Patents

Literature

935 results about "Pressure controlled method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

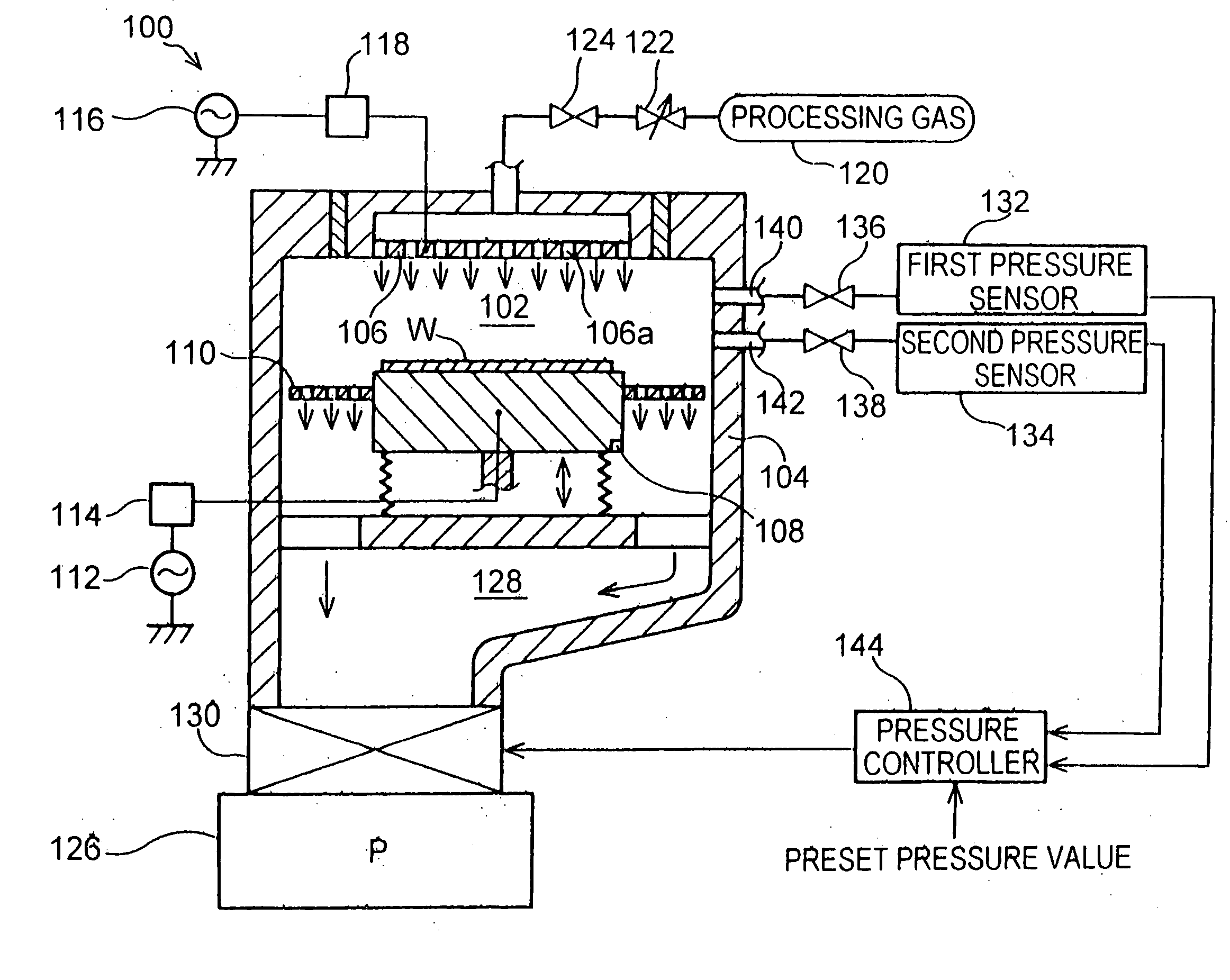

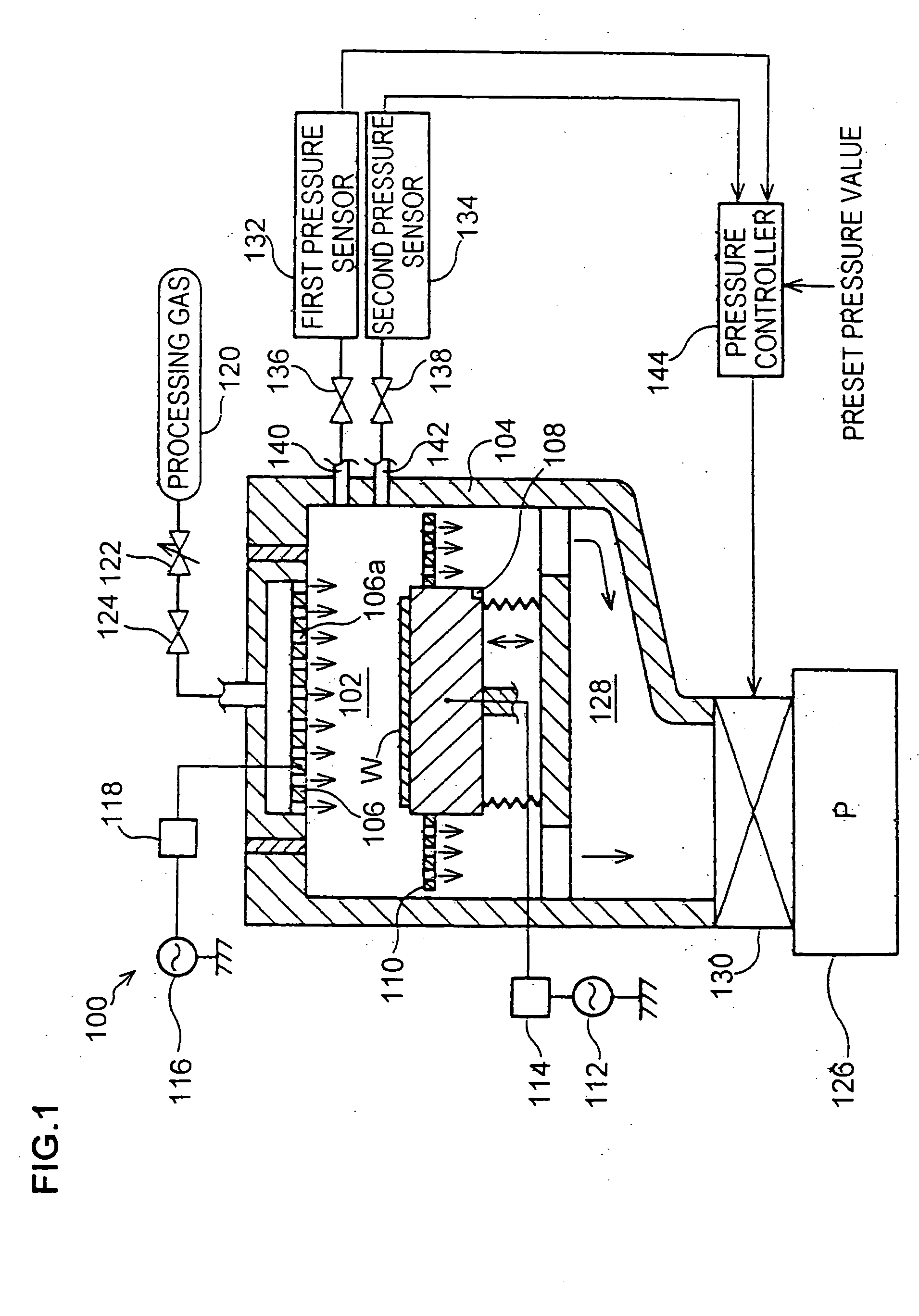

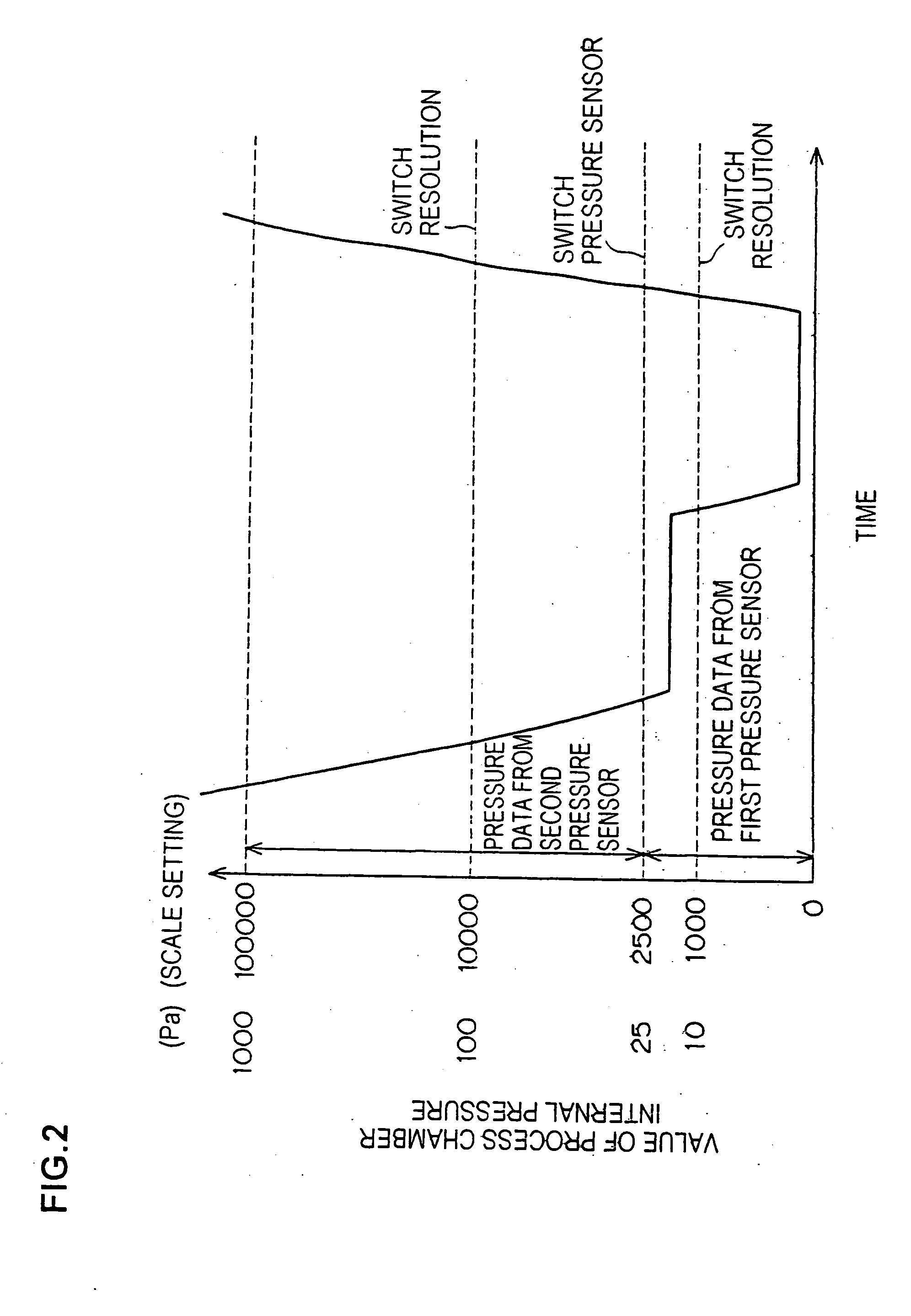

Pressure control method and processing device

InactiveUS20050176258A1Level of control performanceOptimize dataElectric discharge tubesSemiconductor/solid-state device manufacturingImage resolutionEngineering

First and second pressure sensors 132 and 134 that perform pressure detection over different pressure detection ranges from each other detect the pressure within a process chamber 102 of an etching device 100. A pressure controller 144 selects optimal pressure data in correspondence to the pressure inside the process chamber from the pressure data provided by the first and second pressure sensors 132 and 134. It also analyzes the selected pressure data at a resolution selected in correspondence to the pressure inside the process chamber 102 and thus obtains pressure data achieving a predetermined data density. The pressure controller 134 controls a pressure control valve 130 so as to ensure that the pressure data match preset pressure data.

Owner:TOKYO ELECTRON LTD

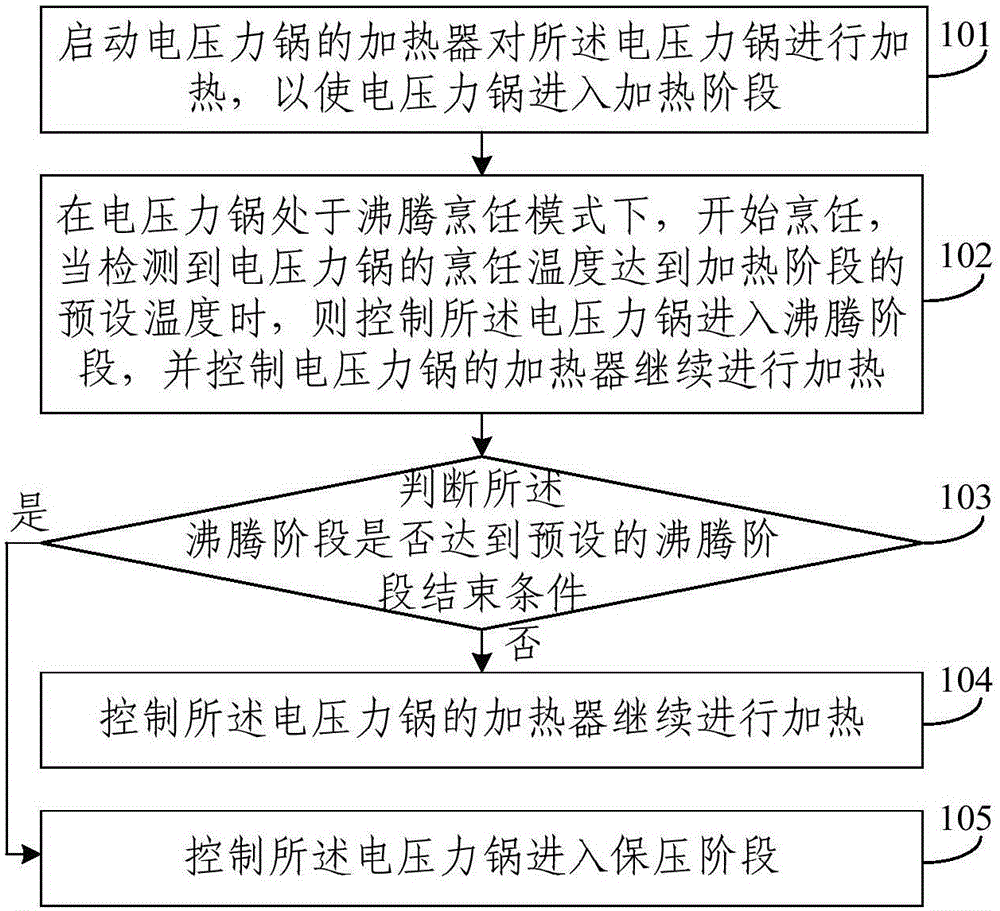

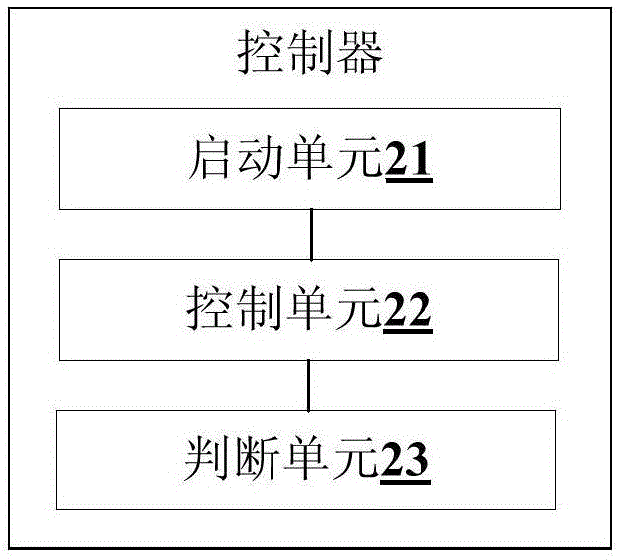

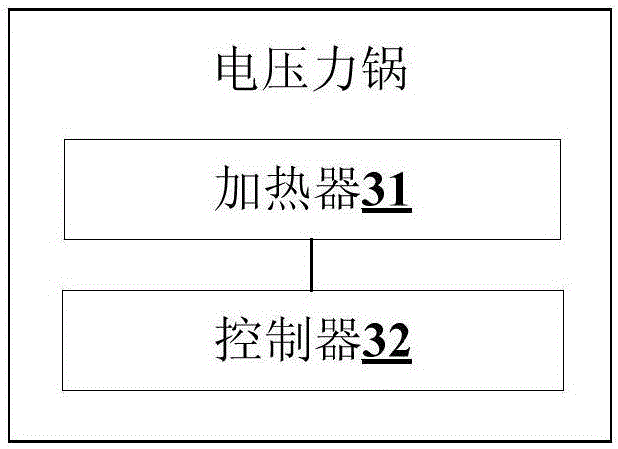

Electronic pressure cooker control method, controller and electronic pressure cooker

ActiveCN105105626AIncreased boiling phaseFully boiledPressure-cookersCooking processPressure controlled method

The invention discloses an electronic pressure cooker control method, a controller and an electronic pressure cooker, wherein the electronic pressure cooker control method comprises: starting a heater of the electronic pressure cooker to heat the electronic pressure cooker so as to make the electronic pressure cooker enter into a heating stage; beginning to cook when the electronic pressure cooker is under a boiling cooking mode; when the cooking temperature of the electronic pressure cooker reaches at the preset temperature of the heating stage, the electronic pressure cooker is controlled into a boiling stage and the heater of the electronic pressure cooker is controlled to continuously heat; judging whether the boiling stage meets the preset finish conditions of the boiling stage or not; if the boiling stage doesn't meet the preset finish conditions of the boiling stage, the heater of the electronic pressure cooker is controlled to continuously heat; and if the boiling stage meets the preset finish conditions of the boiling stage, the electronic pressure cooker is controlled into a pressure maintaining stage. By adopting the electronic pressure control method, the controller and the electronic pressure cooker disclosed by the invention, before the electronic pressure cooker enters the pressure maintaining stage, the boiling stage is increased, thus the problem that the existing electronic pressure cooker is not boiling or is not boiling enough during the cooking process is solved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

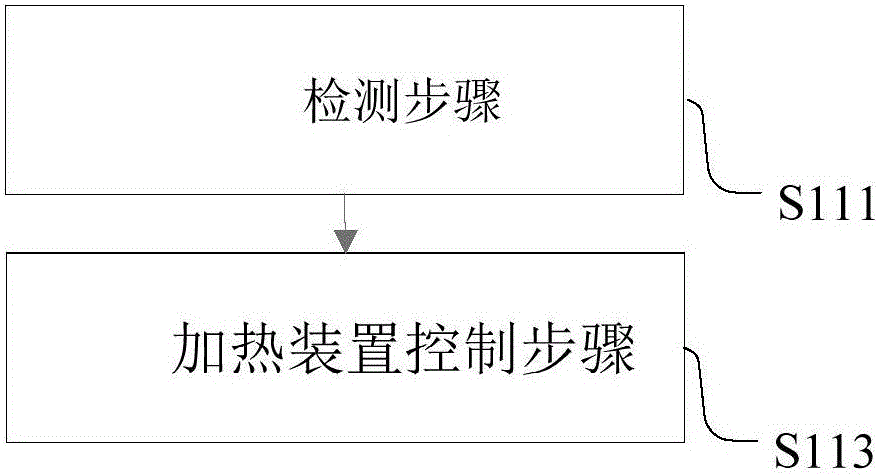

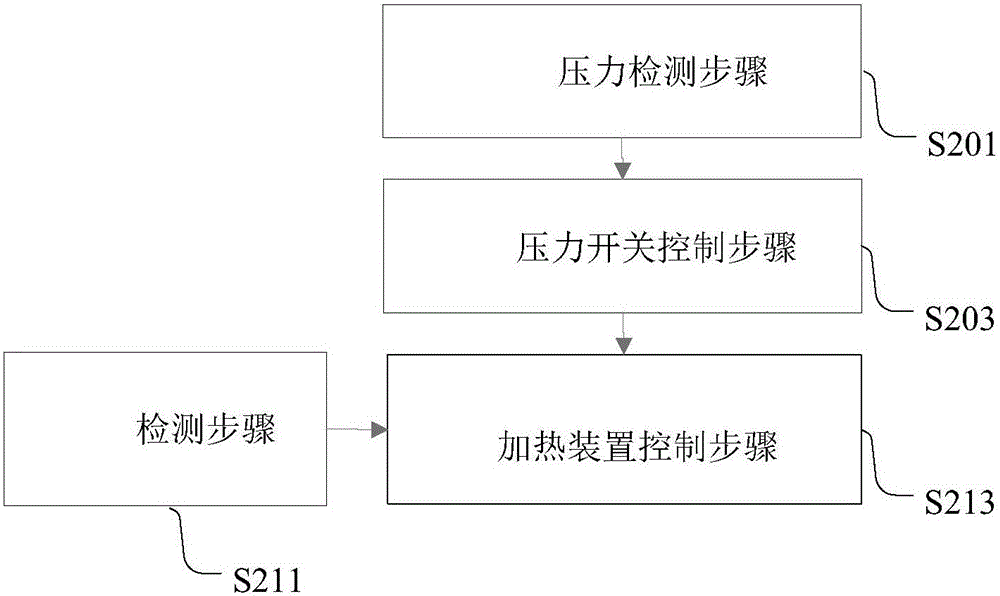

Pressure control method and apparatus of electric pressure cooker, and electric pressure cooker

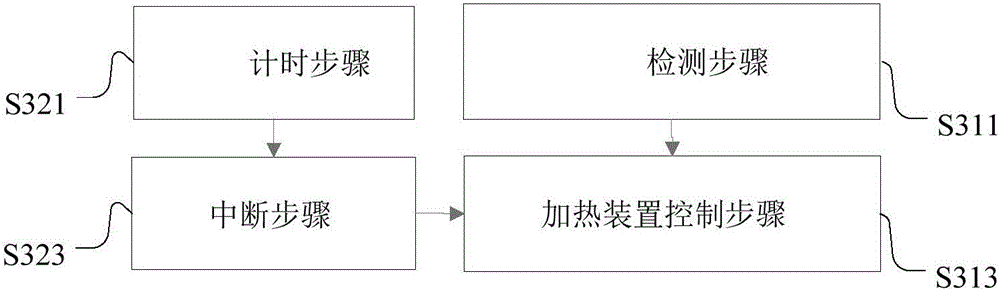

The present invention provides a pressure control method and apparatus of an electric pressure cooker, and the electric pressure cooker. The method comprises a detection step that a temperature wrap disposed at the bottom of the electric pressure cooker detects temperature of the electric pressure cooker; and a heating device control step of controlling on and off of a heating device according to the temperature detected by the temperature wrap when a pressure switch is off, specifically, opening the heating device to heat when the temperature is less than or equal to first temperature, and closing the heating device and stopping heating when the temperature is great than or equal to second temperature, wherein the second temperature is greater than the first temperature, the first temperature is great than or equal to 100 DEG C and less than or equal to 108 DEG C, and the second temperature is great than or equal to 102 DEG C and less than or equal to 110 DEG C. According to the technical scheme, cycle control of the pressure in a certain range is achieved through a single pressure switch without internal temperature-sensitive monitoring, and use functions of the electric pressure cooker are improved.

Owner:GREE ELECTRIC APPLIANCES INC

Pressure control method of electric pressure cooker

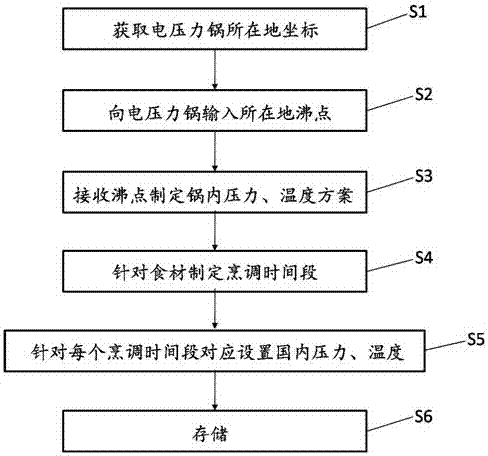

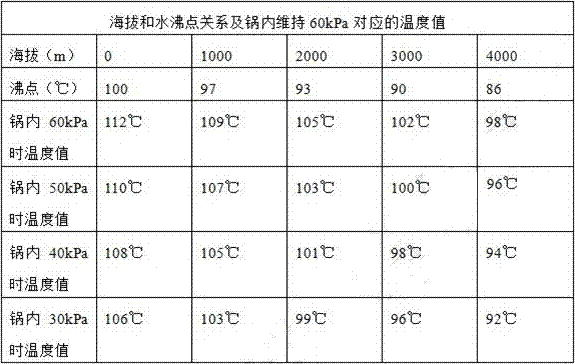

The invention discloses a pressure control method of an electric pressure cooker. The pressure control method comprises the following steps: obtaining the coordinates of the place of the electric pressure cooker; inputting the boiling point of the place of the electric pressure cooker; receiving the boiling point and making a scheme of pressure and temperature in the cooker; setting a cooking time period according to a food material; correspondingly setting the pressure and temperature in the cooker for each cooking time period; storing. According to the pressure control method disclosed by the invention, communication between a mobile terminal and the electric pressure cooker can be realized through the mobile terminal; the position coordinates of the electric pressure cooker are acquired through the mobile terminal; the altitude value of the place is inquired according to the position coordinates, and the boiling point value at the electric pressure cooker is obtained according to the altitude value; a cooking scheme is designated for the food material according to the boiling point value; the method disclosed by the invention realizes independent control of different places, different altitudes and different foods.

Owner:SHANGHAI CHUNMI ELECTRONICS TECH CO LTD

Electronic pressure regulating control method of electric pressure cooker

InactiveCN106913201ATo achieve the purpose of maintaining pressureFlexible controlPressure-cookersFailure rateElectronic temperature

A pressure control method of an electronic pressure cooker includes using a temperature sensor to acquire change of the temperature of the cooker according to a relation between the temperature of the cooker and the pressure; converting the change of the temperature into the change of the pressure; and completing control of the pressure of the cooker through a circuit. An electronic temperature sensor is used to replace a mechanical pressure switch, the regulation control is accurate, and the failure rate is low.

Owner:青岛晟通泰电子科技有限公司

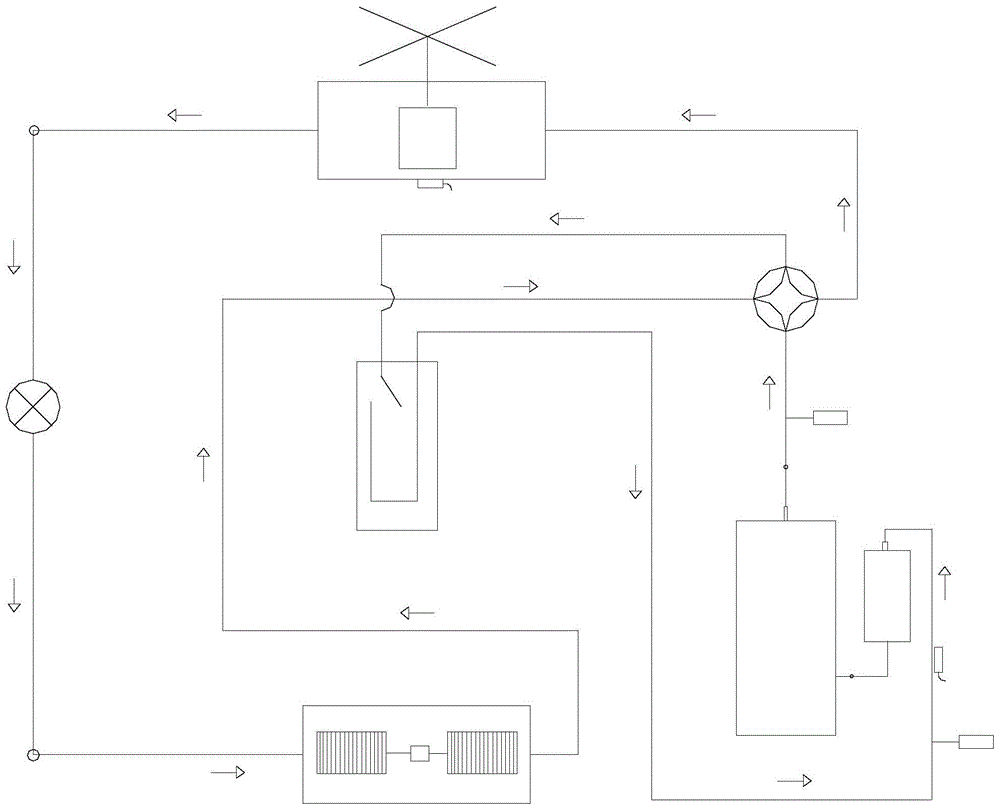

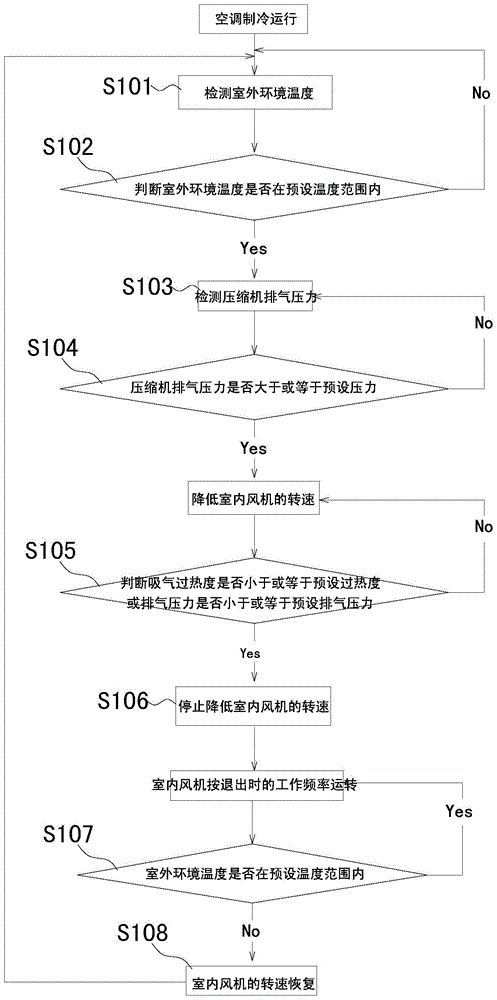

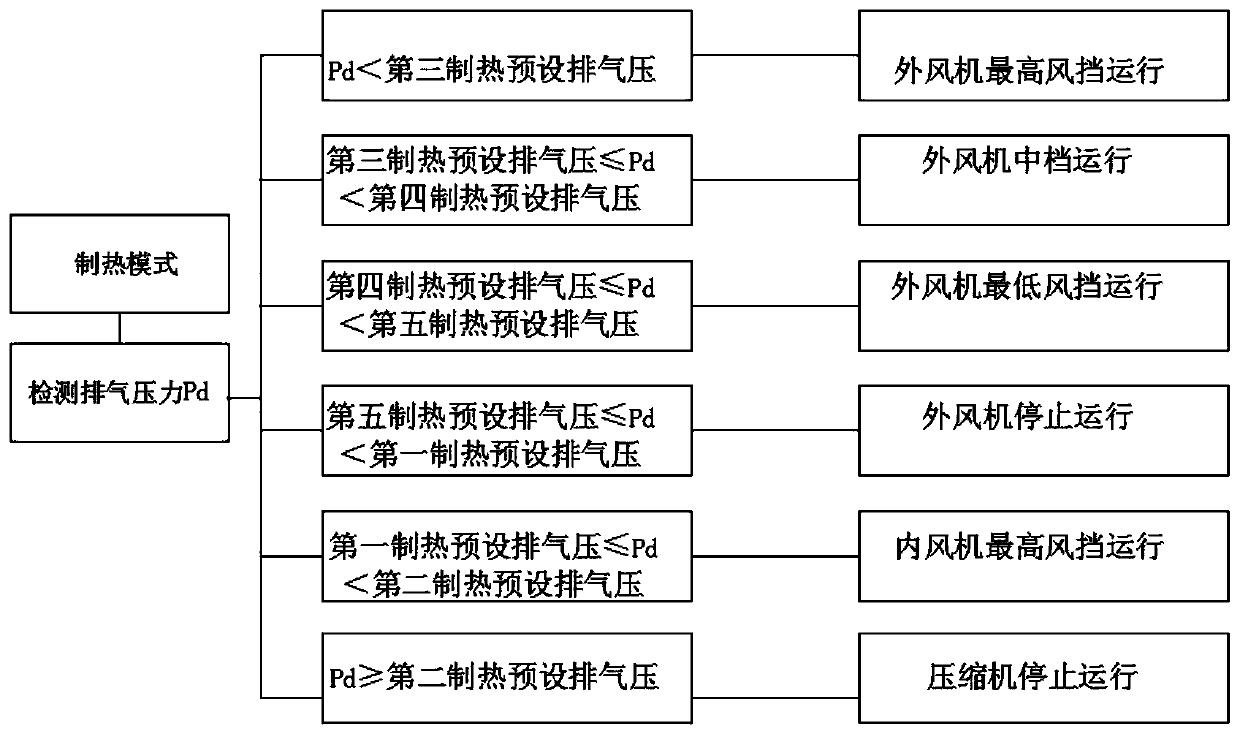

Pressure control method of air conditioning system

ActiveCN104697106AReduce exhaust pressureEffect of exhaust pressureMechanical apparatusSpace heating and ventilation safety systemsSystem pressureAir conditioning

Owner:GREE ELECTRIC APPLIANCES INC

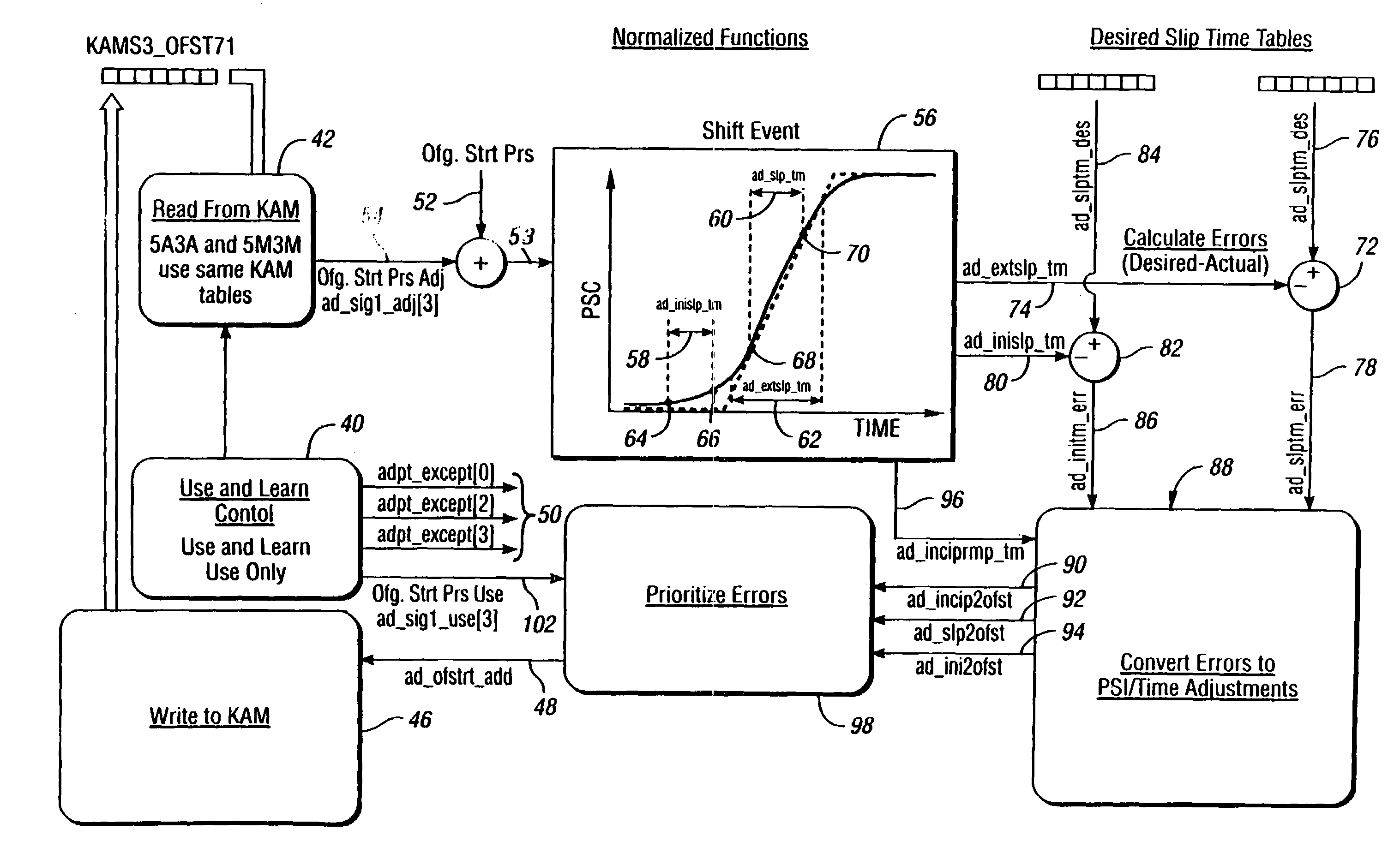

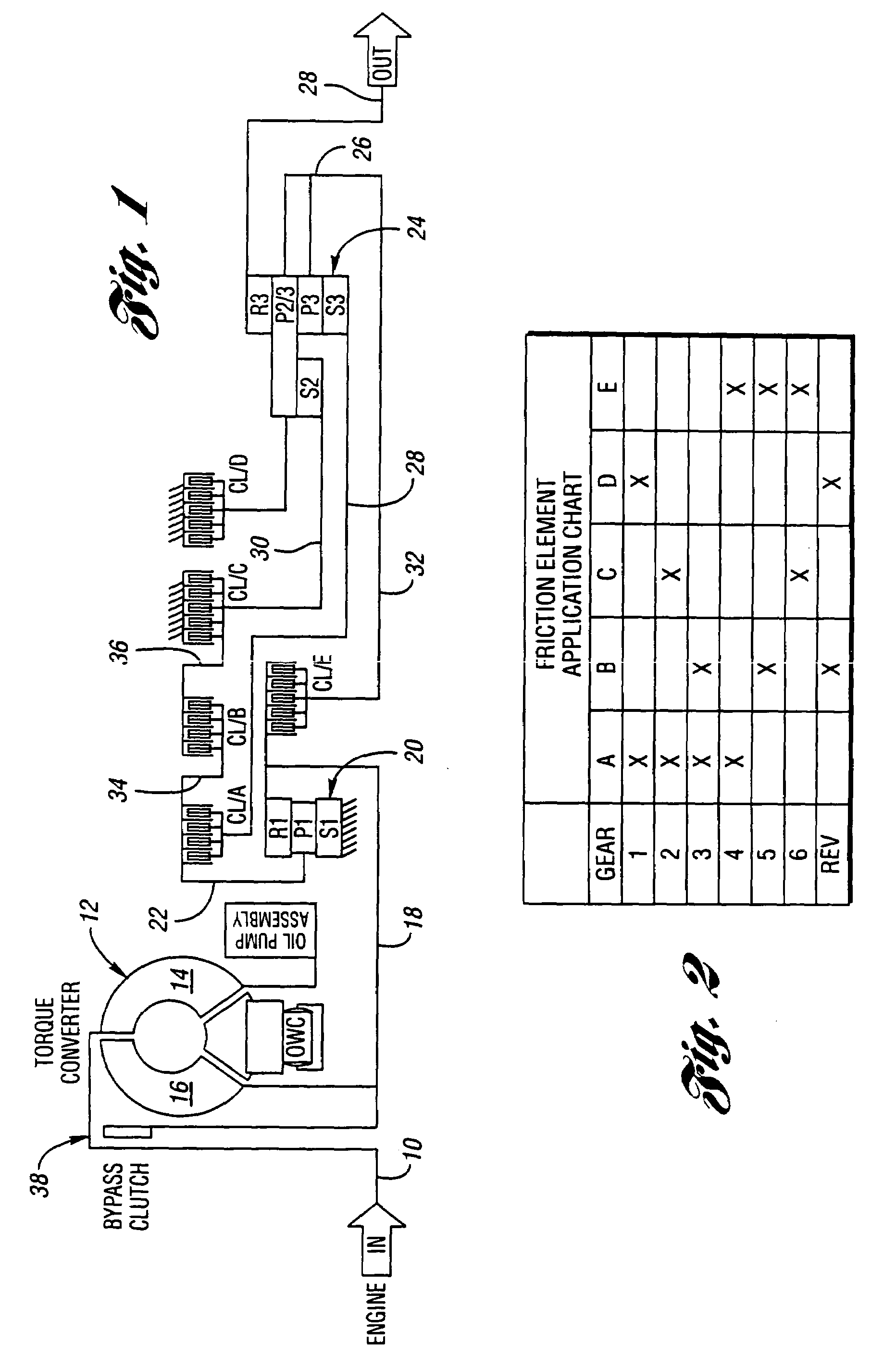

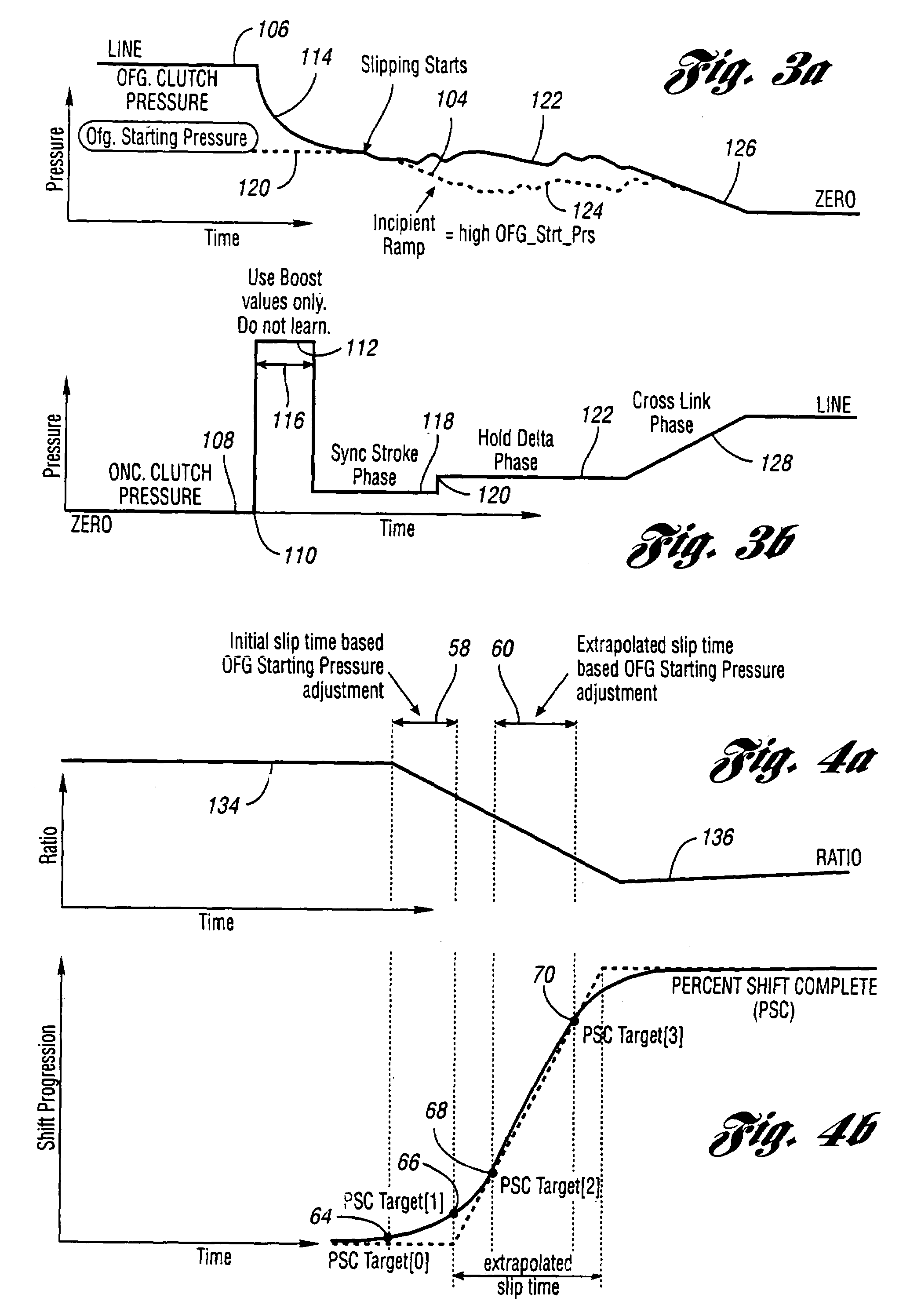

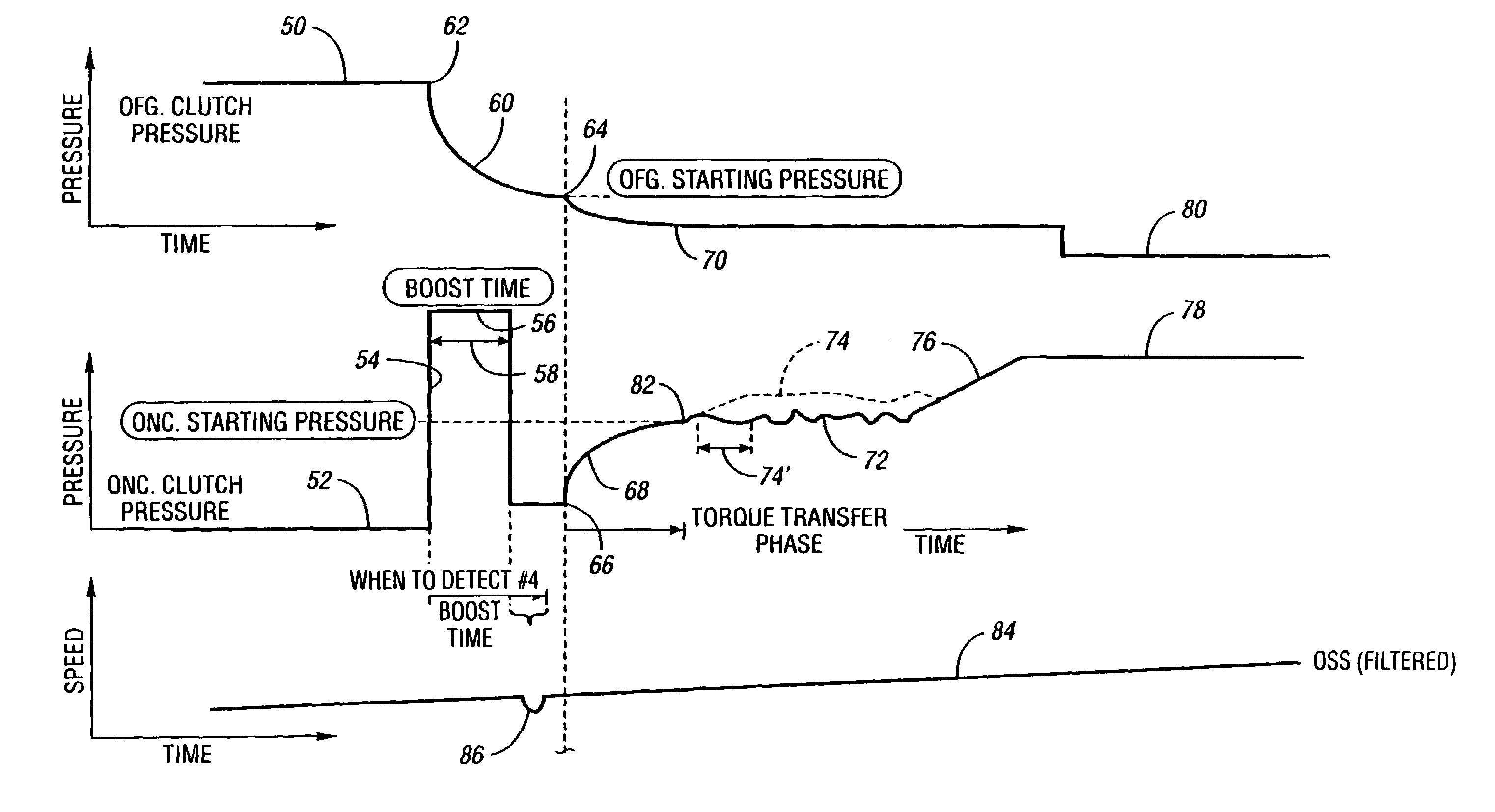

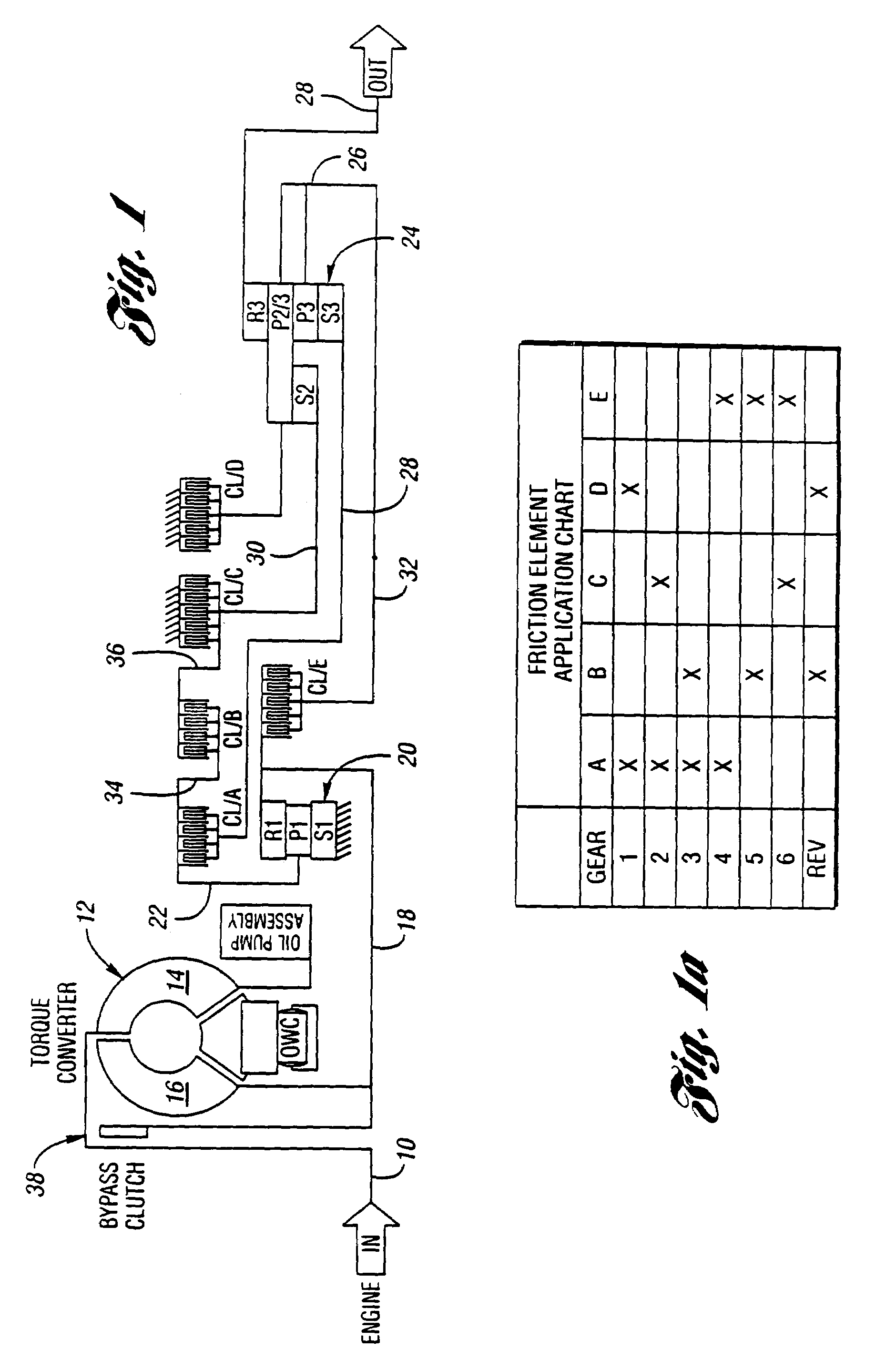

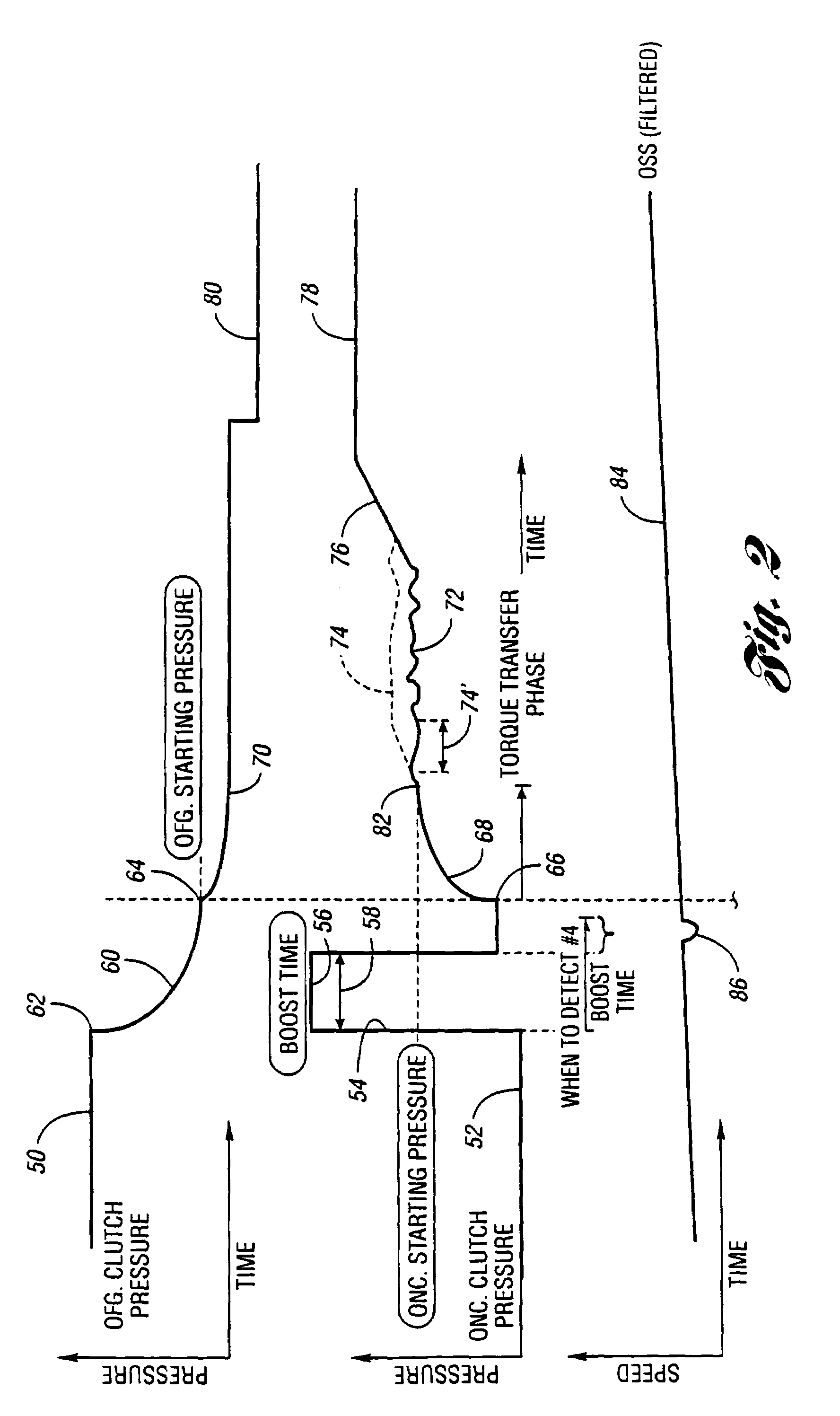

Adaptive pressure control method for synchronous downshifts in a multiple-ratio transmission

ActiveUS7216025B2Eliminate errorsDigital data processing detailsGearing controlAutomatic transmissionControl theory

An adaptive pressure control method for synchronous downshifts in an automatic transmission that uses pressure actuated friction elements. The method uses characteristic parameters that determine downshift quality for both power-on downshifts and power-off downshifts. Selected measured variables are monitored to detect changes in the parameters. Adjustments for the friction elements are made in response to changes in the measured variables.

Owner:FORD GLOBAL TECH LLC

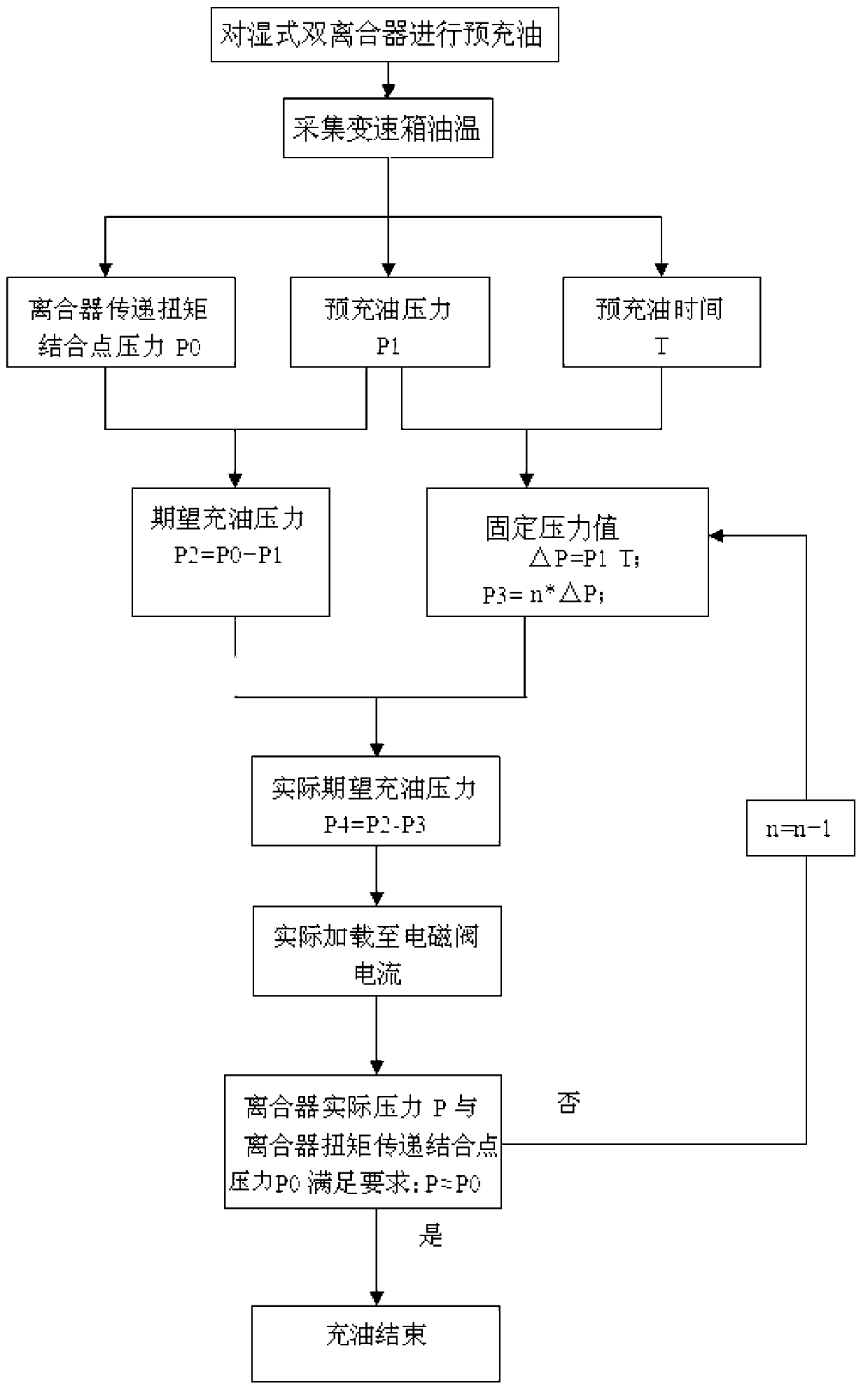

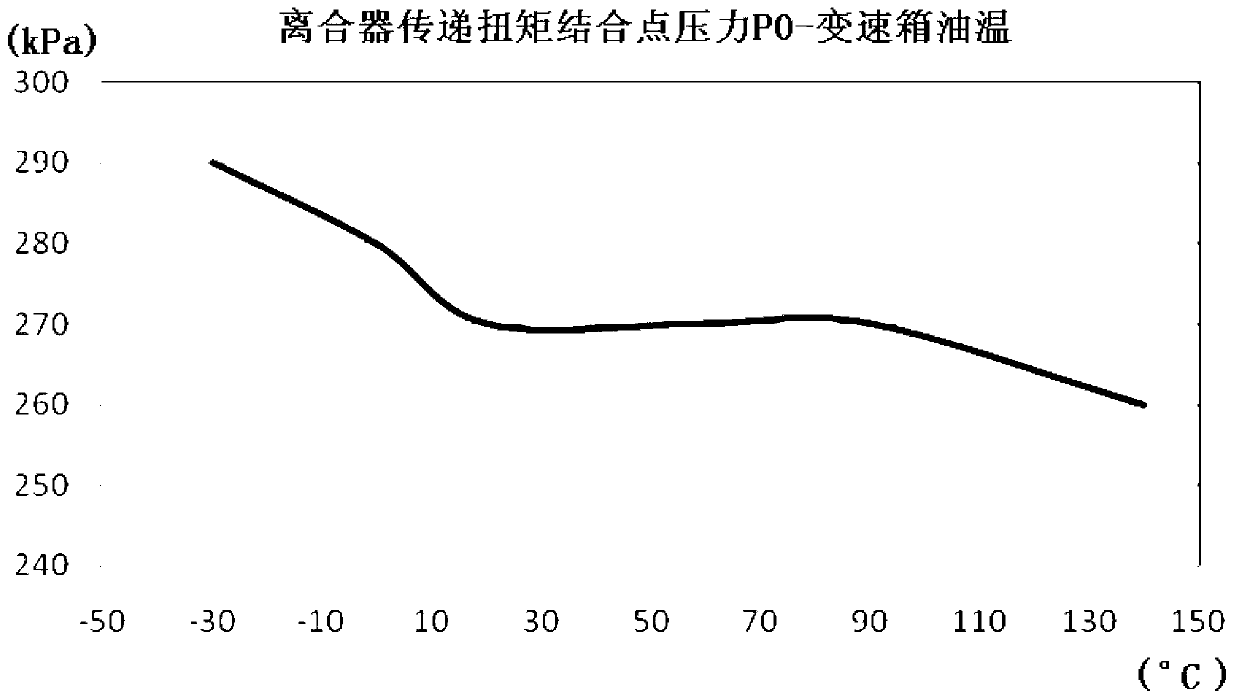

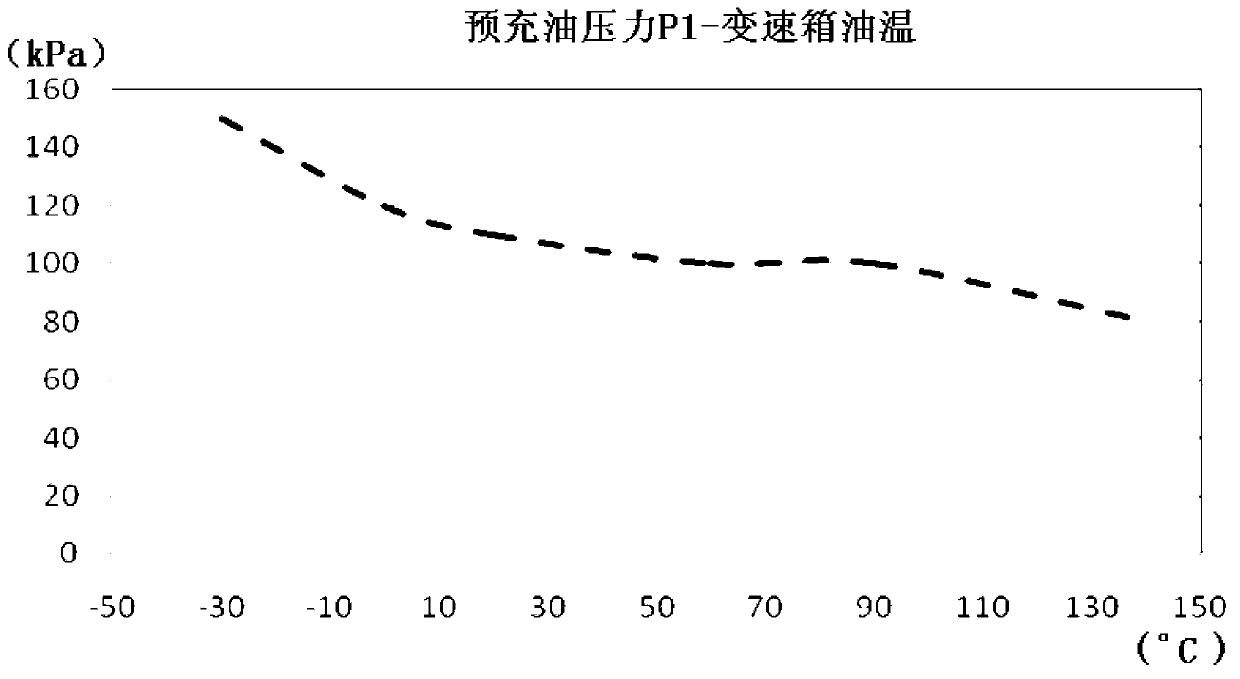

Wet dual-clutch automatic transmission and precharging pressure control method thereof

The invention discloses a wet dual-clutch automatic transmission and a precharging pressure control method thereof. The control method includes the steps: 1, performing oil precharging on duel wet clutches; 2, acquiring clutch torque transmission combination point pressure P0 and oil precharging pressure P1 according to acquired transmission oil temperature; 3, acquiring actual expected oil charging pressure P4 according to the formula that P4=P0+P1; 4, loading electromagnetic valve current corresponding to the P4 to an electromagnetic valve of the clutches according to the actual expected oil charging pressure P4; 5, measuring actual pressure P of the clutches, judging difference between the actual pressure P of the clutches and the clutch torque transmission combination point pressure P0 is within a preset error range or not, if so, executing a step 6, and otherwise, subtracting a fixed pressure value delta P from the actual expected oil charging pressure P4, and then executing the step 4; and 6, finishing oil charging. During oil precharging of the clutches, oil can be charged into a hydraulic oil chamber of each clutch quickly, oil pressure is established, conditions for torque transmission are satisfied, and response is rapid.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

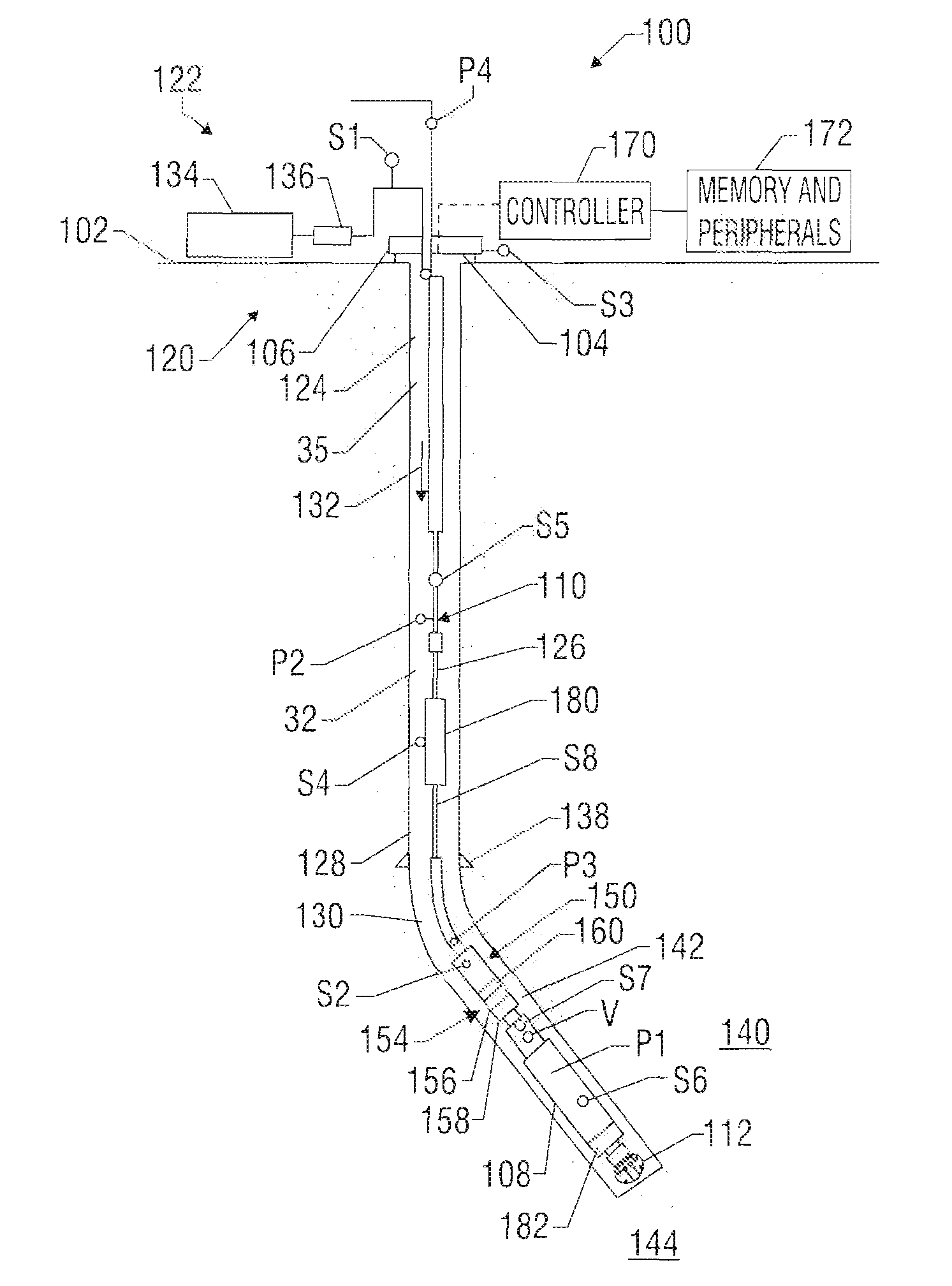

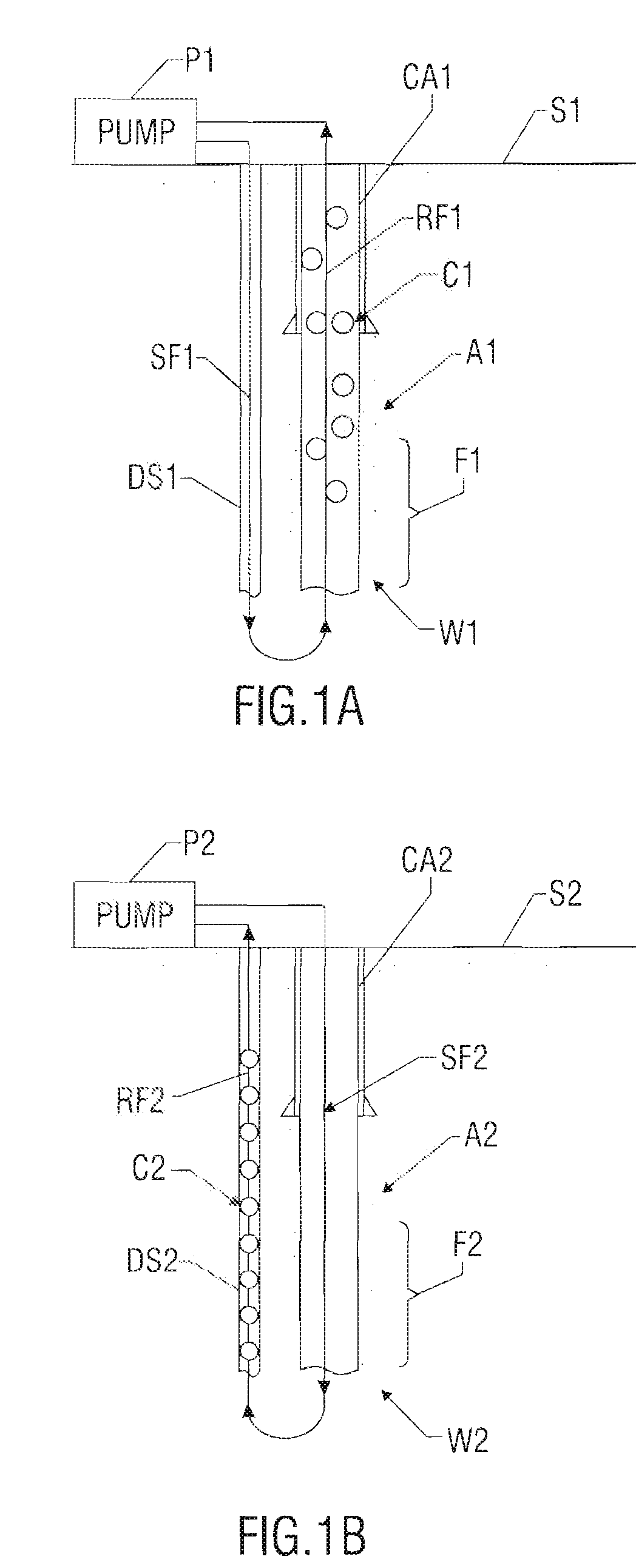

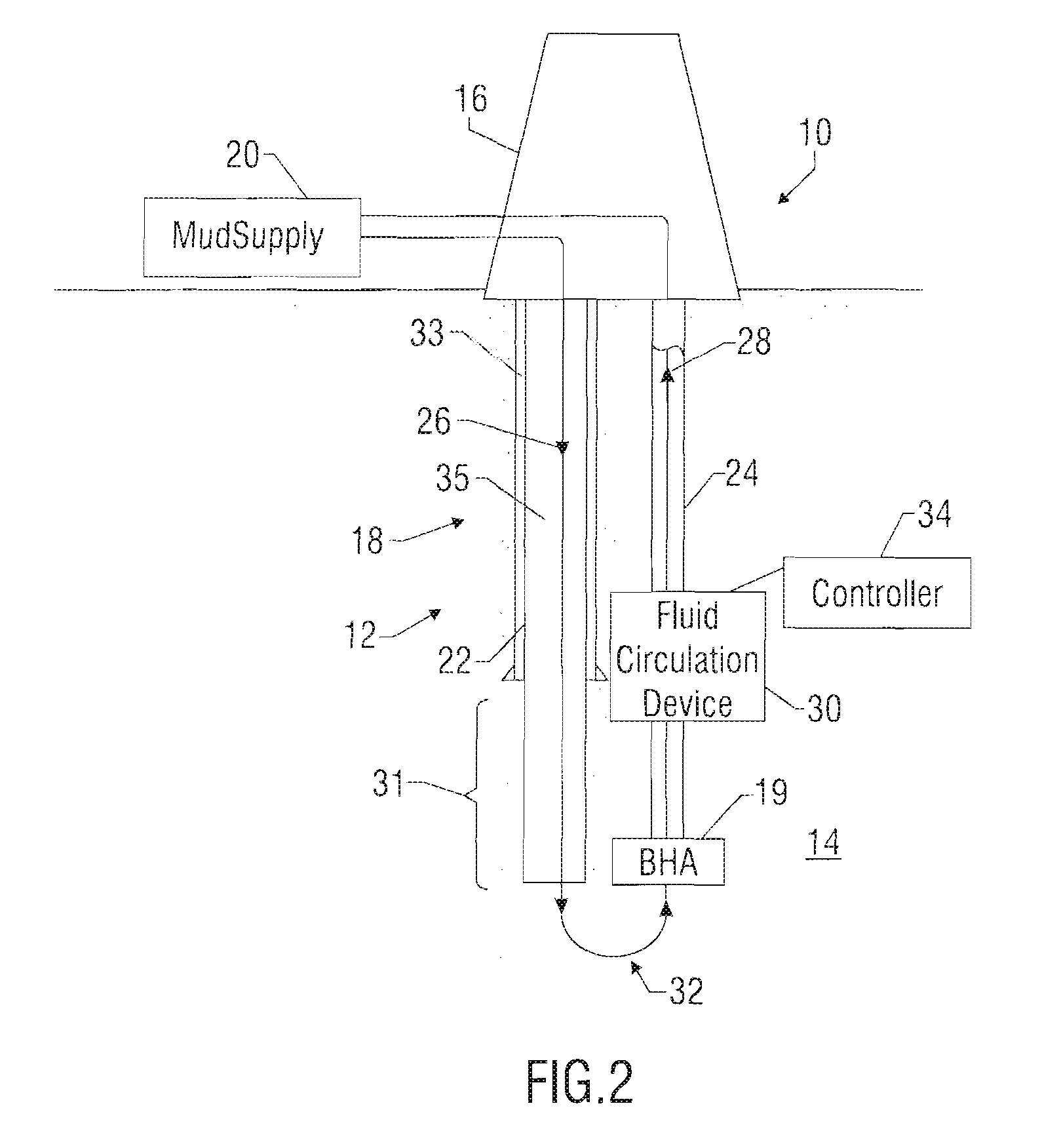

Reverse Circulation Pressure Control Method and System

A system for reverse circulation in a wellbore include equipment for supplying drilling fluid into the wellbore bit via at least an annulus of the wellbore and returning the drilling fluid to a surface location via at least a bore of a wellbore tubular. The system also includes devices for controlling the annulus pressure associated with this reverse circulation. In one embodiment, an active pressure differential device increases the pressure wellbore annulus to at least partially offset a circulating pressure loss. In other embodiments, the system includes devices for decreasing the pressure in the annulus of the wellbore. For offshore application, annulus pressure is decreased to accommodate the pore and fracture pressures of a subsea formation. In still other embodiments, annulus pressure is decreased to cause an underbalanced condition in the well.

Owner:BAKER HUGHES INC

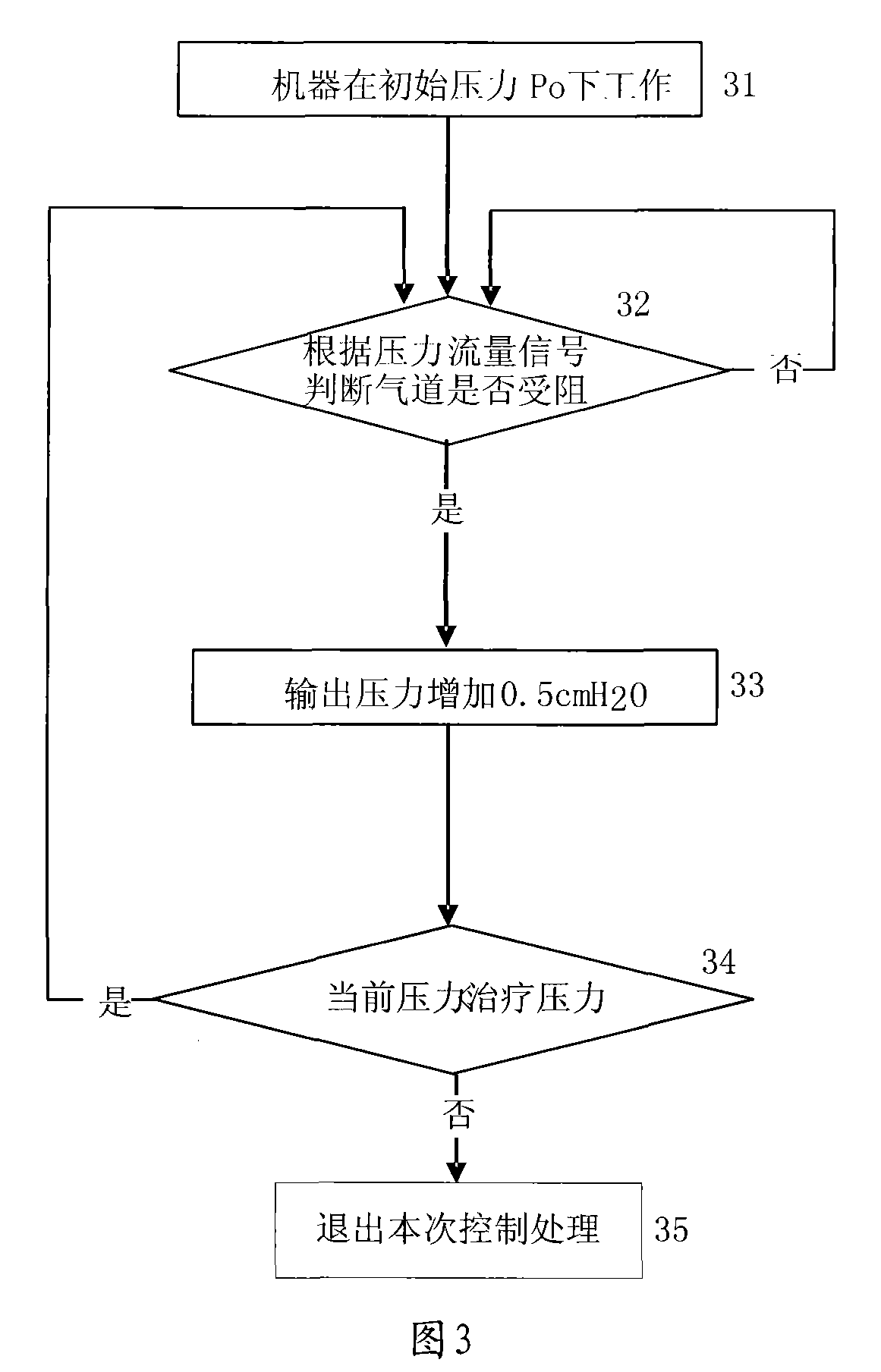

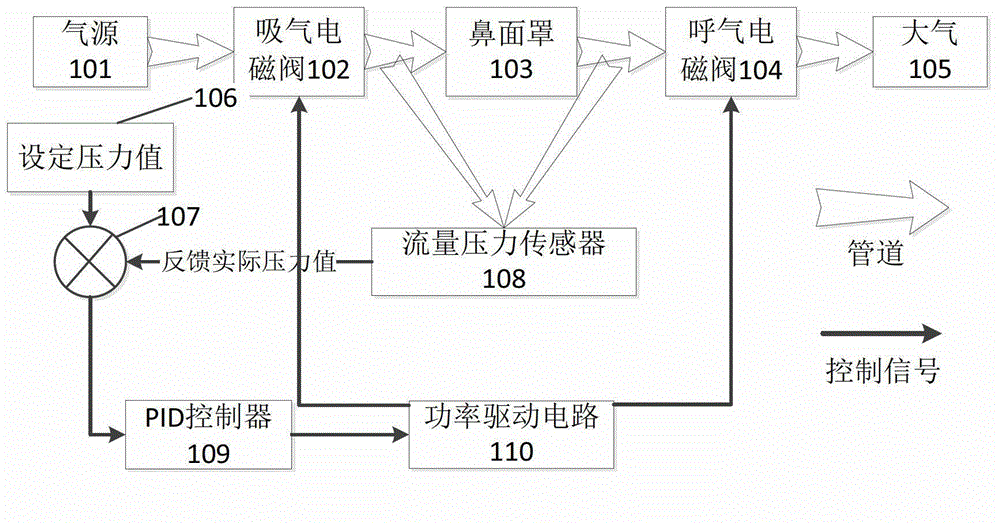

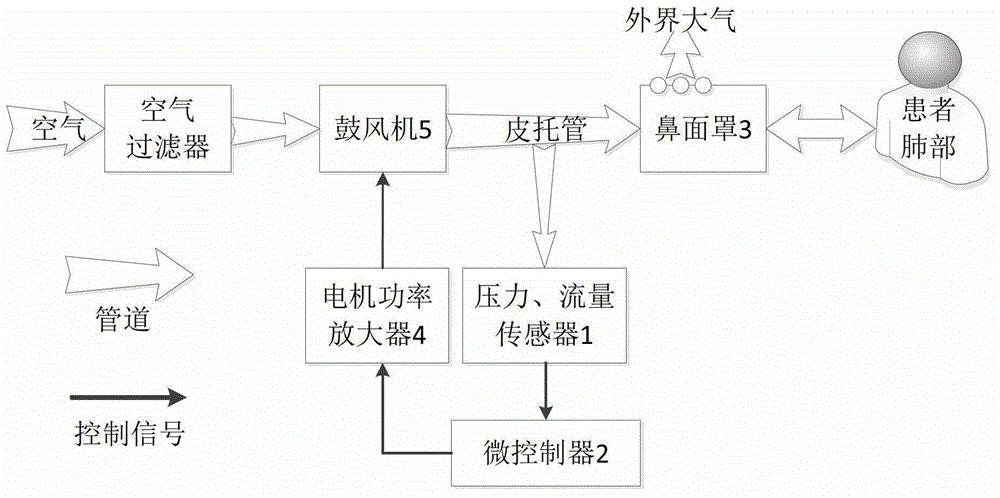

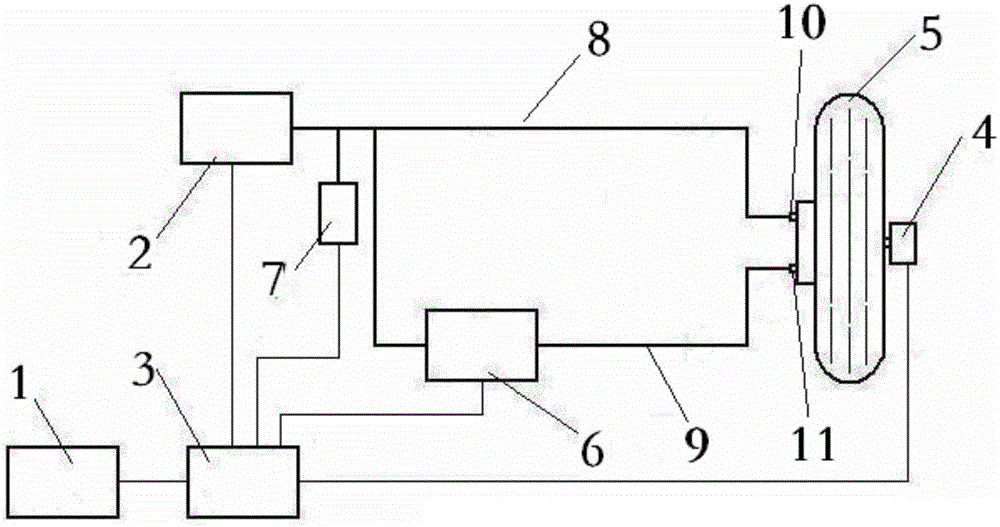

Breathing machine and pressure control method

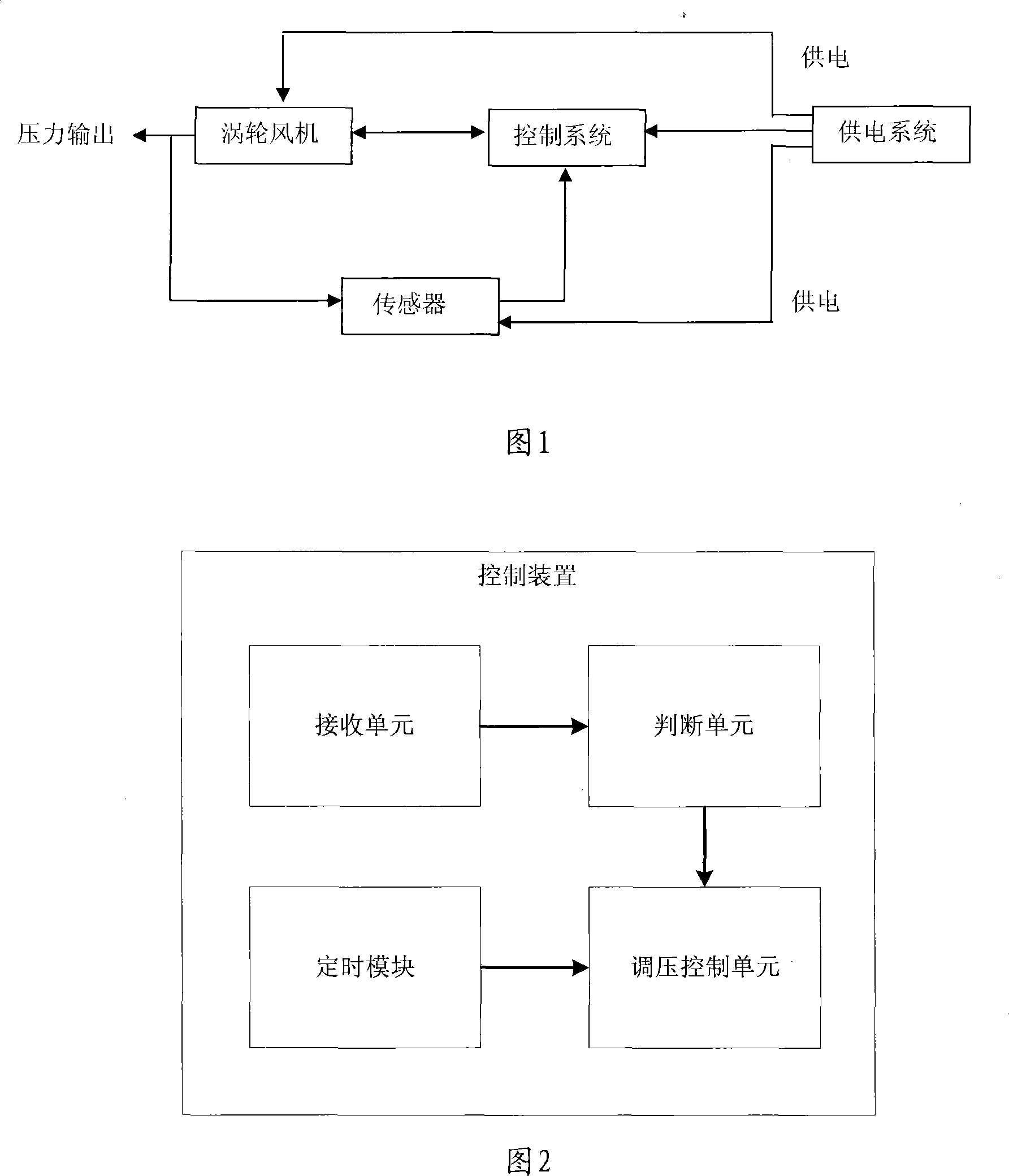

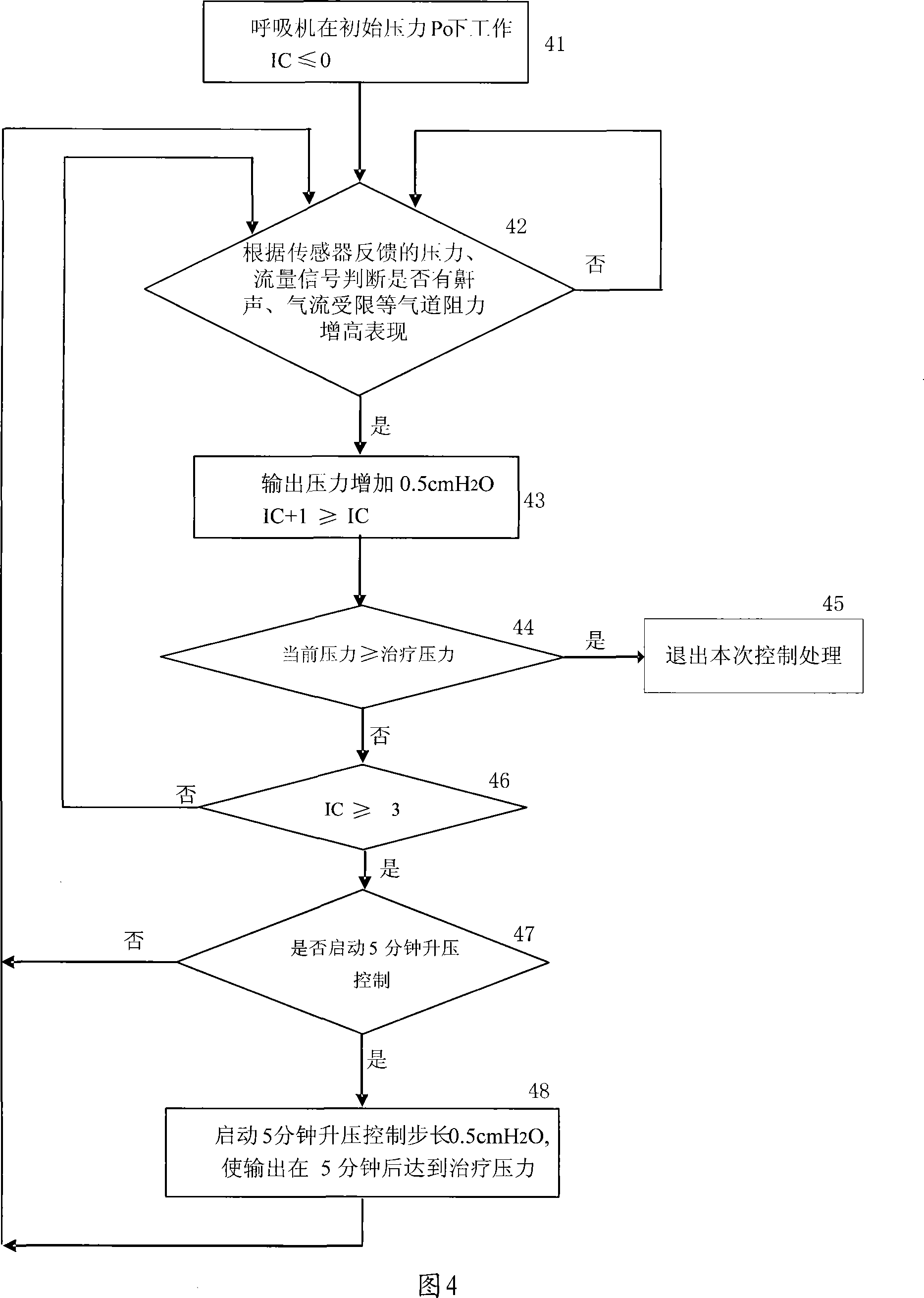

InactiveCN101244305ASimple structureFlexible way to adjust output pressureRespiratorsFluid pressure controlEngineeringTurbine

The invention discloses a ventilator and pressure control method, comprising a casing, a turbine fan, a control device, a sensor, and a power supply device; wherein, the turbine fan is used for producing and outputting wind with certain pressure; the control device is connected with the turbine fan to control the operation of the turbine fan; the sensor is positioned at the pressure output end of the turbine fan; wherein, the feedback end of the sensor is connected with the control device; the power supply device is connected with each part for power supply; which is characterized in that: the pressure / flow rate is detected by the sensor, so that the control device can control the turbine fan according to the feedback of the sensor, and the ventilator can provide different output pressure when the user is under different breathing condition; by monitoring the resistance in the air passage during the sleeping process of the user, pressure can be raised according to need, so that the user will not feel uncomfortable. The ventilator has the advantages of simple structure, flexibility of regulating output pressure and ensured application effect.

Owner:CURATIVE MEDICAL TECH INC

Expansion ratio adjustable pneumatic engine for automobile and its exhaust pressure control method

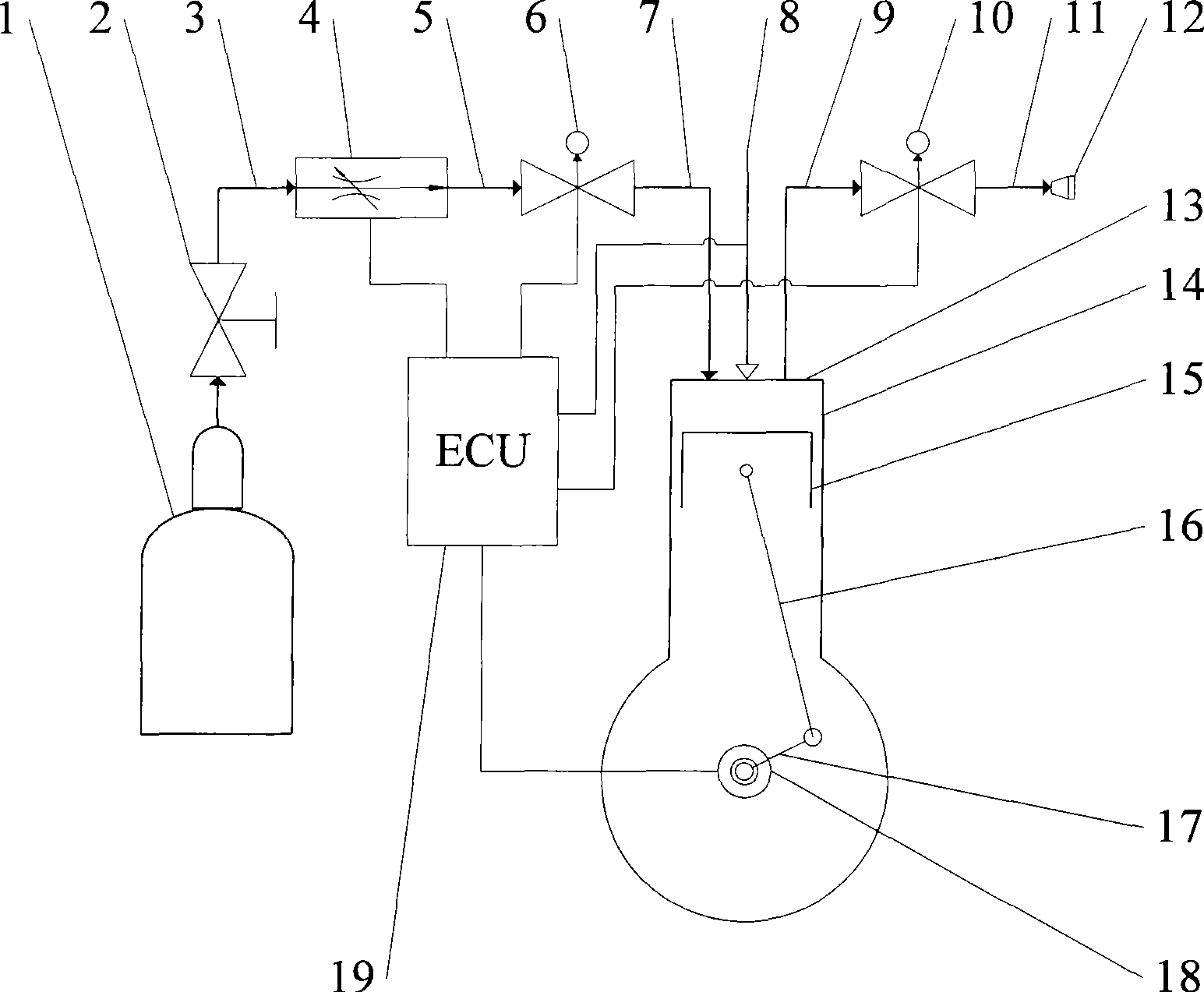

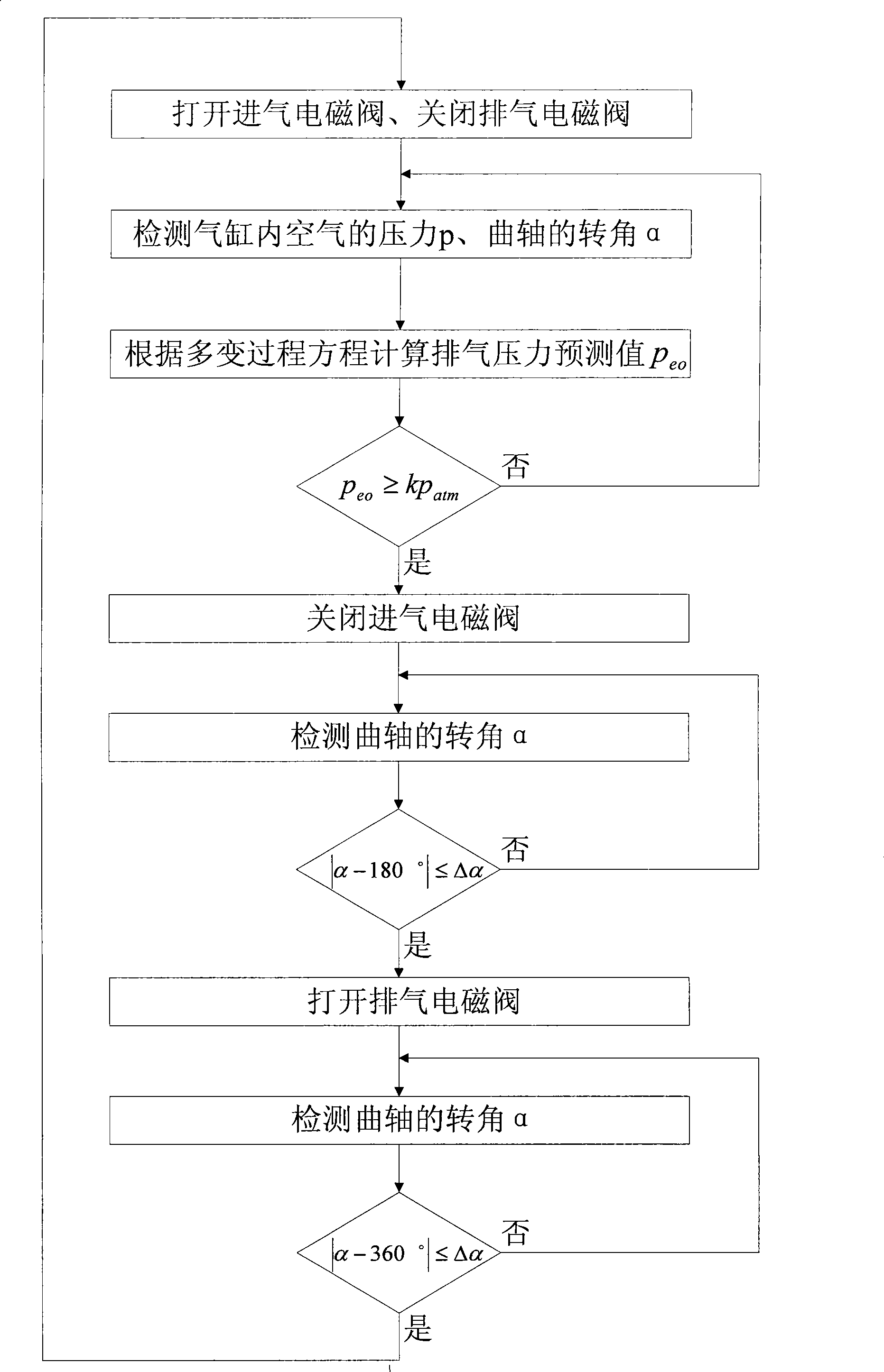

InactiveCN101476490AAvoid lostReduce lossesSafety/regulatory devicesEngines characterised by uniflow principleControl signalEngineering

The invention relates to a pneumatic engine for car use and discloses a pneumatic engine for car use with an adjustable expansion ratio and an exhaust pressure control method. According to the pneumatic engine for car use with the adjustable expansion ratio, compressed air is expanded in a cylinder so as to propel a piston and drive a crankshaft to rotate through a connecting rod and output rotating mechanical work to the outside. The pneumatic engine is characterized in that the pneumatic engine comprises an air inlet electromagnetic valve which is arranged in a cylinder air inlet pipe, an exhaust electromagnetic valve which is arranged in a cylinder exhaust pipe, a pressure sensor which is used for detecting the air pressure inside the cylinder, a photoelectric encoder which is used for detecting a crankshaft rotation angle, and a controller; and the controller makes a policy according to the cylinder air pressure detected by the pressure sensor and the crankshaft rotation angle of the photoelectric encoder, and sends a control signal of opening or closing to the air inlet electromagnetic valve and the exhaust electromagnetic valve. The pneumatic engine reduces the compressed air available energy loss caused by high pressure exhaust, thereby improving the energy conversion rate of the pneumatic engine.

Owner:SOUTH CHINA UNIV OF TECH

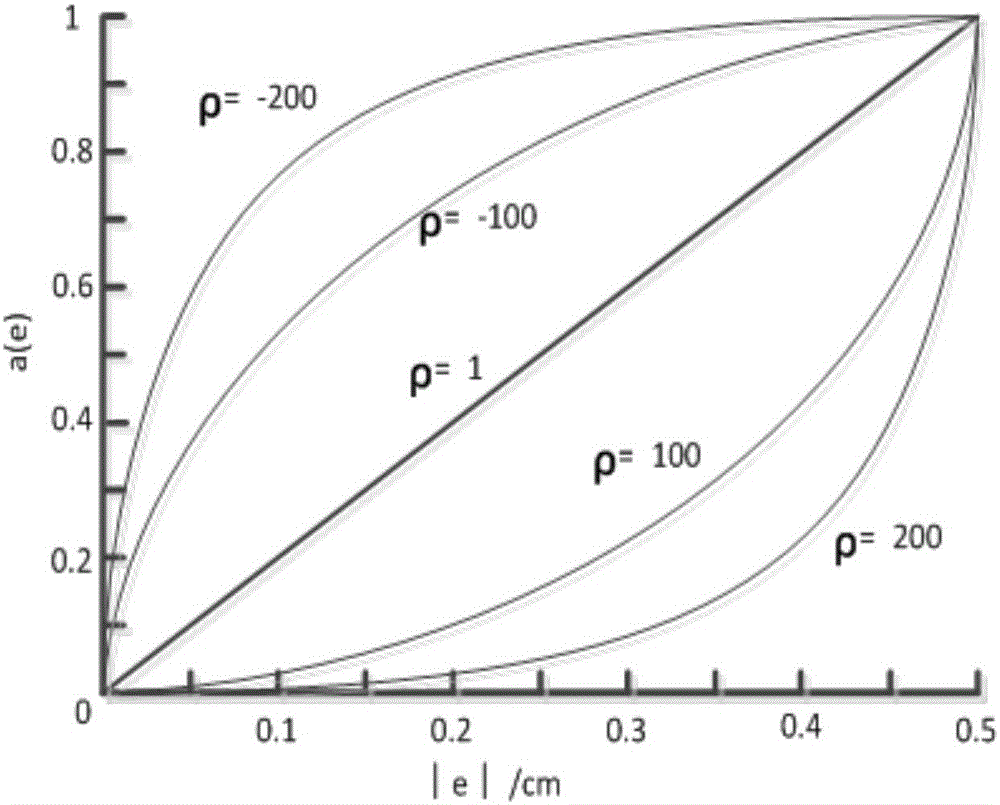

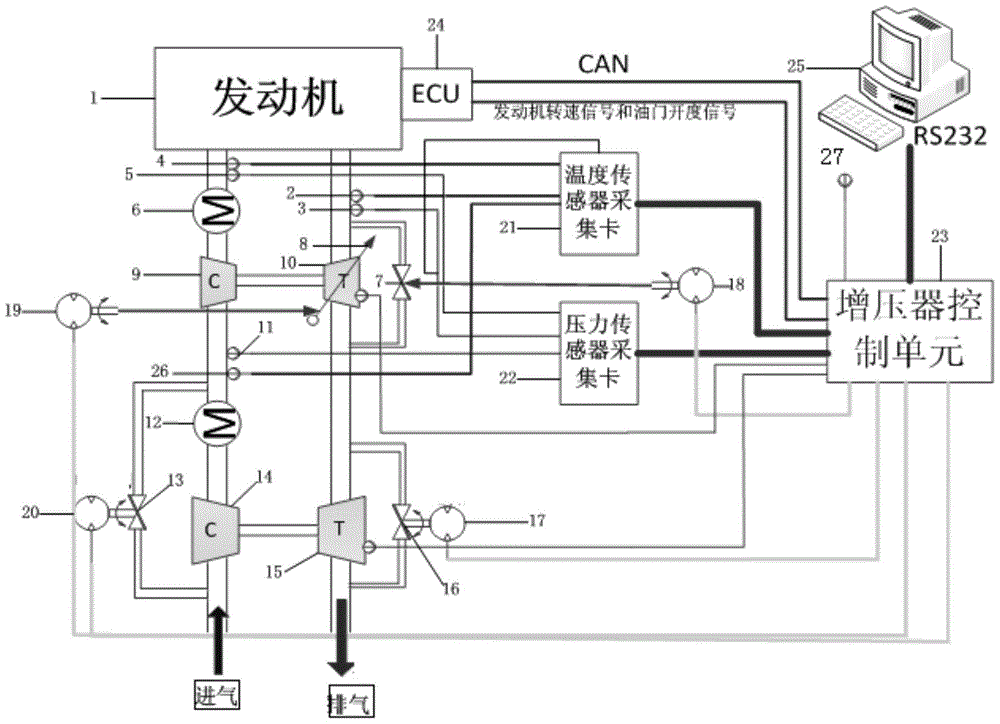

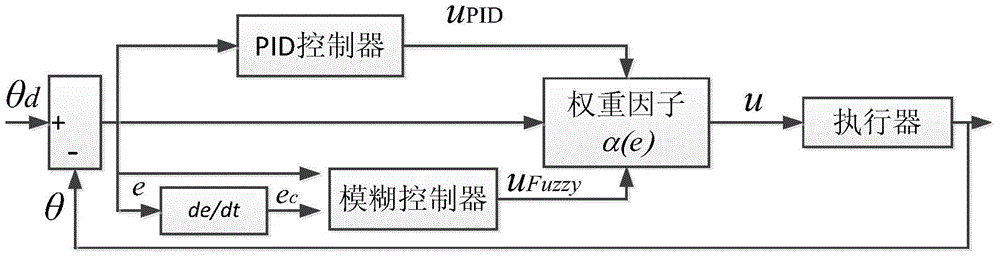

Diesel engine variable-altitude boost pressure control method

ActiveCN105673191APrevent surgeAvoid turbo overspeedInternal combustion piston enginesGas compressorOptimal control

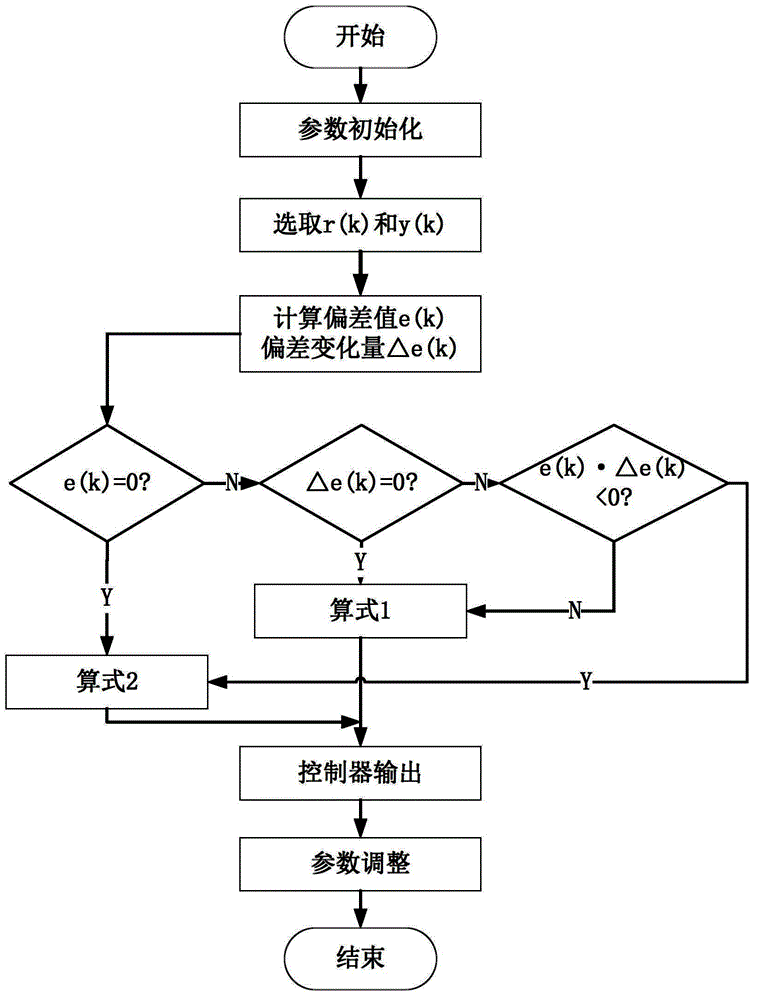

Disclosed is a diesel engine variable-altitude boost pressure control method. Through a two-level adjustable booster controller ECU, according to change of altitude, diesel engine rotation speed and loads, opening of a high-pressure stage VGT vane of a two-level adjustable booster and opening of a high-pressure stage turbine regulating valve and a low-pressure stage turbine regulating valve are controlled in real time, optimal control is conducted on boost pressure in a variable-altitude and variable-working-condition mode, and the purpose that in the 0 m-5500 m altitude range, all performance indicators of a diesel engine are always kept the same as the performance under the plain conditions is achieved. The mode that feedforward control and fuzzy PID control are combined is adopted for the diesel engine variable-altitude boost pressure control method, and the boost pressure can be adjusted in real time according to change of altitude and working conditions of the diesel engine, so that the requirements for best power performance and fuel economy in the steady state working condition and the transient state working condition are met, the objective that power of the diesel engine at the altitude 5500 m fixed point is recovered to 95% or above that on plains is achieved, turbo lag is relieved, and pumping loss work is reduced. Meanwhile, the problems of gas compressor surges, turbine overspeed, excessively high turbine-front discharge temperature and the like are avoided.

Owner:MILITARY TRANSPORTATION UNIV PLA

Breathing machine control method and breathing machine apply control method

ActiveCN103330979ALow costRespiratorsControllers with particular characteristicsMicrocontrollerEngineering

The invention discloses a breathing machine control method and a breathing machine applying the control method. The breathing machine comprises a flow sensor, a pressure sensor, a microcontroller, a motor power amplifier and a blower. The breathing machine adopts a breathing synchronization pressure control method; particularly, the flow sensor detects the change in the flow of a pipeline, an expiration state and an inspiration state of a patient are judged according to a set flow threshold; and further, a preset pressure level is selected for switching according to the breathing state. Generally, when inspiration is converted into expiration in an air path system, man-machine confrontation is caused due to air accumulation at a nasal mask end. Therefore, a deviation between a set inspiration duration and a forecast duration serves as a time stamp of the beginning of the expiration after adjustment. The lower expiratory pressure is selected in advance, so that the pressure can be released timely, the man-machine confrontation is eliminated, and the man-machine synchronism is improved. The control mode meets breathing physiology requirements of people, and the breathing comfort and effectiveness of the patient are guaranteed.

Owner:SUN YAT SEN UNIV

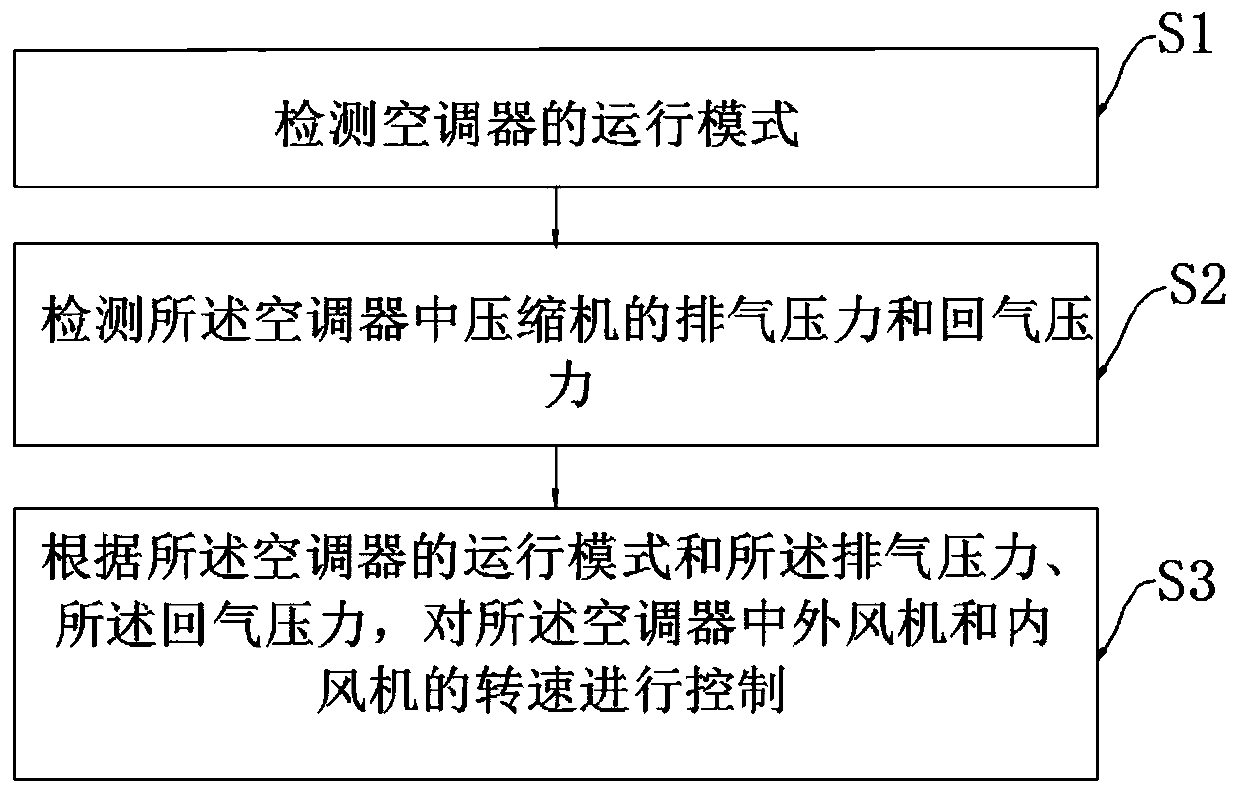

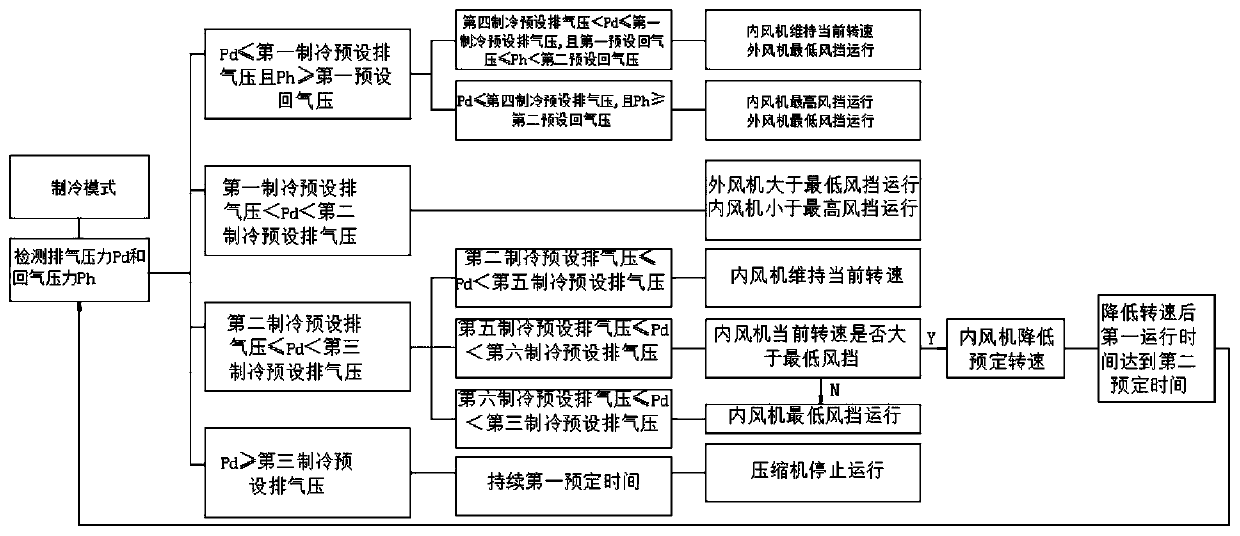

Pressure control method and control device for air conditioner and air conditioner

ActiveCN110410944AImprove accuracyPrevent trippingMechanical apparatusSpace heating and ventilation safety systemsHigh pressureControl theory

The invention provides a pressure control method and control device for an air conditioner and the air conditioner. The pressure control method for the air conditioner comprises the steps that 1, therunning mode of the air conditioner is detected; 2, the air exhaust pressure and the air return pressure of a compressor in the air conditioner are detected; and 3, the rotation speed of an outer fanand an inner fan in the air conditioner is controlled according to the running mode of the air conditioner, the air exhaust pressure and the air return pressure. According to the pressure control method and control device for the air conditioner and the air conditioner, the unit running pressure is continuously detected, the rotation speed of the outer fan or the inner fan is correspondingly adjusted according to comparison of the air exhaust pressure and the air return pressure with a preset value, therefore, the unit running pressure is in an appropriate range value, and the unit jumping phenomenon caused by high-pressure protection or low-pressure protection is prevented; and the control method is high in accuracy, has no delay and is simple and reliable.

Owner:NINGBO AUX ELECTRIC

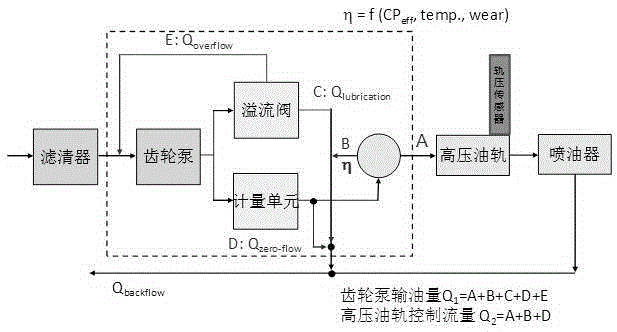

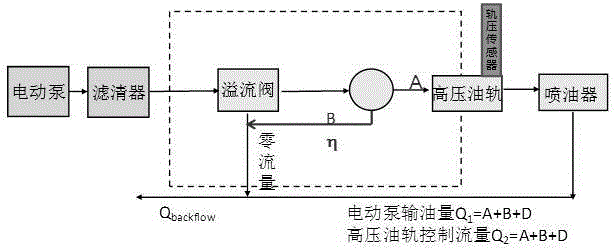

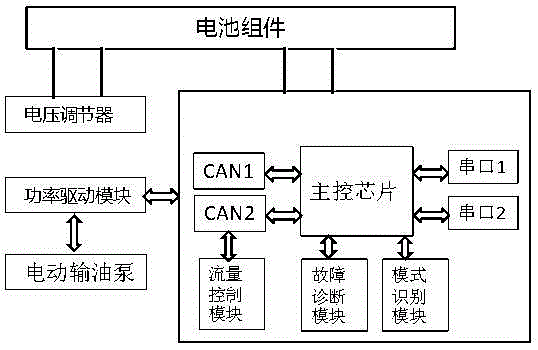

High-pressure common-rail fuel injection pressure control method and system

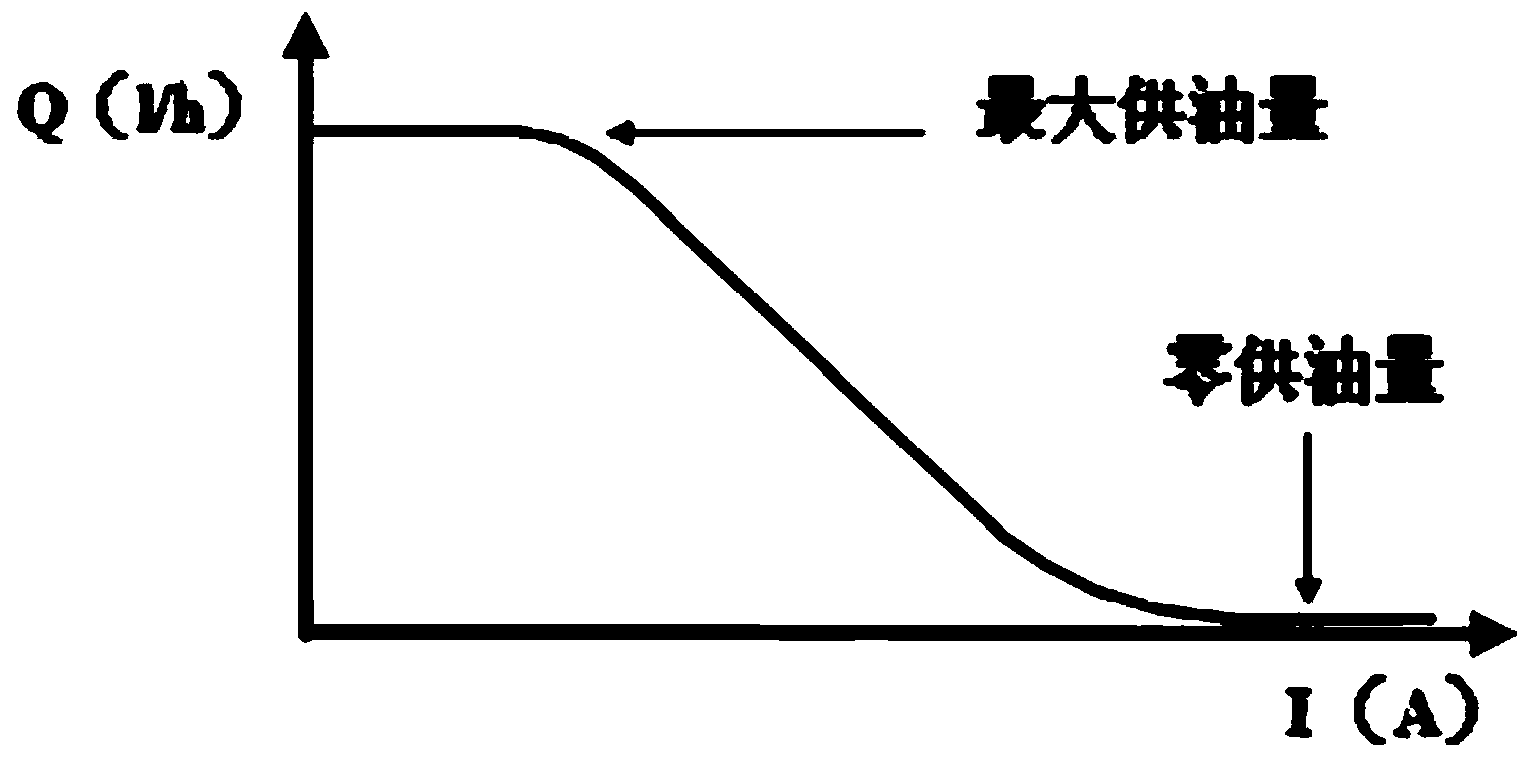

ActiveCN105422296AAvoid loadImprove energy conversion efficiencyElectrical controlMachines/enginesActuatorPwm signals

The invention discloses a high-pressure common-rail fuel injection pressure control method and system. According to the method, an electric fuel delivery pump driven by a DC motor is taken as an actuating element and the high-pressure common-rail fuel injection pressure is adjusted by adjusting the low-pressure fuel output quantity. The method is characterized in that a set fuel injection pressure value and a target driving PWM signal value of the electric fuel delivery pump are calculated by gathering the operating parameters of an engine, and a PWM single duty ratio control logic changes along with switching of the operating condition modes of the engine. According to the invention, the common-rail injection pressure is adjusted by controlling the fuel supply quantity of the electric fuel delivery pump, which avoids unnecessary load of the engine, increases the energy conversion efficiency of the engine and fits the intellectualization, integration and modularization development trend of automobile actuators. The invention changes traditional common-rail fuel injection pressure control and calibration modes, reduces technological dependence on high-pressure common-rail fuel injection system suppliers and contributes to enhancing the independent design and development abilities of engine and diesel vehicle manufacturers.

Owner:苏州达菲特过滤技术股份有限公司

Variable static pressure control method and system for variable air-conditioning system

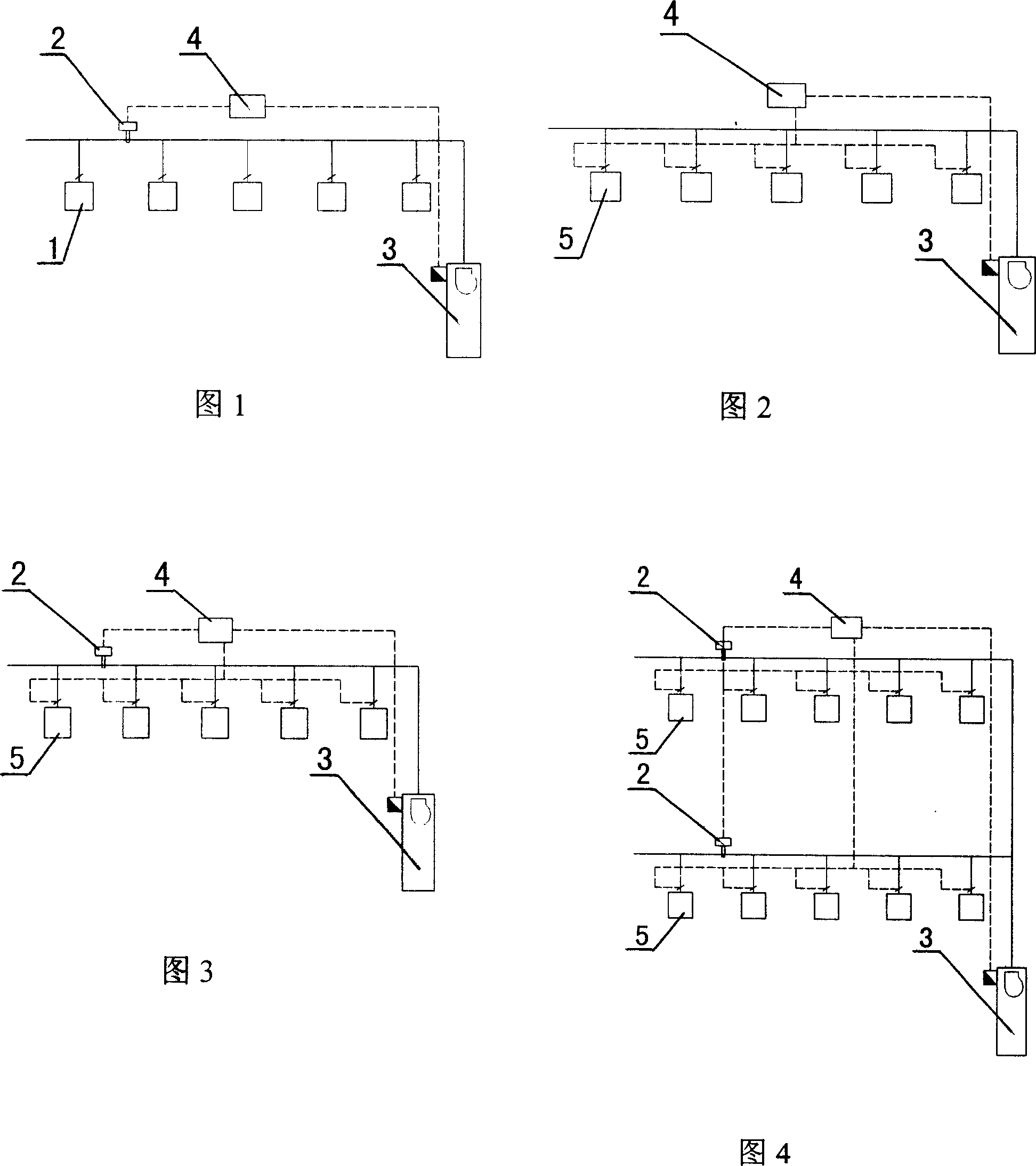

InactiveCN101008519AReduce static pressureSatisfy the demand of air volumeSpace heating and ventilation safety systemsLighting and heating apparatusFrequency changerAir volume

The invention discloses a static-pressure variable control method of wind-variable air conditioning system, which comprises several wind-variable terminal with valve feedback parallel connected on one wind tube of air conditioner which has a fan frequency changer and a wind tube static pressure sensor on the wind tube, while the sensor is connected with one input of controller. The output of controller is connected to the fan frequency changer. The wind-variable terminal is connected to another input of controller. Or the air conditioner has several wind tubes while each tube is arranged with a wind tube static pressure sensor. The invention can adjust the fan frequency via the static pressure of wind tube, to realize stable and reliable control, while it can reduce the static pressure via the valve signal of wind-variable terminal at local load, to save energy.

Owner:杭州华电华源环境工程有限公司

Adaptive pressure control method for achieving synchronous upshifts in a multiple-ratio transmission

An adaptive shift control method for a geared multiple ratio transmission having friction elements for clutches and brakes to establish and disestablish gear ratio changes wherein at least one ratio change involves engagement of one friction element in synchronism with disengagement of another friction element. Operating parameters are adapted throughout the life of the transmission to reduce synchronous errors by developing and learning pressure and time adjustments for the friction elements.

Owner:FORD GLOBAL TECH LLC

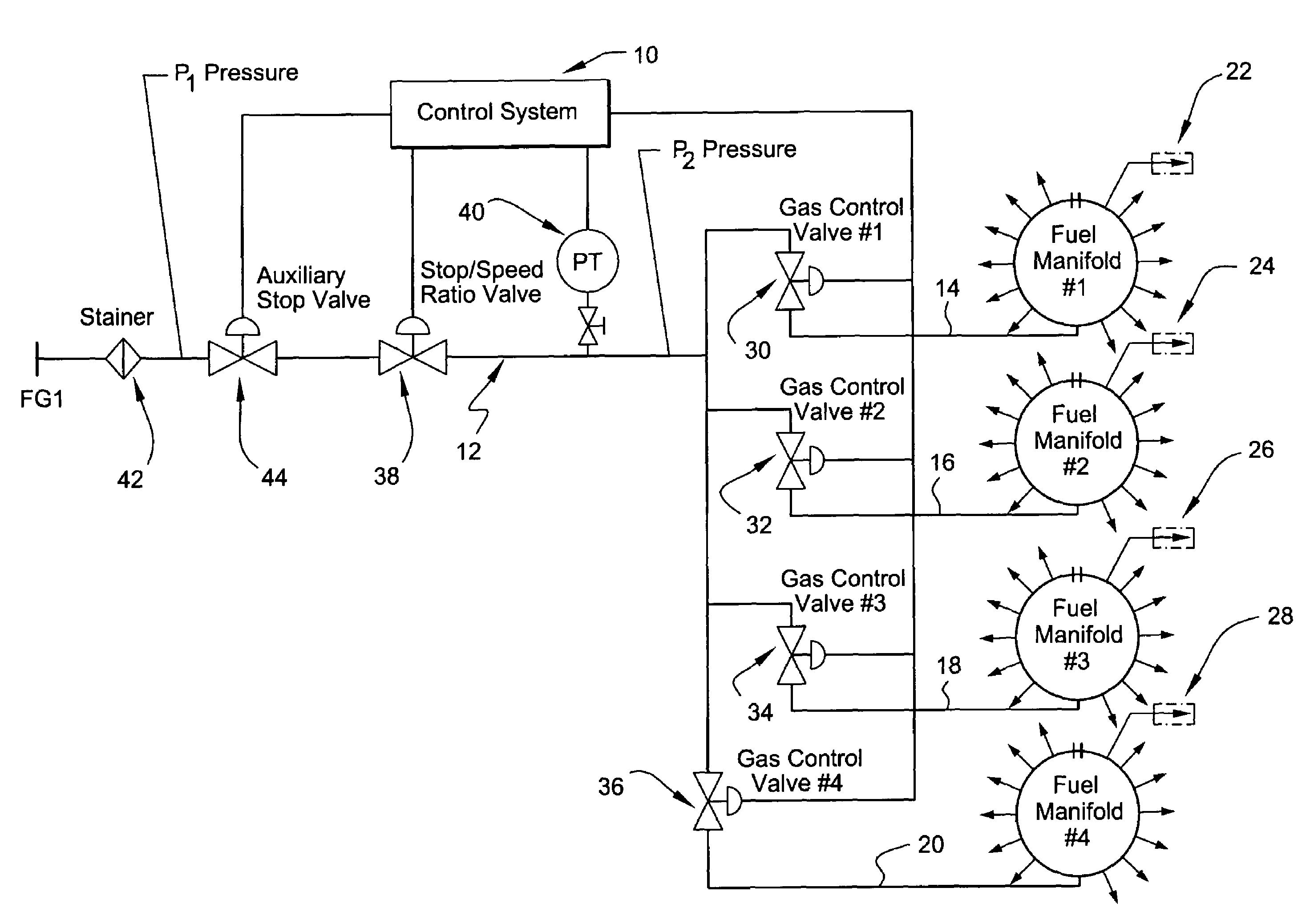

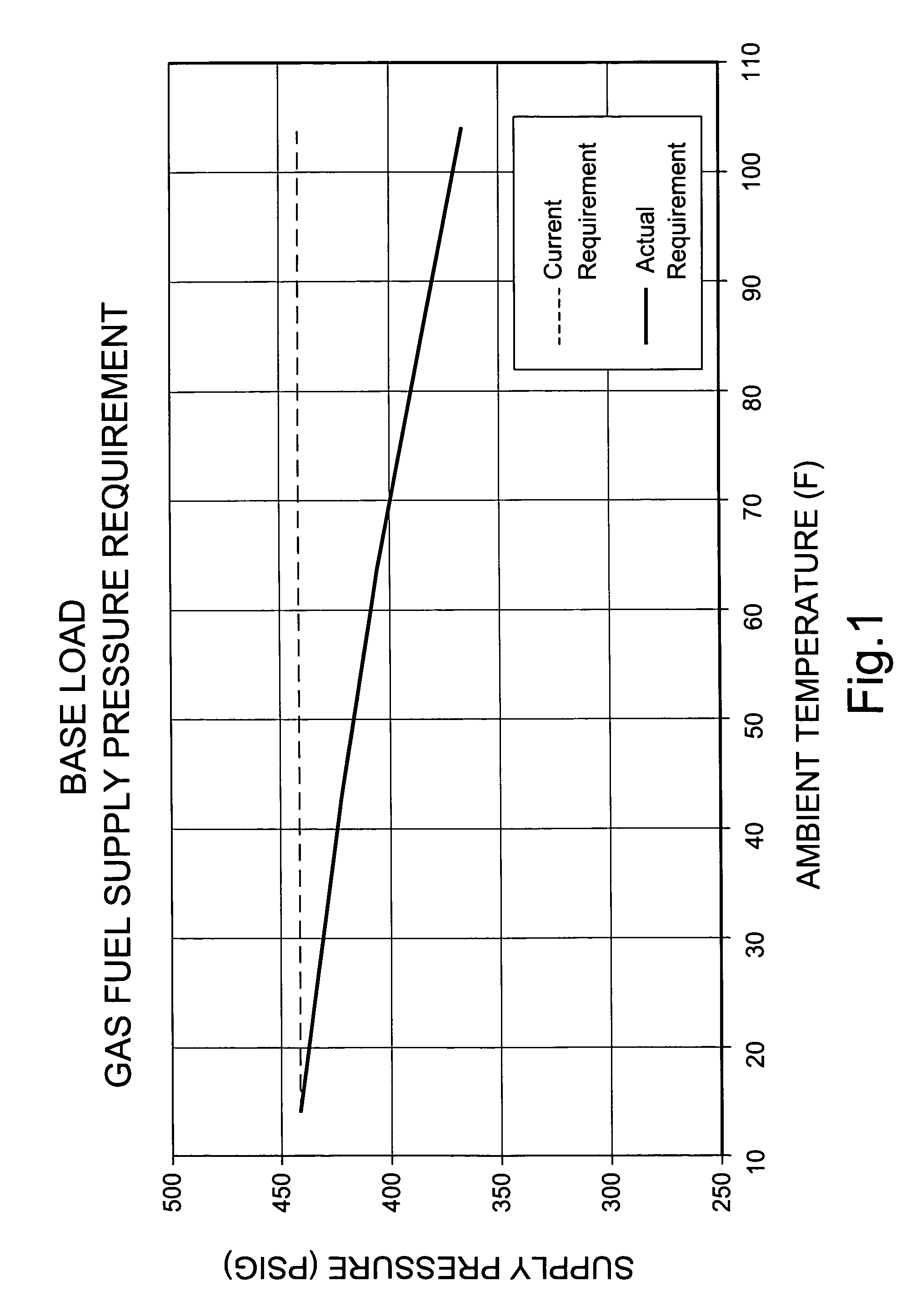

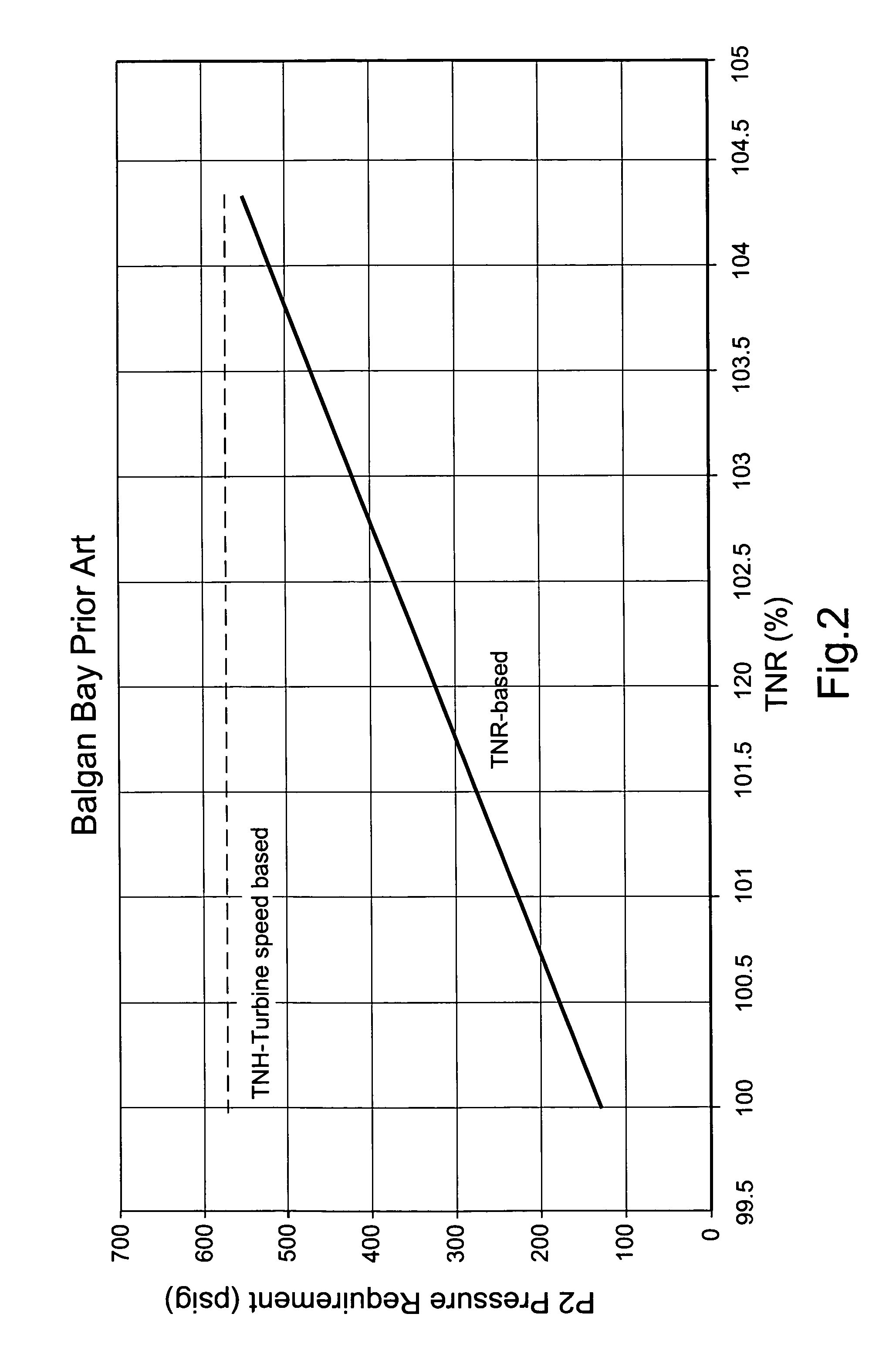

Pressure control method to reduce gas turbine fuel supply pressure requirements

ActiveUS7549293B2Reducing and potentially eliminating needEasy to operateGas turbine plantsTurbine/propulsion fuel controlOperabilityGas turbines

Owner:GE INFRASTRUCTURE TECH INT LLC

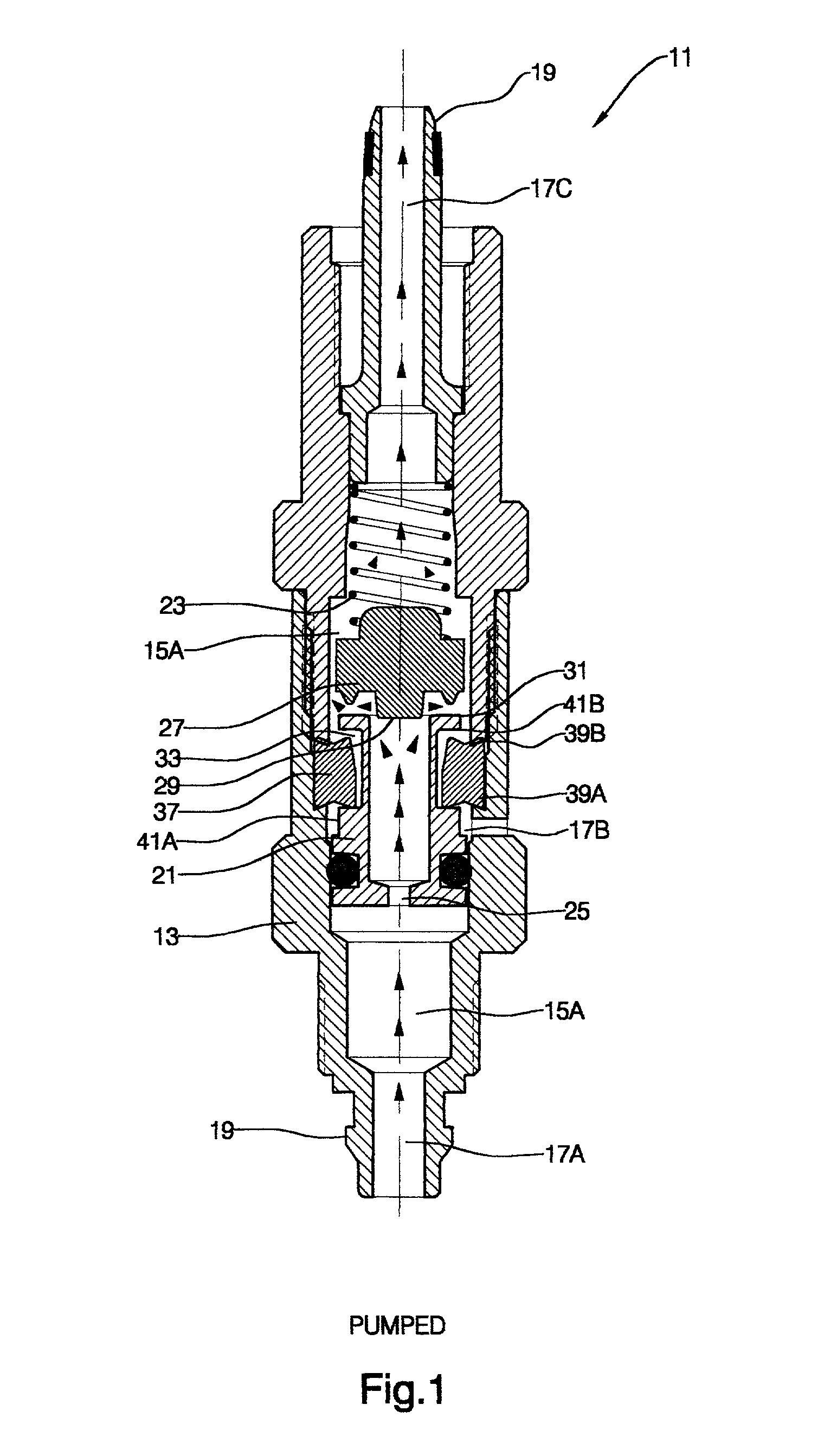

Pressure-controlled three-way valve device for transport vehicle tires and remote pressure control method

InactiveUS20020170597A1Improve reliability and operation speedPromote recoveryLevel controlCheck valvesInlet valveEngineering

A remote pressure-controlled three-way valve device has a plunger axially traversed by an inlet passage normally closed by a spring-urged inlet valve. The plunger's outer sidewall has a recess in which an O-ring extends to abut against the steps of the recess to limit the plunger stroke and keep an outlet passage closed to a venting port formed in the sidewall of the body of the device. O-ring prevents short-circuits between the inlet passage and the vent port and a spring for counteracting friction between the O-ring and the device inner wall. Filters arranged in respective ports connectable to the input air-pressure supply and the tire inner tube provide fixed seats for the springs to bear on. The plunger may dwell in a stable intermediate position that opens the outlet or deflation passage is controlled by sending an air pressure through the inlet port at 50% of the normal pressure.

Owner:COL VEN

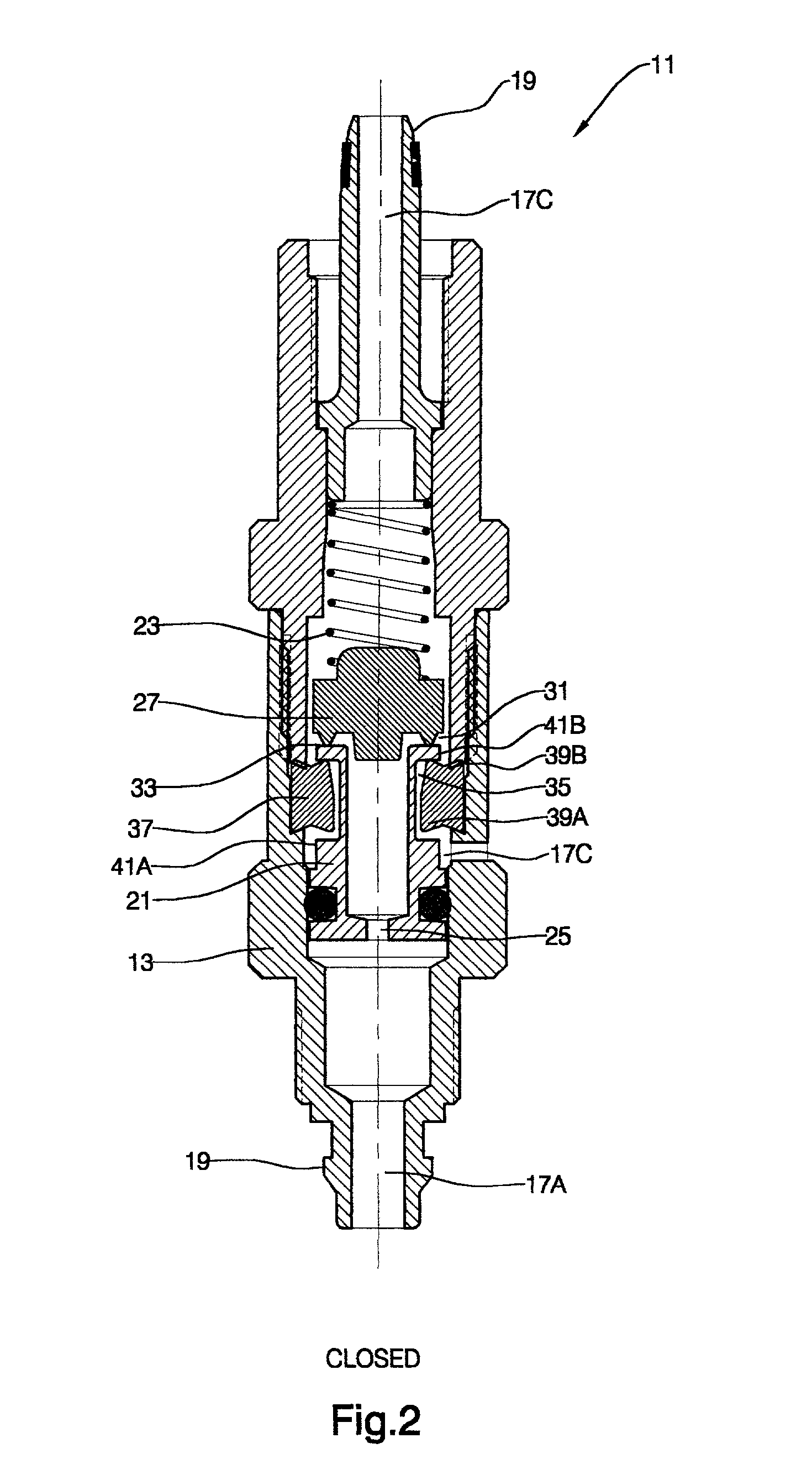

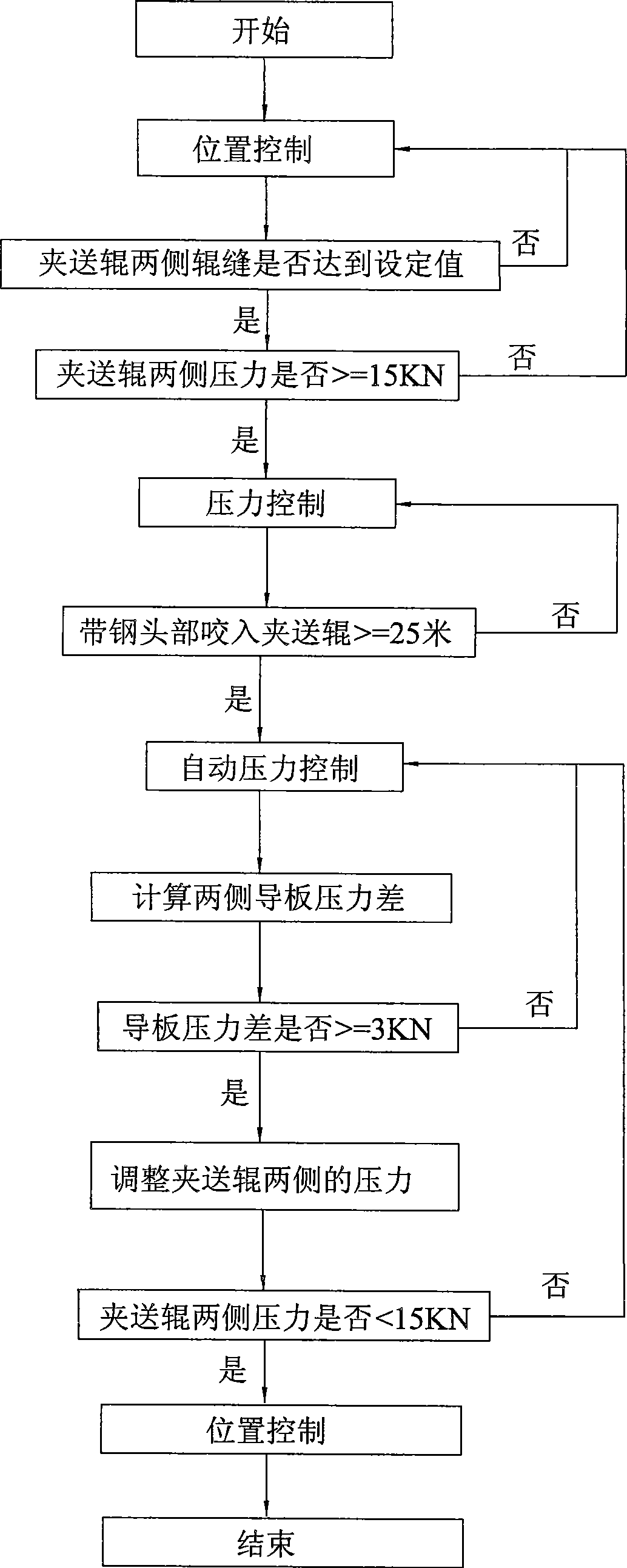

Withdrawal roll pressure control method for coiler

ActiveCN101452297AAvoid reciprocating swimmingControl roll qualityMechanical pressure/force controlContinuous measurementStrip steel

The invention provides a method for controlling pressure of a pinch roller of a reeling machine. The method comprises the following steps: 1, the pressure values of two lateral guide plates on strip steel are measured and are input to a controller; 2, the pressure difference between the two lateral guide plates is calculated; and according to the calculated pressure difference, the wandering direction of the strip steel is judged; 3, according to the pressure values of the two lateral guide plates, the adjusting amounts of two lateral pressure of the pinch roller of the strip steel are calculated; and 4, according to the calculated adjusting amounts of two lateral pressure of the pinch roller, the pressure of the pinch roller at one side of the wandering direction of the strip steel is increased; the pressure at the other side of the pinch roller is reduced; and the steps are repeated. Through continuous measurement and comparison of pressure exerted on the two lateral guide plates when the strip steel wanders, the wandering direction of the strip steel is judged; and the pressure at two sides of the pinch roller is automatically adjusted so as to control the roller slot of the pinch roller and ensure the rolling quality of the strip steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Airplane single-wheel dual-brake-alternative fly-by-wire braking system

InactiveCN105905282AIncrease energy levelsExtended service lifeBraking action transmissionAircraft brake actuating mechanismsCarbon compositesWheel speed sensor

Provided is an airplane single-wheel dual-brake-alternative fly-by-wire braking system. A braking instruction sensor replaces a hydraulic braking valve, and a positive gain electro-hydraulic servo valve is adopted. A braking antiskid control part is composed of an airplane wheel speed sensor, a control box and the electro-hydraulic servo valve. A control device composed of a pressure sensor, a control box and an electromagnetic valve controls an oil path to be opened and closed through a braking pressure control method so that partial braking or overall braking of the braking system can be achieved. Partial braking indicates that a small braking device operates, and overall braking indicates that the small braking device and a large braking device simultaneously operate, so dual braking of an airplane wheel is achieved. The braking system is suitable for the single-wheel dual-brake airplane wheel adopting carbon brakes and can meet the requirement for alternatively using dual brakes of the single wheel, the use state of the carbon brakes is adjusted, the wear-resistant excellent characteristic of the carbon-carbon composite friction materials is brought into full play, the problem that an existing single-wheel single-brake carbon brake disc is large in wear and short in service life is effectively solved, the service life of carbon discs is prolonged, and economic benefits of the carbon discs are improved.

Owner:XIAN AVIATION BRAKE TECH

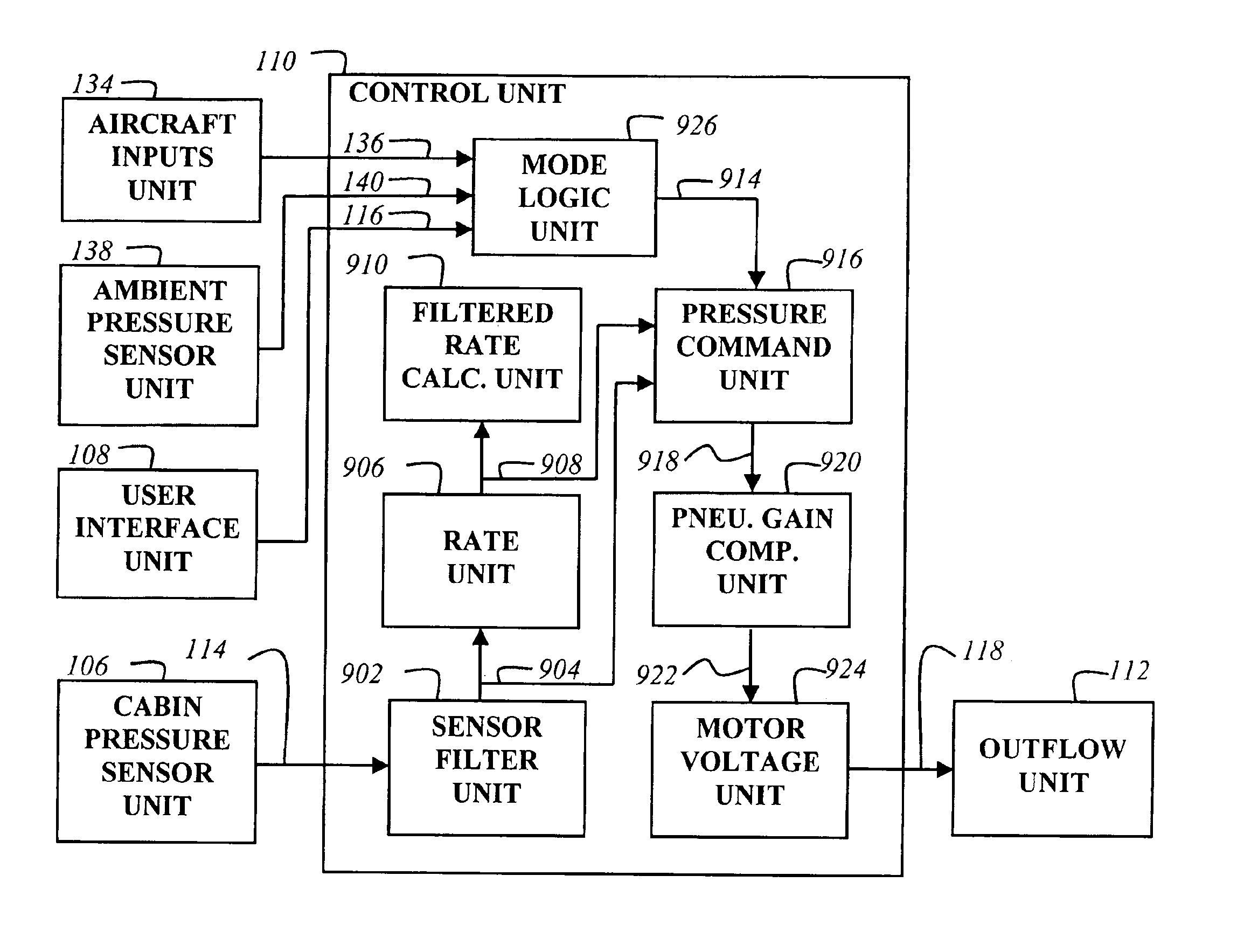

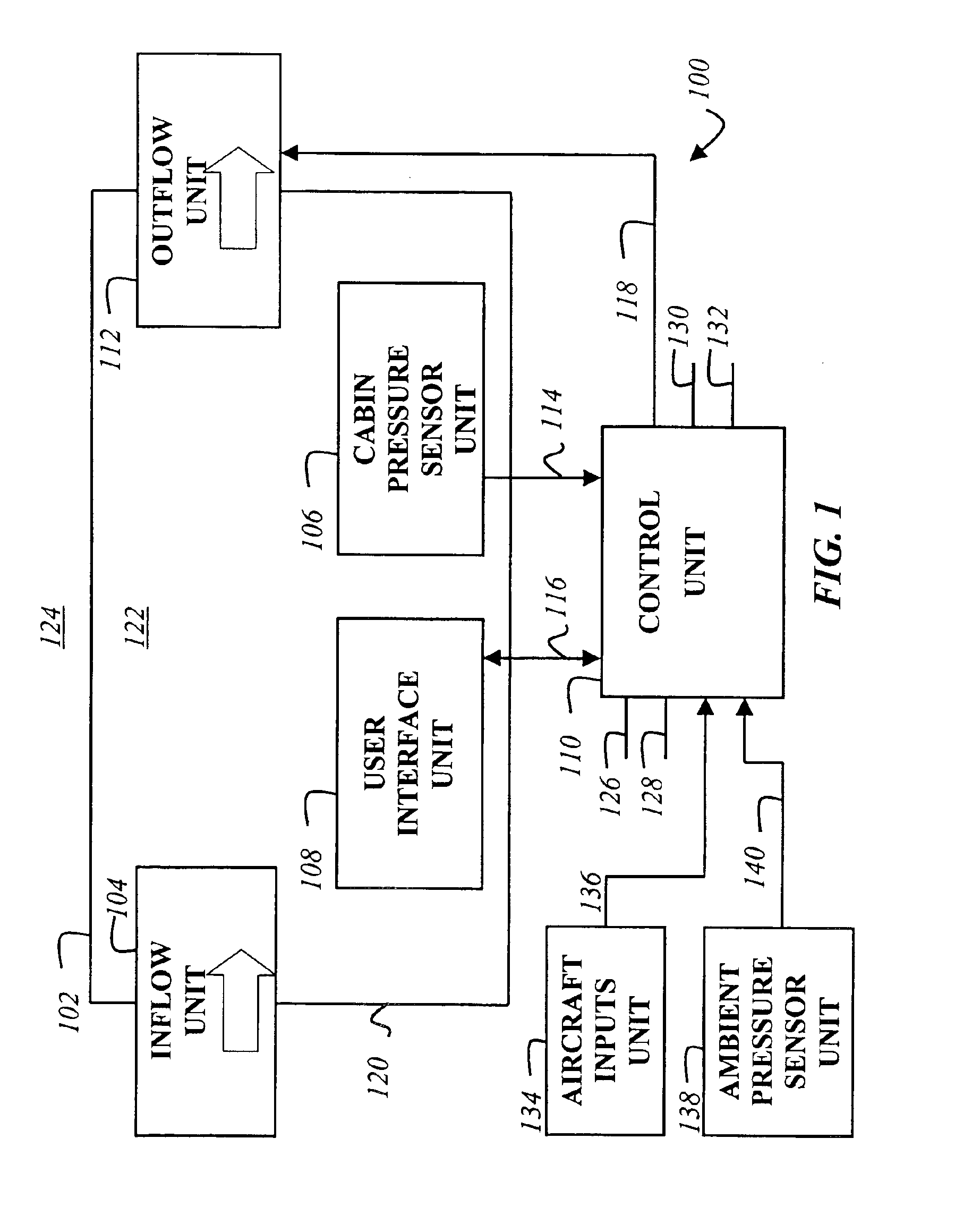

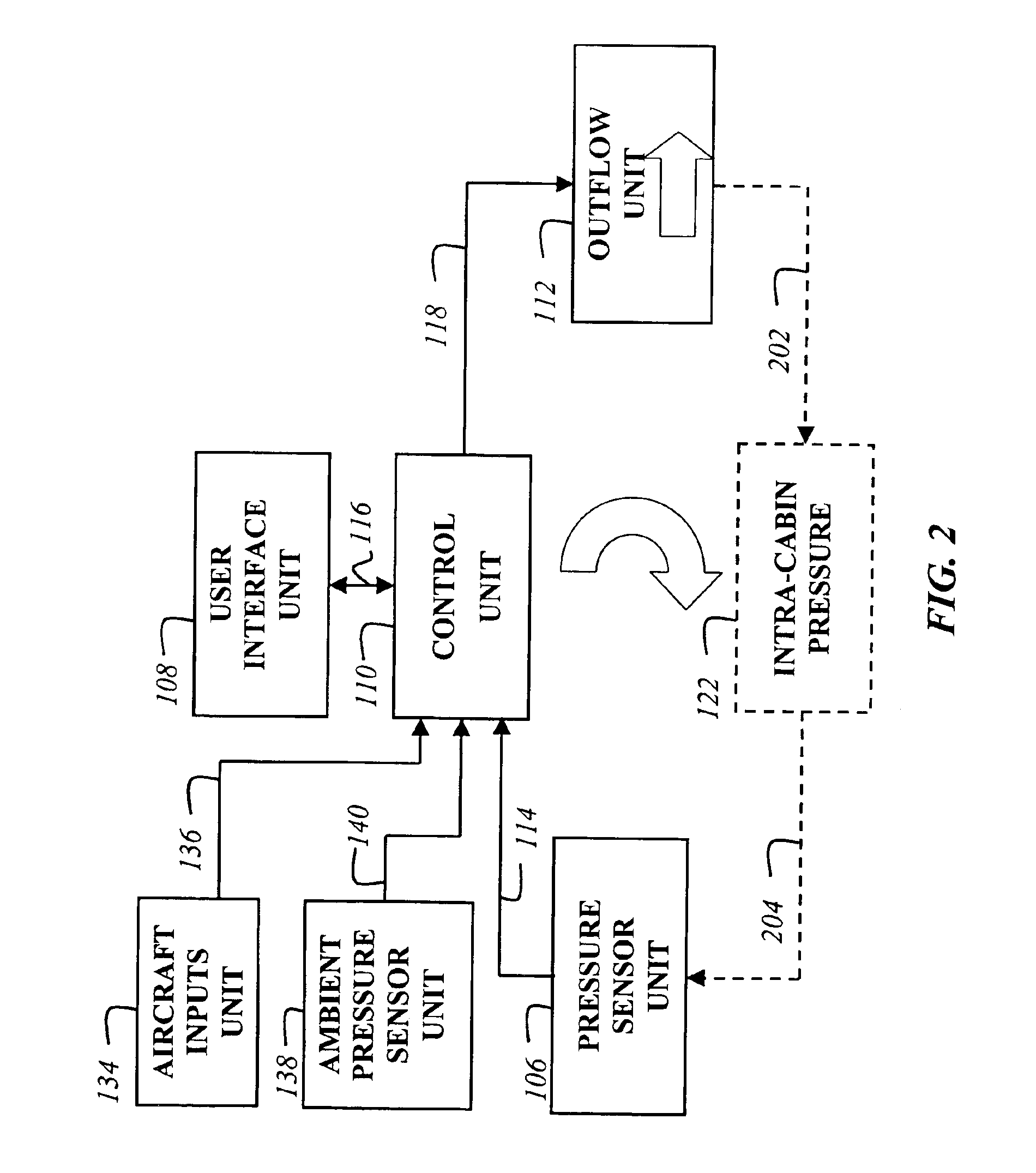

Cabin pressure control method and apparatus using all-electric control without outflow valve position feedback

ActiveUS6979257B2Air-treatment apparatus arrangementsFluid pressure control using electric meansMotor speedControl signal

A pressure control system including an inflow unit for admitting pressurized air into a cabin, an outflow unit including a motor for operating a valve to discharge air from the cabin at a predetermined rate based on an motor control signal that sets the motor speed, a control unit, and an air pressure sensor within the cabin for determining a pressure signal. The control unit receives the pressure signal and computes a pressure rate of change error signal to set the motor control signal. The outflow unit, control unit, and air pressure sensor form a feedback control loop independent of motor speed, valve speed, or valve position feedback.

Owner:HONEYWELL INT INC

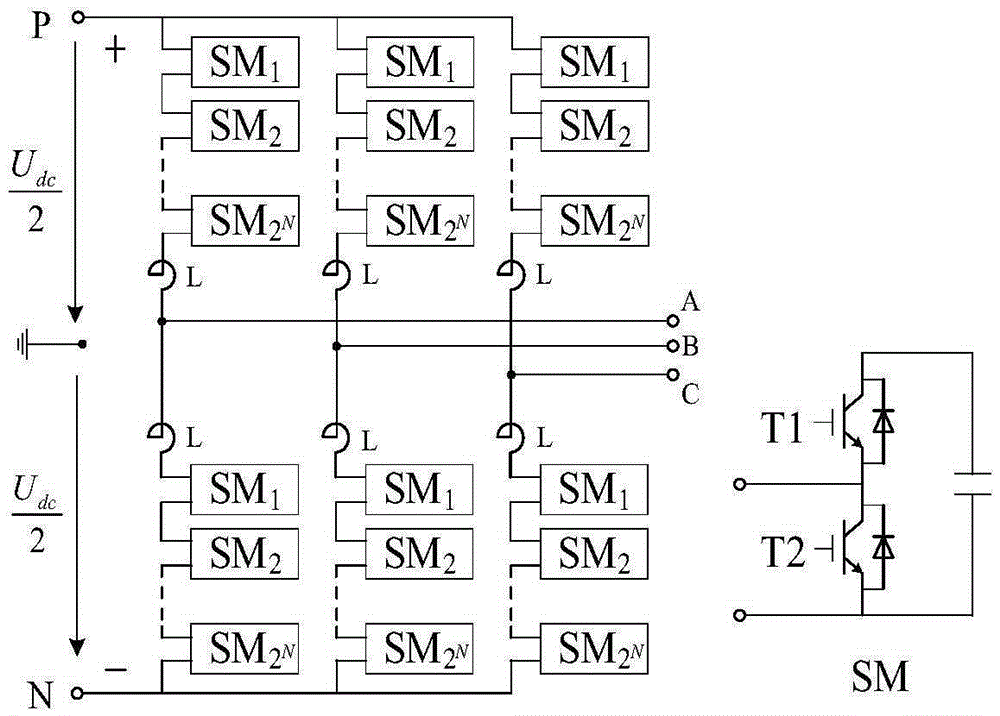

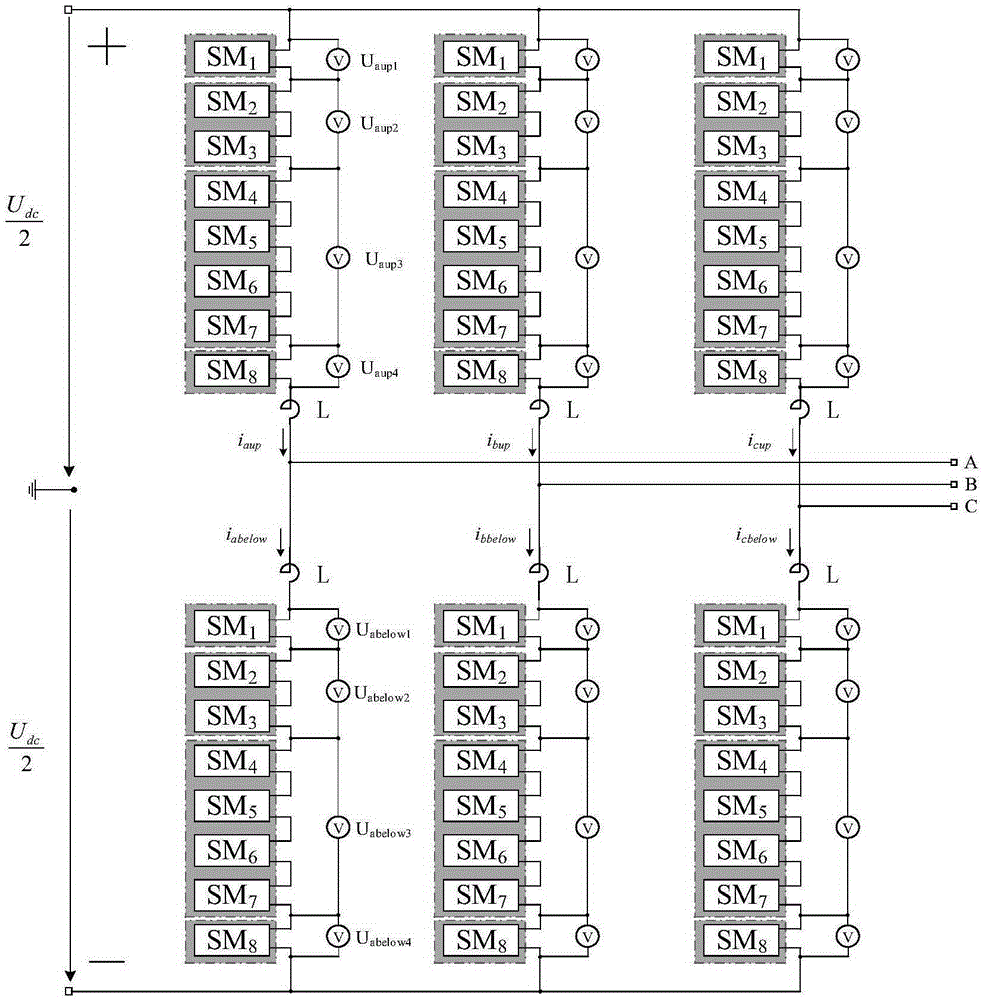

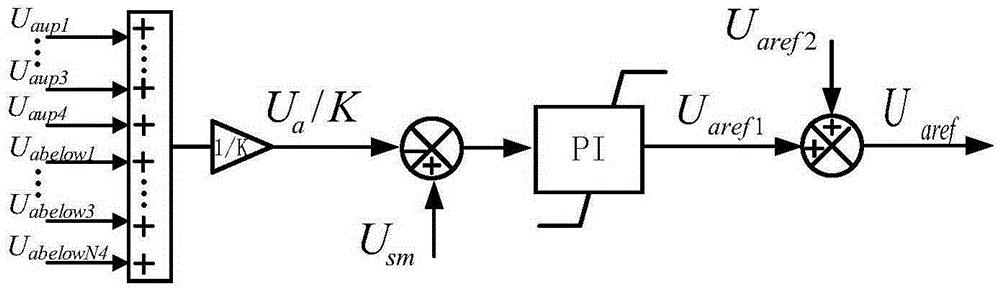

Control method of modular multi-level current converter

The invention discloses a control method of a modular multi-level current converter. According to the control method, 2N sub modules of a bridge arm is divided into N+1 module groups according to 20, 21, 22, and so on, and 2N-1, and 1, and during work, intra-group sub modules in each group are kept the same in state, namely being simultaneously turned on or turned off. Each group is configured with a voltage sensor used for measuring the voltage value of the group. According to such a structure, a voltage stability control method, a voltage recording method, a modulation method and an even pressure control method are designed. Voltage stability control adopts a PI adjustor to stabilize the sum of capacitor voltage of all sub modules of all phases; the voltage recording method is used for saving voltage values of all the module groups; the modulation method is used for determining the on-off state of each module group; even pressure control is used for keeping the average value of the sub modules of a component to be balanced. According to the control method provided by the invention, a control way of grouping sub module groups is adopted, voltage transformers required in an MMC system are greatly reduced, and further, hardware complexity of the system is reduced and the cost of MMC is reduced.

Owner:HUNAN UNIV

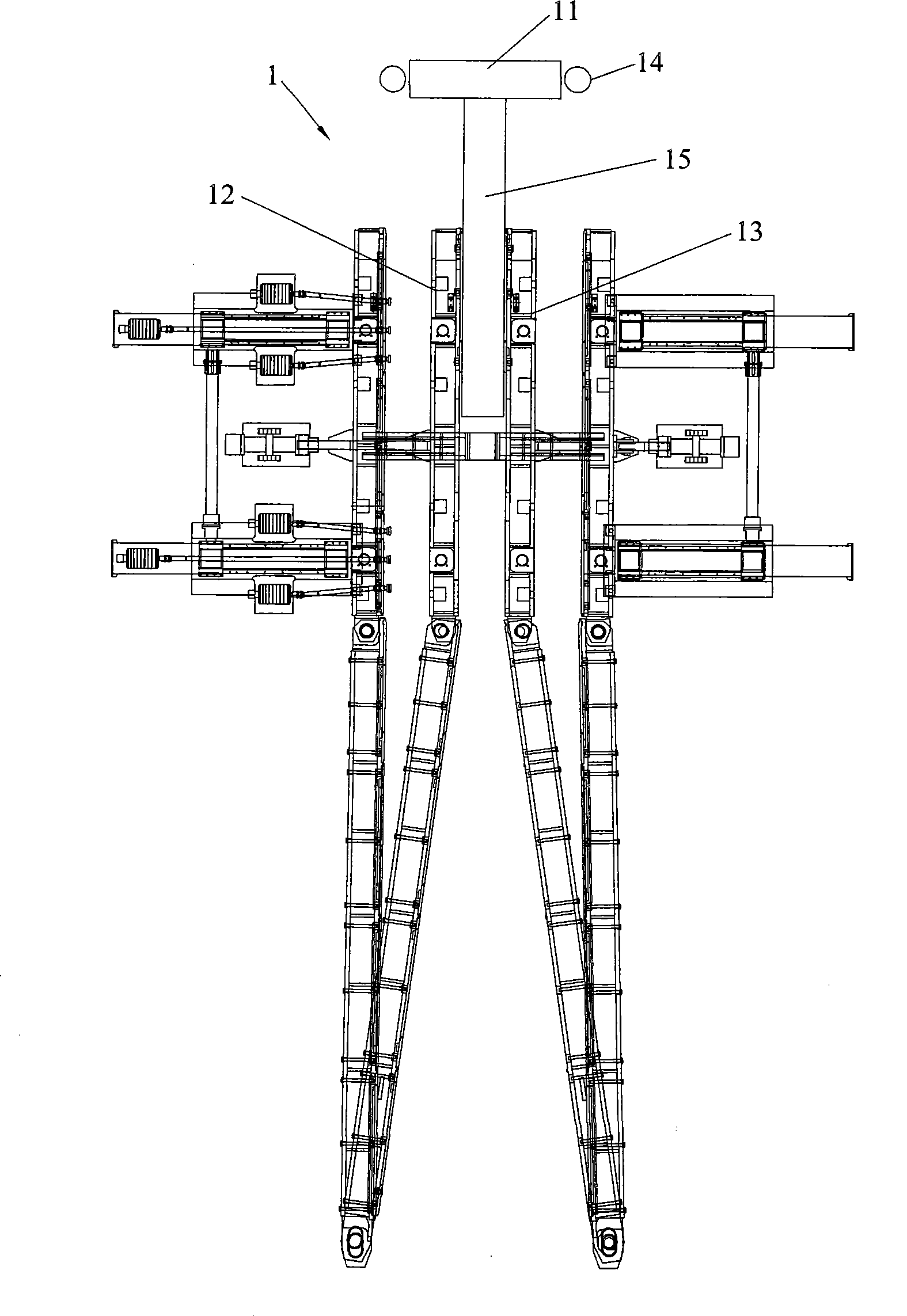

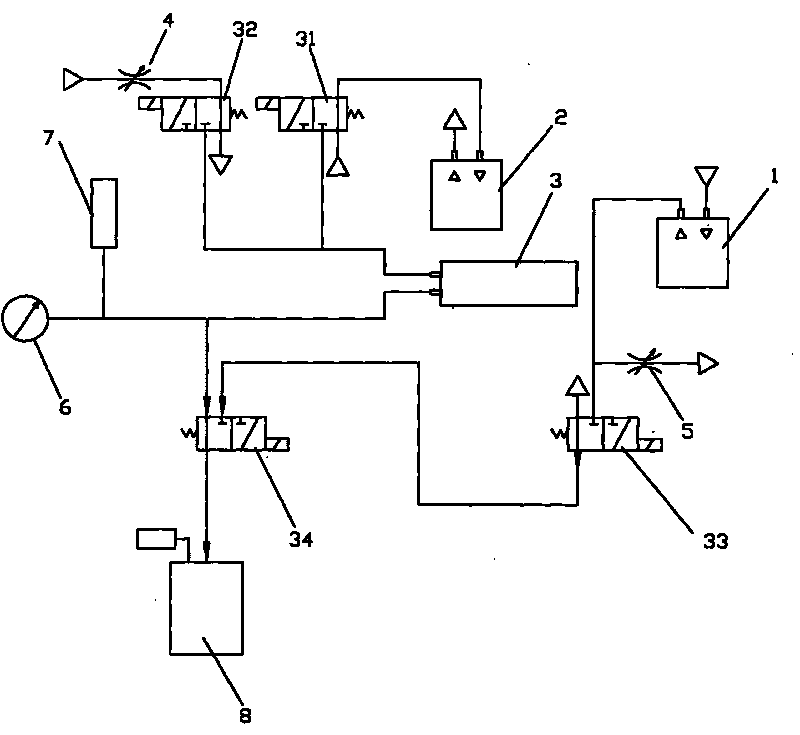

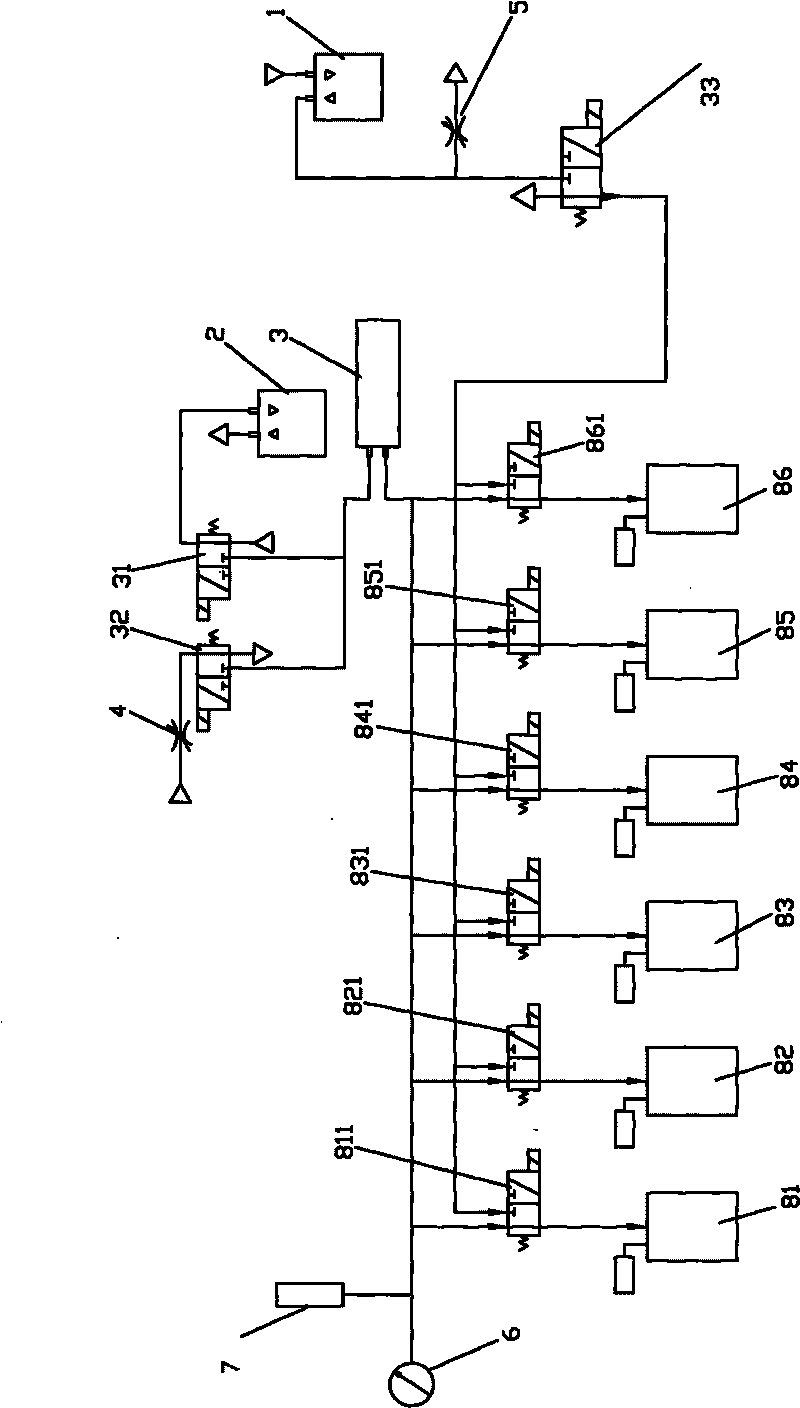

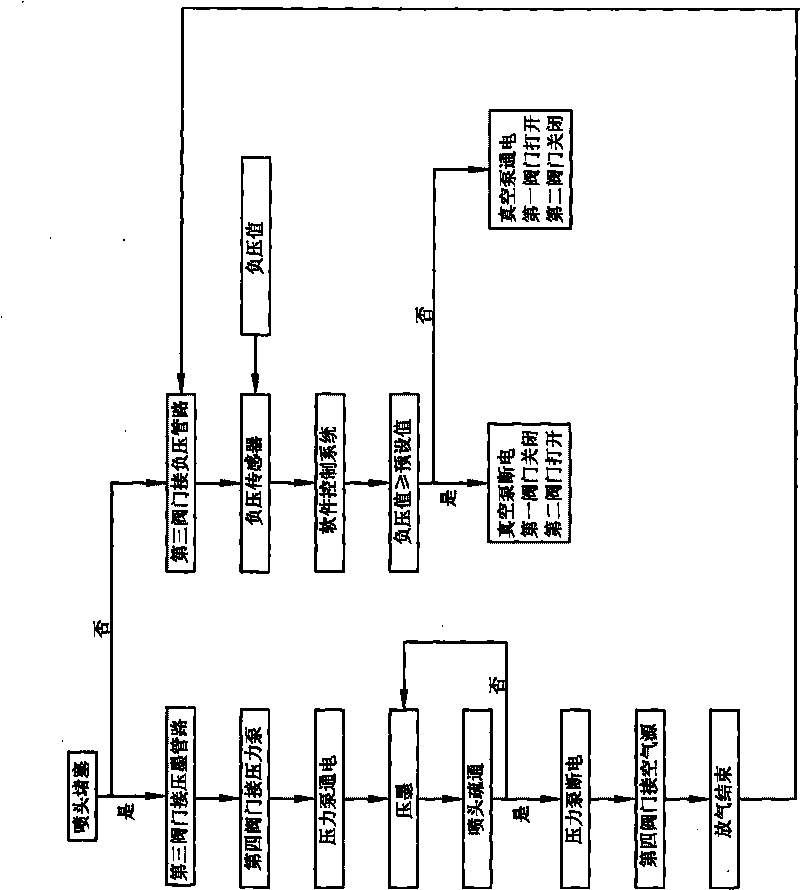

Negative pressure system for nozzle of ink-jet printer and negative pressure control method thereof

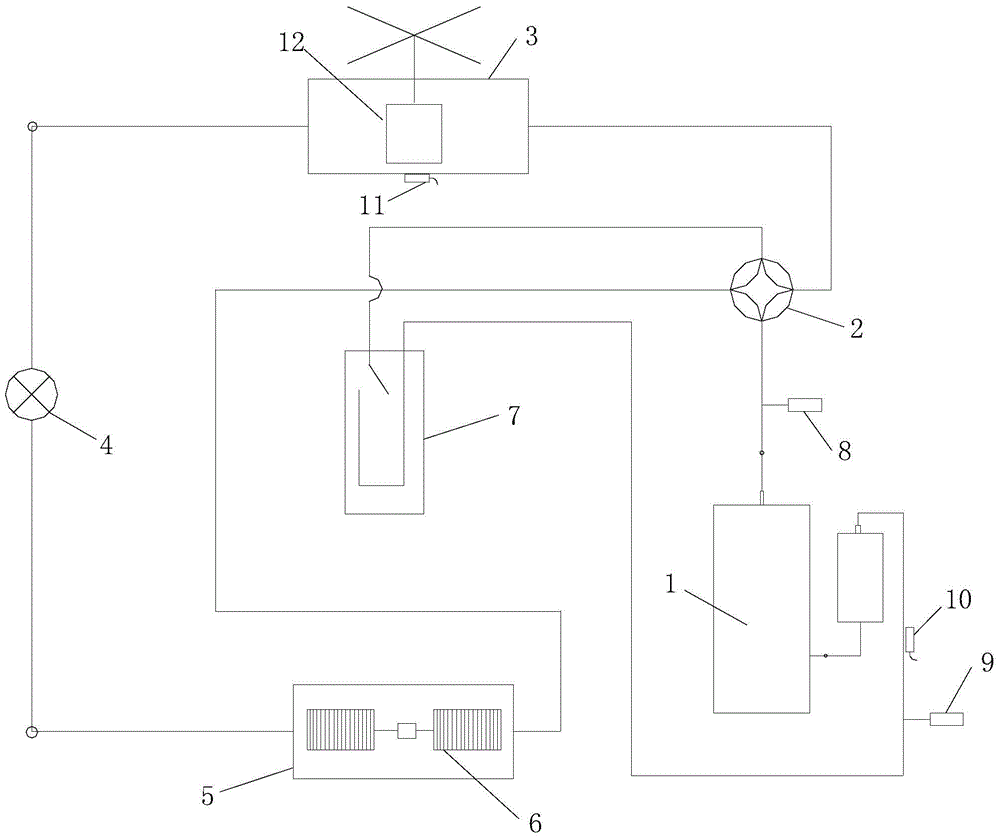

The invention discloses a negative pressure system for a nozzle of an ink-jet printer and a negative pressure control method thereof. The negative pressure system comprises a negative pressure cavity, a vacuum pump, an auxiliary ink box and a control system, wherein the negative pressure cavity is connected with the vacuum pump, an air source and the auxiliary ink box through a plurality of two-position three-way valves respectively; the negative pressure cavity is also connected with a negative pressure sensor for detecting negative pressure in the negative pressure cavity; and the control system controls the open or the close of each two-position three-way valve and the power-on or the power-off of the vacuum pump according to signals fed back by the negative pressure sensor so as to control the negative pressure in the negative pressure cavity accurately, realize continuous, stable, quick and proper ink supply to the nozzle by the auxiliary ink box, and improve the working stability of the printer. The negative pressure system is also connected with an ink pressing system in series through the two-position three-way valves, and the ink pressing system comprises a pressure pump and a flow limiting valve; and when the nozzle is blocked, the nozzle is communicated with the ink pressing system by controlling the two-position three-way valves, the nozzle is dredged by ink pressing, and air is released after the ink pressing is completed so as to prevent other nozzles from dropping ink, and improve the printing quality of the printer.

Owner:BEIJING MEIKEYI

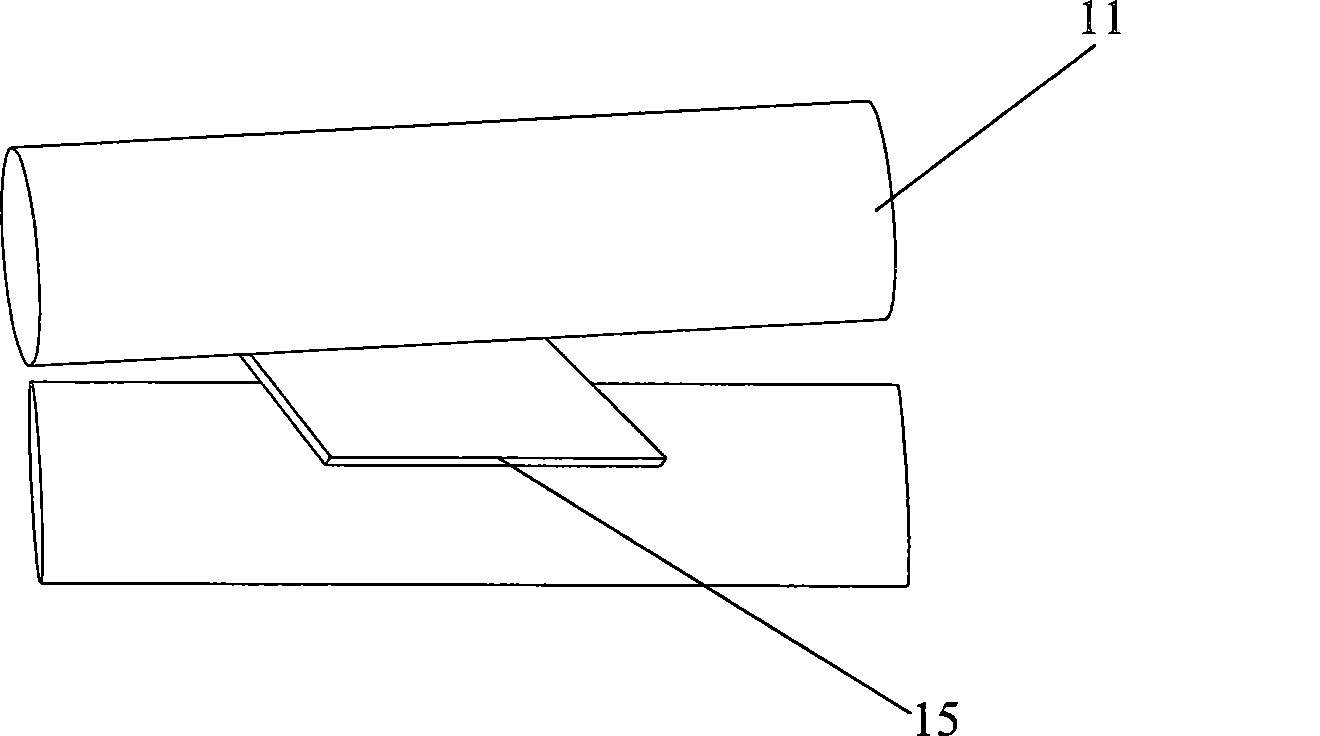

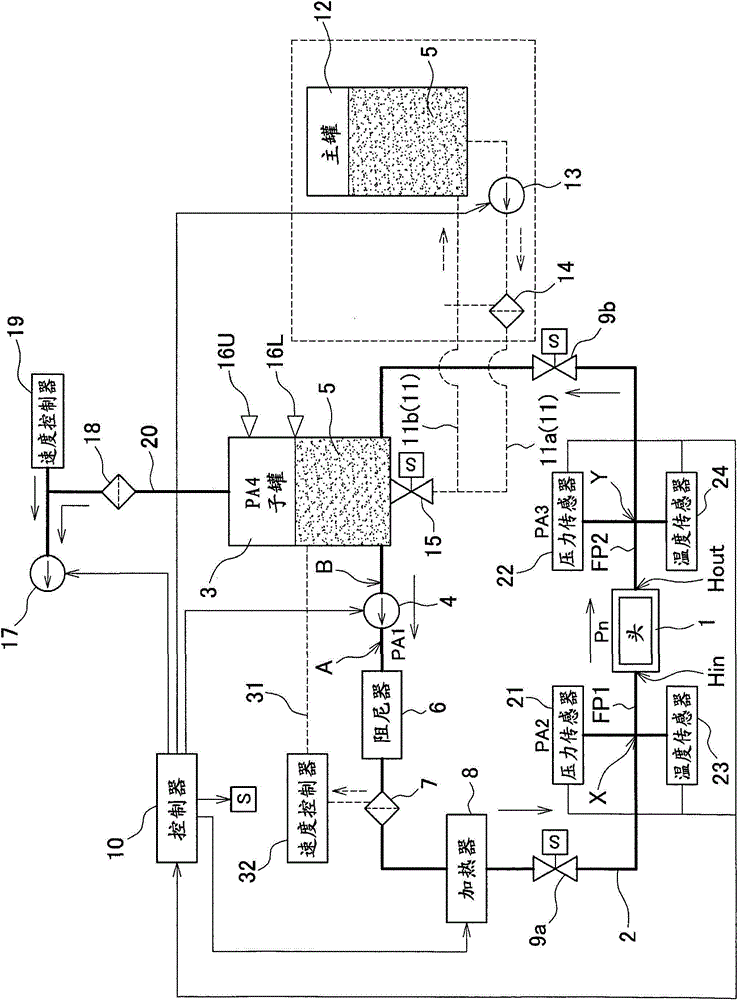

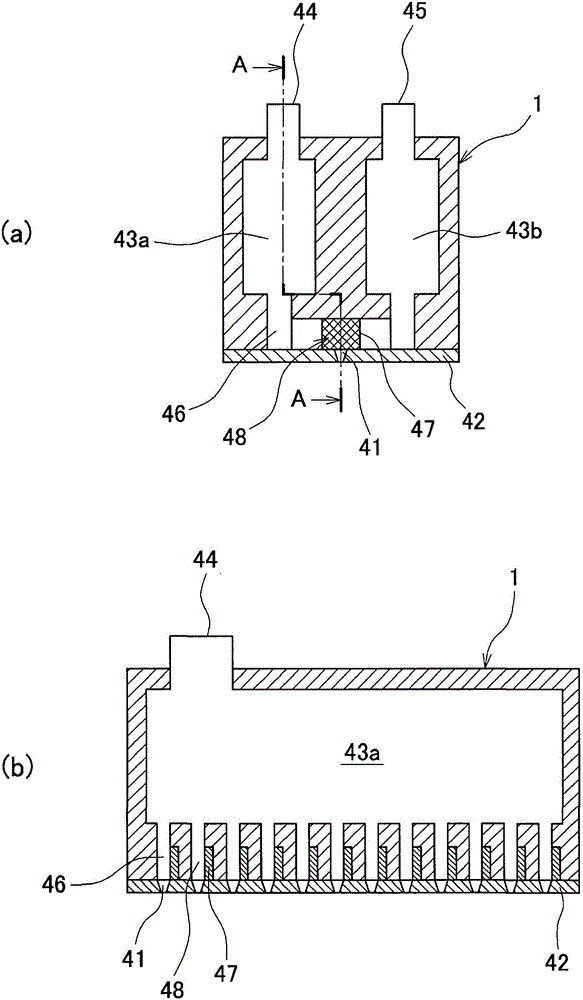

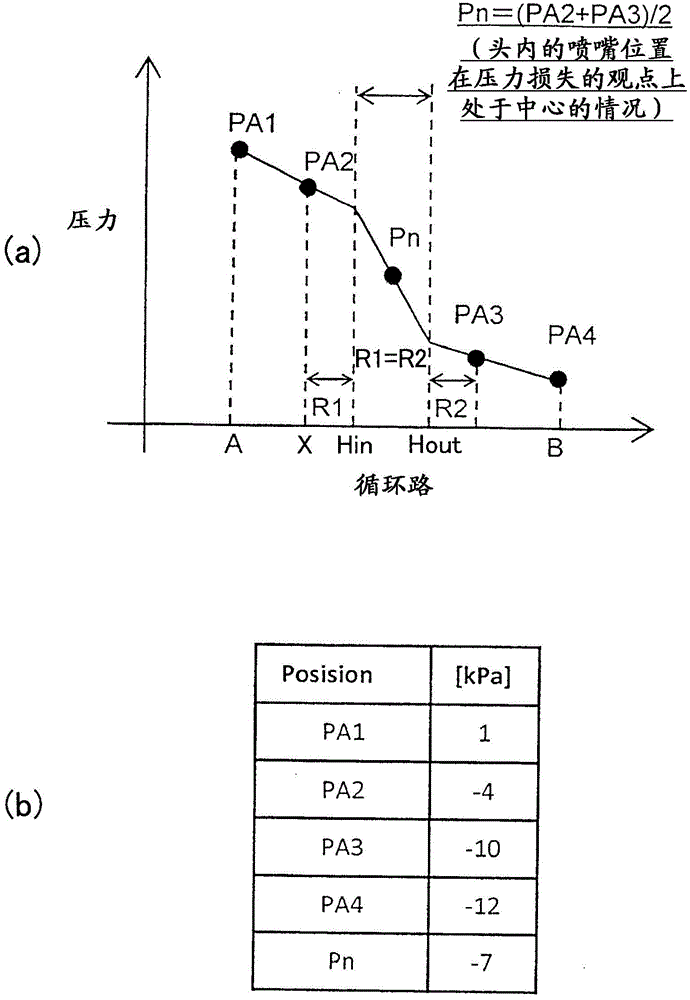

Ink Supply System Used For Ink-jet Printer, And Ink Pressure Control Method In System

The present invention relates to an ink supply system used for an ink-jet printer, and an ink pressure control method in the system. Aiming at an ink gun 1 possessing a nozzle 41 and a pressure chamber 48, the ink is supplied circularly from a sub can 3 via an ink circulation path 2, at the upstream side of the ink gun 1, a pressure sensor 21 is configured, and at the downstream side, a pressure sensor 22 is configured. The flow path resistance R1 between the pressure sensor 21 and the ink gun 1 and the flow path resistance R2 between the pressure sensor 22 and the ink gun 1 are set to be equal R1=R2. A controller 10 calculates the ink pressure at the nozzle 41 according to the detection values of the pressure sensors 21, 22, so that the pressure in the sub can 3 is controlled in a manner of enabling the pressure to be a specified value.

Owner:SEIREN CO LTD

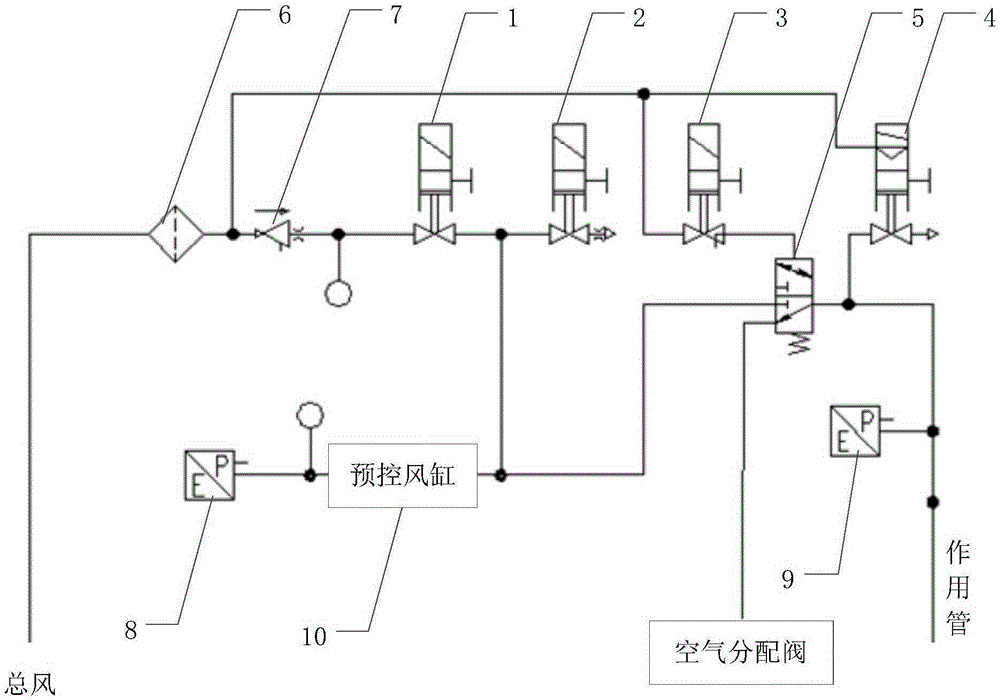

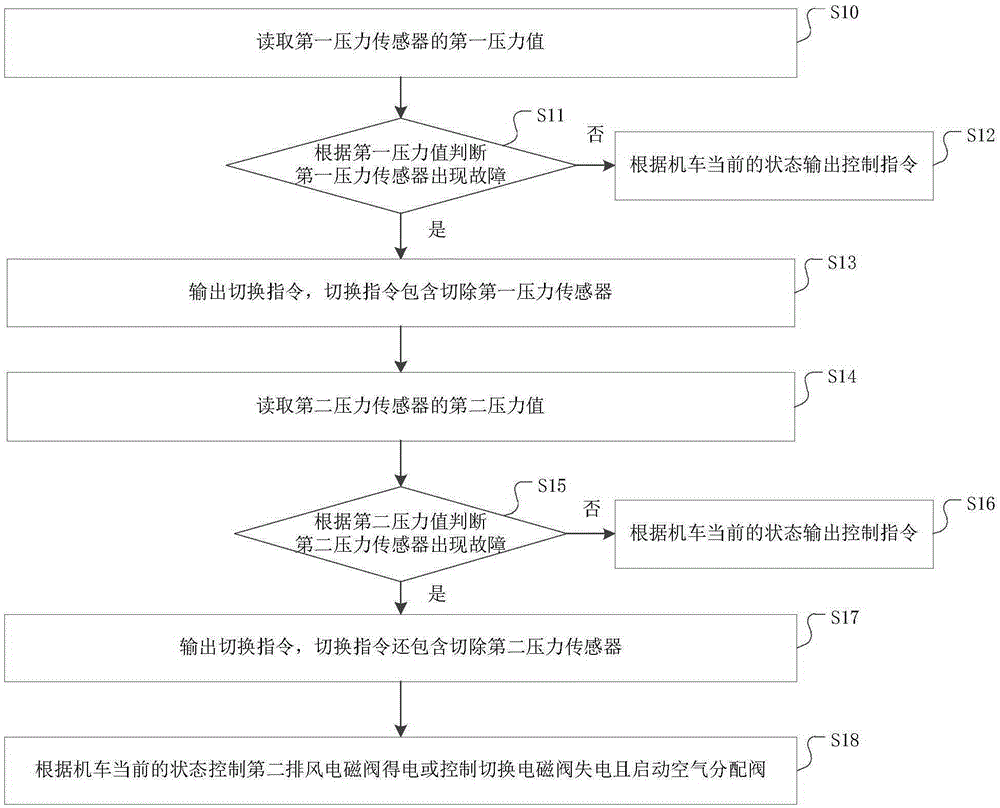

Redundancy device for pressure control of brake cylinder and pressure control method

ActiveCN105235671AImprove reliabilityHigh control precisionBraking action transmissionSolenoid valveAir filter

Disclosed is a redundancy device for pressure control of a brake cylinder. The redundancy device for pressure control of the brake cylinder comprises a total air filter, a pressure regulating valve, an air charging solenoid valve, a first air exhaust solenoid valve and a second air exhaust solenoid valve, and further comprises a first pressure sensor, a switching solenoid valve and a second pressure sensor, wherein the total air filter, the pressure regulating valve, the air charging solenoid valve and the first air exhaust solenoid valve are arranged in a total air inlet in sequence, the second air exhaust solenoid valve is arranged between the total air filter and the pressure regulating valve. Due to the fact that the second pressure sensor is added, a brake control unit can detect whether the first pressure sensor has a fault or not at first, the first pressure sensor is switched to the second pressure sensor under the condition that the first pressure sensor has a fault, double guarantees are achieved, and the reliability of a system is improved. In addition, the brake control unit outputs control instructions according to the states of the first pressure sensor and the second pressure sensor and the current state of a locomotive so as to control the corresponding solenoid valves to change air channels, and therefore the regulating speed is high, and the control accuracy is high.

Owner:QINGDAO SRI TECH CO LTD

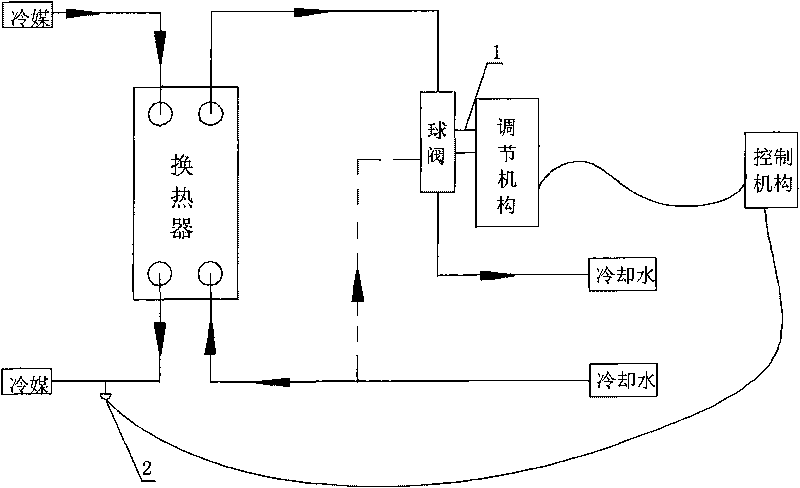

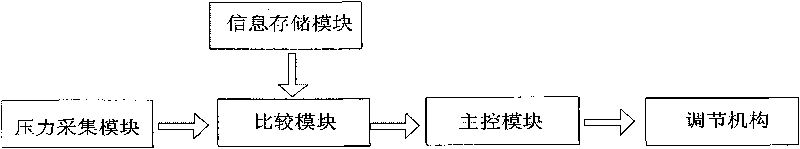

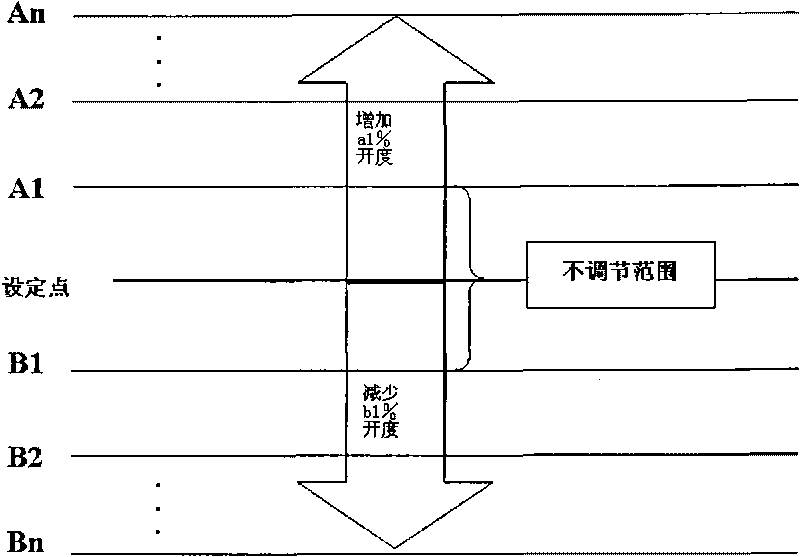

Condensing pressure control device of air conditioning unit and control method thereof

InactiveCN101691945AReduce volumeSimple structureSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringAir conditioning

The invention discloses a condensing pressure control device of an air conditioning unit and a control method thereof. The device comprises a ball valve arranged on a coolant pipeline of a heat exchanger, an adjustment mechanism used for adjusting the opening of the ball valve and a control mechanism used for controlling the actions of the adjustment mechanism, wherein the control mechanism comprises a source information acquisition module, an information storage module, a comparison module and a master control module. The condensing pressure control method for the air conditioning unit comprises that: acquired source information on the coolant pipeline of the heat exchanger is transmitted to the comparison module; the comparison module compares the received source information with pre-stored set information and transmits obtained comparison information to the master control module; and according to the comparison information, the master control module controls the adjustment mechanism to adjust the opening of the ball valve on the coolant pipeline of the heat exchanger. The condensing pressure control device of the air conditioning unit and the control method thereof provided by the invention are reliable in control, high in accuracy and system flexibility and capable of performing real-time monitoring, protecting the valve and being adapted to different compressors and different refrigerants.

Owner:EMERSON NETWORK POWER CO LTD

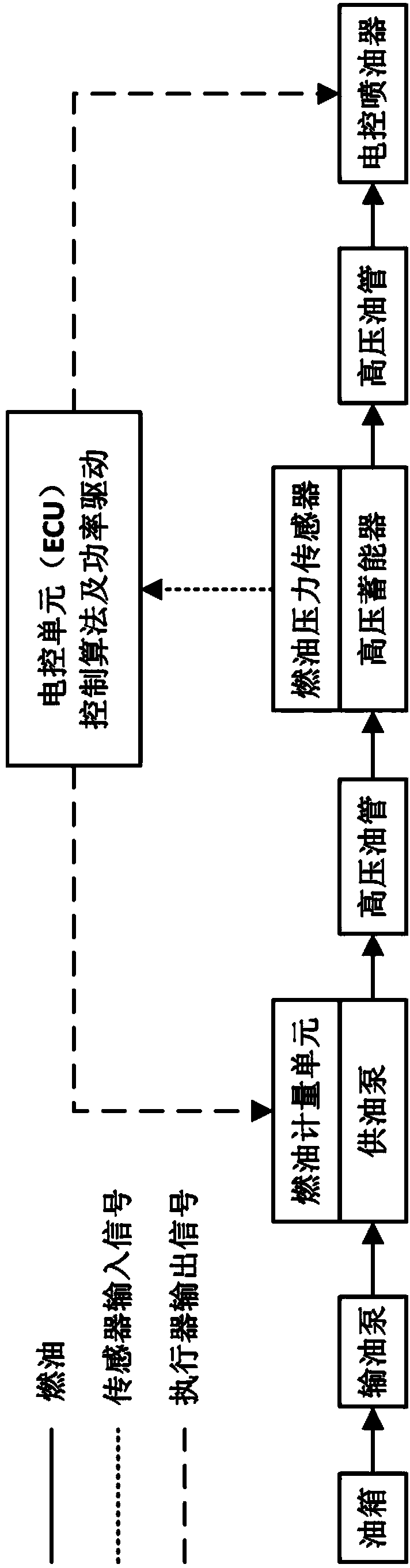

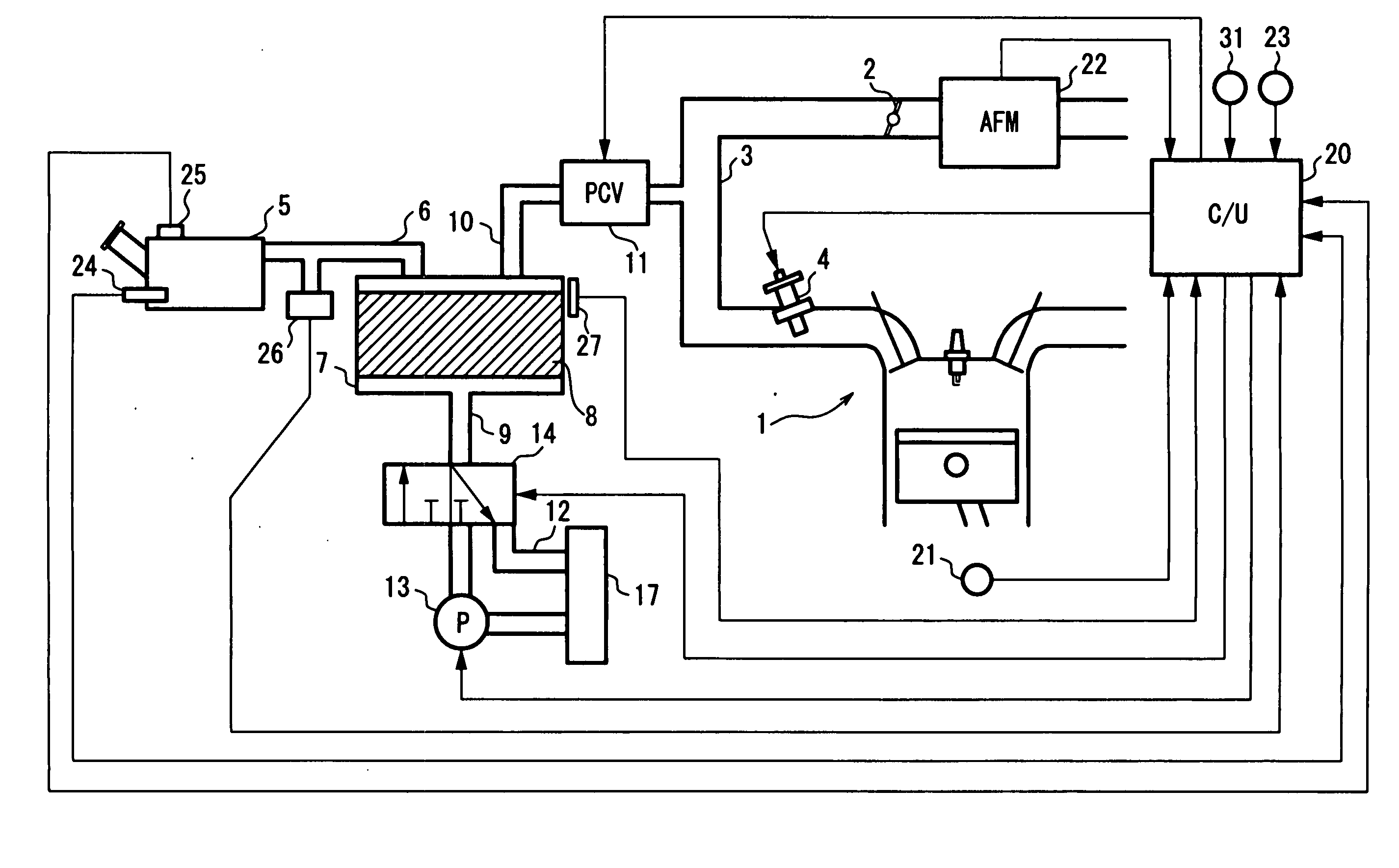

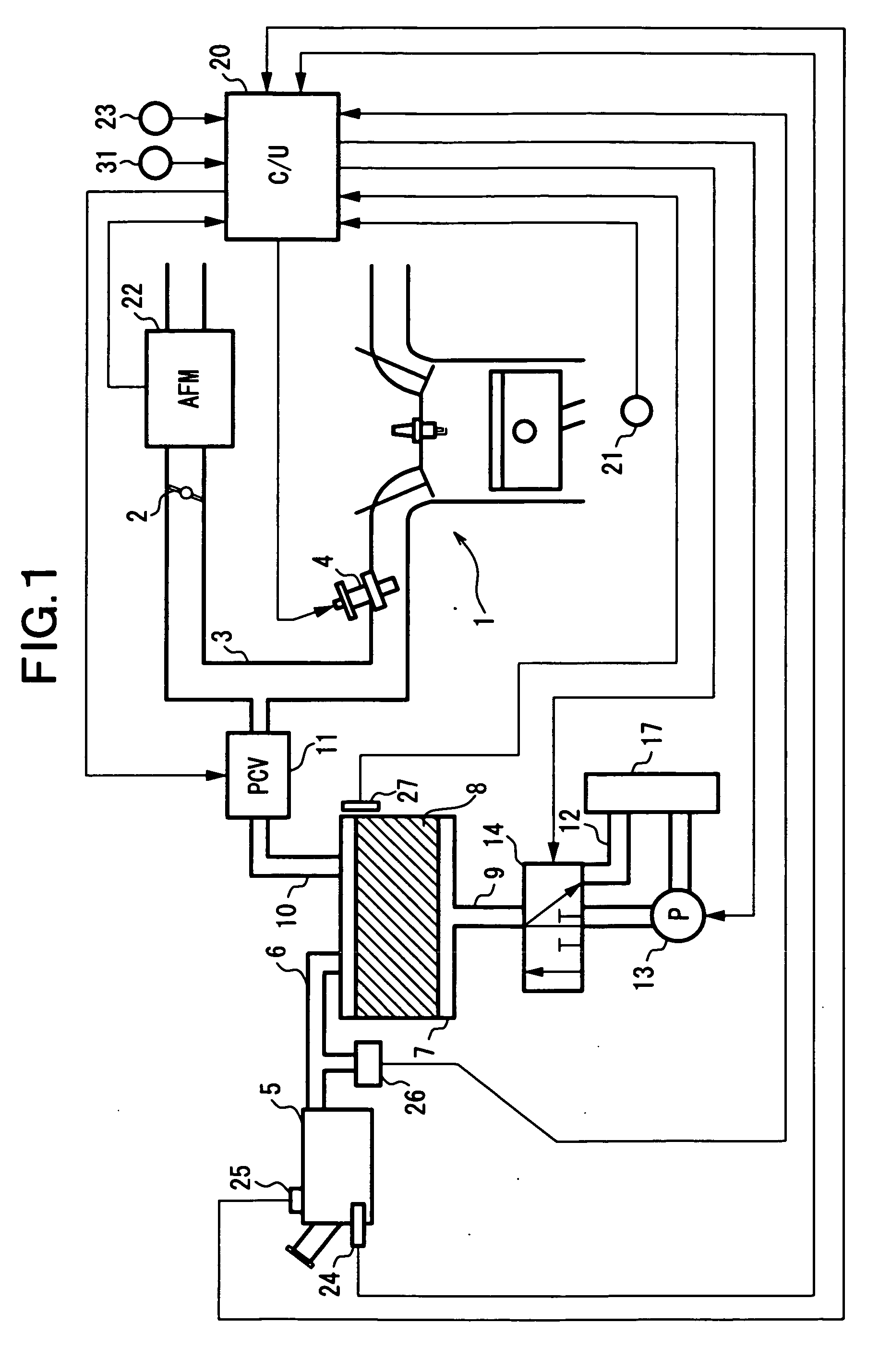

Active disturbance observation-based fuel pressure controller and control method thereof

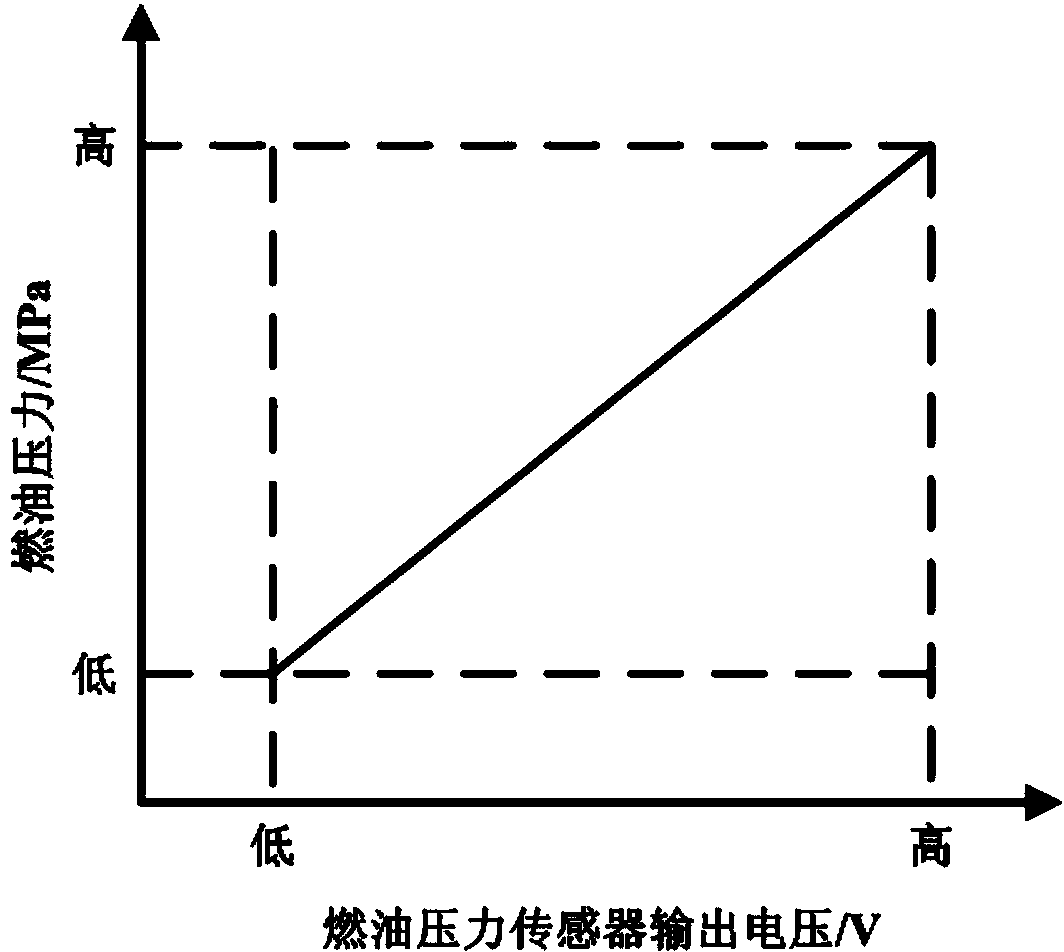

The invention relates to an active disturbance observation-based fuel pressure control method, aims at solving the problems of time-varying characteristics and non-linearity of an internal combustion engine fuel injection system and non-ideal application of traditional PID (proportion integration differentiation) control in fuel pressure control and the like, and provides the method of realizing control on fuel pressure by adopting model-based feedforward control and state observation-based feedback control. The method mainly comprises target fuel pressure computation, fuel pressure sensor practical fuel pressure collection and computation, fuel measuring unit fuel volume flow rate feedback regulation amount computation, fuel measuring unit fuel volume flow rate feedforward control amount computation, conversion of fuel measuring unit fuel volume flow rate into current, conversion of fuel measuring unit current into a PWM (Pulse Width Modulation) duty ratio, fuel measuring unit practical work current measurement and computation, a fuel measuring unit current feedback regulator, fuel measuring unit PWM modulation frequency computation, a fuel measuring unit PWM drive, a fuel measuring unit, a fuel injection system and a fuel pressure active disturbance observer.

Owner:TIANJIN UNIV

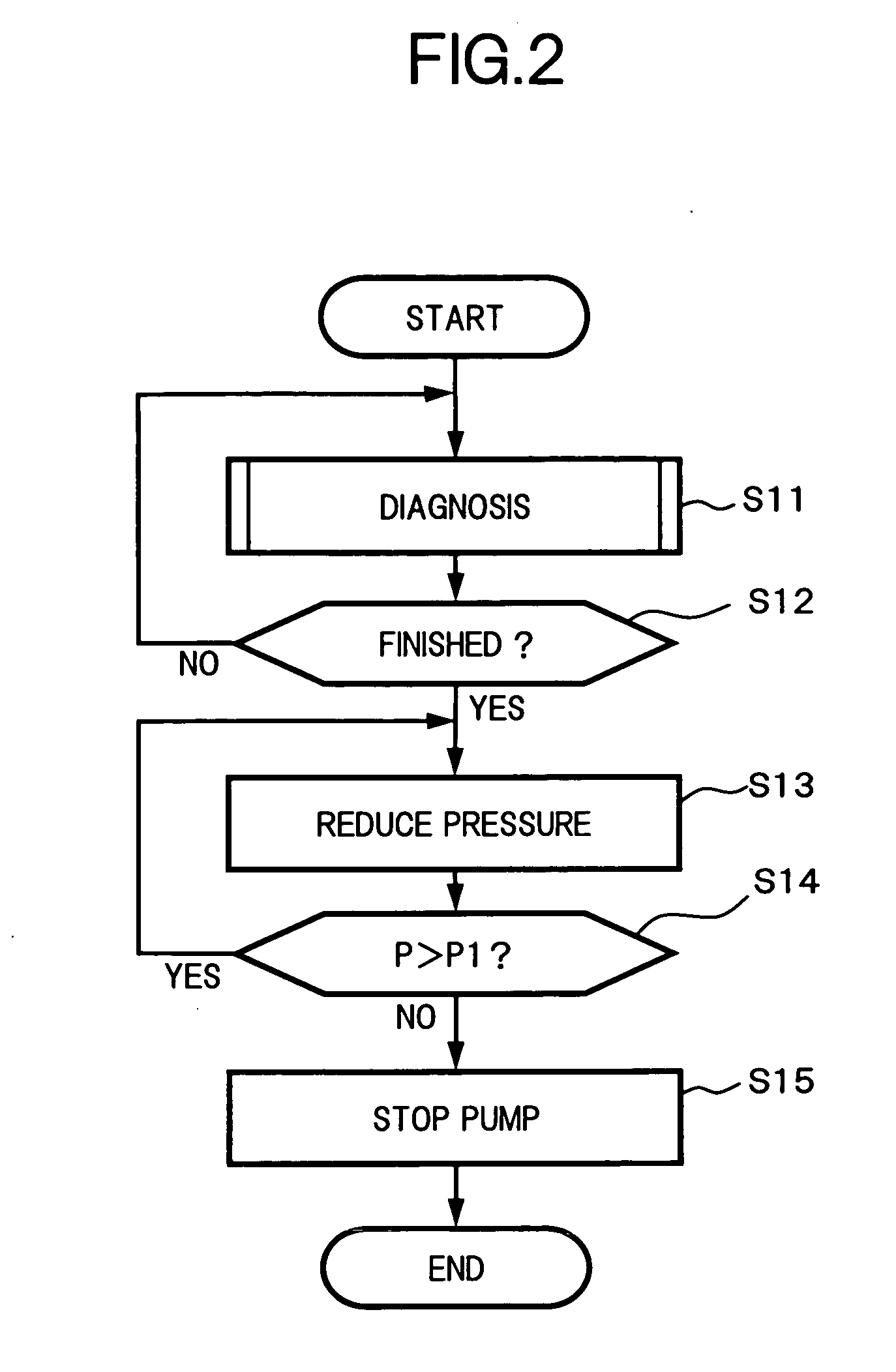

Fuel supply apparatus for and pressure control method of internal combustion engine

InactiveUS20070084274A1Improve the sense of responsibilityNon-fuel substance addition to fuelEngine testingStable stateFuel tank

A leak diagnosing technology in which a diagnostic space capable of being closed is defined which includes therein a fuel tank and a canister, the closed diagnostic space being pressurized by an air pump to diagnose of presence or absence of a leak in the diagnostic space based on whether or not a pressure in the diagnostic space indicates a predetermined pressure change. When the diagnosis is completed, the air pump is reversely rotated to cause a reduction in the pressure in the diagnostic space to thereby quickly return the pressure to a target pressure in a steady state.

Owner:HITACHI LTD

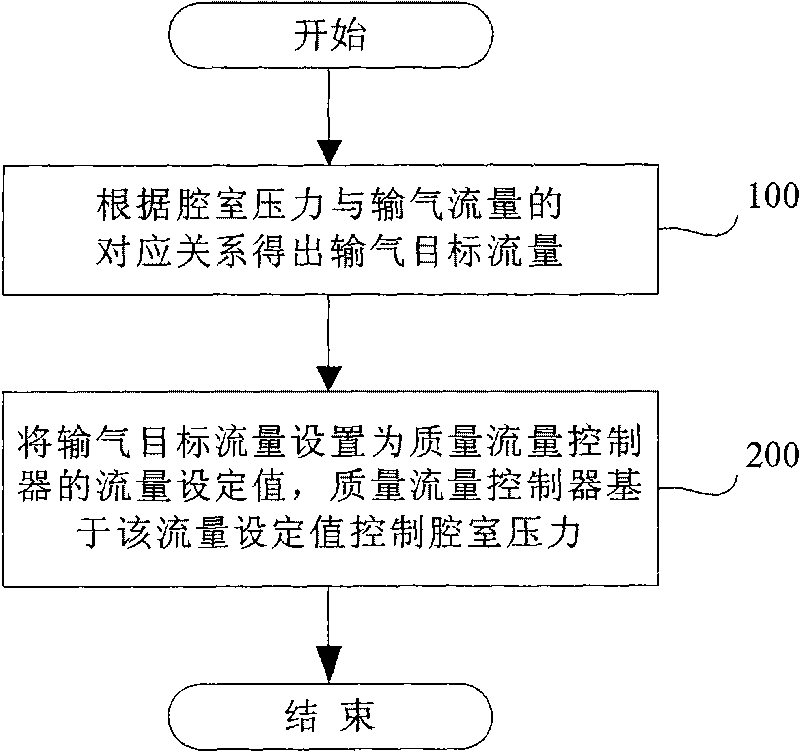

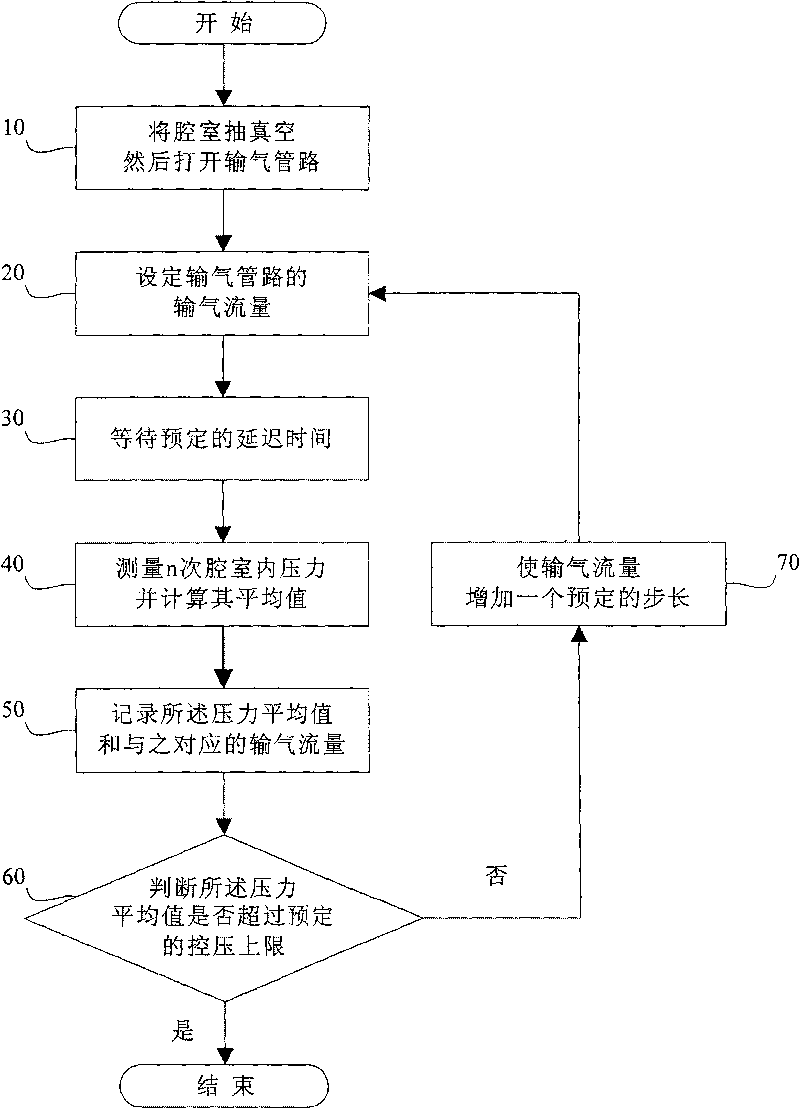

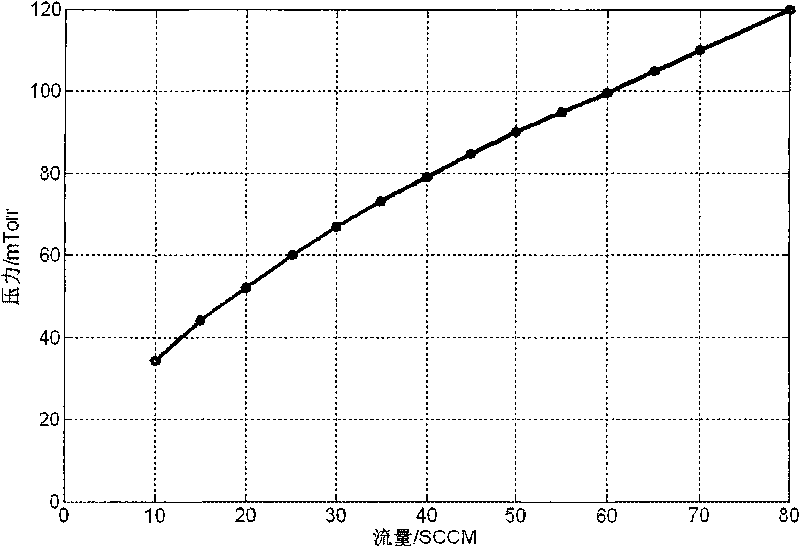

Method, device and system for chamber pressure control

ActiveCN101727111AEffective pressure controlLow costSemiconductor/solid-state device manufacturingFluid pressure control with auxillary non-electric powerControl systemEngineering

The invention provides a chamber pressure control method, which comprises: step 100, acquiring air delivery target flow required when a chamber is in a target pressure according to a corresponding relationship between the pressure of the chamber and the air delivery flow; and step 200, setting the air delivery target flow as a flow setting value of a mass flow controller, wherein the mass flow controller implements air delivery operation on the chamber based on the flow setting value and controls the pressure of the chamber within the target pressure range. The method for controlling the pressure of the chamber also comprises a step of acquiring the corresponding relationship between the pressure of the chamber and the air delivery flow. In addition, the invention also provides a chamber pressure control device, a chamber pressure control system using the method and the chamber pressure control system using the device. An expensive pressure control valve is replaced by adopting the cheaper mass flow controller and the simple control step, and the cost of the process / equipment is saved while effectively controlling the pressure of the chamber.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com