Patents

Literature

215results about How to "Good quality and effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing anti-second-stubble efficient biologic-organic fertilizer

InactiveCN101007746AHigh in nutrientsSimple structureBio-organic fraction processingOrganic fertiliser preparationOrganic fertilizerDomestic animal

The invention discloses a preparing method of anti-heavy stubble highly effective biological organic fertilizer including effective of fertilizer, effective of medicine and unwanted bacterium of inhibiting soil, which comprises the following steps: mixing domestic animal manure zymosis agent, chemical mixing fertilizer and alta-mud in proportions; grinding; getting composite fertilizer; spraying bacterium agent on the surface of composite fertilizer; adding microbiological bacterium agent; mixing; dewatering; pelleting.

Owner:扬州市森大肥业有限公司

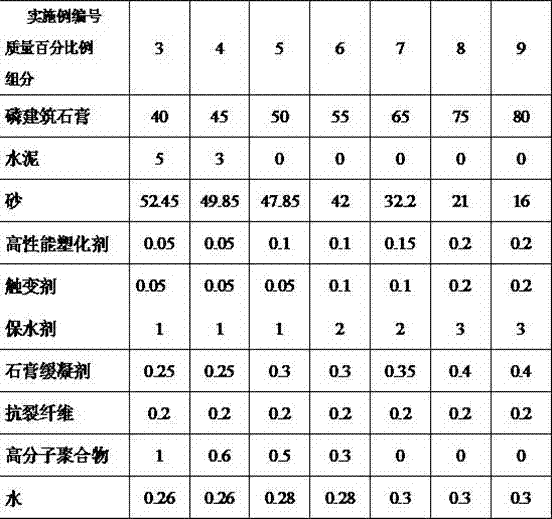

Preparation method of phosphogypsum-based anti-cracking mortar applied to interior insulation of external wall

The invention discloses a preparation method of phosphogypsum-based anti-cracking mortar applied to interior insulation of an external wall. The preparation method is characterized in that the anti-cracking mortar comprises the following components in percentage by mass: 40-80% of building phosphogypsum, 20-50% of dried sand, 0-20% of cement, 0-5% of fly ash, 0-0.2% of a high-performance plasticizer, 0-0.2% of a thixotropic agent, 0.1-0.3% of a water-retaining agent, 0.01-0.4% of a gypsum retarder, 0-3% of a micromolecular polymer and 0-0.25% of anti-cracking fiber. According to the preparation method, the building phosphogypsum prepared by washing and calcining industrial byproduct phosphogypsum is used as a cementing material, so that the problems that a cement-based material is easy to shrink, hollow and crack are solved; through full use of the characteristics of fast setting and hardening, good volume stability and low own ratio of compressive strength to flexural strength of a gypsum material, the anti-cracking mortar, of which the ratio of the compressive strength to the flexural strength is lower than 2.5, the operable time is 1-2h, the final setting time is shorter than 3h, the insulation board bonding strength is higher than 0.10MPa and breakage occurs inside an insulation board, is prepared. The anti-cracking mortar is applied to the interior insulation of the external wall and low in cost, reduces the environment pollution, and is simple in production process, low in energy consumption and good in product performance; compared with other insulation board crack resisting products, the anti-cracking mortar has higher market competitiveness and is strong in practicality.

Owner:四川华邦保和涂料有限公司

Preparing composite of modifing glass fiber reinforced plastics pultrusion section bar and preparation method thereof

The invention is a combination for preparing modified glass fibre reinforced plastic pull-extrude (GFRP) sectionbar including unsaturated polyester resin 92.6-64 (wt.%), nano silicon dioxide 0.5-4, calcium carbonate 5-20, benzoyl peroxide 0.2-2, methyl ketone peroxide 0.2-2, demoulding agent 0.5-2 and mill base 1-6. Batching in the above weight percents, selecting a ultrasonic wave dispersive apparatus to fully disperse the nano silicon dioxide in 2Kg resin; dispersing and blending, where the glue soluting temperature is controlled at 30 plus or minus 2 deg.C and the fully blending and dispersing time is 1 hour; adding in other additives in proportion in turn, fully blending until the mixture is uniform and meets the preset viscosity number; prepring structural sections: pouring the well-prepared glue soluting in a presoaking glue tank and keep constant temperature at 25 plus or minus 2 deg.C; placing the glass yarn felts ccording to a sectionbar perform guiding device to enter in the glue tank for fully soaking with the glue; making the yarn felts soaked with resin glue soluting enter in a well-heated mould for solidification moulding, and pulling into products by a hydraulic drag device, and at last cutting for fixed size.

Owner:天津市金锚科技发展有限公司

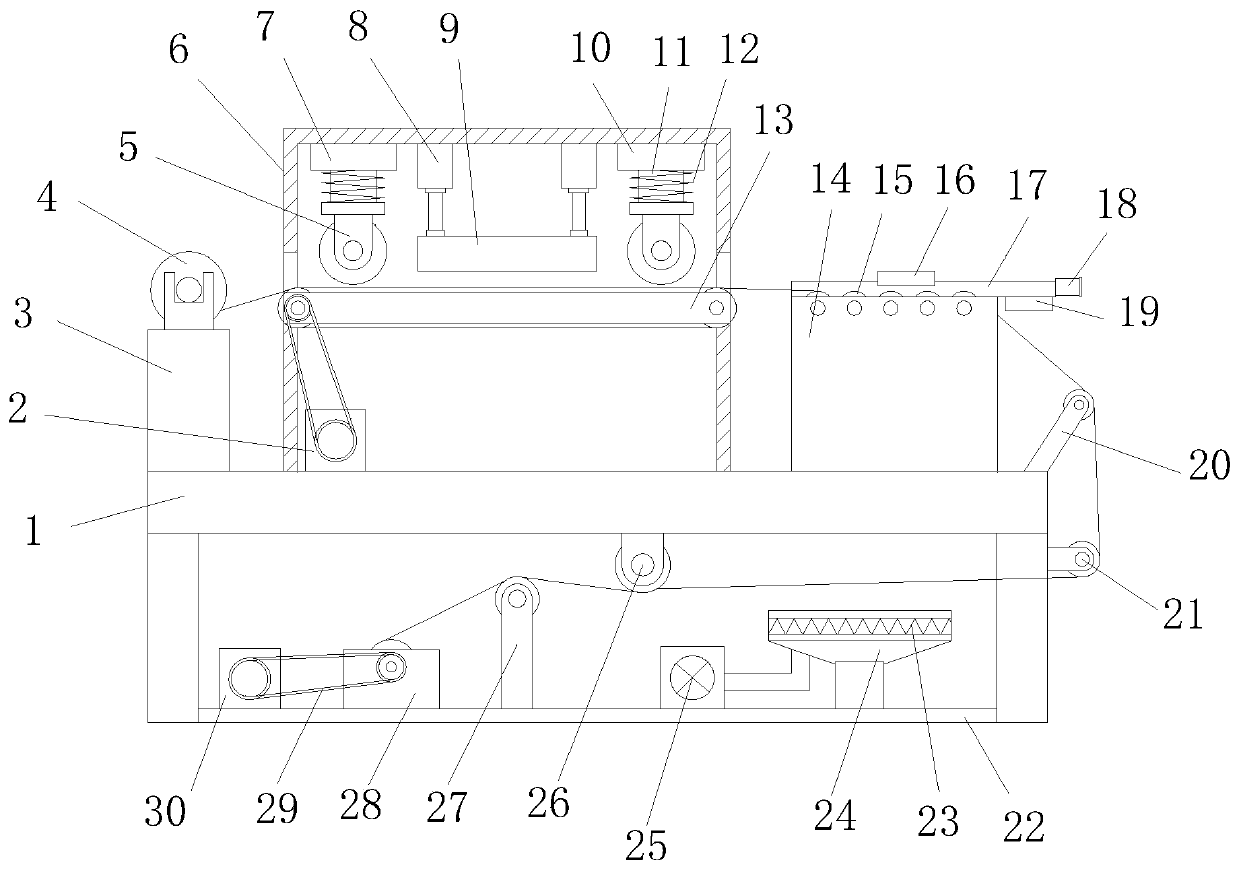

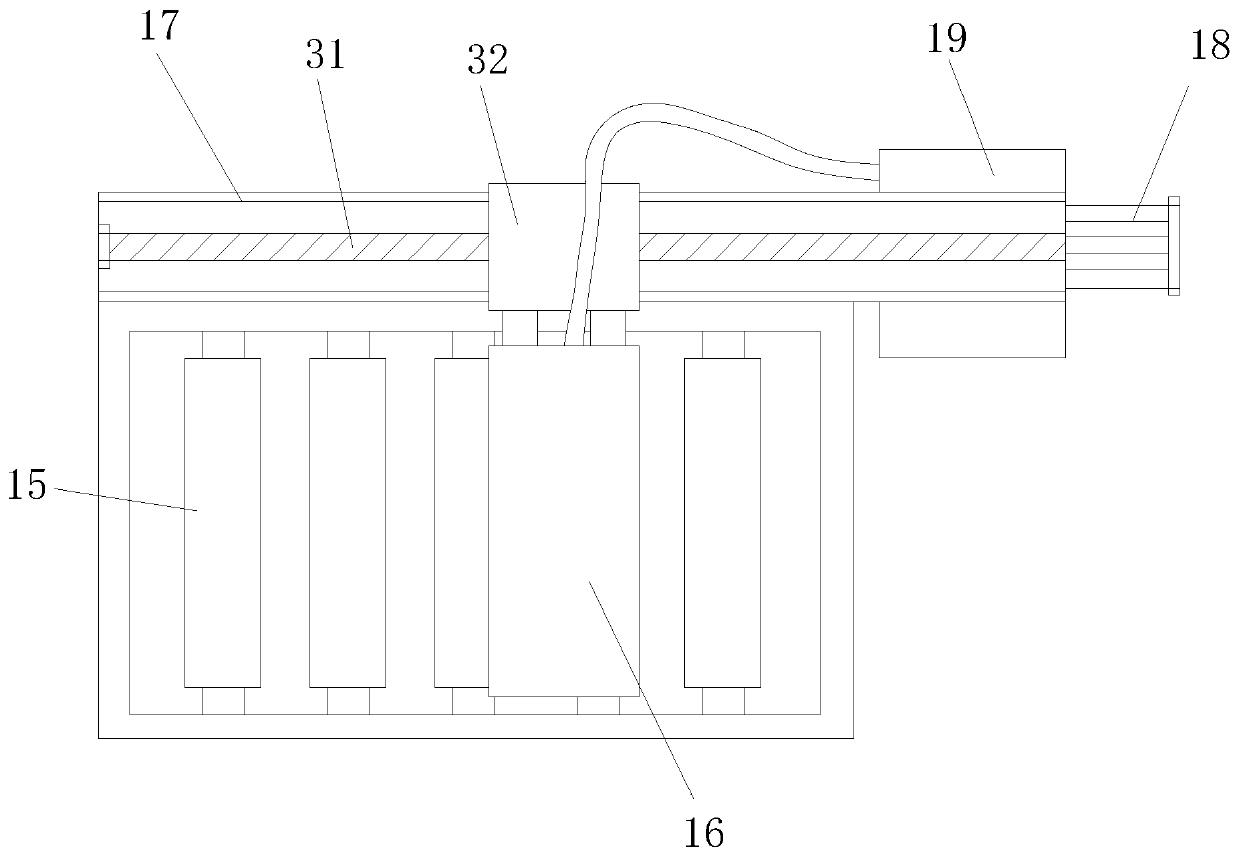

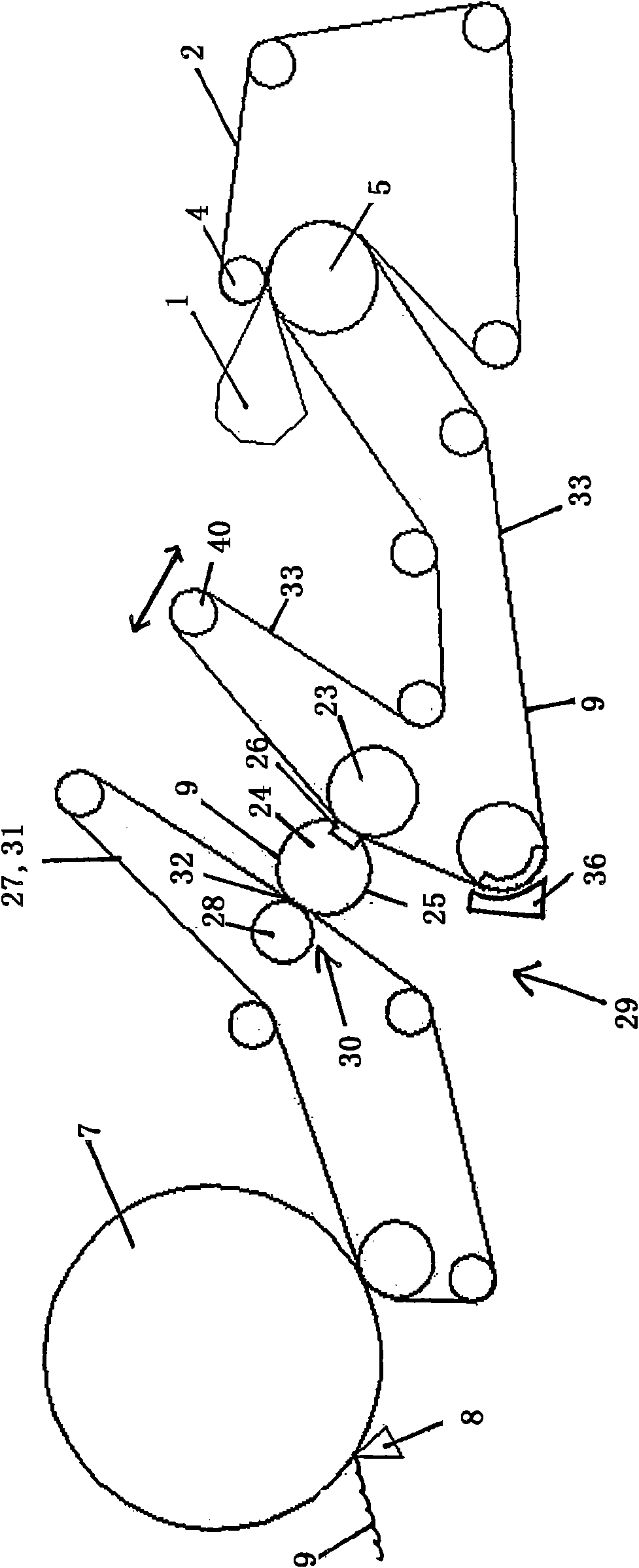

Efficient embossing machine for textile wall paper production

InactiveCN110126451AAvoid damageLow investment costCovering/liningsRotary pressesPaper productionPulp and paper industry

The invention discloses an efficient embossing machine for textile wall paper production. The machine comprises a rack, a uniform pressing device, a stamping device, a drying device and a coiling device, wherein a distributing roller storing rack is fixedly arranged at the upper left end of the rack, and a distributing roller is rotatably mounted at the upper end of the distributing roller storingrack; the uniform pressing device is arranged at the right side of the distributing roller storing rack; the stamping device is arranged at the right side of the uniform pressing device and is fixedly mounted at the upper right side of the rack; a first guide roller is fixedly arranged at the upper right end of the rack; a second guide roller is arranged in the middle of the right side of the rack; a third guide roller is arranged in the middle of the bottom part of the rack; a separating plate is arranged at the inner lower part of the rack; the drying device is arranged at the upper right side of the separating plate; a fourth guide roller is arranged in the middle of the upper part of the separating plate; and the coiling device is arranged at the upper left side of the separating plate. The machine is simple in structure, multifunctional, good in use effect, and high in production efficiency; the product quality is effectively ensured; and the machine is beneficial for popularization.

Owner:苏州前航实业有限公司

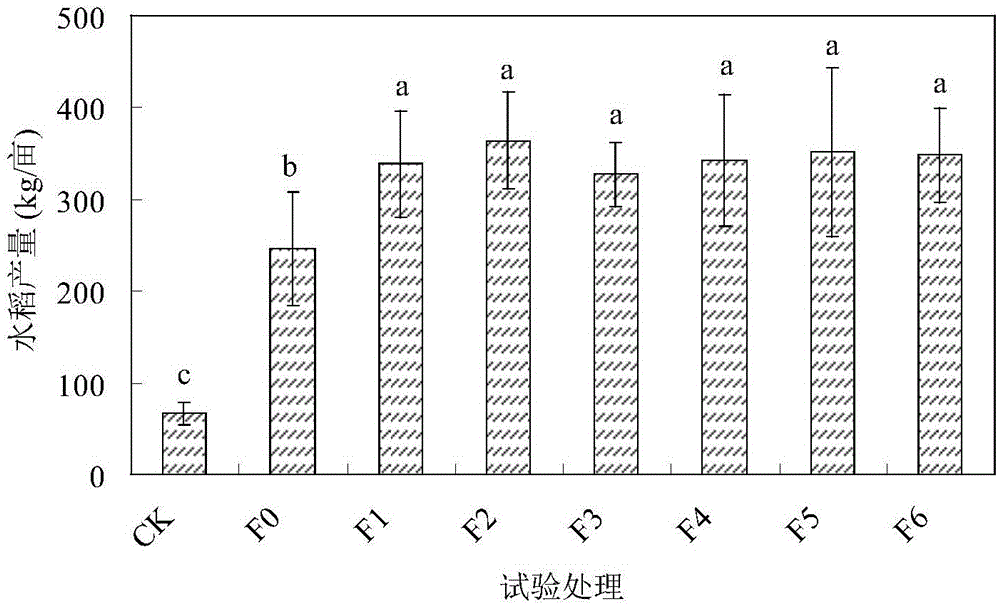

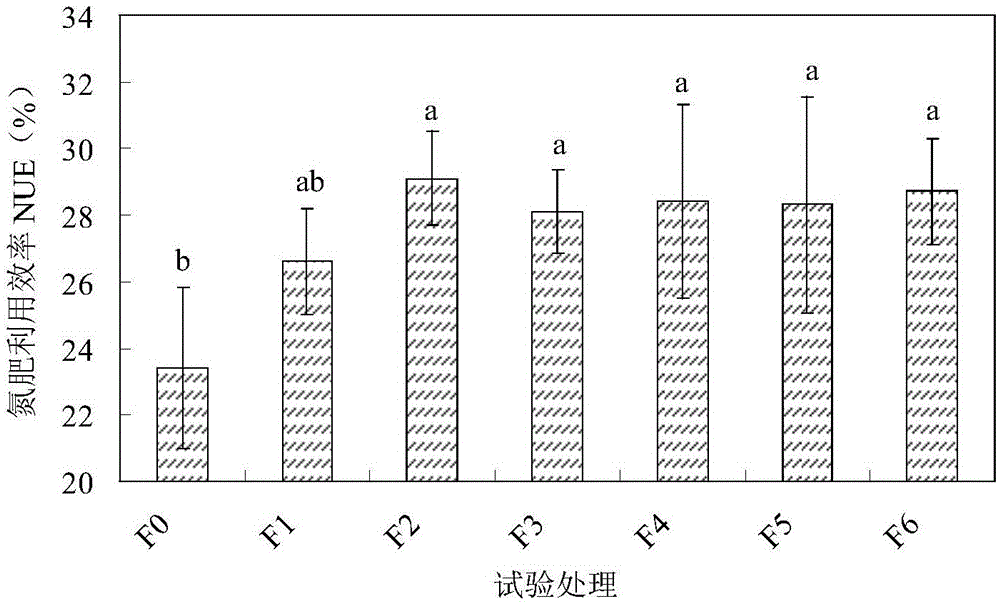

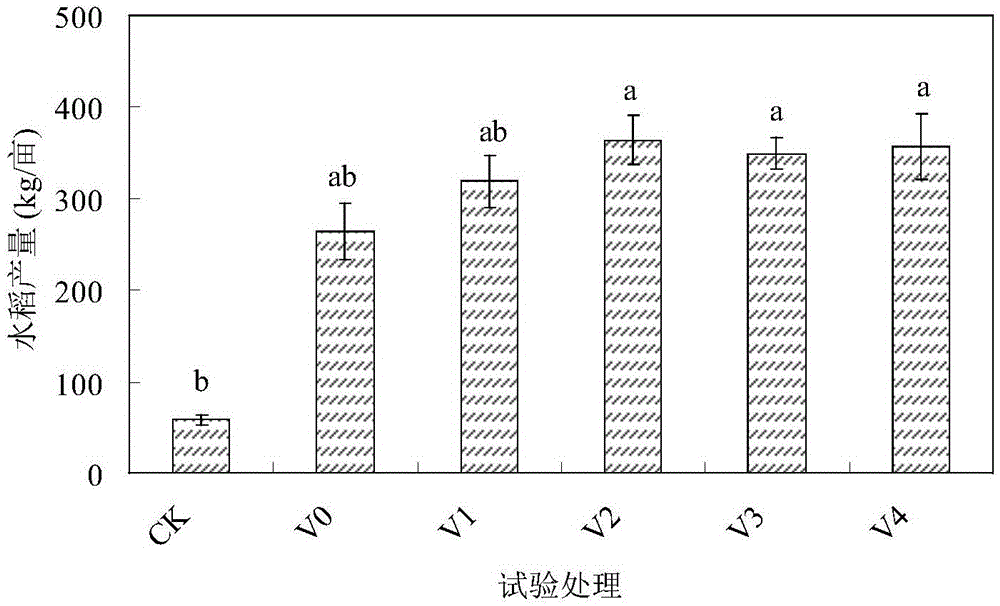

Special rice fertilizer with both soil improvement and fertilizer efficiency functions for coastal saline soil and preparation method and application of special rice fertilizer

ActiveCN105111021AImprove physical and chemical propertiesImprove breathabilityFertilising methodsAgriculture gas emission reductionAlkali soilNitrification inhibitors

The invention discloses a special rice fertilizer with both soil improvement and fertilizer efficiency functions for coastal saline soil and a preparation method and application of the special rice fertilizer. The special rice fertilizer comprises the following components in parts by mass: 35-40 parts of humic acid, 15-20 parts of fulvic acid, 20-25 parts of a composite fertilizer, 15-20 parts of a silicon calcium fertilizer, 1-1.5 parts of a urease inhibitor and 1-1.5 parts of a nitrification inhibitor. According to the invention, the application method combines soil culture, root system activation, crop nourishment and fertilizer efficiency improvement, so the rice fertilizer is low in cost, stable in effect, applicable to mechanical operation, not only applicable to coastal intertidal zones, but also applicable to rice planting in saline-alkali soil in north China or even northwest inland.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI +1

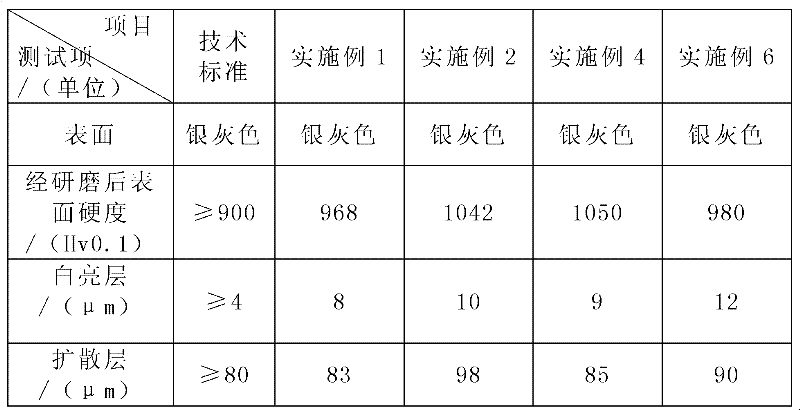

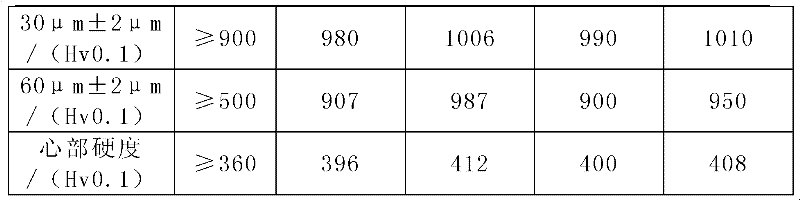

Gas nitriding treatment method of 11Cr17 stainless steel slip sheet

ActiveCN102517541ASimple processReduce manufacturing costSolid state diffusion coatingSlip sheetQuality performance

The invention relates to a gas nitriding treatment method of 11Cr17 stainless steel slip sheet, belonging to the technical field of stainless steel treatment. The invention aims at solving the problems of large erosion on the equipment and products and large environmental pollution of the nitriding method of 11Cr17 stainless steel slip sheet in the prior art. The method of the invention comprisesthe steps of: degreasing and cleaning the slip sheet, performing a passive film removal treatment at 300-450 DEG C to remove the passive film on the surface of the slip sheet; continuously filling ammonia, performing a first stage nitriding treatment at 450-530 DEG C, and performing a second stage nitriding treatment at 530-580 DEG C, and cooling to obtain a nitrided 11Cr17 stainless steel slip sheet. The method of the invention has the advantages of simple technique process, low production cost, small environmental pollution, small erosion on the nitriding equipment and capability of prolonging the service life of the equipment; besides, the obtained product has good quality performance and high erosion resistance.

Owner:浙江百达精工股份有限公司

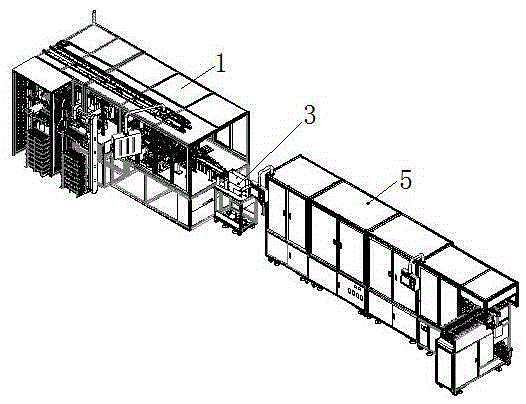

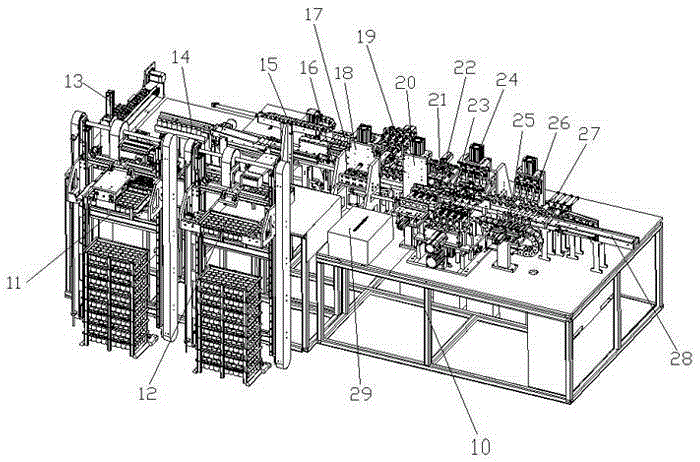

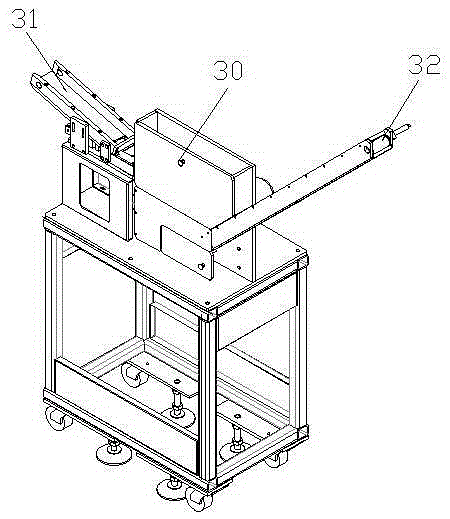

Positive and negative electrode welding and membrane covering assembly line of battery

InactiveCN105428668AImprove intelligenceHigh degree of automationPrimary cell manufactureAssembling battery machinesBattery chargeInternal resistance

The invention provides a positive and negative electrode welding and membrane covering assembly line of a battery. The assembly line comprises a positive and negative electrode welding machine, a membrane covering machine and a cache mechanism, wherein the positive and negative electrode welding machine comprises a battery charging conveyor module and a welding concentricity detector module; the membrane covering machine comprises a battery membrane covering module and a battery boxing module; the cache mechanism comprises a cache box, a battery charging channel and a battery discharging channel. The assembly line can be used for carrying out charging, conveying, positive electrode welding, positive electrode concentricity detection, positive electrode welding, negative electrode concentricity detection, sorting of accepted weld products, battery conveying caching, battery internal resistance testing, battery meson assembly, battery membrane covering, battery membrane baking, sorting of accepted battery products, battery boxing, discharging and recycling in a full automatic way and integrates all these functions into a whole; the assembly line has the advantages of high intelligent level, high automatic operation degree, high detection accuracy, high welding and assembling working efficiency, high yield, good quality effect and low cost; in addition, the assembly line can produce over 55 batteries per minute.

Owner:广东彩扬能源装备有限公司

Plant deep root robust stalk promotor and its preparing method

The plant growth promoter is prepared with the material including tricontanol, salicylic acid, thiourea and abscisic acid vitamin C, protein hydrolysate, ribonucleic acid, urea, potassium dihydrogen sulfate, magnetized water and other 12 kinds of inorganic compounds. It has the functions of raising root system activity in absorbing water and mineral, strengthening photosynthesis, promoting the synthesis of carbohydrate, raising milk filling strength, increasing the accumulation of dry matter, prolonging leaf function stage, etc.

Owner:李生军

Cultural method of meat ducks by using biological fermentation bed

The invention discloses a cultural technology of meat ducks by using a biological fermentation bed, which has no pollution and zero discharge and saves labor and time. The cultural method comprises the following steps of: cultivating by using biological packing materials, wherein beneficial floras of the biological packing materials construct a strong and benign environment; and adsorbing, neutralizing, degrading and converting organic matters in excretion by the biological packing materials. The invention has no obvious odor discharge and no bed washing after selling meat ducks, realizes zero discharge and generates no washing sewage.

Owner:赵克学

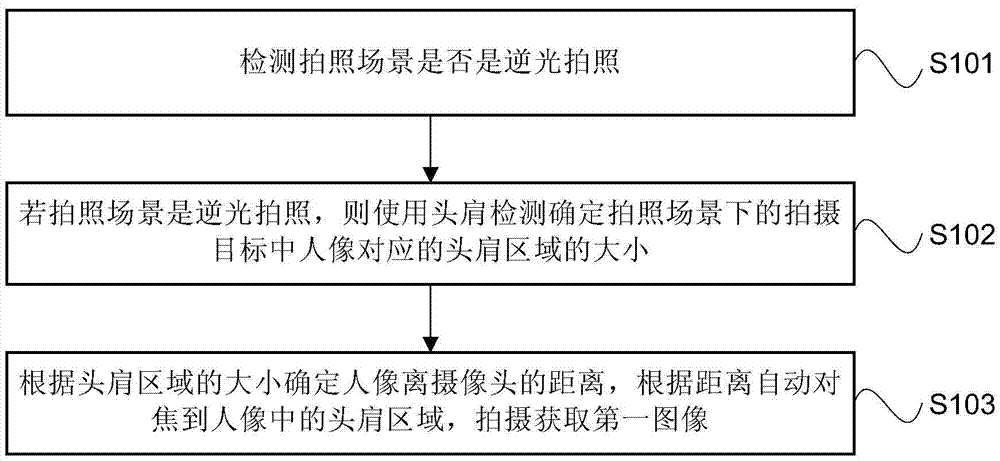

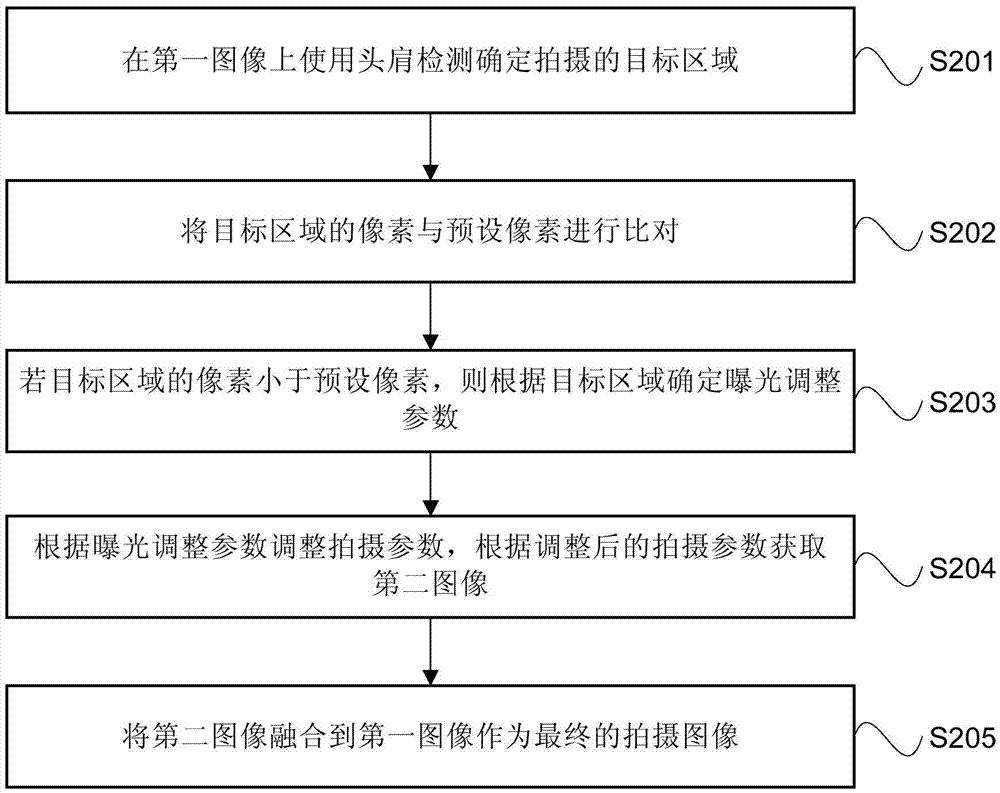

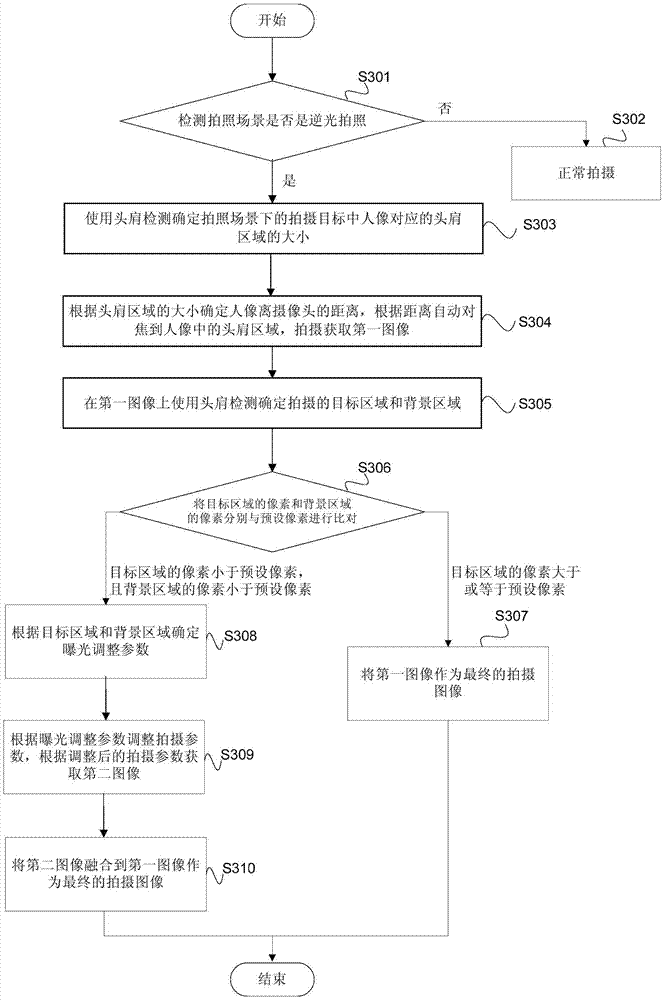

Backlight photographing method and device

ActiveCN105450932AGood quality and effectNo underexposureTelevision system detailsColor television detailsComputer visionHead shoulders

The invention provides a backlight photographing method and device, and the method comprises the steps: detecting whether a photographed scene is photographed in a backlight manner or not; determining the size of a head-shoulder region corresponding to a portrait of a photograph object in the photographed scene through head-shoulder detection if the photographed scene is photographed in the backlight manner; determining the distance from the portrait to a camera according to the size of the head-shoulder region, automatically focusing the head-shoulder region in the portrait according to the distance, and photographing and obtaining a first image; The method and device can effectively detect the head-shoulder region in the portrait in the backlight scene through head-shoulder detection, can achieve the automatic photographing of a clear image of the head-shoulder region in the backlight scene, and cannot cause a black face phenomenon because of poor exposure of a person.

Owner:HUAWEI TECH CO LTD

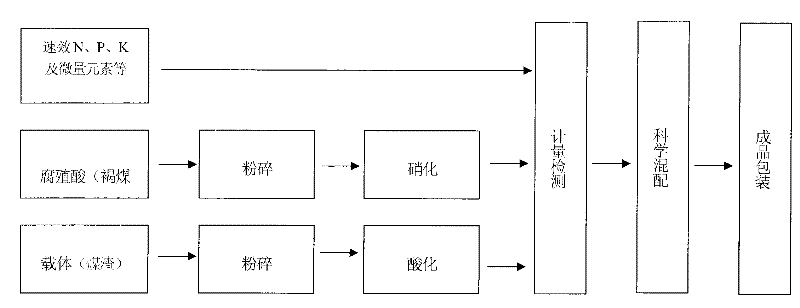

A kind of compound rice seedling raising agent and preparation method thereof

ActiveCN102295482AImprove the overall levelEnhances cold and drought resistanceFertilizer mixturesAmmonium sulfateHumic acid

The invention relates to a composite rice seedling agent and a preparation method thereof. The composite rice seedling agent comprises the following components based on 1000kg: 420-490kg of acidified coal slag, 100-150kg of sulfuric acid, 200-230kg of diammonium phosphate, 70-110kg of ammonium sulfate, 65-85kg of nitro humic acid, 30-40kg of rare earth, 27-35kg of potassium sulfate, 10-12kg of zinc sulfate and 8-10kg of iron sulfate. The composite rice seedling agent provided by the invention can be used for preventing and treating rice seedling blight and improving the disease-resistant capability and development quality of rice seedlings so that the rice seedlings can well thrive.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

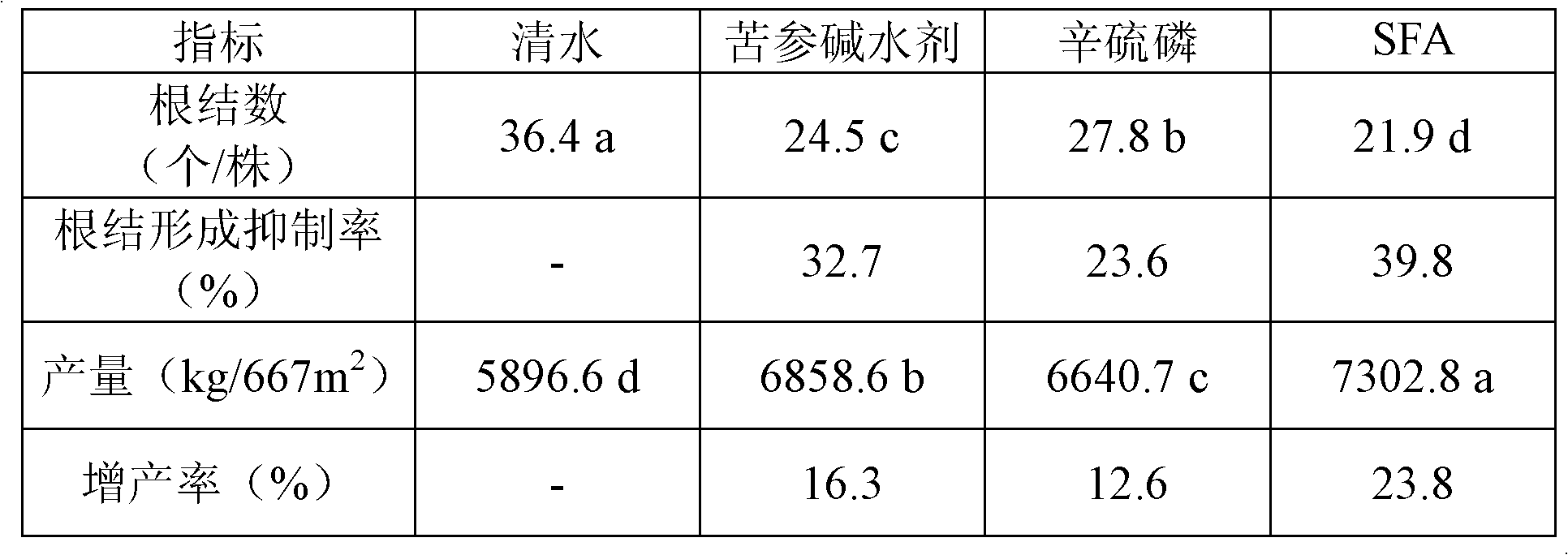

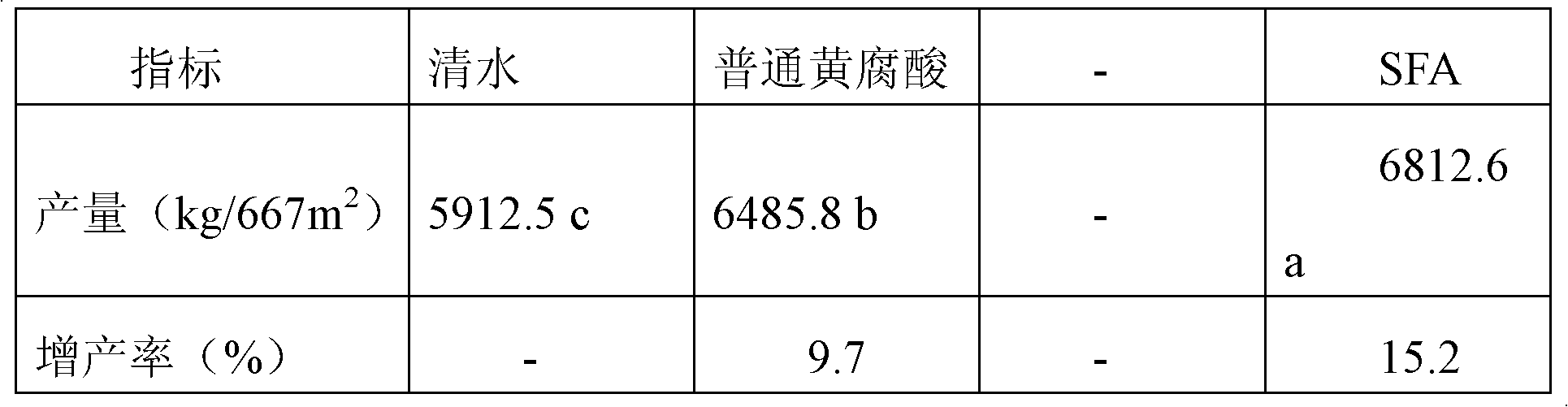

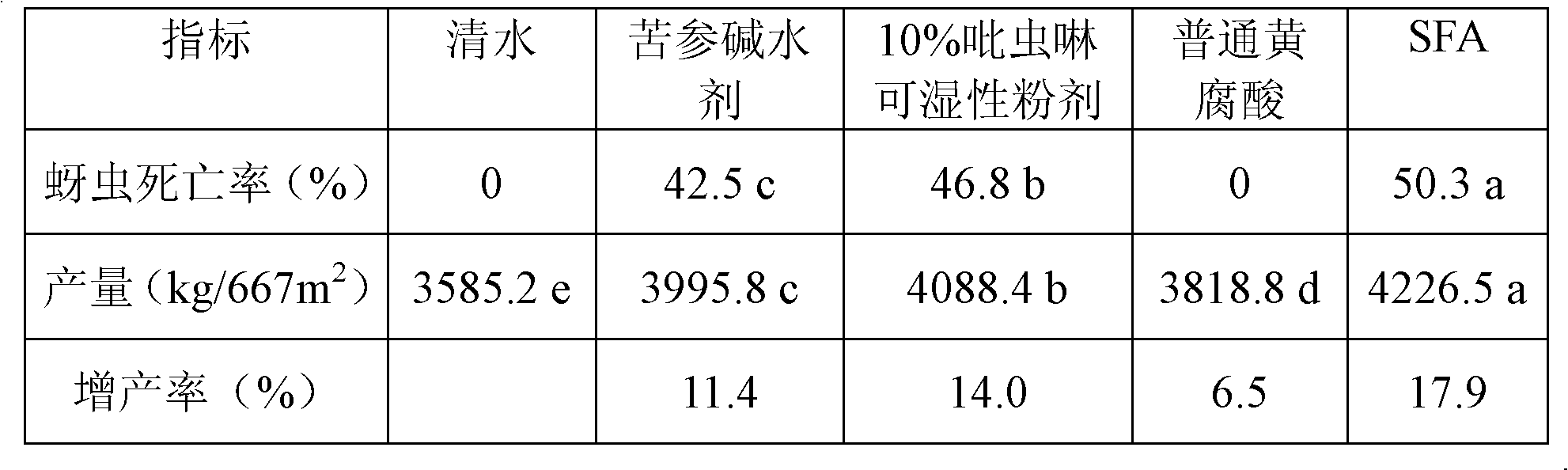

Method for producing insect-resistant fulvic acid by using tobacco waste

InactiveCN102603813ATackling the backlog of pollutionPromote growthOrganic chemistryFertilizer mixturesNicotiana tabacumPotassium

The invention discloses a method for producing insect-resistant fulvic acid by using tobacco waste. The method comprises the following steps of: shredding tobacco waste serving as a raw material including tobacco rods, tobacco forks, tobacco stalks, tobacco flowers, cured tobacco residues, bottom leaves, a part of top leaves and the like produced during the production of tobacco, spraying water for wetting completely, and spraying a catalyst and an oxidant; and oxidizing, and extracting and separating oxidation-degraded materials to obtain liquid insect-resistant fulvic acid which contains a certain amount of nicotine and contains nitrogen, phosphorus, potassium, calcium, magnesium, other trace elements and active ingredients such as soluble saccharides and the like. Due to the adoption of the method, the problem of waste of piled tobacco waste is solved, the tobacco waste is utilized reasonably, environmental pollution is avoided, insect-resistant high-activity fulvic acid is prepared, and good economic benefit and ecological benefit can be achieved.

Owner:NORTHWEST A & F UNIV

Biological all-element fertilizer and preparation method thereof

The invention discloses a biological all-element fertilizer which is prepared from the following raw materials in parts by weight: 70-75 parts of soy bean pulp, 30-34 parts of urea, 30-34 parts of monoammonium phosphate, 10-12 parts of potassium chloride, 5-7 parts of fulvic acid, 2-3 parts of ferrous sulfate, 3-4 parts of zinc sulfate, 2-3 parts of manganese sulfate, 2-3 parts of sodium molybdate, 1-2 parts of sodium selenite, 1-2 parts of zinc oxide, 1-2 parts of sodium naphthaleneacetate, 1-2 parts of DA-6, 1-2 parts of radix euphorbiae ebractealatae powder, 3-4 parts of EM microbial inoculums, 4-6 parts of coating agents and a right amount of water. The biological all-element fertilizer disclosed by the invention is comprehensive in nutrition, can effectively increase the nutritional components contained in soil, can be used for regulating the equalization of nutrients contained in the soil, can effectively promote the growth of a plant and enhance the disease resistance of the plant, is regulable in fastness and slowness, equalized in fertilizer supply and lasting in fertilizer effect. According to the invention, the DA-6 plays roles of regulating growth, promoting rootage, sprouting and blooming, preventing flower drop and fruit drop, forming nonnuclear fruits, promoting precocity, increasing yield and the like and can enhance the drought resistant capacity, chill resistant capacity, disease resistant capacity, salt and alkali resistant capacity and dry hot wind resistant capacity of the plant; the added radix euphorbiae ebractealatae powder prevents the generation of the disease and pest injury of the plant; the fulvic acid can promote the growth of the plant, play an important role on drought resistance, enhance the stress resistant capacity of the plant and play roles of yield increase and quality improvement.

Owner:ZONGYANG COUNTY BAIYUN ECOLOGICAL GARDEN

Ivory tint artistic wood folding fan manufacturing method

InactiveCN1528223AGood quality and effectAchieve mass productionUmbrellasScreen printingComputer Aided Design

The present invention relates to a production method of ivory colour handicraft wooden folding fan, and said production method includes the following steps: folding fan moulding and structure design, its contour dimension and structure size are basically identical to that of traditional sandalwood folding fan; preparing fan edge and fan core by adopting punched porous flower form, using organic combination of computer aided design and screen printing technique to design decorative pattern of the fan; selecting material, utilizing stone-stain wood plate to prepare fan blank, drilling assembling holes; bleaching and drying fan blank, preparing bleaching, solution, said bleaching solution contains hydrogen peroxide, sodium hydroxide solution and alcohol, bleaching, cleaning drying, position, forming, assembling fan, screen printing, perfuming and waxing so as to obtain the invented product.

Owner:NANJING FORESTRY UNIV +1

Preparation method of nutrient for promoting growth of medicinal whole-grass plant

InactiveCN103332976AReduce manufacturing costSimple methodFertilizer mixturesTrace element compositionSide effect

The invention discloses a preparation method of a nutrient for promoting growth of a medicinal whole-grass plant. The nutrient comprises, by weight, 10 to 30% of a nucleotide salt, 20 to 70% of glucose, 10 to 21% of amino acids and 10 to 30% of a medium trace element, wherein the medium trace element is Mn, B, Fe, Zn, Cu or Mo. The nucleotide salt, the amino acids and the medium trace element are crushed and screened and the glucose is added into the mixed powder and the mixture is uniform mixed. The preparation method has a low cost and a small use amount, has simple processes and is suitable for large-scale production and popularization. The nutrient has a reasonable ratio of all the ingredients, strong pertinence, no toxicity, no damage, no residual and no side effects, has effects of improving a yield, income, effects and resistance, can promote growth of a medicinal whole-grass plant and can improve a yield by 40-100%.

Owner:大理州大自然生物科技有限公司

Soil conditioning fertilizer and production method thereof

ActiveCN103274879AThe effect of increasing production is obviousImprove Yield BenefitsFertilizer mixturesHumic acidPhosphate

The invention discloses a soil conditioning fertilizer and relates to the technical field of agricultural fertilizer. The soil conditioning fertilizer is prepared from the following materials in weight parts: 50-100 parts of humic acid, 50-100 parts of dolomite dust, 5-10 parts of dilute sulphuric acid solution, 100-150 parts of monoammonium phosphate, 1-30 parts of urea, 300-350 parts of potassium chloride, and 5-10 parts of zinc sulfate. The experimental results of the field fertilizer efficiency demonstration of the soil conditioning fertilizer on various crops including field crops like crops, commercial crops like soybean and green pepper, as well as melons and fruits and vegetables like Chinese cabbage, grape and radish show that the yield is remarkably increased and the product quality is remarkably improved, the stress resistances like cold resistance, drought resistance, disease resistance and lodging resistance of the crops are remarkably improved, the tastes of the melon, the tomato, the Chinese cabbage, the green pepper, and the like are good, and therefore, the soil conditioning fertilizer is well received by the masses and is worthy of popularization and application.

Owner:临沂草之美医药科技有限公司

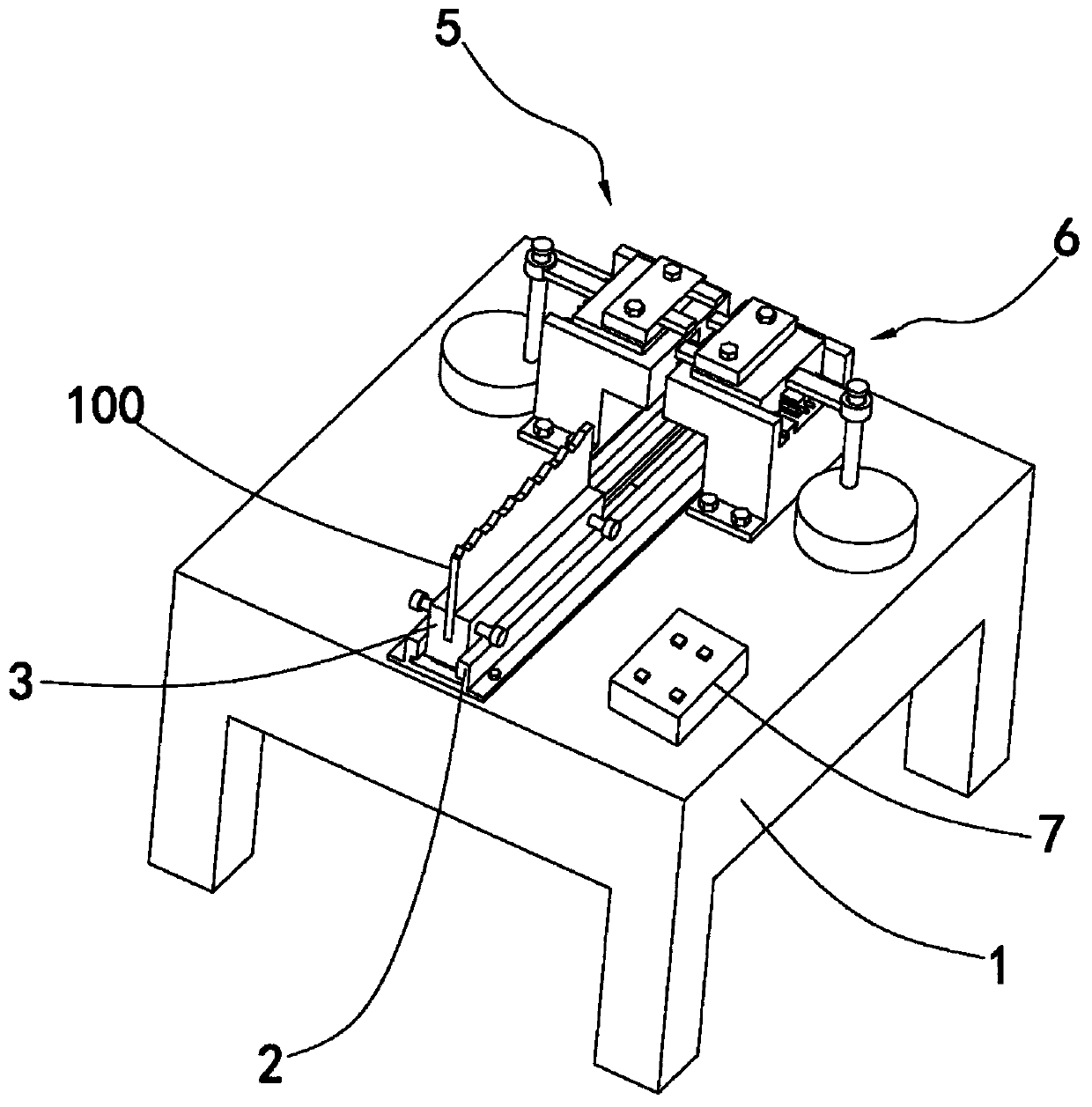

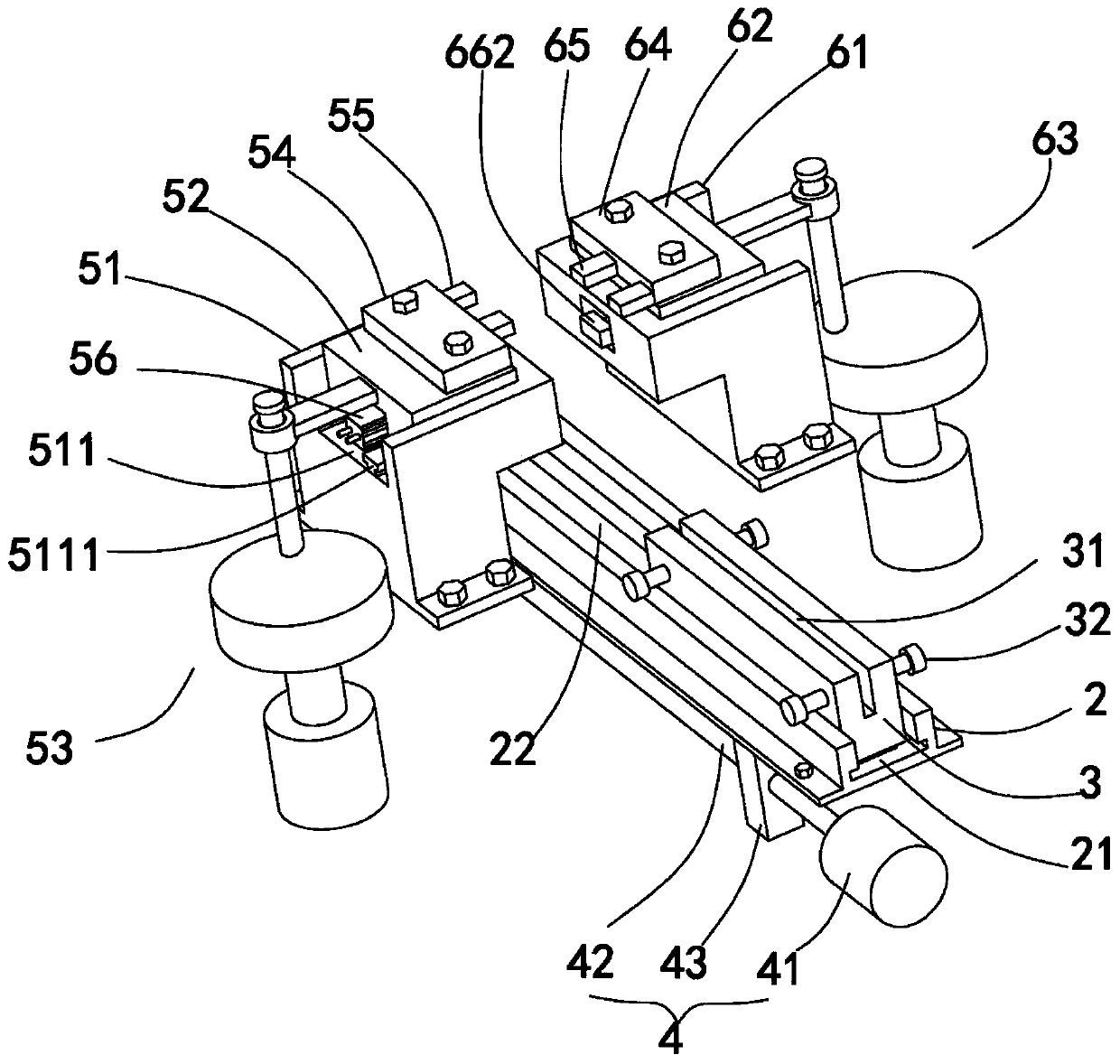

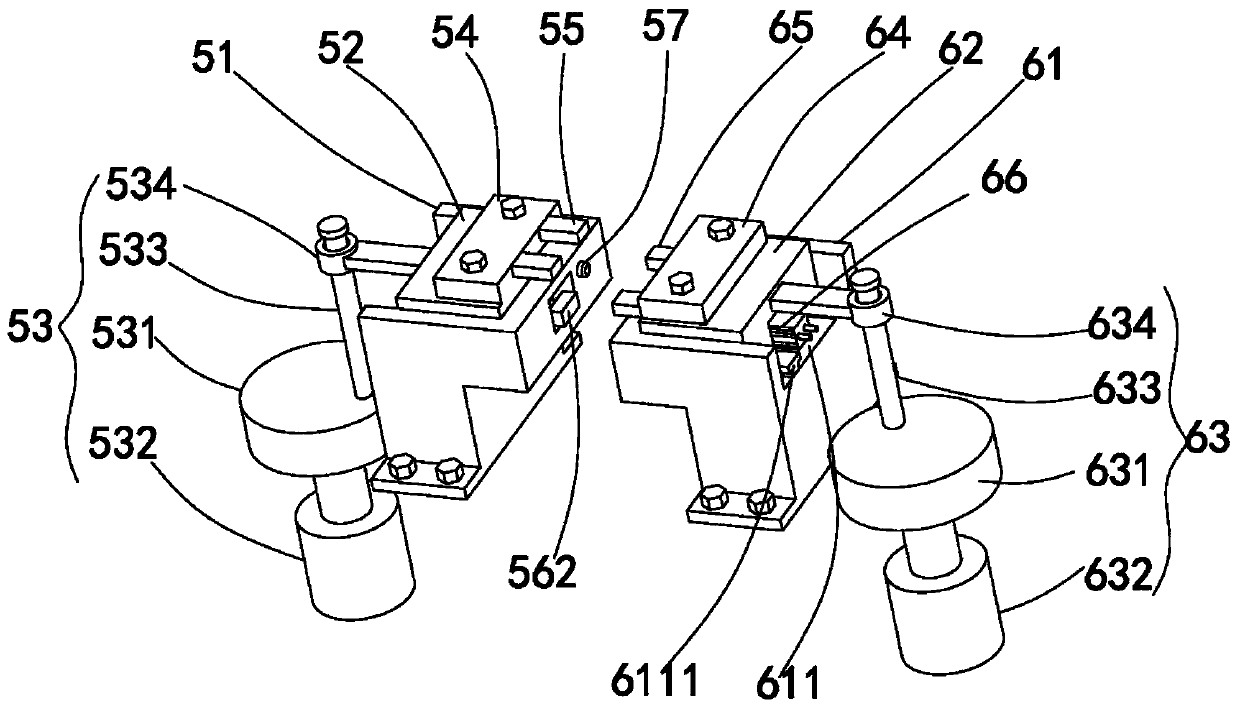

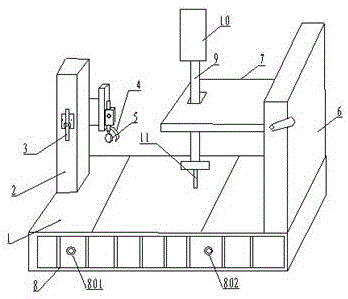

Band saw blade tooth separating mechanism

PendingCN110666246ASimple and fast operationHigh precisionMetal sawing tool makingEngineeringElectric control

The invention provides a band saw blade tooth separating mechanism. The band saw blade tooth separating mechanism comprises a machine table. A sliding seat is fixedly arranged on the machine table from the feeding end to the discharging end of a band saw blade, a fixed seat for loading the band saw blade is arranged on the sliding seat, a first linear module for driving the fixed seat to linearlymove along the sliding seat is arranged at the bottom of the sliding seat, a left tooth separating device and a right tooth separating device are arranged on the two sides of the sliding seat separately, an electric control box is further arranged on the machine table, and the electric control box is connected with the first linear module, the left tooth separating device and the right tooth separating device. A servo motor is used as power drive, by means of a cam transmission principle, the operation is easy and convenient, the precision and the working efficiency are high, tooth separatingis uniform, and the quality effect is ideal.

Owner:HUBEI SHENTIAN NEW MATERIAL TECH CO LTD

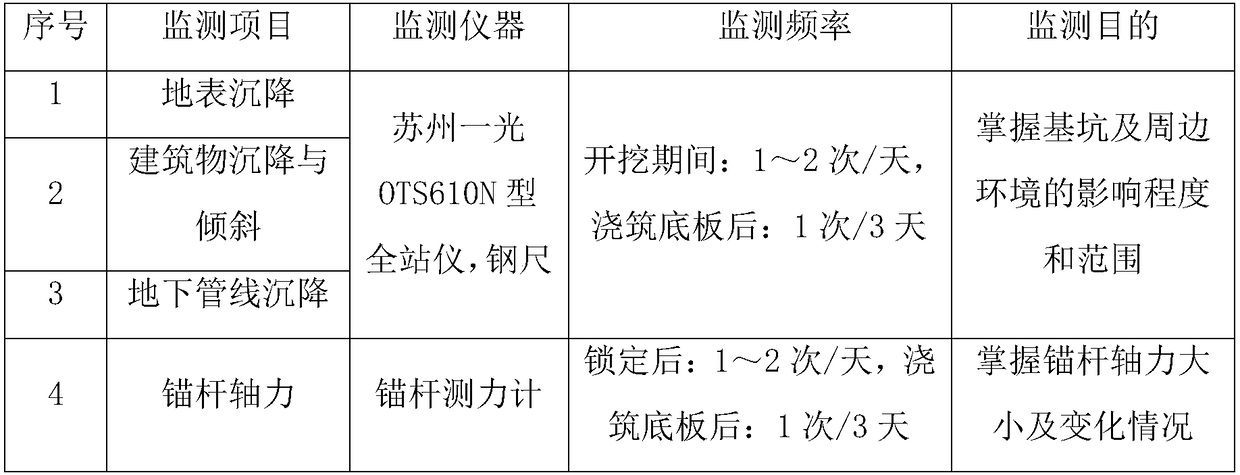

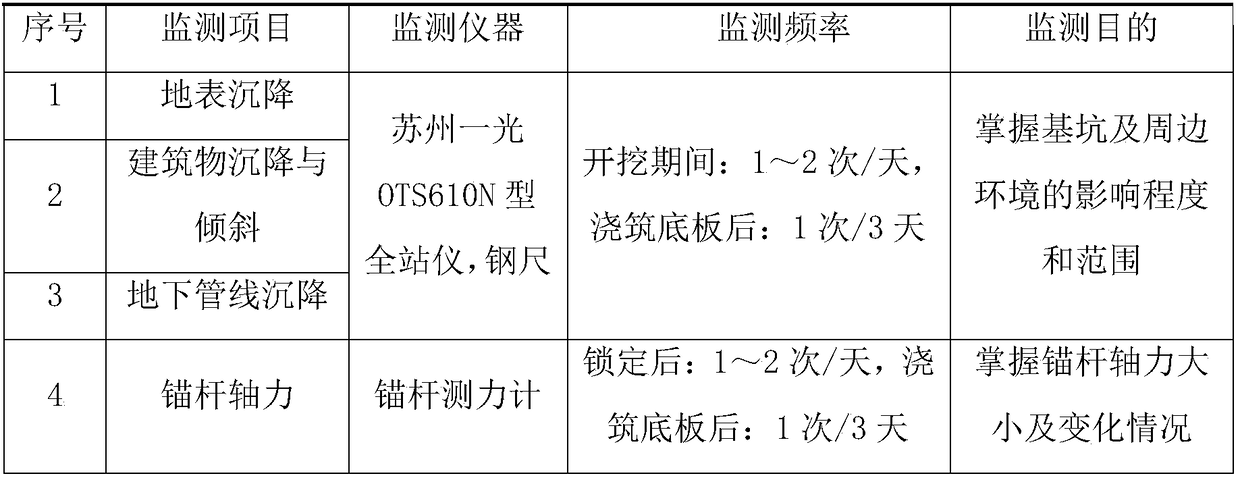

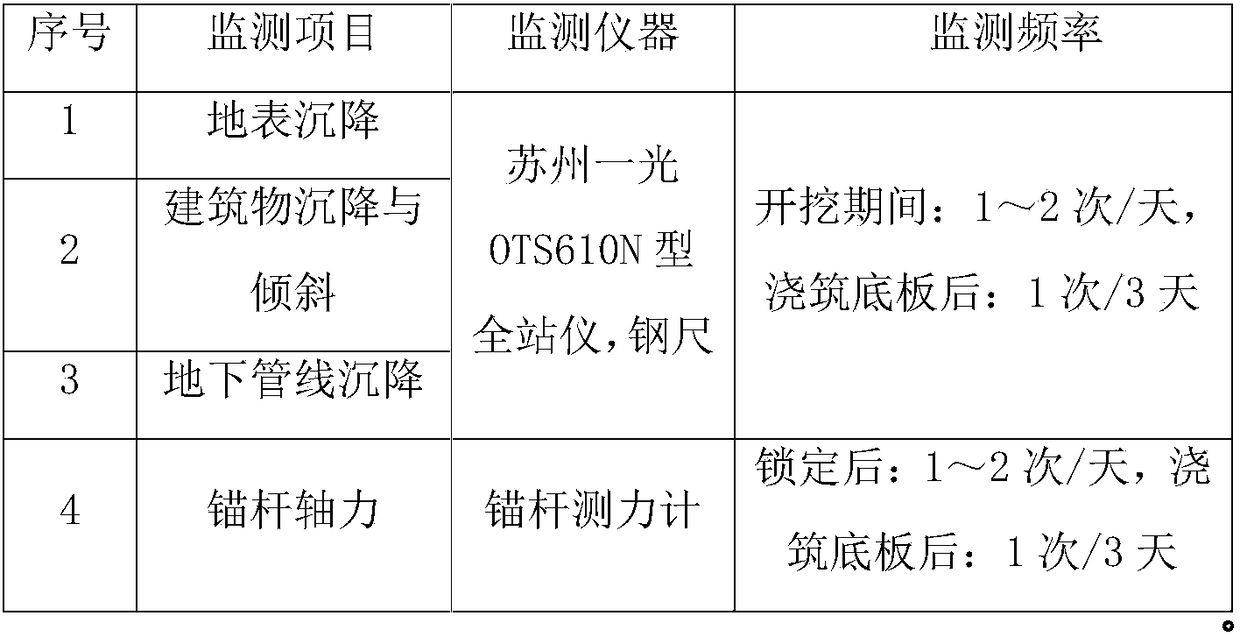

Supporting construction method for miscellaneous fill ultra-deep foundation pit through combination of consolidation grouting and double-row steel pipe piles

ActiveCN108517877AReduce disturbanceFast and easy sealing and groutingExcavationsBulkheads/pilesPressure groutingDouble row

The invention discloses a supporting construction method for a miscellaneous fill ultra-deep foundation pit through combination of consolidation grouting and double-row steel pipe piles. The supporting construction method comprises the following steps that firstly, the steel pipe piles and a grouting soil-retaining structure are constructed; and secondly, rear impact self-advancing anchor rods areconstructed. According to the construction method, the problem that supporting piles and walls of an adjacent building cannot be constructed under the situation of the ultra-deep foundation pit withmiscellaneous fill in the upper portion and rock in the lower portion is solved. By utilizing a combined supporting technology, disturbance to the foundation pit is greatly reduced, and the safety ofthe existing building is effectively protected; and the double-row steel pipe piles are adopted to be combined with the pressure grouting technology and the perforated pipe grouting technology, the soil-retaining structure with the large thickness and good stiffness is formed and replaces a traditional row pile and continuous wall soil-retaining structure, and the technique is simple relatively.

Owner:QINGDAO XINHUAYOU CONSTR GROUP

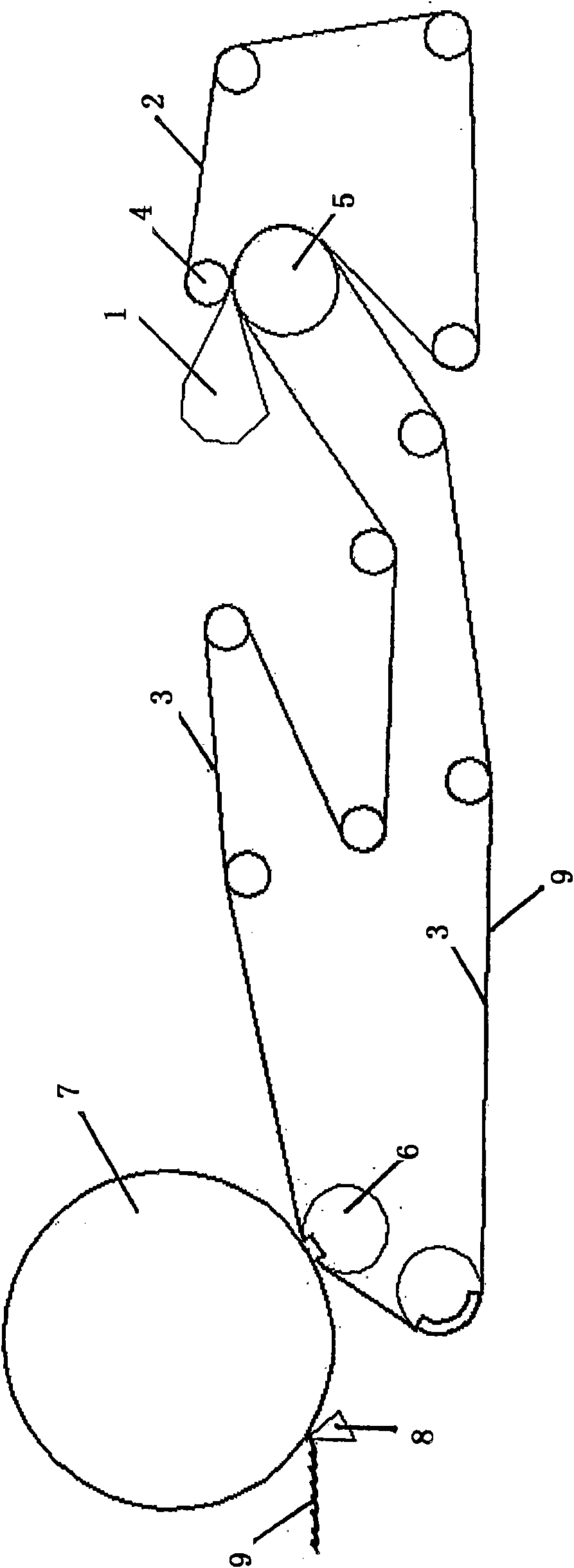

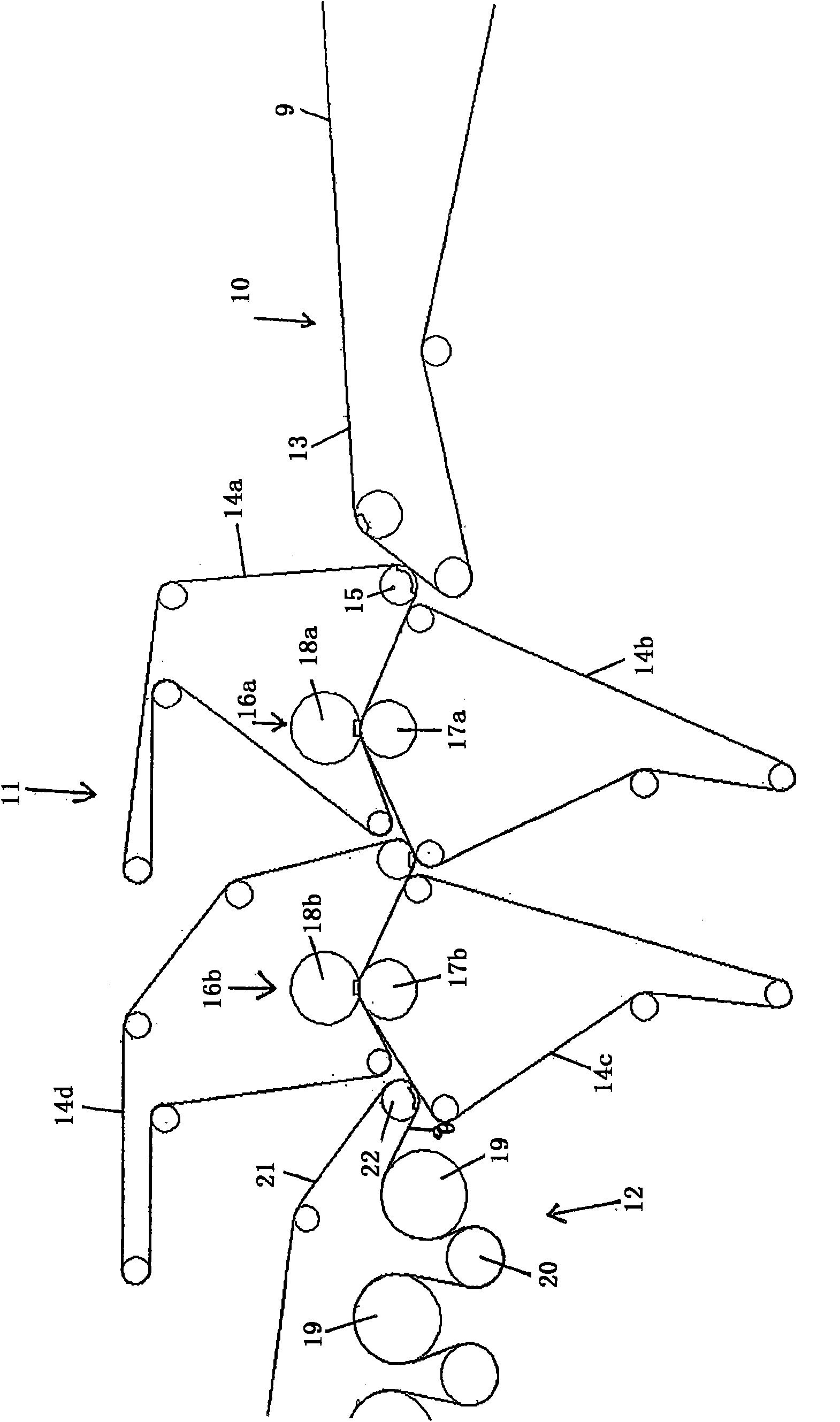

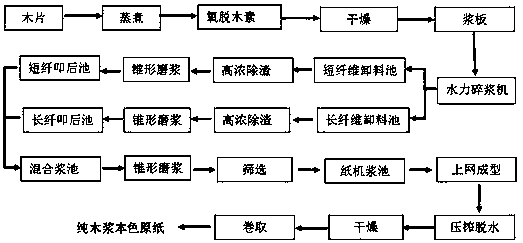

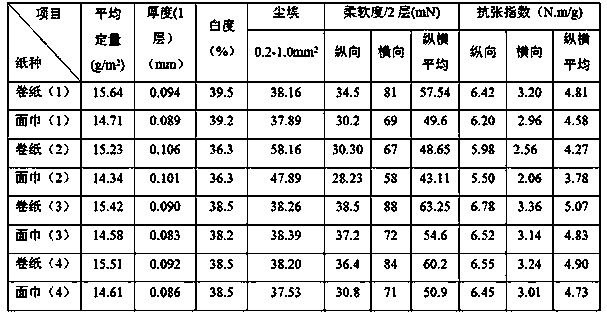

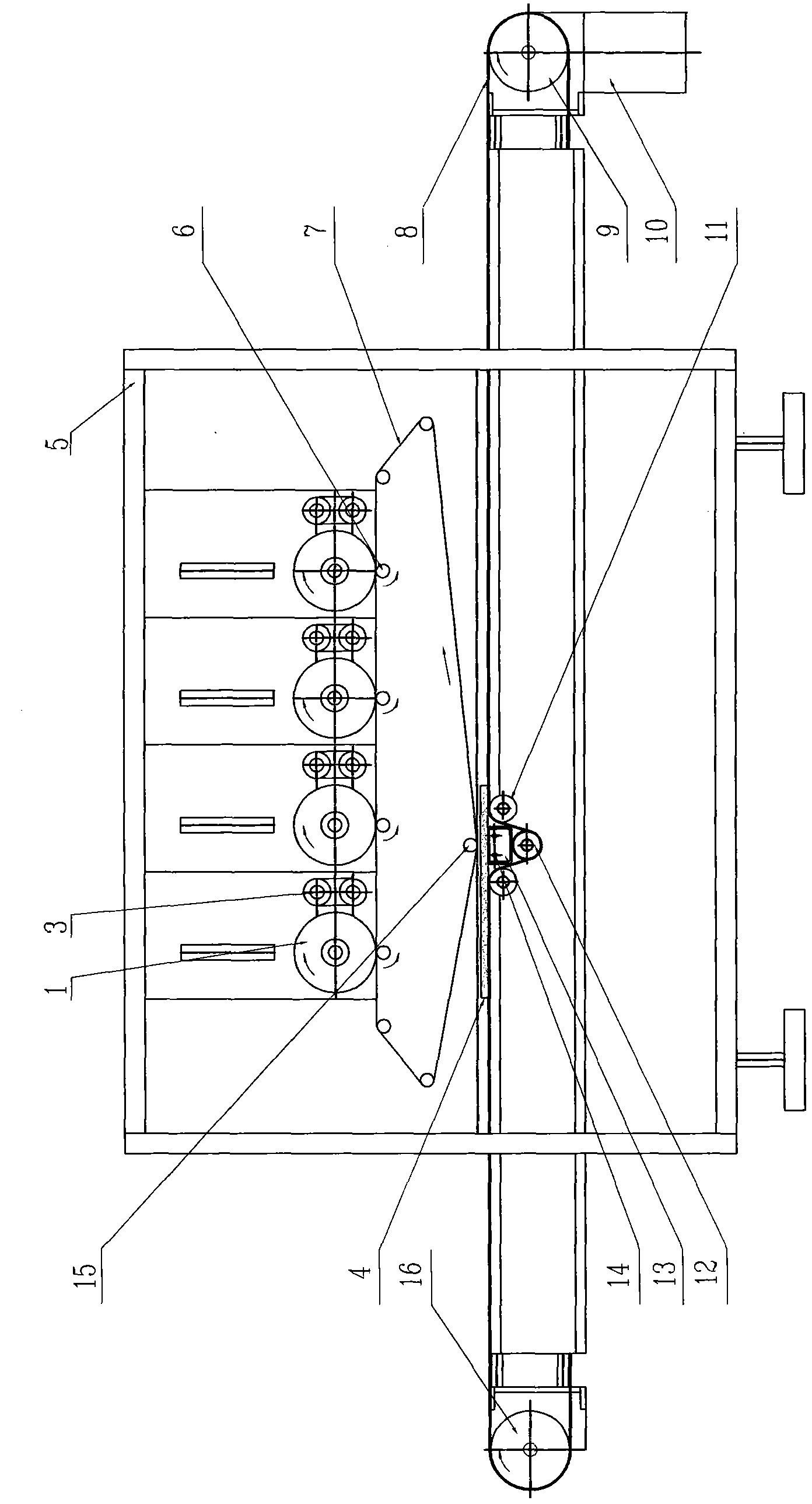

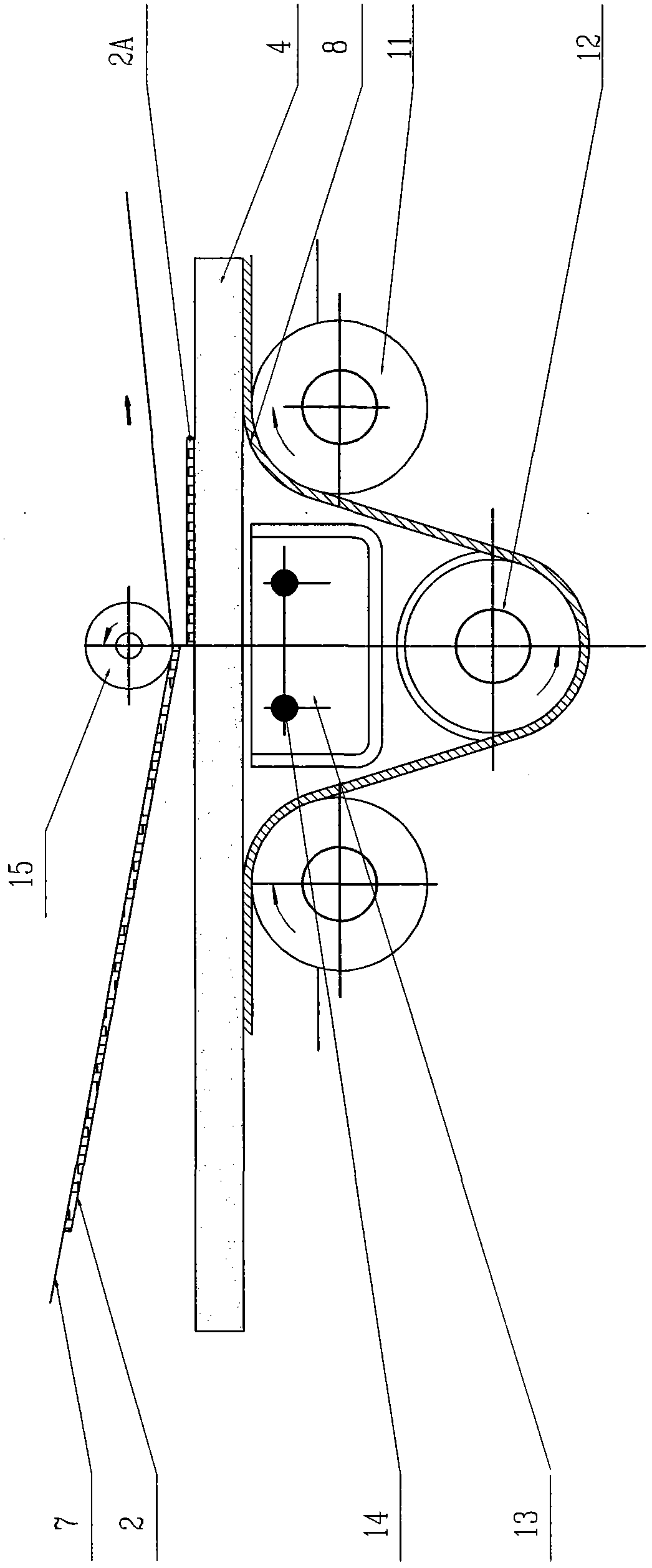

Preparation method of pure wood pulp natural color paper for daily use

ActiveCN108221453AReduce pollutionPromote incomePaper-making machinesEnvironmental resistanceSulfate

The invention discloses a preparation method of a pure wood pulp natural color paper for daily use. The method includes steps of pulping through a sulfate method, and acquiring natural color needle pulp and natural color broad-leaf pulp through dual-section oxygen delignification; grinding the natural color needle pulp and the natural color broad-leaf pulp to respectively obtain needle pulp and broad-leaf pulp; then mixing at ratio and grinding to obtain mixed pulp; shaping and screening pulp through a monolayer flow box and a crescent shaper; squeezing and dewatering in a shoe form; performing high-temperature drying and sterilization; performing dry-method wrinkling to obtain a nature colored health raw paper with fine texture and soft quality. The preparation method saves resource and reduces environment pollution. The prepared pure wood pulp natural color paper for daily use is good in quality performance, stable in product quality; the dust is greatly reduced, the production technique is optimized, matured and advanced; moreover, the papermaking process is environment-friendly. Compared with a straw pulp natural color paper and a bamboo pulp natural color paper, the pure woodpulp natural color paper is better in gloss, high in intensity, softer in paper quality, and can be widely applied to paper processing for family use and various outside healthy use.

Owner:YUNNAN YUNJING FORESTRY & PULP MILL

Laser printing machine for ceramic

The invention relates to a laser printing machine for ceramic. The laser printing machine comprises a stander, a first transfer printing system and a ceramic green brick conveying system, wherein the first transfer printing system comprises at least one selenium photosensitive drum, a ceramic toner with negative static electricity, a laser head and a transfer printing roller; a circulating rotating transfer printing band is arranged between the first transfer printing system and the ceramic green brick conveying system; a closest point to the ceramic green brick conveying system is formed on the lower part of the transfer printing band and is not in contact with the upper surface of a ceramic green brick passing through the closest point, and a clearance of 0.5-3 mm is reserved between the closest point and the upper surface of the ceramic green brick; a positive static electric field capable of adsorbing the ceramic toner with the negative static electricity on the transfer printing band to the surface of the ceramic green brick is arranged just under a position, through which the ceramic green brick corresponding to the closest point passes; the voltage of the positive static electric field is 2,000-20,000 V. Due to the design, the definition and the vividness of pattern lines printed on the surface of the ceramic green brick can be greatly improved, and the color quality of a ceramic brick is improved; meanwhile, after-sale productive maintenance of equipment is reduced, the production efficiency is improved, and the production cost is lowered.

Owner:陆永添

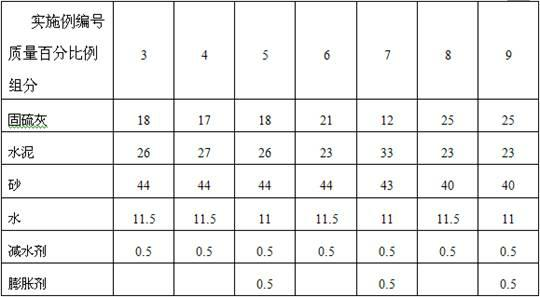

Grouting material containing circulating fluidized bed fuel coal solid sulfur ash

The invention discloses a grouting material containing circulating fluidized bed fuel coal solid sulfur ash. The grouting material containing the circulating fluidized bed fuel coal solid sulfur ash is characterized by comprising the following components in percentage by mass: 10 to 25 percent of solid sulfur ash, 23 to 35 percent of cement, 40 to 55 percent of sand, 0.2 to 0.8 percent of water-reducing agent, 9 to 15 percent of water, 0 to 10 percent of expanding agent and 0 to 1 percent of defoaming agent. The grouting material adopts industrial waste solid sulfur ash as an admixture, utilizes the cinerite activity and the expanding performance of the solid sulfur ash, changes waste into treasure, is low in cost, reduces environmental pollutions, and has a simple production process, low energy consumption, excellent product performance and high practicability.

Owner:SOUTHWEAT UNIV OF SCI & TECH

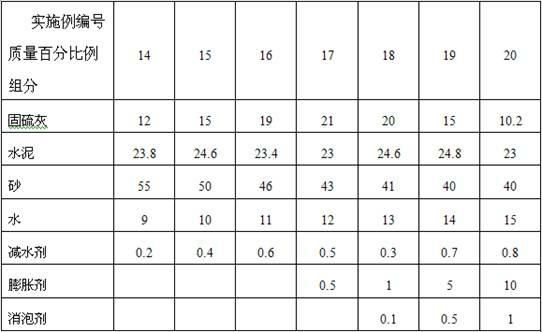

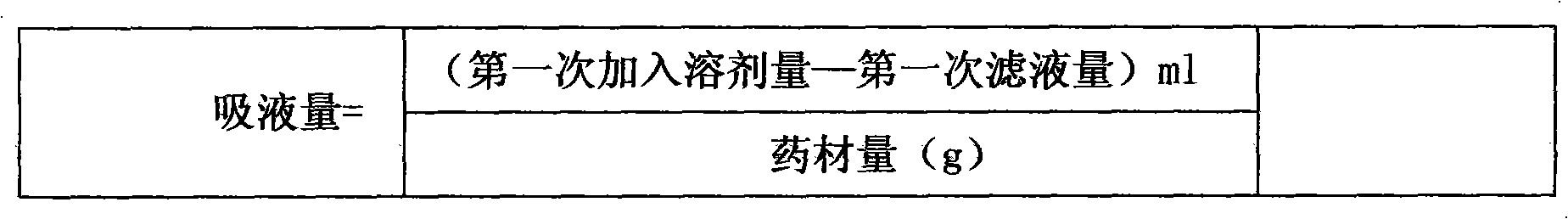

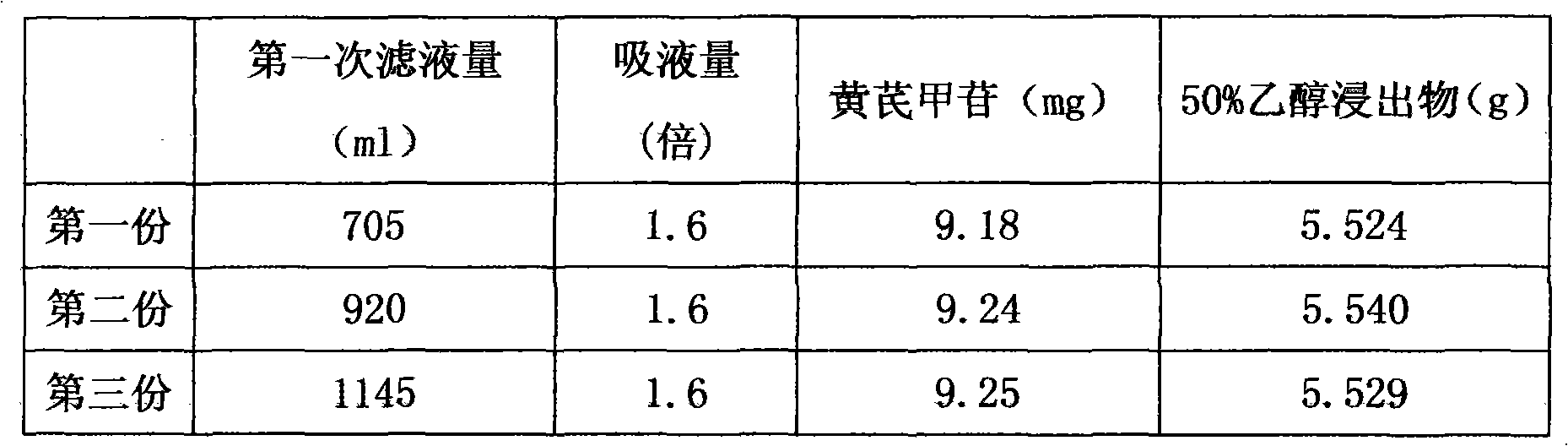

Method for preparing Yixinshu tablets

InactiveCN101804151ALow extraction process costImprove production efficiencyPill deliveryCardiovascular disorderMagnesium stearateOphiopogon

The invention discloses a method for preparing Yixinshu tablets, comprising the following steps of a. taking materials according to the formulation; b. taking ginseng for grinding, sieving by a 100-mesh sieve, and sterilizing for standby application; c. taking the fruit of Chinese magnoliavine and the root of red-rooted salvia for extracting for twice, blending and filtering, concentrating filtrate to have the relative density of 1.12-1.15 (20 DEG C), and obtaining extractum; d. decocting dwarf lilyturf tuber, radix astragali, Ligusticum wallichii and hawthorn for twice, blending decocted liquid, filtering, concentrating filtrate to be 650ml, adding 85% of ethanol with equal quantity, fully stirring, standing still overnight, filtering, concentrating to be the relative density of 1.30-1.36 (80 DEG C), and obtaining water extracted extractum; and e. blending the two extractums, adding ginseng powder and microcrystalline cellulose into the extractum mixture, evenly mixing, sieving by a 160-mesh sieve by using 80% of ethanol, carrying out wet granulation, drying, sieving by a 20-mesh sieve for completing granules, adding dried granules into magnesium stearate, adding right amount of starch, adjusting the total quantity to be 380g, evenly mixing, tabletting to be 1000 tablets, coating film and obtaining the Yixinshu tablets.

Owner:GUANGDONG SINOTAU PHARMA CO LTD

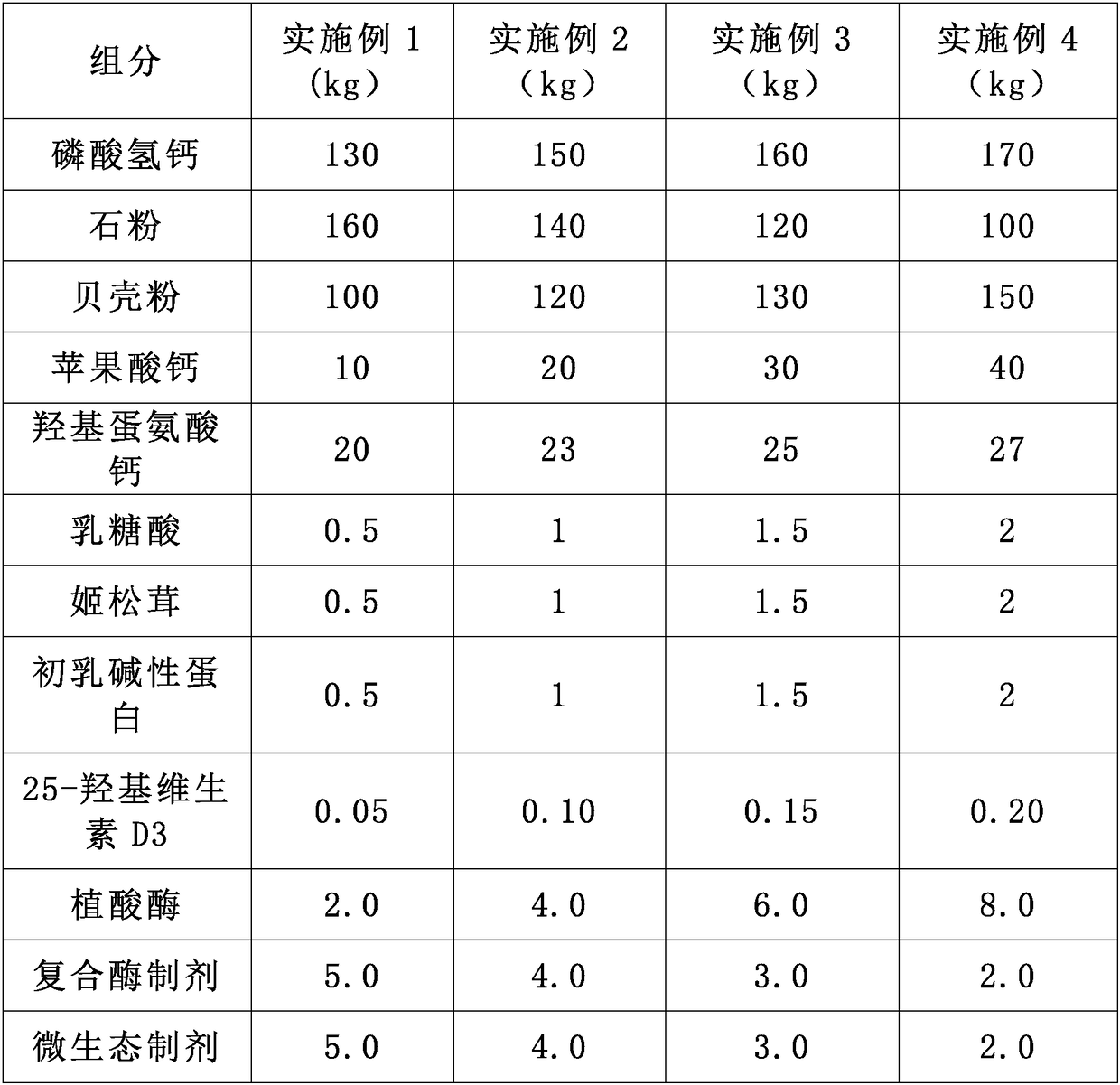

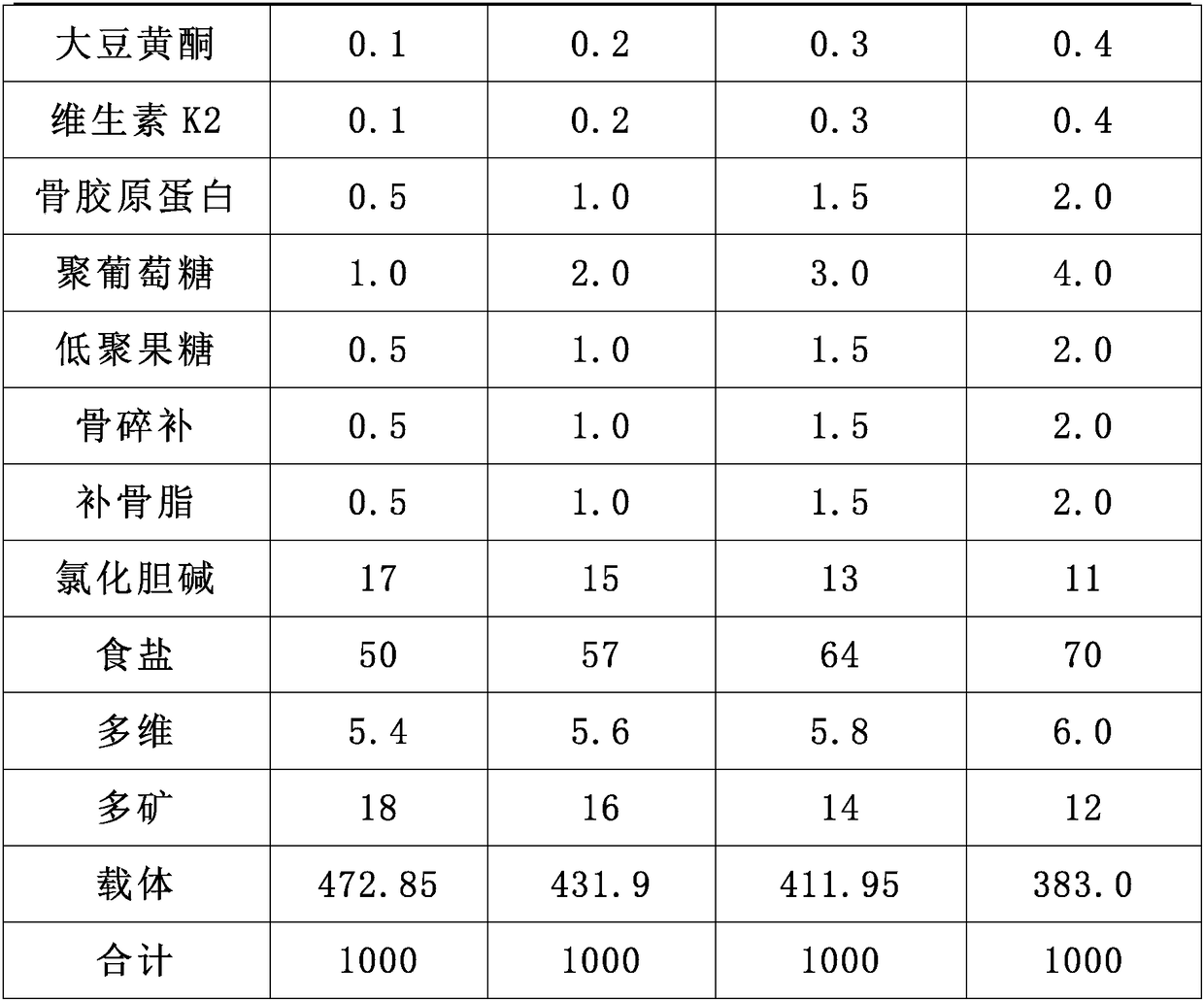

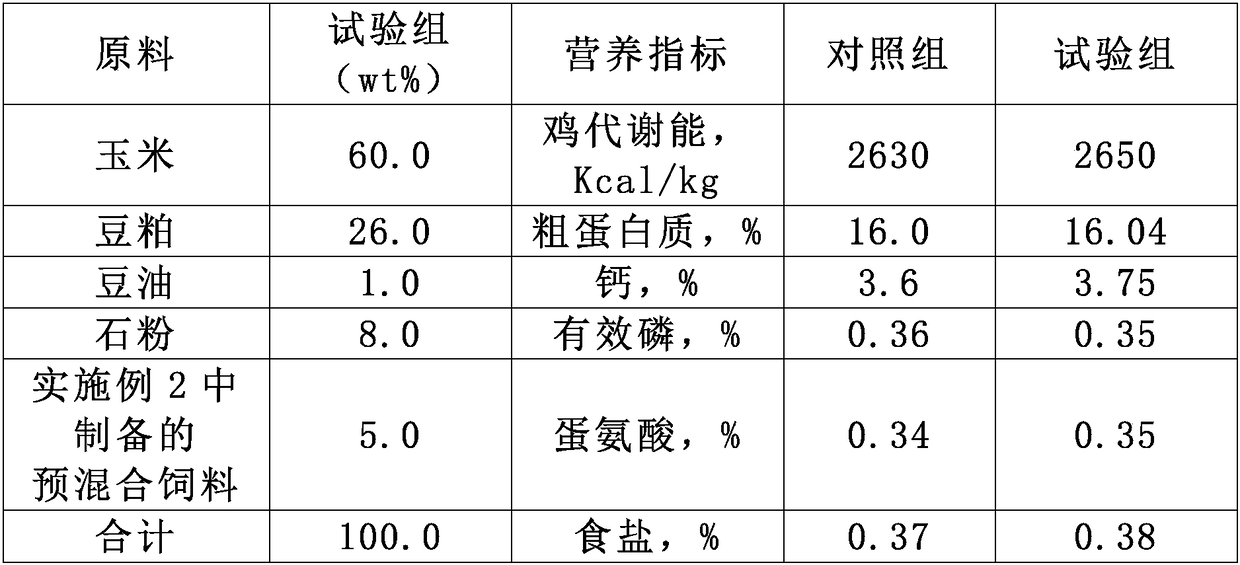

Pre-mixed feed for improving bone density and eggshell quality of laying hens and preparation method thereof

InactiveCN109123181APromote absorptionBroaden the formation processFood processingAnimal feeding stuffVitamin K2Eggshell

The invention provides a pre-mixed feed for improving the bone mineral density and eggshell quality and a preparation method thereof, belonging to the technical field of egg chicken feed. The method comprises the following components in parts by weight: 130-170 parts of calcium hydrogen phosphate, 100-160 parts of stone powder, 100-150 parts of shell powder, 10-40 parts of calcium malate, 20-27 parts of calcium hydroxymethionine, 0.5-2 parts of lactobionic acid, 0.5-2 parts of agaricus blazei and 0.5-2 parts of colostrum alkaline protein, 2-5 parts of hydroxyl vitamin D, 2-8 parts of phytase,2-5 parts of composite enzyme preparation, 2-5 parts of microecological agent, 0.1-0.4 parts of soybean flavone, 0.1-0.4 parts of vitamin K2, 0.5-2 parts of bone collagen, 1-4 parts of polydextrose, 0.5-2 parts of fructo-oligosaccharide, 0.5-2 parts of rhizoma drynariae, 0.5-2 parts of fructus psoraleae and the like. In order to improve the calcium utilization rate, a brand new idea of calcium utilization is provided, that is, three systems of the calcium supplement of the laying hens, that is, a calcium supplementing system, a calcium promotion absorption system and a health system of improving the gastrointestinal.

Owner:播恩集团股份有限公司

Honeycomb ceramic material produced with alumina-chrome slag and its production process

InactiveCN101066881AExcellent slag and corrosion resistanceGood quality and effectCeramicwareSlagVacuum mixing

The present invention discloses one kind of honeycomb ceramic material produced with alumina-chrome slag added with 6-10 wt% binding agent. The production process is the following steps: compounding material, mixing and ball milling, adding binding agent and water and kneading, vacuum mixing, extruding to form, drying and sintering to produce honeycomb ceramic material. The present invention produces honeycomb ceramic material with alumina-chrome slag and has the advantages of rich material source, low cost, excellent anticorrosive performance and long service life.

Owner:潘国明

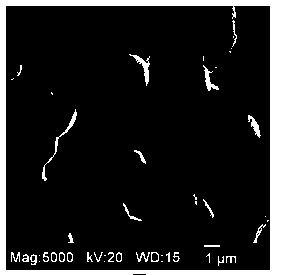

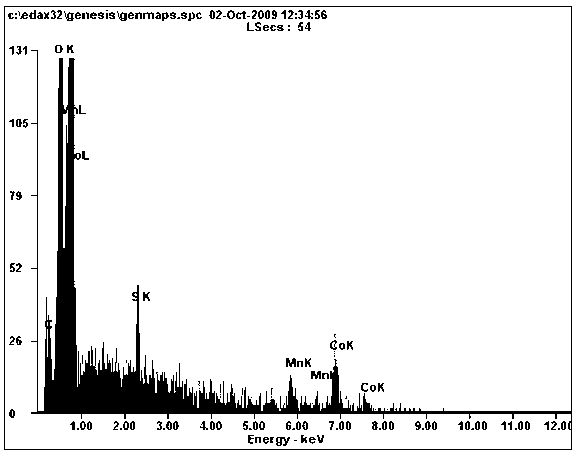

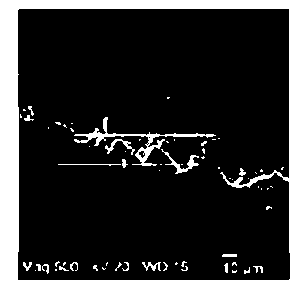

Preparation method of (Mn, Co)3O4 spinel coating

ActiveCN103103592AUniform and dense structureImprove performanceElectrolytic inorganic material coatingAlcoholCeramic coating

The invention relates to a preparation method of a (Mn, Co)3O4 spinel coating, and belongs to the technical fields of preparation and property of a ceramic coating. The preparation method comprises the steps of: mixing by taking (Mn, Co)3O4 powder as a material and taking absolute ethyl alcohol as a solvent, wherein the percent content of mass fraction of the (Mn, Co)3O4 powder is 1-15%; carrying out ultrasonic agitation to obtain (Mn, Co)3O4 powder suspension liquid; then depositing a (Mn, Co)3O4 coating on the surface of a metal substrate under the effect of 200-700V of constant voltage or pulse voltage; and drying and then carrying out high temperature thermal treatment to obtain the (Mn, Co)3O4 spinel coating. The method disclosed by the invention has the advantages of simple technological operation, low cost, good formed coating structure compactness and the like.

Owner:昆明理工大学设计研究院有限公司

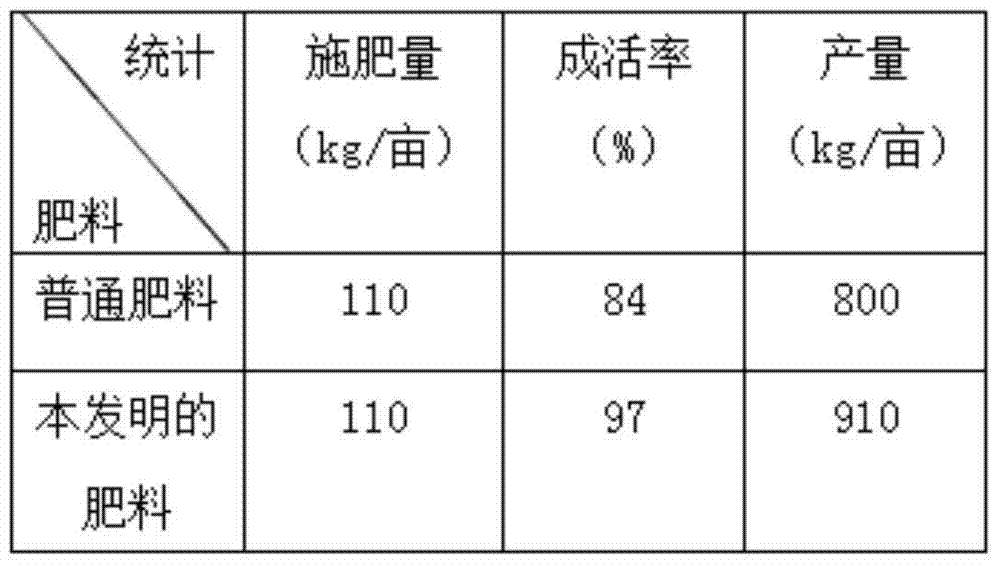

Method for planting Limonium sinense and improving soil fertility in coastal sandy saline-alkali land

InactiveCN108156874ALower pHPromote absorptionBio-organic fraction processingExcrement fertilisersOrganic fertilizerLimonium sinense

The invention discloses a method for planting Limonium sinense and improving the soil fertility in a coastal sandy saline-alkali land. The method improves the coastal sandy saline-alkali land by digging deep trenches, performing drainage, irrigation, and salt elimination, applying an improved sandy saline-alkali land organic fertilizer to soil, and planting the Limonium sinense. The method of theinvention has obvious improvement on the survival rate of the Limonium sinense and the quality of the flowers, and an outstanding improvement effect on the whole sandy saline-alkali land is; and the improvement process is green and environment-friendly. Accordingly, the method is an application technology that is worthy of promotion in a large area.

Owner:WEIFANG YOURONG IND

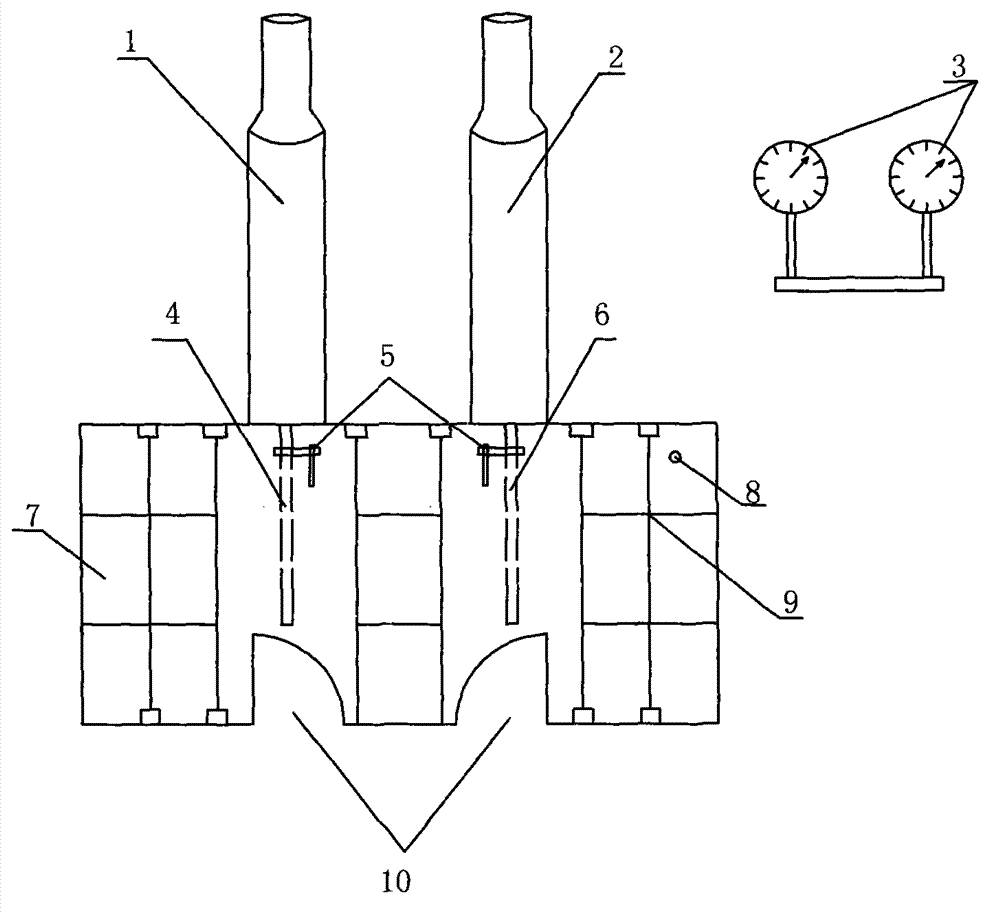

Temperature and humidity automatic control fermentation device in tea production process

InactiveCN102885171AThe process requires stabilityGood quality and effectPre-extraction tea treatmentAutomatic controlWater vapor

The invention discloses a temperature and humidity automatic control fermentation device in tea production process. The device comprises a steam oven (1), a heating furnace (2) and a fermentation chamber (7), wherein the steam oven (1) produces steam which is conveyed to the fermentation chamber (7) through a porous steam pipe; high temperature air is produced by the heating furnace (2) and is conveyed to the fermentation chamber (7) through a porous heating pipe (6); a detection module (8) is arranged in the fermentation chamber (7) and is used for detecting temperature and humidity in the fermentation chamber; the temperature and humidity are displayed on instruments (3); and switch modules (5) control the opening and closing of the porous steam pipe (4) and the porous heating pipe (6) according to the temperature and humidity. The temperature and humidity automatic control fermentation device not only is suitable for black tea production, but also can meet requirements of fermentation production process for fermentation teas, such as yellow tea, dark green tea and pu'er tea; and production practice test for a plurality of teas proves that the production process is stable, and product quality is quite high.

Owner:四川省老茶客茶业有限公司 +1

Cutting-grinding integrated machine

InactiveCN105922013AEasy to adjustReduce labor intensityOther manufacturing equipments/toolsEngineeringCooling pipe

The invention discloses a cutting-grinding integrated machine, which comprises a base. A support pad is provided at a lower end of the base. A hollow cooling pipe is disposed in the base. A working table is disposed on the base, and during machining, a workpiece is placed on the working table. A cutter pillar stand is disposed at one end of the base. A cutter cross beam is connected to the cutter pillar stand with a hand wheel structure provided at the joint of the cutter cross beam and a cutter pillar. A cutting main shaft is connected to the cutter cross beam and a cutter is disposed at a lower end of the cutting main shaft. The cutting-grinding integrated machine provided by the invention is designed with a compact structure, and is convenient for adjustment during workpiece machining, high cutting and grinding efficiency, and high in yield.

Owner:TAICANG DONGHUI MACHINERY PLANT

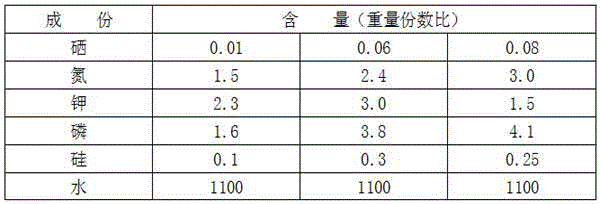

Cultivation method for selenium-rich litchi fruit trees

InactiveCN104303931AGood quality and effectStrong depressionFertilising methodsCultivating equipmentsDiseasePotassium

The invention discloses a cultivation method for selenium-rich litchi fruit trees. The method comprises the following steps of mixing 0.01 to 0.08 part by weight of selenium, 1.5 to 3.0 parts by weight of nitrogen, 1.6 to 3.2 parts by weight of potassium, 1.6 to 4.1 parts by weight of phosphorus, 0.1 to 0.3 part by weight of copper and 1,060 parts by weight of water to prepare a nutrient solution, spraying the nutrient solution to roots once a week before and after the litchi fruit trees bloom respectively, and spraying the nutrient solution to leaves for three times at a spraying interval of 12 days in a fruit expanding stage, wherein matured litchis are selenium-rich. According to the method, inorganic selenium is absorbed and converted into organic selenium by the litchis, so that toxicity is removed, and better disease suppression, yield increasing and litchi quality improvement effects of crops are achieved; the selenium content of produced dried litchi fruits reaches 4.1mg / kg, and the dried litchi fruits are stable in content and nutrient-rich, and become popular health food.

Owner:广西博白县琼达农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com