Method and mechanism for extracting multi-layer thin slab layer by layer

A thin plate and plate surface technology, which is applied in the field of extracting stacked thin plates one by one, method and mechanism, can solve the problems of poor reliability, serious noise, high energy consumption, etc., and achieve the effect of wide application range, high reliability and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

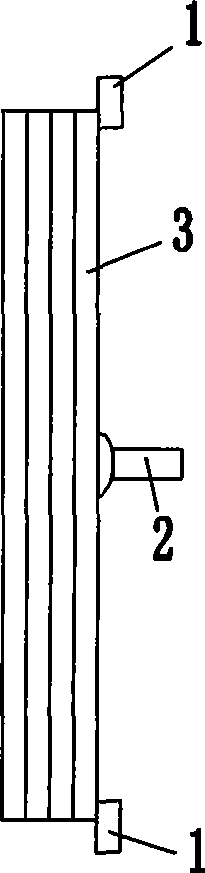

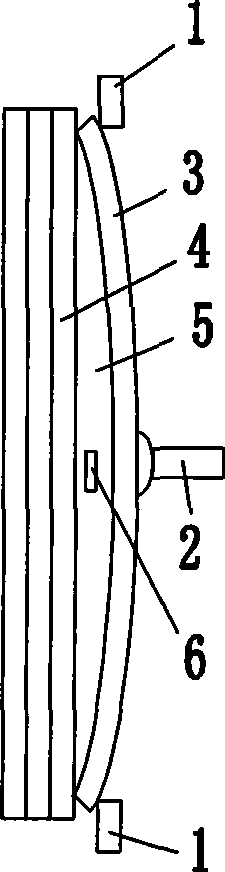

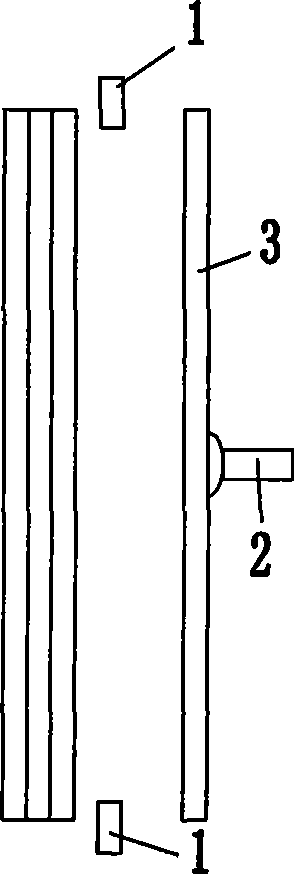

[0013] The method of the invention uses a sucker type manipulator to absorb thin plates layer by layer. The process of picking up the sheet has two stages. In the first stage, first as figure 1 As shown, use the stopper 1 to touch near the edge of the thin plate surface, and then use the suction cup manipulator 2 to suck the surface of the thin plate 3 and pull the thin plate until figure 2 In the state shown, the plate surface of the thin plate 3 is bent and arched under the restriction of the stopper 1 and the pull of the suction cup manipulator 2, and a cavity 5 is formed between the thin plate 3 and the next thin plate 4, and then an insert 6 is inserted into hole 5. In the second stage, from figure 2 At the beginning, continue to use the suction cup type manipulator 2 to suck the plate surface of the thin plate 3 and pull the thin plate to make the thin plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com