Minitype inertial electrical switch capable of regulating and controlling contact time

A contact time, miniature technology, applied in the direction of electrical switches, circuits, electrical components, etc., can solve the problems of unadjustable contact time, no boundary protection of the mass block, damage to the device, etc., to improve the contact effect, facilitate the contact time, increase the The effect of coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

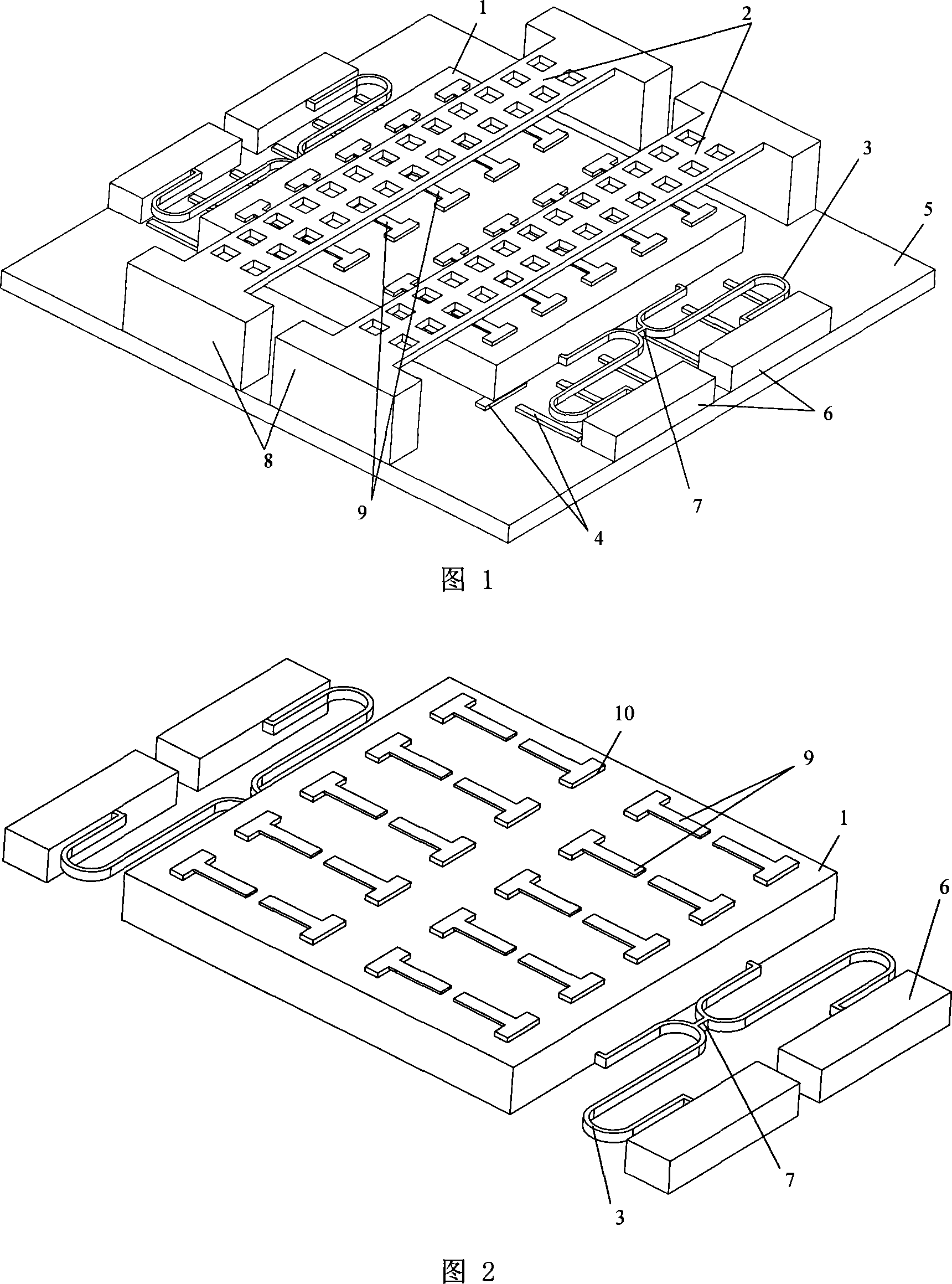

[0027] Embodiment 1 A miniature inertial electrical switch with adjustable contact time with a pair of porous elastic beam fixed electrodes

[0028] As shown in Figure 1, the micro-inertial electrical switch that can control the contact time in this embodiment includes: a mass electrode with a cantilever beam array, a porous elastic beam fixed electrode 2, a conjoined serpentine spring 3, a support layer 4, and an insulating lining Bottom 5, spring support seat 6, porous elastic beam support seat 8; the mass block electrode with cantilever beam array is composed of mass block 1 and cantilever beam array 9 fixed on mass block 1.

[0029] The support layer 4 is located above the insulating substrate 5 and below the mass block 1. The spring support base 6 is fixed on the insulating substrate 5 and located on both sides of the mass block 1. The porous elastic beam support base 8 is also fixed on the insulating substrate 5 and located on the On the other two sides of the mass block 1...

Embodiment 2

[0043] Embodiment 2 A micro-inertial electrical switch with adjustable contact time using a porous elastic beam

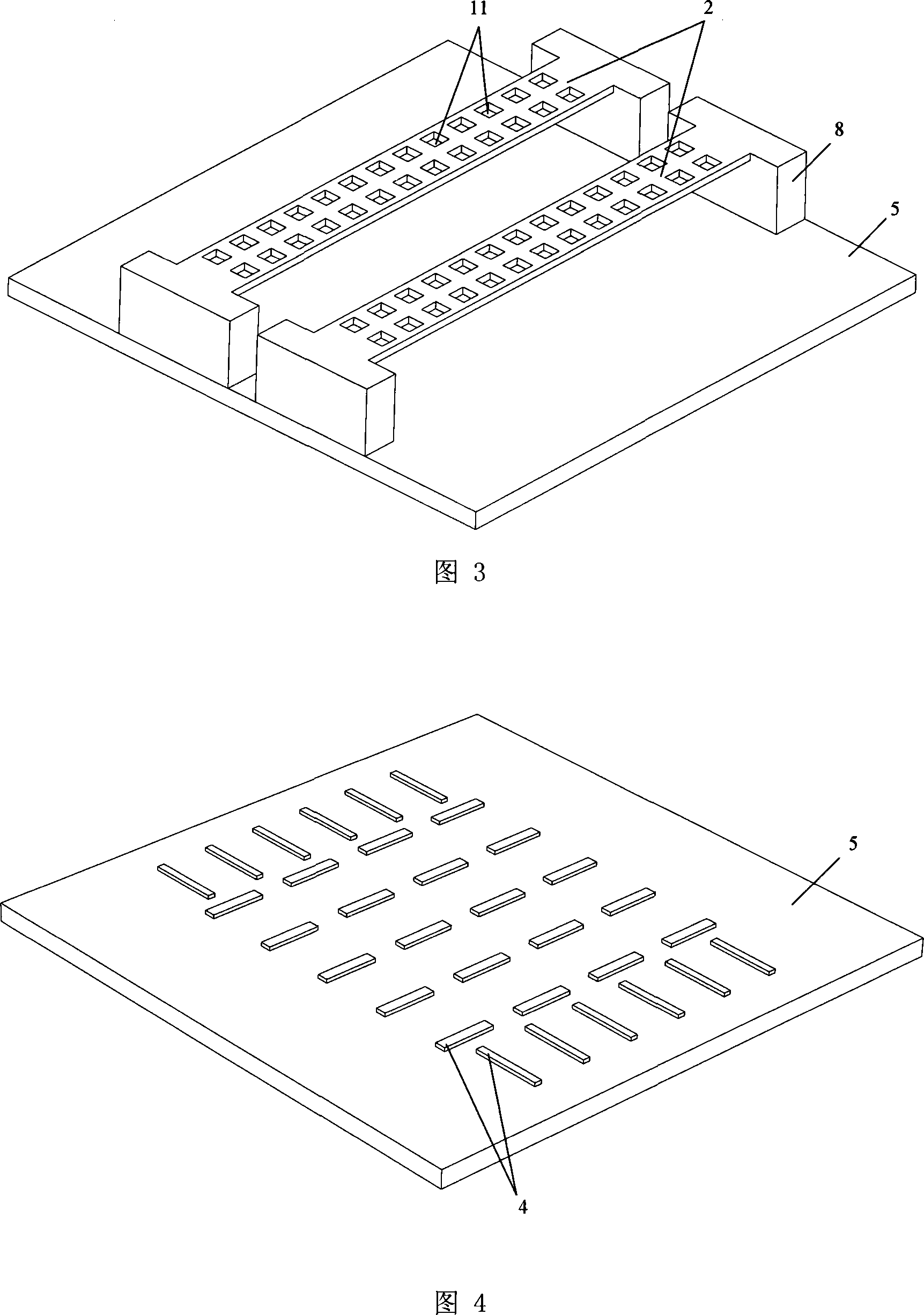

[0044] Fig. 5 is a three-dimensional schematic diagram of a micro-inertial electrical switch with an adjustable contact time using a porous elastic beam. As shown in the figure, the micro-inertial electrical switch uses a porous baffle beam as the fixed electrode 2 of the porous elastic beam. The size of the miniature inertial electrical switch is consistent with that of the miniature inertial electrical switch with adjustable contact time in Embodiment 1, and except for the fixed electrode 2 of the porous elastic beam, the shape and size of other components are consistent with Embodiment 1.

[0045] The contact time of the miniature inertial electrical switch in this embodiment can be adjusted between 20-100 microseconds.

Embodiment 3

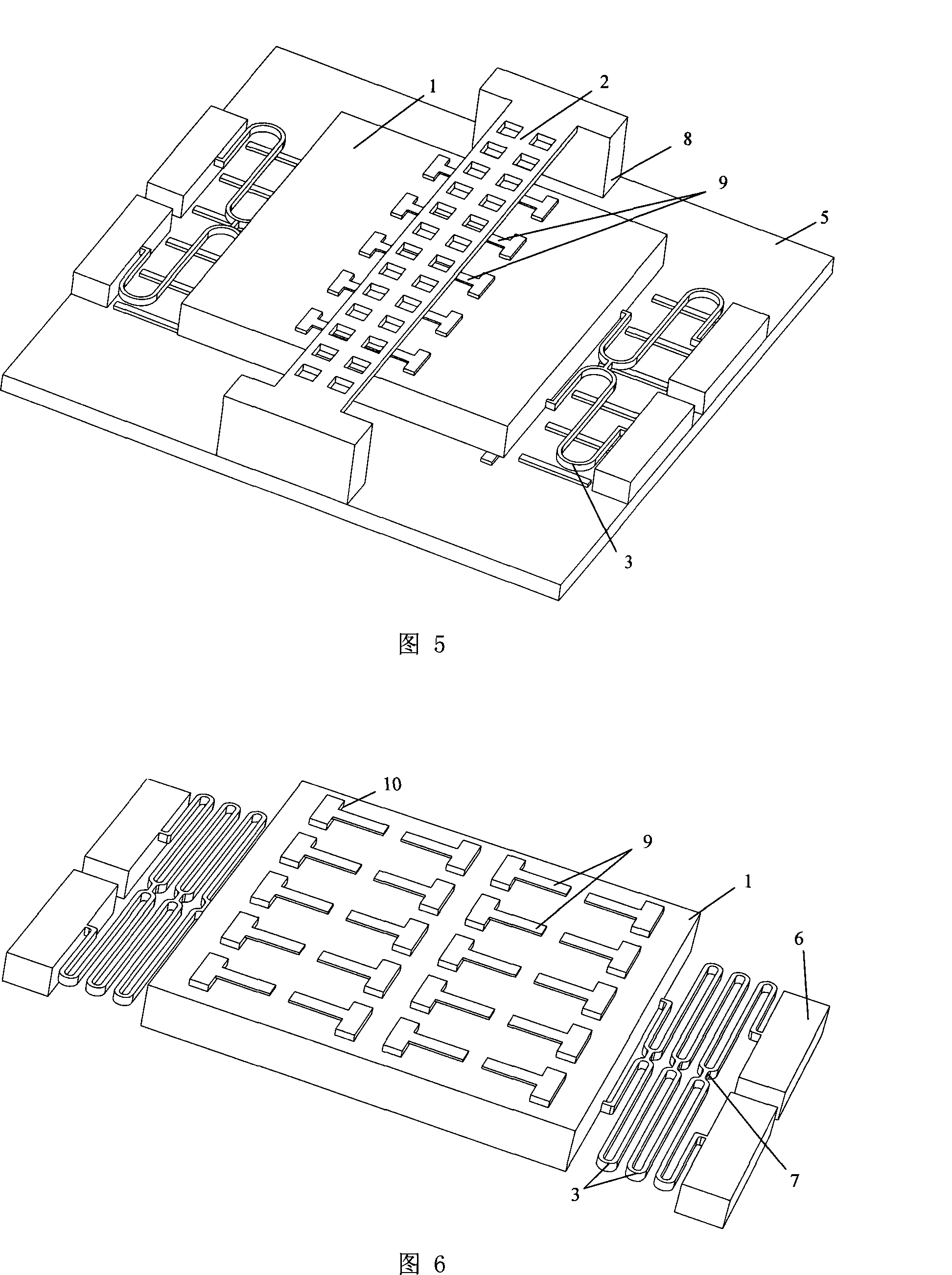

[0046] Embodiment 3 A miniature inertial electrical switch with adjustable contact time with multi-turn conjoined serpentine springs

[0047] Fig. 6 is a structural schematic diagram of a miniature inertial electrical switch with adjustable contact time in this embodiment, as shown in the figure, the conjoined serpentine spring 3 used in the miniature inertial electrical switch is multi-turn, The remaining features of the miniature inertial electrode switch are similar to Embodiment 1.

[0048] The contact time of the miniature inertial electrical switch in this embodiment can be adjusted between 20-200 microseconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com