Negative pressure system for nozzle of ink-jet printer and negative pressure control method thereof

An inkjet printer and negative pressure technology, which is applied in the field of inkjet printer nozzle negative pressure system and its negative pressure control, can solve the problems of affecting printing quality, high negative pressure, and inaccurate negative pressure control, so as to improve work stability , prevent excessive negative pressure, and avoid the effect of downward dripping ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

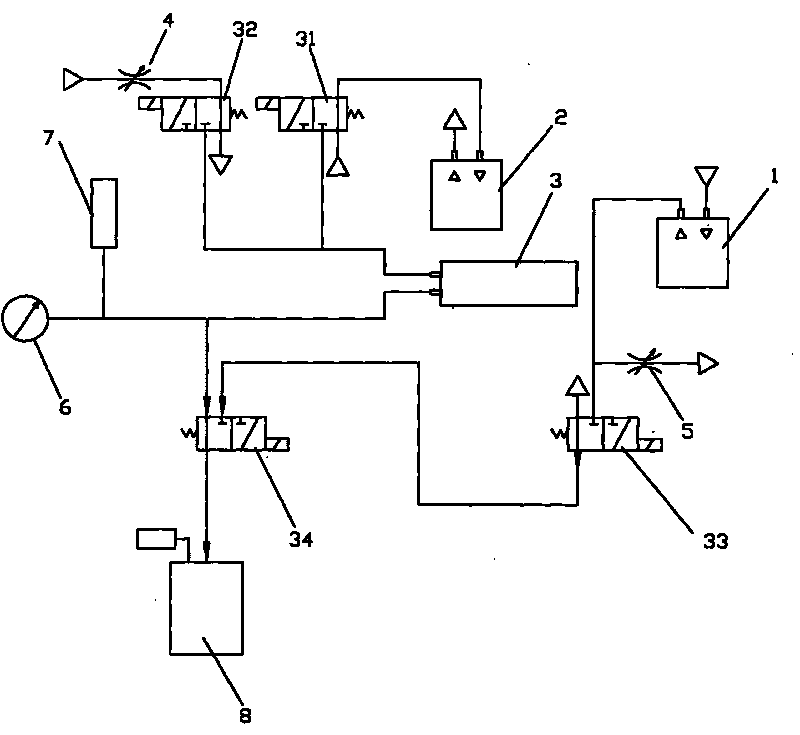

[0023] The present embodiment is provided with the negative pressure system of a sub-ink box in the inkjet printer, as figure 1 As shown, the negative pressure system includes a negative pressure pipeline, an ink pressure pipeline and an auxiliary ink cartridge 8. The negative pressure pipeline is mainly composed of two-position three-way valves 31, 32, a negative pressure chamber 3, a flow limiting valve 4, a vacuum pump 2, The negative pressure gauge 6 and the negative pressure sensor 7 are composed; the ink pressure pipeline is mainly composed of a two-position three-way valve 33 , a flow limiting valve 5 and a pressure pump 1 .

[0024] The secondary ink cartridge 8 is connected to the negative pressure chamber 3 through a two-position three-way valve 34. The connection mode is that one inlet of the two-position three-way valve 34 is connected to the negative pressure chamber 3, and the other inlet is connected to the ink pressure pipeline. The outlet of the two-position t...

Embodiment 2

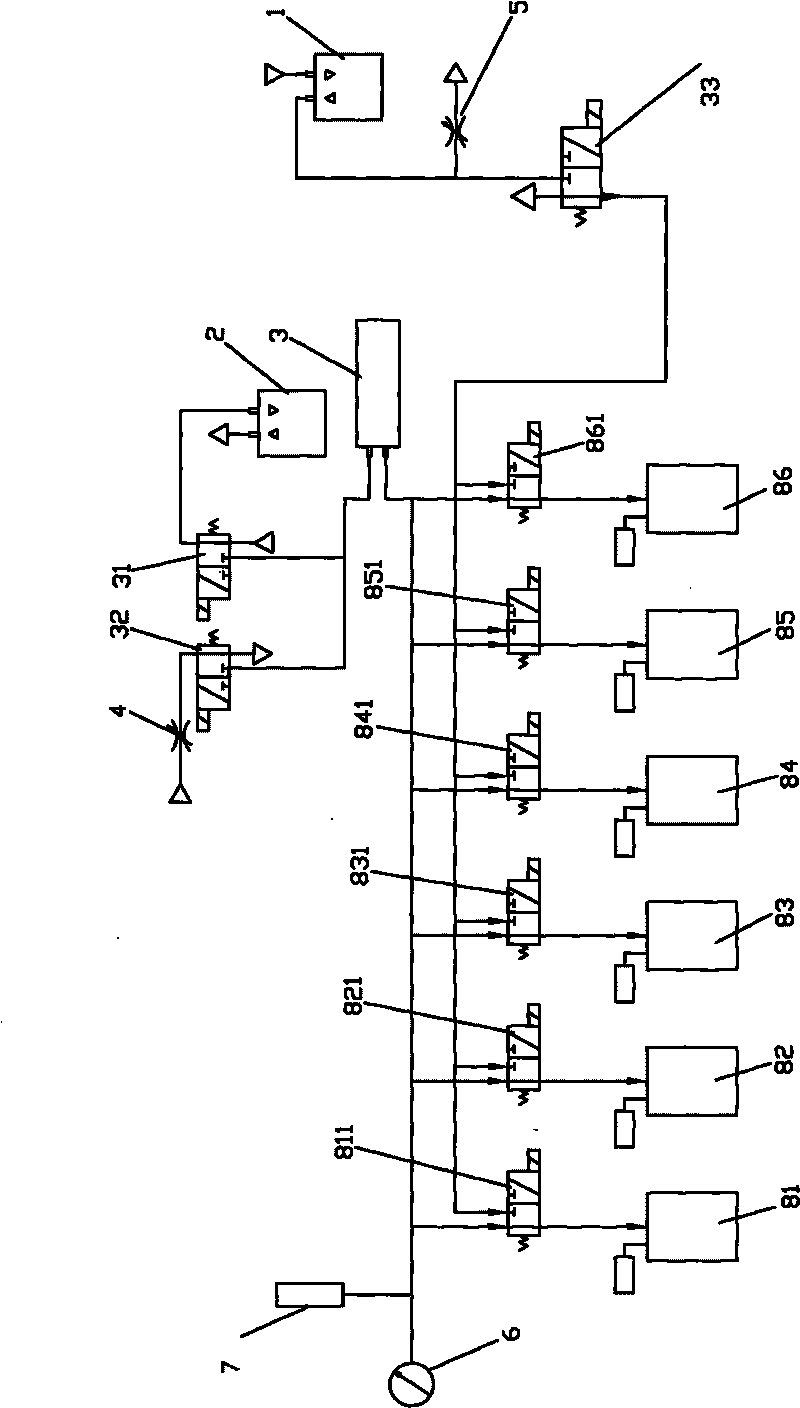

[0027] The number of secondary ink tanks in the negative pressure system of the inkjet printer of the present invention can be designed according to needs, and all the secondary ink tanks are connected in parallel to the negative pressure pipeline and the ink pressure pipeline in series to realize the above functions. This embodiment is a negative pressure inkjet printer equipped with six sets of black, cyan, magenta, yellow, light cyan, and light magenta sub-ink cartridges 81, 82, 83, 84, 85, 86 and a set of ink pressure pipelines. System, wherein the negative pressure system and the control method of negative pressure are identical in structure with embodiment 1, as figure 2As shown, six groups of secondary ink cartridges 81-86 are connected in parallel and connected in series with the negative pressure pipeline and ink pressure pipeline. -86 can switch between negative pressure pipeline and ink pressure pipeline. When the two-position three-way valve 811-861 is in the clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com