Displacement-force compound control lifting system for forging manipulator

A technology for forging manipulators and lifting systems, applied in forging/pressing/hammering machinery, mechanical equipment, manufacturing tools, etc., can solve the problem that the manipulator cannot work efficiently, the lifting force control cannot be achieved, and the proportional pressure valve frequency response Low problems, to achieve the effect of simple structure and control strategy, reduced resistance, and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

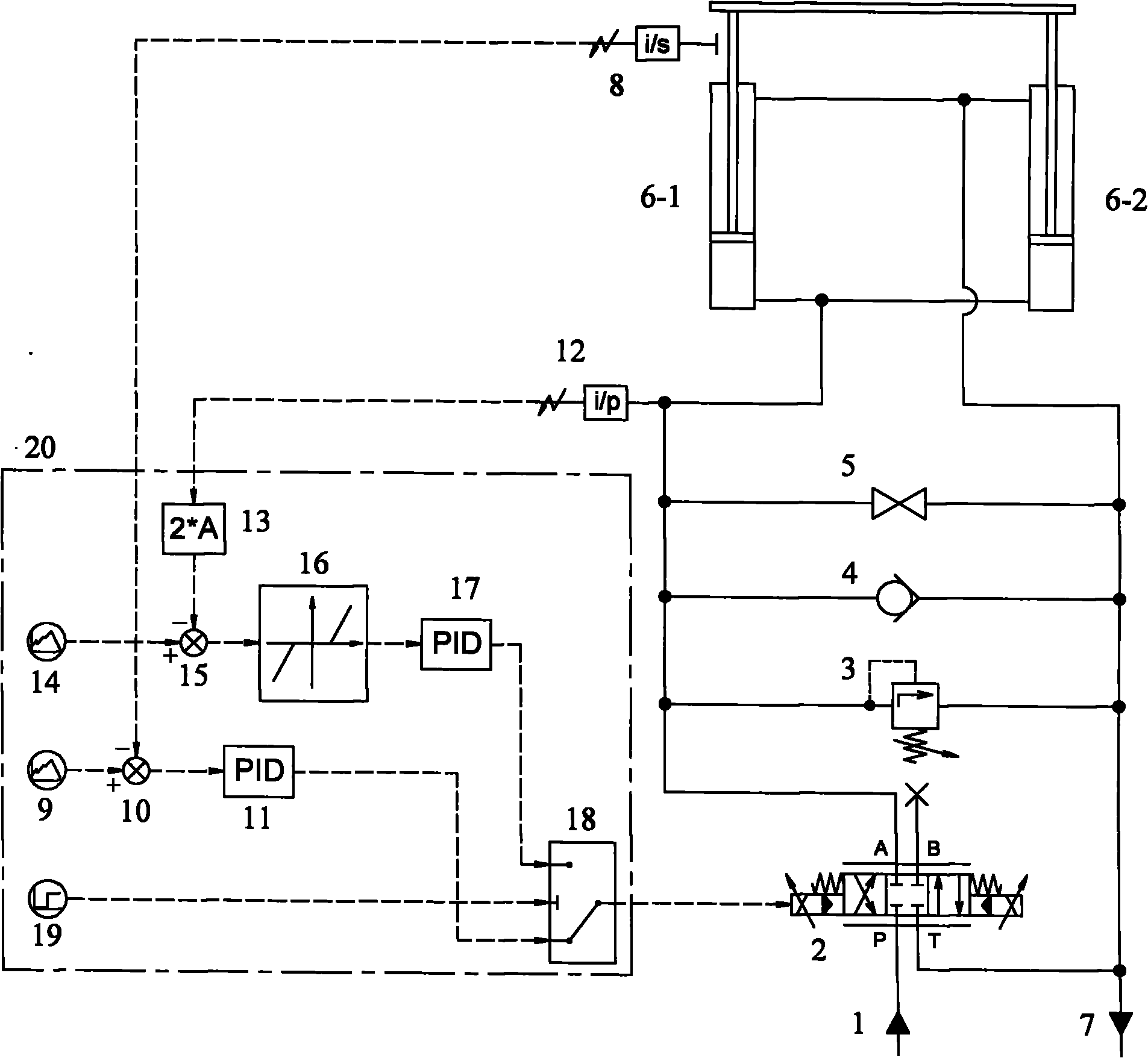

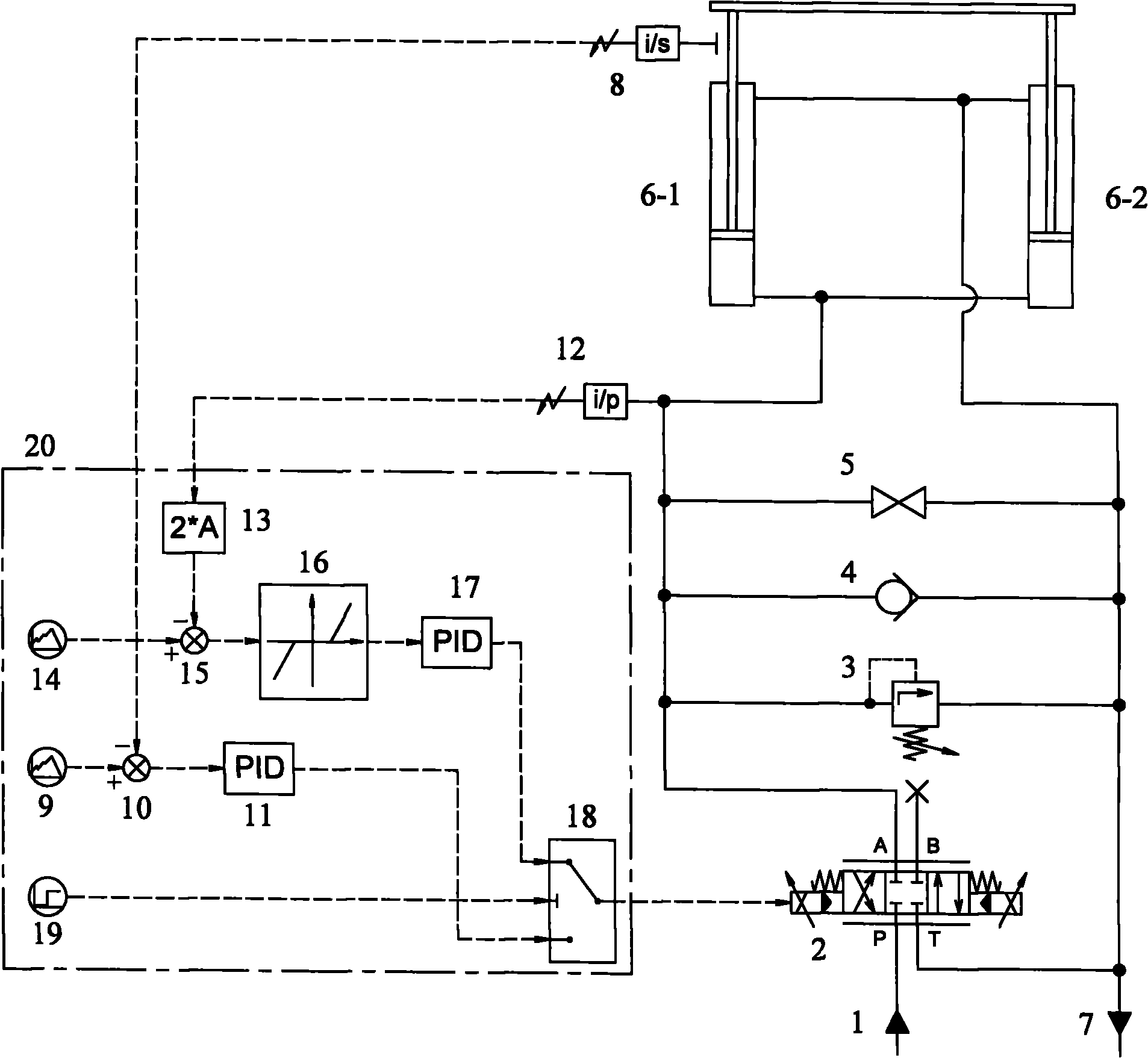

[0018] Embodiment 1. A displacement-force composite control lift system for a forging manipulator, which consists of an oil supply port 1, a proportional servo valve 2, a safety valve 3, a one-way valve 4, a stop valve 5, and a left lift cylinder 6-1 , right lifting cylinder 6-2, oil source and oil return port 7, displacement sensor 8, pressure sensor 12 and displacement-force composite controller 20.

[0019] Port P of proportional servo valve 2 is connected to oil supply port 1 of the oil source; port B of proportional servo valve 2 is sealed; port A of proportional servo valve 2 is connected to the inlet of safety valve 3, the outlet of one-way valve 4, the inlet of stop valve 5, the pressure Sensor 12, left lift cylinder 6-1 lower chamber connected with right lift cylinder 6-2 lower chamber; oil source return port 7 and T port of proportional servo valve 2, safety valve 3 outlet, one-way valve 4 inlet, stop valve 5 outlet, left lifting cylinder 6-1 upper cavity, right lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com