Method for detecting static eccentric fault of built-in permanent magnet synchronous motor for electric vehicle

A permanent magnet synchronous motor, static eccentricity technology, applied in the direction of motor generator testing, using electrical devices, neural learning methods, etc., can solve the problems of difficult mass production detection, complex detection, difficult operation, etc., to achieve simple operation and detection accuracy. The effect of high and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

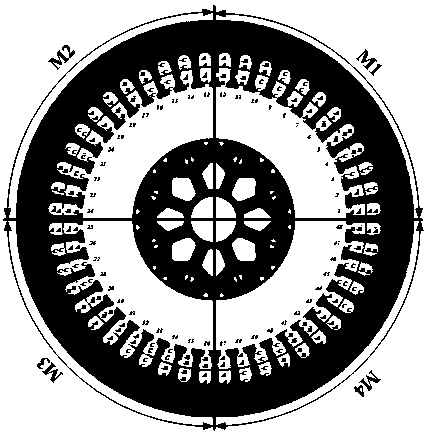

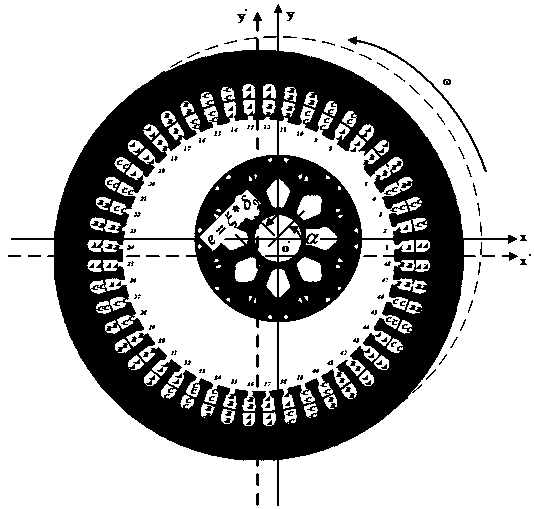

[0056] A V-type built-in permanent magnet synchronous motor for electric vehicles with 8 poles and 48 slots and a rated speed of 5100rpm is the permanent magnet motor to be tested, and the whole process detection is carried out according to the method of the present invention.

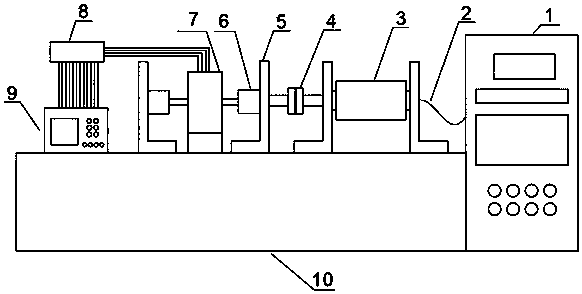

[0057] like figure 1 As shown, it is a schematic diagram of a test bench for no-load back electromotive force of a built-in permanent magnet synchronous motor. The torque drives the measured permanent magnet motor 7 to rotate through the shaft coupling 4 to reach the rated speed. Collect the no-load back EMF of four unit motors, and connect the voltage test lines of each phase of each unit motor to the data acquisition and analysis unit 9 through the junction box 8. 5 is the bracket and 6 is the bearing seat, which is used for fixed support. The whole test is in It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com