Cable Gripper

A cable clip and cable technology, which is applied to pipe supports, mechanical equipment, pipes, etc., can solve the problems of easy falling off of cables, inability to put in grooves, time-consuming and laborious loading and unloading operations, etc., so as to avoid operation accidents and cable damage, loading and unloading operations. Simple and fast, simple and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, the present invention will be further described through specific embodiments in conjunction with the accompanying drawings.

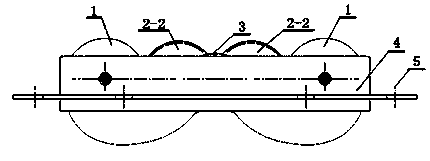

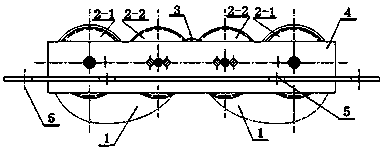

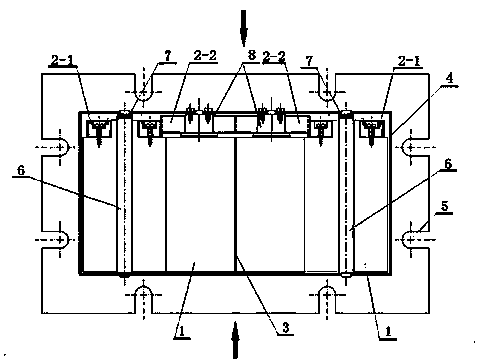

[0035] See Figure 1 ~ Figure 5 , The cable clamp of the present invention includes a frame, a mounting plate 4, and two symmetrically arranged clamping bodies arranged on the mounting plate 4, and the clamped cable 12 is clamped to the two clamping bodies Between; the clamping body includes two cams 1, a torsion spring 7, four synchronization gears; the cable 12 is clamped between the two cams 1 and in contact with the two cams 1, the cam 1 The contour line of the clamping side that is in contact with the supported cable 12 is an involute; the cam 1, torsion spring 7, and synchronization gear are all mounted on the mounting plate 4; the torsion spring 7 is used to enable the cam 1 to rotate Automatically reset, and enable the cam 1 to clamp the clamped cable 12; the synchronization gear includes two driving synchronization gears 2-1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com