Patents

Literature

71results about How to "Little effect of gravity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

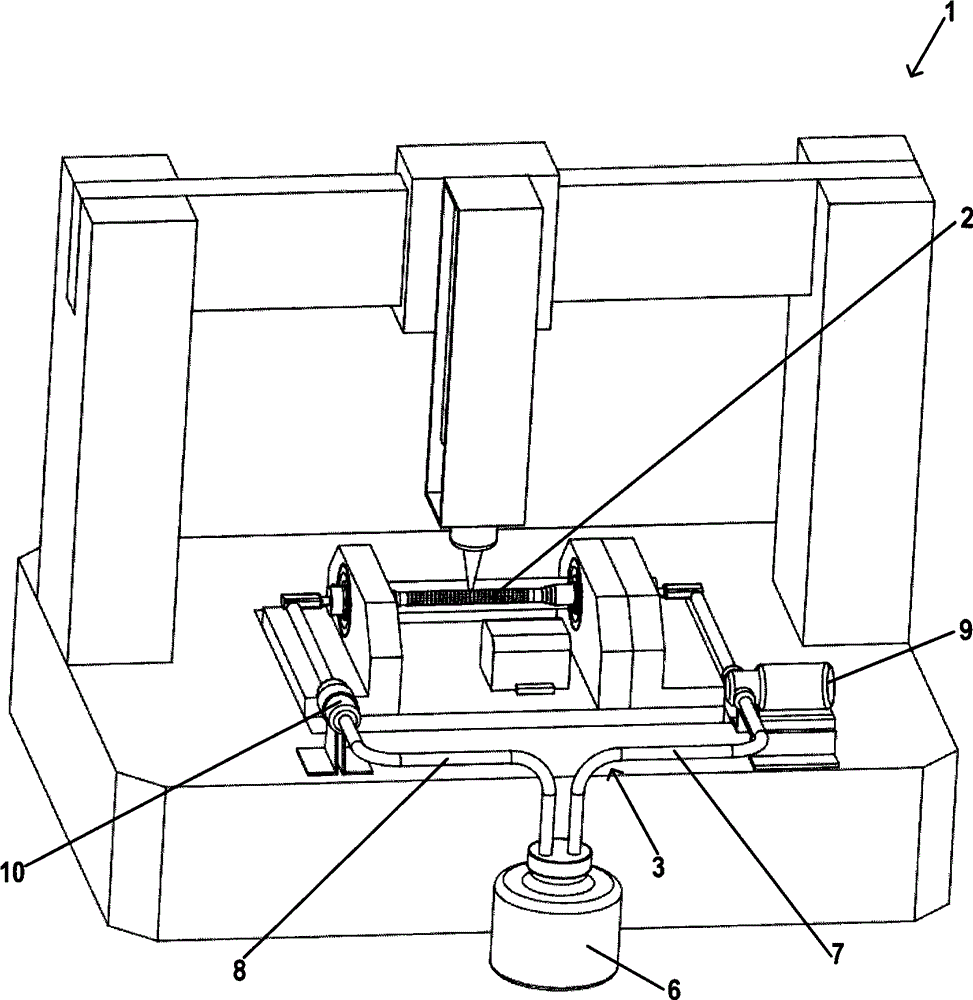

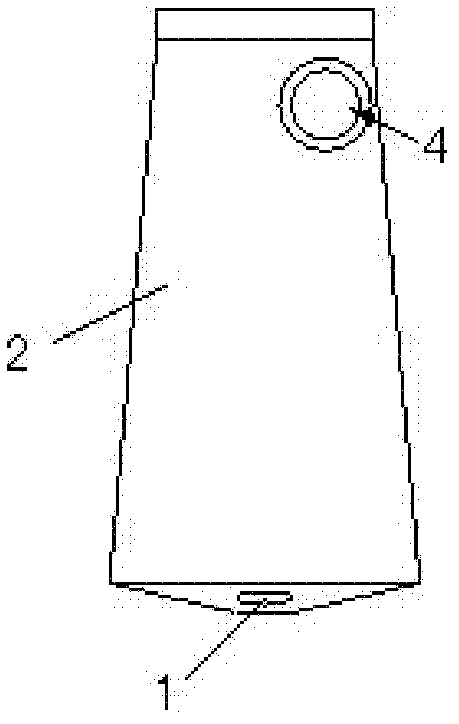

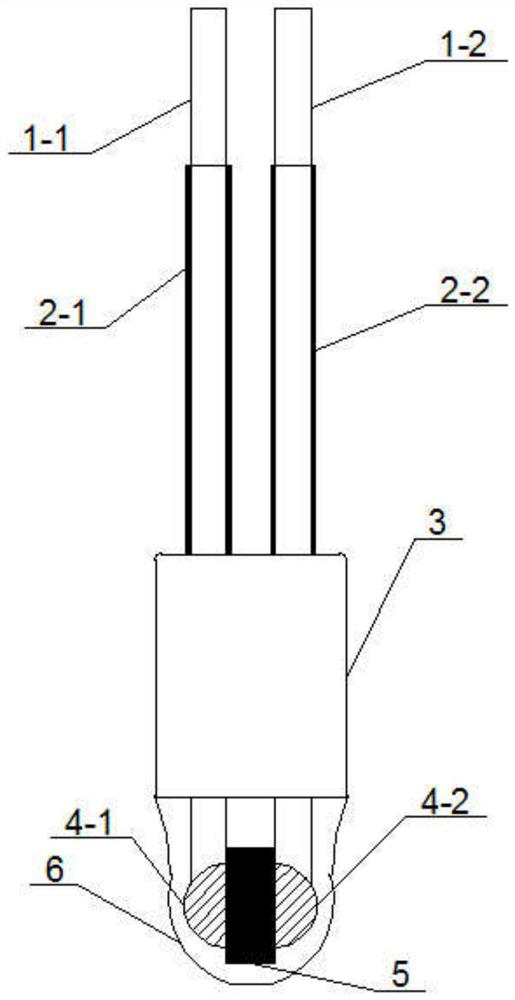

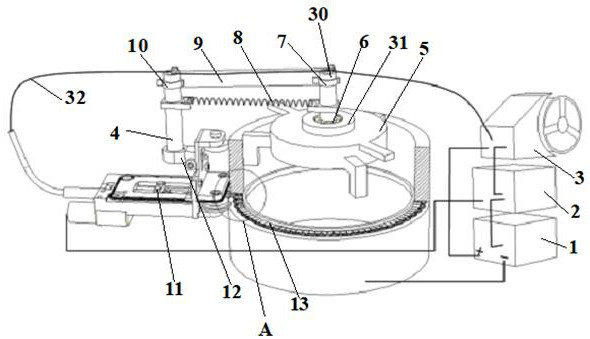

Blood vessel forming device and method for 3D bioprinting

InactiveCN104146794ALess affected by gravityThe overall impact is smallBlood vesselsBiological material testing proceduresBlood Vessel TissueBiomedical engineering

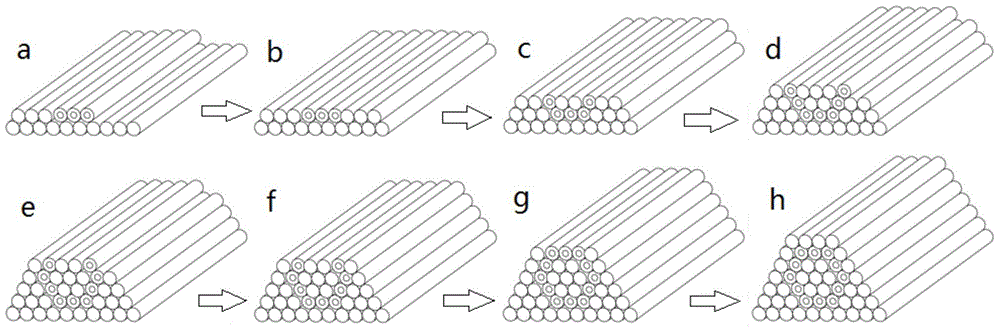

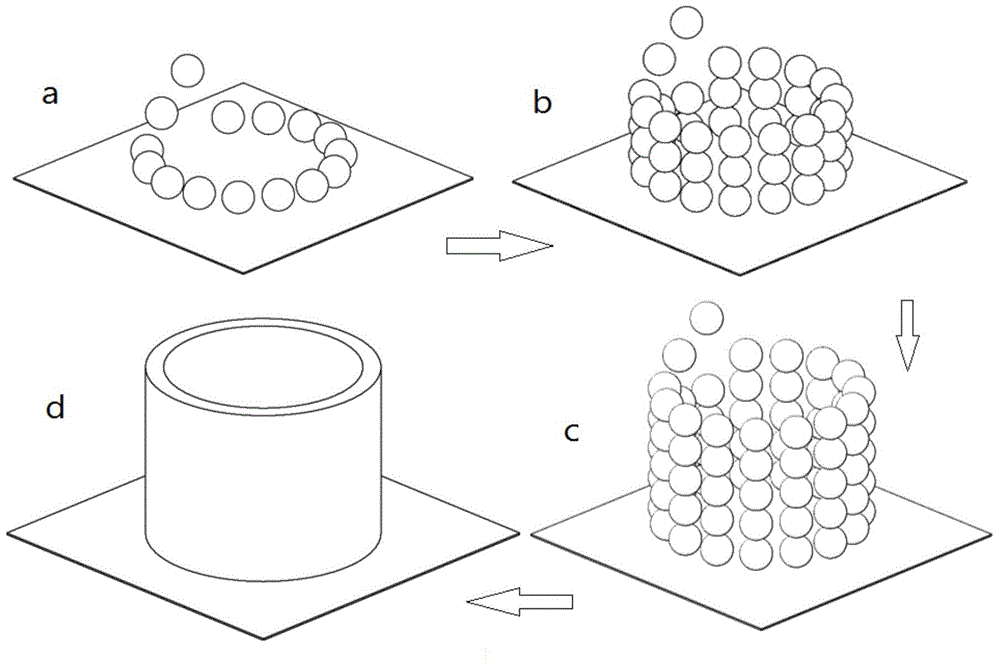

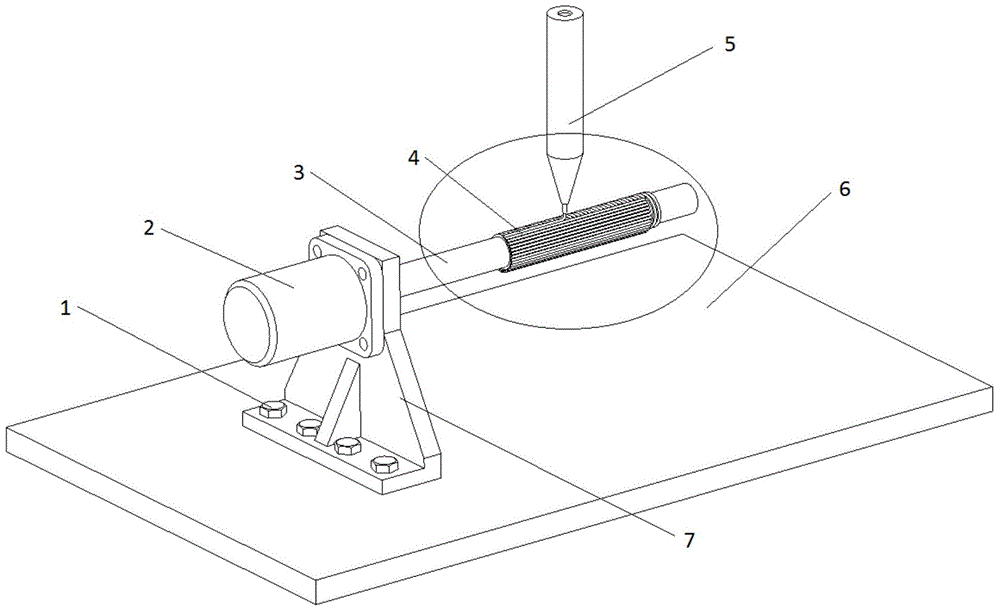

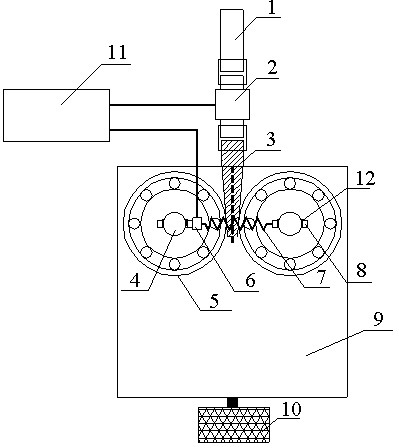

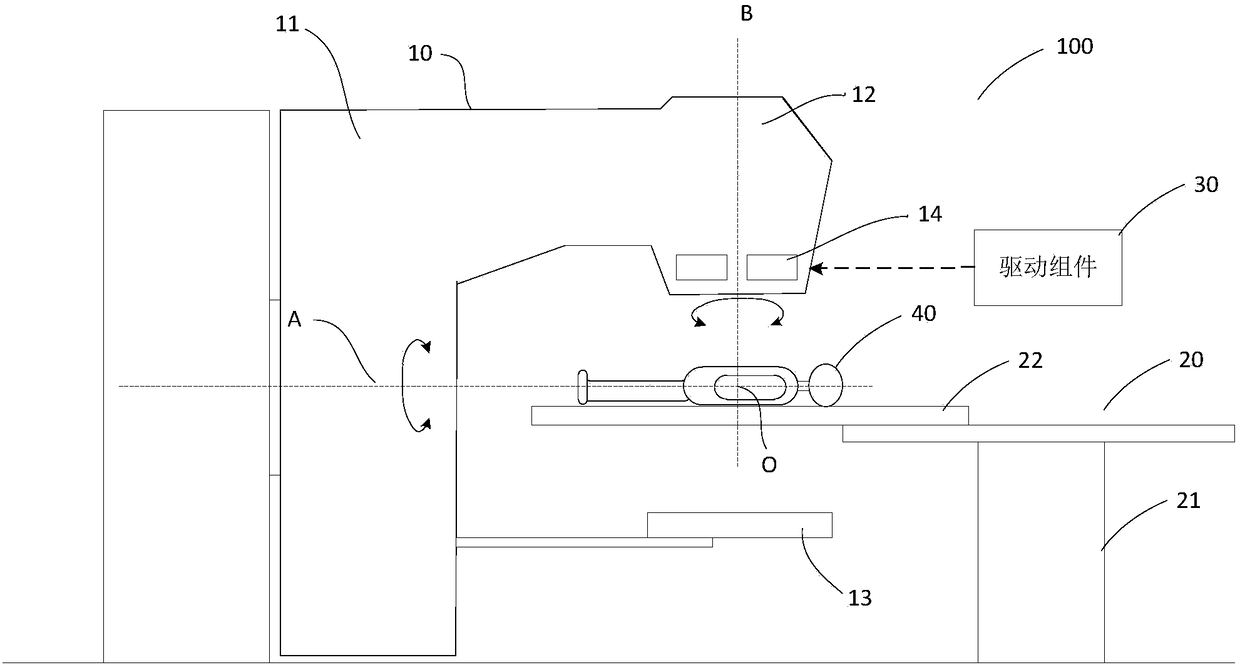

This invention discloses a blood vessel forming device and method for 3D bioprinting. The device and method are used for the bioengineering technology and aim to solve the problems that currently, when blood vessels are printed through the 3D bioprinting technologies, the blood vessels are poor in forming quality and small in forming length. According to the method, biological ink is printed on rotary rods with the surfaces coated with thermo-sensitive hydrogel through the 3D bioprinting technologies, and the needed biological blood vessels can be formed through further biological culture. According to the method, the rotary rods with different diameters and lengths can be prepared for printing the biological blood vessels with different sizes, blood vessel tissue which is uniform in thickness and accurate in printing size can be fast printed, the available 3D printing technologies are diverse, and the device and method are wide in practicability. We call the method a 3D rotational forming printing method (3Denvelop Bioprinting Method).

Owner:周惠兴

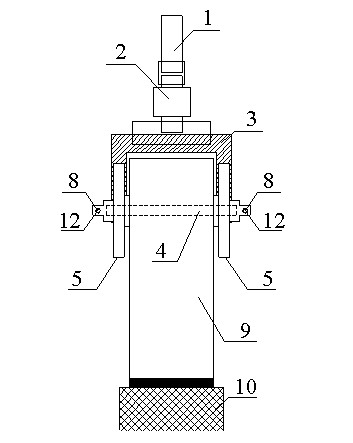

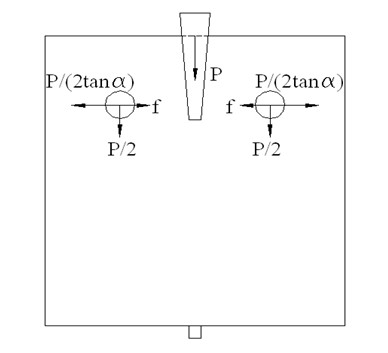

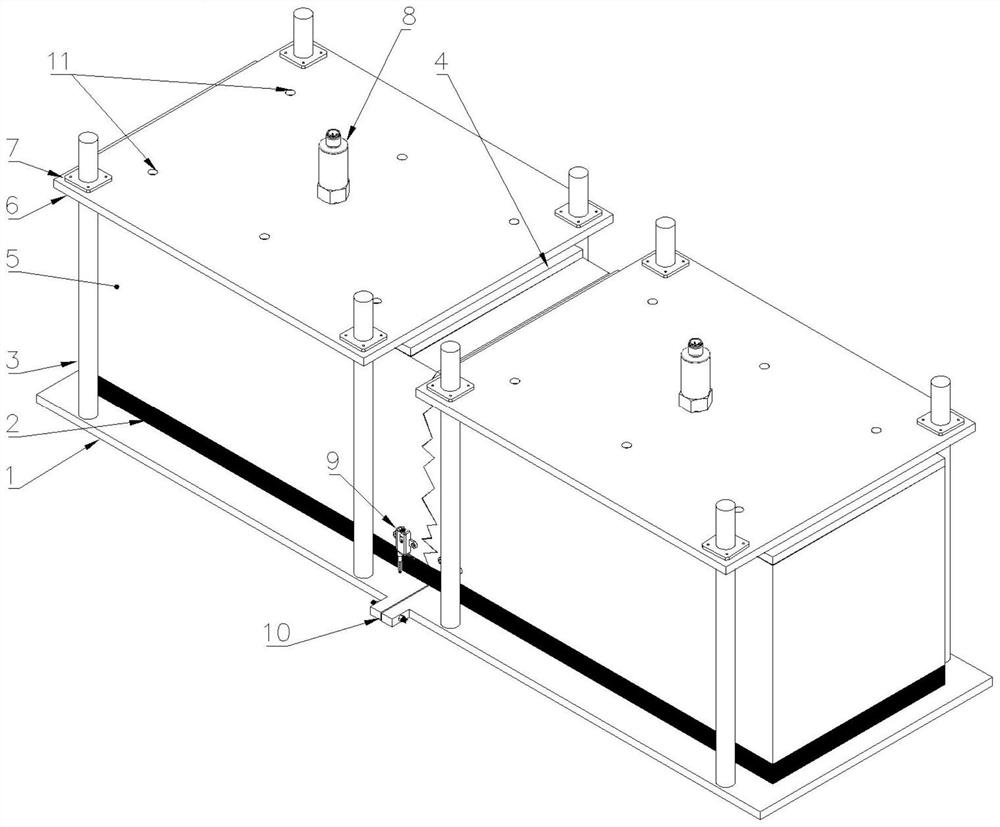

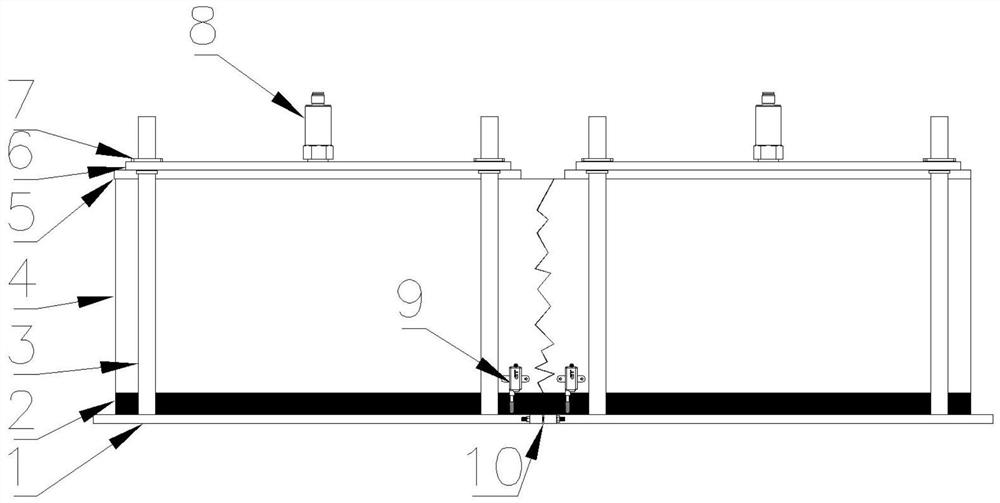

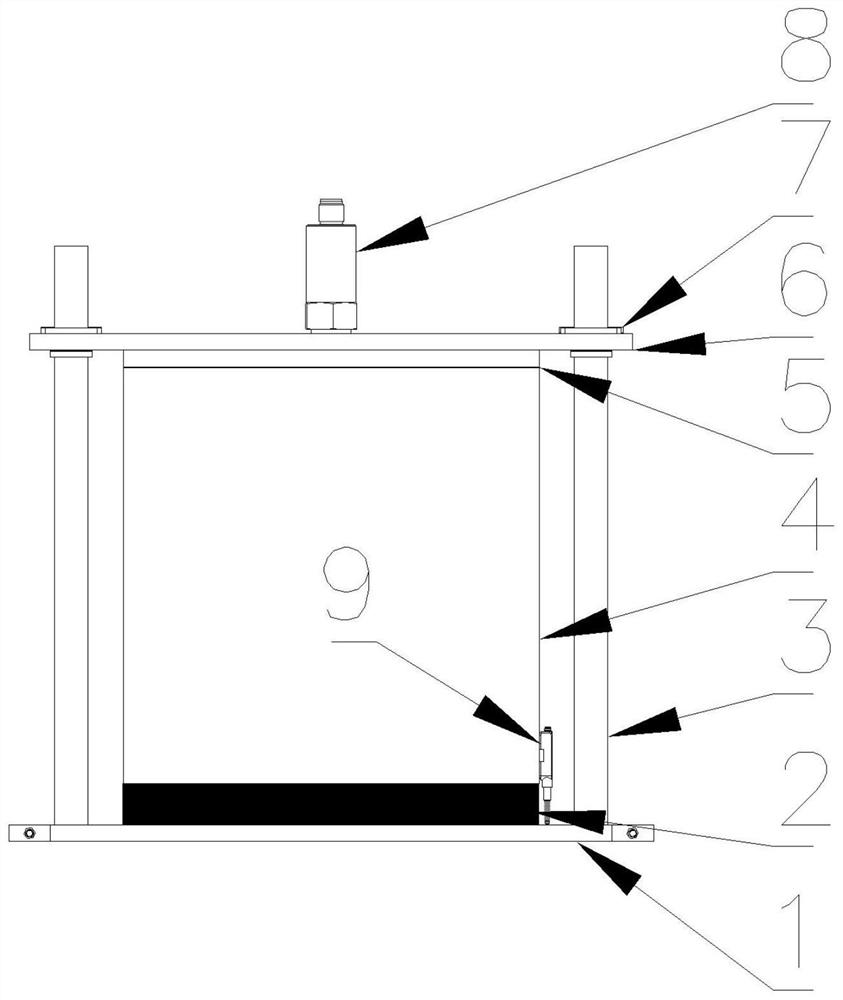

Loading device for concrete material crack growth test under dynamic load

InactiveCN102680341ALittle effect of gravityEasy to operateMaterial strength using repeated/pulsating forcesMaterial CrackForce sensor

The invention relates to a loading device for a concrete material crack growth test under a dynamic load. An actuation head of a fatigue tester is connected with a wedge loading frame through a vertical force sensor; steel shafts are arranged at two quartiles at the upper part of a concrete sample in a penetrating manner; both ends of each steel shaft are respectively and fixedly provided with a bearing and a horizontal stretching rod; a spring is stretched by adjusting a distance of each horizontal stretching rod at the both sides of the steel shaft, so as to supply horizontal pre-compression to the concrete sample; a dynamical data collector is connected by using vertical and horizontal sensors so as to measure actual tension of the spring at different time; an actual acting force acting on the concrete sample at each time can be calculated by a calculation formula provided according to a working principle; and finally, a load is supplied to the concrete sample. The loading device provided by the invention can supply the tension-compression dynamic load for opening and closing a crack for the concrete sample, so that the loading device can be used for testing a crack growth process of a concrete material under the dynamic load.

Owner:HOHAI UNIV

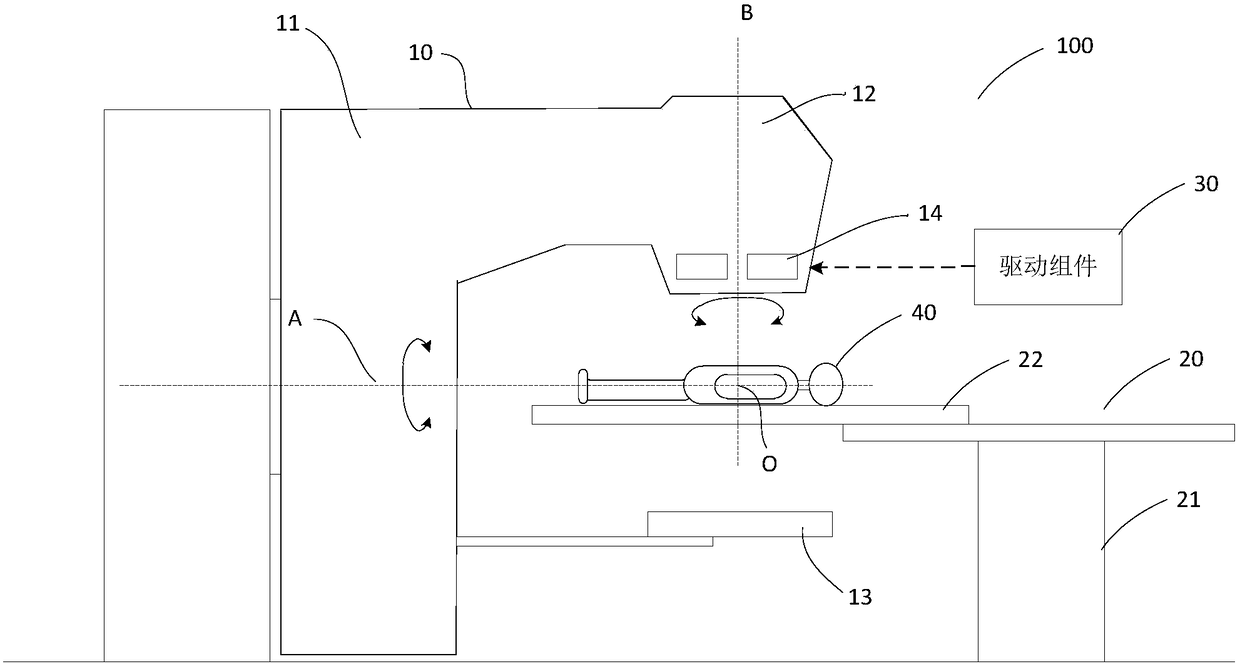

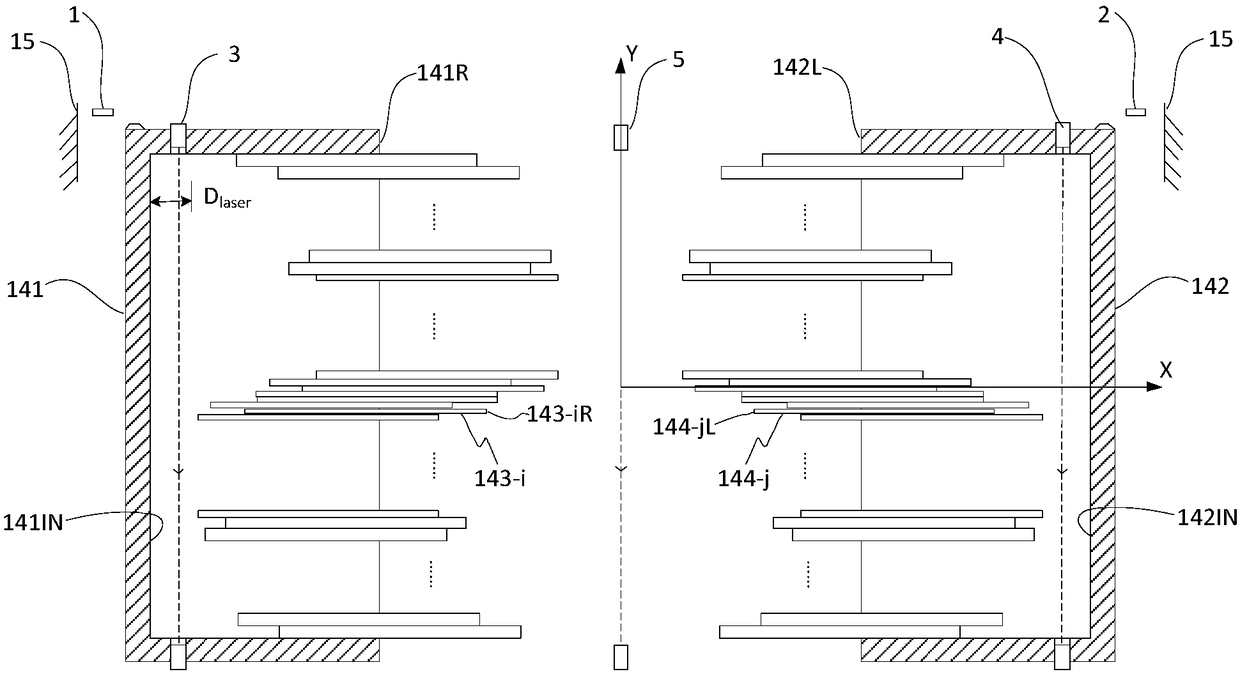

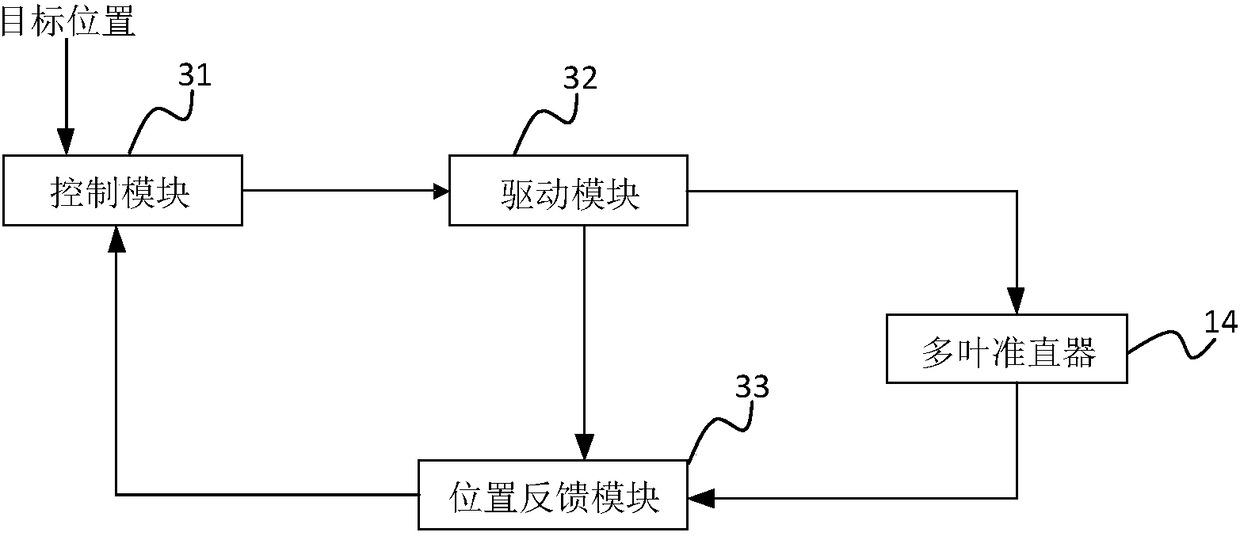

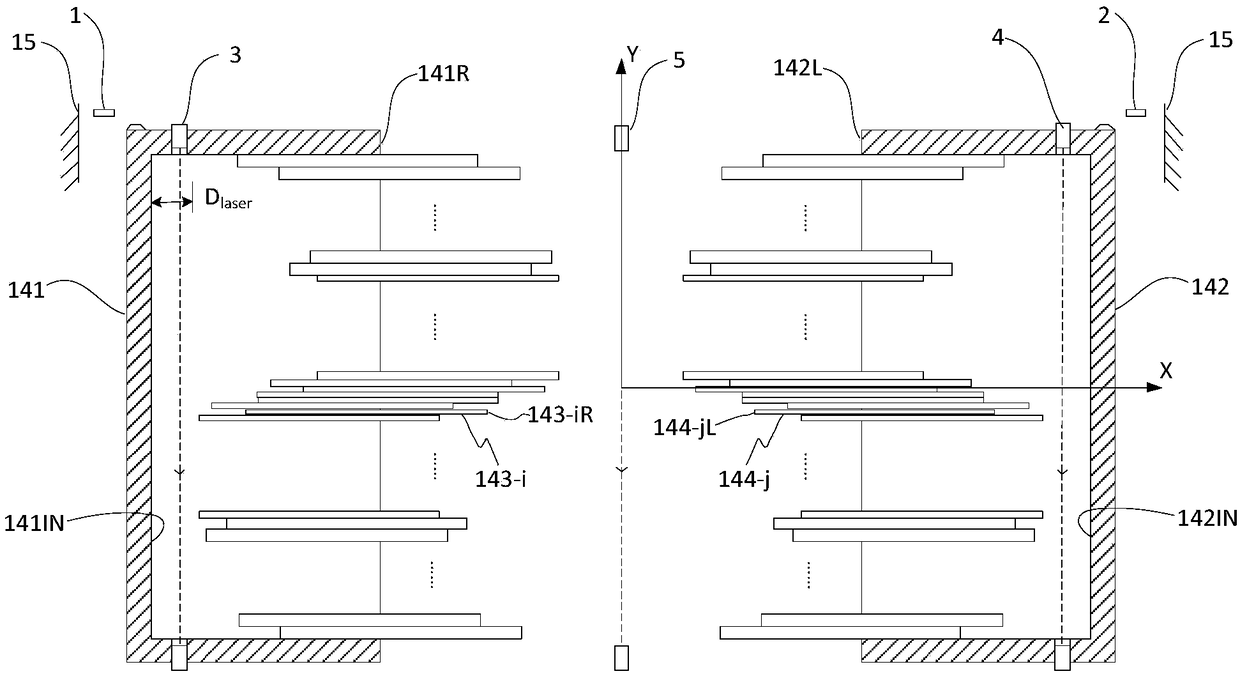

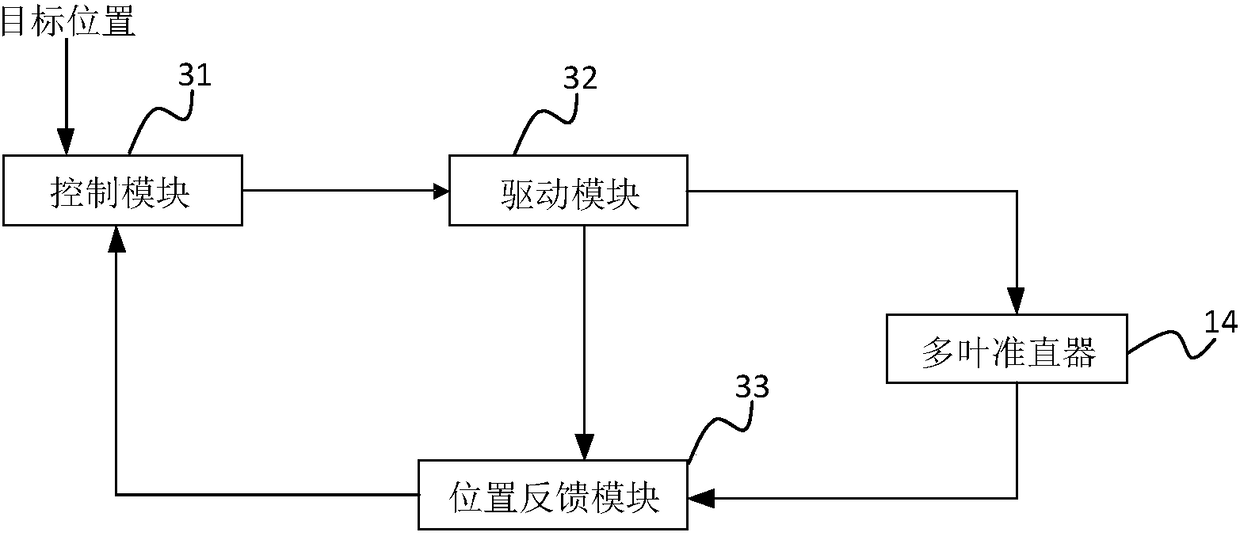

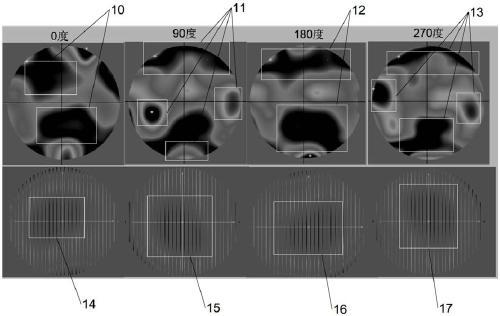

Multi-blade collimator initialization method and radiotherapy system

ActiveCN108096720AShort initialization timeLittle effect of gravityX-ray/gamma-ray/particle-irradiation therapyComputer engineeringEncoder

The invention provides a multi-blade collimator initialization method, wherein the multi-blade collimator comprises a box body and blades arranged in the box body in parallel. The multi-blade collimator initialization method comprises the steps of using a correction switch is for correcting the conversion relation between the blade position and a corresponding main encoder value and an auxiliary encoder value, sequentially moving the blades to a position triggering the correction switch, recording a corresponding main encoder value and an auxiliary encoder value at the trigger moment, correcting the conversion relation between the blade position and the corresponding main encoder value according to the position of the blades at the triggering moment and the corresponding main encoder value, and correcting the conversion relation between the position of the blades and the corresponding auxiliary encoder value according to the position of the blades at the triggering moment and the corresponding auxiliary encoder value. The blade position determined by the multi-blade collimator initialization method is more accurate. The invention further provides a radiotherapy system and a computer readable storage medium.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

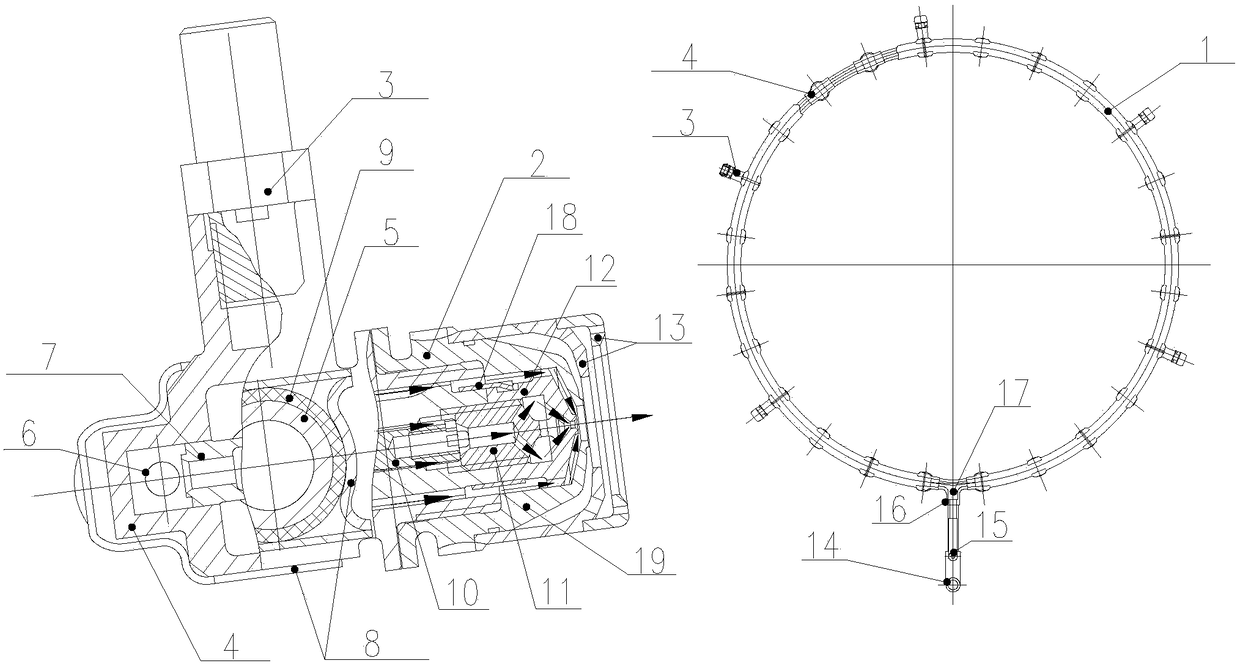

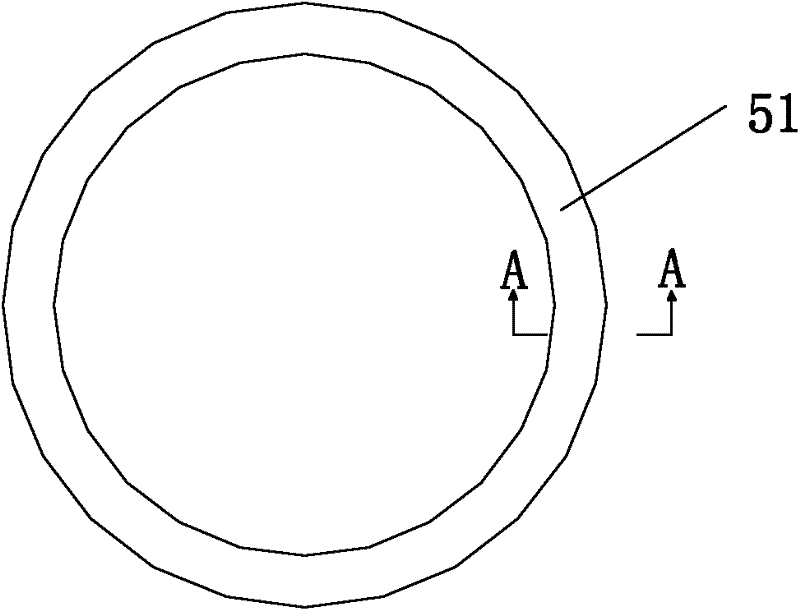

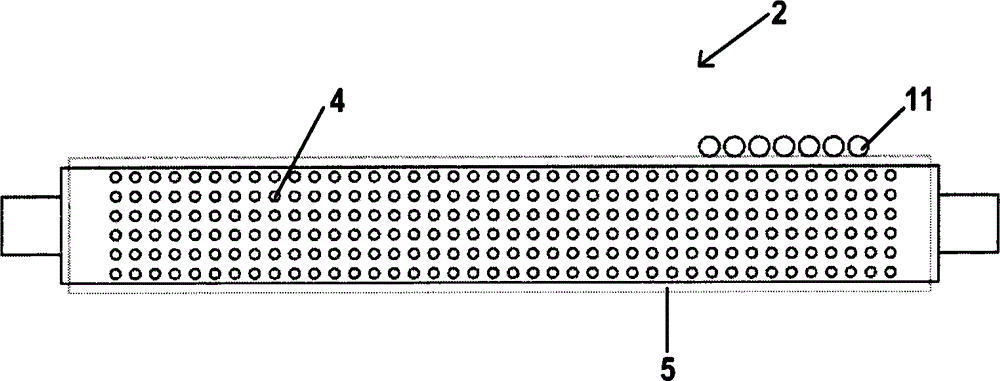

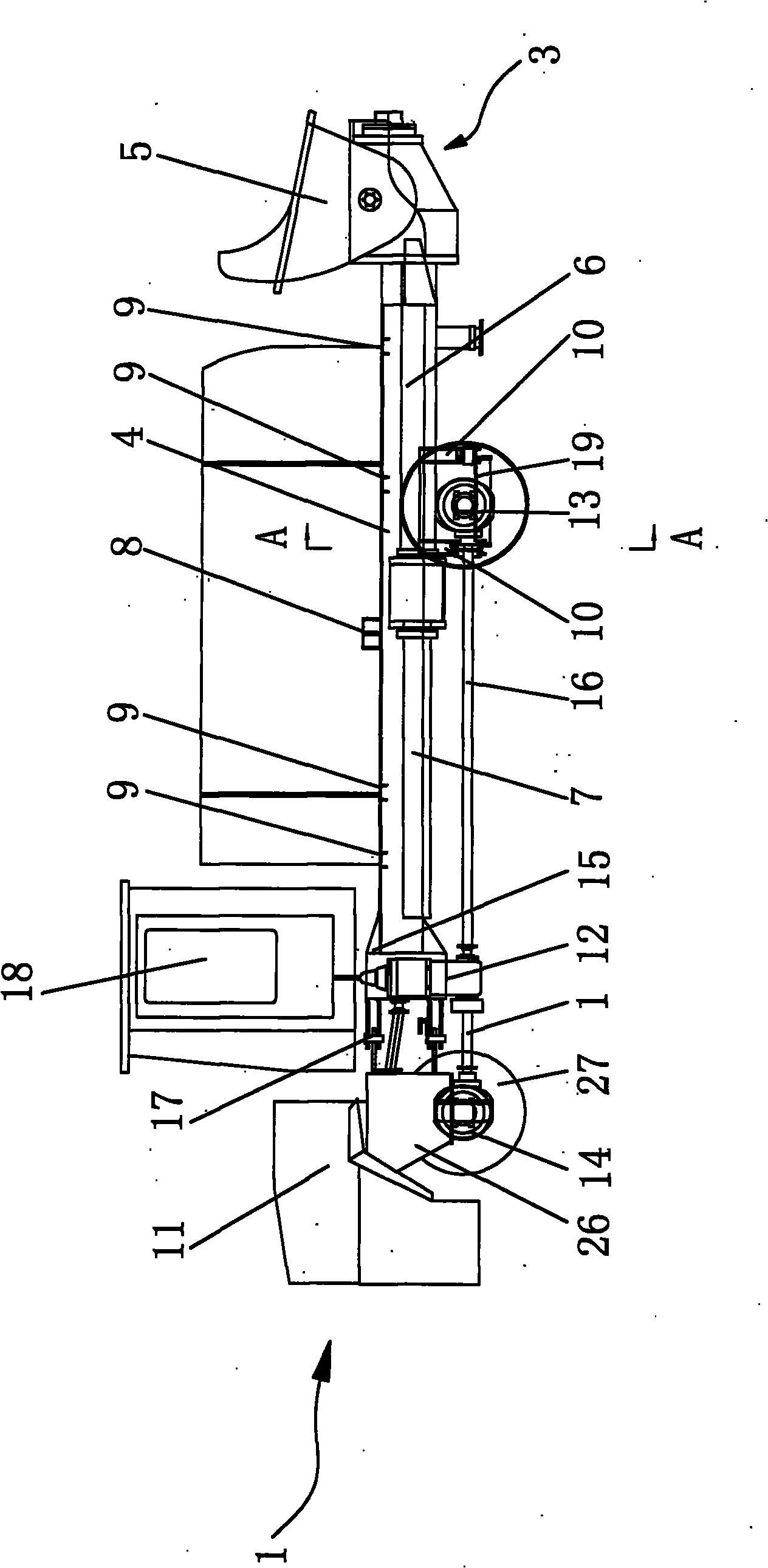

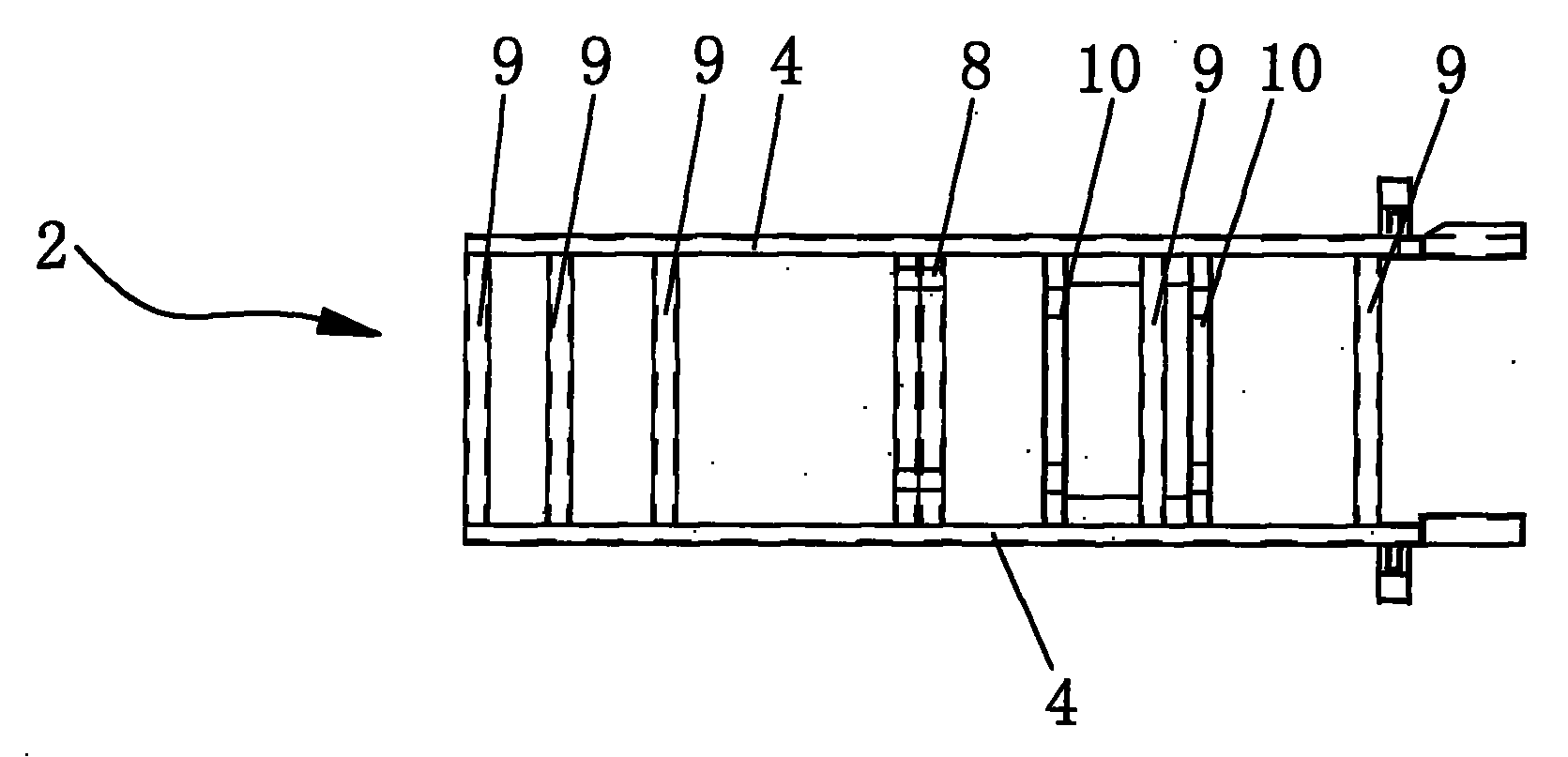

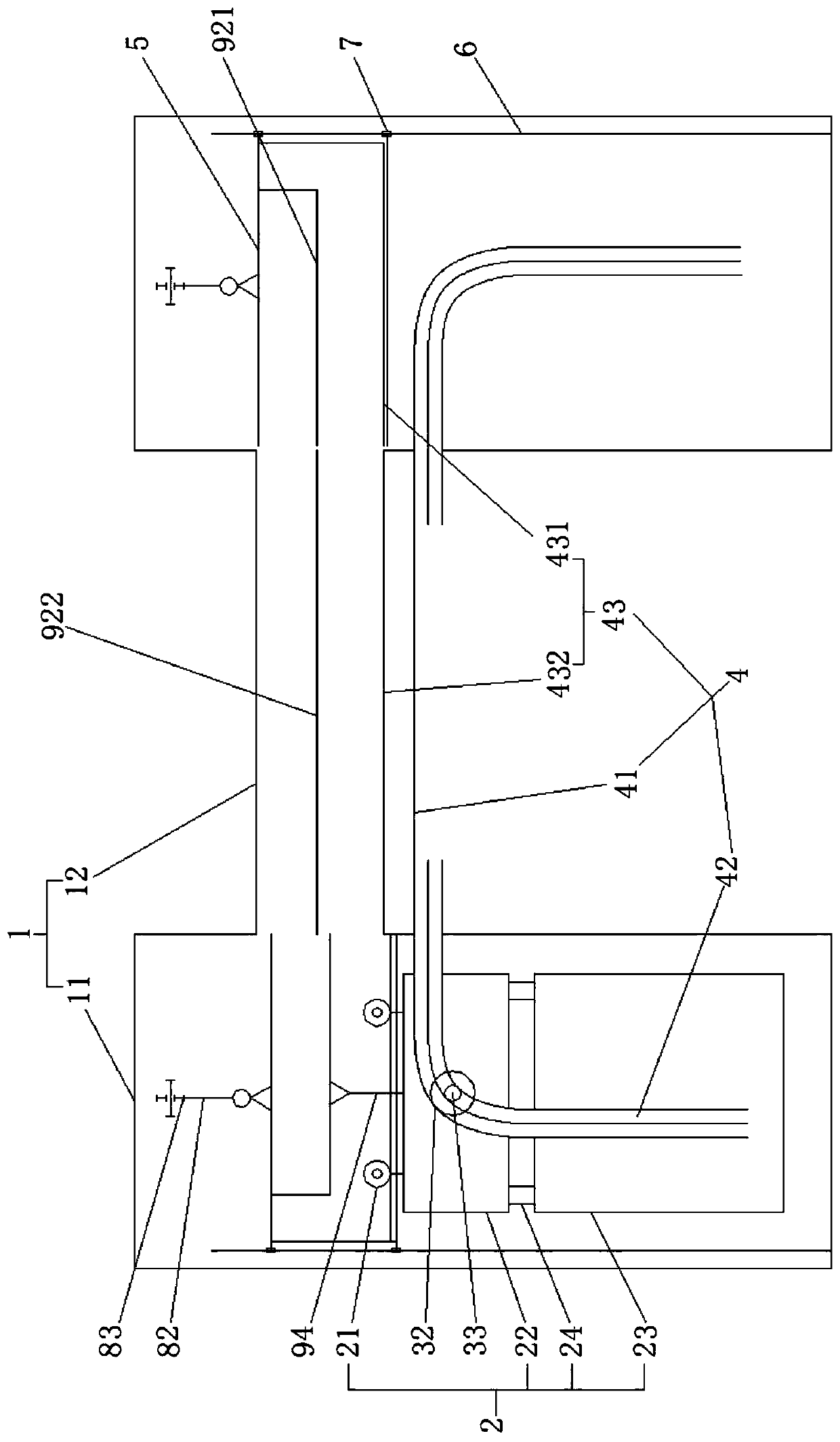

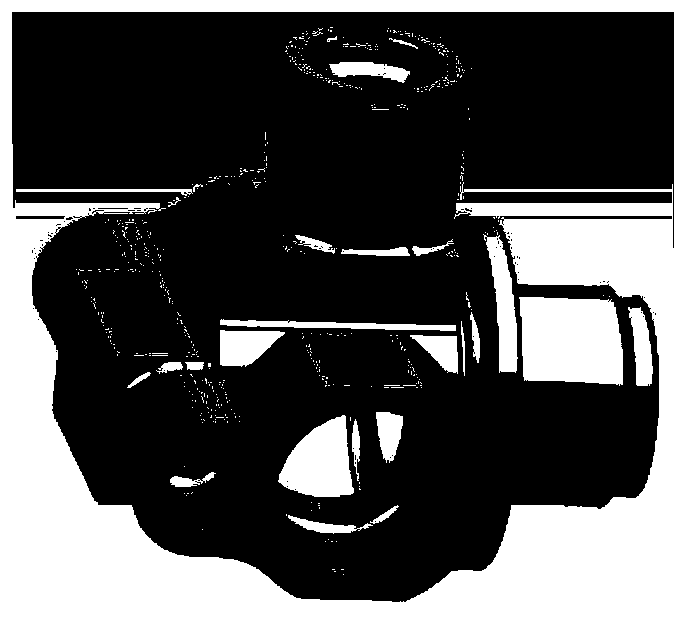

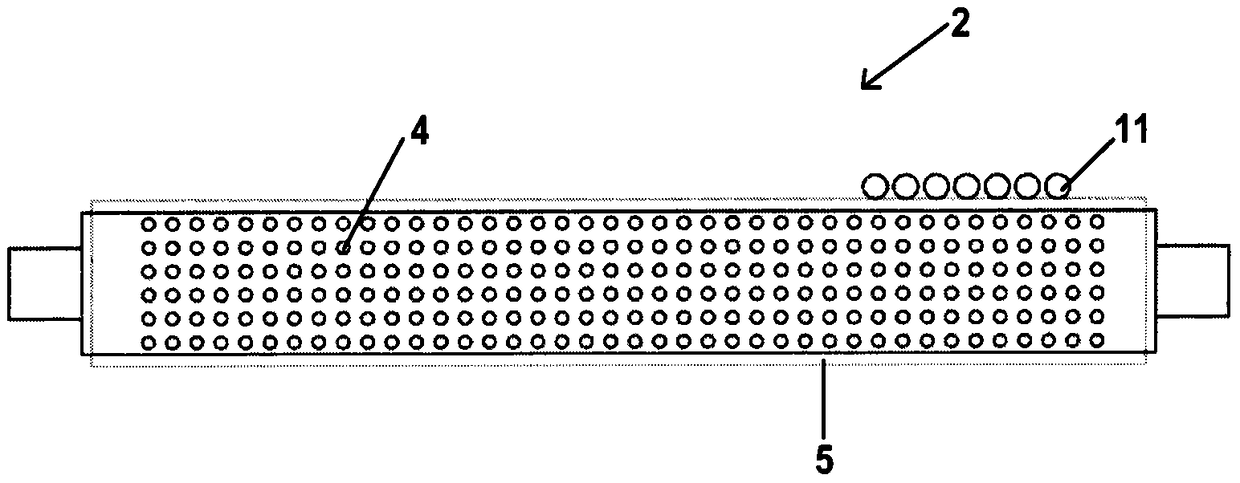

Internal fuel main pipe for double-way fuel conveying and atomization

ActiveCN109140502ACompact structureLittle effect of gravityContinuous combustion chamberCycloneCombustion chamber

The invention discloses an internal fuel main pipe for double-way fuel conveying and atomization. The internal fuel main pipe consists of a main pipe (1) and a nozzle (2); the fuel main pipe is fixedthrough a support column (3) with a ball; a main-way fuel supply pipe (5) and a secondary-way fuel supply pipe (6) are connected through a nozzle shell (4); the heat protection of the pipe is realizedthrough a cover (7) and a thermal insulation layer (8); through a bushing (9) with a thread fuel filter and a thread surface on the surface of a secondary fuel filter (10), the filtration and the stable flowing of fuel are realized; the centrifugal atomization of the fuel is realized through cyclone grooves on a cyclone (11) and a nozzle cyclone (12); and accumulated carbons on the nozzle are reduced through inclined intake holes on a gas cover (13). The fuel main pipe can meet the demands of different fuel supply characteristics of double fuel ways, has the advantages of good atomization effect, compact structure, low mass, low influence on the fuel gravity, difficult accumulation of carbons on the end surface of the nozzle and difficult influence from instable fuel flowing, and is suitable for an aero-engine and a gas turbine combustion chamber.

Owner:中国航发贵阳发动机设计研究所

Initialization method for multi-leaf collimator and radiation therapy system

ActiveCN108211134AShort initialization timeLittle effect of gravityX-ray/gamma-ray/particle-irradiation therapyMulti leaf collimatorComputer vision

The invention provides an initialization method for a multi-leaf collimator. The initialization method comprises the following steps: sequentially moving leaves along the opening direction till corresponding leaf switches are triggered, carrying out moving towards the reverse direction for a section of distance and then stopping moving, during the process of moving the leaves towards the closing direction, recording the a main coder value and an auxiliary coder value corresponding to each leaf when the leaf triggers the corresponding leaf switch, and a main coder value and an auxiliary coder value corresponding to each leaf when the leaf stops; and by utilizing the main coder value and the auxiliary coder value corresponding to each leaf when the leaf triggers the corresponding leaf switchand the main coder value and the auxiliary coder value corresponding to each leaf when the leaf stops, calculating an initial value of a main code and an initial value of an auxiliary coder corresponding to the leaf. The zero position of the leaf determined by the method provided by the invention is more accurate. The invention further provides a radiation therapy system and a computer readable storage medium.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

Parallel composite tank

The invention belongs to the field of fire-fighting fire extinguishing apparatus and especially relates to a parallel composite tank for fire extinguishing of large-scale equipment. The parallel composite tank comprises at least two powder storage tanks, which are for storing, atomizing and mixing dry powder and are in a same horizontal line; an upper air inlet and a lower air inlet are arranged on the top and the bottom of each powder storage tank; a pressure sensor for detecting pressure in each tank is arranged on the top of each powder storage tank; an atomizing device for loosening and atomizing the dry powder is arranged in each powder storage tank; the lower air inlet is connected with the atomizing device; a powder outlet is arranged on a side wall of each powder storage tank; and powder outlets of the at least two powder storage tanks are connected with a dry powder pipeline centralized controller through a connecting pipe. According to the invention, a plurality of powder storage tanks are connected through the dry powder pipeline controller, so as to start different numbers of powder storage tanks, according to fire behavior, to guarantee the amount of dry powder needed by fire extinguishing.

Owner:江苏中瑞电保智能装备有限公司

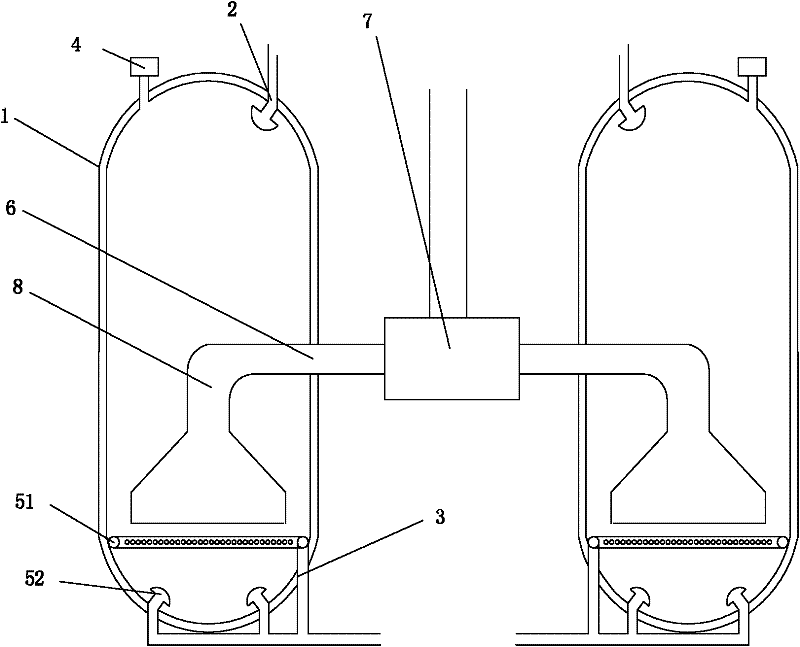

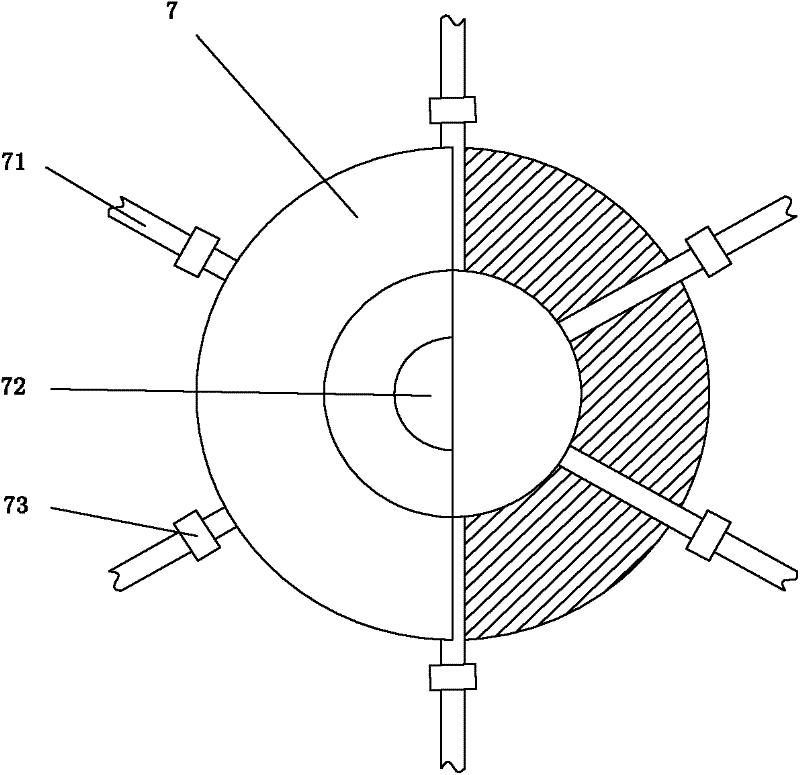

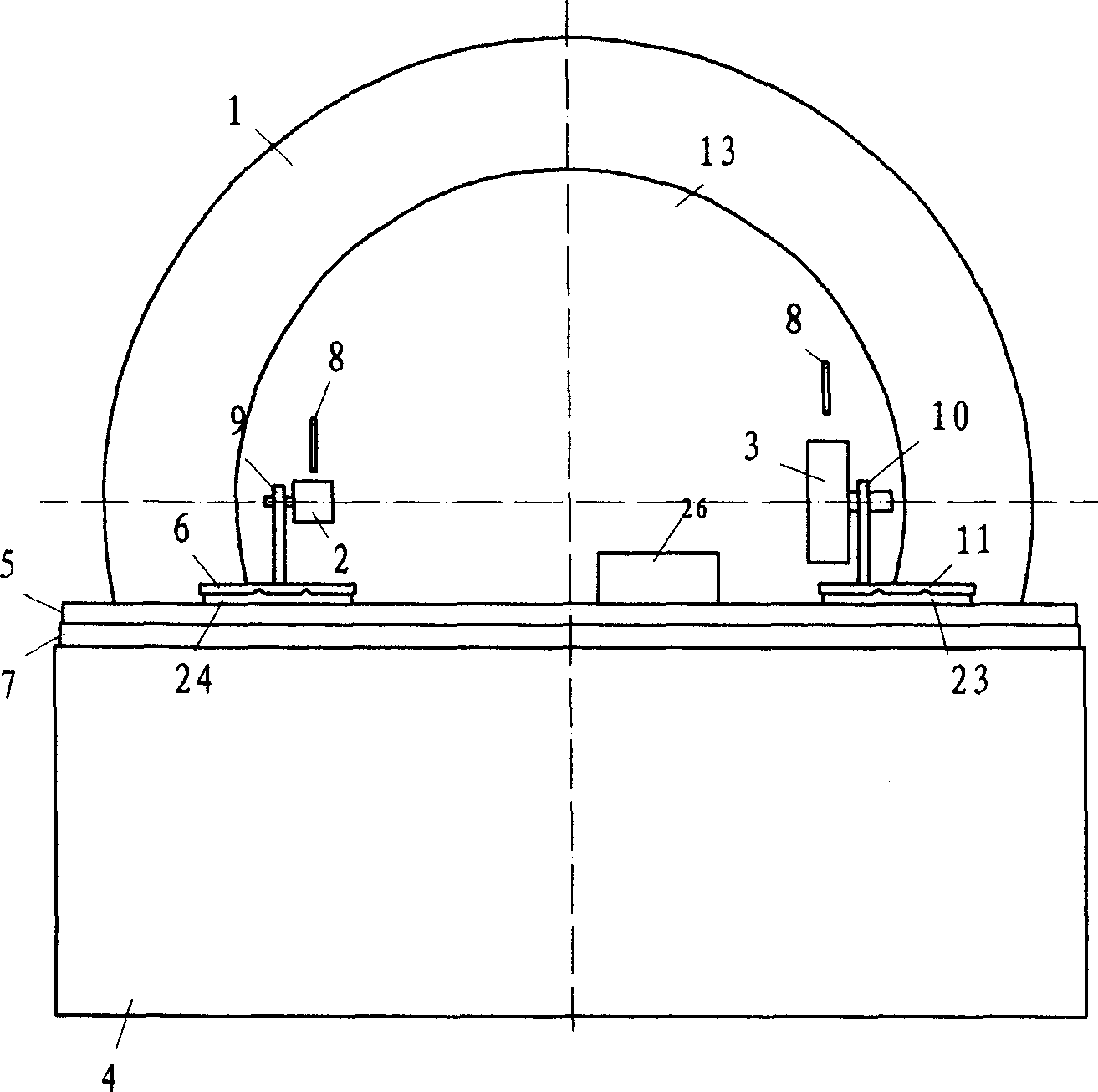

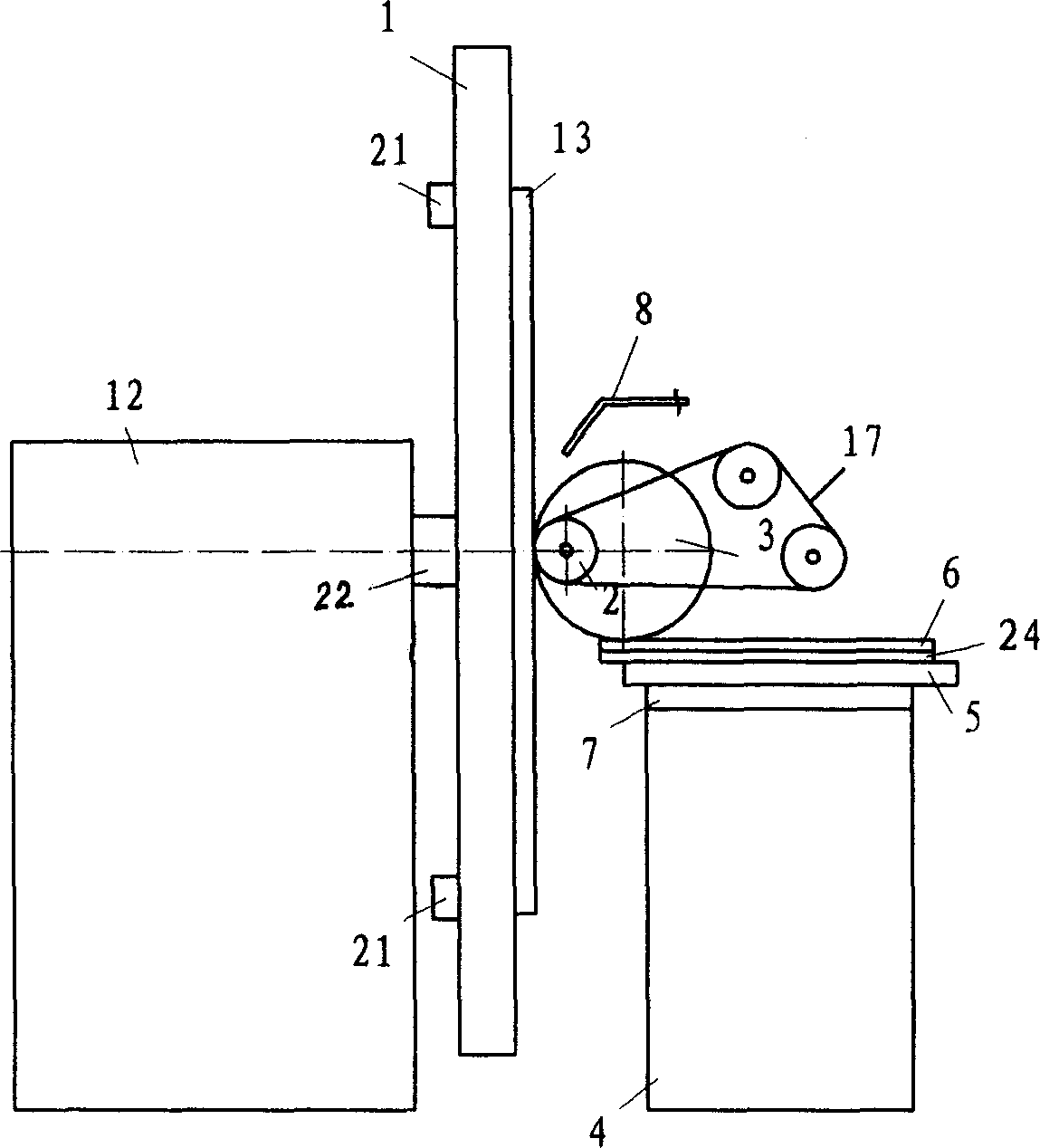

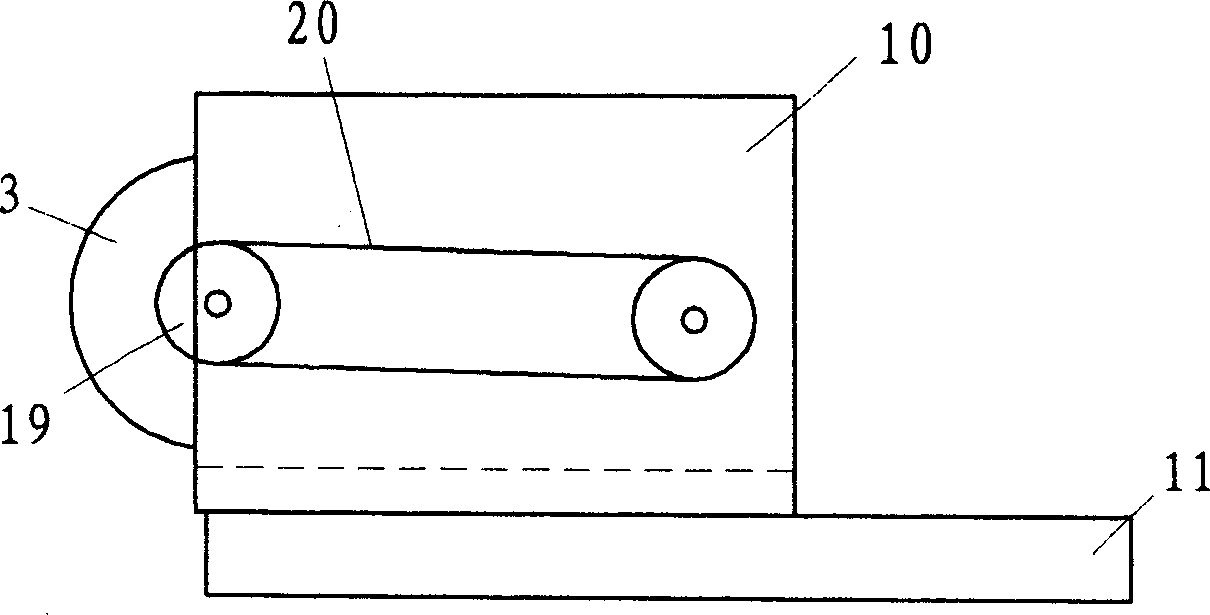

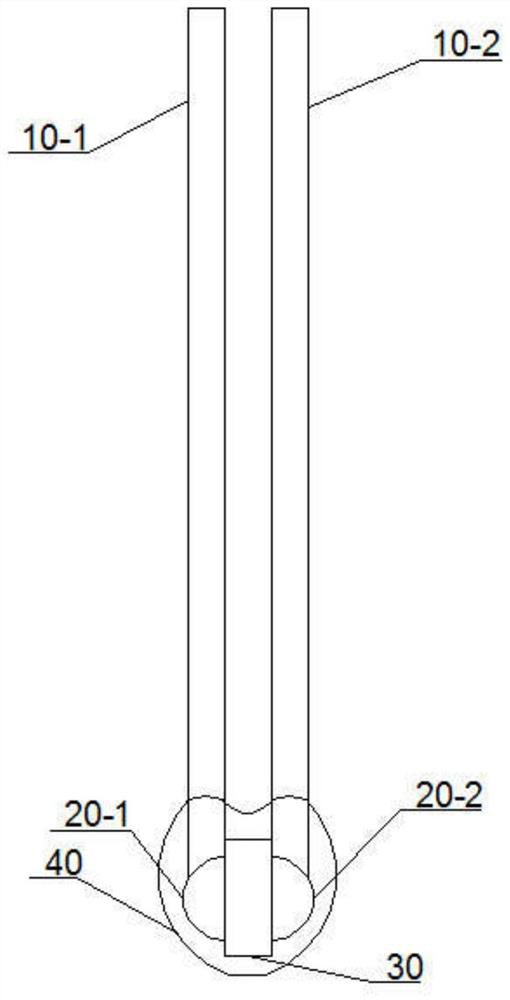

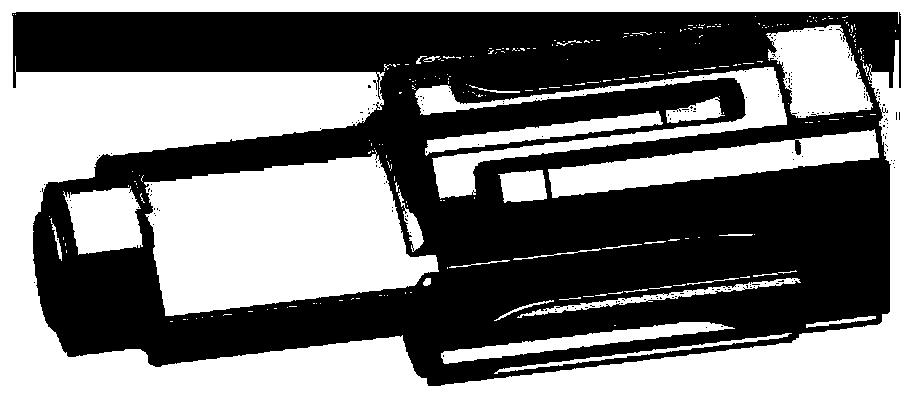

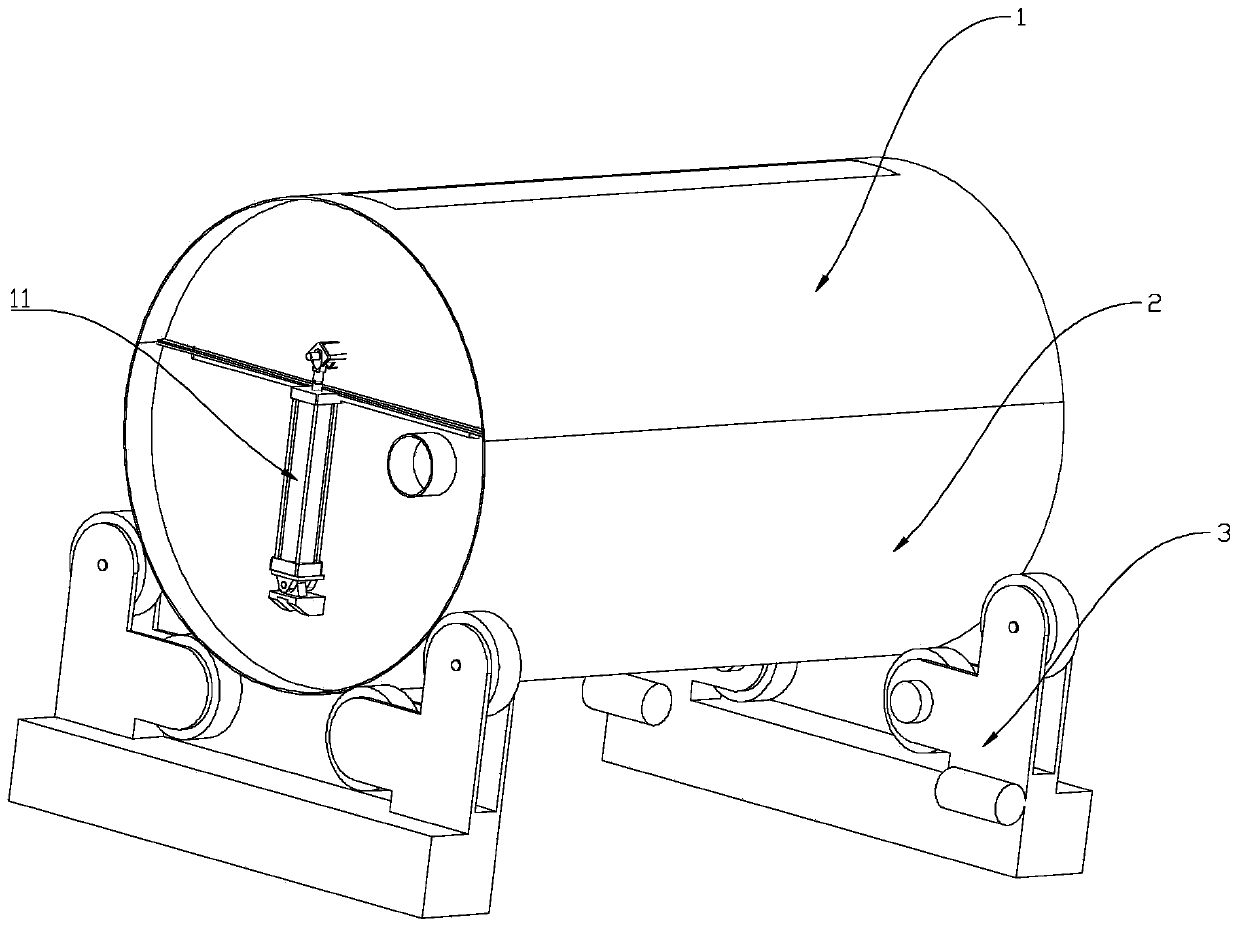

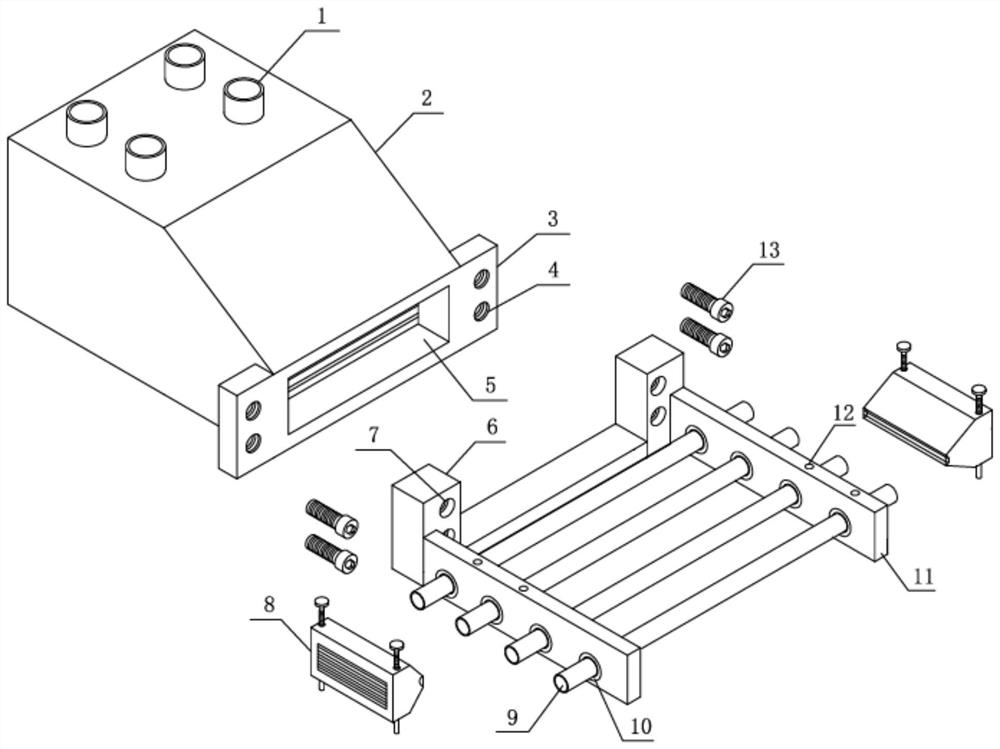

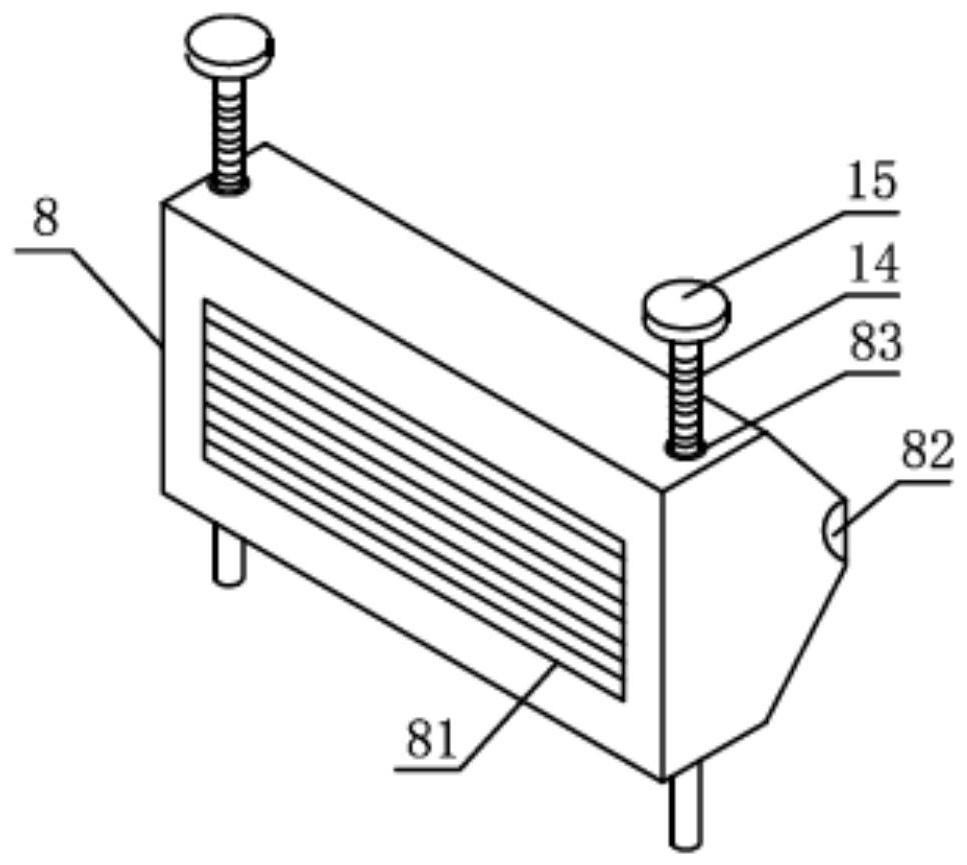

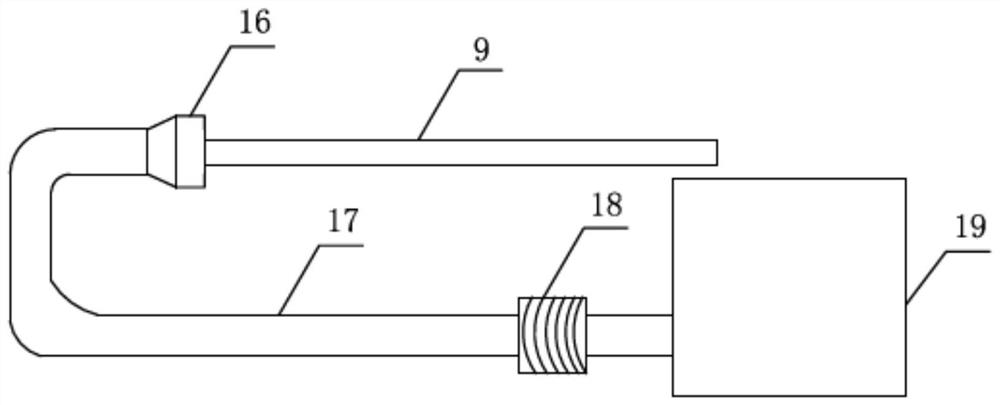

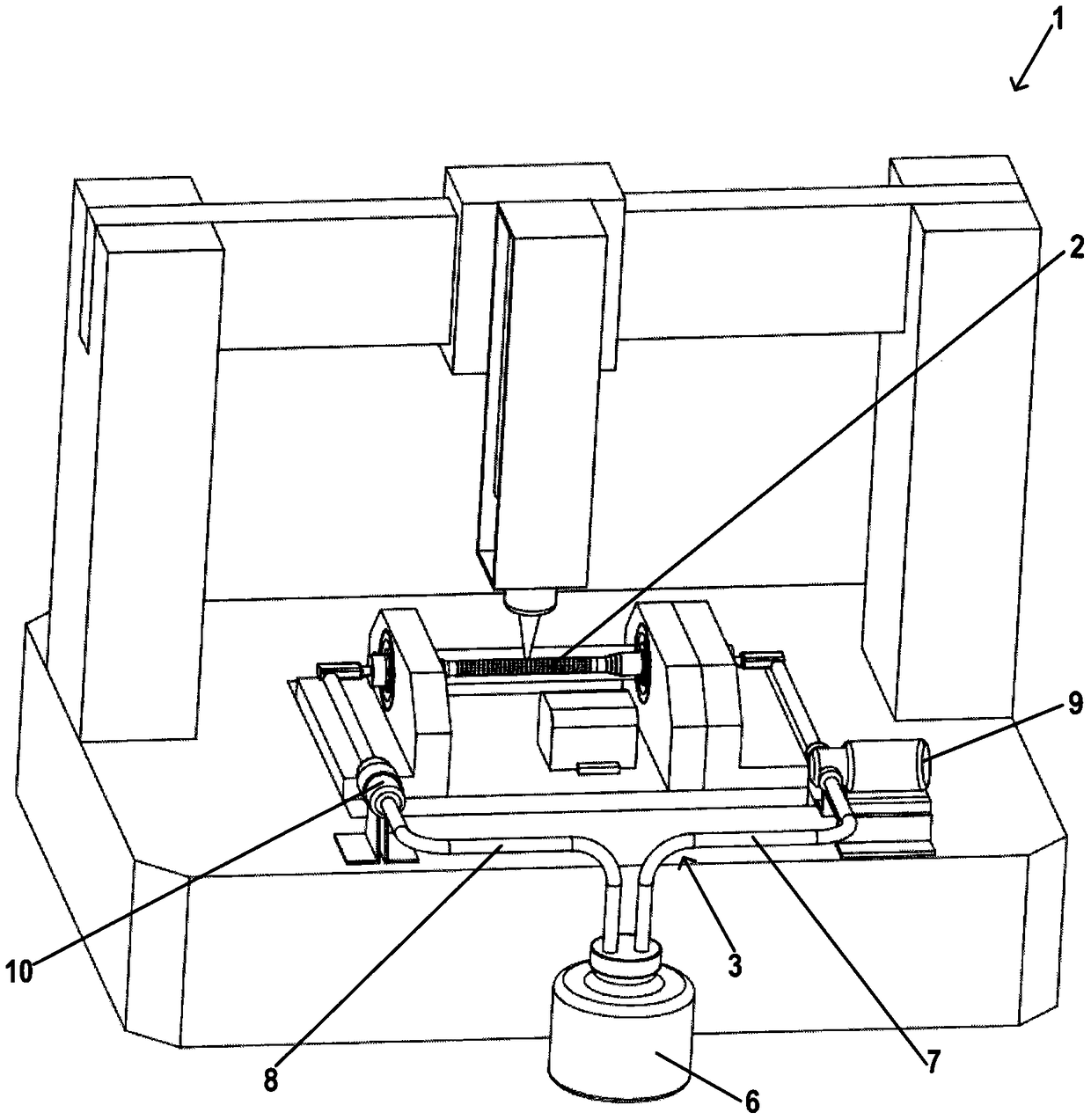

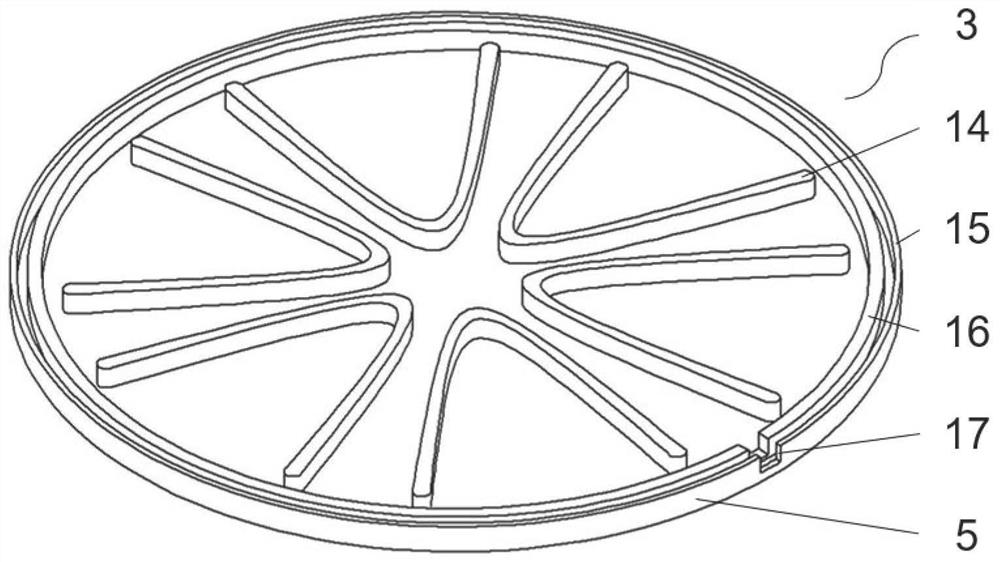

Rotating device for biological printing and usage method of rotating device

ActiveCN106137456AImprove biological activityPromote growth and developmentAdditive manufacturing apparatusTubular organ implantsNutrient solutionDigital printing

The invention provides a rotating rod for 3D biological printing. The rotating rod is horizontally arranged and driven to rotate and is of a hollow structure, and at least one hole is formed in the surface of the rotating rod; in the 3D biological printing process, a nutrient solution passes through the hollow structure, and part of the nutrient solution penetrates out of the holes. The invention further provides a 3D biological printing platform which comprises the rotating rod and a nutrient supply system and can supply nutrients and a method for printing tubular tissue through the biological printing platform. Accordingly, the possibility that the tissue collapses due to the gravity influence is decreased, the novel method for achieving 3D biological printing of the tubular tissue and supplying the nutrients in the printing process is provided, and a wide application prospect is achieved.

Owner:SICHUAN REVOTEK CO LTD

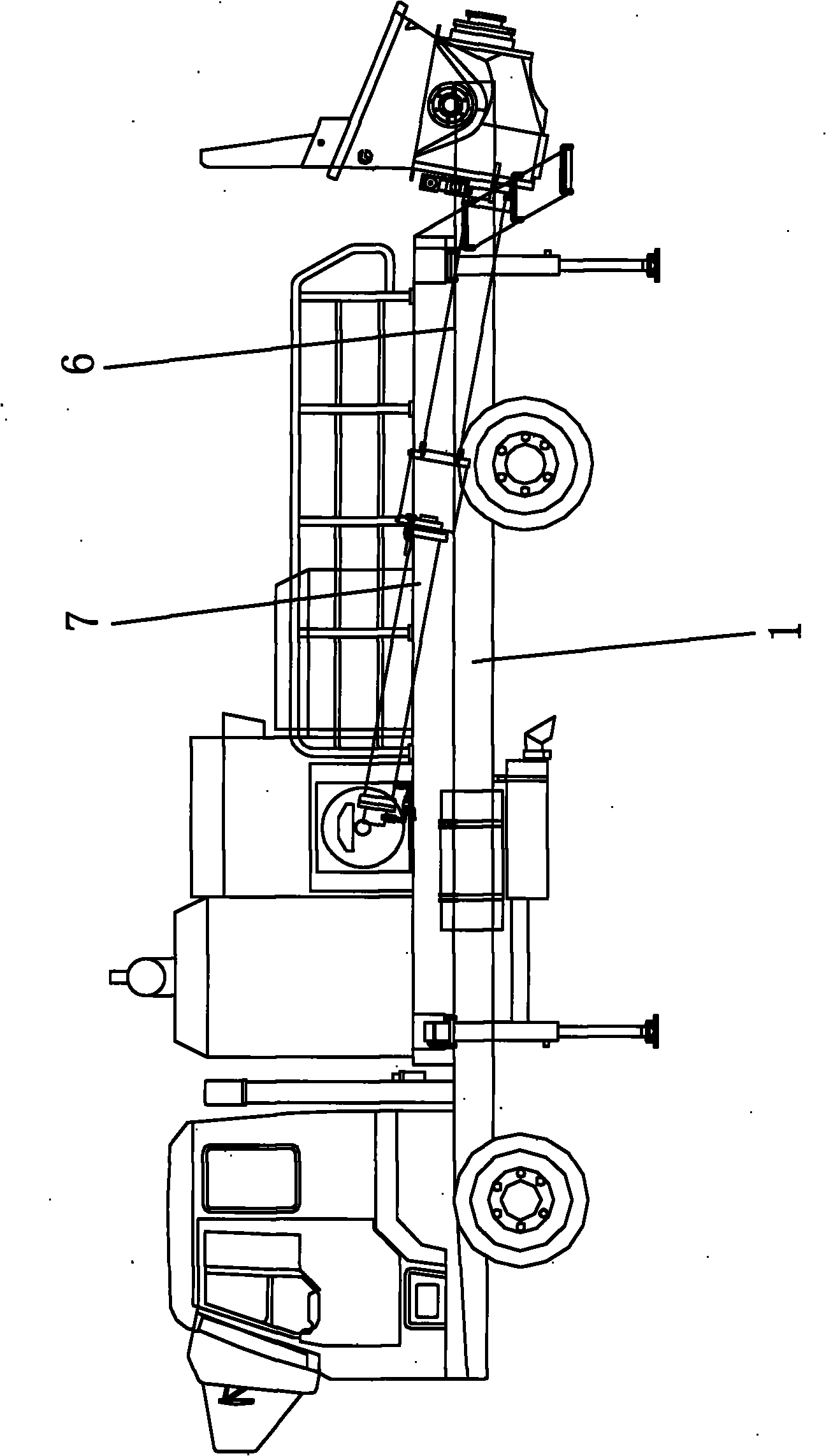

Concrete pump truck

InactiveCN101804797AHorizontal flow is easier than upward suctionImprove pumping performanceConcrete transportationEngineeringMechanical engineering

The invention relates to a concrete pump truck which comprises a main body, a frame, a pumping mechanism, a power mechanism and a steering mechanism, wherein the frame comprises two U-shaped girders which are arranged horizontally; the openings of the two U-shaped girders are opposite to each other and across a crossbeam assembly between the two U-shaped girders; the crossbeam assembly comprises a first crossbeam, a second crossbeam and a third crossbeam; and the center lines of the first crossbeam, the second crossbeam and the third crossbeam are respectively positioned above, on and below the horizontal planes on which the U-shaped crossbeams are located; and the pumping mechanism is horizontally installed in the space erected between the first crossbeam and the third crossbeam. The pumping mechanism of the invention is horizontally arranged, so the pumping mechanism can intake the concrete with higher efficiency, thereby improving the performance of the concrete pump; the U-shaped girders and the running system of the concrete pump truck share common girders, thereby reducing the weight and the cost; and the restriction to the inner space of the girders is reduced, thereby deriving more autotype concrete pump models.

Owner:安良平

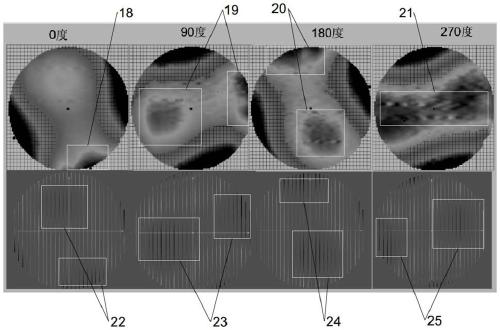

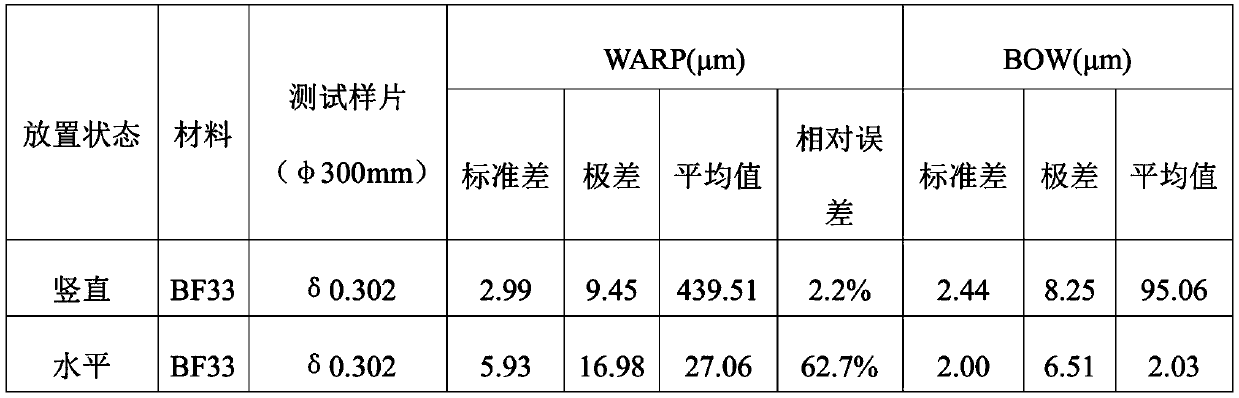

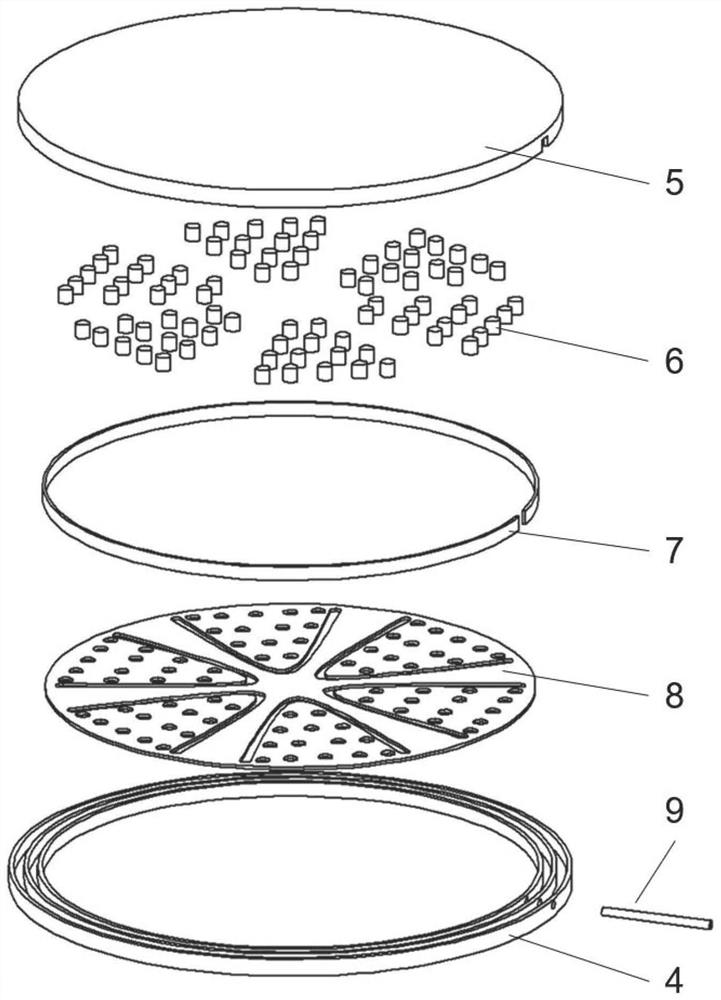

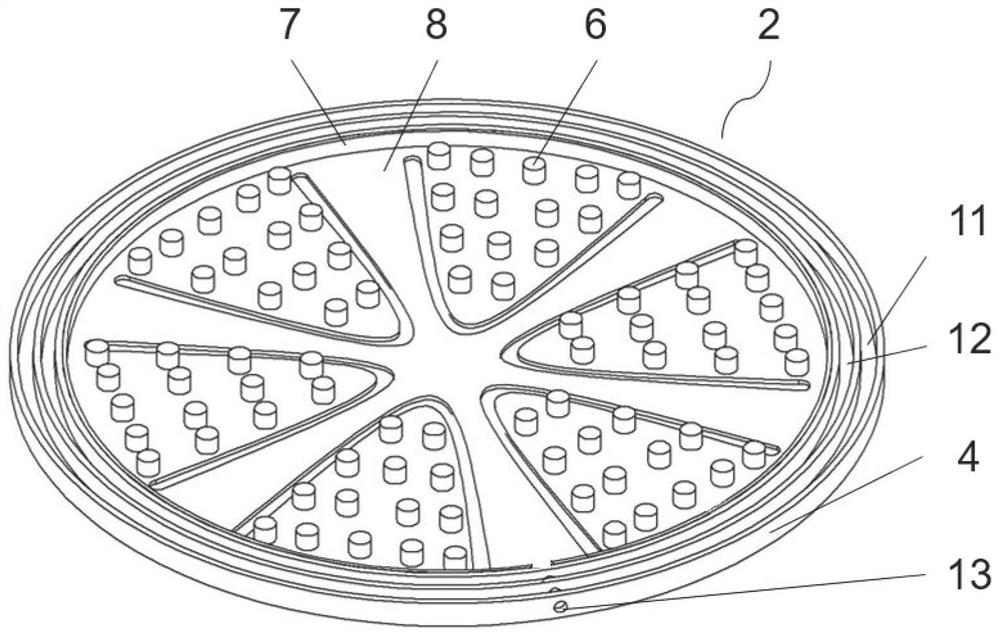

Method for testing warping degree of wafer

ActiveCN111192837AHigh precisionLittle effect of gravitySemiconductor/solid-state device testing/measurementDistance samplingWafer

The invention discloses a method for testing the warping degree of a wafer, and the method comprises the following steps: (1) vertically arranging a standard flat mirror, and enabling the standard flat mirror to be parallel to the direction of gravity; (2) loading a wafer; (3) adjusting the distance between the wafer and the standard flat mirror; (4) adjusting the wafer to be parallel to the standard flat mirror in a face-to-face manner; (5) starting a test module, enabling the test module to perform parallel movement scanning relative to the standard flat mirror, and respectively sampling thedistance from a probe of the sensor to the wafer and the distance from the probe of the sensor to the standard flat mirror through the sensor arranged on the test module; (6) performing data processing program processing on the obtained distance sampling value to obtain a warping degree parameter of the wafer. The method has the advantages that when the wafer is vertically placed for testing, therigidity in the wafer surface is high, the influence of gravity can be greatly reduced, deformation is reduced, and the testing method is convenient and simple.

Owner:JIAXING BAISHENG PHOTOELECTRIC

Vibration wire type digital memory sensor

InactiveCN1743811AEliminate the hassle of manual calculationsSimple structureForce measurement by measuring frquency variationsConverting sensor ouput using wave/particle radiationMems sensorsEngineering

This invention discloses a string vibration type memory sensor, which contains left end base, right end base, sealed casing with enclosed tensioned steel string using left and right end base as support point, permanent magnet and induction windings, a memory, said memory and induction windings respectively connected with secondary instrument in outside of sensor. Said invention not only directly detects the needed physical quantity but also transmits long distance with advantages of simple structure, small volume, light and high measurement precision.

Owner:长沙金码测控科技股份有限公司

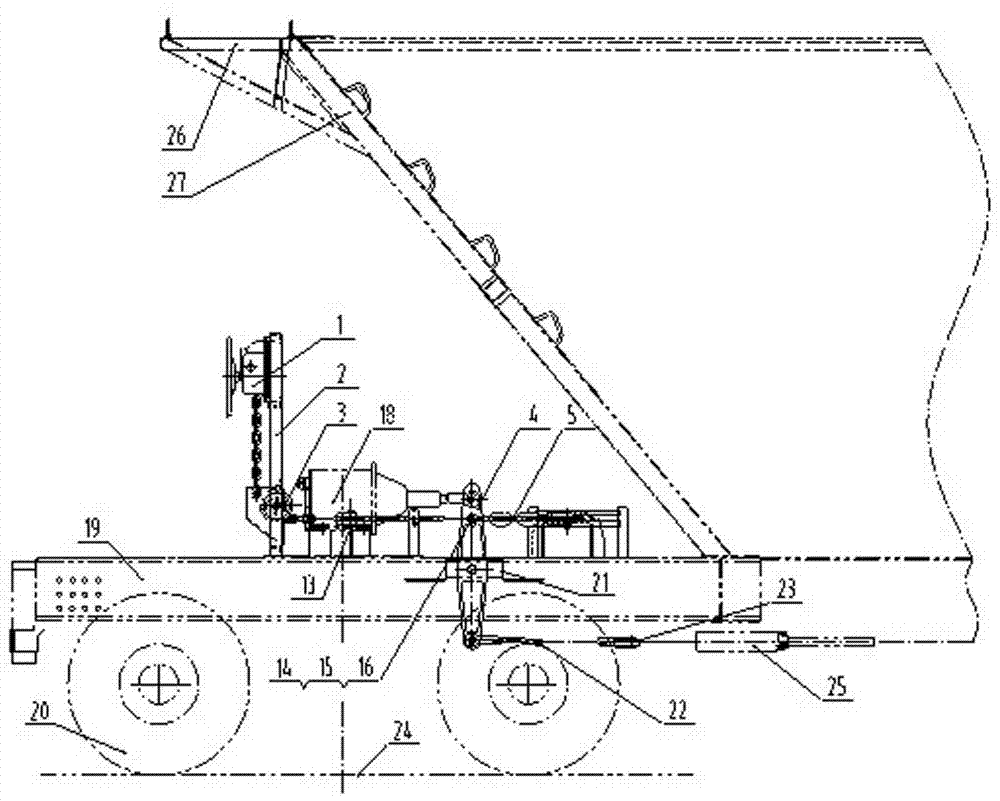

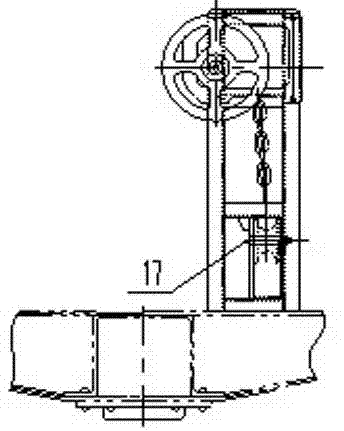

Hand braking device mounted on chassis of railway hopper wagon

The invention belongs to the technical field of a railway wagon and specifically relates to a hand braking device mounted on a chassis of a railway hopper wagon. The problems of the present hand braking device of the railway hopper wagon are solved. The hand braking device comprises a hand brake, a hand brake bracket, a fixed pulley, a chain assembly, a vertical lever assembly, a hand braking shifter lever fulcrum base, a hand braking shifter lever, a hand braking shifter lever supporting frame, a hand brake chain assembly, a hand brake pull rod guiding frame and a hand brake pull rod. The hand braking device is arranged on a floor of the chassis assembly of the hopper wagon; under the condition of no influence on the function of the hand braking device, the possibility of pulling out the supporting frame by a current hand brake pull rod reinforcing rid of the hopper wagon and the problem of influence on the traffic safety caused by the breaking of the hand brake pull rod are thoroughly eliminated; the demand on the traffic safety of the railway wagon is met.

Owner:CRRC TAIYUAN CO LTD

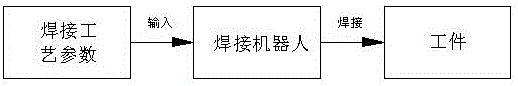

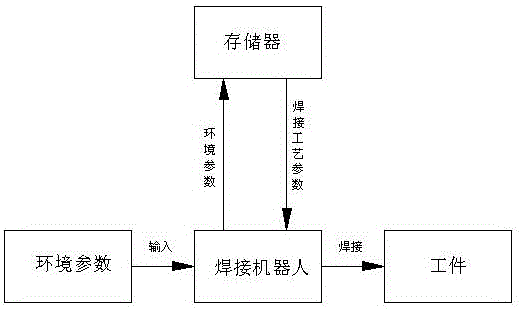

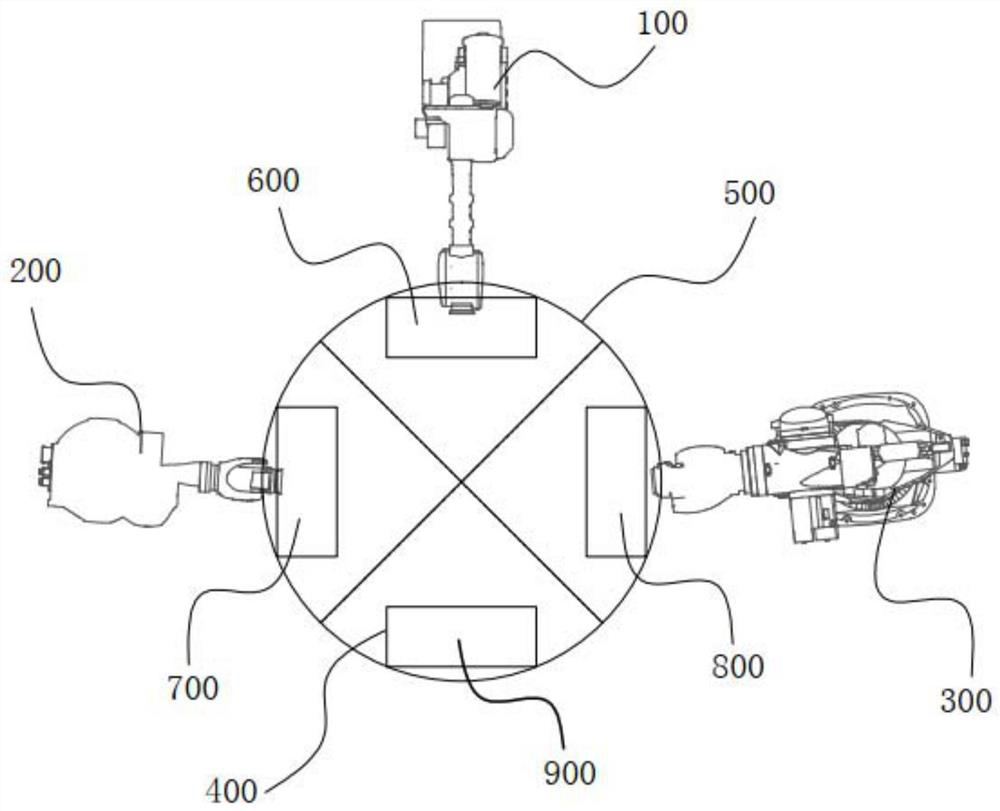

MIG (metal inert gas) welding system

InactiveCN106077915AReduced heat input ratioFast solidificationArc welding apparatusEngineeringGravity effect

The invention discloses an MIG (metal inert gas) welding system and relates to the technical field of workpiece welding. Through combination of a welding robot with equipment such as a welding machine and the like, a stitch welding technology can be performed on a workpiece, then the heat input ratio in a welding operation process can be reduced greatly, the heat accumulation is enabled to be lower, and the workpiece is not prone to burn-through; meanwhile, with adoption of spot welding, rapid solidification can be realized after welding, and then whole-position welding can be realized; further, due to high solidification speed of spot welding and smaller gravity effect, welding forming structures in difference positions are basically the same.

Owner:SHANGHAI FANUC ROBOTICS

Automotive body repairing spraying process

InactiveCN105289956AImprove flatnessNot easy to backlogSpecial surfacesPolyamide coatingsDiluentMechanical engineering

The invention provides an automotive body repairing spraying process and relates to the technical field of spraying processing. The automotive body repairing spraying process comprises the following steps that an area to be repaired is cleaned through detergent and then cleaned up through clear water, and then the surface of a part is cleaned through a finish paint diluent; the area to be repaired is polished to form a bevel opening, the upper portion of the bevel opening is high, and the lower portion of the bevel opening is low; putty powder is sprayed for leveling and is dried, then a tackifier is sprayed and dried, the thickness of the tackifier is made to be uniform through scraping by a rubber scraper, the polished area to be repaired is kept as a bevel all the time, and sanding and side finishing are carried out; the tackifier is sprayed to the polished area to be repaired again and is dried, then medium coating is sprayed for filling and leveling, the polished area to be repaired is kept as the bevel, and an original paint layer on an automotive body is polished completely; and paint and curing agents for the automotive body are diluted and mixed, are obliquely sprayed from the upper portion to the lower portion of the spraying bevel opening after being proportionally mixed, and then are dried. According to the automotive body repairing spraying process, the curing speed is high, the gravity effect is low, the flatness of the sprayed plane is high, and the repairing and restoring effects are good.

Owner:ANHUI LONGJIA TRAFFIC EQUIP

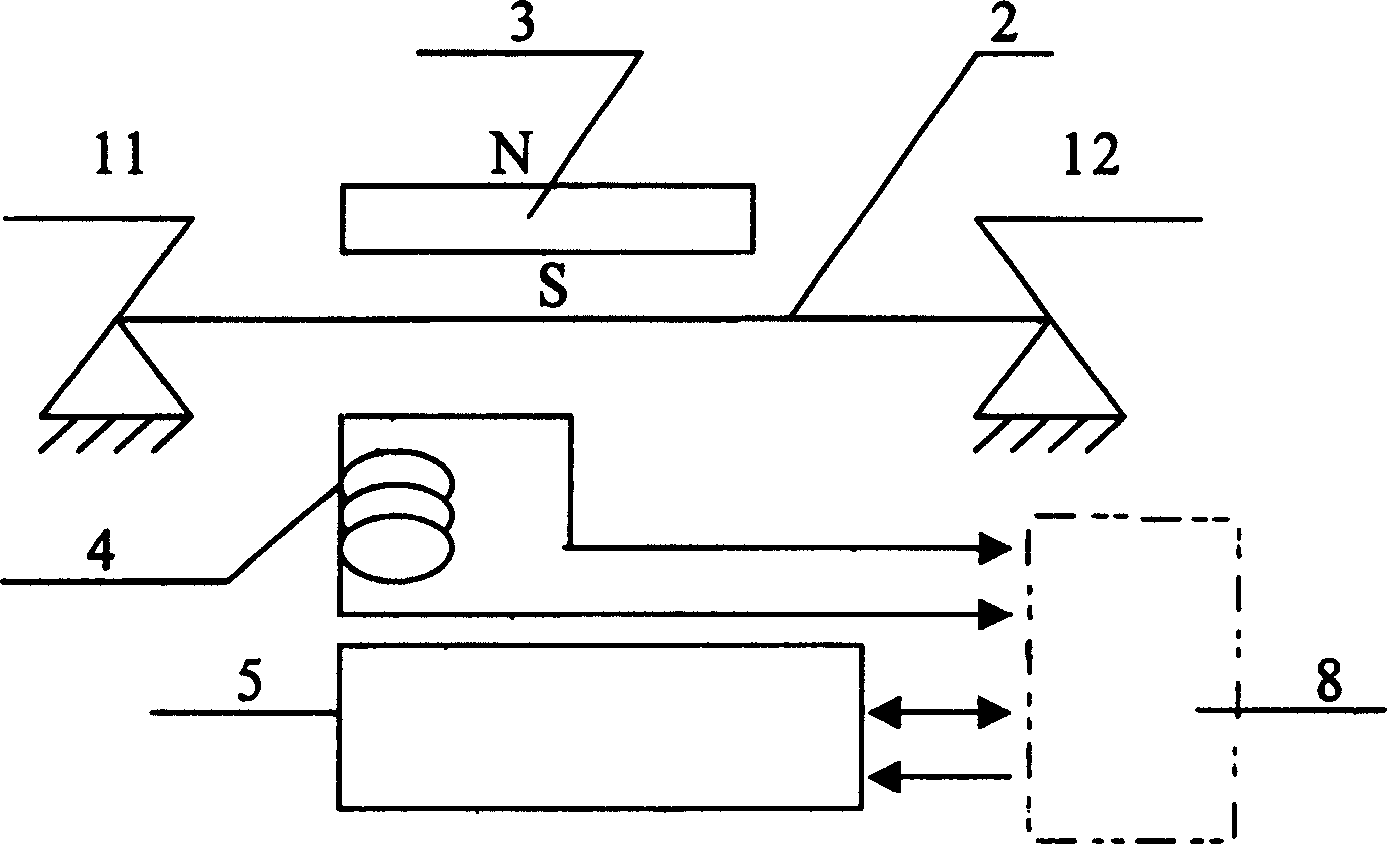

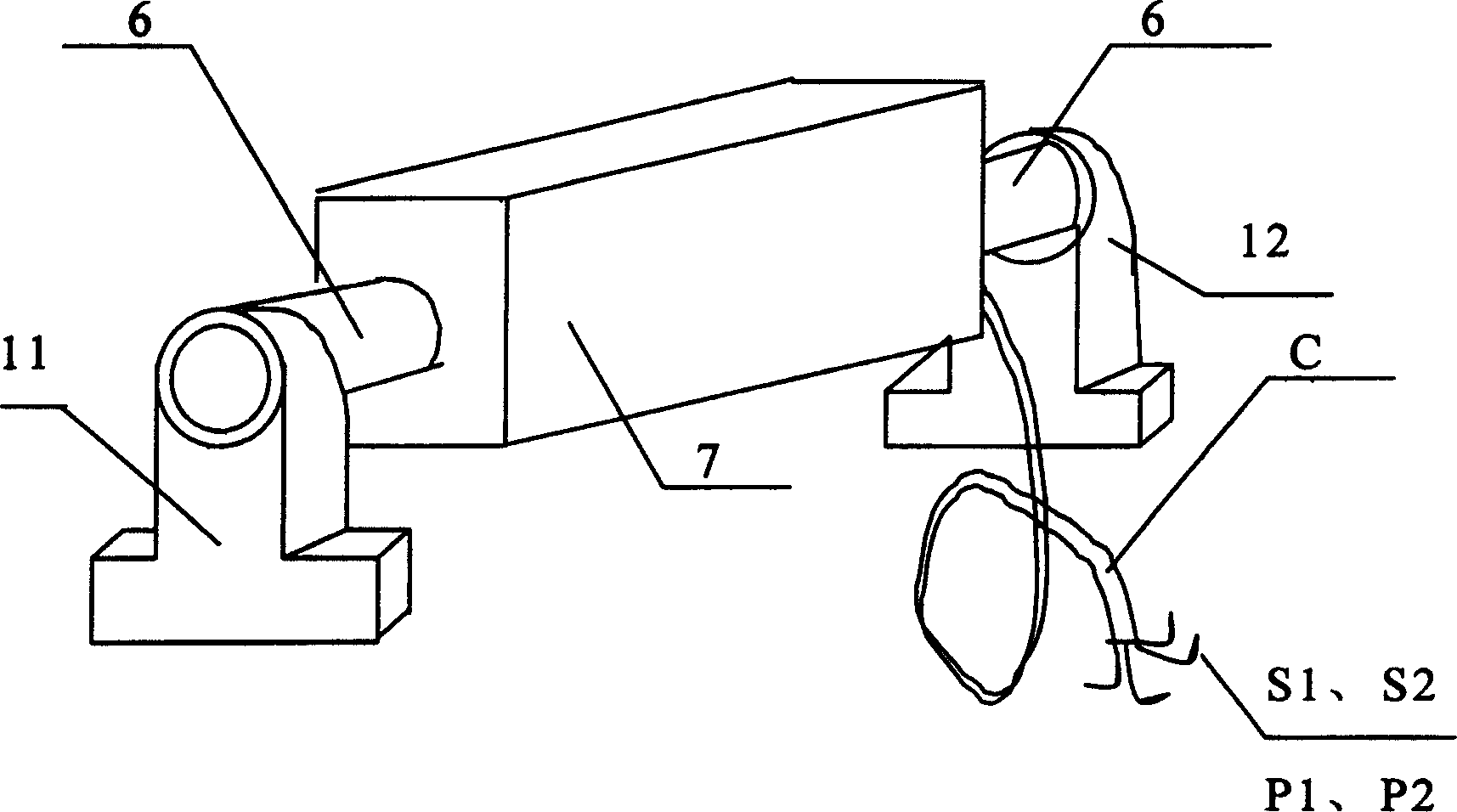

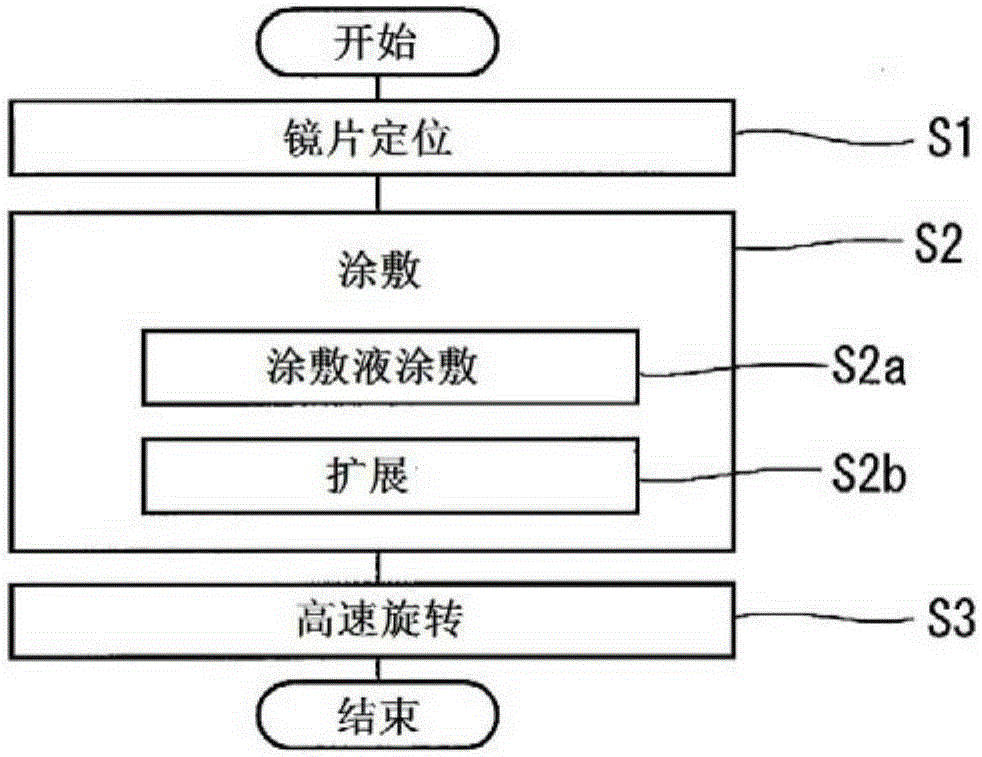

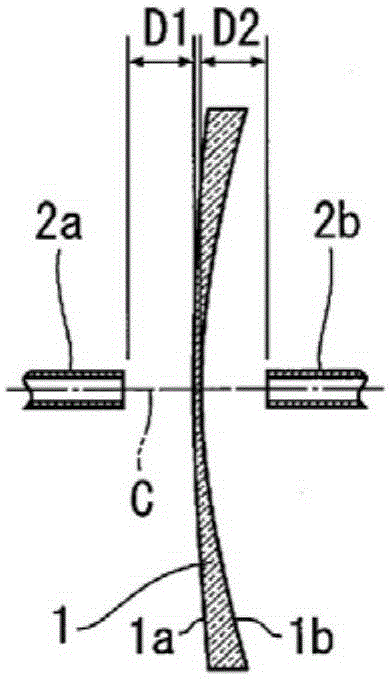

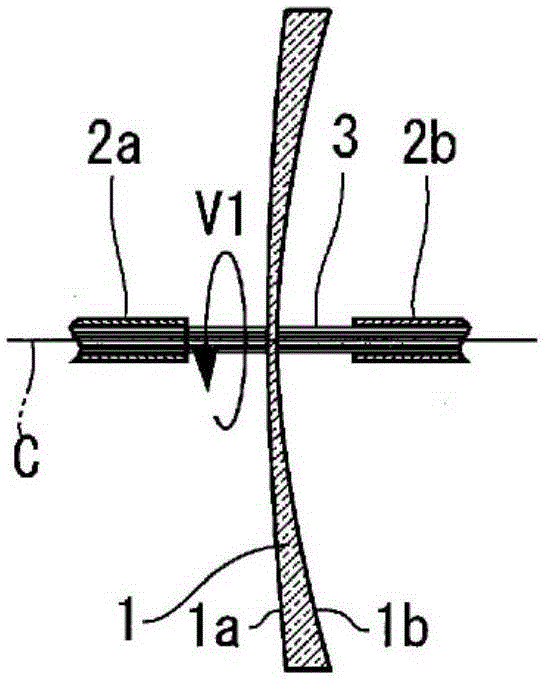

Method for manufacturing spectacle lens and coating device for coating liquid for base material of spectacle lens

InactiveCN105229495ALittle effect of gravityImprove uniformitySpectales/gogglesLiquid surface applicatorsCentre of rotationEngineering

A coating liquid (3) is horizontally jetted from nozzles (2a, 2b) so that lens surfaces (1a, 1b) of a spectacle lens base material (1) arranged so that the optical axis (C) is oriented in the horizontal direction are coated with the coating liquid (3) (step (S2a)). The spectacle lens base material (1) is rotated at a first rotational speed with the optical axis (C) as the rotational center, thus using centrifugal force to coat and spread the coating liquid (3) over the lens surface (step (S2b)). The spectacle lens base material (1) is rotated at a second rotational speed higher than the first rotational speed, thus using centrifugal force to splash the excess (3a) of the coating liquid (3) outside the spectacle lens base material (1) (step (S3)). Thus, a highly uniform film can be formed over the lens surface of a spectacle lens.

Owner:HOYA CORP

Large vertical grinder

InactiveCN1820896AReduce energy consumptionEliminates increased resistancePlane surface grinding machinesMotion resistanceEngineering

The present invention belongs to the field of machining equipment, and is especially large vertical grinder. The large vertical grinder consists of a vertical work table, a driving and transmitting apparatus connected to the work table, a track pedestal opposite to the work table, transverse tracks on the track pedestal and a guide plate stage on the transverse tracks, longitudinal tracks on the guide plate stage and a longitudinal guide plate, a grinding tool and a polishing wheel on the longitudinal guide plate. The grinding tool and the polishing wheel may be controlled in the control desk to move transversely and longitudinally. The present invention can perform grinding and polishing in the same apparatus and has no peripheral drooping, less motion resistance and low power consumption.

Owner:HEIXUANFENG SAW IND

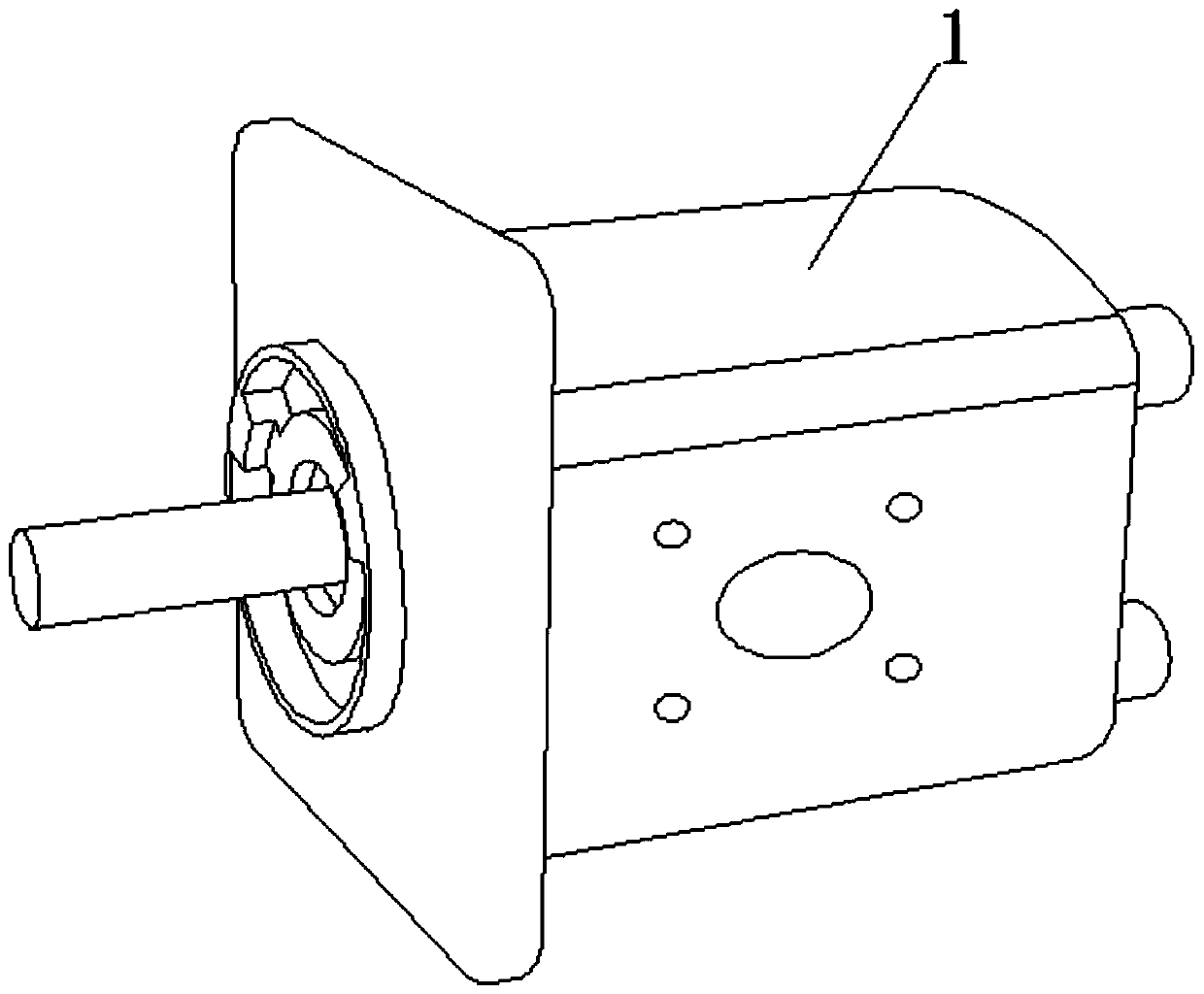

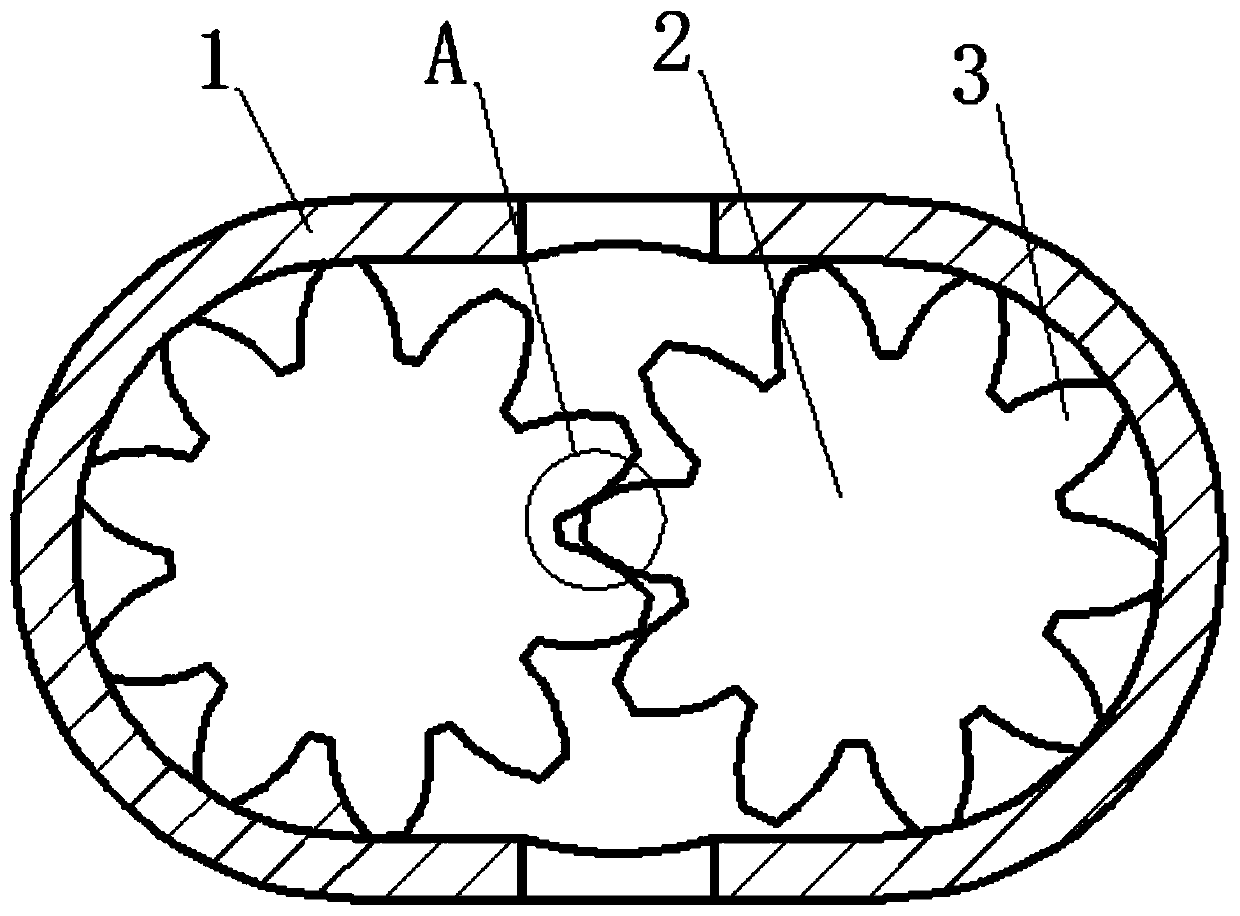

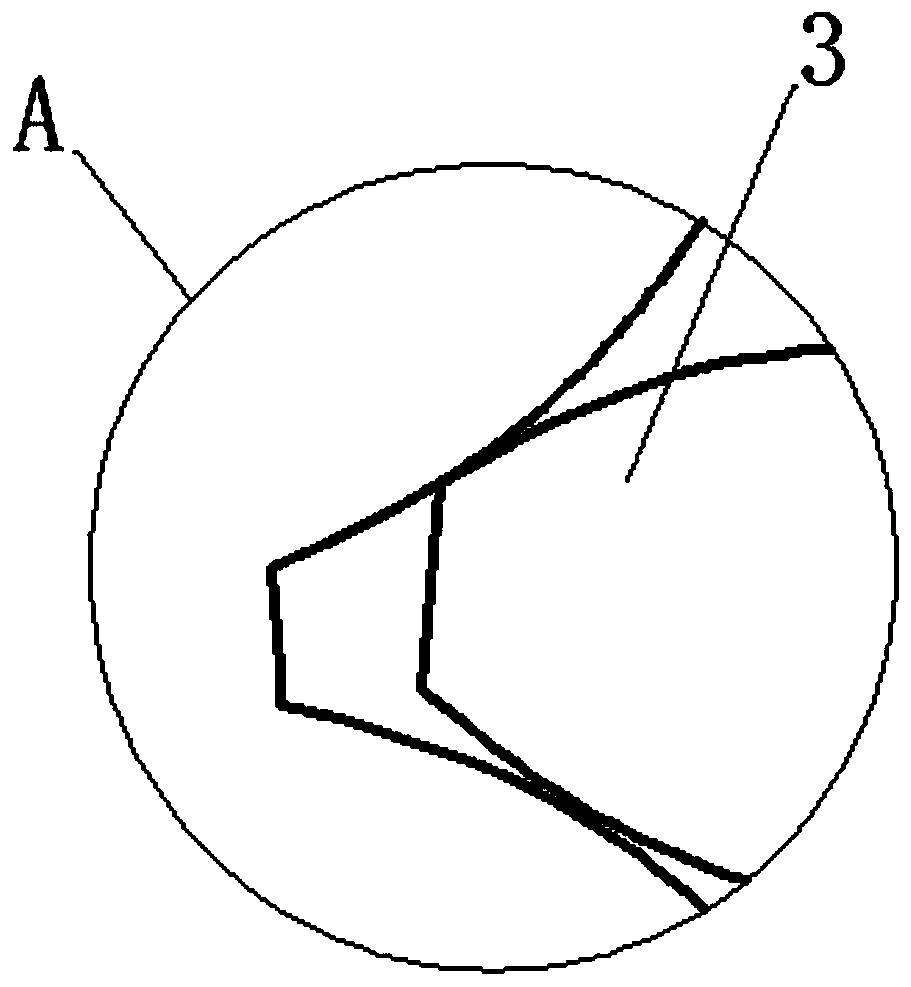

High-bearing gear-type pump motor

ActiveCN109854442AImprove wear resistanceImprove stabilityRotary piston enginesGear pumpWear resistant

The invention discloses a high-bearing gear-type pump motor which belongs to the field of motors. The high-bearing gear-type pump motor comprises a gear pump body, wherein two gears are installed in the gear pump body; the outer end of each gear is fixedly connected with a plurality of teeth which are distributed uniformly; the two gears are in engagement connection by the teeth; a reverse U-shaped cavity is cut inside each of the teeth; a plurality of reinforcement balls are placed on the left inner end and the right inner end of each reverse U-shaped cavity; every two adjacent reinforcementballs touch each other; and a splayed storage bag is placed in the inner end of each reverse U-shaped cavity. Wear resistance on the surface of the teeth is enhanced through use of a nanometer high-temperature wear-resistant composite coating; through cooperative use of the internal reinforcement balls and the splayed storage bags, overall strength of the teeth can be enhanced as use time goes; and energy generated from vibration during engagement can be absorbed by the reinforcement balls, so stability of the two gears during engaged rotation is enhanced and thus the service life of the gearmotor is increased.

Owner:湖南骏高智能科技股份有限公司

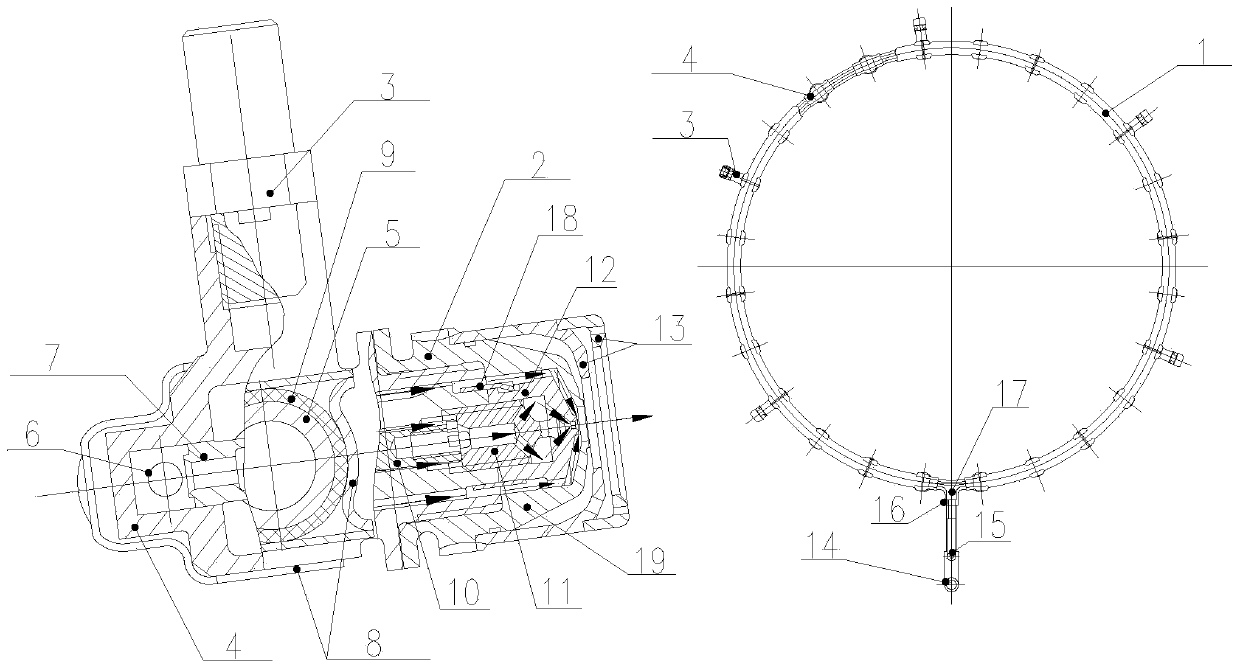

Cyclone refrigerant branching device

InactiveCN102607216ASimple structureIncreased turbulenceFluid circulation arrangementCycloneEngineering

The invention belongs to the technical field of air-conditioners, and particularly relates to a cyclone refrigerant branching device for a heat exchanger of an air-conditioner, which comprises a cylindrical body with one end face closed and the other end face provided with a plurality of branch outlet holes. An inner cavity of the body is an inner branching cavity and communicated with the branch outlet holes. The body side wall at the closed end of the body is provided with a tangential refrigerant inlet hole, and the center line of the tangential refrigerant inlet hole is perpendicular to the center line of the body but not intersected with the same, and close and parallel to the tangent line of the inner wall of the branching cavity to enable refrigerant in a liquid supply pipe inserted into the refrigerant inlet hole to tangentially flow in the branching cavity. The cyclone refrigerant branching device is effective in branching, less susceptible to gravity, flexible in mounting, simple in structure and economically and technically advantageous as processing difficulty is lowered.

Owner:HUNAN UNIV OF SCI & TECH

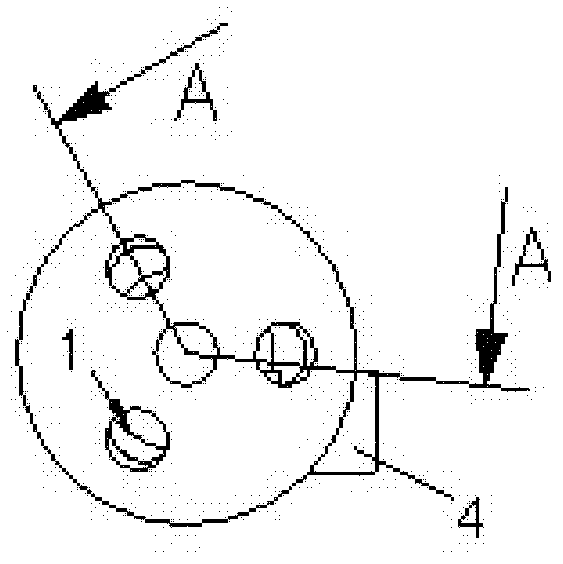

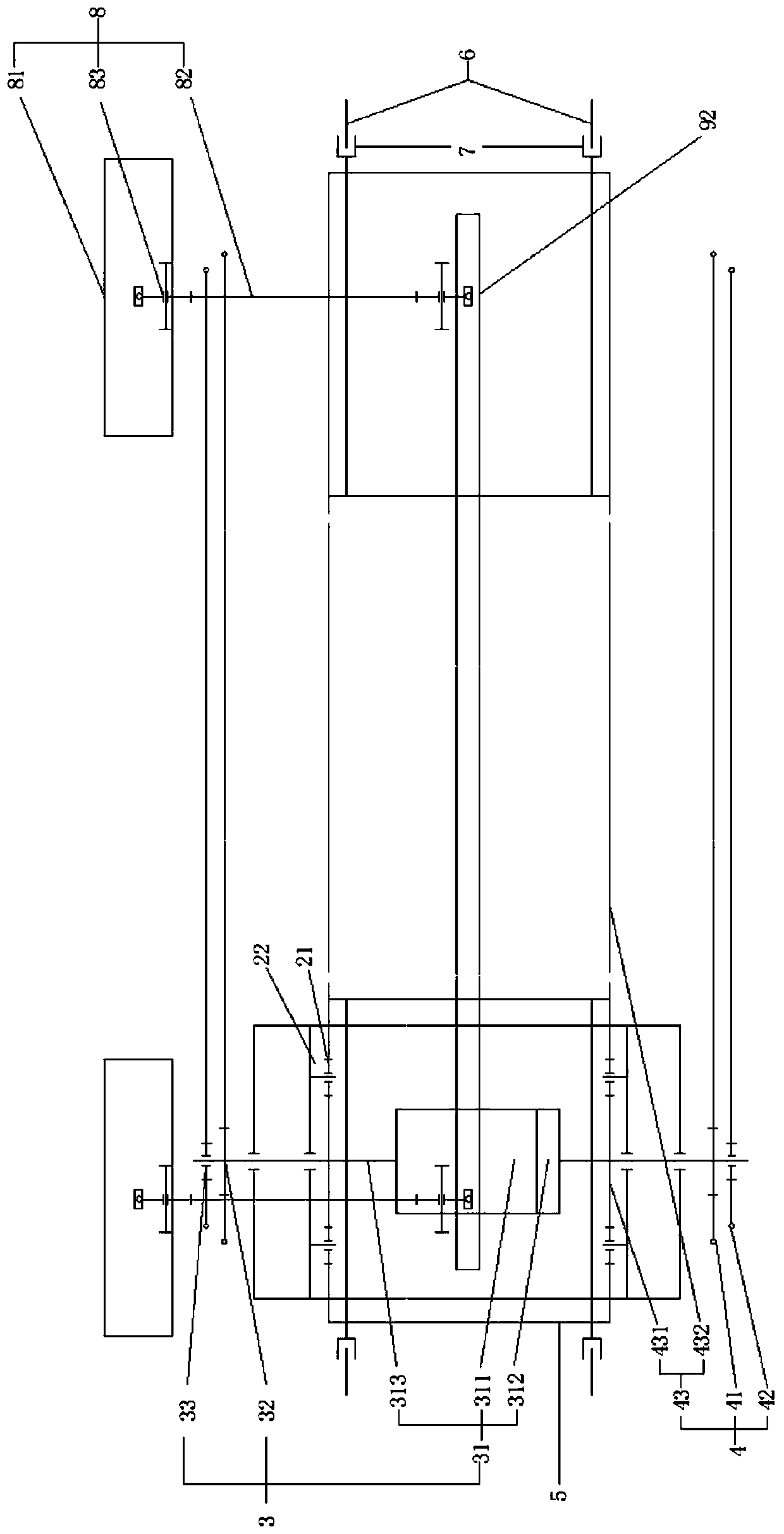

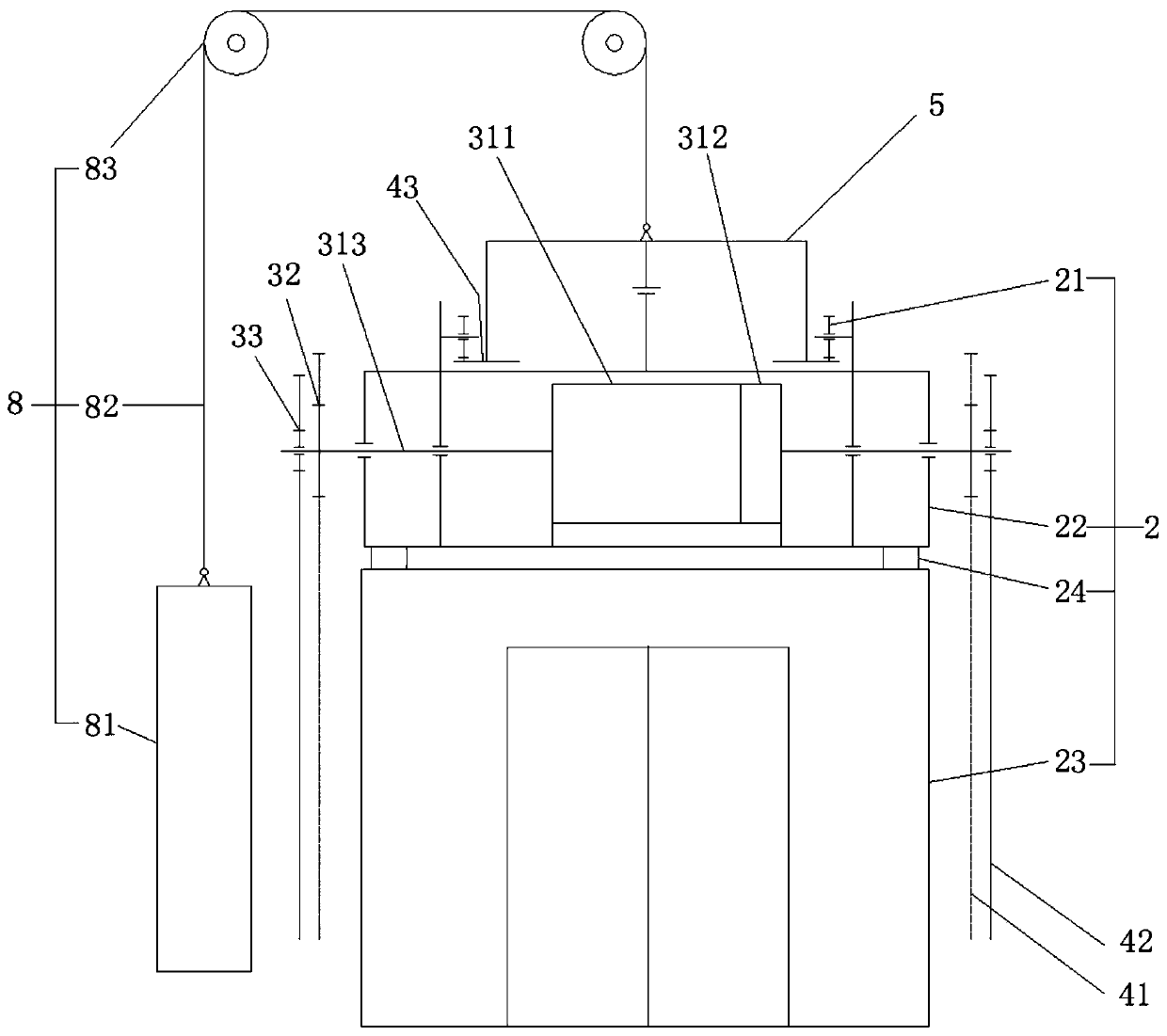

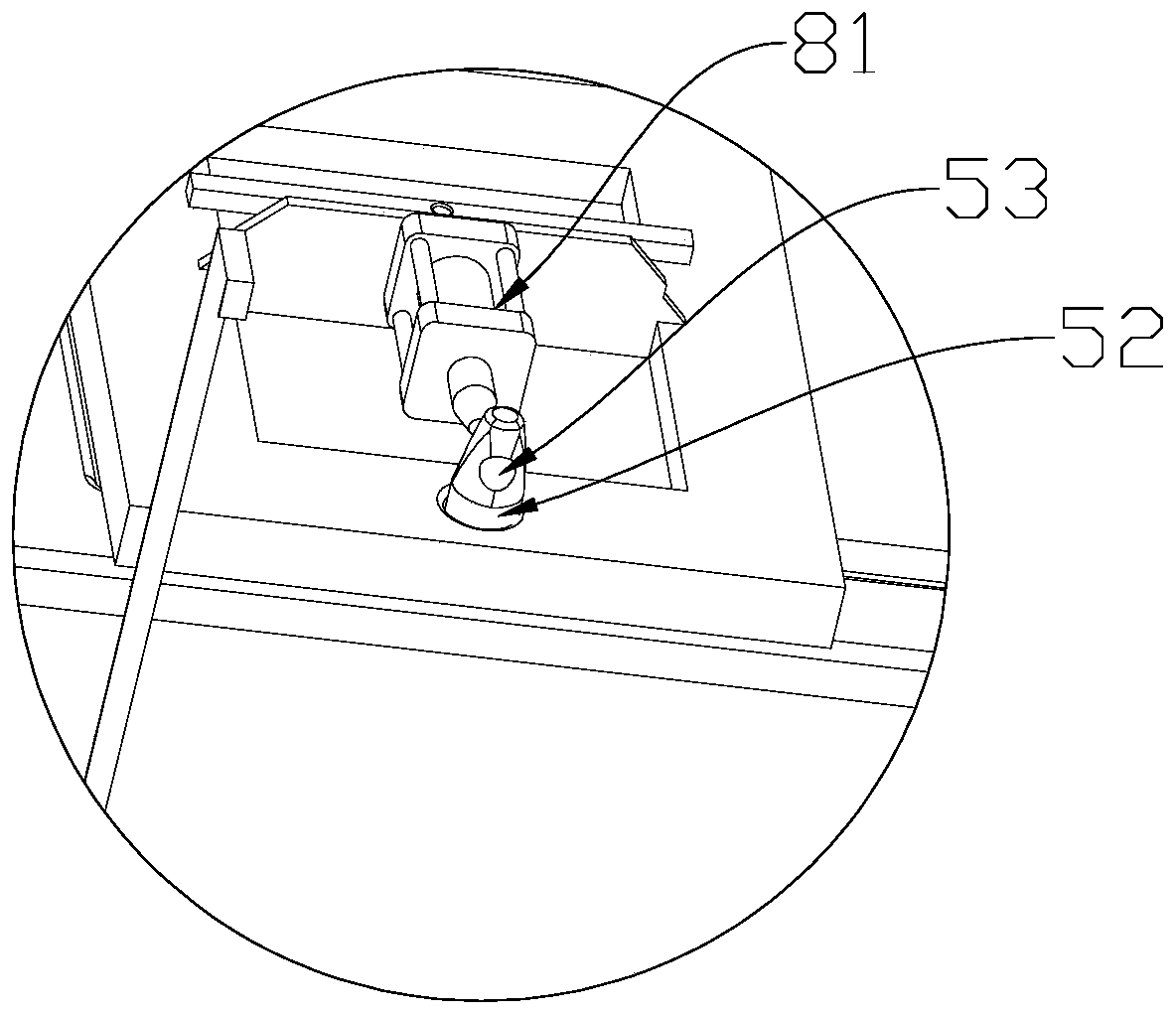

Sand core assembling system and sand core assembling method

PendingCN112496273AQuality improvementLittle effect of gravityFoundry mouldsFoundry coresMechanical engineeringGeotechnical engineering

The invention relates to the field of sand core assembling, in particular to a sand core assembling system and a sand core assembling method. The sand core assembling system comprises a plurality of robot clamps and a mold, wherein the robot clamps are used for arranging multiple sand cores on the mold in the horizontal direction; the robot clamps are further used for driving the clamped to-be-assembled sand cores to be folded with an original sand core on the mold; and / or the mold comprises a driving mechanism used for driving the clamped to-be-assembled sand cores to be folded with the original sand core on the mold. The sand core assembling method is applied to the sand core assembling system. According to the sand core assembling system and the sand core assembling method, the middle sand core with position deviation can be conveniently adjusted, the assembling efficiency can be improved, and the quality of a sand core assembly also can be improved.

Owner:SUZHOU MINGZHI TECH

Subminiature radial glass packaging thermistor and manufacturing method thereof

ActiveCN112038029AHigh compressive strengthImprove self-insulation performanceNegative temperature coefficient thermistorsSilver pasteSlurry

The invention provides a manufacturing method of a subminiature radial glass packaged thermistor. The method comprises the following steps: S1, arranging two lead wires on a porcelain column in a penetrating manner, and enabling the two lead wires to be flush and exposed out of the porcelain column; S2, exposing one end of each of the two lead wires out of the porcelain column to be stained with silver paste; S3, filling a thermosensitive chip between the two lead wires, connecting two electrode ends of the thermosensitive chip with the silver paste adhering ends of the leads respectively, andsintering to form a semi-finished product; S4, preparing glass slurry, and coating the surface of the semi-finished product in S3 with the glass slurry; S5, heating and drying, so that the glass slurry on the surface is preliminarily cured; S6, performing low-temperature sintering on the preliminary cured product obtained in S5 at 450 DEG C to form a thermistor semi-finished product with a glasslayer; and S7, selecting two PI tubes soaked in a PI liquid, respectively installing the PI tubes on the lead wires of the semi-finished thermistor in S5, enabling one end of each PI tube to enter thethrough hole of the porcelain column, and then heating to cure the PI liquid to obtain a finished thermistor. The manufactured product can adapt to smaller sizes, and is low in cost, good in sealingperformance and high in external force resistance strength.

Owner:XIAOGAN HUAGONG GAOLI ELECTRONICS

Road crossing vehicle system

PendingCN110293979AGuaranteed uptimeReduce vibrationConstructionsRailway componentsDrive wheelCross bridge

The invention discloses a road crossing vehicle system. The road crossing vehicle system comprises a structure main body, a road crossing vehicle, a driving device and a rail system, wherein the roadcrossing vehicle, the driving device and the rail system are arranged in the structure main body; the structure main body comprises two vertical shafts and a road crossing bridge communicating with the tops of the two vertical shafts; lifting tables are arranged in the vertical shafts; the driving device comprises a driving source, a driving wheel and a guiding wheel, the driving source is arranged at the top of the road crossing vehicle, and the driving wheel and the guiding wheel stretch out of the two sides of the road crossing vehicle; the rail system comprises driving rails, guiding railsand load bearing rails; the driving rails and the guiding rails are both symmetrically arranged on the two sides of the interior of the structure main body and extend from one vertical shaft to the other vertical shaft through the road crossing bridge along the operating path of the road crossing vehicle, the driving wheel cooperates with the driving rails, and the guiding wheel cooperates with the guiding rails; and the load bearing rails are arranged on the road crossing bridge and the lifting tables, the top of the road crossing vehicle is provided with a wheel set, and the wheel set is matched with the load bearing rails. According to the road crossing vehicle system, it can be achieved that the road crossing vehicle operates continuously and stably by switching from vertical liftingto transverse moving and crosses the road through only one set of driving device.

Owner:黄韩华

Polypropylene automotive plastic part spraying process

InactiveCN105289959AImprove flatnessNot easy to backlogLiquid surface applicatorsPolyurea/polyurethane coatingsPolyolefinLacquer

The invention provides a polypropylene automotive plastic part spraying process and relates to the technical field of spraying processing. The polypropylene automotive plastic part spraying process comprises the following steps that an area to be repaired is cleaned through white vinegar water and then cleaned up through clear water; polishing is carried out to form a bevel opening, the upper portion of the bevel opening is high, and the lower portion of the bevel opening is low; a polyolefin tackifier is sprayed and dried, the polished area to be repaired is kept as a bevel all the time, drying is carried out, and sanding and side finishing are carried out; the polyolefin tackifier is sprayed to the polished area to be repaired again for filling and leveling, the polished area to be repaired is kept as the bevel, an original paint layer on a plastic part is polished completely, and the gloss of the paint layer is removed; the polyolefin tackifier is sprayed for the third time, medium coating is sprayed after drying, flash drying is carried out, a layer of medium coating is sprayed again and scraped evenly, the polished area to be repaired is kept as the bevel, and the surface is ground flush; and acrylic paint and curing agents are diluted and mixed, and are obliquely sprayed from the upper portion to the lower portion of the spraying bevel opening after being proportionally mixed, and drying is carried out. According to the polypropylene automotive plastic part spraying process, the curing speed is high, the gravity effect is low, and the flatness of the sprayed plane is high.

Owner:ANHUI LONGJIA TRAFFIC EQUIP

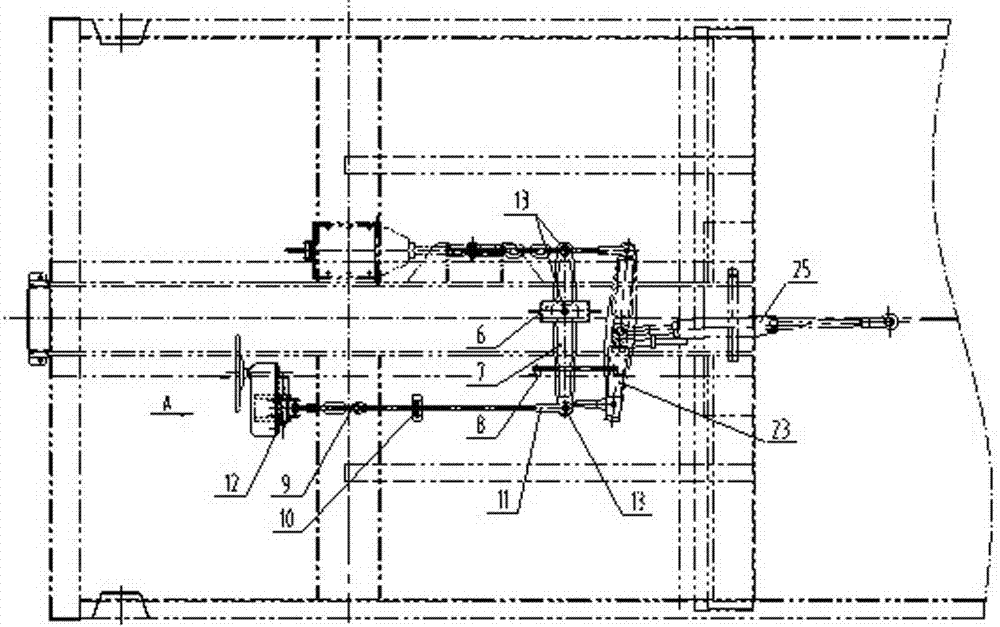

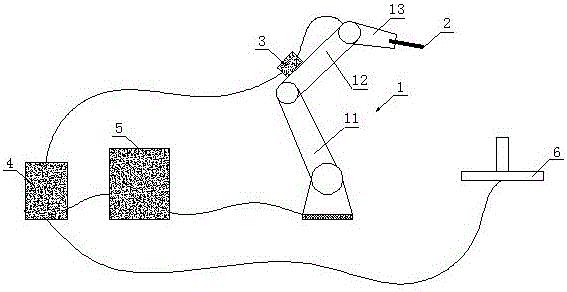

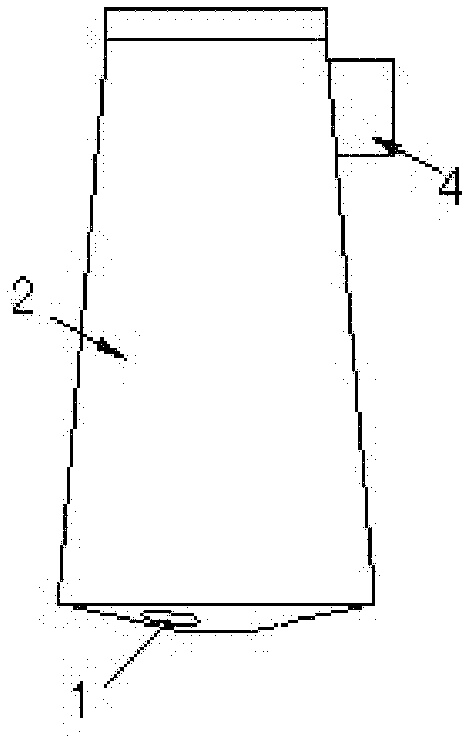

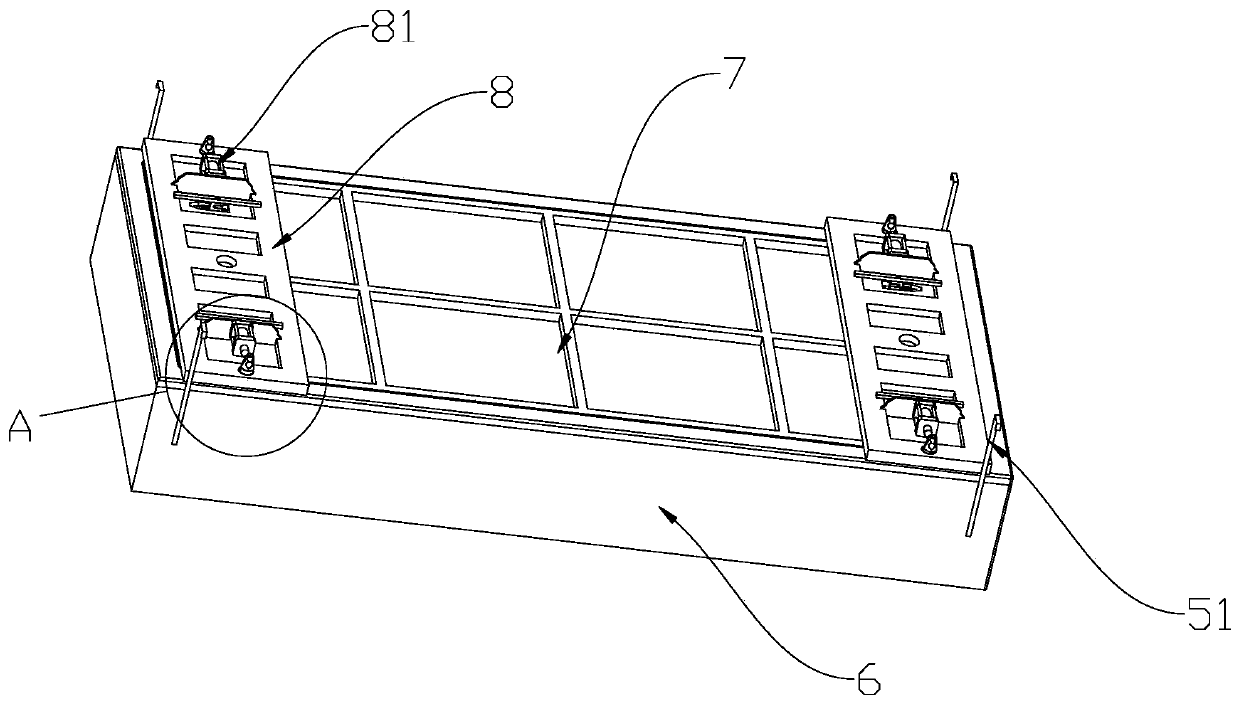

A built-in fuel manifold for dual-circuit fuel delivery and atomization

ActiveCN109140502BCompact structureLittle effect of gravityContinuous combustion chamberCombustion chamberFuel oil

A built-in fuel manifold for dual-circuit fuel delivery and atomization, consisting of manifold (1) and nozzles (2), the fuel manifold is fixed by a pillar with a sphere (3), and the nozzle housing (4) The oil supply pipe (5) of the main oil circuit is connected with the oil supply pipe (6) of the auxiliary oil circuit, the heat protection of the pipeline is realized through the outer cover (7) and the heat insulation layer (8), and the bushing (9) with threaded oil filter The threaded structure on the surface of the auxiliary oil filter (10) realizes the filtration and stable flow of the fuel, realizes the centrifugal atomization of the fuel through the swirl groove on the swirler (11) and the nozzle swirler (12), and realizes the centrifugal atomization of the fuel through the gas hood The oblique air inlet on (13) reduces the carbon deposition of the nozzle. The fuel main pipe can meet the needs of different fuel supply characteristics of the double oil circuit, and has good atomization effect, compact structure, small mass, little influence of fuel gravity, no carbon deposit on the end surface of the nozzle, and not easy to be affected by fuel flow instability. For use in aero-engines and gas turbine combustors.

Owner:中国航发贵阳发动机设计研究所

Loading test device and method for crack load transfer behavior of road material

PendingCN112345391AEasy to operateSimple device structureMaterial strength using repeated/pulsating forcesMaterial CrackNeoprene

Owner:SHENYANG JIANZHU UNIVERSITY

Box type polyurethane foam preparation method

The invention relates to a box type polyurethane foam preparation method. Through the box type polyurethane foam preparation method, it can be ensured that foaming of foaming fluid is implemented at constant temperature, constant pressure and constant humidity all the time, the quality of a foamed material is ensured, and the foamed material with the flush upper surface and uniform density can be obtained.

Owner:重庆丰裕宇科技有限公司

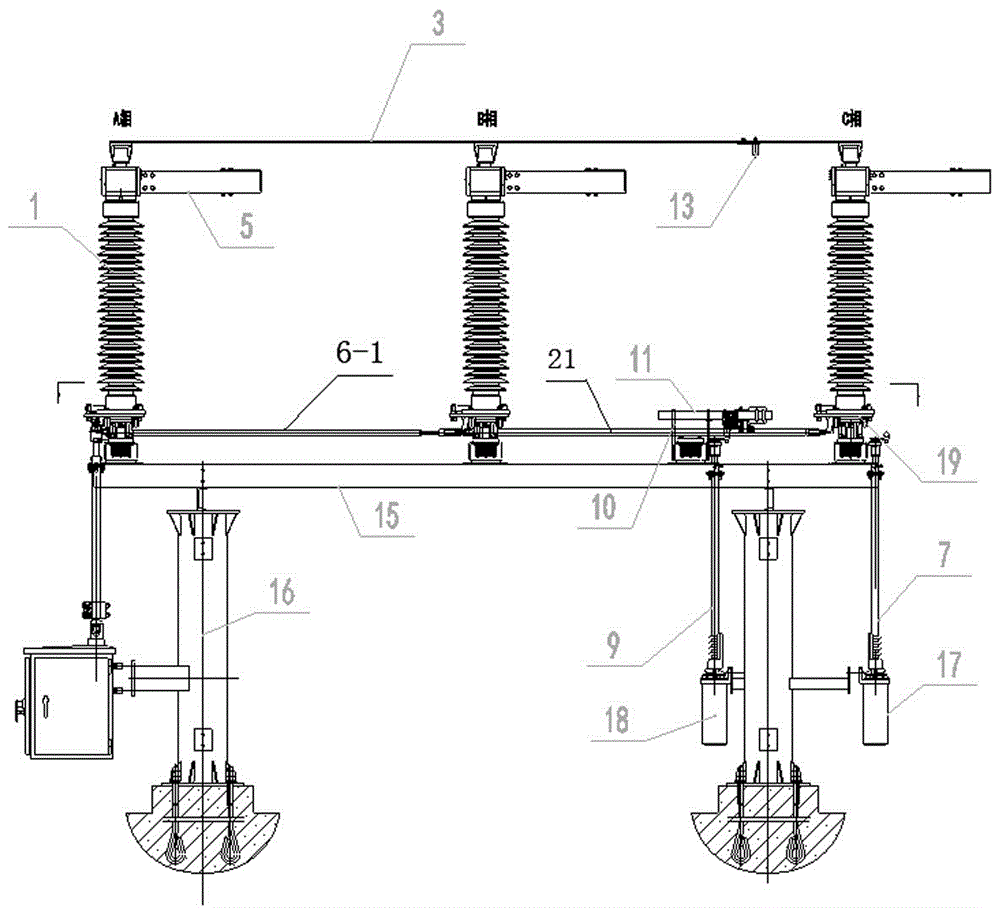

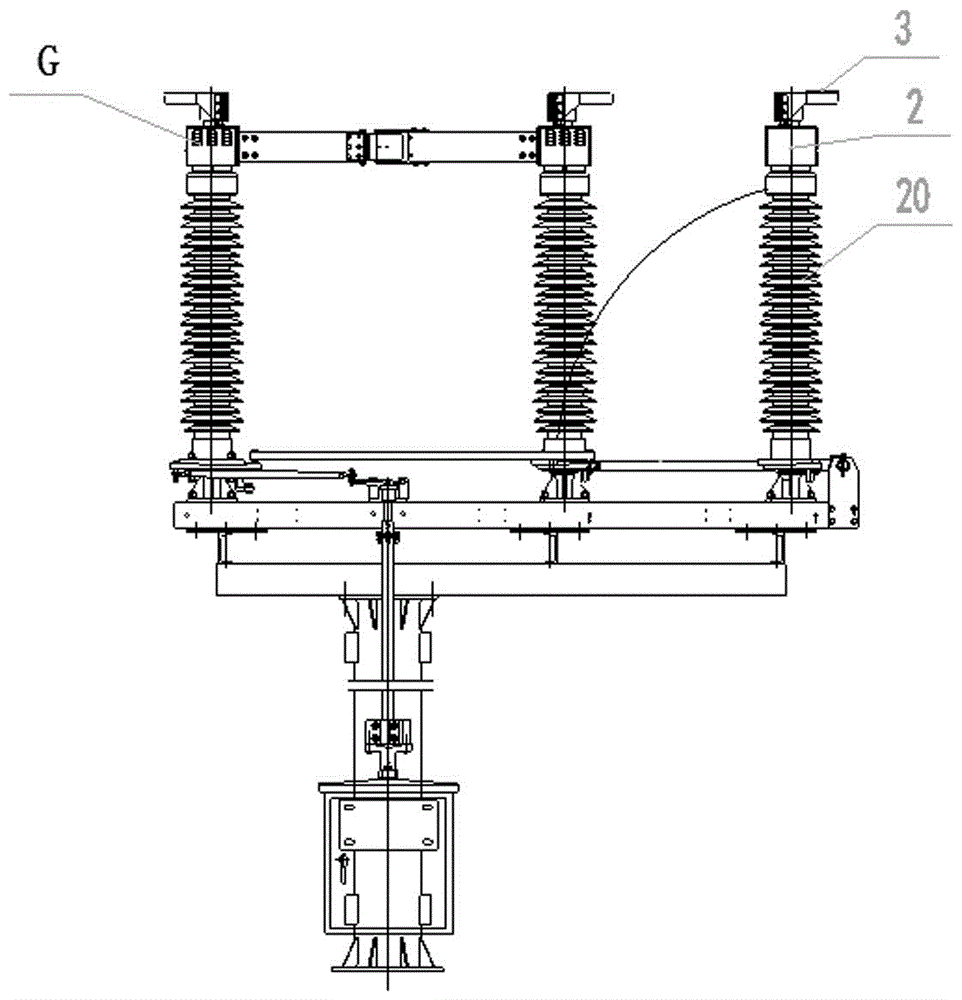

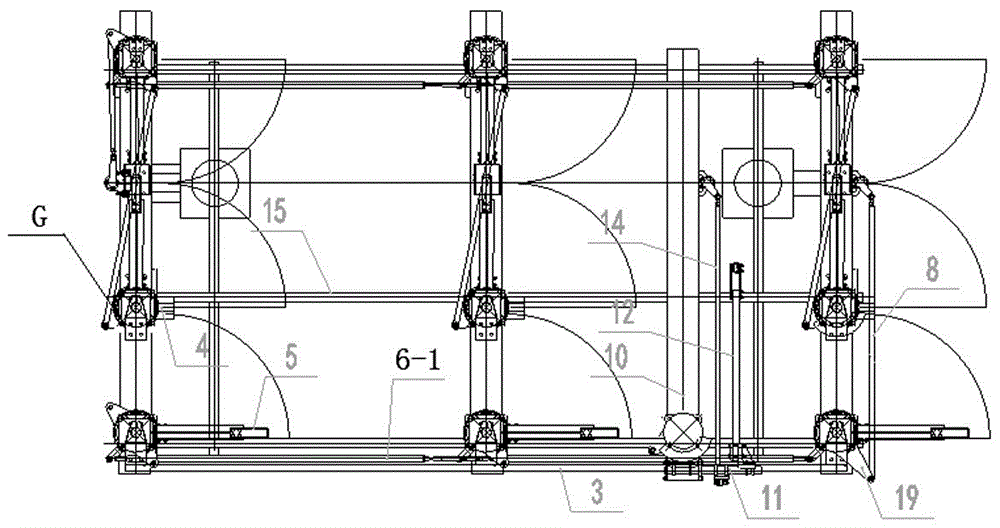

High-voltage isolation switch having ice melting short circuit and normal function switching, and switching method

ActiveCN107527765ASmall operating torqueLittle effect of gravityContact driving mechanismsAir-break switch detailsGeneral functionEngineering

The invention provides a high-voltage isolation switch having ice melting short circuit and normal function switching, and a switching method. The high-voltage isolation switch comprises a mounting rack, and the mounting rack is provided with a short circuit switch operation mechanism. The top part of the mounting rack is provided with a horizontal rack, and the upper part of the horizontal rack is provided with a three-phase high voltage isolation switch body. One end of the rotating porcelain bottle of the three-phase high voltage isolation switch body is provided with a three-phase short circuit isolation switch body. The three-phase short circuit isolation switch body is provided with a short circuit moving contact and a short circuit static contact. The short circuit moving contacts of the three-phase short circuit isolation switch body are respectively connected to a corresponding rotation bearing seat through different rotating porcelain bottles. The rotation bearing seat at the other end of the C-phase high-voltage isolation switch body is connected to a first vertical connecting rod through a first operation pulling rod, and the first vertical connecting rod is connected to a short circuit switch operation mechanism. The invention also provides a switching method of the high-voltage isolation switch having ice melting short circuit and normal function switching. The invention is advantageous in that the ice melting short circuit and the normal functions (like running and grounding) can be quickly switched.

Owner:HUNAN CHANGGAO HIGHVOLTAGE SWITCHGEAR CO LTD

A cooling molding module for four-layer co-extrusion of luggage shell

ActiveCN109318464BSpeed up heat dissipationPlay a dust-proof effectFlat articlesEngineeringFixed wing

The invention discloses a cooling forming module for bag outer shell four-layer co-extrusion. The cooling forming module comprises a four-layer co-extrusion mold and a plate cooling forming device, wherein the four-layer co-extrusion mold comprises a division feed inlet, a confluence discharge opening and fixed wings; and the plate cooling forming device comprises fixed seats, air curtain machines, heat-conducting pipes and side fixed plates. According to the cooling forming module, through design of the air curtain machines, external dust is prevented from falling on a plate before the plateis not cooled, and a dust prevention effect is achieved; and besides, the gravity effect on the outer shell plate before forming is reduced, namely, supporting force between the outer shell plate andthe heat-conducting pipes is reduced, deformation is prevented, and product quality is improved.

Owner:泉州锦林环保高新材料有限公司

An ultra-narrow gap welding device and method for welding pipe fittings

The invention discloses an ultra-narrow gap welding device and method for welding pipe fittings, and relates to the field of welding technology, wherein an ultra-narrow gap welding device for pipe fitting welding includes a welding mechanism, a rotating mechanism and a positioning mechanism The welding mechanism rotates around the positioning mechanism through the rotating mechanism, and the positioning mechanism is arranged inside the pipe to be welded, and the rotating mechanism is connected to the positioning mechanism in rotation; the present invention can carry out transverse welding in the groove with a small gap width, because the groove width is narrow , The energy of the welding line is small, the heat input in the welding process is low, the growth of the molten pool is effectively inhibited, and the collapse of the molten pool is prevented, which can not only effectively solve the defect of the molten pool, but also improve the welding production efficiency; the operation of the present invention It is convenient and easy to move, and overcomes the problems of difficult operation and high technical requirements for operation of large-scale equipment in on-site welding.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

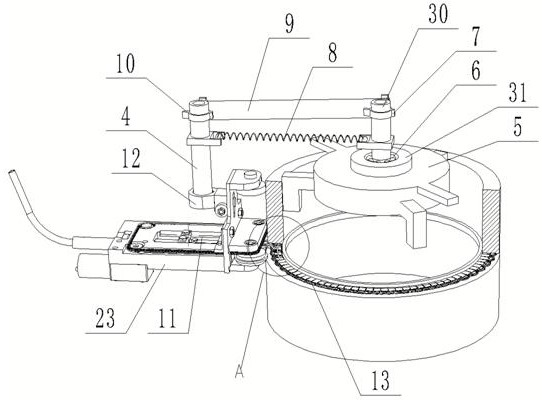

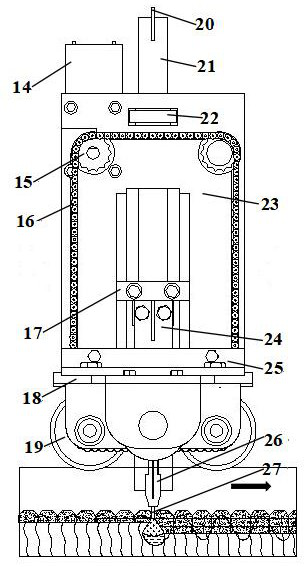

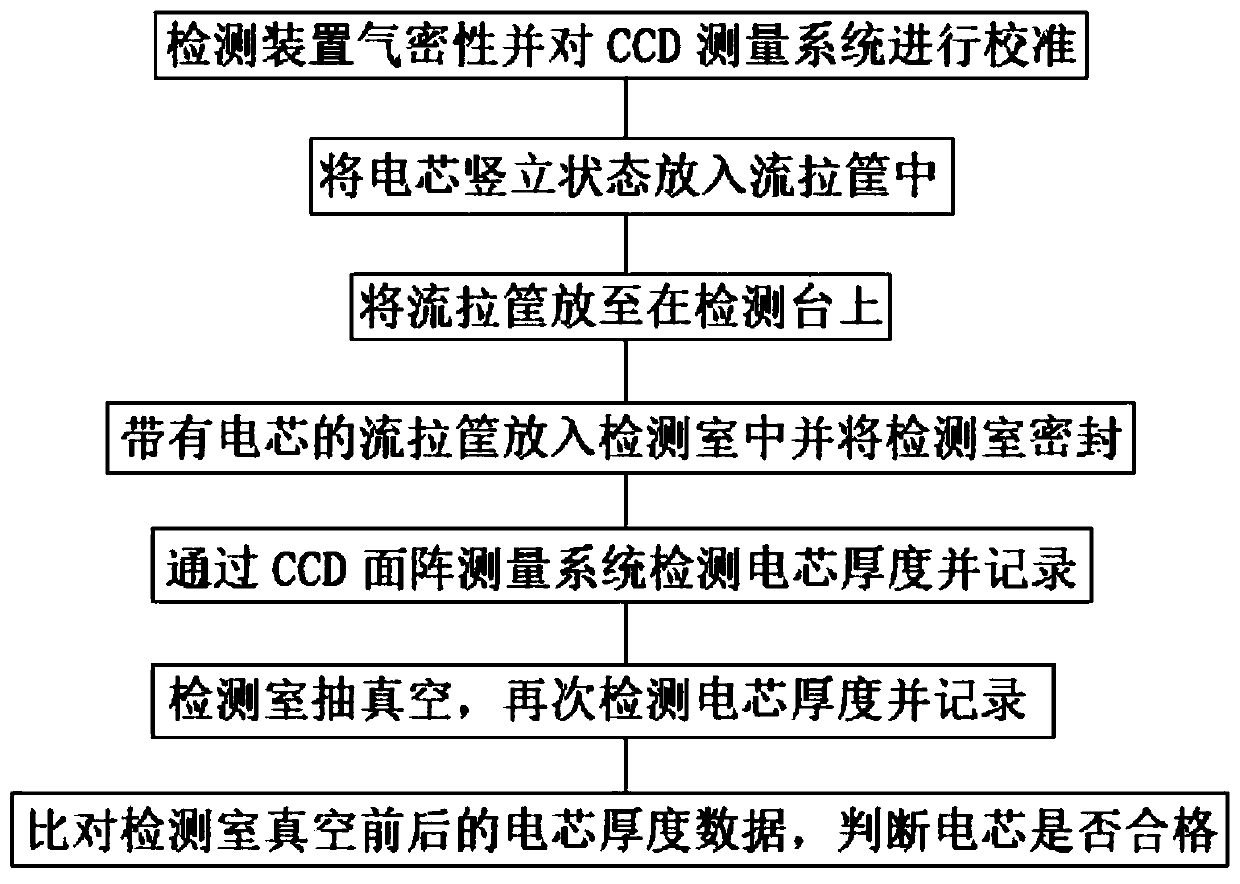

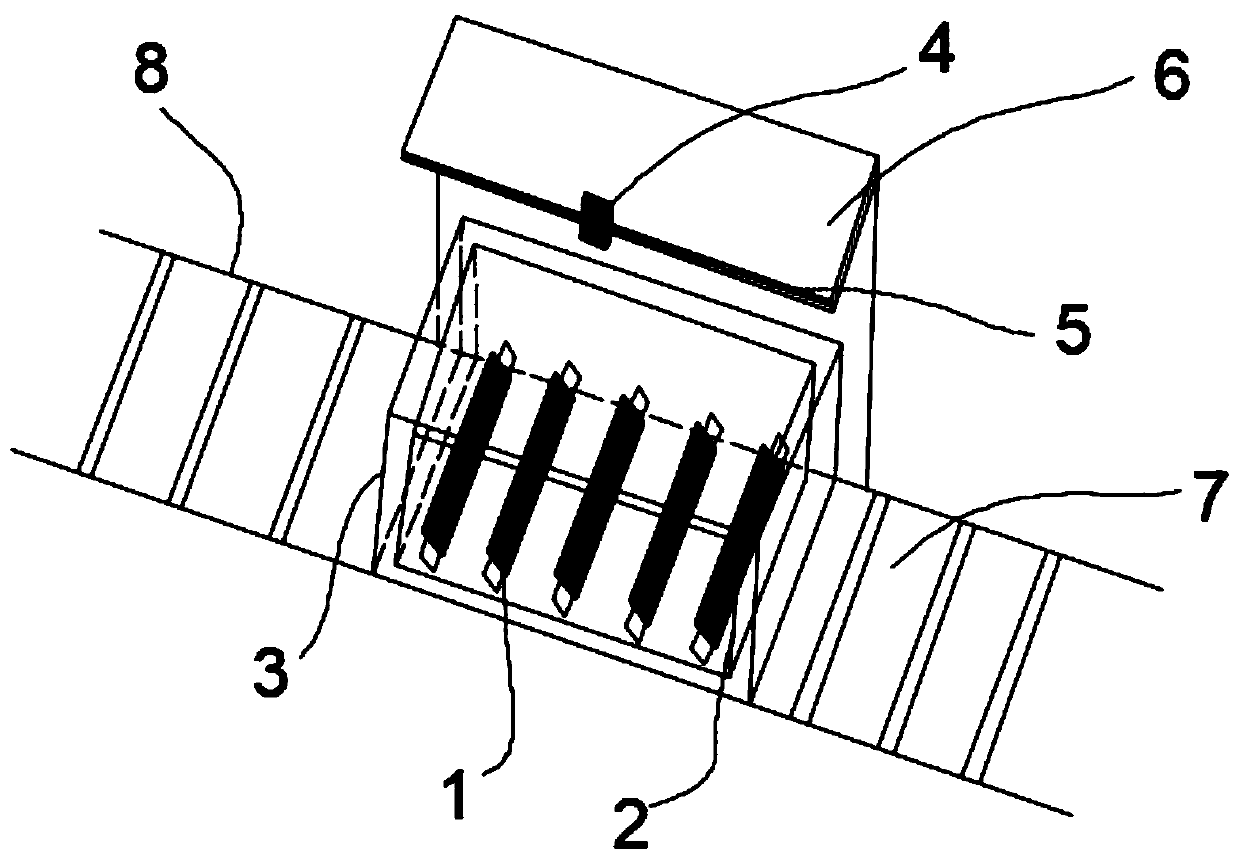

Method and device for detecting air tightness of battery cell

ActiveCN111521354AImprove detection efficiencyIncreasing the thicknessFluid-tightness measurement by detecting dimension changeMechanical engineeringBattery cell

The invention discloses a method for detecting the air tightness of a battery cell. The method comprises the following steps: the airtightness of the device is detected and the CCD measurement systemis calibrated; the battery cell is put into a flow pulling basket in a vertical state; the flow pulling basket is placed on the detection table, the flow pulling basket with the battery cell is placedin the detection chamber, the detection chamber is sealed, the thickness of the battery cell is detected and recorded through the CCD area array measurement system, the detection chamber is vacuumized, the thickness of the battery cell is detected again and recorded, and whether the battery cell is qualified or not is judged by comparing battery cell thickness data before and after the detectionchamber is vacuumized. According to the invention, more than 30 cells can be detected at one time, the detection efficiency is high, and application to actual production is facilitated. According to the invention, the CCD detection system is adopted for surface detection, so that the result is more real and accurate; the battery cell is vertically placed, the influence of gravity on two sides is extremely small, the thickness of the battery cell is obvious, and the bad detection accuracy is greatly improved.

Owner:捷威动力工业嘉兴有限公司

Rotary device for bioprinting and method of use thereof

ActiveCN106137456BImprove biological activityPromote growth and developmentAdditive manufacturing apparatusTubular organ implantsNutrient solutionDigital printing

The invention provides a rotating rod for 3D biological printing. The rotating rod is horizontally arranged and driven to rotate and is of a hollow structure, and at least one hole is formed in the surface of the rotating rod; in the 3D biological printing process, a nutrient solution passes through the hollow structure, and part of the nutrient solution penetrates out of the holes. The invention further provides a 3D biological printing platform which comprises the rotating rod and a nutrient supply system and can supply nutrients and a method for printing tubular tissue through the biological printing platform. Accordingly, the possibility that the tissue collapses due to the gravity influence is decreased, the novel method for achieving 3D biological printing of the tubular tissue and supplying the nutrients in the printing process is provided, and a wide application prospect is achieved.

Owner:SICHUAN REVOTEK CO LTD

Backflow composite flat heat pipe

PendingCN114184069AAchieve reflowExpand the return spaceIndirect heat exchangersEngineeringMechanical engineering

The invention discloses a backflow combined type flat plate heat pipe which comprises an evaporation end, a condensation end, a liquid filling pipe and a liquid working medium. The liquid filling pipe and the condensation end are connected with the evaporation end to form a cavity containing a liquid working medium. The capillary reflux column and the side wall wick are arranged at the evaporation end; the evaporation end is super-hydrophilic, and the condensation end is super-hydrophobic; and the liquid working medium is deionized water. According to the non-wettability of the super-hydrophobic surface and the self-driven bounce phenomenon after liquid drop fusion, when the working angle of a system is that a condensation end is above, a liquid working medium quickly returns to an evaporation end by virtue of gravity, and capillary reflux does not need to play a role; when the condensation end is at the lower part, part of the condensation working medium returns to the evaporation end in a bouncing backflow mode, and the rest of the condensation working medium returns to the evaporation end in a capillary backflow mode through the capillary backflow column and the wall surface wick; meanwhile, a steam guide structure is arranged to promote liquid drops to flow back to the center of the evaporation end. Two backflow modes are combined, the backflow space of the flat heat pipe is expanded, the backflow path is shortened, and the backflow speed is increased.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com