Special transporter for straddle-type monorail car and loading and unloading method

A technology of transportation device and monorail, which is applied in transportation and packaging, transportation of objects, arrangement of loading and unloading vehicles, etc., can solve the problems of site limitation, high loading and unloading cost, and reduced transportation height, etc., and achieves low transportation cost and safety. High, easy and fast loading and unloading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

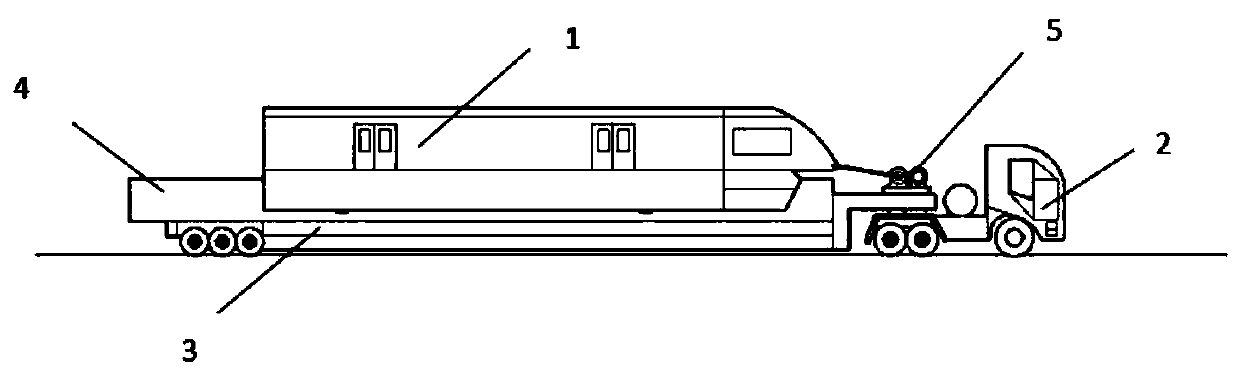

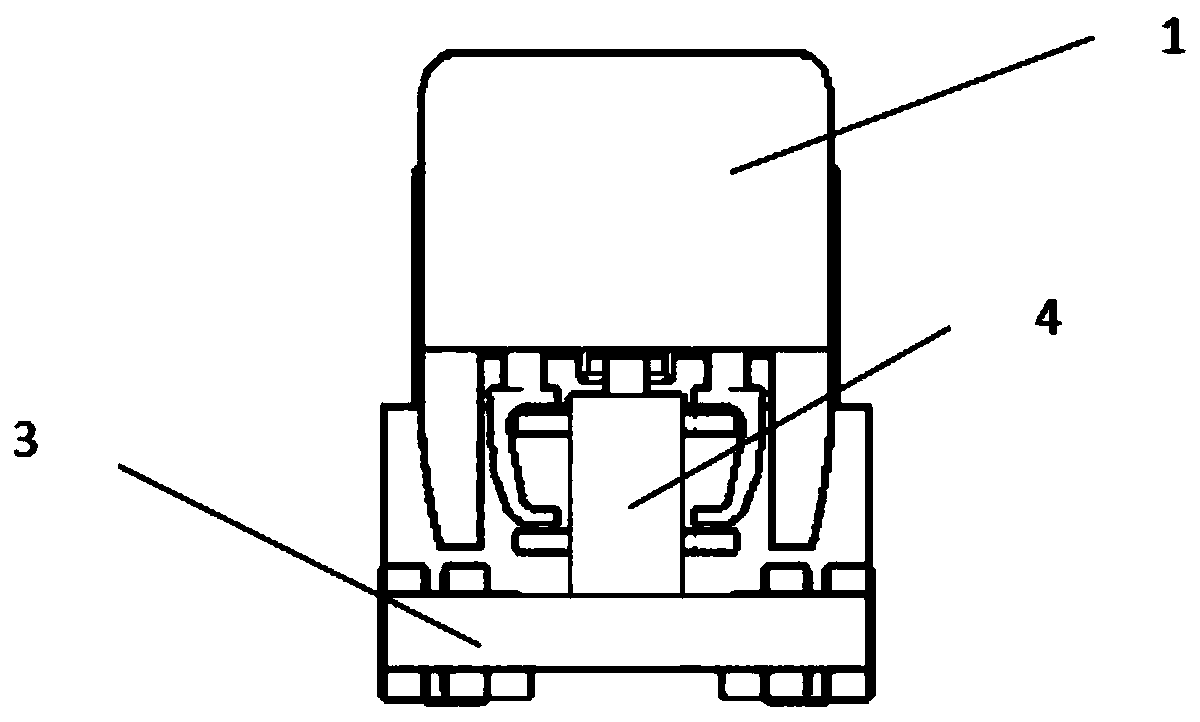

[0021] Such as Figure 1 to Figure 2 As shown, 1 is the monorail car body; 2 is the tractor head; 3 is the transport car board; 4 is the first steel beam, which is used for loading the car body; On a steel beam, the specification of the first steel beam is the same as that of the monorail vehicle, the length of the steel beam is greater than the length of the transport vehicle plate, and the transport vehicle is a low flat transport vehicle and can be lifted in height.

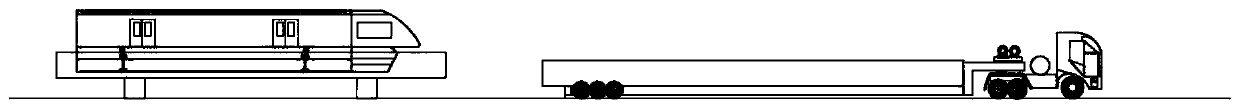

[0022] Such as image 3 , Figure 4 , Figure 5 As shown in , the transport vehicle is poured into the center of the upper steel beam and the lower steel beam of the monorail car body, and the transport vehicle's own hydraulic lifting function is used to raise the transport vehicle plate to the steel beam on the vehicle plate and the lower steel beam of the monorail car. Height level, stop rising.

[0023] Such as Figure 6 , Figure 7 As shown, the hoist is placed at the front end of the vehicle board, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com