Expansion ratio adjustable pneumatic engine for automobile and its exhaust pressure control method

A pneumatic engine, exhaust pressure technology, applied to the direction of the one-way flow engine, engine components, variable displacement engine, etc., can solve the problem of low effective energy utilization, to avoid the loss of effective energy of compressed air, reduce compression Air exergy loss, effect of improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

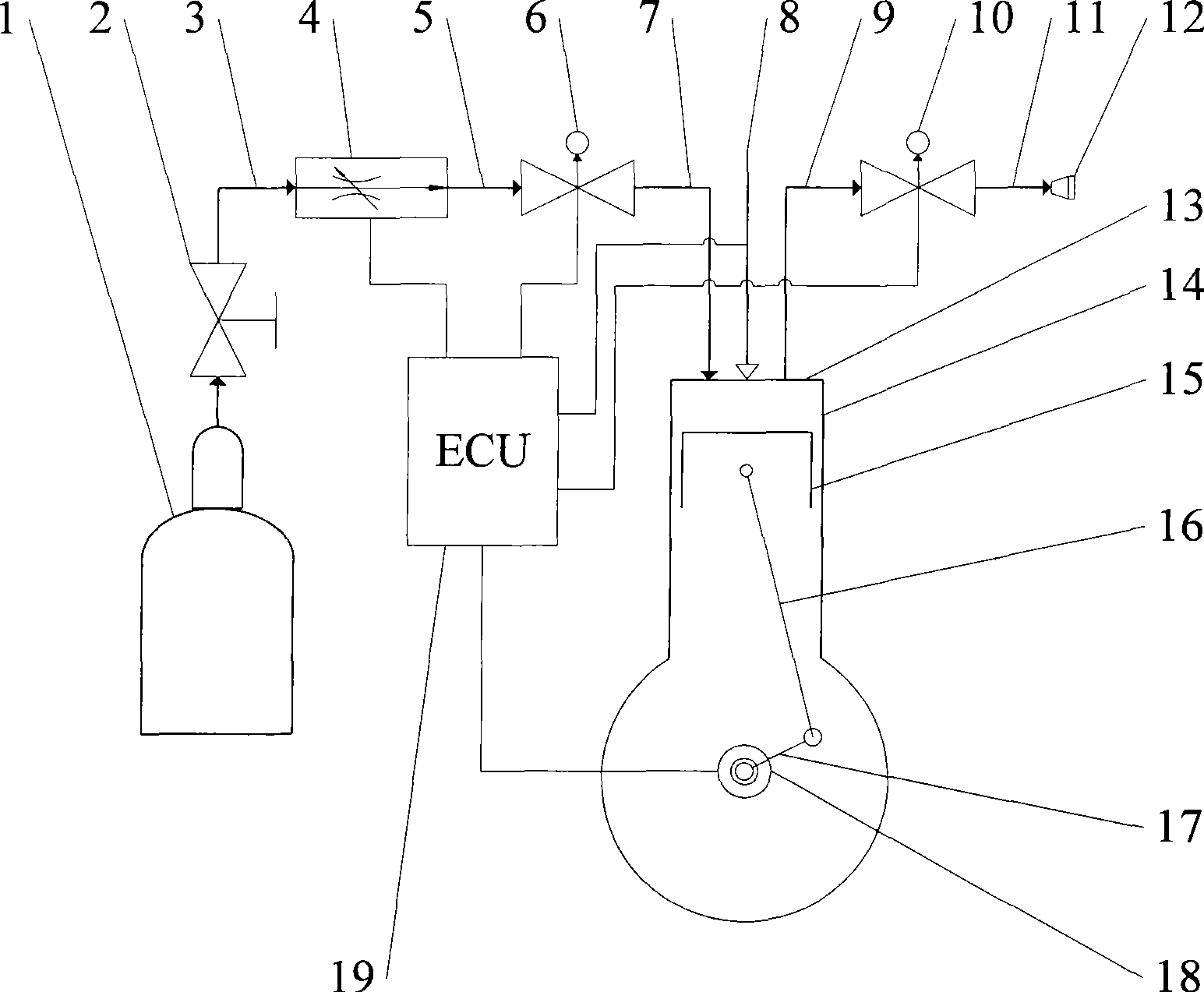

[0028] Such as figure 1 As shown, the vehicle pneumatic engine with adjustable expansion ratio consists of an air storage tank 1, a shut-off valve 2, a high-pressure pipe 3, a flow regulating valve 4, an intermediate pipe 5, an air intake solenoid valve 6, an air intake pipe 7, a cylinder 14, and a cylinder head 13. Piston 15, exhaust pipe 9, exhaust solenoid valve 10, low pressure pipe 11, air outlet 12, pressure sensor 8, connecting rod 16, crankshaft 17, photoelectric encoder 18 and controller 19. The compressed air starts from the air storage tank 1 and passes through the shut-off valve 2, high pressure pipe 3, flow regulating valve 4, intermediate pipe 5, intake solenoid valve 6, intake pipe 7, cylinder 14, exhaust pipe 9, exhaust solenoid valve 10. Low-pressure pipe 11, air outlet 12, and finally discharged into the atmosphere. The high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com