Testing system of hydraulic motor

A test system and hydraulic motor technology, which is applied in fluid pressure actuation system testing, fluid pressure actuation devices, mechanical equipment, etc., can solve the problem of high price, low precision of system pressure adjustment, and inability to meet the needs of construction machinery hydraulic motor tests, etc. problems, to achieve the effect of increasing stability and improving recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be pointed out that the description and sequence of specific structures in this section are only descriptions of specific embodiments, and should not be considered as limiting the protection scope of the present invention. In addition, the embodiments in this section and the features in the embodiments can be combined with each other under the condition of no conflict.

[0025] Please refer to figure 1 , the present invention will be described in further detail below in conjunction with embodiment.

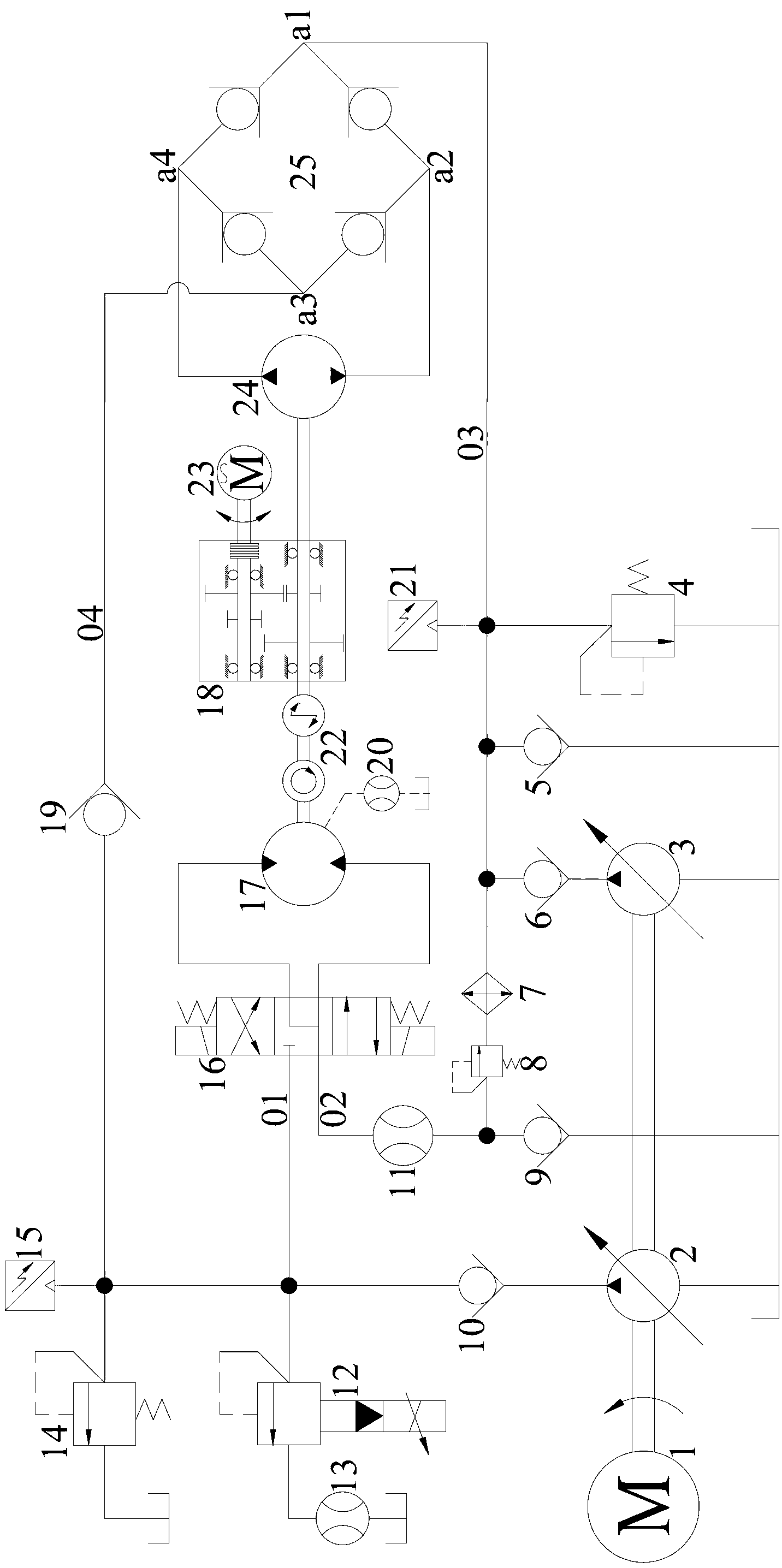

[0026] As shown in the figure, the hydraulic motor test system of this embodiment mainly includes a motor 1, a parallel compensation pump 2, a series compensation pump 3, a first oil circuit 01, a second oil circuit 02, a compensation oil circuit 03, a feedback oil circuit 04, Reversing valve 16, tested motor 17, loading motor 24, gearbox 18, motor 23, bridge hydraulic block 25, etc.

[0027] Wherein, the tested motor 17 is docked with the loading motor 24 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com