Control method for positioning position-pressure of hydraulic cylinder of large-scale forging manipulator

A technology for forging operation and pressure control, which is applied to the driving device of the forging press, etc., which can solve the problems of no front cylinder system, unstable hydraulic cylinder drift, and difficulty in hydraulic cylinder adjustment, achieve speed and control accuracy, and overcome height control difficulties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

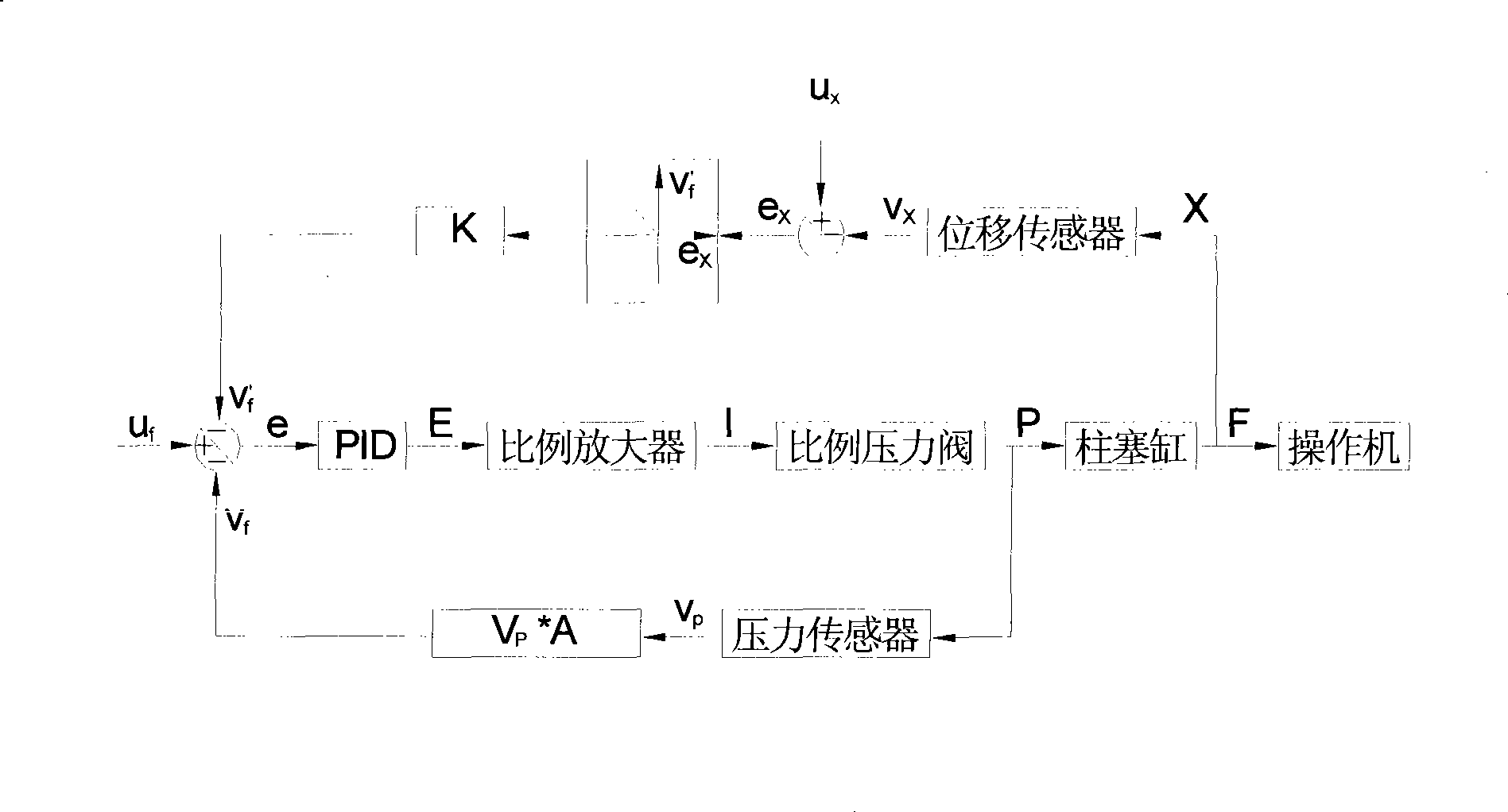

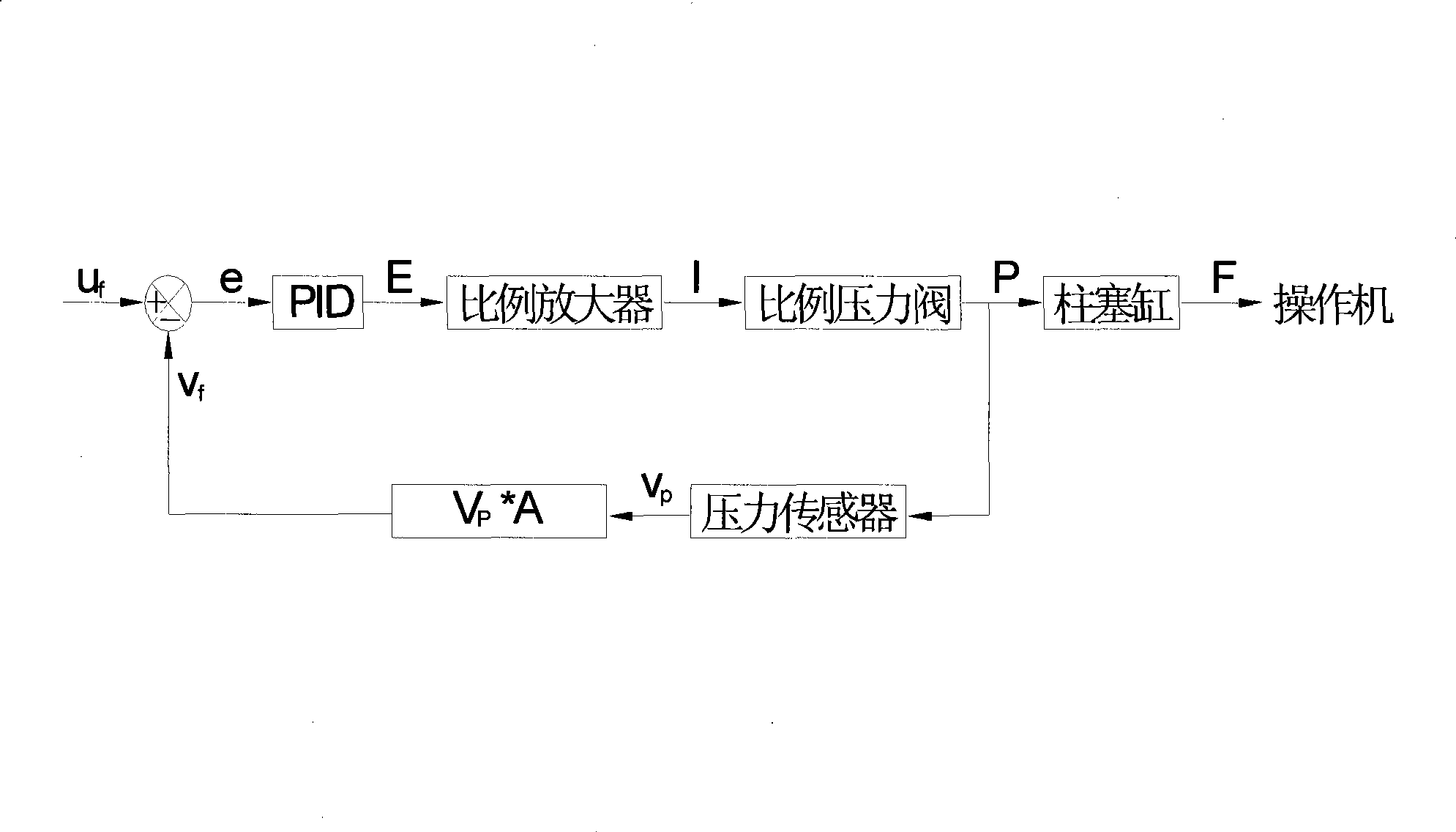

[0018] Such as figure 1 The position-pressure control method for hydraulic cylinder positioning of a large-scale forging manipulator is shown, which is used for the control of the lifting and buffering hydraulic system in front of the manipulator. The front cylinder of the manipulator is a plunger cylinder, which outputs a constant lifting force to support the weight of the workpiece and the clamp rod. During the forging process, when the forging is deformed and the central axis of the forging moves down, the front cylinder automatically follows the workpiece and descends to cooperate with the forging press to complete the forging process; when the forging hammer lifts away from the workpiece, the front cylinder automatically lifts the workpiece away from the anvil , to prepare for the workpiece feeding; when the clamp is grasping and placing the workpiece, the front cylinder automatically moves up and down following the position of the workpiece, so that the height of the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com