Structurally improved polyflow cup for soybean milk machine

A technology of soymilk machine and polyflow cup, which is applied in the field of soymilk machine parts, can solve the problems of poor crushing effect, large cycle radius, and less pulp output, and achieve the advantages of short crushing time, high fine grinding efficiency, and increased grinding and cutting times Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

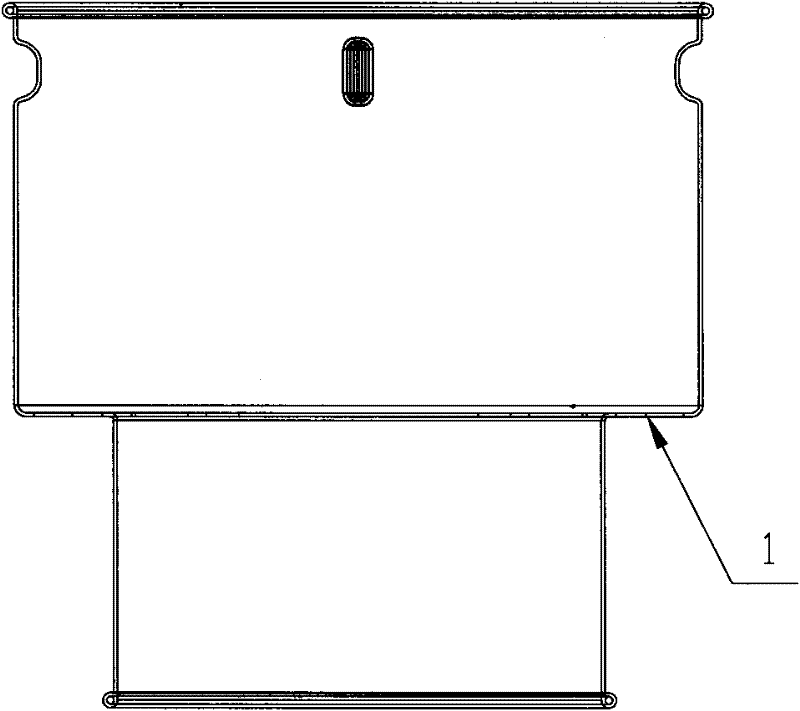

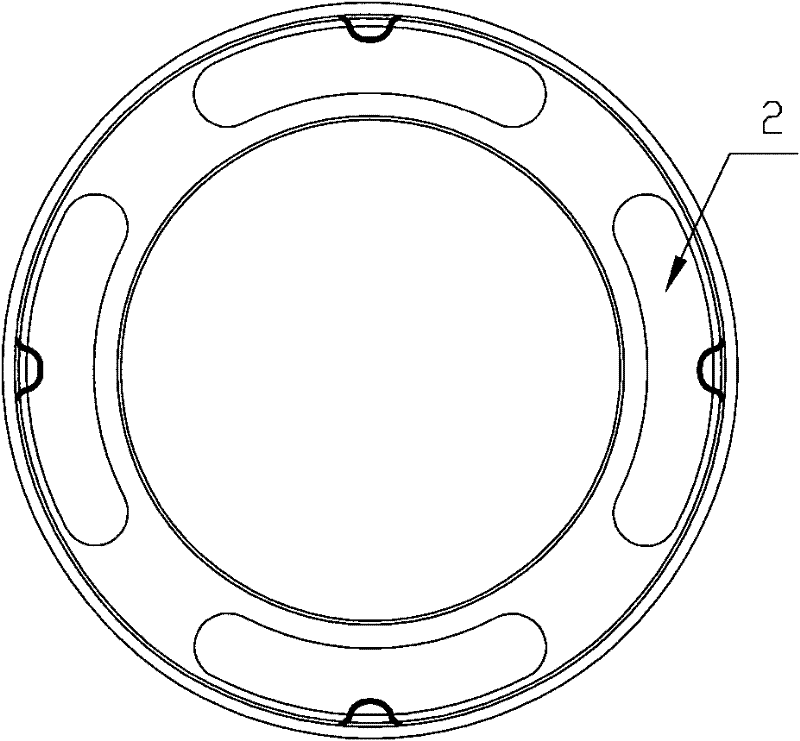

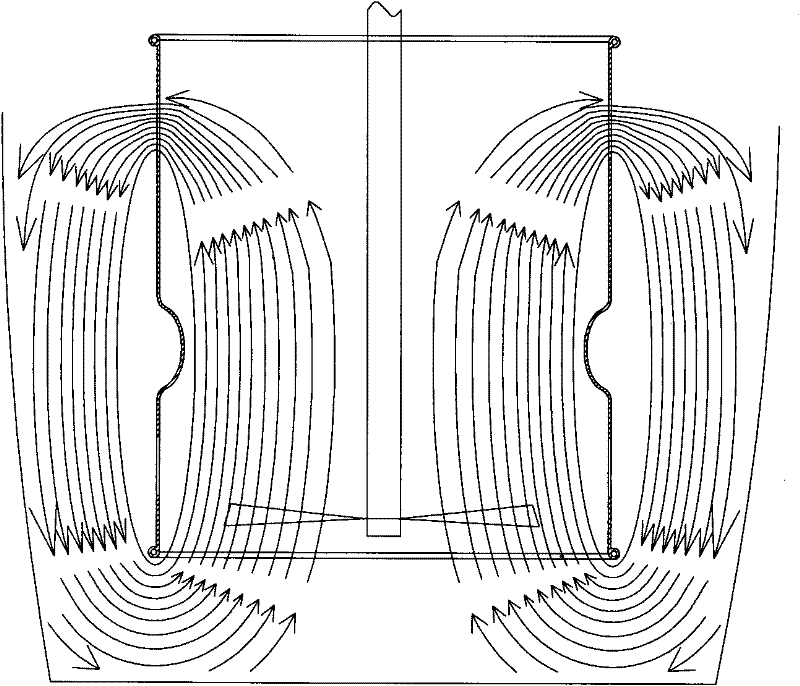

[0014] Embodiment: A structure-improved polyflow cup for soybean milk machine. Based on the direction of use, the cup body is a T-shaped hollow cylinder with a diameter at the upper end greater than that at the lower end. A ring-shaped joint surface is formed at the junction of the upper and lower ends of the cup body 1. At least one through hole 2 is provided on the annular joint surface 1. The through hole 2 on the annular joint surface 1 and the lower end of the cup body form a soymilk circulation channel, and the soymilk is sucked into the cup body from the lower end of the cup body and crushed Finally, it is sprayed from the through hole 2 and then flows to the lower end of the cup body to enter the next cycle, so that the return path of soybean milk is short, the cycle is fast, the refining efficiency is high, and the pulp is more.

[0015] The through holes 2 are evenly distributed on the annular joint surface 1 at the junction of the upper and lower ends of the cup body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com