Mould plasma 3D printing equipment and mould plasma 3D printing method

A 3D printing and plasma technology, applied in the direction of improving process efficiency, improving energy efficiency, additive manufacturing, etc., can solve problems such as high operating costs, long preparation time for mold making, uneven filling of corners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

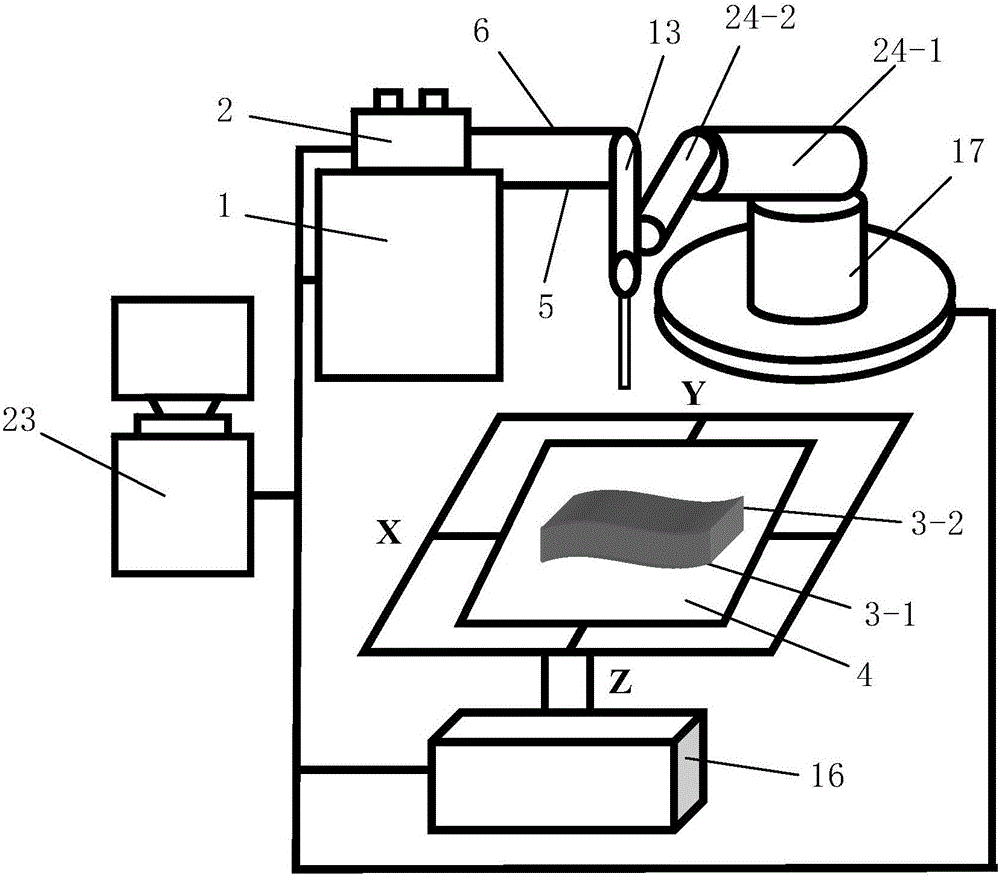

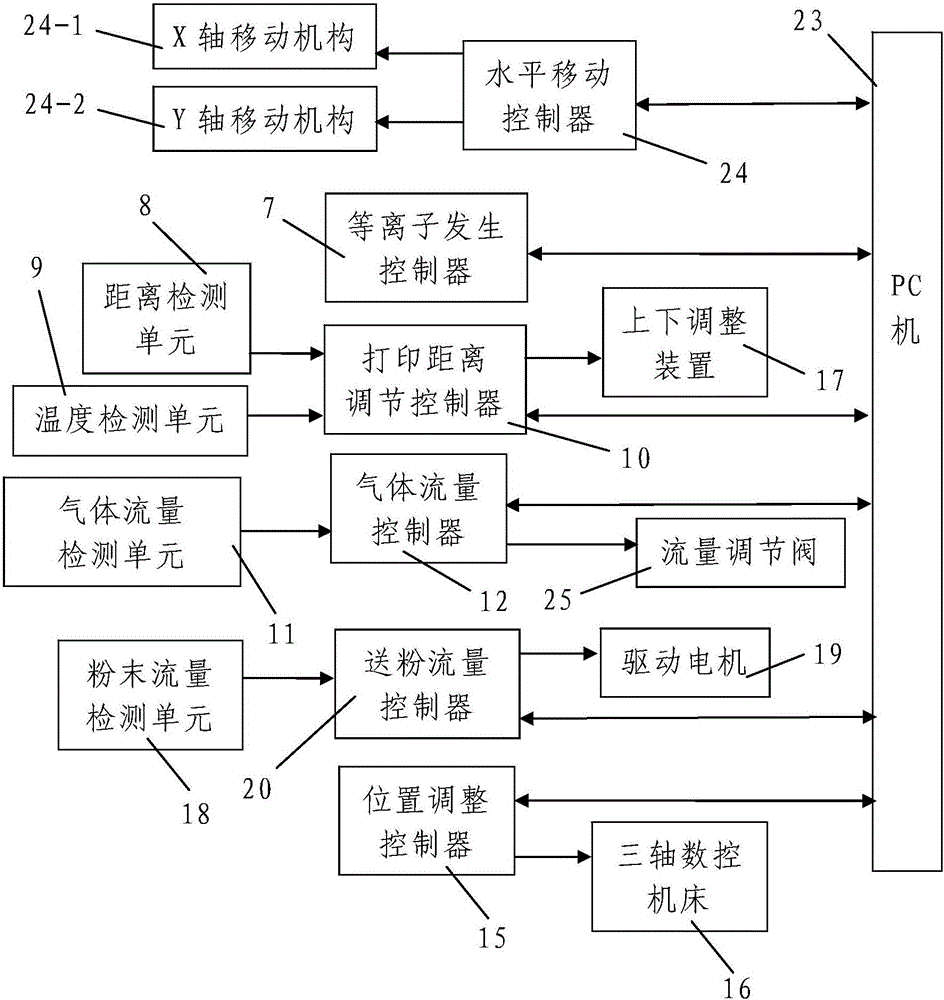

[0086] Such as figure 1 A mold plasma 3D printing equipment shown is composed of a monitoring system, a plasma beam processing system, a horizontal printing table 4 for placing the mold to be formed, and a temporary fixing for temporarily fixing the mold base 3-1 of the mold to be formed. The mold to be formed includes a mold base 3-1 and a molding surface working layer 3-2 arranged on the mold base 3-1; the temporary fixing member is arranged on the horizontal printing table 4.

[0087] The plasma beam processing system consists of a plasma generator equipped with a shower head and used to generate plasma beams, a printing position adjustment device for adjusting the position of the plasma generator, and providing working gas for the plasma generator The gas supply device 1 is composed of a powder feeder 2 for continuously feeding printing materials into the plasma generator, and the plasma generator is located above the horizontal printing platform 4 . The gas supply device...

Embodiment 2

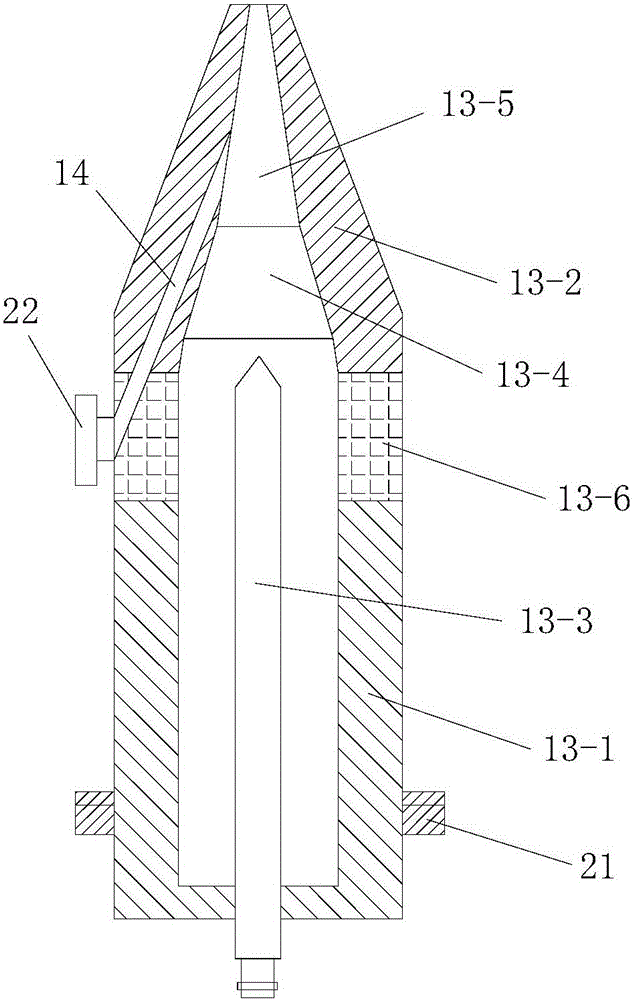

[0191] In this example, if Figure 7 As shown, the mold plasma 3D printing equipment used is different from Embodiment 1 in that: the nozzle 13-5 and the powder circulation channel 14 are arranged coaxially.

[0192] In this way, after changing the direction of the plasma beam through the nozzle 13-5, the thermal load impact of the plasma jet on the anode nozzle 13-2 can be effectively reduced, and the anode ablation condition is improved. At the same time, since the nozzle 13-5 is coaxially arranged with the powder circulation channel 14, the acceleration, heating and melting process of the powder will not be affected, and the use effect is very good.

[0193] In this embodiment, the structure, connection relationship and working principle of the remaining parts of the mold plasma 3D printing equipment are the same as those in Embodiment 1.

[0194] In this embodiment, the mold plasma 3D printing method adopted is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com