Patents

Literature

292 results about "Contact effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The 'eye contact effect' is the phenomenon that perceived eye contact with another human face modulates certain aspects of the concurrent and/or immediately following cognitive processing.

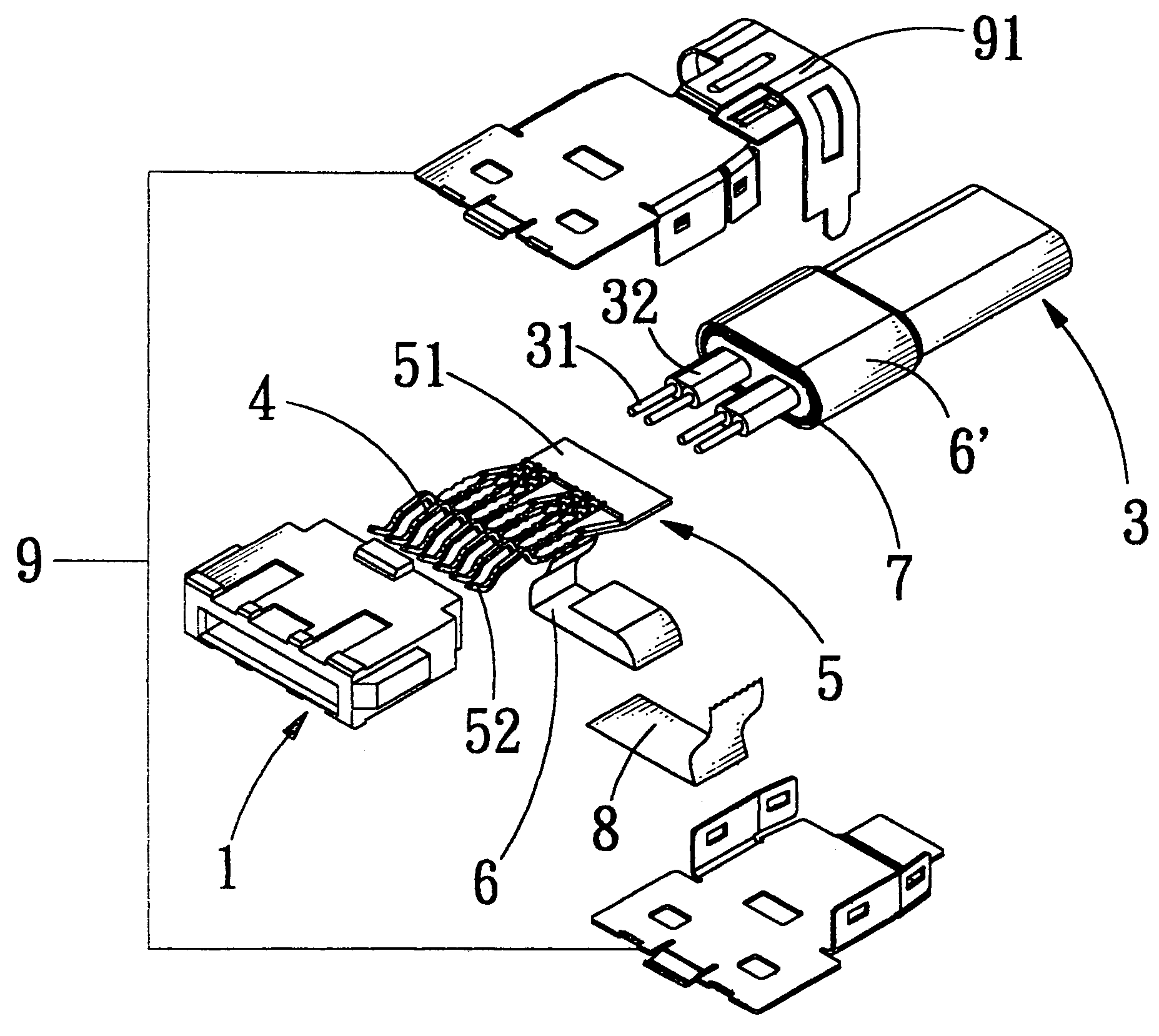

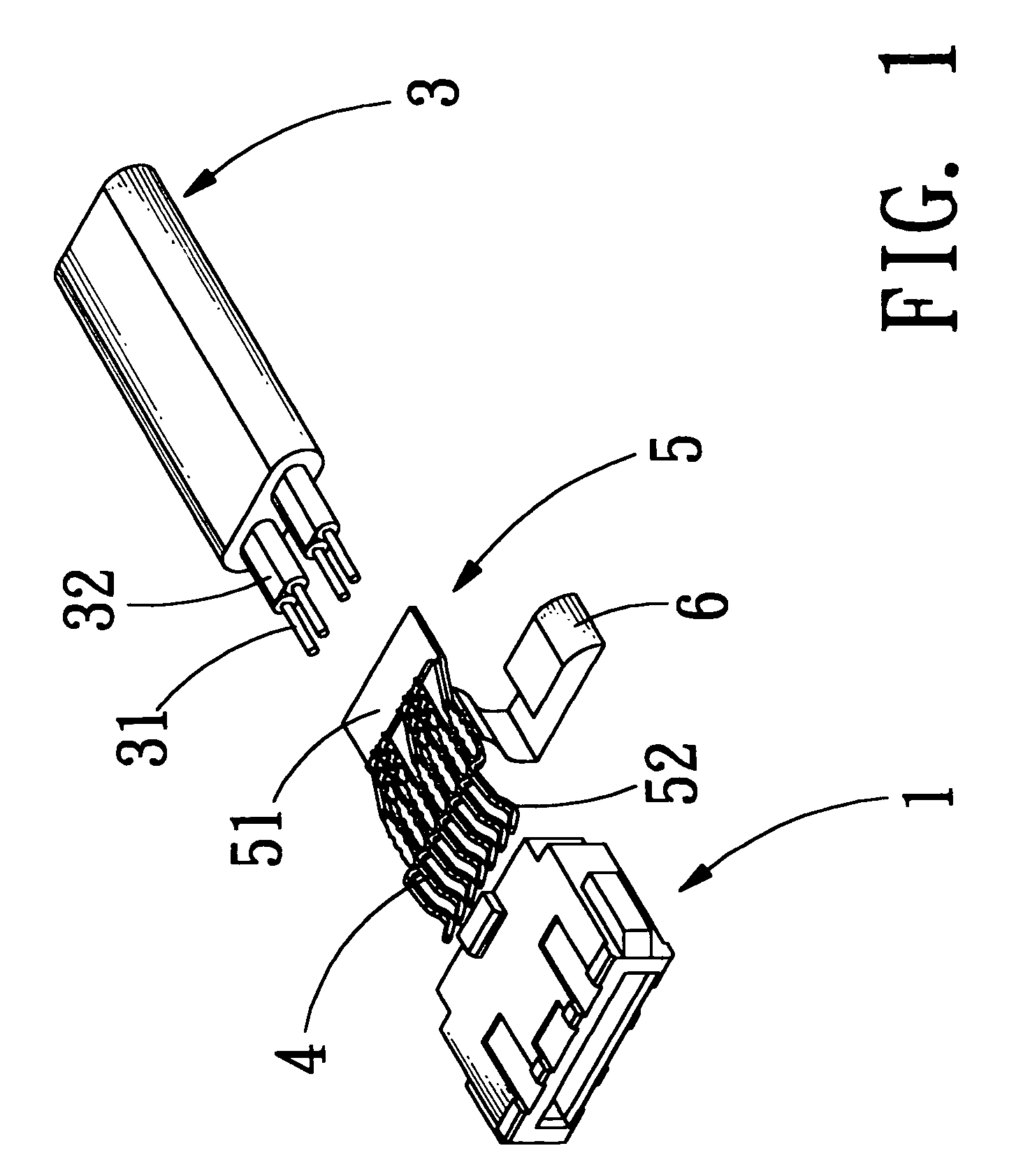

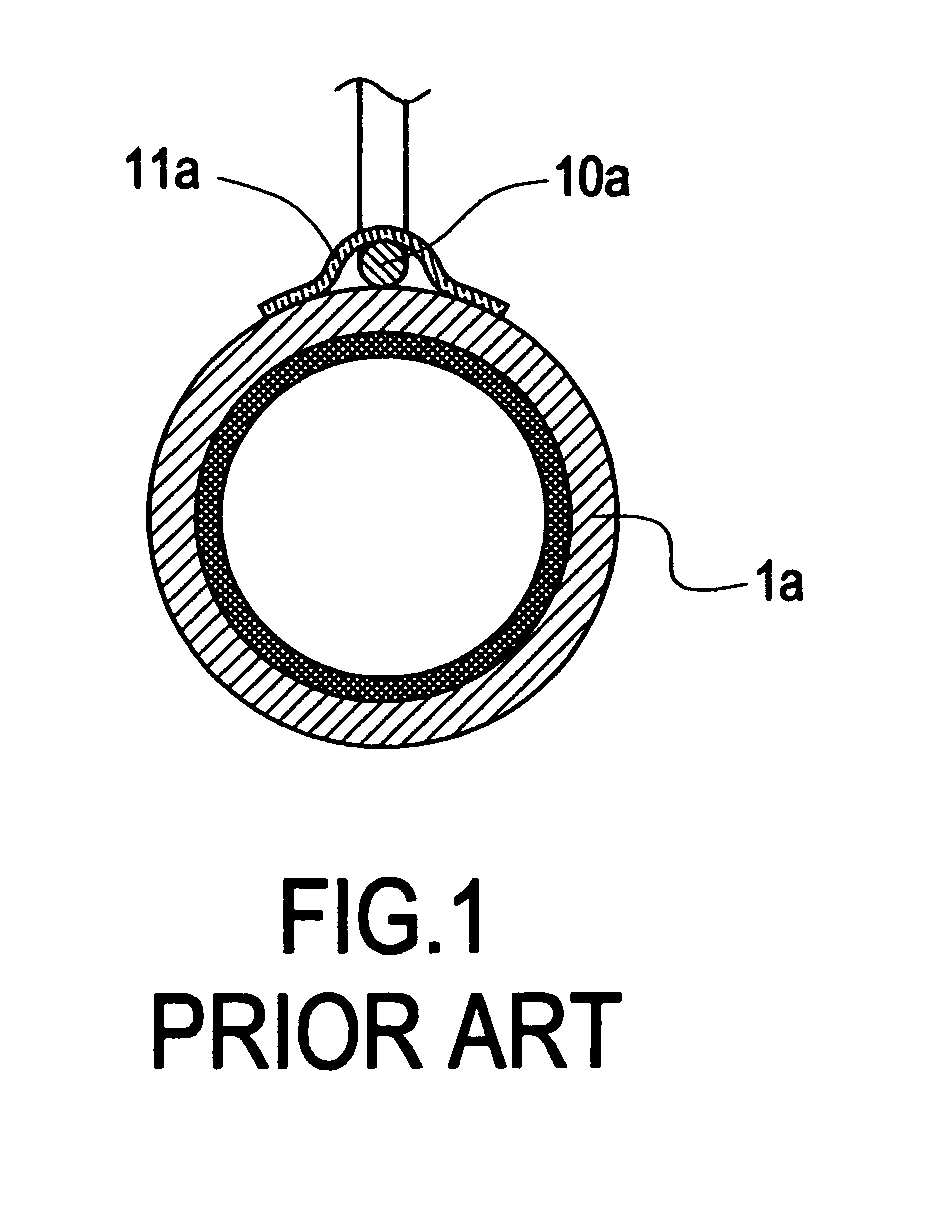

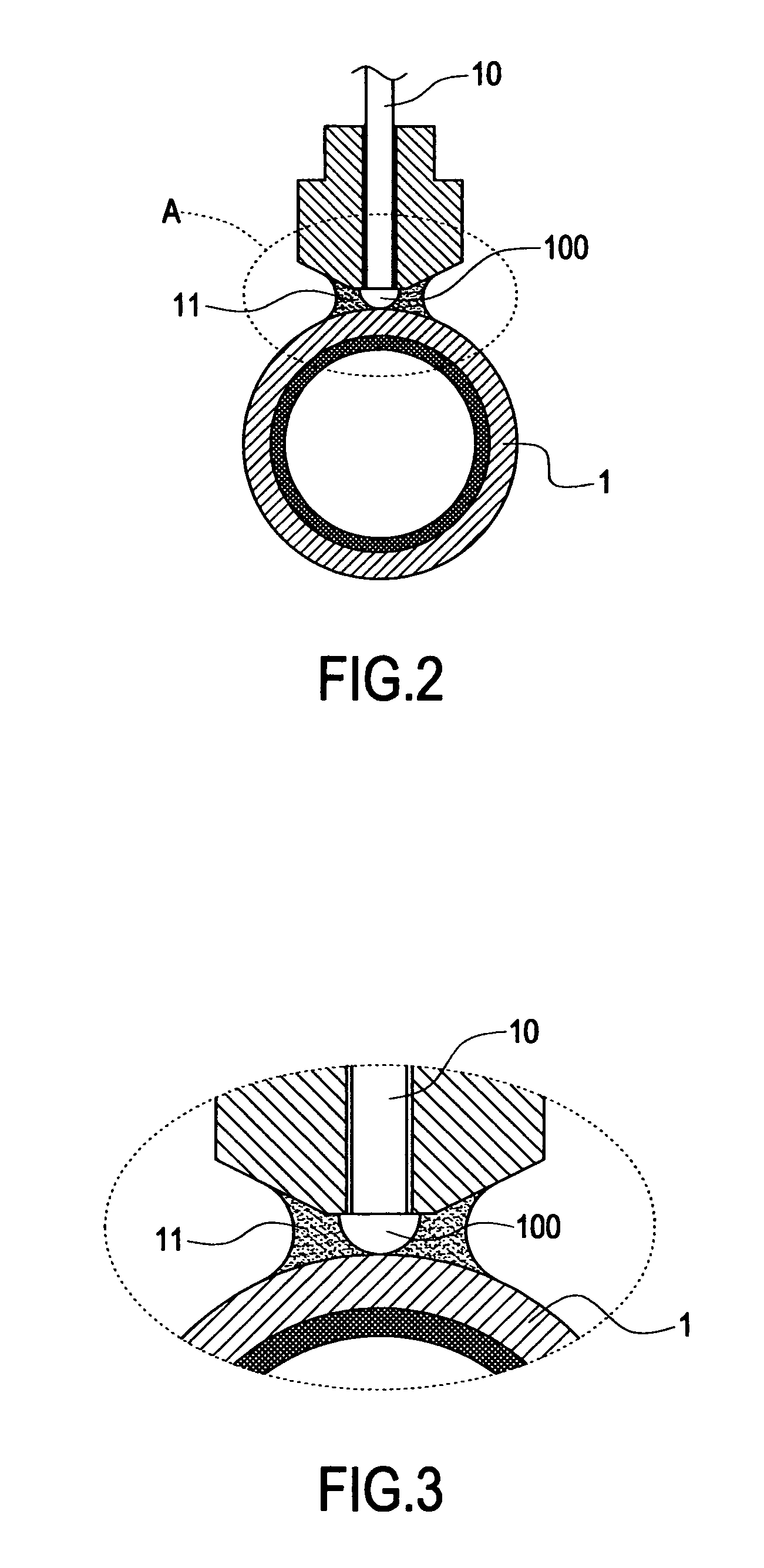

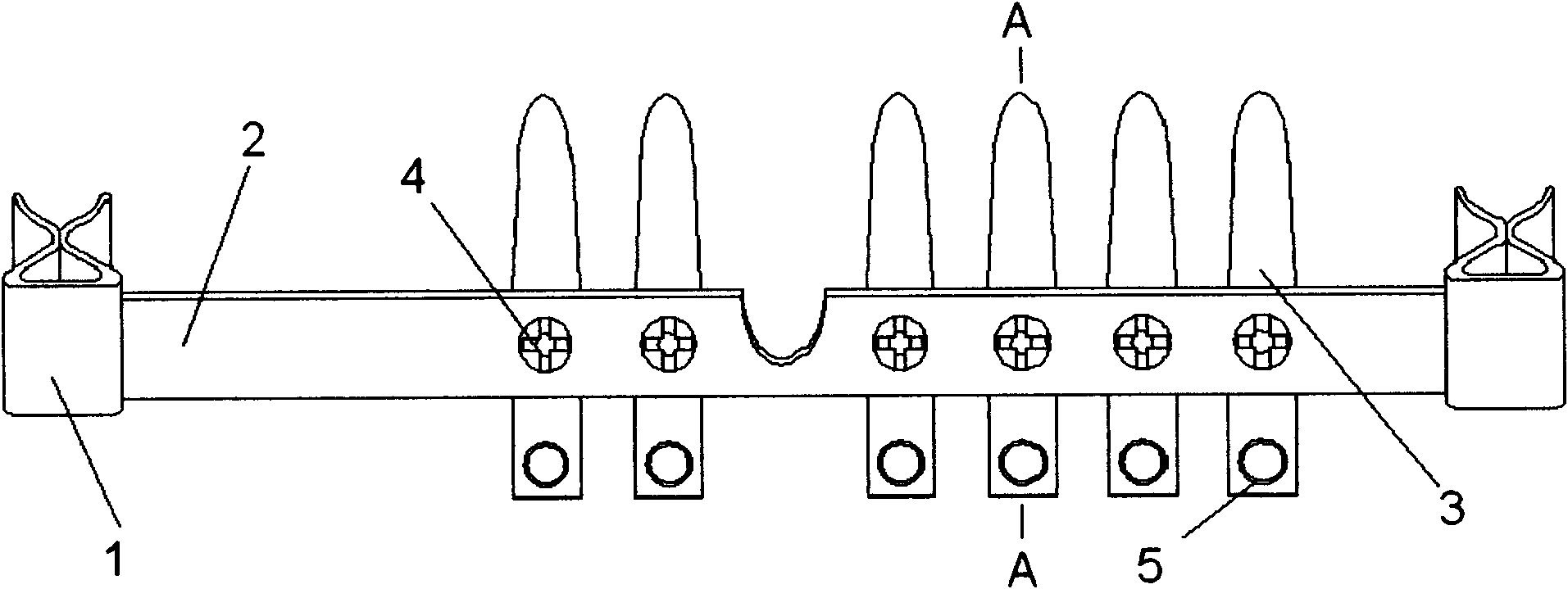

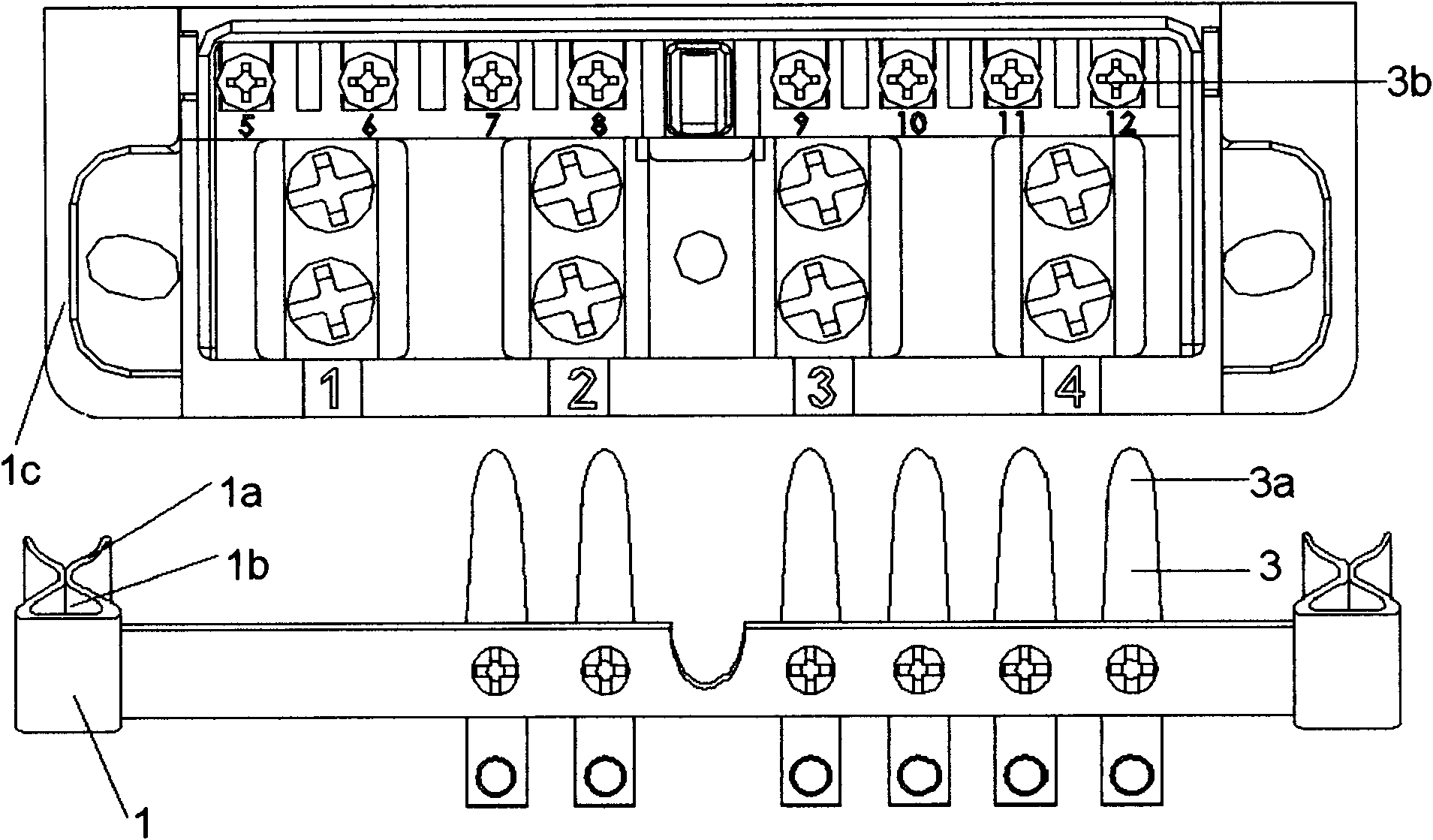

Electrical connector with grounding effect

InactiveUS7214097B1Reduce weldingImprove electrical characteristicsElectrically conductive connectionsTwo-part coupling devicesElectricityBody contact

The present invention relates to an electrical connector with grounding effect, which mainly has grounding part inserted inside the insulating body contacted with the jacket layer enclosed over the signal transmitting units with fixing and contacting effect for generating electrical characteristics, such that the cable assembly of the electrical connector has grounding effect without any grounding line positioned inside cable assembly; wherein, the grounding part has contacting part for providing the jacket layer to contact with, besides it further comprise predetermined grounding terminals extended directly from the grounding part for inserting into the insulating body; such that the cable assembly of the electrical connector of the present invention has grounding effect without any grounding line positioned inside the cable assembly; furthermore, it also can lessen the soldering process and prevent the mistaken probability of the soldering process generated such that the entire assembly process and the relative cost can be reduced.

Owner:ING SHANG LUN

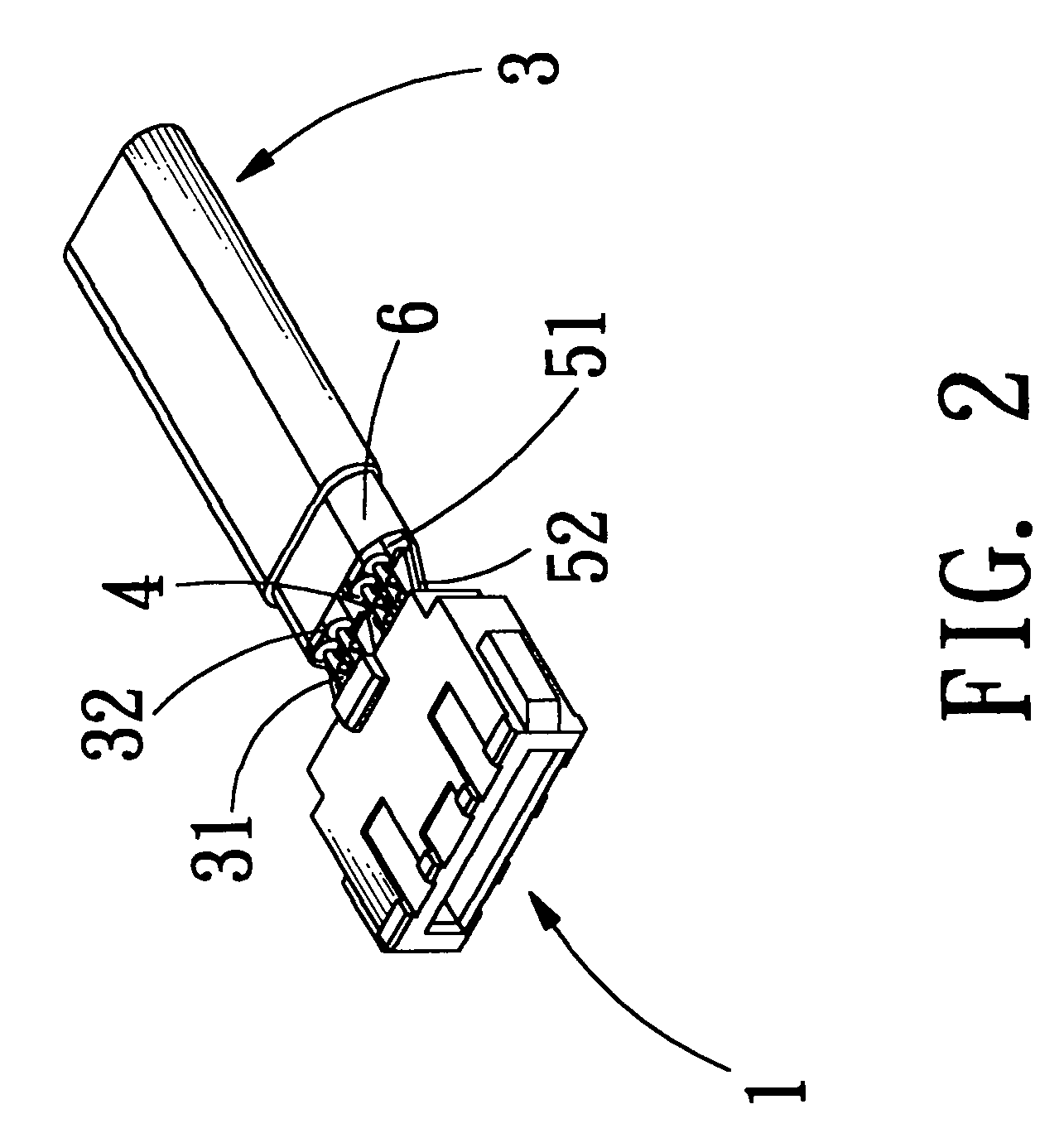

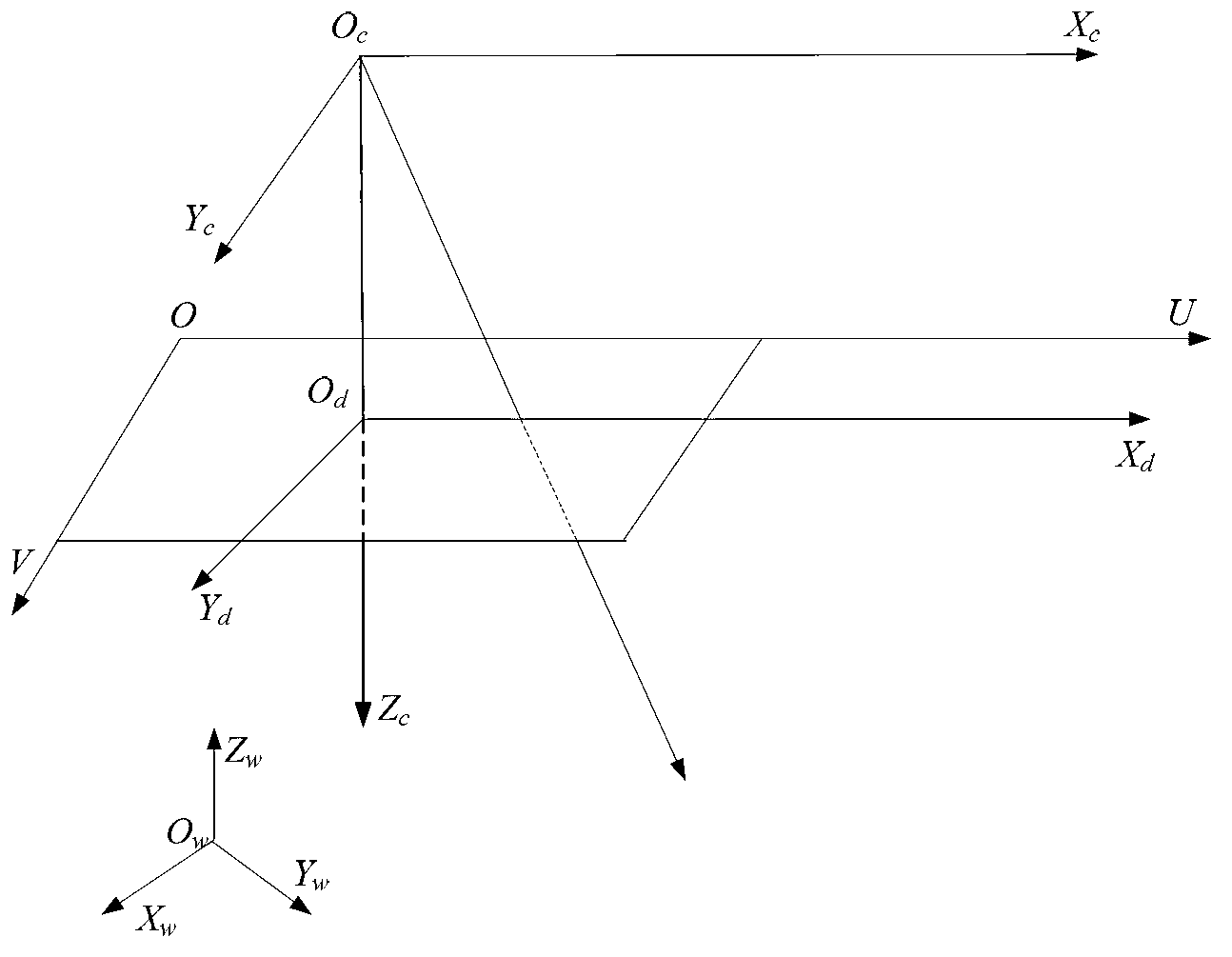

Measuring device and method for vibration of flexible cantilever on basis of machine vision

ActiveCN103267567ASimple detection operationProcessing small amount of dataSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansCamera lensMeasurement device

The invention discloses a measuring device and method for the vibration of a flexible cantilever on the basis of machine vision. The measuring device comprises a fixed bracket, the flexible cantilever, a camera bracket, a CCD (Charge Coupled Device) camera, a lens, a plurality of LED (Light-Emitting Diode) light-emitting tubes and a PC (Personal Computer), wherein one end of the flexible cantilever is fixed on the fixed bracket; all the LED light-emitting tubes are arranged on the upper surface of the flexible cantilever in sequence; the top of the fixed bracket is provided with the camera bracket; the CCD camera is fixed on the camera bracket and is provided with the lens; and an output port of the CCD camera is connected with the PC. The CCD camera measures each frame image of the vibration of the LED light-emitting tubes, and conveys the images to the PC; and the PC processes a detected image sequence, extracts the position of the mass center of the light spots of the LED light-emitting tubes and acquires the vibration displacement of all the LED light-emitting tubes and parameters for reflecting the low-frequency vibration of the flexible cantilever structure. The measuring device and method disclosed by the invention has the advantages that the non-contact effect is achieved, the measuring range is wide and the vibration characteristic of a measured object is not changed and the like, and can be widely applied.

Owner:NANJING UNIV OF SCI & TECH

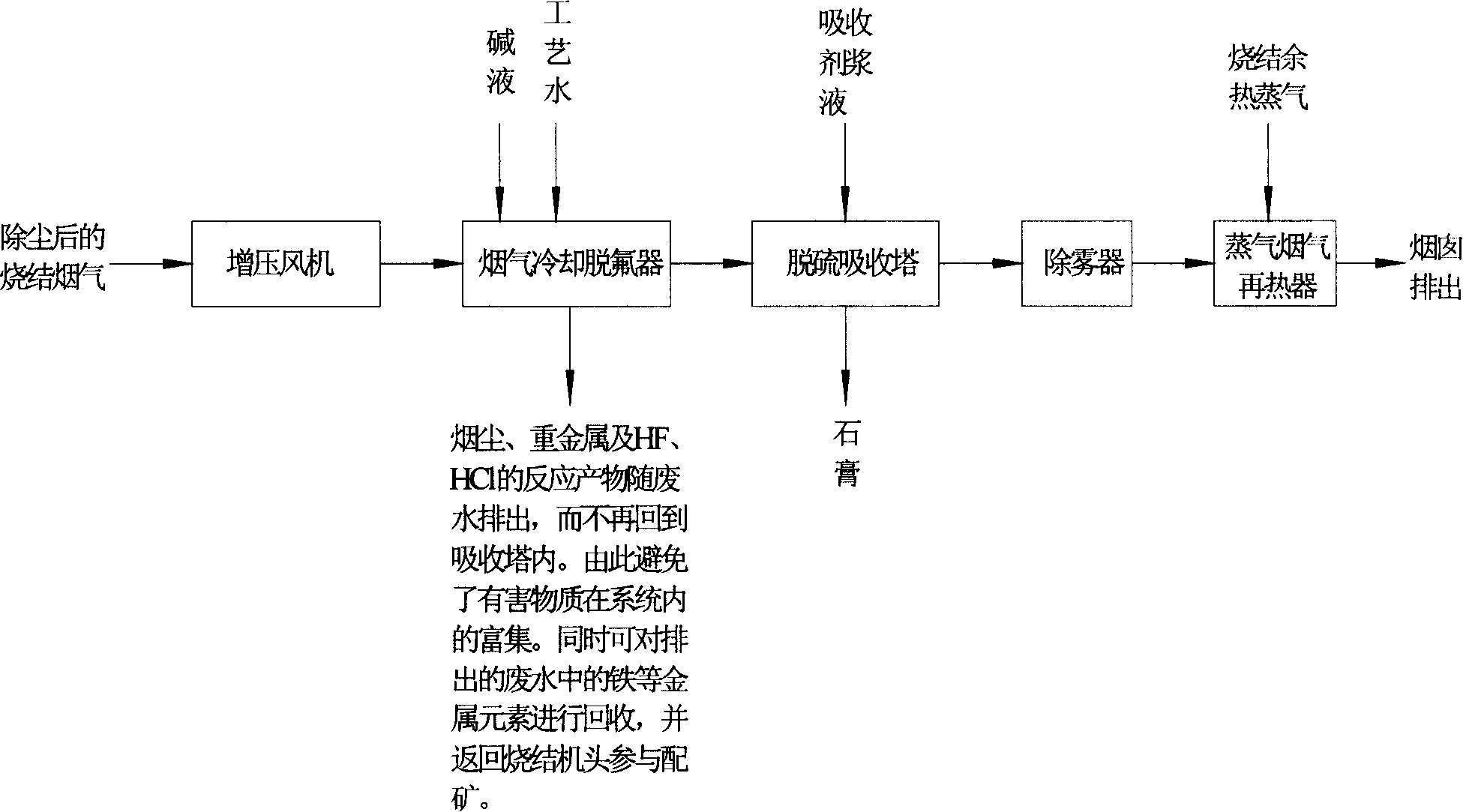

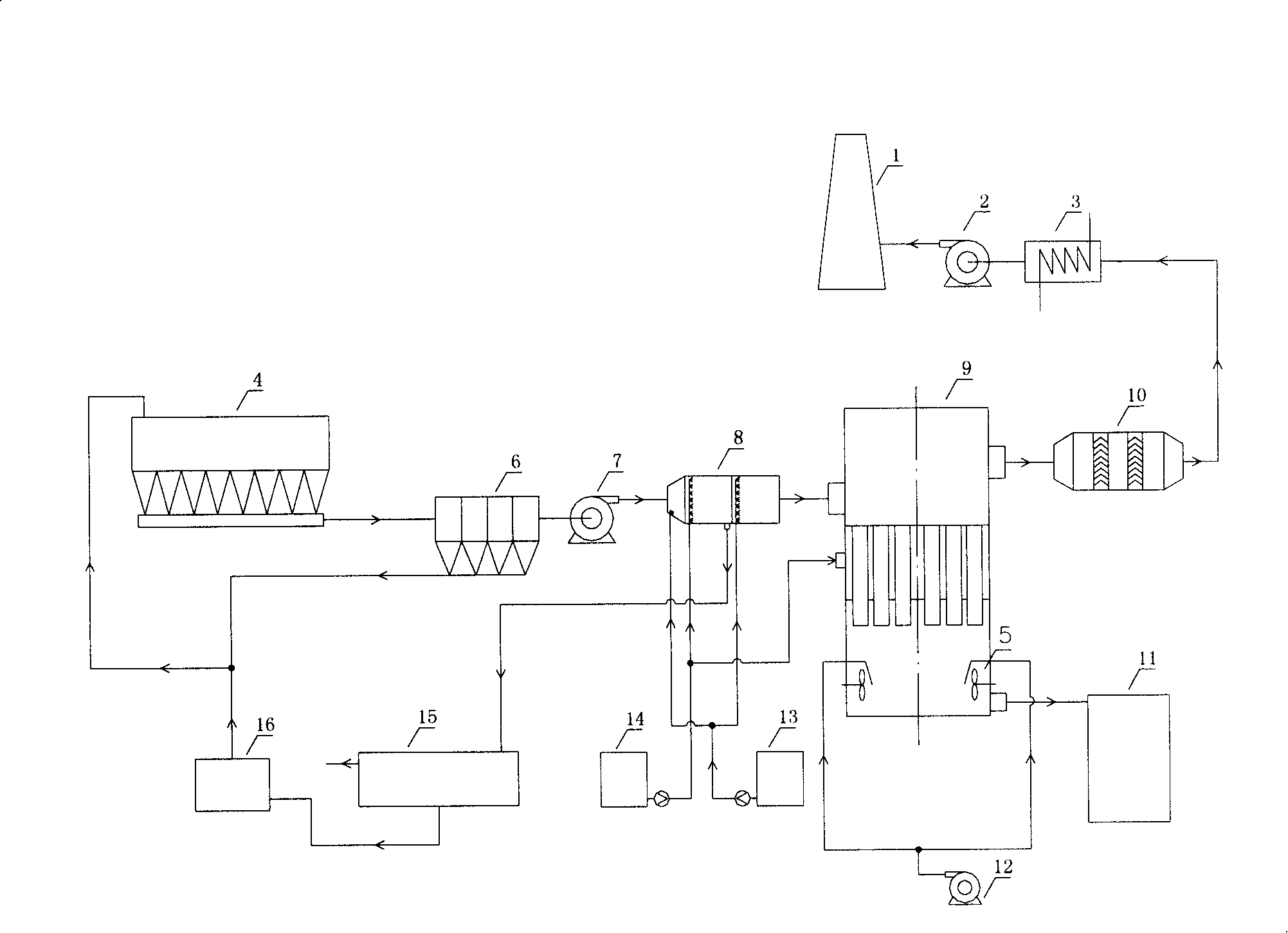

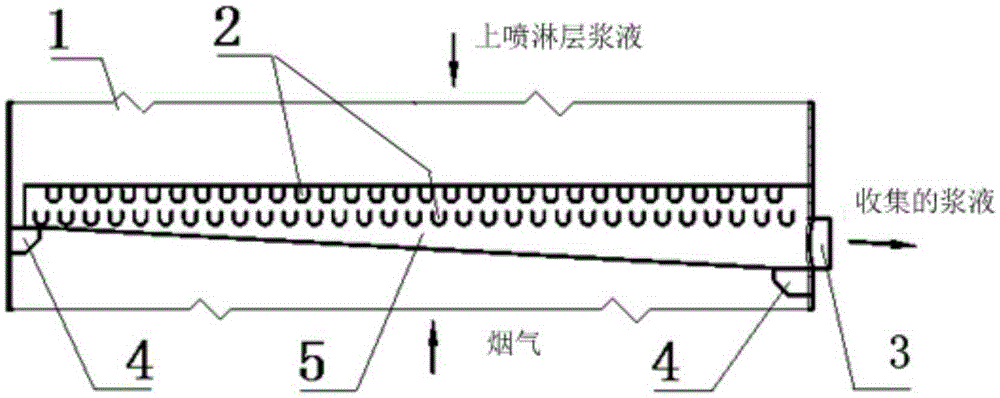

Sintering smoke wet method sulphur removing and dust removing technology

ActiveCN101168118AImprove removal effectGuaranteed thermal safetyGas treatmentDispersed particle separationFlue gasMetallurgy

The invention provides a wet desulfuration and dust-removing technology of sintered flue gas. After the pressure is boosted, the sintered flue gas is firstly processed cooling and defluorination, enabling the HF in the flue gas to be collected by alkaline solution and the temperature of the flue gas to be reduced below 80 DEG C, and then the flue gas enters a highly-effective desulfuration absorption tower. The flue gas is rotatablely punched into a slurry pool with high speed by the function of a rotary current device installed inside a projecting tube arranged inside the tower, and then the flue gas is crushed in the slurry and is fully mixed with the slurry, consequently the process of desulfuration and dust-removing is finished. The pure flue gas after being demisted is discharged from a chimney after being heated by the sintered steam. Above 95% desulfuration efficiency and 99% dust-removing efficiency can be realized by the desulfuration and dust-removing technology. The arrangement of a cooling defluorinated device ensures the hot safety property of the absorption tower and reduces the corrosive degree of the inner tower. The highly-effective desulfuration absorption tower is not provided with a slurry circulation pump, and no moving member is installed inside tower, thereby the contacting effect of gas and liquid is perfect. The reheating method by the sintered steam saves the normal GGH, increases the stability of the systematic operation, and reduces the systematic fabrication cost.

Owner:BAOSHAN IRON & STEEL CO LTD +1

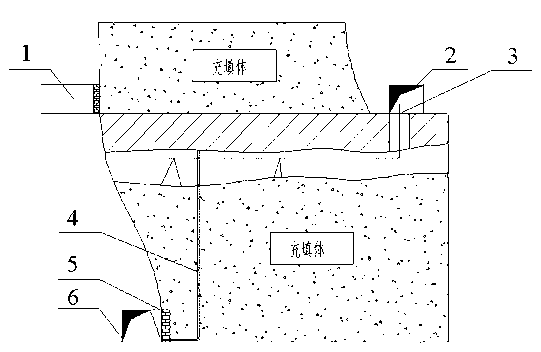

Roof contacting process in goaf filling treating procedure

InactiveCN103233771ALow costGuarantee normal productionMaterial fill-upEngineeringUltimate tensile strength

The invention relates to a roof contacting process in a goaf filling treating procedure and belongs to the technical field of mining engineering. The technical scheme of the roof contacting process in the goaf filling treating procedure includes: detecting a goaf to obtain the coordinate of the top point position of a top plate; drilling a filling drill hole at the top point position of the top plate, and performing cementing filling; installing a three-way plug valve on a filling pipe of the filling drill hole, and guiding a washing pipeline out on the filling pipe through the three-way plug valve; when the position with 1m away from the top point of the top plate is filled, extending the filling pipe to the position farthest from the filling drill hole, and simultaneously, arranging a 1-1.5m temporary retaining wall on the filling drill hole portion; when cement body is full, continuing to fill; and finally opening the three-way plug valve, guiding water away through the washing pipeline and finishing the filling roof contacting work. The roof contacting process is particularly suitable for filling the goaf generated during the filling exploitation process afterwards, is good in filling roof contacting effect and low in working intensity, saves filling roof contacting cost, achieves the roof contacting maximumly, is high in roof contacting efficiency, and ensures normal production of mines.

Owner:HEBEI IRON & STEEL GRP MINING +2

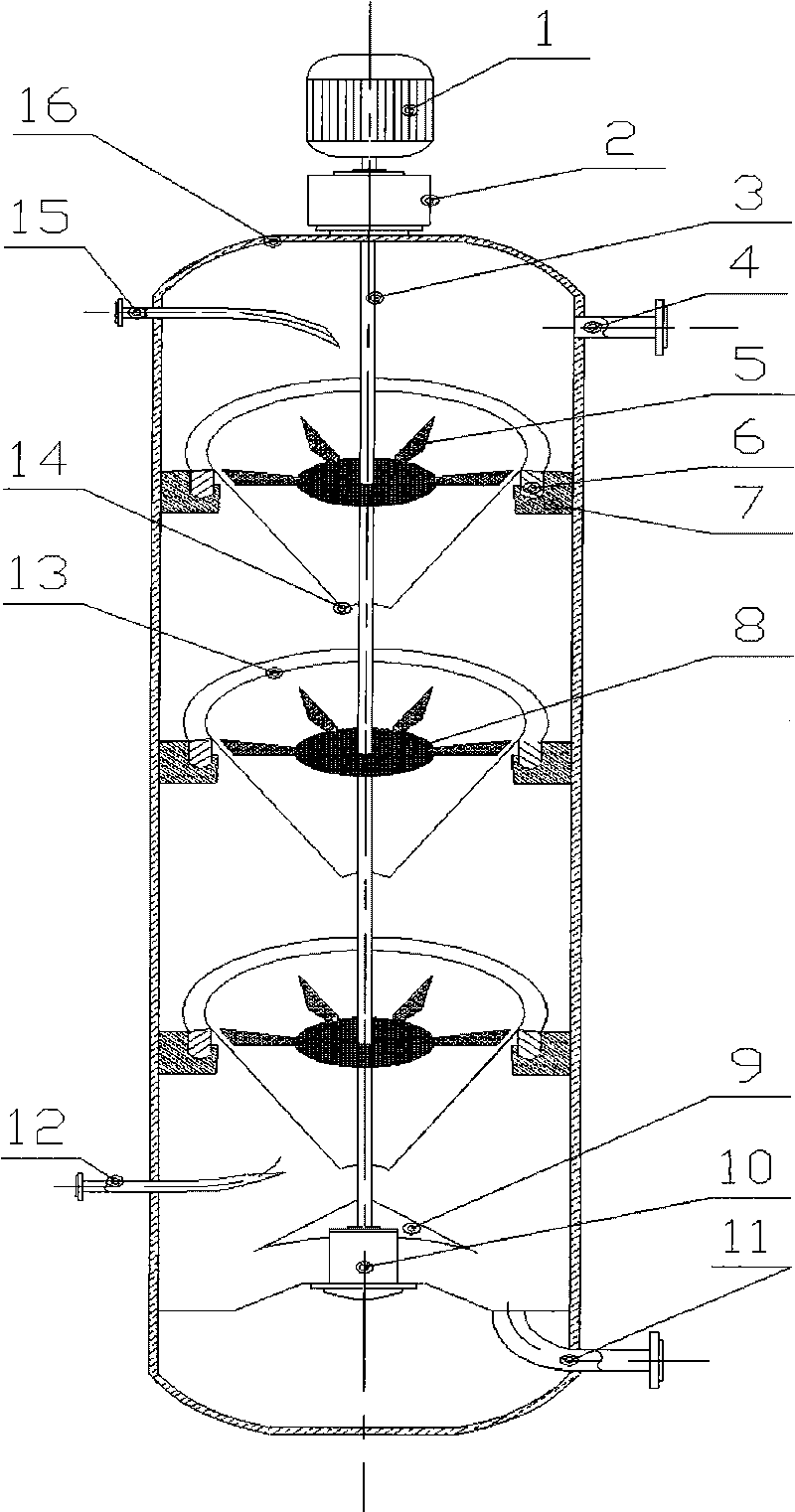

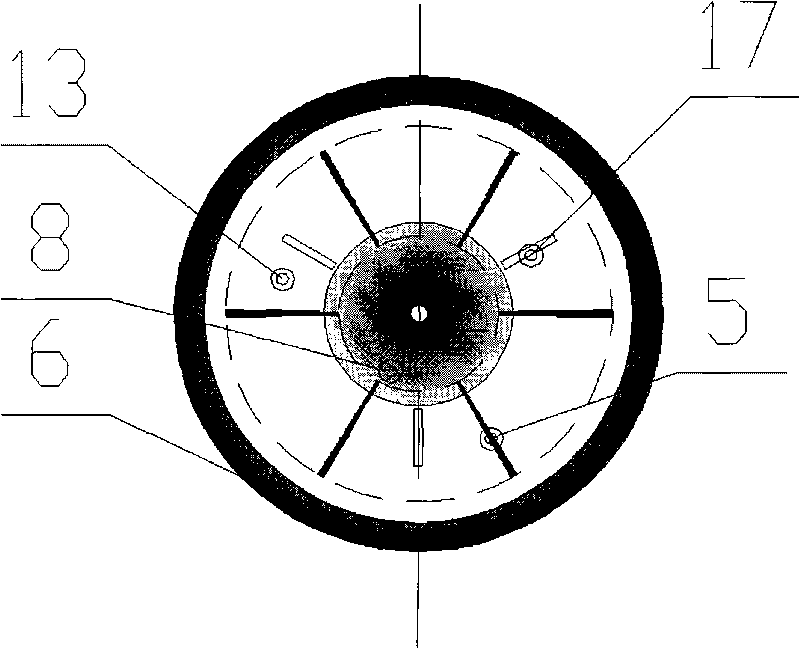

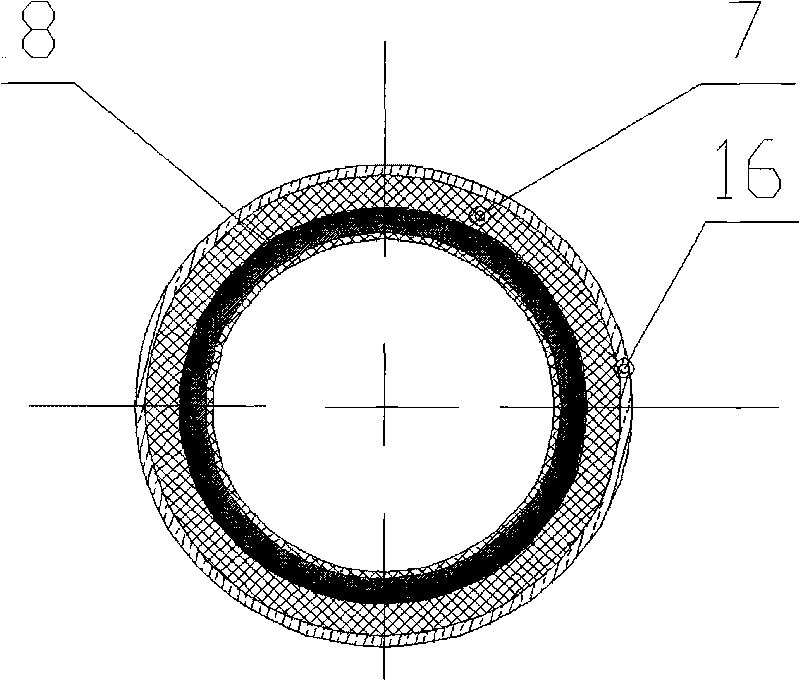

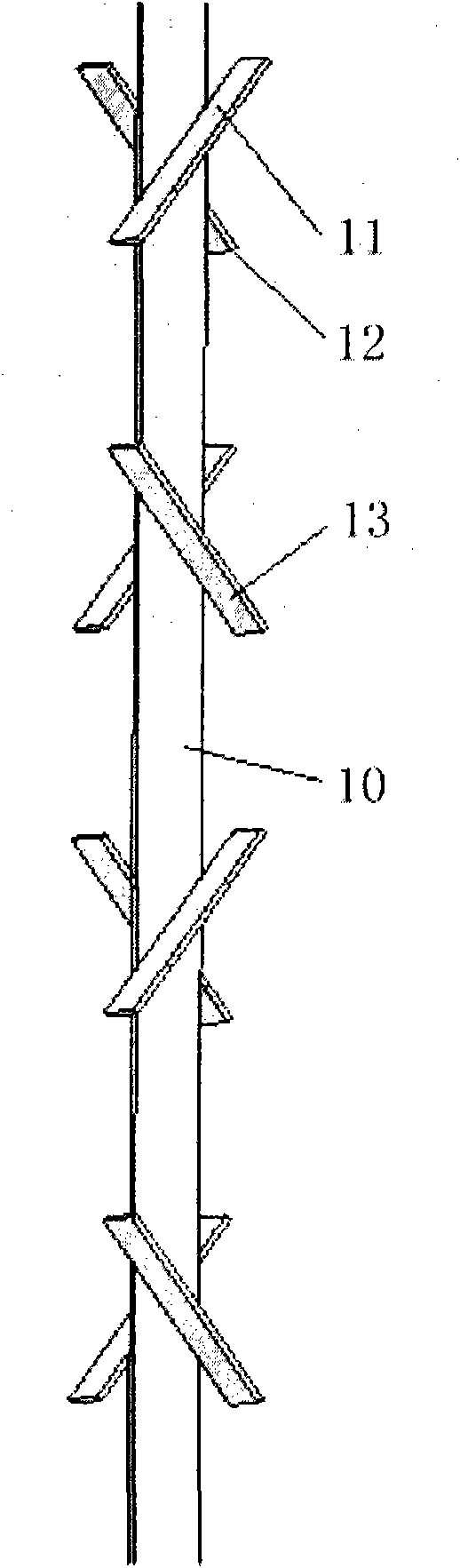

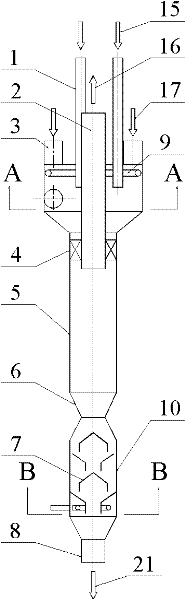

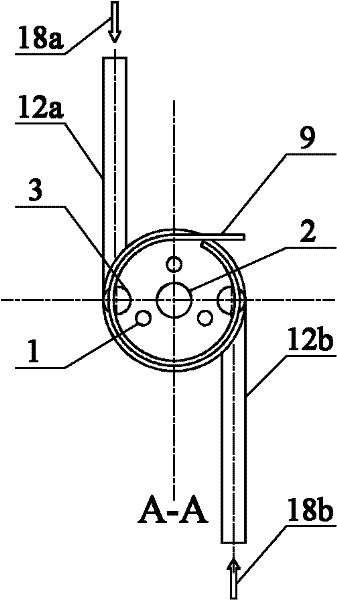

Dynamic rotary rotational flow plate device for strengthening transmission

ActiveCN101716448ASolve AbsorbencyAddress reactivityDispersed particle separationChemical/physical/physico-chemical stationary reactorsEngineeringSolid particle

The invention relates to a dynamic rotary rotational flow plate device for strengthening transmission. The device mainly comprises a tower body and a dynamic rotary rotational flow plate, wherein the tapered rotational flow plate is internally provided with a blade and a blind plate; one end of the blade is welded on the inner wall of the rotational flow plate, while the other end is welded on the blind plate; the blind plate is fixed on a stirring shaft driven by a motor; the side wall of the rotational flow plate is provided with an air inlet hole, and the bottom is provided with a liquid outlet; and the rotational flow plate is sealed with the tower body. The rotational flow plate can be driven by the shirring shaft to rotate together, which increases the gas-liquid contact effect and avoids the deposition of solid particles in a system, thus the device is suitable for absorption, separation and reactions of systems containing solid particles (such as catalysts, and the like) and high-viscosity fluid, can effectively increase the gas-liquid mixing effect, and greatly relieve the corrosion of the fluid to the device. The device has convenient operation and stable running, can besuitable for various materials and systems and has wide industrial application values.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

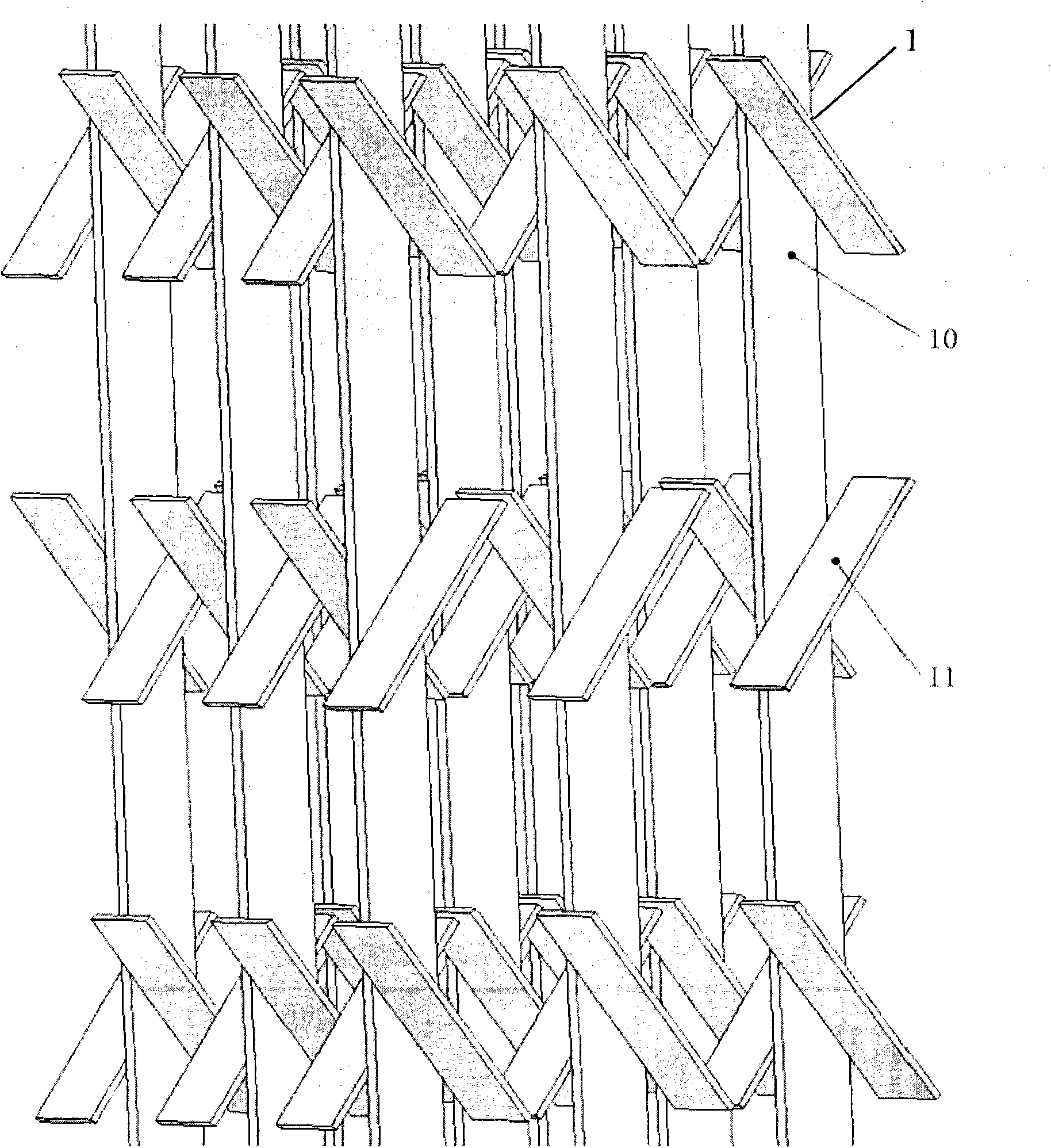

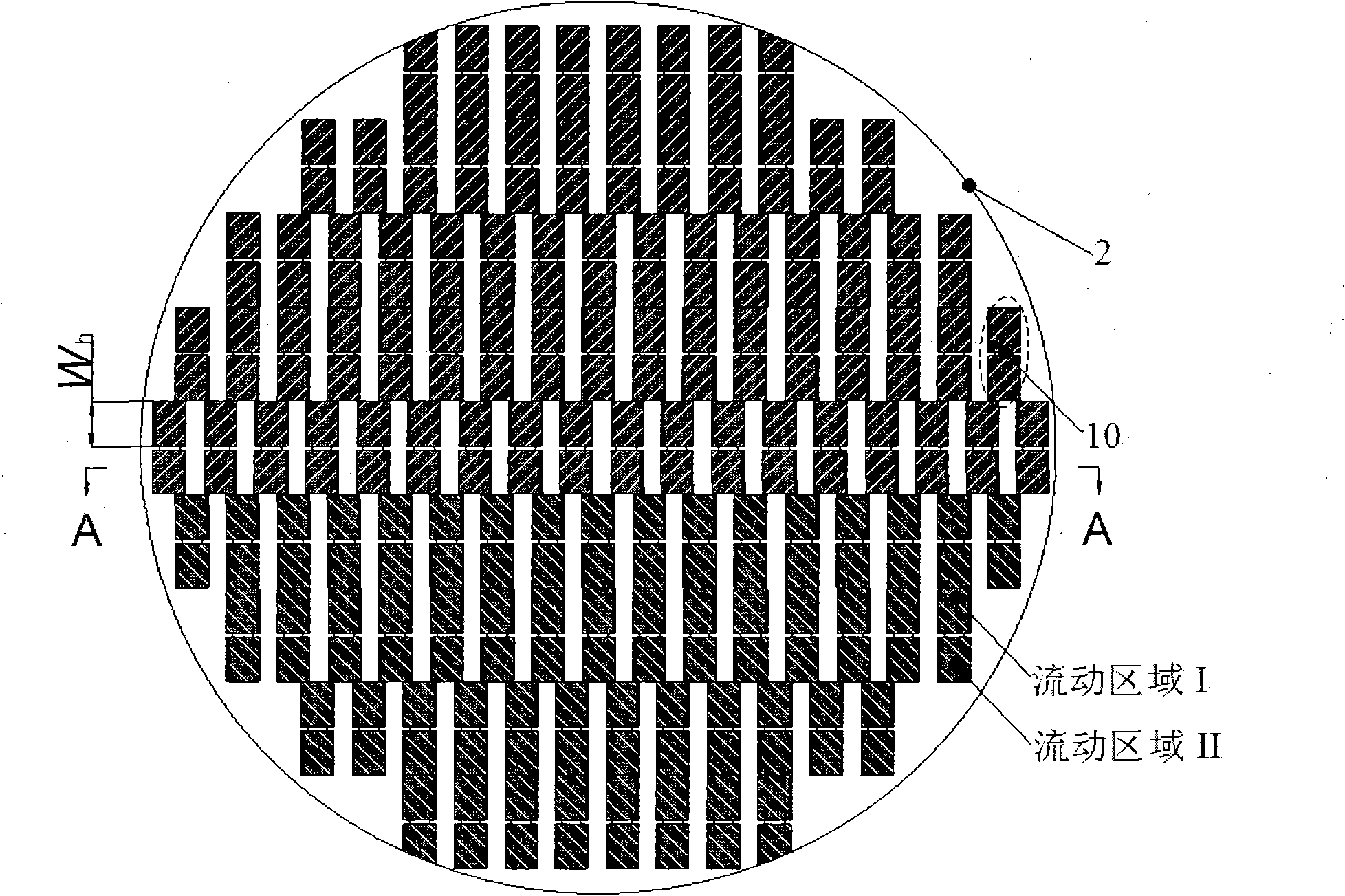

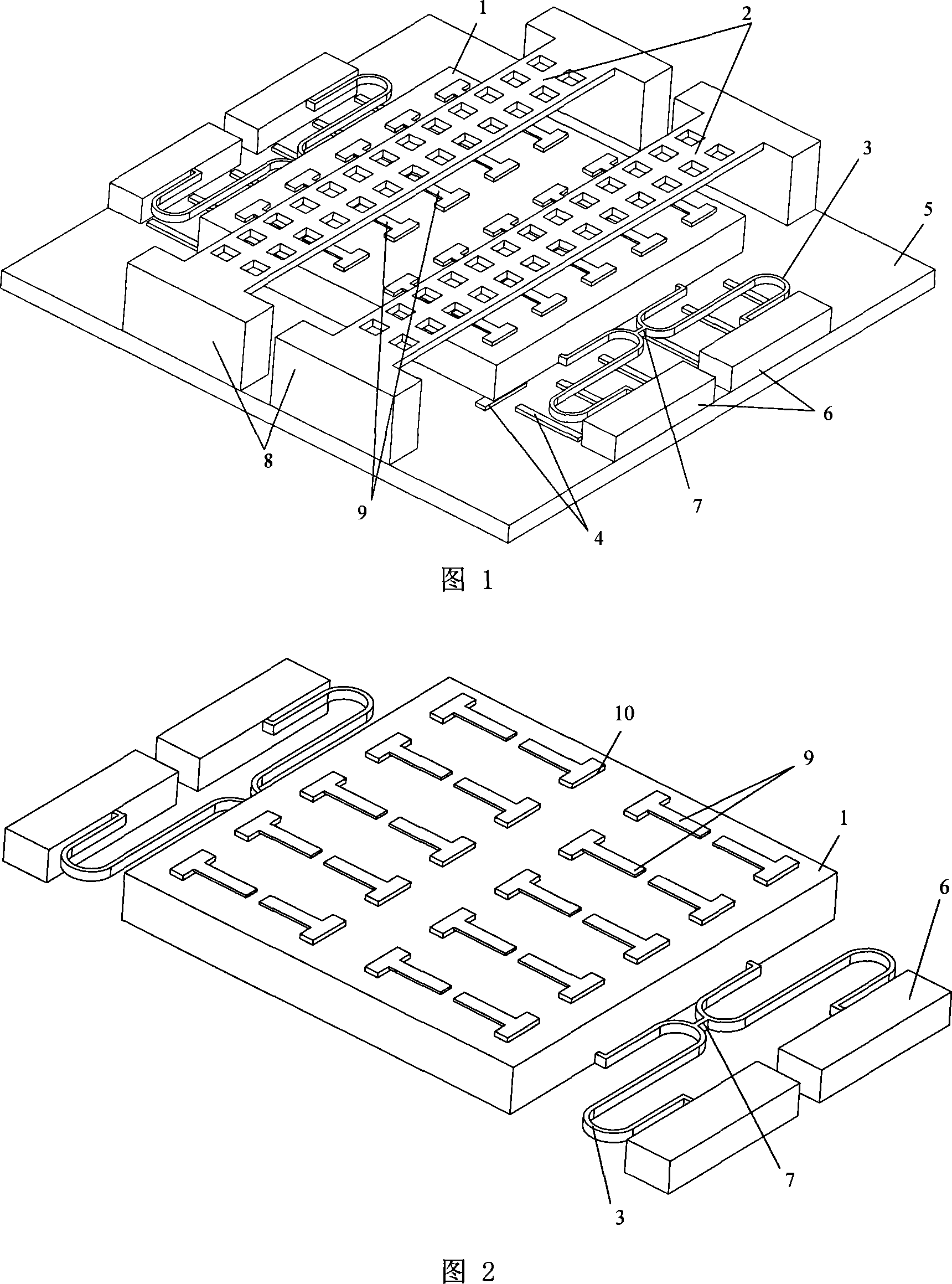

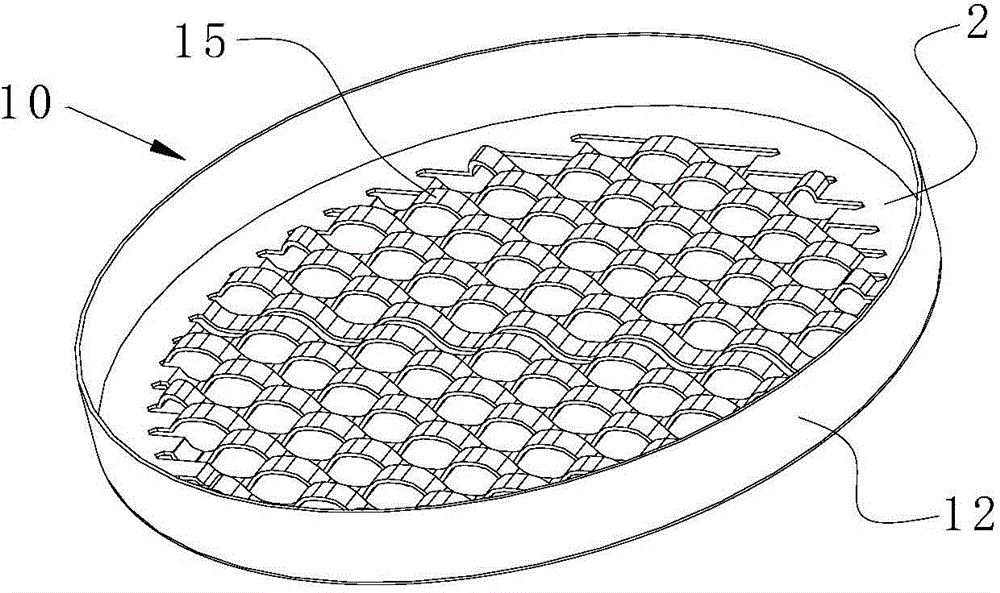

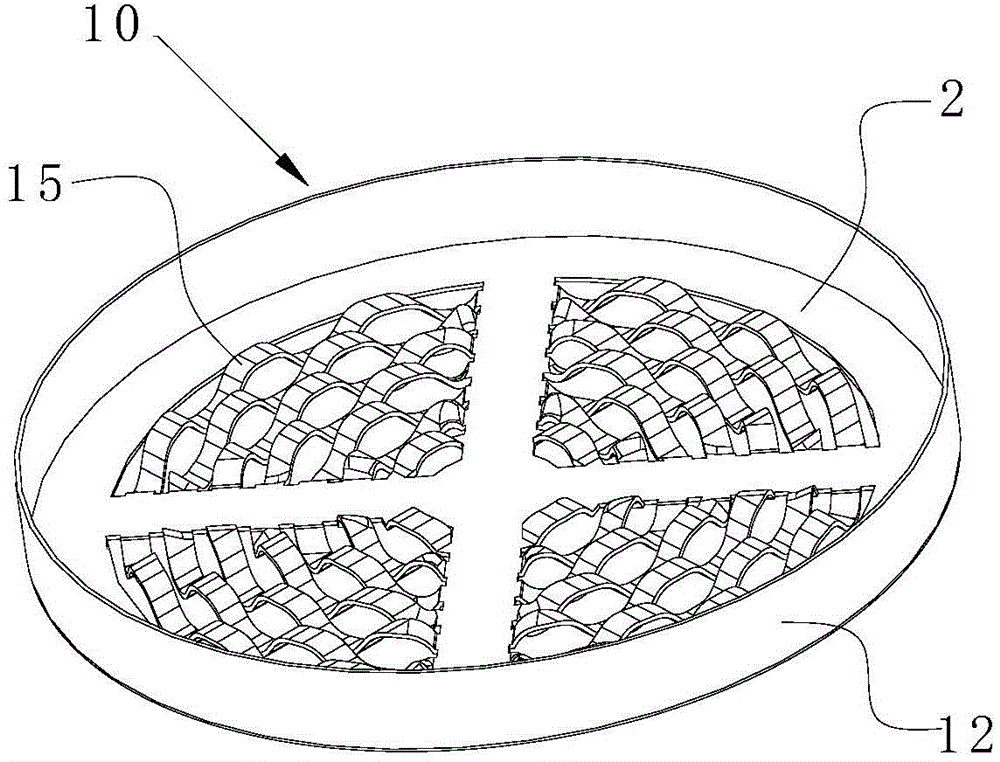

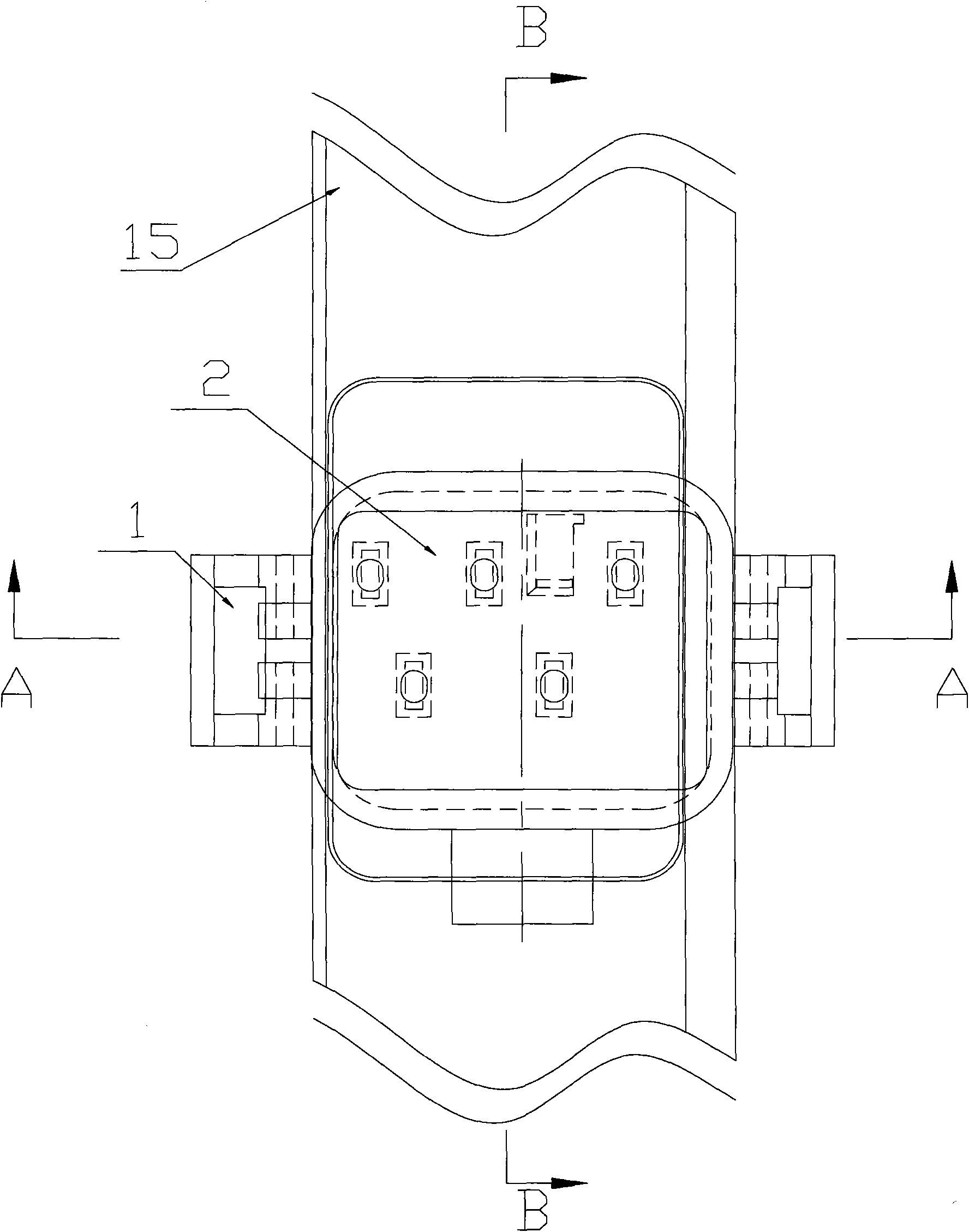

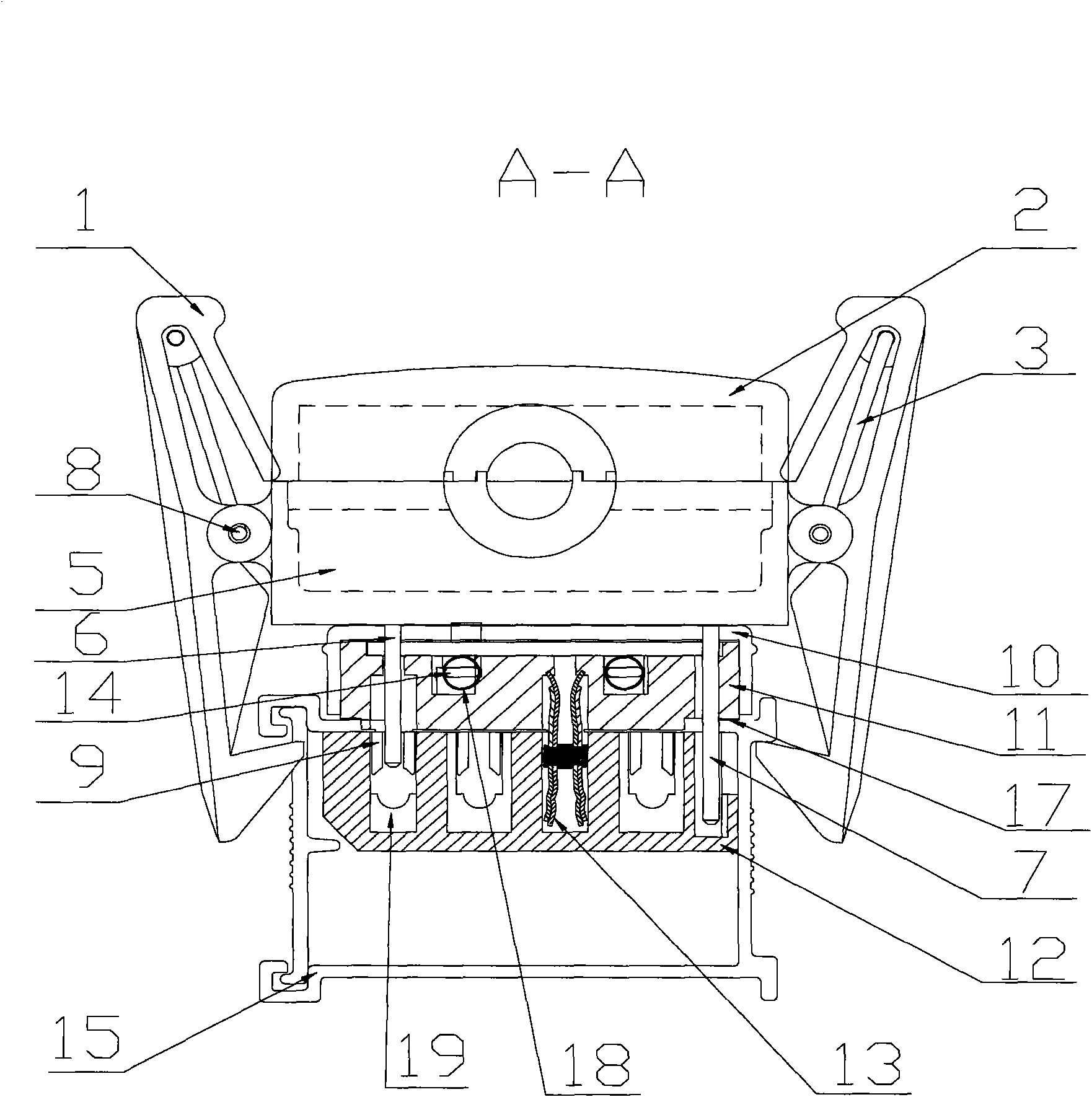

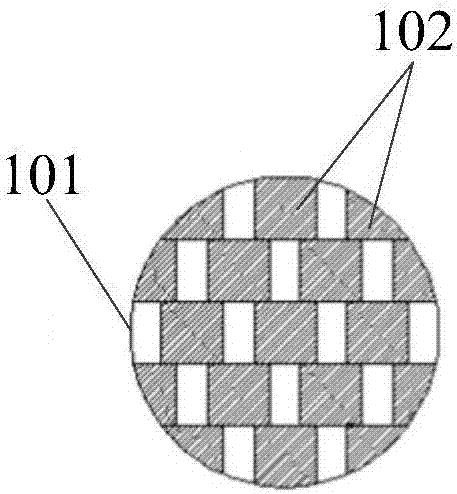

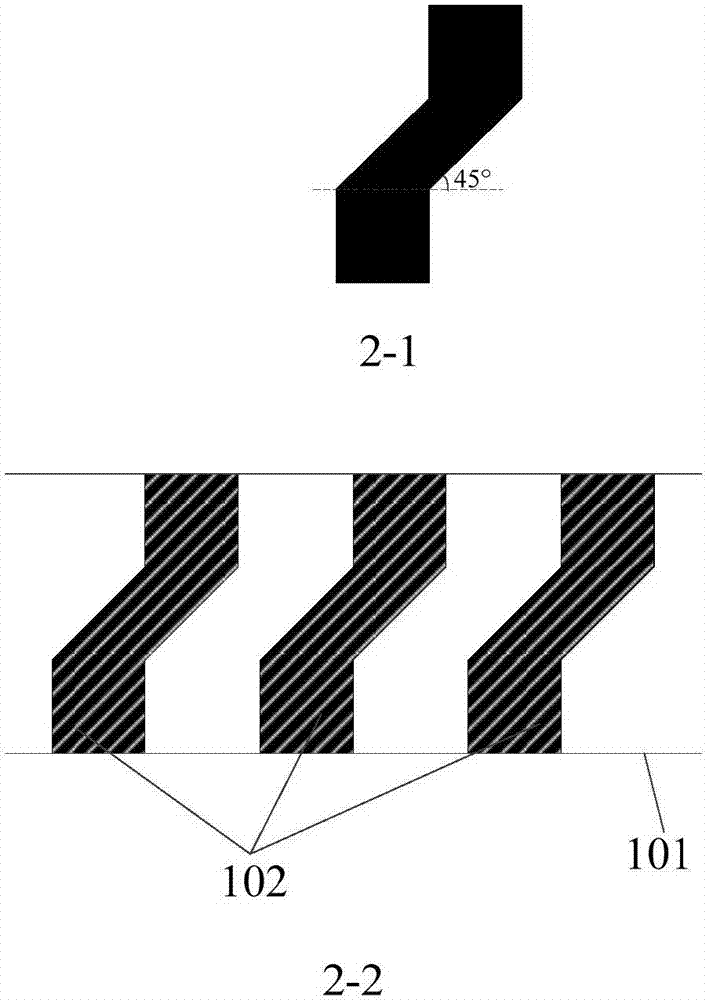

Composite inner component for gas-solid fluidized bed

ActiveCN101912753ASuppress backmixingImproved dwell time distributionChemical/physical/physico-chemical processesGas solidFluidized bed

The invention provides a composite inner component for a gas-solid fluidized bed, which comprises a plurality of component group units which are vertically arranged in parallel, wherein each component group unit comprises a vertical component, both sides of each vertical component are respectively provided with a plurality of inclined guide vanes, and the inclination directions of the upper and lower adjacent guide vanes on the same side are opposite, so that gas-phase and solid-phase media flow in a zigzag mode when passing through the vertical components; and both sides of the vertical components on the same height are provided with two guide vanes which are basically symmetric, and the inclination directions of the two guide vanes are opposite, so that the gas-phase and solid-phase media flow in a crossed mode when passing through the two vanes. The inner component can effectively enhance the contact effect of gas and solid in the fluidized bed and inhibit the back mixing of gas phase and solid phase. The inner component is applicable to wider operation range, and is more flexible to arrange and convenient to install, overhaul and reform in the practical industrial fluidized bed. The invention also provides a gas-solid fluidized bed provided with the inner component.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

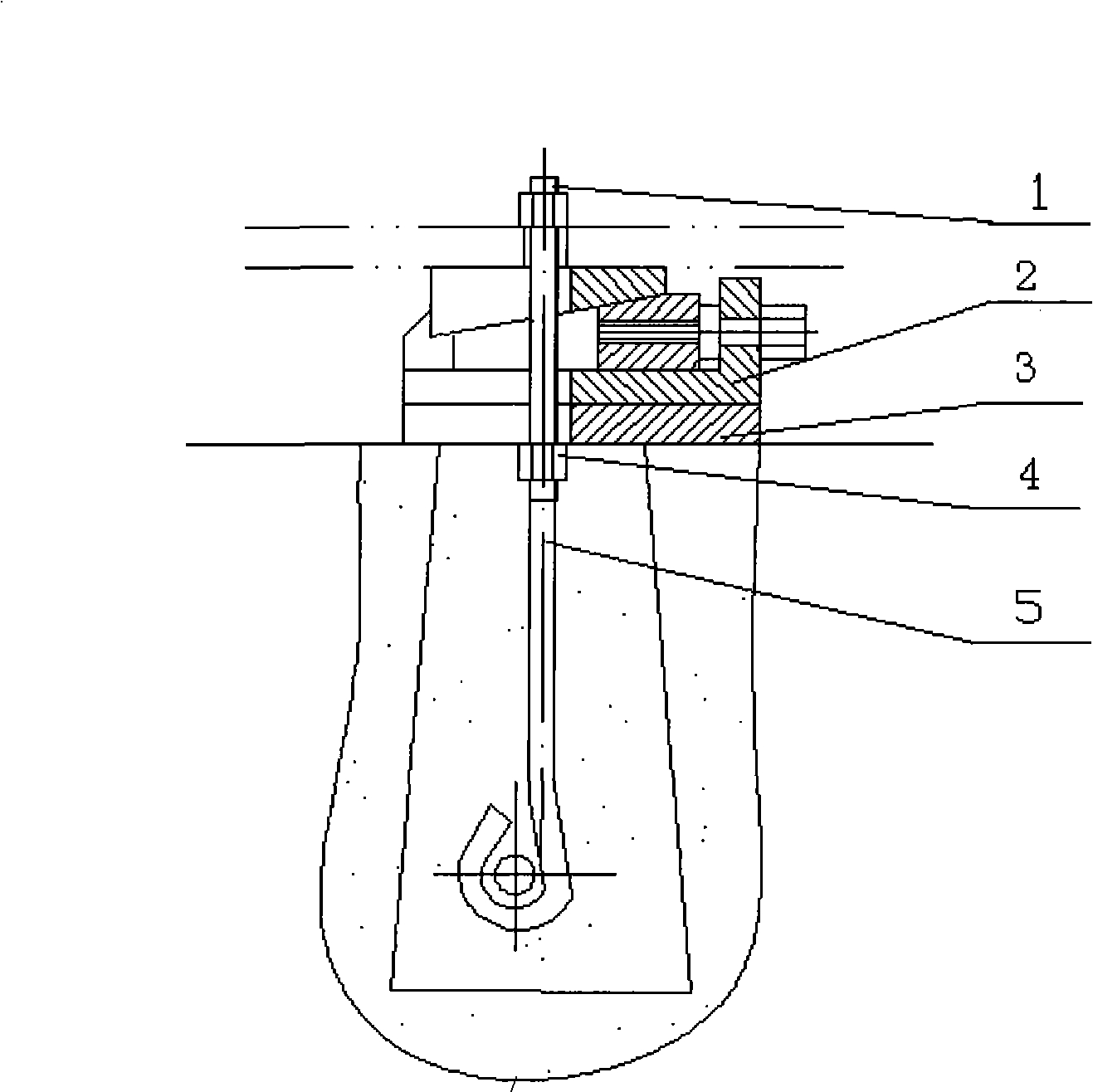

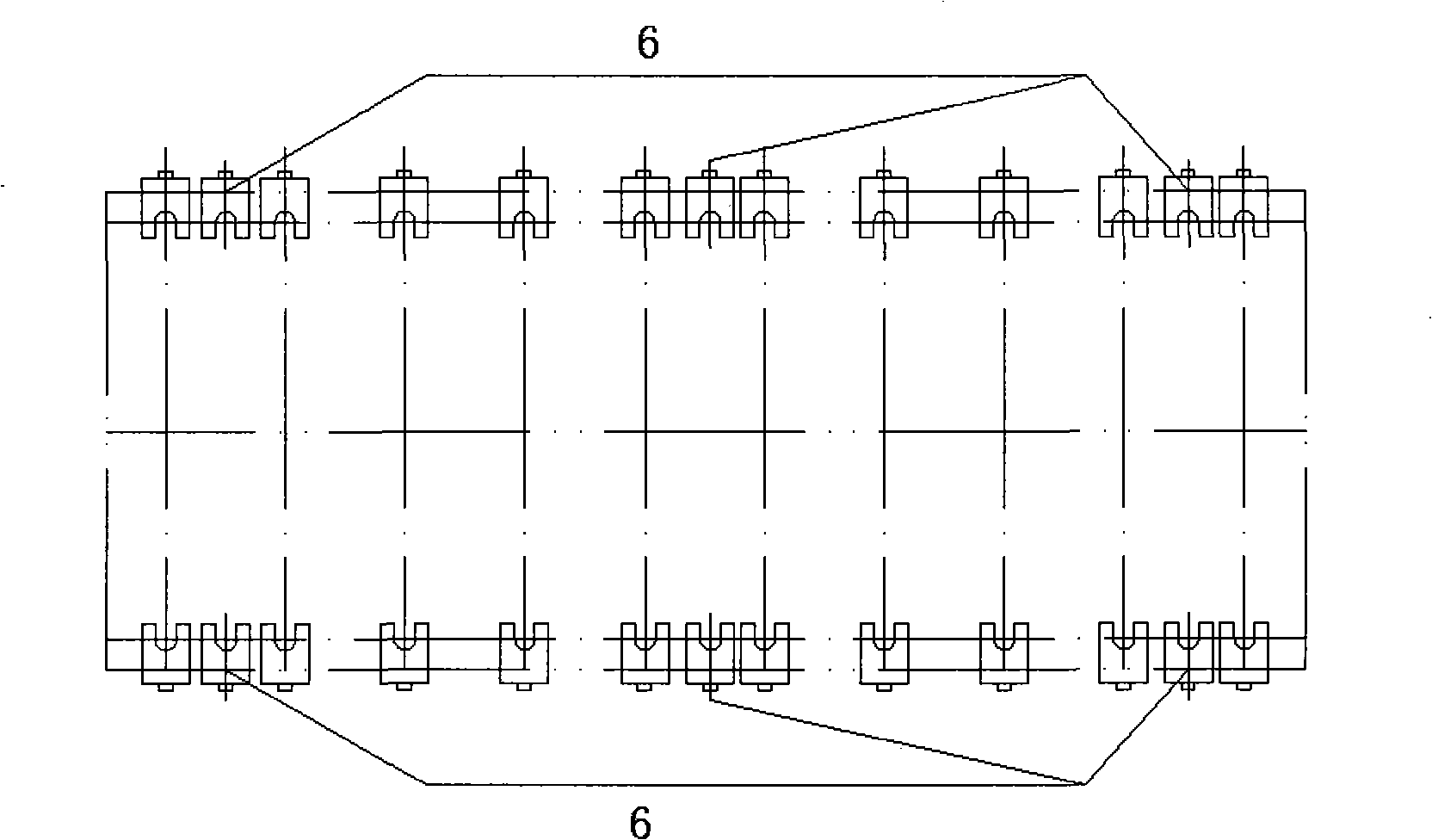

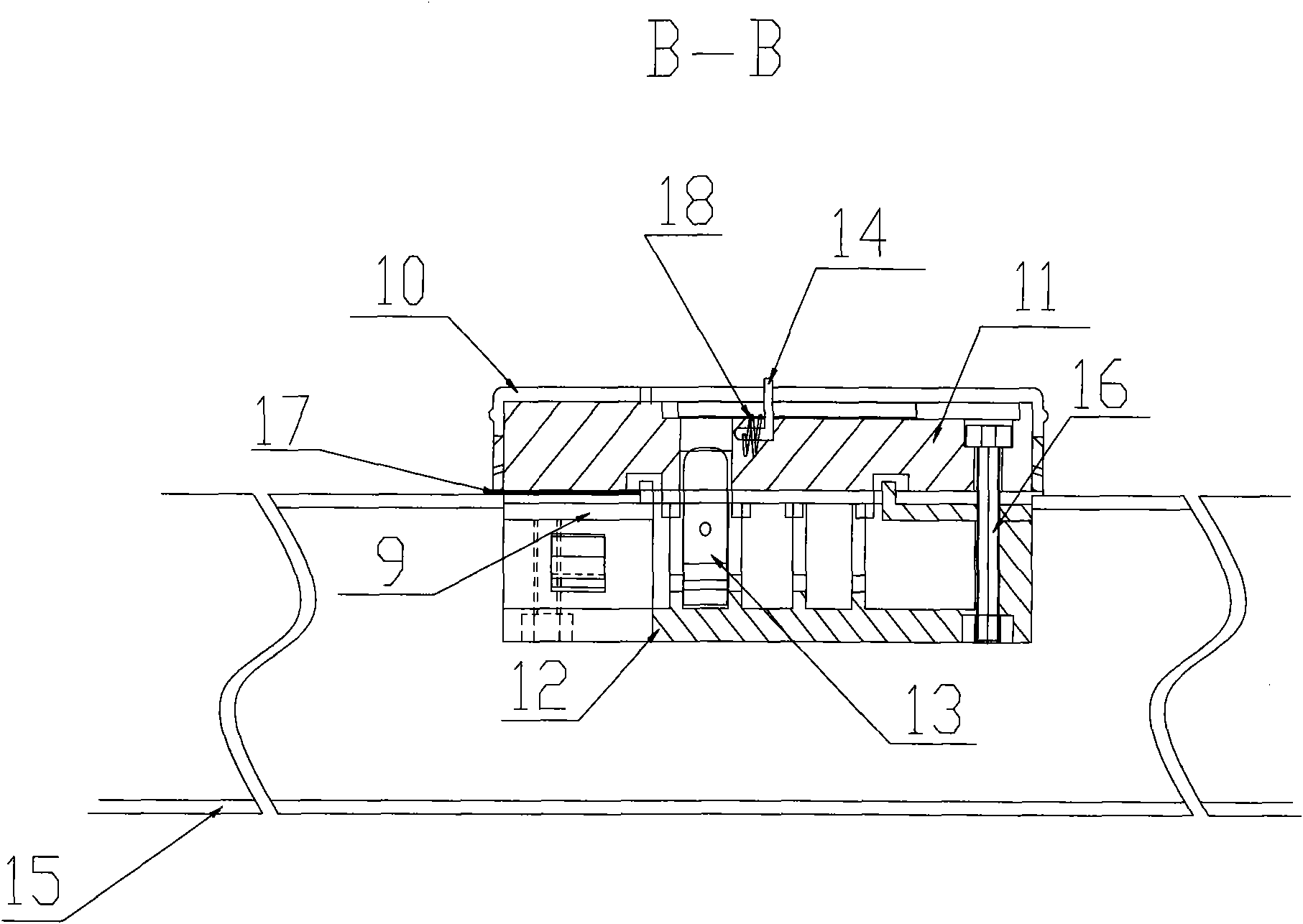

Secondary grouting construction method of machine setting

ActiveCN101343879AGuaranteed long-lasting stabilityQuality assuranceFoundation engineeringMachine toolContact effects

The invention relates to a mother machine installation secondary grouting working method. The mother machine installation secondary grouting working method is performed according to the procedures: firstly, the preparation work for the secondary grouting, the base body of the mother machine is hanged up, the anchorage bolts are installed, the anchorage bolts, the adjustable iron pads and the backing plates are fixed on the base body of the mother machine through nuts, part of the adjustable iron pads and backing plates are positioned beside the foundation holes for supporting, and the foundation parts are hanged onto the supporting iron pads; secondly, the mother machine is roughly adjusted with a level meter; thirdly, the foundation secondary grouting is performed until the no hollow cavity or concave pit is found under the backing plate; fourthly, foundation maintenance is performed. Through the connection of the adjustable iron pads, the anchorage bolts and the backing plates with the foundation of the mother machine before the grouting in the invention, the secondary grouting is performed, to cause the foundation to be completely contacted with the adjustable iron pads, the foundation quality is guaranteed, the backing plates are grouted together with the foundation after the secondary grouting, and if the adjustable iron pad is damaged, the adjustable iron pad can be replaced arbitrarily, and the contacting effect of the adjustable iron pads with the foundation is not influenced.

Owner:JIER MACHINE TOOL GROUP

Method for measuring temperature of heat pipe

InactiveUS20070237202A1Low viscosityImprove thermal stabilityThermometer detailsThermometer applicationsElectrical resistance and conductanceEngineering

A method for measuring the temperature of a heat pipe includes the steps of: firstly preparing a thermal couple wire formed at one end thereof with a temperature-sensing head, pressing the temperature-sensing head on the surface of the heat pipe to be measured, and a proper amount of a fluid medium is filled between the temperature-sensing head and the surface of the heat pipe. The fluid medium can be water, oil or flowable paste having lower viscosity. Due to the cohesion of the fluid medium, it can fill the gap between the temperature-sensing head and the surface of the heat pipe. As a result, the stability of the thermal contact resistance between the point-contact of the temperature-sensing head and the heat pipe is increased due to the filling of the fluid medium. Also, the contact effect is greatly enhanced to reduce the thermal contact resistance.

Owner:JAFFE

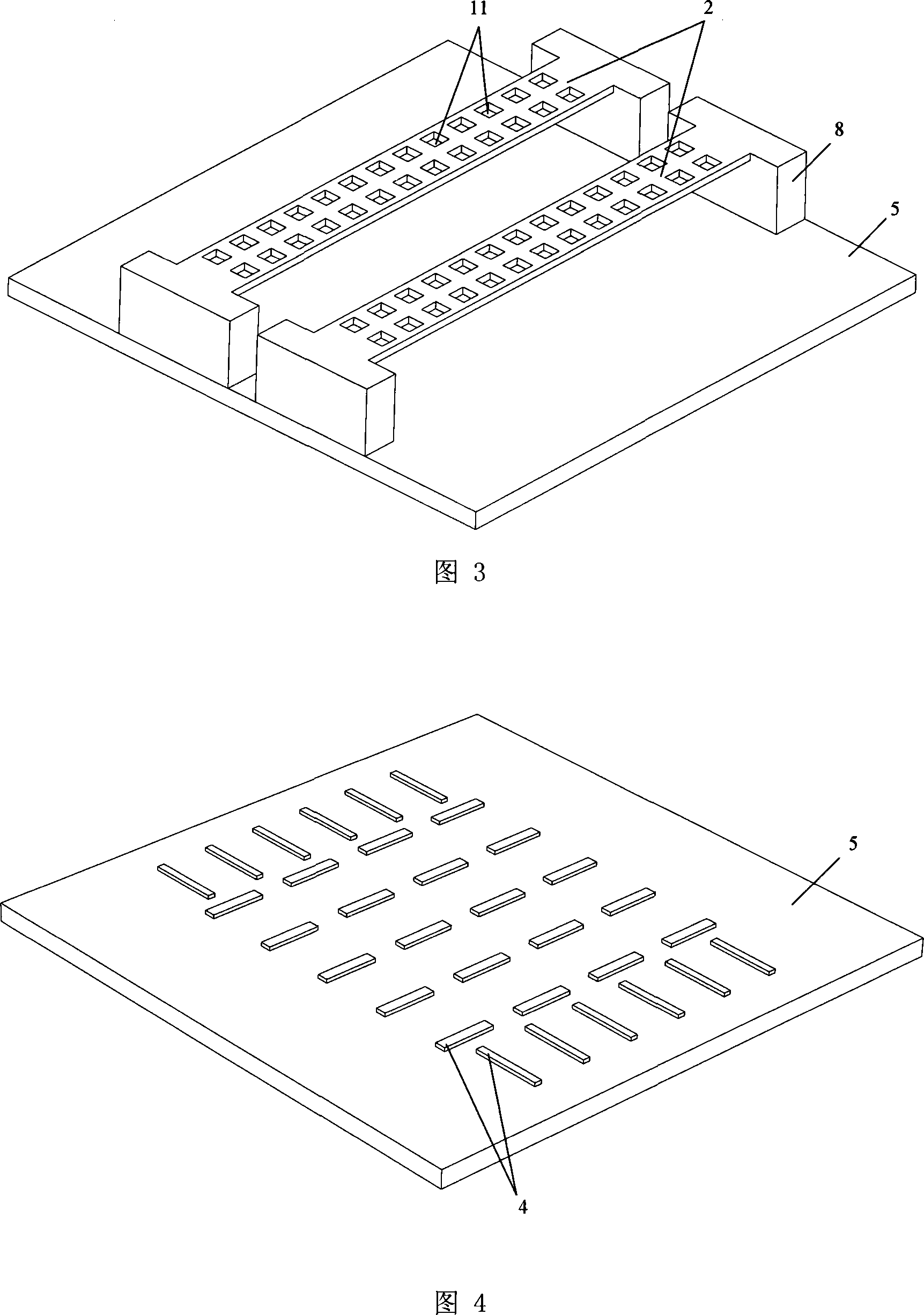

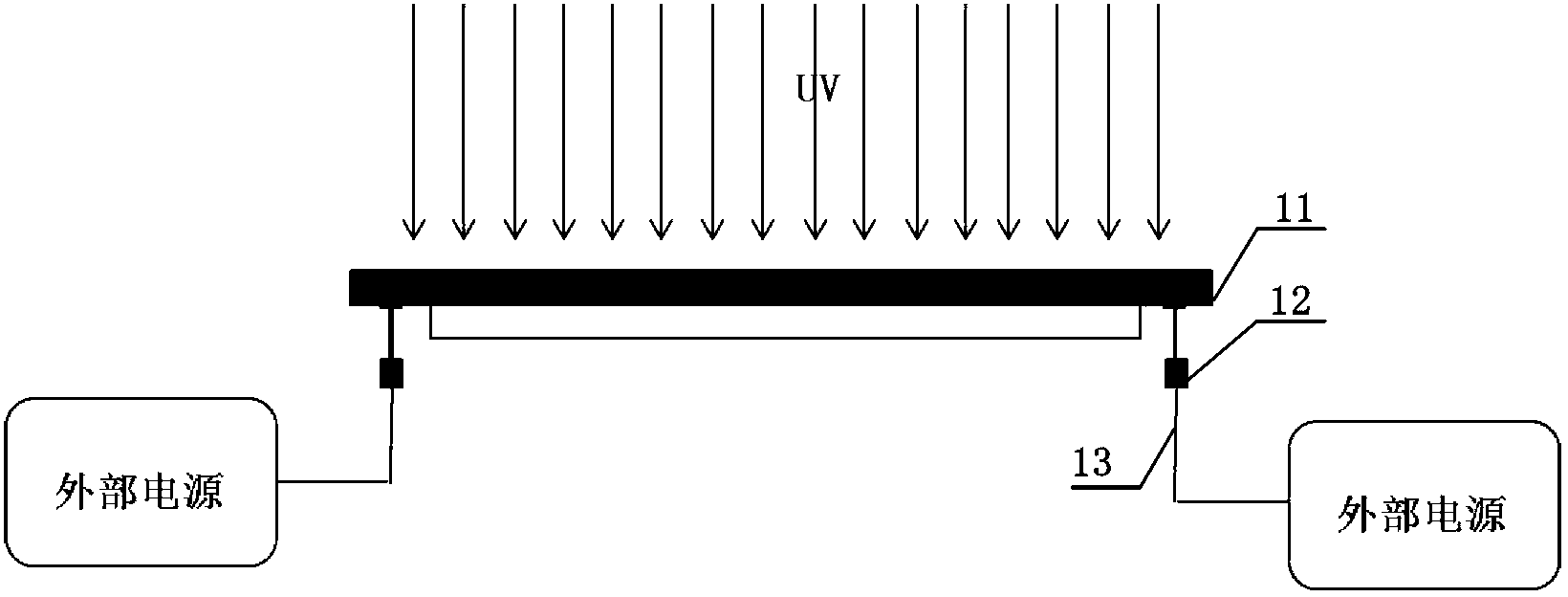

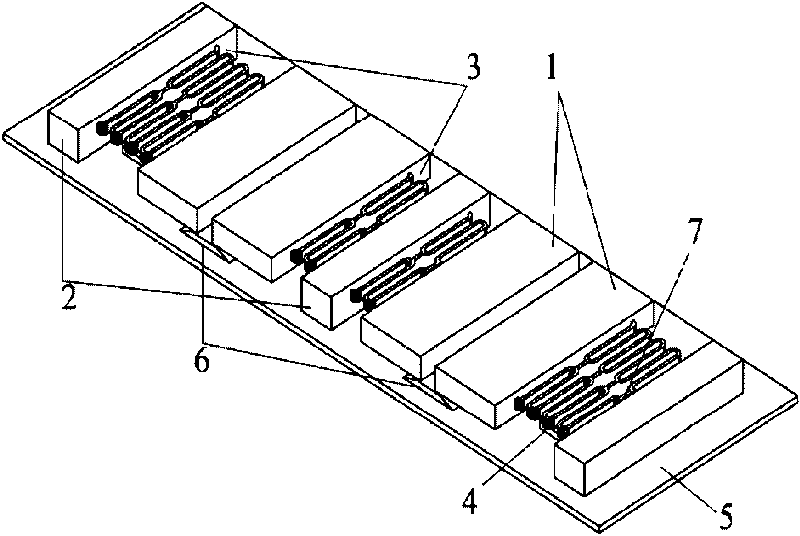

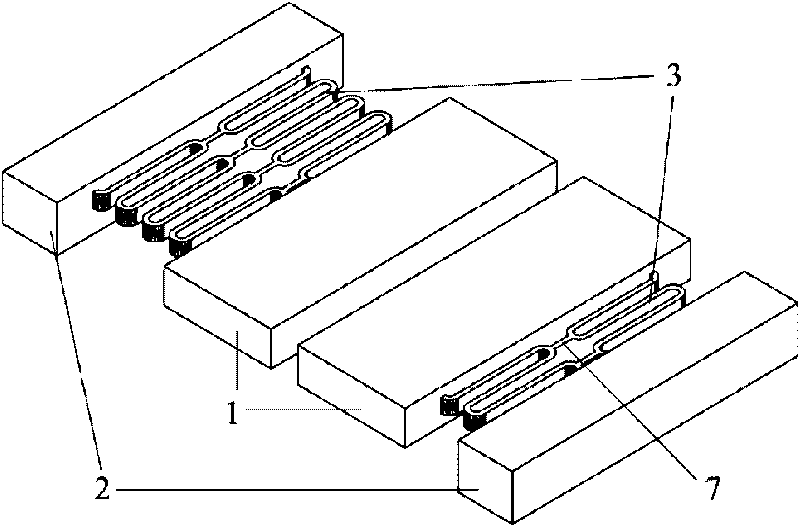

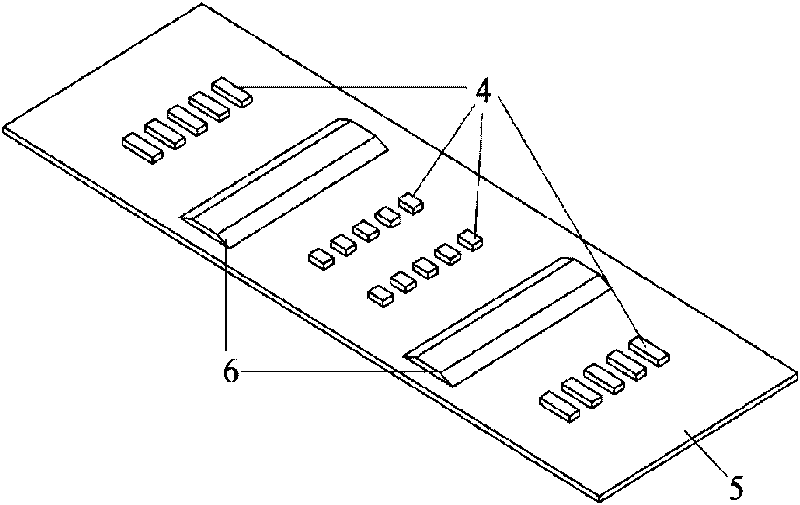

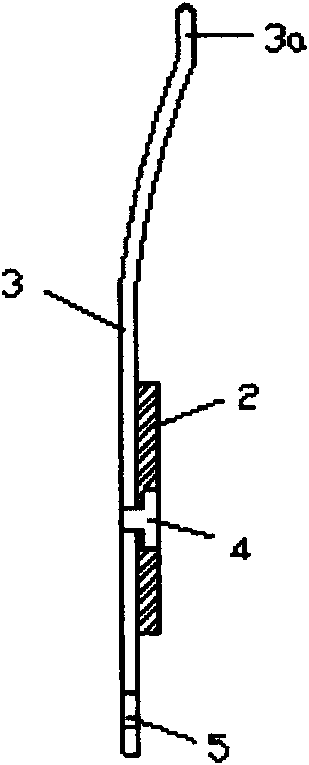

Minitype inertial electrical switch capable of regulating and controlling contact time

InactiveCN101174518AAdjust contact timeImprove contact effectElectric switchesCantilevered beamContact time

The invention relates to a minitype inertia electrical switch which can adjust the contact time, belonging to the micro electromechanical system technical field. The invention is characterized in that: a mass block electrode with a cantilever beam array comprises a mass block and a cantilever beam array fixed to the mass block; the cantilever beam array is positioned below a fixed electrode of a porous elastic beam; a support layer is positioned above an insulated base and below the mass block; the support unit of a spring and the support unit of the porous elastic beam fixed to the insulated base are positioned around the mass block; a joint snake shaped spring connected with the mass block is hung in the air by the support unit of the spring; the fixed electrode of the porous elastic beam positioned above the mass block is hung in the air by the support unit of the porous elastic beam, and a gap is positioned between the fixed electrode of the porous elastic beam and the cantilever beam array. The invention has the advantages of improving the contact effect of the movable mass electrode and the fixed electrode of the elastic beam, adjusting the contact time of the two electrodes of the minitype inertia switch conveniently, and improving the coordination of the movement of the mass block with the joint snake shaped spring caused by the outside acceleration.

Owner:SHANGHAI JIAO TONG UNIV

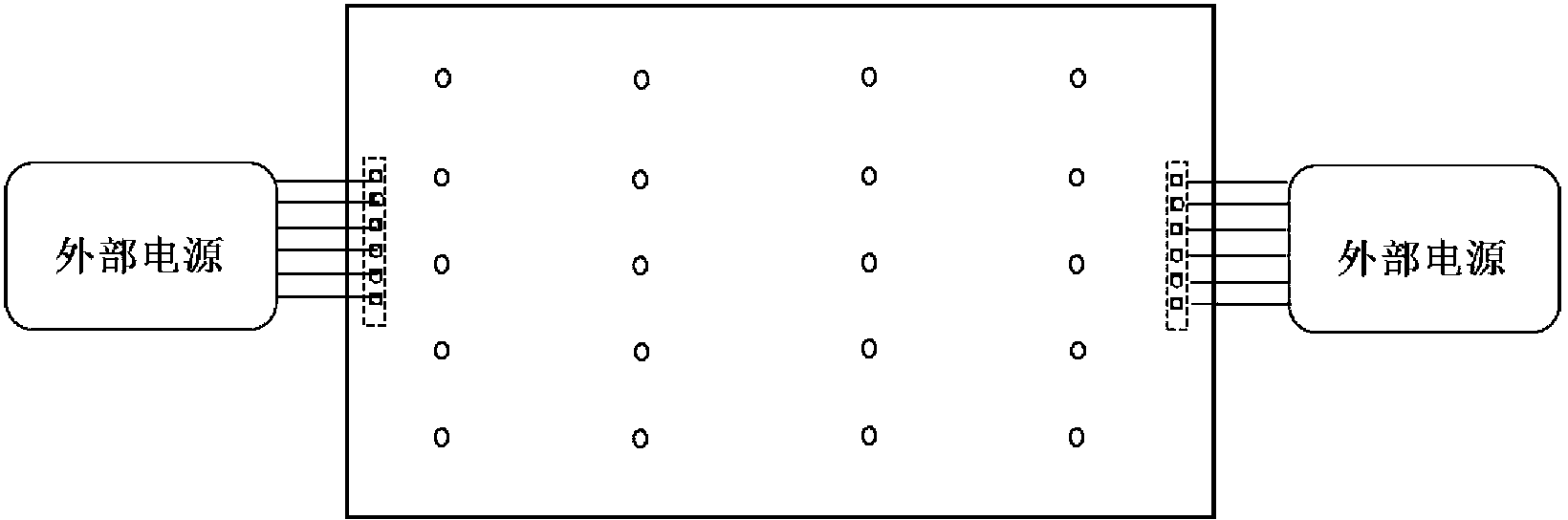

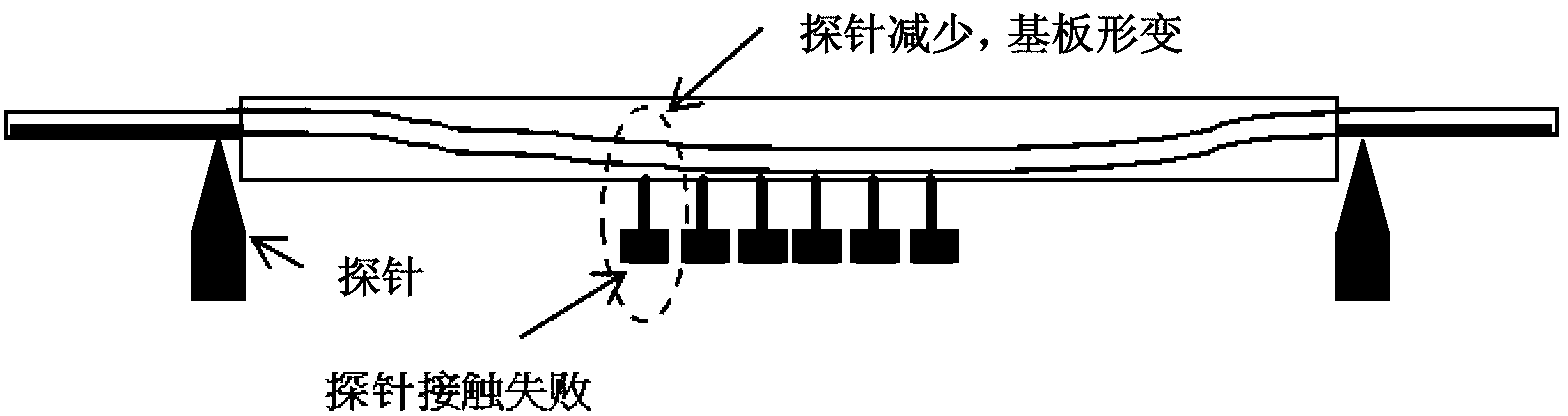

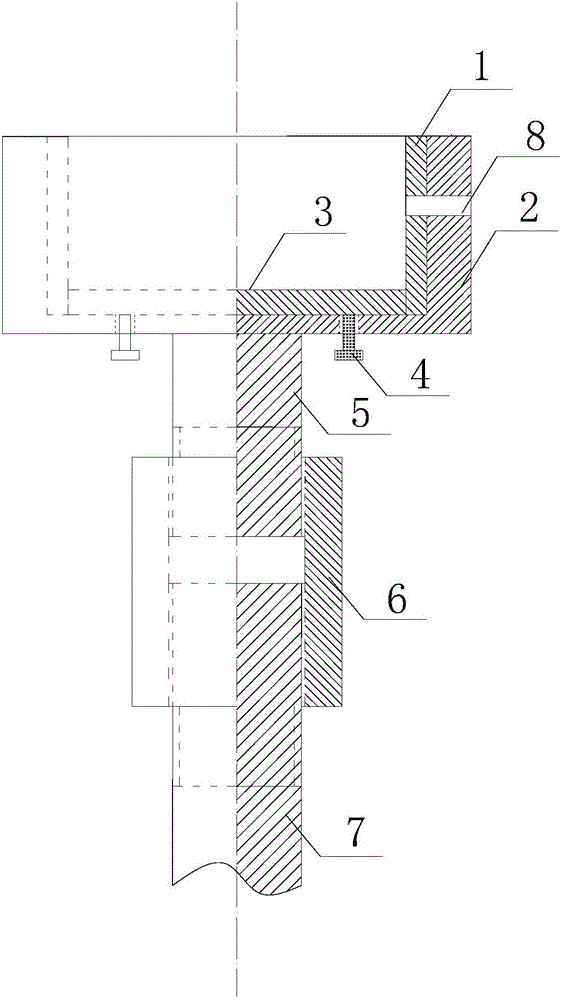

Probe module for detecting contacting effect

ActiveCN103323635AEasy to findEliminate timeStatic indicating devicesElectrical measurement instrument detailsElectricityDevice Monitor

The invention discloses a probe module for detecting a contacting effect. In the process of liquid crystal alignment, the probe module is used for detecting the contacting effect of the probe module self and a substrate external test circuit of an LCD panel. The probe module for detecting the contacting effect comprises at least two telescopic probes and a resistance monitoring device, wherein the at least two telescopic probes are mutually insulated, the resistance monitoring device is electrically connected with the at least two mutually-insulated telescopic probes, and the resistance monitoring device monitors the resistance between the at least two mutually-insulated telescopic probes to judge the contacting effect of the at least two mutually-insulated telescopic probes and a contact surface. According to the probe module for detecting the contacting effect, due to the facts that a plurality of contact points are formed between the probe module and a contact object and the contact points are in mutual independence, the resistance monitoring device of the probe module is used so that the resistance values among a plurality of probes obtained through measurement can be used for timely judging the contacting effect between the probes and the contact object, and thus cause seeking and handling time due to abnormal monitoring currents in an existing liquid crystal alignment process is saved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

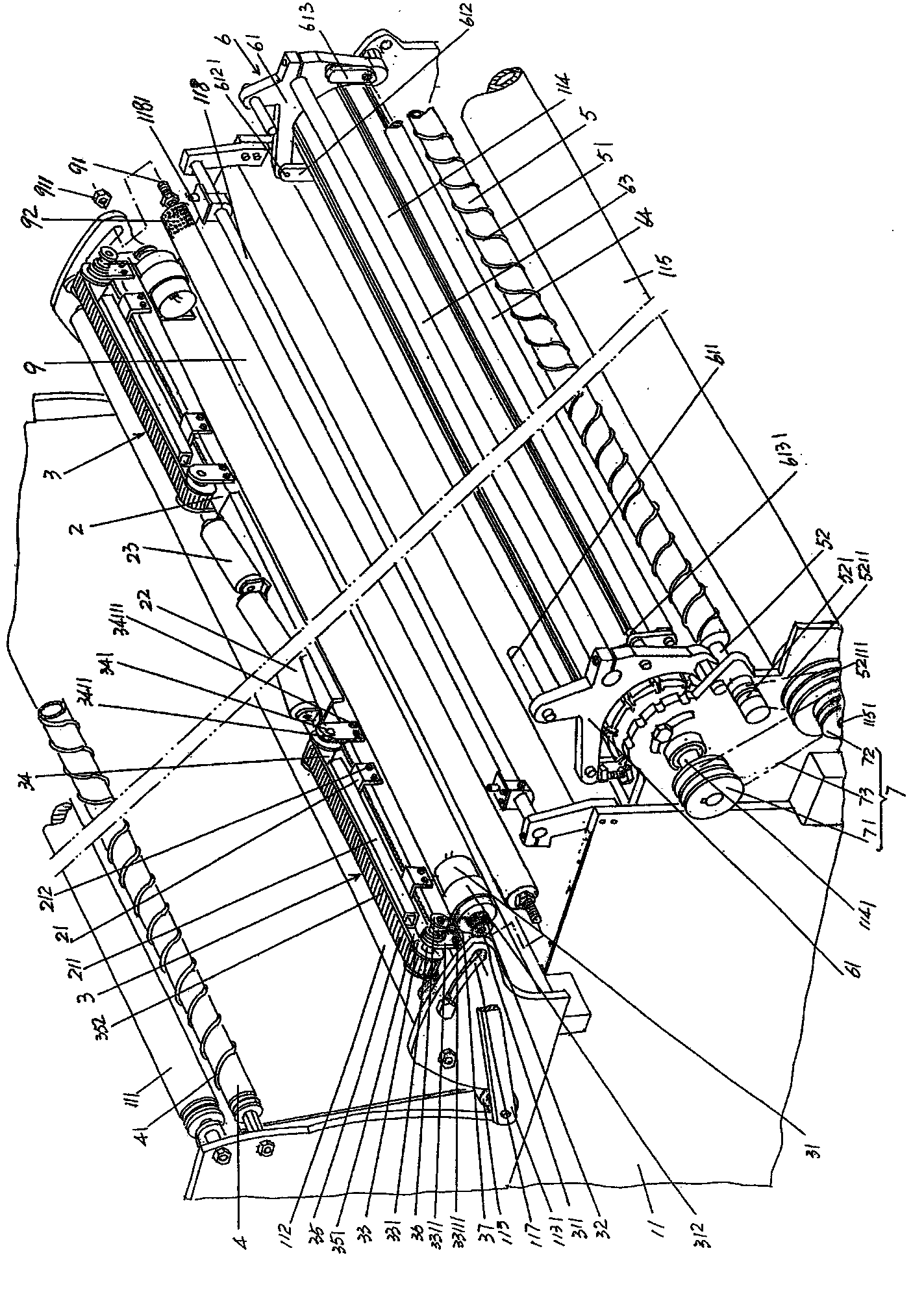

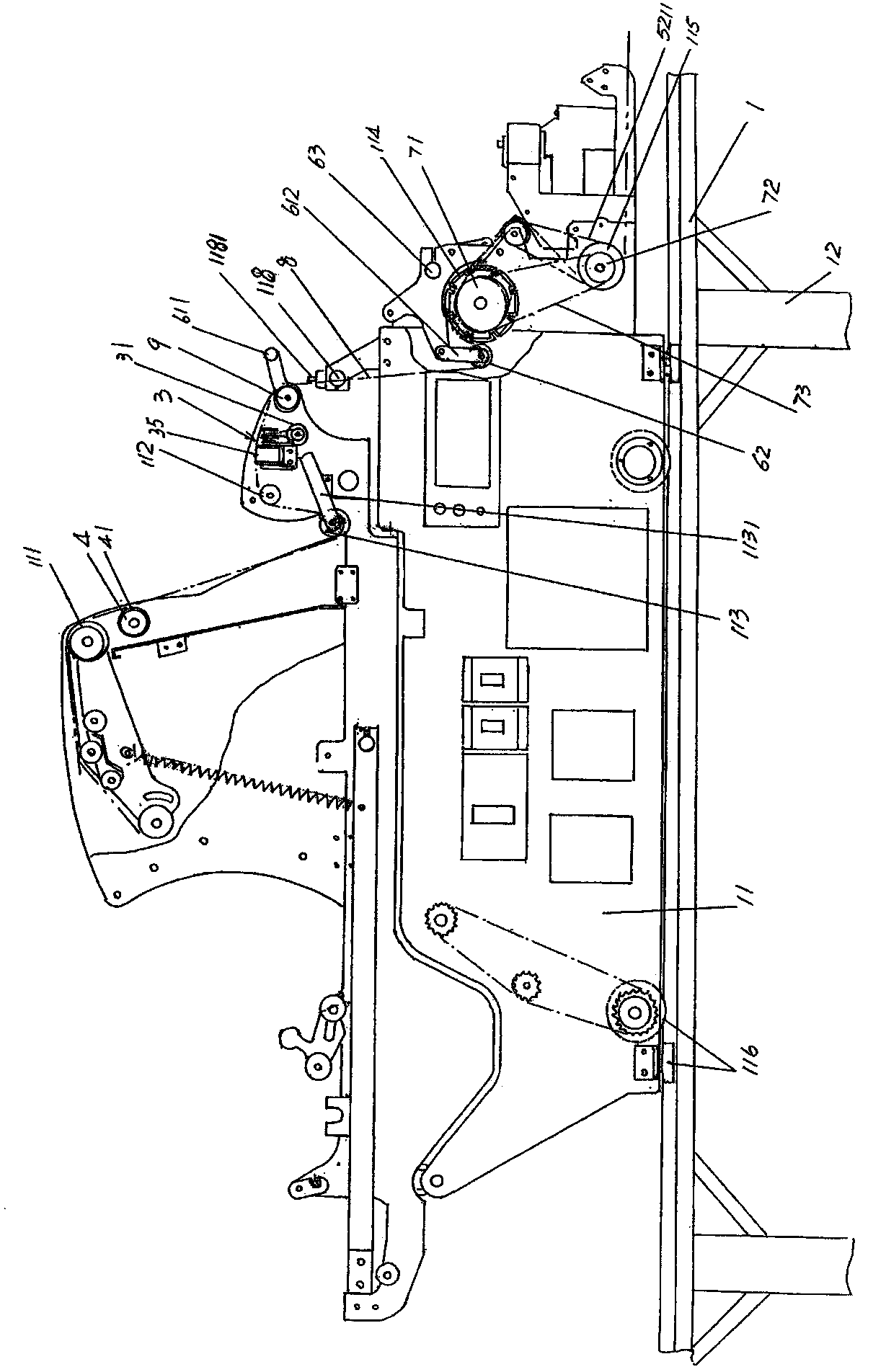

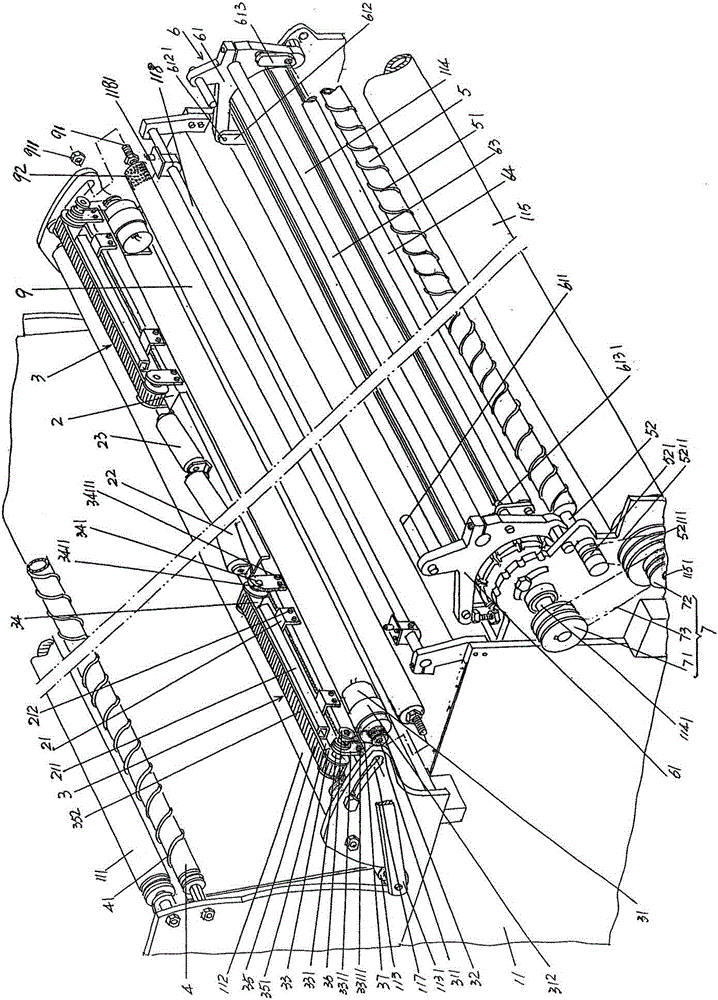

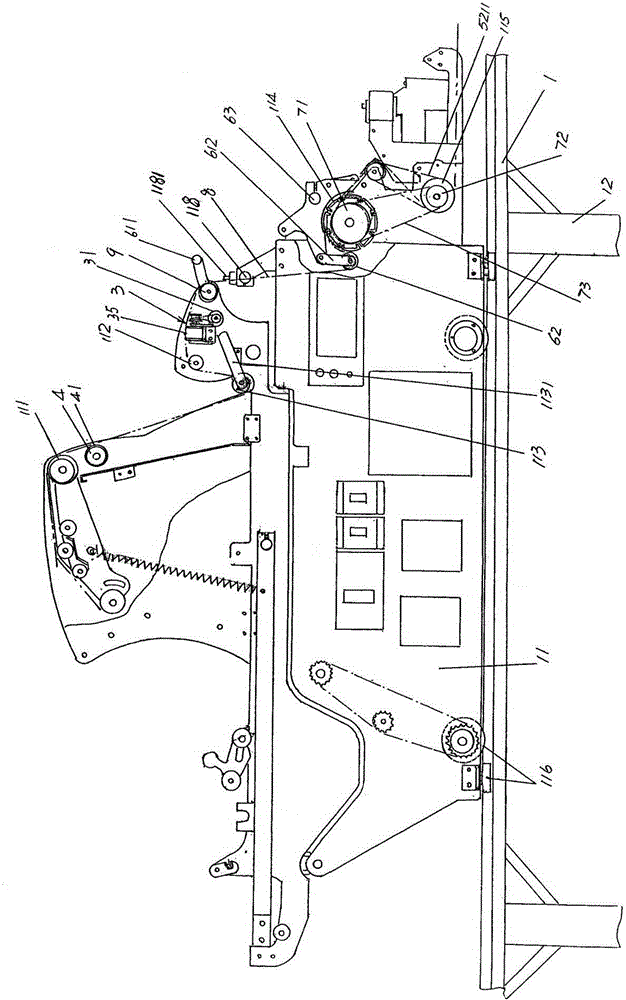

Edge peeling and positioning device of spreading machine

ActiveCN104003231ABlock replyPrevent swimmingUnfolding thin materialsWebs handlingEngineeringContact effects

An edge peeling and positioning device of a spreading machine belongs to the field of clothing machines. The spreading machine comprises a spreading table, a machine frame is arranged on the spreading table and provided with an upper cloth guiding roller, a lower cloth guiding roller, a cloth pressing roller, a large cloth spreading roller and a lower cloth spreading roller. The edge peeling and positioning device comprises a beam and a pair of toothed belt type edge peeling mechanisms and is characterized by further comprising a front cloth expanding roller, a rear cloth expanding roller and a peeled and expanded cloth edge maintaining roller, wherein the front cloth expanding roller is supported on the machine frame and provided with front cloth expanding threads, the rear cloth expanding roller is provided with rear cloth expanding threads, and the peeled and expanded cloth edge maintaining roller is provided with flanges; the beam is fixedly provided with a pair of belt supporting unit seats, which extend into an edge peeling toothed belt cavity and are fixedly provided with belt supporting units, and the belt supporting units are arranged inside the edge peeling toothed belt cavity and are in contact with the inner side of the edge peeling toothed belt. The edge peeling and positioning device of the spreading machine enables the cloth edges of both sides in the length direction of cloth spread on the spreading table to maintain a trim state, prevents both sides the cloth from moving towards the middle, eliminates the deflection of the edge peeling toothed belt and improves the integral contact effects of the edge peeling toothed belt with the cloth edges.

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

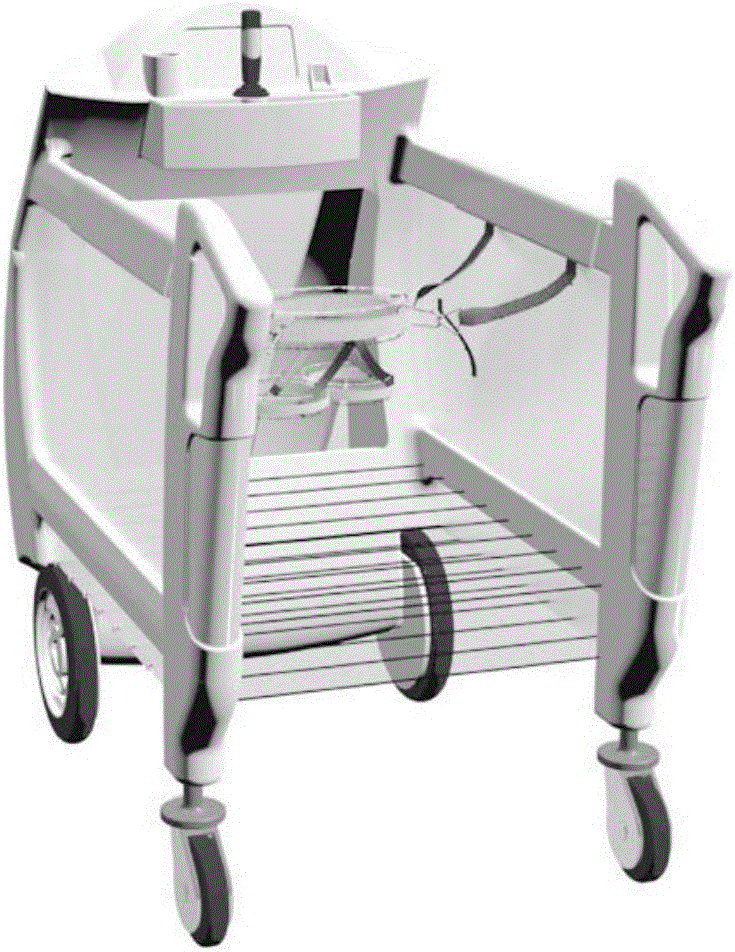

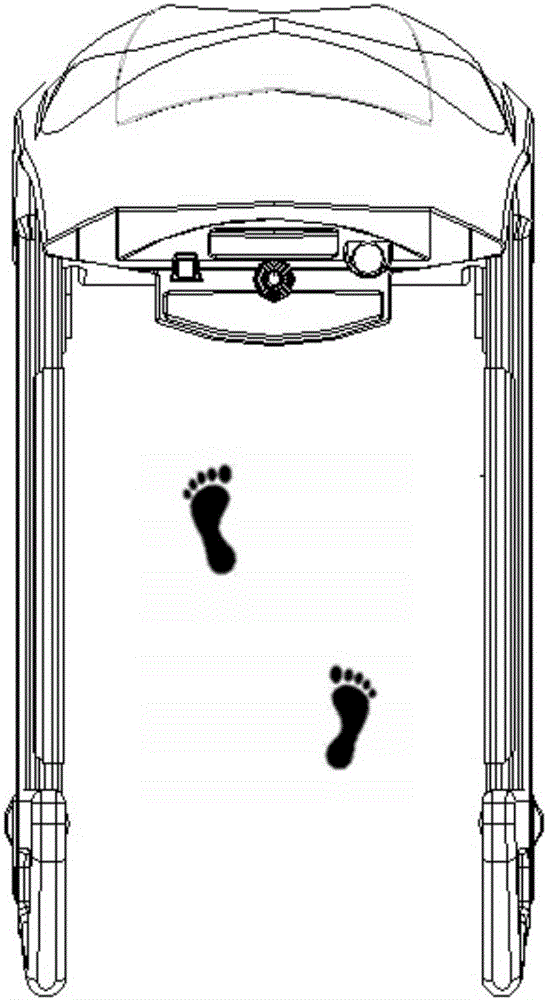

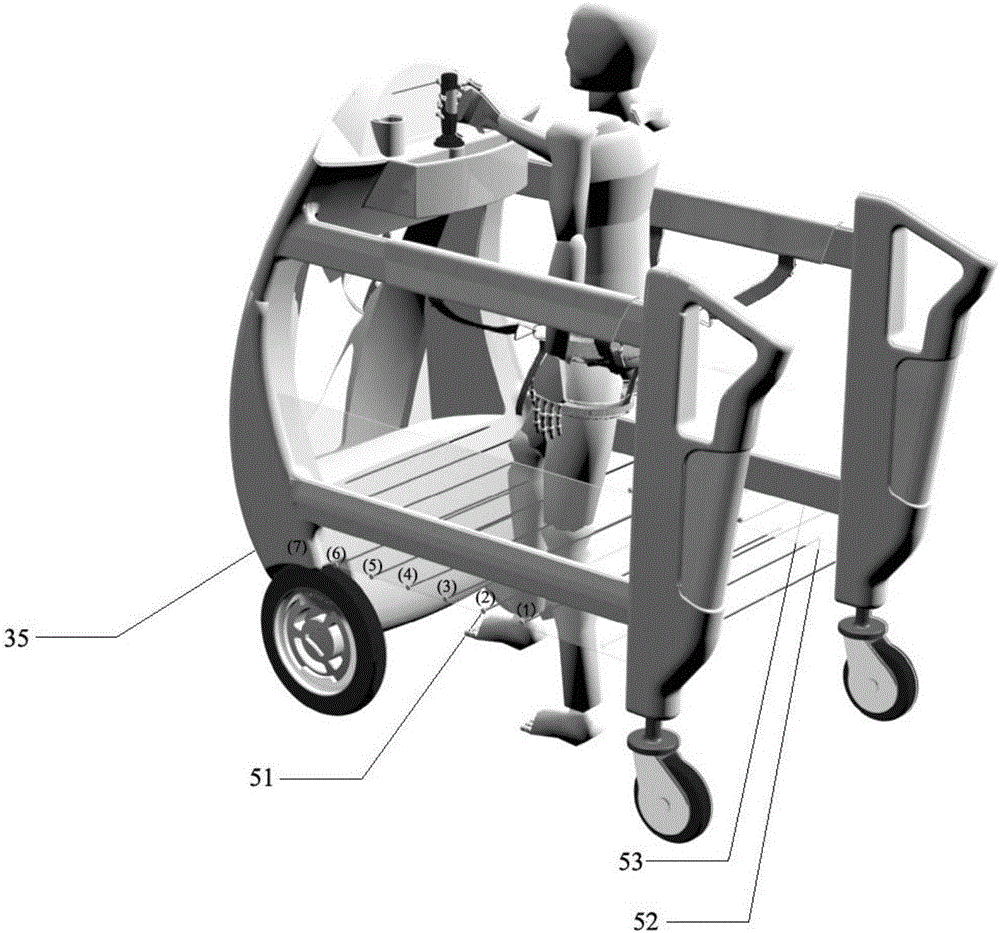

Human lower limb rehabilitation training robot with intelligent safety protection

ActiveCN106726340AImprove securityImprove accuracyChiropractic devicesWalking aidsMedical equipmentOpto electronic

The invention relates to a human lower limb rehabilitation training robot with intelligent safety protection, and belongs to the technical field of medical equipment. A transmitter emits light beams constantly to a receiver by pointing the receiver. The emitted light is either received by the receiver or blocked by a to-be-tested object. The receiver converts the received light signals into electrical signals. A detection circuit is used for detecting the electrical signals outputted by the receiver, filtering out the impurities to obtain effective signals and transmitting the effective signals to a main control board. The optoelectronic inspection method has the advantages of being high in precision, fast in response, capable of achieving the non-contact effect and the like. The detectable parameters are abundant, the sensor structure is simple, the mechanism is flexible and the size is small. The main control board fuses the two types of information collected from both a tensile force sensor and a photoelectric sensor by using program algorithms for falling judgment. The two types of signals from both the photoelectric sensor and the tensile force sensor are fused for the judgment, therefore the accuracy of the judgment is increased, particularly for the falling judgment, and the safety performance of the robot is enhanced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

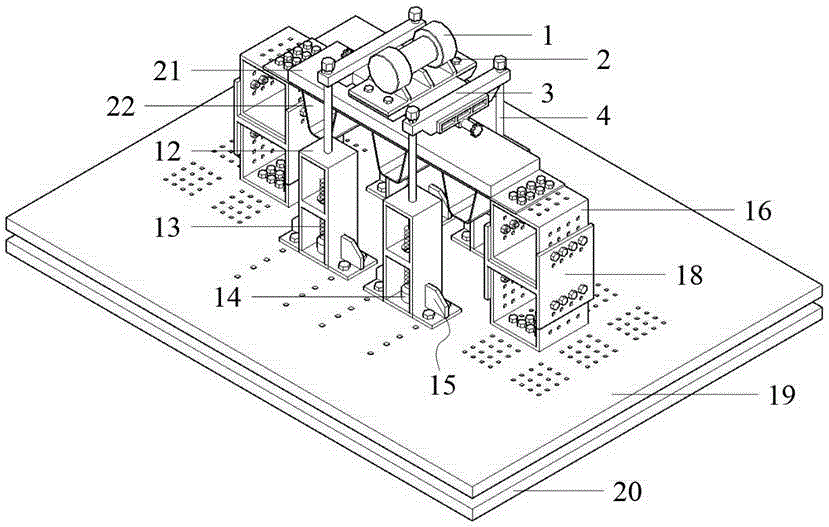

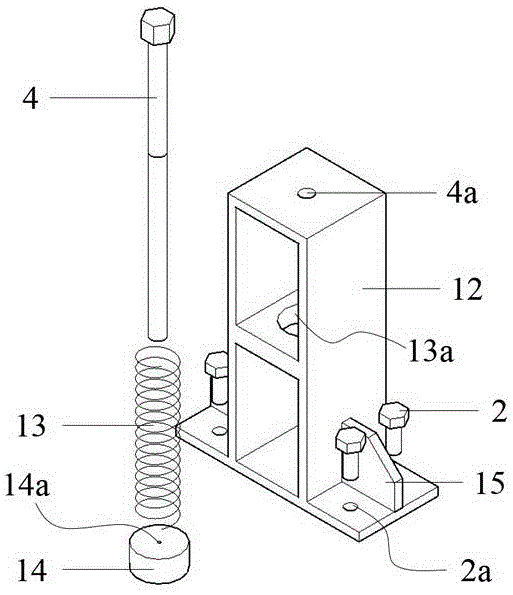

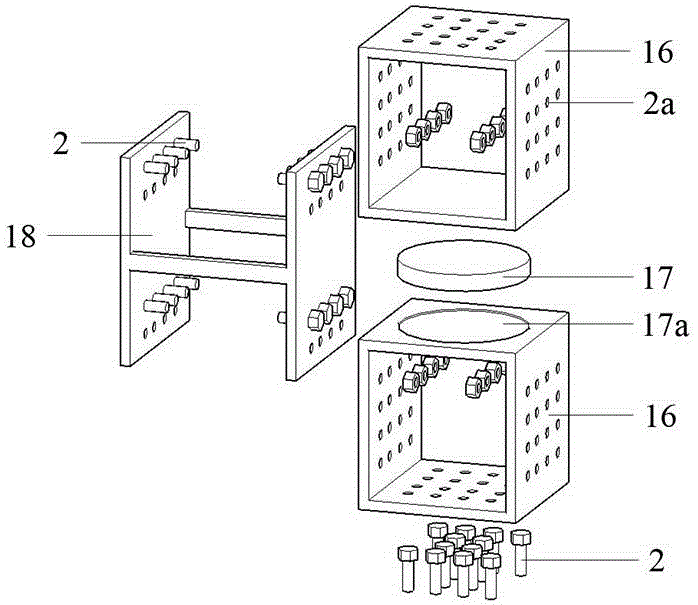

Fatigue test device taking coupling effect of steel bridge decking and pavement layer into consideration

ActiveCN106679908AHigh simulationImprove test efficiencyElasticity measurementTest efficiencyFixed frame

The invention discloses a fatigue test device taking a coupling effect of a steel bridge decking and a pavement layer into consideration. The fatigue test device comprises a fatigue tester fixing pedestal, a rubber actuation head, a tester pedestal fixed frame, a frame and a frame fixing base plate, the frame accommodates a local steel bridge decking model with a pavement layer, and a fatigue tester acts a bending fatigue load on a testpiece via the rubber actuation head to simulate the practical contact effect between wheels and decking pavement. A connecting spring in the tester pedestal fixed frame enables that the bottom of the rubber actuation head clings to the surface of the testpiece. The frame fixing base plate is provided with a bolt hole group so as to adapt to installation of test pieces of different sizes. The device changes a fixation manner of the testpiece and a transfer mode of the fatigue load to apply the fatigue load to the local testpiece of the steel bridge decking with the pavement layer. Practical bearing conditions of the steel bridge decking and the pavement layer under the coupling effect can be simulated effectively, the test efficiency is improved substantially, and the test cost is reduced.

Owner:HOHAI UNIV

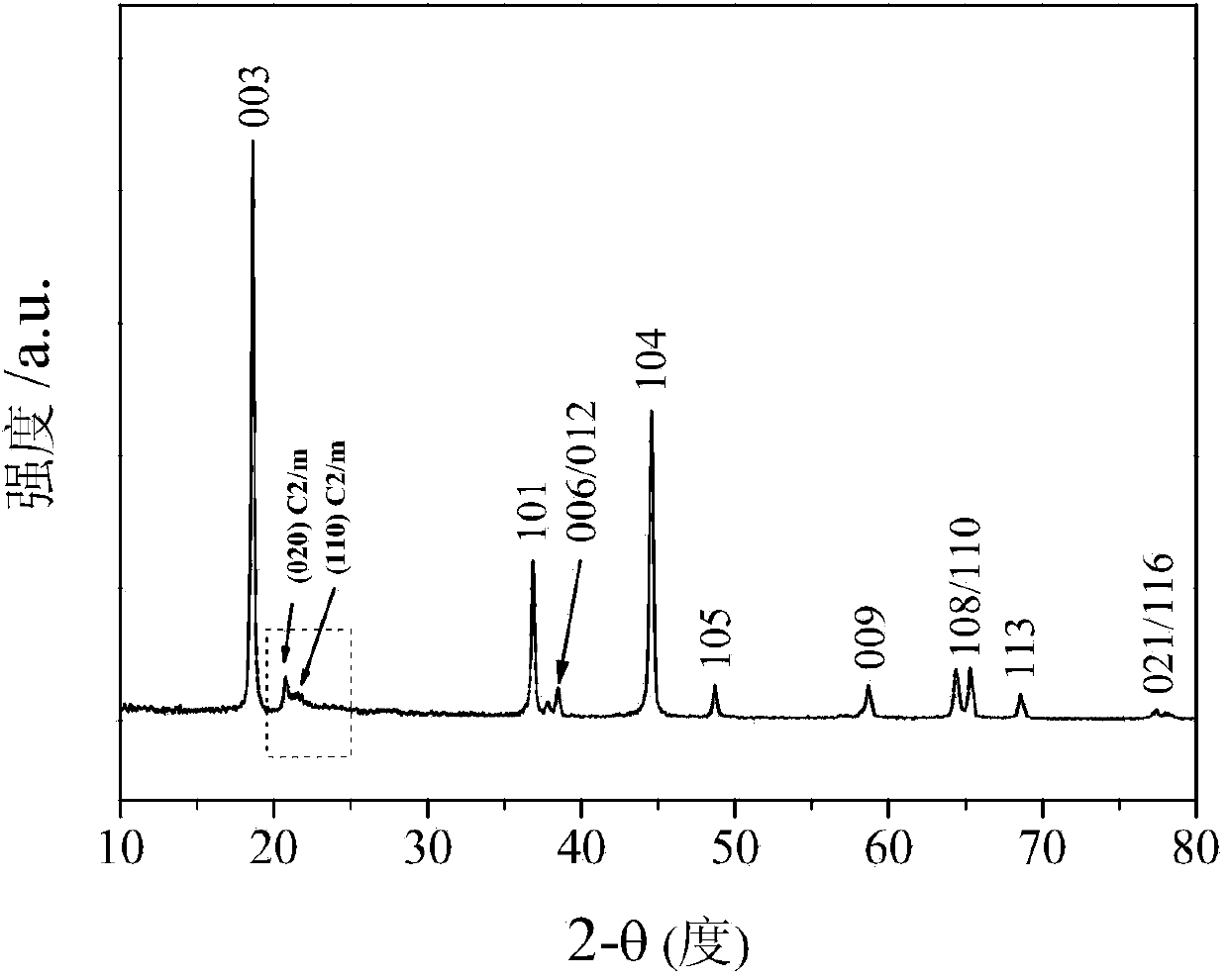

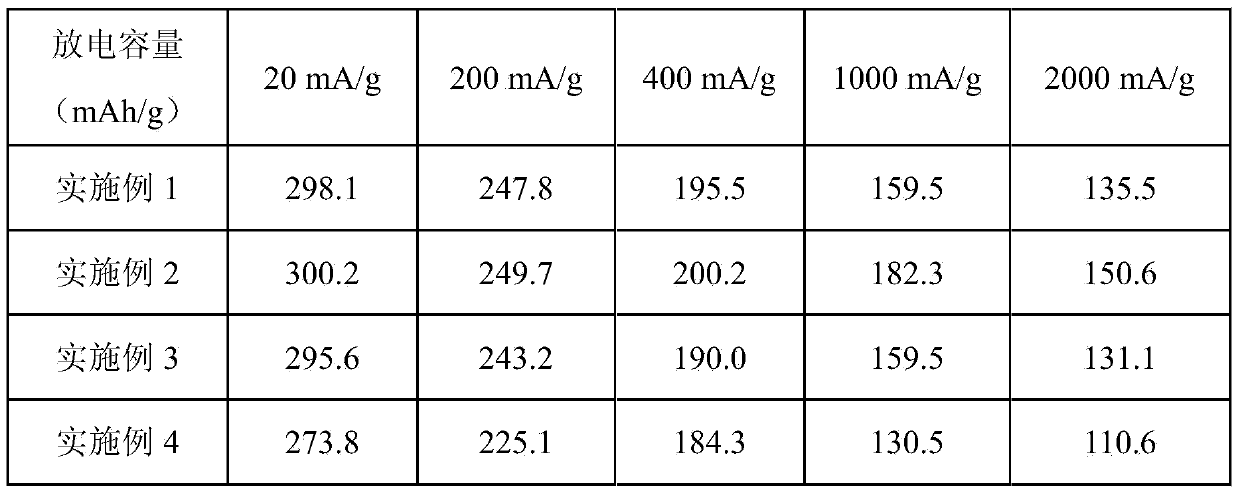

Reticular porous lithium-manganese-rich-based positive electrode material for lithium ion cell and preparation method of material

ActiveCN103474646AImproved magnification performanceNo need for precise temperature controlMaterial nanotechnologyCell electrodesNickel saltManganese

The invention discloses a preparation method of a reticular porous lithium-manganese-rich-based positive electrode material for a lithium ion cell. The preparation method comprises the following steps: dissolving lithium salt, nickel salt, manganese salt and cobalt salt into deionized water according to a certain ratio, so as to form a transparent solution; adding appropriate amount of cane sugar serving as a complexing agent according to the added metal salts, so as to form a transparent solution; heating for evaporating the solution, so as to remove water and obtain colloidal sol, and finally obtain gel; calcining the gel for 1-6 hours at the temperature of 400-600 DEG C, and then calcining the gel for 10-30 hours at the temperature of 700-950 DEG C, so as to finally form the reticular porous lithium-manganese-rich-based positive electrode material for the lithium ion cell. The preparation method is simple in process, the obtained reticular porous lithium-manganese-rich-based positive electrode material has excellent contact effect between particles and large specific surface area, thus the rate capability of the material is improved.

Owner:SHENZHEN KEXIN COMM TECH

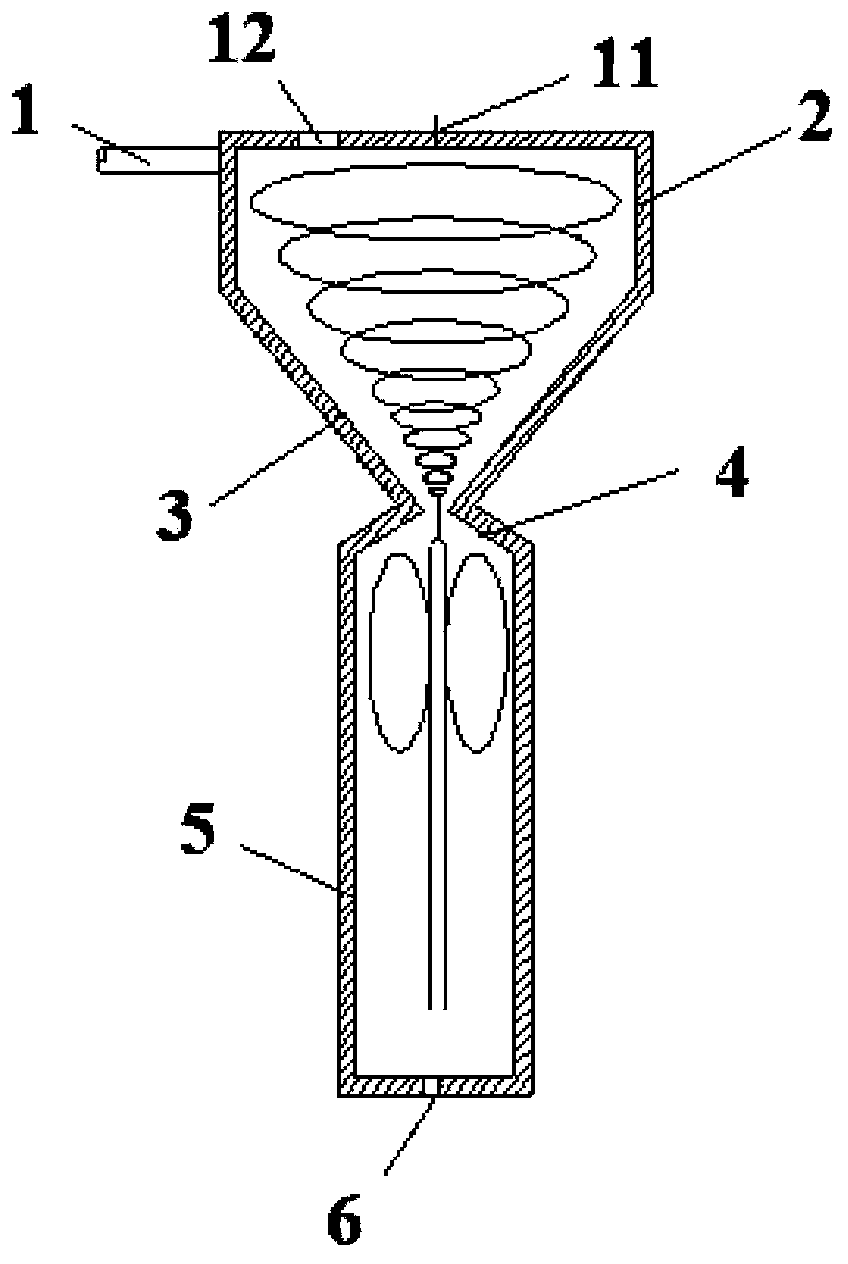

Vortex-type mixing sedimentation integrated reactor

InactiveCN103351043ASimple structureLow water speedWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationWater flowMechanical equipment

The invention discloses a vortex-type mixing sedimentation integrated reactor which comprises a first cylinder, a contraction cone, an expansion cone and a second cylinder, and the first cylinder, the contraction cone, the expansion cone and the second cylinder are mutually connected, or the second cylinder is connected with a precipitation zone through a guide plate. A water flow tangentially enters the first cylinder, and flows downward while rotation. In the part of the contraction cone the flow rate of the water flow becomes greater because the section becomes smaller. When the water flow enters into the expansion cone, because the section suddenly largens and because of longitudinal jet entrainment of water, a larger backflow zone appears at near-wall places of the expansion cone and the second cylinder and negative pressure is generated. In the process, drugs moves along with the water flow, and has an excellent contact effect with the water flow, so that the waste of the drugs can be reduced and the drug dosage can be reduced. The water flow passes through the part of the second cylinder, has an extremely low flow rate, and meets the requirements for getting into a sedimentation tank. Through use of integrated reactor, mechanical equipment for mixing is needless, energy consumption and maintenance difficulties are reduced, and the operation cost and repair cost are saved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

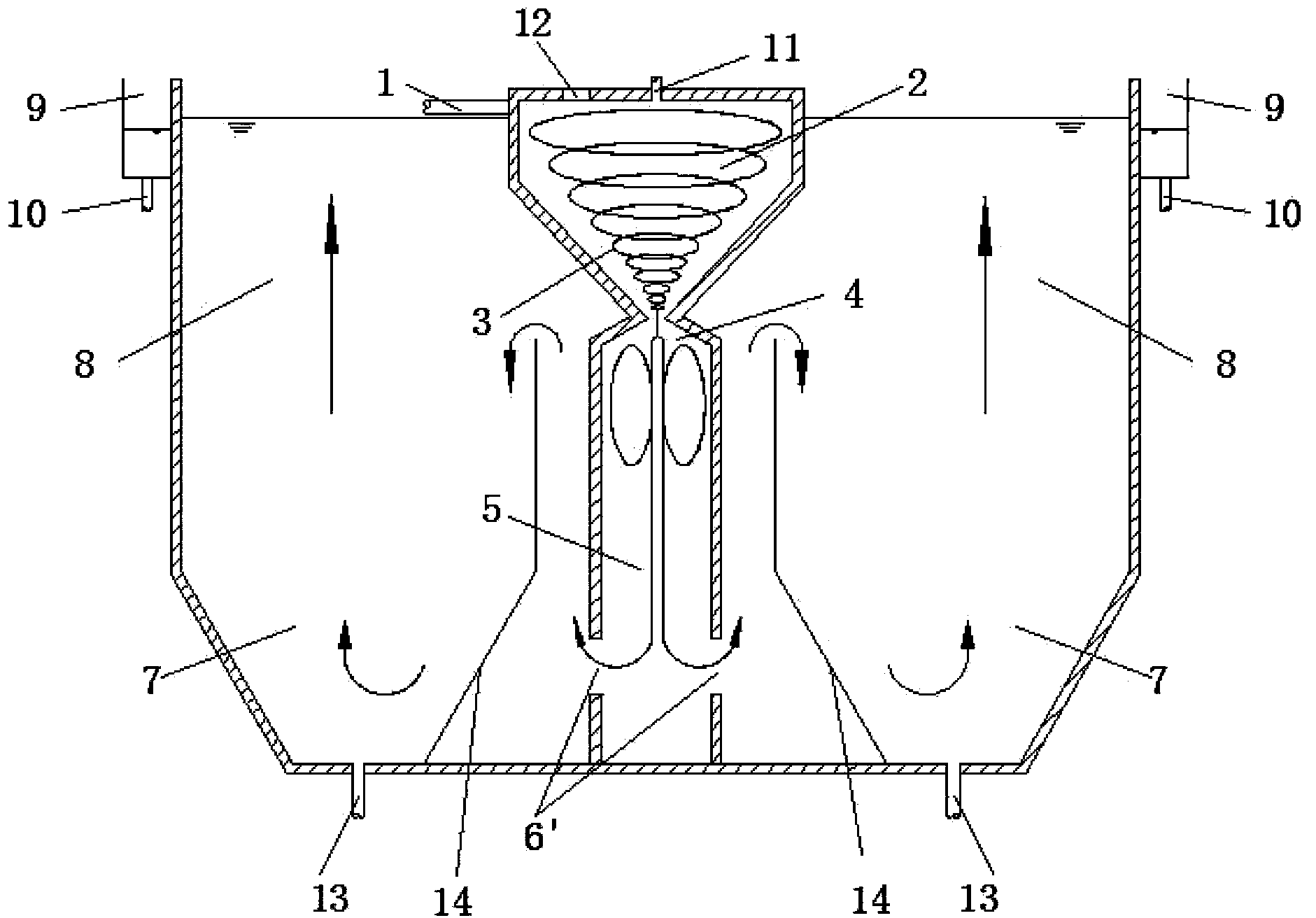

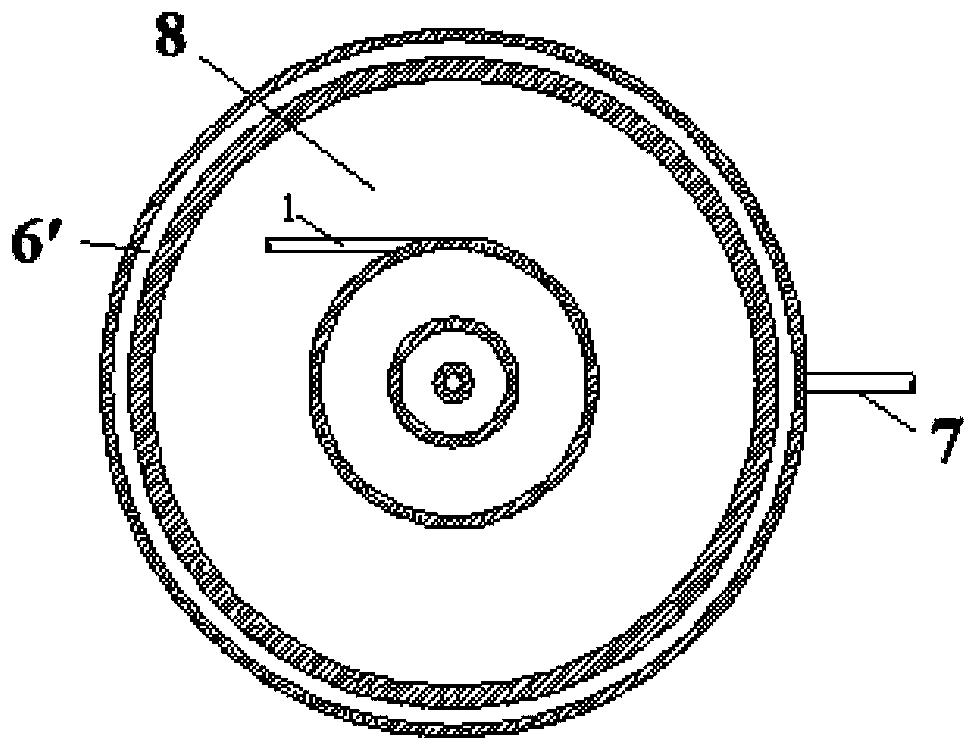

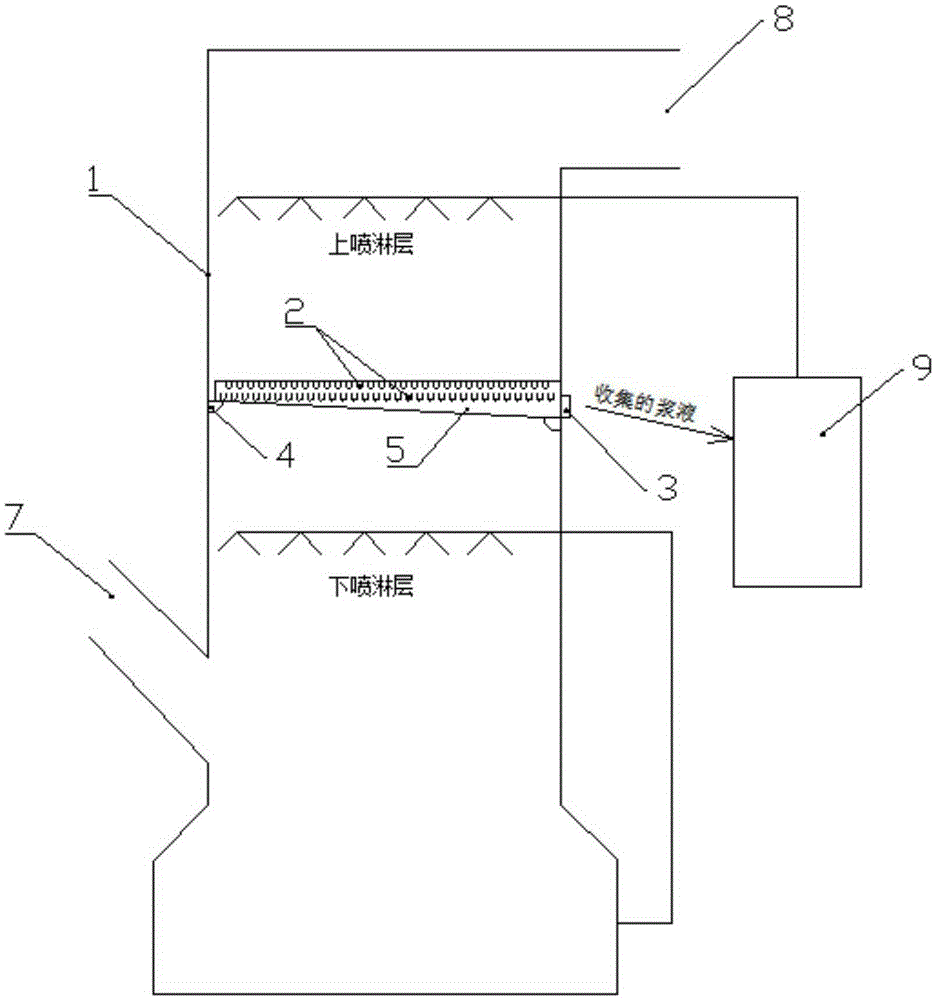

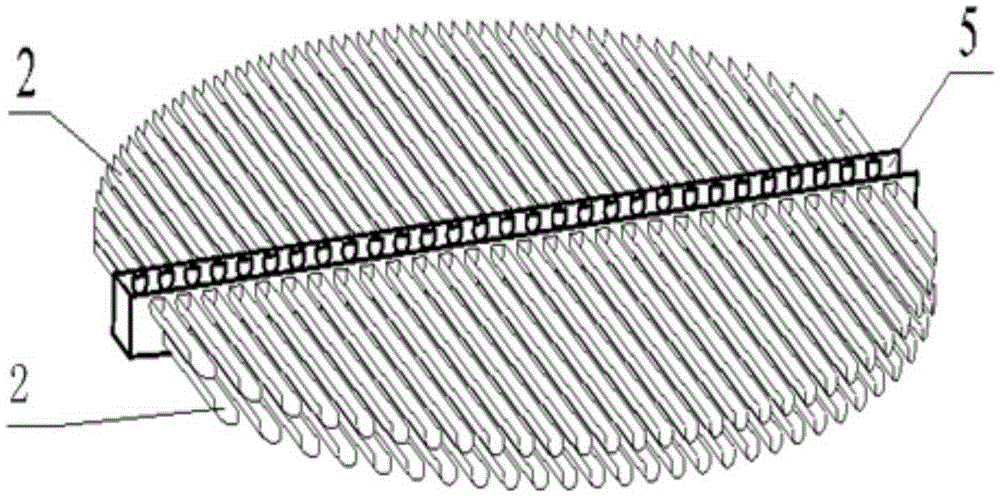

Single-tower dual-cycle wet flue gas desulfurization tower and tube groove type liquid collection device

ActiveCN105413444ALittle resistance lossReduce resistanceGas treatmentDispersed particle separationFlue gasFriction loss

The invention provides a single-tower dual-cycle wet flue gas desulfurization tower and a tube groove type liquid collection device, and belongs to the technical field of flue gas desulfurization. The desulfurization tower comprises a tower body, the bottom of the tower body is provided with a flue gas inlet, the top of the tower body is provided with a flue gas outlet, an upper spray layer and a lower spray layer are arranged on the portion, between the flue gas inlet and the flue gas outlet, inside the tower body, and the tube groove type liquid collection device is installed between the upper spray layer and the lower spray layer and separates slurry of the upper spray layer from slurry of the lower spray layer; the tube groove type liquid collection device comprises multiple liquid collection tube grooves which are formed for multiple layers in the longitudinal direction, the two adjacent layers of the liquid collection tube grooves are arranged in a staggered mode, the liquid collection tube grooves are arranged in an inclined mode, and the lower ends of the liquid collection tube grooves are communicated with a diversion groove. According to the single-tower dual-cycle wet flue gas desulfurization tower and the tube groove type liquid collection device, the flow field is uniformly distributed, the resistance loss of the structural design is small, and the contact effect between the gas and liquid is good. Therefore, the slurry of the upper spray layer can be collected, the system resistance can be reduced, and the desulphurization efficiency is improved.

Owner:SHANDONG UNIV

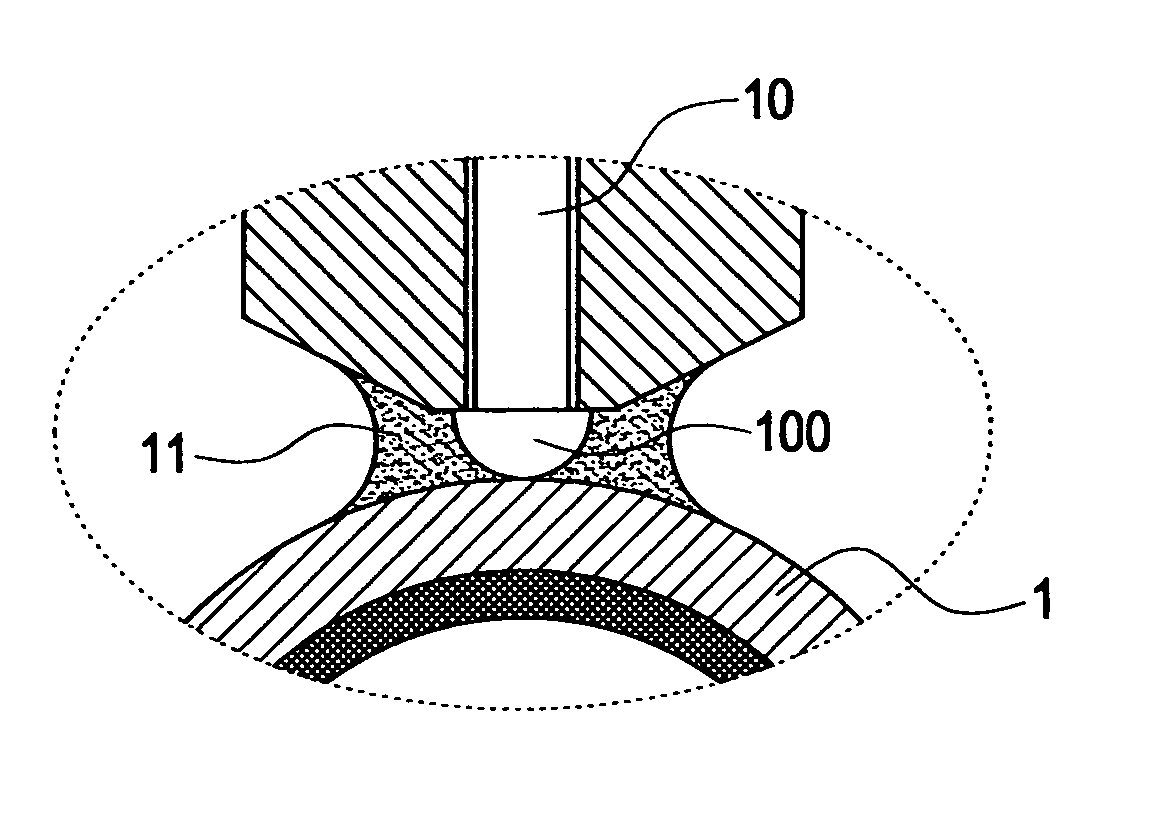

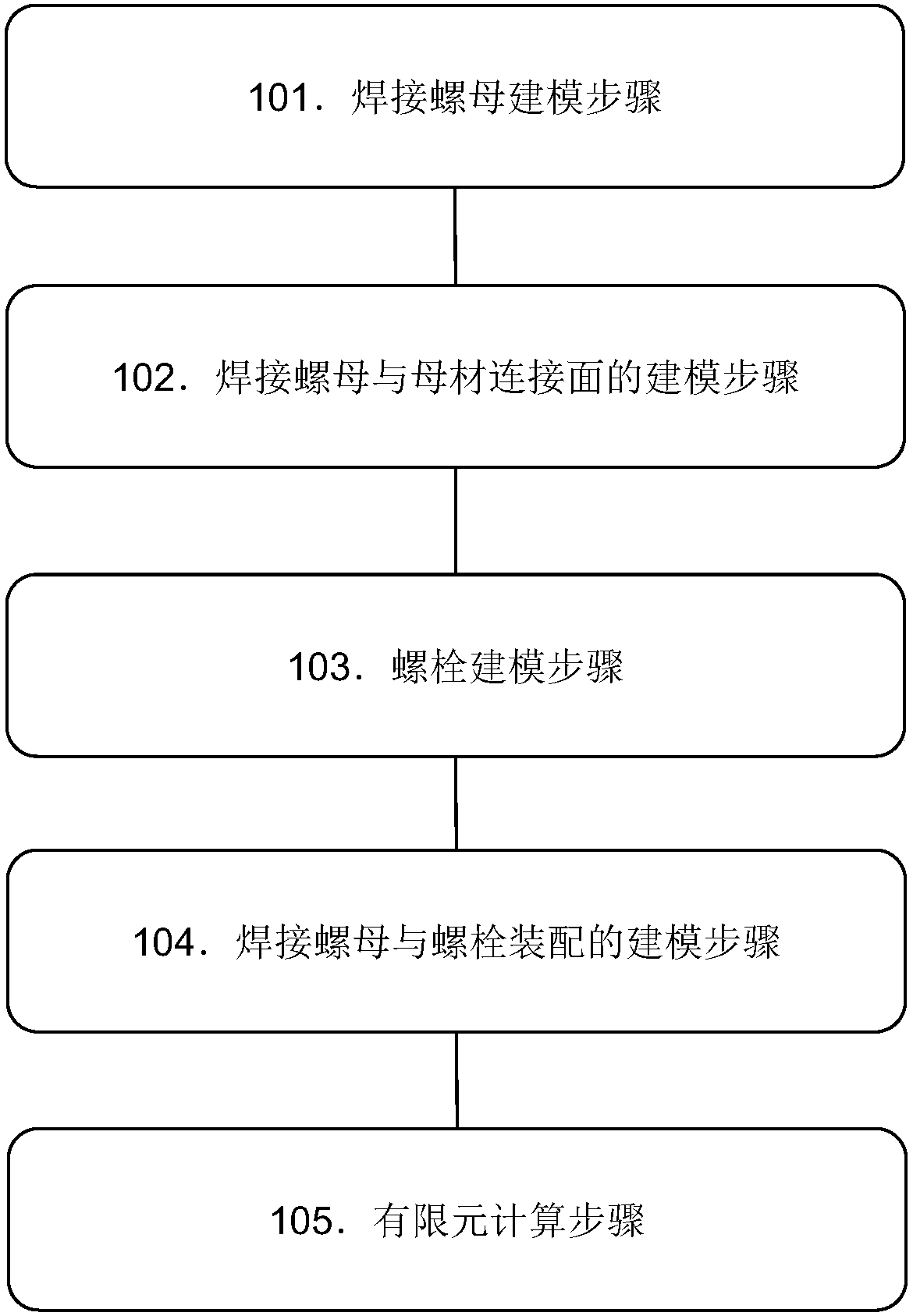

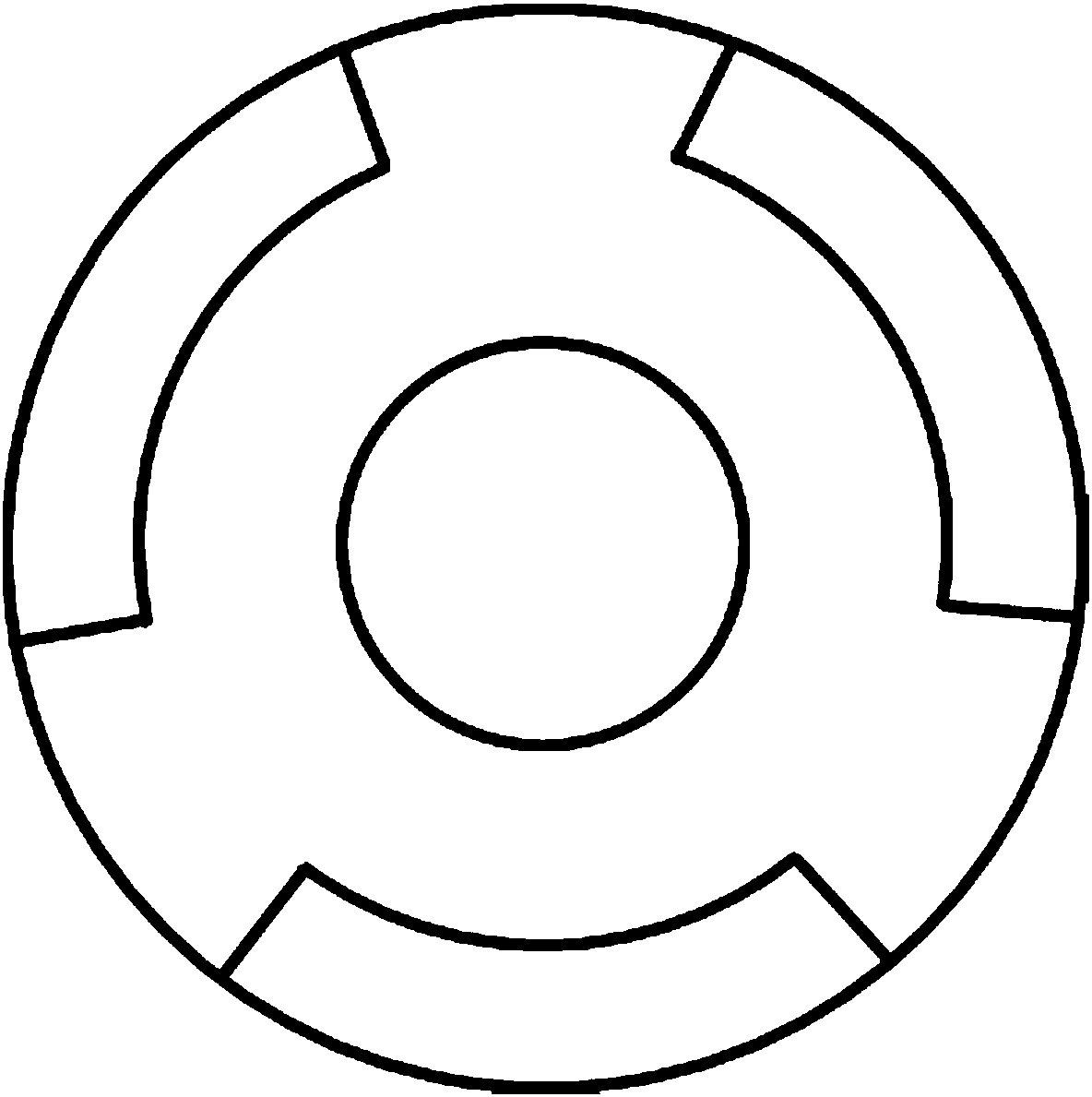

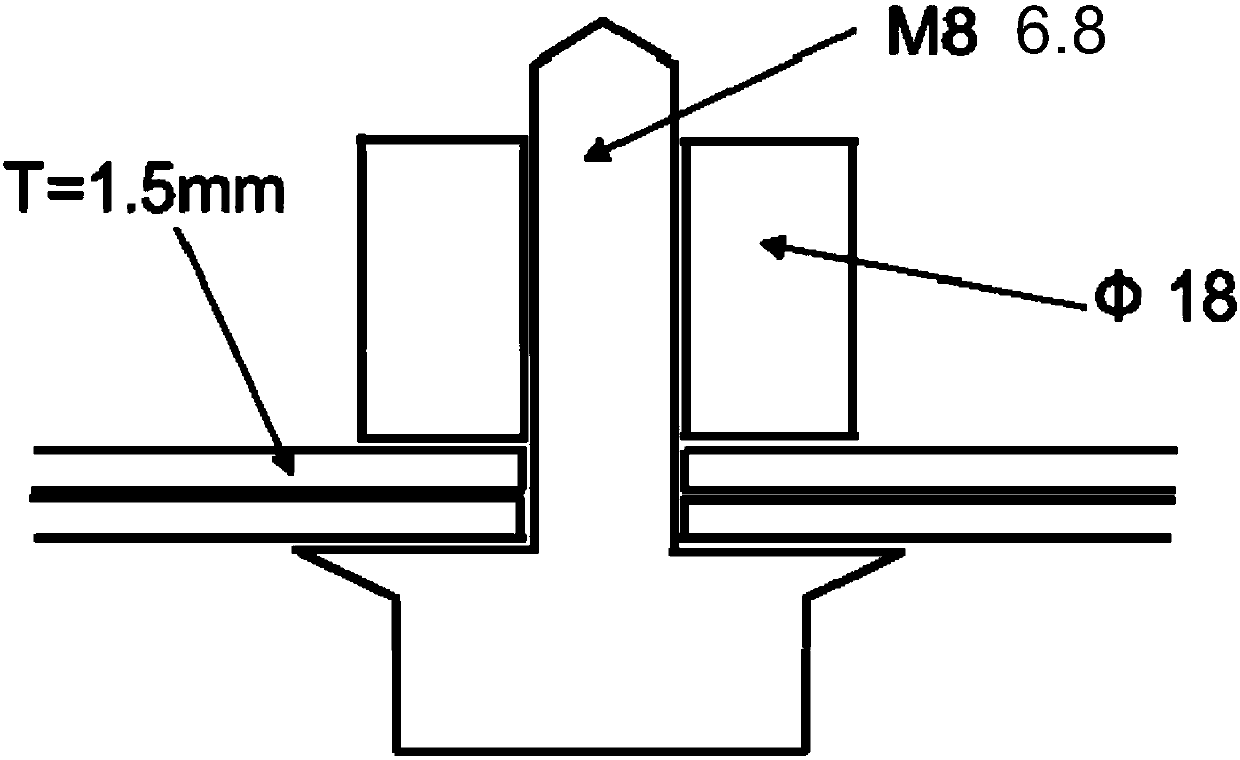

Welding nut finite element modeling method based on automobile fatigue simulation

ActiveCN107563072AAccurate stress distributionEasy to masterSpecial data processing applicationsStress distributionEngineering

The invention discloses a welding nut finite element modeling method based on automobile fatigue simulation. The method includes the following steps that welding nut modeling is conducted, wherein a solid element network of a welding nut and a base metal is established through point adding and projection; modeling of a welding-nut and base-metal connection surface is conducted, wherein contact modeling is conducted on a bonding wire, the welding nut and the base metal; modeling of a bolt is conducted, wherein the bolt matched with the welding nut is subjected to modeling; modeling of assemblyof the welding nut and the bolt is conducted, wherein modeling of connection of the bolt and the welding nut is conducted, and pretightening force of the bolt is set; finite element calculation is conducted, the established model is moved into a fatigue finite element calculation model, and through the simulation of a finite element program, the force bearing mode of the finite element welding nutis obtained. The method not only considers the connection structure of a welding place, but also considers the contact effect of the nut to a plate, the deformation behavior of the welding nut in thefatigue simulation can be accurately simulated, and accurate plate stress distribution is obtained.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

Mine adhesive tape tearing intelligent detecting system based on machine vision

InactiveCN103387123AEfficient identificationWith non-contactControl devices for conveyorsFeature extractionImaging processing

The invention provides a mine adhesive tape tearing intelligent detecting system based on machine vision, belongs to the technical field of detection and particularly relates to the mine adhesive tape tearing intelligent detecting system based on the machine vision. The invention provides the mine adhesive tape tearing intelligent detecting system based on the machine vision with the advantages that the precision is high, the speed is high, the non-contact effect is realized, and the repeatability dynamic measurement is adopted. The mine adhesive tape tearing intelligent detecting system comprises an image collecting system, an image processing system and an image analyzing and identifying system and is structurally and mainly characterized in that the image collecting system consists of a machine vision system and a light source and pickup system, the image processing system consists of an image preprocessing part and an image cutting part, and the image analyzing and identifying system consists of a feature extraction part and an understanding and identifying part.

Owner:刘晓奇

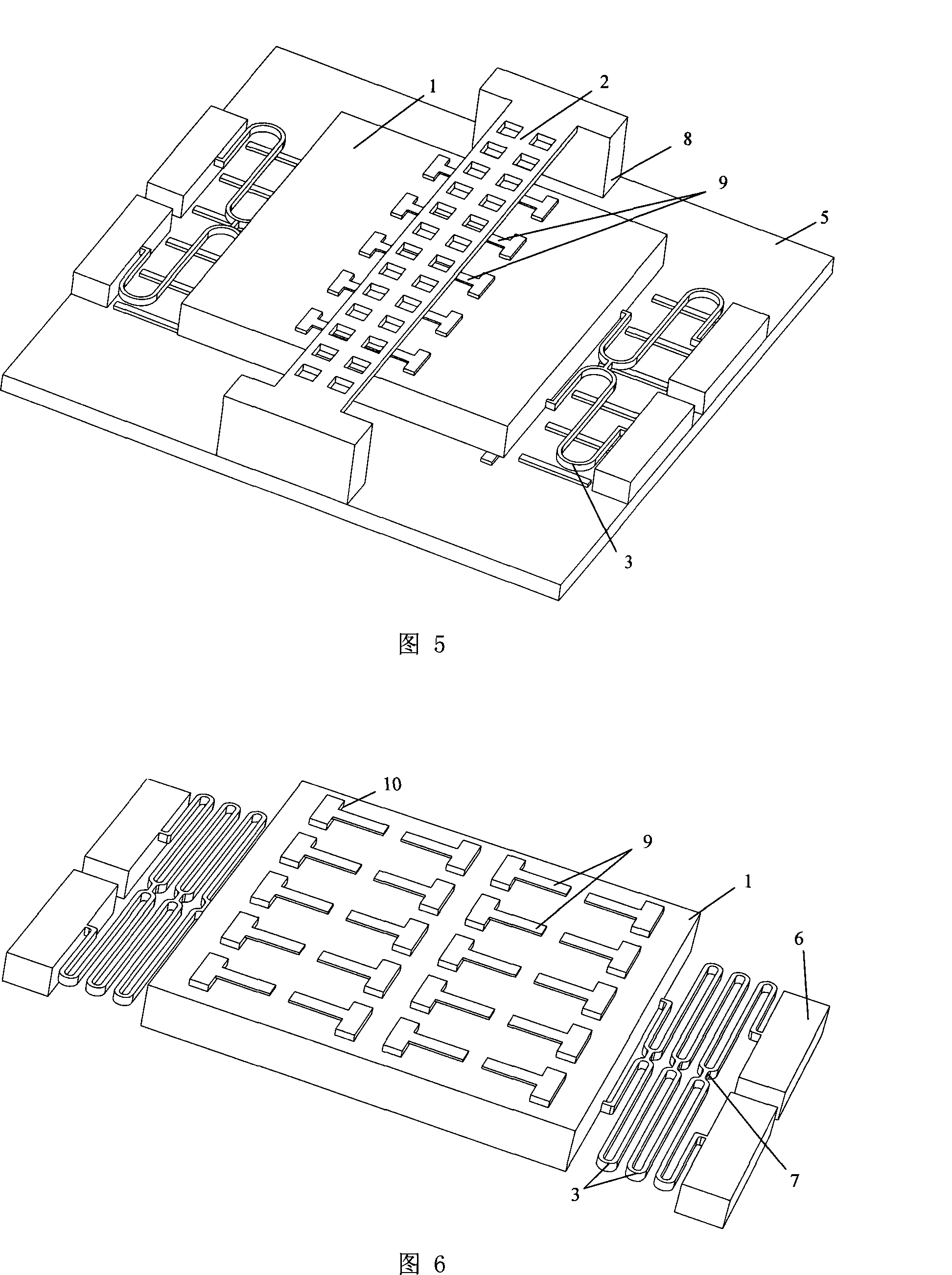

Normally closed micro-mechanical inertia electrical switch

InactiveCN101699604AEasy to controlImprove contact effectElectric switchesImpact accelerationContact electrode

The invention discloses a normally closed micro-mechanical inertia electrical switch, and belongs to the technical field of micro-electro-mechanical engineering. The normally closed micro-mechanical inertia electrical switch comprises an insulating substrate, a siamesed serpentine spring, a support layer, a fixed contact electrode, a spring support seat, a mass block electrode and a continuum between springs, wherein the fixed contact electrode and the support layer are all positioned on the insulating substrate; the mass block electrode is positioned above the fixed contact electrode, and is contacted with the fixed contact electrode; the spring support seat is fixed on the insulating substrate and positioned on two sides of the support layer; the siamesed serpentine spring is positioned above the support layer; one end of the siamesed serpentine spring is connected with the spring support seat, while the other end is connected with the mass block electrode; and the continuum between the springs is positioned in the middle of the siamesed serpentine spring and is connected with the siamesed serpentine spring on the two side. The normally closed micro-mechanical inertia electrical switch effectively improves the contact effect between the mass block electrode and the fixed contact electrode; and the mass block electrode cannot collide with the spring support seat violently under outside impact acceleration, so the damage to devices is effectively prevented.

Owner:SHANGHAI JIAO TONG UNIV

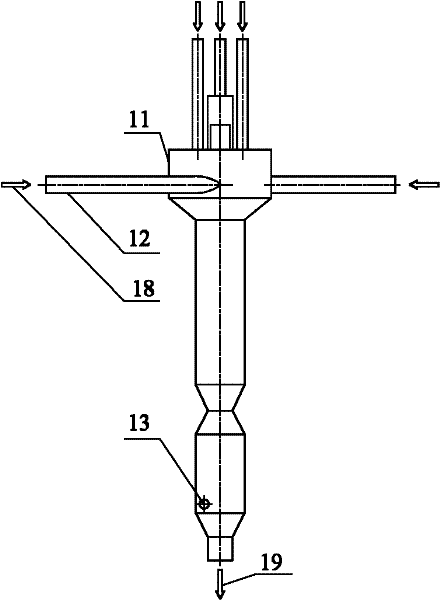

Axial-flow ultrashort contact cyclone reactor

ActiveCN102533311AShort stayImprove contact efficiencyCatalytic crackingChemical/physical processesRetention periodCyclone

The invention discloses an axial-flow ultrashort contact cyclone reactor, which is technically characterized in that: raw materials and catalysts are mixed in a mixing cavity, and perform three-dimensional spiral motion in an annular space under the guidance of guide vanes, the turbulivity is high and a catalyst-oil contact effect is good. The axial-flow ultrashort contact cyclone reactor has the advantages that: all components in the reactor are fully contacted, quickly reacted, and separated while reacted, so that reaction and separation are carried out synchronously; when the axial-flow ultrashort contact cyclone reactor is applied to the heavy oil and poor oil processing technological process such as heavy oil catalytic cracking, residual oil hydrocracking and heavy oil cracking for preparing ethylene, a problem of overcracking caused by overlong retention period and backmixing of oil, gas and a catalyst in the reactor can be avoided, a problem of equipment coking in the conventional reaction process can be avoided, and the on-stream time of the device is prolonged.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

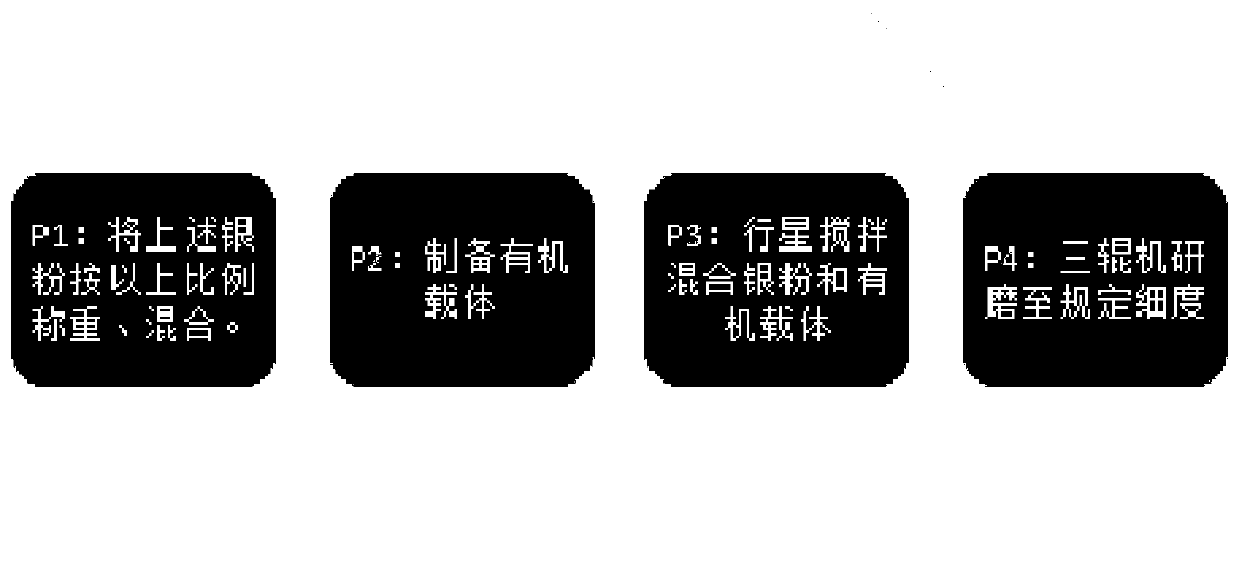

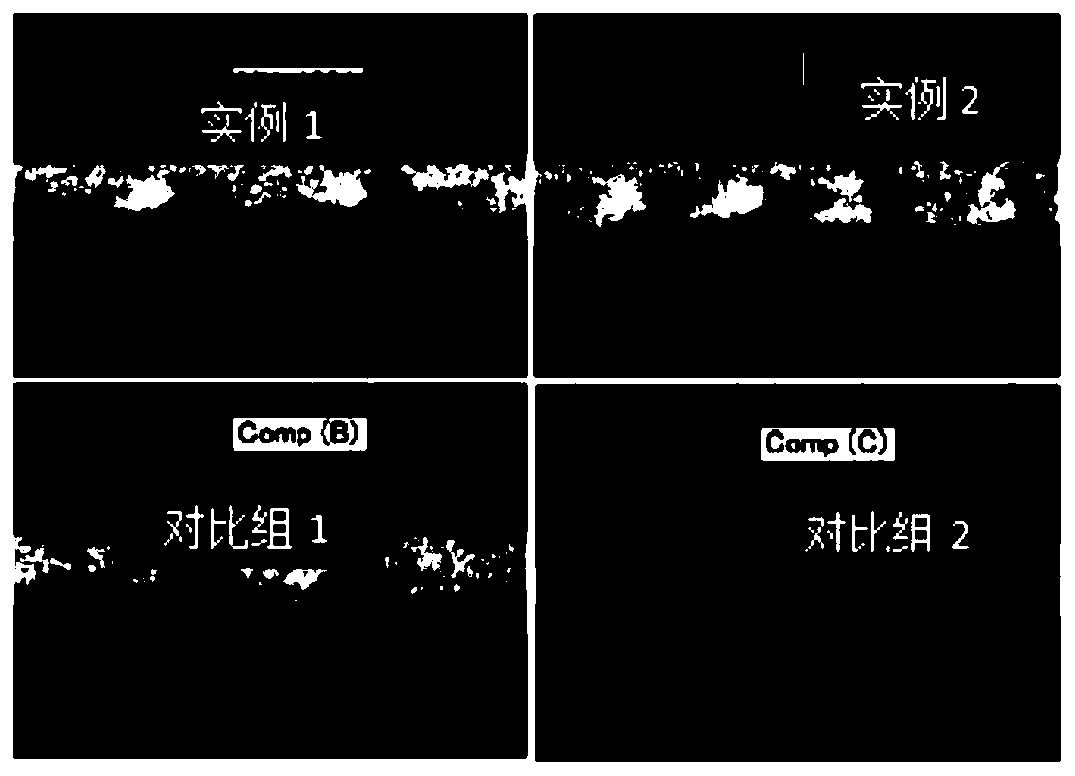

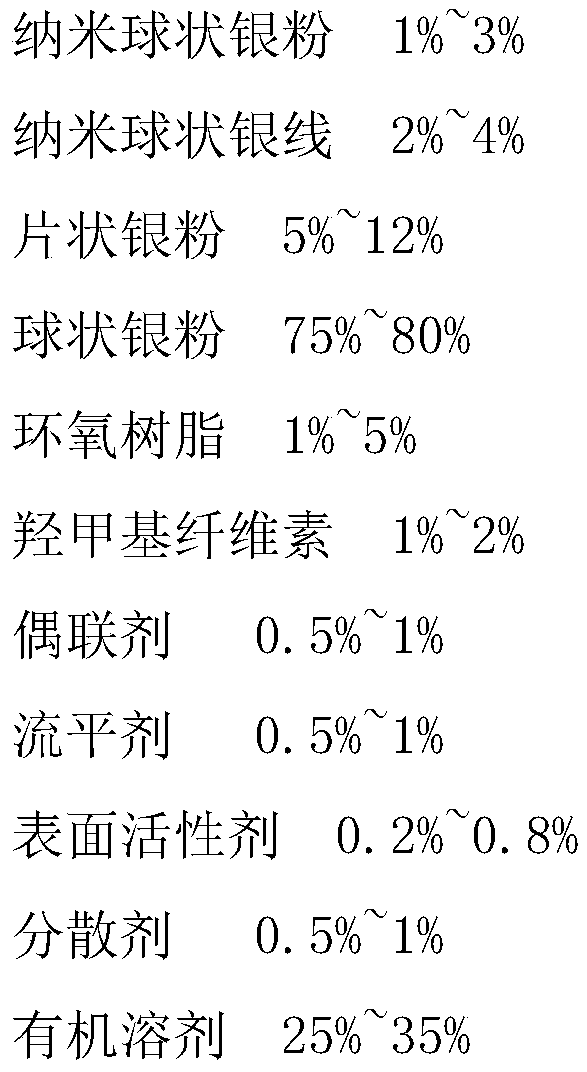

Heterojunction cell low-temperature silver paste and preparation method thereof

InactiveCN109801735AGuaranteed to shapeGuaranteed welding tensionNon-conductive material with dispersed conductive materialPhotovoltaic energy generationHeterojunctionSilver paste

The invention discloses heterojunction cell low-temperature silver paste, which comprises the following raw materials by weight: 1%-3% of nano spherical silver powder, 2%-4% of nano spherical silver wires, 5%-12% of flake silver powder, 75%-80% of spherical silver powder, 1%-5% of epoxy resin, 1%-2% of hydroxymethyl cellulose, 0.5%-1% of a coupling agent, 0.5%-1% of a leveling agent, 0.2%-0.8% ofa surfactant, 0.5%-1% of a dispersant and 25%-35% of an organic solvent. The heterojunction cell low-temperature silver paste provided by the invention creatively chooses four kinds of silver powder with different shapes and different specifications for matching, each kinds of silver powder takes its advantages to reduce the contact resistance, the flake silver powder ensures a certain welding tension, the resistance after sintering is greatly reduced through the contact between surfaces, and a good contact effect with ITO on the upper layer of an amorphous silicon film of the HIT is achieved.

Owner:上海银浆科技有限公司

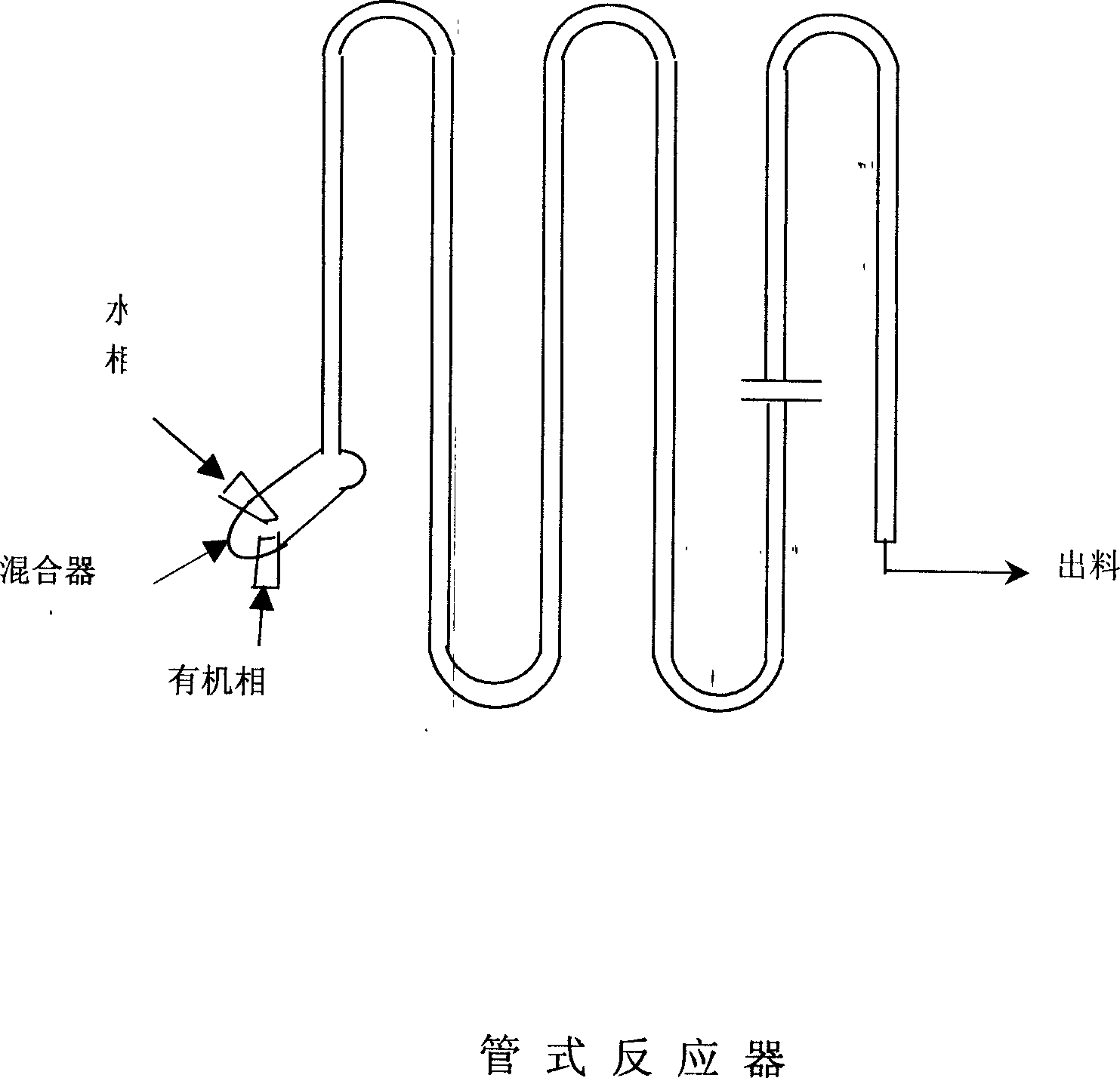

Production of diphenyl carbonate by triphosgene or solid phosgene

InactiveCN101074193AEliminate running, dripping and leakingHigh recovery ratePreparation from organic carbonatesCarbonate esterPolycarbonate

Production of diphenyl carbonate from trichloromethyl-carbonate ester adopts tubular reactor to increase contact effect and has more yield.

Owner:赵云

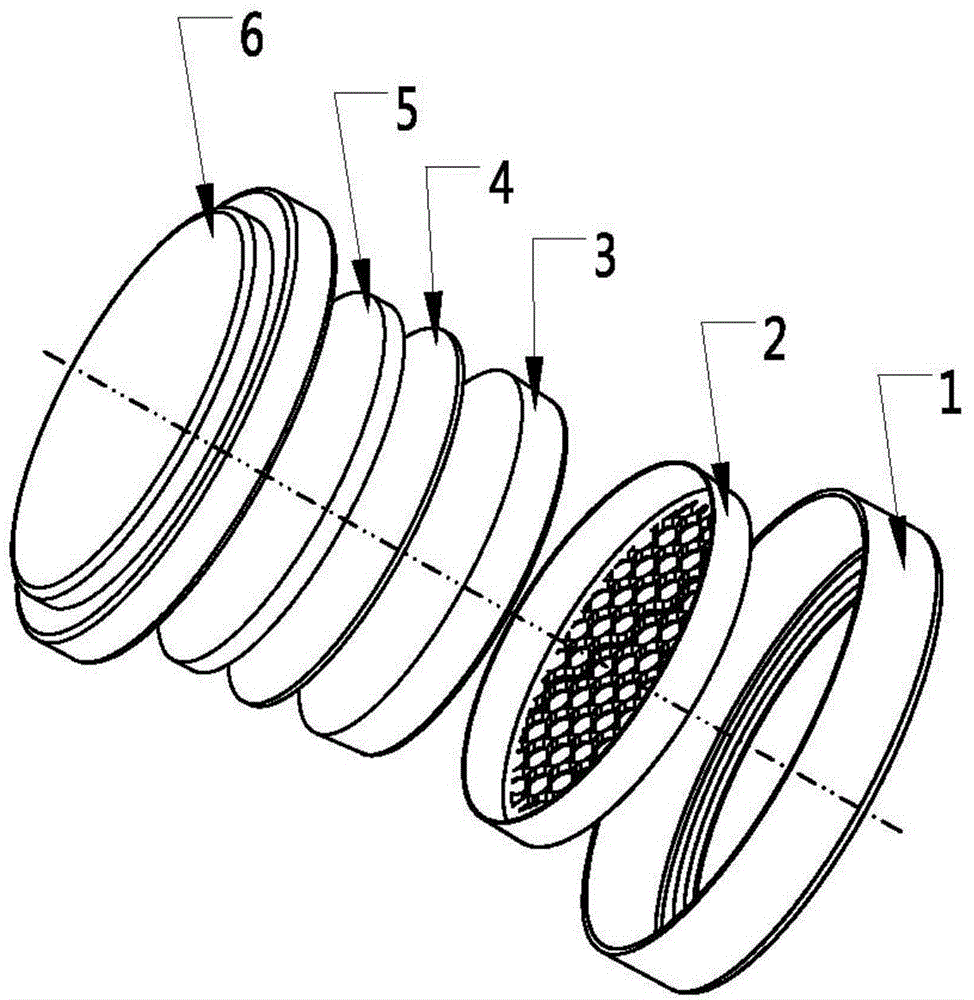

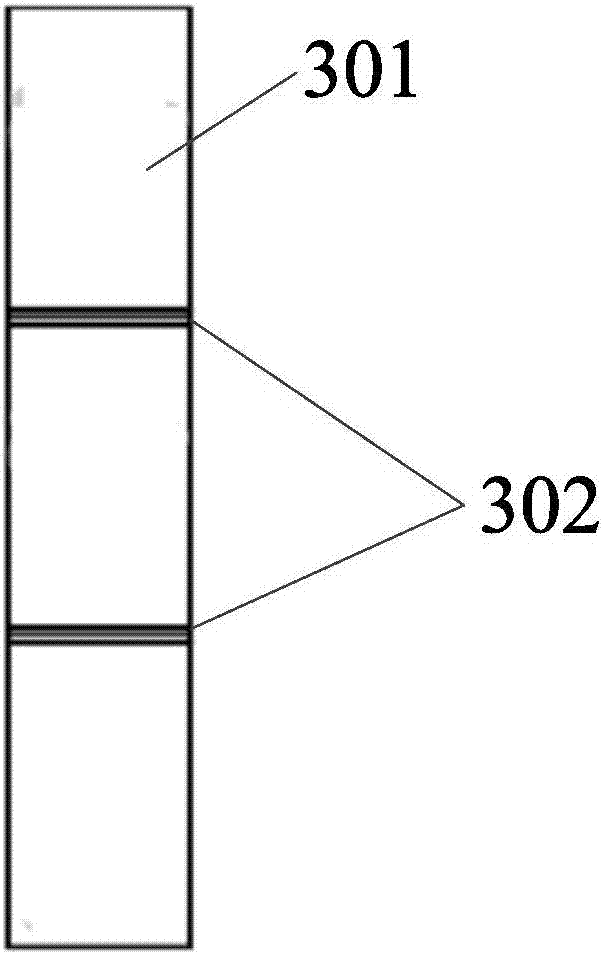

Button cell and button cell current collector

ActiveCN103606684AIncrease elasticityGuaranteed contact effectElectrode carriers/collectorsLithiumButton battery

The invention discloses a button cell, comprising a positive cap, a positive plate, a diaphragm, a lithium sheet and a negative cap, which are stacked successively, wherein a current collection grid is arranged between the positive cap and the positive plate; the current collection grid comprises a plurality of parallel current collector sheets curved and bent repeatedly relative to a base plane of the current collection grid; the repeatedly curved and bent current collector sheets provide elasticity for the current collection grid, absorb an internal dimension error due to large dimensional tolerance of internal components of the cell or consumption of interior materials, and ensure and always maintain good contact effect and conductivity between internal components of the cell, thereby reducing the internal resistance of the cell, and increasing the discharging current and the cell capacity. The invention also discloses a button cell current collector which comprises the current collection grid, wherein the current collection grid comprises the plurality of parallel integrated impact-molded current collector sheets curved and bent repeatedly relative to the base plane of the current collection grid. The current collector ensures and always maintains a good contact effect for the interior of the cell to which the current collector is applied, reduces the internal resistance of the cell, and increases the discharging current and the cell capacity.

Owner:EVE ENERGY CO LTD

Plug and socket combining device of illuminating bus slot

InactiveCN101644422AAffect contact effectImprove stabilityElectric circuit arrangementsCoupling device detailsEngineeringCopper

The invention discloses a plug and socket combining device of an illuminating bus slot. A socket seat of a socket device is fixed into a slot body; the upper surface of the slot body is provided witha sliding door seat; the sliding door seat and the socket seat form a fixing device; the top of the sliding door seat is fixed with a sliding door cover; an upper cover and a lower cover of a plug device are arranged on the upper part of the sliding door cover; copper sheet pins are fixed into the lower cover; both sides of the upper cover and the lower cover are respectively fixed with a side ear; a torsional spring is arranged between the upper part of each side ear and the lower cover; a central hole of the torsional spring is fixed by a bolt; the upper end of each side ear is higher than the upper cover, and the lower end of each side ear is clamped in the corresponding concave position of the slot body. The socket device avoids influencing the plug contact effect due to temperature rise in using a daily plug, enhances the connection fastness and reliability and has high protecting grade.

Owner:JIANGSU YINONE ELECTRIC

Internal component, fluid bed reactor and application method

ActiveCN107281981AReduce thermal stressEfficient crushingChemical/physical processesGas solidEngineering

The invention provides an internal component, a fluid bed reactor containing the internal component and an application method. The fluid bed reactor is divided into at least two reaction spaces, connected in series, from top to bottom by a baffle in the internal component, and each pore channel in the baffle is communicated with two reaction spaces adjacent to the internal component. When bubbles entrained with particles in the first reaction space adjacent to the internal component enter the pore channel of the component, the bubbles are broken and crushed by the pore channel, gas with crushed bubbles uniformly enters a second reaction space adjacent to the internal component, and most of catalyst particles carried by the bubbles are settled back into the first reaction space. Because the internal component can effectively crush the bubbles during operation, the contact effect between gas and solid phases is enhanced. Meanwhile, the gas in the first reaction space directly enters the second reaction space, and the catalyst particles in the first reaction space are effectively prevented from entering the second reaction space so as to realize gas-solid-phase separation, so that gas-solid backmixing is effectively inhibited.

Owner:TSINGHUA UNIV

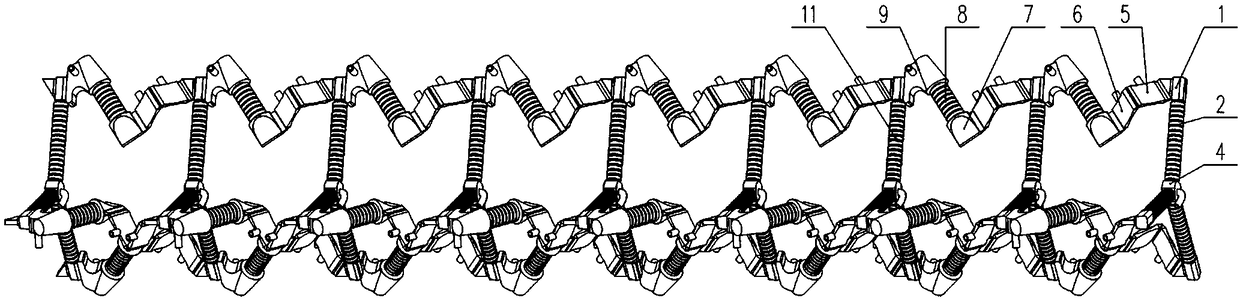

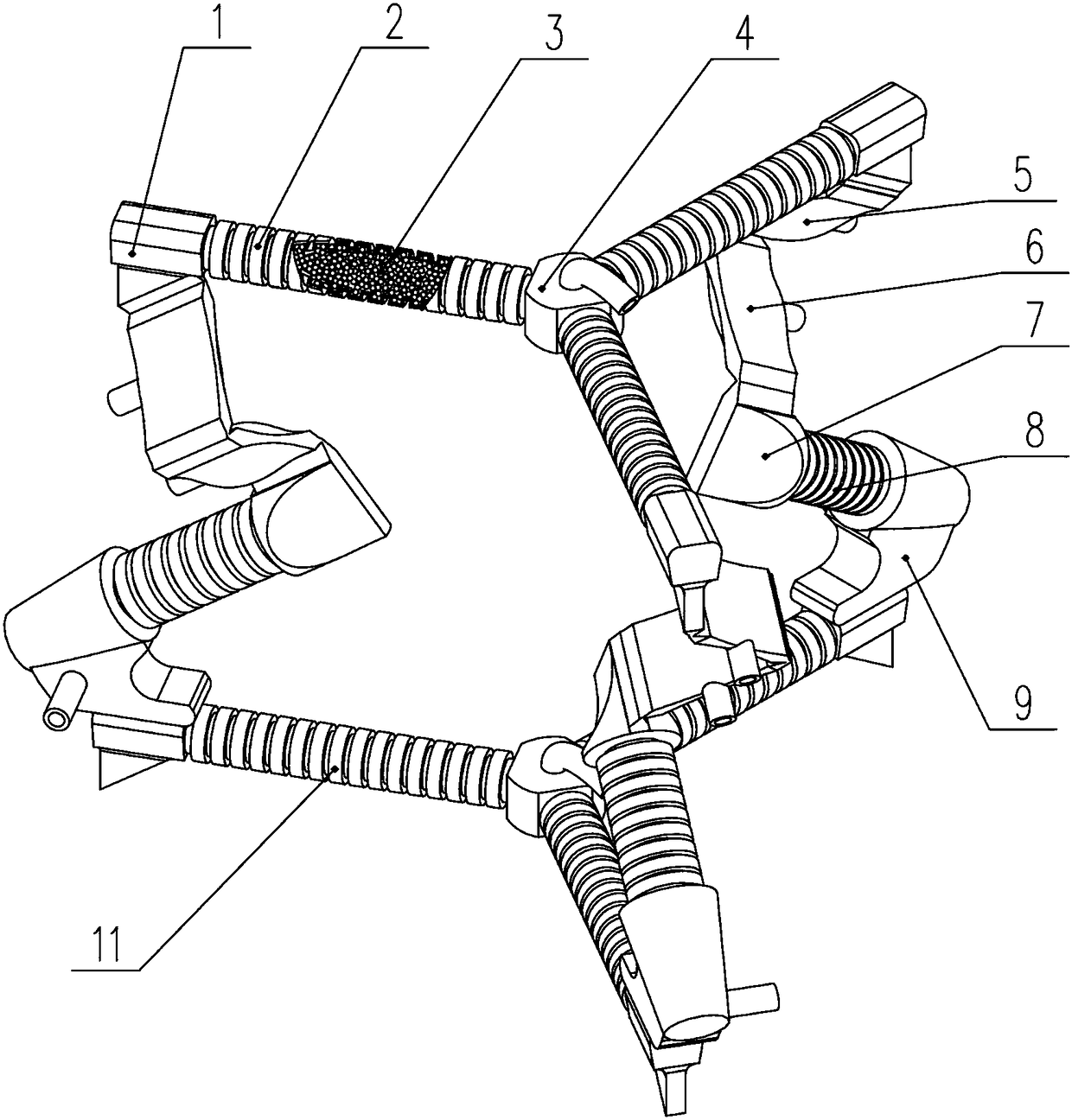

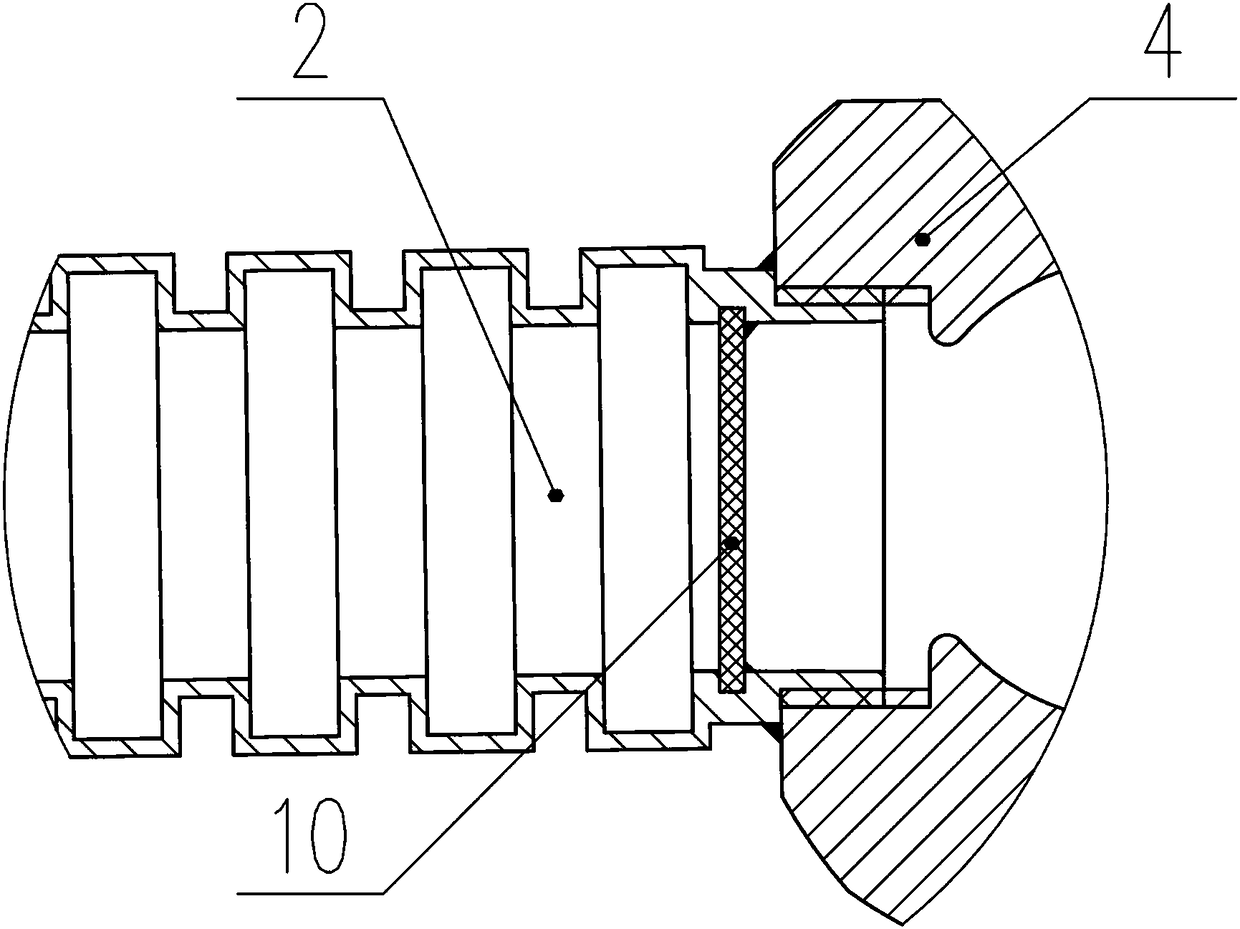

Fully-compliant deformable robot with controllable rigidity

ActiveCN108436898AGuaranteed contact effectMaintain propertiesProgramme-controlled manipulatorTerrainEngineering

The invention relates to a fully-compliant deformable robot with the controllable rigidity. The fully-compliant deformable robot with the controllable rigidity mainly comprises first fixing ends, sleeve shells, abrasive particle spheres, air suction fixing ends, first air bag rods, second air bag rods, first fixing ends, second telescopic sleeves, inflation control ends, seal nets and first telescopic sleeves. According to the fully-compliant deformable robot with the controllable rigidity provided by the invention, the rigidity of connecting rods can be controlled according to the demands ofdifferent occasions, so that a contact effect of a robot body and a contact substance can be better ensured, an original characteristic of a parallel mechanism can be ensured, and the fully-compliantdeformable robot can be deformed and moved through control; and when the rigidity of one section is lower, the mechanism at the section does not have the characteristic of the parallel mechanism, butthe joint part is flexible so as to be deformed at will, and an upper platform and a lower platform can be radially contracted to a small extent, so that the robot can favorably enter a complicated terrain and carry out suspension and sharp turning. The fully-compliant deformable robot with the controllable rigidity provided by the invention is fully compliant so as to have better performances during detecting and rescuing processes.

Owner:YANSHAN UNIV

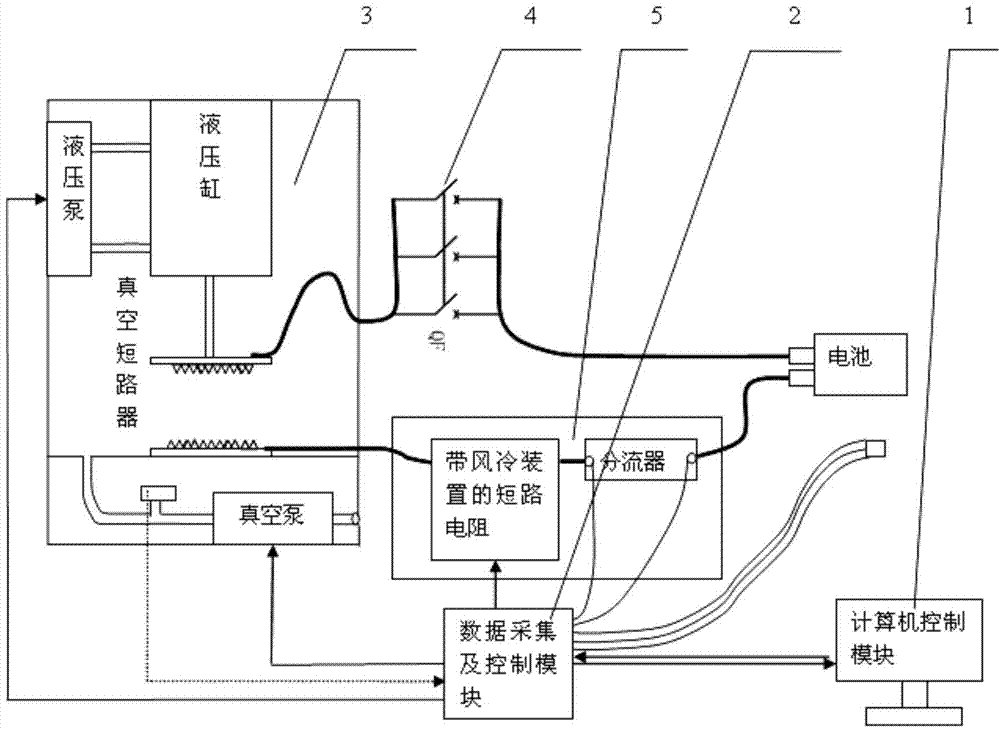

Ultralarge current battery short circuit test device

ActiveCN103698645AReduce contact resistanceAvoid arcingElectrical testingOpen-circuit testElectrical battery

The invention belongs to the technical field of evaluation devices for the safety performance of a battery, and particularly relates to an ultralarge current battery short circuit test device. In the technical scheme, a vacuum pump needs to be started for vacuumizing before a short circuit test, when vacuum degree collected by a data collecting and controlling module achieves the demands, a computer control module sends a switching value command to the data collecting and control module, and a power pump unit of a vacuum breaker starts or closes a short circuit board, wherein the vacuumizing operation is used for preventing the short circuit board from being oxidated during high-temperature contacting and for not increasing the contacting resistance, so the phenomena of oxidation, sparks and arc pulling during the disconnection existing under the aerobic environment in the prior art are avoided; besides, the copper short circuit is made to be sawtooth-shaped, conductive paste is smeared, so the contacting area and the contacting effect are increased; a short circuit resistor is arranged and an air cooling device is arranged, so stable temperature of the resistor in a loop is ensured and the stable resistance value in the loop is ensured.

Owner:CHINA NORTH VEHICLE RES INST

Shrapnel-type wire connector of auxiliary terminal of intelligent electric energy meter

InactiveCN102193079ACrimping pressure is smallEasy to fixTime integral measurementFault toleranceContact effects

The invention provides a shrapnel-type wire connector of an auxiliary terminal of an intelligent electric energy meter. The shrapnel-type wire connector comprises metal shrapnel which is connected with a fixed board; fasteners are fixedly connected to both ends of the fixed board; and a welding hole is formed at the tail end of the metal shrapnel. By adoption of the structure, the shrapnel-type wire connector has advantages of good contact effect and high fault tolerance rate; the contactable area when the metal shrapnel is contacted with a terminal screw is larger than the contactable area when the metal shrapnel is contacted with a terminal hole; virtual connection can be avoided; moreover, as compaction pressure of the shrapnel is smaller, the shrapnel-type wire connector is easy to fix.

Owner:贾旭敏

Pressure cell fast positioning and fixing device

InactiveCN106323527AImmune to impact damageReasonable structureApparatus for force/torque/work measurementPressure cellEngineering

The present invention relates to a pressure cell fixing device. The pressure cell fixing device is composed of a carrying base and a lifting bracket; the carrying base is semi-closed hollow cylinder-shaped; a fine adjustment plate is movably arranged in the cavity of the carrying base; the bottom of the carrying base is symmetrically provided with four fine adjustment bolts; the upper end heads of the fine adjustment bolts are matched with the bottom of the fine adjustment plate; the lifting bracket is composed of an upper spiral bracket, a lower spiral bracket and a rotating handle; the upper end head of the upper spiral bracket is fixedly connected with the bottom of the carrying base; the device can rise and descend rapidly by adjusting the rotating handle; and the complete attachment of a pressure cell to the surface of surrounding rock can be realized by means of the fine adjustment bolts, an optimal contact effect can be achieved, and accurate measurement can be realized. The pressure cell fast positioning and fixing device of the invention has the advantages of reasonable structure, simple installation, high environmental adaptability and fast and flexible operation, and is especially suitable for the fast positioning and fixing of a pressure cell between tunnel surrounding rock and a steel arch support structure in underground construction.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Stripping and fixing device of stretching machine

ActiveCN104003231BBlock replyPrevent swimmingUnfolding thin materialsWebs handlingScrew threadContact effects

An edge peeling and positioning device of a spreading machine belongs to the field of clothing machines. The spreading machine comprises a spreading table, a machine frame is arranged on the spreading table and provided with an upper cloth guiding roller, a lower cloth guiding roller, a cloth pressing roller, a large cloth spreading roller and a lower cloth spreading roller. The edge peeling and positioning device comprises a beam and a pair of toothed belt type edge peeling mechanisms and is characterized by further comprising a front cloth expanding roller, a rear cloth expanding roller and a peeled and expanded cloth edge maintaining roller, wherein the front cloth expanding roller is supported on the machine frame and provided with front cloth expanding threads, the rear cloth expanding roller is provided with rear cloth expanding threads, and the peeled and expanded cloth edge maintaining roller is provided with flanges; the beam is fixedly provided with a pair of belt supporting unit seats, which extend into an edge peeling toothed belt cavity and are fixedly provided with belt supporting units, and the belt supporting units are arranged inside the edge peeling toothed belt cavity and are in contact with the inner side of the edge peeling toothed belt. The edge peeling and positioning device of the spreading machine enables the cloth edges of both sides in the length direction of cloth spread on the spreading table to maintain a trim state, prevents both sides the cloth from moving towards the middle, eliminates the deflection of the edge peeling toothed belt and improves the integral contact effects of the edge peeling toothed belt with the cloth edges.

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com