MIG (metal inert gas) welding system

A welding system and welding process technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of different welding forming operations, high heat input, breakdown of welding workpieces, etc., and achieve fast solidification speed and heat input ratio Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

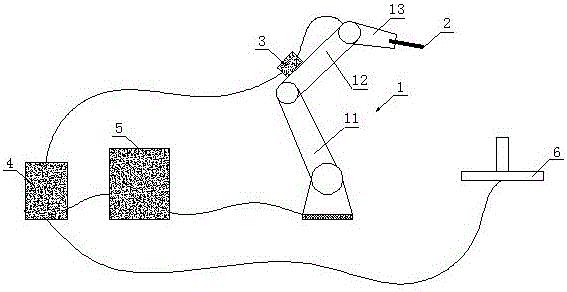

[0035] Such as figure 1 As shown, the present embodiment is a kind of MIG welding system, which can be mainly applied to the process of welding the workpiece 6, and realizes the continuous spot welding of the workpiece to be welded by combining welding robots, welding machines, robot control cabinets, etc. (Stitch Welding), which may include:

[0036] The welding robot 1 is fixed on the bottom plate or a corresponding platform near the above-mentioned workpiece (such as near the workbench for fixing the workpiece for welding), so as to use the welding robot 1 to perform subsequent welding operations on the workpiece 6; wherein , the welding robot 1 can have a bottom bracket (such as a machine hand), a boom 11 that is pivotally connected to the bracket, a small arm 12 that is pivotally connected to the boom 11, and a Wrist 13 (it should be noted that the terms of anthropomorphic limbs such as big arm, forearm and wrist here refer to the structure of the corresponding part of t...

Embodiment 2

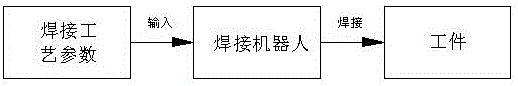

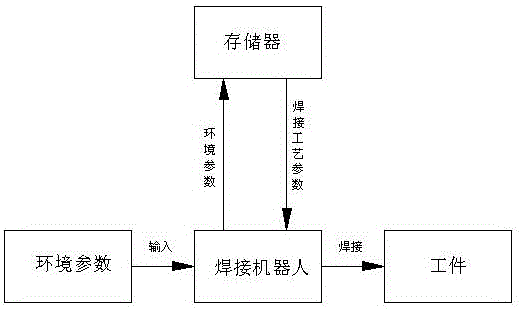

[0042] On the basis of the above-mentioned first embodiment, since welding process parameters such as welding current value, welding voltage value and welding speed value need to be input before the welding process is performed, the subsequent welding operation can be accurately realized. , that is, the selection of the above welding process parameters is the focus of the welding process using robots, which can directly affect the quality of subsequent welding. Once the input is wrong, it will even cause defects such as damage and damage to the workpiece and fixture; if it is carried out manually When inputting welding process parameters, such as figure 2 As shown, after the welding process parameters are manually input, the welding robot will directly perform corresponding welding operations on the workpiece according to the welding process parameters, that is, the quality of the operator will directly affect the quality of the welding process, which is not conducive to the q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com