Special free-forging hydraulic unit and use method thereof

A hydraulic unit, free technology, applied in forging presses, forging presses, driving devices of forging presses, etc., can solve the problems of large vibration, low product dimensional accuracy, large equipment investment, etc., to reduce height and width, reduce equipment weight , the effect of reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

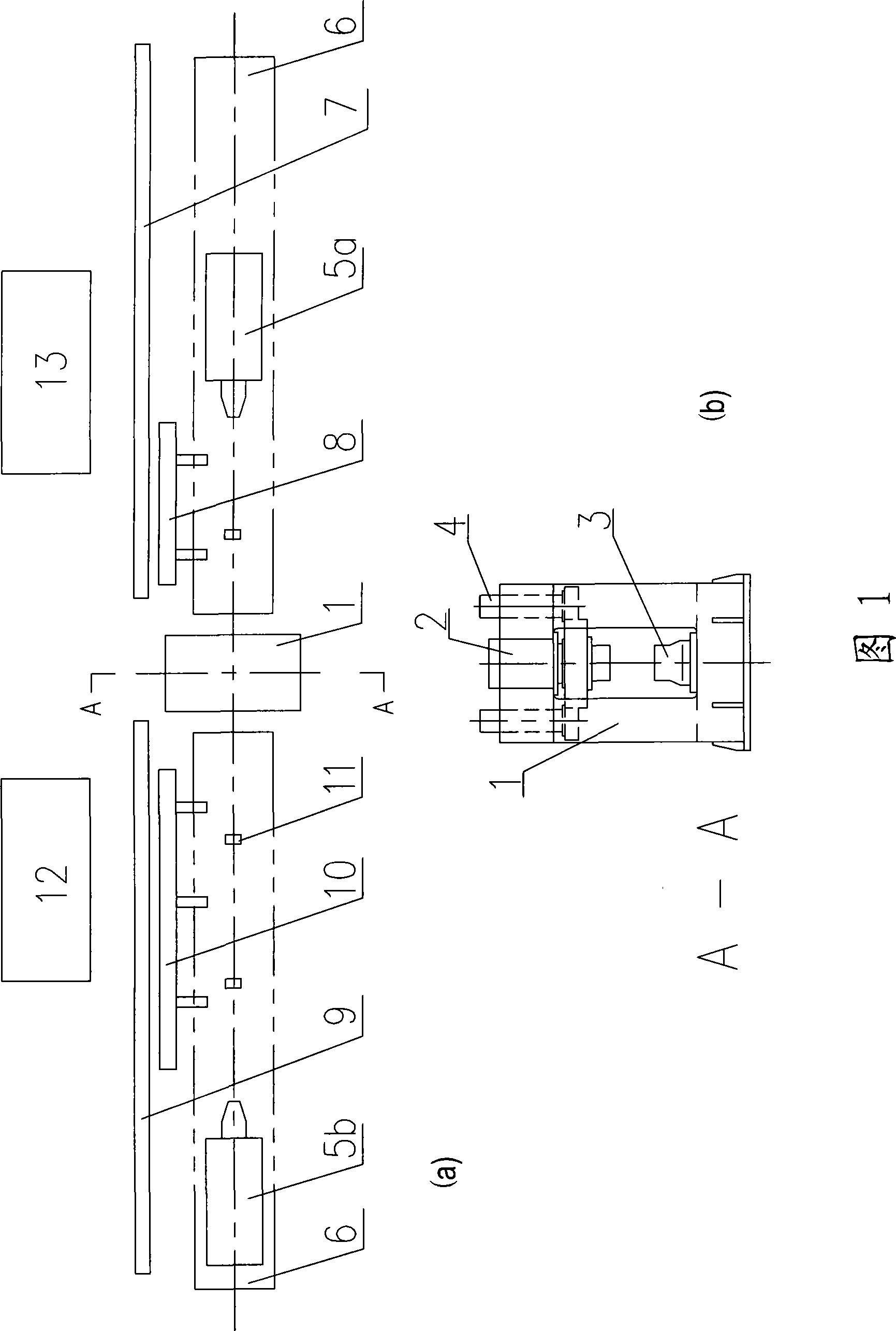

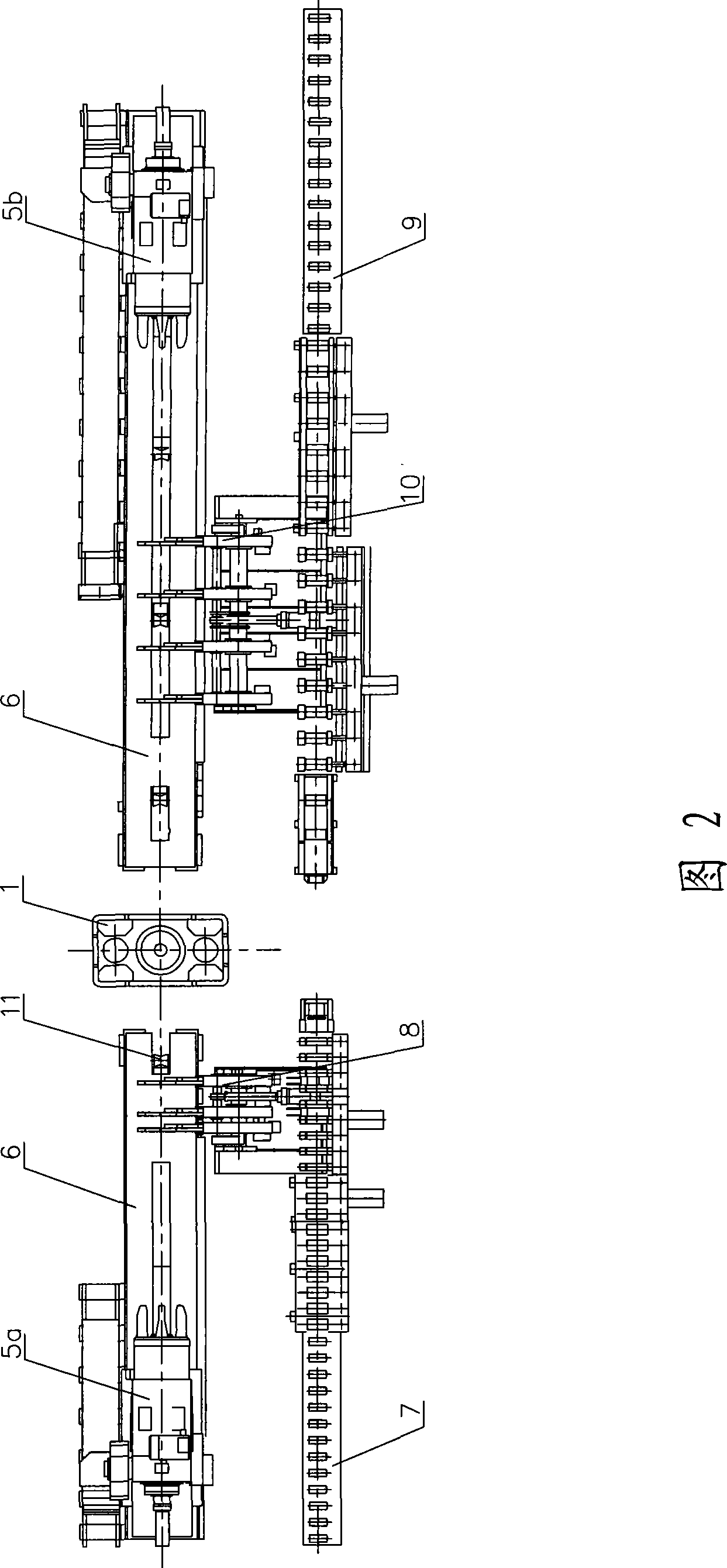

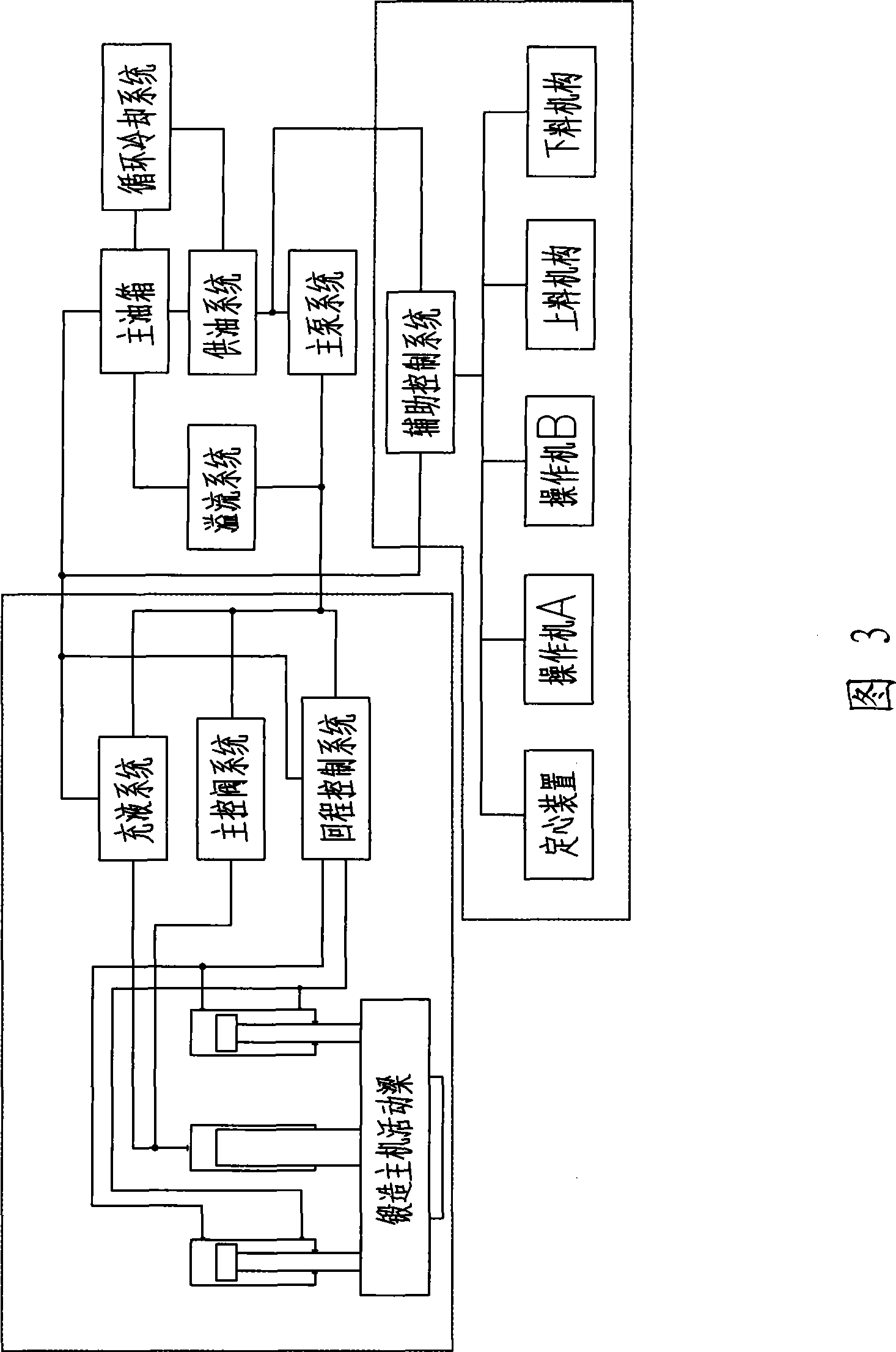

[0053] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation and structure of the special free forging hydraulic unit and its use method proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , method of use, steps, features and effects thereof are detailed as follows.

[0054] The present invention adopts the design parameters of the main forging machine that is compatible with the product specifications of forging shafts, and uses a pair of forging anvils to reduce the size and weight of the forging main machine mechanical equipment compared with the general free forging hydraulic press equipment; The adaptable and compact structural layout of the equipment can realize automatic operation and constitute a special free forging hydraulic unit.

[0055] The specifications of the forging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com