Cellular oxygen carrier chemical-looping reforming reactor

A reforming reactor and honeycomb-shaped technology, which is applied in the field of honeycomb oxygen carrier reactors, can solve the problems of difficult to achieve isothermal operation, serious equipment wear, high energy consumption, etc., and achieve low energy loss, long service life of equipment, high conversion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

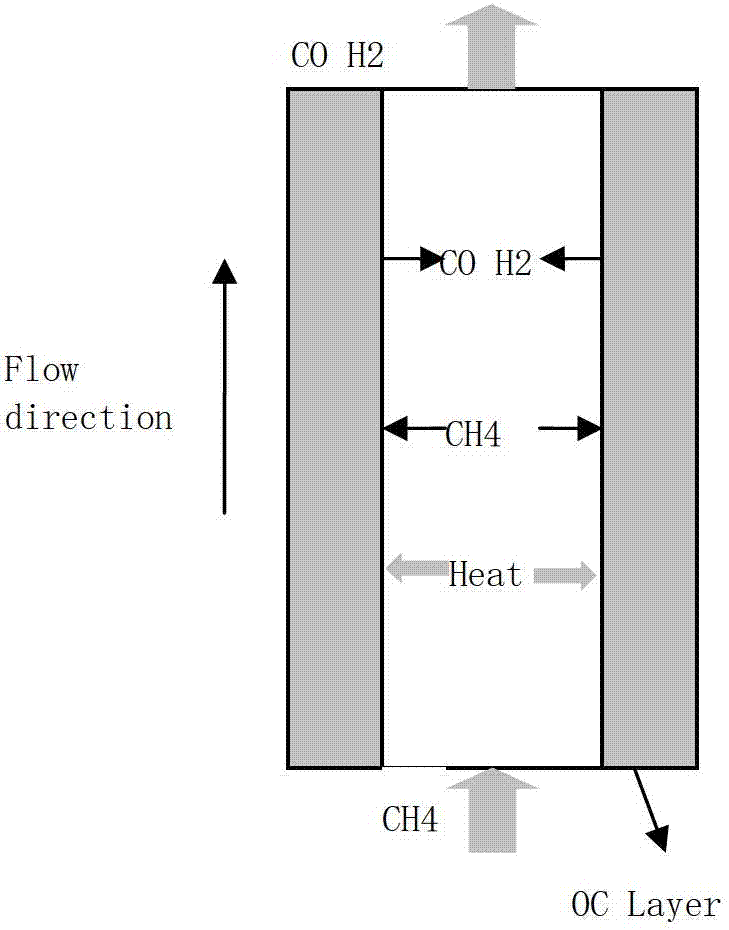

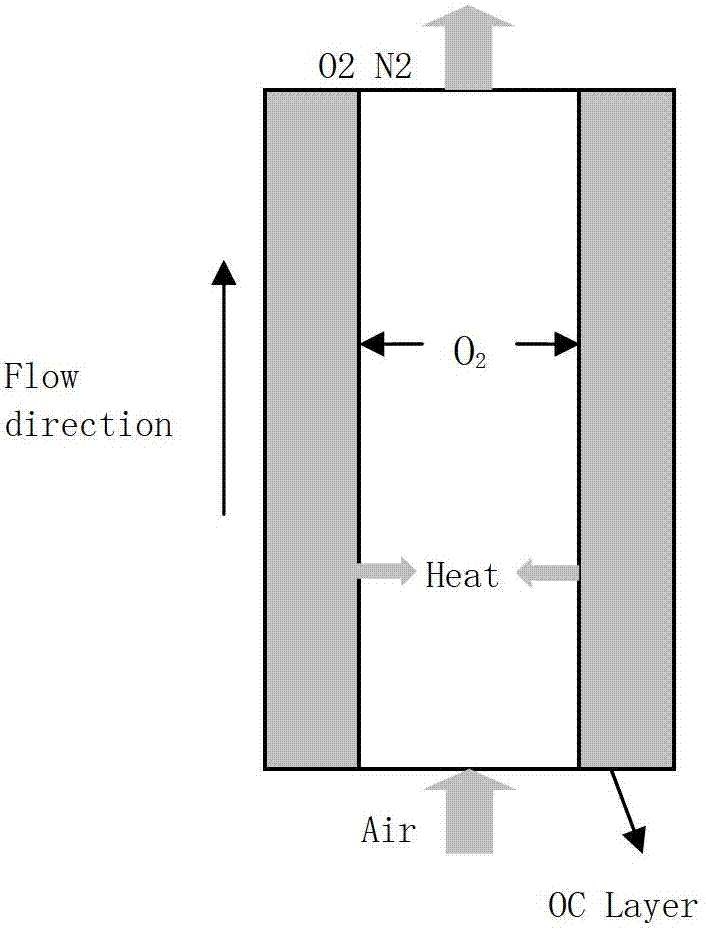

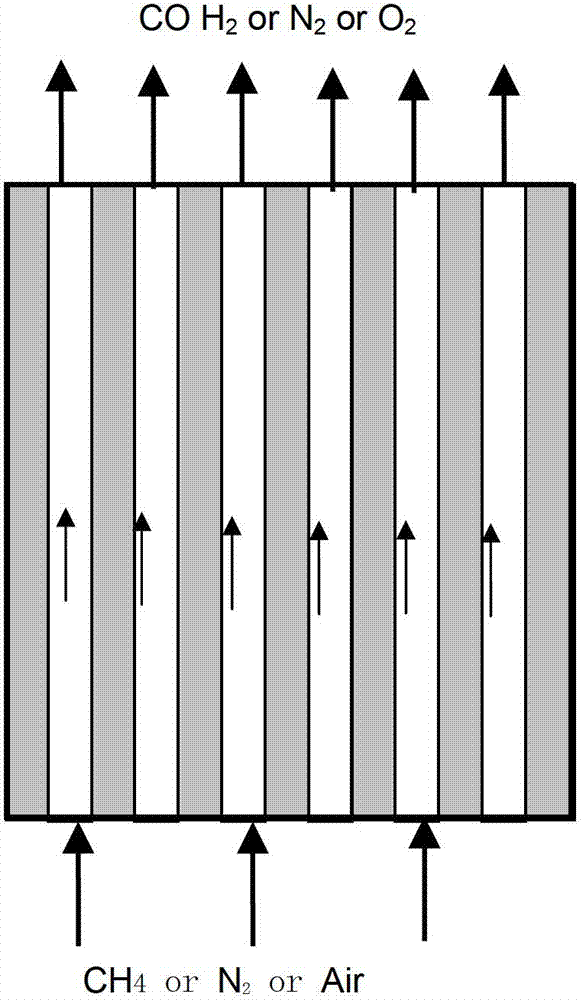

[0025] LaFeO3 is selected as the oxygen carrier material, and the reactor oxygen carrier 6 is made after high-temperature pressing and sintering. The oxygen carrier is cylindrical, with a diameter of 1000mm and a height of 2000mm. There are honeycomb channels 7 with a diameter of 3mm inside, and the channels are parallel to the main axis of the cylinder. The oxygen carrier is connected to the outer wall 5 of the reactor and is made of high-temperature-resistant stainless steel (904L). The outer wall of the reactor is heated by a furnace-type heating system. The gas storage area 3 at the bottom of the reactor and the gas collection area 9 at the top of the reactor have a diameter of 1000 mm and a height of 300 mm. The gas inlet 1 at the bottom of the reactor is controlled by a three-way solenoid valve.

[0026] During operation, turn on the external heating system of the reactor, control the reactor at 850°C-900°C, fuel (CH 4 ), air, and inert gas (N2) alternately enter the r...

Embodiment 2

[0028] Since the operation process and devices of each embodiment are the same, the specific implementation operation process is the same as that of Embodiment 1, and will not be repeated here, only the implementation conditions and implementation results are listed in the following table.

[0029]

Embodiment 3

[0031] Since the operation process and devices of each embodiment are the same, the specific implementation operation process is the same as that of Embodiment 1, and will not be repeated here, only the implementation conditions and implementation results are listed in the following table.

[0032]

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com