Method for constructing poured airtight walls of coal mines

A construction method and closed wall technology, which is applied to mining equipment, mining equipment, earthwork drilling and mining, etc., to achieve the effects of simple wall structure, improved efficiency, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

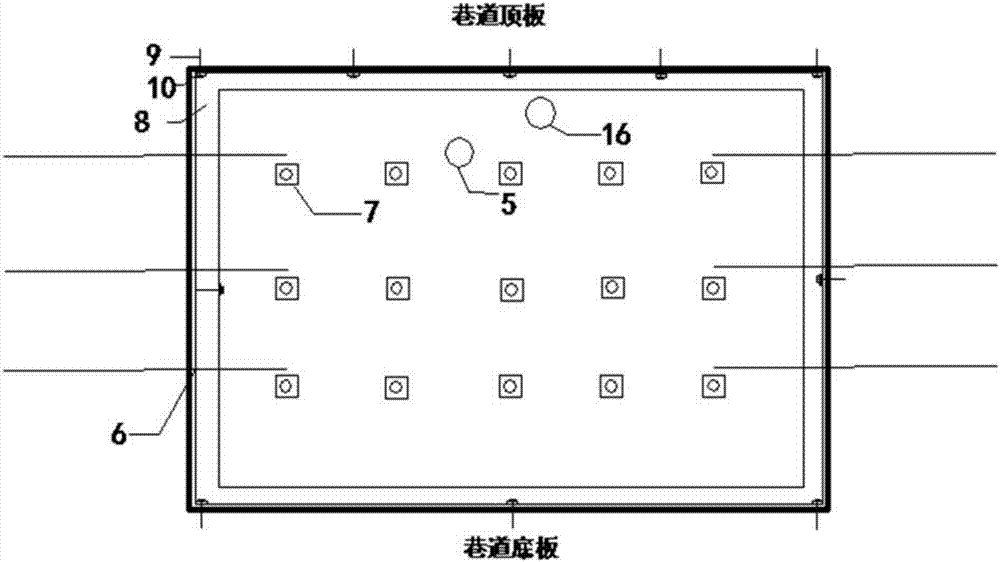

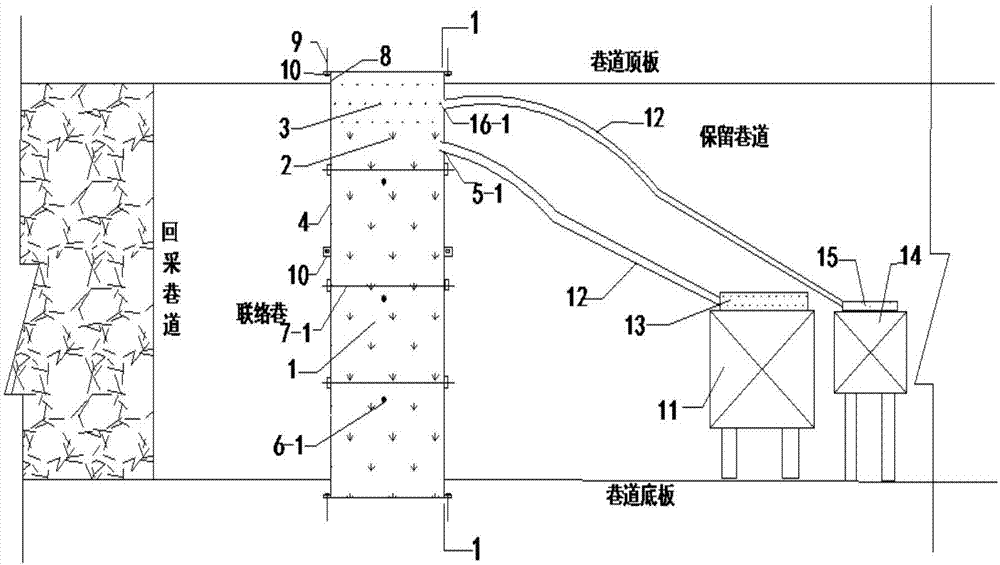

[0048] see figure 1 and figure 2 , the coal mine pouring airtight wall construction method of the present invention is specifically:

[0049] 1), the airtight wall is mainly composed of a flexible mold 4, a solidified filling body 2, and an expansion filling body 3;

[0050] 2), according to the size, shape and function of the airtight wall, make the corresponding flexible mold 4 in advance. The flexible mold 4 is composed of flame-retardant, anti-static and water-seepage fiber cloth, and the lower grouting hole 5 and the upper grouting hole are arranged on it. Hole 16, anchor rod hole 6, anchor bolt hole 7, mold fixing hole 10, pouring is divided into two stages, first pouring solidified filling body 2 to the lower part, and then pouring expansion filling body 3 to the upper part;

[0051] 3) According to the requirements, it is necessary to cut grooves 8 in the surrounding rock at the position of the airtight wall 1 in advance;

[0052] 4), the bolt holes 6 are laid in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com