Motor accelerated lifetime test method and system

A technology of accelerated life test and motor speed, which is used in engine testing, machine/structural component testing, measuring devices, etc. It can solve the problems of low accuracy of motor accelerated life test time, shorten the test time and improve reliability. , to ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

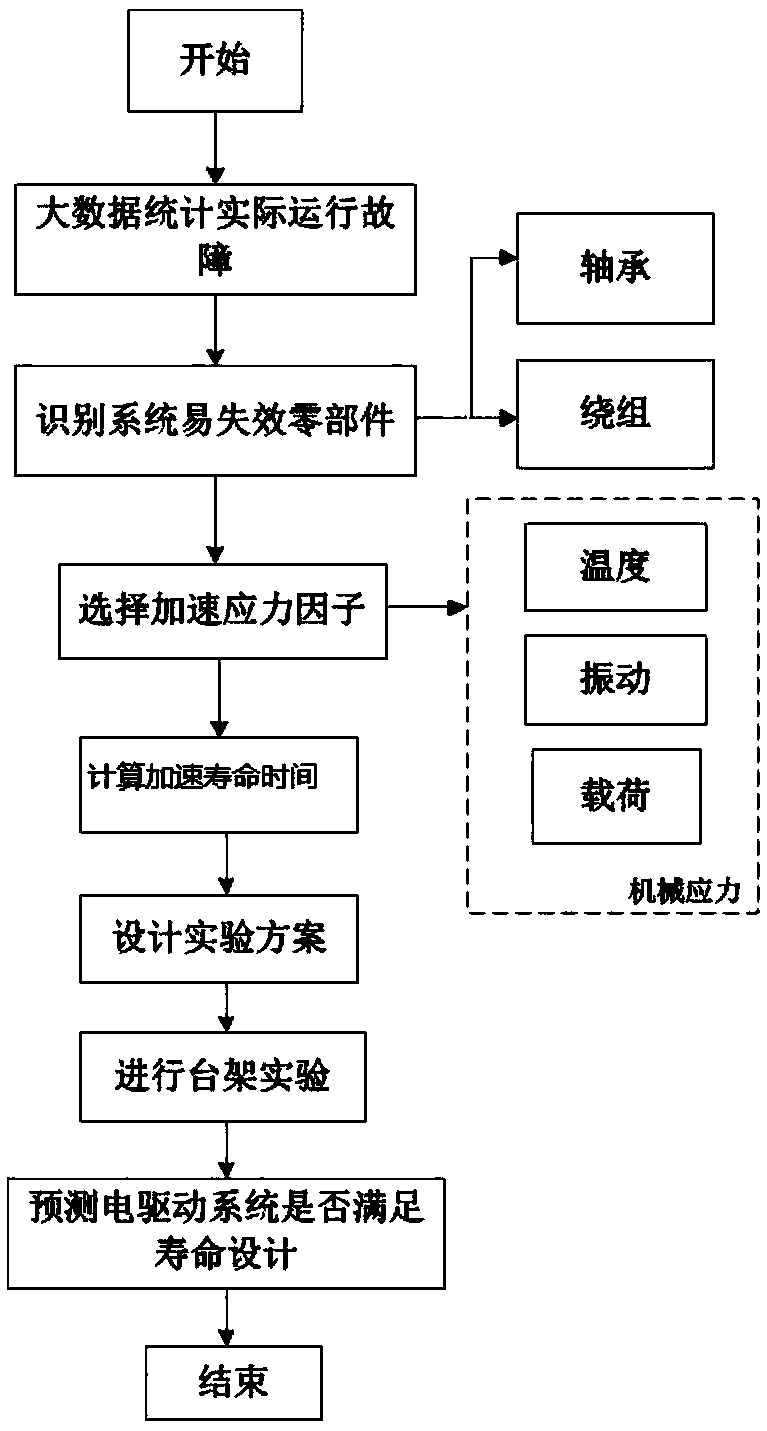

[0045] like figure 1 As shown, firstly, the failure modes and failure mechanisms that are prone to occur in the motor during the actual operation of the vehicle are counted through big data, the parts that are prone to failure in the system are identified, and the main factors causing failure are further analyzed, including environmental factors, electrical and mechanical stress factors, etc. For the motor bearings and windings of the weak parts obtained in the previous analysis, the statistical analysis theory of the failure compliance of the weak parts is analyzed separately, and then the acceleration factor is calculated for the failure rate compliance of the weak parts, according to the reliability, confidence and life requirements. Determine the final accelerated life test time, design the test method, and conduct the test on the bench to predict whether the motor system meets the design life.

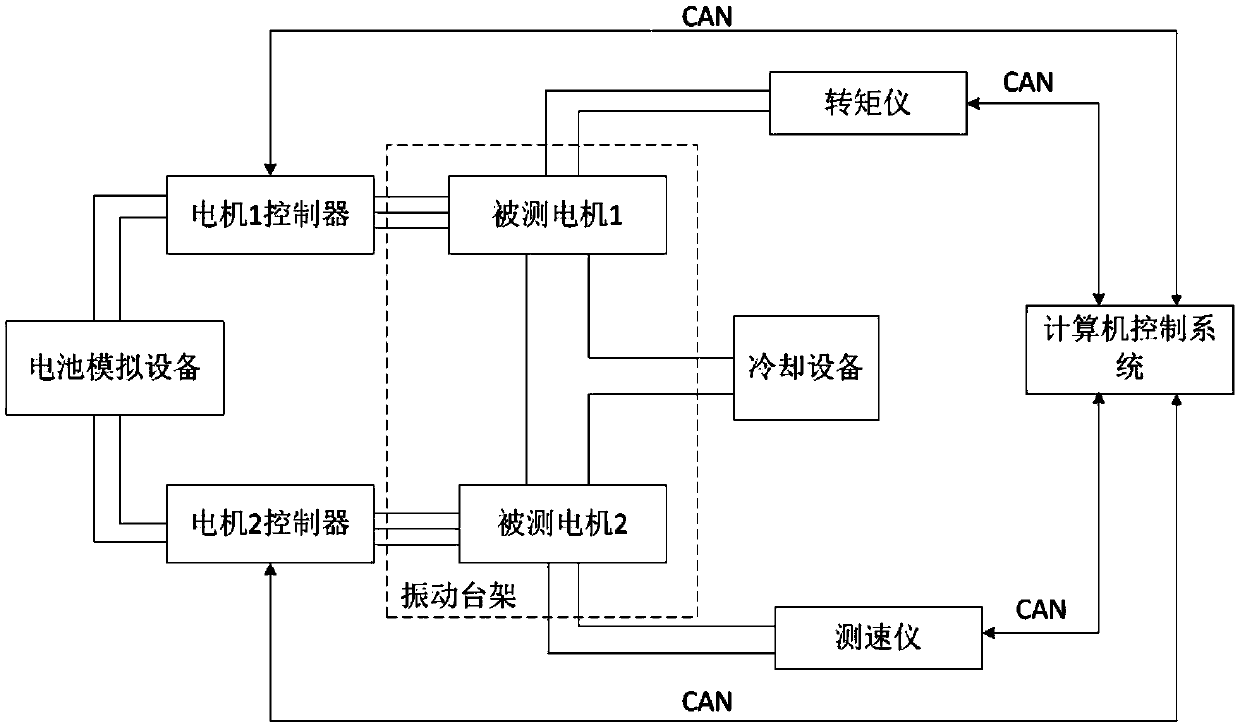

[0046] like figure 2 As shown, the life of the motor system is predicted th...

Embodiment 2

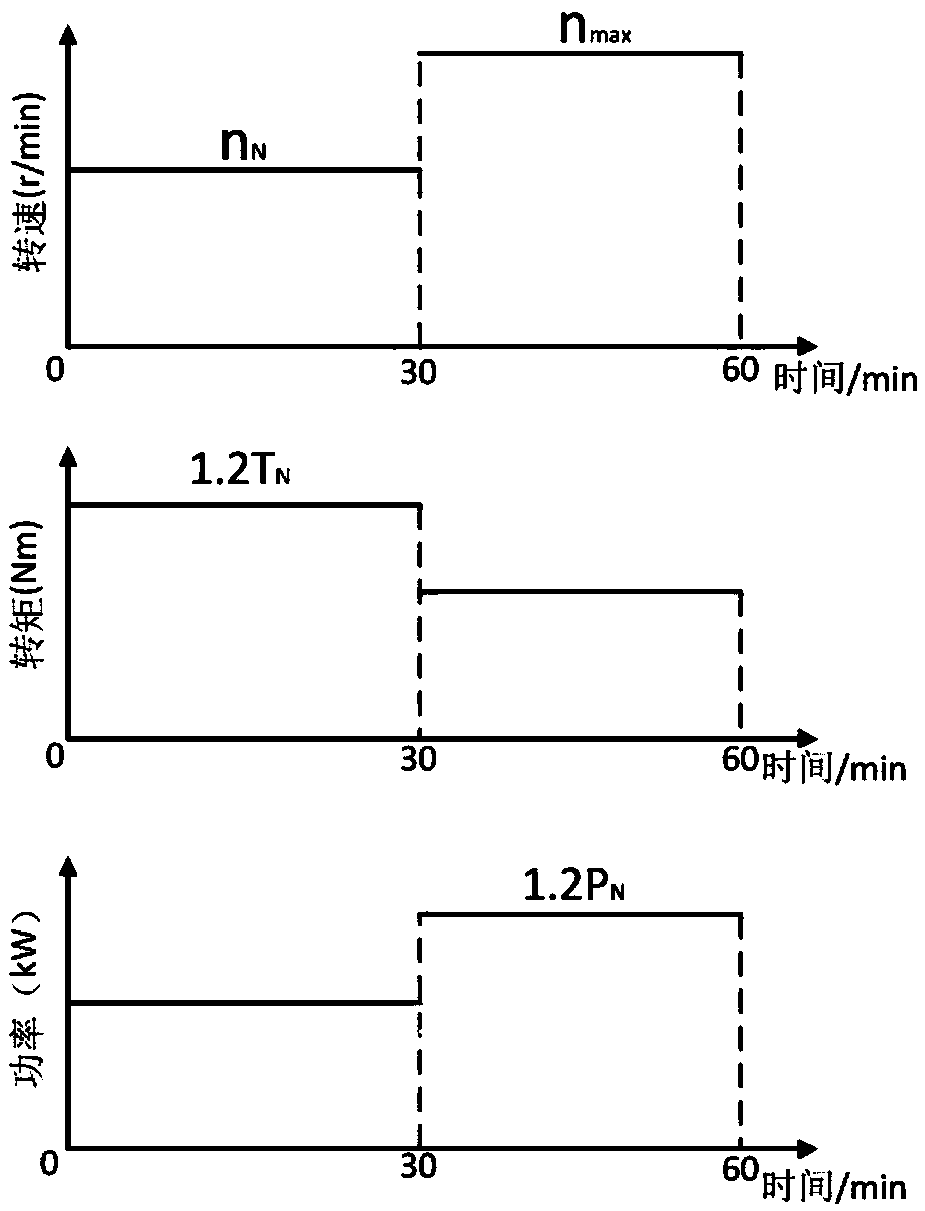

[0063] In this embodiment, the temperature of the winding is also selected as the acceleration stress. First, the total test time of the winding is determined according to the number of samples, reliability and confidence through statistical rules, and then the acceleration factor of the winding is determined according to the actual operating condition of the winding, and finally the acceleration of the winding is determined. Life test time, design an accelerated life test bench, real-time monitoring of test failures, and finally determine whether the life of this batch of motors meets the design life through the test results.

[0064] The determination of the accelerated life time of the winding in this embodiment includes the following steps:

[0065] 1) The calculation process of the conventional life test time of the motor winding is as follows:

[0066] The failure of the motor windings satisfies the exponential distribution, and its failure rate λ c As shown in formula ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com