Patents

Literature

273results about How to "Avoid vacuuming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

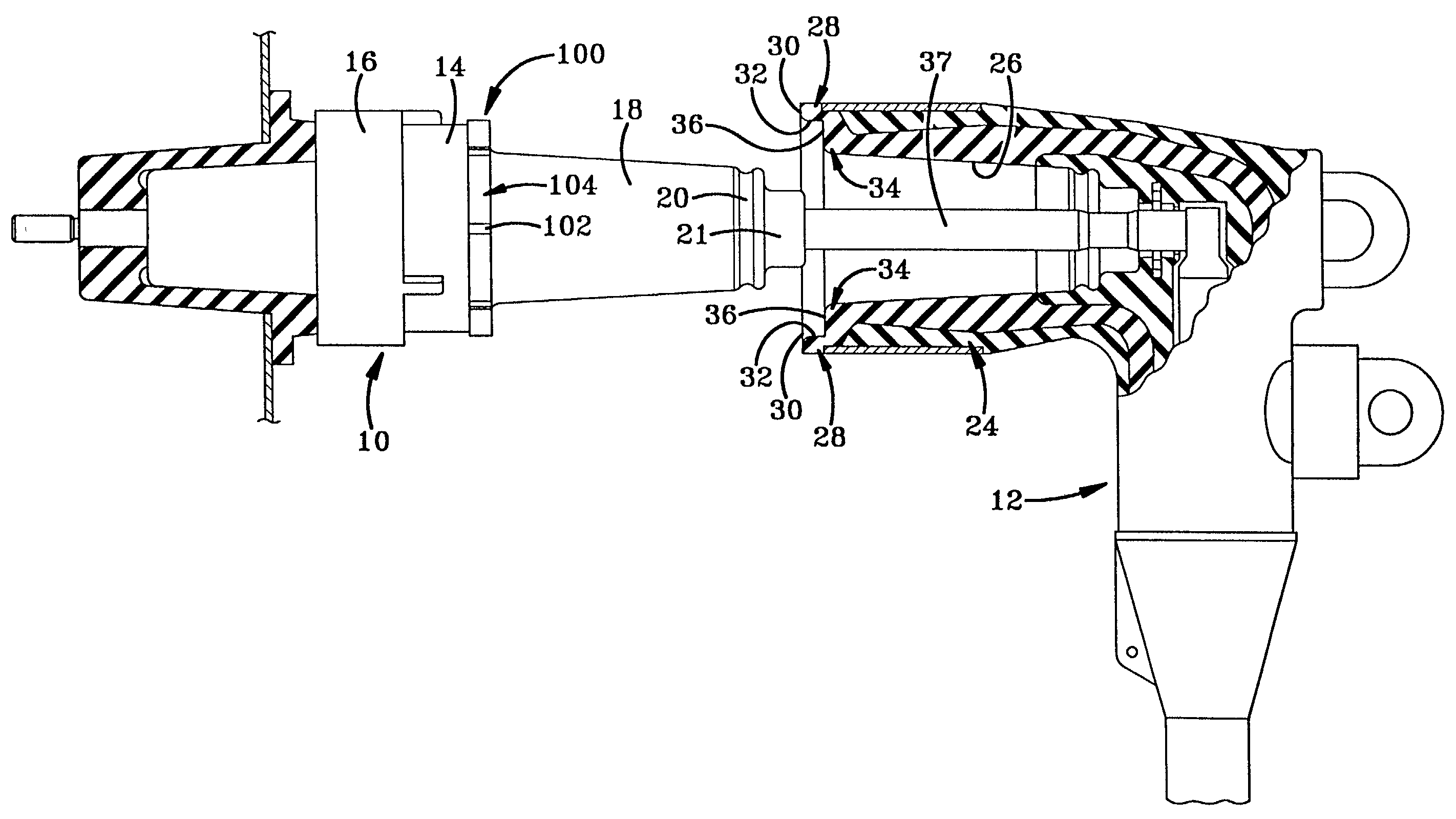

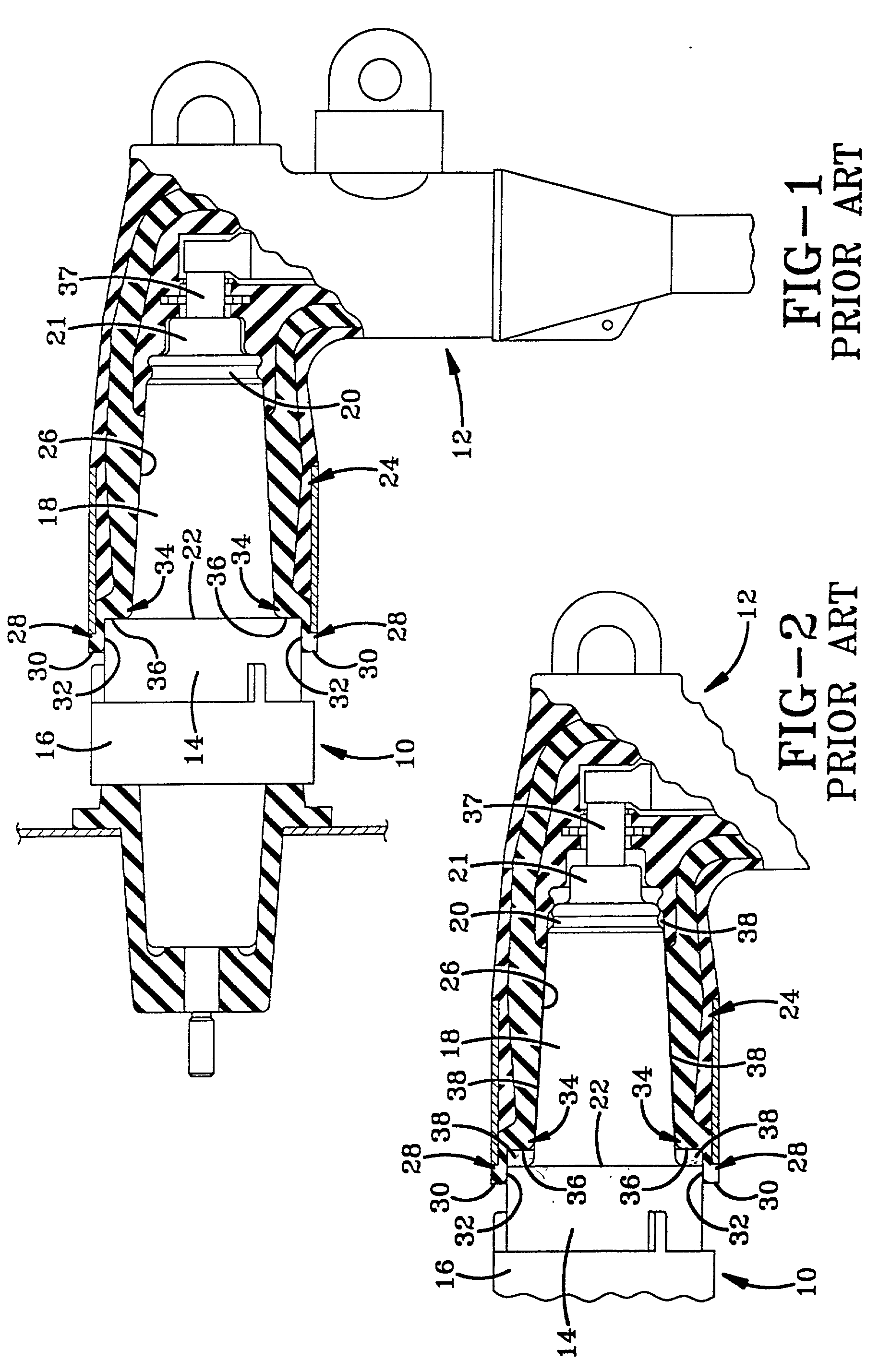

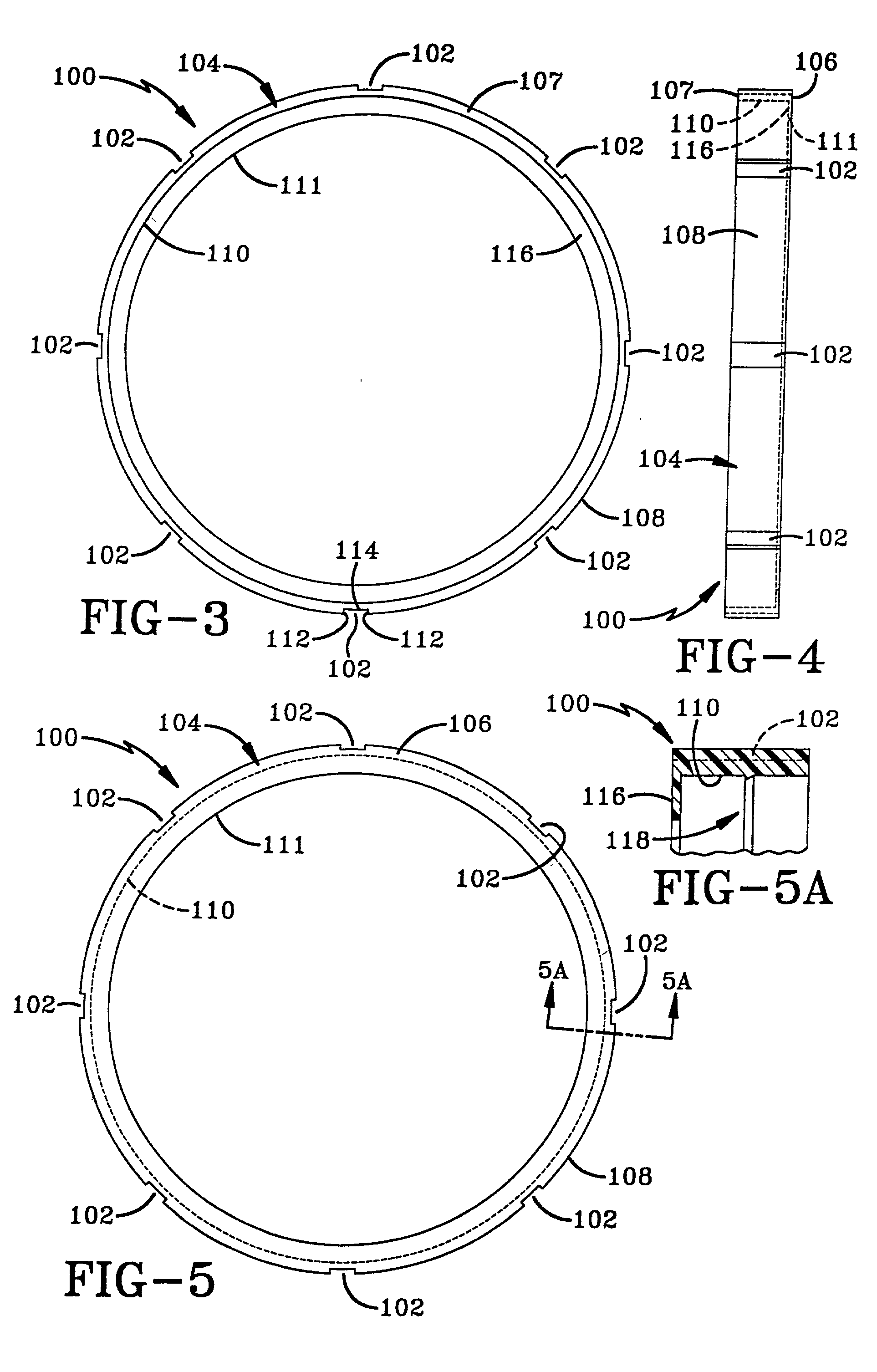

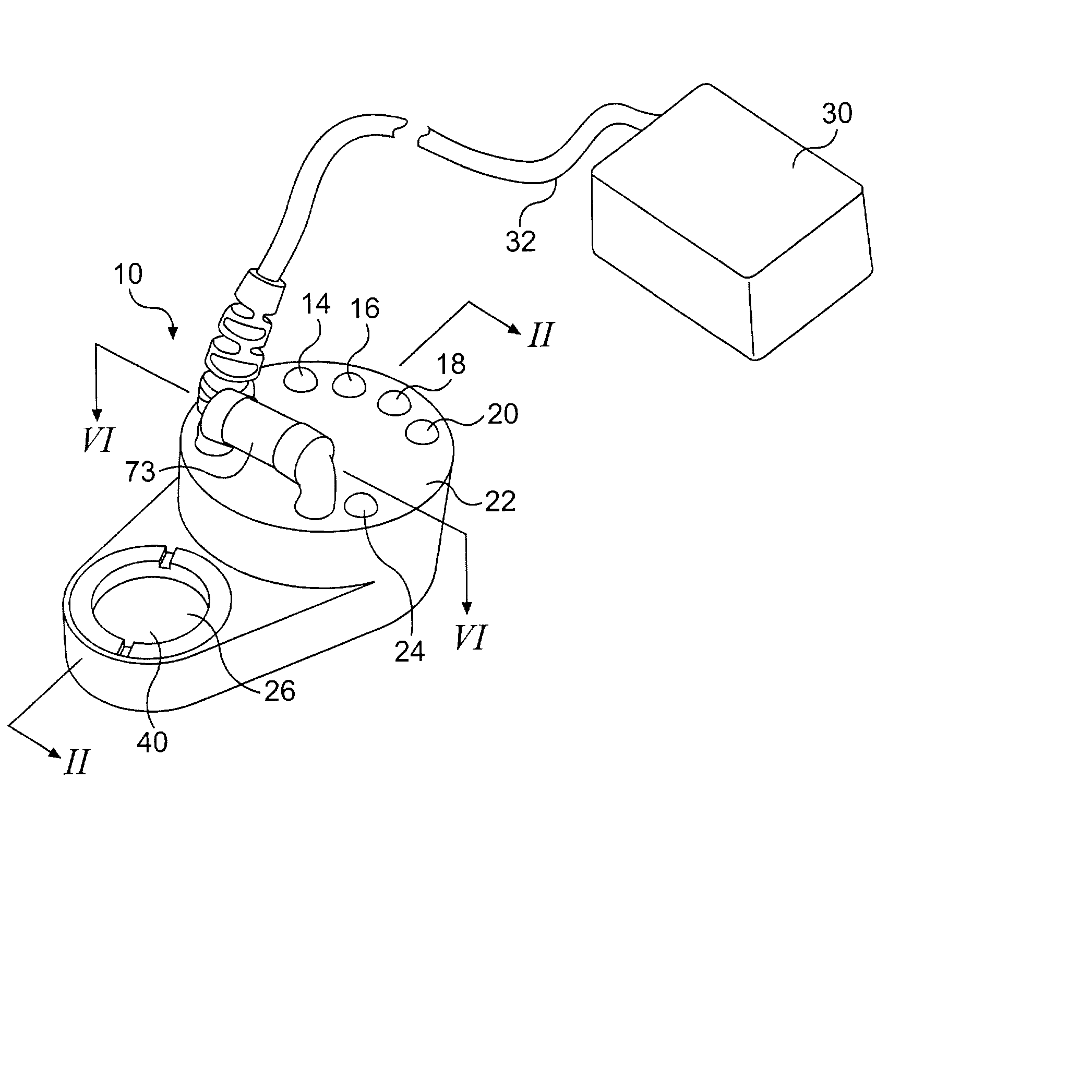

Anti-flashover ring for a bushing insert

InactiveUS20020055290A1Avoid flashoverAvoid vacuumingCouplings bases/casesUnwanted magnetic/electric effect reduction/preventionElectrical probeElectrical and Electronics engineering

The anti-flashover ring of the present invention includes a substantially cylindrical body having an outer surface with a plurality of passageways thereon. Each of the passageways pass from one of the sidewalls through the body to the other of the sidewalls of the ring. The passageways function to provide fluid communication between the atmosphere surrounding an accessory product such as a bushing insert and the interior of a connector mounted thereon when the connector is being pulled off the bushing insert. The fluid communication prevents a vacuum from forming between the connector and the bushing insert that can lead to a flashover between an electrical probe in the connector and a ground shield of the bushing insert. The anti-flashover ring is also configured to provide an indication to the operator installing the connector of when the connector is fully installed on the bushing insert. Such indication is provided by providing the ring with a width that is equal to length of the lip of the connector when the connector is fully installed. As such, the operator installing the connector continues to push on the connector until the end of the lip aligns with the end of the ring.

Owner:JAZOWSKI ROY E +1

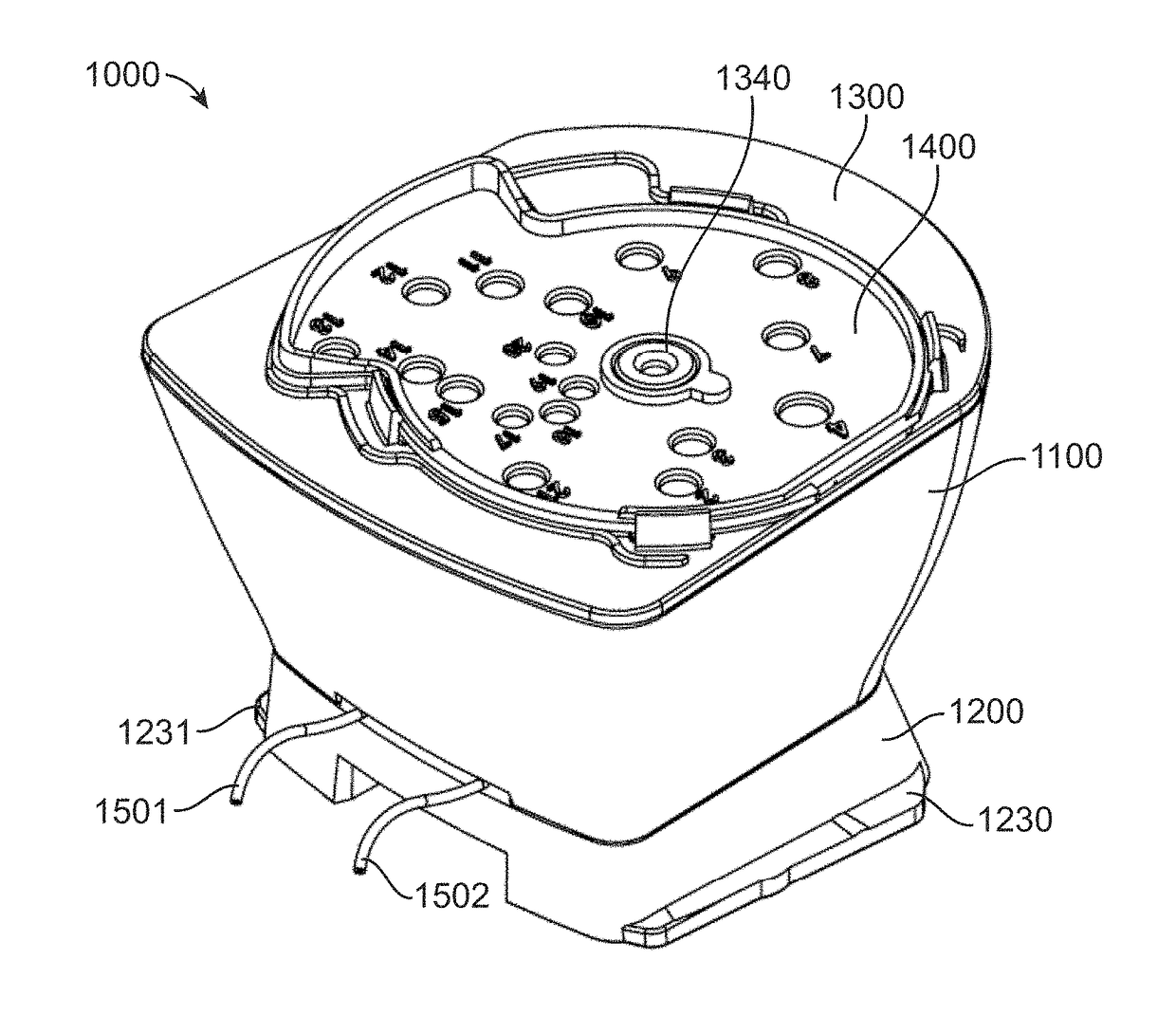

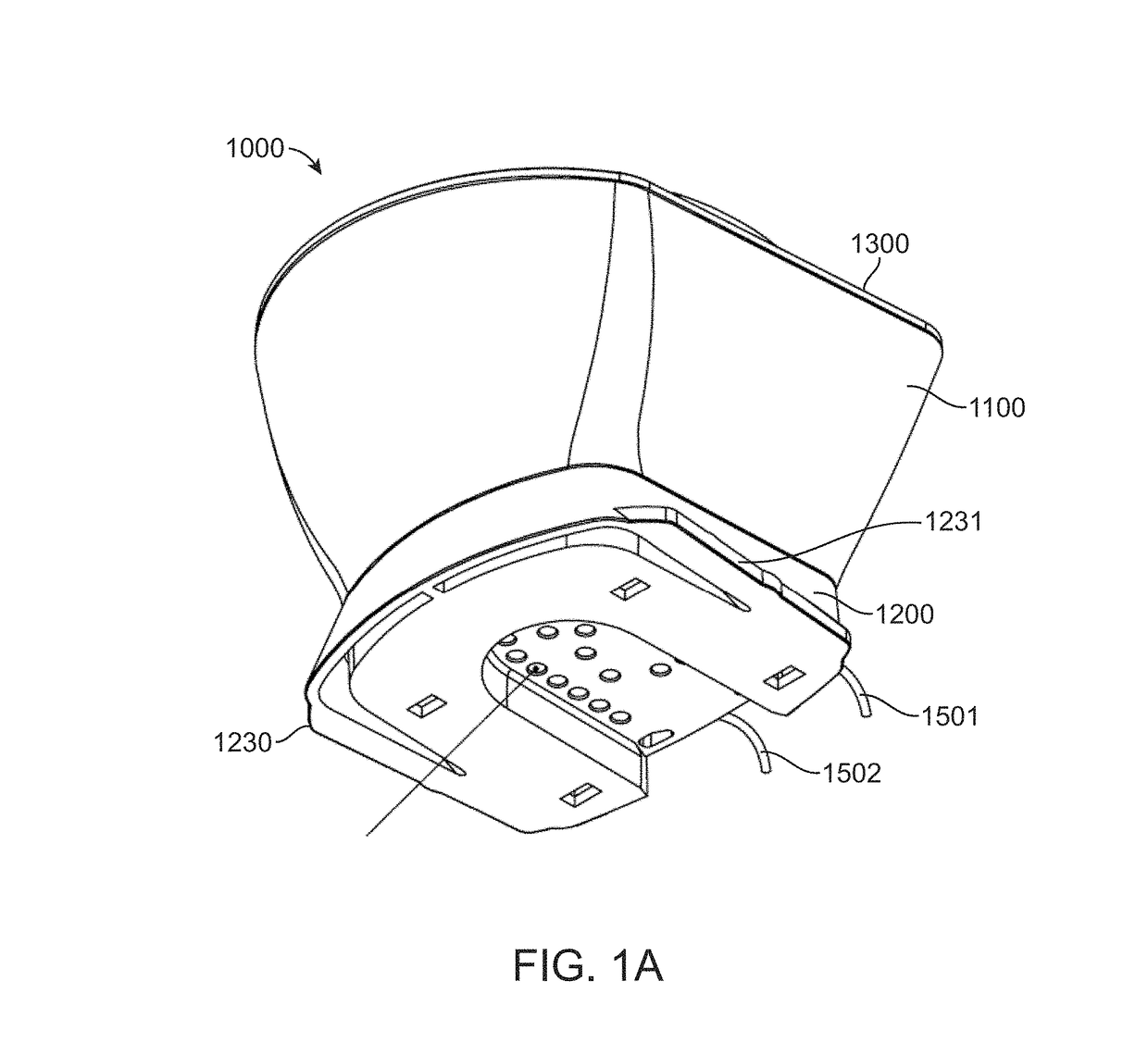

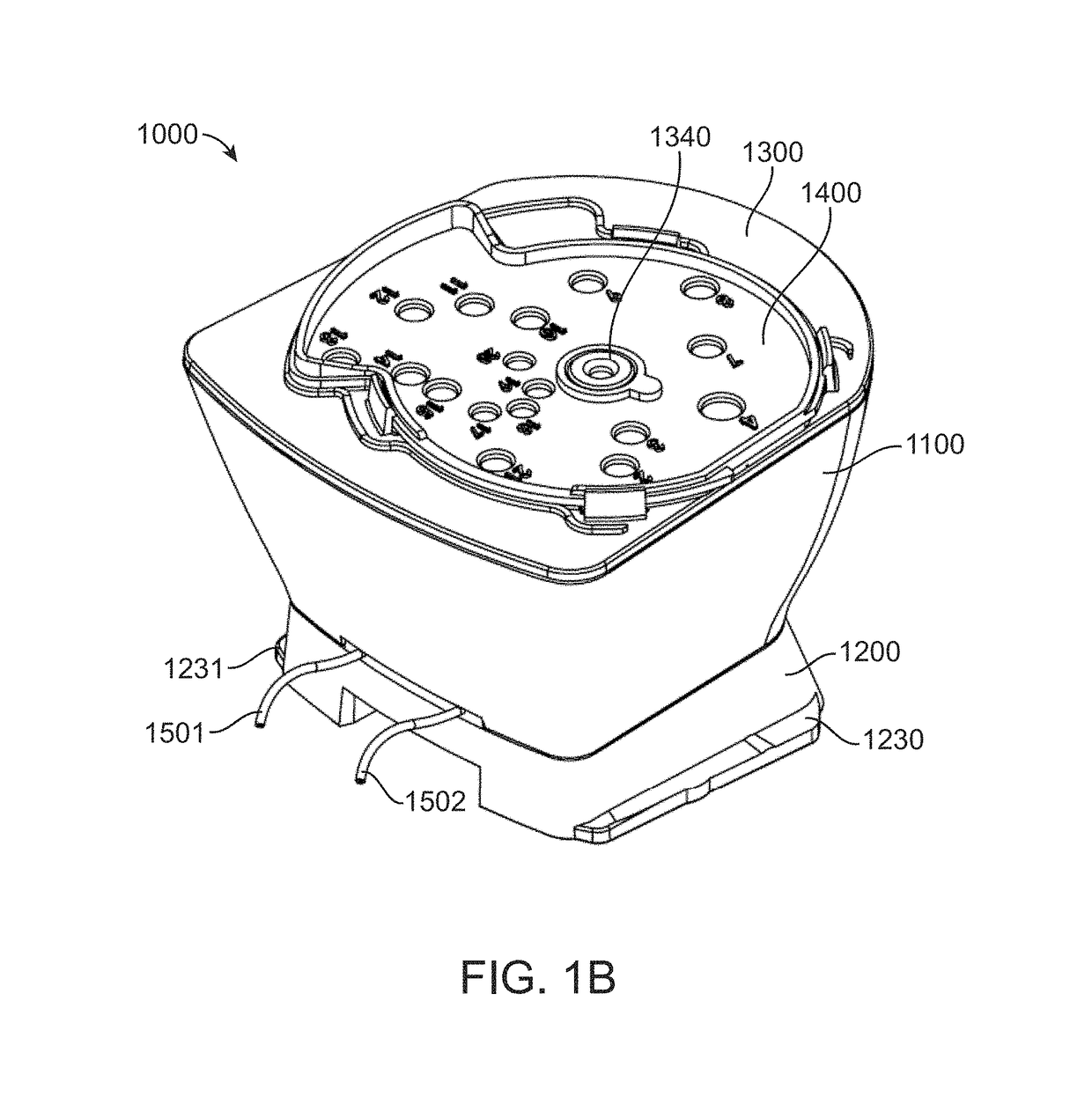

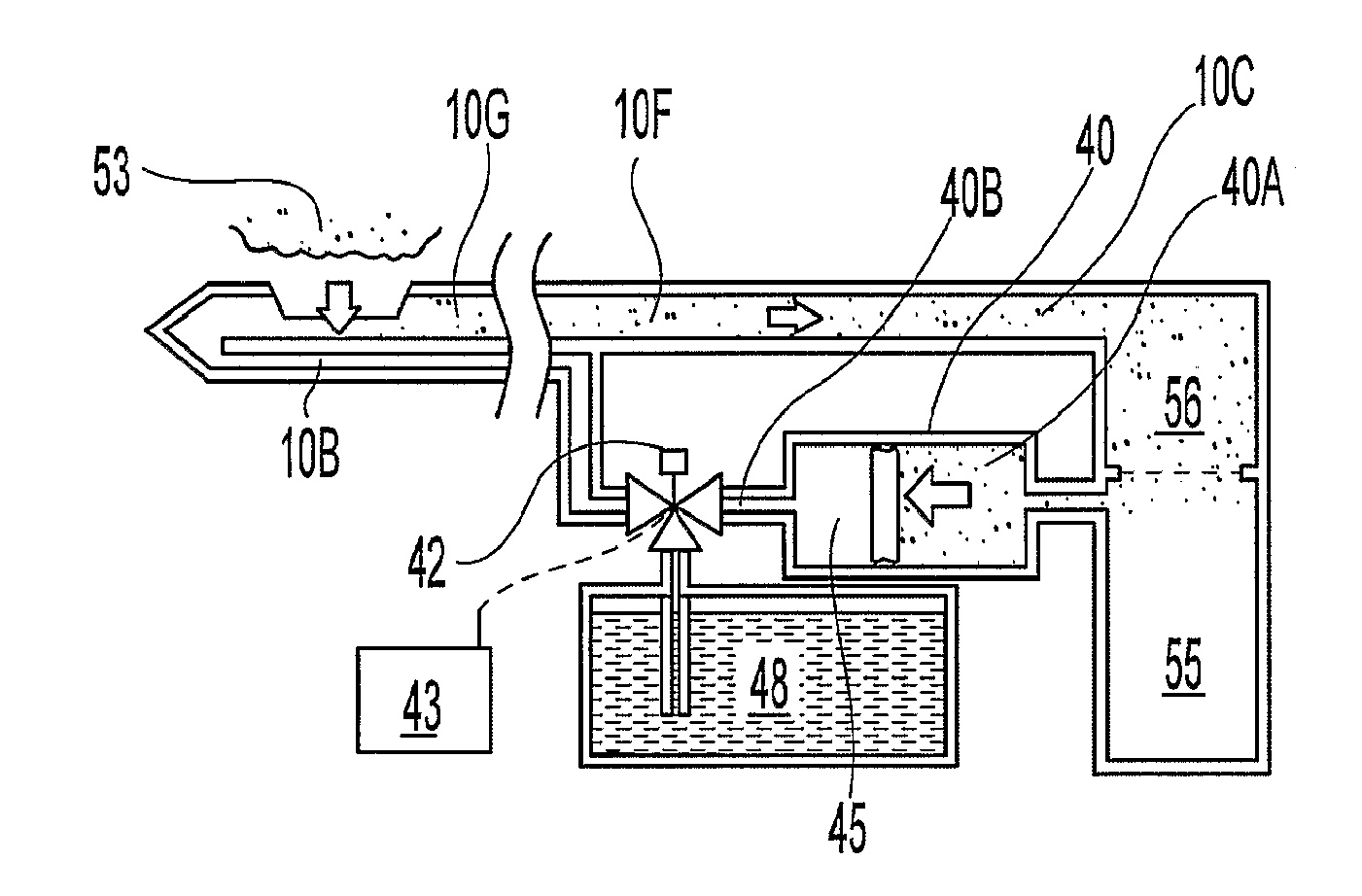

Fluidic apparatus and methods useful for chemical and biological reactions

ActiveUS20180280975A1Improve accuracyMinimize cross contaminationComponent separationMicrobiological testing/measurementElastomerDiaphragm valve

A reagent cartridge including (a) a support having reservoirs; (b) a main channel within the support, the channel having first and second ends exiting the support; (c) a pump channel that connects to the main channel between the first and second ends; (d) a valve manifold in the support, including (i) a first passage at the first end of the main channel, (ii) a second passage at the second end of the main channel, (iii) a first master valve between the pump channel and the first end of the main channel, (iv) a second master valve between the pump channel and the second end of the main channel, and (v) reservoir valves for regulating flow from individual reservoirs to the main channel. The valves can be normally closed diaphragm valves formed by magnetic pistons attached to an elastomeric sheet that is sandwiched in the support.

Owner:PACIFIC BIOSCIENCES

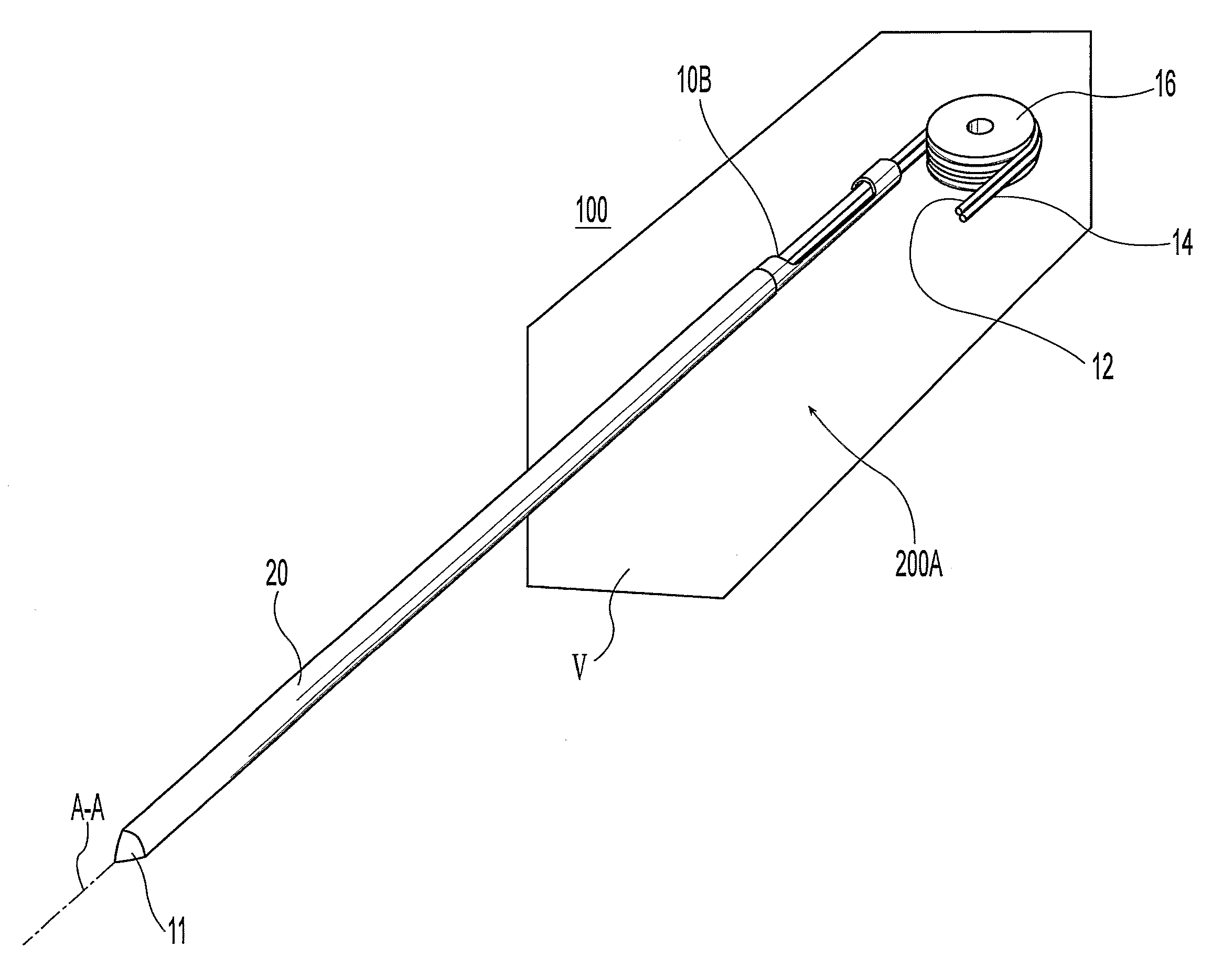

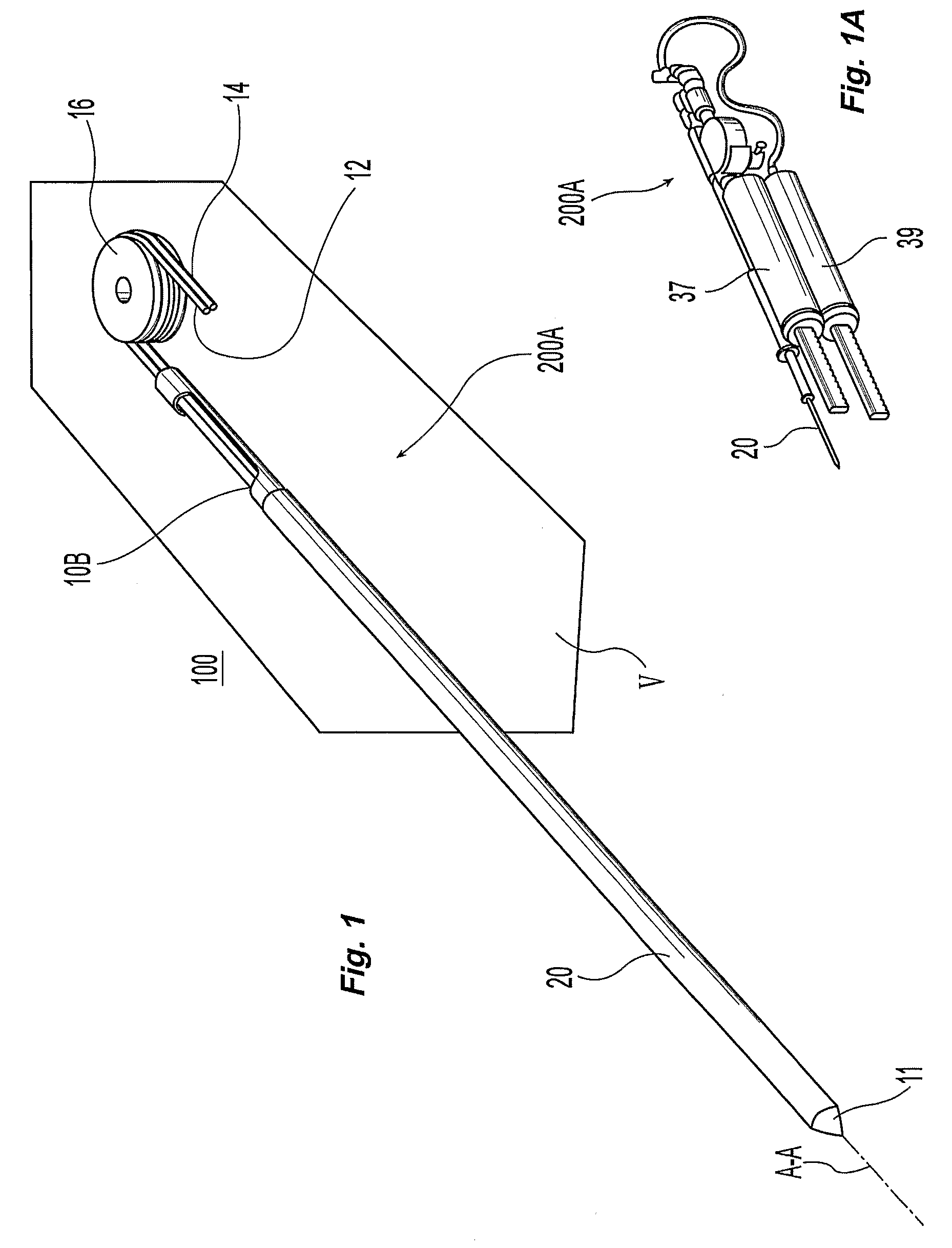

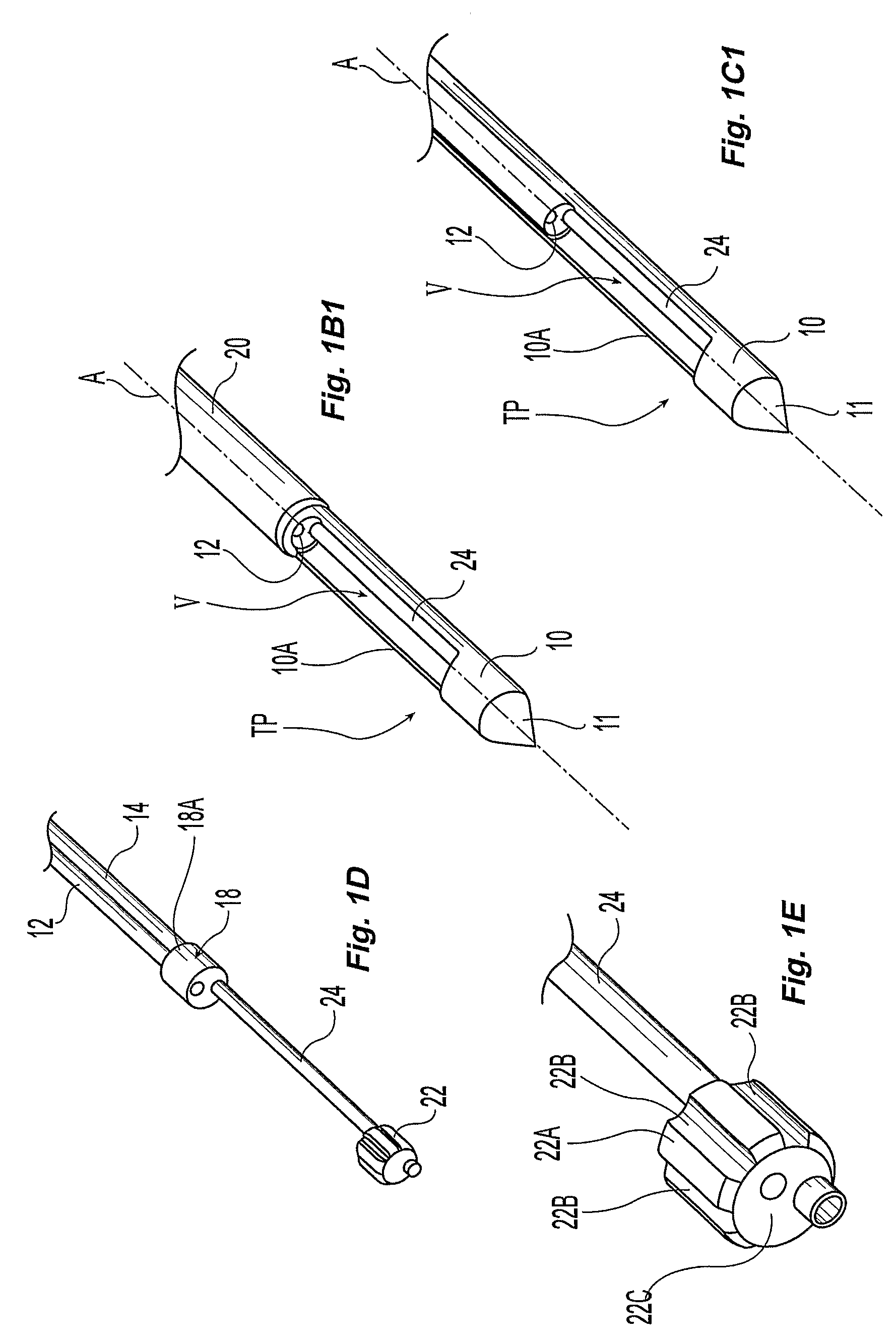

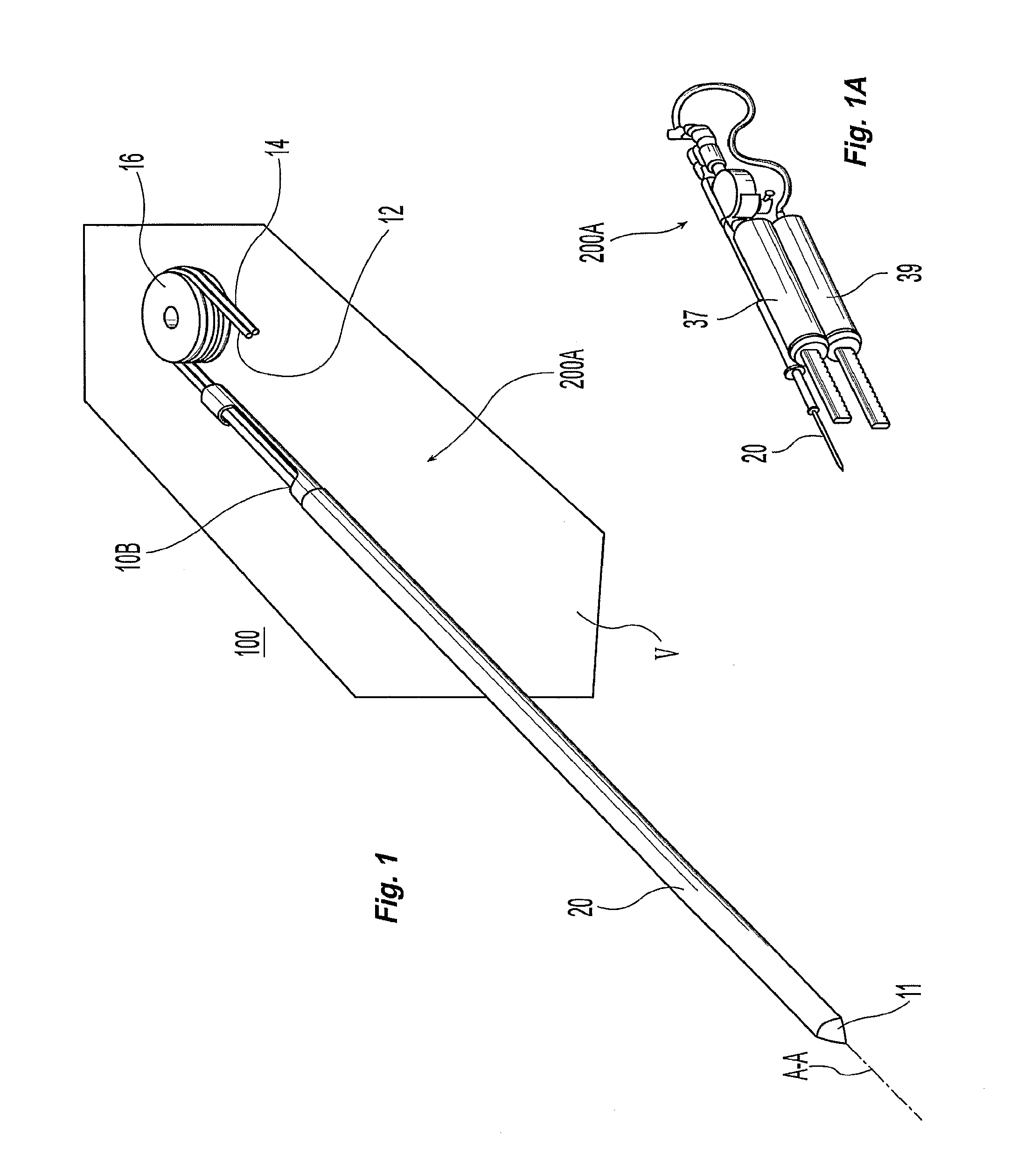

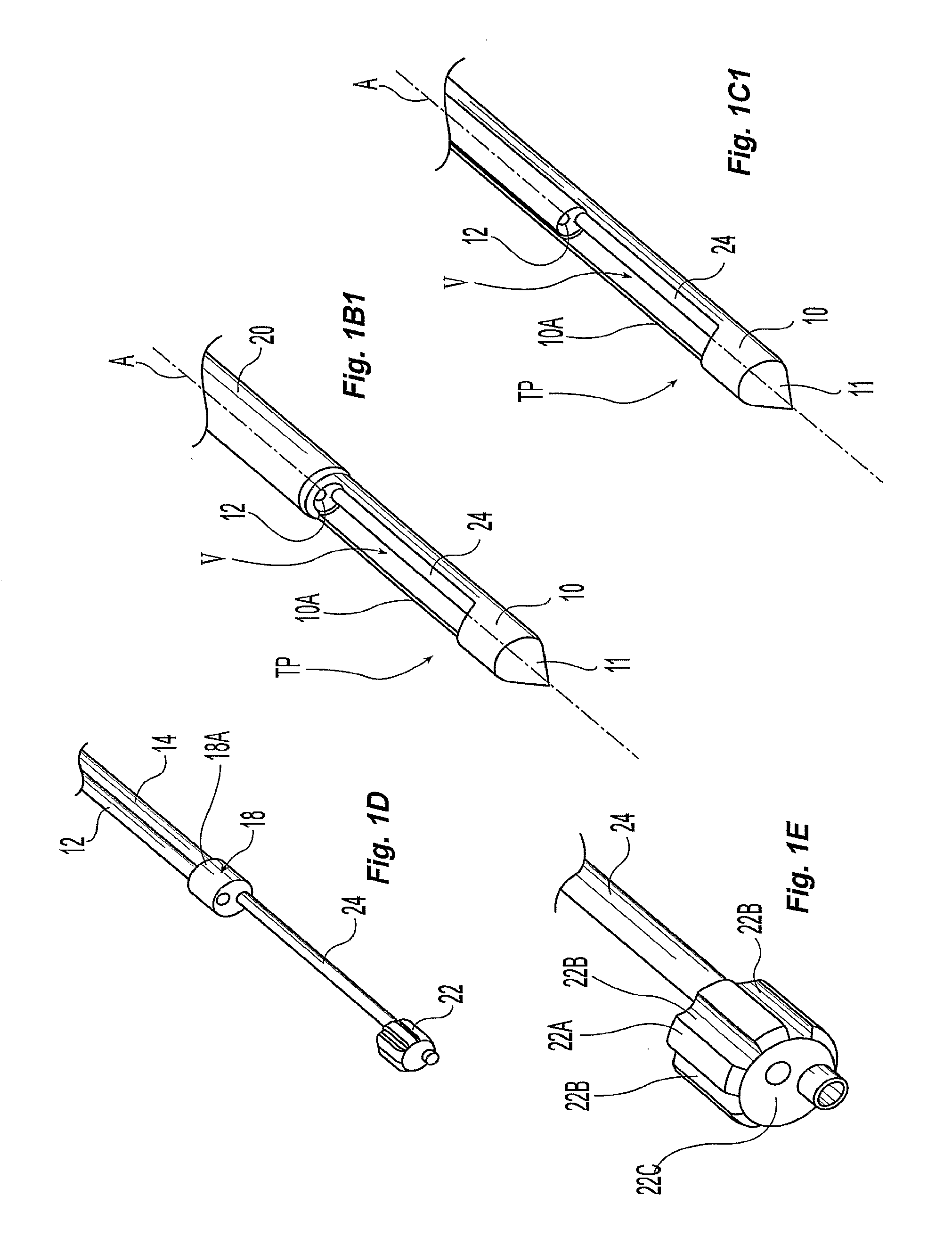

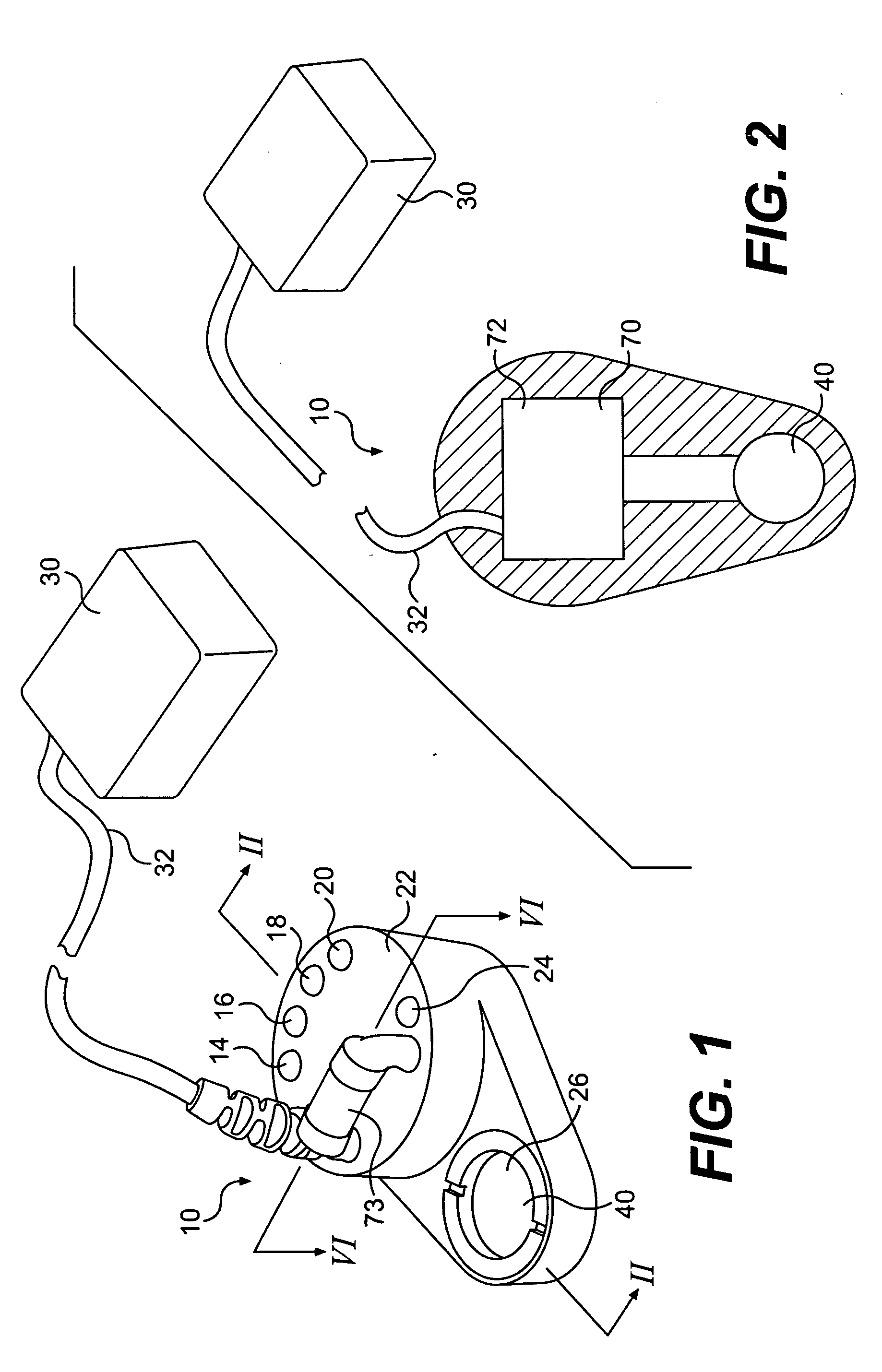

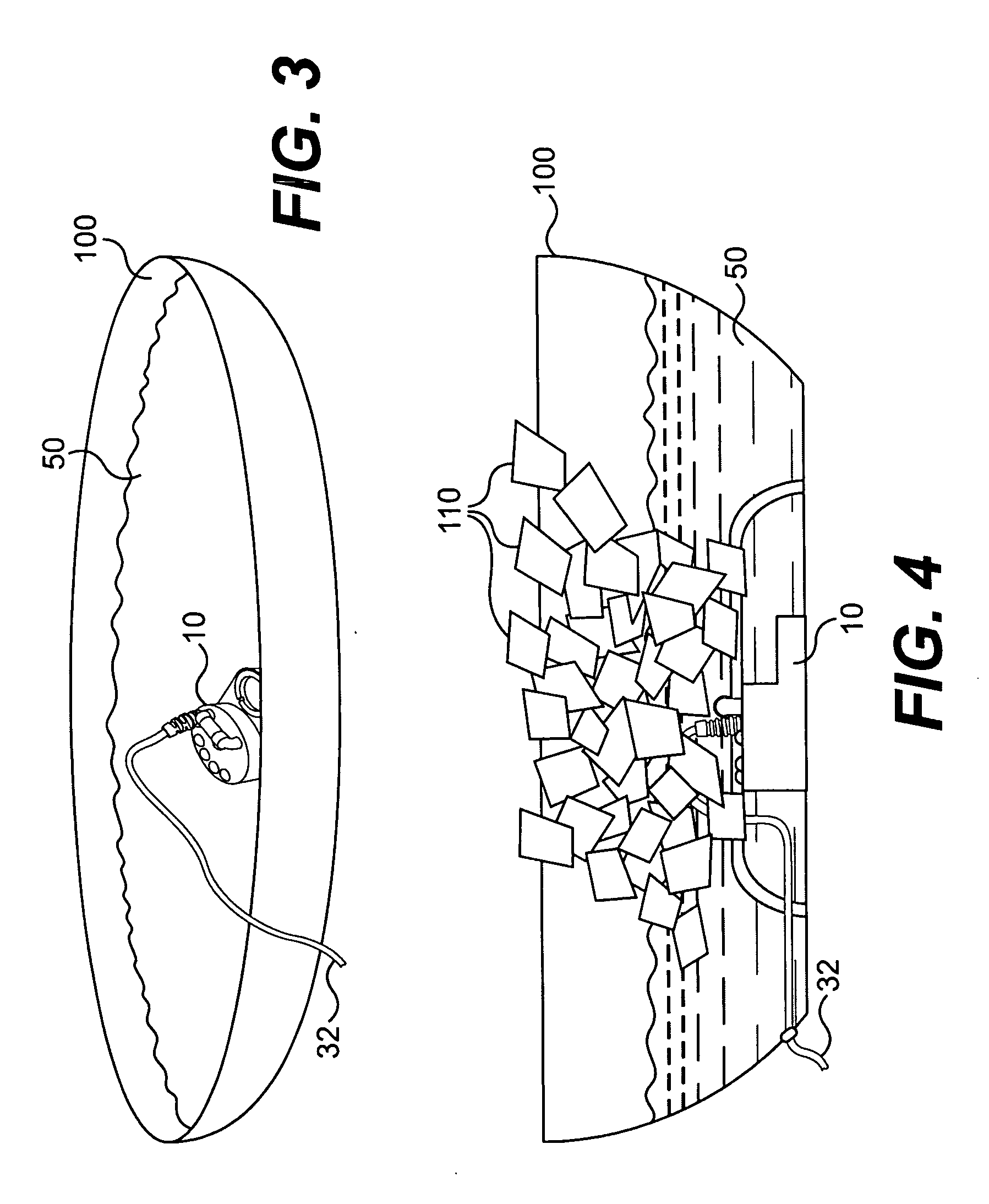

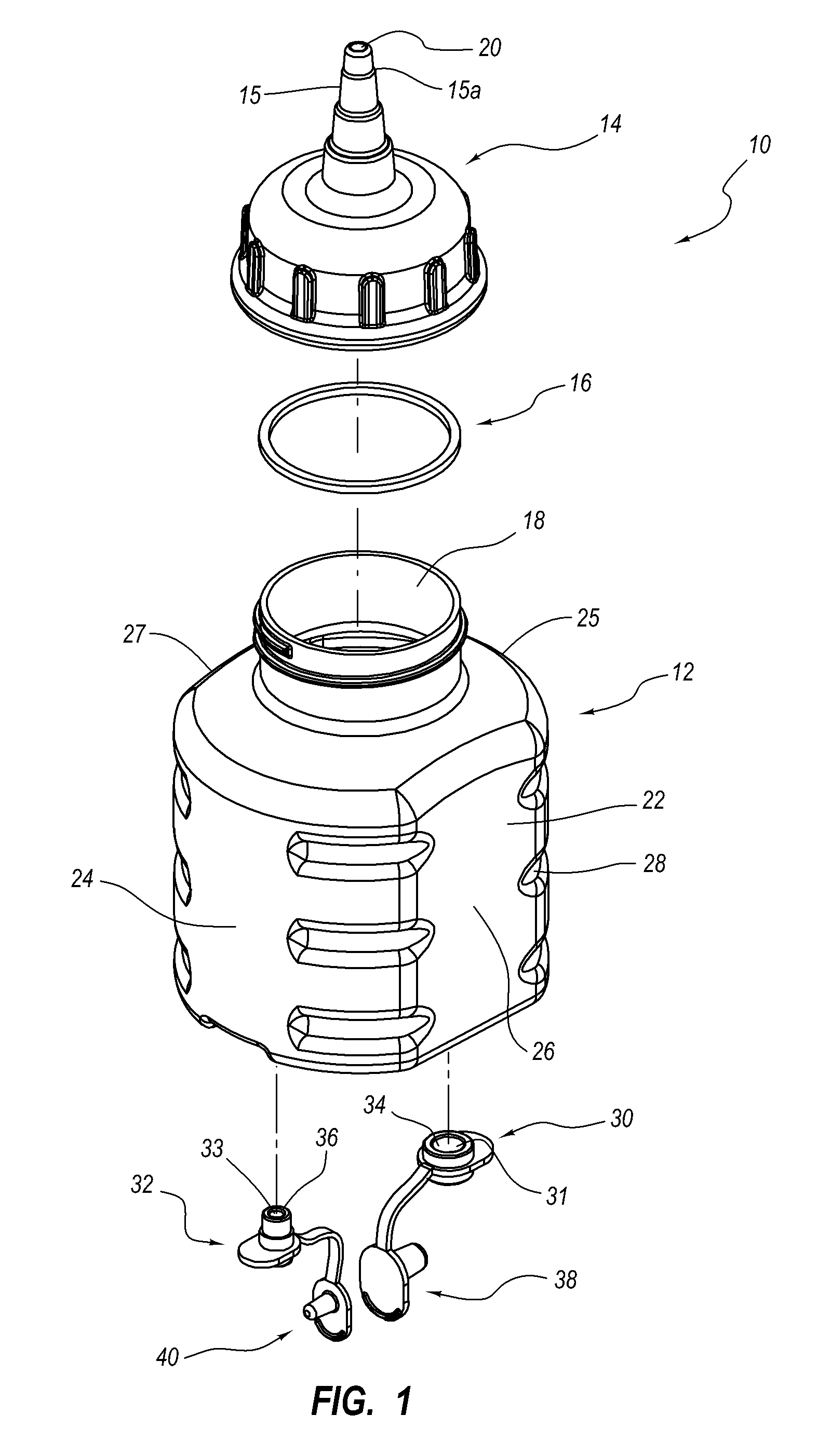

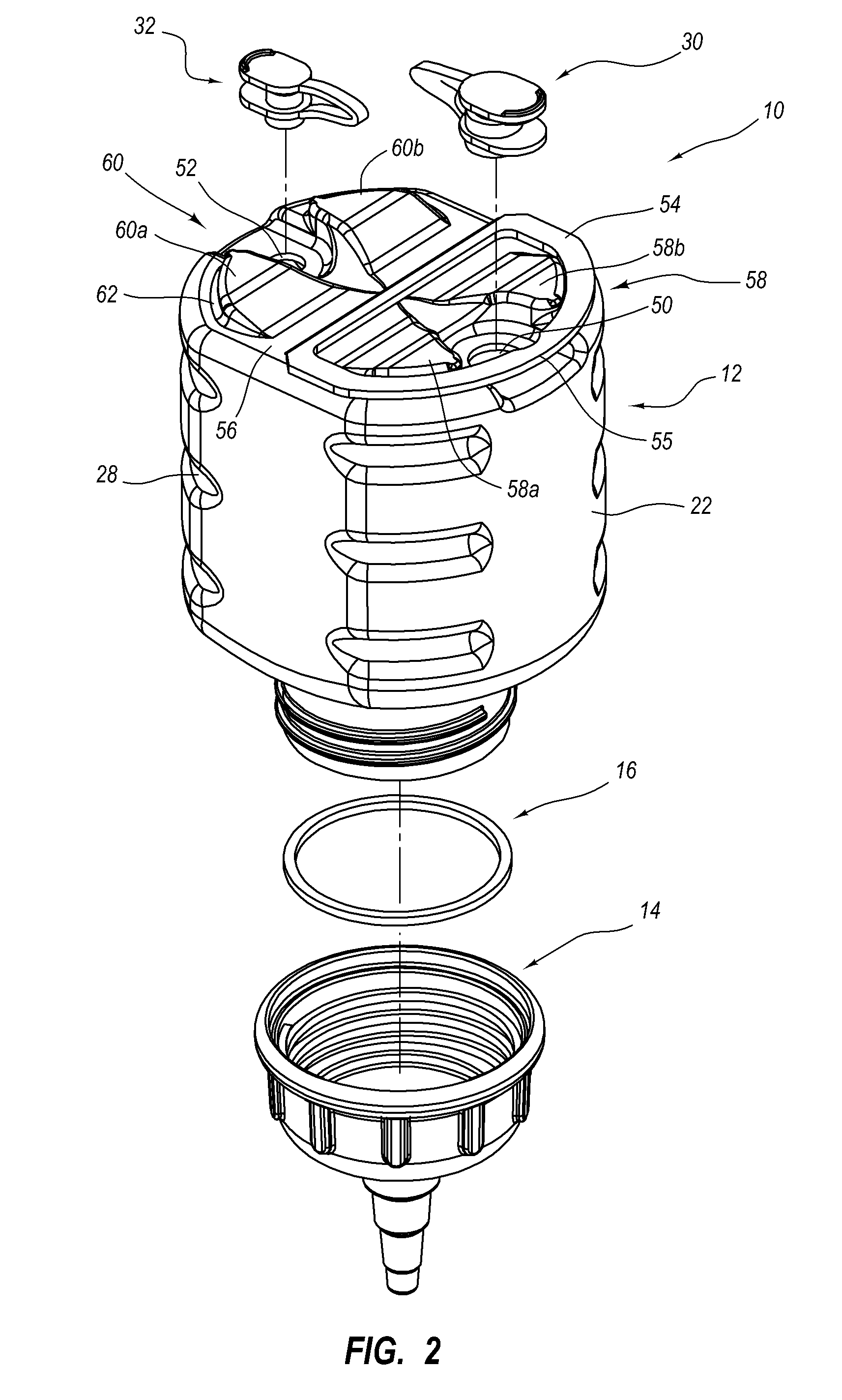

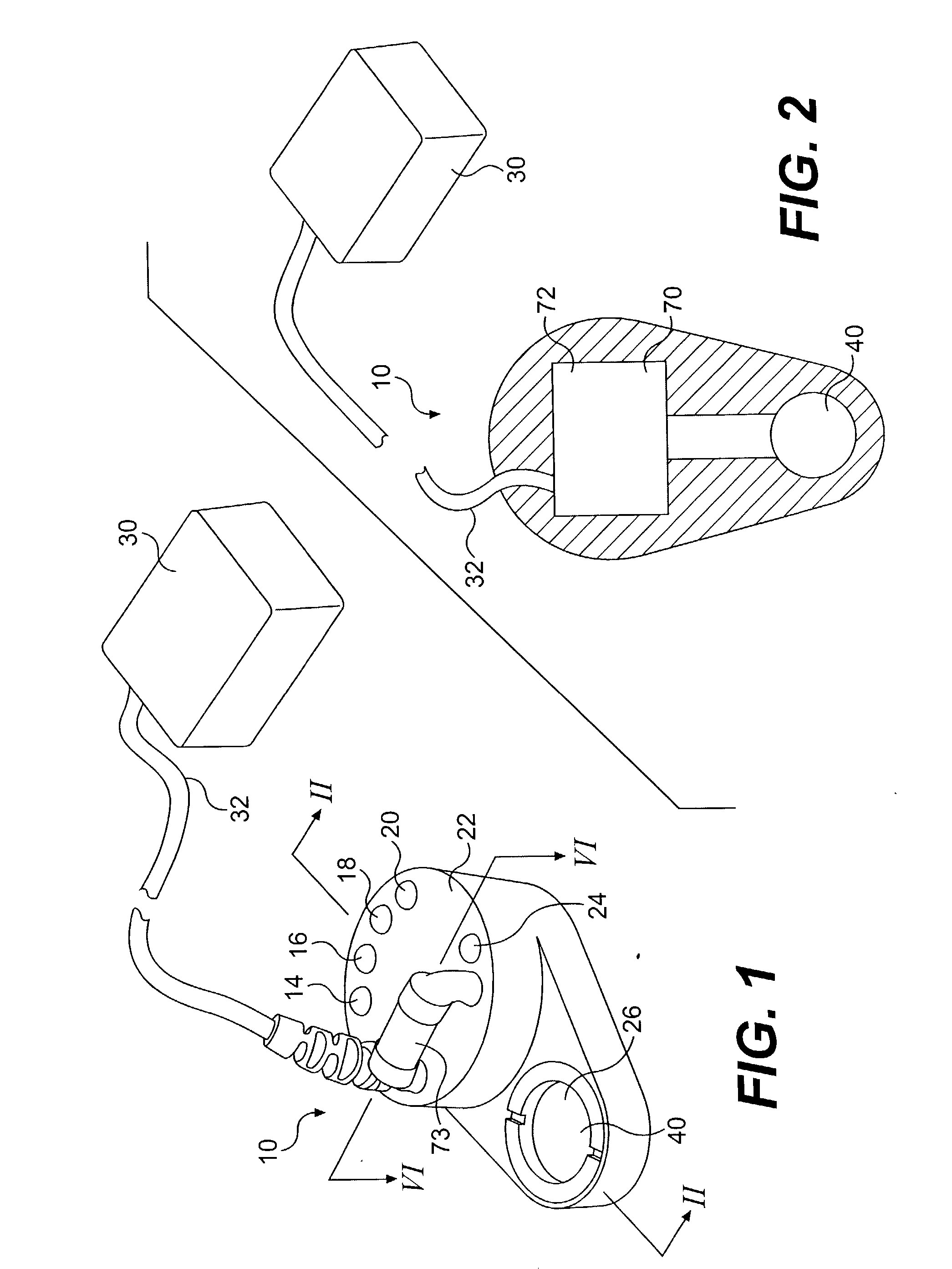

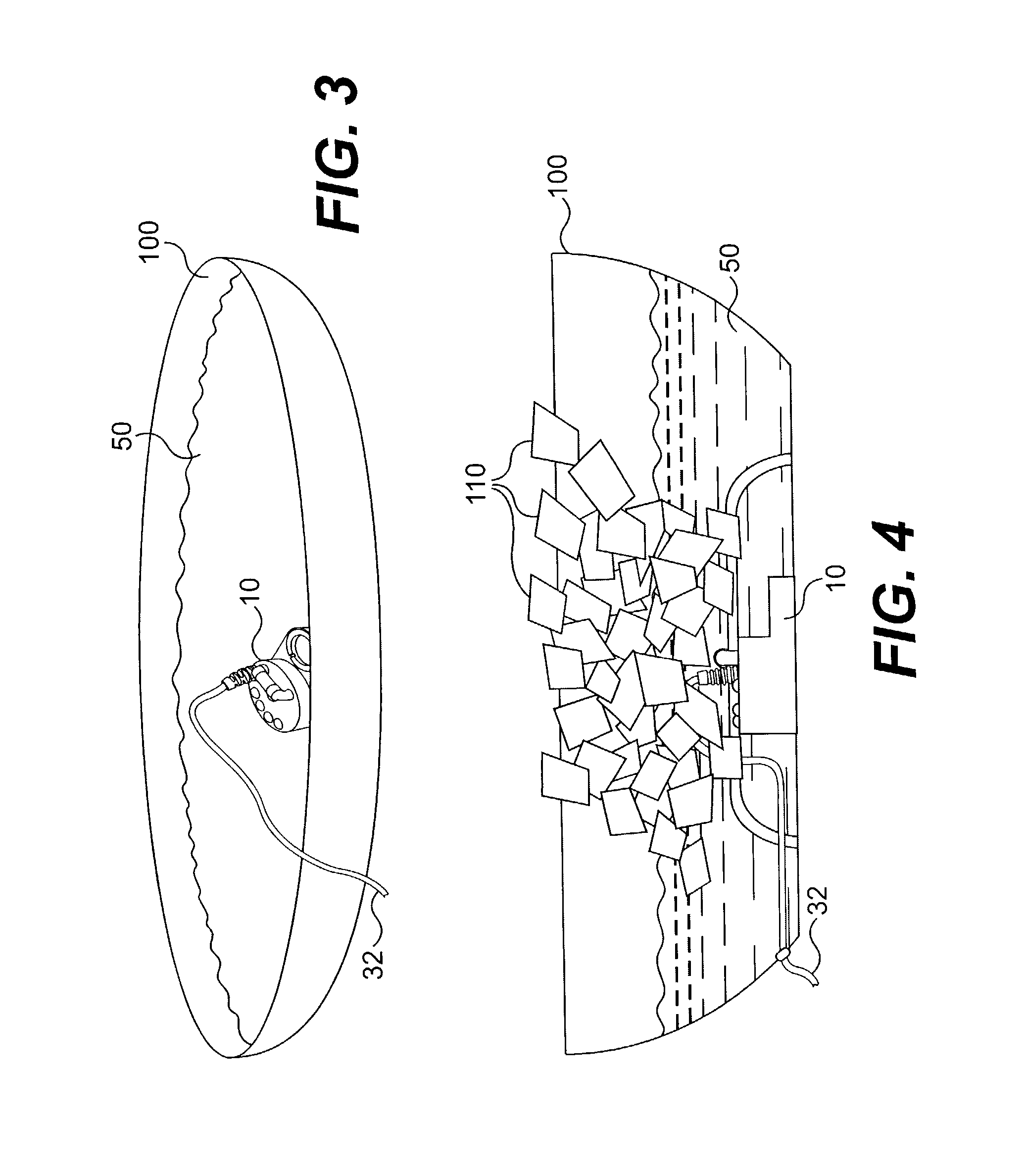

Single-insertion, multiple sample biopsy device with integrated markers

ActiveUS8267868B2Effective rigidityAvoid vacuumingSurgeryVaccination/ovulation diagnosticsBiopsy deviceBiomedical engineering

Owner:CR BARD INC

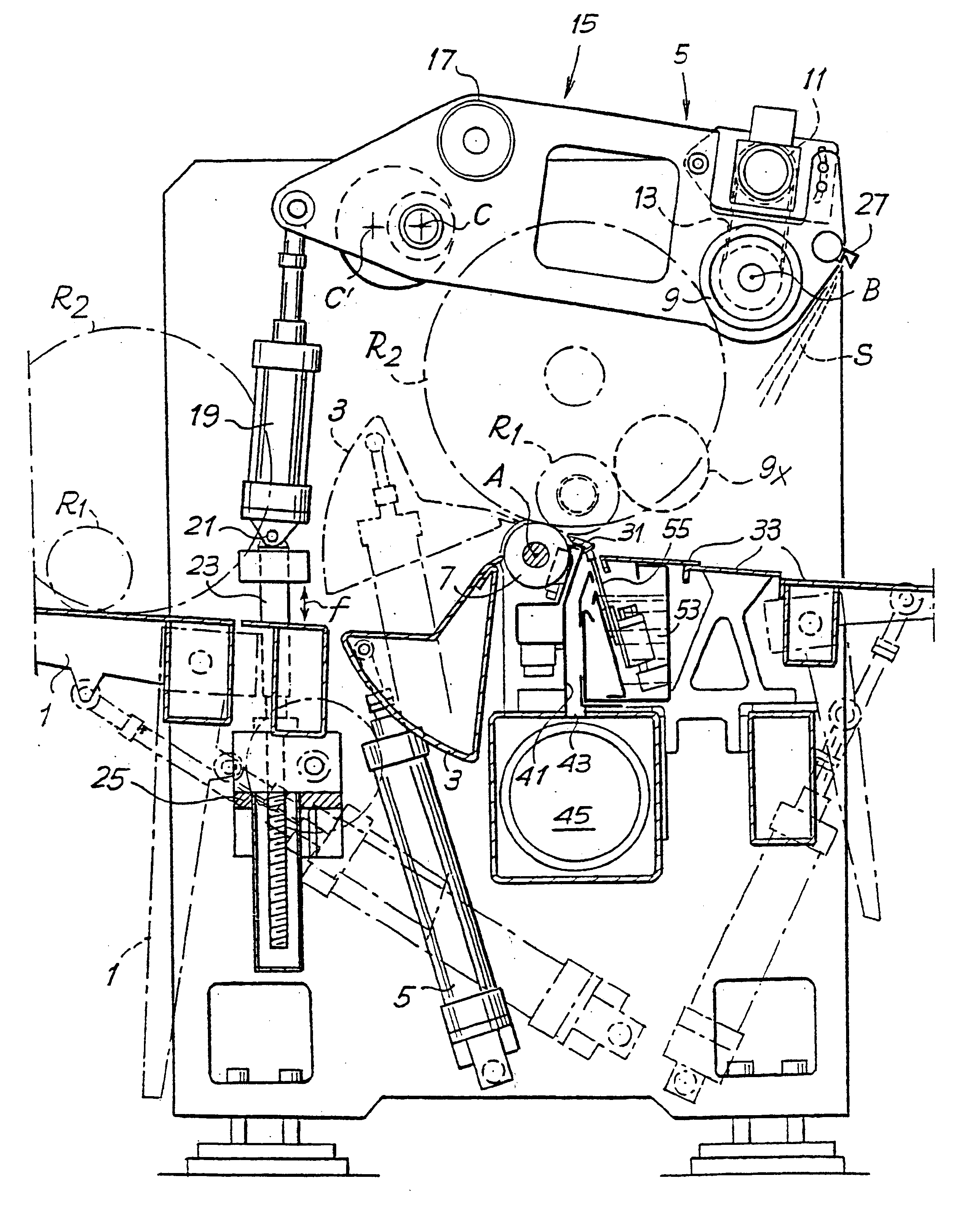

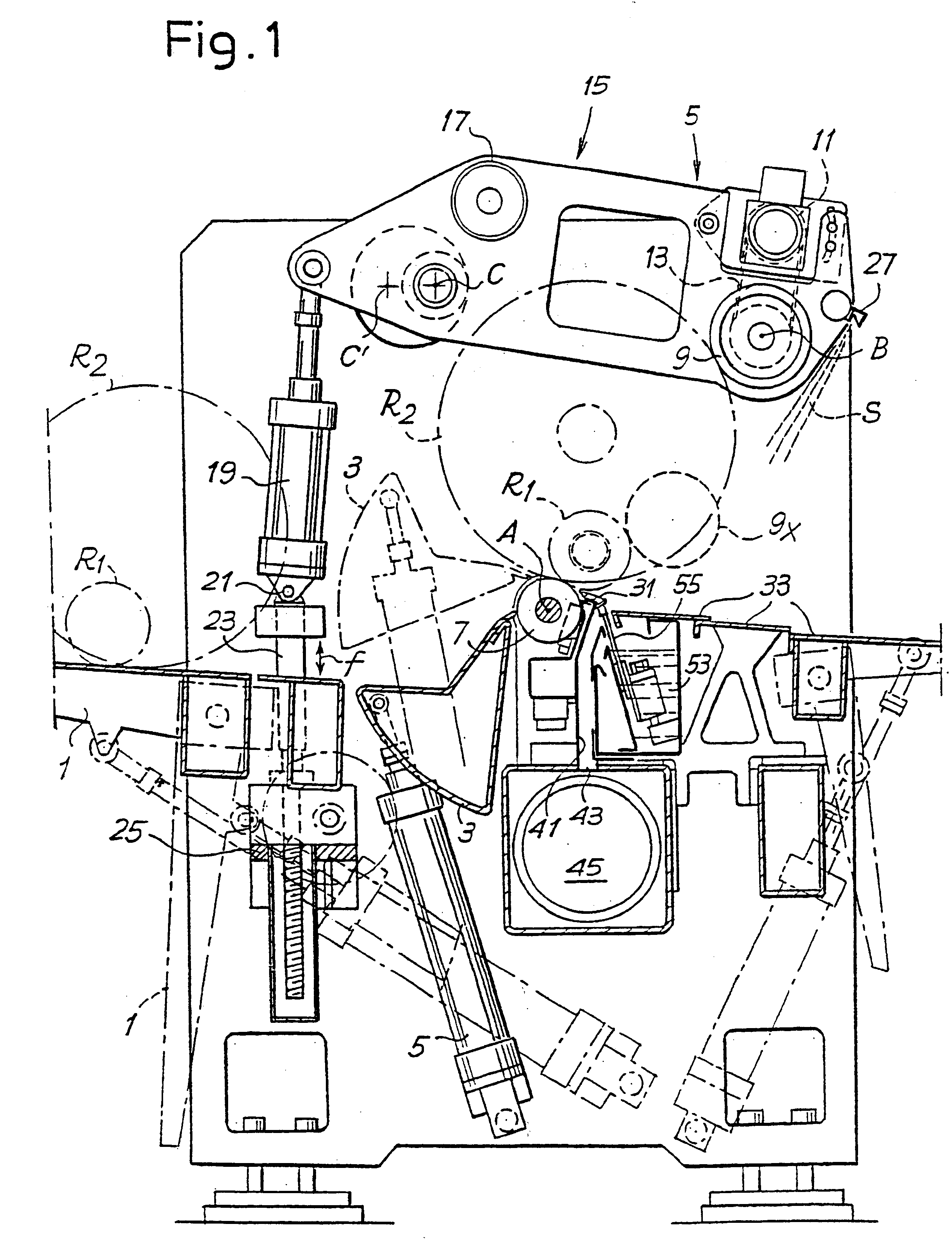

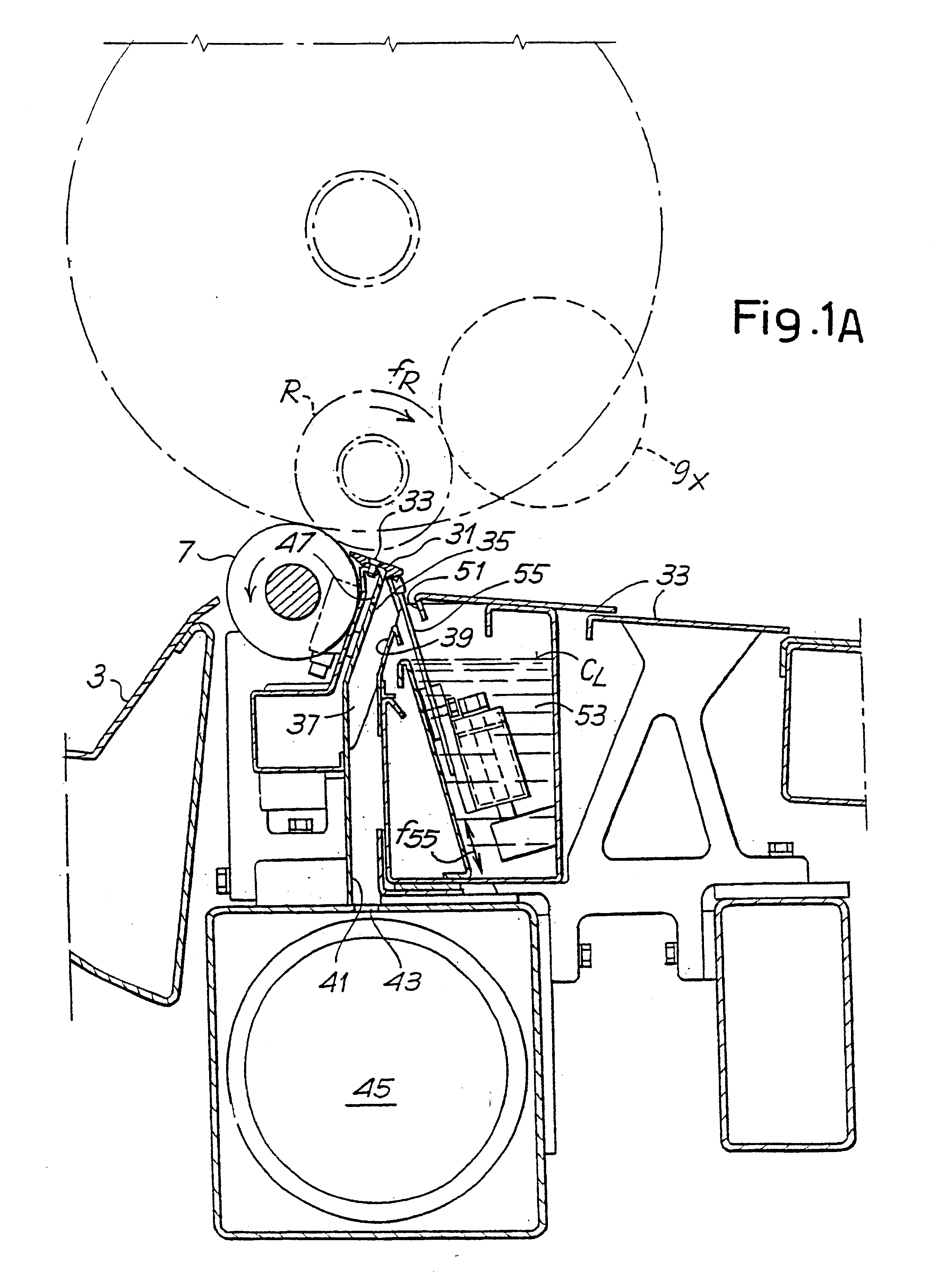

Device for gluing rolls of web material and associated method

InactiveUS6682623B1Improve adhesionEasy to operateLayered productsLabelling machinesMechanical engineering

The device comprises: a feed path for a roll to be glued; along said path a station for unwinding and positioning the tail edge of the roll; in said unwinding and positioning station, a first movable member (7) and a second movable member (9) make contact with said roll (R). A glue dispenser comprising a glue reservoir (53) and a dispensing element (55) movable along a dispensing path is also provided.

Owner:FABIO PERINI SPA

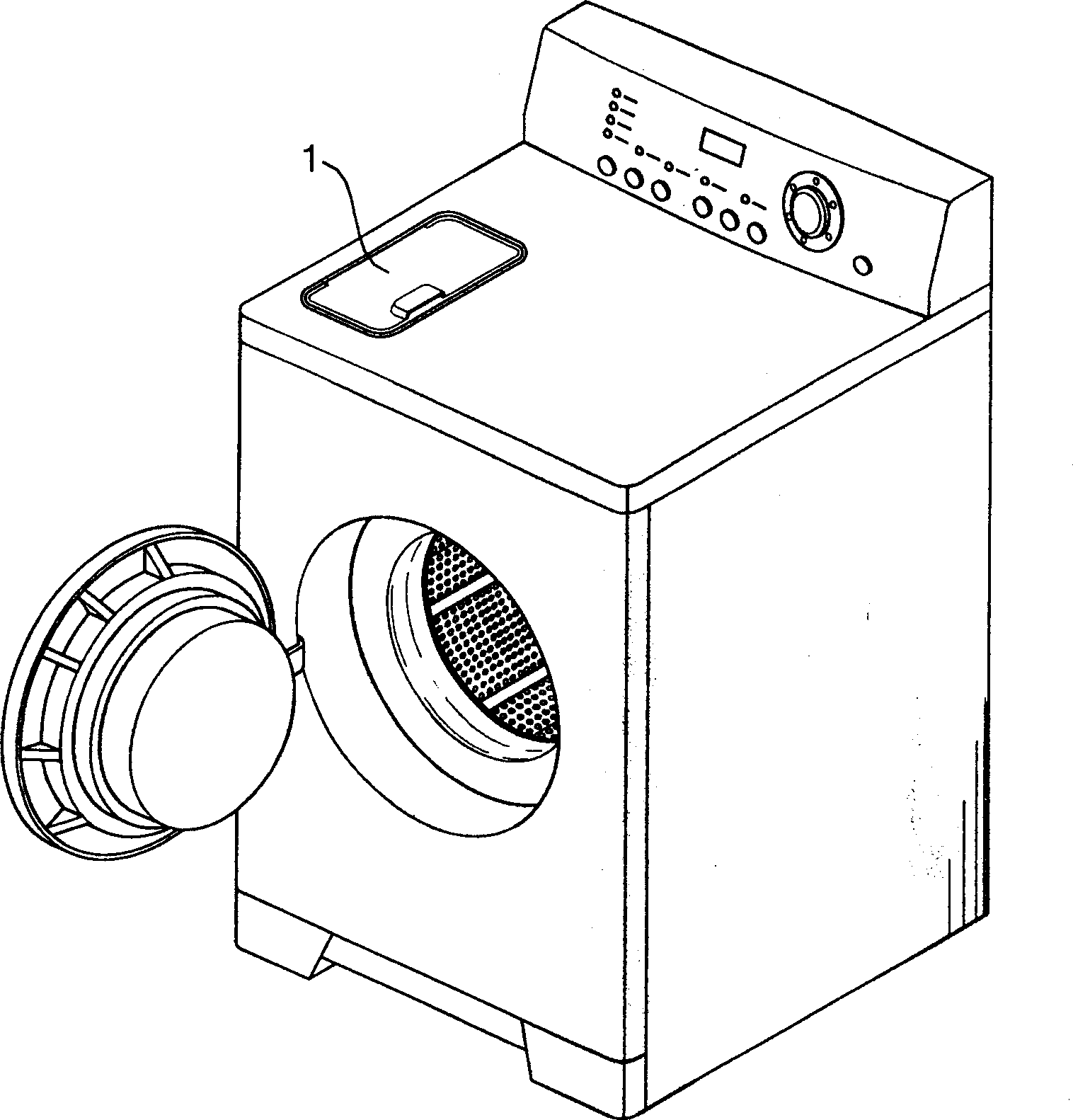

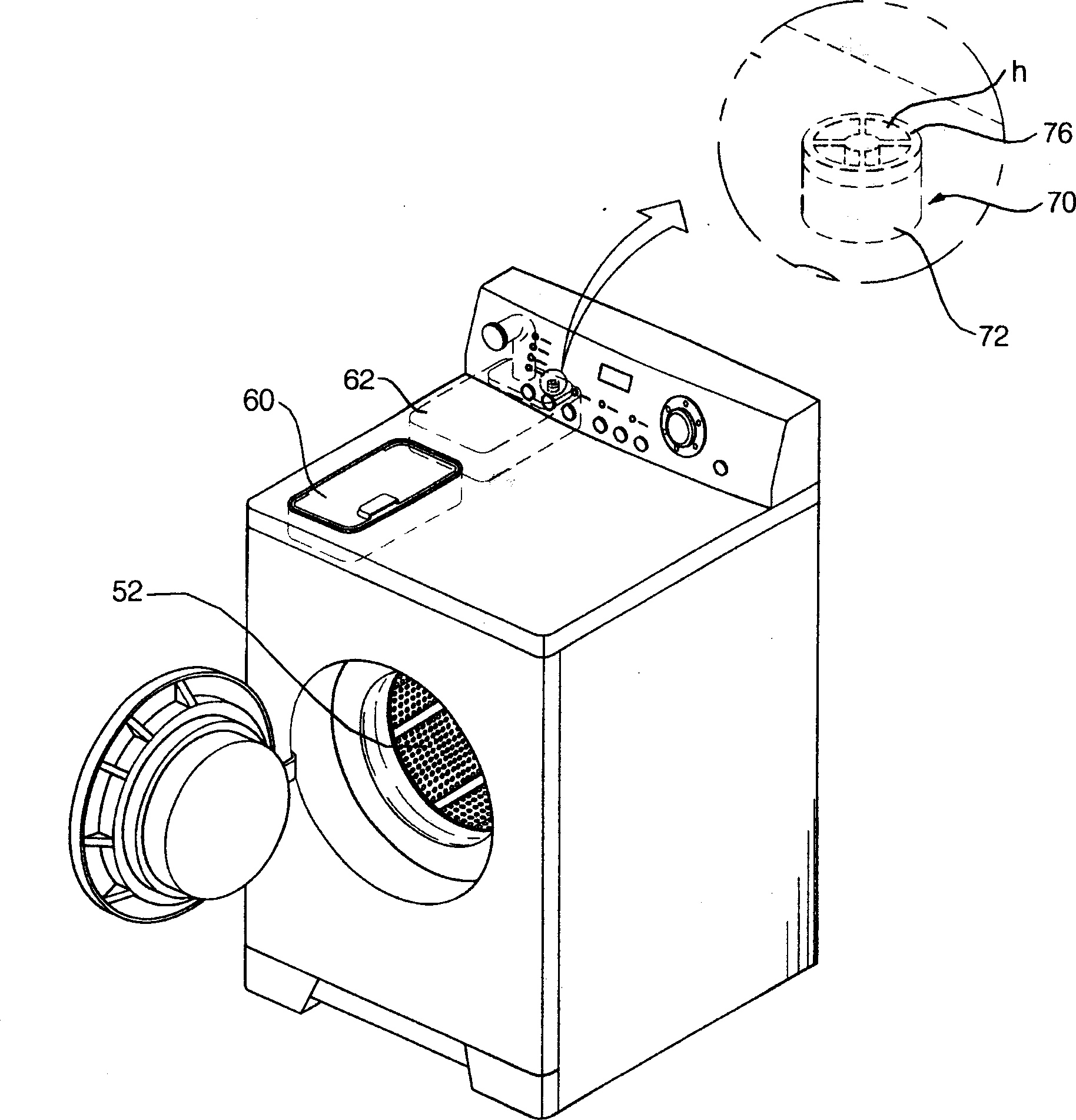

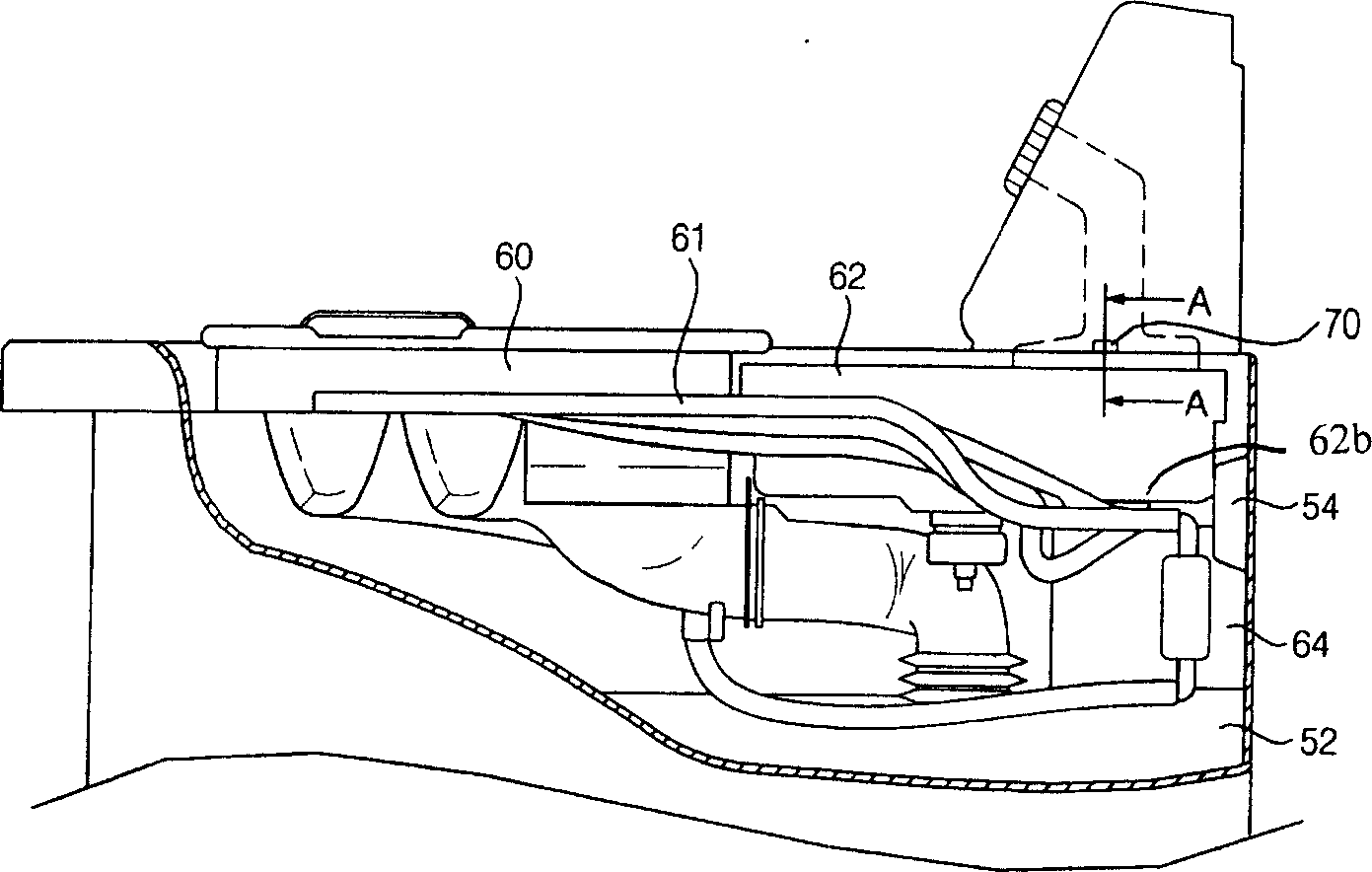

Detergent put-in device for washing machine

InactiveCN1749473ASimple structureAvoid vacuumingOther washing machinesTextiles and paperOrganic chemistry

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

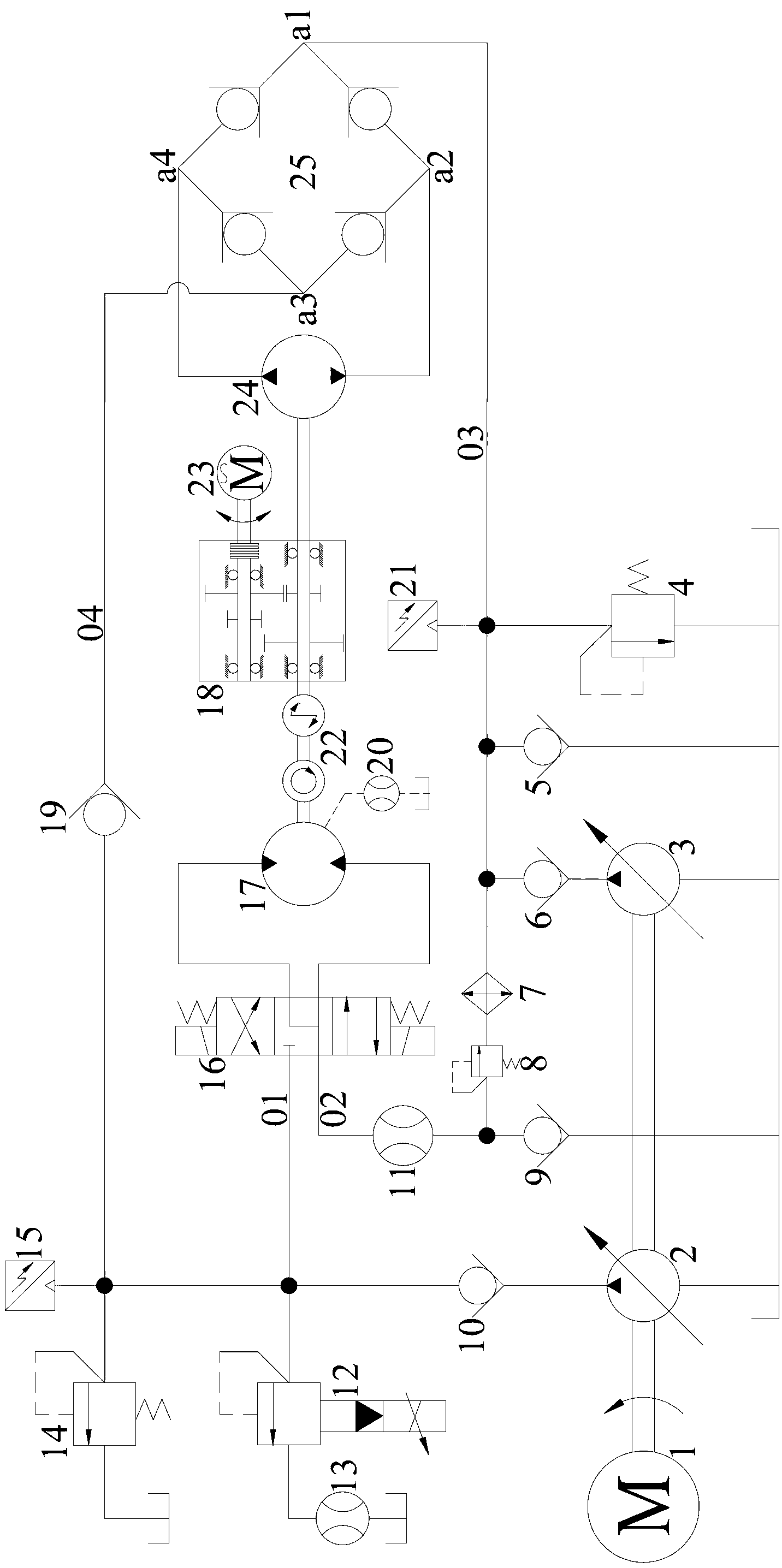

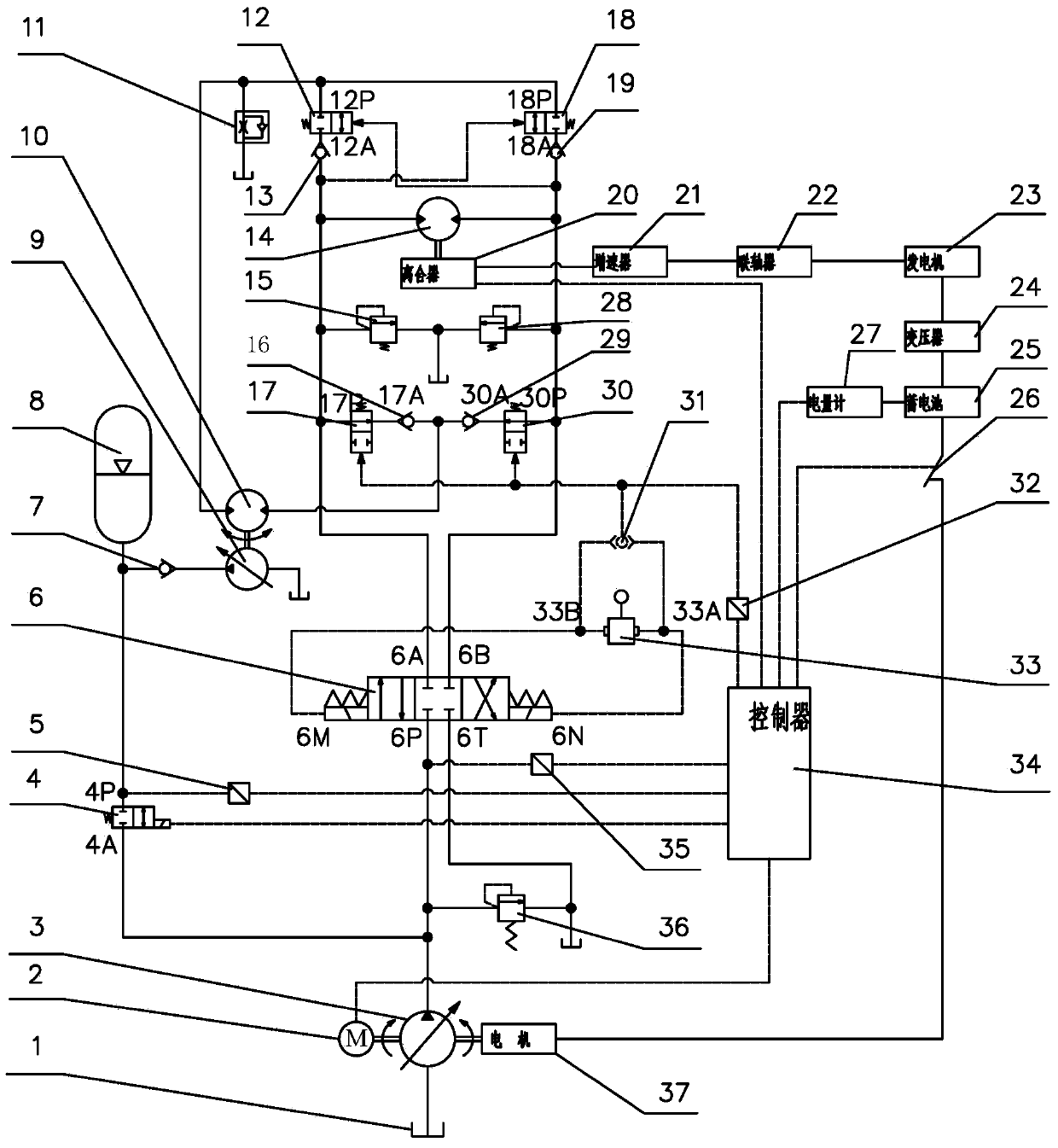

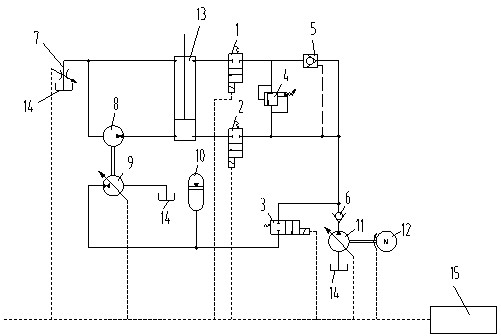

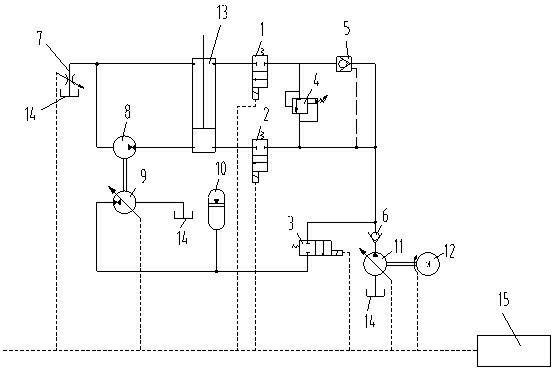

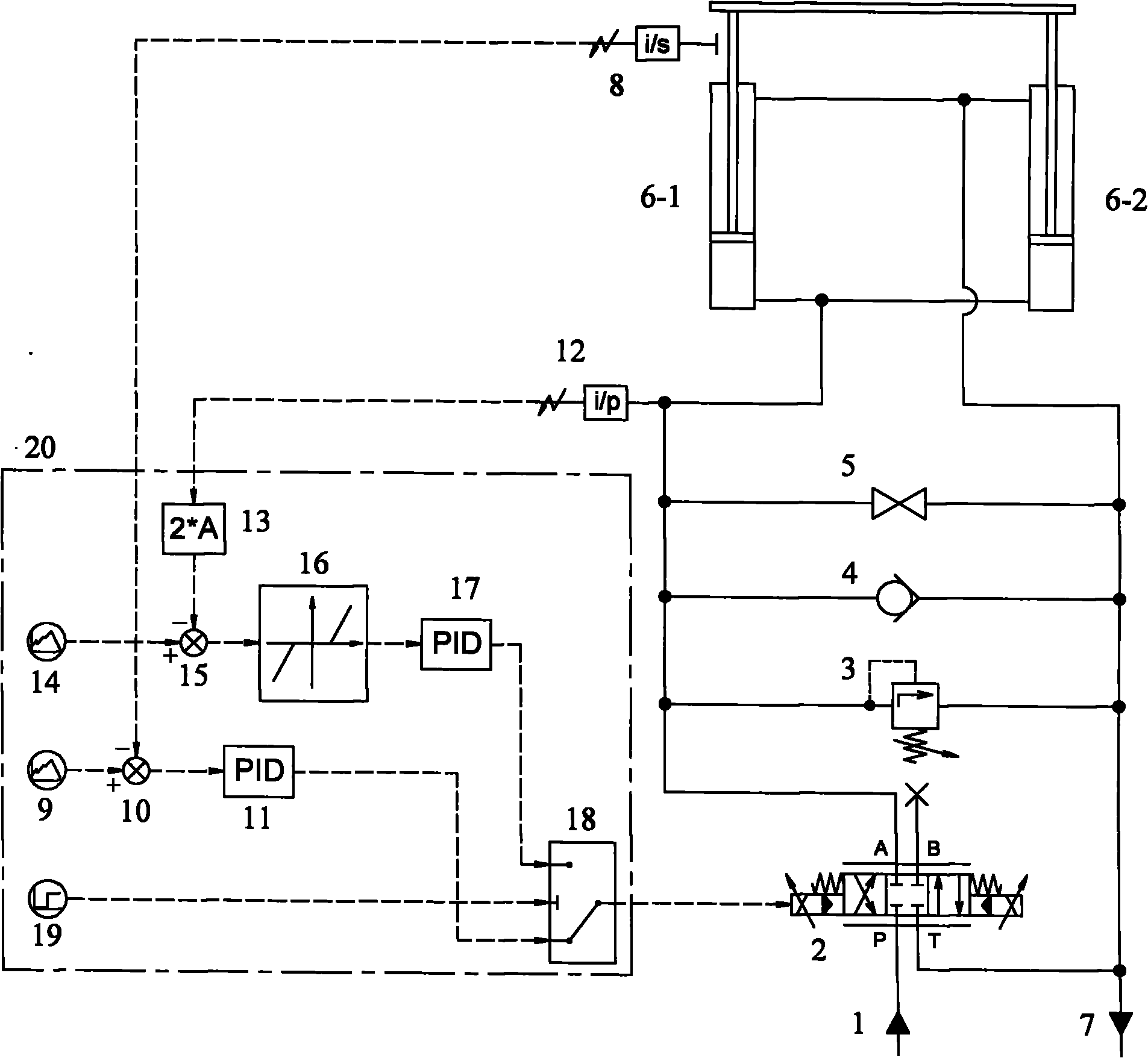

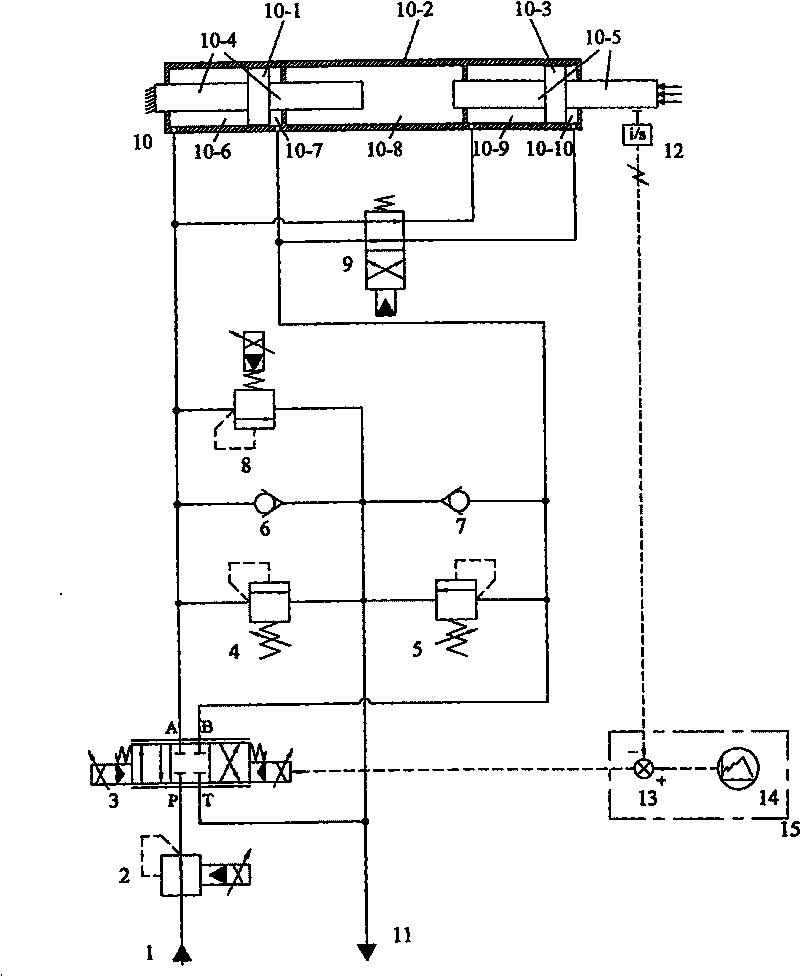

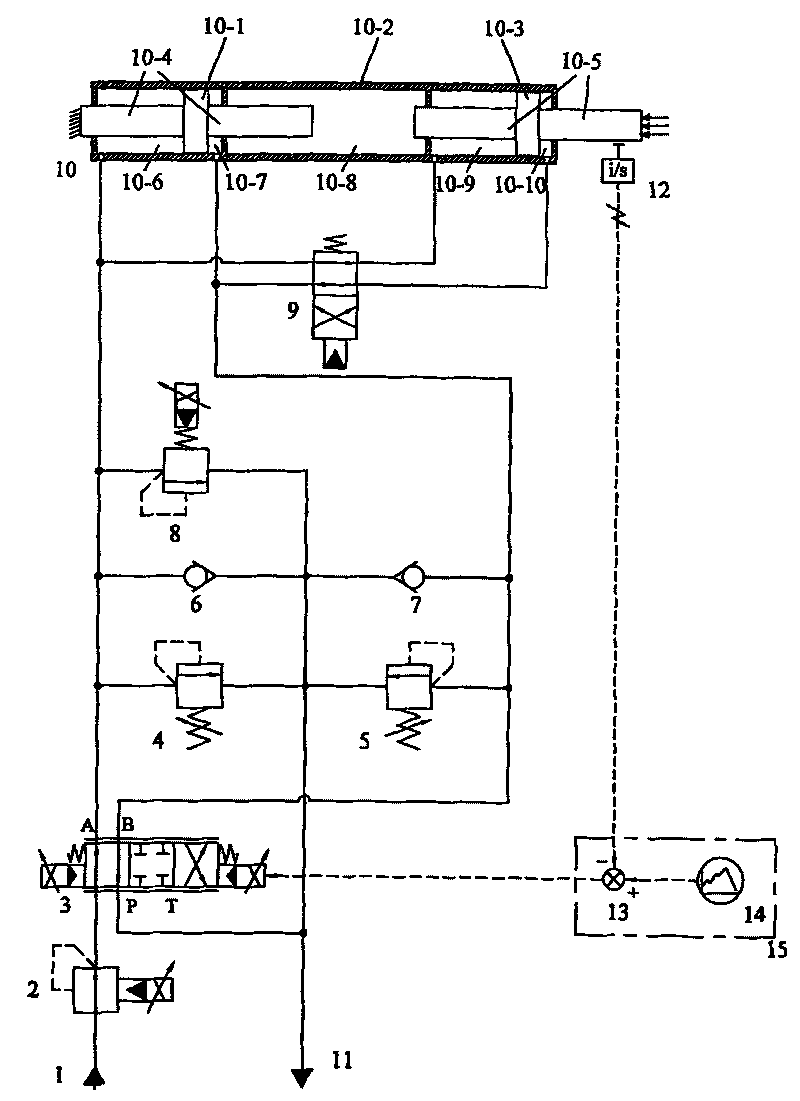

Testing system of hydraulic motor

InactiveCN102937125AImprove stabilityImprove recycling efficiencyFluid-pressure actuator testingHydraulic motorInlet channel

The invention relates to the technical field of motor tests and discloses a testing system of a hydraulic motor. The testing system of the hydraulic motor comprises a motor, a speed changing box, a tested motor, a loading motor, a first oil way, a second oil way, a feedback oil way and a compensation oil way. The speed changing box is provided with an acceleration gear and a deceleration gear, the input end of the speed changing box is in driving connection with the output end of the motor, the loading motor is butted with the tested motor through a power shaft, the output end of the speed changing box is in driving connection with the power shaft, the first oil way serves as an oil inlet channel of the tested motor, the second oil way serves as an oil return channel of the tested motor, the oil outlet end of the feedback oil way is communicated with the first oil way, and the oil outlet end of the feedback oil way selectively supplies oil for the oil inlet end of the feedback oil way or supplies oil for the oil inlet end of the feedback oil way through the loading motor. By means of the testing system, mechanical and hydraulic compensation power recovery modes or the hydraulic compensation power recovery mode can be selected according to needs, and testing requirements for power tests, service life tests, batch tests and the like on most majority of hydraulic motors can be met.

Owner:SANY AUTOMOBILE MFG CO LTD

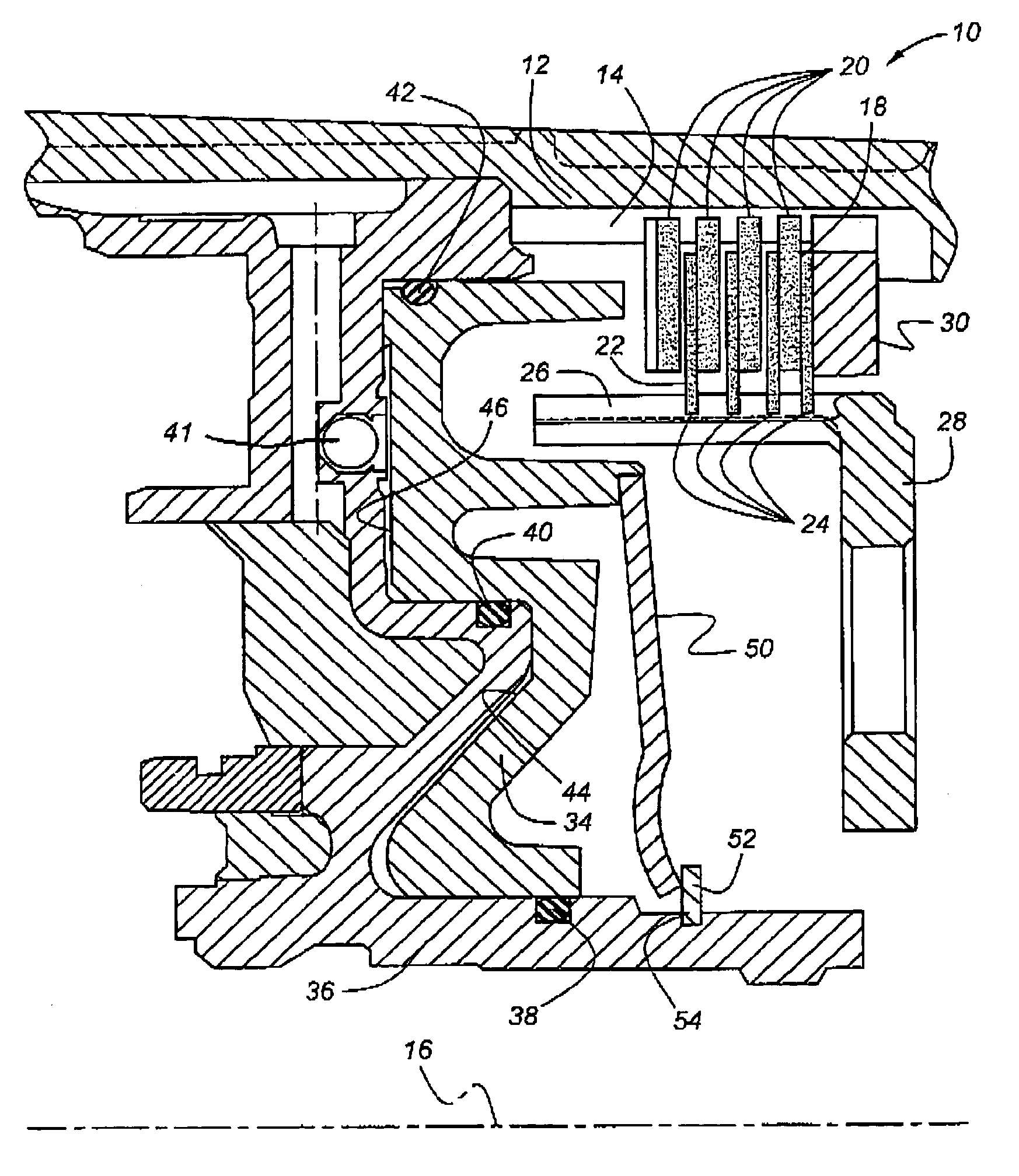

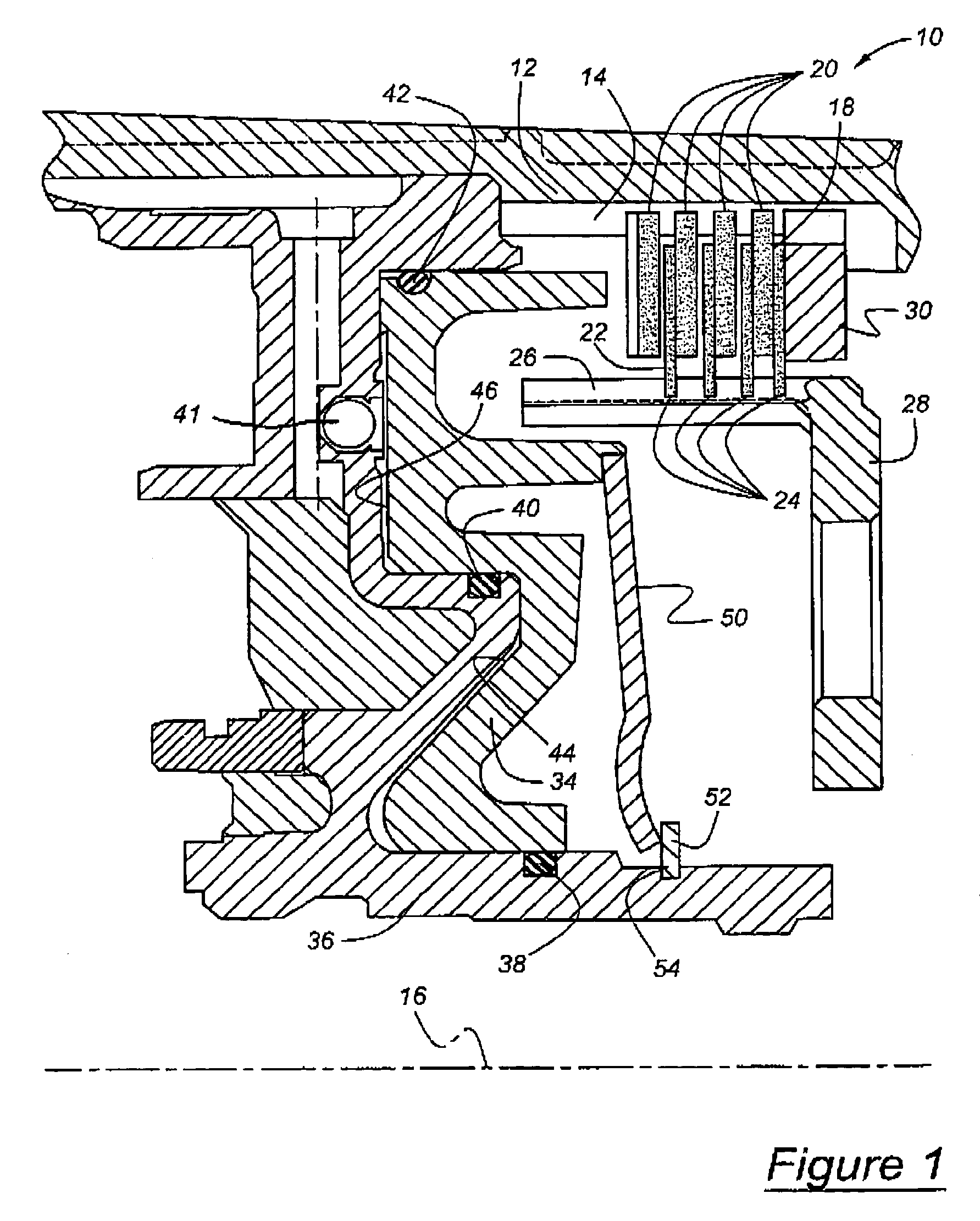

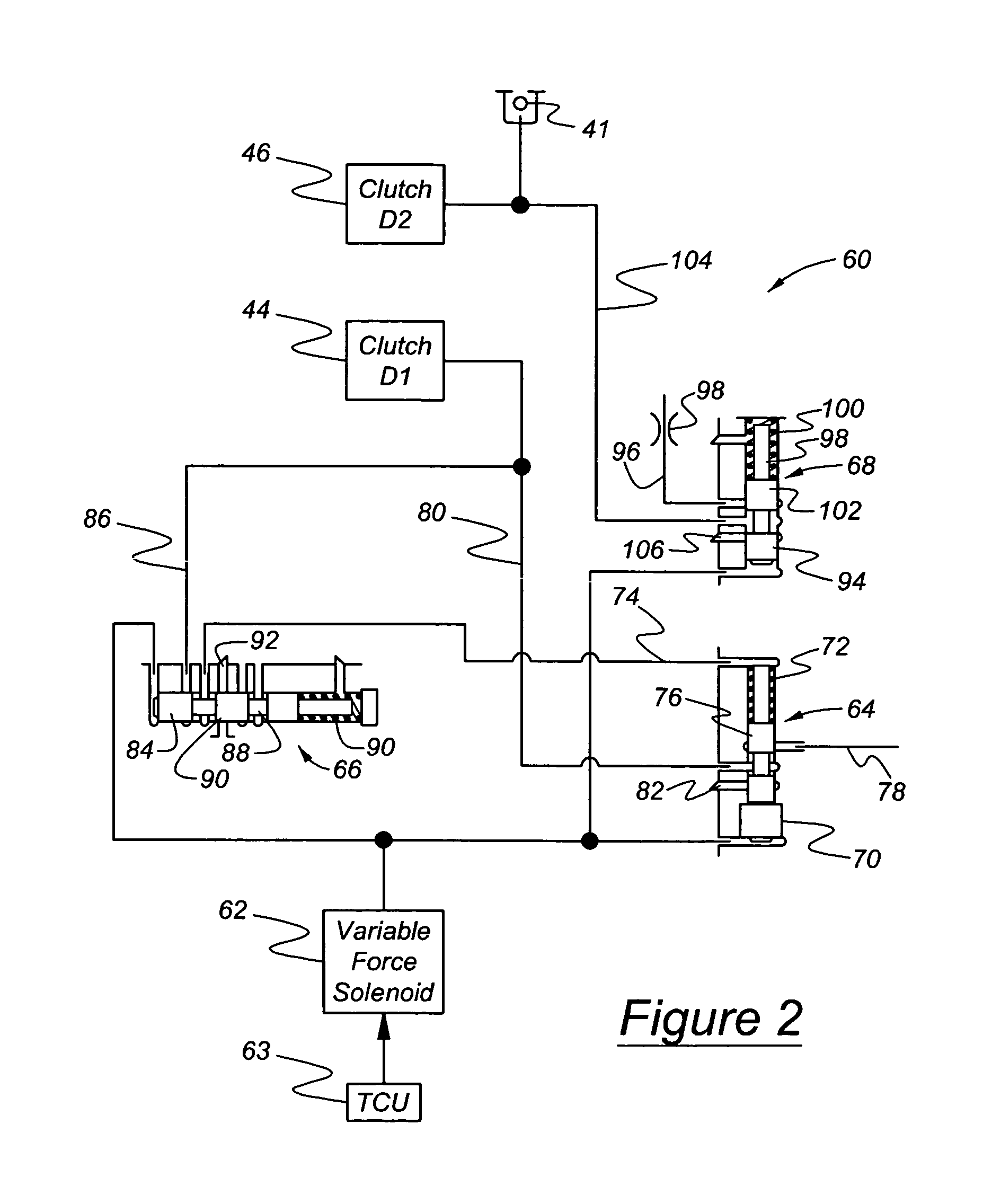

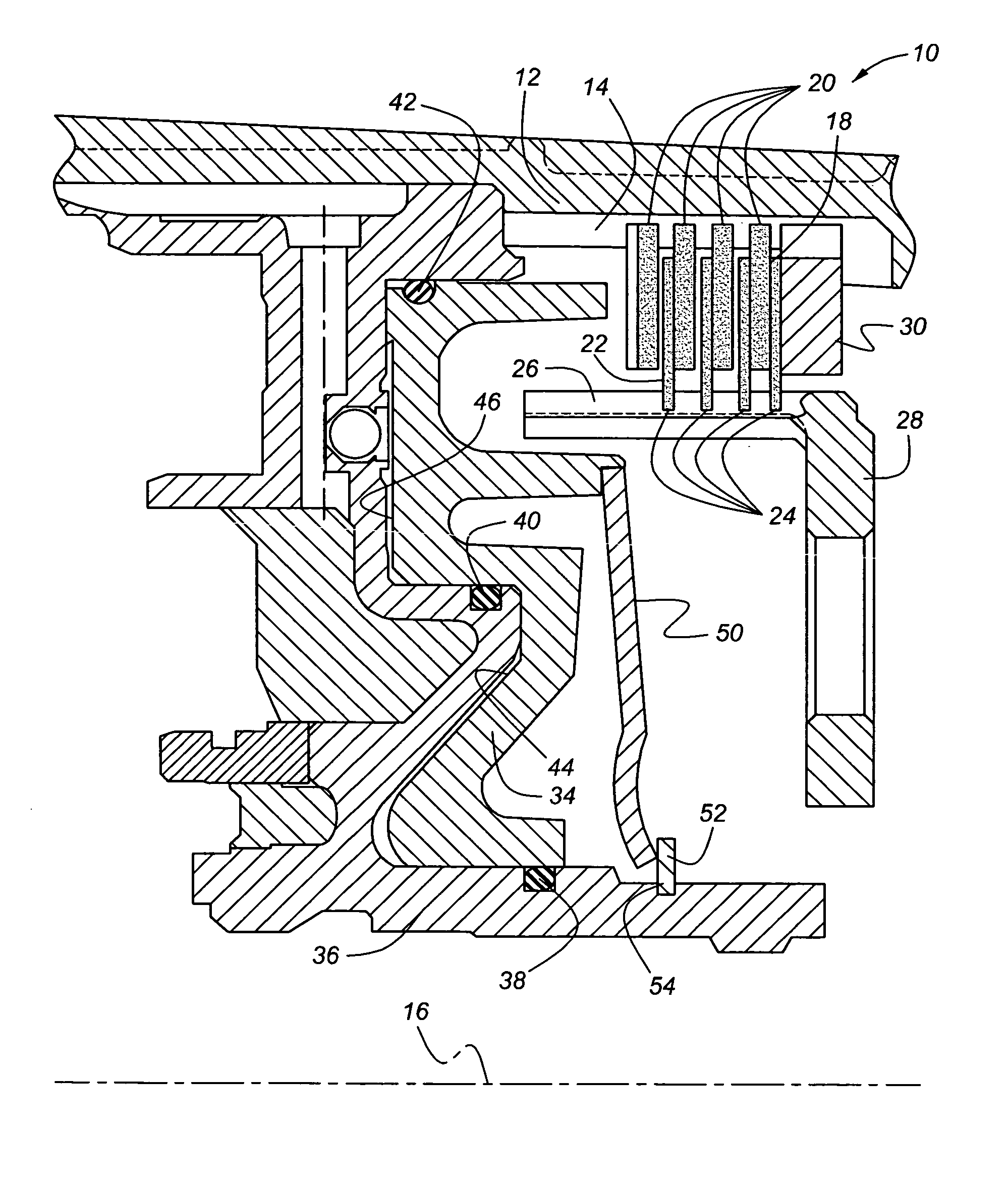

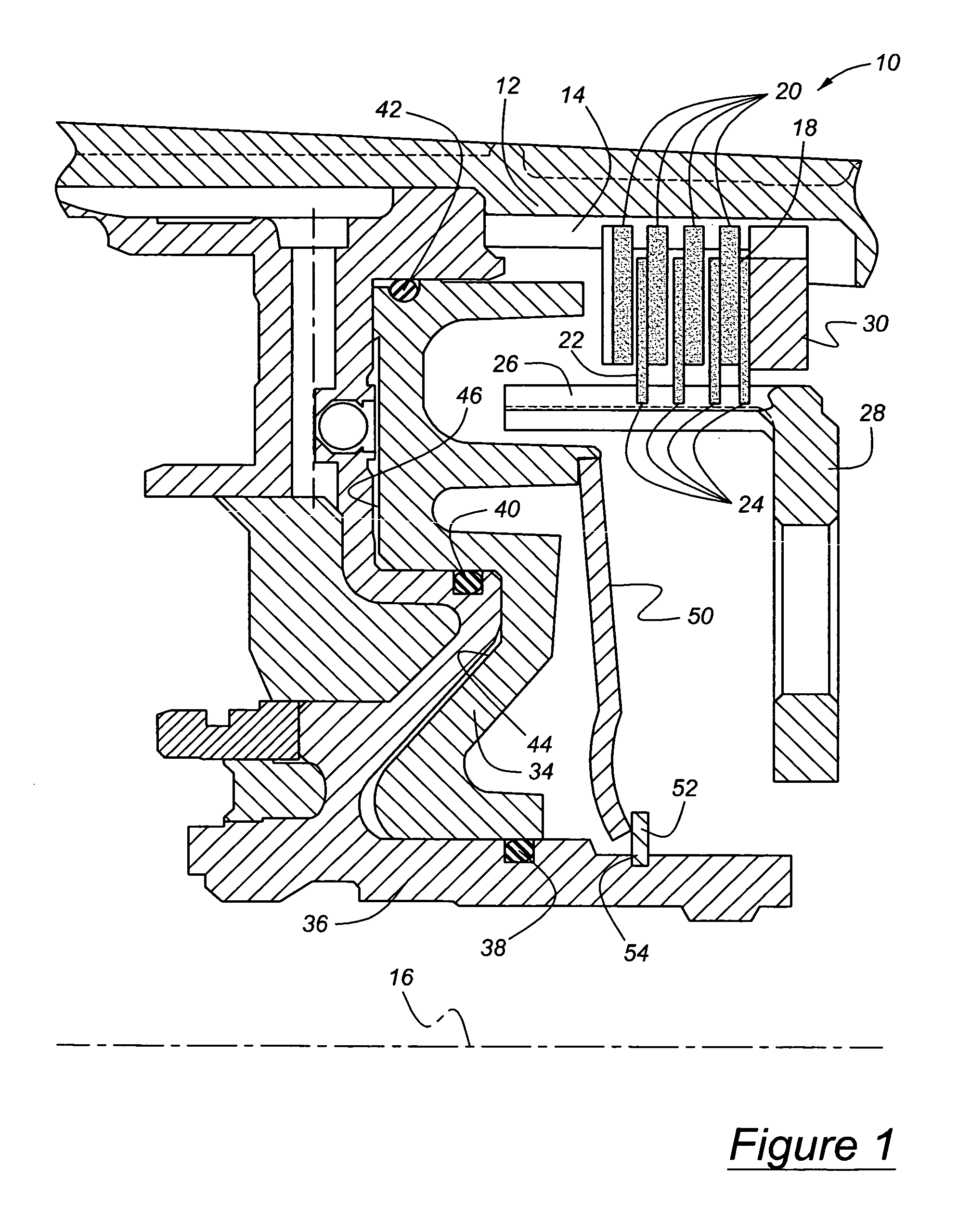

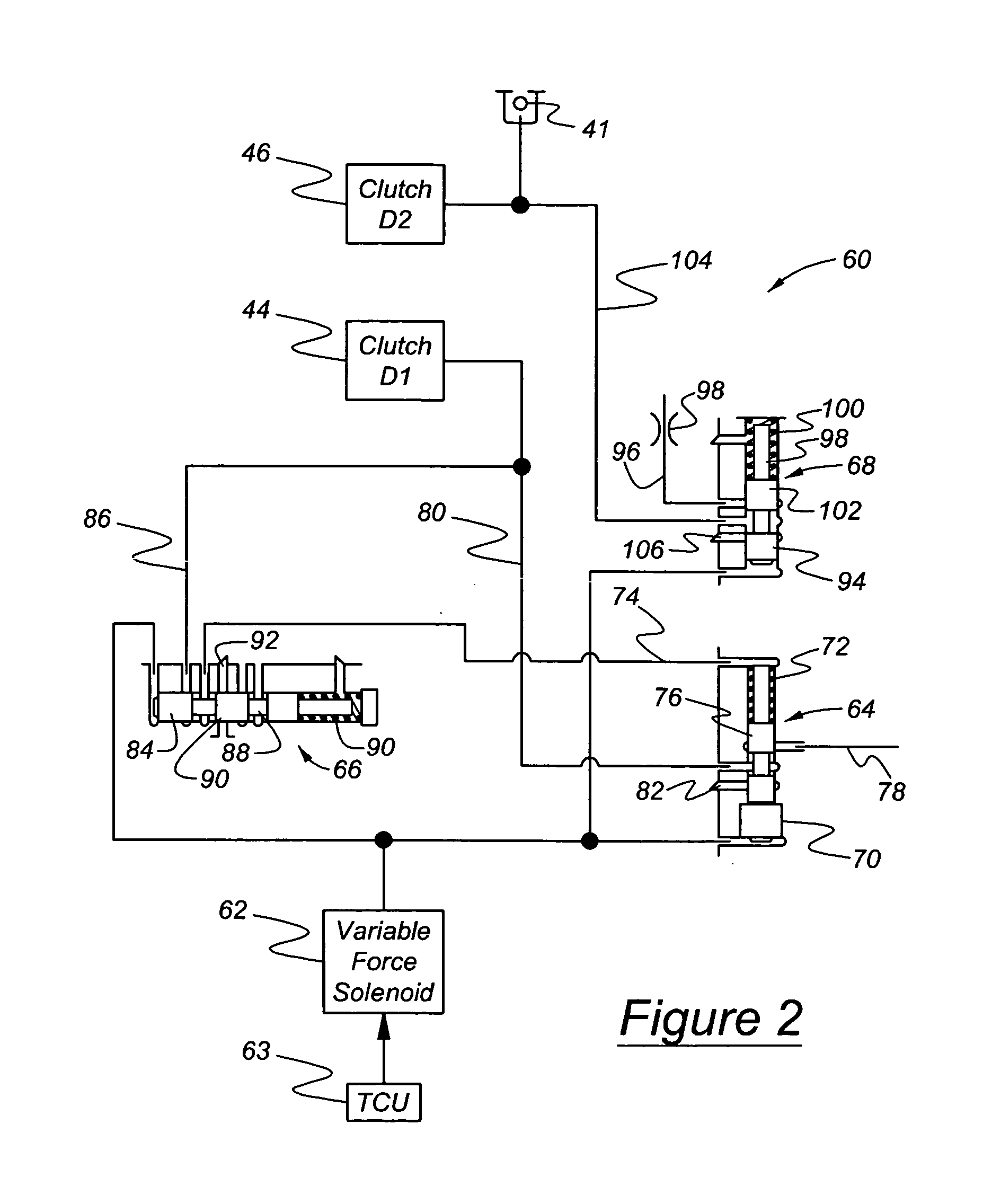

Dual area piston for transmission clutch and sequential control therefor

InactiveUS7104380B2Fast response timeLow dynamic gainFluid actuated clutchesFriction clutchesEngineeringPiston

A system for actuating a clutch that alternately driveably connects and disconnects components, includes a clutch having a piston that includes a first apply area and a second apply area, a fluid pressure source, a source of variable control pressure, and a control coupled with the fluid pressure source and operative in response to the control pressure to engage the clutch initially by increasing pressure steadily at the first apply area up to a first magnitude followed by a rapid increase in pressure at the first apply area and the second apply area above the first magnitude to a second magnitude.

Owner:FORD GLOBAL TECH LLC

Dual area piston for transmission clutch and sequential control therefor

InactiveUS20060054444A1Fast response timeLow dynamic gainFluid actuated clutchesFriction clutchesEngineeringPiston

A system for actuating a clutch that alternately driveably connects and disconnects components, includes a clutch having a piston that includes a first apply area and a second apply area, a fluid pressure source, a source of variable control pressure, and a control coupled with the fluid pressure source and operative in response to the control pressure to engage the clutch initially by increasing pressure steadily at the first apply area up to a first magnitude followed by a rapid increase in pressure at the first apply area and the second apply area above the first magnitude to a second magnitude.

Owner:FORD GLOBAL TECH LLC

Single-insertion, multiple sample biopsy device with integrated markers

ActiveUS20120323140A1Effective rigidityAvoid vacuumingSurgical needlesVaccination/ovulation diagnosticsBiopsy devicePathology

Owner:CR BARD INC

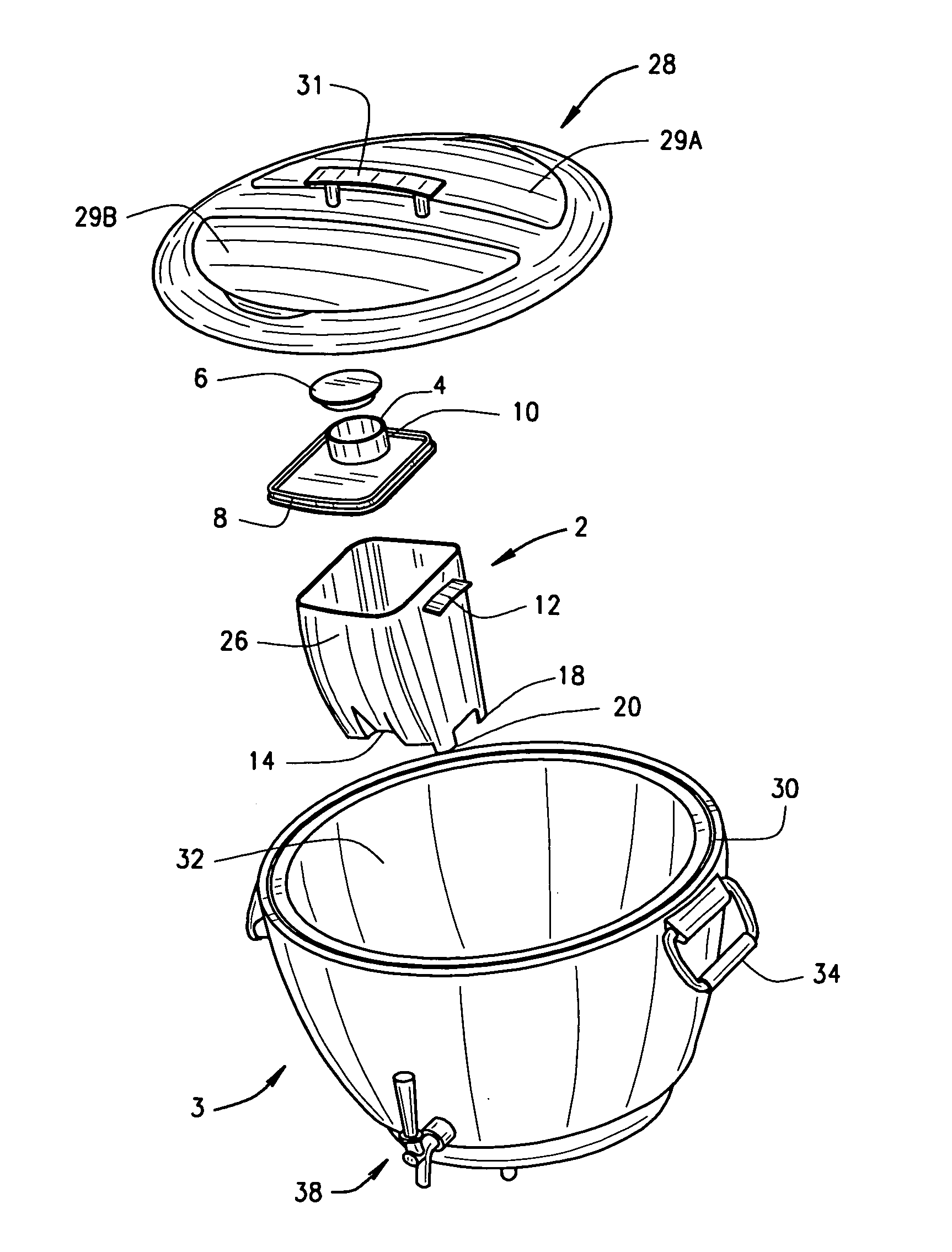

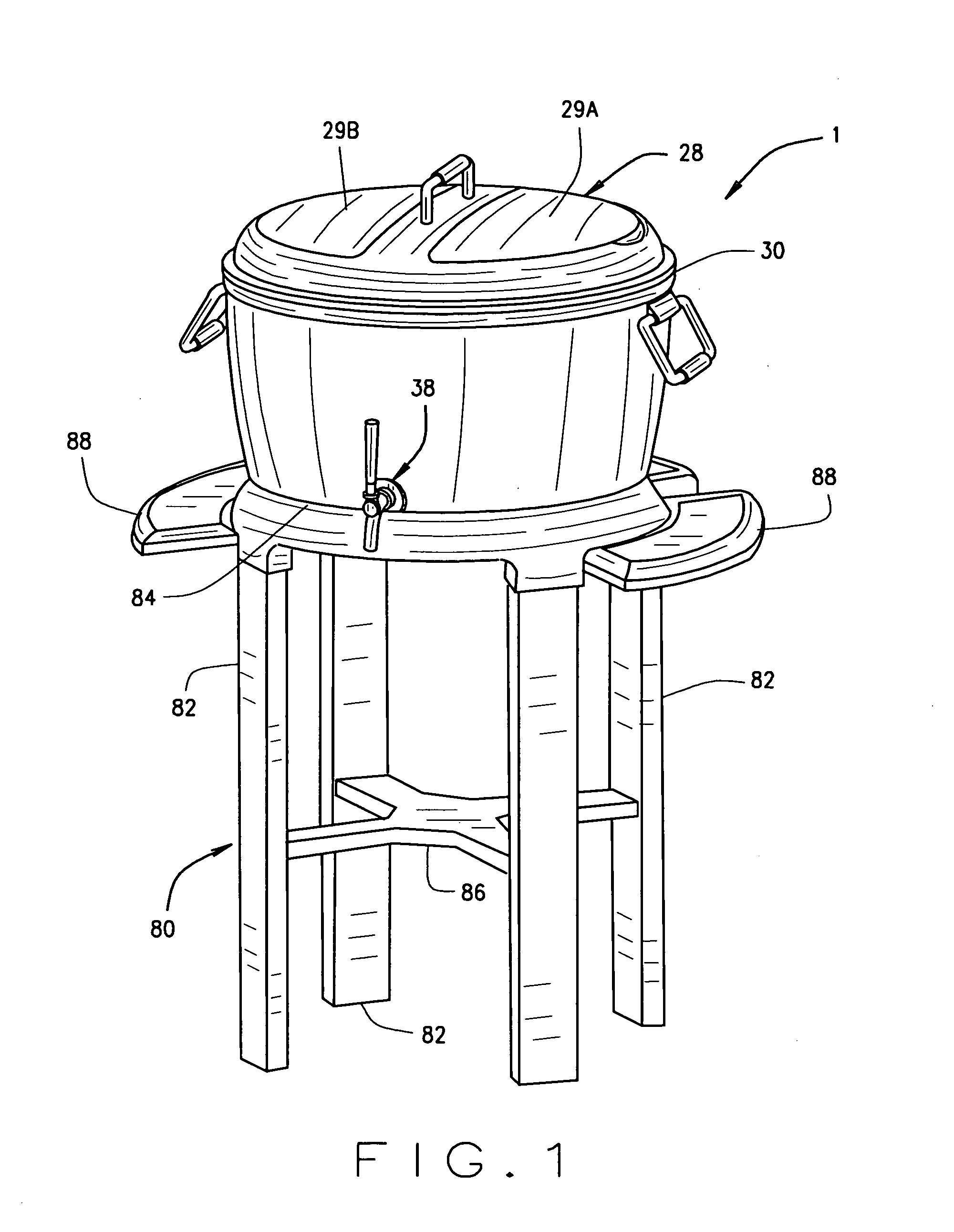

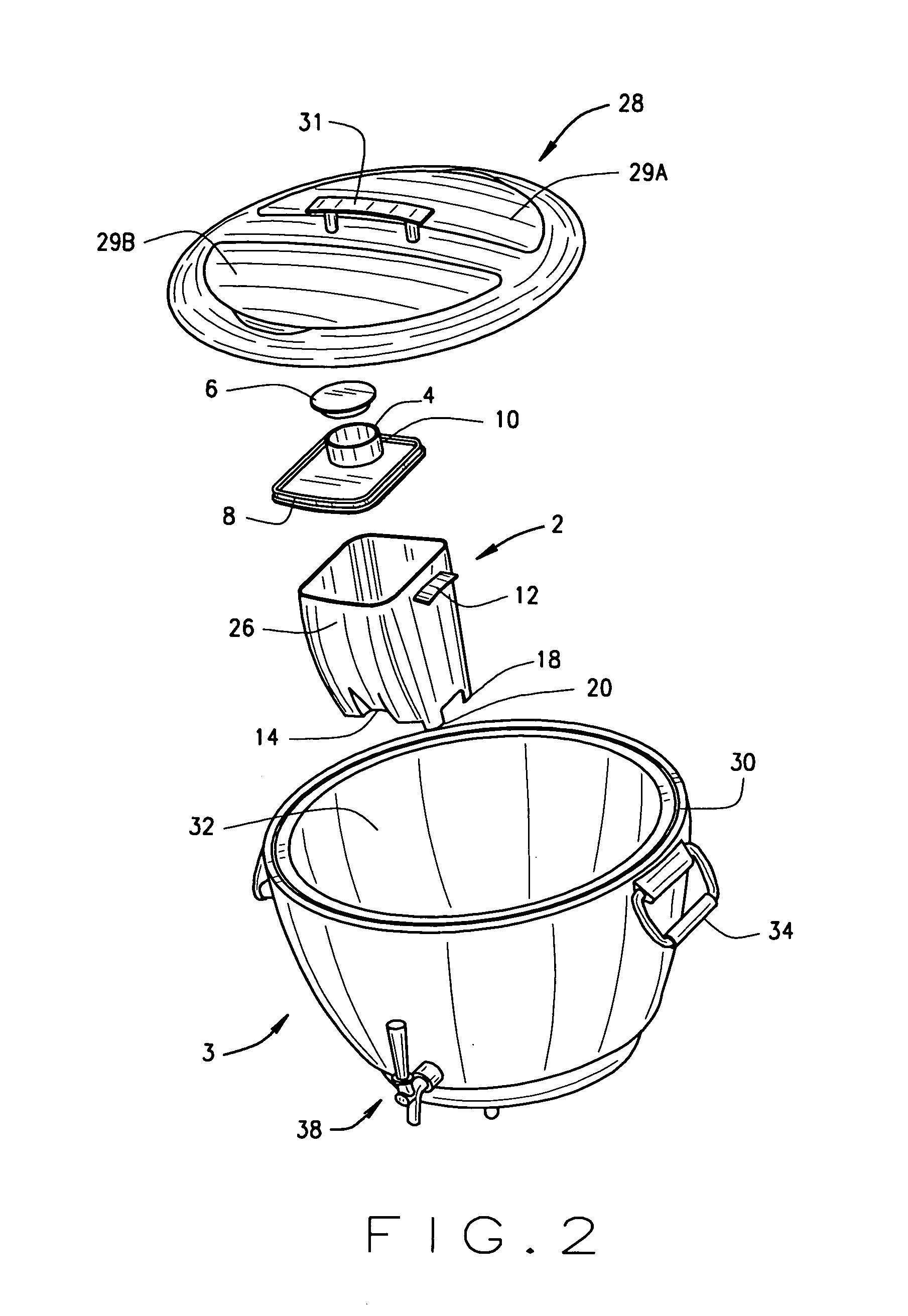

Beverage cooling and dispensing unit

InactiveUS20070277547A1Improve distributionEasy accessLighting and heating apparatusLiquid flow controllersCouplingChiller

A beverage and cooling dispensing apparatus for holding both containerized and non-containerized beverages including a cooler unit adaptable for holding and cooling containerized products such as bottled and canned beverages and other chilled products, an internal container adaptable for holding non-containerized free-standing beverages which is positionable within the main cooler unit, and a dispensing mechanism accessible from the exterior of the cooler unit for dispensing the non-containerized beverage from the internal container. The internal container includes a first coupling mechanism which is engageable with a second coupling mechanism associated with the dispensing mechanism for providing fluid communication between the dispensing mechanism and the internal container when the first and second coupling mechanisms are engaged.

Owner:SUNBEAN PROD INC

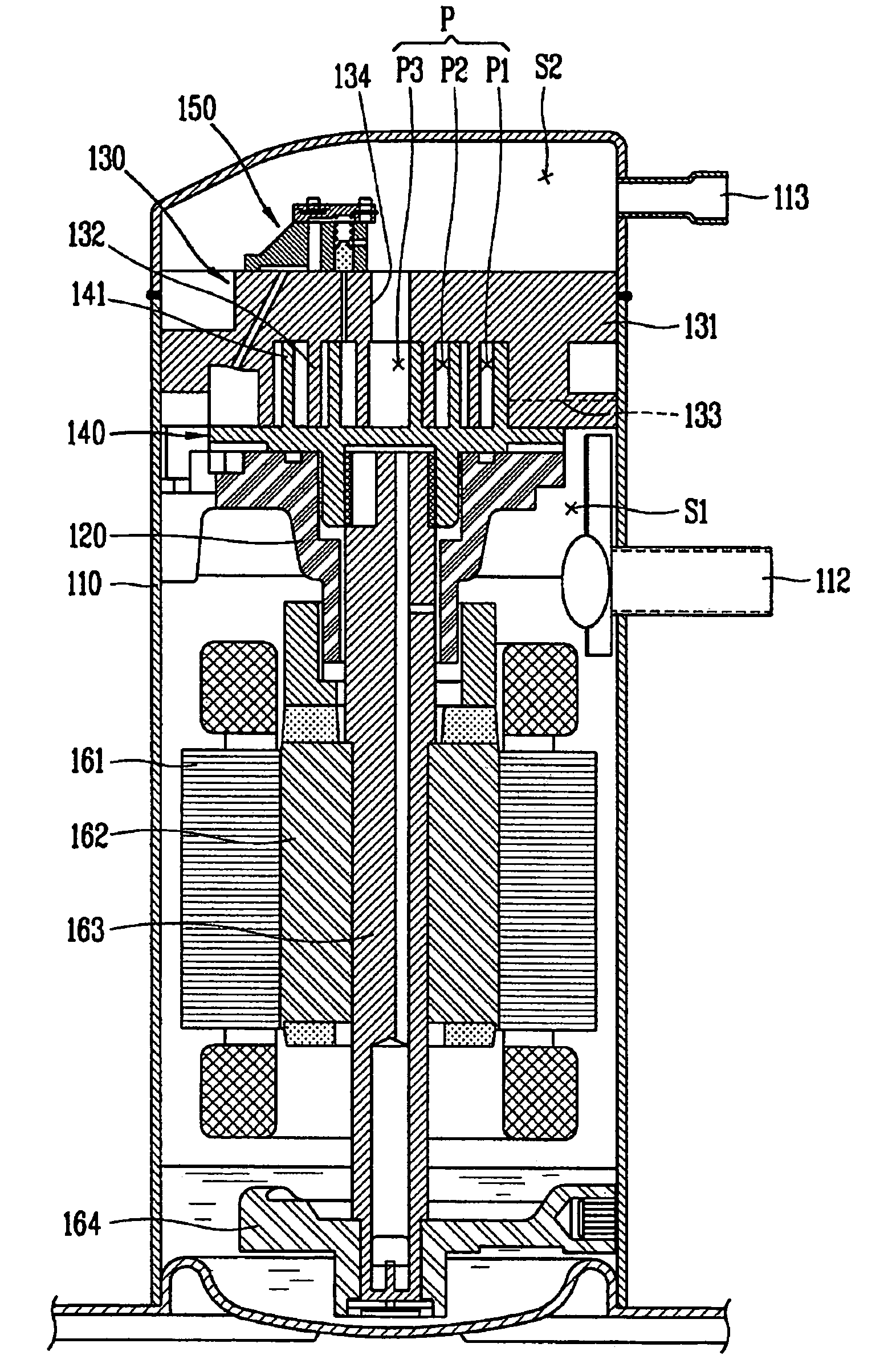

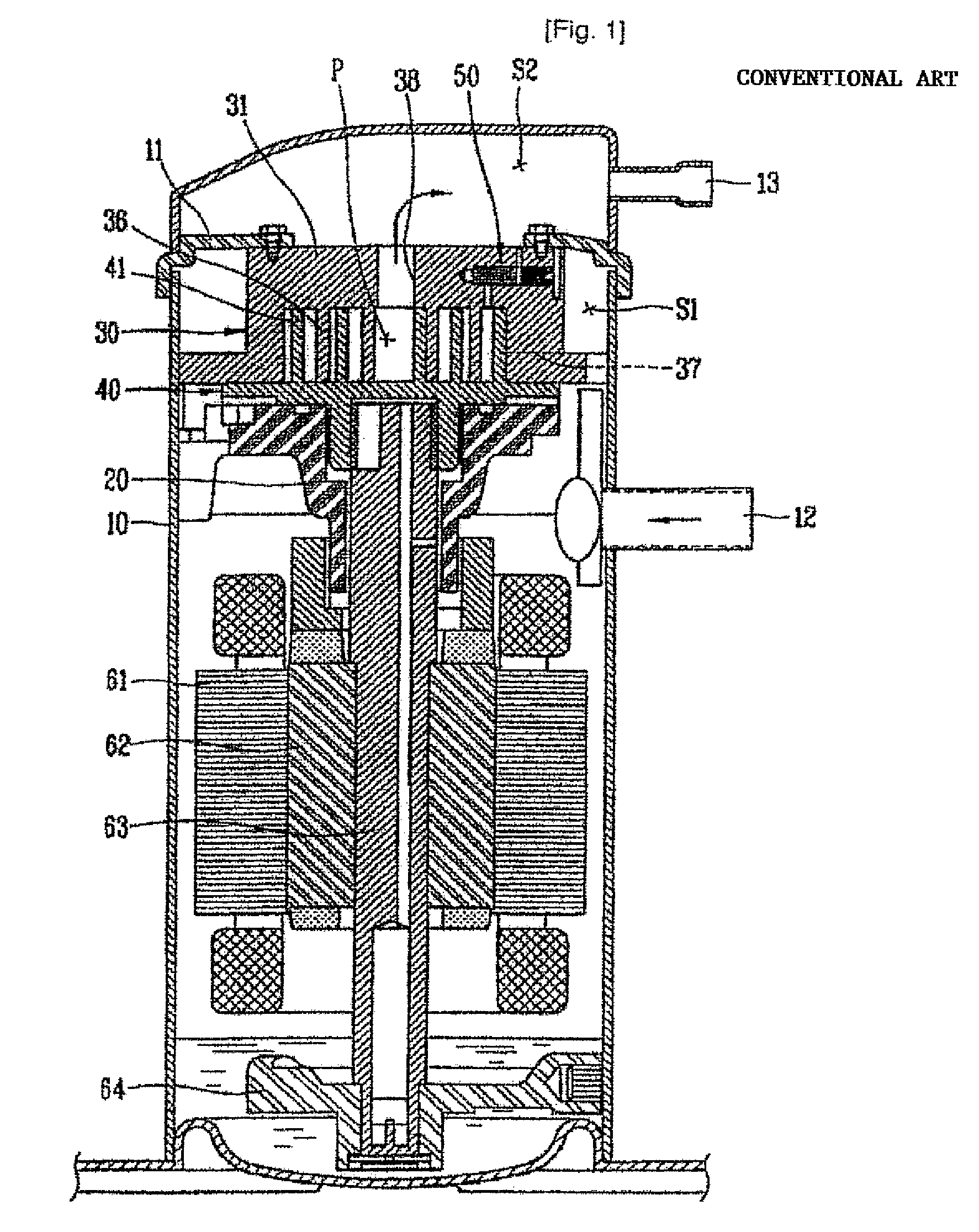

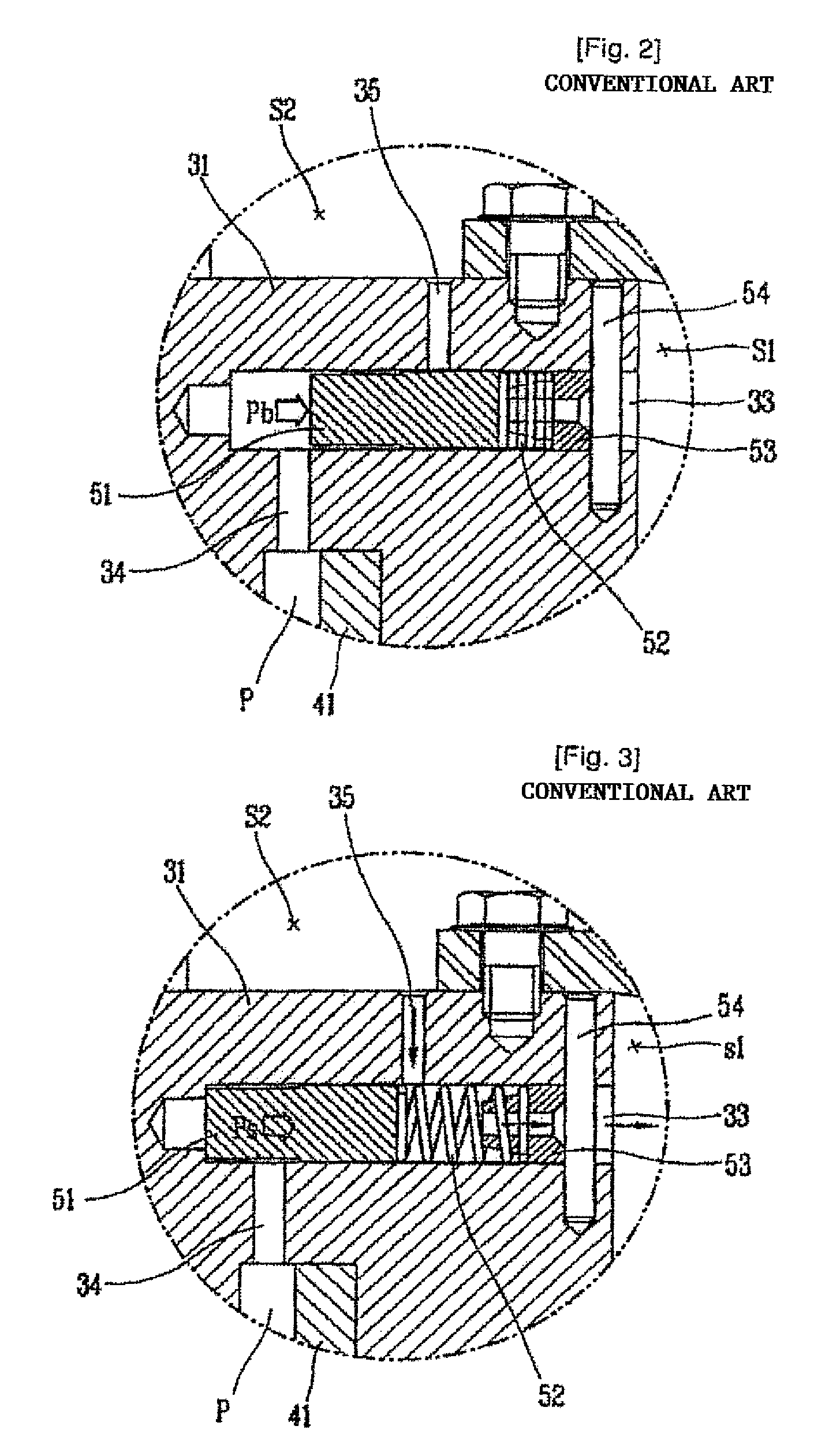

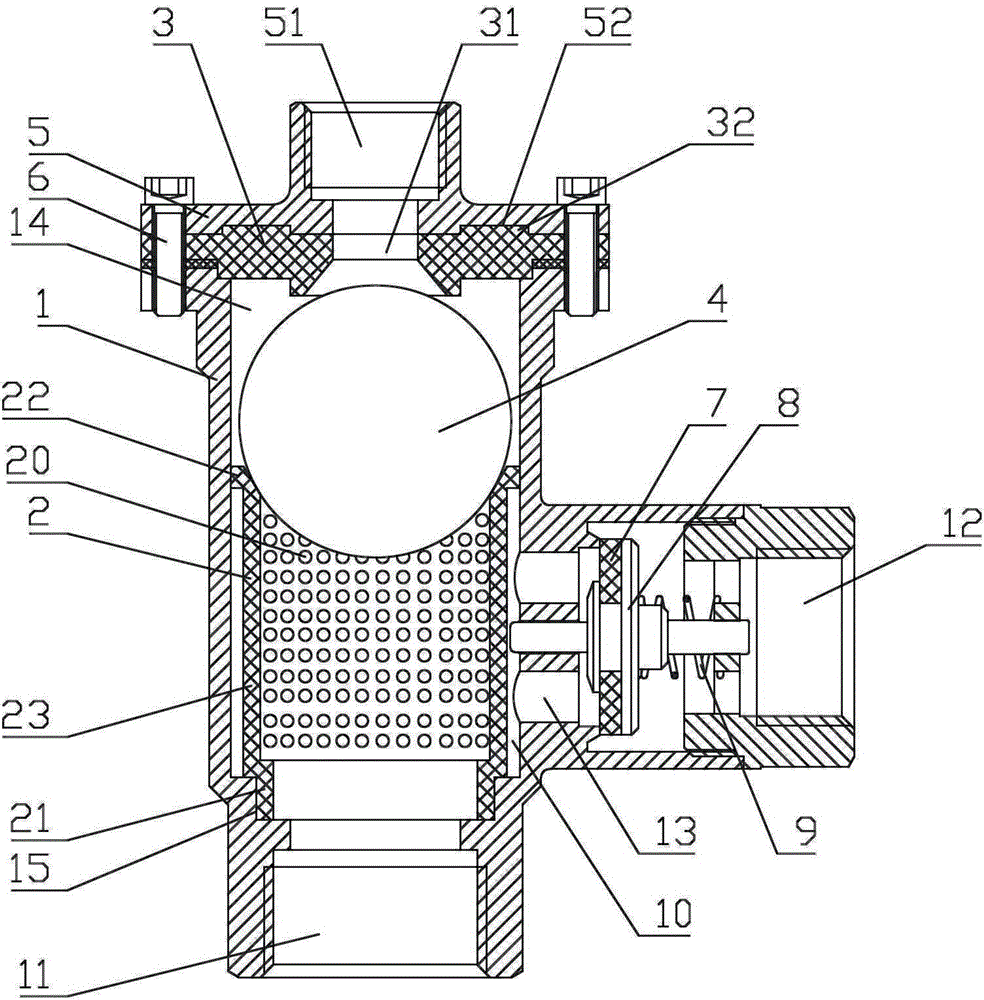

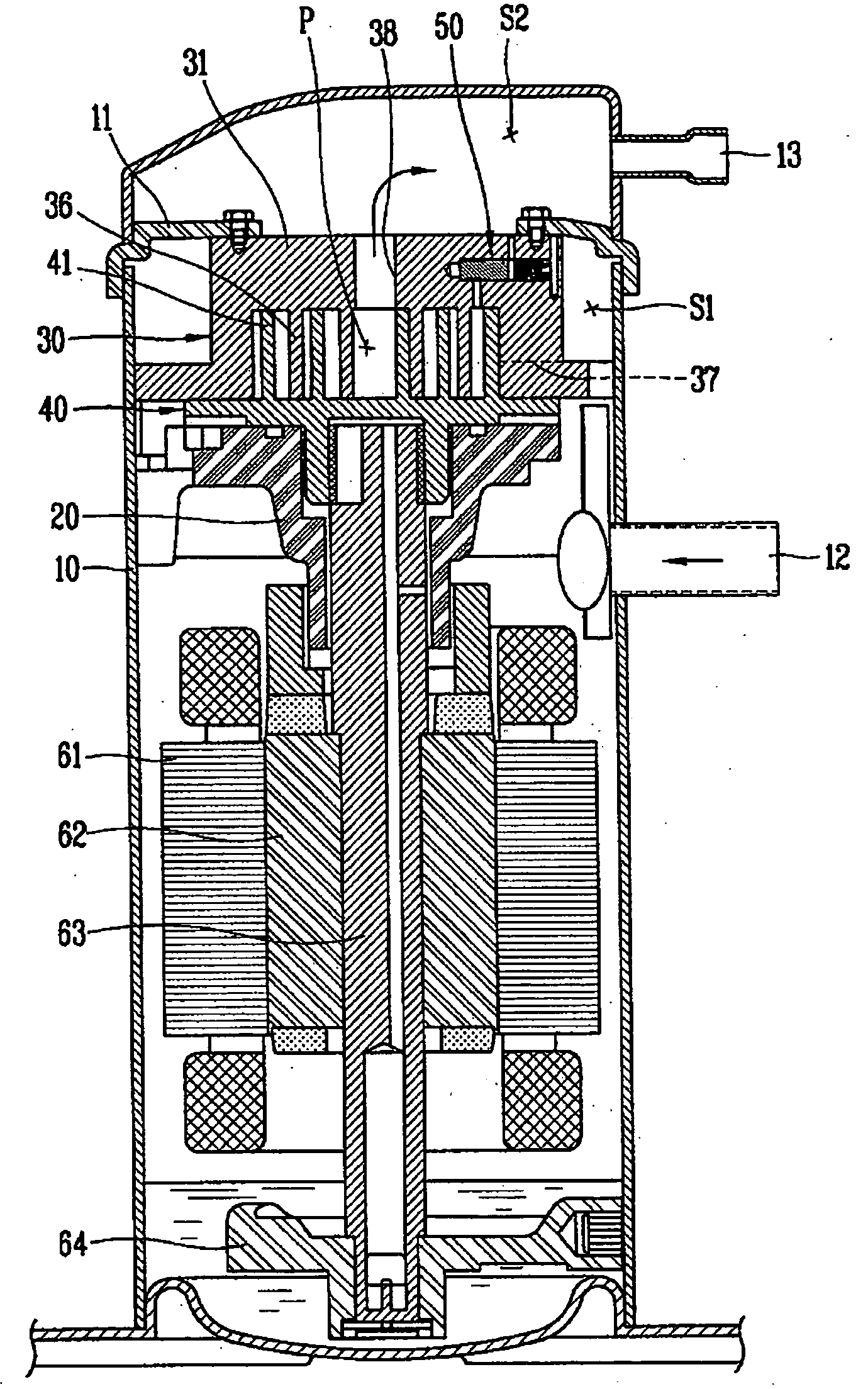

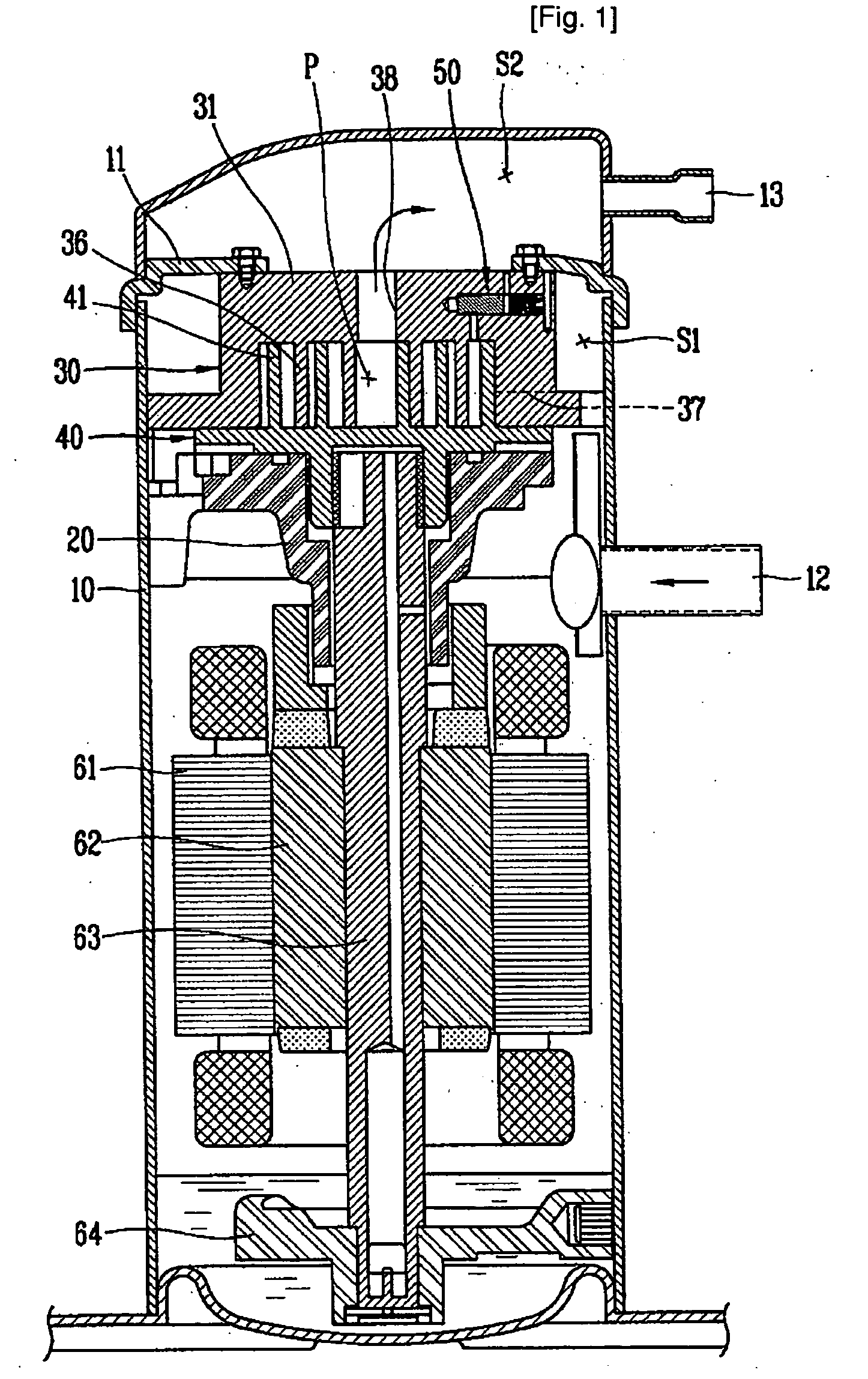

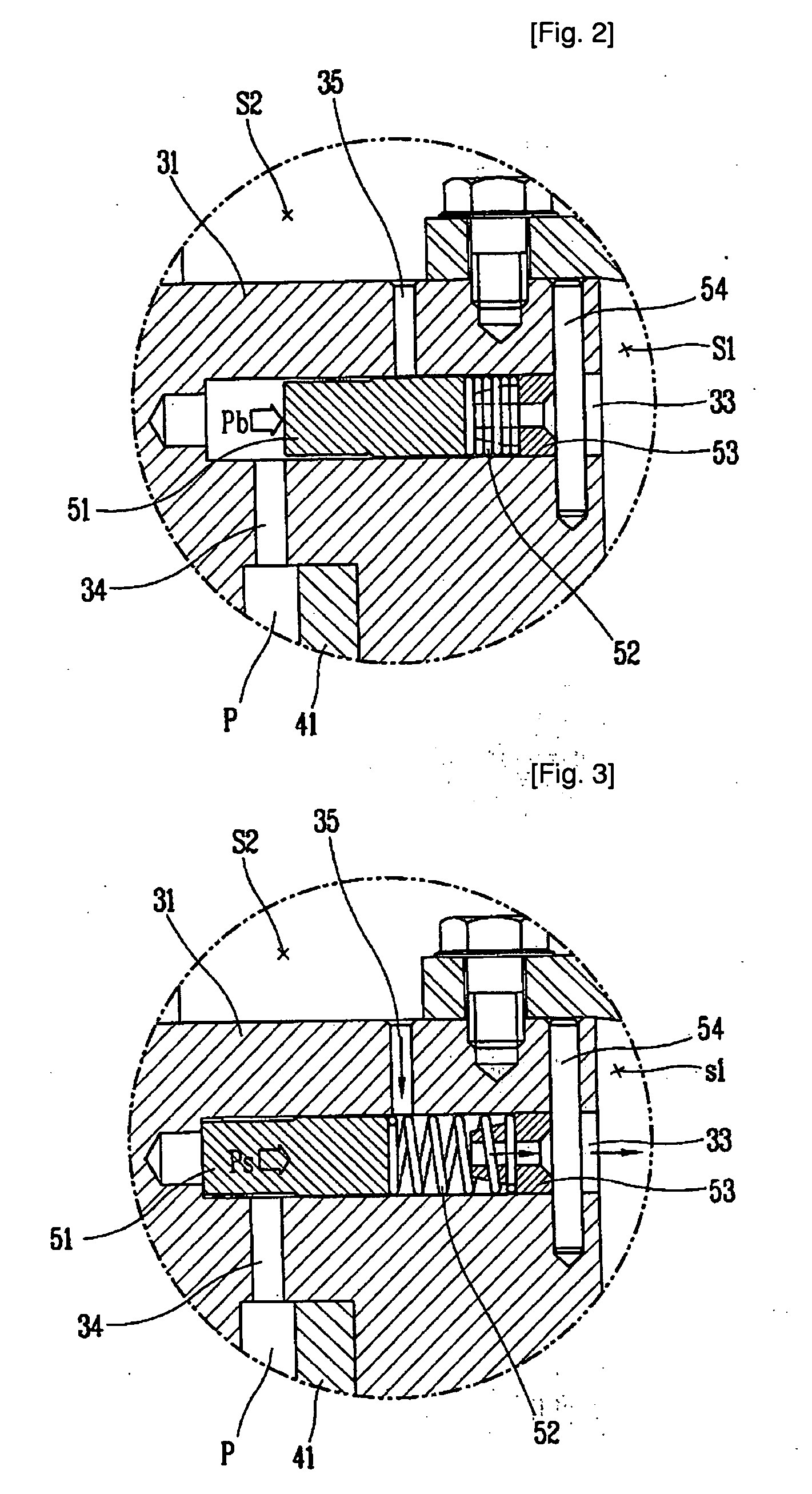

Apparatus for preventing vacuum of scroll compressor

ActiveUS7695257B2Guaranteed uptimeImprove efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeForeign matterProduction rate

An apparatus for preventing vacuum of a scroll compressor is provided. The apparatus includes a fixed scroll having a bypass hole, through which a suction chamber of a casing is connected to a discharge chamber of the casing; a valve block having an inner channel, through which the bypass hole of the fixed scroll is connected to the discharge chamber of the casing, and fixedly installed at the fixed scroll; and a valve member disposed between the bypass hole of the fixed scroll and the inner channel of the valve block. Since the apparatus is assembled at an outer periphery of the fixed scroll, a processing error of the fixed scroll is prevented, thereby reducing production costs. Also, since foreign materials generated when a refrigerant channel is processed do not remain in a valve hole, the valve member is prevented from being mal-operated, productivity is enhanced, and fabrication costs reduced.

Owner:LG ELECTRONICS INC

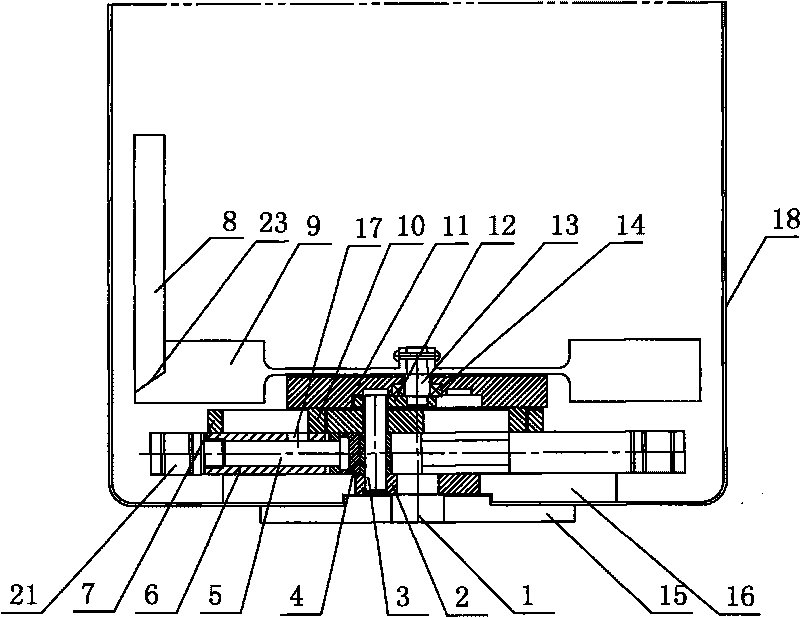

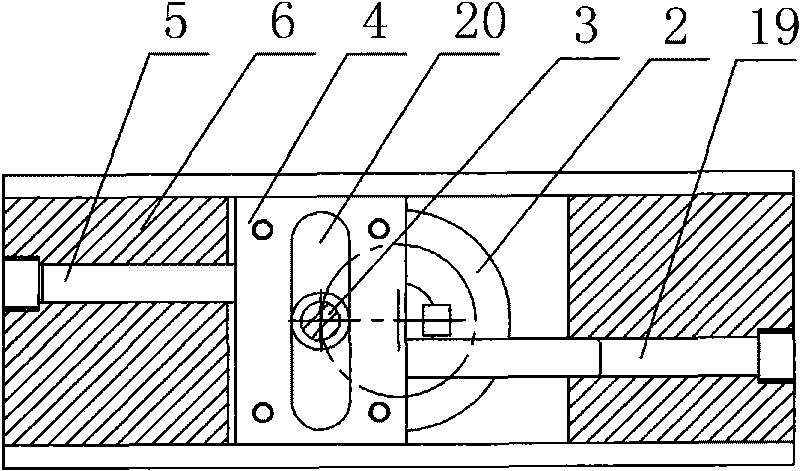

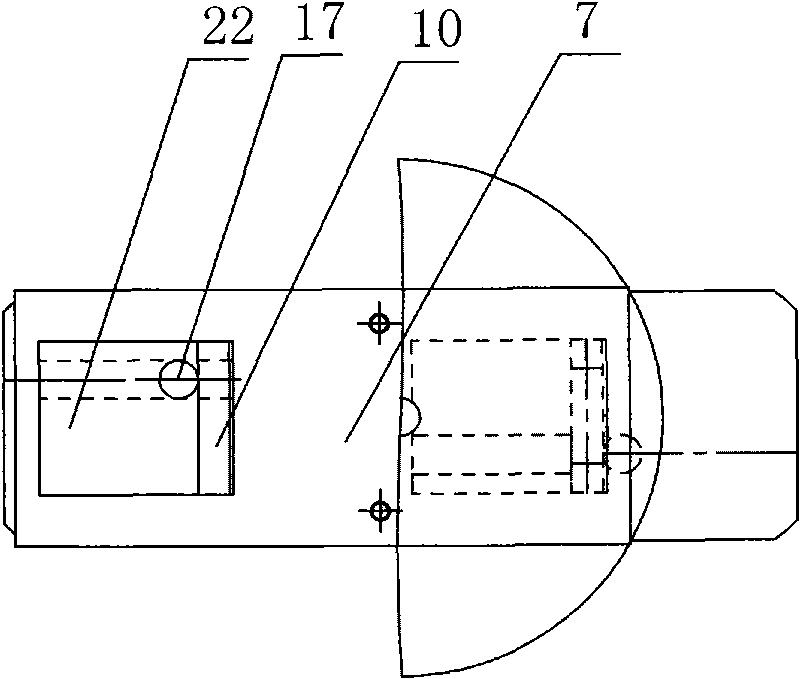

Electrical grease filling machine

The invention relates to an electrical grease filling machine which belongs to the technical field of mechanical equipment, in particular to an electrical grease filling machine. The electrical grease filling machine comprises a speed reducer shaft, an eccentric disc, a driving shaft, a slide block, a piston, a cylinder, a moving block, an oil stirring piece, an oil press plate, a fixed block, a bottom plate, a connecting block, a spiral oil press device driving shaft, a bearing, an outer flange, an inner flange, an oil inlet, an oil tank, a piston hole, a through groove, an oil outlet hole, a square hole and an oil press piece. The electrical grease filling machine can suck grease having higher viscosity and prevent air appearing in oil.

Owner:扬州市晨辉机械有限公司

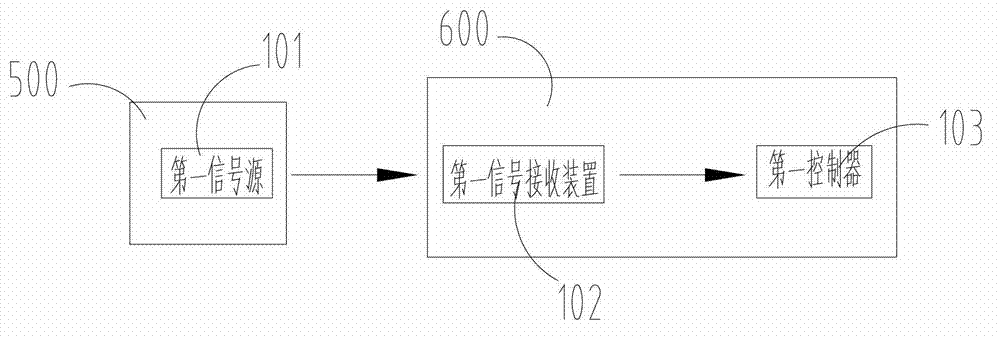

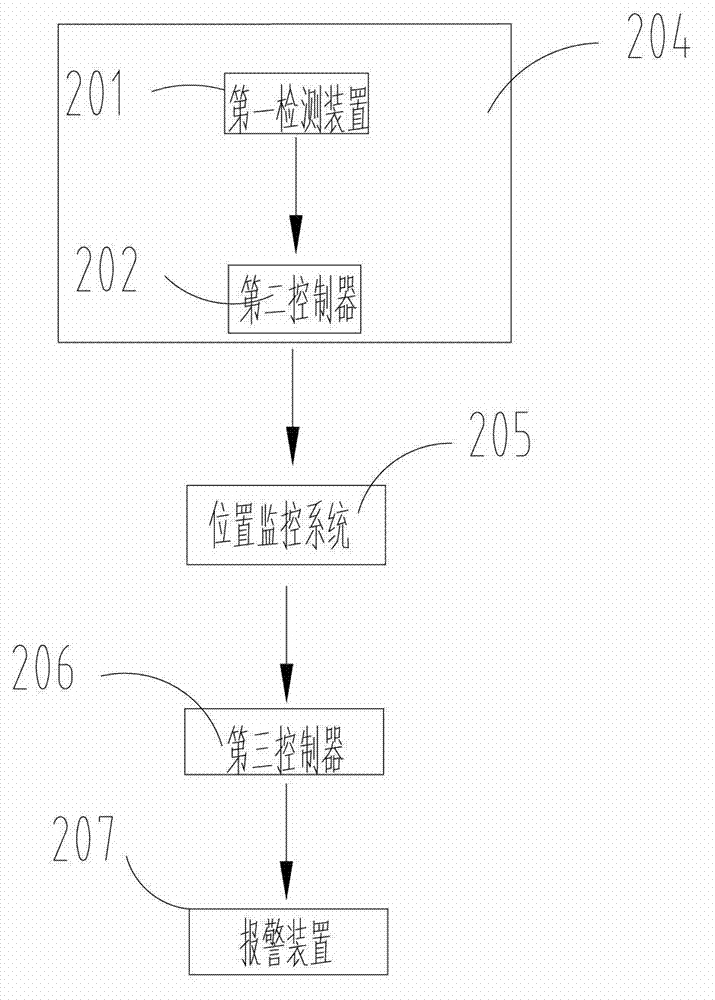

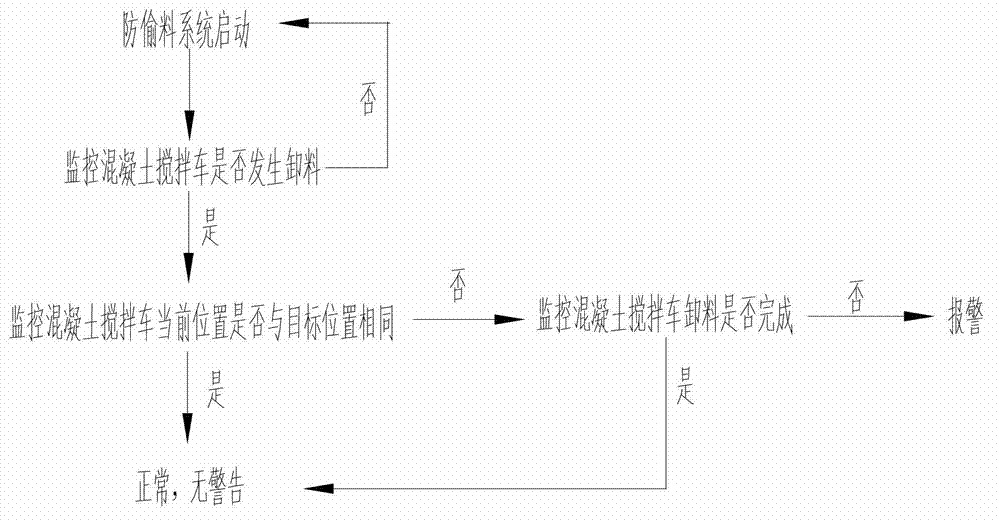

Concrete mixer truck and operation method and system by matching concrete mixer truck with concrete pumping equipment

ActiveCN102773921AImprove matching efficiencyAvoid vacuumingConcrete transportationDischarging apparatusMonitoring systemEngineering

The invention discloses an operation method of by matching a concrete mixer truck with a concrete pumping equipment, The method comprises a discharging step and a truck moving step. In the discharging step, the concrete mixer truck discharges materials to the concrete pumping equipment, and monitors whether the discharging of the materials of the concrete mixer truck is completed. In the truck moving step, after the materials are discharged by the concrete mixer truck, the concrete mixer truck is moved away. The invention also discloses a matching operation system which realizes the matching operation method. The matching operation system comprises a discharging monitoring system used for monitoring whether the materials are discharged by the concrete mixer truck, so that the concrete mixer truck is moved away in time. The invention also discloses a concrete mixer truck using the matching operation system. As whether the materials are discharged can be monitored by the matching operation method and system provided by the invention, after the materials are discharged, the concrete mixer truck can be moved away in time for changing into a new concrete mixer truck, so that the matching operation efficiency can be effectively improved, and the pumping equipment is effectively prevented from sucking the air.

Owner:ZOOMLION HEAVY IND CO LTD

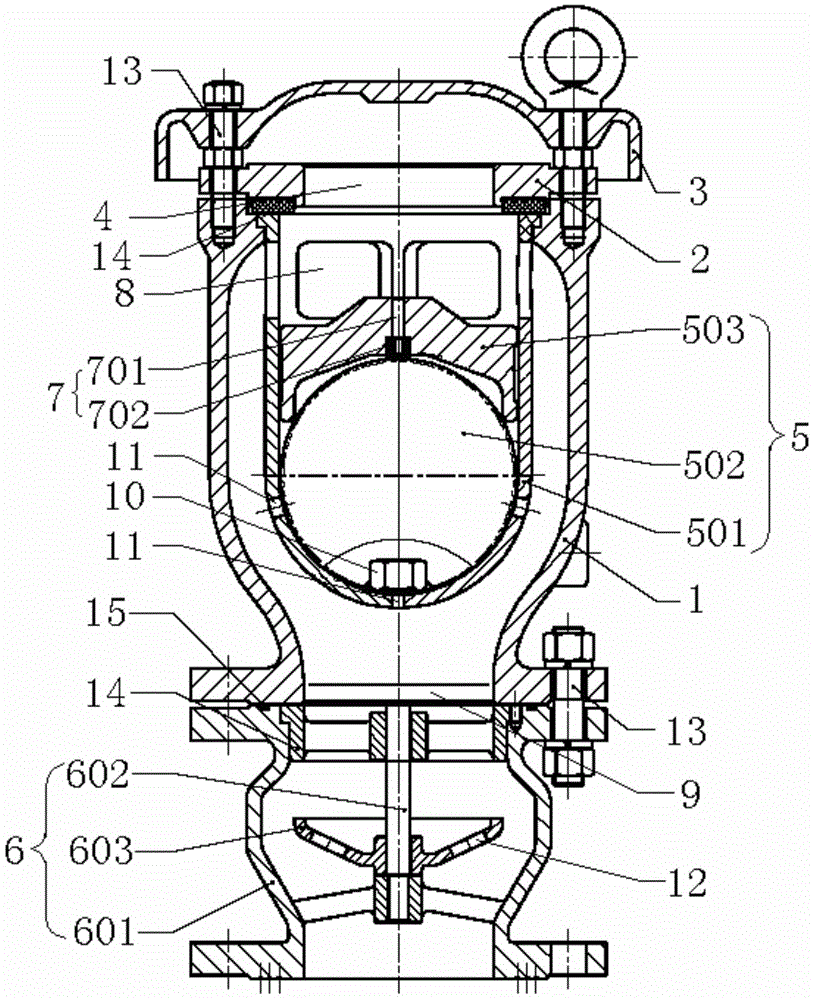

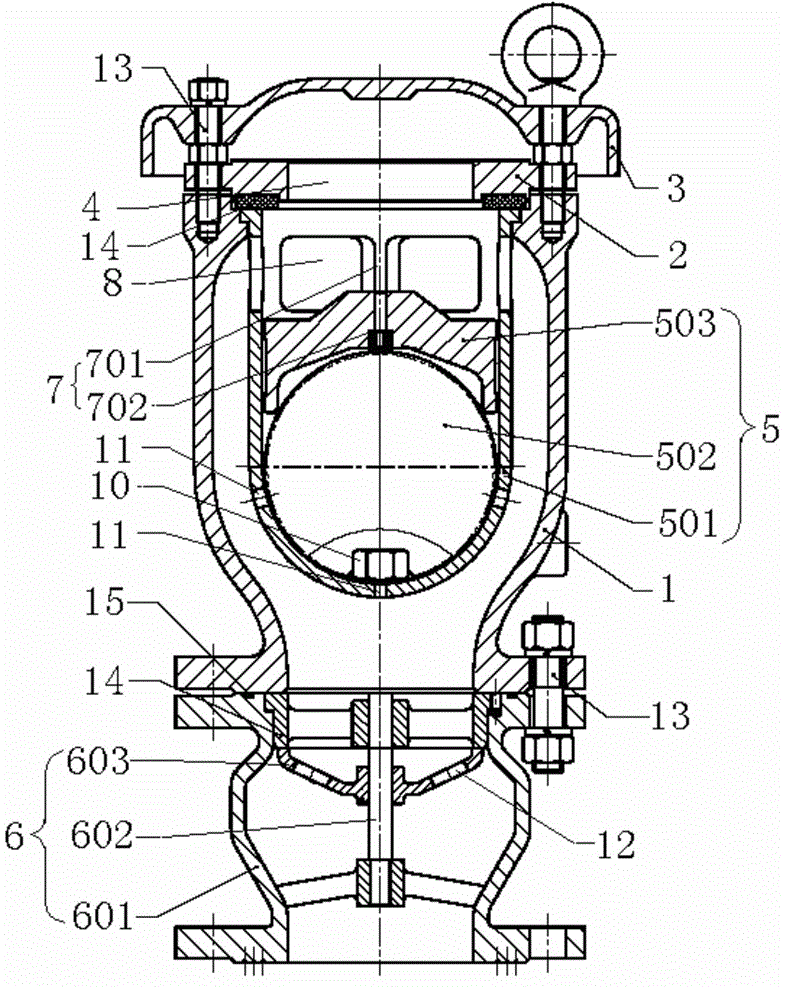

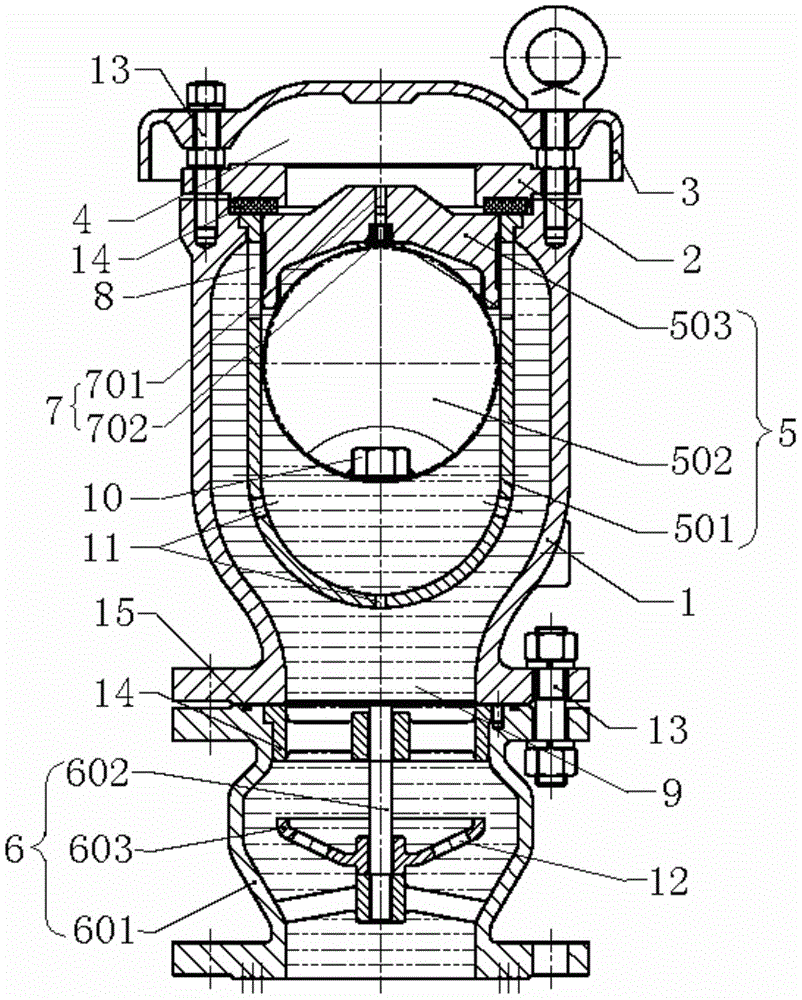

Water hammer air valve and water hammer gas discharging method during pipeline use

ActiveCN104896184AAvoid blowingAvoid air blockageValve members for absorbing fluid energyPipe elementsEngineeringWater hammer

The invention discloses a water hammer air valve and a water hammer gas discharging method during pipeline use. The water hammer air valve comprises a valve body, a bonnet and a protective cover, wherein the bonnet is provided with an opening, the protective cover is disposed on the opening, the valve body is provided with a valve opening for being communicated with a pipeline, a high-speed gas feeding and discharging device which is used for discharging gases stayed in the pipeline during water filling to the outside and shutting down the valve after pipeline water filling is completed is disposed in the inner cavity of the valve body, the output end of the high-speed gas feeding and discharging device is communicated with the outside through the opening of the bonnet, and the valve opening of the valve body is communicated with a bottom gas discharging throttling device for limiting the gas displacement of the pipeline to the inner cavity of the valve body; a trace gas discharging device for discharging mixed, residual and / or precipitated gases in the pipeline to the outside through the opening of the bonnet after the high-speed gas feeding and discharging device shuts down the valve is further disposed in the high-speed gas feeding and discharging device. By the water hammer air valve, water hammer reduction and pipeline safety protection are achieved, blowing blocking during high-speed gas discharging is avoided, and valve closing water hammer is eliminated.

Owner:ZHUZHOU SOUTHERN VALVE

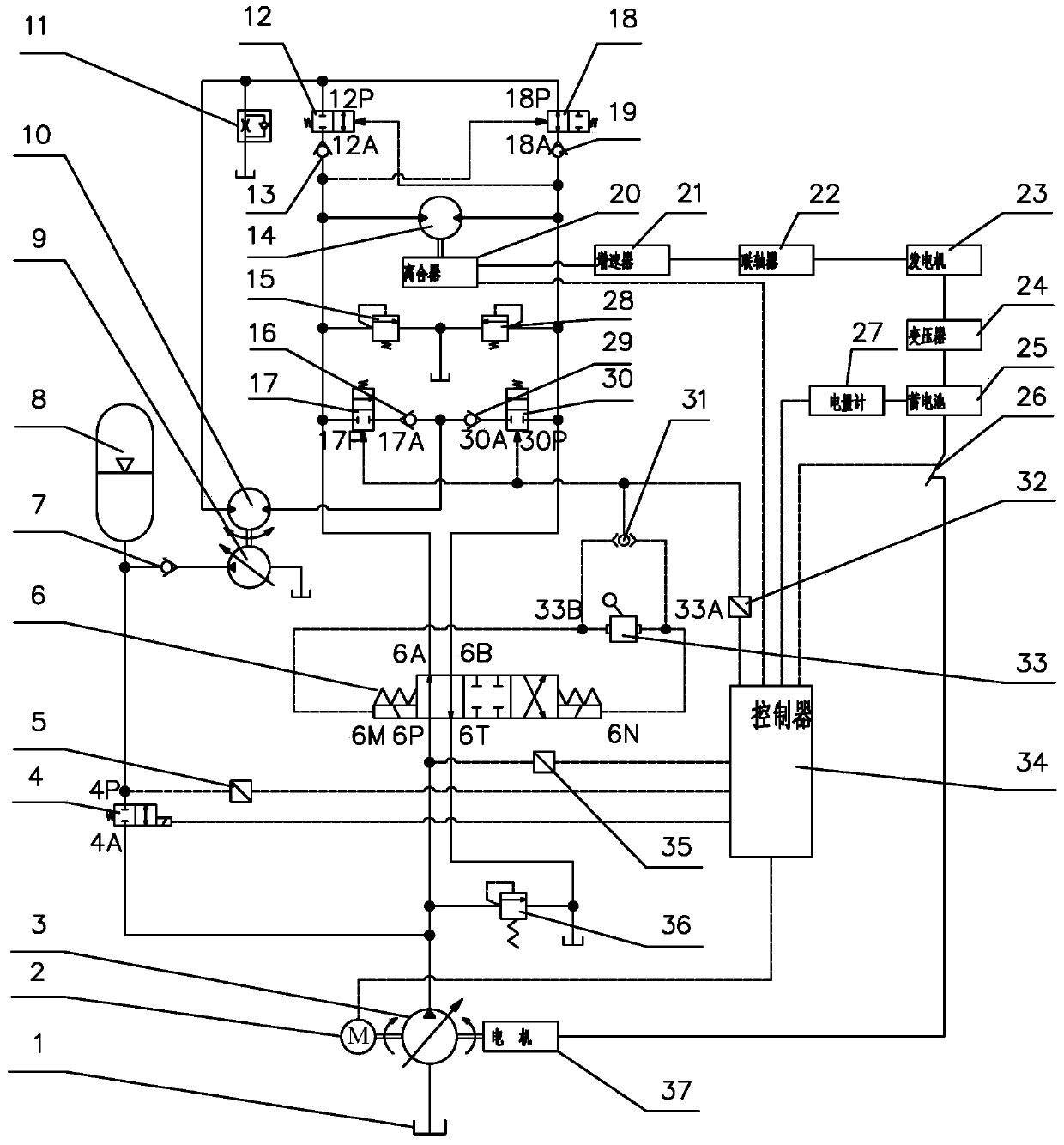

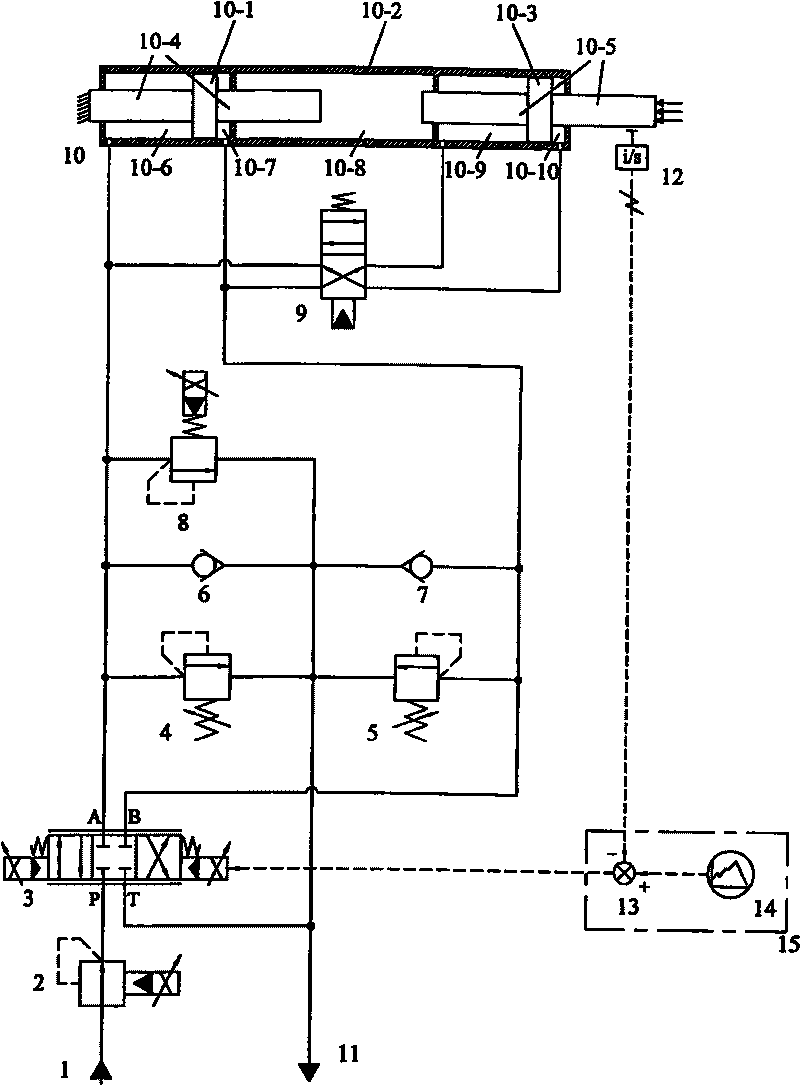

Hydraulic rotary braking energy-saving control system

ActiveCN103470557AAchieve regenerationImprove work efficiencyServomotor componentsServomotorsControl systemTransformer

The invention discloses a hydraulic rotary braking energy-saving control system. The hydraulic rotary braking energy-saving control system comprises an oil tank, an engine, a first variable pump, an electromagnetic directional control valve, a three-position four-way directional control valve, a first one-way valve, an energy accumulator, a second variable pump, a first motor, a first pilot operated directional control valve, a second one-way valve, a rotary motor, a second overflow valve, a fourth one-way valve, a second pilot operated directional control valve, a third pilot operated directional control valve, a third one-way valve, a clutch, a speed increasing gear, a coupler, a generator, a transformer, a storage battery, a motor-operated switch, a third overflow valve, a fifth one-way valve, a fourth pilot operated directional control valve, a controller, a first overflow valve and a motor. On the basis of an energy recycling device, a novel energy storage mode is added for the hydraulic rotary braking energy-saving control system, so that energy of high braking torque generated during rotary braking every time is converted, and is stored in the storage battery in the form of electric energy, and the energy recycling efficiency in the rotary braking process can be high.

Owner:NANJING UNIV OF TECH +1

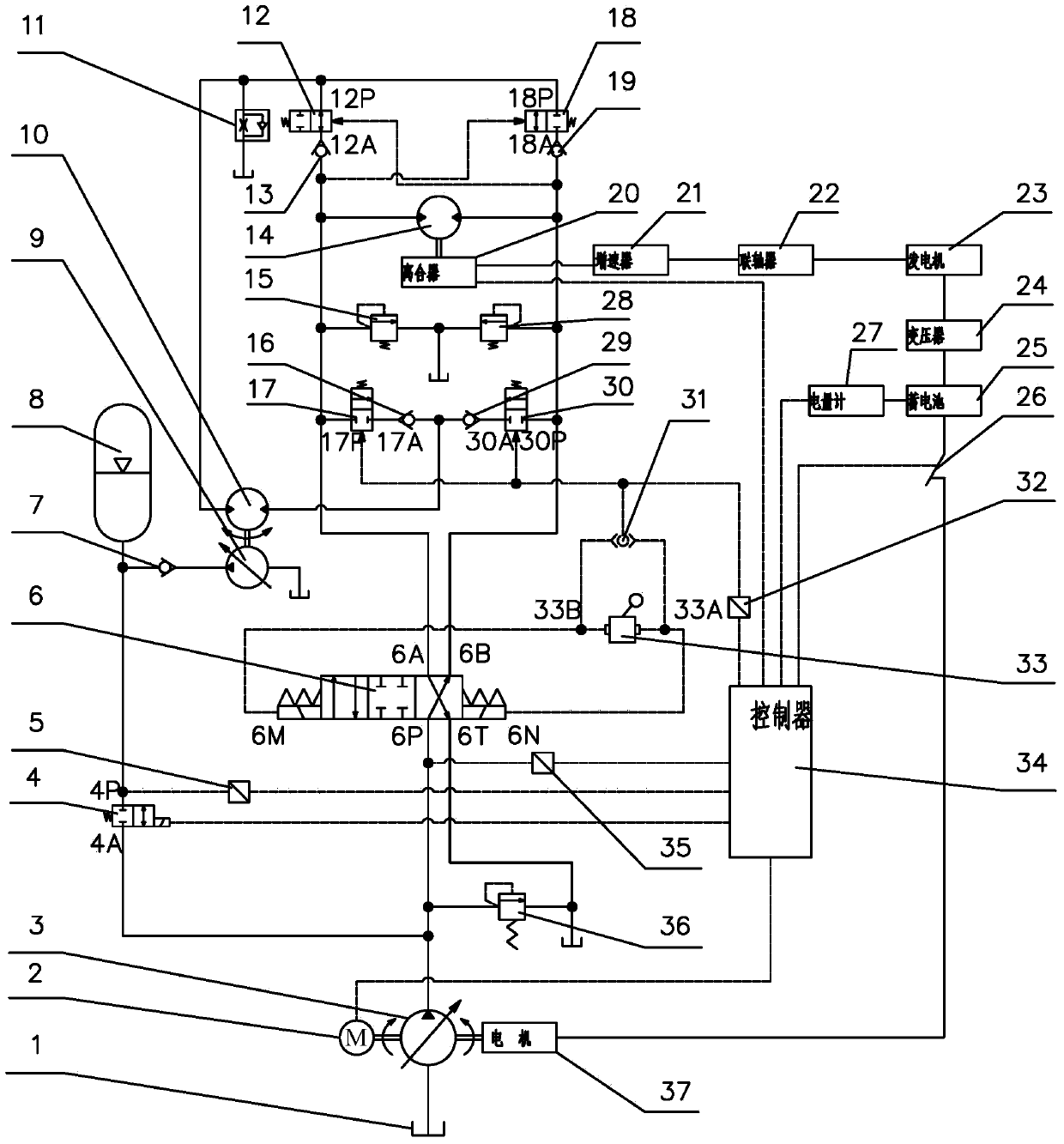

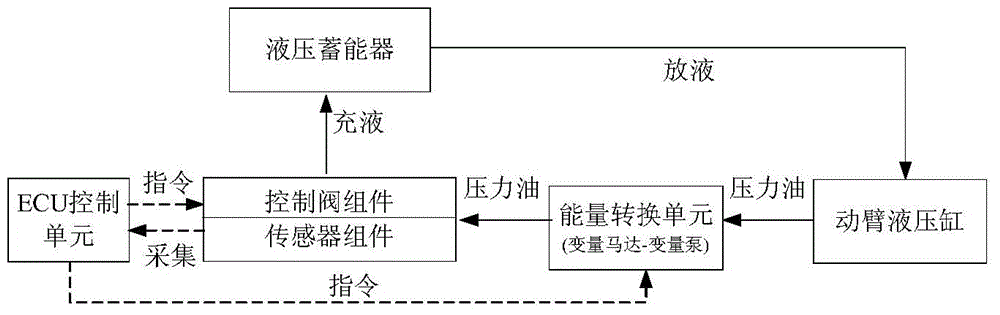

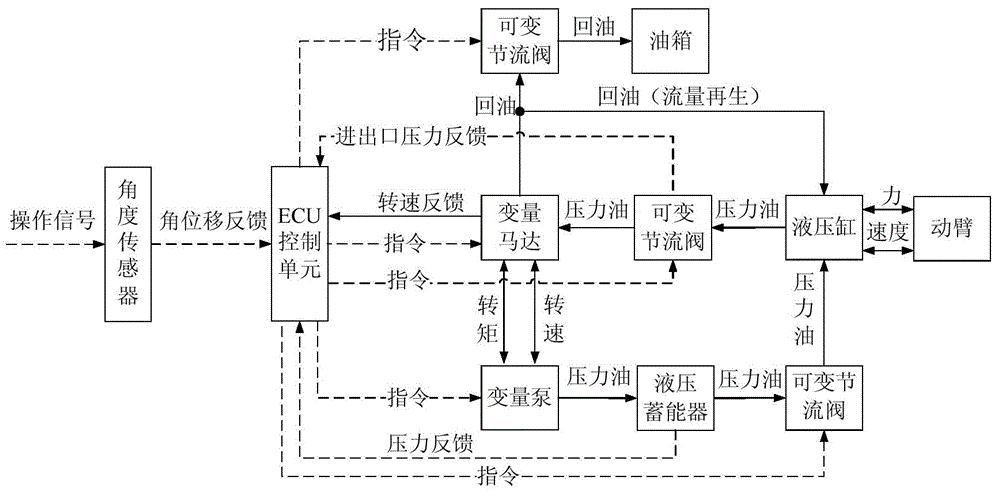

Hydraulic type energy recovery system for potential energy of boom of excavator

InactiveCN104613055AImprove recycling efficiencyAchieve regenerationActuator accumulatorsFluid-pressure actuator componentsTraffic volumePotential energy

A hydraulic type energy recovery system for potential energy of a boom of an excavator comprises a variable motor, two variable pumps, an energy accumulator, a control valve, an ECU, a pressure sensor, a revolution speed transducer, a hydraulic cylinder, an oil tank and an engine. Aiming at solving the problems that a great deal of potential energy of a boom of an existing hydraulic excavator under the working condition of severe change is wasted, a hydraulic type energy recovery system is arranged in parallel on the basis of not changing a hydraulic system and the operation performance of the existing excavator; the hydraulic type energy recovery system can recover the potential energy generated when the boom is released downwards, achieve flow regeneration of the boom in order to reduce oil consumption of the hydraulic excavator, and achieve the purpose of saving energy and reducing consumption.

Owner:FUJIAN UNIV OF TECH

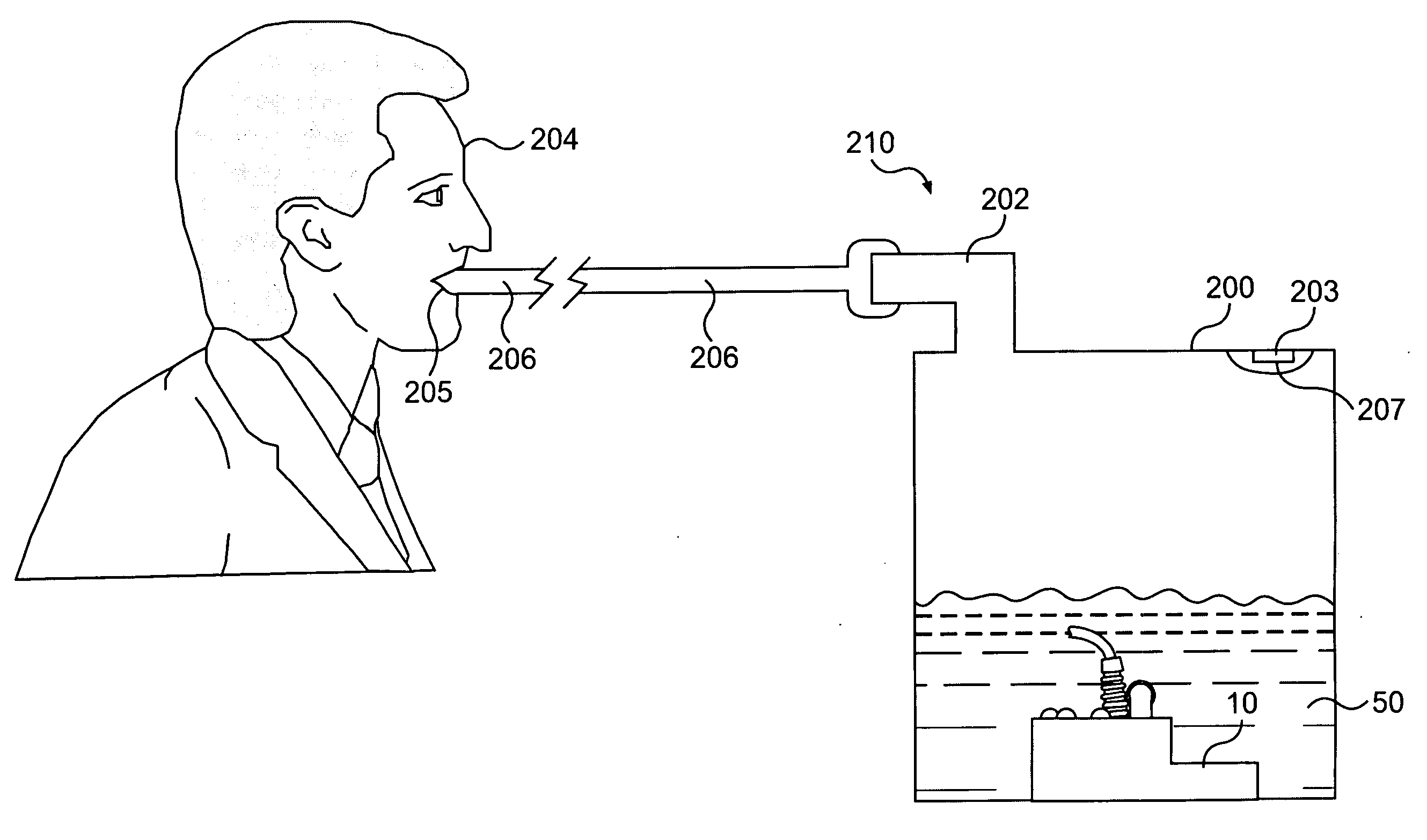

Ultrasonic fog maker and methods of drug delivery and air freshening

InactiveUS20050045734A1Avoid vacuumingReduce pressureRespiratorsLighting and heating apparatusMedicineVisual appearance

Owner:PALANTIC TRADING

Vacuum anti-siphon backflow preventing valve

InactiveCN103062453AProtection deformationProtection from being brokenCheck valvesStationary filtering element filtersSiphonUrban water supply

The invention discloses a vacuum anti-siphon backflow preventing valve and relates to a fluid medium pipeline control part. The valve comprises a valve body, a water inlet and a water outlet are arranged on the valve body, a valve cavity communicated with the water inlet is arranged on the valve body, a valve opening is arranged between the valve cavity and the water outlet to communicate the valve cavity with the water outlet, and a valve clack component enabling media to flow unidirectionally from the valve cavity to the water outlet is arranged in the water outlet. An air outlet for communicating the valve cavity with the outside is arranged at the top of the valve body. A support filter screen covering the valve opening is arranged in the cavity. A buoyancy seal component is arranged at the air outlet for sealing the air outlet when media flow forward from the water inlet to the water outlet or opening the air outlet when media flow reversely from the valve cavity to the water inlet. By means of the vacuum anti-siphon backflow preventing valve, the structure is simplified, backflow is prevented effectively, air in the valve cavity can be discharged rapidly when media get back to forward flow, and functions of impurity filtering and purifying are provided. The valve is mainly applied to pipeline systems in need of anti-pollution check, such as urban water supply systems.

Owner:ZHEJIANG DUNAN INTELLIGENT CONTROL TECH CO LTD

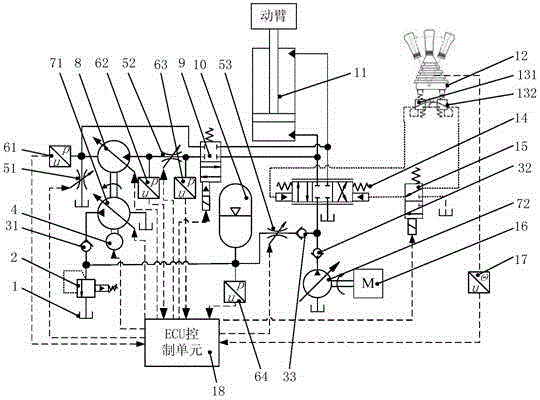

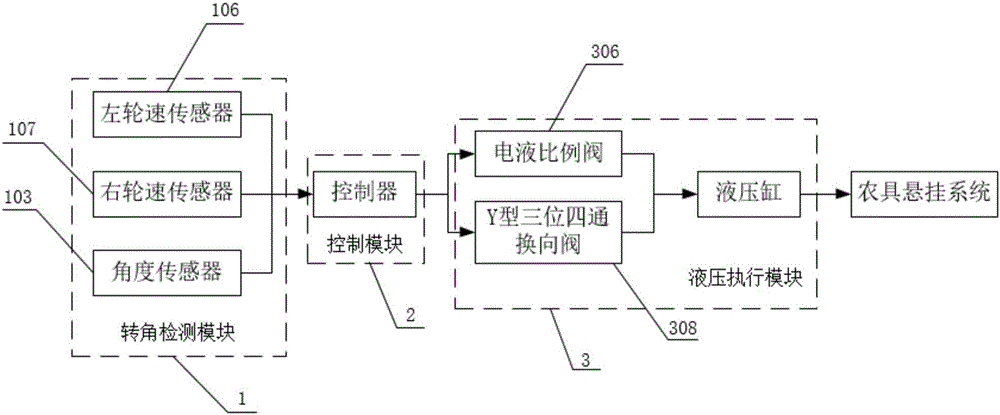

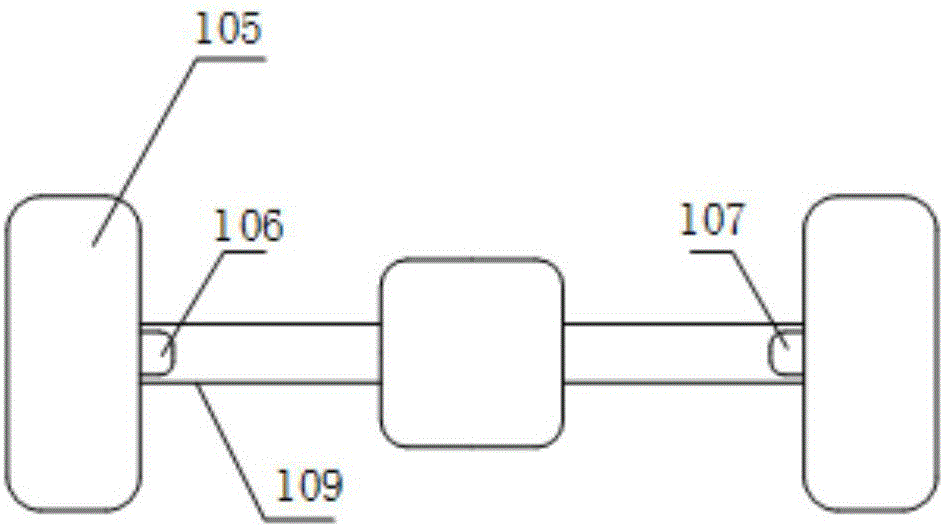

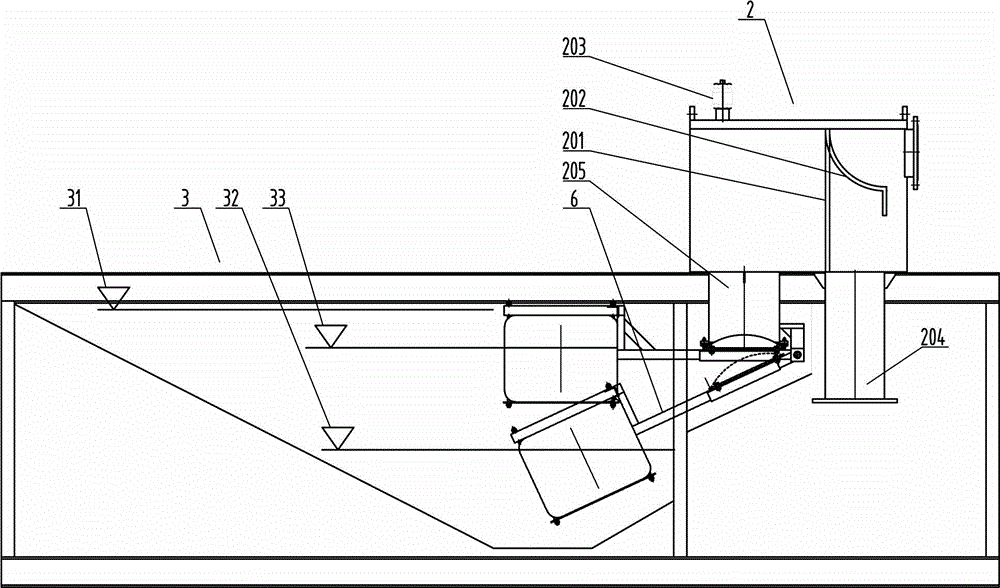

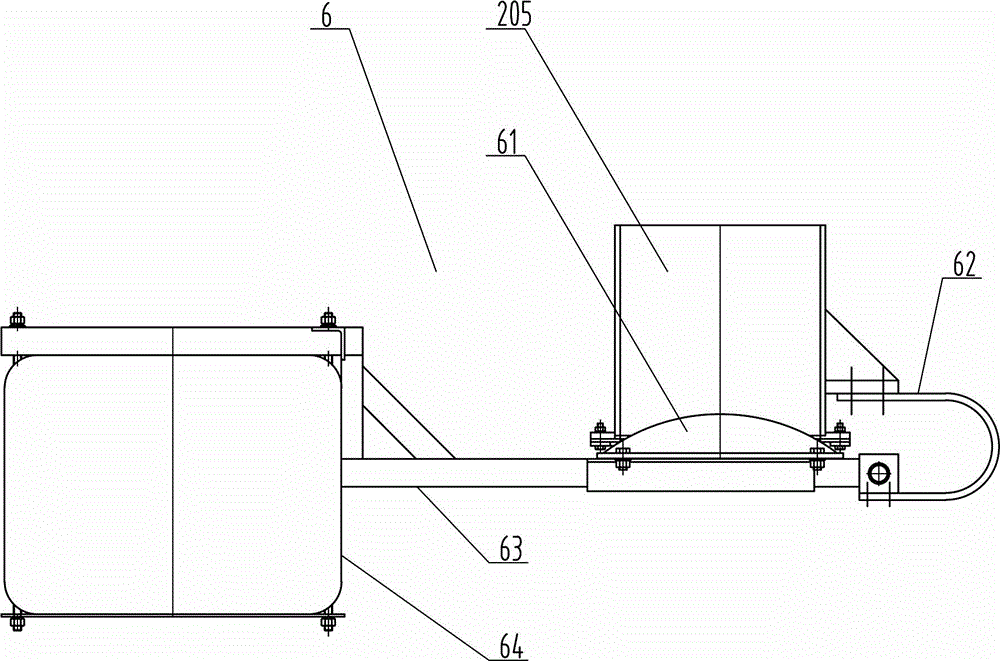

Electro-hydraulic hanging field end self-adaptive lifting device for tractor and control method

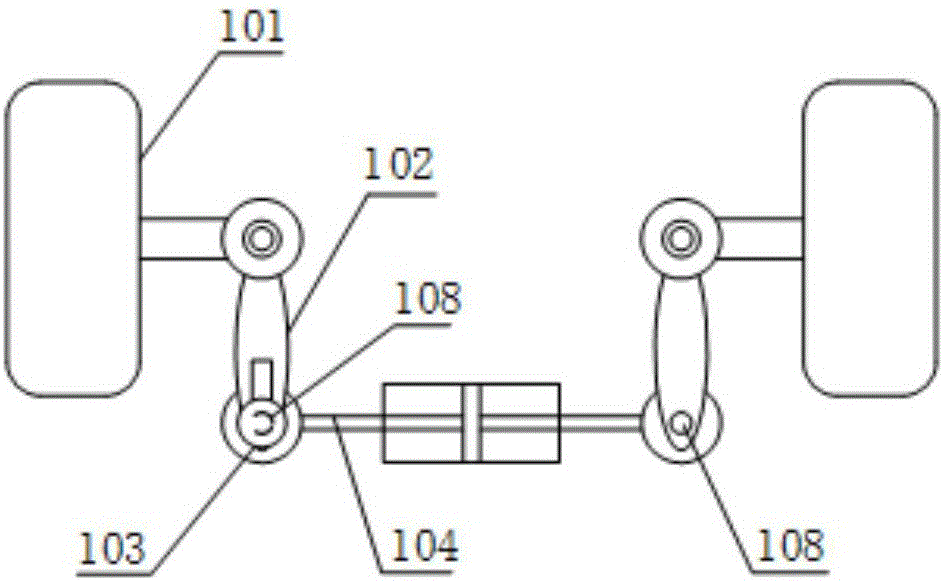

InactiveCN106612682AOptimize layoutSimple structureAgricultural machinesHydraulic cylinderTurn angle

The invention belongs to the field of agricultural machines, and relates to an electro-hydraulic hanging field end self-adaptive lifting device for a tractor, and a control method. The self-adaptive lifting device includes a turning monitoring module, a control module, and a hydraulic execution module; the turning monitoring module can recognize the speed of a left driving wheel and a right left driving wheel and the turning angle of a turning wheel, and can send a monitored signal to a controller; the control module can determine the turning time of the tractor at a field end according to the received speed of the left driving wheel and the right left driving wheel, and the recieved turning angle signal of the turning wheel, and the controller can send a command to an electro-hydraulic proportional valve and a reversing valve so as to control lifting of a hanging system; the hydraulic execution module can achieve lifting and falling of the hanging system according to the command of the controller, can keep a farm implement at a certain working position; and a hydraulic system can timely supply flow to a hydraulic cylinder through a one-way valve when the farm implement rapidly falls down, and cavitation can be avoided. Compared with the prior art, the electro-hydraulic hanging field end self-adaptive lifting device is high in automatic level, is simple to operate, and can greatly reduce the labor cost.

Owner:JIANGSU UNIV

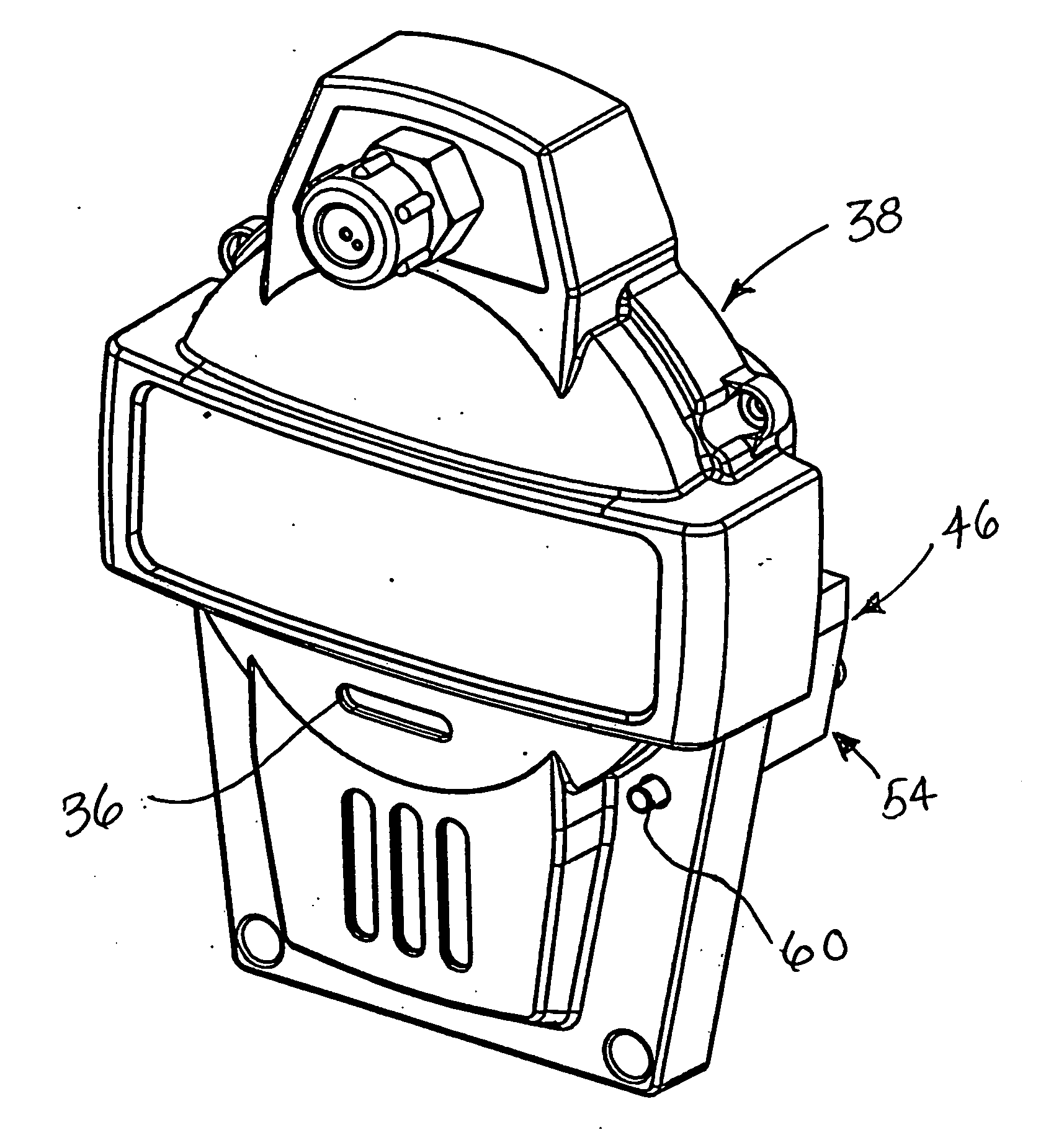

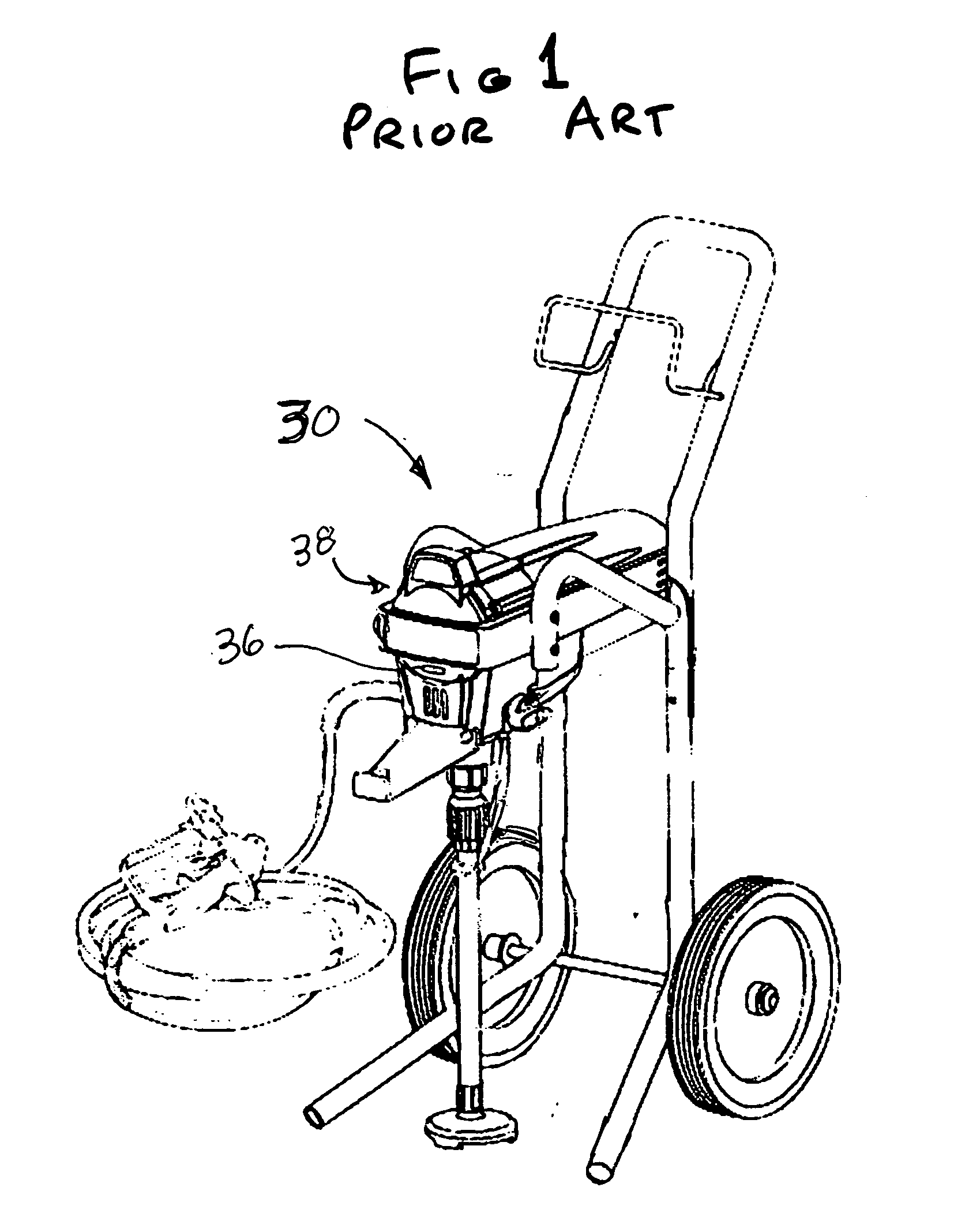

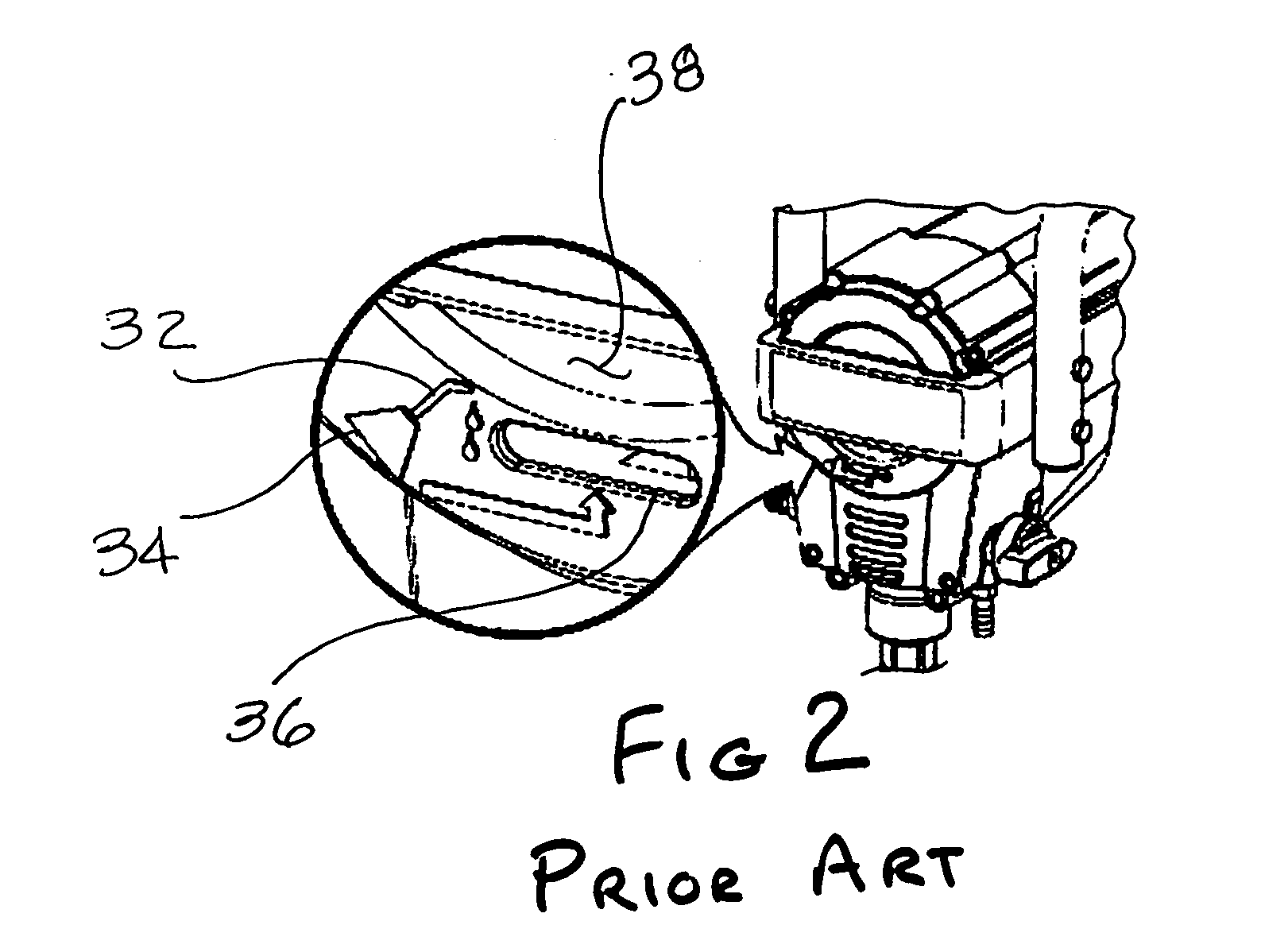

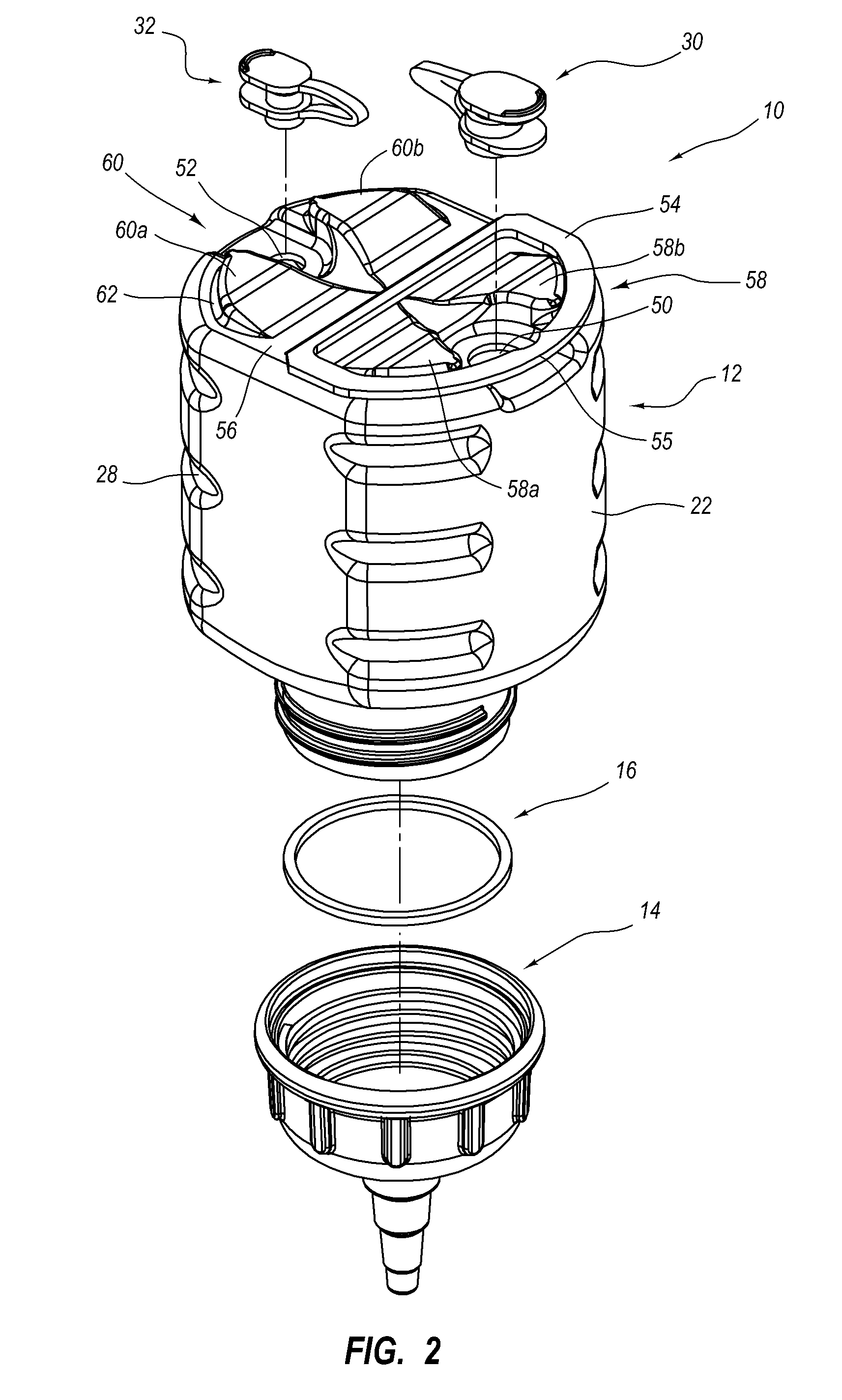

On board oil reservoir for lubricating piston paint pump

ActiveUS20070137938A1Avoid vacuumingPositive displacement pump componentsManual lubricationBreatherOn board

Apparatus and method for on-board lubrication of a paint pumping piston including a reservoir for lubricant and a lubricant dispensing mechanism for delivering a predetermined repeatable amount of lubricant upon manual actuation of the lubricant dispensing mechanism. In one embodiment, a section of tubing acts as the reservoir, and in another embodiment, the reservoir is formed by a transparent or translucent chamber located adjacent an aperture in a pump housing to enable visual inspection of the level of lubricant in the reservoir. A lubricant delivery piston is actuated by an extension thereof projecting through an aperture in the housing, and a lubricant discharge nozzle is located adjacent the paint pumping piston proximate a bushing supporting the paint pumping piston. A breather valve prevents a vacuum in the reservoir as the lubricant is dispensed.

Owner:WAGNER SPRAY TECH CORP

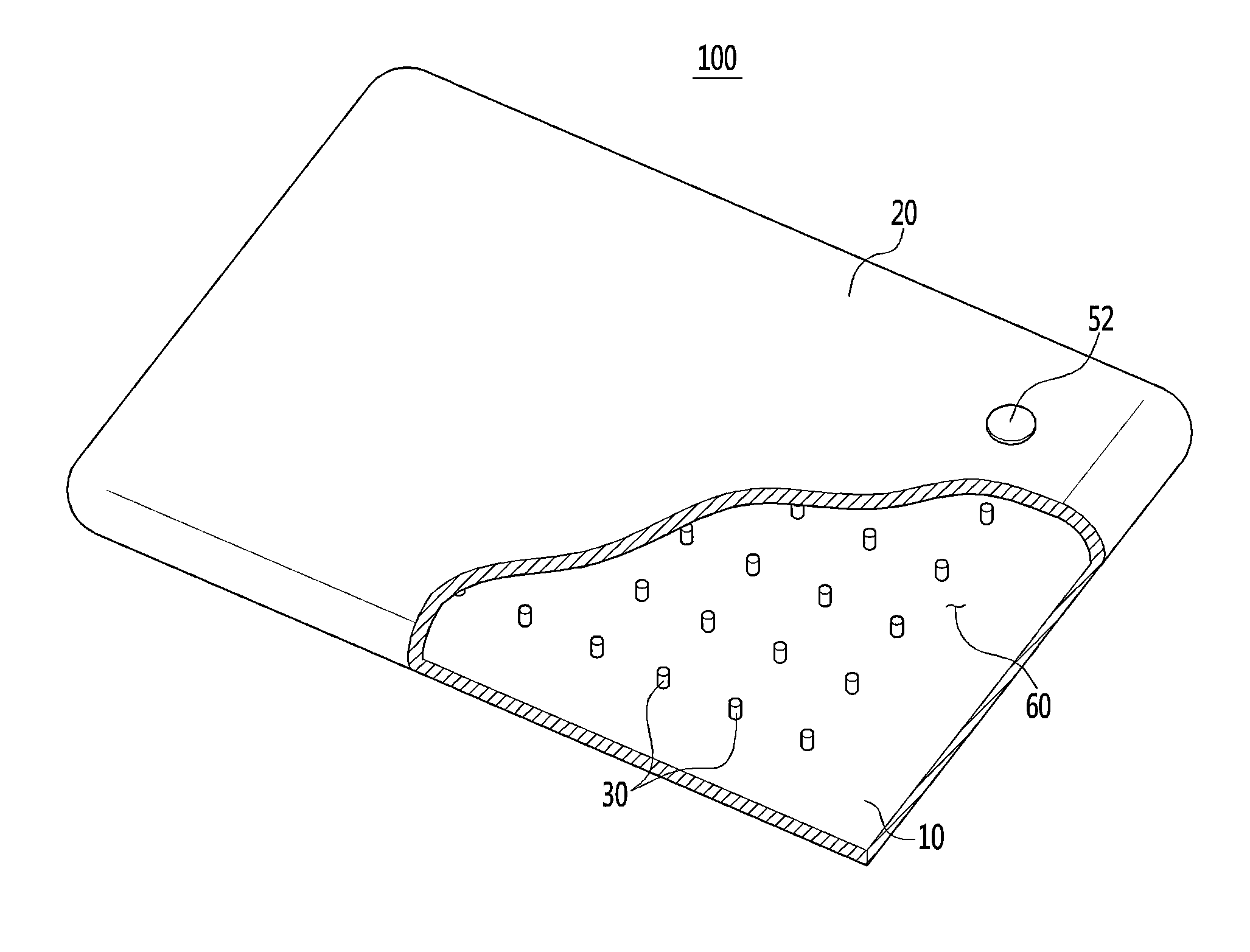

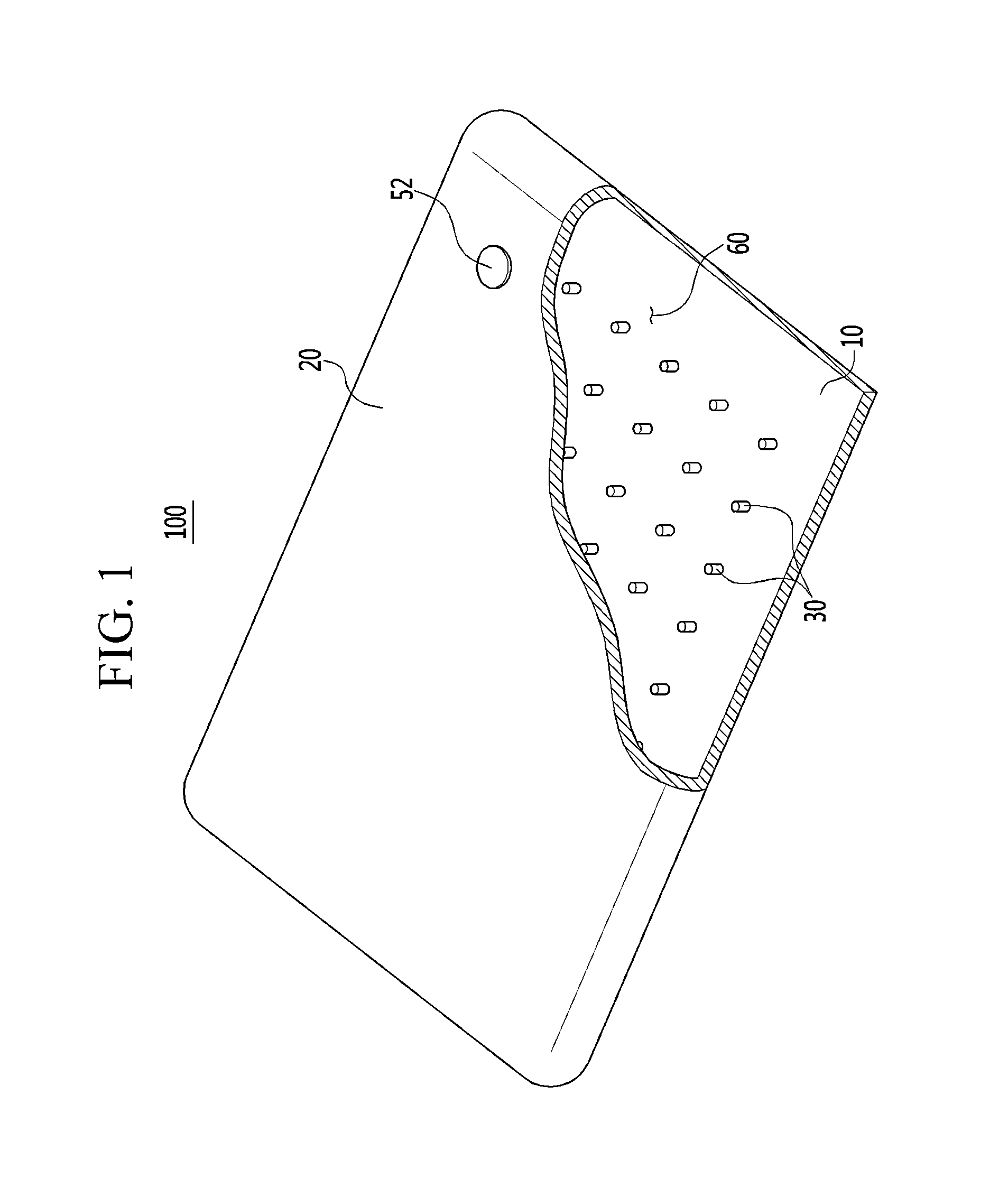

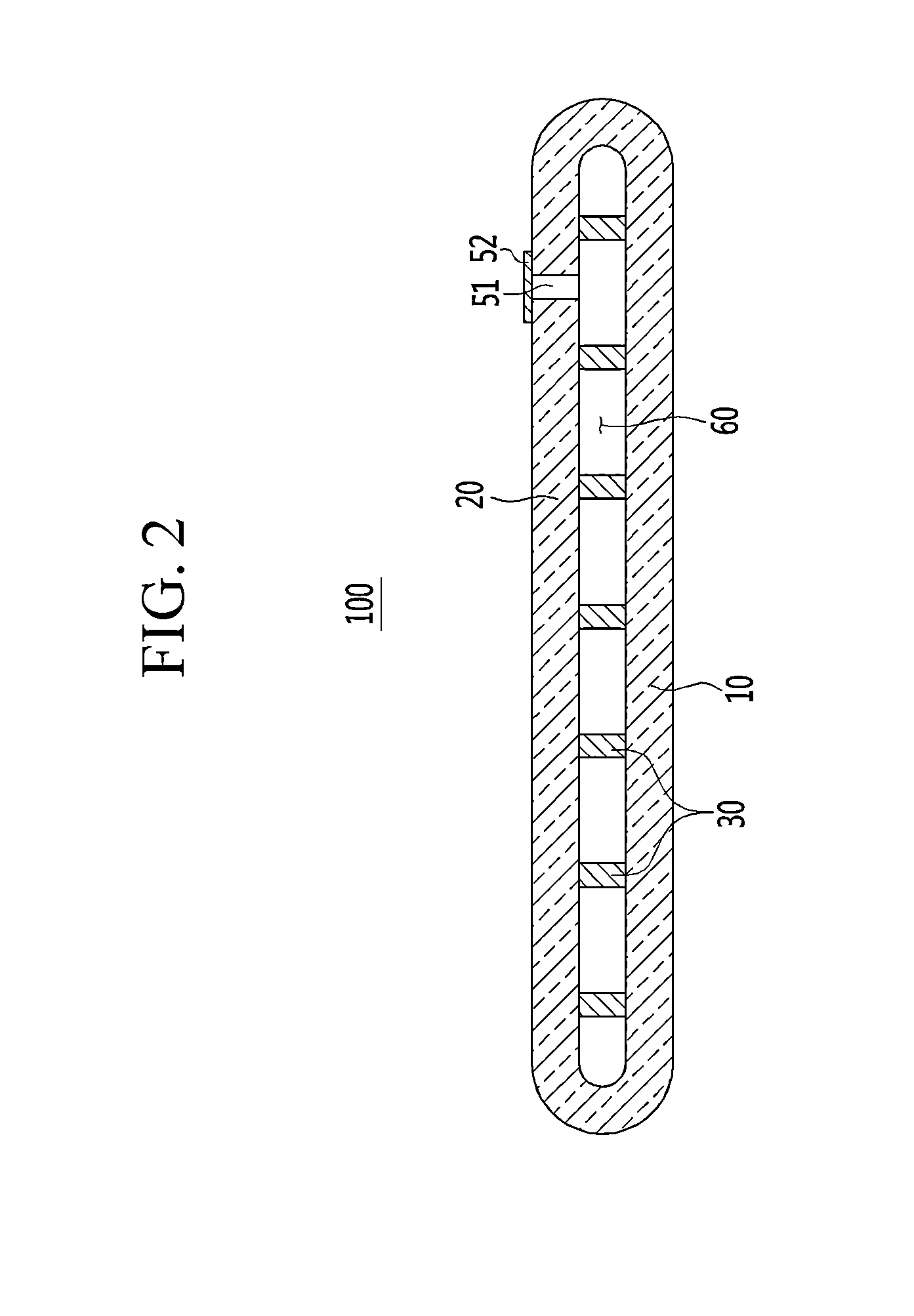

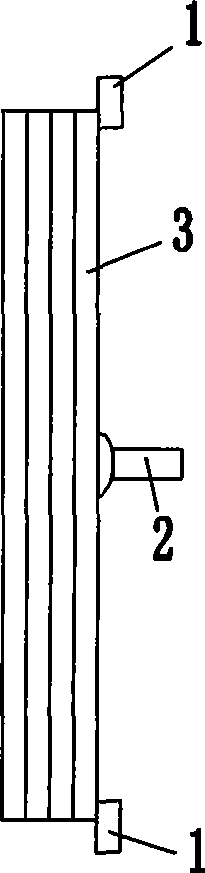

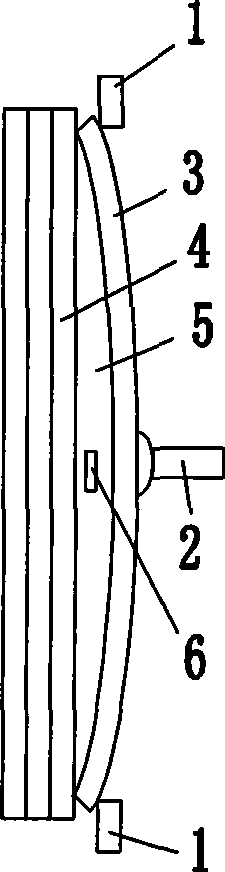

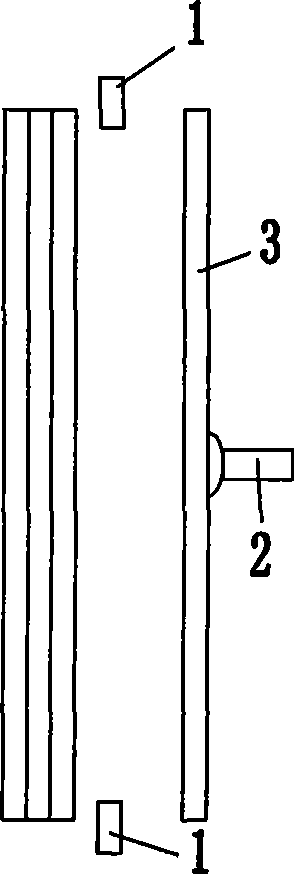

Vacuum glass panel and manufacturing method of same

ActiveUS20130273296A1Improve bearing capacityHigh compressive strengthLayered productsClimate change adaptationEngineeringSilicon dioxide

Disclosed are a vacuum glass panel and a manufacturing method of the same. The vacuum glass panel according to the present invention includes a first glass plate, a second glass plate facing the first glass plate with a vacuum space therebetween, an edge of the second glass plate being in contact with the first glass plate, and a plurality of spacers disposed between the first glass plate and the second glass plates to separate the first glass plate and the second glass plate from each other. The plurality of spacers are formed of a glass including alumina (Al2O3) particles and silica (SiO2) particles.

Owner:KONGJU NAT UNIV IND UNIV COOPERATION FOUND

Oil cylinder energy recovery and regeneration system

InactiveCN102588396AAchieve recyclingAvoid vacuumingFluid-pressure actuator componentsHydraulic cylinderEngineering

The invention discloses an oil cylinder energy recovery and regeneration system, which comprises a hydraulic cylinder, an oil tank, a constant-displacement motor, an energy accumulator and an engine. One end of a rod-less cavity of the hydraulic cylinder is connected with one end of the constant-displacement motor, the other end of the constant-displacement motor is divided into two channels respectively connected with the oil tank and one end of a rod-end cavity of the hydraulic cylinder, a first variable-capacity pump is connected with the constant-displacement motor, one end of the first variable-capacity pump is connected with the oil tank, and the other end of the first variable-capacity pump is connected with the energy accumulator. A second variable-capacity pump is connected with the engine, one end of the second variable-capacity pump is connected with the oil tank, the other end of the second variable-capacity pump is connected with a first one-way valve, and the first one-way valve is connected with the energy accumulator through a first reversing valve. The other end of the rod-end cavity of the hydraulic cylinder is connected with the first one-way valve through a second reversing valve, the other end of the rod-less cavity of the hydraulic cylinder is connected with the first one-way valve through a third reversing valve. The oil cylinder energy recovery and regeneration system has the advantages that flow required for interlock of a movable arm is reduced effectively while time recovery time is prolonged effectively.

Owner:SANY HEAVY MACHINERY

Method and mechanism for extracting multi-layer thin slab layer by layer

InactiveCN101503152AImprove reliabilityReduce energy consumptionConveyor partsArticle separationThin slabEngineering

The invention discloses a method for extracting a multi-layer thin plate layer by layer and a mechanism for extracting a multi-layer thin plate using same. The mechanism is essentially characterized in that the mechanism is provided with a baffle block; the top of the baffle block is contacted with the neighborhood of the plane edge of a first layer thin plate at the exit of a stock bin; and a movable plug-in module is arranged near the exit of the stock bin. The method is essentially characterized in that when a sucker-type mechanical hand absorbs the thin plate, the baffle block is used for enforcing the thin plate to be bent, arced and deformed, and the plug-in module is inserted between the arced thin plate and the next layer thin plate, thereby effectively preventing the two layer thin plates from being taken out simultaneously. The invention has the advantages that only one layer thin plate can be taken out at once and reliability is high.

Owner:佛山市一鼎科技有限公司

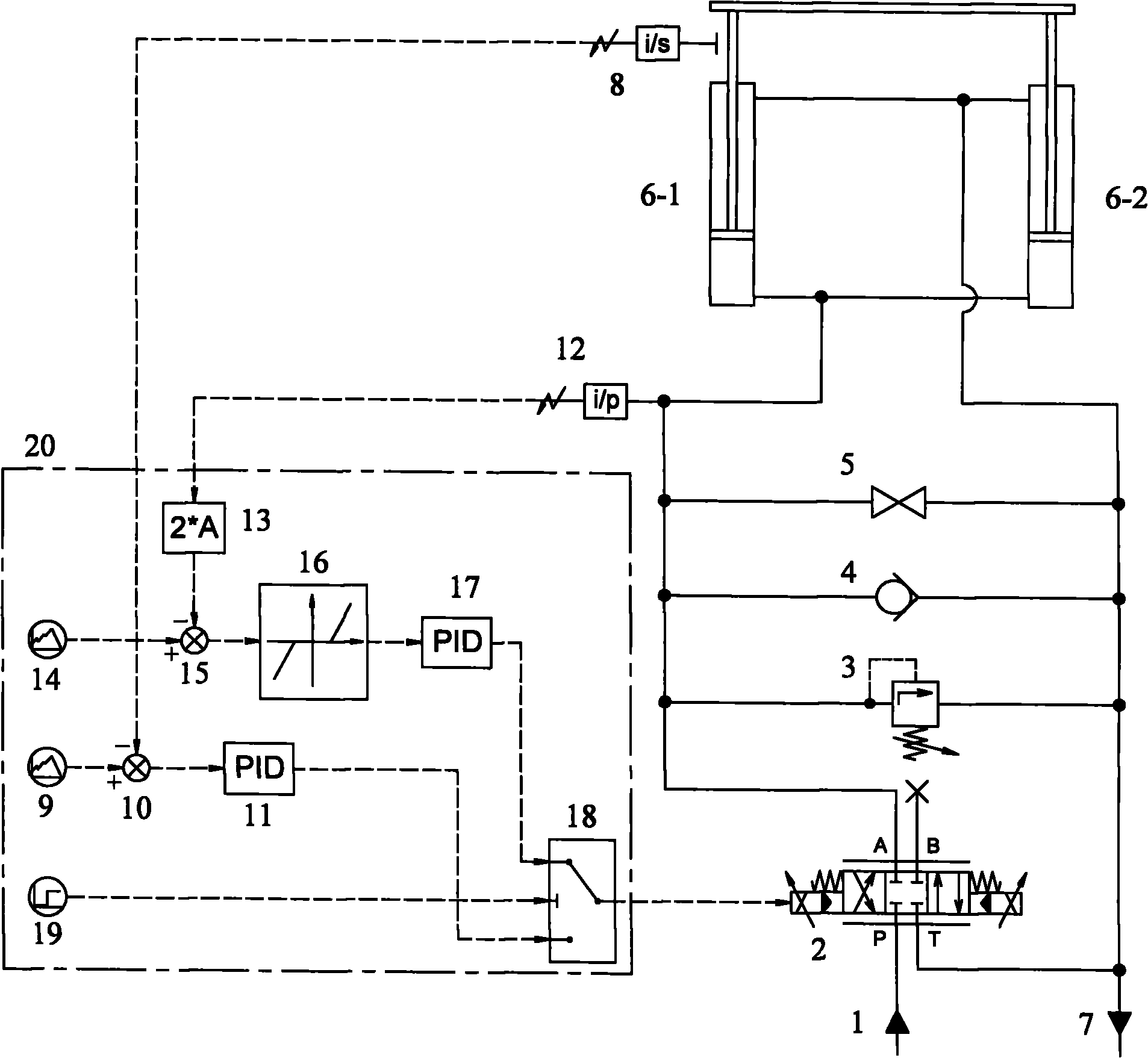

Displacement-force compound control lifting system for forging manipulator

InactiveCN102114517APrecise control of vertical displacementLower resistanceServomotorsForging/hammering/pressing machinesForging manipulatorControl theory

The invention discloses a displacement-force compound control lifting system for a forging manipulator. A port P of a proportional servo valve (2) is connected with an oil supply port (1) of an oil source; a port A of the proportional servo valve (2) is respectively connected with an inlet of a safety valve (3), an outlet of a check valve (4), an inlet of a stop valve (5), a pressure sensor (12) and lower cavities of two lifting cylinders; an oil return port (7) of the oil source is respectively connected with a port T of the proportional servo valve (2), an outlet of the safety valve (3), an inlet of the check valve (4), an outlet of the stop valve (5) and upper cavities of the two lifting cylinders; mechanisms at top ends of piston rods of the two lifting cylinders are fixedly connected; a displacement sensor (8) is internally arranged on the piston rods; and a signal output end of the displacement sensor (8), a signal output end of the pressure sensor (12) and a signal input end of the proportional servo valve (2) are connected with a displacement-force compound controller through signals. Due to the adoption of the system, the response speed can be increased, and the compliance in the vertical direction can be improved.

Owner:ZHEJIANG UNIV

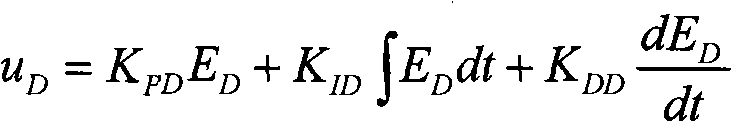

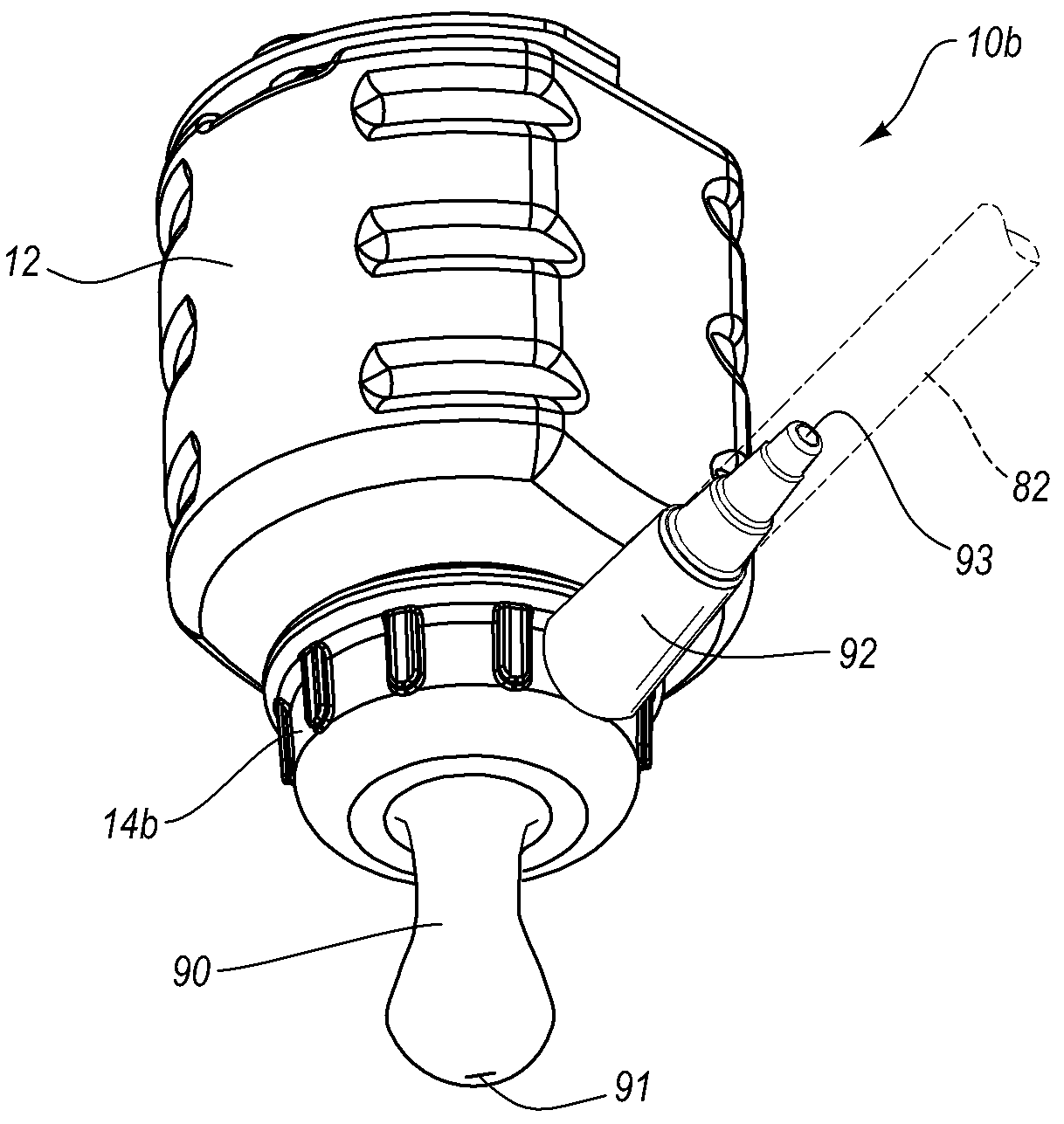

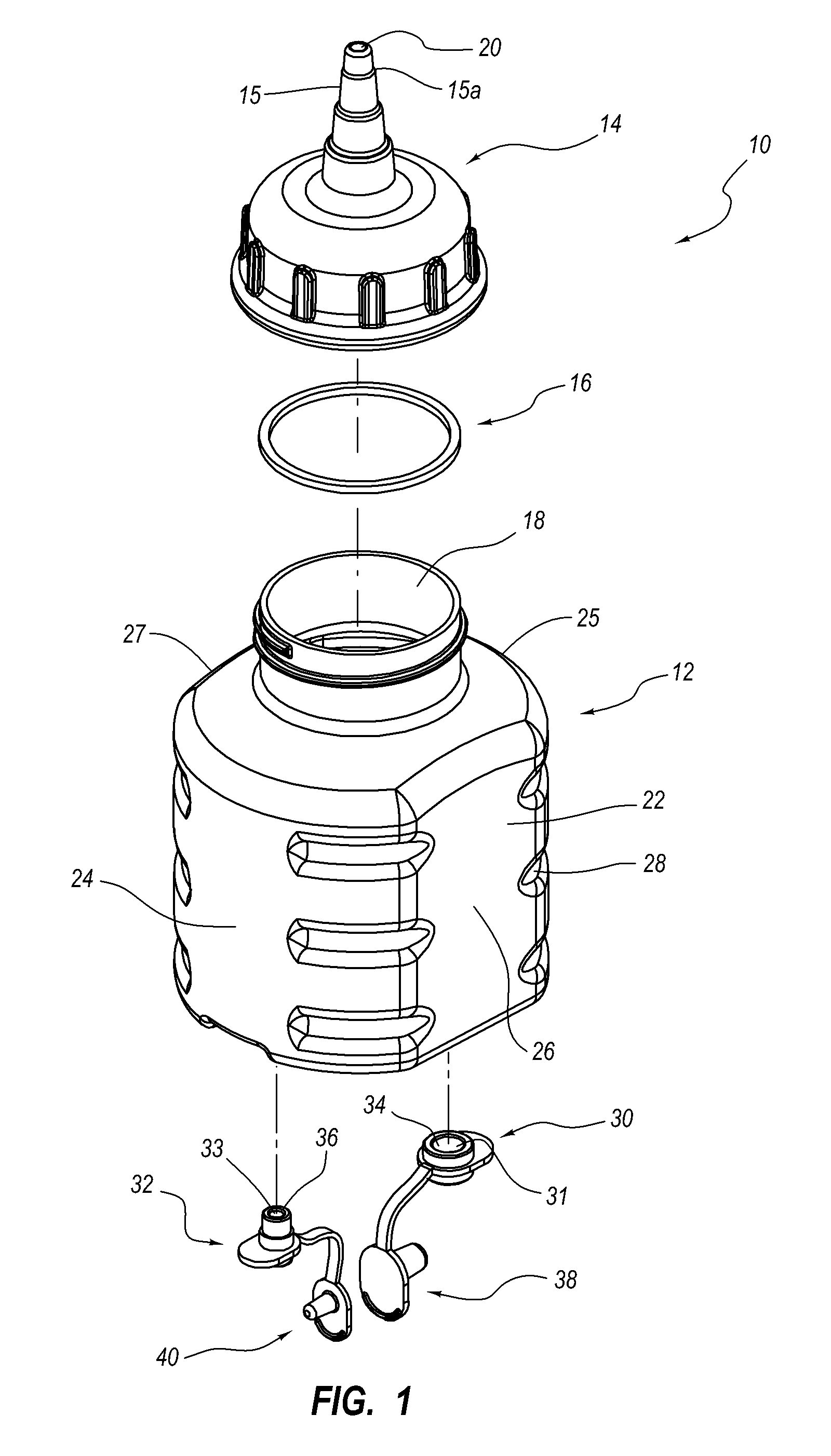

Bottle for delivering nutrients to an enteral feeding tube

InactiveUS20080103475A1Eliminate SpillsEliminate overflowDiagnosticsSurgeryEnteral feedingsEngineering

An enteral feeding device, includes a system for delivering liquid nutrients to an enteral feeding tube. The device includes: (a) a container, having first, second and third openings; (b) a tip configured to be coupled to the container, the tip having an opening in fluid communication with the first opening of the container, the second opening of the container configured such that nutrient can be delivered to the second opening and the third opening configured to receive nutrient or to allow gas expelled from the patient (e.g., through burping) to flow there through.

Owner:HENDRICKS WILLIAM

Hydraulic system of horizontal buffer cylinder of forging and pressing operating machine

InactiveCN101704059AEasy to switchImprove reliabilityServomotor componentsForging press drivesFeeding forceProportional control

The invention discloses a hydraulic system of a horizontal buffer cylinder of a forging and pressing operating machine, which comprises an oil-feed port, a proportional pressure-reducing valve, a proportional directional valve, two safety valves, two check valves, a proportional overflow valve, an electromagnetic directional valve, a buffer cylinder, an oil return port, a displacement sensor and a displacement controller. The invention realizes the passive buffering of the buffer cylinder and the switching of an active feeding function through controlling the electromagnetic directional valve, realizes the control of passive buffering force through regulating the proportional overflow valve, realizes the control of active feeding force and buffering restoring force through regulating the proportional pressure-reducing valve, and realizes active feeding displacement and speed accurate control through the displacement closed-loop control of the proportional directional valve. The invention can finish the passive buffering and the active feeding function required by the horizontal buffering of the forging and pressing operating machine and realize the proportional control of force and displacement; and the hydraulic system has the advantages of simple structure and multiple functions.

Owner:ZHEJIANG UNIV

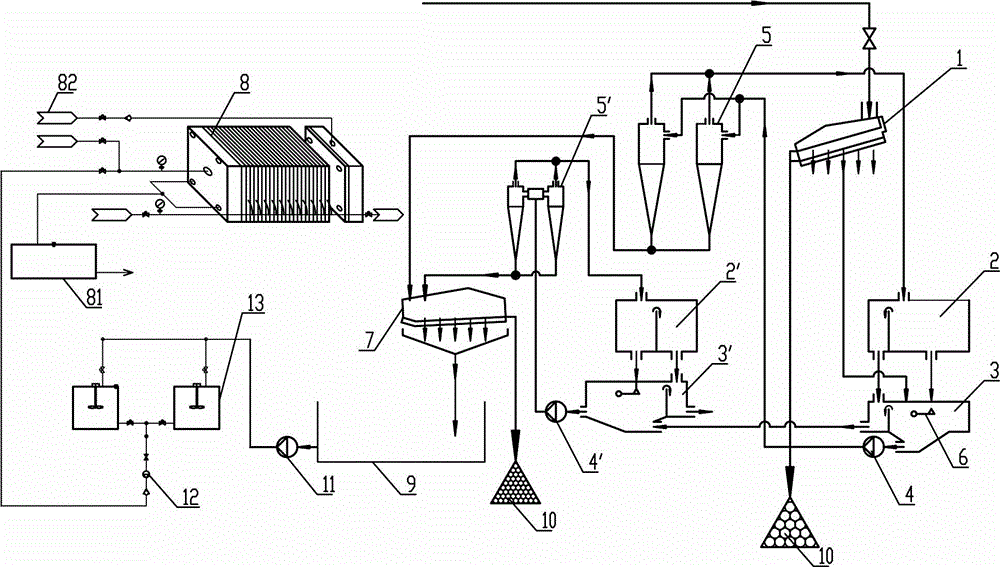

Sludge treatment system

ActiveCN105152517AAvoid vacuumingOvercoming fragileSludge treatment by de-watering/drying/thickeningCycloneFilter press

The invention relates to a sludge treatment system. An underflow opening of a pre-screen is connected with a first slurry storage tank; an underflow opening of the first slurry storage tank is connected with an inlet of a primary cyclone through a first slurry pump; an overflow port of the primary cyclone is connected with a liquid inlet port of a first overflow box; an underflow opening of the primary cyclone is connected with an underflow collecting tank; an overflow port of the first overflow box is connected with a second slurry storage tank; an underflow opening of the second slurry storage tank is connected with an inlet of a secondary cyclone through a second slurry pump; an underflow opening of the secondary cyclone is connected with the underflow collecting tank; an overflow port of the secondary cyclone is connected with a liquid inlet port of a second overflow box; a slurry discharge port of the second overflow box is connected with the second slurry storage tank; the underflow collecting tank is connected with a filter press or centrifuge; and a liquid level balance valve is arranged and used for plugging the slurry discharge port of the overflow box along with the liquid level height. The process route is optimized to enhance the sludge treatment efficiency. The slurry storage tanks capable of automatically implementing liquid level balance are matched to avoid idle suction of the slurry pump.

Owner:三川德青工程机械有限公司

Ultrasonic fog maker and methods of drug delivery and air freshening

InactiveUS20030094508A1Avoid vacuumingPressure at outlet is greatly reducedRespiratorsLighting and heating apparatusMedicineVisual perception

An ultrasonic fog generator creates a fog of a liquid such as water. The visual appearance of the fog may be altered such as by being illuminated by one or more lights having one or more colors. Further, the fog may be used to deliver pharmaceuticals to one or both of the lungs of a patient.

Owner:PALANTIC TRADING

Apparatus For Preventing Vacuum Of Scroll Compressor

ActiveUS20090074593A1Smooth operationEnhancing reliability and efficiency of compressorRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeRefrigerantProduction rate

An apparatus for preventing vacuum of a scroll compressor, comprising: a fixed scroll having a bypass hole through which a suction chamber of a casing is connected to a discharge chamber of the casing; a valve block having an inner channel through which the bypass hole of the fixed scroll is connected to the discharge chamber of the casing, and fixedly installed at the fixed scroll; and a valve member disposed between the bypass hole of the fixed scroll and the inner channel of the valve block, for opening and closing between the bypass hole and the inner channel. Since the apparatus is assembled at an outer periphery of the fixed scroll, a processing error of the fixed scroll is prevented thereby to reduce a production cost. Also, since foreign materials generated when a refrigerant channel is processed does not remain in a valve hole, the valve member is prevented from being mal-operated, a productivity is enhanced, and a fabrication cost is reduced.

Owner:LG ELECTRONICS INC

Bottle for delivering nutrients to an enteral feeding tube

InactiveUS7799008B2Easy to controlEliminates spill and overflowDiagnosticsSurgeryEnteral feedingsBottle

An enteral feeding device, includes a system for delivering liquid nutrients to an enteral feeding tube. The device includes: (a) a container, having first, second and third openings; (b) a tip configured to be coupled to the container, the tip having an opening in fluid communication with the first opening of the container, the second opening of the container configured such that nutrient can be delivered to the second opening and the third opening configured to receive nutrient or to allow gas expelled from the patient (e.g., through burping) to flow there through.

Owner:HENDRICKS WILLIAM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com