Patents

Literature

639results about How to "Avoid Explosion Hazards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxidation barrier coatings for silicon based ceramics

ActiveUS20050112381A1Avoid Explosion HazardsContinuous combustion chamberBlade accessoriesElectron beam physical vapor depositionGas phase

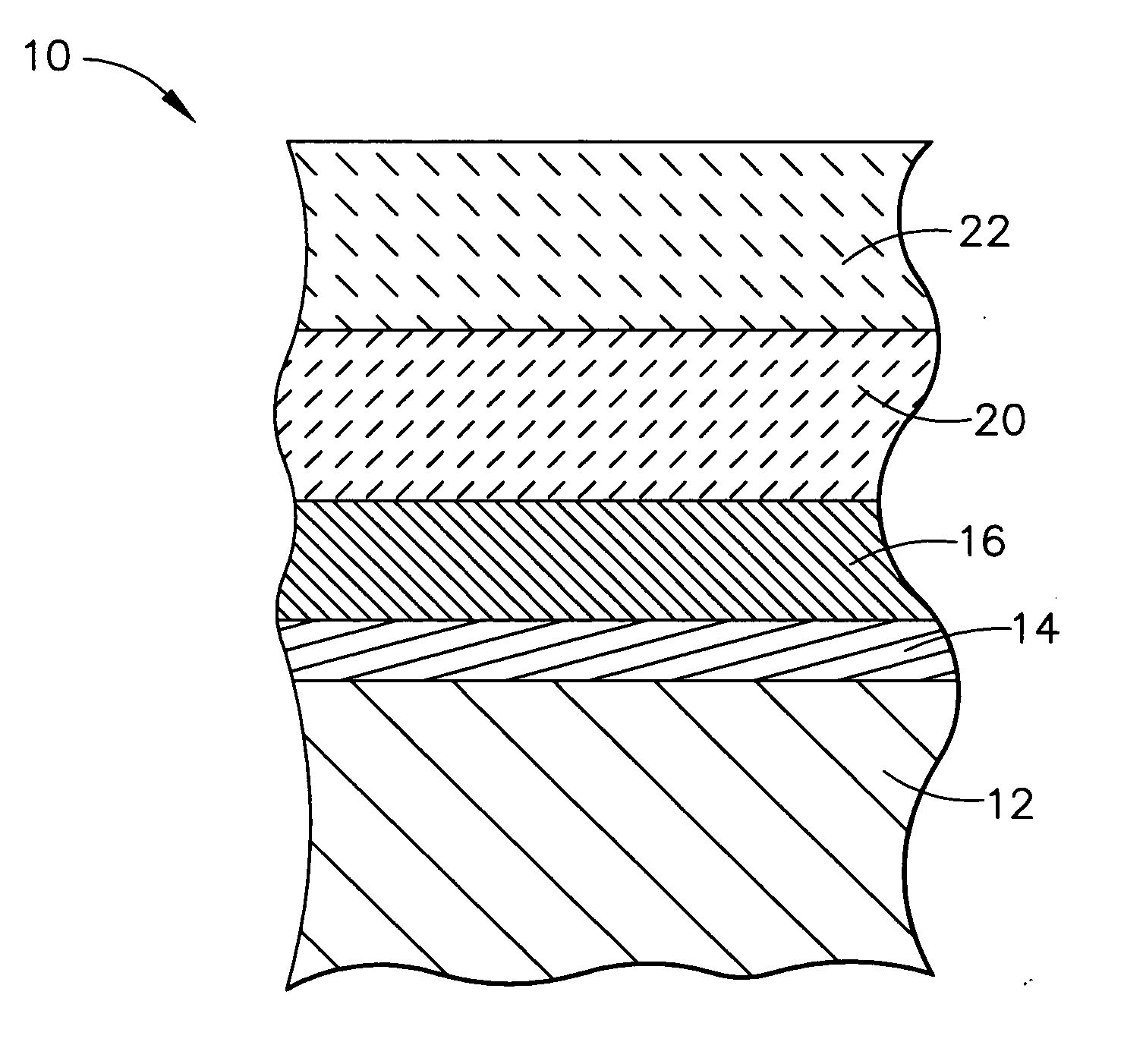

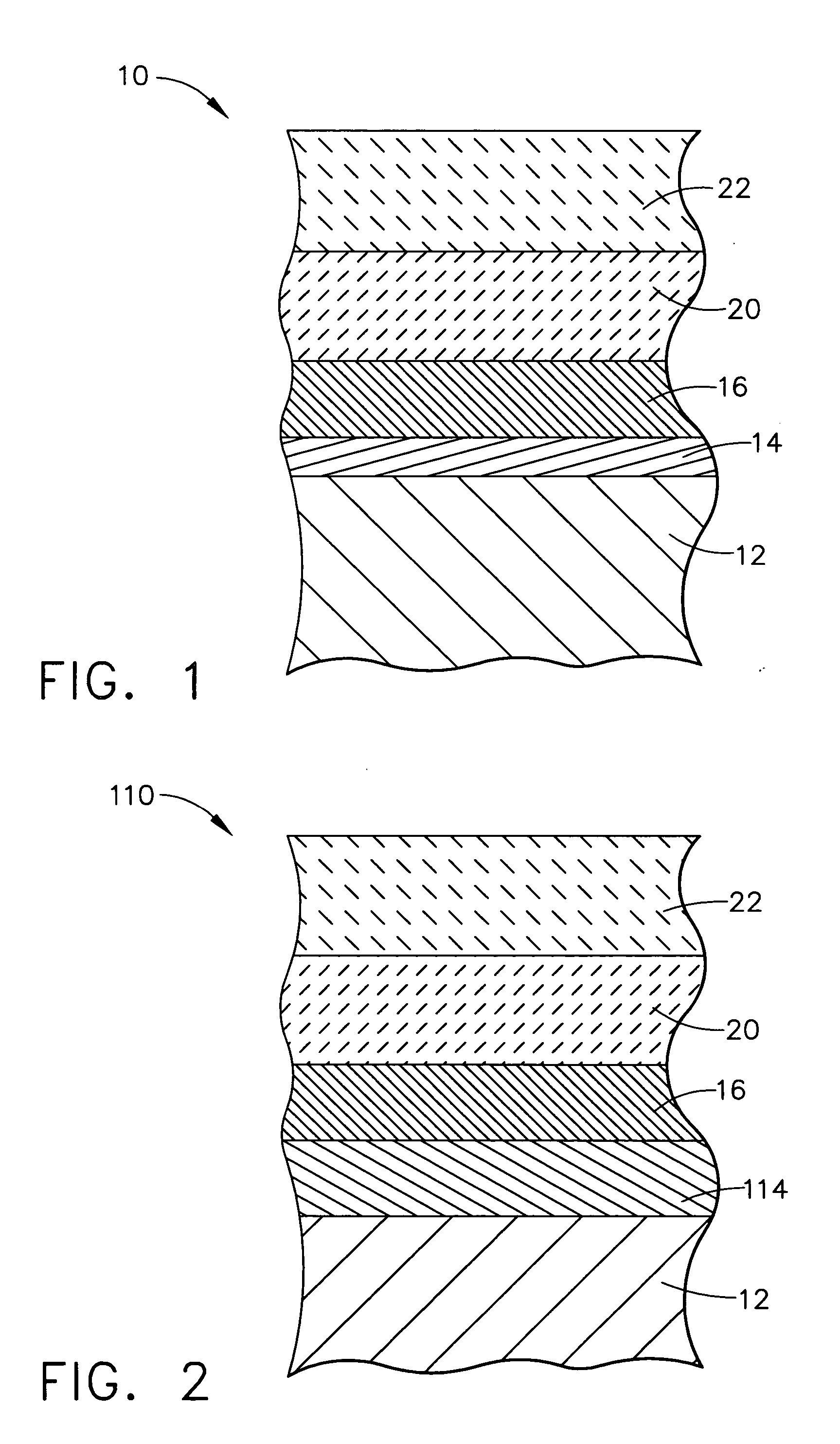

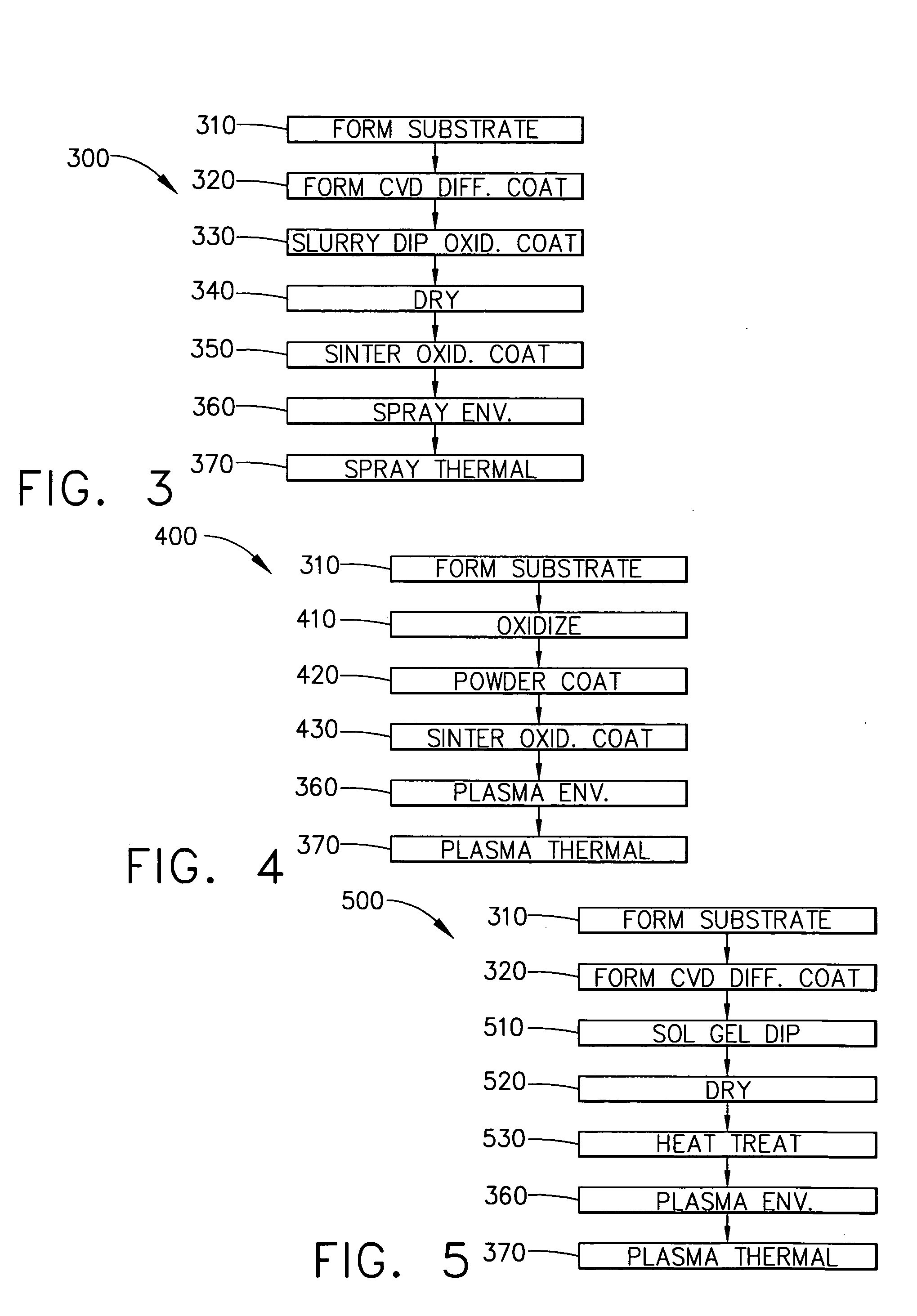

A protective barrier coating system including a diffusion barrier coating and an oxidation barrier coating and method for use in protecting silicon-based ceramic turbine engine components. A complete barrier coating system includes a thermal barrier coating of stabilized zirconia and an environmental barrier coating of an alloyed tantalum oxide. The oxidation barrier coating includes a layer of metallic silicates formed on a substrate of silicon nitride or silicon carbide to be protected. The oxidation barrier coating can include silicates of scandium, ytterbia or yttrium. The oxidation barrier coating may also include an inner layer of Si2ON2 between the diffusion barrier and the metallic silicate layer. The oxidation barrier coating can be applied to the substrate by spraying, slurry dipping and sintering, by a sol-gel process followed by sintering, by plasma spray, or by electron beam-physical vapor deposition. The diffusion layer of essentially pure Si3N4 can be applied to the substrate to prevent the migration of damaging cations from the protective layers to the substrate and is preferably formed by chemical vapor deposition. A method for protecting silicon based substrates can comprise a step of forming an oxidation barrier coating on a substrate, where a step of forming the oxidation barrier includes a step of sintering the oxidation barrier and substrate in a wet gas containing hydrogen.

Owner:HONEYWELL INT INC

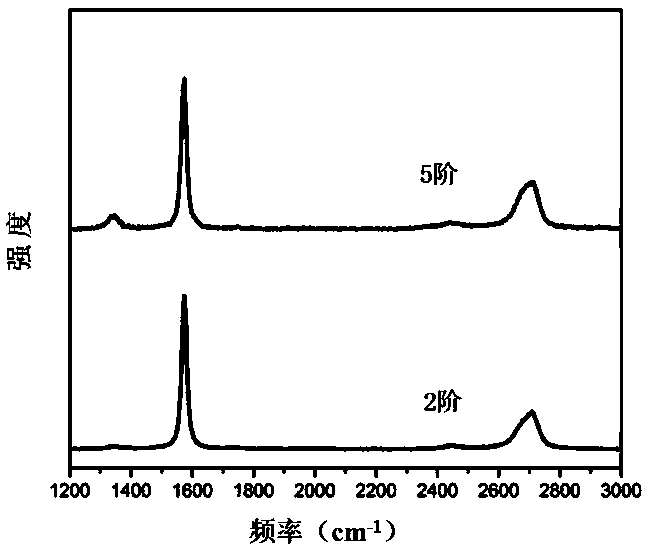

Method for preparing large-size high-quality graphene with controllable number of layers

The invention discloses a method for preparing large-size high-quality graphene with controllable number of layers, wherein graphite powder or flake graphite is mainly adopted as a raw material. The method specifically comprises the steps of intercalating the graphite raw material by virtue of an intercalating agent to initially weaken the intercalation interaction force and obtain different orders of graphite intercalation compounds (GICs); soaking the GICs in an appropriate expander, and then under the case that an auxiliary agent is added or not, enabling the intercalation materials to be quickly reacted with the expander to release a gases to obtain highly expanded wormlike graphene aggregate and further to cause the distances among graphene lamellar layers to be increased; and after certain processing, peeling, and then repeatedly centrifuging and dispersing to obtain a graphene dispersion with different numbers of layers. According to the method disclosed by the invention, the intercalation-expansion-peeling process is involved, raw materials are cheap, the reaction process is simple and easily controlled, and the number of layers of graphene is precisely controlled; the obtained graphene lamellar layers have the advantages of few defects, large size, high conductivity, high yield and the like, the large-scale industrial production is easily implemented, and the problems of high cost, low productivity, poor quality, small size, uncontrollable number of layers and the like in an existing graphene preparation technology are solved.

Owner:安徽百特新材料科技有限公司

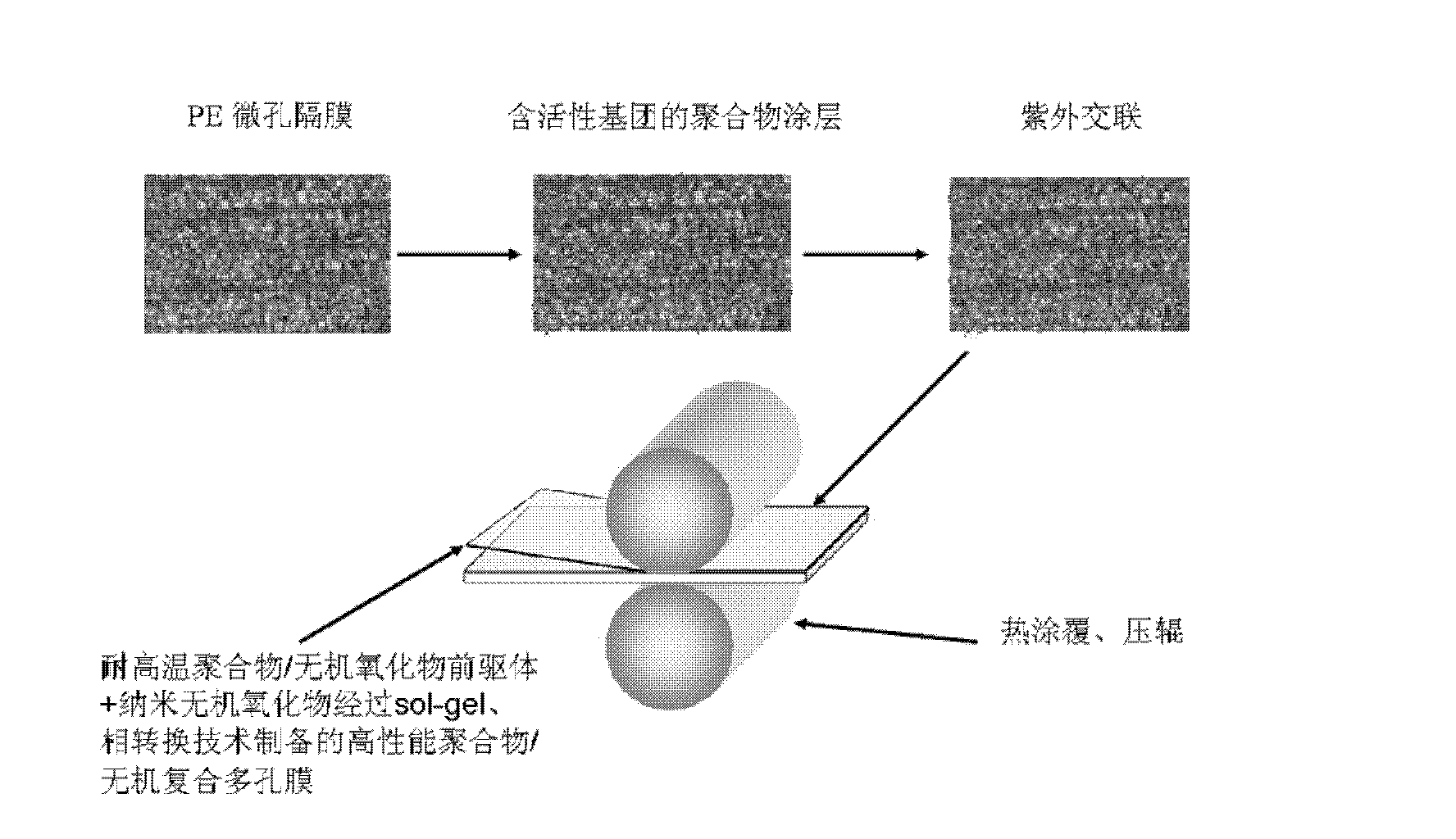

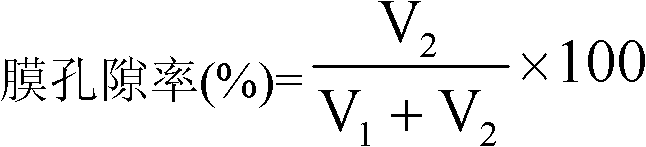

Composite microporous membrane used as lithium ion battery diaphragm as well as preparation method and application thereof

ActiveCN102122704AImprove bonding strengthEasy to prepareCell component detailsPolyolefinHigh performance polymer

The invention discloses a composite microporous membrane used as a lithium ion battery diaphragm as well as a preparation method and application thereof. The composite microporous membrane is prepared by the following steps of: steeping a polyolefin porous framework membrane in a modified liquid a and carrying out radiation crosslinking to obtain a modified framework membrane; preparing a modified liquid b, steeping the modified framework membrane in the modified liquid b and adding a sol-gel reaction catalytic agent to carry out a sol-gel condensation reaction; and immersing the modified membrane in a phase transforming agent solution, carrying out phase conversion to form a membrane and then drying to obtain a high-performance polymer / inorganic composite microporous membrane. In the invention, the preparation process is simple and the industrialization is easy to realize; the obtained composite microporous membrane has high air permeability, good electrolyte-favoring performance andhigh temperature resistance, a composite layer and the framework polyolefin membrane have good adhesion strength and cannot be separated when being placed in a lithium ion electrolyte solution with very good adhesion and without power-dropping and shedding. By means of the product of the invention, a series of defects in the prior art can be overcome.

Owner:河南惠强新能源材料科技股份有限公司

Hydrophobic multicomponent catalyst useful for direct oxidation of hydrogen to hydrogen peroxide

InactiveUS6346228B1High selectivitySelectivity for in directHydrogen peroxideCatalyst protectionHydrogenHydrophobic polymer

The present invention relates to a novel hydrophobic multicomponent catalyst useful in the direct oxidation of hydrogen to hydrogen peroxide and to a method for the preparation of such catalyst. More specifically, this invention relates to a novel hydrophobic muticomponent catalyst comprising a hydrophobic polymer membrane deposited on a Pd containing acidic catalyst, useful for the direct oxidation of hydrogen by oxygen to hydrogen peroxide, an a method for preparing the same.

Owner:COUNCIL OF SCI & IND RES

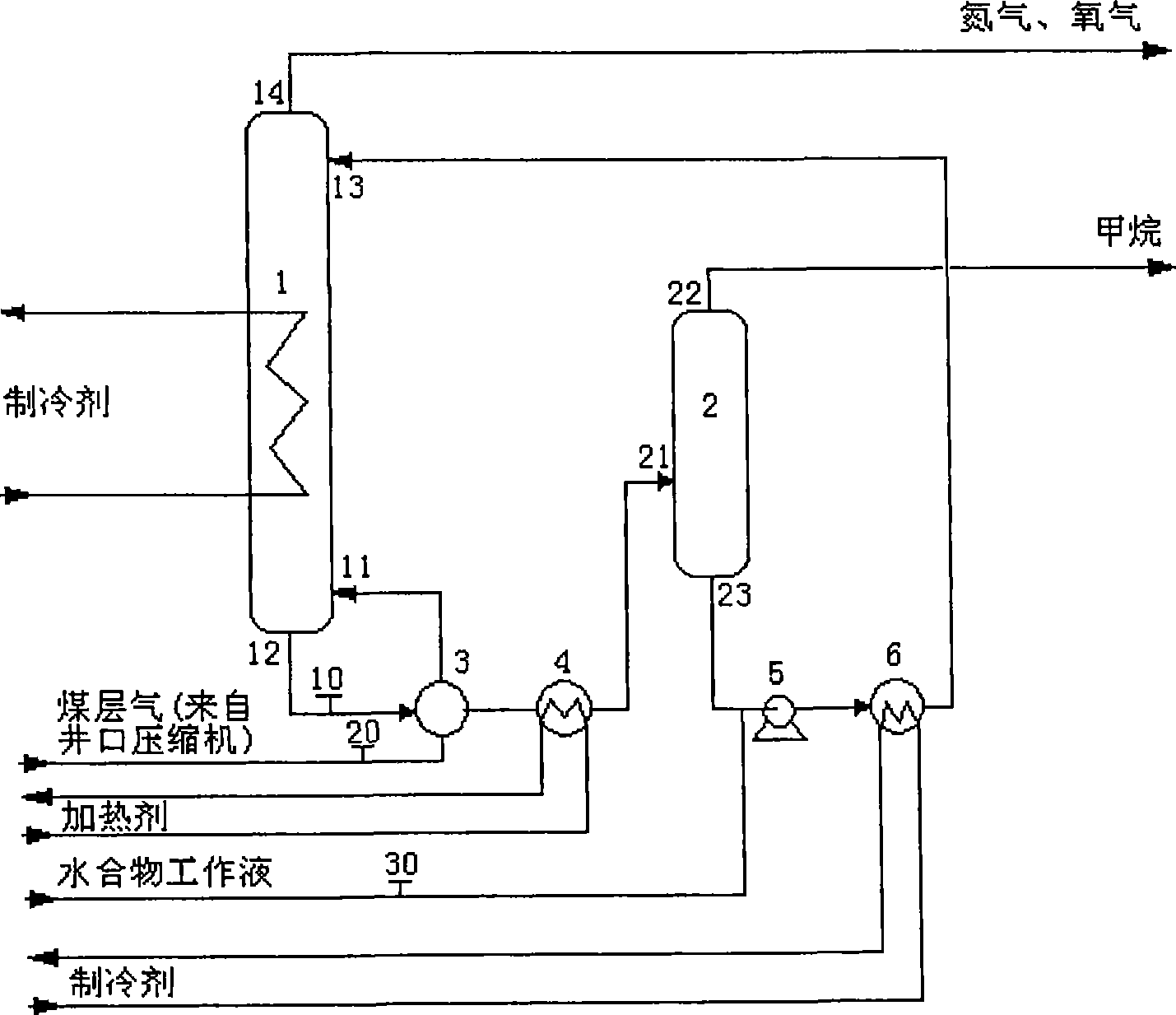

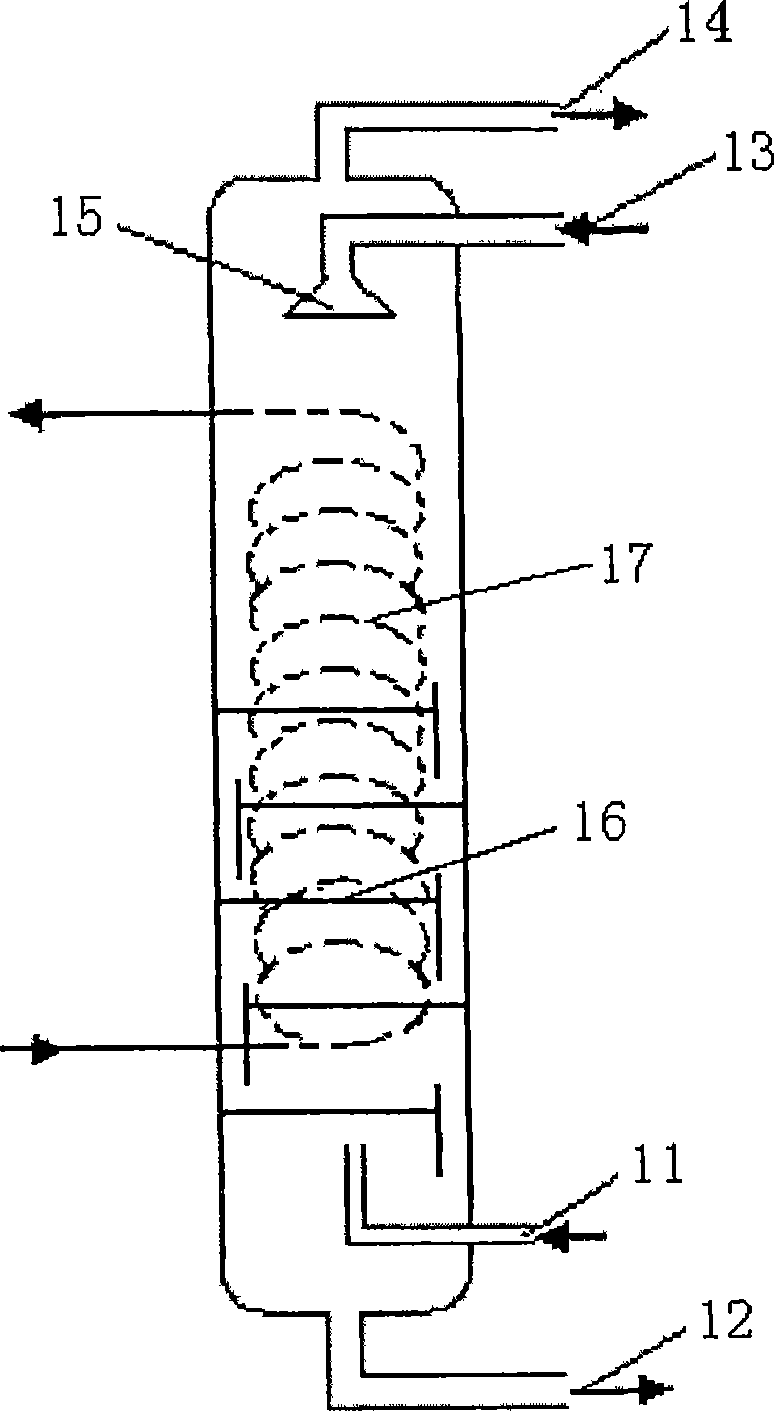

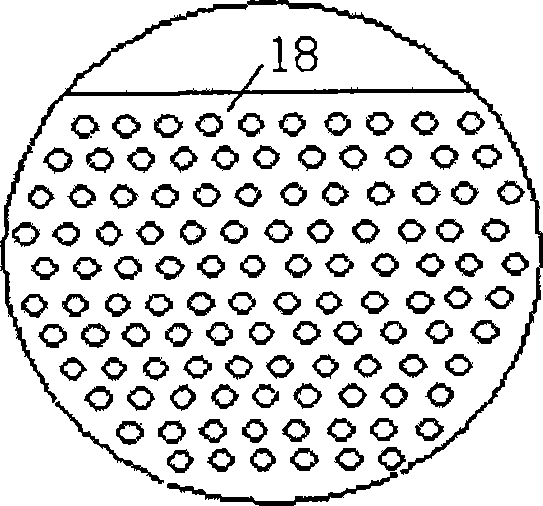

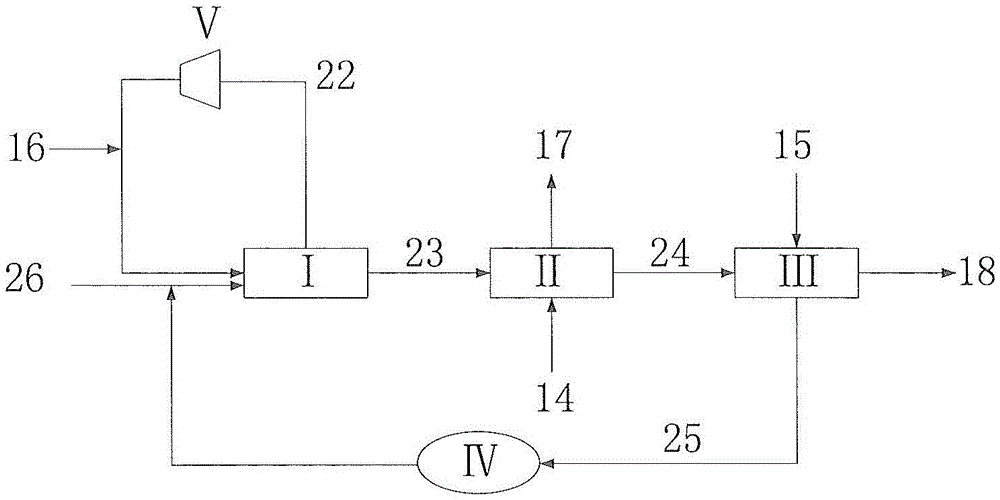

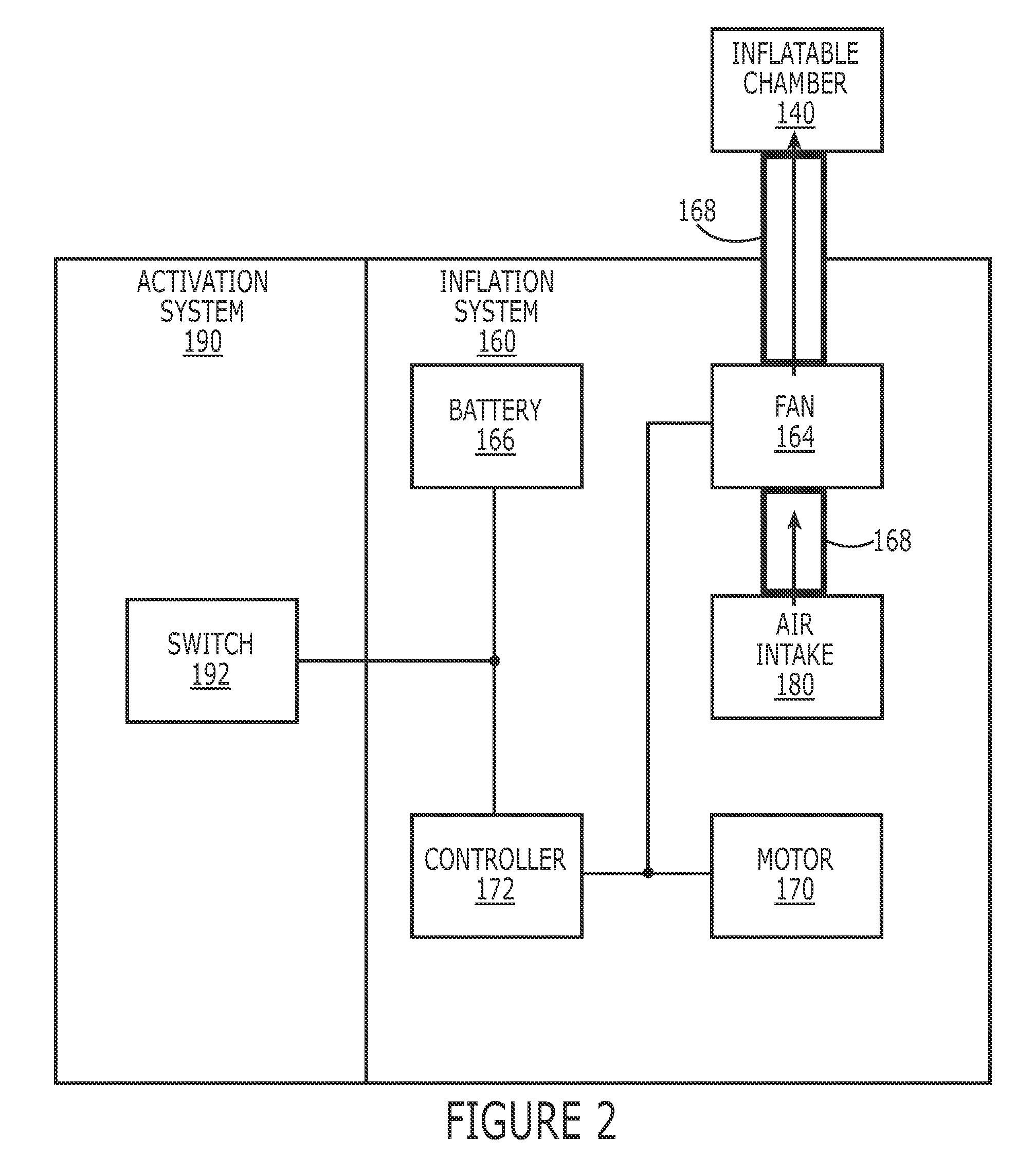

Method and device for low-pressure processing of coal bed gas

InactiveCN101530719AReduce concentrationEmission reductionDispersed particle separationAbsorption purification/separationHydration reactionHigh concentration

The invention relates to a method for low-pressure processing of coal bed gas, comprising the steps of: introducing the coal bed gas into a hydration reactor from the bottom part of a hydration reactor so as to be contacted with hydrate working liquid in the hydration reactor, leading methane contained in the coal bed gas and water in the hydrate working liquid to generate hydration reaction to form a hydrate which is removed from the coal bed gas; meanwhile, the purified gas is obtained after the methane in the coal bed gas is removed; wherein the operation pressure of the hydration reactor is 0.11-0.85MPa, and the temperature is 3-18 DEG C. The formed hydrate can be further introduced into a hydrate decomposition device for decomposition, thereby obtaining the methane with high concentration. The invention simultaneously relates to a device for realizing the method for low-pressure processing of the coal bed gas. The invention can safely purify the oxygen-containing coal bed gas under lower pressure and remove the contained methane to be lower than 0.05 molar fraction, thereby reducing the emission of the methane, reducing the greenhouse effect and simultaneously avoiding the risk of explosion.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

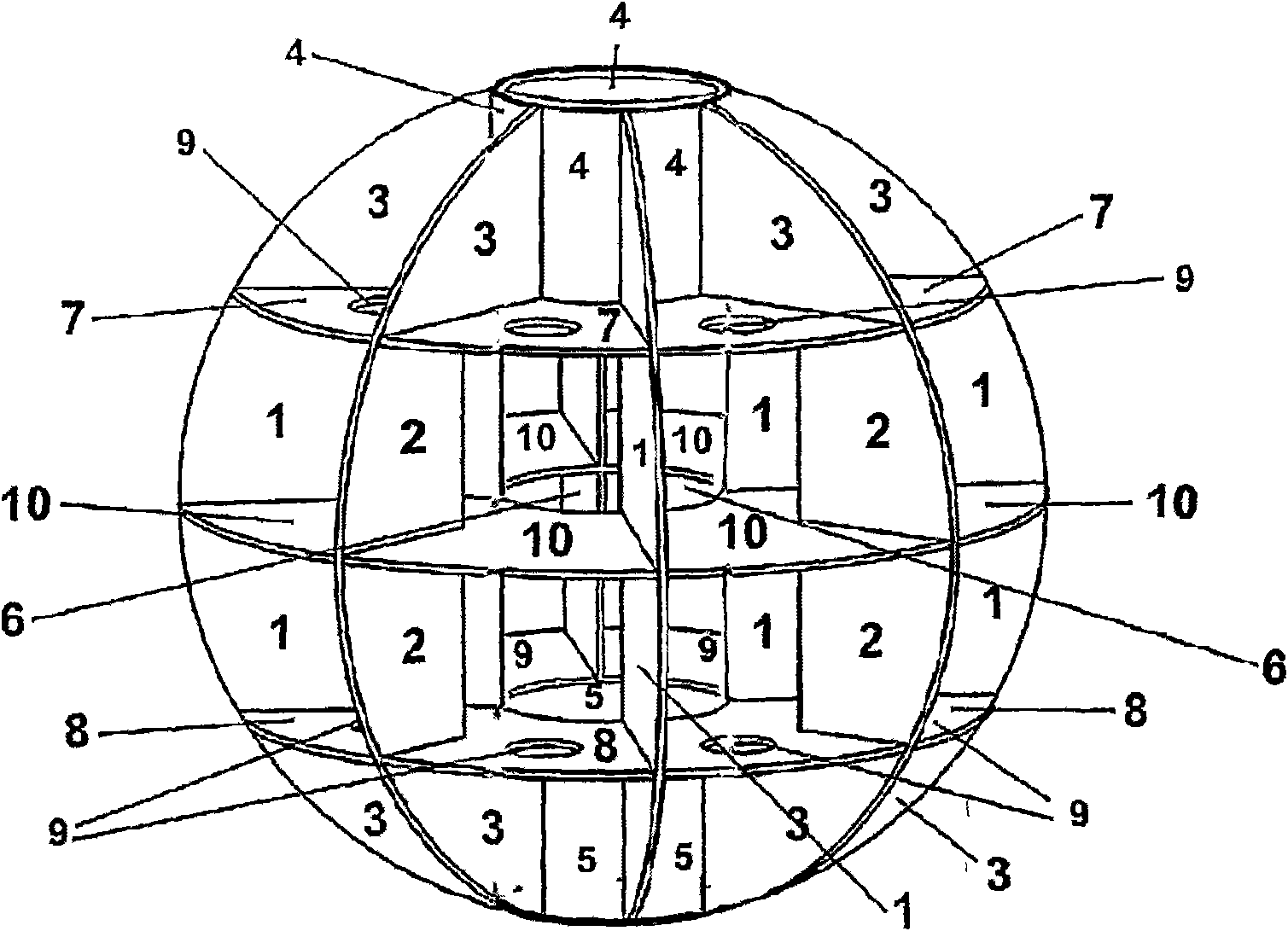

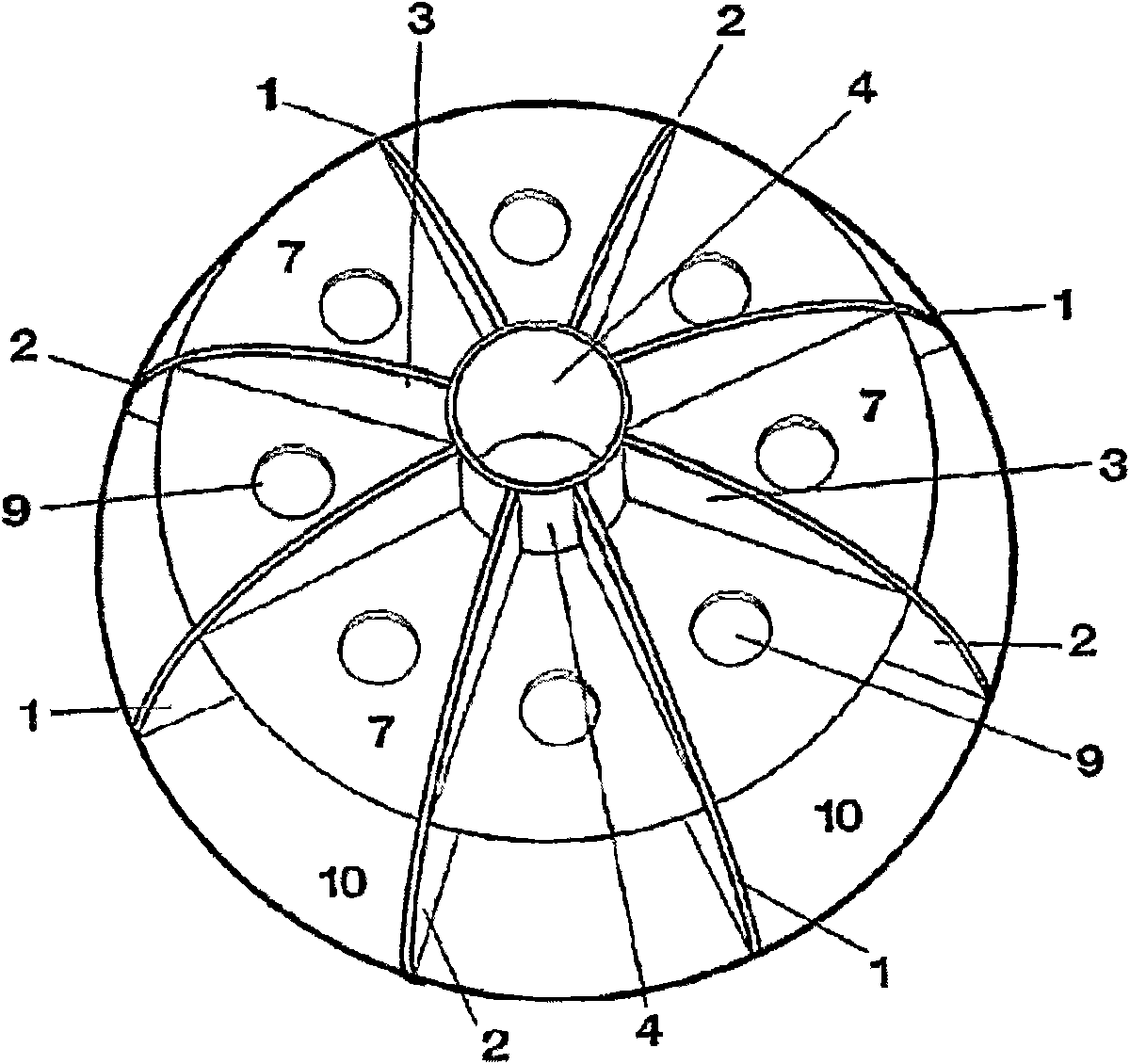

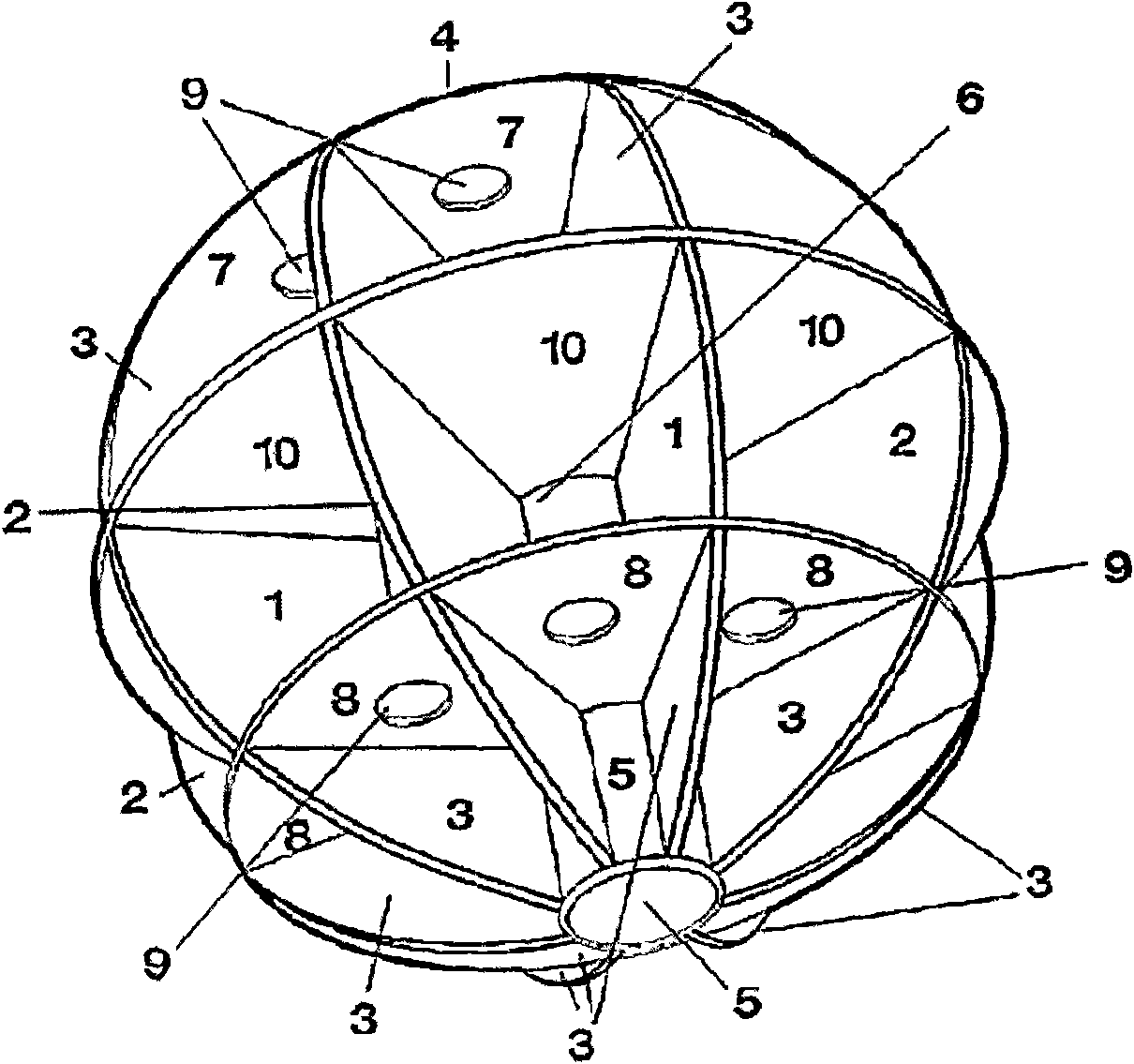

Spherical filling body

The invention relates to the production of a spherical hollow filling body for filling containers for combustible and inflammable liquids or gases, and to a method for the especially advantageous usesthereof, for example, for preventing explosive combustion processes and explosions, for extinguishing fires, as protection against corrosion in tanks, for separating fuels and water, as protection ag ainst bacteria and fungi in fuel tanks, as protection against theft, for reducing hydrocarbon emissions, for increasing the stability and safety of tanks in the event of a crash, for reducing the boil-off effect of hydrogen, for applications in the chemical industry, for deriving static electricity from fuel containers, for protection against electromagnetic interferences, for reducing and slowingdown the B.L.E.V.E. effect, for increasing the filling quantity of gas containers, for heating and cooling liquids and gases, and for reducing evaporation loss. The invention also relates to methodsfor producing the filling body. Figure 1 shows a spherical filling body according to the invention, consisting of a plurality of disk-type circular vertical surfaces (1, 2 and 3) and a plurality of disk-type circular horizontal surfaces (7, 8 and 10) which are parallel to each other. A circular opening (6) is located in the centre of the horizontal surface (10), said opening forming an axial continuous tube in the centre, from the top (4) to the bottom (5), together with the upper, inwardly open, circular sleeve-type body (4) and the lower, inwardly open, circular sleeve-type body (5), the inner diameters of the sleeve-type, inwardly open circular bodies (4 and 5) and the circular opening (6) being identical. The vertical surfaces (1) extend from the outer edge of the spherical body to theedge of each circular opening (4, 5 and 6) of the parallel horizontal surfaces (7, 10 and 8) respectively surrounding the openings.

Owner:托马斯·K·斯特尔泽尔

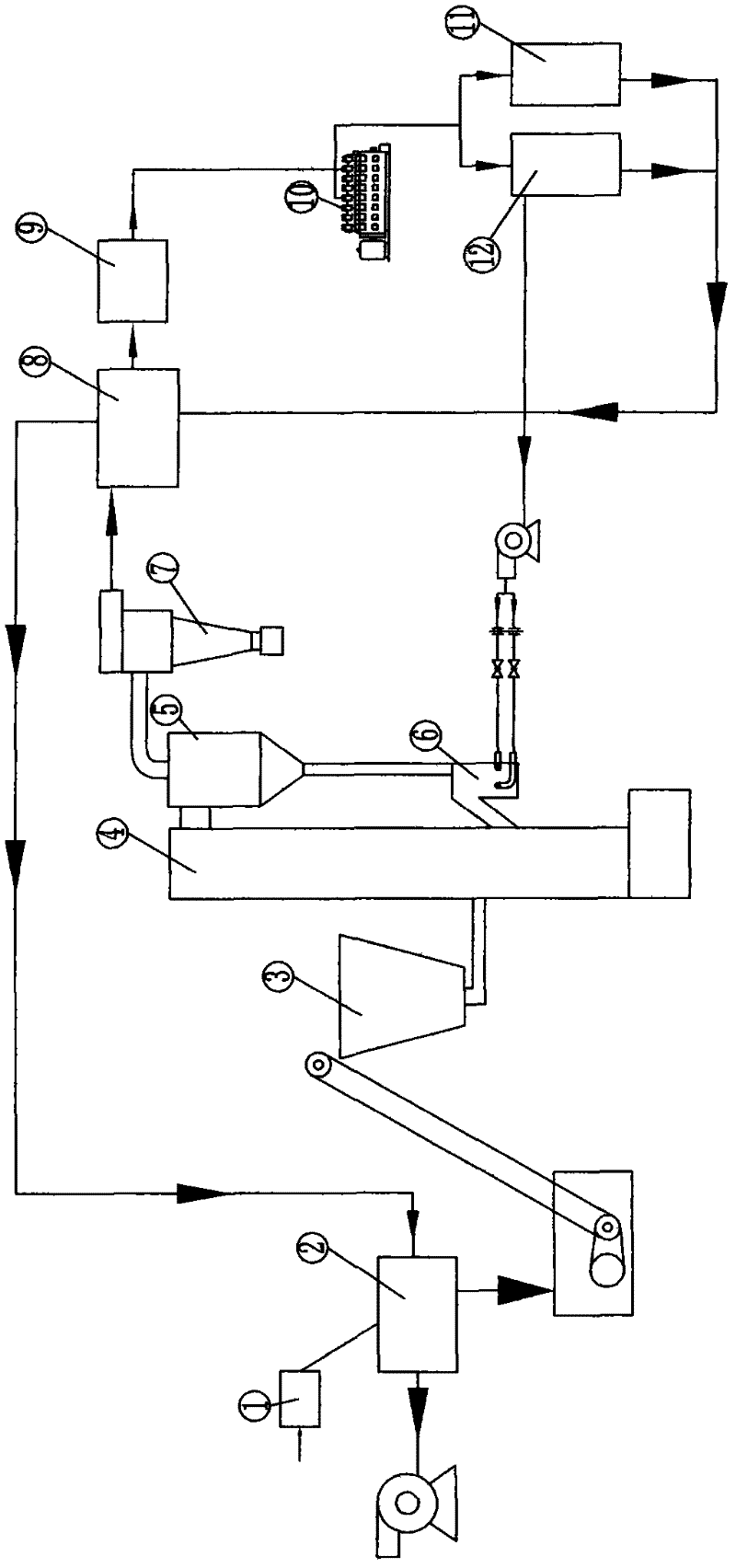

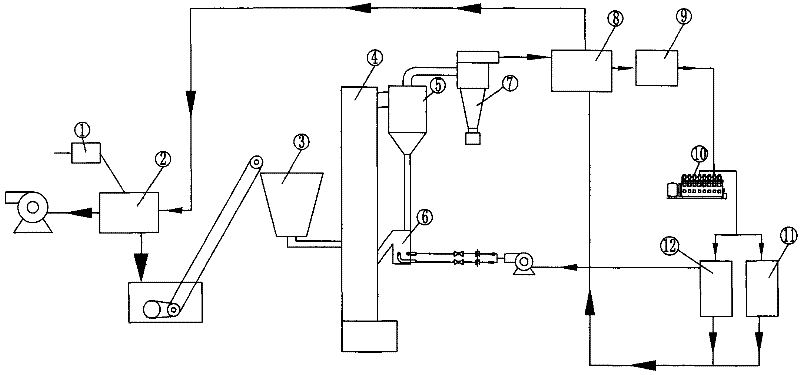

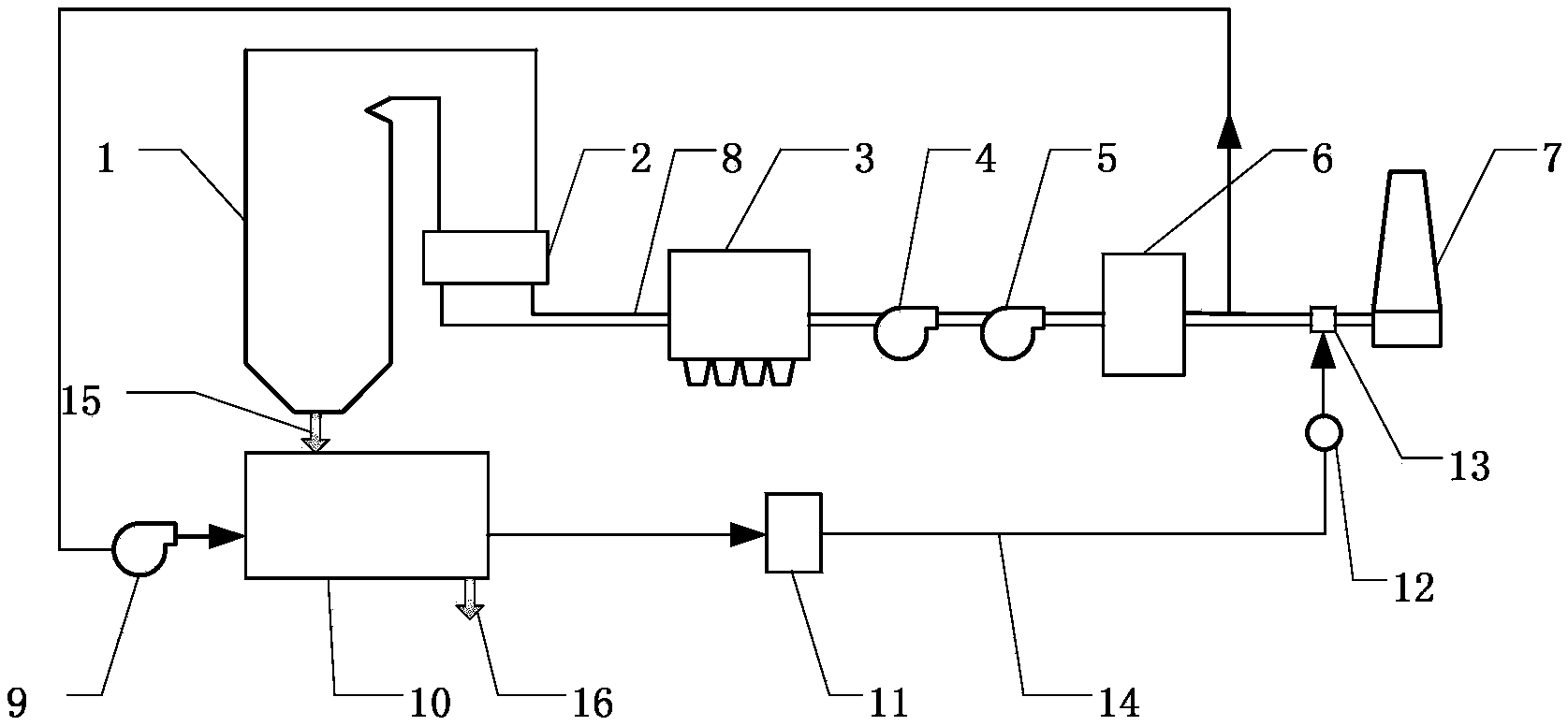

Biomass gasification generation system

InactiveCN102417831AImprove energy utilizationImprove adaptabilityInternal combustion piston enginesEnergy inputAir preheaterGas passing

The invention discloses a biomass gasification generation system. In the system, biomass is crushed and dried and then enters a gasification furnace, the air which is preheated by an air preheater is injected in the gasification furnace from the bottom and then reacts with the biomass to generate high temperature gas, gas-solid separation is performed to the product, the unreacted carbon residue is collected and sent back to the gasification furnace through a returning device to further react, the separated high temperature gas enters a cyclone dust collector for dedusting and then enters a gas-flue gas heat exchanger, the cooled gas passes through a purification device to decoke, dedust and further cool, the gas passing through the purification device is sent to an internal combustion generating set to generate power, a part of high temperature flue gas discharged from the internal combustion generating set enters the air preheater to preheat the air, and the other part enters a waste heat boiler to generate steam. A part of low temperature flue gas from the air preheater and the waste heat boiler is used as the fluidized air of the returning device, the other part enters the gas-flue gas heat exchanger for heating, and the heated flue gas enters a drier to dry the biomass raw material. The biomass gasification generation system recycles the sensible heat of the high temperature gas to dry the biomass raw material and also recycles the sensible heat of the flue gas discharged from the internal combustion generating set to preheat air and generate steam, thus energy can be fully utilized; and the flue gas at the outlet of the internal combustion generating set is used as the fluidized air of the returning device to increase the operating stability of the gasification system.

Owner:HEFEI DEBO BIOENERGY SCI & TECH

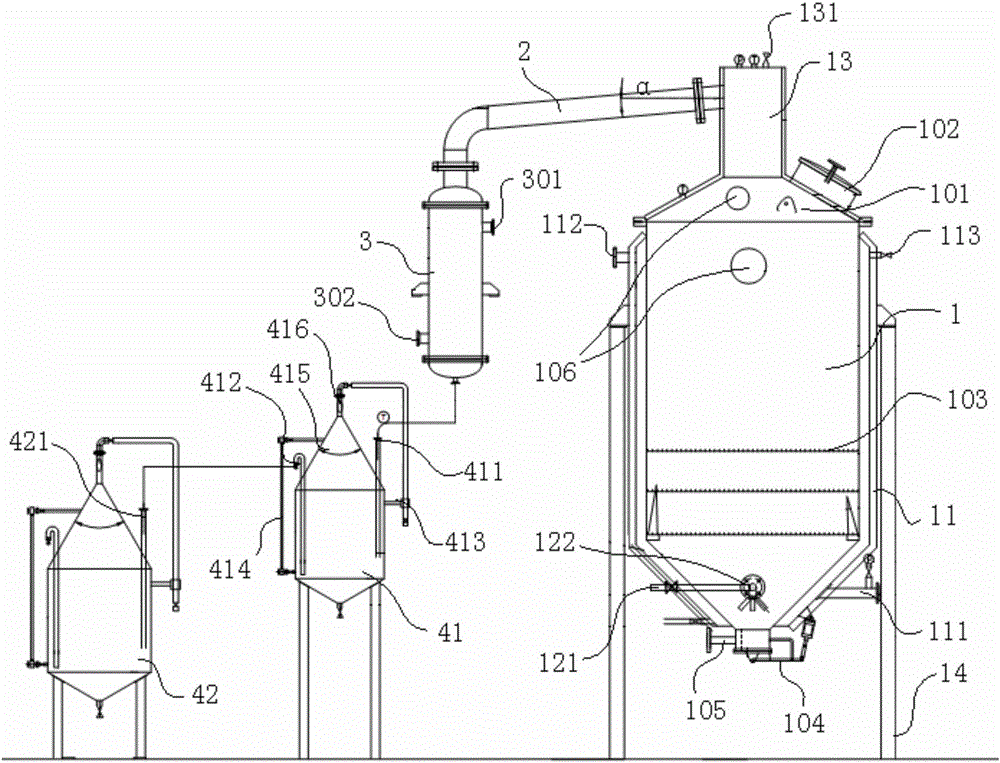

Litsea cubeba oil distillation separation equipment and technology

InactiveCN106350230AAvoid Oxidative DamageMeet safety requirementsEssential-oils/perfumesDistillationWastewater

The invention discloses litsea cubeba oil distillation separation equipment and a technology. The litsea cubeba oil distillation separation equipment comprises a distillation still, a condenser and oil-water separators, wherein the distillation still, the condenser and the oil-water separators are connected in series; a jacket covers the outside of the distillation still; heating media are introduced into the jacket; the inside of the distillation still is also connected with a steam pipeline in the distillation still, and external normal pressure heating distillation and internal pressurization heating distillation can be respectively realized; the top of the distillation still is provided with a distillation column section, and the distillation column section is connected with the inlet of the condenser through an inclined air duct; the oil-water separators are in two-stage serial connection, wherein the oil-water feeding hole of the first-stage oil-water separator is connected with the outlet of the condenser, the oil-water feeding hole of the second-stage oil-water separator is connected with the water outlet of the first-stage oil-water separator, and the water outlet of the second-stage oil-water separator is connected with a storage tank through a pump. According to different specification requirements of litsea cubeba essential oil, underwater distillation and overwater distillation are realized, pressurization distillation also can be realized, heat energy use ratio is high, energy consumption is lowered by 5-10%, a wastewater quantity is reduced by 10-30%, and the oil extraction rate and the quality of the litsea cubeba essential oil can be improved.

Owner:YONGZHOU SAMSHIANG FLAVOURS & FRAGRANCES CORP

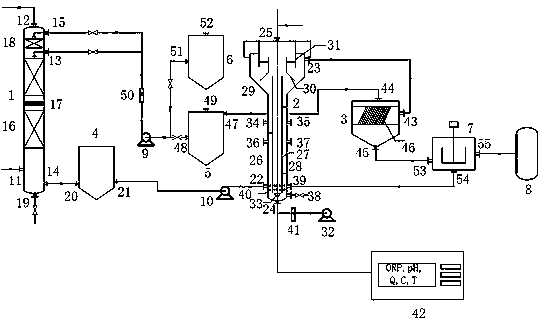

Microorganism desulfurizing and sulfur recycling method

InactiveCN105498470AAvoid cloggingReduce energy consumptionChemical industryDispersed particle separationMicroorganismAbsorption column

A microorganism desulfurizing and sulfur recycling method. A gas material flow containing hydrogen sulfide is fed into an absorption column and then is subjected to chemical absorption with an alkali solution sprayed from the top of the column in a counter-contact manner, wherein treated purified gas is discharged out from the top of the absorption column. A back-washing apparatus is arranged in the absorption column to wash the sulfur attached to a filling material. A rich solution, in which the hydrogen sulfide is dissolved, is fed into a rich solution tank from the bottom of the absorption column and then is fed into a bio-reactor for aeration, so that a carrier, on which desulfurization bacteria is immobilized, is fluidized and the sulfide in the absorption solution is biologically oxidized to generate elementary sulfur. The regenerated solution containing the sulfur then is fed into a settling tank through an overflow weir of the bio-reactor and a supernatant liquid is fed into a barren solution tank. The supernatant liquid then is fed back to the absorption column for being recycled through a barren solution pump. Sulfur slurry in the bottom layer is discharged through the bottom of the settling tank and then is subjected to solid-liquid separation in a centrifugal machine to obtain biological sulfur. A separated filtrate is fed back to the bio-reactor for being recycled. The bio-desulfurization technology is green and environment-friendly, is energy-saving and emission-reducing and can recycle resources, and has social, economical and environmental benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

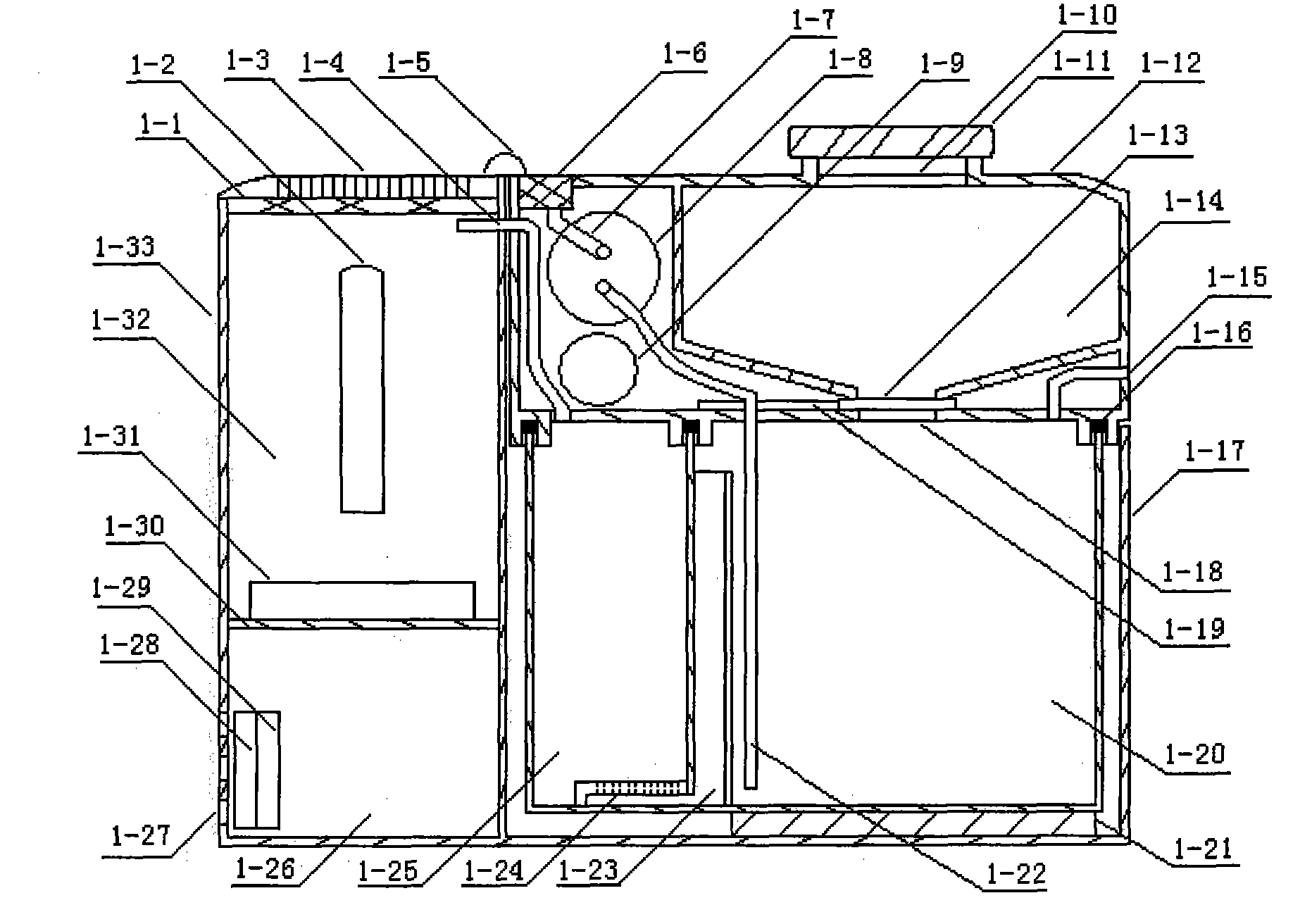

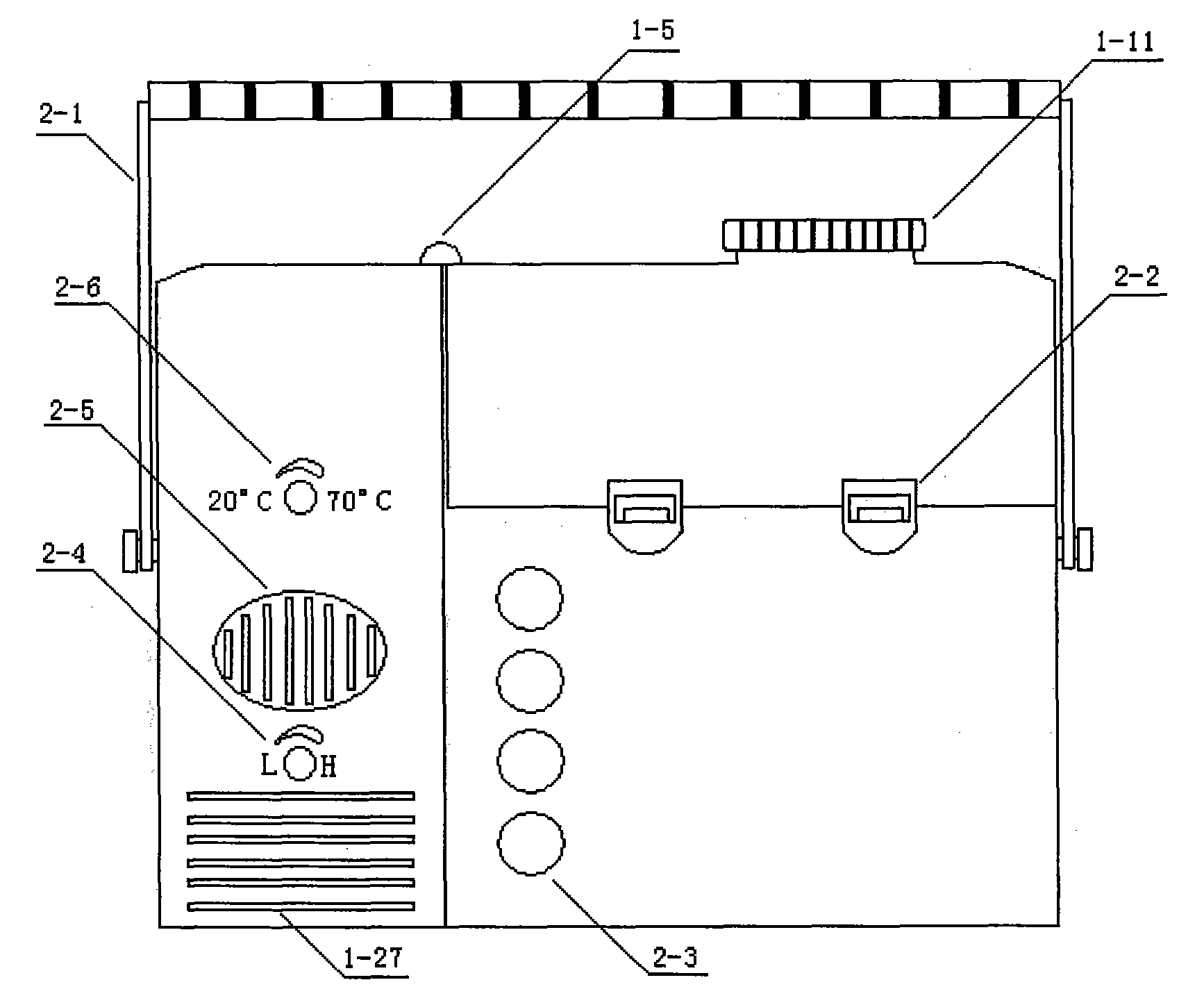

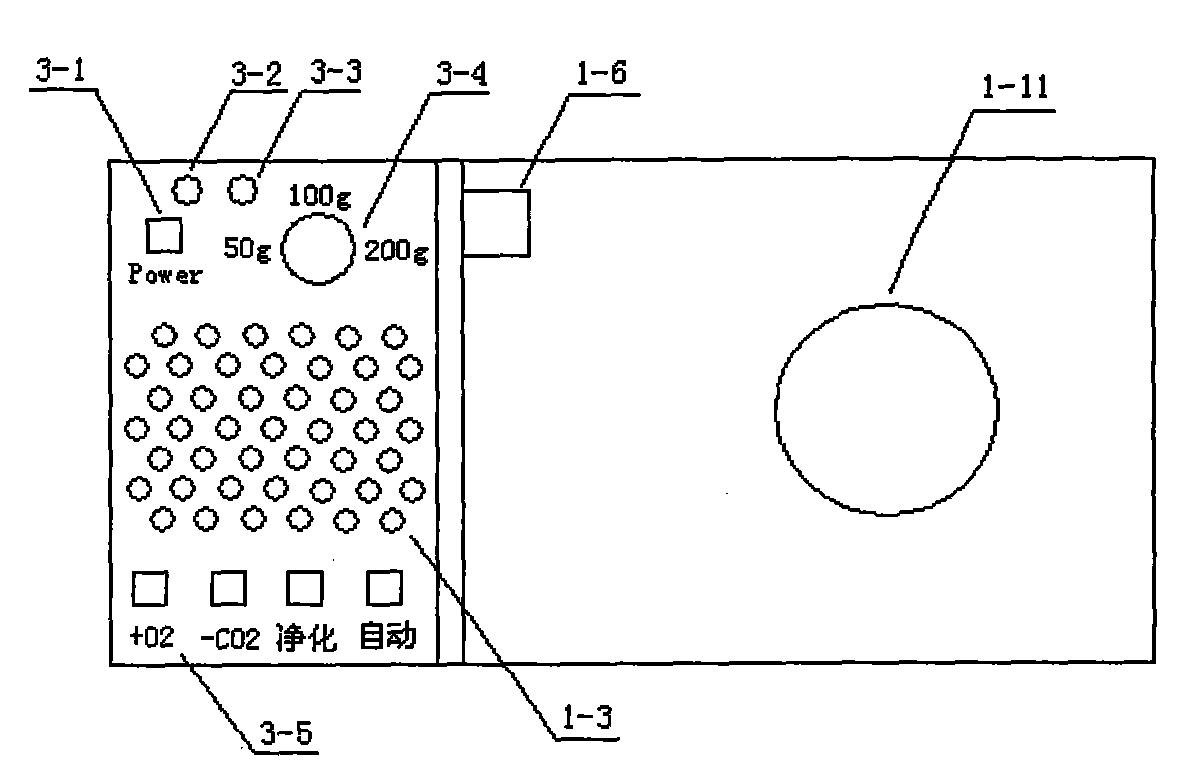

Multifunctional air purifier with functions of oxygen supplement and carbon dioxide absorption and oxygen supplement and carbon dioxide absorption method

InactiveCN103453587ANo pollutionMeet the use requirementsProductsSpace heating and ventilation safety systemsParticulatesSuspended particles

A multifunctional air purifier with functions of oxygen supplement and carbon dioxide comprises six function modules. The air purification module is used for killing bacteria and viruses and degrading various pollutants such as formaldehyde and benzene by high-energy positive oxygen ions generated by an ionization tube; high-energy negative oxygen ions can clear various suspended particles in air, such as PM2.5. The chemical oxygen production module supplements oxygen by using calcium peroxide and the like as oxygen producing agent. The CO2 absorption and PM2.5 removal module is capable of removing inorganic pollutants such as carbon dioxide and various suspended particles in air, including PM2.5, by calcium hydroxide and water in oxygen production waste liquid. The vehicular power module provides three USB interfaces and a standard power interface (+5V / 500mA). The harmful gas alarm module has the function of warning on over-standard density of carbon monoxide, methylbenzene, ammonia and the like. The electronic control module is used for controlling ordered operation of a whole system.

Owner:易菊芳

Method for preparing hydrogen peroxide

ActiveCN104418309AImprove hydrogen efficiencyAvoid air lockPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogen peroxide breakdownHydrogen

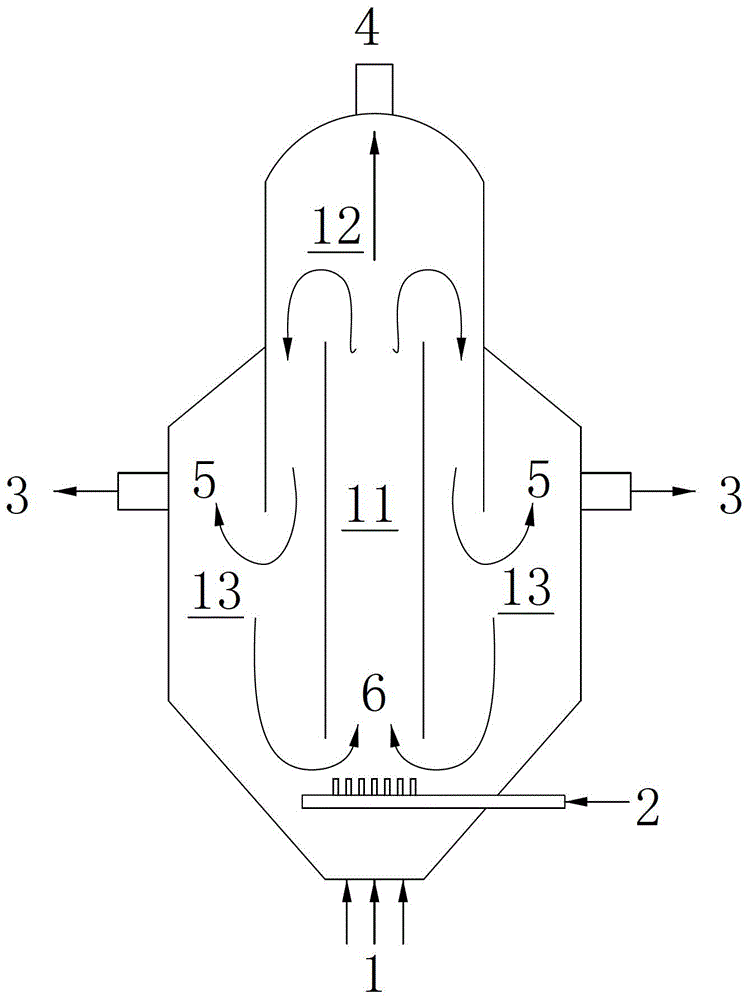

The invention discloses a method for preparing hydrogen peroxide. A working liquid and a hydrogen-containing gas are introduced into a slurry bed reactor; a hydrogenated liquid is obtained by reaction in the existence of a catalyst; the hydrogenated liquid reacts with oxygen to obtain the hydrogenated liquid containing hydrogen peroxide in an oxidation reactor; oxidized liquid is extracted and separated from an extraction tower to obtain a hydrogen peroxide solution and working liquid; the slurry bed reactor comprises a cap (12), an expanding section (13) and a draft tube (11); the expanding section (13) is positioned at the lower part of the cap (12); the pipe diameter of the expanding section (13) is greater than that of the cap; the draft tube (11) is arranged in the expanding section (13); the pipe diameter of the draft tube (11) is smaller than that of the cap (12); a bottom opening of the cap (12) extends into the expanding section (13); the outer wall of the cap (12) is connected with the top of the expanding section (13); an upper opening of the draft tube (11) extends into the cap (12); and an opening is formed in the lower part of the draft tube (11). The method disclosed by the invention is stable to operate, and easy for realization of industrial enlargement; no alkali is introduced in the process of preparing hydrogen peroxide; and the risk of explosion caused by hydrogen peroxide decomposition is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

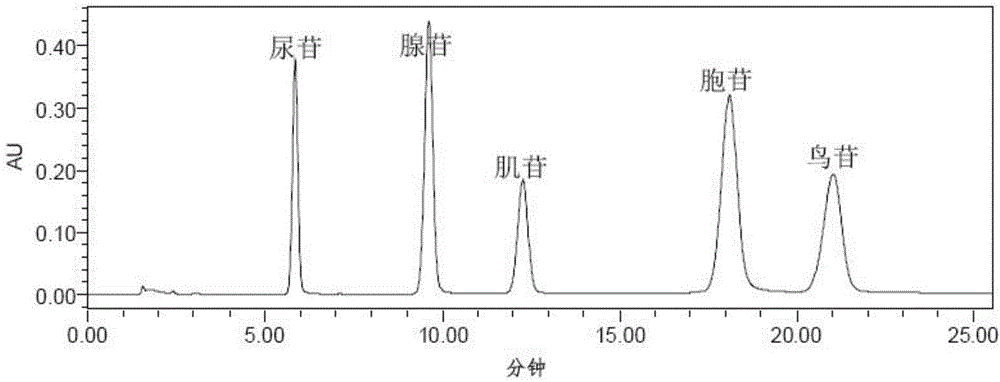

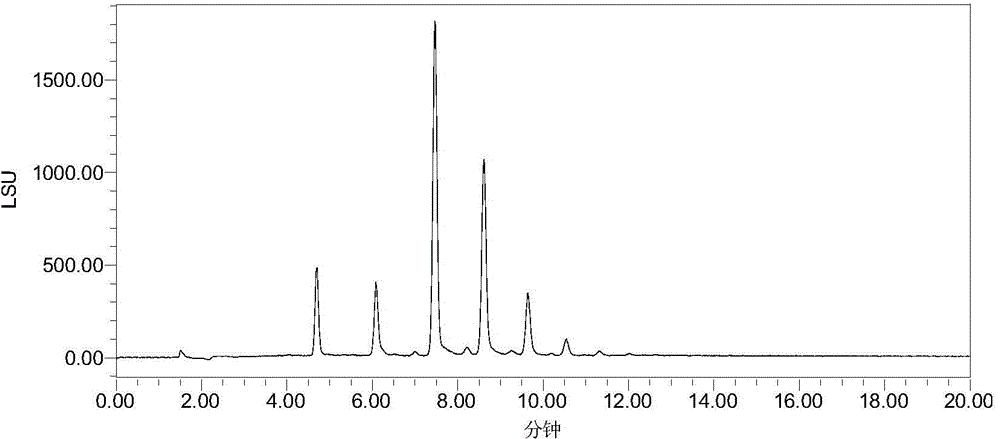

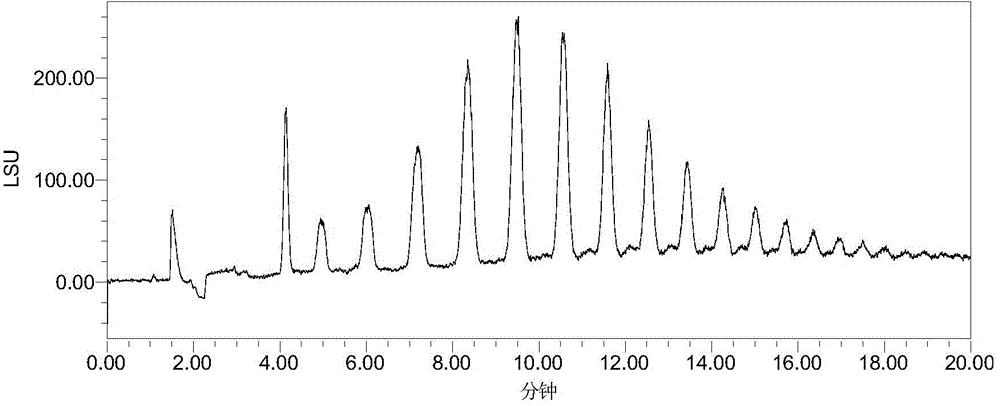

Preparation method of liquid chromatographic stationary phrase and glycosyl-bonded stationary phrase

InactiveCN105749887ANovel structureImprove hydrophilicityOther chemical processesChromatographic separationChemical reaction

The invention relates to a liquid chromatographic stationary phrase, specifically to a preparation method of a liquid chromatographic stationary phrase and a glycosyl-bonded stationary phrase. A glycosyl-bonded silica gel stationary phase is prepared through a sulfydryl-alkene click chemical reaction free of heavy-metal catalysis. According to the method, sulfydryl groups are introduced on the surface of silica gel to prepare a sulfydryl silica gel intermediate; and through an addition reaction of sulfydryl groups and alkenyl groups, alkenyl saccharide molecules are bonded to the surface of silica gel. The method is free of heavy-metal catalysis, and therefore, the final product is free of heavy-metal residues, and adverse effects of heavy metals on performance of the product can be totally avoided. The preparation method is simple and reliable in process, mild in reaction condition, quite easy for massive preparation, and wide in application range. The glycosyl-bonded stationary phrase can be used as a separating material for hydrophilic interaction liquid chromatography, and is widely applied to selective separation of polar compounds, such as oligosaccharide, glycopeptide, glycoprotein, polypeptide, and nucleoside.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

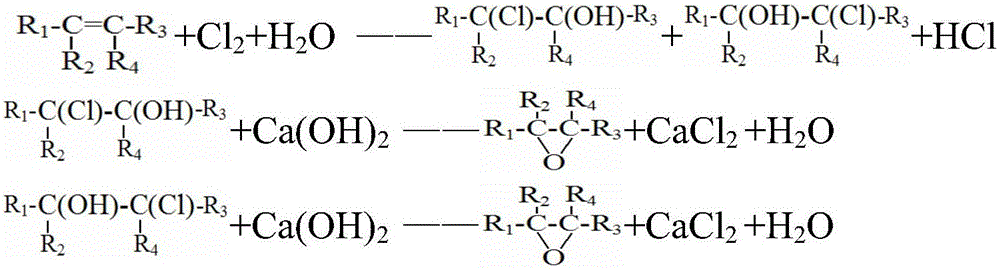

Method for preparing halogenohydrin and epoxide

ActiveCN106518624AEasily damagedSolve intractableWater contaminantsDispersed particle separationHalogenWastewater

Owner:JIANGXI SUKEER NEW MATERIAL

Automatic ignition powder for gas generator of air bag restraint system of automobile and preparation method of automatic ignition powder

ActiveCN105777458AEasy to igniteAppropriate thermal decomposition temperatureNon-explosive/non-thermic compositionsDecompositionRare earth

The invention provides automatic ignition powder for a gas generator of an air bag restraint system of an automobile and a preparation method of the automatic ignition powder.The automatic ignition powder contains fuel, oxidant and flame accelerator; the flame accelerator is rare earth and perovskite type composite metal oxide; the general formula of the flame accelerator is La1-xAxMnO3, wherein A is Ce and / or Cu, and x is greater than zero and less than one.According to the automatic ignition powder, the specific flame accelerator is adopted and can effectively promote a redox reaction in the powder, thereby thermal decomposition of the automatic ignition powder is promoted, the decomposition temperature of the powder is lowered, and automatic ignition performance of the powder is improved.

Owner:BYD CO LTD

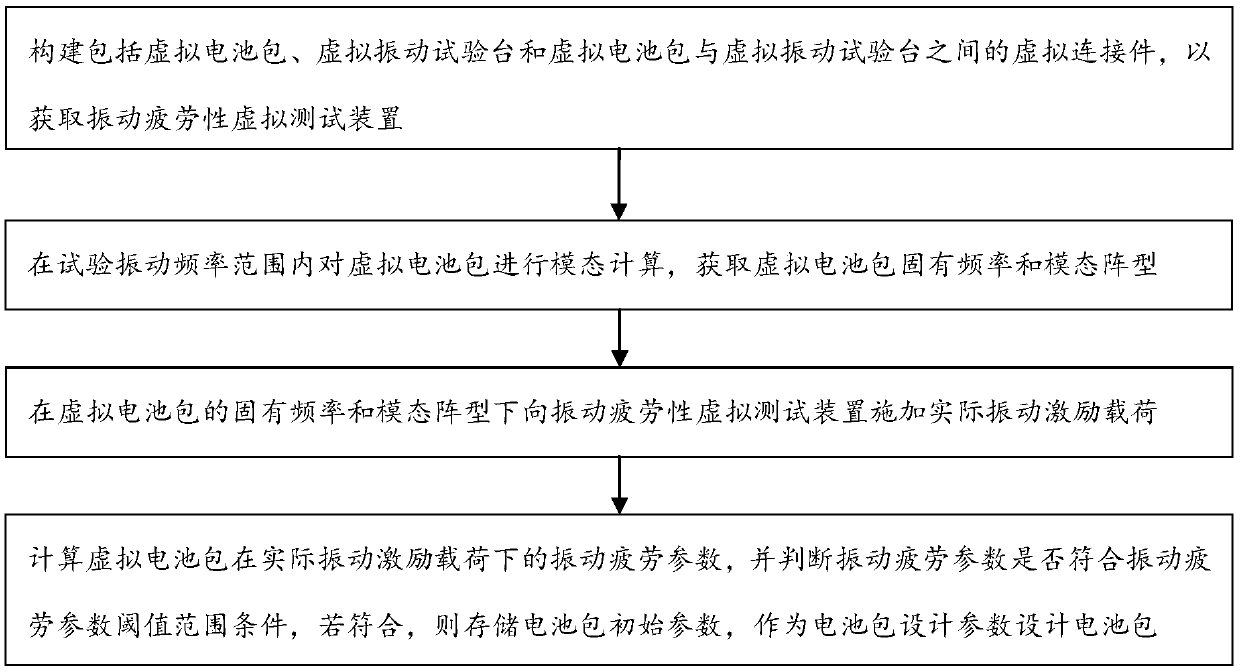

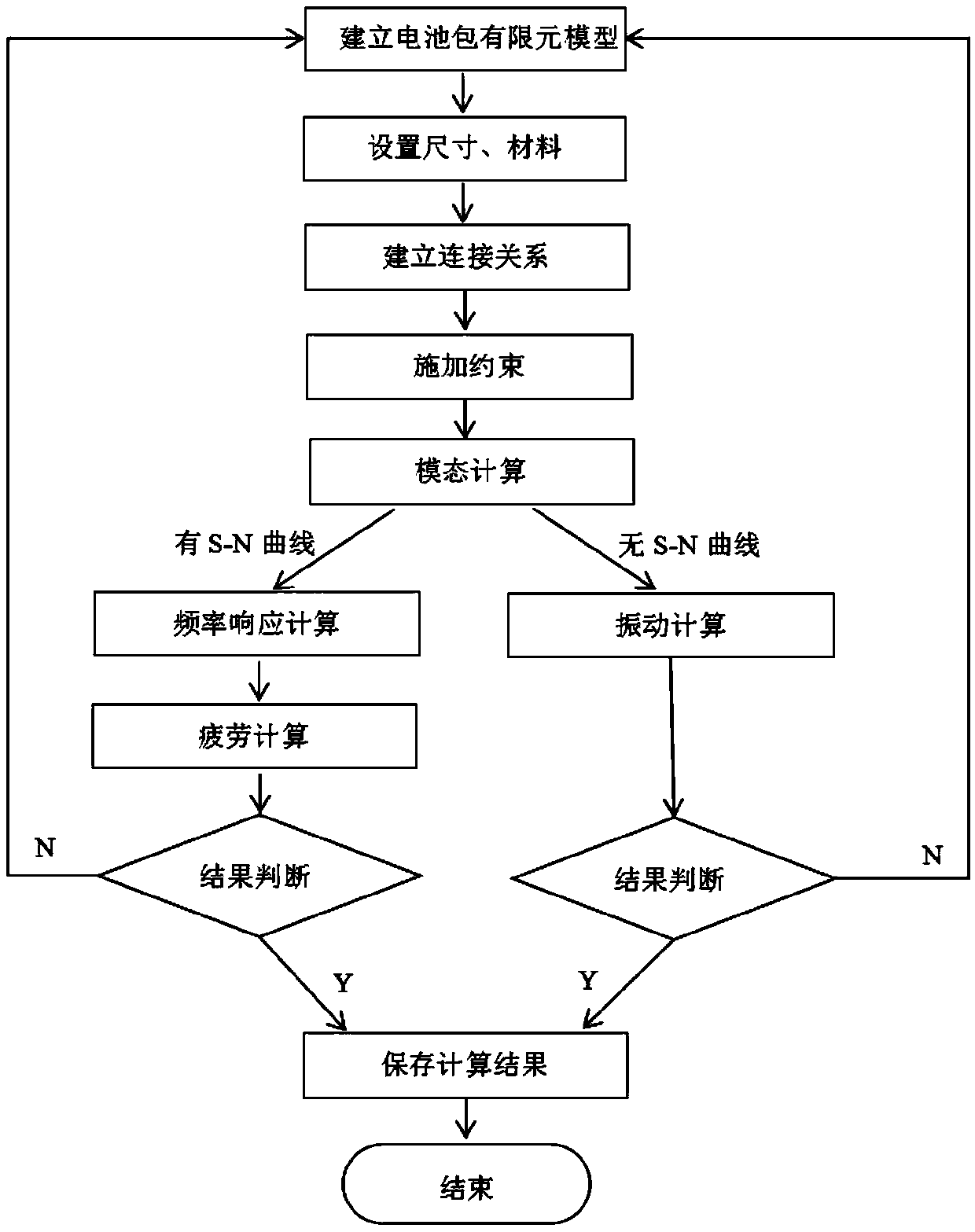

CAE-based vibration fatigue simulation test method of new energy vehicle battery pack

The invention relates to a CAE-based vibration fatigue simulation test method of a new energy vehicle battery pack.The CAE-based vibration fatigue simulation test method comprises the steps that virtual connection parts among a virtual battery pack, a virtual vibration test bench and a virtual battery pack and a virtual vibration test bench areconstructed to obtain a vibration fatigue virtual testdevice; modal calculation is performed on the virtual battery pack within the test vibration frequency range, and the natural frequency and modal matrix of the virtual battery pack are obtained; andactual vibration excitation load is applied to the vibration fatigue virtual test device under the natural frequency and modal matrix of the virtual battery pack; and the vibration fatigue parametersof the virtual battery pack under the actual vibration excitation load are calculated, whether the vibration fatigue parameters meet the vibration fatigue parameter threshold range conditions or not is determined, and if so, the initial parameters of the battery pack are stored to be taken as the design parameters of the battery pack for designing the battery pack. The CAE-based vibration fatiguesimulation test method evaluates whether the virtual battery pack is subjected to vibration fatigue damage or not during the test, and reduces the test cost of the battery pack design.

Owner:BEIDOU AEROSPACE AUTOMOBILE BEIJING CO LTD

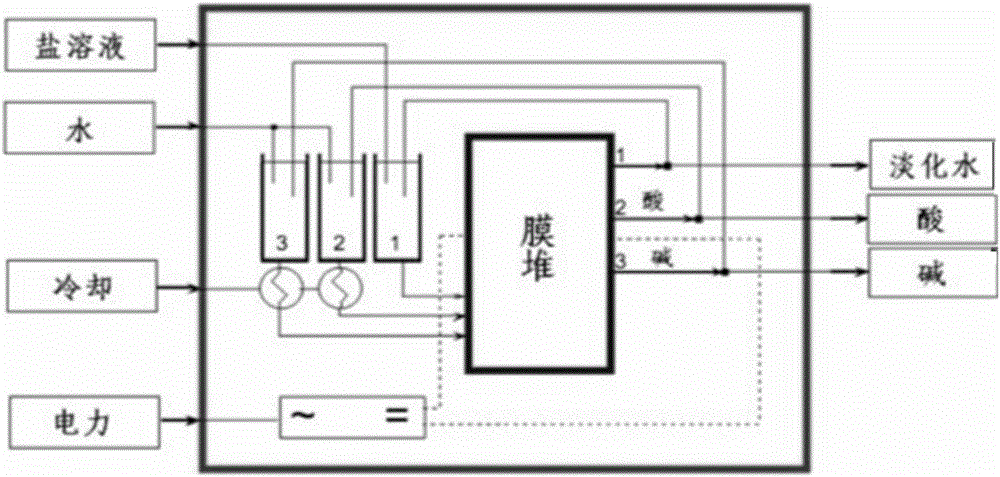

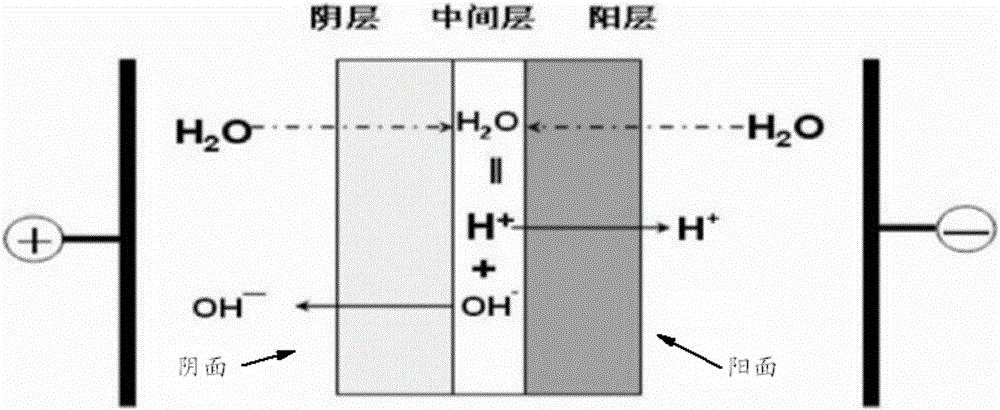

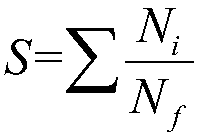

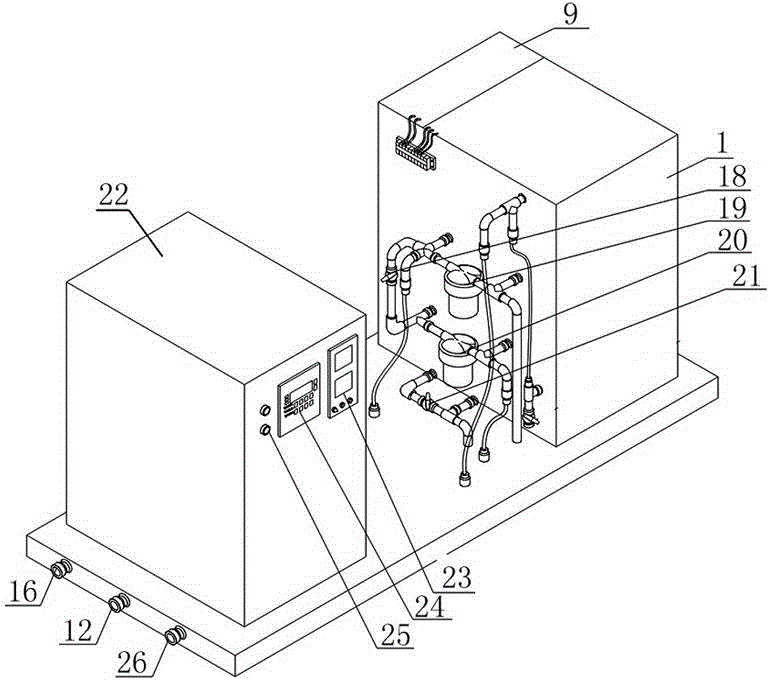

Chlorine dioxide generator adopting high-efficiency electrolytic method

The invention relates to a chlorine dioxide generator adopting a high-efficiency electrolytic method. The chlorine dioxide generator mainly comprises a chlorine dioxide electrolytic module, a soluble salt system, an electrolytic salt quantitative adding system, an alkaline liquid circulating discharge system and a programmable logic controller (PLC) control system. The chlorine dioxide generator has the characteristics of compact and reasonable structure, high electrolytic efficiency, simple production, mounting and maintenance of equipment, intelligent control, flexibility, convenience, high safety performance and the like.

Owner:江西富诚生态环境科技集团有限公司

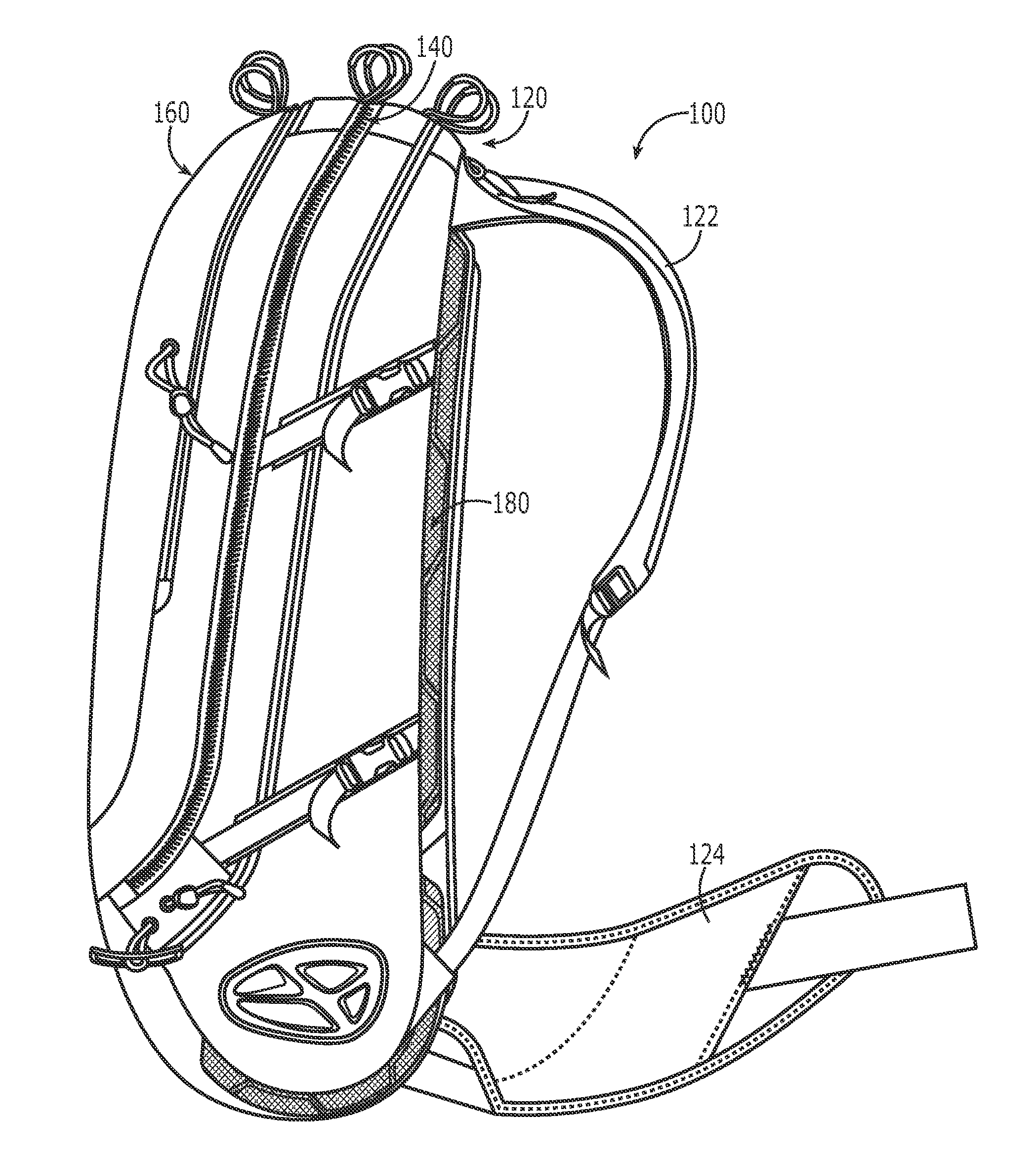

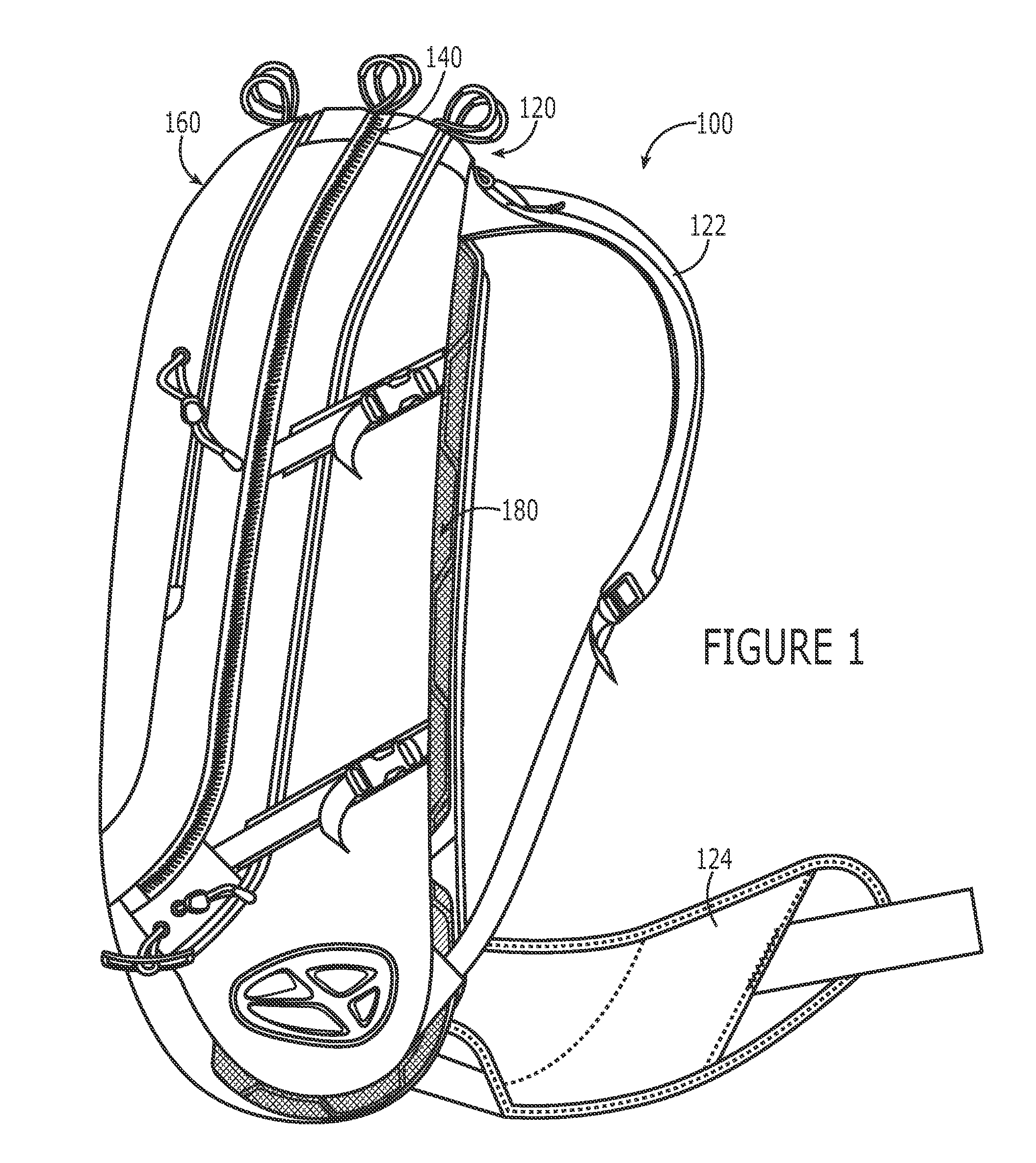

Systems and methods for inflatable avalanche protection with reinflation

ActiveUS8851948B2Avoid Explosion HazardsOvercome limitationsChemical protectionHeat protectionThree dimensional shapeSystem configuration

Owner:BLACK DIAMOND EQUIPMENT

Method and system for recycling residual heat of ash and slag of liquid slag-tapping boiler

InactiveCN103776045ASave waterAvoid it happening againLighting and heating apparatusDiffusing capacityFlue

The invention discloses a method and a system for recycling the residual heat of ash and slag of a liquid slag-tapping boiler. The method comprises the following steps of by using cold air or partially desulfurized clean smoke gas as a cooling medium, granulating and cooling liquid slag generated by the boiler in a liquid-slag dry-cooling device; sending generated dedusted hot air or hot smoke gas into a flue which is positioned between desulfurizing equipment and a chimney, and mixing and heating the desulfurized clean smoke gas. According to the method, heat in the liquid slag is replaced through the air or the desulfurized smoke gas and is utilized for heating the desulfurized clean smoke gas, so that the heat of the liquid slag can be effectively recycled, the problem of great physical heat loss of the ash and the slag of the liquid slag-tapping boiler is solved, and the economical property of a liquid slag-tapping boiler set is improved. The smoke temperature at the inlet of the chimney is increased by utilizing the residual heat of the liquid slag, so that the chimney can be prevented from being corroded, and the lifting and diffusing capacity of the smoke gas is improved.

Owner:XI AN JIAOTONG UNIV

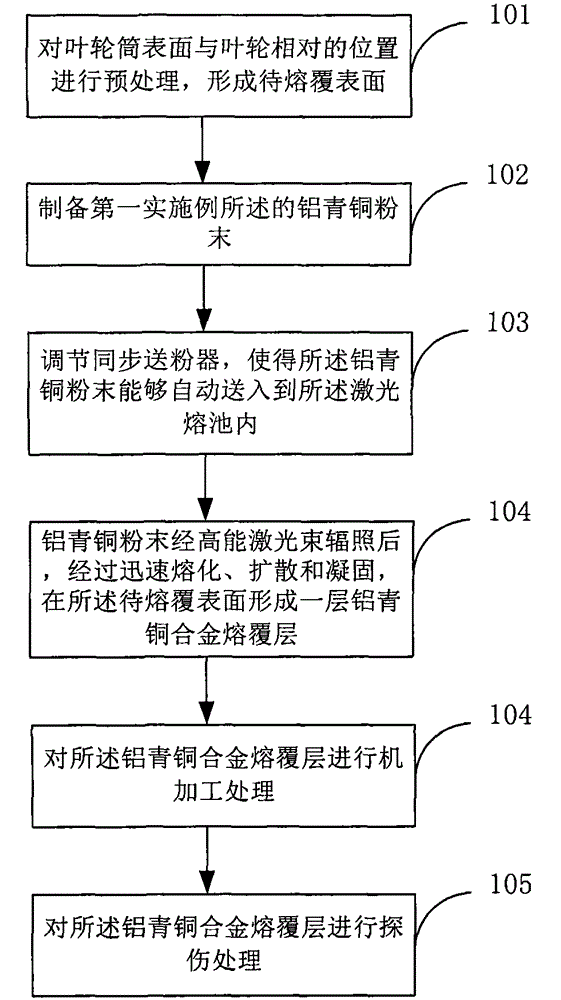

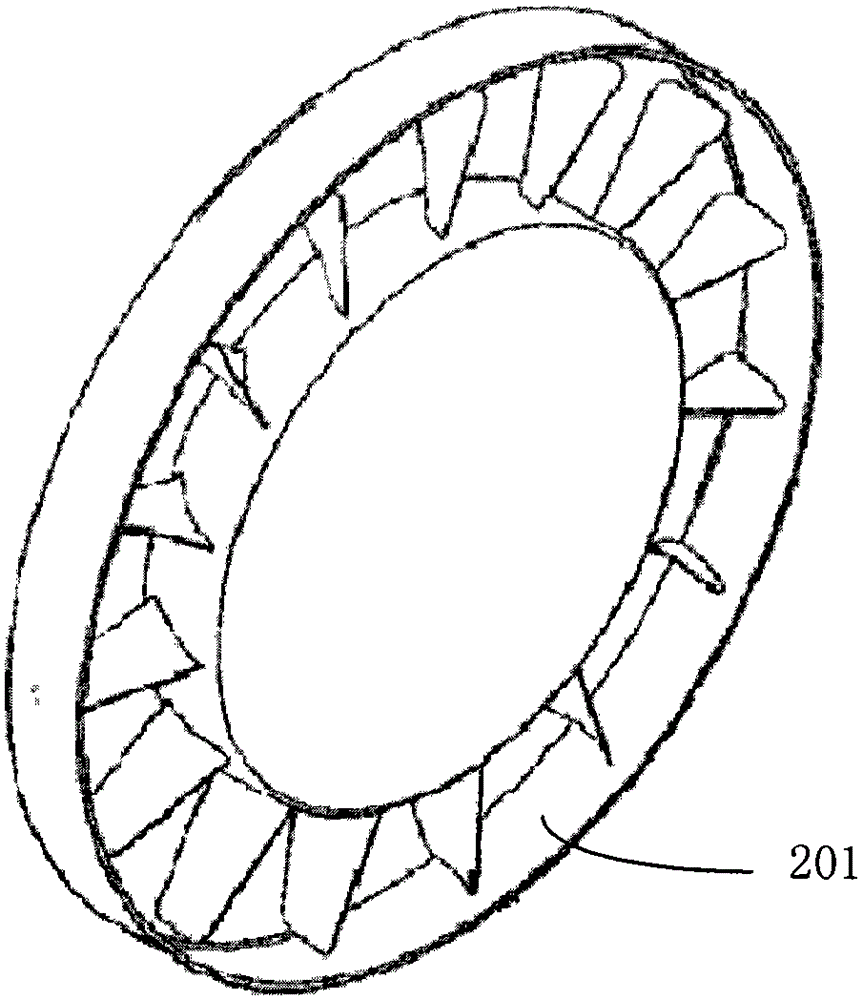

Non-spark aluminum bronze powder for laser cladding, preparation method and cladding method

ActiveCN105088005AAvoid Explosion HazardsAvoid safety hazardsMetallic material coating processesHigh energyAlloy

The invention provides non-spark aluminum bronze powder for laser cladding, a preparation method and a cladding method. No dangerous high-energy spark is generated to an alloy layer clad with aluminum bronze powder, and therefore the situation that high-energy sparks are generated by friction of a coal mine ventilation fan to cause gas explosion hazards is avoided. The non-spark aluminum bronze powder for laser cladding comprises C smaller than 0.03%, Si smaller than 0.05%, Mn smaller than 0.10%, S smaller than 0.006%, Cr smaller than 0.5%, Ni smaller than 0.5%, 83%-87% of Cu, 6%-10% of Al and Fe smaller than 6.5%. The method for cladding the non-spark alloy layer with aluminum bronze through lasers is used for replacing a traditional brass riveting process for the surface of an impeller barrel, a non-spark protection layer combined with base material alloy is used for replacing a mechanically-combined non-spark layer, and potential safety hazards possibly caused by failures of a copper riveting protection layer are avoided.

Owner:山西玉华再制造科技有限公司 +2

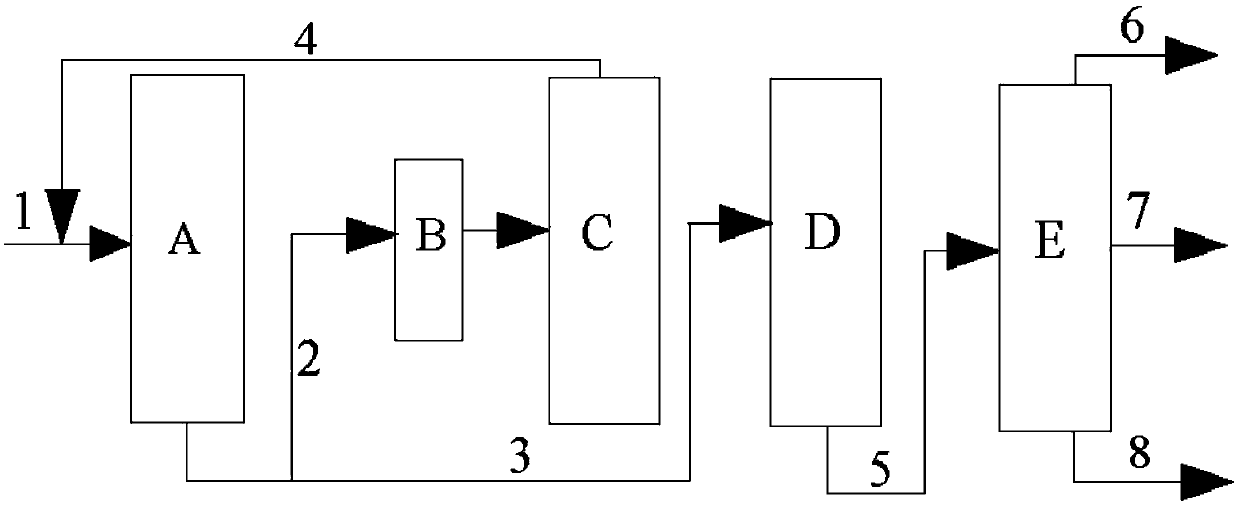

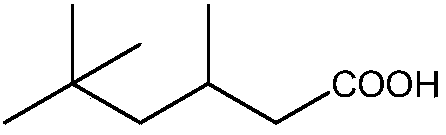

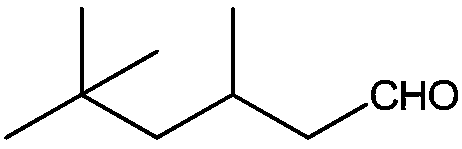

System and method for preparing isononanoic acid and method for preparing metal organic skeletal catalyst

ActiveCN108047027AHigh selectivityPromote decompositionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDecompositionMetal-organic framework

The invention provides a system and method for preparing isononanoic acid and a method for preparing a metal organic skeletal catalyst. The system includes an oxidation reactor used for oxidizing isononylaldehyde to isononanoic acid; a cooler used for cooling a part of material flow that flows out of the oxidation reactor; a metal ion separator used for separating excessive metal ions from the material flow that flows out of the cooler; a peroxide decomposition reactor used for decomposing a peroxide in the other part of the material flow that flows out of the oxidation reactor; and a rectification apparatus used for separating the material flow that flows out of the peroxide decomposition reactor to obtain the isononanoic acid product, wherein the material outlet of the metal ion separator is connected to the material inlet of the oxidation reactor. The invention further provides an isononanoic acid preparation method that is good in selectivity and safety and high in yield.

Owner:WANHUA CHEM GRP CO LTD

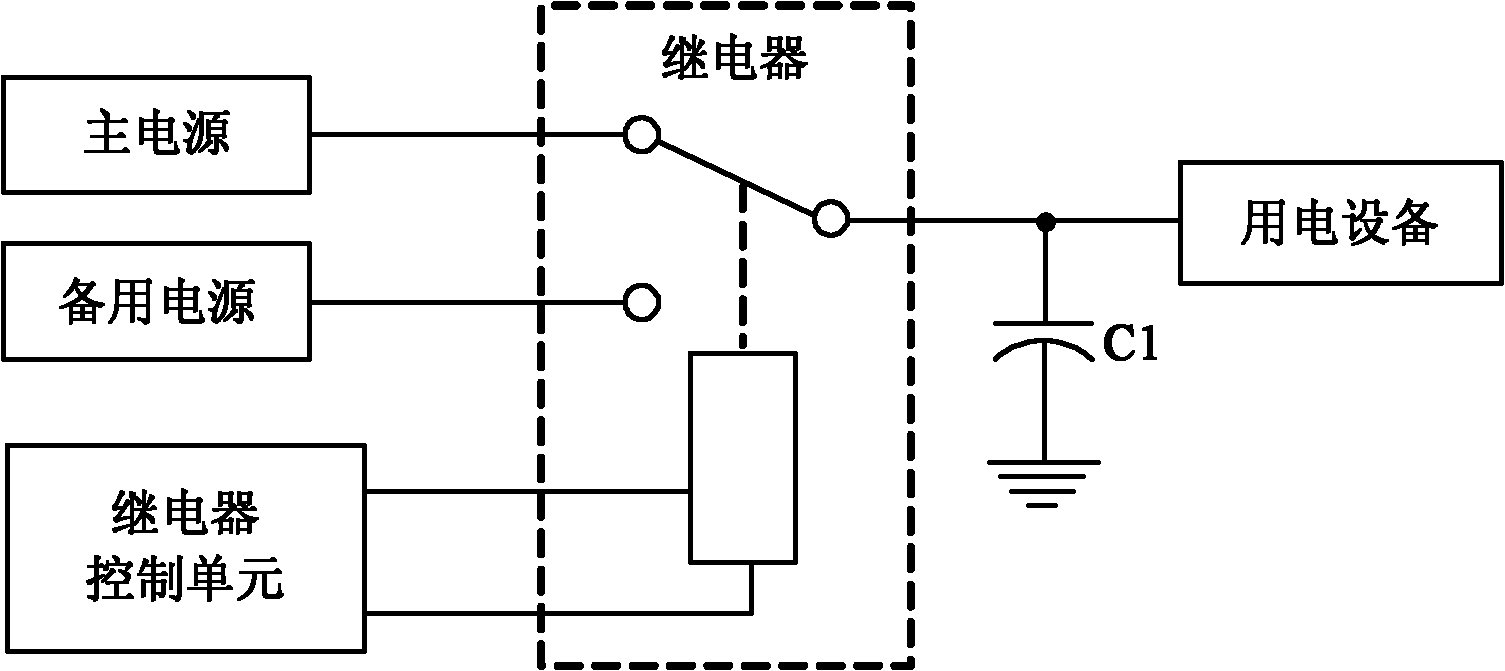

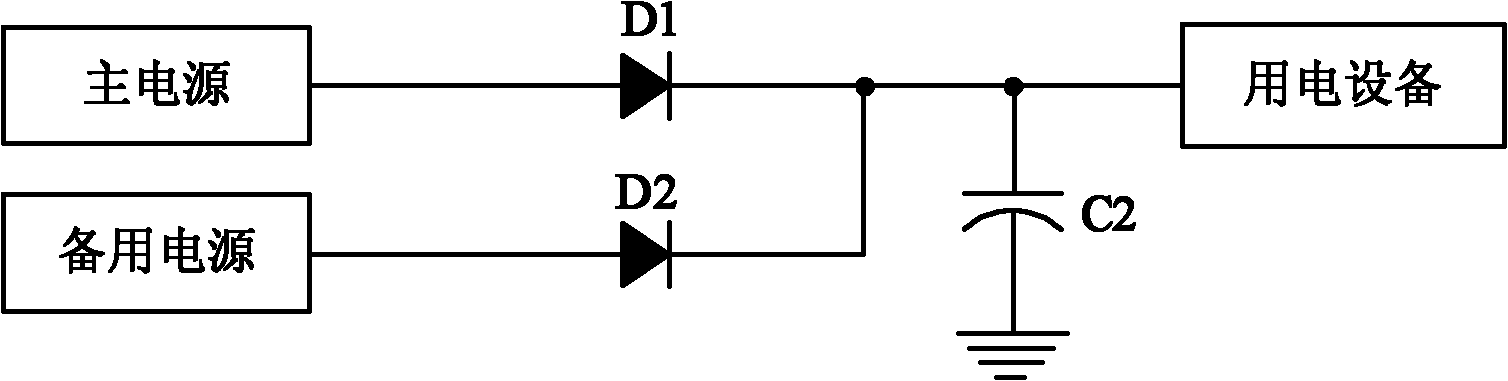

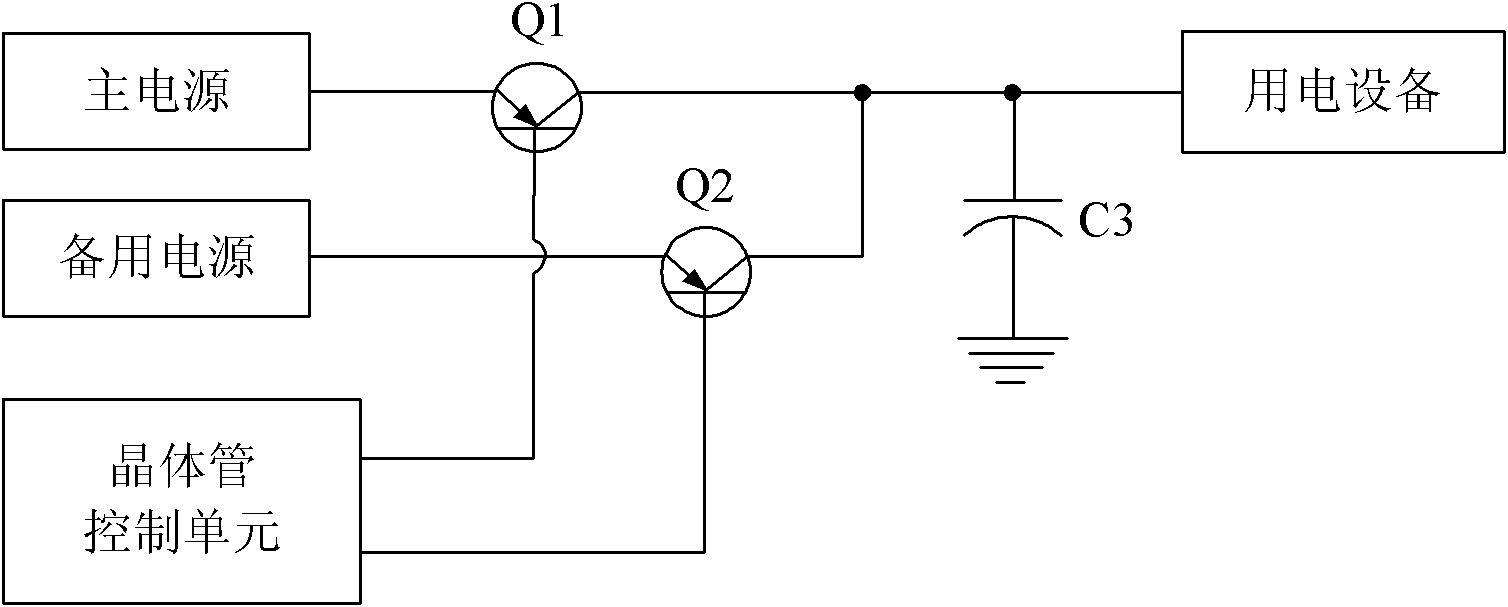

Dual-power stable-switching device and method

ActiveCN101895148APrevent over dischargePlay a protective effectEmergency power supply arrangementsCapacitanceElectricity

The invention relates to a dual-power stable-switching device, which is used for providing stable switching for a main power supply and a spare power supply, which supply power to electric equipment. The dual-power stable-switching device comprises a main / spare power supply switching unit, a relay control unit, a charging management unit, a main power supply switching auxiliary unit and a spare power supply switching auxiliary unit. The invention also relates to a dual-power stable-switching method. When the dual-power stable-switching device and the method are used, the defect of easy power failure of the electric equipment can be overcome, the load voltage fluctuation is small, no large-capacity capacitors are required for auxiliary switching and use in combination with a radiator is avoided.

Owner:HYTERA COMM CORP

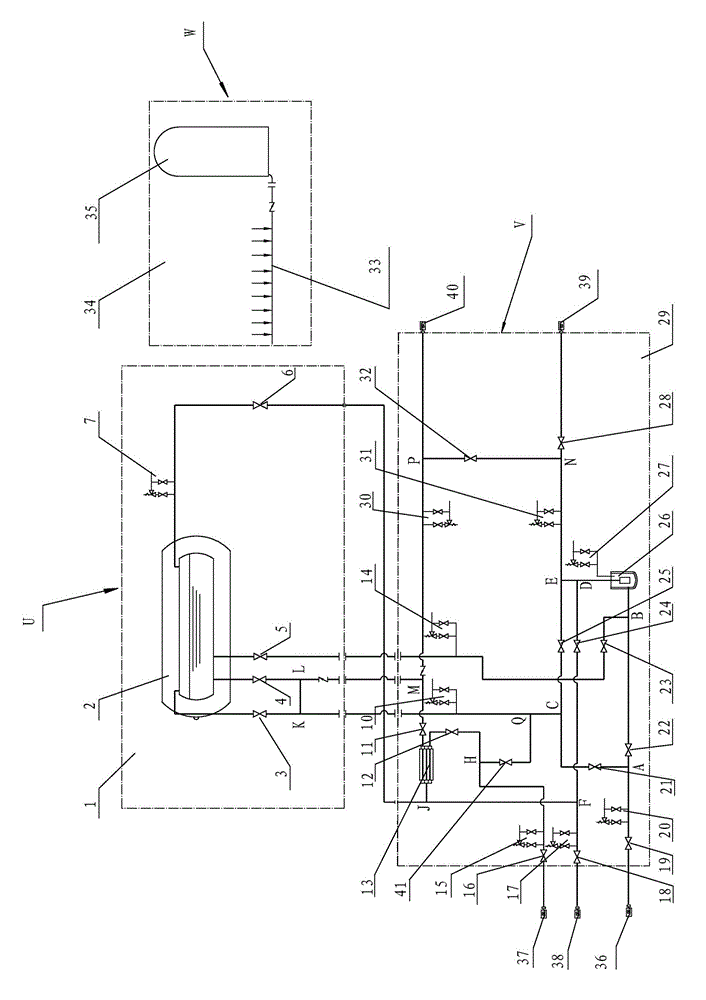

Unloading and liquid adding device for skid-type liquid adding station and unloading and liquid adding method

ActiveCN102913752AReduce the temperatureRelieve pressureContainer discharging methodsContainer filling under pressureNatural gas storageProcess engineering

The invention discloses an unloading and liquid adding device for a skid-type liquid adding station and an unloading and liquid adding method. The device comprises a storage tank prying block, a liquid adding prying block and a gas collecting prying block, wherein the storage tank prying block comprises a storage tank prying block base, a liquefied natural gas storage tank, a temperature preservation pipeline and a plurality of stop valves and a plurality of safety relief valves, wherein the plurality of stop valves and the plurality of safety relief valves are arranged on the temperature preservation pipeline; the liquid adding prying block comprises a liquid adding prying block base, an immersed pump, a pressurization and gasification device, a temperature preservation pipeline and a plurality of stop valves and a plurality of safety relief valves, wherein the plurality of stop valves and the plurality of safety relief valves are arranged on the temperature preservation pipeline; and the gas collecting prying block comprises a gas collecting prying block base, a gaseous natural gas storage tank and a temperature preservation pipeline. The device can achieve partial pipeline rapid precooling before unload and liquid adding, and has the function of collecting relieving gases, improves the safety and reliability, and reduces resource waste.

Owner:ZHANGJIAGANG FURUI SPECIAL EQUIP CO LTD

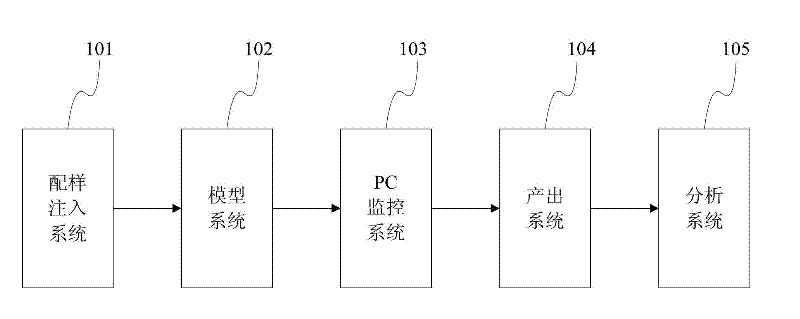

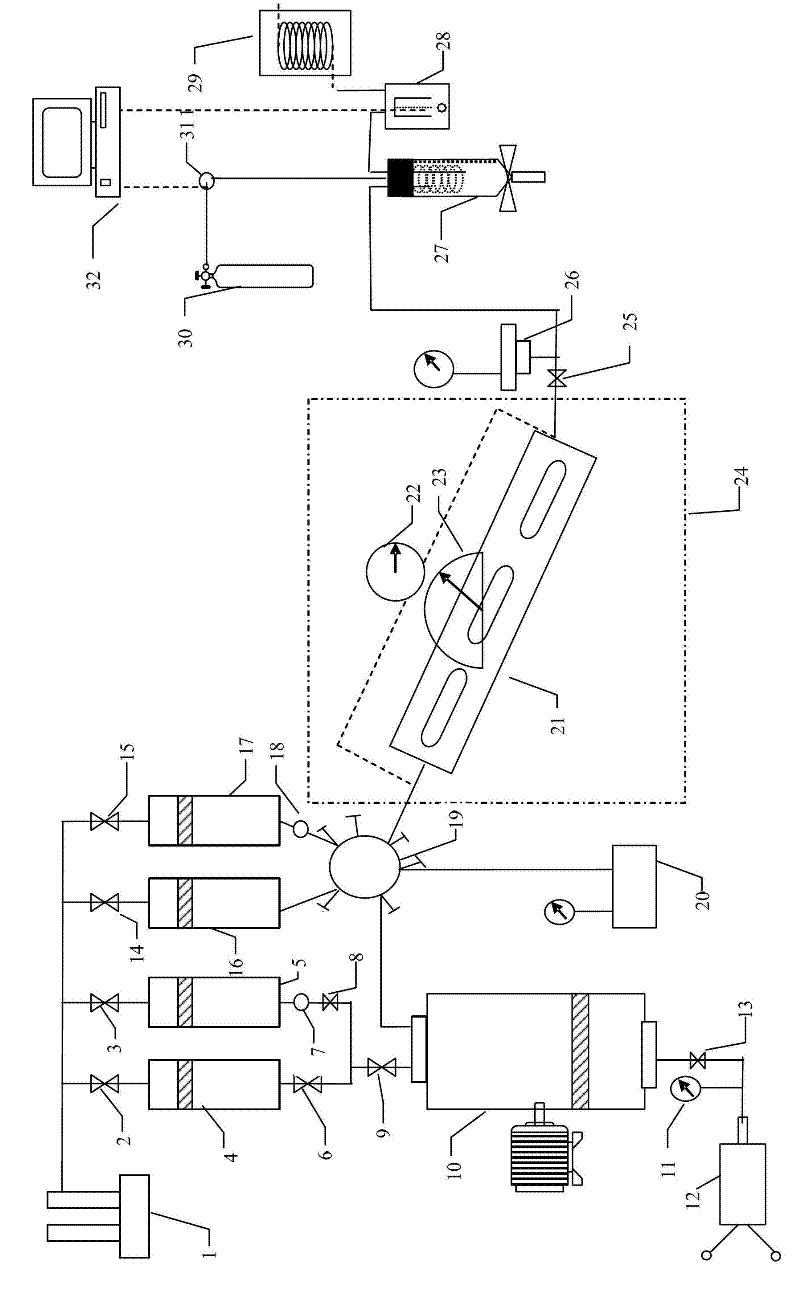

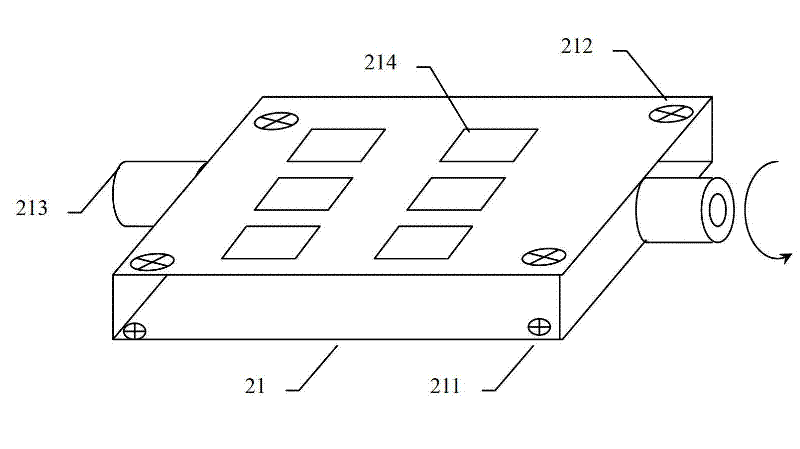

Top air-injection gravity auxiliary driving oil-extraction two-dimensional physical simulation experiment system

ActiveCN102654046AEnsure consistencyExperimental results are reliableSurveyFluid removalPilot systemGas phase

The invention discloses a top air-injection gravity auxiliary driving oil-extraction two-dimensional physical simulation experiment system, comprising a sample injection system, a simulation system, an output system, a PC (personal computer) monitoring system and a gas chromatograph-mass spectrometer, wherein the sample injection system comprises an ISO (international standard organization) high-precision calculation pump, a dead oil piston container, a natural gas piston container and a sample preparer; the simulation system comprises the ISO high-precision calculation pump, a formation water piston container, an air piston container, a three-way valve, a high-pressure bin, an inclined angle marking device and a two-dimensional sand filling model; the output system comprises a separator, a helium tank and a gas meter; and the PC monitoring system comprises a PC monitoring computer and a gas flow quality controller. Through an experiment system disclosed by the invention, the consistency of a sample and in-place oil can be ensured so that an experiment result is more real and reliable, and an online monitoring function for samples of an output system is exerted, and the real-time and automation degrees are improved.

Owner:PETROCHINA CO LTD

Method for purifying yellow phosphorus by using methods of activated carbon adsorption together with dilute nitric acid rinsing

ActiveCN102107859AAdequate adsorption capacityImprove adsorption capacityPhosphorus compoundsHigh concentrationActivated carbon

The invention discloses a method for purifying yellow phosphorus by adopting methods of activated carbon adsorption together with dilute nitric acid rinsing. Firstly, activated carbon and molten industrial yellow phosphorus are mixed and stirred in a refining kettle, and after the adsorption is completed, the activated carbon is separated from the yellow phosphorus by a filter machine; then the processed yellow phosphorus is circularly rinsed with dilute nitric acid in an acid pickling tower; residual organic matters, arsenic and low-price metal ions in the yellow phosphorus, which are not adsorbed by the activated carbon, are oxidized by utilizing the oxidizability of the dilute nitric acid; and afterwards, the yellow phosphorus is circularly rinsed in a water washing tower by using deionized water, thereby completing yellow phosphorus purification. The invention adopts a process with treatment methods of activated carbon adsorption, dilute nitric acid rinsing and deionized water rinsing, and integrates the advantages of various methods; and the content of arsenic in the acquired yellow phosphorus is reduced to below 20 ppm, so that high-purity yellow phosphorus satisfying the requirement for producing electronic grade phosphoric acid can be acquired, and the hidden danger of explosion caused by using high concentration nitric acid is avoided.

Owner:湖北兴福电子材料股份有限公司

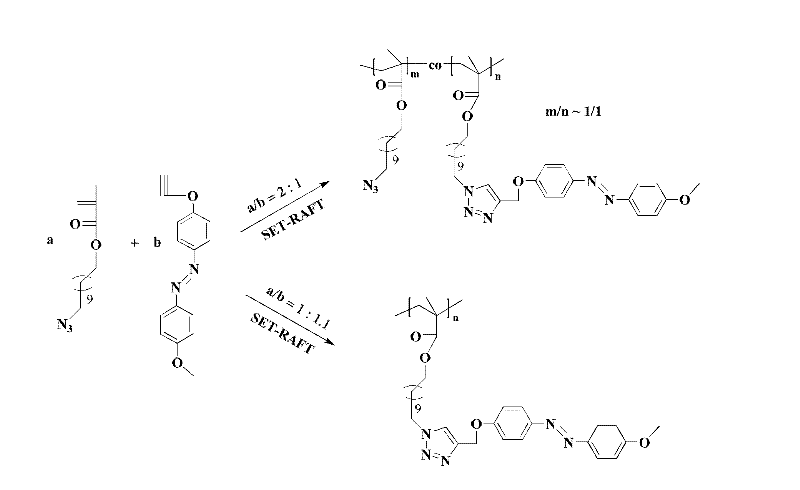

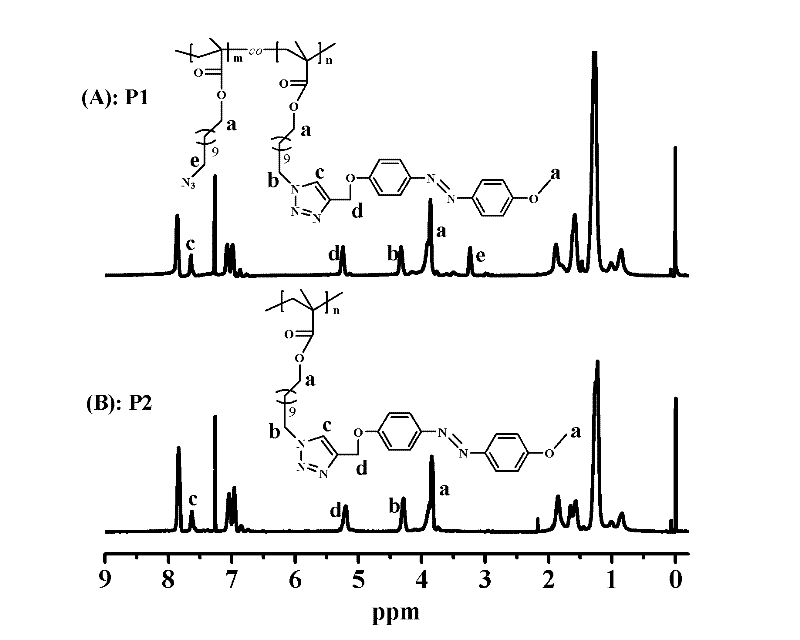

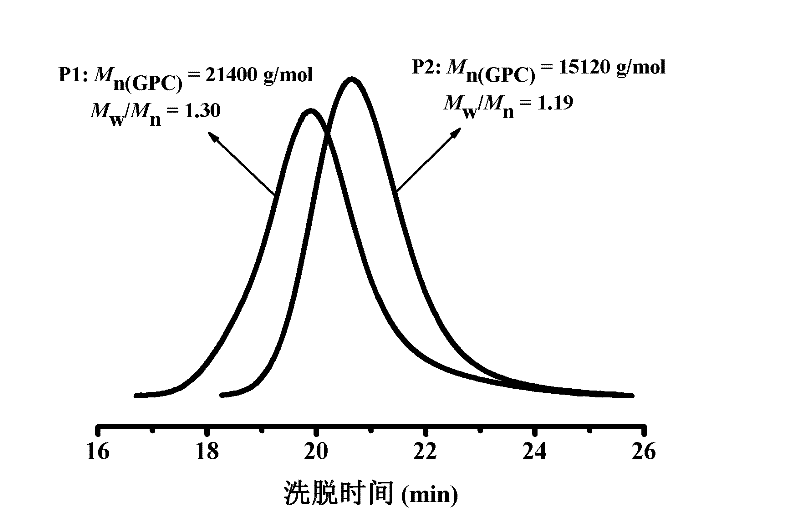

Side chain functional polymer and preparation method thereof

The invention discloses a side chain functional polymer and a preparation method thereof. A polymerization system consists of a monomer, an initiator, a chain transfer agent, a catalyst, a coordination agent and a coupling component, wherein the monomer is undecyl azidomethacrylic ester; the catalyst is copper; the coordination agent is N,N,N',N'',N''-pentamethyldiethylenetriamine; the coupling component is 4-methyoxyl-4'-propynyloxy azobenzene; single electron transfer (SET) is adopted for initiation to produce a free radical; polymerization reaction of the monomer is performed by a method for performing chain propagation in a reversible addition fragmentation chain transfer (RAFT) mode; meanwhile, click chemical reaction is performed; and monovalent copper is used for catalyzing an azide group and an alkynyl group in the coupling component to perform cycloaddition reaction so as to obtain the side chain functional polymer. Since the SET-RAFT method and the click chemical method are combined, the side chain functional polymer can be obtained by only one-step reaction; and thus, the reaction steps are reduced, the waste rate of the raw materials is reduced, rational utilization ofthe resources is realized, side reaction is basically avoided, and troublesome purification operation is avoided.

Owner:SUZHOU UNIV

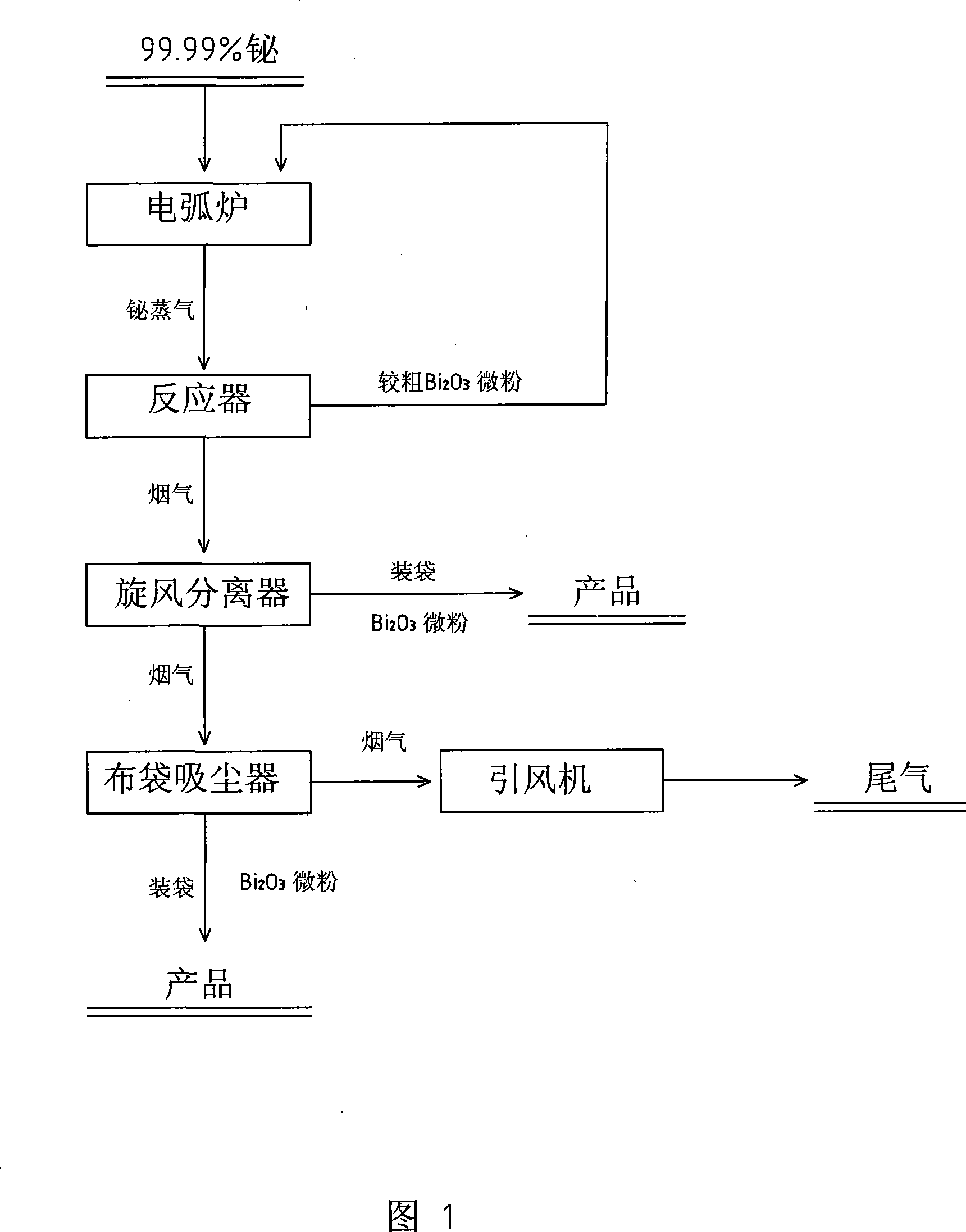

Method for producing high purity nano-level bismuth oxide micro-powder

InactiveCN101186337AFine granularityShorten the timeNanostructure manufactureBismuth compoundsMaterials preparationElectric arc furnace

The invention relates to a manufacturing method of bismuth oxide fine powder with high purity nanometer grade, which pertains to the technical field of nanometer material preparation technology. The invention uses an electric arc furnace for heating, in which metal bismuth is melted and evaporated. The reaction between the bismuth vapor and the oxygen in air produces the bismuth oxide fine powder with high purity nanometer grade. Since the reaction happens in gas phase, the granularity of the bismuth oxide fine powder with high purity nanometer grade is very fine; the average granularity is no more than 1 micron. Then the bismuth oxide fine powder with high purity nanometer grade is gained by two-level dust collecting. The invention has simple technique and low requirements on a device, dispersant is not required to be added and no toxic and hazardous emissions are produced to influence the environment in the production process.

Owner:HUNAN XIANGYUN FINE CHEM MFG

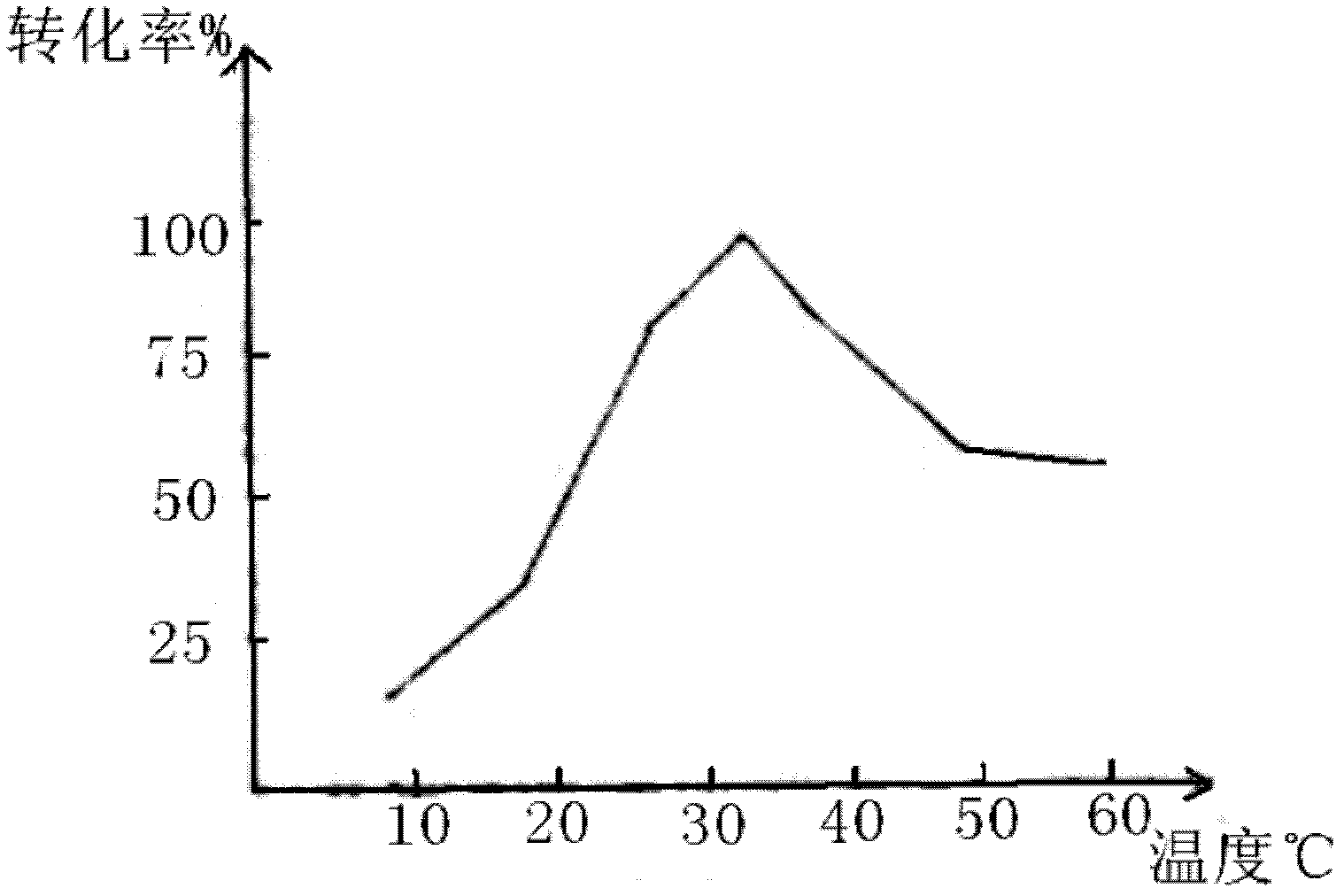

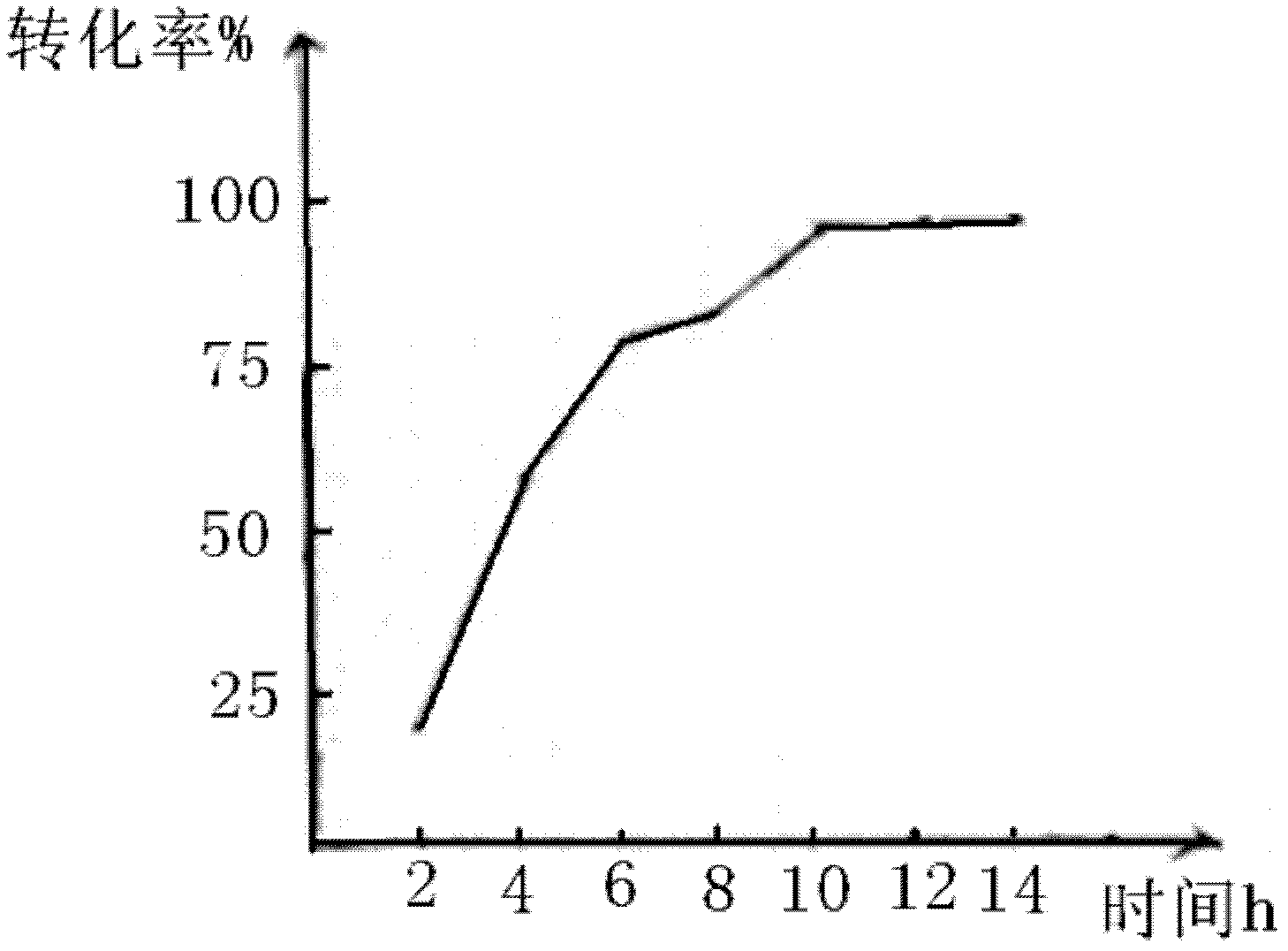

Preparation method of 2-phenylpropionic acid

ActiveCN102351684AAvoid Explosion HazardsSimple processPreparation from nitrilesHydrolysisReaction step

The invention discloses a preparation method of 2-phenylpropionic acid. The method comprises the following steps: stirring and reacting styrene and hydrochloric acid solution with the mass concentration of 20-30% used as raw materials for 8-14 hours at the temperature of 30-40 DEG C, standing and layering, water-washing an oil layer to obtain alpha-chloro-ethylbenzene, and further sequentially performing cyanidation and hydrolysis on alpha-chloro-ethylbenzene so as to prepare 2-phenylpropionic acid. The method adopts styrene as the raw material for direct chlorination, thereby reducing the reaction steps, being easy to control the conditions and being simple in equipment; and furthermore, the obtained product is stable in quality and high in purity, and the benefits are significantly improved.

Owner:CHANGZHOU TIANHUA PHARMA

Method for desulfurization cogenerating of hydrogen and sulfuric acid

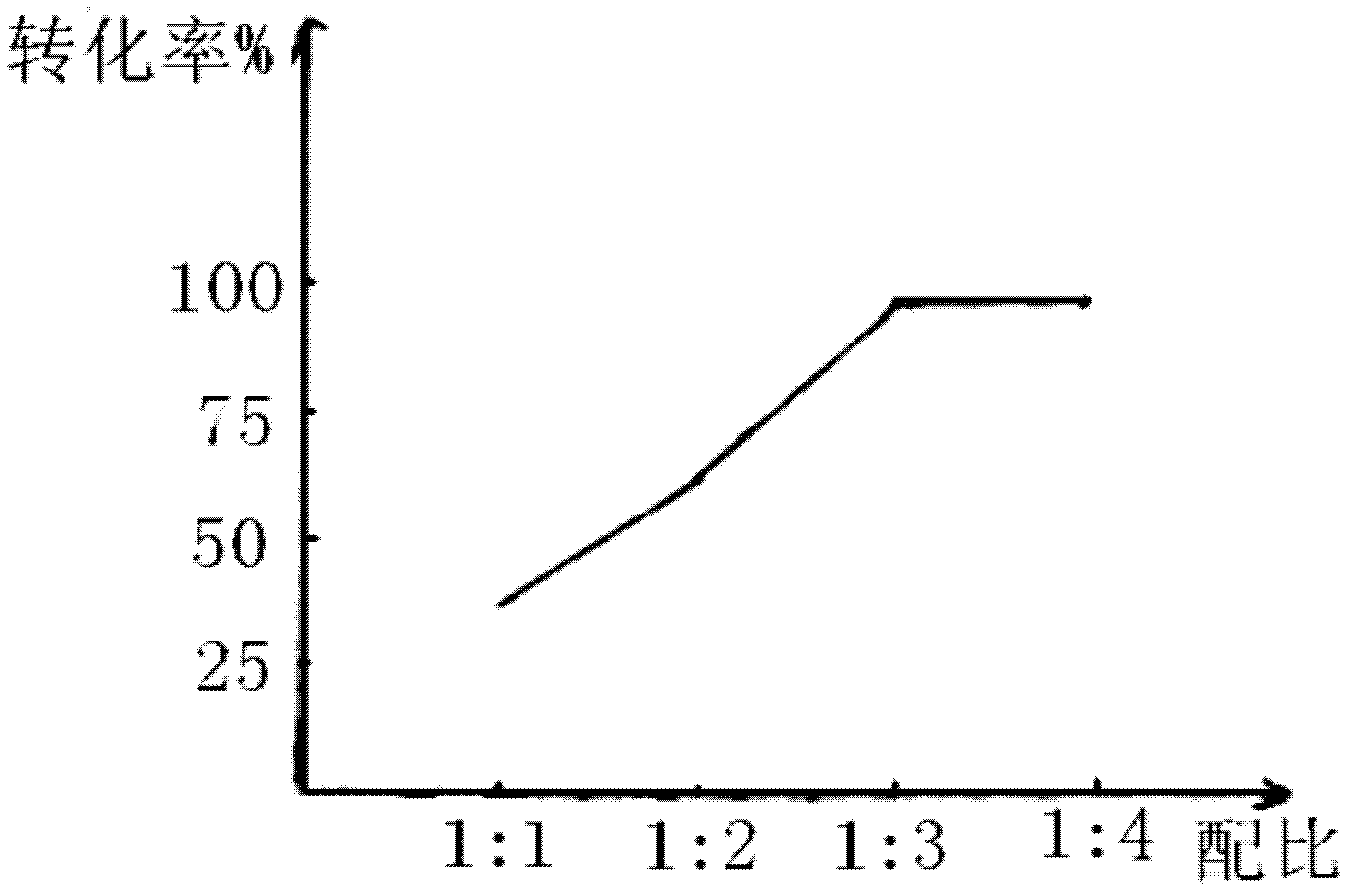

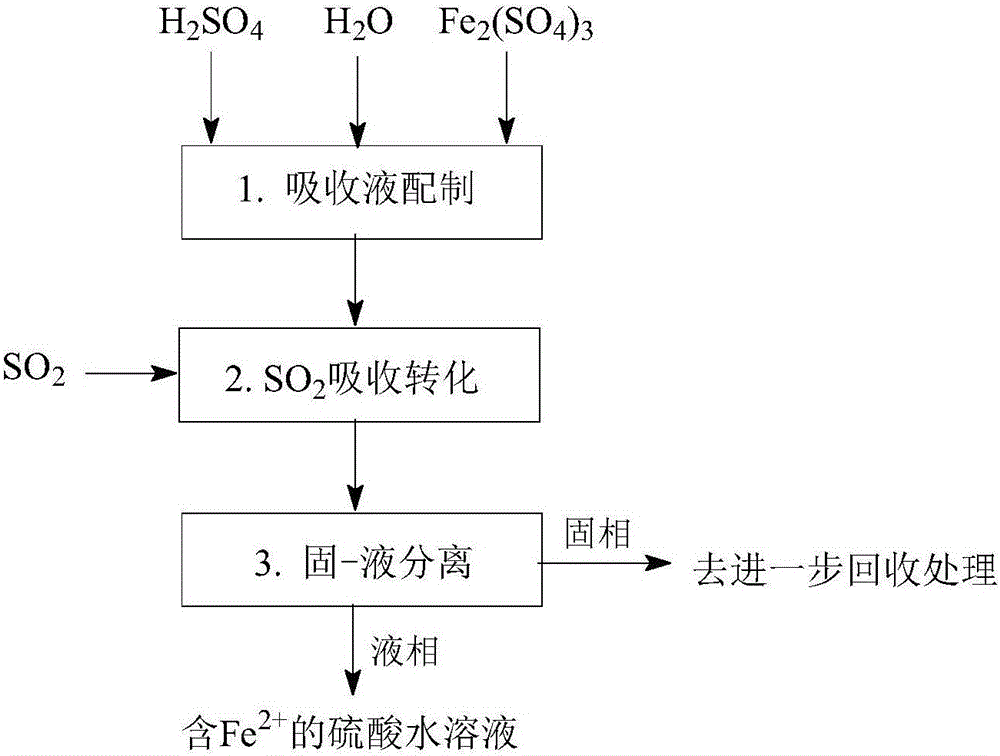

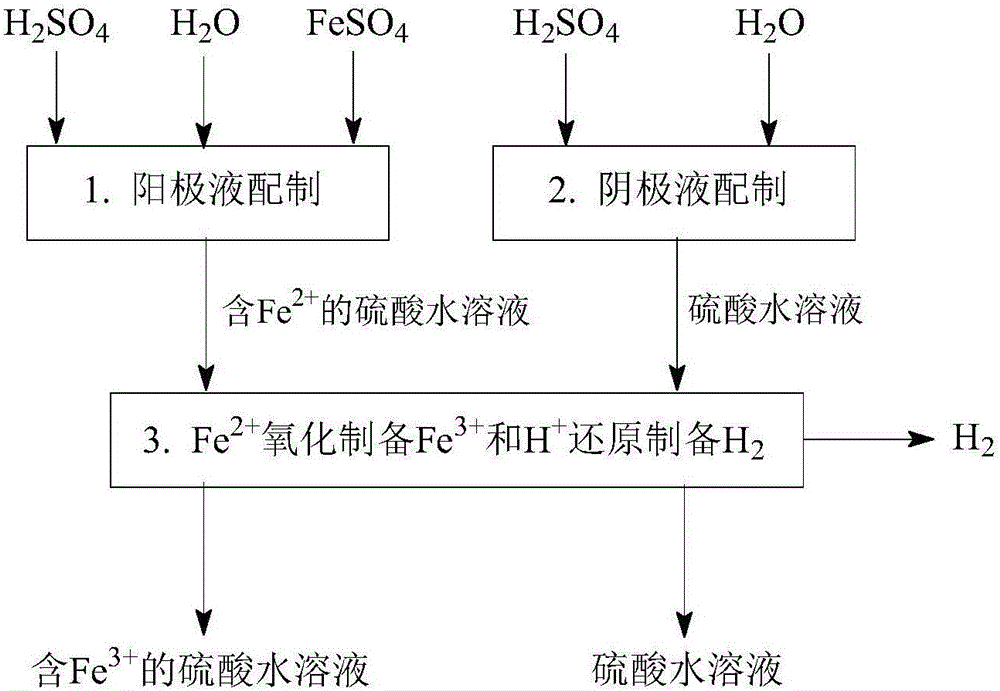

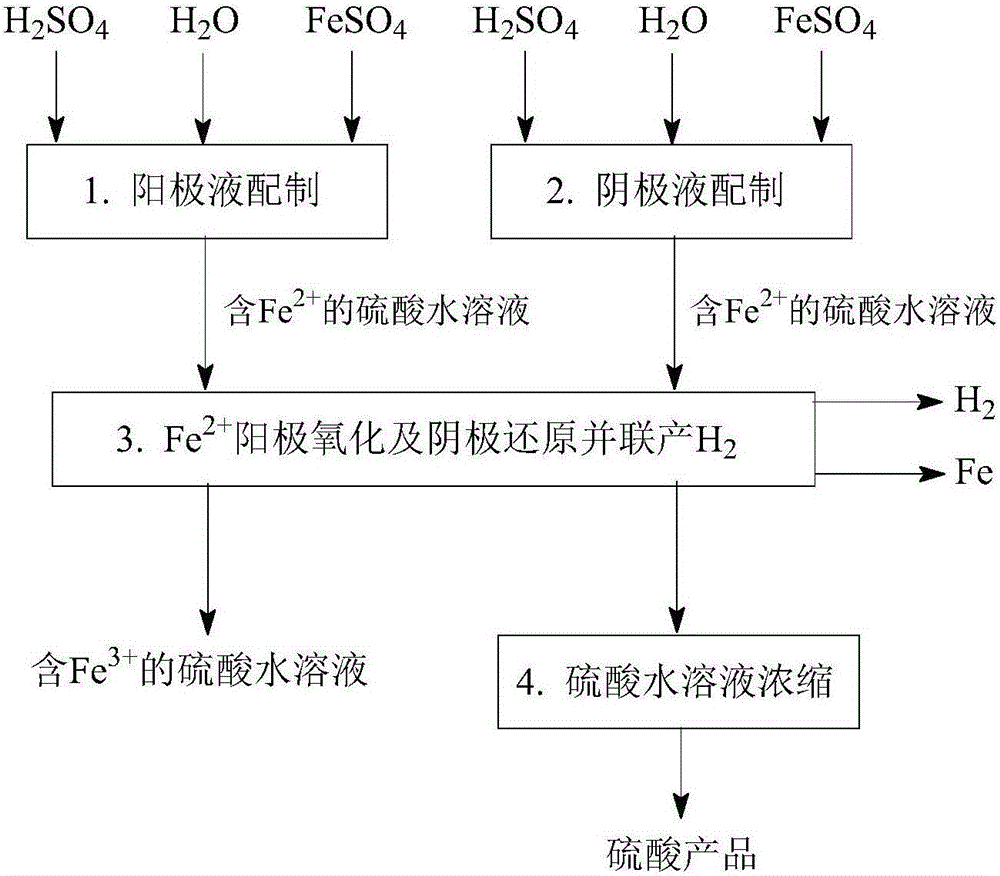

ActiveCN106039964AAchieve regenerationOvercoming the fatal flawElectrolysis componentsDispersed particle separationHydrogenGas phase

The invention discloses a method for desulfurization cogenerating of hydrogen and sulfuric acid. The method includes three main steps, namely SO2 absorption and conversion, Fe3+regeneration and H2 cogeneration and F2+removal and H2 cogeneration. In the method, a Fe3+ / F2+ electrochemical pair is adopted as a process catalyst, indirect electrochemical oxidation is realized, sulfur dioxide in a gas phase is removed by using a sulfuric acid water solution wet method, and hydrogen and sulfuric acid can be cogenerated at the same time. The method is high in process efficiency and energy utilization rate, low in equipment investment and production cost, safe and reliable in process and conducive to large-scale industrialization, and is an environment-friendly technology for desulfurization, comprehensive utilization of sulfur dioxide and cogeneration of hydrogen and sulfuric acid.

Owner:YANGZHOU UNIV

Bathing nursing equipment

The invention discloses bathing nursing equipment which comprises a water tank and an ozone generator. The ozone generator is communicated with the water tank. The bathing nursing equipment is characterized in that the water tank is a closed water tank, an exhaust pressure relief hole is formed in the water tank, and an ozone tail gas treatment device is arranged on the exhaust pressure relief hole; the bathing nursing equipment is further provided with an ozone gas circulating pump, so that un-dissolved ozone which is gathered above liquid level of the water tank can be injected into water again to be recycled. The bathing nursing equipment is further provided with a temperature and water level sensor, so that water level can be monitored, the water storage quantity of the water tank can be computed, the temperature of the water can be monitored, the ozone generator can generate the ozone under the control of the water storage quantity of the water tank and the temperature of the water, and the ozone can have set dissolved concentration; the bathing nursing equipment is further provided with a controller, and the controller is connected with the ozone generator, the ozone gas circulating pump and the temperature and water level sensor. The bathing nursing equipment has the advantages that the quantity of ozone which overflows to the atmosphere can be effectively reduced, accordingly, the human health can be prevented from being impaired by excessive ozone in the air, and the bathing nursing equipment is safe, is high in efficiency and has high market value.

Owner:于华新

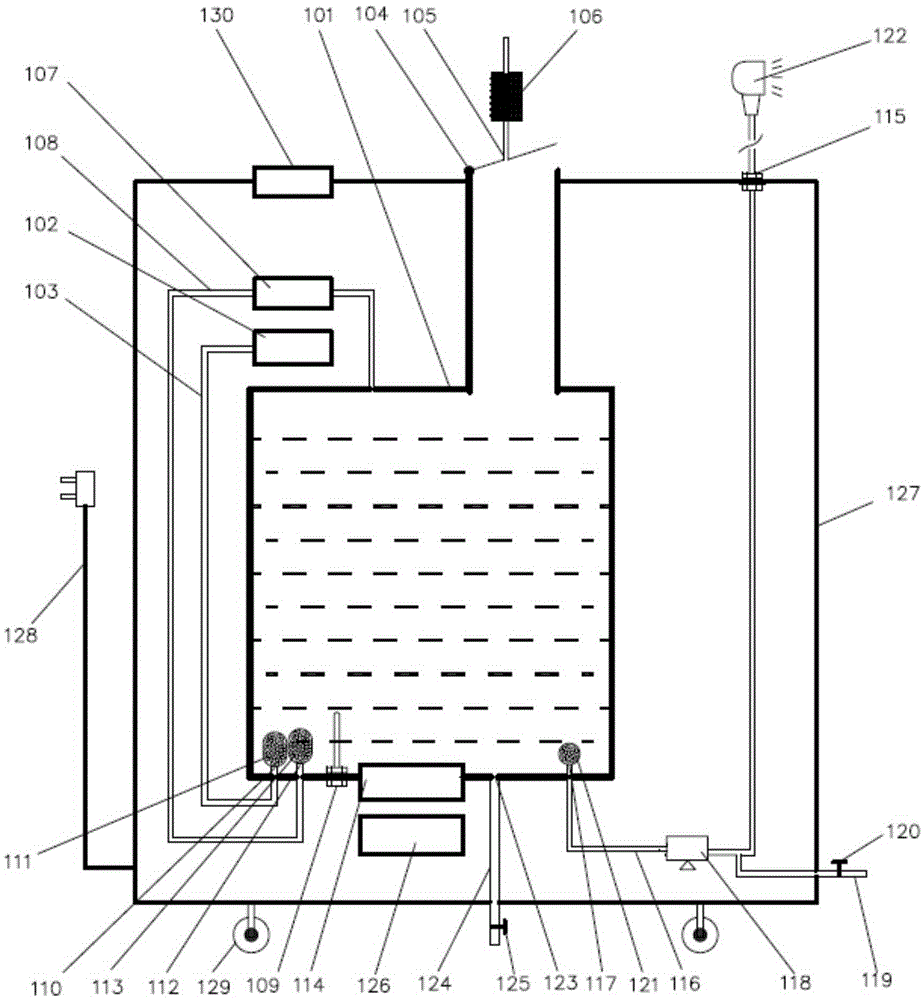

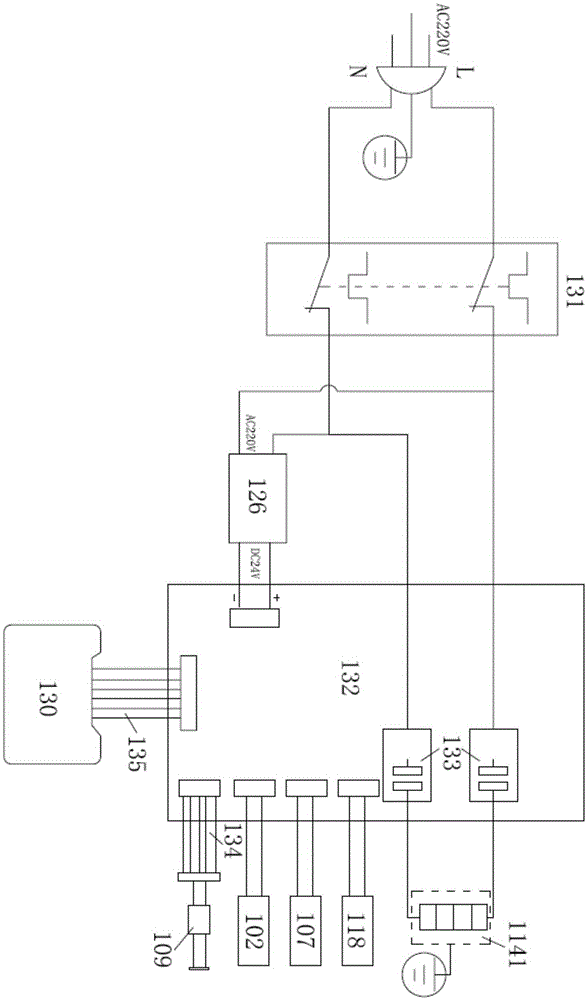

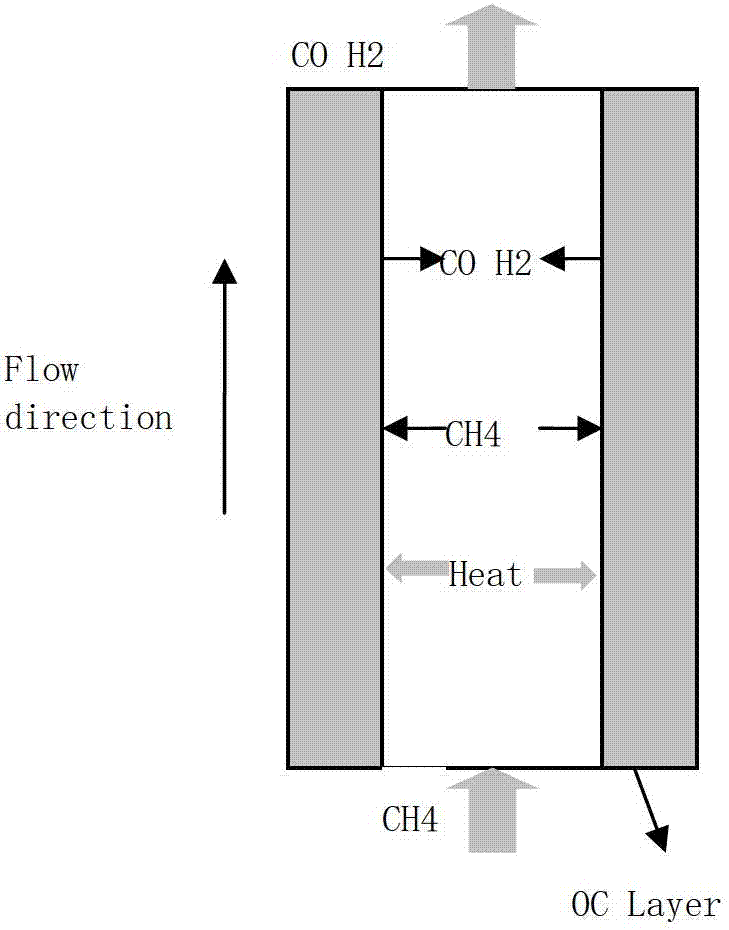

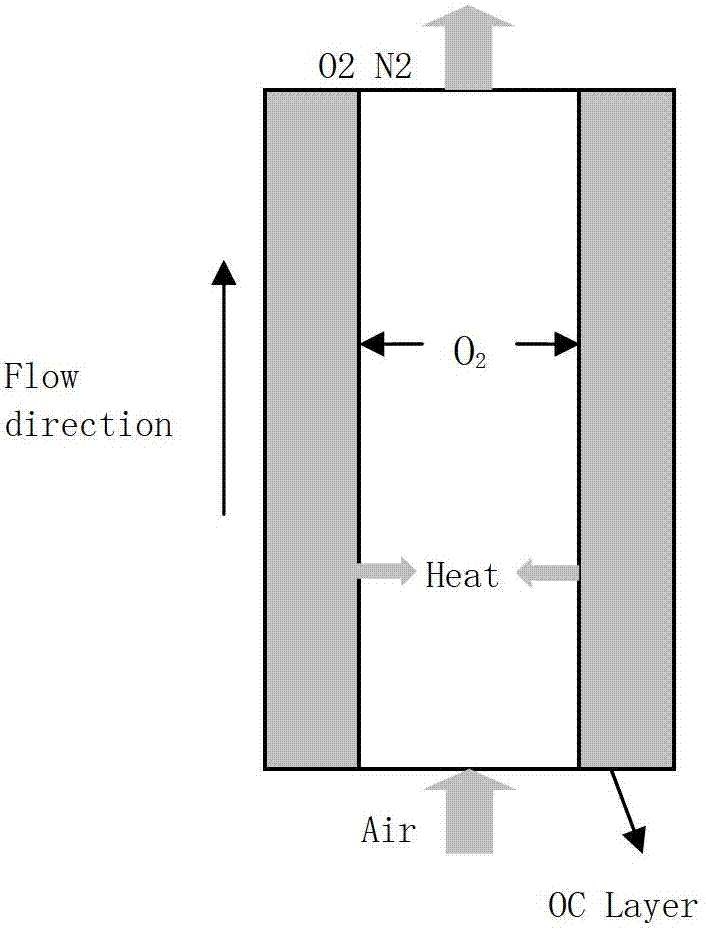

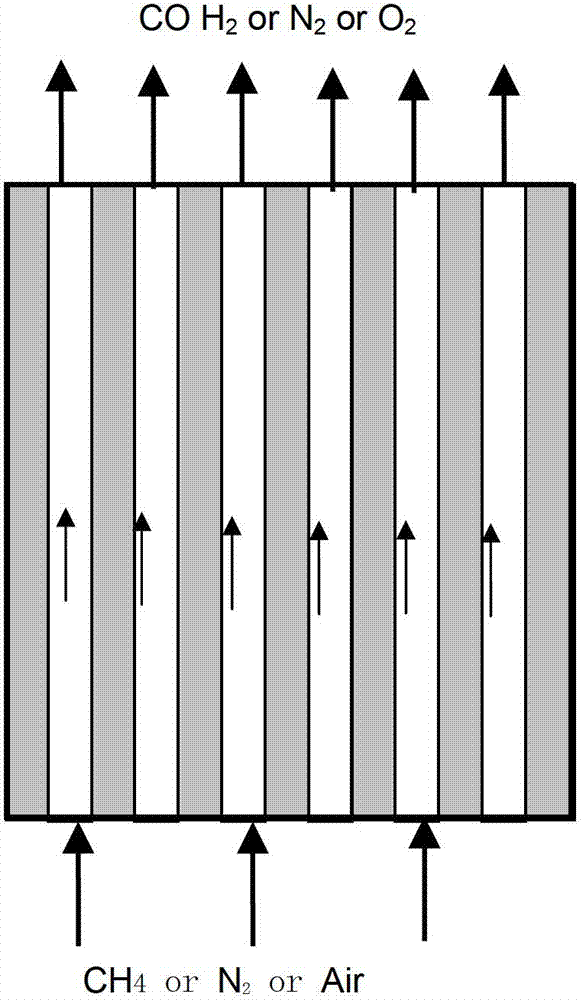

Cellular oxygen carrier chemical-looping reforming reactor

InactiveCN103204464AImprove conversion rateHigh selectivityHydrogen productionReaction temperatureEngineering

The invention discloses a cellular oxygen carrier chemical-looping reforming reactor. The cellular oxygen carrier chemical-looping reforming reactor comprises a reactor main body which comprises an outer wall and an outer heating barrel, wherein cellular oxygen carriers are formed in the outer wall and the outer heating barrel and are jointed with the outer wall and the inner wall of the outer heating barrel, and cellular pore paths parallel to the outer wall and a main shaft of the outer heating barrel are arranged in the cellular oxygen carrier and are pairwise spaced; and the tops of the outer wall and the outer heating barrel are connected with a top gas collecting region through upper flanges, the bottoms of the outer wall and the outer heating barrel are connected with a bottom gas storage region through lower flanges, a tail gas outlet is connected outside the top gas collecting region, a tee-junction gas inlet is connected outside the bottom gas storage region, and the bottom gas storage region is internally provided with a radiation type gas pre-distribution device connected with the tee-junction gas inlet. The cellular oxygen carriers have the advantages of having heat storage function, being capable of helping the reactor to maintain reaction temperature, alleviating the thermal load of external heating equipment and being beneficial to the stable proceeding of reaction.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com