Patents

Literature

485 results about "Motor test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

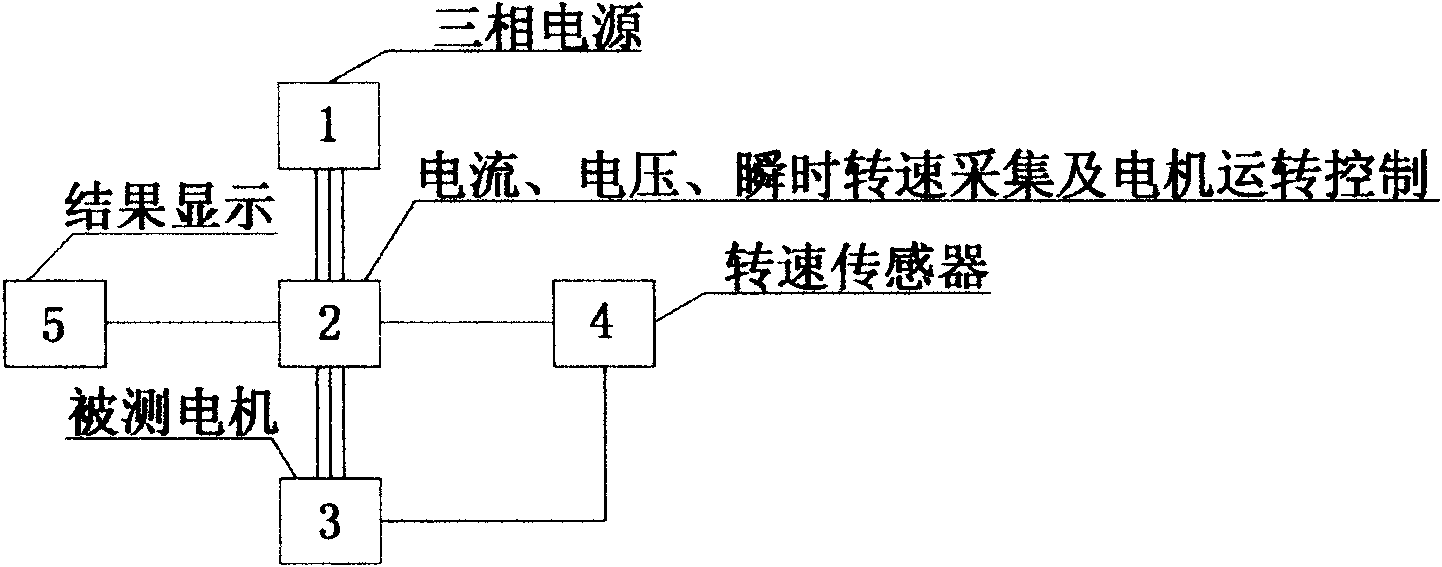

Brushless servo motor tester

InactiveUS20070229018A1Accurate operationSimplified determinationMotor/generator/converter stoppersSynchronous motors startersMotor testingControl theory

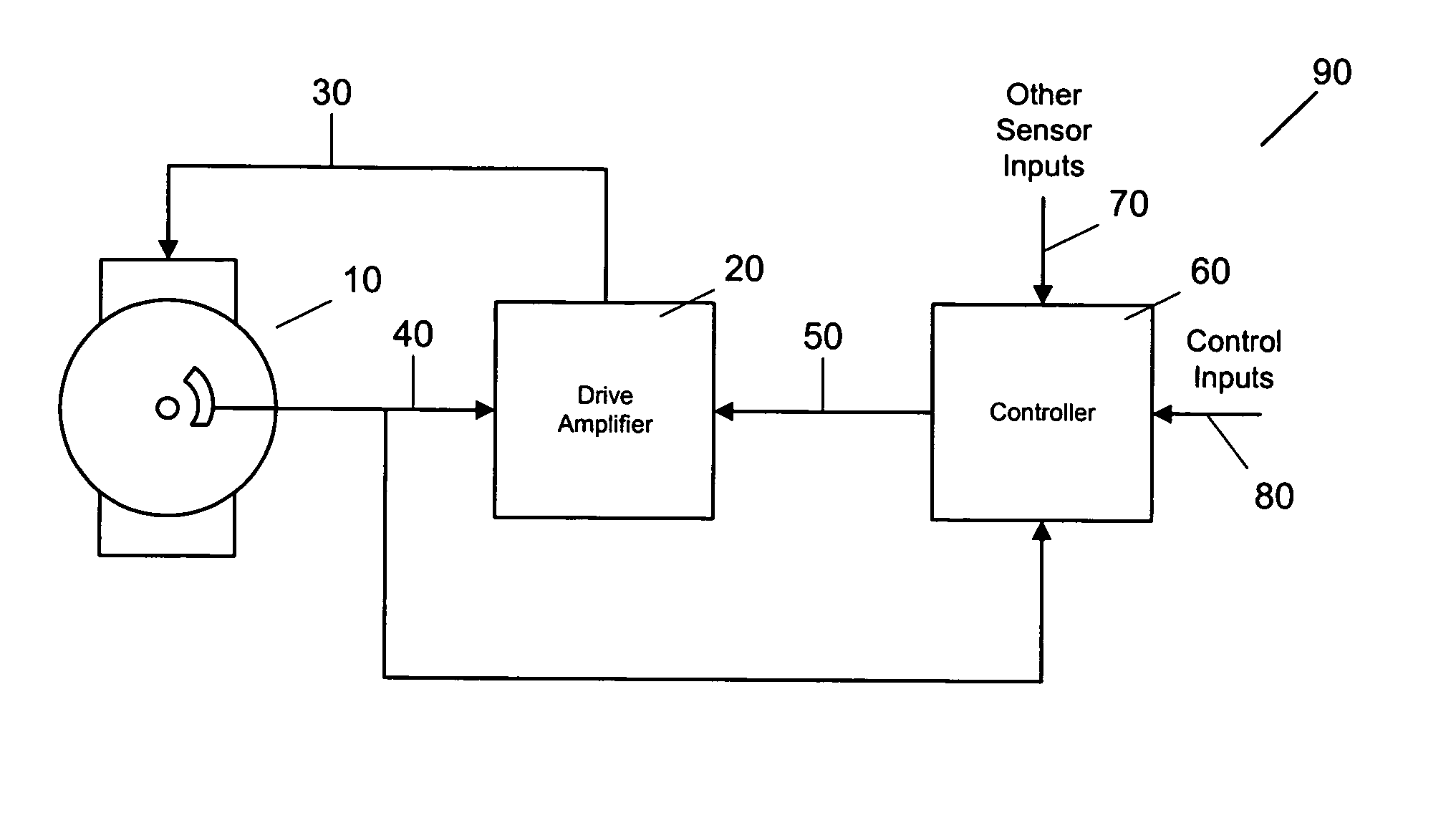

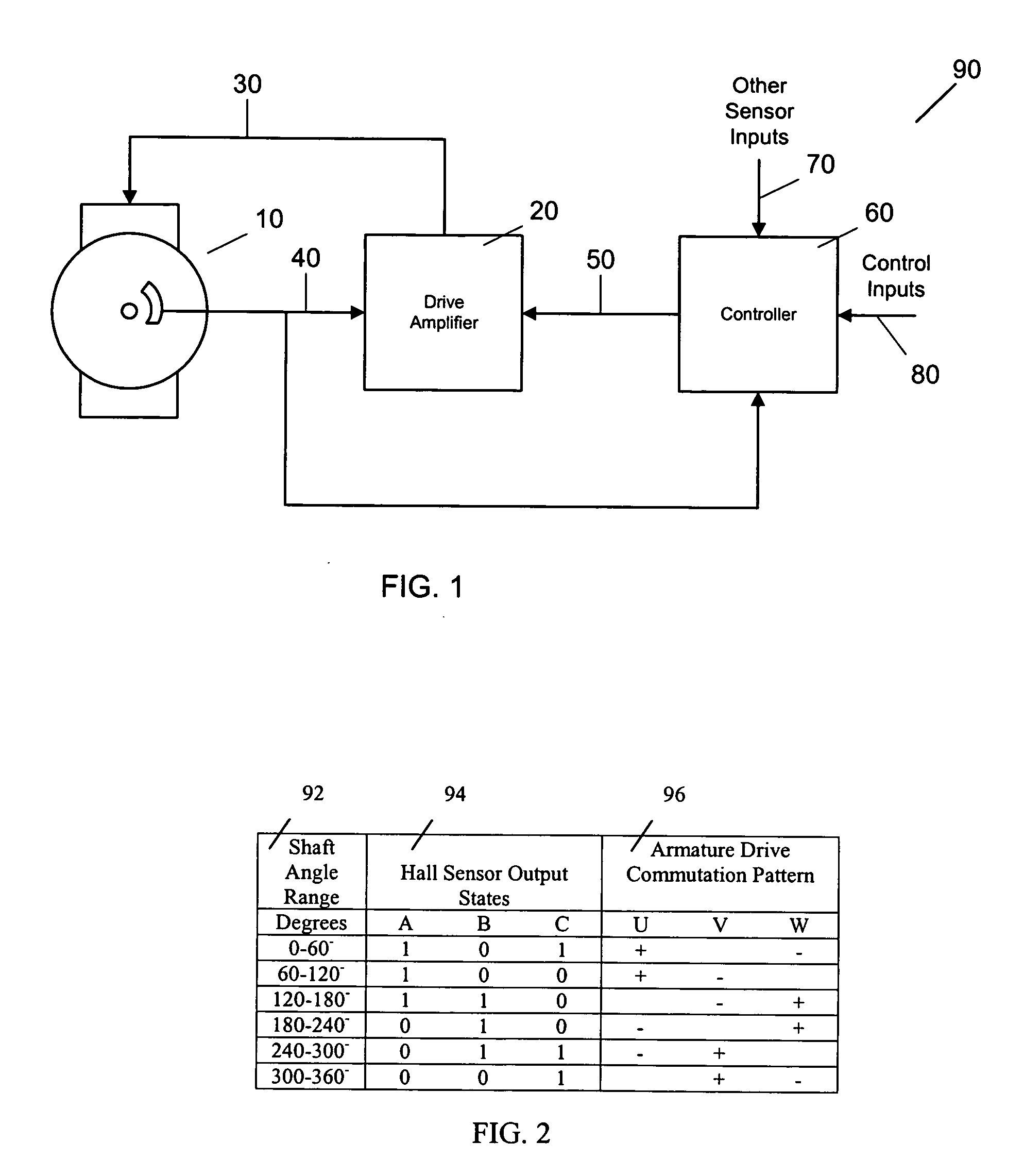

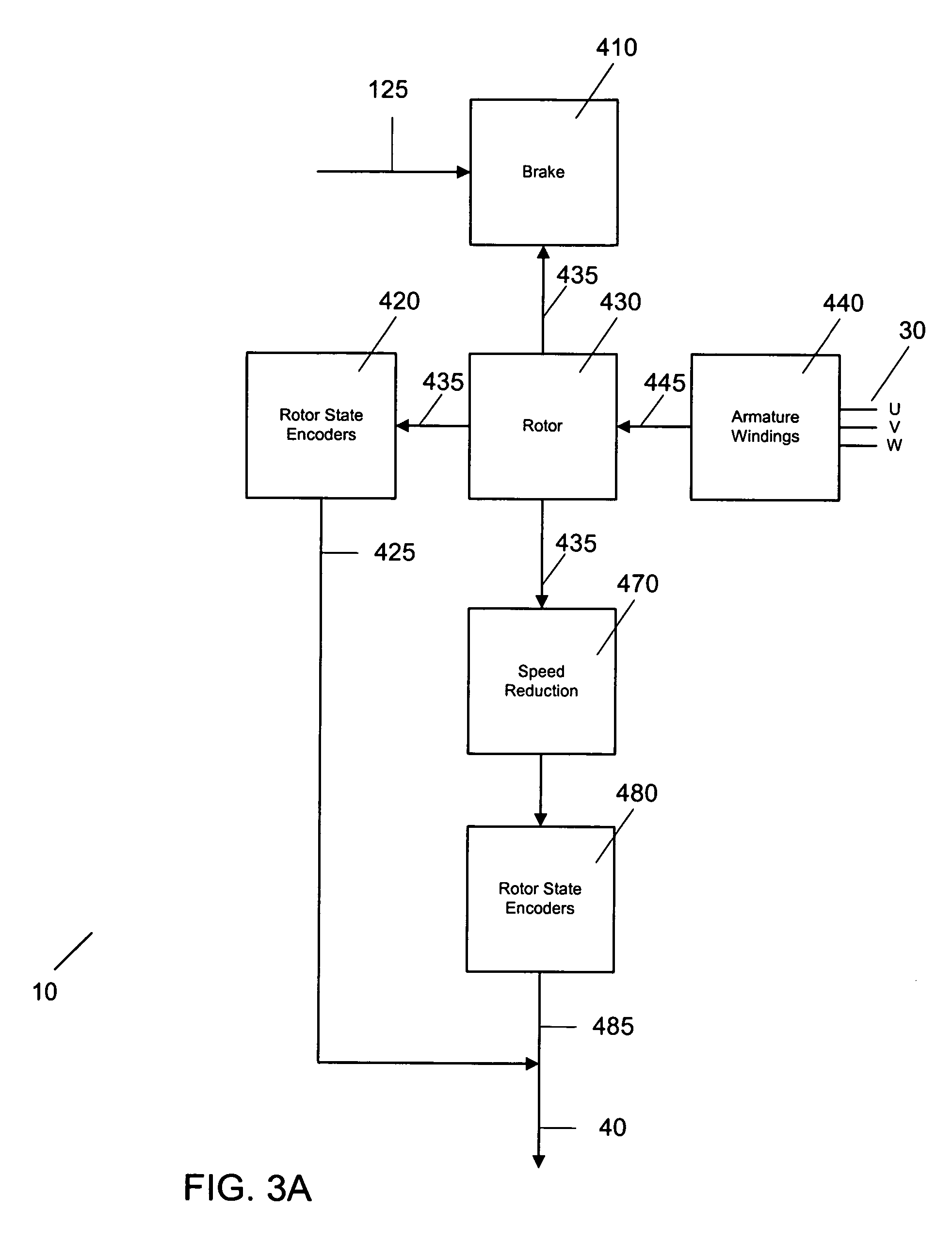

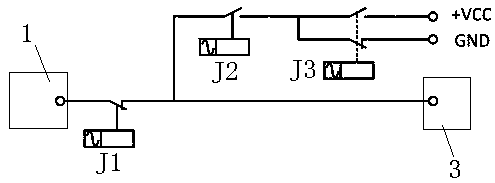

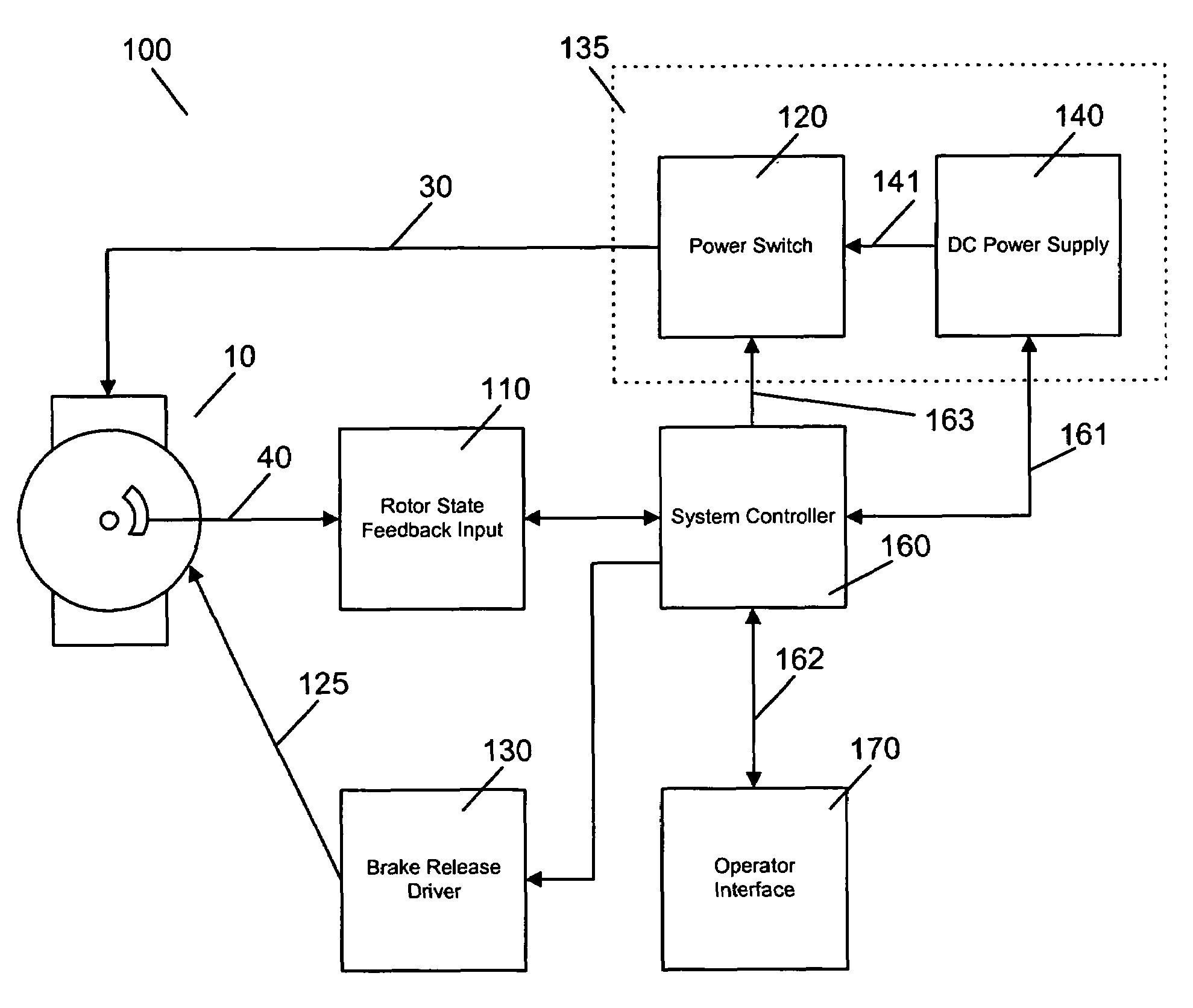

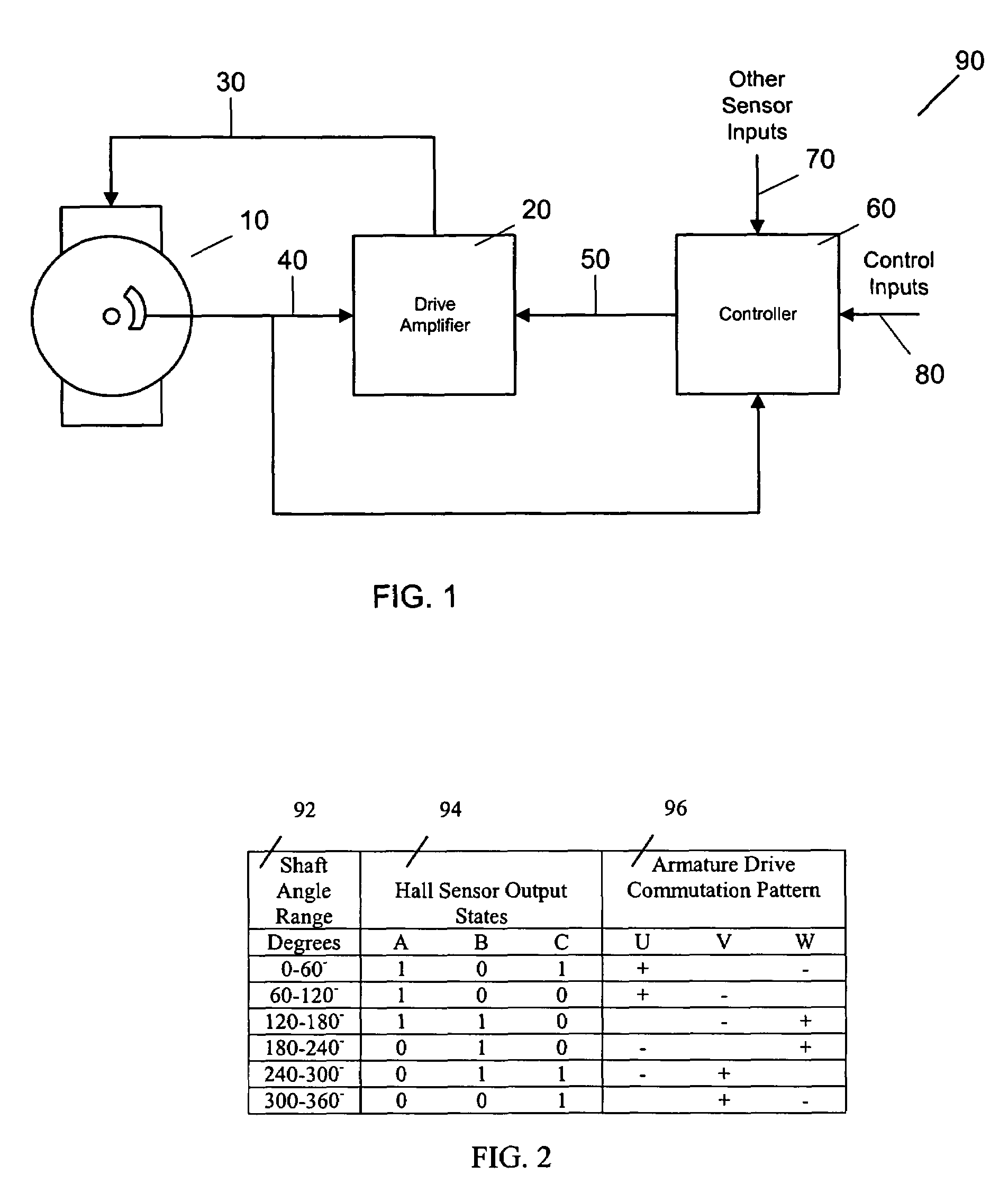

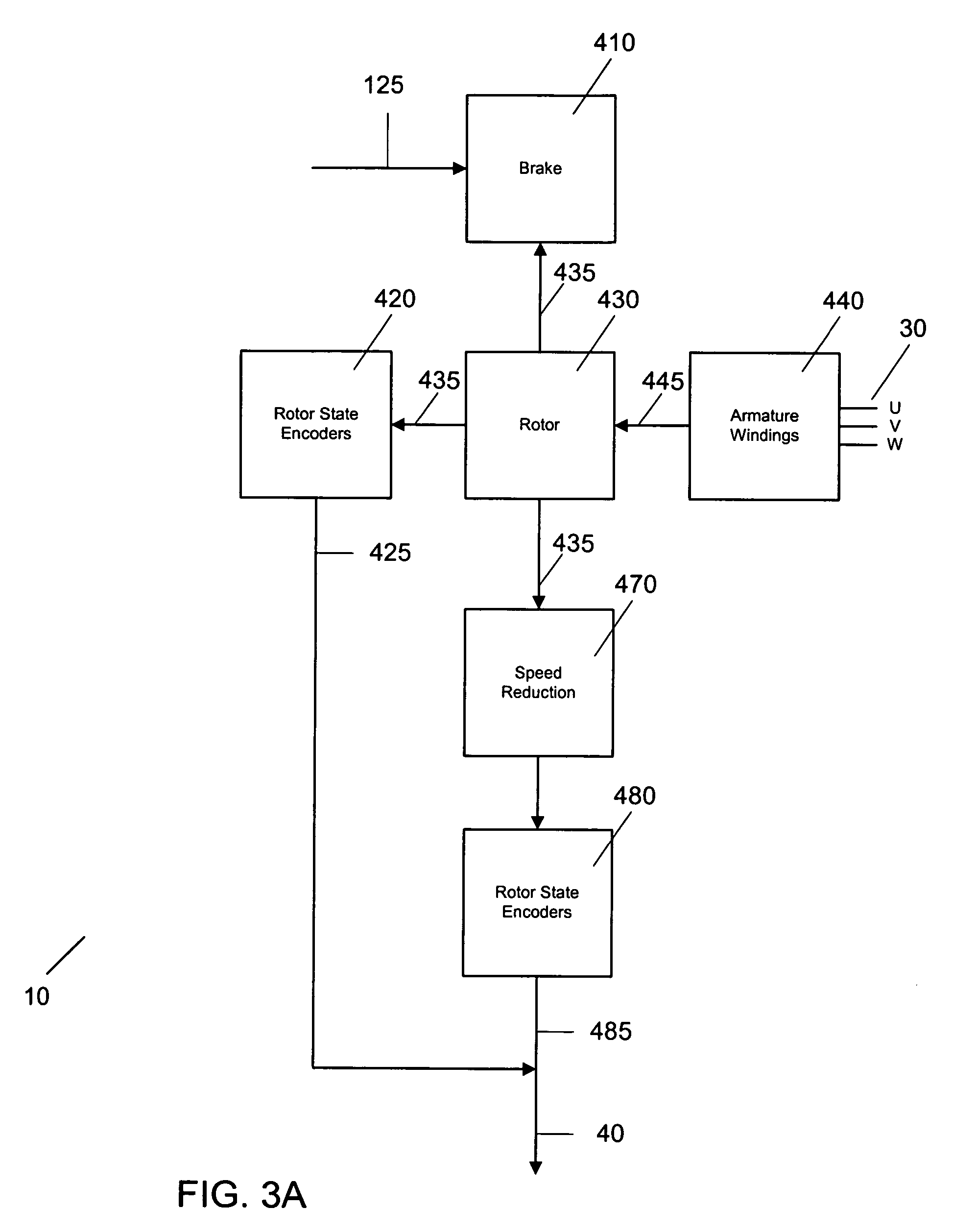

A permanent magnet brushless (PMBL) servo motor test apparatus and method allow testing of a motor in place. A set of static and dynamic tests is performed to determine proper motor operation of armature windings and rotor feedback devices. The test system of the present invention displaces the motor drive system. The test system comprises an armature driver, a feedback device input, and a system controller. The armature windings of the motor-under-test are driven in a polarity sequence according to a test sequence, whereby the rotor is driven in a series of rotations. Angle feedback is tested at a plurality of said rotations. Rotor velocity outputs are tested during said rotations. Armature current and voltage are determined at a plurality of said rotations and winding balance is tested. Said power switch is also operative to apply a voltage between the armature windings and the motor case to test for fault current flow. In another embodiment of the invention, motor identification is decoded by the system into motor configuration and motor operation parameters, necessary to test the motor. Motor identification may be entered by an operator or captured from machine readable tags such as a barcode tag or an RFID tag.

Owner:MITCHELL ELECTRONICS

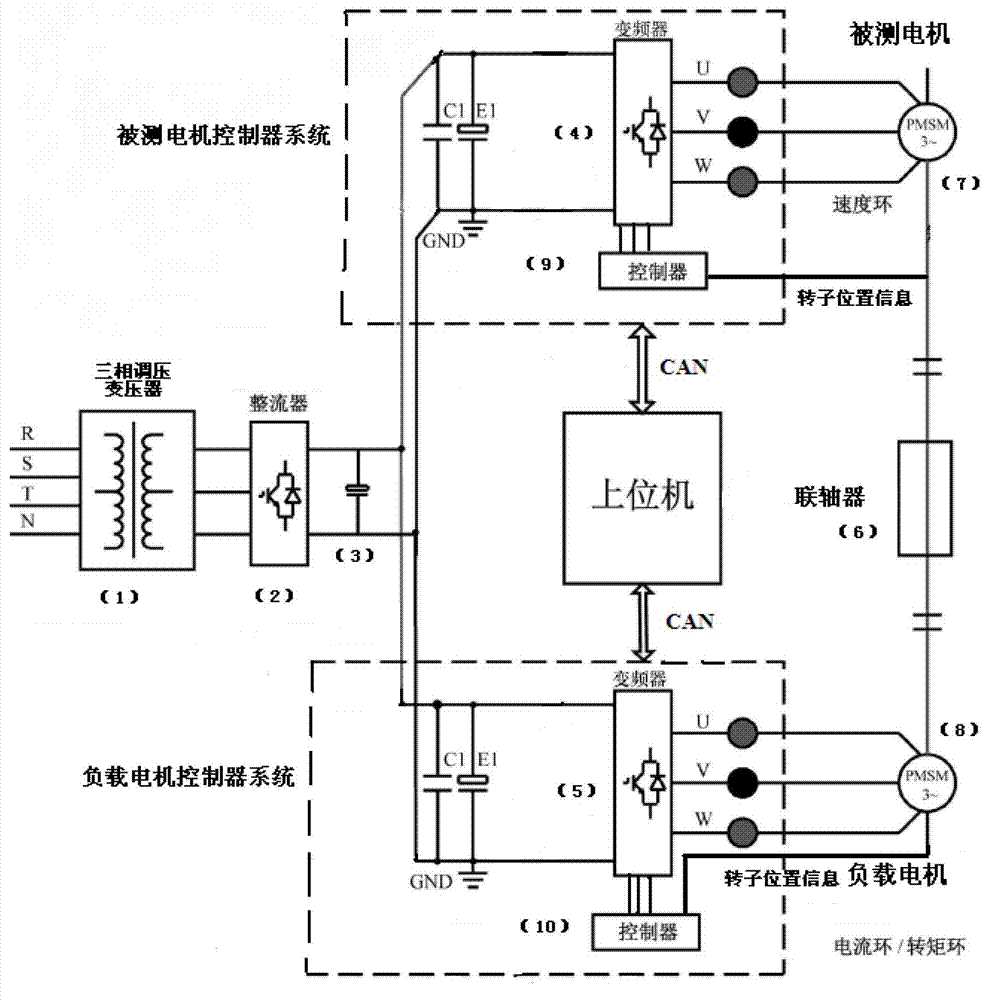

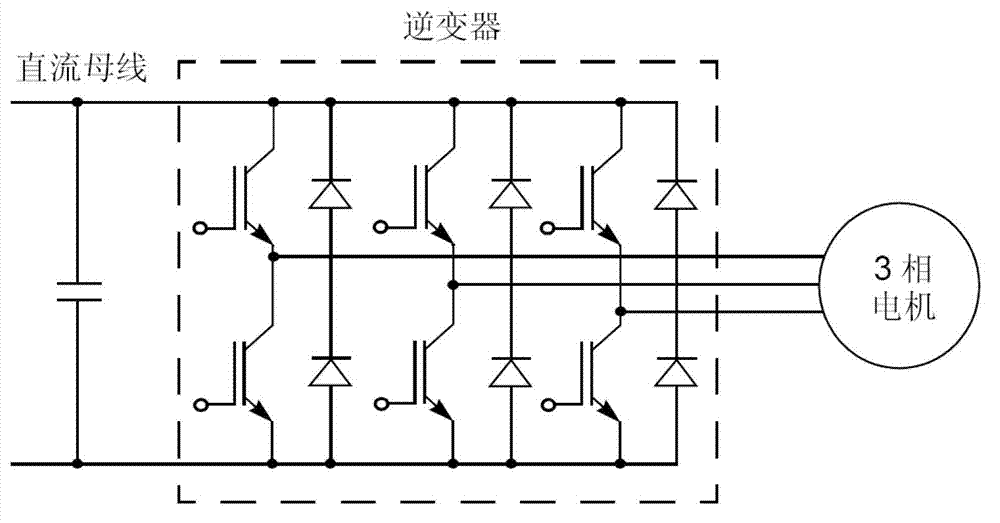

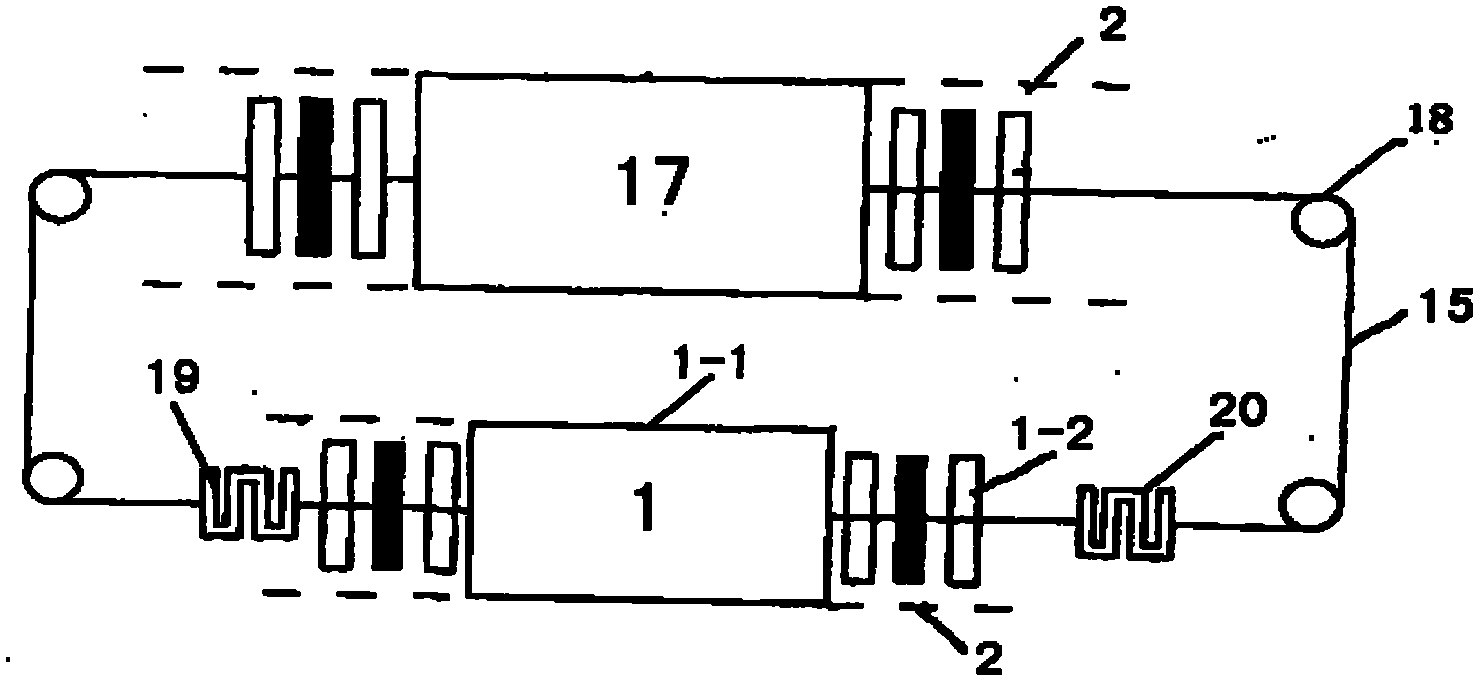

Motor twin trawling platform used for motor test

InactiveCN103163460AImprove efficiencyHigh moment of inertia ratioDynamo-electric machine testingMotor testingElectricity

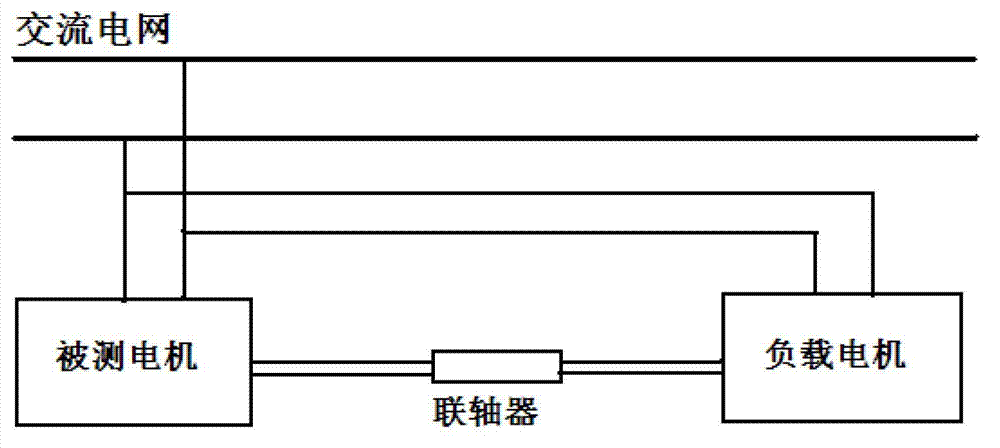

The invention discloses a motor twin trawling platform used for a motor test. The motor twin trawling platform used for the motor test comprises a transformer, a rectifier, a filter, a tested motor, a master control system, a load motor, a coupler and two motor control systems. The rectifier is connected with the transformer, two ends of the filter are respectively connected with two output ends of the rectifier, a tested motor control system and a load motor control system are both connected with the filter, the load motor is connected with the load motor control system, a tested motor output shaft is connected with an output shaft of the load motor through the coupler, and the tested motor control system and the load motor control system are both connected with the master control system. The whole system of the motor twin trawling platform used for the motor test can be miniaturized, the motor can be output through random torque so as to enable the motor twin trawling test to be diversified, electricity is saved, and efficiency can be obviously improved.

Owner:ANHUI ZHONGJIA ZHIRUI TECH

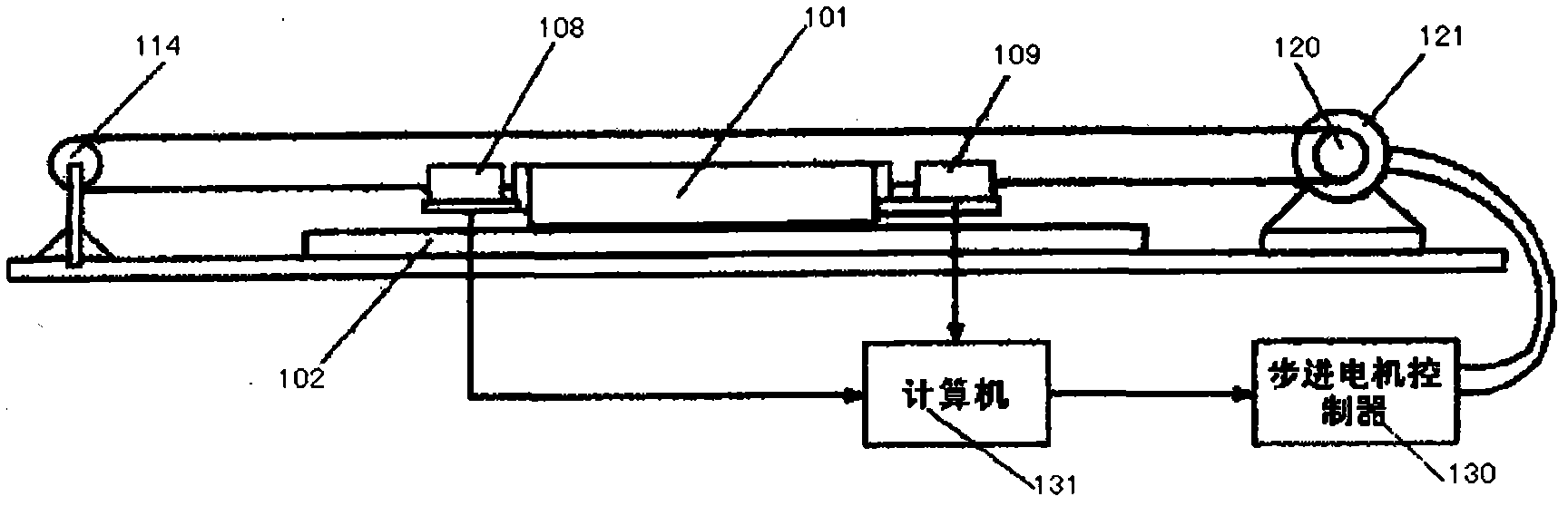

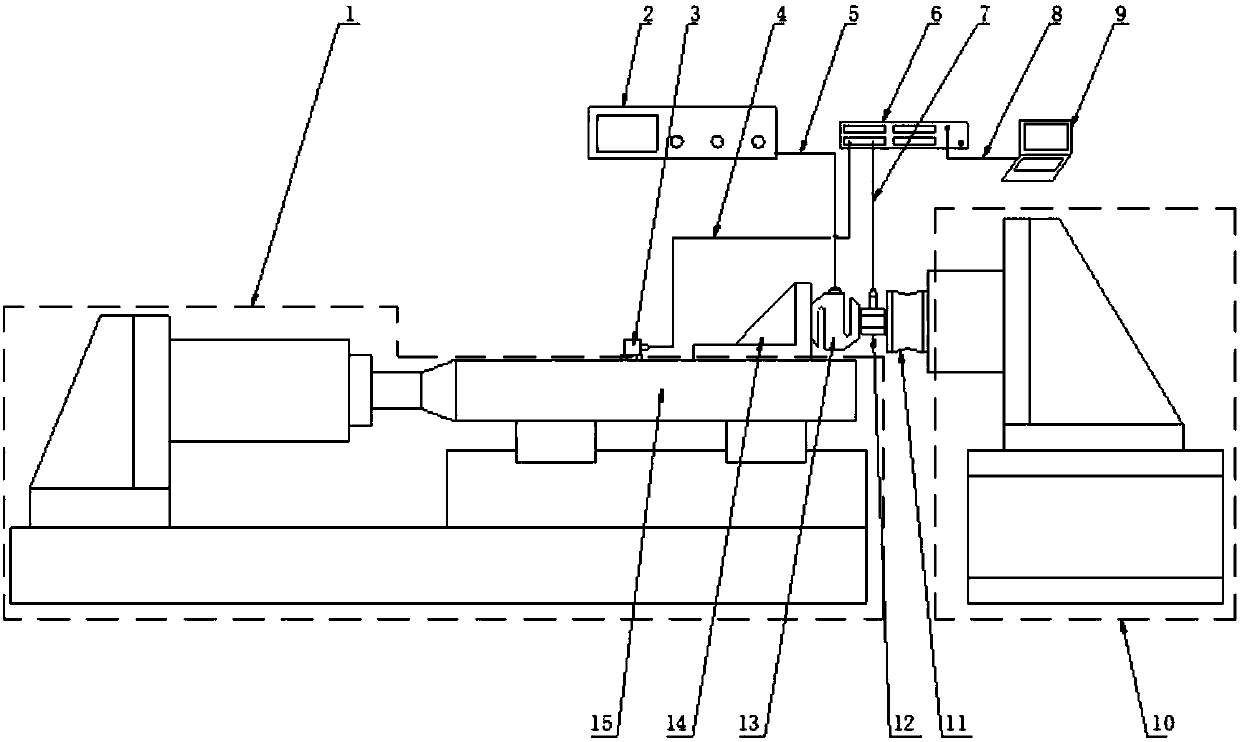

Comprehensive test device for linear motor motion system

InactiveCN101980037APrecise positioningConducive to the study of the limit output stateDynamo-electric machine testingLow speedTorque motor

The invention discloses a comprehensive test device for a linear motor motion system, which belongs to the field of motor test equipment. The comprehensive test device consists of a tested linear motor, a rotating servo motor, a torque motor, a sensor module and a transmission mechanism. Linear motion guide rails and a linear position sensor are fixed on a workbench; a linear motor primary section is arranged on the linear motion guide rails; the output of a controller is connected with each sensor through one communication interface; the sensors transmit position, acceleration, tensile forceand temperature measurement signals obtained in a test process through the communication interfaces; and the rotating servo motor, the torque motor and the linear motor realize coordinated motion with the controller through communication interfaces. The test device can finish the plurality of tests of dynamic stiffness tests, thrust coefficient determination, temperature rise tests, low-speed motion characteristic tests and the like on a linear motor-driven machine tool feeding system, and solve the problems of absence of a complete set of test device, low test accuracy and low repeatability of the linear motor-driven machine tool feeding system.

Owner:TSINGHUA UNIV

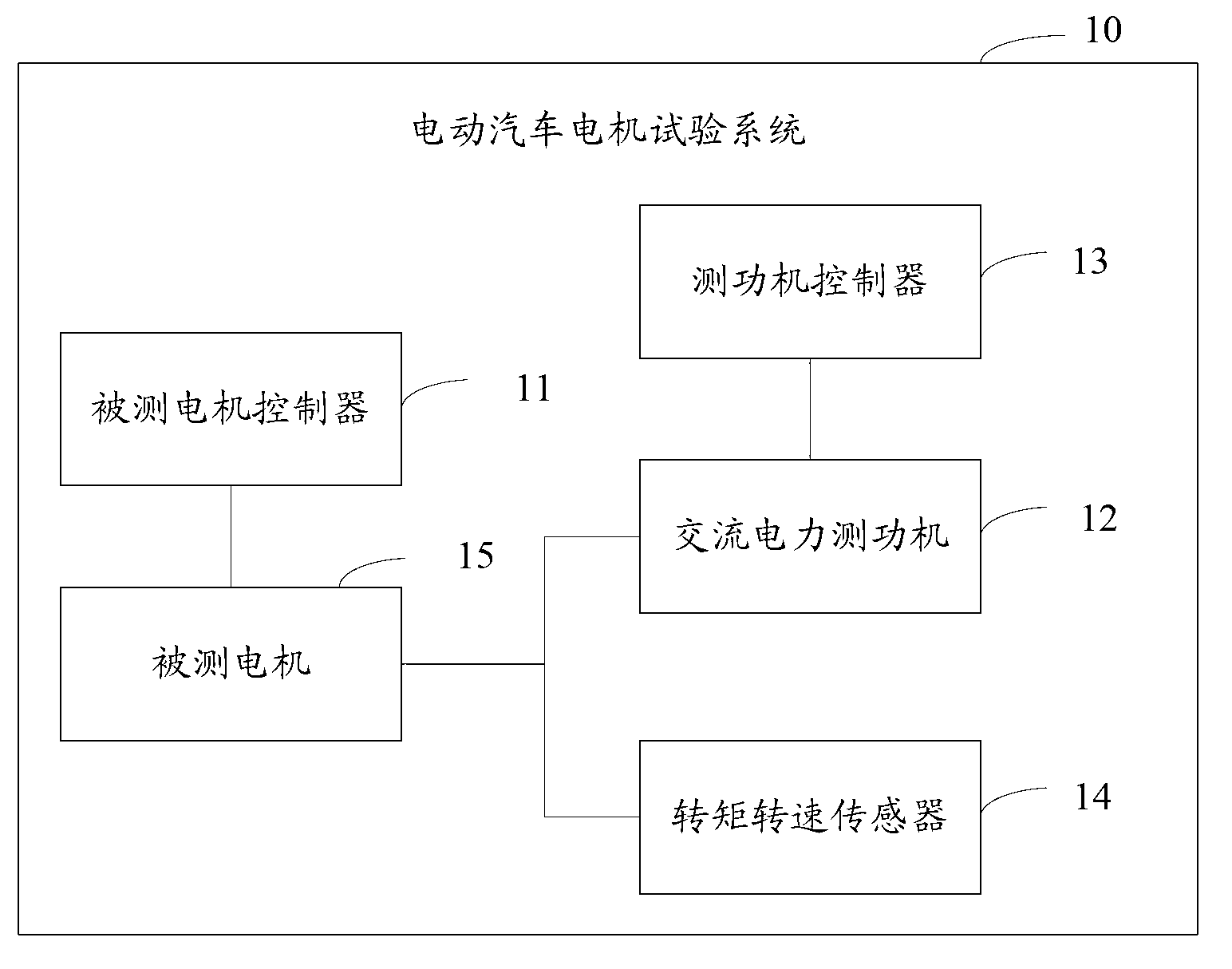

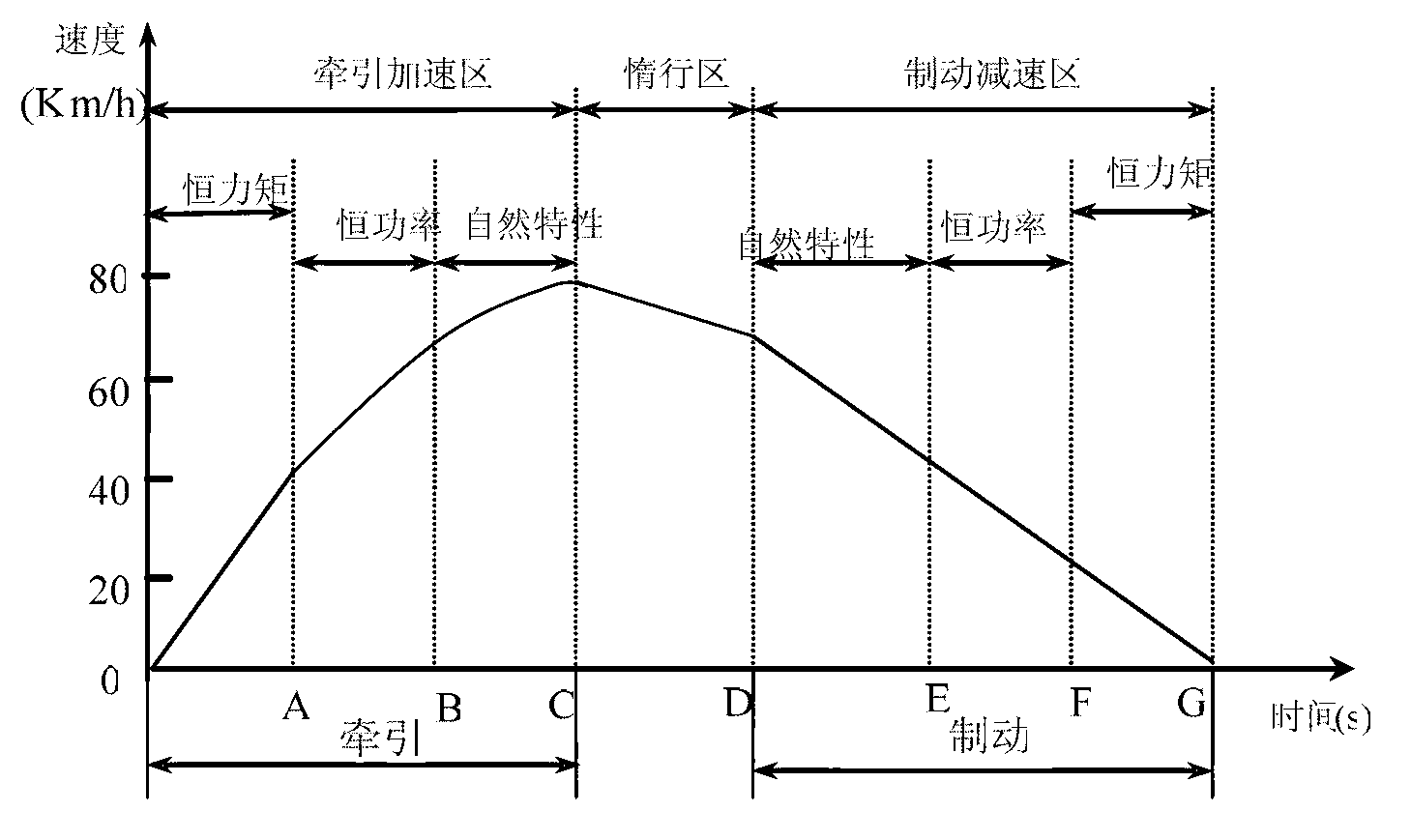

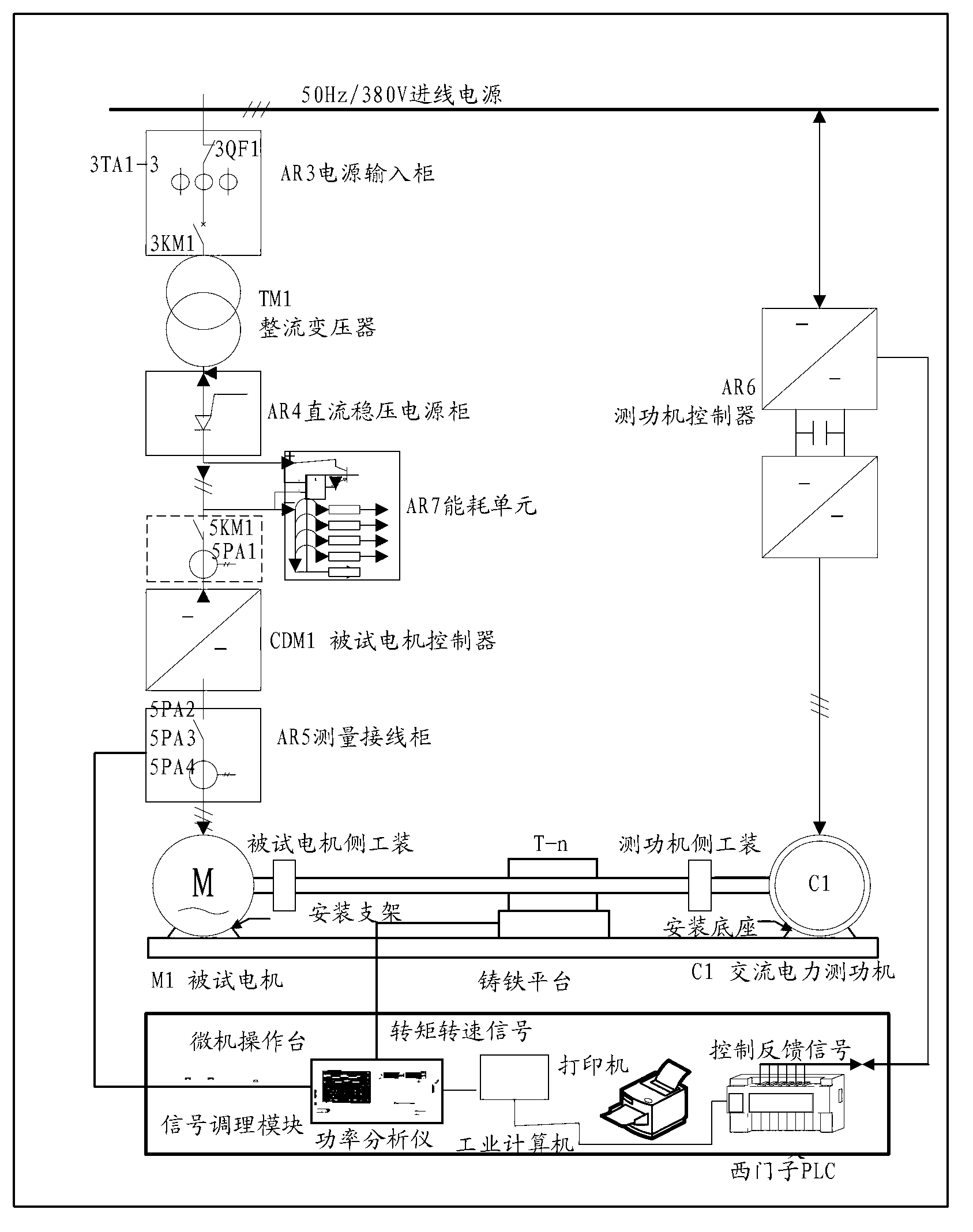

Motor test system and control method for electric vehicle

The invention discloses a motor test system for an electric vehicle, and solves the problems that a motor test system in the prior art can not meet neither constant-torque loading when an electric vehicle motor runs below the rated rotational speed nor constant-power loading when the electric vehicle motor runs above the rated rotational speed. The motor test system comprises a tested-motor controller connected with a tested motor and used for controlling the state of the tested motor simulating the operation of the electric vehicle, an AC power dynamometer connected with the output terminal of the shaft of the tested motor and used for providing a load for the tested motor and the controller so as to simulate the required power output during actual operation of the electric vehicle, a dynamometer controller connected with the dynamometer and used for controlling the dynamometer to provide a resisting force for both the tested motor and the tested-motor controller when the tested motor simulates the operation of the electric vehicle, and a rotational speed and torque sensor connected with the output shaft of the tested motor and used for measuring both the rotational speed and the torque of the tested motor. The motor test system can improve the accuracy in testing the electric vehicle motor.

Owner:株洲中达特科电子科技有限公司

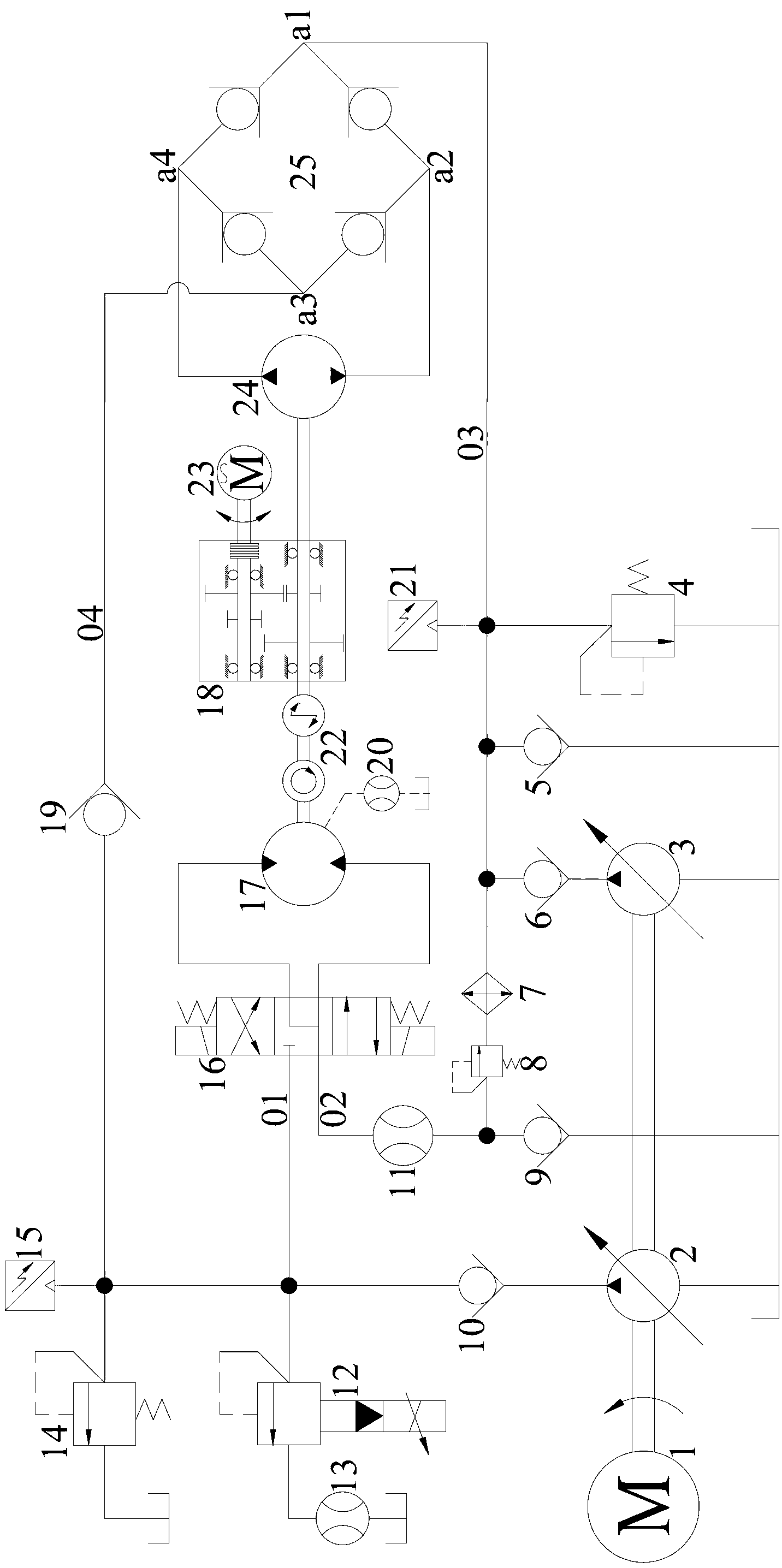

Testing system of hydraulic motor

InactiveCN102937125AImprove stabilityImprove recycling efficiencyFluid-pressure actuator testingHydraulic motorInlet channel

The invention relates to the technical field of motor tests and discloses a testing system of a hydraulic motor. The testing system of the hydraulic motor comprises a motor, a speed changing box, a tested motor, a loading motor, a first oil way, a second oil way, a feedback oil way and a compensation oil way. The speed changing box is provided with an acceleration gear and a deceleration gear, the input end of the speed changing box is in driving connection with the output end of the motor, the loading motor is butted with the tested motor through a power shaft, the output end of the speed changing box is in driving connection with the power shaft, the first oil way serves as an oil inlet channel of the tested motor, the second oil way serves as an oil return channel of the tested motor, the oil outlet end of the feedback oil way is communicated with the first oil way, and the oil outlet end of the feedback oil way selectively supplies oil for the oil inlet end of the feedback oil way or supplies oil for the oil inlet end of the feedback oil way through the loading motor. By means of the testing system, mechanical and hydraulic compensation power recovery modes or the hydraulic compensation power recovery mode can be selected according to needs, and testing requirements for power tests, service life tests, batch tests and the like on most majority of hydraulic motors can be met.

Owner:SANY AUTOMOBILE MFG CO LTD

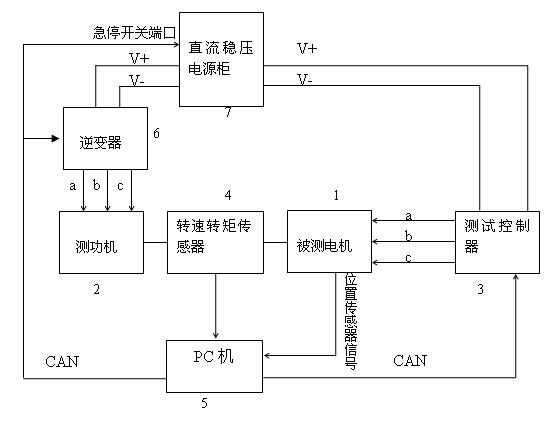

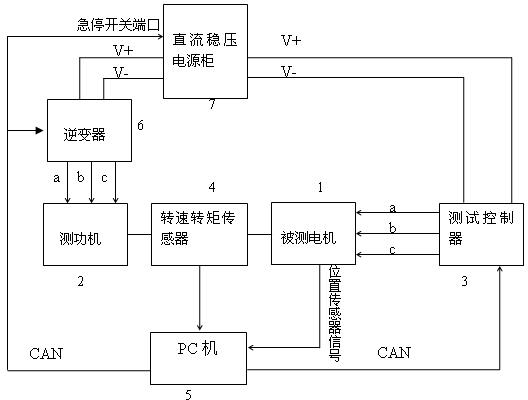

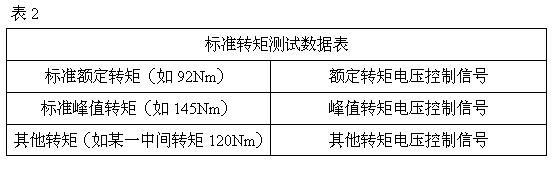

Delivery test system and method for motor for pure electric vehicle

ActiveCN102495367AGuarantee factory qualityMeet the testing requirementsDynamo-electric machine testingMotor testingArea network

The invention relates to a motor test system, which comprises a test controller, an inverter, a power tester, a rotating speed and torque sensor, a direct-current voltage stabilization power supply cabinet and a personal computer (PC). The invention also provides a method for testing a motor for an electric vehicle based on the test system. According to the test method, a whole rack test system is controlled through controller area network (CAN) communication; a rotating speed and torque measurement command is sent based on standard test data; rotating speed and torque data is fed back in real time by the rotating speed and torque sensor; and the feedback data is compared with standard data to judge whether the external characteristic of the motor is qualified. By the test system and the test method, the external characteristic of the tested motor can be detected accurately and efficiently, so that the delivery quality of the motor can be guaranteed; furthermore, the test process is high in automation degree and precise in test; and the method is easy to operate and low in cost, and has very wide application prospect.

Owner:奇瑞新能源汽车股份有限公司

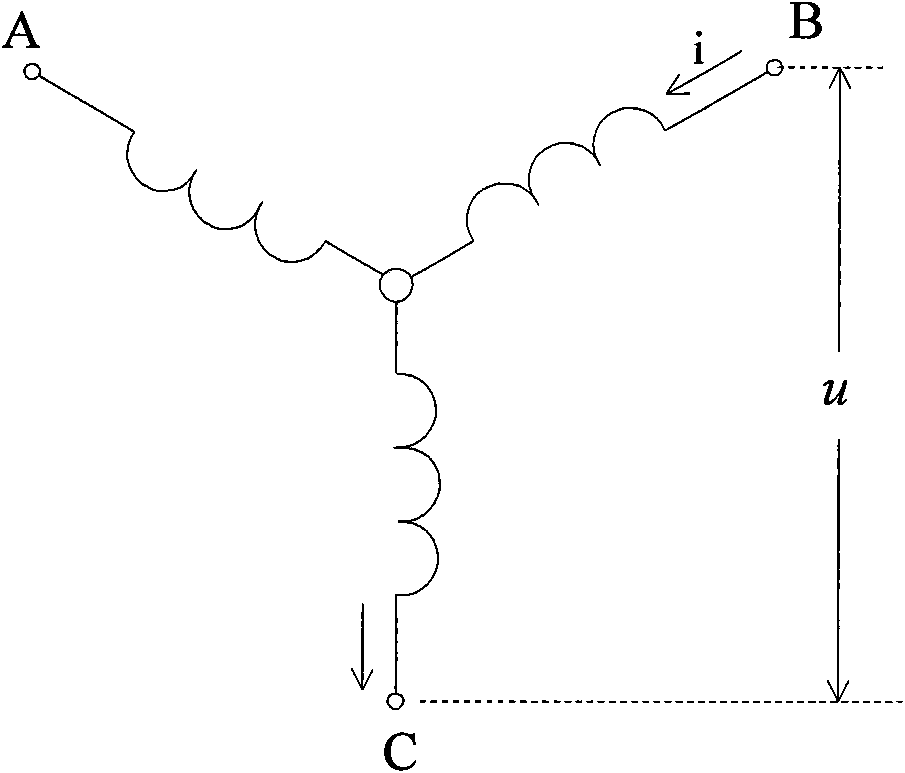

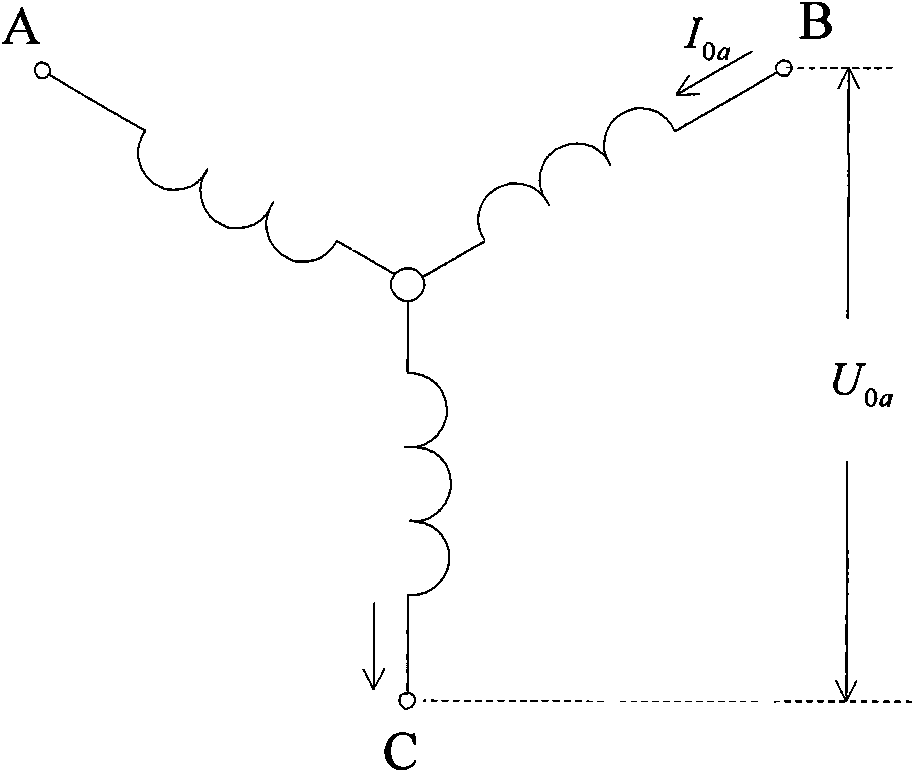

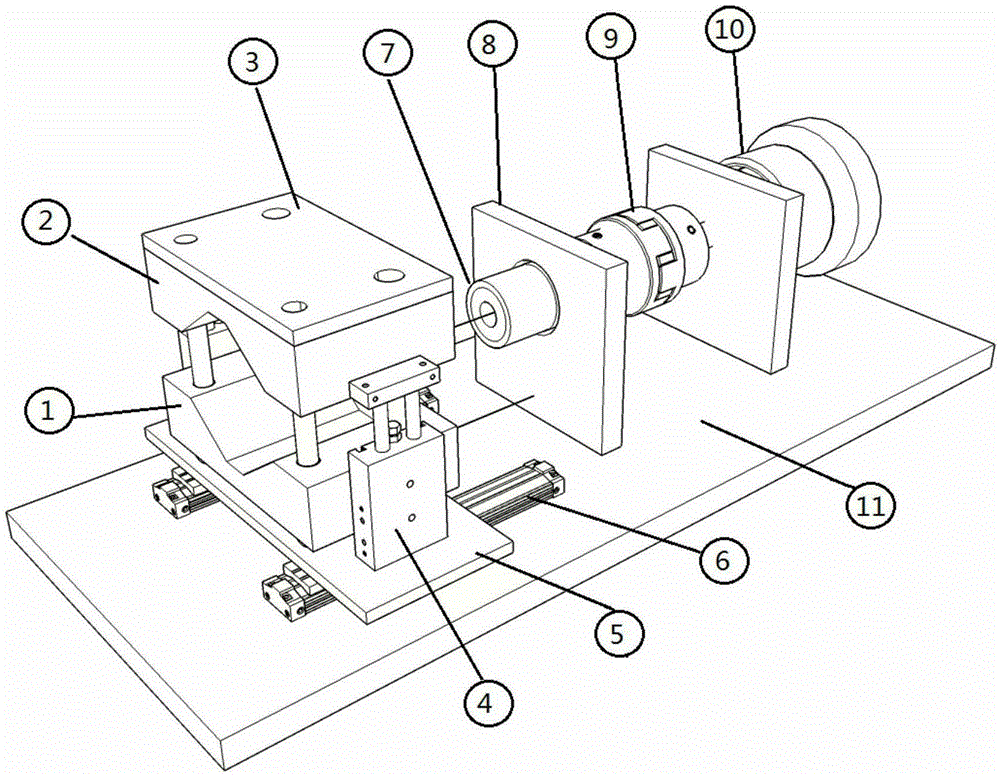

Method for testing parameters of synchronous motor and device for achieving same

ActiveCN101603997AAvoid influenceSimple structureCurrent/voltage measurementWork measurementSynchronous motorElectric machine

The invention provides a method for testing parameters of a synchronous motor and a device for achieving the same, which relate to the field of motor tests. The method and the device solve the problems of low testing accuracy of quadrature and direct axis inductance parameters, complex method for testing moment coefficient, and strong dependency on driver performance in the prior method. The method comprises the following steps: energizing any two phases in three phases of windings of a tested synchronous motor with single-phase alternating current (square root 2I sin omega t), driving a rotor of the tested synchronous motor with an external force to rotate at a uniform speed for at least one revolution, testing voltage signals at two ends of the energized windings, and obtaining the quadrature axis and direct axis inductances of Lq and Ld respectively of the tested synchronous motor according to the voltage signals; and energizing any two phases of the three phases of the windings of the tested synchronous motor with direct current I1, driving the motor of the tested synchronous motor with the external force to rotate at a uniform speed for at least one revolution, and calculating the moment coefficient KT of the tested synchronous motor according to the tested maximum moment value Tmax1. The method and the device are applied to the field of testing the parameters of the synchronous motor.

Owner:HARBIN INST OF TECH

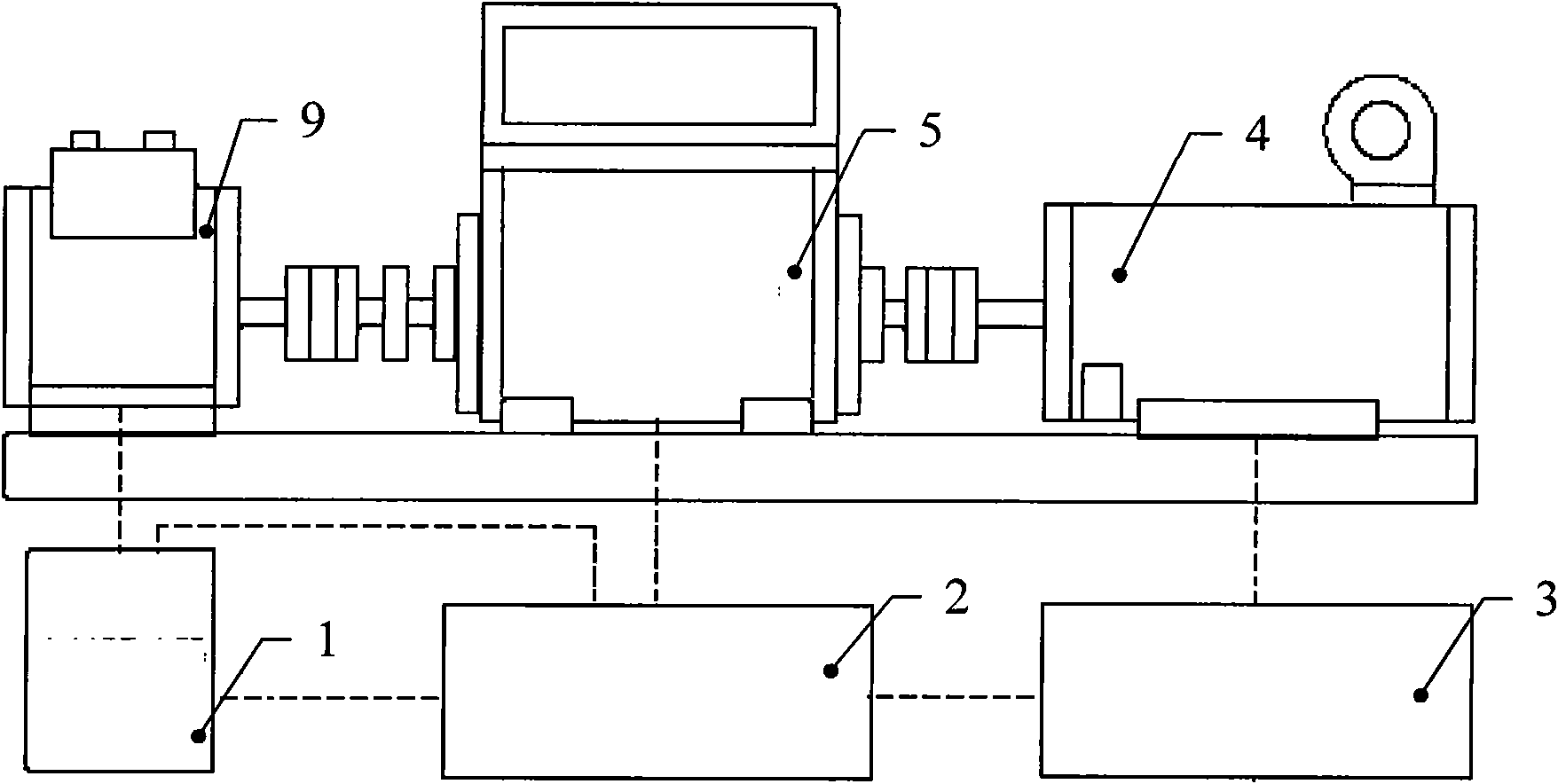

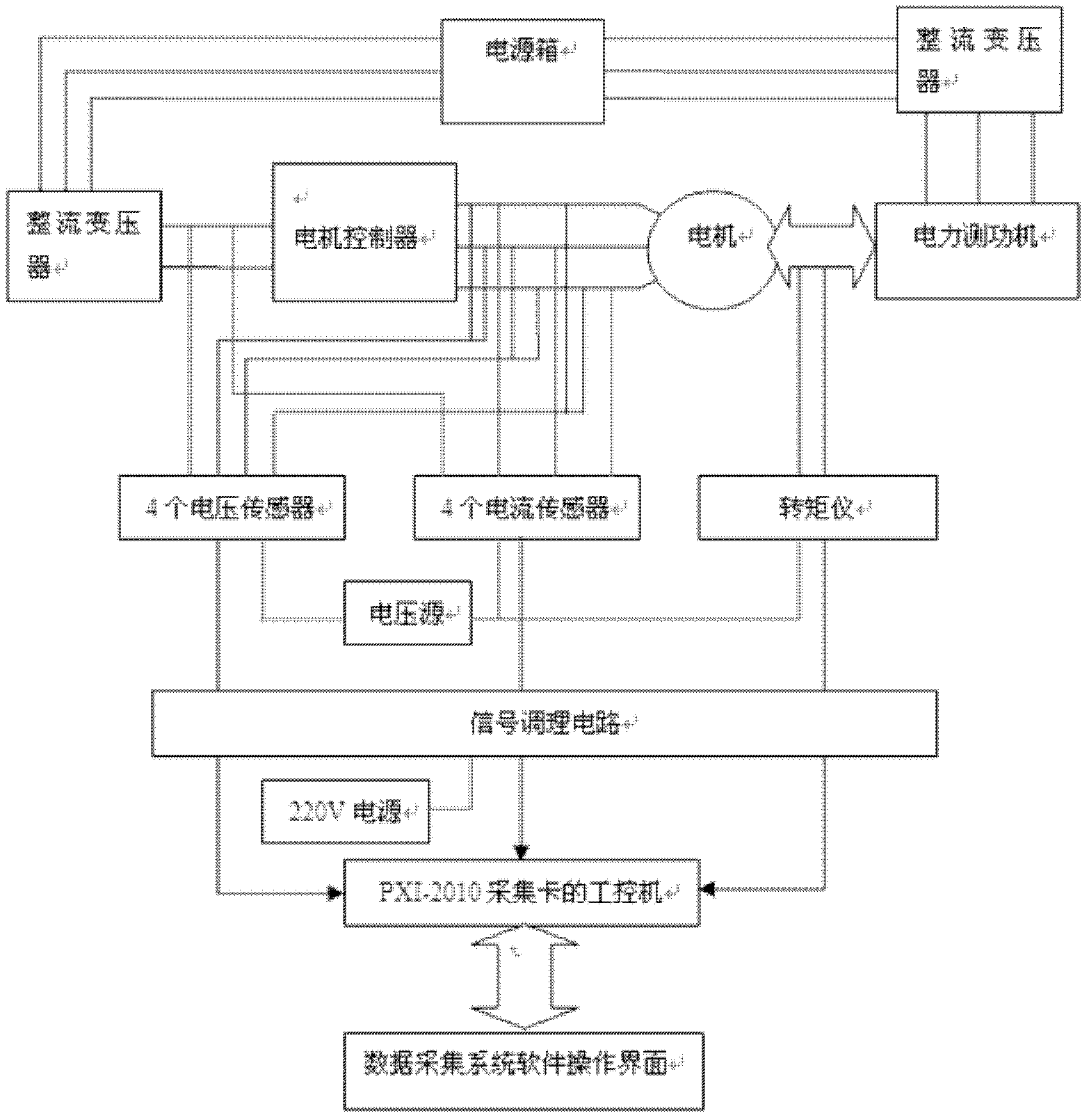

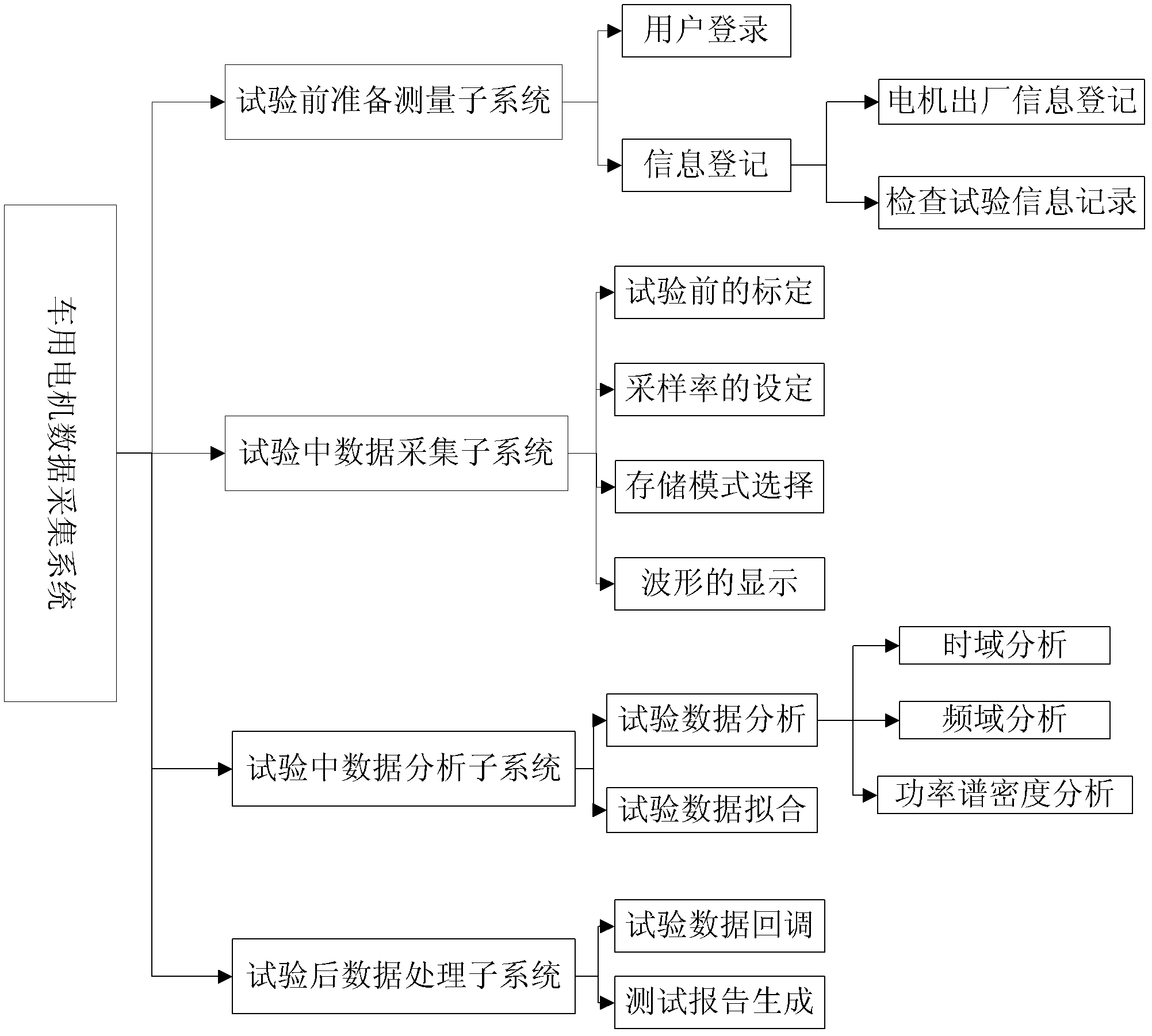

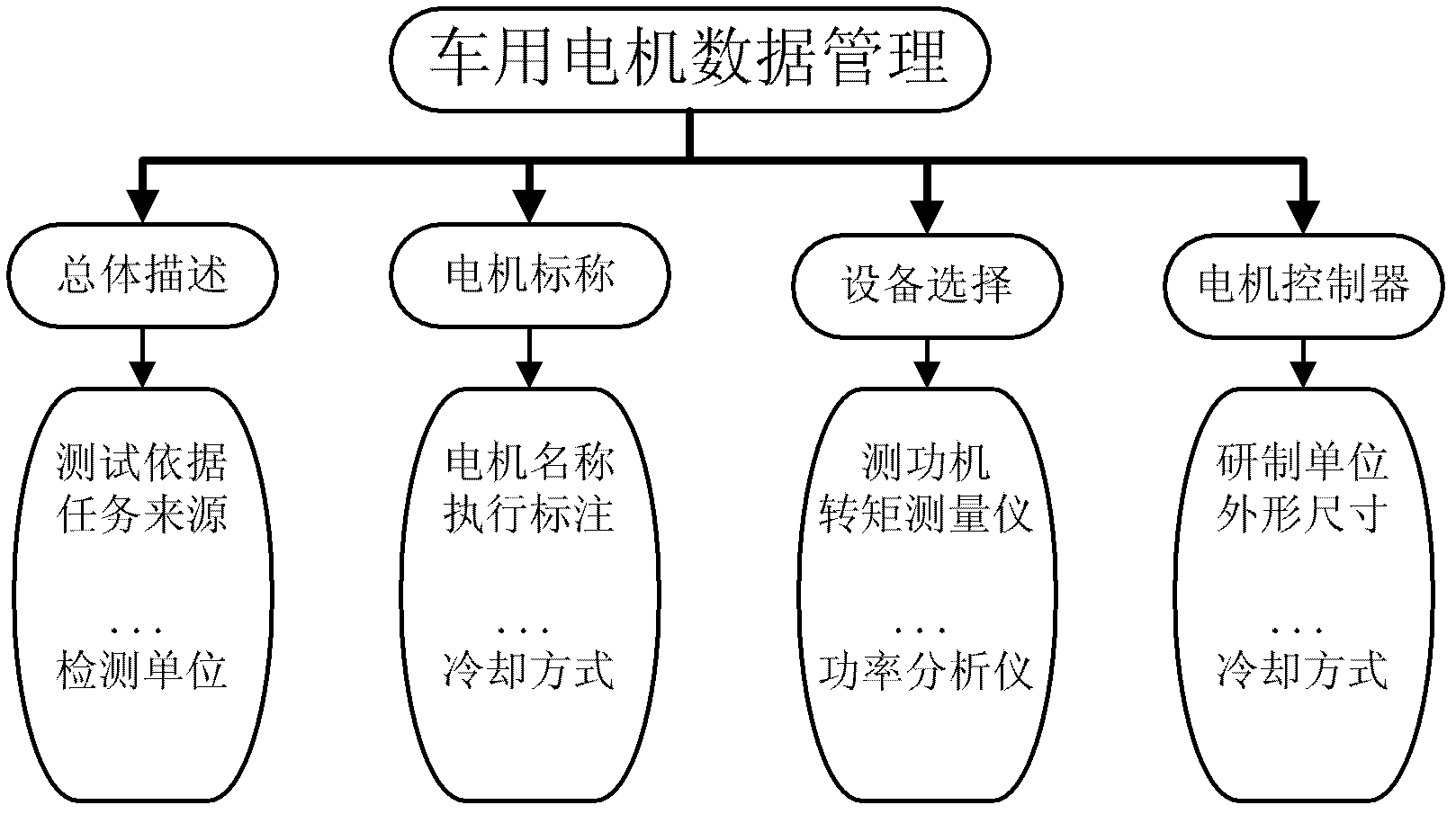

Vehicle driving motor test stand data acquisition system based on LabVIEW

InactiveCN102645634ANo count lossShorten test timeDynamo-electric machine testingDisplay boardResource Management System

The invention relates to a vehicle driving motor test stand data acquisition system based on LabVIEW, which is used for acquiring data in a vehicle driving motor test stand. The data acquisition system comprises the test stand and a data acquisition system. The test stand is used for realizing test for a vehicle driving motor, and the data acquisition system matches with the test stand and consists of a sensor, a data acquirer and a computer with a LabView development platform. The vehicle driving motor test stand data acquisition system can guarantee that stored test data cannot be lost when acquired at a high speed and waveforms are displayed in real time, callback and frequency-domain of data of the waveforms are realized after a test, and a test report in a fixed format is generated. In addition, the vehicle driving motor test stand data acquisition system can be used for evaluating performances of an electric vehicle with hybrid energy sources and optimizing a control strategy of a hybrid energy resource management system, is used as a meter display board and the like of the electric vehicle with the hybrid energy sources and a pure electric vehicle, and is a currently available electric vehicle data acquisition system with complete functions.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

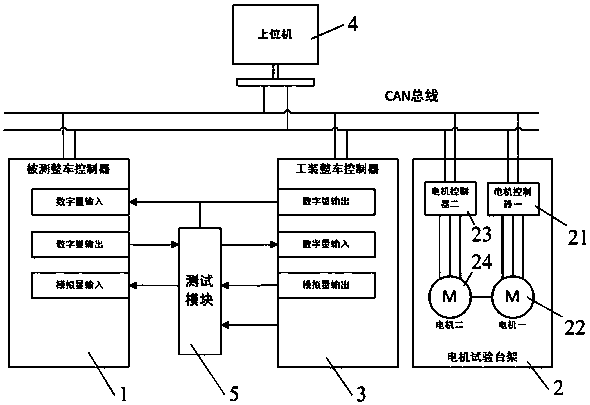

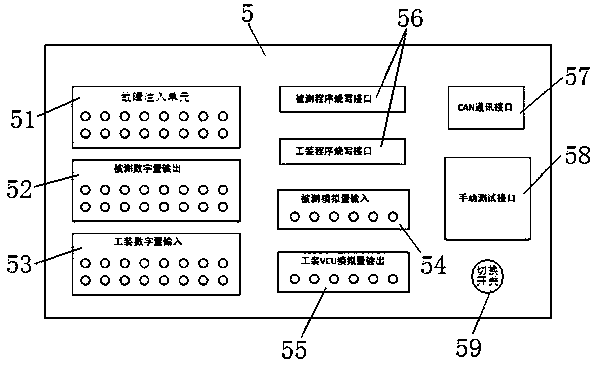

Automatic test device and method for vehicle control unit of new energy vehicle

ActiveCN108227669AEnsure safetyImprove test efficiencyElectric testing/monitoringNew energyTest fixture

The invention discloses an automatic test device and method for the vehicle control unit of a new energy vehicle. The device is composed of a tested vehicle control unit, a tool vehicle control unit used for realizing vehicle model data interaction and modification and interactively connected with the tested vehicle control unit, a test module used for program burning, test mode switching and datainteraction between the two vehicle control units, a principal computer used for test process detection control and storage, and a motor test bench used for test condition simulation. The method comprises the following steps: the system is initialized, the principal computer sends a control command to start the tested vehicle control unit, and the tested vehicle control unit controls the runningof a motor through a motor controller of the motor test bench; and test items are started, and the principal computer displays and stores the data of the test items. The test efficiency is improved, and the cost is reduced. The automatic test device and method are easy to operate, and have strong adaptability. The development efficiency of the vehicle control technology is improved, and the vehicle control performance and safety are ensured.

Owner:SHANGHAI DAJUN TECH

Brushless servo motor tester

A permanent magnet brushless (PMBL) servo motor test apparatus and method allow testing of a motor in place. A set of static and dynamic tests is performed to determine proper motor operation of armature windings and rotor feedback devices. The test system of the present invention displaces the motor drive system. The test system comprises an armature driver, a feedback device input, and a system controller. The armature windings of the motor-under-test are driven in a polarity sequence according to a test sequence, whereby the rotor is driven in a series of rotations. Angle feedback is tested at a plurality of said rotations. Rotor velocity outputs are tested during said rotations. Armature current and voltage are determined at a plurality of said rotations and winding balance is tested. Said power switch is also operative to apply a voltage between the armature windings and the motor case to test for fault current flow.In another embodiment of the invention, motor identification is decoded by the system into motor configuration and motor operation parameters, necessary to test the motor. Motor identification may be entered by an operator or captured from machine readable tags such as a barcode tag or an RFID tag.

Owner:MITCHELL ELECTRONICS

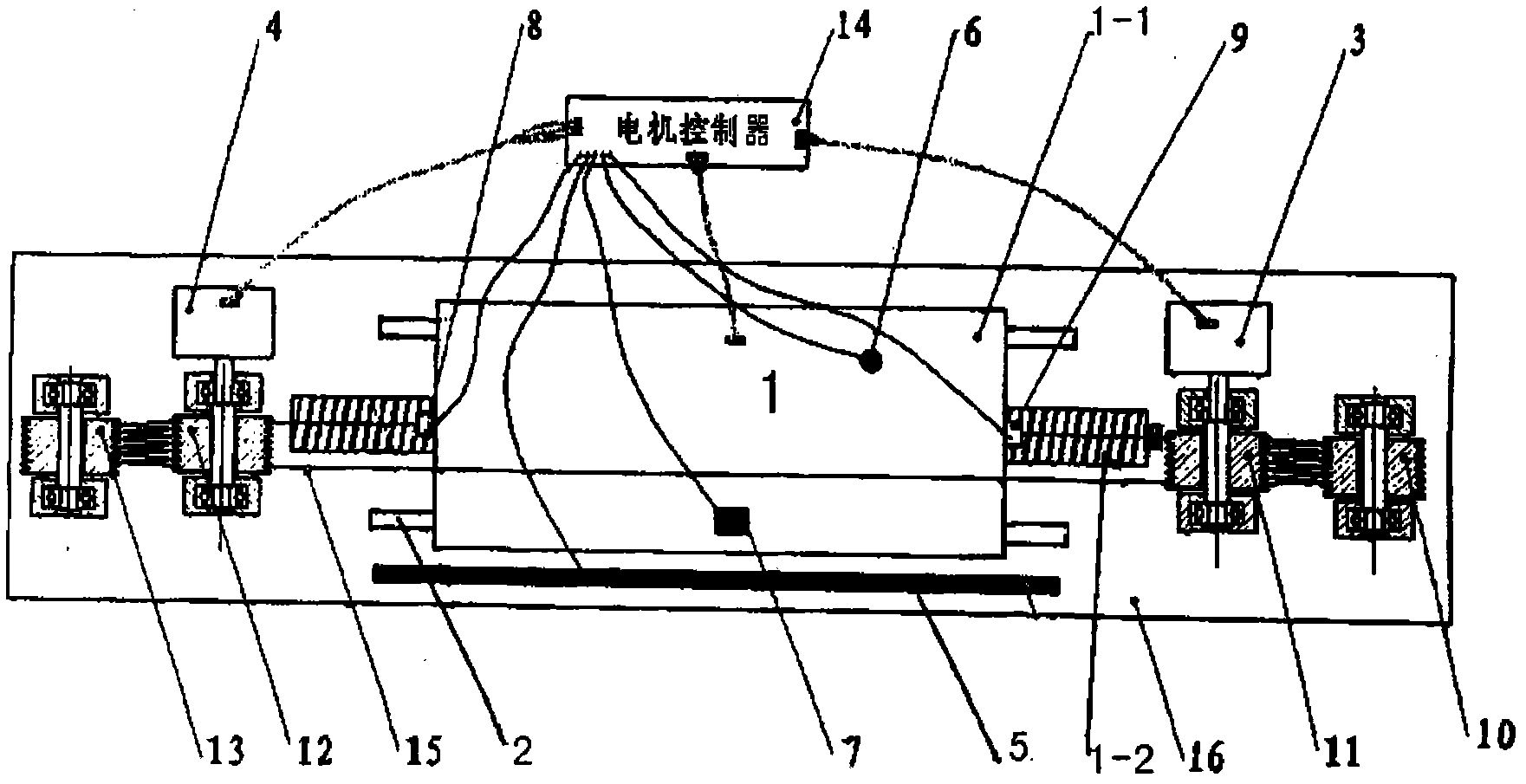

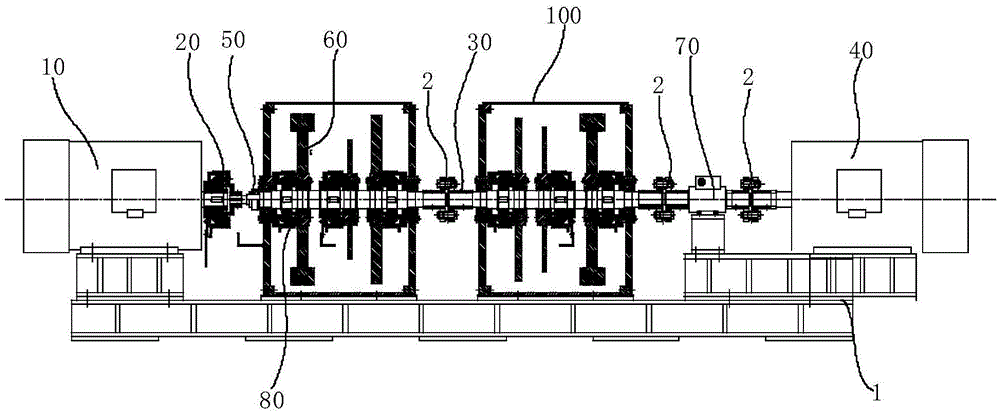

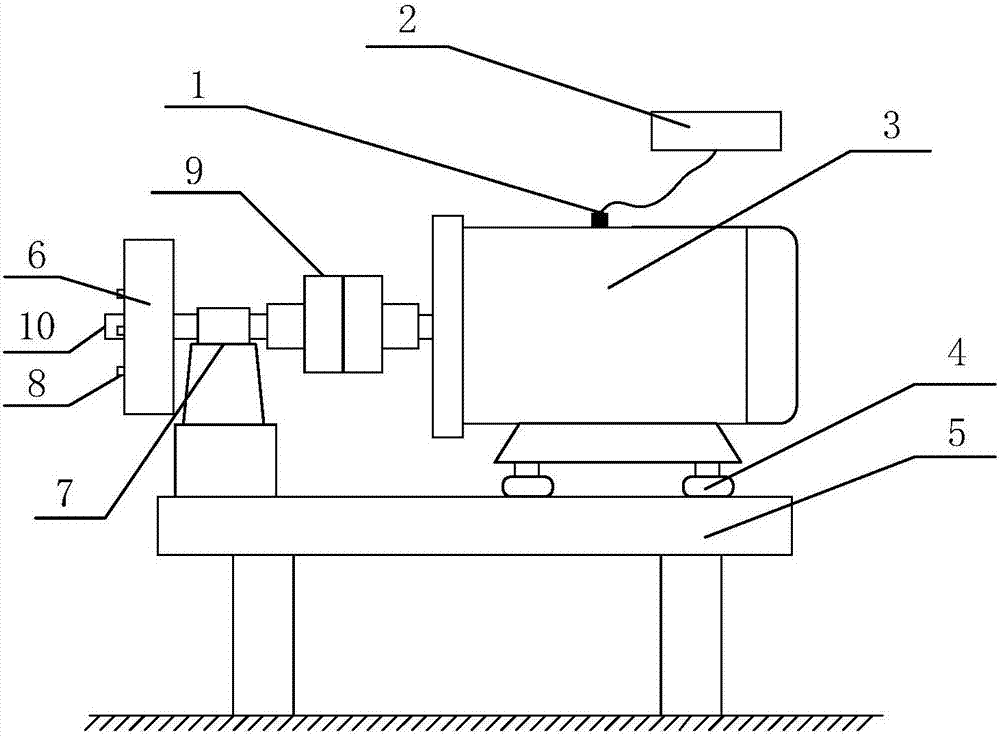

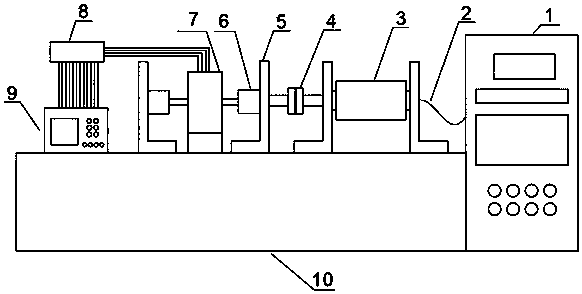

Servo motor test bench and test method

ActiveCN102109399AIntuitive test resultsThe test result is simpleWork measurementTorque measurementMotor testingControl theory

The invention relates to a servo motor test bench and a test method. The invention aims to provide a servo motor test bench which has high detection precision and is not related to the rotating speed of a motor, and a test method. The servo motor test bench comprises a test bench and a load motor mounted on the test bench; a rotor of the load motor is connected with a rotor of a to-be-tested servo motor; a stator of the to-be-tested servo motor is fixedly connected with the test bench; a stator of the load motor is movably connected with the test bench; and the test bench is also provided with a pressure sensor for detecting the rotation moment of the stator of the load motor. The servo motor test bench has the advantages that the torque change process of the to-be-tested servo motor can be detected when the to-be-tested servo motor is subjected to load change, the detection precision is not affected by the given velocity value, the requirement for the torque detection of the large-range speed value of the servo motor can be met, and the detection results are visual and brief.

Owner:菲仕绿能科技(北京)有限公司

High-rotation speed and large-torque brake motor test bench

InactiveCN105652203AEasy to install and debugEasy to analyze and studyDynamo-electric machine testingSystem design processDrive motor

The invention relates to a high-rotation speed and large-torque brake motor test bench. The motor shaft of a driving motor is connected with one end of a load rotation shaft through a first electromagnetic clutch; the other end of the load rotation shaft is connected with a motor to be tested through a coupling; a speed testing sensor, load flywheel discs and a torque sensor are sequentially connected onto the load rotation shaft from the driving motor to the motor to be tested; a variable-frequency and variable-speed motor is adopted as the driving motor; and the driving motor is connected with the load flywheel discs through the electromagnetic clutch. In the operating process of the system, dynamic disconnection can be realized, so that the influence of the kinetic energy of the rotor of the driving motor on a test can be eliminated; a computer transmits signals to a PLC according to rotational inertia required by the test, so that the electromagnetic clutch mechanism can be controlled. The maximum torque of the test bench can reach 2000N*m, and the maximum rotation speed of the test bench can reach 3500rpm. In the design process of the system, a computer control system simple and easy to operate is adopted, and a safe and reliable PLC interlocking detection system is adopted; and output data are processed by the computer, and an intuitive curve graph can be drawn, and therefore, the analysis research of product performance can be facilitated.

Owner:ANHUI WEINENG MOTOR

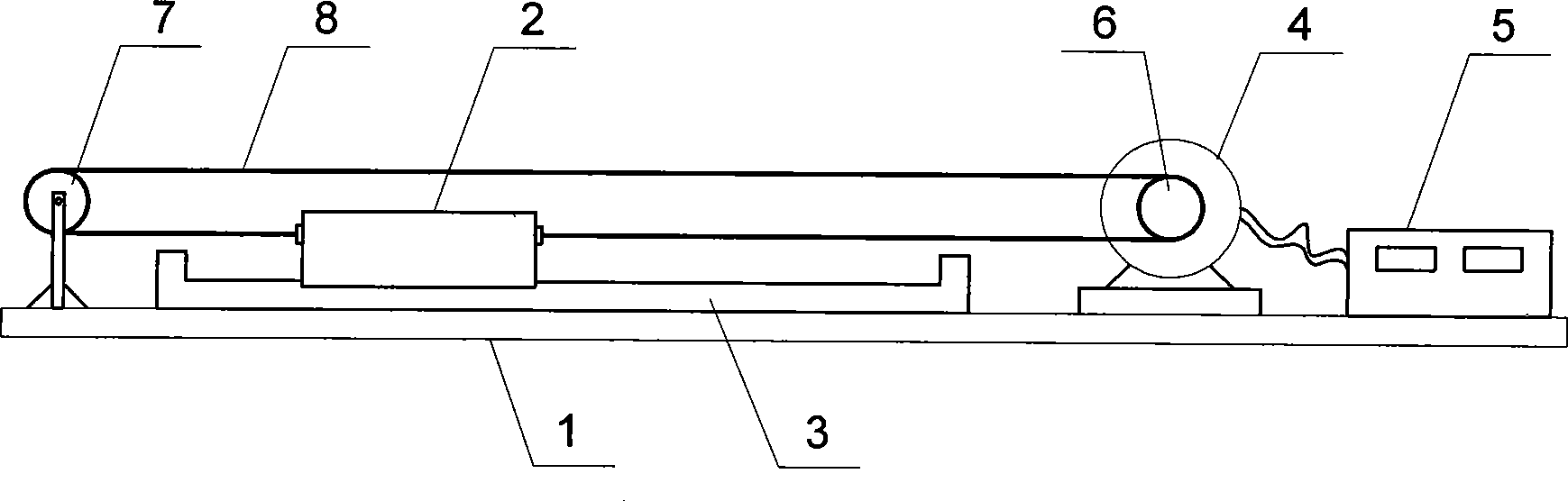

Novel motor test platform

InactiveCN101975924ARealize intelligenceMiniaturizationDynamo-electric machine testingMotor testingCoupling

The invention relates to a novel motor test platform, which comprises a stand, wherein a load is arranged on the stand; the load is connected with a tested motor through a coupler; the load is an eddy current loader; and torque, speed and power meters, torque and speed sensors and the automatic controller of the eddy current loader are arranged in the stand. The motor test platform overcomes the drawback that the common motor test platform can only test the parameters such as voltage and current of the tested motor and has difficulty in regulating the torque of the load and a large volume, and is intelligent and small and can be widely used.

Owner:JIANGSU HUIBO ROBOTICS TECH CO LTD

Asynchronous motor test system based on labview platform

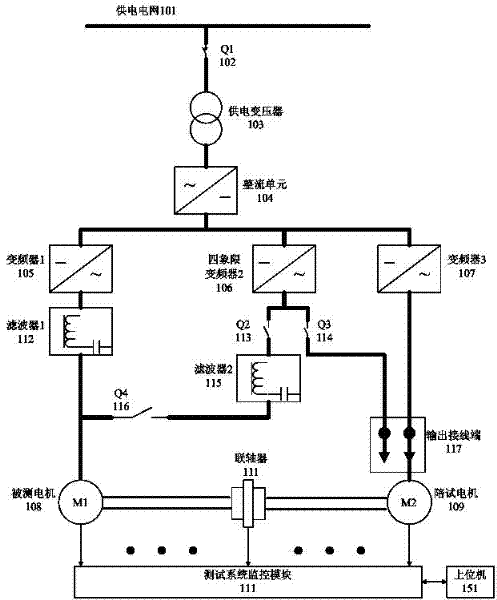

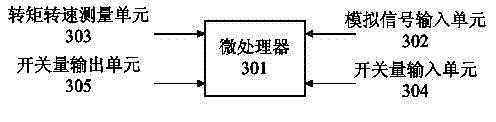

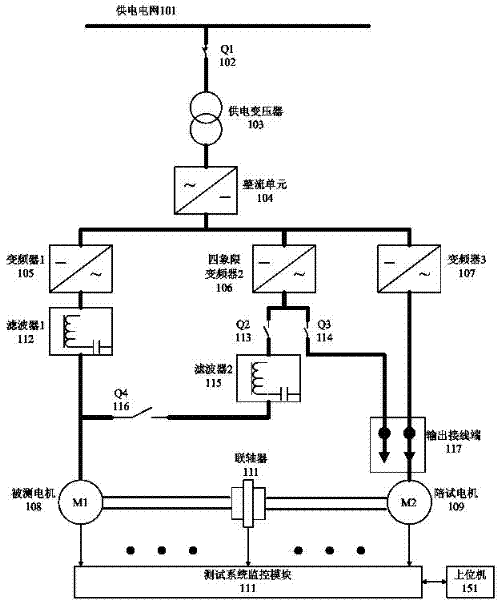

ActiveCN102520354AMeet the test requirementsImprove performanceVisual/graphical programmingDynamo-electric machine testingFrequency changerFour quadrants

The invention provides an asynchronous motor test system based on a labview platform. The system comprises a power supply transformer, a rectification unit, a frequency converter 1, a four-quadrant frequency converter 2, a frequency converter 3, a tested motor, an accompany test motor, and a test system monitoring module. The power supply transformer is connected with an electrical network. The rectification unit is connected with the frequency converter 1, the four-quadrant frequency converter 2, and the frequency converter 3. The frequency converter 1 is connected with a filter 1 and then is connected with the tested motor. The tested motor is connected with the accompany test motor through a coupler. The accompany test motor is connected with the four-quadrant frequency converter 2 or the frequency converter 3 according to an actual condition. The filter 1 and a filter 2 are connected through a parallel operation control unit. The test system monitoring module is used for monitoring state and performance parameters of the frequency converter, the test motor and the accompany test motor. Simultaneously, acquired data is sent to a host computer of the system, and functions of data real-time acquisition and processing, real-time display, storage playback, automatic determination and the like are realized. According to the test system, each performance test of an asynchronous motor in a wide power scope segment can be realized.

Owner:南通致远船舶设计有限公司

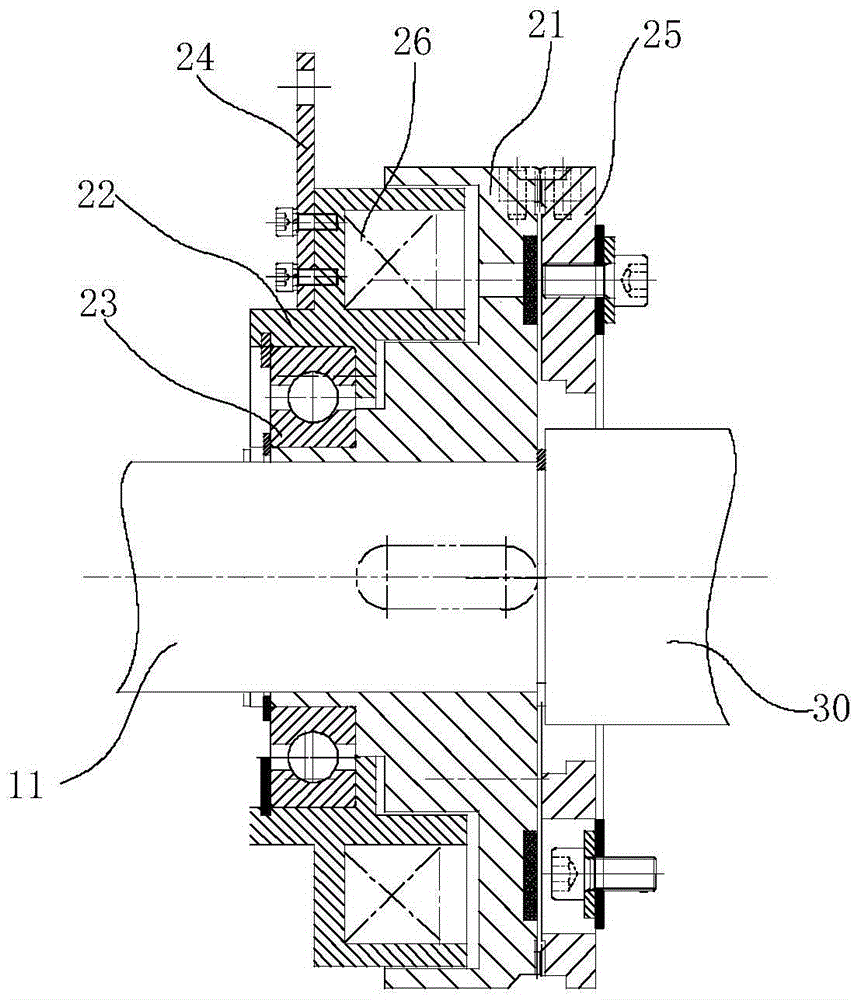

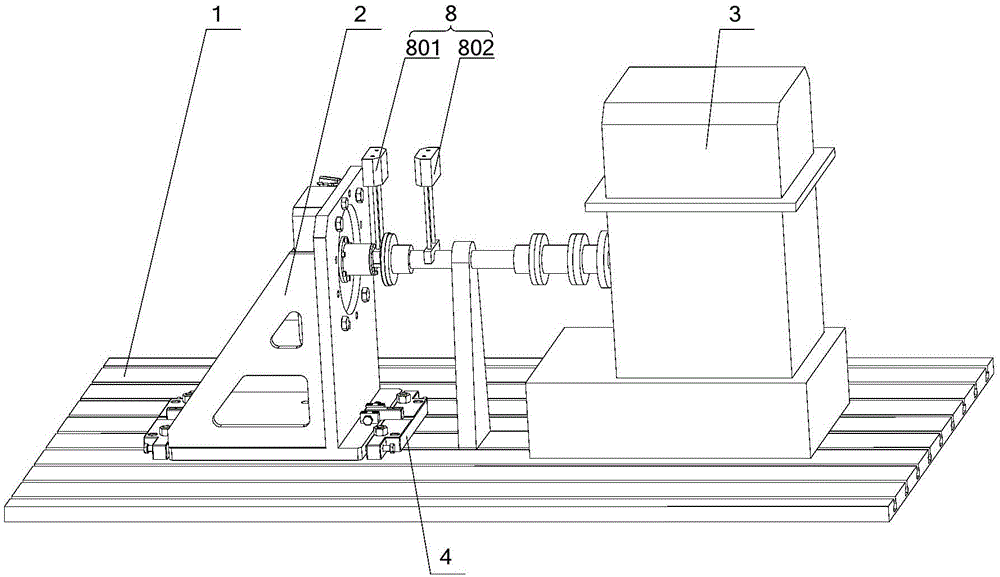

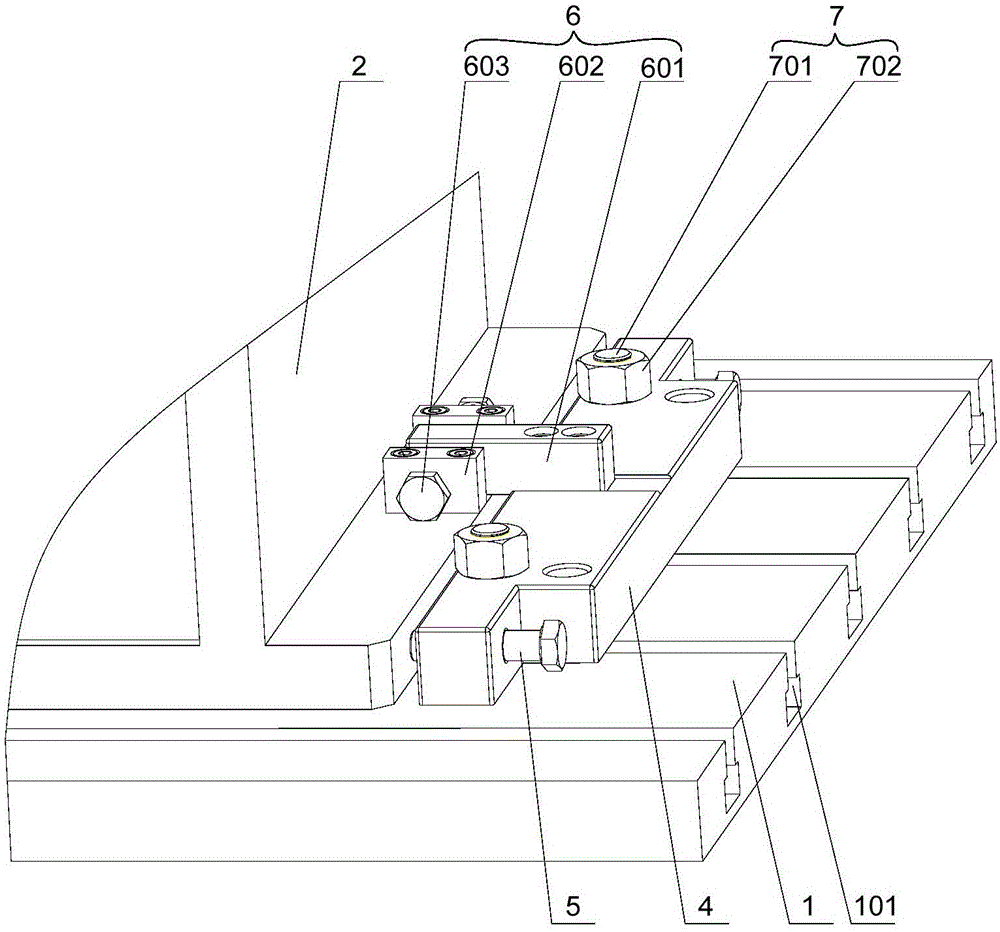

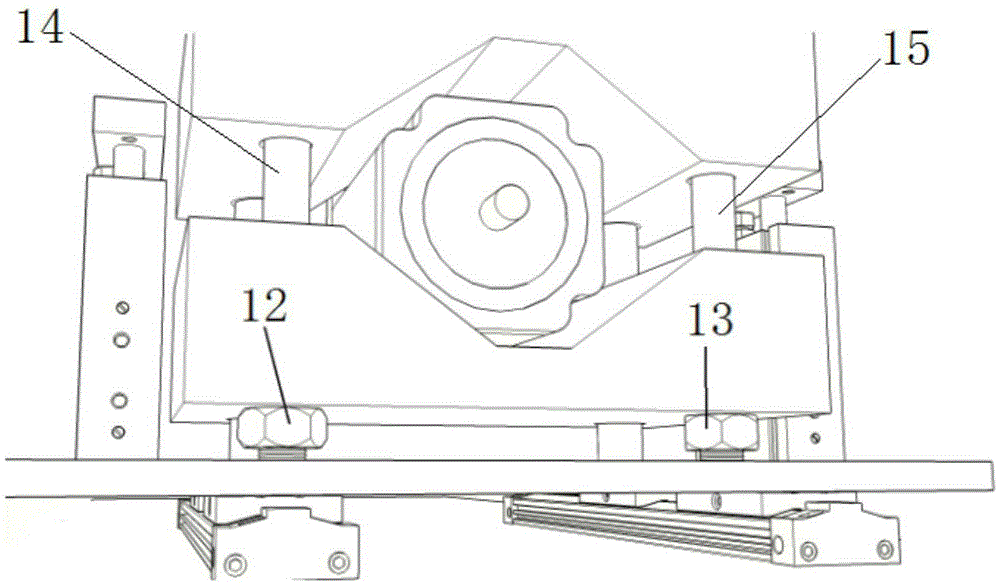

Motor test bench centering system

ActiveCN105021850AImprove operational efficiencyPrecisely control the amount of adjustmentUsing optical meansMeasurement instrument housingDynamometerControl theory

The invention discloses a motor test bench centering system, which comprises two sets of centering slight adjustment devices in matched connection with the front side and the rear side of a base of test tooling respectively. Each set of centering slight adjustment device comprises an adjustment support, a horizontal coaxiality adjustment assembly, and a vertical coaxiality adjustment assembly, wherein the first part of the horizontal coaxiality adjustment assembly is fixed on the adjustment support, the second part is fixed on the test tooling, and the first part and the second part are matched for adjusting the position of the test tooling along the radial direction of the output shaft of the test tooling in a horizontal plane; the vertical coaxiality adjustment assembly is fixed on the adjustment support and can be in supporting connection onto the bottom part of the test tooling for adjusting the position of the test tooling in the vertical direction. According to the motor test bench centering system, the horizontal coaxiality adjustment assemblies and the vertical coaxiality adjustment assemblies of the two sets of centering slight adjustment devices carry out slight adjustment on the horizontal coaxiality and the vertical coaxiality between the output shaft of the test tooling and the output shaft of a dynamometer, the position adjustment amount can be precisely controlled, centering operation is simplified, and the centering efficiency is improved.

Owner:深蓝汽车科技有限公司

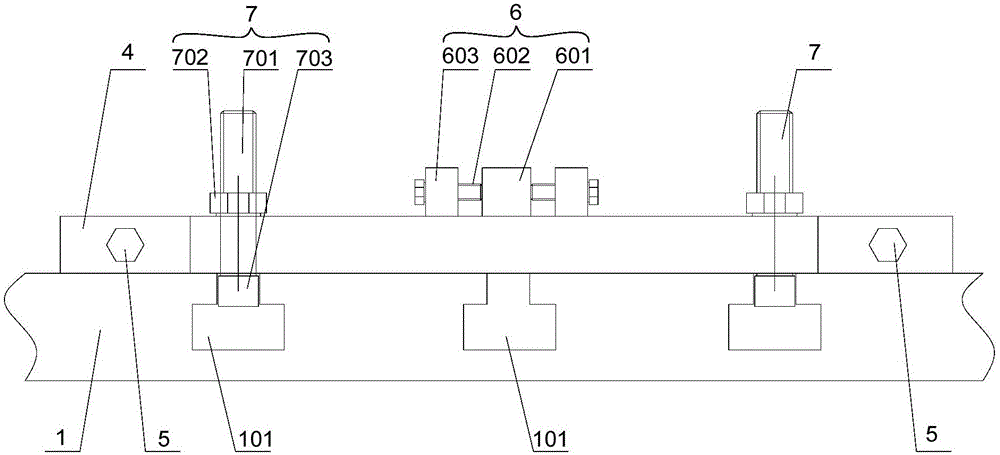

Method for testing partial performances of three-phase asynchronous motors

InactiveCN101629860ALow costReduce consumptionStatic/dynamic balance measurementWork measurementElectric machineThree phase asynchronous motor

The invention provides a method for testing partial performances of three-phase asynchronous motors, which is mainly applied to the factory test and after-maintenance test on three-phase asynchronous motors, and can also be used for the quick verification of newly designed technical schemes for motors. The method comprises the steps of utilizing the inherent no-load operation characteristic of a three-phase asynchronous motor to measure the rotation inertia of a tested motor rotor and measuring the torque, output power, efficiency and other partial parameter indexes of the motor according to the change of the corresponding instantaneous speed of the rotor in different states and the operation parameters of the motor, thereby leaving out the part of applying analog load in the prior motor test method.

Owner:赵健身

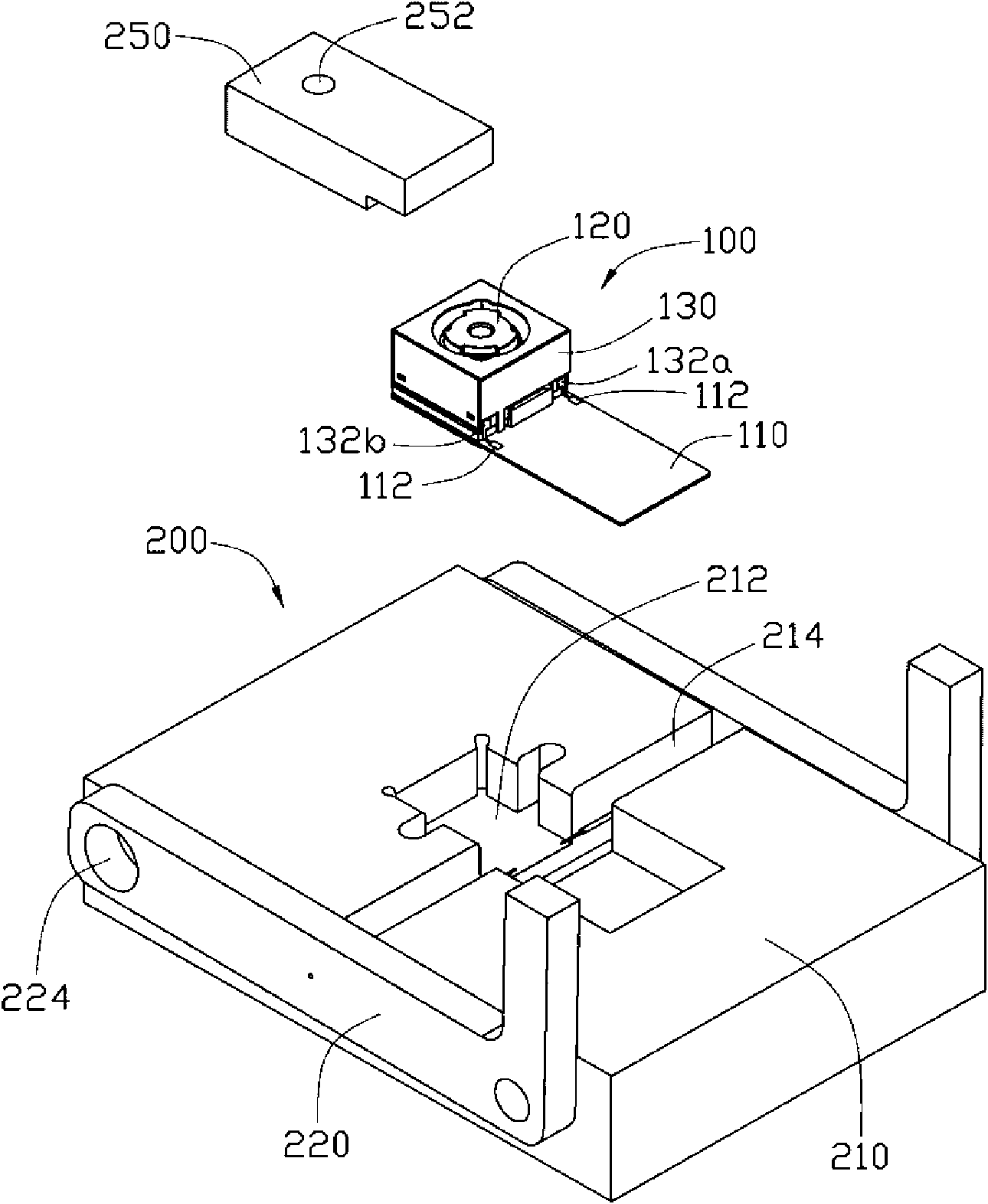

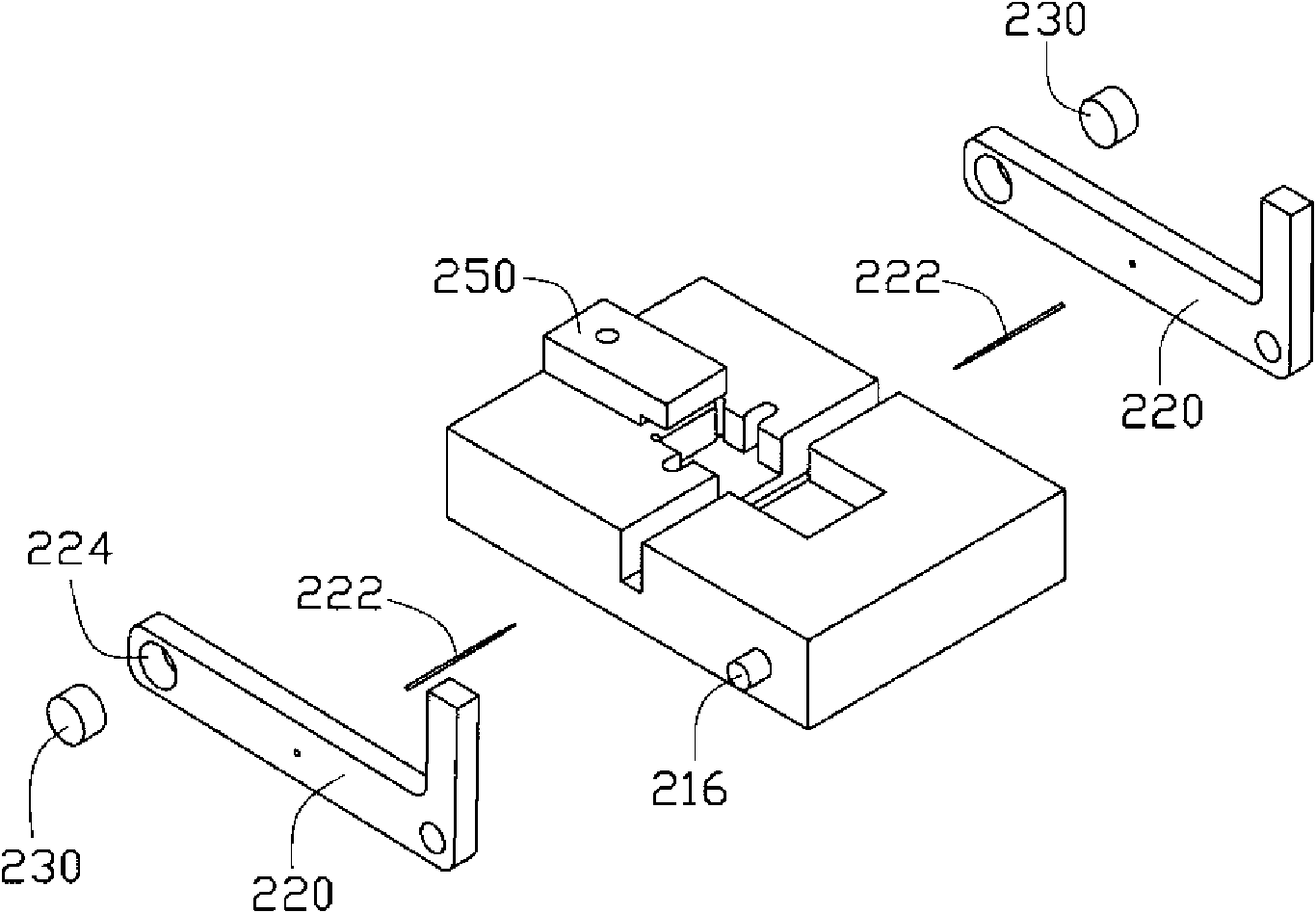

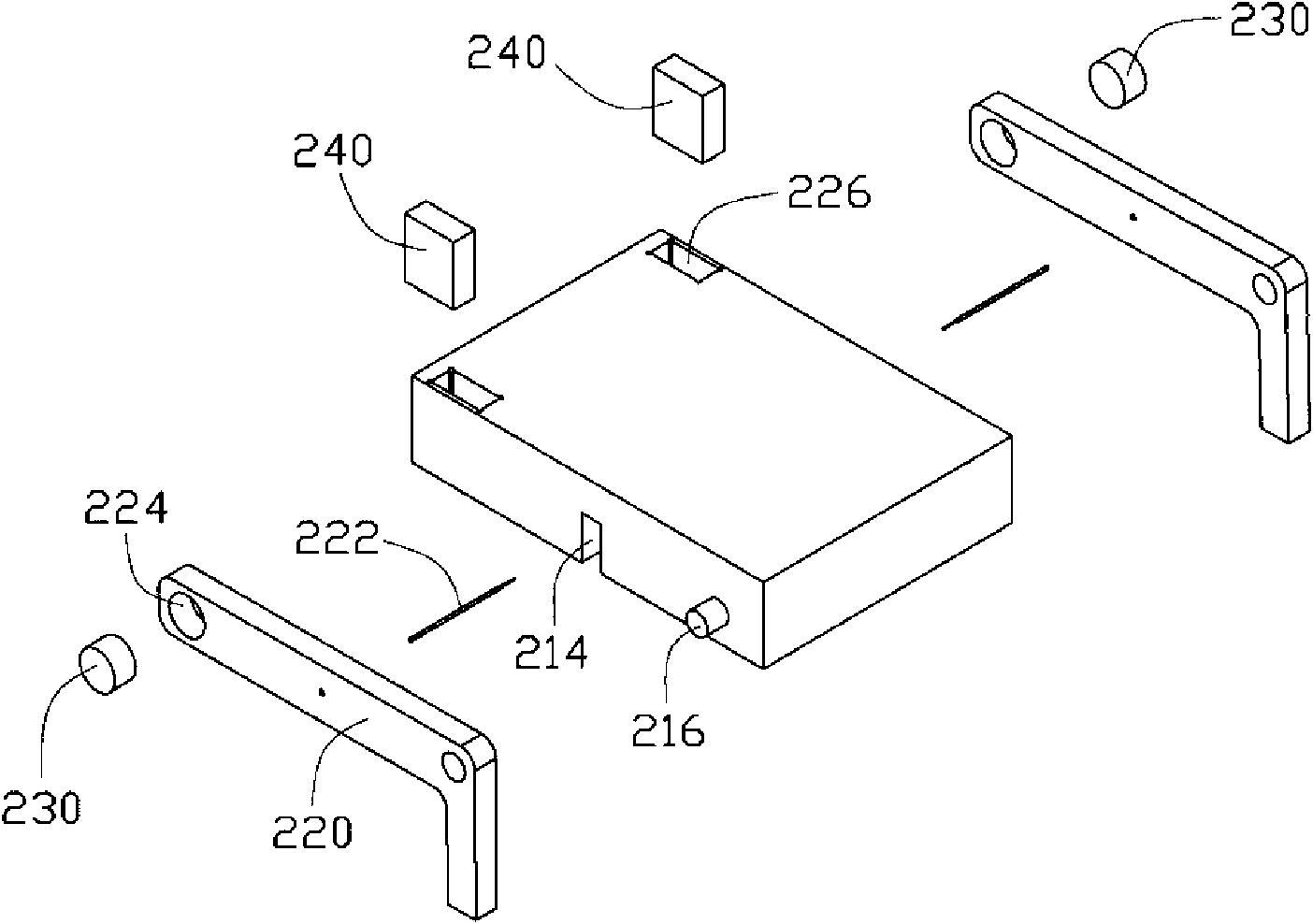

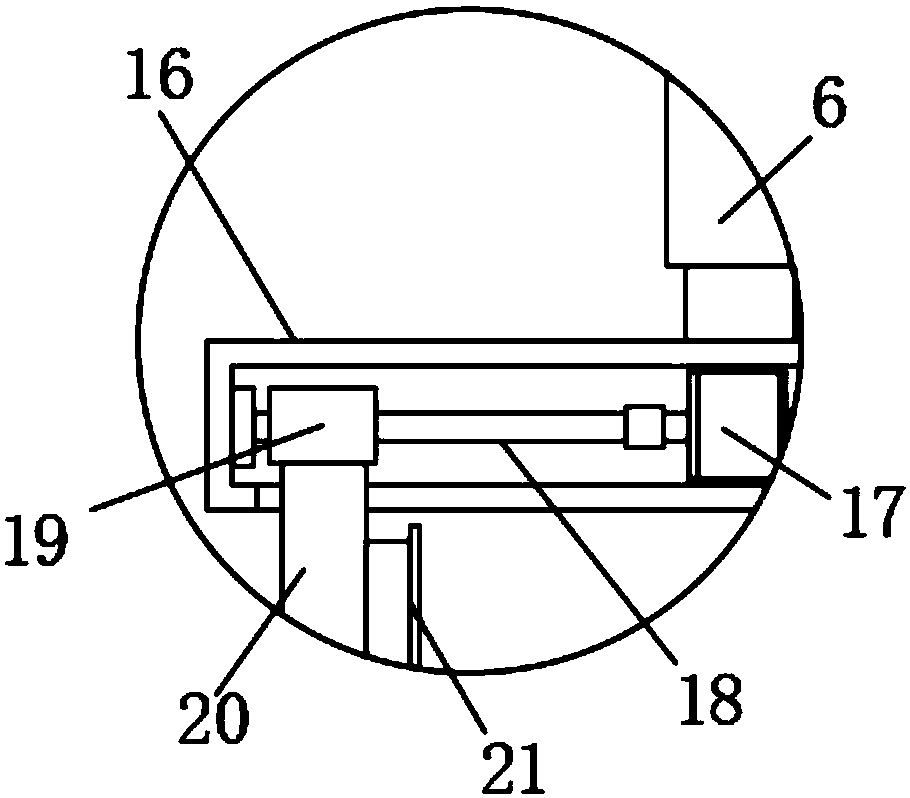

Voice coil motor testing device and auxiliary device thereof

The invention provides a voice coil motor testing device comprising a pedestal and two probe seats, wherein the pedestal is provided with a first containing slot used for containing a voice coil motor and a groove communicated with the first containing slot; the groove extends towards two sides of the pedestal from the first containing slot; the two probe seats are respectively pivoted to two sides of the pedestal, where the groove is arranged; and each probe seat is provided with a probe which can be embedded or be far away from the groove relative to the rotation of a pivot along with the probe seat, thereby respectively contacting or being far away from the current input end and the current output end of the voice coil motor to be tested and realizing power-on or power-off control on the voice coil motor. The voice coil motor testing device also comprises a range finder used for measuring the moving distance of the electrified voice coil motor and comparing the distance with a standard value.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

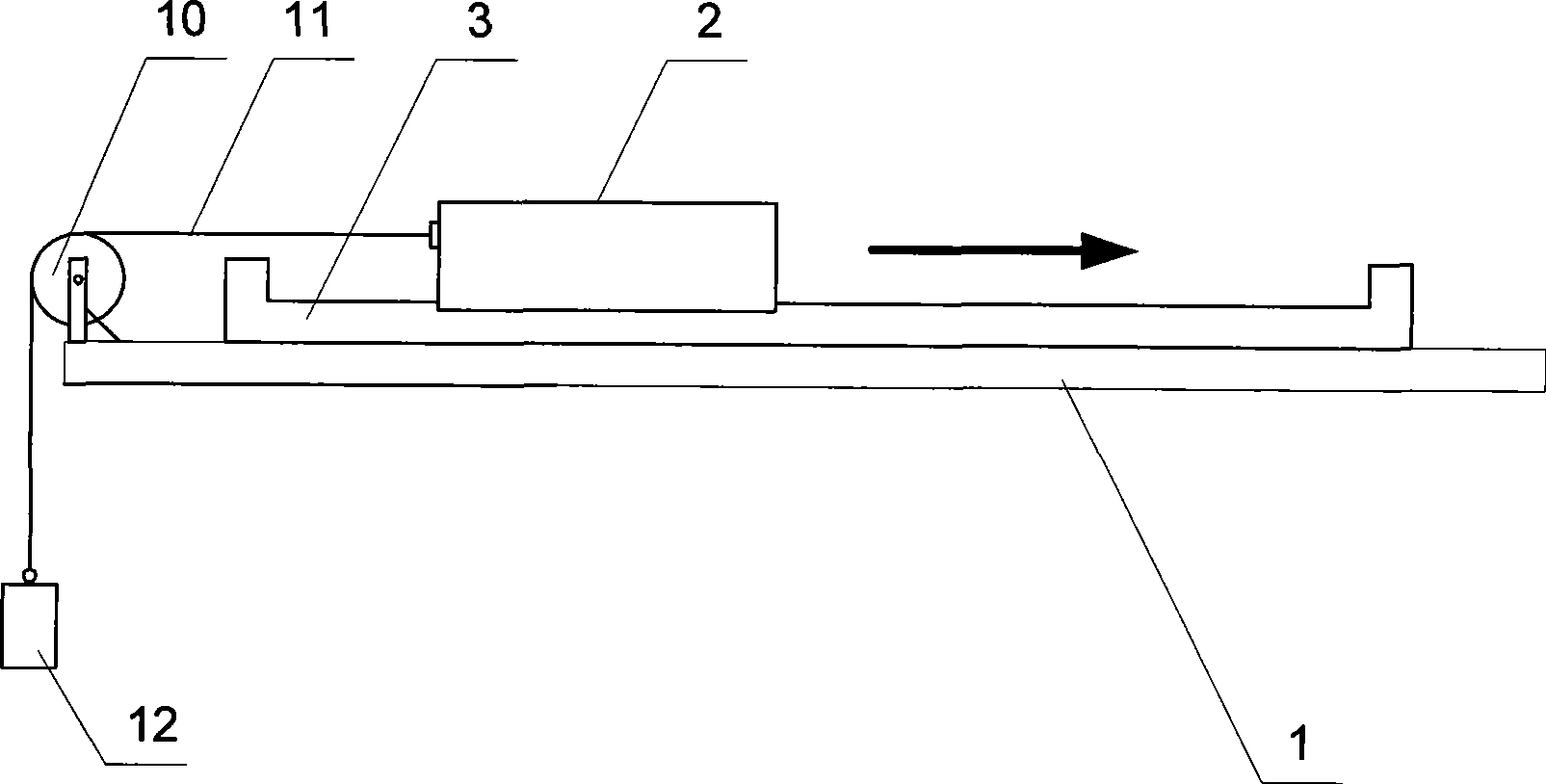

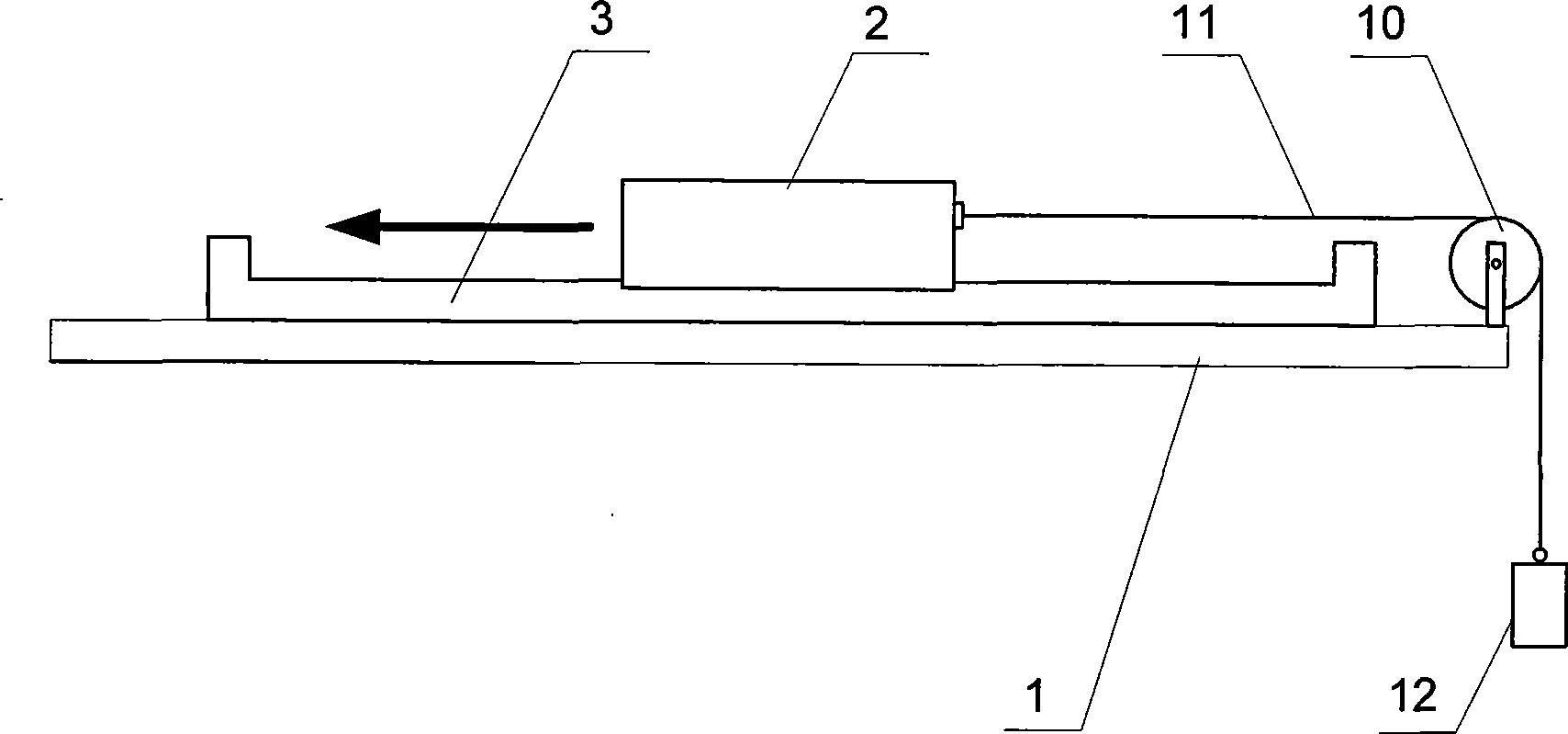

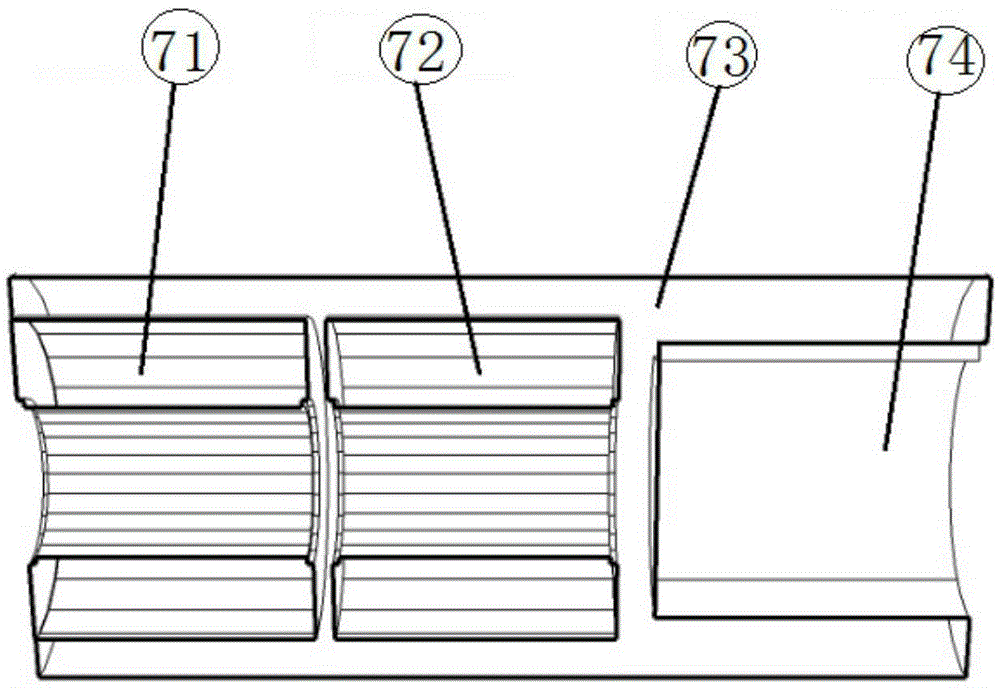

Device for testing constant thrust load of continuous linear motor

InactiveCN101520353AImplement two-way testingEfficient deliveryApparatus for force/torque/work measurementElectric machineLinear motor

The invention relates to a device for testing the constant thrust load of a continuous linear motor, belonging to the field of motor test and aiming to solve the problems of one-way measurement, complicated measuring process and poor precision of a tester which adopts loaded weights to test the constant thrust of the linear motor. The device for testing the constant thrust load of the continuous linear motor comprises a test platform, the linear motor, a magnetic powder brake, a direct current supply, a first synchronizing wheel, a second synchronizing wheel and a synchronizing belt, wherein the linear motor comprises a linear motor mover and a linear motor rotor and is arranged on the test platform and between the first synchronizing wheel and the second synchronizing wheel; one end of the test platform is provided with the magnetic powder brake, and an output shaft of the magnetic powder brake is fixedly connected with the first synchronizing wheel; both ends of the synchronizing belt are respectively connected with both ends of the mover of the linear motor, the mover of the linear motor drives the first synchronizing wheel and the second synchronizing wheel to rotate by the synchronizing belt, and the direct current supply provides the magnetic powder brake with direct current. The tester is used for measuring the constant thrust of the linear motor.

Owner:HARBIN INST OF TECH

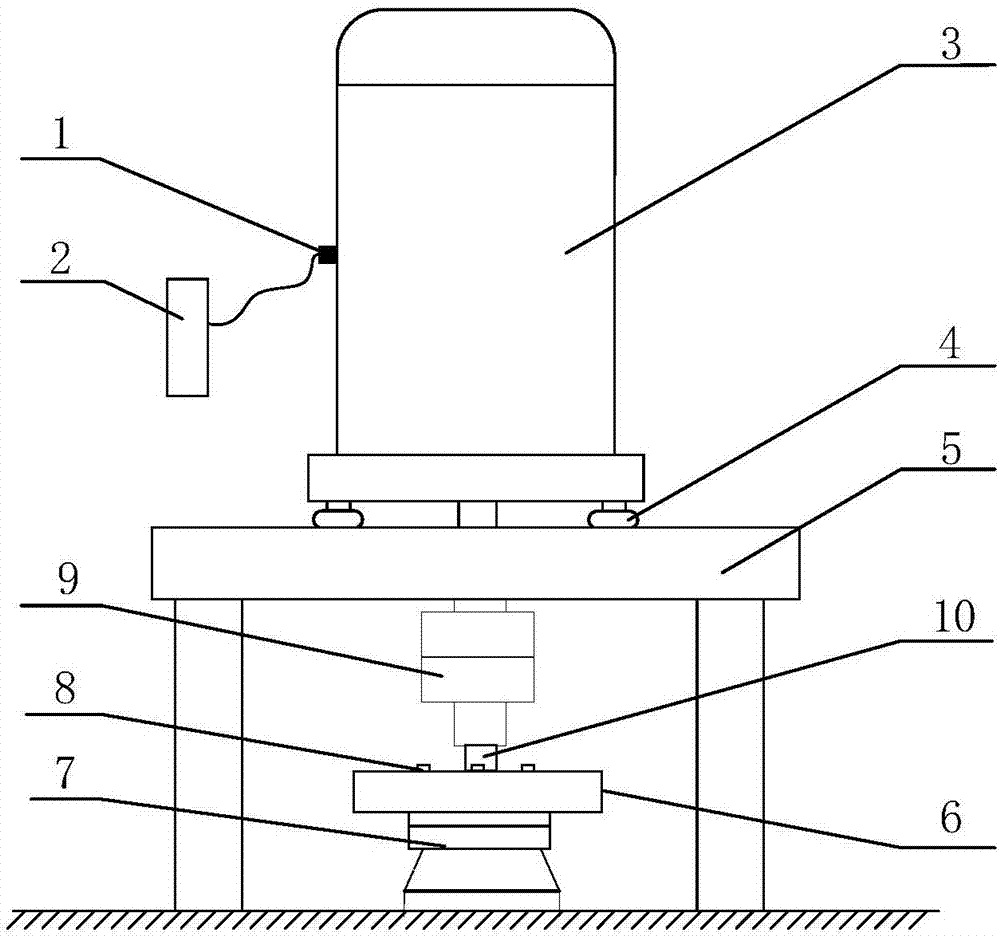

Suspended cushion static and dynamic rigidity test system and method

ActiveCN107631886AImprove vibration and noise comfort levelImprove efficiencyVehicle suspension/damping testingElasticity measurementEngineeringForce sensor

The invention relates to the technical field of engine test equipment and particularly relates to a suspended cushion static and dynamic rigidity test system and method. According to the test system,a work station and a fixed tool are oppositely arranged, the work station is sequentially provided with a static force sensor and a dynamic force sensor, the dynamic force sensor and the fixed tool are oppositely clamped at two ends of a to-be-tested suspended cushion, the work station can move relative to the fixed tool to drive the static force sensor and the dynamic force sensor to sequentiallyextrude the suspended cushion, the vibration direction of the work station is perpendicular to the moving direction, through extruding the suspended cushion by the work station for multiple times, static rigidity detection on the suspended cushion is carried out, after the suspended cushion is extruded to the pre-compressed position, dynamic rigidity detection on the suspended cushion is carriedout through multi-time vibration of the work station. The system is advantaged in that static rigidity detection and dynamic rigidity detection can be realized through one-time test, and efficiency and accuracy of static rigidity detection and dynamic rigidity detection of the suspended cushion are improved.

Owner:WEICHAI POWER CO LTD

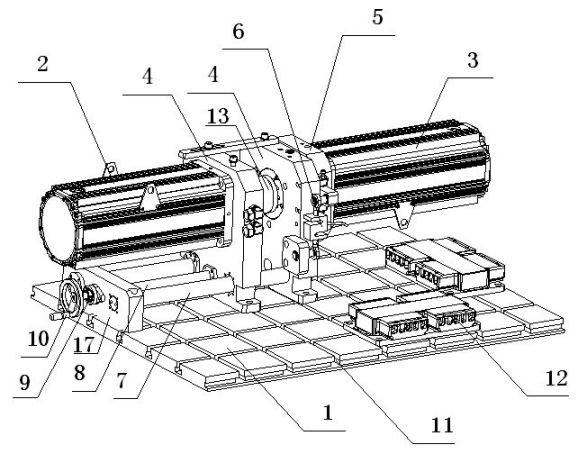

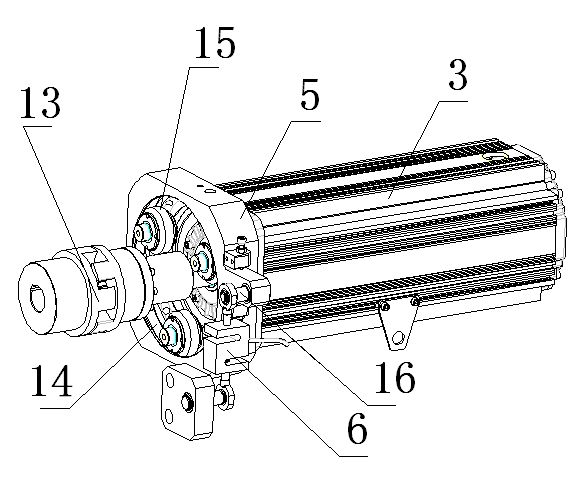

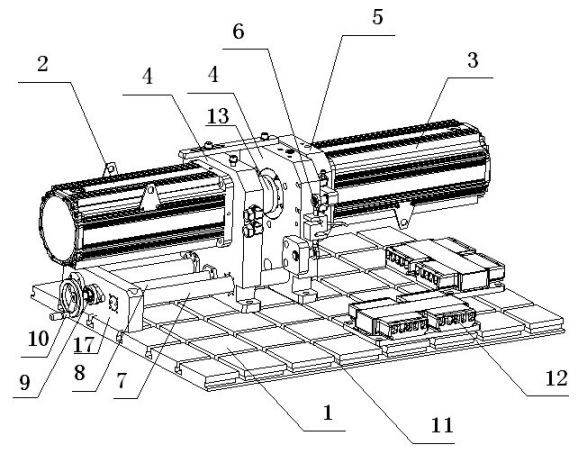

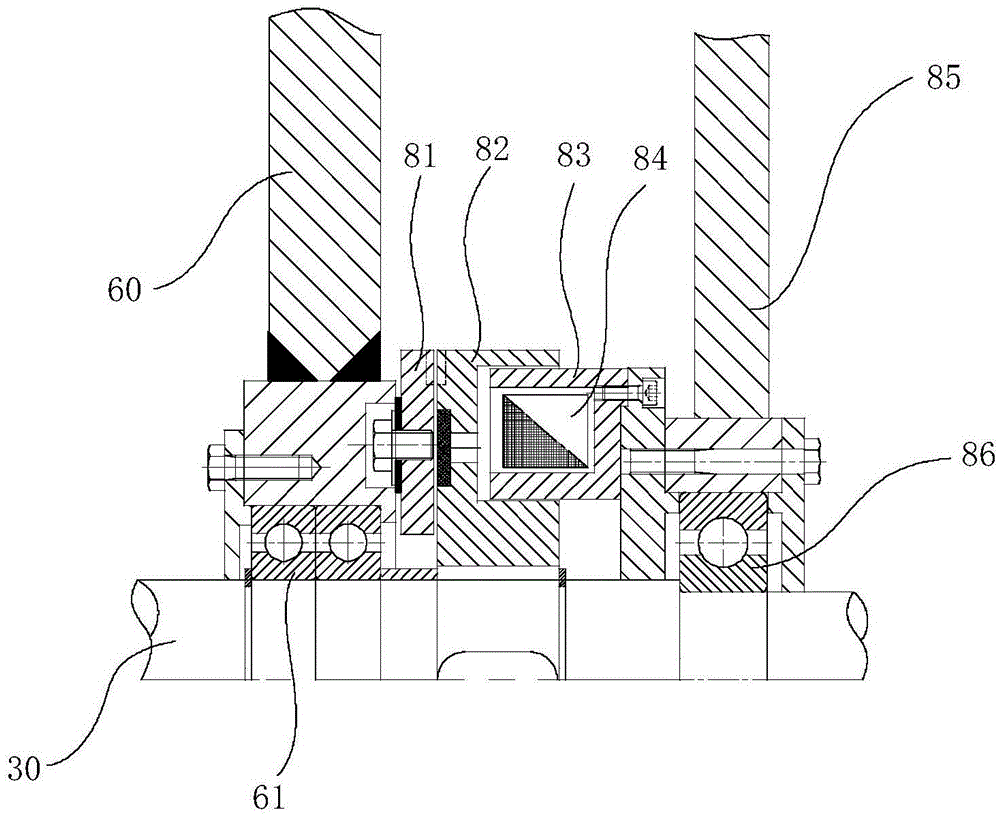

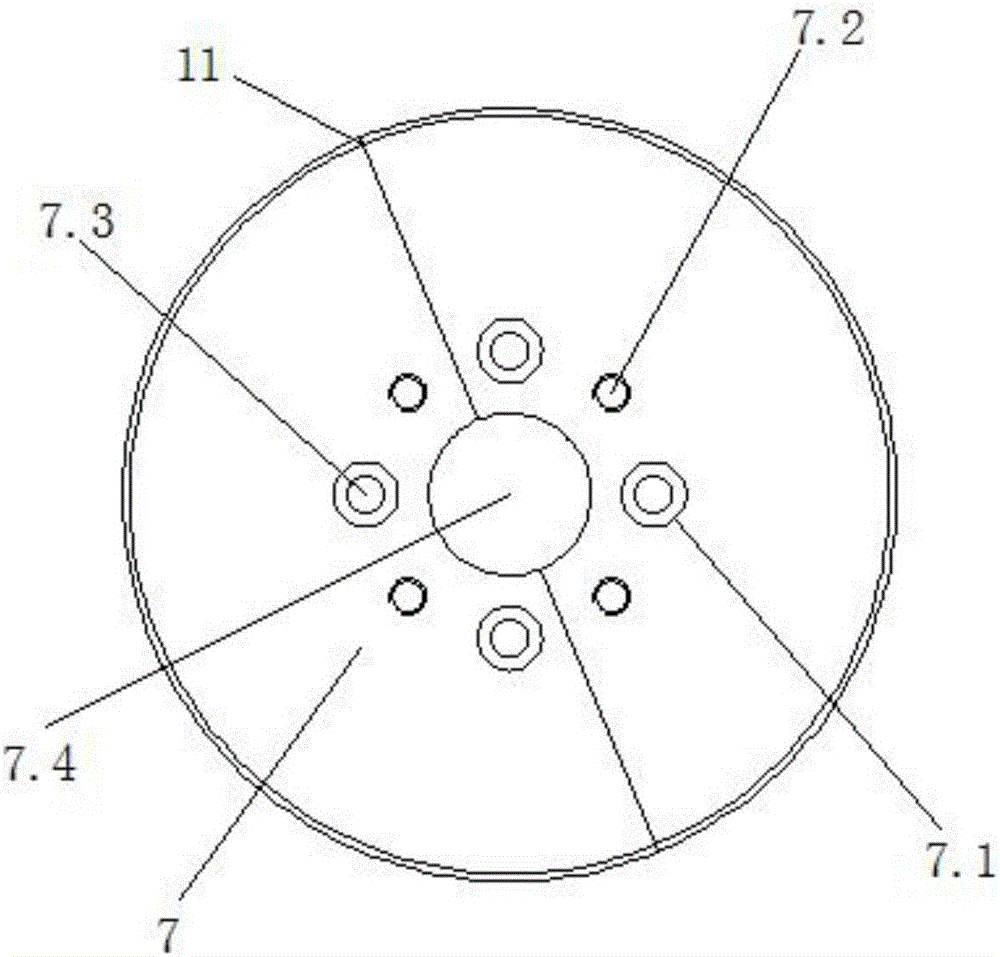

Automatic rapid clamping device for motor tests and use method of automatic rapid clamping device

InactiveCN105353308AQuick clampingSolve the problem of the precise rotation angle of the assembled motor shaftMeasurement instrument housingDynamo-electric machine testingCouplingEngineering

The invention relates to an automatic rapid clamping device for motor tests. The automatic rapid clamping device comprises a substrate platform as well as an adjustable motor fixing module and an arbitrary angle inserting shaft connecting structure which are arranged on the substrate platform, wherein the adjustable motor fixing module includes a V-shaped locking block lower structure and a V-shaped locking block upper structure which are used for locking a motor; the automatic rapid clamping device further comprises a locking block pushing plate, a pulling and clamping functional air cylinder, an adjustable motor fixing module substrate and pneumatic slide stage guide rails; the adjustable motor fixing module is provided with a guide column A and a guide column B which are vertical to the adjustable motor fixing module substrate; the arbitrary angle inserting shaft connecting structure includes an arbitrary angle inserting shaft connecting shaft, a bearing flange, a coupling and a load device, wherein the arbitrary angle inserting shaft connecting shaft is composed of a first one-way bearing, a second one-way bearing, a shaft sleeve and a keyway type shaft hole; the arbitrary angle inserting shaft connecting shaft is installed in the bearing of the bearing flange; one end of the arbitrary angle inserting shaft connecting shaft is assembled on the coupling, and therefore, the transmission of torque can be realized; and the coupling and the load device are fixed on the bearing flange.

Owner:昆山凯捷特电子研发科技有限公司

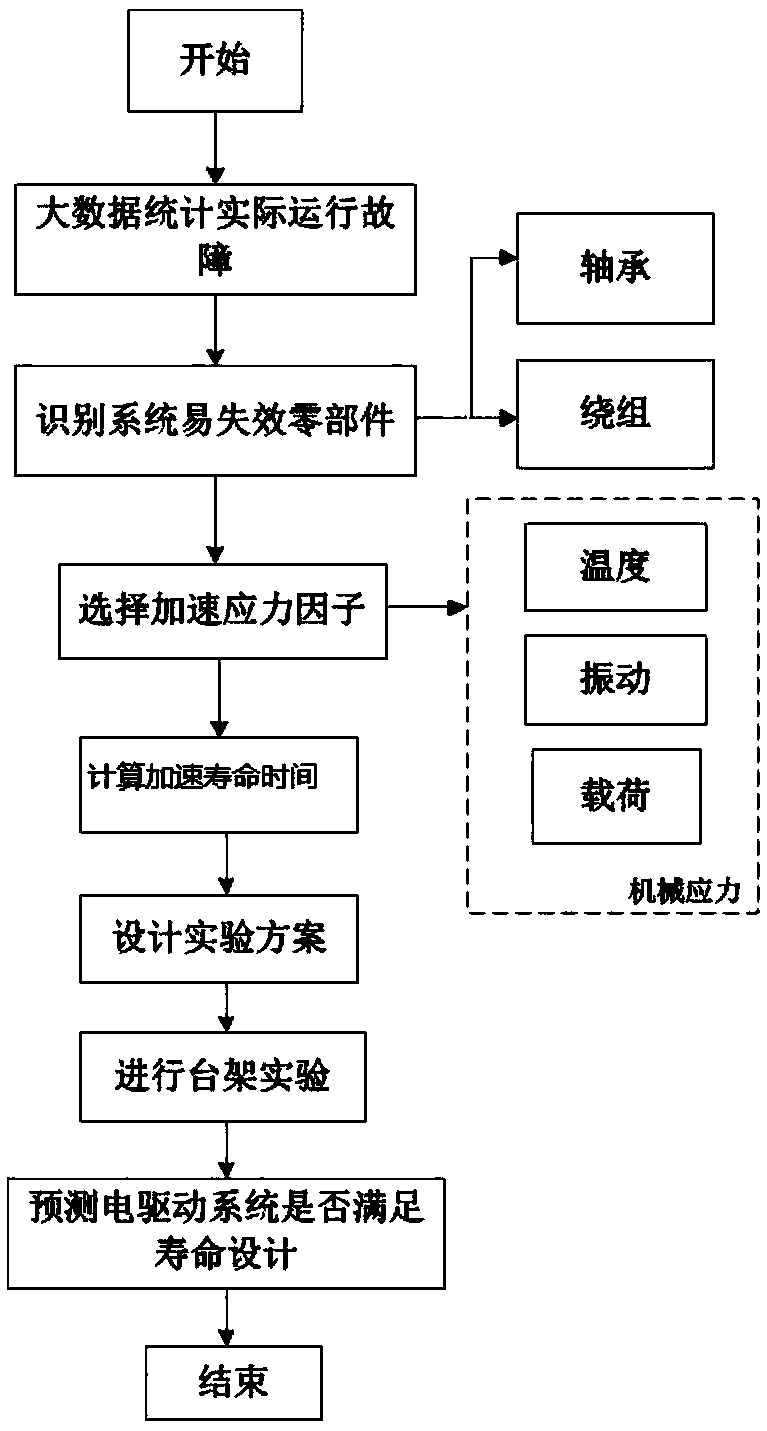

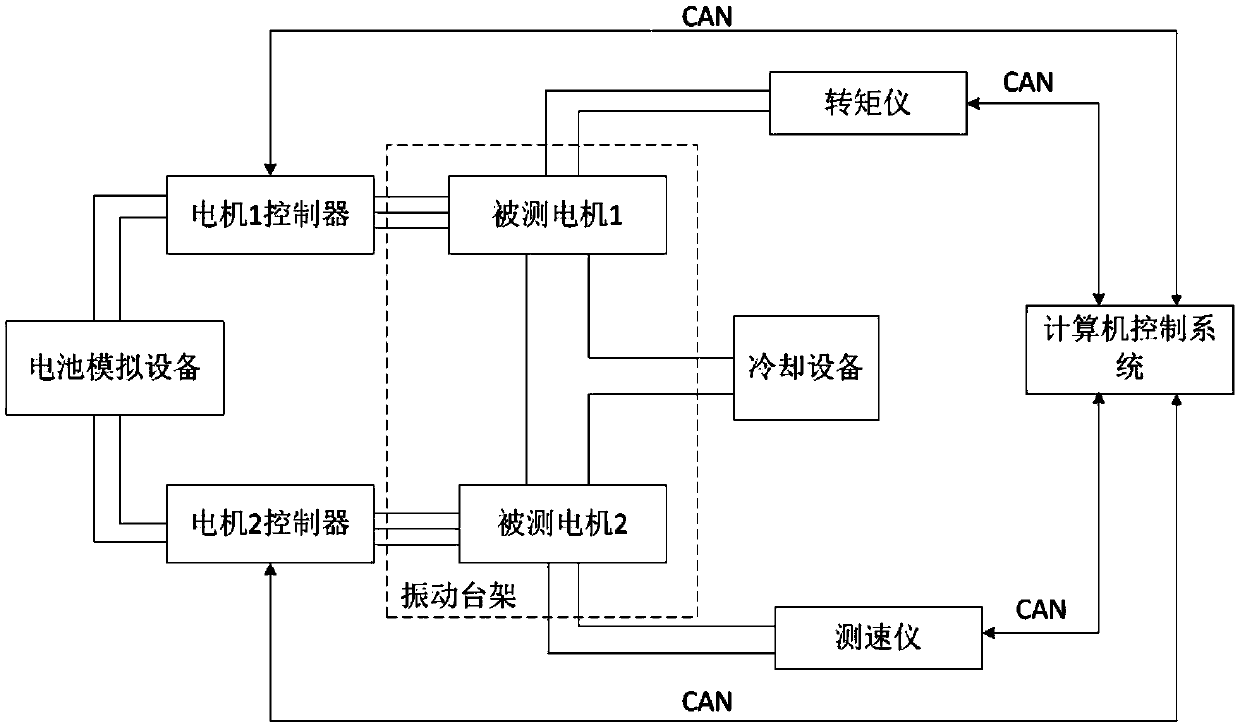

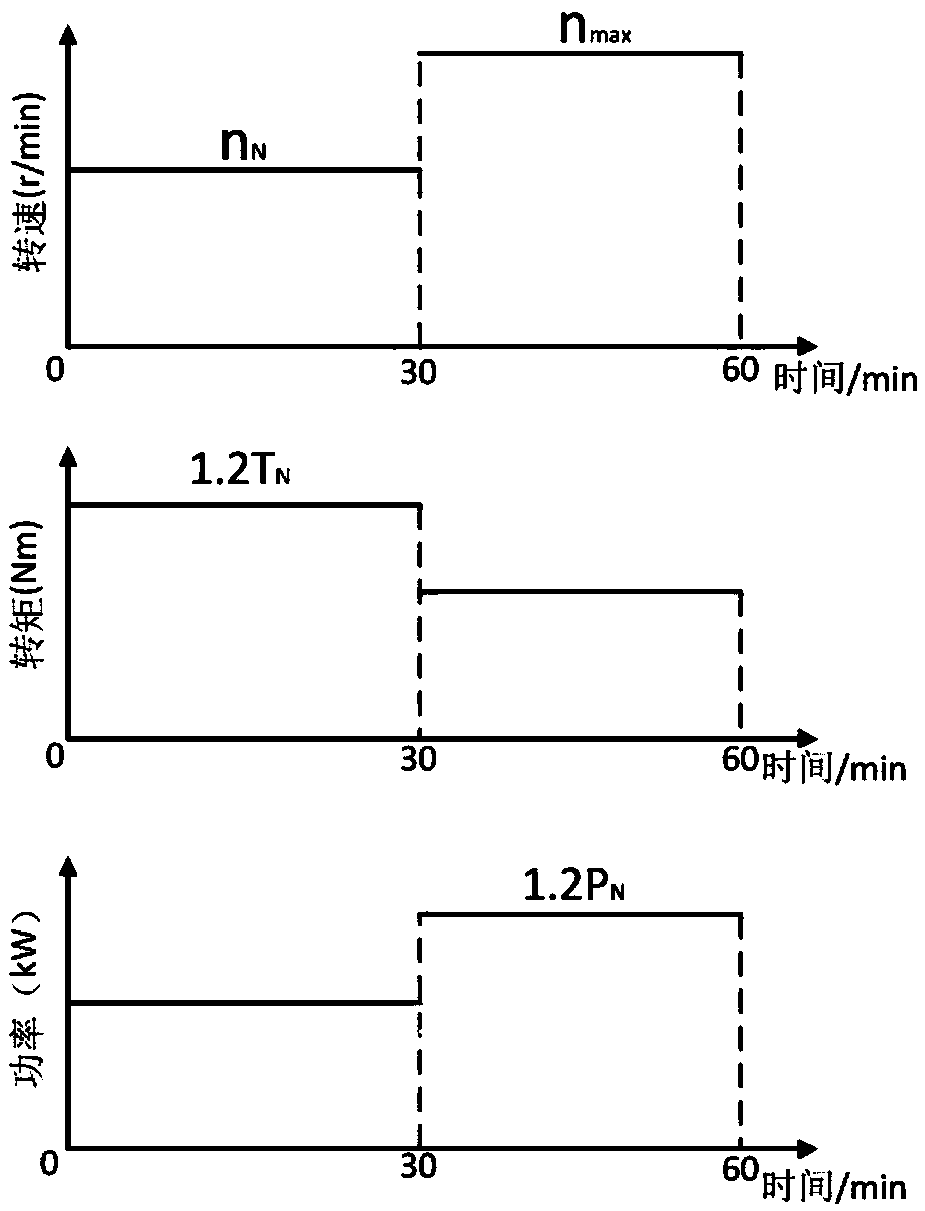

Motor accelerated lifetime test method and system

The invention provides a motor accelerated lifetime test method and system. The motor accelerated lifetime test method comprises the steps of firstly, selecting a bearing as a factor of affecting motor lifetime, and calculating conventional lifetime test time of the bearing; secondly, calculating a factor acceleration factor according to an equivalent dynamic load borne by the bearing, a motor rotational speed and acceleration power spectrum density; thirdly, calculating accelerated lifetime test time of the bearing; and finally, loading a parameter required by motor test, applying vibration load spectrum, allowing a to-be-measured motor to continuously run within the accelerated lifetime test time for accelerated lifetime test, and judging whether the to-be-measured motor is in failure ornot. By the motor accelerated lifetime test method, a vibration factor generated during the vehicle running process is considered, so that the accelerated lifetime test is more approximate to a realcondition, and the motor lifetime test time can be reduced; and the motor lifetime can be accurately obtained, a relevant person is convenient to timely acquire the motor lifetime, a new motor is replaced in advance when the motor lifetime is almost ended, so that normal running of the whole running is ensured.

Owner:ZHENGZHOU YUTONG BUS CO LTD

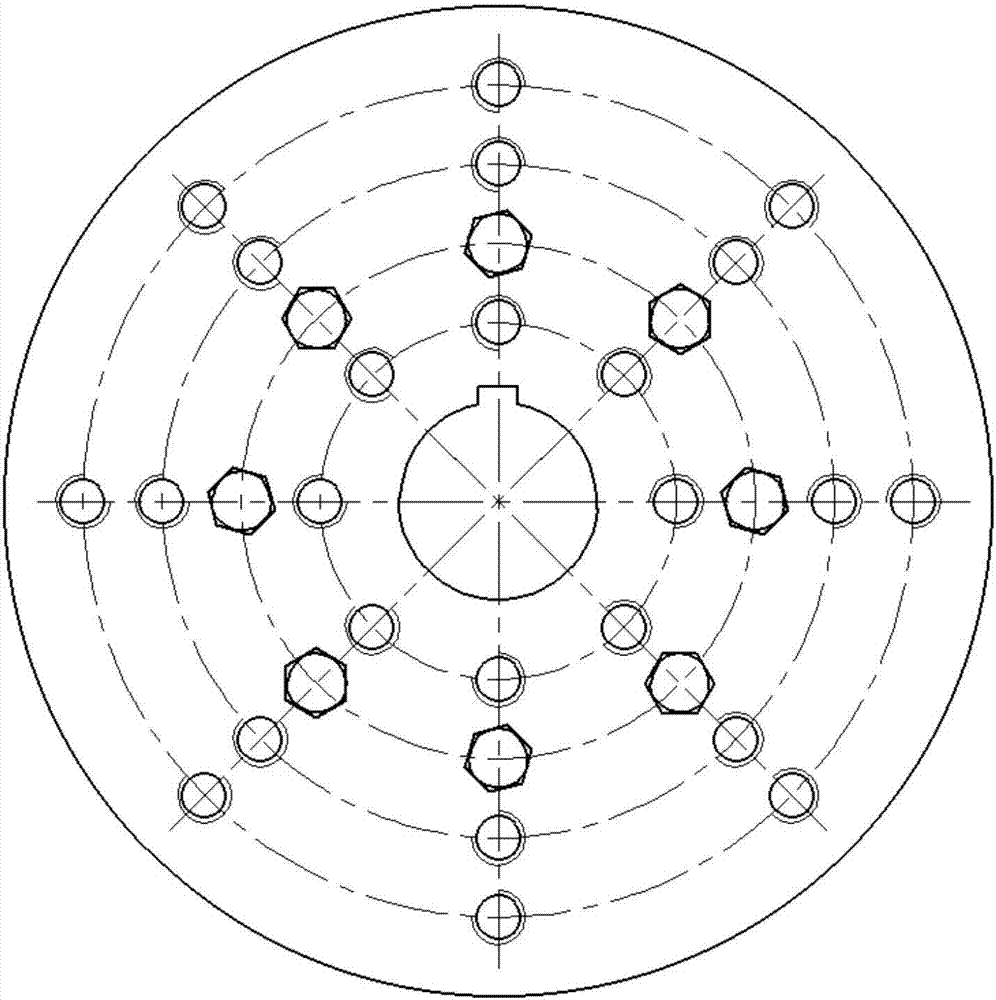

Motor vibration characteristic frequency detection device and method

ActiveCN107246948ASmall impact of test vibrationEliminate the problem of inaccurate judgment caused by excessive frequency offsetVibration testingMotor testingControl theory

The invention provides a motor vibration characteristic frequency detection device. The device comprises a mounting base, a flywheel disk, counterweight mass blocks, an air flotation bearing, a flexible coupling, a carrying shaft, an acceleration sensor, a vibration test analyzer and a vibration isolator; a motor is mounted on the mounting base through the vibration isolator; the shaft of the motor is connected with the carrying shaft through the elastic coupling; the carrying shaft is supported by the air flotation bearing; the carrying shaft is provided with the flywheel disk; inertia adjustment holes are evenly distributed in the flywheel disk along a radial direction; the counterweight mass blocks are installed in the inertia adjustment holes; and the acceleration sensor is mounted on the outer surface of the motor and is connected with the vibration test analyzer through a wire. The motor vibration characteristic frequency detection device of the invention has the advantages of convenient installation and adjustment, low test cost, long sampling time, fast separation, adjustable load inertia and high repeatability. The influence of external vibration on motor test vibration is small; and an electromagnetic excitation frequency and a natural frequency can be detected and separated out with only one-time signal continuous acquisition required.

Owner:HARBIN ENG UNIV

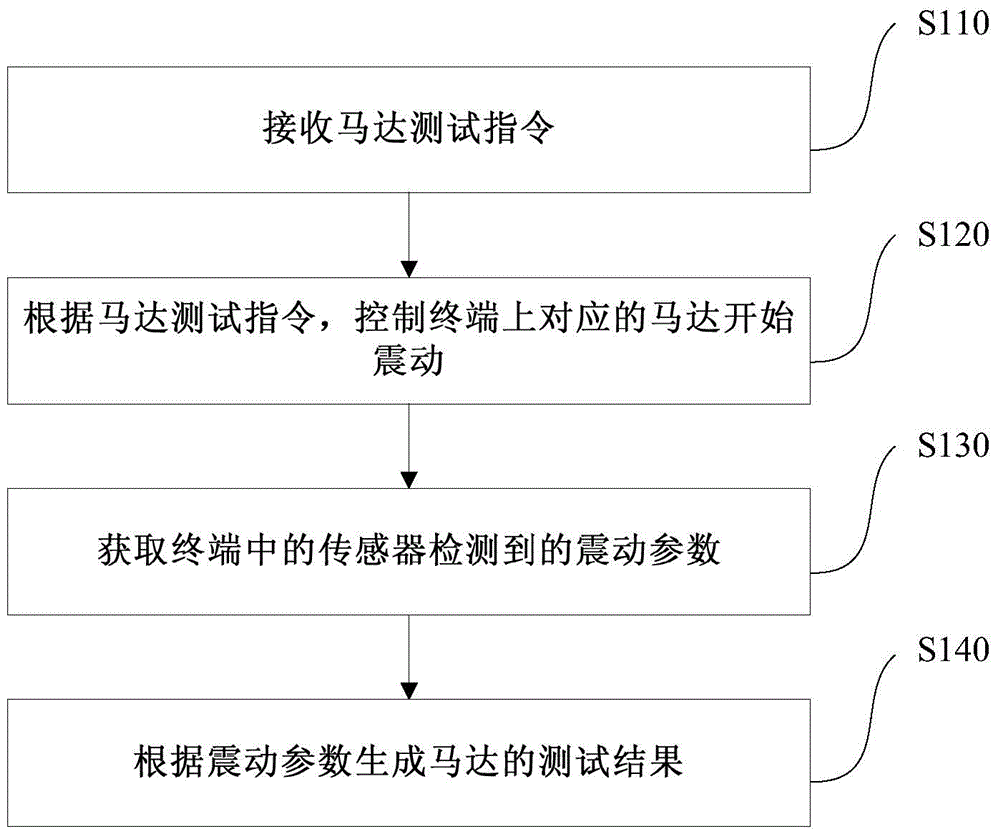

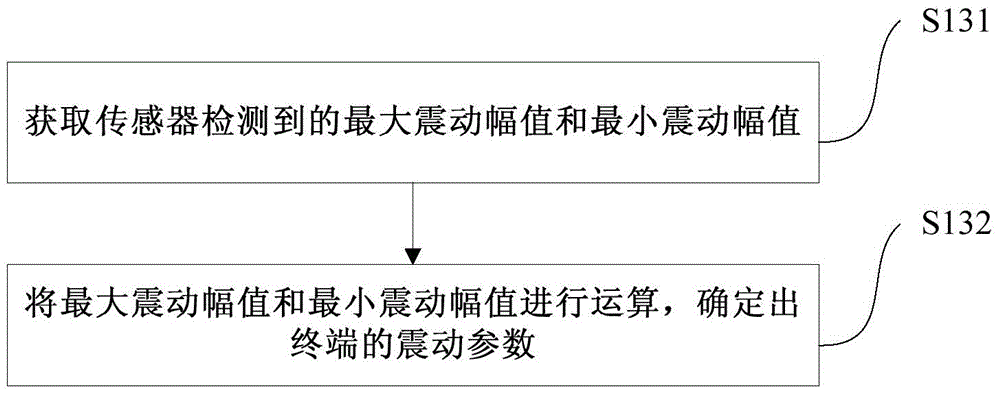

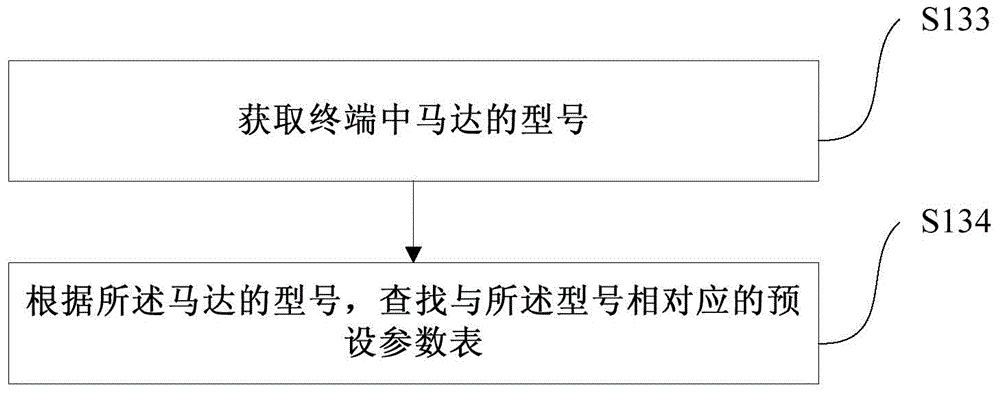

Terminal motor test method and device

ActiveCN106154158AAccurate judgmentAvoid problems that cause lower test accuracySubsonic/sonic/ultrasonic wave measurementDynamo-electric machine testingVisual inspectionComputer terminal

The present invention provides a terminal motor test method and device, which is applied to a mobile terminal. The method comprises: receiving a motor test instruction; controlling the shocking of the corresponding motor on the terminal according to the motor test instruction; obtaining the shock parameters detected by a sensor in the terminal; and generating the test result of the motor according to the shock parameters. In the condition without using external devices, the terminal motor test method and device can rapidly and accurately determine whether the motor is qualified or not and avoid the problem that the test accuracy is low caused by using the mutual visual inspection to determine whether the motor is qualified or not.

Owner:XIAOMI INC

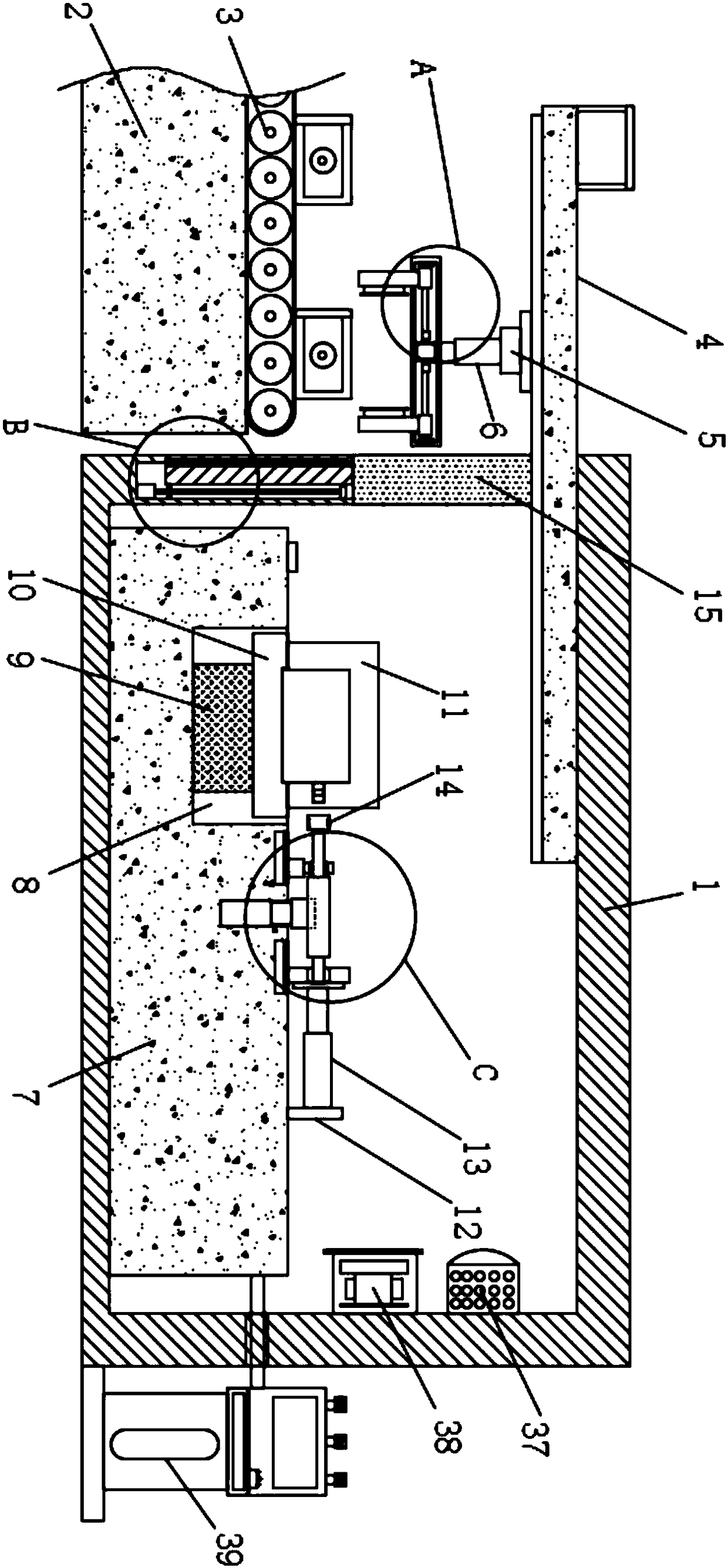

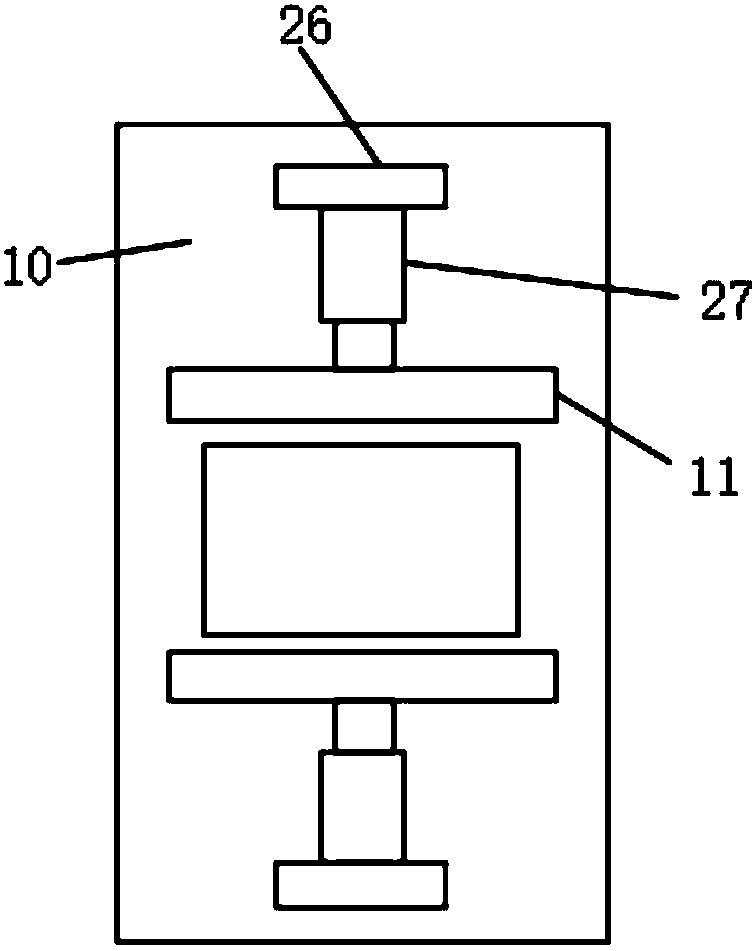

Performance test platform enabling convenience in fixing new energy motor

ActiveCN108375736ASolve runnabilitySolve usabilityDynamo-electric machine testingProduction lineNew energy

The invention belongs to the new energy motor test field and relates to a performance test platform enabling convenience in fixing a new energy motor. The invention aims to solve a problem that an existing testing device cannot simulate the performance of a motor during actual operation and is not suitable for being used in a production line. The performance test platform includes a conveying mechanism and a test box body; the conveying mechanism is disposed at the side surface of the test box body; a horizontally-arranged electric sliding table is mounted at the inner top wall of the test boxbody; one end of the electric sliding table extends from an opening portion to a position above the conveying mechanism; the sliding end of the electric sliding table is disposed downwards; a rotating cylinder is fixed to the sliding end of the electric sliding table; the rotating end of the rotating cylinder is disposed downwards; a vertically-arranged push rod motor is fixed to the rotating endof the rotating cylinder; the lower end of the push rod motor is provided with a clamping device; a lifting sound insulation device is installed below the opening portion; and the inner bottom wall of the test box body is provided with a test base. With the performance test platform enabling convenience in fixing the new energy motor of the invention adopted, the performance of the motor during actual operation can be simulated. The performance test platform is suitable for being used in the production line.

Owner:广东松科智能科技有限公司 +1

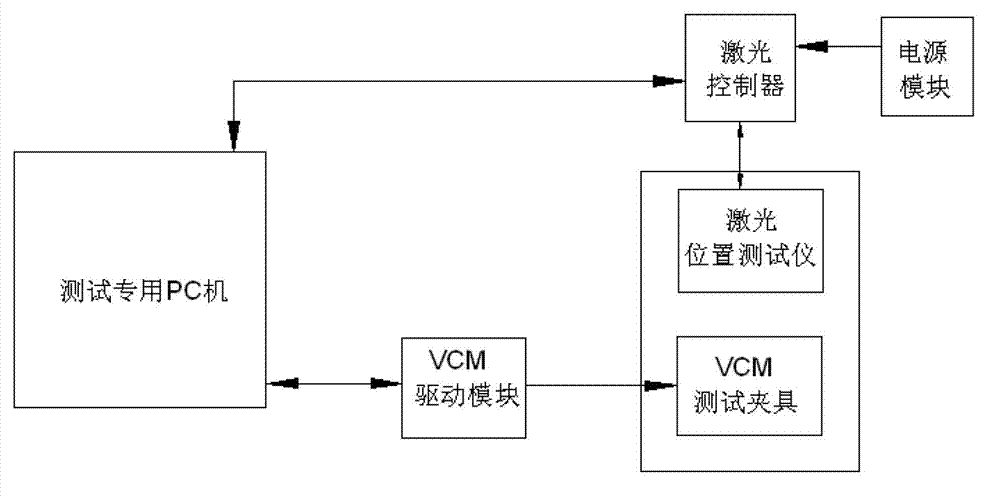

VCM (Voice Coil Motor) motor performance test system and test method

The invention discloses a VCM (Voice Coil Motor) motor performance test system and test method. The test system comprises a VCM motor test fixture, a VCM driving module, a special test PC (Personal Computer), a laser controller, a laser position tester and a power supply module, wherein the VCM driving module can drive and control the current of a VCM motor to be tested and can be communicated with the special test PC; the special test PC has a visual interface and can be communicated with the VCM driving module; the laser position tester can detect the displacement data of the VCM motor to be tested under different driving currents and transmit the displacement data to the laser controller, and the laser controller can process the displacement data and transmit to the special test PC; and the power supply module can provide a power supply for the laser controller and the VCM motor to be tested. The test system can simply, conveniently and accurately test and evaluate the starting current and the linear fall-back characteristic of the VCM motor and further evaluate whether the VCM motor conforms to the requirement.

Owner:KUNSHAN Q TECH CO LTD

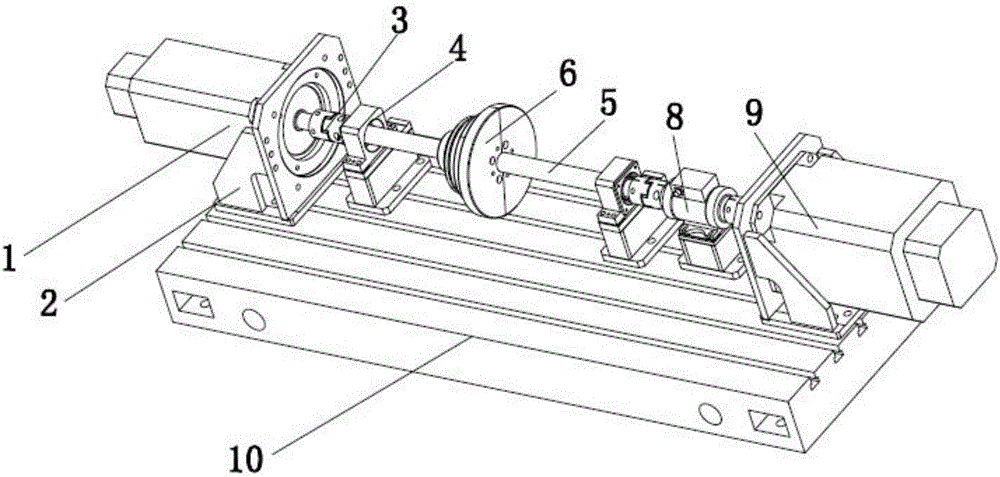

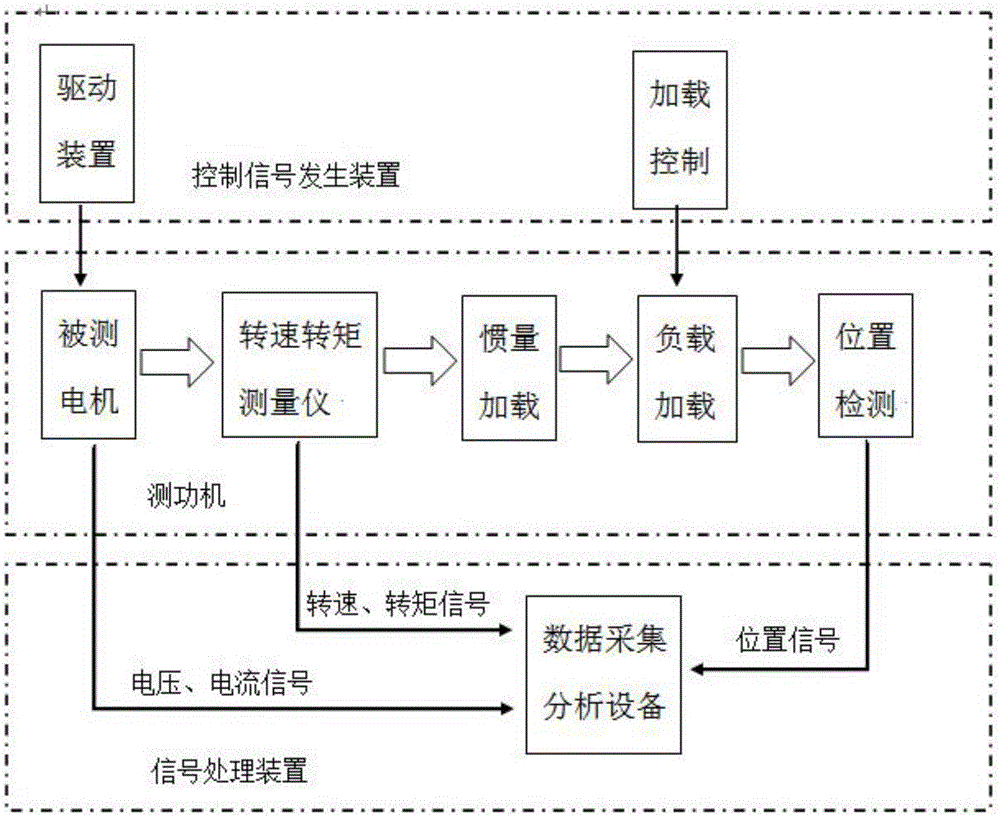

Motor performance testing system

The invention discloses a motor performance testing system which comprises a driving device, a motor to be tested, a loading control device, loading equipment, and data acquisition and analysis equipment. The driving device is electrically connected to the motor to be tested. The output shaft of the motor to be tested is axially connected to one end of a transmission shaft through a coupler. The other end of the transmission shaft is connected to the loading equipment through a transmission gear set. The loading equipment is electrically connected to the loading control device. The coupler is equipped with a torque rotation speed sensor. The transmission shaft is equipped with a combined inertia plate group for adjusting an inertia load. A position sensor is arranged between the transmission gear set and the loading equipment. The data acquisition and analysis equipment is connected to the motor to be tested, the torque rotation speed sensor and the position sensor. According to the motor performance testing system, the high precision position detection can be provided, at the same time the inertia load can be adjusted, the simulation of various working conditions is facilitated, and the system is especially suitable for the motor tests of all working conditions.

Owner:WUHAN HUAZHONG NUMERICAL CONTROL

Detecting and evaluating system for overhaul health condition of three-phase asynchronous high-voltage motor

The invention belongs to the field of motor test and particularly belongs to a detecting and evaluating system for the overhaul health condition of a three-phase asynchronous high-voltage motor. The detecting and evaluating system for the overhaul health condition of the three-phase asynchronous high-voltage motor comprises a bottom layer raw data extraction module, a data acquisition module, a data analyzing and processing module and a human-machine interface, wherein the bottom layer raw data extraction module is used for transmitting raw data extracted from a motor body to be tested to the data acquisition module; the data acquisition module is used for acquiring the raw data and transmitting the raw data to the data analyzing and processing module; and after the raw data are analyzed and processed by the data analyzing and processing module, a characteristic parameter is displayed by the human-machine interface. The invention provides the detecting and evaluating system for the overhaul health condition of the three-phase asynchronous high-voltage motor, and the detecting and evaluating system can realize online test data recording, online parameter monitoring and analyzing and automatic generation of maintaining and reporting functions of health condition of the motor and can fuse online data with offline data.

Owner:TAIYUAN UNIV OF TECH

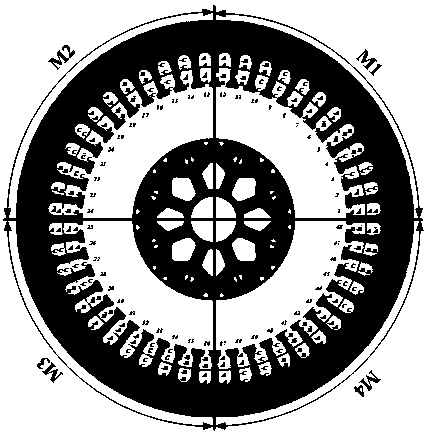

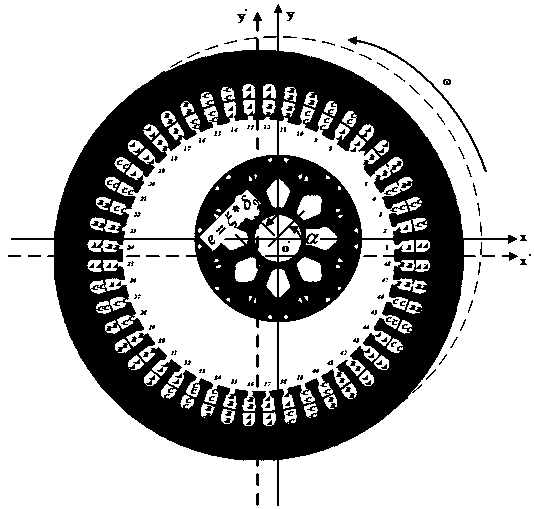

Method for detecting static eccentric fault of built-in permanent magnet synchronous motor for electric vehicle

ActiveCN110703091ASimple structureSimple and fast operationUsing electrical meansNeural architecturesElectric machinePermanent magnet synchronous motor

The invention provides a method for detecting a static eccentric fault of a built-in permanent magnet synchronous motor for an electric vehicle, and relates to a motor test method. The steps are as follows: determining the number of unit motors in the permanent magnet motor; setting winding voltage test lines of the unit motors; testing a no-load counter electromotive force of each phase of each unit motor; extracting a maximum or minimum value of the no-load counter electromotive force of each phase of each unit motor, figuring out an average value of the maximum or minimum values of the no-load counter electromotive forces of various phases of various unit motors, and calculating a distortion rate delta of each unit motor; if delta is equal to 0, indicating that no static eccentricity occurs; if delta is not equal to 0, testing known standard motors with different eccentricity ratios, obtaining a corresponding relationship between the distortion rate of each unit motor and a static eccentric circumferential angle, and establishing a data prediction model; and importing the delta into the established data prediction model to obtain the static eccentric circumferential angle and the static eccentricity ratio of a permanent magnet motor to be tested. The method provided by the invention has the advantages of simple principle, convenient use, higher versatility and high accuracy.

Owner:HARBIN INST OF TECH AT WEIHAI +1

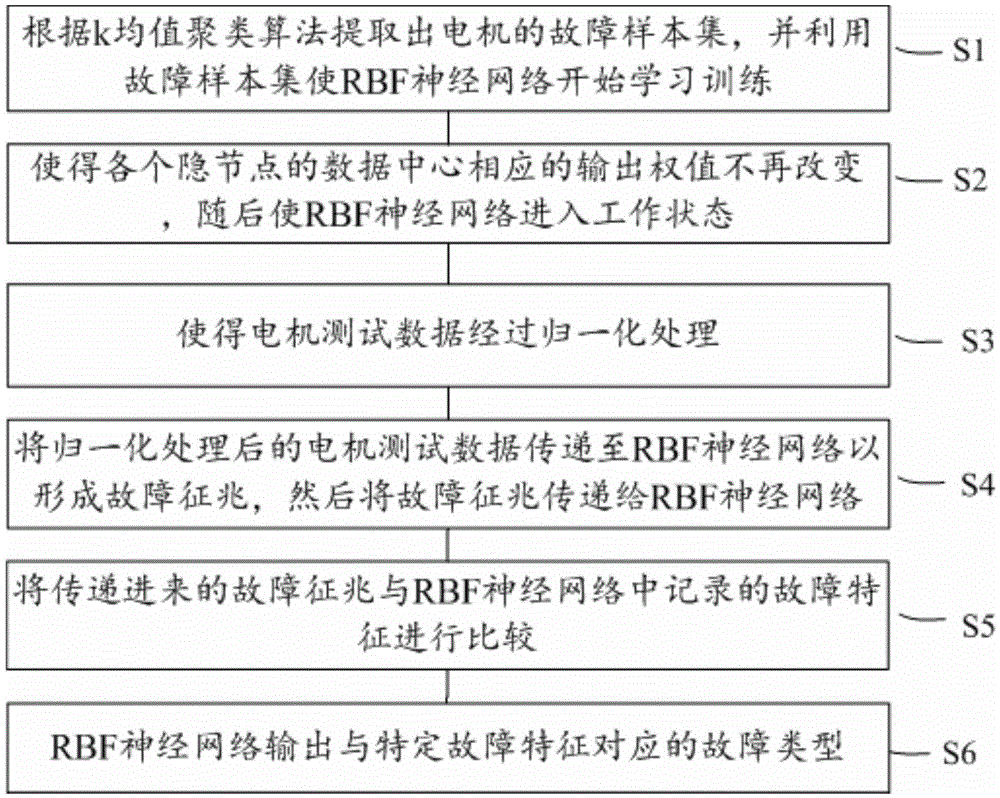

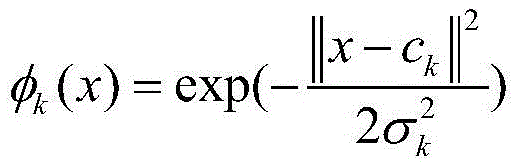

Motor fault diagnosis method based on k-means RBF neural network algorithm

InactiveCN105487009AStable structureImprove generalizationNeural architecturesNeural learning methodsData centerNetwork output

The invention relates to a motor fault diagnosis method based on a k-means RBF neural network algorithm. The method comprises that a motor fault sample set is extracted according to a k-means clustering algorithm, and the RBF neural network starts learning training by utilizing the fault sample set; after that the RBF neural network completes training, corresponding output weights of data centers of hidden nodes are not changed any more, the RBF neural network enters a working state then, and the trained RBF neural network records a fault feature via a data center and the connection weight; motor test data is normalized; the normalized motor test data is transmitted to the RBF neural network to form a fault symptom, and the fault symptom is transmitted to the RBF neural network; the transmitted fault symptom is compared with the fault feature recorded in the RBF neural network; and when the similarity between the transmitted fault symptom and the fault feature recorded in the RBF neural network, the RBF neural network transmits a fault type corresponding to the specific fault feature.

Owner:SHANGHAI DIANJI UNIV

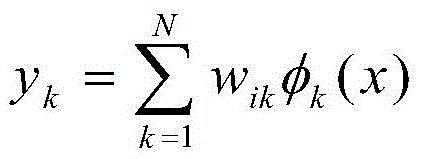

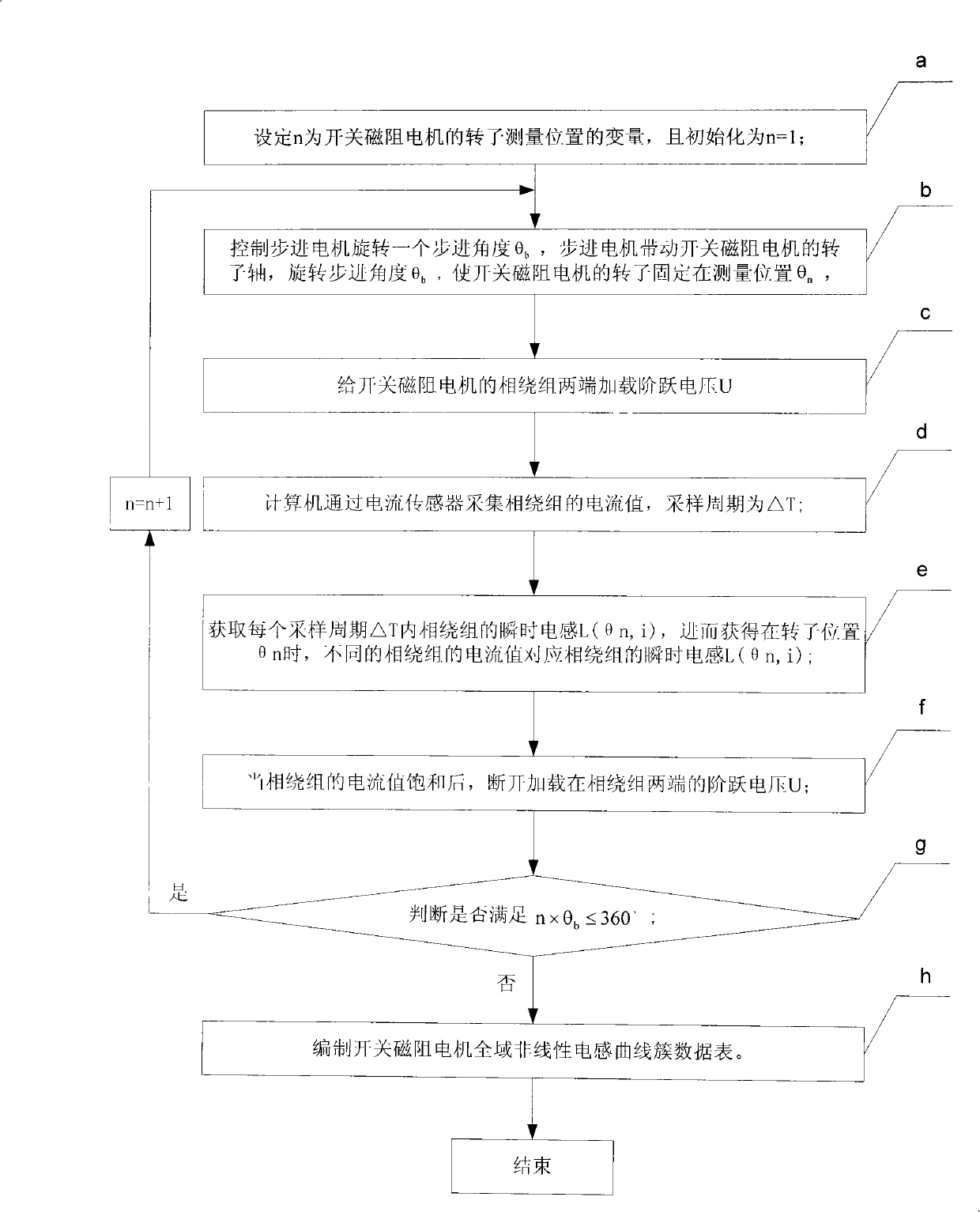

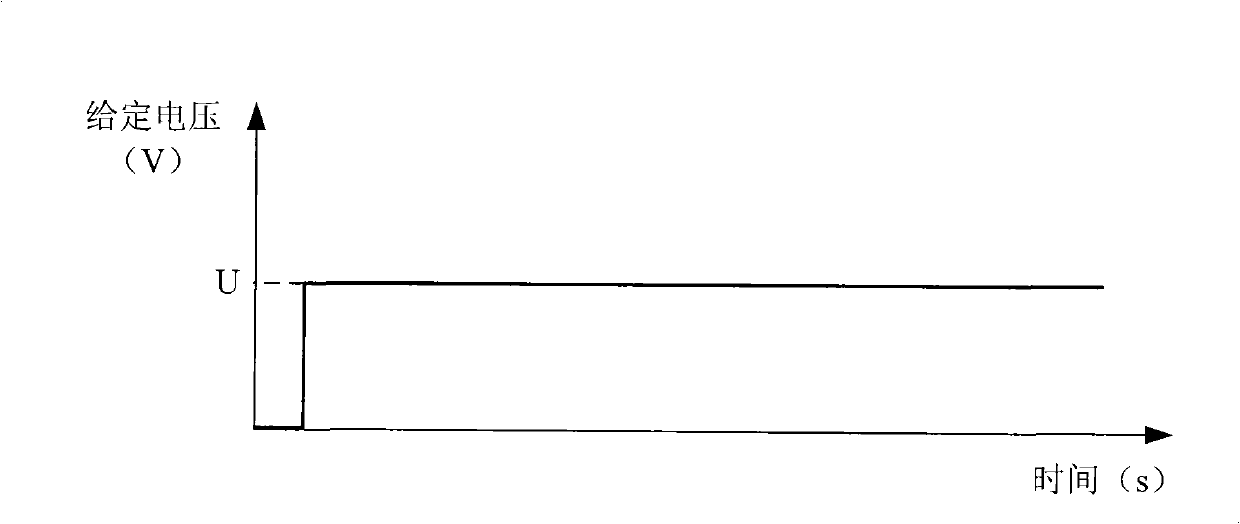

Control method of constant torque of switched reluctance motor

InactiveCN101526823AGood constant torque effectReduce torque rippleMechanical power/torque controlProgramme control in sequence/logic controllersMotor testingControl manner

A control method for constant torque of a switched reluctance motor is disclosed, belonging to the field of motor test. The inventive aims at solving the problem that torque pulsation is large when a conventional speed and current double closed-loop control manner is used to control the torque of the switched reluctance motor. The inventive method comprises the steps that: in order to ensure that the switched reluctance motor outputs constantly in accordance with the set torque, a reference current is given at first, a transient inductance corresponding to the reference current is then obtained by inquiring an universe nonlinear inductance curve family data sheet of the switched reluctance motor, an inductance slope corresponding to the transient inductance is further obtained, an output phase winding current is calculated in accordance with the formula i=square root (2T / K<L>), and whether the difference value between the phase winding current and the reference current is in a permissible error range is judged, if not, the phase winding current, which is calculated, is assigned to the reference current and is recalculated in accordance with the method, multiple circulations are implemented until the condition is satisfied, and the output phase winding current is loaded at two ends of the phase winding of the switched reluctance motor to realize control of the constant torque of the switched reluctance motor.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com