Intelligent control system for vertical mill based on fuzzy PID (proportion integration differentiation) algorithm

An intelligent control system, intelligent control technology, applied in general control system, control/regulation system, adaptive control, etc., can solve difficult to meet process requirements and sorting efficiency, system output and control variable steady-state error, PID control It is difficult to obtain the effect and other problems, to achieve the effect of qualified output and fineness, small overshoot, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing, and the flow process and principle of this method are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

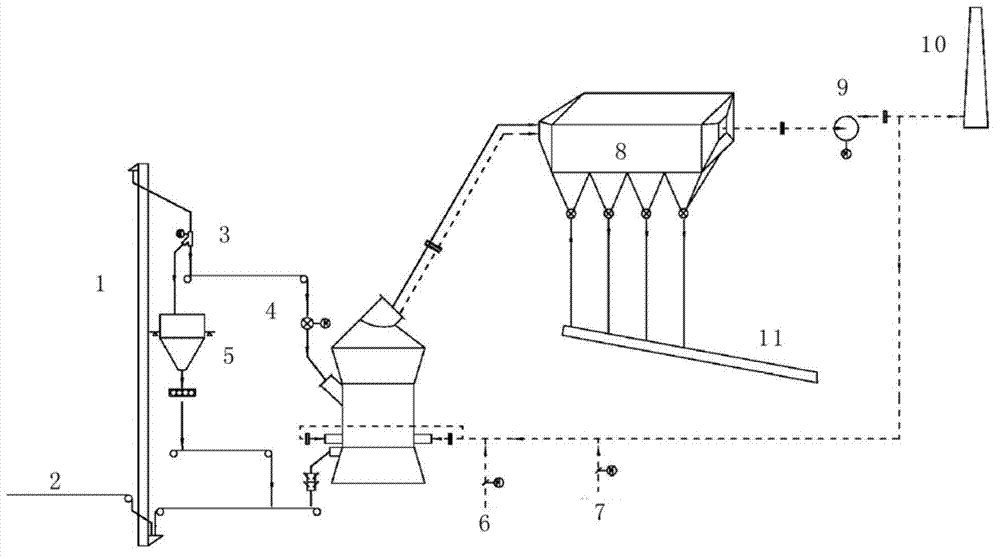

[0045] The present invention takes the TVR46 / 23 vertical mill slag production line as an example to illustrate the realization process of the intelligent control system. Its production process diagram is as follows figure 1 shown.

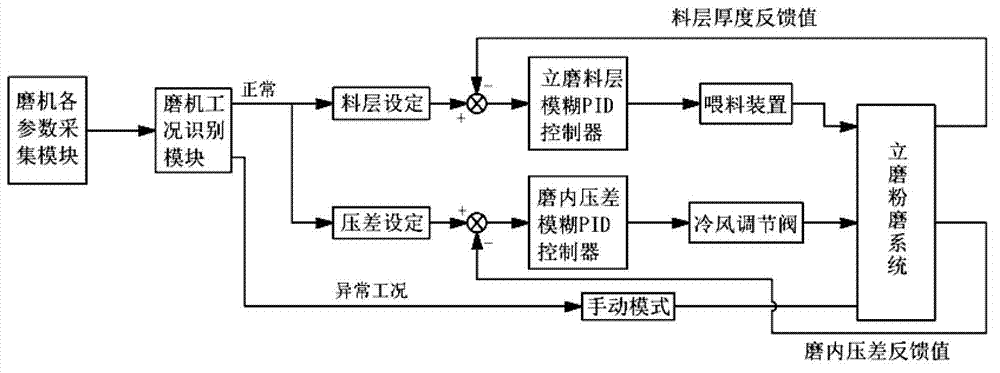

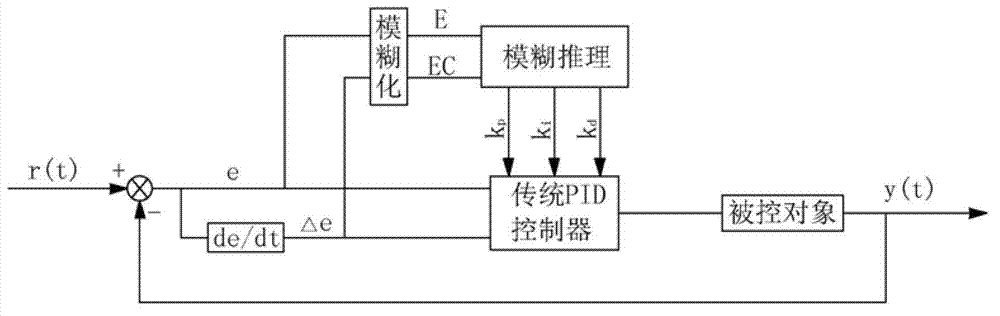

[0046] 1. Overview of intelligent control system of vertical mill

[0047] The control of the vertical mill is to reduce the vibration value of the vertical mill as much as possible to ensure the stable operation of the vertical mill while ensuring the fineness, output and humidity of the slag product. In actual production, the thickness of the material layer and the pressure difference inside the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com