Patents

Literature

112 results about "Forging manipulator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

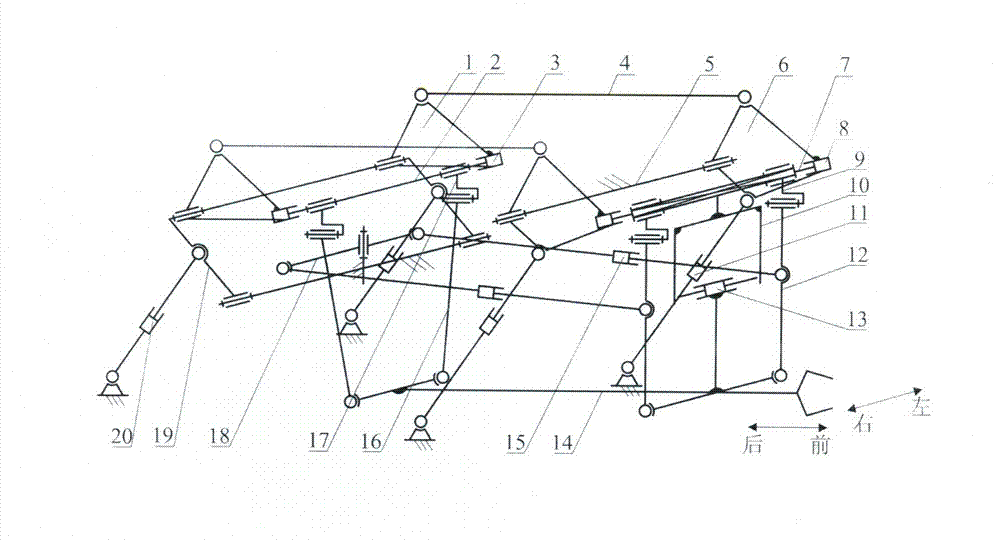

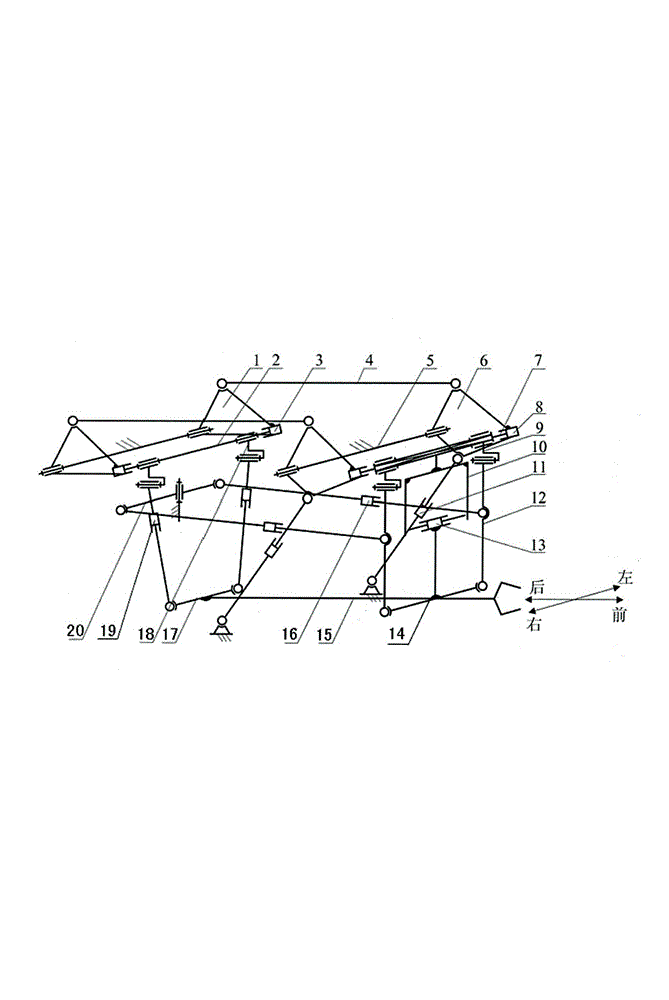

Forging manipulator lifting mechanism with inclined rear suspension rods

InactiveCN101879571AImprove carrying capacityReduce stressForging/hammering/pressing machinesForging manipulatorMechanical engineering technology

The invention relates to a forging manipulator lifting mechanism with inclined rear suspension rods in the technical field of the mechanical engineering, which is characterized in that the upper ends of two front suspension rods (12) are respectively connected at the lower ends of two front connecting pieces (9) by rotating hinges; the upper ends of the two front connecting pieces (9) are respectively connected on both sides of a movable frame (10) by rotating hinges; the movable frame (10) can move left and right on a front sliding rod (7); two rear suspension rods (16) are arranged symmetrically right and left in an inclined mode; the upper ends of the two rear suspension rods (16) are respectively connected at the lower ends of two rear connecting pieces (17) by rotating hinges; the upper ends of the two rear connecting pieces (17) are respectively connected on both sides of a rear sliding rod (2) by rotating hinges; two pitching linear drivers (4) are horizontally arranged on the top of a lifting arm front and back; and the front ends of the two pitching linear drivers (4) are respectively connected on both sides of a front lifting arm (6) by spherical hinges, while the rear ends thereof are respectively connected on both sides of a rear lifting arm (1) by spherical hinges. The forging manipulator lifting mechanism with the inclined rear suspension rods has the characteristics of high bearing capability, easy installation, long service life and the like and is suitable for forging operation of large-scale / ultra large forgings.

Owner:YANSHAN UNIV

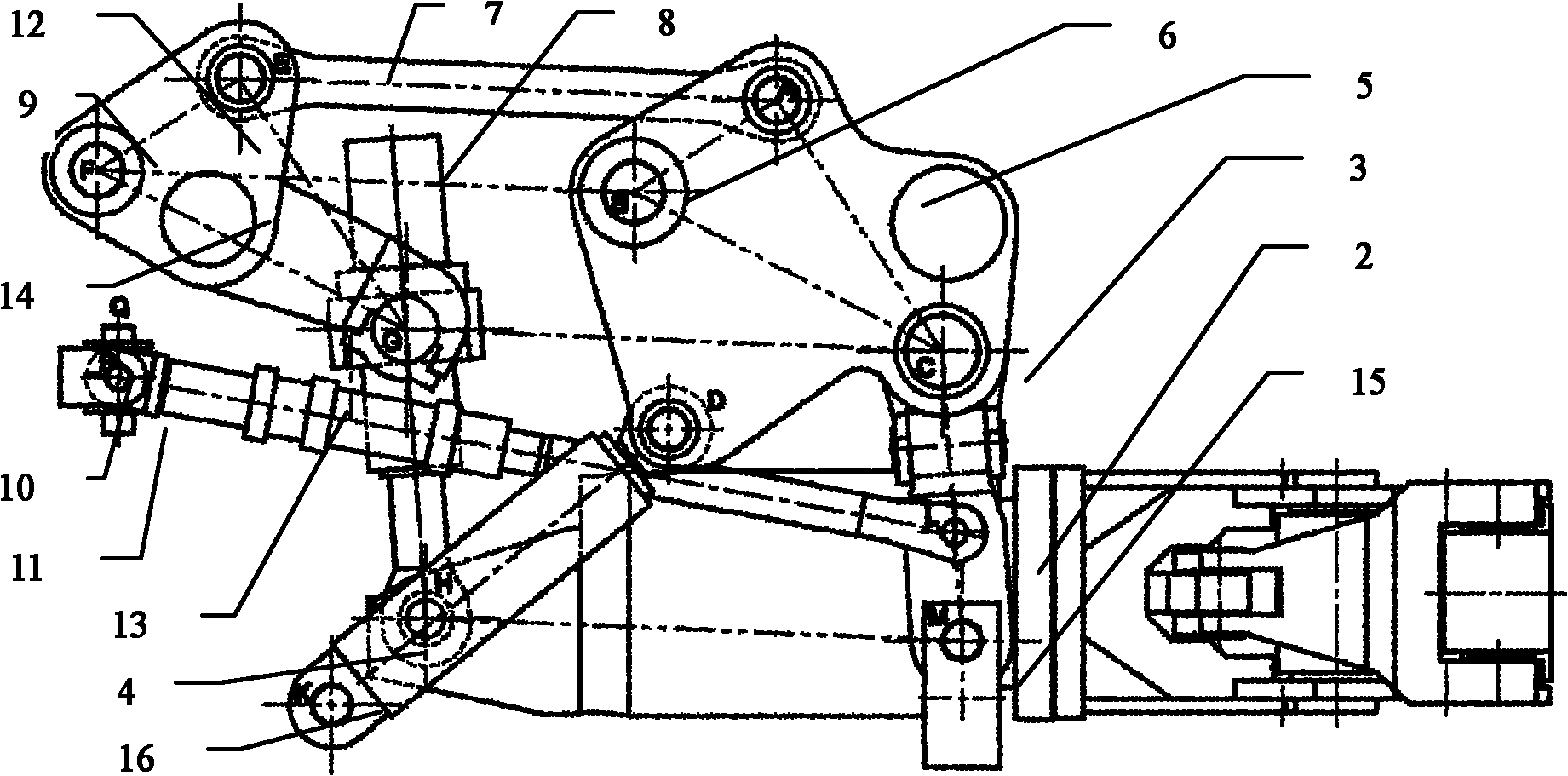

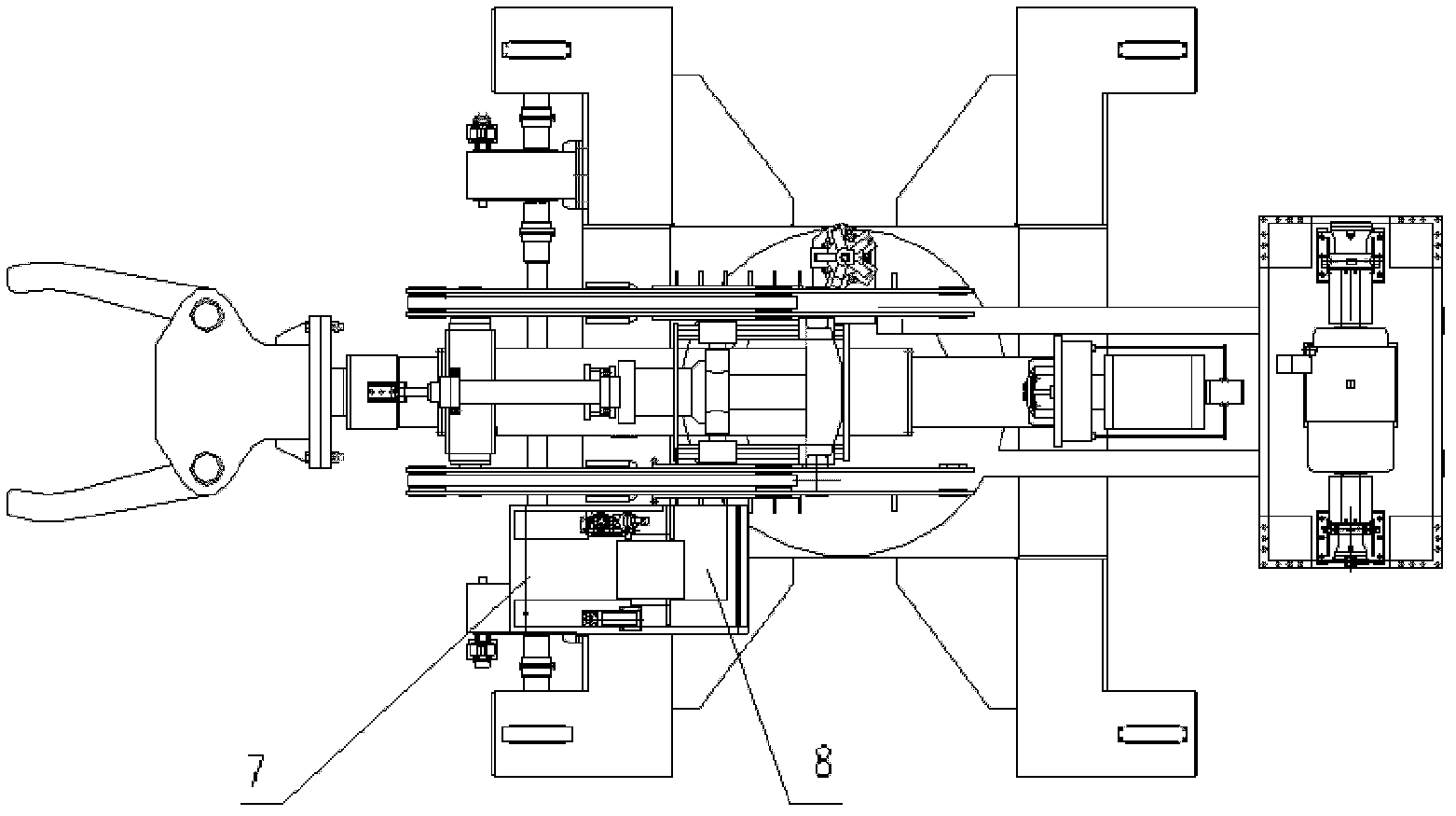

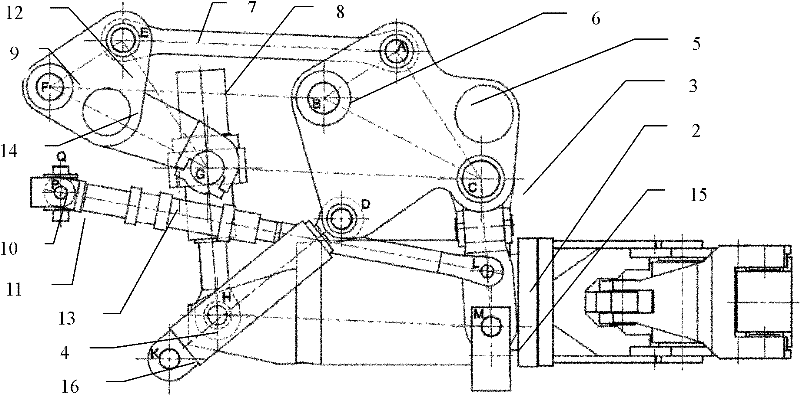

Claw beam lifting mechanism for forging manipulator

InactiveCN102019340AHigh movement precisionGuaranteed motion accuracyForging/hammering/pressing machinesVehicle frameRange of motion

The invention discloses a claw beam lifting mechanism for a forging manipulator, applied to forging industry. The claw beam lifting mechanism mainly comprises a front lifting part, a rear lifting part, a synchronous connector rod, a lifting cylinder, a pitching cylinder and a buffering part, a front fixing shaft in the front lifting part, a rear fixing shaft in the rear lifting part and the lower end of the lifting cylinder are respectively connected with a large machine frame through hinges, the synchronous connecting rod is arranged overhead and always moves in a range above a connecting line of a front fixing hinge point and a rear fixing hinge point of a claw beam lifting and pitching mechanism and the large machine frame, front ends of two buffering cylinders are respectively connected with tow front lifting connecting rods through hinges, the rear ends of the two buffering cylinders are respectively articulated with two ends of a compensating beam, and the middle part of the compensating beam is connected with the middle part of the large machine frame by a hinge through a beam fixing shaft. The claw beam lifting mechanism has novel and scientific design concept, reasonable stress application, high movement precision, simple structure, low manufacturing cost and is convenient to install, adjust and maintain. The invention not only reduces the manufacturing cost of the lifting mechanism under the condition of ensuring the movement precision, but also thoroughly solves the problems that the front fixing shaft and a shaft sleeve matched with the front fixing shaft are worn easily and a side plate of a machine needs to be thickened specifically.

Owner:SHENYANG HEAVY MACHINERY GROUP

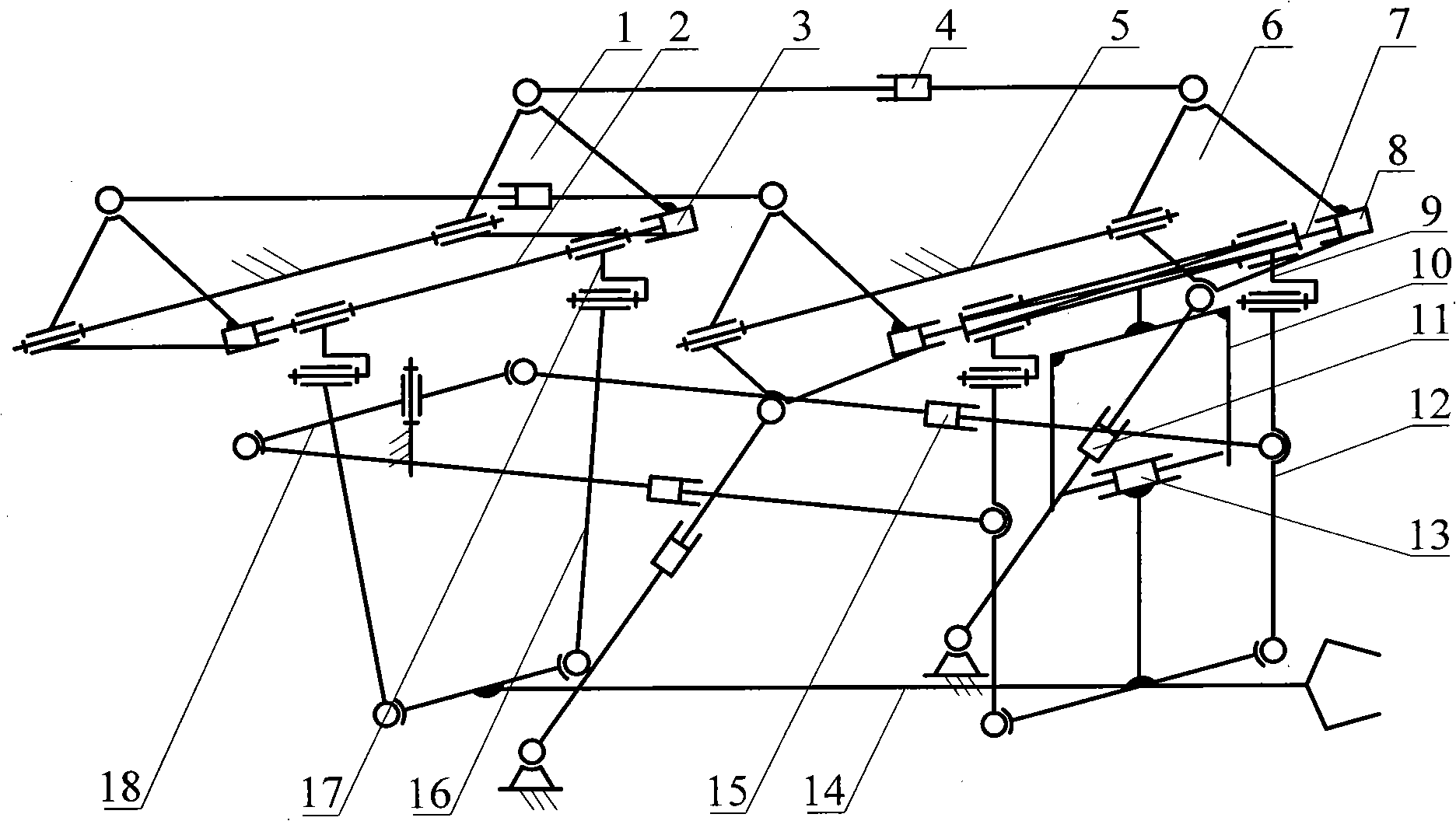

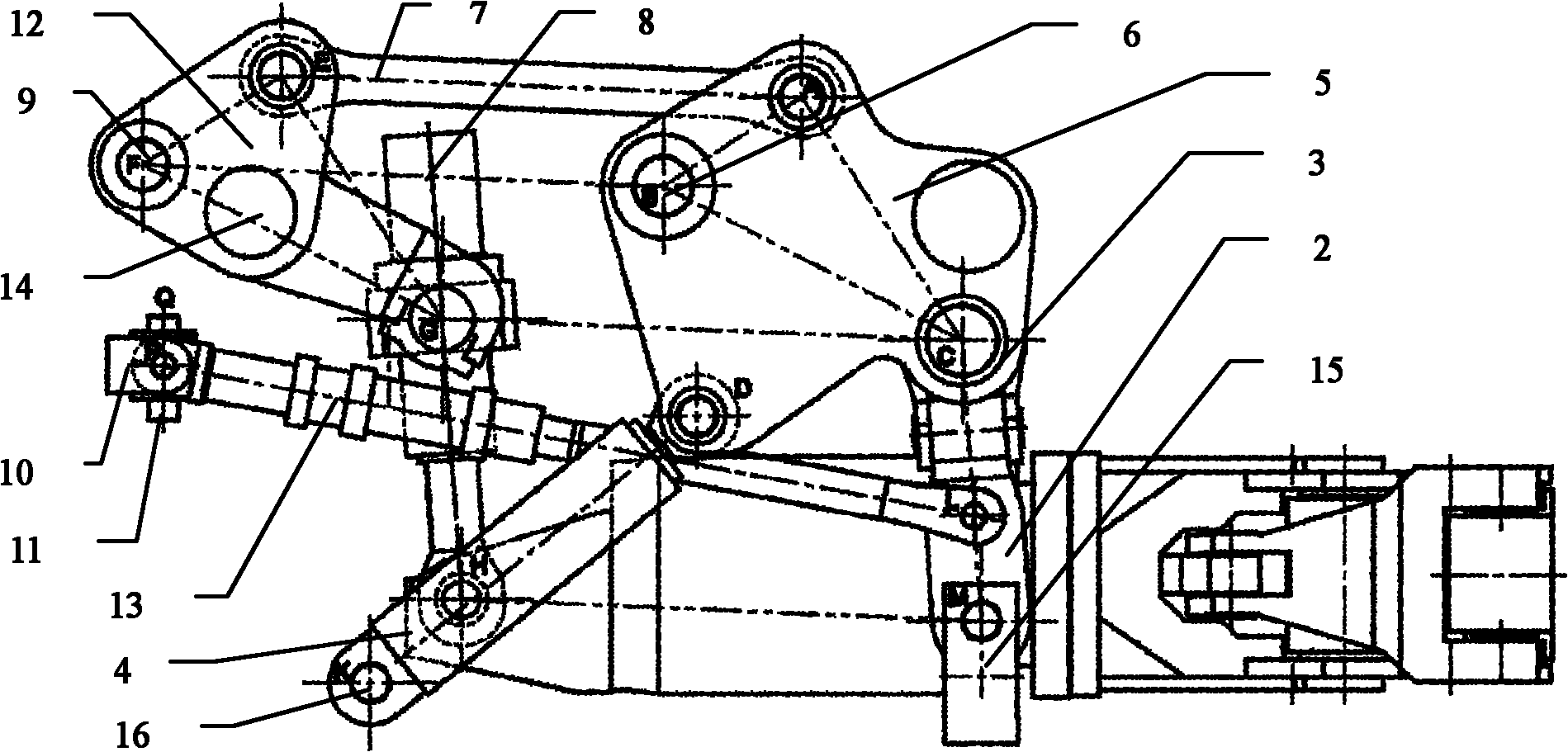

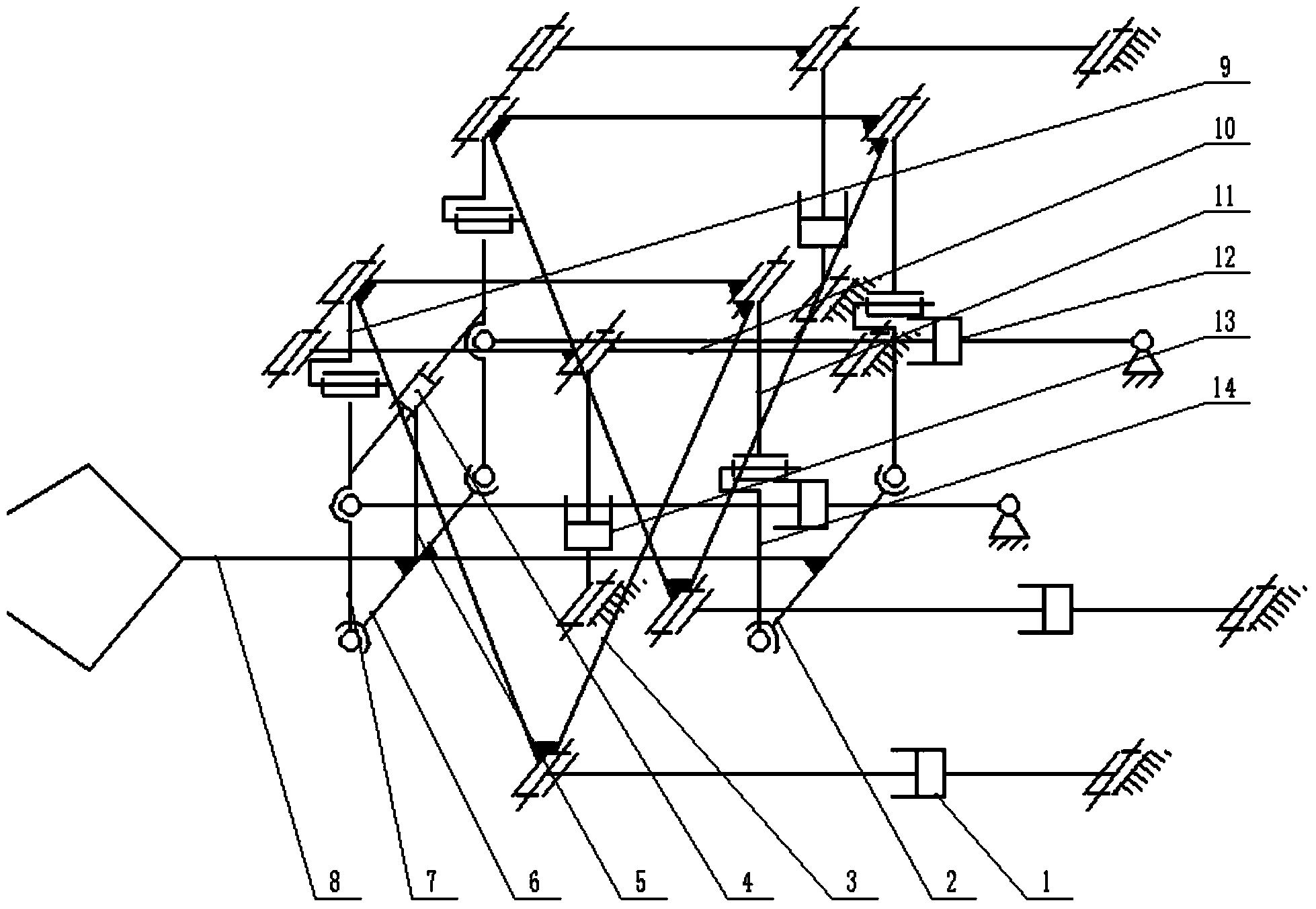

Lifting mechanism of parallel connecting lever type large-tonnage forging manipulator

InactiveCN102728764AImprove carrying capacityReduce stressForging/hammering/pressing machinesForging manipulatorEngineering

A lifting mechanism of a parallel connecting lever type large-tonnage forging manipulator is mainly characterized in that the front part and the rear part of a nipping lever are respectively connected with the lower ends of a front suspension lever and a rear suspension lever, the upper ends of the front and rear suspension levers are respectively connected on front and rear sliding levers by connecting pieces, left and right linear drivers are arranged at two ends of the front and rear sliding levers and are connected with front and rear lifting arms, and the other end of the lifting arm is connected with a rack. The lower arms of the two front lifting arms are connected with the upper ends of the two linear lifting drivers, the upper arms of the front lifting arms are connected with the front end of a horizontal synchronous lever, the rear end of the synchronous lever is connected with the upper arms of the rear lifting arms, the other ends of the two rear lifting arms are connected with one end of a pitching arm, and the other end of the pitching arm is connected with the rack. The middle parts of the two pitching arms are also connected with the upper ends of linear pitching drivers. The lifting mechanism reduces the stress at the connection part of the rack hinges, greatly improves the whole bearing capacity and transmission efficiency of the manipulator, is applicable to forging operation of large-tonnage forged pieces, and can also ensure the lifting parallelism of the nipping lever.

Owner:YANSHAN UNIV

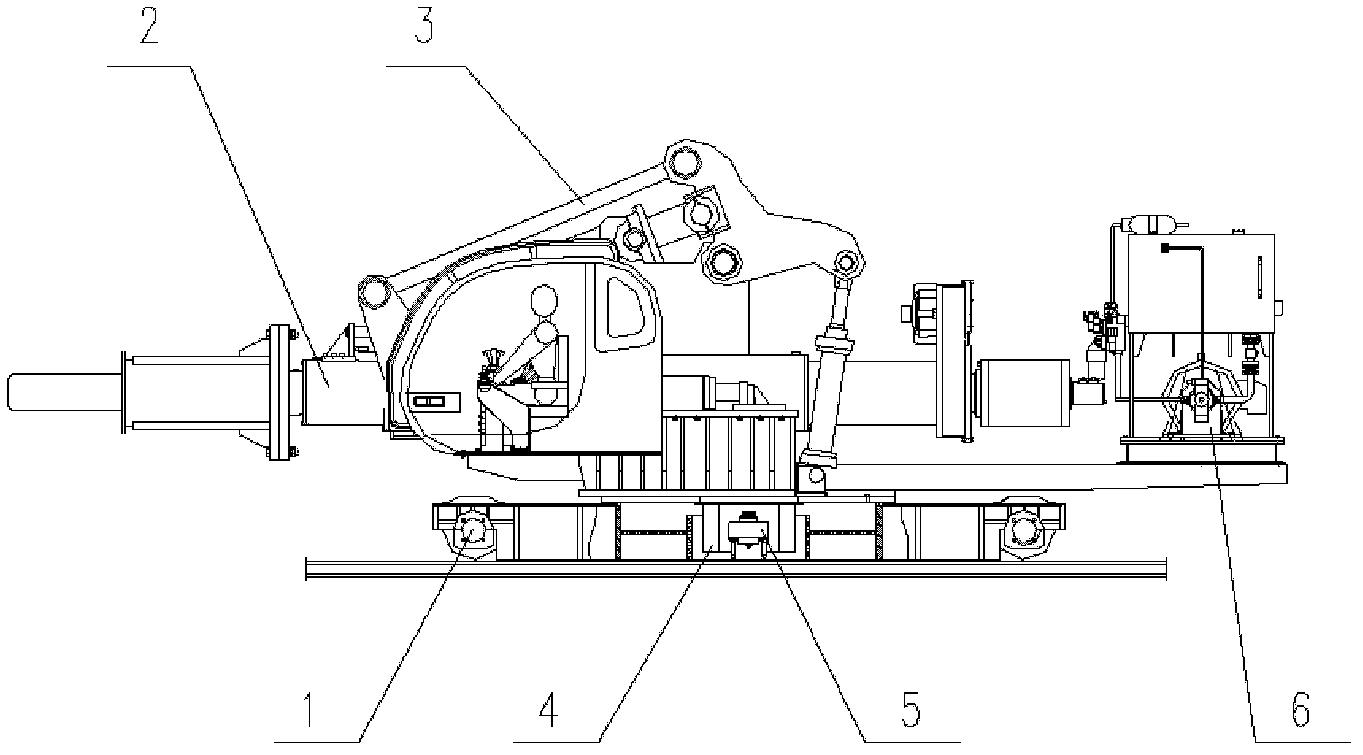

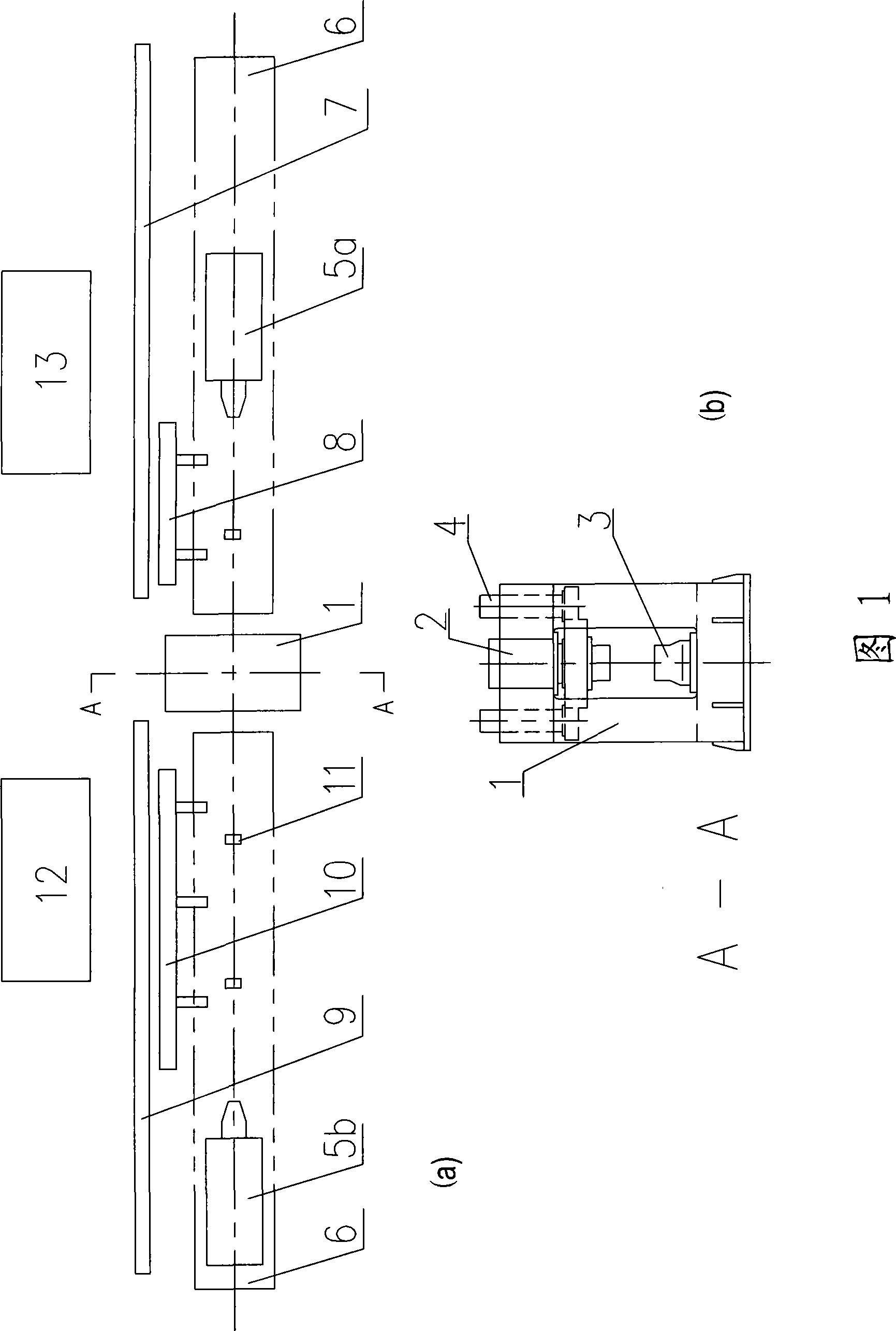

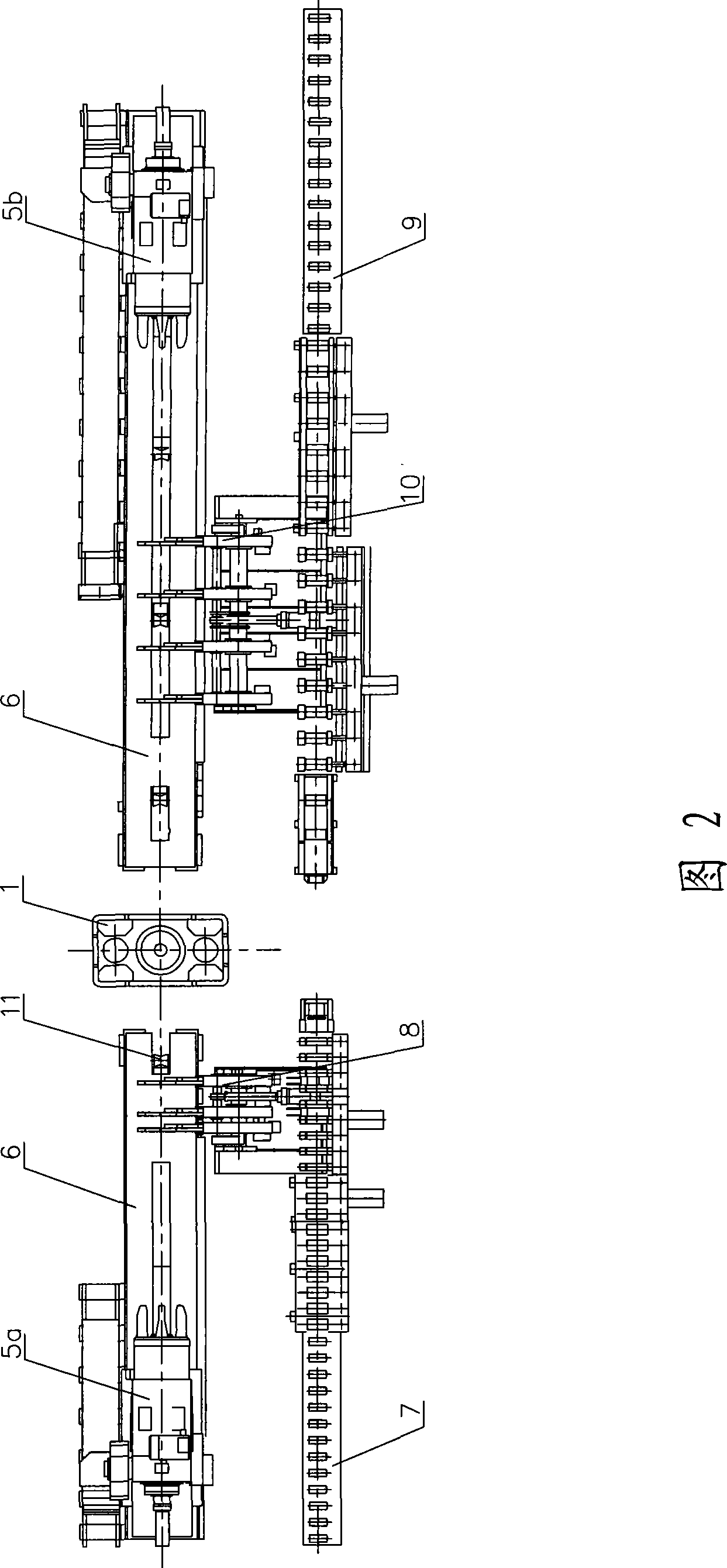

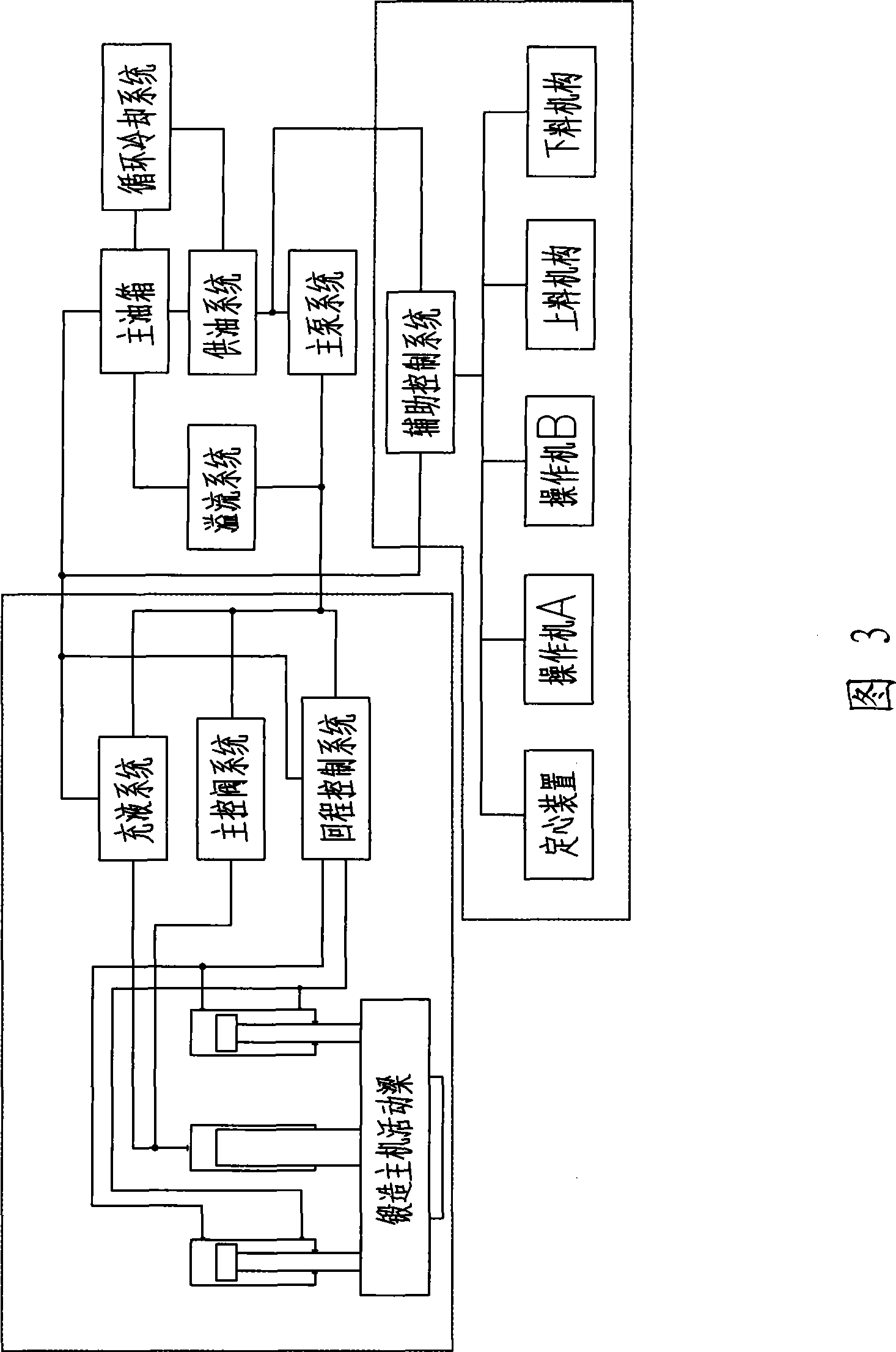

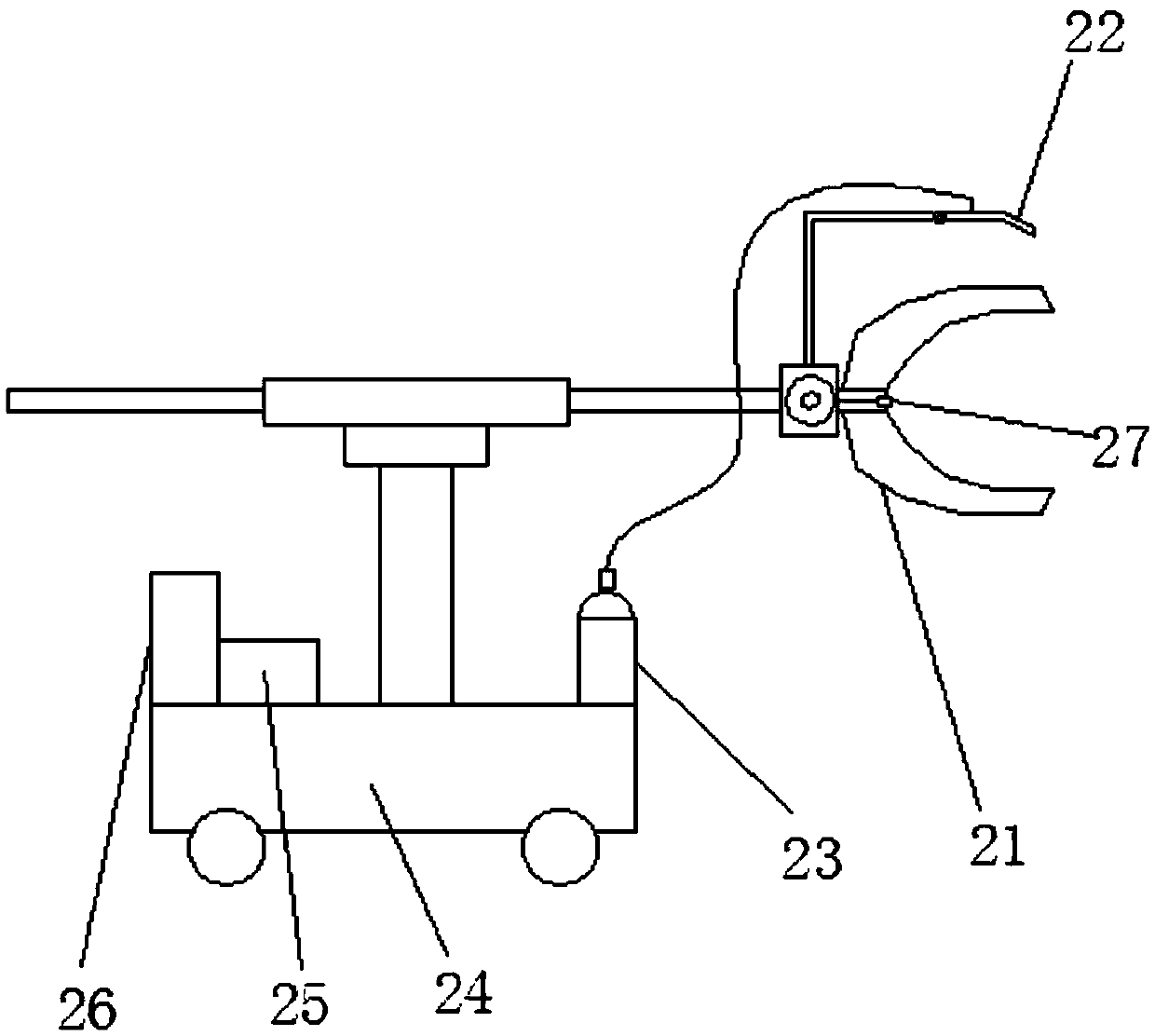

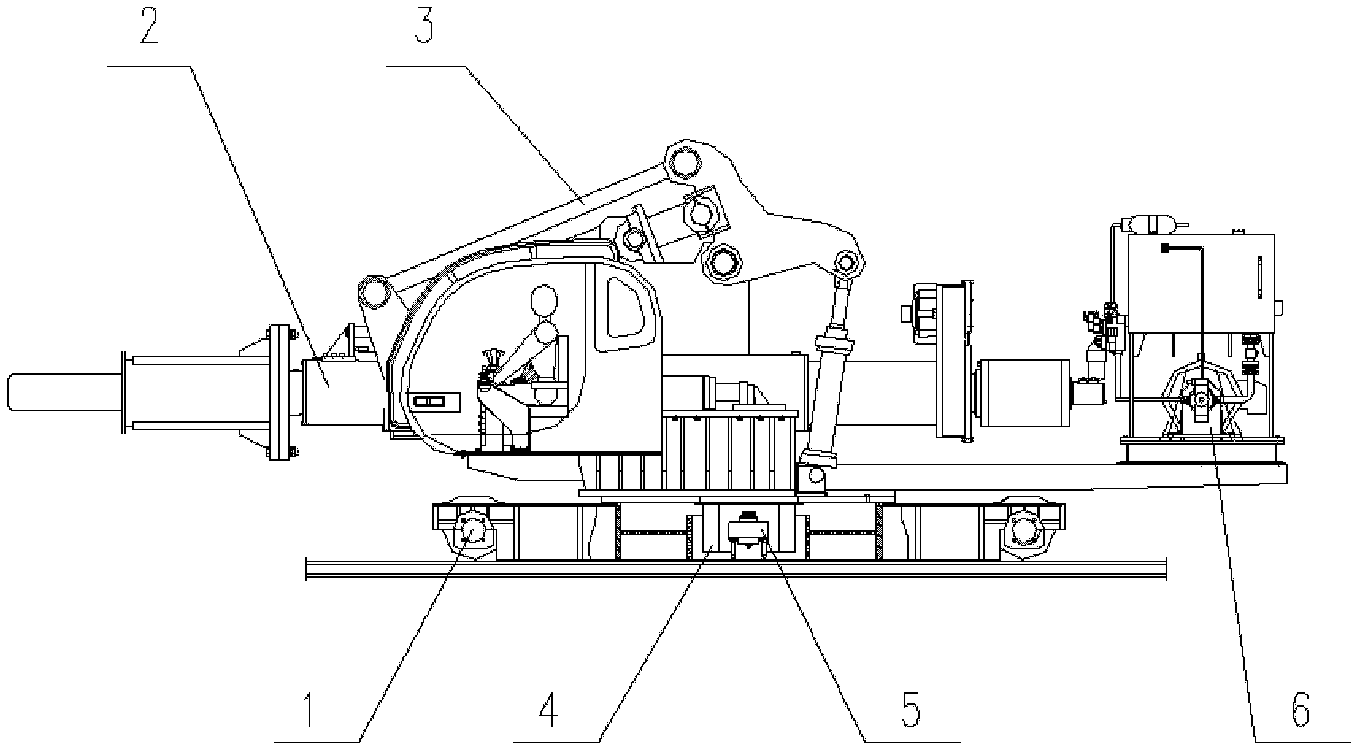

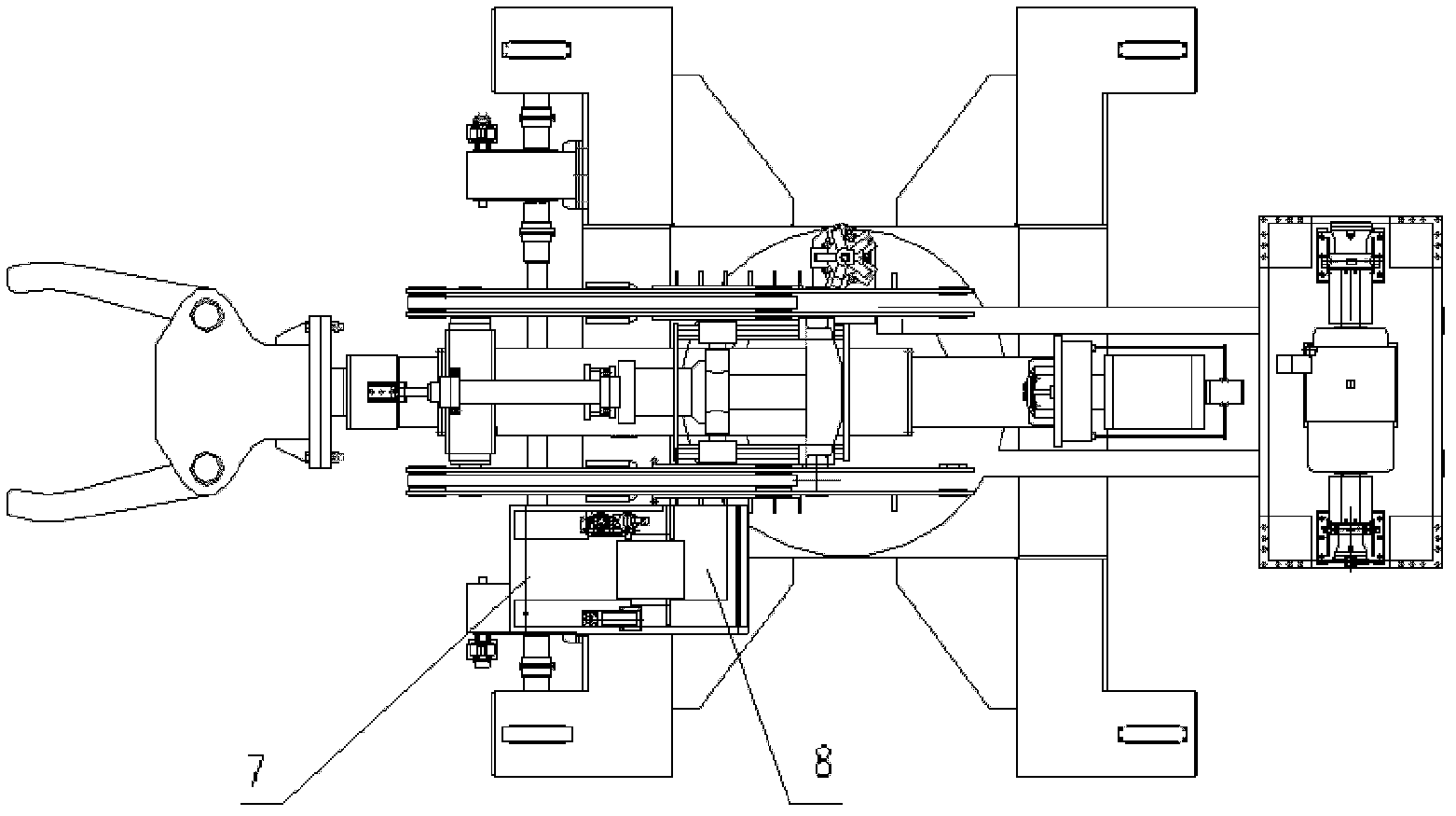

Multifunctional hydraulic track forging manipulator

ActiveCN102430684AExpand the scope of workReduce intermediate auxiliary timeForging/hammering/pressing machinesForging manipulatorControl system

A multifunctional hydraulic track forging manipulator is disclosed, and comprises a body travelling device connected with a four connecting rod mechanism. Both a rotary oil connector and a conductive slip ring are connected with the body travelling device; a hydraulic control system, an electric control system and an operating cab are respectively connected with the four connecting rod mechanism;the electric controls system is installed in a space of the operating cab; the whole device is located on a ground track of a workshop; and the four connecting rod mechanism is connected with a pincers frame so as to form an integral piece. The body travelling device supports the whole four connecting rod mechanism and the pincers frame. The pincers frame is a structure of multilayer sleeve so that the claw beam of the pincers frame is retractable, thereby effectively expanding the working range of the manipulator and realizing the functions of the manipulator and a charging and discharging machine on a same manipulator. The invention improves the production efficiency and eliminates the danger of workers in the process of conveying the forging materials.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

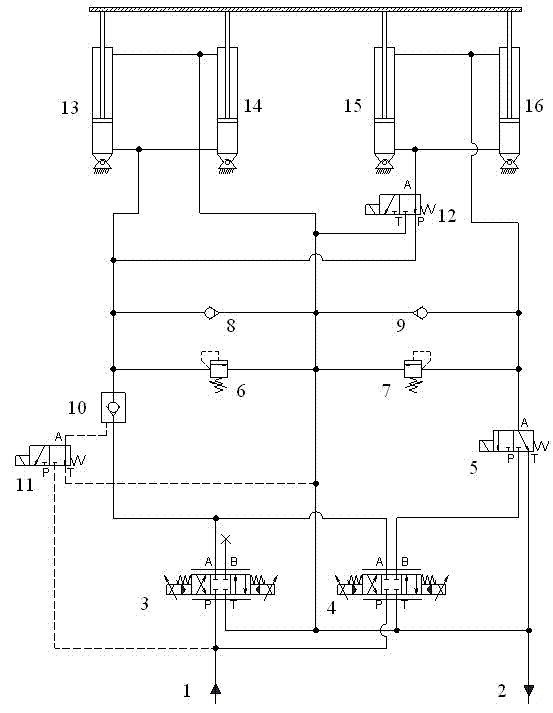

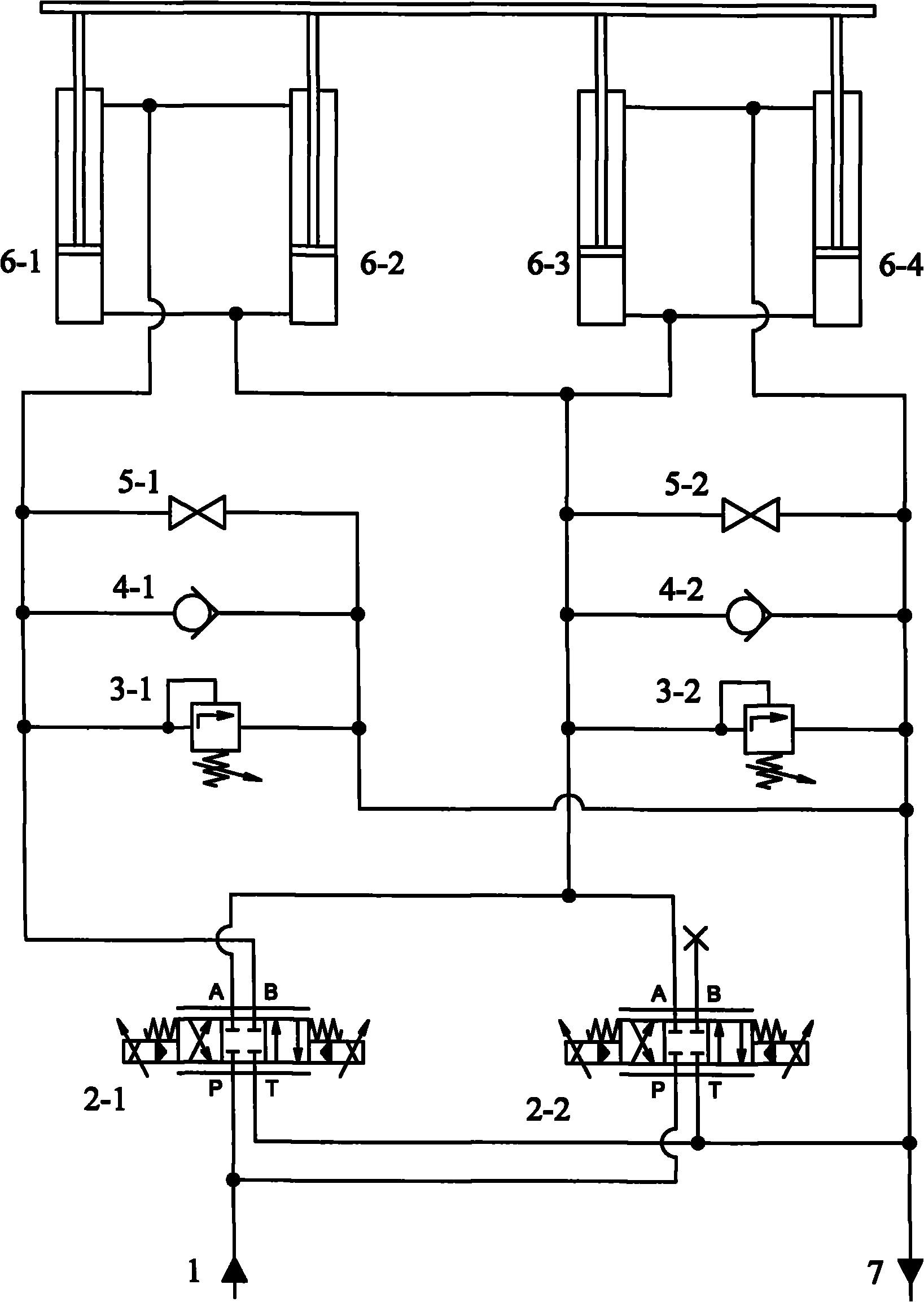

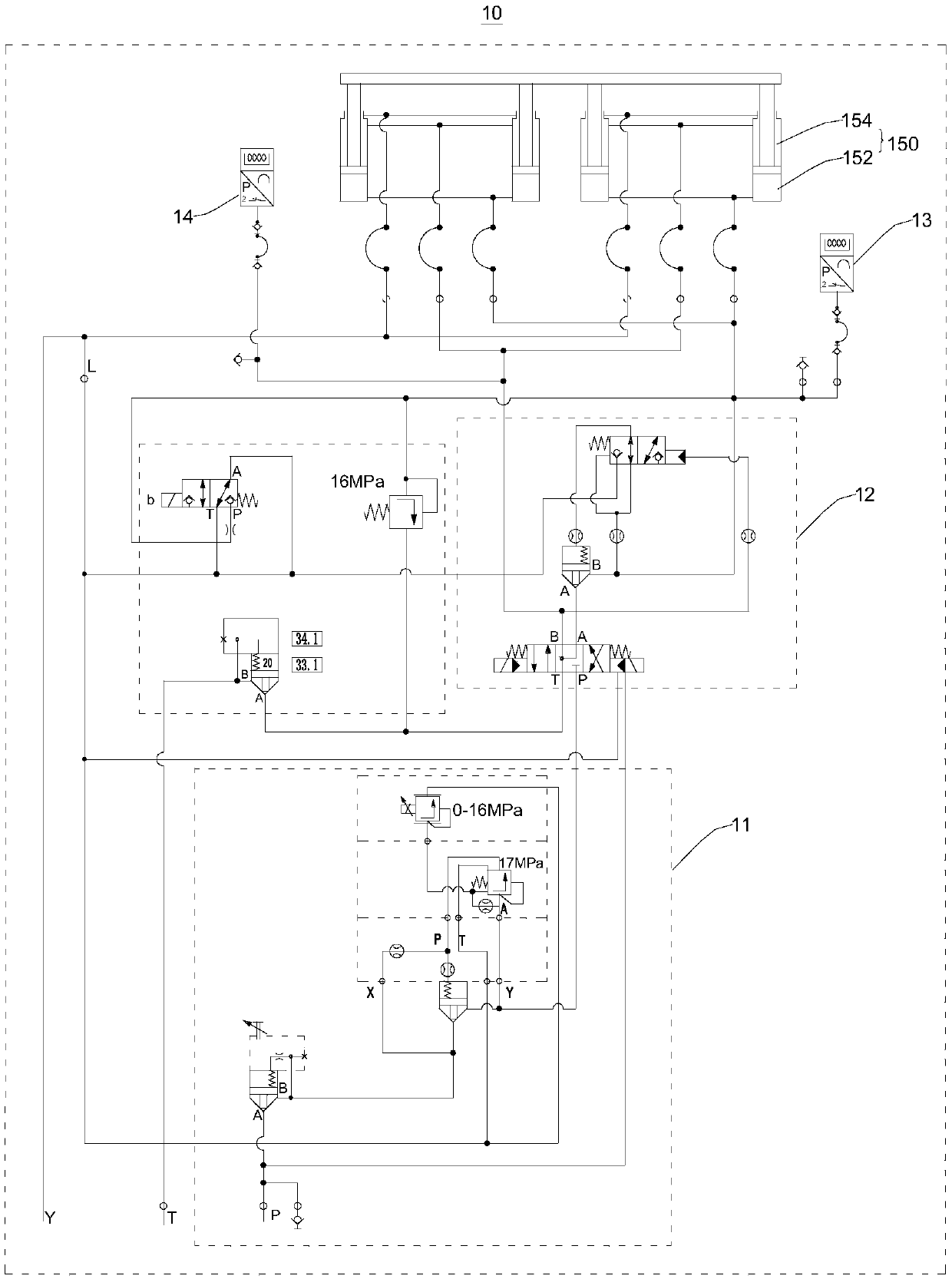

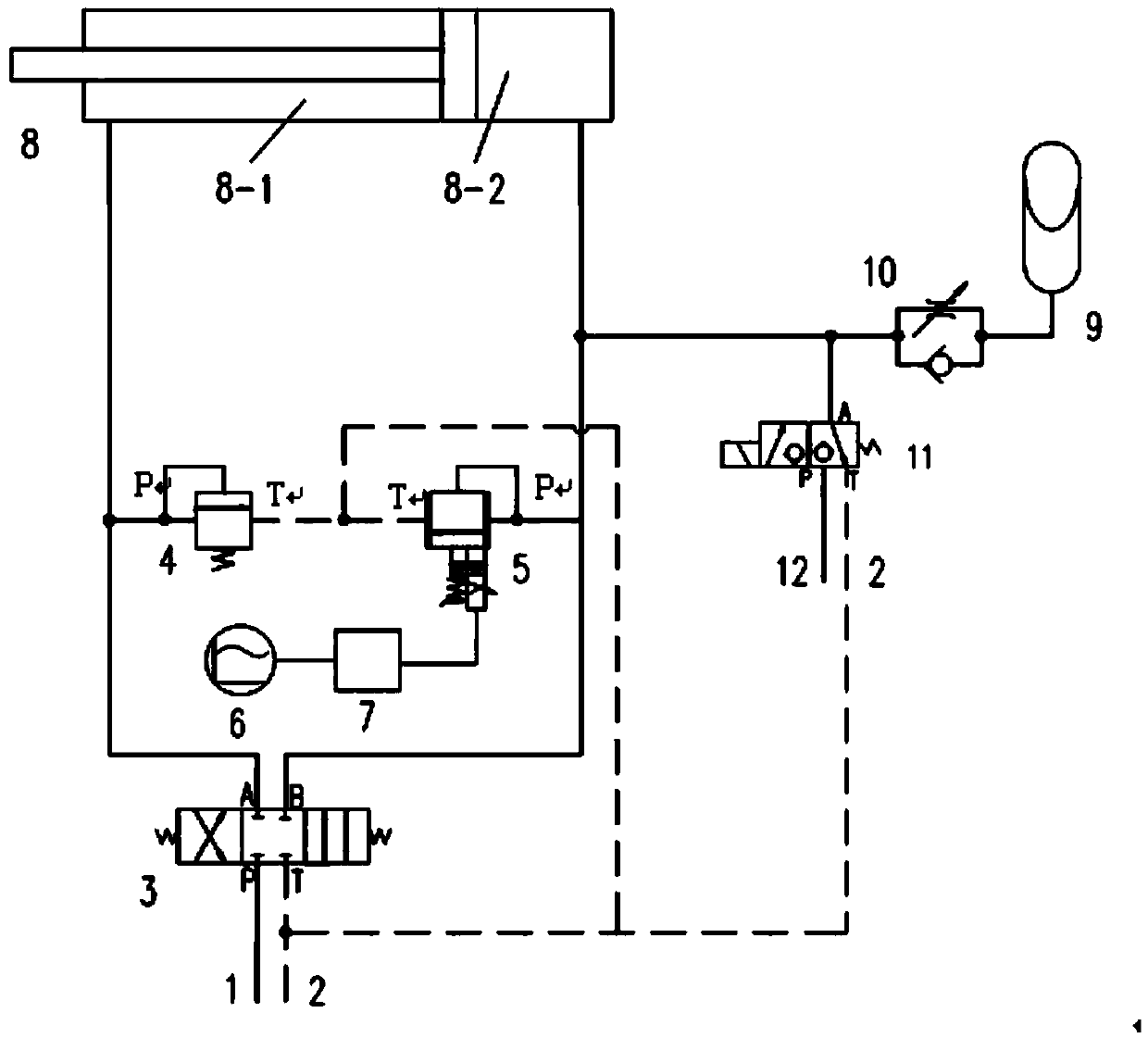

Front and back lifting hydraulic system for energy-saving forging manipulator

InactiveCN102756066AEasy to controlGuaranteed heavy load capacityServomotorsForging/hammering/pressing machinesHydraulic cylinderSynchronous control

The invention discloses a front and back lifting hydraulic system for an energy-saving forging manipulator. The front and back lifting hydraulic system consists of an oil source supply port, a symmetrical proportion directional valve, an asymmetrical proportion directional valve, two electromagnetic directional valves, two safety valves, two one-way valves, a hydraulic one-way valve, four lifting cylinders and an oil source return port, wherein the two electromagnetic directional valves are used for selecting bearing hydraulic cylinders through switching. According to the invention, aiming at forging manipulator lifting system with rigidly synchronous piston rods of four hydraulic cylinders, two proportion directional vlaves are connected in parallel for driving by adopting a manner that the hydraulic cylinders are connected in parallel for concentrative control, so that the synchronous control is simple. The switching of the electromagnetic directional valves of the system can select the number of the bearing hydraulic cylinders, realizes the switching of heavy-load driving and fast driving modes, can effectively improve the fastness and energy-saving property of the system in light load on the premise of ensuring the heavy load capability of the system.

Owner:ZHEJIANG UNIV

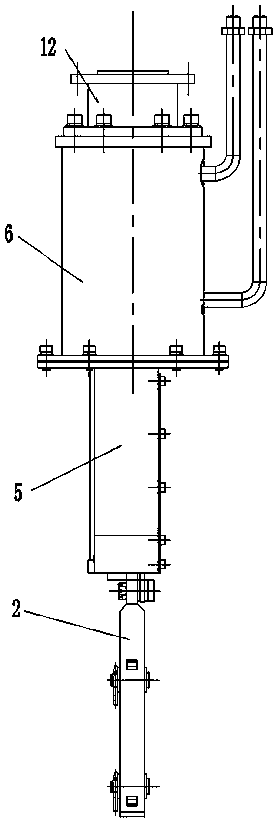

Special free-forging hydraulic unit and use method thereof

ActiveCN101456059AReduce the overall heightReduce widthForging/hammering/pressing machinesForging press detailsAutomatic controlForging manipulator

The invention relates to a special free forging hydraulic unit and a use method thereof. The special free forging hydraulic unit comprises a mechanical device of a main forging machine, a mechanical device of an assistant system, a hydraulic drive system for the main machine and the assistant system, and an electric automatic control device, wherein the mechanical device of the main forging machine comprises a main sealing frame, a work oil cylinder, a forging anvil mechanical assembly and a return cylinder mechanical assembly; and the mechanical device of the assistant system comprises a forging mechanical manipulator, a forging mechanical manipulator, a manipulator walk under carriage, a guide rail, a feeding roller way, a feeding manipulator, a discharging roller way, a discharging manipulator and an automatic centering mechanism. The special free forging hydraulic unit can adopt a hybrid operation mode combining a manual mode and a full automatic mode, not only can satisfy the requirement of product production and achieve production efficiency higher than a general free forging hydraulic press, but also effectively reduces investment cost of the devices.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

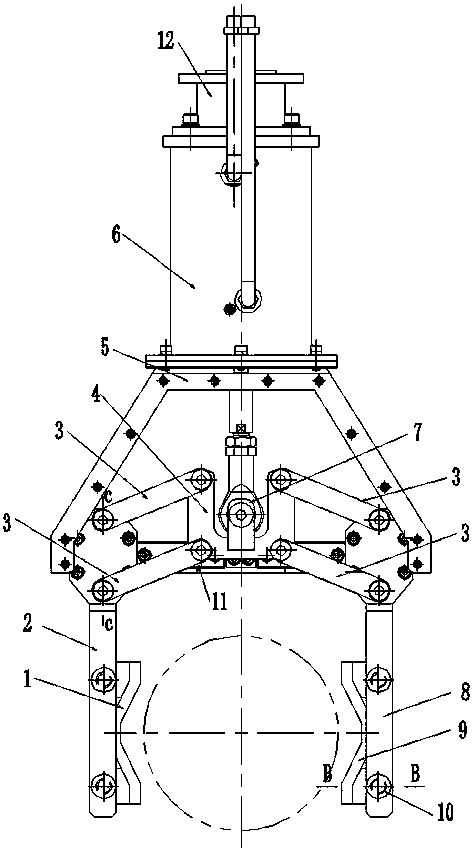

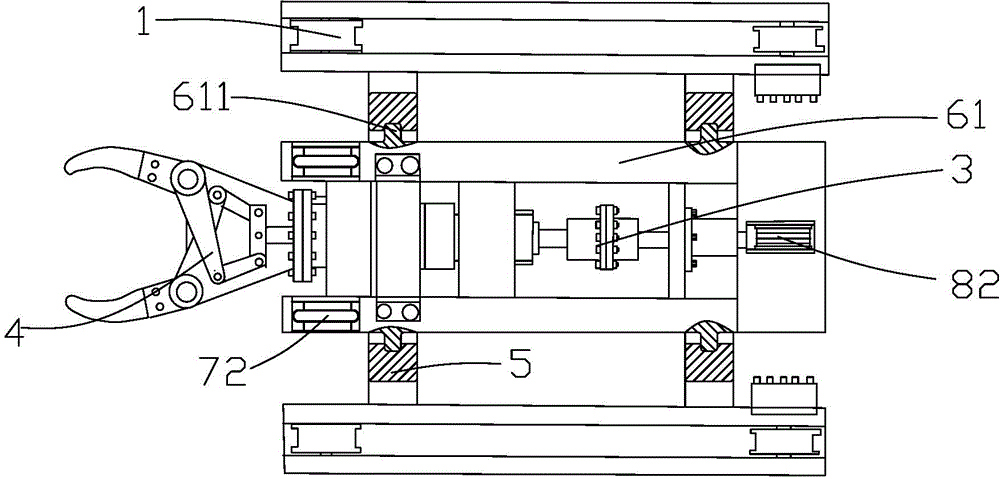

Center fixation type quick clamping mechanical hand used for forging robot

InactiveCN107717972AAchieve a fixed purposeRapid productionProgramme-controlled manipulatorGripping headsFast handoverForging manipulator

The invention discloses a center fixation type quick clamping mechanical hand used for a forging robot. The center fixation type quick clamping mechanical hand comprises a clamp base, wherein a heat-resistant air cylinder is longitudinally arranged on the rear part of the clamp base; the rear end of the heat-resistant air cylinder is fixedly equipped with a connecting flange; a central pulling disc is fixedly arranged on a piston rod of the heat-resistant air cylinder through a connecting pin device; the central pulling disc, a left clamping claw fixed base and a right clamping claw fixed baseseparately form a parallel four-bar linkage mechanism; and the purpose of keeping the clamping center of the mechanical hand unchanged by symmetrically controlling synchronous movement of the left clamping claw fixed base and the right clamping claw fixed base in the left-right direction through the central pulling disc and transversely arranging a high-temperature-resistant guide rail; and a left clamping claw and a right clamping claw are separately connected on the left clamping claw fixed base and the right clamping claw fixed base through quick replacing mechanisms. The center fixation type quick clamping mechanical hand disclosed by the invention can be used for quickly producing in case of not switching procedures for workpieces of different specifications, one clamping claw can meet workpiece clamping needs within certain outer diameter range, and replacing times of the clamping claws are reduced.

Owner:SHIYAN HANTANG ELECTROMECHANICAL ENG

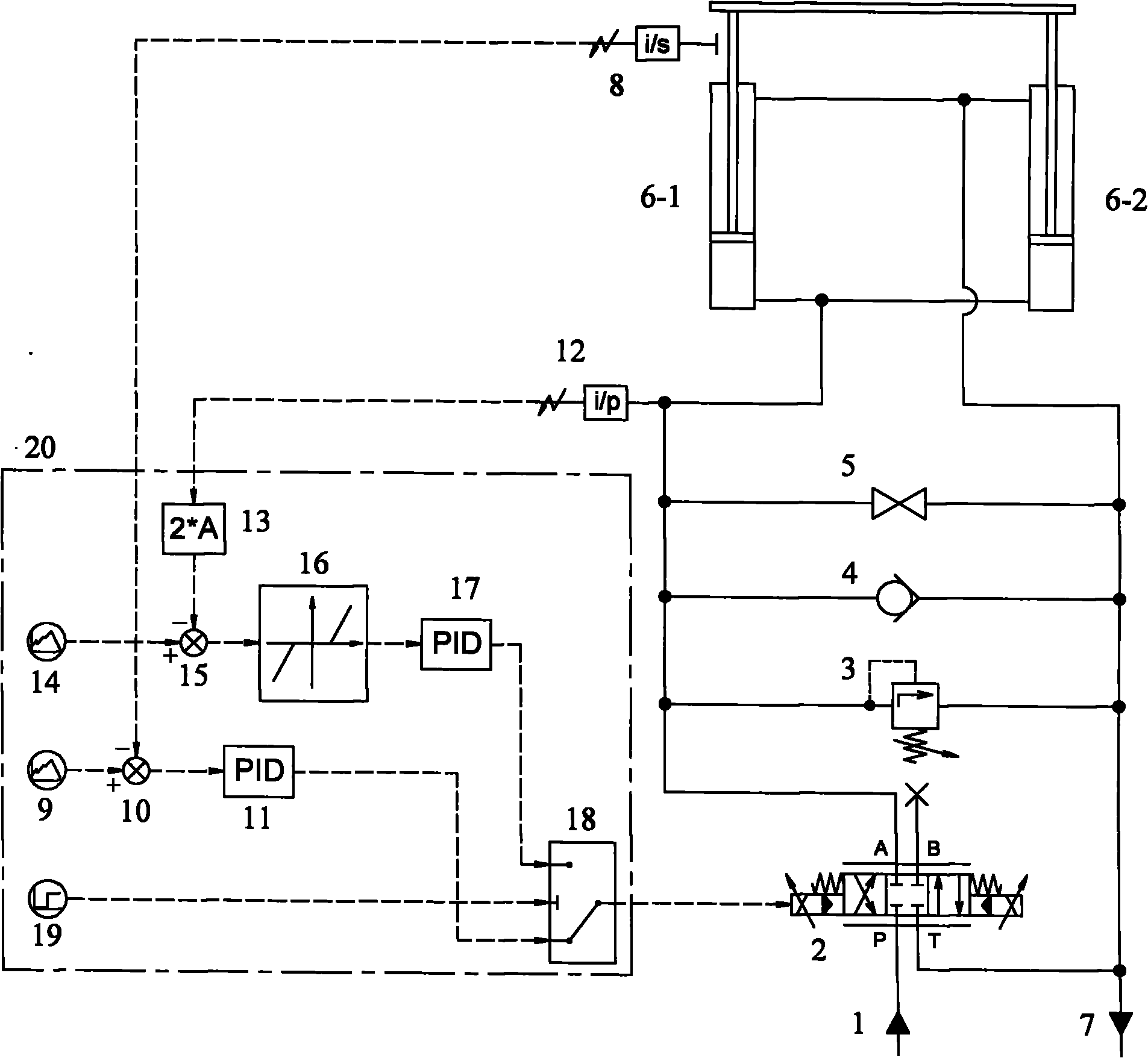

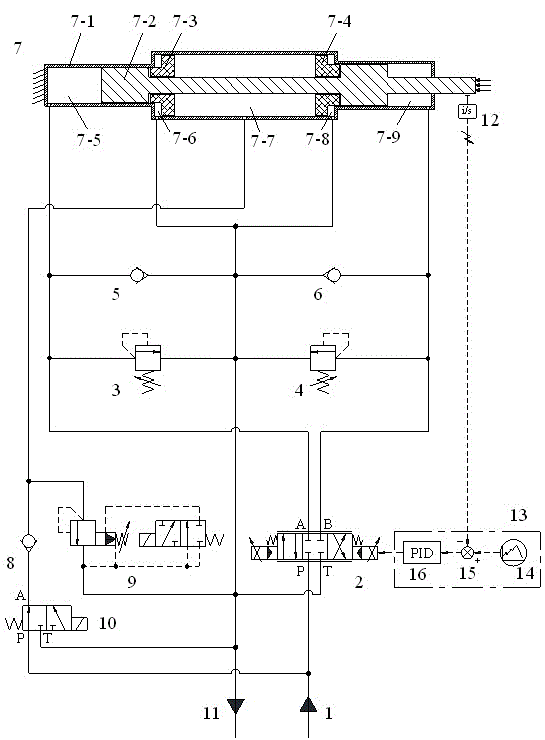

Displacement-force compound control lifting system for forging manipulator

InactiveCN102114517APrecise control of vertical displacementLower resistanceServomotorsForging/hammering/pressing machinesForging manipulatorControl theory

The invention discloses a displacement-force compound control lifting system for a forging manipulator. A port P of a proportional servo valve (2) is connected with an oil supply port (1) of an oil source; a port A of the proportional servo valve (2) is respectively connected with an inlet of a safety valve (3), an outlet of a check valve (4), an inlet of a stop valve (5), a pressure sensor (12) and lower cavities of two lifting cylinders; an oil return port (7) of the oil source is respectively connected with a port T of the proportional servo valve (2), an outlet of the safety valve (3), an inlet of the check valve (4), an outlet of the stop valve (5) and upper cavities of the two lifting cylinders; mechanisms at top ends of piston rods of the two lifting cylinders are fixedly connected; a displacement sensor (8) is internally arranged on the piston rods; and a signal output end of the displacement sensor (8), a signal output end of the pressure sensor (12) and a signal input end of the proportional servo valve (2) are connected with a displacement-force compound controller through signals. Due to the adoption of the system, the response speed can be increased, and the compliance in the vertical direction can be improved.

Owner:ZHEJIANG UNIV

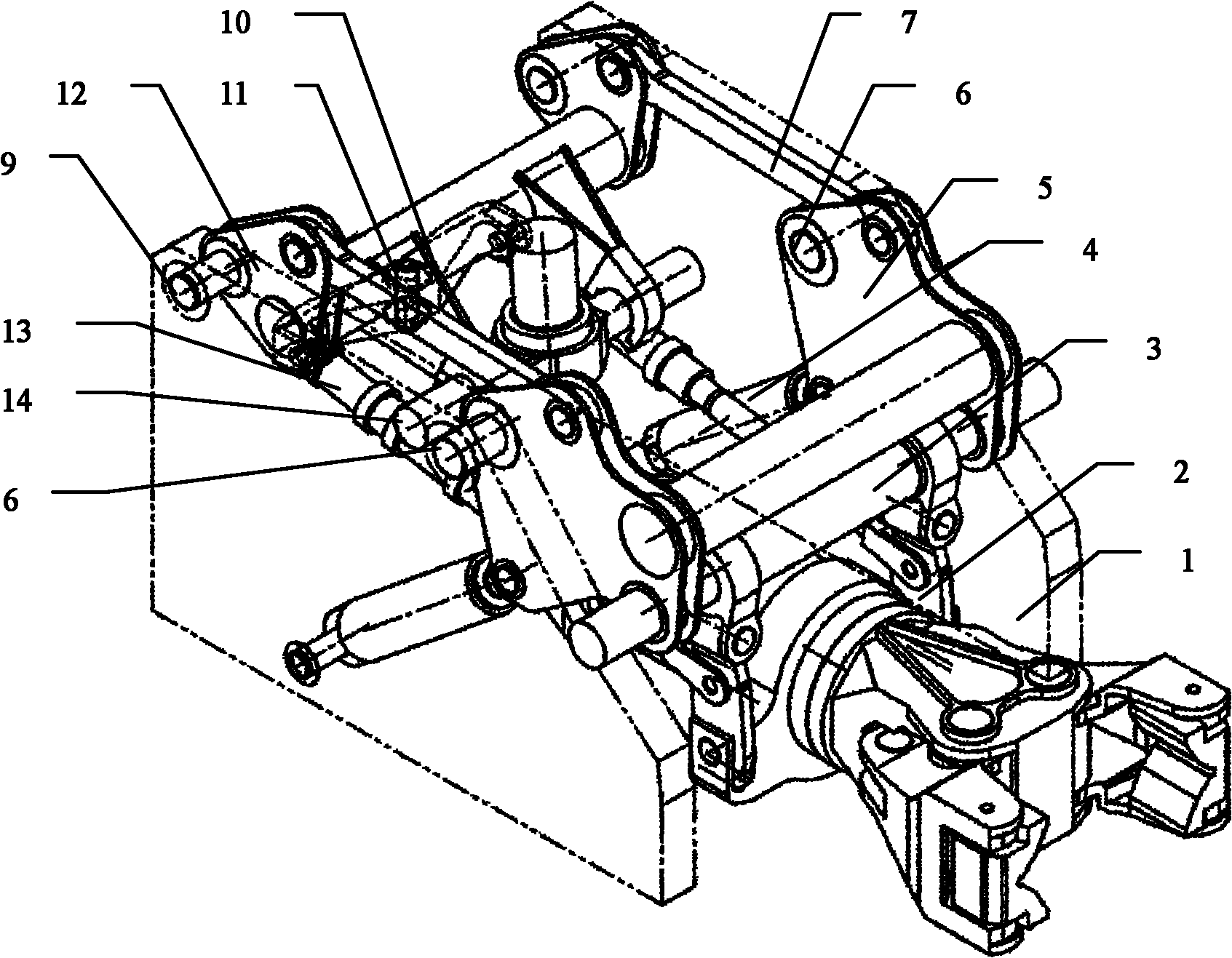

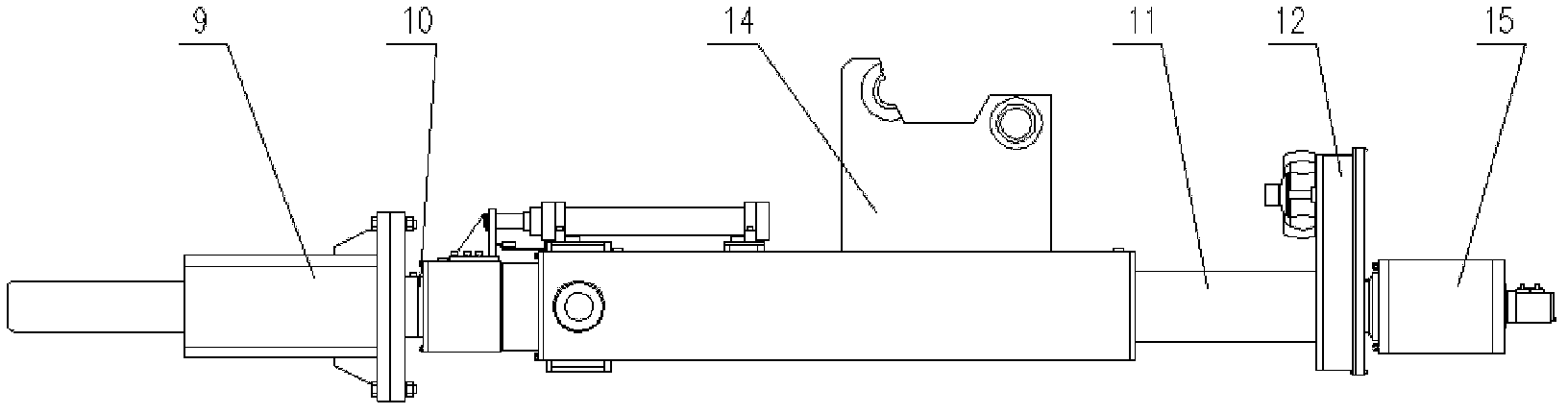

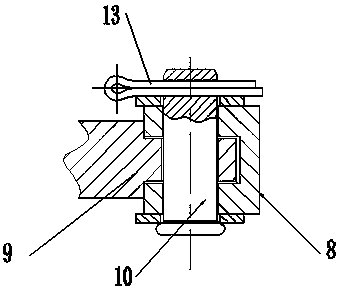

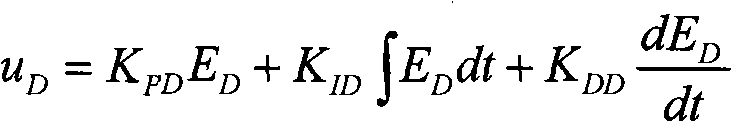

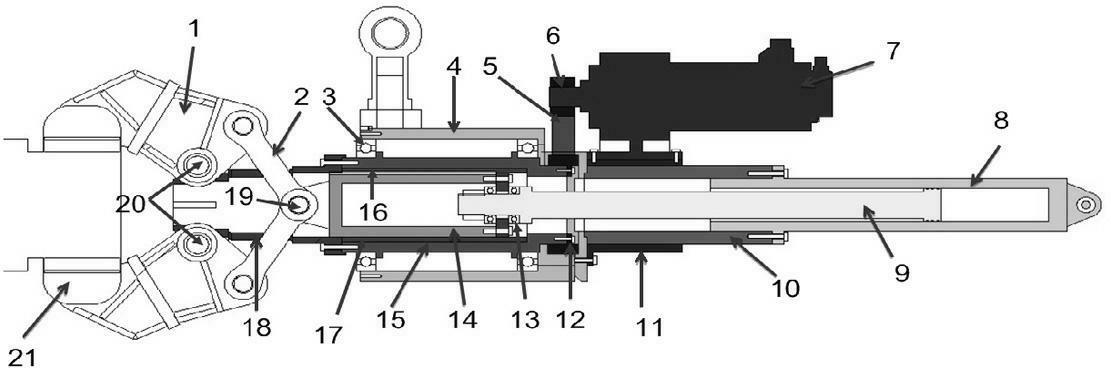

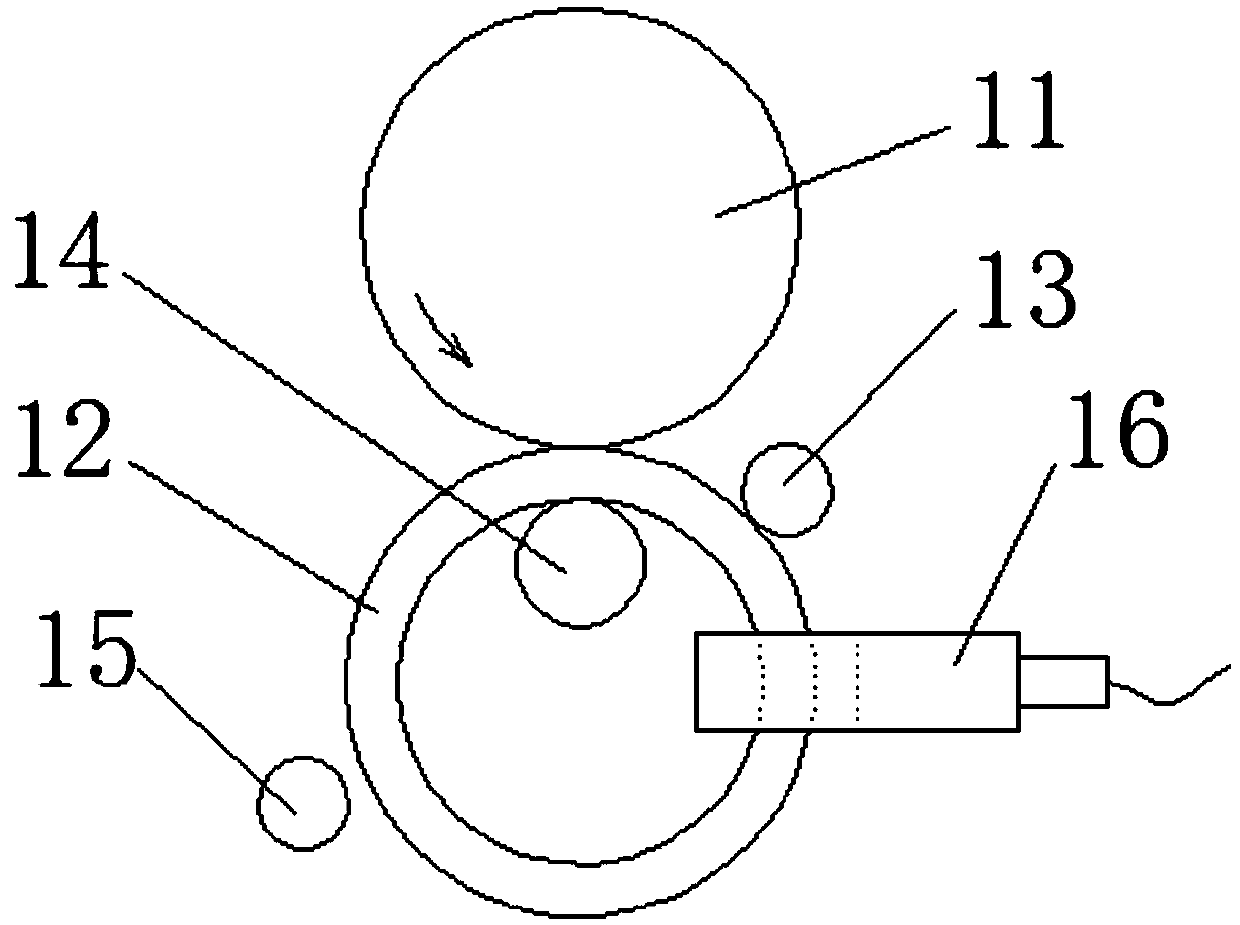

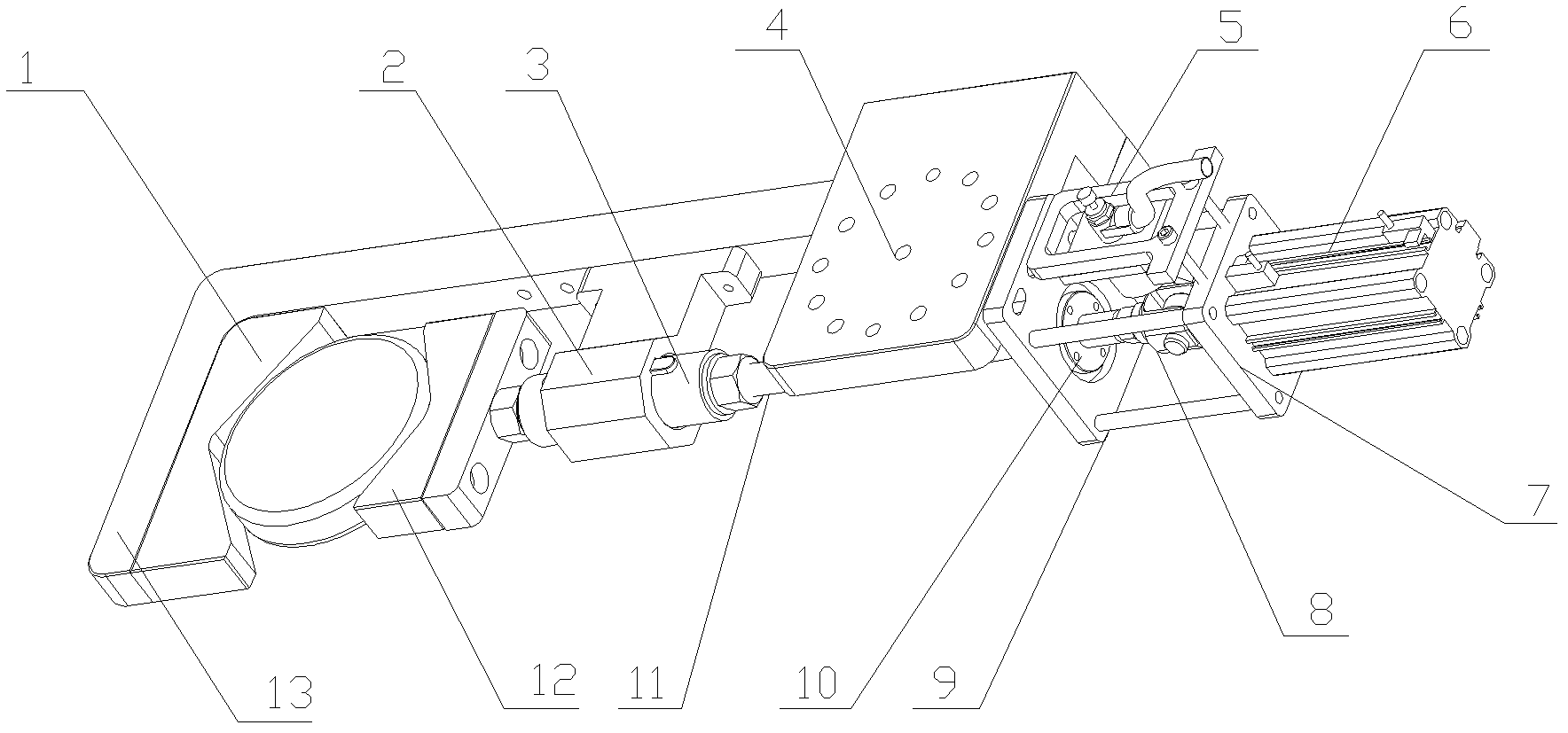

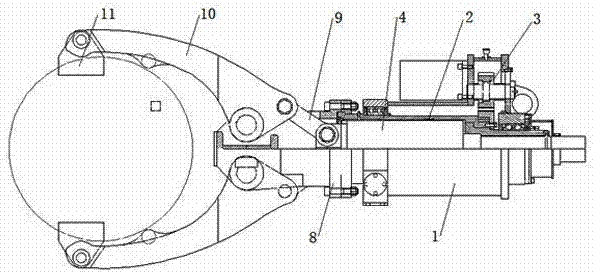

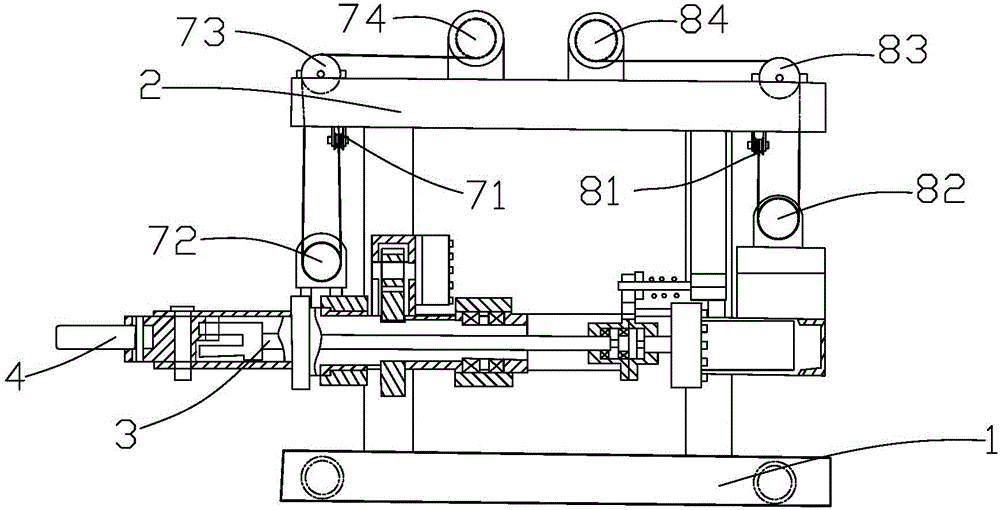

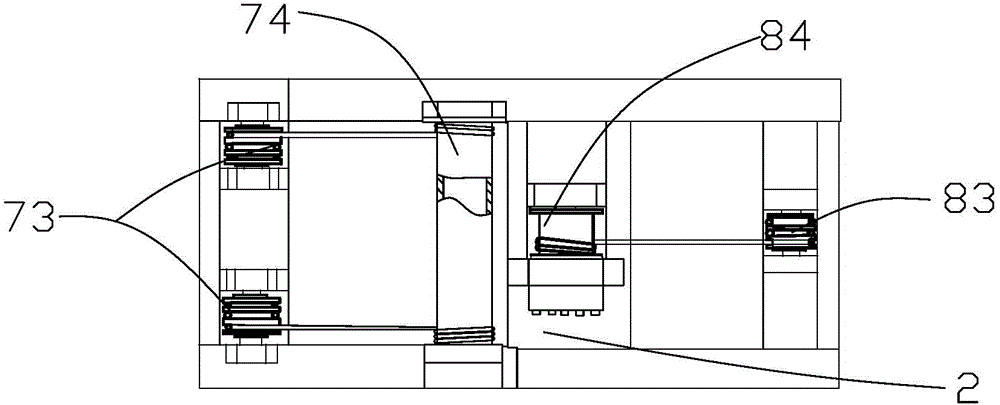

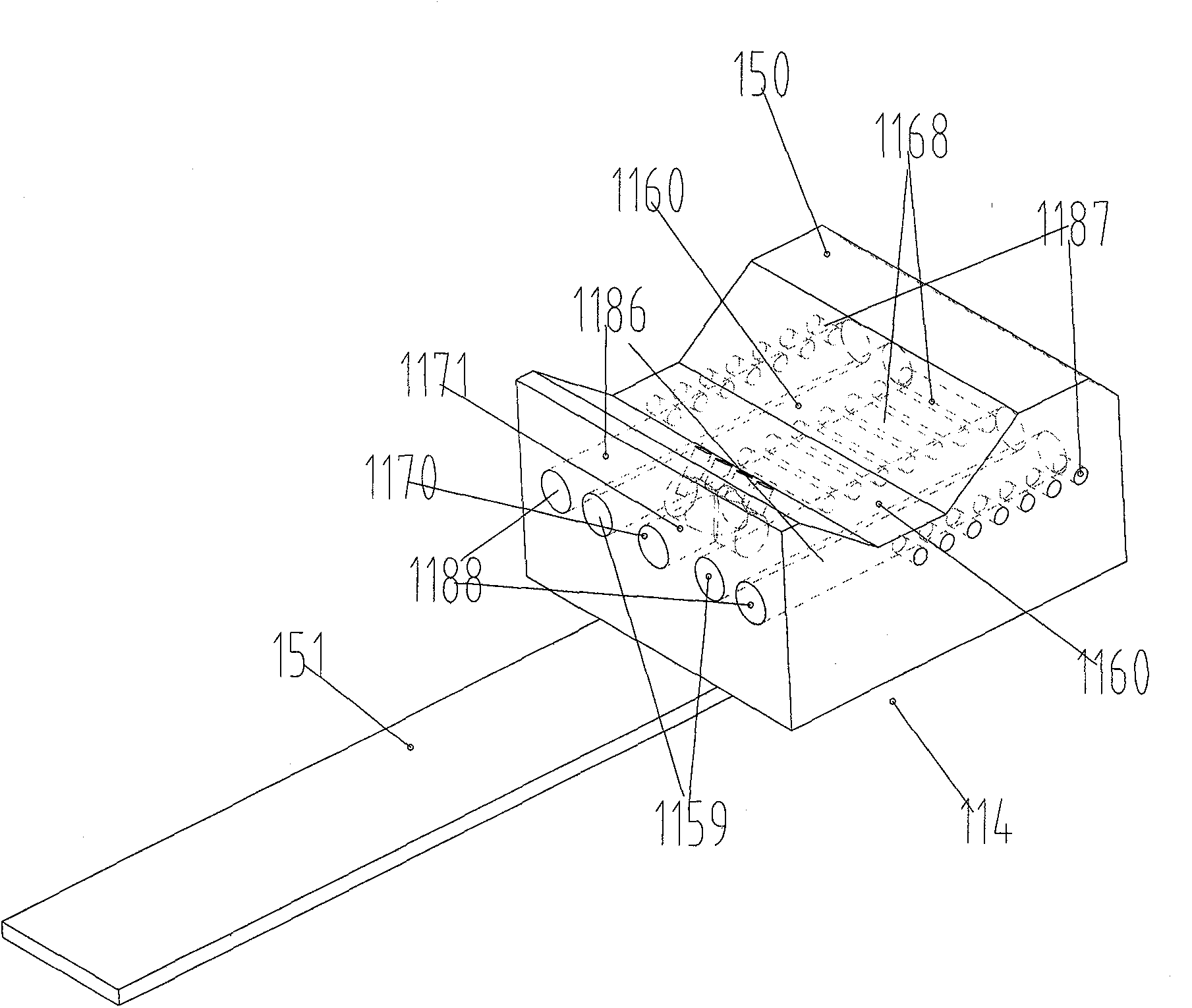

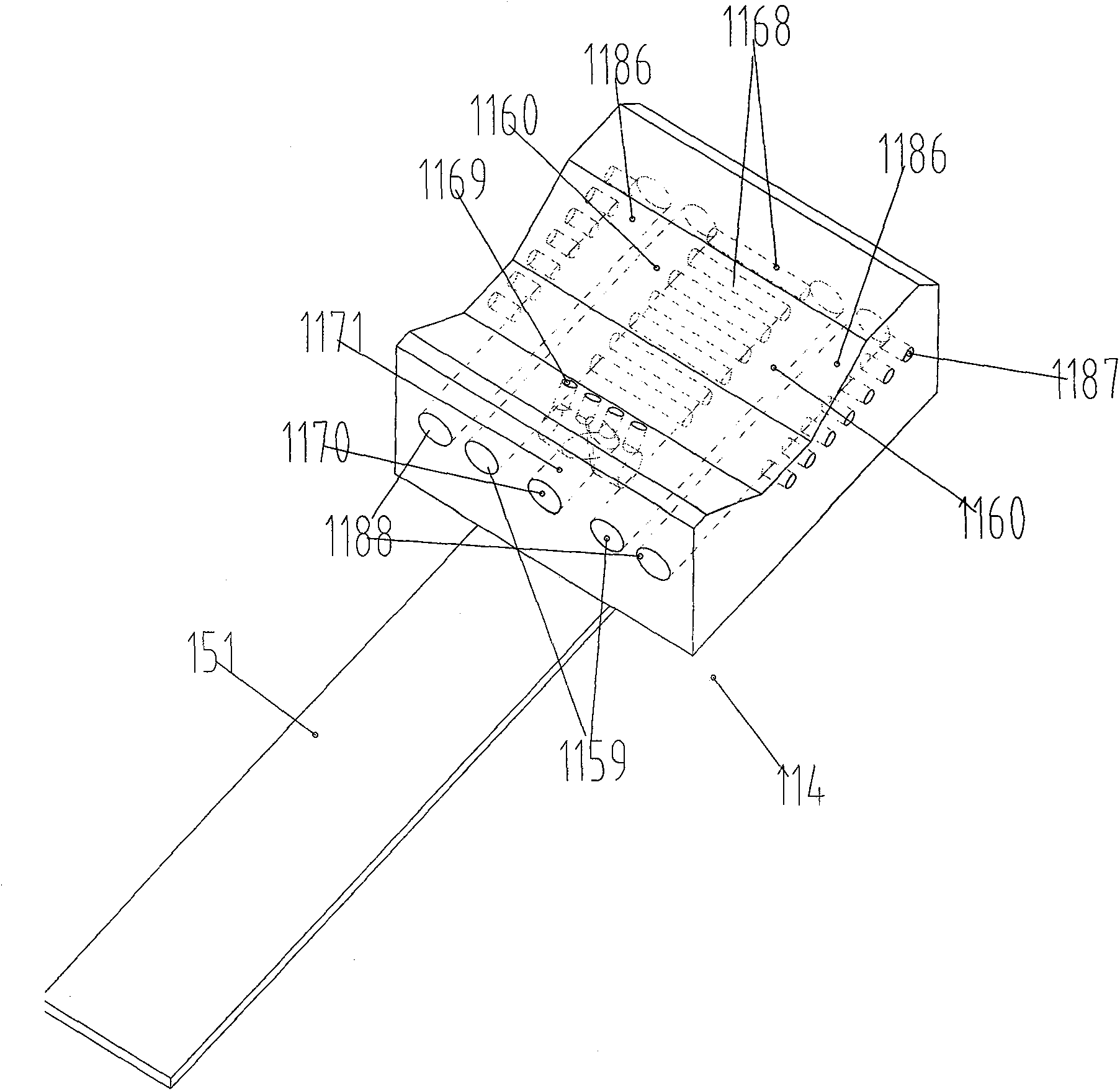

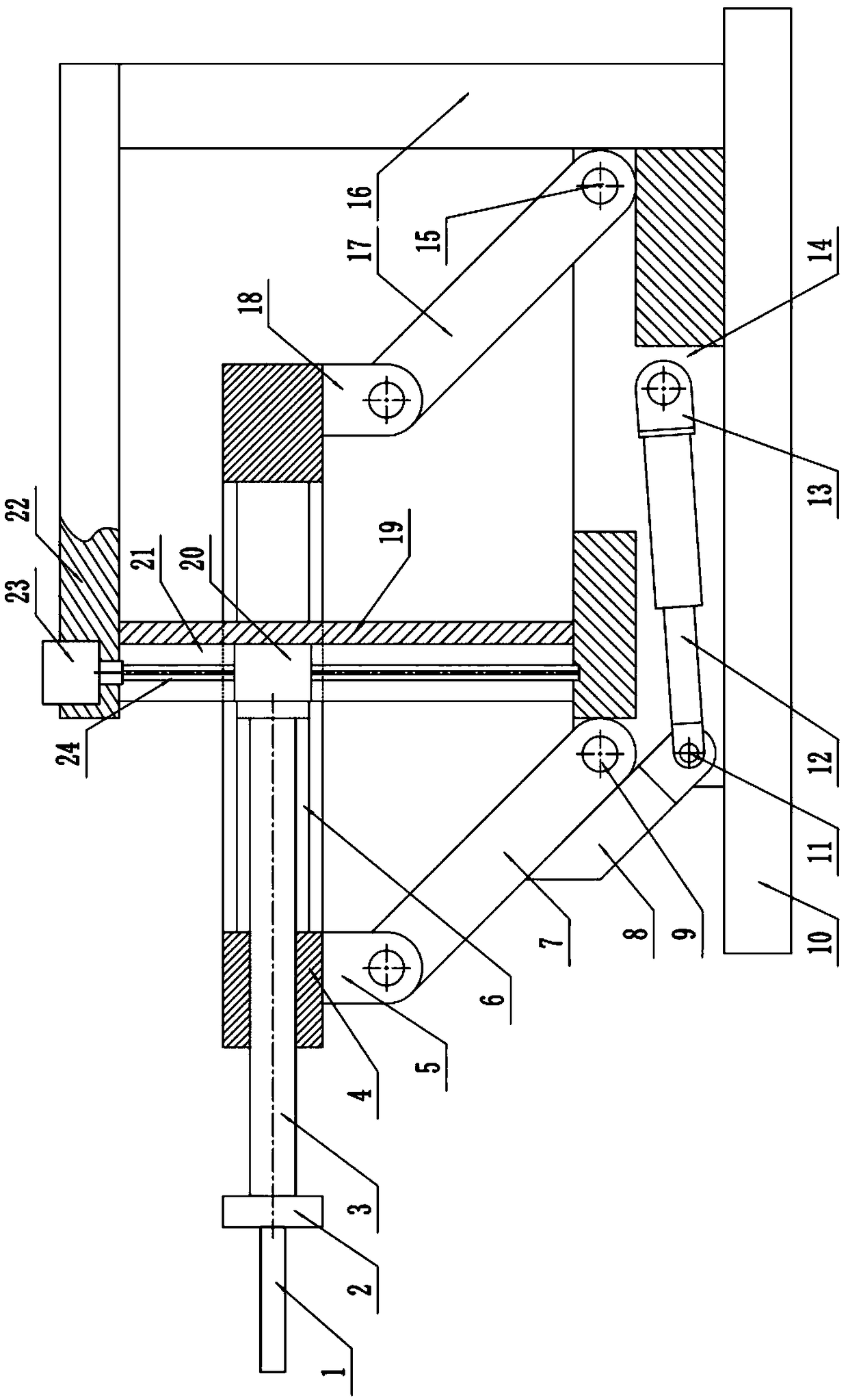

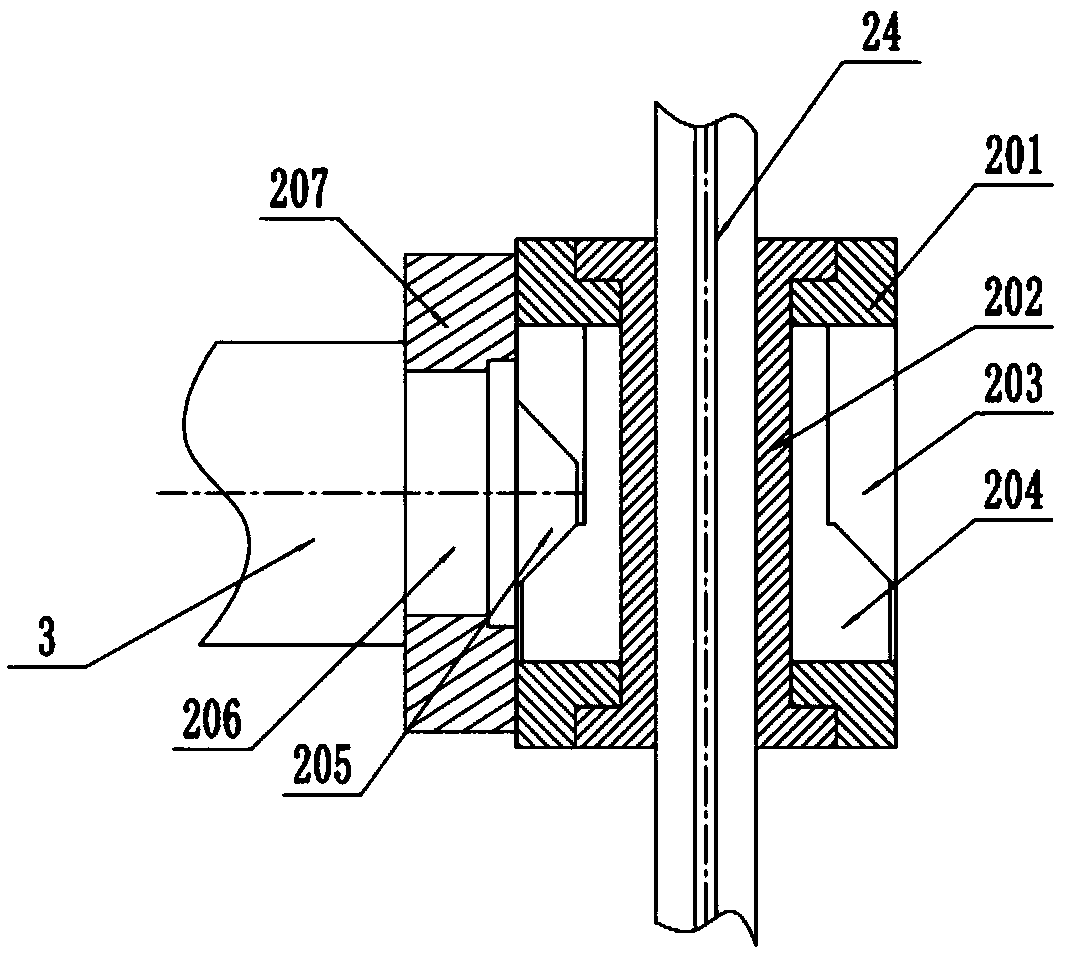

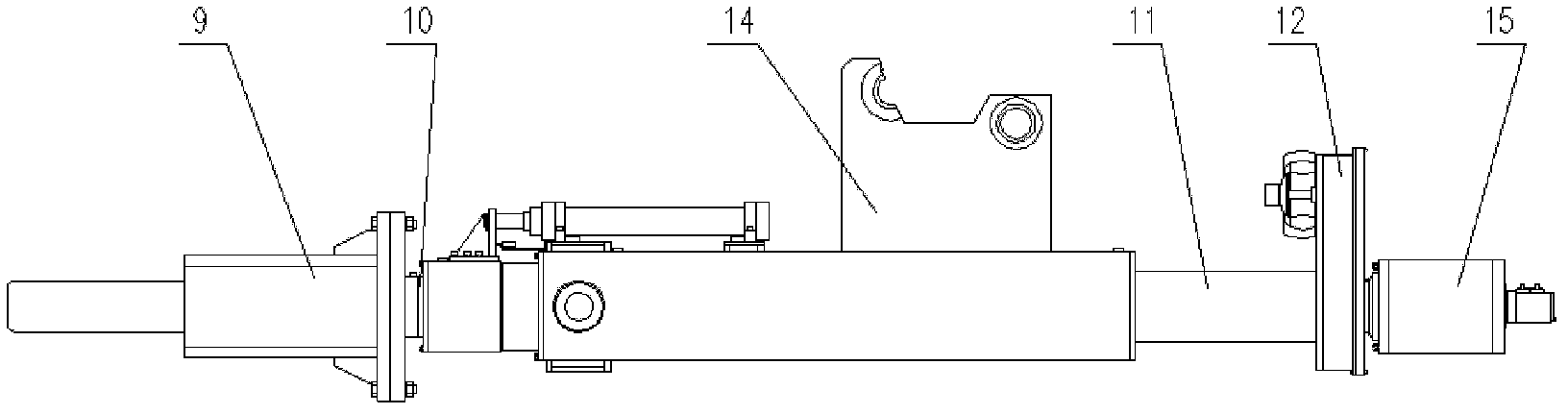

Claw rod mechanism of forging manipulator

InactiveCN102581198ASimple structureEasy to manufactureForging/hammering/pressing machinesStructural reliabilityBall bearing

The invention relates to a claw rod mechanism of a forging manipulator, which mainly comprises a jaw clamping mechanism and a claw arm rotating mechanism, wherein the jaw clamping mechanism comprises a claw arm (1), a connecting rod (2), a hydraulic piston cylinder (8), a piston rod (9), a thrust bearing A (12), a thrust bearing B (13), a connecting piece (14), a claw shell B (18), a pin A (19), a pin B (20) and a jaw (21); and the claw arm rotating mechanism mainly comprises a deep groove ball bearing (3), a claw shell A (4), a synchronous belt (5), a small belt wheel (6), a rotary driver (7), a claw shell C (10), a large belt wheel (11), the thrust bearing A (12), the thrust bearing B (13), the connecting piece (14), a rotating body (15), a guiding key (16) and a barrel sleeve (17). The claw rod mechanism of the forging manipulator has the advantages of a simple structure, a regular shape of each member and being easy in manufacturing and disassembly; and the piston rod and the oil cylinder have no torque loads so that the claw rod mechanism is high in structural reliability.

Owner:广州市优斯兰敦金属制品有限公司

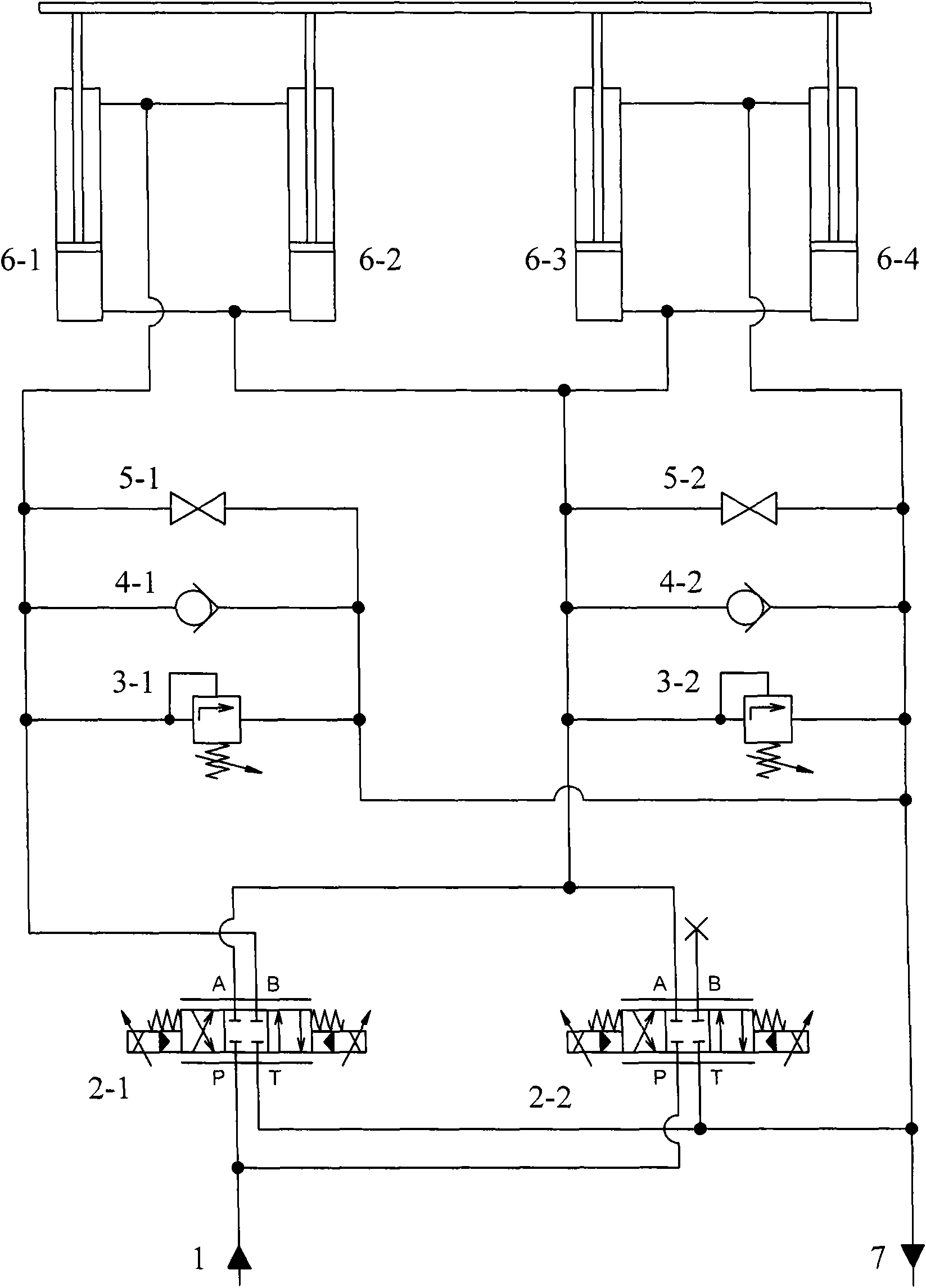

Hydraulic parallel driving system for fore-and-aft lifting of forging manipulator

InactiveCN102114516AGood synchronizationAvoid stress changesServomotorsForging/hammering/pressing machinesForging manipulatorEngineering

The invention discloses a hydraulic parallel driving system for fore-and-aft lifting of a forging manipulator. The P port of a nonsymmetrical proportional servo valve (2-1) is respectively connected with an oil supply port (1) of an oil source and the P port of a symmetrical proportional servo valve (2-2); the A port of the nonsymmetrical proportional servo valve (2-1) is respectively connected with the A port of the symmetrical proportional servo valve (2-2), the inlet of a lower cavity safety valve (3-2) and the like; the B port of the nonsymmetrical proportional servo valve (2-1) is respectively connected with the inlet of an upper cavity safety valve (3-1), the outlet of an upper cavity one-way valve (4-1), the inlet of an upper cavity cut-off valve (5-1) and the like; the B port of the symmetrical proportional servo valve (2-2) is plugged; an oil return port (7) of the oil source is respectively connected with the T port of the nonsymmetrical proportional servo valve (2-1), the T port of the symmetrical proportional servo valve (2-2), and the like; and the top ends of the piston rods of four lift cylinders are mechanically consolidated. The hydraulic parallel driving system disclosed by the invention can solve the problem of synchronous driving of fore-and-aft lifting systems of the existing forging manipulator.

Owner:ZHEJIANG UNIV

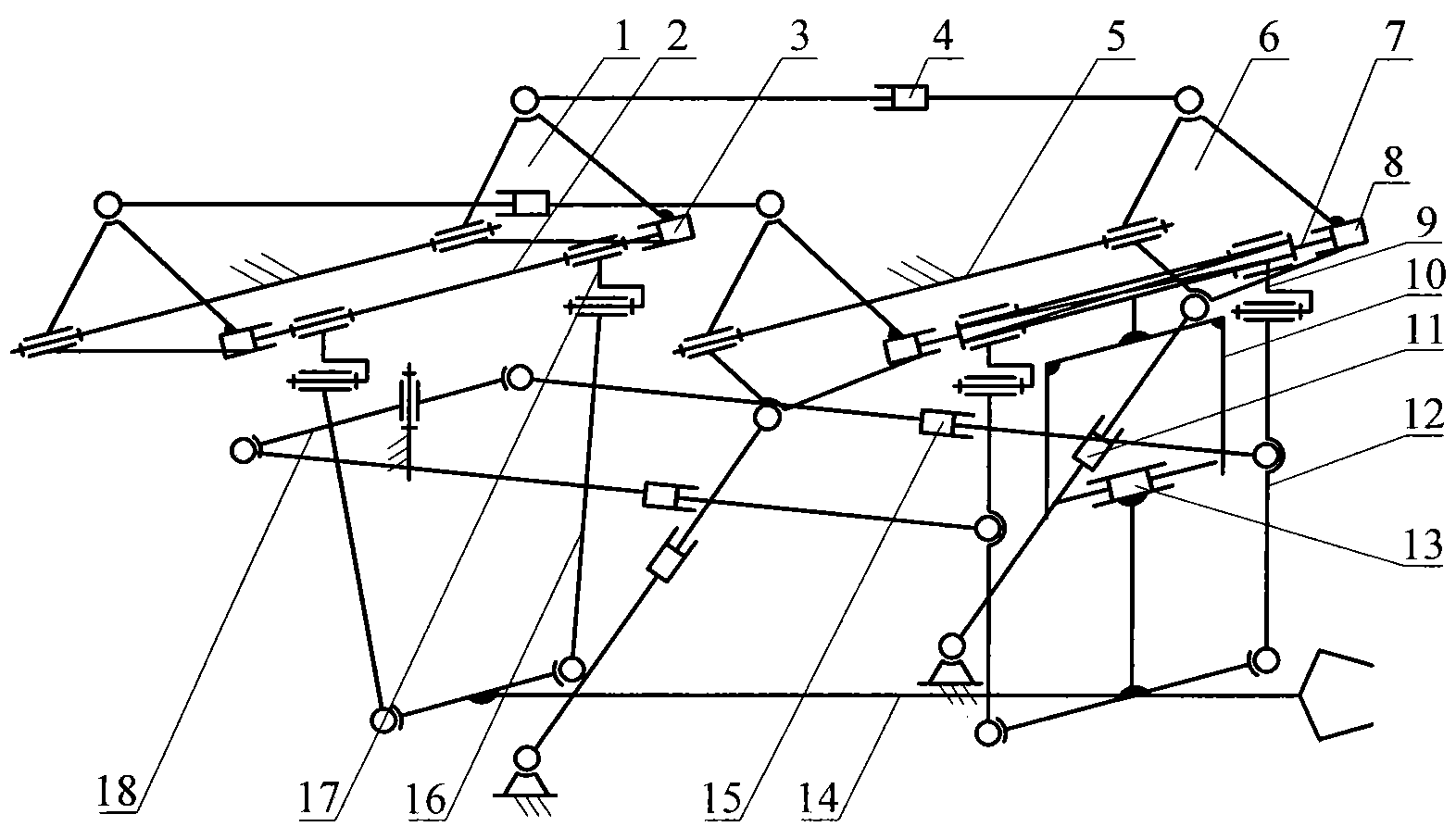

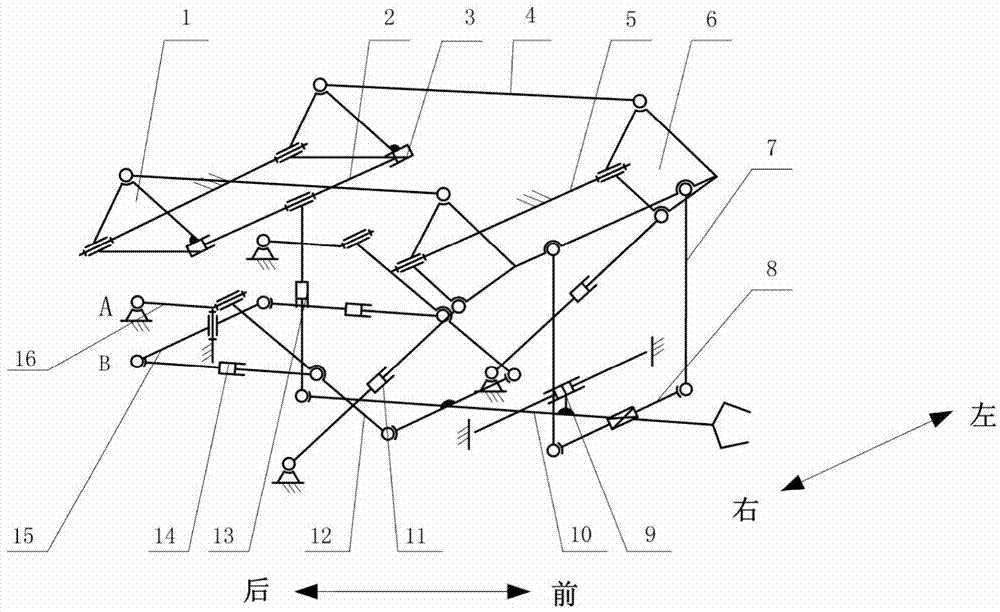

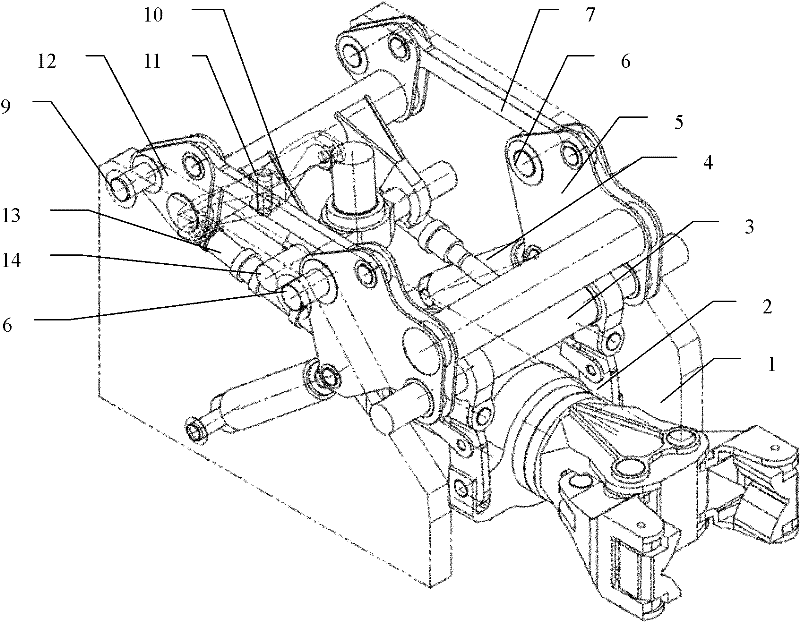

Parallel rod type forging manipulator lifting mechanism with slantly-arranged pitching linear actuator

InactiveCN103056266AReduce stressImprove carrying capacityForging/hammering/pressing machinesForging manipulatorLinear actuator

The invention discloses a parallel rod type forging manipulator lifting mechanism with a slantly-arranged pitching linear actuator. The lifting mechanism comprises a lifting device, a swing device, a front-back-left-right shock absorber, a claw beam and a frame, the front portion of the claw beam is connected with the lower ends of two forward mounting rods, the upper ends of the two forward mounting rods are connected onto a front sliding rod through connection pieces, a left linear actuator and a right linear actuator are arranged at two ends of a front-back sliding rod and, a front-back actuator is connected with a front-back lifting arm, and the other end of the front-back lifting arm is connected with the frame. Lower arms of two front lifting arms are connected with upper ends of two lifting linear actuators, upper arms of the front lifting arms are connected with the front ends of a horizontal synchronization rod, and the back end of the synchronization rod is connected with an upper arm of a back lifting arm. The lifting mechanism is characterized in that the back portion of the claw beam is connected with two slantly-arranged pitching linear actuators, the upper ends of the slantly-arranged pitching linear actuators are connected onto the back sliding rod through connection pieces. The parallel rod type forging manipulator lifting mechanism is high in pitching motion transmission efficiency, small in stress at frame hinging connection positions, strong in whole bearing capacity of the manipulator, simple in structure, and prone to guarantee lifting parallelism degree of the claw beam.

Owner:YANSHAN UNIV

Hydraulic system of buffering cylinder of forging manipulator

InactiveCN102744345AFunction increaseIntegrated cushioningFluid-pressure actuatorsForging press drivesProportional controlLoop control

The invention discloses a hydraulic system of a buffering cylinder of a forging manipulator. The hydraulic system comprises an oil source oil supply opening, a proportional direction valve, an overflow valve, a one-way valve, the buffering cylinder, a pilot overflow valve, an electromagnetic direction valve, an oil source oil return opening, a displacement sensor, a displacement set signal, a subtractor and a PID (proportion integration differentiation) controller. A combined type multi-cavity structure of the buffering cylinder of the forging manipulator is utilized, a passive buffering system with the pilot overflow valve and an active displacement closed-loop control system with the proportional direction valve are integrated on the buffering cylinder, a passive buffering function of a clamp of the manipulator can be realized, and furthermore, a required displacement closed-loop control function of the buffering system of the forging manipulator is also realized. The hydraulic system has the advantages of simplicity in control and multiple functions. By a multi-cavity buffering mode of the buffering cylinder of the system, higher buffering force can be provided by the buffering cylinder with the same diameter. Besides, because proportional control elements are fewer, the reliability of the system is high.

Owner:ZHEJIANG UNIV

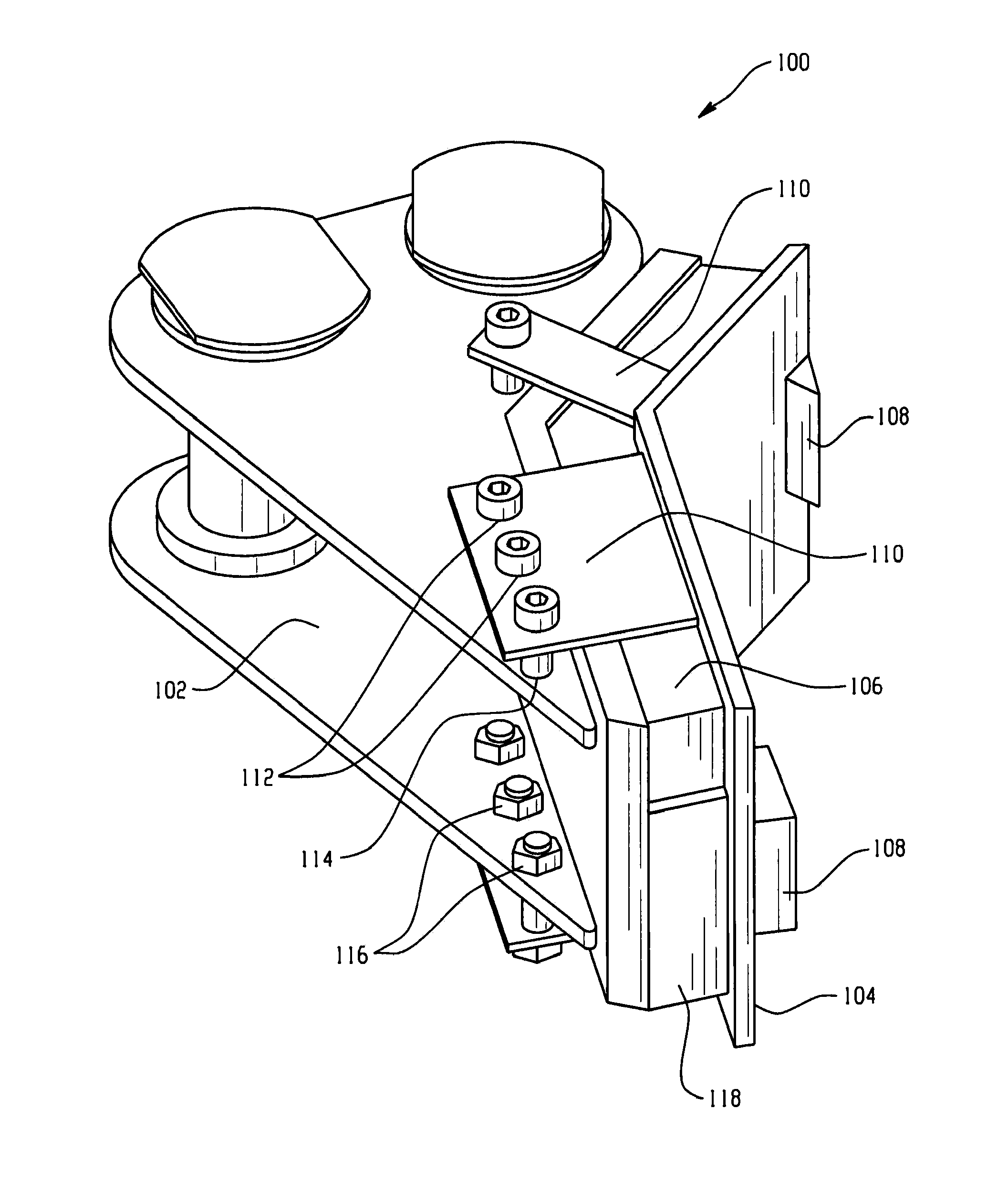

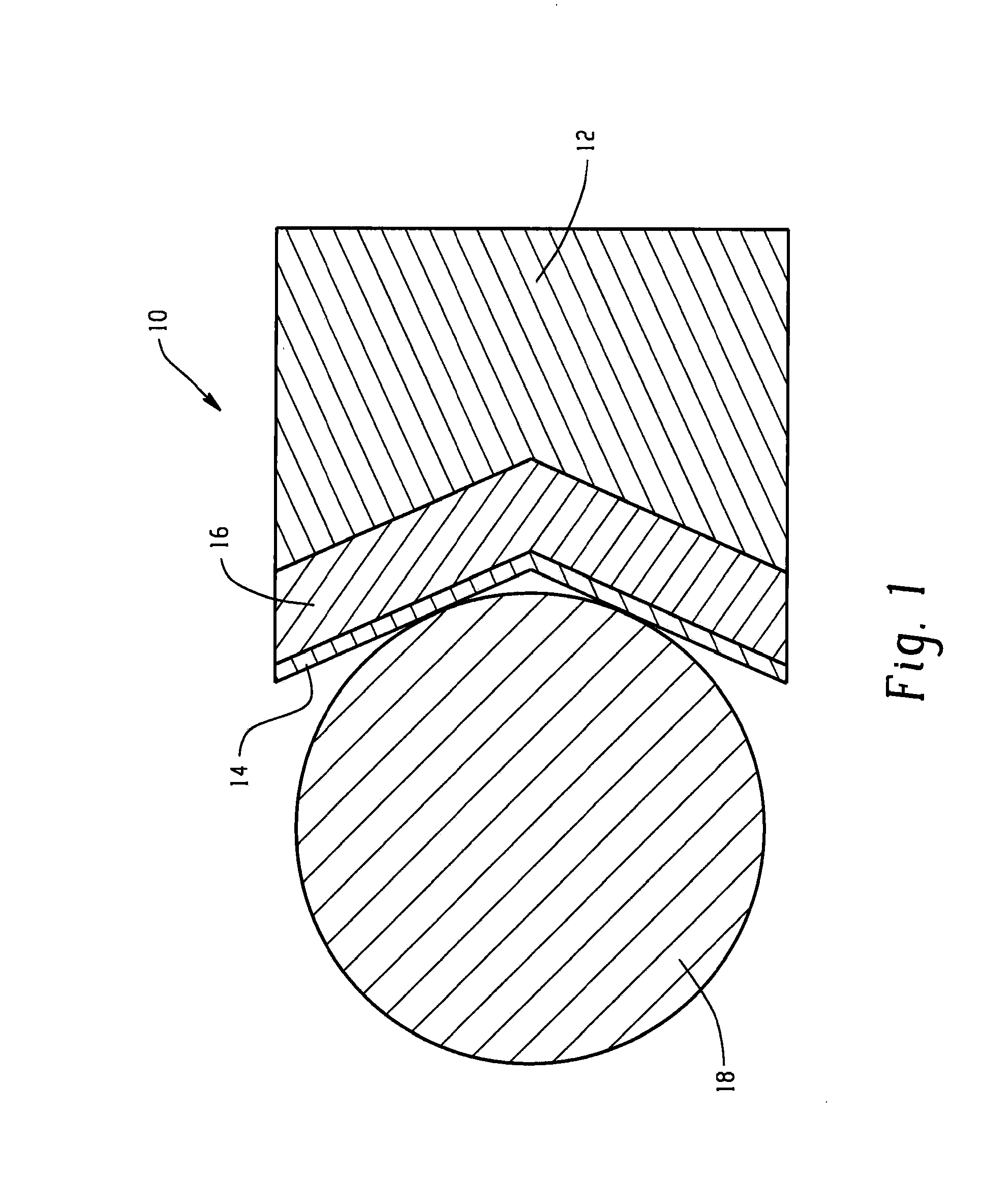

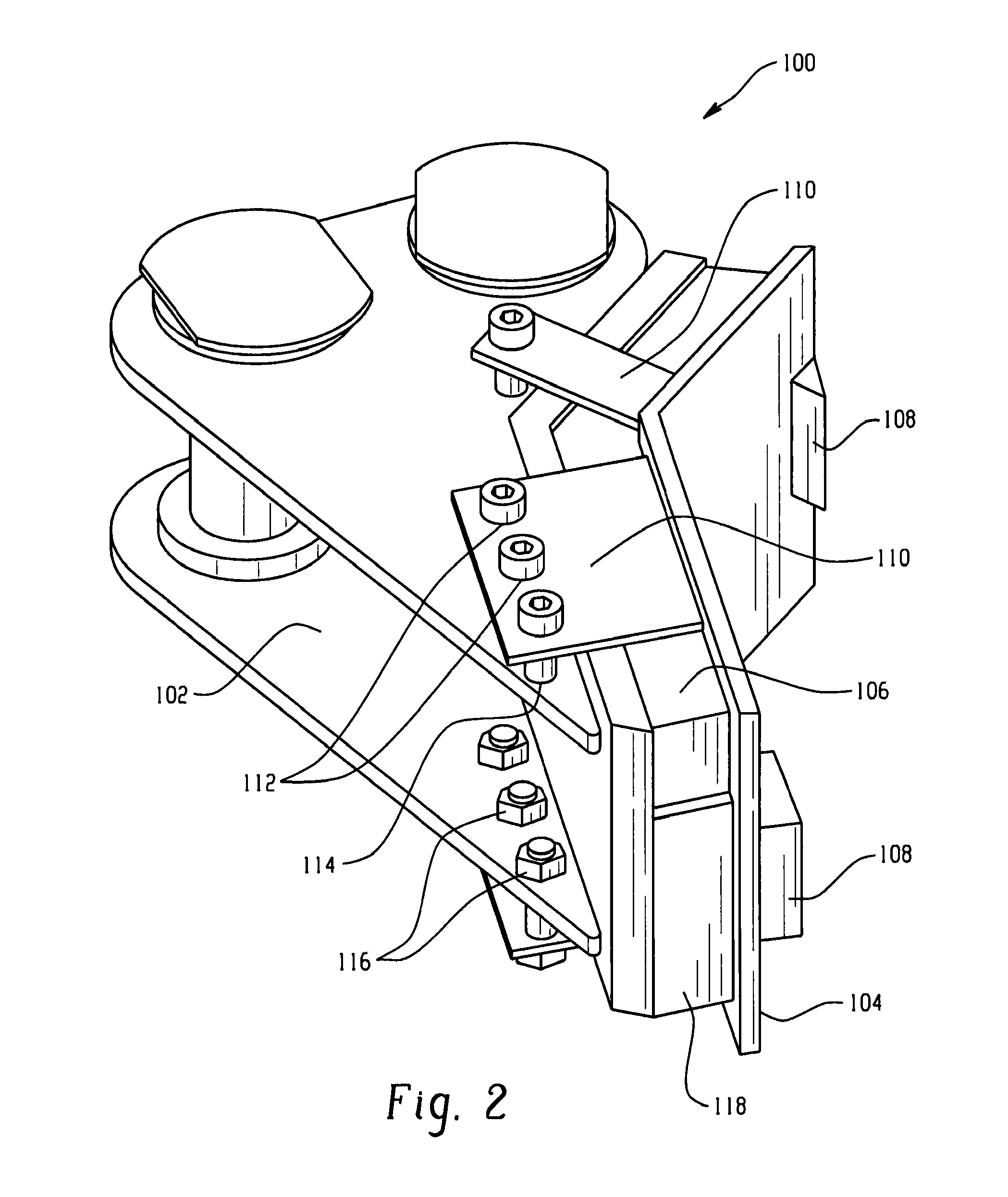

Gripper assembly for a manipulator and method of use

InactiveUS20130174632A1Prevent heat transferMetal-working feeding devicesGripping headsForging manipulatorEngineering

A gripper assembly for a forging manipulator includes a main body configured to be in operative communication with the manipulator; a contact plate attached to the main body and configured to be in physical communication with a heated metal part; and an insulating plate disposed between the main body and the contact plate, wherein the insulating plate is configured to substantially prevent heat transfer from the heated metal part to the main body.

Owner:FIRTH RIXSON

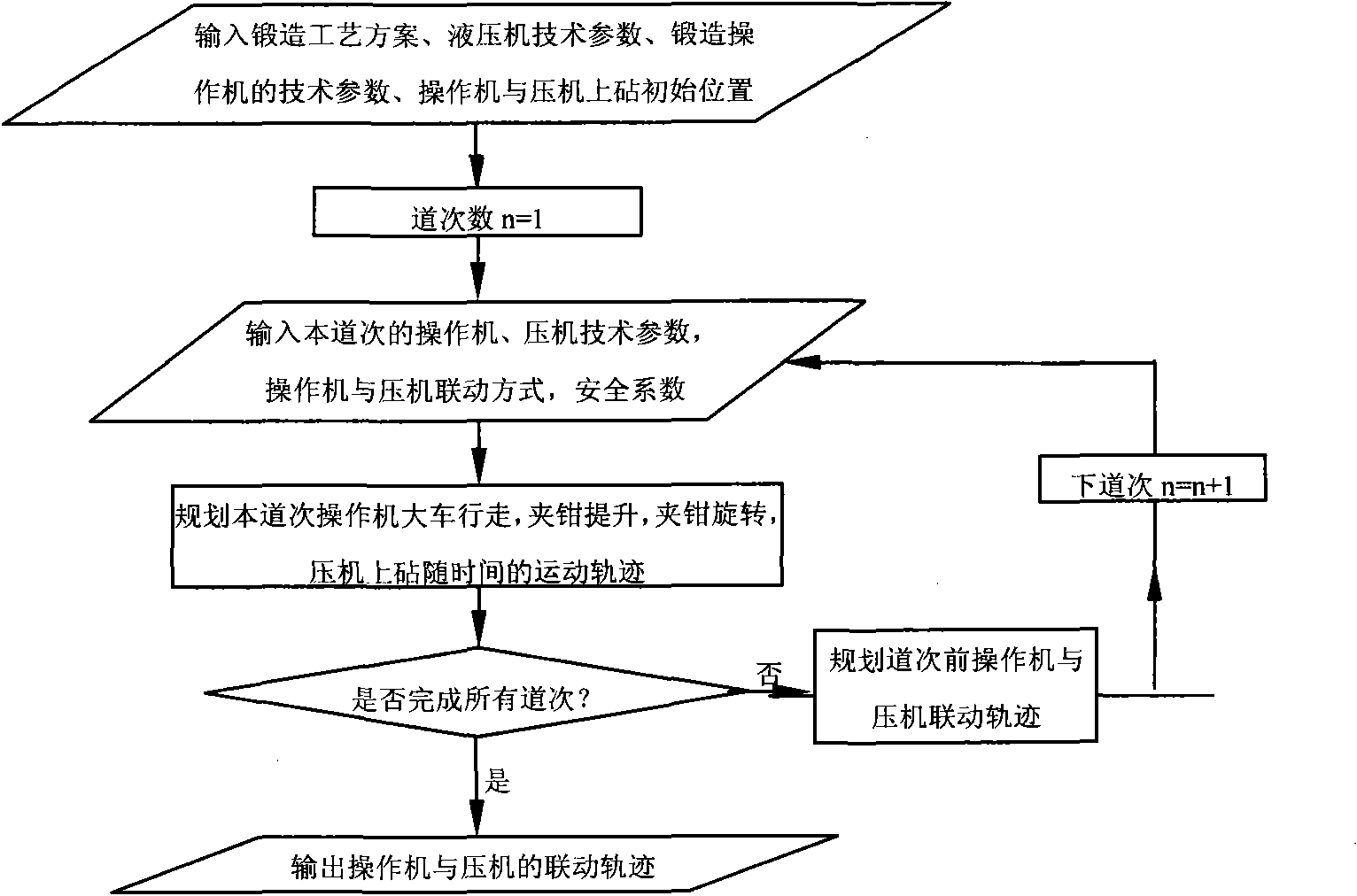

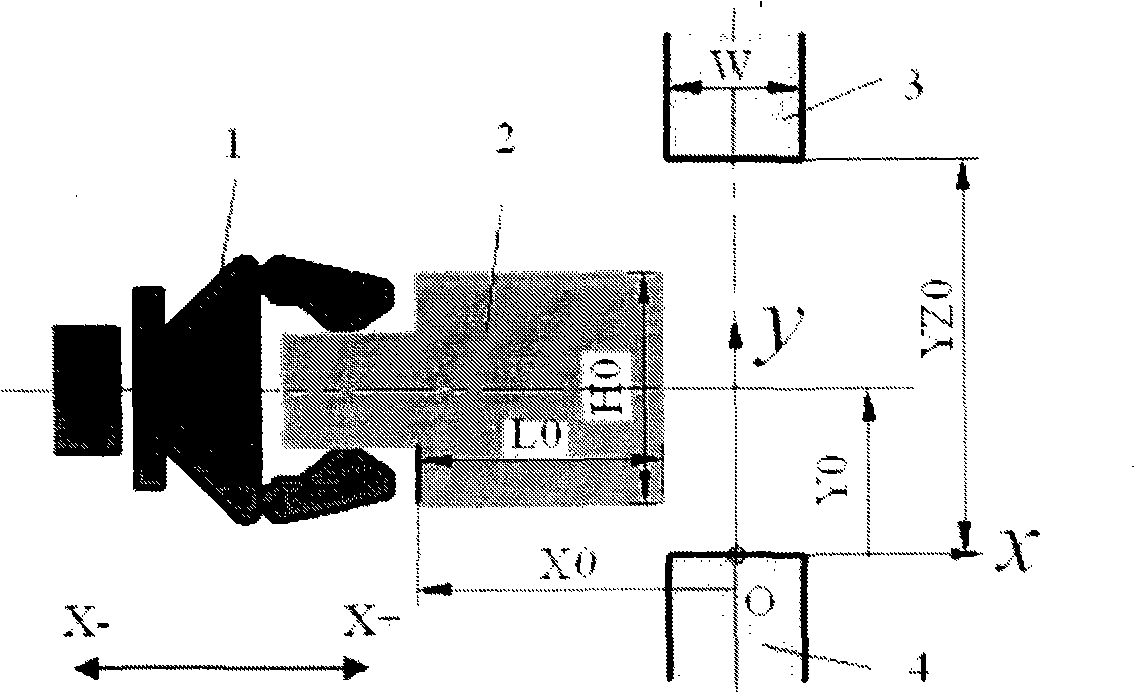

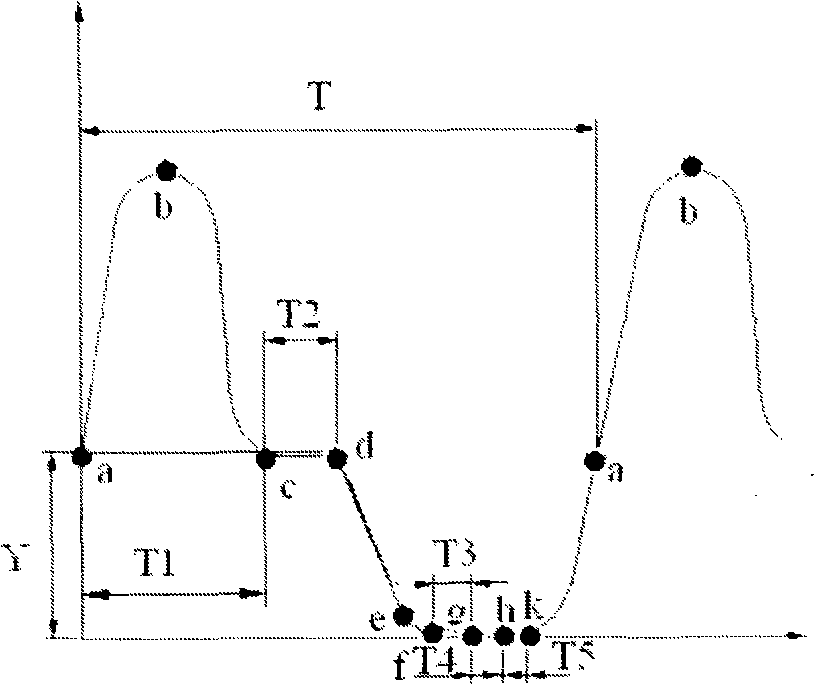

Method for planning linkage track of automatic forging manipulator and pressing machine

The invention discloses a method for planning a linkage track of an automatic forging manipulator and a pressing machine. The method comprises the following steps of: 1. designing and calculating a flat anvil drawing process scheme; 2. planning and performing the linkage track of the manipulator and the pressing machine in the process scheme; and 3. evaluating the reasonability of the linkage track. The invention provides the method for planning the linkage track of the automatic forging manipulator and the pressing machine and proposes a method for evaluating the reasonability of the linkage track.

Owner:CENT SOUTH UNIV

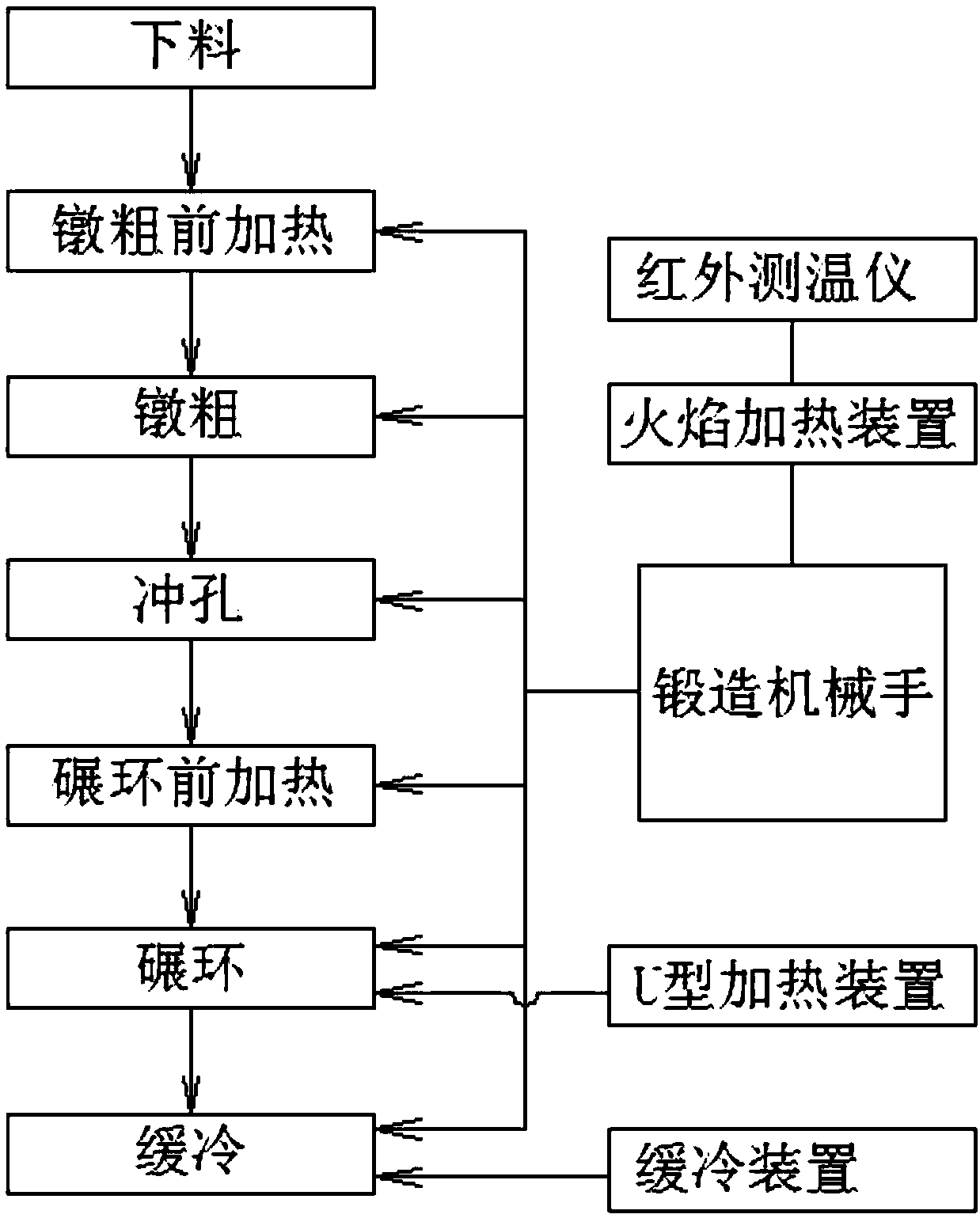

Forging process and equipment for high-temperature-resistant and high-pressure-resistant stainless steel ring

InactiveCN109590417ARealize the heating effectRealize the insulation effectPiercing pressesHeating/cooling devicesPunchingForging manipulator

The invention relates to the technical field of forging and discloses forging process and equipment for a high-temperature-resistant and high-pressure-resistant stainless steel ring. The forging process comprises the following process steps of step 10, blanking, step 20, heating before upsetting, step 30, upsetting, step 40, punching, step 50, heating before ring milling, step 60, ring milling andstep 70, slow cooling. The stainless steel ring is transferred in each forging workstage and between workstages by using a forging manipulator, the front end of the forging manipulator is provided with an infrared thermometer for online measuring of the temperature of a blank and a flame heating device for online heating and heat preservation of the blank, and the forging manipulator turns on theflame heating device in the process of transferring the blank to carry out heating and heat preservation on the blank of the stainless steel ring. By the adoption of the forging process and equipment, good control over the temperature of the blank of the stainless steel ring in the forging process is realized, so that the forging quality is improved, and the forging energy consumption is reduced.

Owner:JIANGYIN HENGRUN RING FORGING

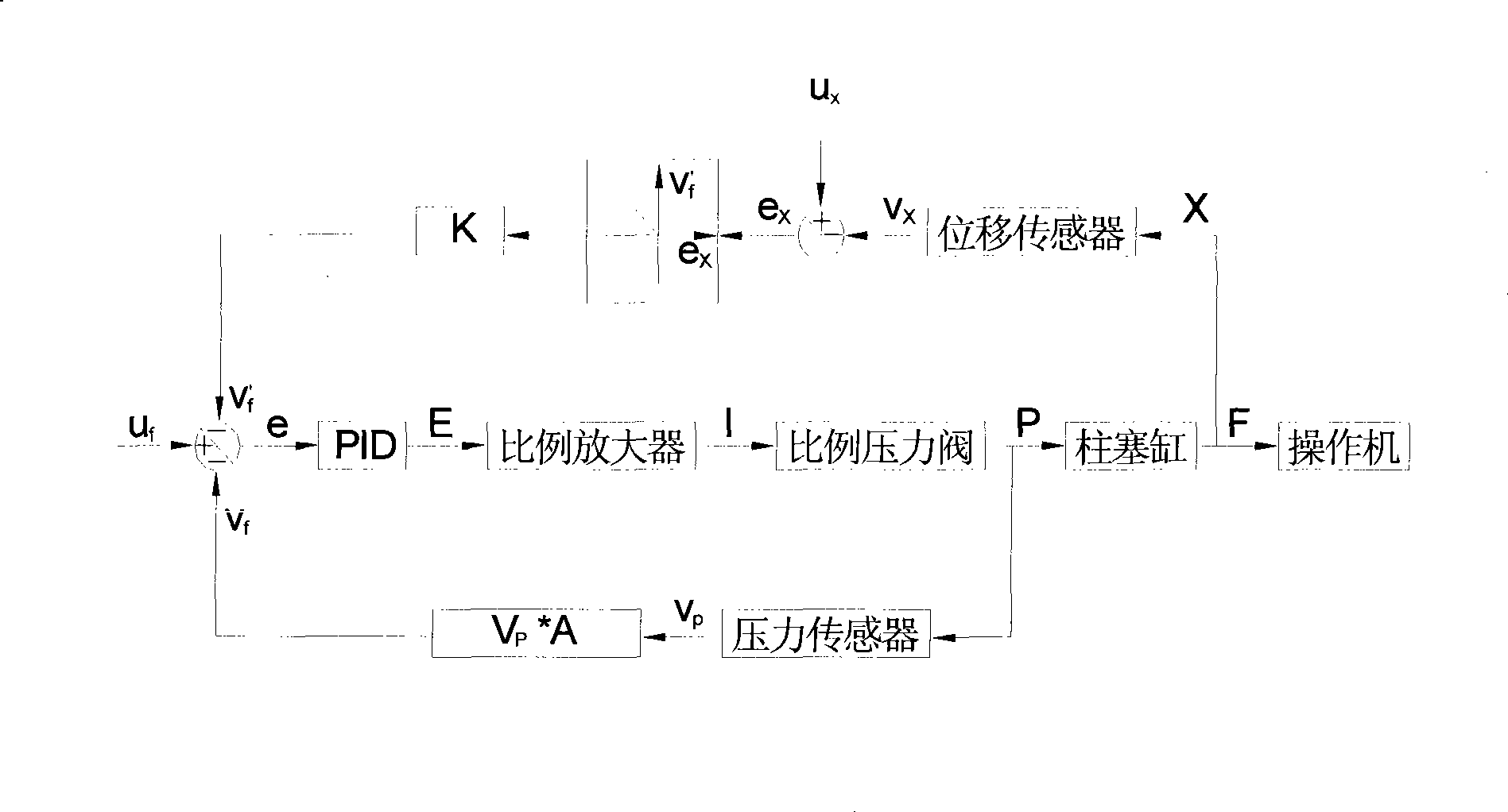

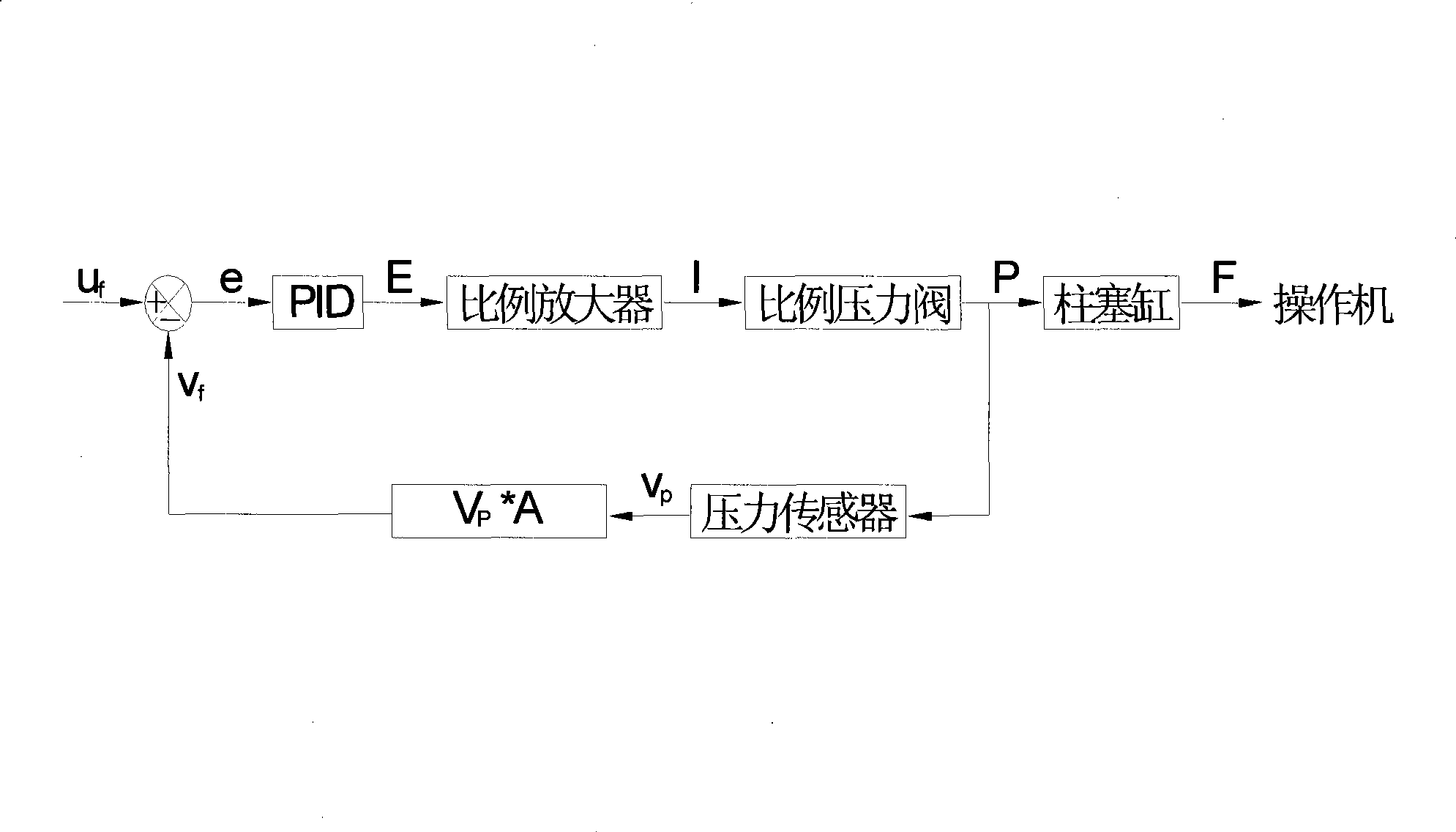

Control method for positioning position-pressure of hydraulic cylinder of large-scale forging manipulator

ActiveCN101444817AThe key to overcoming height control difficultiesControl speedForging press drivesEngineeringPiston

The invention discloses a control method for positioning position-pressure of a hydraulic cylinder of a large-scale forging manipulator. The control process comprises the following steps: firstly, an uplift force value uf is predicated according to the weight of a work piece to be as system input; secondly, uf is compared with a practical uplift force vf, PID adjustment is performed according to the difference value e, and a proportional pressure valve is driven through a proportional amplifier to adjust the uplift force P; thirdly, when the practical uplift force V is close to an instruction uplift force, the difference value e is approximate to zero, and the uplift force F of the hydraulic cylinder is controlled to be above an expected value; fourthly, when gravity and forging down force are larger than the uplift force of the hydraulic cylinder, the piston of the hydraulic cylinder is compressed, and the manipulator is moved downward; conversely, the piston of the hydraulic cylinder extends out, and the manipulator is uplifted. The method is characterized in that after the manipulator is uplifted, position feed back signal Vx is compared with expected height value Ux, when Vx is smaller than Ux, the system adopts the conventional pressure control mode; conversely when Vx is larger than Ux, negative feedback cause the reducing of the output pressure, the uplifting of the hydraulic cylinder is stopped, and the system is shifted into the position-pressure control method.

Owner:CHINA FIRST HEAVY IND +1

Loading and unloading flexible mechanical gripper for forging

InactiveCN102513493ARapid positioningQuick grabForging/hammering/pressing machinesForging manipulatorOptical axis

The invention relates to a gripper device for forging, particularly provides a flexible mechanical gripper for forging production enterprises to automatically clamp high-temperature forged parts of different dimensions in a high-temperature environment, and aims to provide a flexible mechanical gripper applied to automatic loading and unloading on forging equipment. The loading and unloading flexible mechanical gripper for forging is provided with a forging manipulator fixing seat, a gripper component and a driving component are arranged on the forging manipulator fixing seat, the gripper component comprises a fixed mechanical clamping jaw, a moving mechanical clamping jaw and a polished shaft push rod which are fixed to the tail end of the forging manipulator fixing seat, the driving component comprises a cylinder and a cylinder block which are fixed to the upper end of the forging manipulator fixing seat, the cylinder block is provided with a radiating polished shaft, an extension bar of the cylinder is connected with the polished shaft push rod through a radiating gap connector, and a copper bush guide seat for guiding the polished shaft push rod is arranged on the cylinder block.

Owner:CHANGZHOU INST OF ADVANCED MFG TECH

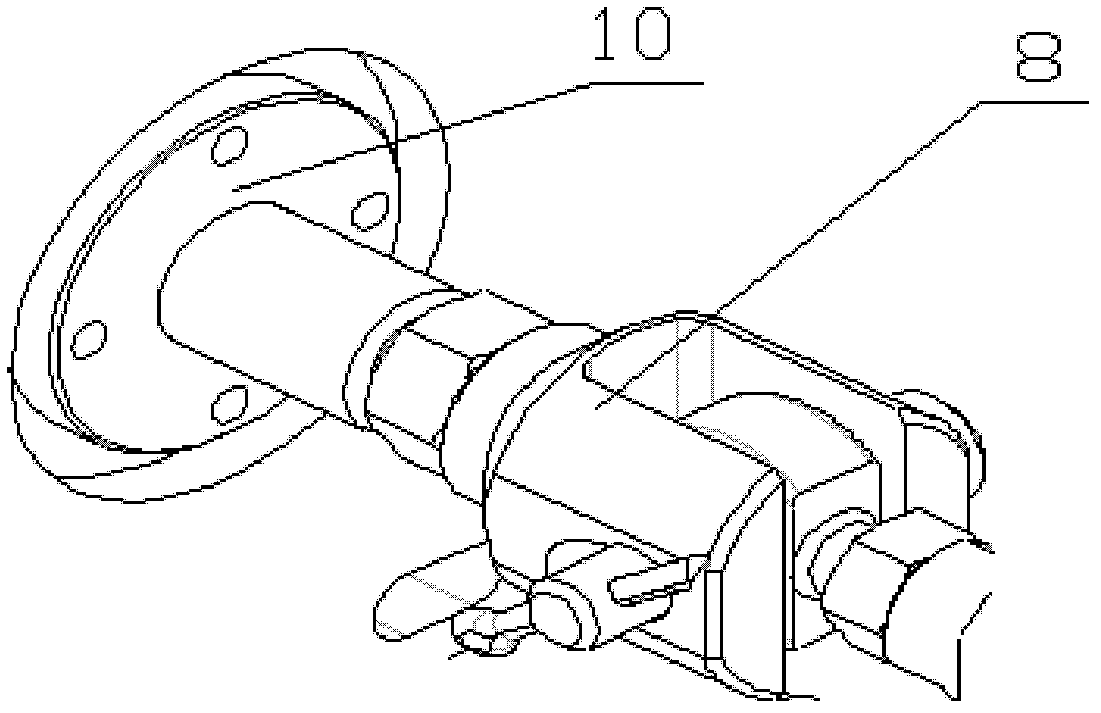

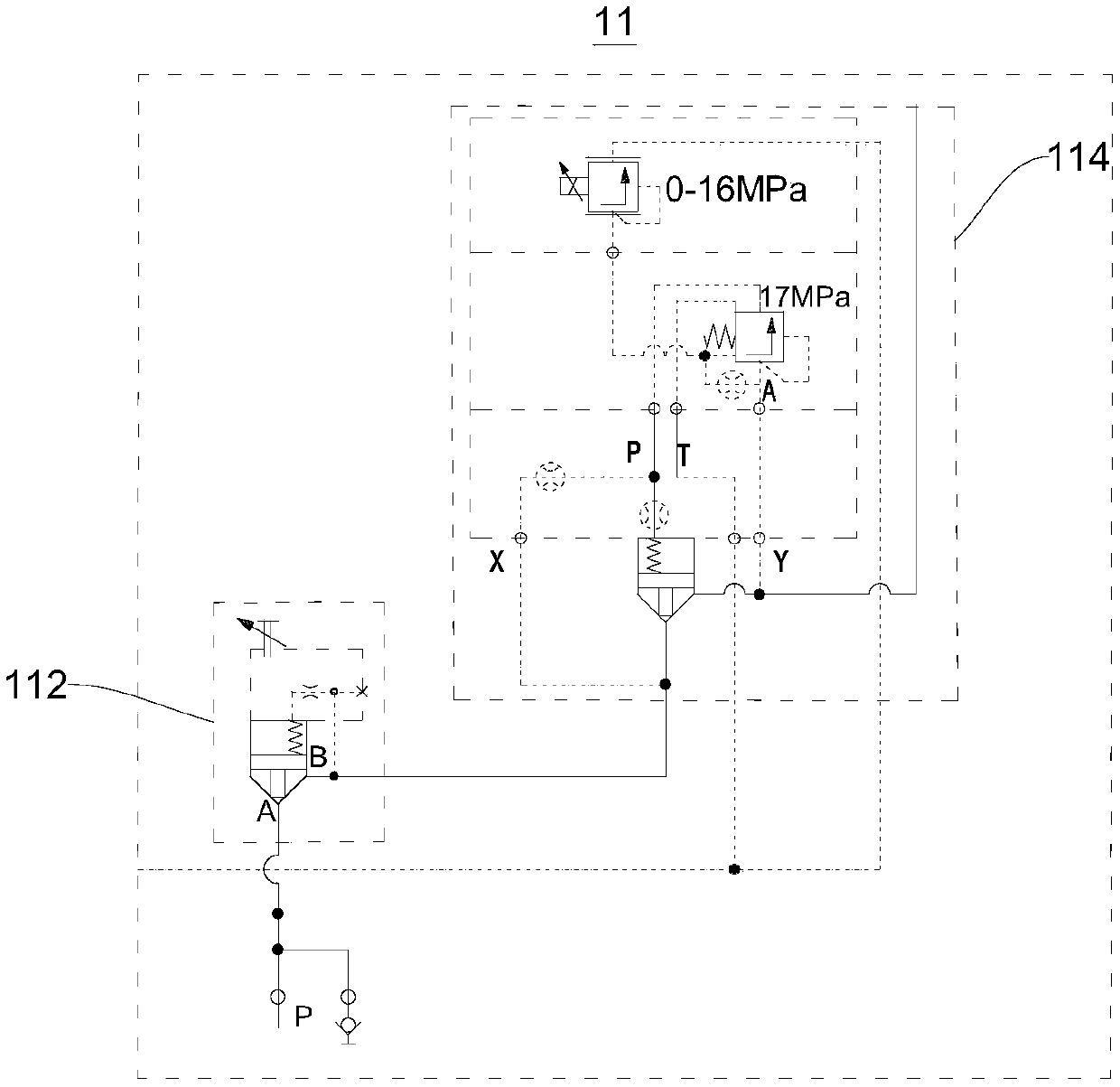

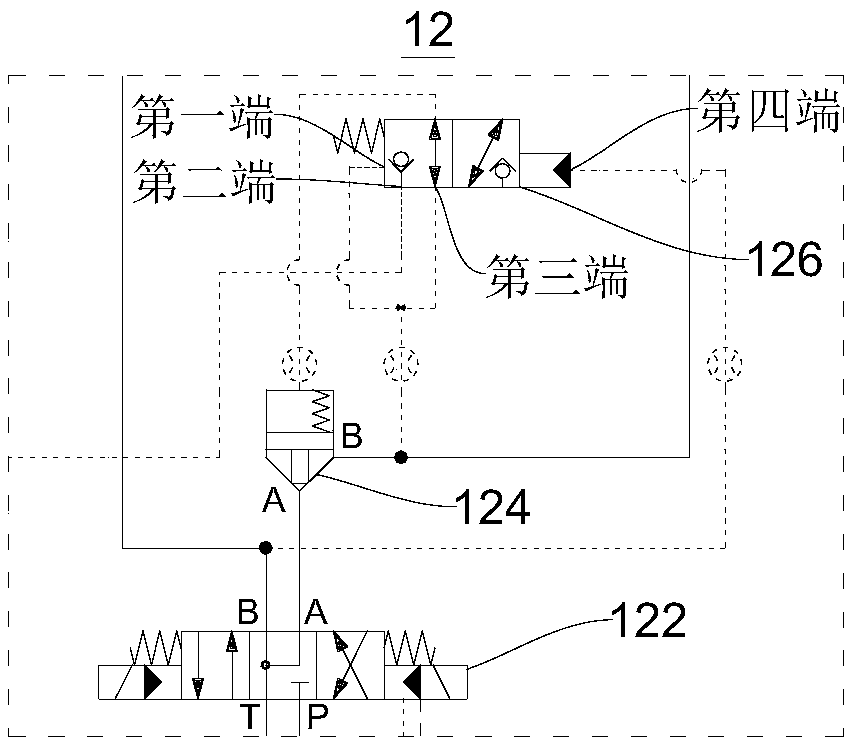

Clamping control system and radial forging manipulator

PendingCN109570426AEasy to controlFlexible controlForging/hammering/pressing machinesForging press drivesMagnetic exchangeForging manipulator

The invention provides a clamping control system and a radial forging manipulator and belongs to the technical field of machining equipment. The clamping control system comprises an oil supply valve set, a main control valve set, a first pressure sensor, a second pressure sensor and an oil cylinder; the main control valve set comprises a magnetic exchange valve and a pilot-operated check valve; the oil inlet end of the magnetic exchange valve is connected with the oil supply valve set; the magnetic exchange valve comprises a first oil supply end, a second oil supply end and an oil return end;the first oil supply end is connected with the oil inlet end of the pilot-operated check valve, and the second oil supply end is connected with the oil cylinder; a rodless cavity of the oil cylinder is connected with the oil outlet end of the pilot-operated check valve and a rod cavity of the oil cylinder is connected with the second oil supply end; the first pressure sensor is connected with therodless cavity; and the second pressure sensor is connected with the rod cavity. According to the clamping control system, the clamping pressure is regulated and controlled automatically in real timebased on real-time pressure data collected by the pressure sensors, and therefore the flexibility and accuracy of control over clamping and forging pressure are improved.

Owner:青岛海德马克智能装备有限公司

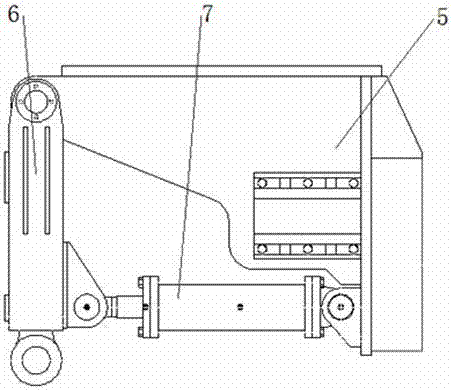

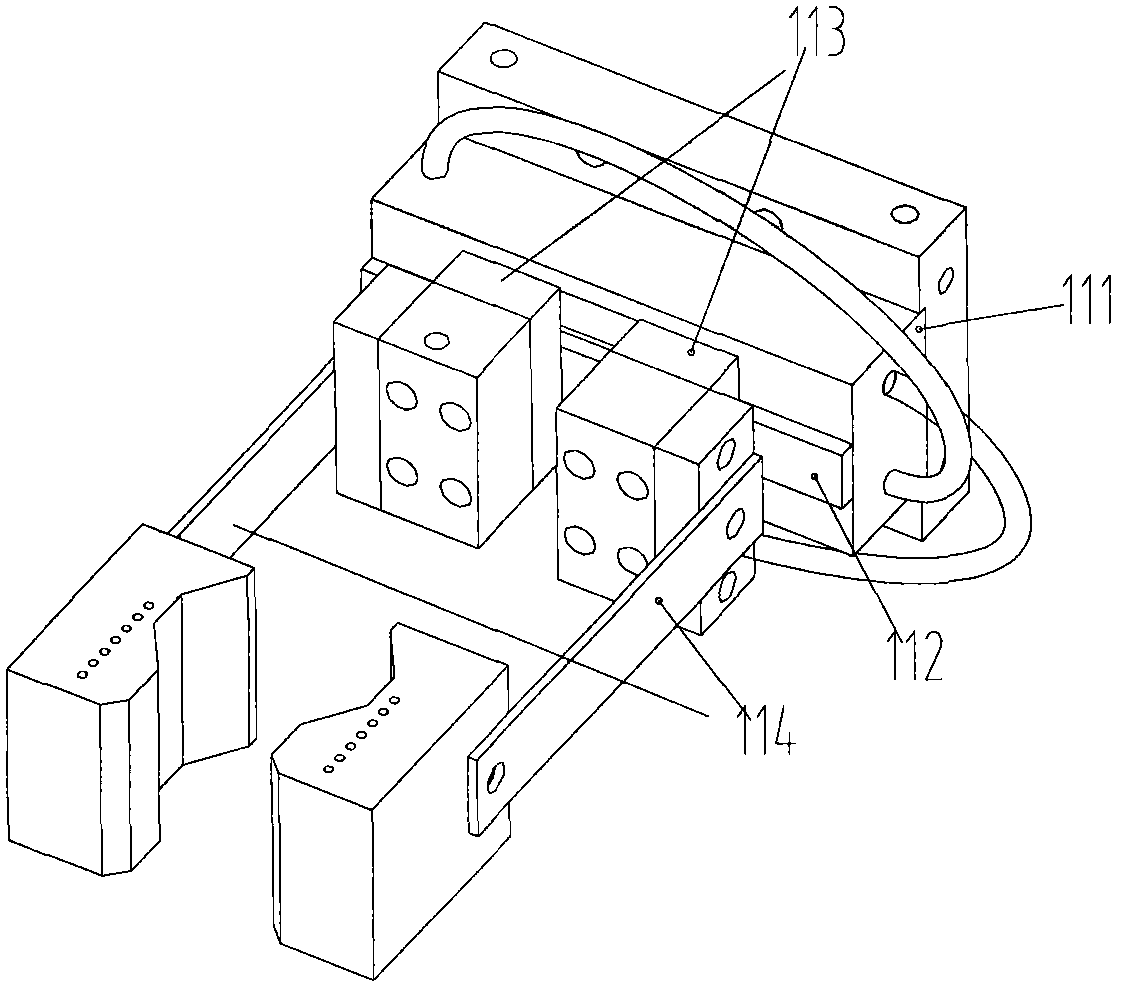

Clamp rack assembly of trackless forging manipulator

PendingCN107352469AFirmly connectedComplete cushioning and shock absorptionNon-rotating vibration suppressionLifting devicesForging manipulatorGear wheel

The invention discloses a clamp rack assembly of a trackless forging manipulator. The clamp rack assembly comprises a clamp rack body, wherein a lifting arm, a perpendicular buffer and a horizontal buffer are arranged on the outer side of the clamp rack body; the bottom end of the perpendicular buffer is connected with the outer end of the horizontal buffer; the clamp rack body is connected with a forklift through the lifting arm, the perpendicular buffer and the horizontal buffer; a hollow shaft is mounted on the middle part in the clamp rack body; a transmission gear is mounted at one side of the rear end of the hollow shaft; a clamping oil cylinder is mounted above the hollow shaft; a clamp head is mounted at the front side of the clamping oil cylinder; the two sides of the clamp head are fixedly connected with connecting plates; the connecting plates are rotatably connected with clamping arms; and front ends of the clamping arms are inwards equipped to be clamp openings. The assembly is reliable in work and operation, and is flexible and convenient to operate.

Owner:SHANXI CHENHUI FORGING EQUIP MFG CO LTD

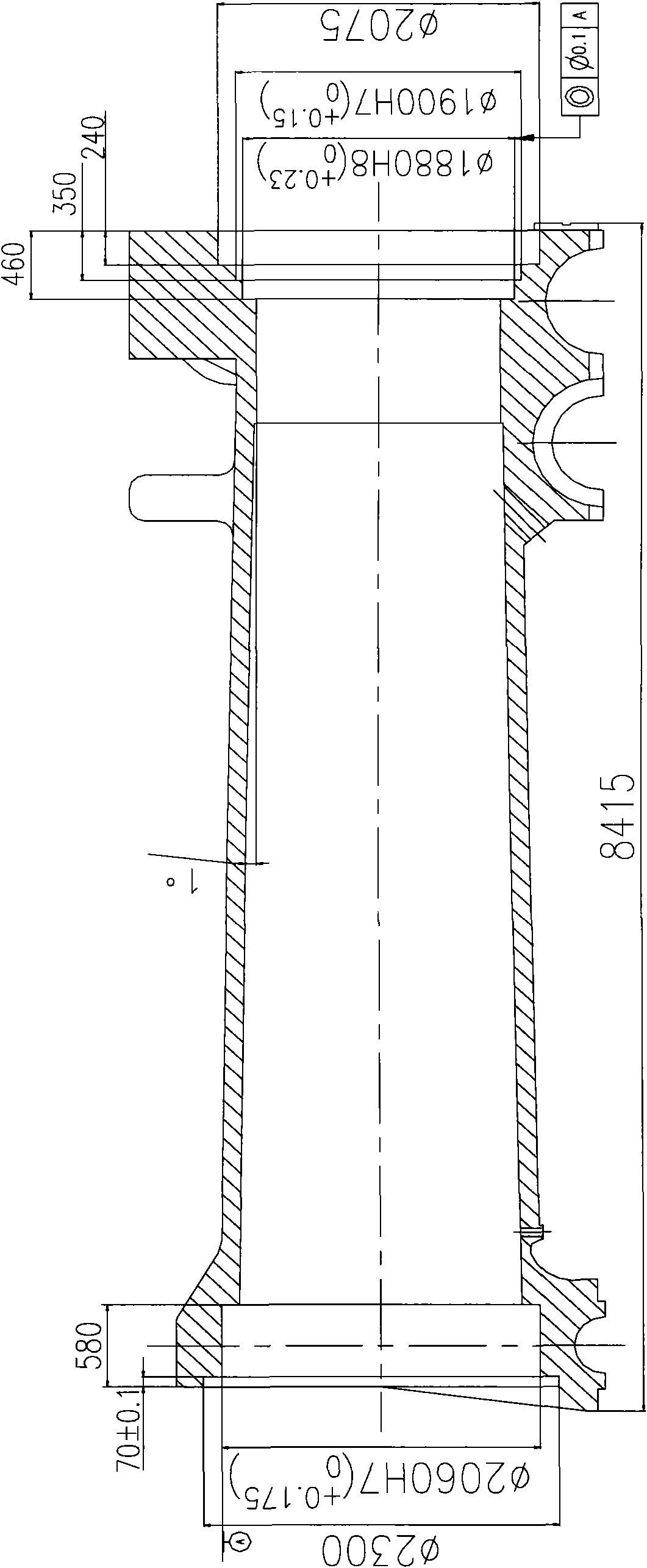

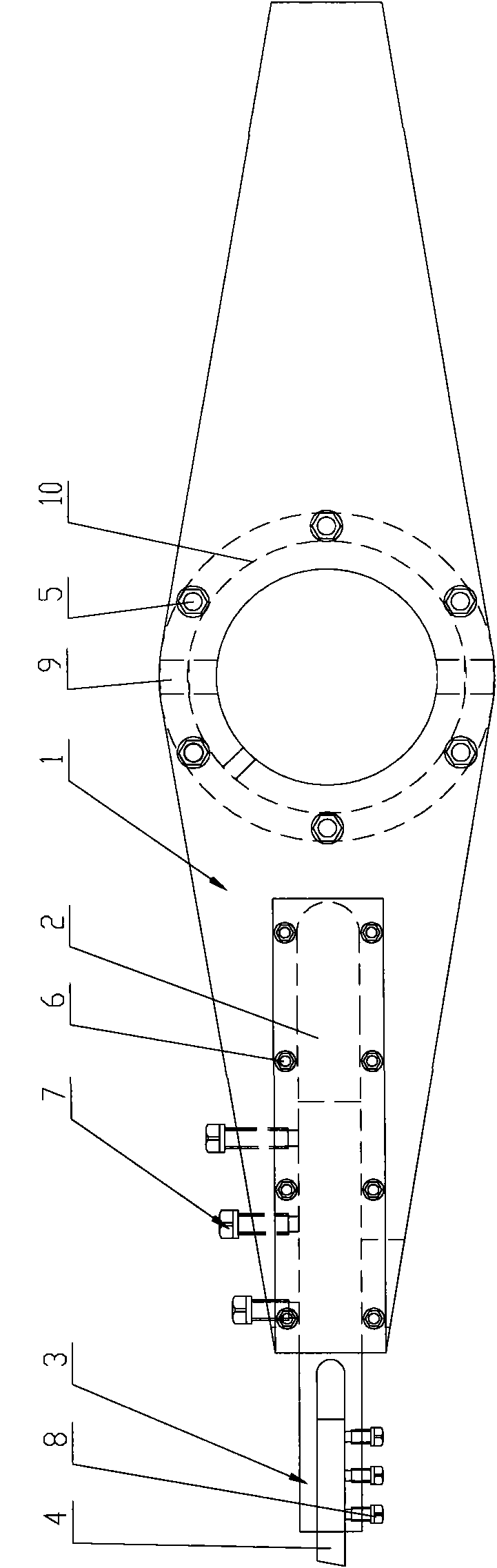

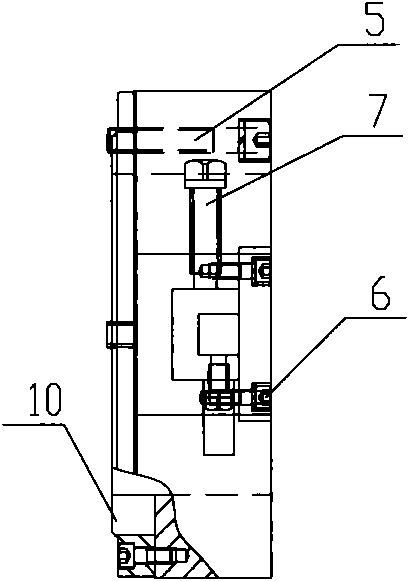

Machining method and cutter head of support tube in large-scale track forging manipulator

ActiveCN101850398AImprove rigidityEasy to processTurning toolsForging/hammering/pressing machinesSheet steelForging manipulator

The invention discloses a machining method of a support tube in a large-scale track forging manipulator, comprising the following steps of: firstly, segmentation rough finishing: respectively rough turning a tube head hole and a tube tail hole based on size requirements, and turning and butting to weld roots of connecting ends of a tube head, a tube body and a tube tail, wherein the pore diameters of the tube head hole and the tube tail hole are both no less than 1.7 m; secondly, welding every two segments to form a whole body; thirdly, semi-finishing: rough and fine milling both end surfaces of a workpiece to enable the both end surfaces to be parallel, and respectively arranging a technological steel plate as an alignment and measurement datum plane on the same side surface and the same top surface of both end holes; and fourthly, fine finishing. The invention can be used for machining the support tube with the diameter of bearing holes at both ends being no less than 1.7 m by adopting a machining cutter head for a large diameter hole and can ensure the axiality position accuracy of the bearing holes at both ends of the support tube by utilizing the alignment and measurement datum plane.

Owner:上海电气上重碾磨特装设备有限公司 +1

Large-tonnage lifting mechanism for trackless forging manipulator

InactiveCN104014706ASimple structureImprove carrying capacityForging/hammering/pressing machinesForging manipulatorEngineering

The invention discloses a large-tonnage lifting mechanism for a trackless forging manipulator. The front portion and the rear portion of a main clamp shaft are fixedly connected with a front cross bar and a rear cross bar respectively, the two ends of a front connection bar are hinged to the front cross bar and a front hanging bar, and the two ends of a rear connection bar are hinged to the rear cross bar and a rear hanging bar. A left-to-right horizontal buffering cylinder is fixedly connected to the front portion of the main clamp shaft, and the two ends of the left-to-right horizontal buffering cylinder abut against the front hanging bar. The other end of the front hanging bar and the other end of the rear hanging bar are connected with the front endpoints and the rear endpoints of a pair of triangular frames, and inclined cylinders are connected with the lower endpoints of the triangular frames and a machine frame. Upper connection bars are connected with the front endpoints of the triangular frames and the machine frame. A front-to-back horizontal buffering cylinder is connected with the front hanging bar and the machine frame. Lifting cylinders are hinged to the middle portions of the upper connection bars and the machine frame. The large-tonnage lifting mechanism is symmetrically distributed with the main clamp shaft as the center and is simple in structure, good in synchronism and high in bearing capacity, the lifting motion trail of a clamp is close to a straight line, the position accuracy is high, and the view of a driver control console is wide.

Owner:YANSHAN UNIV

Jaw clamping hydraulic system of forging manipulator

InactiveCN103629169AStable clampingReliable clampingServomotorsForging/hammering/pressing machinesAudio power amplifierForging manipulator

The invention provides a jaw clamping hydraulic system of a forging manipulator. A three-position four-way directional valve is connected with an oil supply port, an oil return port, a clamping oil cylinder opening cavity and a clamping oil cylinder clamping cavity. An overflow valve is connected with the clamping oil cylinder opening cavity, the oil return port and the clamping oil cylinder clamping cavity. A proportional overflow valve and a signal input port of a clamping pressure signal setting machine are connected with an amplifier. The clamping oil cylinder clamping cavity is connected with an energy accumulator through a one-way throttle valve and connected with the pressure maintaining oil supply port through the directional valve. The directional valve is connected with the pressure maintaining oil supply port, the oil return port and the clamping oil cylinder clamping cavity. Clamping pressure is controlled through the proportional overflow valve, pressure maintaining oil is supplied to a clamping oil cylinder in the clamping process, and therefore it is guaranteed that clamping is stable and reliable, and the jaw clamping hydraulic system has the advantages of being easy to control, high in reliability, and suitable for application occasions high in power and flow and variable in load.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

The transmission device that drives the lifting and moving of the tong frame on the forging manipulator

ActiveCN103920842BIncreased vertical liftForging/hammering/pressing machinesForging manipulatorTurning frames

A transmission device for driving clamp frame to lift and move on a forging manipulator comprises a big frame, the clamp frame, a top platform and four uprights. The uprights are vertically fixed on the upper end face of the big frame respectively, the clamp frame is disposed on the inner sides of the uprights, the top platform is fixed at the tops of the uprights, a sliding groove is arranged on the inner side of each upright, sliding rails matched with the sliding grooves are arranged on the outer side of a longitudinal beam, and a transmission device which is composed of a shaft roller, a pulley and a steel wire rope is arranged at each of the front end of the clamp frame, the rear end of the clamp frame, the front end of the top platform and the rear end of the top platform to drive the front end and the rear end to lift and move. By adopting a lifting driving unit, composed of the shaft rollers, the pulleys and the steel wire ropes, of the clamp frame, vertical lifting amplitude of the clamp frame is enabled to be increased greatly, and range of an inclination angle formed relatively to a horizontal plane is obviously widened.

Owner:山东荣升重型机械股份有限公司

Compound forging manipulator

ActiveCN103878285AIncrease temperatureReduce the temperatureProgramme-controlled manipulatorForging/hammering/pressing machinesForging manipulatorRoom temperature

The invention relates to industrial automation device, in particular to an automation manipulator. The compound forging manipulator comprises a gripper and a finger. The gripper comprises a finger body, a guide rail, pistons, a plunger pin and sliders. The finger is fixedly connected to the sliders and comprises a finger tip and a bridge, one end of the bridge is fixedly connected to the sliders while the other end of the same is fixedly connected with the finger, and a clamping face is arranged on the finger. When a workpiece is impacted or bumped, affections of impact on the gripper can be avoided or reduced due to an elastic function of the finger. Graphite can be sprayed to a die while the workpiece is gripped simultaneously, so that production efficiency is improved; liquid fed into an inlet flows out of an outlet via a channel, heat accumulated through the fingers is taken away by the flowing liquid, temperature of the fingers can be greatly reduced, and the finger can be kept at constant temperature under working conditions; meanwhile, the high-temperature workpiece is subjected to quenching treatment.

Owner:ZHEJIANG WEILI METALFORMING MACHINERY

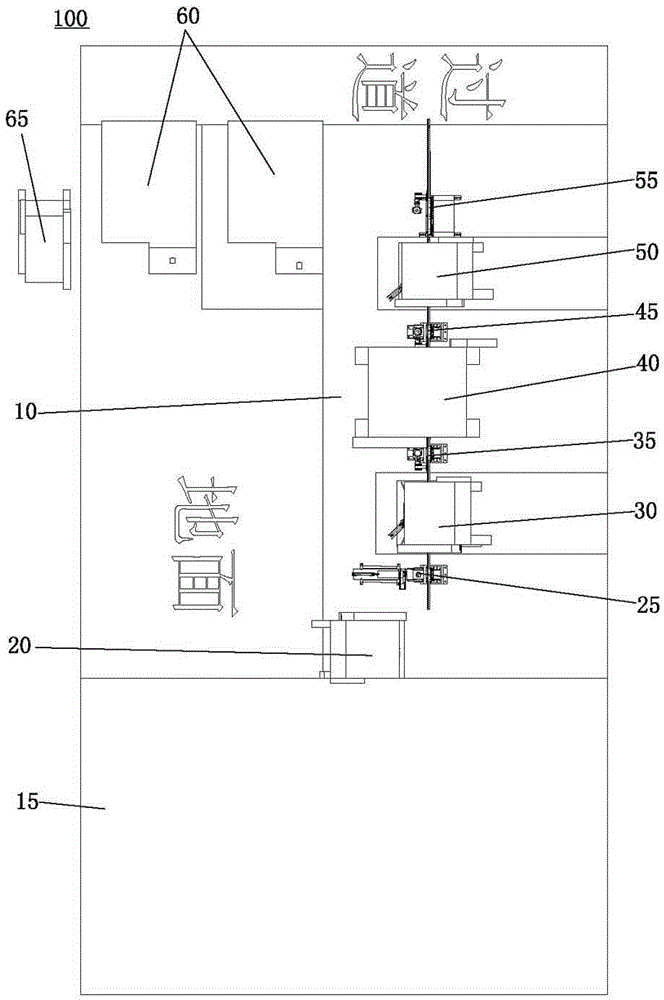

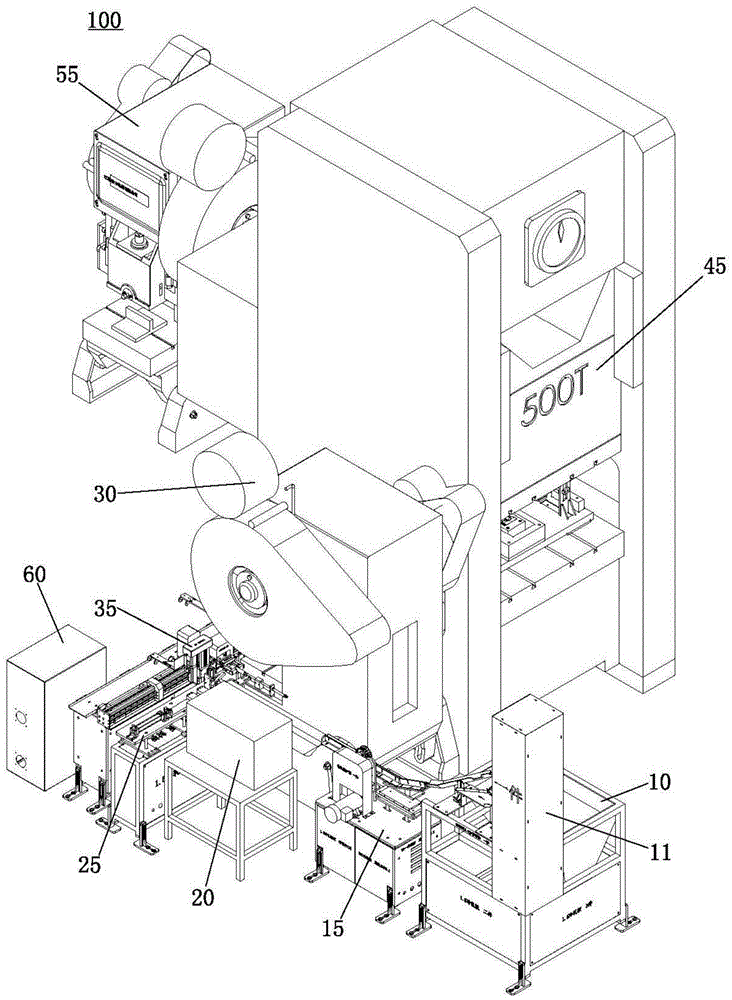

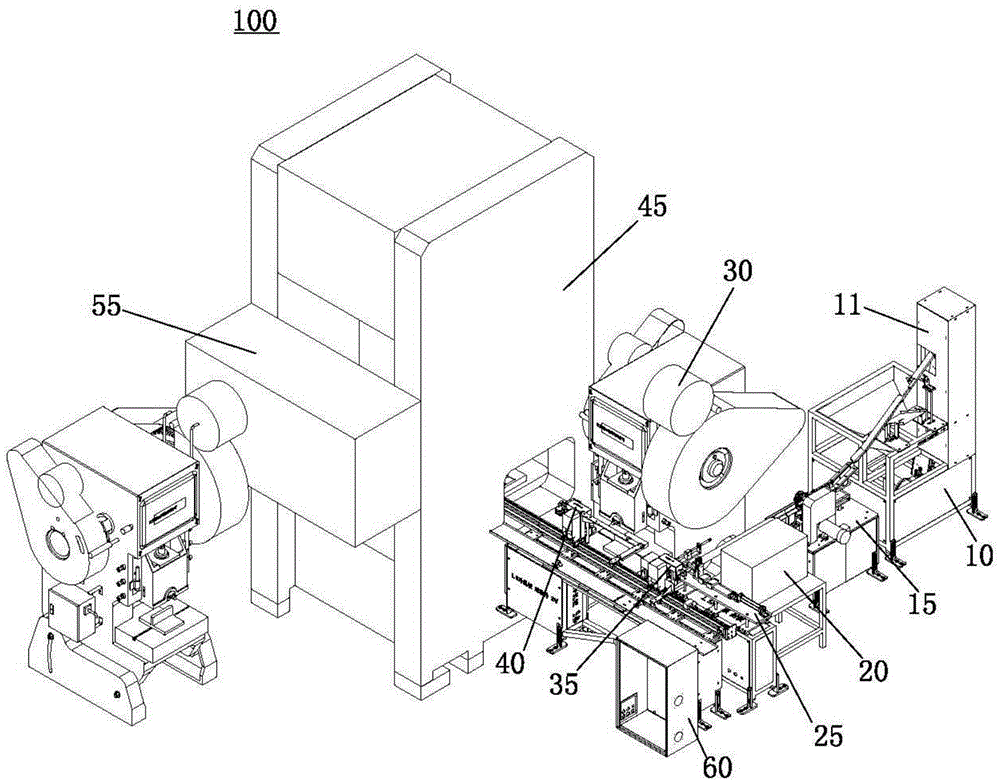

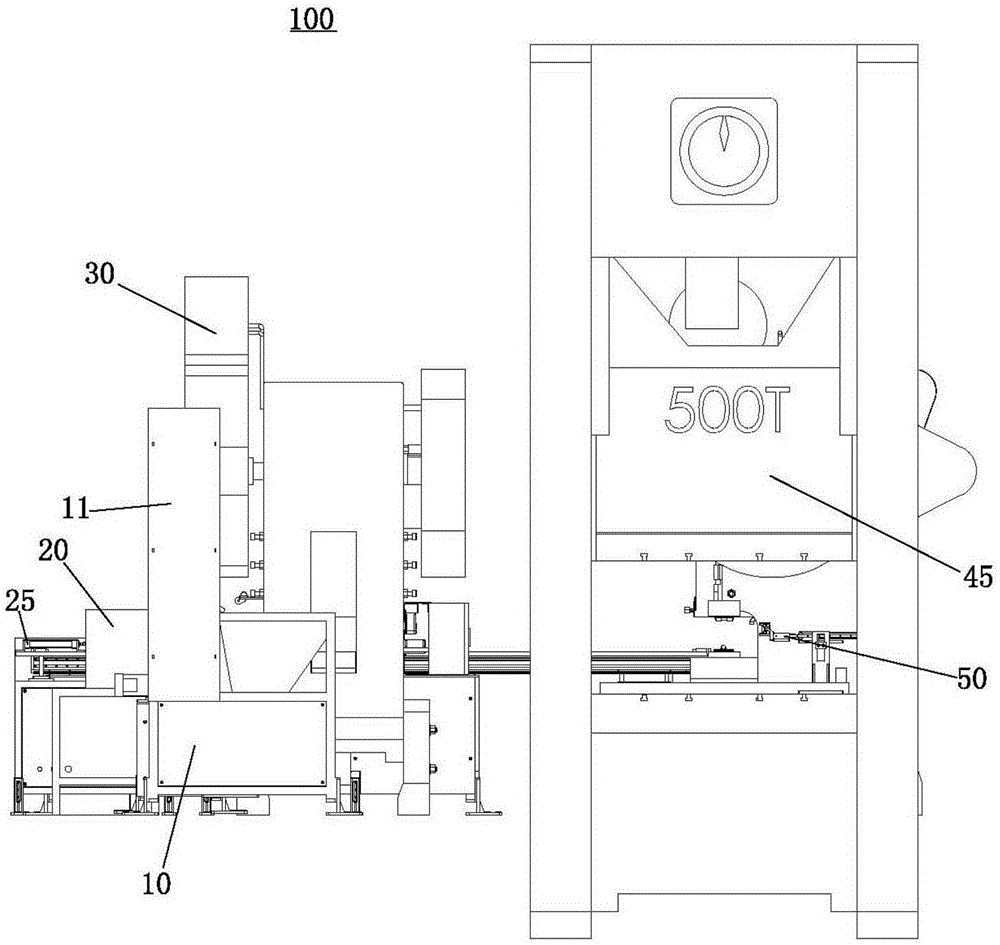

Full-automatic bearing production line adopting forging manipulators

InactiveCN104690556AIncrease productivityImprove securityOther manufacturing equipments/toolsEngine componentsProduction linePunch press

The invention discloses a full-automatic bearing production line adopting forging manipulators. The full-automatic bearing production line comprises a control system, a punch press table, a blanking punch press rack as well as a blanking punch press, a first forging manipulator, a flat upsetting punch press, a second forging manipulator, a forming punch press, a third forging manipulator, a bottom cutting punch press, a fourth forging manipulator, at least one ring rolling machine and a shaping punch press which are electrically connected with the control system, wherein the blanking punch press rack is arranged in front of the punch press table; the blanking punch press, the first forging manipulator, the flat upsetting punch press, the second forging manipulator, the forming punch press, the third forging manipulator, the bottom cutting punch press and the fourth forging manipulator are mounted on the punch press table sequentially from front to back; and the at least one ring rolling machine and the shaping punch press are arranged on one side of the rear end of the punch press table sequentially. The full-automatic bearing production line adopting the forging manipulators realizes automatic processing from punching to shaping, and is high in production efficiency and good in safety.

Owner:东莞辉科机器人自动化股份有限公司

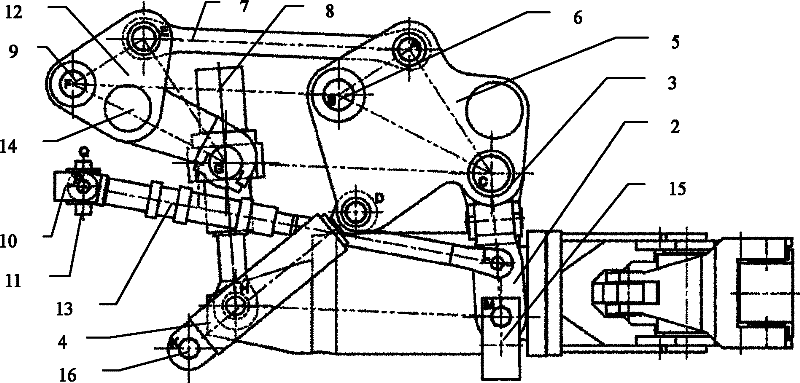

Completely-decoupled type forging manipulator lifting mechanism

ActiveCN103894533AAchieve decouplingForging/hammering/pressing machinesForging manipulatorEngineering

A completely-decoupled type forging manipulator lifting mechanism mainly comprises a lifting device, a swinging device, a front and rear buffer device, a pincers rod and a machine frame. The lifting device comprises a claw beam, a front sliding rod, a pair of front suspension rods, a front lifting arm, a pair of synchronous rods, a rear lifting arm, a rear sliding rod, a pitching linear driver and a pair of lifting linear drivers. The swinging device comprises a left front linear driver and a right front linear driver which form one pair, and a left rear linear driver and a right rear linear driver which form one pair. The front and rear buffer device is composed of a pair of front and rear buffer linear drivers and an approximate linear output four-bar mechanism composed of two connecting rods. The approximate linear output four-bar mechanism directly serves as the front and rear buffer device of a manipulator, and complete decoupling of lifting movement and horizontal movement is achieved.

Owner:YANSHAN UNIV

Clamp parallel lifting mechanism for forging manipulator

ActiveCN109047617AIncreased range of parallel liftGuaranteed to move up and downForging/hammering/pressing machinesForging manipulatorEngineering

The invention discloses a clamp parallel lifting mechanism for a forging manipulator. The clamp parallel lifting mechanism comprises a clamp, an operating frame, a flange plate, a clamp arm, a liftingseat, a first fixing seat, a chute body, a first connecting rod, a connecting block, a first connecting shaft, a pin shaft, an oil cylinder, a rotating seat, a base, a second connecting shaft, a connecting frame, a second connecting rod, a second fixing seat, a guide seat, a transmission device, a guide groove, a cross beam, a motor and a transmission rod. According to the clamp parallel liftingmechanism for the forging manipulator, the structure is reasonable and simple; the clamp is directly driven to move up and down in parallel by a parallel four-bar linkage mechanism, so that the lifting efficiency is high, and meanwhile the parallel lifting range of the clamp is greatly expanded; and the transmission device can only move up and down in the guide groove and move left and right in the chute body, so that the transmission device can move up and down in parallel along with the clamp, and it is ensured that the transmission device can transmit the power of the transmission rod to the clamp for accurate rotation, so that the forging working efficiency and the quality of forged products are greatly improved.

Owner:浙江联大锻压有限公司

Claw beam lifting mechanism for forging manipulator

InactiveCN102019340BHigh movement precisionGuaranteed motion accuracyForging/hammering/pressing machinesVehicle frameRange of motion

Owner:SHENYANG HEAVY MACHINERY GROUP

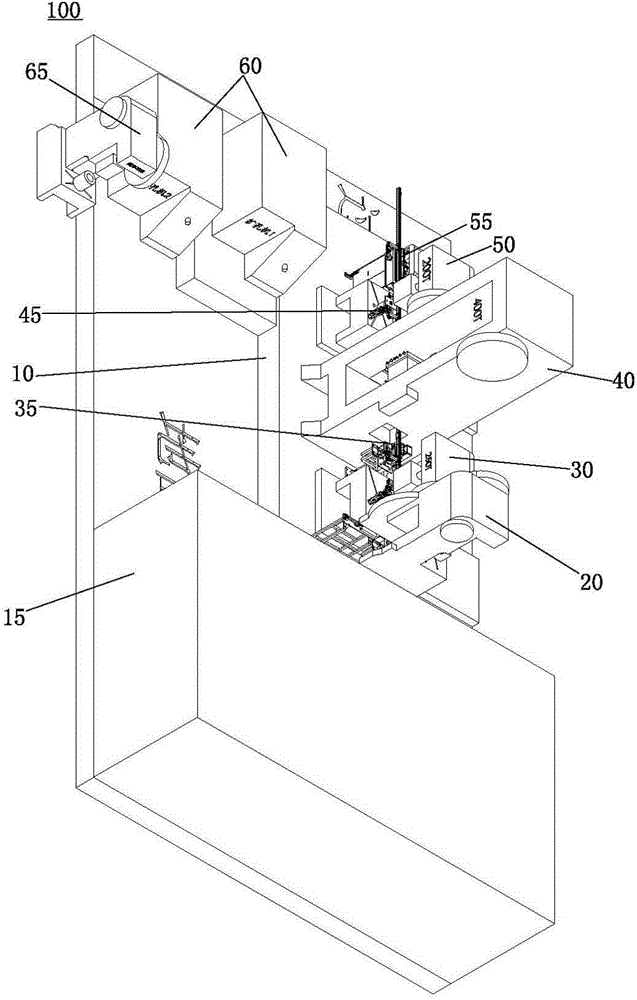

Fully automatic fastener forging manipulator production line

ActiveCN104439014BRealize automated productionIncrease productivityForging/hammering/pressing machinesProduction linePunch press

The invention discloses a full automatic fastener forging and pressing manipulator production line. The full automatic fastener forging and pressing manipulator production line comprises a control system, a storage box, an automatic elevator, a roller feeding device, a high frequency heating furnace, a feeding machine, a flattening punch, a first manipulator, a second manipulator, a forging and pressing punch and a power distribution cabinet, wherein the automatic elevator, the roller feeding device, the high frequency heating furnace, the feeding machine, the flattening punch, the first manipulator, the second manipulator, the forging and pressing punch and the power distribution cabinet are electrically connected with the control system. The automatic elevator is used for elevating materials in the storage box, adjusting the direction and conveying the materials to the roller feeding device, the roller feeding device is used for conveying the materials to the high frequency heating furnace, the high frequency heating furnace is used for heating the materials to a set temperature, the heated materials are conveyed to a locating position through the feeding machine and located to be clamped by the first manipulator, the first manipulator is used for clamping the materials and conveying the materials to the flattening punch, and the materials are flattened for the first time, then rotated by 90 degrees and flattened for the second time. The second manipulator is used for clamping a product and moving the product to the forging and pressing punch for forging and pressing forming. The power distribution cabinet is arranged on one side of the first manipulator. Through the full automatic fastener forging and pressing manipulator production line, automatic production of fasteners is achieved, and production efficiency is improved.

Owner:东莞辉科机器人自动化股份有限公司

Multifunctional hydraulic track forging manipulator

ActiveCN102430684BExpand the scope of workReduce intermediate auxiliary timeForging/hammering/pressing machinesControl systemForging manipulator

A multifunctional hydraulic track forging manipulator is disclosed, and comprises a body travelling device connected with a four connecting rod mechanism. Both a rotary oil connector and a conductive slip ring are connected with the body travelling device; a hydraulic control system, an electric control system and an operating cab are respectively connected with the four connecting rod mechanism; the electric controls system is installed in a space of the operating cab; the whole device is located on a ground track of a workshop; and the four connecting rod mechanism is connected with a pincers frame so as to form an integral piece. The body travelling device supports the whole four connecting rod mechanism and the pincers frame. The pincers frame is a structure of multilayer sleeve so that the claw beam of the pincers frame is retractable, thereby effectively expanding the working range of the manipulator and realizing the functions of the manipulator and a charging and discharging machine on a same manipulator. The invention improves the production efficiency and eliminates the danger of workers in the process of conveying the forging materials.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com