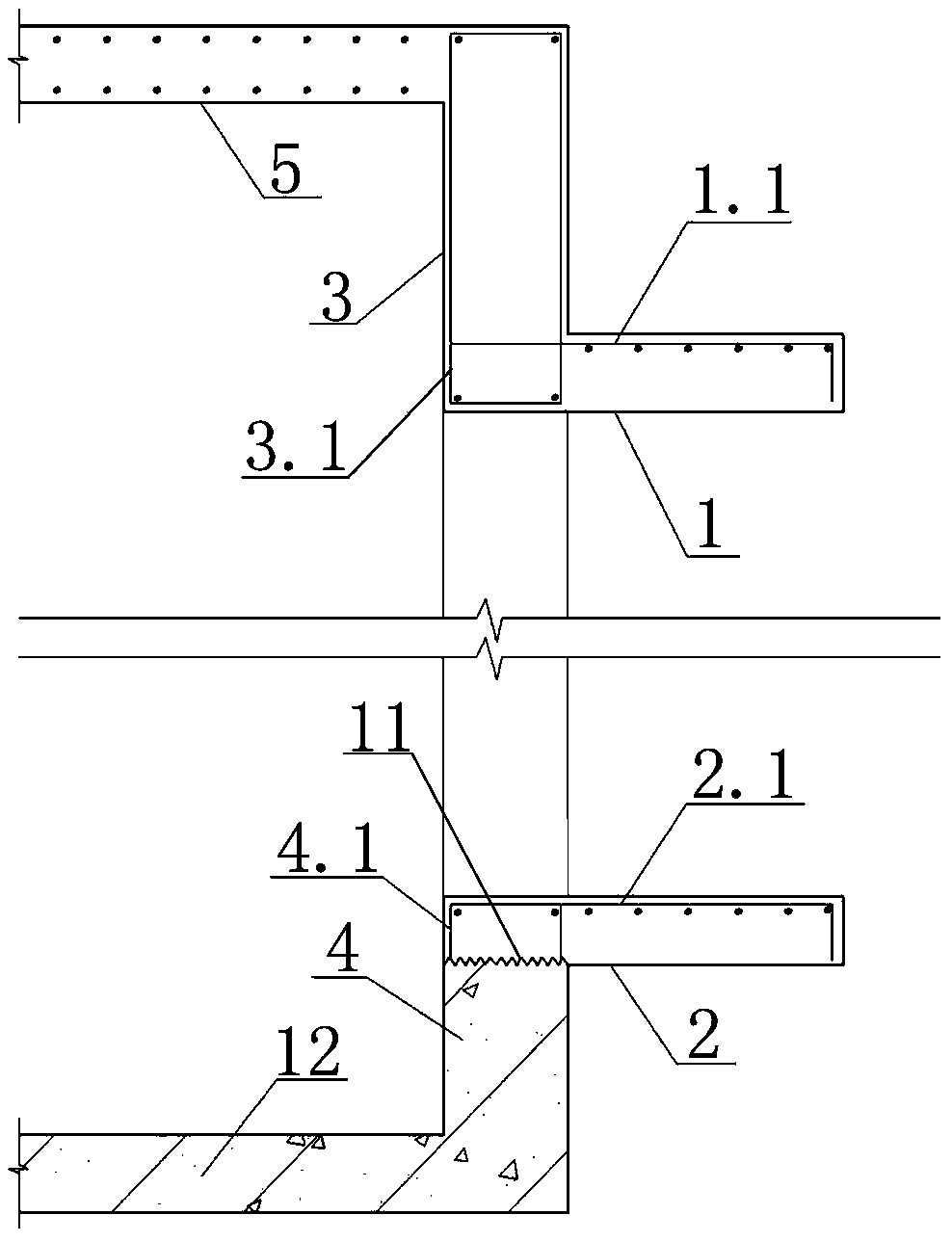

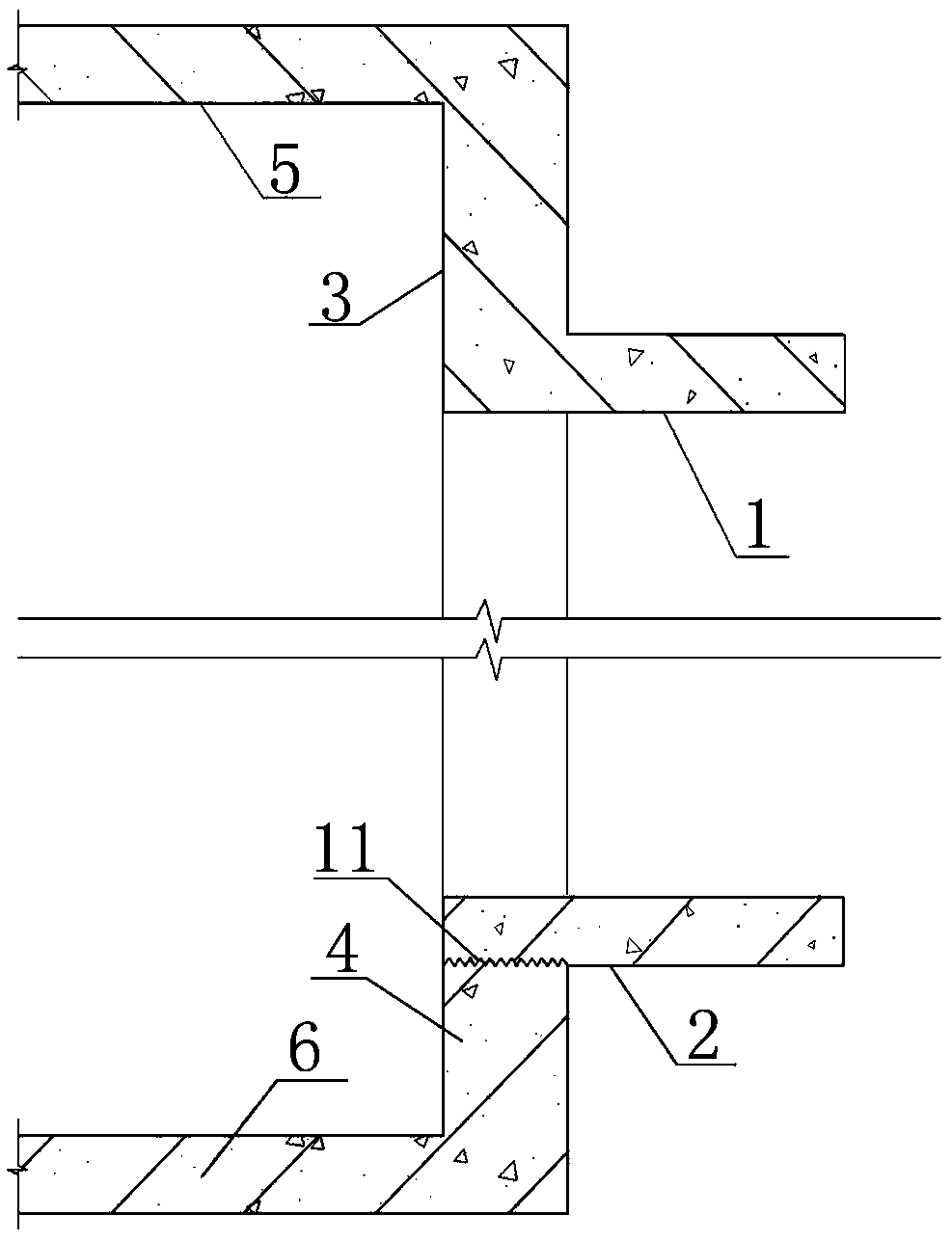

Cantilever bay window board concrete overall pouring structure and construction method thereof

The invention provides a cantilever bay window board concrete overall pouring structure and a construction method of the cantilever bay window board concrete overall pouring structure. An upper bay window board is formed together with an above-window coupling beam and an upper layer floor through concrete overall pouring, and the inner end of an upper bay window board reinforcing steel bar of the upper bay window board extends into the above-window coupling beam to be anchored. A lower bay window board is formed together with the upper portion of a below-window coupling beam through concrete overall pouring, and the inner end of a lower bay window board reinforcing steel bar of the lower bay window board extends into the below-window coupling beam to be anchored. According to the cantilever bay window board concrete overall pouring structure and the construction method, the positions of the bay window boards are reserved in the construction process of a concrete wall, the upper bay window board and the above-window coupling beam are simultaneously formed together with the upper layer floor through pouring, the lower bay window board and the upper portion of the below-window coupling beam are simultaneously formed through pouring, the integrity is good, cracks of the root portions of the bay window boards are effectively eliminated, leakage and potential safety hazards caused by the cracks are effectively eliminated, later-period maintenance and processing expenses of a bay window are reduced, and the cantilever bay window board concrete overall pouring structure and the construction method can be widely applied to non-floor type bay window construction of a cast-in-place concrete shear wall structure house.

Owner:BEIJING URBAN CONSTR SIXTH GRP

Rapid electric arc fused deposition and laser shock forging combined part forming method and device

ActiveCN107262930AGrain refinementGuaranteed forming qualityAdditive manufacturing apparatusArc welding apparatusNumerical controlEngineering

Owner:GUANGDONG UNIV OF TECH

Welding method of high-nickel alloy and stainless steel dissimilar metal

InactiveCN101508053AMeet performance requirementsImprove welding efficiencyArc welding apparatusWelding/cutting media/materialsImpulse frequencyAustenite

The invention discloses a dissimilar intermetallic welding method for high nickel alloy and stainless steel, which adopts pulsed tungsten argon arc welding, and welding technological parameters comprise that: the background current is between 20 and 50A, the impulse current is between 28 and 60A, the impulse duration is between 5 and 10s, the impulse frequency is between 35 and 75Hz, the welding voltage is between 8 and 12V, the welding speed is between 1.0 and 2.6mm / s, the inert gas flow rate is between 5 and 12L / min, the distance between a nozzle of a welding torch and a workpiece is between 5 and 10mm, and the included angle between a tungsten electrode of the welding torch and a weldment is between 70 and 85DEG. The method adopted has the advantages of high welding efficiency, low cost and convenient and flexible operation, can obtain welding joints without defects of cracks, pores and the like, and can meet the use requirement of a heterogenous composite structure of high nickel casting alloy and austenitic stainless steel.

Owner:SHANDONG UNIV

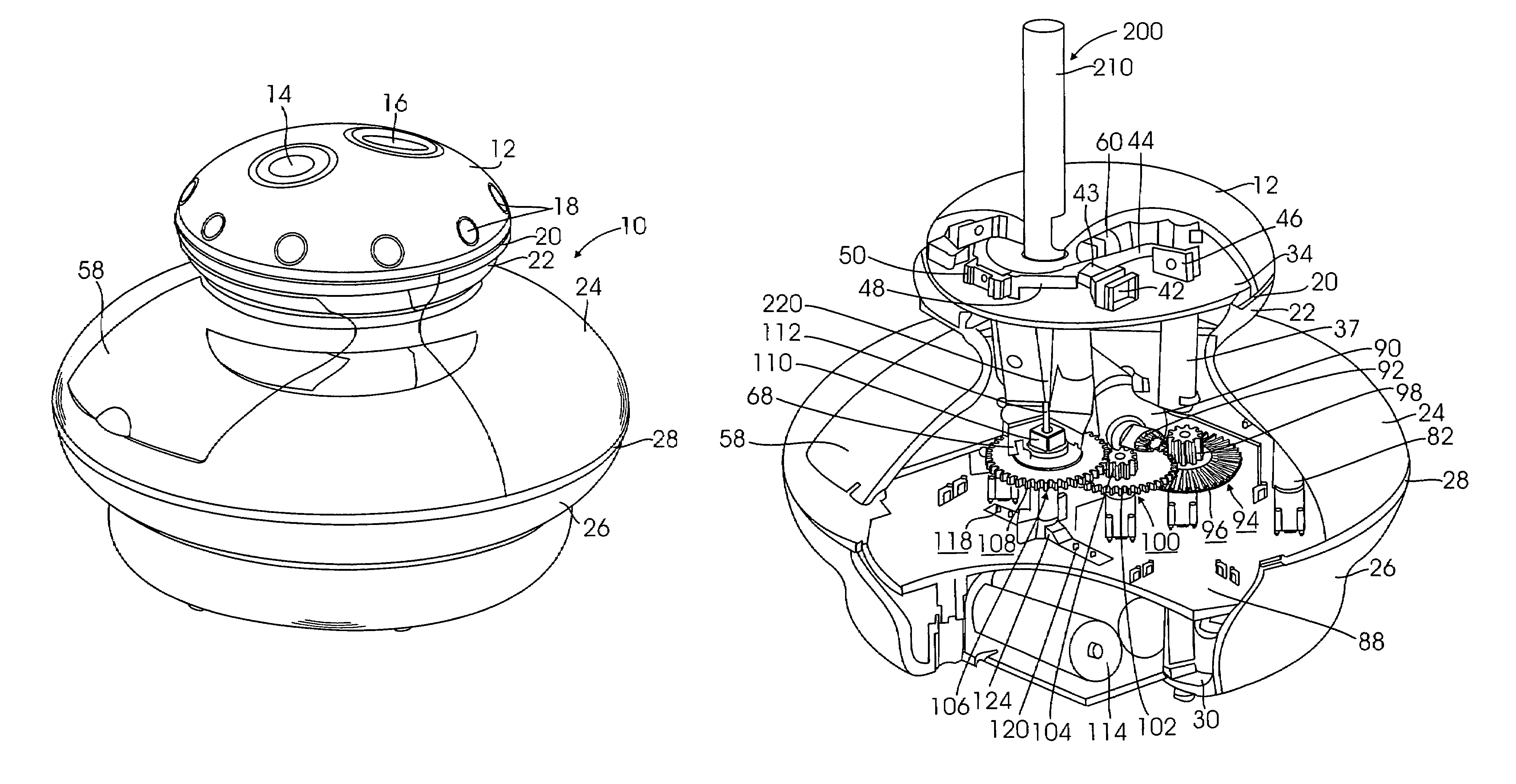

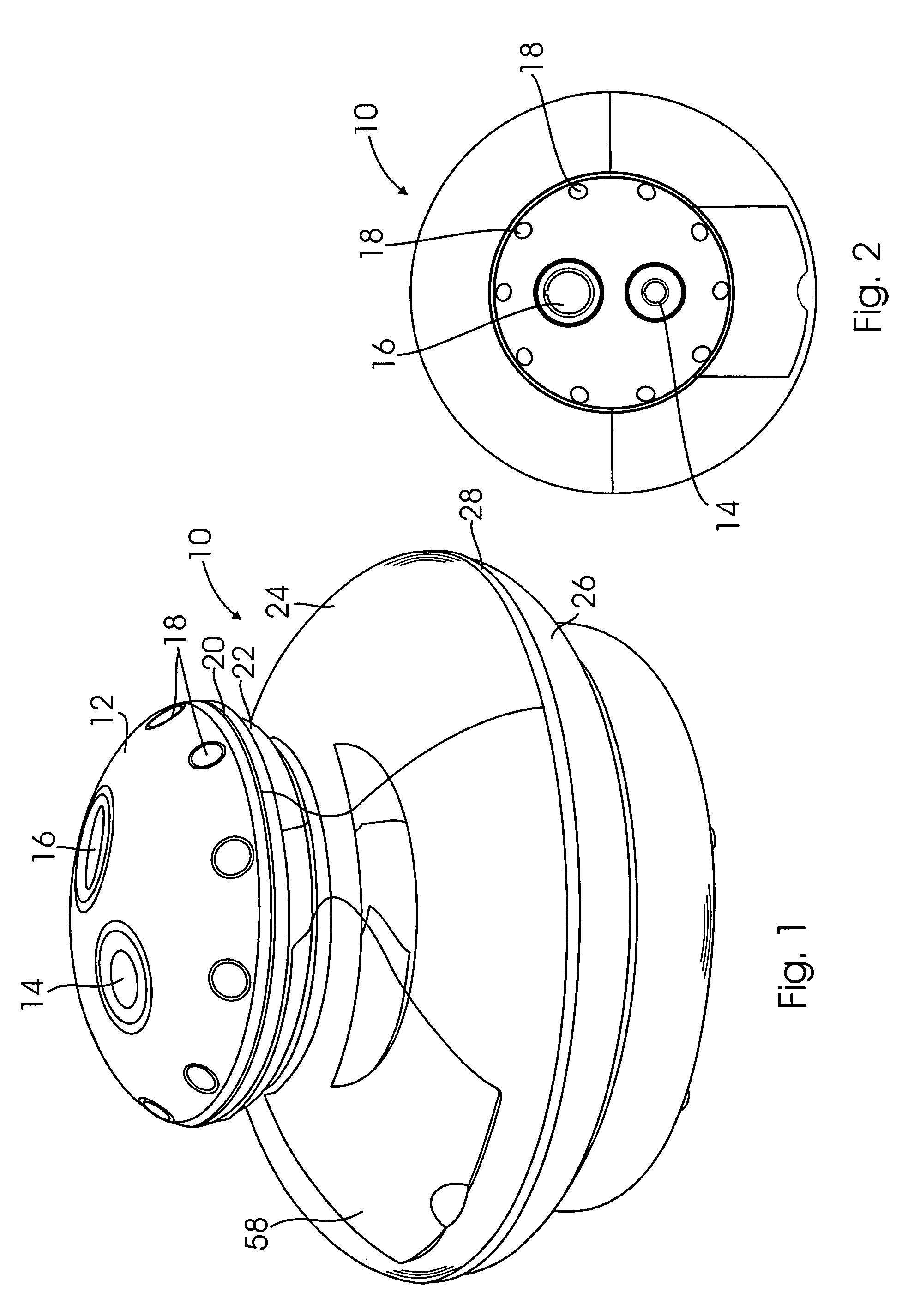

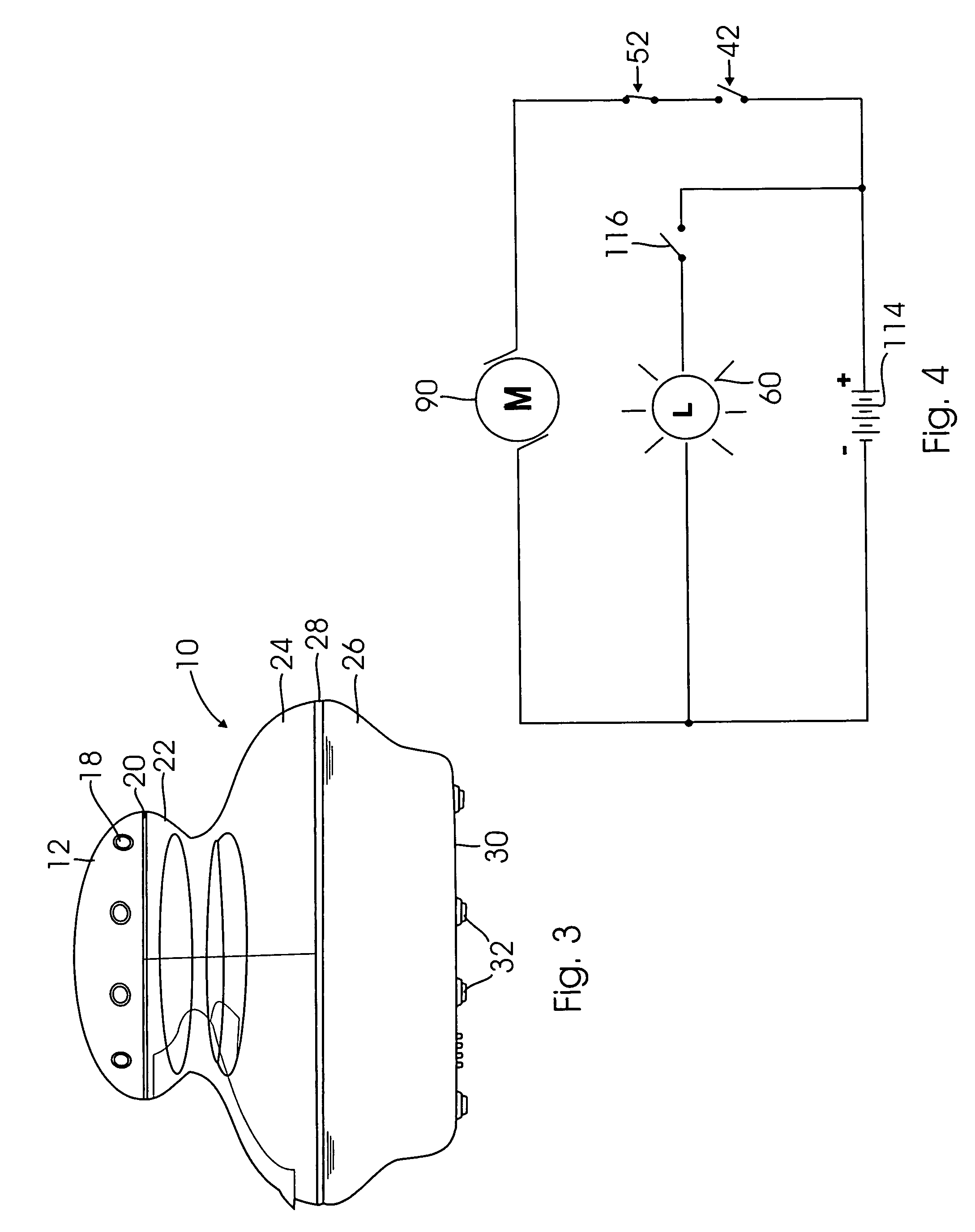

Electrically powered rapid sharpening cosmetic pencil sharpener

InactiveUS7472728B1Quickly sharpenedCrack and breakSharpenersMulti-purpose machinesParaffin waxBiomedical engineering

The present invention is a novel electrically powered cosmetic pencil sharpener which firmly sits on a flat surface to avoid shaking during the sharpening process and firmly grips the cosmetic pencil tip to enable the apparatus to rapidly sharpen the paraffin wax tip within three (3) seconds so that the tip will not shatter or crack. The apparatus rapidly sharpens the cosmetic pencil so that its applicator end is formed at a thirty (30) degree angle with a flat tip so as to provide an ideal applicator end. The apparatus includes an indicator light that tells the individual that the sharpening process is complete.

Owner:BEAUTY POINTS

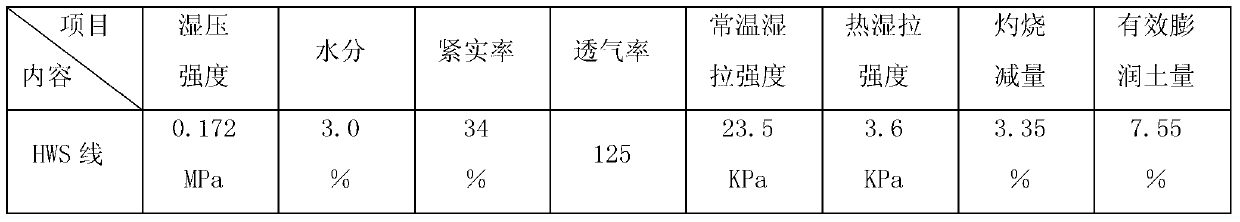

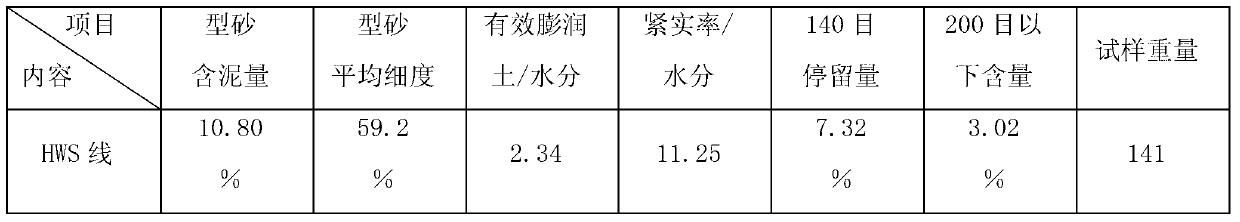

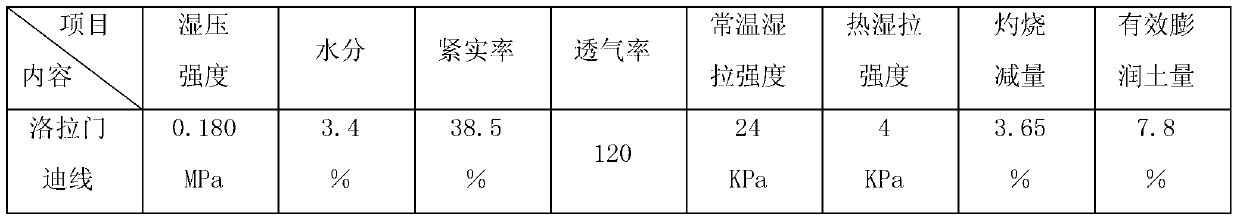

Sand mixing process for molding clay green sand

ActiveCN103341589AGuaranteed comprehensive performanceImproved ejection qualityMould handling/dressing devicesCoalMoisture

The invention provides a sand mixing process for molding clay green sand. The process comprises the following steps of: (1) proportioning the following materials in parts by weight: 97-100 parts of old sand, 0-3 parts of fresh sand, 0.8-1.2 parts of bentonite, and 0.2-0.6 part of pulverized coal; (2) orderly putting the proportioned materials into a sand mixer for mixing for 8-20 seconds in a drying manner; and then adding wet sand which is 0.8-2% of total mass of the sand for mixing for 80-130 seconds; and (3) detecting the mixed casting sand, wherein the casting sand accords with the following indexes: the compaction rate / moisture is 10.0-11.5; the effective bentonite / moisture is 2.1-2.5; the 140-mesh retention amount is 6.0-9.0%; and the content of triple-screen which is less than 200 meshes is 2.8-3.5%. By adopting the sand mixing process, the combination property of the casting sand is ensured; and the purposes of improving the drawing quality, reducing sand shakeout of a casting and the blowhole rejection rate, delaying and removing cracks of a sand mold, and the like are achieved.

Owner:上海圣德曼铸造海安有限公司

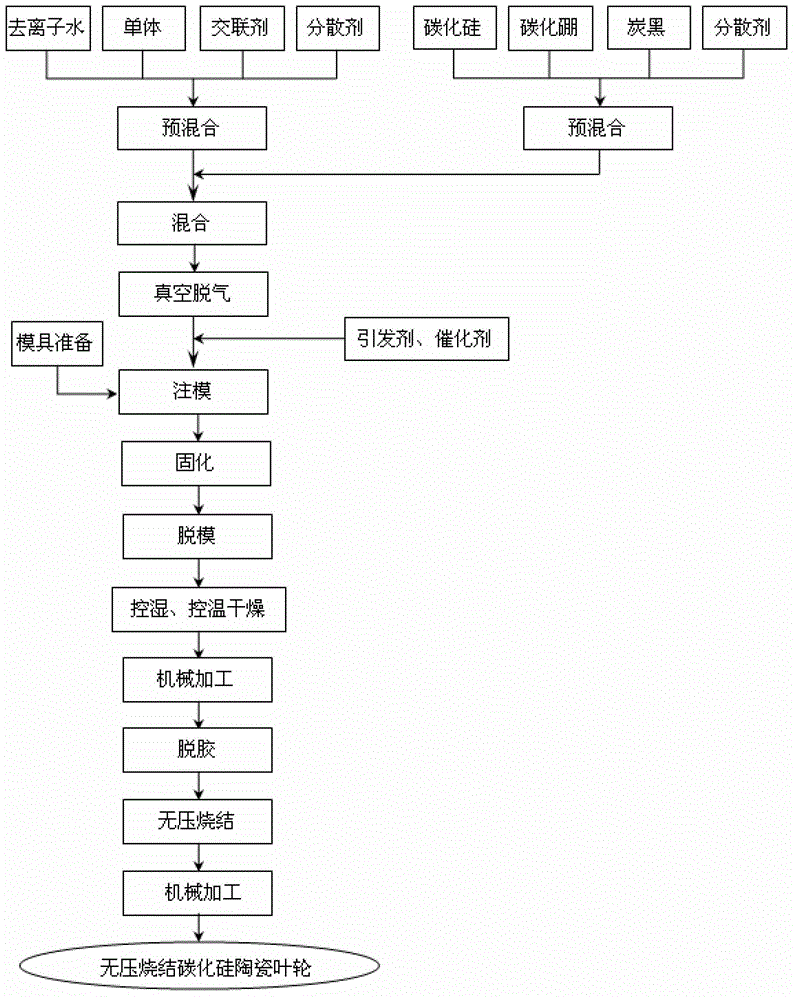

Method for preparing silicon carbide ceramic impeller through gel casting and pressureless sintering

ActiveCN102875150AAvoid uneven dispersionOvercome defects such as uneven curingCarbide siliconGel casting

The invention discloses a method for preparing a silicon carbide ceramic impeller through gel casting and pressureless sintering, and provides a preparation method of a pressureless sintered silicon carbide ceramic impeller with a complex and accurate shape characteristic and an external diameter size capable of reaching over 160 mm. A silicon carbide solid-phase sintering formula system of a boron-containing sintering auxiliary agent and a gel casting and pressureless sintering process are adopted; and the method comprises eight steps of: preparing ceramic slurry; performing injection molding; demolding; drying; machining; degumming; performing pressureless sintering; and machining. According to the method, the technical problems of non-uniform mixing of large-scale ceramic slurry in gel casting, dryness, crack and deformation in a pressureless sintering process and the like are solved, and finally, preparation of the pressureless sintered silicon carbide ceramic impeller is realized. The impeller has good performance such as corrosion resistance, wear resistance, high temperature resistance and the like, and can be widely applied to a centrifugal pump for corrosive liquid conveying of various industries.

Owner:UNIV OF SCI & TECH BEIJING

Molten preparation method of ultrahigh molecular weight polyethylene fiber

ActiveCN104250862AImprove processing performanceGood for melt deliveryMelt spinning methodsMonocomponent polyolefin artificial filamentMelt spinningAntioxidant

The invention relates to a molten preparation method of ultrahigh molecular weight polyethylene fiber, and the molten preparation method is characterized by comprising the following steps: a. ultrahigh molecular weight polyethylene, internal modifier organic nano phosphate, and an antioxidant are fully mixed in a high speed mixer, then are added into a twin screw extruder for mixing and granulating to obtain modified masterbatch, the screw the temperature is 150 to 250 DEG C; b. the modified masterbatch, the ultra high molecular weight polyethylene and an external modifier fluorine elastomer are fully mixed in a high-speed mixer, then added into the twin screw extruder for melt spinning, and are cooled in water bath to obtain nascent fiber, the screw segment temperature is 150 to 260 DEG C, the water bath temperature is 5-20 DEG C; and c. the nascent fiber is processed by 3-stage stretching at 80 to 150 DEG C, and the total stretching ratio is 10-20 times.

Owner:JIANGSU LIUJIA TECH CO LTD

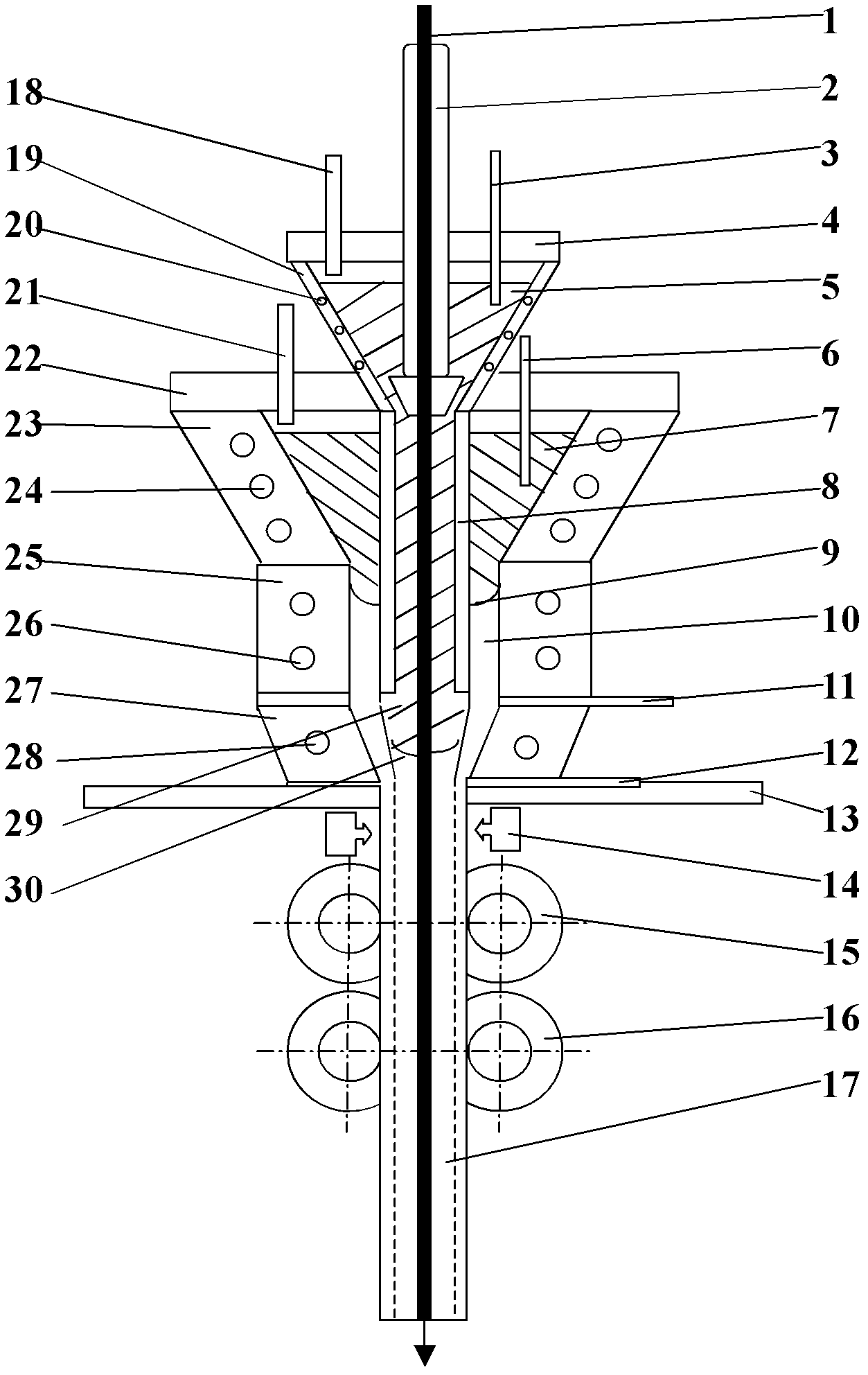

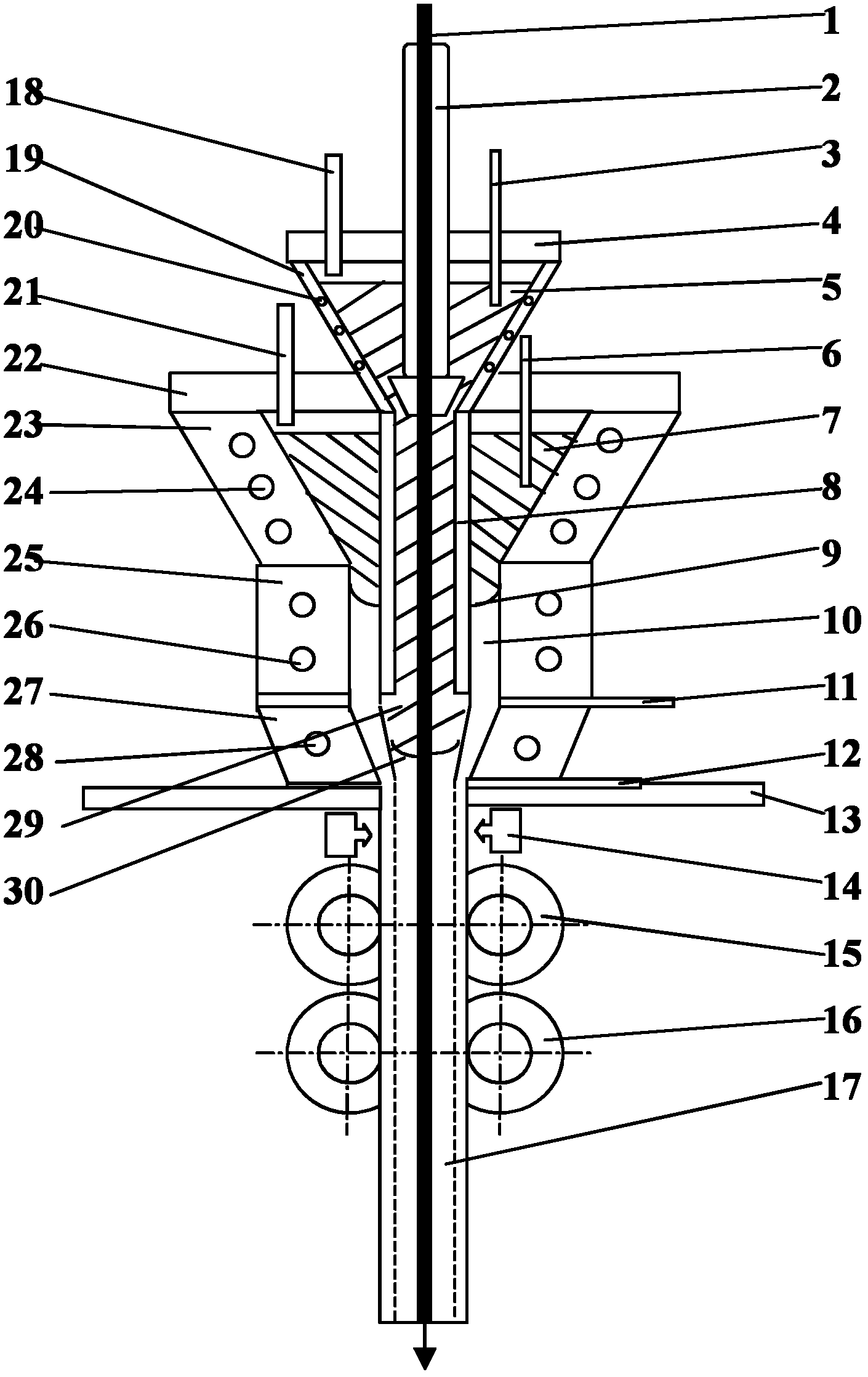

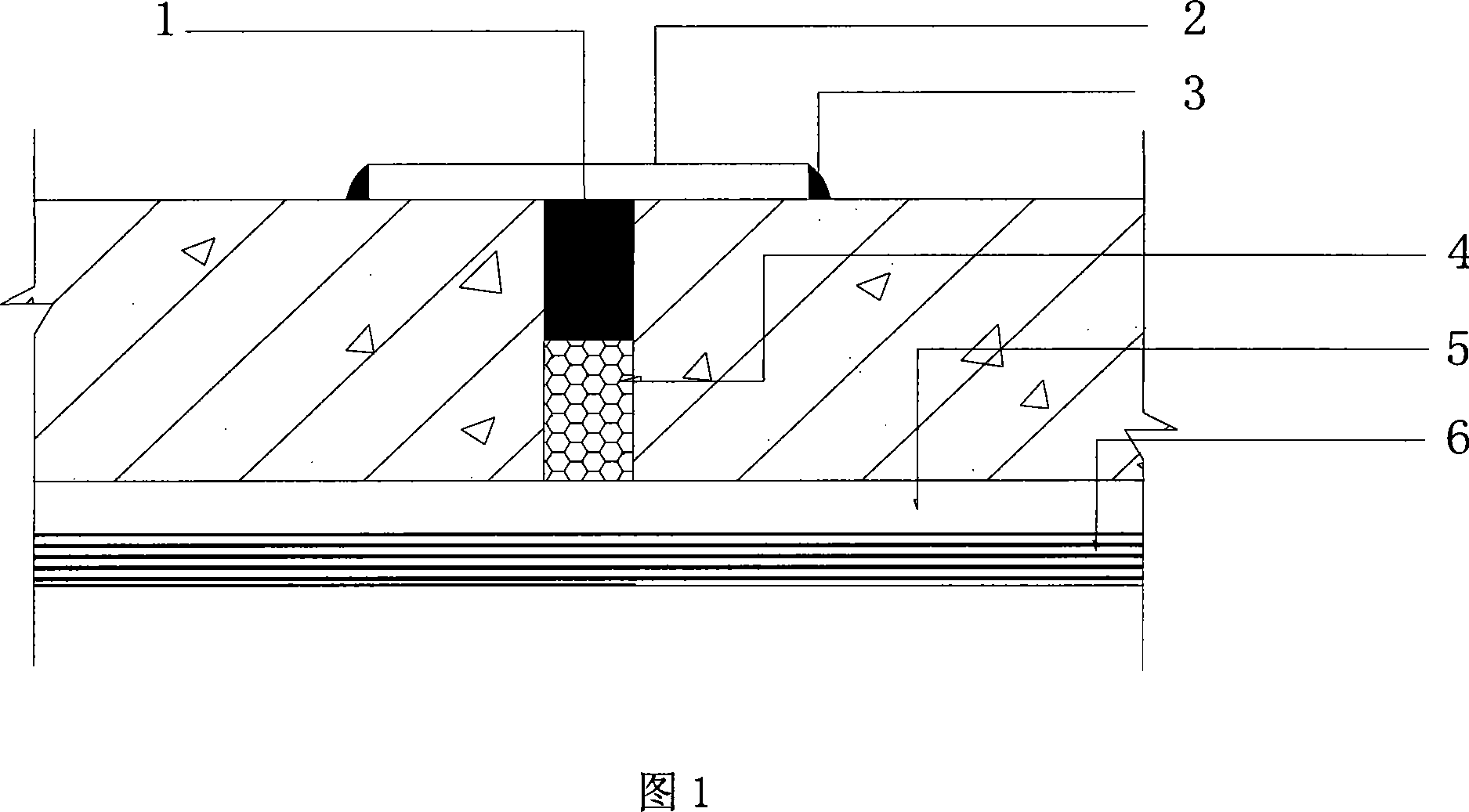

Pressure core-filling continuous casting equipment and process for double-metal-bag long carbon fiber composite material

The invention provides pressure core-filling continuous casting equipment and a process for a double-metal-bag long carbon fiber composite material. The continuous casting equipment is composed of an inner-layer metal plug rod, a carbon fiber guide pipe, an inner-layer metal thermodetector, an inner-layer metal pressurizing cover, an outer-layer metal thermodetector, a core filling pipe, an outer-layer metal pipe thermodetector, a composite interface pressurizing device, a heat-insulating and water-stopping plate, a secondary cooling device, a drawing roller, a finishing roller, an inner-layer metal liquid pressurizing pipe, an inner-layer metal temperature control furnace, an outer-layer metal liquid pressurizing pipe, an outer-layer metal pressurizing cover, an outer-layer metal liquid temperature control furnace, an outer-layer metal liquid temperature control crystallizer, a composite interface pressurizing device, a heating element and a temperature control element. Inner-layer metal is smelted and insulated in the inner-layer metal temperature control furnace and is filled into a condensed outer-layer metal pipe inner hole and one bundle of long carbon fibers through the core filling pipe, so as to be fused and condensed with the inner-layer metal and the carbon fibers to form a composite material. The speed of core-filling and continuous casting is controlled by the drawing roller and an outer-layer metal pipe casting blank is pressurized to be ejected out from the outer-layer metal liquid temperature control crystallizer.

Owner:UNIV OF SCI & TECH BEIJING

Memorial created for cremation remains and processes for making same

ActiveUS20050071964A1Eliminate cracksSolid waste disposalTransportation and packagingParticulatesFaceting

A memorial for deceased humans or animals in which the cremated residue or ash is blended or mixed with particulate glass, the mixture being heated to form a liquid pool of glass with the cremation residue or ash dispersed, infused and / or absorbed therein, the molten glass and ash being removed from the heat source after a suitable time period and transferred to a mold in the shape of the memorial, the mold allowed to cool until the memorial sets, the memorial then removed from the mold and reheated in an annealing oven at a suitable temperature for a suitable time so as to eliminate possible cracking and scoring, the memorial once removed from the annealing oven can be further cut, polished, faceted, engraved or the like. The initial mixture of particulate glass and cremation residue and ash can be further combined with a coloring agent if so desired before heating or before transfer to the memorial mold.

Owner:VOGEL HAROLD C +1

Pouring concrete separating crack structure and construction method thereof

The invention relates to a separation joint structure, comprising polystyrene plate located at the lower part and elaterite sand located at the upper part. Waterproof coiled material is covered above the elaterite sand and sealing material is coated between waterproof coiled material and fine stone concrete. In construction, according to the position of presetting separation joint wire is snapped. Plain cement puddle with 3%-5% of waterproof powder is used to mount the strip of polystyrene plate. When it is used on the ground the width of it is 10-20mm and when it is used on the roof surface. The thickness of strip is equal to the thickness of fine stone concrete. After the strip of polystyrene plate is mounted for 24 hours fine stone concrete is poured. After fine stone concrete is maintained for 7-10 days 20mm of the upper part in plate joint is shoveled by flat spade. Elaterite sand is mounted; then waterproof coiled material is pasted on tar sand; and then sealing material is coated between waterproof coiled material and fine stone concrete. The invention can eliminate cracks on the ground or on the roof surface generated by expand on heating and contract on cooling of fine stone concrete and decrease damage to the component. The purpose that the separation joint can not be cracked is achieved.

Owner:HEBEI CONSTR GRP CO LTD

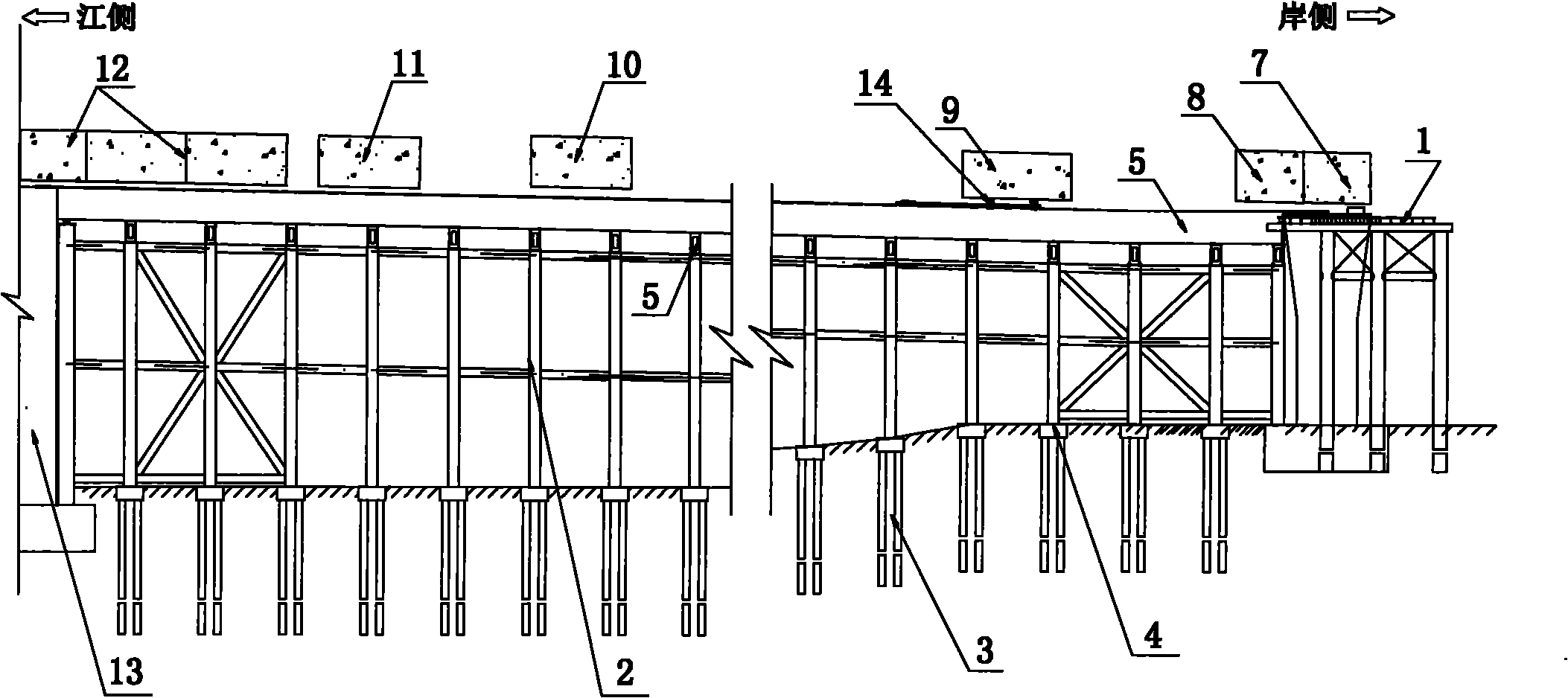

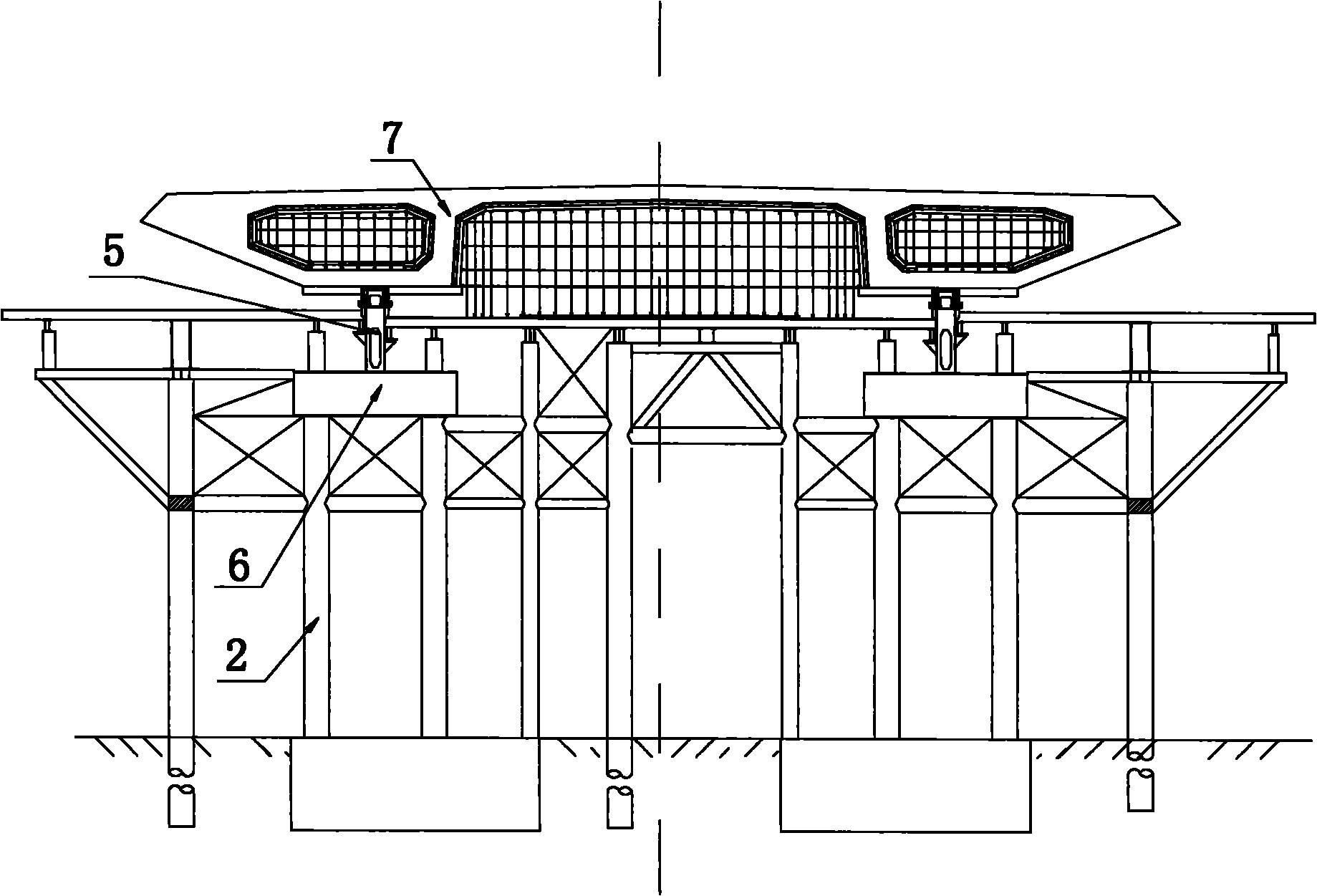

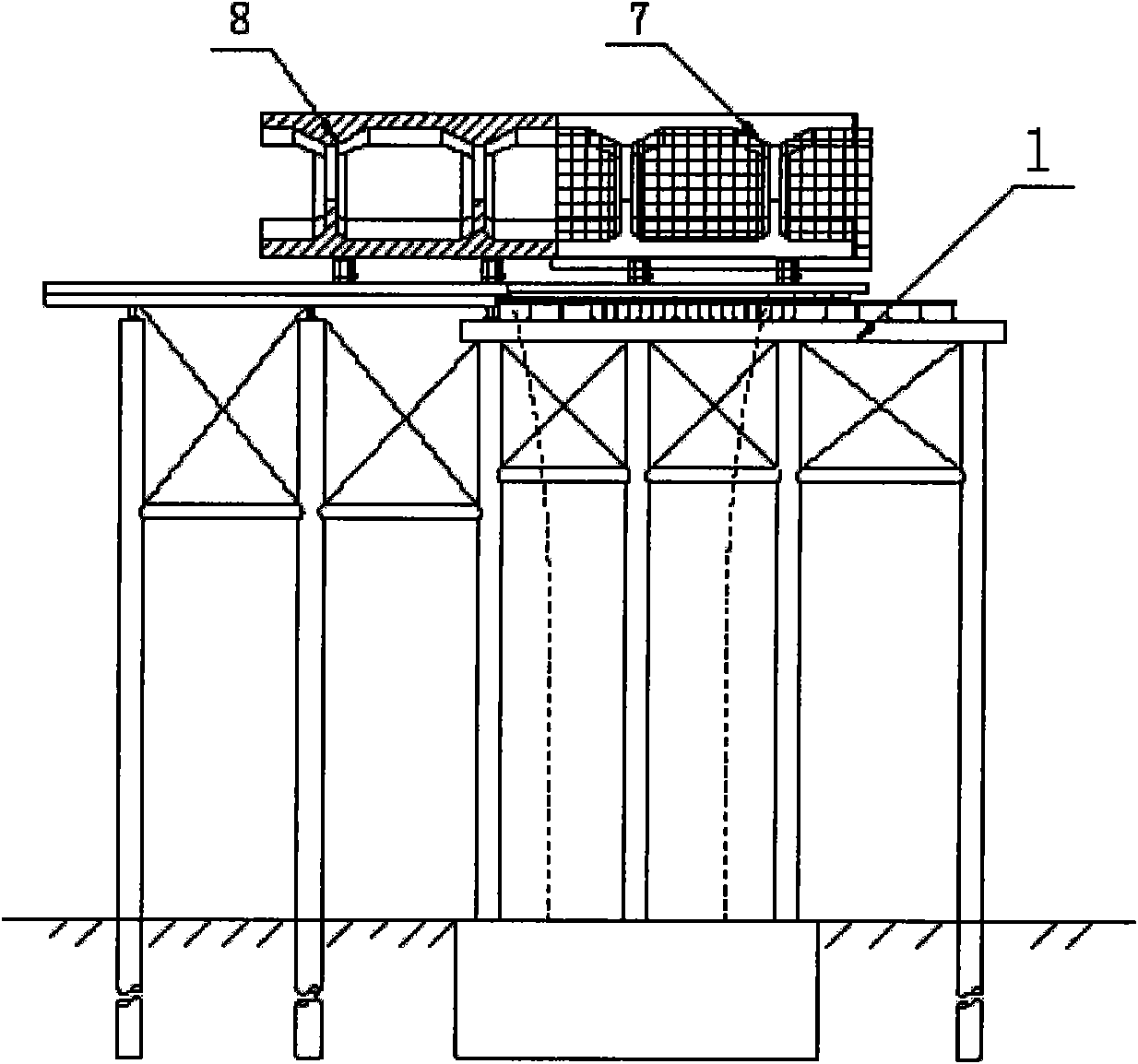

Construction method for high-altitude section prefabricating, beam moving, beam storing and assembling of large concrete box beam

ActiveCN101985826AEliminate cracksPrevent itself from crackingBridge erection/assemblyBridge materialsSteel tubeBox girder

The invention discloses a construction method for high-altitude section prefabricating, beam moving, beam storing and assembling of a large concrete box beam, which is characterized by comprising the following steps: 1) erecting a high-pile prefabricated platform; 2) erecting beam moving steel tube supports and steel slide rails between the high-pile prefabricated platform and a pier; 3) pouring a matched beam section on the high-pile prefabricated platform; 4) using the poured matched beam section as the end die at one end of the next new beam section to be poured and pouring the new beam section; 5) after pouring the new beam section, transporting the matched beam section to the design position as the beam section to be assembled and simultaneously moving the new beam section forward as the next matched beam section; 6) longitudinally moving the beam section to be assembled to the matching surface of the end of the assembled beam section as the beam section to be assembled and adjusting the position of the beam section to be assembled to ensure the beam section to be assembled to conform to the requirement of split joint with the assembled beam section on the pier; and 7) carrying out split joint on the beam section to be assembled and the assembled beam section. By section prefabricating and long-time beam storing of the beam sections, the construction method effectively ensures the prefabricated beam sections to complete most contraction deformation of the beam body in free state and eliminates the contraction difference of the adjacent beam sections caused by different ages, thus eliminating cracks.

Owner:HUNAN ROAD & BRIDGE CONSTR GROUP

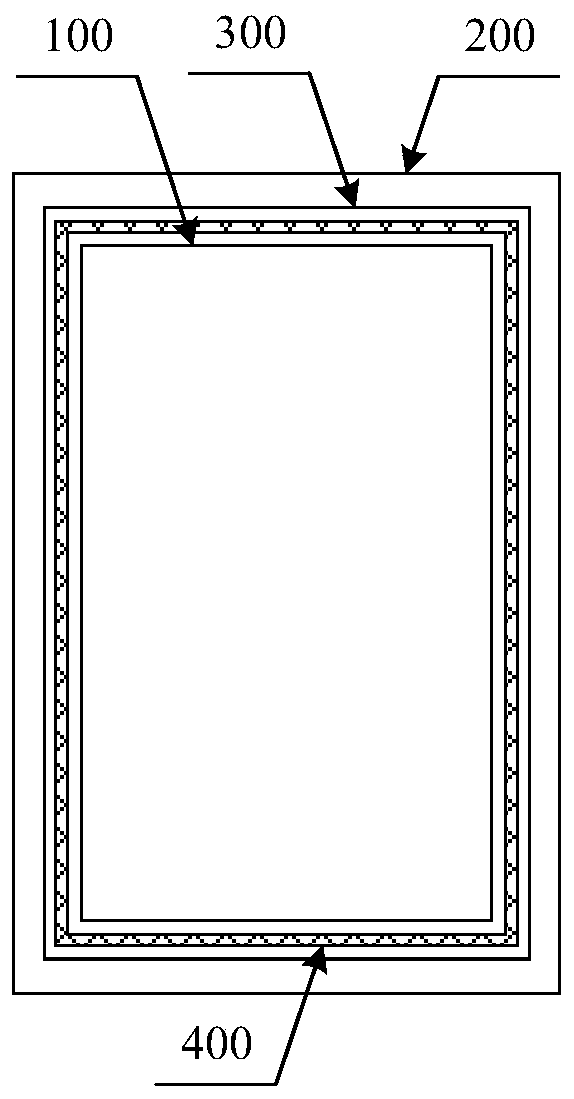

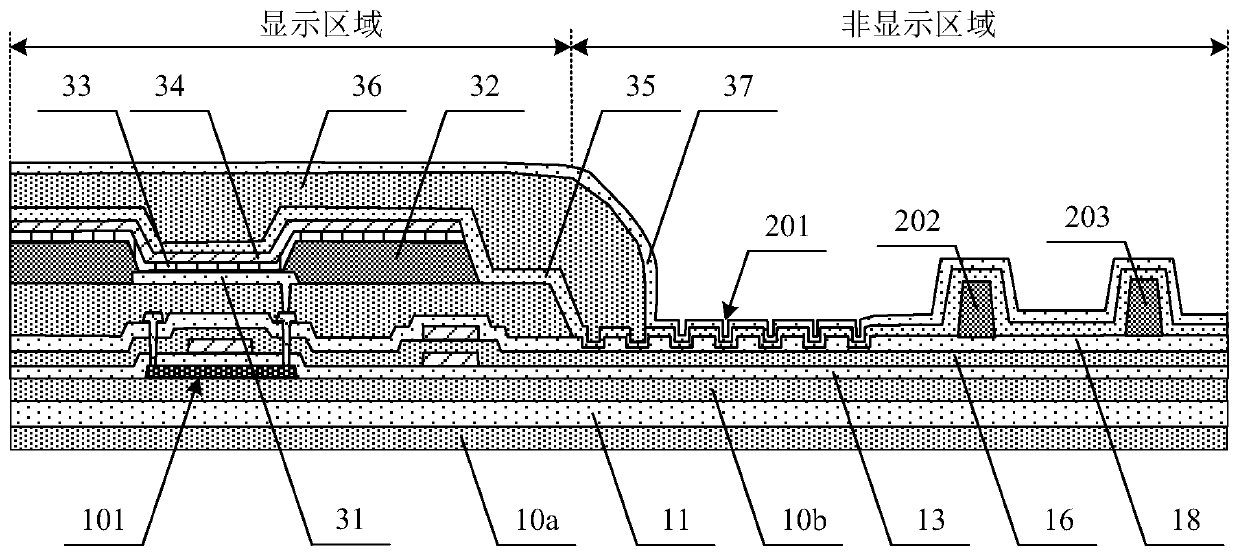

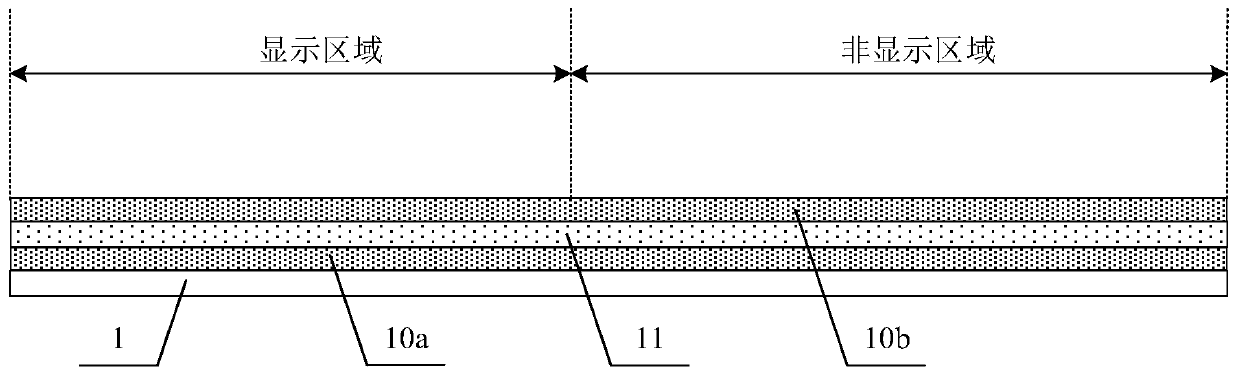

Display substrate, preparation method thereof, and display device

ActiveCN110120463AGuaranteed validityGuaranteed reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingConvex structureDisplay device

The invention provides a display substrate, a preparation method thereof, and a display device. The display substrate comprises a display area and a non-display area. The non-display area comprises afunctional layer, a retaining wall arranged on the functional layer, and an inorganic packaging layer covering the functional layer and the retaining wall. Between the display area and the retaining wall, the functional layer comprises a plurality of grooves arranged at intervals, so that a concave-convex structure is formed on the contact surface of the functional layer and the inorganic packaging layer. According to the invention, the plurality of grooves are formed in the area between the display area and the retaining wall at intervals, so a concave-convex structure is formed on the contact surface of the functional layer and the inorganic packaging layer, thereby increasing the bonding force of the film layer in the area, avoiding the delamination or cracking of an area between the display area and the retaining wall, avoiding a water and oxygen invasion path formed by delamination or cracking, and effectively guaranteeing the effectiveness and reliability of packaging. Moreover,the display substrate is low in manufacturing cost, is easy in process implementation and the like.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com