High-rotation speed and large-torque brake motor test bench

A brake motor and high torque technology, applied in the field of test equipment, can solve the problems that it is difficult to meet the detection requirements of high speed and high torque, and achieve the effect of easy installation and debugging, and easy analysis and research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

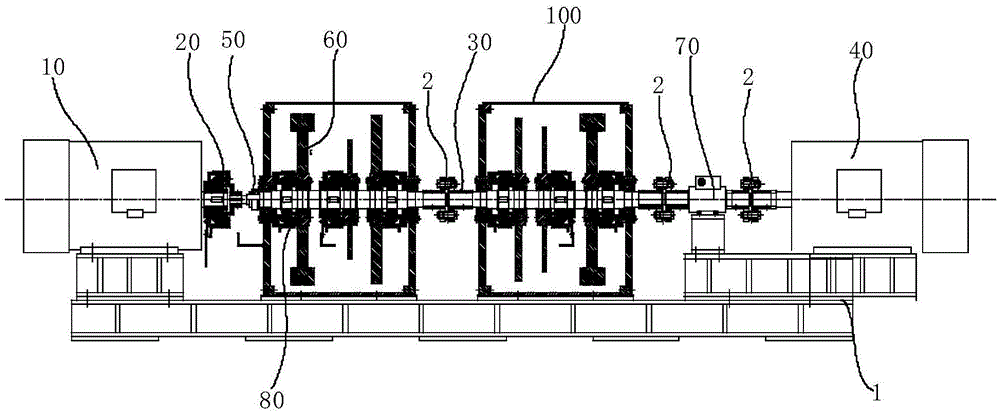

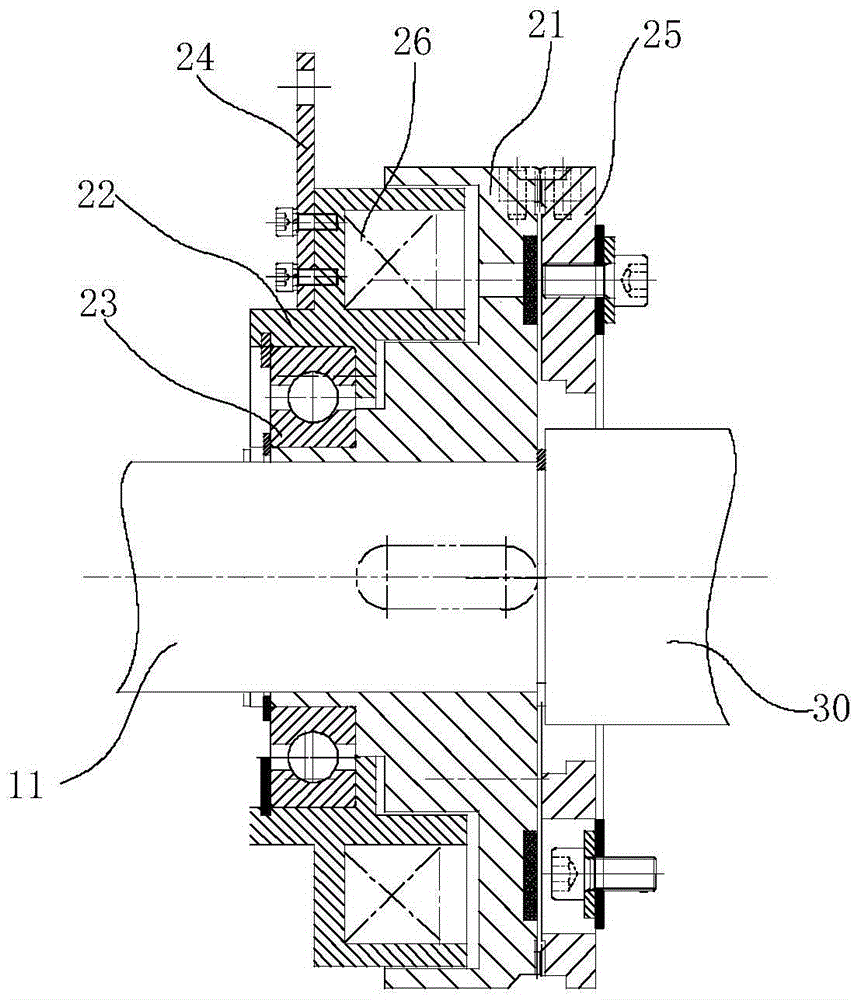

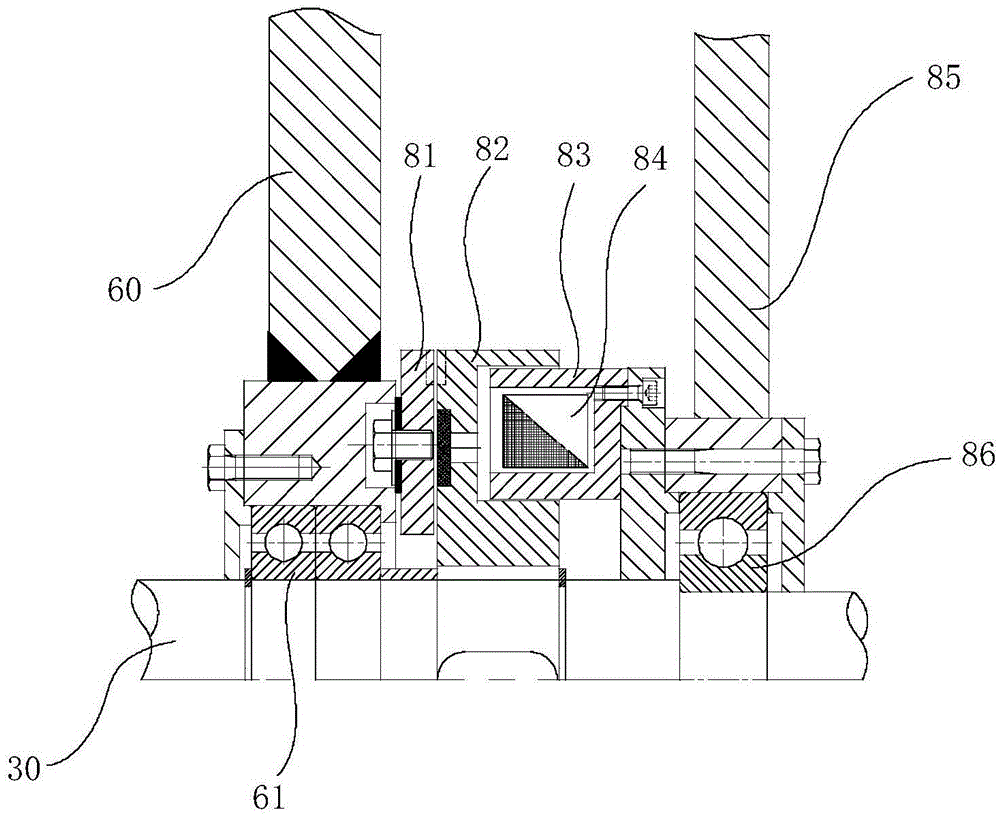

[0014] to combine figure 1 , 2 , high speed and high torque brake motor test bench, the motor shaft 11 of the driving motor 10 is connected to one end of the load shaft 30 by the first electromagnetic clutch 20, and the other end of the load shaft 30 is connected to the brake motor 40 to be tested by a coupling A speed sensor 50 , a load flywheel disc 60 , and a torque sensor 70 are sequentially connected to the load shaft 30 in the direction from the drive motor 10 to the brake motor 40 to be tested.

[0015] The driving motor 10 is a variable frequency speed regulating motor, connected with the load shaft 30 through the first electromagnetic clutch 20, and can realize dynamic disengagement during operation, so as to eliminate the influence of the rotor kinetic energy of the driving motor 10 on the experiment. The speed sensor 50 feeds back the rotational speed sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com