Patents

Literature

340results about How to "Stable thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

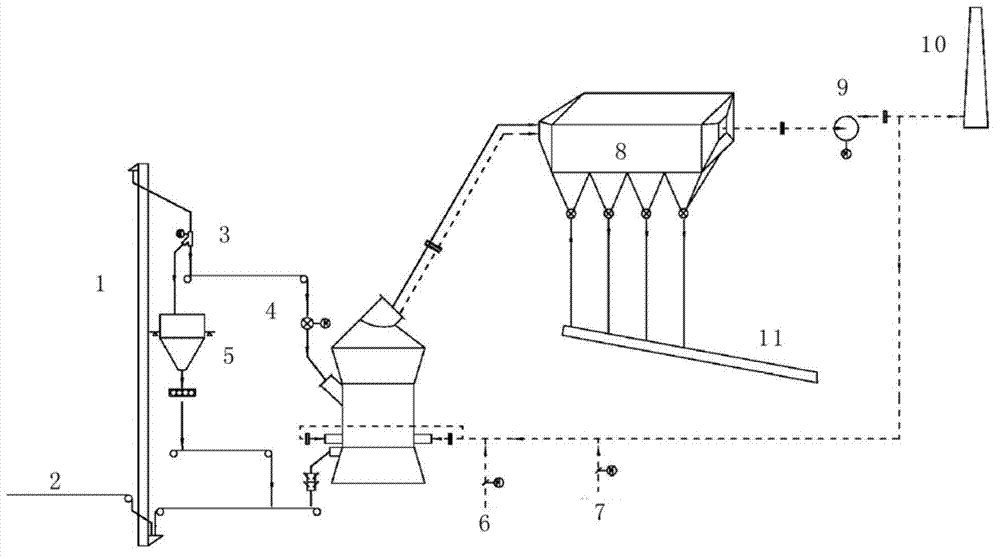

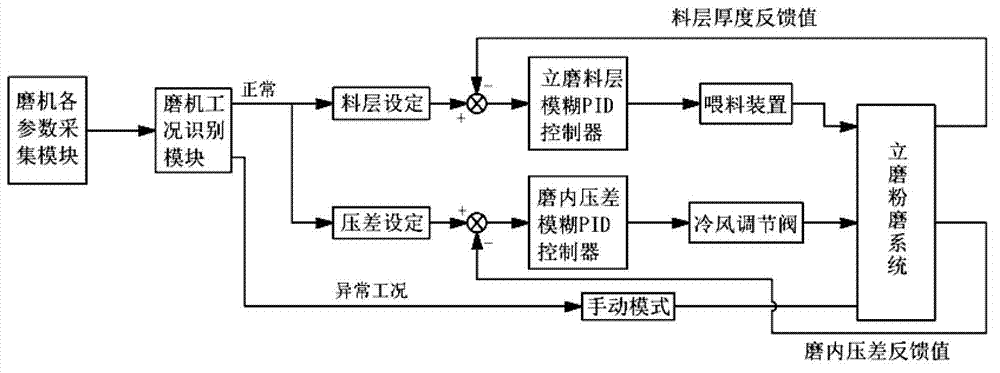

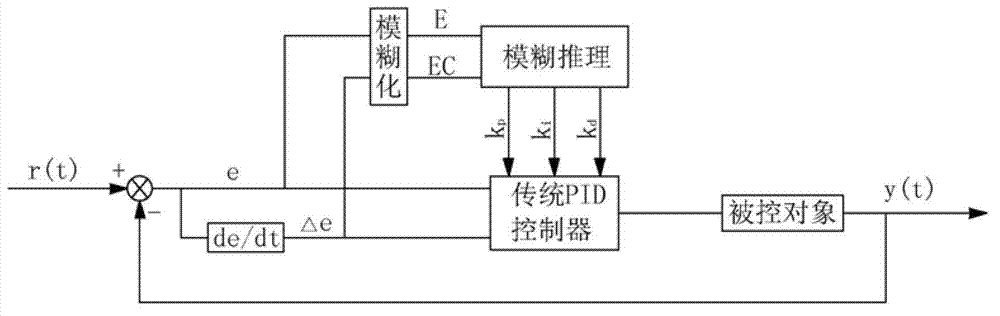

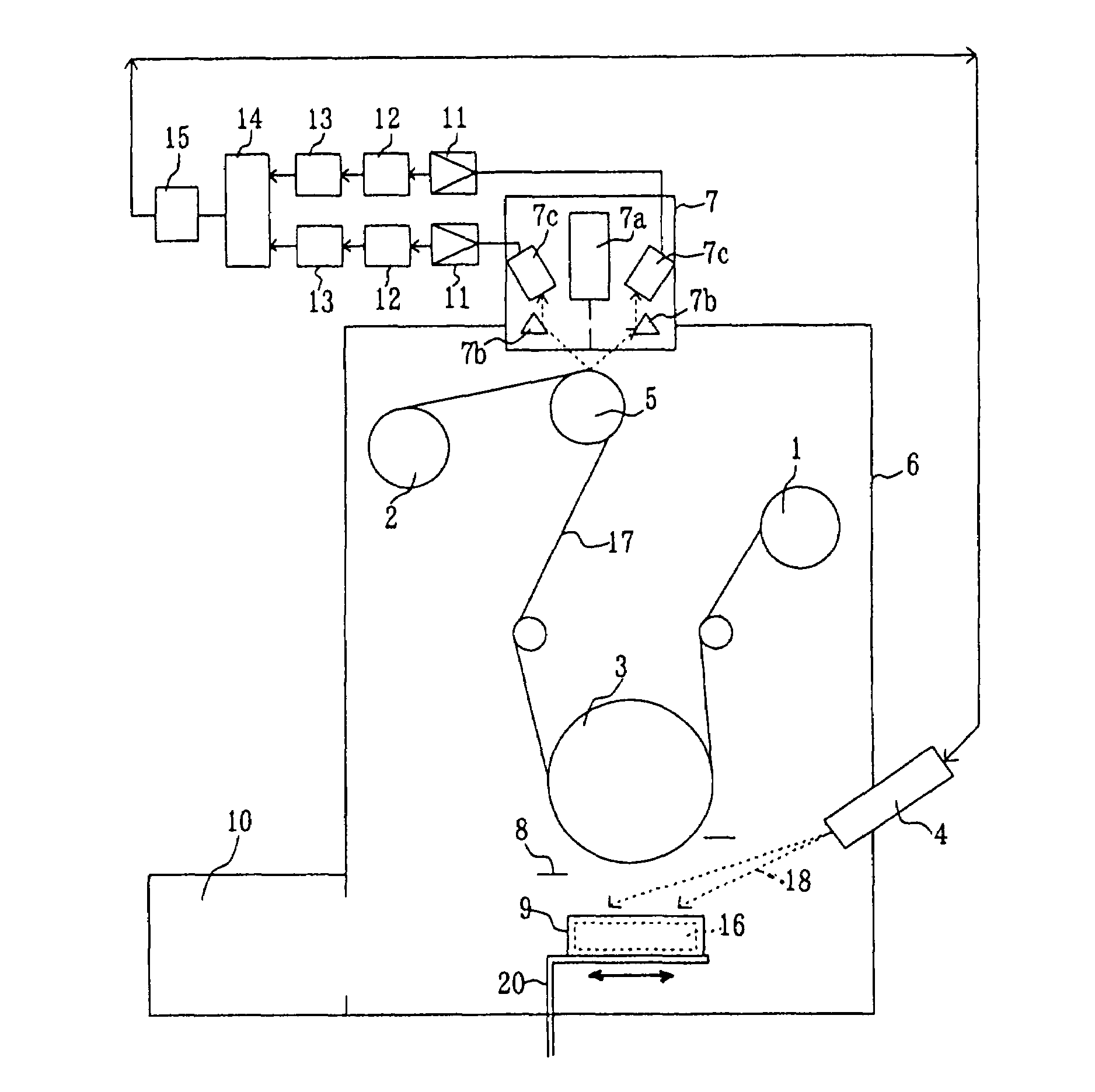

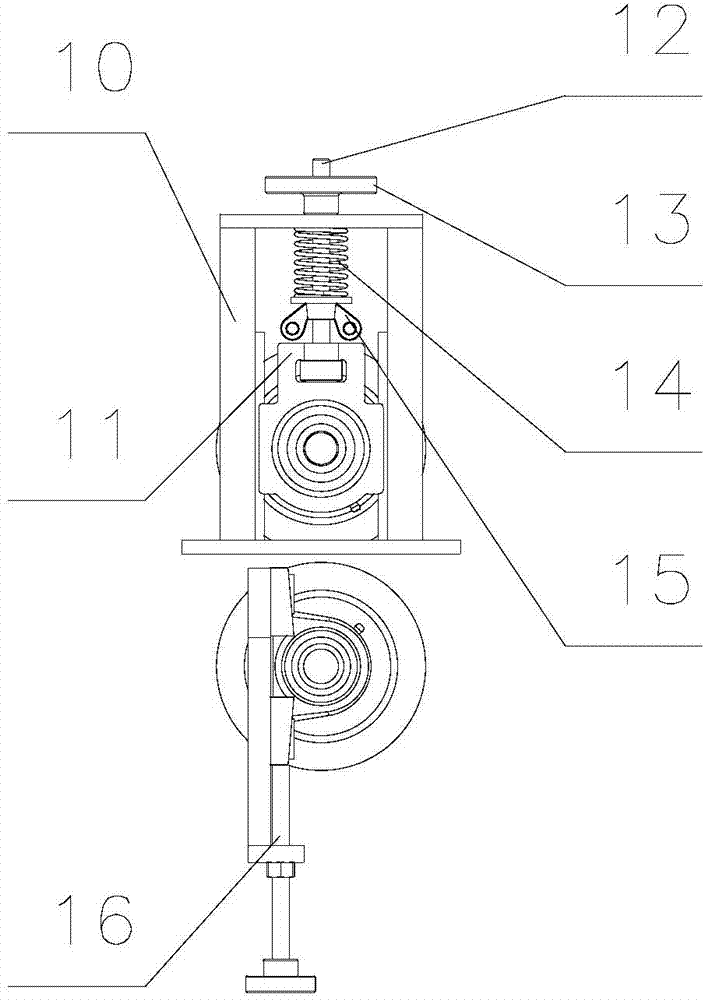

Intelligent control system for vertical mill based on fuzzy PID (proportion integration differentiation) algorithm

ActiveCN103028480AStable thicknessStable mill internal pressure differenceGrain treatmentsAdaptive controlCold airProportion integration differentiation

The invention relates to the technical field of control on production equipment, and particularly relates to an intelligent control system for a vertical mill based on a fuzzy PID (proportion integration differentiation) algorithm. The intelligent control system comprises the vertical mill, a dust remover and a feeding device, wherein the feeding device comprises an unloader, a bucket elevator and a storage bin; and the intelligent control system is characterized in that an air inlet in the bottom of the vertical mill is connected with a fan via a pipeline, a cold-air device and a hot-air stove are arranged on the pipeline between the air inlet and the fan, a cold-air adjusting valve and a hot-air adjusting valve are respectively arranged on the cold-air device and the hot-air stove, a vertical mill material layer PID controller is arranged on the feeding device, and an in-mill pressure difference fuzzy PID controller is arranged on the cold-air adjusting valve. According to the intelligent control system disclosed by the invention, mathematical models of the change of the vertical mill material layer thickness and an in-mill pressure difference along with parameters of a feeding amount, a mill inlet hot-air temperature and the like can be established only by inputting and outputting data without analyzing the complex grinding process of the vertical mill; and the intelligent control system is simple in process, high in adaptability, fast in the dynamic response time of a controller algorithm, high in robustness, high in control accuracy, and good in market prospect.

Owner:SHANGHAI TRIUMPH ENERGY CONSERVATION ENG TECH CO LTD

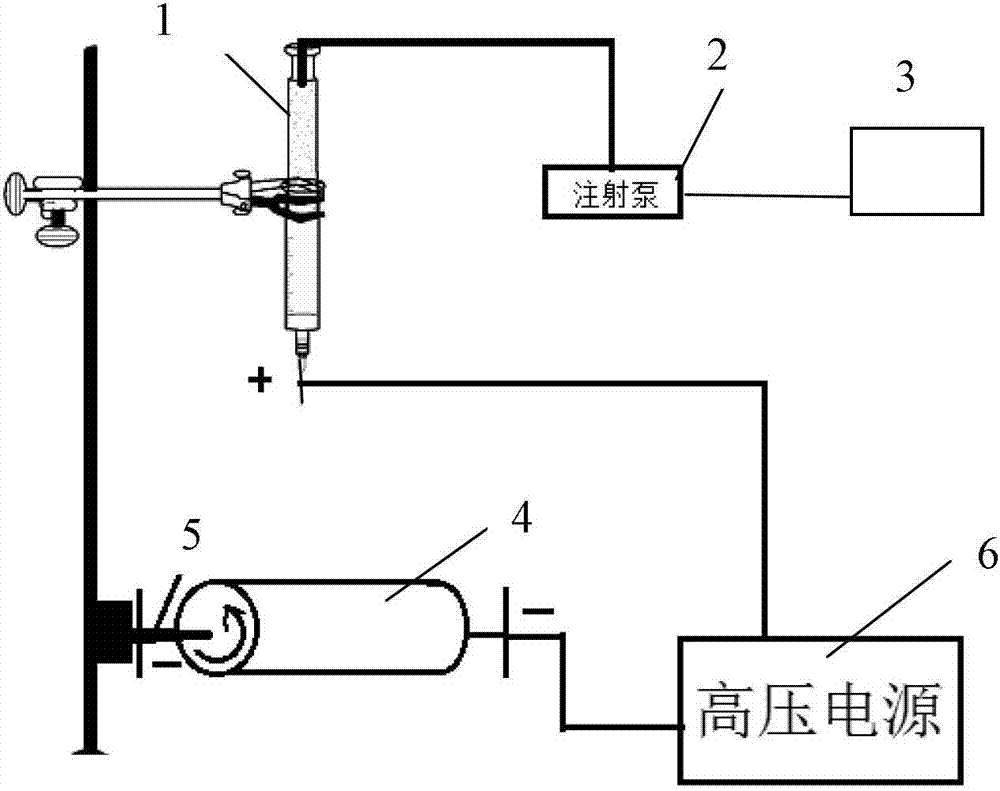

Preparation method of multilayer sandwich type electrostatic-spinning polymer nanofiber composite membrane

ActiveCN103481624AIncrease the areaSimple structureLamination ancillary operationsLaminationFiberPolymer science

The invention discloses a preparation method of a multilayer sandwich type electrostatic-spinning polymer nanofiber composite membrane. The preparation method comprises the steps of firstly, spinning a polymer spinning liquid into a fiber membrane in an electrostatic manner, then spraying a spraying liquid containing inorganic nano-particles to the surface of the electrostatic-spinning fiber membrane by virtue of a jetting technique, continuously spinning the fiber membrane, and repeatedly carrying out the steps according to specific conditions so as to prepare the multilayer sandwich type composite membrane. As the inorganic nano-particles are adhered to the surface of the fiber membrane, not only can the ultrahigh specific area and the specific structural advantage of a nanofiber be brought into full play, but also the selectable ranges of the spraying liquid and the polymer spinning liquid are flexible, so that spraying liquids containing different inorganic nano-particles can be sprayed to electrostatic-spinning fiber membranes made from different raw materials according to actual demands so as to prepare sandwich type composite membranes with different functions, stable structures and good properties, and the application range of the electrostatic-spinning polymer nanofiber composite membranes is expanded.

Owner:河北立格新材料科技股份有限公司

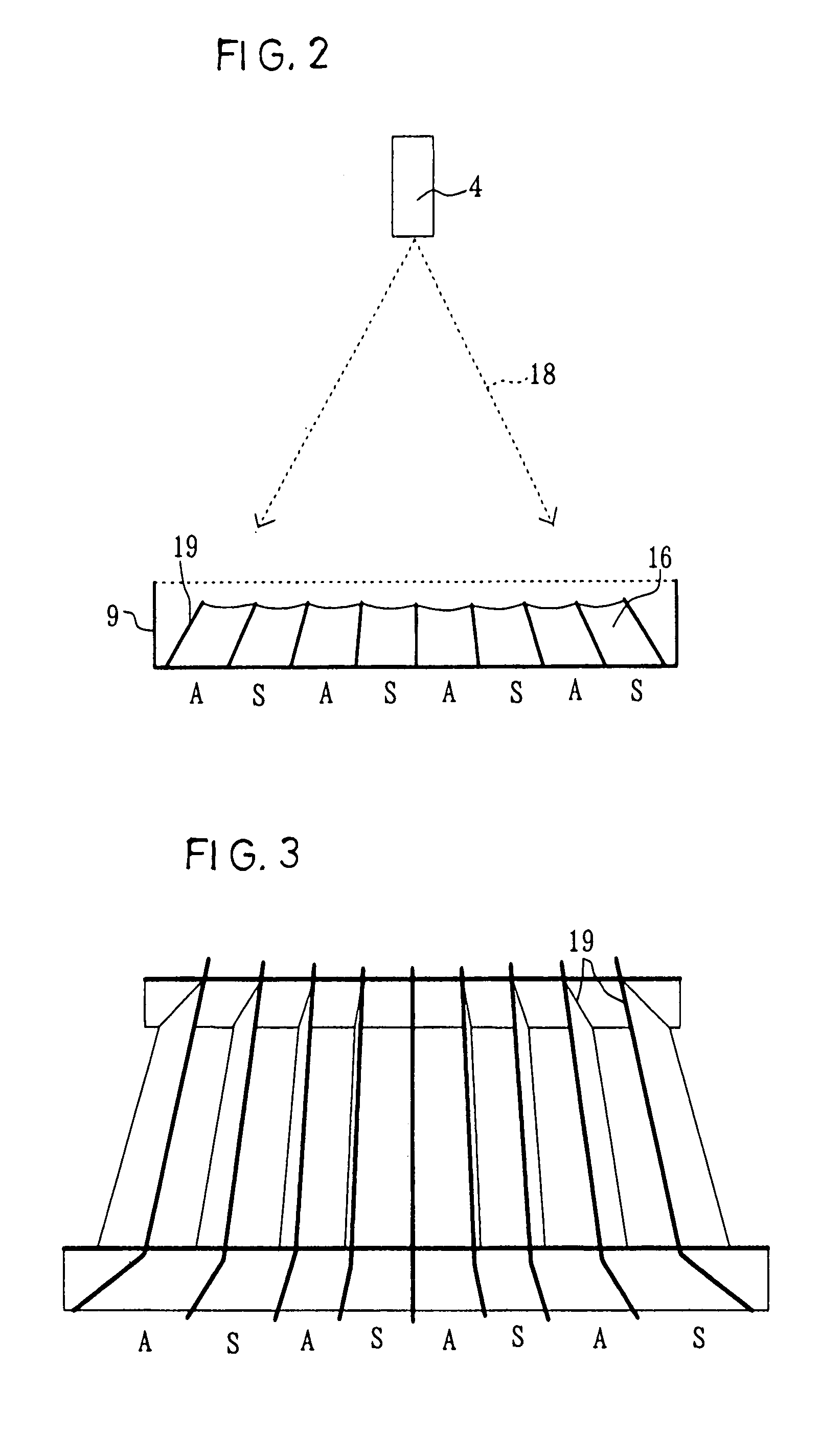

Conductive Paste, Solar Cell Manufactured Using Conductive Paste, Screen Printing Method and Solar Cell Formed Using Screen Printing Method

InactiveUS20070158621A1Avoid conductionSimple processConductive materialNon-conductive material with dispersed conductive materialConductive pasteScreen printing

Owner:KYOCERA CORP

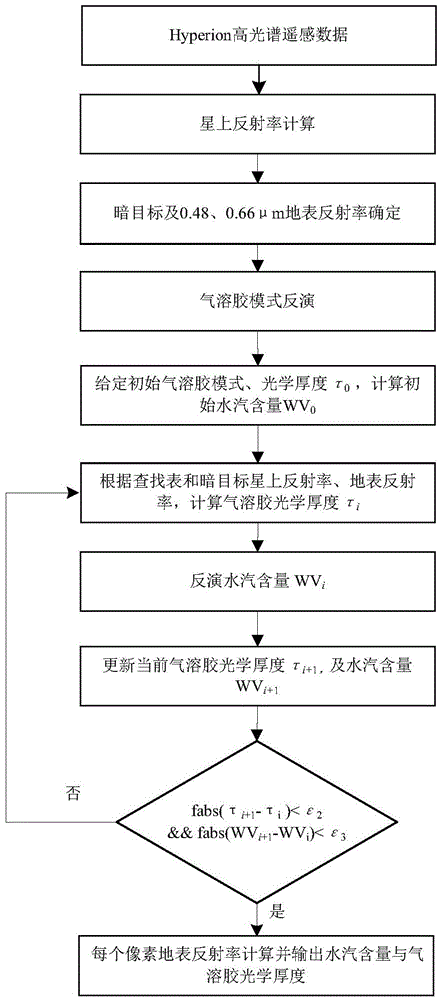

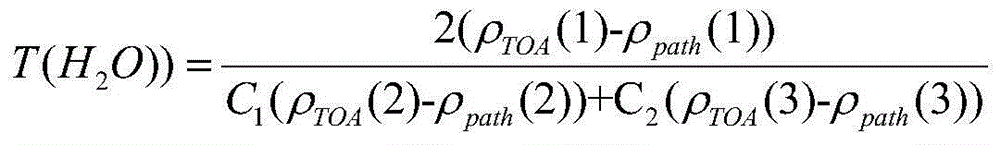

Atmospheric correction method and system for hyperspectral remote sensing image

InactiveCN104483663AImprove accuracyEliminate interactionElectromagnetic wave reradiationICT adaptationWave bandMutual influence

The invention discloses an atmospheric correction method and system for a hyperspectral remote sensing image. The method comprises steps as follows: step one, surface reflectance and observation apparent reflectance of a blue waveband and a red waveband of a dark object are acquired according to satellite signals; step two, an aerosol mode is inversed based on the satellite signals; step three, moisture content is inversed based on the satellite signals and the current atmospheric aerosol mode; and step four, the remote sensing image is subjected to atmospheric correction according to the current atmospheric aerosol mode and the current moisture content obtained through inversion. Matched aerosol modes are established according to characteristics of different areas, and the aerosol mode is inversed firstly before atmospheric correction, so that the accuracy of atmospheric correction is improved; mutual influence of moisture content and aerosol is comprehensively considered, the aerosol optical thickness and the moisture content are subjected to synergic inversion, and mutual influence of the aerosol optical thickness and the moisture content can be further eliminated.

Owner:WUHAN UNIV +1

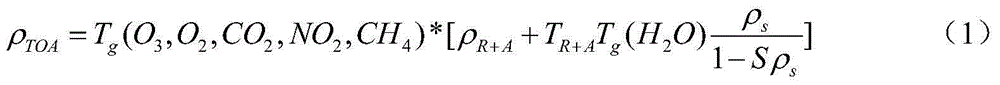

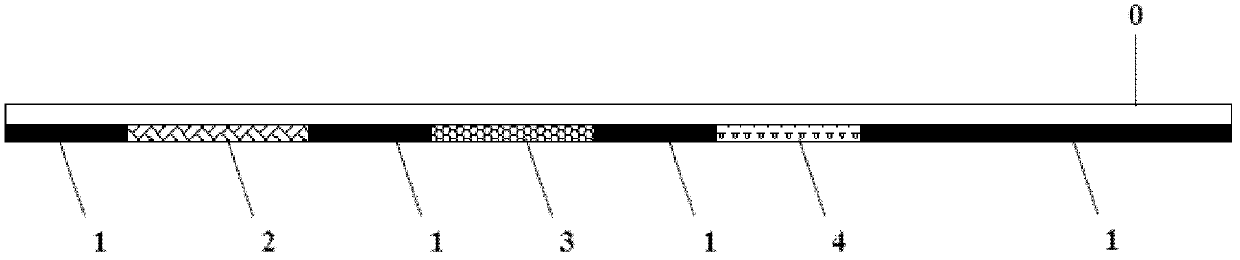

Liquid crystal display panel, method for producing same and display device

InactiveCN102707504AControl thicknessControl stable thicknessNon-linear opticsContact pressureDisplay device

The invention provides a liquid crystal display panel, a method for producing the same and a display device, wherein the liquid crystal display panel comprises an array baseplate, a color film baseplate and a liquid crystal layer filled between the array baseplate and the color film baseplate, wherein a spacer and an isolation frame are also arranged between the array baseplate and the color film baseplate, and the spacer and / or the isolation frame is made from piezoelectric materials. According to the liquid crystal display panel, the spacer and the isolation frame are made from piezoelectric materials, when the liquid crystal display panel is subjected to the action of the outside pressure, the piezoelectric effect is utilized to apply a certain voltage on the piezoelectric cylindrical spacer and the isolation frame which are deformed, so the piezoelectric cylindrical spacer and the isolation frame can be enabled to return to the original shapes, the functions of controlling and stabilizing the thickness of a liquid crystal box are obtained, and the problem that the thickness of the liquid crystal box is difficult to control and stabilize due to the fact that the traditional organic material cylindrical spacer suffers from permanent deformation under the action of the long-term contact pressure is solved.

Owner:BOE TECH GRP CO LTD +1

Display apparatus and antireflection substance

InactiveUS7405005B2Improve reliabilityIncrease production capacityVacuum evaporation coatingSputtering coatingRefractive indexMoisture

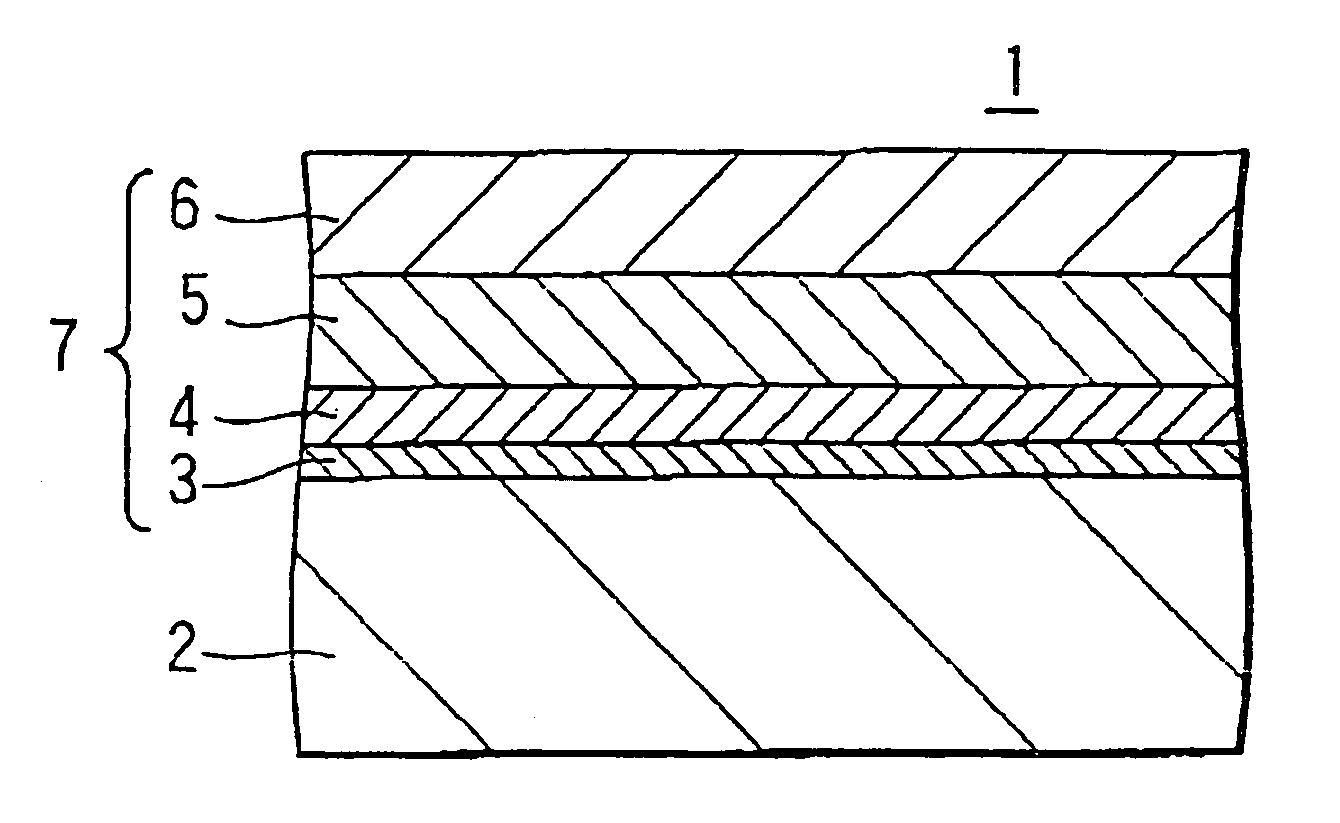

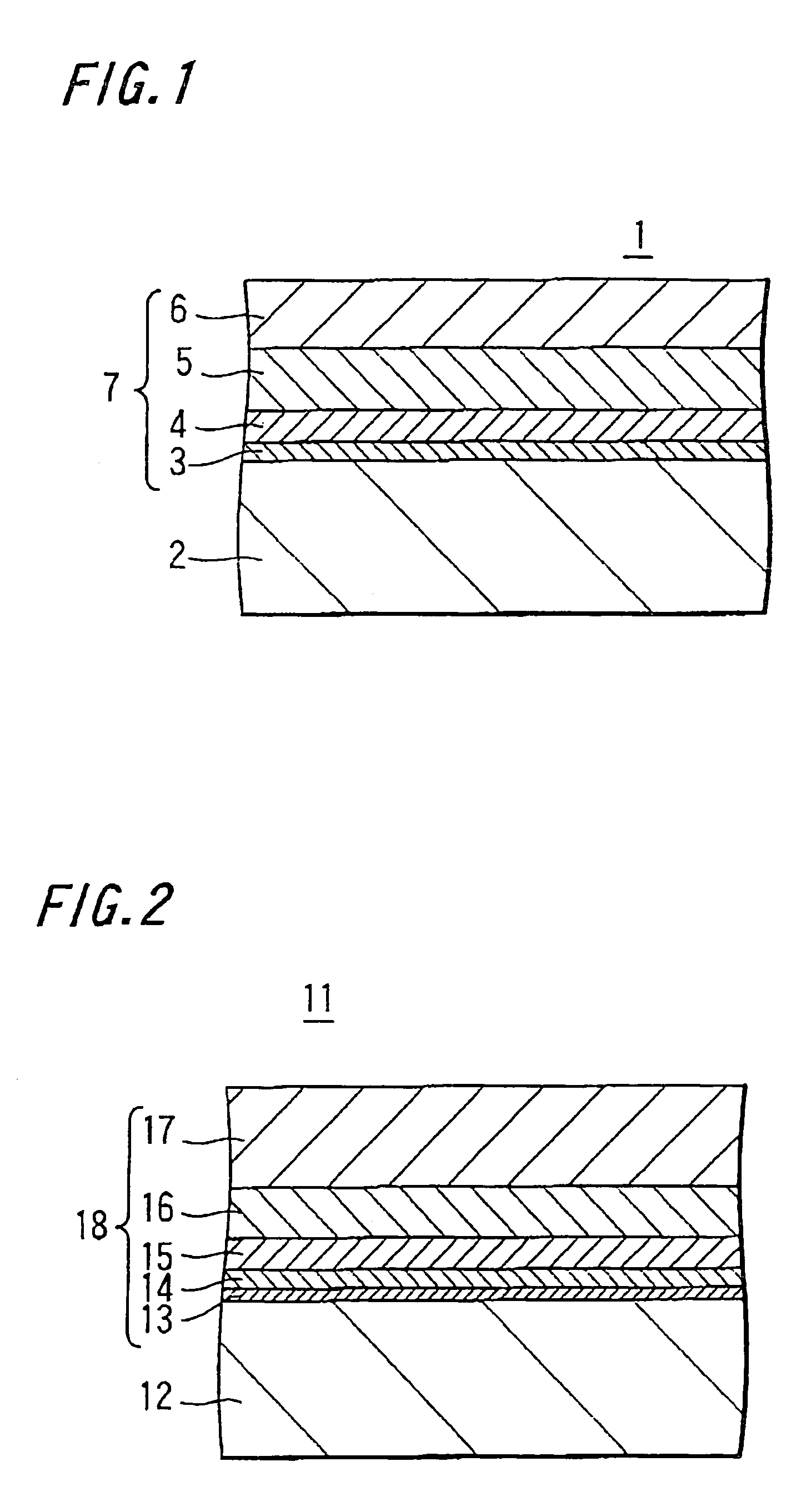

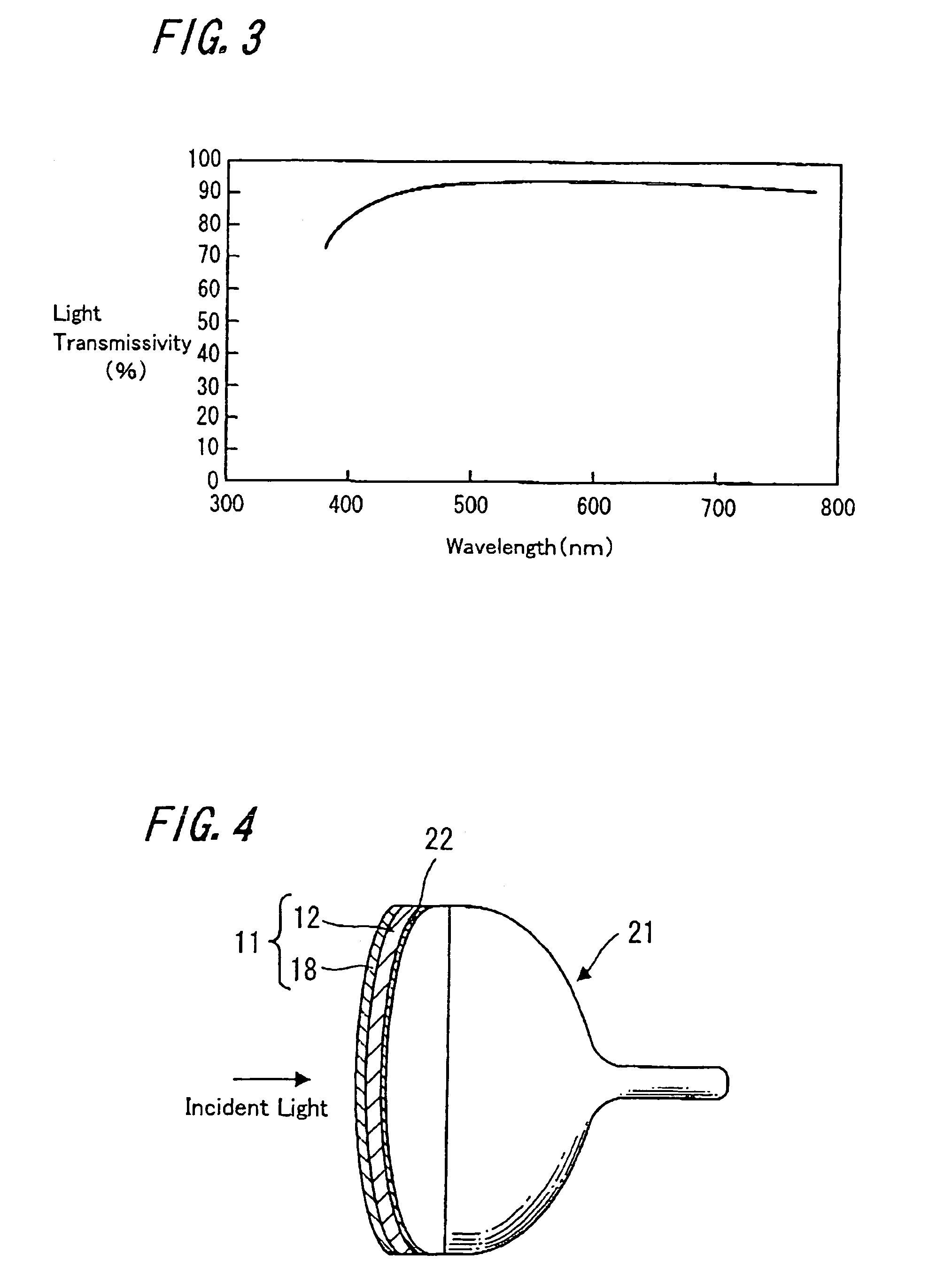

The present invention provides an antireflection substance such as an antireflection film having a low moisture-permeable characteristic, high quality and high reliability, and also provides a display apparatus comprising this antireflection substance. The antireflection substance according to the present invention includes an antireflection film formed on a transparent substrate, the antireflection film being composed of a multiple layer in which a first layer serving as an adhesion-improving layer, a second layer serving as a barrier layer against moisture, a third layer, a fourth layer and a fifth layer are laminated in this order, and in which the second layer and the fourth layer are each set to have a refractive index higher than that of the third layer and the fifth layer. The display apparatus according to the present invention comprises this antireflection substance on its display surface.

Owner:SONY CORP

Preparation method of formicary-shaped porous silicon for lithium ion battery

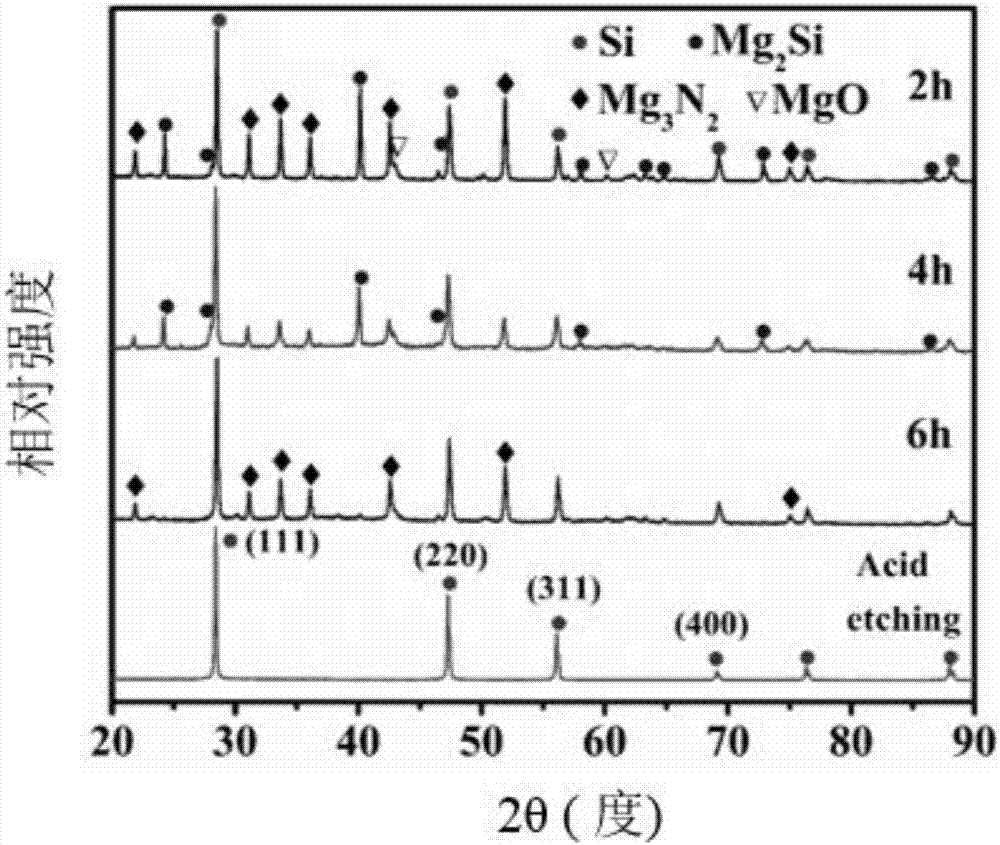

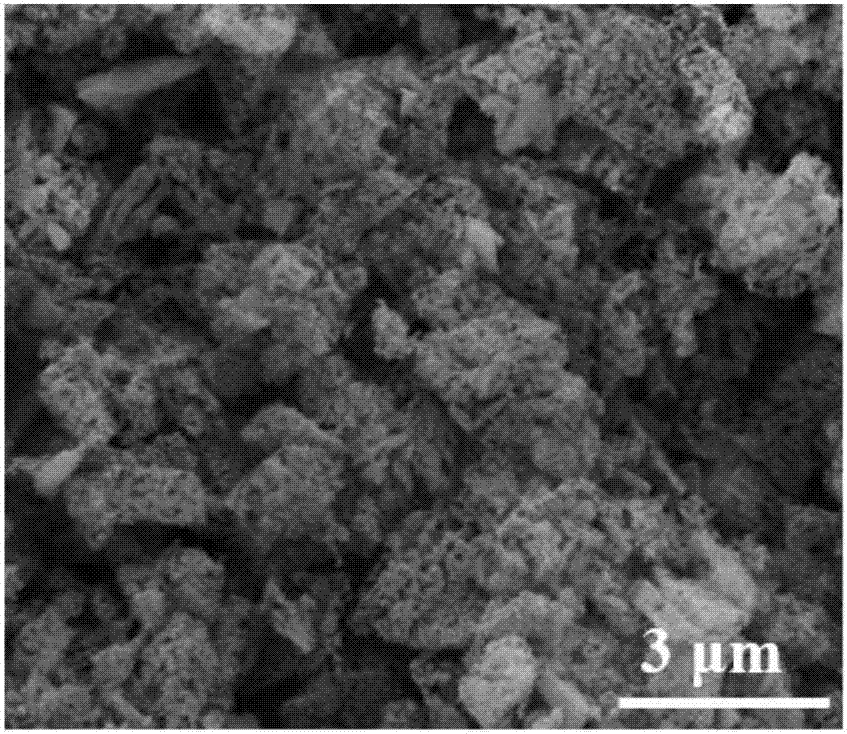

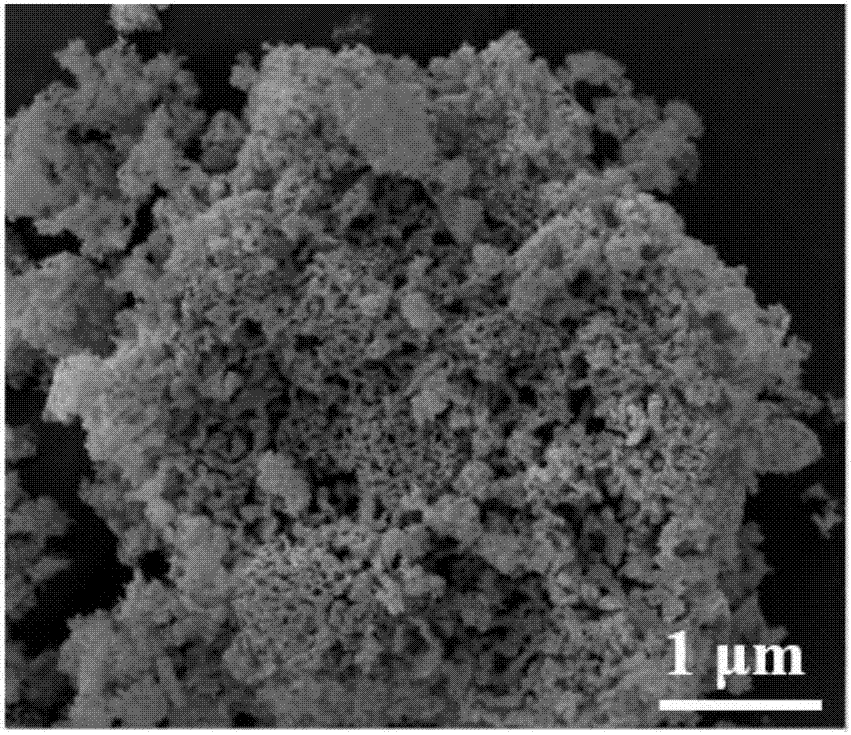

ActiveCN107215874ASave raw materialsThe synthesis method is simpleCell electrodesSecondary cellsLithium-ion batteryReaction step

The invention discloses a preparation method of formicary-shaped porous silicon for a lithium ion battery. The preparation method comprises the following steps: (1) enabling a magnesium silicide raw material to react for 2 to 24h in an ammonia gas atmosphere at a temperature of 600 to 900 DEG C, and obtaining a crude product containing porous silicon (3Mg2Si+4NH3 to 3Si+2Mg3N2+6H2), wherein a particle size of the magnesium silicide raw material is 0.2 to 10 micrometers; and (2) acid pickling the crude product containing the porous silicon to obtain the formicary-shaped porous silicon for the lithium ion battery. By improving an overall process flow of the porous silicon key preparation method and parameters and conditions of various reaction steps, compared with the prior art, the preparation method has the advantage of simplicity and easiness, a great number of porous micrometer silicon can be obtained by directly heating the obtained magnesium silicide in ammonia gas (or mixed gas of the ammonia gas and inert gas), and the yield is high.

Owner:WUHAN UNIV OF SCI & TECH

A kind of production method of titanium-aluminum composite plate

InactiveCN102284833AStable thicknessNo noise pollutionWelding/soldering/cutting articlesNon-electric welding apparatusMetal coatingTitanium

The invention relates to a production method of titanium-aluminium composite plates. The production method comprises the following technical points: compositing titanium sheets and aluminium plates together by adopting a diffusion welding technology so as to form the titanium-aluminium composite plates; carrying out leveling on the titanium-aluminium composite plates, and then fixing two titanium-aluminium composite plates as a group by adopting a mechanical method; arranging the combined titanium-aluminium composite plates in a heating furnace, carrying out warm rolling under the condition that the temperature of the composite plates is 350-450 DEG C, maintaining the reduction in pass to be between 8% and 16%, and carrying out 4-7 passes in total; disconnecting the combination of the composite plates by warm rolling, carrying out cold rolling on single composite plate, maintaining the reduction in pass to be between 6% and 12%, and carrying out 3-7 passes in total. The composite plates is treated by diffusion welding and then warm rolling, so that the limitation of difficult thickness processing and purchase of the raw titanium sheets in the diffusion welding process of the titanium-aluminium composite plates is overcome, a thinner firm metal coating layer can be obtained, and further the application of the titanium-aluminium composite plates is wider and more economical.

Owner:宋洪海

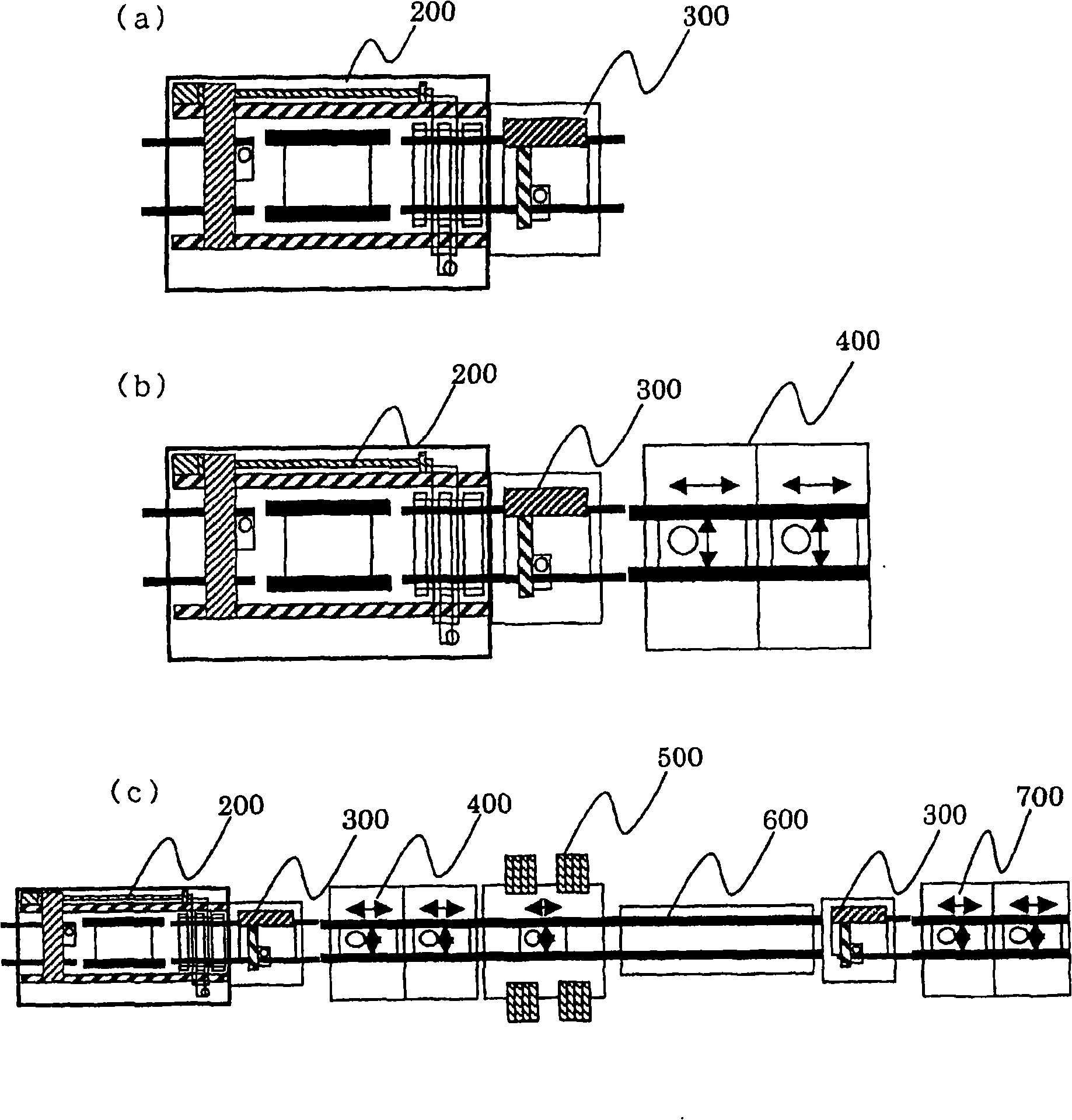

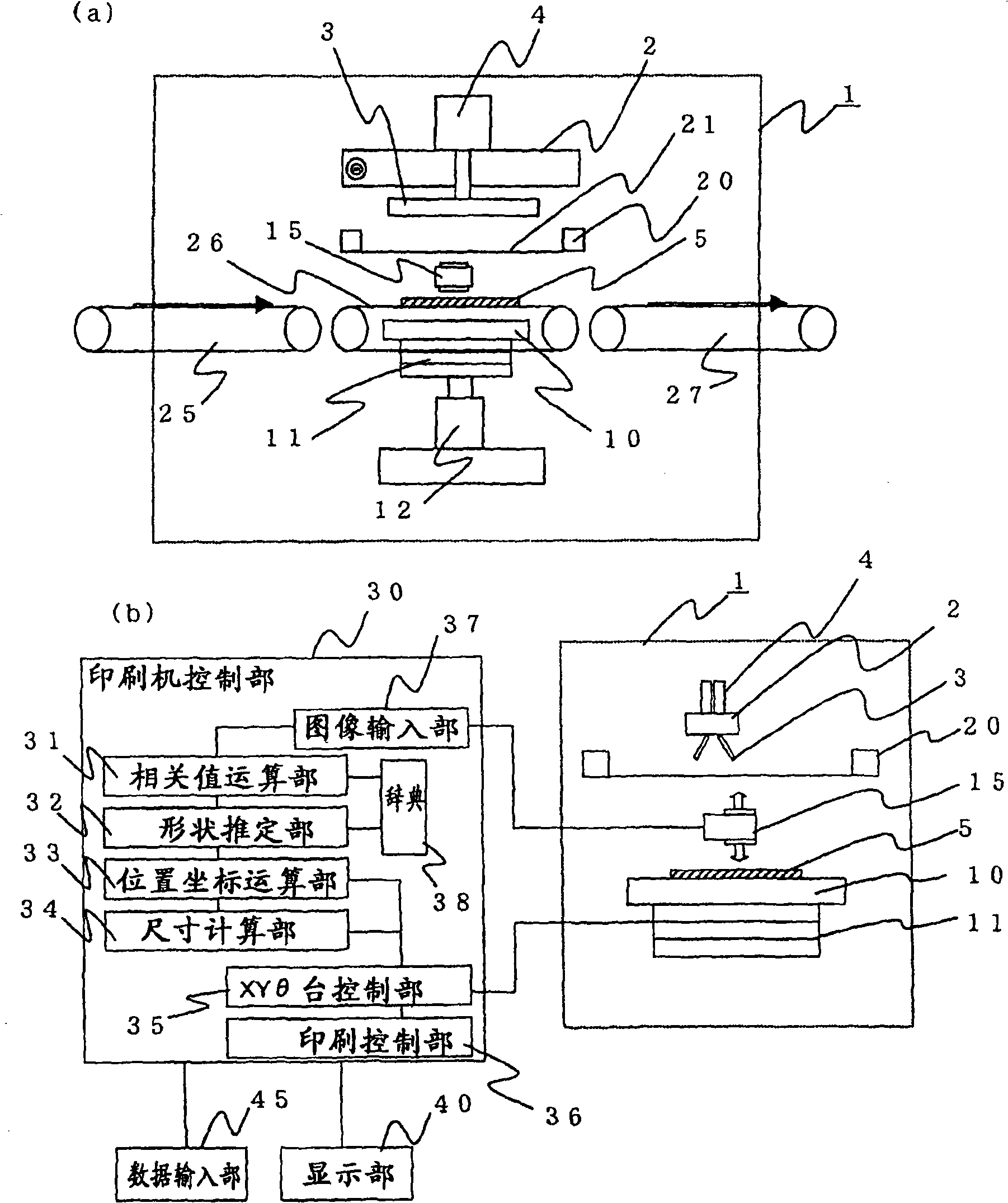

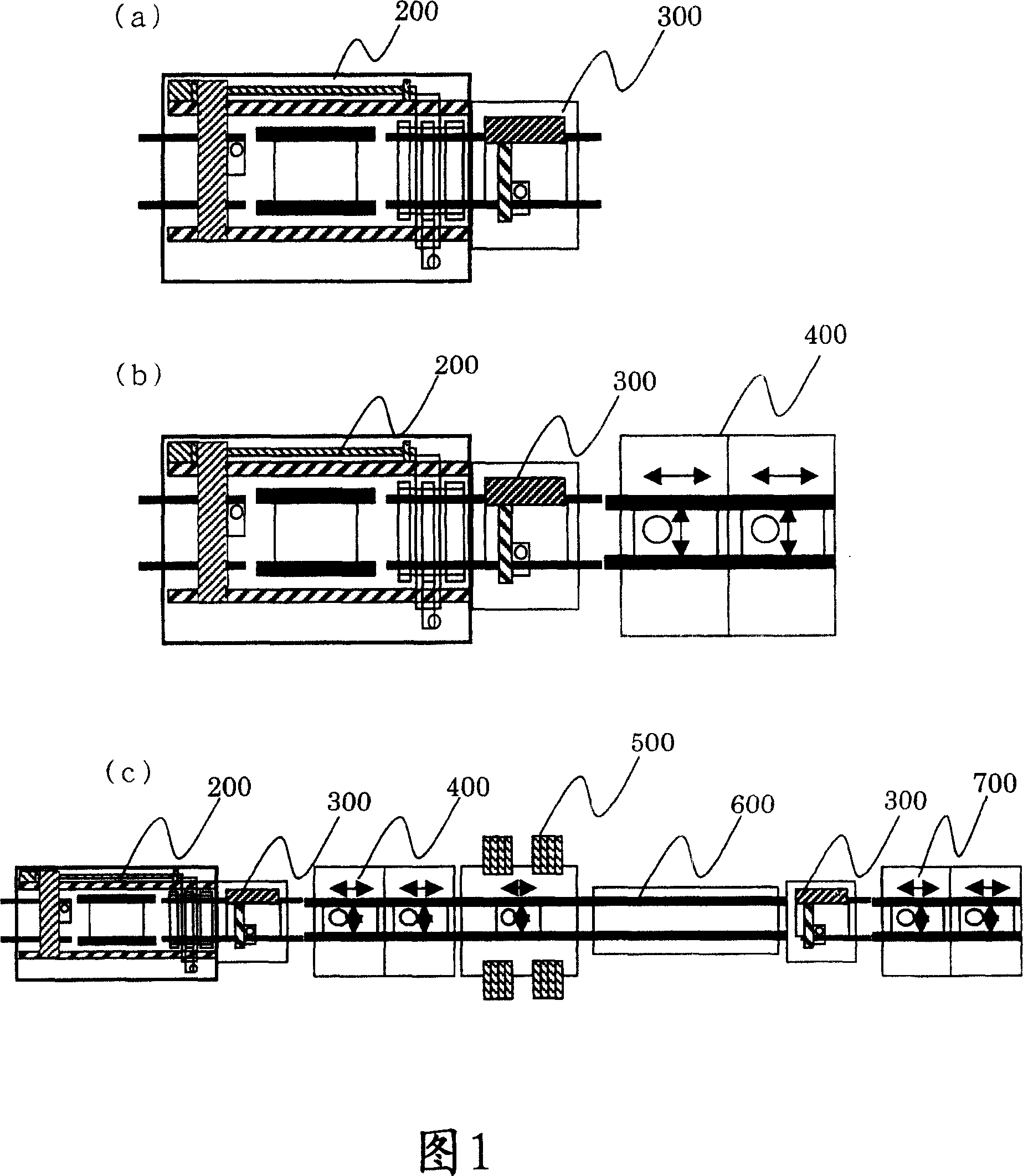

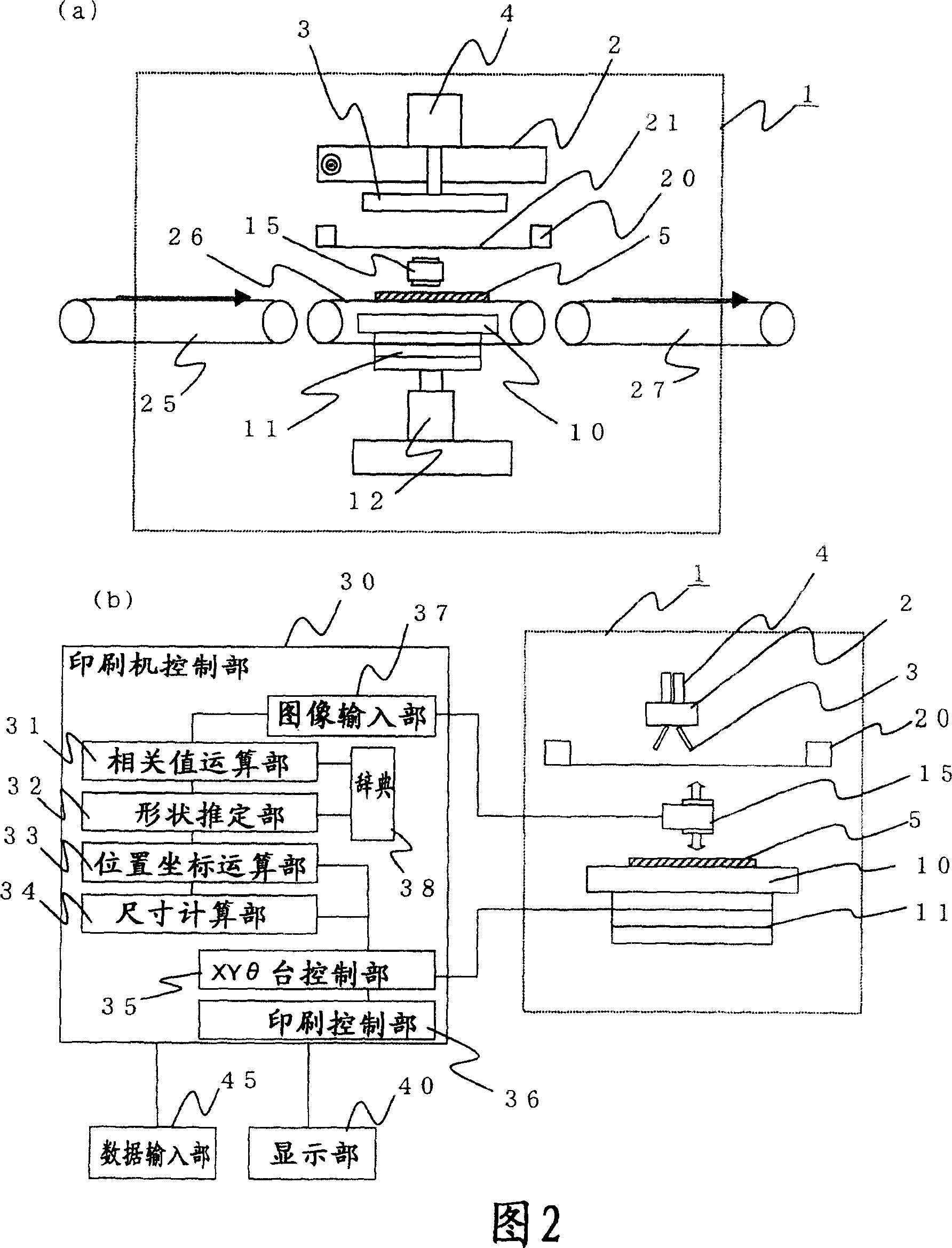

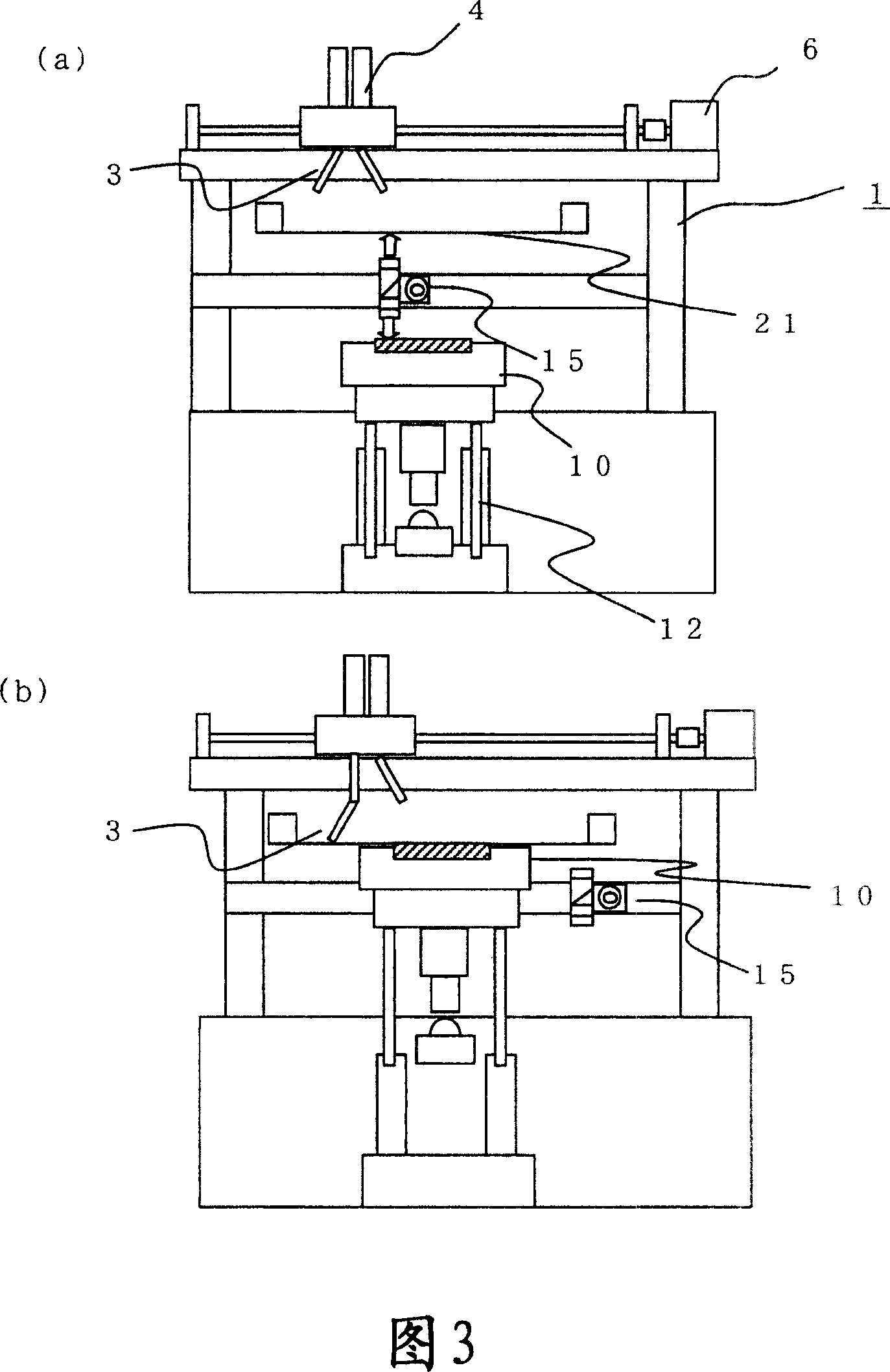

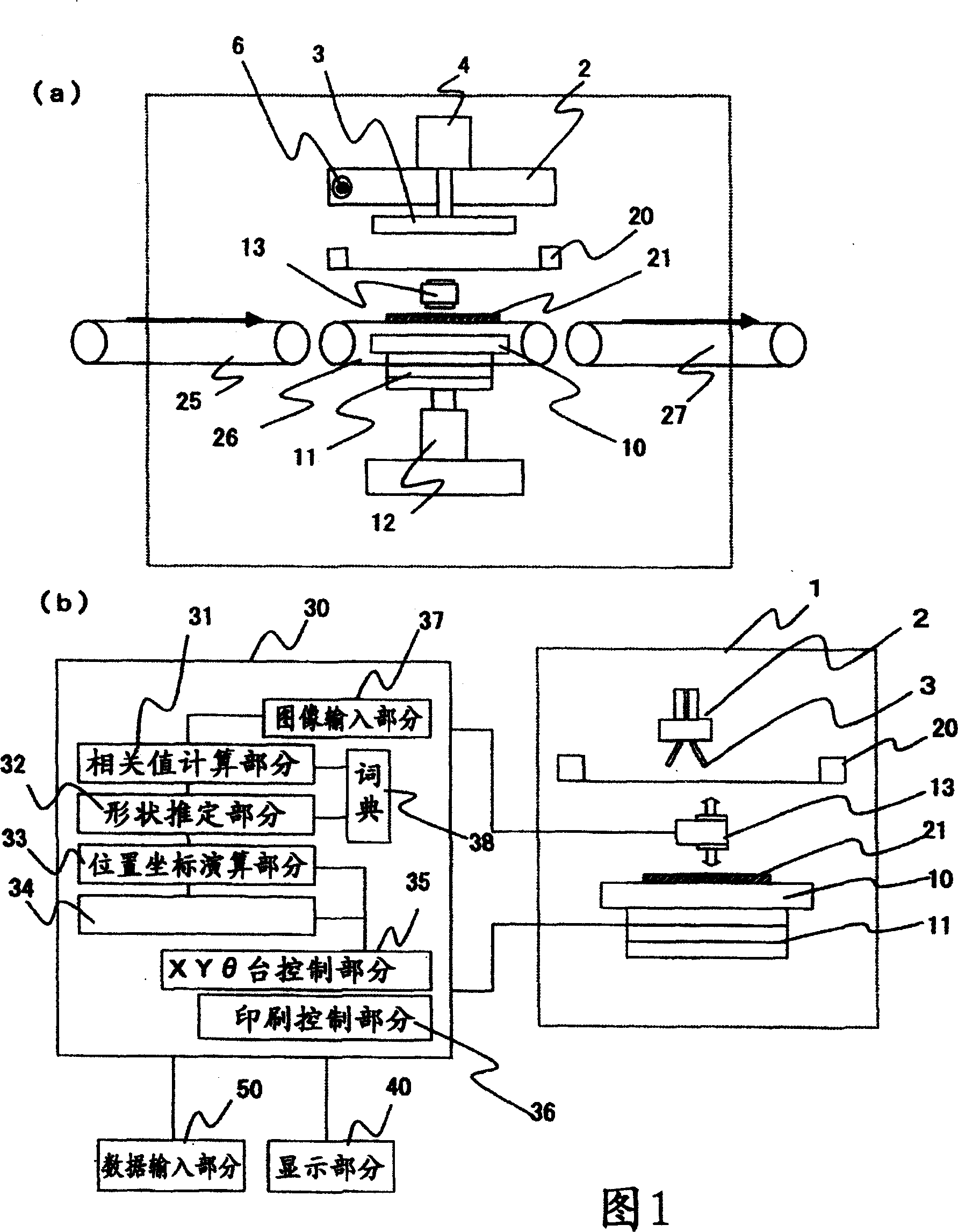

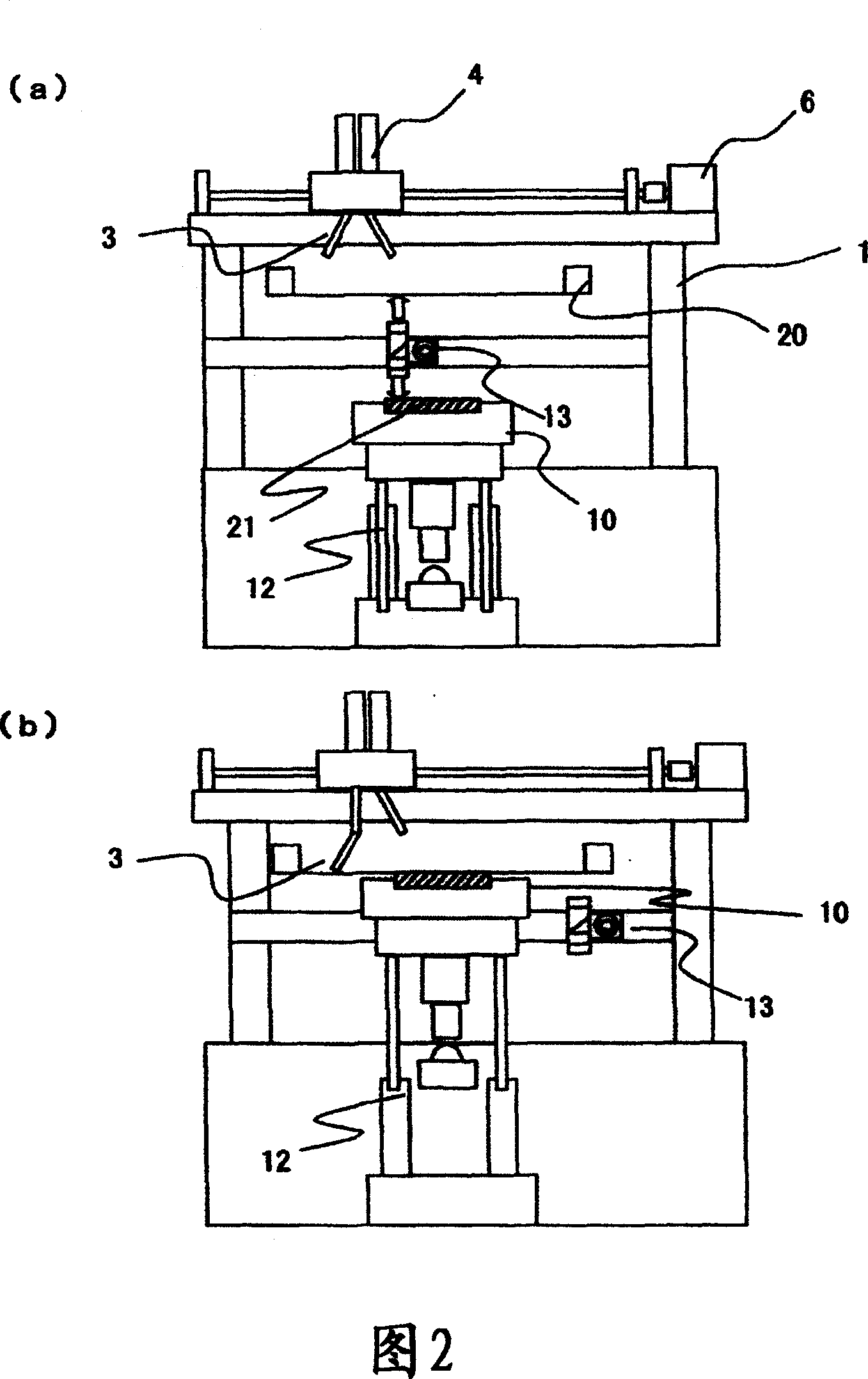

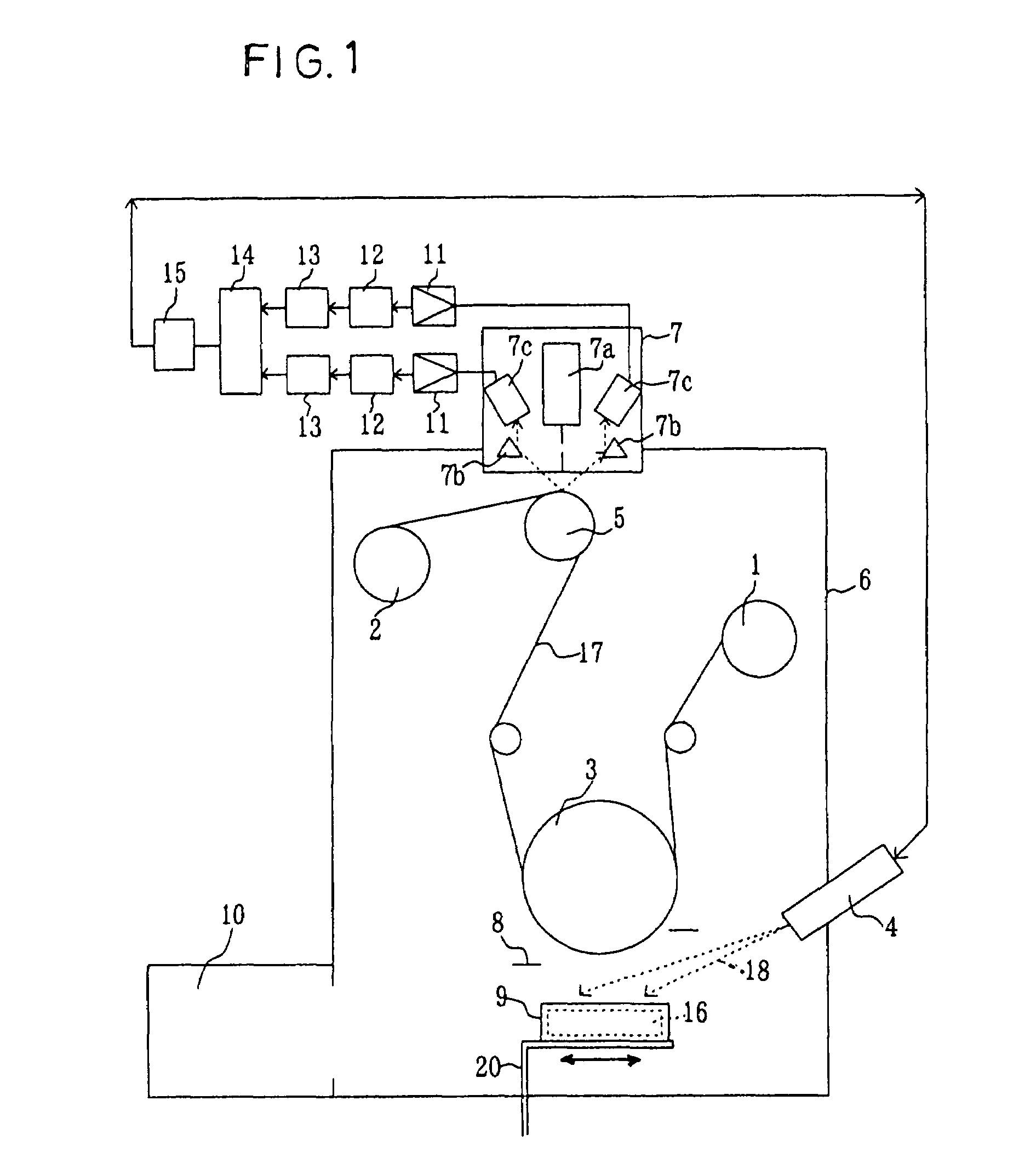

Screen printing equipment and printing system having the same

InactiveCN101318399AReduce distortion distortionStable thicknessPrinted circuit assemblingScreen printersEngineeringPrinting press

The invention provides a silk screen printing device and printing system. In the solder printing system equipped with the silk screen printing device, the invention increases the printing precision of the silk screen printing device while needing to repair the badness not repaired in the system even having printing badness in the silk screen printing device so as to improve the production efficiency of the product. Such that the printing device used in the printing of the silk screen printing device is made in the structure of using the metallic printing device having two stage elasticity and in the structure of the checking unit for checking the printing state after printing and the distributor unit of repairing the badness of the printing substrate according to the checking result, and using the system reflected in the next substrate by using the result sent to the silk screen printing device.

Owner:HITACHI LTD

Continuous casting mould fluxes and preparation method thereof

The invention provides continuous casting protection slag, which contains a calcium-contained compound, a silicon-contained compound and an aluminum-contained compound, wherein the protection slag also contains an addictive; the addictive selects from one or more of compounds which make the melting point and the viscocity in the melting state of the protection slag reduced; the dosage of the addictive makes the melting point of the protection slag reduced to be between 1,070 and 1,170 DEG C, and the viscocity of the protection slag at the temperature of 1,300 DEG C reduced to be between 0.2 and 0.4 Pa.S; and based on oxide, the weight ratio of the calcium-contained compound to the silicon-contained compound of the protection slag is between 0.95 and 1.15, and the weight ratio of the aluminum-contained compound to the silicon-contained compound is between 0.15 and 0.5. Compared with the prior continuous casting protection slag, the continuous casting protection slag provided by the invention can effectively reduce longitudinal cracks, transverse cracks and subsurface meshy cracks on the surface of casting banks, and the splitting defect rate of steel finished products subjected to casting blank rolling is lower.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Novel prescription of CSP diversion agent and preparation method thereof

InactiveCN1994624AStable thicknessProportionally largeMelt-holding vesselsInvestment materialGraphite

The invention relates to a guide agent and relative preparation, used in CSP smelt factory, wherein it uses chromic sand, quartz sand, magnesium sand, feldspar sand, and graphite, to be screened, mixed and dried. Compared with present guide agent, it has better sinter degree, stable thickness, and better high-temperature resistance, etc. And the test proves that its steel pack self-open rate can reach 98-100%.

Owner:XIXIA TONGYU METALLURGICAL PROTECTION MATERIAL

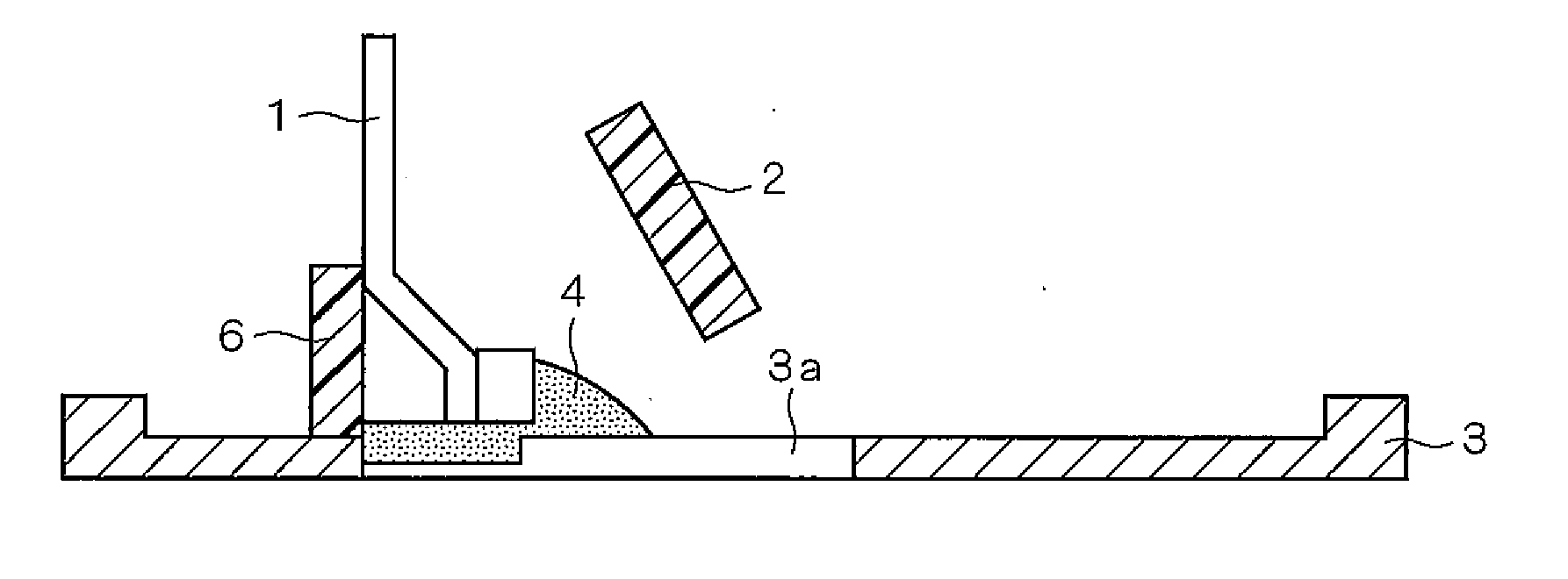

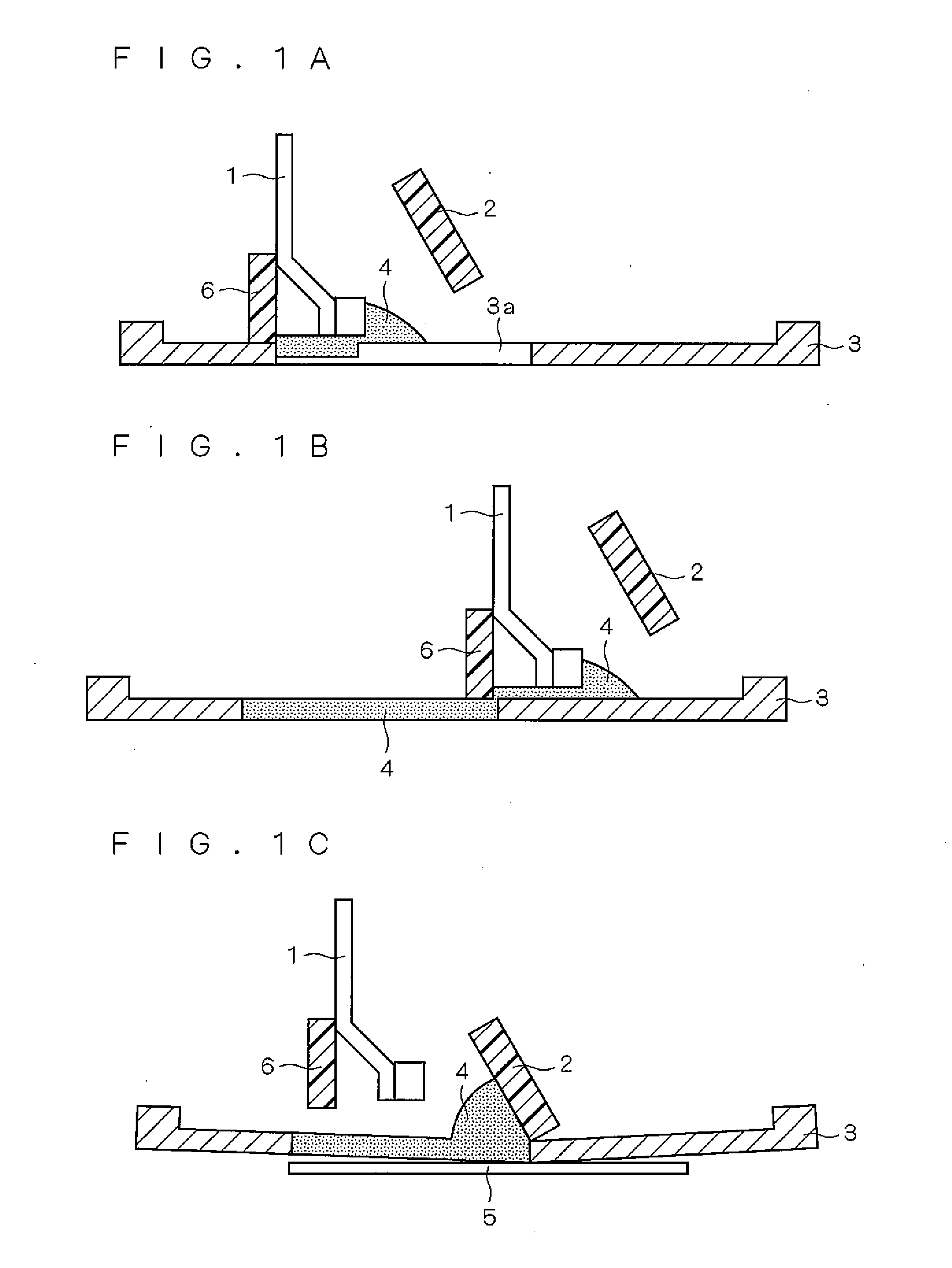

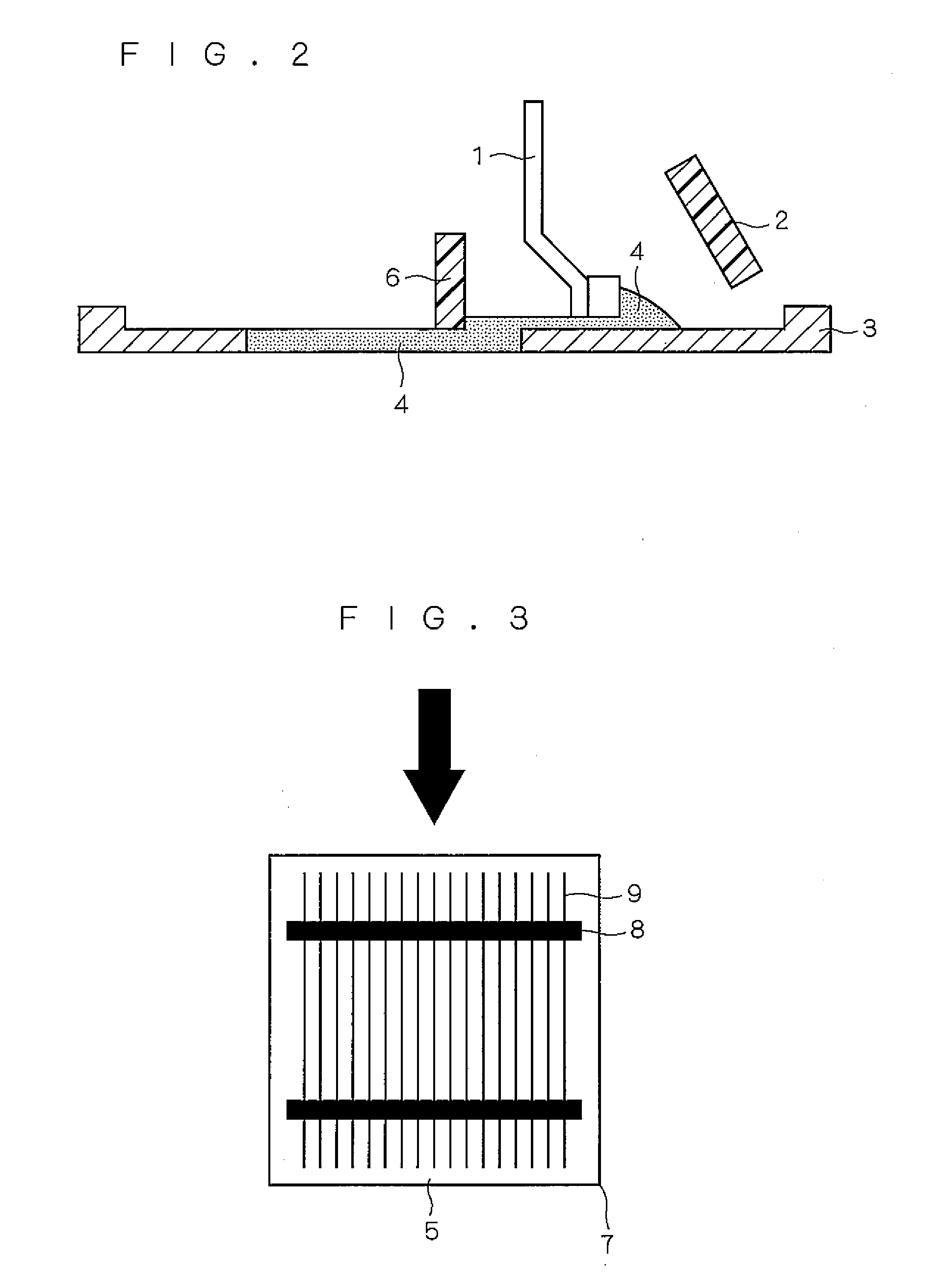

Silk screen printing device and printing system comprising same

InactiveCN1939716AReduce distortion distortionStable thicknessScreen printersConductive pattern formationPrinting pressSolder paste

The present invention provides a silk screen printing device and printing system comprising the same. In the soldering paste printing system provided with the silk screen printing device, the printing precision of the silk screen printing device is obtained, at the same time the disfigurement which can be repaired in the system is repaired in the system if printing disfigurement occurs in the silk screen printing device, and the product productivity is improved. Therefore, the squeegee used in the printing process of the silk screen printing device is made to a structure using a metal squeegee having two stages of elasticity, and is to a structure of a detecting unit configured to detect the printing state after the printing process is finished and a dispenser unit used for repairing the disfigurement of the printing substrate according to the detecting results; and a system in which the detecting results are transmitted to the silk screen printing device and responded in the printing process of the next substrate is adopted.

Owner:HITACHI LTD

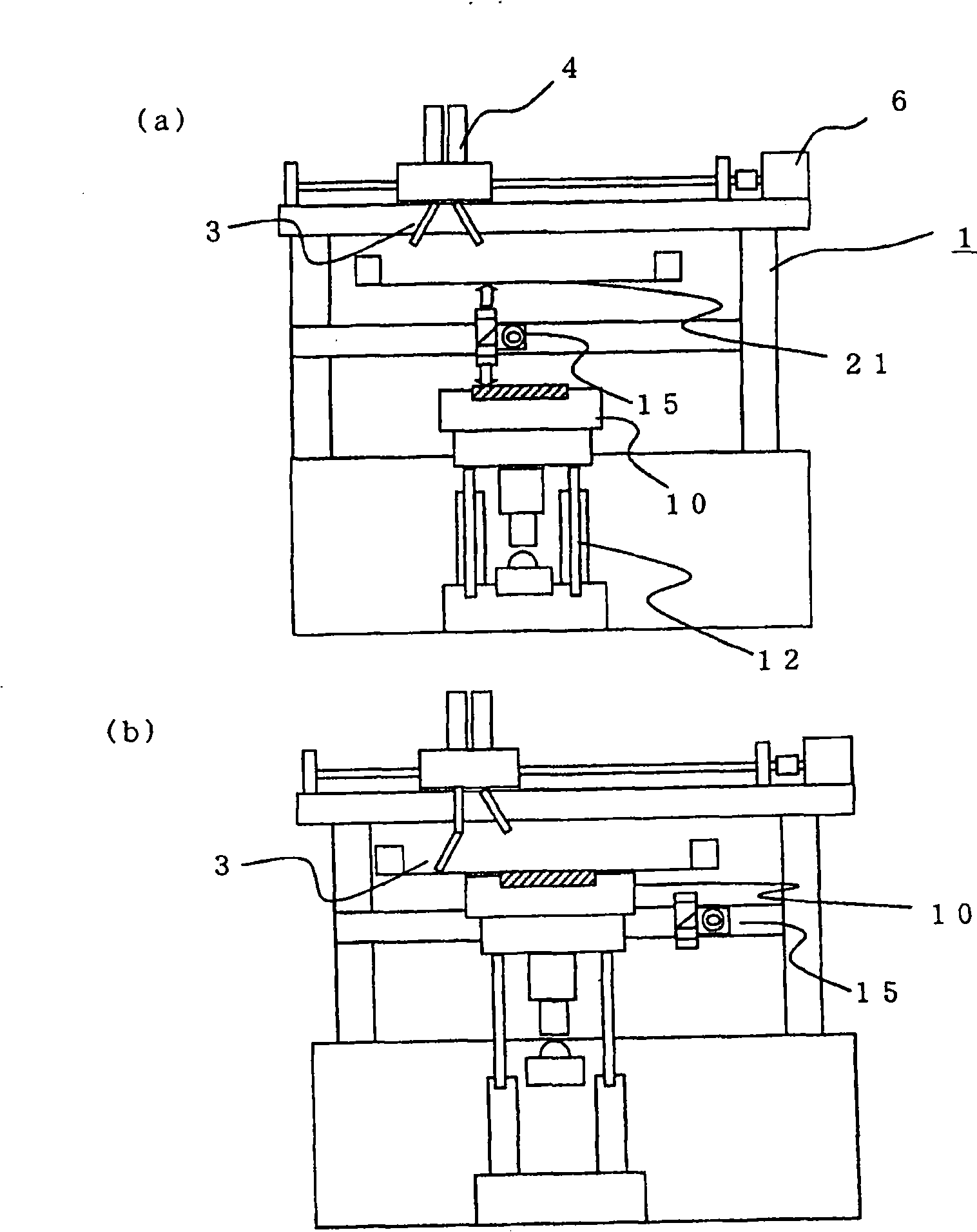

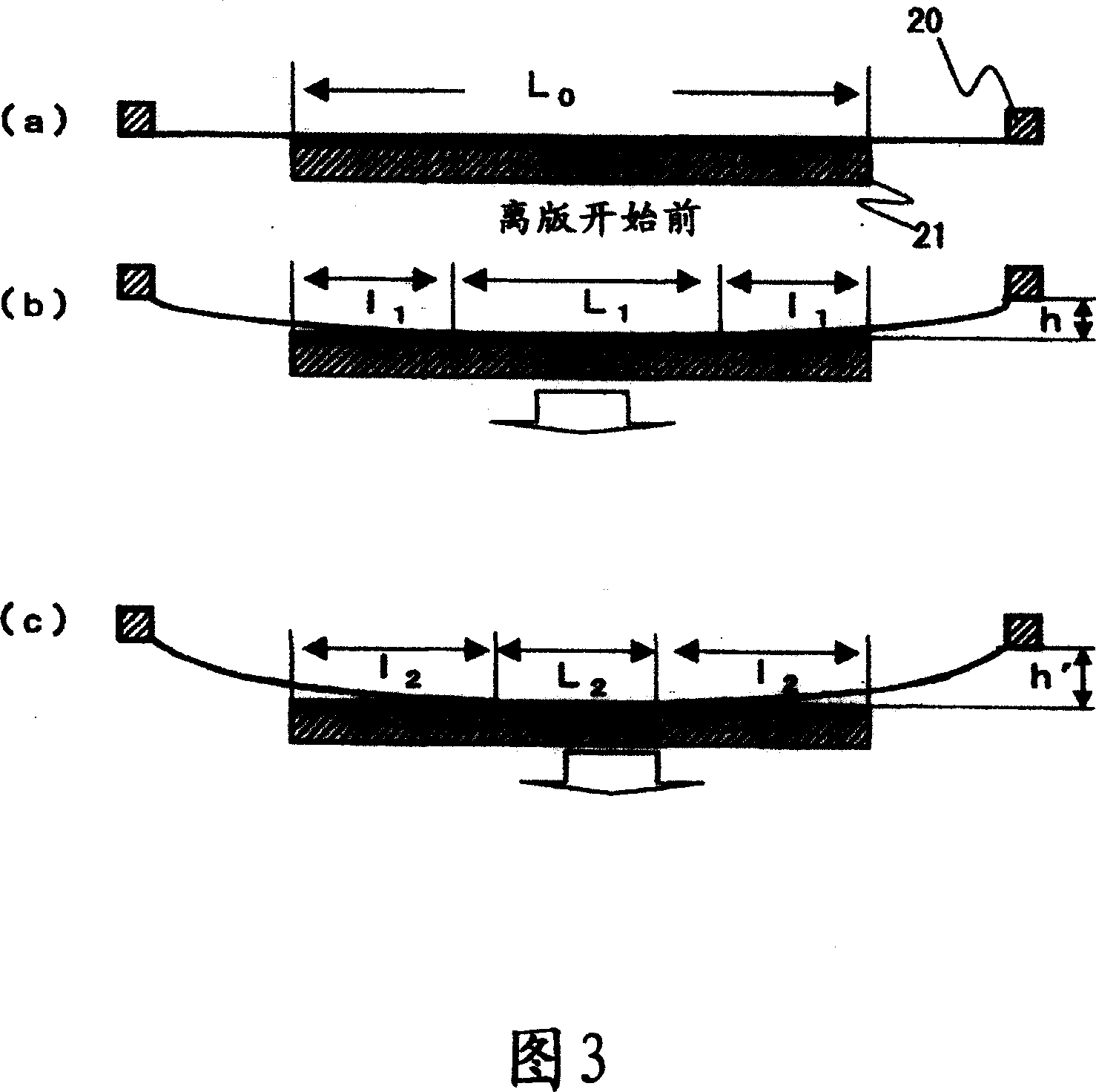

Silk-screen printing device

InactiveCN101045360AImprove yieldImprove printing qualityPrinted circuit assemblingScreen printersScreen printingBaseboard

Provided is a screen printing apparatus. In the forming of the protrude electrode using the screen printing method, resulting the adhesive force of the solder paste which is transferred by many opening-part groups and the metal mask, the departing of the printing board starts from the perimeter part, finally the middle part of the metal mask departs from the printing board, the occurring of this phenomenon is the main reason for the defective printing which concludes the thickness error of the printing film ,the printing deficiency and so on. Using the different thickness of the mentioned mask component sheet, or the different material, or the different elastic coefficient, connect every mask component sheet which is set on the accessory pattern of the printing baseboard or at all the patterns formed in the scheduled area, and the adjusting equipment which accords to the mentioned connection status and can reproduce random curve is also provided.

Owner:HITACHI LTD

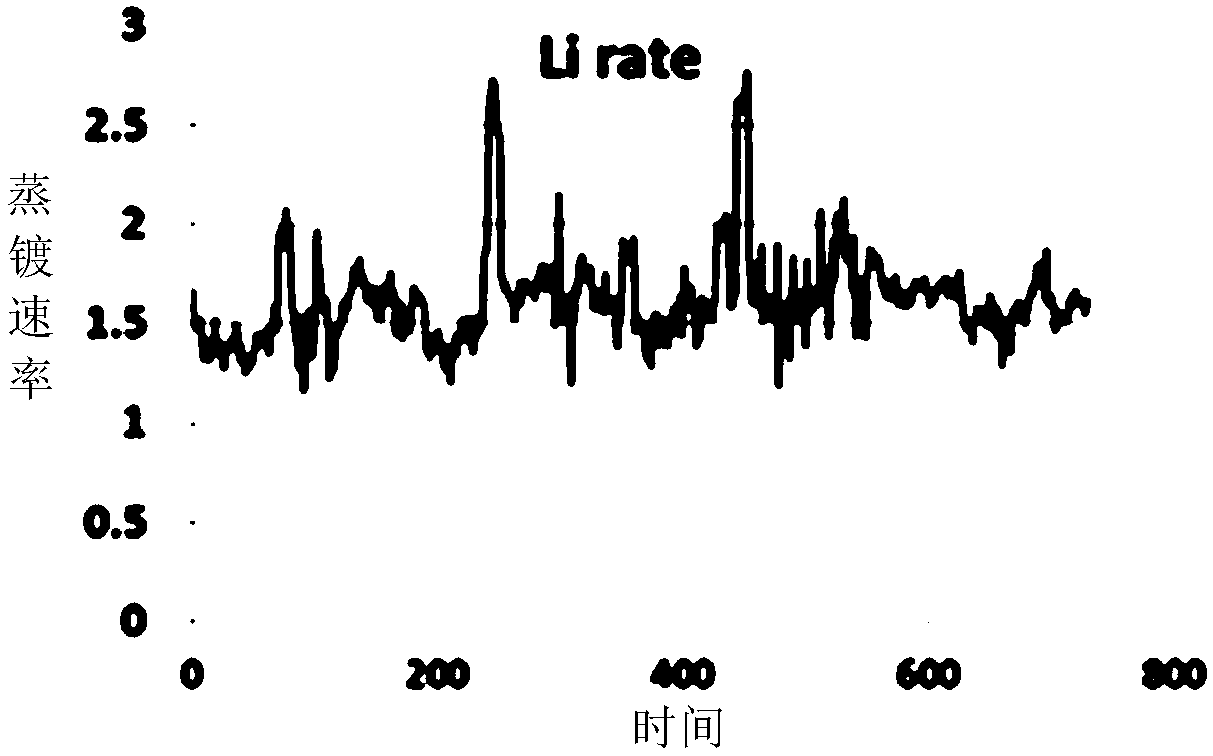

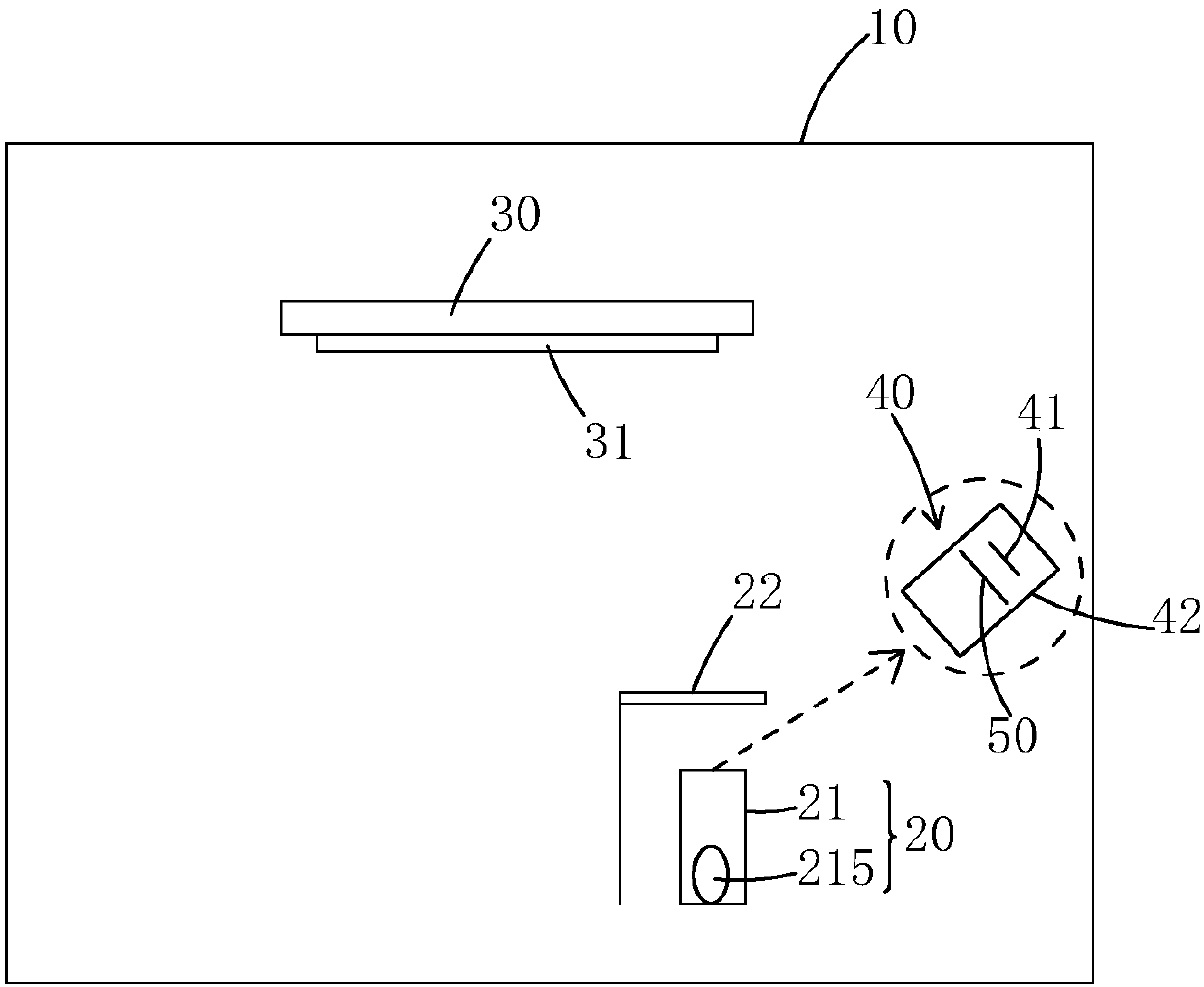

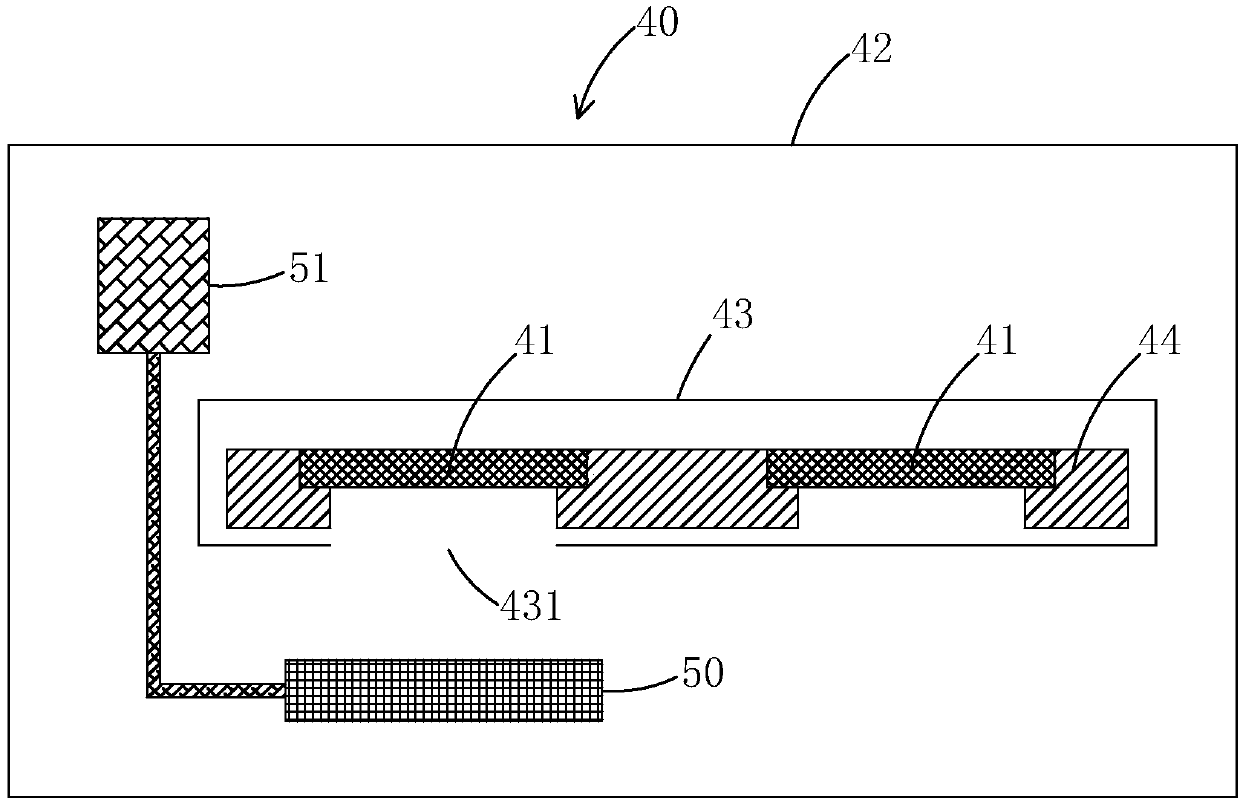

Evaporating device and evaporating method

ActiveCN107779822AAvoid depositionMonitor thicknessVacuum evaporation coatingSputtering coatingParticle physicsCrystal oscillator

The invention provides an evaporating device and an evaporating method. According to the evaporating device disclosed by the invention, a crystal oscillator sheet baffle plate is arranged between an evaporation source and a crystal oscillator sheet, and the crystal oscillator sheet baffle plate can switch between two positions, namely a position shielding the crystal oscillator sheet and a position not shielding the crystal oscillator sheet; when the crystal oscillator sheet baffle plate is in the position shielding the crystal oscillator sheet, evaporation material deposits to the crystal oscillator sheet baffle plate, so as to prevent the evaporation material from depositing to the crystal oscillator sheet; and when the crystal oscillator sheet baffle plate is in the position not shielding the crystal oscillator sheet, the evaporation material deposits to the crystal oscillator sheet. When the evaporation device disclosed by the invention is applied to an evaporation process, in theinitial stage of evaporation, namely the evaporation stage of impurities on the surface of to-be-evaporated material, the crystal oscillator sheet baffle plate is in the position shielding the crystaloscillator sheet, so as to prevent impurities from depositing to the surface of the crystal oscillator sheet; and after evaporation of the impurities on the surface of the to-be-evaporated material is completed, the crystal oscillator sheet baffle plate is in the position not shielding the crystal oscillator sheet, and the evaporation material deposits to the surface of the crystal oscillator sheet, so that an evaporation rate monitoring device acquires a steady evaporation rate.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

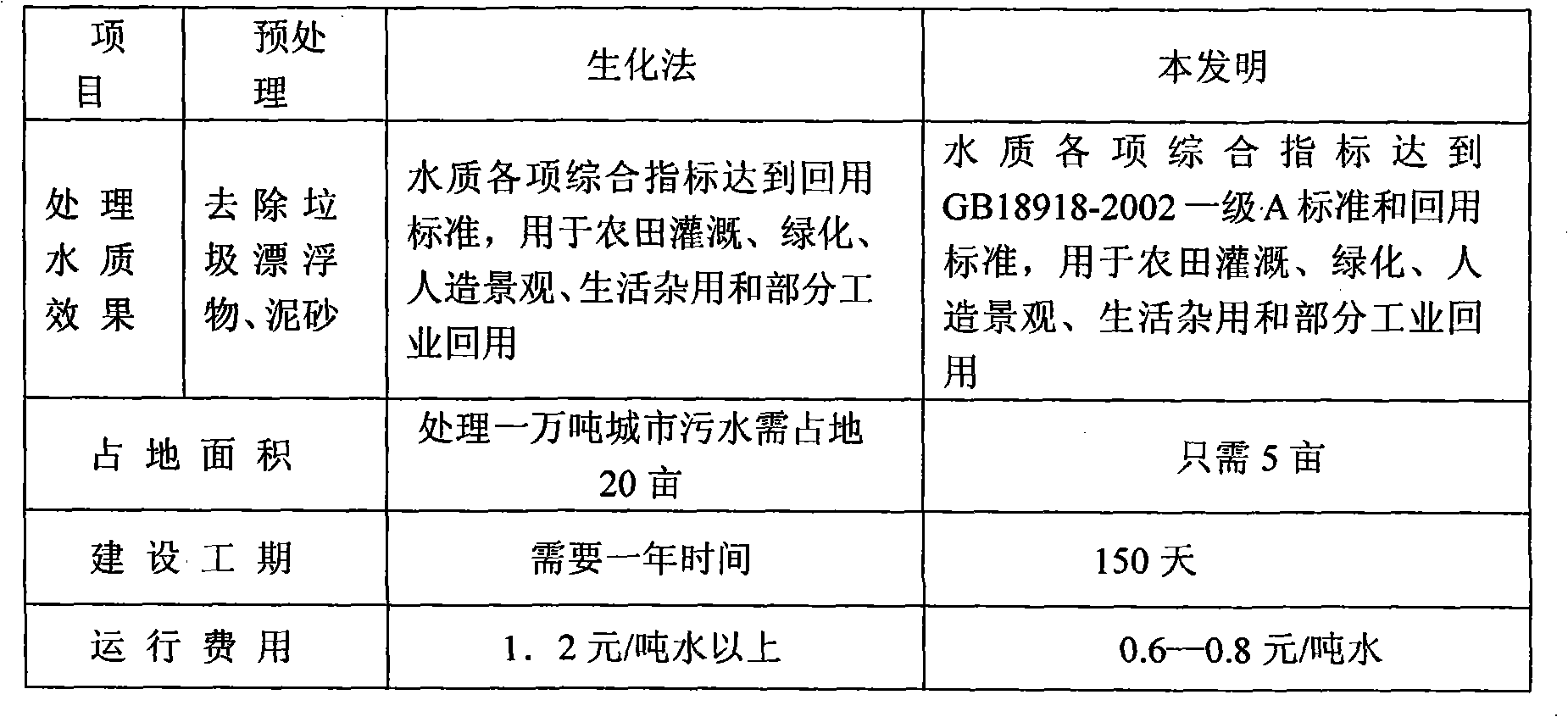

Zero-discharge purifying treatment method for mine wastewater and mine domestic sewage

InactiveCN101565247AHigh densityGood water permeabilityWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentFlocculationImpeller

The invention relates to a zero-discharge purifying treatment method for mine wastewater and mine domestic sewage. The method adopts the technical scheme that after the sewage passes through a grid, the supernatant enters in an equalizing tank; the sewage after pretreatment enters in a lifting pump sump for a purifier, when the sewage water level in the lifting pump sump for the purifier is raised to the upper limit water level, a composite water treatment agent in a chemical feeder and the sewage simultaneously pass through a lifting pump impeller and a pipeline mixer and then enter in a nanofihration circulating purifier after being sufficiently mixed, the sewage and the composite water treatment agent rapidly form a flocculation cake layer in the nanofihration circulating purifier and the sewage is filtered through the flocculation cake layer; the filtrate enters in a high-efficiency denitriding purifier through an intermediate pool and stays for 2-4 h; the sewage after secondary treatment enters in a strong-carbon adsorption purifier for purification; the purified water enters in a water purifying tank and a disinfectant is added. The invention has the advantages that the cost is low, and the water quality after treatment can meet the standard of the regenerated recycle-water.

Owner:邢殿满

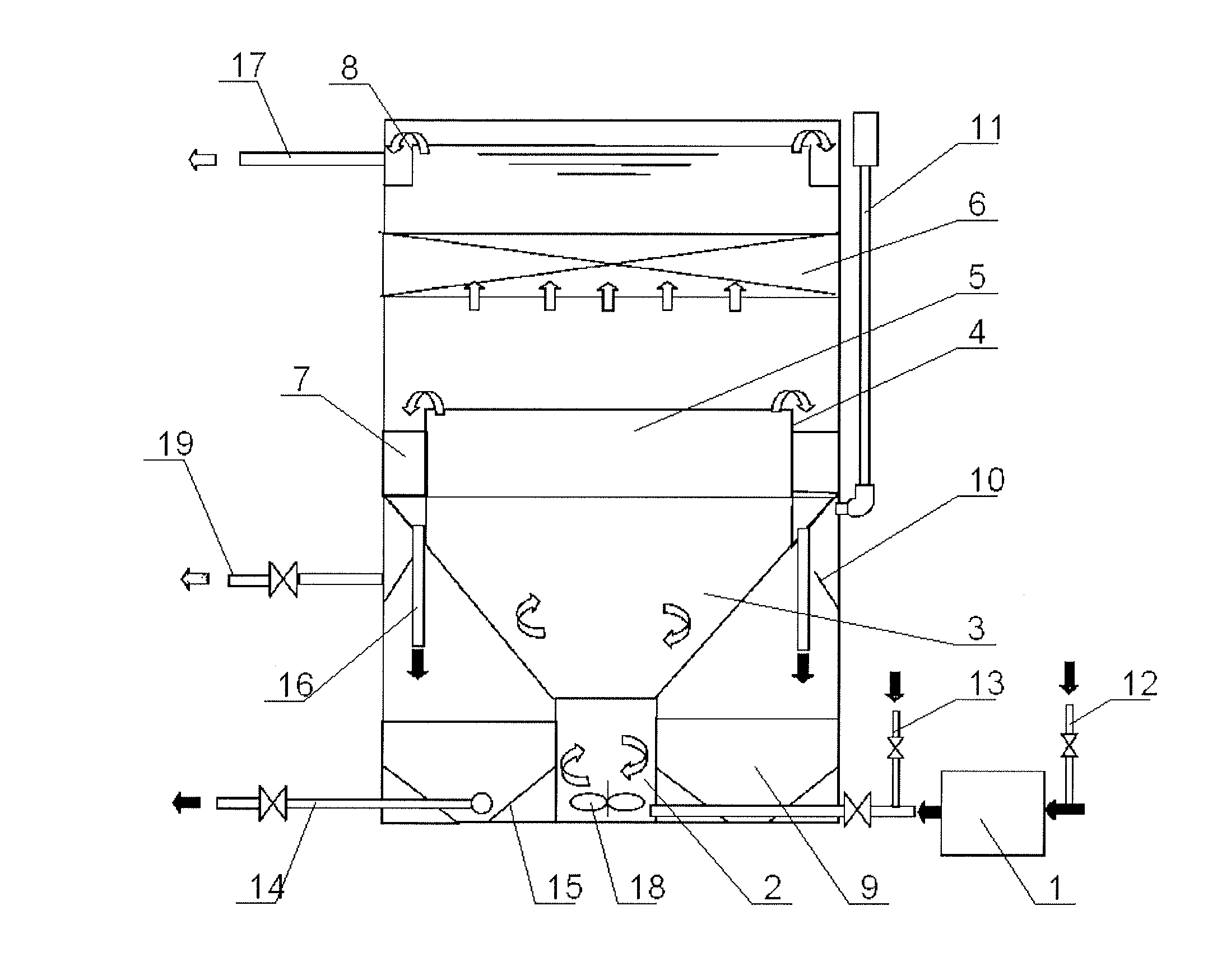

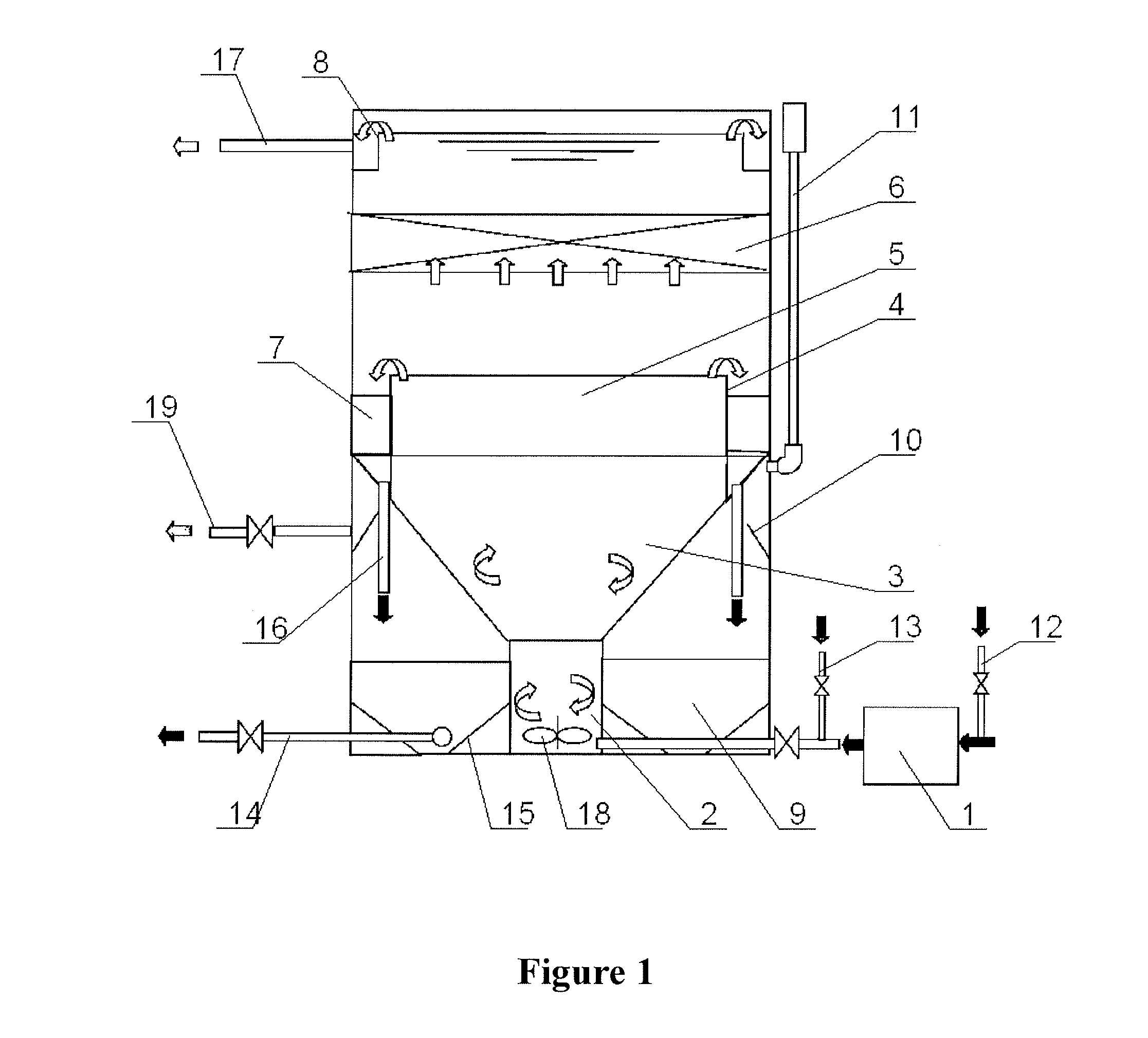

Device for Purifying Oily Wastewater

InactiveUS20130062272A1Increase settling velocityStrong turbulenceWaste water treatment from quariesSludge treatmentFlocculationFiltration

There is disclosed a device for purifying oily wastewater, including a vertical tank of an atmospheric pressure, inside which a central coagulation reaction tube, a reverse cone-shaped cyclone flocculation stage, a suspended sludge filtering zone and a purified water commutation stage of inclined plates are included from bottom to top sequentially, oily wastewater is sequentially subjected to a coagulation reaction, suspended sludge filtering and a purified water commutation process and then discharged, a sludge collecting groove collects and guides the suspended sludge to a sludge concentrating zone for further sedimentation and concentration processes and then discharges it to external to the tank, in this way, the purification reaction, flocculation and fine filtration of wastewater and the sludge concentration process are integrated within the same wastewater purifying device. Thus, the device is equivalent to the existing wastewater pretreatment system plus a fine filtration system.

Owner:BEIJING OTC ENERGY & ENVIRONMENT ENGINEERING PUBLIC LIMITED COMPANY

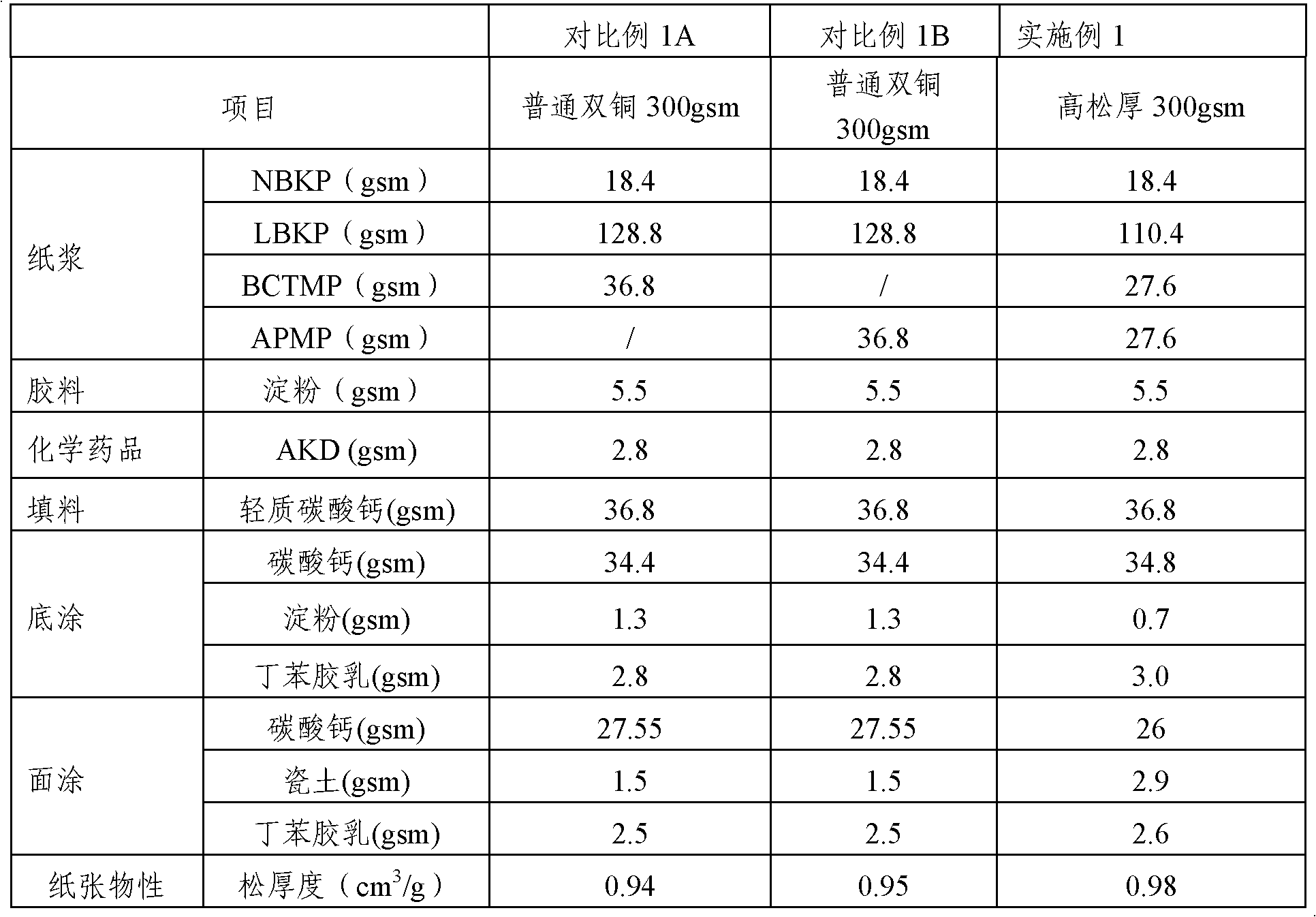

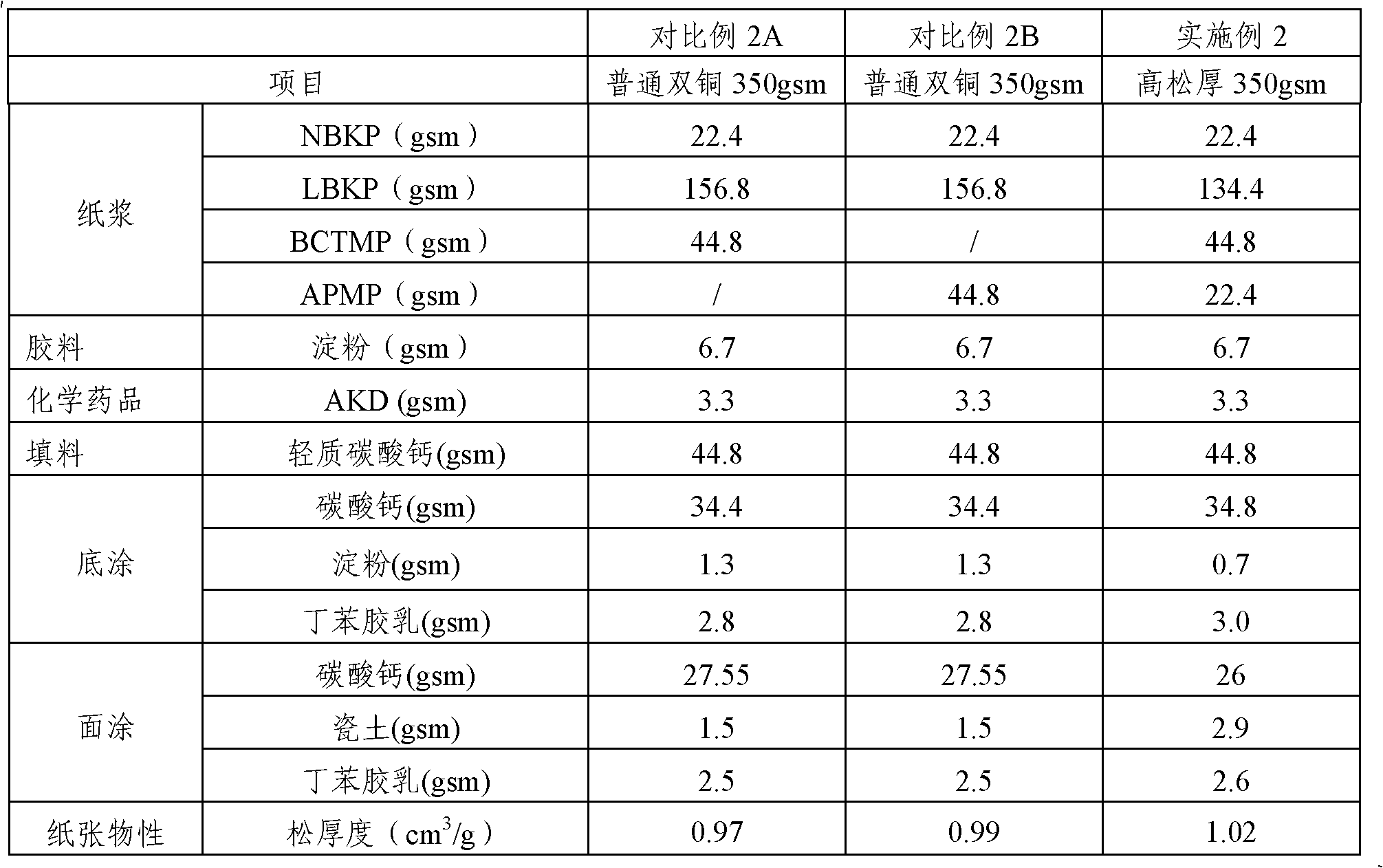

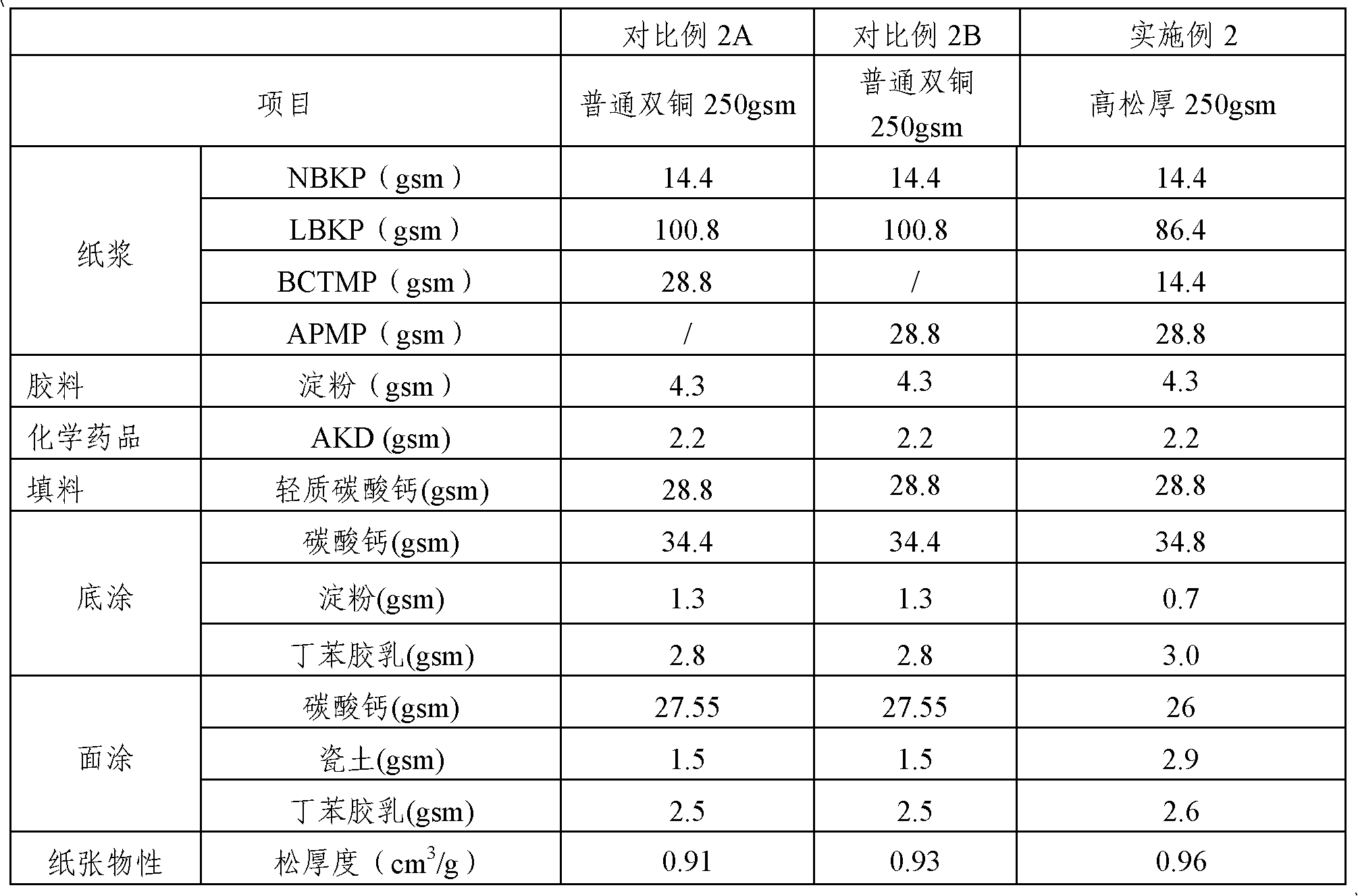

Paper pulp and high-bulk energy-saving environment-friendly card prepared from same

ActiveCN102535240AStable qualityAvoid overproductionCoatings with pigmentsSynthetic cellulose/non-cellulose material pulp/paperGramHardwood

The invention discloses paper pulp and a high-bulk energy-saving environment-friendly card prepared from the same. The paper pulp is prepared from the following components in percentage by weight: 1 to 10 percent of bleached sulfate softwood pulp, 30 to 70 percent of bleached sulfate hardwood pulp, 20 to 50 percent of chemithermomechanical pulp, and 10 to 30 percent of alkaline peroxide mechanical pulp. The invention also provides the copperplate card prepared from the paper pulp and other components. The paper made with the paper pulp is high in bulk, the gram weight of the paper is effectively controlled to be in a certain range, the paper pulp is prevented from being put into production excessively, and the defibrination energy consumption of a paper machine is reduced correspondingly, so that the effects of environment friendliness and energy saving are effectively achieved.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

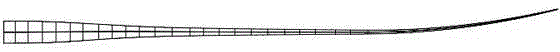

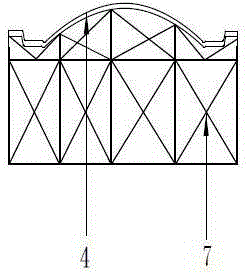

Method for manufacturing wind power blade crossbeam mold

The invention belongs to the technical field of wind power generation and particularly relates to a method for manufacturing a wind power blade crossbeam mold. The method for manufacturing the wind power blade crossbeam mold comprises the steps that a blade male mold body is manufactured, and a blade female mold body is remanufactured on the blade male mold body; and after the blade female mold body is manufactured, a standard blade crossbeam model is manufactured on the blade female mold body, and then a blade crossbeam male mold body is remanufactured on the blade crossbeam model. According to the method for manufacturing the wind power blade crossbeam mold, a gap between a blade shell and an anti-shear web can be accurately controlled or adjusted; when the crossbeam male mold body is used for producing a crossbeam, it seems that all layers of the crossbeam become longer gradually one by one through a unique step-shaped structure of the crossbeam male mold body, namely each layer can be covered with the layer above; the probability that the mechanical property is reduced due to the fact that the structure of the crossbeam is damaged can be avoided or lowered to the maximum extent.

Owner:LUOYANG SUNRUI WIND TURBINE BLADE

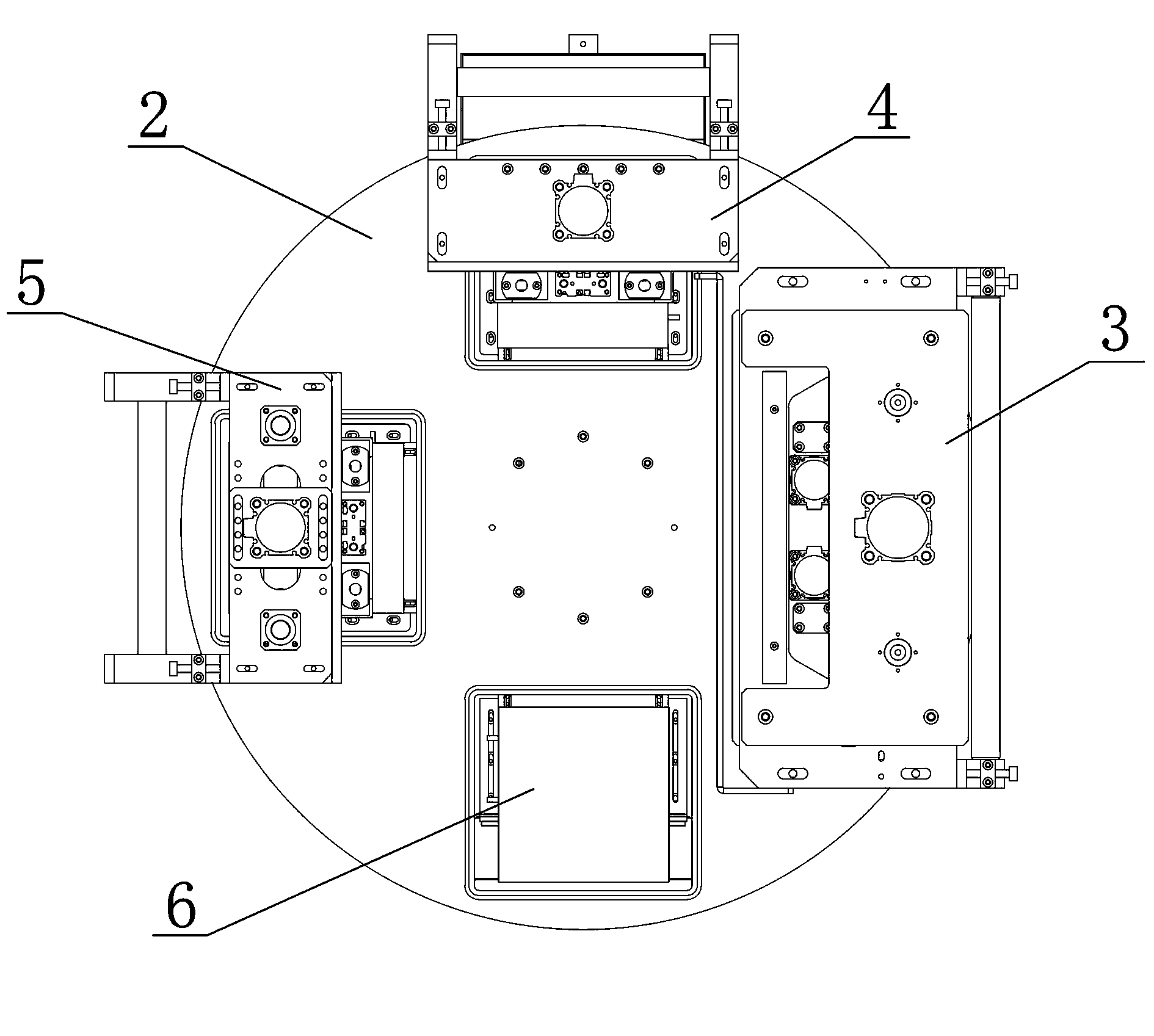

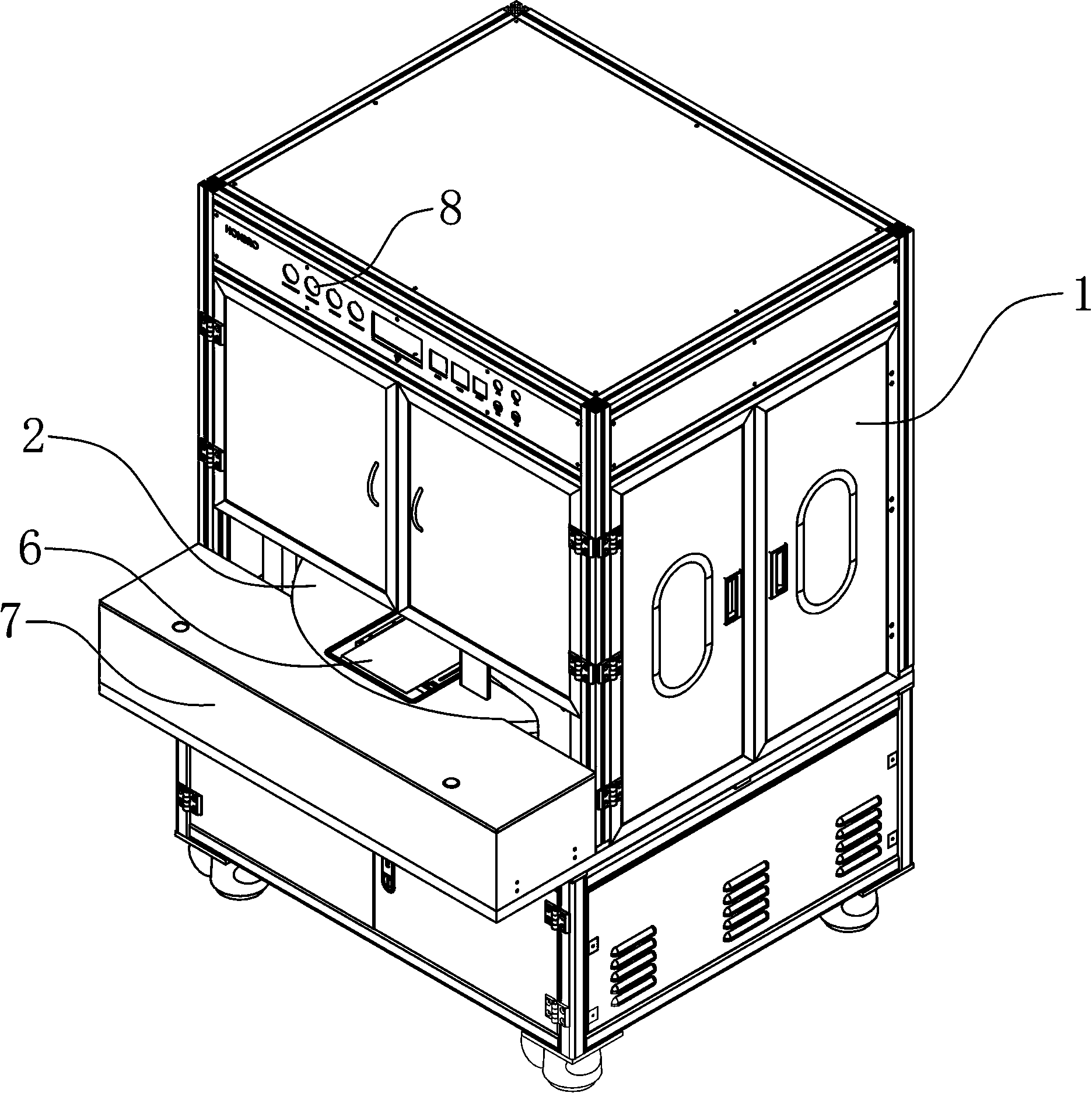

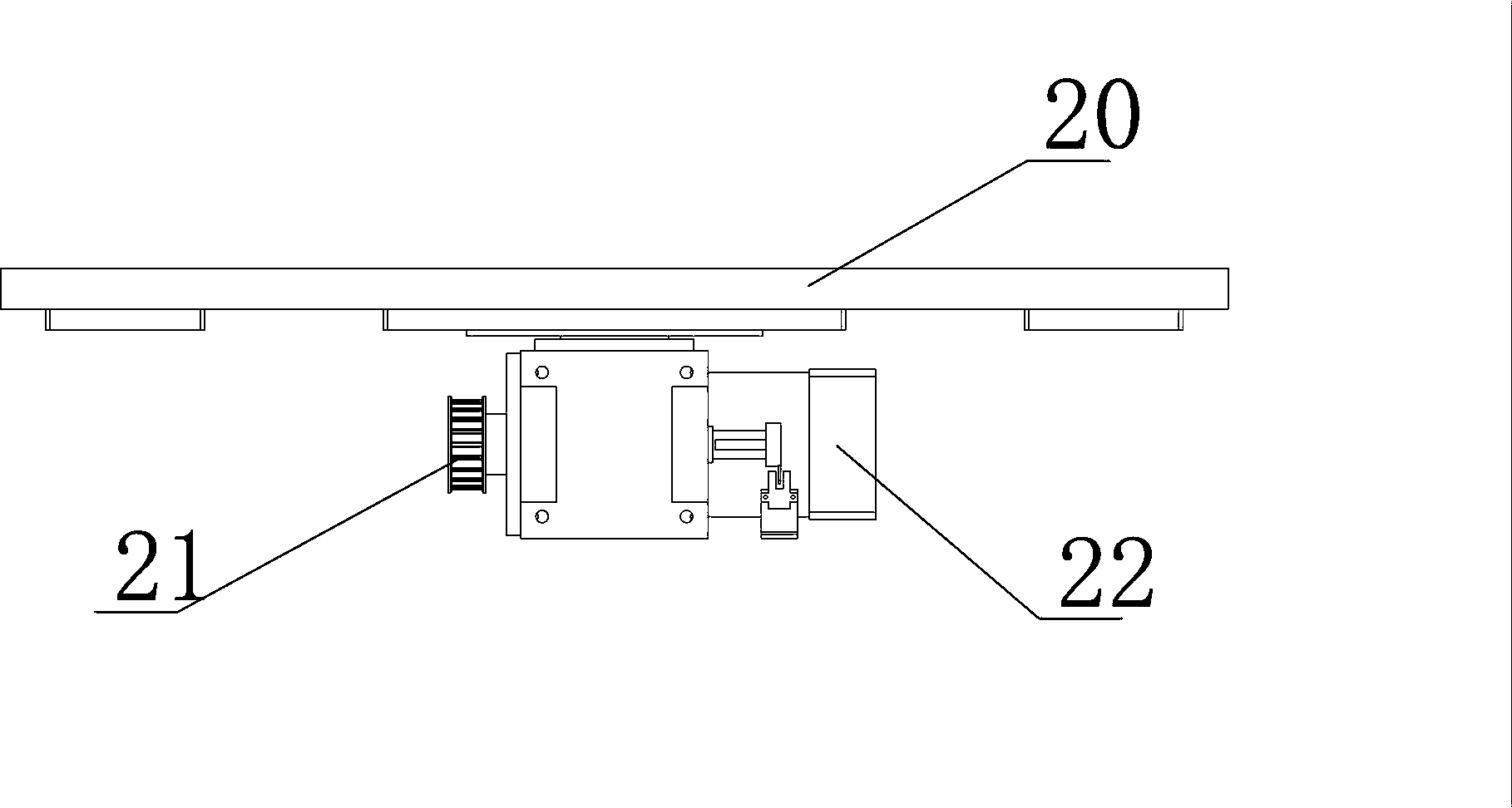

Vacuum packaging, edge cutting and secondary packaging machine

ActiveCN103490097AImprove production efficiencyCompact structureAssembling battery machinesFinal product manufactureMachine buildingEngineering

The invention discloses a vacuum packaging, edge cutting and secondary packaging machine which is characterized by comprising a machine case, a rotary disc mechanism, a vacuum packaging mechanism, an edge cutting mechanism (4) and a secondary packaging mechanism. The rotary disc mechanism is arranged inside the machine case, and the vacuum packaging mechanism, the edge cutting mechanism (4) and the secondary packaging mechanism are respectively arranged in the quartering directions of the circumference of the rotary disc mechanism. The rotary disc mechanism comprises a circular rotary disc, a cutting device and a motor, a feeding station and at least two machining stations are evenly arranged on the rotary disc at intervals in the circumferential direction, and a piece to be machined is placed on the feeding station. The vacuum packaging, edge cutting and secondary packaging machine is compact in structure, saves space and enables the structure to be optimized, the production efficiency is improved through reasonable combinations, the production cost is saved, the productivity achieves 4-6PPM, the packaging thickness and non-packaging areas are accurately and stably controlled, the edge cutting accuracy achieves + / -0.2MM, the product pass percent of the whole machine is higher than 99.9%, and the interactive rate is higher than 97%. According to the vacuum packaging, edge cutting and secondary packaging machine, unified standardization is carried out on parts of various structures or with similar functions in a traditional vacuum packaging, edge cutting and secondary packaging machine, the manufacturing efficiency of the machine is greatly improved, and equipment maintenance difficulty is simplified.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

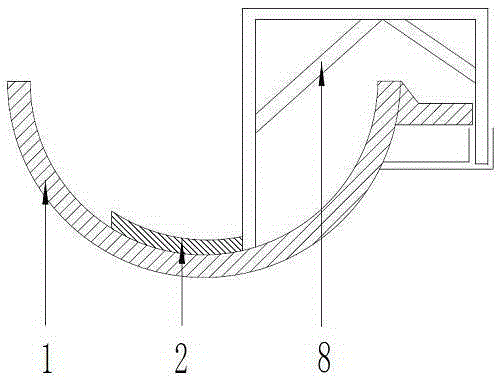

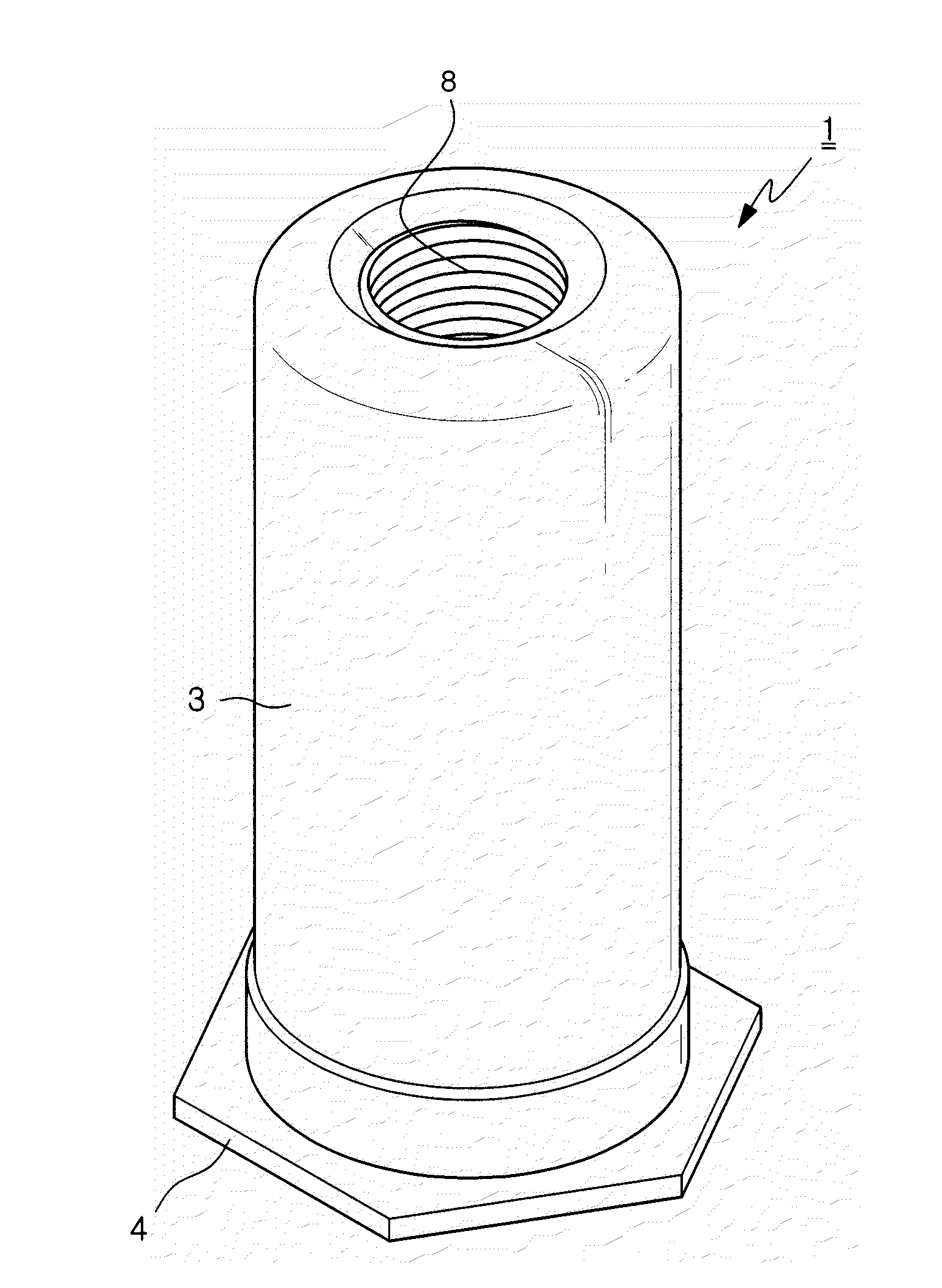

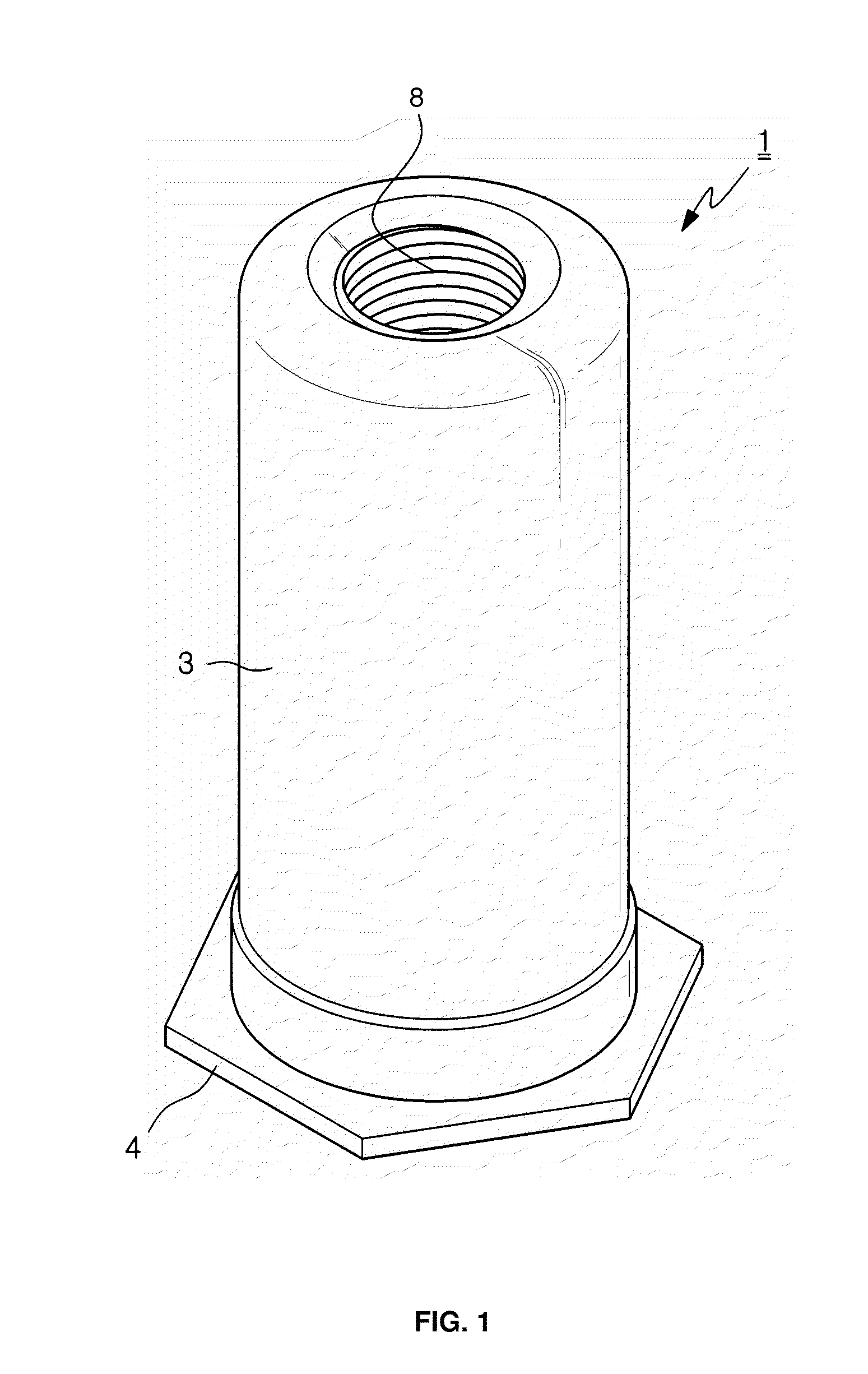

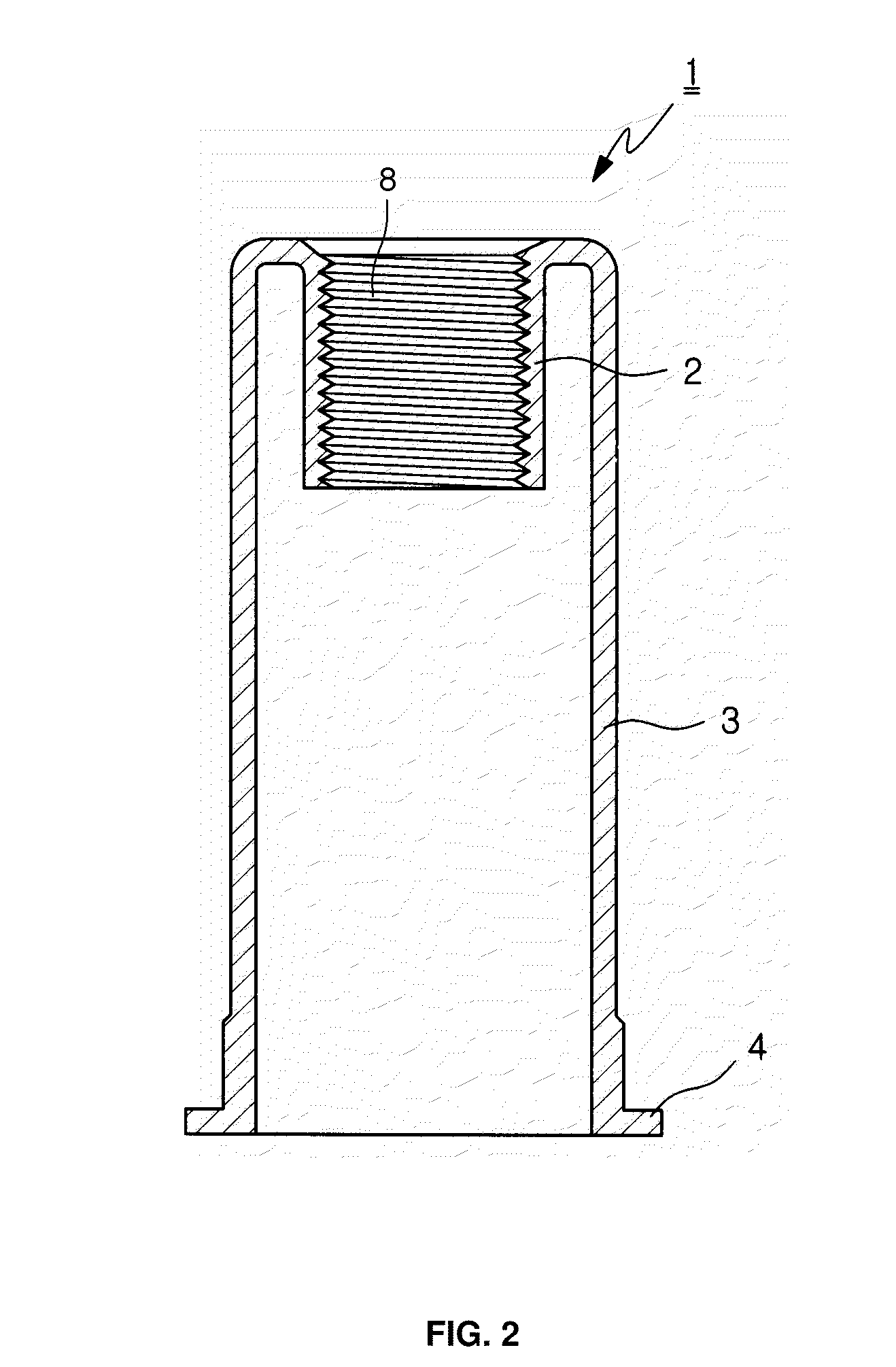

Coupling boss and method for fabricating the same

InactiveUS20080314112A1Power maximizationStable thicknessNutsLiquid/solution decomposition chemical coatingCouplingSurface roughness

Disclosed therein are a coupling boss and a method for fabricating a coupling boss, that a collar part is formed through a collar drawing process using a metal plate material, and then, a body part of the coupling boss is firmly combined to a substrate plate through processes of deep drawing, tapping, cleansing, plating and iron coining in order, thereby maximizing competitive power in price, miniaturizing the coupling boss in size, and maximizing tensile strength, compression strength, and surface roughness. In this instance, a more stable material thickness can be kept by performing a collar drawing process or a curling process when a screw part of the coupling boss is formed. The processes of: forming a collar part (2) through a collar drawing process for forming a screw part (8) of the coupling boss (1) using a metal plate material; forming a body part (3) and a flange part (4) on the metal plate material, on which the collar part (2) is formed, through a deep drawing process; and tapping to form the screw part (8) on the inner peripheral portion of the collar part (2) and the processes of: forming a body part (3) and a flange part (4) by a deep drawing process using a metal plate material; forming a collar part (2) on the body part (3) by a curling process; and tapping to form a screw part (8) on the inner peripheral portion of the collar part (2) are performed selectively. After that, the formed coupling boss (1) is firmly combined to a substrate plate (5) through the processes of cleansing, plating, and iron coining.

Owner:PARK SANG BONG +1

Functional roll film and vacuum evaporation apparatus capable of producing the functional roll film

InactiveUS7666490B1Accurate measurementComposition is stableVacuum evaporation coatingSputtering coatingPlastic filmRoll film

A functional roll film comprises a plastic film which is transparent and having gas barrier properties, and provided at its at least one surface with an inorganic oxide layer, and which can be wound; wherein a maximum thickness of the inorganic oxide layer is 1.5 times of a minimum thickness.

Owner:TOYO TOYOBO CO LTD

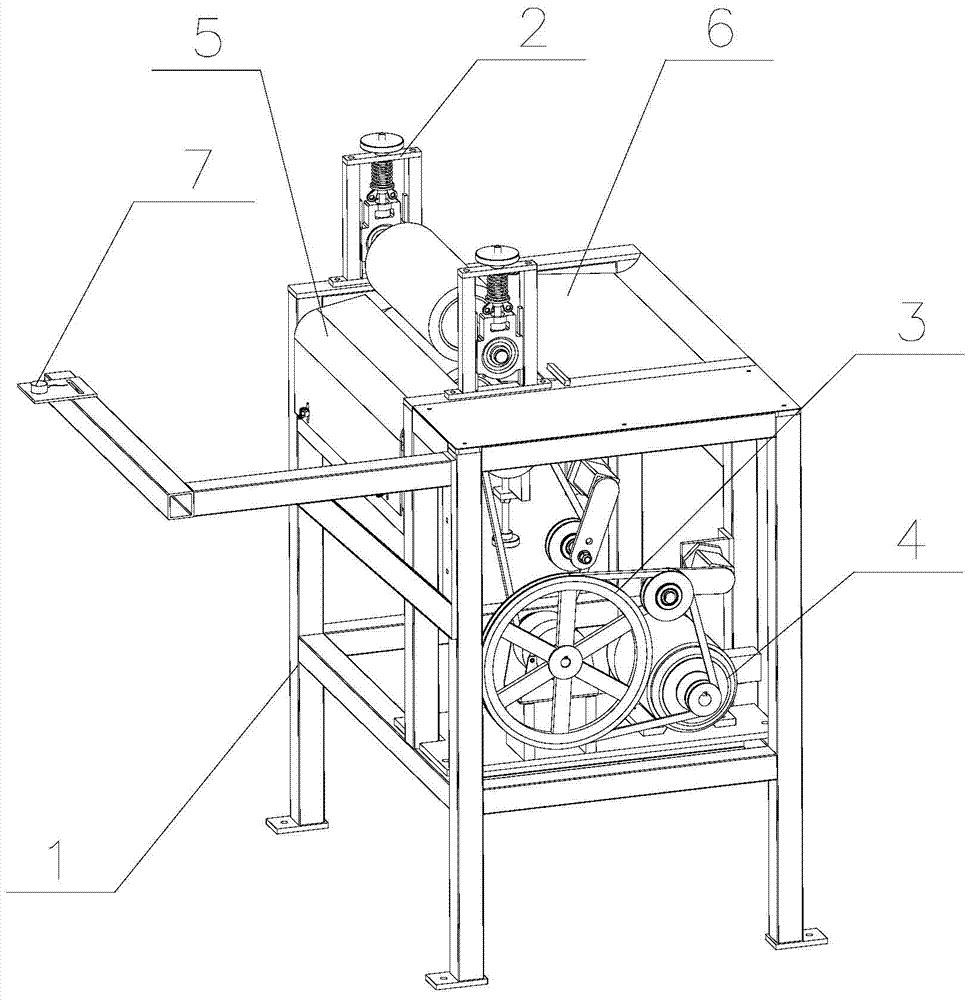

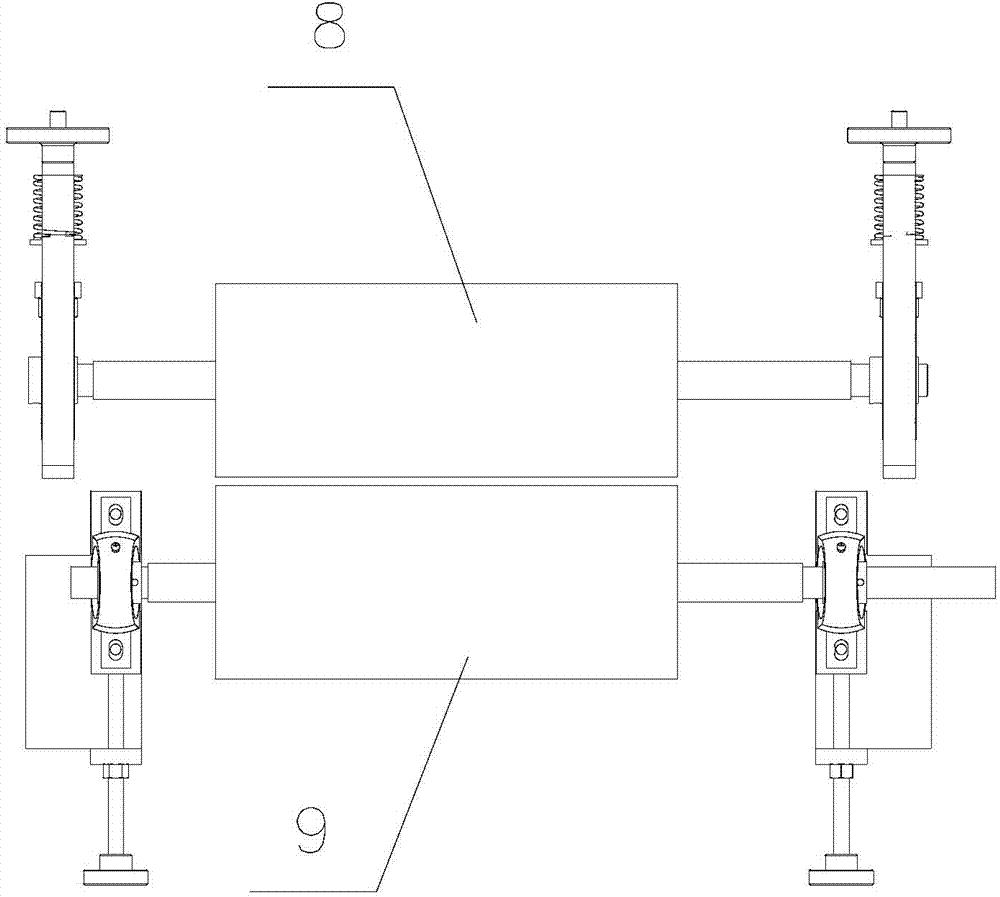

Novel thin strip tractor

The invention discloses a novel thin strip tractor which comprises a stand, a traction device, an actuator and a transmission system at the minimum. The traction device is installed on the stand, double rollers which are arranged in parallel in the vertical direction are arranged on the traction device, a lower roller is fixed, an upper roller is adjustable in a floating mode, the transmission system is provided with a magnetic powder type clutch, the input end of the magnetic powder type clutch is connected with the actuator, and the output end of the magnetic powder type clutch transfers power to the traction device. According to the tractor, a double roller traction mode is adopted, a roller gap and pressure can be adjustable manually, a pole plate subjected to plate coating is uniform in thickness, the magnetic powder type clutch is arranged on the transmission system, rigid transmission is changed into flexible transmission, the power of the actuator is driven to be transferred, it is guaranteed that the traction speed changes smoothly, the fluctuation of traction force is little, so that the deformation of the pole plate is reduced, the rejection rate is reduced, the product quality is improved, the structure is simple, the manufacturing is convenient, the processing cost is low, and the production efficiency is high.

Owner:中国船舶重工集团衡远科技有限公司

Super-white and super-thick float glass and preparation method thereof

The invention relates to the field of glass making and in particular relates to super-white and super-thick float glass and a preparation method thereof. A raw material formula of the super-white and super-thick float glass is designed, an edge roller control technology is adopted, from a first pair of edge controllers to the last pair of edge controllers, an inward component force produced by virtue of speed difference and negative angle of each pair of edge rollers is utilized for controlling the speed difference to be 15-50m / h; runner temperature is controlled to be (1100-1105)+ / -1 DEG C; molten tin slot outlet temperature is controlled to be 625+ / -5 DEG C; pulling amount of each edge roller is controlled to be 560-610t / d, plate width is controlled to be 4000-4100mm, inner teeth are 3580-3860mm wide, and Vmain is 135-165m / h; and the prepared glass is good in transmittance, high in whiteness, small in colour difference, ultraviolet-resistant and non-glare. Optical distortion angle is more than 55 degrees, the produced glass plate is wide, and thickness and inner teeth are stable.

Owner:ZHANGZHOU KIBING GLASS +3

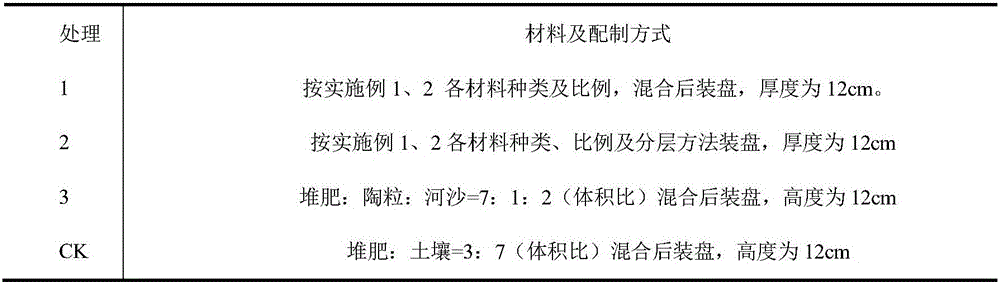

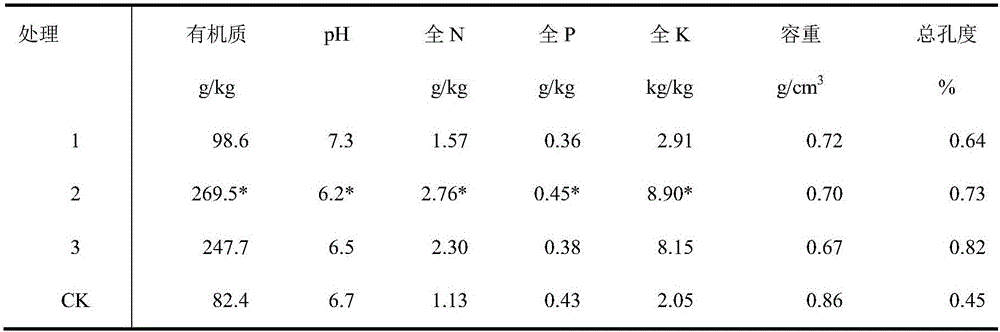

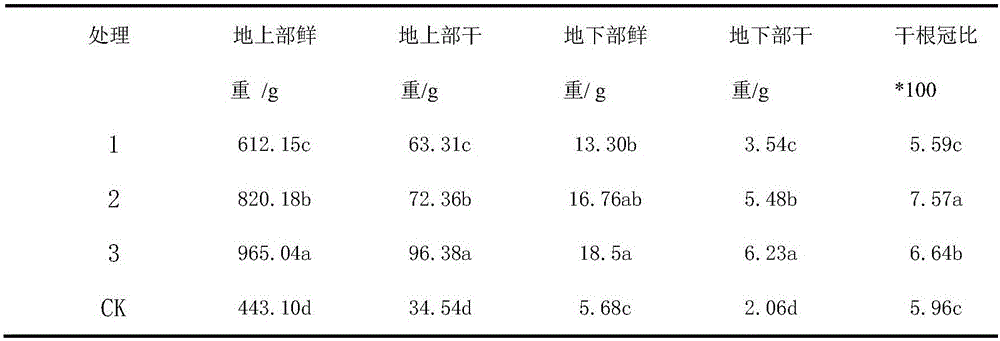

Red-spotted stonecrop plant roof greening matrix and preparing method thereof

ActiveCN105724208APromote growth and reproductionAdjust water permeabilityGrowth substratesCulture mediaBrickPeat

The invention belongs to the field of growing matrixes of plants, and mainly relates to a red-spotted stonecrop plant roof greening matrix and a preparing method thereof. The red-spotted stonecrop plant roof greening matrix is characterized in that the red-spotted stonecrop plant roof greening matrix is prepared from, by volume, 15-20 parts of organic mixture, 3-5 parts of perlite, 5-10 parts of coal cinder and 15-20 parts of brick rubbles, and the layering preparation method is adopted; the organic mixture comprises compost, peat, kieselguhr particles, vermiculite and zeolite. The red-spotted stonecrop plant roof greening matrix and the preparing method thereof have the advantages that the nutritional conditions of an organic material layer are rich, high water permeation and gas permeability are achieved, and a moisture and fertilizer preserving function is achieved; the plant adverse resistance and the stability of a planting system can be improved, and the effect of guaranteeing the long-term stability of the planting system and a good rainwater damming function are achieved.

Owner:SHENZHEN XIANHU BOTANICAL GARDEN ADMINISTRATION

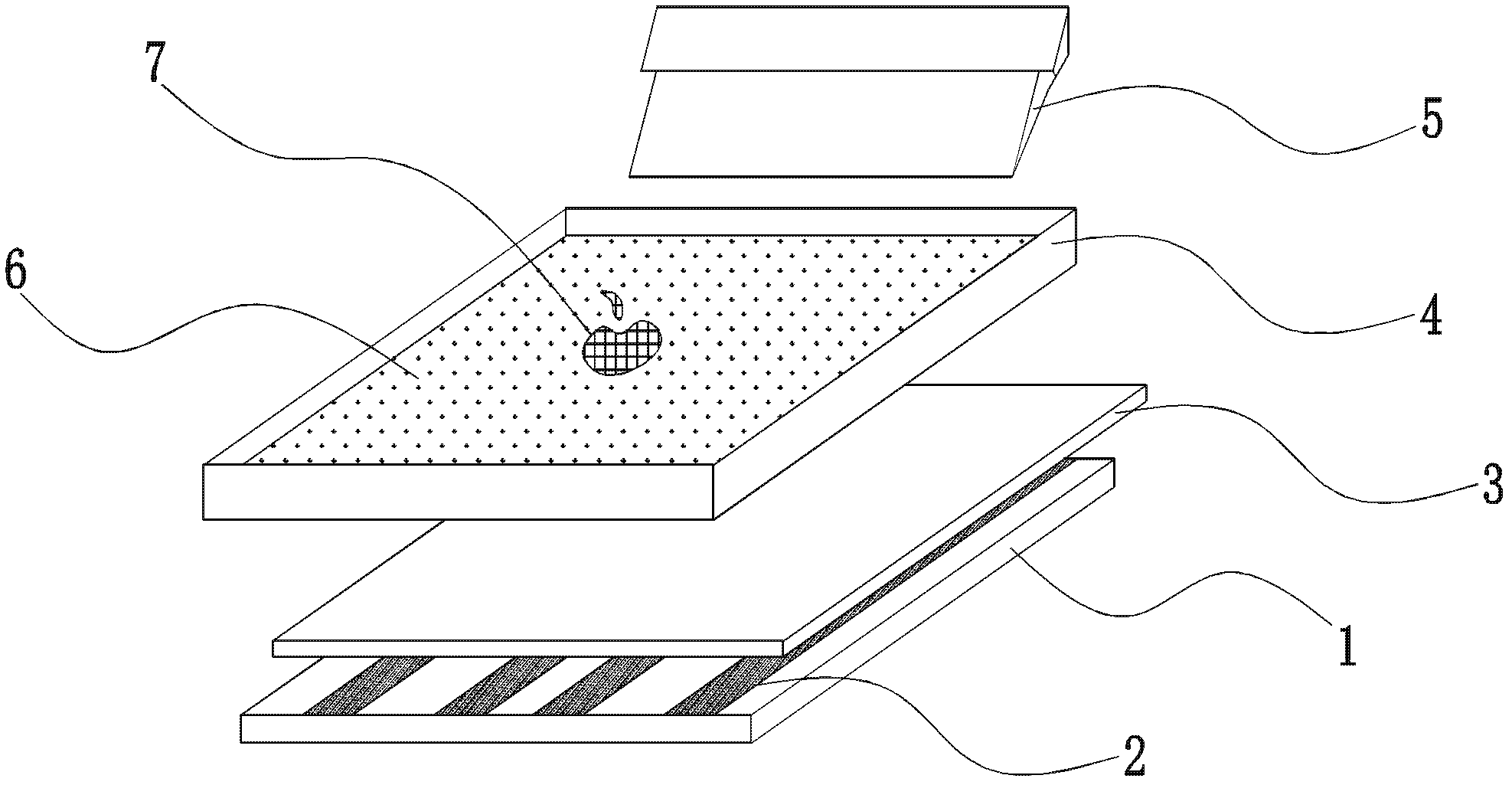

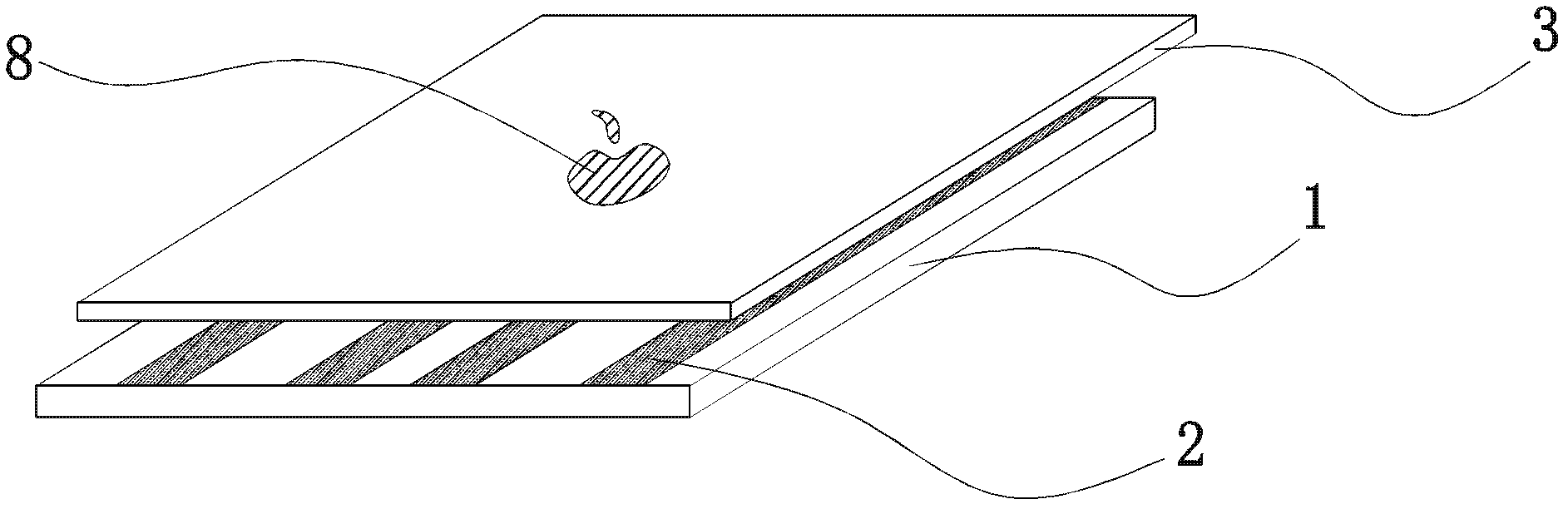

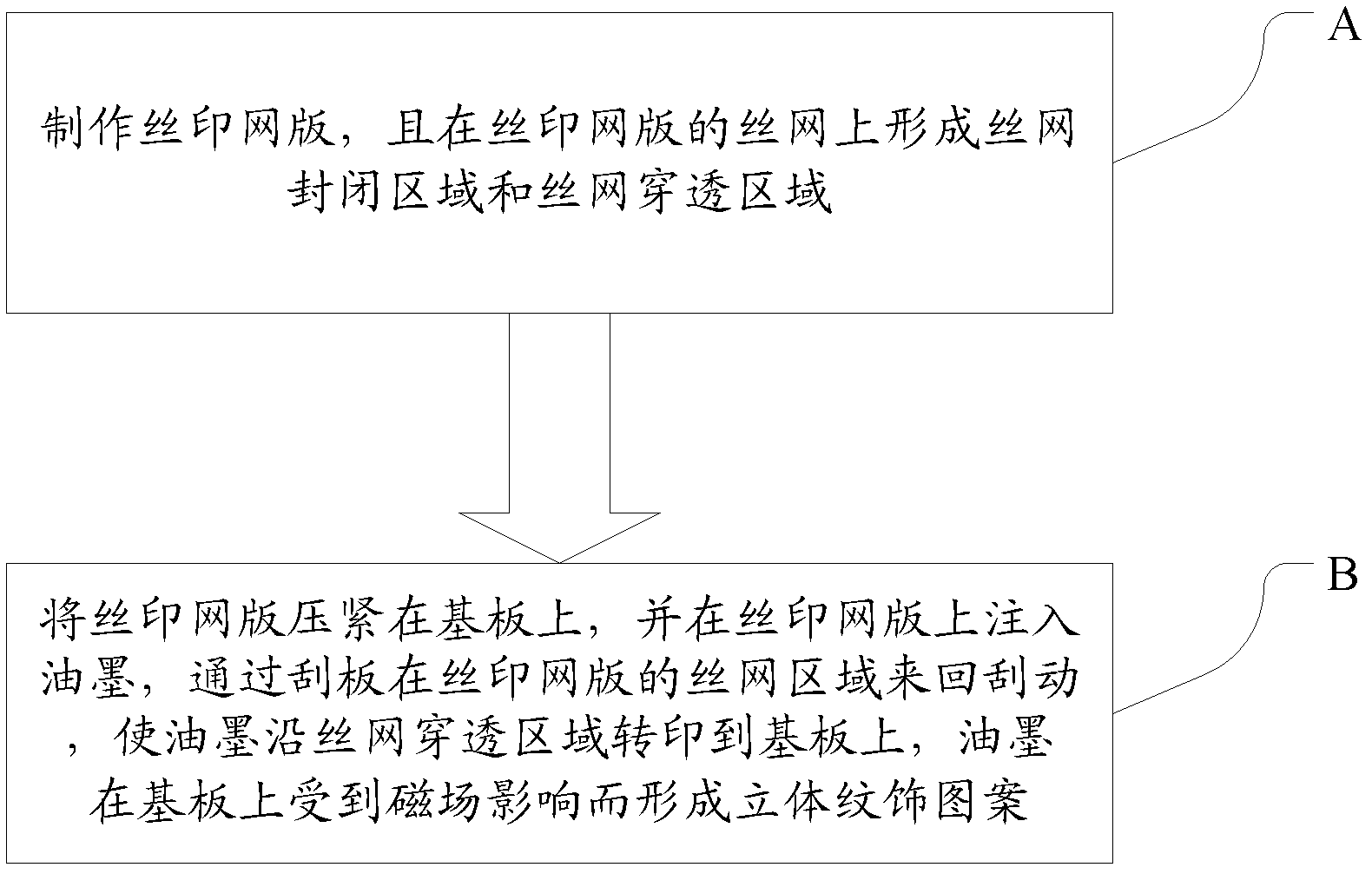

Printing device and method of three-dimensional ornamentation silk screen

InactiveCN103009786AStable thicknessEasy and quick to makeScreen printersOther printing apparatusScreen printingEngineering

The invention discloses a printing device and a printing method of a three-dimensional ornamentation silk screen. The printing method comprises the following steps of: A, manufacturing a silk screen printing plate, and forming a silk screen sealing area and a silk screen penetrating area on a silk screen of the silk screen printing plate; and B, pressing the silk screen printing plate on a substrate, and injecting oil ink on the silk screen printing plate; scraping a scraper in a silk screen area of the silk screen printing plate back and forth, so that the oil ink is transferred to the substrate along the silk screen penetrating area, and the oil ink forms a three-dimensional ornamentation pattern under the influence of a magnetic field. According to the printing method provided by the invention, the silk screen sealing area and the silk screen penetrating area are arranged on the silk screen of the silk screen printing plate; the silk screen printing plate is tightly pressed on the substrate; the oil ink is injected on the silk screen printing plate; and the scraper scrapes in the silk screen area of the silk screen printing plate back and forth, so that the oil ink is transferred to the substrate along the silk screen penetrating area. Compared with the prior art, a manufacturing manner provided by the invention is simple and rapid; the oil ink on the silk screen printing plate can be circularly used for multiple times, so that the cost is lower; and furthermore, the thickness stability of the three-dimensional formed pattern can be ensured by using the scraper.

Owner:潘美珍

Casting powder for continuous casting crystallizer and preparation method of casting powder

The invention discloses casting powder for a continuous casting crystallizer. The casting powder comprises raw materials in parts by weight as follows: 3.5-15 parts of fluorite, 35-55 parts of aedelforsite, 5-15 parts of alkali, 0-2 parts of lithium carbonate, 0-10 parts of diaspore, 0-6 parts of a cement clinker, 1-5 parts of magnesia powder, 2-5 parts of pyrolusite, 0-8 parts of sodium fluoride, 0-5 parts of barium carbonate, 0-5 parts of bentonite, 1-4 parts of coke, 0-8 parts of a carburant, 1-3 parts of carbon black and 1-2 parts of a binder. According to the casting powder, the preparation cost is low; the recovery rate of the casting powder is larger than or equal to 98.5%; the color of the casting powder is uniform; the granularity is uniform; the granulation rate is high; dust is reduced; the melting point of the casting powder is low; the viscosity is low; after the casting powder is added into the crystallizer, the casting powder is melted uniformly and shows excellent spreadability, heat retaining property and adsorptive property; heat is transferred uniformly all around the crystallizer, and the lubrication is excellent; and defects such as concave pits, impurities and the like don't exist on the surface of a casting blank, the internal quality is excellent, and the qualified rate of the casting blank is equal to or larger than 99.8%.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

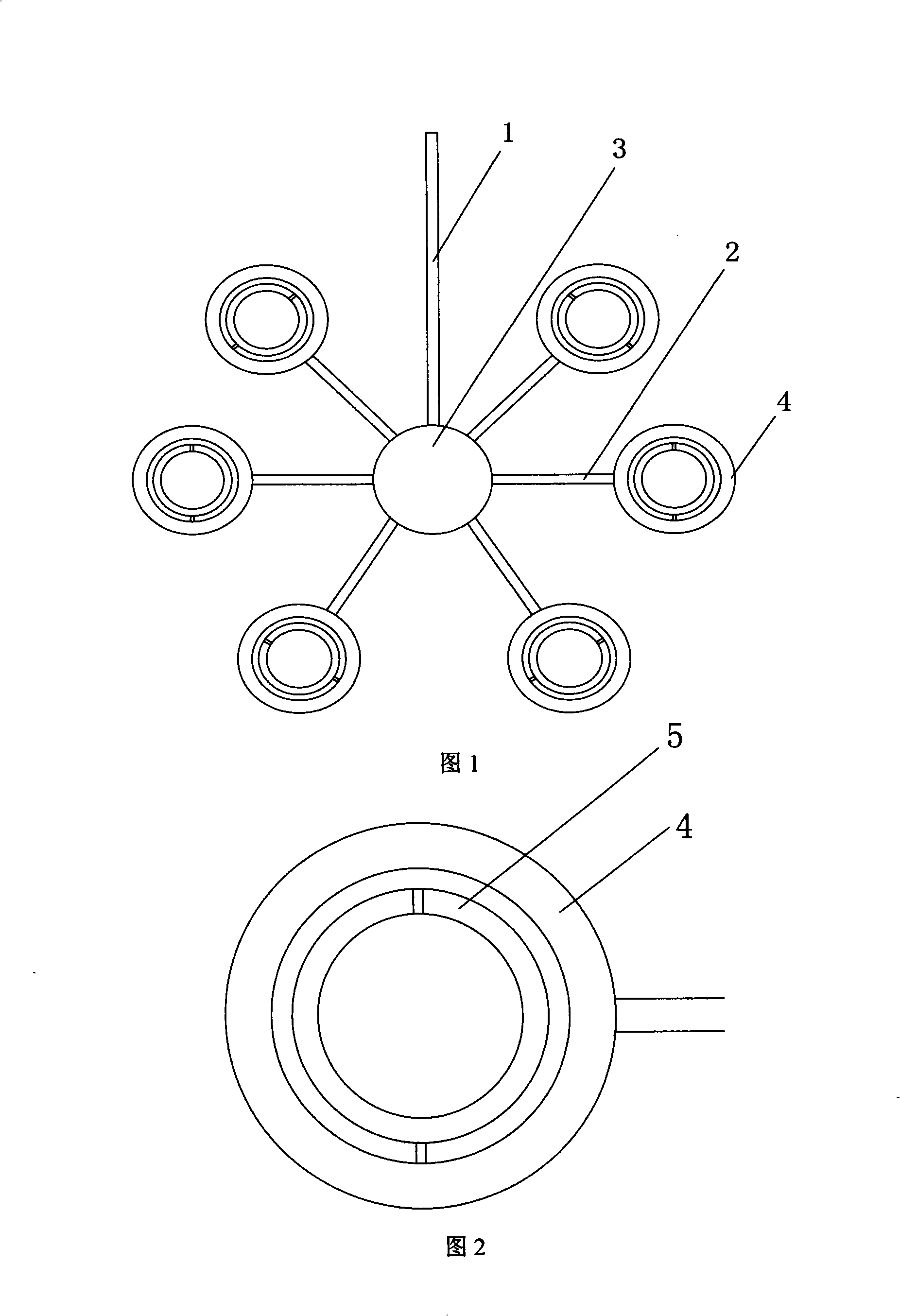

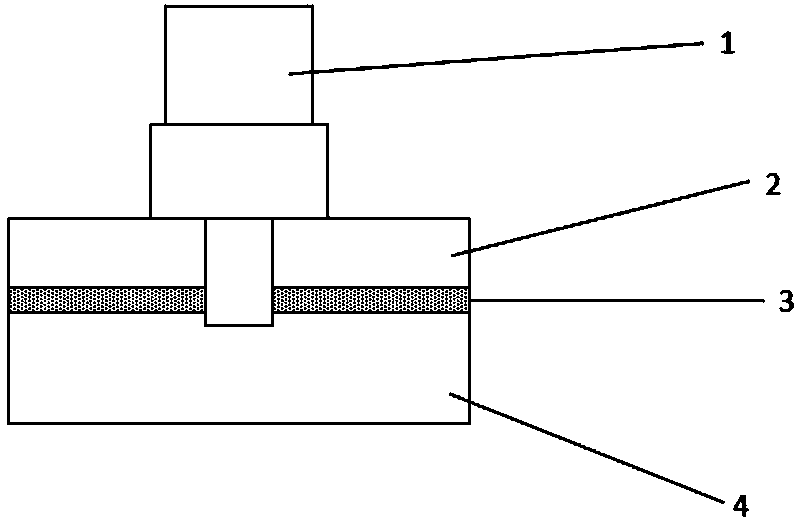

Functional end face chromium plating method for piston ring and special jig

ActiveCN101343768AEasy and fast loading and unloadingIncrease productivityPiston ringsElectrolysis componentsEngravingPiston ring

The invention provides a piston ring function end chrome plating method. The piston ring function end chrome plating method comprises the procedures of oil elimination, clamp loading, electrolysis degreasing, water washing, tank entering and preheating, reverse engraving, chrome plating, tank discharging and rinsing, and clap unloading. The invention also provides a special clamping tool used for the chrome plating method, the clamping tool comprises a conduction rod, a lifting stem, a central conducting round block and piston ring installing rings, wherein one end of the conducting rod is connected with the central conducting round block, the other ends are connected with the piston ring installing rings, and one end of the lifting stem is also connected with the central conducting round block. The piston ring function end chrome plating method of the invention has the advantages: firstly, the loading and unloading of the piston and the chrome plating clamping tool are convenient and rapid, and the production efficiency is high; secondly, the technology flow is simple and practical, and the processing control difficulty is small; thirdly, the uniformity of the chrome layer of the same ring is good, and the thickness of the chrome plating layer is guaranteed to be between 0.02 to 0.025 mm; simultaneously the thickness of the chrome layer of the whole batch is stable, and the uniformity of the chrome layer of the whole end surface of the same ring can be guaranteed to be less than and equal to 0.005 mm.

Owner:NANJING FAYN PISTON RING

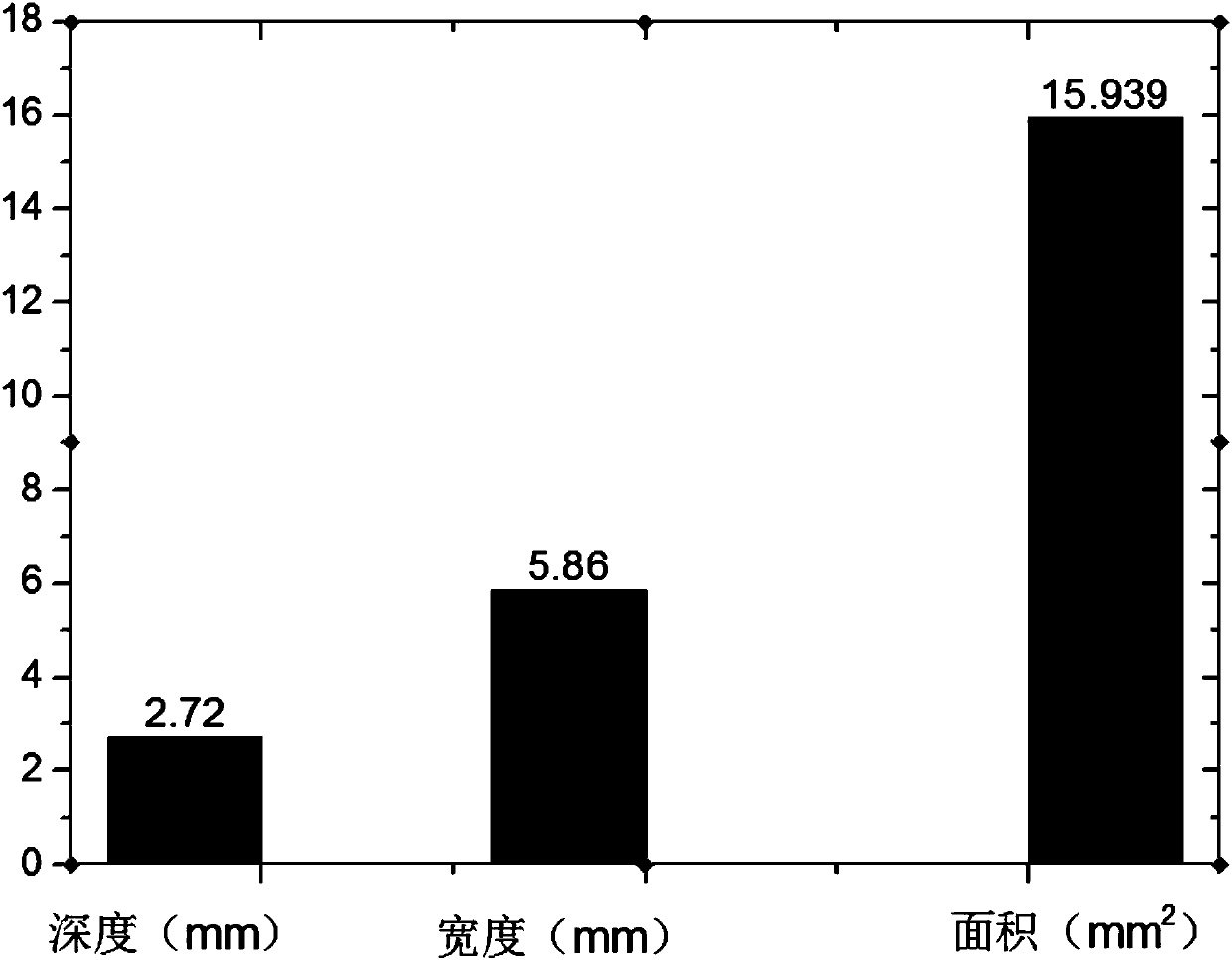

Production method for improving surface quality of thin-gauge pipeline steel

InactiveCN110066965AChange easy to fall off and damageImprove surface qualitySteel platesSmelting process

The invention discloses a production method for improving the surface quality of thin-gauge pipeline steel. Chemical components comprise, by mass percent, 0.040%-0.080% of C, 0.10%-0.30% of Si, 1.20%-1.90% of Mn, not larger than 0.015% of P, not larger than 0.0030% of S, not larger than 0.30% of Ni, not larger than 0.30% of Cr, not larger than 0.20% of Cu, not larger than 0.070% of Nb, not largerthan 0.15% of Mo, not larger than 0.01% of V, 0.005%-0.02% of Ti, not larger than 0.0050% of N, 0.001%-0.003% of Ca, 0.010%-0.050% of Al and the balance Fe and inevitable impurities. Through the smelting process, the surface quality of a cast blank is optimized and improved, the rolling forming technology is adjusted, the integrity of scale on the surface of a steel plate is improved, a corrosion-resisting pipeline steel plate with high surface quality is obtained, and the product quality is improved.

Owner:NANJING IRON & STEEL CO LTD

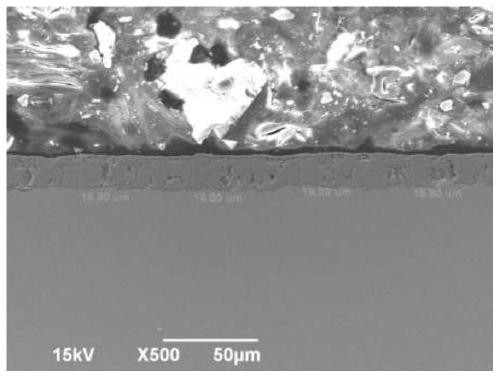

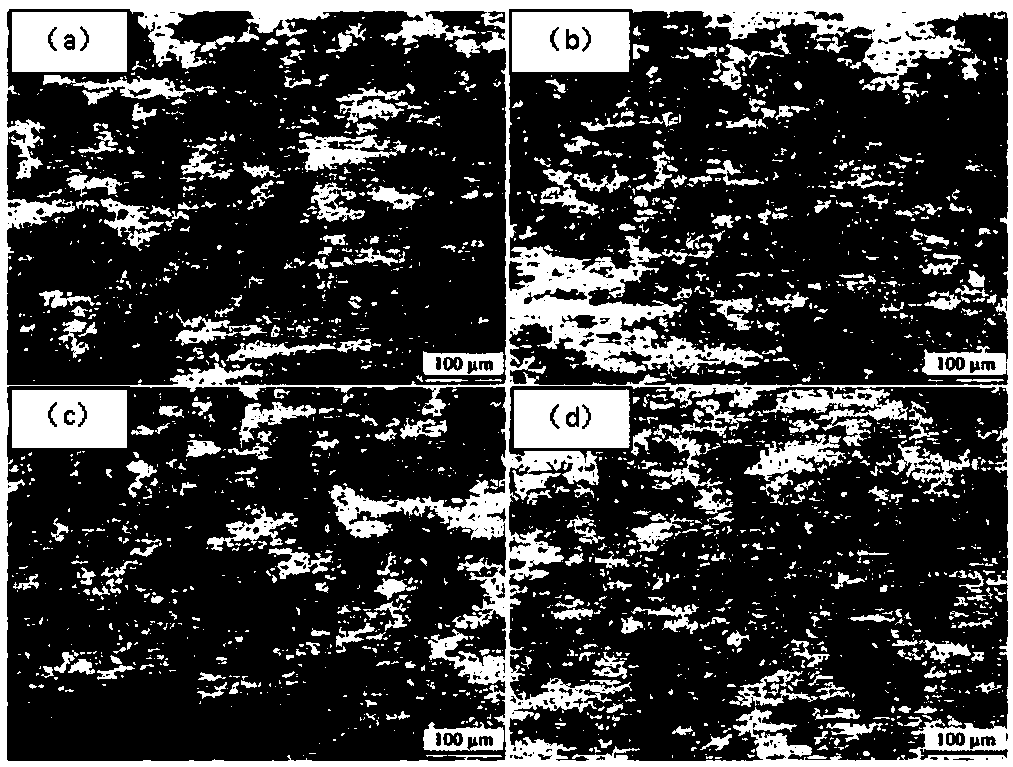

Metal-based surface composite material and preparation method thereof

InactiveCN107757060AImprove bindingSimple processLamination ancillary operationsLaminationPolyvinyl alcoholAdhesive

The invention discloses a metal-based surface composite material and a preparation method thereof. The preparation method comprises the following steps: uniformly coating a lower plate with enhanced granules such as silicon carbide by using organic adhesive, covering the lower plate with a thin upper plate, and performing stirring and friction treatment on the upper plate by using a stirring headwith a needle under the conditions that the rotating speed of a stirring and friction machine is 1000 to 2500 rpm and the welding speed is 30 to 200 mm / min to obtain the granule enhanced metal-based surface composite material. The organic adhesive comprises polyvinyl alcohol. The enhanced granules comprise silicon carbide and aluminum oxide. The metal plate can be aluminum alloy or magnesium alloy.

Owner:XI AN JIAOTONG UNIV

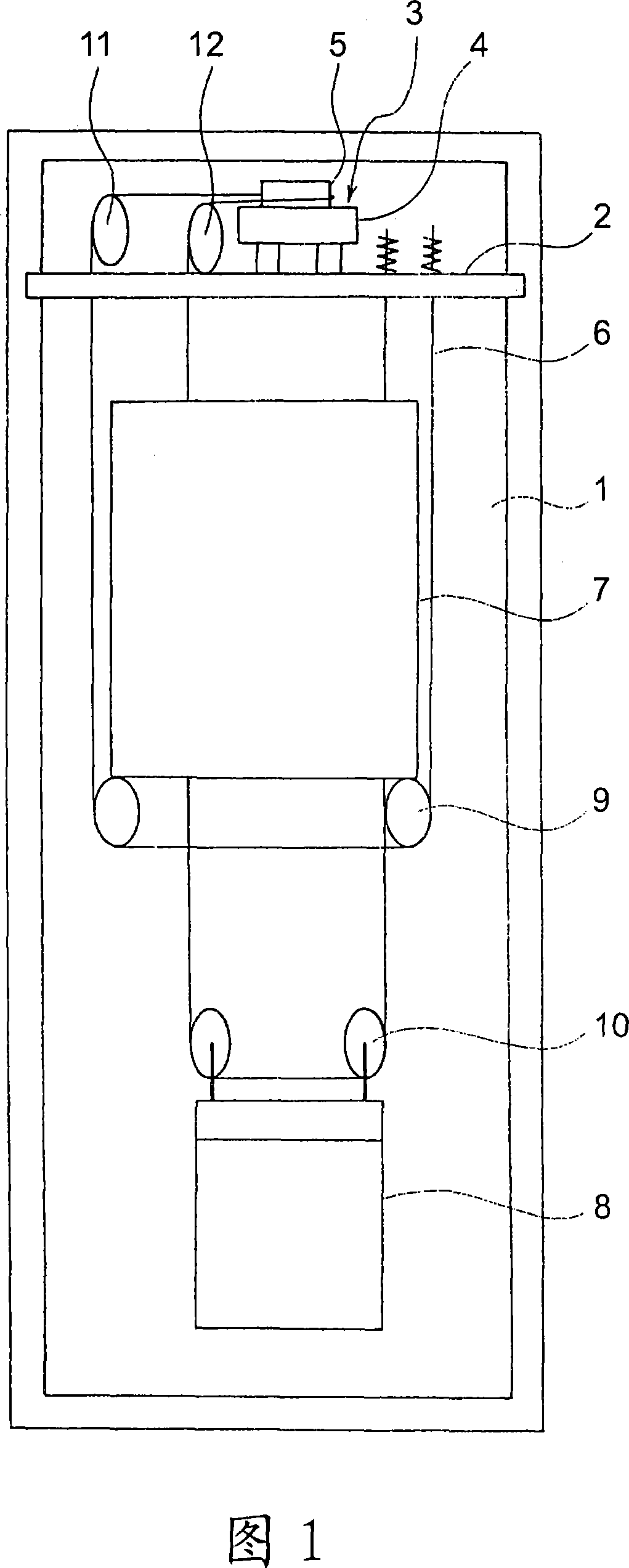

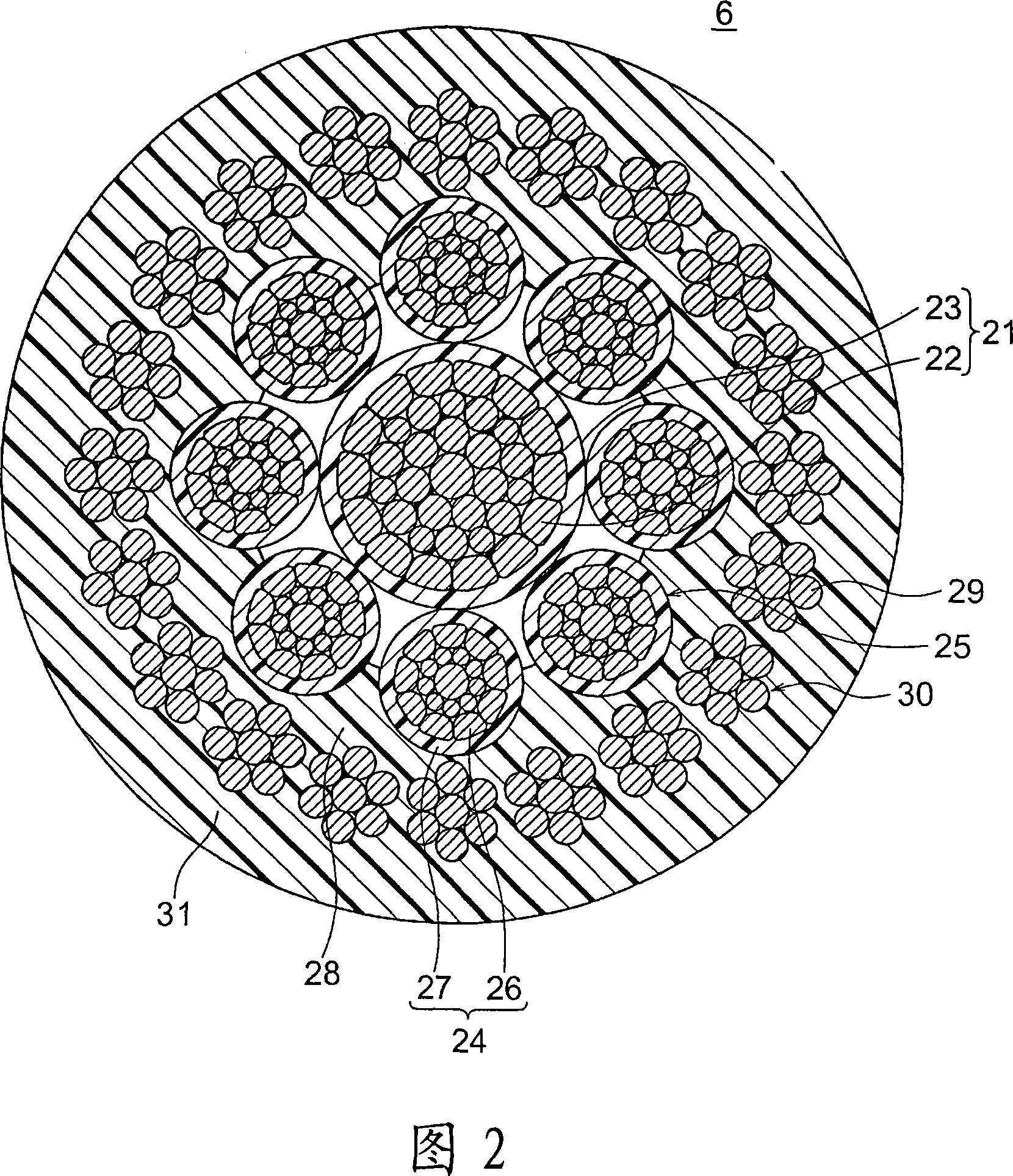

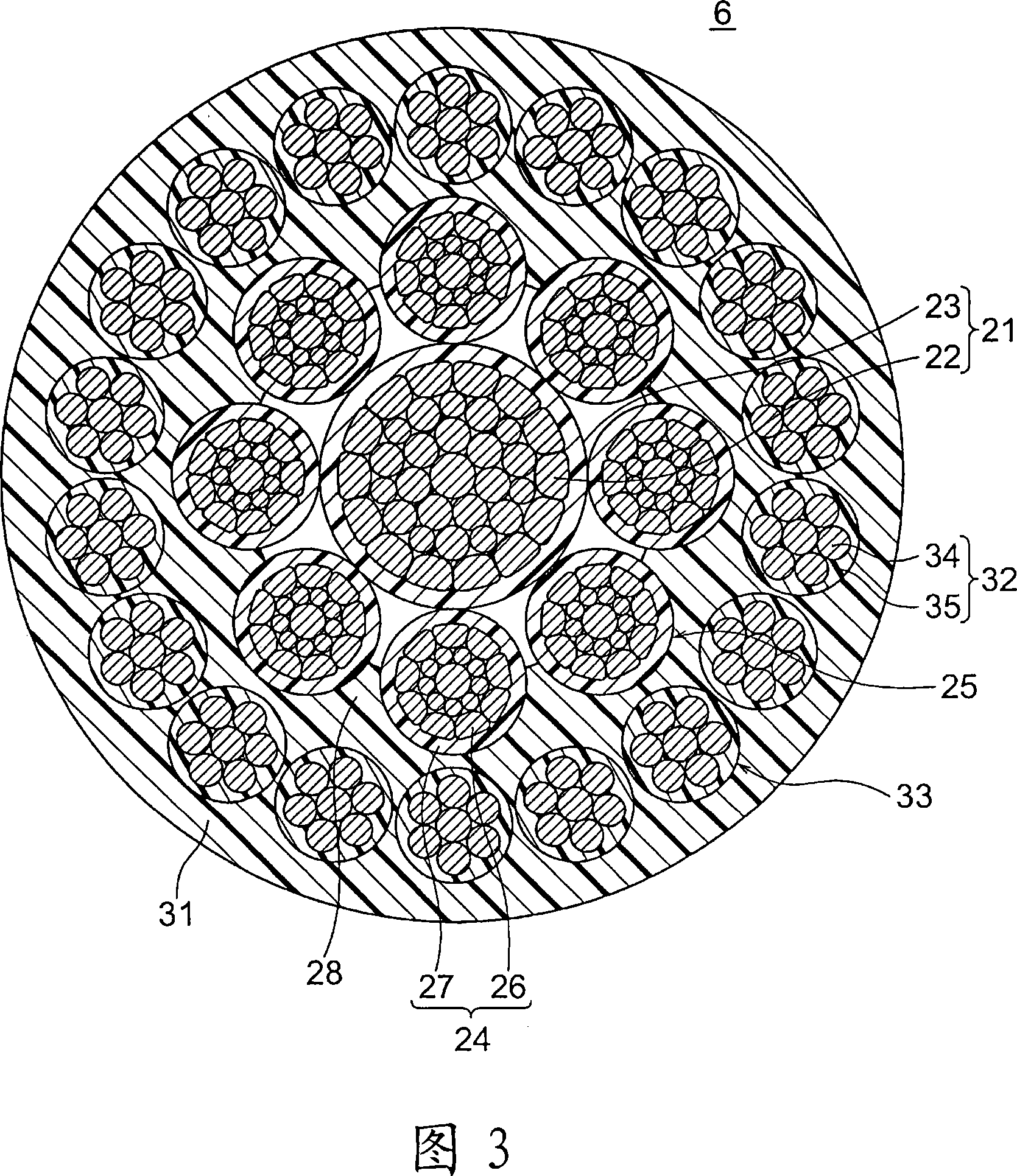

Elevator using cable and method for manufacturing same

A rope for elevator in which a core rope comprises a core rope body, and its resin core rope coating. An inner layer strand aggregate comprises a plurality of inner layer strands stranded around the core rope on the outer circumference thereof. Each inner layer strand comprises an inner layer strand body, and its resin inner layer strand coating. An outer layer strand aggregate comprises a plurality of outer layer strands stranded on the outer circumference of the inner layer strand aggregate. Each outer layer strand has an outer layer strand body. The outer layer strand aggregate is coated with a resin outer layer coating. The inner layer strand body and the inner layer strand coating are bonded through adhesive, and the outer layer strand and the outer layer coating are bonded through adhesive.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com