Patents

Literature

52results about How to "Shorten return path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

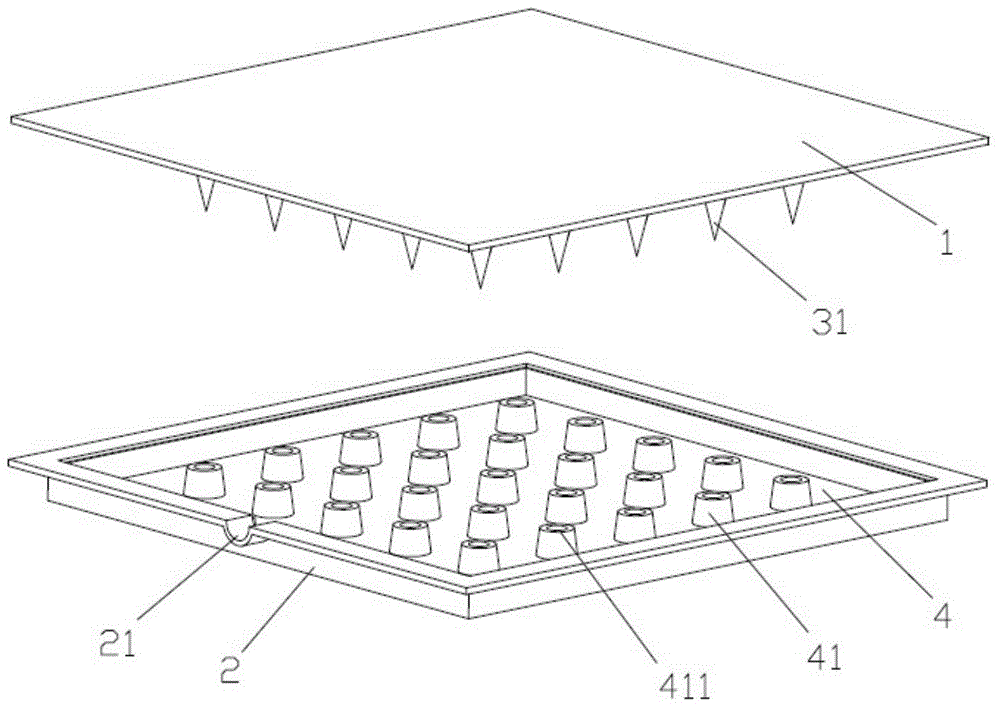

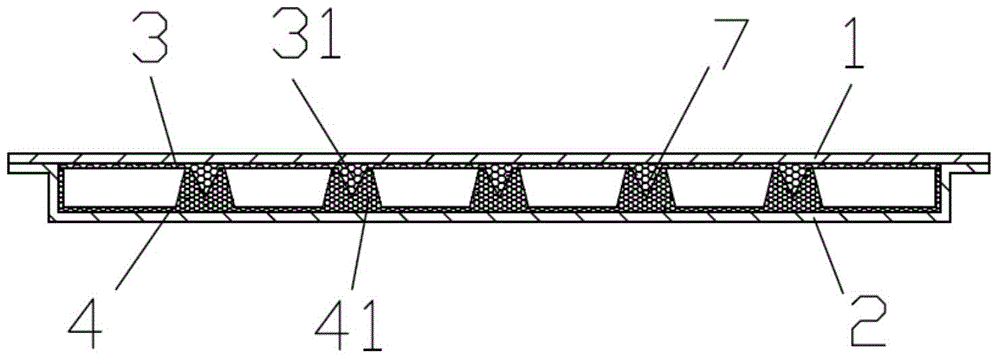

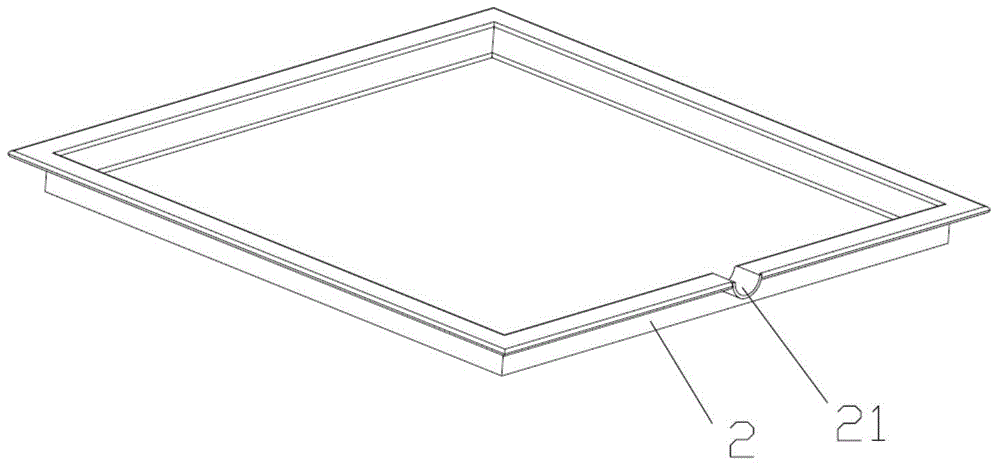

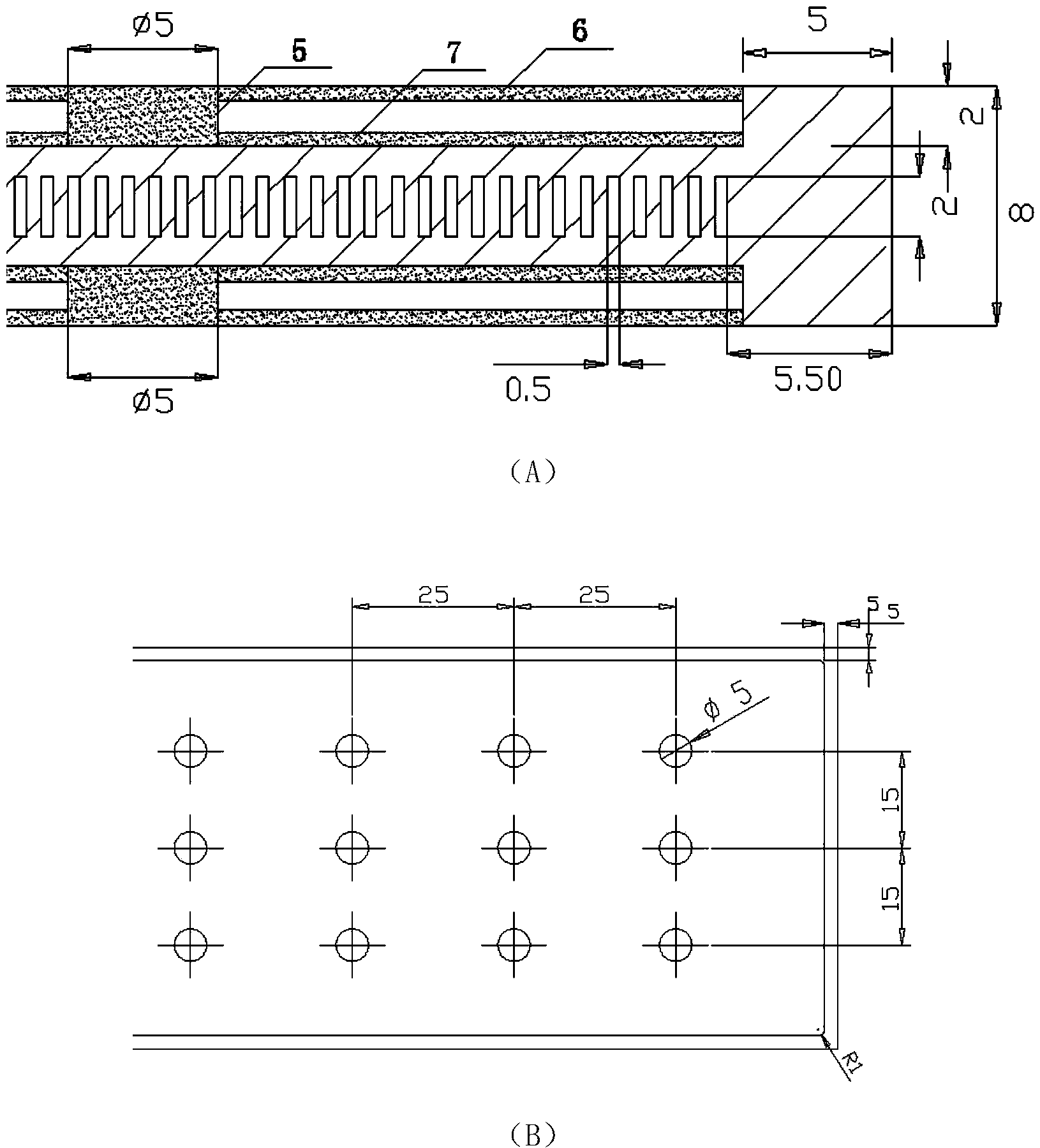

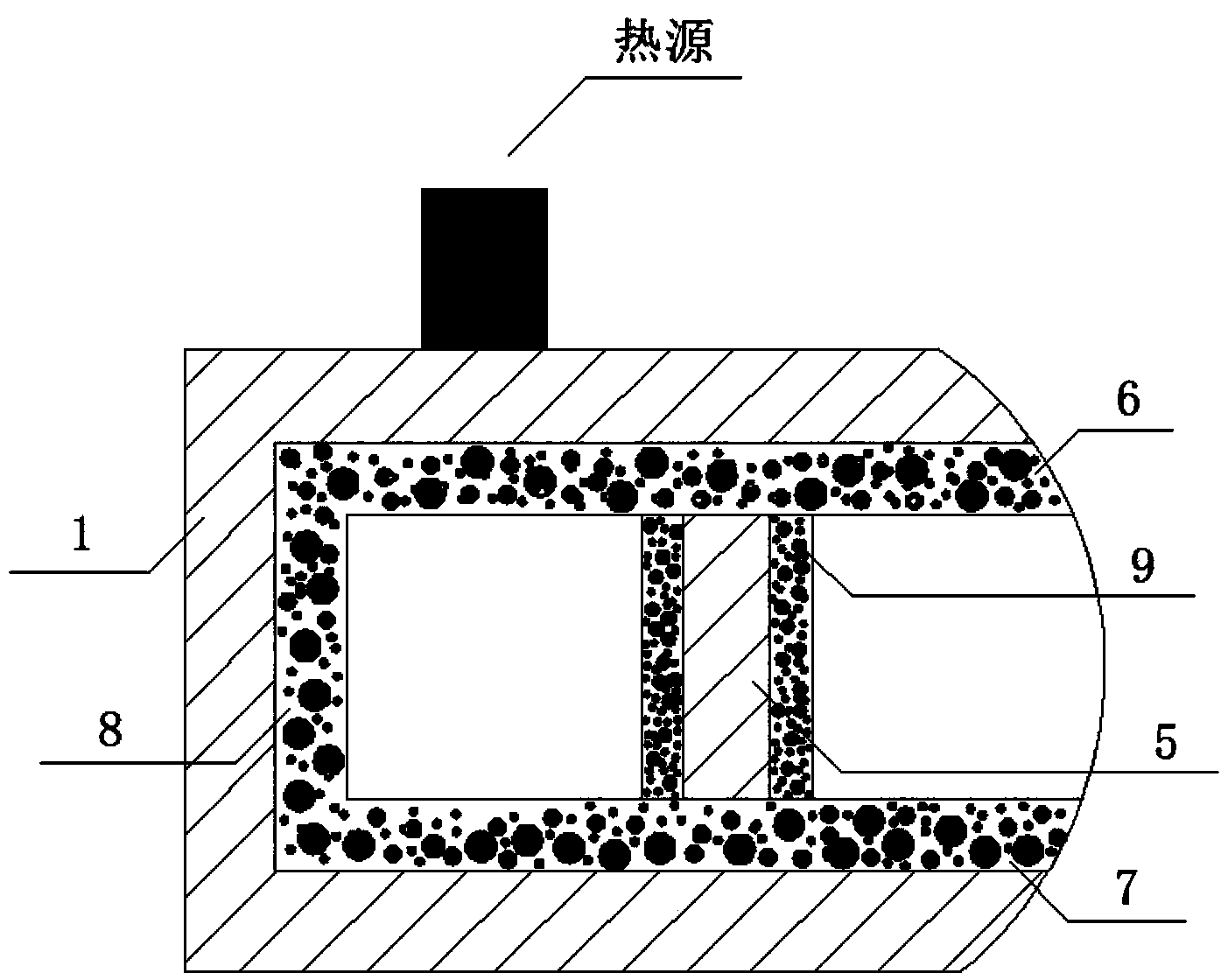

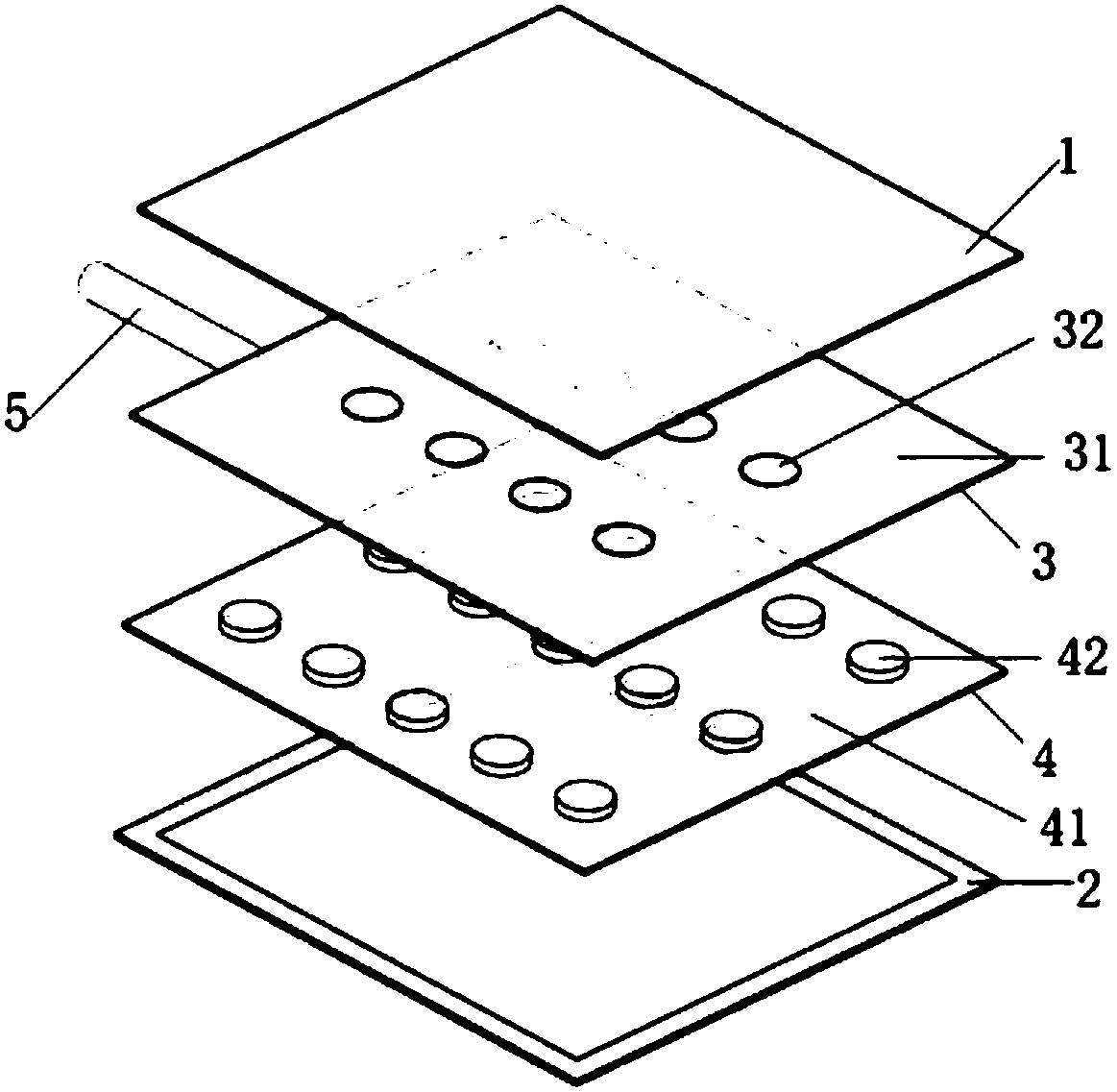

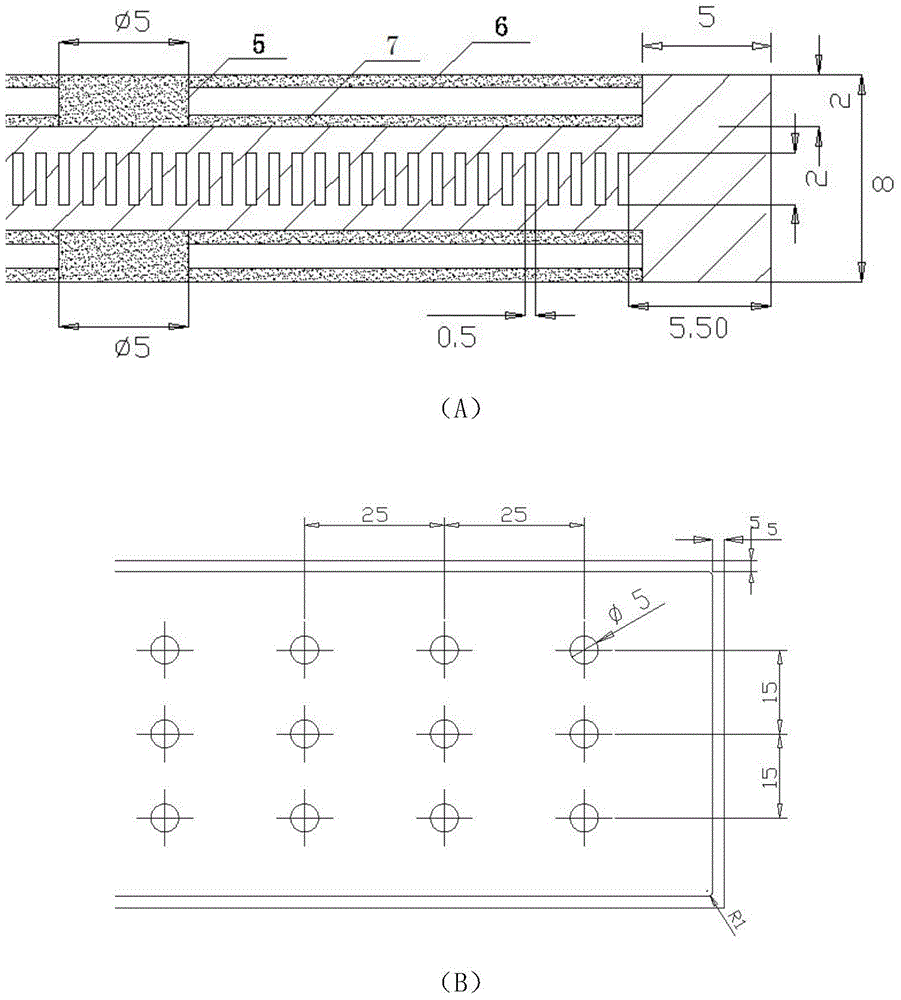

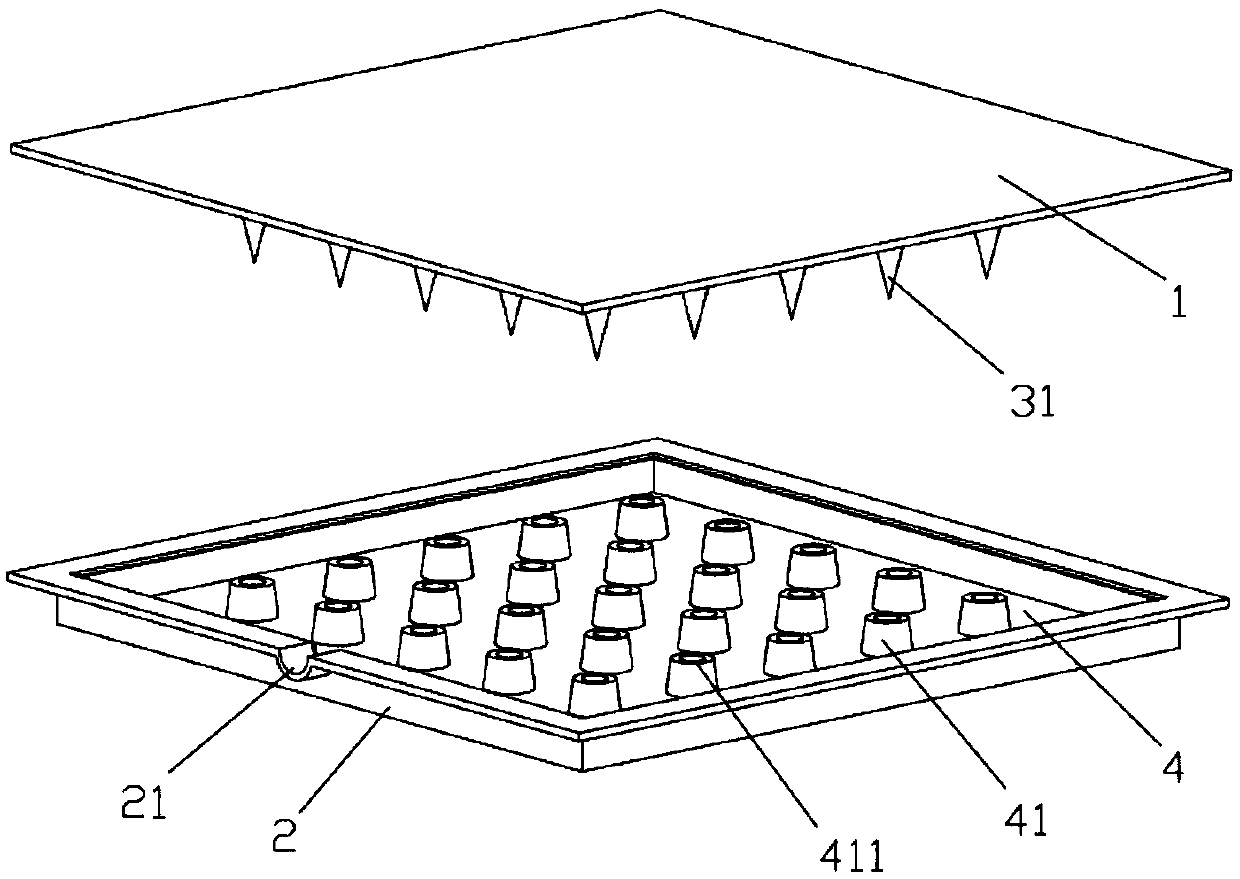

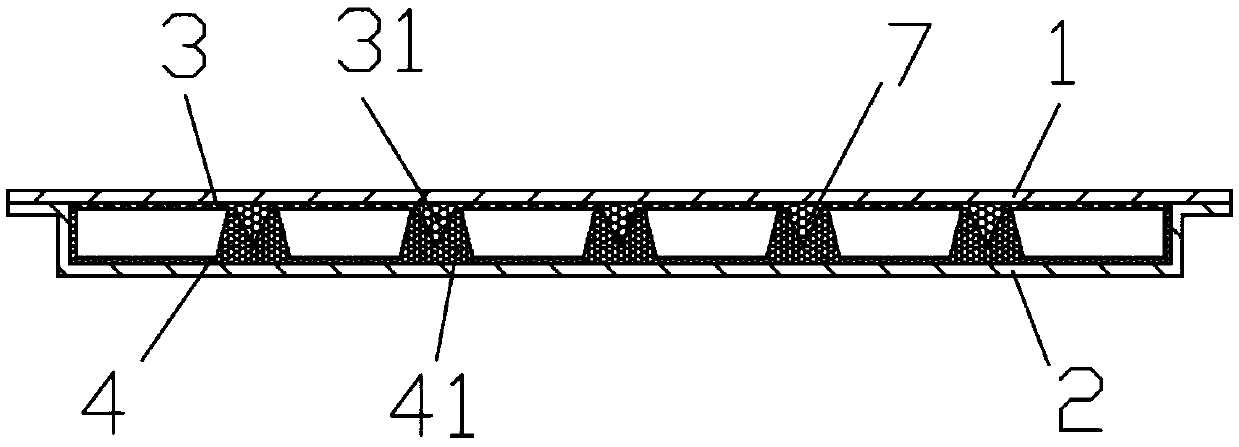

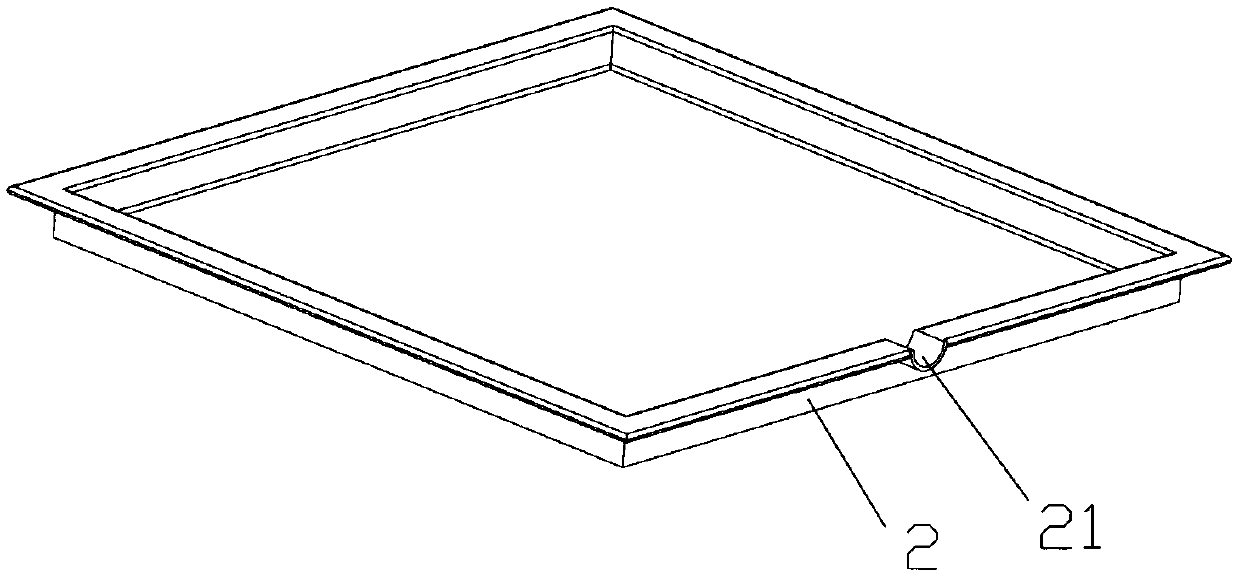

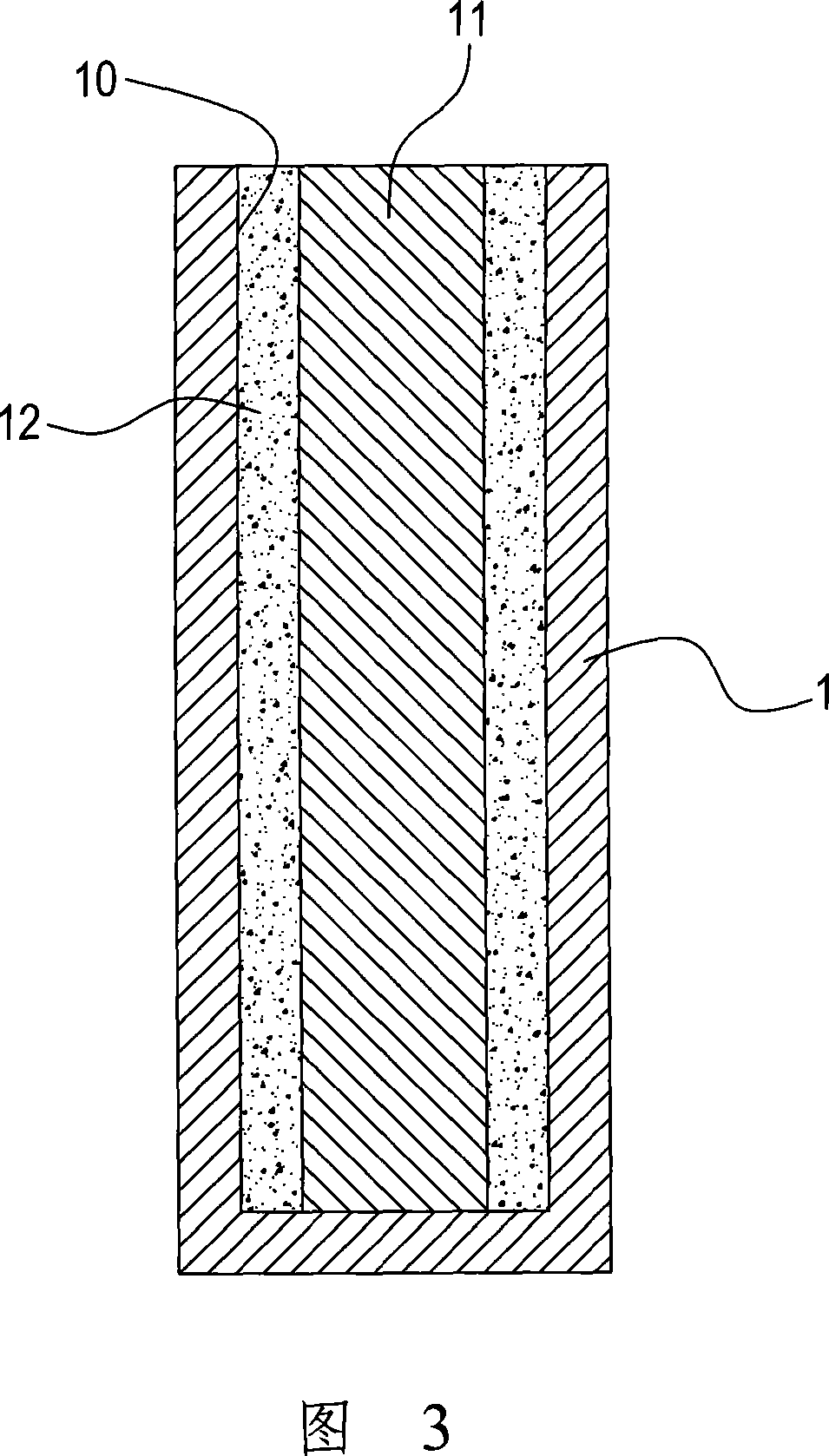

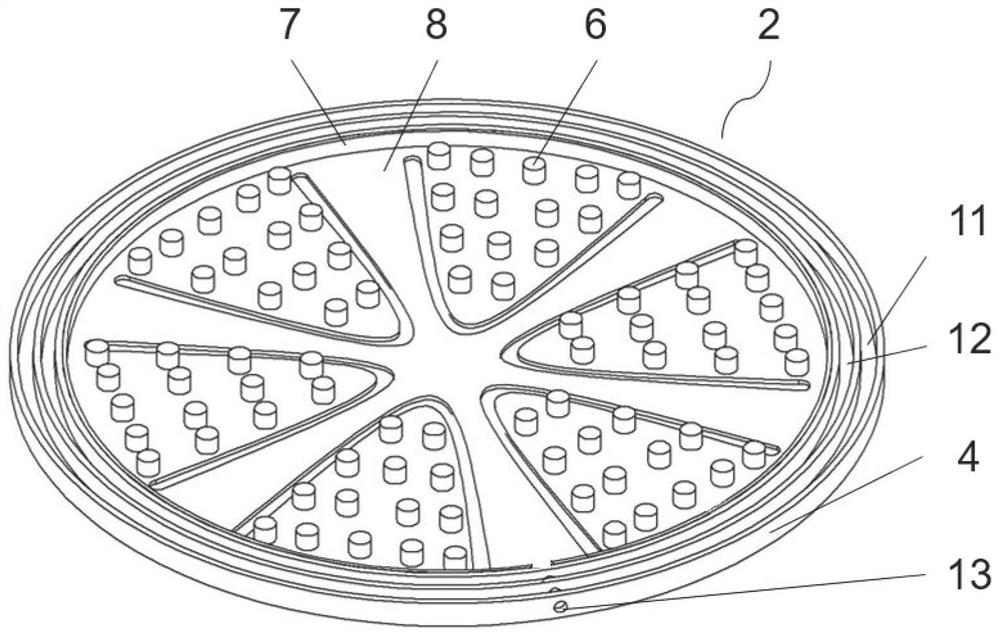

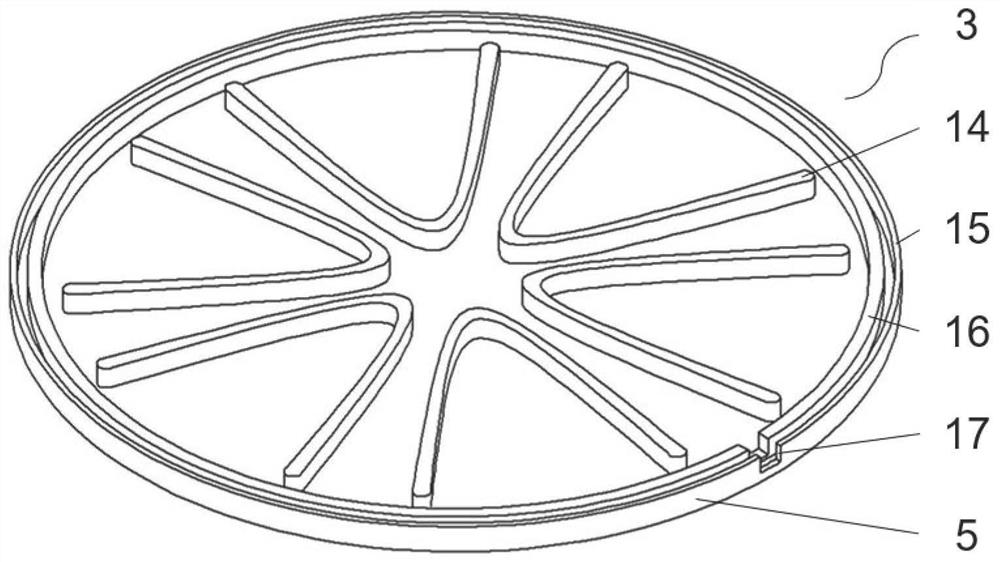

Panel heat pipe with embedded porous wick and manufacturing method thereof

InactiveCN104534906ARaise the capillary limitShorten return pathIndirect heat exchangersVapor liquidCapillary pressure

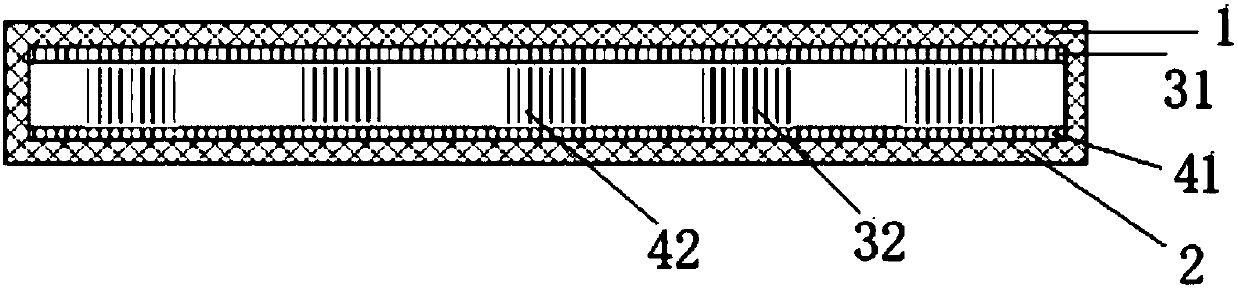

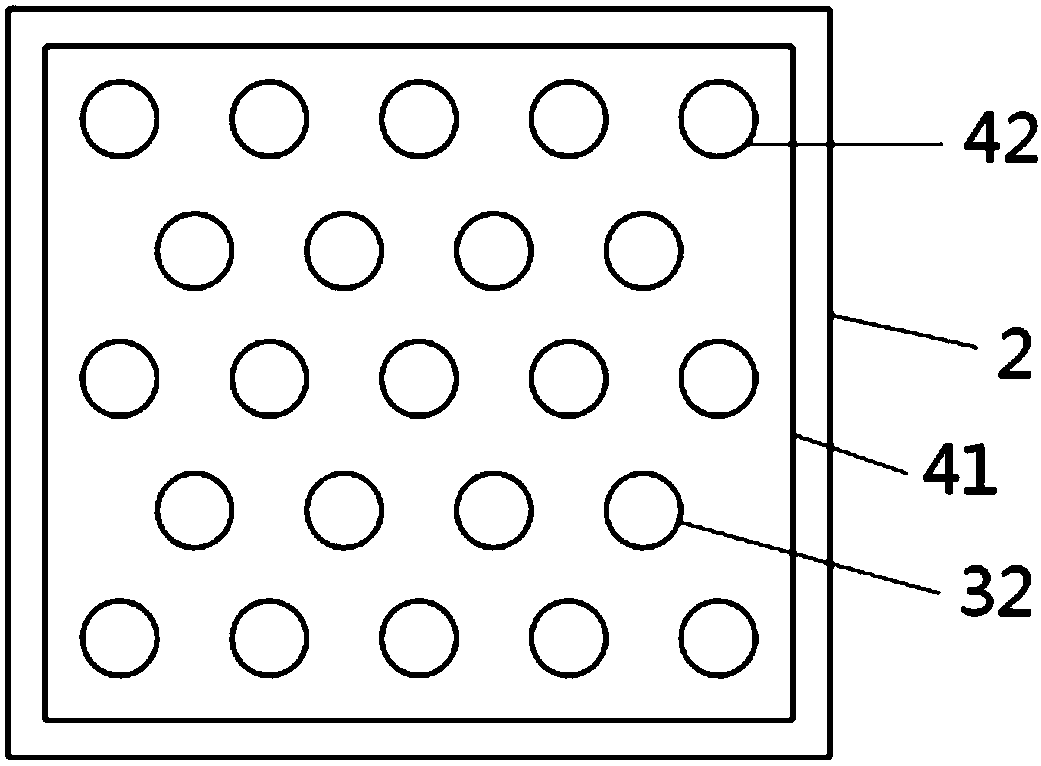

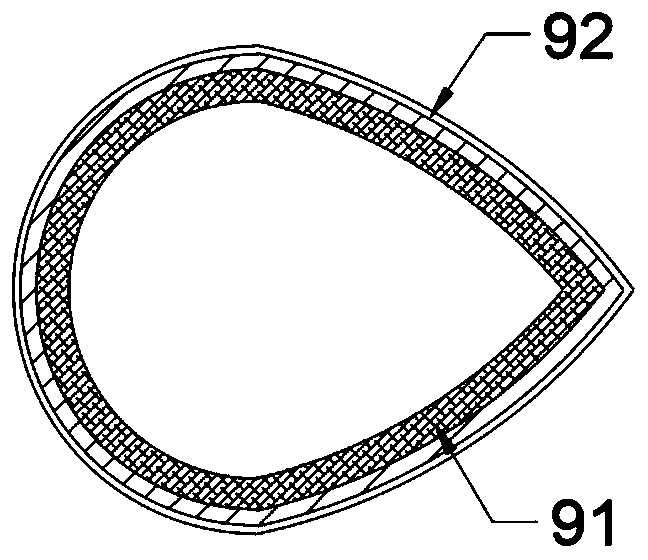

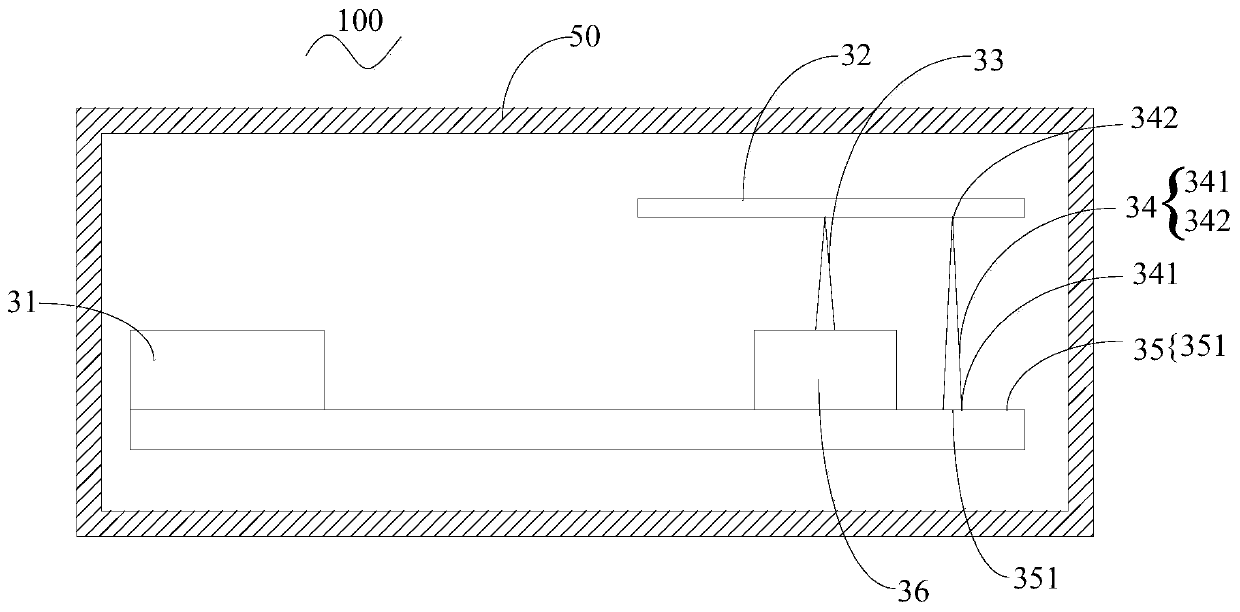

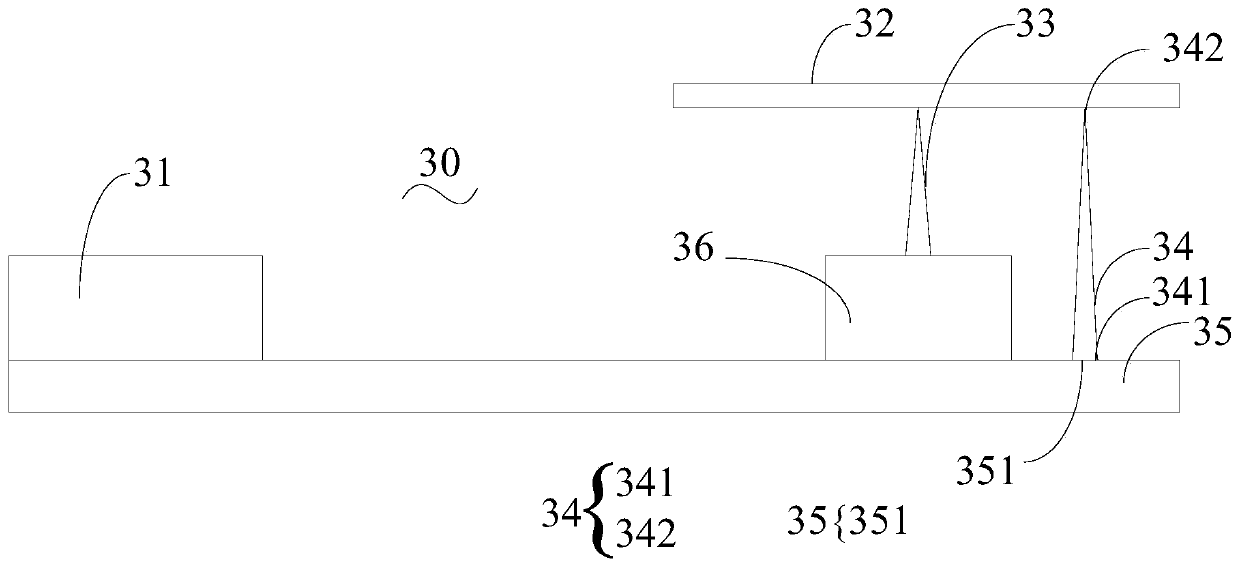

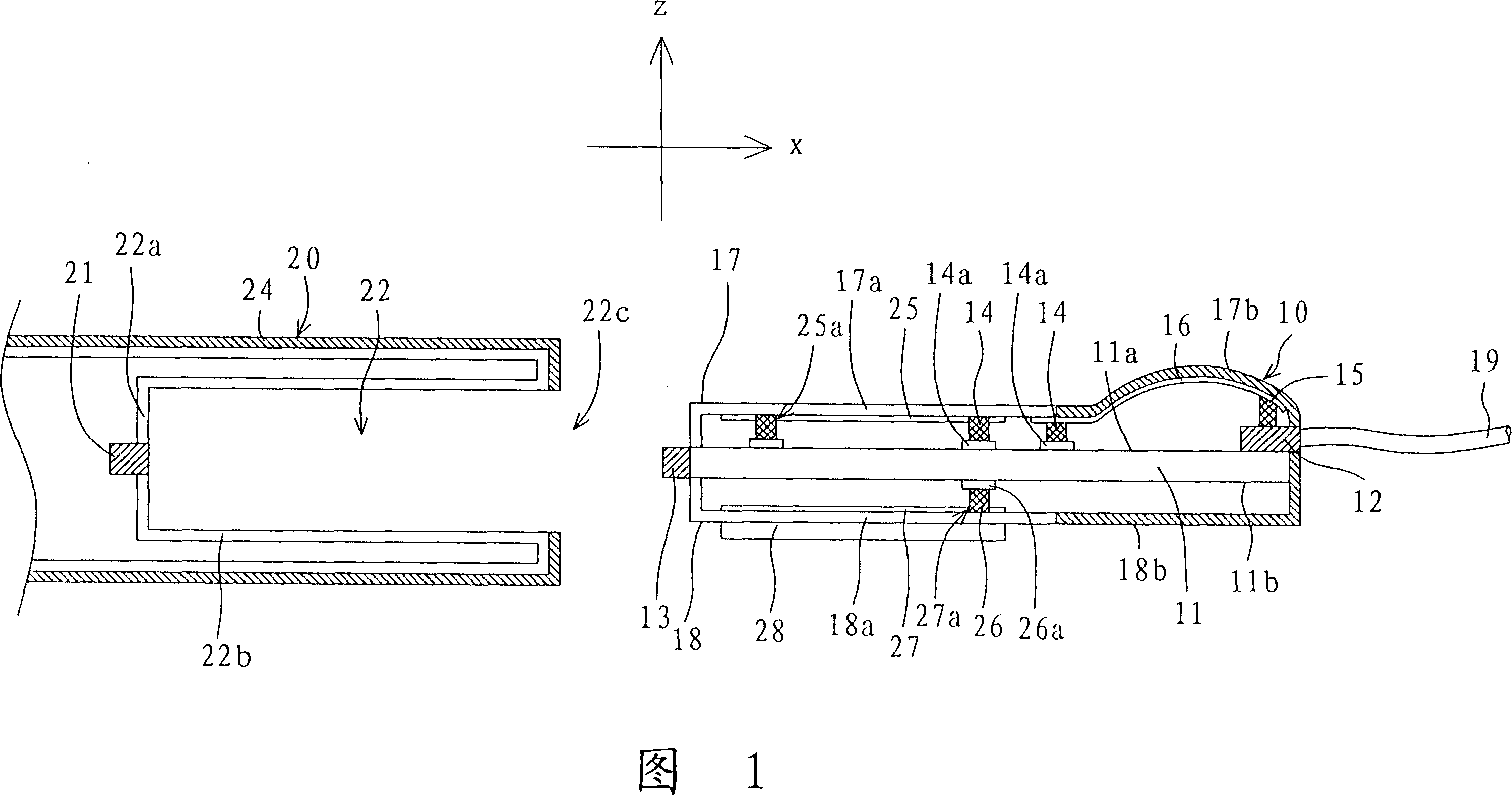

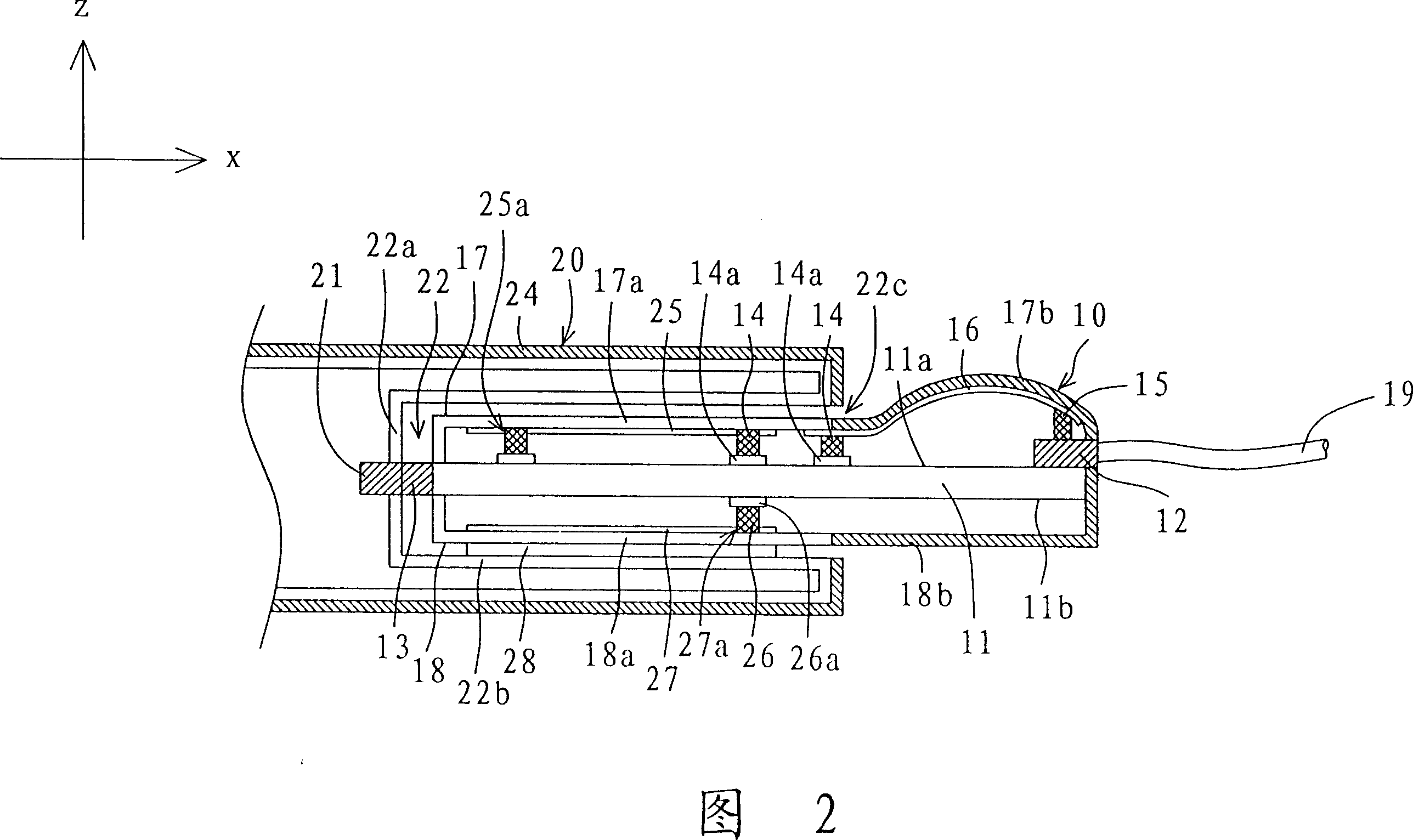

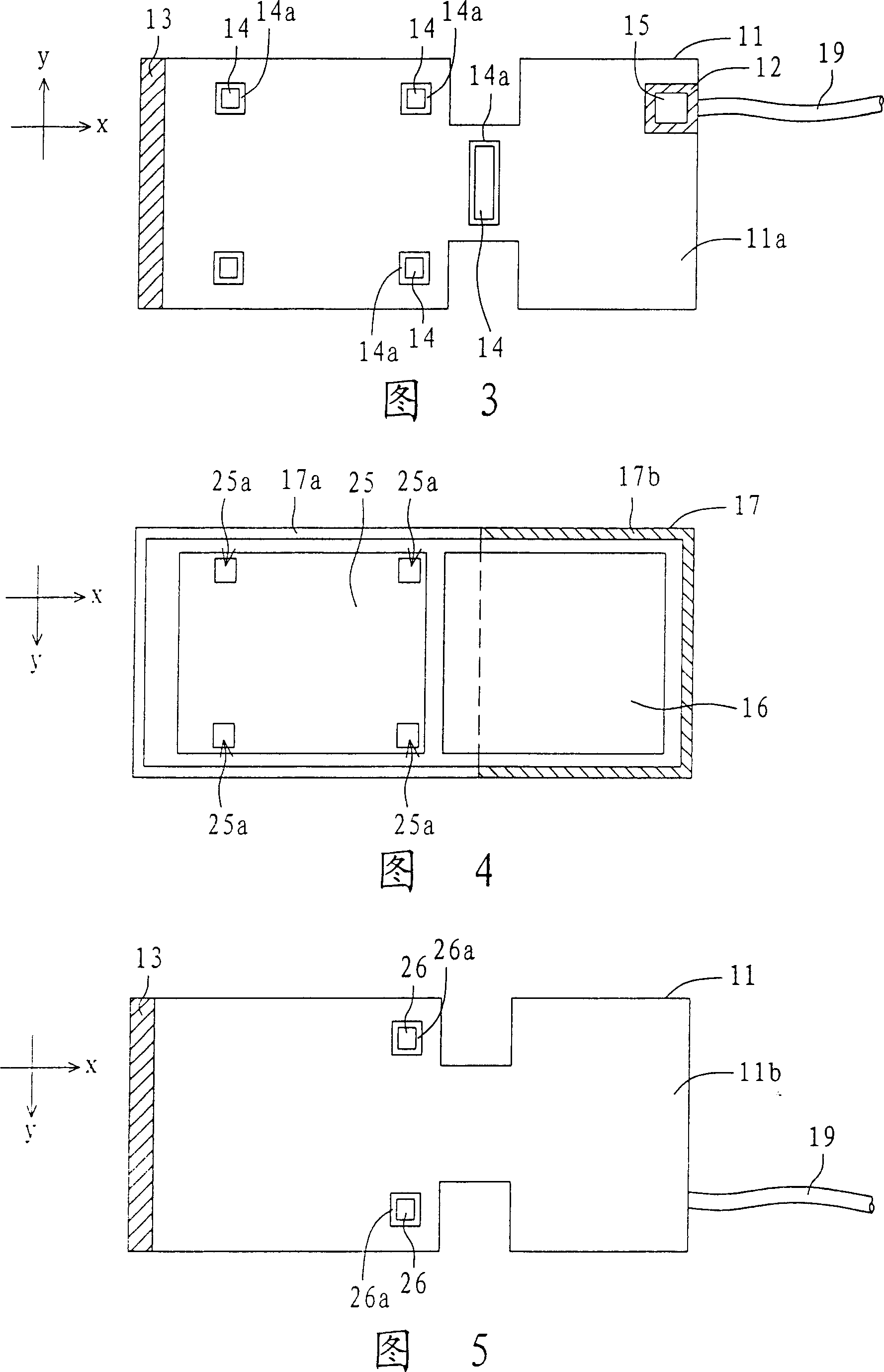

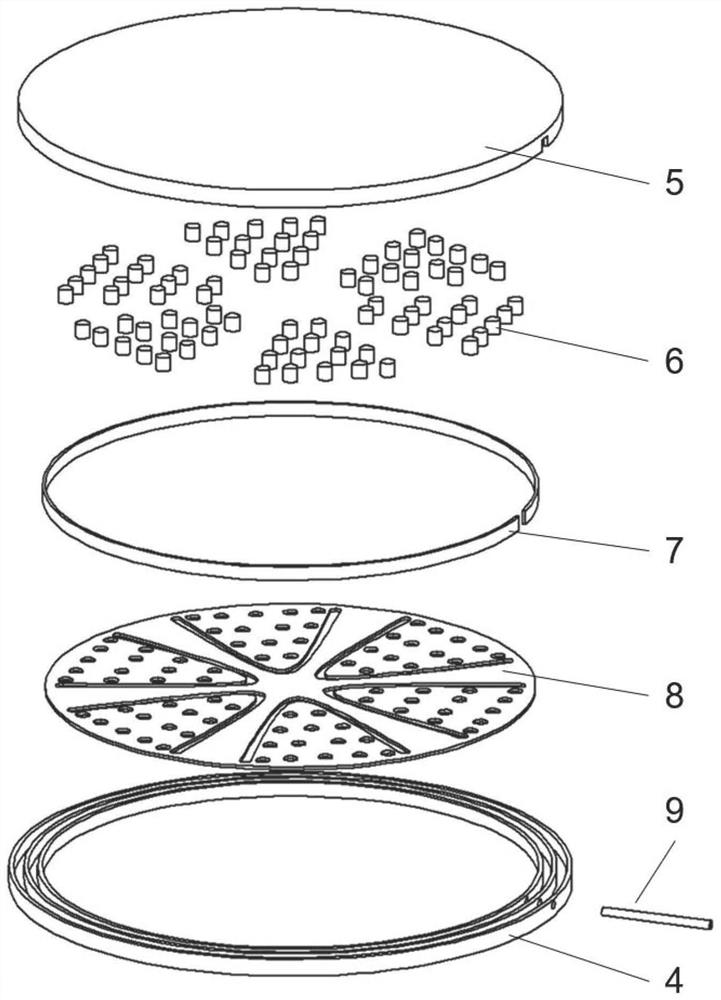

The invention provides a panel heat pipe with an embedded porous wick and a manufacturing method thereof. The panel heat pipe comprises an upper metal cover plate, a lower metal cover plate, and a closed cavity is formed between the upper metal cover plate and the lower metal cover plate in a welded and sealed mode. The cavity is filled with liquid working media. The inner surface of the cavity is divided into an evaporation face and a condensation face. The condensation face and the evaporation face are paved with a thin-layer porous wick structure formed by sintering metal powder particles. Sintering porous columns with inner grooves which are distributed in an array mode are machined on the evaporation face. Porous protrusions matched with the inner grooves are machined in the condensation face. The sintering porous columns and the porous protrusions are in close fit to form an embedded porous structure column. A working medium backflow channel is formed in the embedded porous structure column. According to the panel heat pipe, the capillary pressure is improved, the working medium backflow speed is remarkably increased, vapor-liquid two-phase separation is achieved, and the heat transfer performance is greatly improved; meanwhile, the embedded wick plays a supporting column role, and panel heat pipe inward sinking or crack deformation or other problems are effectively avoided.

Owner:XIAMEN UNIV

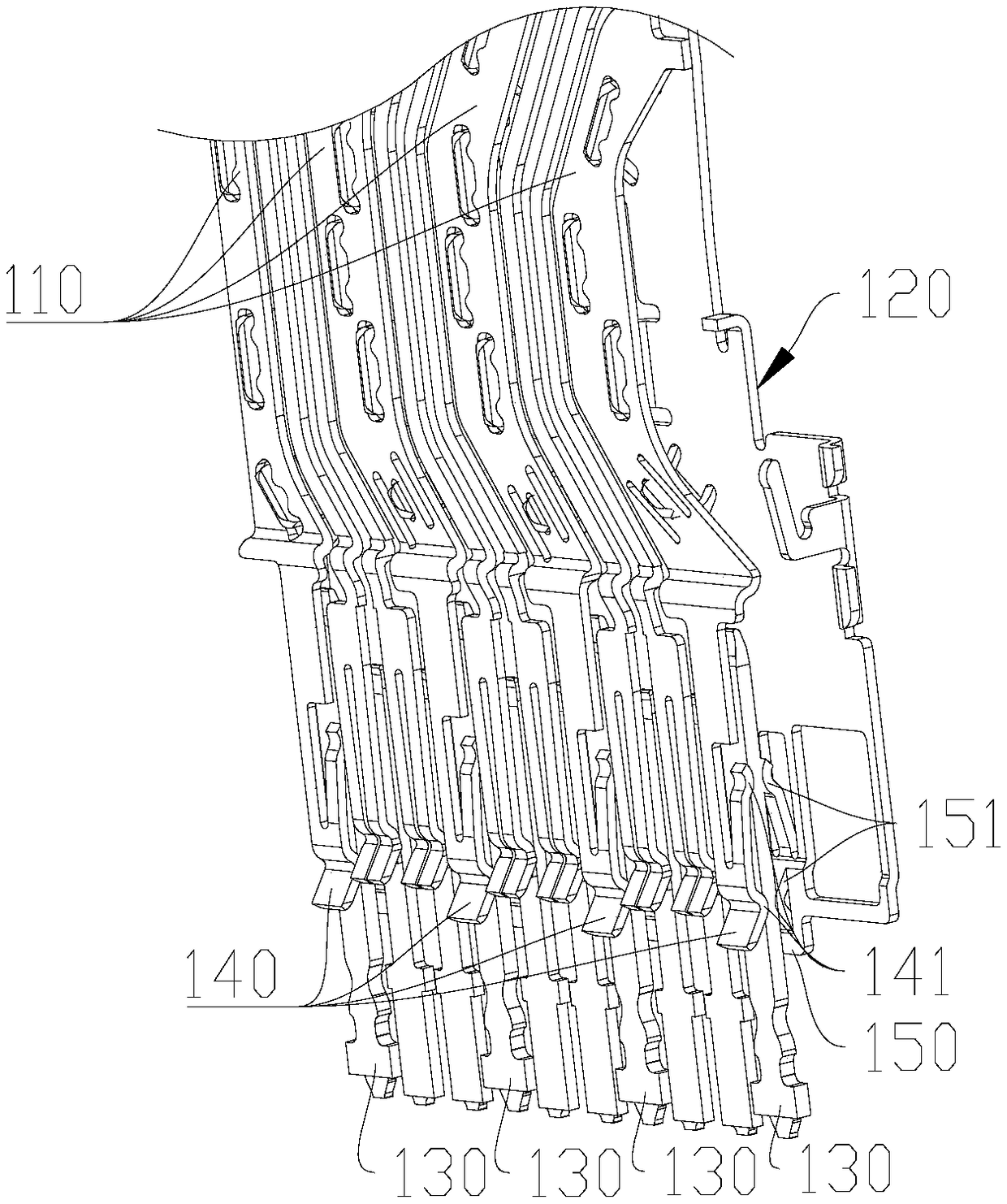

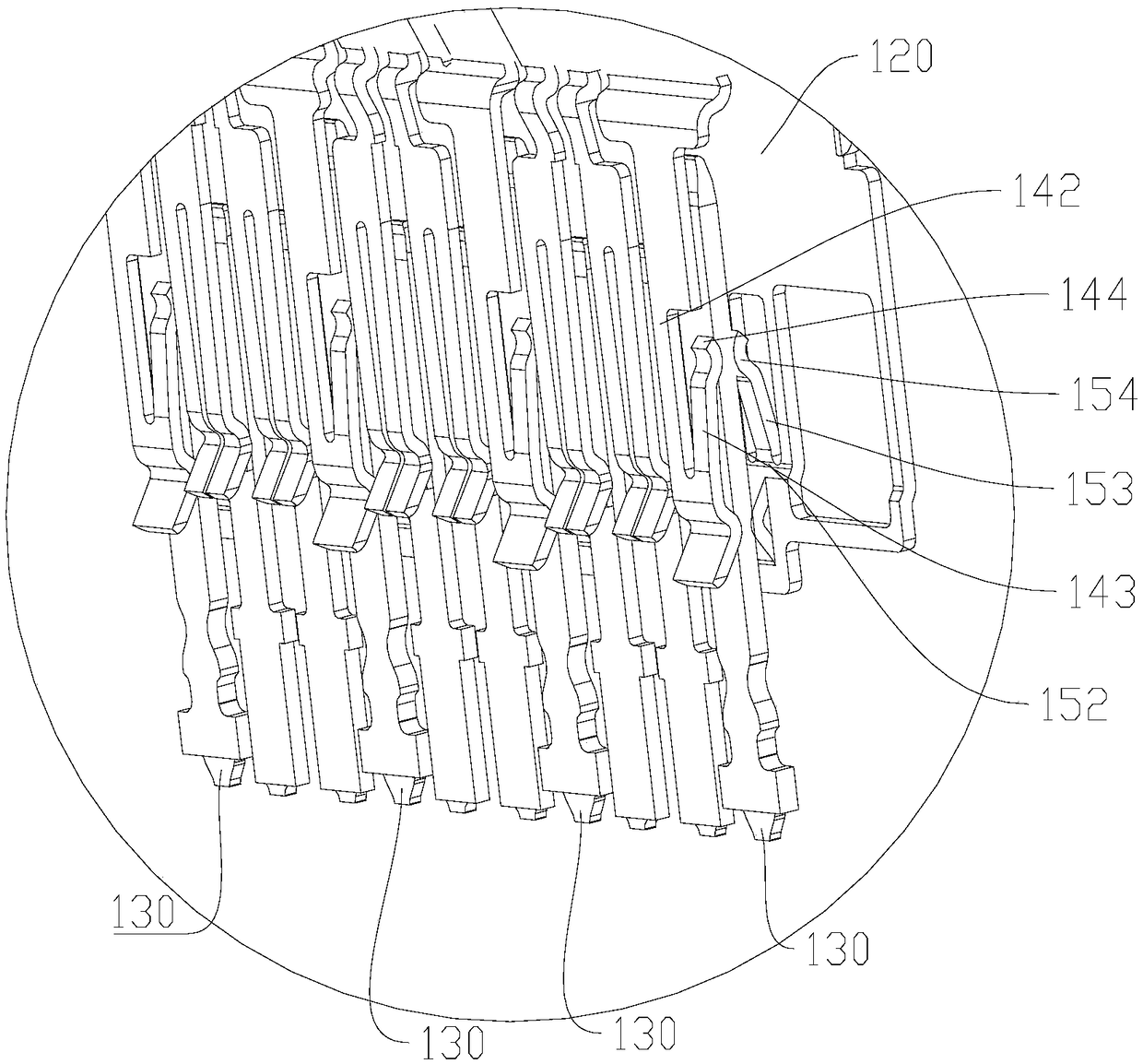

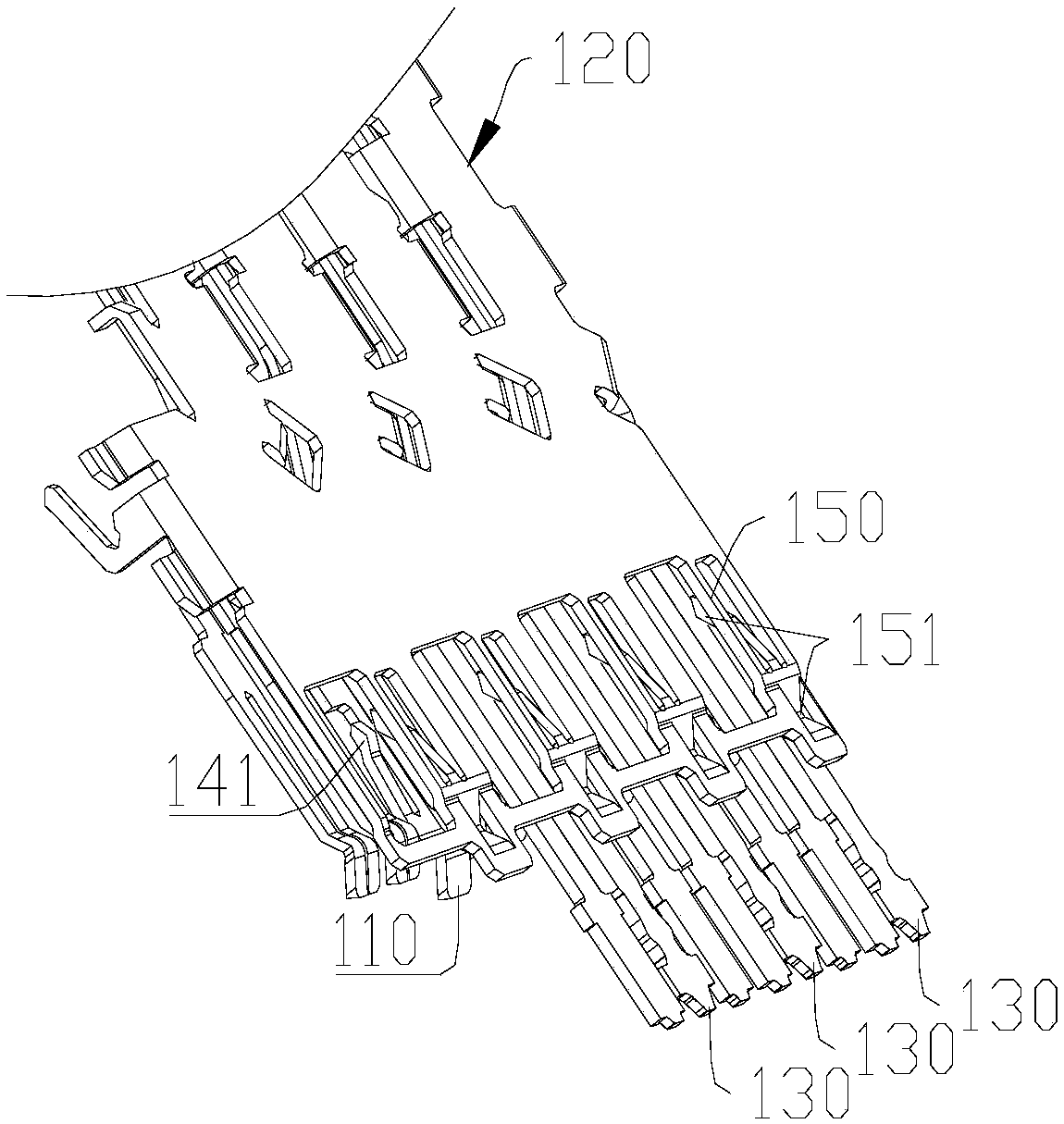

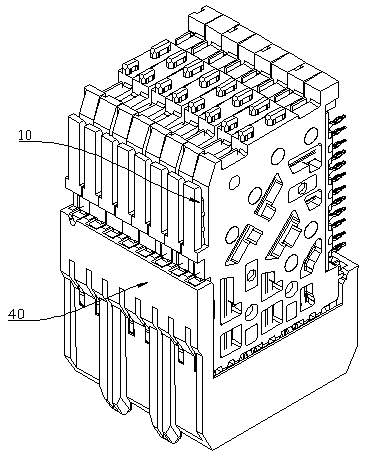

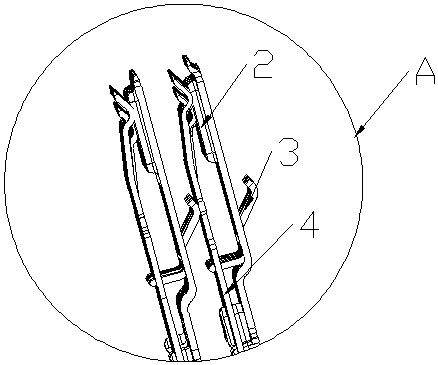

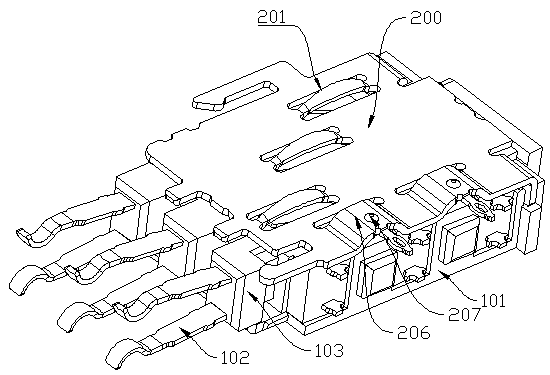

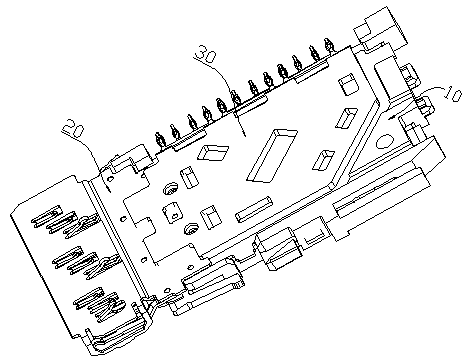

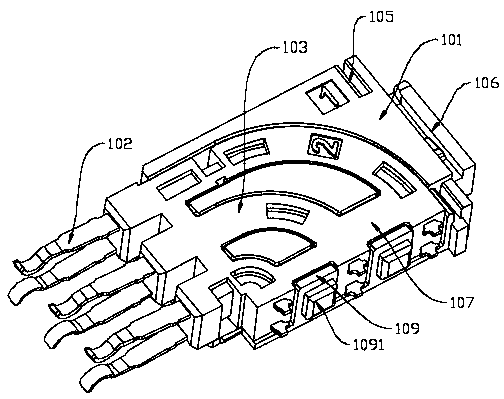

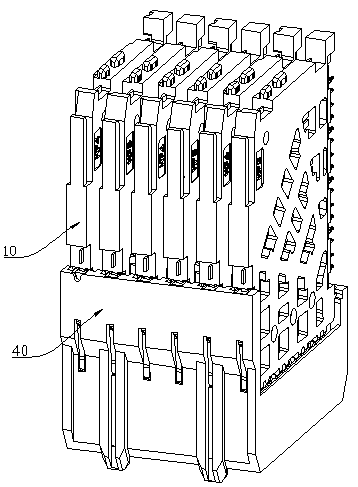

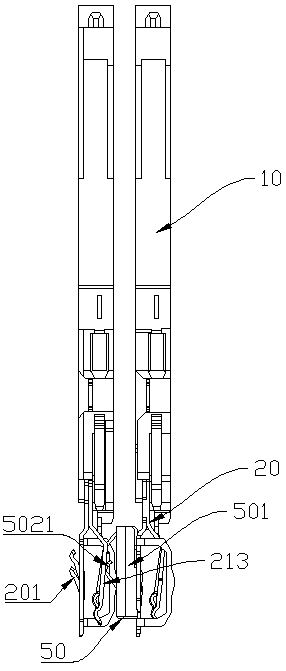

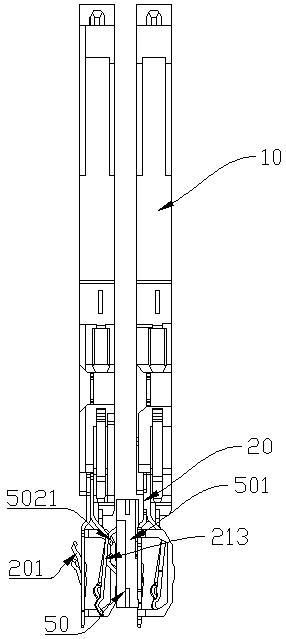

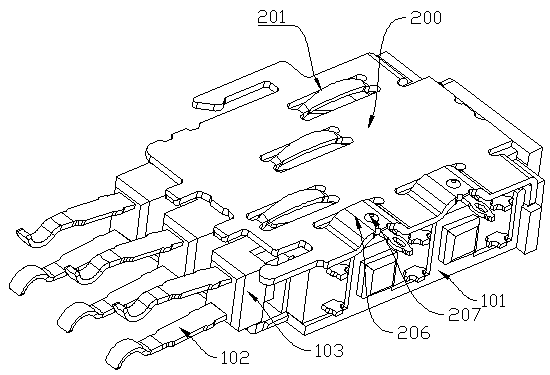

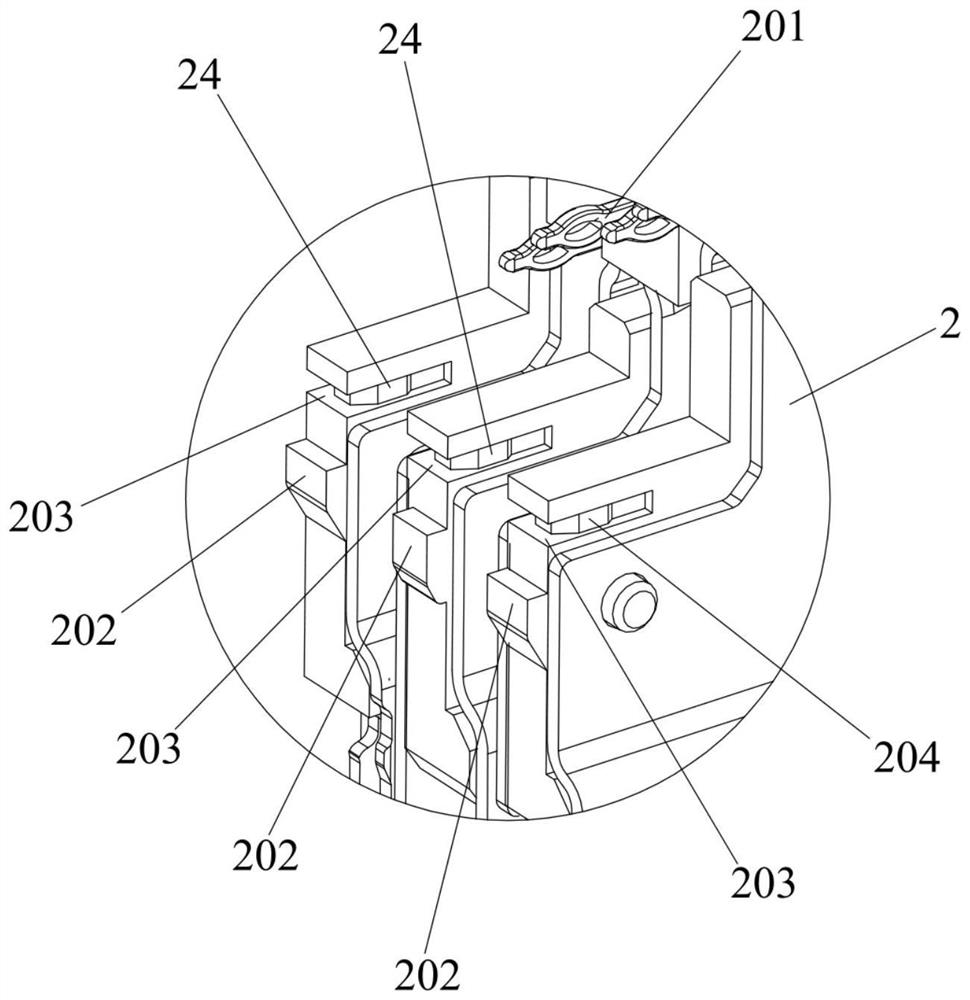

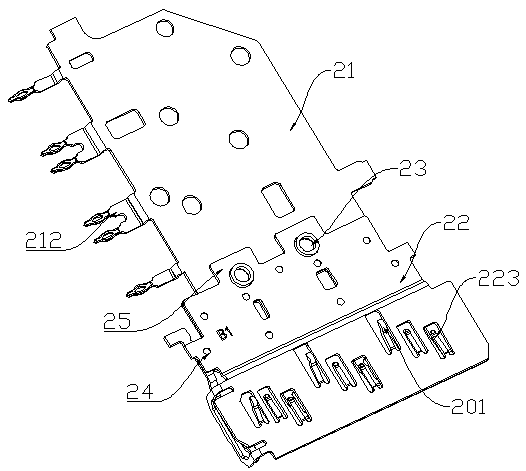

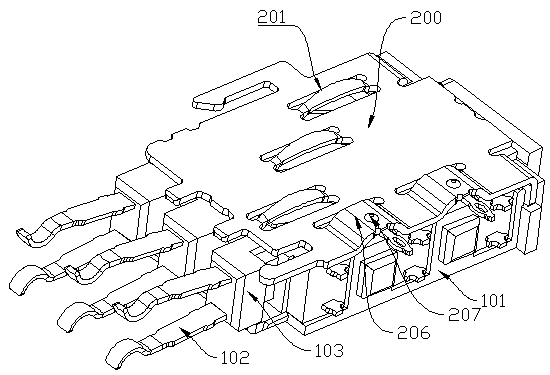

Multi-contact electrical connector and electronic apparatus

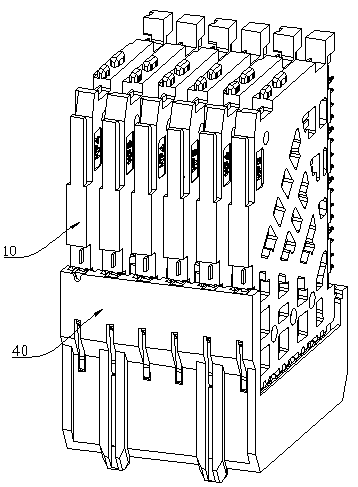

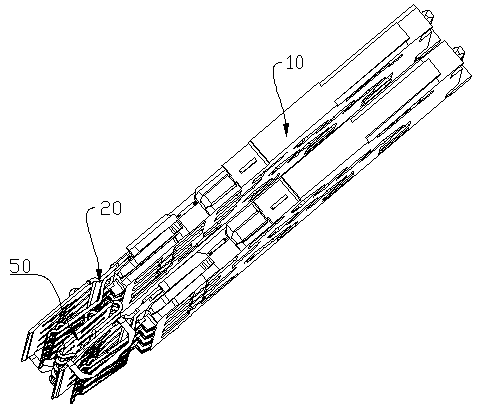

ActiveCN109088200AIncrease distribution channelsShorten return pathCoupling contact membersCoupling protective earth/shielding arrangementsElectrical connectorElectrical and Electronics engineering

A multi-contact electrical connector and an electronic apparatus provided by the embodiment of the invention are matched with an interconnecting connector, the interconnecting connector comprises a pin, the electrical connector comprises a ground wire and a shield, the shield is a plate-shaped shield, and the plate-shaped shield can be connected with the ground wire; an end of the ground wire is aground wire contact end, and the ground wire contact end is provided with a plurality of convex first contacts; the end of the shield is a shield contact end, and the shield contact end is provided with a plurality of protruding second contacts, and the protruding direction of the second contacts is opposite to the protruding direction of the first contacts. The ground wire contact end and the shield contact end contact end are in effective contact with the pin, and a plurality of first contacts of the ground wire contact end are in contact with the pin, and a plurality of second contacts ofthe shield contact end are in contact with the pin.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

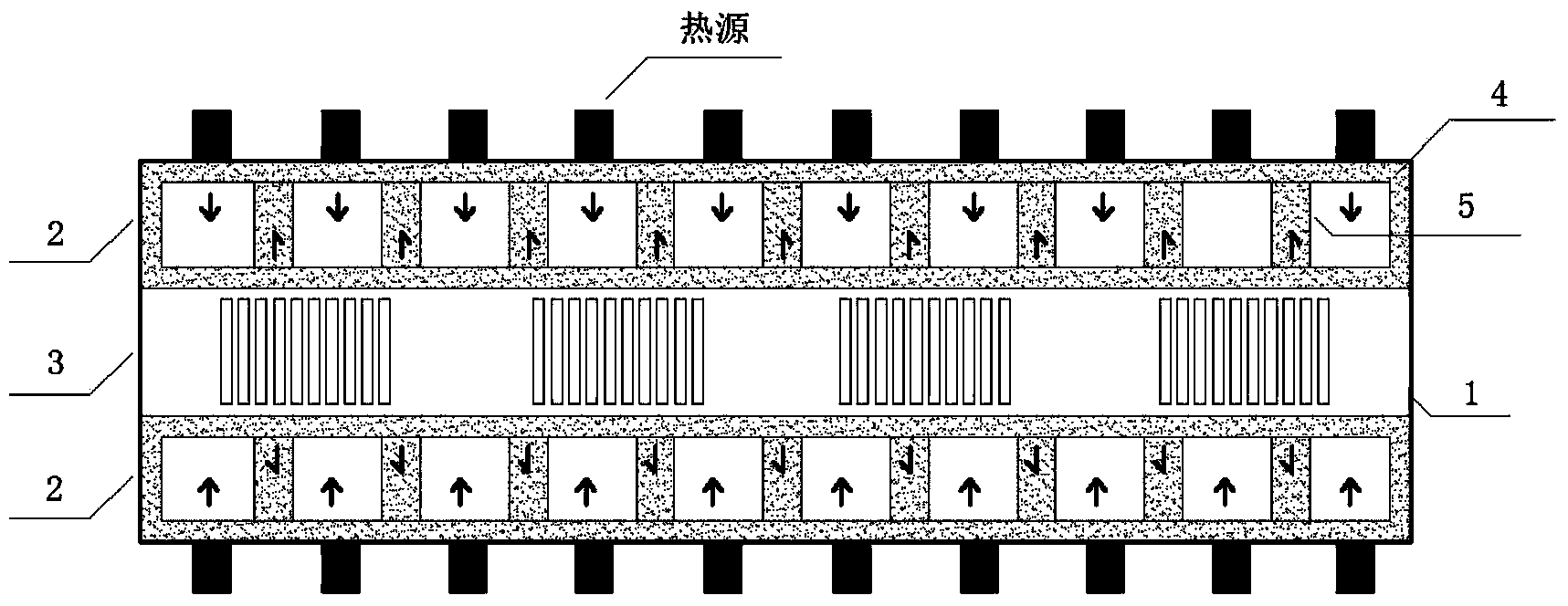

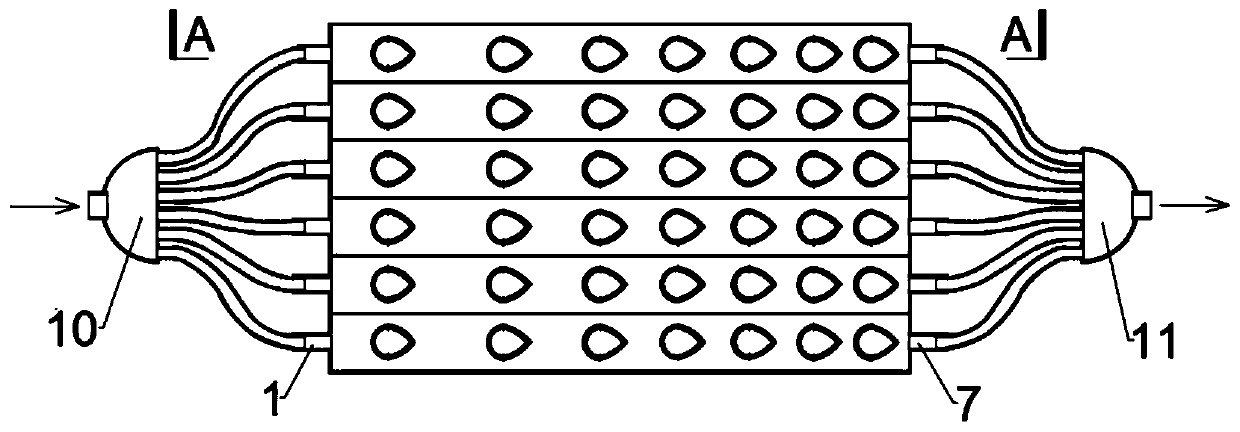

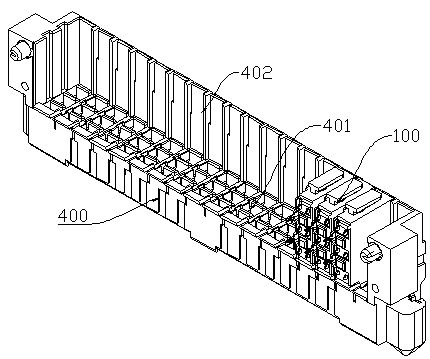

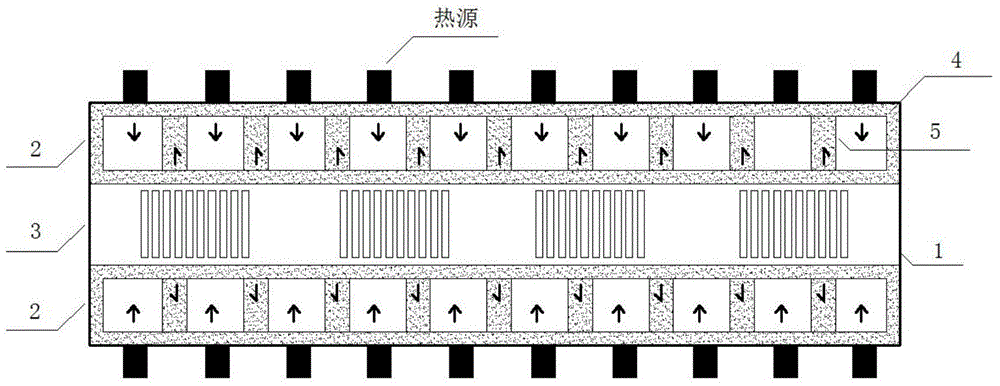

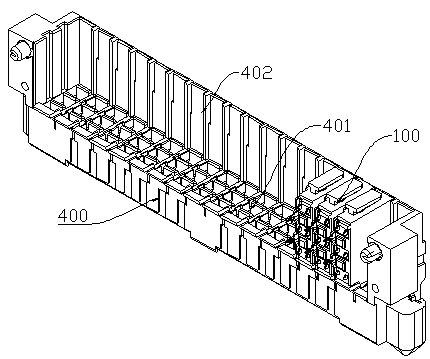

Temperature averaging device of steam chamber heat pipe/microchannel cold plate composite structure

ActiveCN103415192AShorten return pathImprove heat transfer effectCooling/ventilation/heating modificationsEngineeringCold plate

The invention discloses a temperature averaging device of a steam chamber heat pipe / microchannel cold plate composite structure. The device comprises a metal shell, steam cavity heat pipe layers and a microchannel cold plate layer, wherein the microchannel cold plate layer is located between the two steam cavity heat pipe layers, and the steam cavity heat pipe layers and the microchannel cold plate layer are all located in the metal shell. The liquid working medium phase-change heat exchange method is adopted for the device to transmit a large amount of heat in a gasified latent heat mode, and therefore the heat exchange capacity is remarkably improved. Because only one face of an existing steam cavity heat pipe is an evaporating face and is small in area, the utilization area of the whole is limited. The upper face and the lower face of the temperature averaging device of the composite structure are both evaporating faces, therefore, electronic components with high heating flux can be distributed on both the whole surface of the upper face and the whole surface of the lower face, the utilization rate is obviously improved, and the temperature averaging device of the composite structure can meet the thermal control requirements of the electronic components with high heating flux in the electronic industry field better. The temperature averaging device of the steam chamber heat pipe / microchannel cold plate composite structure is smaller in height, the height of a single microchannel cold plate layer in the prior art is 9mm, but the overall height of the temperature averaging device of the steam chamber heat pipe / microchannel cold plate composite structure is not larger than 9 mm.

Owner:NANJING UNIV OF SCI & TECH

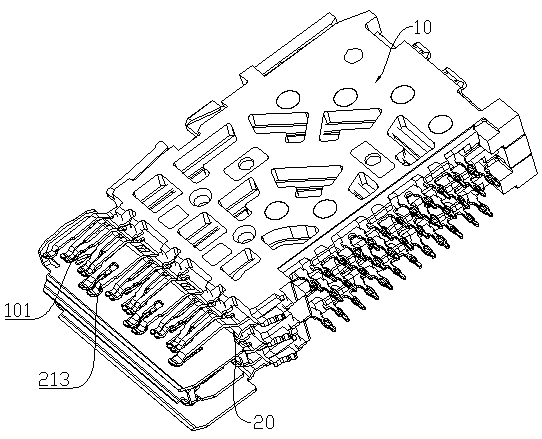

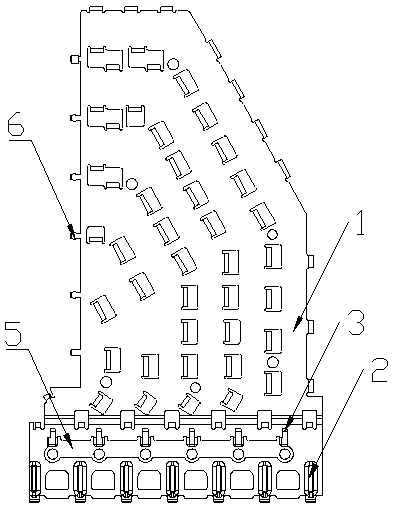

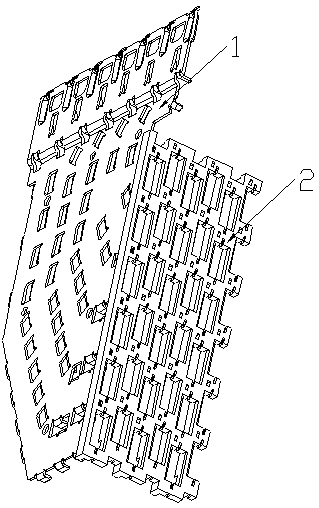

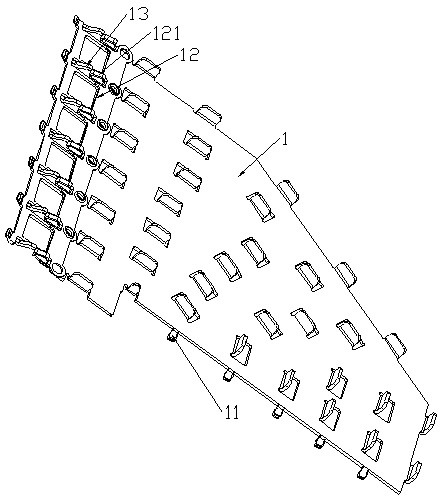

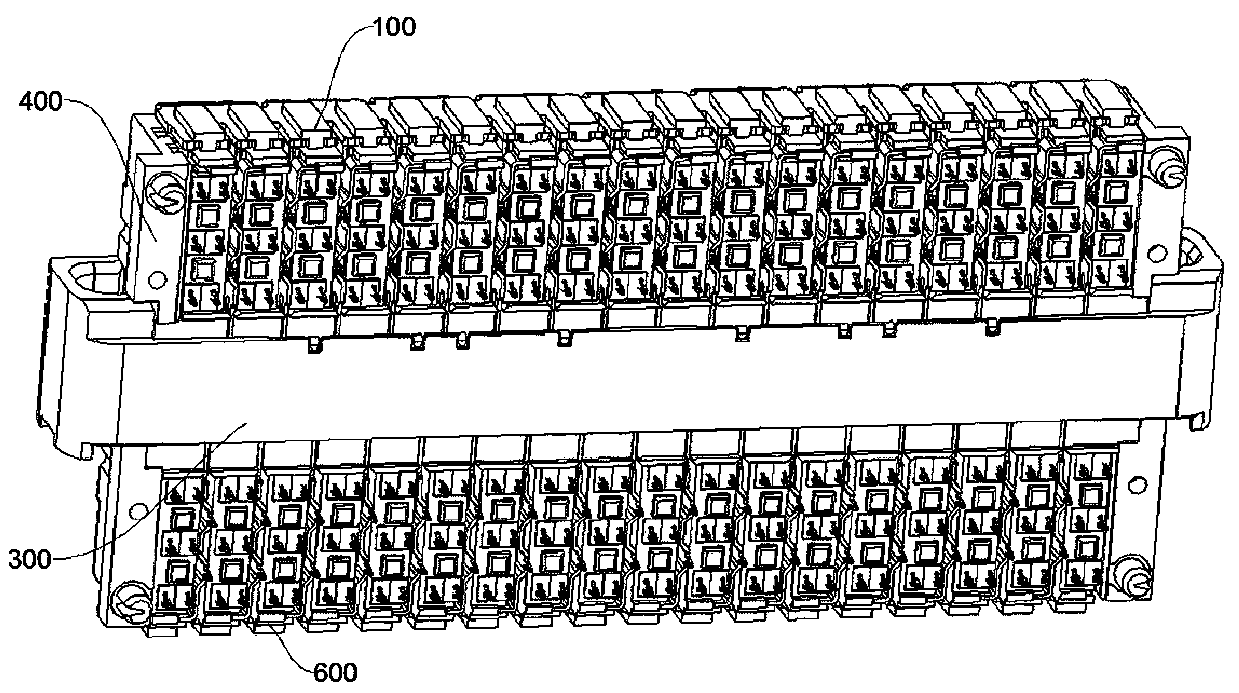

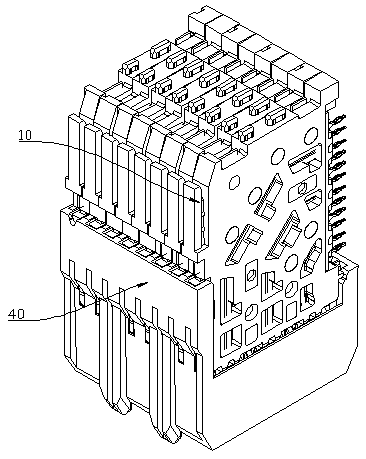

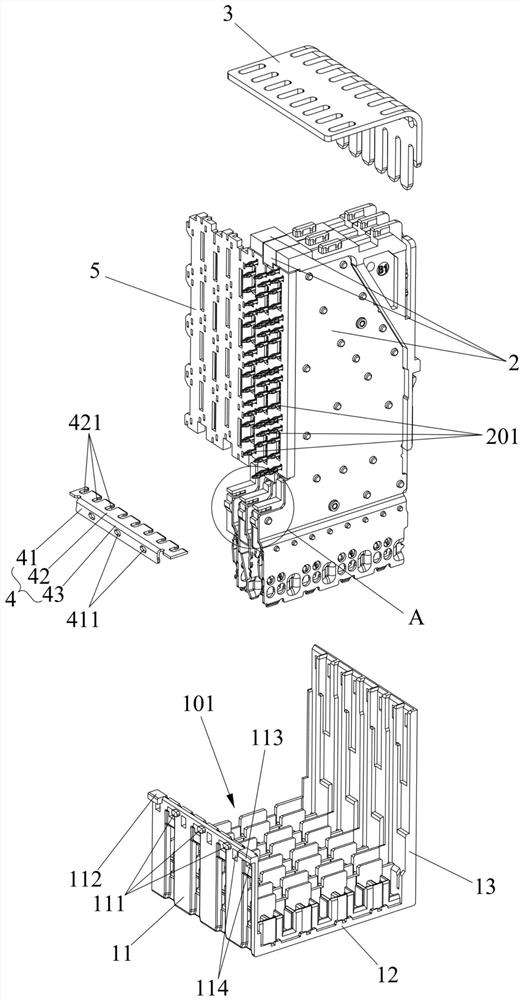

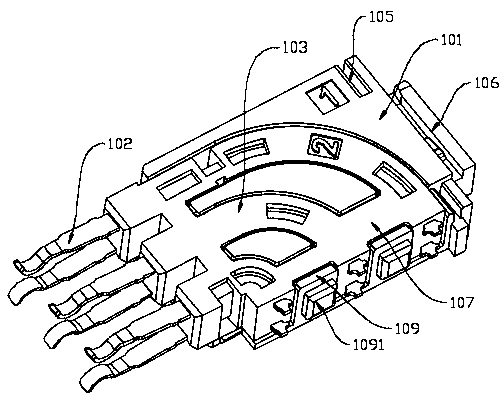

Module structure for high-speed connector and high-speed connector

PendingCN109830849AEnsure consistencyImprove performanceCoupling contact membersCoupling protective earth/shielding arrangementsDifferential signalingComputer module

The invention discloses a module structure for a high-speed connector and a high-speed connector. The module structure comprises a signal transmission module and a shielding component disposed on thesignal transmission module, wherein the signal transmission module is provided therein with differential signal terminals at intervals; the differential signal terminals have differential pair pins; and the vertical distance A between the shielding component and the differential signal terminals in the signal transmission module and the center distance B of the differential pair pins satisfy: A<B / 8. By limiting the distance between the shielding component and a signal wire, the module structure ensures a low impedance change of the differential pairs as much as possible, thereby improving theperformance of the connector.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

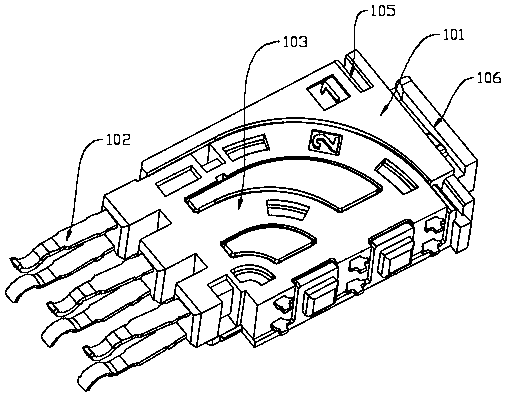

Shielding plate, module structure and electrical connector

PendingCN110011095AClose contactShorten return pathCoupling contact membersCoupling protective earth/shielding arrangementsEngineeringElectrical and Electronics engineering

The invention discloses a shielding plate, a conductive end protective sheet, a module structure and an electrical connector. The shielding plate comprises more than two main shielding plates, one ends, connected with the male end of an electrical connector, of the main shielding plates are provided with bulges and first contact terminals; the bulges are configured to be in contact with the male end of the connector, the first contact terminals are configured to butt against the grounding wirings corresponding to the adjacent main shielding plates, two sides of the main shielding plates are respectively provided with the bulges and the first contact terminals, pressure is applied to the grounding wirings corresponding to the adjacent shielding plates through the first contact terminals sothat close contact is formed among the male end of the connector and the bulges and the corresponding grounding wirings, the backflow path is reduced and the crosstalk is reduced.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

Liquid absorbing core and supporting column integrated structure flat plate heat pipe based on carbon nano tube array

PendingCN107764117AImprove thermal conductivityHigh thermal conductivityIndirect heat exchangersWorking fluidCarbon nanotube

The invention discloses a liquid absorbing core and supporting column integrated structure flat plate heat pipe based on a carbon nano tube array. The liquid absorbing core and supporting column integrated structure flat plate heat pipe based on the carbon nano tube array comprises an upper metal cover plate, a lower metal cover plate and upper and lower metal cover plate liquid absorbing core andsupporting column integrated structures generated on the inner sides of the upper metal cover plate and the lower metal cover plate; the upper metal cover plate and the lower metal cover plate form aclosed cavity by means of edge sealing, and the vacuumized closed cavity is internally filled with work liquid; the upper and lower metal cover plate liquid absorbing core and supporting column integrated structures comprise thin-layer carbon nano tubes growing on the inner surfaces of the metal cover plates and a plurality of vertical carbon nano tubes continuously growing in specific areas of the thin-layer carbon nano tubes, and the thin-layer carbon nano tubes and the vertical carbon nano tubes form flat plate heat pipe capillary cores and flat plate heat pipe supporting columns correspondingly; and the upper and lower metal cover plate supporting columns are arranged in a staggered manner, and the liquid absorbing core and supporting column integrated structure with a staggered arrangement type is formed. The liquid absorbing core and supporting column integrated structure flat plate heat pipe based on the carbon nano tube array has the beneficial effects of being high in heat conductivity, small in size, small in weight and the like, the heat transfer performance of the flat plate heat pipe can be guaranteed, and the mechanical strength safety during heat pipe running can also be achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

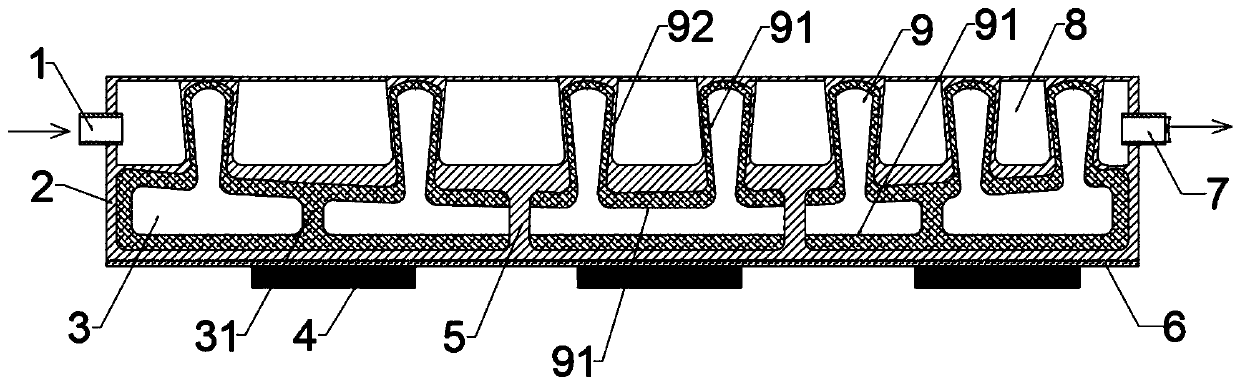

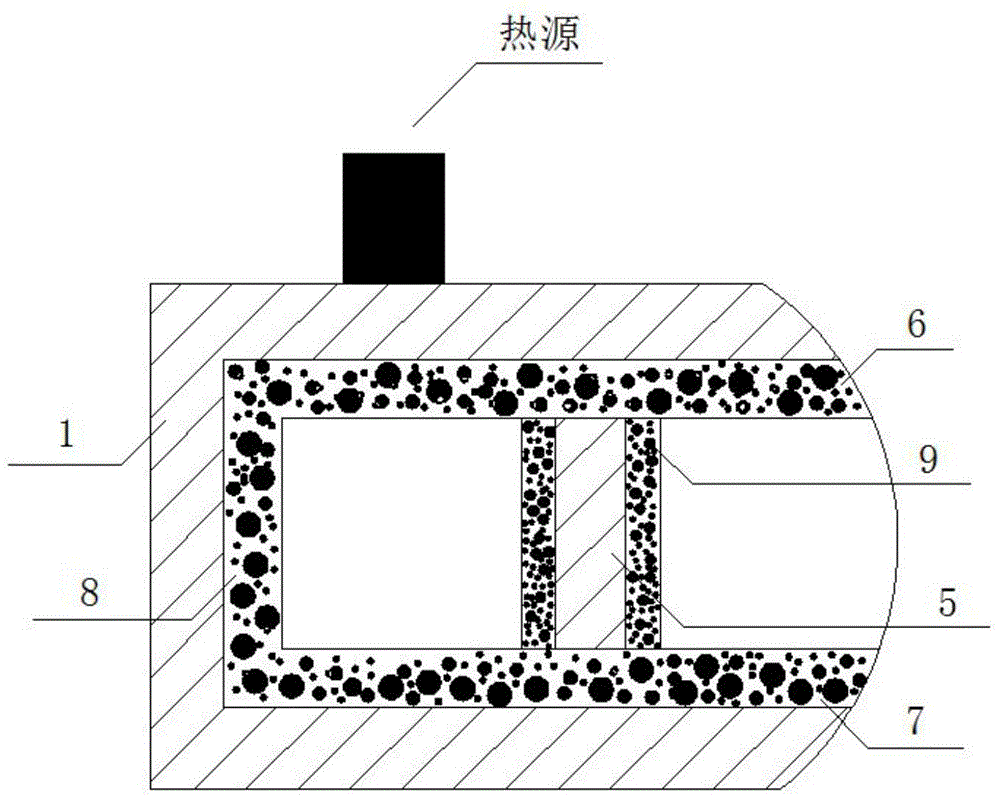

Composite liquid-cooling heat pipe radiator

ActiveCN111083911AImprove cooling effectIncrease cooling areaSemiconductor/solid-state device detailsSolid-state devicesRefrigerantCooling fluid

The invention belongs to the technical field of heat transfer, and particularly relates to a composite liquid-cooling heat pipe radiator. The composite liquid-cooling heat pipe radiator comprises a flat plate heat pipe, wherein heat generated by a heating component is transferred to a bottom plate of the flat plate heat pipe, a top plate of the flat plate heat pipe is provided with protrusions perpendicular to the bottom plate of the flat plate heat pipe, the protrusions form a tubular heat pipe, and an inner cavity of the flat plate heat pipe is communicated with an inner cavity of the tubular heat pipe. The composite liquid-cooling heat pipe radiator further comprises a shell. The flat plate heat pipe and the tubular heat pipe are both located in the shell, and the bottom plate of the flat heat pipe is attached to the bottom surface of the shell in a sealed mode; an area defined by the outer surface of the flat plate heat pipe, the outer surface of the tubular heat pipe and the innerwall of the shell forms a cooling liquid channel; and the shell is provided with a cooling liquid inlet and a cooling liquid outlet. According to the radiator, the tubular heat pipe is combined withthe flat plate heat pipe, so that the radiator can be attached to a flat surface of the heating component and has a good radiating effect; and meanwhile, heat released by a refrigerant of a condensation section is taken away through liquid cooling, and compared with air convection heat dissipation, the heat exchange capacity of the composite heat pipe with the outside is improved.

Owner:ZHEJIANG UNIV

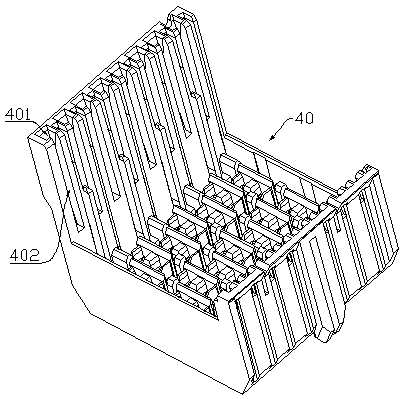

Shielding plate, conductive end protection piece, module structure and electric connector

PendingCN109818211ASimple structureEasy to processCoupling protective earth/shielding arrangementsElectricityComputer module

The invention discloses a shielding plate, a conductive end protection piece, a module structure and an electric connector. The shielding plate comprises a main shielding plate, and the main shieldingplate is sequentially provided with a connecting piece which is inserted into the conductive end protection sheet along one side close to the conductive end protection piece. The connecting piece andthe main shielding plate are arranged on the same plane; and the conductive end protecting piece is matched with the shielding plate and is provided with a connecting hole for being spliced with theconnecting piece. The shielding plate and the conductive end protection piece are in plug-in connection, and a plurality of sheet-shaped or columnar connecting pieces are sequentially arranged along one side of the main shielding plate. Compared with a connector where an elastic piece is punched on a shielding plate, the connector can shorten the backflow path and reduce crosstalk, keeps a simplestructure while reducing the crosstalk, and does not affect the machining efficiency.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

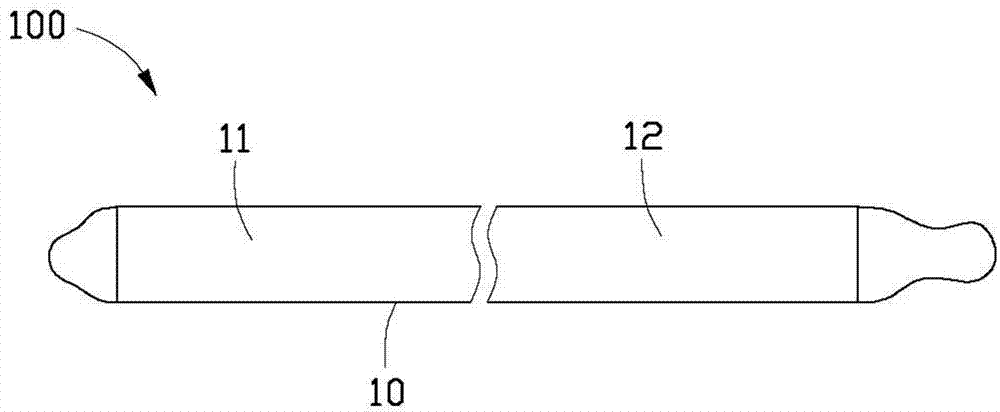

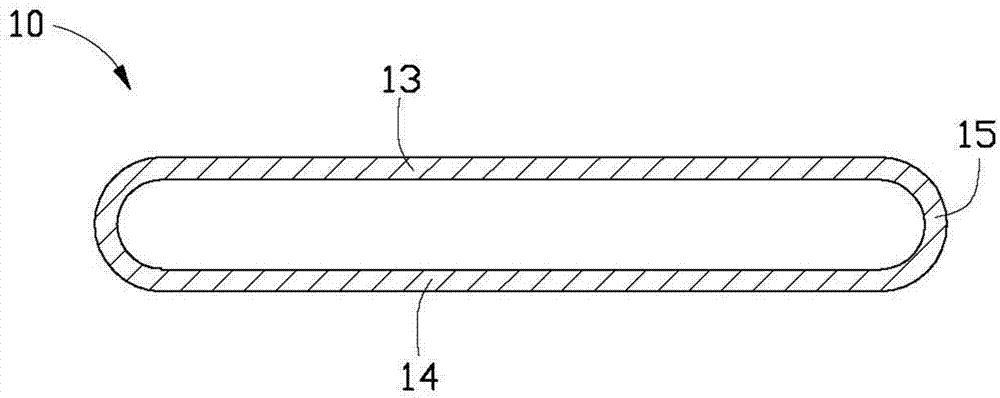

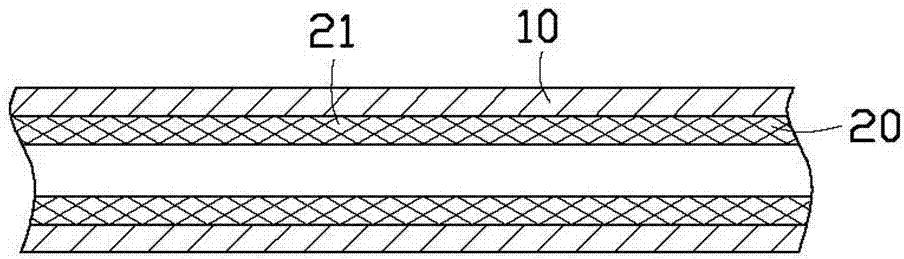

Heat pipe

InactiveCN103363829AImprove performanceShorten return pathIndirect heat exchangersWorking fluidEvaporation

Owner:FURUI PRECISE COMPONENT (KUNSHAN) CO LTD +1

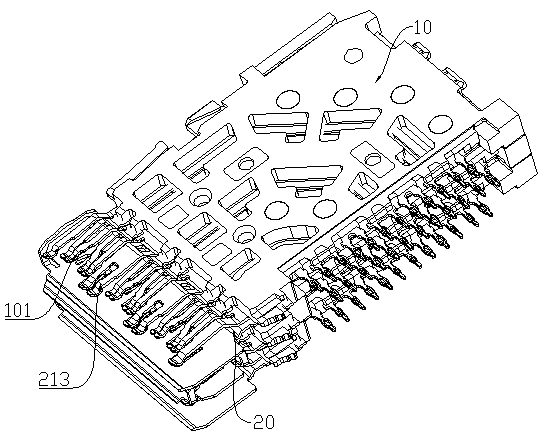

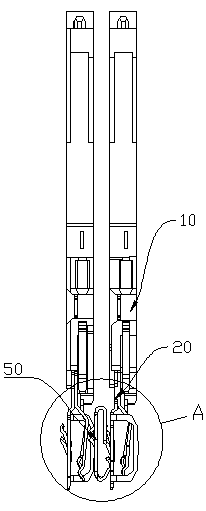

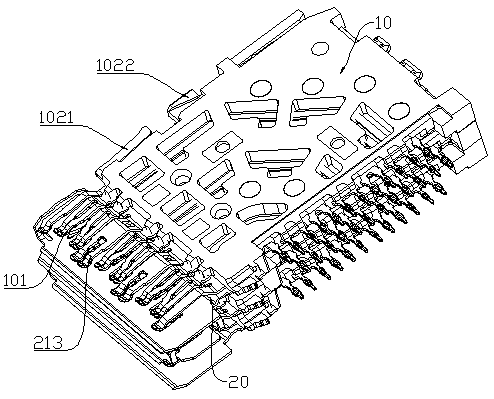

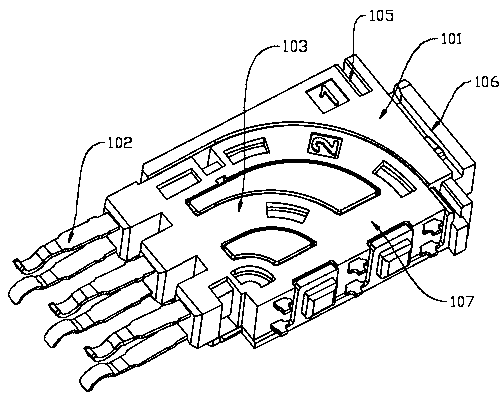

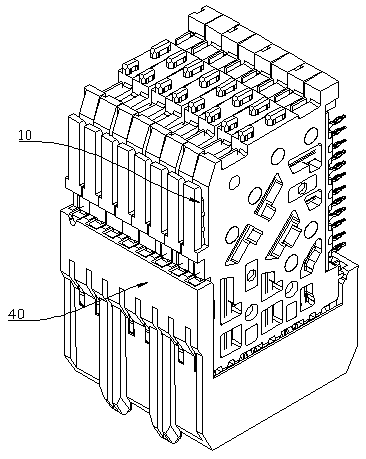

Female-end connector for high-speed differential signal connector

PendingCN109510035AReduce mutual interferenceEasy to fixCoupling contact membersPlastic packagingComputer module

The invention discloses a female-end connector for a high-speed differential signal connector. The female-end connector comprises a female-end base and a plurality of female-end signal transmission modules arranged side by side on the female-end base. The female-end signal transmission modules include signal transmission modules and metal shielding plates fixed at the signal transmission modules.The signal transmission modules include module housings, signal transmission reeds and plastic packaging modules; a plurality of recessed cavities are arranged at the module housings; the signal transmission reeds are installed in the recessed cavities; the plastic packaging modules cover the recessed cavities and seal the recessed cavities, so that enclosed signal channels are formed in the signal transmission reeds. Protruding teeth that are fixed and communicated with the female-end base are arranged at the lower end portion of the metal shielding plates. Besides, convex hull structures arearranged at positions, corresponding to the protruding teeth, on the female-end base. Therefore, the mutual interference between differential signal pairs is reduced and the return path is reduced.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

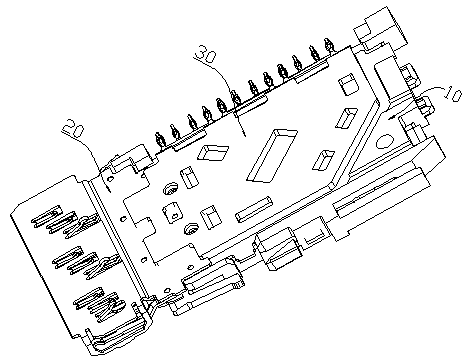

Module structure for high-speed connector and high-speed connector

PendingCN109830850AGuaranteed distanceEnsure consistencyCoupling contact membersCoupling protective earth/shielding arrangementsDifferential signalingEngineering

The invention discloses a module structure for a high-speed connector and a high-speed connector. The module structure comprises a signal transmission module, a shielding component and a secondary plastic package plate, wherein the secondary plastic package plate plastically packages the signal transmission module and the shielding component together; the secondary plastic package plate is provided with a plastic package rib at a position close to the fisheye needle of the signal transmission module; and a convex tooth for holding the fisheye needle is disposed at a position on the plastic package rib corresponding to the fisheye needle. The signal transmission module and the shielding component are closely combined by means of secondary plastic package, thereby ensuring the distance between the shielding component and a signal wire, and the impedance consistency of a wiring area. The second plastic package is also performed at a fisheye side so as to prevent the protruding deformationof the differential signal wire or the shielding component in the left-right direction, thereby contributing to optimizing the fisheye root impedance.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

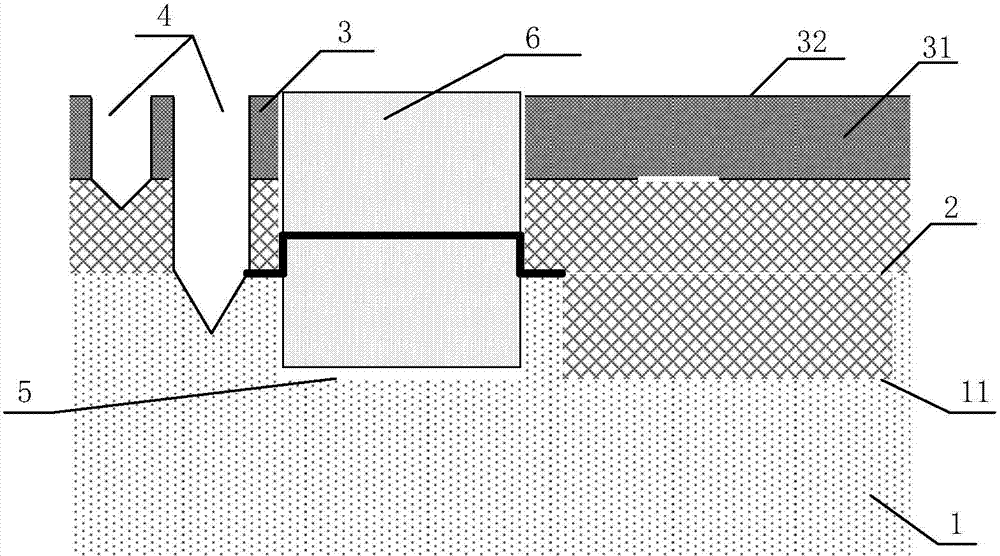

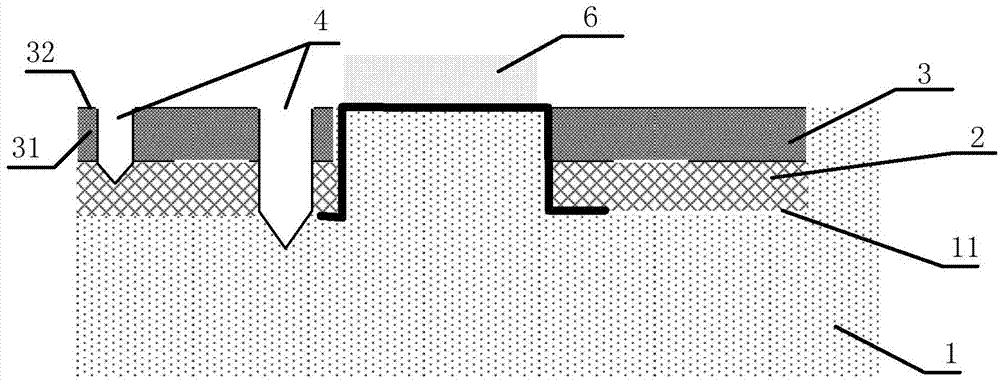

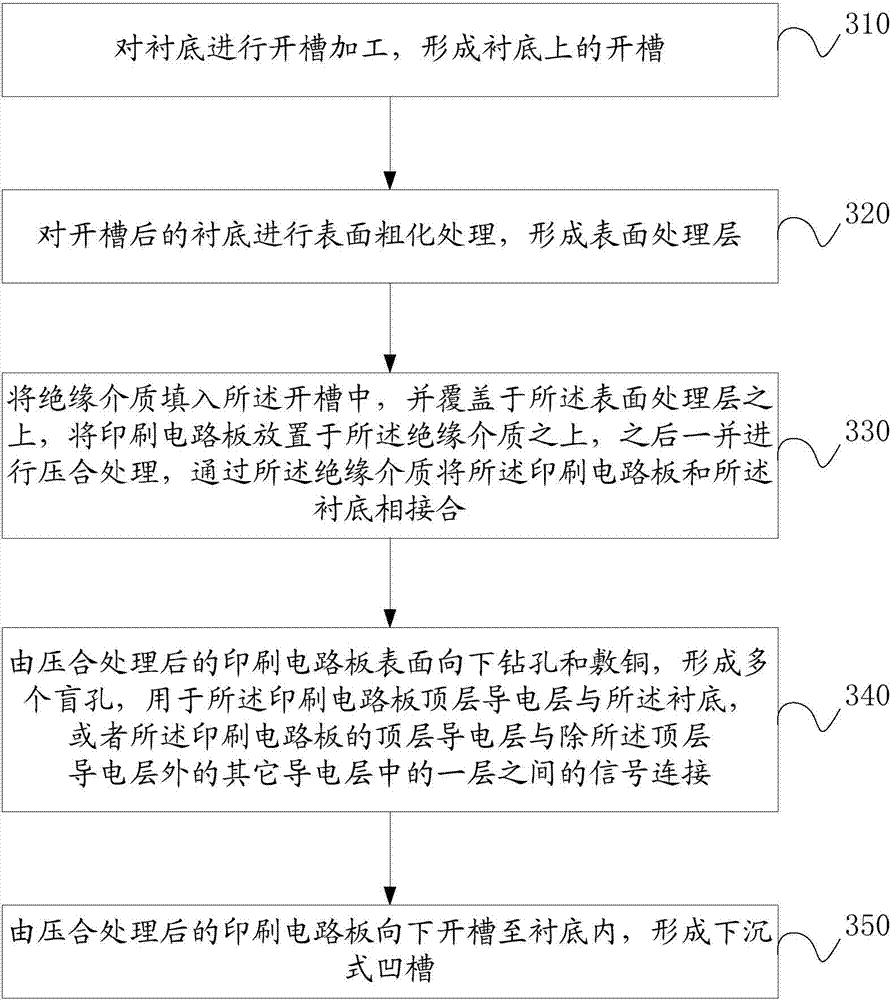

Circuit board of power amplifier and manufacturing method of circuit board

ActiveCN103533749AShorten return pathImprove cooling effectElectrical connection printed elementsCircuit susbtrate materialsAudio power amplifierEngineering

An embodiment of the invention discloses a circuit board of a power amplifier and a manufacturing method of the circuit board. The circuit board comprises a substrate, an insulation dielectric layer, a PCB (printed circuit board), blind holes and a sunken type groove, wherein a groove is formed in the substrate; a surface treatment layer subjected to roughening treatment is arranged on the upper surface of the substrate; the insulation media layer is arranged in the groove, and the surface treatment layer is covered with the insulation dielectric layer ; the PCB comprises at least one core plate; conducting layers are arranged on two sides of each core plate; the PCB is arranged on the insulation dielectric layer and is connected with the insulation dielectric layer through the bottom core plate of the PCB and the conducting layer on the lower side of the bottom core plate; the blind holes are formed between the top conducting layer and the substrate or among other conducting layers besides the top conducting layer in the PCB; conducting materials are arranged on the inner walls of the blind holes; the top conducting layer of the PCB is in signal connection with the substrate or other conducting layers besides the top conducting layer through the blind holes; and the sunken type groove is formed between the top conducting layer of the PCB and the substrate, and the bottom of the sunken type groove is located in the substrate.

Owner:HUAWEI TECH CO LTD

Steam chamber heat pipe/microchannel cold plate composite structure temperature equalization device

ActiveCN103415192BShorten return pathImprove heat transfer effectCooling/ventilation/heating modificationsEngineeringCold plate

The invention discloses a temperature averaging device of a steam chamber heat pipe / microchannel cold plate composite structure. The device comprises a metal shell, steam cavity heat pipe layers and a microchannel cold plate layer, wherein the microchannel cold plate layer is located between the two steam cavity heat pipe layers, and the steam cavity heat pipe layers and the microchannel cold plate layer are all located in the metal shell. The liquid working medium phase-change heat exchange method is adopted for the device to transmit a large amount of heat in a gasified latent heat mode, and therefore the heat exchange capacity is remarkably improved. Because only one face of an existing steam cavity heat pipe is an evaporating face and is small in area, the utilization area of the whole is limited. The upper face and the lower face of the temperature averaging device of the composite structure are both evaporating faces, therefore, electronic components with high heating flux can be distributed on both the whole surface of the upper face and the whole surface of the lower face, the utilization rate is obviously improved, and the temperature averaging device of the composite structure can meet the thermal control requirements of the electronic components with high heating flux in the electronic industry field better. The temperature averaging device of the steam chamber heat pipe / microchannel cold plate composite structure is smaller in height, the height of a single microchannel cold plate layer in the prior art is 9mm, but the overall height of the temperature averaging device of the steam chamber heat pipe / microchannel cold plate composite structure is not larger than 9 mm.

Owner:NANJING UNIV OF SCI & TECH

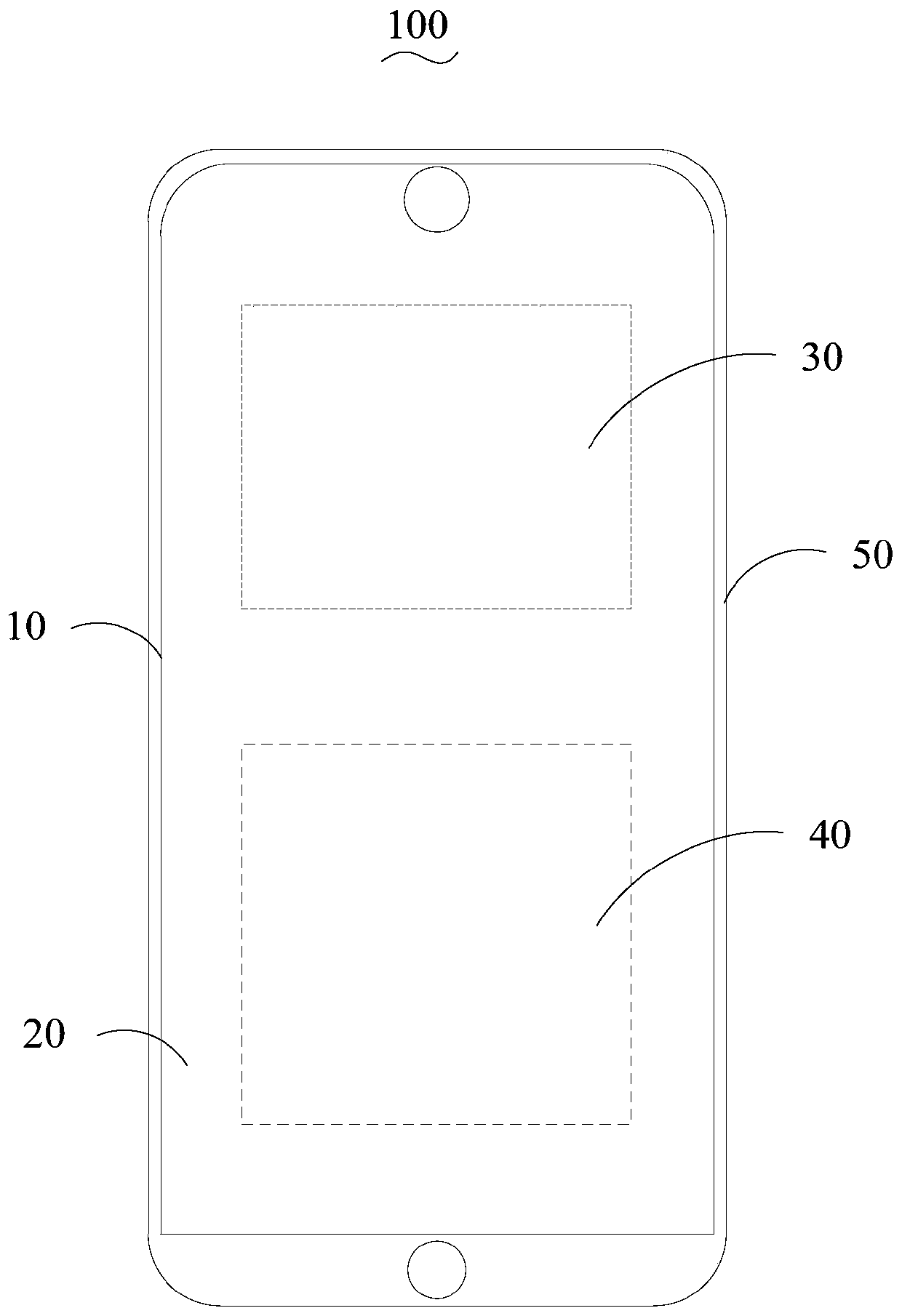

Antenna device and mobile terminal

InactiveCN111478021AOptimize the connection methodImprove yieldAntenna supports/mountingsAntenna earthingsFeed lineEngineering

The embodiment of the invention provides an antenna device and a mobile terminal. The antenna device comprises a front shell, and a main board, an antenna small board, an antenna radiator, a feed point elastic sheet and a grounding elastic sheet which are arranged in the front shell, wherein the feed point elastic sheet is arranged on the antenna small board and is used for connecting the feed line on the antenna small board with the antenna radiator, the grounding elastic sheet is arranged on the front shell, the first end of the grounding elastic sheet is connected to the grounding point onthe front shell, the second end of the grounding elastic sheet is connected to the antenna radiator, and the grounding point on the front shell is connected to the ground wire of the main board. According to the embodiment of the invention, the antenna grounding connection mode is improved, so that the antenna grounding yield is improved, the current return path is shortened, and the antenna performance and the overall performance of the mobile terminal are improved.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

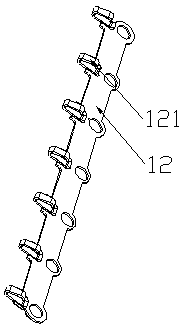

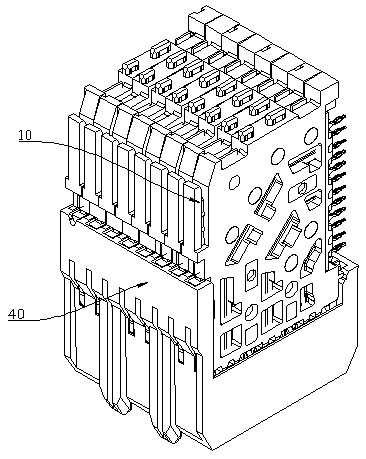

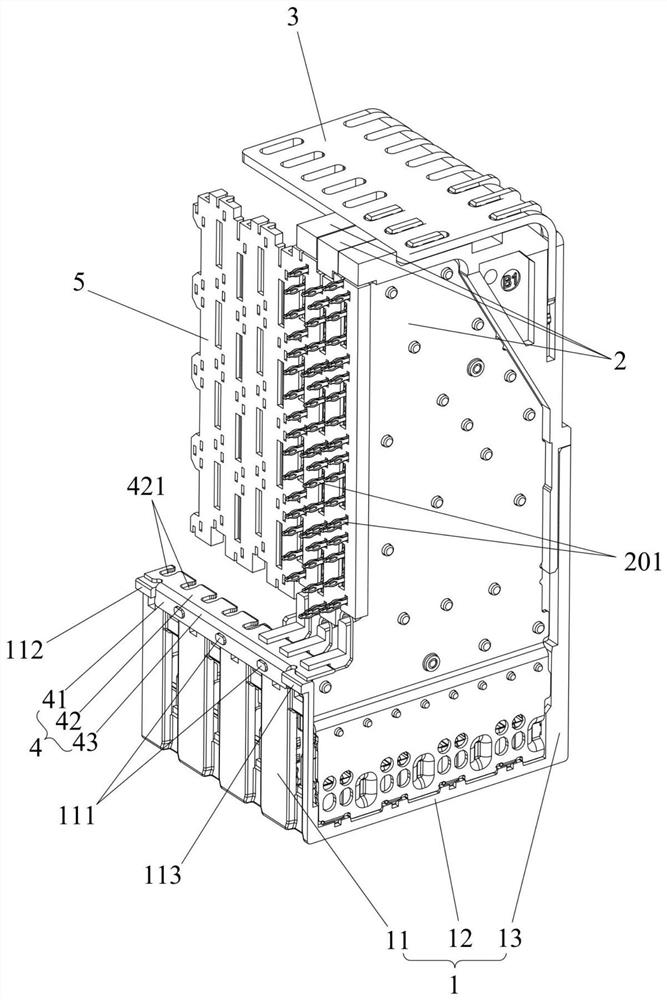

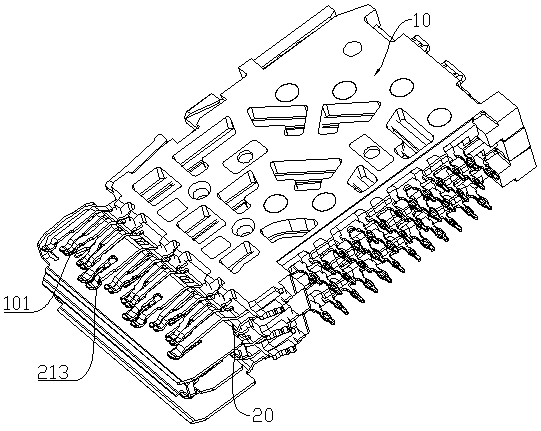

Module structure for high-speed connector and high-speed connector

PendingCN109921238AAchieve conductionShorten return pathCoupling contact membersClamped/spring connectionsEngineeringCrosstalk

The invention discloses a module structure for a high-speed connector and the high-speed connector. The module structure comprises signal transmission modules and shielding components arranged on thesignal transmission modules, and the shielding components on the adjacent signal transmission modules are connected through intermediate connecting pieces. According to the invention, the intermediateconnecting piece is arranged between the two modules, the shielding components on the adjacent signal transmission modules can be connected through the intermediate connecting pieces, and the conduction of the shielding components on the adjacent modules is realized, so that the reflux path is shortened, and the crosstalk is reduced.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

High speed differential signal connector

PendingCN109546468AEasy to fixShorten return pathSecuring/insulating coupling contact membersCoupling contact membersDifferential signalingEngineering

The invention discloses a high speed differential signal connector. The high speed differential signal connector includes a male end connector and a female end connector that are in mutual plug fit; the female end connector includes a female end base and a plurality of female end signal transmission modules that are plugged in parallel on the female end base; each of the female end signal transmission modules includes a signal transmission module and a metal shield plate fixed on the signal transmission module; the lower end portion of the metal shield plate is provided with protruding teeth for fixing and conducting with the female end base; and convex hull structures are disposed on the female end base corresponding to the protruding teeth. In the high speed differential signal connector, the protruding teeth are disposed at the lower end portion of the metal shield plate, and at the same time, the matching convex hull structures are disposed on the female end base to facilitate fixation of the female end signal transmission modules and the metal shield plates, and at the same time, the metal shield plates can communicate with the female end base to form a relatively short backflow path, thus facilitating shortening the backflow path of a differential signal.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

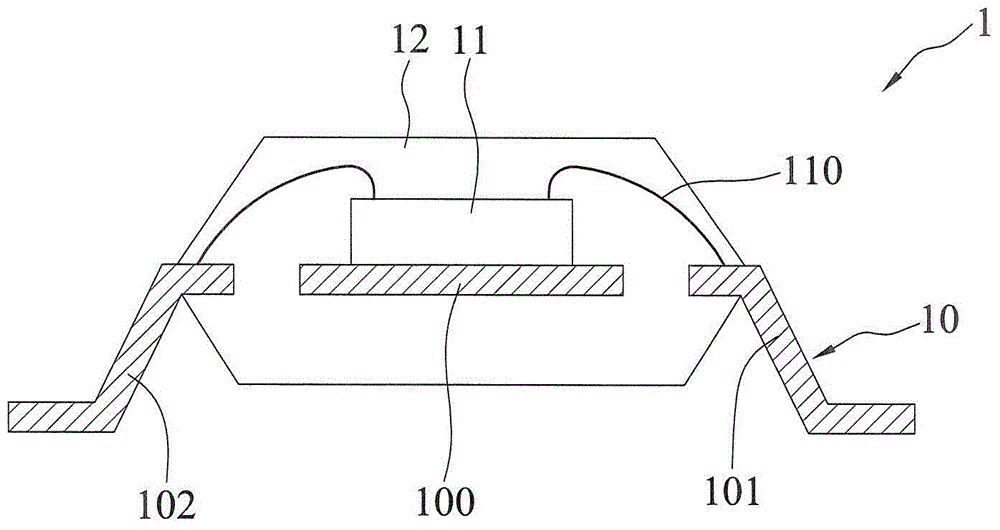

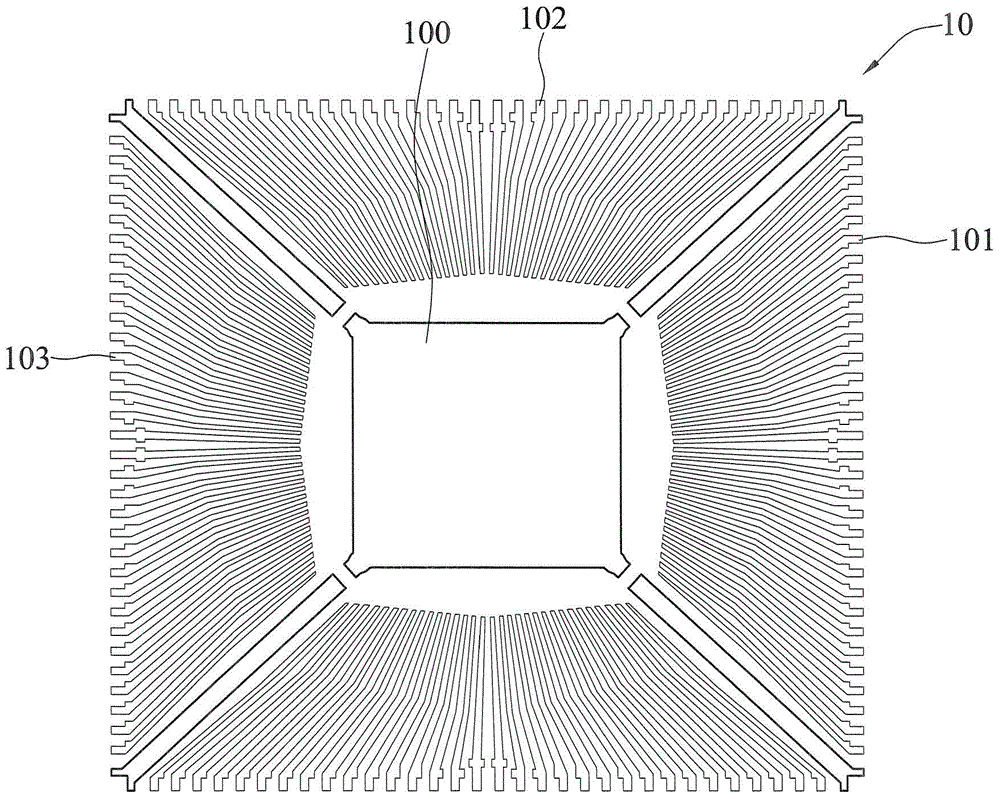

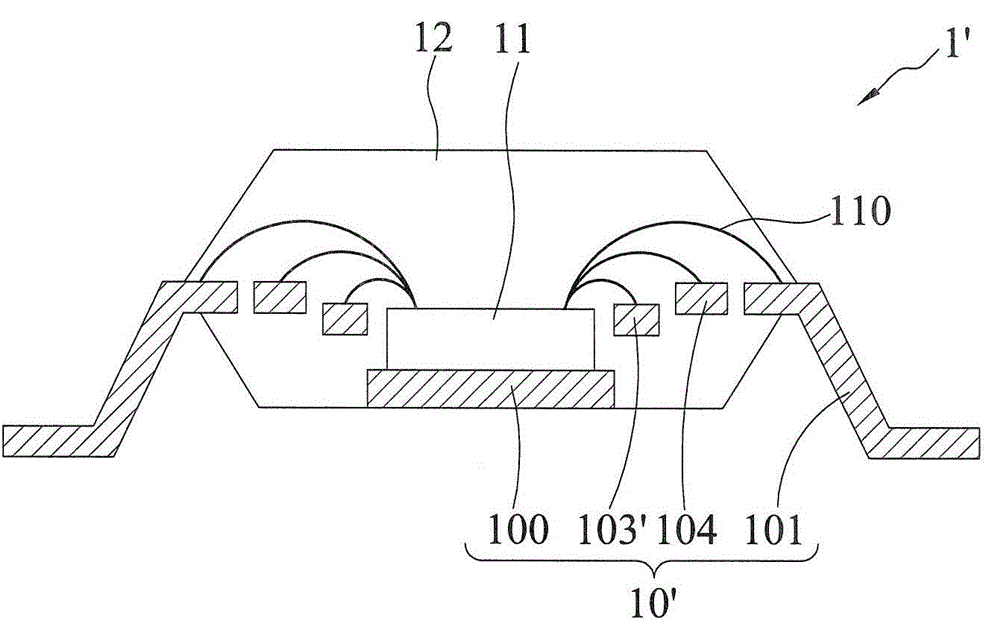

Semiconductor package and lead rack

ActiveCN104658986AExcellent electrical propertiesReduce inductanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A semiconductor package is disclosed, which includes: a die paddle portion; a plurality of conductive portions circumventing the die paddle portion; a power bus bar and a ground bus bar formed around the periphery of the die paddle portion; a semiconductor element attached to the die paddle portion and electrically connected to the conductive portions, the power bus bar, and the ground bus bar by a plurality of bonding wires; and an encapsulant encapsulating the semiconductor element and the bonding wires. The ground bus bar extends outward along the power bus bar and is mutually configured with the power bus bar so as to reduce the loop inductance and resistance of the power bus bar while in use.

Owner:SILICONWARE PRECISION IND CO LTD

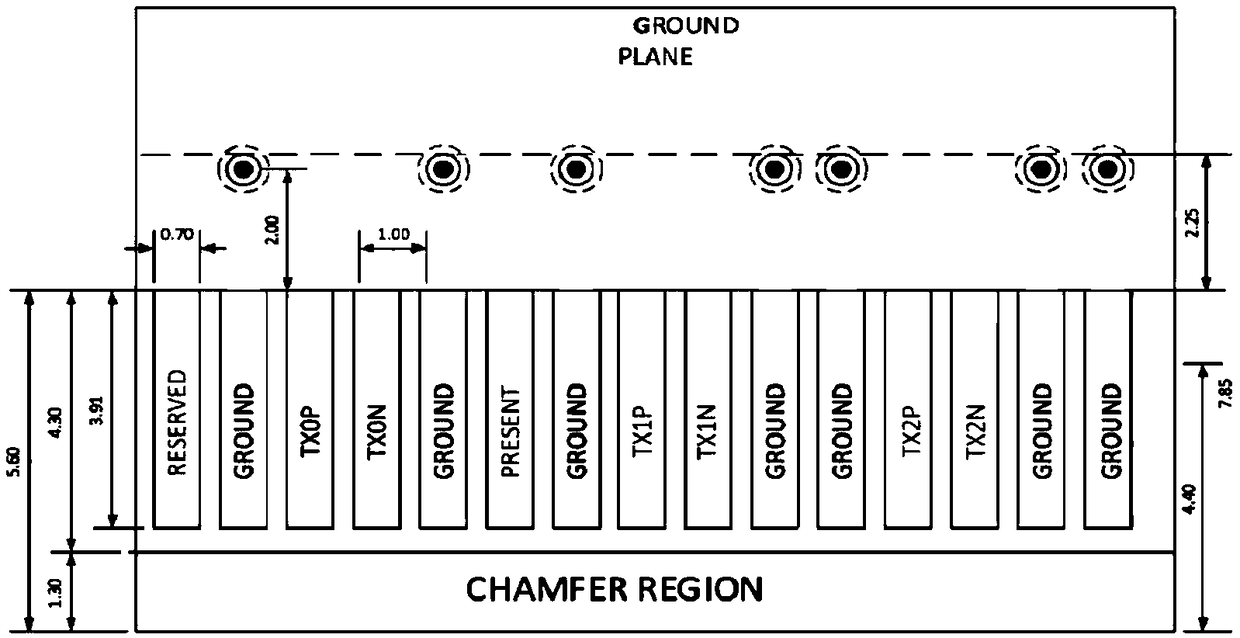

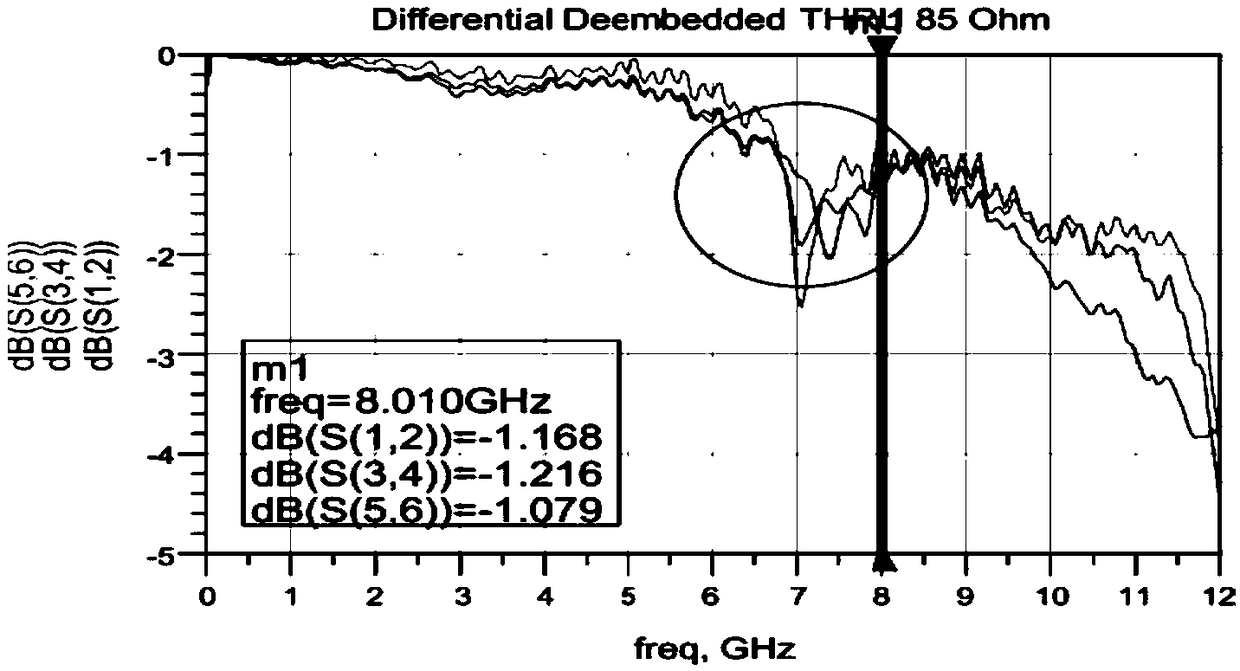

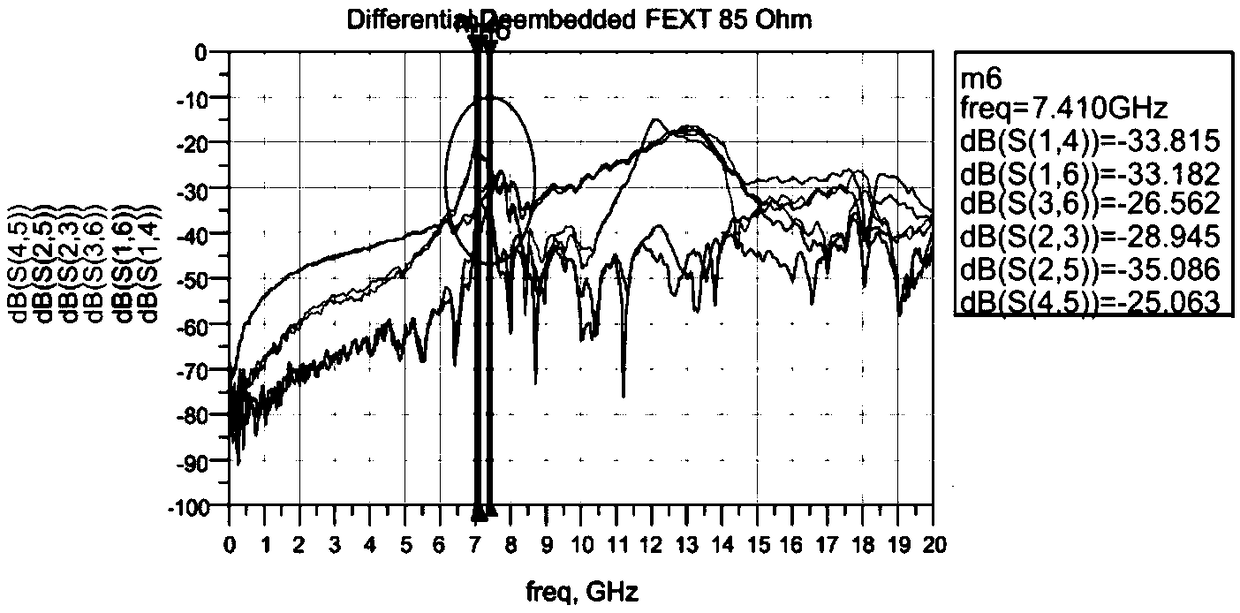

Design method of layout at board card golden finger and server board card

ActiveCN108966497AShort quantityIncrease the number ofCross-talk/noise/interference reductionHigh frequency circuit adaptationsUltrasound attenuationDesign methods

The present invention discloses a design method of layout at a board card golden finger and a server board card. The design method comprises the steps of: setting the quantity of GND via interconnected with GND pins according to the types of the GND pins on the board card golden finger and a space between a golden finger on the board card and the GND vias to allow the GND vias interconnected withthe GND pins to reach the maximum quantity; and combining and interconnecting the GND pins with all the GND vias matched with the GND pins to form a signal return path; in the signal return path, getting all the GND vias tightly close to the matching GND pins to minimize the length of the signal return path. The design method can greatly reduce the degree of attenuation in the transmission processof high-speed signals and can effectively optimize the signal return path so as to avoid generation of resonance points on a high-frequency section by a signal insertion loss waveform, near-end cross-talk frequency domain waveform and far-end cross-talk frequency domain waveform, facilitate improvement of the quality of signal transmission and improve the operation stability of the whole system.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Electric connector device

PendingCN109950749AAchieve conductionShorten return pathCoupling protective earth/shielding arrangementsElectricityElectroplating

The invention discloses an electric connector device. The electric connector device comprises a plurality of overlapped module structures. Each module is structurally provided with a shielding assembly. The middle parts of shielding assemblies on adjacent modules structures are connected through a middle connecting piece. The middle connecting piece comprises a plastic electroplating shell and contact connecting pieces arranged in the plastic electroplating shell at intervals. The contact connecting pieces are provided with connecting contacts connected with the shielding assemblies. One shielding assembly is in contact with the plastic electroplating shell. Adjacent shielding assemblies are in contact with connecting contacts on the above contact connecting piece. By means of the middle connecting piece arranged between every two modules, the shielding assemblies on adjacent signal transmission modules can be connected through the middle connecting piece. The conduction of the shielding assemblies on the adjacent modules is achieved. Therefore, the backflow path is shortened, and the crosstalk is reduced.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

Module structure for high-speed connector and high-speed connector

PendingCN109830848AImprove stabilityEnsure consistencyCoupling contact membersCoupling protective earth/shielding arrangementsEngineeringMechanical engineering

The invention discloses a module structure for a high-speed connector and a high-speed connector. The high-speed connector comprises a mounting base and a signal transmission module inserted into themounting base. The signal transmission module is composed of a plastic package casing and a differential signal terminal. The side surface of the plastic package case that is in contact with the mounting base is provided with a positioning hook and a wedge structure in the insertion direction. The positioning hook matches an insertion groove in the mounting base. The wedge structure matches a wedge-shaped groove on the end portion of the side wall of the mounting base. By disposing the wedge structure on the module structure, and by means of the cooperation of the wedge structure and the wedge-shaped groove, the positioning hook can enter the positioning insertion groove of the base according to a predetermined path, thereby improving the stability of the structure and ensuring the consistency of the differential impedance.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

Female-end connector for high-speed differential signal connector

PendingCN109510031AReduce mutual interferenceEasy to fixCoupling contact membersPlastic packagingEngineering

The invention discloses a female-end connector for a high-speed differential signal connector. The female-end connector comprises a female-end base and a plurality of female-end signal transmission modules arranged side by side on the female-end base. The female-end signal transmission modules include signal transmission modules and metal shielding plates fixed at the signal transmission modules.The signal transmission modules include module housings, signal transmission reeds and plastic packaging modules; a plurality of recessed cavities are arranged at the module housings; the signal transmission reeds are installed in the recessed cavities; the plastic packaging modules corresponding to the recessed cavities one by one cover the recessed cavities and seal the recessed cavities, so that enclosed signal channels are formed in the signal transmission reeds. The plastic packaging modules at the adjacent recessed cavities are connected by cross ribs for integration; and cross ribs areconnected near the end portions of the plastic packaging modules. Therefore, the mutual interference between differential signal pairs is reduced.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

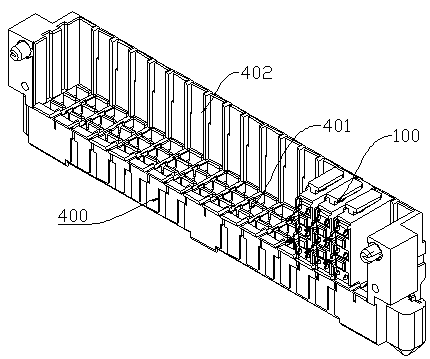

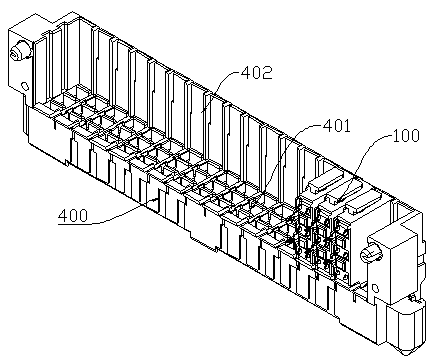

High-speed backboard connector

PendingCN113904181AReduce wall thickness requirementsReduce crosstalk effectsSecuring/insulating coupling contact membersCoupling protective earth/shielding arrangementsLap jointEngineering

The invention relates to the field of connectors, and discloses a high-speed backboard connector. The high-speed backboard connector comprises a female end base, signal modules and a grounding piece, a containing groove is formed in the female end base, the signal modules are inserted into the containing groove side by side, the signal modules comprise the first signal module and the second signal module which are arranged adjacently, the first signal module comprises a first convex hull shielding piece and a first elastic piece shielding piece, the second signal module comprises a second convex hull shielding piece, the grounding piece is arranged between the female end base and the first signal module, and the grounding piece is in lap joint with the first convex hull shielding piece, the first elastic piece shielding piece and the second convex hull shielding piece at the same time to form a surrounding type shielding structure so as to achieve the purposes of shortening a backflow path and optimizing crosstalk. Especially for a signal module which is located at the edge of the female end base and cannot achieve effective shielding, surrounding type shielding of the signal module is achieved, the shielding effect is good, the backflow path is short, and the crosstalk influence of differential signal transmission is reduced.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

Shielding component and module structure for high-speed connector, and high-speed connector

PendingCN109768438APrecise control of relative position and sizeEnsure consistencyCoupling protective earth/shielding arrangementsLaserElectrical and Electronics engineering

The invention discloses a shielding component and a module structure for a high-speed connector, and the high-speed connector. The module structure comprises a signal transmission module and the shielding component mounted on the signal transmission module, wherein the shielding component comprises a first shielding member and a second shielding member, which are fixed by a guiding column. The invention fixes the first shielding member and the second shielding member by means of a guiding column and laser welding, etc., and can accurately control the relative positional size between the firstshielding member and the second shielding member after fixing, thereby ensuring the consistency of differential impedance.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

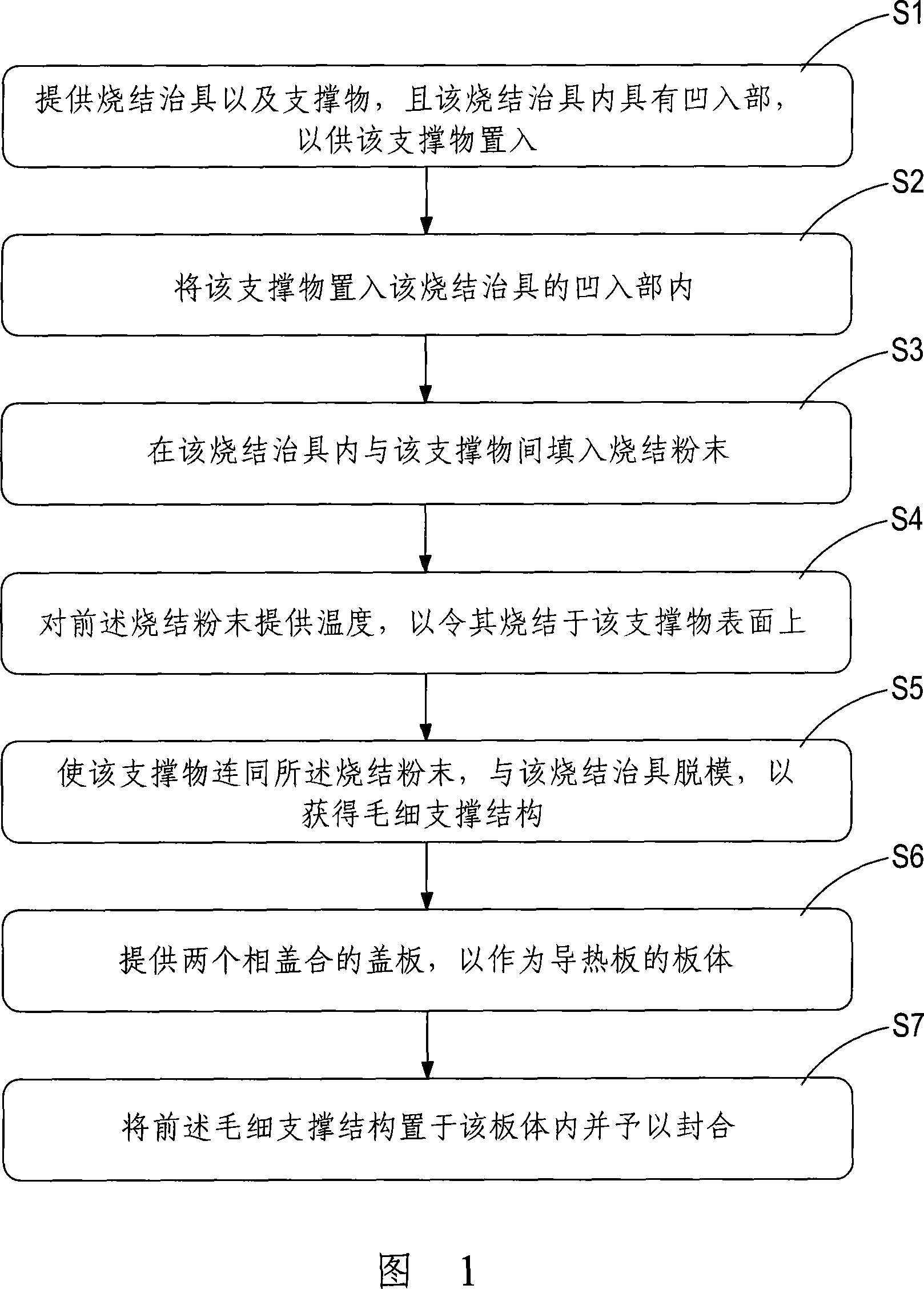

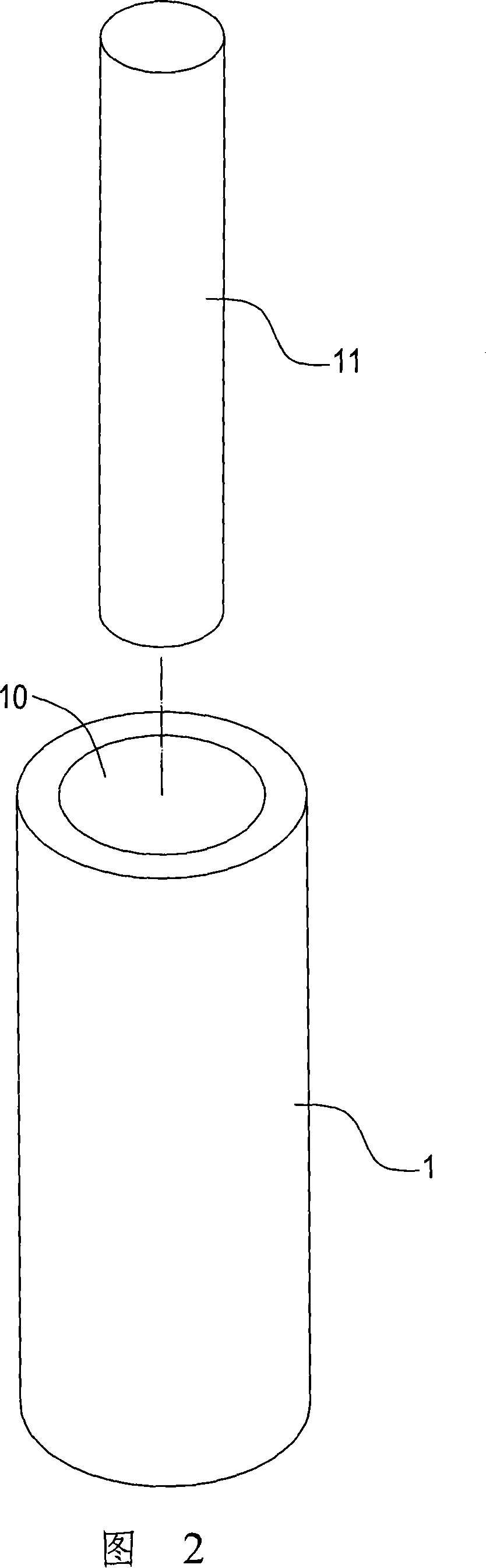

Flat heat pipe with nested porous liquid-absorbing core and manufacturing method thereof

InactiveCN104534906BRaise the capillary limitShorten return pathIndirect heat exchangersVapor liquidCapillary pressure

The invention provides a panel heat pipe with an embedded porous wick and a manufacturing method thereof. The panel heat pipe comprises an upper metal cover plate, a lower metal cover plate, and a closed cavity is formed between the upper metal cover plate and the lower metal cover plate in a welded and sealed mode. The cavity is filled with liquid working media. The inner surface of the cavity is divided into an evaporation face and a condensation face. The condensation face and the evaporation face are paved with a thin-layer porous wick structure formed by sintering metal powder particles. Sintering porous columns with inner grooves which are distributed in an array mode are machined on the evaporation face. Porous protrusions matched with the inner grooves are machined in the condensation face. The sintering porous columns and the porous protrusions are in close fit to form an embedded porous structure column. A working medium backflow channel is formed in the embedded porous structure column. According to the panel heat pipe, the capillary pressure is improved, the working medium backflow speed is remarkably increased, vapor-liquid two-phase separation is achieved, and the heat transfer performance is greatly improved; meanwhile, the embedded wick plays a supporting column role, and panel heat pipe inward sinking or crack deformation or other problems are effectively avoided.

Owner:XIAMEN UNIV

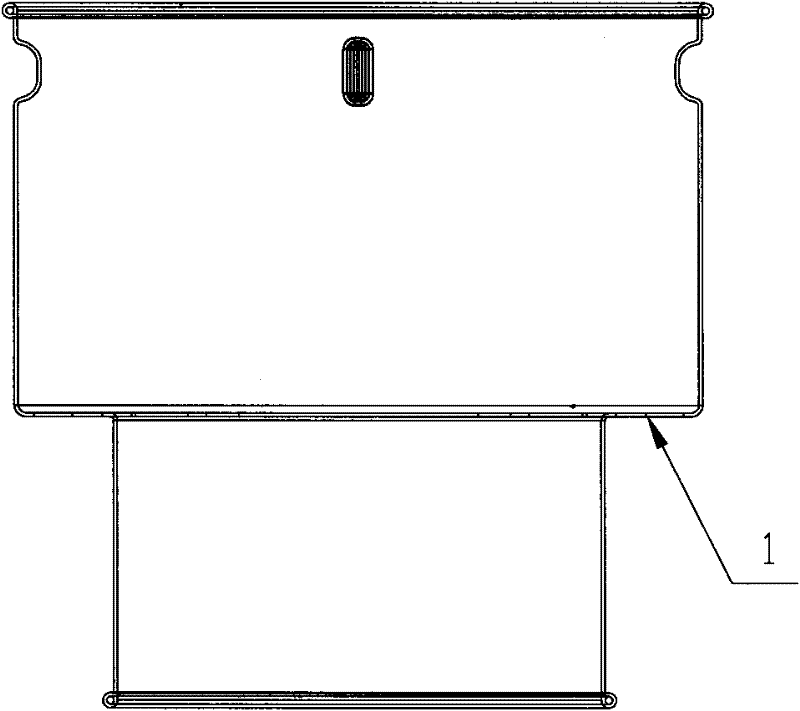

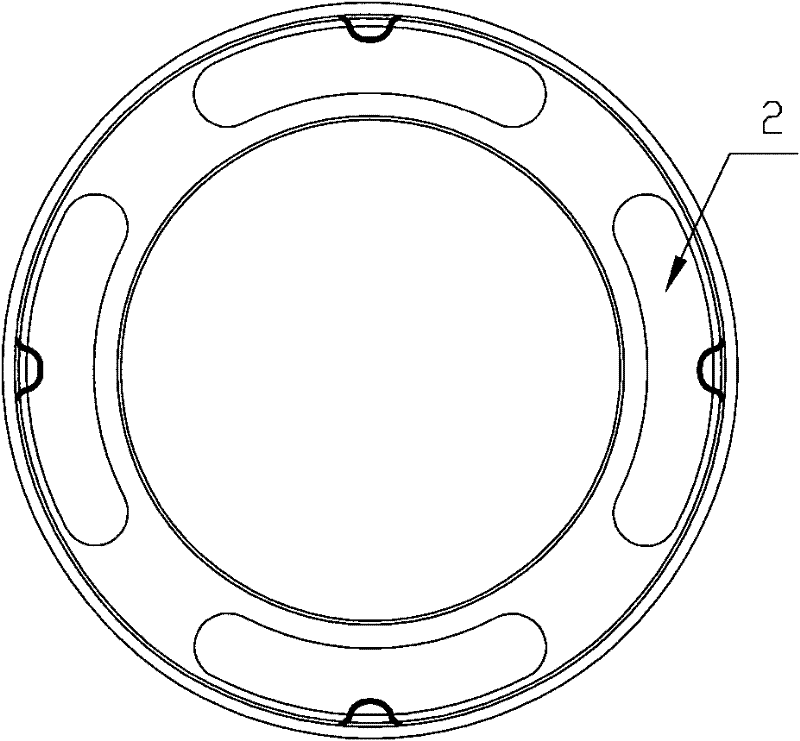

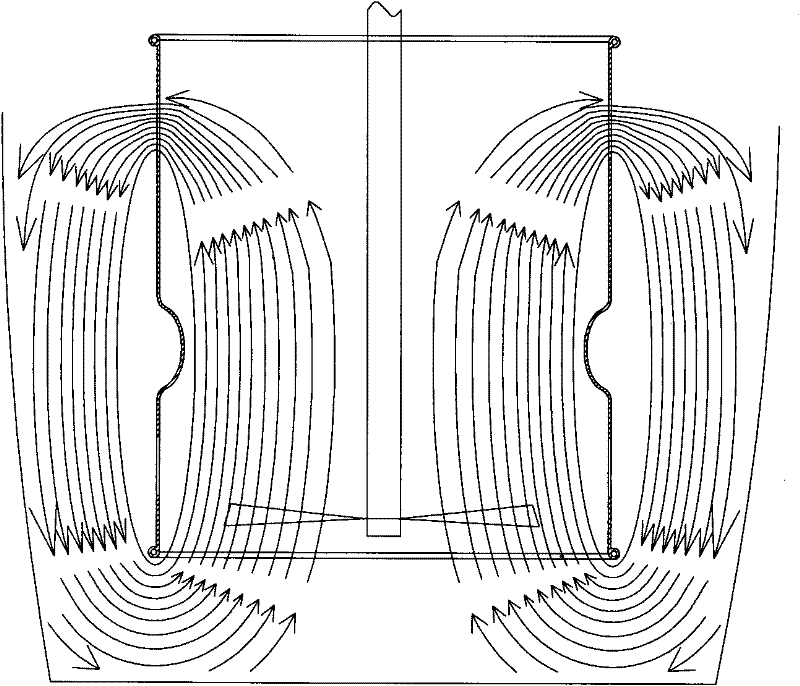

Structurally improved polyflow cup for soybean milk machine

InactiveCN102283580AShorten return pathShort crushing timeBeverage vesselsMilk substitutesEngineeringJoint surface

The invention discloses a flow-concentrating cup for a soybean milk machine with improved structure. Based on the direction of use, the cup body is a T-shaped hollow cylinder with a diameter at the upper end greater than that at the lower end. On the surface, at least one through hole is provided on the annular joint surface. The present invention adopts a double-ring structure. The through hole on the annular joint surface and the lower end of the cup form a soymilk circulation channel, which greatly shortens the soymilk return path, so that the unit time The number of internal grinding and cutting is greatly increased, which makes the fine grinding efficiency of the soymilk machine high, the crushing time of the soymilk machine is short, and the pulp yield is high.

Owner:KUSN GOLDBERRY ELECTRONICS

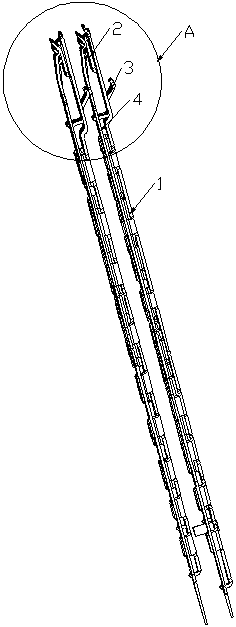

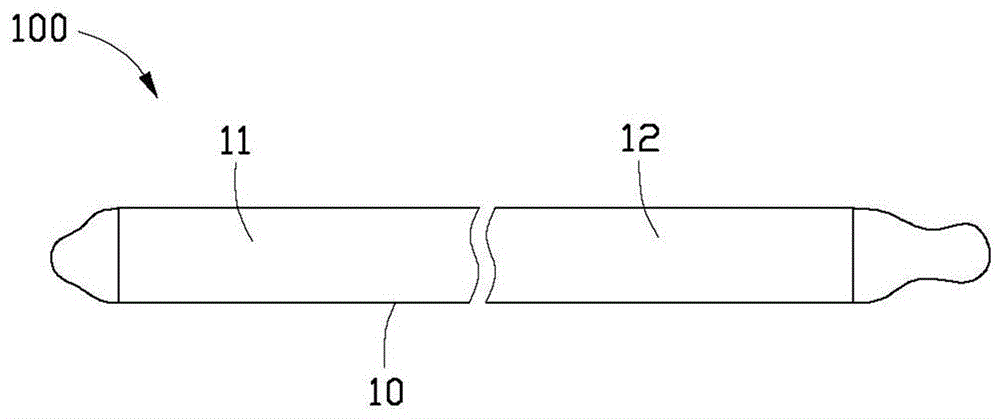

Heat pipe

InactiveCN103363829BImprove performanceShorten return pathIndirect heat exchangersWorking fluidSquare mesh

A heat pipe, comprising a pipe body and at least one capillary structure disposed in the pipe body, the at least one layer of capillary structure includes a plurality of braided grids, the grids of the at least one layer of capillary structure are rhombus, each rhombus The grid has two opposite first included angles, and the two first included angles are less than 90 degrees. Compared with the prior art, the above-mentioned heat pipe has at least one layer of capillary structure grid set in a rhombus shape. When the working fluid in the tube flows along the edge of the grid, the path is replaced by the hypotenuse of the two right angles of the traditional square grid, shortening the working time. The return path of the fluid along the axial direction of the pipe body. At the same time, the first included angle of each grid is set to be less than 90 degrees. The continuous transition of the distance reduces the backflow resistance of the working fluid along the direction perpendicular to the line connecting the vertices of the two first included angles, and greatly improves the heat transfer efficiency of the working fluid along the axial direction, thereby improving the performance of the heat pipe.

Owner:FURUI PRECISE COMPONENT (KUNSHAN) CO LTD +1

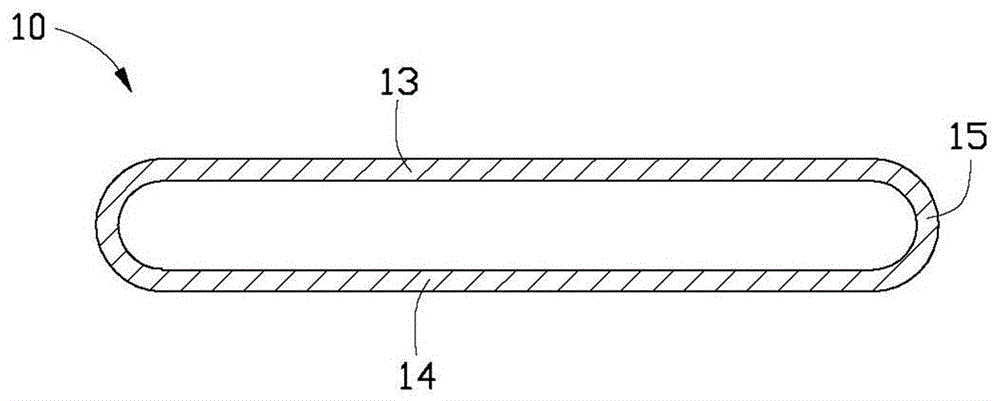

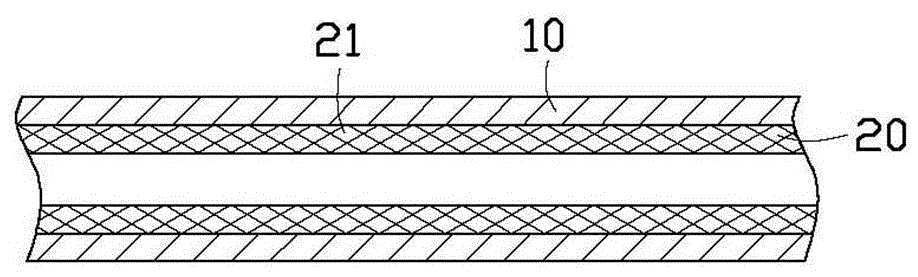

Heat-conducting plate with wick supporting structures and method for manufacturing same

ActiveCN101526319BGood heat transfer performanceSmooth returnIndirect heat exchangersWorking fluidHeat conducting

The invention provides a heat-conducting plate with wick supporting structures, which comprises a hollow plate body and two or more wick supporting structures, wherein the internal wall of the plate body is attached with wick tissues, the wick supporting structures vertically support and are uniformly distributed inside the plate body and in a cylindrical shape and the circumferential surfaces ofthe cylinder shapes are provided with sintered powder wick which contacts the wick tissues attached to the inner wall of the plate body so as to form a wick flow pass. Moreover, the invention also provides a method for manufacturing the heat-conducting plate with the wick supporting structures. The supporting structure inside the heat-conducting plate also has wick tissues which allow working fluid to flow back smoothly to improve the heat transfer effect of the heat-conducting plate.

Owner:NIDEC CHAUN-CHOUNG TECH CORP

Female-end connector for high-speed differential signal connector

PendingCN109510032AReduce mutual interferenceEasy to fixCoupling contact membersPlastic packagingComputer module

The invention discloses a female-end connector for a high-speed differential signal connector. The female-end connector comprises a female-end base and a plurality of female-end signal transmission modules arranged side by side on the female-end base. The female-end signal transmission modules include signal transmission modules and metal shielding plates fixed at the signal transmission modules.The signal transmission modules include module housings, signal transmission reeds and plastic packaging modules; a plurality of recessed cavities are arranged at the module housings; the signal transmission reeds are installed in the recessed cavities; pressing plates are arranged at the sides with the recessed cavities of the module housings at intervals and are arranged between the adjacent recessed cavities; square bosses are arranged at the pressing plates; the plastic packaging modules cover the recessed cavities and seal the recessed cavities, so that enclosed signal channels are formedin the signal transmission reeds; and gaps are formed between the plastic packaging modules and the pressing plates. Therefore, a phenomenon of insufficient contact caused by unevenness of the bossesin various directions among the plurality of components is avoided.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

Computer interface cark

InactiveCN100361042CShorten return pathAvoid accumulationElectrical apparatusDigital data processing detailsElectrical conductorBus interface

The computer interface card includes a circuit board, a first connector, a second connector, first conductors, a second conductor, a third conductor, an upper cover and a base. Being setup a side of the circuit board, the first connector is in use for connecting to a cable. Being setup the other side of the circuit board, the second connector is in use for connecting to the third conductor and first conductors electrically. Transmission interface between second and third conductors includes PCMCIA, Card Bus or Express Card bus interface. The first conductor is connected to ground terminal of the circuit board electrically, and the second conductor is connected to metal case of the first connector. The upper cover and the base are in clip connection so as to clip the circuit board. The upper cover and the base possess an upper metal cover and a lower metal base. The upper metal cover is connected to the first conductors and the lower metal base electrically.

Owner:AVERMEDIA TECH

Backflow composite flat heat pipe

PendingCN114184069AAchieve reflowExpand the return spaceIndirect heat exchangersEngineeringMechanical engineering

The invention discloses a backflow combined type flat plate heat pipe which comprises an evaporation end, a condensation end, a liquid filling pipe and a liquid working medium. The liquid filling pipe and the condensation end are connected with the evaporation end to form a cavity containing a liquid working medium. The capillary reflux column and the side wall wick are arranged at the evaporation end; the evaporation end is super-hydrophilic, and the condensation end is super-hydrophobic; and the liquid working medium is deionized water. According to the non-wettability of the super-hydrophobic surface and the self-driven bounce phenomenon after liquid drop fusion, when the working angle of a system is that a condensation end is above, a liquid working medium quickly returns to an evaporation end by virtue of gravity, and capillary reflux does not need to play a role; when the condensation end is at the lower part, part of the condensation working medium returns to the evaporation end in a bouncing backflow mode, and the rest of the condensation working medium returns to the evaporation end in a capillary backflow mode through the capillary backflow column and the wall surface wick; meanwhile, a steam guide structure is arranged to promote liquid drops to flow back to the center of the evaporation end. Two backflow modes are combined, the backflow space of the flat heat pipe is expanded, the backflow path is shortened, and the backflow speed is increased.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com