Cantilever bay window board concrete overall pouring structure and construction method thereof

A technology of integral pouring and construction method, which is applied in the direction of building structure, construction, and building material processing, etc., which can solve the problems of low construction efficiency, poor bearing capacity and durability of bay window structures, etc., achieve good integrity and eliminate root cracking , The effect of structural safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

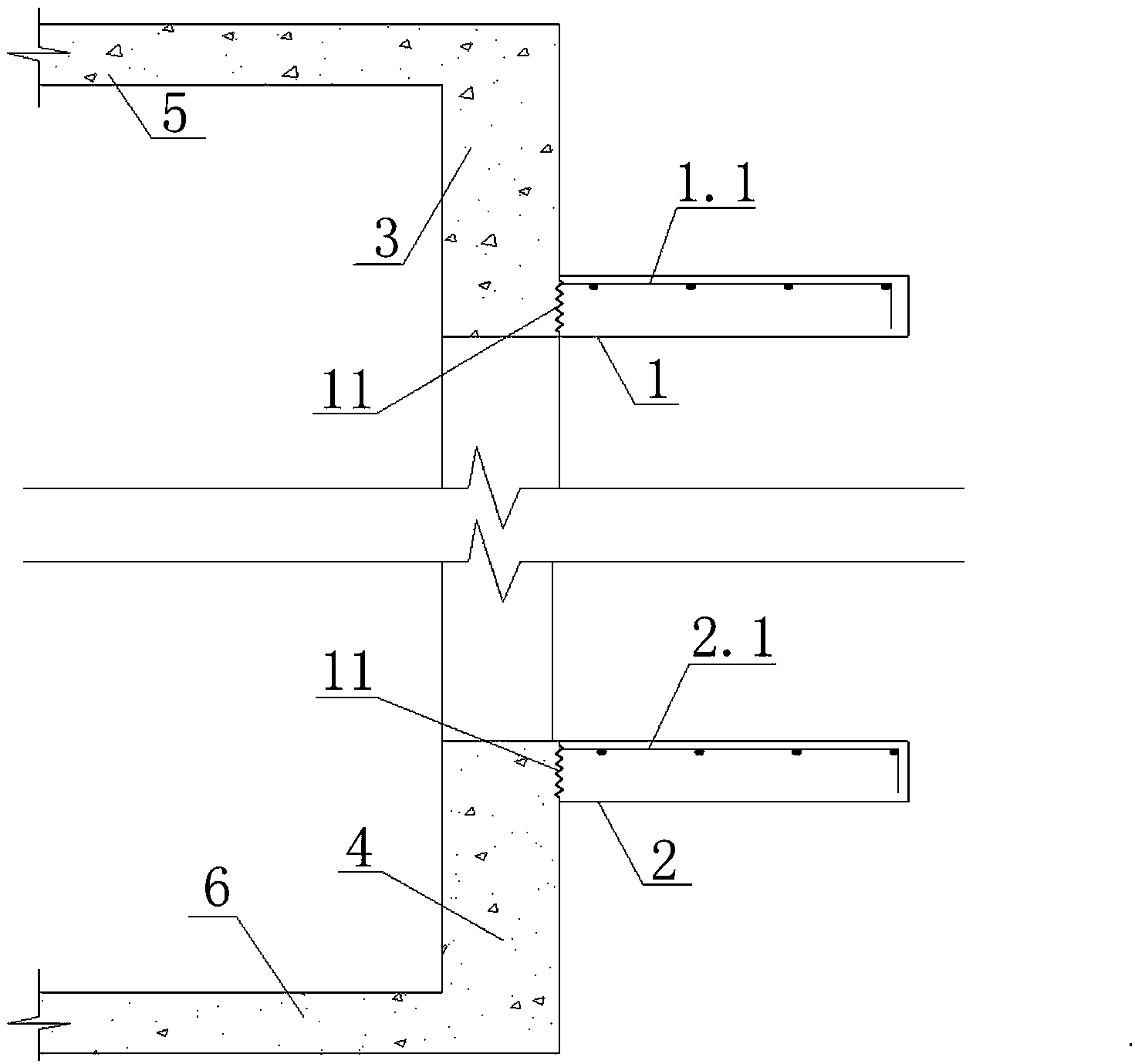

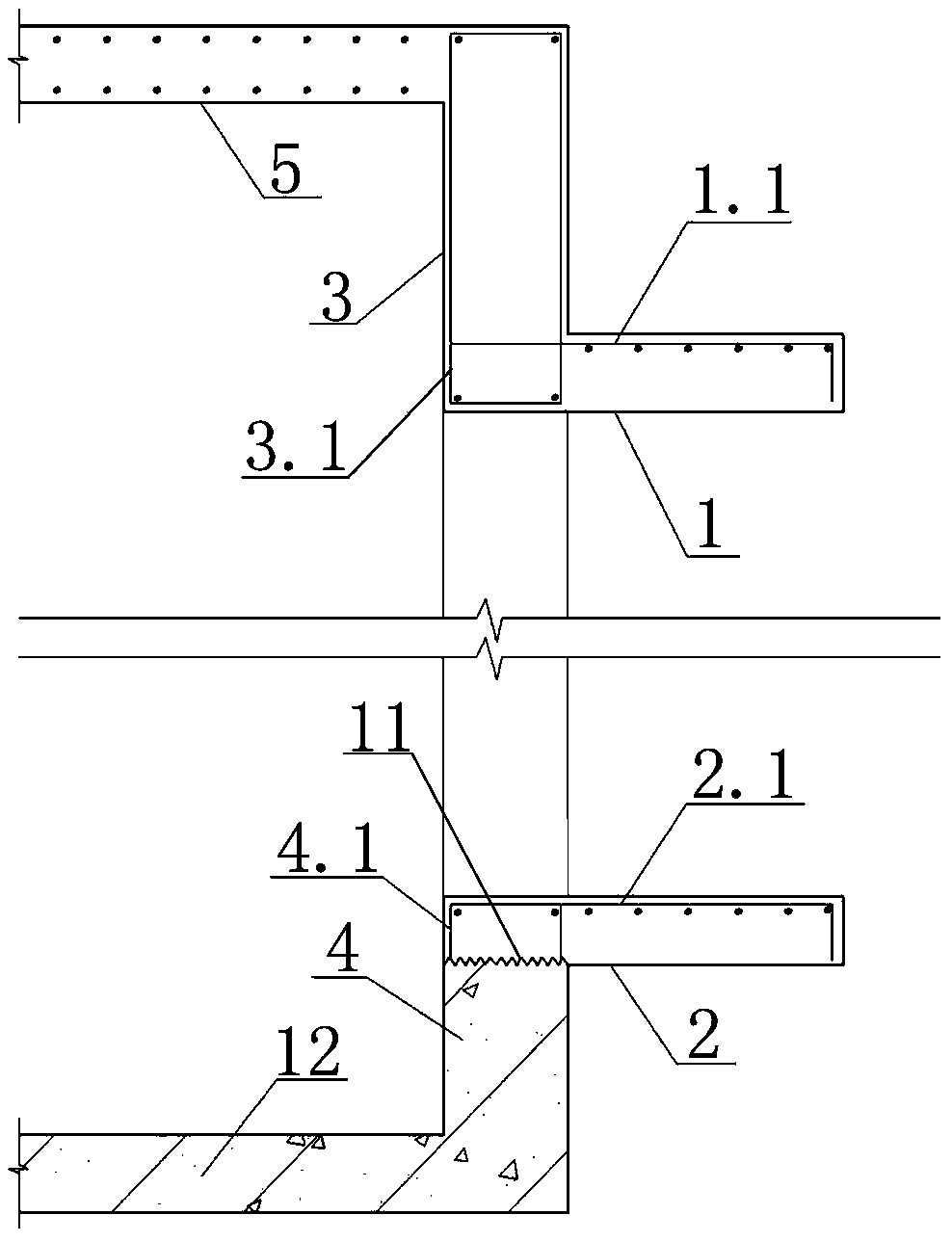

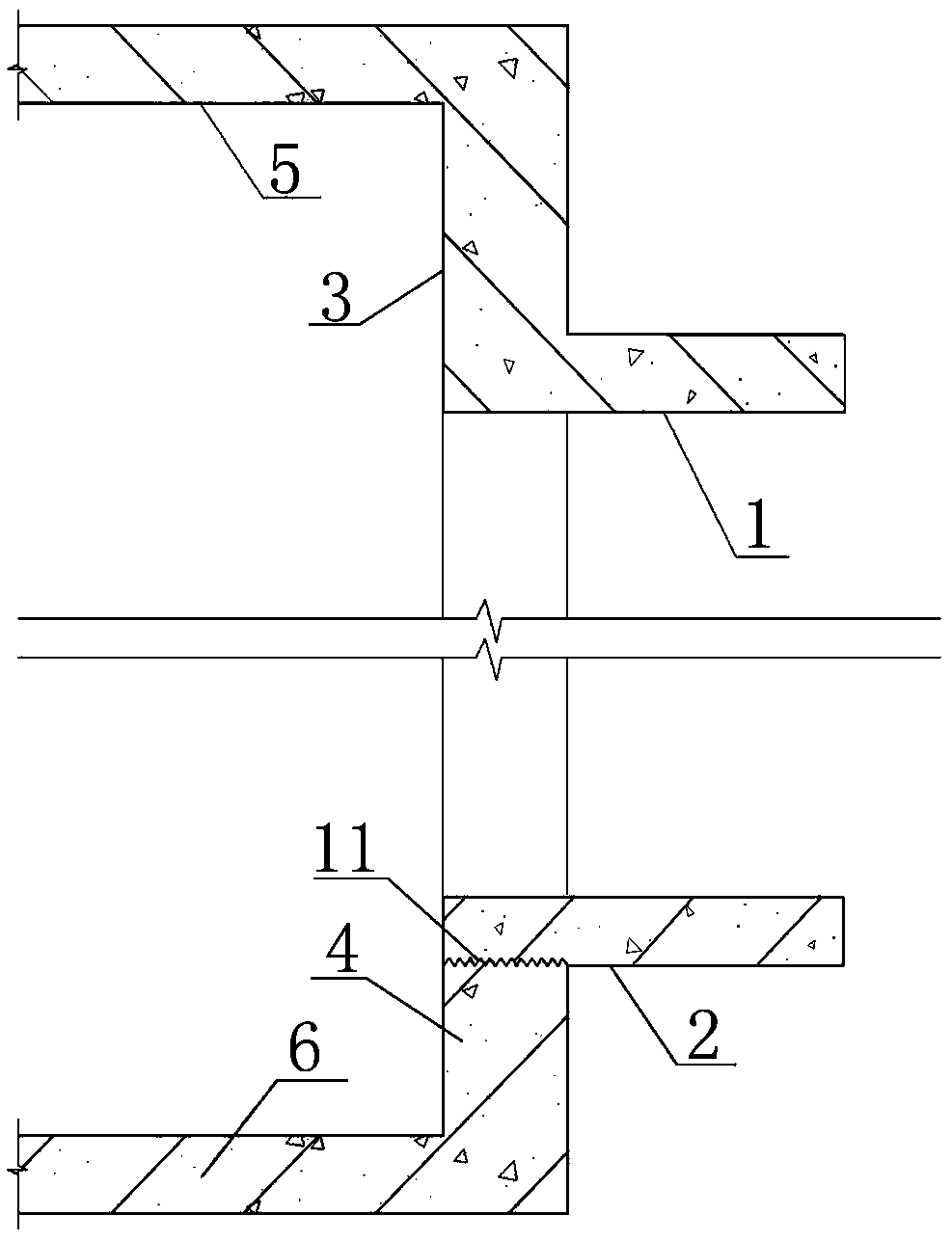

[0042] Examples see figure 2 , image 3 As shown, the integral concrete pouring structure of the cantilever bay window panel includes an upper bay window panel 1 and a lower bay window panel 2, and the concrete of the upper bay window panel 1, the upper window beam 3 and the upper floor 5 is integrally poured and formed. , the inner end of the upper bay window panel reinforcing bar 1.1 of the upper bay window panel 1 extends into the upper connecting beam 3 of the window for anchoring.

[0043] The lower bay window panel 2 and the concrete on the upper part of the lower bay window panel 4 are integrally poured into shape, and the inner end of the lower bay window panel steel bar 2.1 of the lower bay window panel 2 extends into the lower window beam 4 for anchoring.

[0044] The upper bay window panel reinforcement 1.1 is located at the upper part of the upper bay window panel 1 . The lower bay window panel reinforcing bar 2.1 is located at the lower bay window panel 2 top. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com