Application of nanometer aluminum oxide-based composite ceramic coating

A nano-alumina and composite ceramic technology, applied in coating, metal material coating process, melt spraying and other directions, can solve the problems of high raw material cost and low insulation performance of coating, achieve low porosity and improve insulation performance , the effect of reducing intrinsic internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

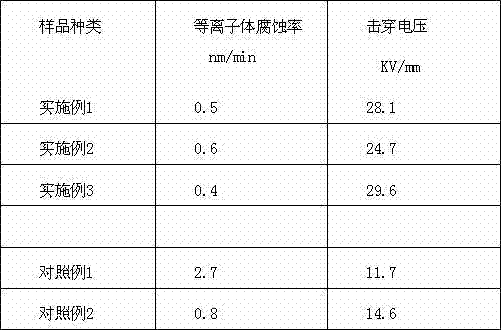

Examples

Embodiment 1

[0013] Example 1: Preparation of nano-alumina-based composite ceramic coating on the surface of the bottom plate of dry etching equipment

[0014] (1) Preparation of alumina-based fine powder: Weigh 50 grams of alumina, zirconia and lanthanum oxide mixed powder (weight percentage distribution is 38.6wt% alumina, 42.4wt% lanthanum oxide and 19wt% zirconia), Add 75 ml of alcohol and 200 g of alumina balls, wet ball mill and mix for 24 hours, then dry at 100°C, pass through a 100-mesh sieve to obtain alumina-based fine powder;

[0015] (2) Spray ceramic coating: Use the bottom plate of dry etching equipment as the base material for coating spraying. Before spraying, the bottom plate is sandblasted to remove surface pollutants and roughen the surface. Atmospheric plasma spraying equipment is used for spraying, and the alumina-based fine powder obtained in step (1) is evenly sprayed on the bottom plate. The spraying parameters are: argon gas 40 L / Min, hydrogen gas 10 L / Min, voltage...

Embodiment 2

[0017] Example 2: In Electrostatic chuck surface of vacuum deposition equipment Preparation of alumina-based composite ceramic coating

[0018] (1) Preparation of alumina-based fine powder: alumina-zirconia-yttria composite material as raw material, (weight percentage ratio is 55.8wt% alumina, 28.6wt% yttrium oxide and 15.6wt% zirconia), and According to the method described in Example 1, ball milling was carried out to obtain alumina-based fine powder;

[0019] (2) Spray ceramic coating: according to the method described in Example 1, spray the alumina-based fine powder obtained in step (1) onto the surface of the electrostatic chuck of the vacuum deposition equipment to form a coating of 1000-1100 μm by plasma spraying method . In addition, a coating of about 200 μm was sprayed at the same time for testing and comparison.

[0020] The coating obtained in this example was analyzed with a scanning electron microscope (SEM), and the results showed that the alumina-zirconia...

Embodiment 3

[0021] Example 3: In The inner surface of the cavity of the dry etching equipment Preparation of nano-alumina composite ceramic coating

[0022] (1) Preparation of alumina-based fine powder: alumina-zirconia-yttria composite material as raw material, (weight percentage ratio is 55.8wt% alumina, 28.6wt% yttrium oxide and 15.6wt% zirconia), and According to the method described in Example 1, ball milling was carried out to obtain alumina-based fine powder;

[0023] (2) Spray ceramic coating: The inner surface of the cavity of the dry etching equipment is used as the substrate material for coating spraying, and the substrate is sandblasted before spraying. Spraying uses supersonic flame spraying (HVOF) equipment to uniformly spray the alumina-based powder obtained in step (1) onto the substrate. The spraying parameters are: oxygen 240 L / Min, propane 72 L / Min, compressed air 400 L / Min Min, the thickness of the formed coating is 1800-1900 μm. In addition, a coating of about 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com