Remote three-dimensional micro-deformation visual on-line monitoring method and system

A micro-deformation and monitoring system technology, applied in the field of visual measurement, can solve the problems of difficulty in meeting the measurement requirements of large-scale equipment and industrial sites, high cost, complex system, etc., and achieve reliable separation of field and monitoring space, convenient installation and debugging, and reliable transmission. Effect

Inactive Publication Date: 2010-09-15

TSINGHUA UNIV

View PDF6 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the laser triangulation measurement technology, the light is collimated and irradiated on the measurement target, and the reflected light enters the photodetector for indirect measurement such as displacement and deformation; usually a single photodetector can only monitor one-dimensional information, and it is necessary to measure the space For three-dimensional parameters, it is necessary to increase the number of detectors or make the detectors and the measurement object rotate relative to each other; while binocular vision measurement uses two sets of detection systems for target imaging, and uses spatial coordinate transformation to realize three-dimensional monitoring. Relatively speaking, the system is more complicated and the cost is high. , it can be seen that it is difficult to meet the measurement needs of large-scale equipment and industrial sites by using traditional measurement methods

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

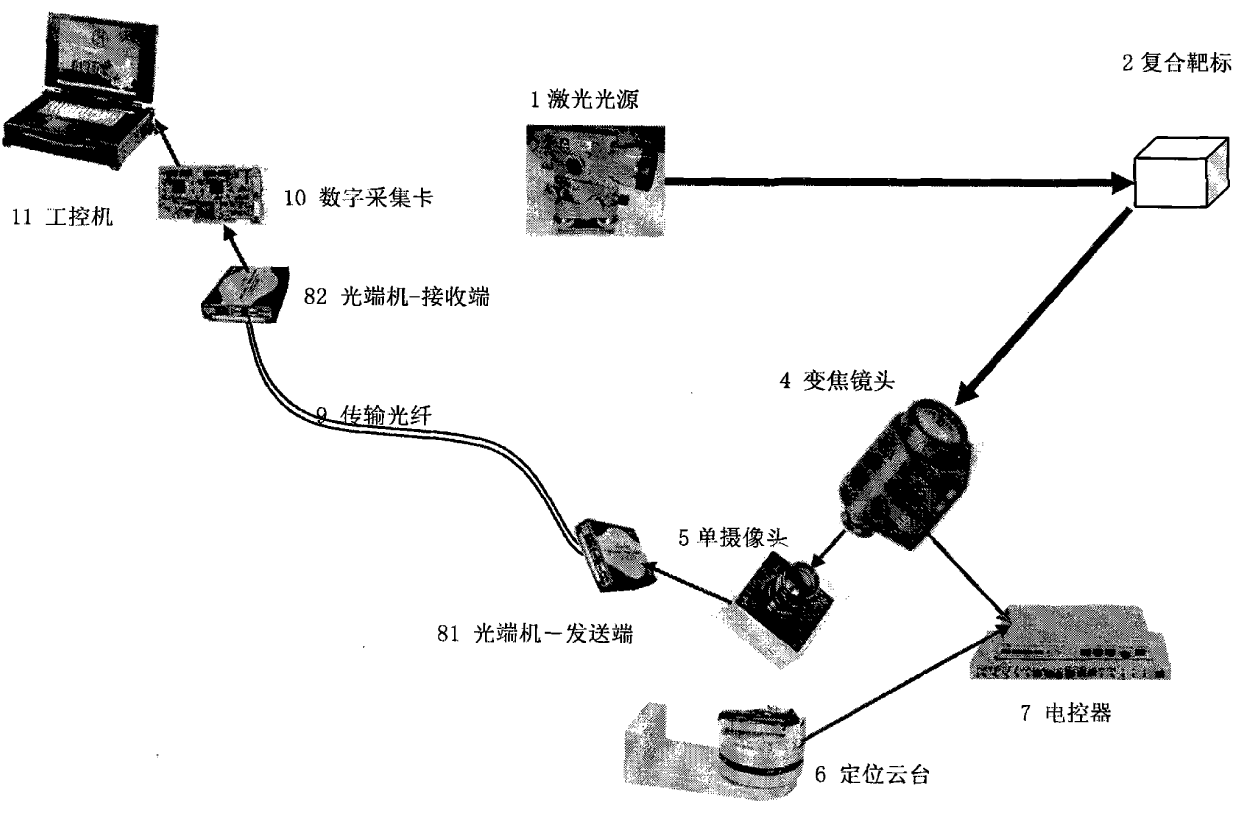

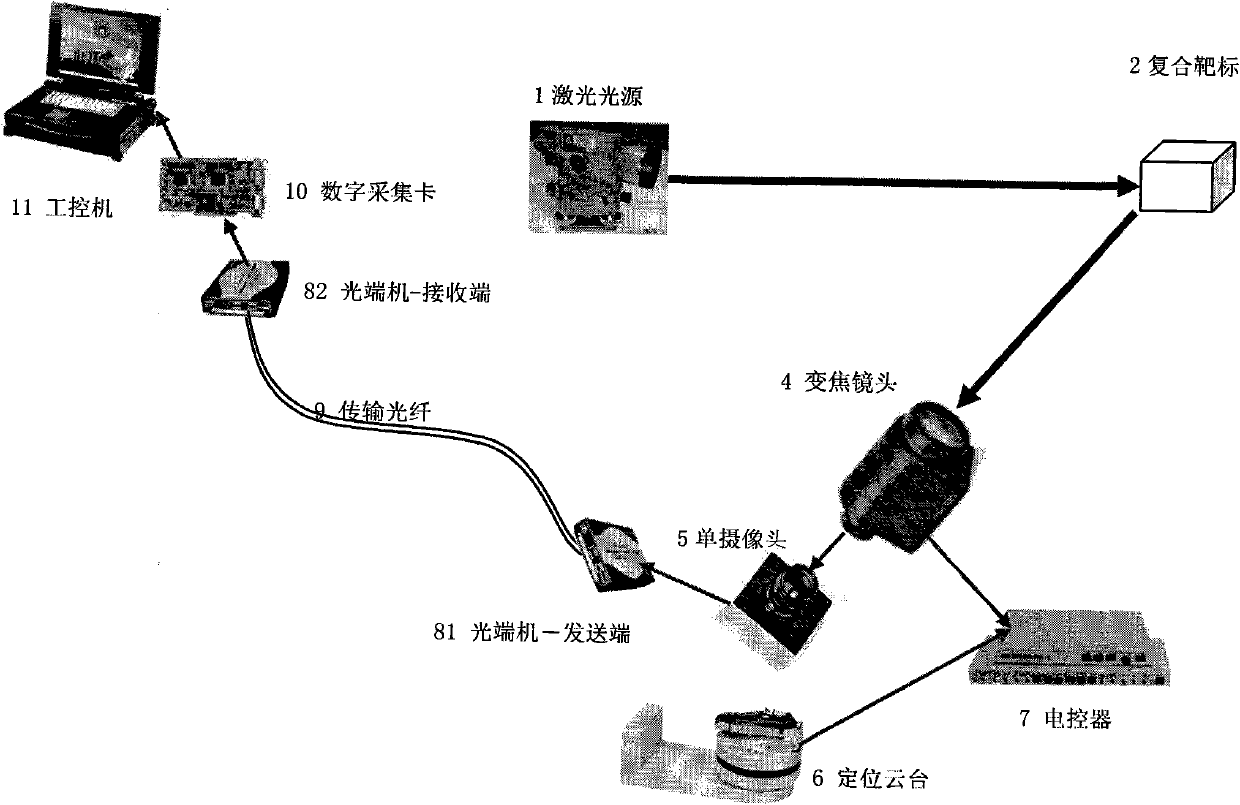

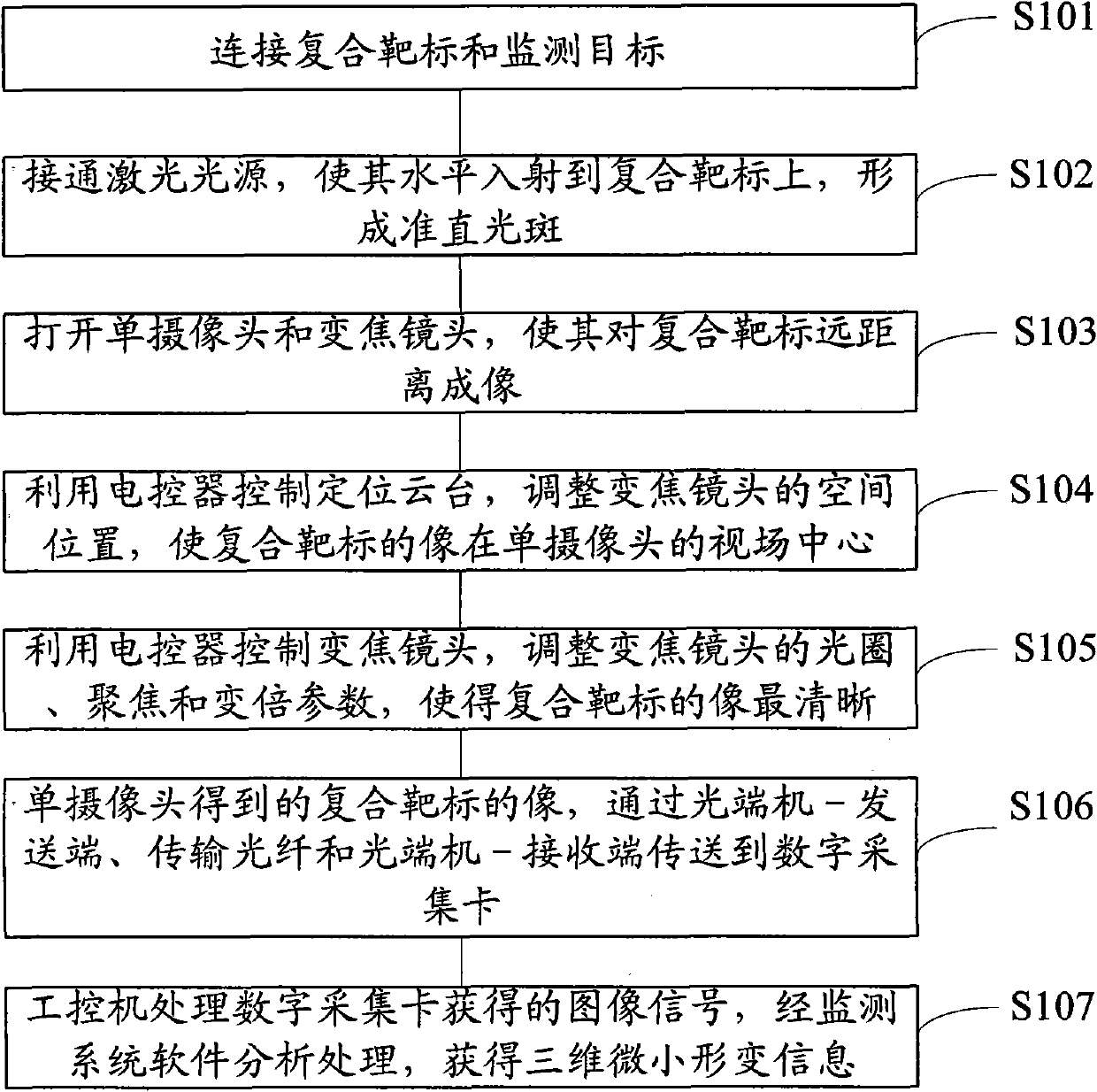

The invention provides remote three-dimensional micro-deformation visual on-line monitoring method and system. The system comprises a composite target, a laser source, a visual detector, a positioning holder, an electric controller, an optical fiber transmission device, a digital acquisition card and an industrial control computer. The visual detector and the laser source in the system can realize three-dimensional monitoring, the overall design structure is simple, and the processes of installation and debugging are convenient; meanwhile, the electric zoom is used for carrying out visual detection to realize the purposes of adjustable monitoring distance and high measuring accuracy; and a digital camera and the optical fiber transmission device are combined to realize reliable transmission of remote signals and separation of the field and the monitoring space, and the composite target realizes integration of different target monitoring.

Description

technical field The invention relates to the technical field of visual measurement, in particular to a long-distance three-dimensional micro-deformation visual online monitoring method and system. Background technique Displacement or deformation measurement plays an important role in many different fields, such as: mechanical processing, construction, field measurement, and monitoring of equipment online status or finished product characteristics (deformation, speed, etc.) in industrial production, etc., generally requires certain measurement accuracy and fast measurement speed. Commonly used measurement methods in engineering applications include: dial indicator measurement method, optical theodolite, electronic theodolite, level and linear differential transformer method, etc., which are characterized by simple instruments and easy operation, but these methods can only be used for short-term, short-term Distance and manual measurement have the disadvantages of time-consu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01B11/16

Inventor 李玉和祁鑫胡小根

Owner TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com