Drive system and control method for pick-and-place basket of vending machine

A drive system and self-service vending machine technology, applied in the direction of coin-operated equipment for distributing discrete items, instruments, coin-operated equipment for distributing discrete items, etc., can solve problems such as complexity, low reliability, and complex structure , to achieve the effect of quickly opening and closing the door card

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

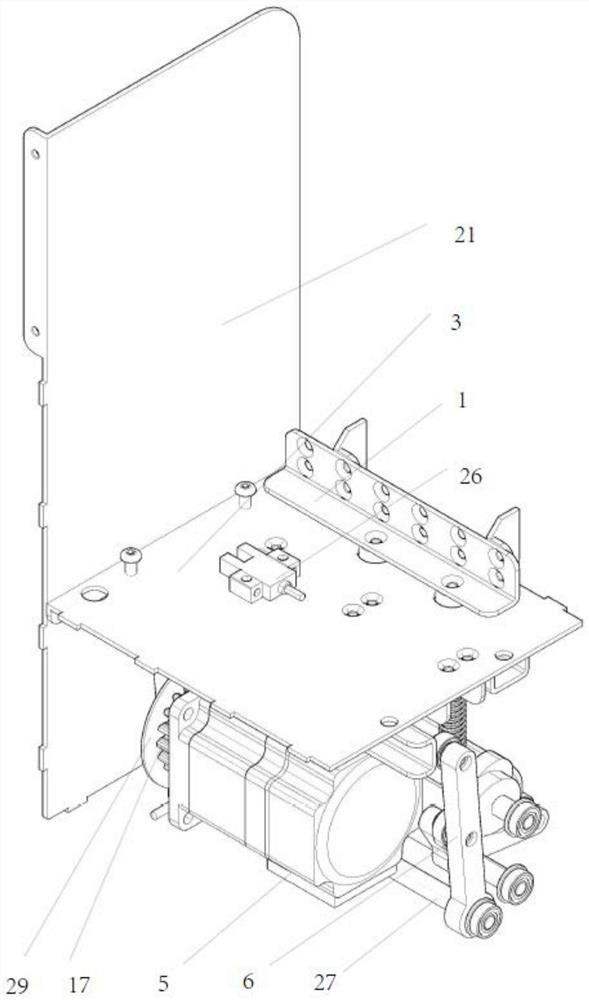

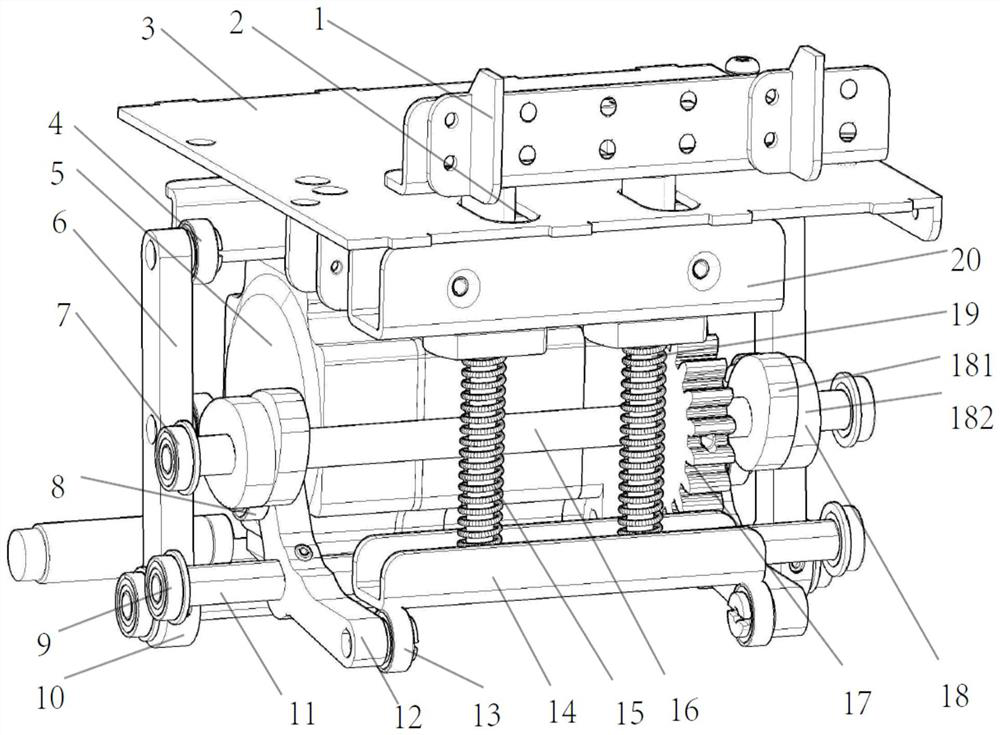

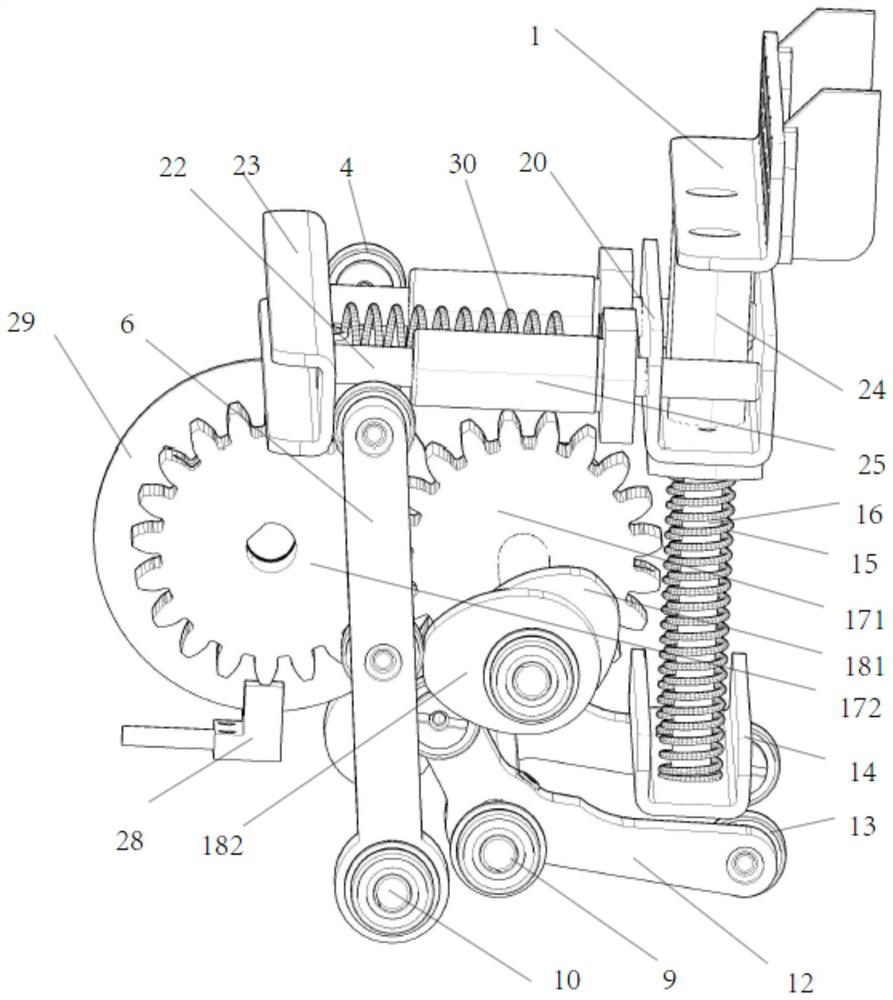

[0022] refer to Figure 1-Figure 4 , the self-service vending machine pick-and-place basket drive system includes a frame 21, a motor 5 fixed on the frame 21, a gear set 17, a double-cam structure 18, a curved ruler-shaped drive rod 12, a ruler-shaped drive rod 6, a push Frame 1, a first connection structure and a second connection structure; the motor 21 drives the double-cam structure 18 to rotate through the gear set 17, and the double-cam structure 18 includes a first cam 181 and a second cam 182 that rotate synchronously. The curved surfaces of the curved surfaces are mutually staggered at an angle of 90-150 degrees, and the stroke is time-sharing, and the stroke of the first cam 181 and the stroke of the second cam 182 are mutually staggered; the middle part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com