Flowmeter with middle through-hole movable throttling element connected with elastic membranes or bellows

A technology of throttling elements and elastic diaphragms, which is applied to the volume/mass flow generated by mechanical effects, and the detection of fluid flow by measuring differential pressure. It can solve the problems of complex manufacturing and debugging of flowmeters, and affect measurement accuracy. Simple, cost-effective, high precision, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

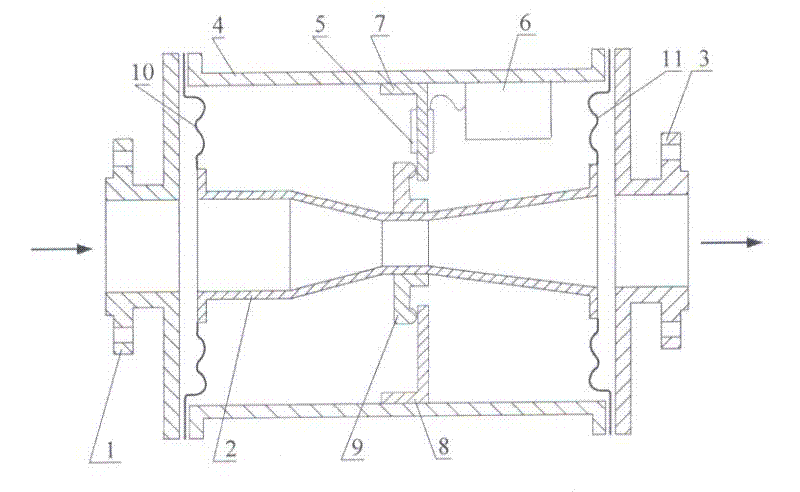

[0015] exist figure 1 In the embodiment, use two annular corrugated elastic membranes 10,11 with edge corrugations, the inner edges of the annular front elastic membrane 10 and the rear elastic membrane 11 are connected with the entrance of the Venturi tube 2 respectively. The outer edge of the front elastic membrane 10 and the rear elastic membrane 11 are sealed and connected with the front end tube 1 and the rear end tube 3 respectively. The casing frame 4 is rigidly connected with the front end pipe 1 and the rear end pipe 3, so that the distance between the two end pipes can be fixed, and other components can be installed thereon. The detection cantilever beam 7 and the balance cantilever beam 8 are installed on the chassis frame 4, the detection cantilever beam 7 is affixed with the strain gauge 5, and the balance cantilever beam 8 is not affixed with the strain gauge, the purpose of setting the balance cantilever beam 8 is to balance the detection The additional moment ...

Embodiment 2

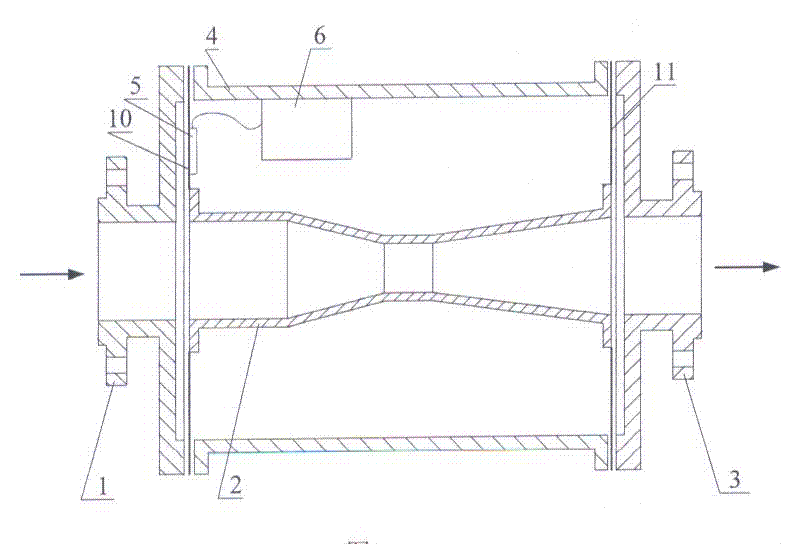

[0035] exist figure 2 In the implementation scheme, it can be seen that this example and figure 1 The embodiments are substantially the same in structure, with only the following two differences. First, in figure 2 In, two ring-shaped planar diaphragms 10, 11 are used instead of figure 1 There are two corrugated elastic diaphragms 10, 11 with corrugated edges. The inner edge of the flat front elastic diaphragm 10 is in sealing connection with the inlet end of the Venturi tube 2, and its outer edge is in sealing connection with the front end tube 1; The inner edge of the diaphragm 11 is sealingly connected with the outlet end of the Venturi tube 2, and its outer edge is sealingly connected with the rear end pipe 3; The dimple corresponding to the effective area of the diaphragm allows the Venturi tube 2 to have a margin to move left and right along the axial direction. Second, the strain gauge 5 is pasted on the front plane diaphragm 10, and the detection cantilever bea...

Embodiment 3

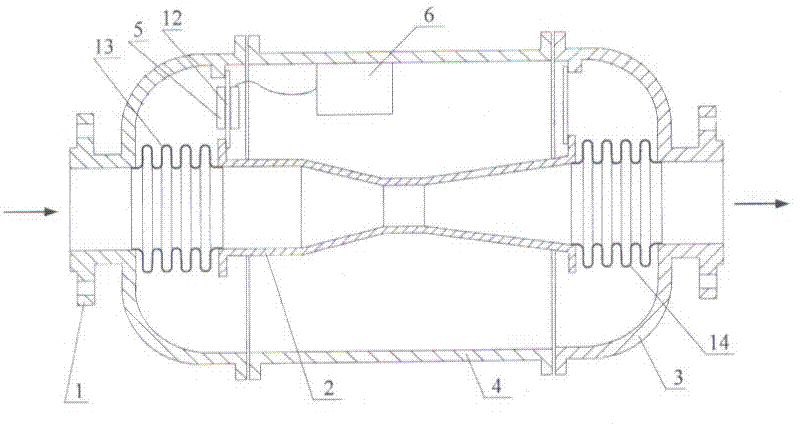

[0038] exist image 3 In the embodiment of the present invention, two U-shaped bellows 13, 14 are used, the front end of the front bellows 13 is in sealing connection with the front end pipe 1, and its rear end is in sealing connection with the inlet end of the Venturi tube 2; the front end of the back bellows 14 is in sealing connection with The outlet end of the Venturi tube 2 is in sealing connection, and its rear end is in sealing connection with the rear end pipe 3 . The weight of the Venturi tube 2 is supported by two elastic metal straps 12, and the strain gauge 5 is pasted on the metal straps 12. The metal sheet sling 12 is made of very thin elastic metal sheet, its stiffness coefficient along the pipeline axis is very small, and the rebound force generated by its deformation is also very small, so it can be considered that the thrust force on the Venturi tube 2 is F Balanced only by the rebound force of the two bellows. However, the deflection deformation of the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com