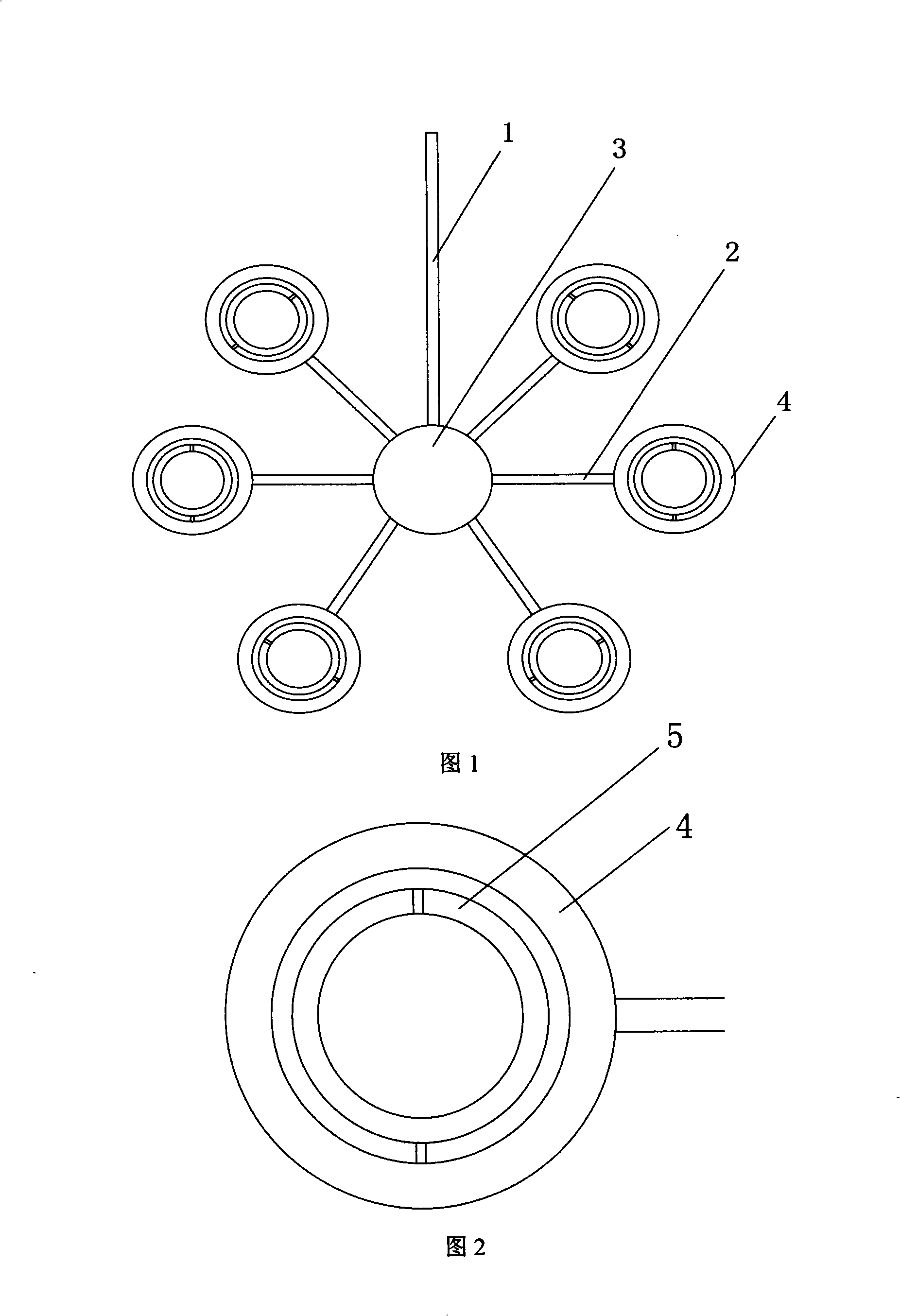

Functional end face chromium plating method for piston ring and special jig

A special fixture and piston ring technology, applied in piston rings, household appliances, applications, etc., can solve the problems of affecting the piston ring processing yield, poor thickness uniformity of the chromium layer, poor bonding strength of the chromium layer, etc., and achieves less difficulty in processing control. , The thickness of the chromium layer is stable and the uniformity of the chromium layer is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: The described piston ring functional end face chrome plating method comprises the following steps:

[0026] 1. Pre-degreasing: Use commercially available XH-35D degreasing agent (Shanghai Xianghe Phosphating Co., Ltd.) 20g / l to clean the piston ring to remove oil and surface impurities.

[0027] 2. Clamping: Put the pre-degreased piston ring to be plated into the chrome-plated fixture, and install the cathodic protection gasket.

[0028] 3. Electrolytic degreasing: immerse the plating fixture in the electrolyte, and each liter of electrolyte contains the following components and weight:

[0029] Na 2 CO 3 : 40g, Na 3 PO 4 : 30g, XH-35D degreaser: 20g.

[0030] Electrolysis conditions are: cathode current density Dk = 2A / dm 2 , Temperature: 70°C, Time: 3min.

[0031] 4. Water washing: use running water to rinse the electrolyzed chrome-plated fixture.

[0032] 5. Preheat in the tank for 10 seconds.

[0033] 6. Anti-engraving: current density D A =5...

Embodiment 2

[0041] 1. Pre-degreasing: Use commercially available XH-35D degreasing agent (Shanghai Xianghe Phosphating Co., Ltd.) 30g / l to clean the piston ring to remove oil and surface impurities.

[0042] 2. Clamping: Put the pre-degreased piston ring to be plated into the chrome-plated fixture, and install the cathodic protection gasket.

[0043] 3. Electrolytic degreasing: immerse the plating fixture in the electrolyte, and each liter of electrolyte contains the following substances.

[0044] Na 2 CO 3 : 80g, Na 3 PO 4 : 60g, XH-35D degreaser: 30g.

[0045] Electrolysis conditions are: cathode current density Dk = 20A / dm 2 Temperature: 80°C Time: 5min.

[0046] 4. Water washing: use running water to rinse the electrolyzed chrome-plated tooling.

[0047] 5. Preheat the tank for 30 seconds.

[0048] 6. Anti-engraving: current density D A =10A / dm 2 , temperature 62°C, time 40s.

[0049] 7. Chromium plating: current density Dk=40A / dm 2 , temperature 62°C, time 40min.

[0050...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com