Preparation method of (Mn, Co)3O4 spinel coating

A technology of spinel coating and deposition layer, which is applied in the field of preparation of 3O4 spinel coating, can solve the problems of high cost, unstable coating, complex process, etc., and achieve low cost, reduced impact, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

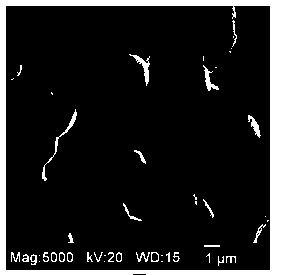

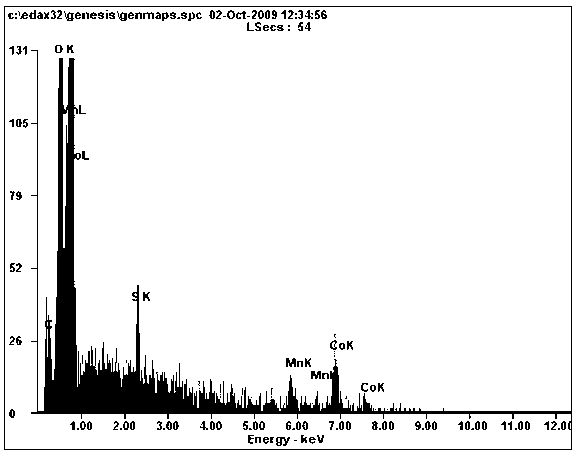

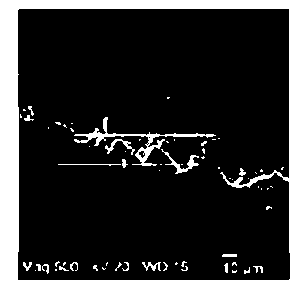

Image

Examples

Embodiment 1

[0030] Embodiment 1: (Mn, Co) of the present embodiment 3 o 4 The preparation steps of the spinel coating include:

[0031] (1) Will (Mn,Co) 3 o 4 The powder and absolute ethanol are prepared according to a certain ratio, and the solution is prepared by ultrasonic stirring at room temperature (Mn, Co) 3 o 4 Powder suspension; (Mn,Co) 3 o4 Powder is Co 3 o 4 and Mn 3 o 4 The mass ratio of the mixed powder is 0.5:1.5, and the particle size of the mixed powder is 0.8 μm. (Mn,Co) 3 o 4 The solid-liquid ratio of powder and absolute ethanol is 0.2g:80mL. Ultrasonic stirring is the use of ultrasonic waves with a frequency of 20KHz, for the configured (Mn, Co) 3 o 4 The mixed solution of powder and absolute ethanol was stirred for 3 times, and the time for each treatment was 30 minutes, and the interval between each treatment was 50 minutes.

[0032] (2) The prepared (Mn,Co) 3 o 4 Put the powder suspension into the electrodeposition device, use the alloy substrate wit...

Embodiment 2

[0034] Embodiment 2: (Mn, Co) of the present embodiment 3 o 4 The preparation steps of the spinel coating include:

[0035] (1) Will (Mn,Co) 3 o 4 The powder and absolute ethanol are prepared according to a certain ratio, and the solution is prepared by ultrasonic stirring at room temperature (Mn, Co) 3 o 4 Powder suspension; (Mn,Co) 3 o 4 Powder is Co 3 o 4 and Mn 3 o 4 The mass ratio of the mixed powder is 0.8:0.5, and the particle size of the mixed powder is less than 1 μm. (Mn,Co) 3 o 4 The solid-liquid ratio of powder and absolute ethanol is 5g: 100mL. Ultrasonic stirring is the use of ultrasonic waves with a frequency of 80KHz, for the configured (Mn, Co) 3 o 4 The mixture of powder and absolute ethanol was stirred for 4 times, each treatment time was 60 minutes, and the interval between each treatment was 10 minutes.

[0036] (2) The prepared (Mn,Co) 3 o 4 Put the powder suspension into the electrodeposition device, use the alloy substrate with surface...

Embodiment 3

[0038] Embodiment 3: (Mn, Co) of the present embodiment 3 o 4 The preparation steps of the spinel coating include:

[0039] (1) Will (Mn, Co) 3 o 4 The powder and absolute ethanol are prepared according to a certain ratio, and the solution is prepared by ultrasonic stirring at room temperature (Mn, Co) 3 o 4 Powder suspension; (Mn,Co) 3 o 4 Powder is Co 3 o 4 and Mn 3 o 4 The mass ratio of the mixed powder is 1.5:1, and the particle size of the mixed powder is less than 1 μm. (Mn,Co) 3 o 4 The solid-liquid ratio of powder and absolute ethanol is 3g: 60mL. Ultrasonic stirring is the use of ultrasonic waves with a frequency of 100KHz, for the configured (Mn, Co) 3 o 4 The mixture of powder and absolute ethanol was stirred and treated 5 times, each treatment time was 90 minutes, and the interval between each treatment was 60 minutes.

[0040] (2) The prepared (Mn,Co) 3 o 4 Put the powder suspension into the electrodeposition device, use the alloy substrate with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com