Patents

Literature

347 results about "Tee junction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

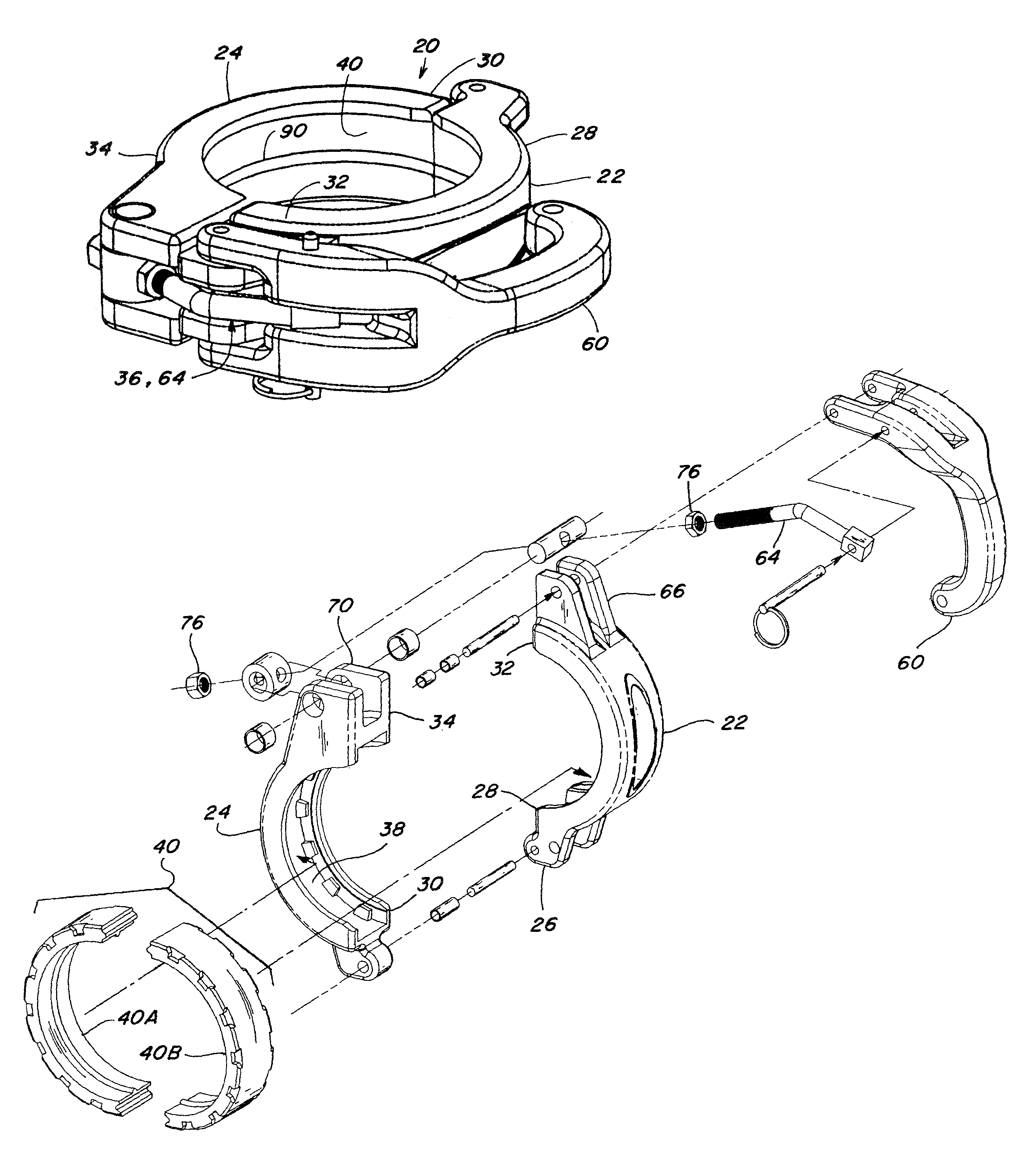

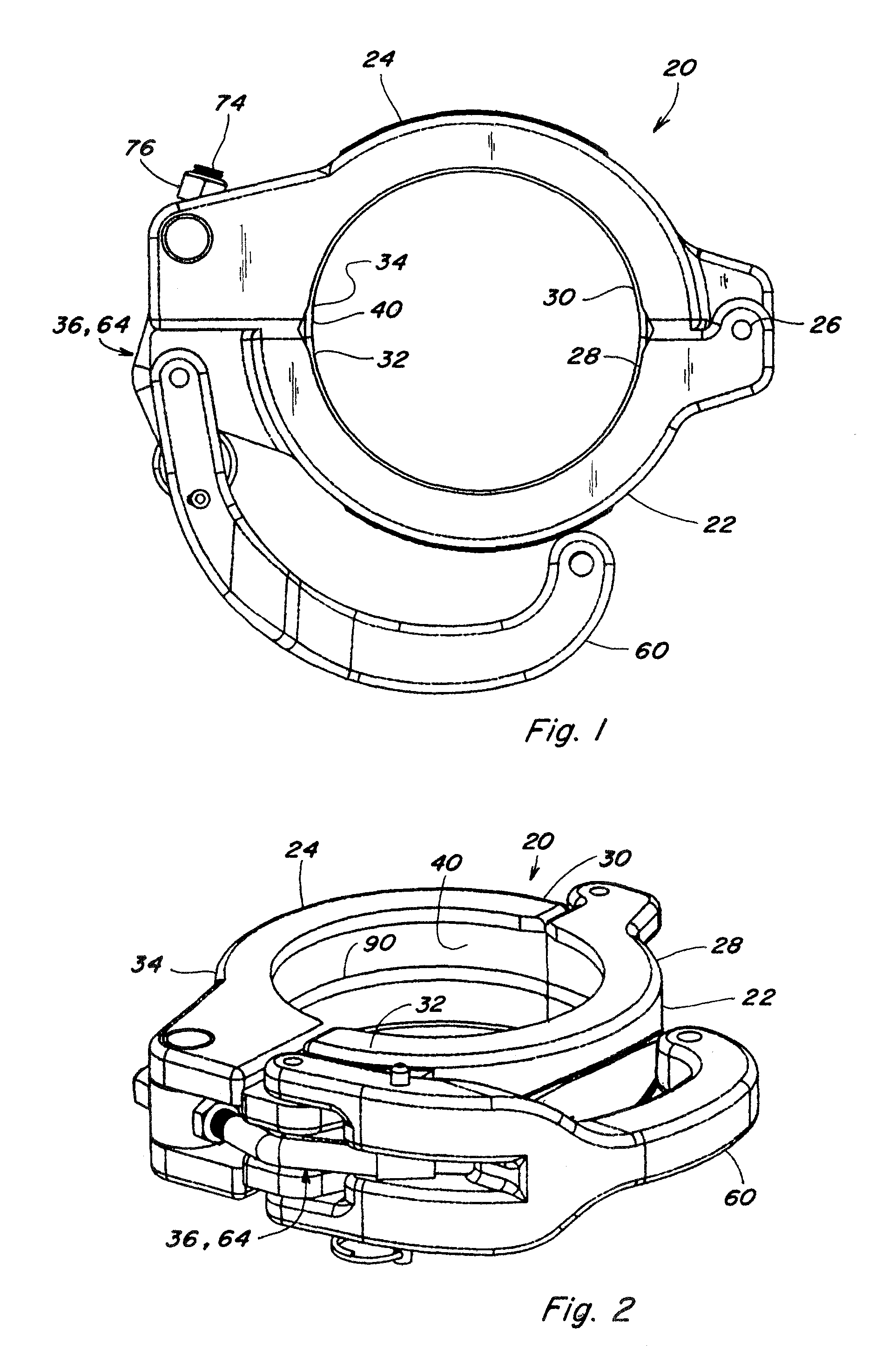

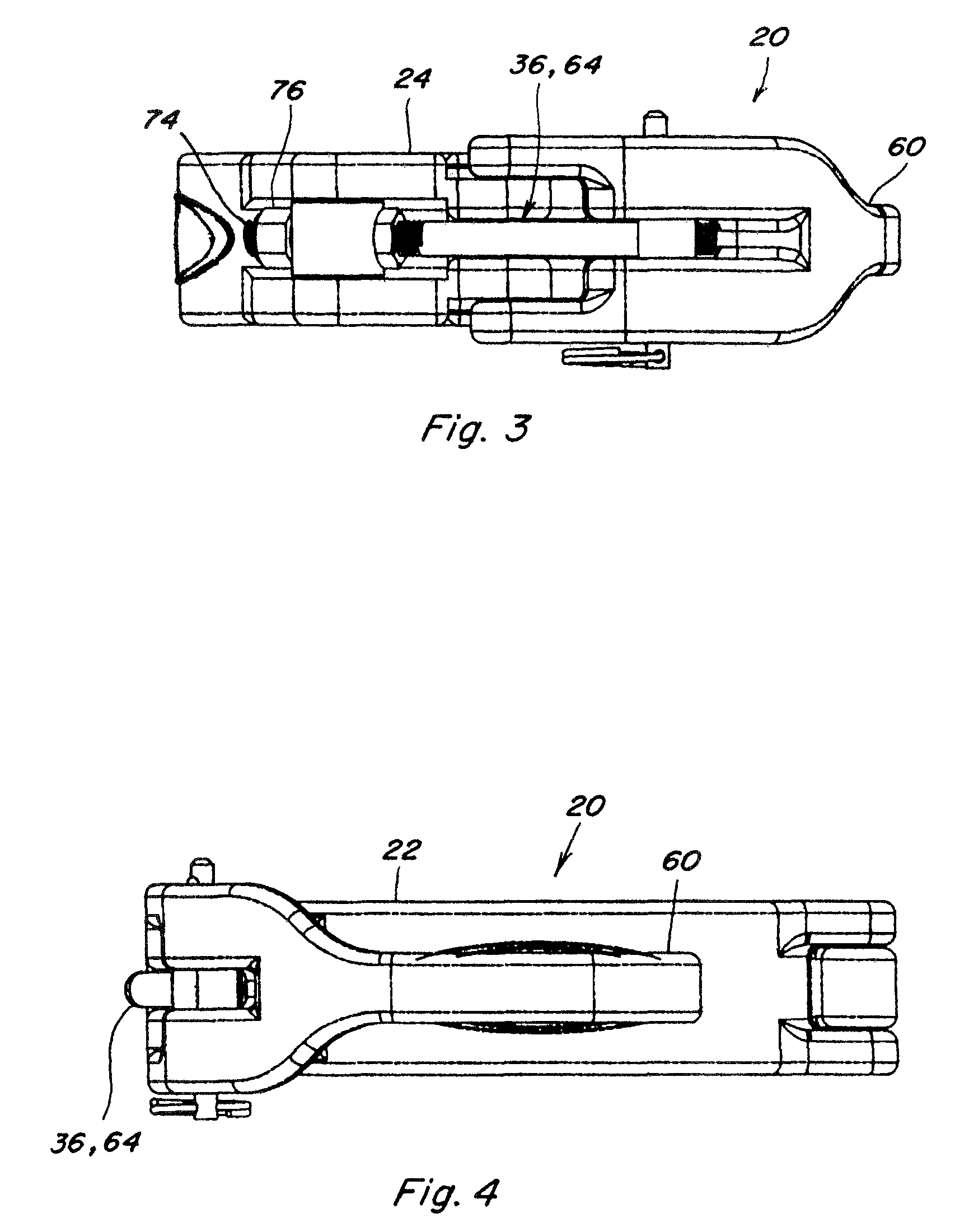

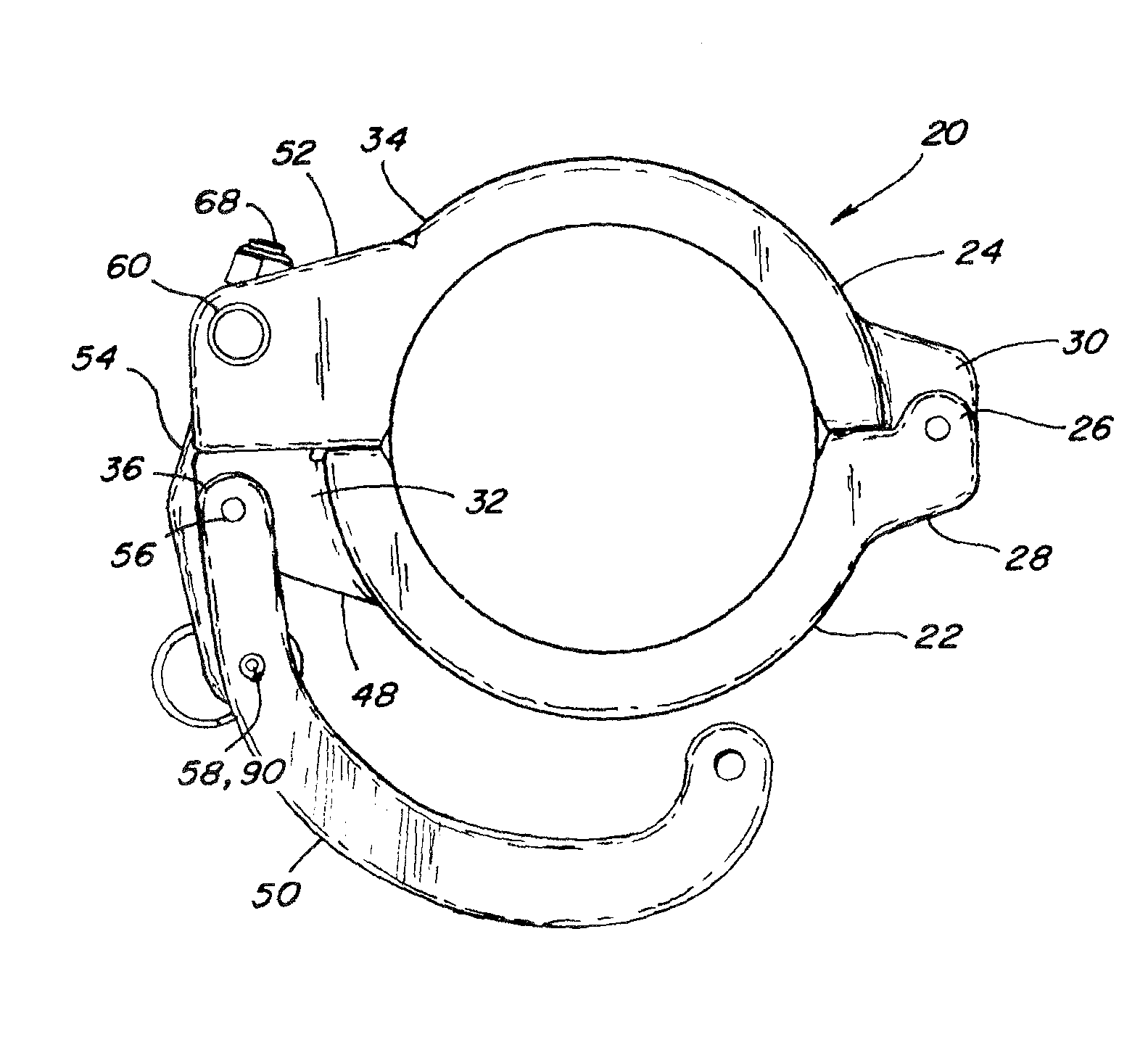

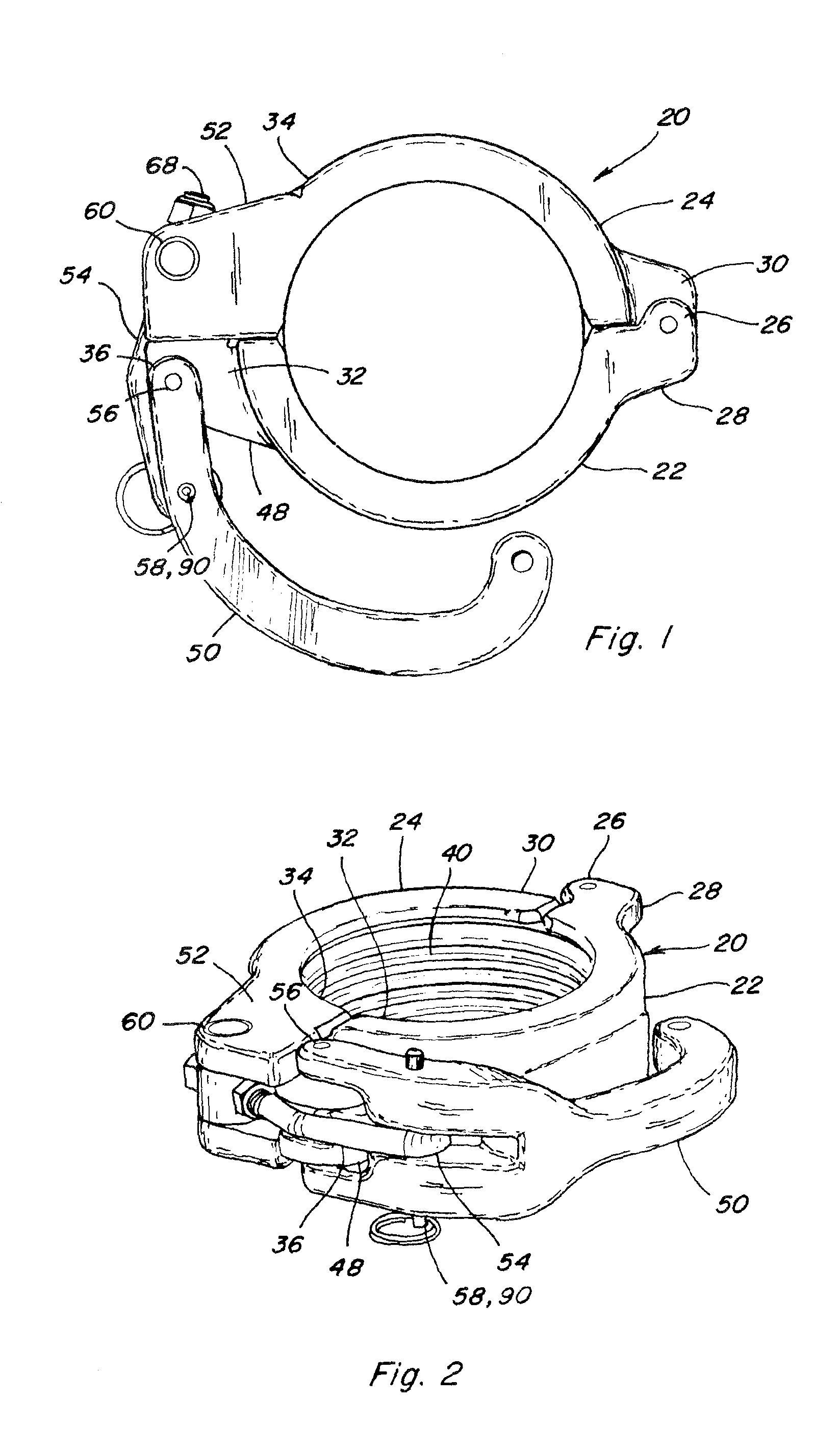

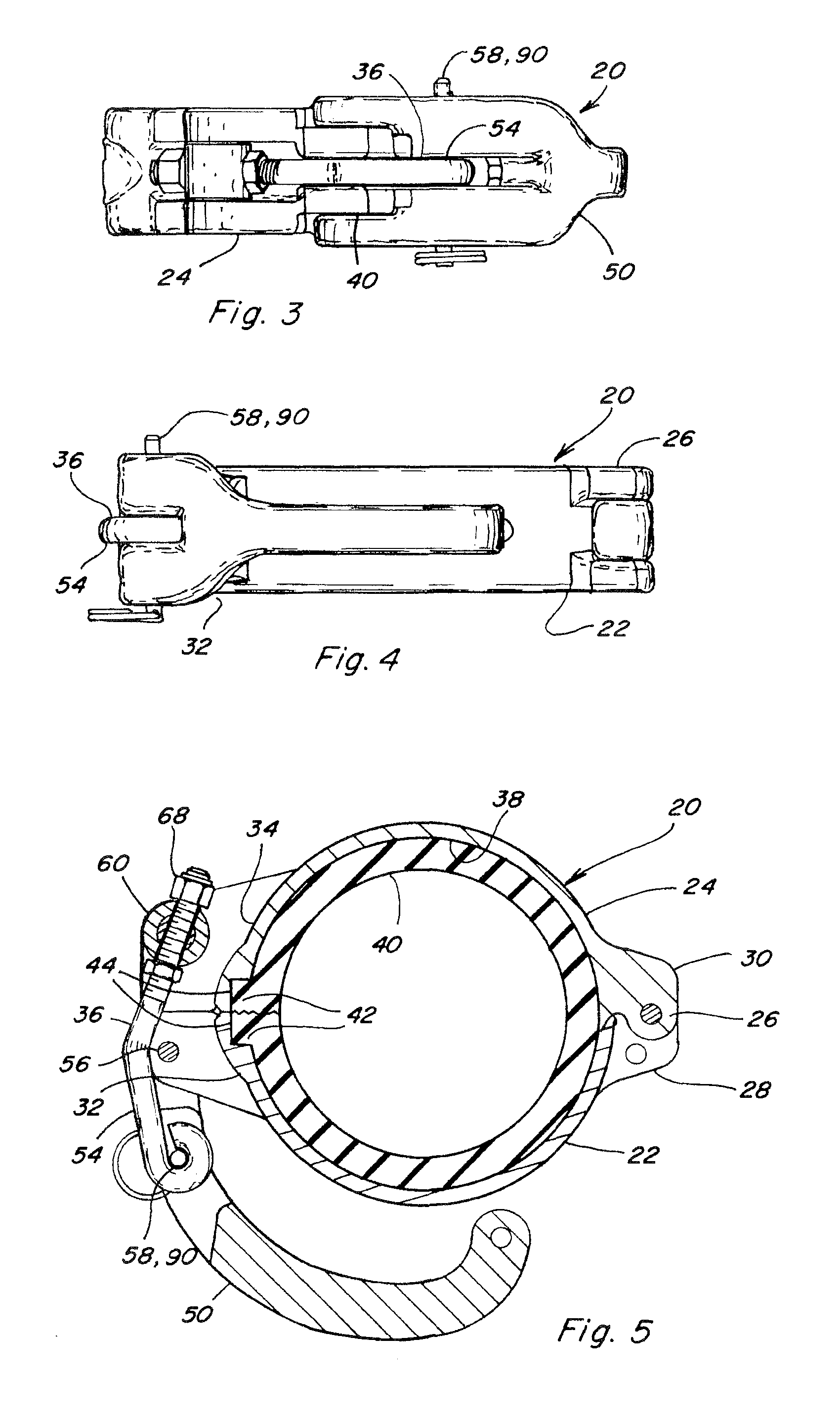

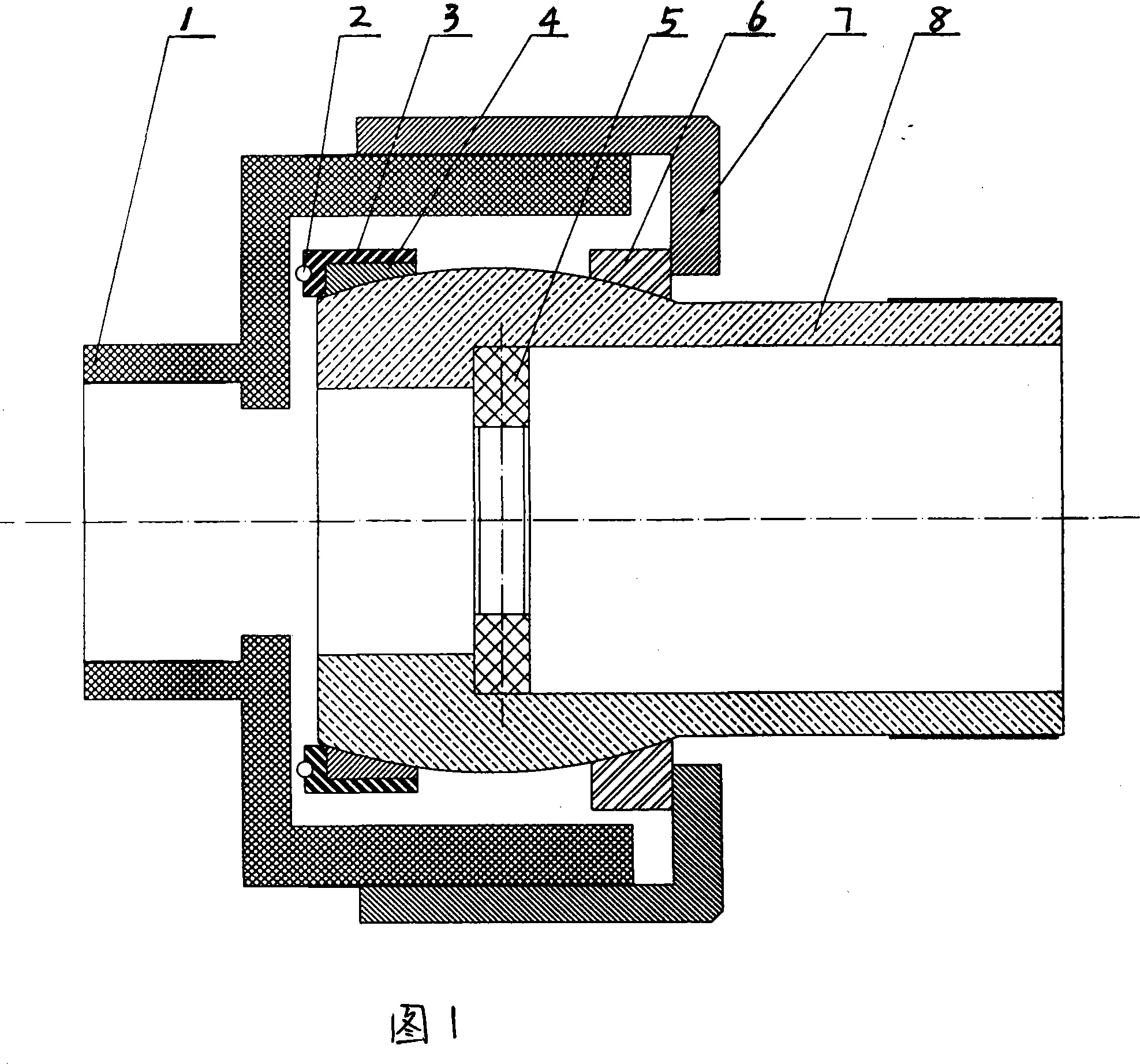

Pipe coupler and gasket with positive retention and sealing capability

A coupler for joining a pipe to another pipe, a tee, or other fitting, and more particularly, to a coupler which provides positive retention of the gasket about the circumference of the coupler sufficiently to precisely position and hold the gasket during placement about pipe ends and / or fittings to be coupled, and which provides controlled circumferential compression of the gasket during coupling, for positive sealing when the coupler is closed, while allowing one handed handling and operation during placement and coupling, such that the other hand can be used for supporting a pipe to be coupled, and which is operable for releasing and breaking loose the coupler and associated gasket from a pipe during uncoupling.

Owner:BRAY INT INC

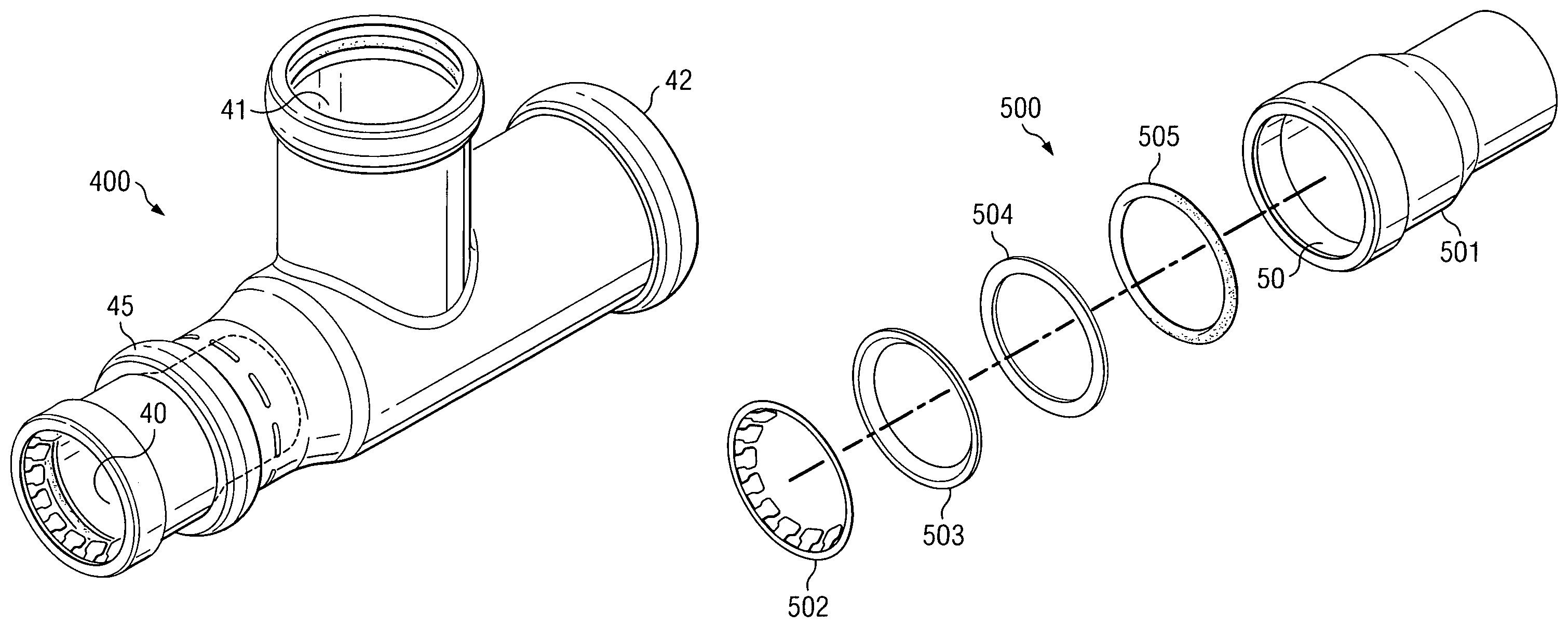

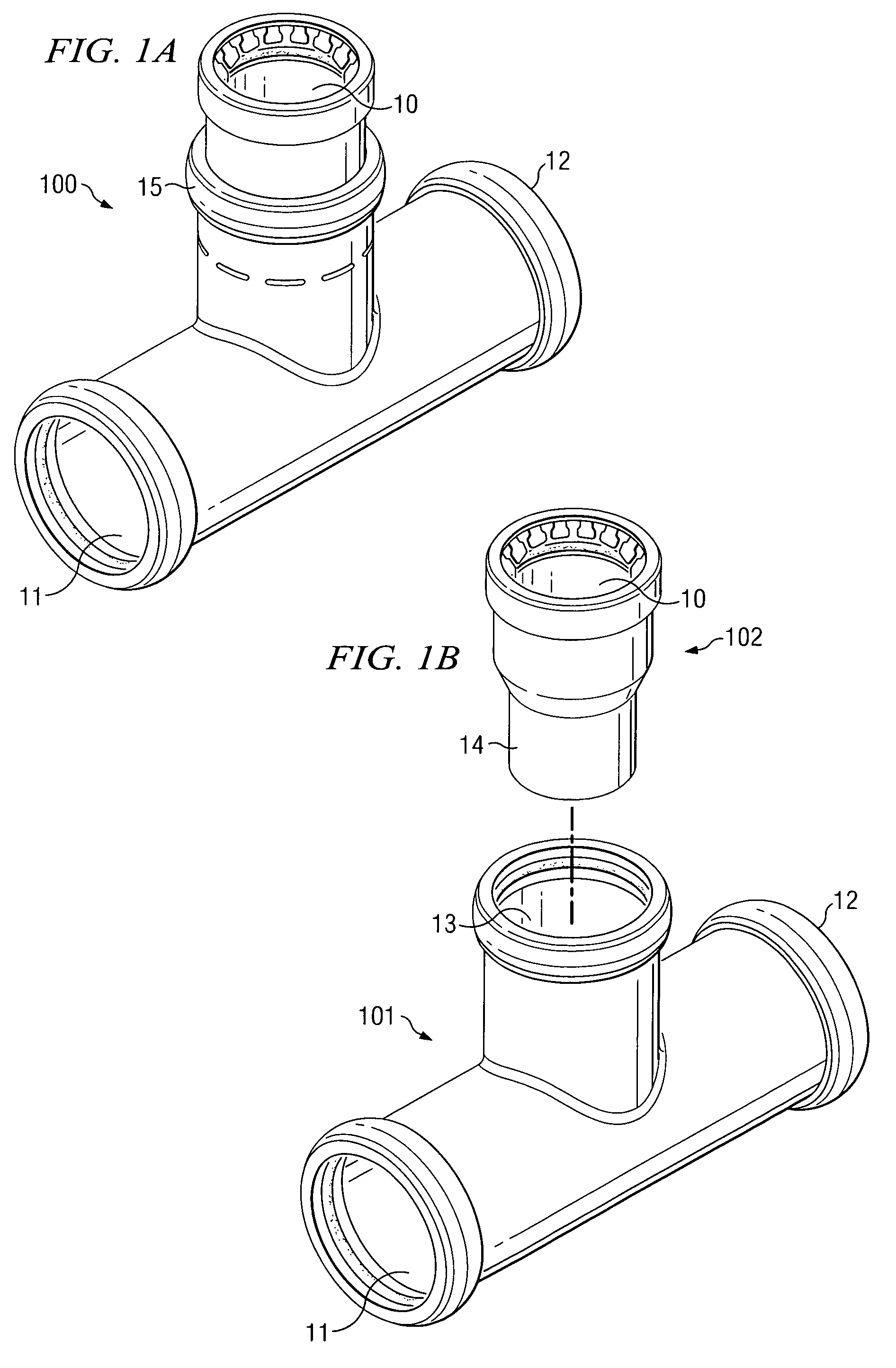

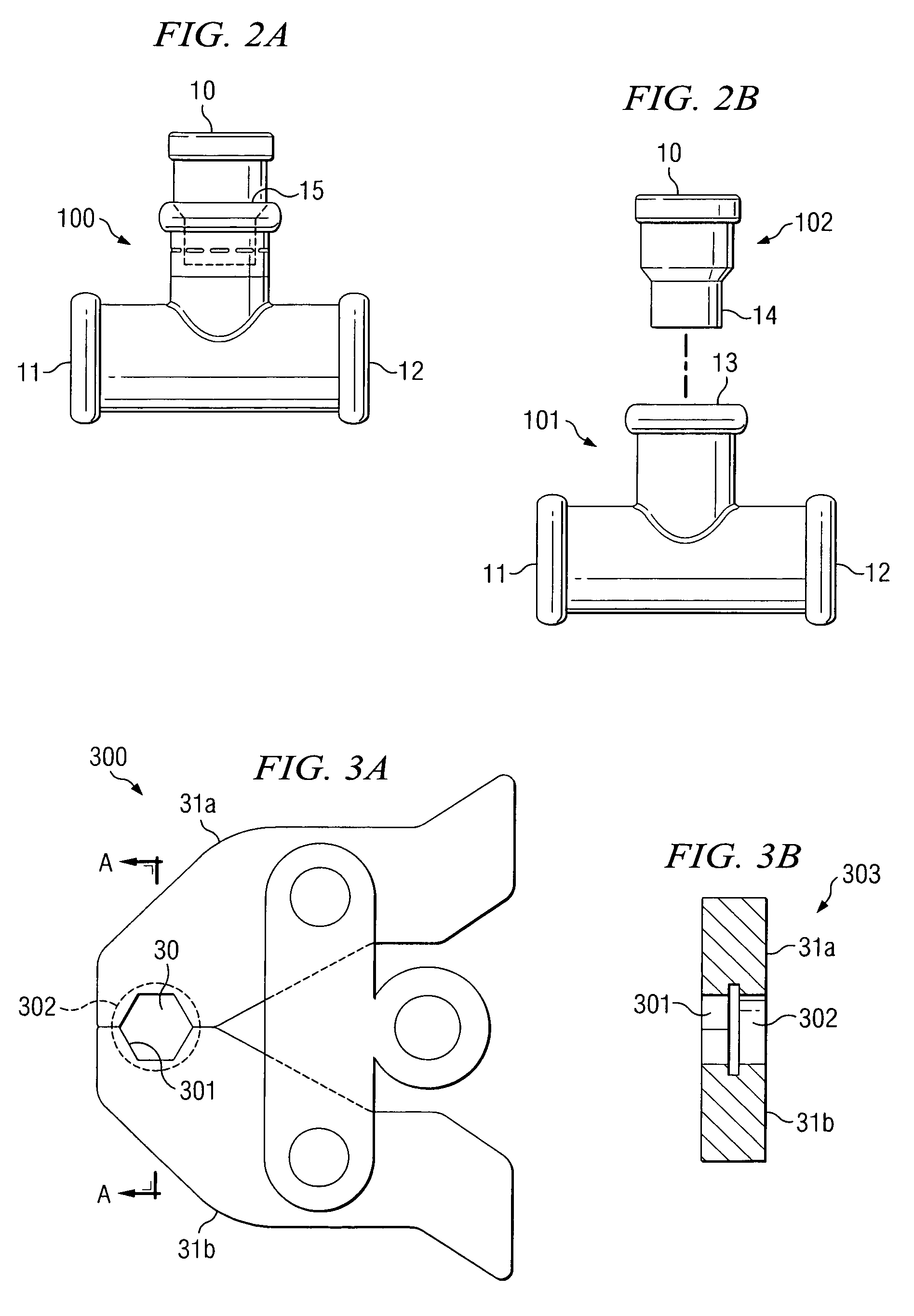

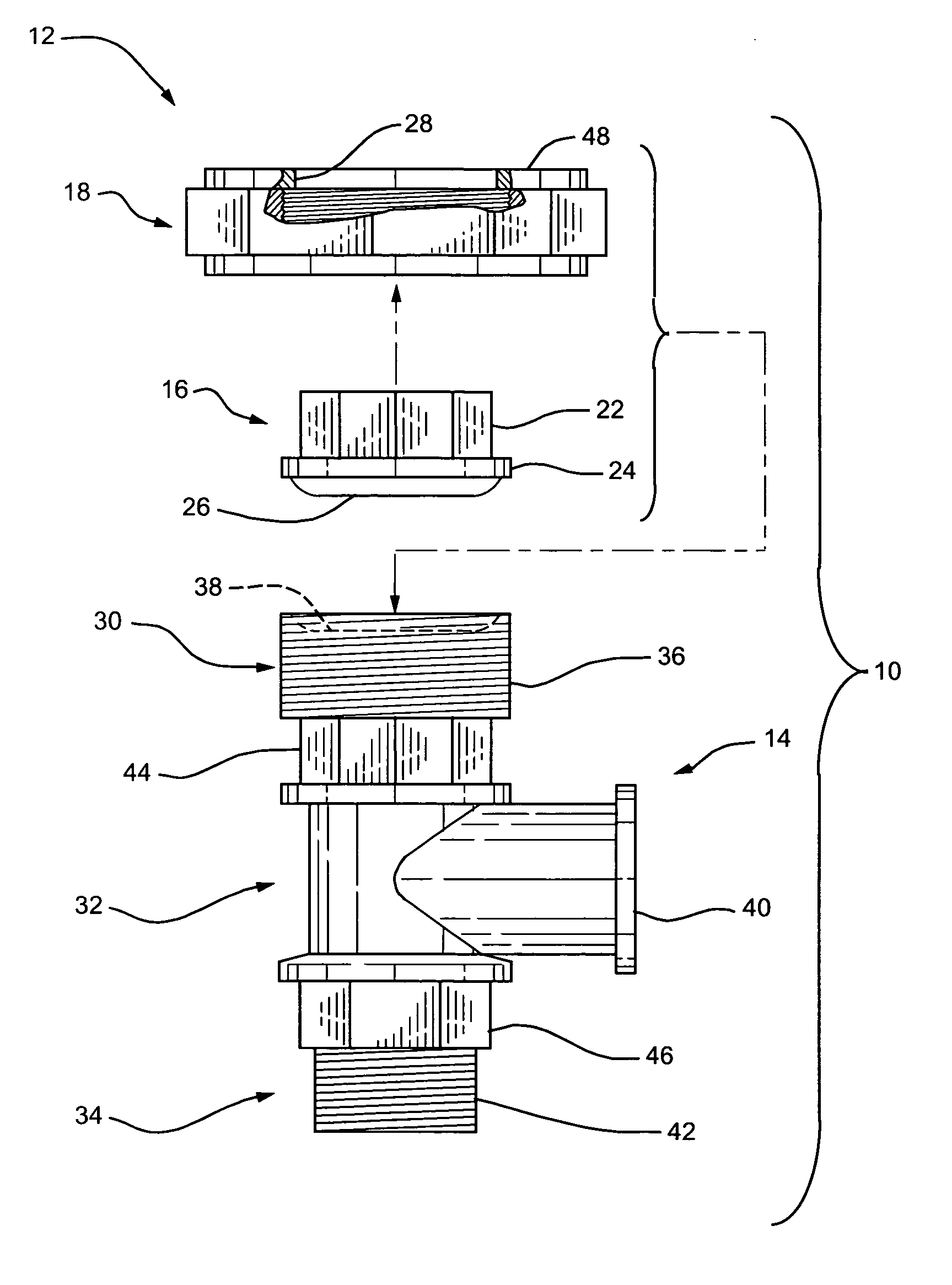

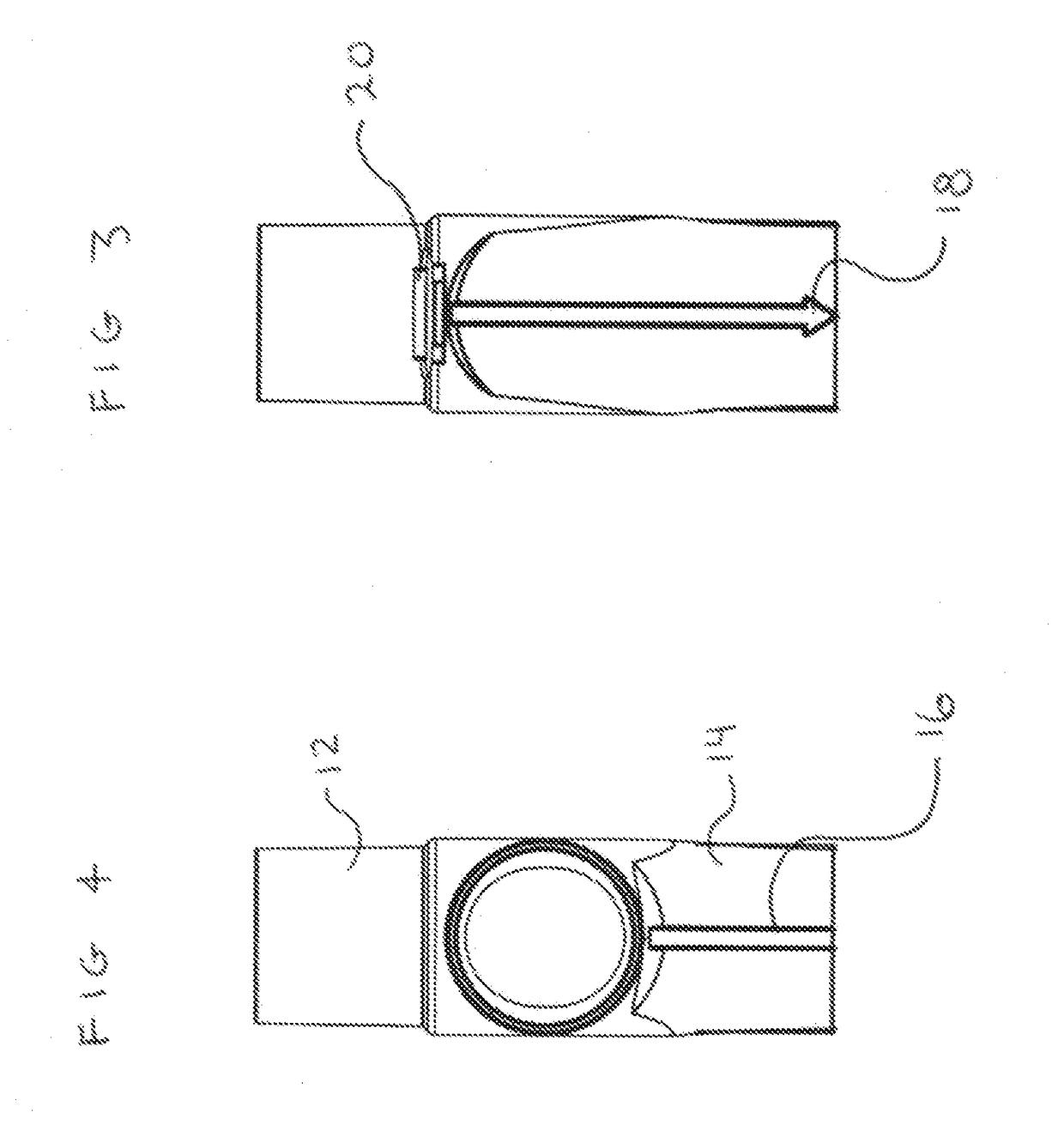

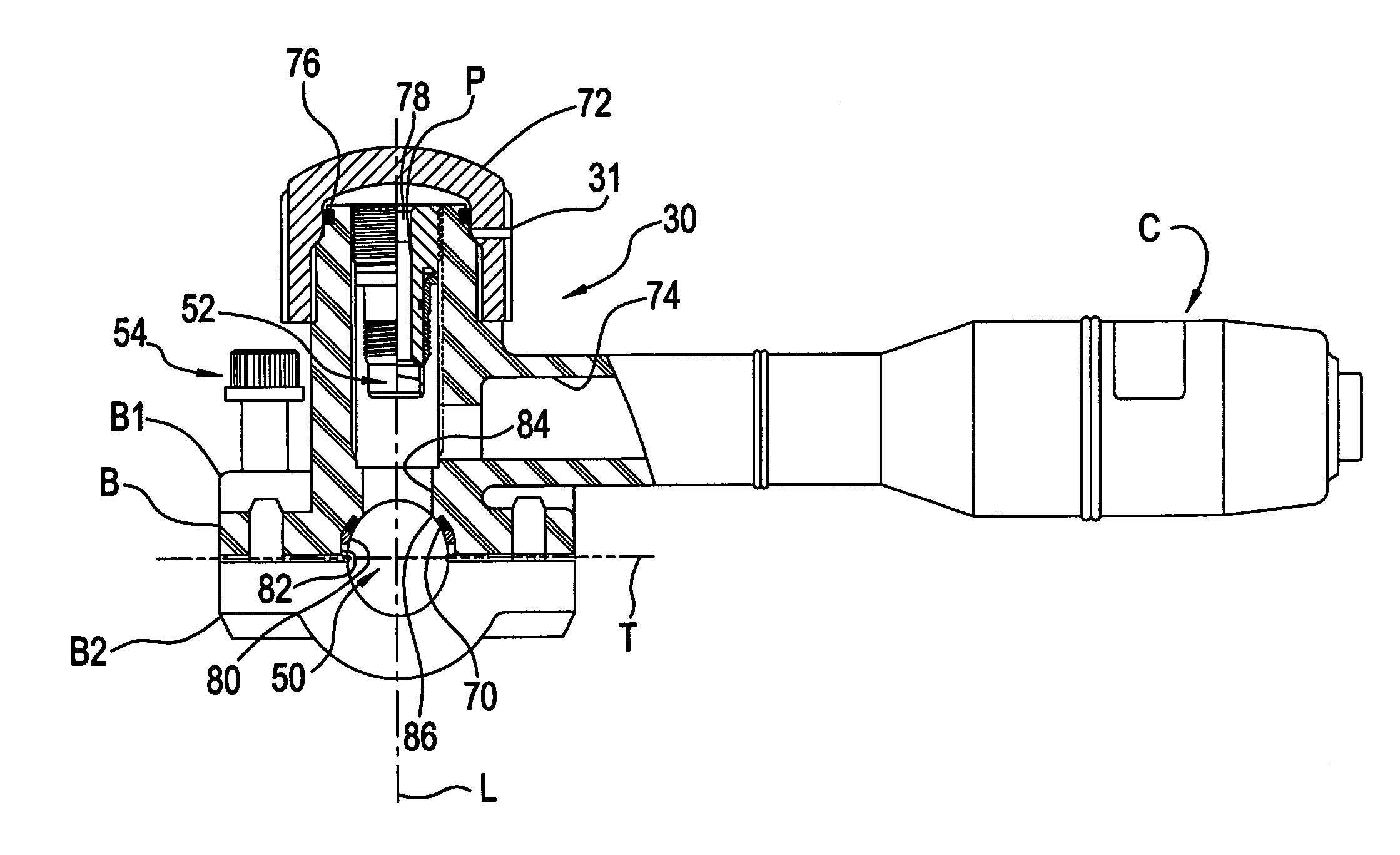

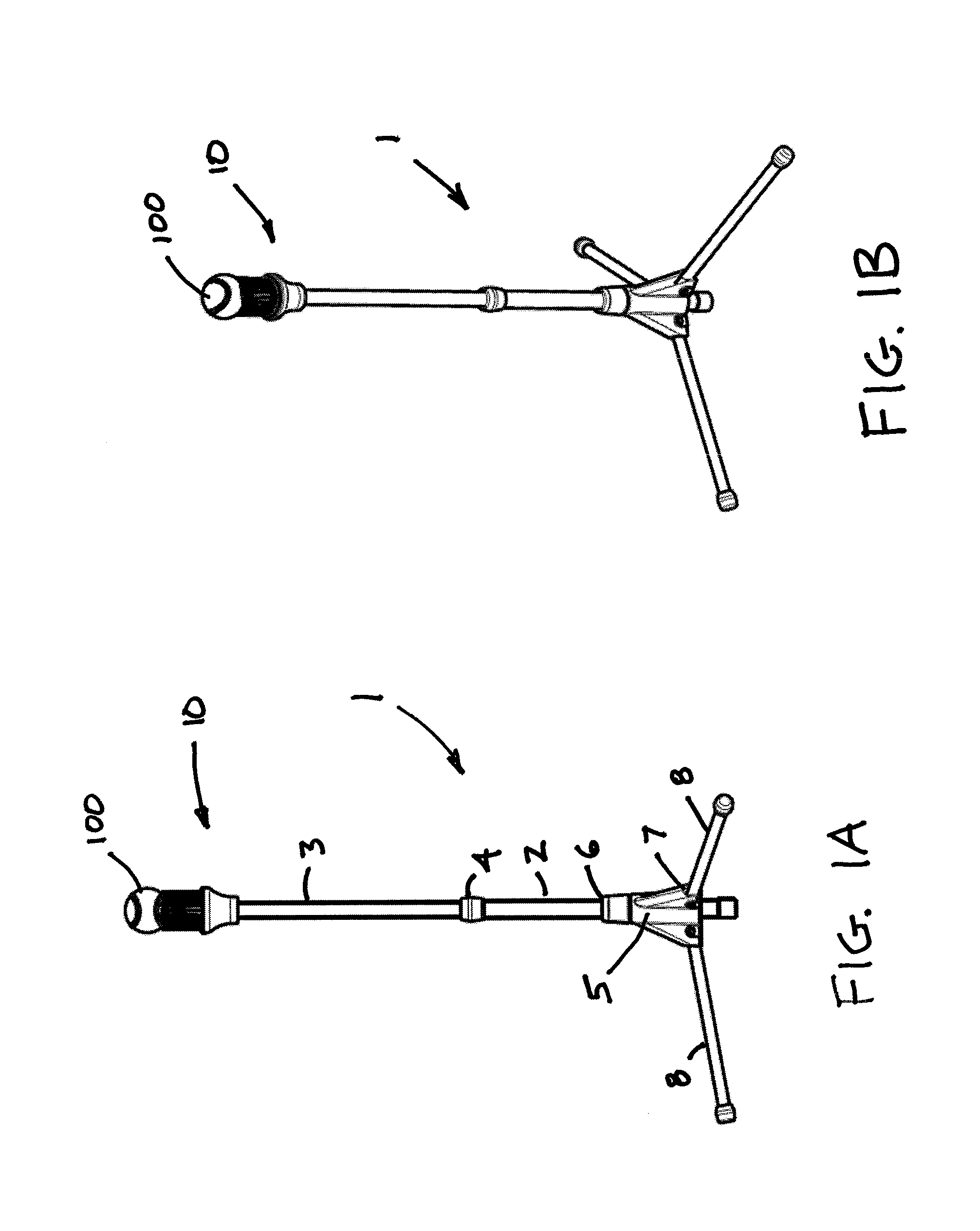

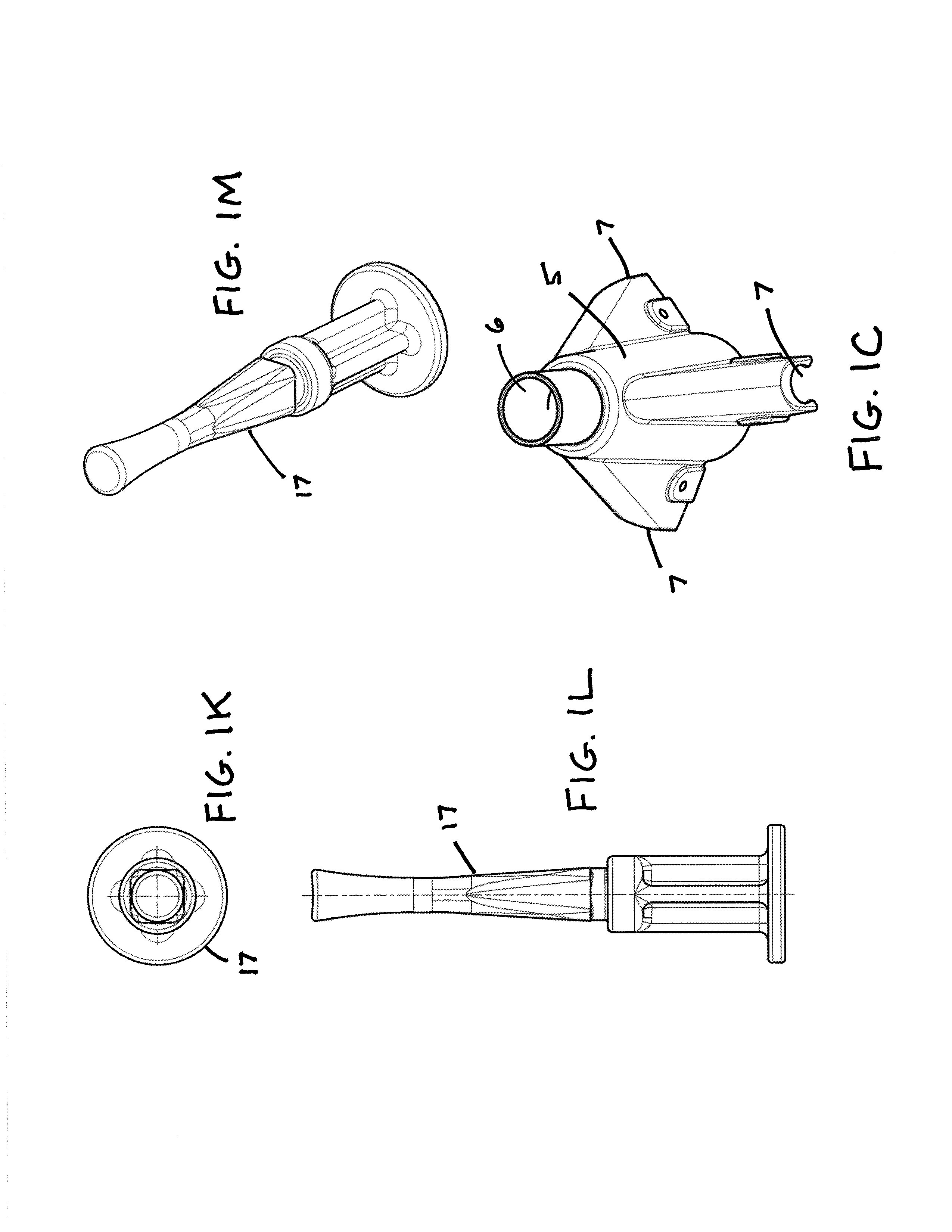

Transition tee coupling

InactiveUS7686346B1Installation time for fittingReduce the time required for installationSleeve/socket jointsFluid pressure sealed jointsCouplingEngineering

An improved coupling, such as a transition tee coupling, is described having press-connect fittings on the ends and a push-connect fitting on the outlet. The improved transition tee coupling is formed using a reduced-outlet tee having press-connect fittings on all three sockets. An unfinished end of a tailpiece having a push-connect fitting on the opposite end is inserted into the outlet socket of the press-connect tee. The press-connect fitting of the outlet tee is crimped using a special press tool jaw that does not damage the push fitting on the tailpiece.

Owner:ELKHART PRODS CORP

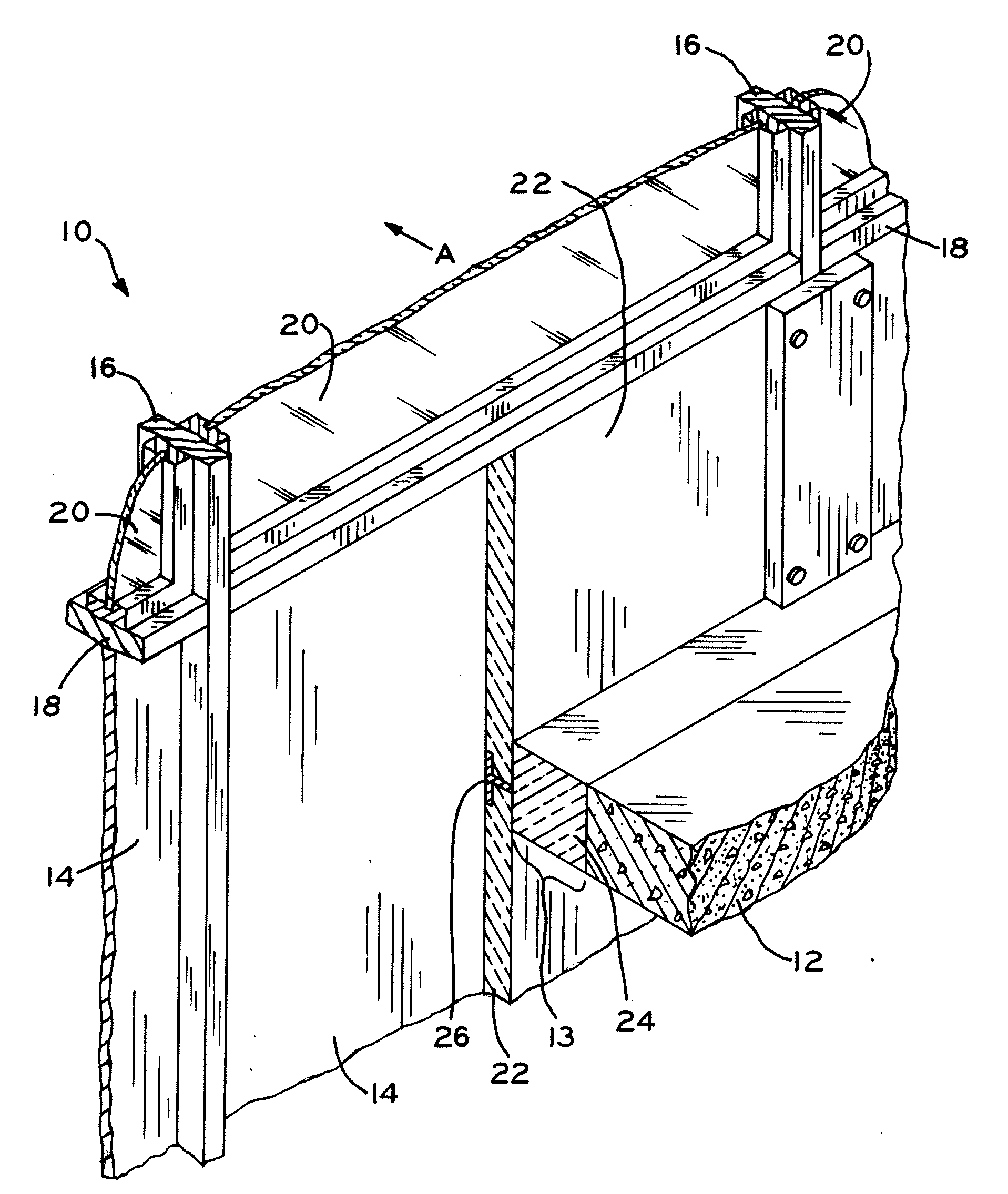

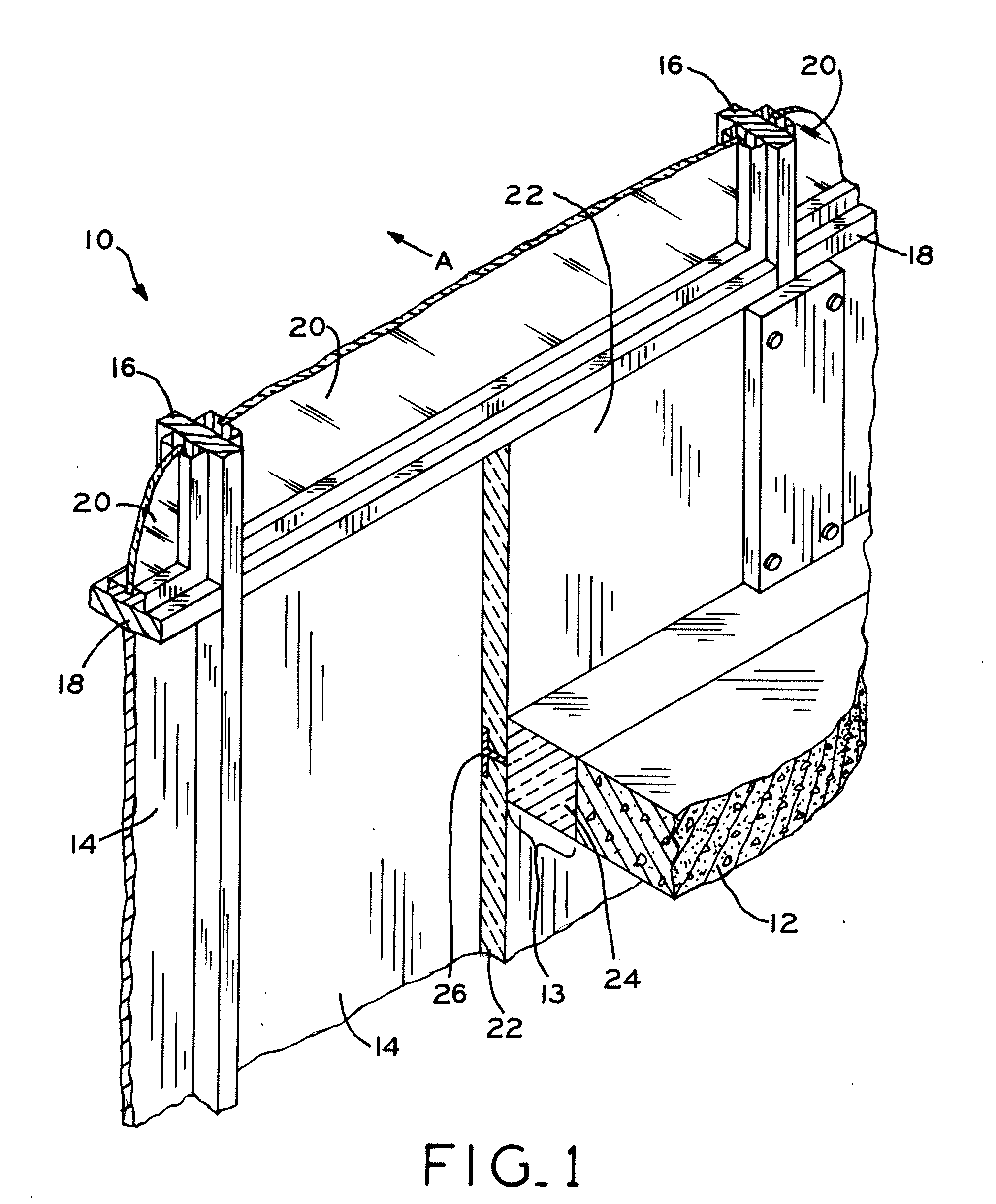

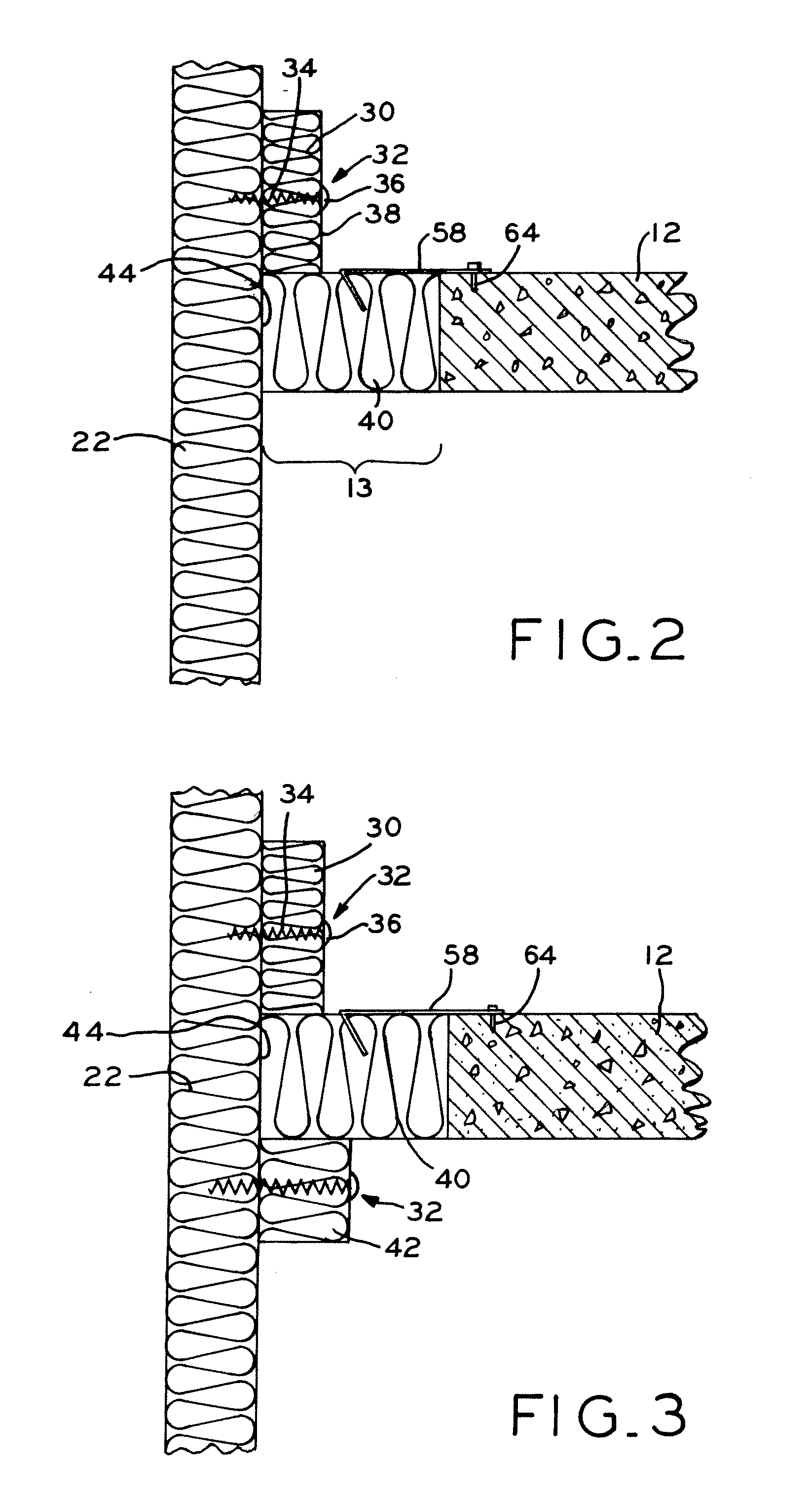

Methods and apparatuses for positioning and securing safing insulation

The present invention provides methods and apparatuses for securing safing insulation in the gap formed between a spandrel and a slab. Additionally, the present invention eliminates the need for stiffening tees and / or stiffening brackets. In one exemplary embodiment, the present invention utilizes a first portion of safing secured to spandrel insulation positioned in an exterior wall structure and a second portion of safing insulation positioned adjacent to the first portion of safing insulation and between the spandrel insulation and the slab. By fixedly securing the first portion of safing insulation to the spandrel insulation, any deformation of the spandrel insulation caused by the forces exerted by the compressed second portion of safing insulation on spandrel insulation results in the first portion of safing insulation moving with the spandrel insulation.

Owner:THERMAFIBER

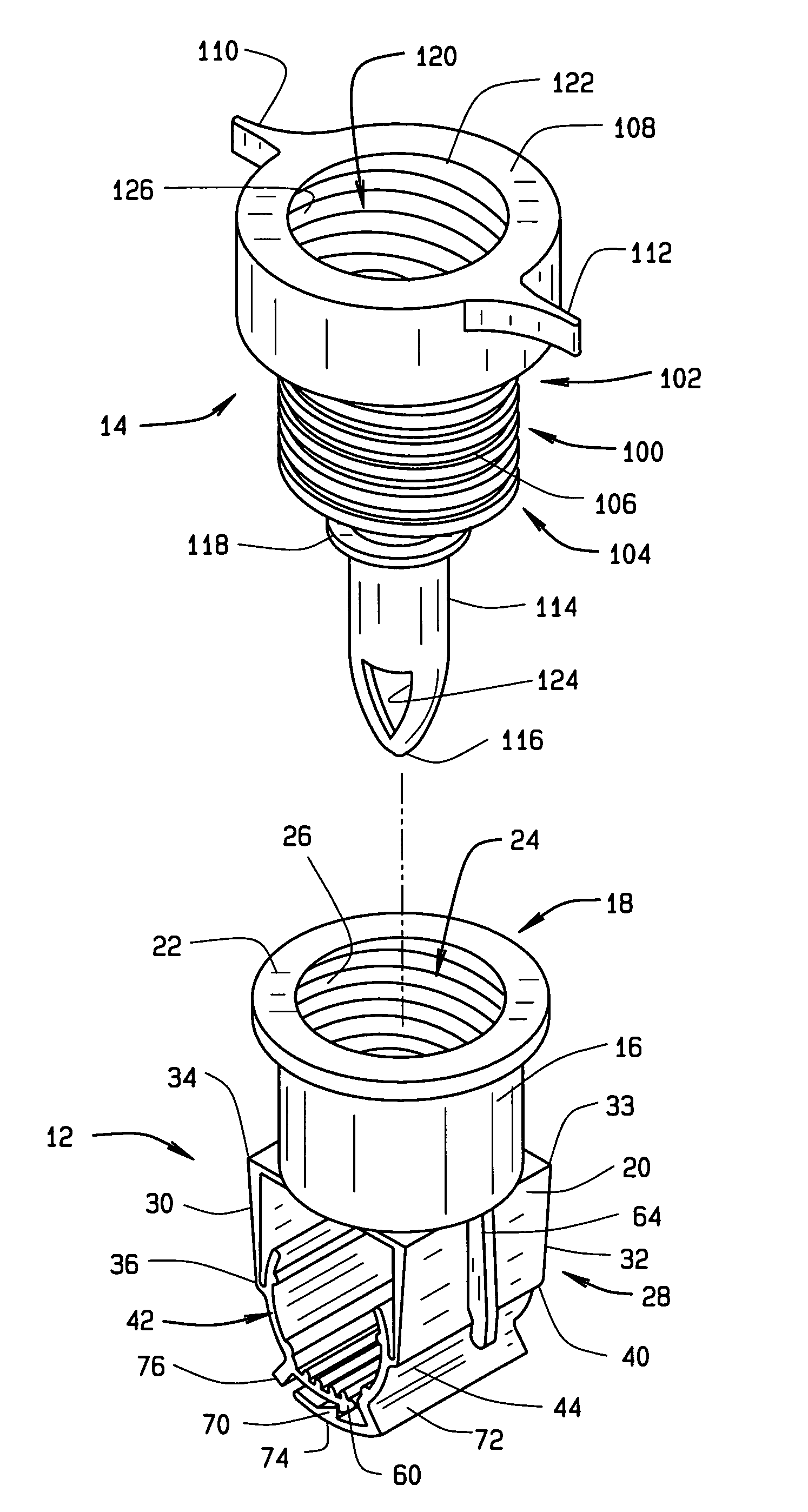

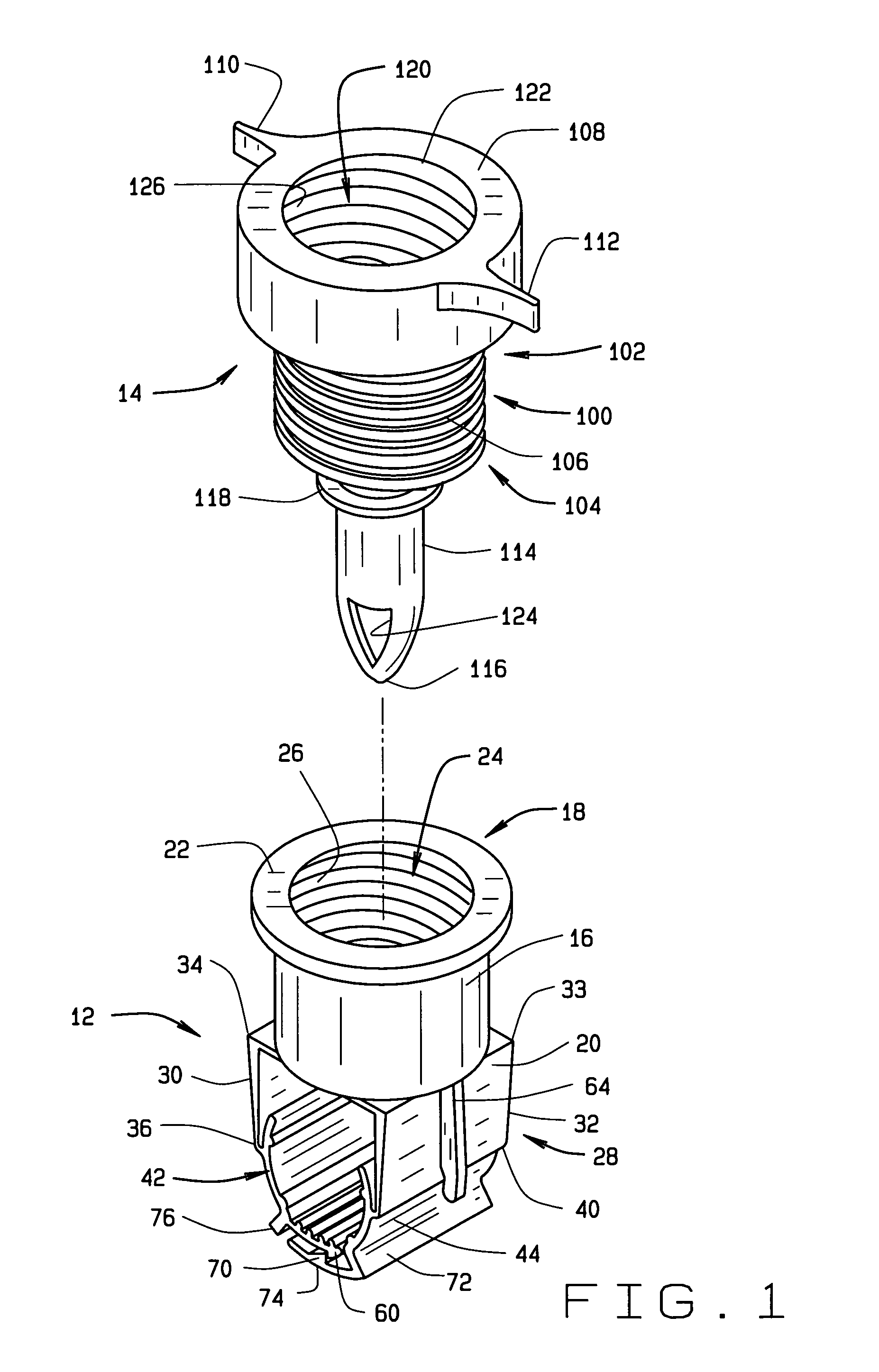

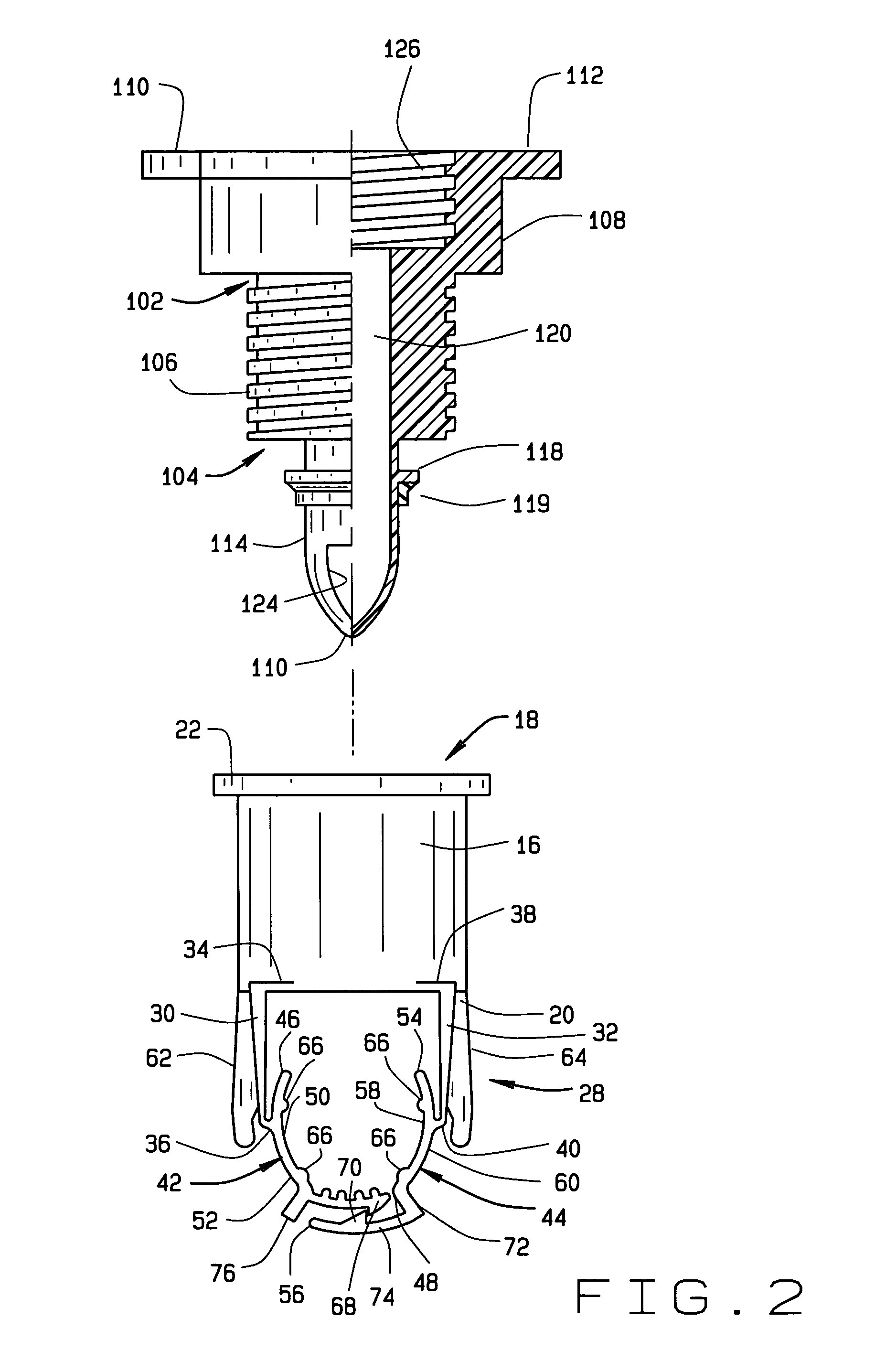

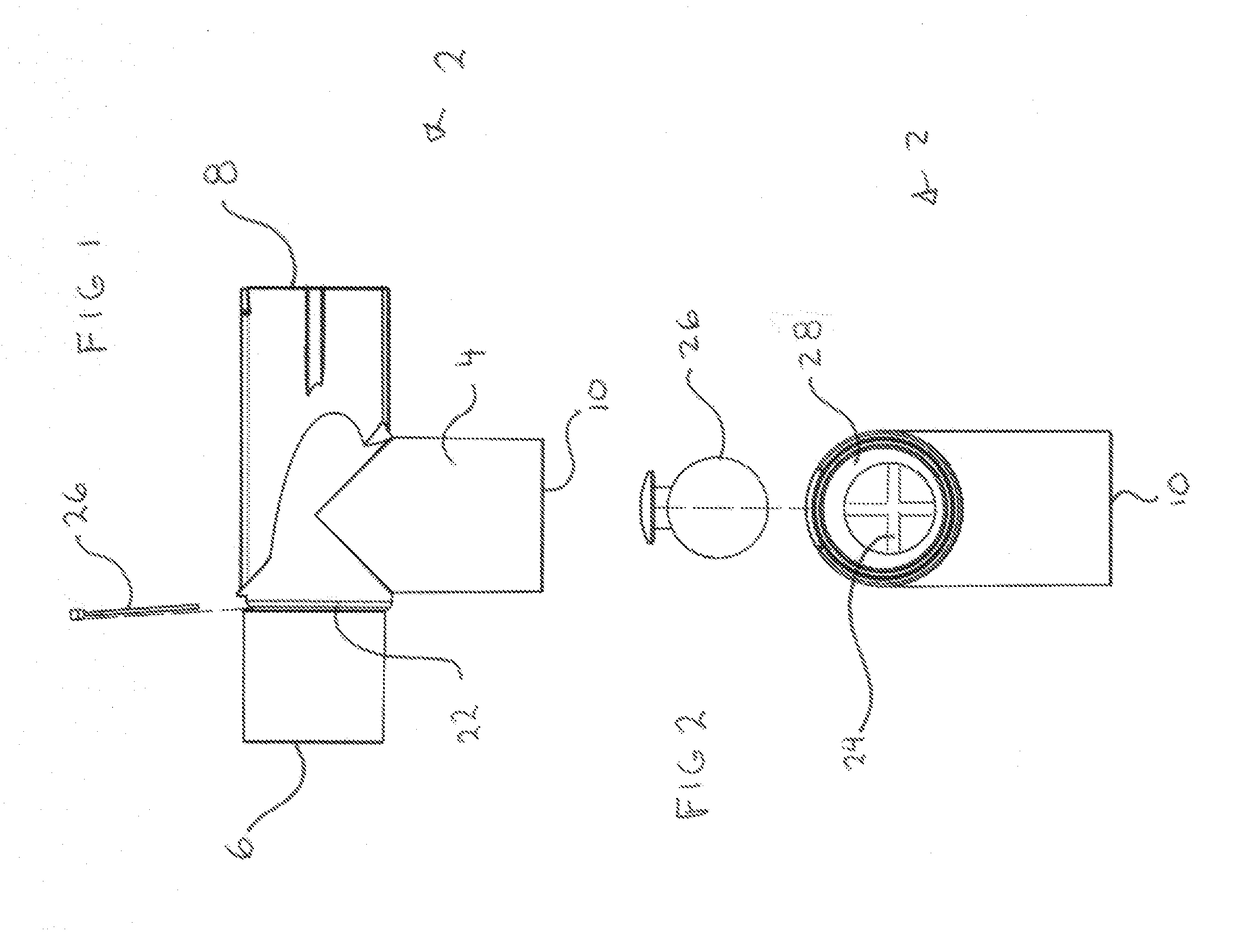

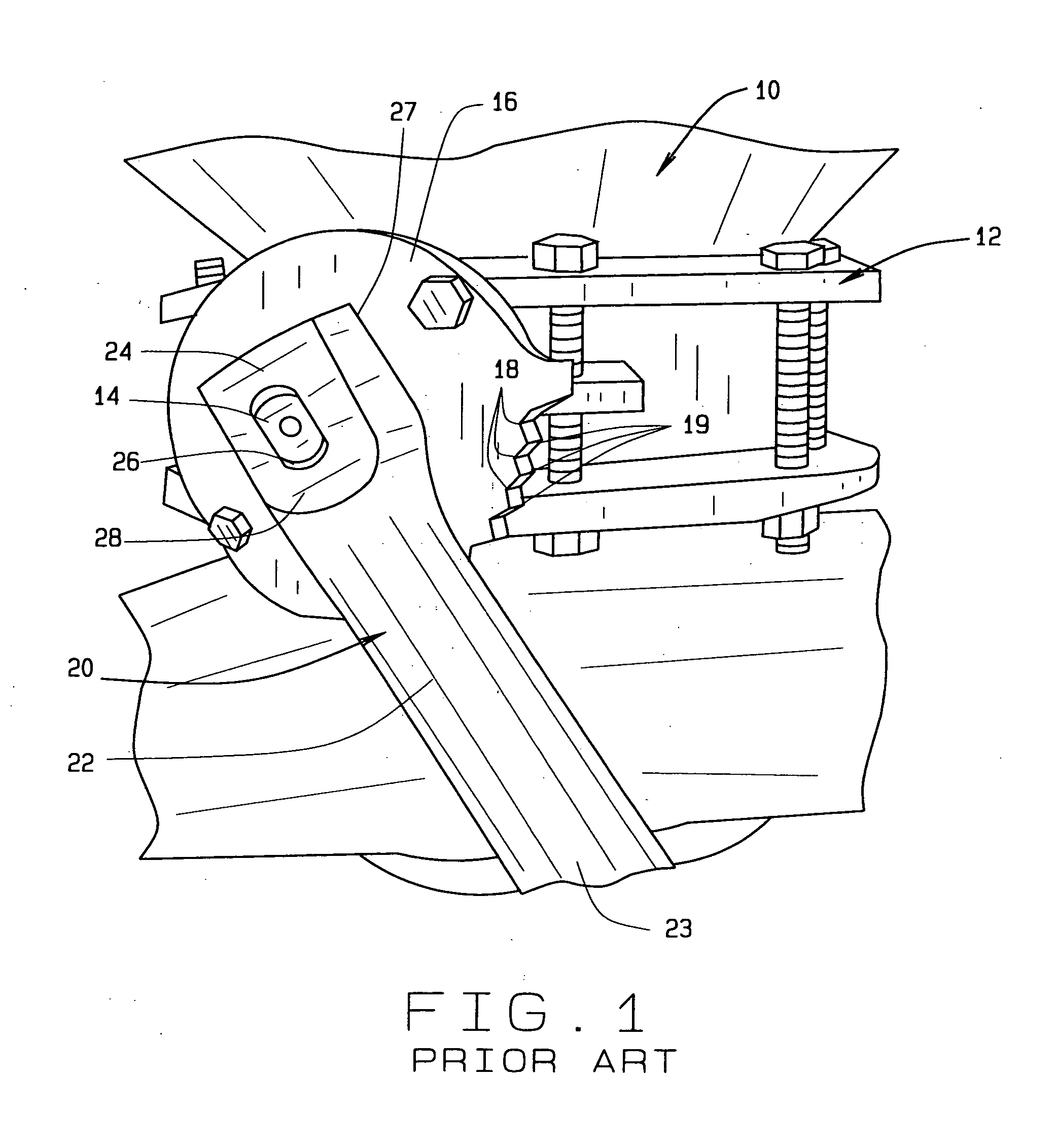

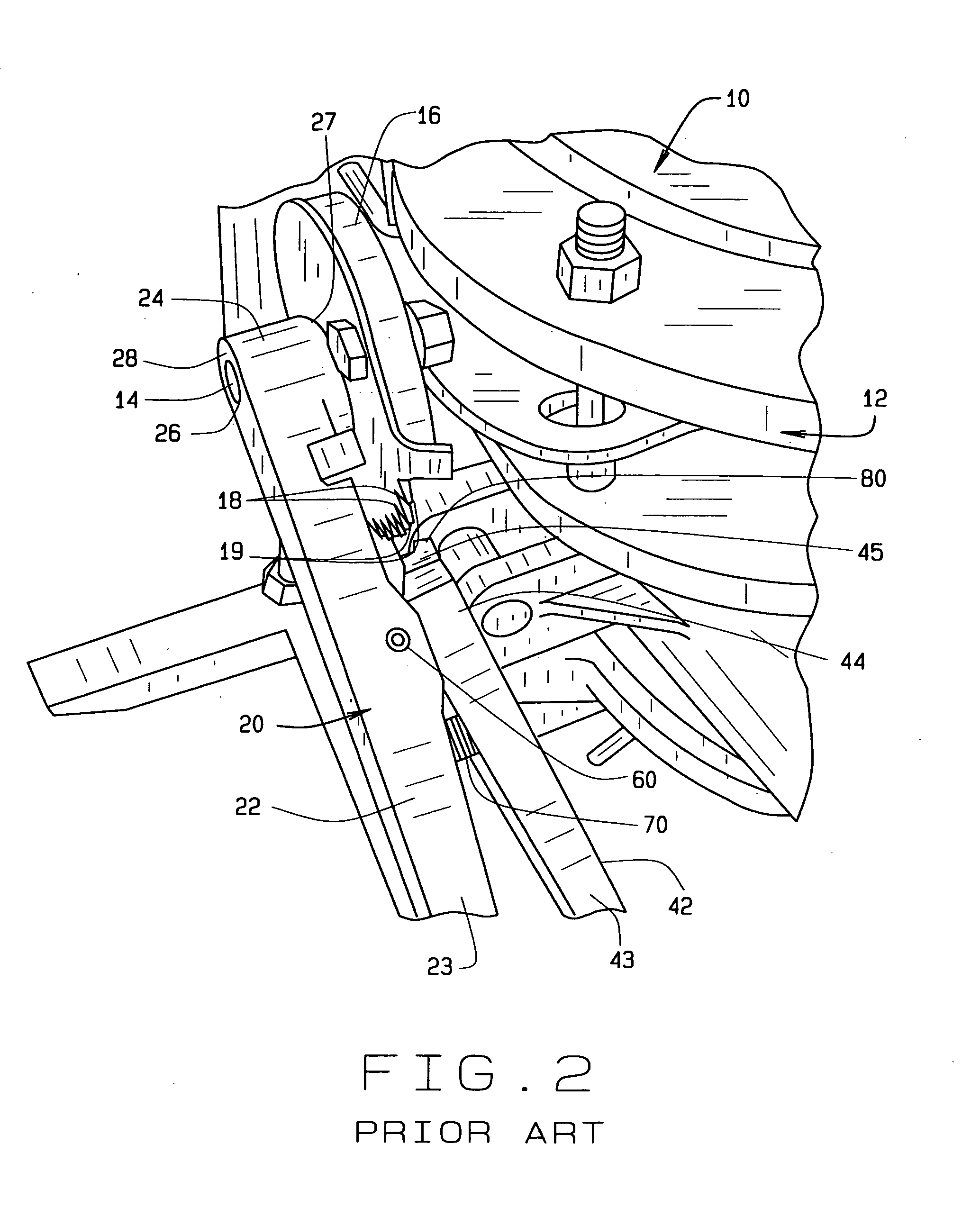

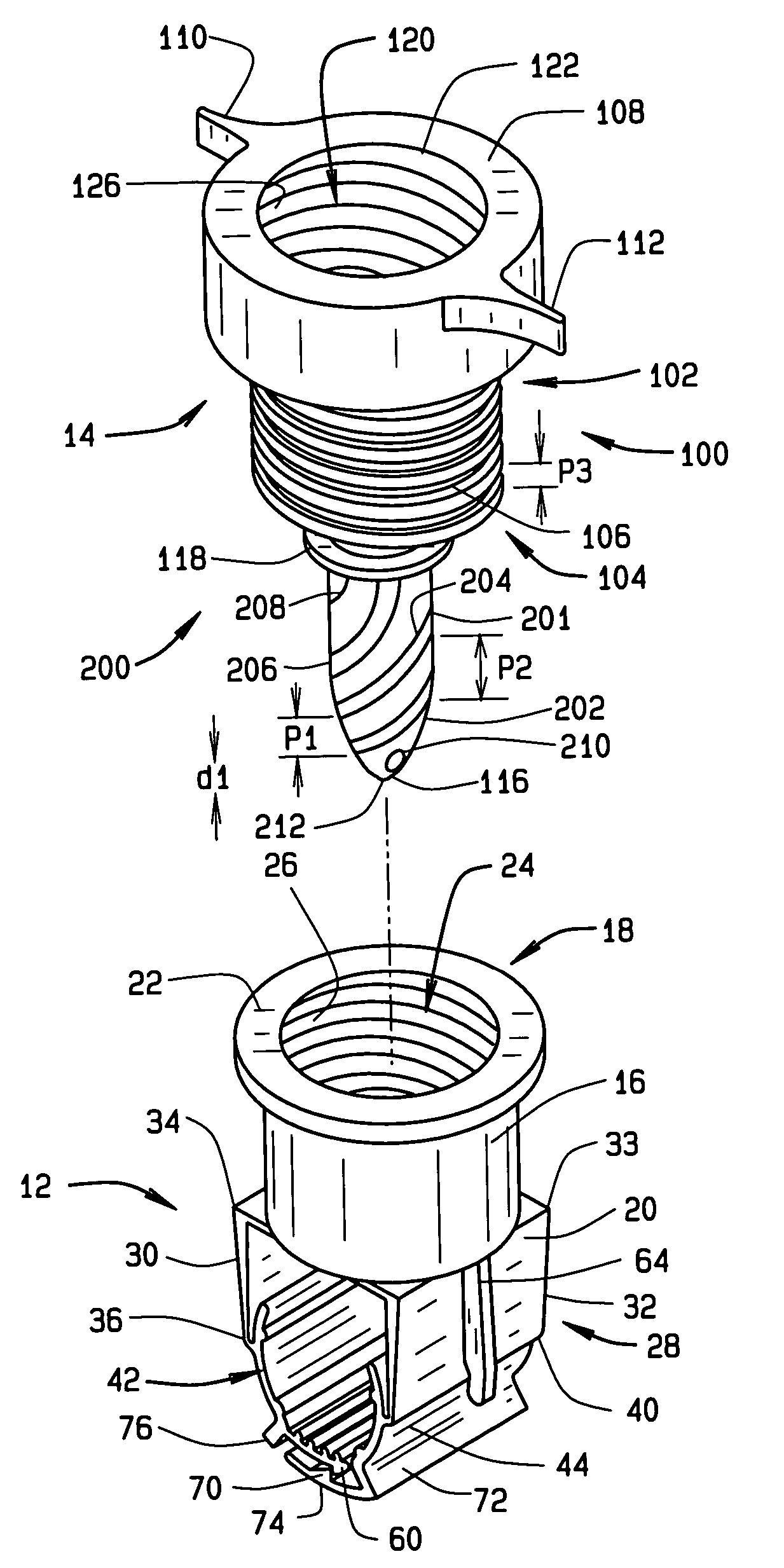

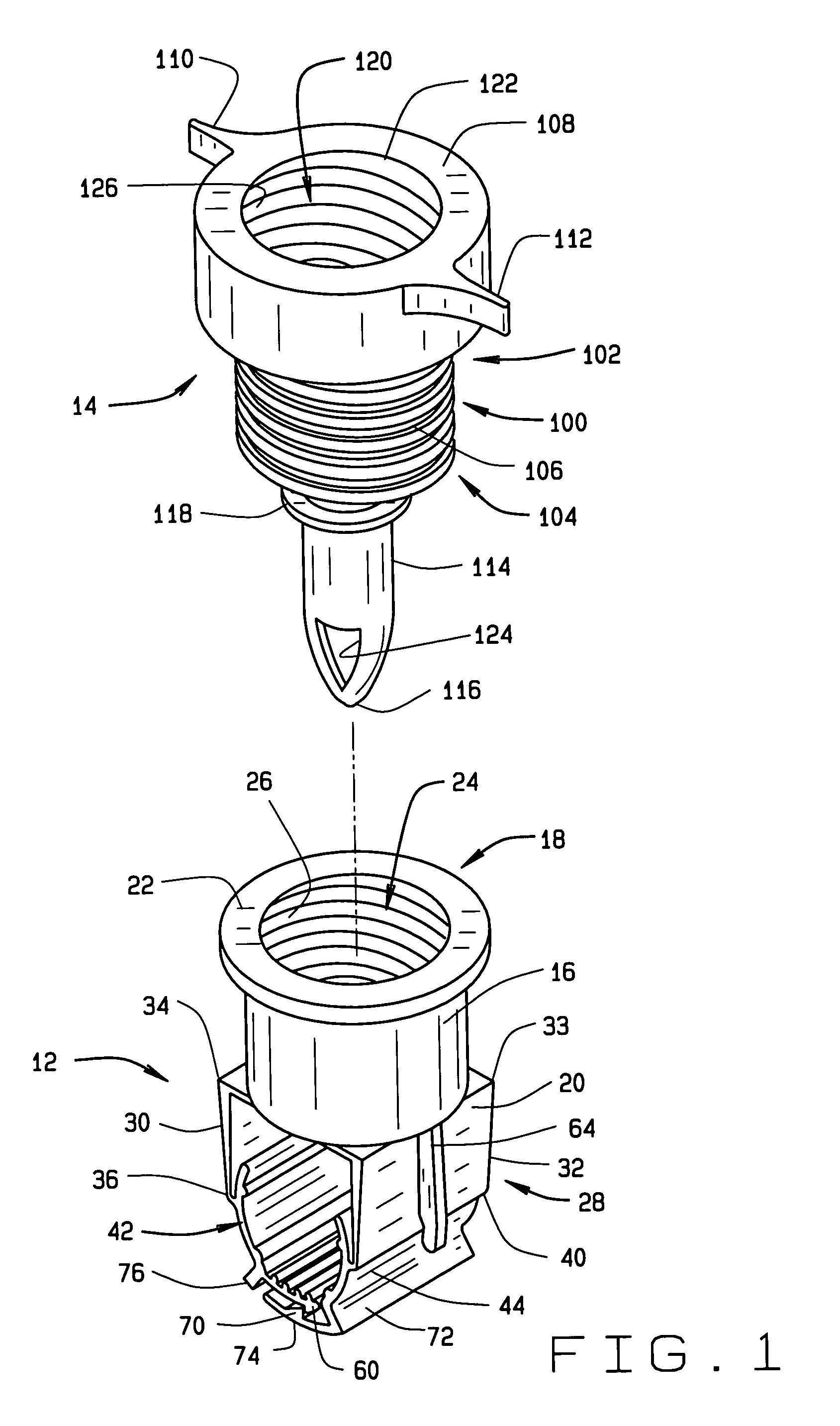

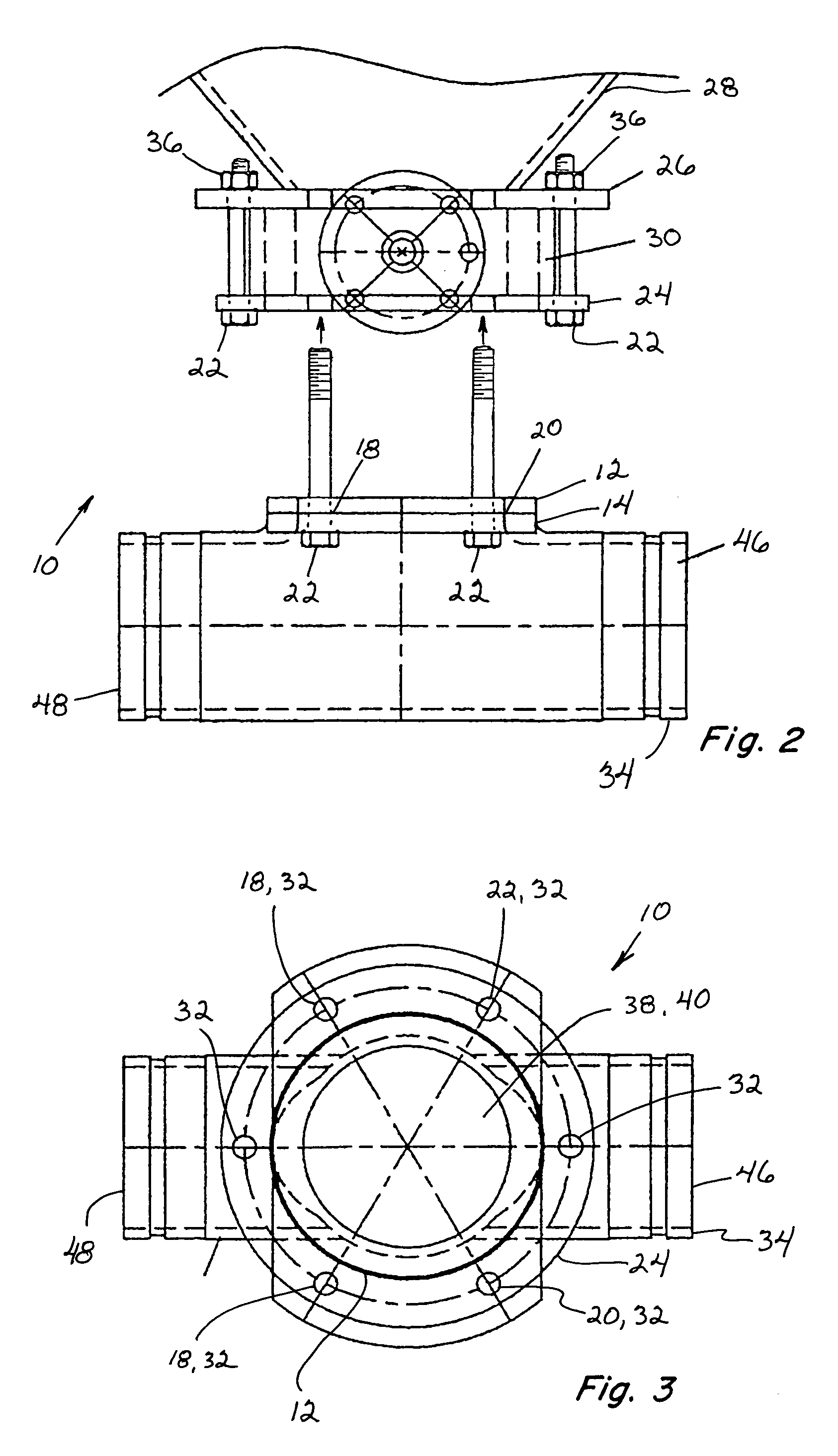

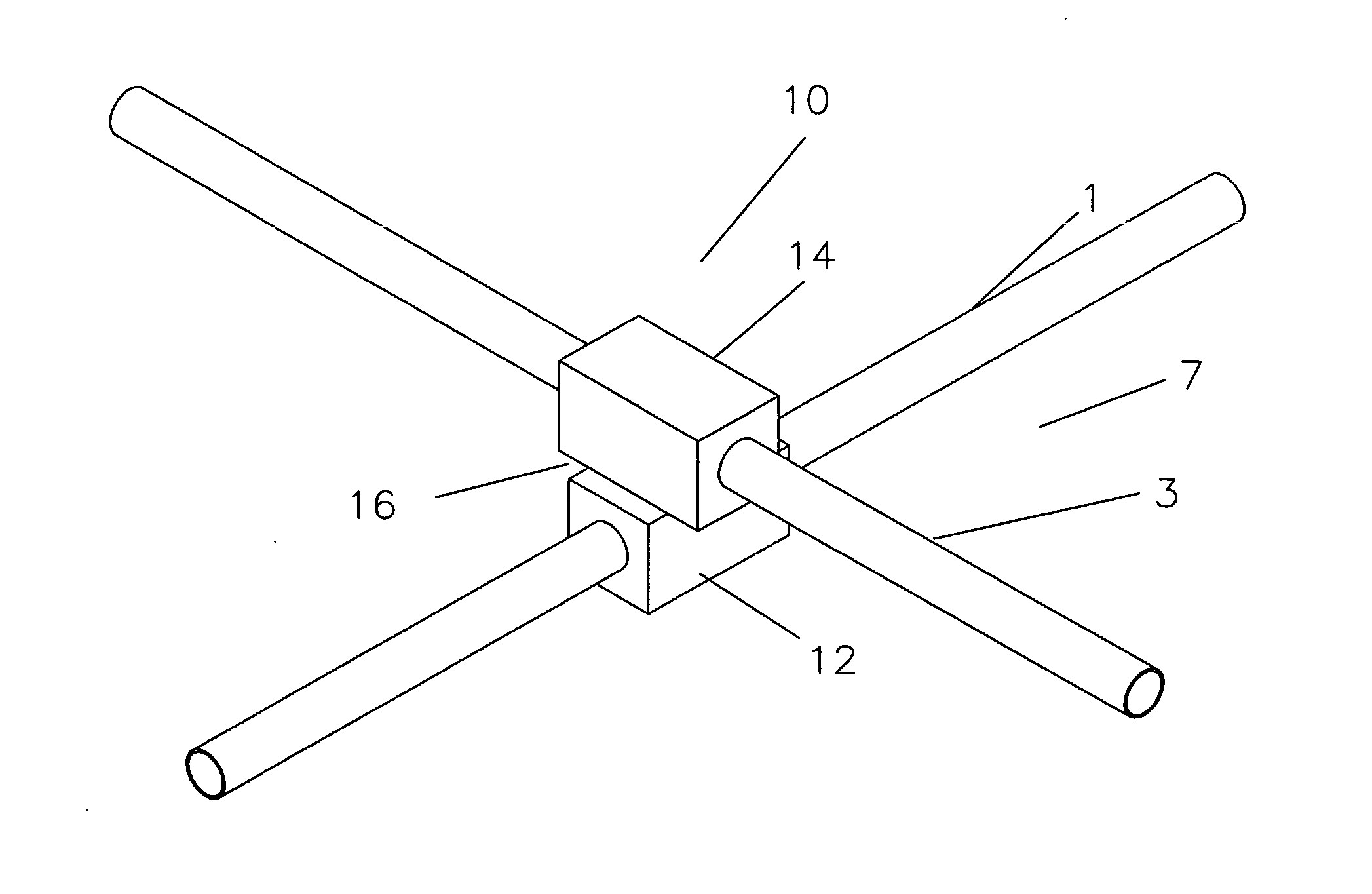

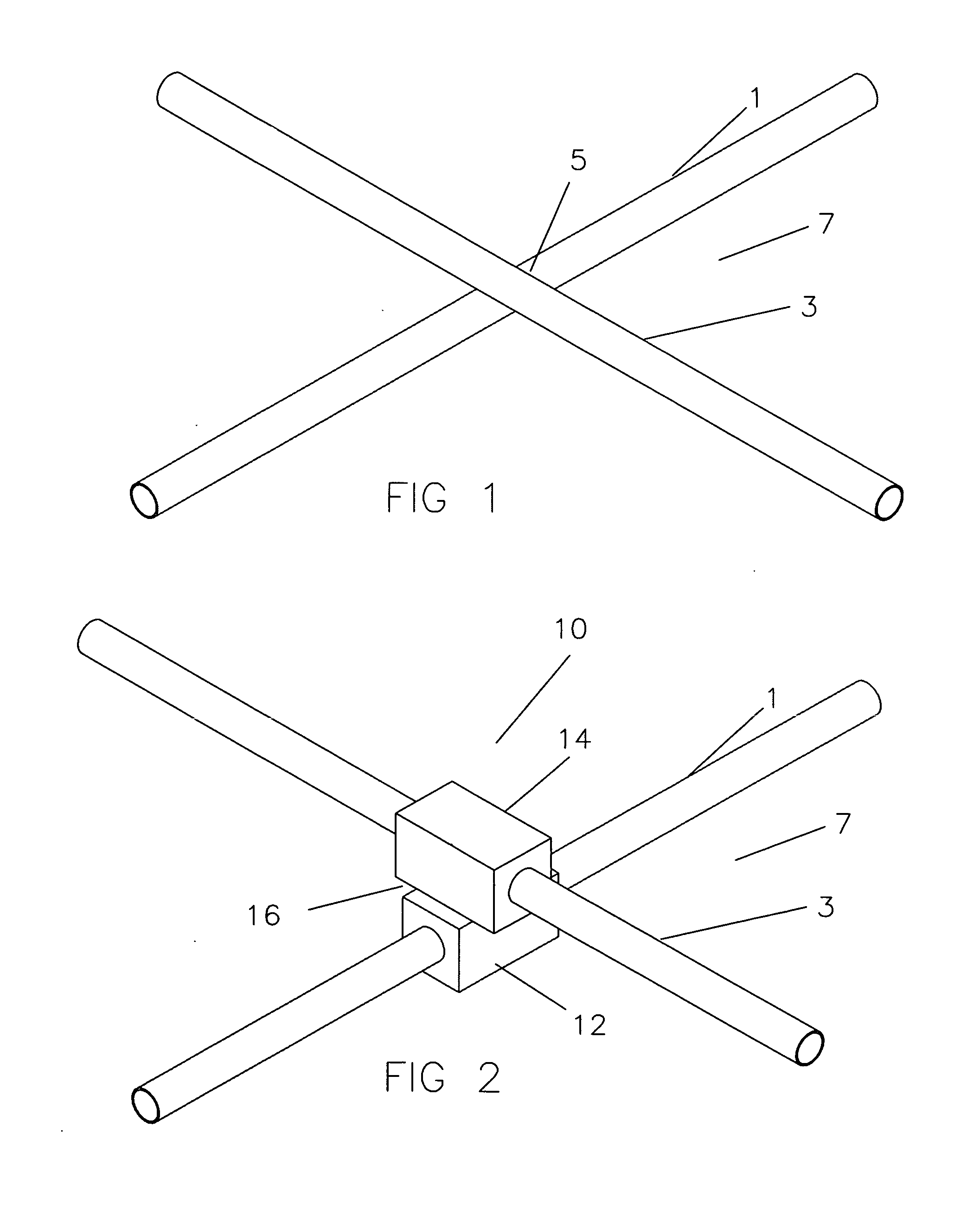

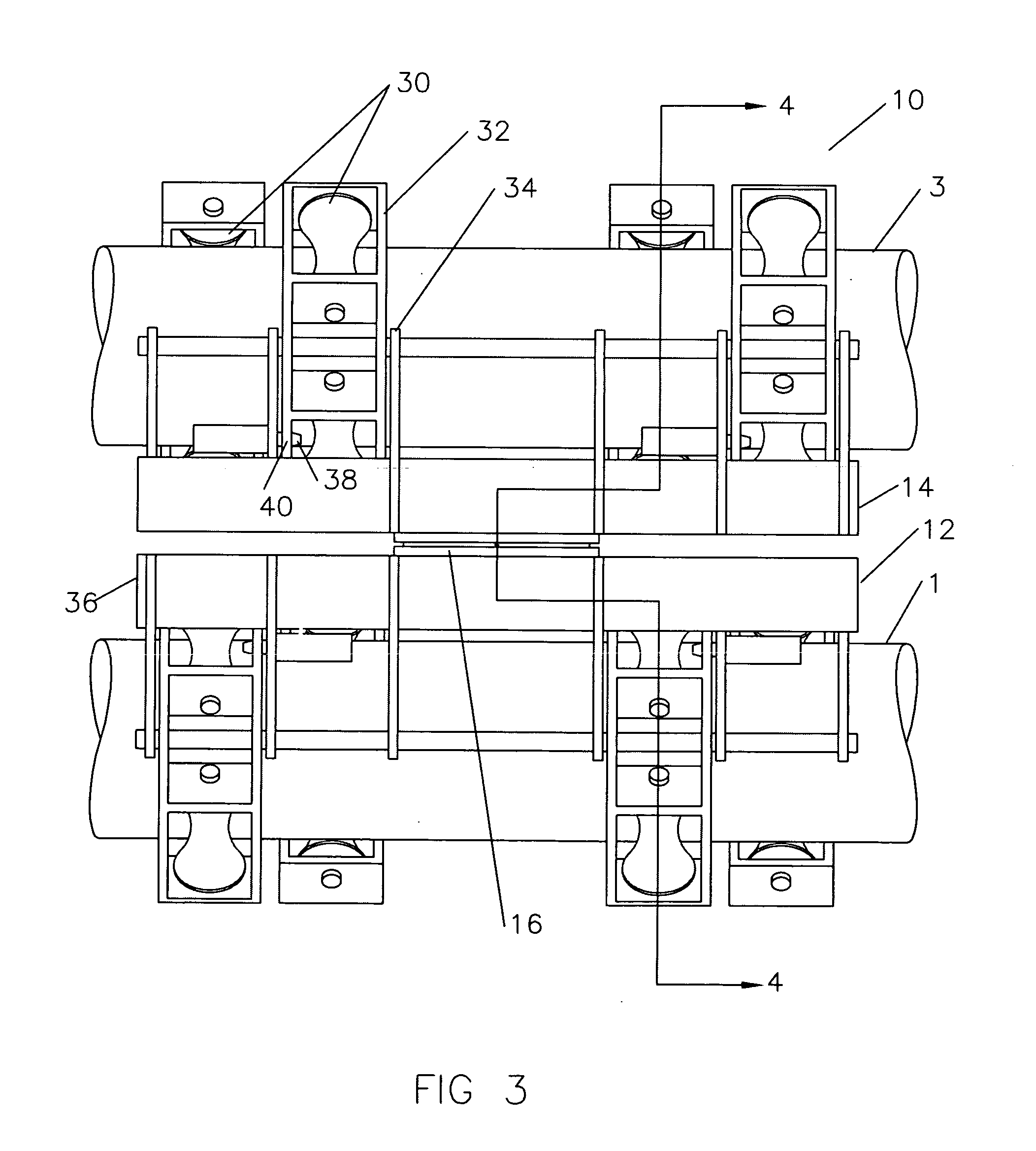

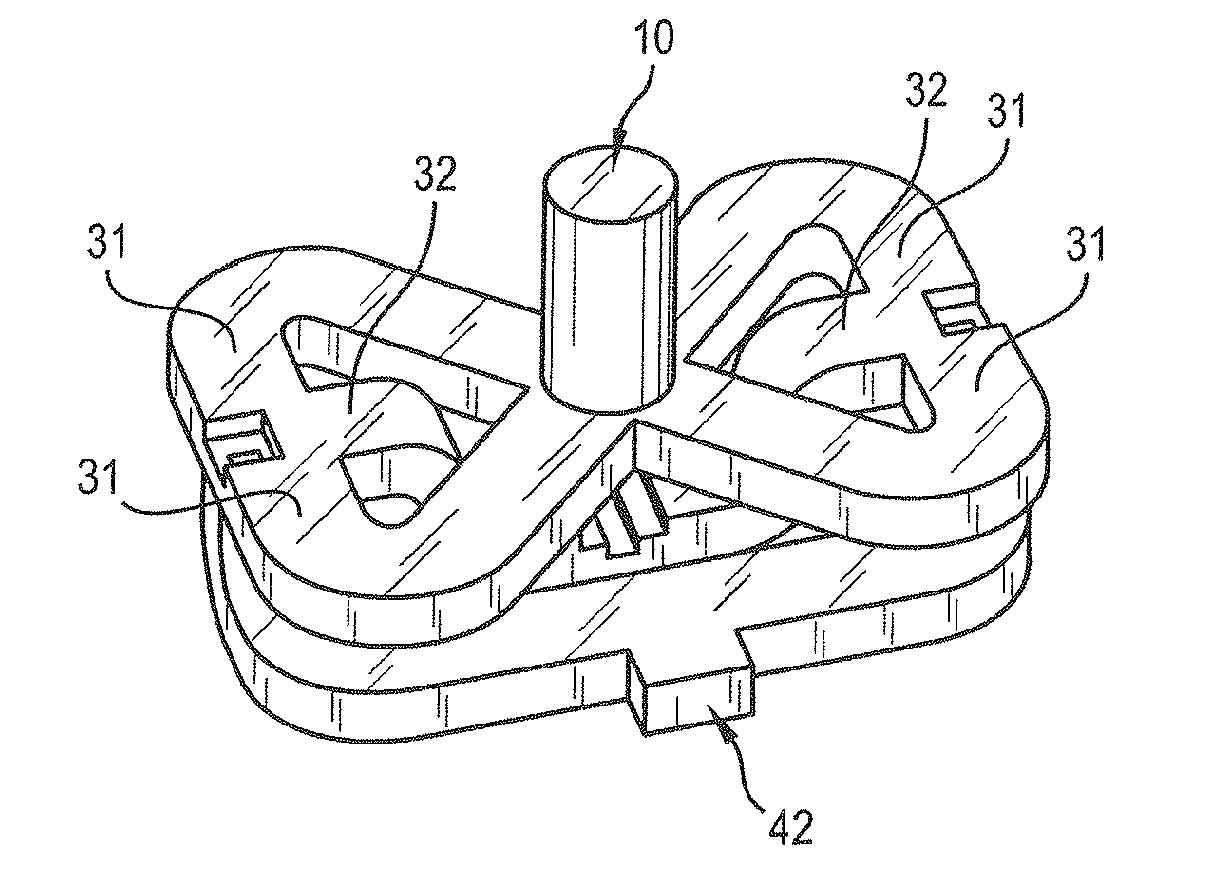

Saddle tee and tap for irrigation lines

InactiveUS6986532B1The process is convenient and fastValve arrangementsWatering devicesLine tubingEngineering

A saddle tee and tap combination for making a fluid connection with an irrigation line in an irrigation system. The saddle tee includes a base having a passage therethrough, and a clamp thereon for engaging an irrigation line. The clamp holds the irrigation line in alignment with the passage, and compresses the irrigation line into an generally oval cross-section elongated in the direction of the axis of the passageway. The tap has a tip with a pointed end adapted to be inserted into the passageway so that the pointed end penetrates the wall of the irrigation line engaged in the clamp, in the direction of the elongation of the cross section.

Owner:KING TECH OF MISSOURI LLC

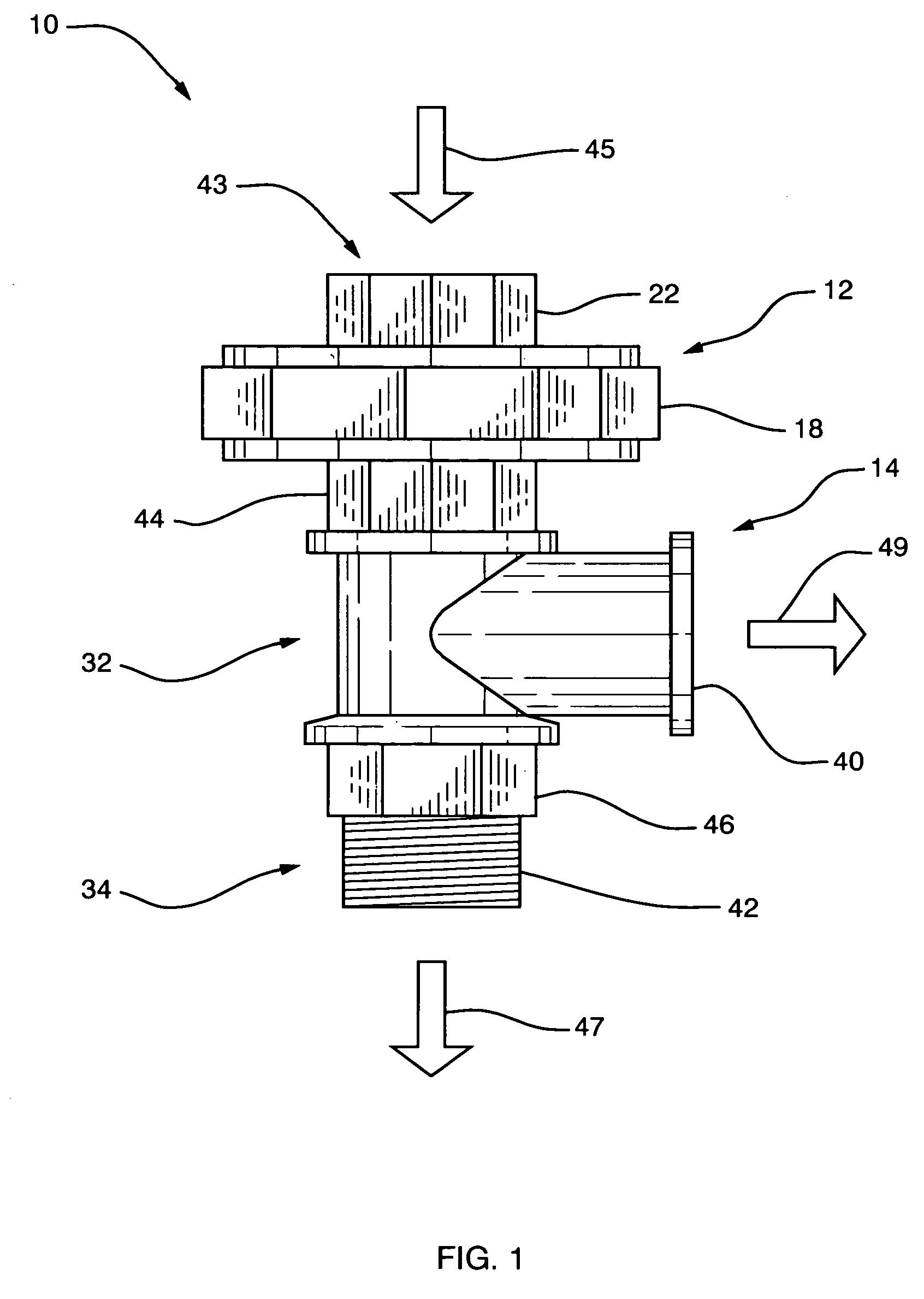

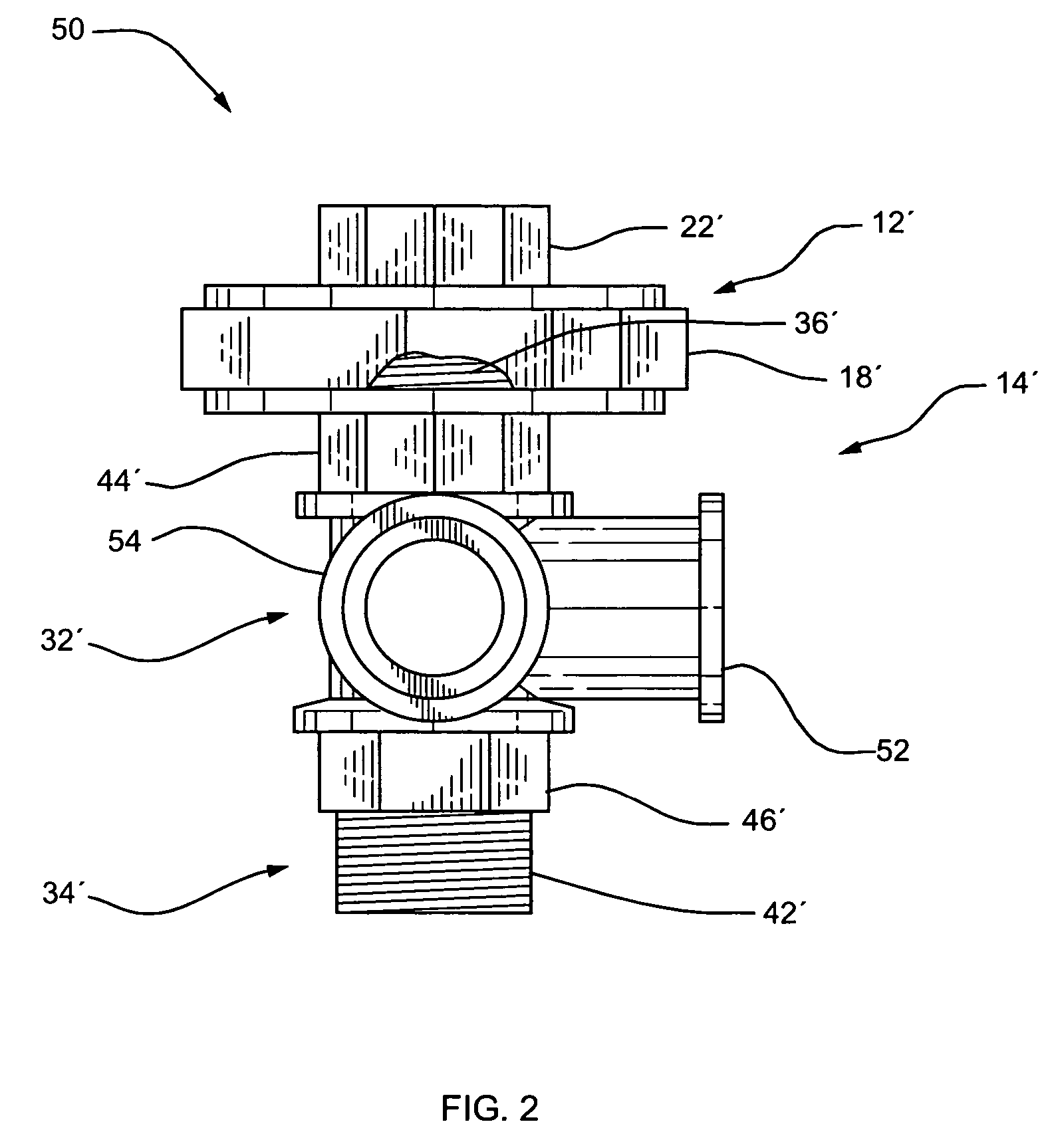

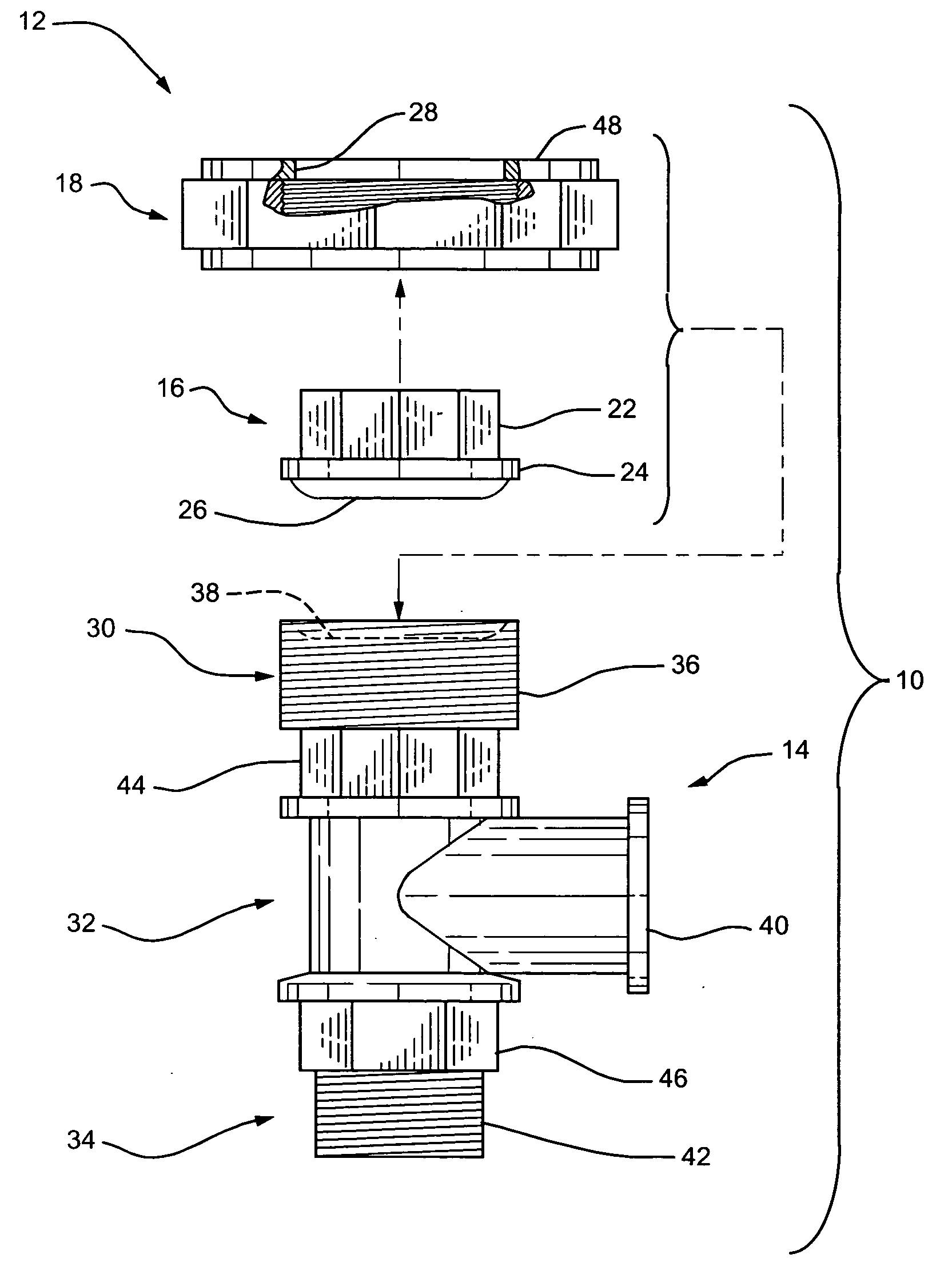

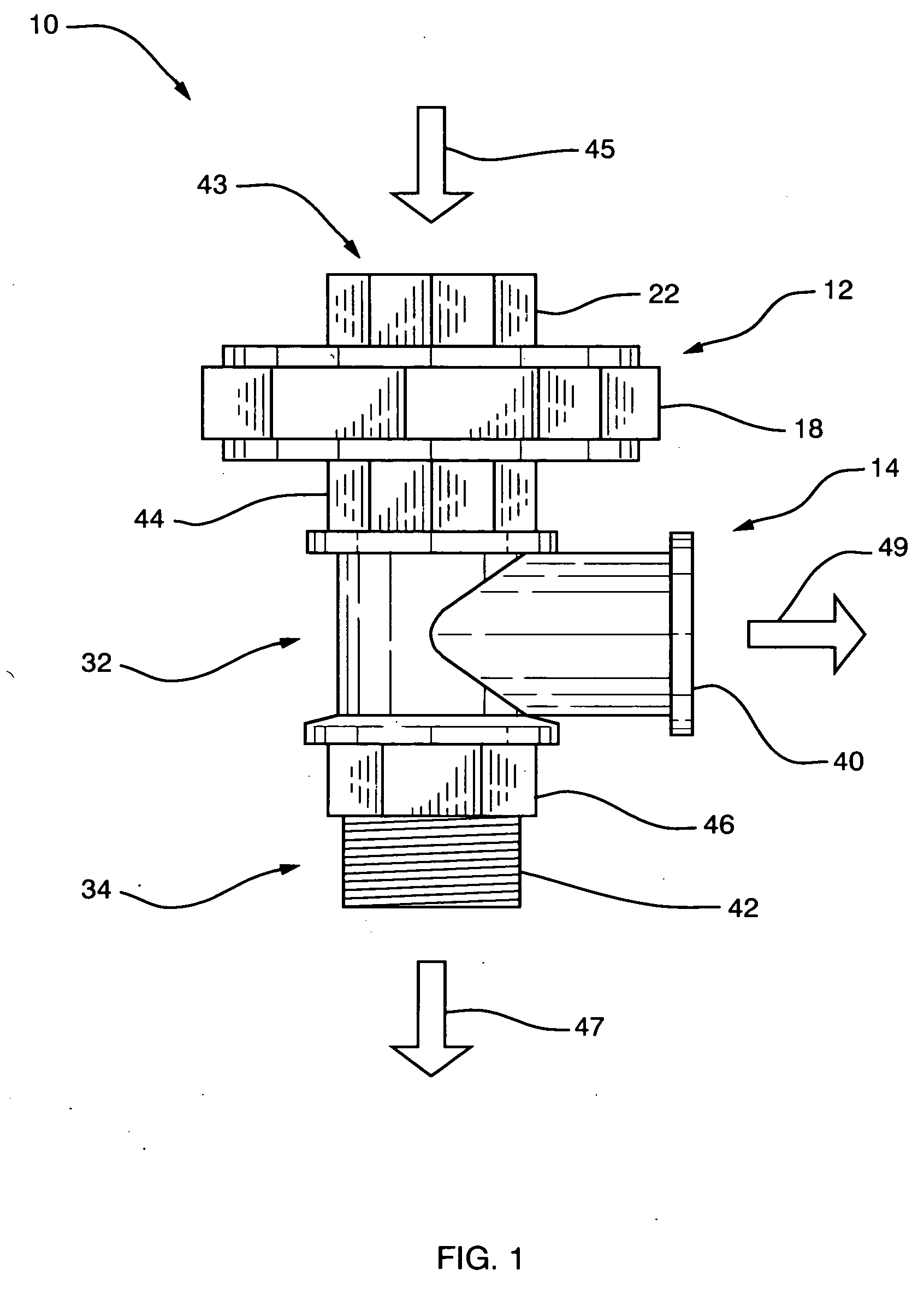

Quick connect and quick disconnect plumbing apparatus

InactiveUS7156425B2Facilitates installation and connectionQuick connectionFluid pressure sealed jointsPipeline expansion-compensationLine tubingThermal water

A plumbing apparatus for connecting a tankless hot water heater to a cold water supply line and a hot water outlet line includes a union and a tee that are interconnected to one another. A first connector at one end of the union is provided for connecting the union to the tankless hot water heater. A second connector at a free end of the tee is provided for connecting the tee to either the cold water supply line or the hot water outlet line. The tee is provided with a branch for connecting the plumbing apparatus to a plumbing device. A passage formed in the union and tee permits fluid to flow there through and through the branch.

Owner:ATKINSON MANUEL DIAZ

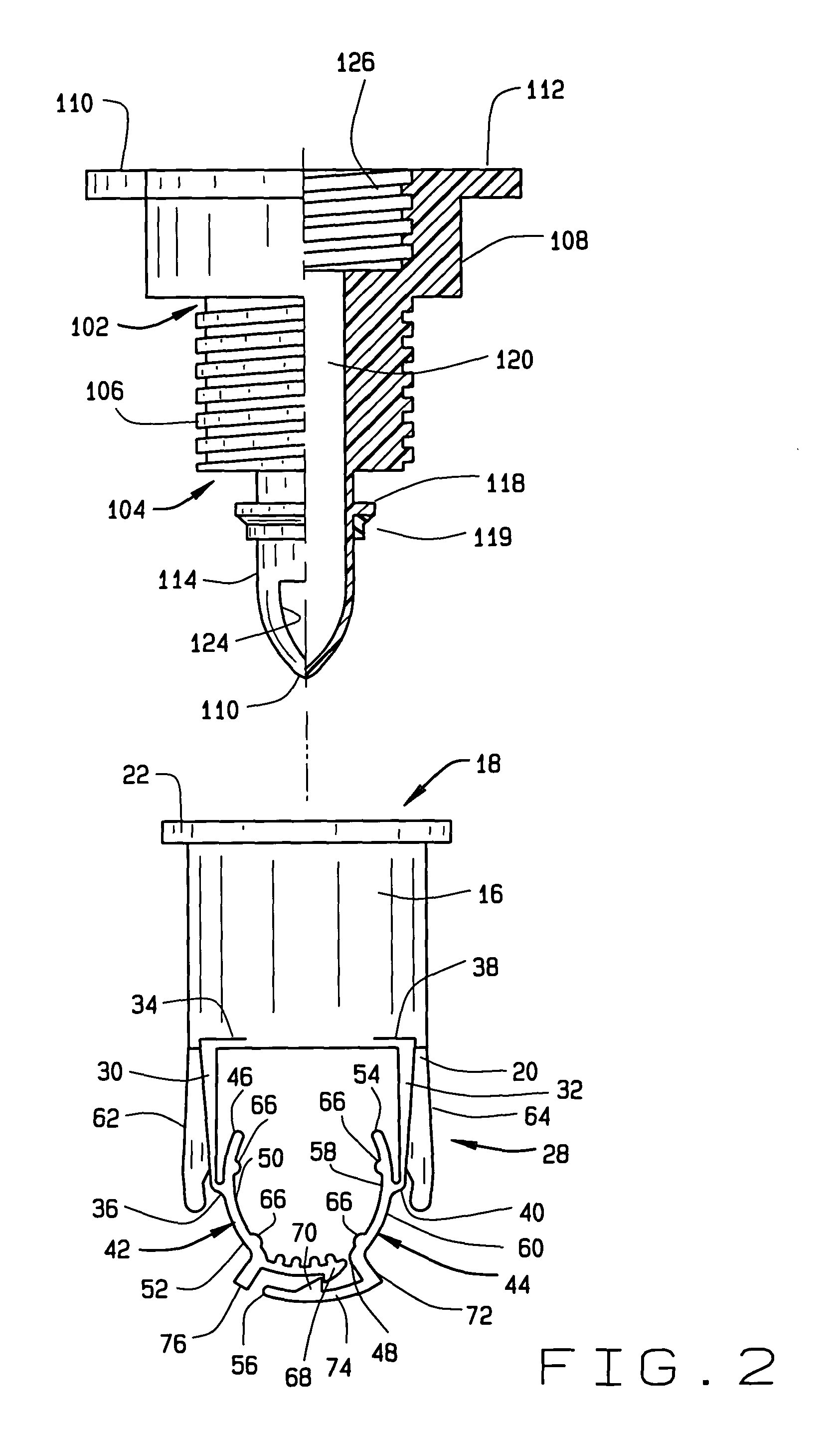

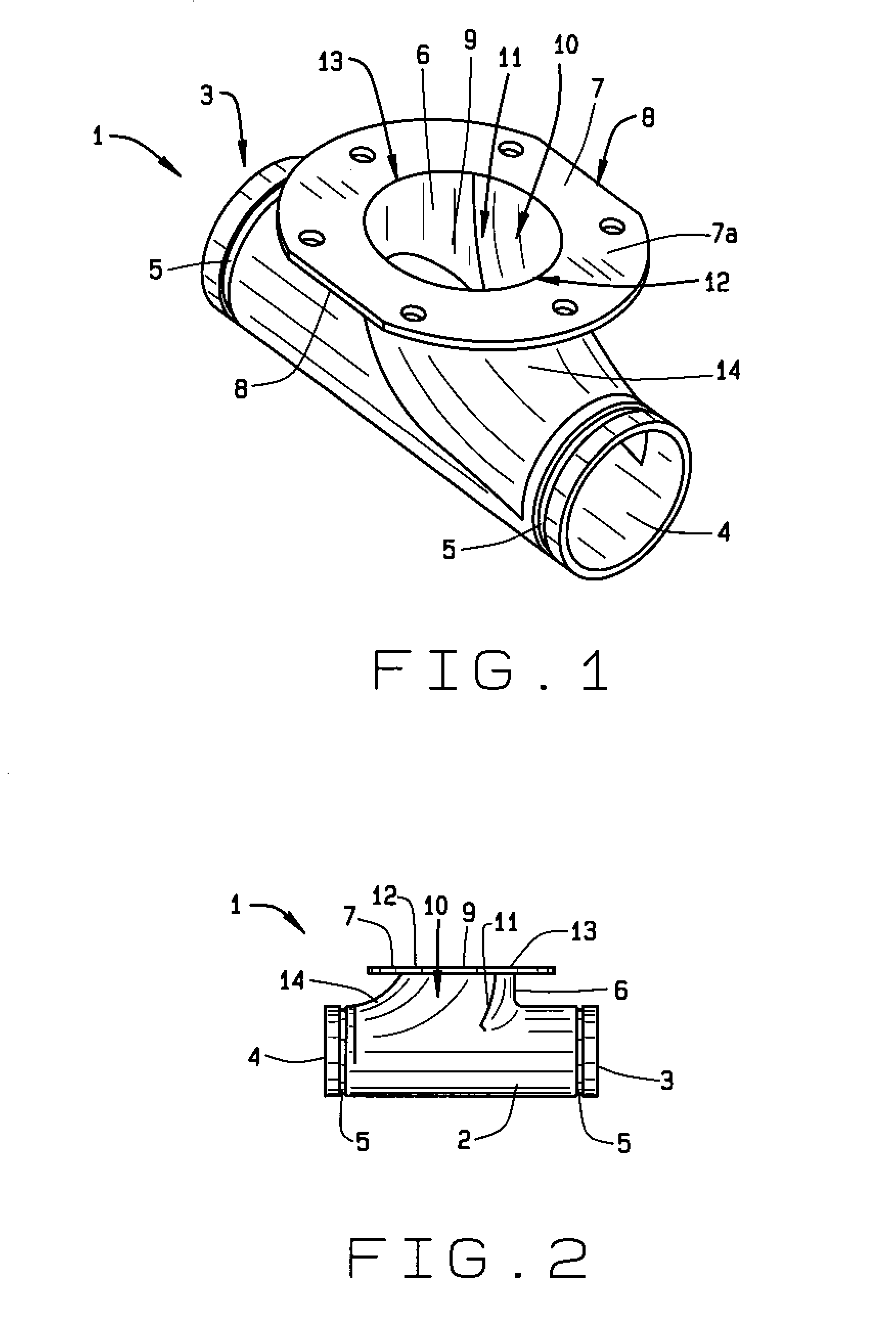

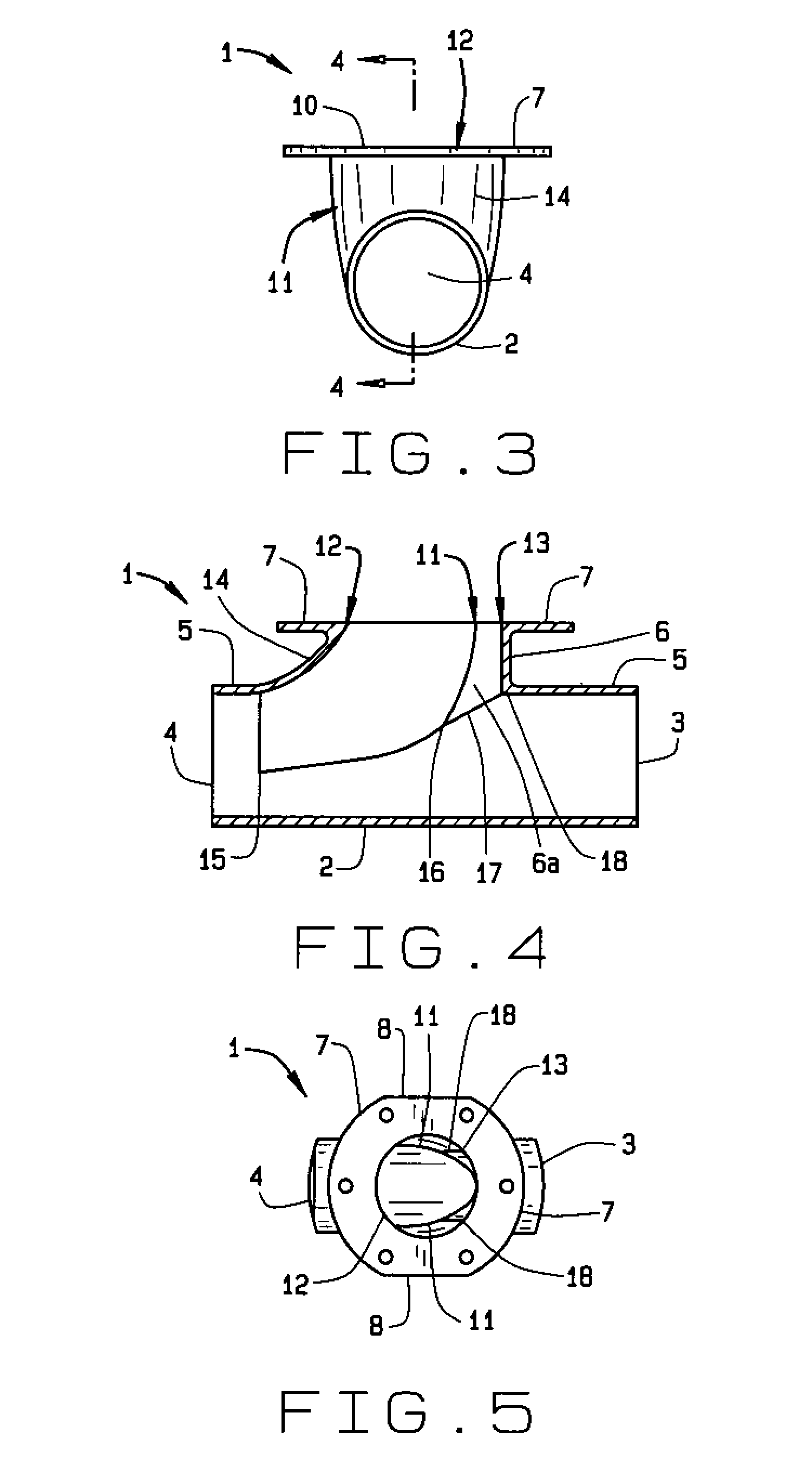

Respiratory Tee Piece

InactiveUS20170065789A1Minimal lossMinimizing condensation lossRespiratorsInhalatorsNebulizerInhalation

A Tee piece that functions as device to direct dual, alternating respiratory therapies to a patient. It has a centrally located low pressure actuated one way valve that connects the inhalation and exhalation paths to the specific therapy devices. The gravity hung valve has a low pressure activation and an offset, angled seat that allows the valve itself to be completely removed from the path of the medicated aerosol particles so as to minimize the potential for particle condensation by collision with the valve. The valve forms a holding chamber for the medicated aerosol increasing the efficiency of the nebulizer cycle. The physical design of the Tee piece's outside surface prevents reverse connection, which is a common problem and the oval shape of the PEP port eliminates blow-off of the PEP device by excessive back pressure.

Owner:MEDICA HLDG LLC

Quick connect and quick disconnect plumbing apparatus

InactiveUS20050104371A1Easy to installFirmly connectedFluid pressure sealed jointsPipeline expansion-compensationStructural engineeringTee junction

A quick connect and quick disconnect plumbing apparatus that is configured to interconnect a first device and a second device. The plumbing apparatus comprises a union and a tee. The union has first and second ends. A first connecting means at the first end of the union is provided for connecting the union to the first device. The tee has first and second ends. The second end of the union is operatively connected to the first end of the tee. A second connecting means at the second end of the tee is provided for connecting the tee to the second device. The tee is provided with a branch for connecting the plumbing apparatus to a third device. A passage formed in the union and tee permits fluid to flow from the first end of the union to the second end of the tee and through the branch.

Owner:ATKINSON MANUEL DIAZ

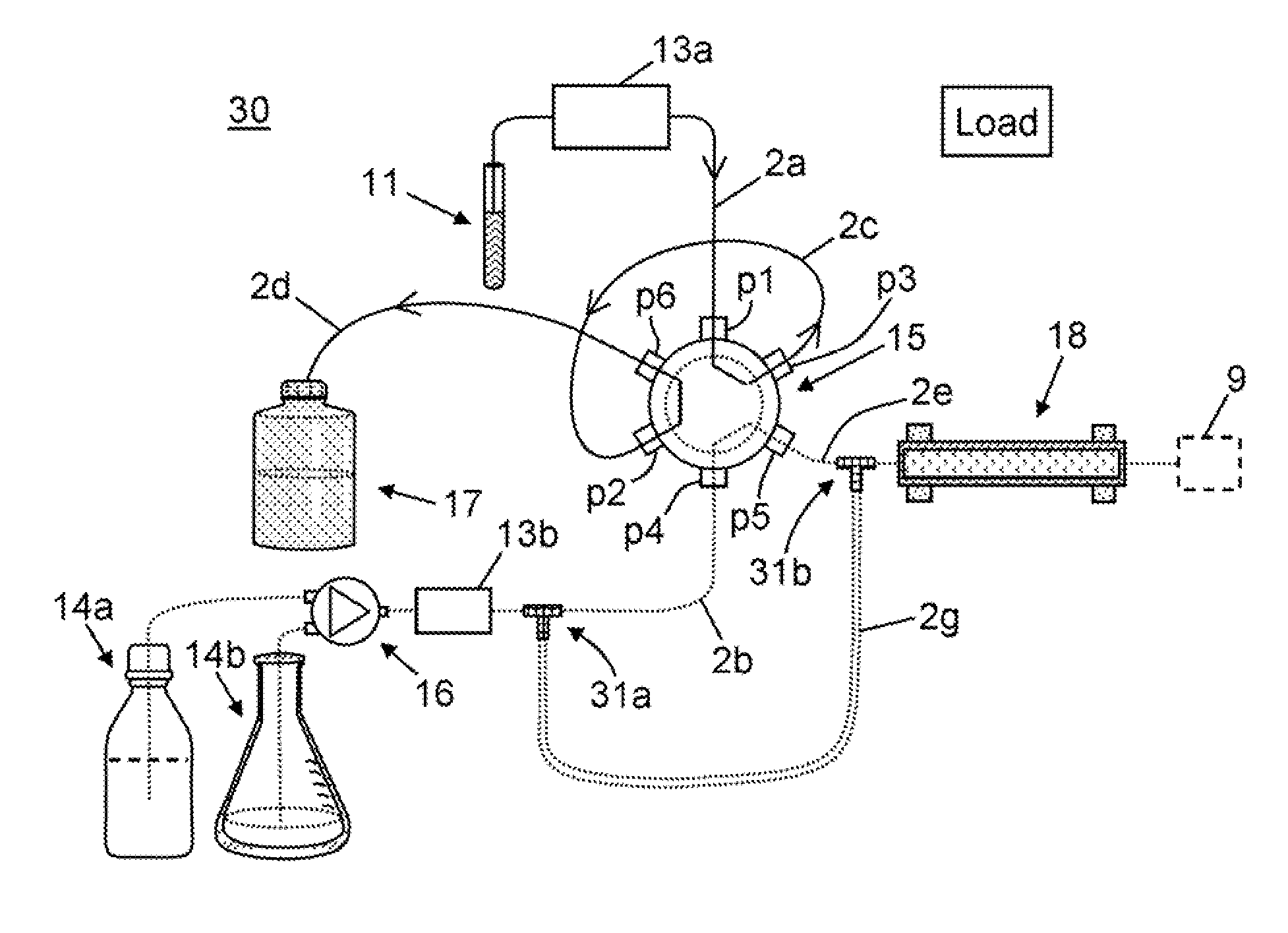

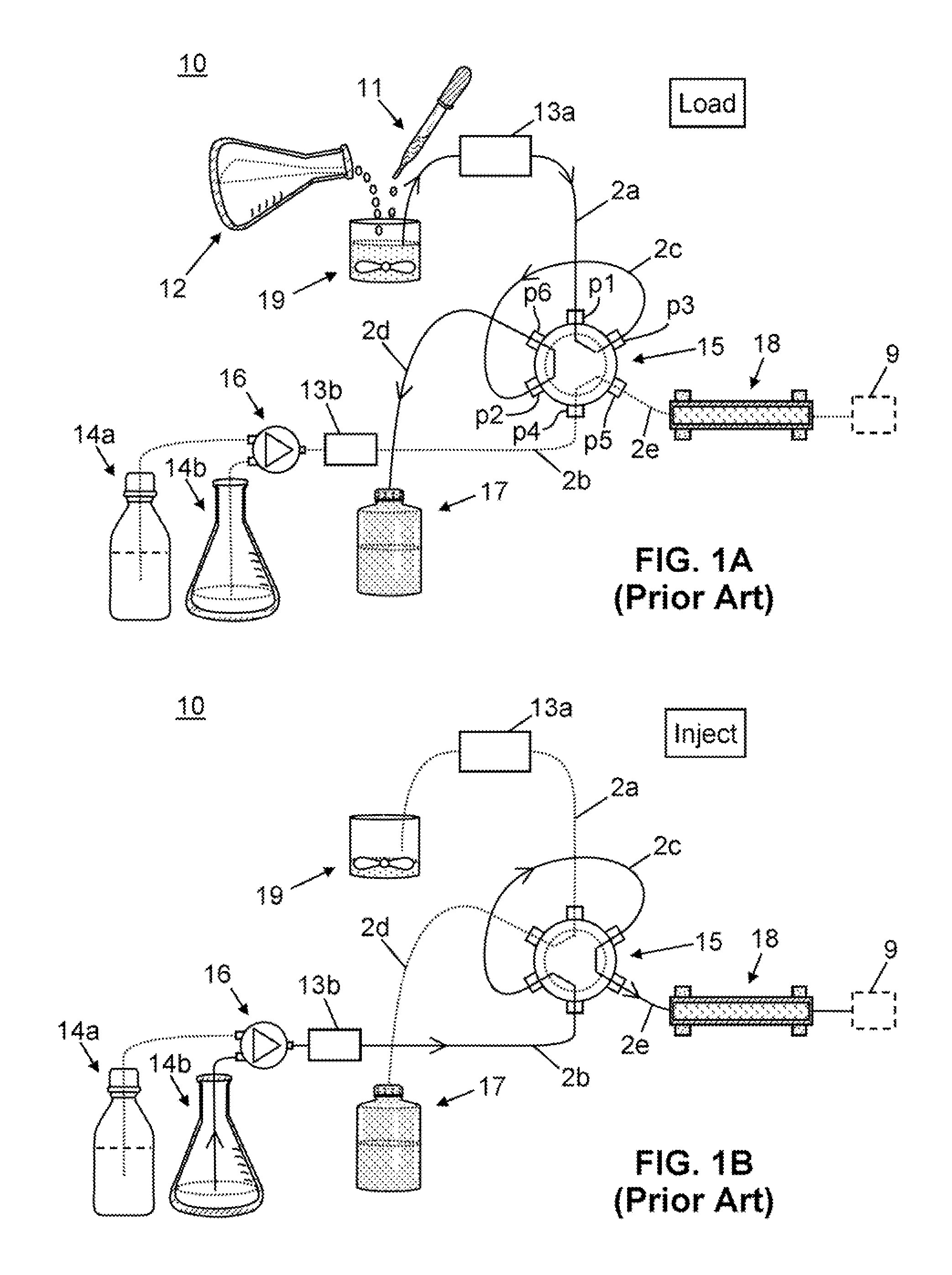

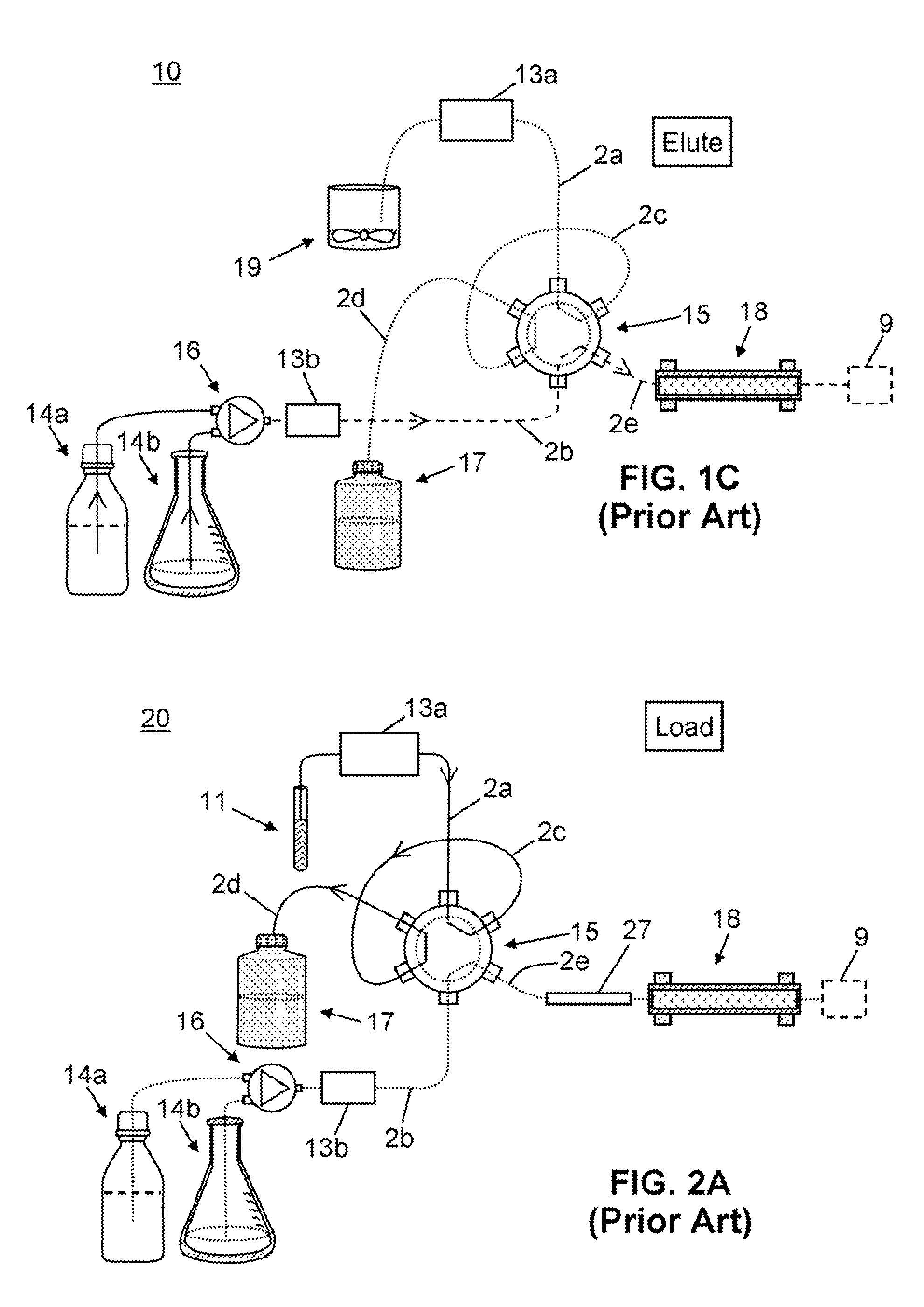

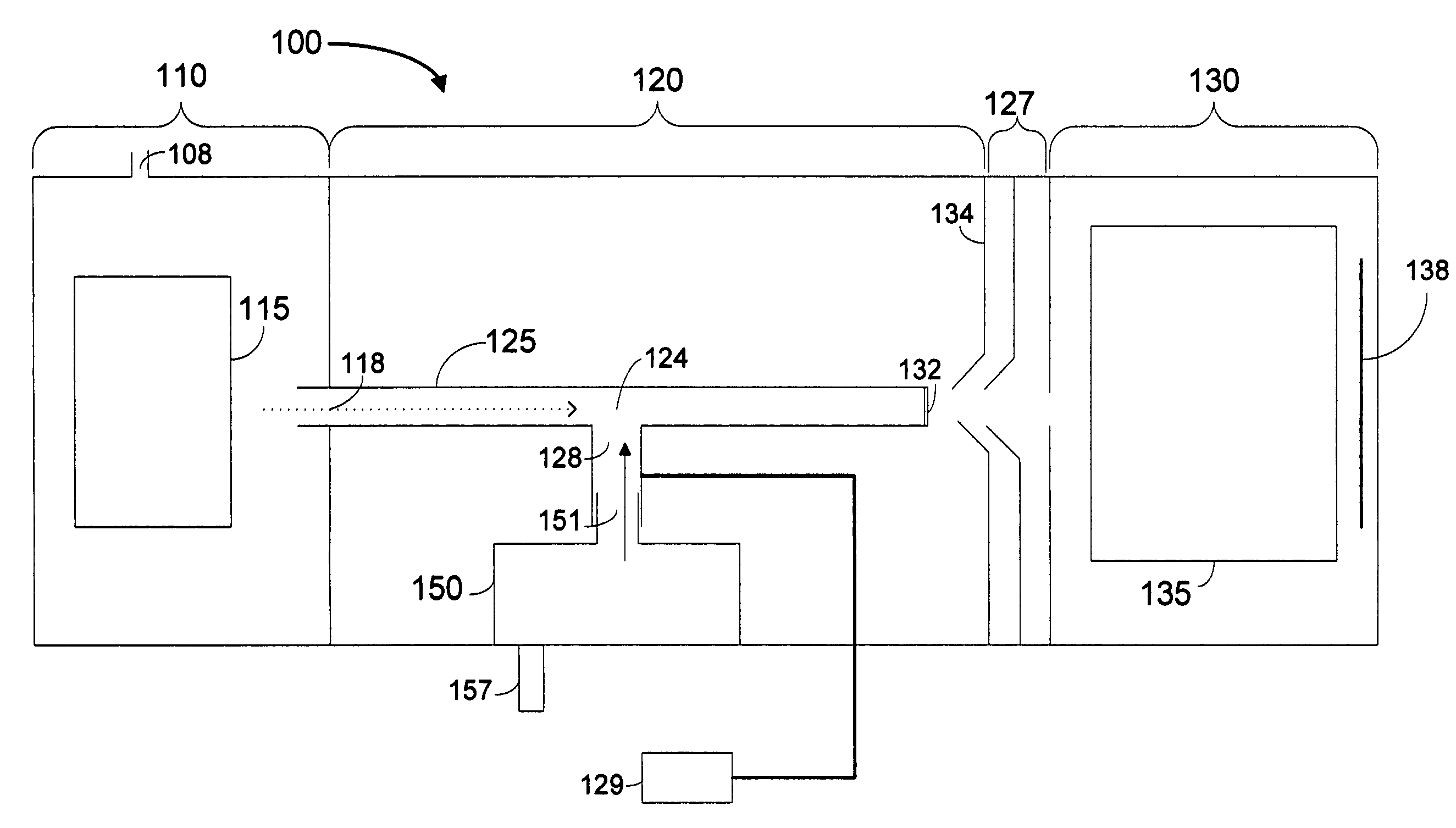

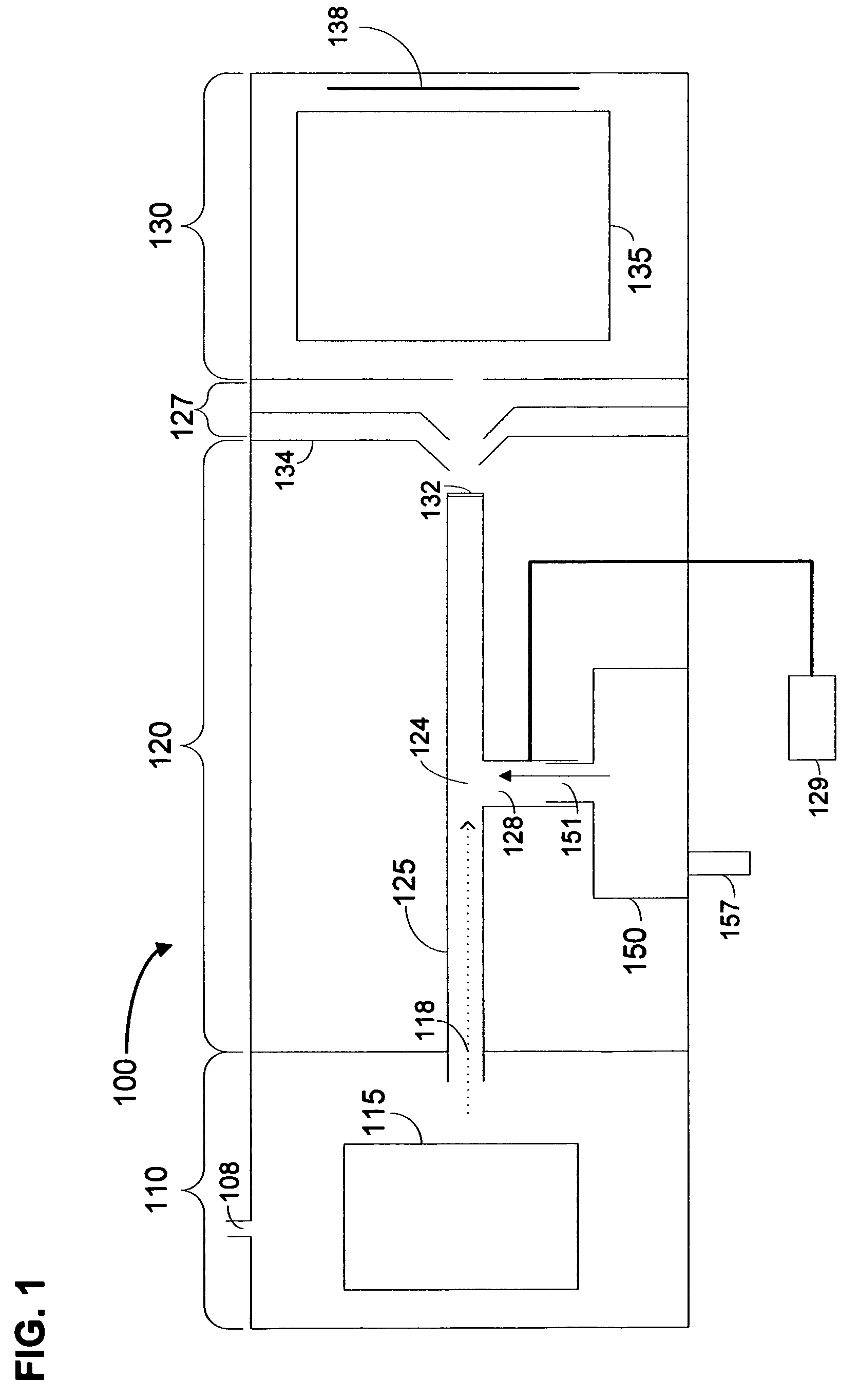

Method and Apparatus for Split-Flow-Mixing Liquid Chromatography

InactiveUS20140061133A1Ion-exchange process apparatusComponent separationChromatographic separationAnalyte

A method for chromatographically separating analytes of a liquid sample comprises: (i) providing the sample in a conduit; (ii) providing a solvent for the sample; (iii) causing the solvent to simultaneously flow into the conduit so as to expel the sample from the conduit and flow into and through a second conduit so as to exit said second conduit; (iv) simultaneously providing the expelled sample and the exited solvent to a mixing tee-junction such that the expelled sample and the exited solvent mix thereat; (v) providing the mixture of the expelled sample and the exited solvent to a chromatographic column such that the analytes are transferred to the column and are chromatographically separated therein under the influence of a flow of the solvent, or a different solvent or a mixture of solvents.

Owner:THERMO FINNIGAN

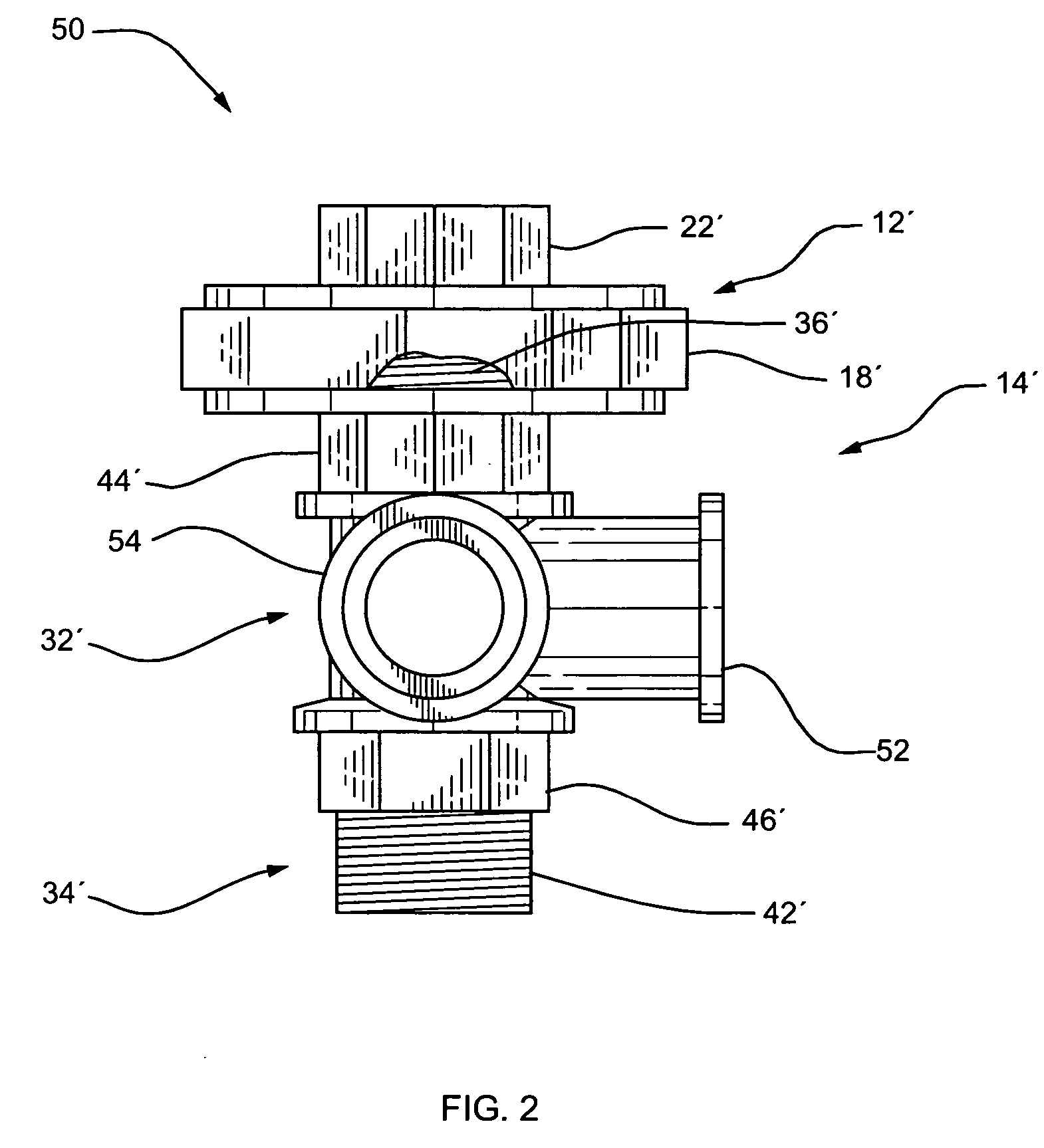

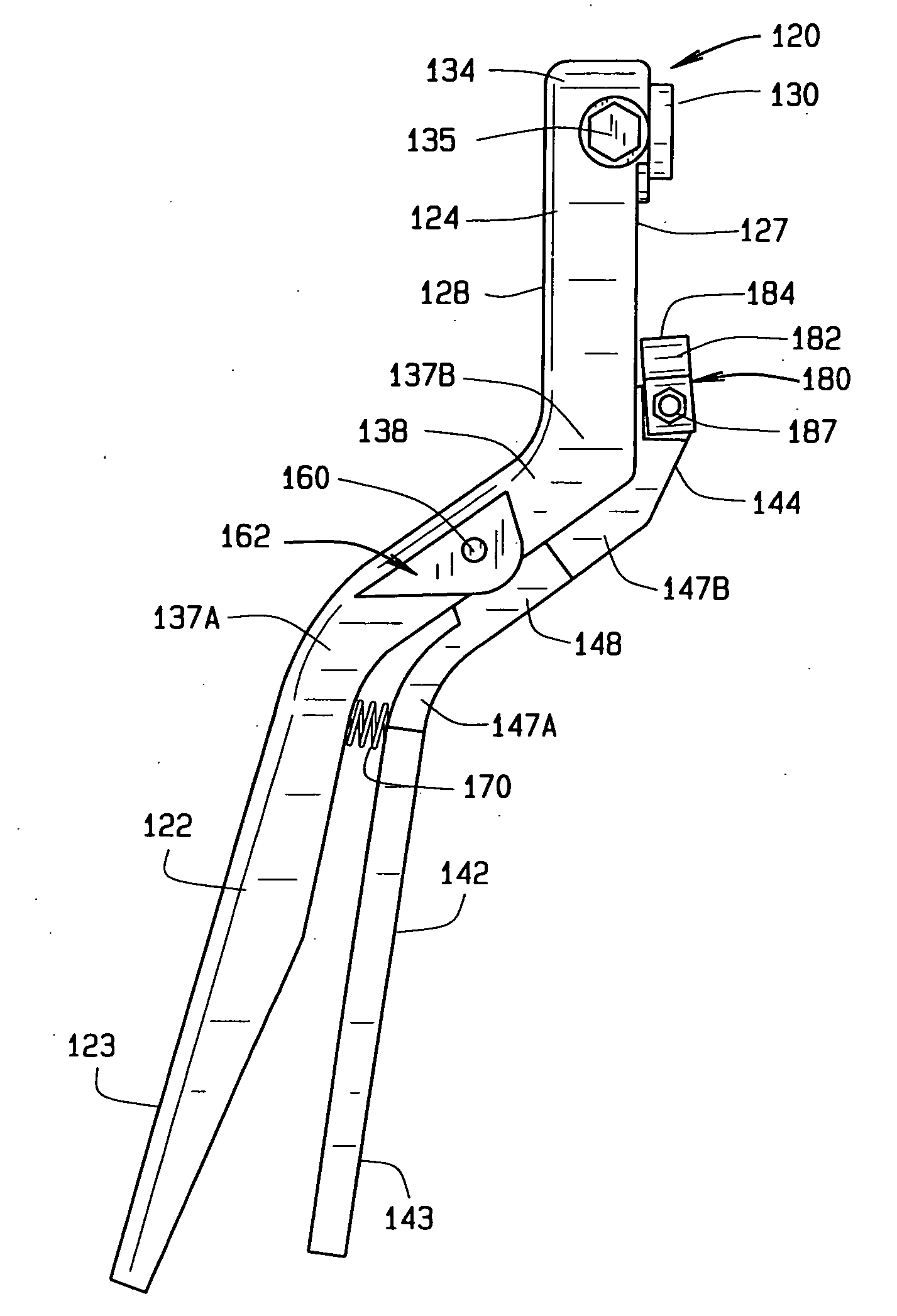

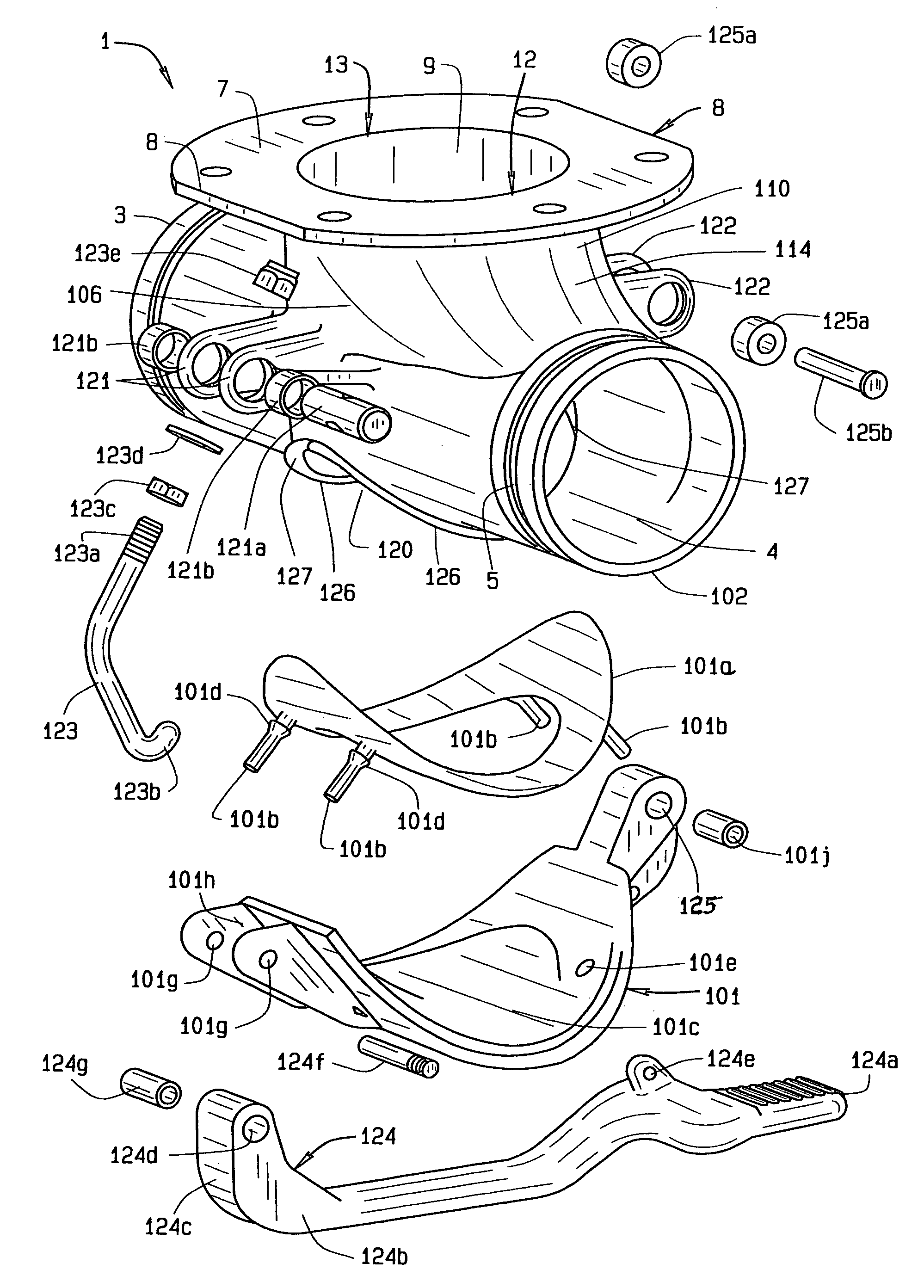

Valve handle for butterfly valve for bulk commodity hopper with tee

ActiveUS20120261602A1Conveniently struckEasy to wearOperating means/releasing devices for valvesLoading/unloading vehicle arrangmentButterfly valveValve stem

A valve handle for a bulk commodity hopper valve, the handle including an extended handle bar member, with a valve stem socket opening near its distal end, a shorter lock lever member positioned to extend the handle bar member, the members have various bends to provide clearance from interfering with the equipment to which the handle mounts, and a lock lever member having a lever tip that can enter into engagement, or release, with valve lock notches at the end of the handle bar member.

Owner:BULK TANK

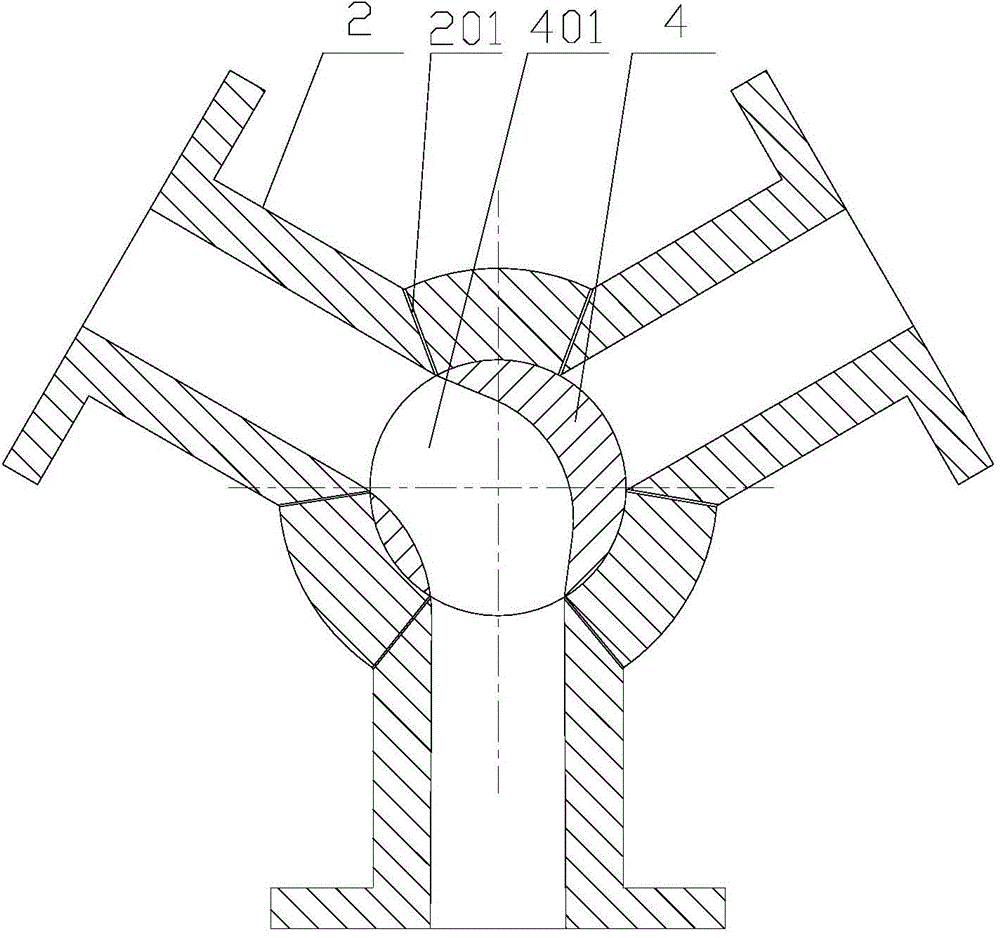

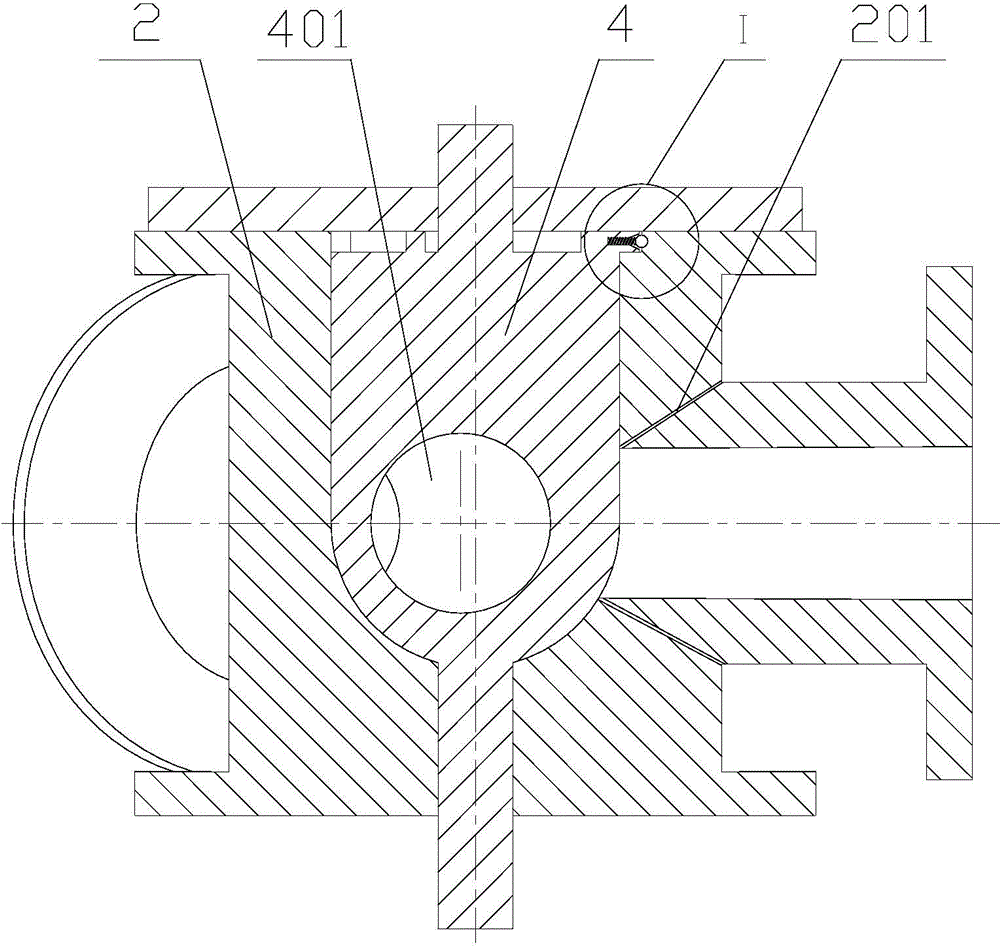

Tee reversing valve

InactiveCN104896147AAvoid cloggingAvoid corrosionMultiple way valvesValve housingsEngineeringTee junction

The invention discloses a tee reversing valve. The reversing valve comprises a valve body and a valve core rotatably inserted in the valve body, and is characterized in that three pipe openings at 120 DEG angles from each other are arranged on the valve body; each of the pipe openings comprises a liquid inlet and two liquid outlets; multiple cleaning water holes communicated with the pipe openings are arranged in the valve body; a liquid circulation hole is arranged in the valve core and used for communicating the liquid inlet and one of the liquid outlets, and closing the other liquid outlet; and a layer of ceramic is plated on the inner surface of the liquid circulation hole. The tee reserving valve is capable of bearing bigger pressure of liquid flows and quickly reversing, and the valve core rotates to change the flowing direction.

Owner:WUHAN UNIV OF TECH

Saddle tee and tap for irrigation lines

InactiveUS7150476B2The process is convenient and fastValve arrangementsPipe elementsLine tubingEngineering

A saddle tee and tap combination for making a fluid connection with an irrigation line in an irrigation system. The saddle tee includes a base having a passage therethrough, and a clamp thereon for engaging an irrigation line. The clamp holds the irrigation line in alignment with the passage, and compresses the irrigation line into an generally oval cross-section elongated in the direction of the axis of the passageway. The tap has a tip with a pointed end adapted to be inserted into the passageway so that the pointed end penetrates the wall of the irrigation line engaged in the clamp, in the direction of the elongation of the cross section.

Owner:KING TECH OF MISSOURI LLC

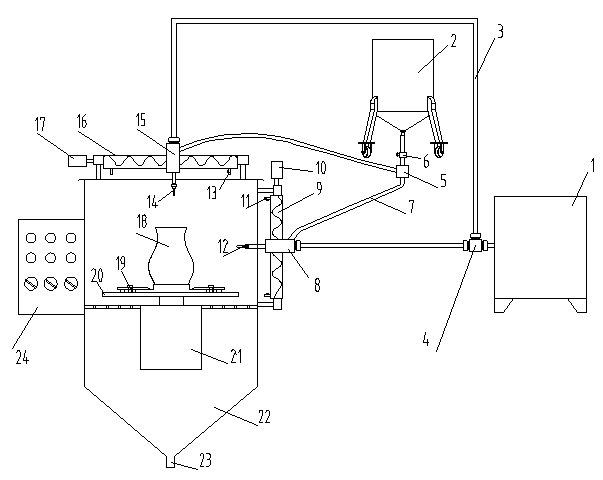

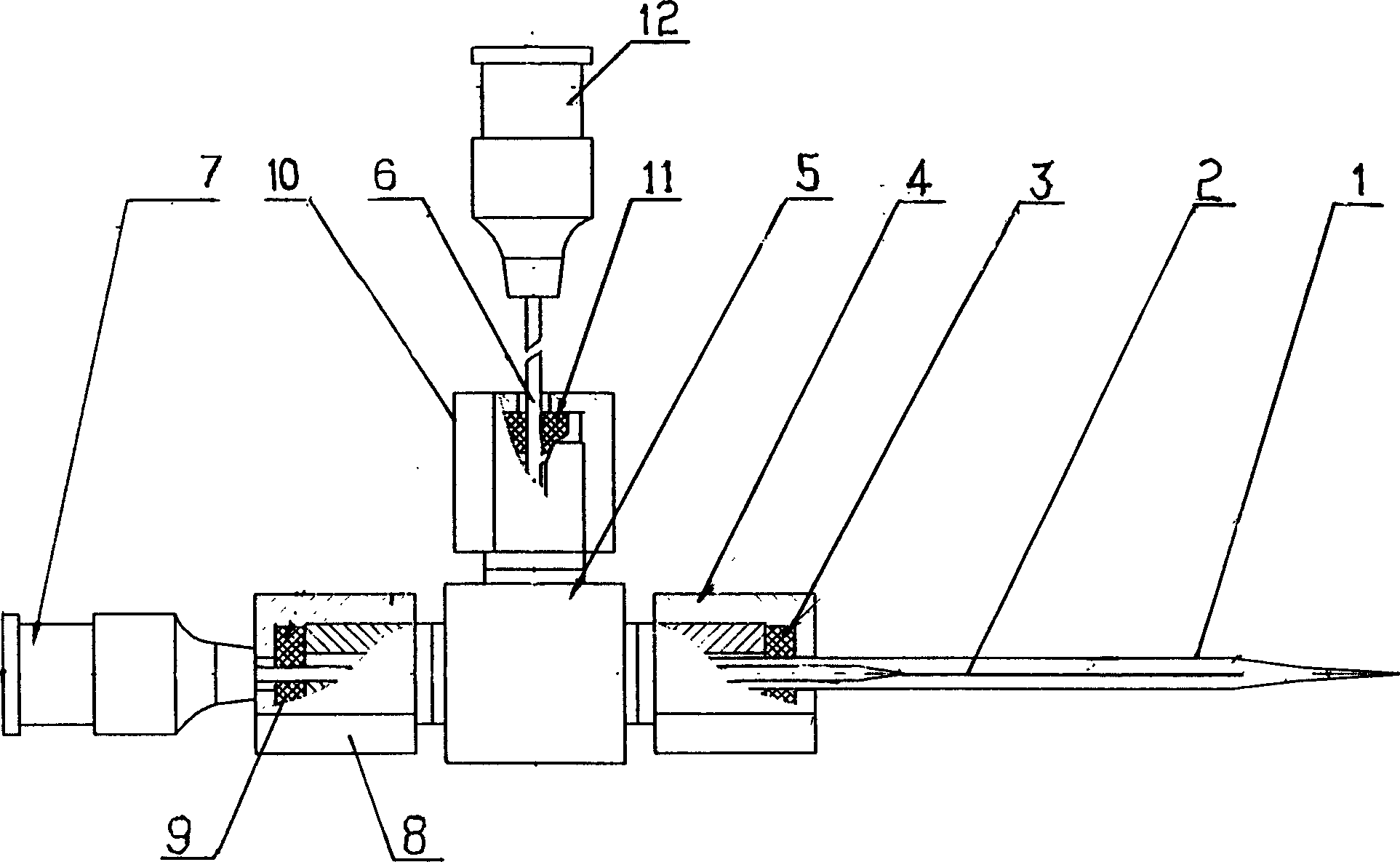

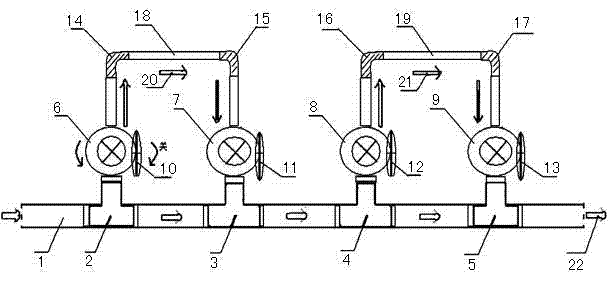

3D printout surface sand blasting processing machine

InactiveCN104290040AGood consistency of finishImprove the finishAbrasive machine appurtenancesAbrasive blasting machinesUltra high pressureSand blasting

The invention relates to surface sand blasting processing equipment, in particular to a 3D printout surface sand blasting processing machine. The 3D printout surface sand blasting processing machine comprises an ultrahigh pressure generator, a sand storage tank, a sand inlet hose connected between the sand storage tank and mixing cavities, an electromagnetic valve arranged on the sand inlet hose, a sand outlet tee joint arranged below the electromagnetic valve, a high-pressure water pipe connected between the ultrahigh pressure generator and the mixing cavities, and a high-pressure tee joint arranged on the high-pressure water pipe. A nozzle A is connected below the mixing cavity A; a nozzle B is connected below the mixing cavity B; a Z-direction lead screw is arranged on the right side face of a sand blasting box; an X-direction lead screw is arranged above the sand blasting box; a Z-direction motor is arranged at the upper end of the Z-direction lead screw; an X-direction motor is arranged at the left end of the X-direction lead screw; a rotating motor is arranged below a rotating working table; a workpiece is pressed on the rotating working table through a workpiece pressing block; an electric control box is arranged on the left side face of the sand blasting box; the electric control box can set time so as to control the ultrahigh pressure generator and the electromagnetic valve to be started and stopped; the rotating speed of the X-direction motor, the Z-direction motor and the rotating motor can be adjusted.

Owner:江苏旭升水射流科技有限公司

Dual flange tee

InactiveUS7568496B2Low profileAvoid hard activationPipeline expansion-compensationLiquid transferring devicesEngineeringTee junction

The dual flange hopper tee or other fitting connects to the bottom of a hopper for use in unloading the contents thereof, and has a relatively low profile for ground clearance. When used in conjunction with a valve, the tee or other fitting can be removed from the hopper without requiring removal of the valve, and can allow opening of the valve without interfering with flow through a horizontal pipe section of the fitting.

Owner:BRAY INT INC

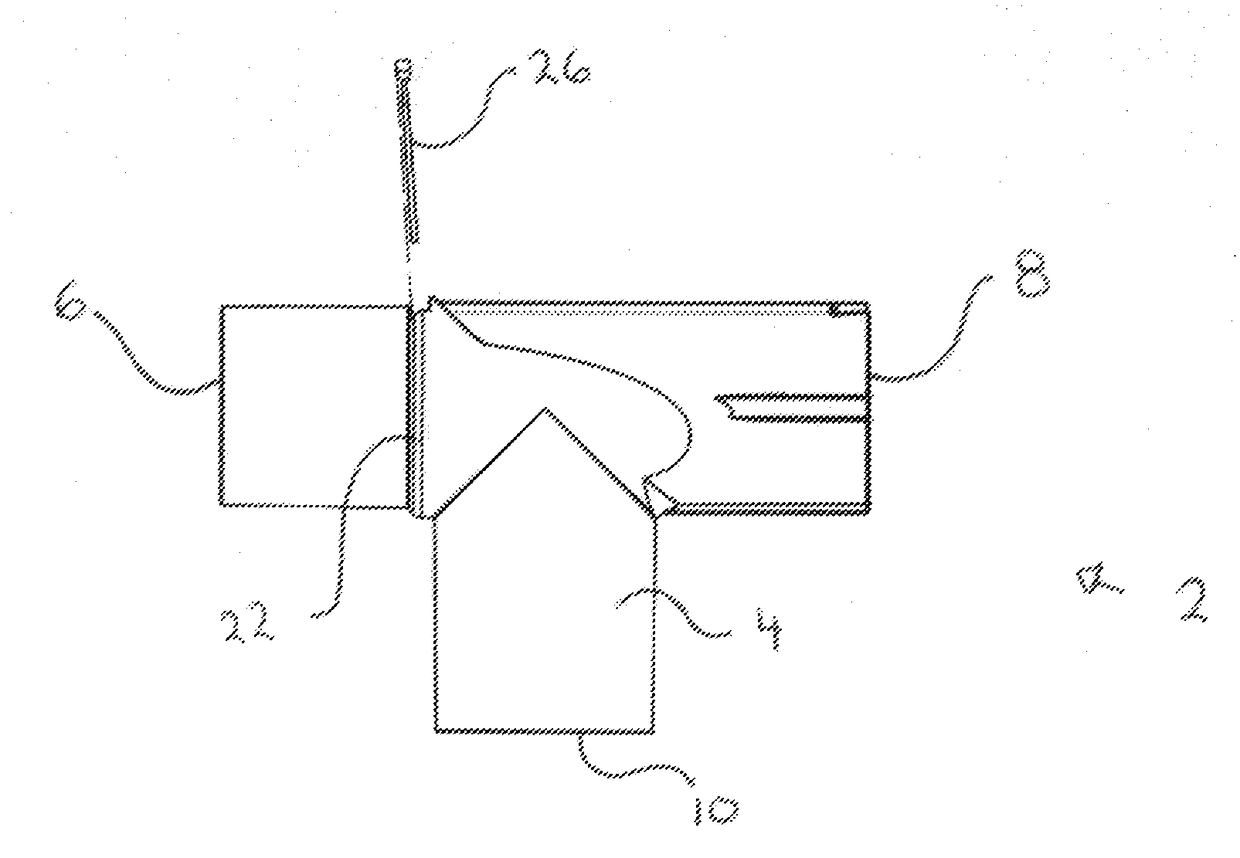

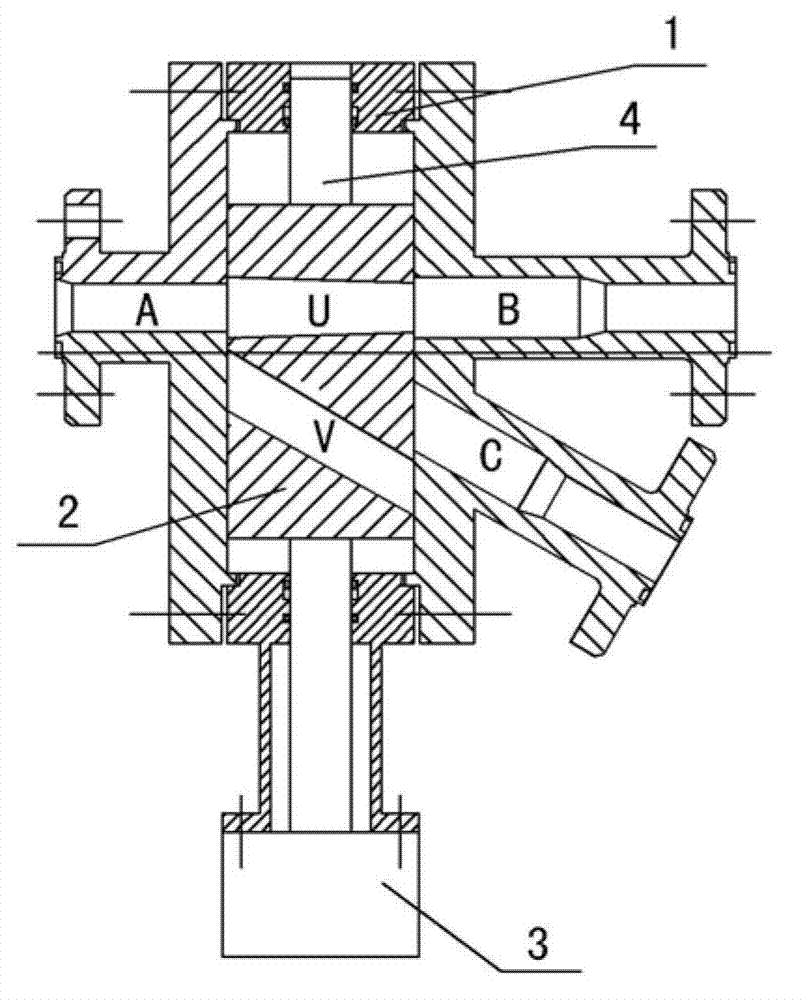

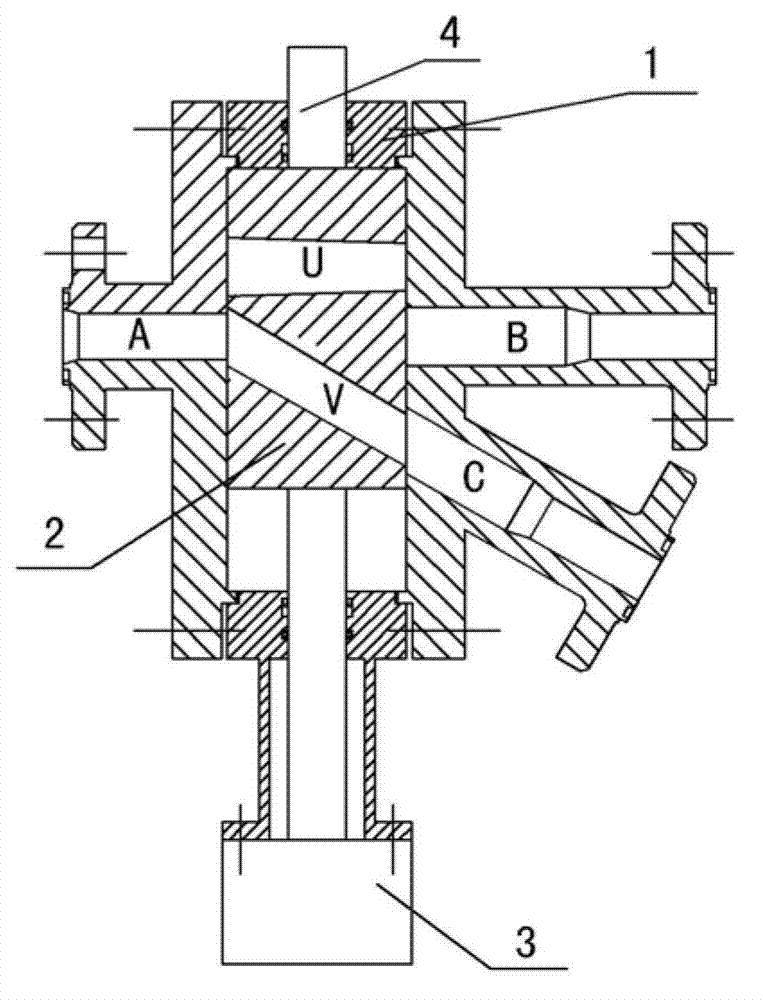

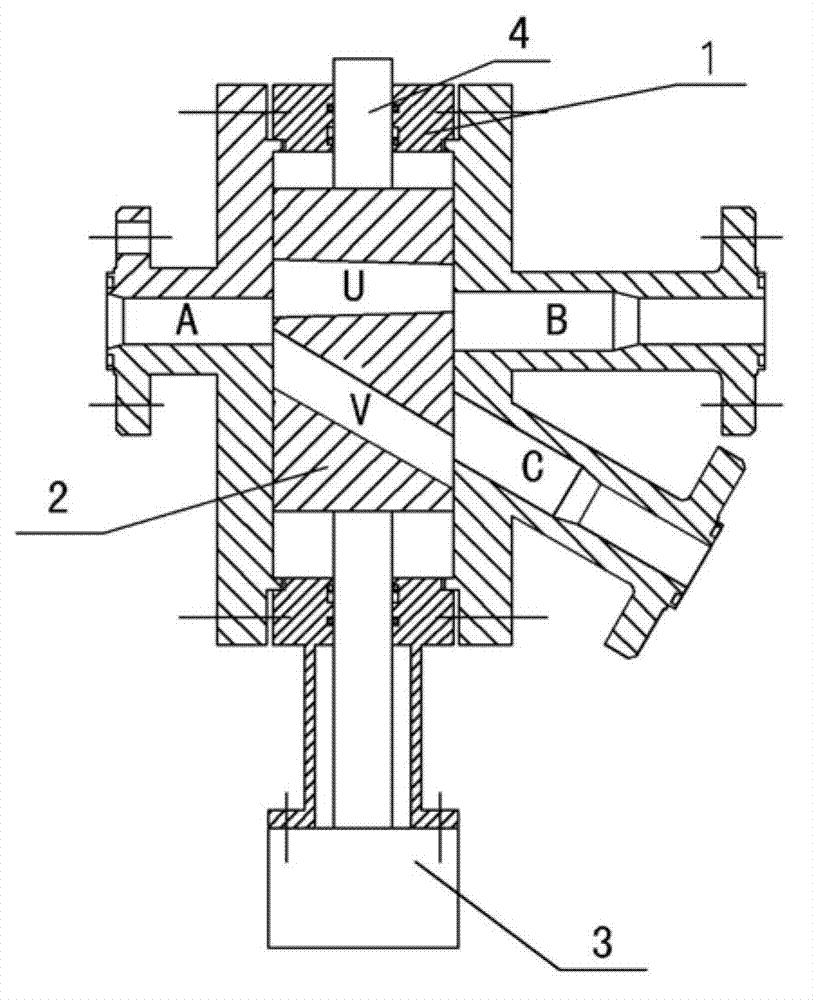

Slide powder-feeding three-way reversing valve

ActiveCN102818047AReduce wearPrevent compactionMultiple way valvesValve housingsEngineeringOperational stability

The invention discloses a slide powder-feeding three-way reversing valve which is characterized in that a columnar valve cavity is reserved in a valve body with one inlet and two outlets, a double-flow-passage columnar spool which can slide linearly along the columnar valve cavity is disposed in the same; a valve body inlet passage A, a valve body outlet passage B and a valve body outlet passage C are arranged on the valve body; the a valve body outlet passage B is coaxial with the valve body inlet passage A, an acute included angle a is formed by outflow directions of the valve body outlet passage B and the valve body outlet passage C, axis of each valve body passage is on a plane M; a spool passage U and a spool passage V are arranged in the columnar spool; and different positions of the columnar spool in the columnar valve cavity correspond to different on and off states. By the slide powder-feeding three-way reversing valve, operational stability of a powder feeding device is improved effectively and service life of the device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +2

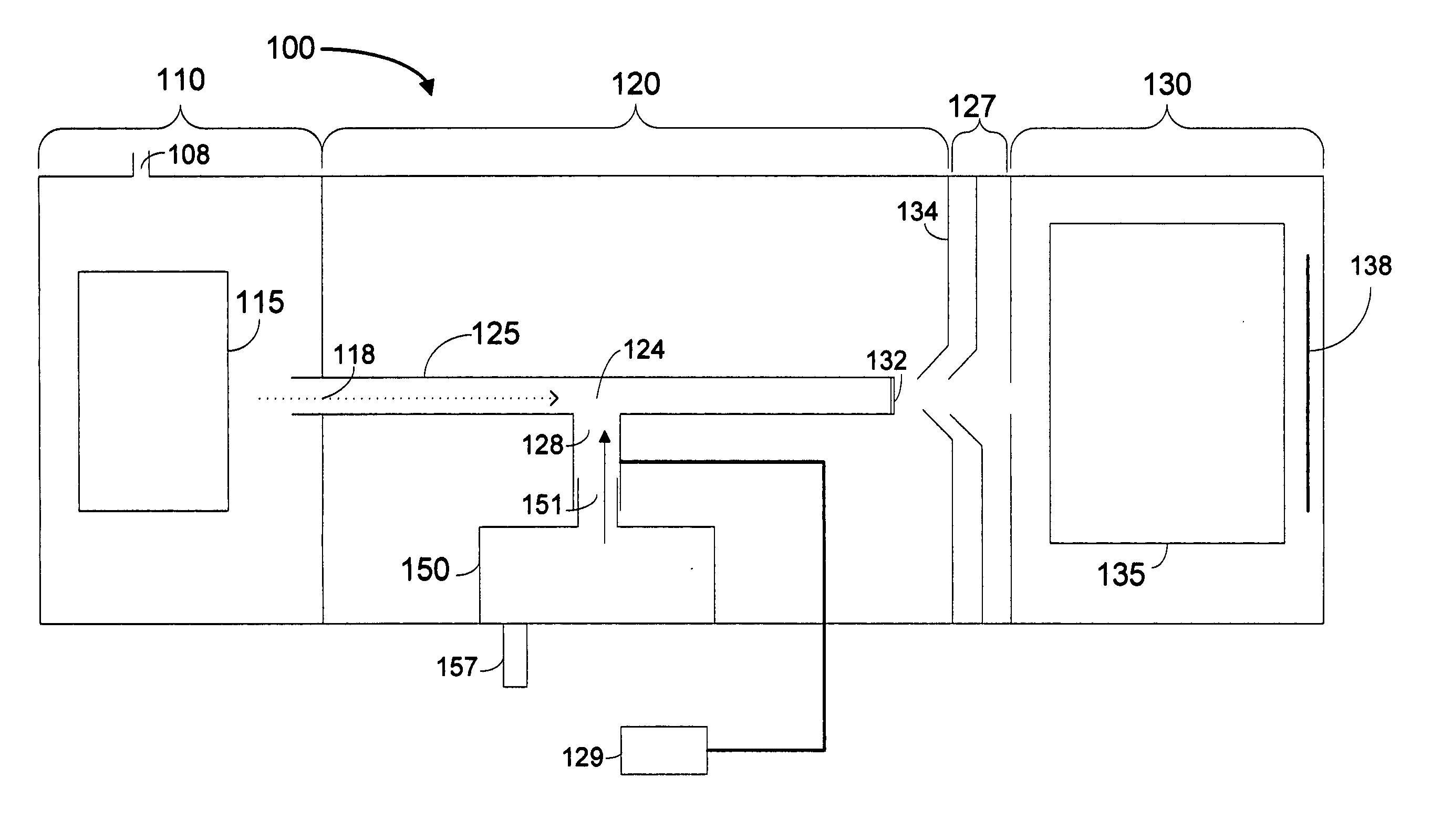

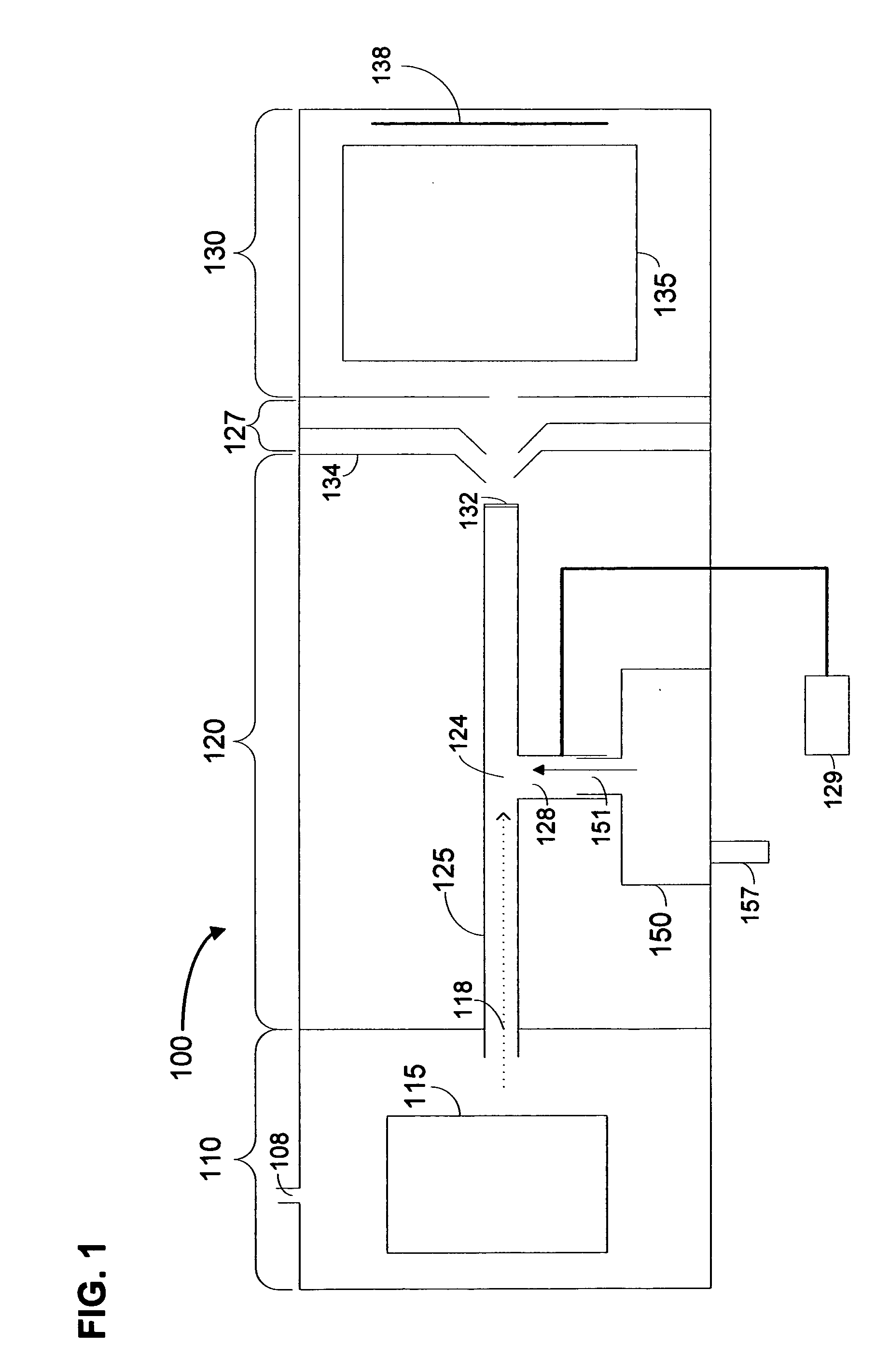

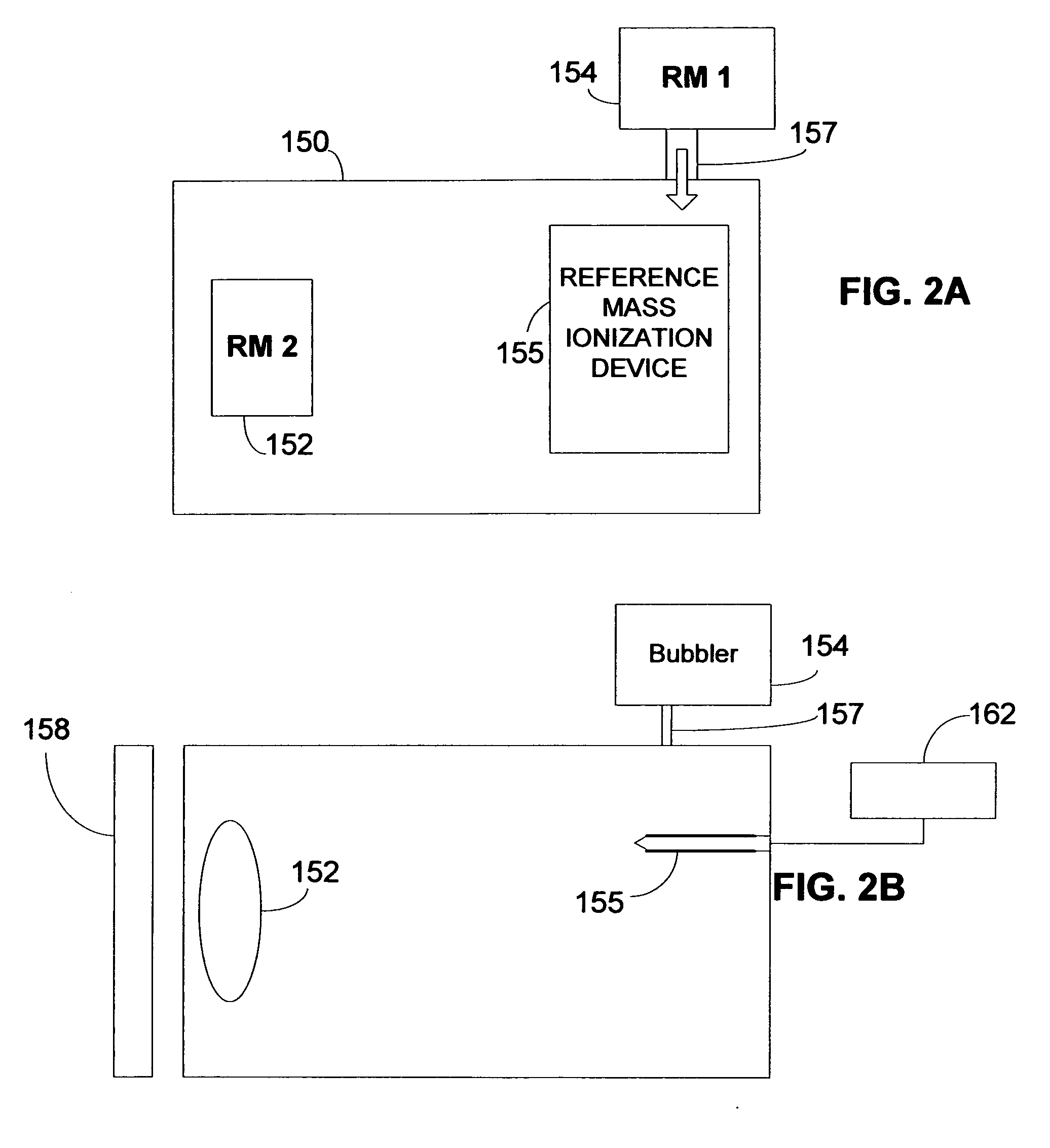

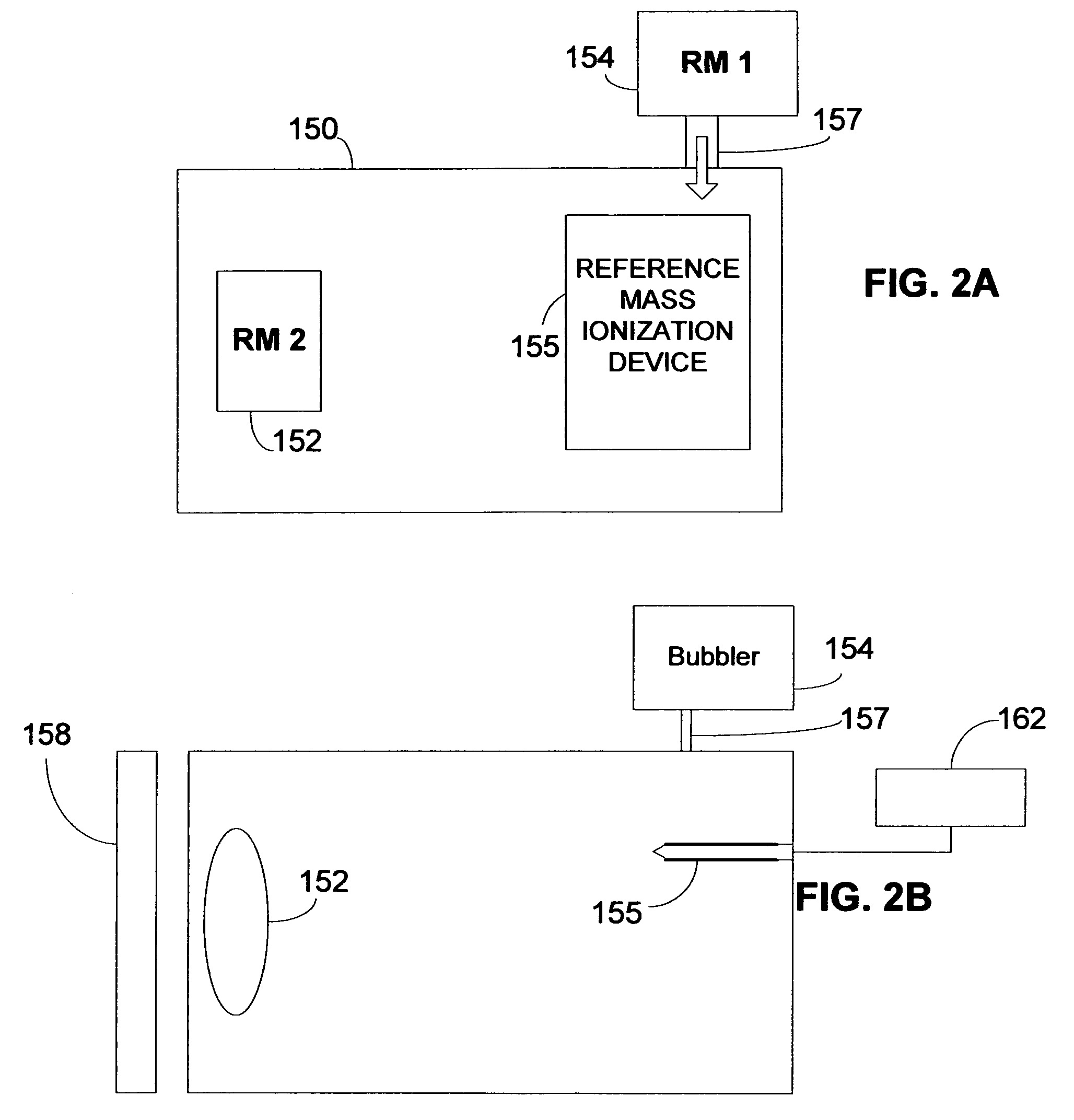

Reference mass introduction via a capillary

A mass calibration apparatus for a mass spectrometer includes a capillary, an analyte ion source coupled to the capillary at a first point, a reference mass ion source coupled to the capillary at a second point, downstream from the first point and a mass analyzer coupled to the capillary at a third point downstream from the first and second points. The reference mass ion source may be coupled to the capillary via a tee junction. The reference mass ion source includes a chamber, an ionization device situated within the chamber and one or more reference mass sources that are situated internally within the chamber or are situated external to and coupled to the chamber.

Owner:AGILENT TECH INC

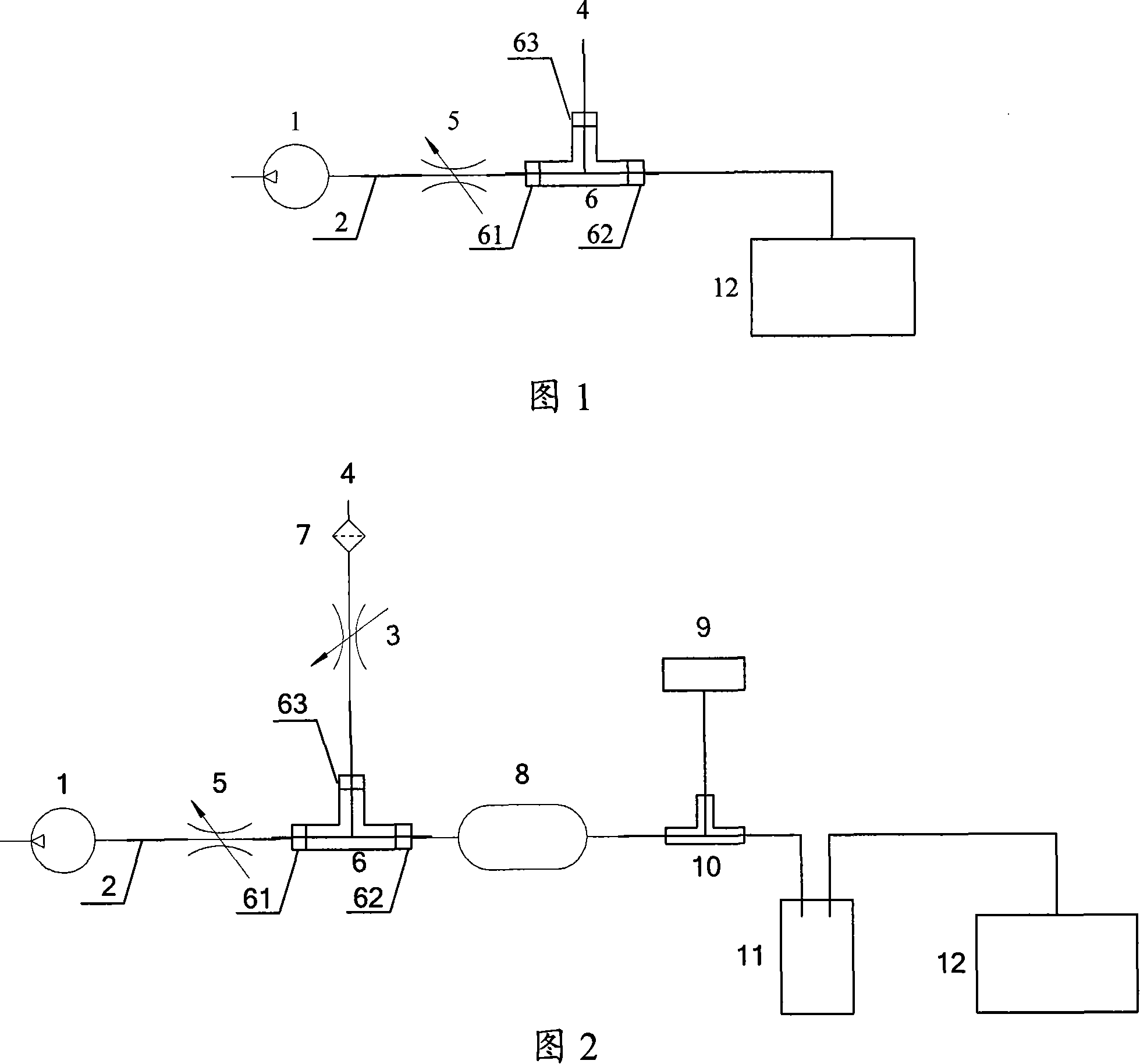

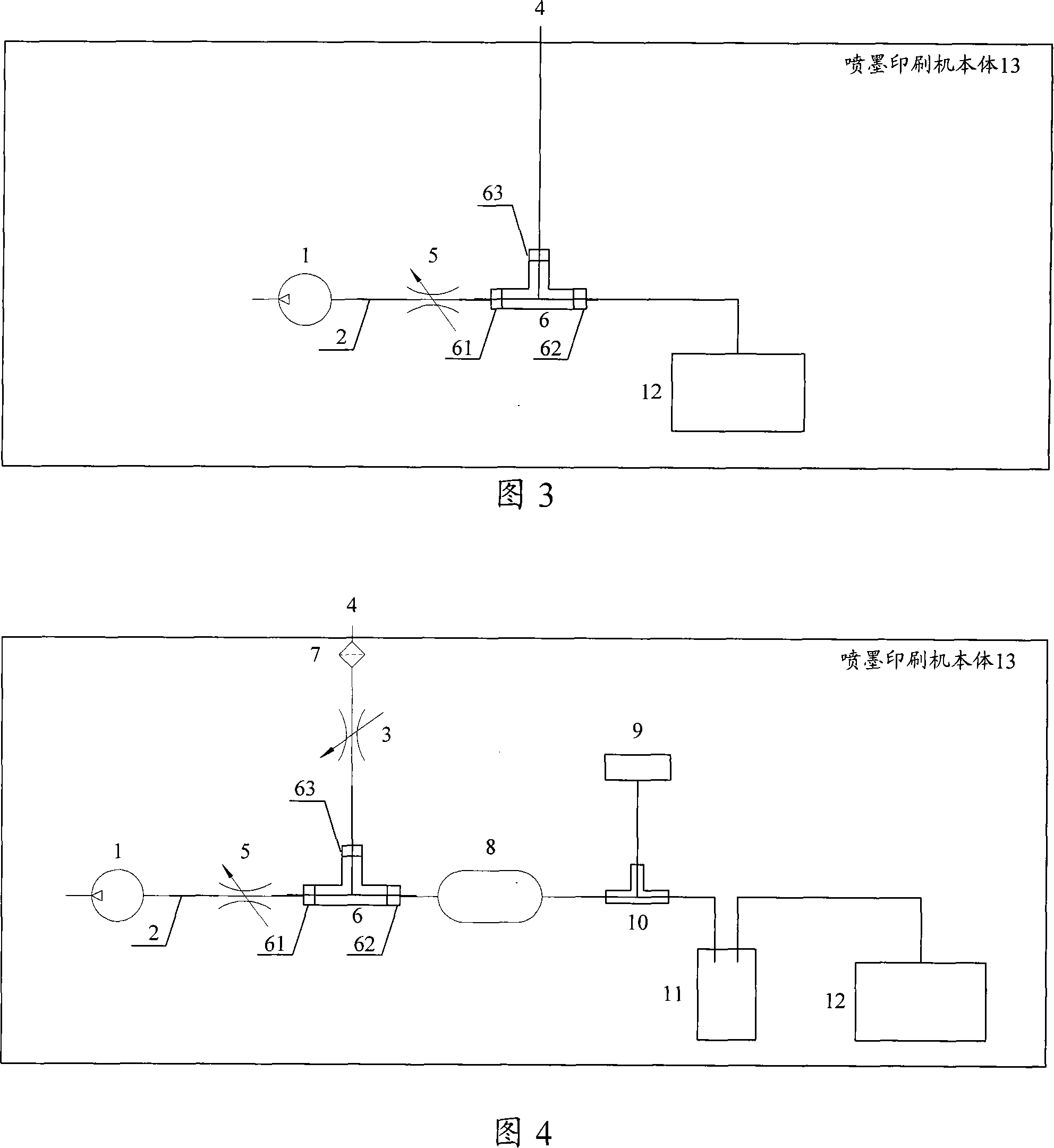

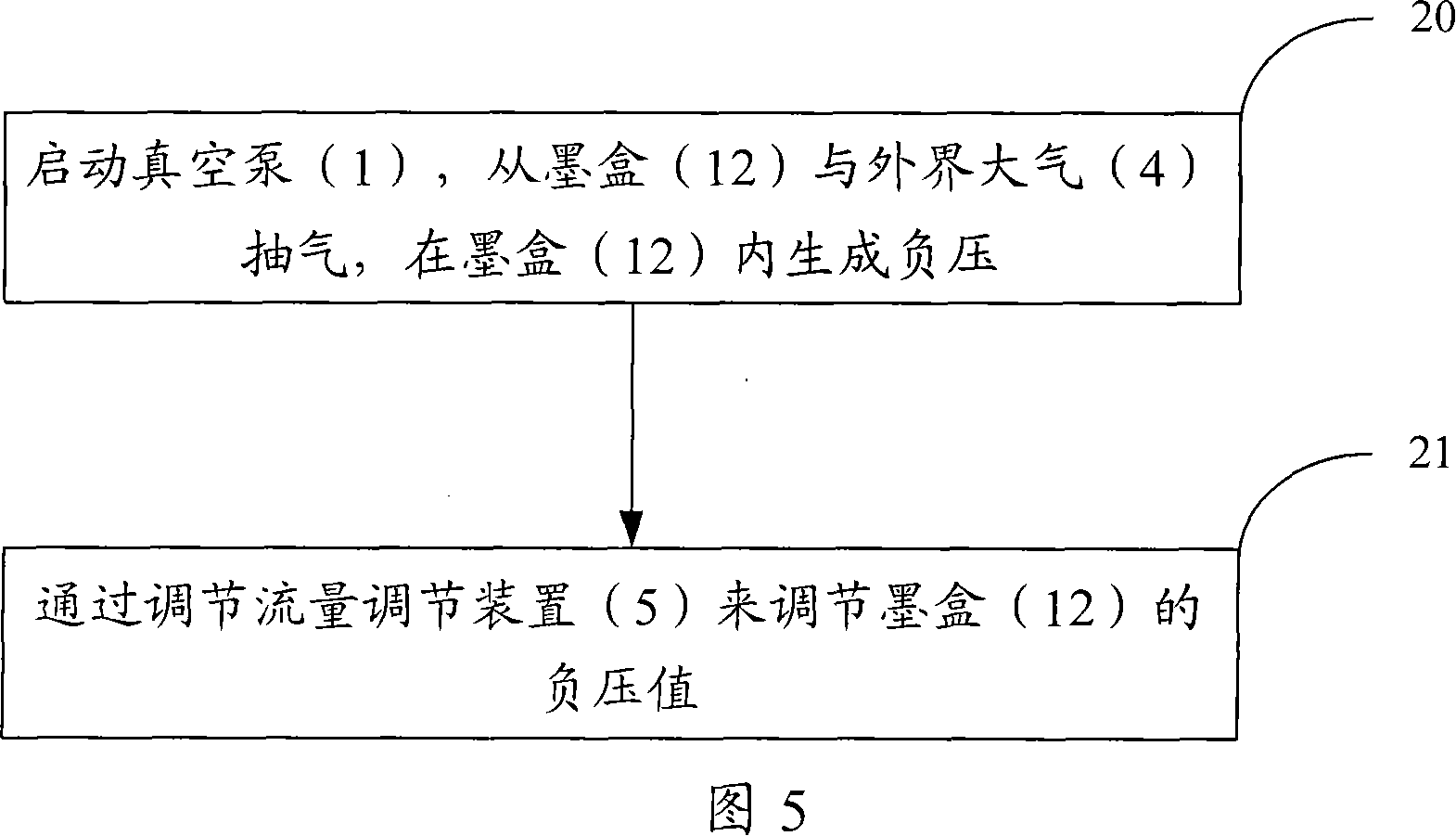

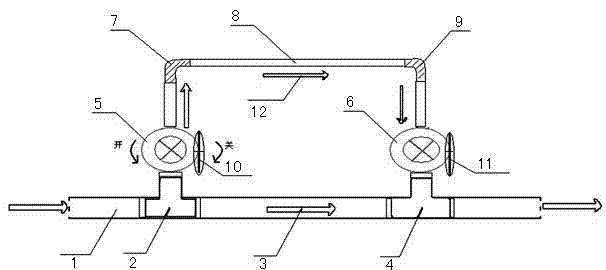

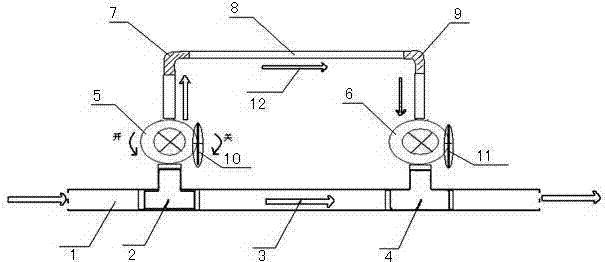

Negative pressure generating device, method and ink-jet printer

InactiveCN101138908AReduce negative pressureImprove anti-interference abilityPrintingEngineeringAtmospheric pressure

An embodiment of the present invention discloses a subpressure generating device. In order to solve the problem that the prior subpressure generating device can not produce lower stable subpressure and does not have better capacity of resisting disturbance at the same time. The device is provided with a vacuum pump (1), a pumping end of which is connected with a first flow rate adjusting device (5), another end of which is connected with an air outlet end (61) of a tee junction (6), and a port (62) of the tee junction (6) is connected with an ink cartridge (12), and an air inlet end (63) of the tee junction (6) is connected with atmosphere (4). Because the flow rate adjusting device (5) has certain function of resisting towards the undulation of a pumping velocity of the vacuum pump (1), and the pumping function of the air outlet end (61) inside the tee junction (6) and the air entering function of the air inlet end (63) have certain self-regulating ability towards the air pressure of the port (62), the device can produce lower stable subpressure and at the same time has better capacity of resisting disturbance.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

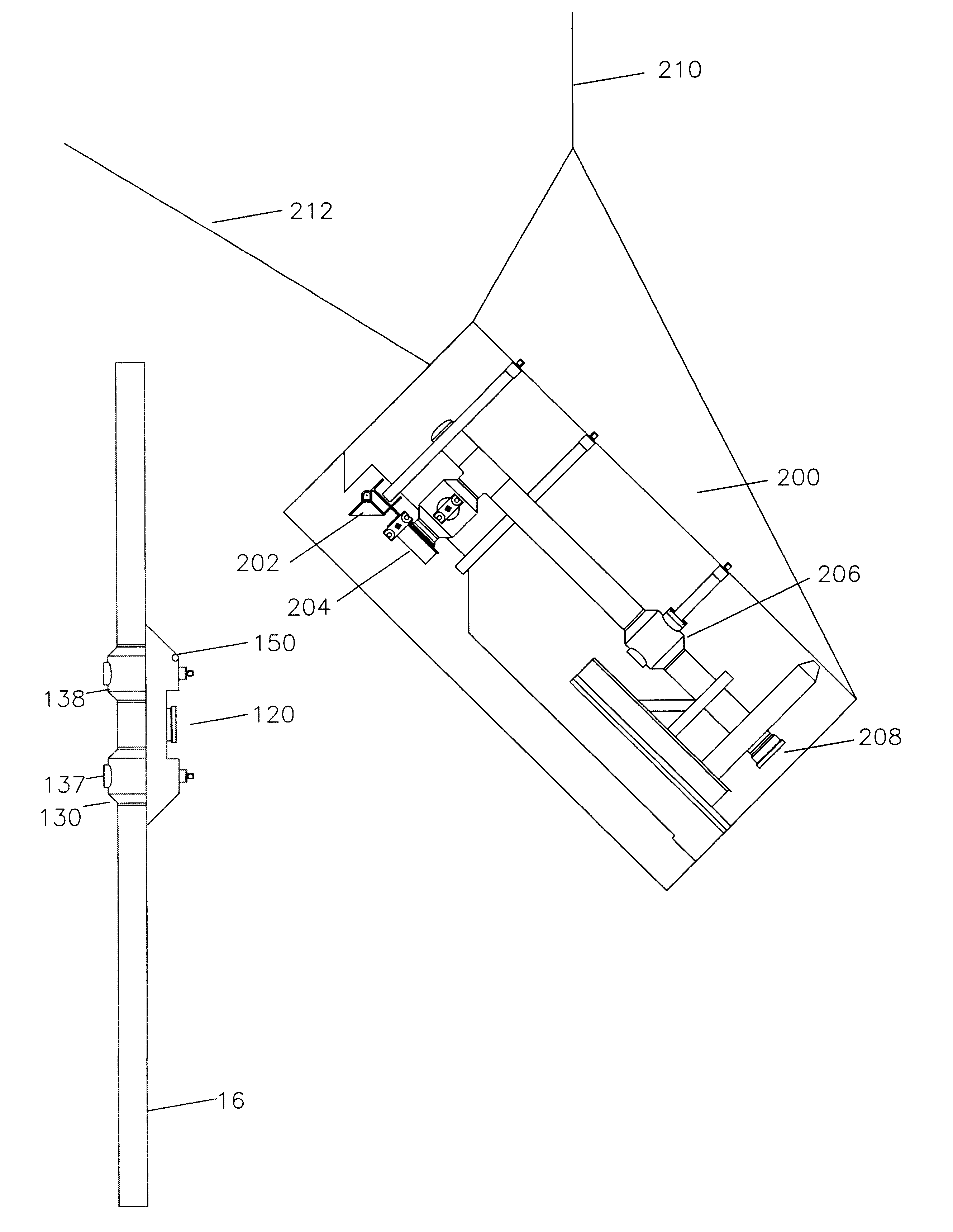

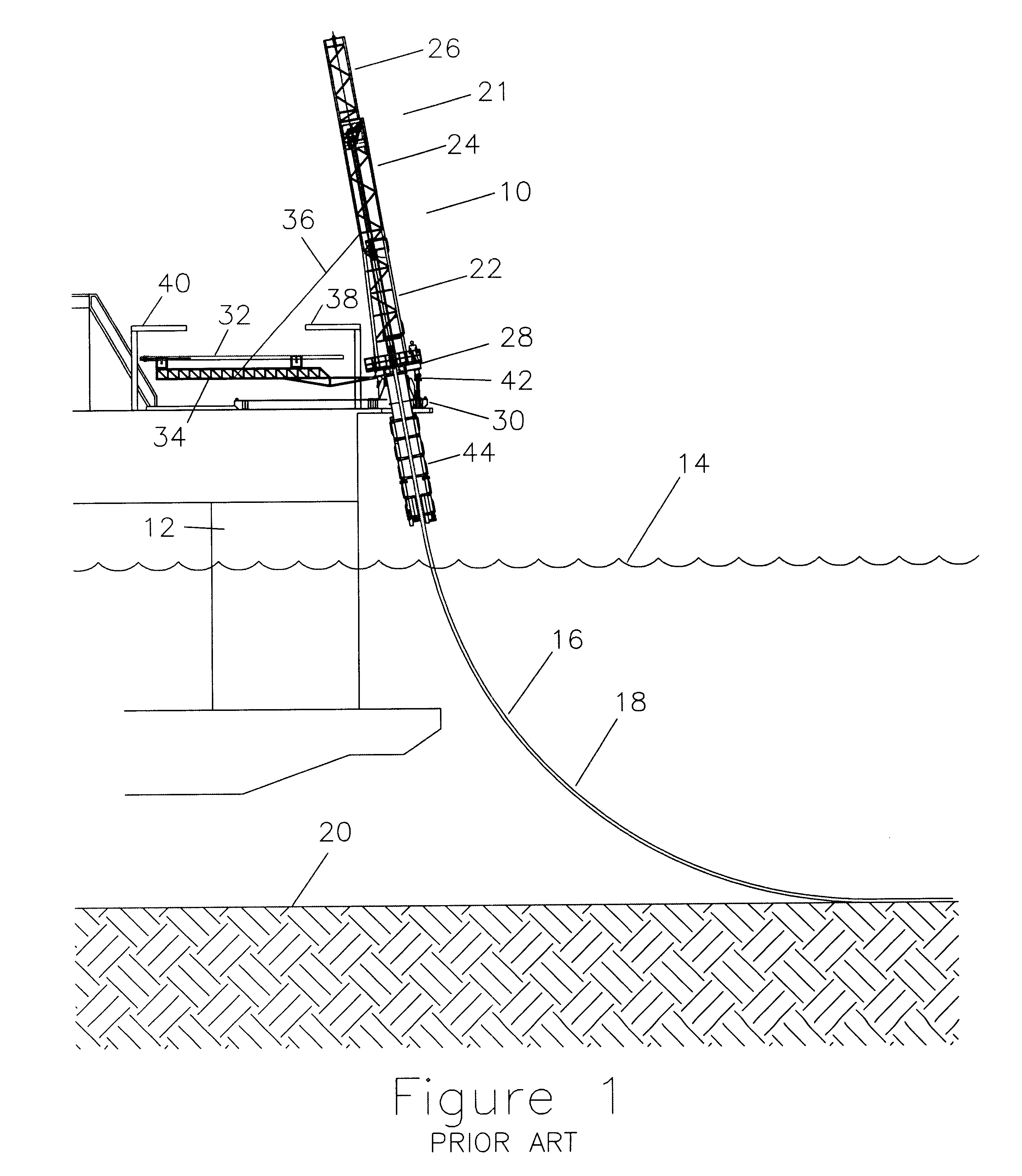

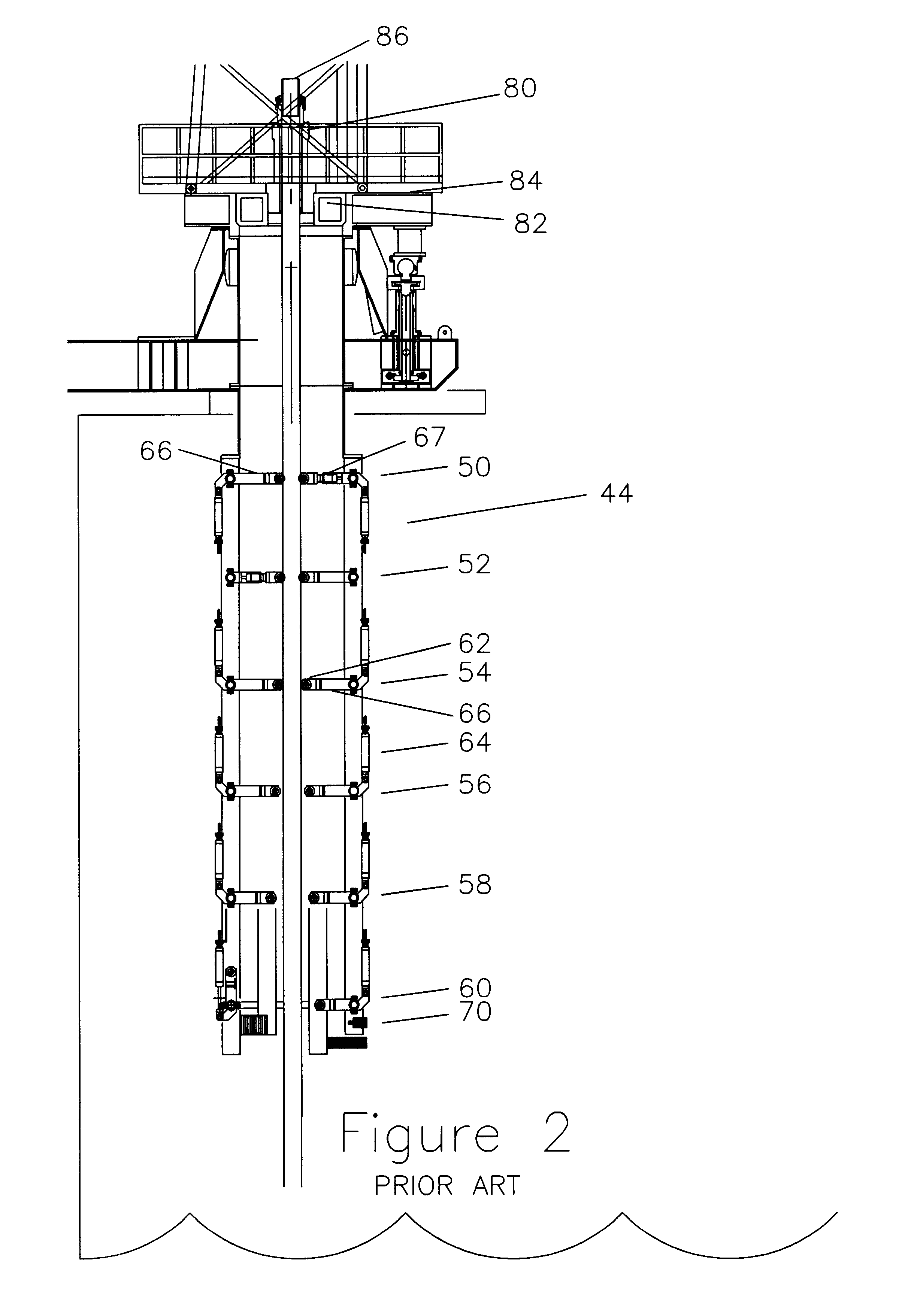

Method for attaching subsea manifold to pipeline tee

InactiveUS6435771B1Prevent floodingPipe supportsPipe laying and repairOcean bottomMarine engineering

A method for attaching subsea manifolds to subsea pipelines which includes attaching a tee member into the pipeline on a vessel, running the portion of the pipeline through support structures which would not pass the manifold, and to an underwater location between the vessel and the ocean floor, then attaching the manifold to the tee section, and then lowering the tee and manifold to the ocean floor.

Owner:REEL POWER LICENSING

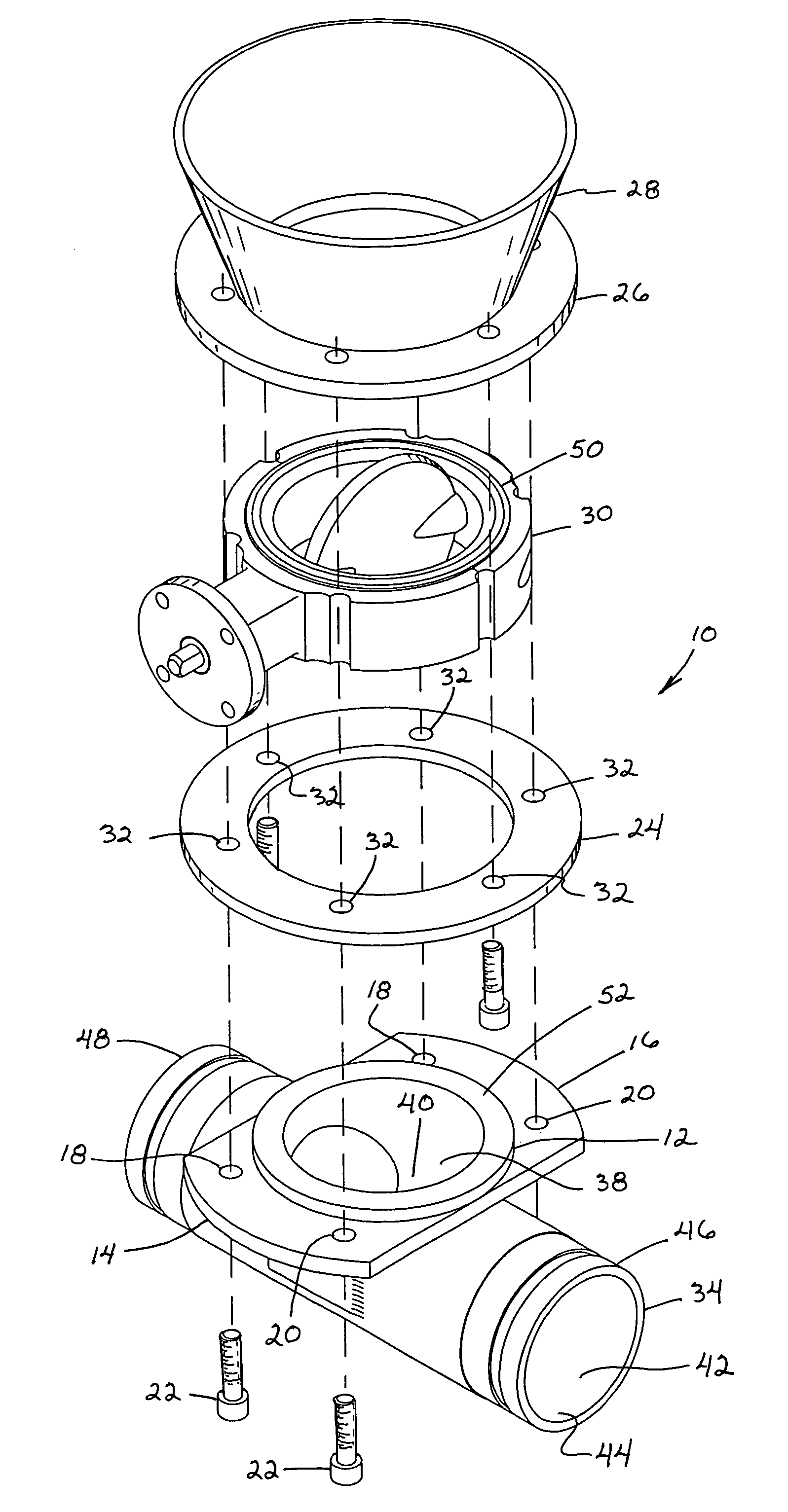

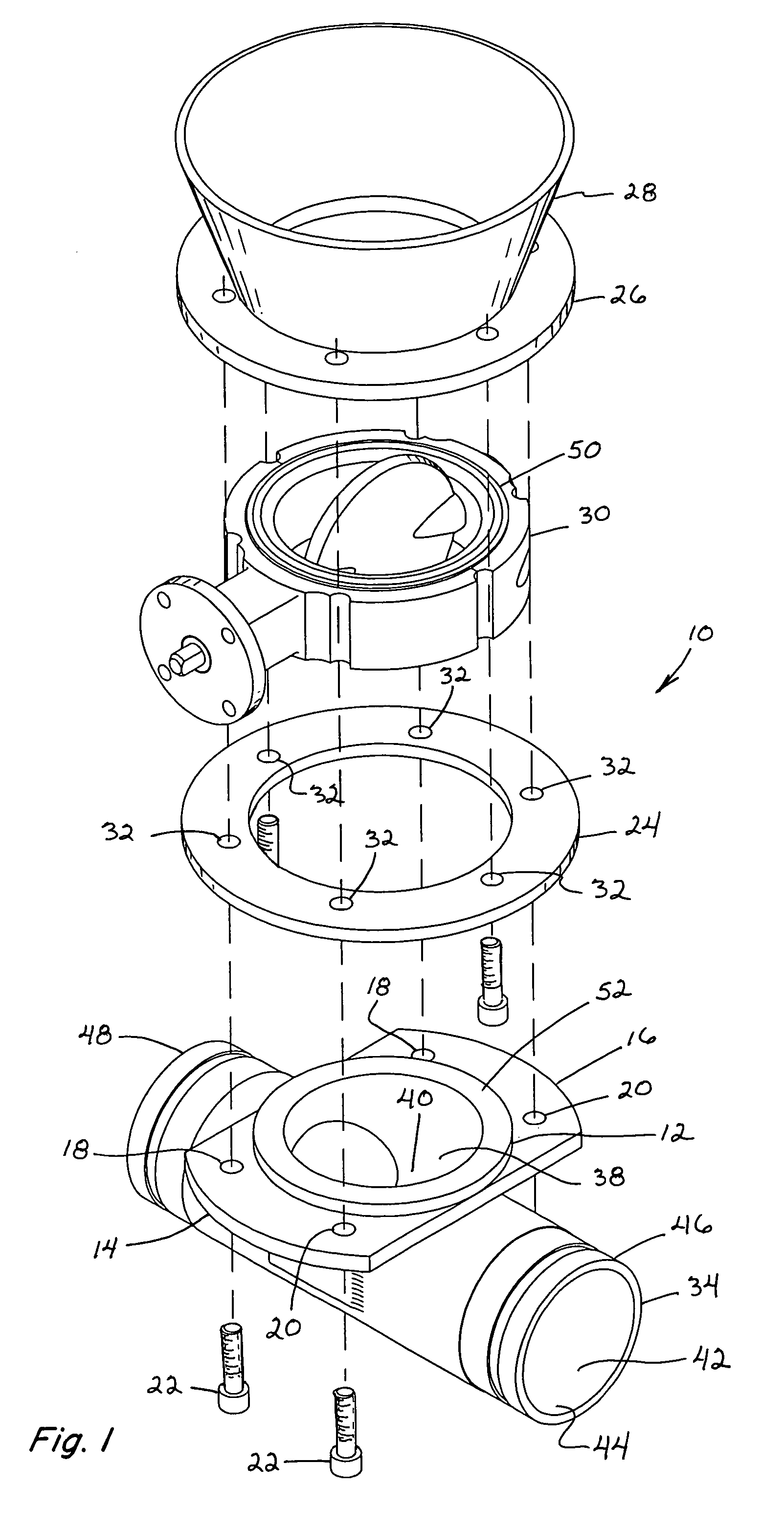

Pipe coupler and coupling system with positive retention and sealing capability

InactiveUS20100038903A1Eliminate needEasy to operateSleeve/socket jointsFlanged jointsCoupling systemEngineering

A coupler for joining a pipe to another pipe, a tee, or other fitting, which provides positive retention of a gasket about the circumference of the coupler sufficiently to precisely position and hold the gasket during placement about pipe ends and / or fittings to be coupled, and which provides controlled circumferential compression of the gasket during coupling, for positive sealing when the coupler is closed, and which provides a coupling system allowing one handed handling and operation during placement and coupling, such that the other hand can be used for supporting a pipe to be coupled, and which is operable for releasing and breaking loose the coupler and associated gasket from a pipe during uncoupling.

Owner:ULTRAFLO

Movable pipeline tee

ActiveUS20110081203A1Prevent coating damagePrevent resultant corrosionPipe supportsPipe laying and repairOcean bottomTee junction

The method of protecting two subsea pipelines which cross each other in a subsea environment from damaging one another when subsea currents slide the upper pipeline along the upper surface of the lower pipeline by providing roller around the upper pipeline and rollers around the lower pipeline which are connected together by a rotatable connection which allows the sets of roller to match the angle of the pipeline.

Owner:VANDER LINDEN III PAUL G +1

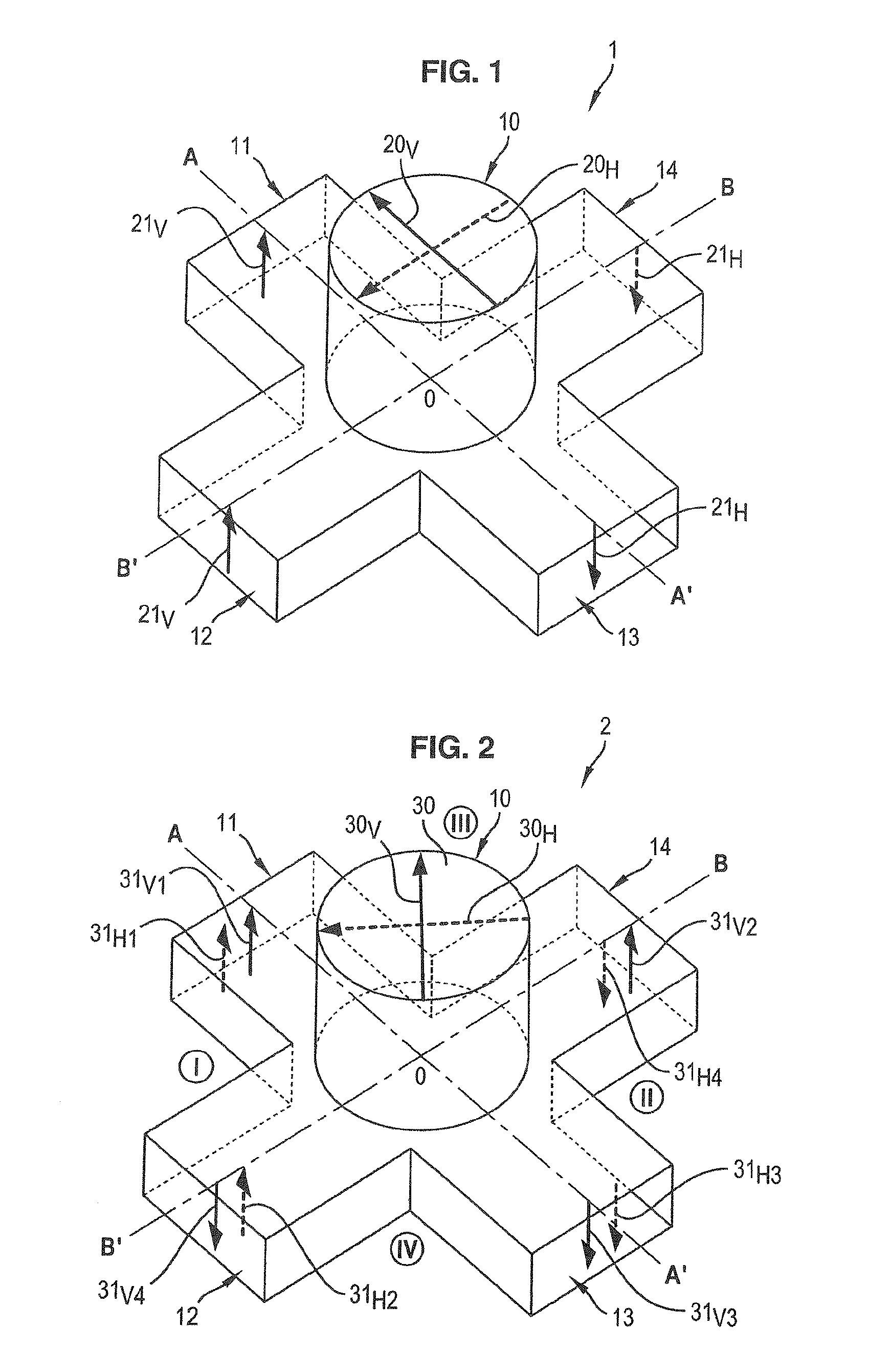

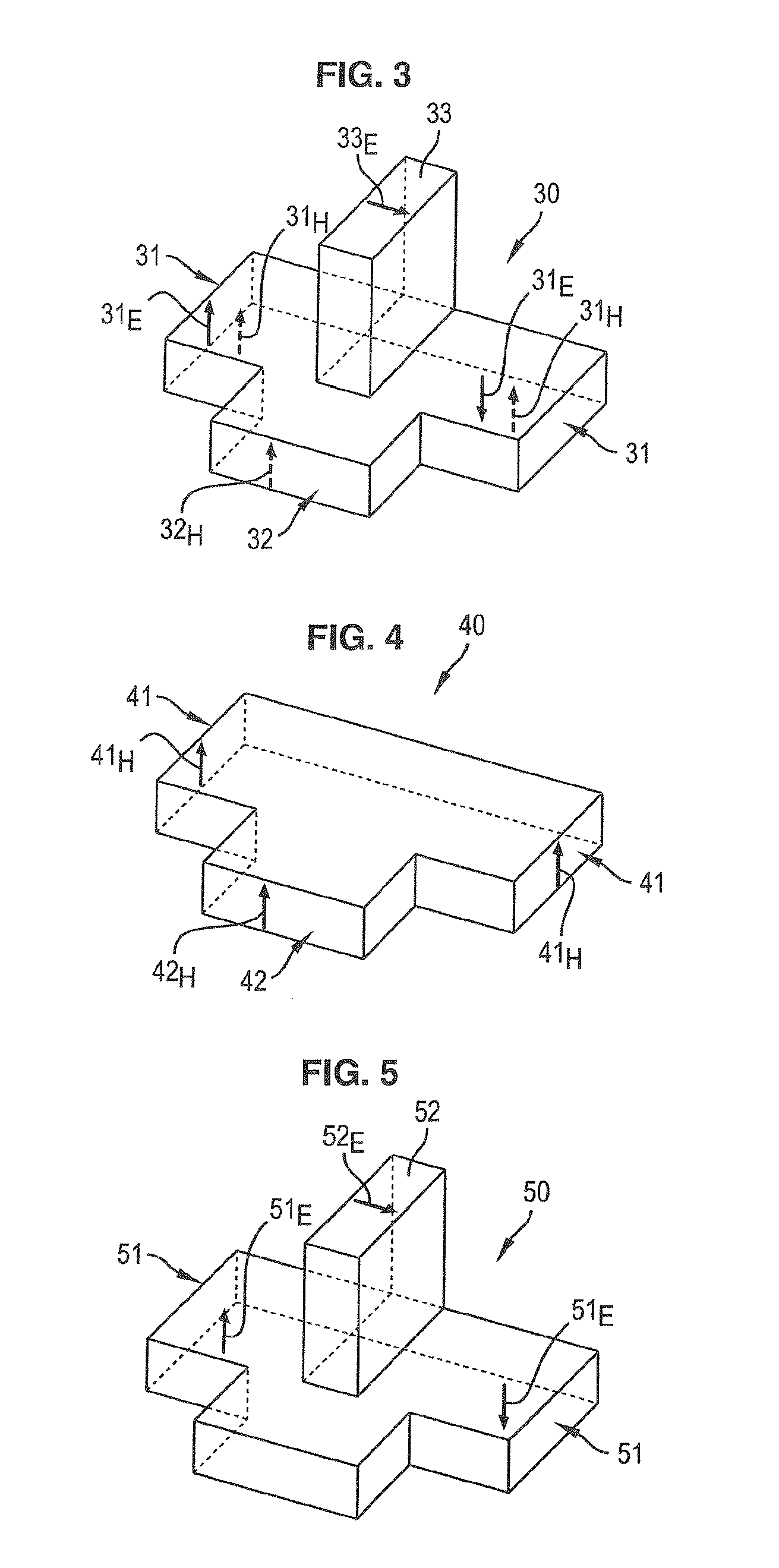

Waveguide orthomode transducer

ActiveUS20120032867A1Improve performanceReduce the numberAntennas earthing switches associationCoupling devicesFour quadrantsClassical mechanics

A waveguide orthomode transducer, comprises: a junction having a main waveguide and four auxiliary waveguides lying along the two orthogonal main axis of the junction and defining four quadrants; a combination network comprising: two magic tees, each having an E-port, two opposed common-ports, and a H-port; an H-plane tee junction having a Σ-port and two opposed common-ports; and an E-plane tee junction having a Δ-port and two opposed common-ports. Two auxiliary waveguides define a first quadrant are respectively connected to the common-ports of one of the magic tees and the two other secondary waveguides defining a second quadrant opposite to the first quadrant are connected to the common-ports of the other magic tee. The tee junctions are used to connect similar magic tee ports so that the transducer separates towards two different outputs two orthogonally polarized signals entering at the main waveguide. Reciprocally, two signals entering respectively in the Σ-port and the Δ-port of the tees junctions are combined with orthogonal polarizations in the main waveguide.

Owner:CENT NAT DETUD SPATIALES C N E S

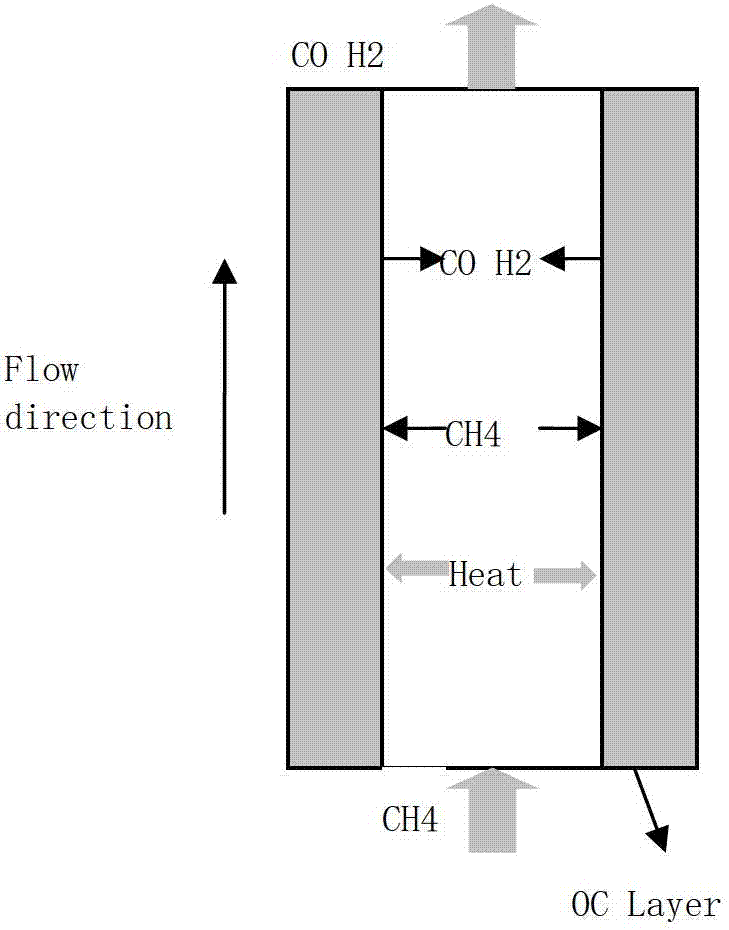

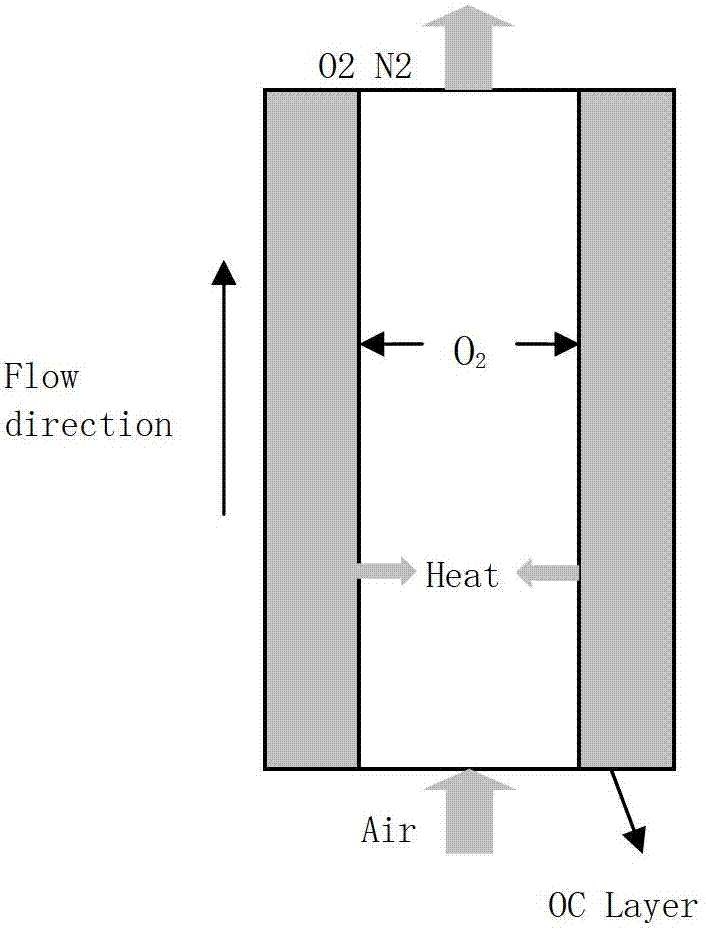

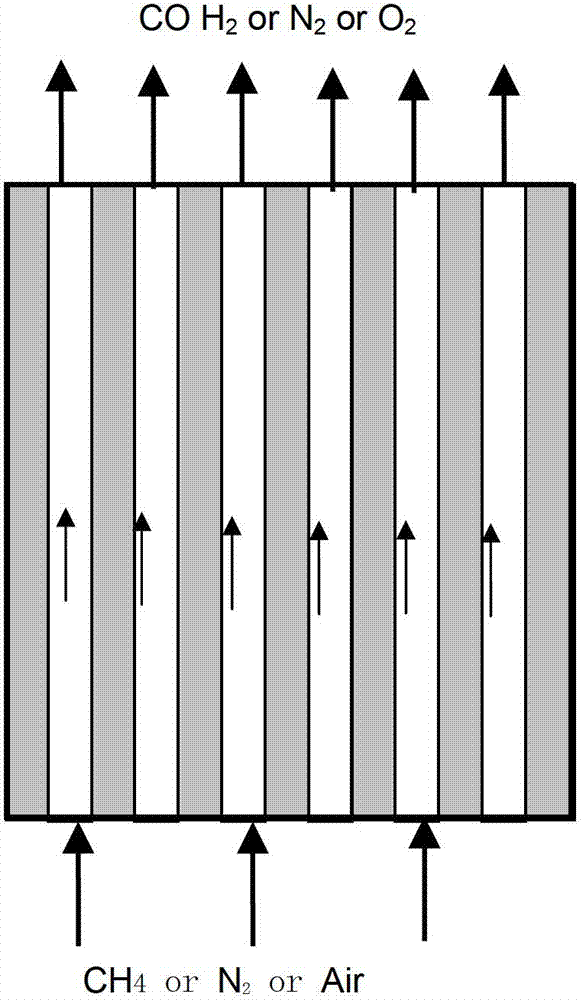

Cellular oxygen carrier chemical-looping reforming reactor

InactiveCN103204464AImprove conversion rateHigh selectivityHydrogen productionReaction temperatureEngineering

The invention discloses a cellular oxygen carrier chemical-looping reforming reactor. The cellular oxygen carrier chemical-looping reforming reactor comprises a reactor main body which comprises an outer wall and an outer heating barrel, wherein cellular oxygen carriers are formed in the outer wall and the outer heating barrel and are jointed with the outer wall and the inner wall of the outer heating barrel, and cellular pore paths parallel to the outer wall and a main shaft of the outer heating barrel are arranged in the cellular oxygen carrier and are pairwise spaced; and the tops of the outer wall and the outer heating barrel are connected with a top gas collecting region through upper flanges, the bottoms of the outer wall and the outer heating barrel are connected with a bottom gas storage region through lower flanges, a tail gas outlet is connected outside the top gas collecting region, a tee-junction gas inlet is connected outside the bottom gas storage region, and the bottom gas storage region is internally provided with a radiation type gas pre-distribution device connected with the tee-junction gas inlet. The cellular oxygen carriers have the advantages of having heat storage function, being capable of helping the reactor to maintain reaction temperature, alleviating the thermal load of external heating equipment and being beneficial to the stable proceeding of reaction.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

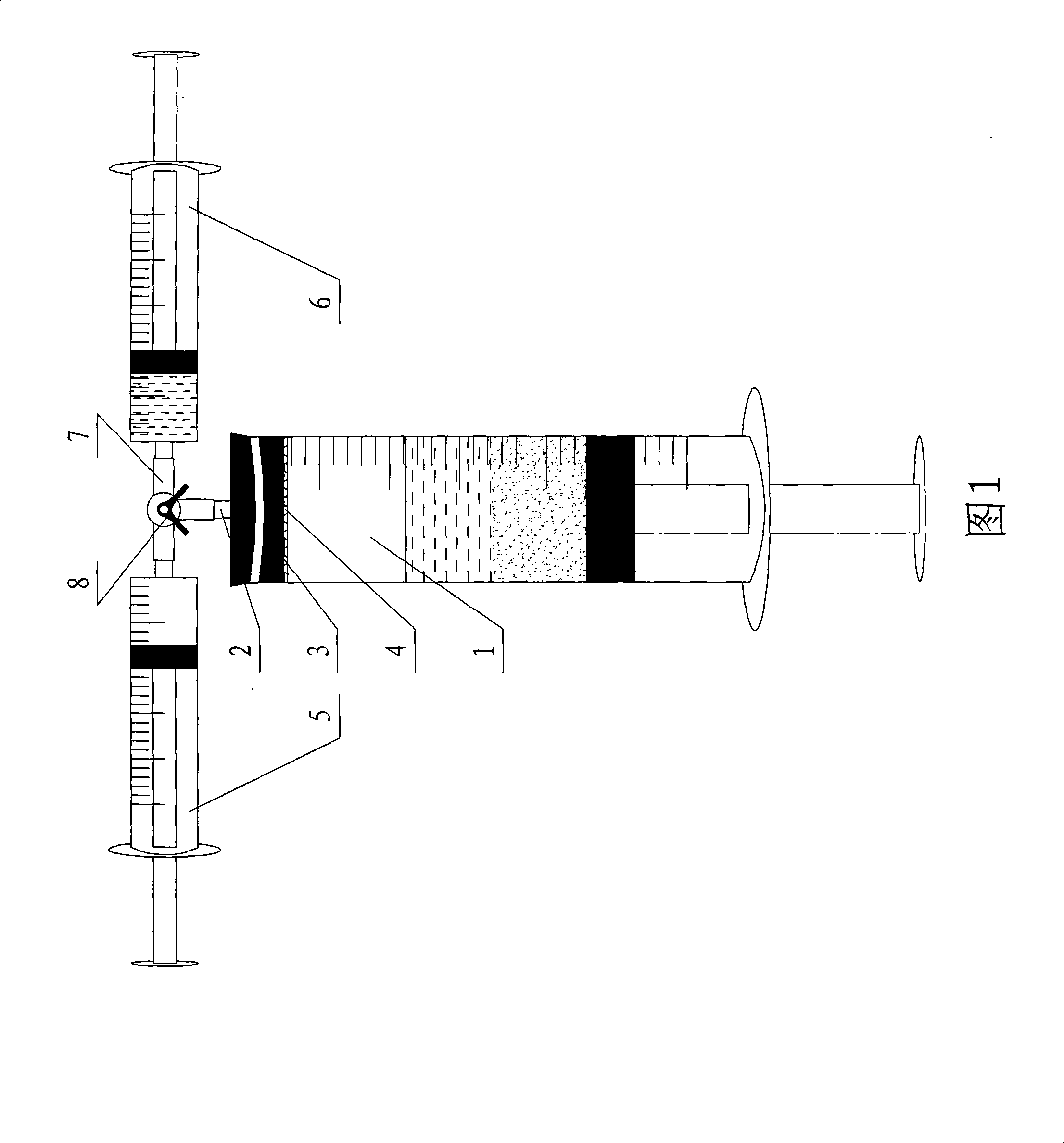

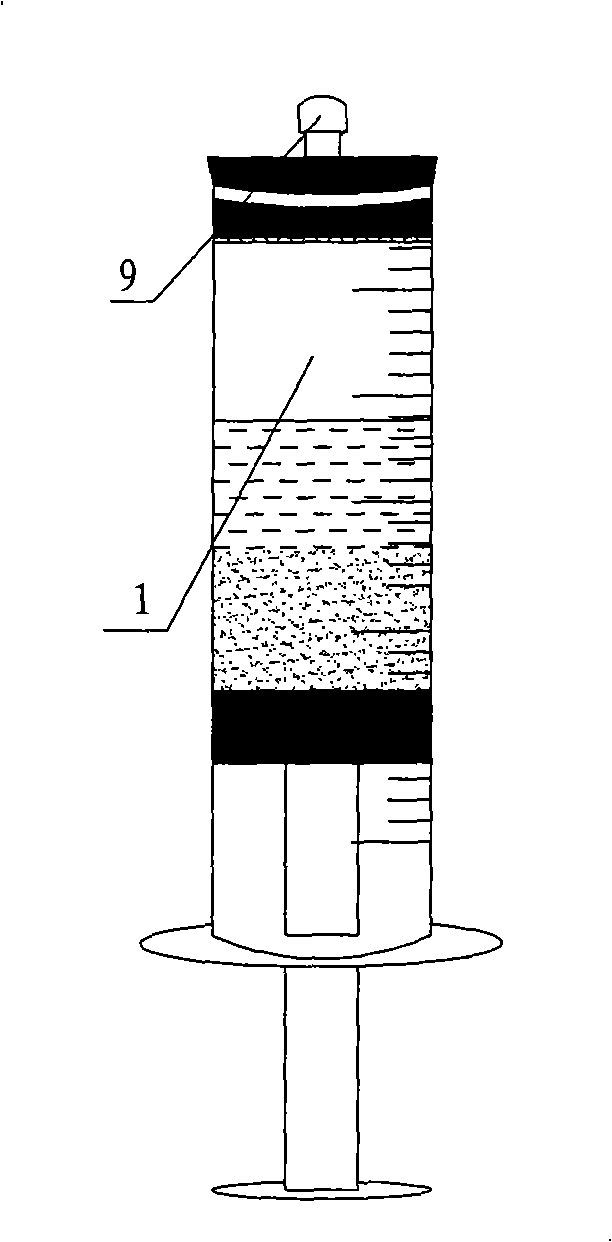

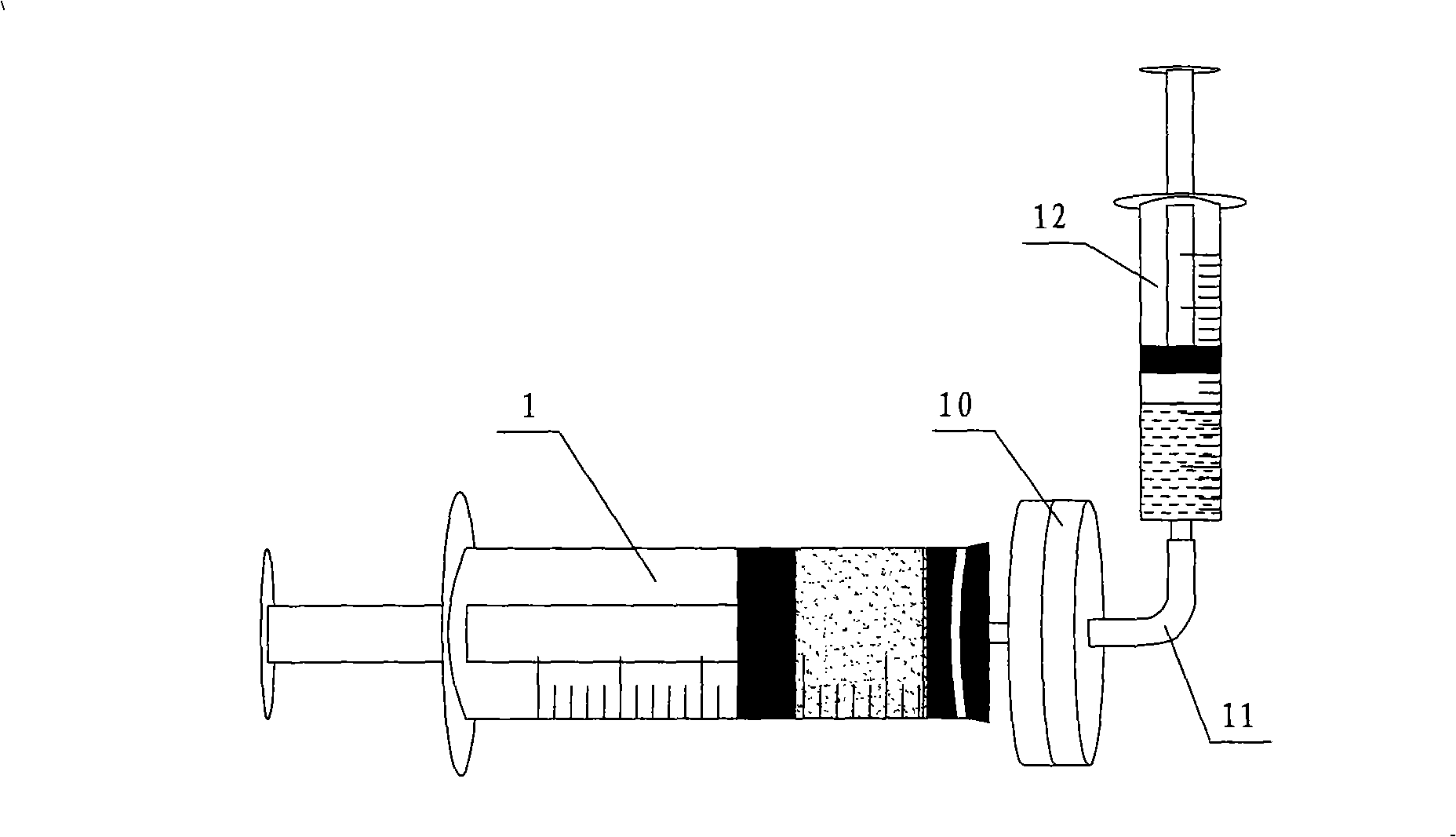

Soil anaerobic leaching method and device thereof

InactiveCN101322885AEasy extractionLeach GuaranteeSolvent extractionPreparing sample for investigationEngineeringTee junction

The invention relates to soil extract, in particular to a simple and anaerobic soil extraction method which can be used in laboratories or in the open and a device thereof; during extraction, a sample is pushed into a sample hose; and then the sample hose is connected with a liquid filling tube which is filled with extract liquid and an air filling tube which is filled with air through a tee junction; after aeration and extraction, the sample hose is taken down and oscillated; during filtering, the sample hose is connected with a syringe-film evaporator which is connected with a liquid collecting tube through a draught tube; a piston of the sample hose is pushed so as to carry out a filtering process; the filtrate enters the liquid collecting tube immediately; the filtrate in the liquid collecting tube is the sample after anaerobic extraction. The soil extraction method of the invention has simple structure, convenient operation and wide application, is economical and practical; the quantity and the intensity of liquid injection can be regulated and controlled; the application is wide and the extract on a plurality of reducing substances and other substances in the soil can be carried out according to requirements.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

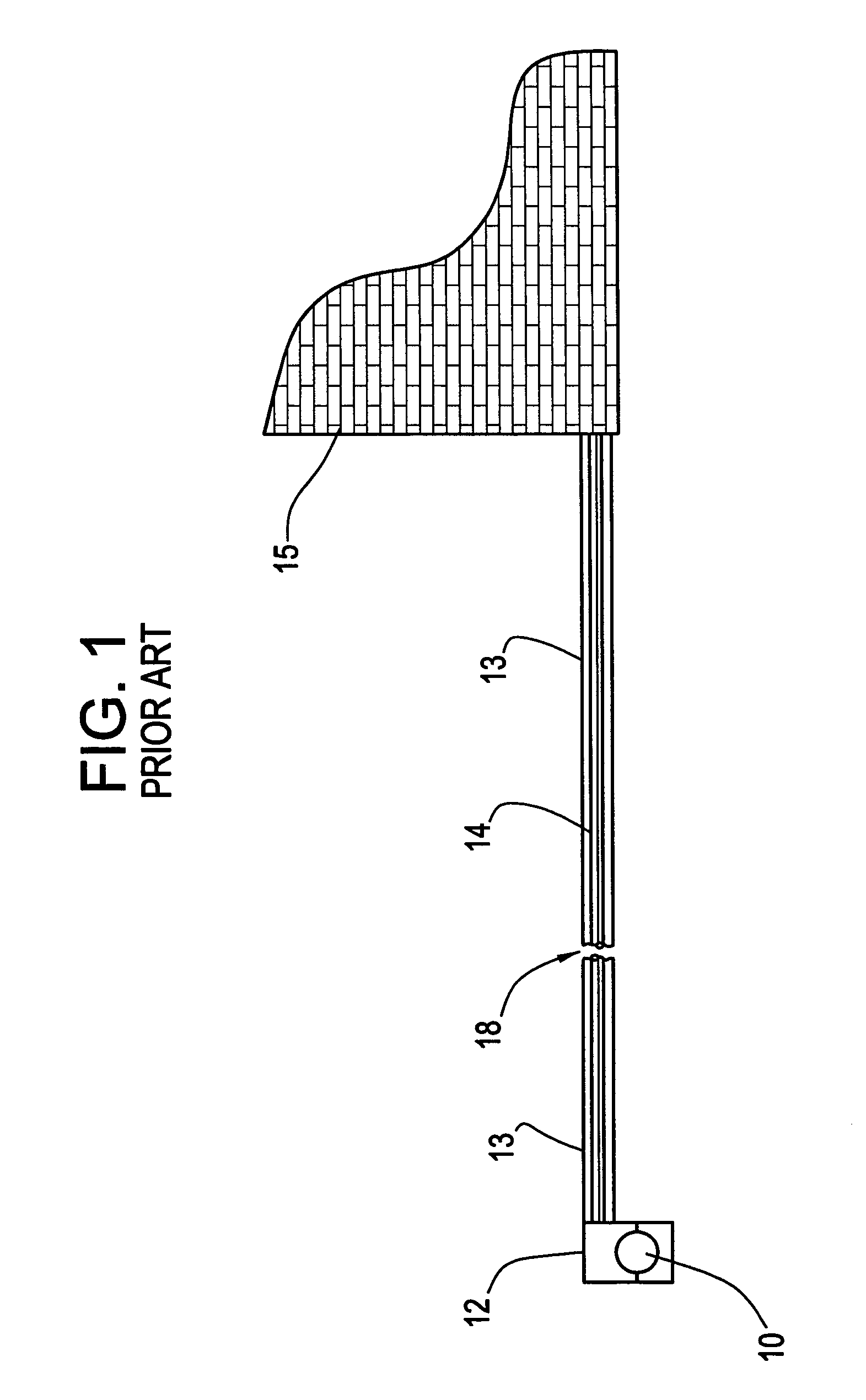

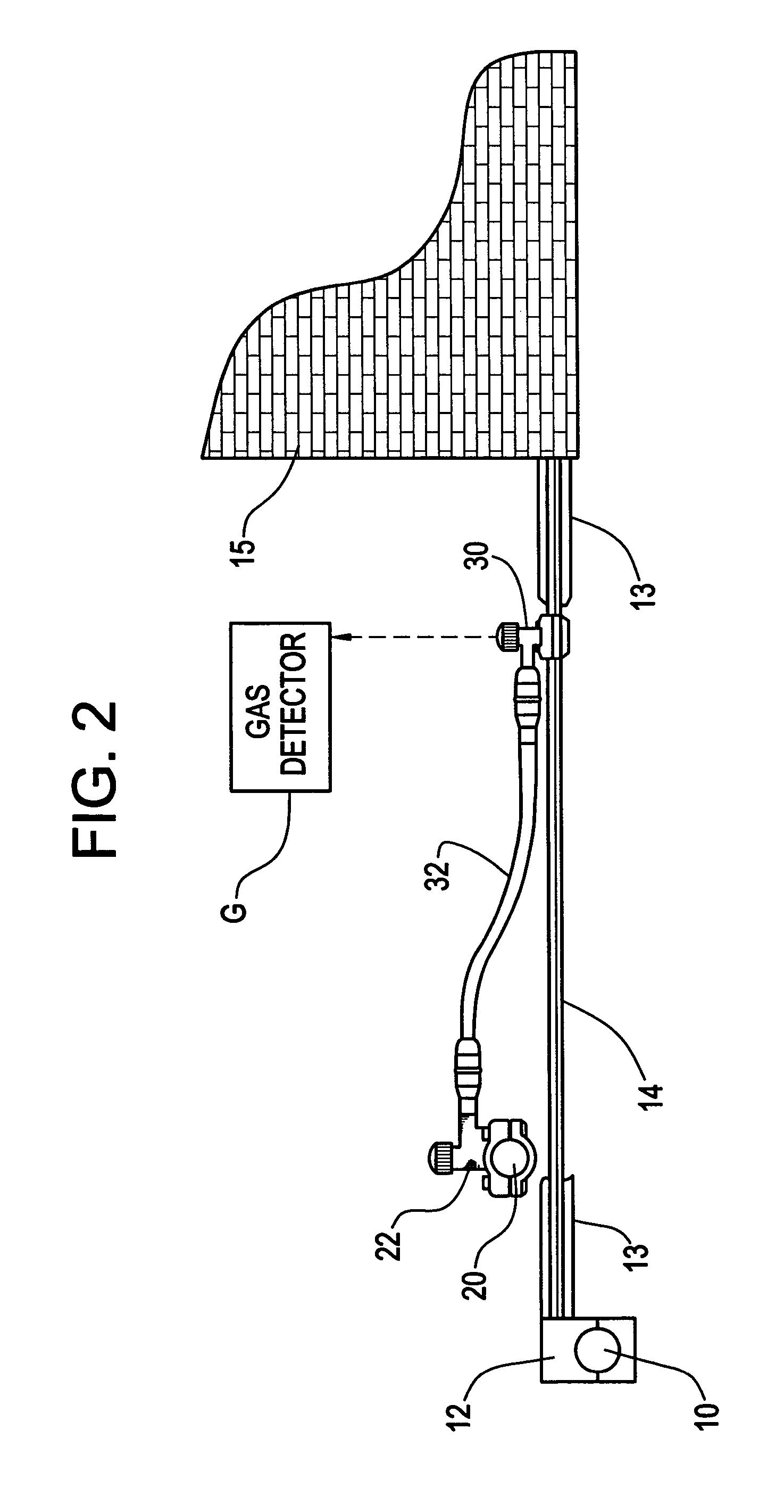

No interrupt service tee and method

A method of replacing a gas main that supplies gas to a recipient through an existing service line includes connecting a first tapping tee to the new gas main and connecting a second tapping tee to the existing service line that communicates with a downstream recipient. Branch passages of the first and second tapping tees are fluidically connected together by a connecting conduit. The new gas main is then tapped with the first tee so that gas flows from the new gas main into the connecting conduit up to the second tee. All air is bled from the connecting conduit between the first and second tees, and the existing service line is then tapped with the second tee so that gas is supplied to the recipient through both the existing service line and the connecting conduit. Gas flow to the recipient from the old main is then terminated. The second tee is a specially configured tapping tee specifically adapted for bleeding air from the connecting conduit that interconnects the first and second tees. This tee also utilizes a non-cylindrical bore for holding the conduit to be tapped to inhibit collapsing of the conduit during tapping operations.

Owner:ELSTER PERFECTION CORP

Nano-liter spraying device

InactiveCN1558230AEasy to manufactureEasy to operateComponent separationSpray discharge apparatusSprayerMass spectrometry

The Nasheng sprayer for mass spectrographic analysis consists of one tee junction, one spraying head, one injection needle and molybdenum filament. The spraying head is connected with one end of the tee junction hermetically, the molybdenum filament is welded to the tip of the needle, the needle is inserted into the other end of the tee junction, the front end of the molybdenum filament is stretched into the tip of the spraying head, and the third port of the tee junction is used as air passage. The molybdenum filament provides electric contact and the air passage provides auxiliary air for assisting spraying. The sprayer has convenient making, simple operation, high spraying stability and wide application foreground.

Owner:FUDAN UNIV

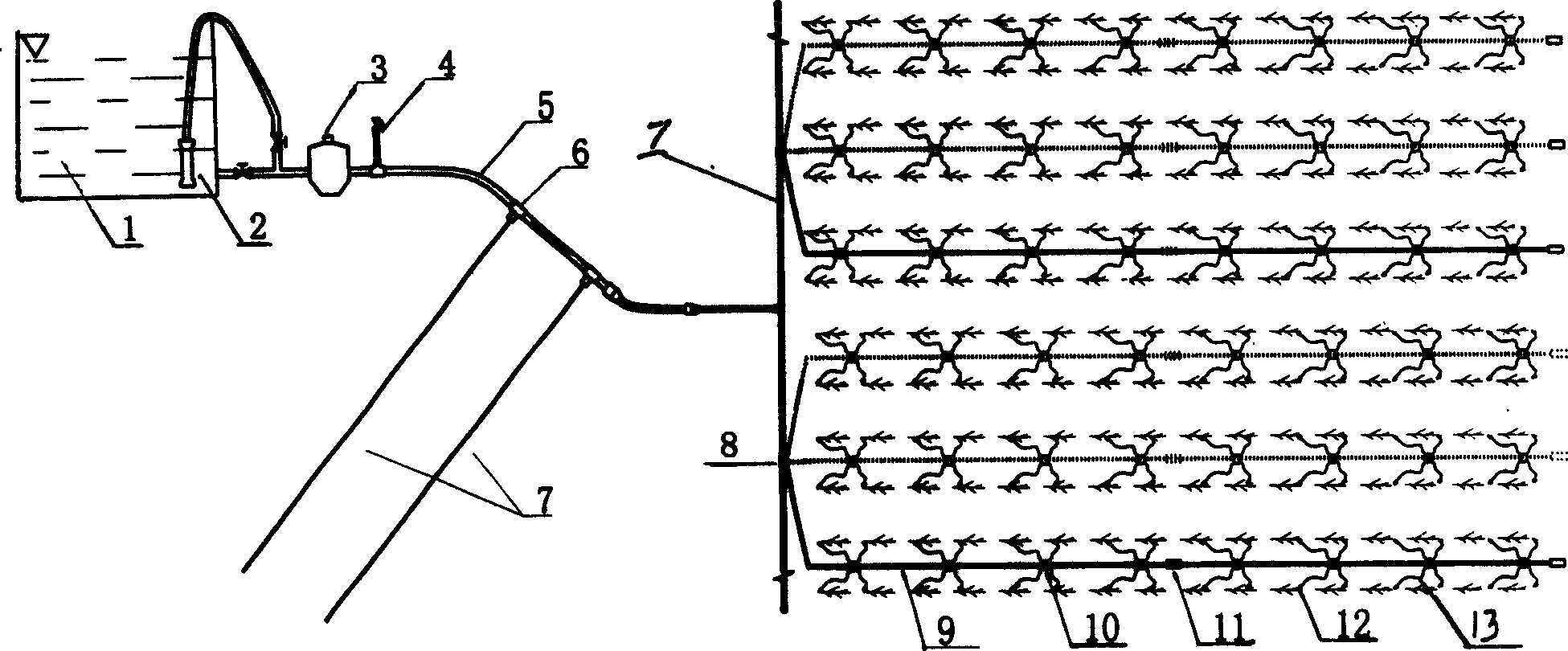

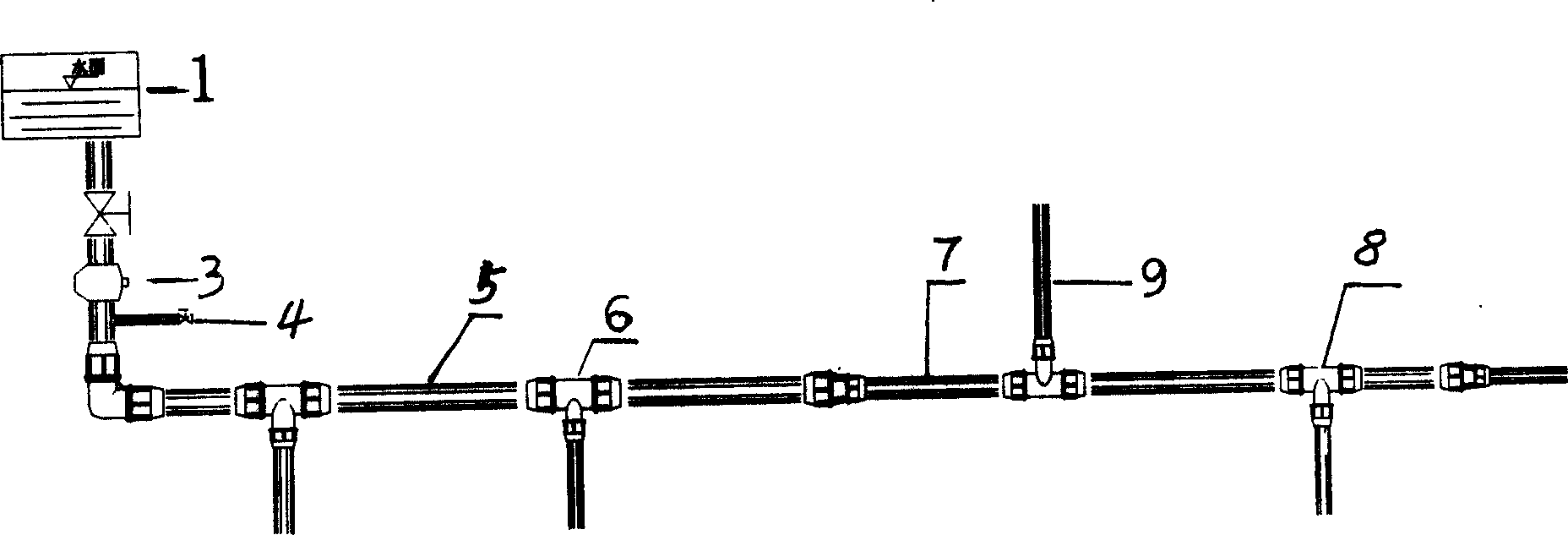

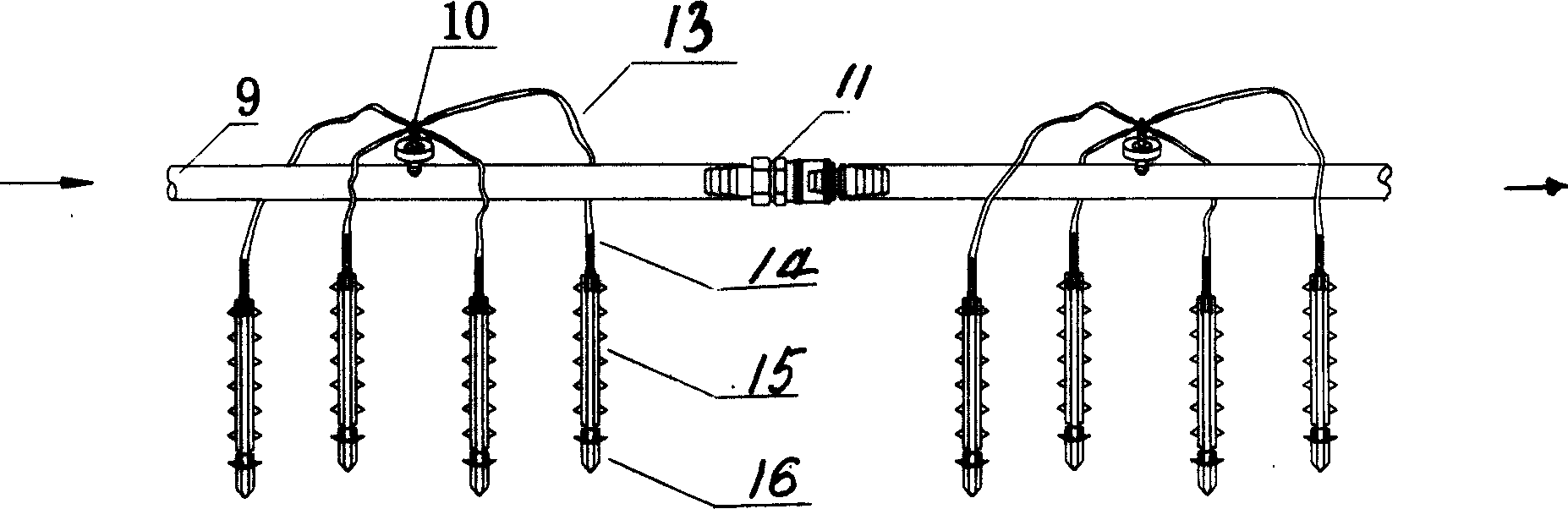

Movable underground drip irrigation device

The invention discloses a movable underground drip irrigation apparatus comprising main pipes, branch pipes, capillary pipes and plug-in type underground drip irrigation apparatus characterized by that, the front end of the pipe is connected to a water storage equipment with pressure pump, the main pipe near the water storage equipment is connected in turn to a filter and an air evacuation valve, the main pipe is connected to a plurality of branch pipes through a rapid branch joint and a quick-speed reducer union, each branch pipe is connected with at least two capillary pipes, each of which comprises at least a capillary pipe section, which are coupled with express connector for easy loading and unloading, and are provided with 20-30 flow controllers in uniform distribution.

Owner:FARMLAND IRRIGATION RES INST CHINESE ACAD OF AGRI SCI

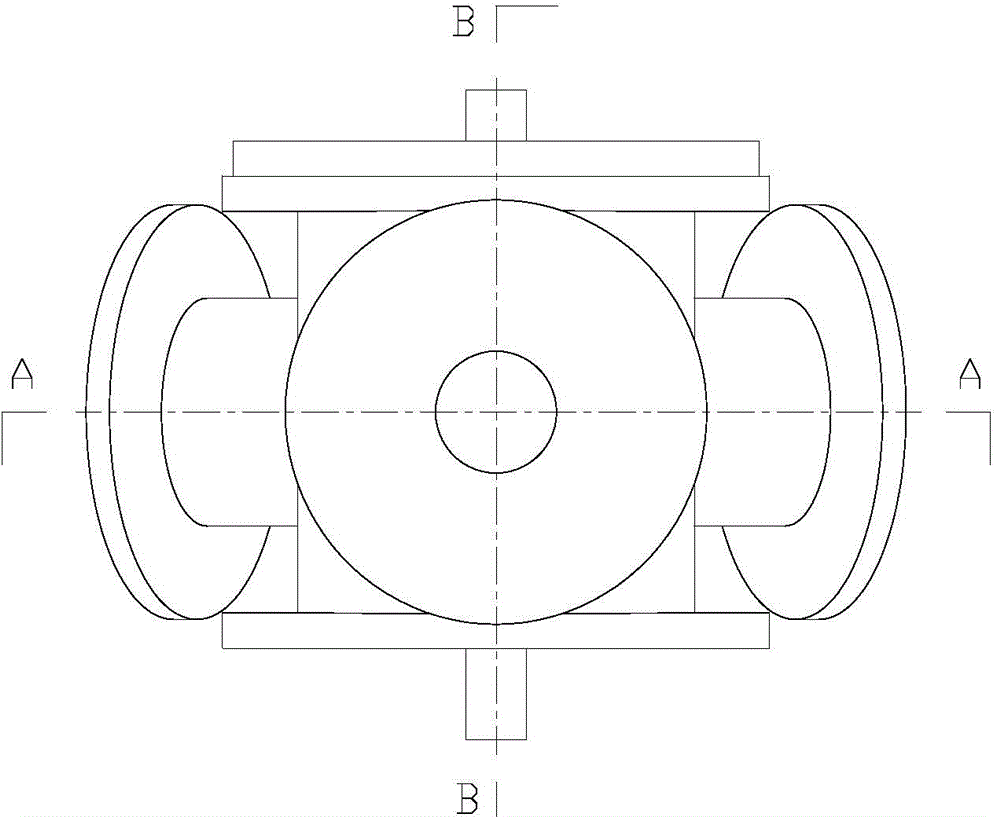

Fluted hopper tee

ActiveUS8091925B2Reduce frictionIncrease frictionPipeline expansion-compensationLarge containersFluteCurve shape

Owner:BULK TANK

Double-cock ball throwing device and ball throwing method

ActiveCN102383775ARealize manual operationSmooth entryFluid removalWell/borehole valve arrangementsLine tubingSteel ball

The invention relates to a double-cock ball throwing device and a ball throwing method. The device is characterized by comprising two T-shaped high-pressure tee joints arranged in the front and the back of a high-pressure main pipeline, wherein the raised ends of the two T-shaped high-pressure tee joints are respectively connected with cocks; the two cocks are respectively connected with two ends of the same high-pressure pipeline through high-pressure elbows, so that a loop is formed in the high-pressure pipeline; and the cocks are provided with cock rocking handles. Through a set of ball throwing system consisting of the two T-shaped high-pressure tee joints, the two cocks and a plurality of high-pressure pipelines, nylon balls are thrown by manually operating the cocks; a process of throwing balls without stopping a pump in the midway is realized by filling a certain number of nylon balls or steel balls into the high-pressure pipeline between the two cocks in advance; a space of 5 to 8 millimeters is respectively formed in the two cocks in construction, so that the pressure of the high-pressure pipelines of two sections and the middle of the cocks is balanced all the time, and the nylon balls can smoothly enter a shaft; and by arranging multistage double cocks on the main pipeline, the number of the thrown balls can be controlled, and meanwhile, the sequence of throwing different balls can be randomly controlled.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Pumping unit polish rod centralized connecting device

InactiveCN101205801ASolve pollutionReduce labor intensitySealing/packingButt jointMaterial consumption

The invention discloses a pumping unit polished rod centering connecting device for connecting a well head tee pipe of an oil field pumping well with a plurality of packing boxes, consisting of a well head tee junction cavity, a translational movable ball seat, a movable ball joint connector, a nylon lining and a ball joint press cap , wherein, the translational movable ball seat is arranged inside the well head tee junction cavity; the movable ball joint connector is arranged inside the transitional movable ball seat; the nylon lining is sleeved inside the movable ball joint connector; the ball joint press cap is in threaded connection with the well head tee junction cavity. The invention replaces the prior inflexible connection of collar clamps and can butt joint with various packing boxes; the structure is simple, convenient and compact, and the device has offset and centering functions under the effect of the translational ball seat and a ball joint, thereby a polished rod is made to be automatically centered. Therefore, the invention solves the environmental pollution problem due to eccentric wear and oil leakage of packings, and has the advantages of reduction of personnel labor intensity, reduction of material consumption and improvement of management level.

Owner:陈敏

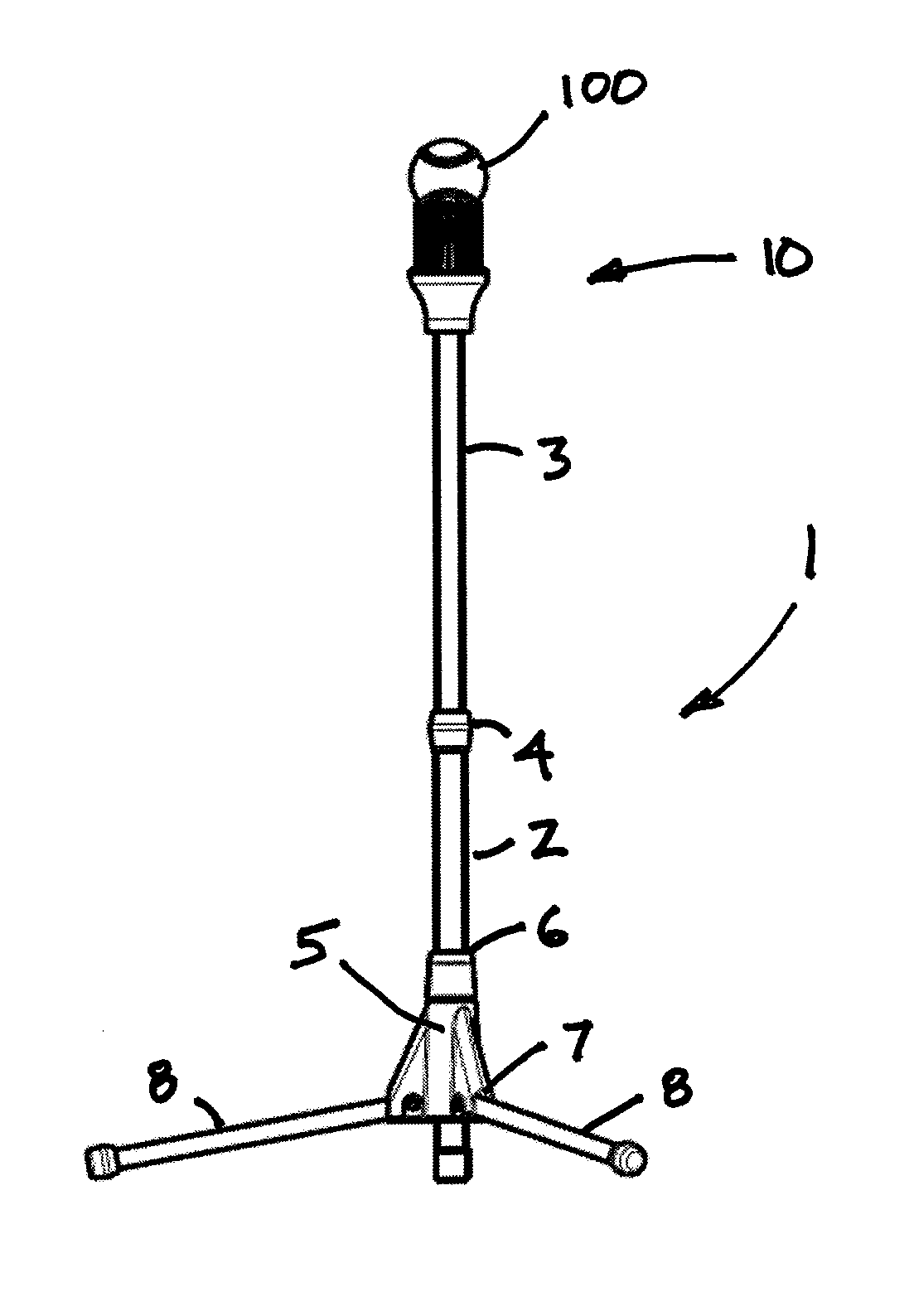

Training device, system and method for improving a baseball player's swing of a baseball bat

A swing training device has an upright vertical support which is height-adjustable and multiple training attachments for working on a batter's different skill sets. The attachments include a regular batting tee, a “cast away” batting tee, an “in and out” batting tee, and a “perfect cut” batting tee. Each tee is interchangeable with the others, each being used with the vertical support.

Owner:MEIER JOHNNY M +1

Reference mass introduction via a capillary

A mass calibration apparatus for a mass spectrometer includes a capillary, an analyte ion source coupled to the capillary at a first point, a reference mass ion source coupled to the capillary at a second point, downstream from the first point and a mass analyzer coupled to the capillary at a third point downstream from the first and second points. The reference mass ion source may be coupled to the capillary via a tee junction. The reference mass ion source includes a chamber, an ionization device situated within the chamber and one or more reference mass sources that are situated internally within the chamber or are situated external to and coupled to the chamber.

Owner:AGILENT TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com