Backflow composite flat heat pipe

A flat heat pipe and composite technology, applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of unstable heat dissipation, heat source temperature rise, and greater impact on operating performance, so as to increase the critical heat flux density and shorten the The effect of reflow path and expansion of reflow space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to clearly define the protection scope of the present invention.

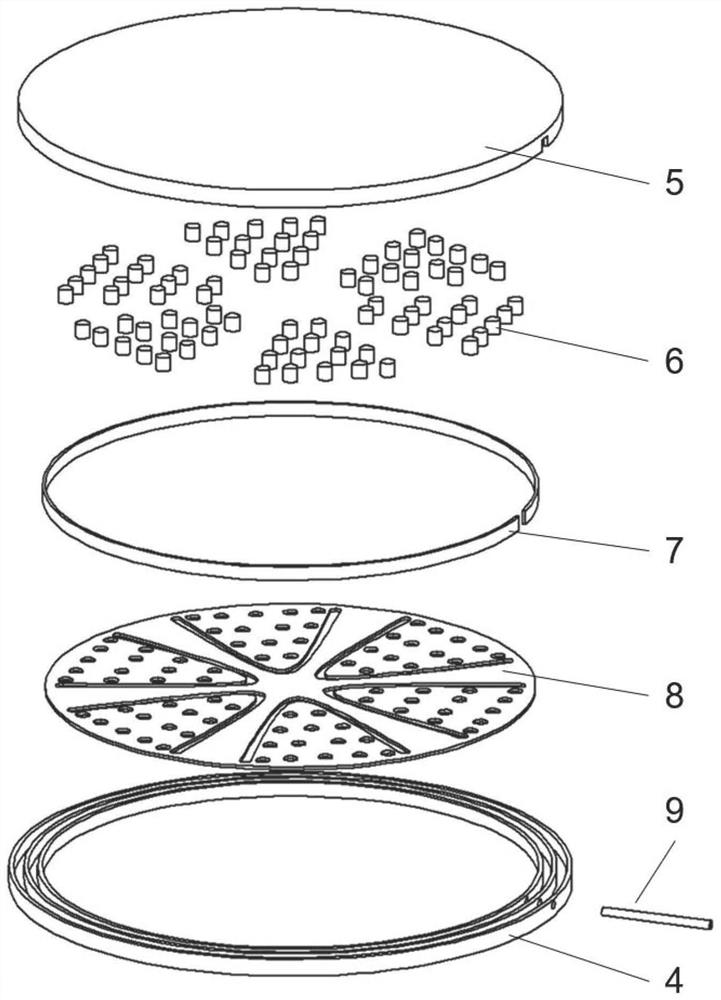

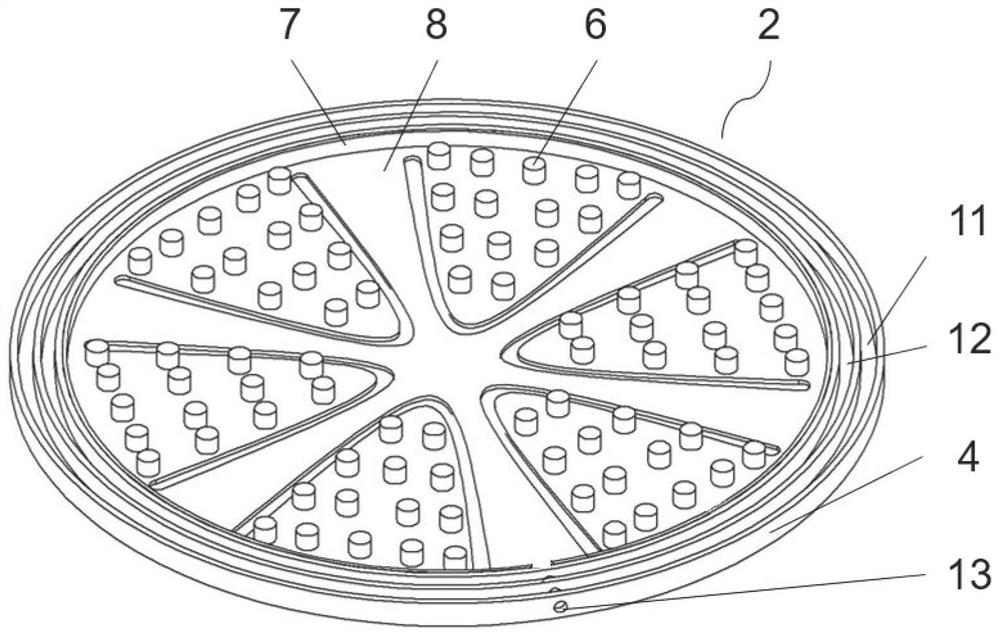

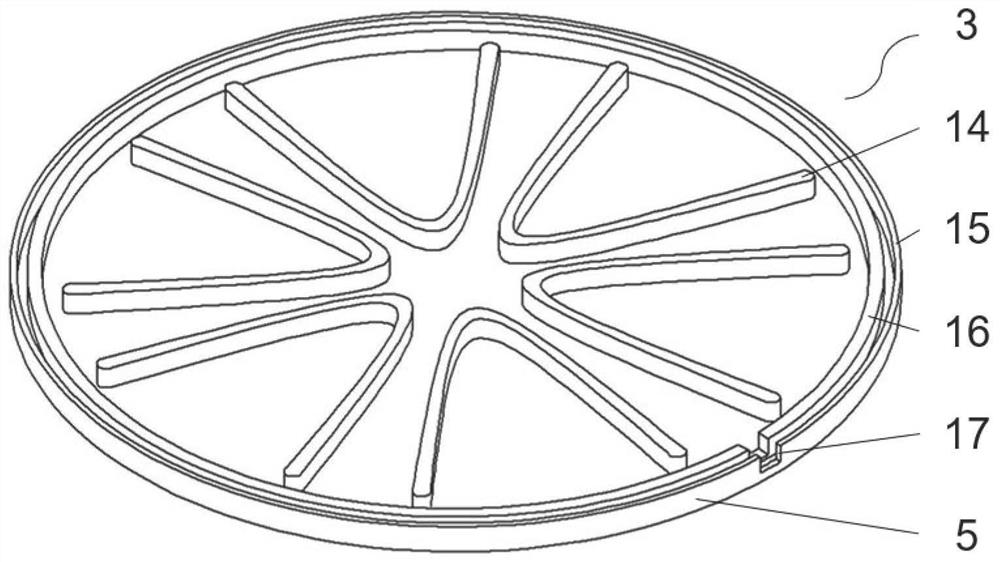

[0030] The invention discloses a reflux composite flat heat pipe 1. The system structure is as follows: figure 1 As shown, the structure of the evaporation end 2 is as follows figure 2 As shown, the structure of the condensation end 3 is as follows image 3 shown. This embodiment is a hollow cylindrical flat plate. The structural materials are selected as follows: the evaporation cover plate 4, the condensation cover plate 5 and the liquid filling pipe 9 are made of copper; the capillary return column 6, the wall surface liquid absorption core 7 and the bottom surface liquid absorption core 8 Deionized water.

[0031] In the figure, the evaporating end 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com