Tee joint type automatic temperature control valve

An automatic control valve and three-way technology, applied to multi-way valves, valve details, valve devices, etc., can solve the problems of difficult maintenance, low temperature control accuracy, complex structure, etc., and achieve reliable operation, high temperature control accuracy, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

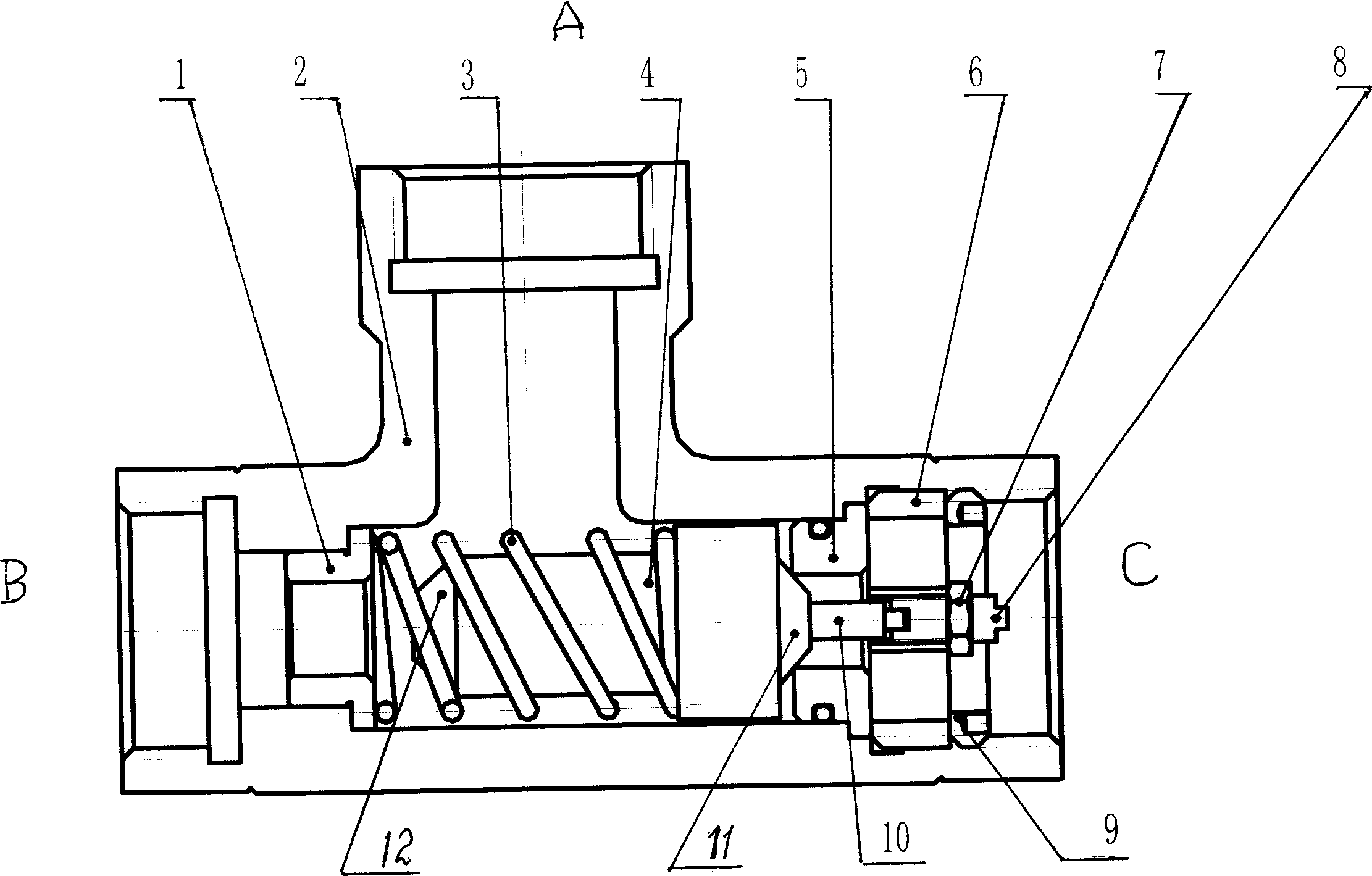

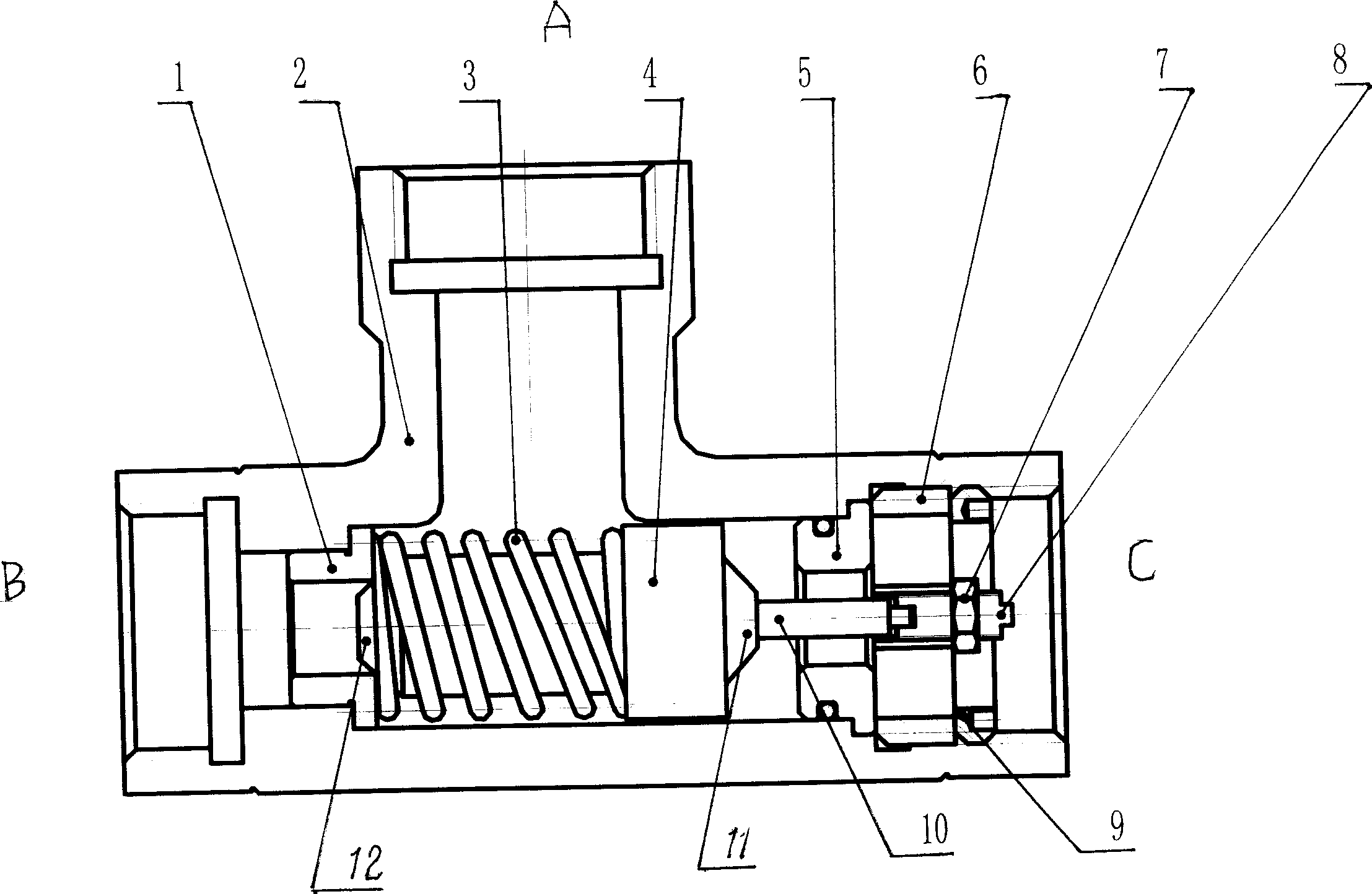

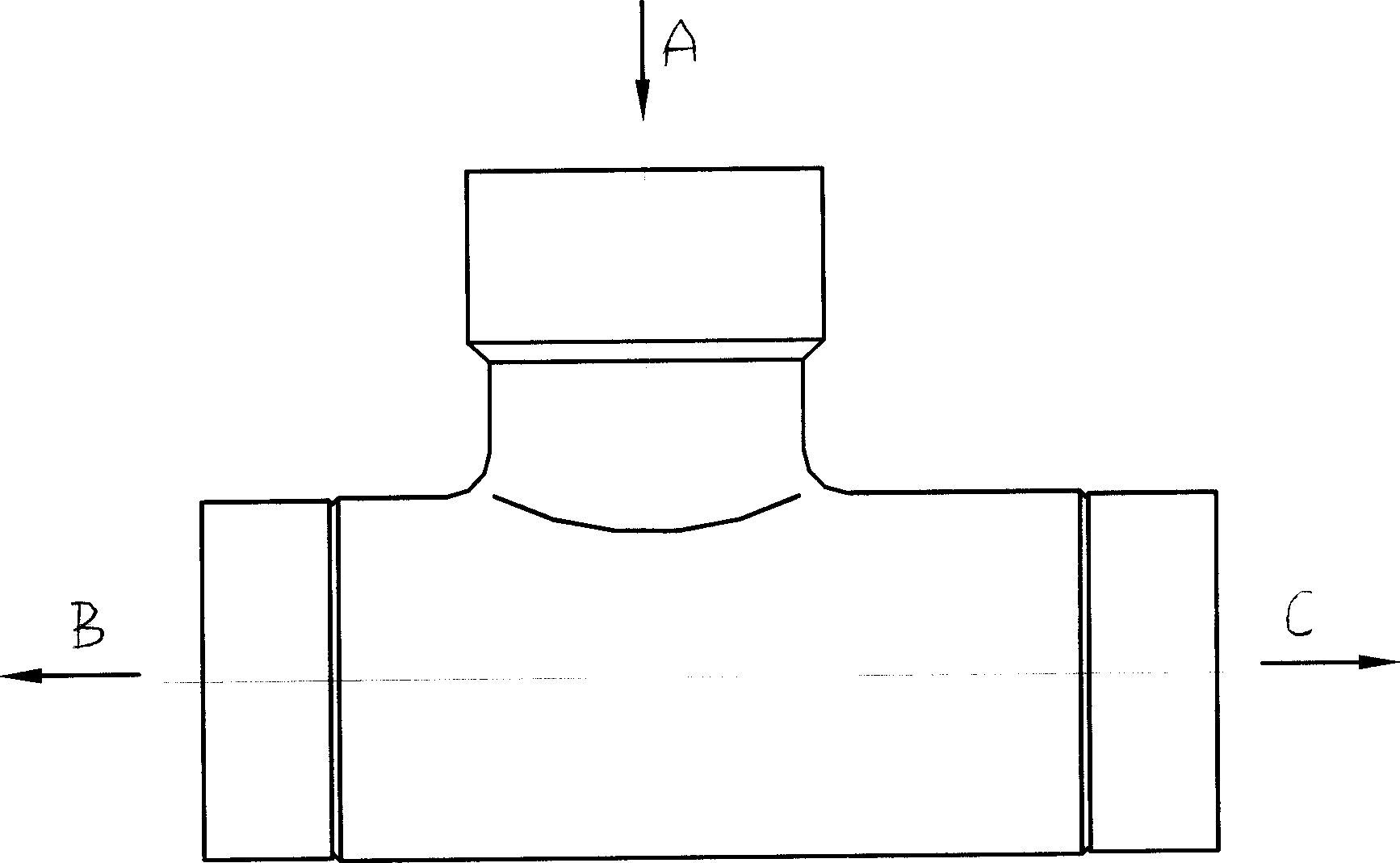

[0044] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6. A three-way valve body 2 composed of three ports A, B, and C. A stepped circular tube low-temperature port valve seat 1 with both ends of the cavity is installed at the B end of the valve body 2 cavity, and the low-temperature port valve seat 1 has a small The outer circle is in interference fit with the inner hole of the valve body 2 cavity, and the counterbore in the valve body 2 cavity is lapped and fixed with the outer circle of the valve seat 1 of the low temperature port; There is an adjusting screw ring 6 with a liquid medium flow hole 13 on it, and the adjusting screw ring 6 is fixed on the valve body 2 through external threads and internal threads on the valve body 2, and a locking adjusting screw is installed on the inner wall of the valve body 2 Fixing ring 9 in ring 6 position. A stepped circular tube high-temperature port valve seat 5 with openings at both ends is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com