Production method for improving surface quality of thin-gauge pipeline steel

A technology of surface quality and production method, applied in the production field of improving the surface quality of thin-gauge pipeline steel, can solve the problems of uneven damage of iron oxide scale, large surface deformation of steel plate, large rolling deformation, etc. The effect of surface quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

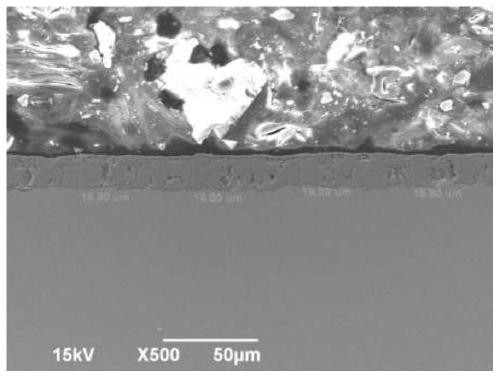

Image

Examples

Embodiment 1

[0066] This embodiment provides a production method for improving the surface quality of thin-gauge pipeline steel, the steel grade is 5LB grade, the blank adopts a 150mm*2560mm section blank, and the product specification is 11.1mm*3304mm;

[0067] S1, its chemical composition and mass percentage are as follows: C: 0.050%~0.080%, Si: 0.20%~0.30%, Mn: 1.20%~1.50%, P≤0.015%, S≤0.0030%, Ni≤0.20%, Cr ≤0.30%, Cu≤0.20%, Nb≤0.070%, Mo≤0.15%, V≤0.01%, Ti: 0.005%~0.02%, N≤0.0050%, Ca: 0.001%~0.003%, Al: 0.010%~ 0.050%, the balance is Fe and unavoidable impurities;

[0068] S2. The desulfurization station uses lime and magnesium powder for compound desulfurization. After desulfurization, the slag is cleaned. S: 0.0020% in the molten iron, and S: 0.008% after the converter;

[0069] S3. Steelmaking adopts the process route of BOF→LF furnace refining→RH refining→continuous casting. The tapping temperature of the converter is 1660°C, and the tapping adopts pre-melted refining slag + acti...

Embodiment 2

[0077] This embodiment provides a production method for improving the surface quality of thin-gauge pipeline steel, the steel grade is X65M grade, the blank adopts a 150mm*2580mm section blank, and the product specification is 9.5mm*2360mm;

[0078] S1, its chemical composition and mass percentage are as follows: C: 0.040%~0.060%, Si: 0.10%~0.30%, Mn: 1.30%~1.60%, P≤0.015%, S≤0.0030%, Ni≤0.20%, Cr ≤0.20%, Cu≤0.20%, Nb: 0.030%~0.070%, Mo≤0.15%, V≤0.01%, Ti: 0.005%~0.02%, N≤0.0050%, Ca: 0.001%~0.003%, Al: 0.010%~0.050%, the balance is Fe and unavoidable impurities;

[0079] S2. The desulfurization station uses lime and magnesium powder for composite desulfurization. After desulfurization, the slag is cleaned. S: 0.0020% in the molten iron, and S: 0.006% after the converter;

[0080] S3. Steelmaking adopts the process route of BOF → LF furnace refining → RH refining → continuous casting. The tapping temperature of the converter is 1645°C, and the tapping is carried out by pre-me...

Embodiment 3

[0088] This embodiment provides a production method for improving the surface quality of thin-gauge pipeline steel, the steel grade is X70M grade, the blank adopts a 150mm*2460mm section blank, and the product specification is 6.4mm*3110mm;

[0089] S1, its chemical composition and mass percentage are as follows: C: 0.050%~0.070%, Si: 0.15%~0.25%, Mn: 1.50%~1.80%, P≤0.015%, S≤0.0030%, Ni≤0.20%, Cr :0.10%~0.30%, Cu≤0.20%, Nb:0.040%~0.070%, Mo≤0.15%, V≤0.01%, Ti: 0.005%~0.02%, N≤0.0050%, Ca: 0.001%~0.003% , Al: 0.010% ~ 0.050%, the balance is Fe and unavoidable impurities;

[0090] S2. The desulfurization station uses lime and magnesium powder for compound desulfurization. After desulfurization, the slag is cleaned. S: 0.0020% in the molten iron, and S: 0.008% after the converter;

[0091] S3. Steelmaking adopts the process route of BOF→LF furnace refining→RH refining→continuous casting. The tapping temperature of the converter is 1659°C, and the tapping adopts pre-melted refin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com