Yttrium iron garnet film material and preparing method thereof

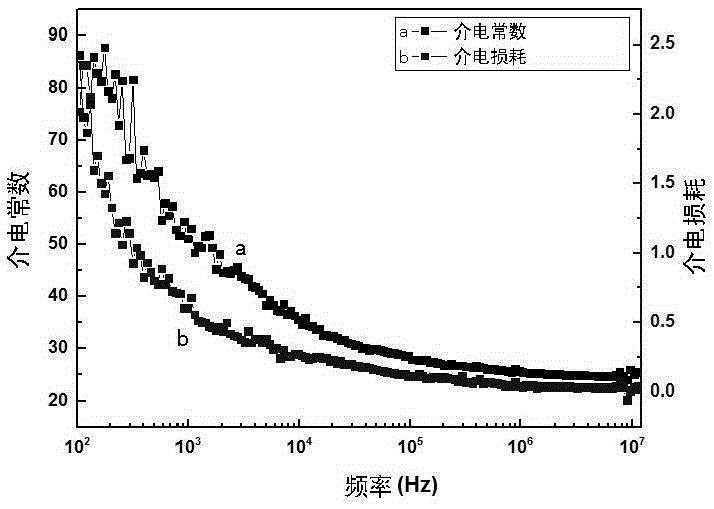

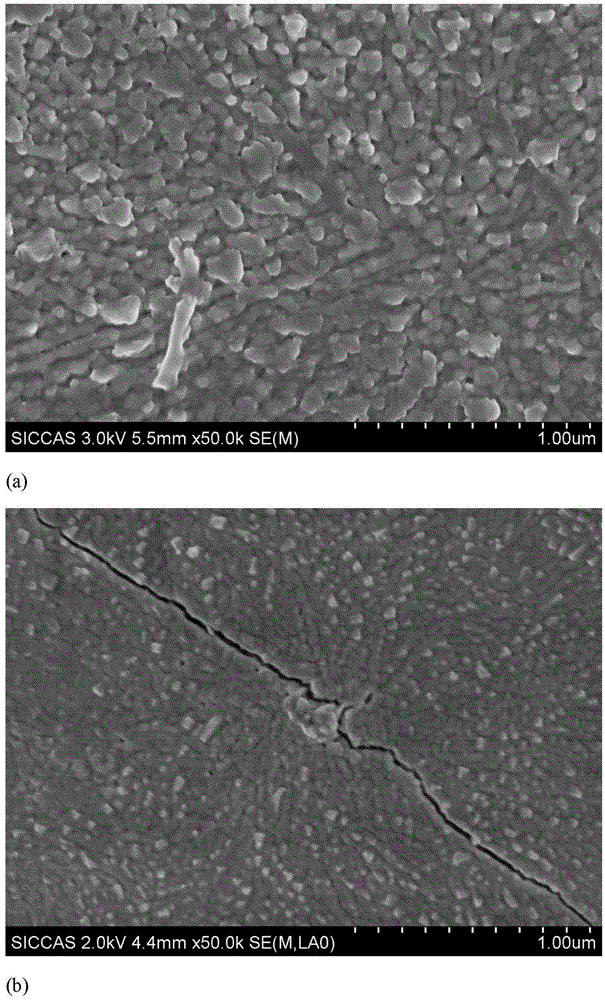

A technology of yttrium iron garnet and thin film, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of high cost, easy cracking of thin film, cumbersome process, etc., and achieve low dielectric loss and method The process is simple and easy, and the effect of low coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides a kind of preparation method of the yttrium iron garnet thin film that sputtering epitaxy on Si substrate comprises the following steps:

[0028] Step 1: cleaning the substrate surface;

[0029] Step 2: sputtering a thin film on the substrate in a high vacuum environment;

[0030] Step 3: slow annealing of the film material.

[0031] The substrate can be Si(100) / SiO 2 . Substrates can be purchased commercially or prepared by yourself. The substrate that adopts in the present invention is then purchased from commercial, and the substrate total thickness is about 0.5mm, and the SiO of one deck 300nm is covered on the surface 2 . Because the thermal expansion coefficients of Si and YIG are very different (Si is 4.7×10 -6 / °C, YIG is 10.4×10 -6 / ℃), adding a layer of SiO 2 (The coefficient of thermal expansion is 5.5×10 -6 / °C) can play a role in buffering thermal stress. Si substrates with different orientations can also be selected...

Embodiment

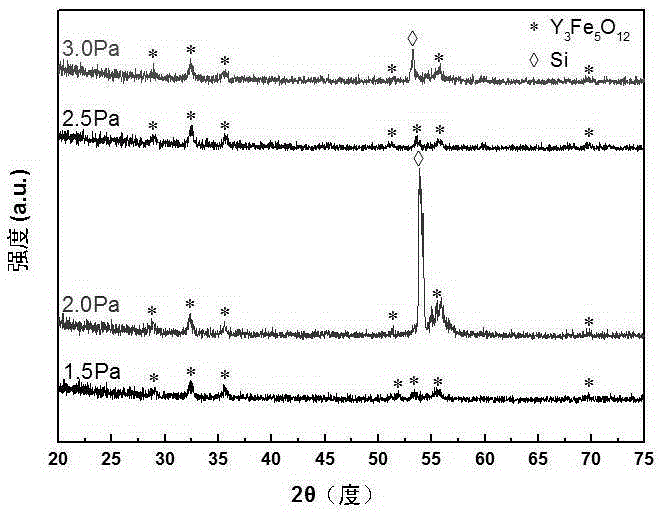

[0048] The present invention adopts figure 1 The shown equipment, sputtering yttrium iron garnet film, the specific preparation method is:

[0049] Step 1: First, clean Si(100) / SiO 2 The substrate surface, the cleaning process is:

[0050] (1) Ultrasonic cleaning with acetone for 10 minutes;

[0051] (2) Ultrasonic cleaning with alcohol for 10 minutes;

[0052] (3) Ultrasonic cleaning with deionized water for 10 minutes;

[0053] (4) drying.

[0054] Step 2: sputtering a thin film on the substrate in a high vacuum environment, the specific process is:

[0055] (1) Fix the cleaned substrate on the substrate table, Y 3 Fe 5 o 12 The target is fixed on the target table of the magnetron sputtering molding system, and both the substrate table and the target table are placed in the sputtering chamber of the magnetron sputtering molding system;

[0056] (2) Combining mechanical pump and molecular pump to evacuate the sputtering chamber until the indoor air pressure is lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

| Coercive field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com